Peanut sheller

A technology for shelling machine and peanuts, which is applied in the fields of shelling, pod removal, food science, etc., can solve problems such as unfavorable peanuts and affect the efficiency of peanut shelling, and achieve the effects of improving shelling efficiency, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention.

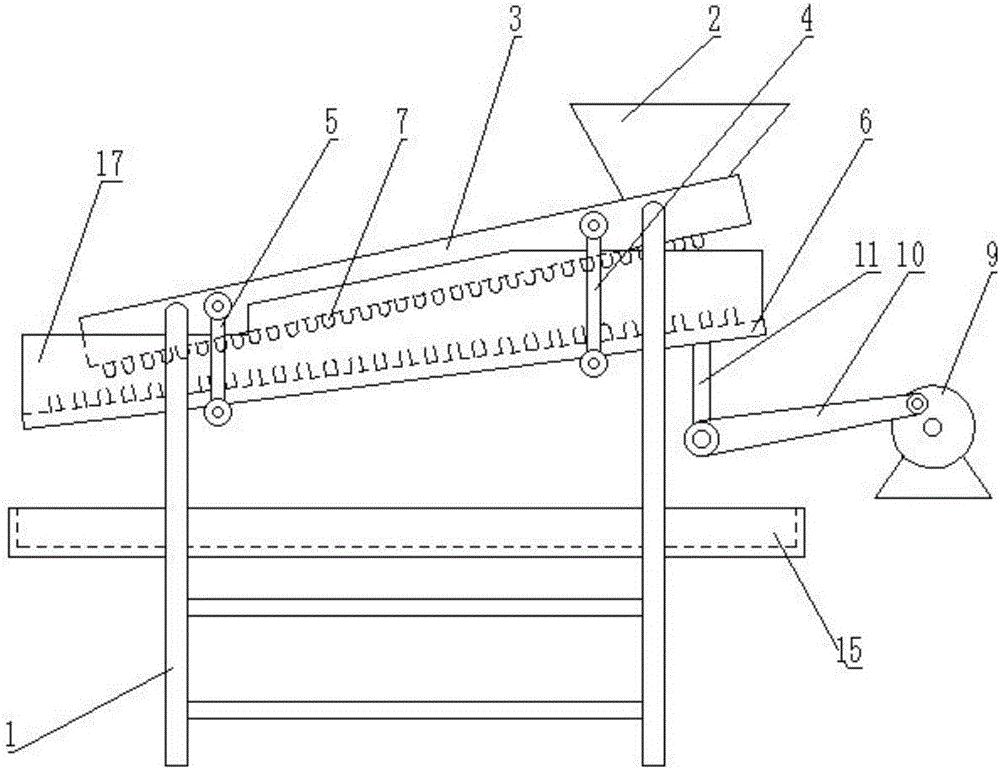

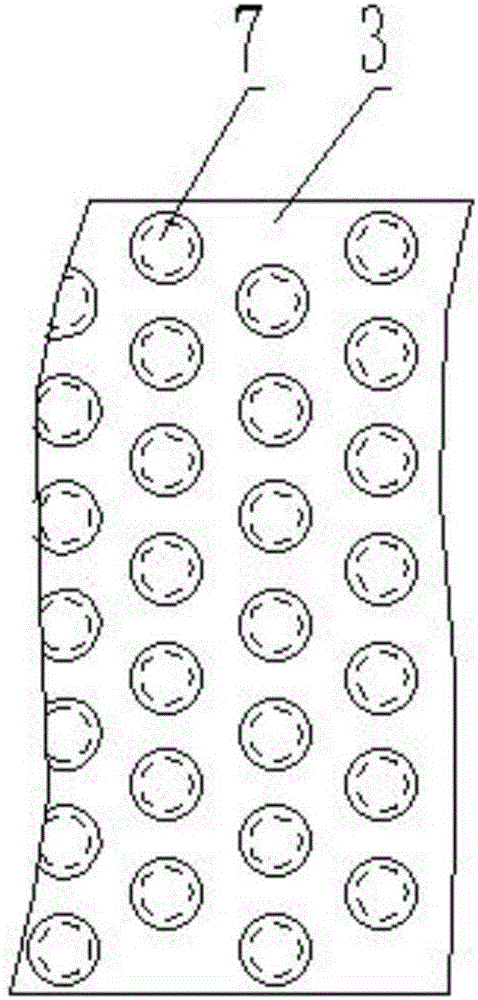

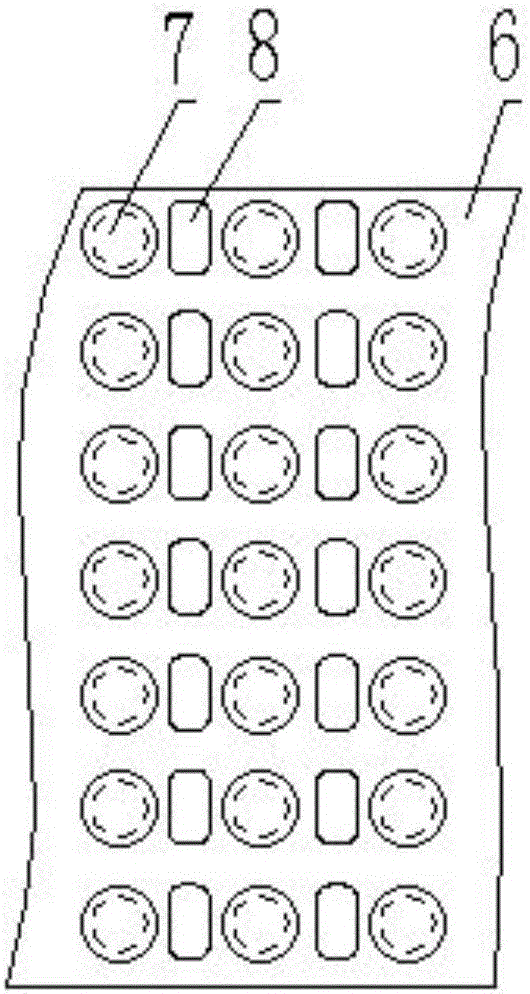

[0021] like Figure 1-4 Shown, a kind of peanut peeling machine comprises frame 1, feeding hopper 2, shelling mechanism and driving mechanism, and described shelling mechanism comprises the upper jaw plate 3 that is fixedly installed on the frame, and through long articulated rod 4 and The short hinge rod 5 is hingedly installed on the lower jaw plate 6 below the upper jaw plate 3, the angle between the upper jaw plate 3 and the horizontal line is 6-10°, the angle between the lower jaw plate 6 and the horizontal line is 2-4°, the lower surface of the upper jaw plate 3 and the upper surface of the lower jaw plate 6 are provided with a plurality of rows of evenly spaced raised shelling units 7; the feeding hopper 2 is installed on the upper jaw plate 3, and the lower part of the outlet below the feeding hopper 2 is facing the lower jaw plate 6, so The lower jaw plate 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com