Automatic cleaning device and cleaning method thereof

A technology of automatic cleaning and cleaning liquid, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as difficult cleaning of equipment, time-consuming and labor-intensive cleaning work, and the impact of aerosols, etc., to achieve reduction Effect of small impact, high cleaning efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

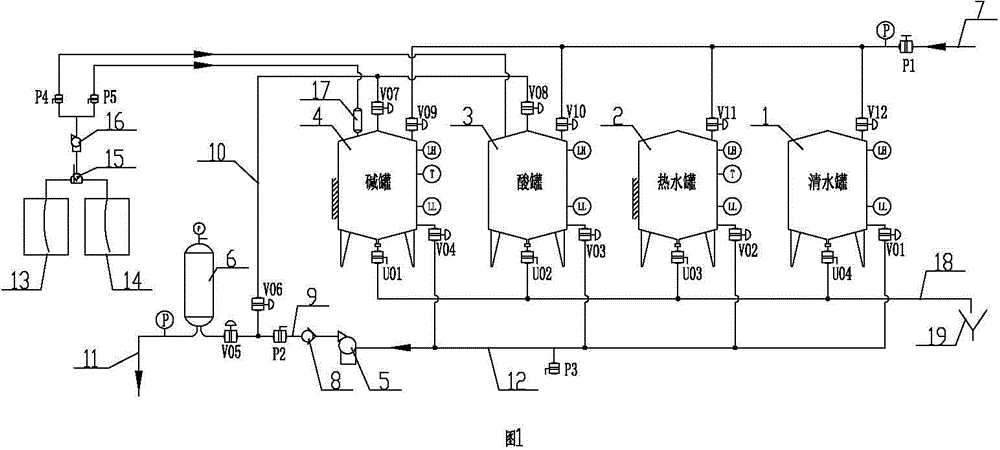

[0041] Example 1: as attached figure 1 As shown, the automatic cleaning device includes a clean water tank 1, a hot water tank 2, an acid tank 3, an alkali tank 4, a cleaning liquid pump 5, a cleaning liquid filter 6 and an electric control box; The upper parts of the tank 3 and the alkali tank 4 are respectively provided with pneumatic water inlet valves, and the water inlets of each pneumatic water inlet valve are respectively connected with the water inlet pipe 7 with the water inlet manual valve P1; the clean water tank 1, the hot water tank 2, the acid tank 3. The lower end of the alkali tank 4 is respectively provided with a manual blowdown valve; the acid tank 3 and the alkali tank 4 are installed with an acid-base adding device, the upper part of the alkali tank 4 is installed with a pneumatic mixed alkali circulation valve V07, and the upper part of the acid tank 3 is installed with a pneumatic mixed acid Circulation valve V08; the lower parts of the clean water ta...

Embodiment 2

[0048] Example 2: as attached figure 1 As shown, one of the cleaning methods using the above-mentioned automatic cleaning device is carried out according to the following steps:

[0049] The first step, after opening the water inlet manual valve P1, automatically open the hot water tank pneumatic water inlet valve V11, the clean water tank pneumatic water inlet valve V12, the alkali tank pneumatic water inlet valve V09 and the acid tank pneumatic water inlet valve V10, to the clean water tank. 1. Add water to hot water tank 2, acid tank 3 and alkali tank 4,

[0050] The acid solution is added to the acid tank 3 by manually opening the three-way ball valve 15, the acid-base adding pump 16 and the acid-adding manual butterfly valve P4, and the pneumatic acid supply valve V03, the circulation pipe pneumatic valve V06 and the pneumatic mixed acid circulation valve V08 are automatically opened, and the Start the cleaning liquid pump 5 to run for 10 minutes to carry out acid...

Embodiment 3

[0060] Embodiment 3: as attached figure 1 As shown, the second cleaning method using the above-mentioned automatic cleaning device is carried out as follows:

[0061] The first step, after opening the water inlet manual valve P1, automatically open the hot water tank pneumatic water inlet valve V11 and the clean water tank pneumatic water inlet valve V12, add water to the clean water tank 1 and the hot water tank 2, and put the water in the hot water tank 2. The water is heated to 80 degrees Celsius to 95 degrees Celsius;

[0062] In the second step, the liquid outlet of the cleaning pipe 11 is communicated with the inner cavity of the equipment to be cleaned;

[0063] The third step, automatically open the pneumatic water supply valve V01 and the connecting pipe pneumatic valve V05, start the cleaning liquid pump 5, manually open the emptying valve of the equipment to be cleaned, and rinse with clean water;

[0064] The fourth step, automatically open the pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com