Patents

Literature

232results about How to "No escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

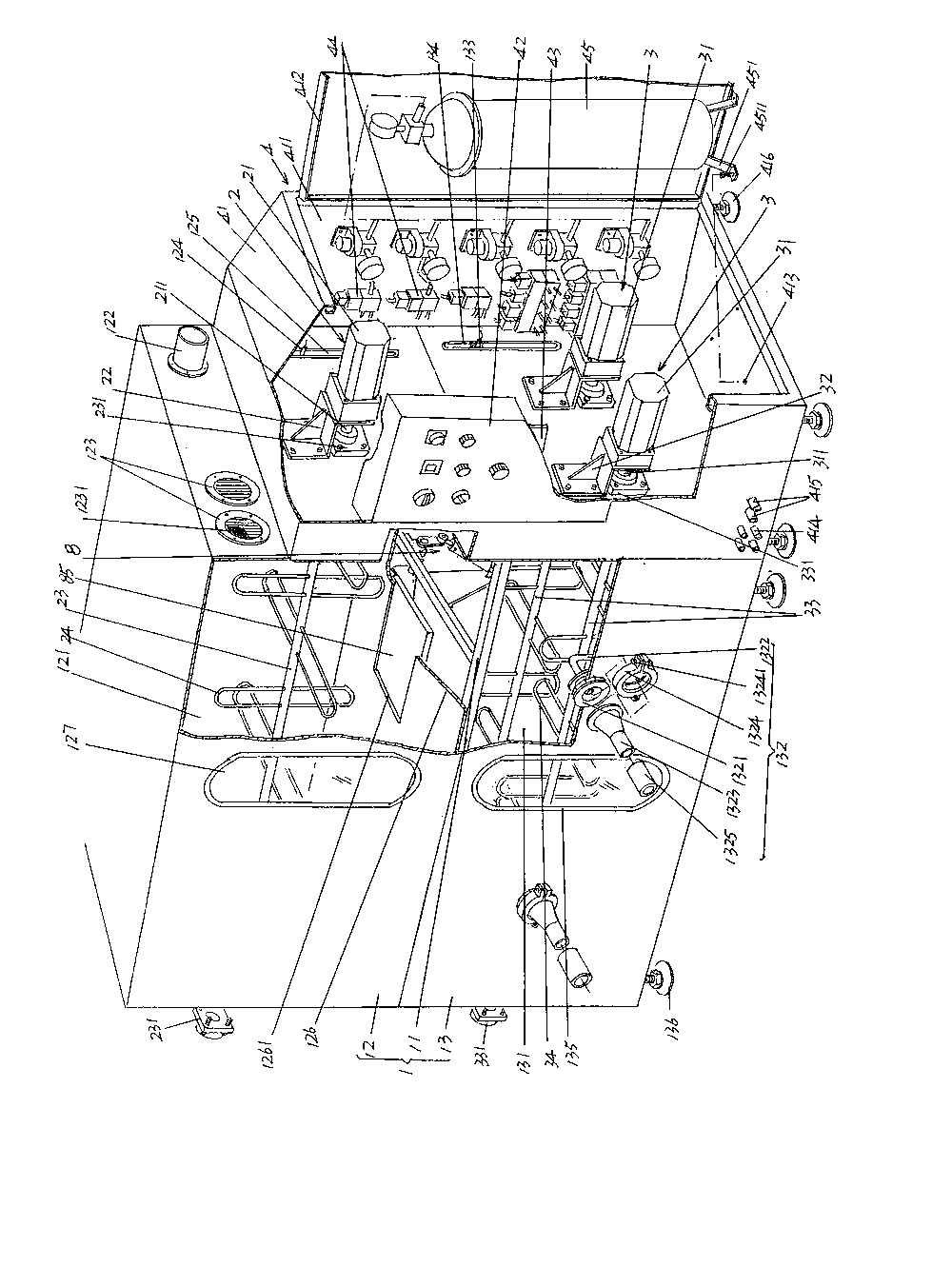

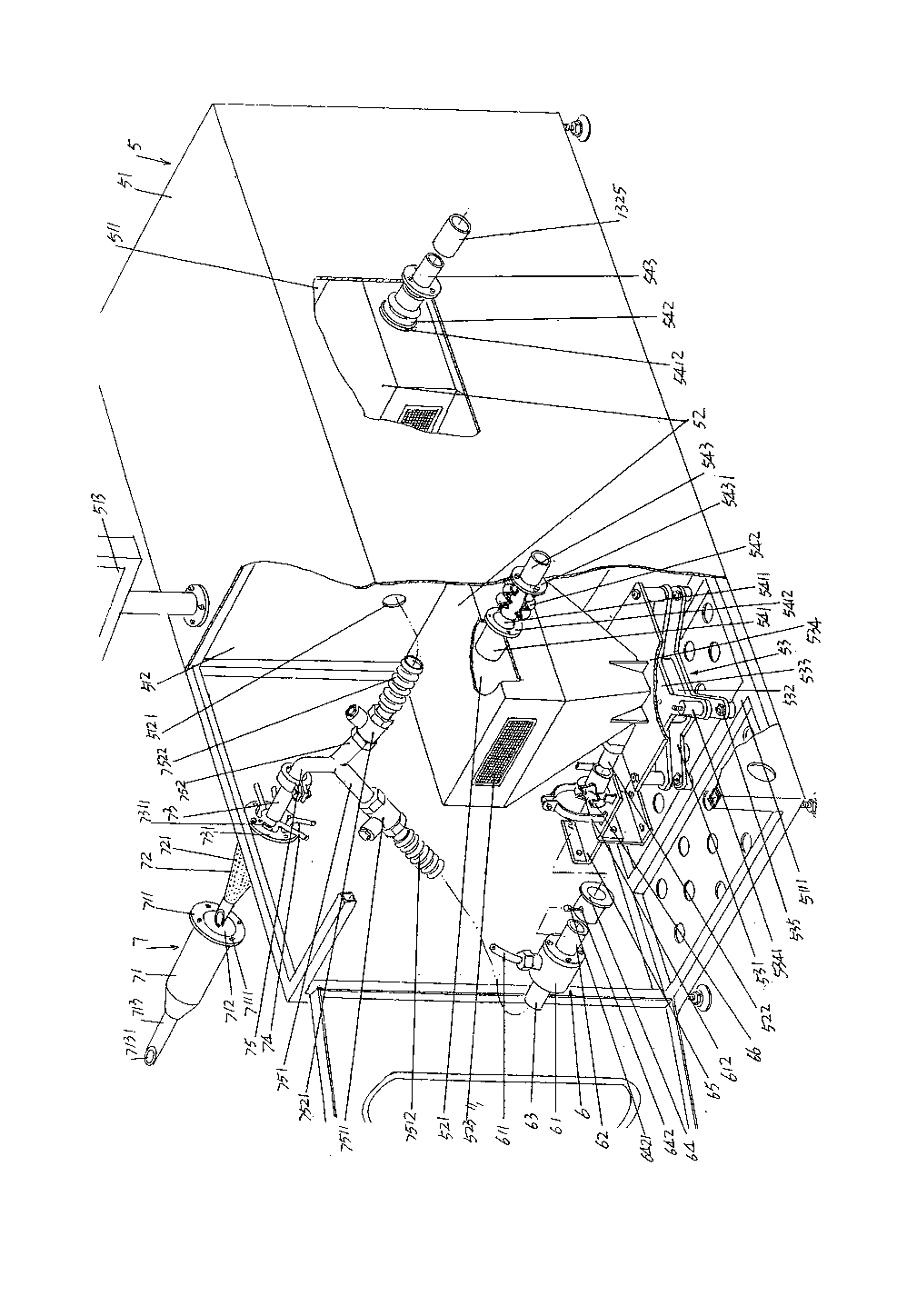

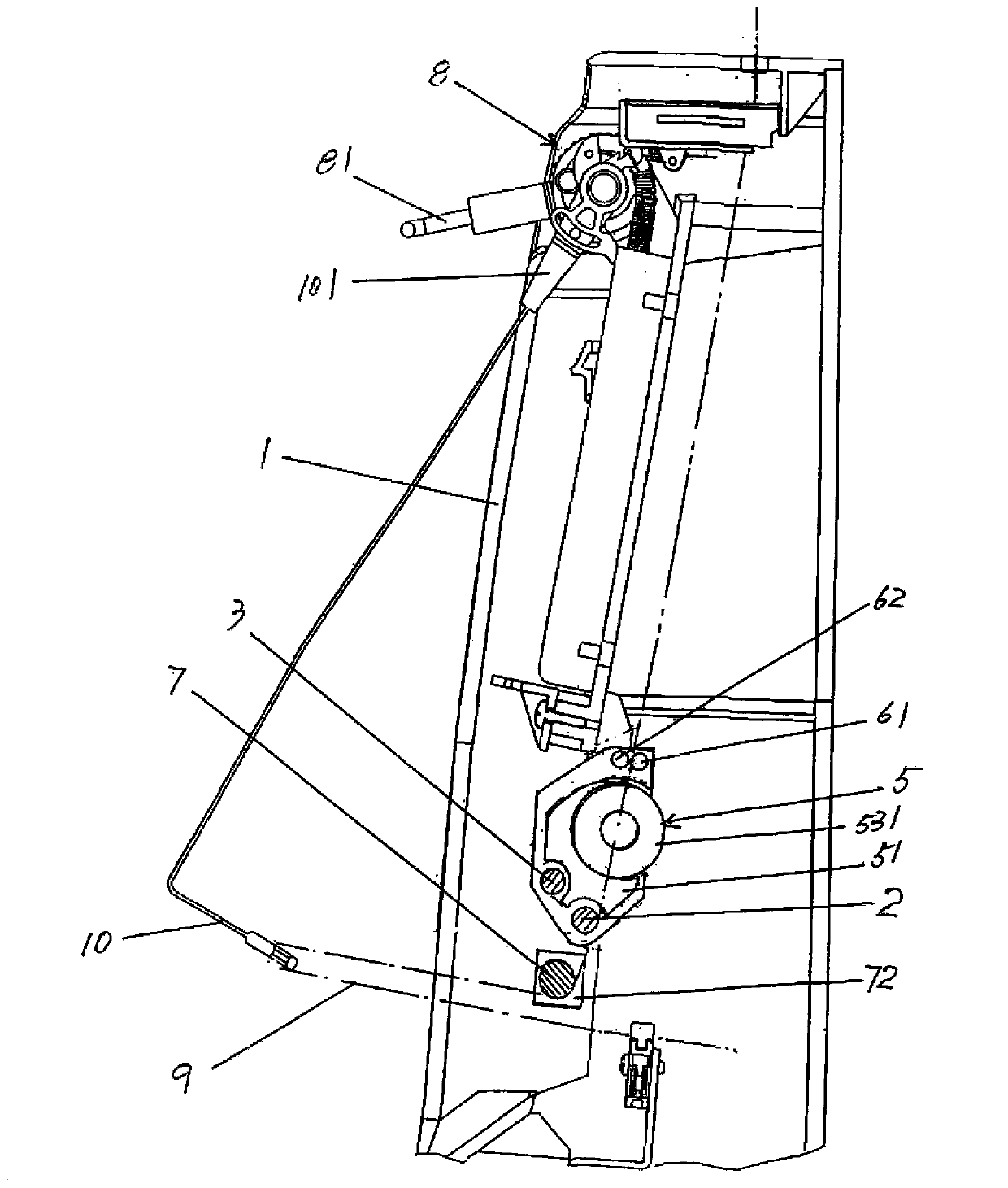

Automatic down filling machine

ActiveCN103101871AReduce escapeNo escapeUpholstery manufactureClothes making applicancesMagnetic valveEngineering

The invention discloses an automatic down filling machine, and belongs to the technical filed of a stowage unit for down and feather filled products. The automatic down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanism, an electrical automatic control mechanism, a pair of weighing metering mechanisms, a pair of down output mechanisms, a pair of down filling heads and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. The first down stirring mechanism is used for stirring down in a down storage box cavity, and the second down stirring mechanism is used for stirring down in a down delivering box cavity. The pair of weighing metering mechanisms is connected with a pair of down leading out connector pipelines on two sides of the down delivering box, the pair of down output mechanisms is connected with the pair of weighing metering mechanisms, the pair of down filling heads is connected with the pair of down output mechanisms in a matched mode, and the box cavity channel start-and-stop mechanism is placed on the box frame. The electrical automatic control mechanism is provided with an electrical box body, a control panel, a programmable controller, a group of magnetic valves and a high-pressure air storage tank. The automatic down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, showing good down filling efficiency, reducing operation intensity of workers, eradicating down wasting and showing good automatic control effect.

Owner:苏州比阳特服装设备有限公司

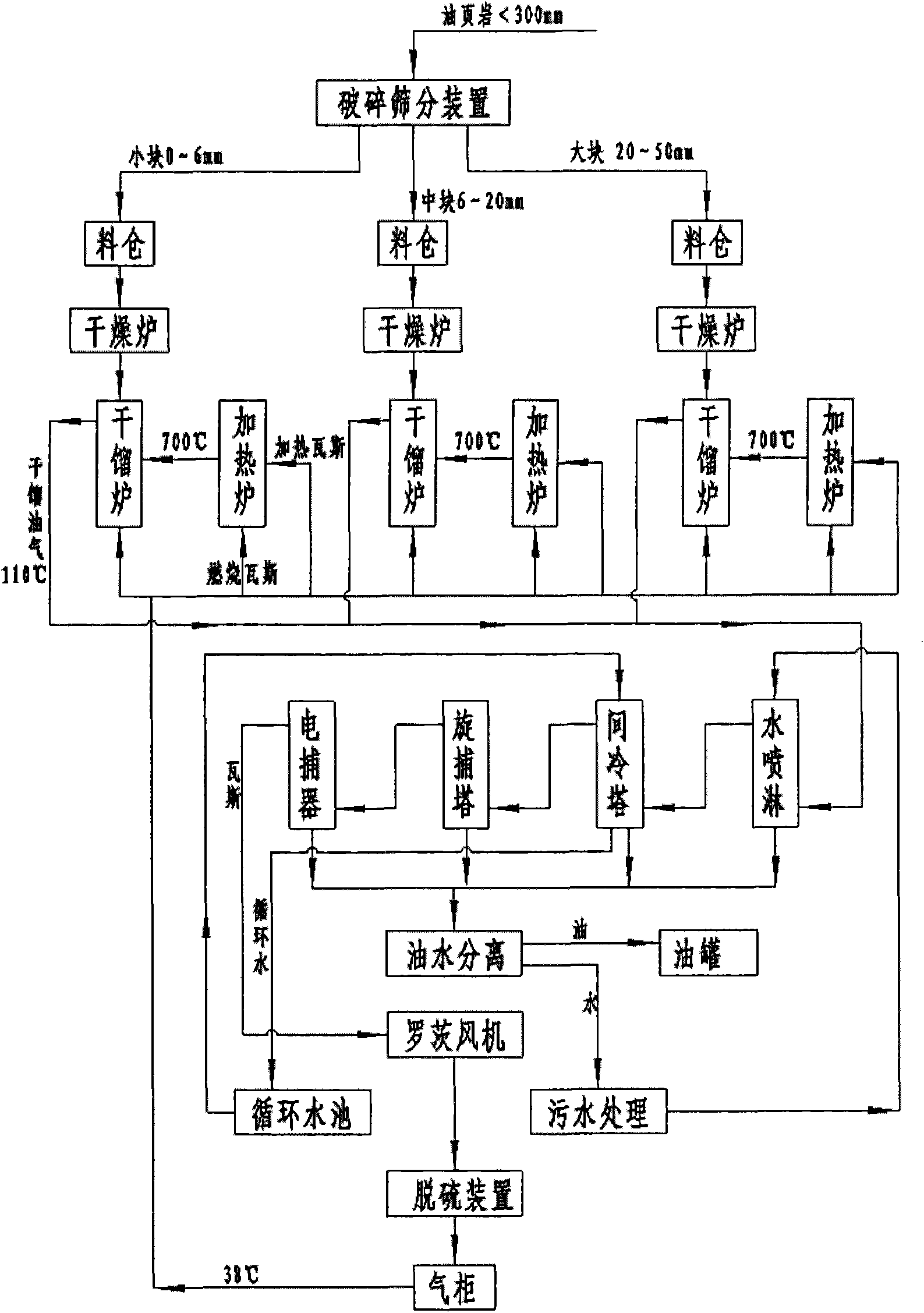

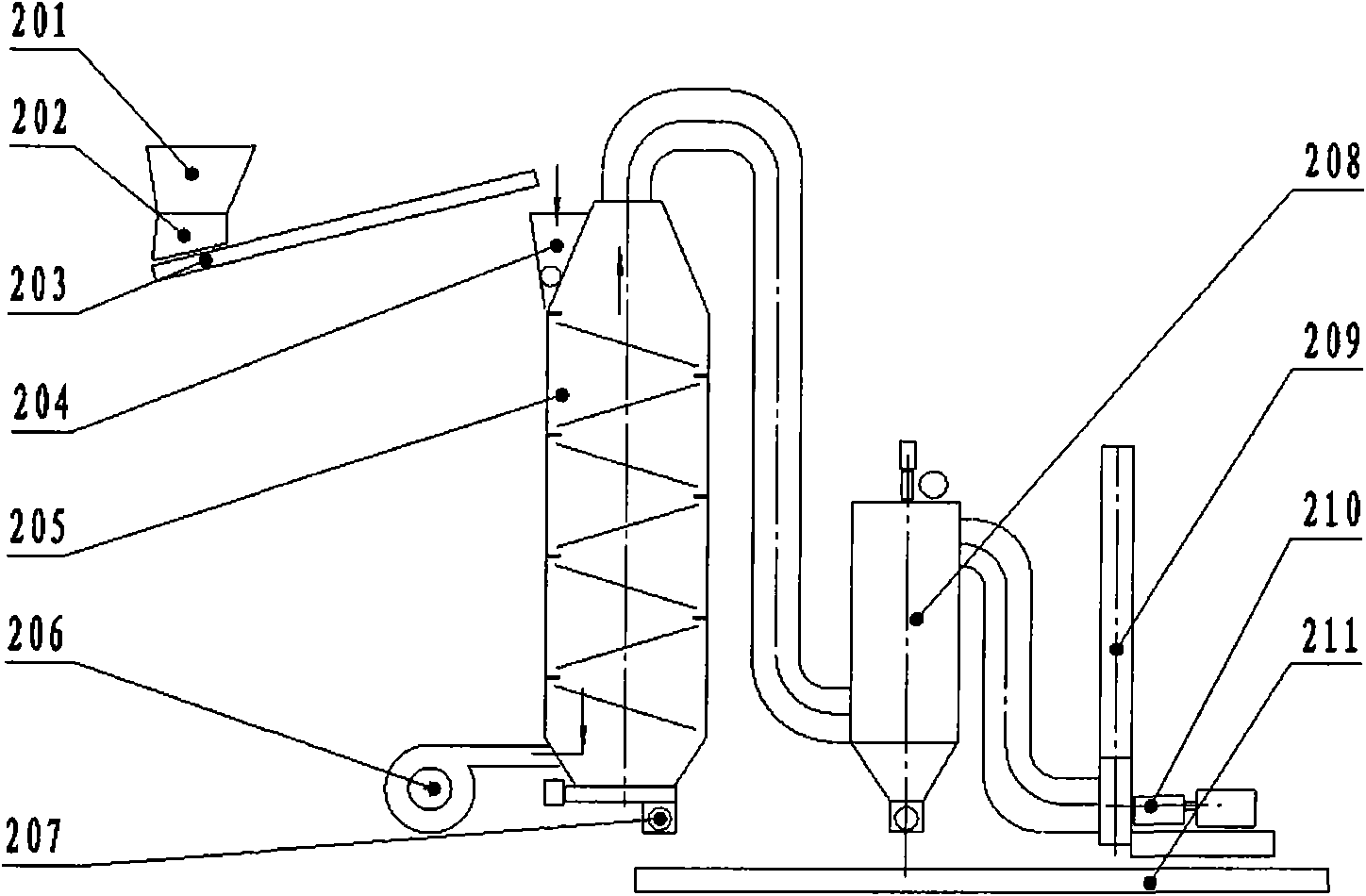

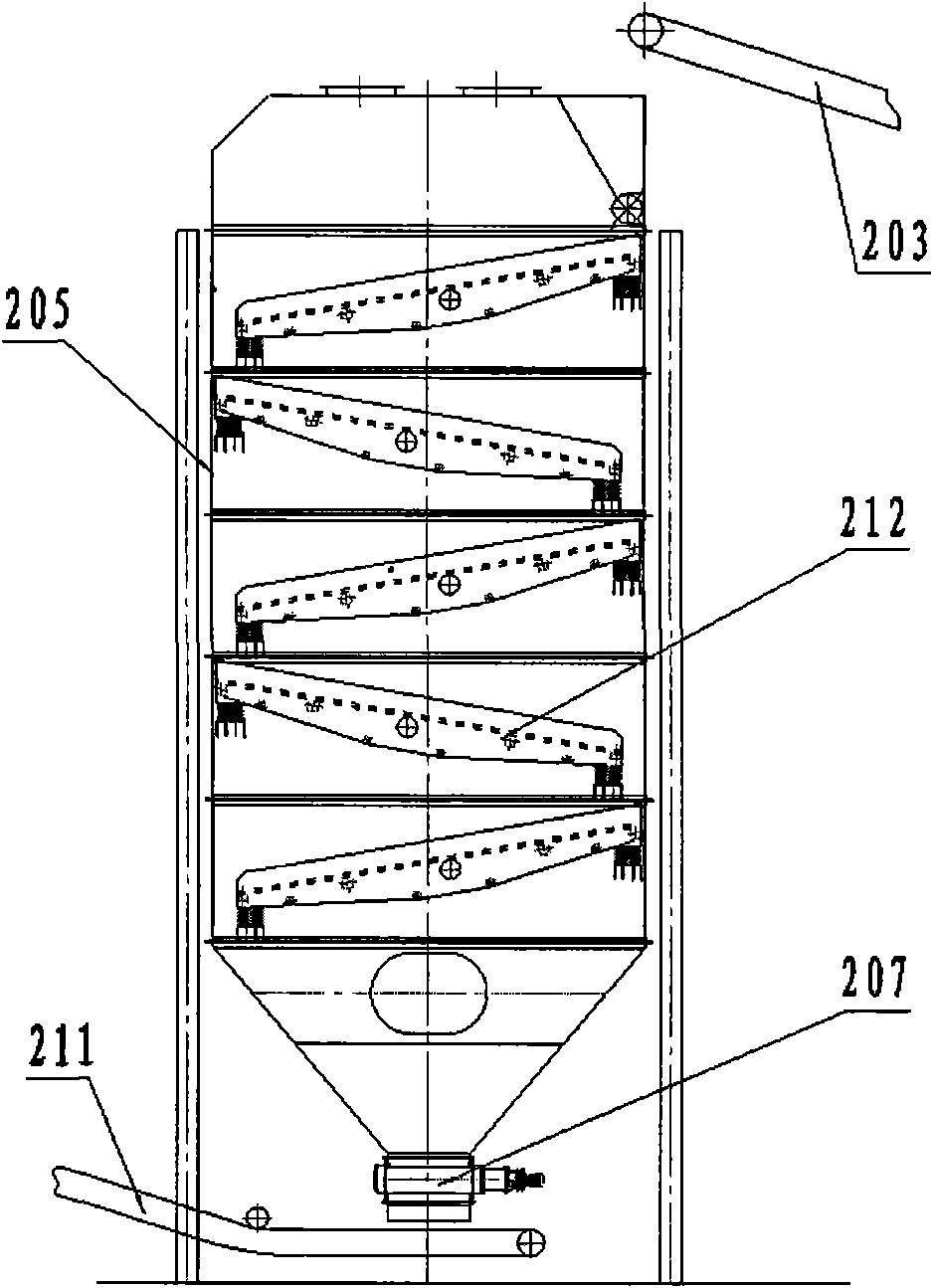

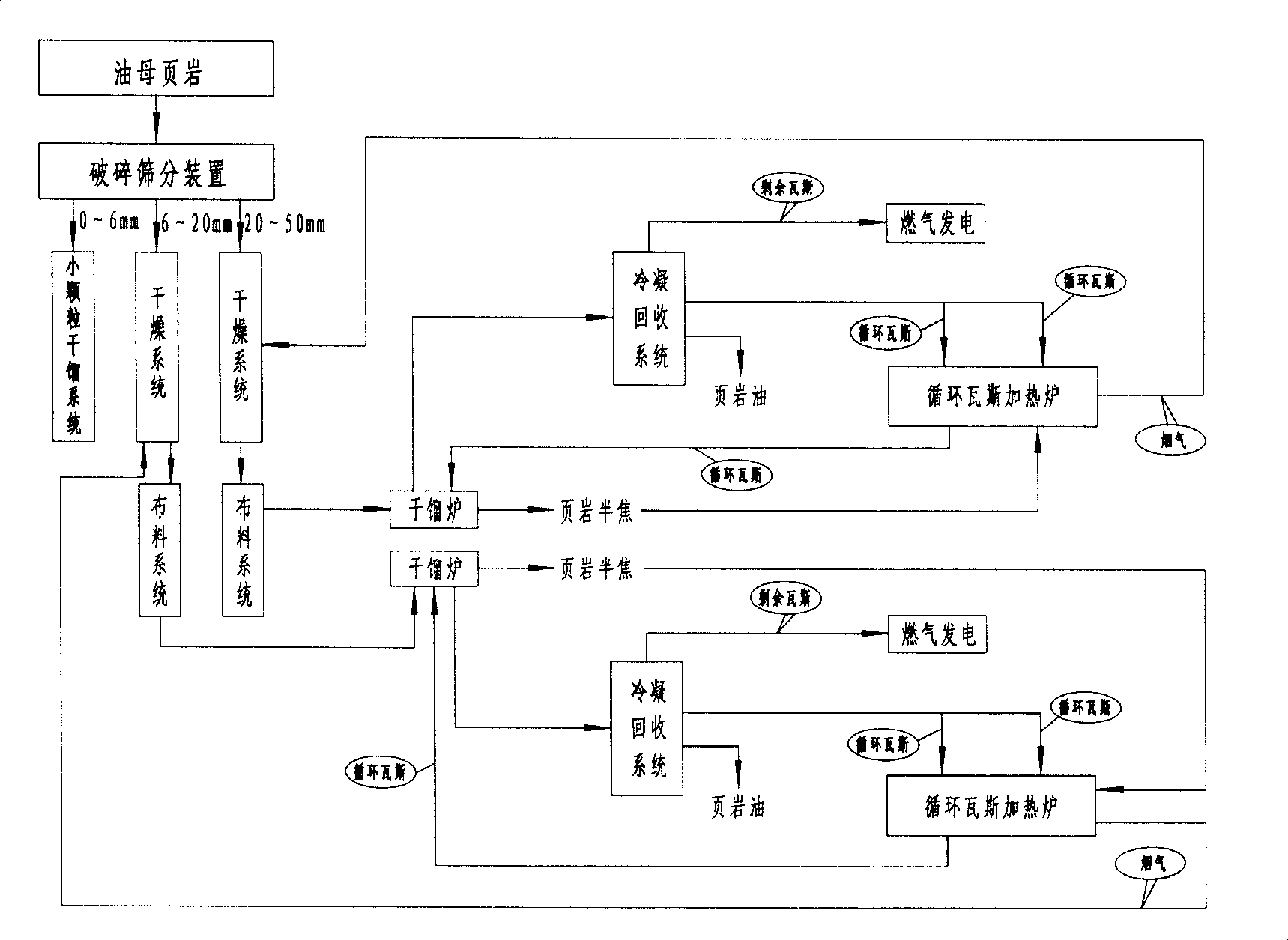

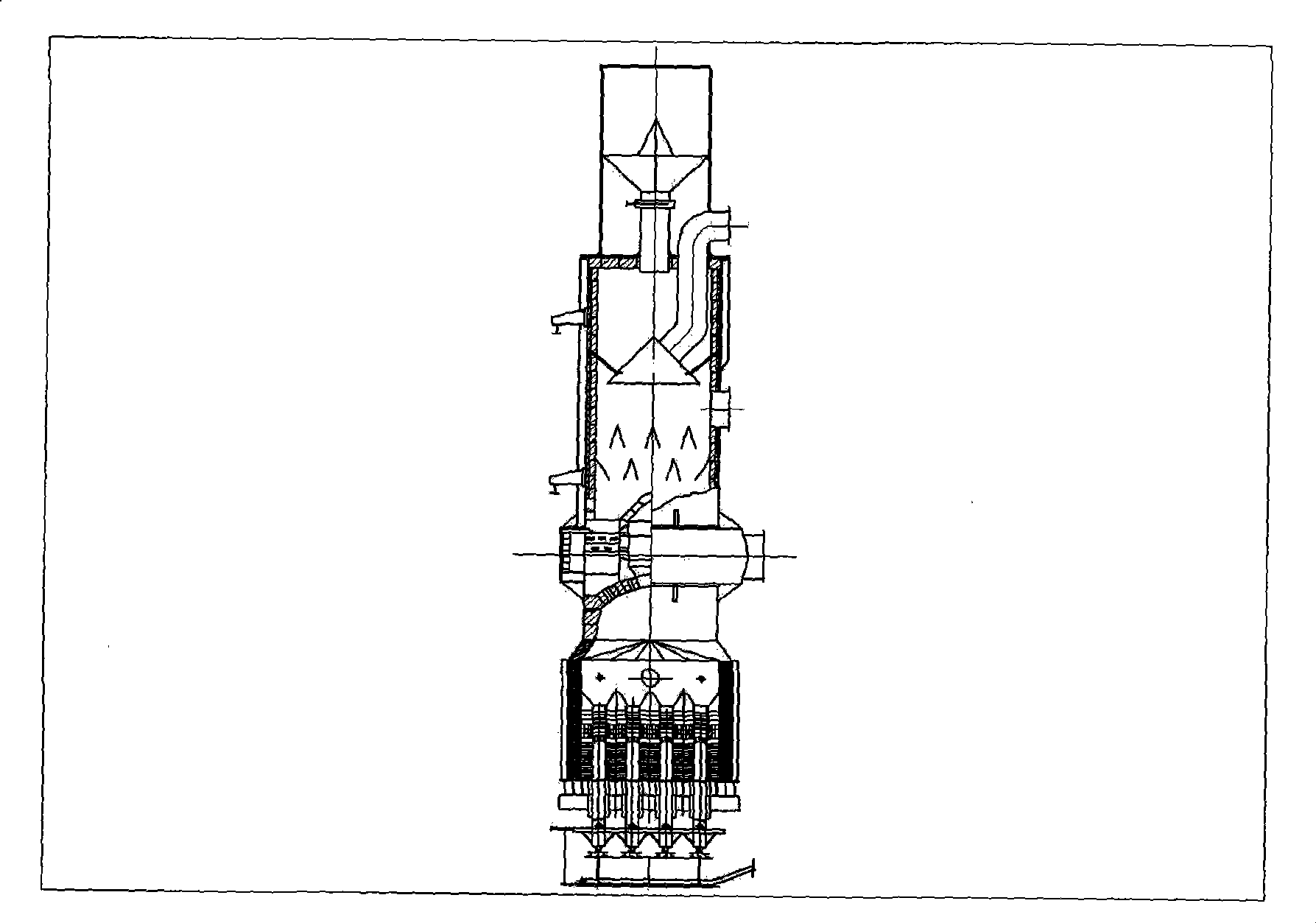

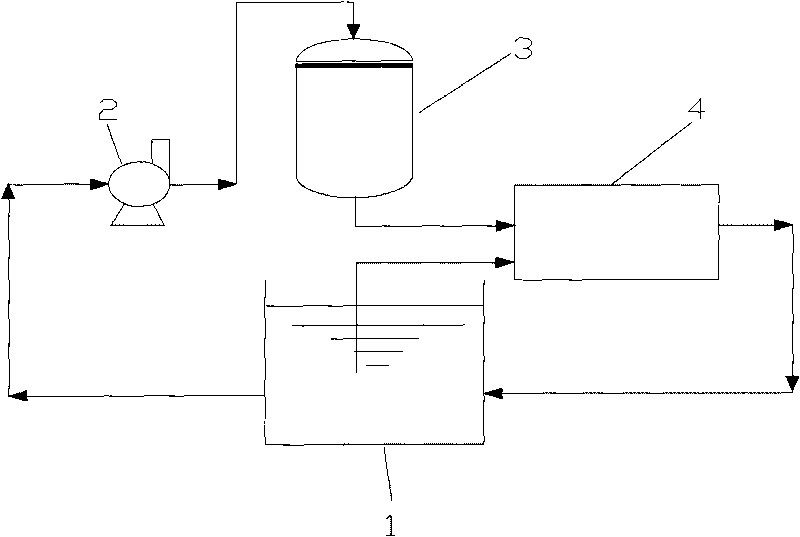

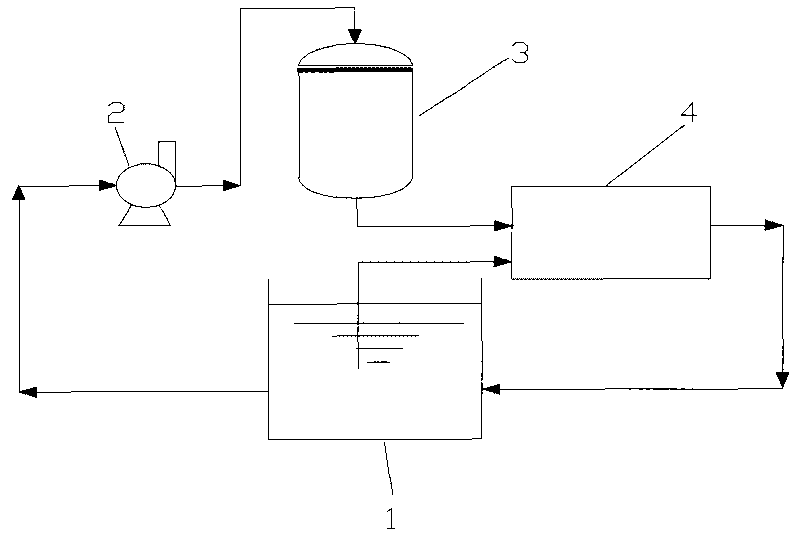

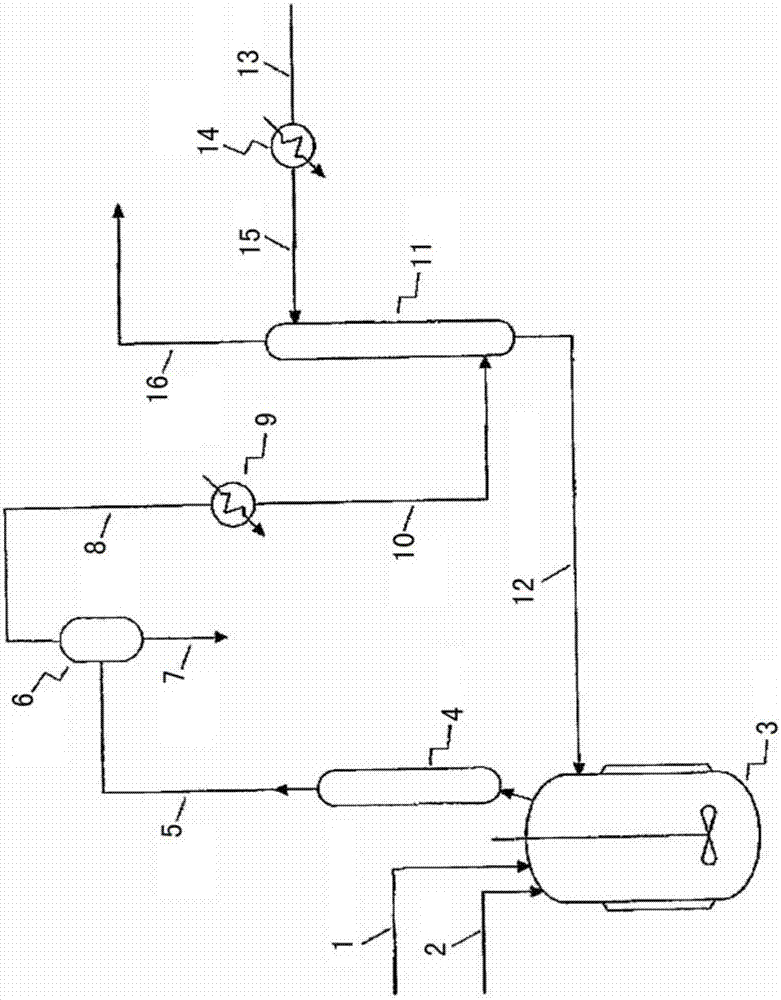

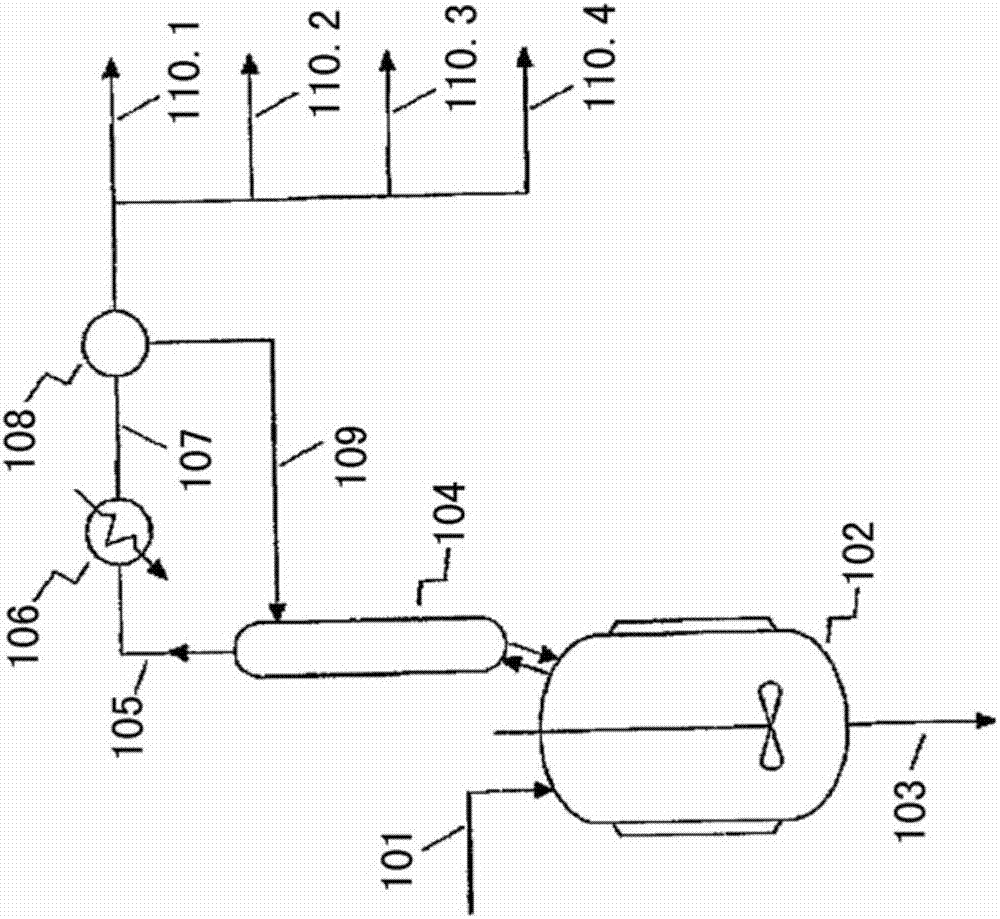

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

Maintenance method for alkaline non-cyanide plating copper

The invention discloses a maintaining method for an alkalescent non-cyanide cuprodine. The method uses indissoluble anode, cathode in the alkalescent non-cyanide cuprodine liquor as the galvanized workpiece, adds cupric salt, complexing agents and additives and adjusts the pH value of the galvanizing liquor to control the current dense range between 0.1-7A / dm2; the galvanizing time is between 1min to 72h; then the galvanizing liquor is filtered; the galvanizing liquor is processed air bend or moves the workpiece while galvanizing. The invention uses the indissoluble anode comprising stainless steel, DSA coating, titanium, platinum, graphite which is simple to use, innoxious, harmless; the invention has a low production cost and even, smooth and shining fine galvanizing layer by using the indissoluble anode. The technique maintaining method of the invention has a simple operation, great stability of galvanizing liquor and convenient maintenance for the galvanizing liquor.

Owner:广州市二轻研究所股份有限公司

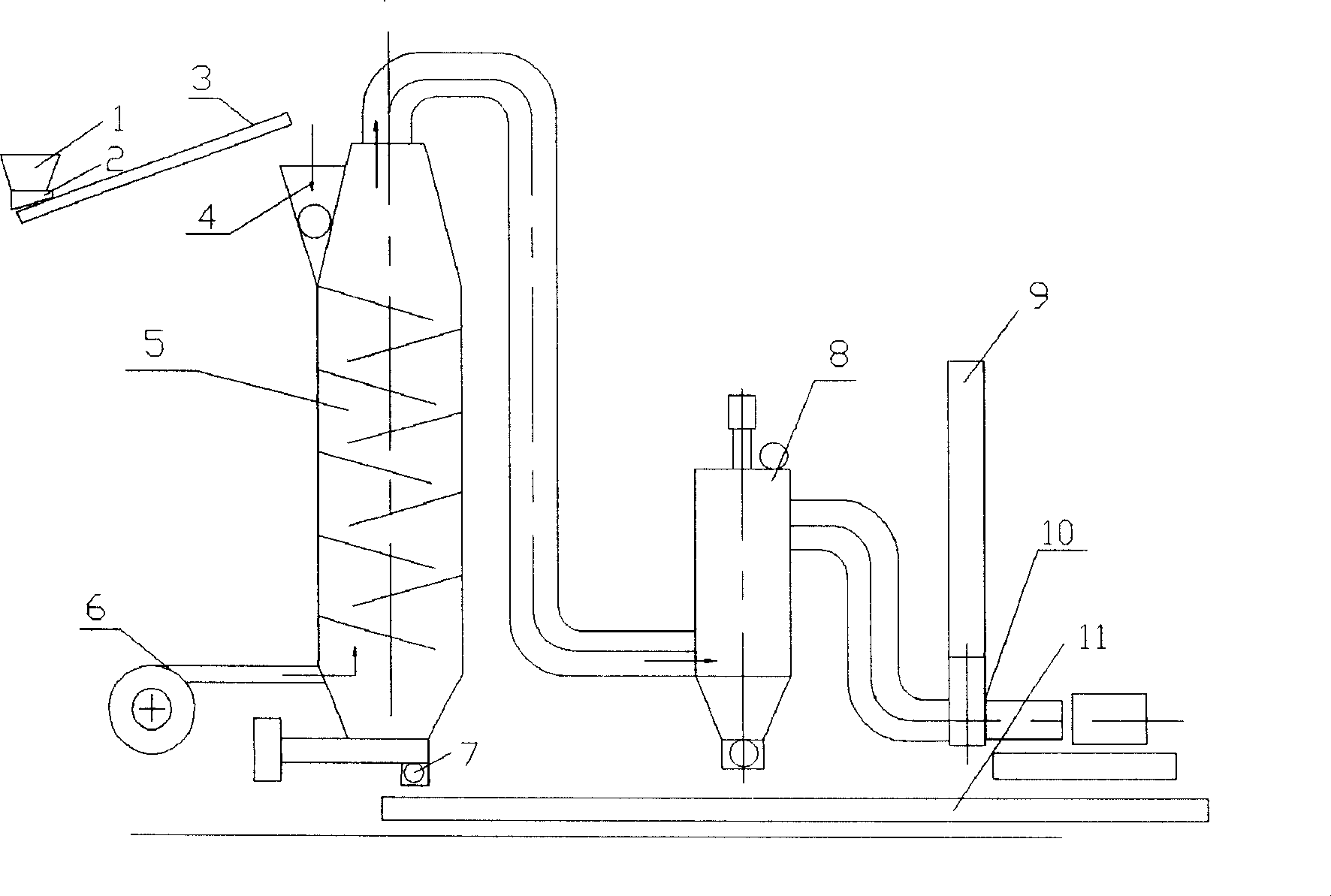

Gas full-circulation oil-shale grading dry distillation technique and apparatus

InactiveCN101381609AHigh recovery rateNo emissionsSpecial form destructive distillationElectricityCooling tower

The invention relates to a process for carrying out fractionation to oil shale by utilizing gas as a thermal carrier under the condition of whole circulation. The oil shale is divided into three classes with different specifications: 0 to 6 millimeters, 6 to 20 millimeters and 20 to 50 millimeters; and the oil shale enters different carbonization furnaces for carbonization. The daily handling capacity of each set of the carbonization furnace is 1,000 tons. The oil shale is crushed and sifted, is dried and heated to the temperature of over 50 DEG C by smoke gas and enters the carbonization furnaces with different specifications for carbonization. The inside of the carbonization furnace is provided with feed distribution perforated wall which is matched with the particle size of the oil shale and a gas distribution structure. Thermal circulating gas is heated to the temperature of 700 DEG C in a heating furnace and is evenly and continuously transported to the middle part of the carbonization furnaces. Cold circulating gas enters from the lower part of the carbonization furnaces; carbonized carbocoal is cooled to the temperature of 250 DEG C, is discharged to a water-sealed carbocoal pool, is cooled to the temperature of 80 DEG C and is discharged to the outside of the furnace. One part of the carbocoal is transported to the heating furnace, is mixed with the gas for combustion; and one part of the carbocoal is transported to a power plant as a fuel. Carbonized oil gas passes through a cooling tower and is subjected to oil collection by an electric catcher and performs oil-gas-water separation; oil enters a storage tank; and water enters a circulating water pool. One part of the gas is used as the thermal carrier and is circularly used. One part of the gas is used as the fuel for the heating furnace; and one part of the gas is used as fuel gas for power generation. The theoretical oil yield of the process can reach over 90 percent.

Owner:辽宁成大能源科技有限公司 +1

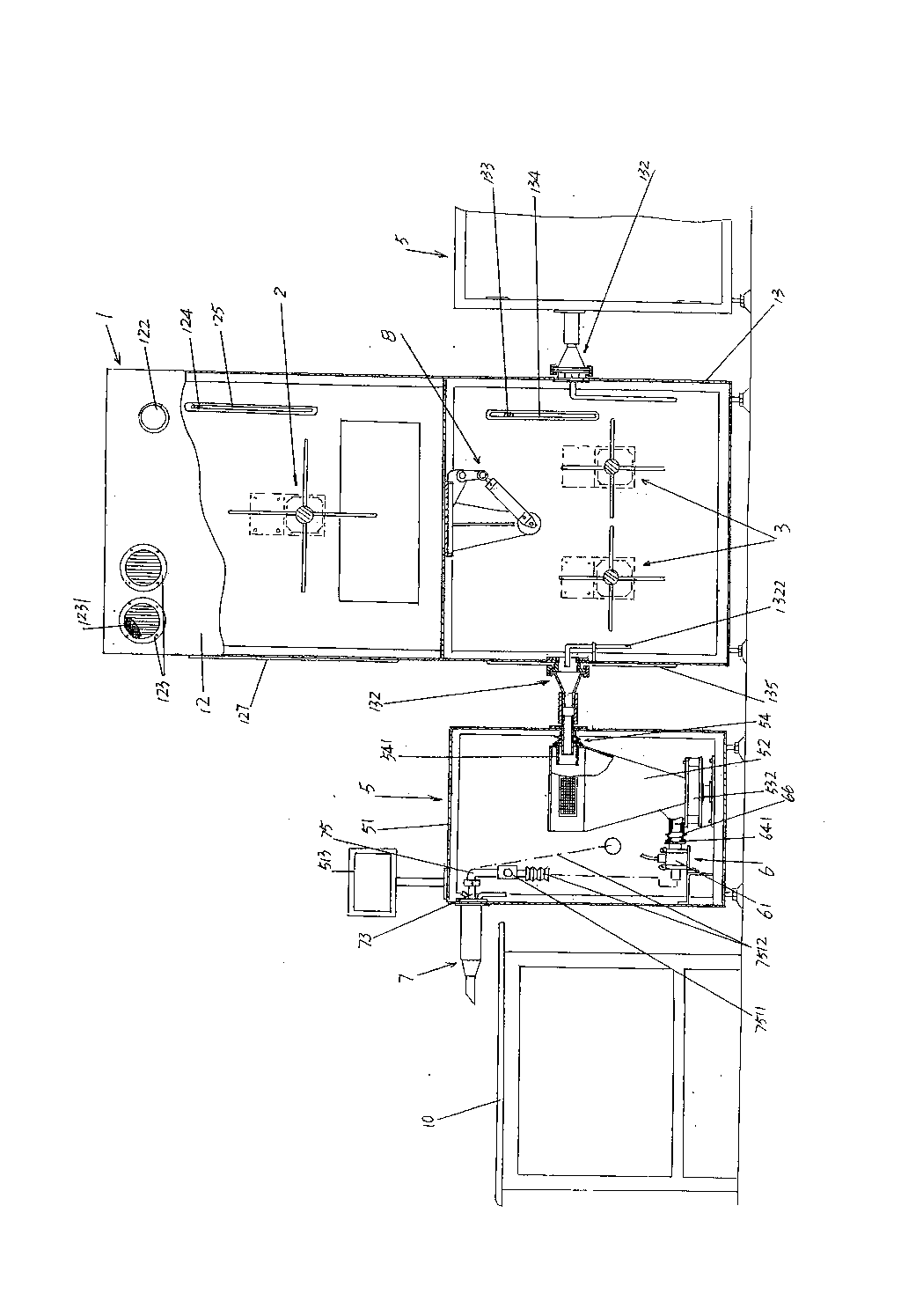

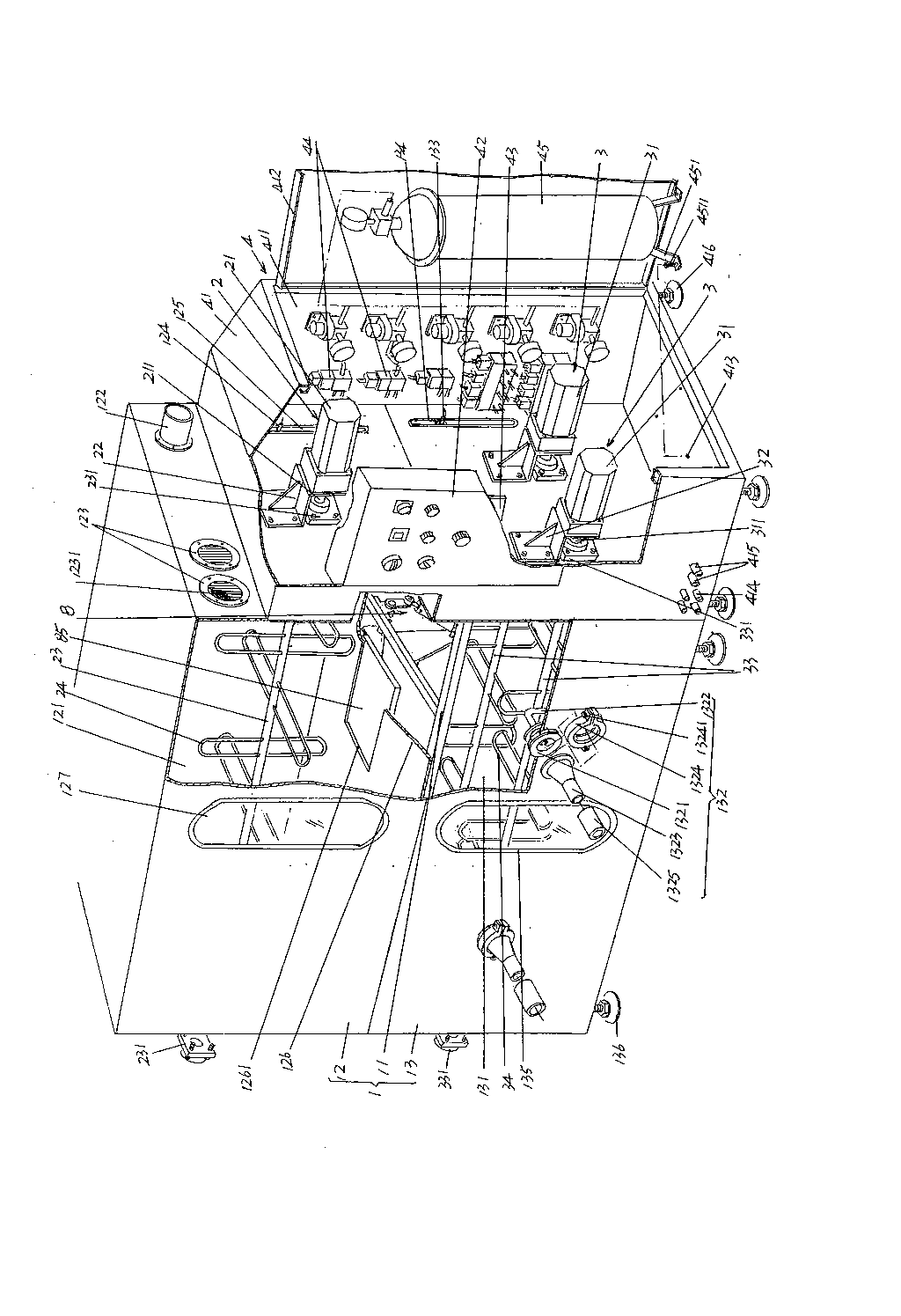

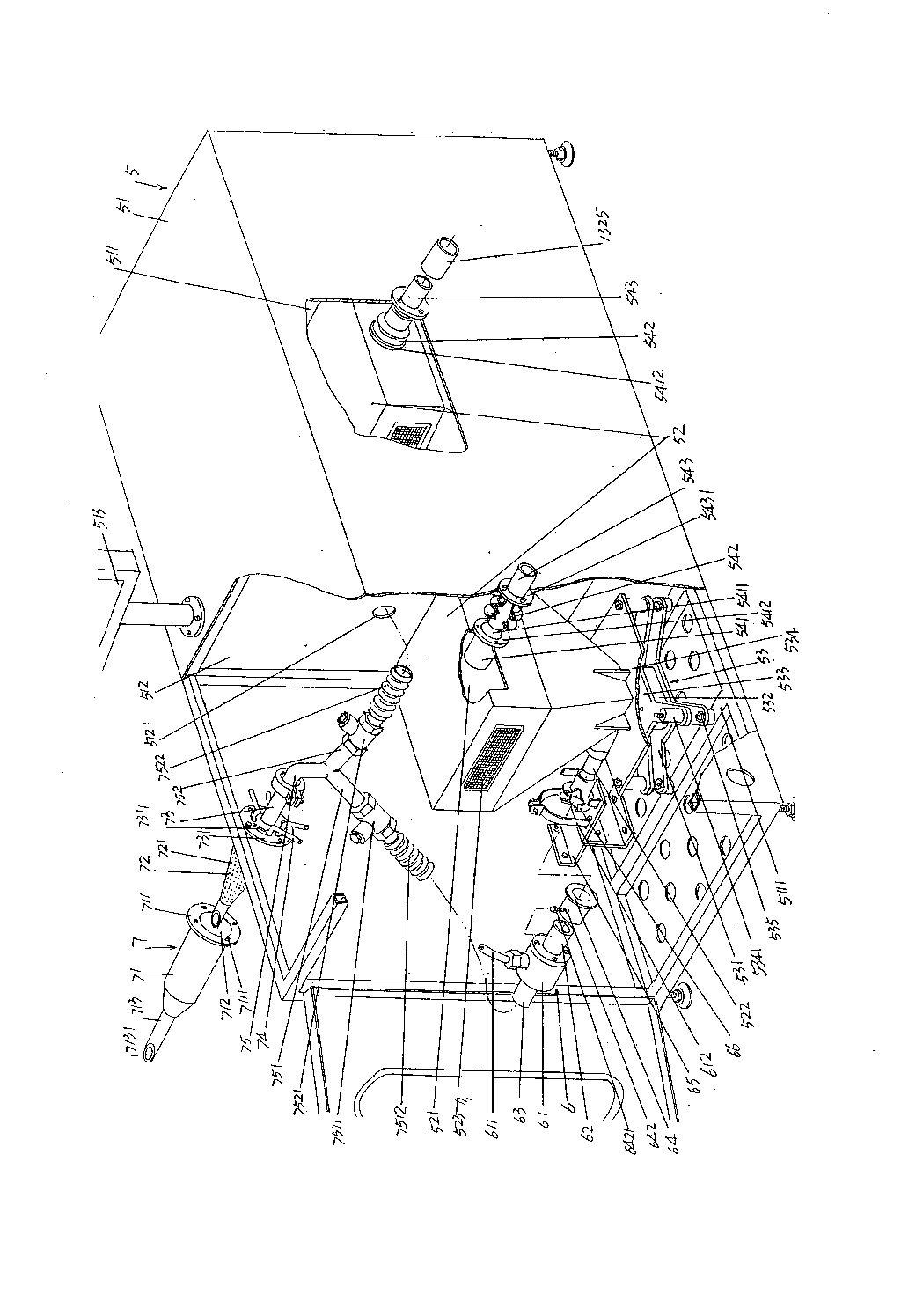

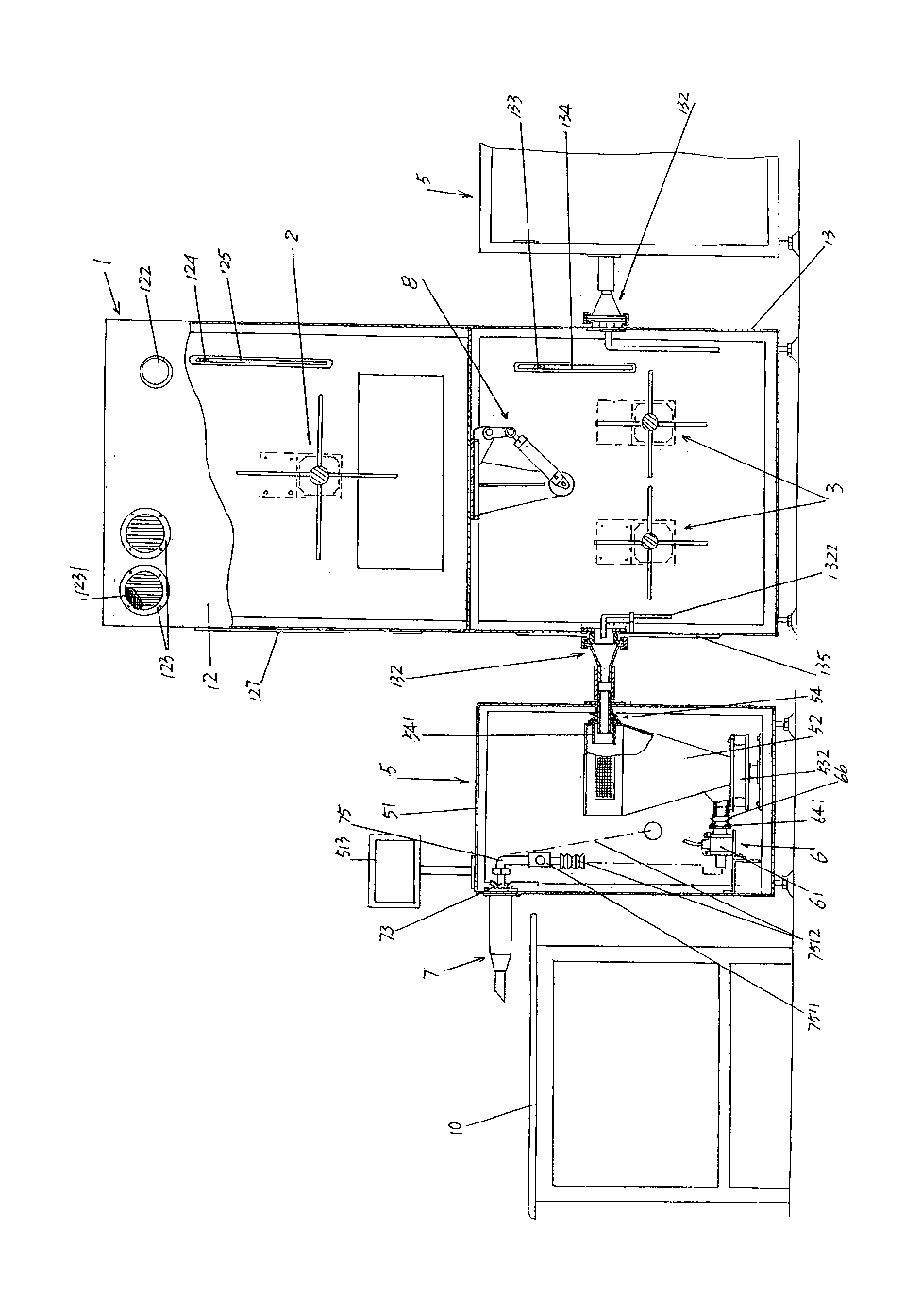

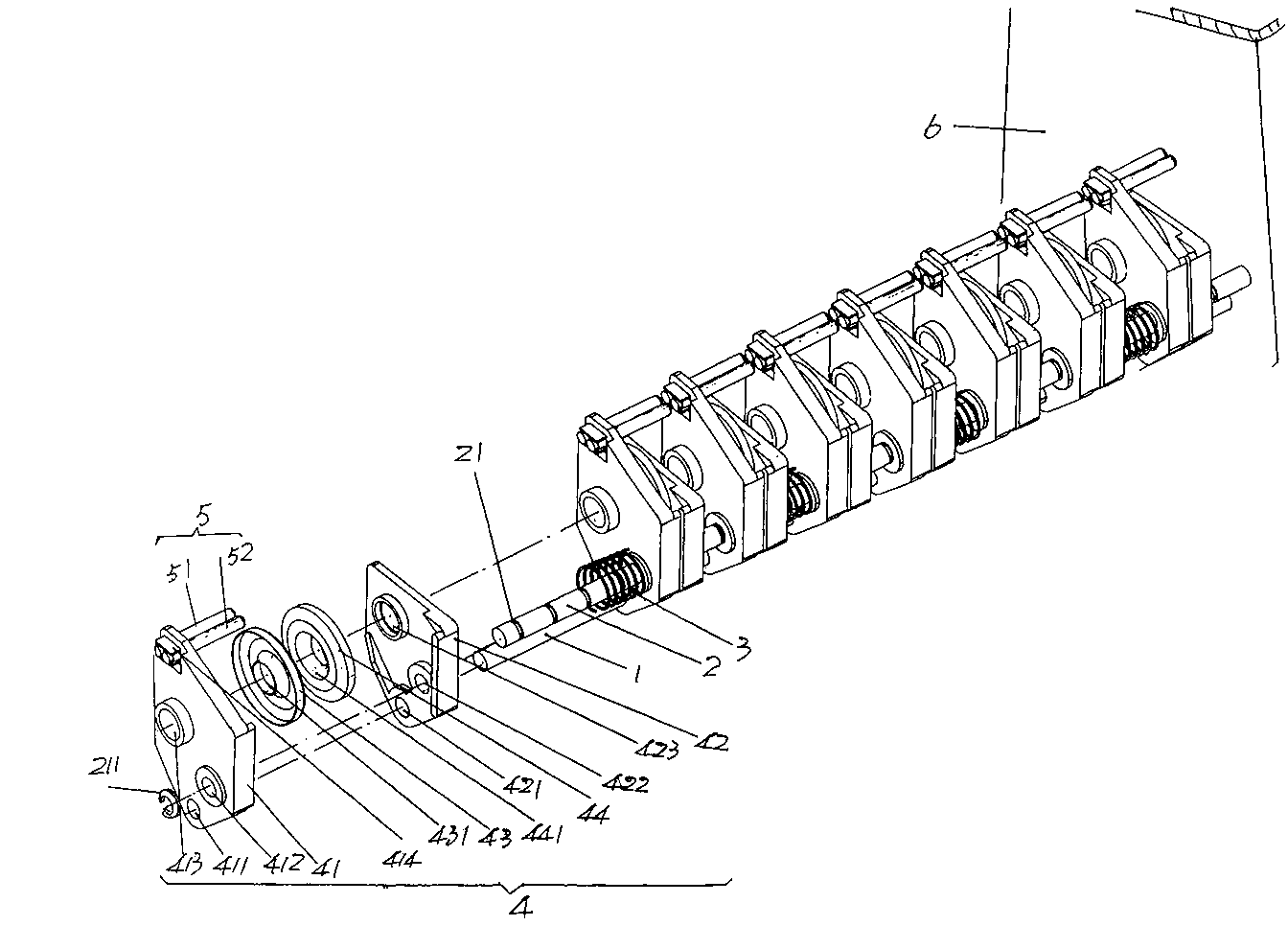

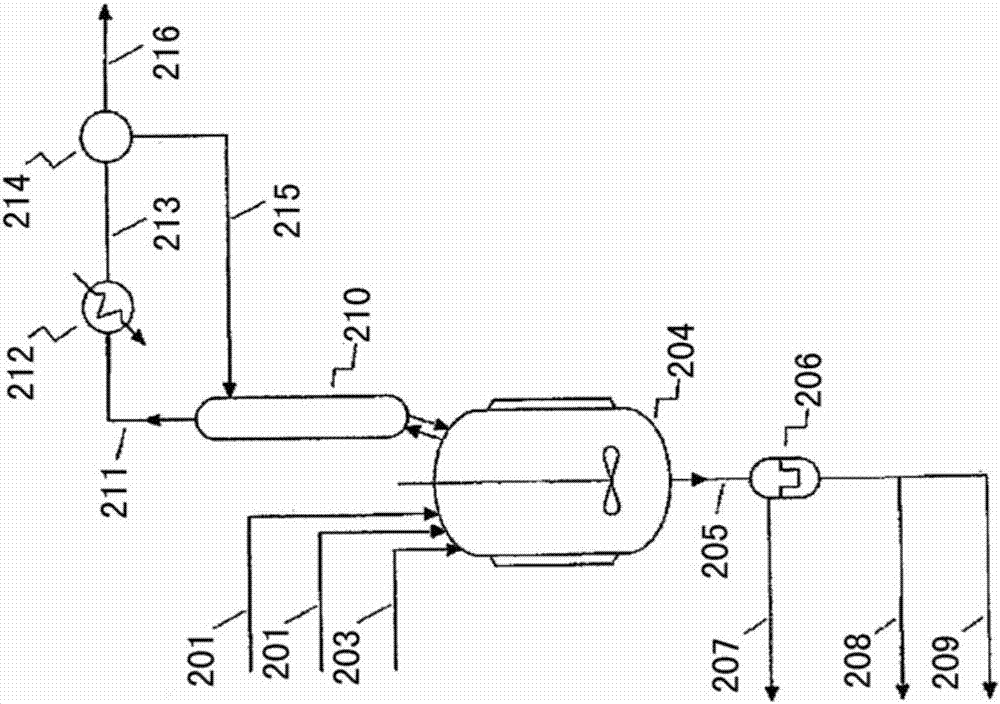

Automatically quantitative down filling machine

ActiveCN103101873AQuantity GuaranteeGuaranteed cleanlinessUpholstery manufactureClothes making applicancesAutomatic controlClean environment

The invention discloses an automatically quantitative down filling machine, and belongs to the technical field of stowage equipment for down and feather filled products. The automatically quantitative down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanisms, an electrical automatic control mechanism, a weighing metering mechanism, a down output mechanism, a down filling head and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. A down lead-in connector, an air window and a down storage quantity signal collector are placed on the down storage box in a matched mode, and a down lead-out connector and a down quantity signal collector are placed on the down delivering box in a matched mode. The first stirring mechanism is used for stirring down inside a down storage box cavity, and the second stirring mechanism is used for stirring down inside a down delivering box cavity. The electrical automatic control mechanism is placed on one side of the box body in a matched mode. The weighing metering mechanism is connected with a down lead-out connector pipeline of the down delivering box, the down output mechanism is connected with the weighing metering mechanism, the down filling head is connected with the down output mechanism in a matched mode, and the box cavity channel start-and-stop mechanism is matched with a bottom plate of the down storage box. The automatically quantitative down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, being good in down filling efficiency and light in operation intensity, guaranteeing a clean environment of operation site and eradicating down wasting.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

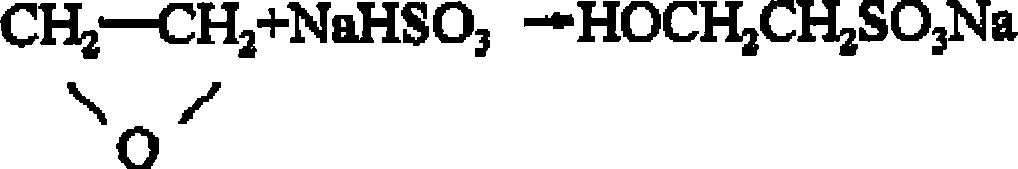

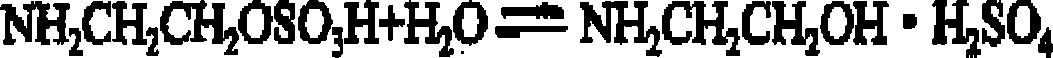

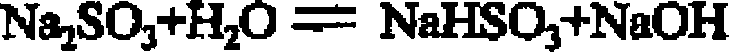

Method for synthesizing taurine

InactiveCN101100449ANo escapeImprove economySulfonic acid preparationTaurine synthesisChemical synthesis

Synthesis of taurine is carried out by: reducing esterified product of cholamine with ammonium sulfite as reducer, separating to generate crude product, and re-crystallizing to obtain final product. It's economical, has no SO2 gas discharge and has friendly production environment and can separate out taurine and sulfate at low temperature.

Owner:JIANGSU YUANYANG PHARMA

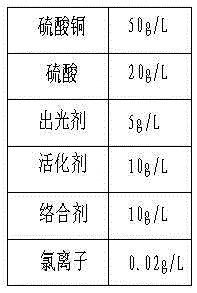

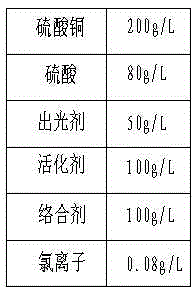

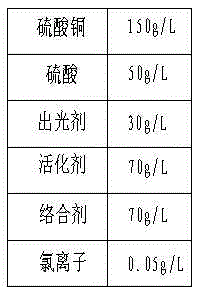

Copper plating liquid and process for direct cyanide-free acid copper plating on steel substrate

The invention relates to a copper plating liquid and process for direct cyanide-free acid copper plating on a steel substrate, belonging to the technical field of copper plating. The copper plating liquid comprises copper sulphate, sulfuric acid, deionized water, chloride ion, a desmutting agent, an activator and a complexing agent, wherein concentrations of the copper sulphate, the sulfuric acid, the chloride ion, the desmutting agent, the activator and the complexing agent are 50 to 200 g / L, 20 to 80 g / L, 0.02 to 0.08 g / L, 5 to 50 g / L, 10 to 100 g / L and 10 to 100 g / L, respectively, and the weight of deionized water is 400 to 900 g. Compared with the prior art, the invention has the following advantages: the copper plating liquid can realize direct copper plating on the steel substrate without pre-plating; an obtained plating is fine and shiny and has good bonding strength; after continuous electroplating on a steel band copper plating production line for 10 years, the copper plating liquid can still be normally used; and the copper plating liquid can be used for continuous electroplating of steel bands, steel wires and steel pipes and for rack plating, barrel plating and the like of steel members.

Owner:张志梁

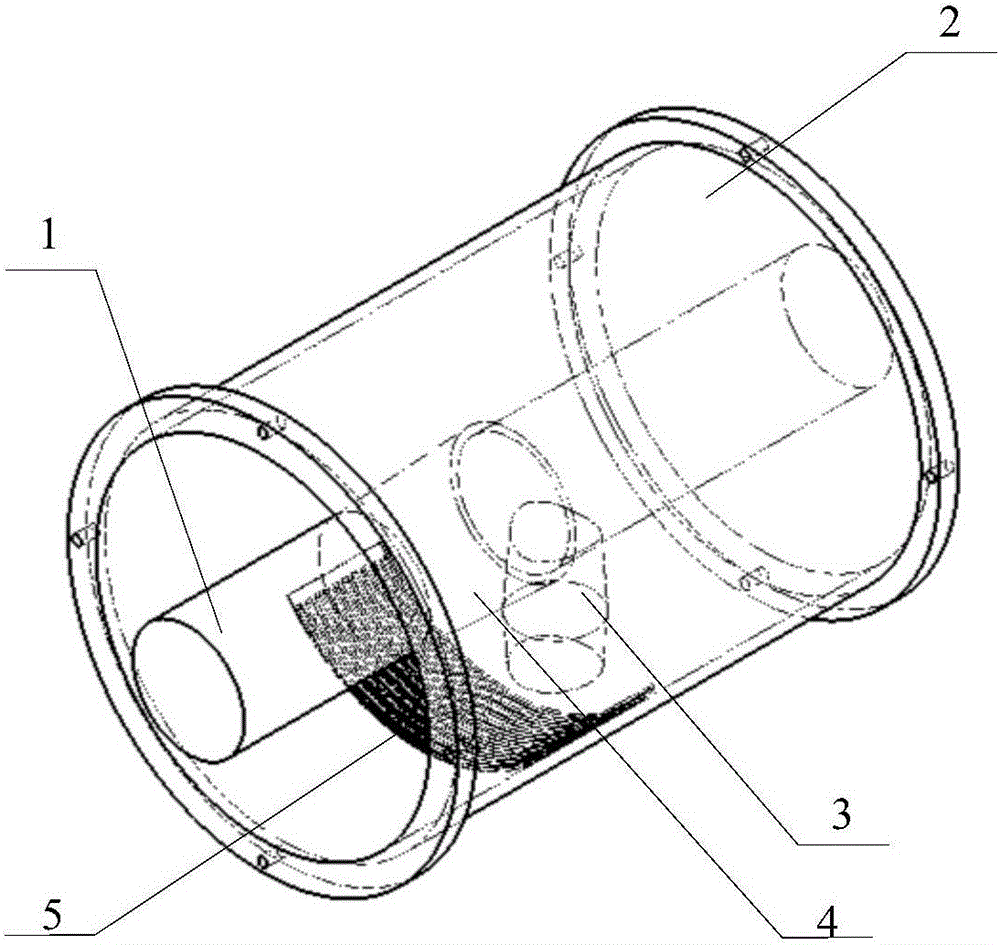

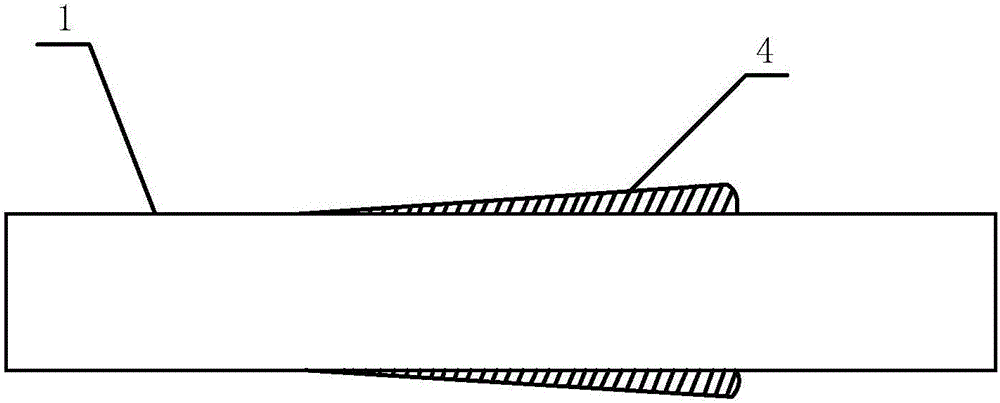

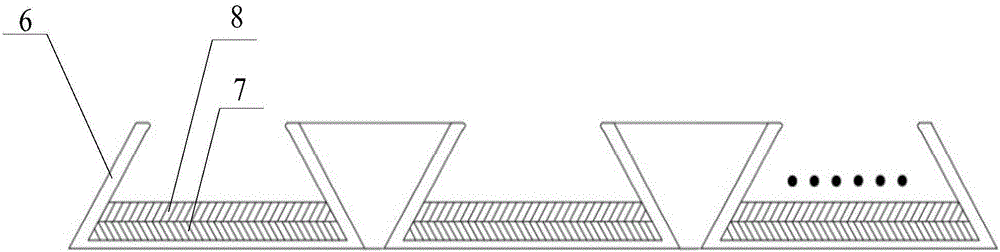

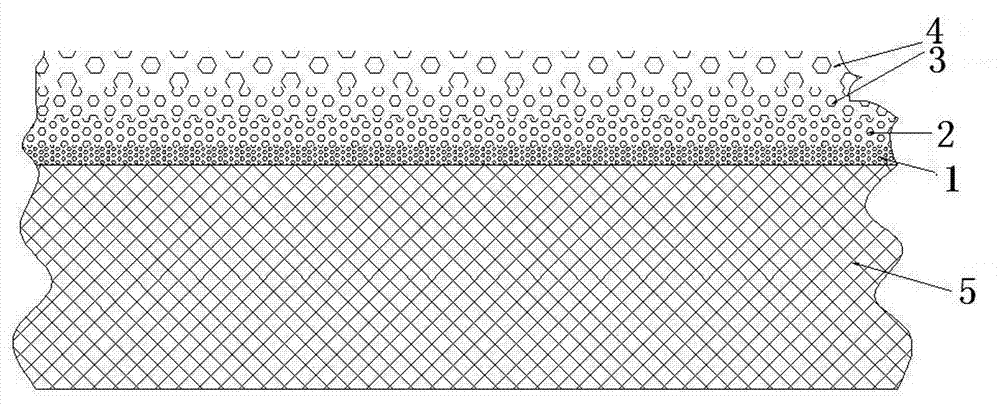

Metal particle trap for direct-current gas-insulated power transmission line

InactiveCN105149096AAging does not occurSolve agingElectric supply techniquesElectrode constructionsEpoxyElectrical conductor

The invention discloses a metal particle trap for a direct-current gas-insulated power transmission line. The metal particle trap is composed of a driving electrode and a metal particle trapping groove. A direct-current GIL aluminum alloy conductor and a pillar insulator for a direct current GIL are arranged inside a direct-current GIL aluminum alloy shell. The driving electrode is installed nearby the pillar insulator for the direct-current GIL on the direct-current GIL aluminum alloy conductor. The metal particle trapping groove is installed inside a direct-current GIL cavity, so that the inclined face of the driving electrode faces the bottom metal particle trapping groove. The metal particle trapping groove comprises three layers which are the inward-concave type metal shielding groove, an epoxy resin insulation pad and the high-viscidity hot melt adhesive coating in sequence from bottom to top. The metal particle trapping groove is used for capturing and limiting particles, the inward-concave type metal shielding groove in the bottommost layer generates a low electric field area, the epoxy resin insulation pad on the middle layer coats the whole bottom of the inward-concave type metal shielding groove, and the high-viscidity hot melt adhesive coating on the uppermost layer can control and trap particles moving at a high speed.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

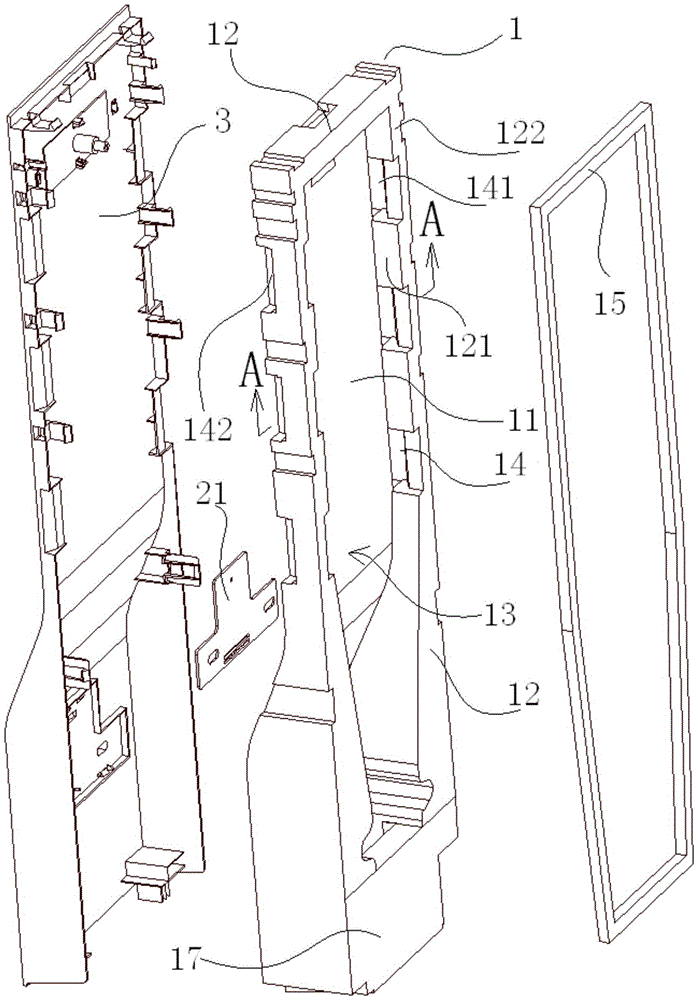

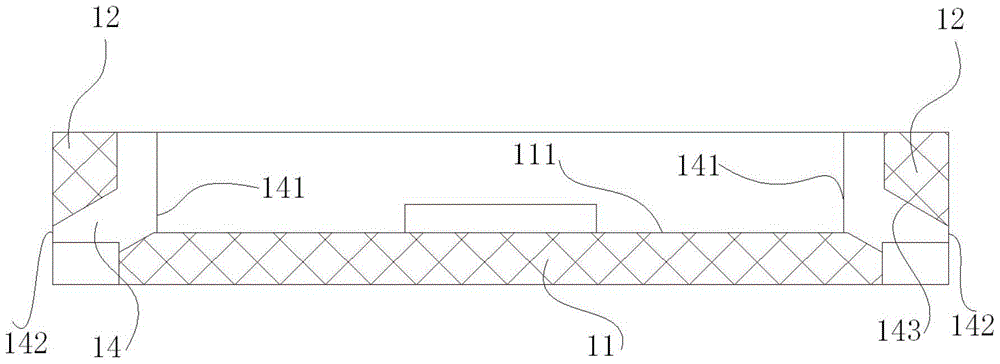

Air duct assembly of air-cooled refrigerator and air-cooled refrigerator

ActiveCN105716353AReduce manufacturing costShorten the timeLighting and heating apparatusCooling fluid circulationCold airRefrigerated temperature

The embodiment of the invention provides an air duct assembly of an air-cooled refrigerator and the air-cooled refrigerator, relates to the technical field of air-cooled refrigerators, and aims to solve the problems that the production cost is high and the assembly efficiency is low due to the fact that a conventional air-cooled refrigerator avoids cold air loss. The air duct assembly of the air-cooled refrigerator comprises air duct foam, wherein the air duct foam comprises a base plate, an air duct foam cover plate, and a convex edge formed on the surface of one side of the base plate; the convex edge is used for defining an air duct of the air-cooled refrigerator; the air duct foam cover plate is arranged at an air inlet of the air duct; and the surface, away from the base plate, of the convex edge and the surface, away from the base plate, of the air duct foam cover plate define a closed annular surface. The air duct assembly is applicable to air-cooled refrigerators.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

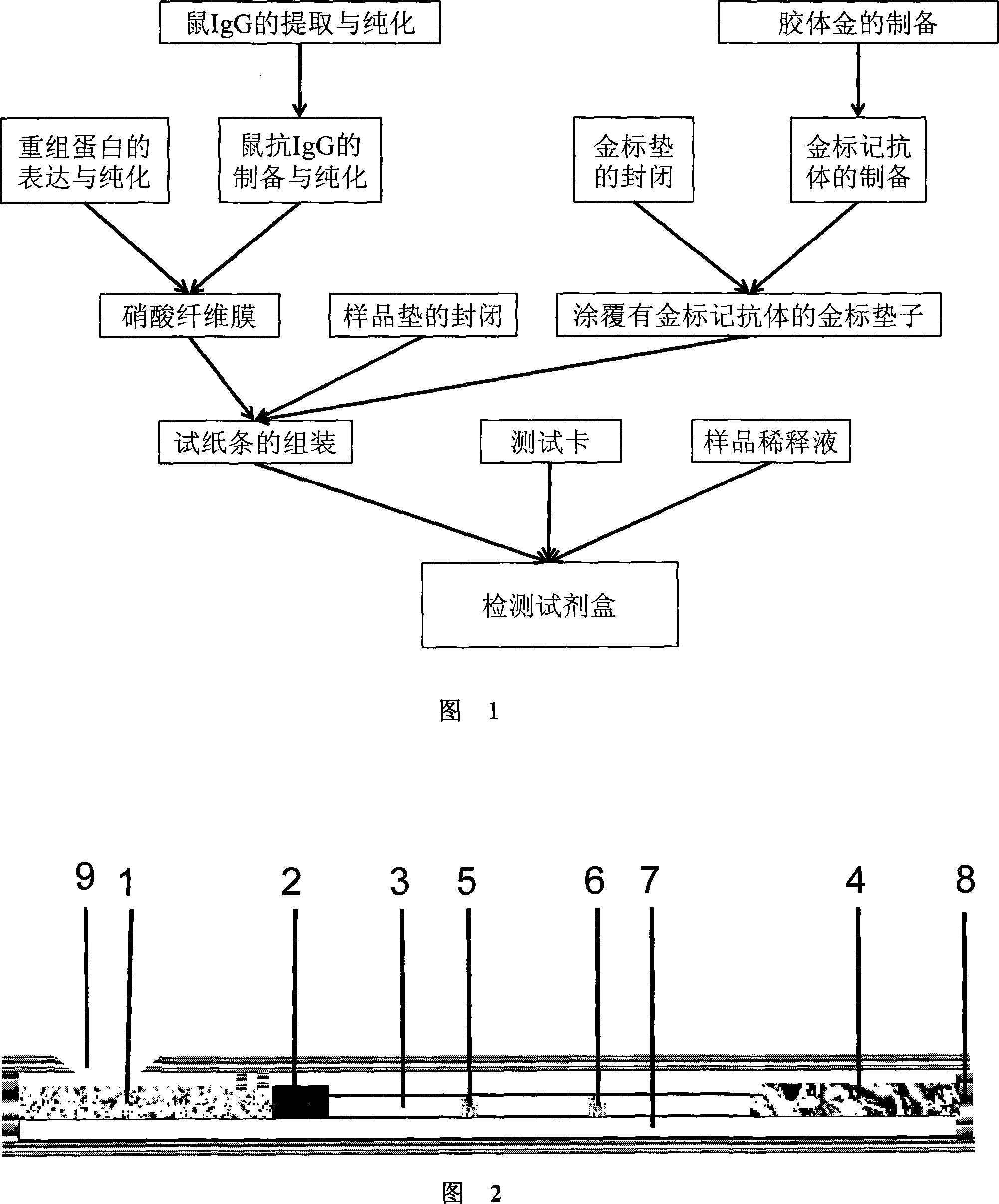

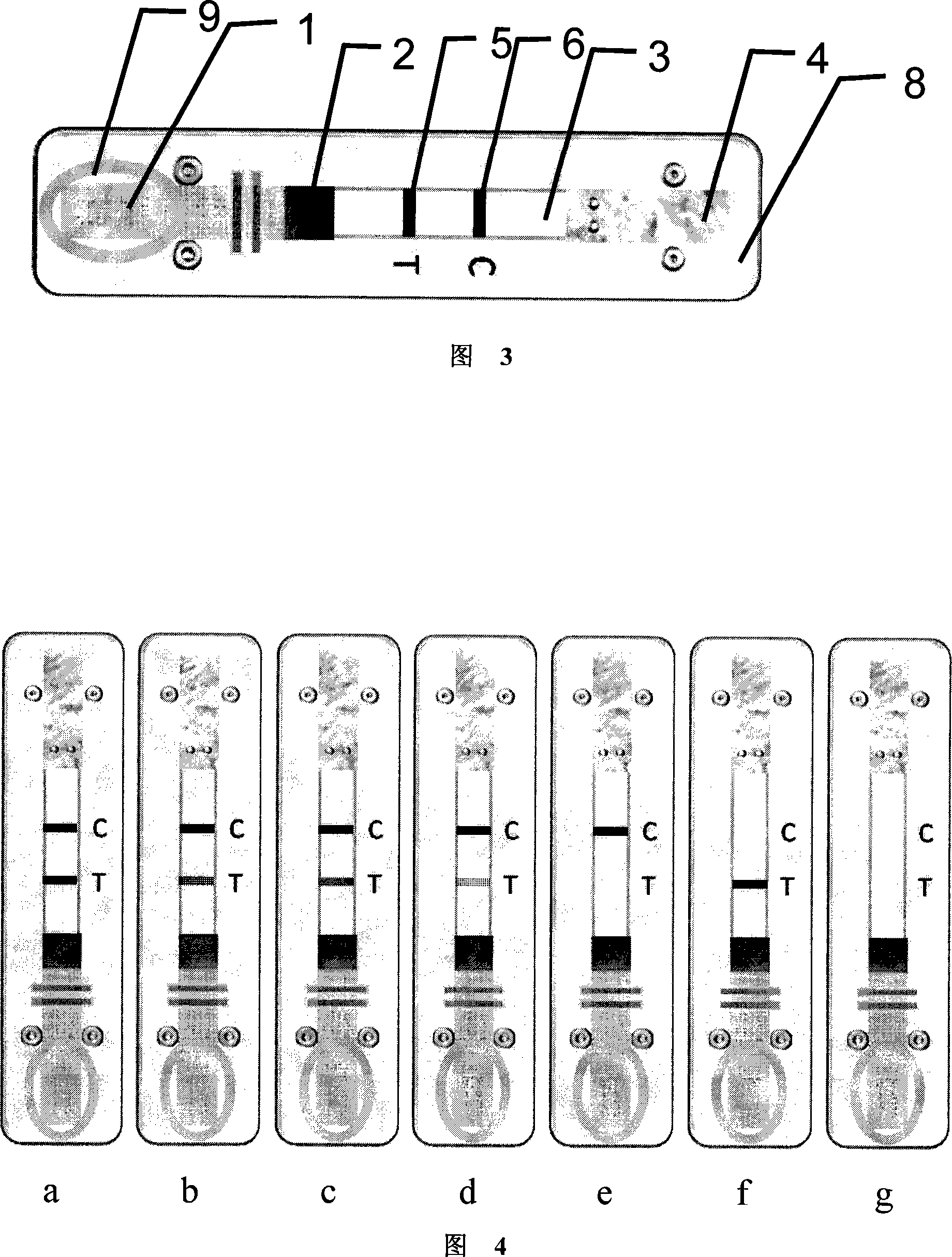

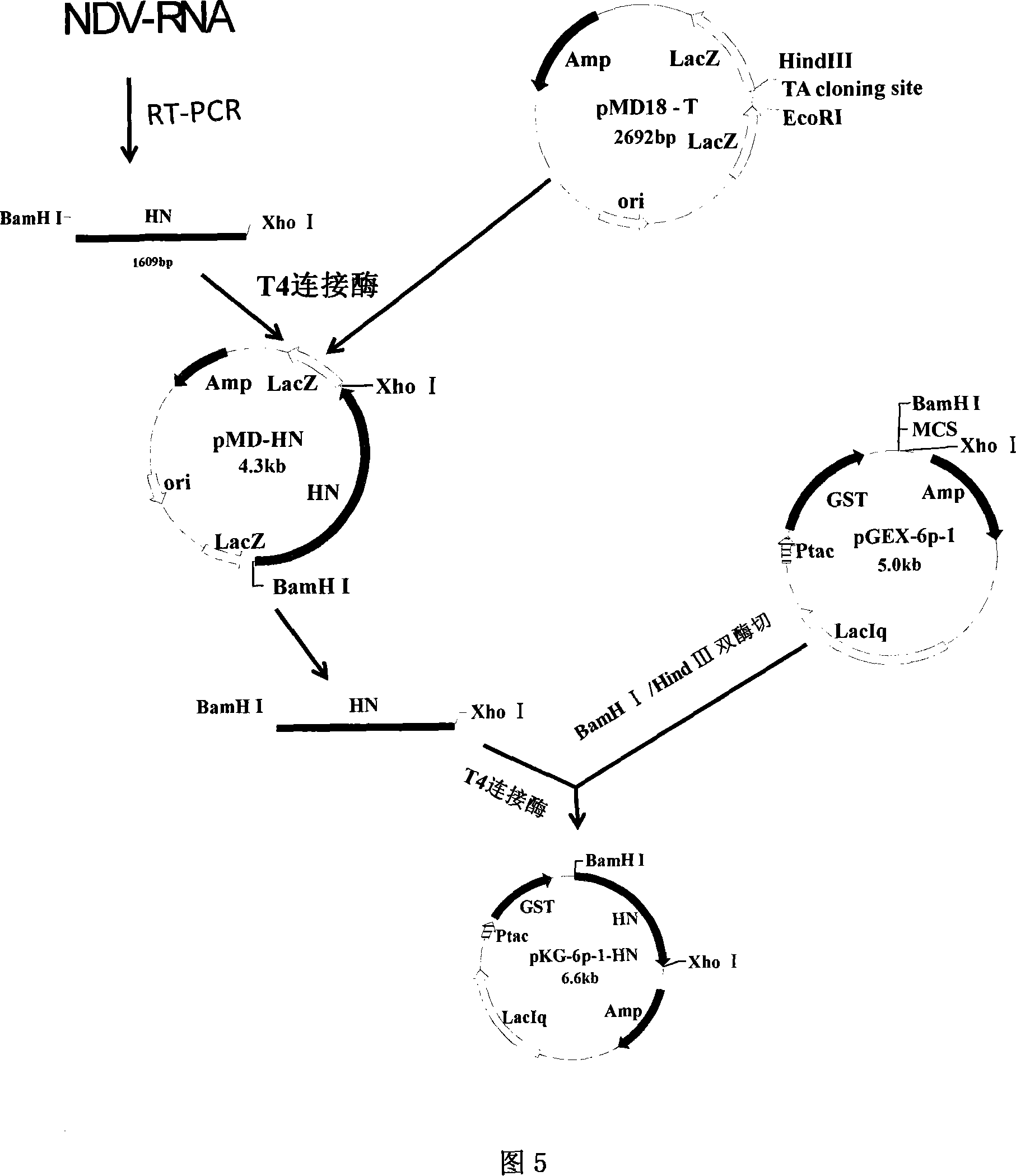

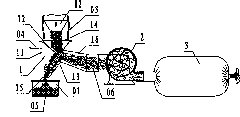

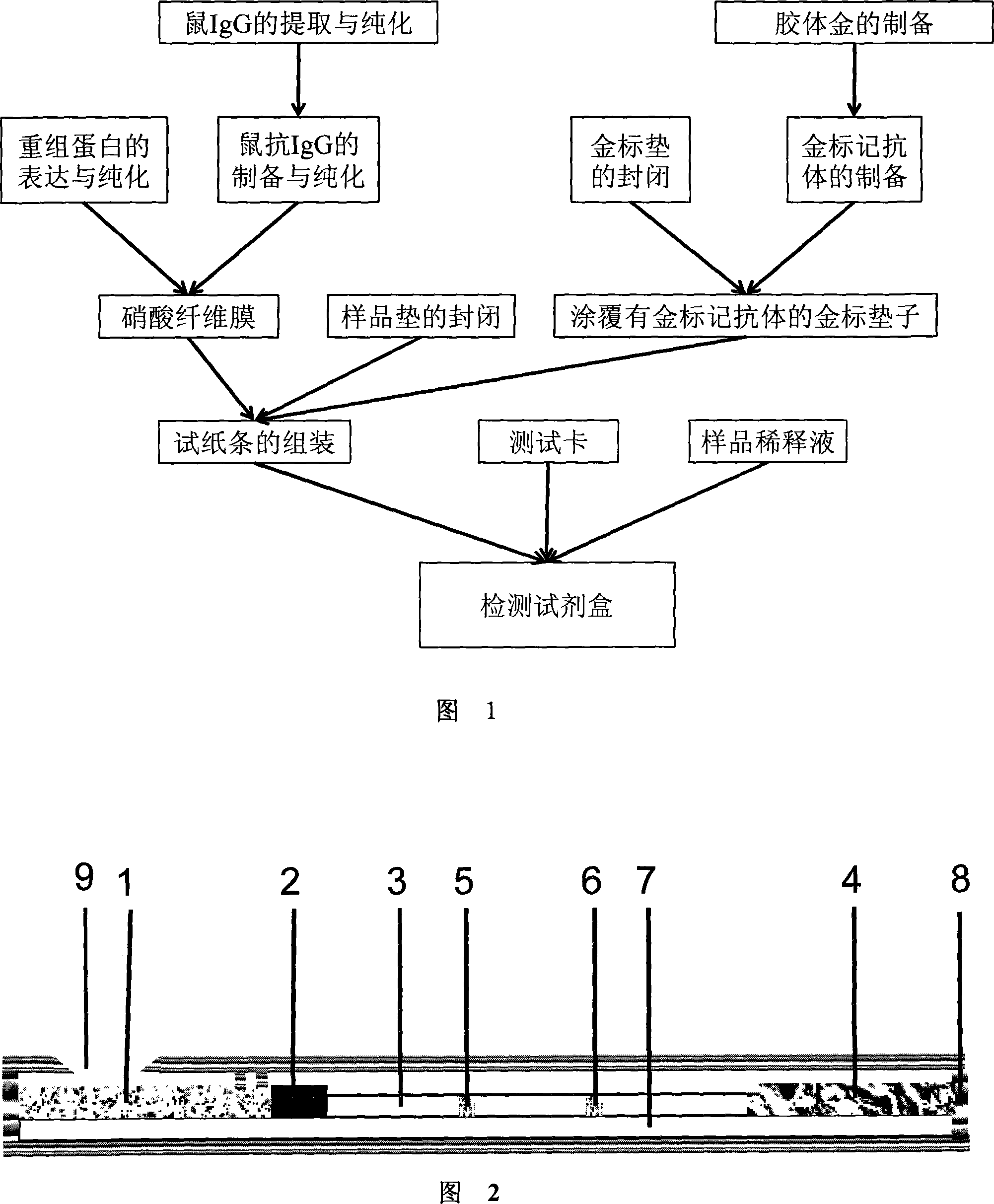

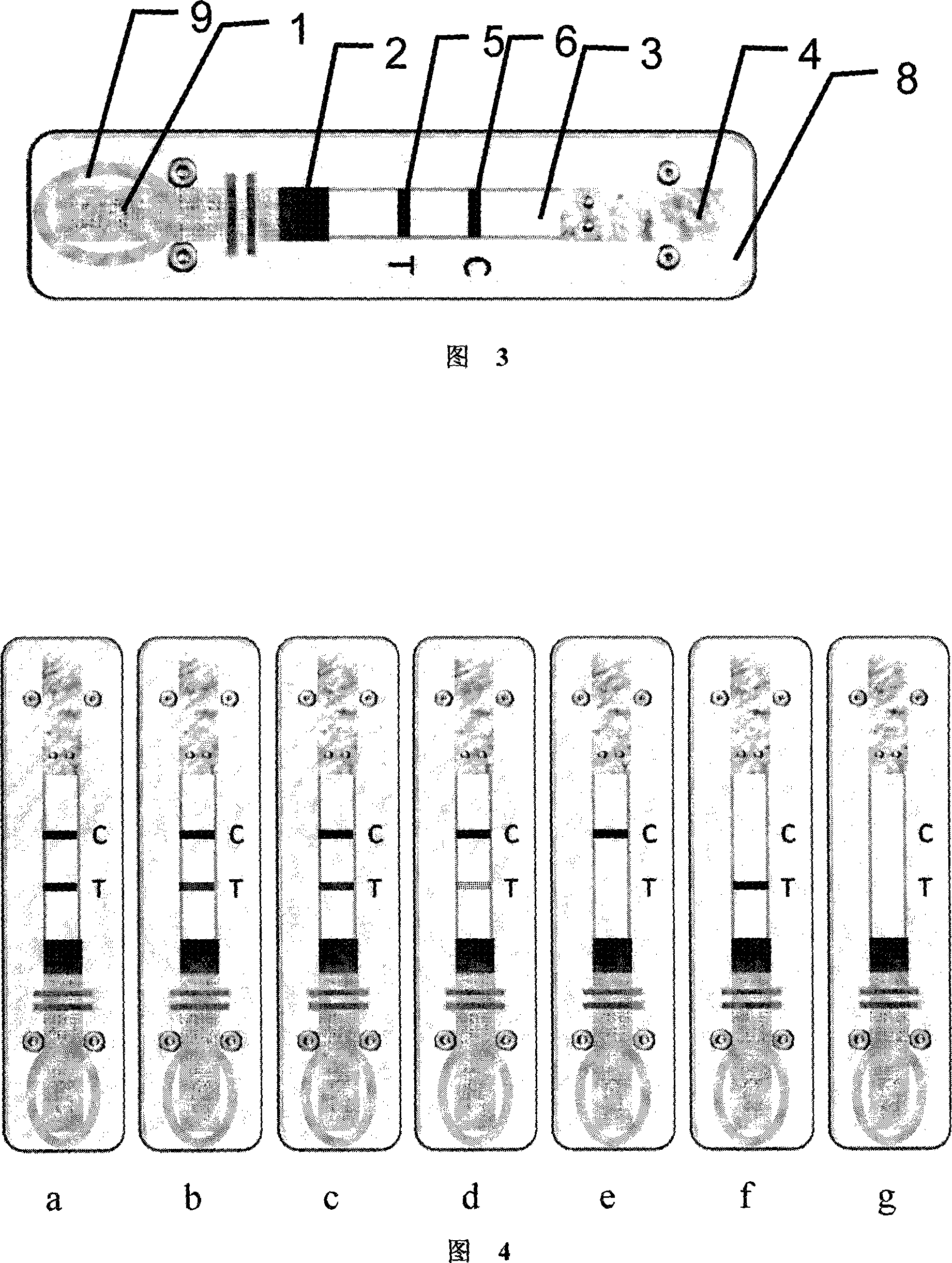

Newcastle disease immune body immune colloidal gold fast detecting reagent kit and its application

The invention belongs to the immunity application field, which relates to the related fields of animal molecular biochemistry and the immunology, etc. The invention discloses a reagent kit used for fast testing the antibody of Newcastle Disease, which comprises a case body, and the test paper card and sample diluent equipped inside the case body, wherein, the test paper card is formed by the absorption pad, nitrocellulose membrane, gold-label pad and sample pad affixed in turn on the non-absorbent supporting flake by taking the sample pad, absorption pad and the HN recombinant proteins coated with the Newcastle Disease as the detection line and the HN recombinant proteins coated with anti-mouse IgG as nitrocellulose membrane of the quality control line. The reagent kit used for testing the corresponding antibody has the obvious advantages of strong specificity, high sensitivity, easy operation and fast diagnosis.

Owner:HUAZHONG AGRI UNIV

Separation device of plastic particles and dust by negative-pressure air power

InactiveCN101797561AEliminate the sorting processAvoid flyingGas current separationWorking environmentEngineering

The invention discloses a separation device of plastic particles and dust by negative-pressure air power, which comprises a separator (1), a draft fan (2) and a dust-collecting bag (3). The device comprising the separator (1), the draft fan (2) and the dust-collecting bag (3) adopts the technical scheme of sucking dust and separating plastic particles and dust by utilizing negative-pressure air power and overcomes the problems and the defects of great dust danger, high labor cost for secondary separation and low production efficiency of the prior art. The device is arranged at a discharging hole of a plastic pulverizer, finishes the crushing and separating procedures of plastics by one step and blows the dust into the dust-collecting bag to prevent the dust from flying, and the production of crushing and recycling plastics reaches the aims of no dust escape, working environment purification, procedure simplification, labor cost reduction and production efficiency improvement.

Owner:NINGHAI XINCHENG AUTOMOBILE PARTS CO LTD

Single-component waterproof coating material and method of preparing the same

InactiveCN101343446ASimple construction processConstruction safetyAntifouling/underwater paintsPaints with biocidesLatex particleSolvent

The invention discloses single component waterproof coating and the preparation method. 50 percent to 80 percent of emulsion, latent solvent, dispersing agent and wetting agent are mixed with 40 percent to 60 percent of anti-foaming agent and are stirred at the rotating speed of 300 rpm to 700 rpm, pigment and filler are added during the stirring process, then the dispersing operation is performed at the rotating speed of 2000 rpm to 4000 rpm, slurry with the fineness lesser 50 um is obtained, and the residual anti-foaming agent is added. After the anti-foaming operation is performed, anticorrosion agent, film forming auxiliary agent, residual emulsion, thickening agent and water are added and evenly stirred at the rotational speed of 300rpm to 700 rpm, and the single component waterproof coating is obtained. The method has the advantages that the construction technology of the coating is simple and convenient, the film-forming process is finished mainly depending on the volatilization of the water and the interfusion of the latex particles, no VOC is discharged, no organic solvent is effused, the single component waterproof coating has no environmental pollution and combustion, the construction is safe, and the coating is an environmental protective-type single component waterproof coating.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

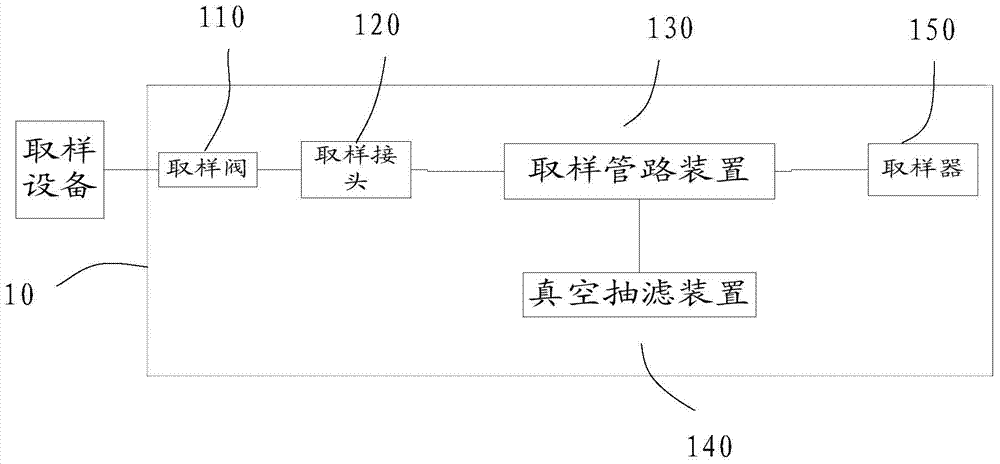

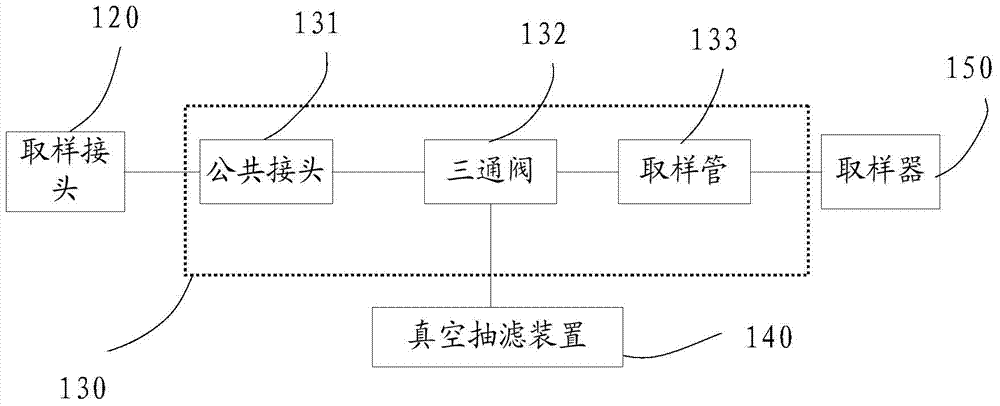

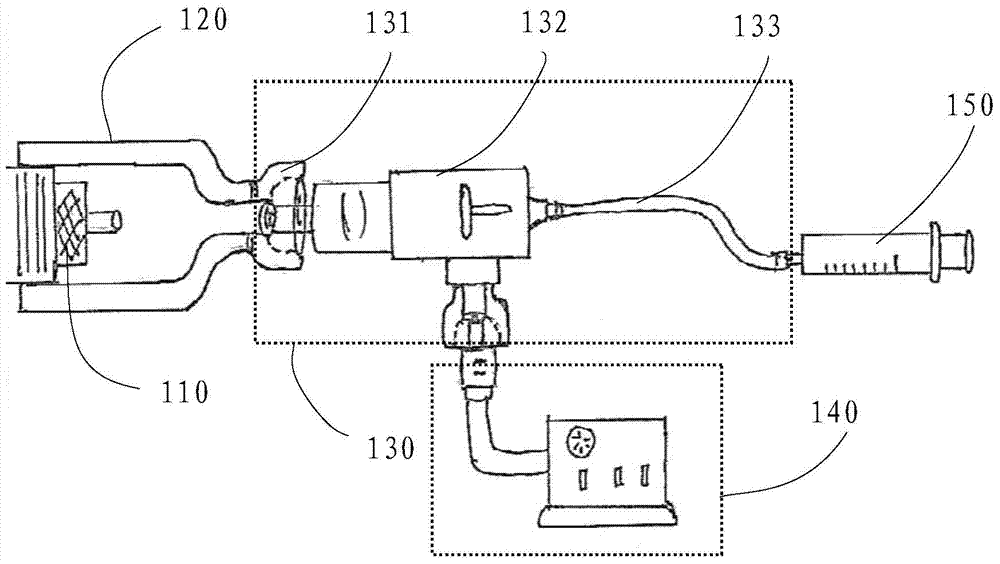

Sampling device and sampling method for gas content of insulating oil

The invention discloses a sampling device and a sampling method for the gas content of insulating oil. The sampling device for the gas content of the insulating oil comprises a sampling joint, a sampling pipeline device of which one end is connected with the sampling joint, a sampler detachably connected with the other end of the sampling pipeline device, and a vacuum suction filtration device connected with the sampling pipeline device. The sampling device can improve the accuracy of a test result, is easy to operate is mounted conveniently and quickly and can realize hot-line work.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

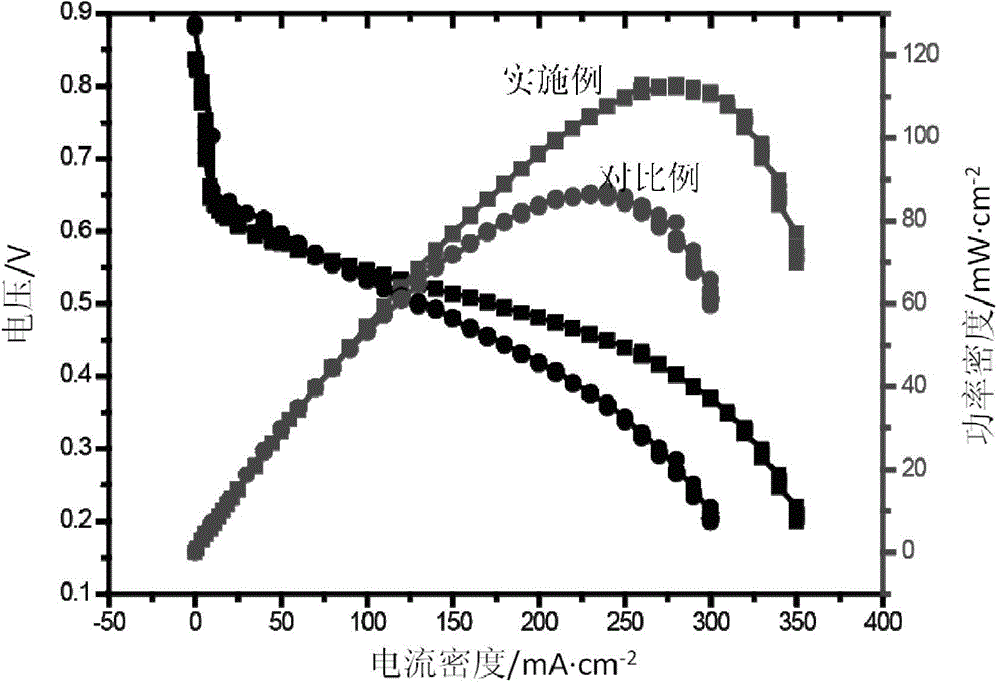

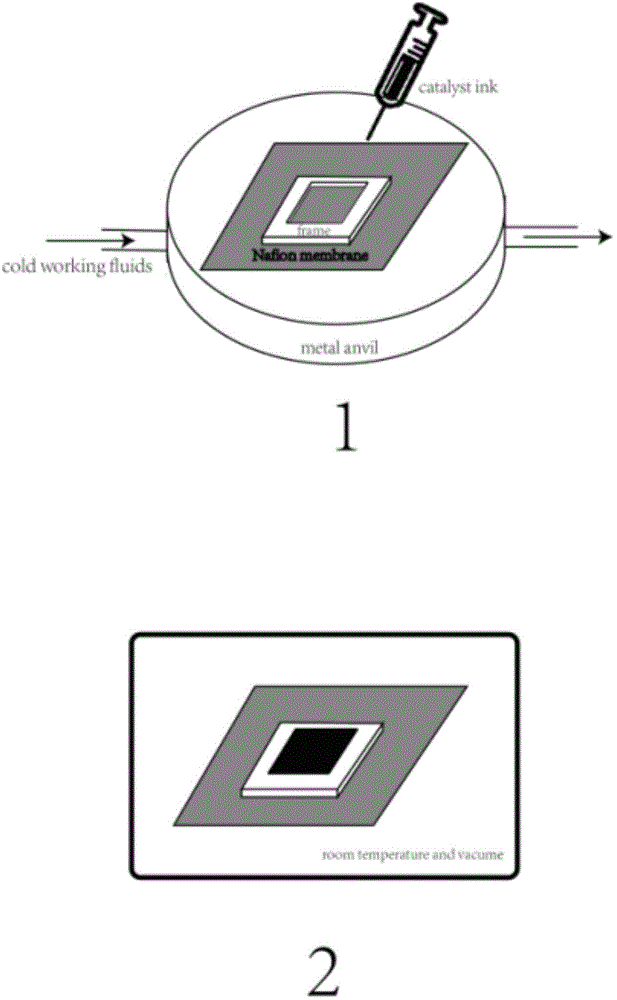

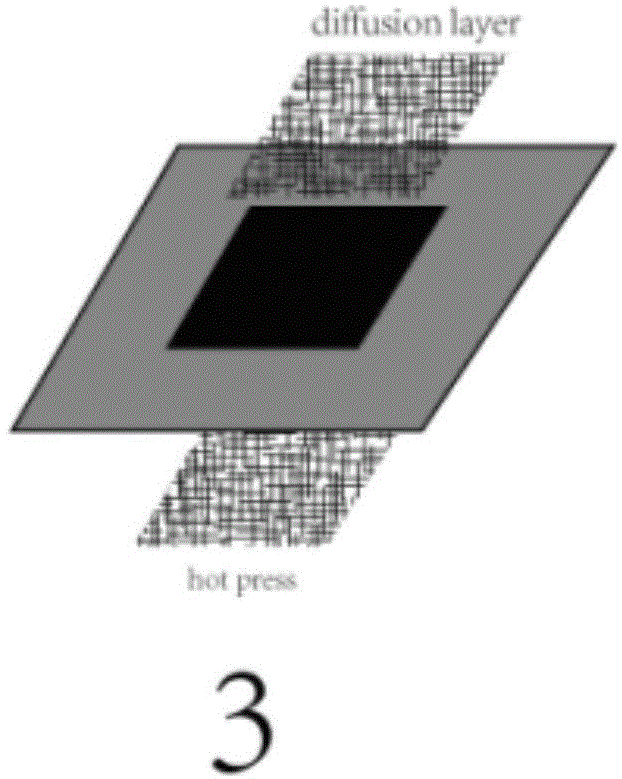

Fuel cell catalyst layer and membrane electrode subassembly and preparation method thereof

A fuel cell membrane electrode subassembly comprises an electrolyte membrane and catalyst layers attached to two sides of the electrolyte membrane. The catalyst layer is a porous thin-layer with a conductive high-molecular polymer-electrocatalyst as the framework. Thickness of the thin-layer is 10-500 microns; pore diameter of the thin-layer is 1-50 microns; and pore wall thickness is 0.1-1 micron. When the electrolyte membrane is a proton exchange membrane, the conductive high-molecular polymer is a cationic conductive high-molecular polymer. When the electrolyte membrane is an alkaline anion-exchange membrane, the conductive high-molecular polymer is an anionic conductive high-molecular polymer. A preparation method of the catalyst layer comprises the following steps: dispersing catalyst slurry on a substrate surface, refrigerating below 0 DEG C for no less than 5 h, and carrying out vacuum drying so as to obtain a catalyst layer attached to the substrate surface. The catalyst slurry comprises an electrocatalyst, a conductive high-molecular polymer and solvent water. In comparison with the prior art, the product of the invention has low loss late of catalyst and good repeatability, is not influenced by environmental factor and is easy for batch preparation. The catalyst in the catalyst layer or the membrane electrode subassembly prepared by the method has advantages of uniform distribution, high utilization rate, controllable pore structure and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

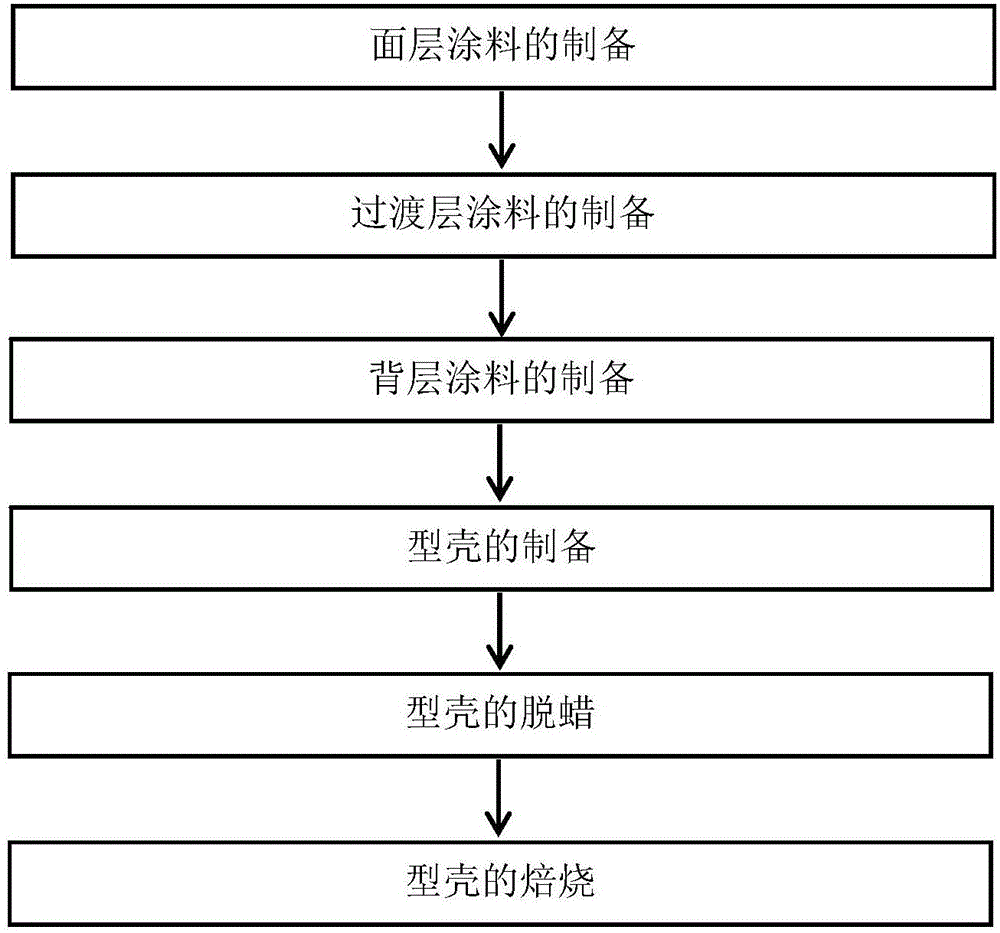

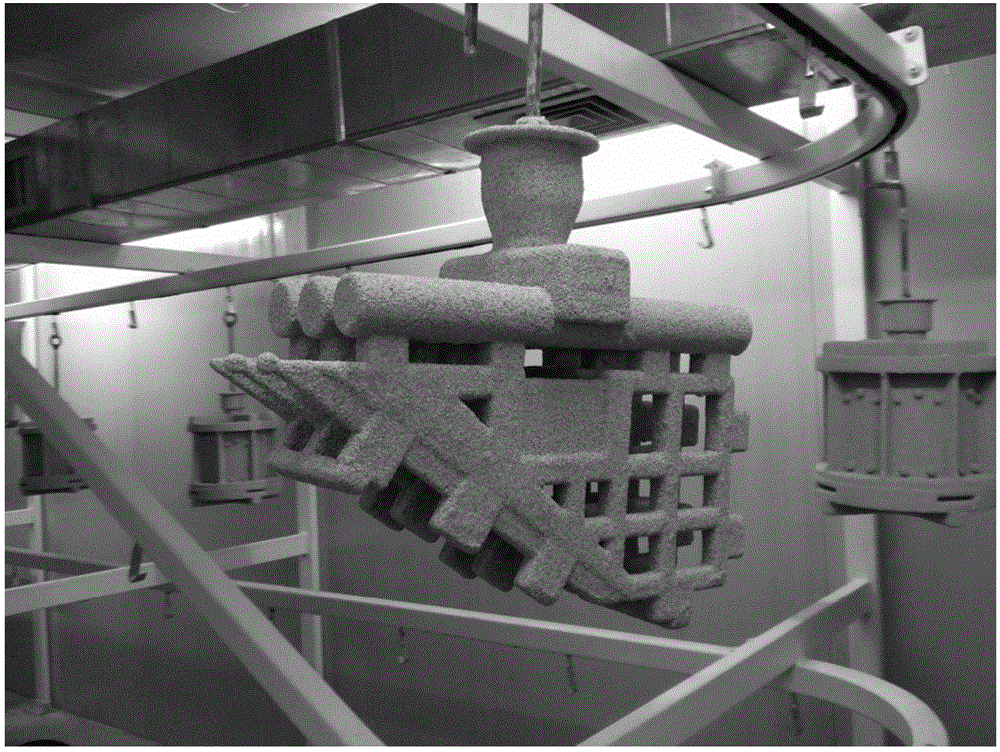

Anti-interface reaction composite ceramic shell

The invention relates to an anti-interface reaction composite ceramic shell. The shell consists of a surface layer and a reinforcing layer, the surface layer is made of yttria powder as refractory powder, yttria sand as refractory aggregate and silica sol as binder by adopting a multi-coating method, the reinforcing layer is made of electro-fused mullite powder as refractory powder, electro-fused corundum sand as refractory aggregate and silica sol as binder by adopting the multi-coating method, the reinforcing layer is fixed on the top surface of the surface layer, and the reinforcing layer and the surface layer are of an integrated structure; the total thickness of the shell is 5mm to 13mm, wherein the thickness of the surface layer is 0.15mm to 1.4mm. After the shell produced by the method is roasted, the surface of the cavity of the shell is smooth and does not have cracks, the surface does not have floating sand and floating powder, and the shape of a blade wax pattern is completely and clearly copied.

Owner:SHENYANG RES INST OF FOUNDRY

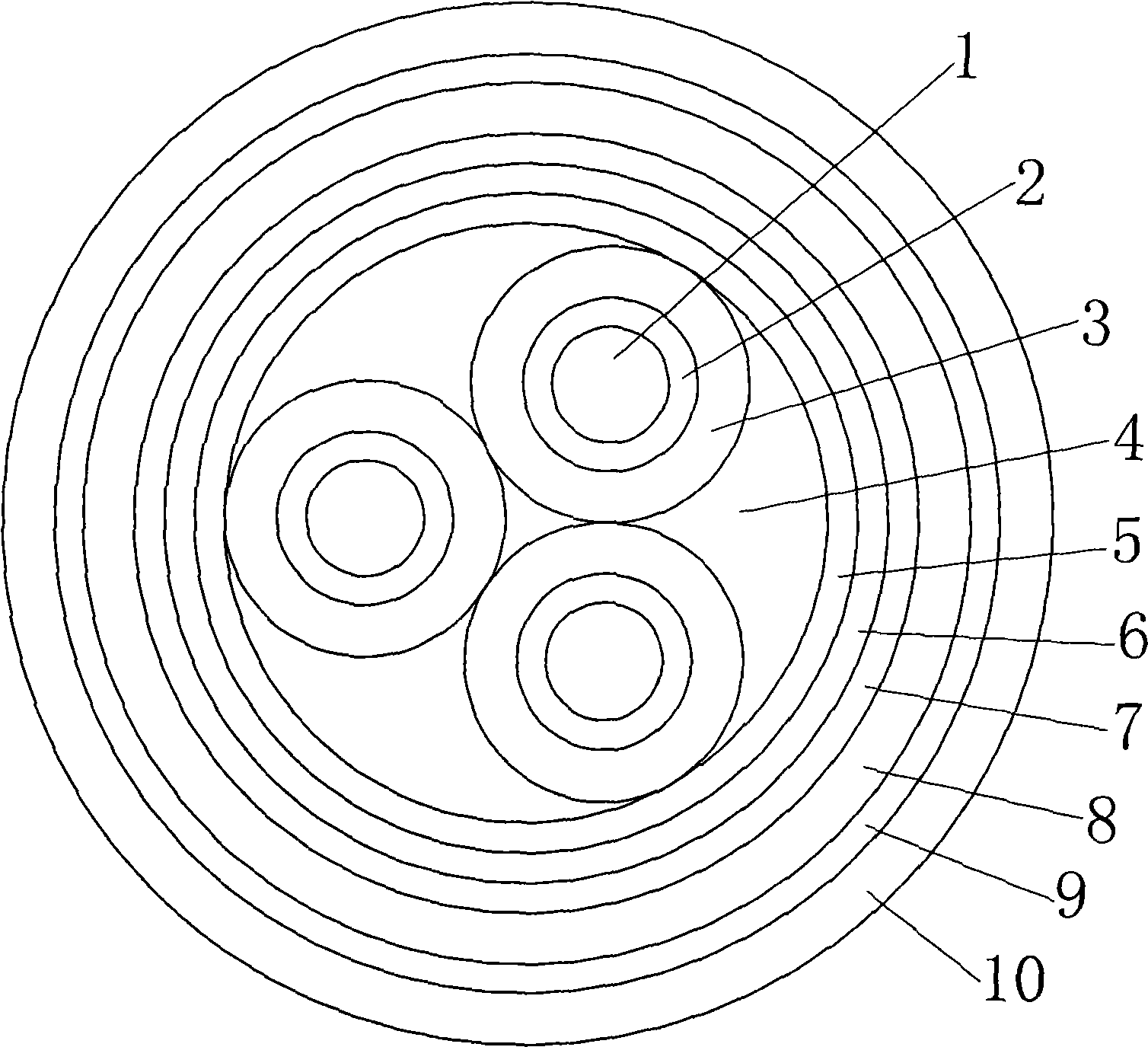

Rat-proof and ant-proof inflaming-retarding environment-friendly power cable

InactiveCN103985473APrevent immersionNo escapePower cables with screens/conductive layersInsulated cablesPolyesterMica

The invention discloses a rat-proof and ant-proof inflaming-retarding environment-friendly power cable. A cable core of the power cable is formed by twisting a plurality of insulation wire cores. Each insulation wire core is composed of a conductor, an inner mica tape fireproof layer and an insulation layer from inside to outside. Gaps among the wire cores are provided with a packing layer. A lining layer is arranged outside the packing layer. A metal shielding layer is arranged outside the lining layer. A water-blocking polyester band, a waterproof isolation layer, an outer mica tape fireproof layer, an outer band wrapping layer, a restrictive coating, an insulation layer and rat-proof and ant-proof synthesis neoprene tape are arranged outside the metal shielding layer. The rat-proof and ant-proof synthesis neoprene tape is wrapped with an inner rat-proof and ant-proof synthesis neoprene sheath, the inner rat-proof and ant-proof synthesis neoprene sheath is longitudinally wrapped with an embossed alloy aluminum plastic composite belt, and the outmost layer is wrapped with an outer rubber sheath.

Owner:NANAN GUOGAO BUILDING MATERIAL TECH

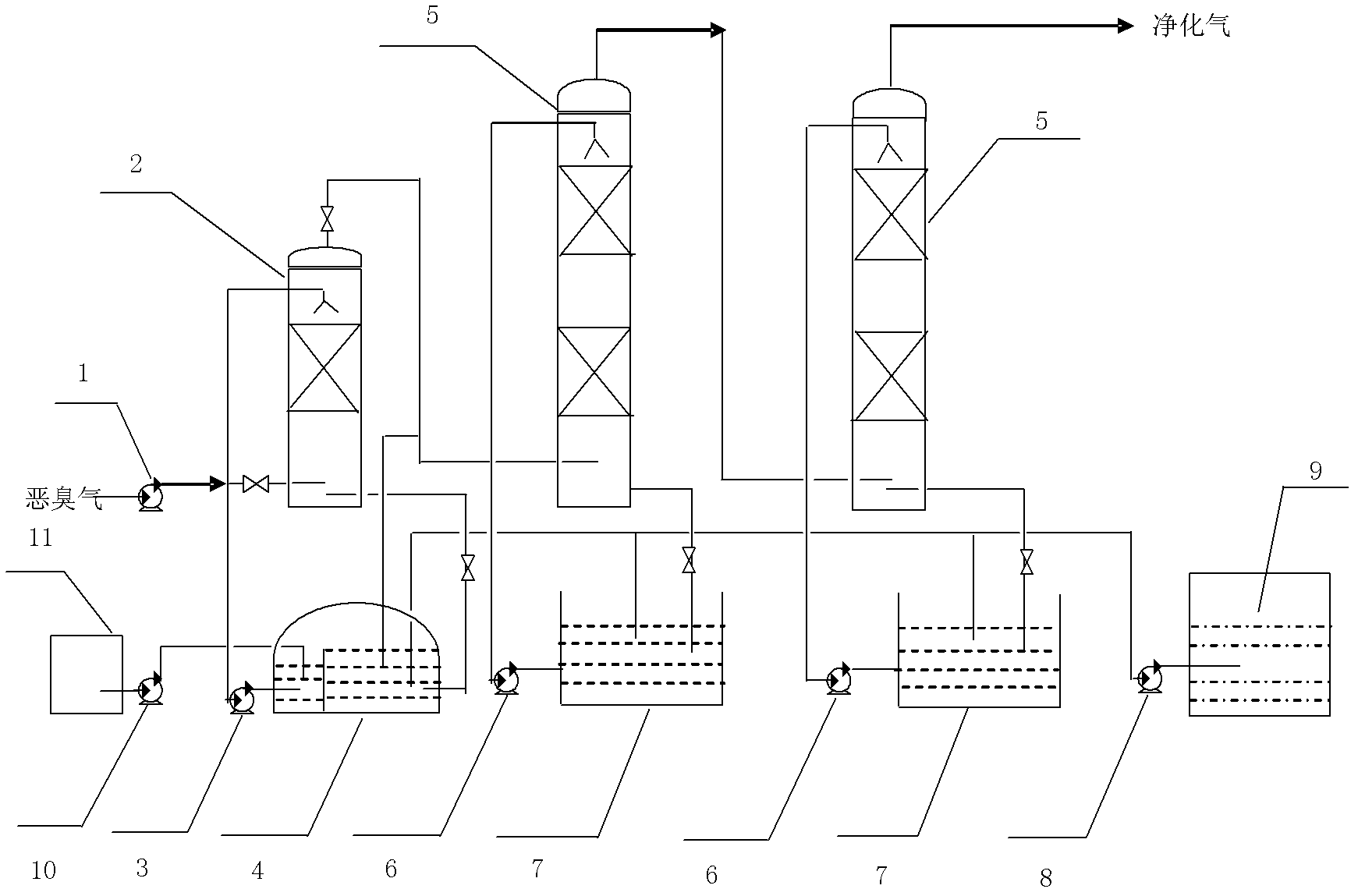

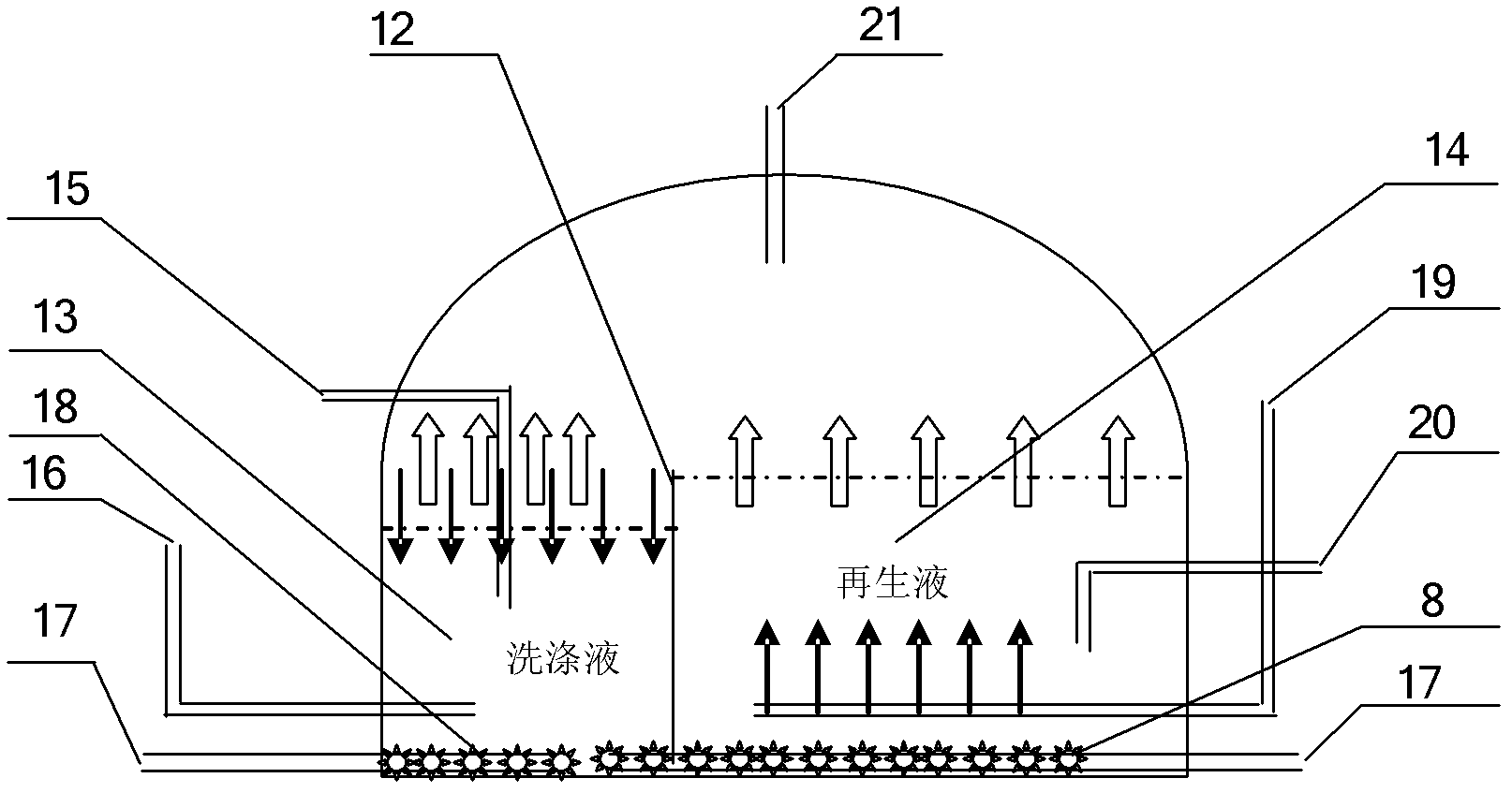

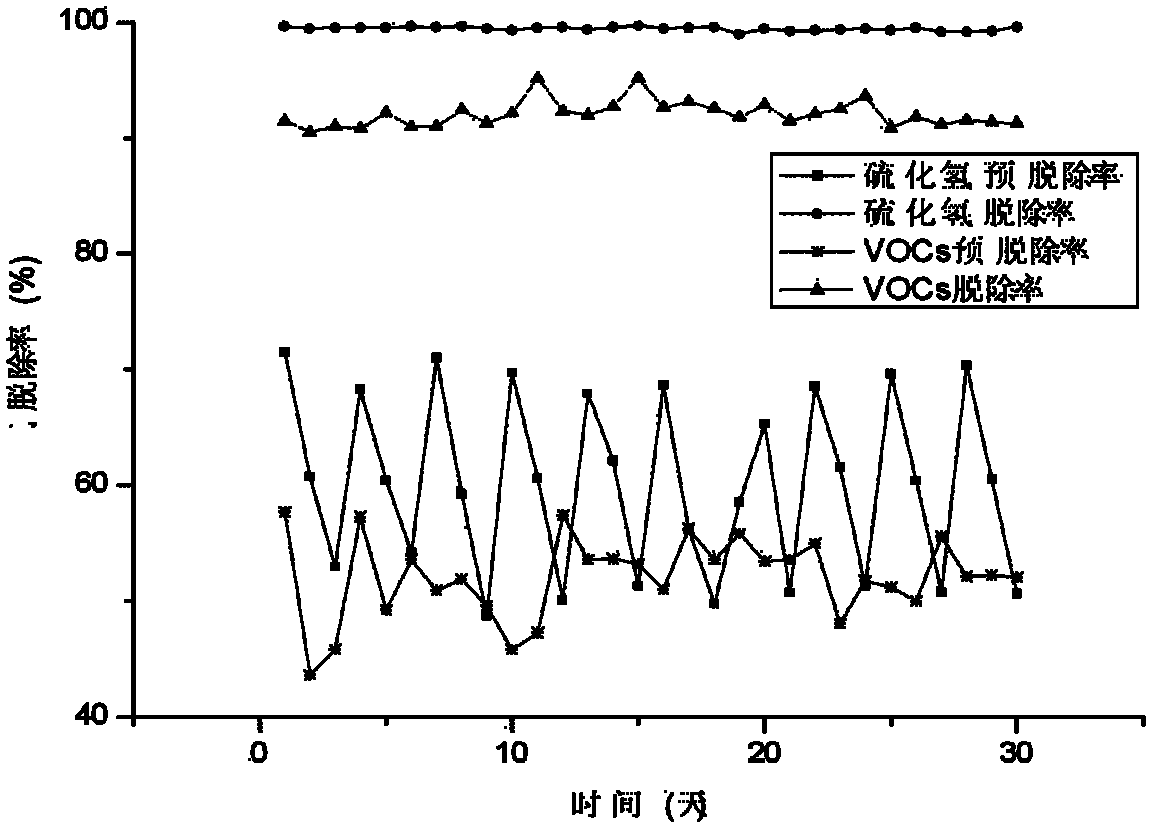

Method for processing foul gas through using biological combined technology

ActiveCN102921293AEasy to operateThe system is stableDispersed particle separationAir quality improvementTrickling filterEngineering

The invention provides a method for processing a foul gas through using a biological combined technology. The method comprises the following steps: 1, sending the foul gas to the lower portion of a biological washing tower, allowing the foul gas to contact with a biological washing liquid which is sprayed from the top of the tower and comes from the washing segment of a biological washing liquid tank in a countercurrent manner and to stay for 8-10s, and allowing the biological washing liquid to flow out from the bottom of the biological washing tower and enter the biological washing tank; and 2, allowing the foul gas treated by the biological washing tower to enter the bottom of a biological trickling filter tower, to contact with a cycle liquid sprayed from the top of the biological trickling filter tower in a countercurrent manner and to stay for 20-30s, directly discharging after two-level biological trickling filter treatment, and allowing the cycle liquid to flow out from the bottom of the biological trickling filter tower and to enter the cycle liquid tank of the biological trickling filter tower, wherein the biological washing liquid tank comprises the washing segment and a regeneration segment. The method enables the whole foul gas removal rate after the treatment to reach above 95%, and has the advantages of stable running and low operation cost.

Owner:PETROCHINA CO LTD

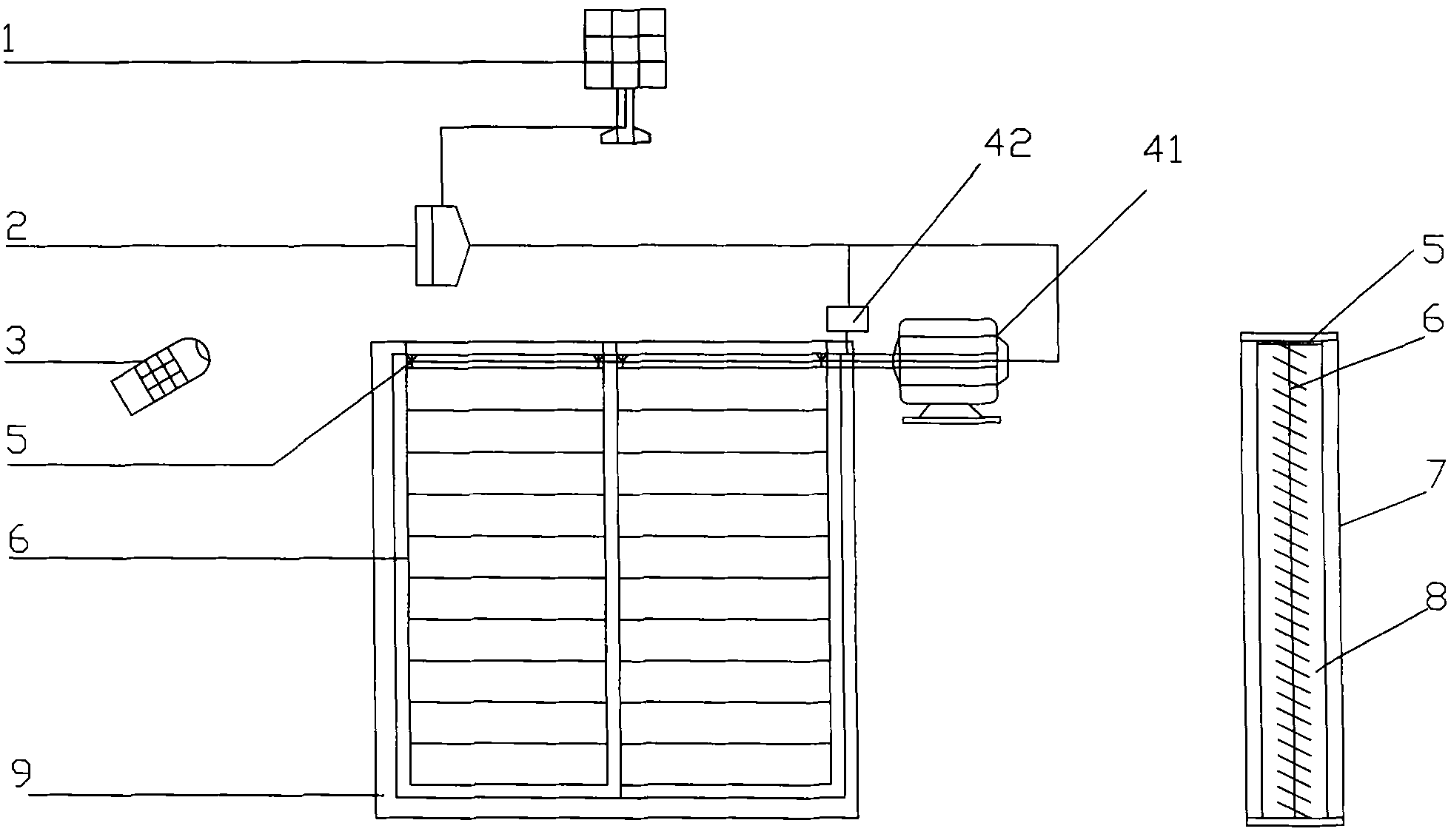

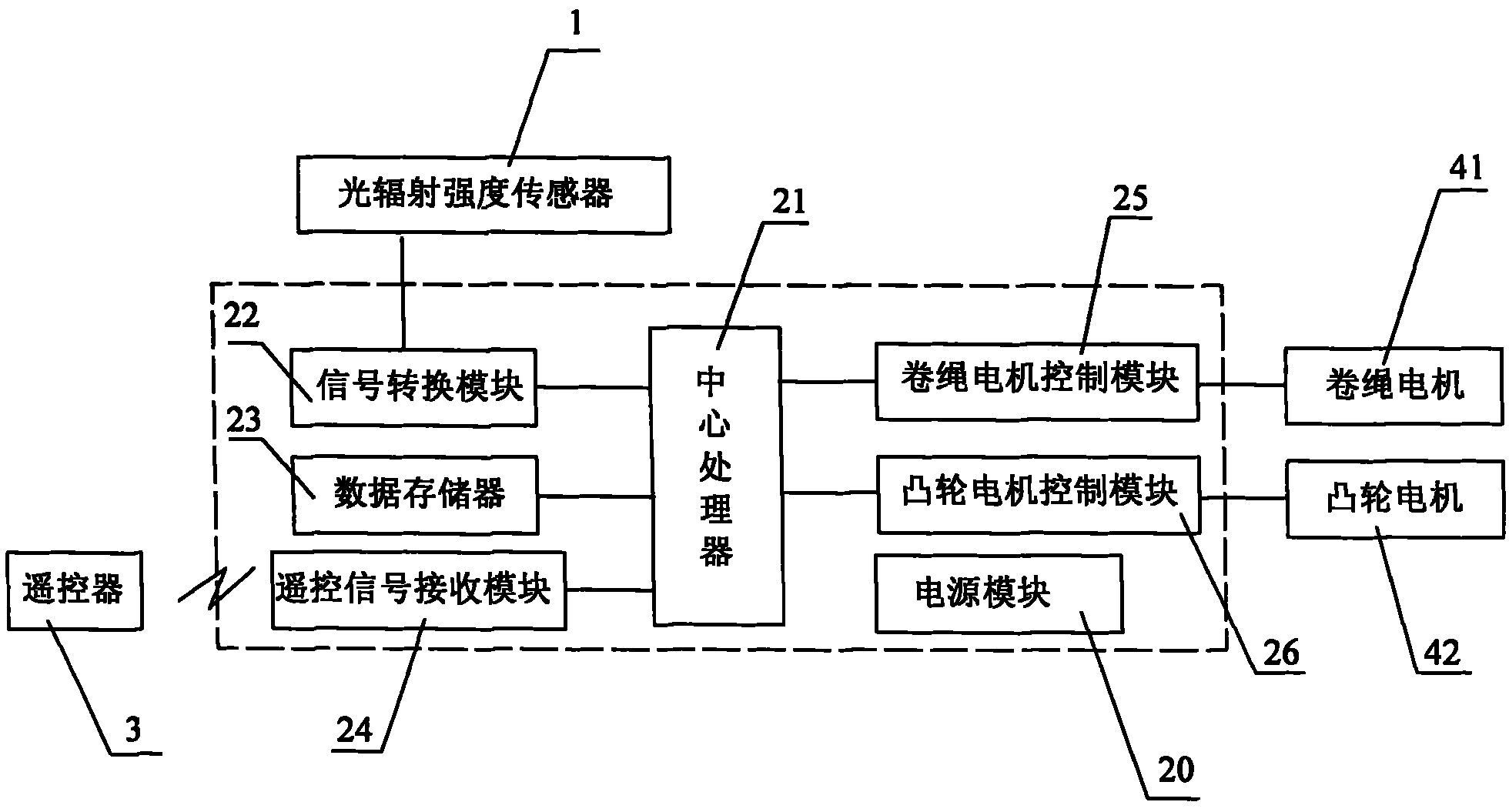

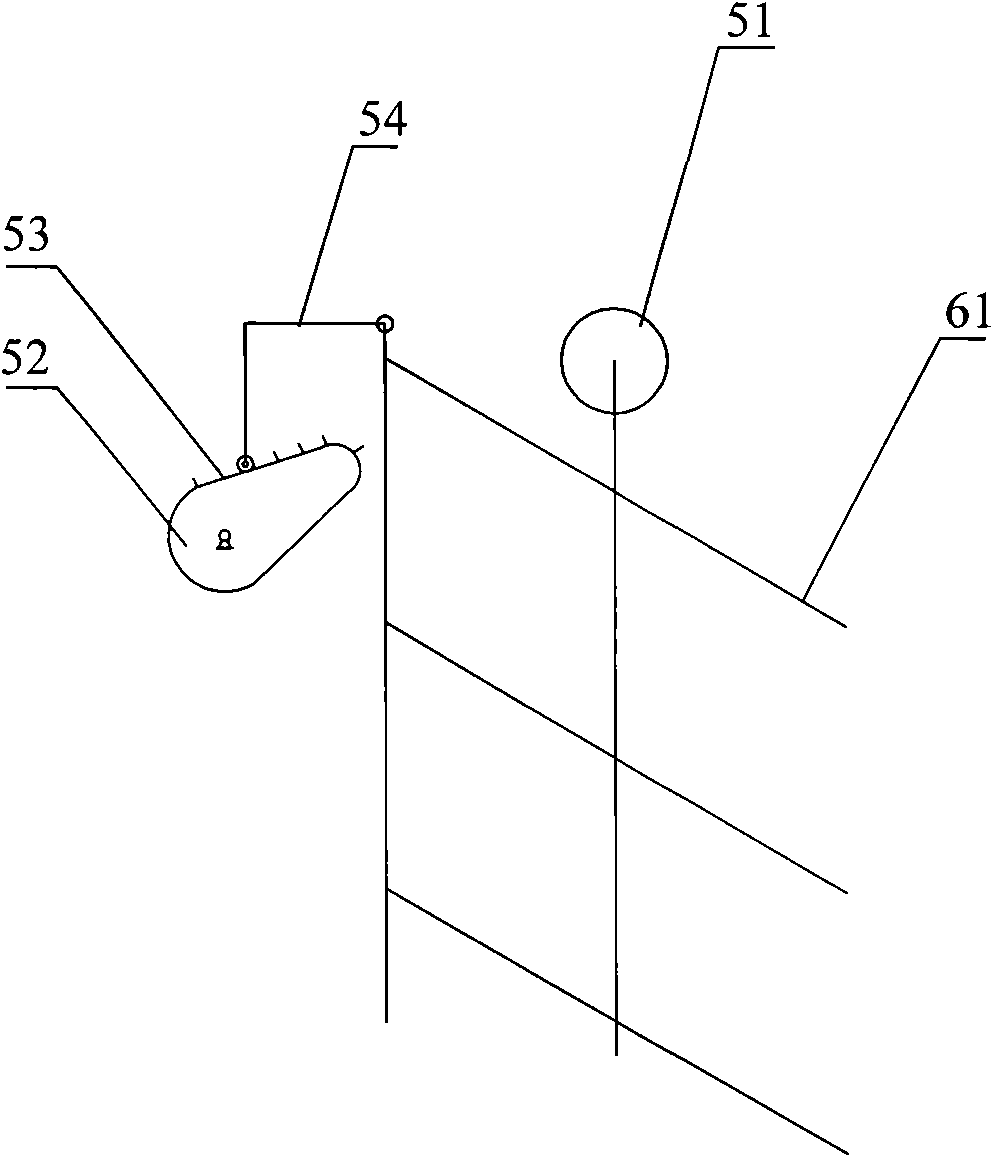

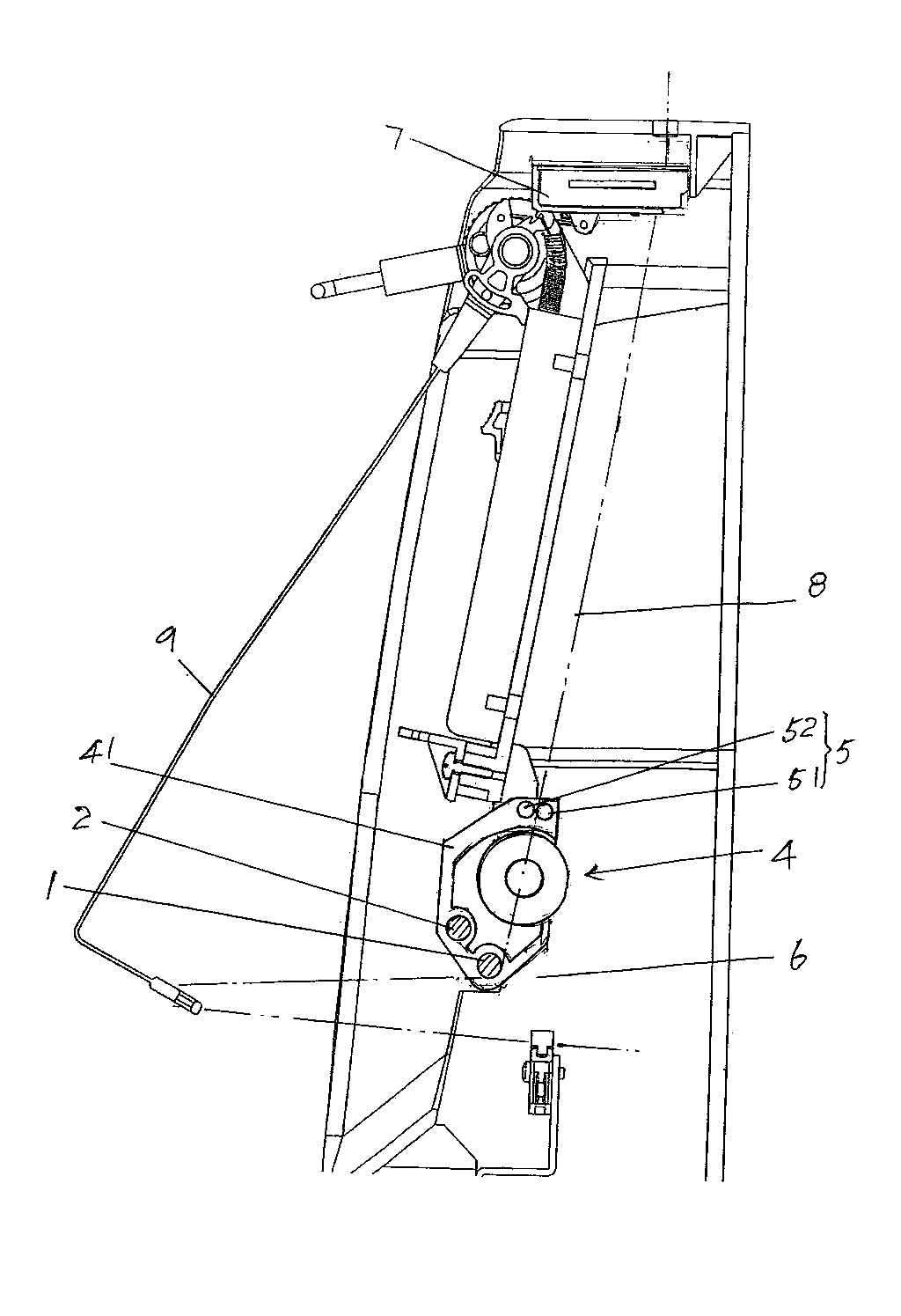

Intelligent door, window and sunshade integrated device

InactiveCN101975017ARealize automatic adjustment functionLower heat transfer coefficientInsect protectionLight protection screensOptical radiationVitreous Bodies

The invention discloses an intelligent door, window and sunshade integrated device. The device comprises an intelligent control system, a window frame system and a sunshade shutter system, wherein the intelligent control system comprises an optical radiation intensity sensor (1), a signal receiving control component (2) and the like; the window frame system comprises a frame (9); a heat insulation hollow vitreous body (7) is arranged in the frame (9); the sunshade shutter system comprises a blind (6) which consists of a dentiform scroll component (5) and aluminum foil leaves (61); the dentiform scroll component (5) is used for controlling the rolling of the blind (6) and an overturning angle of the aluminum foil leaves (61); the blind (6) and the dentiform scroll component (5) are arranged in the cavity of the heat insulation hollow vitreous body (7); and the cavity of the heat insulation hollow vitreous body (7) is full of inert gas (8). The device can not only automatically adjust the blind according to the intensity of light rays, but also has very good functions of sun shading and heat shielding.

Owner:ZHEJIANG UNIV

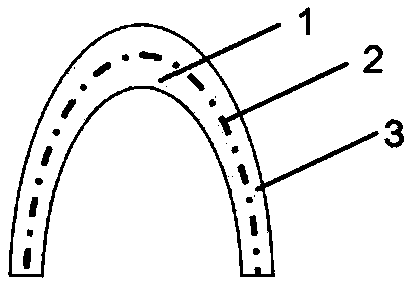

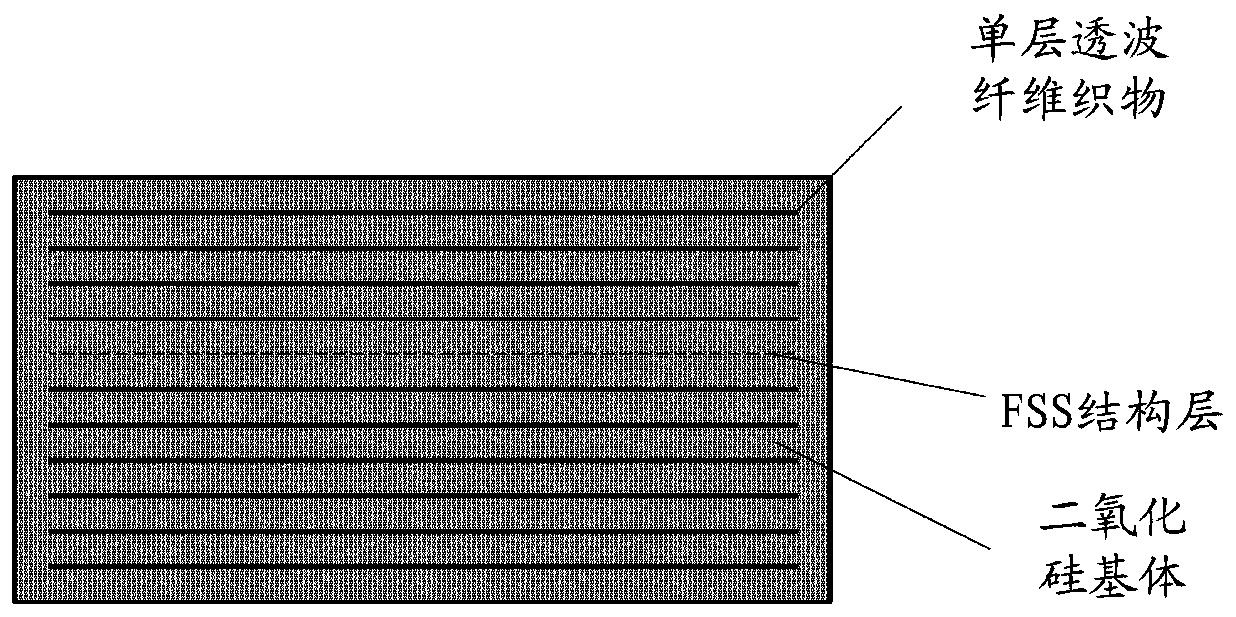

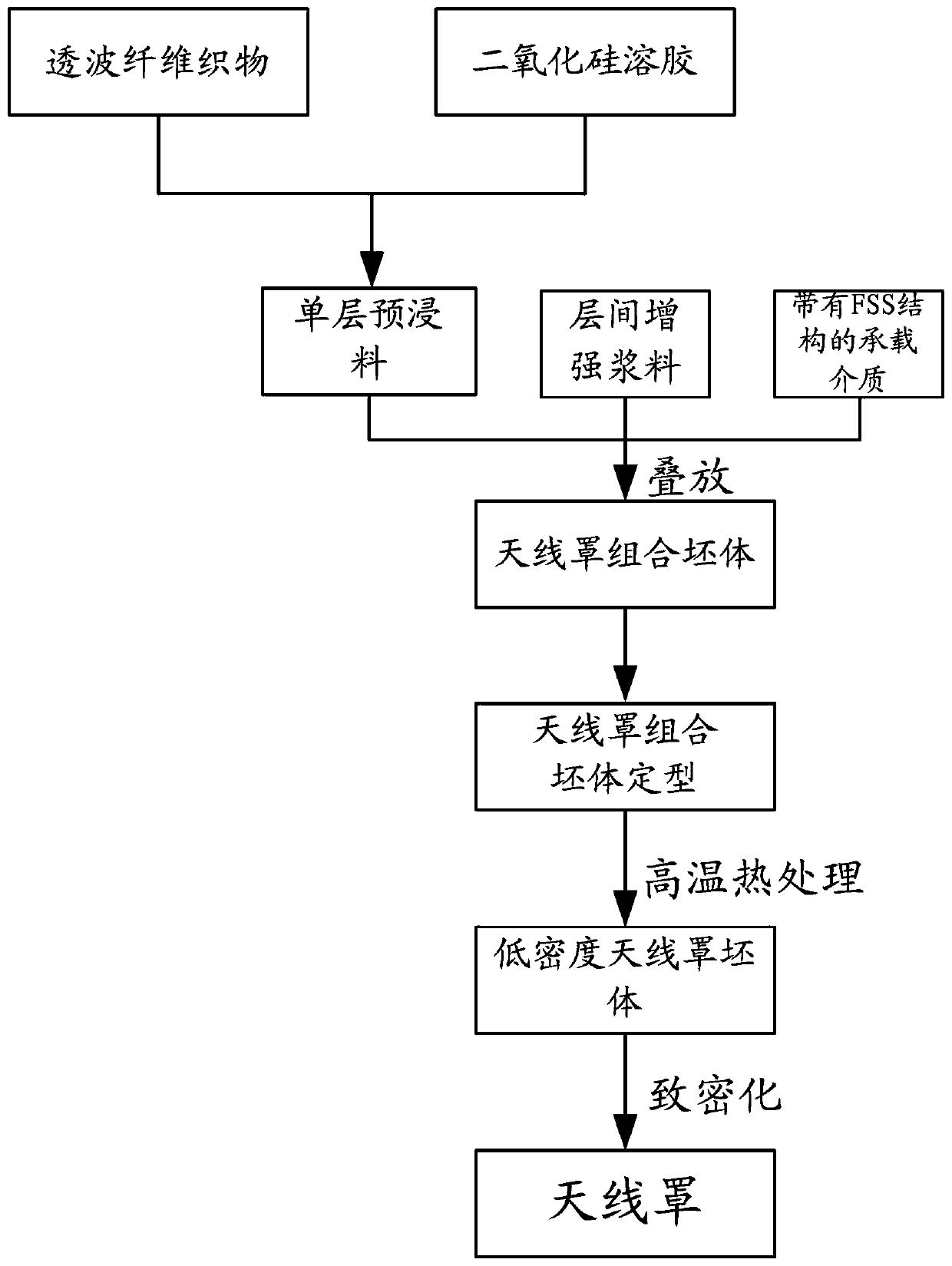

High-temperature-resistant frequency selective surface antenna cover and preparation method thereof

ActiveCN109786961AStable structureImprove adaptabilityRadiating element housingsEngineeringSilicon dioxide

The invention provides a high-temperature-resistant frequency selective surface antenna cover and a preparation method thereof, a layered structure is adopted, the antenna cover is composed of a bearing layer, at least one layer of FSS (frequency selective surface) structural layer and an anti-ablation / washing layer, the bearing layer and the anti-ablation / washing layer are a plurality of layers of 2D and / or 2.5D fabric reinforced silicon dioxide-based ceramic materials, and the FSS structural layer, the bearing layer and the anti-ablation / washing layer are integrally formed by adopting a gluedipping-gel technology. According to the antenna cover and the preparation method in the invention, a single-layer or multi-layer FSS structure is prepared inside the fiber-reinforced silicon dioxide-based ceramic material, the FSS structure is stable, the FSS structure is good in environmental adaptability under the protection of the fiber-reinforced silicon dioxide-based ceramic material, the application field is wider, and engineering application of the technology is facilitated.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

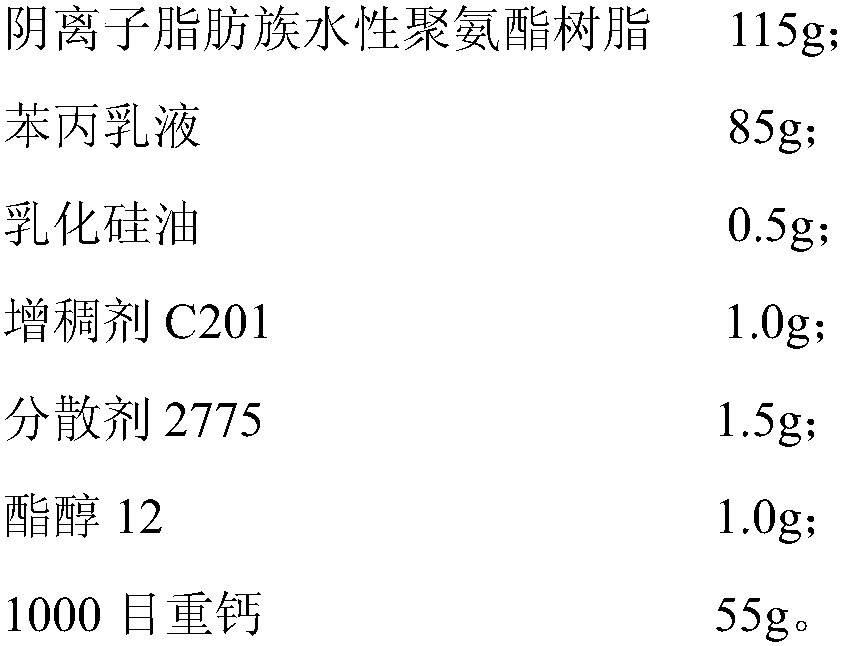

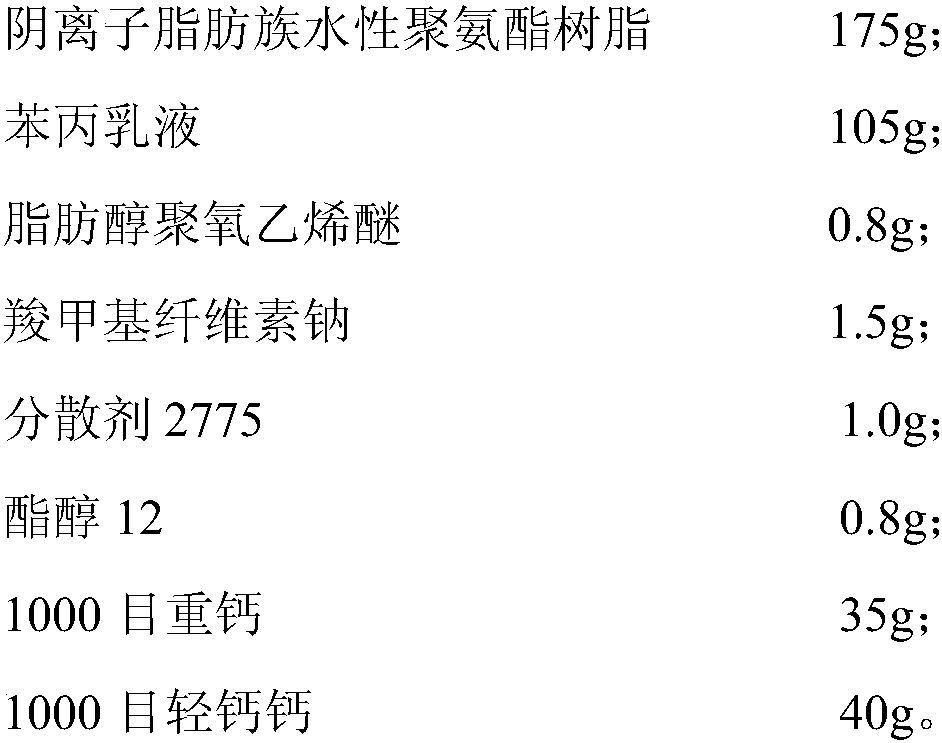

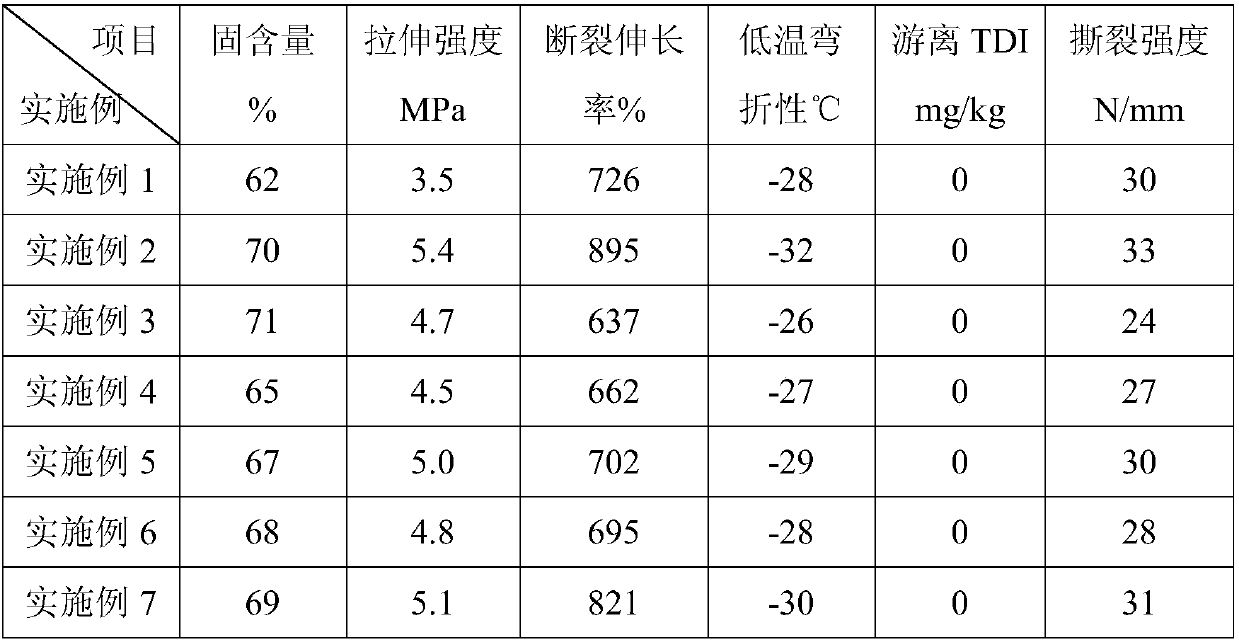

High-elongation waterborne polyurethane waterproof coating and preparation method

InactiveCN107858087AThe production process is simpleReduce energy consumptionPolyurea/polyurethane coatingsEmulsionPolymer science

The invention provides a high-elongation waterborne polyurethane waterproof coating which is prepared from the following components in percentage by mass: 15-60% of waterborne resin component, 10-55%of waterborne emulsion component, 0.5-4% of coalescing agent, 0.1-3% of antifoaming agent, 0.5-4% of thickening agent, 0.5-4% of dispersing agent and 10-40% of filler. The invention solves the problemof the prior art that a large amount of diisocyanate is applied and consequently the hard segment content is excessively high and the obtained polyurethane is very crisp and has poor low-temperaturebending property and low elongation at break, and provides a preparation method for preparing a high-elongation waterborne polyurethane waterproof coating at a room temperature of 15-35 DEG C.

Owner:山东鑫达鲁鑫防水材料有限公司

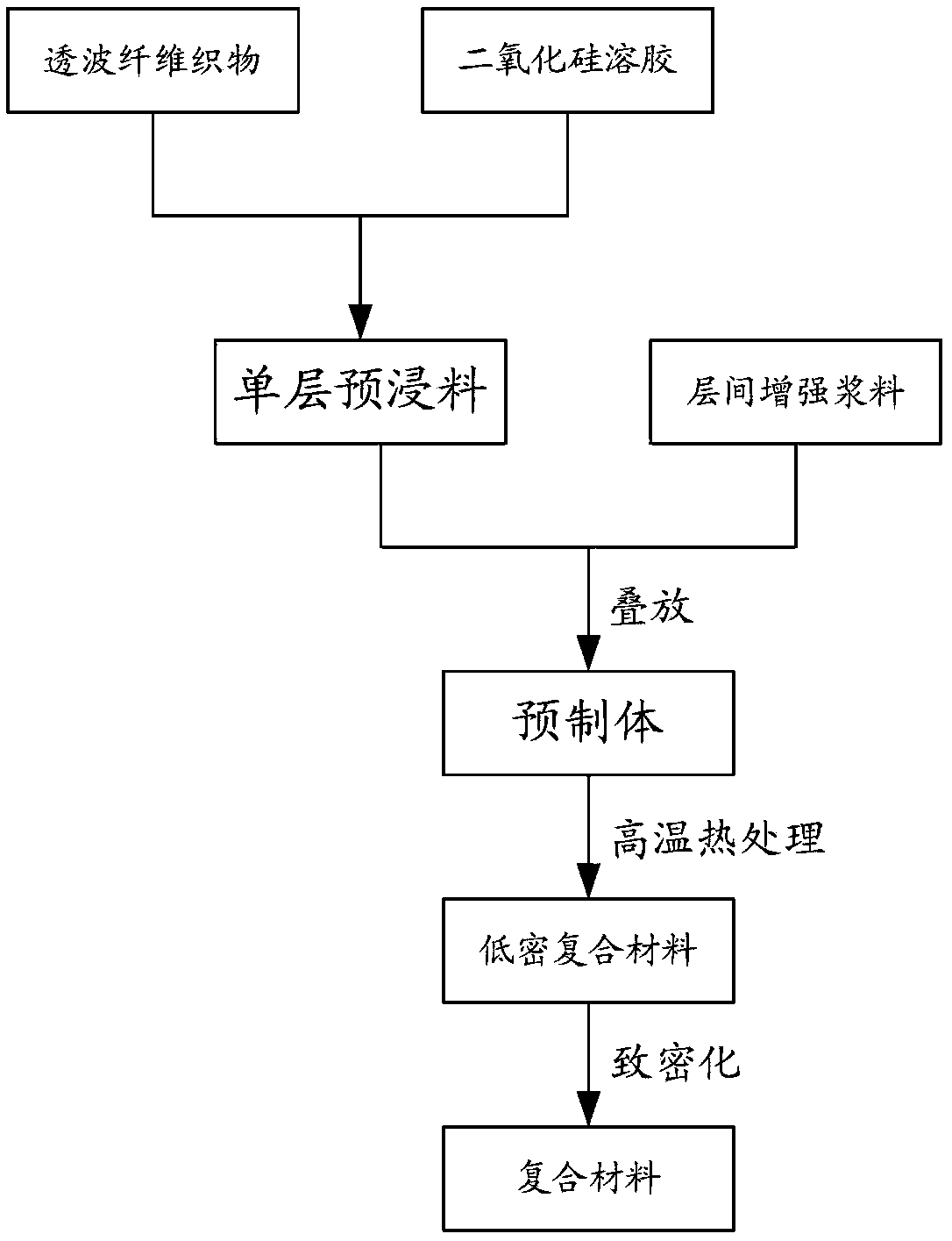

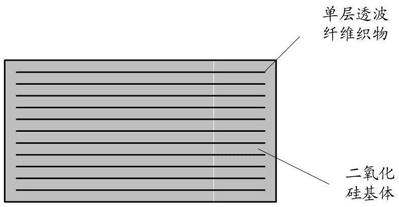

Fiber-strengthened ceramic-based wave-transmitting material and preparation method thereof

ActiveCN109456074AImprove interlayer strengthPrepreg hand lay-up process is practicalSilicon oxideCeramic

The invention provides a fiber-strengthened ceramic-based wave-transmitting material and a preparation method thereof. A plurality of fiber layers strengthen a silicon dioxide matrix and are distributed in the silicon dioxide matrix in parallel. Through adhesion of interlayer strengthened slurry, the interlayer strength of a 2D fiber strengthened silicon dioxide-based composite is greatly improved, so that the prepreg hand laying technology of a fiber-strengthened ceramic-based wave-transmitting composite is more practical, and the application range of the material is expanded.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

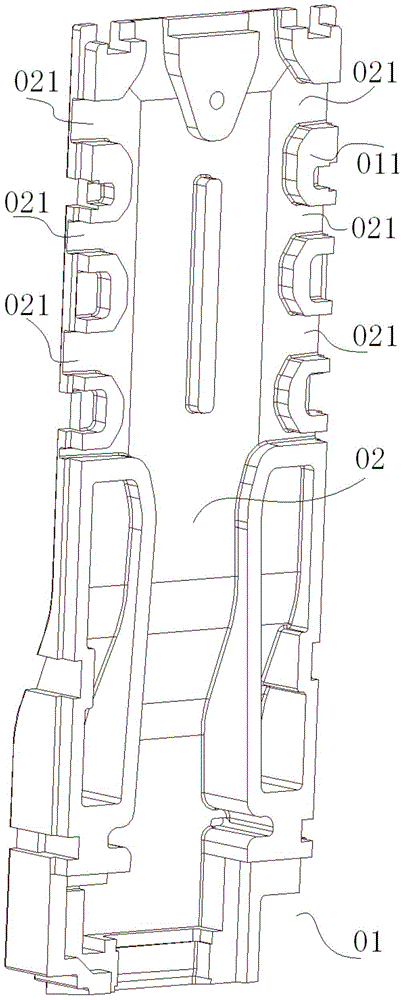

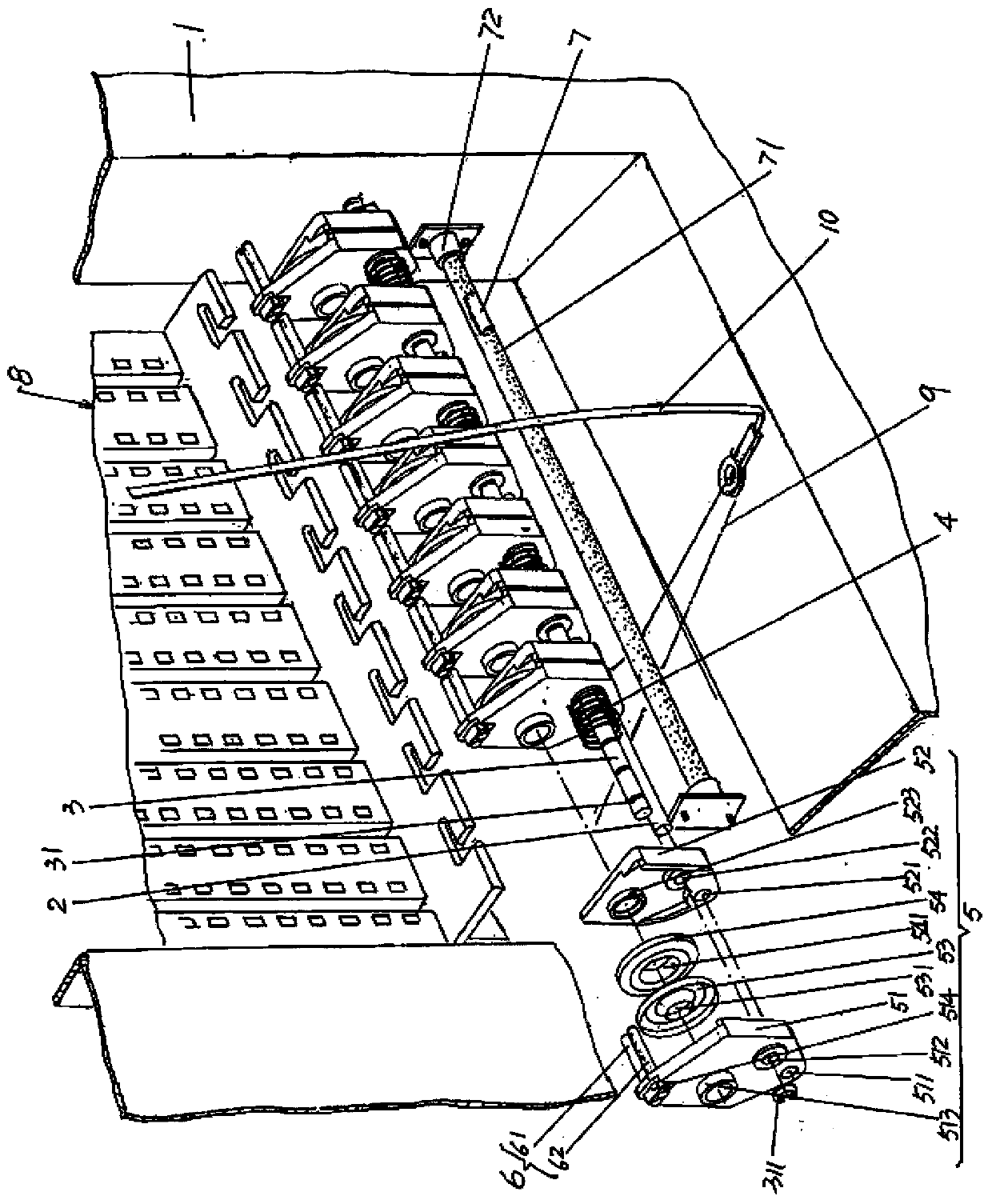

Directional yarn guide mechanism of computer flat knitting machine

The invention provides a directional yarn guide mechanism of a computer flat knitting machine, which belongs to the technical field of auxiliary members of the computer flat knitting machine. The directed yarn guide mechanism comprises a yarn guide roller, a spring rod, a group of chuck seat springs and a group of yarn clamping devices, wherein the spring rod is parallel to the yarn guide roller; the group of chuck seat springs is sleeved on the spring rod; the group of yarn clamping devices is arranged on the yarn guide roller and the spring rod; and a yarn guider is arranged on each yarn clamping device and is correspondingly positioned above the yarn guide roller. The directional yarn guide mechanism has the advantages that acting force is provided for adjacent yarn clamping devices by the chuck seat springs arranged on the spring rod, so yarn passing through the yarn guiders is led out from the yarn guide roller under the clamping and the protection of the yarn clamping devices; since the yarn sequentially passes through the yarn guiders, the yarn clamping devices and the yarn guide roller, a good directional effect is achieved, the condition that the yarn escapes from the yarn clamping devices cannot occur and the yarn can be smoothly guided to a knitting mechanism.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

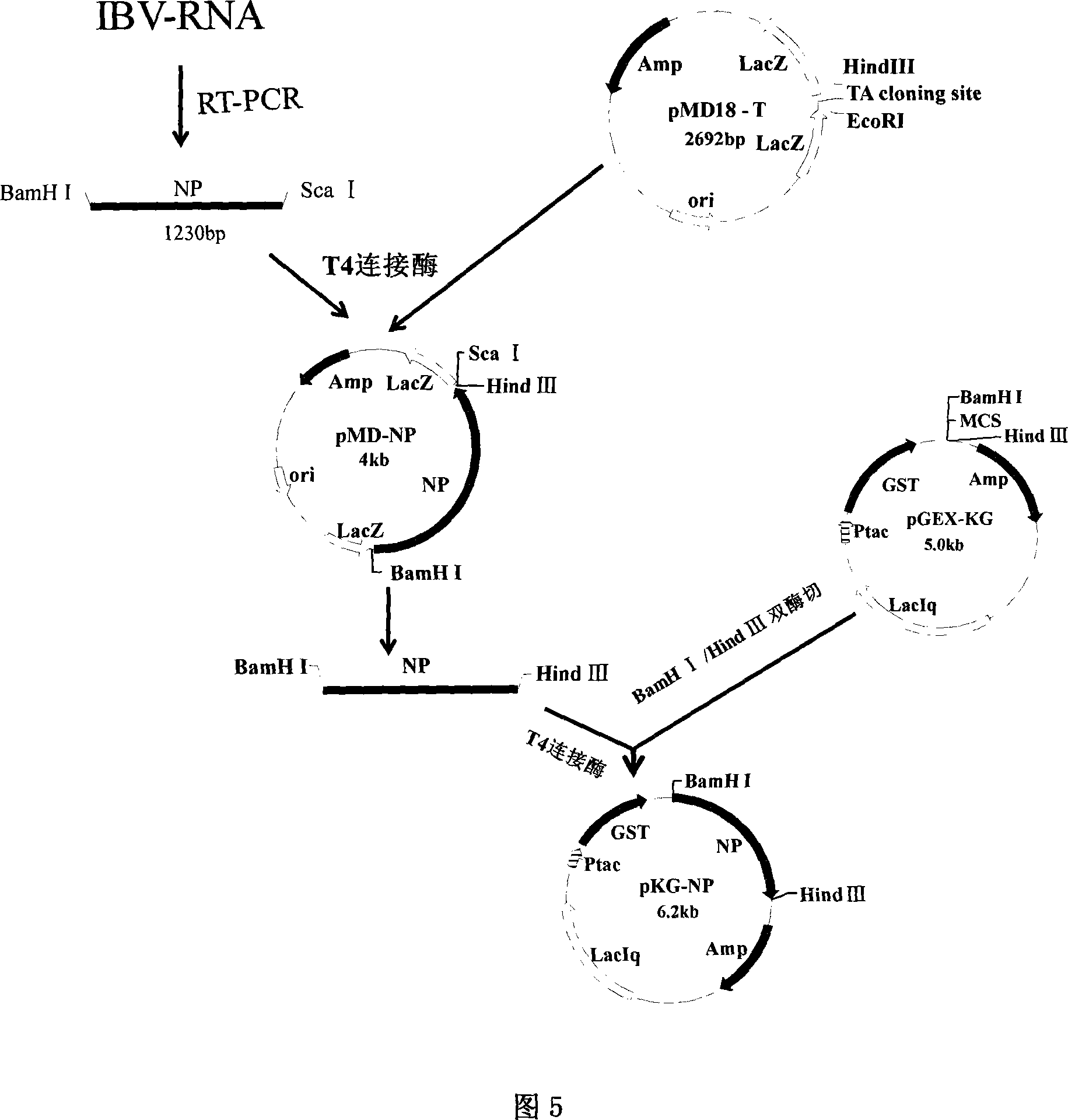

Chicken infectious bronchitis immune body immune colloidal gold fast detecting reagent kit and its application

The invention belongs to the immunity application field, which relates to the related fields of animal molecular biochemistry and the immunology, etc. The invention discloses a reagent kit respectively used for antibody of infectious bronchitis of chicken, which comprises a case body, and the test paper card and sample diluent equipped inside the case body, wherein, the test paper card is formed by the absorption pad, nitrocellulose membrane, gold-label pad and sample pad affixed in turn on the non-absorbent supporting flake by taking the sample pad, absorption pad and the NP recombinant proteins coated with the nucleocapsid of the infectious bronchitis of chicken as the detection line and the NP recombinant proteins coated with anti-mouse IgG as nitrocellulose membrane of the quality control line. The reagent kit used for testing the corresponding antibody has the obvious advantages of strong specificity, high sensitivity, easy operation and fast diagnosis.

Owner:HUAZHONG AGRI UNIV

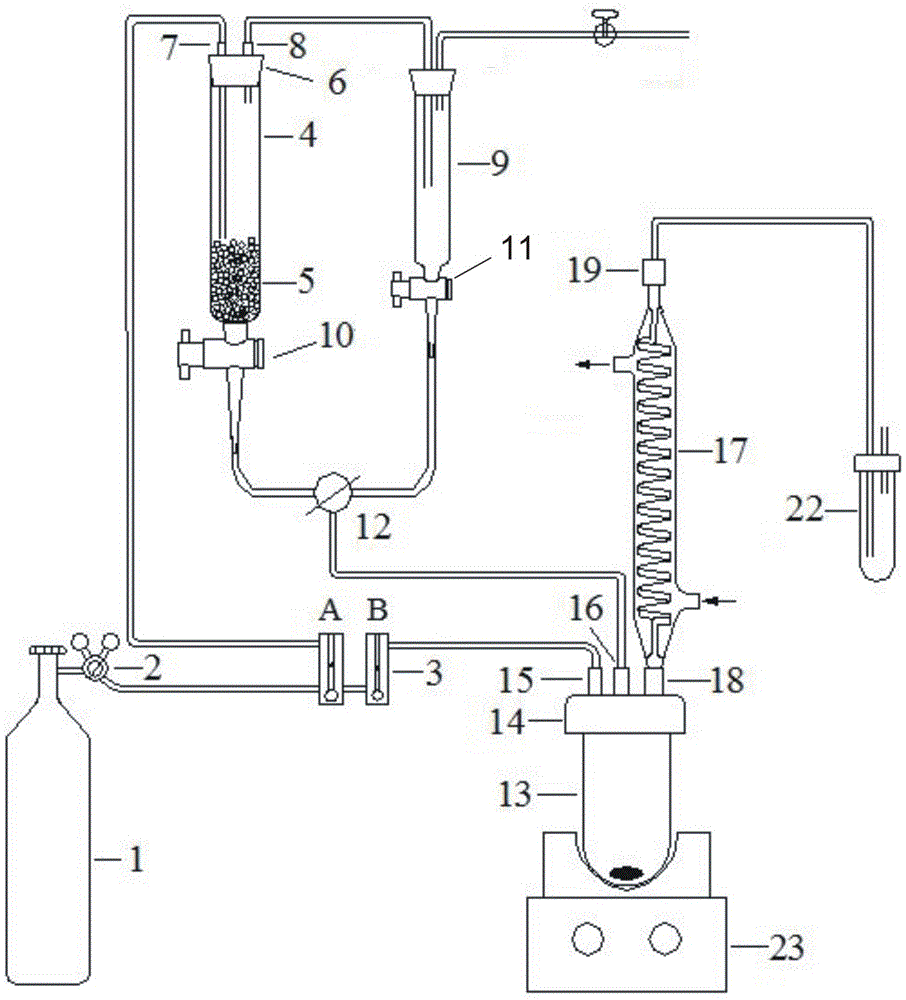

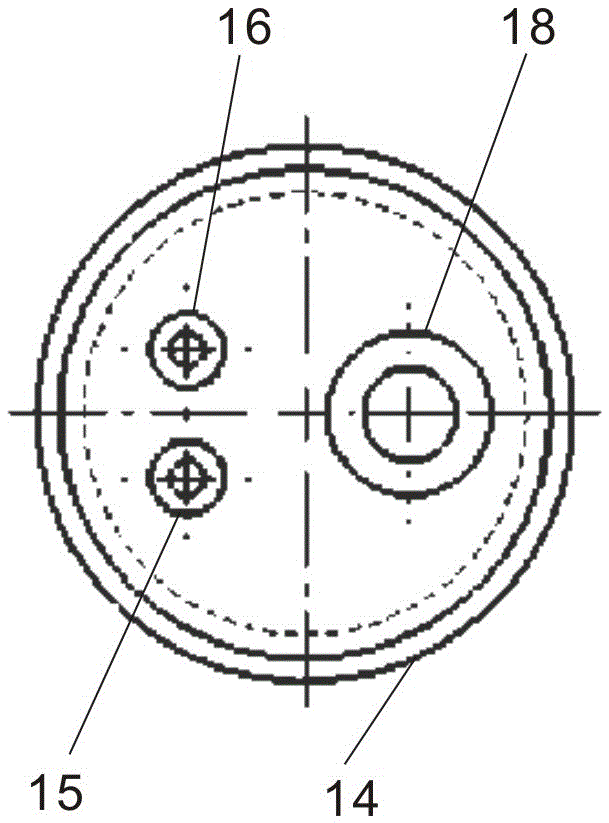

Experimental apparatus for continuous extraction of various forms of sulfur in sediment sample

The invention discloses an experimental apparatus for continuous extraction of various forms of sulfur in a sediment sample. The apparatus comprises four units. A sample reaction and extraction unit comprises a reaction vessel, a condenser pipe and a magnetic stirrer; and the reaction vessel is placed on the magnetic stirrer. A reaction reagent addition and preparation unit includes a chromatography column, a cylindrical separating funnel and a three-way selector valve; the chromatography column is used to prepare a chromium chloride solution and add the chromium chloride solution to the reaction vessel; the cylindrical separating funnel is used for adding acid to the reaction vessel; and the three-way selector valve switches to add different solutions. A nitrogen air passage unit comprises a nitrogen bottle, a pressure reducing valve and gas flow meters; the nitrogen gas is connected to the two gas flow meters by pipes; and one gas flow meter is connected with a gas inlet on the upper end of the chromatography column, and the other gas flow meter is communicated with a gas inlet on the reaction vessel. A gas absorption unit is a gas absorption tube. The apparatus has the advantages of simple structure, good air tightness, high extraction efficiency, and easy and fast operation, and can effectively and continuously extract six forms of sulfur in one sediment sample.

Owner:上海航鸿工程管理有限公司

Directional yarn guide mechanism of computer flat knitting machine

The invention discloses a directional yarn guide mechanism of a computer flat knitting machine, and belongs to the technical field of auxiliary components of computer flat knitting machines. The computer flat knitting machine comprises a headstock, and the directional yarn guide mechanism comprises a yarn guide roller, a spring rod, a set of yarn clamping springs, a set of yarn clamping devices and a set of yarn guide devices. The directional yarn guide mechanism of the computer flat knitting machine is characterized by further comprising a yarn damping roller, the yarn damping roller is fixed to the corresponding headstock wall of the headstock at the position corresponding to the lower side portion of the yarn guide roller, and a yarn-friendly layer is bonded on the surface of the yarn damping roller. According to the directional yarn guide mechanism of the computer flat knitting machine, the good directional effect is achieved, yarns are prevented from being disengaged from the yarn clamping device, the yarns are guaranteed to be led into a knitting mechanism, a false alarm is avoided, normal operation of the computer flat knitting machine is ensured, whole machine cost is not increased, and using cost is saved.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

Device and method for purifying and sterilizing swimming pool water

InactiveCN101704564AImprove sanitationKeep clean and hygienicWater treatment compoundsSpecific water treatment objectivesElectrolysisWater cycling

The invention provides a device and a method for purifying and sterilizing swimming pool water, and relates to water treatment. A swimming pool, a water circulation pump, a nano catalytic micro electrolysis tank and a filter are arranged. The water inlet of the water circulation pump is connected with a swimming pool water circulation port; the water outlet of the water circulation pump is connected with the water outlet of the micro electrolysis tank through one water outlet of a tee; the water outlet of the micro electrolysis tank is connected with the water inlet of the filter; the other water outlet of the tee is connected with the water inlet of the filter; and the water outlet of the filter is connected with the swimming pool water inlet. Through a water taking pump and the tee, a part of the swimming pool water is input into the micro electrolysis tank to be catalyzed and micro-electrolyzed and enters the filter through a water outlet of the micro electrolysis tank; and the other part enters the filter and is mixed with the micro-electrolyzed water, strong oxidizing substances generated by catalytic micro-electrolysis are utilized to kill algae, microorganism and viruses in the swimming pool water and make suspended solids, colloids, bacteria and the like form bigger grains, the filter filters to remove the bigger grains, and then the sterilized and purified water is obtained.

Owner:BOYING XIAMEN SCI & TECH

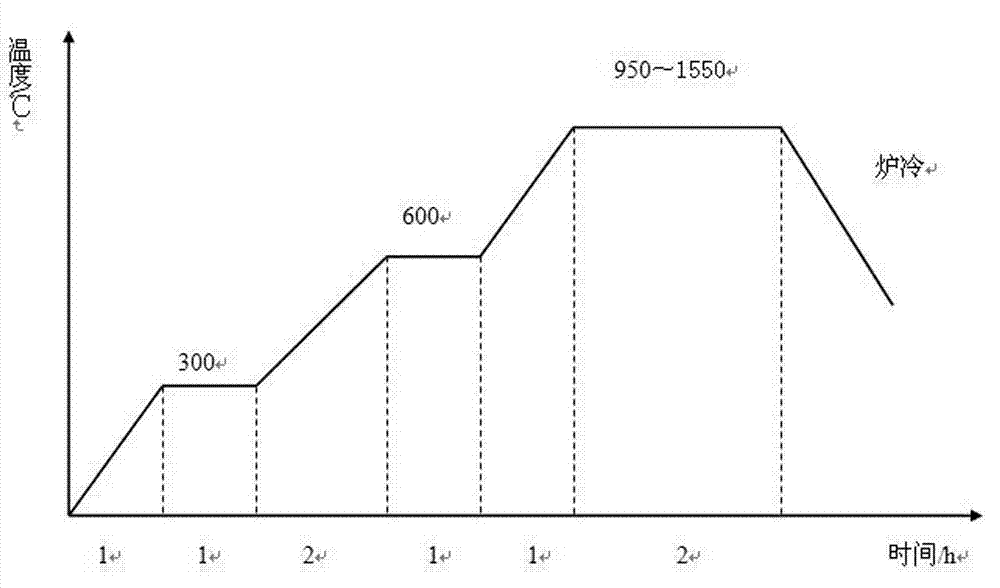

Preparation method of yttrium oxide moulding shell used for casting

ActiveCN106493287ASolve the problem of water back dissolutionSolve the breathability problemFoundry mouldsFoundry coresHuman healthTitanium alloy

The invention discloses a preparation method of an yttrium oxide moulding shell used for titanium alloy precision casting. A moulding shell surface layer coating comprises yttrium oxide refractory powder, ammonium zirconium carbonate binder, a wetting agent and a defoaming agent. The preparation method includes the steps of preparation of the surface layer coating, preparation of a back layer coating, preparation of the moulding shell, dewaxing, calcinations and the like. By means of the yttrium oxide moulding shell used for titanium alloy precision casting and the preparation method thereof, the problems that an existing moulding shell is prone to redissolution under the influence of water in the preparation and dewaxing processes, and steam dewaxing cannot be achieved are solved. The binder used for the coating is made of ammonium zirconium carbonate and is low in price, and the prepared coating is stable and reliable and cannot generate redissolution after being dried under the influence of water. The prepared surface layer coating is good in smearing performance and high in refractoriness, steam dewaxing is adopted, no pollution is caused to the environment, and the prepared surface layer moulding shell has no influence on the human health. The prepared yttrium oxide moulding shell is wide in application range, an interface reaction layer is small, titanium alloy casts are high in precision, performance is excellent, and later-period finishing is conducted easily.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

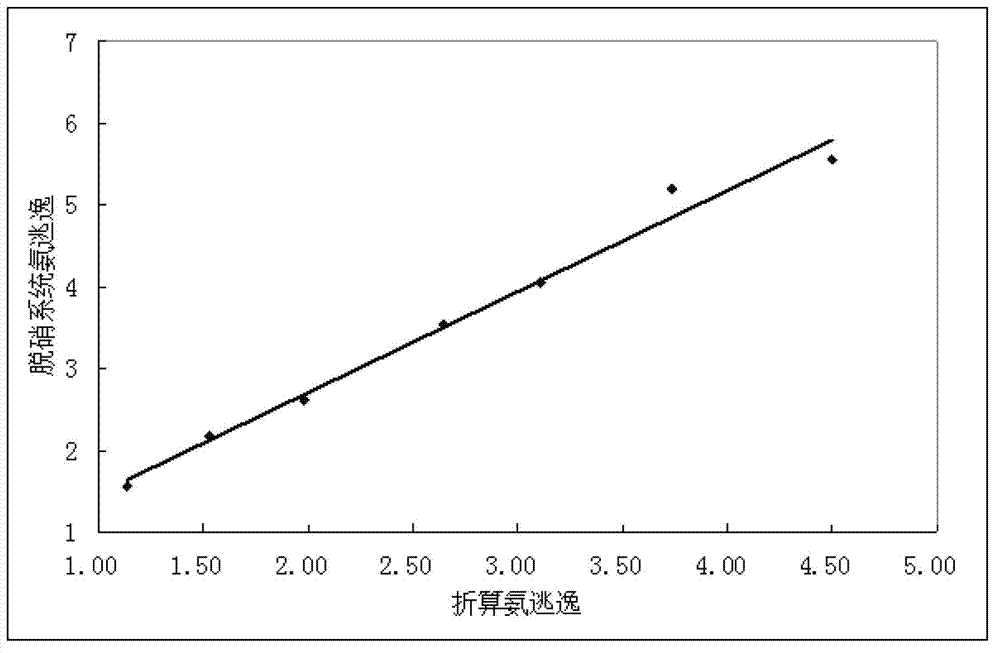

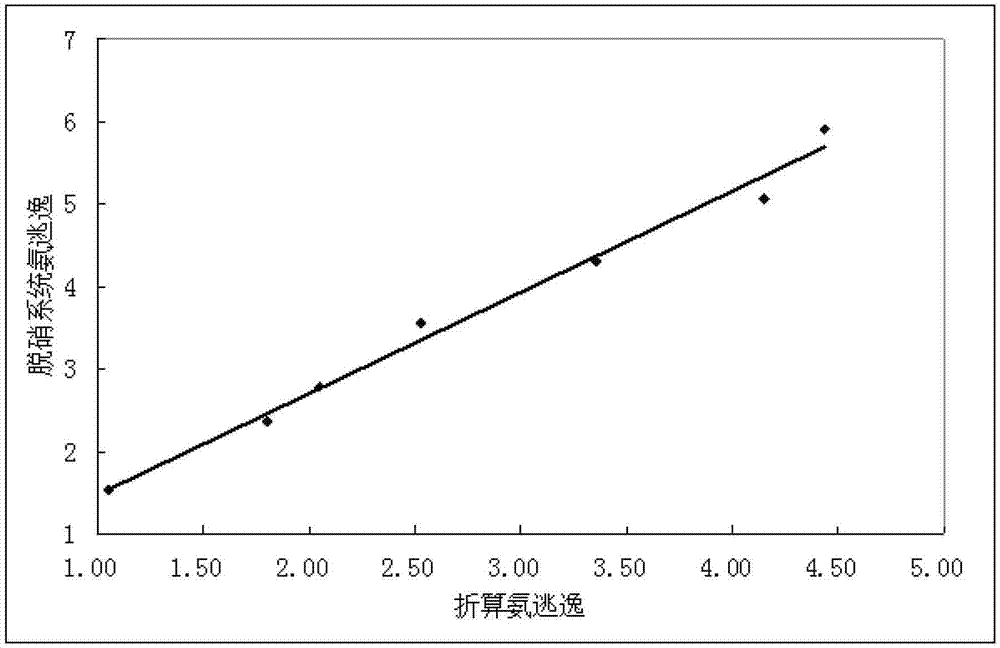

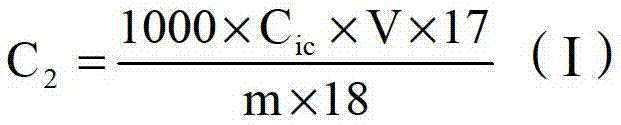

Method for detecting ammonia escape of flue gas denitrification system

The invention provides a method for detecting ammonia escape of a flue gas denitrification system. The method includes that flying ash of a first electric field ash hopper of an electrofilter serves as a detection object. Researches show that by analyzing, an excellent linear relationship is existed between ammonia escape converted by ammonia content in first electric field flying ash of the electrofilter and ammonia escape of the flue gas denitrification system, the flying ash of the first electric field ash hopper of the electrofiler is mixed with water to obtain to-be-detected sample solution, the water-to-ash ratio is controlled to be (20-100):2 while the pH (potential of hydrogen) value of the to-be-detected sample solution is controlled to be 6.0-6.8, most of and even all of ammonia in the flying ash is enabled to be solved in the water without ammonia escape, and accordingly an accurate result is obtained. Therefore, the detection result, obtained by the method, of ammonia escape of the flue gas denitrification system is more accurate, and is stable as not being affected by equipment failure.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Process

InactiveCN107001190ARealize continuous productionRealize comprehensive utilizationPreparation by hydrogen halide split-offPreparation by halogen replacementAlkyl transferReaction zone

Disclosed is a process for preparing a highly pure 1,1,1,2,3-pentachloropropane product. The method comprises 1-a) providing a reaction mixture comprising ethylene, carbon tetrachloride and a catalyst in a principal alkylation zone to produce 1,1,1,3-tetrachloropropane in the reaction mixture; 1-b) treating the reaction mixture obtained in step 1-a) to obtain a 1,1,1,3-tetrachloropropane feedstock; 2-a) contacting the 1,1,1,3-tetrachloropropane feedstock with a catalyst in a dehydrochlorination zone to produce a reaction mixture comprising 1,1,1,3-tetrachloropropane and 1,1,3-trichloropropene; 2-b) treating the reaction mixture obtained in step 2-a) to obtain a 1,1,3-trichloropropene feedstock; 3-a) contacting the 1,1,3-trichloropropene feedstock with chlorine in a reaction zone to produce a reaction mixture containing 1,1,1,2,3-pentachloropropane and 1,1,3-trichloropropene, the reaction zone being different from the dehydrochlorination zone; and 3-b) treating the reaction mixture obtained in step 3-a) to obtain the highly pure 1,1,1,2,3-pentachloropropane product.

Owner:SPOLEK PRO CHEMICKOU A HUTNI VYROBU

Environment friendly nano composite high polymer electric cable

ActiveCN101477850AAvoid corrosionPrevent immersionPlastic/resin/waxes insulatorsInsulated cablesPolyesterElectrical conductor

The invention discloses an environment-friendly nano-composite polymer power cable. Multiple insulated conductors are intertwisted to form a cable core; a packing layer is arranged in a cable core gap; each insulated conductor consists of a conductor, a mica wrapped refractory layer and an insulating layer from inward to outward; the cable is characterized in that the insulating layer is manufactured by adopting a polyethylene montmorillonite nano-composite; and a waterproof polyester tape, a halogen-free glass fiber tape, a mica tape refractory layer, an oxygen insulation waterproof layer, a stainless steel strip armored layer and a restrictive coating successively covers outside the cable core and the packing layer. The cable has the advantages of high environmental protection performance, good ant and rat prevention performance, fire performance and radial and axial waterproof performance and the like, and high mechanical strength; and during burning, little smoke and no harmful haloid acid substance is produced.

Owner:ANHUI HUAXING CABLE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com