Copper plating liquid and process for direct cyanide-free acid copper plating on steel substrate

An acidic copper and steel plating technology, applied in the field of copper plating solution, can solve the problems of poor bonding force, achieve long life, simple maintenance of plating solution, and reduce investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

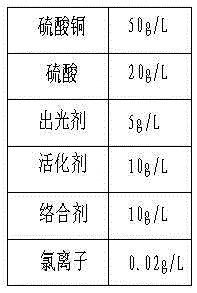

[0045] In this embodiment, the formula of the electroplating solution is:

[0046]

[0047] In the electroplating solution, the cathode current density is 1A / dm2, the temperature of the electroplating solution is 40°C, the electroplating time is 60 minutes, and the phosphorous copper anode contains 0.5% phosphorus.

[0048] The following is the cyanic-free copper plating process, including the following steps:

[0049] Step 1: In order to go through the steel parts grinding and rust removal, chemical degreasing, hot water washing, water washing, pickling, water washing, electro degreasing, hot water washing, ultrasonic cleaning and acid activation (H 2 SO 4 10%);

[0050] Step 2: Put copper sulfate, sulfuric acid, chloride ion, luminous agent, activator, complexing agent in a container with a volume of 1000 ml according to the concentration ratio, and then add deionized water or distilled water to 1000 ml, and stir evenly until completely dissolved Obtain a plating solution. Put the ...

Embodiment 2

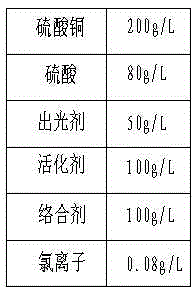

[0052] In this embodiment, the formula of the electroplating solution is:

[0053]

[0054] In the electroplating solution, the cathode current density is 8A / dm2, the temperature of the electroplating solution is 15°C, the electroplating time is 10 minutes, and the phosphorous copper anode contains 0.2% phosphorous.

[0055] The copper plating process of this embodiment is the same as that of Embodiment 1, and will not be described in detail here.

Embodiment 3

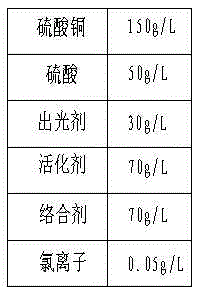

[0057] In this embodiment, the formula of the electroplating solution is:

[0058]

[0059] In the electroplating solution, the cathode current density is 5A / dm2, the temperature of the electroplating solution is 30°C, the electroplating time is 40 minutes, and the phosphorous copper anode contains 0.3% phosphorus.

[0060] The copper plating process of this embodiment is the same as that of Embodiment 1, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com