Preparation method of yttrium oxide moulding shell used for casting

A technology of yttrium oxide and precision casting, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, etc. It can solve the problems that the yttrium oxide shell cannot be dewaxed by steam, can not be dewaxed by steam, and the material remelts when it encounters water. Improve dimensional stability and high temperature strength, facilitate preparation and storage, and reduce the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

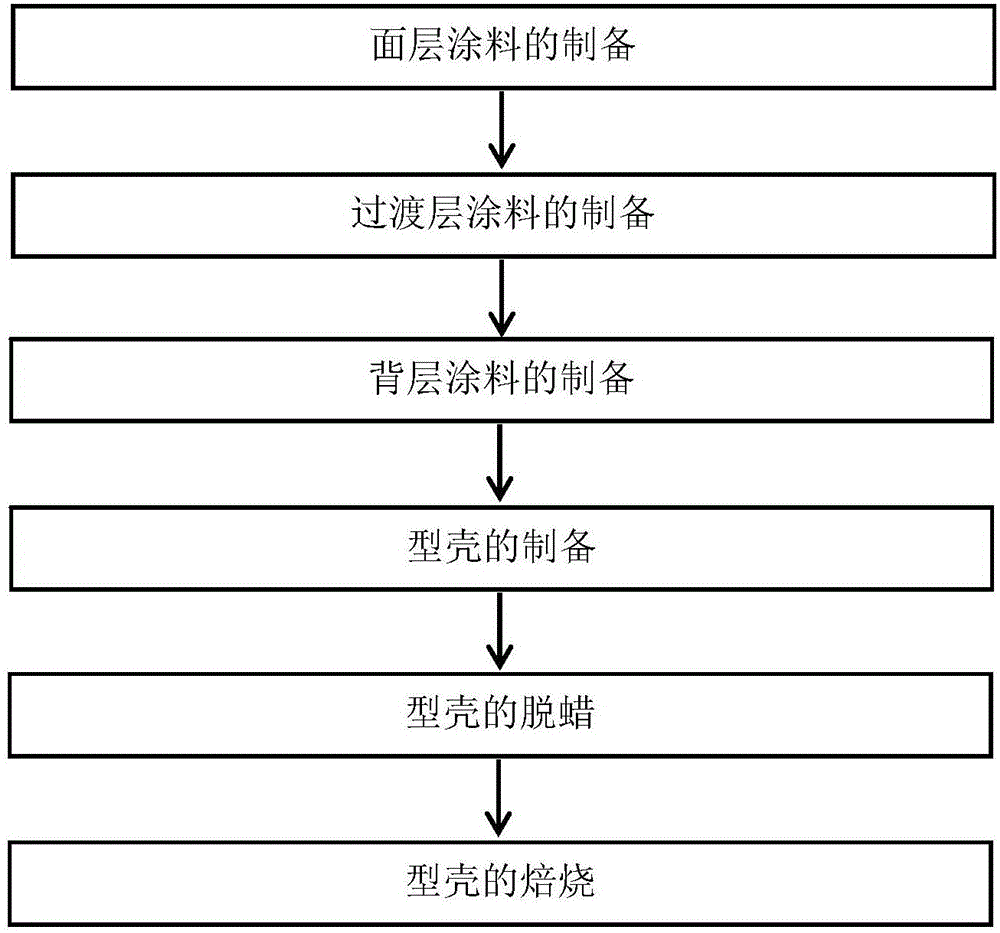

[0037] A preparation method for an yttrium oxide mold shell for titanium alloy precision casting, comprising the following steps:

[0038](1) Preparation of surface coating: Weigh refractory powder, binder, wetting agent and defoamer, wherein the mass ratio of refractory powder to binder (powder-liquid ratio) is 2~5, wetting The volume of the agent is 0.05%~0.5% of the volume of the binder, and the volume of the defoamer is 0.1%~0.6% of the volume of the binder. The refractory powder is yttrium oxide powder less than 325 meshes obtained after crushing and screening, the binder is ammonium zirconium carbonate, the wetting agent is JFC, and the defoaming agent is n-octanol. Add the weighed refractory powder into the binder and stir for 3h~8h, then add the weighed wetting agent and defoamer into the surface coating, and continue stirring for 12h~48h to obtain titanium alloy precision casting Topcoat with yttrium oxide type shells.

[0039] (2) Preparation of transition layer co...

Embodiment 1

[0045] A preparation method for an yttrium oxide mold shell for titanium alloy precision casting, comprising the following steps:

[0046] (1) Preparation of surface coating: weigh 3Kg of refractory powder, measure 1L of binder, 1mL of wetting agent and 2mL of defoamer. The refractory powder is fused yttrium oxide less than 325 meshes, the binder is ammonium zirconium carbonate, the wetting agent is JFC, and the defoaming agent is n-octanol. Add the weighed refractory powder into the binder and stir for 8 hours, then add the weighed wetting agent and defoamer into the surface coating, and continue stirring for 16 hours to obtain the yttrium oxide type for titanium alloy precision casting. Shell topcoat. The temperature of the working environment for the preparation of the surface coating is controlled at 20°C, the relative humidity is controlled at 50%, the temperature of the surface coating is controlled at 15°C, and the flow cup viscosity of the top coating is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com