Process for preparing composite nonwoven wallpaper

A preparation process and non-woven technology, which is applied in the field of preparation process of composite non-woven wallpaper, can solve the problems of non-bacterial, air-tight, and sound-absorbing, etc., and achieve the effect of easy to be affected by moisture, wide application field, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

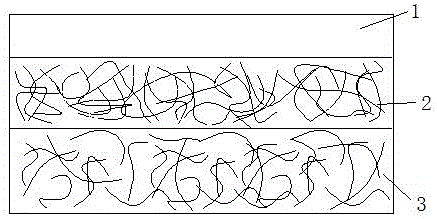

[0029] Such as figure 1 A composite non-woven wallpaper shown, comprising an upper layer 1, a middle layer 2 and a lower layer 3, the middle layer 2 is located between the upper layer 1 and the lower layer 3; the upper layer 1 has a surface density of 10 to 20 g / m 2 , the middle layer 2 adopts wet-laid, spunlace or thermal bonding reinforcement technology, and the surface density is 100~200g / m 2 , the lower layer 3 adopts carding, needle punching or thermal bonding reinforcement technology, and the surface density is 300~400g / m 2 .

[0030] Wherein, the upper layer 1 is a polytetrafluoroethylene gas-permeable membrane material, and the upper layer 1 has the characteristics of waterproof, moisture-proof, anti-fouling, and breathable. The middle layer 2 adopts wood pulp fiber content of 20%~30%, flax fiber content of 50%~70%, length of 4~7mm, ES fiber content of 10%~20%, length of 4~7mm, adopts wet-laid netting, spunlace Or thermal bonding reinforcement technology, prepare 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com