Patents

Literature

1573results about How to "Breathable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

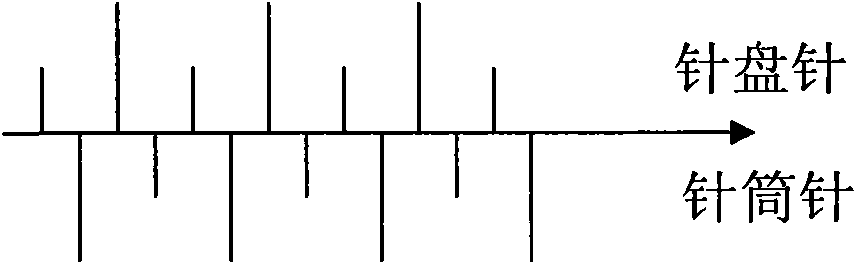

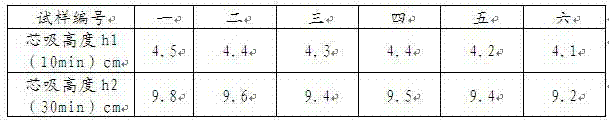

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Fabric capable of preventing electromagnetic radiation

InactiveCN101942729AElastic fit and comfortableHarm reductionWeft knittingWarp knittingYarnSilver plate

The invention relates to a fabric capable of preventing electromagnetic radiation, which is knitted or weaved. The warp and the abb of the fabric comprise covering yarn. The covering yarn takes one of silver plating fiber, carbon fiber and carbon black organic fiber as core yarn and takes comfortable fiber as skin yarn; the silver plating fiber is formed by carrying out silver plating on synthetic fiber; the weight ratio of the corn yarn to the skin yarn is 10-70:30-90; and the comfortable fiber is one of cotton, wool, silk, hemp, viscose, bamboo fiber, bamboo carbon fiber, soybean fiber, PLA fiber, alginate fibre, milk fiber and pearl fiber. The invention can shield electromagnetic wave, and the shield effect is above 99%. The skin yarn in the covering yarn adopts natural fiber, and the natural fiber on the outer layer has the characteristics of moisture absorption, ventilation and comfort.

Owner:汕头市奥山服饰有限公司

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

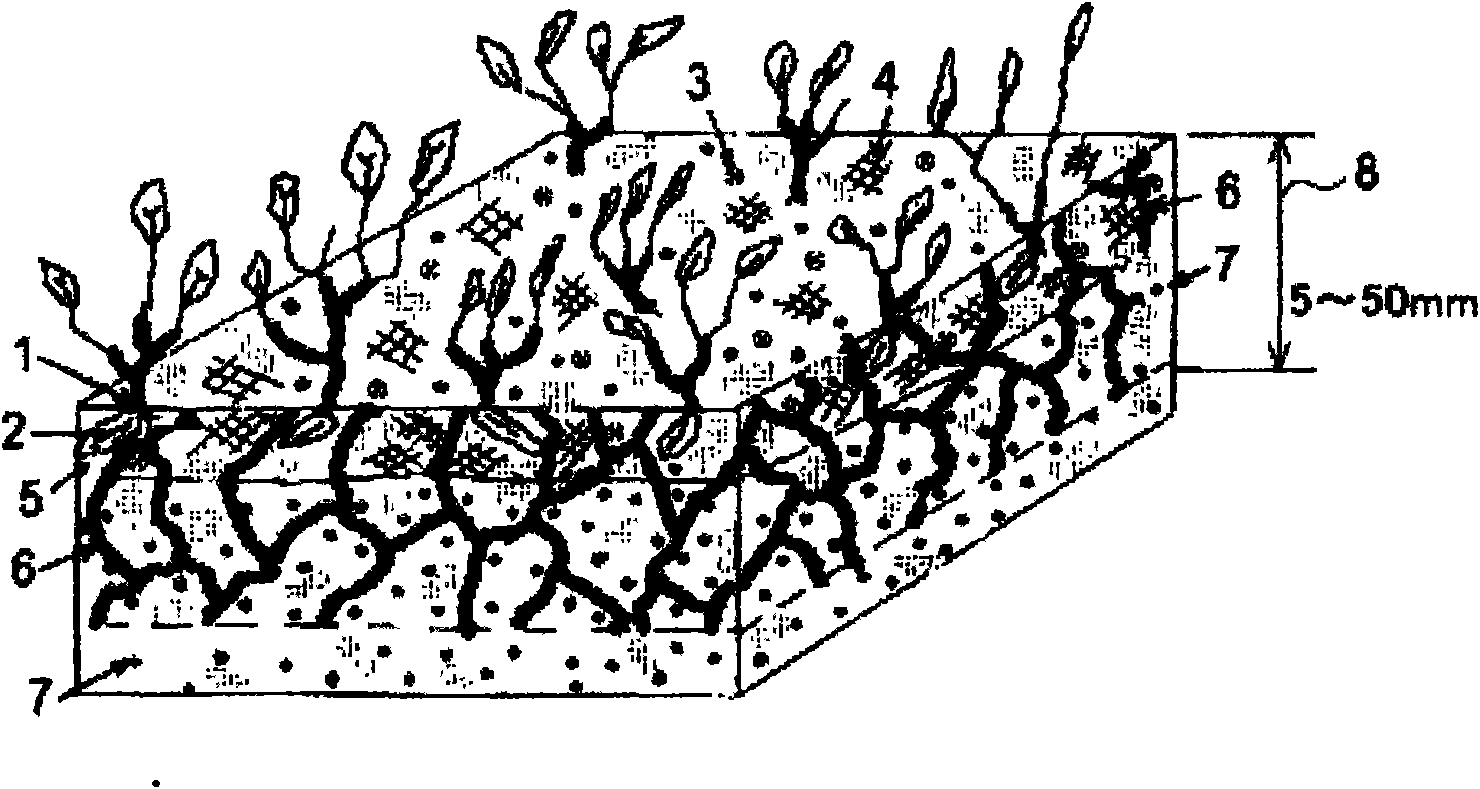

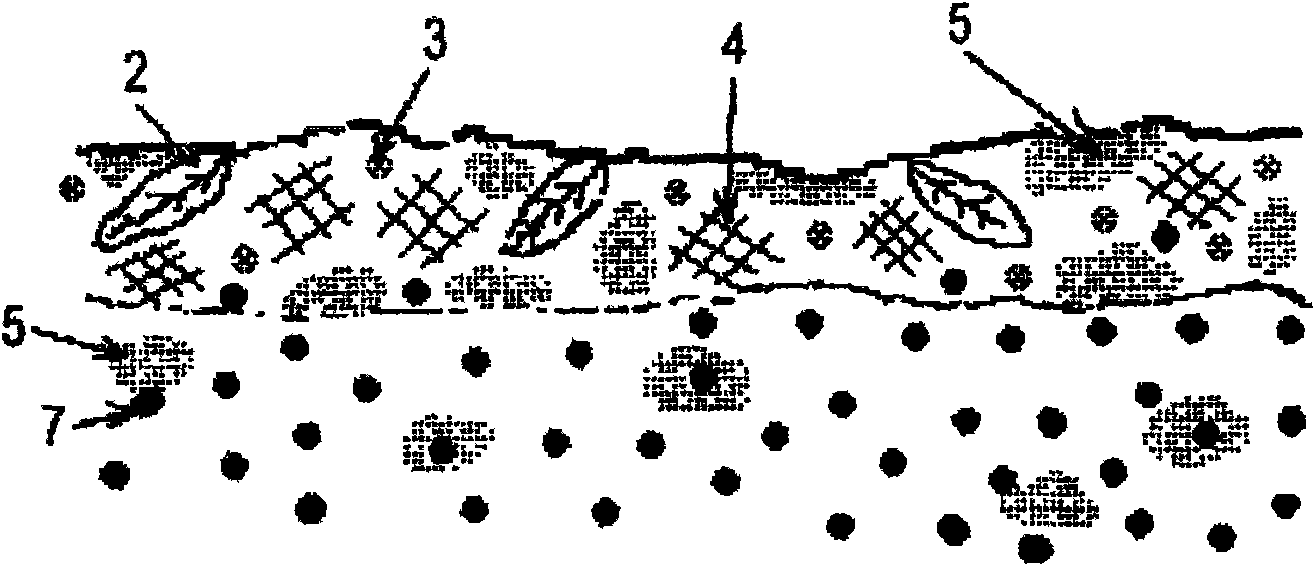

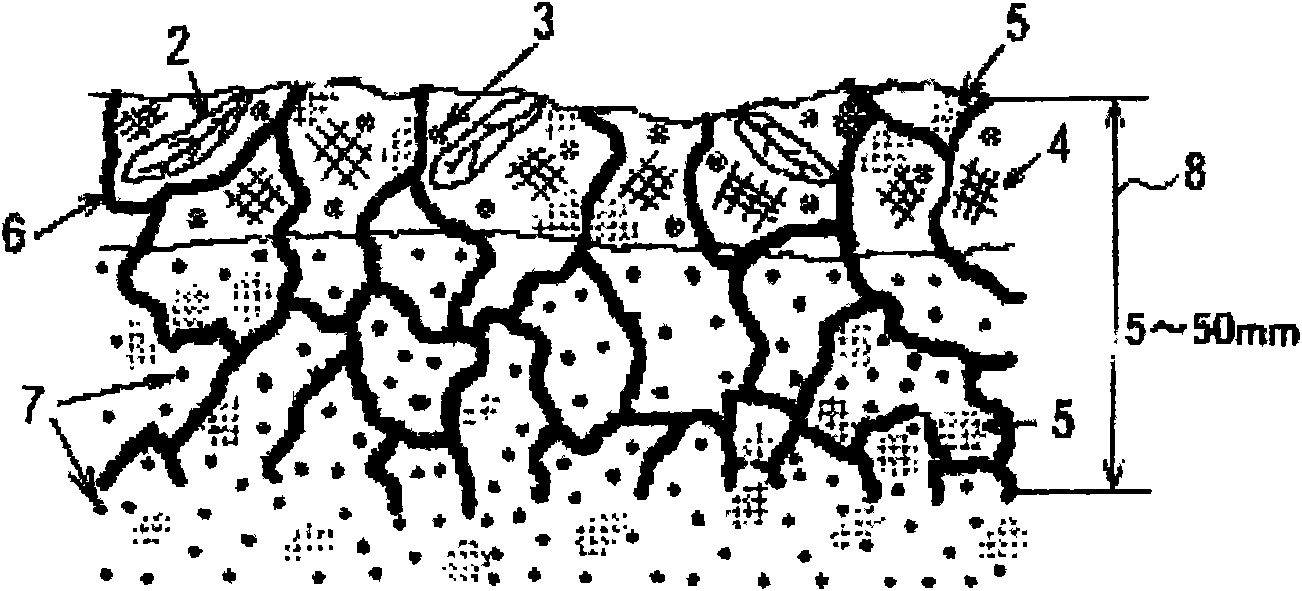

Desert control method of chemical sand-fixing greening technology based on organic composite materials

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

Planting method of famous and precious Chinese herb medicine dendrobium officinale

InactiveCN103004421AConducive to accumulation of emissionsAccelerate evaporationHorticultureFertilizer mixturesPlant rootsEvaporation

The invention relates to a planting method of famous and precious Chinese herb medicine dendrobium officinale, and the method is characterized in that a cultivation bed of a plantation trough with an undulated bottom is established under a certain facility environment, multiple mixed organic matrixes mainly comprising pine bark are paved, a nondestructive planting technology for stretching tissue culture seedling roots is adopted, and scientific and reasonable dendrobium officinale planting method adopting comprehensive cultivation measures such as a photo and temperature control technology, a fertilizer control technology, an insect and harmful organism nuisanceless control technology and a sustainable harvesting technology is adopted in different growth seasons and for different plants according to the biological characteristics of the dendrobium officinale; and due to the adoption of the method, the ventilation, moisture evaporation and moistening functions of a plant root environment can be enhanced, and harmful substances influencing the growth of the plant can be eliminated in time, so that the plant can grow strong, active components are highly concentrated, the resistance is enhanced, a purpose of high yield and excellent quality can be realized, the high yield and stable yield of the dendrobium officinale can be guaranteed, the product quality is excellent, sustainability for harvesting the dendrobium officinale for multiple years can be realized, and super high yield of fresh products about 600kg per Mu every year can be realized after the method is put into production.

Owner:MAOMING HUISHENGYUAN BIOLOGICAL SCI & TECH

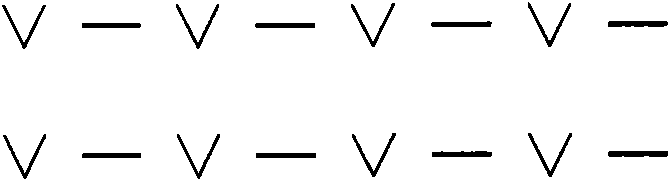

Production technology for antibiosis moisture exhausting sock

InactiveCN104195735AHas antibacterial propertiesFunctionalFabric breaking/softeningWeft knittingAntibiosisYarn

The invention discloses a production technology for an antibiosis moisture exhausting sock. The production technology includes the steps of firstly, preparing materials, wherein fiber used for knitting a fiber layer of the sock body is prepared through a yarn covering or yarn doubling method, knitted base yarn is manufactured, and components of the materials of the base yarn include 20% to 65% of natural bamboo fiber; secondly, dyeing the yarn through a sock dyeing machine; thirdly, conducting softening, wherein softening is conducted on the base yarn through softeners; fourthly, conducting knitting, wherein the base yarn is knitted into the sock body through a knitting machine, the base yarn of the natural bamboo fiber is knitted to form the sock body, and the sock body is sewn; fifthly, conducting disinfection, wherein antibiosis process treatment is conducted on the sock body through a sanitizer WS-8810 and an anti-bacterium agent; sixthly, conducting post processing, wherein the processed sock body is shaped to obtain a finished sock body. The sock has the antibiosis function and the sweat discharging function at the same time, is good in breathability, comfortable and soft and can still keep the extremely-strong antibiosis performance after being repeatedly washed.

Owner:浙江久渔针纺织有限公司

Protogenic alpine azalea introduction and acclimatization method

InactiveCN101095399ASeedling realizationAchieve growthCultivating equipmentsSoilless cultivationCuckooGreenhouse

The invention discloses a method for cultivating original alpine cuckoo, which comprises following steps: setting brandreth with its height being one meter in green house or booth, placing permeable and ventilating plastic crate on brandreth, feeding the plastic crate with 50-70% of humus soil or sward, 20-30% of perlite and 10-20% of decomposed wood dust, taking said mixing soil as culture medium, laying planus on said mixing soil, sowing original alpine cuckoo seed on planus, watering with normal procedure. The rate of emergence is 85%, and it is suitable to be used in south part of China.

Owner:戴悦

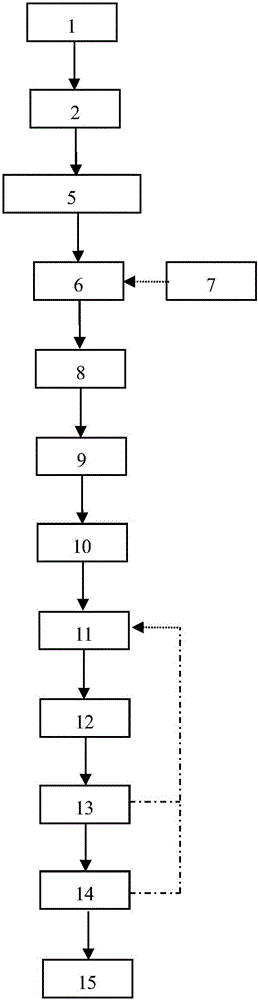

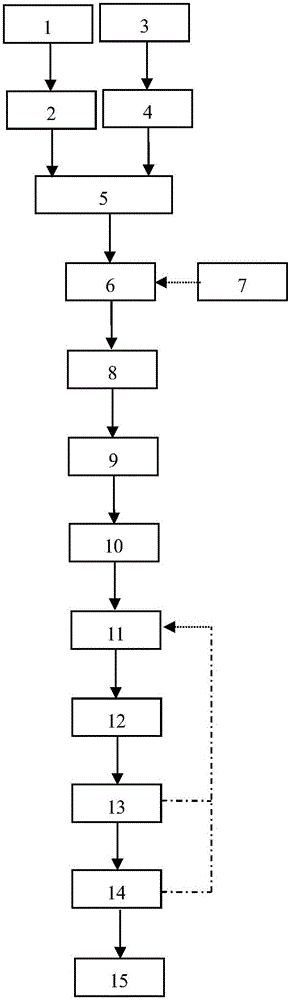

Method and device for preparing ceramsite from sludge pyrolytic biochar

ActiveCN106007776AAchieving mass utilizationEfficient curingCeramic materials productionCeramicwareSludgeBiochar

The invention discloses a method and device for preparing ceramsite from sludge pyrolytic biochar. The method includes the steps that powder grinding, humidifying, pelleting, low-temperature drying, middle-temperature presintering, high-temperature sintering and cooling are carried out on the sludge pyrolytic biochar to obtain the ceramsite. The device comprises a quantitative feeding device, a water adding device, a humidifying device, a forming and pelleting device, a drying device, a middle-temperature presintering device, a high-temperature sintering device and a cooling device. The sludge pyrolytic biochar is used for preparing the ceramsite, large-scale utilization of the sludge pyrolytic biochar is achieved, heavy metal element in the sludge pyrolytic biochar is further efficiently solidified and passivated, potential heavy metal accumulated pollution of the sludge pyrolytic biochar in the land using process is avoided, and the method and device are particularly suitable for resource utilization of sludge pyrolytic biochar with heavy metal content exceeding standard. The method is simple, practical, low in equipment investment and low in cost and has good economic benefits and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Bamboo fiber knitting fabric

The present invention relates to one kind of bamboo fiber knitting fabric with blended bamboo fiber yarn as facing layer and spandex or chinlon yarn covered with the bamboo fiber. It features that the blended bamboo fiber yarn consists of bamboo fiber in 50-70 wt% and cotton, Modal, Tencel, wool, cashmere or Dacron in 30-50 wt%, and has count of 20-60 s and twist multiplier of 330-345. The bamboo fiber knitting fabric has the excellent performance of bamboo, including moisture absorption, permeation, health care and antibiotic property, etc. as well as improved costume performance and size stability, and is one kind of high grade comfortable material for underwear.

Owner:北京铜牛集团有限公司

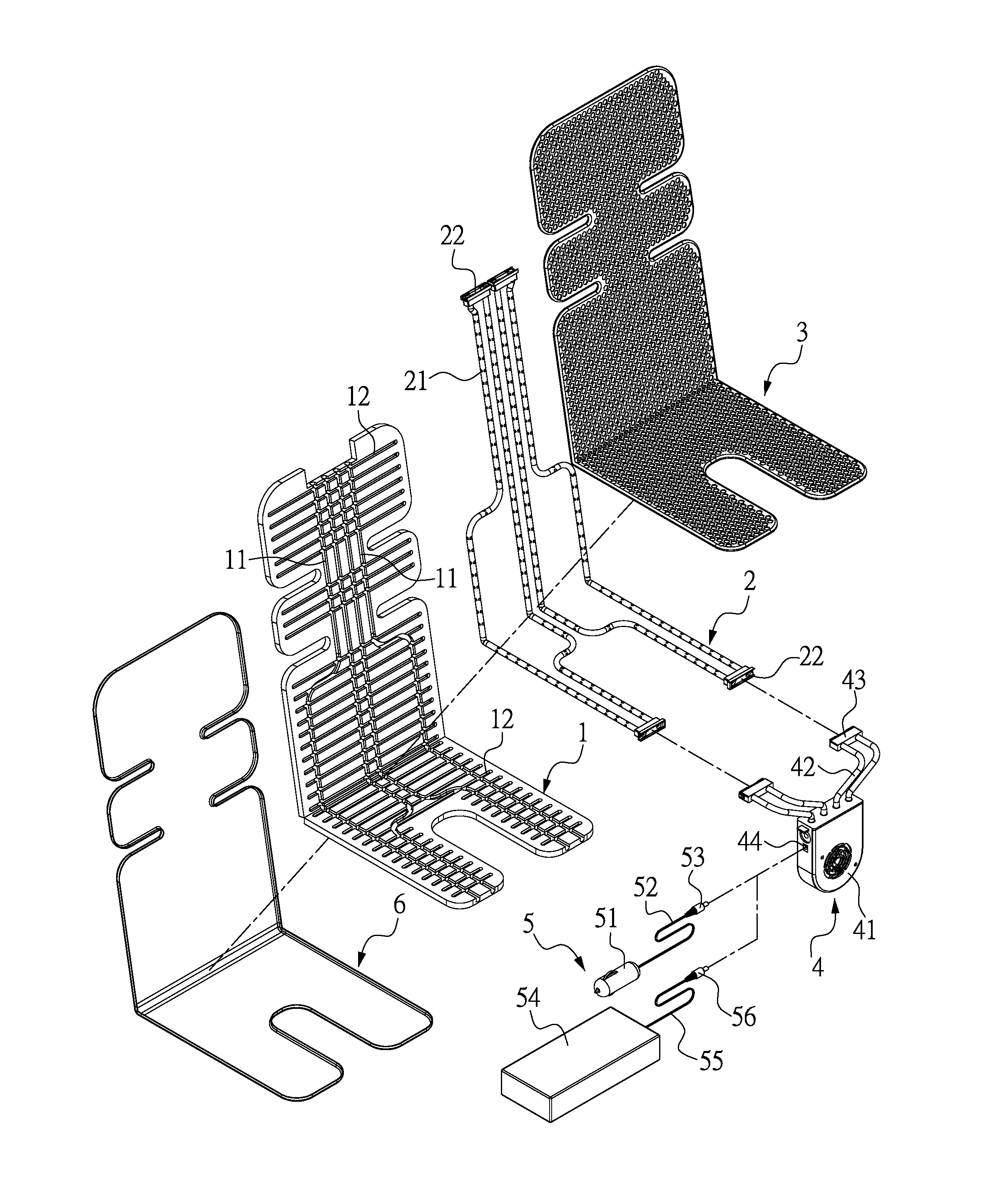

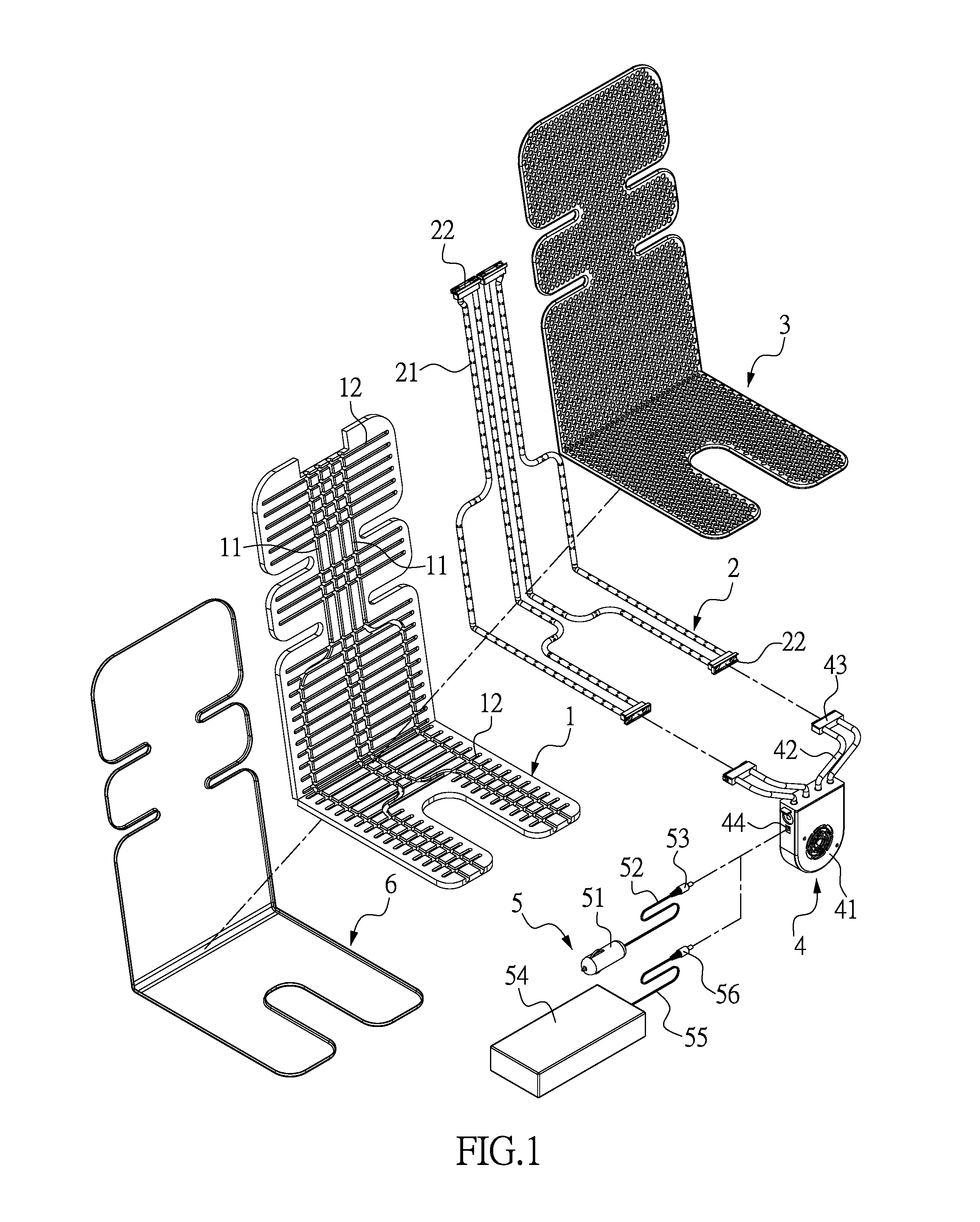

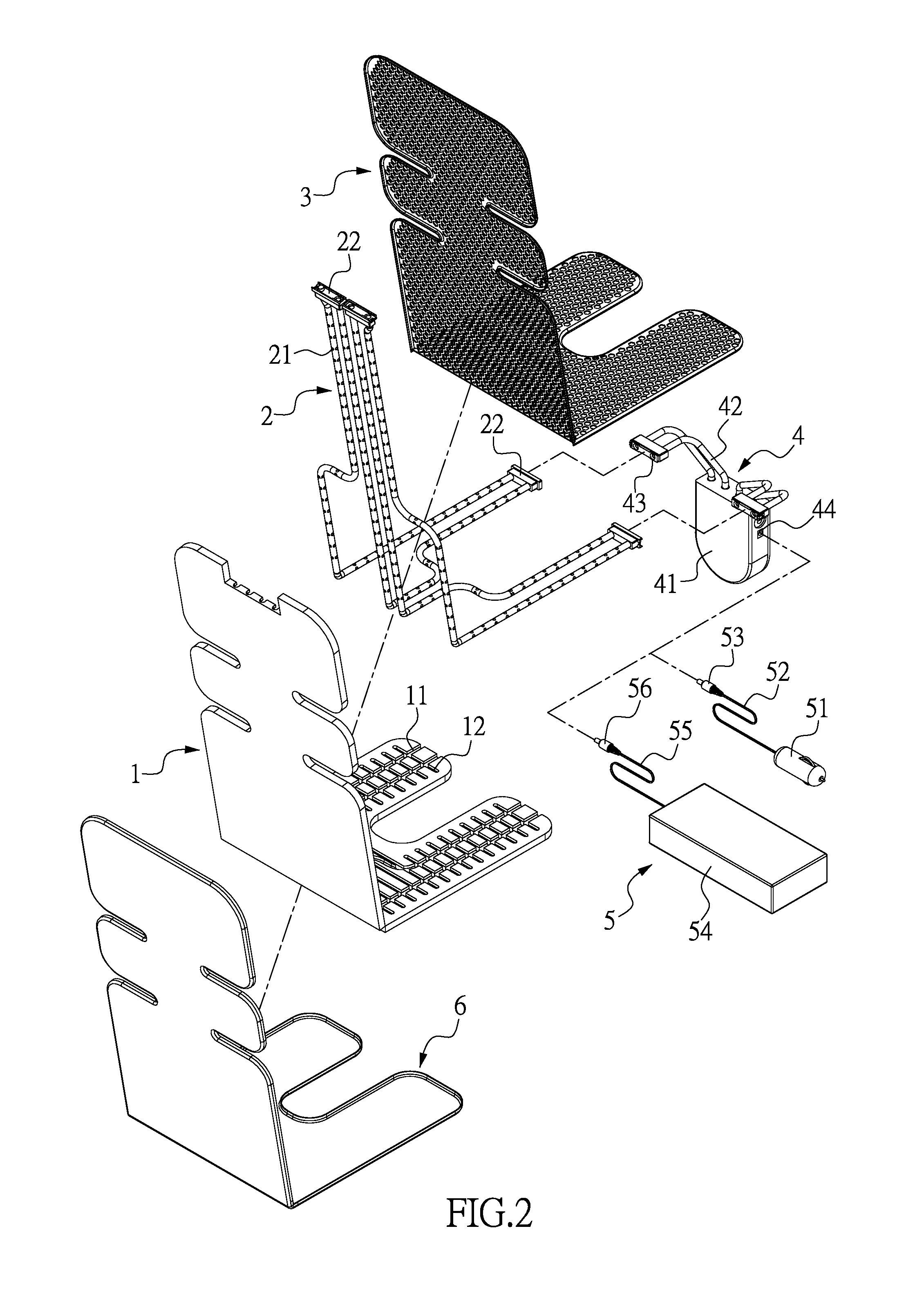

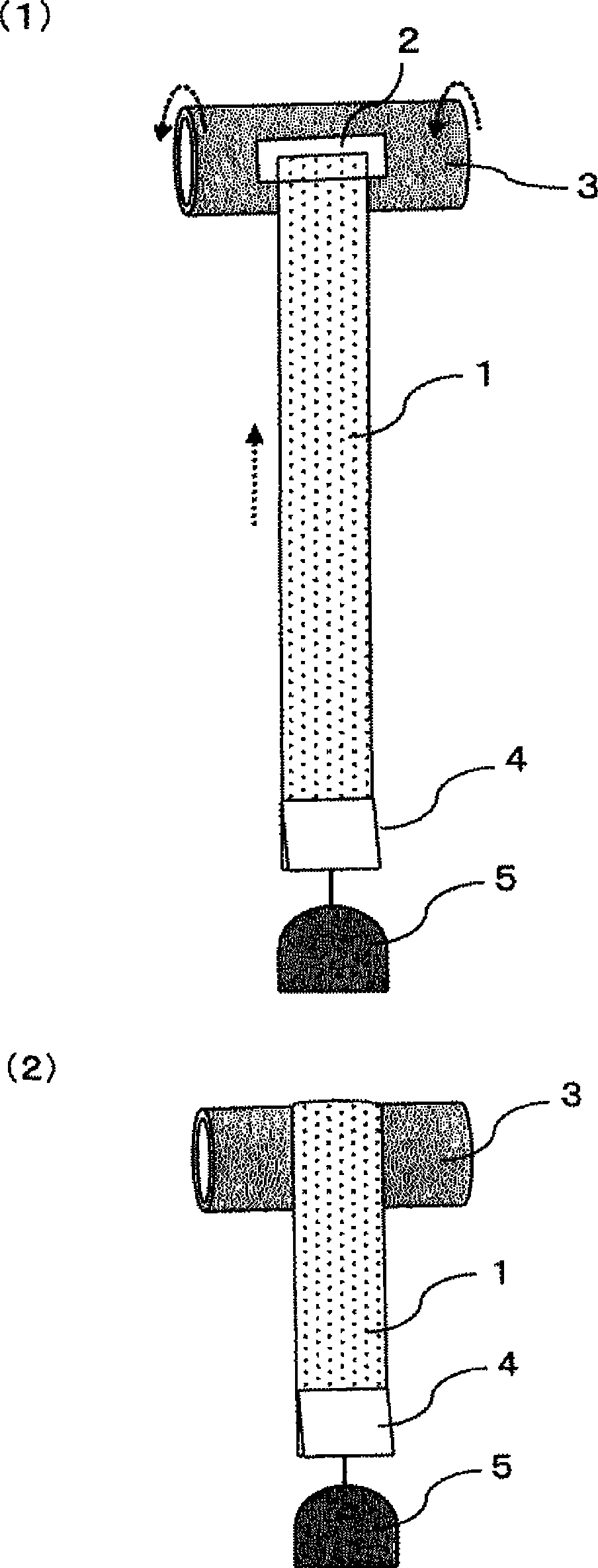

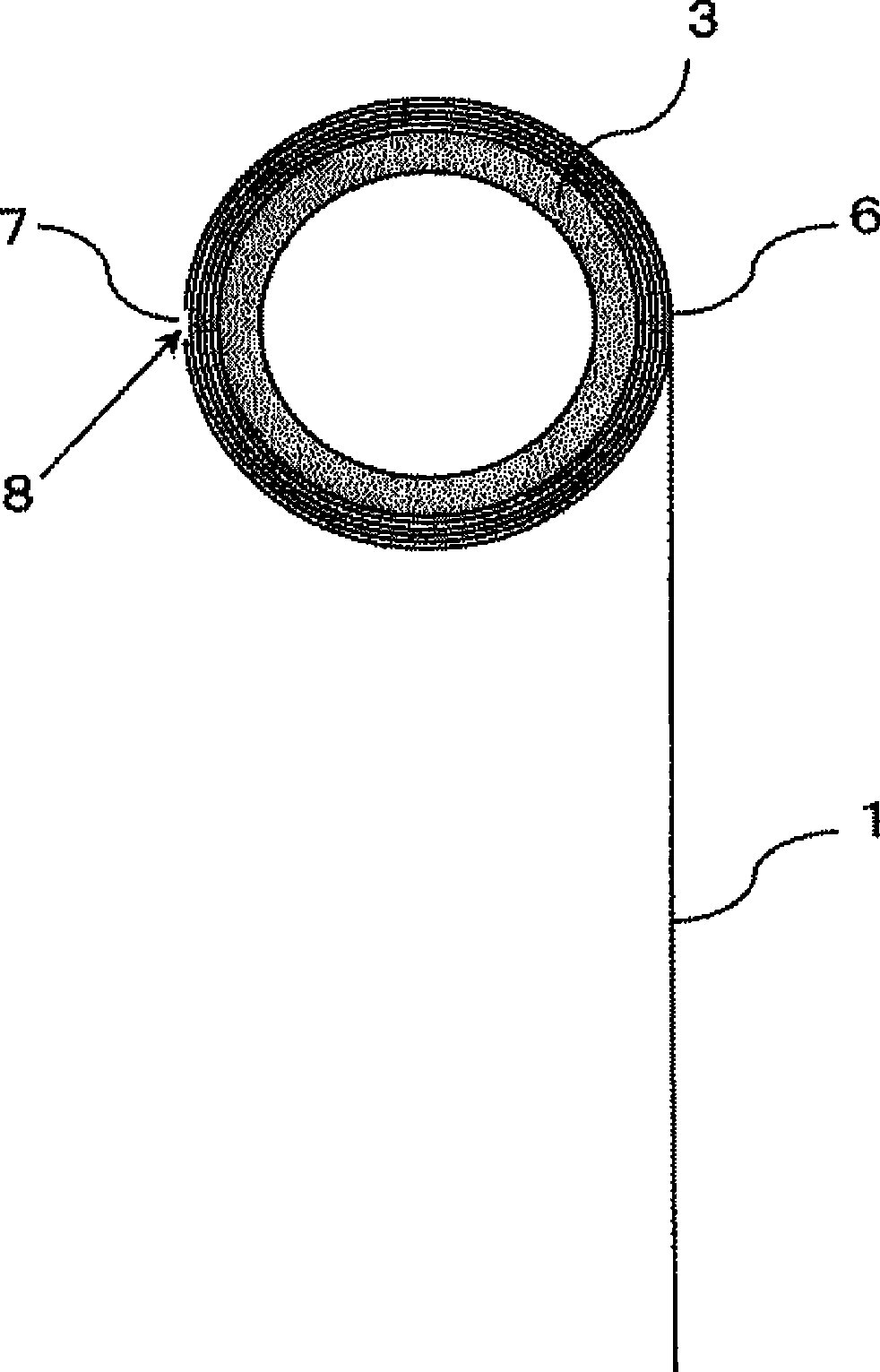

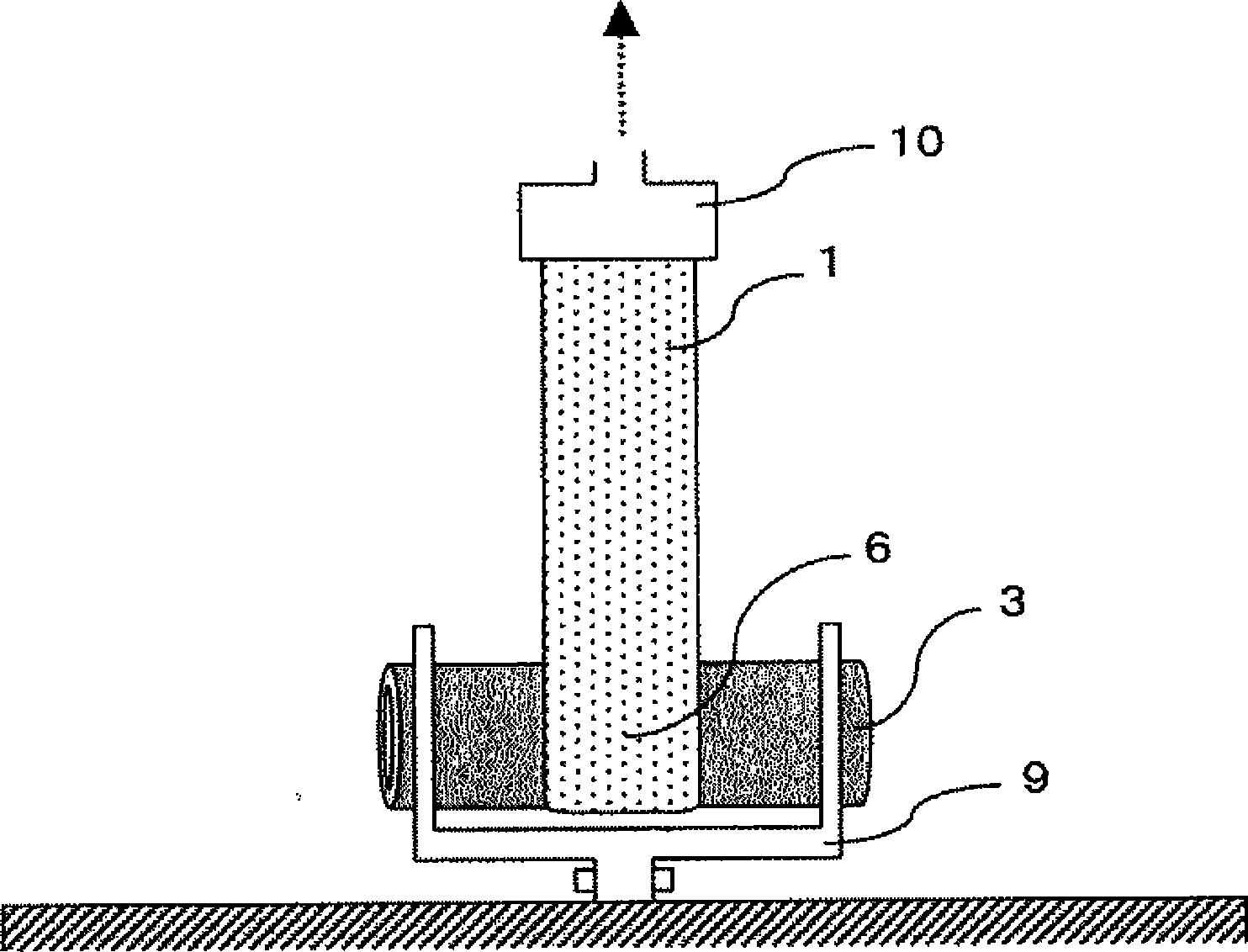

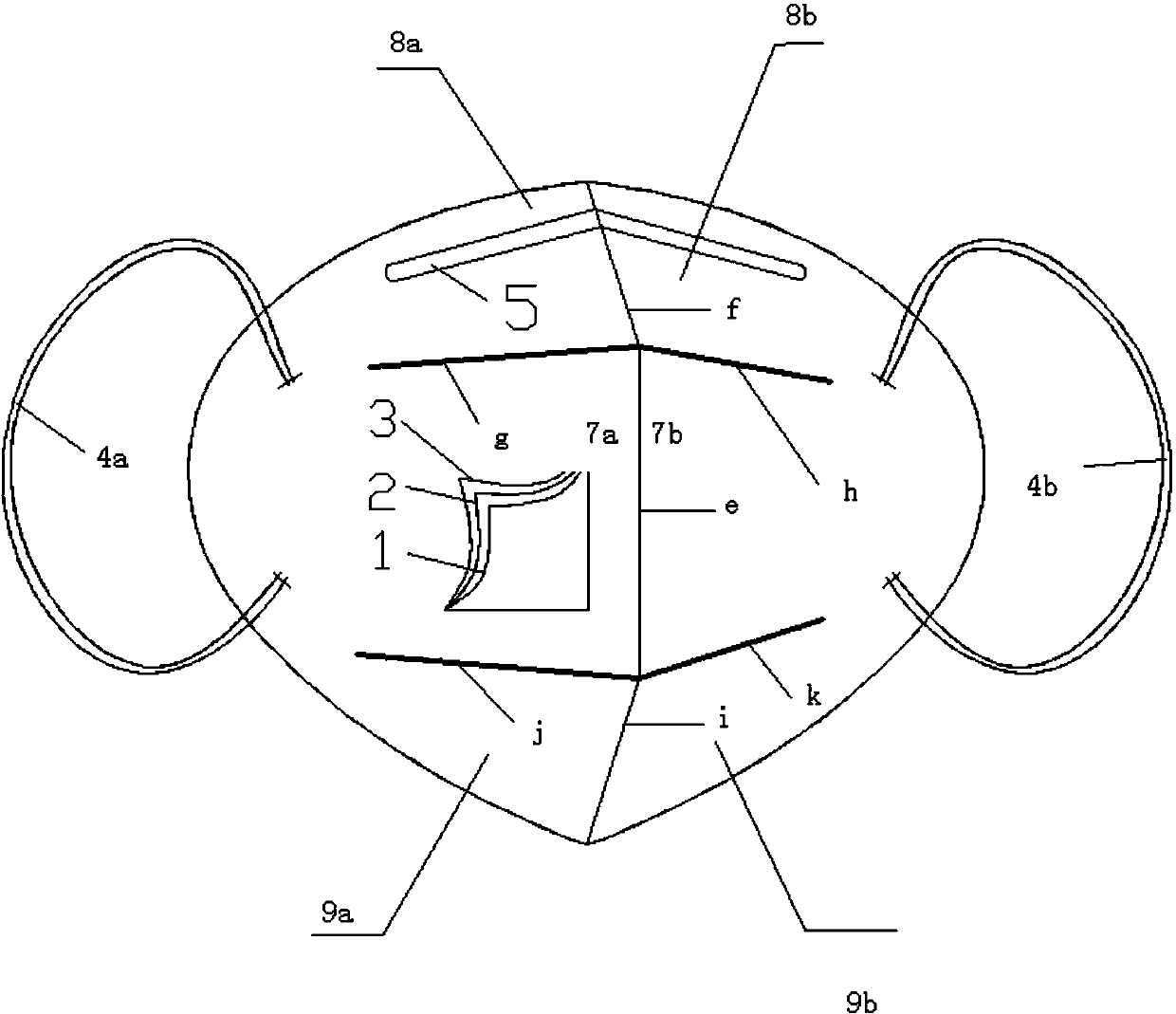

Breathable seat cushioning and seating device for children

InactiveUS20150061331A1Avoid stuffinessPrevent becoming uncomfortableSeat coveringsSeat heating/ventillating devicesCushioningPerspiration

A breathable seat cushioning device includes a seat body, a plurality of air conduits, an air permeable body, a fan module, and a heater. The seat body has a plurality of receiving grooves longitudinally arranged thereon. The air conduits have a plurality of air outlets arranged thereon. The air conduits are disposed in the receiving grooves. The air permeable body covers a surface of the seat body. The fan module is connected to the air conduits and has a casing and at least one blade pivotally coupled to the interior of the casing. The heater is arranged inside or outside the fan module. As a result, active ventilation is provided to prevent poor air permeability which can cause unpleasant seating conditions such as stuffy, perspiration, to children sitting on the breathable seat cushioning device. Moreover, warm air flow can be provided during colder environment.

Owner:YANG CHING LUN

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

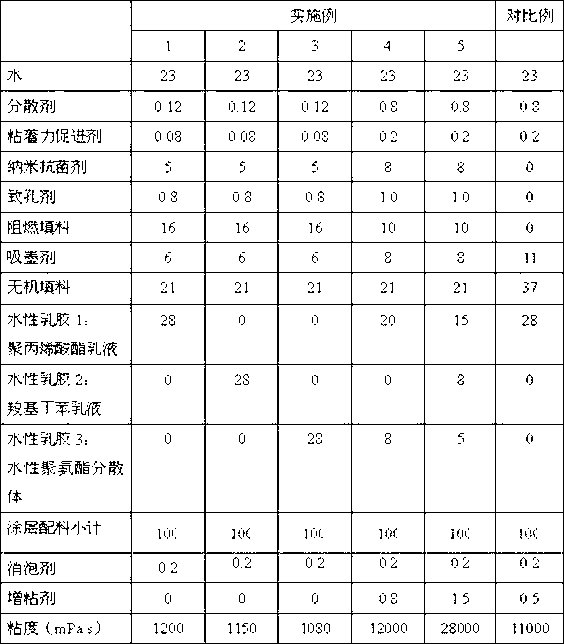

Method for preparing novel environment-friendly wallpaper based on high-filling synthetic paper

InactiveCN103015655ABreathableImprove mildew resistanceCovering/liningsAntifouling/underwater paintsPlasticizerVolatile substance

The invention relates to a method for preparing a piece of novel environment-friendly wallpaper by a high-filling synthetic paper. The high-filling composite paper (also known as a replaceable plant fiber paper) is used as a base material, a coating material is coated on the base material to form a transparent coating, the coating material contains a water emulsion, a nano antibacterial, a pore-foaming agent, a flame retardant filler, an ink absorbing agent and the like, and a novel environment-friendly wallpaper with the waterproof, ventilating, mildewproof and flame retardant performances is manufactured by rotary screen, flat screen and gravure printing methods. Compared with the PVC (polyvinyl chloride) wallpaper, the novel environment-friendly wallpaper has the advantage that the coating and the printing are carried out at low temperature, the temperature is lower than 100 DEG C, and the temperature of the PVC wallpaper reaches to 220 DEG C during foaming and drying, so the energy-saving effect is favorably realized. Compared with the existing wallpaper, the novel environment-friendly wallpaper has the advantage that heavy metals, formaldehyde, plasticizers, VOC (volatile organic compounds) and the PVC are not contained, so the environment-friendly, ecological and health effects are realized.

Owner:宋旭

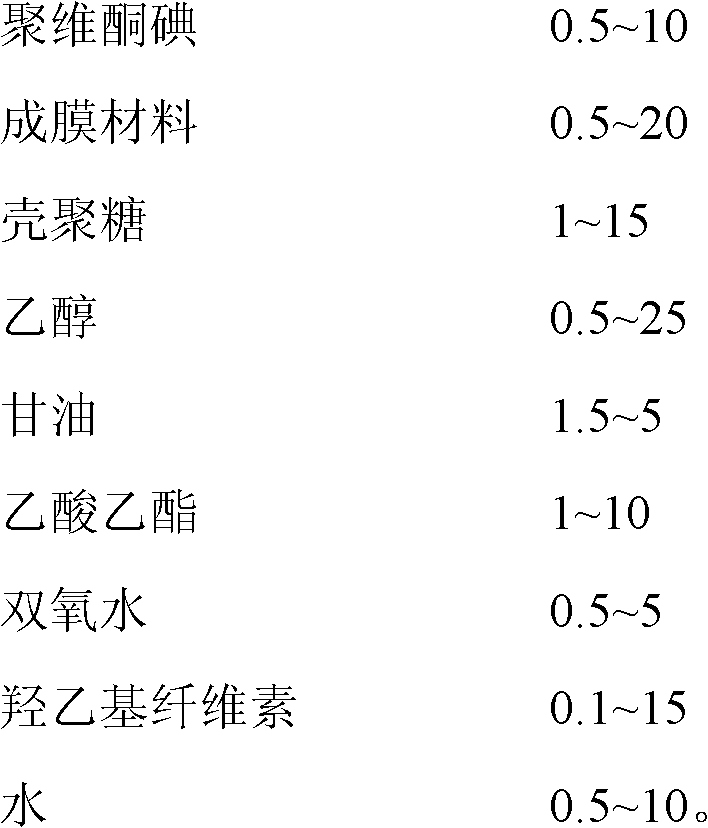

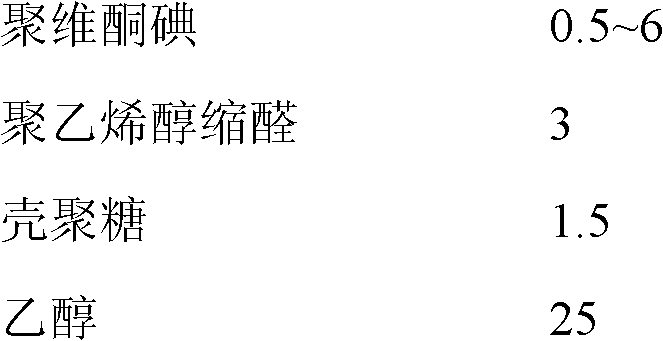

Liquid bandage containing povidone iodine and preparation method thereof

The invention relates to the field of medical wound dressing, in particular to liquid bandage containing povidone iodine and a preparation method thereof, belonging to the technical field of medical treatment. The liquid bandage containing povidone iodine is characterized in that hydrogen peroxide is added into the formula of ordinary liquid bandage to achieve good effect. On one hand, hydrogen peroxide has very good hole forming effect on the liquid bandage, and hydrogen peroxide releases oxygen to achieve hole forming agent action through releasing a self disproportionated reaction.

Owner:IVIEW THERAPEUTICS TECH WUHU CO LTD

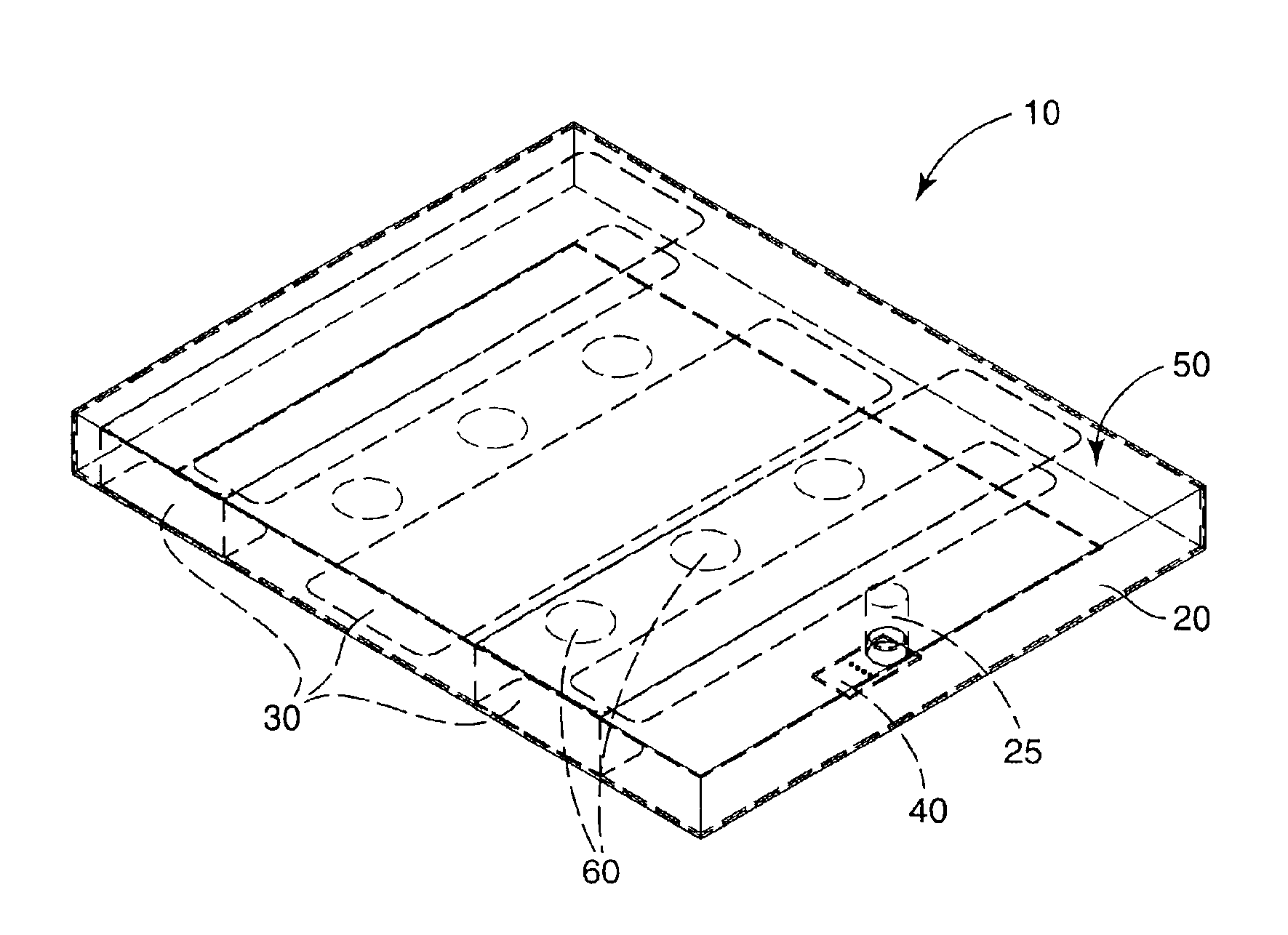

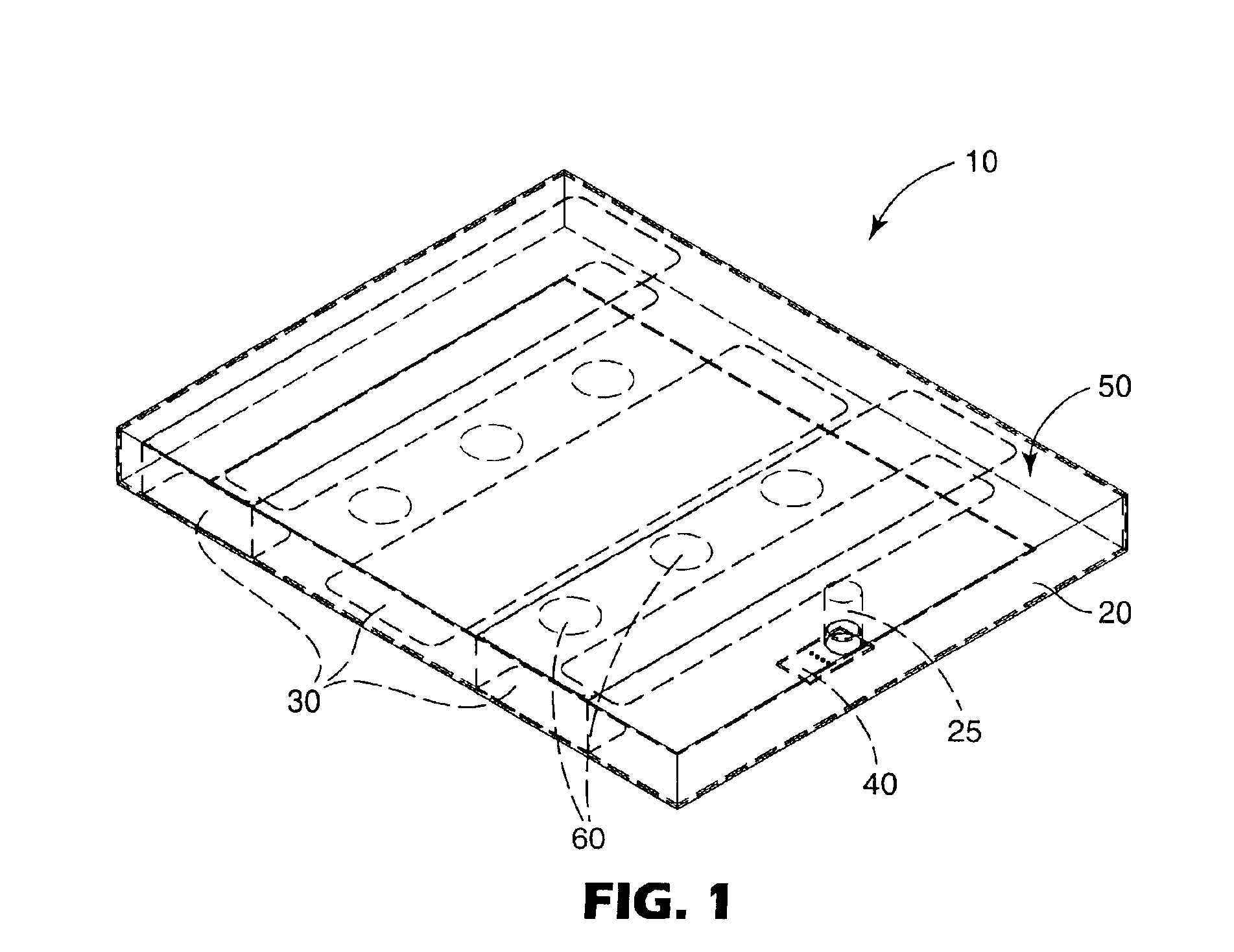

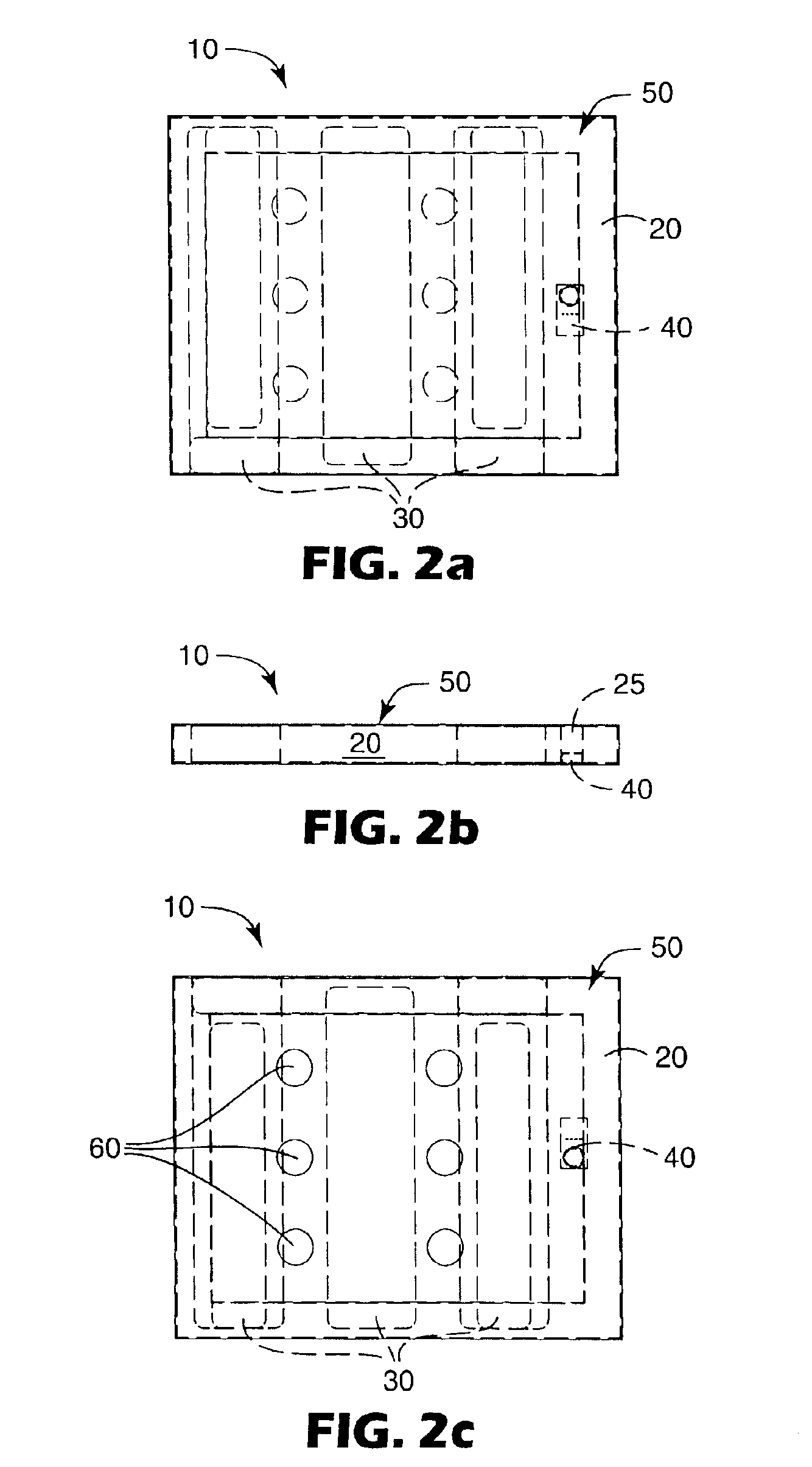

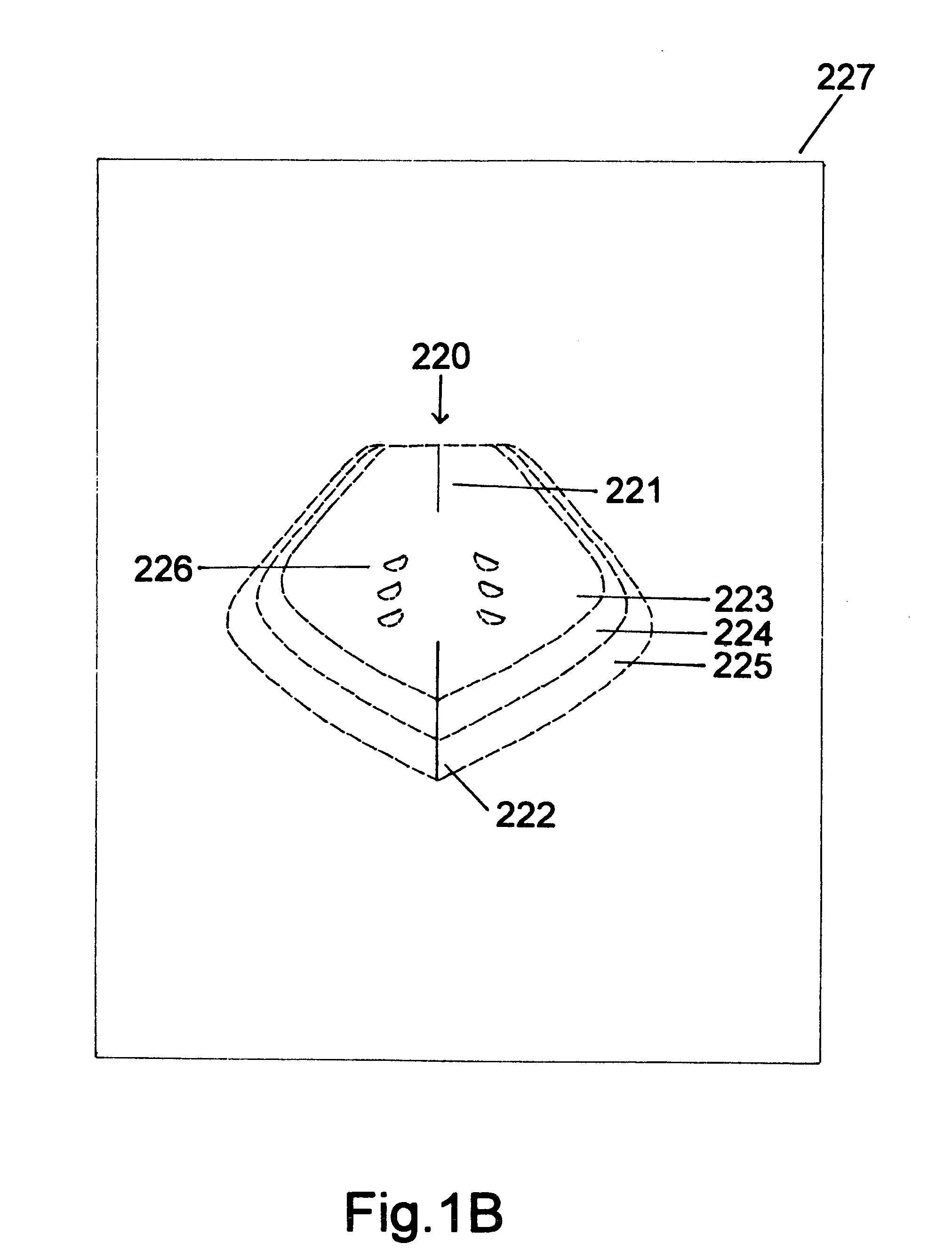

Breathable moisture barrier for an occupant sensing system

InactiveUS6906534B2Track rapid changeBreathableVehicle seatsResistance/reactance/impedenceElectricityWater vapor

A breathable moisture barrier suitable for use in enclosing flexible electrodes, foam substrate and other electrical components within a substantially liquid impervious environment without significantly impairing the ability of electrical sensors to accurately measure temperature and humidity variations within the surrounding environment such as the seating compartment of an automobile. It is further disclosed that a breathable polymeric material having a sufficiently high moisture vapor transmission rate (MVTR) will permit water vapor to be transported across the barrier and quickly reach equilibrium within the enclosed seat sensor mat assembly and to allow the humidity compensation of the occupant sensing system to function correctly. The breathable moisture barrier of the present invention provides a sufficiently high MVTR to allow rapid humidity equilibration within the sensor mat so as to better track rapid changes in the passenger compartment environmental conditions upon starting the car and applying either air conditioning or heating.

Owner:3M INNOVATIVE PROPERTIES CO

Sintered permeable environmental-friendly brick produced by using ceramic waste residue and manufacturing method thereof

ActiveCN101955349AMitigate the heat island effectGuaranteed water circulationSolid waste managementClimate change adaptationTunnel kilnBrick

The invention relates to a sintered permeable environmental-friendly brick produced by using ceramic waste residue and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: stirring ceramic waste residue powder, waste glass powder, waste porcelain fragment powder, municipal foundation waste sludge powder, calcium oxide, calcium sulfate, bentonite, talcpowder, garbage ash residue powder, waste plant powder and water serving as raw materials to form a wet mixture, and performing mechanical vibration and extrusion molding to obtain the lower-layer brick of the permeable brick; uniformly distributing a layer of fine fabric on the upper part of the lower-layer brick of the permeable brick by using a secondary distributing machine, manufacturing a ceramic waste residue sintered permeable environmental-friendly unburned brick under the pressure of 25 to 30Mpa and naturally drying; and feeding the molded and naturally-dried ceramic waste residue permeable environmental-friendly unburned brick into a tunnel kiln for roasting, controlling the temperature to be between 1,150 and 1,200 DEG C and burning the unburned brick to obtain the ceramic waste residue sintered permeable environmental-friendly brick product. Different specifications of vegetation bricks can also be prepared from the raw materials. The product has the advantages of certain water permeability, air permeability and water retentivity, multiple functions of reducing temperature and noise, regulating climate, eliminating urban heat island effect, improving air quality, maintaining surface water circulation and the like, high strength, no pollution, low cost and good benefit, and meets the requirements of energy conservation, emission reduction, environmental protection, and the development of low carbon economy in China.

Owner:清远绿由环保科技有限公司

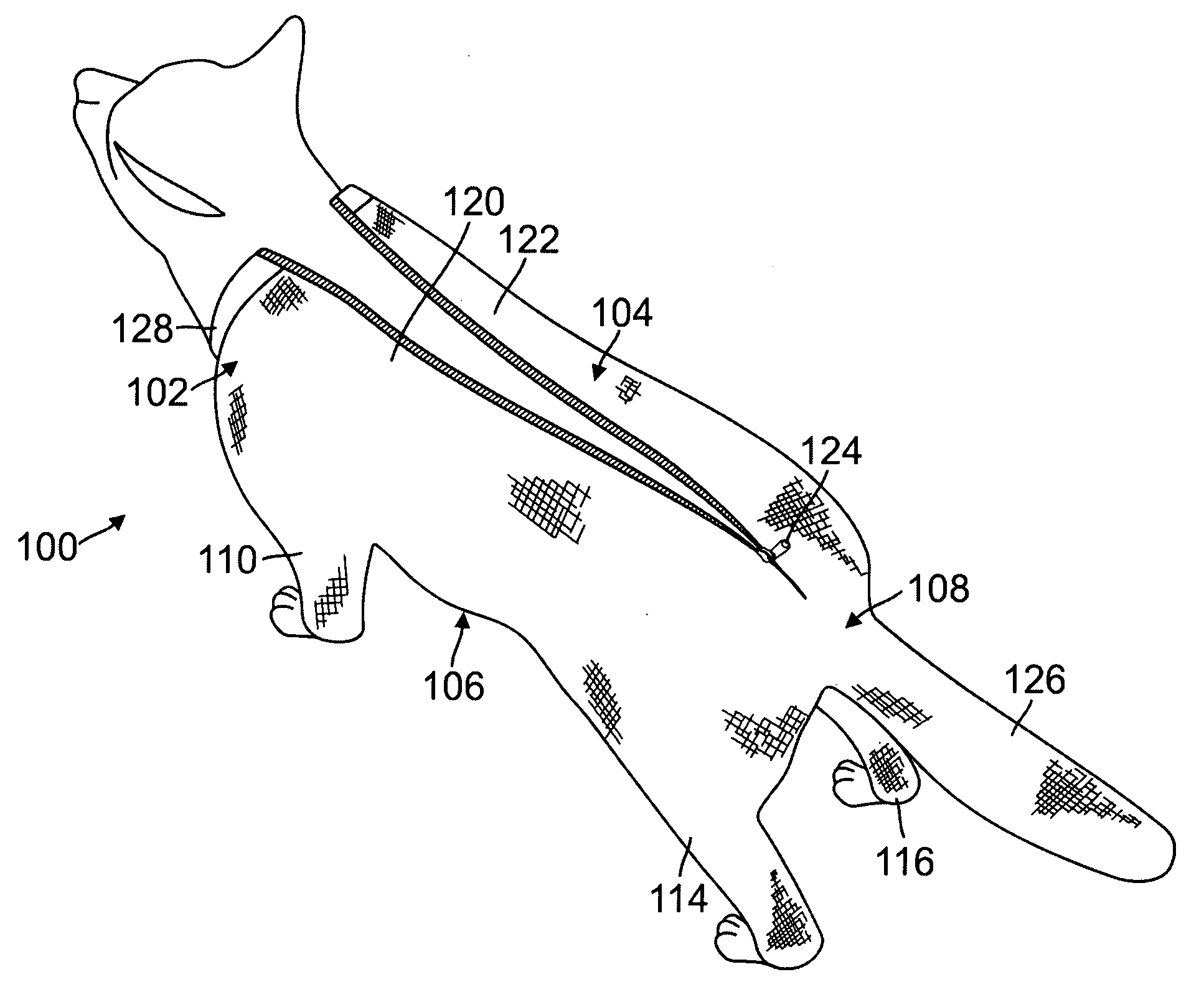

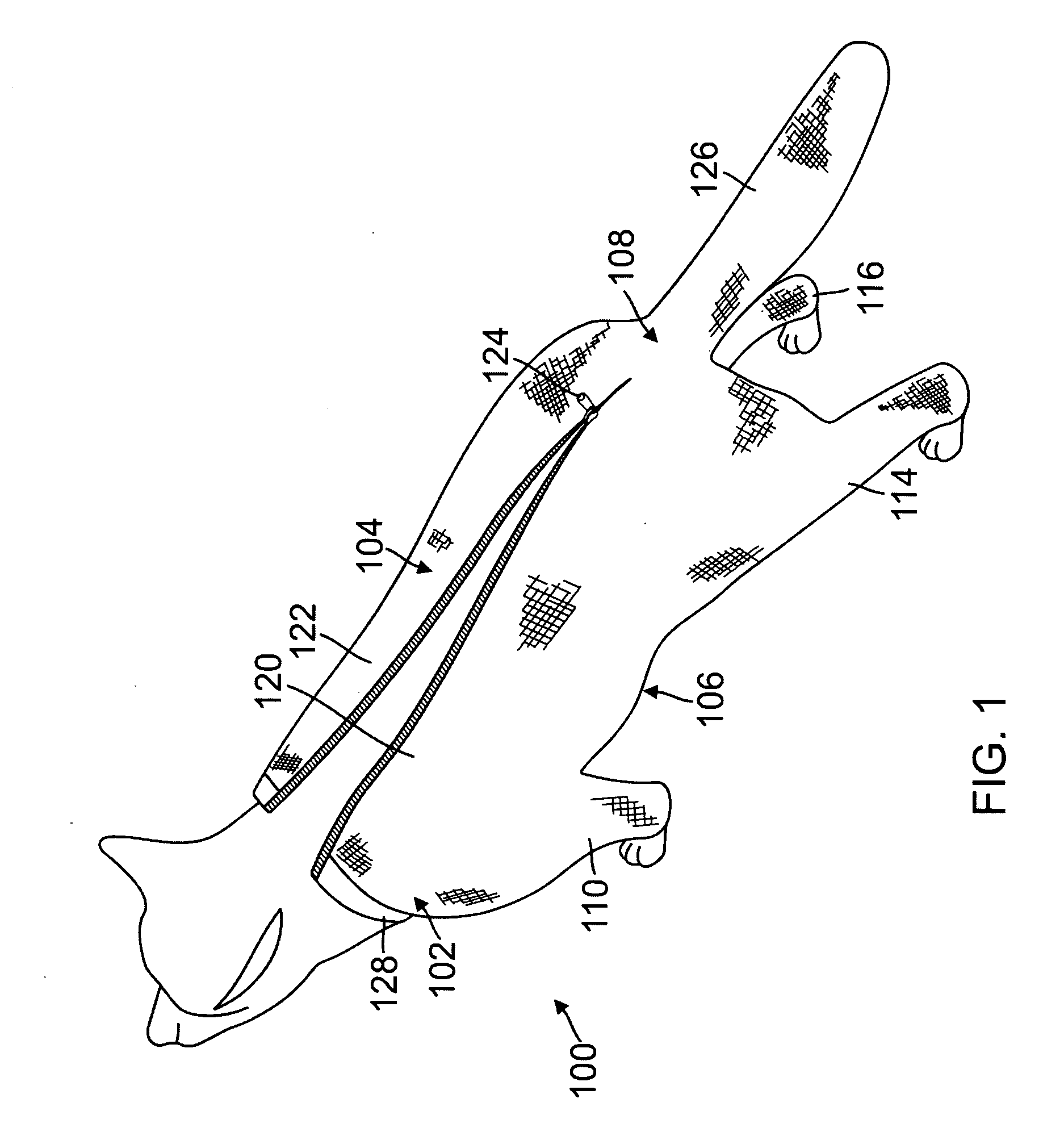

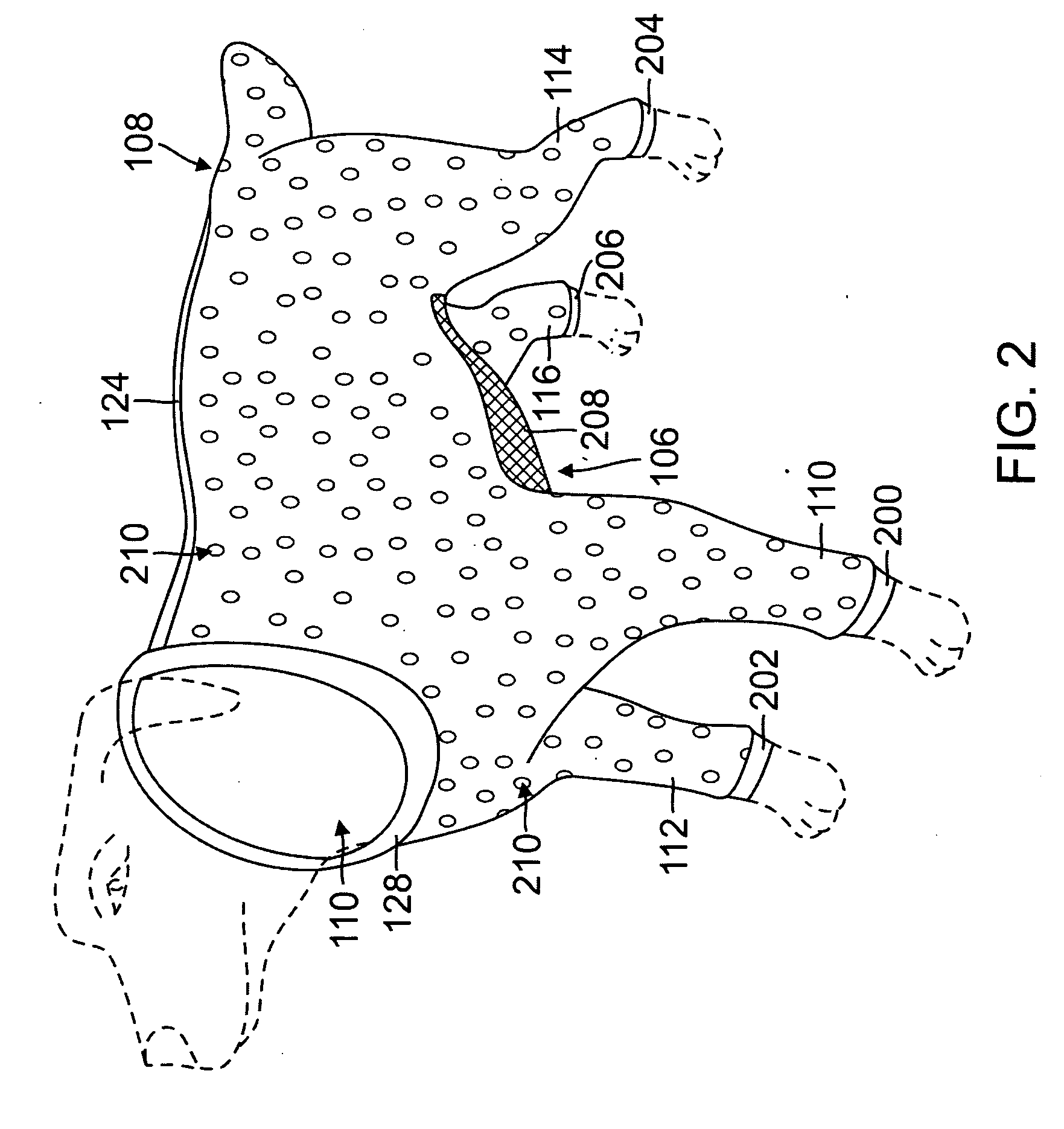

Disposable pet garment

A one-piece pet garment having an anterior portion, a dorsal portion adjacent to the anterior portion, a ventral portion opposite the dorsal portion and adjacent to the anterior portion, and a posterior portion adjacent to the dorsal and the ventral portions and opposite the anterior portion, wherein the anterior portion comprises a head orifice, and a the ventral portion comprises a plurality of sleeves. The pet garment may be made of a biodegradable, disposable material or an elastic material. The pet garment may further comprise perforations for ventilation. The pet garment may be treated with a flea and tick repellant.

Owner:WILLIAMS WALTER LEE

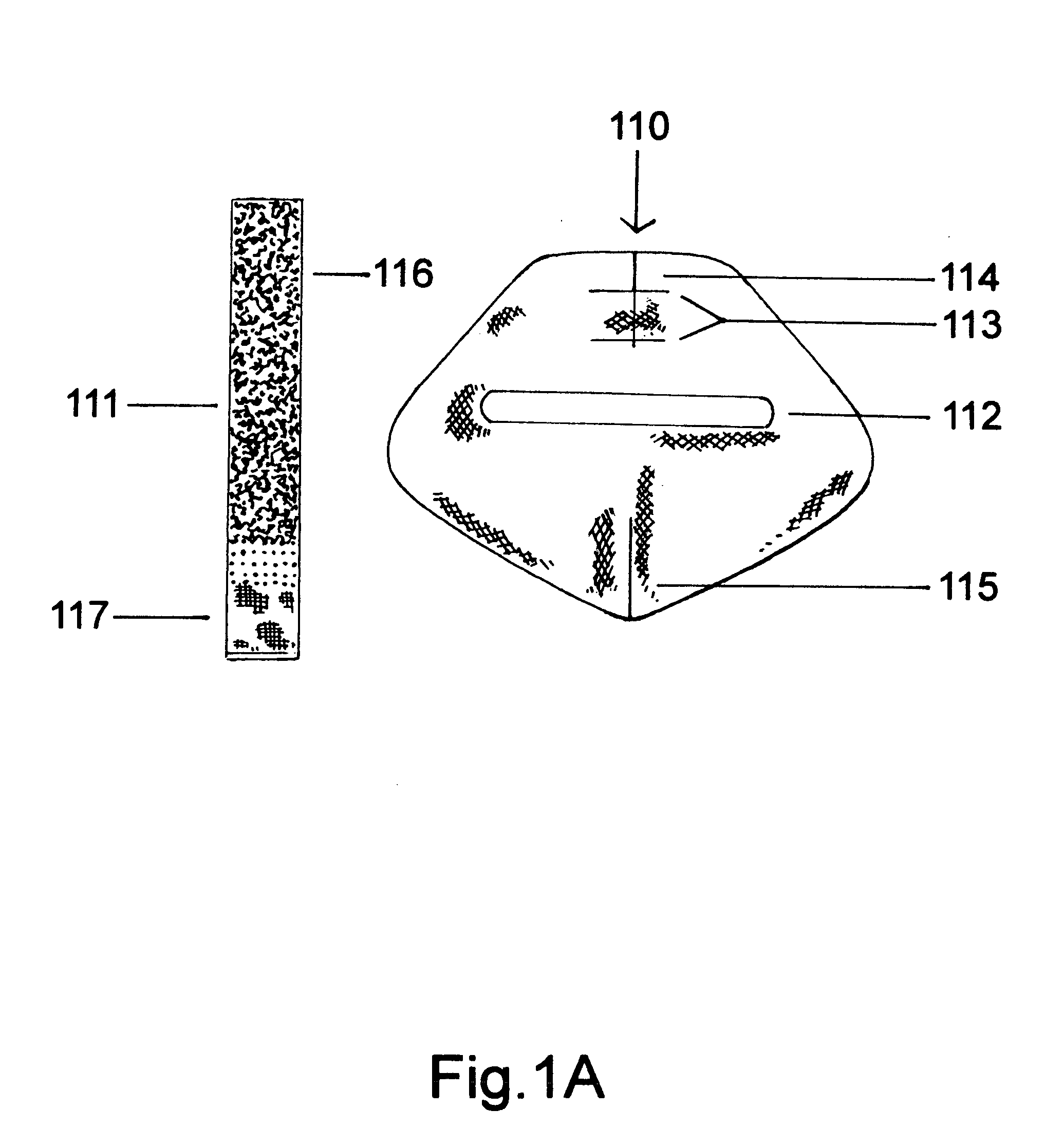

Nose cover

InactiveUS20070250976A1Provide protectionLight weightBreathing protectionEye treatmentNoseEngineering

A nose cover or nose protector, for adventurers, sports fans, and people who love outdoor activities, comprises a nose piece formed from sheets of paper, plastic, fabric, foam, laminated materials, pressure heat cut and seal materials, and / or die-cut materials to fit and cover the nose. Additional materials of adhesive pieces and soft metal sheets are used to fold and contour the nose cover onto the wearer's nose. A corresponding “hook and loop” strap or “hook” patch is used to connect the nose cover to the bridge of eyewear. This nose cover can also consist of heat packs, cold packs, and / or medicated packs to comfort the user. The nose cover can be used with or without eyewear, and with variety of optional accessories.

Owner:BELIVEAU ROBERT

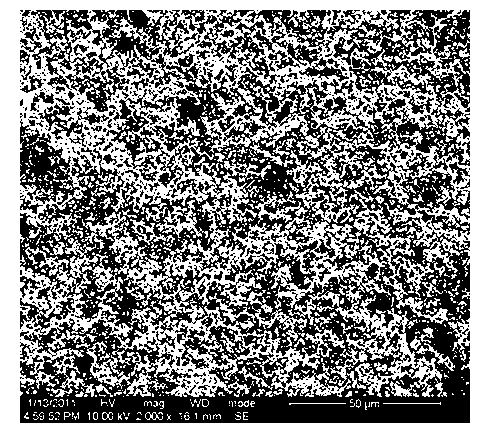

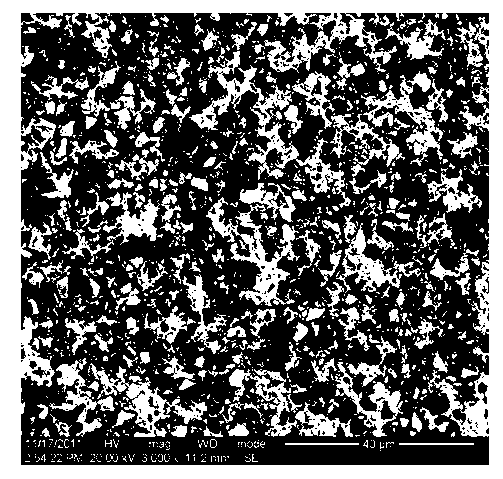

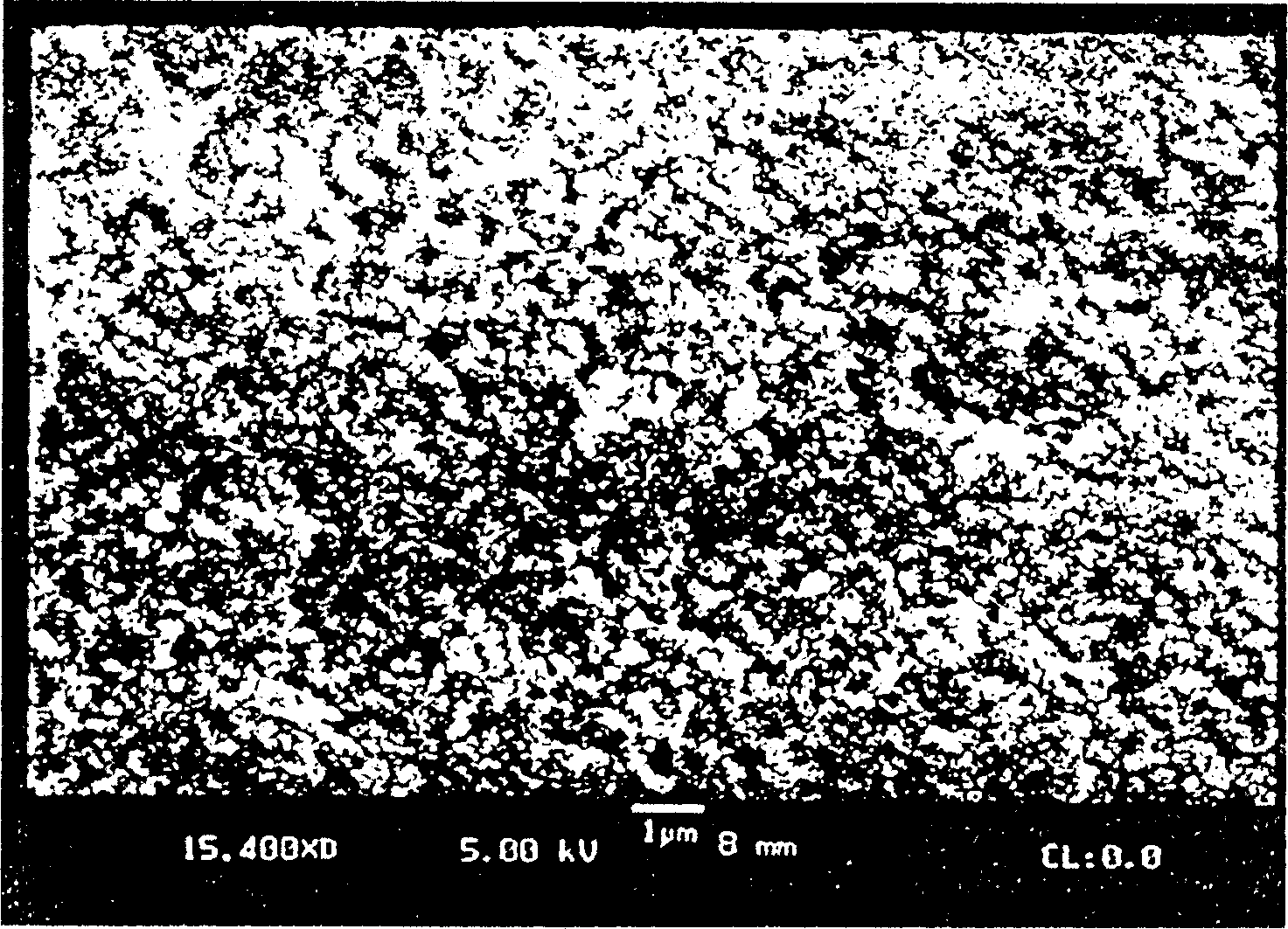

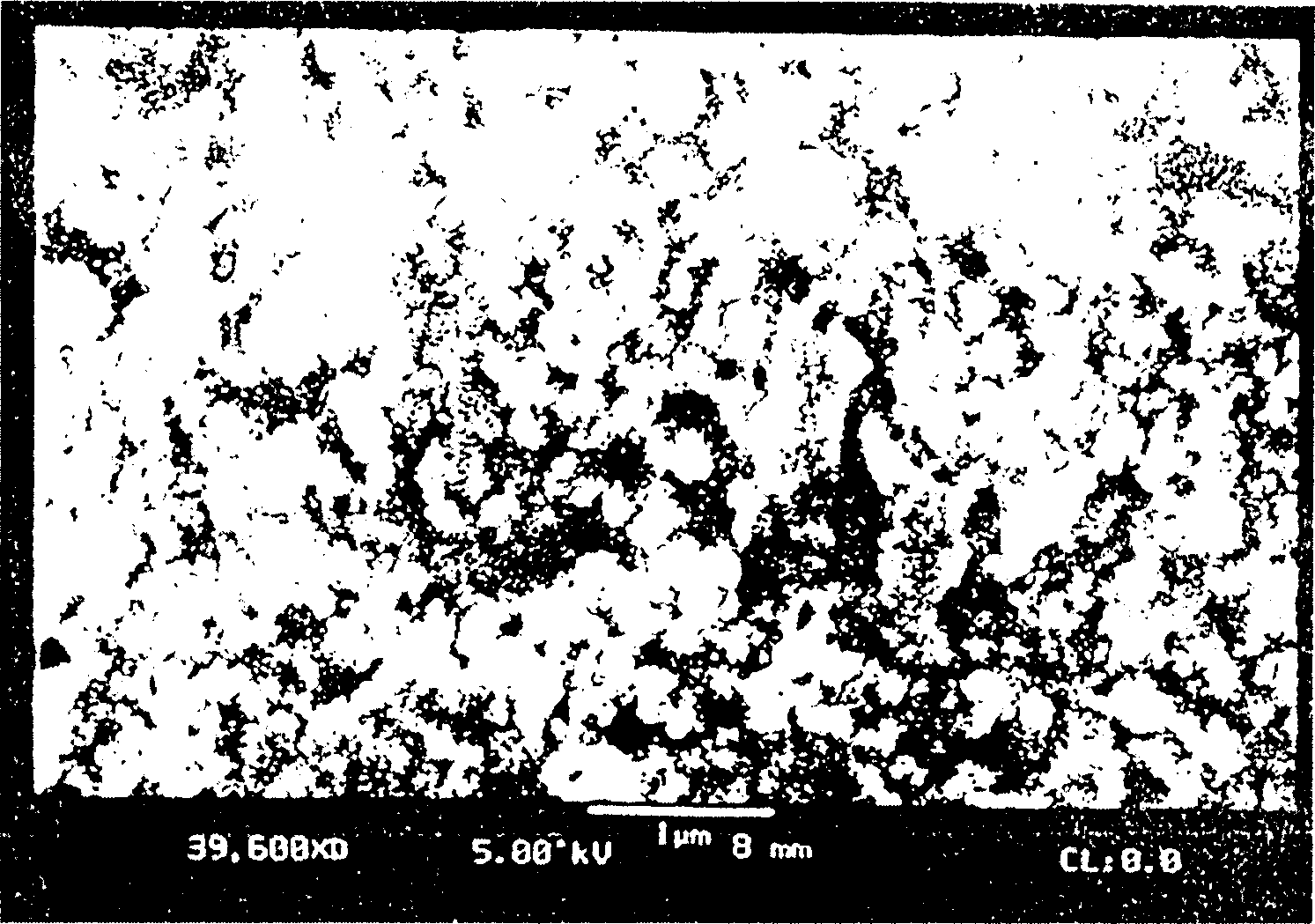

Nano-silver porous silicone rubber/polyurethane-containing double-layer artificial skin and preparation method thereof

InactiveCN103948960ACapable of absorbing effusionWaterproofAbsorbent padsProsthesisFoaming agentSolvent

The invention discloses a nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin and a preparation method thereof. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin is characterized in that the artificial skin contains a dermis and epidermis double-layer structure; a dermis layer is prepared from loose porous polyurethane; an epidermis layer is prepared from antibacterial agent-containing silicone rubber. A preparation method of the dermis layer comprises the following steps: dissolving the polyurethane, adding a pore-foaming agent, defoaming, carrying out curtain coating so as to form a film, volatilizing a solvent, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a porous polyurethane film. A preparation method of the epidermis layer comprises the following steps: dissolving a silicone rubber precursor, carrying out ultrasonic dispersion on a nano-silver solution, adding the pore-foaming agent, defoaming, carrying out blade coating or curtain coating so as to form a film, volatilizing a solvent, curing so as to obtain an embryonic film, soaking so as to leach out the pore-foaming agent, and drying so as to obtain a silicone rubber microporous film. The preparation method of the double-layer artificial skin comprises the following steps: coating the polyurethane film with polyvinyl alcohol, acid liquor and a crosslinking agent, then covering the polyurethane film by using the silicone rubber film, volatilizing a solvent, and carrying out heat treatment so as to obtain the double-layer artificial skin. The nano-silver porous silicone rubber / polyurethane-containing double-layer artificial skin has the effects of water resistance, air permeability, bacterial inhibition, virus killing and effective absorption of hydrops.

Owner:SICHUAN UNIV +1

Stretch nonwoven fabric and tapes

ActiveCN101522972ABreathableImprove scalabilityAdhesive dressingsWoven fabricsPolymer scienceNonwoven fabric

To produce a nonwoven fabric comprising a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure. In the nonwoven fabric, the conjugated fibers are arranged in a direction approximately parallel to a surface direction of the nonwoven fabric and crimped. In addition, the conjugated fibers have an average curvature radius of fiber crimp of 20 to 200 [mu]m and the crimps are distributed approximately uniformly in a thickness direction of the nonwoven fabric. The nonwoven fabric is substantially free from an adhesive agent. In the nonwoven fabric, each fiber is substantially not melt-bonded to another. The conjugated fiber may comprise a polyalkylene arylate-series resin and a modified polyalkylene arylate-series resin and have a side-by-side or eccentric sheath-core form. Since the bimetal form conjugated fibers having specific crimps are appropriately entangled with each other, the nonwoven fabric has a high stretchability and is easily torn by hand, without using scissors. The nonwoven fabric is suitable for a tape such as a bandage or a supporter.

Owner:KURARAY CO LTD

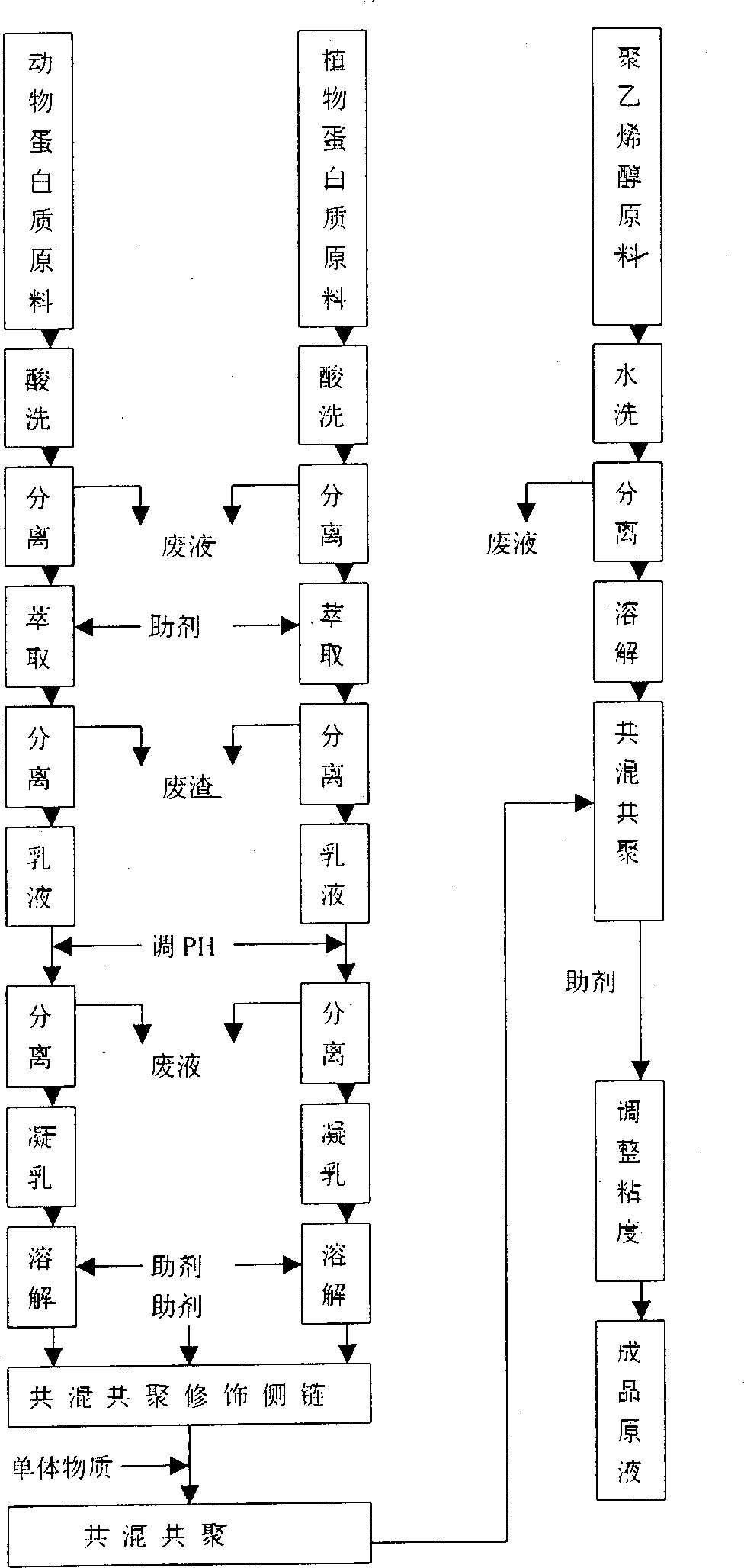

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

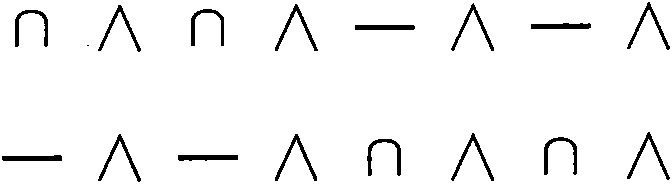

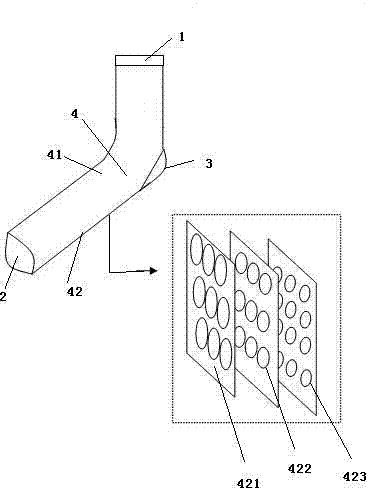

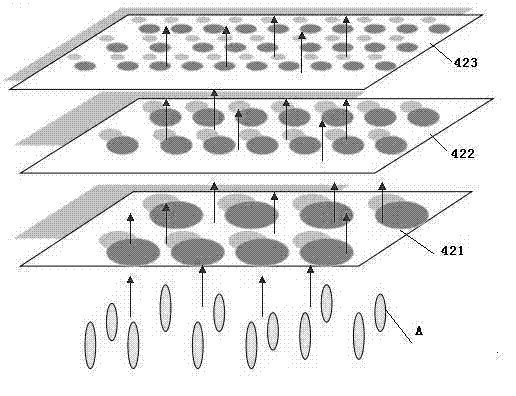

Socks and preparing method thereof

The invention relates to a pair of socks and a preparing method thereof, in particular to the socks which can meet the requirement of thermal-wet comfort and have an anti-pilling function, and the preparing method of the socks. Sock heads and sock roots are made of bamboo fiber, cotton, special-shaped cross section polyester fiber, nylon and spandex, sock bodies are made of bamboo fiber, cotton, special-shaped cross section polyester fiber and spandex, wherein the materials are weighed in percentage by mass: the special-shaped cross section polyester fiber is 10-50%, the cotton is 5-60%, the bamboo fiber is 10-50%, and the spandex is 1-5%,the sock bodies comprise sock surfaces and sock soles at the bottoms of the sock surfaces, the diameters of capillary tubes in the materials are gradually reduced along the direction from the sock soles to the sock surfaces, the sock soles are of multi-layer eyed structures and comprise outer layers, middle layers and inner layers, the inner layers are used for being directly contacted with the skin and are blended yarns of special-shaped cross section polyester fiber and spandex, and the middle layers or / and the outer layers are blended yarns of special-shaped cross section polyester fiber, cotton, bamboo fiber and spandex. The socks have excellent thermal-wet comfort and the anti-pilling function.

Owner:HEYE HEALTH TECH CO LTD

Microporous membrane, preparing method and use

InactiveCN1552757AProtection against erosionWaterproof, breathable and moisture permeablePolymer scienceSolvent

A millipore film is prepared from synthetic resin, thermoplastic elastomer, inorganic powder, lubricant and antibacterial agent through proportional mixing, filming and pore forming in solvent. It can be used for virus preventing clothing, diving suit, mountaineering wear, etc. Its advantages are high weight, good heat insulation, high air and moisture permeability, and high tension strength.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

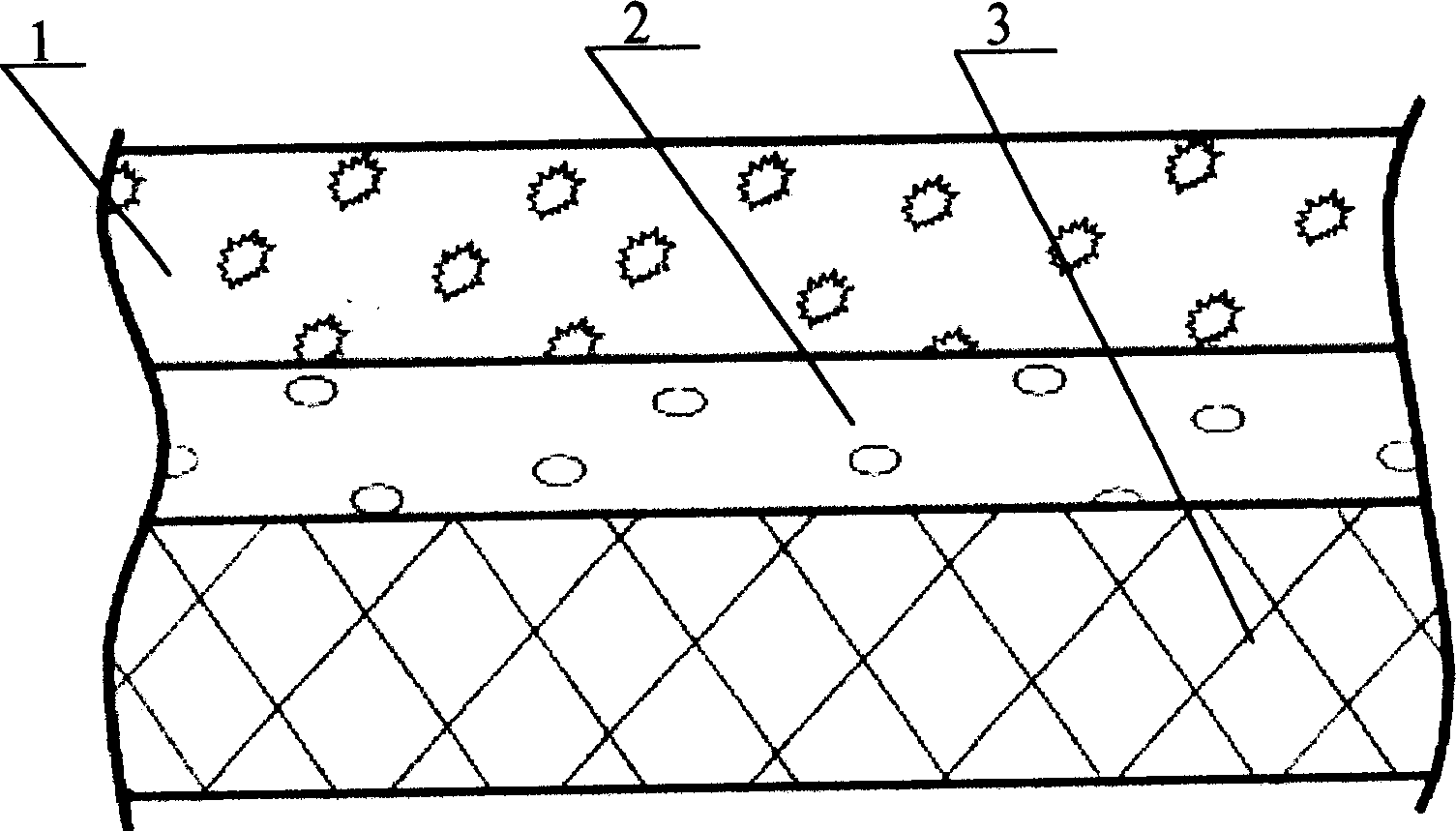

Multi-layer coating fabric

InactiveCN1676745ANot stiffIt has the characteristics of not being hard, and it is also breathableTextiles and paperPolyurethane adhesiveKetone

This invention discloses a kind of multi-layer-pasting fabric, made with the method of pasting at least 2 layers of different slurries on one layer of base cloth. The components of the slurry-pasting surface layer is (by weight): polyurethane resinI30-60%, polyurethane resin II 30-50%, cross linkerI1-5%, cross linker II 0.5-3.5%, accelerator I 0.5-10%, accelerator II 0.5-5%, fire retardant 2-5%, antiseptic and mildew preventive 1-2%, dimethyl formamide 0-2%, toluene 3-5% and methyl ethyl ketone 1-2%. The components of the slurry-pasting bottom layer is (by weight): polyurethane adhesive 80-100% and dimethyl formamide 0-20%. The coldness resistance of this invention is nice, and even at -60deg.C the paintcoat will not turn fragile, crack, get deformed or become hard. At the same time, it has the merits of aeration, fire resistance and antisepsis, with the air permeability of over 1000g / square meter, antisepsis of 1 level and the fire resistance reaching the nation standard. In a word, it is more fit to be used in cold.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

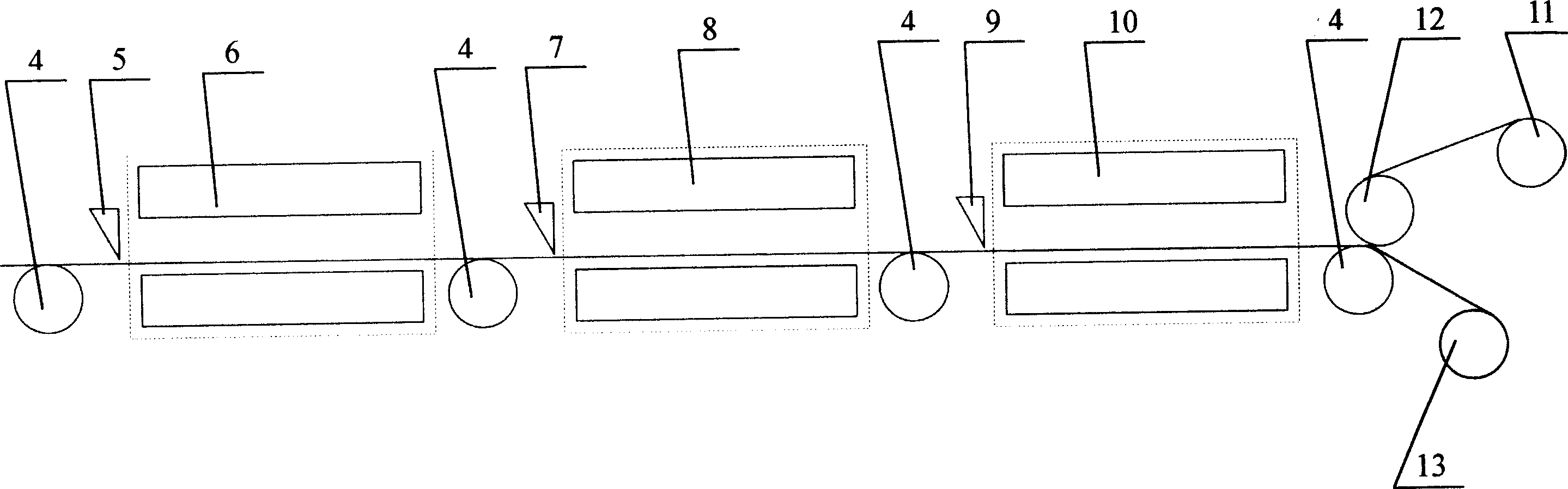

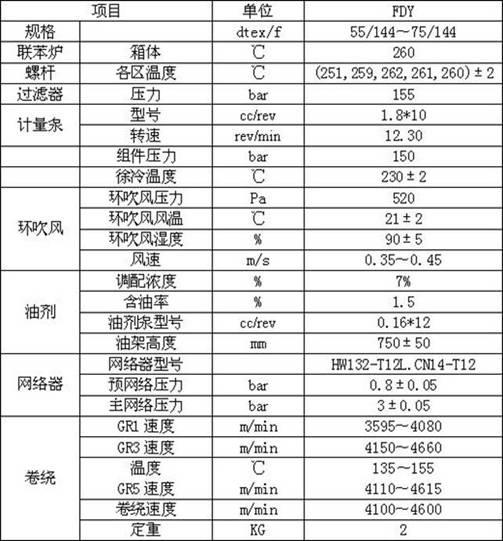

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

Organic and inorganic composite insulation material

ActiveCN102219460ARaw materials are easy to getReduce pollutionCement productionCombustionThermal insulation

The invention discloses an organic and inorganic composite insulation material which is a composite material prepared from an organic material as aggregate and an inorganic material as a bonder by stirring in a mixed way, moulding and forming at normal temperature or extruding and forming at high temperature. The proportion of the organic material to the inorganic material in parts by weight is (5-25): (75-95). The organic material is polystyrene foam or polyvinyl chloride foam or polyurethane foam. The inorganic material is aluminium silicate geological polymer material. The organic and inorganic composite insulation material prepared by the invention not only has good thermal insulation performance but also is advantageous for bonding to the inorganic material, such as a wall body and the like and is simple for construction and low in cost; and compared with the traditional organic insulation material, the organic and inorganic composite insulation material has the advantages of high strength, difficult combustion, low water absorption, low deformation, air permeability, light weight and the like.

Owner:GUANGXI UNIV

Water wall paint for external wall

The present invention features that by selecting different sort and amount of emulsion and assistants, four kinds of wall finish paint, including styrene-acrylate wall finish paint, acrylate wall finish paint, organosilicon modified acrylate wall finish paint and high elasticicty wall finish paint, of different performance / cost ratio are proposed. They features the introduction of hydroxyethyl cellulose and non-transparent hollow polymer. Therefore, the outer wall finish paint has excellent alkali resistance, color maintaining property, antifouling property, ultraviolet ray resistance, freeze thawing resistance, waterproof property, etc.

Owner:GUANGDONG BADESE CHEM

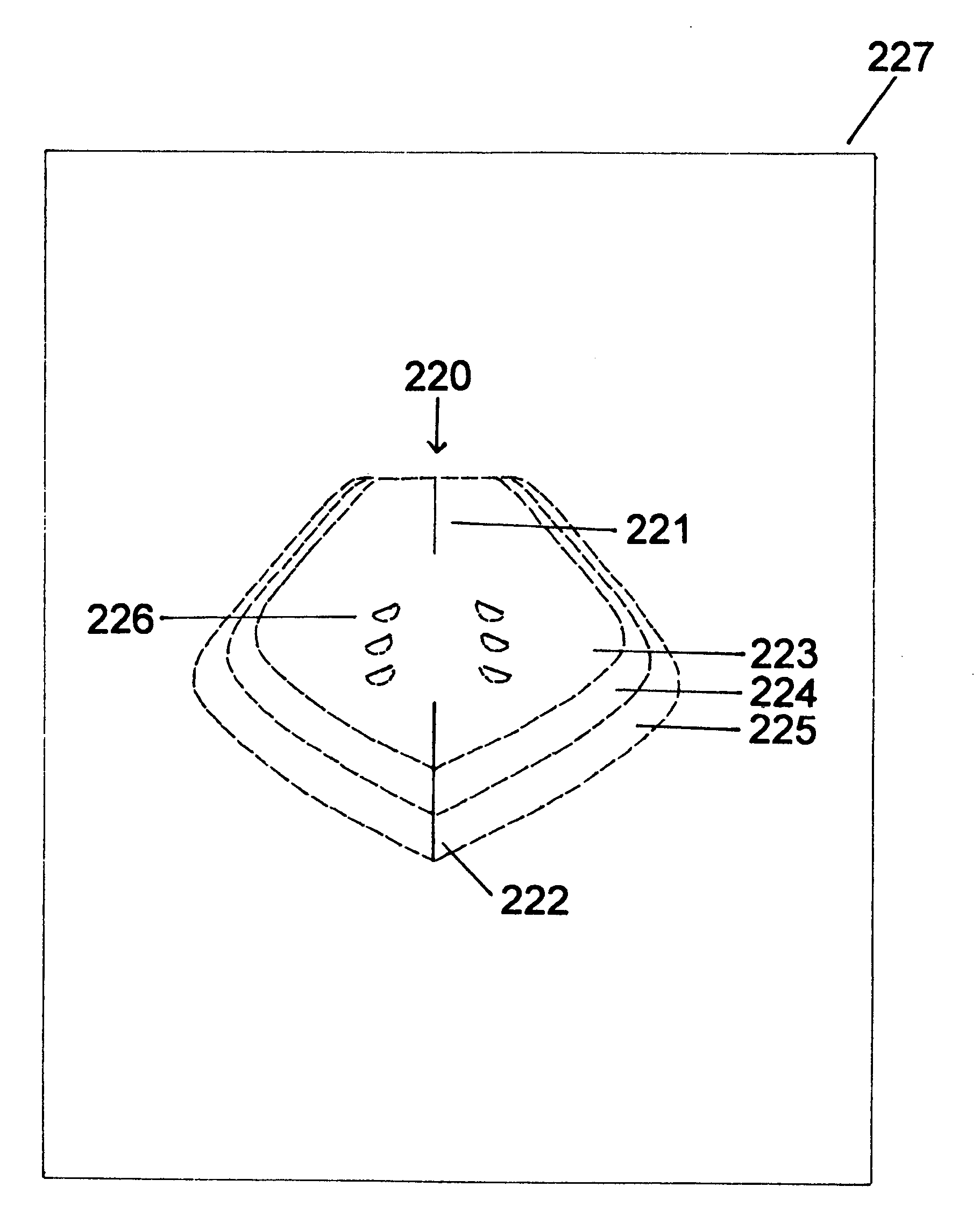

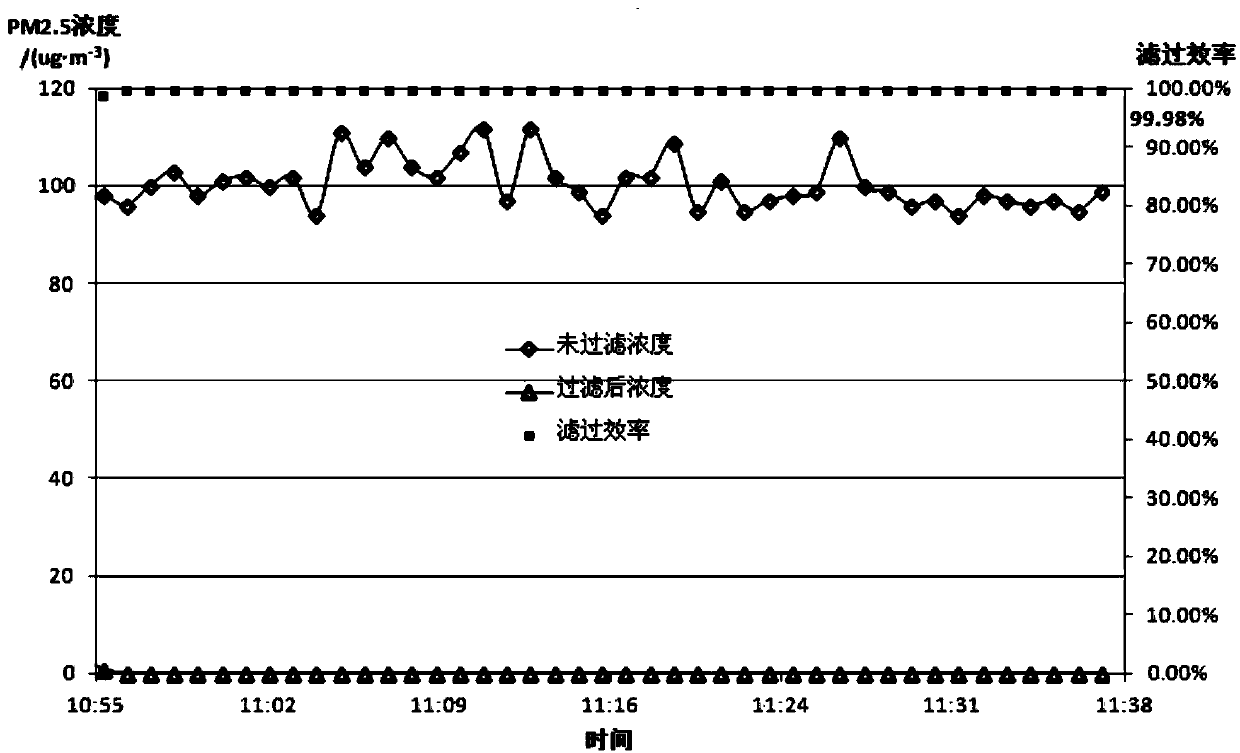

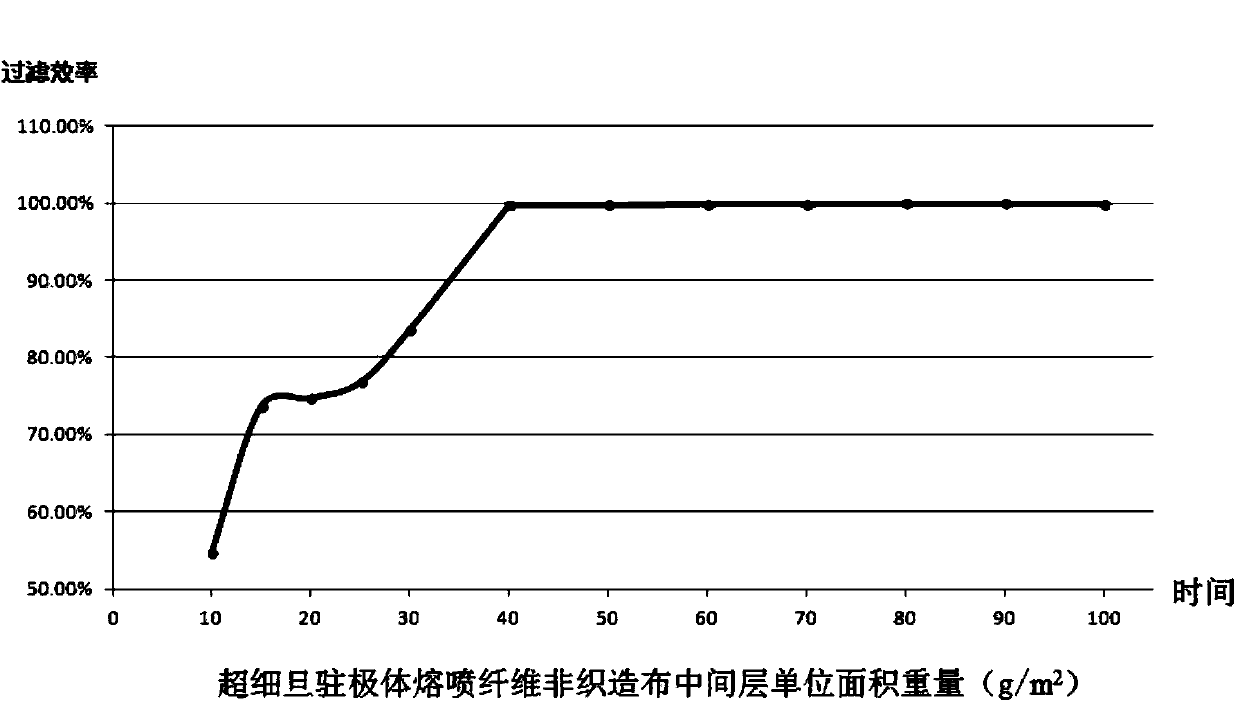

PM2.5C type mouth mask efficient in filtering

The invention relates to a PM2.5C type mouth mask efficient in filtering. The mouth mask comprises a mouth mask body, and the two sides of the mouth mask body extend out to form a pair of portions hung on ears. The mouth mask body comprises a left mouth and nose piece portion, a right mouth and nose piece portion, a left nose bridge piece portion, a right nose bridge piece portion, a left jaw piece portion and a right jaw piece portion, wherein the edge of the left nose bridge piece portion and the edge of the right nose bridge piece portion are combined, the mouth mask body is of a three-layer structure to form a laminated shape, and the weight of a middle layer made of ultra-fine electret melt-blown fiber non-woven cloth per unit area is 20-60g / m2. The PM2.5C type mouth mask efficient in filtering integrates air permeability, weight, wearing comfort and PM2.5 filtering efficiency of a mouth mask at a high level. The PM2.5 filtering efficiency of the mouth mask can reach more than 99% at most, the mouth mask is low in weight, and air permeability and comfort of the mouth mask are guaranteed at the same time. Water mist is prevented from being generated on lenses, warm air is prevented from accumulating on the inner side of the mouth mask, and bacteria are prevented from growing.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com