Patents

Literature

512results about How to "Hygroscopic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabric capable of preventing electromagnetic radiation

InactiveCN101942729AElastic fit and comfortableHarm reductionWeft knittingWarp knittingYarnSilver plate

The invention relates to a fabric capable of preventing electromagnetic radiation, which is knitted or weaved. The warp and the abb of the fabric comprise covering yarn. The covering yarn takes one of silver plating fiber, carbon fiber and carbon black organic fiber as core yarn and takes comfortable fiber as skin yarn; the silver plating fiber is formed by carrying out silver plating on synthetic fiber; the weight ratio of the corn yarn to the skin yarn is 10-70:30-90; and the comfortable fiber is one of cotton, wool, silk, hemp, viscose, bamboo fiber, bamboo carbon fiber, soybean fiber, PLA fiber, alginate fibre, milk fiber and pearl fiber. The invention can shield electromagnetic wave, and the shield effect is above 99%. The skin yarn in the covering yarn adopts natural fiber, and the natural fiber on the outer layer has the characteristics of moisture absorption, ventilation and comfort.

Owner:汕头市奥山服饰有限公司

Method for preparing flame-proof viscose fiber

InactiveCN101215726ASimple and convenient filteringFilter is not easy to clogFlame-proof filament manufactureMonocomponent cellulose artificial filamentPolymer scienceEmulsion

The invention discloses a process for preparing flame retarding cellulose viscose, which adopts pyrophosphate exchange reaction flame retardant particle whose mean particle diameter is <= 1.0um, non-ionic surface active agent, dispersing agent and solvent water to mix and obtain flame retardant emulsion, each percentage by weight is pyrophosphate exchange reaction flame retardant 20-45 wt%, non-ionic surface active agent 5-10 wt% and dispersing agent 0.5-1.0 wt%, and residue is solvent water. The process for preparation comprises adding pyrophosphate exchange reaction flame retardant of flame retardant emulsion which is corresponded to alpha cellulose 15-30 % into spinning original liquid which is filtered to mix, shaping spinning by adopting spinning bath which is low acid, low salt, low temperature and high zinc. The spinning original liquid of the invention has simple and convenient preparation, fiber does not contain halogen elements, which avoids environmental pollution, when in burning, the invention is not melted, while charring only happens to keep the original shape of fiber, the invention prevents dripping which is melted in high temperature from scalding human body, and flame retardant is distributed evenly in adhesive, which can not smolder after leaving fire and easy to be self-extinguished.

Owner:CHTC HELON

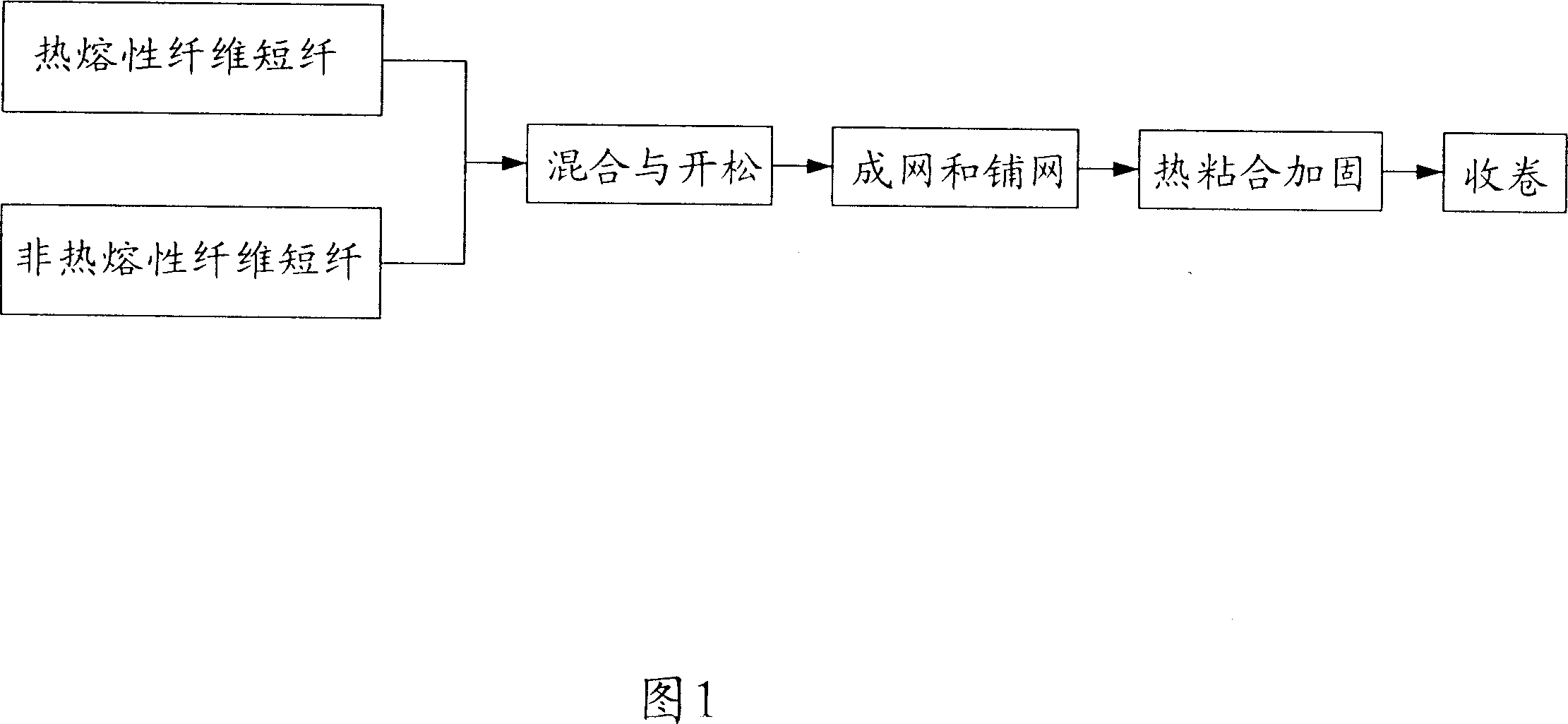

Nonwovens and machining method thereof

The invention discloses a non-woven cloth and relative production, wherein the non-woven cloth is formed by non-hot-melt staple fiber whose mass content is not lower than 30% and hot-melt composite staple fiber, via thermal adhesive fixing method. And the invention utilizes the character that the surface of the hot-melt composite staple fiber has heated fusion function, and the invention uses thermal adhesive fixing method to fuse the face of hot-melt composite staple fiber to adhere the non-hot melt staple fiber to form non-woven cloth, therefore, the produced non-woven cloth has damp adsorption property, soft property, and flexibility, without sensibility on human body. And the invention utilizes the hot-wind non-woven device or thermal rolling non-woven device with low energy consumption and low cost.

Owner:谢继华 +1

Coolmax fiber yarn dyed fabric and manufacturing method thereof

InactiveCN102080293AImprove warp evennessGood economic benefitsSynthetic fibresBiochemical fibre treatmentYarnEngineering

The invention provides a Coolmax fiber yarn dyed fabric and a processing technique thereof. In the invention, a Coolmax / cotton blended yarn is adopted, a fine-spun or poplin or oxford-spun or jacquard weave fabric is taken as a fabric texture, and the processing technique of the Coolmax fiber yarn dyed fabric adopts a special treatment method in yarn dyeing weaving. The Coolmax fiber yarn dyed fabric has the beneficial effects that the section of the adopted Coolmax fiber is in a unique four-pipe shape and is hollow, and the tube wall of the fiber is air permeable so that the fabric has excellent characteristics such as hygroscopicity, sweat exhaust, air permeability and the like due to the unique physical structure of the fiber, thus sweat on skins can be exhausted at any time and then transmitted to the fabric surface for rapid evaporation so that skins keep dry and comfortable. By means of breakthrough of the product in research and development as well as process, reference is provided for the development of top-grade personalized textile fabrics, guidance is provided for market development, and good economic benefit is created for enterprises.

Owner:TIANJIN TEXTILE ENG RES INST

High-elasticity conductive fiber and preparation method thereof

The invention relates to a high-elasticity conductive fiber and a preparation method thereof. The preparation method includes that firstly, elastic yarns are subjected to preprocessing, secondly, a metal nanowire dispersion liquid is used for impregnating and coating the preprocessed elastic yarns and metal nanowires can be adsorbed to the surface of the elastic yarns, and thirdly, the elastic yarns with the metal nanowires adsorbed to the surface are subjected to hydrogen plasma processing or thermal processing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

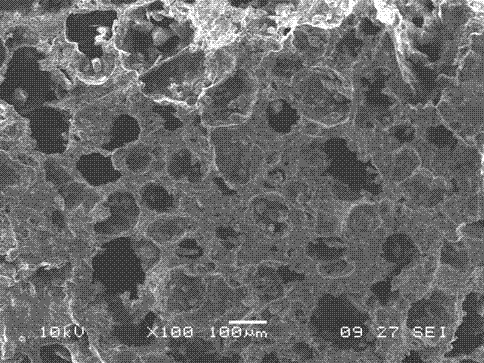

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

Bamboo fiber knitting fabric

The present invention relates to one kind of bamboo fiber knitting fabric with blended bamboo fiber yarn as facing layer and spandex or chinlon yarn covered with the bamboo fiber. It features that the blended bamboo fiber yarn consists of bamboo fiber in 50-70 wt% and cotton, Modal, Tencel, wool, cashmere or Dacron in 30-50 wt%, and has count of 20-60 s and twist multiplier of 330-345. The bamboo fiber knitting fabric has the excellent performance of bamboo, including moisture absorption, permeation, health care and antibiotic property, etc. as well as improved costume performance and size stability, and is one kind of high grade comfortable material for underwear.

Owner:北京铜牛集团有限公司

Antibacterial, moisture-absorbent and warming knitted fabric and manufacturing method thereof

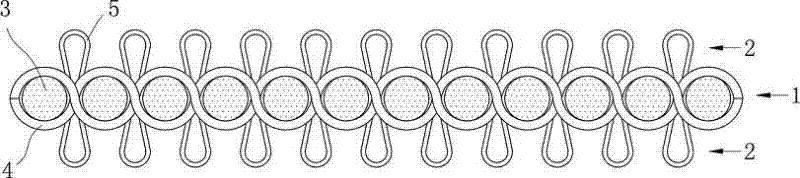

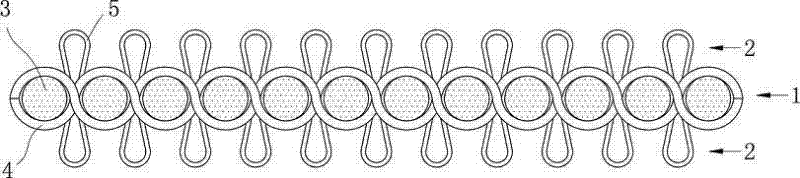

The invention discloses antibacterial, moisture-absorbent and warming knitted fabric and a manufacturing method thereof. The antibacterial, moisture-absorbent and warming knitted fabric has a double-layer structure, wherein an outer layer of the fabric has a mesh structure woven from blended yarns which are blended from cellulosic fibers and nanosilver antibacterial agent-containing profiled polyester fibers; an inner layer of the fabric has a plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and the inner layer and the outer layer are connected through polyester filaments with grooved sections. The manufacturing method comprises the following steps: for the outer layer of the fabric, manufacturing the mesh structure woven from the blended yarns which are blended from the cellulosic fibers and the nanosilver antibacterial agent-containing profiled polyester fibers; for the inner layer of the fabric, manufacturing the plain structure woven from the nanosilver antibacterial agent-containing profiled polyester fibers; and connecting the inner layer and the outer layer through the polyester filaments with the grooved sections. The antibacterial, moisture-absorbent and warming knitted fabric can meet requirements on moisture absorption for quick drying as well as wearing comfort, can meet an increasingly strong requirement on antibacterial sanitation and has a good warming effect.

Owner:SHANGHAI JIALE

Processing method of instant seasoning grilled squid strips

The invention relates to a processing method of instant seasoning grilled squid strips, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is uniformly mixed with seasoning and cured, dried, aired and baked into grilled dried squid with the water content being controlled to be 17 percent + / - 1 percent; the grilled dried squid is torn into strips; and the grilled squid strips are detected by metal and packaged to obtain finished products. The processing method has reasonable procedures, is simple in preparation, and easily realizes large-scale production. The seasoning for curing is mixed scientifically, so that the freshness and the flavor of the squid product are improved, and the product is not dry, hard and crispy. The seasoning grilled squid strips which are prepared through the method maintain the nutrition of the squid, have golden color, and the special baking aroma of marine food products, and the product has tough texture, is chewy and dainty in saline taste and sweetness, has delicious taste and long storage life, can be eaten conveniently only after a package is opened, and is ideal leisure food.

Owner:RONGCHENG HONGWEI FOOD

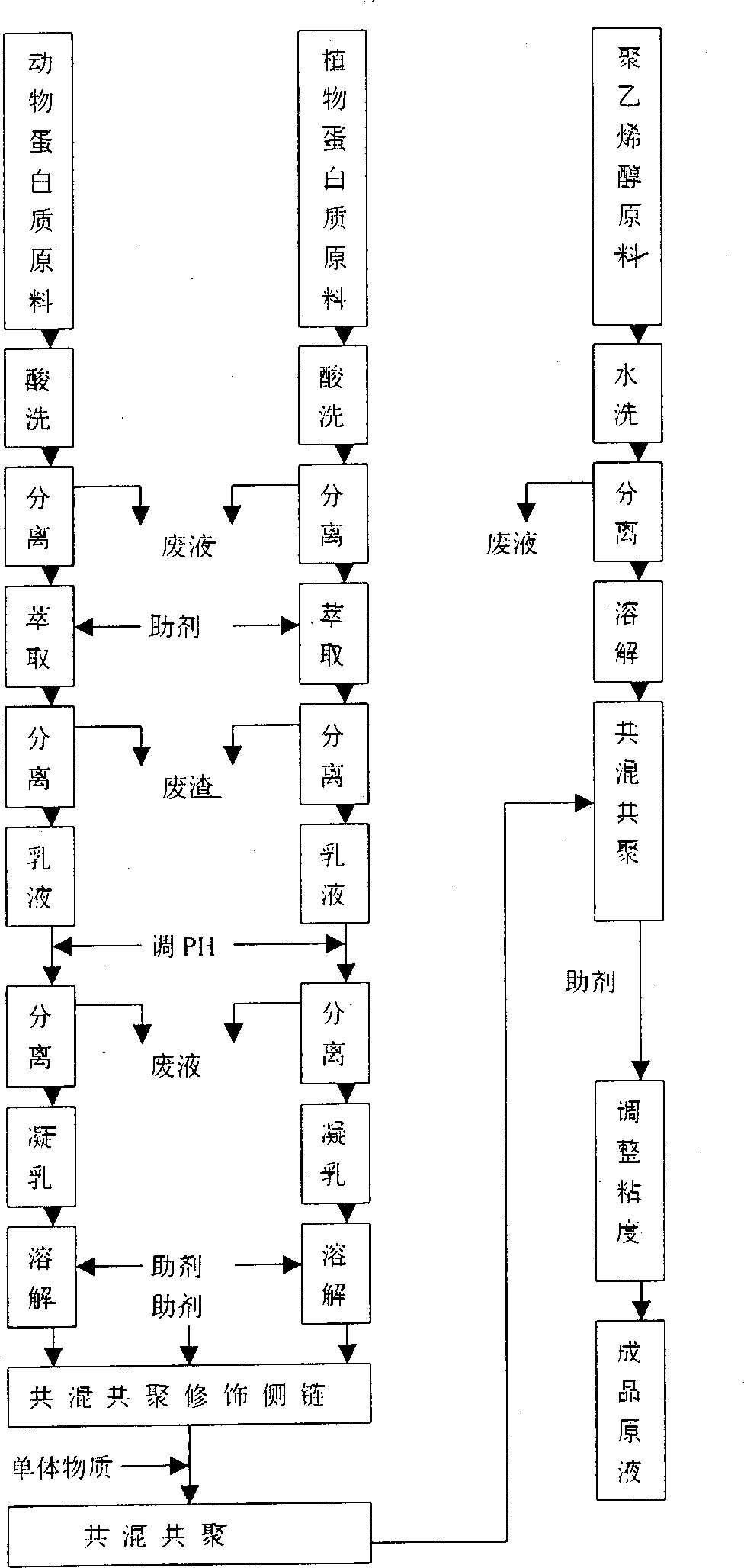

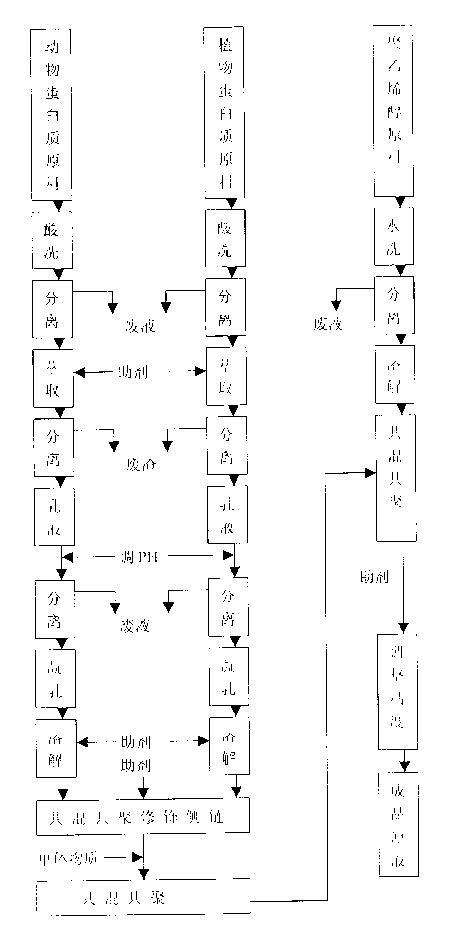

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

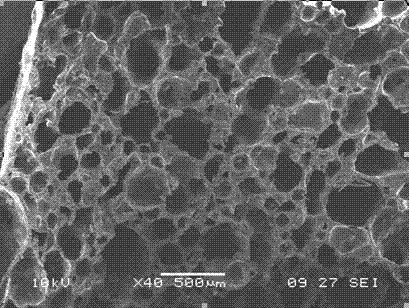

Loofah antimicrobial health-care material and uses thereof

InactiveCN101347131AStrong specific surface areaFast adsorption-desorption speedBiocideDisinfectantsBiotechnologyFiber

The present invention provides four loofah vegetable sponge antibacterial health care materials and the application thereof. The four loofah vegetable sponge antibacterial health care materials are mainly characterized in that the four materials all contain the loofah fiber component and have the approximately same efficacy of antibacterial health care; wherein, material A contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder, loofah vegetable sponge fiber active carbon or loofah begetable sponge fiber compound active carbon and bamboo pyroligneous antibacterial liquor; material B contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder and loofah vegetable sponge fiber active carbon or loofah vegetable sponge fiber compound active carbon; material C contains loofah vegetable sponge fiber tablet or loofah vegetable sponge fiber powder and bamboo pyroligneous antibacterial liquor; material D contains loofah vegetable sponge fiber active carbon or loofah vegetable sponge fiber compound active carbon and bamboo pyroligneous antibacterial liquor. The materials of the present invention are taken as the additive in preparing antibacterial health care fiber and textile, washing product, craftwork, vessel, present box and packaging box, sports article, furniture and paint or building decoration material or are used for purifying water and air and absorbing harmful substances.

Owner:袁会文

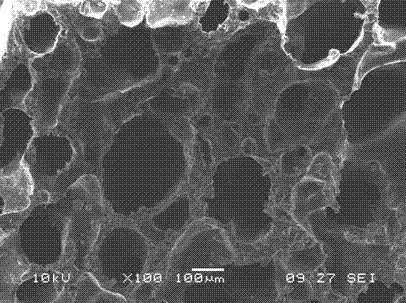

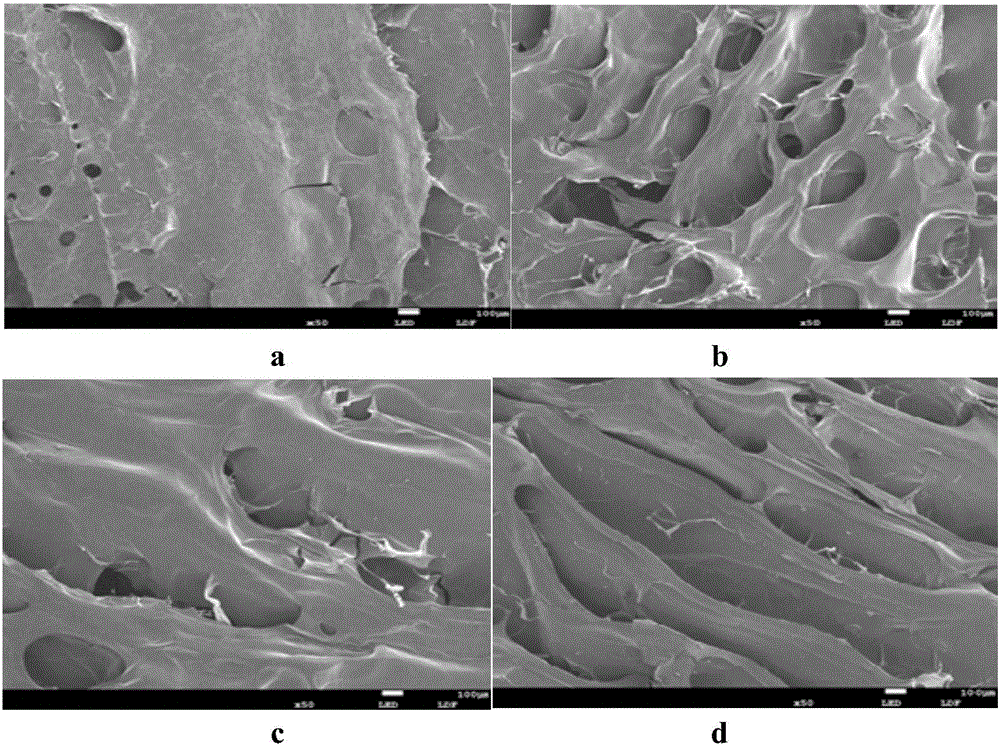

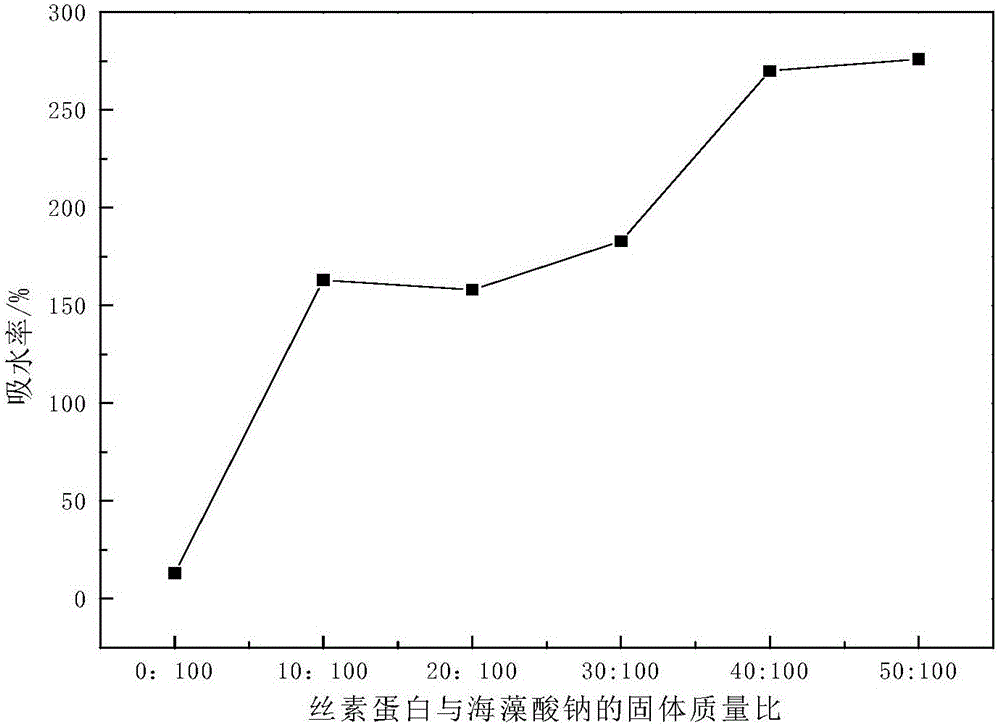

Preparation method of alginate and silk fibroin composite sponge

The invention discloses a preparation method of alginate and silk fibroin composite sponge. Dried and sheared silkworm cocoons are degummed, fibroin fibers obtained after degumming is dissolved in a mixed solution including calcium chloride, ethanol and water, and a yellowish-brown solution is obtained. A pure silk fibroin solution is obtained with a dialysis and centrifugation method and mixed with a sodium alginate solution, the mixture is stirred, blended and freeze-dried, the dried product is immersed into a prepared solution (the mass ratio of calcium chloride to glycerin to ethanol being 7:3:90) and is taken out to be dried, and the composite sponge is obtained. The composite sponge is prepared from alginate and silk fibroin, and the application of the sponge material in actual production is expanded; compared with other sponge materials, the alginate and silk fibroin composite sponge has the excellent and outstanding characteristics of being economical, environment-friendly, good in biocompatibility and degradability and the like and can be applied to the fields such as medical dressing, cosmetic articles, architectural ornament and the like.

Owner:DALIAN POLYTECHNIC UNIVERSITY

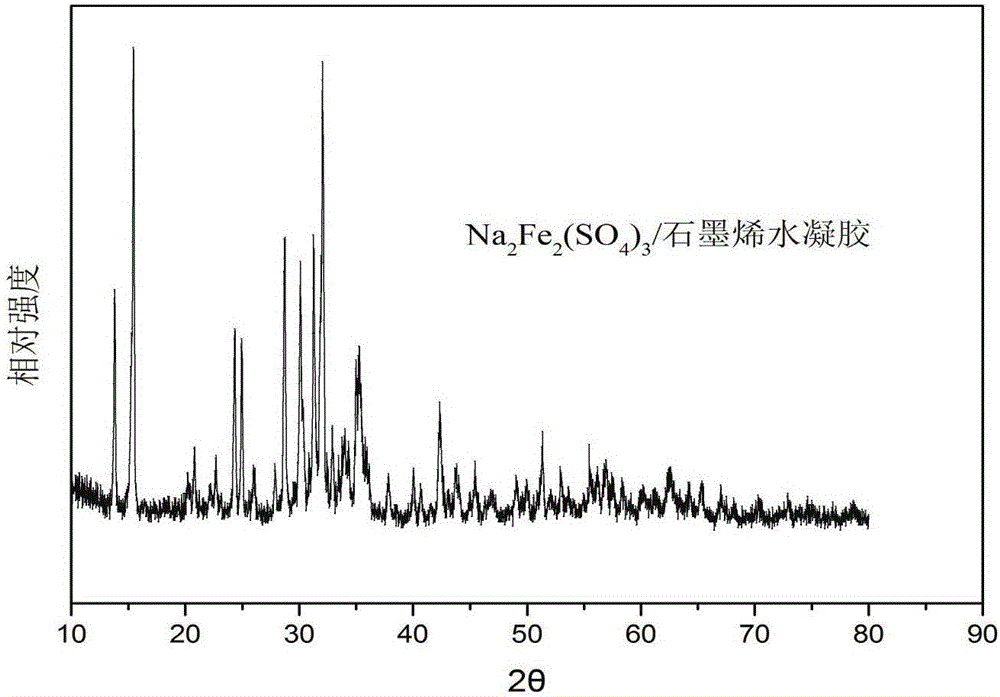

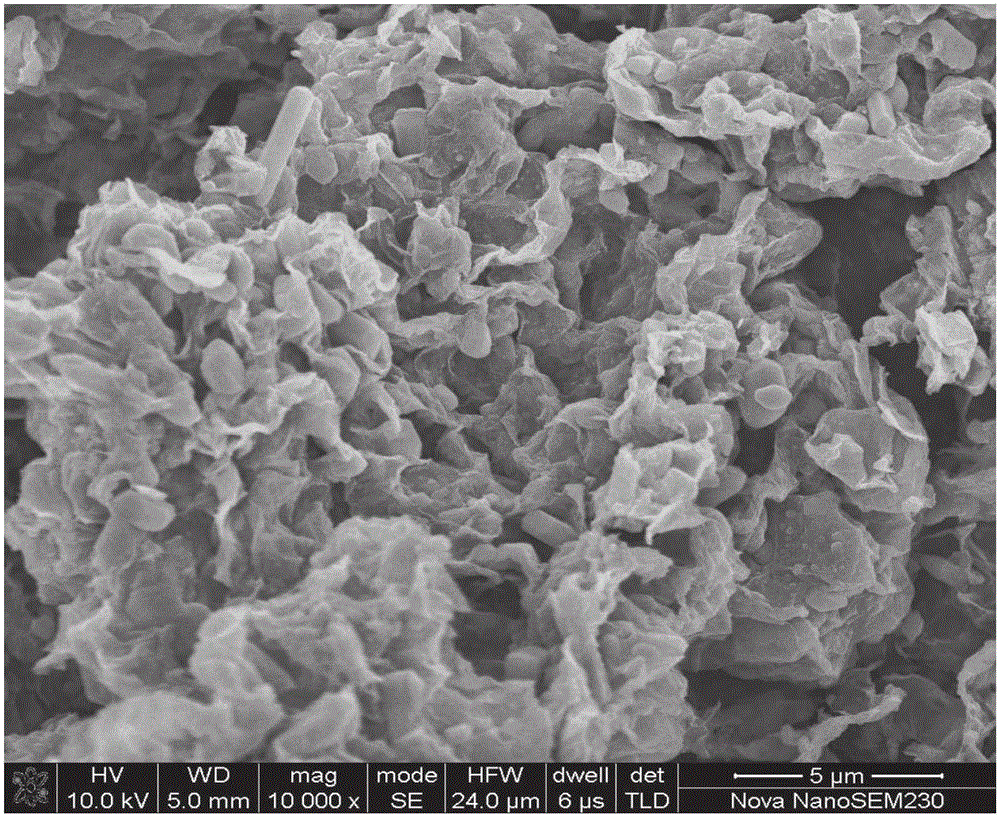

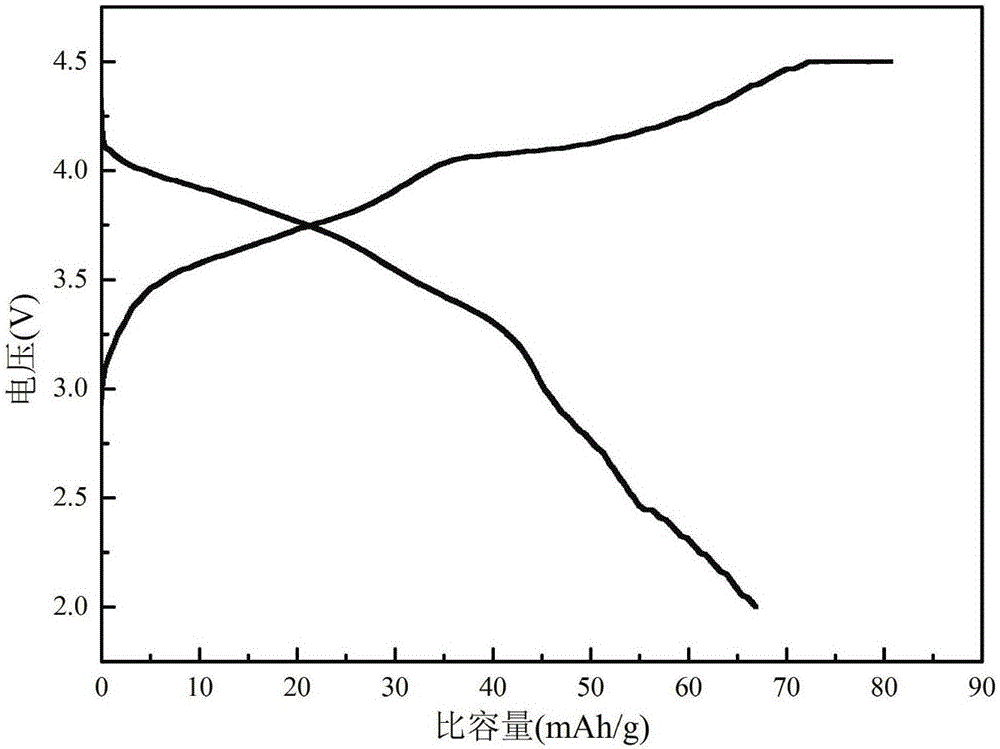

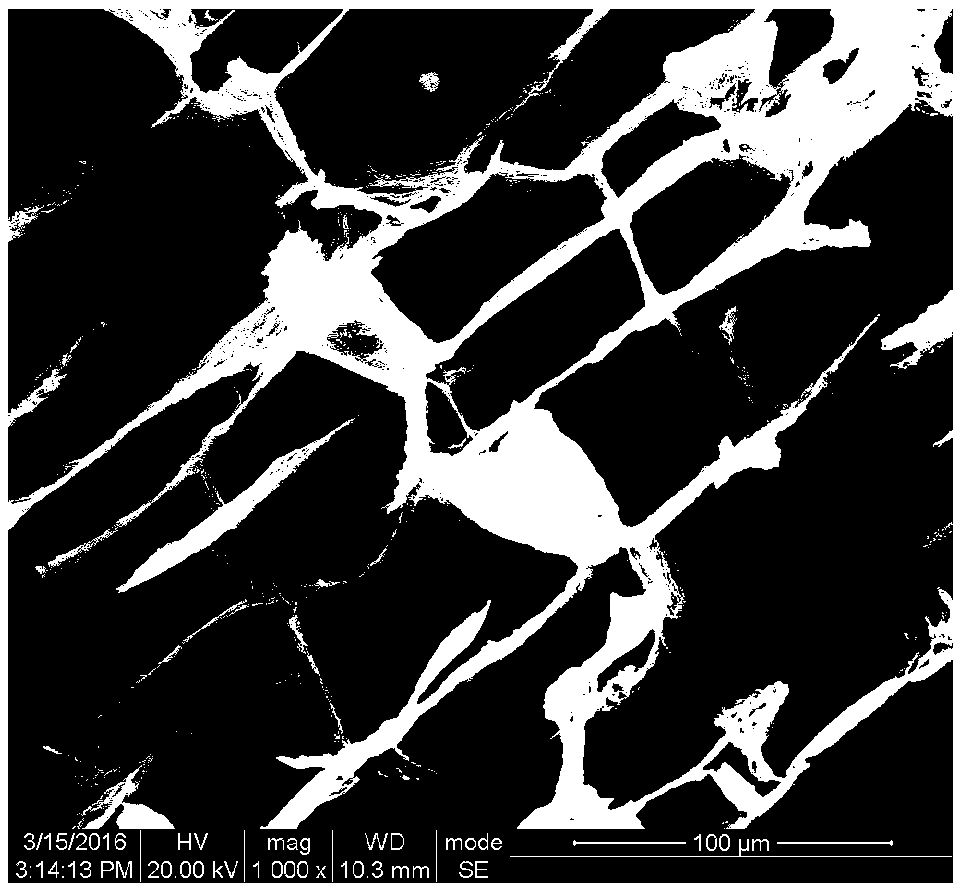

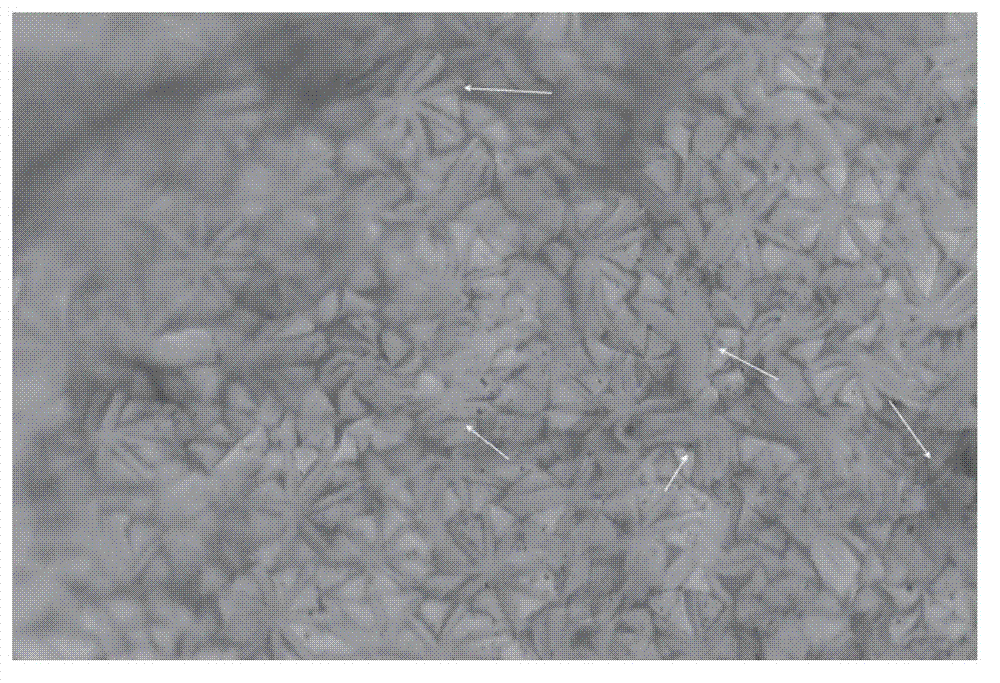

Sodium ferrous sulfate/graphene composite positive electrode material for sodium ion battery, and preparation method thereof

ActiveCN106848236AImproved rate performanceGood electrical conductivityCell electrodesSecondary cellsCvd grapheneIon

The present invention discloses a Na2Fe2(SO4)3 / graphene composite positive electrode material for a sodium ion battery. The Na2Fe2(SO4)3 / graphene composite positive electrode material comprises graphene having a three-dimensional structure, wherein Na2Fe2(SO4)3 is compounded on the graphene surface in an in-situ compounding manner. The invention further discloses a preparation method of the composite positive electrode material. The preparation method comprises: dispersing graphene oxide, a sodium source, a sulfur source and a ferrous salt in water to obtain a suspension, carrying out a hydrothermal reaction on the obtained suspension at a temperature of 90-140 DEG C, carrying out solid-liquid separation on the hydrothermal reaction product, carrying out liquid nitrogen quenching, and drying to obtain a precursor; and carrying out calcination treatment on the precursor to obtain the composite positive electrode material. According to the present invention, the active substance and the carbon substrate are tightly bound, the coating is good, and the good physical and chemical properties are provided; the synthesis method is simple, the condition is mild, and the yield is high; the active substance is uniformly dispersed in the prepared composite material; and with the application of the prepared composite material as the sodium ion positive electrode material, the advantages of high specific capacity, high working voltage, good cycle stability and excellent rate performance are provided.

Owner:CENT SOUTH UNIV

Union yarn of terylene fibers, viscose fibers and bamboo fibers, and production method thereof

The invention provides a union yarn of terylene fibers, viscose fibers and bamboo fibers, and a production method thereof. The union yarn comprises the following components by mass percentage: 78-85%of terylene fibers, 5-15% of viscose fibers and 5-15% of bamboo fibers. Since the union yarn of terylene fibers, viscose fibers and bamboo fibers fully combines the favorable properties of terylene fibers, viscose fibers and bamboo fibers, the respective defects are eliminated. The fabrics made of the union yarn have the advantages of high acid resistance, alkaline resistance, strength, heat resistance, elasticity, wrinkling resistance, wear resistance, hydroscopic property, ventilation property and dyeing property and can resist bacteria, prevent bacteria and resist ultraviolet radiation.

Owner:NANTONG SUZHONG TEXTILE

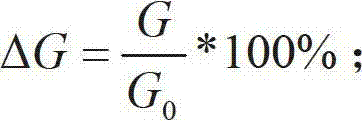

Method for producing high-hygroscopicity acrylic fibers

InactiveCN101914852ALittle mechanical damageGood hygroscopicityFibre typesPolymer scienceReaction temperature

The invention relates to a method for producing high-hygroscopicity acrylic fibers, which is characterized by directly adding the acrylic fibers to mixed solution formed by sodium hydroxide or potassium hydroxide and guanidine reagents, carrying out hydrolysis and cyclization for 10-200min under the reaction temperature of 50-200 DEG C and carrying out cleaning and drying to produce the high-hygroscopicity acrylic fibers; or firstly adding the acrylic fibers to mixed solution formed by guanidine reagents and sodium hydroxide or potassium hydroxide to be soaked for 3-30min, then extruding the acrylic fibers until the water content is 50-500% and finally placing the extruded acrylic fibers into a steam setting vessel to be dry-steamed or steamed for 10-200min at 50-200 DEG C and carrying out cleaning and drying to produce the high-hygroscopicity acrylic fibers. The method can process the acrylic fibers into high-hygroscopicity acrylic fibers only by adopting the simple acrylic fiber hydrolyzing and crosslinking processes, has the advantages of simple production process, low equipment investment and low production cost and is easy to realize industrialization.

Owner:SHANDONG UNIV OF TECH

Flame-retardant fiber composite and fabric produced therefrom.

ActiveCN1806071AImprove featuresImprove flame retardant performanceWoven fabricsNon-woven fabricsFiberCellulose

A flame-retardant fiber composite which comprises: 20 to 85 wt.% fibers (A) comprising 100 parts by weight of a polymer containing at least 17 wt.% halogen atoms and 0.5 to 50 parts by weight of an antimony compound; 5 to 80 wt.% heat-resistant fibers (B); 0 to 40 wt.% cellulosic fibers (C); and 0 to 40 wt.% flammable fibers (D). When used in applications such as indoor furniture or beddings, the composite further improves the flame retardancy of materials and enables the materials to be used in fields where higher flame retardancy is required.

Owner:KANEKA CORP

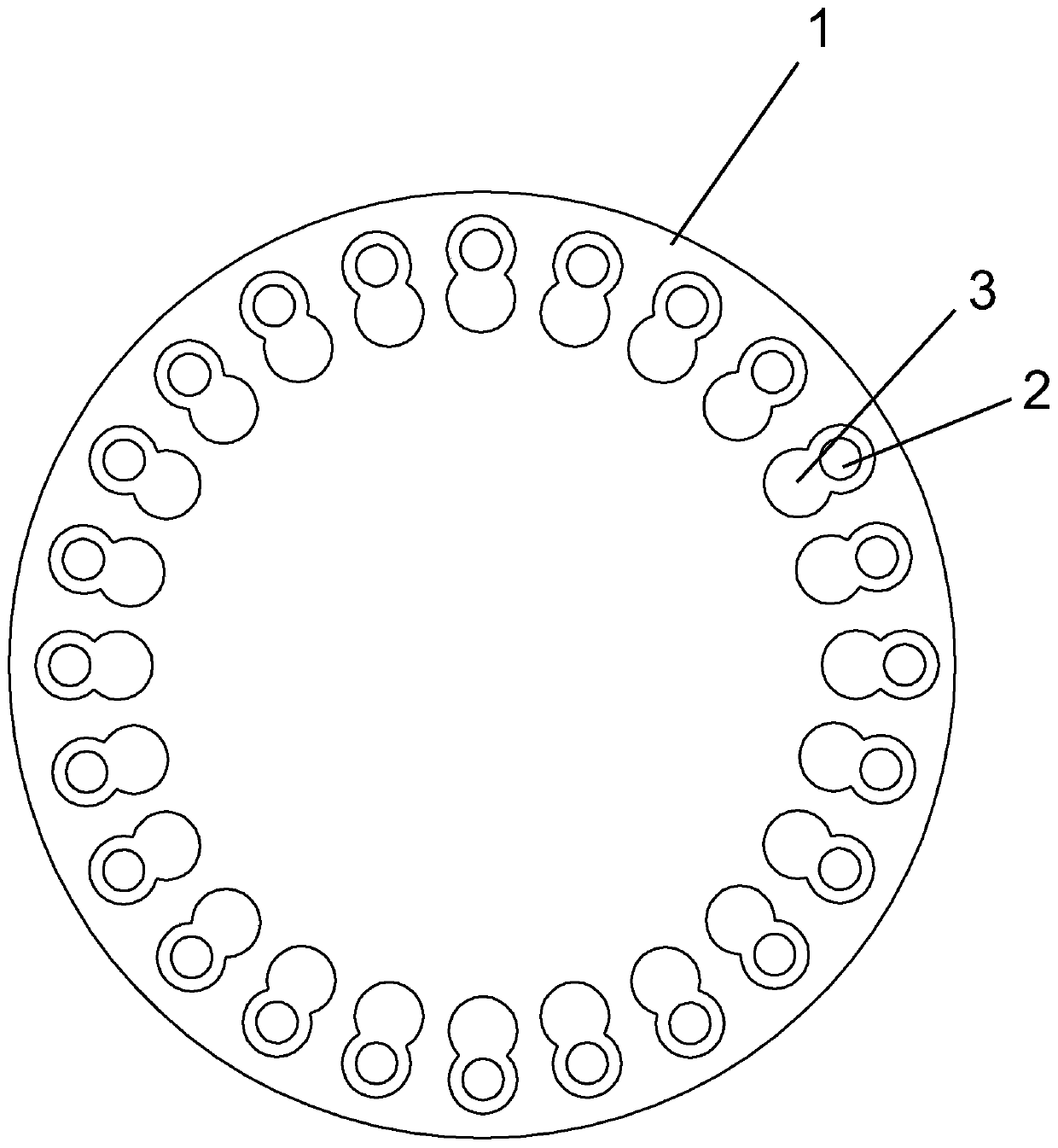

Antistatic, moisture-regaining and dyeable core pattern complex fiber and fabric made by same

InactiveCN103233285AGood hygroscopicityDry and soft feelSynthetic resin layered productsFilament/thread formingFiberPolymer science

The invention provides an antistatic, moisture-regaining and dyeable core pattern complex fiber and fabric made by the same. The core pattern complex fiber comprises a leather layer and a core layer, wherein the mass ratio of the leather layer to the core layer is 90 / 10 to 10 / 90; the core layer is made of polyhydroxy fibre or muti-carboxylic fibre with good hygroscopicity, dyeability and anti-static function; the leather layer is melt-spinnable superpolymer; and the complex fiber has various functions of good mechanical strength, hygroscopicity, anti-static function, dyeability and the like. The fabric made by combining the core pattern complex fiber with photocatalyst coating has the advantages that the fabric is antimicrobial and is disinfected; organic pollutants such as formaldehyde can be effectively removed; and the sustainability and the safety are high.

Owner:世纪宝姿(厦门)实业有限公司

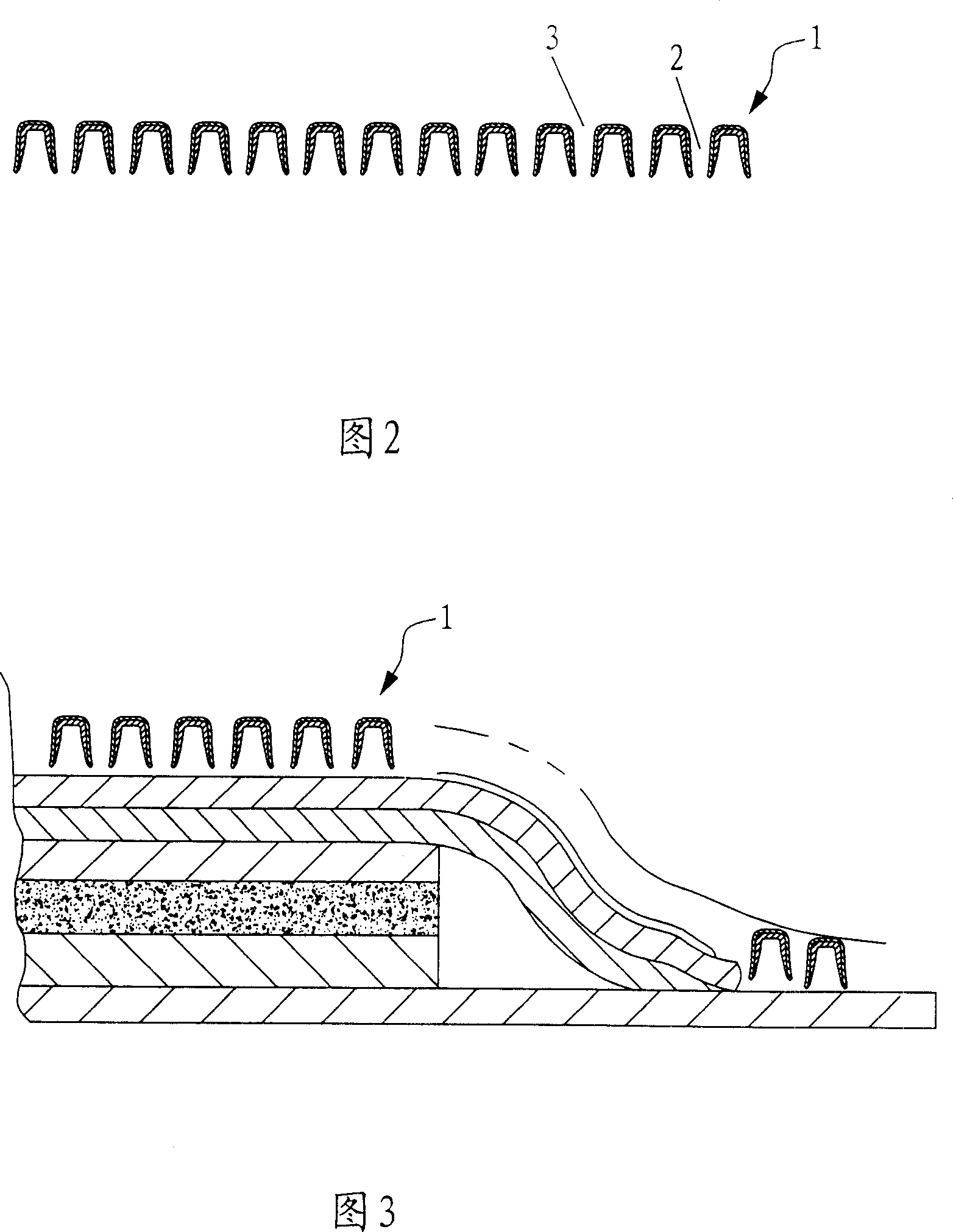

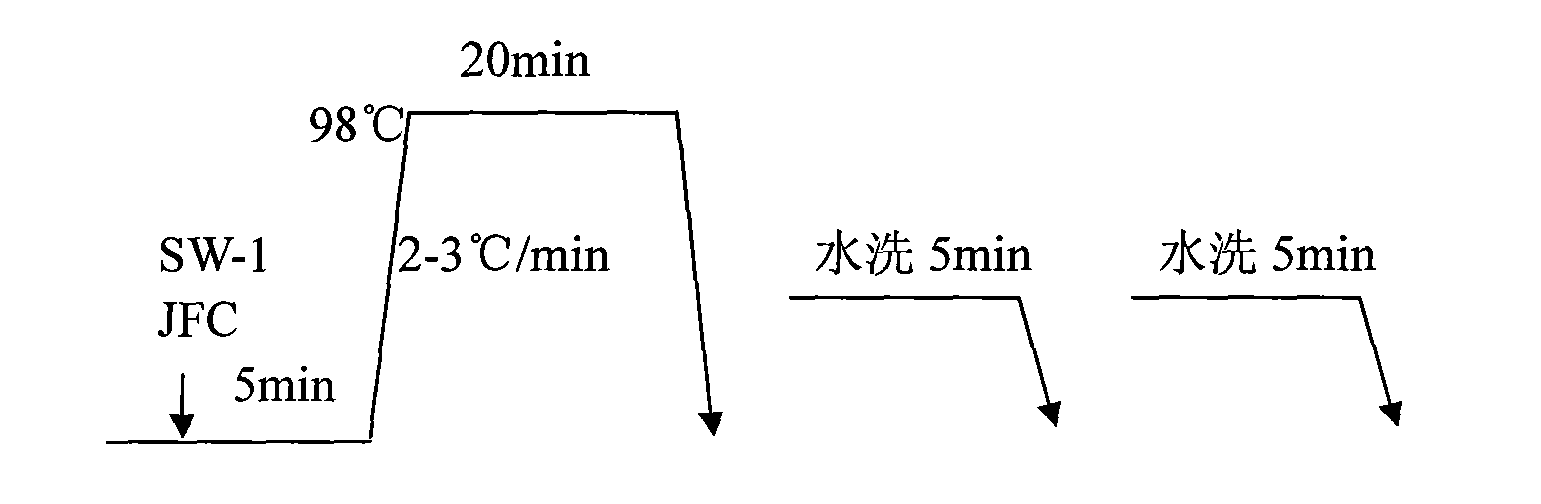

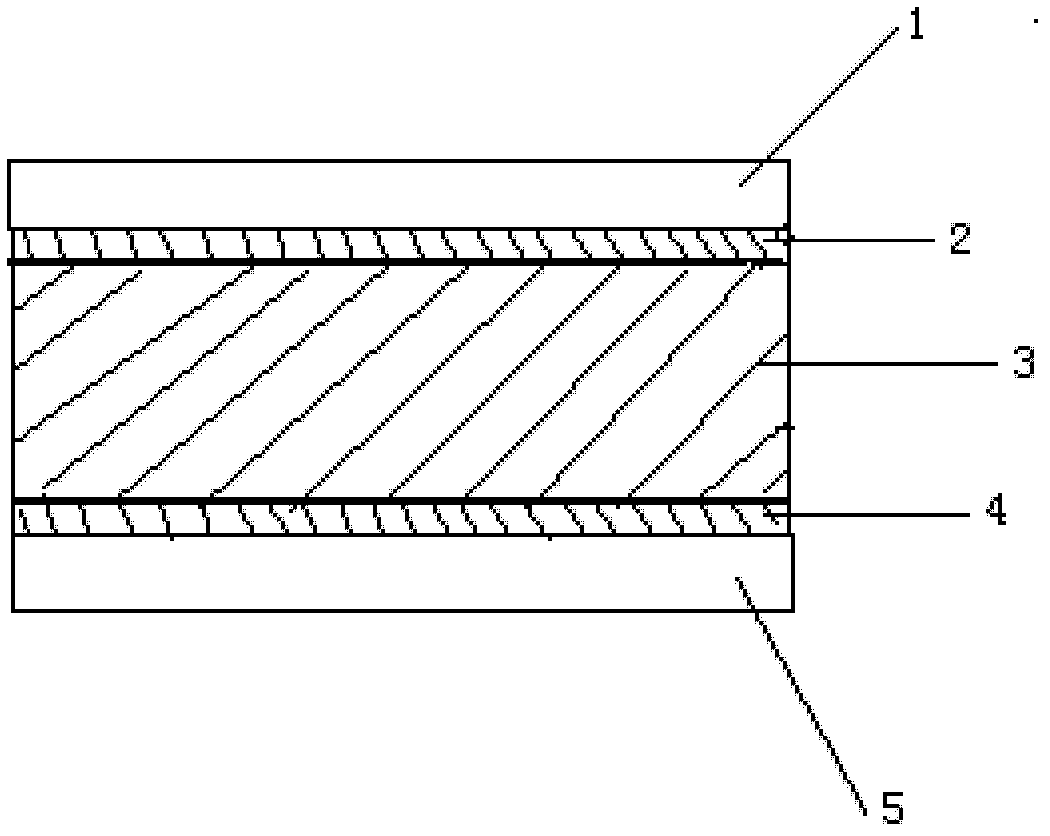

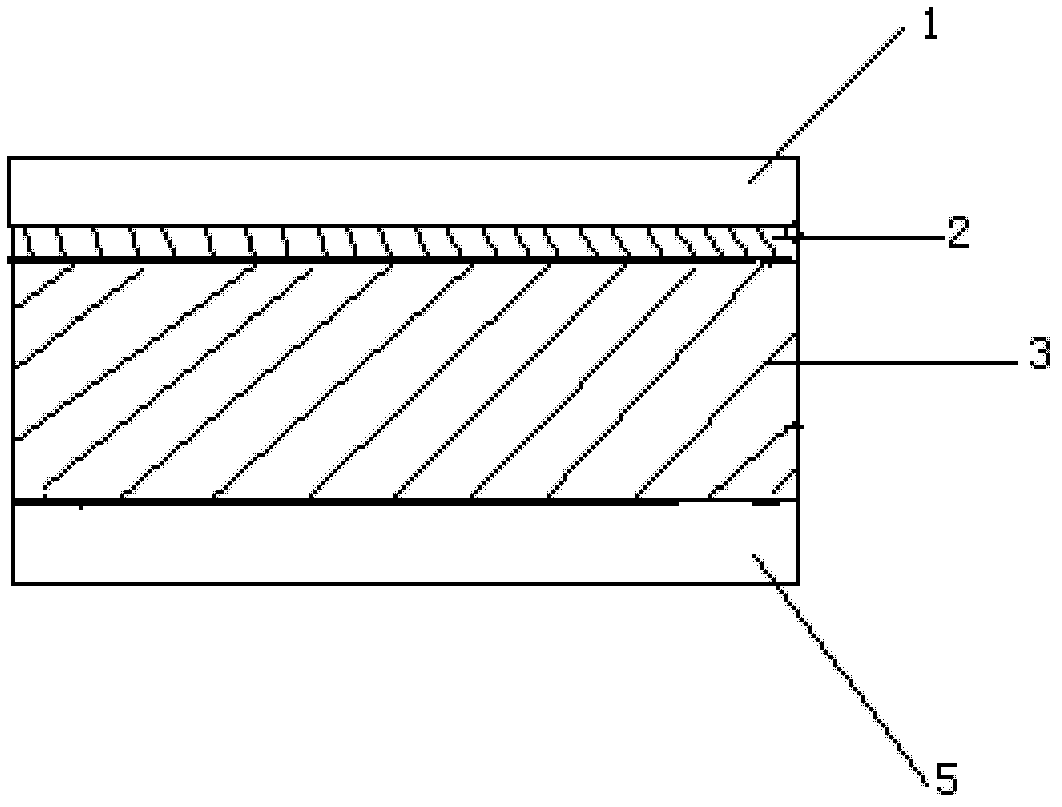

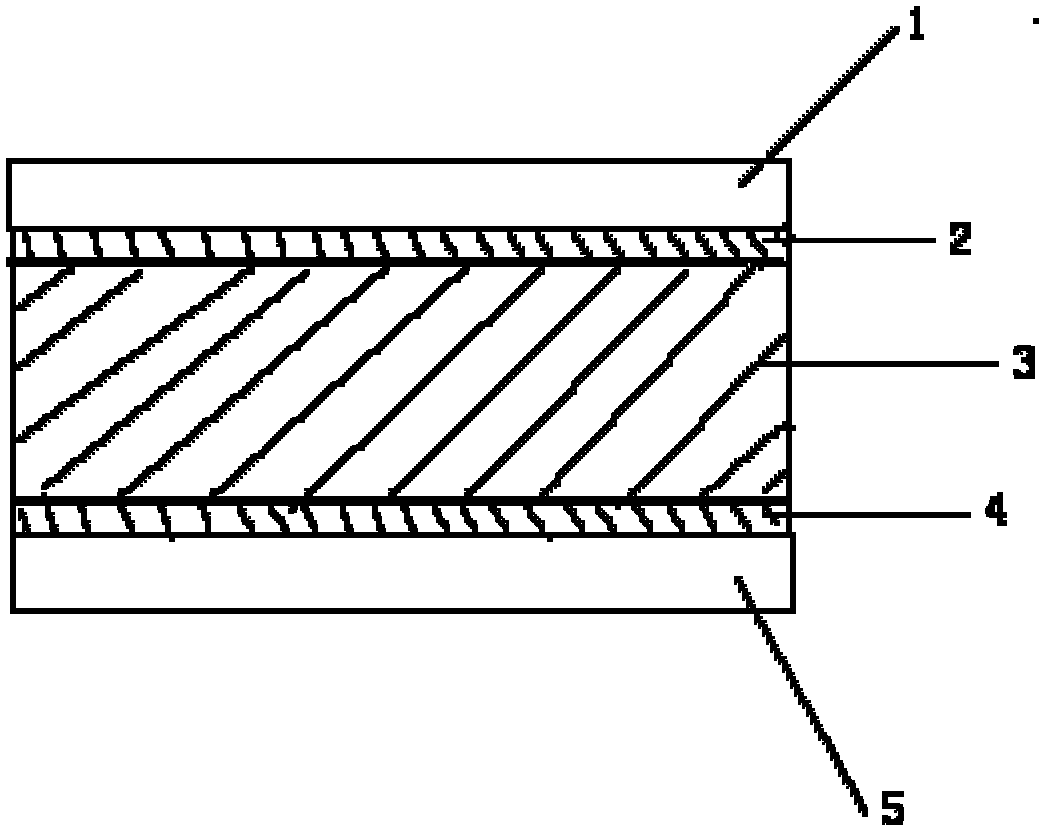

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Blended yarn of jute fiber, cotton fiber and viscose fiber and application of blended yarn

InactiveCN102493059AHygroscopicMoisture retentionBiochemical fibre treatmentBleaching apparatusYarnMoisture absorption

The invention discloses a blended yarn of a jute fiber, a cotton fiber and a viscose fiber. The blended yarn is made by blending the following raw materials in percentage by weight: 30 to 50 percent of jute fiber, 22 to 30 percent of cotton fiber and 20 to 48 percent of viscose fiber. By blending the jute fiber, the cotton fiber and the viscose fiber in a reasonable proportion, the blended yarn overcomes the defects that the jute fabric is rough and hard and easy to drape, and has the characteristics of moisture absorption, air permeability and antibacterium and the like of the jute fiber; besides, the blended yarn has the advantages of softness, smoothness, breathability, antistatic performance, and the like, and rich color can be obtained by dyeing. Blended fabric made of the yarn is applied to undershirts, sportswear, coats and the like.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Additive of printing paste as well as preparation method and using method of additive

ActiveCN103556502AImprove the use environment and production environmentHigh yieldDyeing processChemistryPropylene glycol

The invention provides an additive of printing paste as well as a preparation method and a using method of the additive. The additive can be used for solving the problems in the prior art that dust flying exists, a product is easy to aggregate during dissolution and cannot be fully dissolved, and a stirring mixed material has relatively poor uniformity. Polyethylene glycol, propylene glycol, glycerin and triethanolamine in the additive have certain viscosity, can be mixed and dissolved in water, but cannot dissolve sodium alginate, and therefore, after the additive is added, the additive cannot damage the viscosity of the printing paste, also does not enable the sodium alginate to aggregate due to swelling and is beneficial to the improvement of the dispersibility of the sodium alginate in water. The additive has certain moisture absorption and is adhered to the surfaces of particles, and the tiny particles are spliced together through the additive, so that the dust flying is avoided, and the uniformity of the mixed material is improved.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

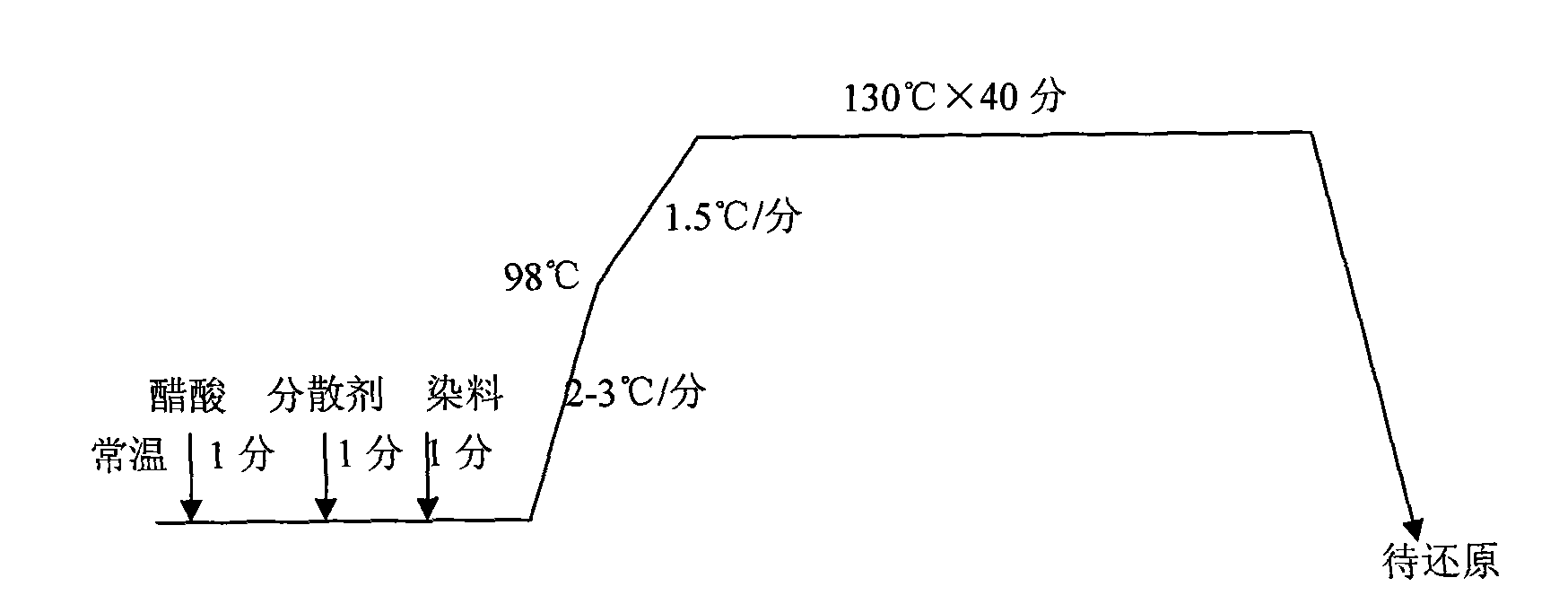

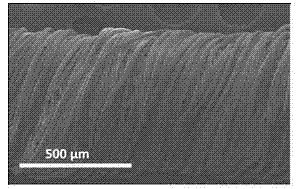

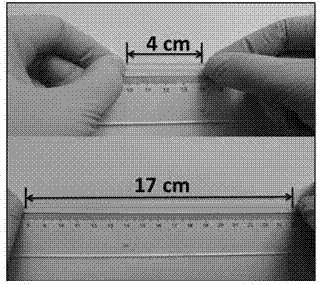

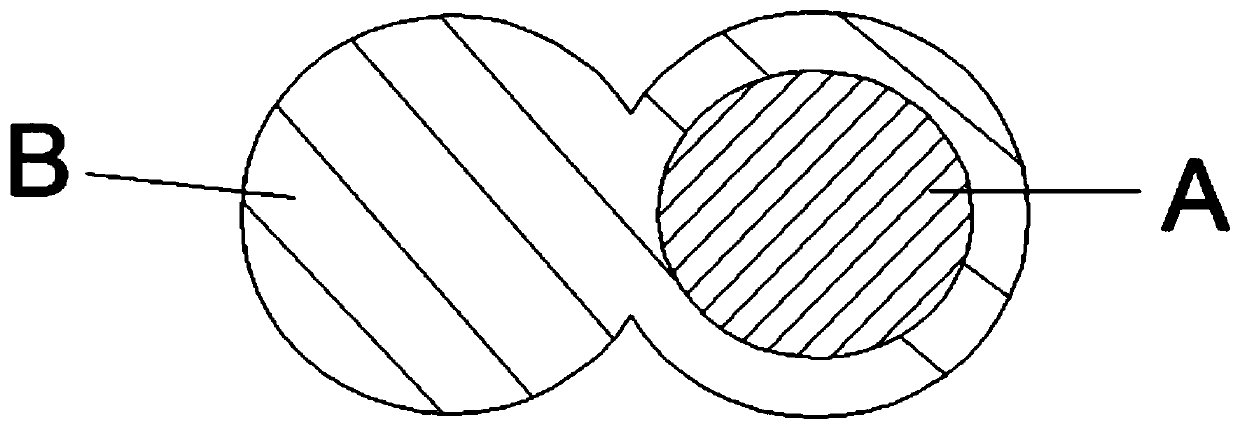

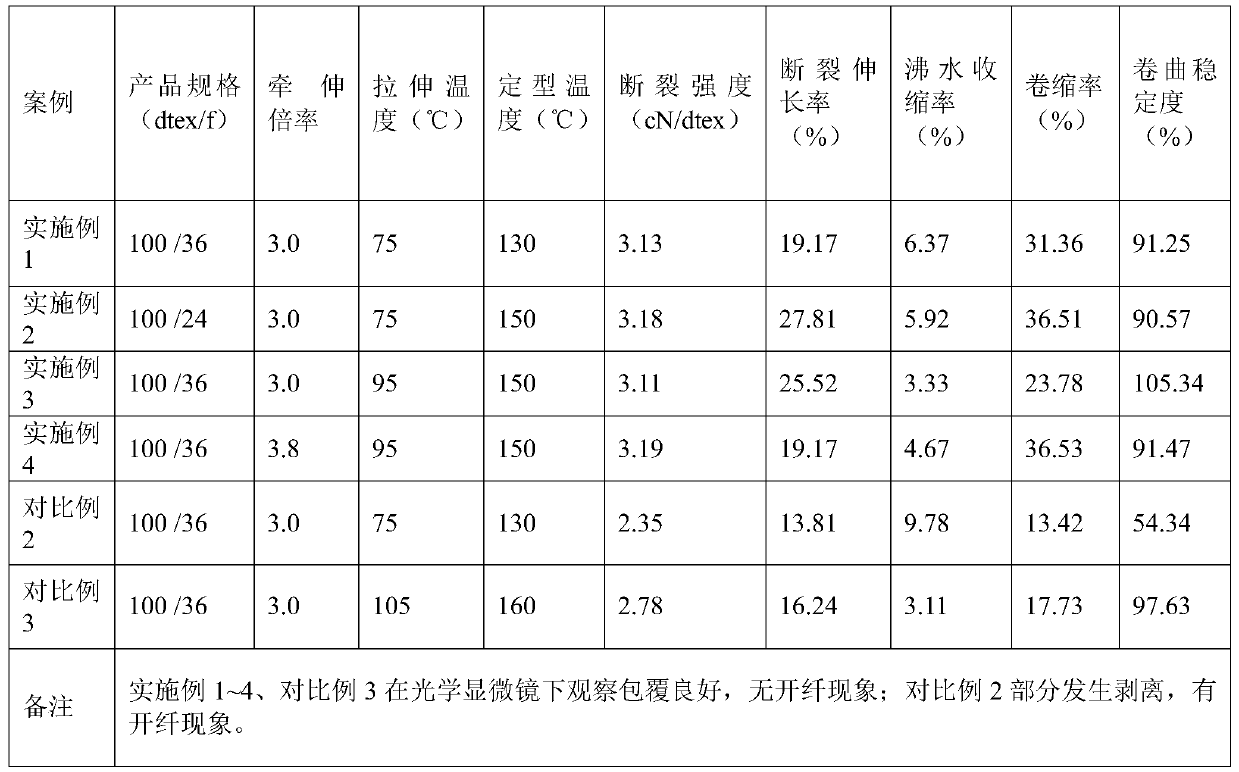

Preparation method of polyester-nylon parallel composite elastic fiber

ActiveCN110644073AIncrease melt viscosityPromote charcoalFlame-proof filament manufactureMelt spinning methodsPolyesterFiber

The invention relates to the field of chemical fibers and discloses a preparation method of a polyester-nylon parallel composite elastic fiber, wherein PET (polyethylene terephthalate) and nylon 6 aretaken as two parallel components, then the PET and nylon 6 are respectively subjected to melt extrusion through a screw extruder, the melts enter a two-component composite spinning assembly and a skin-core composite spinneret plate with a special design, and the sprayed melt is cooled, the cooled melt is oiled, and the oiled material is stretched and shaped and wound to obtain the polyester-nylonparallel composite elastic fiber, having the advantages of moisture absorption, air permeability, pilling resistance, bulkiness, high elasticity, fabric stiffness and the like. Compared with the current polyester-nylon composite fibers, the polyester-nylon composite fiber has better elasticity, and higher added value, and the problem of fiber opening of parallel polyester-nylon composite fibers is solved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

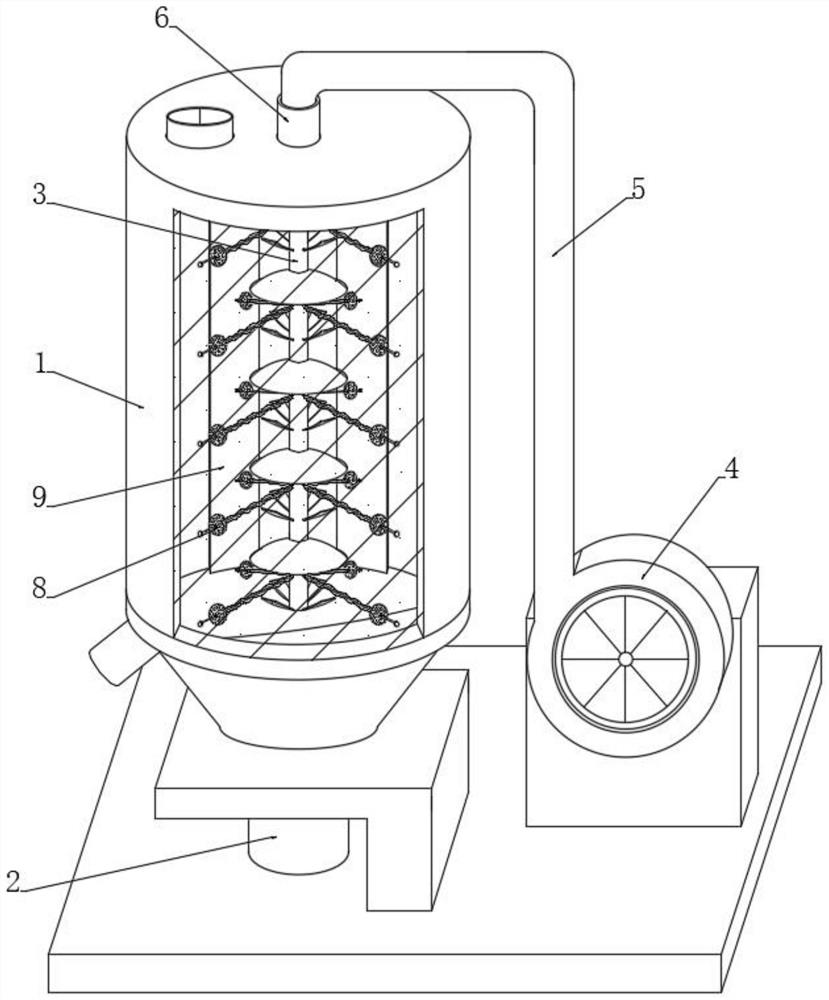

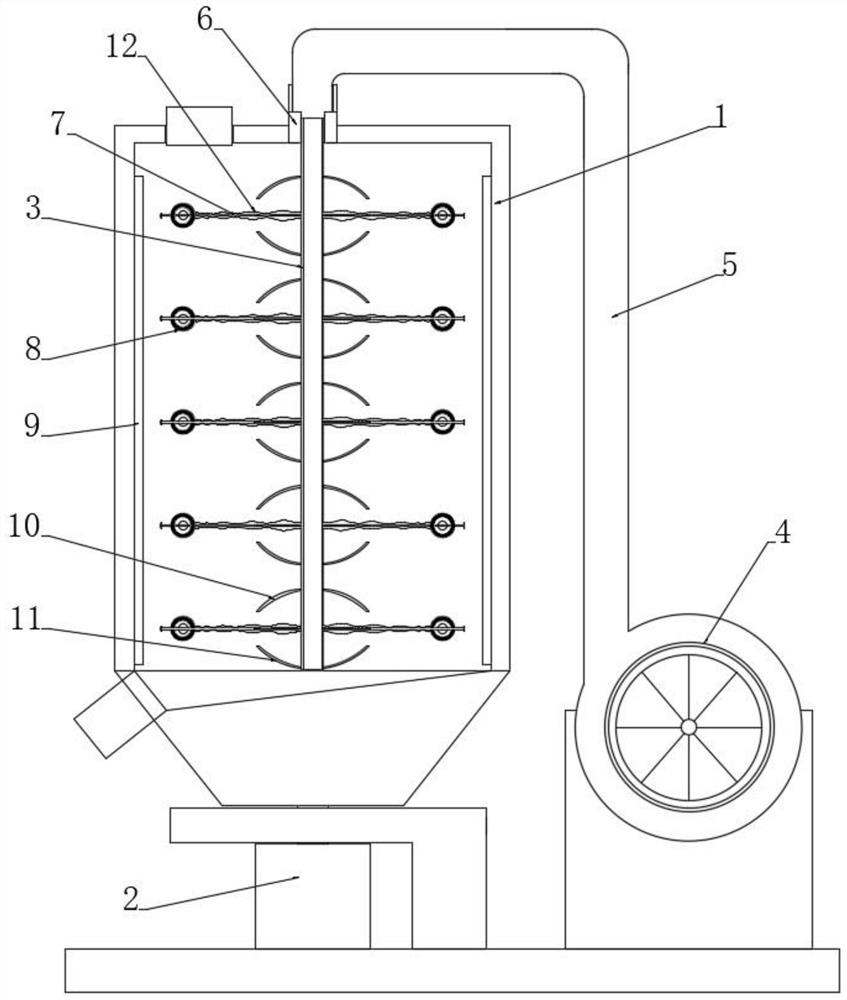

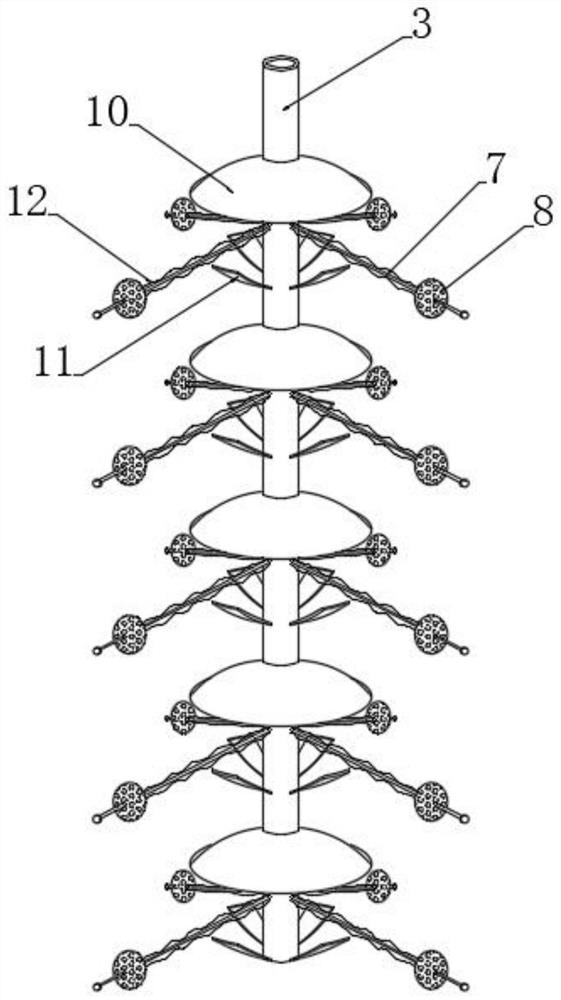

Dynamic dehumidification device for drying plastic particles

InactiveCN112212623AImprove dehumidification effectPlay a magnetic roleDrying gas arrangementsDrying chambers/containersMoisture absorptionMagnetic shield

The invention discloses a dynamic dehumidification device for drying plastic particles, and belongs to the technical field of plastic particle processing. Moisture on the plastic particles is absorbedand dried through magnetic dehumidification balls, and before the magnetic dehumidification balls absorb the moisture, magnet layers can magnetically absorb hollow magnetic balls, and after the magnetic dehumidification balls absorb the moisture to a certain degree, outer moisture absorption expansion layers absorb water and expands to extrude inner elastic magnetic shielding layers, inner elastic magnetic shielding layers are extruded to be tightly attached to the hollow magnetic balls, so that a certain magnetic shielding effect on the hollow magnetic balls is achieved; and the magnetic dehumidification balls are reset inwards under the action of extension springs, and after a drying part is dried and the outer moisture absorption expansion layers lose water, the inner elastic magneticshielding layers expand outwards to weaken the shielding effect on the hollow magnetic balls, when the magnetic attraction force of the magnet layers to the hollow magnetic balls is larger than the tensile force of the extension springs, the magnetic dehumidification balls are pulled to move outwards, reciprocating dynamic movement is matched with a rotating dehumidification cylinder, and the gooddehumidification effect on the plastic particles is effectively achieved.

Owner:林建金

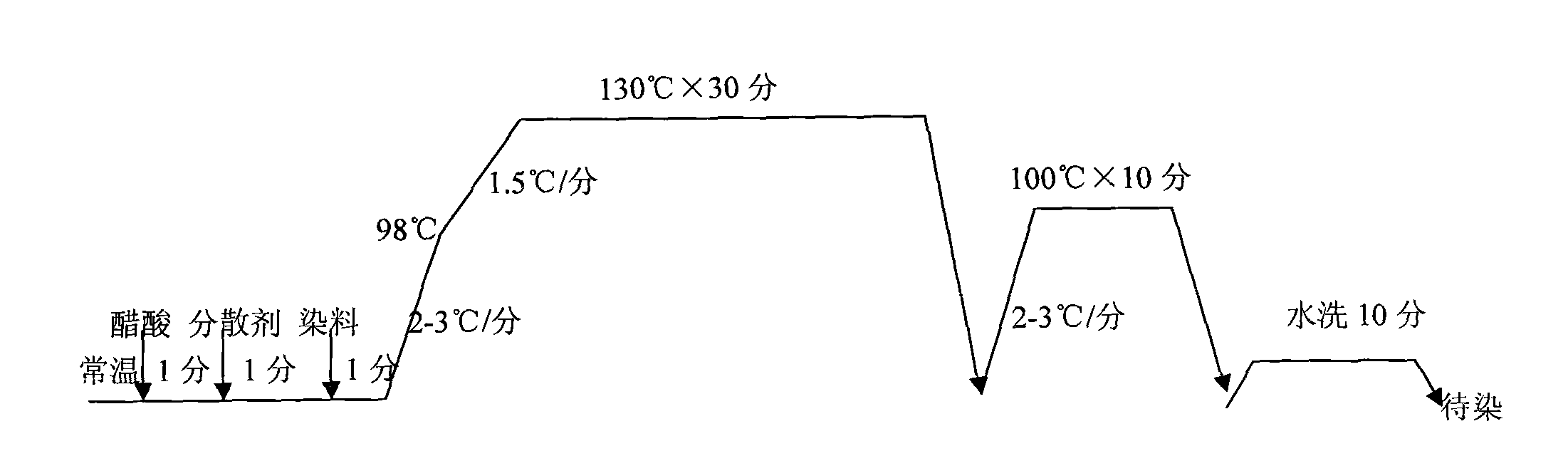

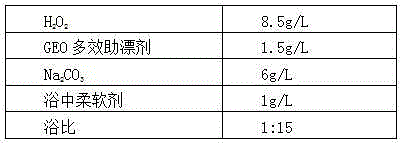

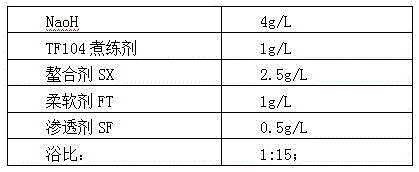

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

Anti-ultraviolet elastic fabric and production method thereof

InactiveCN101942736ASoft and plumpNon-irritatingFibre treatmentWoven fabricsExtensibilityUltraviolet

The invention discloses an anti-ultraviolet elastic fabric. Warp and weft yarns of the fabric at least comprise one full dull yarn, wherein the weft yarn at least comprises one elastic yarn; and the prepared finished product has weft extensibility of 5 to 30 percent and elastic recovery of over 80 percent, is comfortable to wear and has high size stability. The finished product has transmittance resistance of over 95 percent; the anti-ultraviolet UPF value is over 50; and the fabric has cool feel and a moisture absorption and fast drying function and is an ideal recreational material for autumn and summer.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Bamboo fiber and mulberry silk blended yarn towel and production process thereof

InactiveCN102493100AHigh strengthImprove breathabilityFibre treatmentBleaching apparatusFiberPolymer science

Provided are a bamboo fiber and mulberry silk blended yarn towel and a production process thereof. The bamboo fiber and mulberry silk blended yarn towel comprises a base cloth layer and wool warps, wherein the base cloth layer is formed by body warps and weft yarns, and the wool warps penetrate through interweaving holes formed by the body warps and the weft yarns to form terry layers on one surface or two surfaces of the base cloth layer. The wool warps are blended yarns formed by bamboo fibers and the mulberry silk, and the body warps and the weft yarns of the base cloth layer are pure cotton yarns or pure mulberry silk yarns or blended yarns formed by cotton and the mulberry silk. The production process comprises the steps of yarn warping, warp sizing, machine weaving, dyeing treatment, cutting, sewing and finishing and the like. The towel not only integrates soft and smooth features, good air permeability, moisture absorption and moisture releasability of the bamboo fibers and the mulberry silk and outstanding antibacterial and health-care effects, but also has the advantages of being high in abrasion resistance and strength, long in service life, low in price and the like. The novel product with high quality and price benefits and the appropriate production process of the novel product are provided for towel textile fabrics.

Owner:HUZHOU SICHOUFU TEXTILE

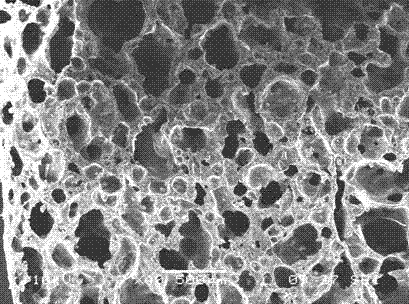

High-strength low-heat-conductivity grade A noninflammable aerogel foam and preparation and application thereof

ActiveCN108264372ALow thermal conductivityGood mechanical propertiesCeramicwareHigh intensityLimiting oxygen index

The invention provides a high-strength low-heat-conductivity superhydrophobic polymer matrix noninflammable aerogel material, comprising, by weight, 0.5-10.0 parts of inorganic particles, 0.03-2.0 parts of a branched polymer binder, 0-2.0 parts of a crosslinkable polymer, 0-1.0 part of a crosslinking agent, and 0-3 parts of a surfactant. The invention also discloses a preparation method of the material; the material has the density of 5-100 kg / m<3>, specific modulus of 10-150 MP cm<3> / g, heat conductivity coefficient of 0.010-0.070 W / (m K), extreme oxygen index of higher than 50%, combustion heat value of 1.0-4.0 MJ / kg, good superhydrophobicity and water contact angle of greater than 150.0 DEG. Before and after combustion, the material has high strength and structural stability, and secondary damage possibly caused by shrinking or collapse after burning is decreased to maximum extent.

Owner:SICHUAN UNIV

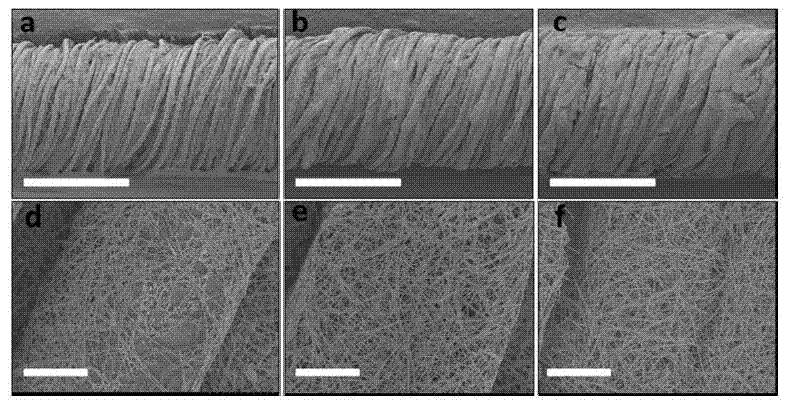

Method for manufacturing split type fiber knitted wiping cloth

InactiveCN103088532AOvercoming uneven fiber openingOvercoming problems such as poor shrinkageWeft knittingFibre treatmentFiberPolyester

The invention relates to a wiping cloth manufacturing method, in particular to a method for manufacturing split type fiber knitted wiping cloth. By using orange slice type polyester and nylon composite filaments as raw materials, the method for manufacturing the split type fiber knitted wiping cloth comprises the following processes of: a) weaving; b) de-oiling treatment; c) alkali peeling splitting; d) sizing; and e) cutting and cleaning. By adoption of the method, the technical problems of non-uniformity in splitting and low shrinkage of the conventional wiping cloth are solved.

Owner:SHANGHAI CHALLENGE TEXTILE

Textile material

InactiveCN102817248AImprove insulation effectHygroscopicTextiles and paperBiocompatibility TestingMoisture absorption

The invention provides a textile material consisting of the following components by mass: 50%-70% of cotton fiber, 10%-20% of bamboo carbon fiber, 5%-12% of chitosan fiber, 5%-15% of terylene and 7%-12% of acrylic fiber. The textile material has the following benefits that: the fiber material has the functions of warm keeping, moisture absorption and air ventilation; the chitosan fiber has biological activity and biocompatibility and can effectively restrain golden yellow staphylococcus, colon bacillus and tritirachium album and the like; and the bamboo carbon fiber has the function of moisture absorption.

Owner:太仓市璜泾飞达制衣厂

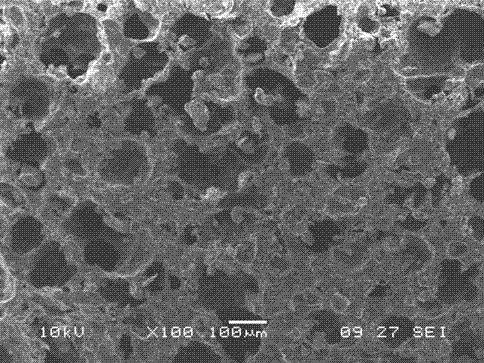

Light-colored microporous EPDM sponge rubber and preparation method thereof

The invention relates to rubber and a preparation method thereof, and provides a light-colored microporous EPDM sponge rubber which is advantageous in uniform pore, large expansion ratio and less compression permanent deformation and is suitable for producing sealing strip products, and a simple and feasible preparation method thereof. The light-colored microporous EPDM sponge rubber is made from EPDM sponge rubber, foaming agents, reinforcing fillers, plasticizers, anti-aging agents, colorants, vulcanizers and other vulcanizing additives. The colorants may be rutile titanium dioxide, fluorescent whiteners and ultramarines; the foaming agents, such as azobisformamide (AC), 4,4'-oxydibenzenesulfonyl hydrazide (OBSH) and urea, are heated to decompose to release gases; the types and consumptions of vulcanizers and vulcanizing additives can be changed. The light-colored microporous EPDM sponge rubber can be used in combination with white building materials, and the application range of rubber materials is increased.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

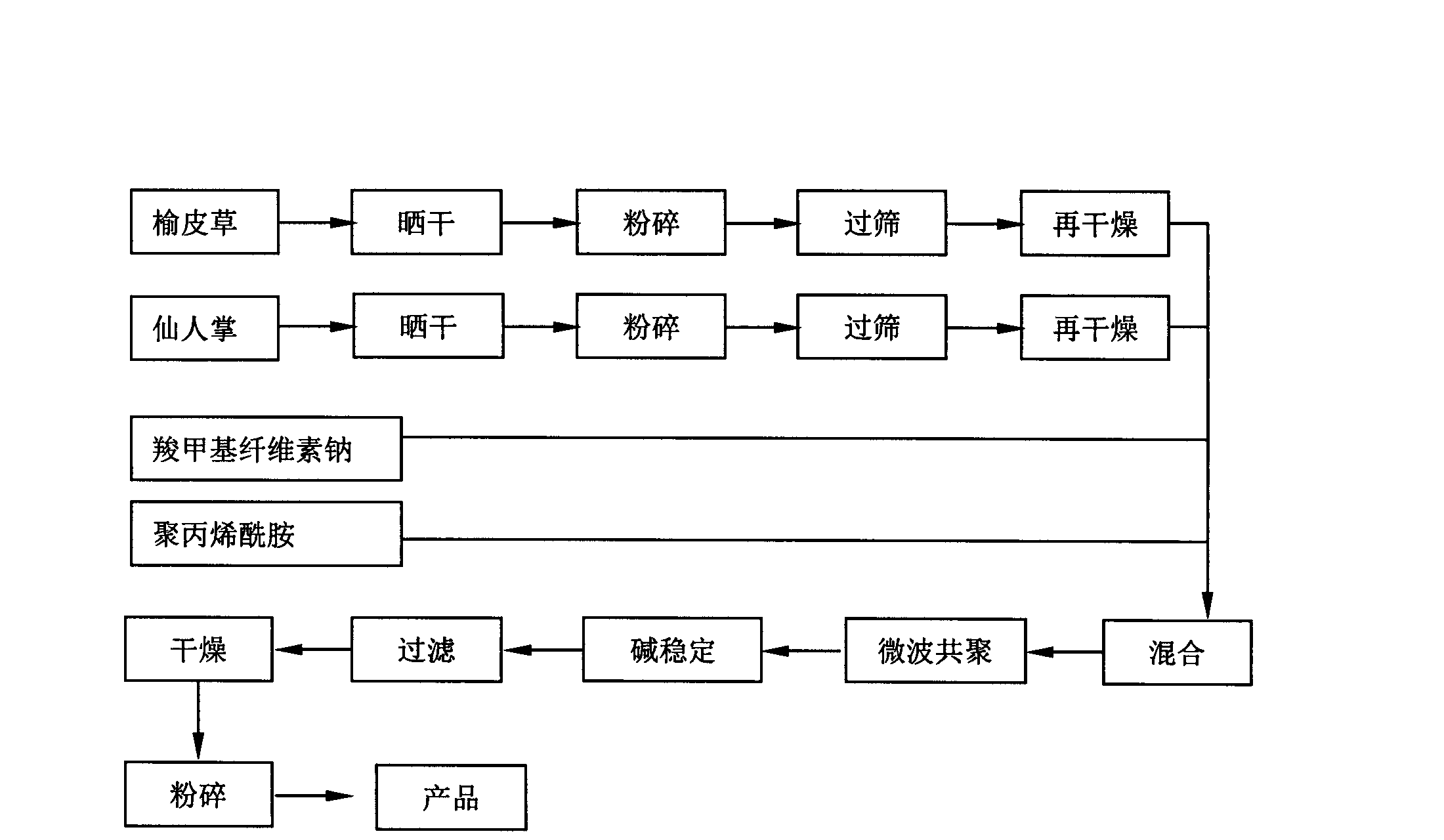

Composite type polymeric flocculant

InactiveCN101633527AHygroscopicHas biodegradable propertiesWater/sewage treatment by flocculation/precipitationCarboxymethyl celluloseSludge

The invention relates to a composite type polymeric flocculant which is mainly applied to the fields such as sewage treatment, sludge thickening, paper pulp recovery, petroleum extraction, etc. The composite type polymeric flocculant is characterized by being prepared by raw materials by weight percent: 40-45% of elm bark grass powder, 30-35% of cactus powder, 5-10% of sodium carboxymethyl cellulose and 15-20% of polyacrylamide. The flocculant can be normally used at higher temperature and under the condition of wider range of pH value.

Owner:WUHAN JINPO ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com