Patents

Literature

649 results about "Thermal adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal adhesive is a type of thermally conductive glue used for electronic components and heat sinks. It can be available as a paste (similar to thermal paste) or as a double-sided tape. It is commonly used to bond integrated circuits to heatsinks where there are no other mounting mechanisms available.

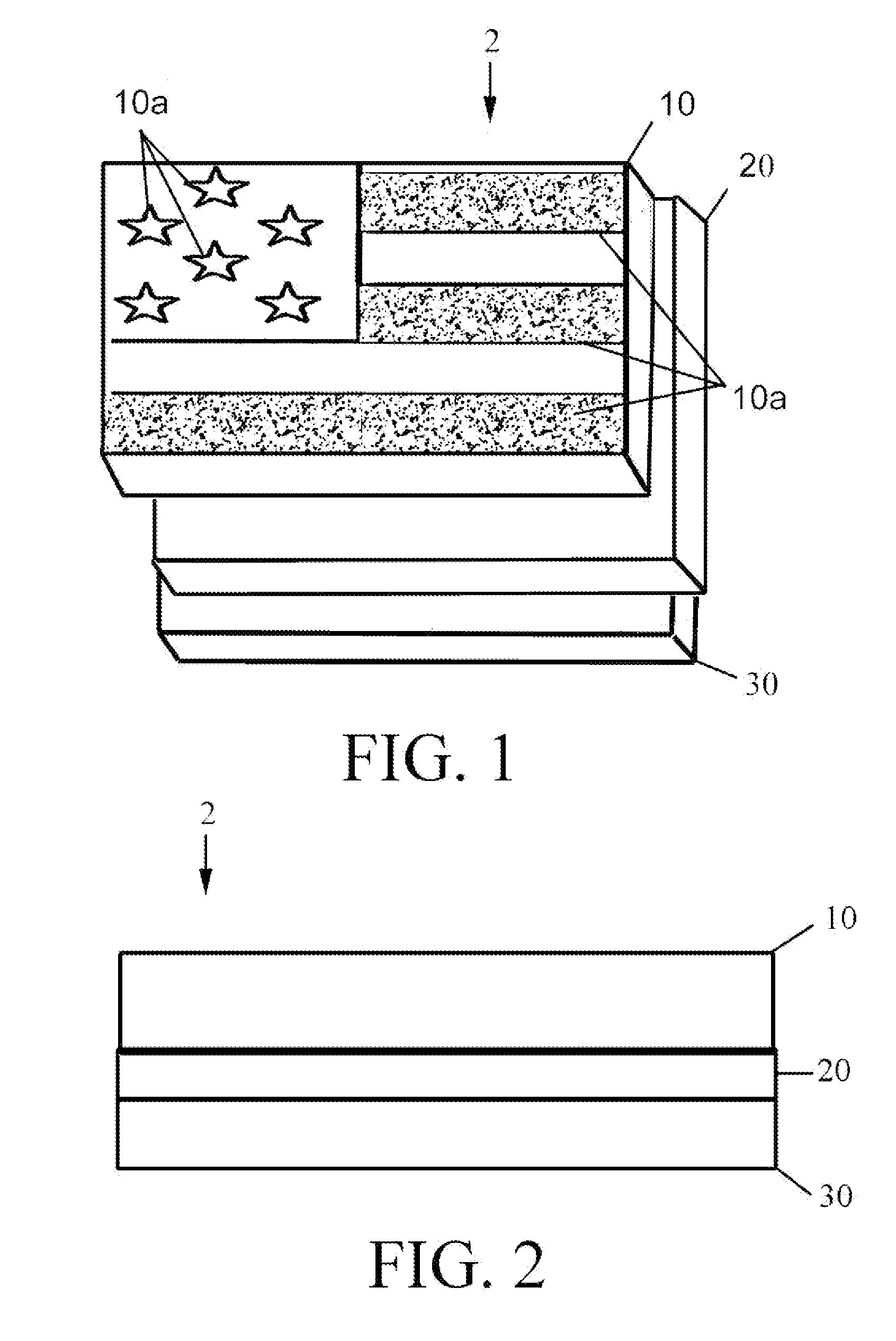

Double-side thermally conductive adhesive tape for plastic-packaged electronic components

InactiveUS20020012762A1Easy `` peel and stick '' installationPrecise thermal and adhesive propertiesInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringElectronic component

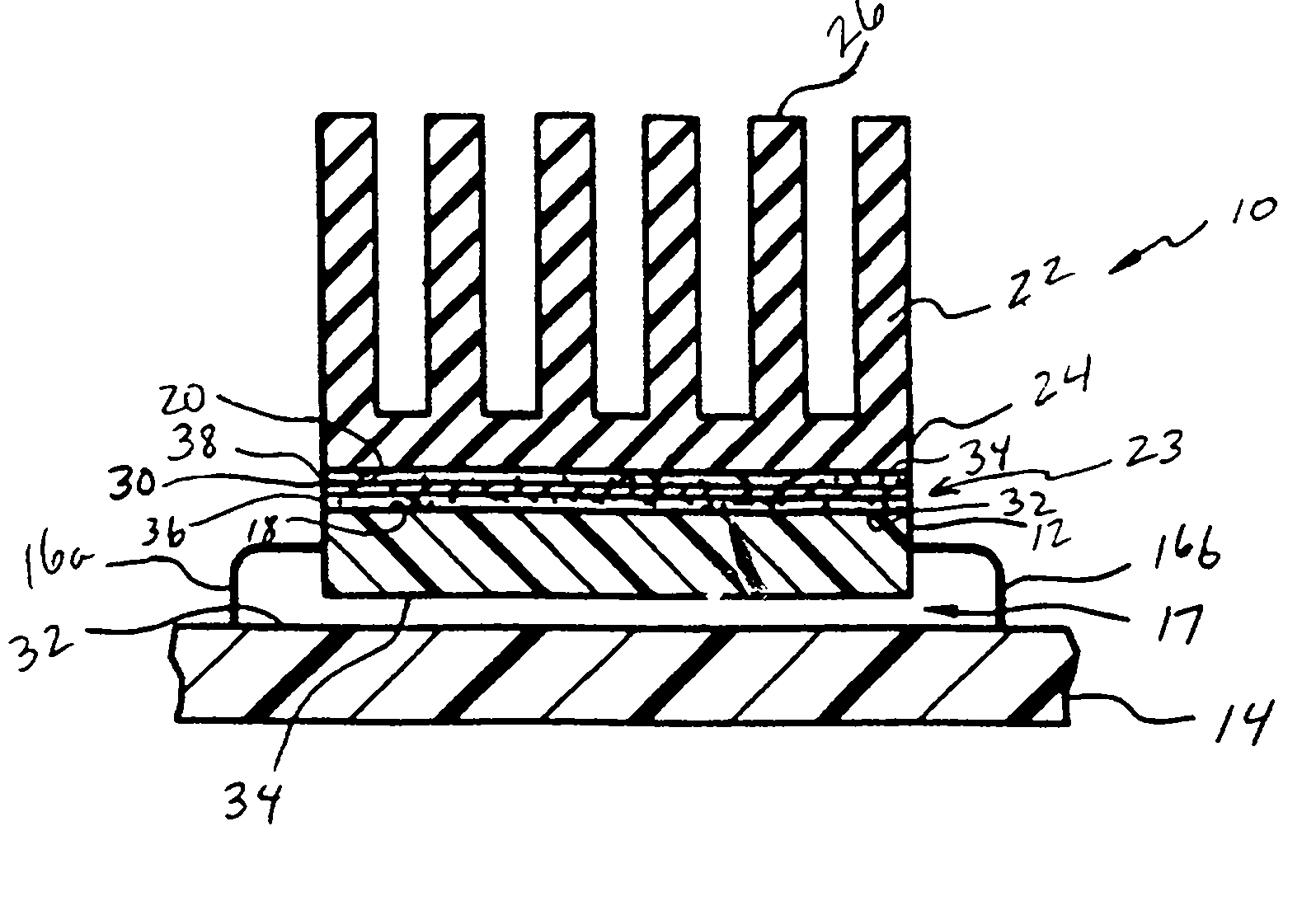

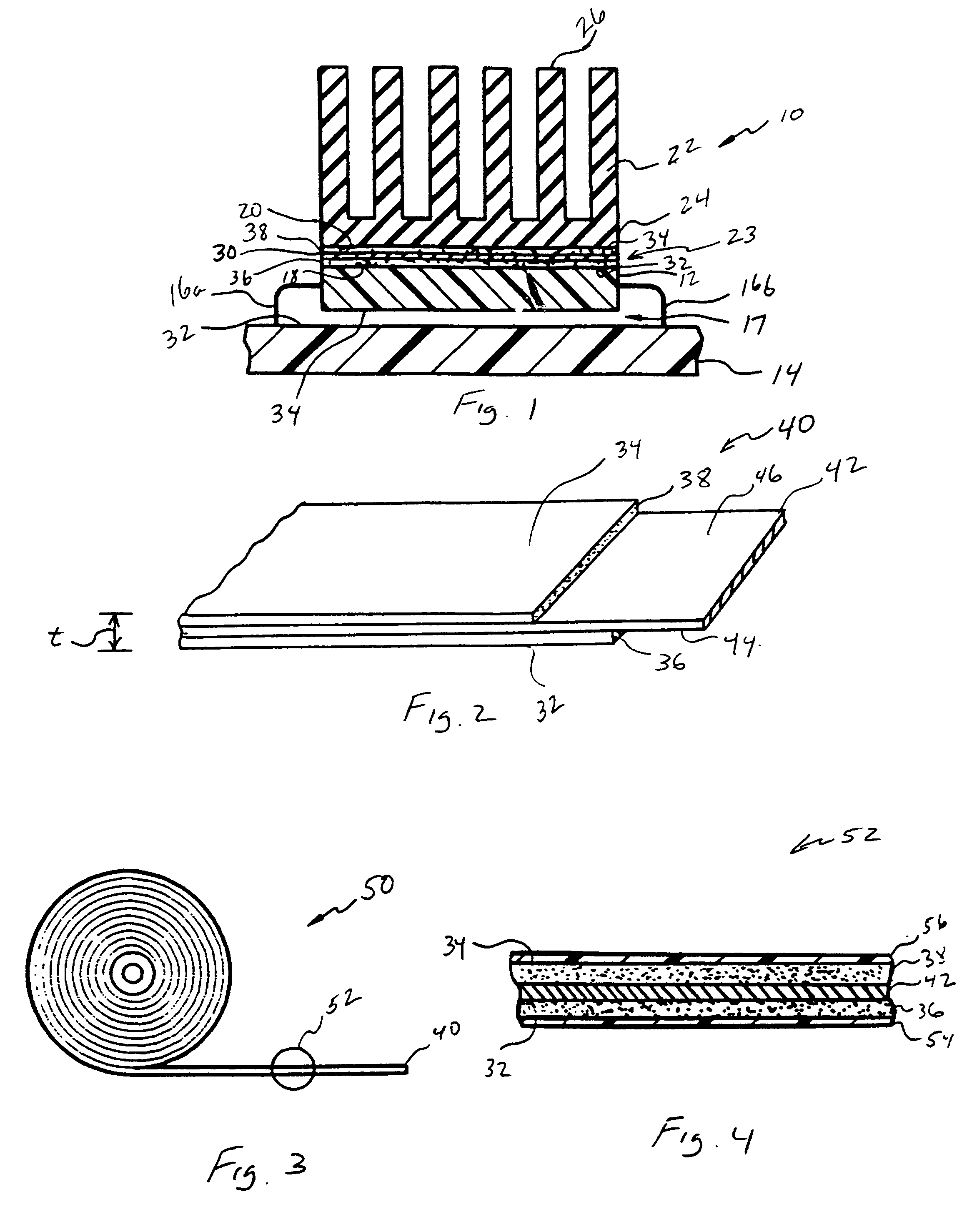

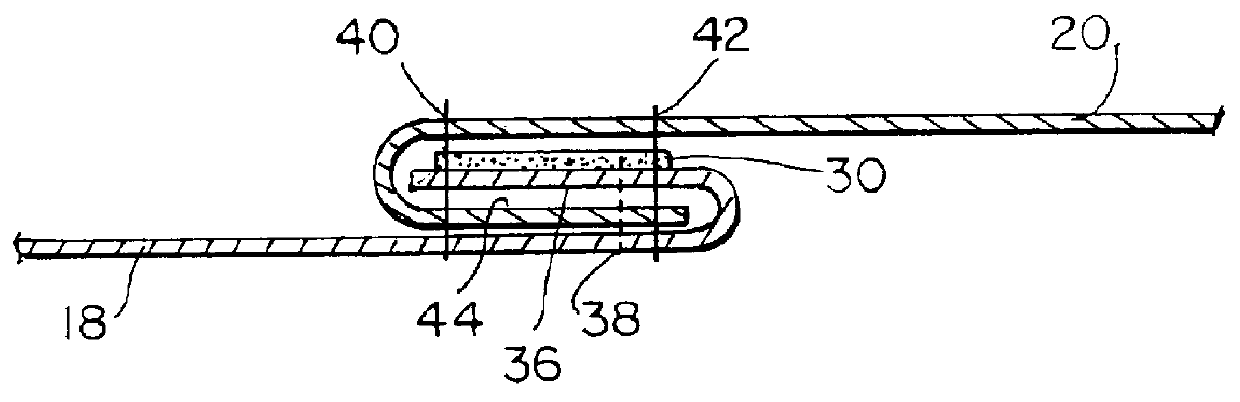

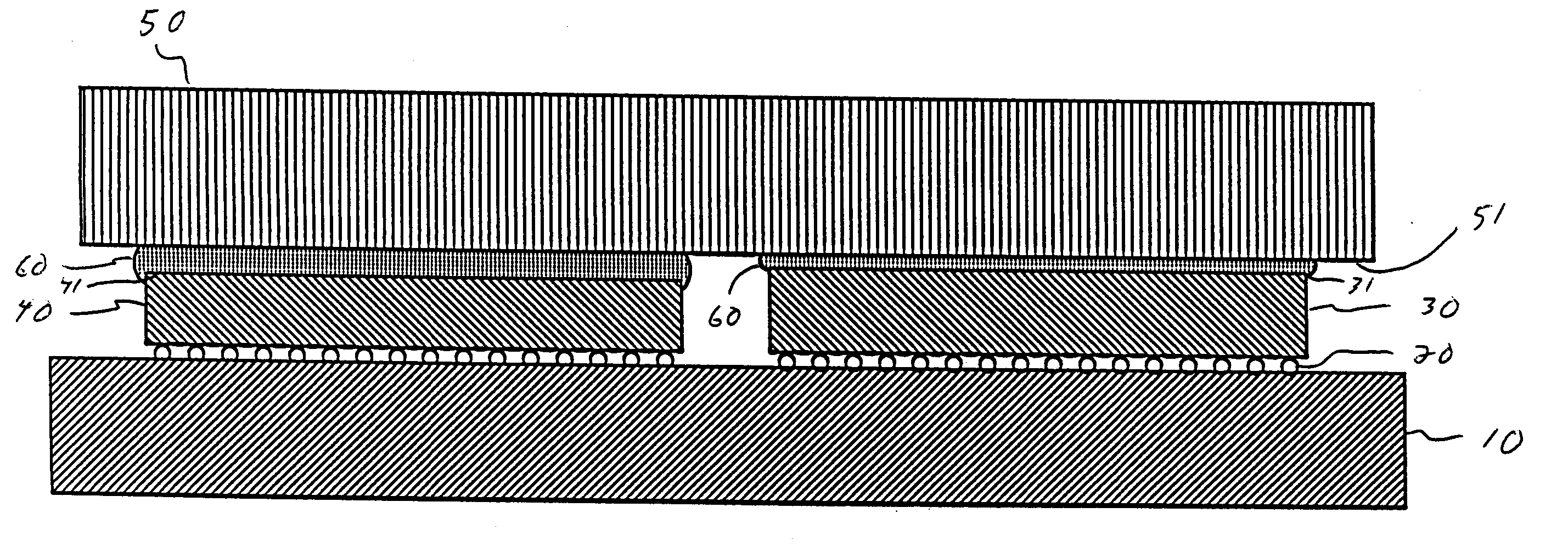

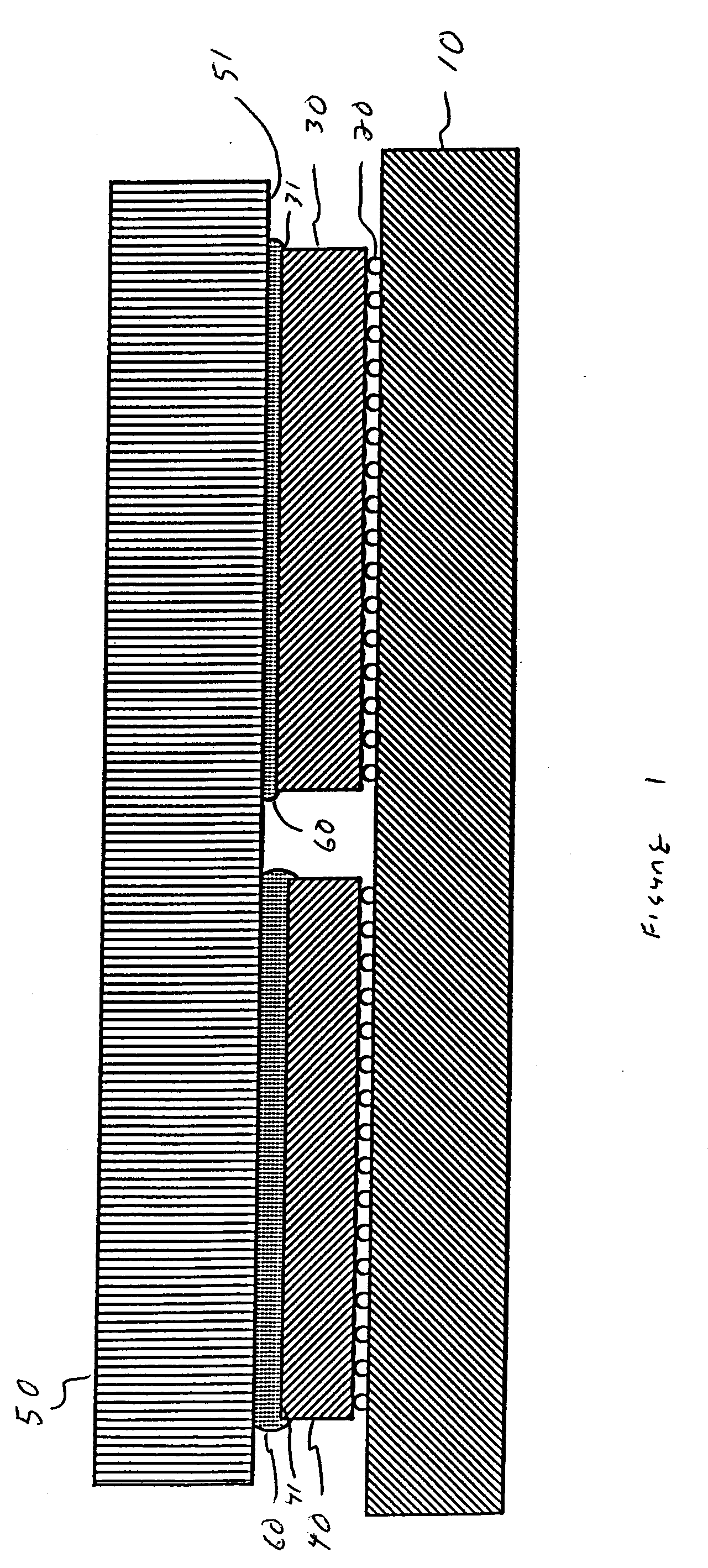

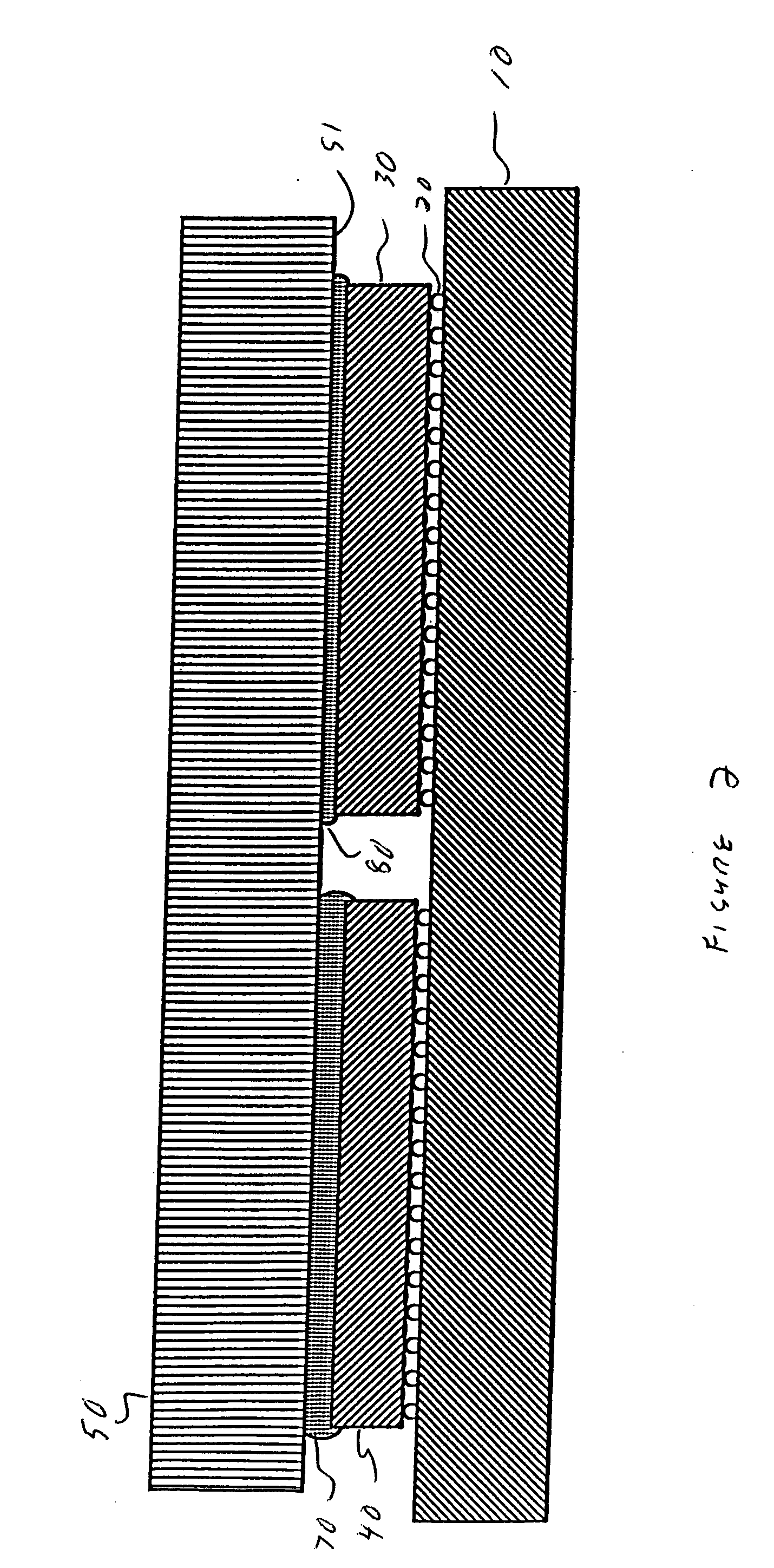

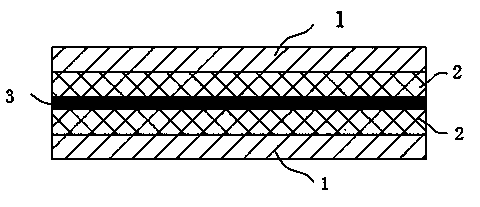

A thermally conductive interface, which may be in the form of a double-sided, pressure sensitive adhesive tape, disposable intermediate a heat-generating source having a first heat transfer surface formed of a first material having a low surface energy, and a thermal dissipation member having a second heat transfer surface which is formed of a second material having a surface energy substantially higher than the surface energy of the first material, and which is disposable opposite the first heat transfer surface of the heat-generating source in a spaced-apart, heat transfer adjacency therewith. The interface includes a first pressure sensitive adhesive (PSA) surface which is bondable under pressure to at least a portion of the first heat transfer surface of the heat-generating source, and an opposing second pressure sensitive adhesive (PSA) surface bondable under pressure to at least a portion of the second heat transfer surface of the heat-generating source. The first PSA surface is presented from a layer of a thermally-conductive, first pressure sensitive adhesive composition, preferably silicone-based, having an affinity to the first heat transfer surface of the heat generating source. In turn, the second PSA surface is presented from a layer of a second pressure sensitive adhesive composition, preferably acrylic-based, different from the first composition and having an affinity to the second heat transfer surface of the thermal dissipation member. The interface is particularly adapted for bonding a plastic packaged electronic component to a metal heat sink.

Owner:PARKER INTANGIBLES LLC

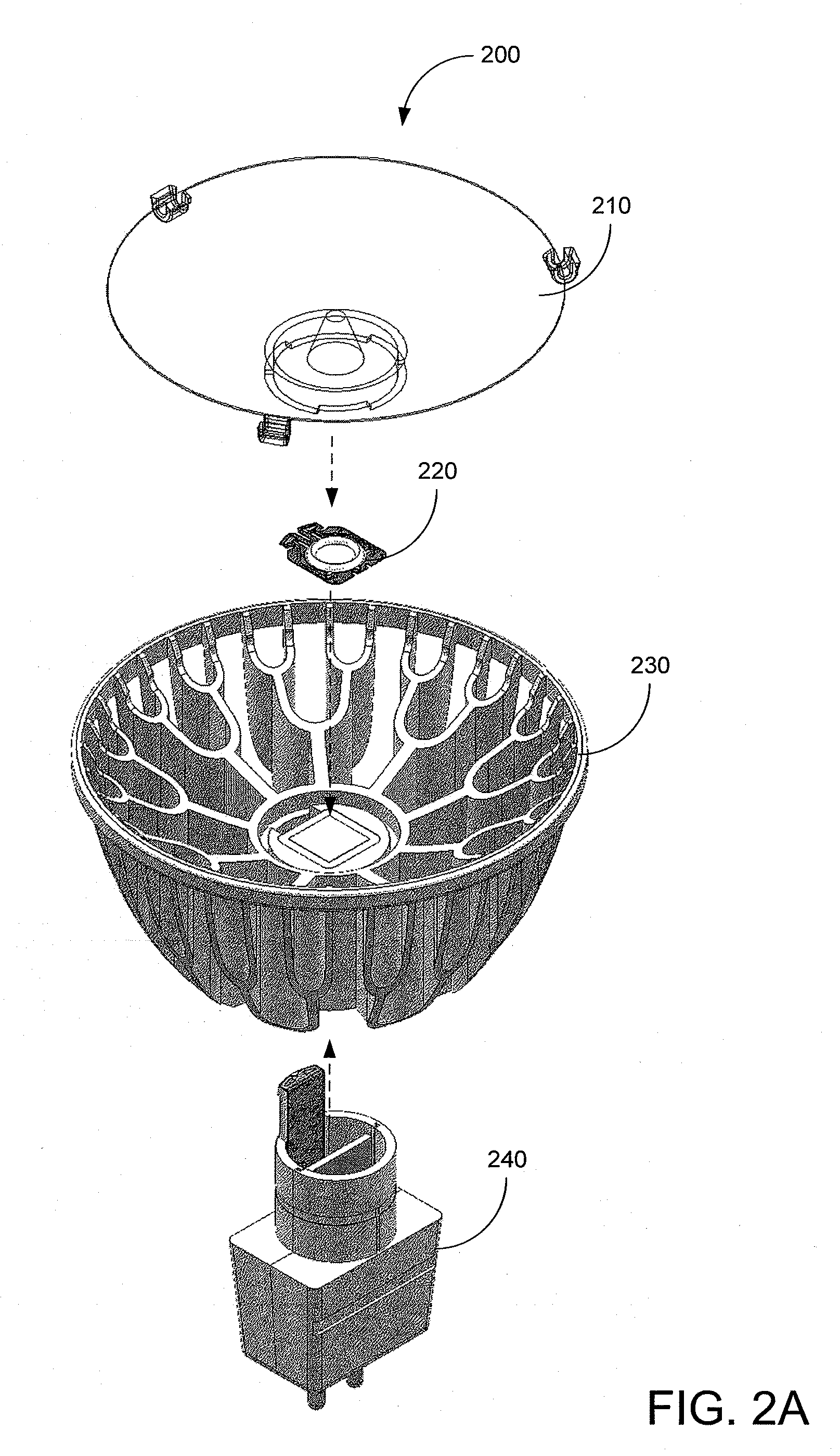

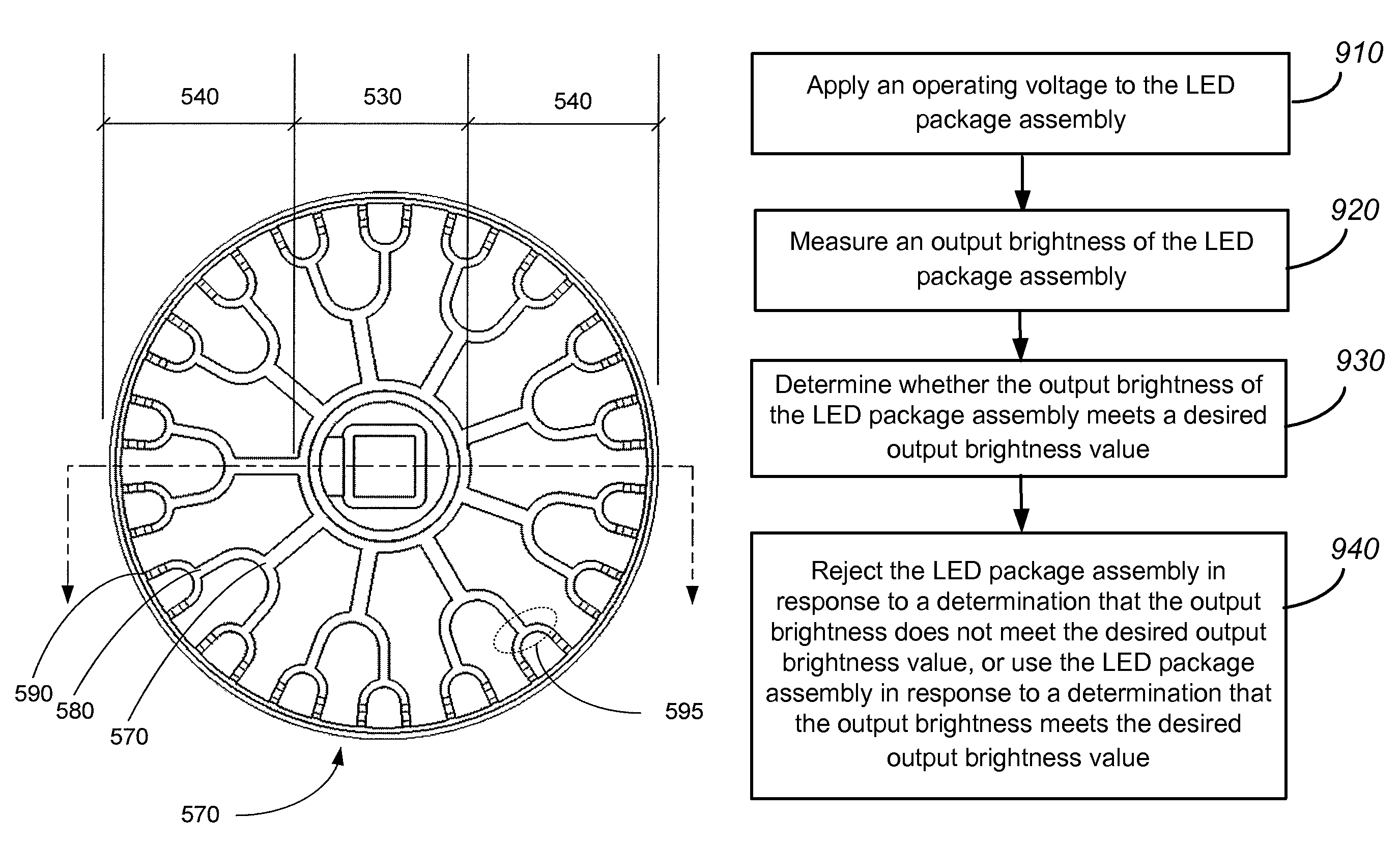

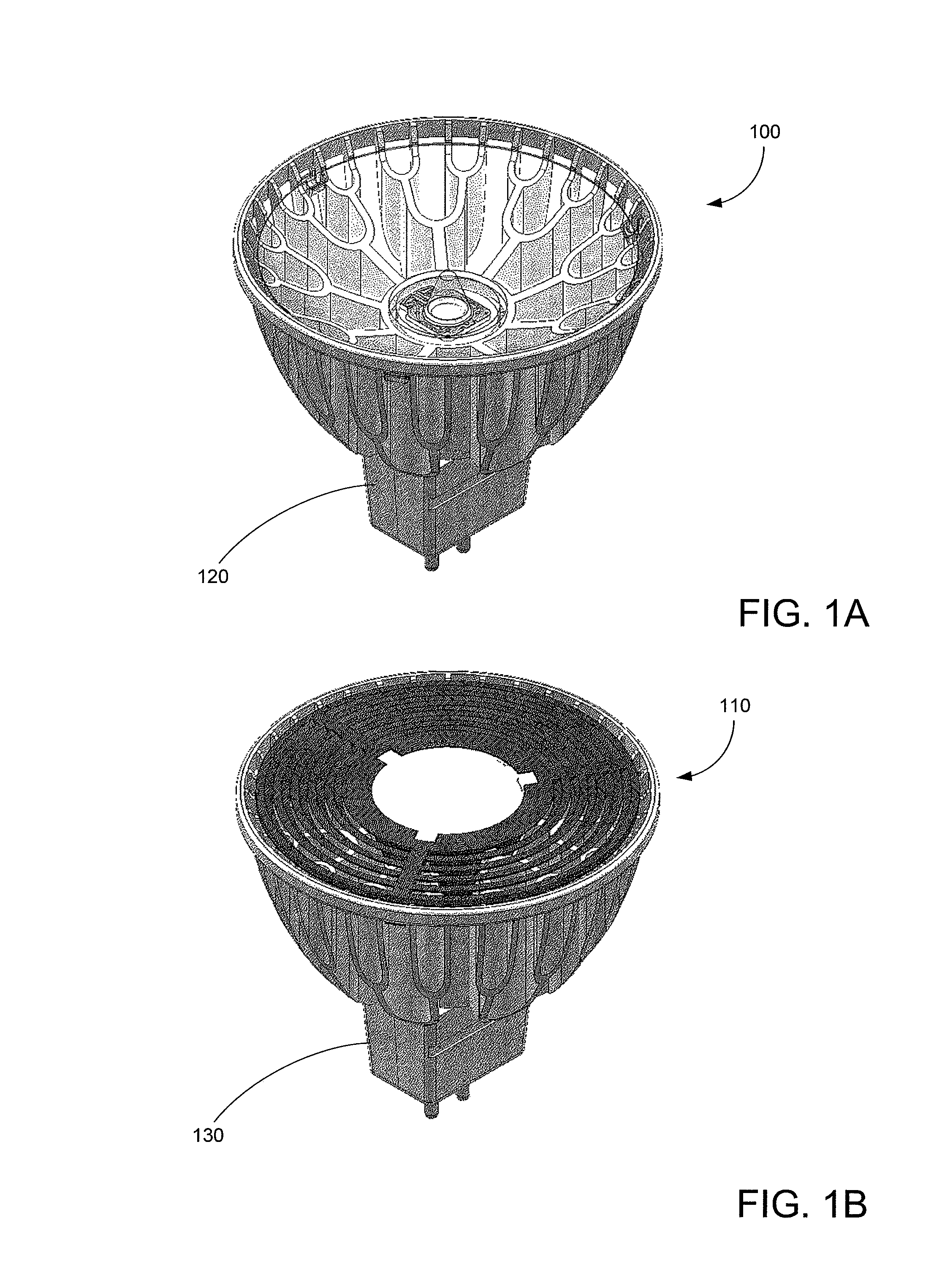

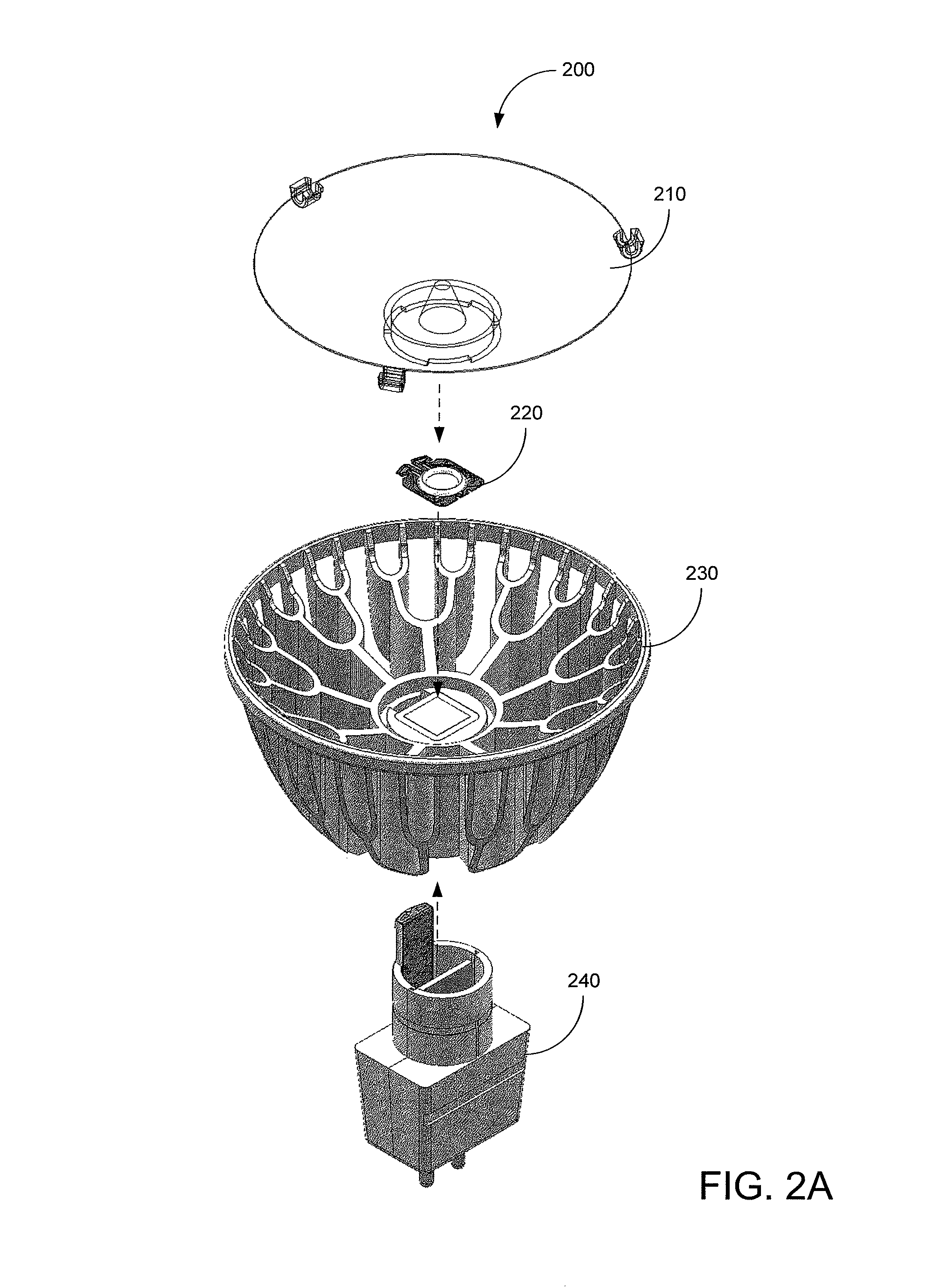

Modular LED Lamp and Manufacturing Methods

InactiveUS20110204780A1Ease of mass productionElimination of hand wiringLighting support devicesPoint-like light sourceEngineeringThermal adhesive

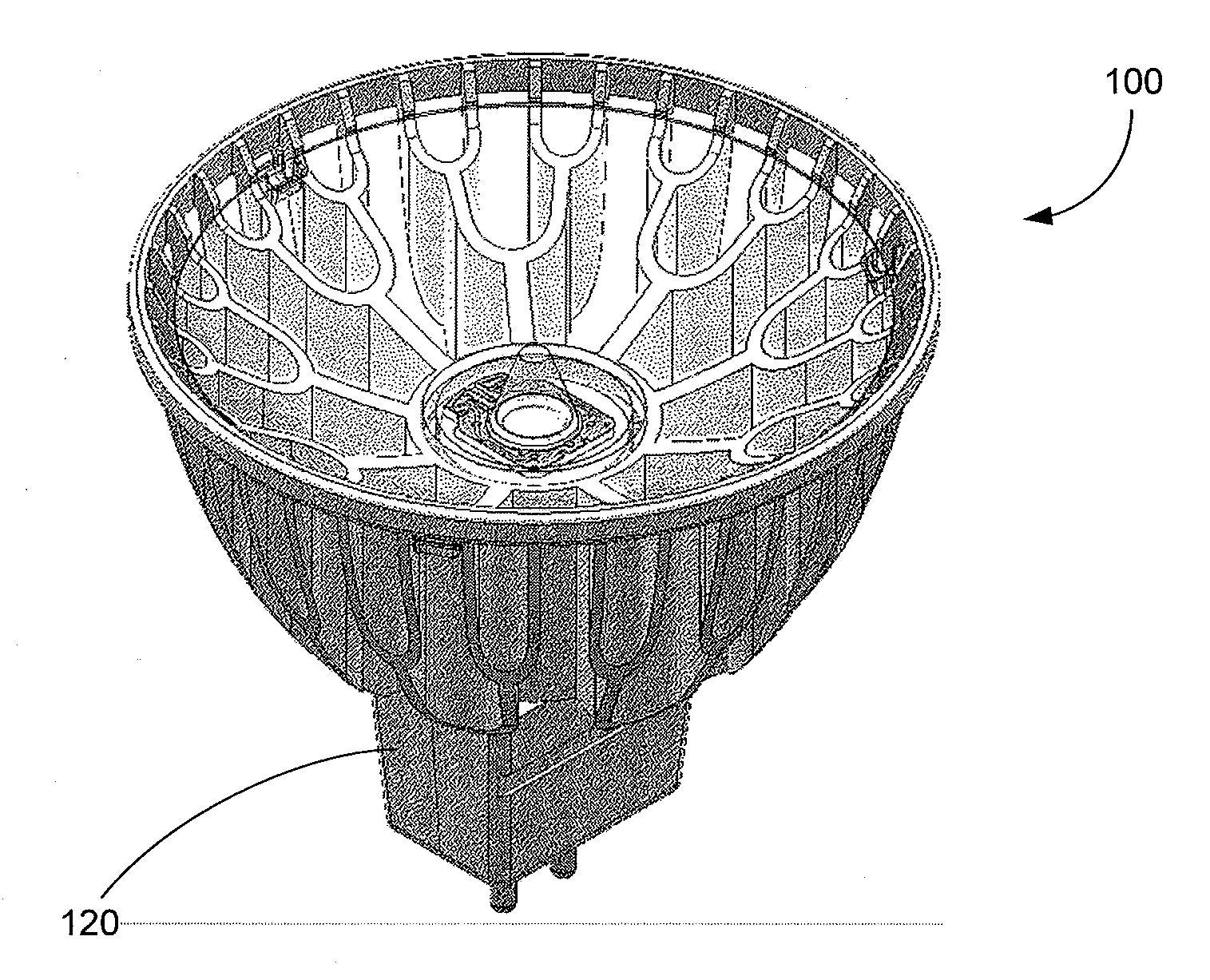

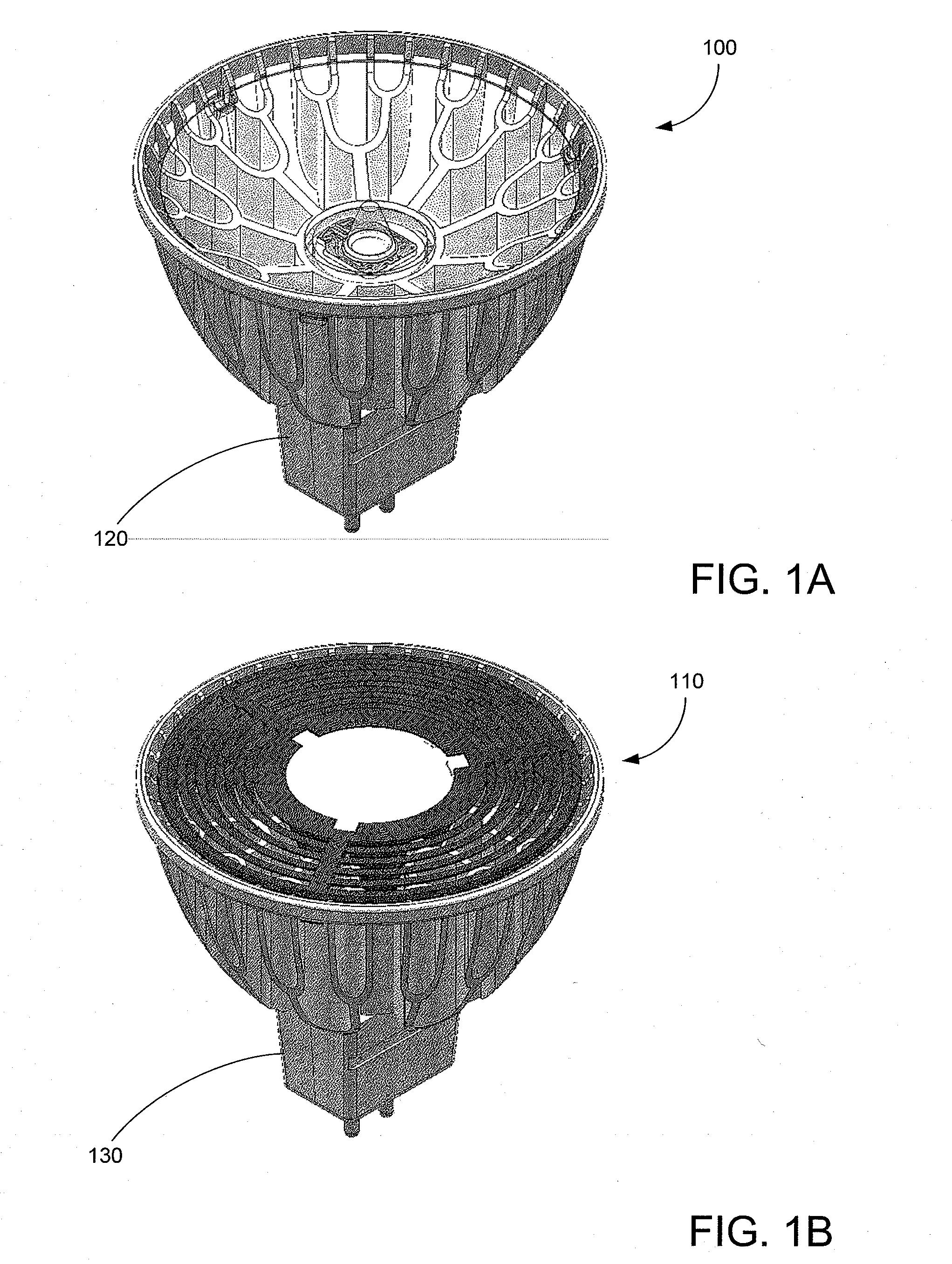

A method for forming a light source includes receiving an LED light module having a plurality of LEDs on a silicon substrate coupled to a flexible printed circuit and bonding the LED light module directly to a heat-sink with a thermal adhesive A base module with LED driver circuits is inserted into an interior channel of the heat sink and contacts of the LED driver circuits are connected to the LED light module.

Owner:KORRUS INC

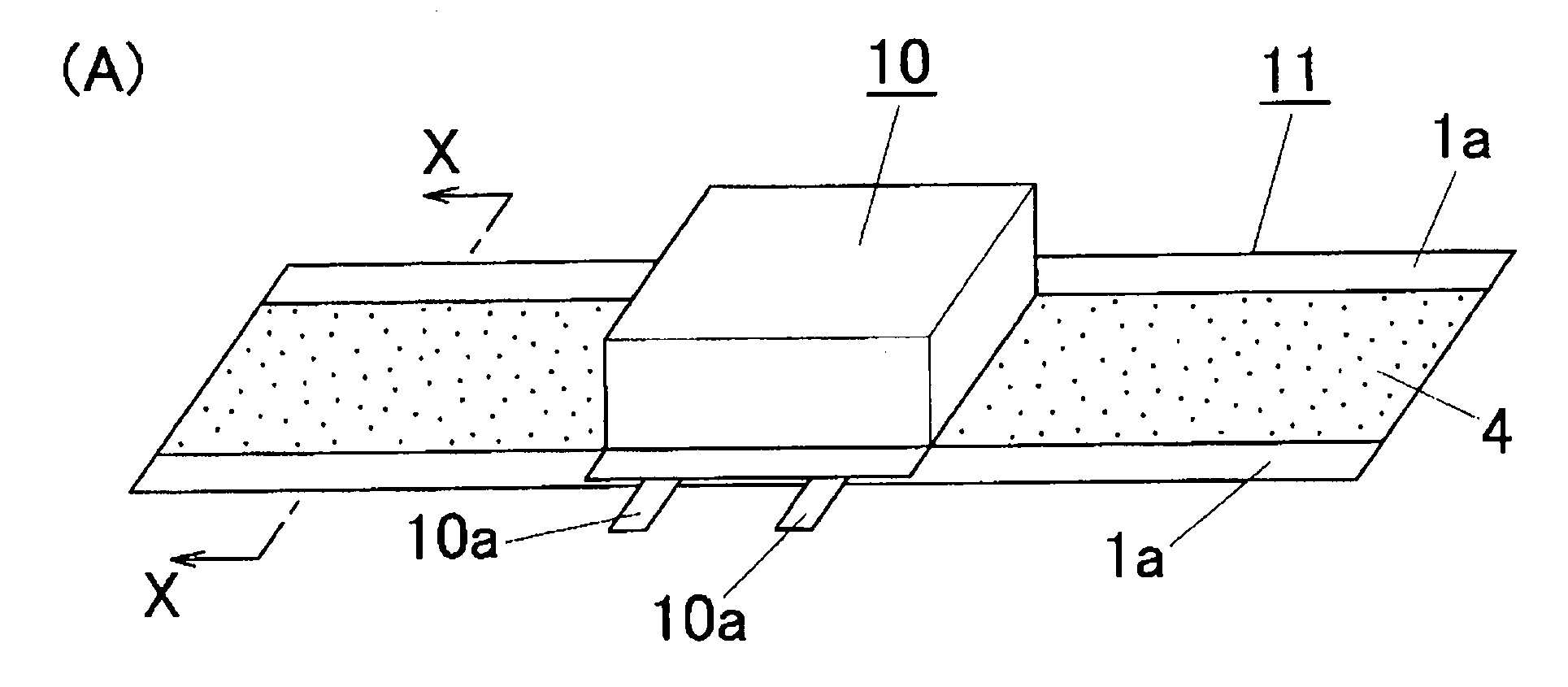

Slim type backlight unit

InactiveUS20070139929A1Less thickness and weightLight weightPoint-like light sourceLighting support devicesHeat conductingEngineering

A backlight unit of the invention is reduced in thickness, weight and manufacturing costs but improved in heat releasing efficiency. In the backlight unit, a flexible printed circuit board has at least one through hole perforated therein. An LED package is disposed on a top portion of the flexible printed circuit board corresponding to the through hole. The backlight unit of the invention employs the flexible printed circuit board in place of a metal printed circuit board as a means to conduct current to the LED package. This produces a slimmer and lighter backlight unit and also saves manufacturing costs. In addition, the LED package is directly bonded onto a bottom plate by a heat conducting adhesive, thereby ensuring heat generated from the LED package to be released more quickly.

Owner:SAMSUNG ELECTRONICS CO LTD

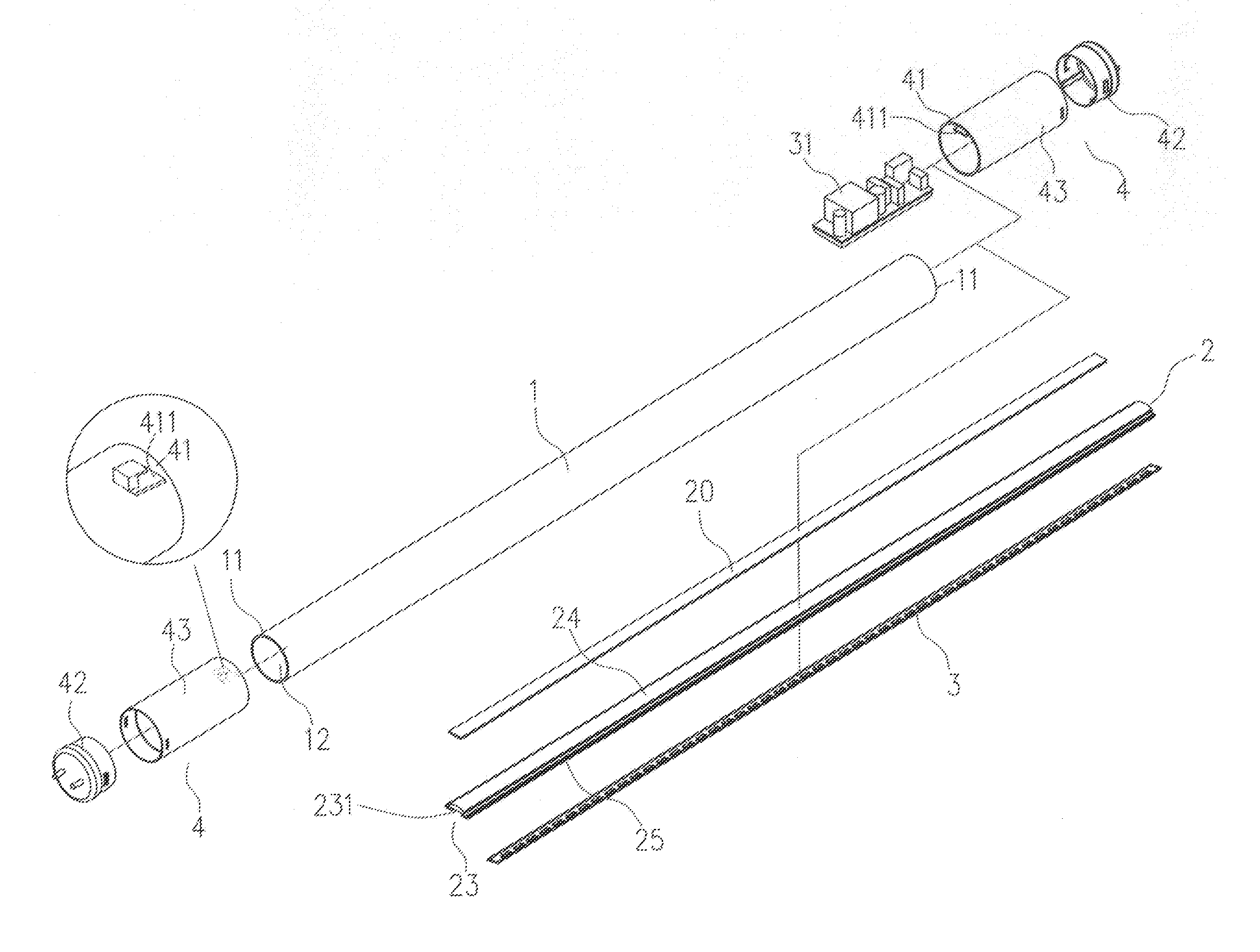

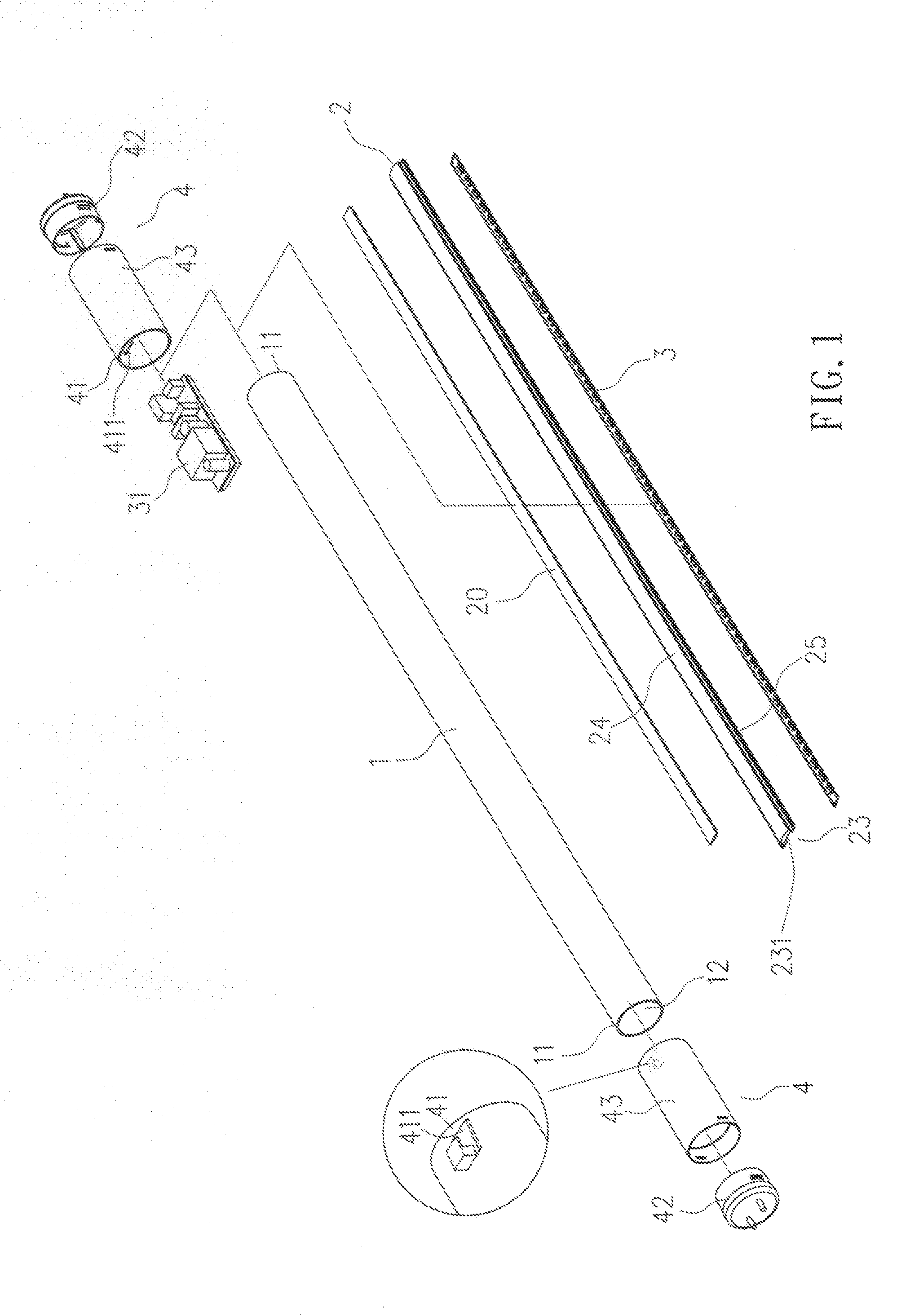

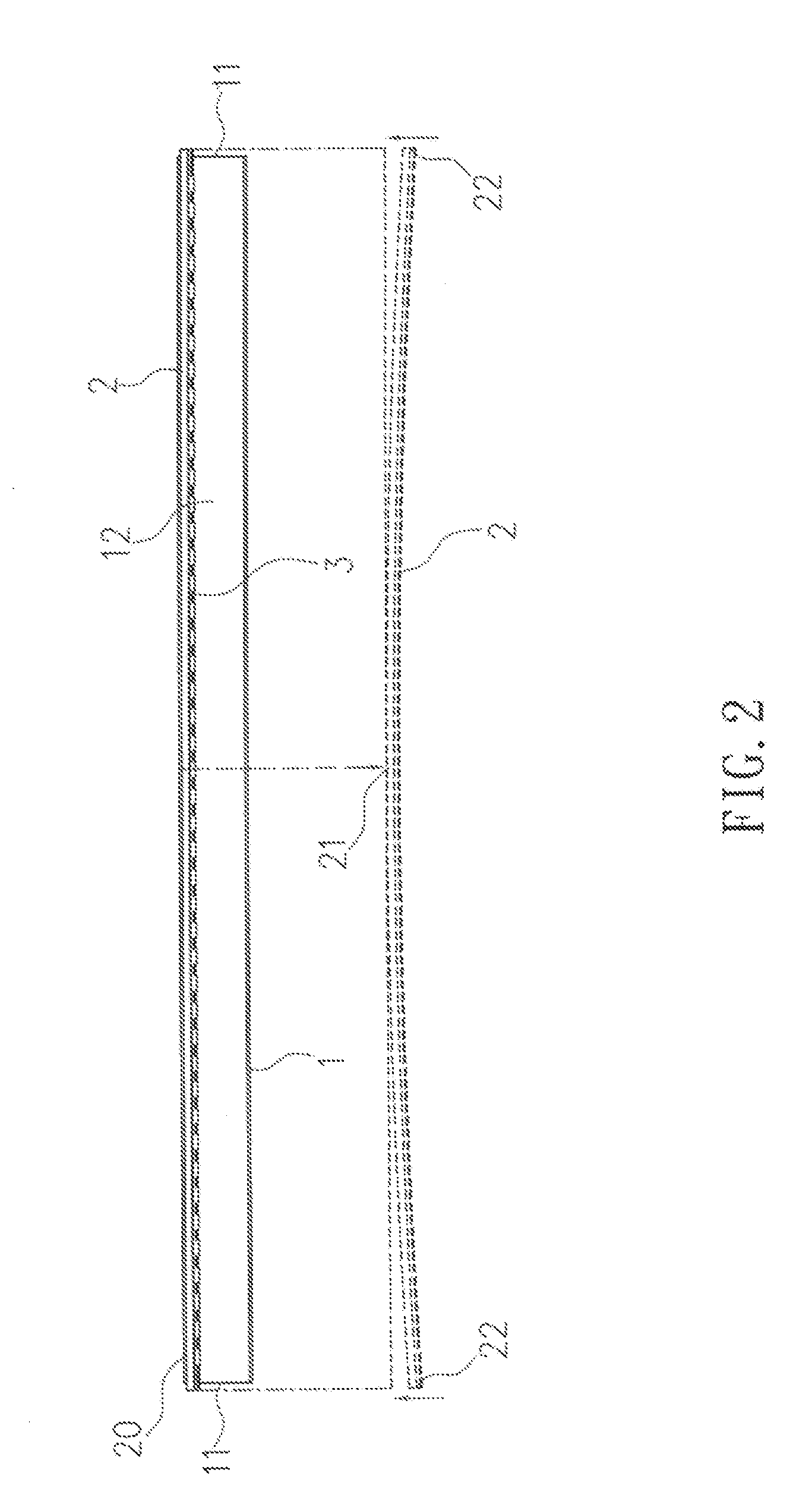

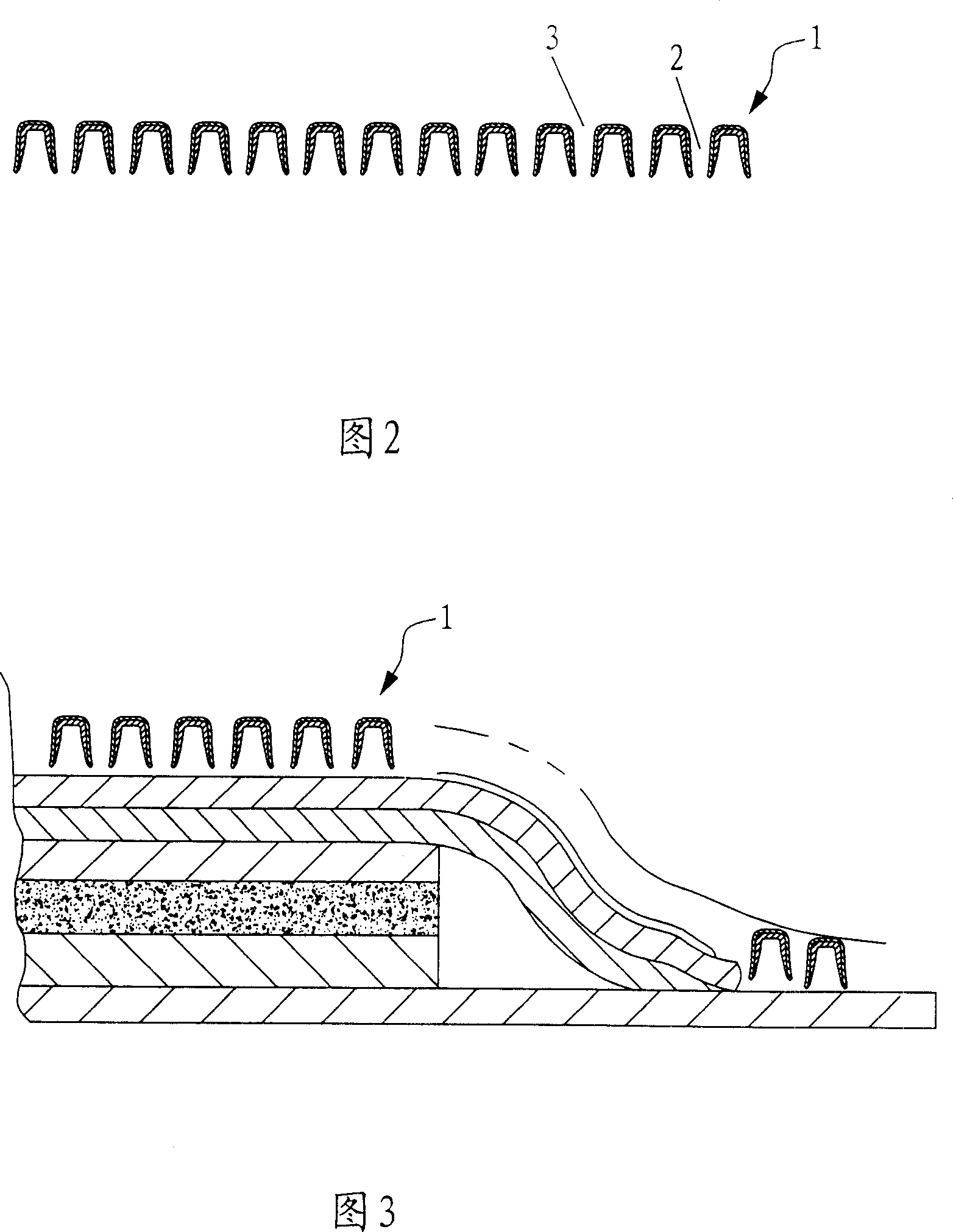

LED tube lamp structure

InactiveUS20140009923A1Extended service lifeContact tightLighting heating/cooling arrangementsSemiconductor devices for light sourcesThermal adhesiveLED circuit

An LED tube lamp structure includes a heat-transferring and light-pervious glass tube; a heat-dissipation metal base in the form of an elongated strip with a predetermined curve and bonded to an inner surface of the glass tube via a thermal adhesive; an LED chip circuit board fitted in a receiving seat on a front side of the heat-dissipation metal base and connected to an LED driving circuit; and two electrode covers fitted on two open ends of the glass tube and internally provided with an insertion section each. The heat-dissipation metal base has two ends inserted into the two insertion sections to have an upward tension for tightly contacting with the glass tube. Therefore, heat produced by the LED tube lamp is effectively transferred to the glass tube and dissipated into ambient air to extend the service life of the LED tube lamp.

Owner:FIN CORE +1

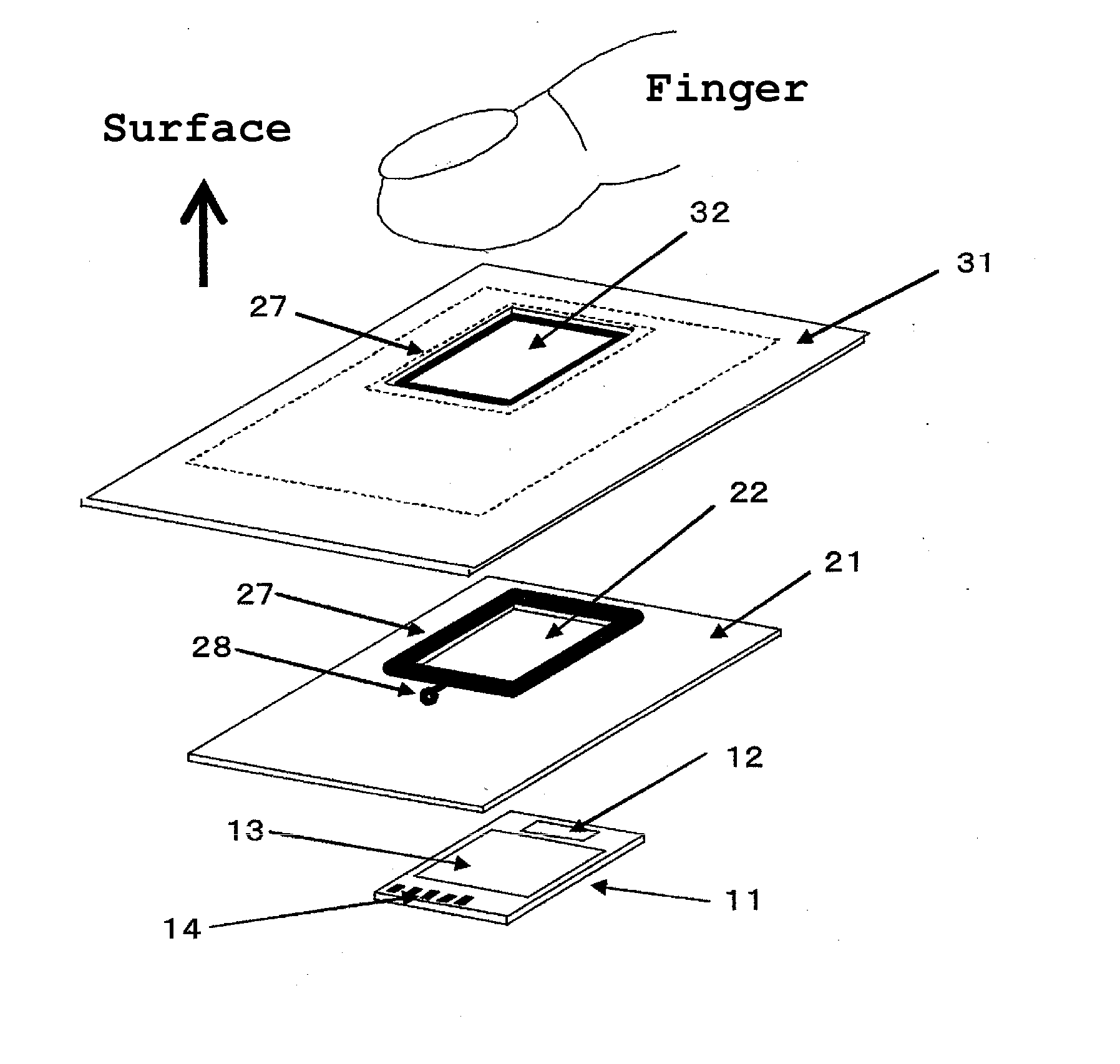

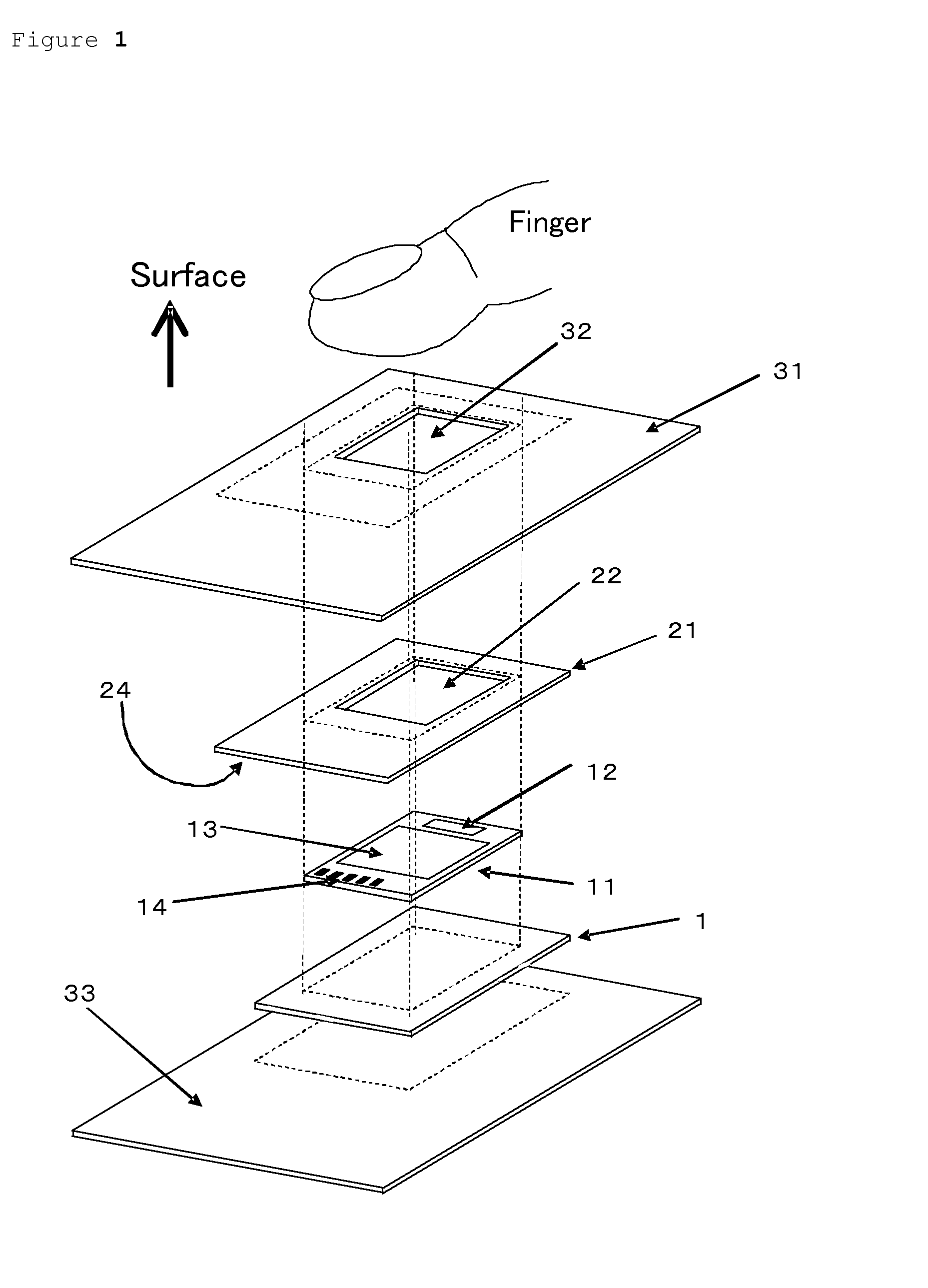

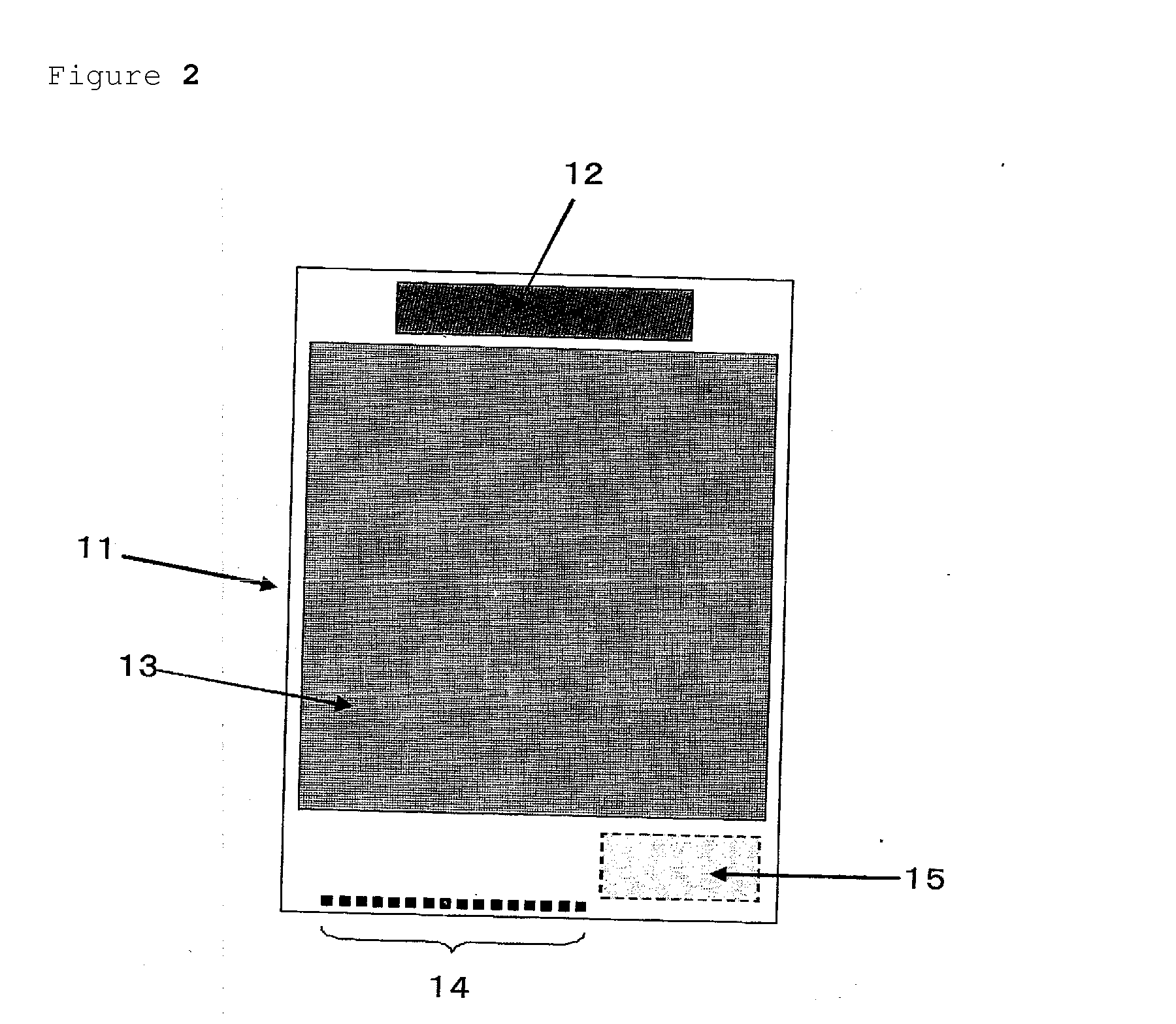

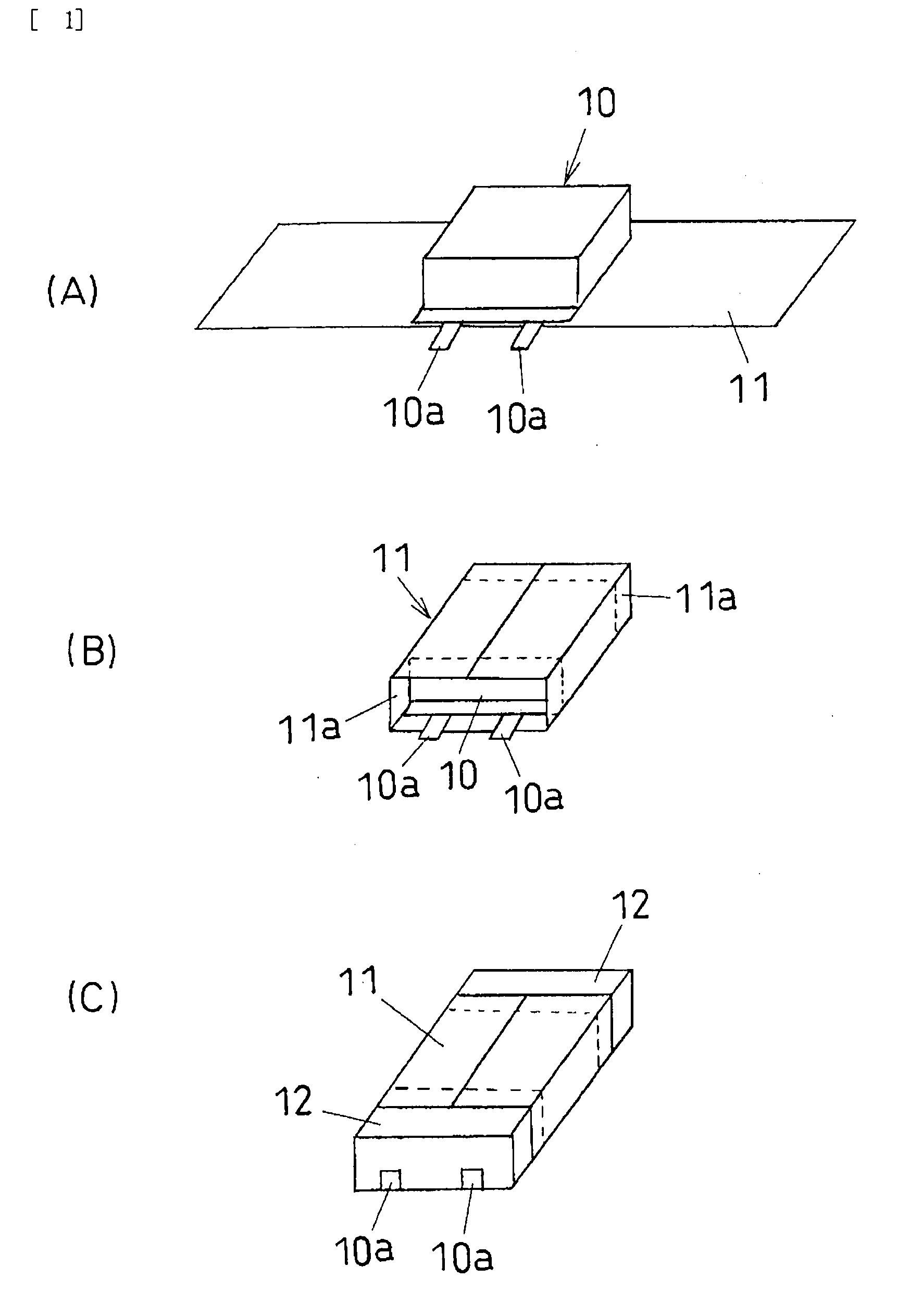

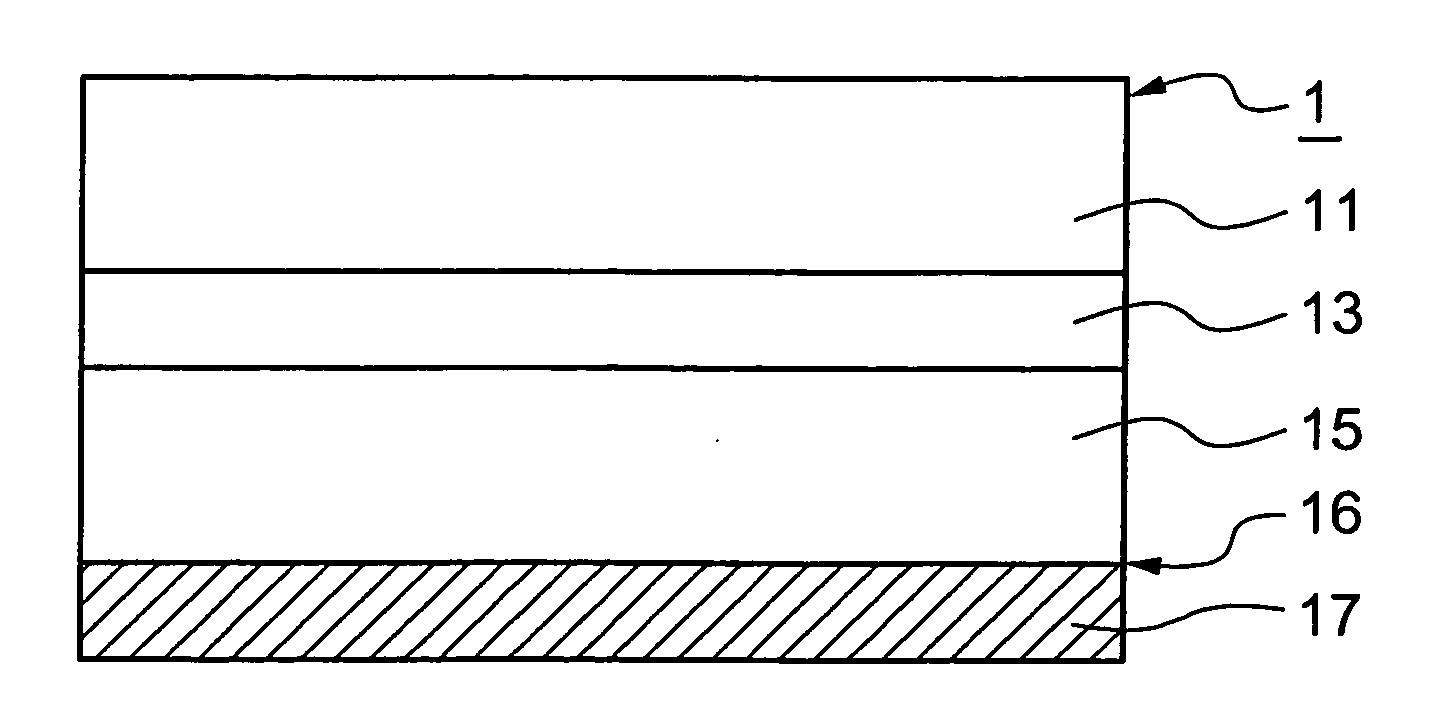

Smartcard integrated with a fingerprint image acquisition sensor and a method for manufacturing the smartcard

InactiveUS20120049309A1High yieldLow production costSolid-state devicesRecord carriers used with machinesThermoplasticInternational standard

The ProblemsTo provide a smartcard that embeds a fingerprint image acquisition sensor, having thickens of 0.76 mm or less compiling with the International Standard organization (ISO).Means for Solving the ProblemA smartcard comprising a core substrate which is configured with a film substrate 21 on which a fingerprint image acquisition sensor IC chip 11, an electric circuit pattern and accompanying electrical, and a reinforcing metal or composite plate 1 which is adhered to the back surface of the fingerprint image acquisition sensor IC chip 11; an over sheets 31 and an under sheet 33, which are made of thermoplastic or paper, sandwiching the core substrate 33, where the over sheet 31 and the under sheet 33 are attached with a thermal adhesive sheet, which functions as a mechanical buffer to protect the electrical components from external stress. The adhesive sheet is made of urethane rubber or similar substance.

Owner:KIYOMOTO SHOICHI +1

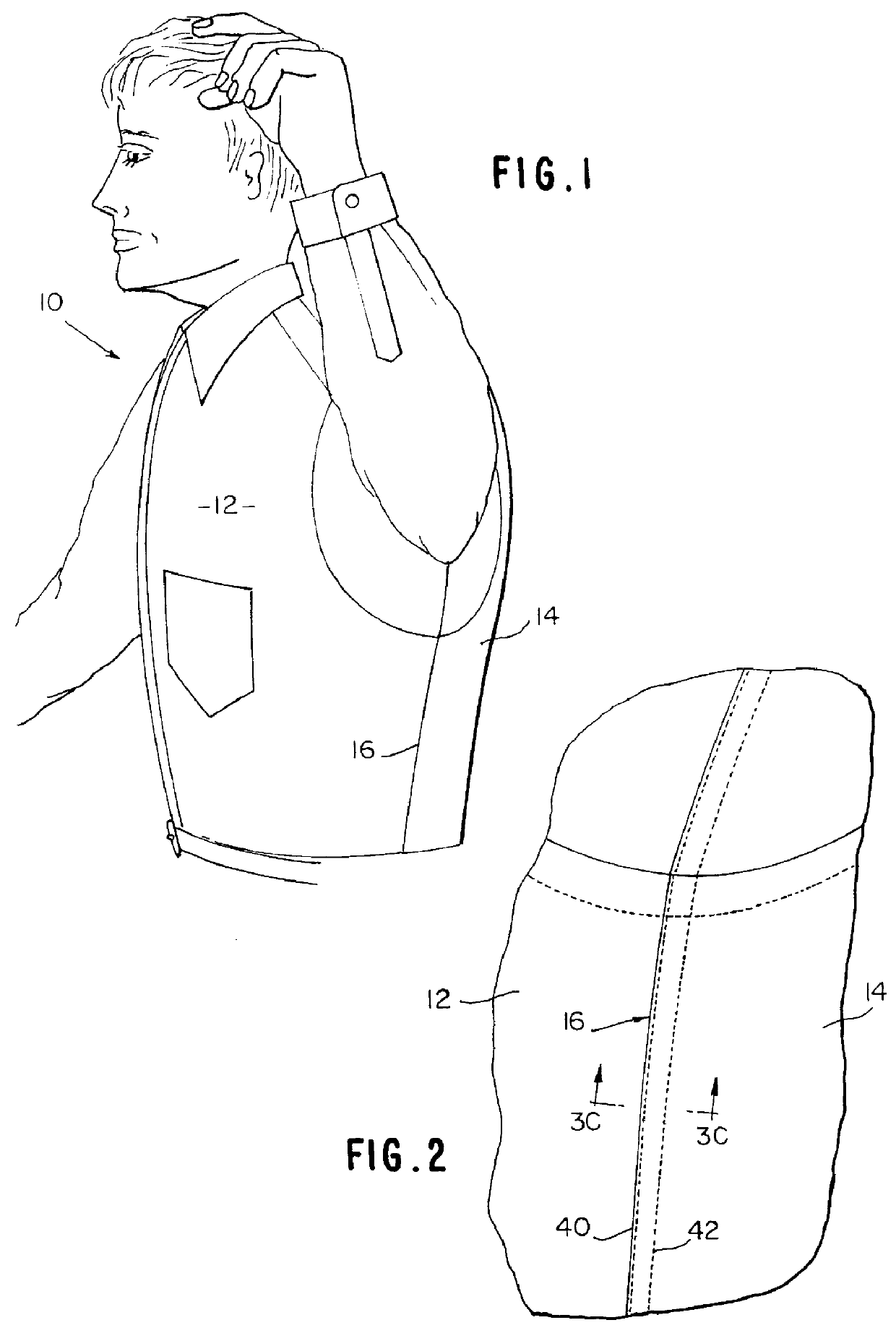

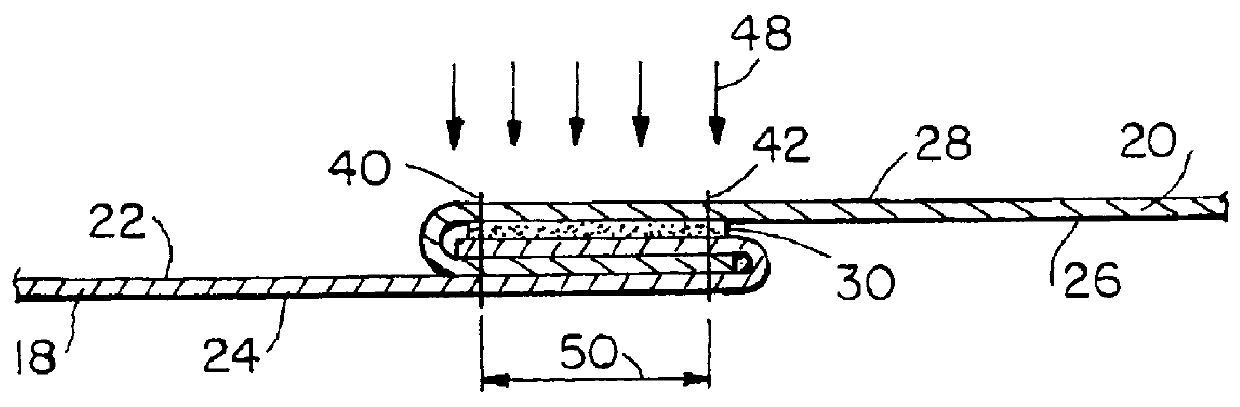

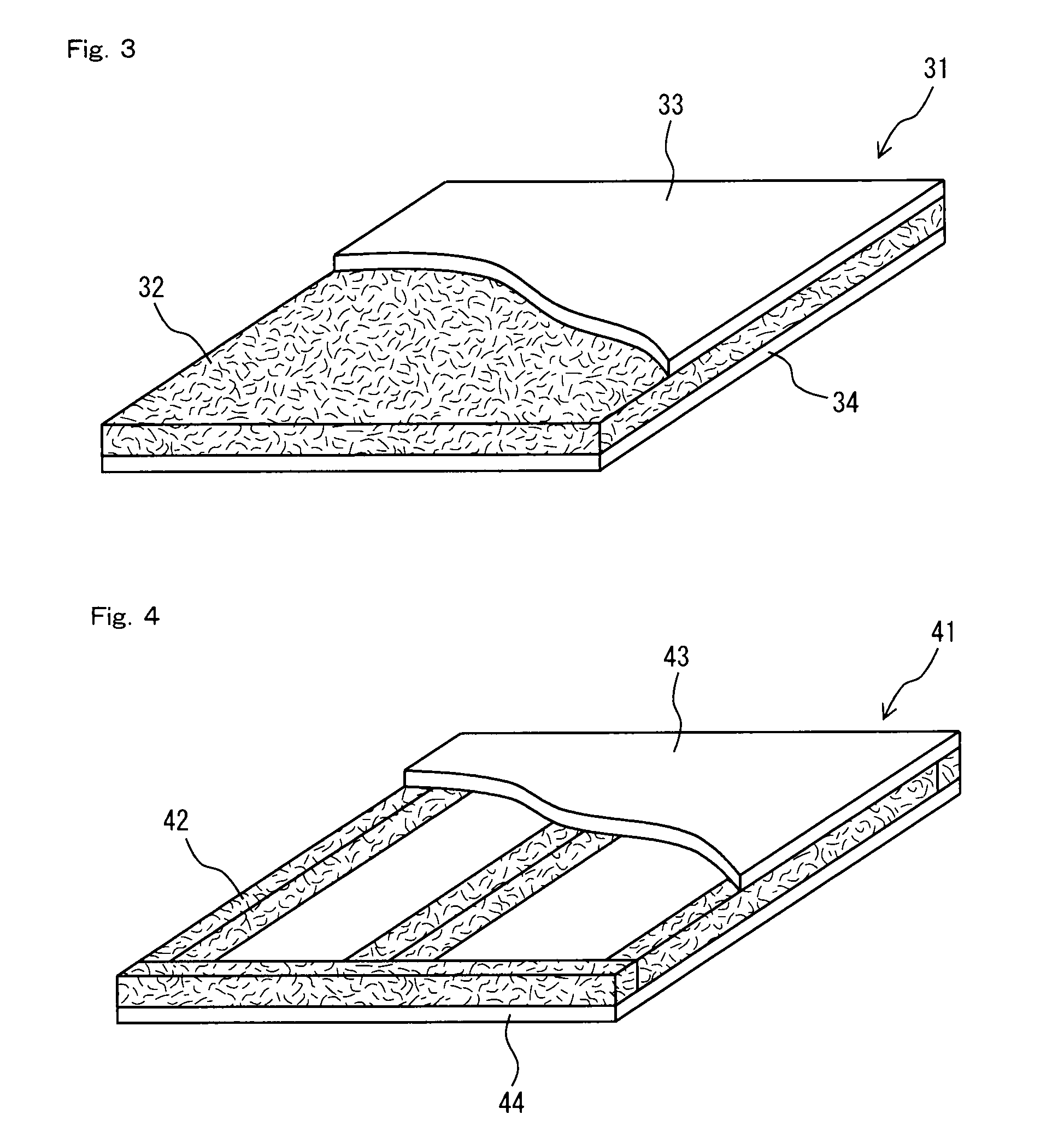

Pucker free garment side seam and method for production

A pucker free garment seam providing a garment with a tailored and wrinkle free appearance. The pucker free seam and method for production utilizes a bonding strip which contains at least a thermal adhesive component which is inserted between first and second garment components sewn together along the seam. A sufficient amount of heat and pressure is applied to the seam which causes the adhesive of the bonding strip to flow onto the surfaces of the garment components and into interstices thereby creating a seam and permanently bonding the first and second garment components together along the seam to eliminate puckering associated with shrinkage of the sewing thread.

Owner:TALTECH MACAO

Buffer substrate and use thereof

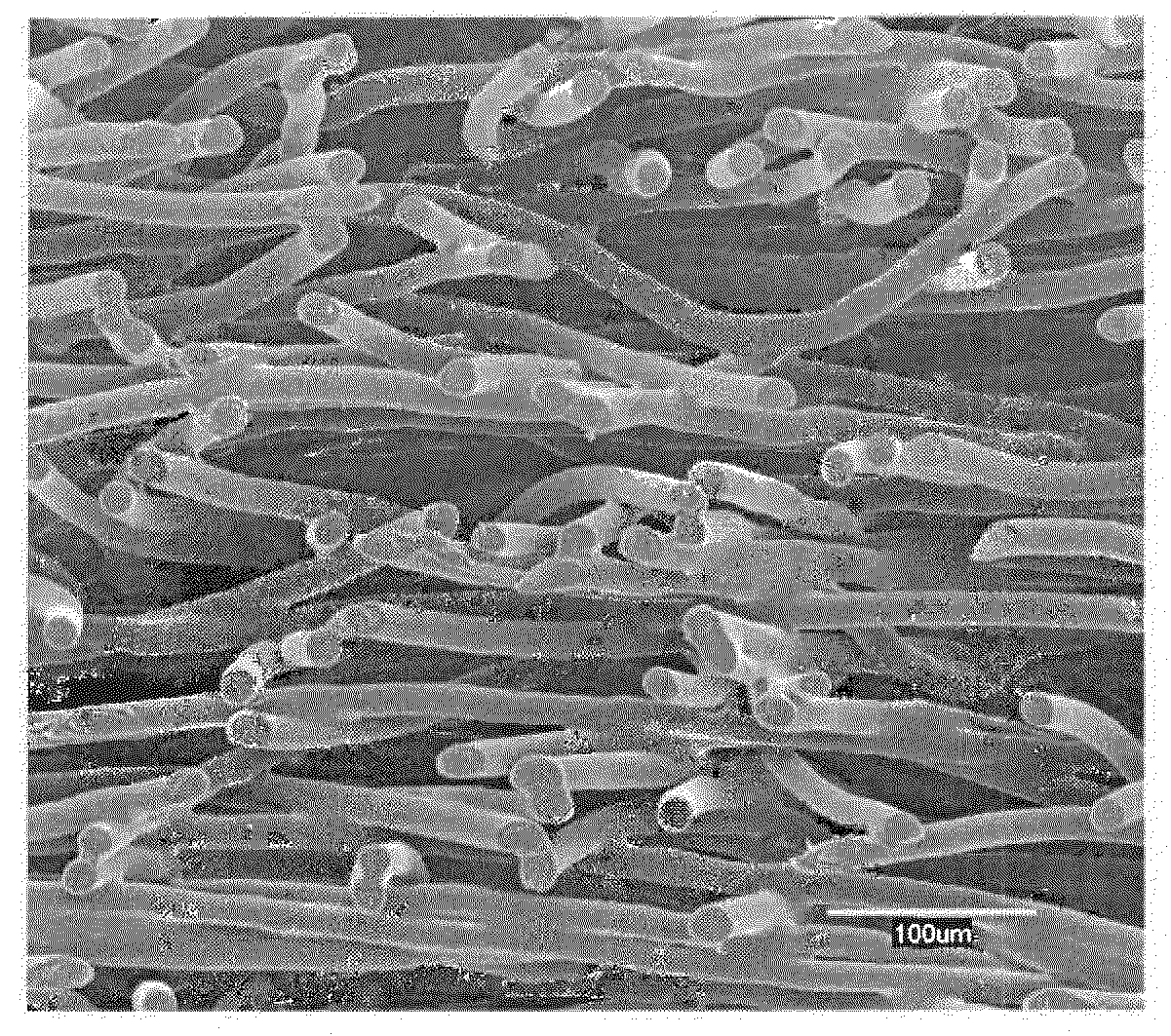

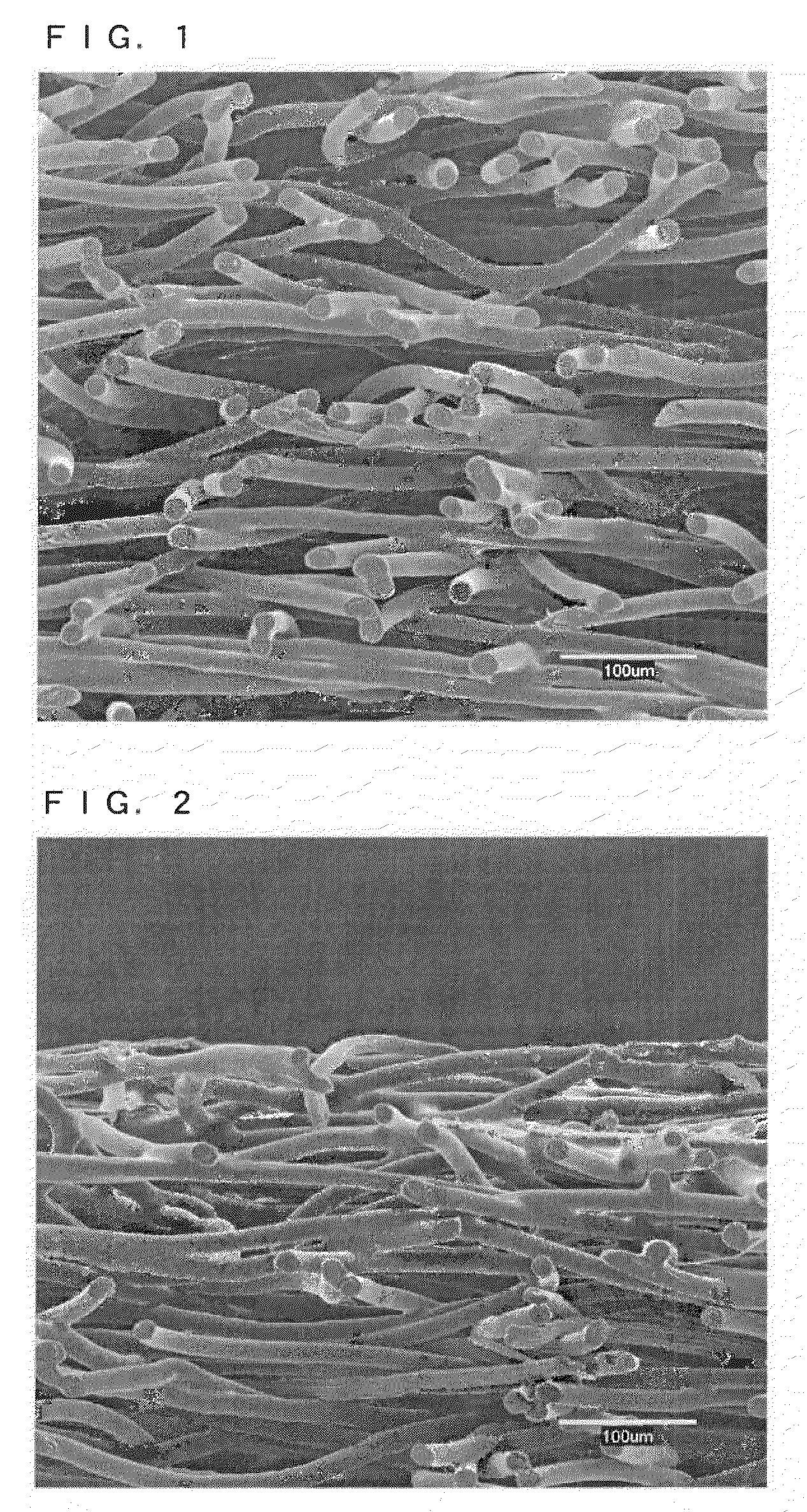

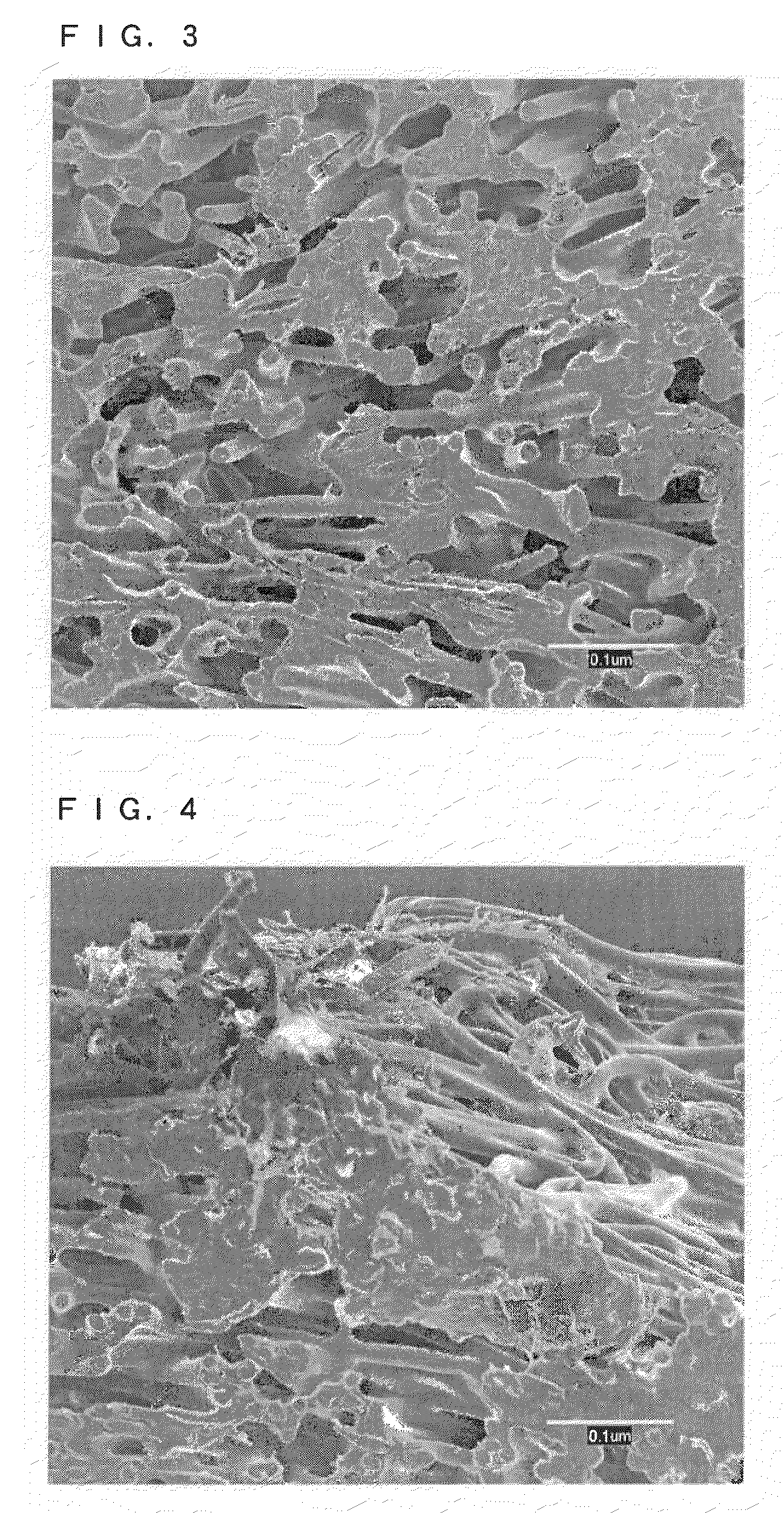

ActiveUS20100203788A1Improve breathabilityImprove buffering effectInsolesLaminationFiberPolymer science

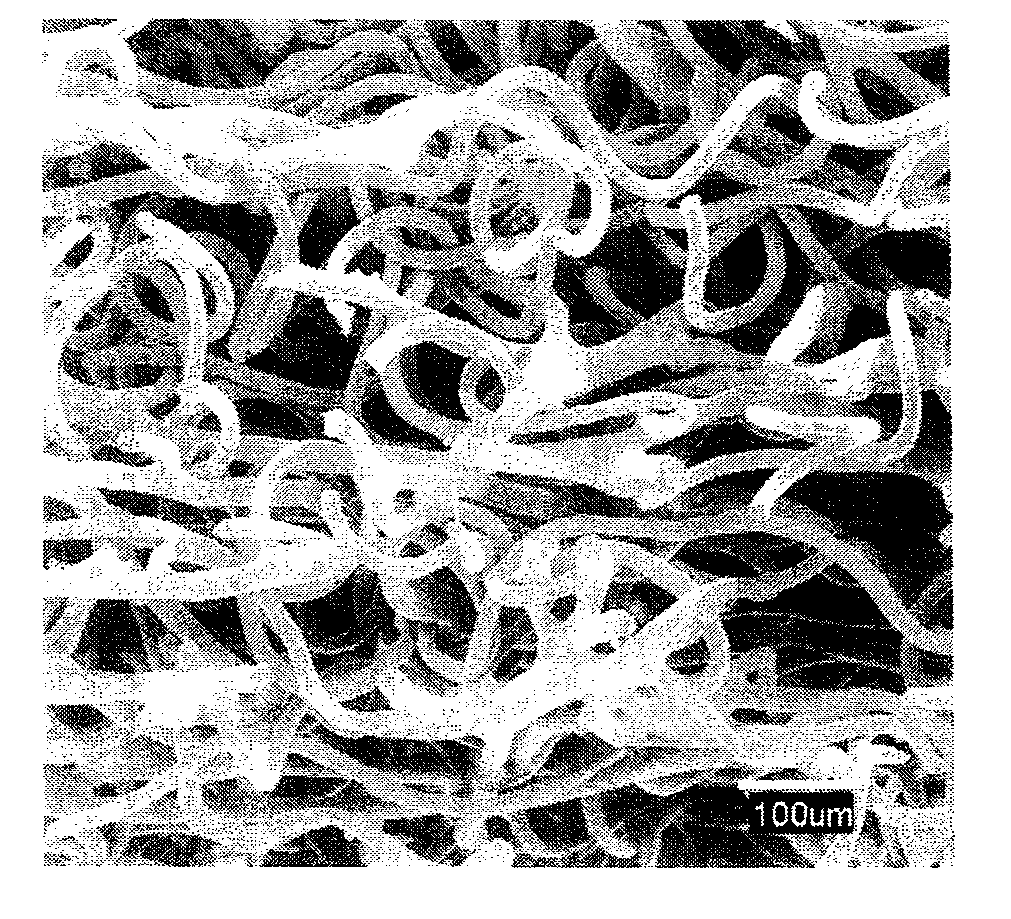

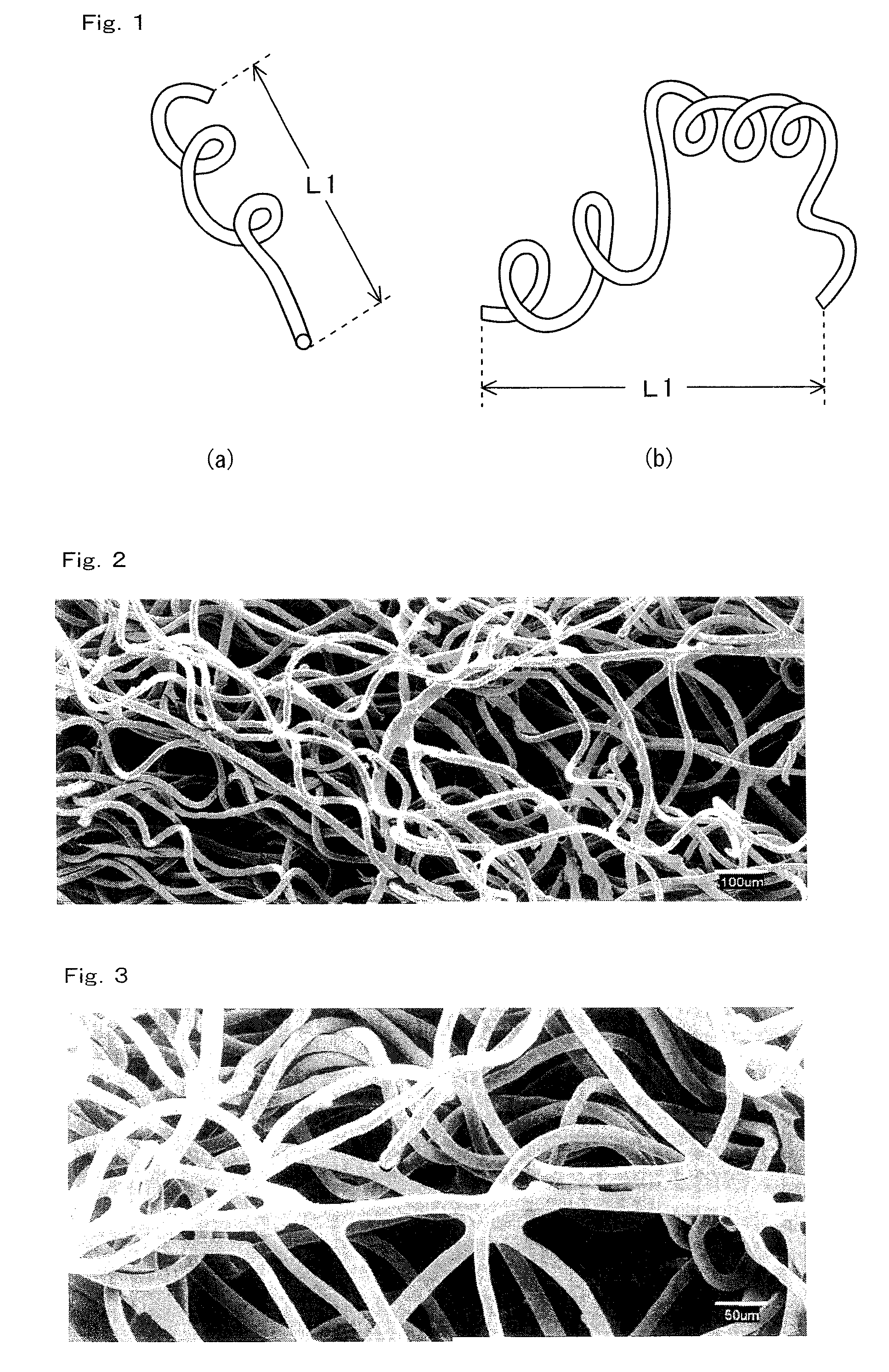

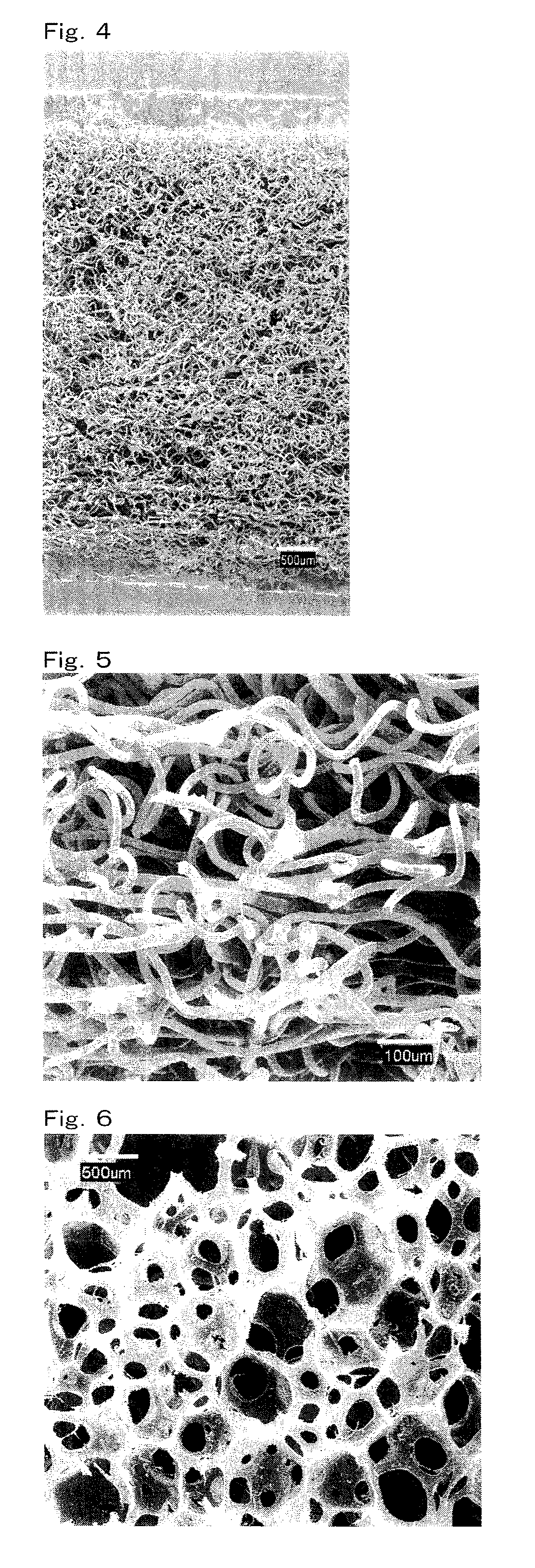

In a nonwoven fiber assembly which comprises a fiber comprising a thermal adhesive fiber under moisture and in which the fiber are entangled with each other, the fibers are bonded at contacting points of the fibers by melting the thermal adhesive fiber under moisture to distribute the bonded points approximately uniformly, thereby obtaining a buffer substrate. The buffer substrate may further comprises a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure, and the conjugated fibers may have an approximately uniform crimps having an average curvature radius of 20 to 200 μm and are entangled with the fibers constituting the nonwoven fiber assembly. The buffer substrate can be obtained by a method comprising the steps of: forming a web from the fiber comprising the thermal adhesive fiber under moisture; and subjecting the obtained fiber web to a heat and moisture treatment with a high-temperature water vapor to melt the thermal adhesive fiber under moisture for bonding the fibers. The buffer substrate has a high air-permeability, an excellent cushion property and softness.

Owner:KURARAY CO LTD

Molded object having nonwoven fibrous structure

ActiveUS20090130939A1Increased bending stressImprove toughnessErasing devicesConstruction materialPolyesterApparent density

To prepare a shaped product comprising a thermal adhesive fiber under moisture and having a fiber aggregate nonwoven structure. In the shaped product, the thermal adhesive fibers under moisture are melted to bond to fibers constituting the fiber aggregate nonwoven structure and the bonded fiber ratio is not more than 85%. The shaped product has an apparent density of 0.05 to 0.7 g / cm3, a maximum bending stress of not less than 0.05 MPa in at least one direction, and a bending stress of not less than ⅕ of the maximum bending stress at 1.5 times as large as the bending deflection at the maximum bending stress. The moistenable-thermal adhesive fiber may be a sheath-core form conjugated fiber comprising a sheath part comprising an ethylene-vinyl alcohol-series copolymer and a core part comprising a polyester-series resin. Such a shaped product can be used for a building board or the like since the shaped product has a high bending stress although the product is light and has a low density.

Owner:KURARAY CO LTD

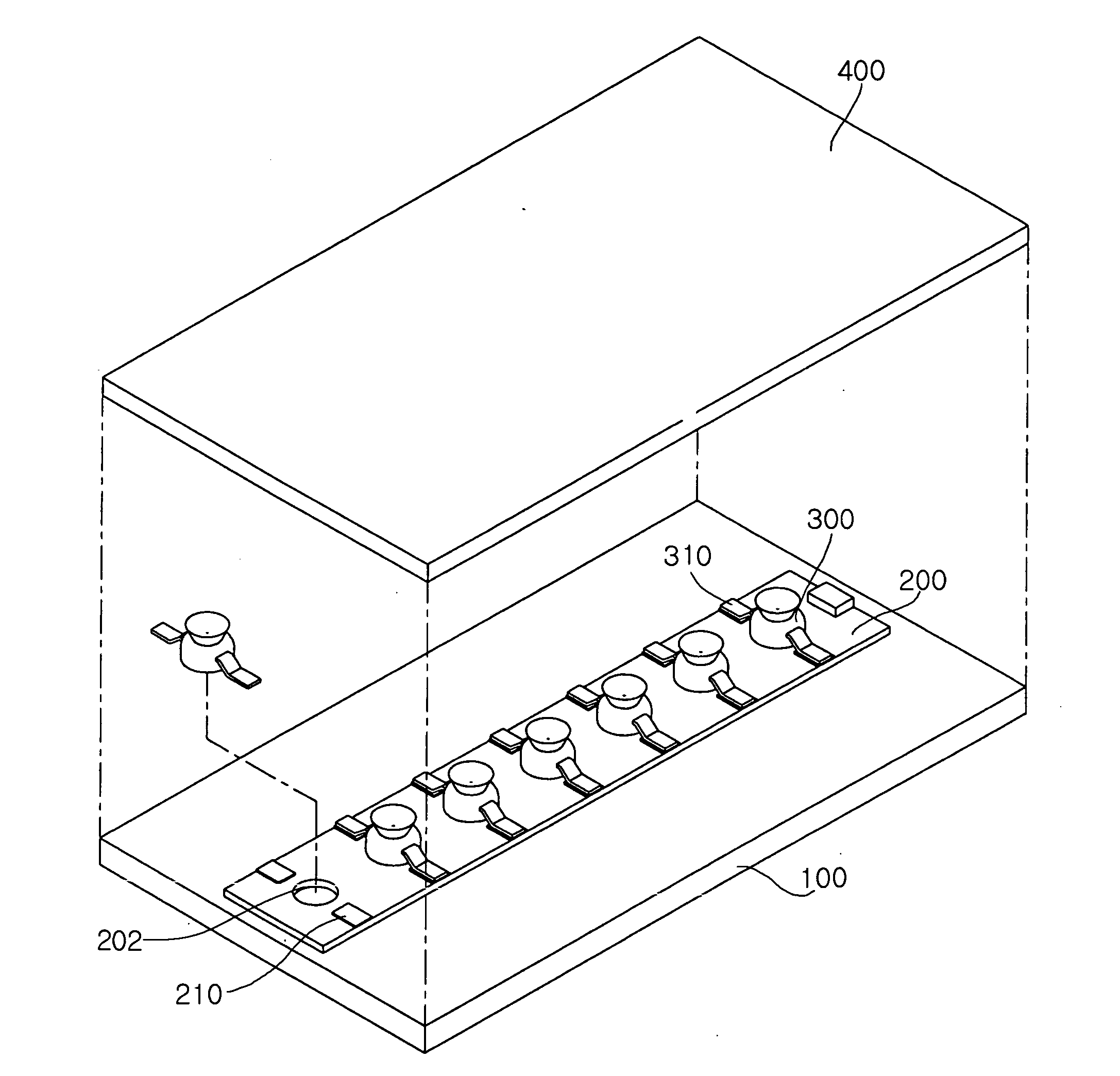

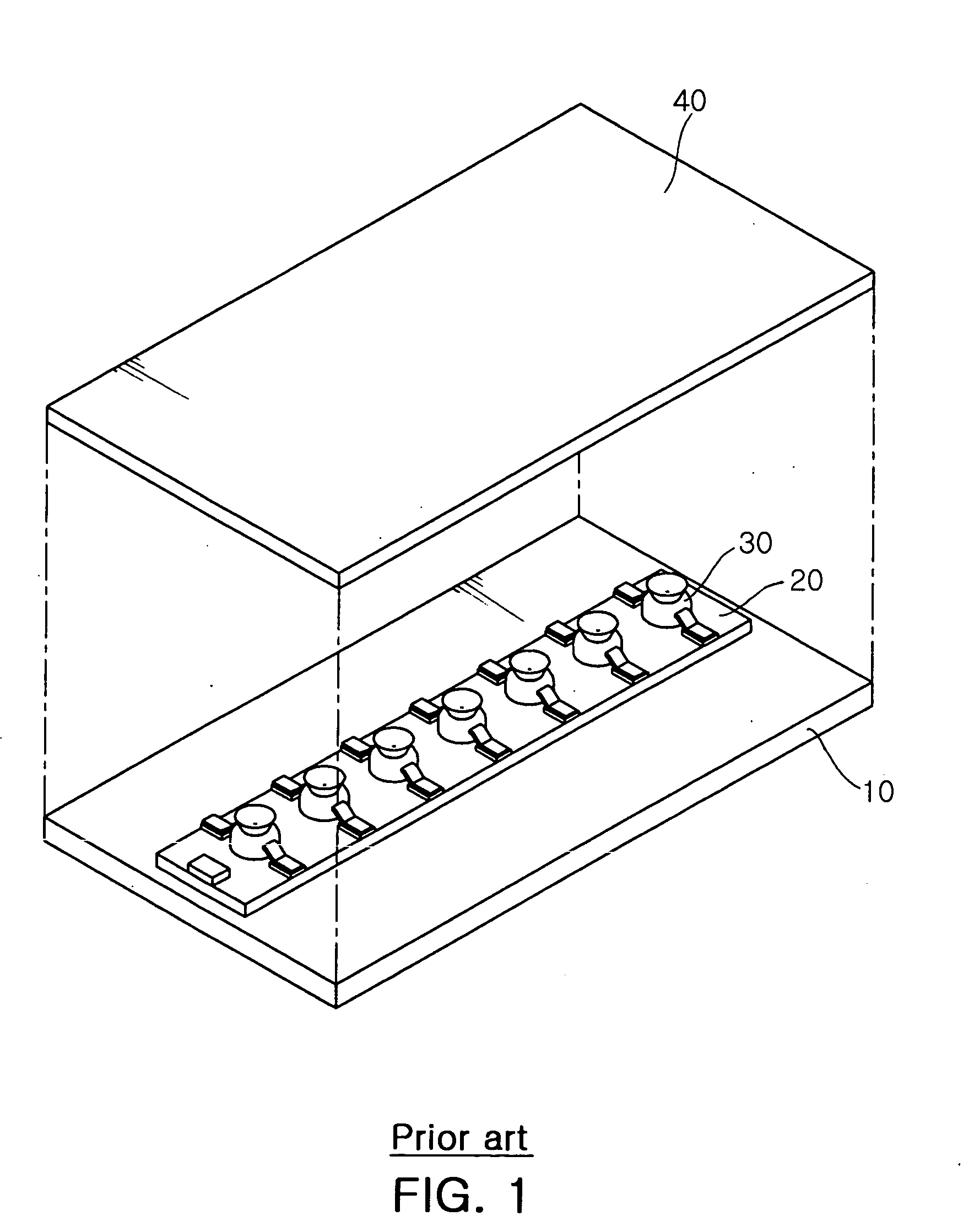

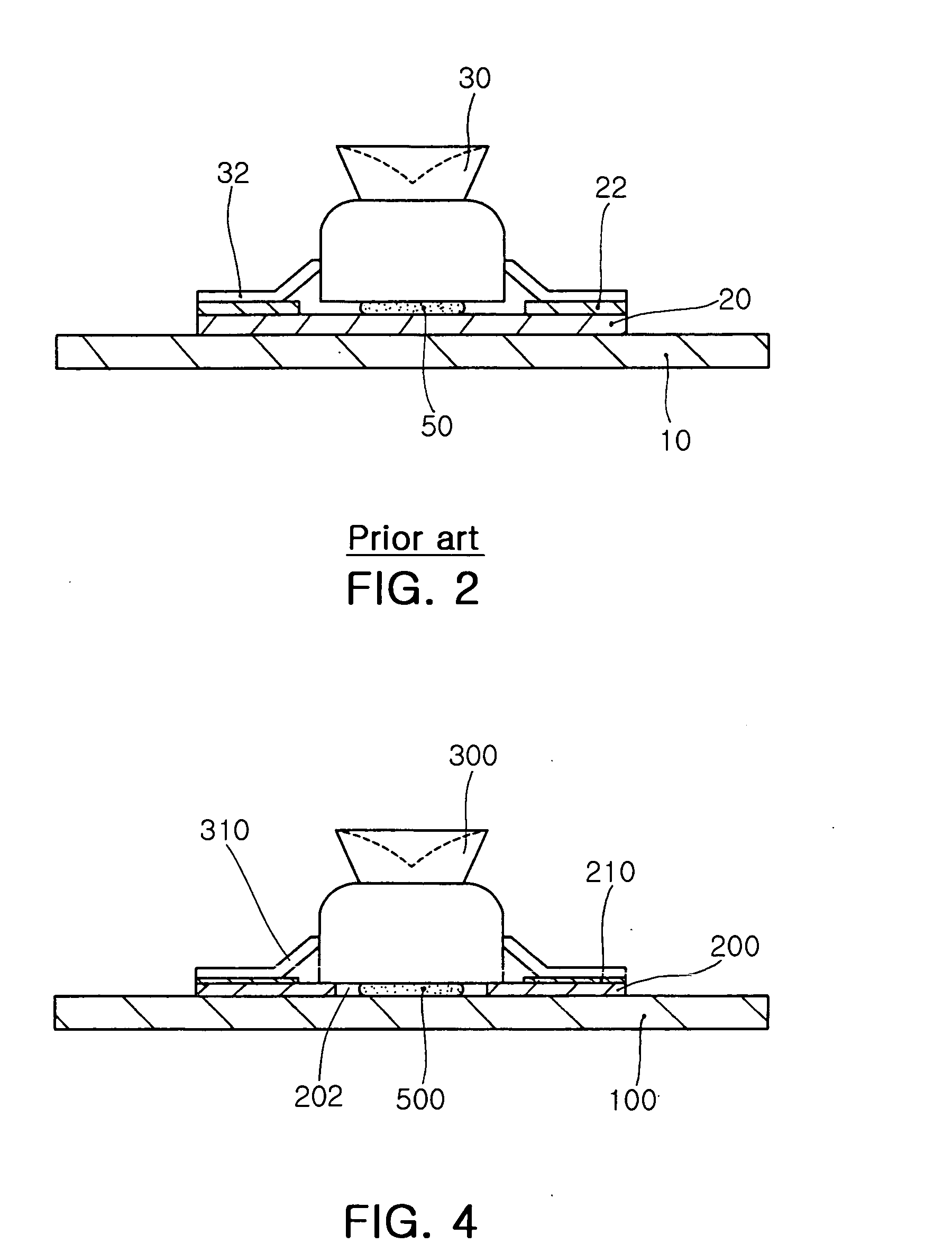

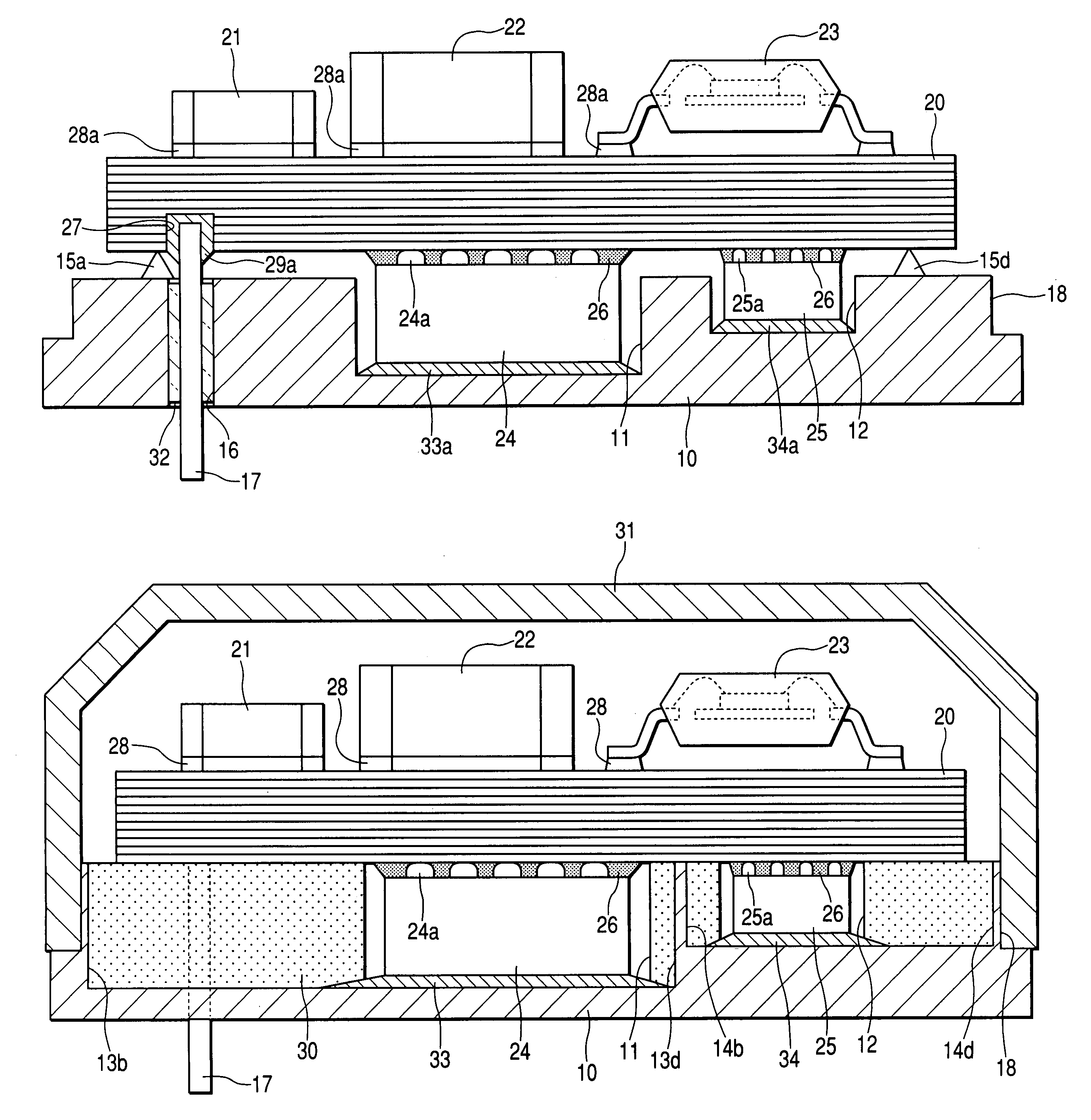

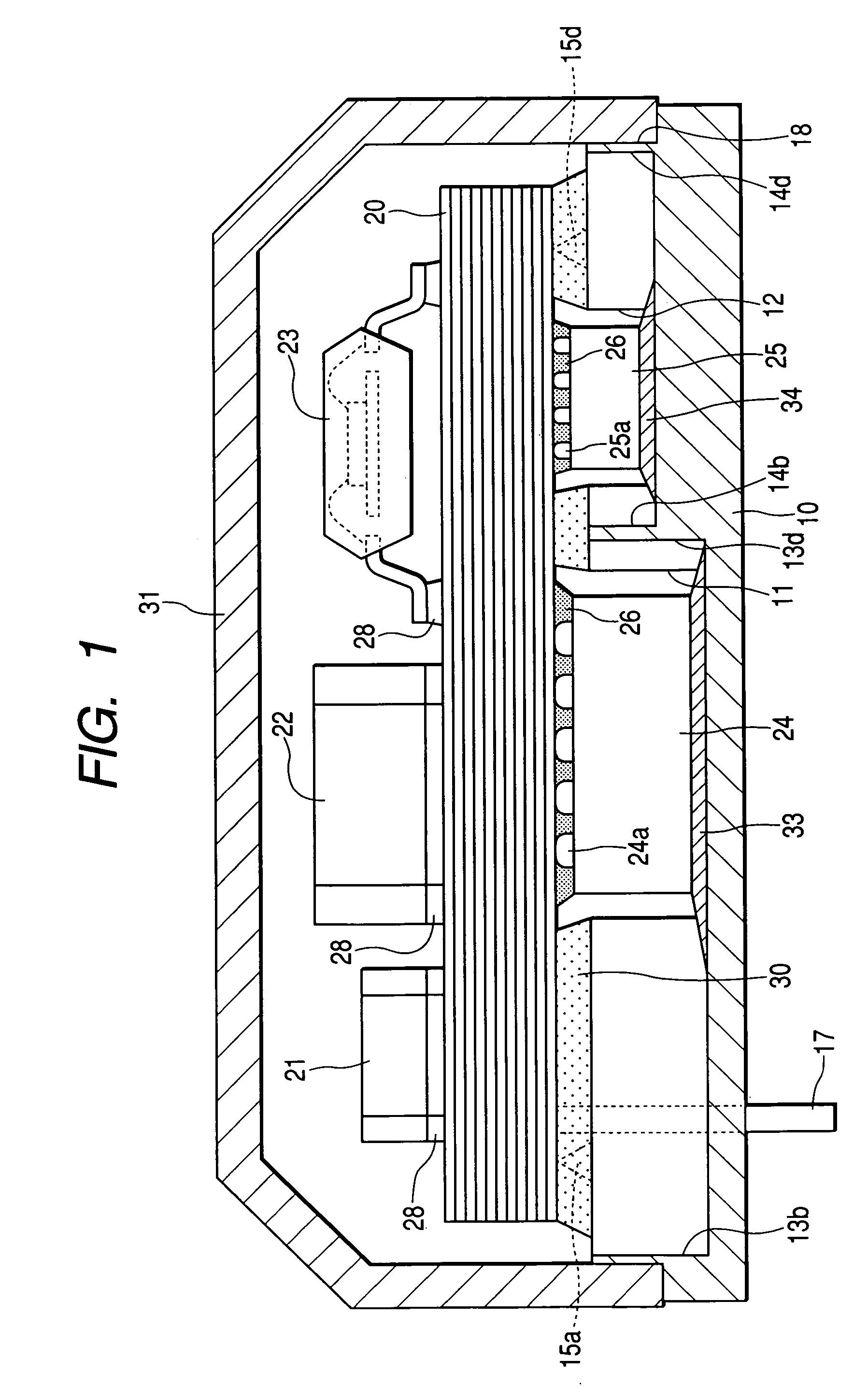

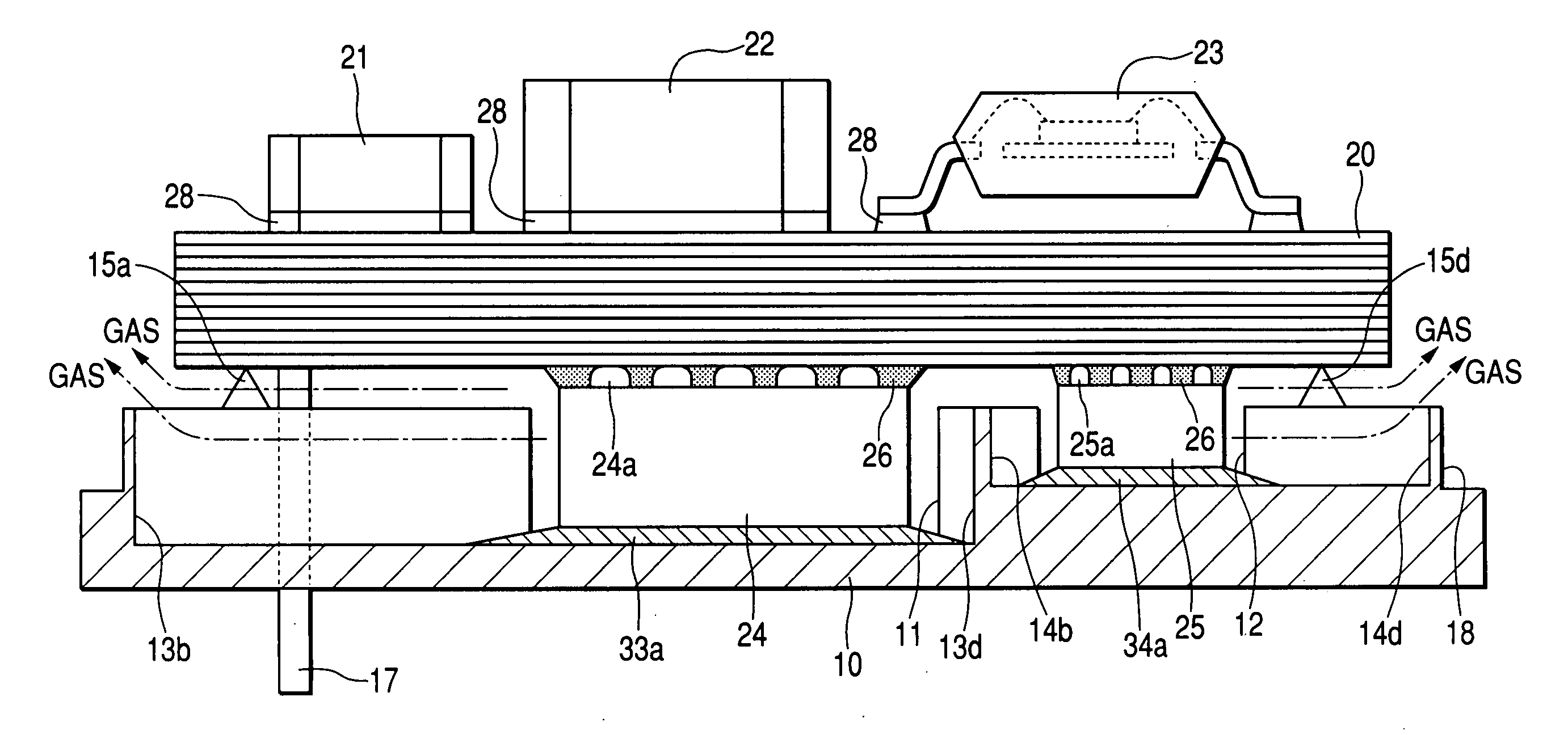

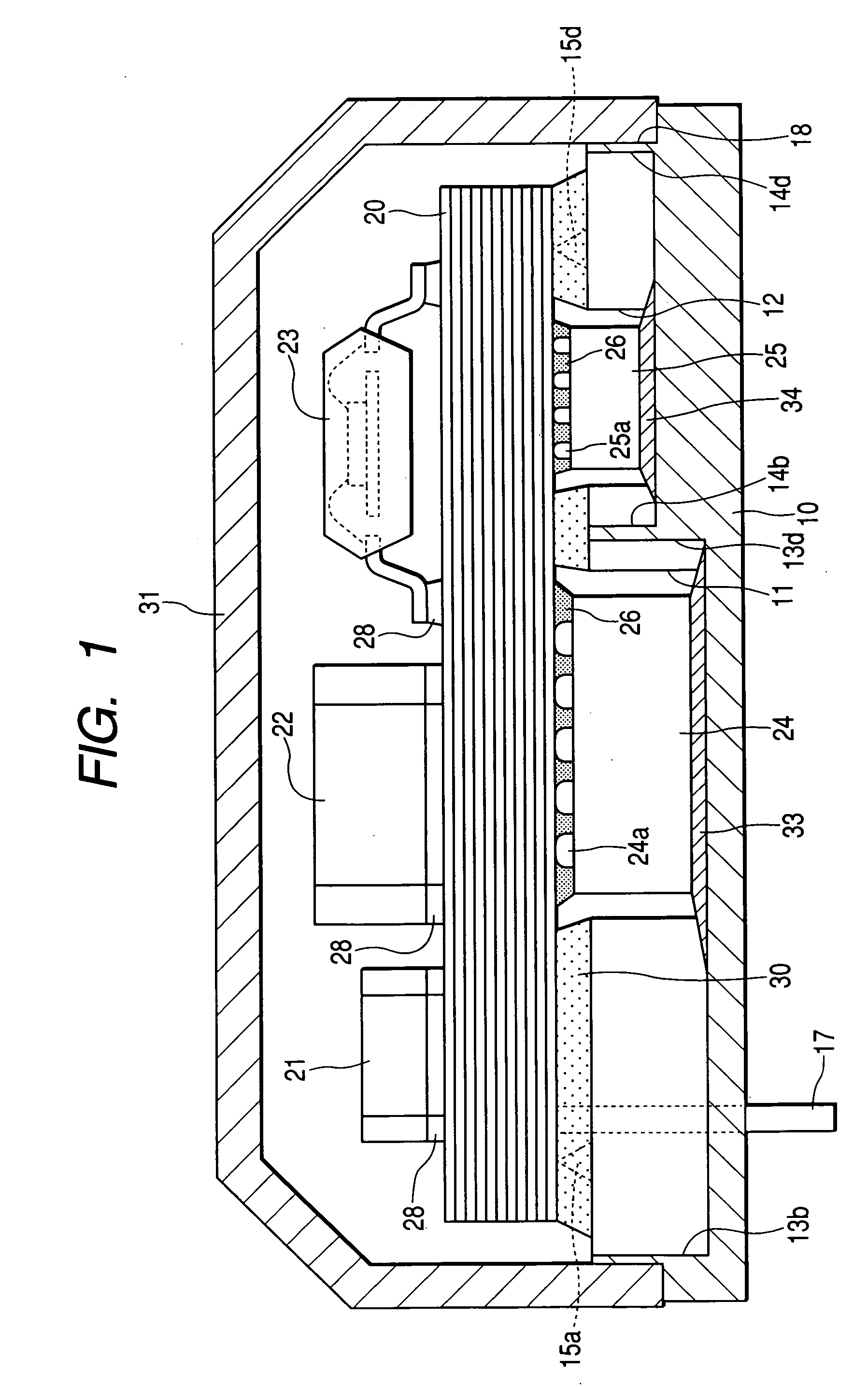

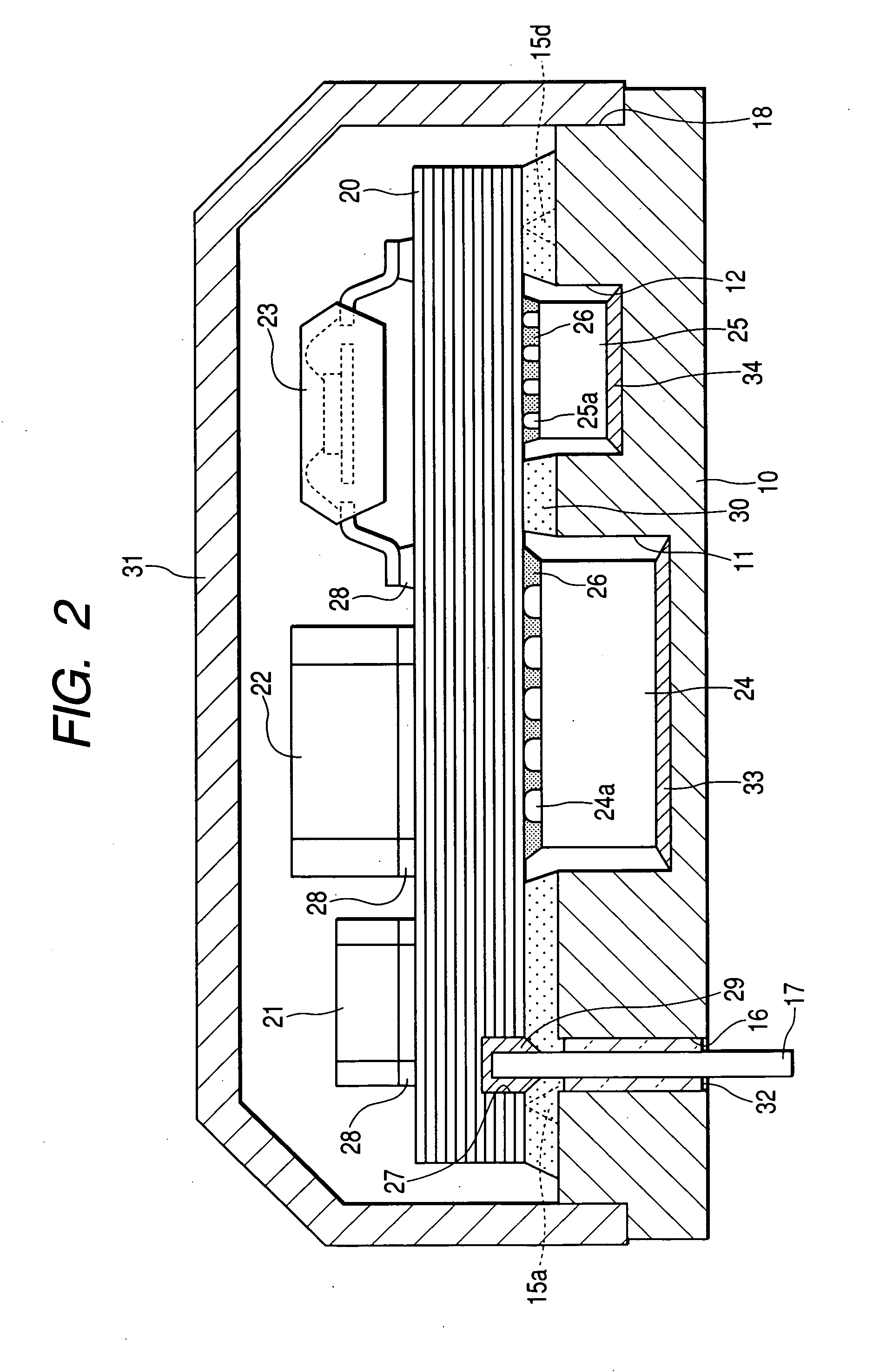

Electronic device

InactiveUS7375974B2Eliminating and reducing voidImprove cooling effectPrinted circuit assemblingPrinted circuit aspectsThermal adhesiveElectronic component

A circuit board is disposed on a support plate, with electronic components mounted on this circuit board being accommodated in recessed portions of the support plate. Thermal adhesive members intervene between rear surfaces of the electronic components and bottom surfaces of the recessed portions of the support plate. The support plate has degassing grooves. Furthermore, the support plate has raised portions provided on its upper surface for supporting the circuit board in a floated condition with a gap between them.

Owner:DENSO CORP

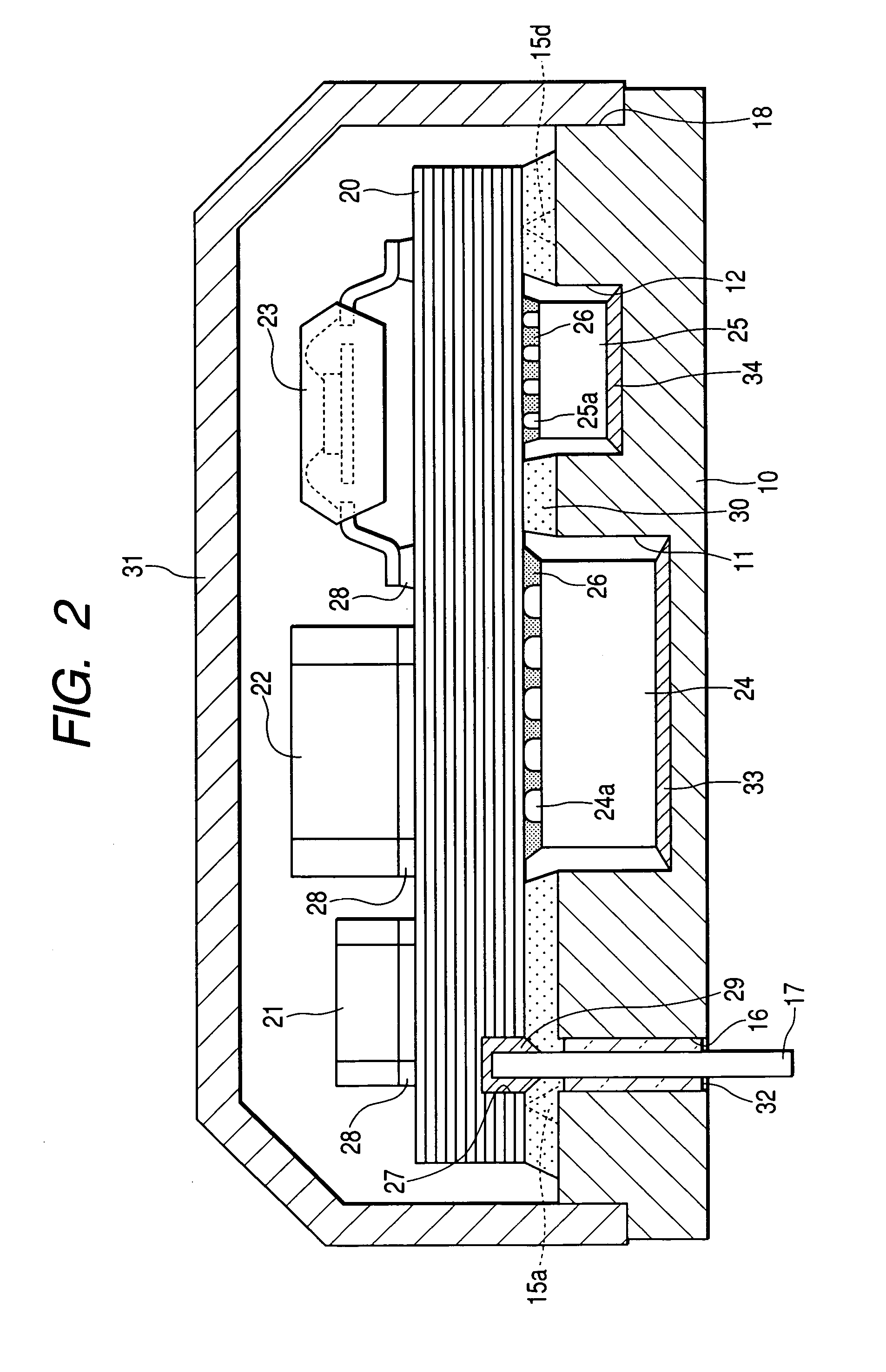

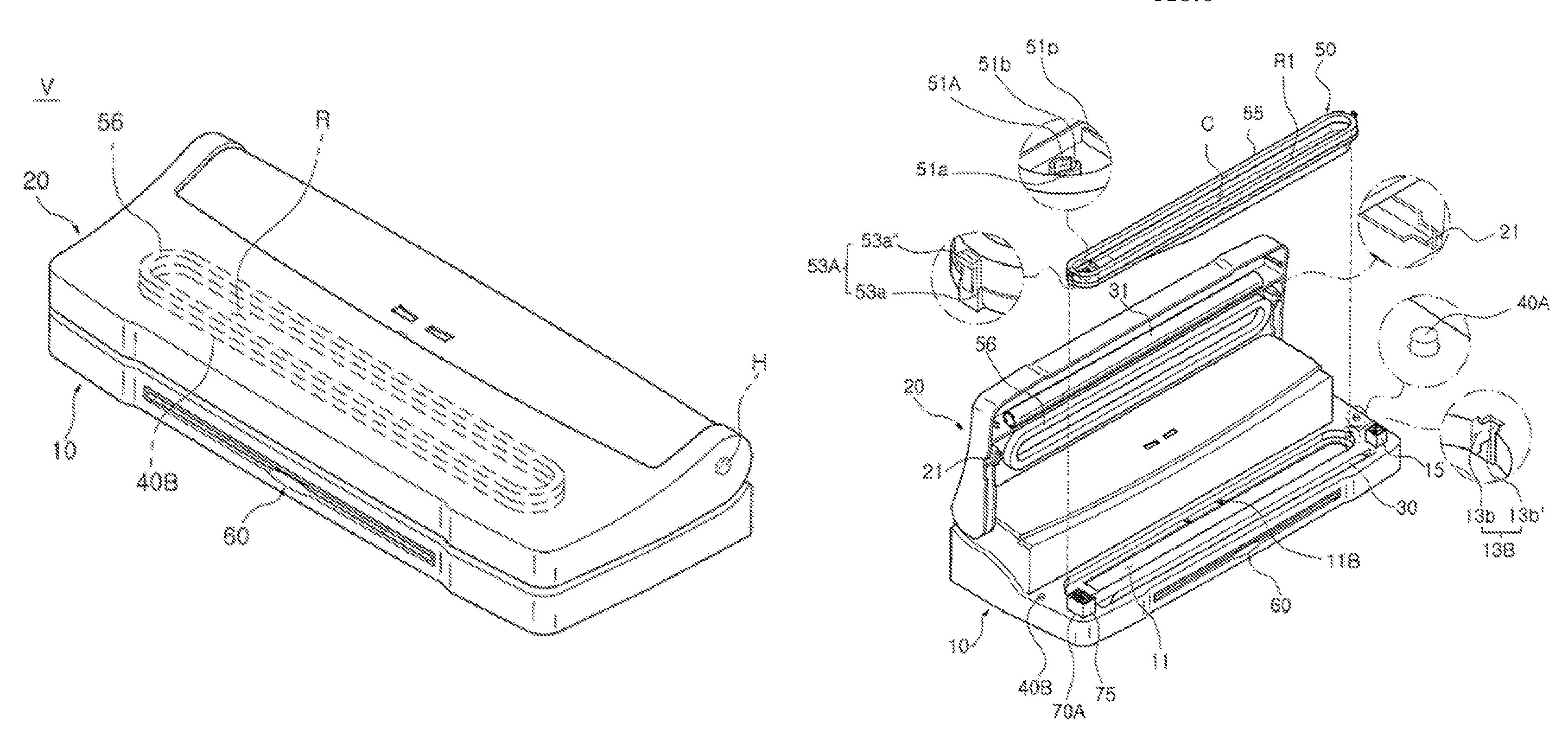

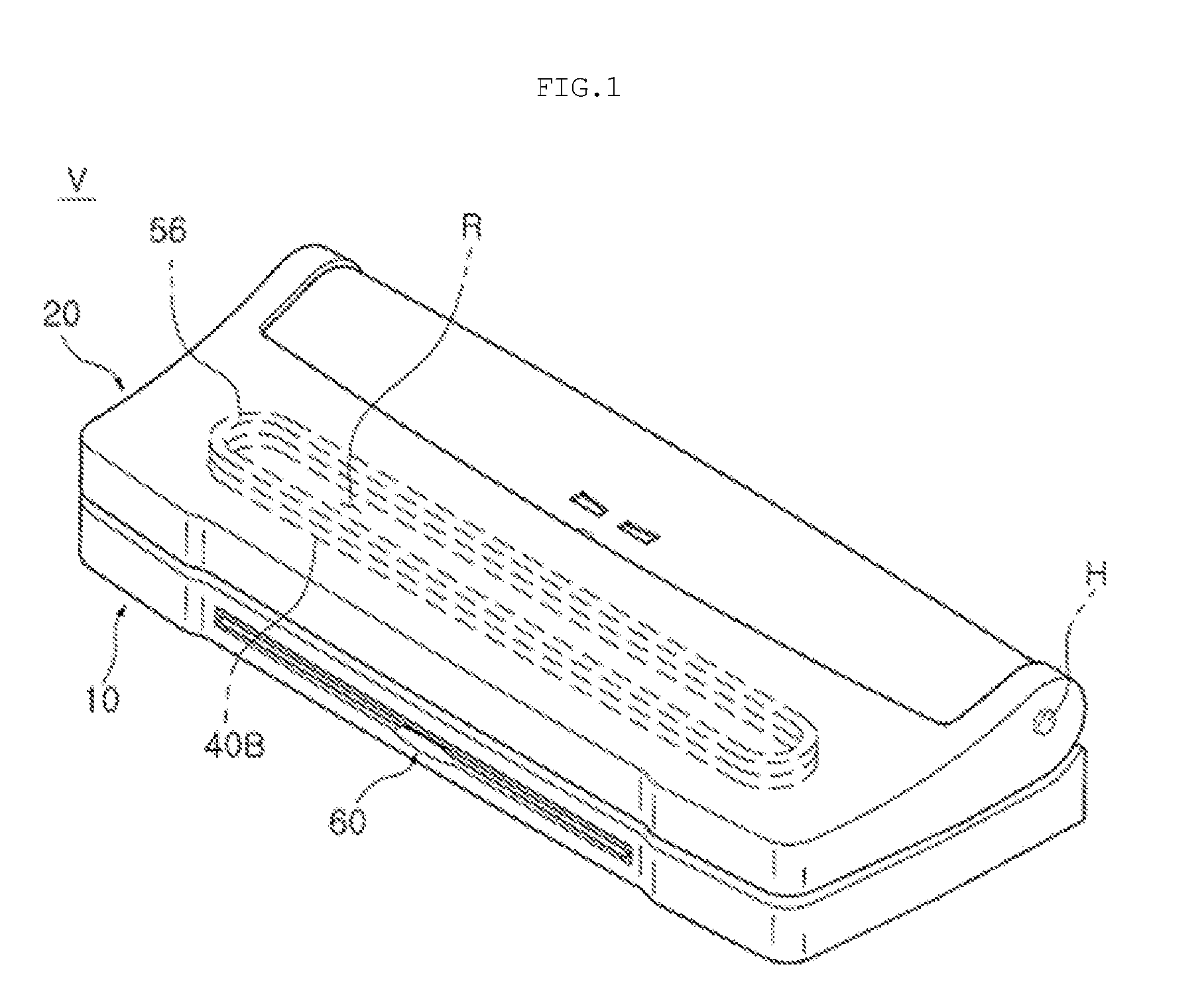

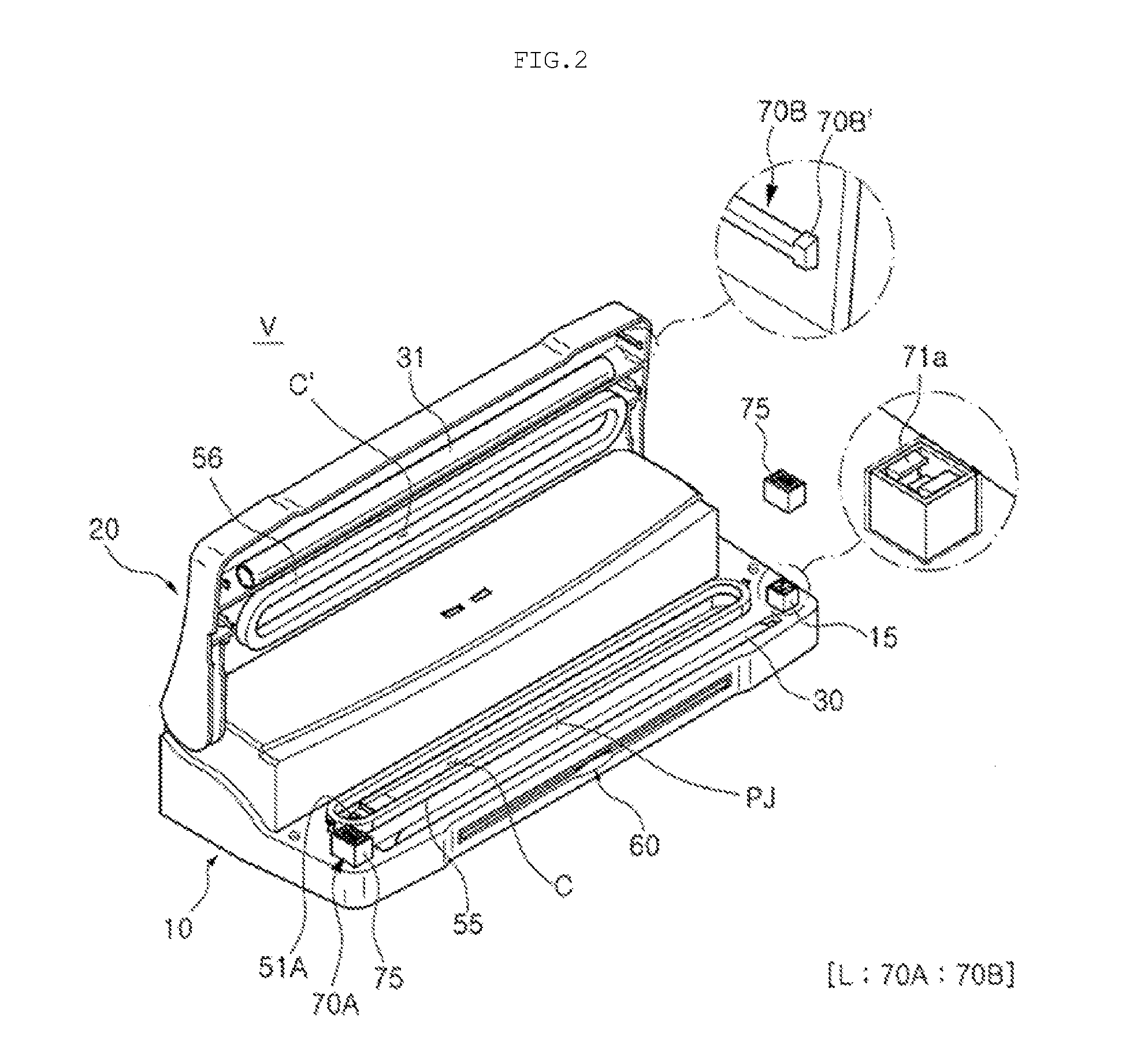

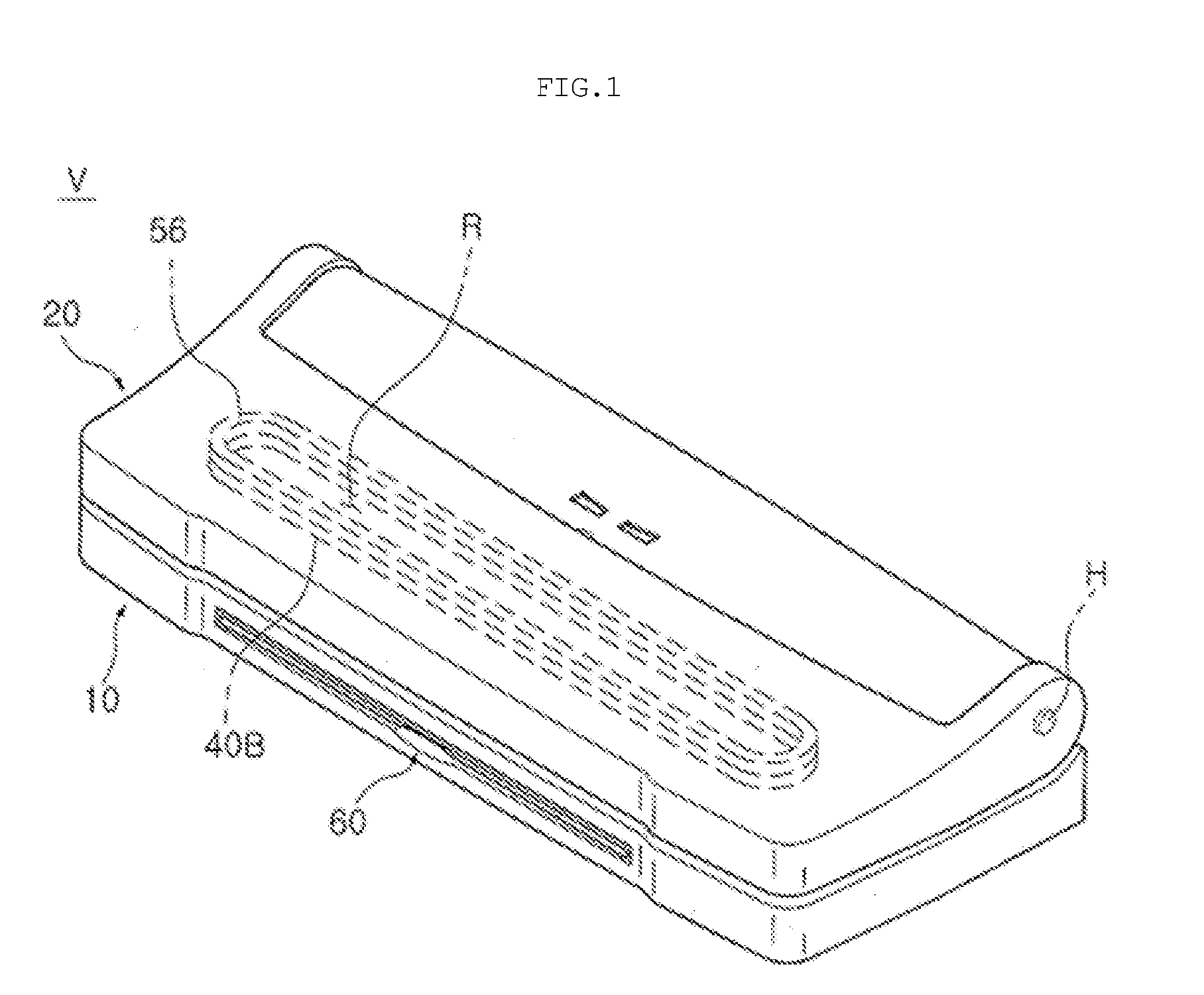

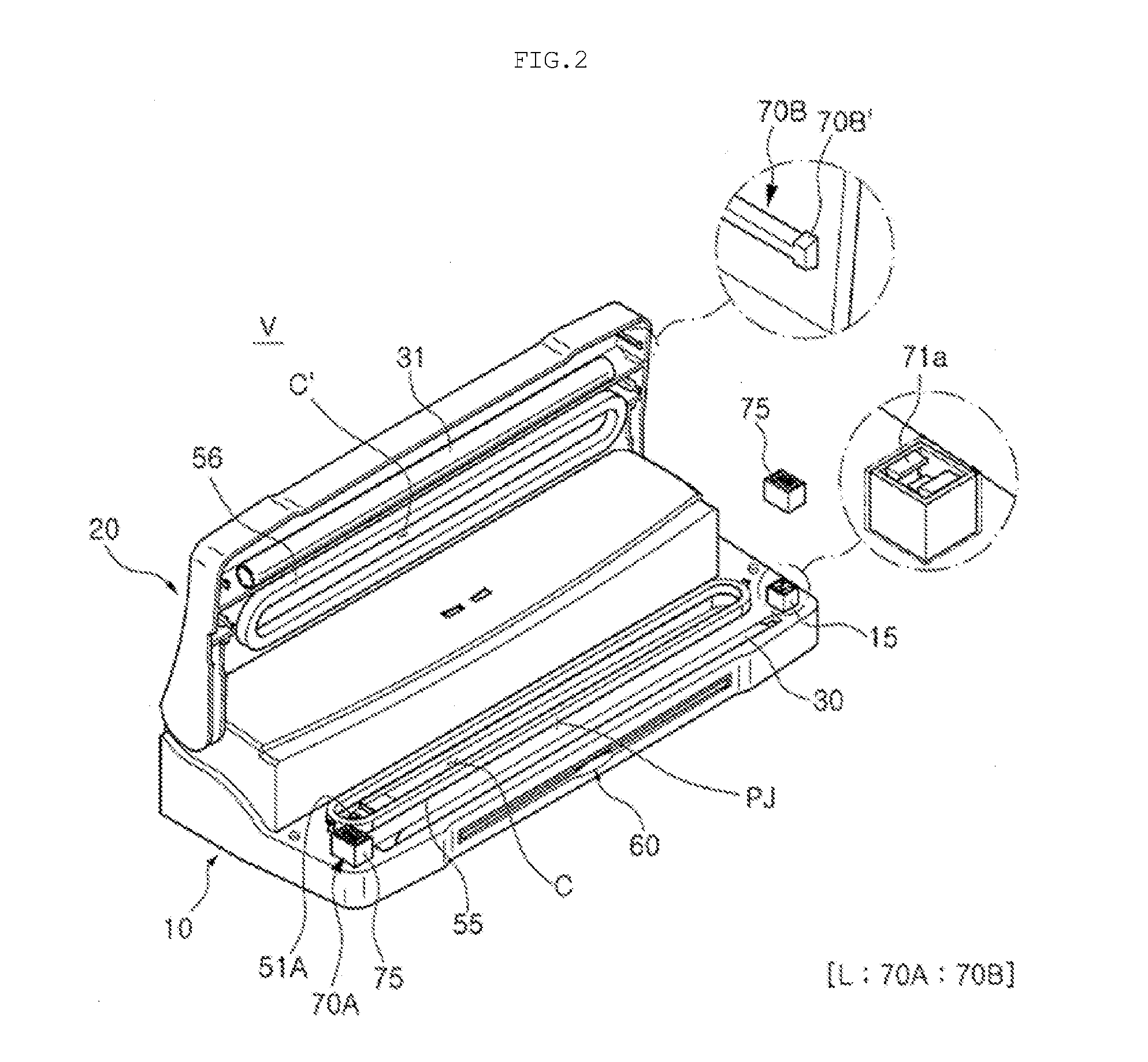

Vacuum sealer

InactiveUS7540127B2Easy constructionPackaging by pressurising/gasifyingShock-sensitive articlesThermal adhesivePulp and paper industry

Disclosed herein is a vacuum sealer, which exhausts air from a thermal adhesive vacuum bag containing products and then heats and seals the open end of the vacuum bag. The vacuum sealer includes a lower body. An upper body is pivotably mounted to the lower body in such a way as to engage with the lower body. A heater is installed in either or both the lower body or / and the upper body, and heats and seals a vacuum bag. A vacuum space creating member is installed in either or both the lower body or / and the upper body, and isolates an end of the vacuum bag which is evacuated from an exterior, thus creating a vacuum space. A vacuum pump is coupled via a tube to an exhaust hole communicating with the vacuum space created by the vacuum space creating member.

Owner:SUNG YI JE

Electronic device

InactiveUS20050201069A1Eliminating and reducing voidImprove cooling effectPrinted circuit assemblingPrinted circuit aspectsEngineeringThermal adhesive

A circuit board is disposed on a support plate, with electronic components mounted on this circuit board being accommodated in recessed portions of the support plate. Thermal adhesive members intervene between rear surfaces of the electronic components and bottom surfaces of the recessed portions of the support plate. The support plate has degassing grooves. Furthermore, the support plate has raised portions provided on its upper surface for supporting the circuit board in a floated condition with a gap between them.

Owner:DENSO CORP

Modular LED lamp and manufacturing methods

InactiveUS8324835B2Increasing device cost and sizeImprove heat transfer performancePoint-like light sourceLighting support devicesEngineeringThermal adhesive

A method for forming a light source includes receiving an LED light module having a plurality of LEDs on a silicon substrate coupled to a flexible printed circuit and bonding the LED light module directly to a heat-sink with a thermal adhesive A base module with LED driver circuits is inserted into an interior channel of the heat sink and contacts of the LED driver circuits are connected to the LED light module.

Owner:KORRUS INC

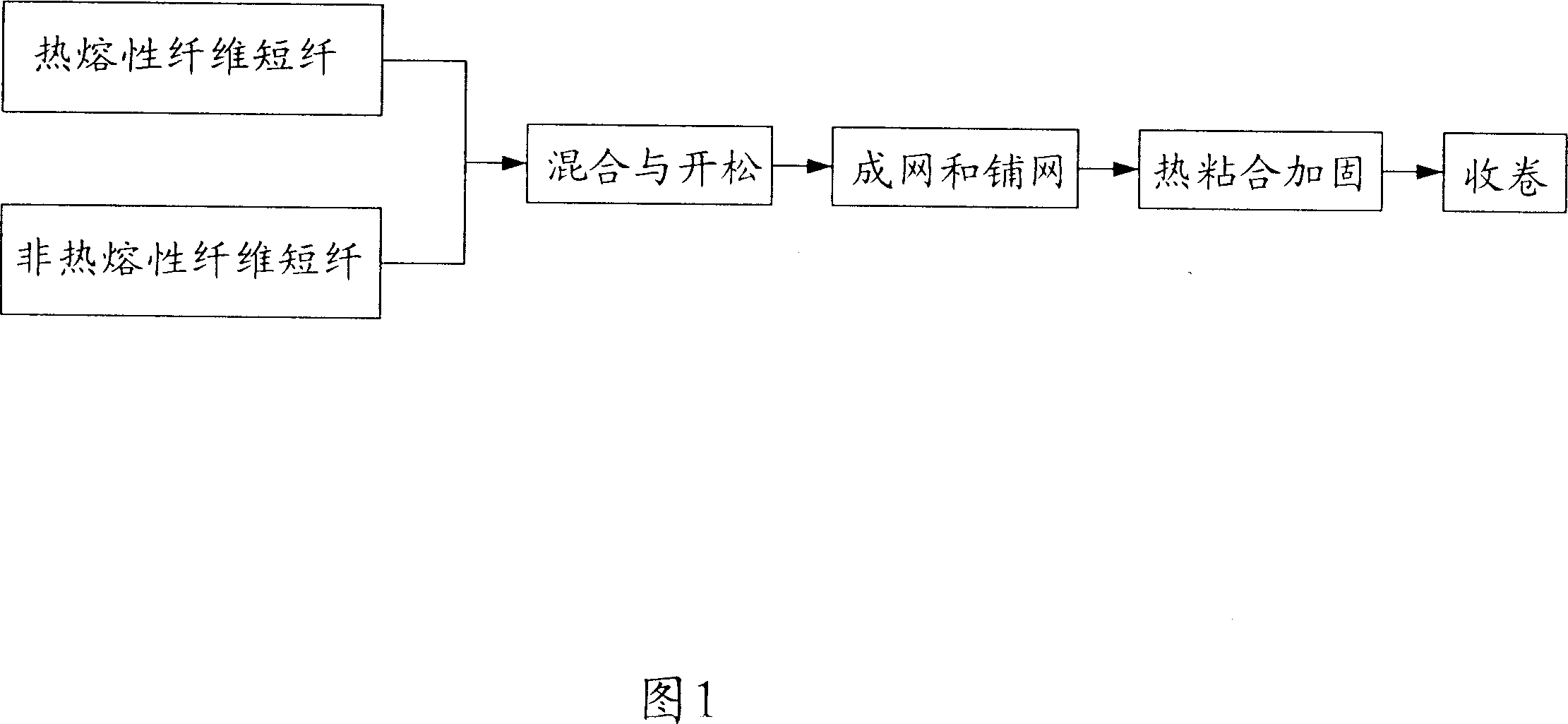

Nonwovens and machining method thereof

The invention discloses a non-woven cloth and relative production, wherein the non-woven cloth is formed by non-hot-melt staple fiber whose mass content is not lower than 30% and hot-melt composite staple fiber, via thermal adhesive fixing method. And the invention utilizes the character that the surface of the hot-melt composite staple fiber has heated fusion function, and the invention uses thermal adhesive fixing method to fuse the face of hot-melt composite staple fiber to adhere the non-hot melt staple fiber to form non-woven cloth, therefore, the produced non-woven cloth has damp adsorption property, soft property, and flexibility, without sensibility on human body. And the invention utilizes the hot-wind non-woven device or thermal rolling non-woven device with low energy consumption and low cost.

Owner:谢继华 +1

Graphene-filled isotropic high-performance heat-conducting adhesive and preparation method

InactiveCN102433098AImprove thermal conductivityHigh bonding strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention especially relates to a graphene-filled isotropic high-performance heat-conducting adhesive, which belongs to the technical field of preparation of heat-conducting adhesives. The invention aims to overcome the defects of low heat conductivity, low bonding strength and the like of existing heat-conducting adhesives. Graphene prepared by using the method of ball milling is utilized as a heat-conducting filling material after surface treatment to prepare the high-performance heat-conducting adhesive. The invention also provides a preparation method for a composition of the heat-conducting adhesive. The heat-conducting adhesive prepared in the invention can be widely applied in the fields of liquid crystal display devices and the like and produces a very remarkable effect.

Owner:常州碳润新材料科技有限公司 +1

Vacuum Sealer

InactiveUS20070199283A1Easy constructionPackaging under vacuum/special atmosphereShock-sensitive articlesEngineeringPulp and paper industry

Owner:SUNG YI JE

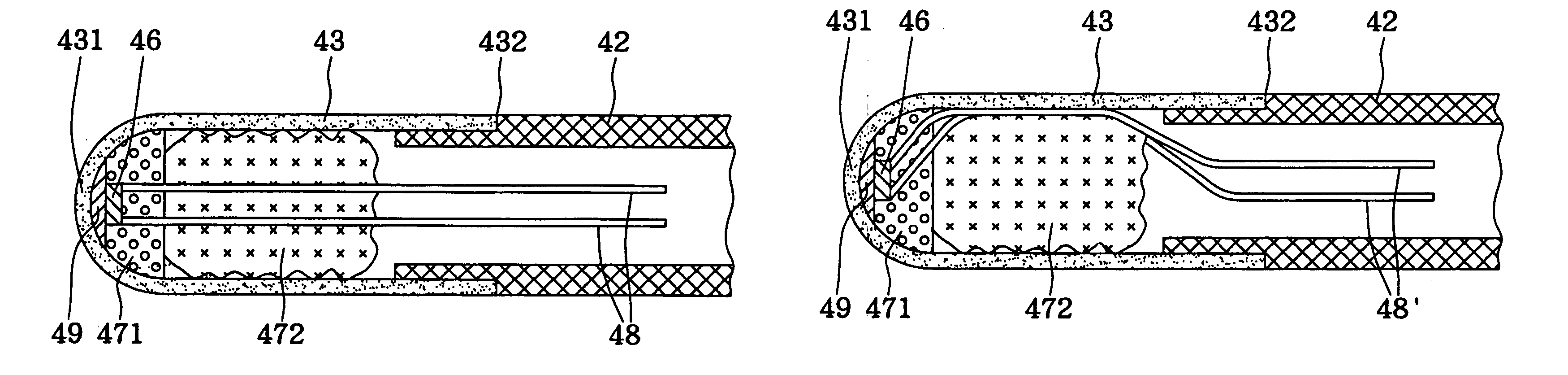

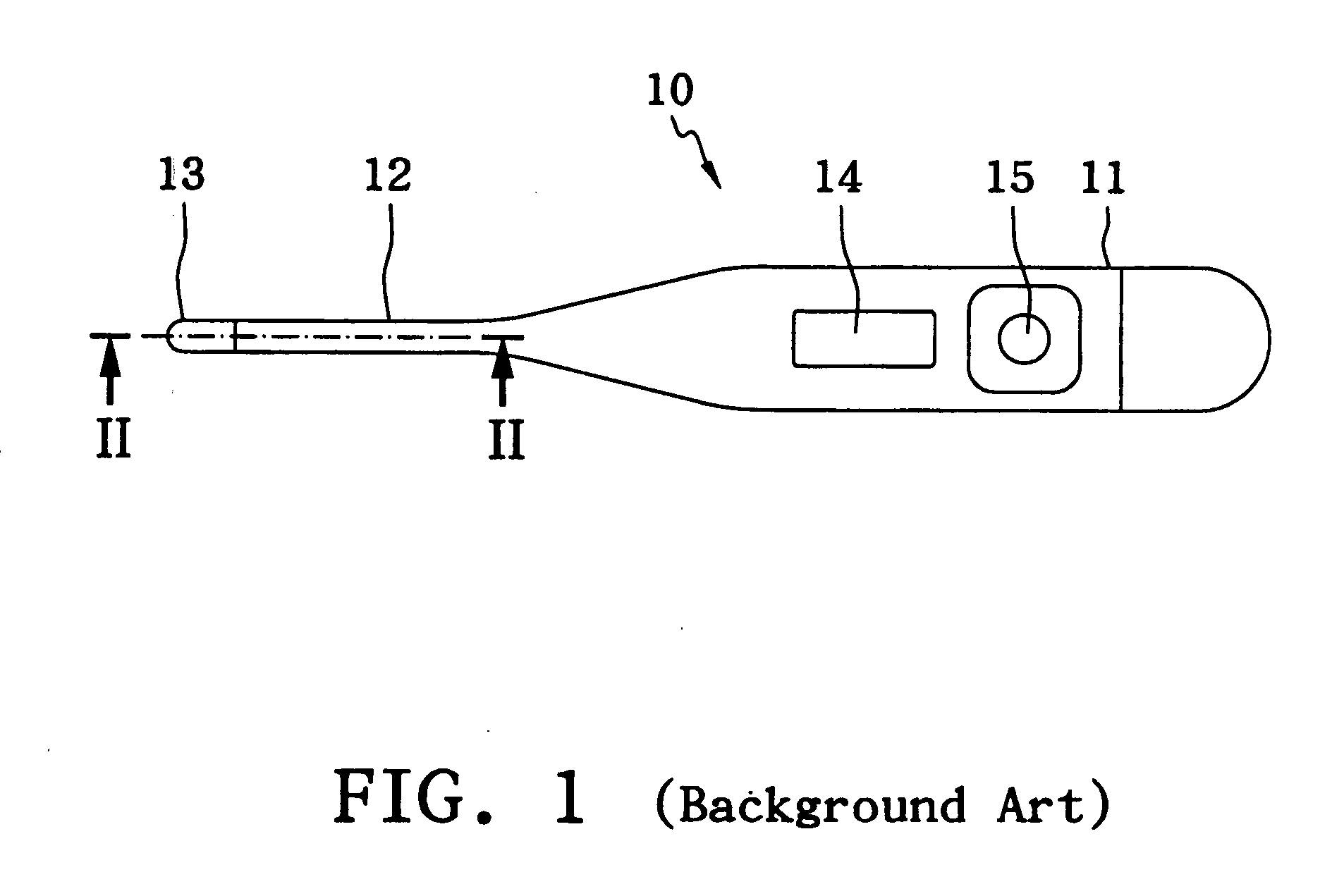

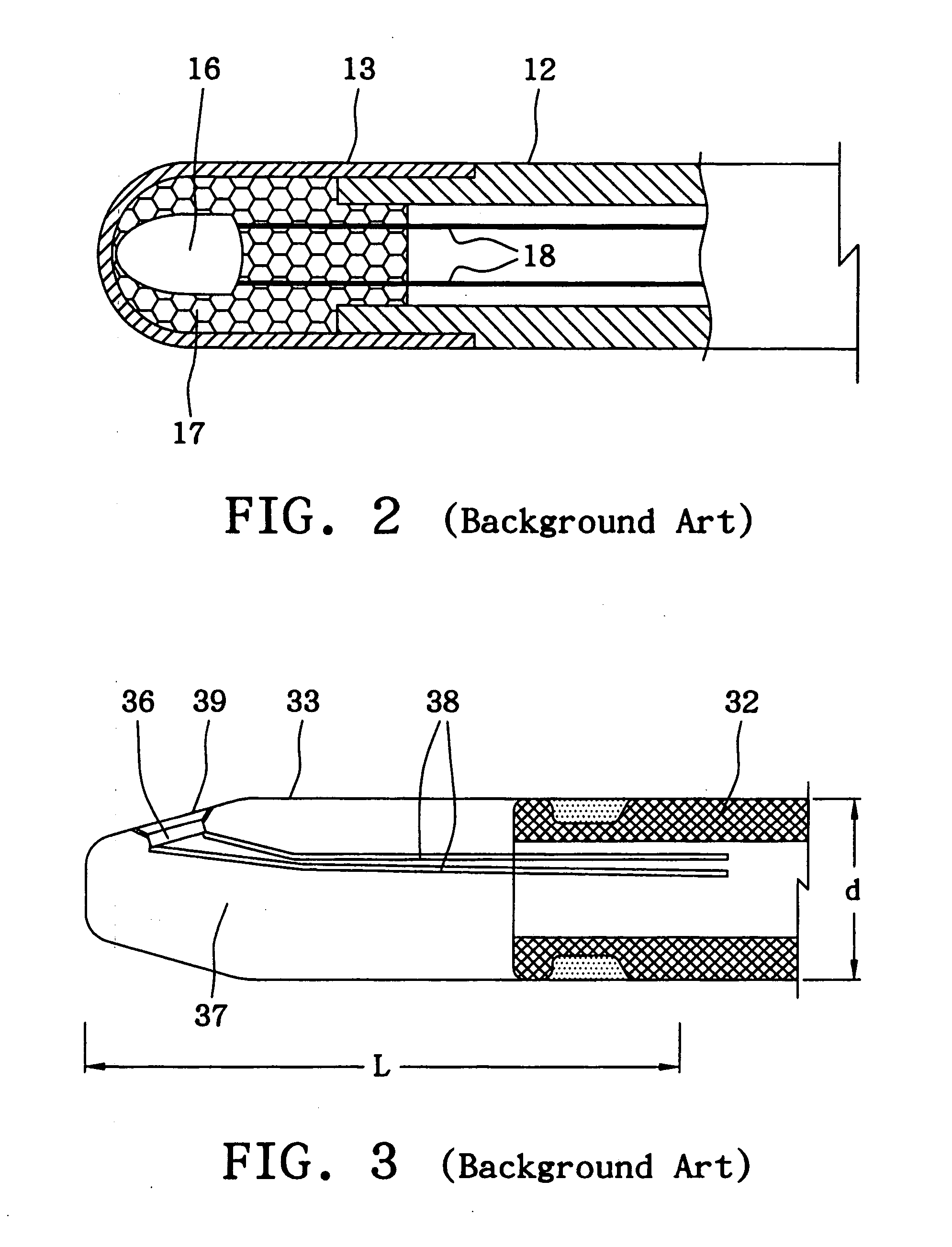

Electrical thermometer

InactiveUS20050094707A1Measurement time is increasedHeating fastThermometer detailsThermometers using electric/magnetic elementsThermal adhesiveThermal sensors

An electrical thermometer comprises a metallic tip and a main body equipped with a probe portion. The front end of the probe portion is fitted into the opening of the metallic tip, which resembles a shell with a blunt end. The probe portion is formed on the main body. A thermal sensor, which is immersed and fixed in thermally conductive glue, is positioned inside the front inner end of the metallic tip. The remaining space within the metallic tip is filled up with a good thermally insulator. The metallic tip can be rapidly heated up with body temperature whenever touched, and the heat will be transferred to the thermal sensor via the thermally conductive glue. In additional, the thermally insulator can stop succeeding heat transfer.

Owner:ORIENTAL SYST TECH

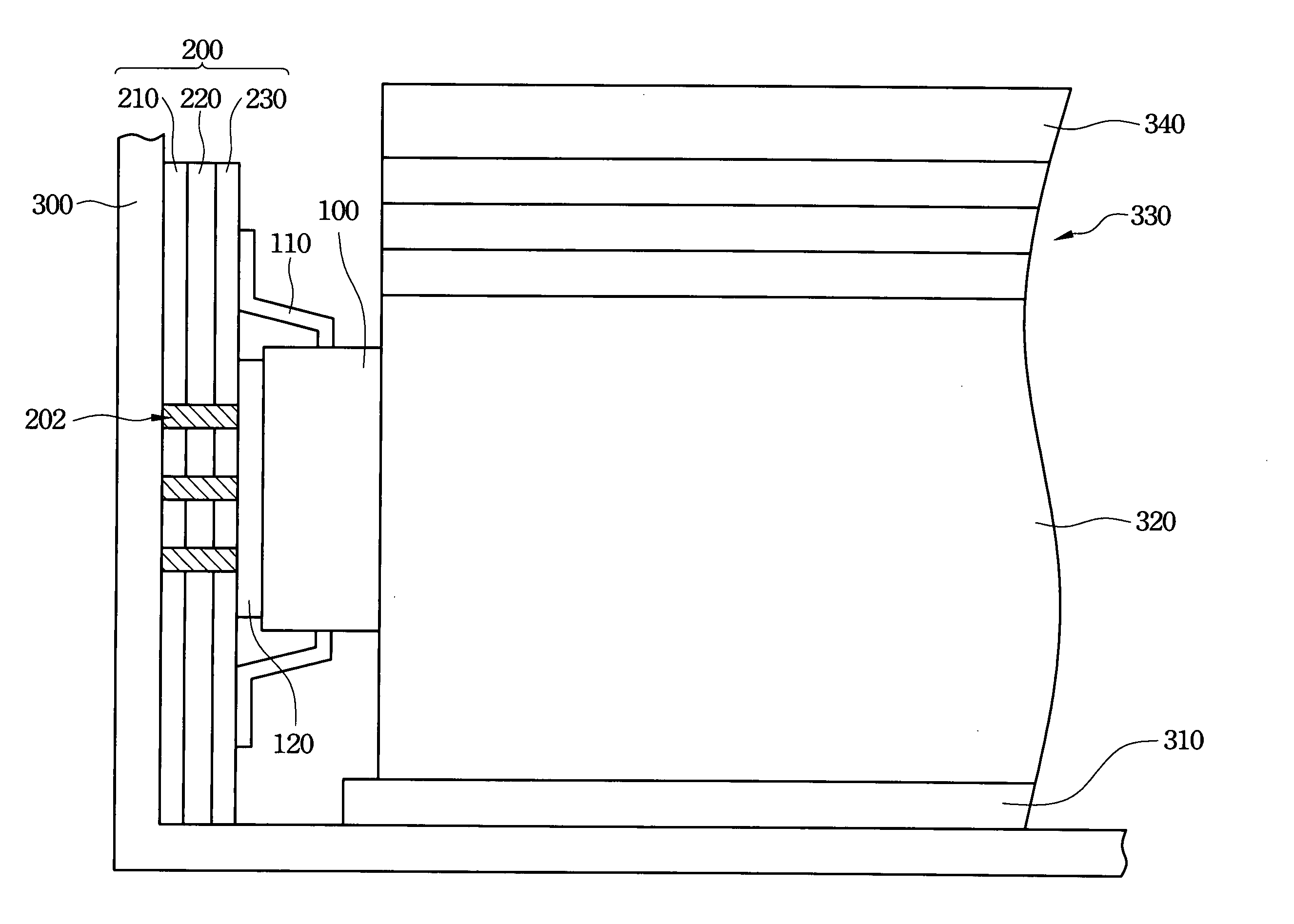

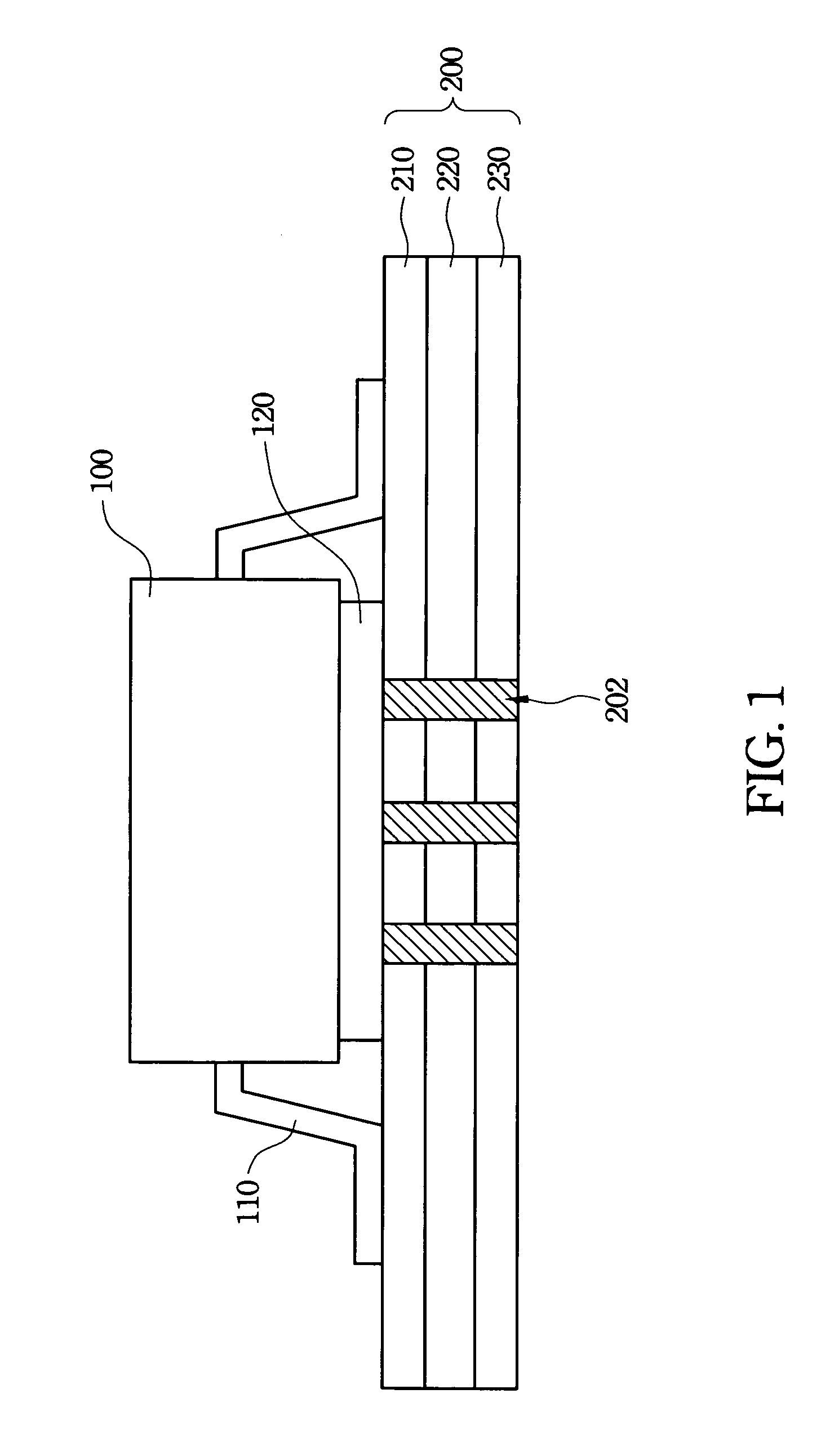

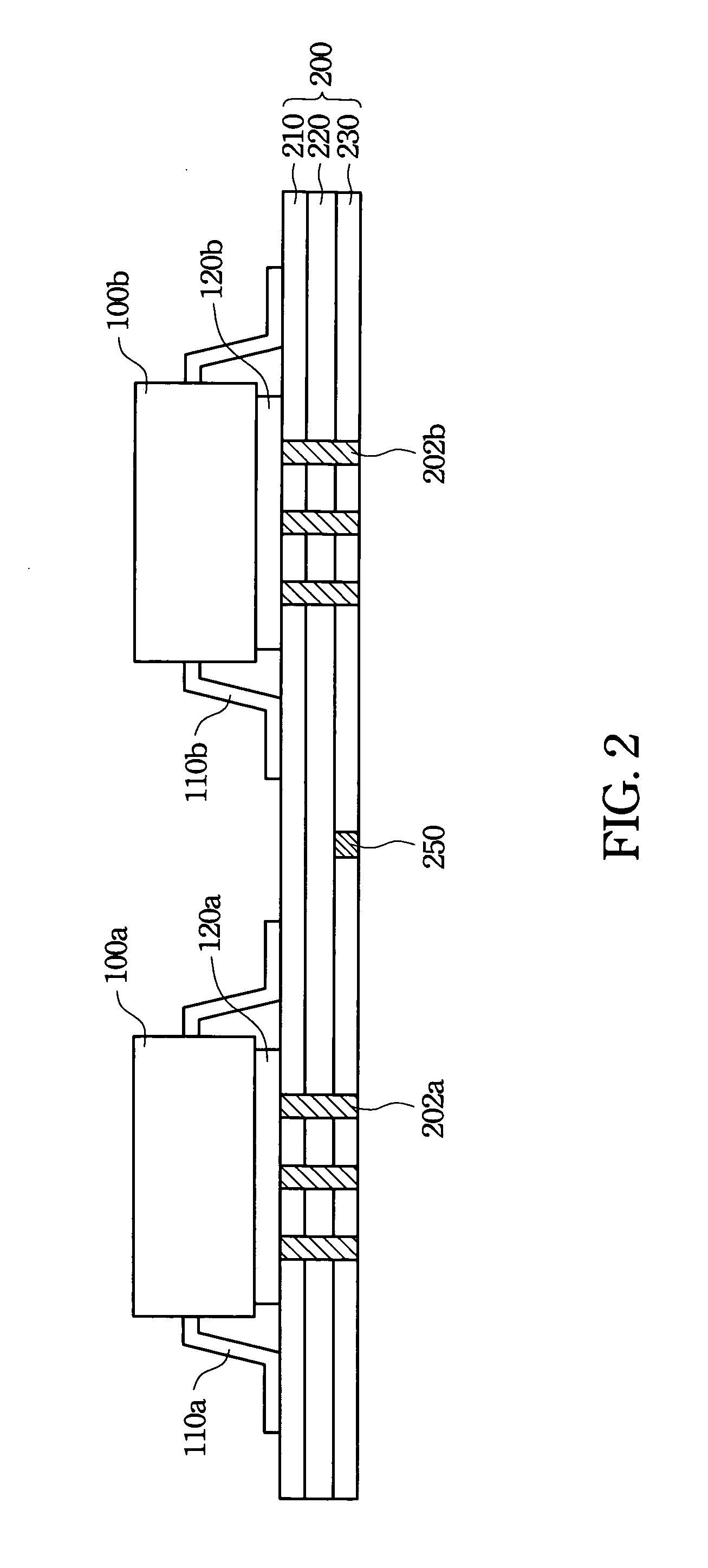

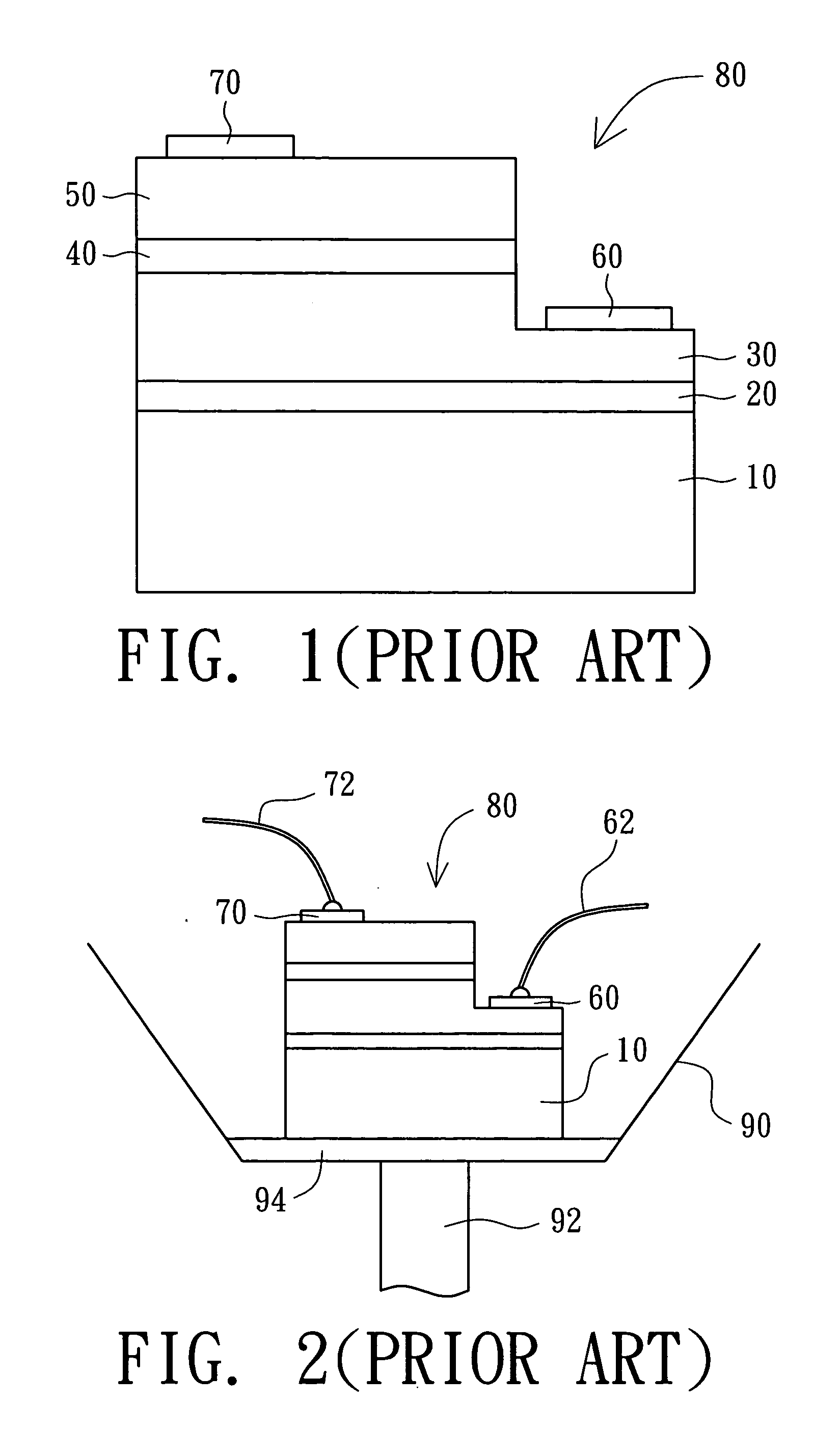

Heat dissipation structure of backlight module

ActiveUS20070229753A1Small sizeLow costSemiconductor/solid-state device detailsSolid-state devicesElectricityConductive materials

The heat dissipation structure of the backlight module of the present invention comprises a circuit board, a heat-conductive element (such as thermally conductive glue) and a light-emitting diode (LED) chip, wherein the circuit board has an electric circuit layer and a heat conductive layer respectively formed on two opposite surfaces thereof. The circuit board has a plurality of through holes penetrating through the electric circuit layer and the heat-conductive layer of the circuit board, wherein each of the through holes is filled with heat-conductive material. The heat-conductive element is placed on the circuit layer and covers the through holes, and the LED chip is disposed on the heat-conductive element and is electrically connected to the electric circuit layer.

Owner:AU OPTRONICS CORP

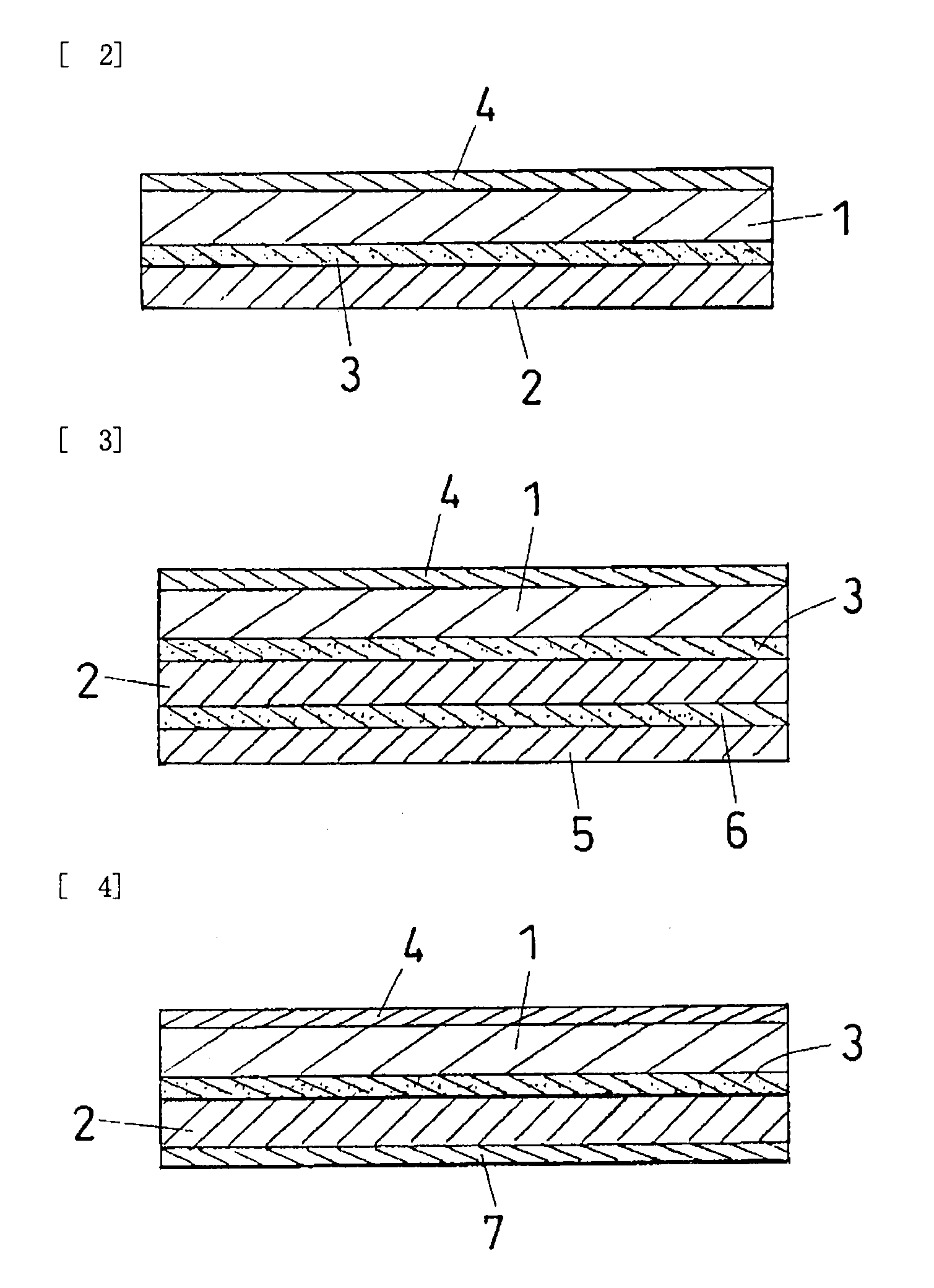

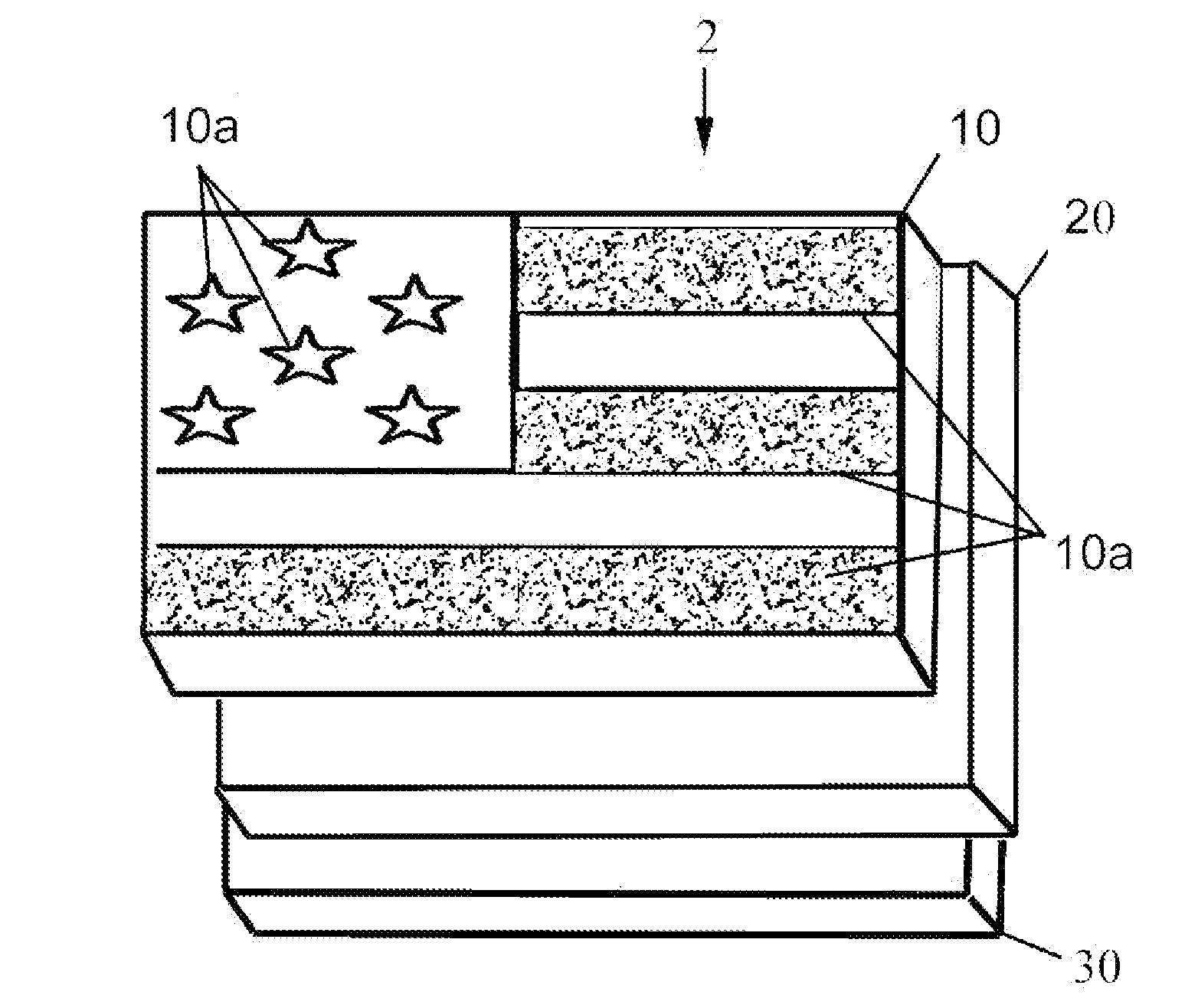

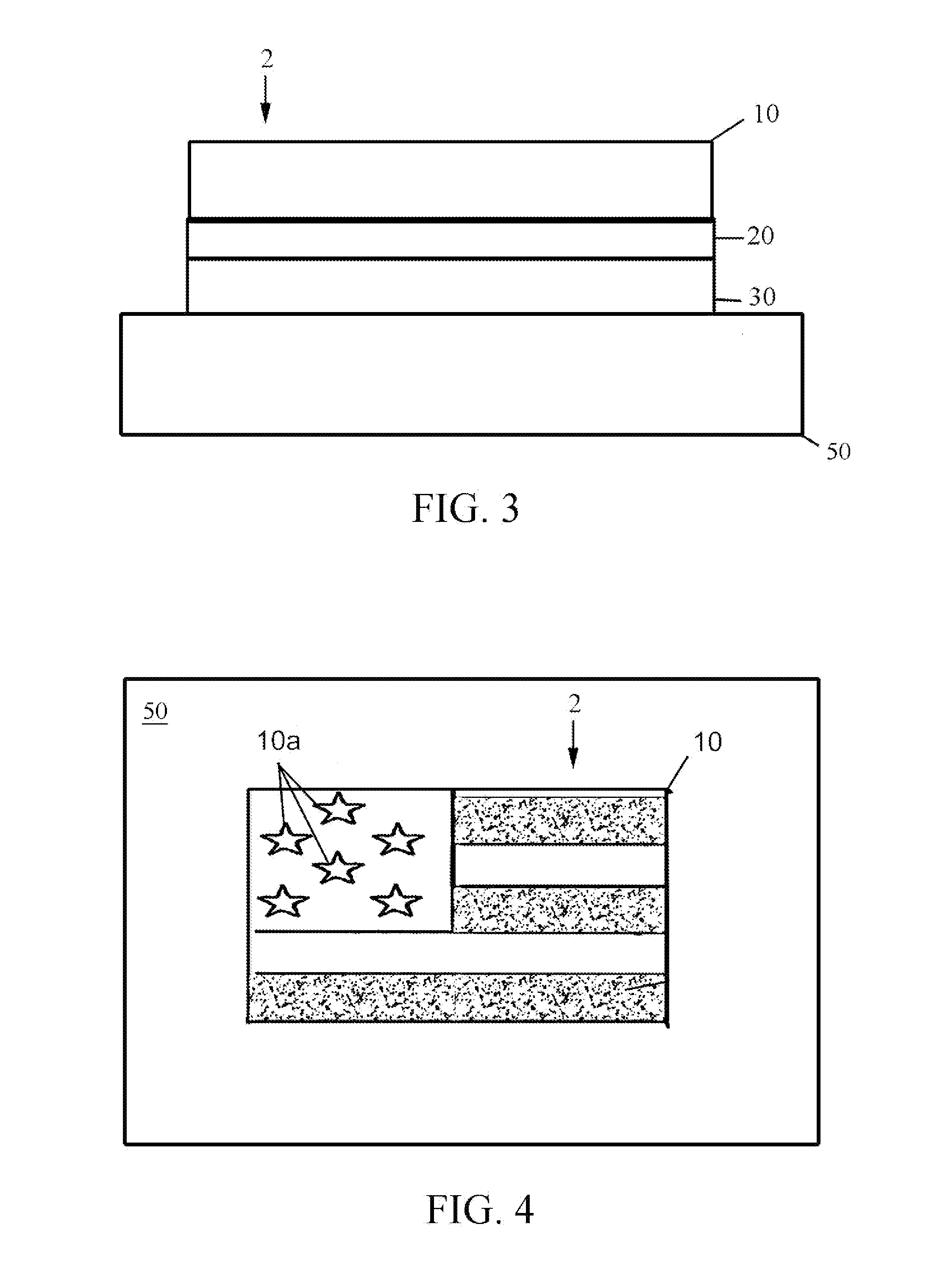

Laminate packing material for battery and laminate battery

ActiveUS20100040942A1Reduce in quantitySimplification of battery production lineSynthetic resin layered productsJackets/cases materialsMetallic foilThermal adhesive

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

Multiple power density chip structure

InactiveUS20060038281A1Reduce thermal resistanceImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesThin layerSemiconductor chip

A multiple power density packaging structure with two or more semiconductor chips on a common wiring substrate having a common thermal spreader with a planar surface in thermal contact with the non-active surfaces of the chips. The semiconductor chips have different cooling requirements and some of the chips are thinned to insure that the chips requiring the lowest thermal resistance has the thinnest layer of a thermal adhesive or metal or solder interface between the chip and thermal spreader.

Owner:GLOBALFOUNDRIES INC

High heat conduction metal foil layer/graphene metal mixed layer composite heat radiation film

InactiveCN106384730ASolve inefficiencyImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayMetal foil

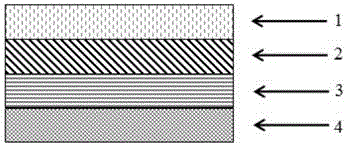

The invention relates to a high head conduction metal foil layer / graphene metal mixing layer composite heat radiation film. The high heat conduction metal foil layer / graphene metal mixed layer composite heat radiation film comprises a graphene metal mixed layer, a metal foil layer, a heat-conducting glue layer and a base layer; the metal foil layer is arranged between the graphene metal mixed layer and the heat-conducting glue layer; and the heat-conducting glue layer is arranged between the metal foil layer and the base layer. The high heat conduction metal foil layer / graphene metal mixing layer composite heat radiation film adopts graphene-and-metal-particle mixed slurry as a high heat-conducting layer, uses more effective heat conduction between the graphene and the metal particles, and provides a thermal interface having good heat radiation. The heat-conducting layer is adhered to the metal foil layer, the heat-conducting glue layer and the base layer to form a vertical heat-conducting effect, solves a problem that a traditional heat radiation product is low in efficiency, and can be widely applied to products having high heat productivity like an electronic device, a liquid crystal display screen, etc.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

Heat conducting adhesive tape and preparation method thereof

InactiveCN104087186AImprove uniformityImprove thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceMetal foil

The invention discloses a heat conducting adhesive tape and a preparation method thereof. The heat conducting adhesive tape adopts a metal foil as the substrate, the upper surface and the lower surface of the substrate are coated with a high performance heat conducting glue, and the outer layer of the heat conducting glue is release paper. The high performance heat conducting glue is composed of the following substances by weight part: 100 of an acrylic pressure-sensitive adhesive, 50-200 of a heat conducting filler, 0.1-1.5 of a coupling agent, 0.1-1.5 of a cross-linking agent, and 4-10 of a solvent. The preparation method includes the steps of pretreatment, glue preparation, coating, drying and the like. The heat conducting adhesive tape provided by the invention has the characteristics of good heat conducting uniformity, high heat conducting coefficient, high bonding strength, high temperature resistance and insulation, etc., and can be widely applied in bonding of LED, flexible circuit boards, microprocessors, printed circuit boards and the like with heat radiating devices.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Thermal lamination module

InactiveUS20060263570A1Improved thermal managementHeat dissipationSynthetic resin layered productsSolid-state devicesThermal adhesiveEngineering

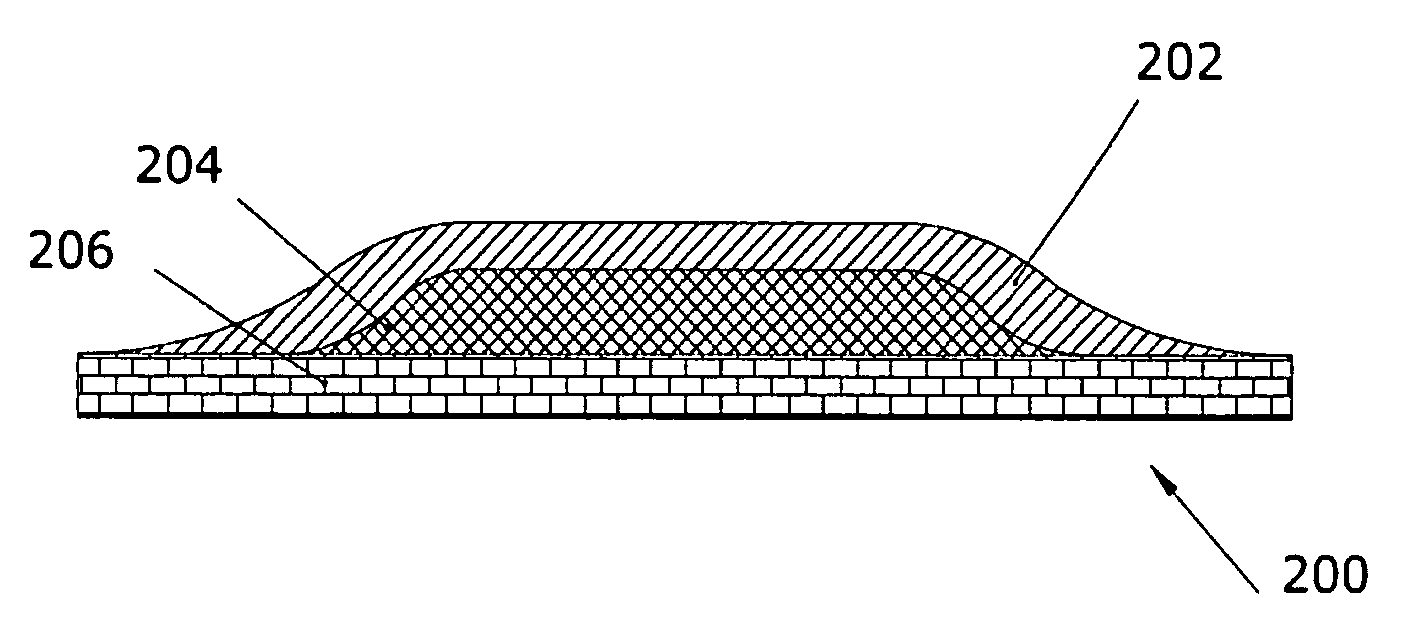

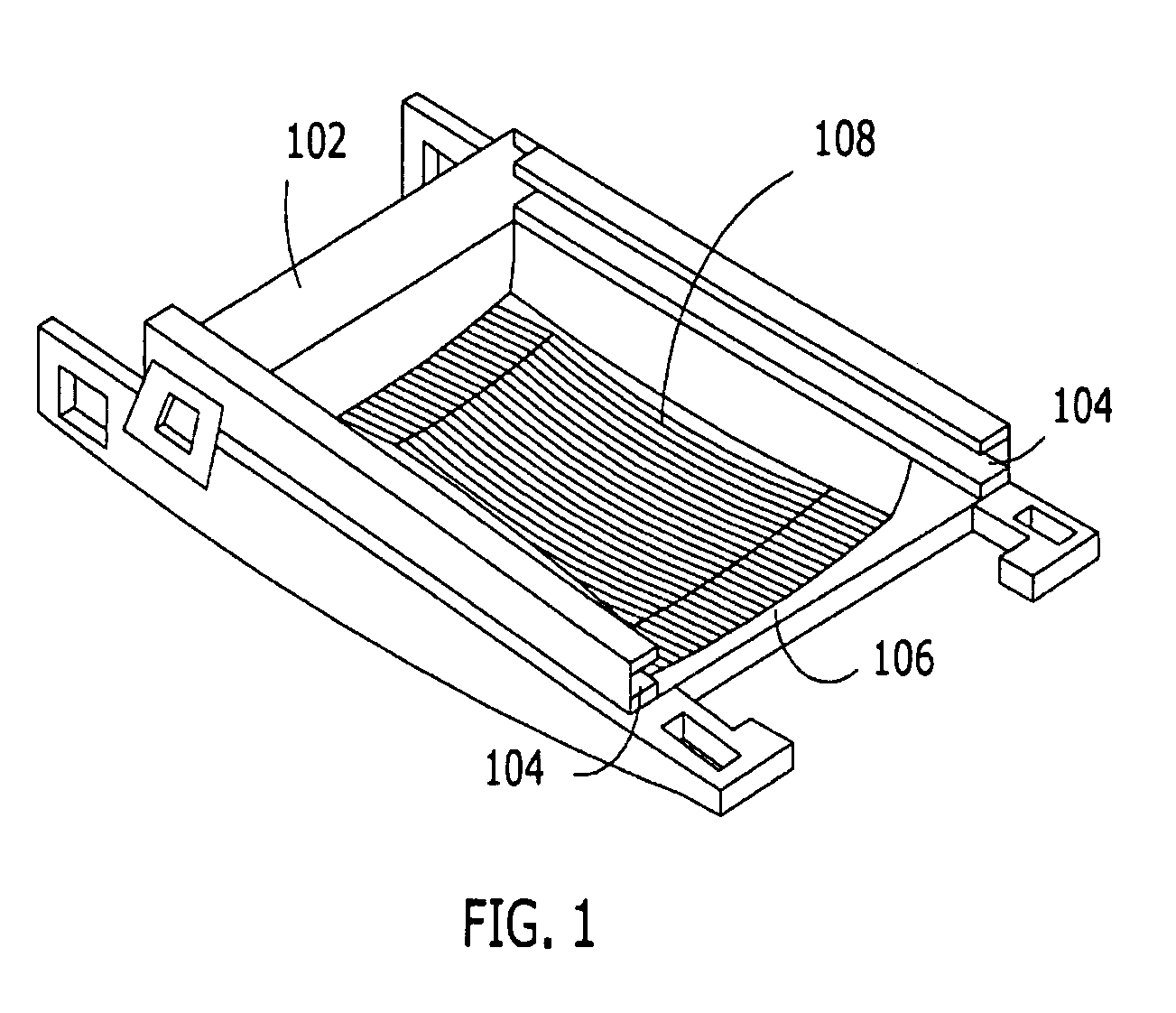

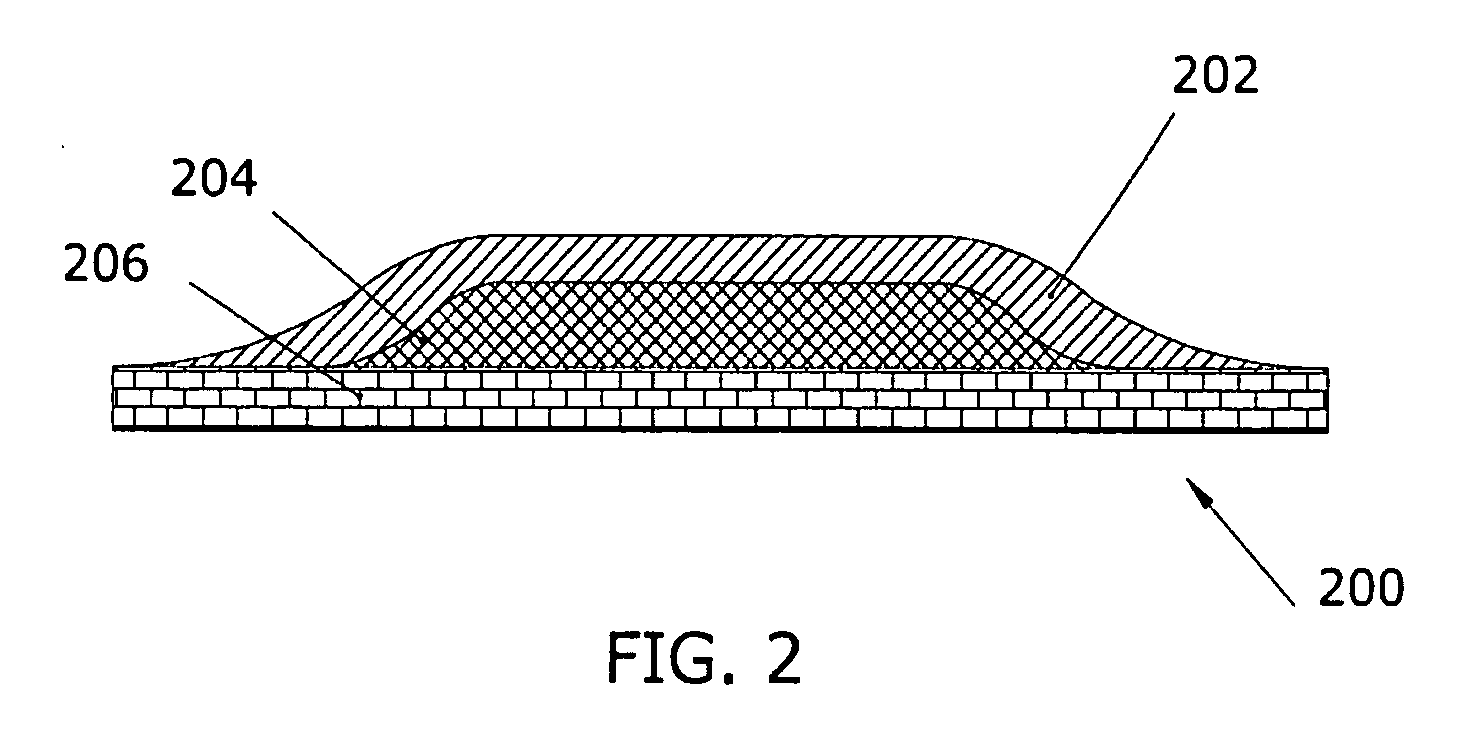

The present invention discloses a thermal laminate for the dissipation of heat generated in the vicinity of an installed PCMCIA card. The thermal laminate includes a top film layer, a middle gap filler layer and a bottom layer. The top film layer provides a protective, non-resistive, low friction surface with a soft conformal interface for enhancing the workability of the thermal laminate. The middle gap filler layer is disposed underneath the top film layer and provides a conformal thermal pathway for the heat radiation emitted from the installed PCMCIA card. The bottom layer is disposed underneath the middle gap filler layer and provides a grip to the middle gap filler layer and the top film layer. The bottom layer is made from either a thermal adhesive layer or a copper foil layer. The thermal laminate utilizes sliding contacts for proper housing between a PCMCIA card surface and a heat sink surface to provide better thermal management within an assembly.

Owner:PARKER HANNIFIN CORP

Preparation method of Al2O3/BN composite powder heat-conductive filler for heat-conductive adhesive

InactiveCN1970667AExtended service lifeImprove insulation performanceNon-macromolecular adhesive additivesPigment treatment with organosilicon compoundsEpoxyConductive polymer

The invention discloses a making method of Al2O3 / BN composite powder conductive fill of heat conductive adhesive, which comprises the following steps: (1) making BN clad nanometer alumina powder through gel-sol method; (2) grafting to modify the powder through multi-functional compound with isocyanic acid group. The invetnio is compatible with epoxide resin to bind and pack electronic device, which possesses excellent radiation effect.

Owner:SHANGHAI UNIV

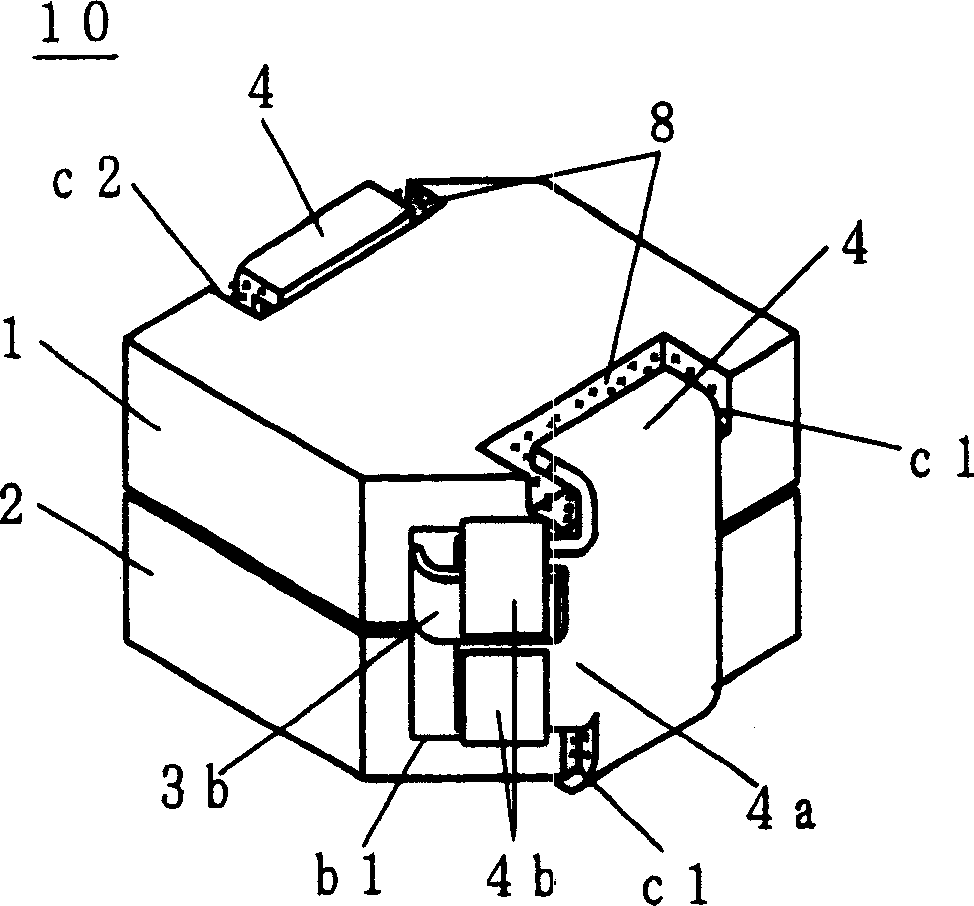

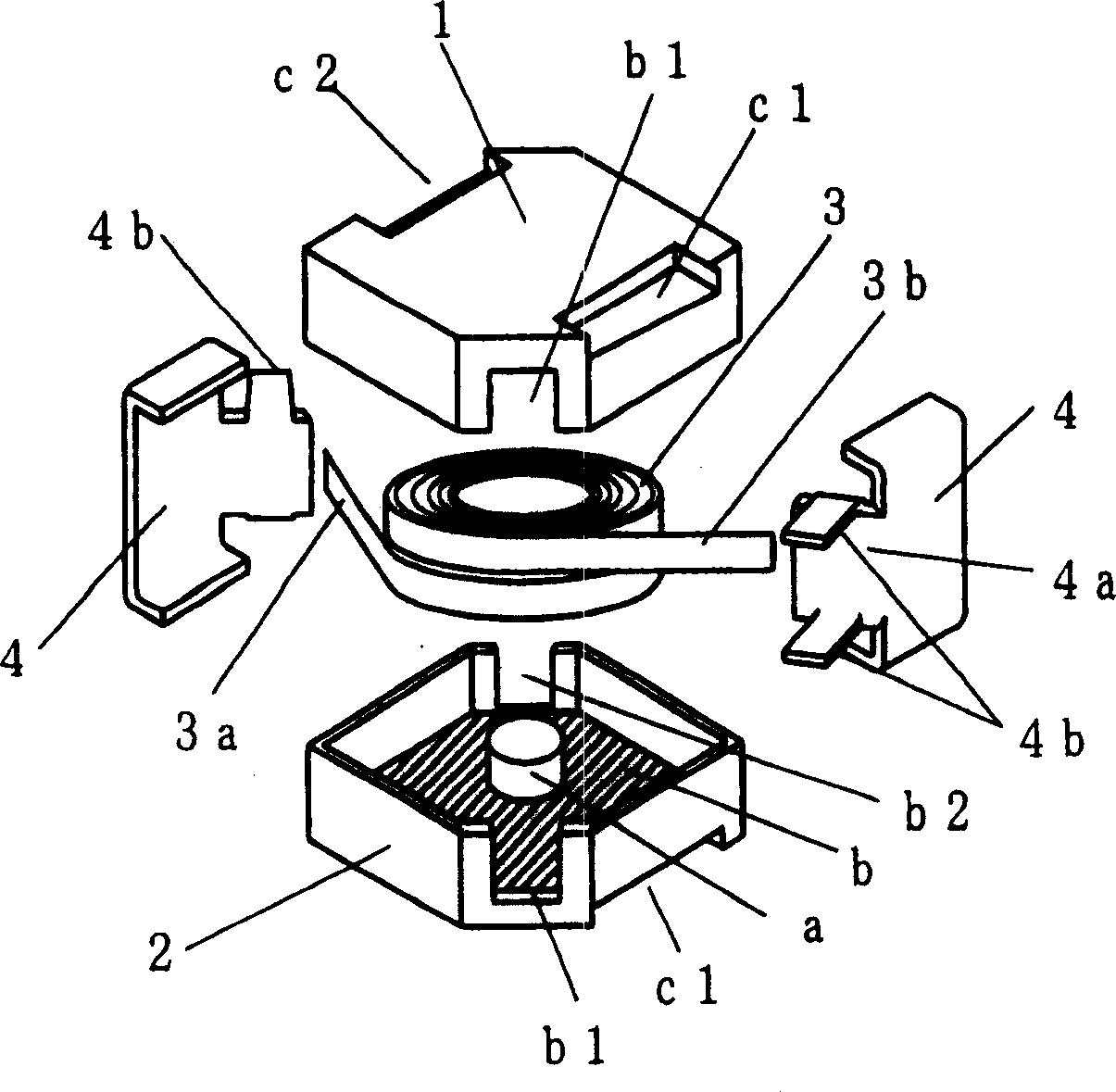

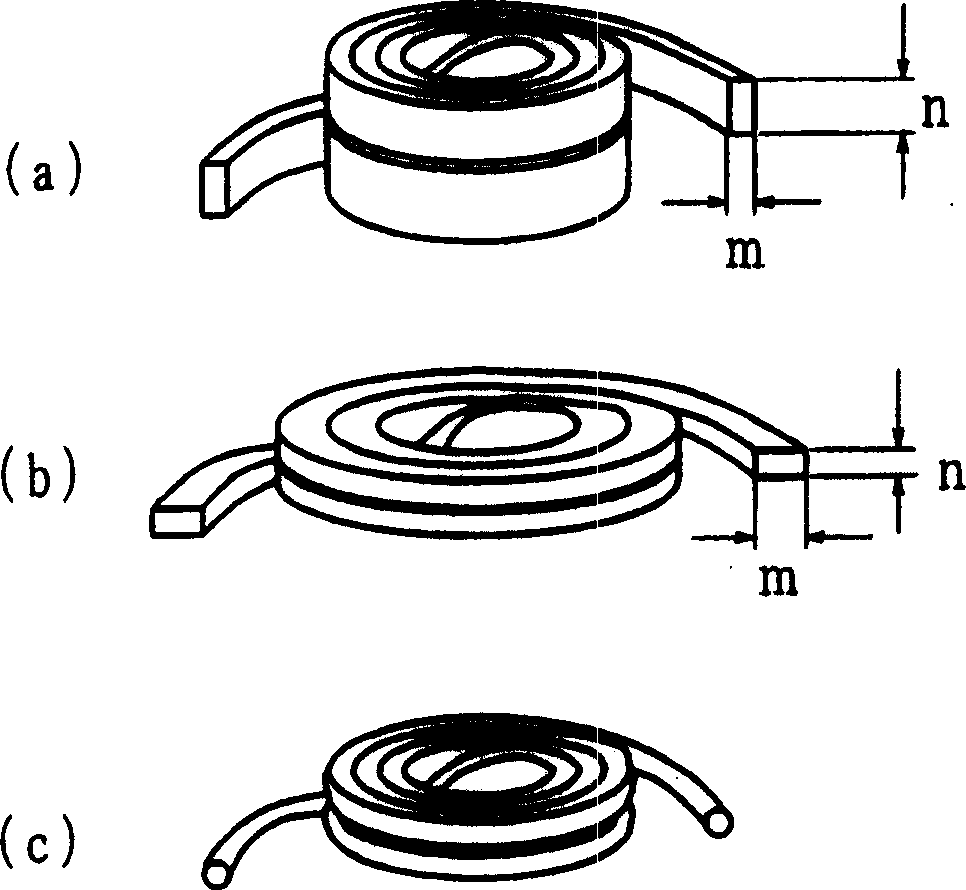

Surface mounted sensor

InactiveCN1619723ANo damageHigh drop impact resistanceTransformers/inductances coils/windings/connectionsInductance with magnetic coreBobbinSurface mounting

It is an object of the present invention to provide a surface mount type inductor in which a winding end can be joined to a connection electrode without bending, and the reliability of fixing the magnetic core can be improved. In a surface mount type inductor that accommodates two dimpled pot cores and an air core coil inside, the dimpled pot core has a core as a winding core inside, and the upper A pair of opposite end faces are provided with terminal engagement recesses, and a pair of opposite cutouts are provided at lower ends of the side faces. The air-core coil is wound by an insulated coated wire with a thermal adhesive layer on the surface. The winding initial end and the winding end end of the winding are drawn out to the outer circumference of the winding, which is a so-called α-coil coil. A connection terminal having a U-shaped cross-section and a terminal engaging recess that is configured to sandwich two pot-shaped magnetic cores with dimples combined together, and further has a terminal extending from the center of one end of the connection terminal. the connection part.

Owner:TOKO KABUSHIKI KAISHA

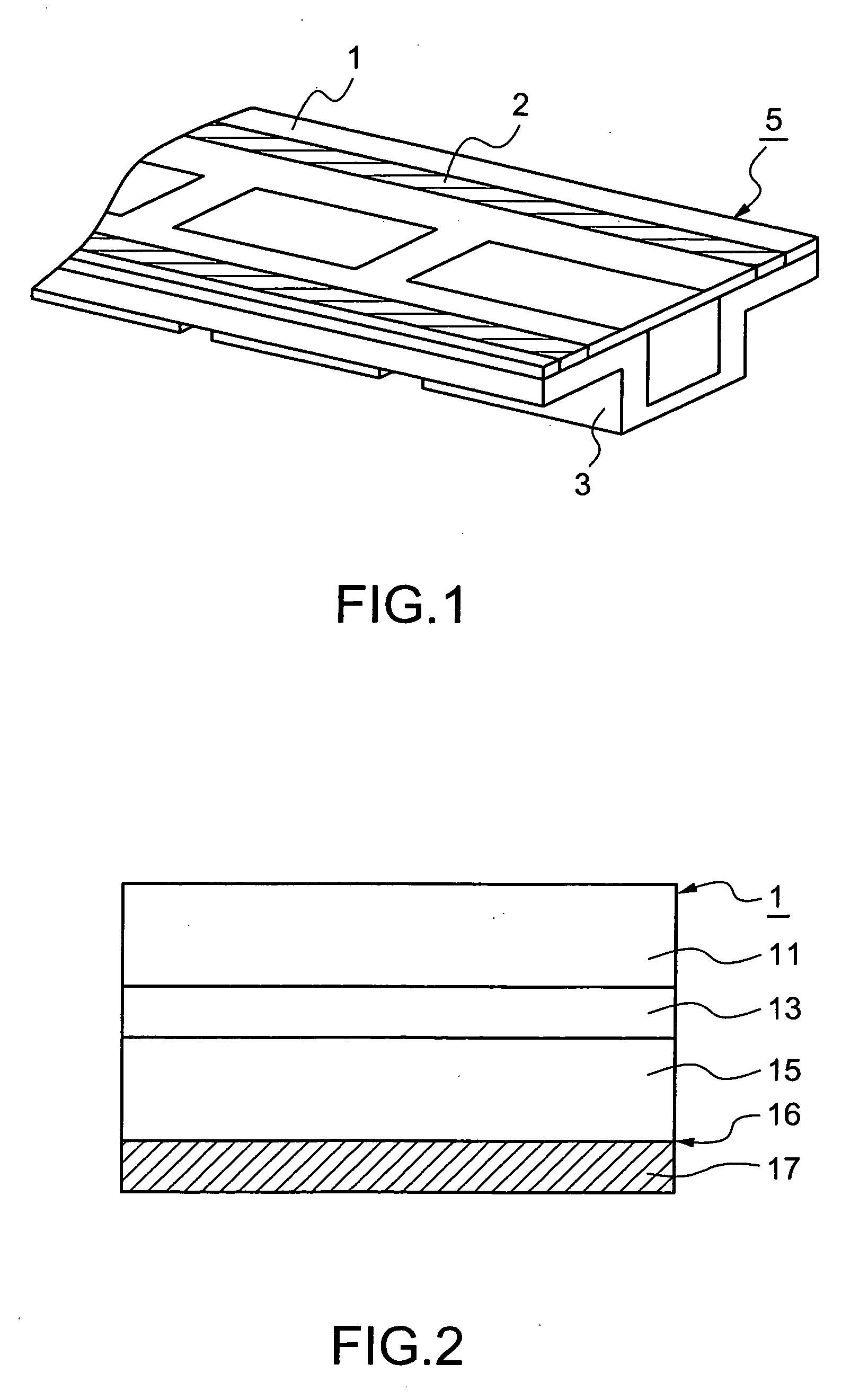

Textile embellishments that permanently bond to waterproof and/or waterproof-breathable fabrics

InactiveUS20110053450A1Excellent bonding compatibilityLaborious and time-consumingGarment special featuresDecorative surface effectsChemical LinkageSympaTex

A new product and process for producing an integrated textile embellishments such as patches, emblems, appliqués, labels and cut textile parts (including woven, knits and nonwoven structures made of both natural and or synthetic fibers) incorporating adhesives that permanently bond by heat-sealing to waterproof and / or waterproof-breathable fabrics including Gore-Tex®, Sympatex™ and other fabrics having durable water repellant finishes (DWR). This eliminates the tedious and cost intensive sewing operations previously needed to attach textile embellishments to such fabrics. The product and process includes a top layer decorative element, a second layer bonded to the top layer through lamination or chemical bonding to create a more uniform or smooth surface, and a thermal adhesive layer bonded to the second layer and capable of heat-application to textile based textile based products such as apparel and or accessories, headwear, outdoor furnishings and luggage. Products of this type can survive multiple washes and are desired by manufactures for their ease of application, saving time, money and reducing complexity in the application process

Owner:BAQAI NAVAID +1

Electronic part taping packaging cover tape

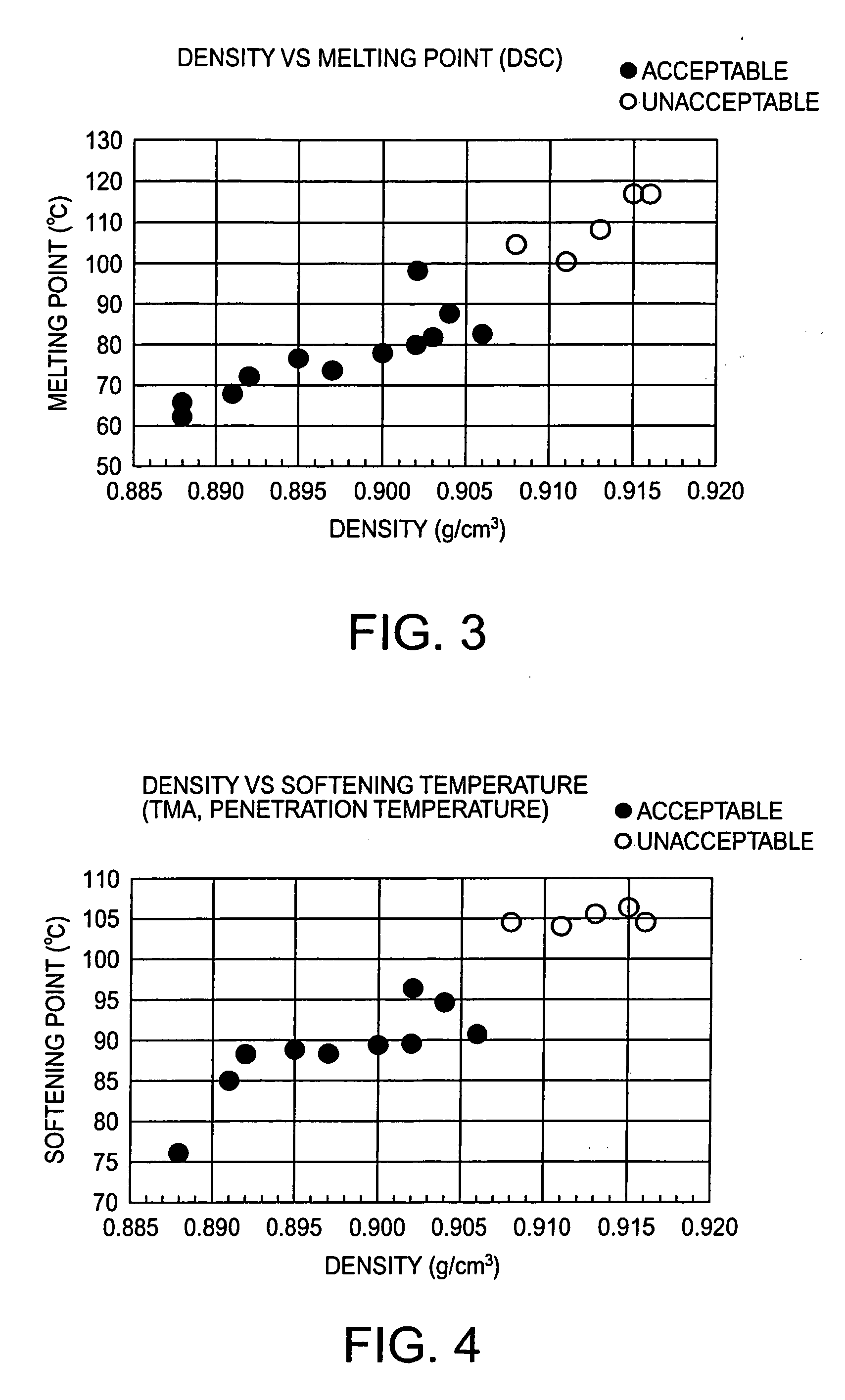

InactiveUS20060199005A1Stable heat-sealing propertySatisfactory propertyFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The present invention relates to a cover tape for tape packaging electronic components that heat-seals a carrier tape accommodating therein electronic components. A cover tape for tape packaging electronic components according to the present invention includes a substrate film layer, a soft material layer, and a thermal adhesive layer. The soft material layer is formed of metallocene linear low-density polyethylene having a specific gravity in a range of from 0.888 to 0.907.

Owner:DAI NIPPON PRINTING CO LTD

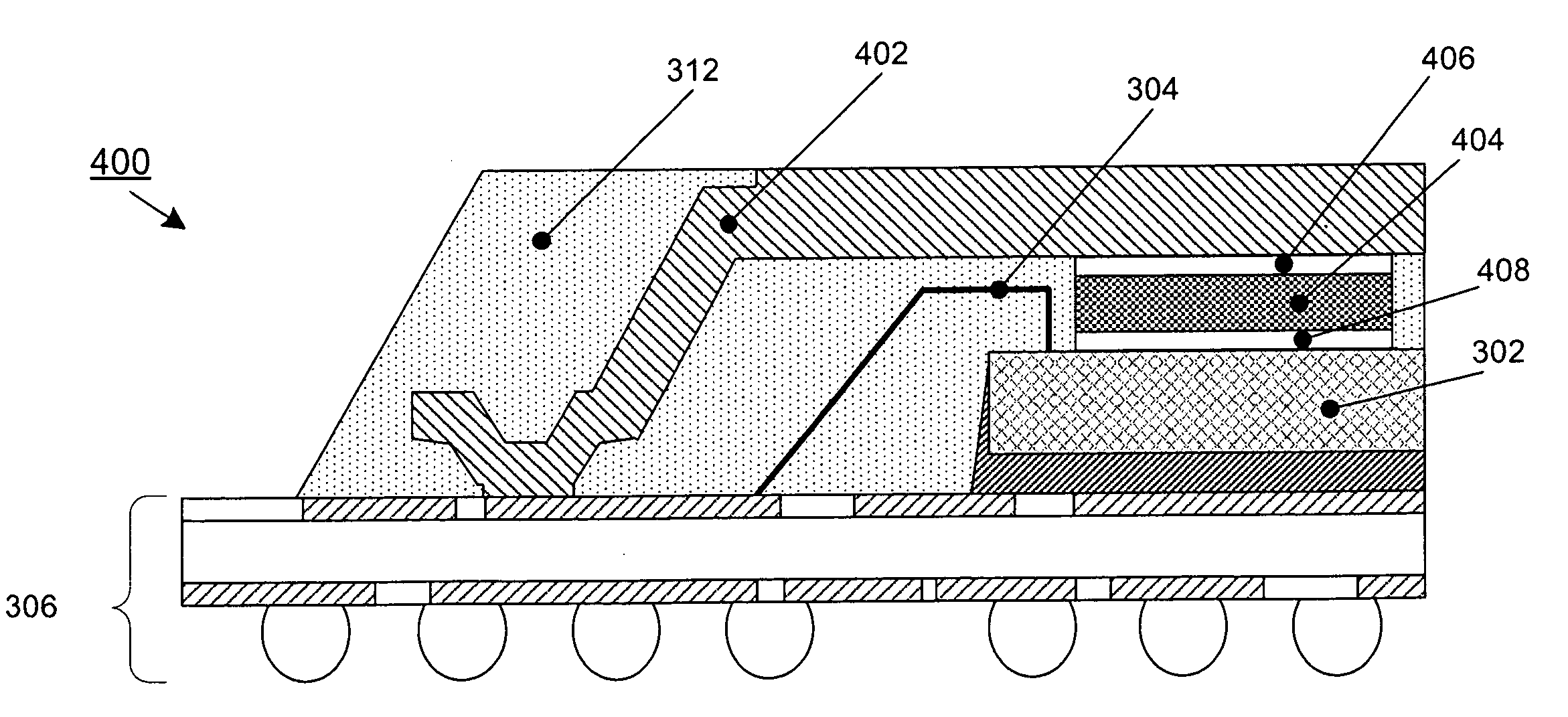

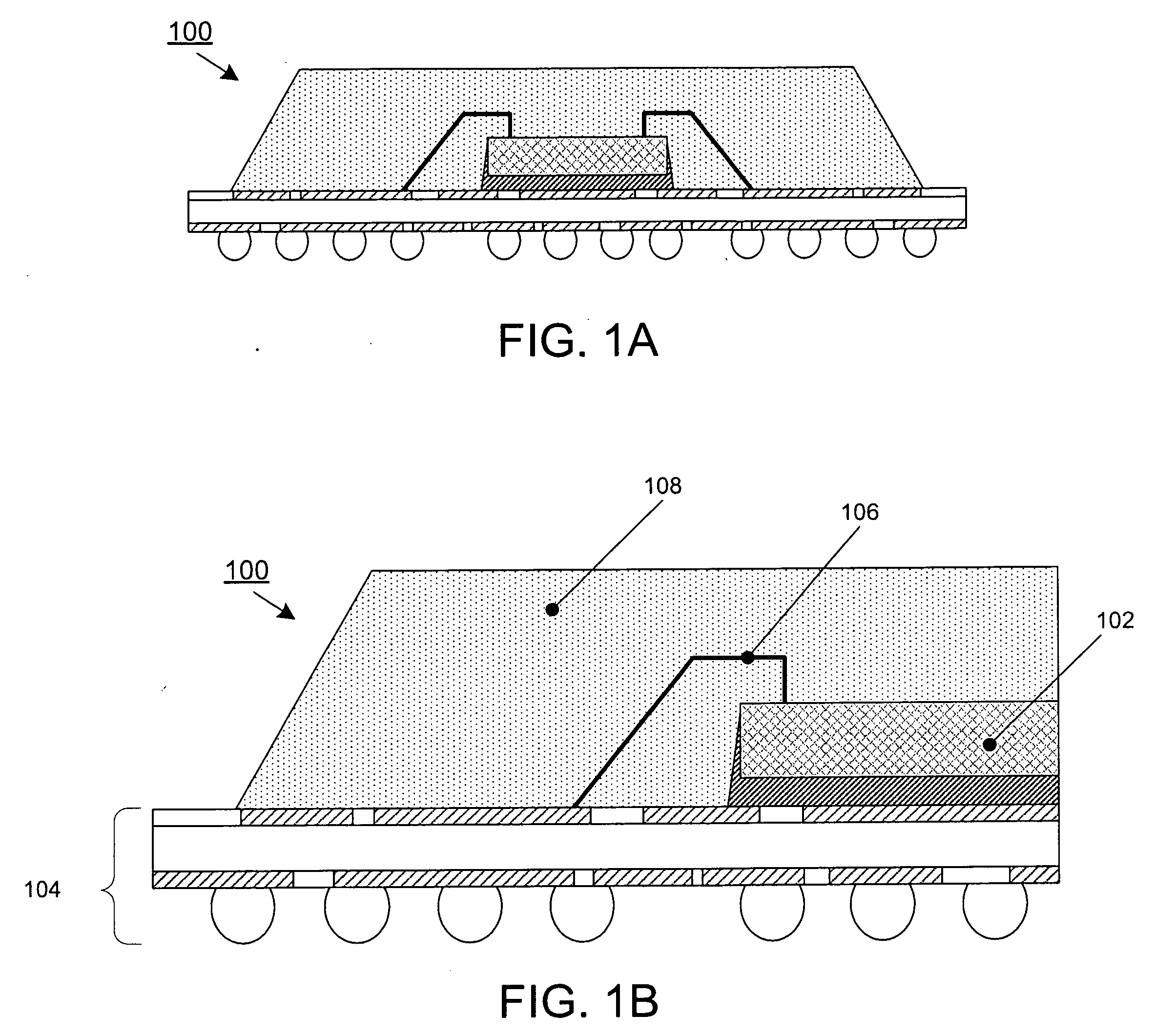

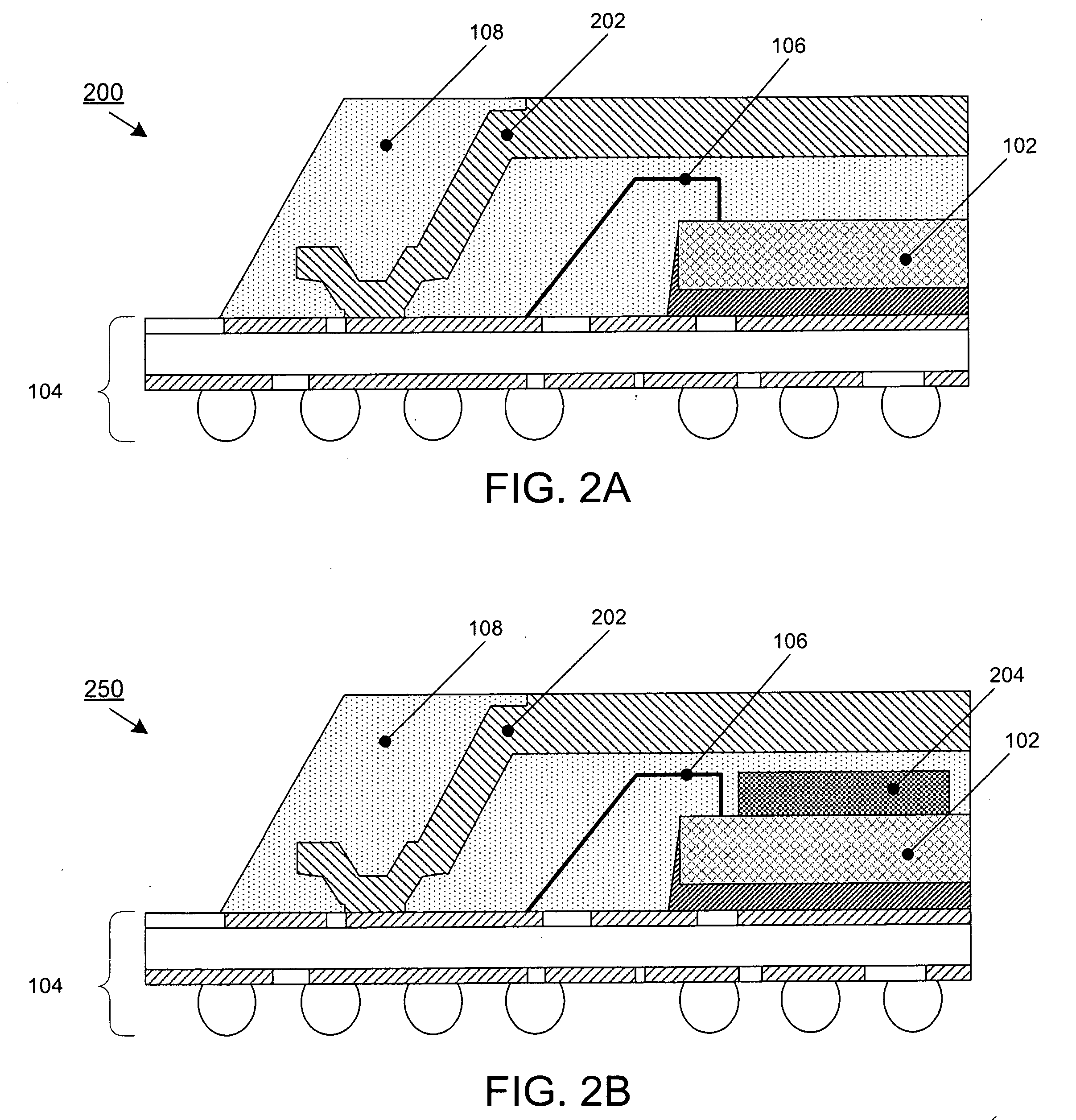

Enhanced Thermal Dissipation Ball Grid Array Package

ActiveUS20090243086A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

In a semiconductor chip, a thermal adhesive is used to bond an internal heat spreader to an active functional die. In an alternative embodiment a dummy die is place directly on top of the active functional die and a thermal adhesive is used to bond an internal heat spreader to the dummy die. This provides a direct and relatively low thermal conductivity path from the heat source, i.e., the functional device to the top of the package, that is, the internal metal heat spreader which is also exposed to the air.

Owner:SYNAPTICS INC

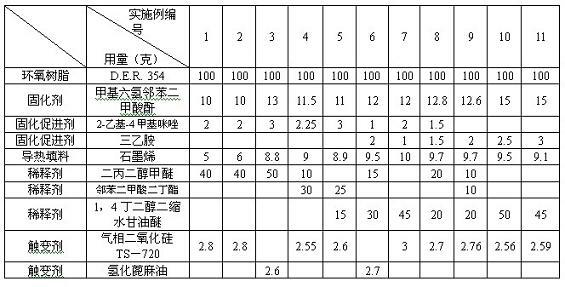

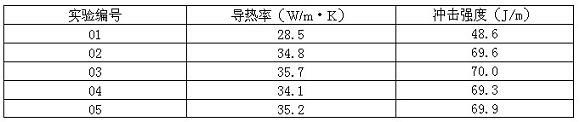

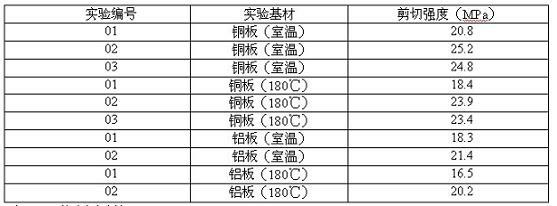

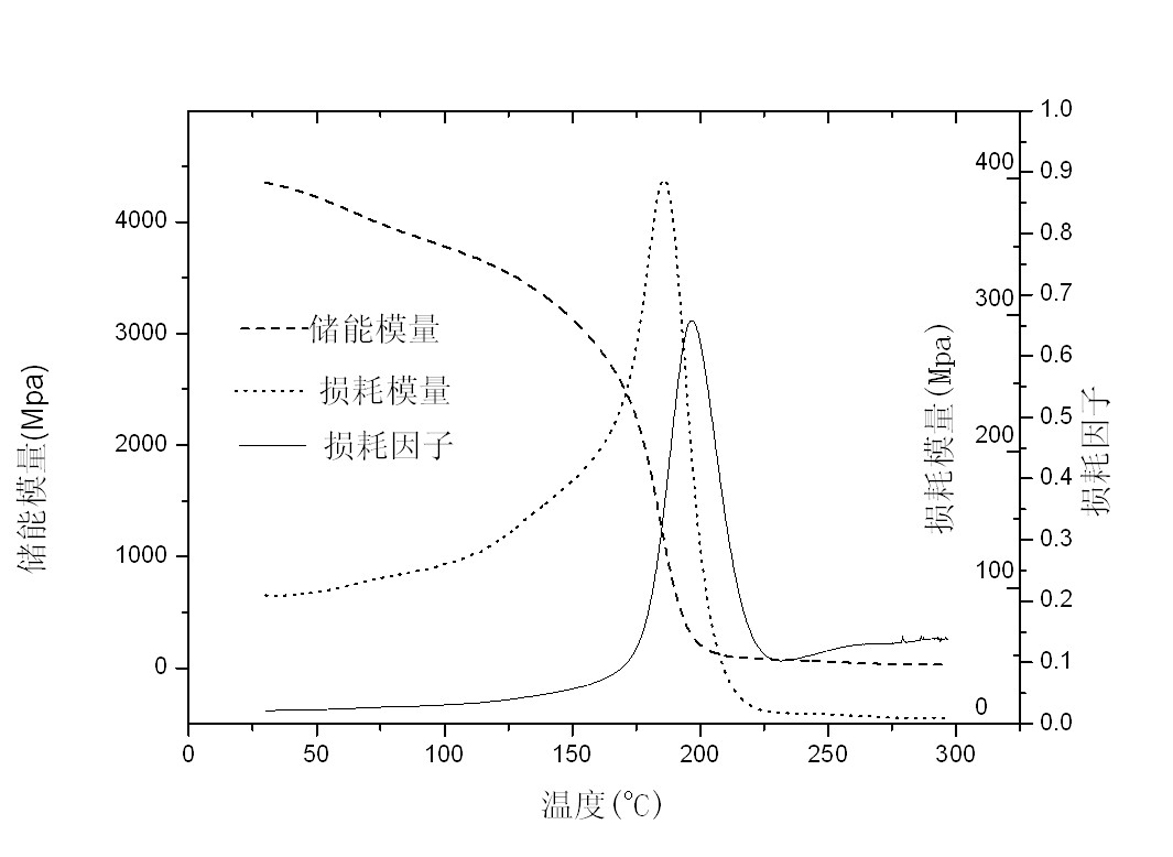

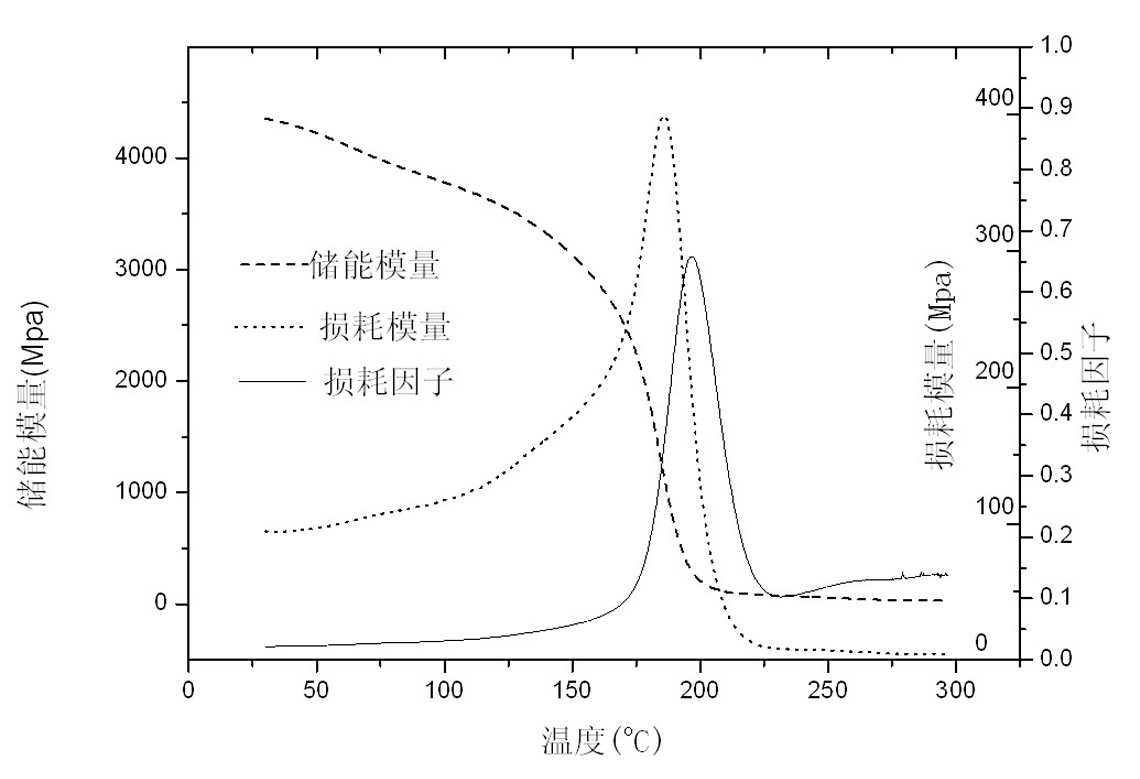

High-temperature-resistant and high thermal conductive adhesive and preparation method thereof

ActiveCN102020963AReduce bond strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention provides a high-temperature-resistant and high thermal conductive adhesive, which mainly comprises epoxy resins, curing agents, curing accelerators and high thermal conductive packing; the adhesive simultaneously has the performances of high temperature resistance and high thermal conductivity, and has an obvious cost advantage. The invention also provides a method for preparing thehigh-temperature-resistant and high thermal conductive adhesive, which comprises the following steps: uniformly dispersing the curing agents and the curing accelerators into the epoxy resins; then mixing the obtained mixture with the high thermal conductive packing; and uniformly grinding the obtained product by a grinding machine. Through the method provided by the invention, the high-temperature-resistant and high thermal conductive pasty adhesive can be obtained. Test results show that the glass transition temperature of the cured high-temperature-resistant and high thermal conductive adhesive is higher than 150 DEG C; the bond strength can be more than 16Mpa, and after the adhesive is roasted at a temperature of 260 DEG C, the bond strength is down by no less than 5 percent; and the coefficient of heat conductivity can reach 4.0 W / m.K.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

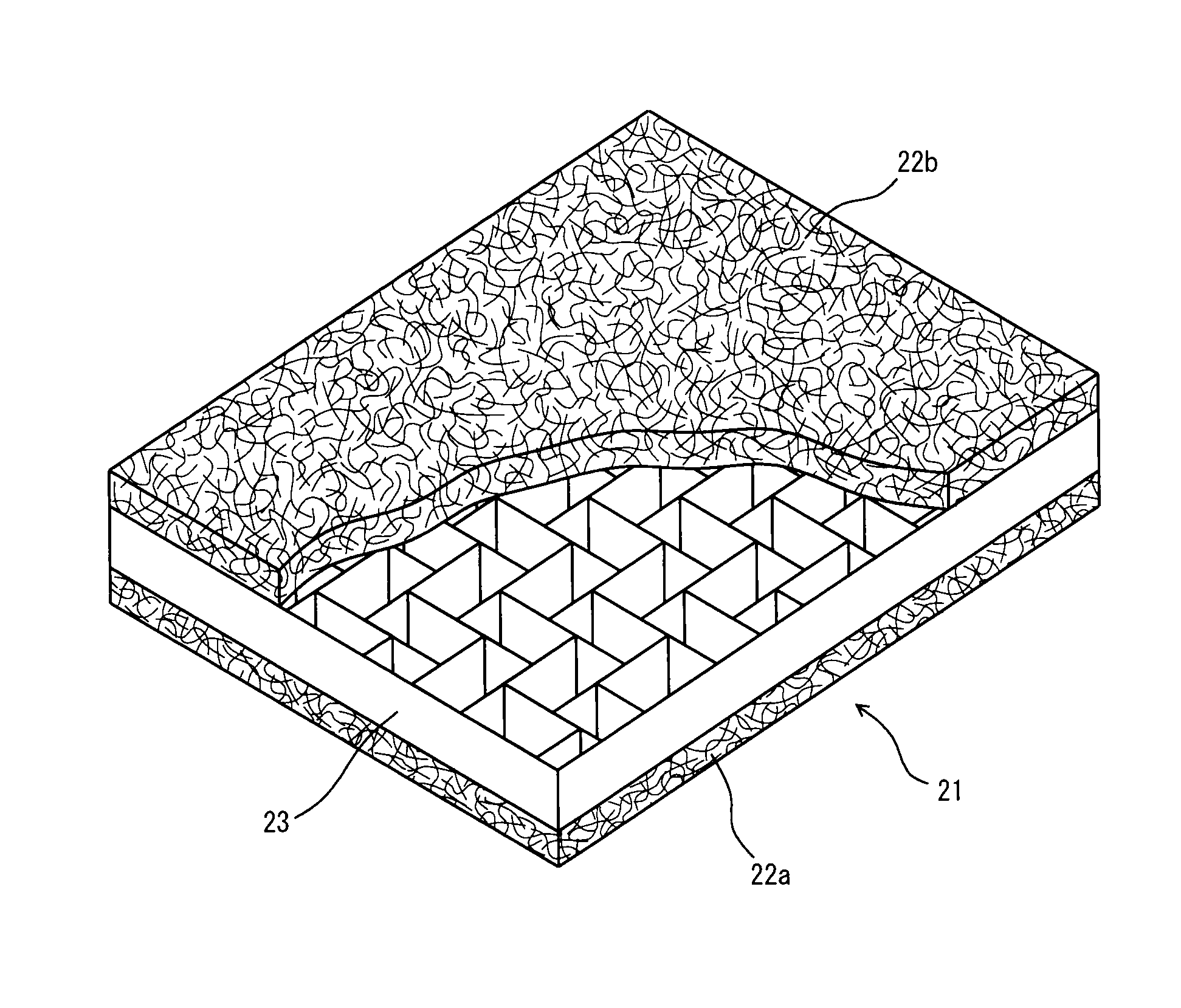

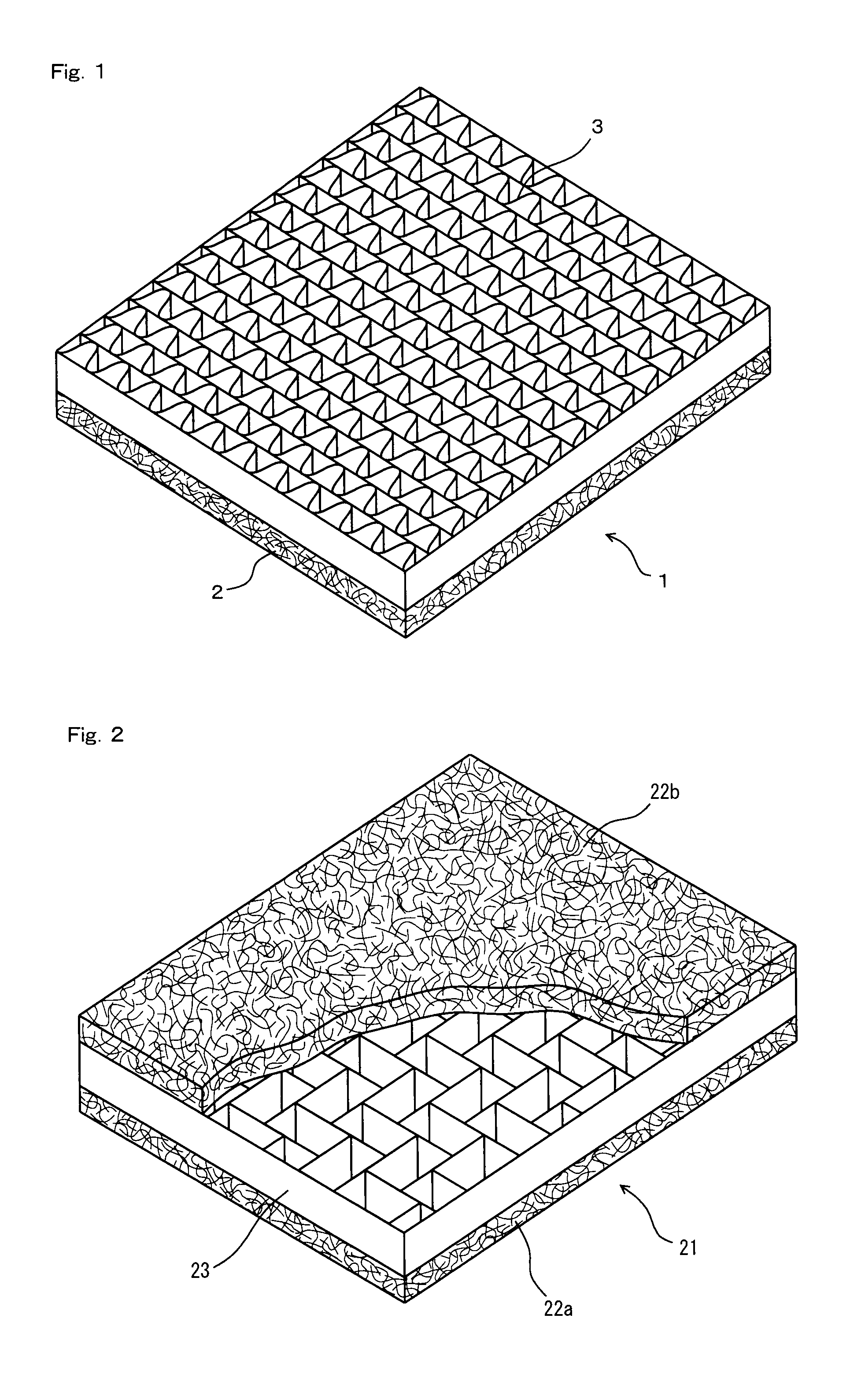

Soundproof panel and soundproof structure

A soundproof panel comprising a nonwoven structural member and a board member is prepared. The nonwoven structural member comprises a thermal adhesive fiber under moisture which is melt-bonded to a fiber of the structural member to fix the fibers. The soundproof panel may be a soundproof panel 1 comprising a nonwoven structural member 2 and a honeycomb member 3 stacked thereto. Moreover, the soundproof panel may be a soundproof panel comprising a board-like nonwoven structural member and first and second surface members stacked to first and second sides of the board-like nonwoven structural member, respectively. Further, the soundproof panel may be a soundproof panel having first and second surface members stacked through a square-pole rail member comprising a nonwoven structural member. The soundproof panel of the present invention has toughness for the lightweight design and has excellent sound absorption and sound insulation properties.

Owner:KURARAY CO LTD

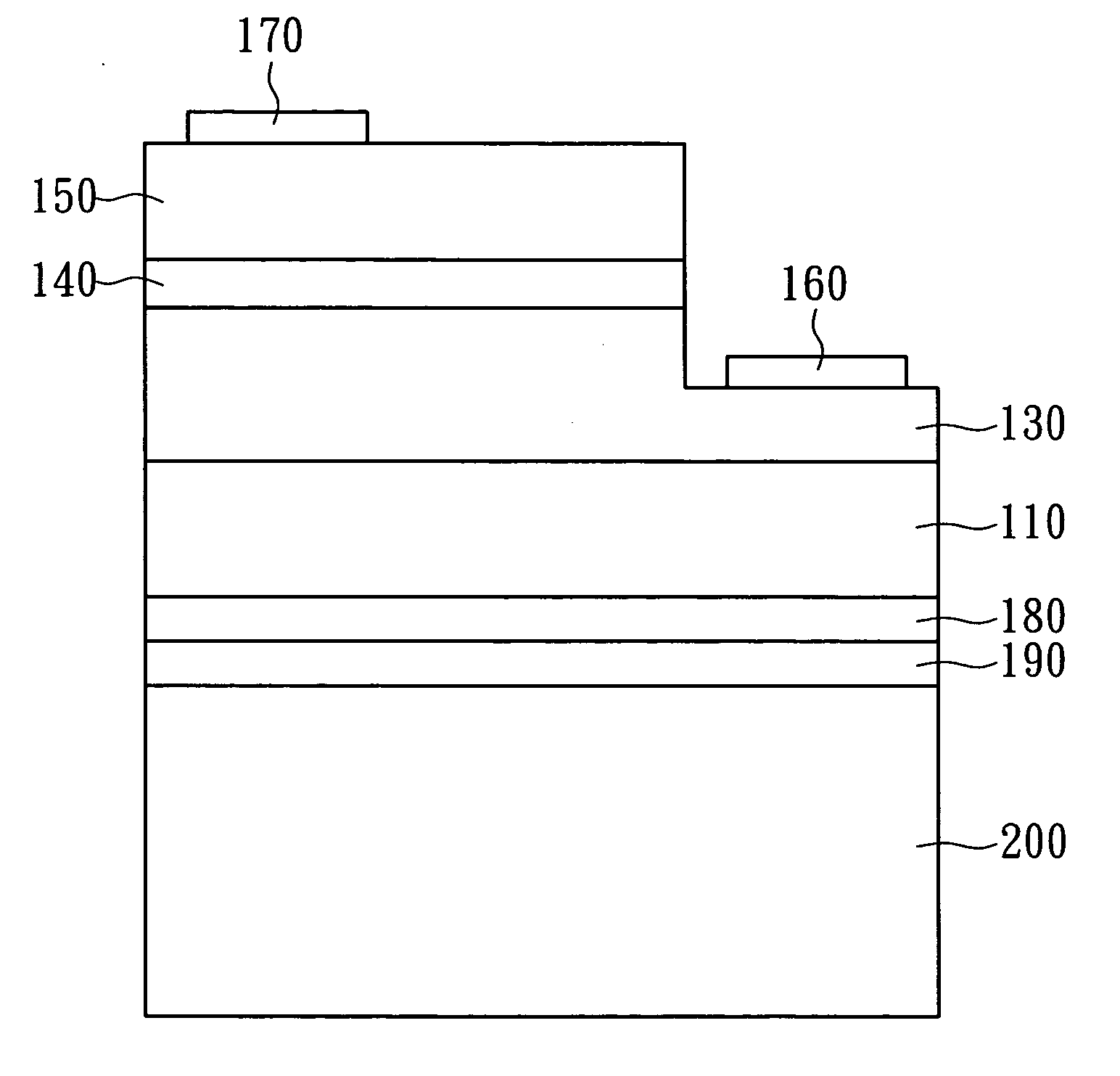

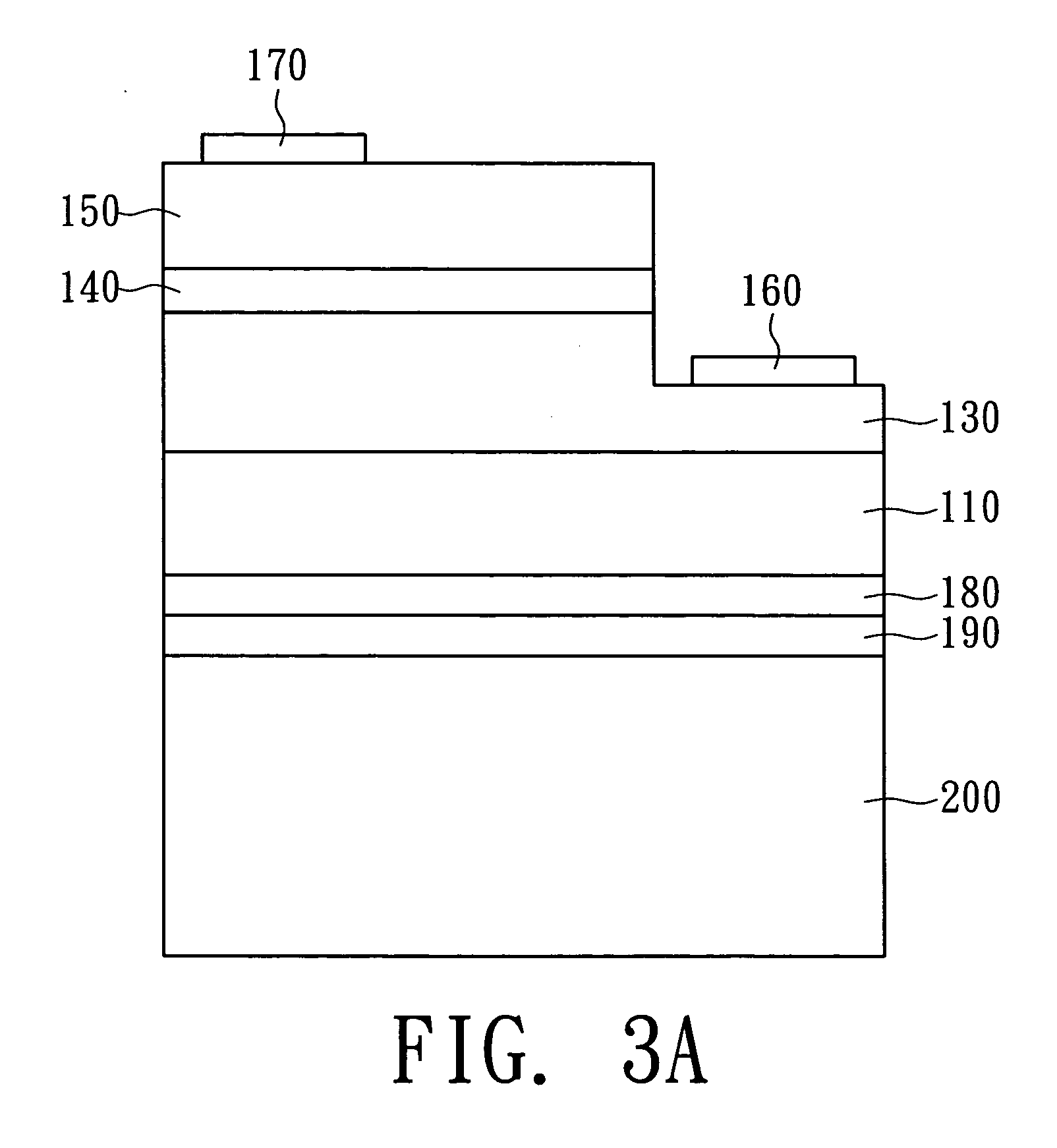

Light emitting diode and method of making the same

InactiveUS20050274971A1Reduce heat resistance requirementsReduce thicknessSolid-state devicesSemiconductor devicesThermal adhesiveReflective layer

A light emitting diode (LED) and a method of making the same are disclosed. The present invention is featured in that the LED comprises a transparent heat-conductive glue, a reflective layer, and a carrier, etc, wherein the transparent heat-conductive glue is used to adhere the epitaxial structure and the carrier of the LED; the reflective layer can make the light emitted by the epitaxial structure to be reflected more efficiently; and the carrier is used to enhance the heat-dissipation effect of the LED. Moreover, the transparent heat-conductive glue and the reflective layer can be replaced with one single adhesive reflective layer having functions of adhesion and reflection simultaneously.

Owner:EPISTAR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com