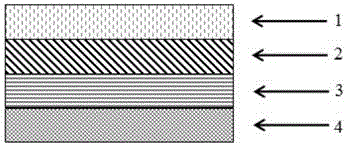

High heat conduction metal foil layer/graphene metal mixed layer composite heat radiation film

A technology of metal foil layer and heat dissipation film, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of heavy weight, high price, easy oxidation, etc., achieve excellent heat dissipation performance, solve The effect of inefficient, efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for manufacturing a high thermal conductivity metal foil layer / graphene metal mixed layer composite heat dissipation film, the specific steps are as follows:

[0039] (1) Preparation: high-quality graphene, copper metal particles (particle size: 15μm), polyurethane, copper foil with uniform thickness (thickness: 25μm, thermal conductivity not less than 300W / mk), thermal silica gel (thickness: 15μm, thermal conductivity: Less than 2W / mk, peel strength not less than 10N / cm), release film (thickness 30μm);

[0040] (2) Preparation of graphene and metal particle mixed slurry: graphene and copper particle mass example is 8:1, obtains the mixture that does not have adhesion performance; Then add appropriate amount of polyurethane to increase slurry viscosity, polyurethane and previously prepared mixture quality The ratio is 1:5;

[0041] (3) using a coating machine, the graphene and copper particle mixed slurry described in step (2) is evenly coated on one side of t...

Embodiment 2

[0047] A method for manufacturing a high thermal conductivity metal foil layer / graphene metal mixed layer composite heat dissipation film, the specific steps are as follows:

[0048] (1) Preparation: high-quality graphene, aluminum metal particles (particle size: 10 μm), polyurethane, uniform thickness copper foil (thickness 35 μm, thermal conductivity not less than 300W / mk), heat-conducting pressure-sensitive adhesive (thickness 25 μm, thermal conductivity Coefficient not less than 2W / mk, peel strength not less than 10N / cm), polyester film (thickness 30μm);

[0049] (2) Prepare graphene and metal particle mixed slurry: graphene and aluminum particle mass example is 6:1, obtains the mixture that does not have adhesion performance; Then add appropriate amount of polyurethane to increase slurry viscosity, polyurethane and previously prepared mixture quality The ratio is 1:5;

[0050] (3) Using a coating machine, the graphene and aluminum particle mixed slurry described in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com