Multi-station automatic sampling inspection and production returning method based on AGV

A multi-station, automatic technology, applied in the direction of comprehensive factory control, comprehensive factory control, electric/hybrid power, etc., can solve the problem of unfavorable workpiece detection result information statistics, induction, fault tracking is difficult, can not guarantee the efficiency of sampling and re-production and other problems, to achieve the effect of stabilizing sampling inspection and re-production efficiency, improving quality control level, and realizing fully intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and modifications without departing from the concept of the present invention.

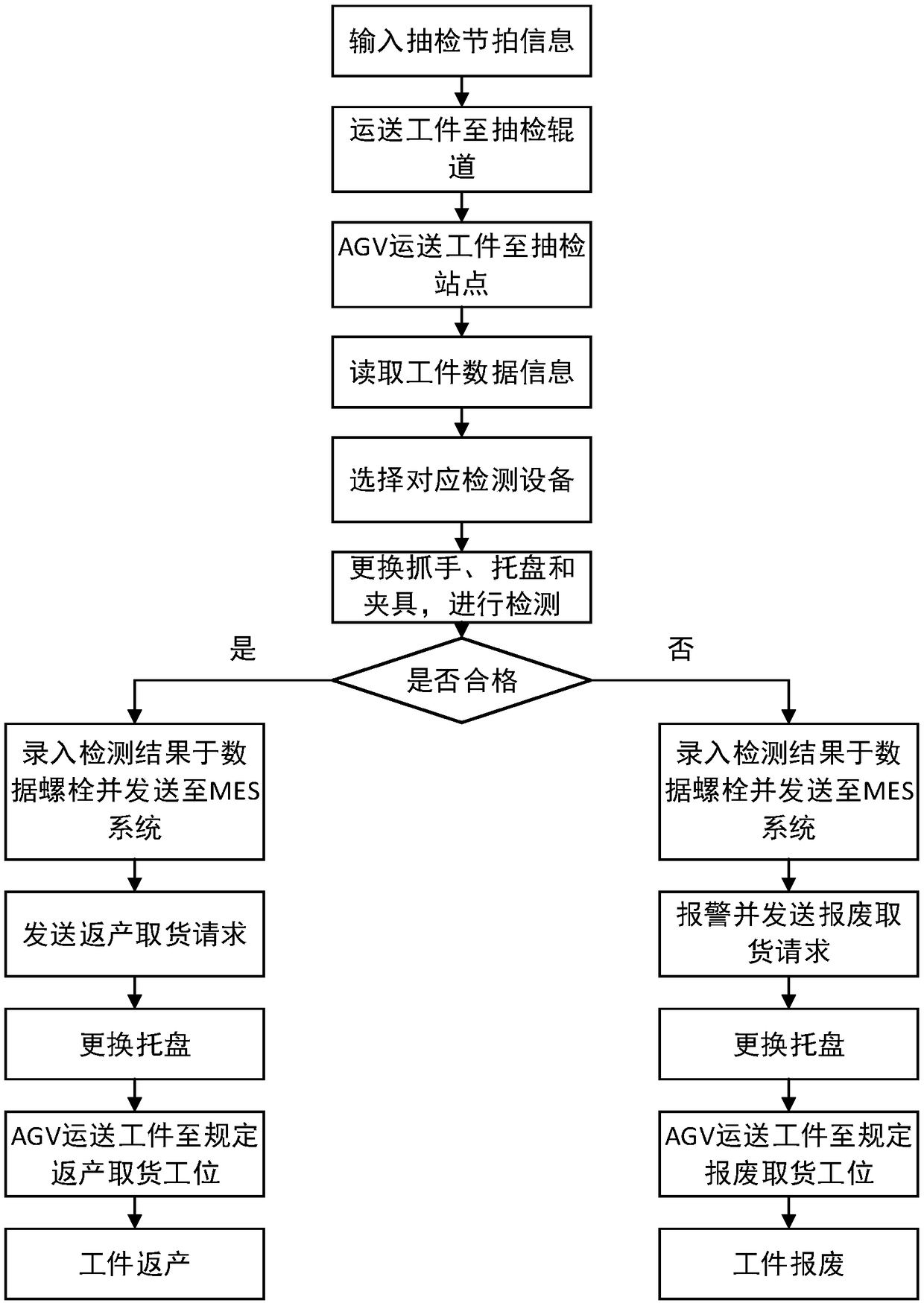

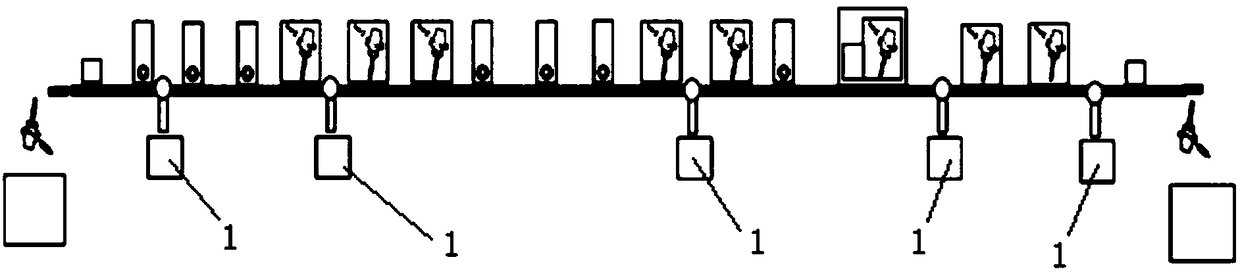

[0043] The method adopted by the present invention to solve the technical problem is an AGV-based multi-station automatic sampling inspection and production return scheme. This solution belongs to the field of equipment production, and is especially suitable for automotive powertrain production lines with production cycle requirements, including manufacturing enterprise production process execution system (MES system), logistics handling / transmission system, AGV, information data module, multi-axis robot, Sampling inspection device, pallet, gripper library, fixture lib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com