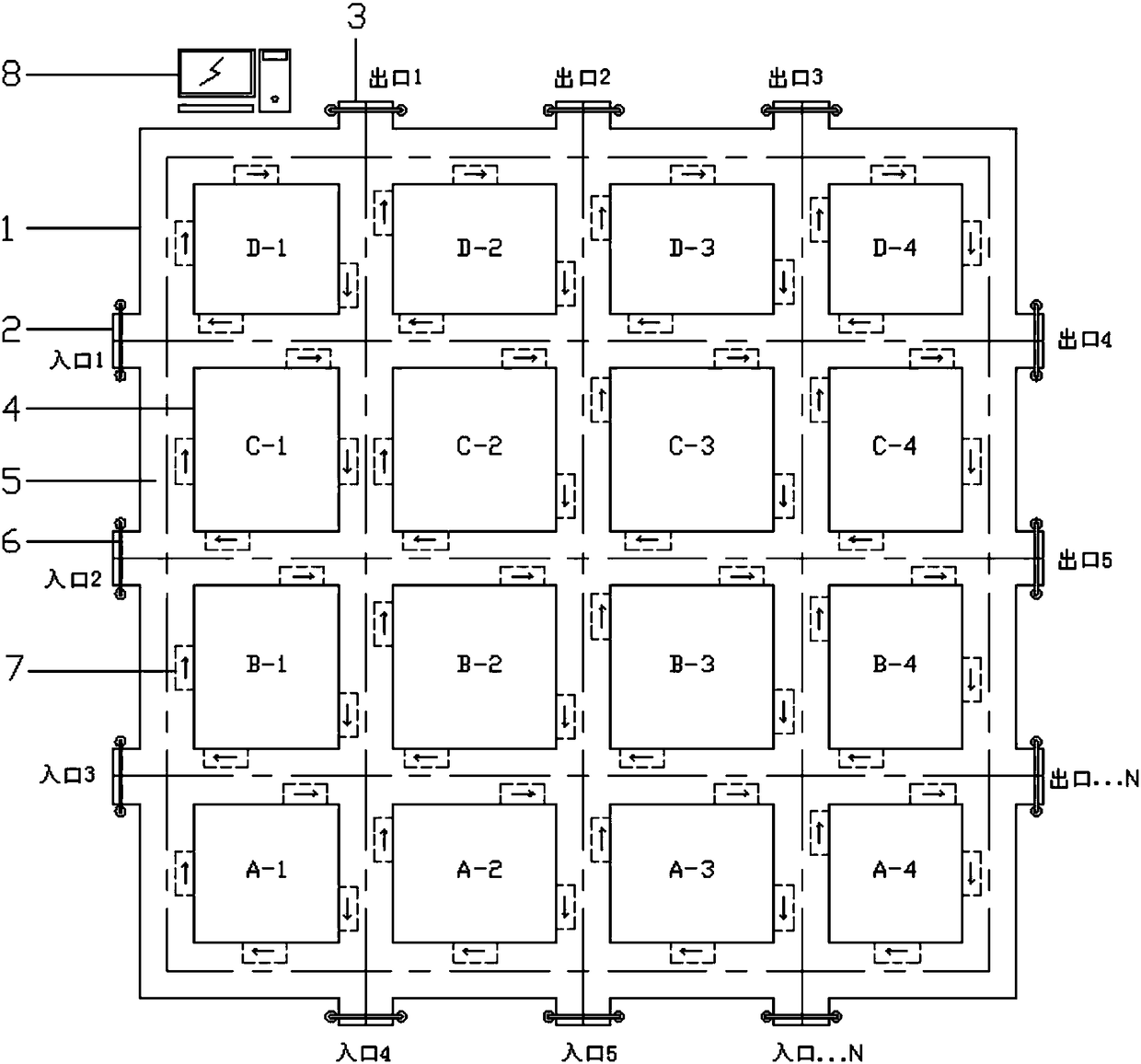

Digital factory logistics warehouse

A warehouse and logistics technology, applied in the field of freight transportation, can solve the problems of inconvenient viewing, inability to realize remote monitoring and management of warehouses, and inability to realize intelligent warehouse management system, so as to improve the market competitiveness of enterprises, realize automatic management, and realize batch management. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0033] Warehouse Clerk:

[0034]The warehousing clerk sends the vehicle carrier information and cargo information to the warehouse server in advance, and the warehouse server controls and specifies the corresponding digitally coded warehouse in real time according to the cargo status identified by the inventory status recognition device of the digitally coded warehouse 4, and sends the warehouse The digital code or location of the warehouse is sent to the warehousing clerk. When the warehousing clerk arrives at the entrance of the designated digital coded warehouse, the barcode recognition device installed at the entrance will identify the vehicle information through the barcode scanning device of the vehicle. At the same time, The vehicle identification device and the order identification device collect and identify vehicle information, vehicle carrier information, and cargo information. When the identified information is consistent with the information reserved by the warehou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com