Patents

Literature

1167results about How to "Realize automatic delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

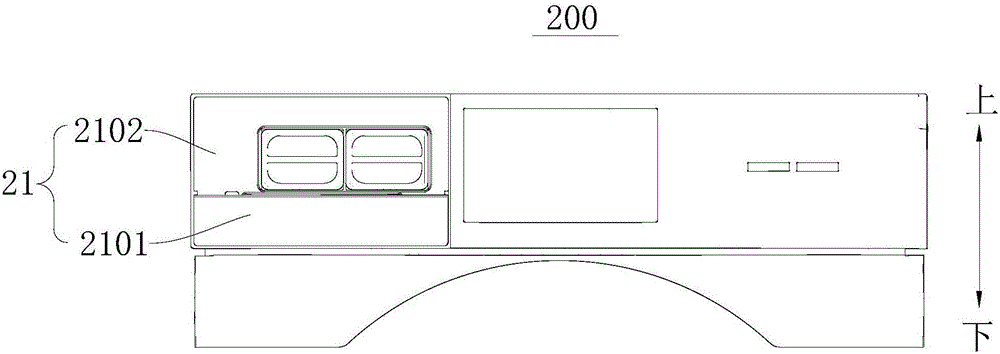

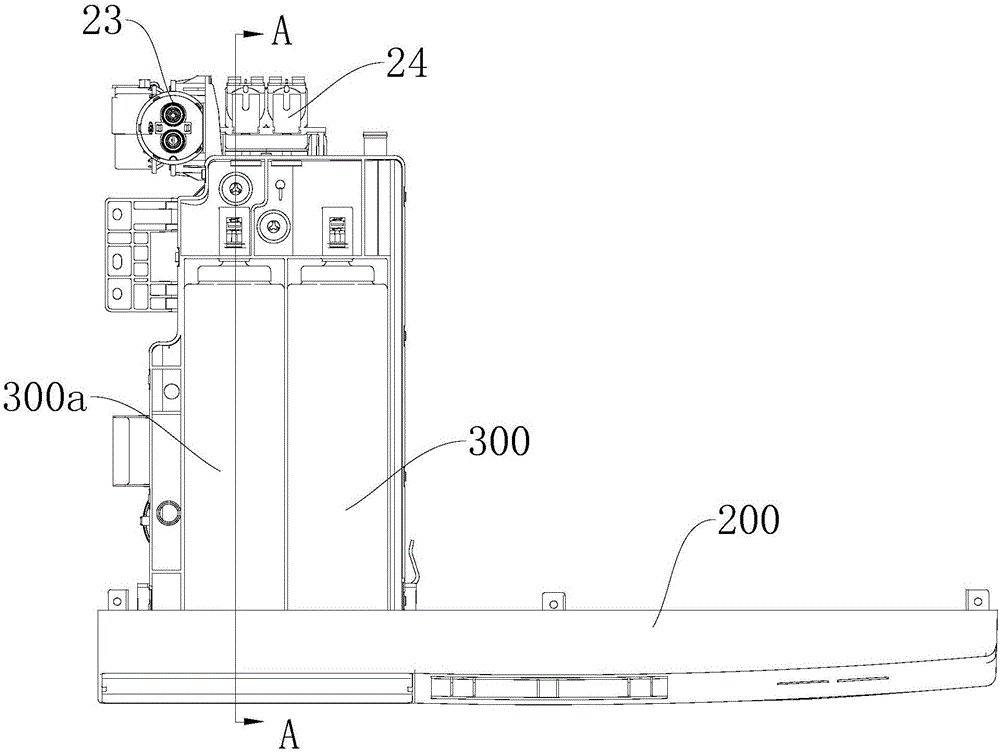

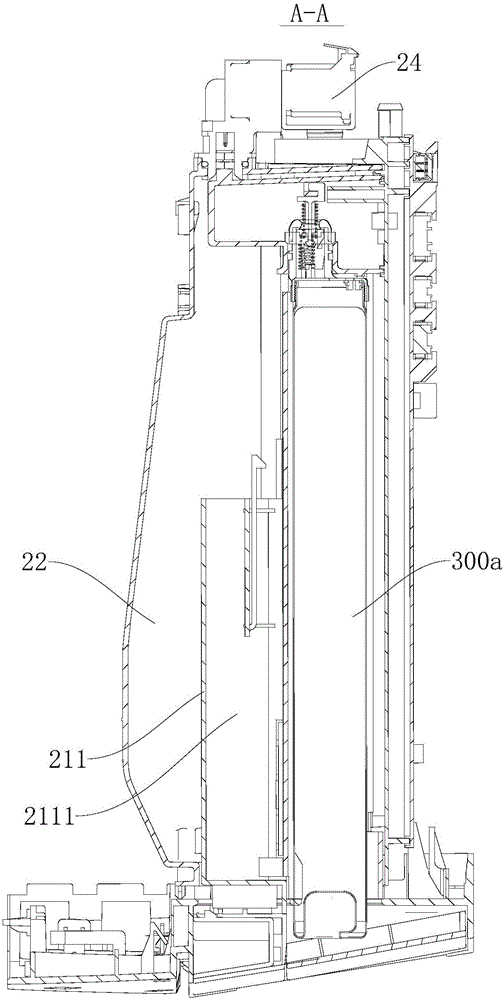

Detergent bottle, detergent dropping device used for washing machine and washing machine

InactiveCN106436188ARealize automatic deliveryExtended use timeOther washing machinesTextiles and paperEngineeringBottle

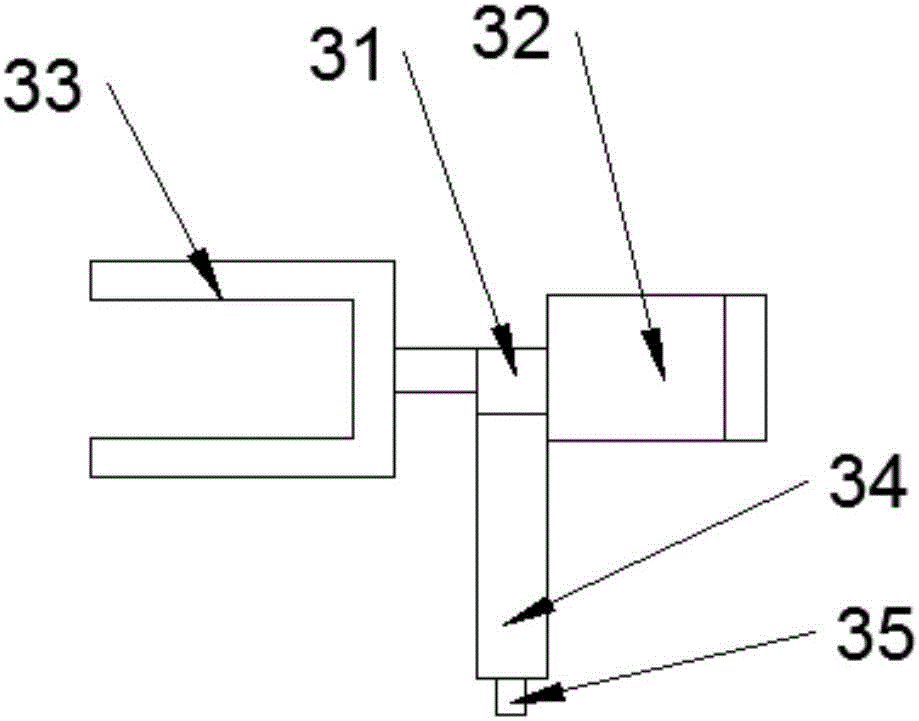

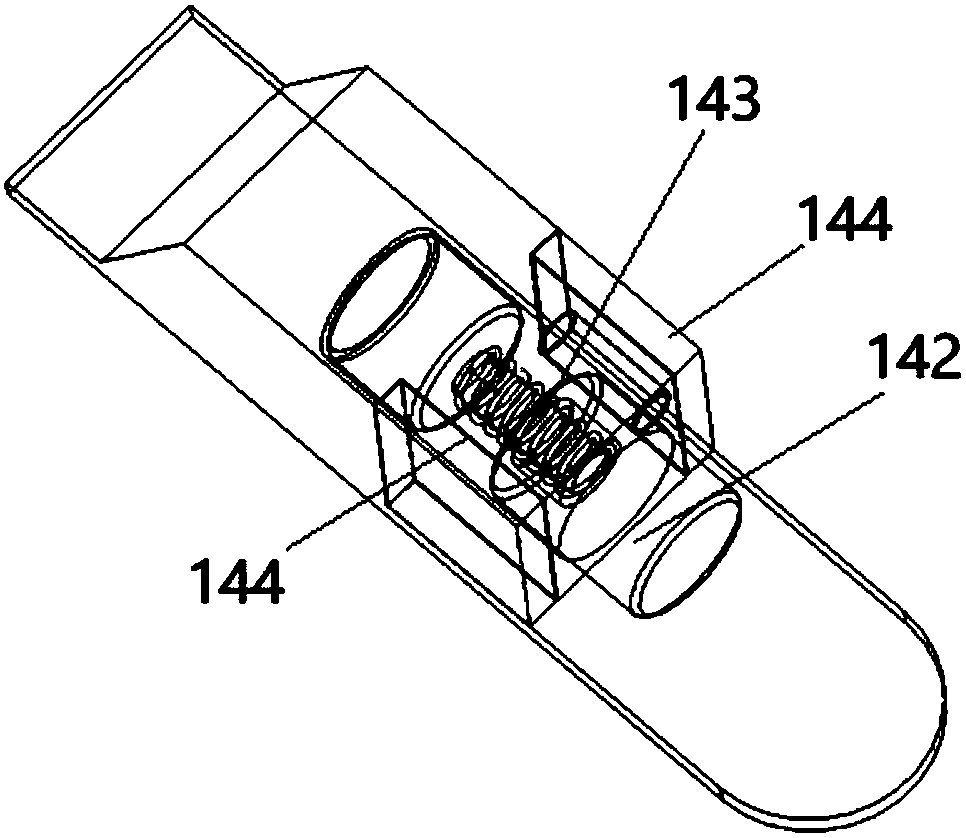

The invention discloses a detergent bottle, a detergent dropping device used for washing machine and a washing machine. The detergent dropping device comprises a bottle body and a one-way valve. A detergent accommodation space are divided in the bottle body, breathable holes communicated with the detergent accommodation space is arranged on the bottle body, and the breathable holes are communicated with a one-way air inlet structure; the one-way valve is connected to the bottle body, the one-way valve comprises a valve body, a valve core and a restoration part, one end of the valve body is communicated with the detergent accommodation space, and the other end of the valve body is provided with a liquid outlet; the valve core is movably arranged in the valve body at the position where the liquid outlet is opened and closed; the restoration part is connected to the valve body and the valve core respectively and drives the valve core to close the liquid outlet. According to the detergent bottle, the detergent bottle can be put in the detergent dropping device directly for use, so as to achieve automatic dropping of a detergent, the operation is simple and convenient, the capacity of the detergent bottle is big, the service time is long, the one-way valve can seal the bottle body after pouring is completed, and the detergent is not prone to deterioration.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

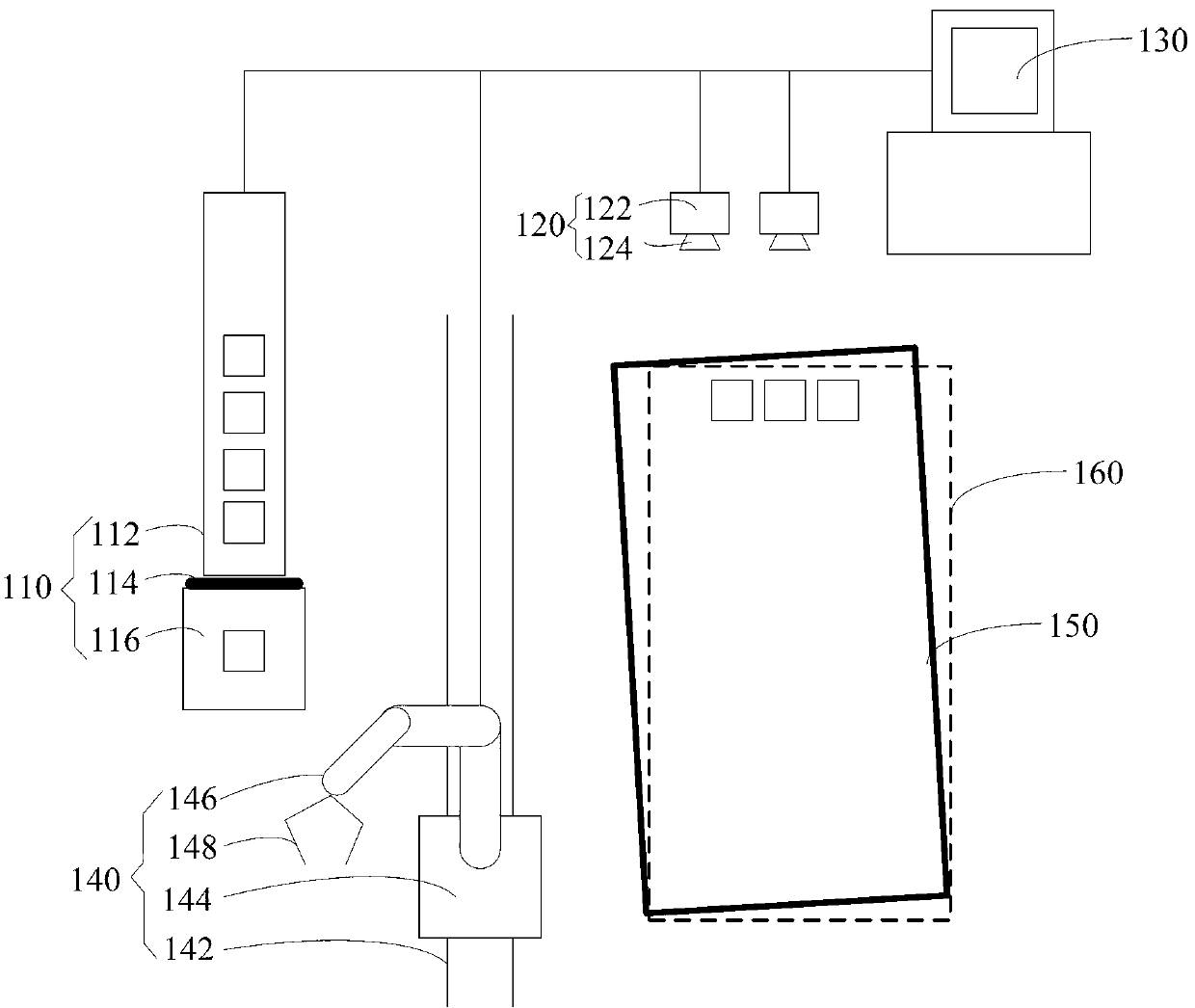

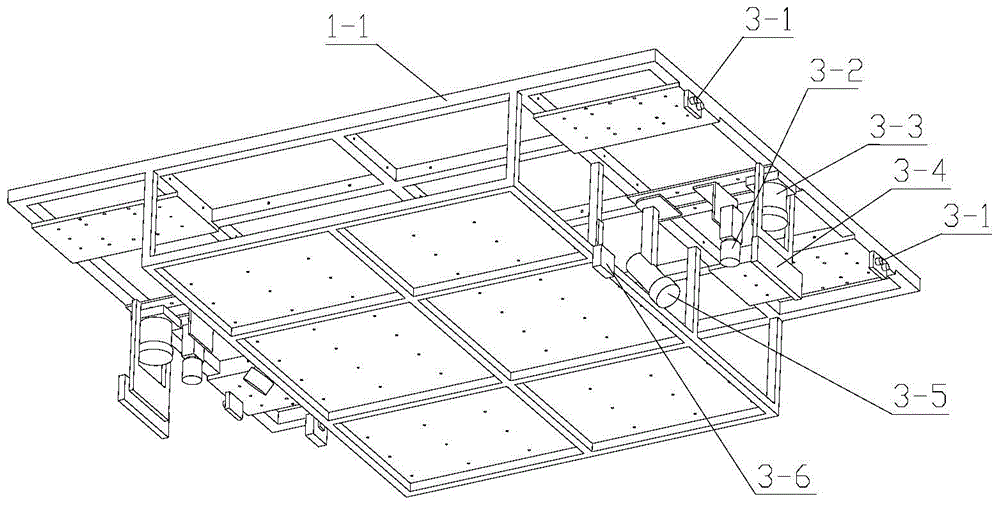

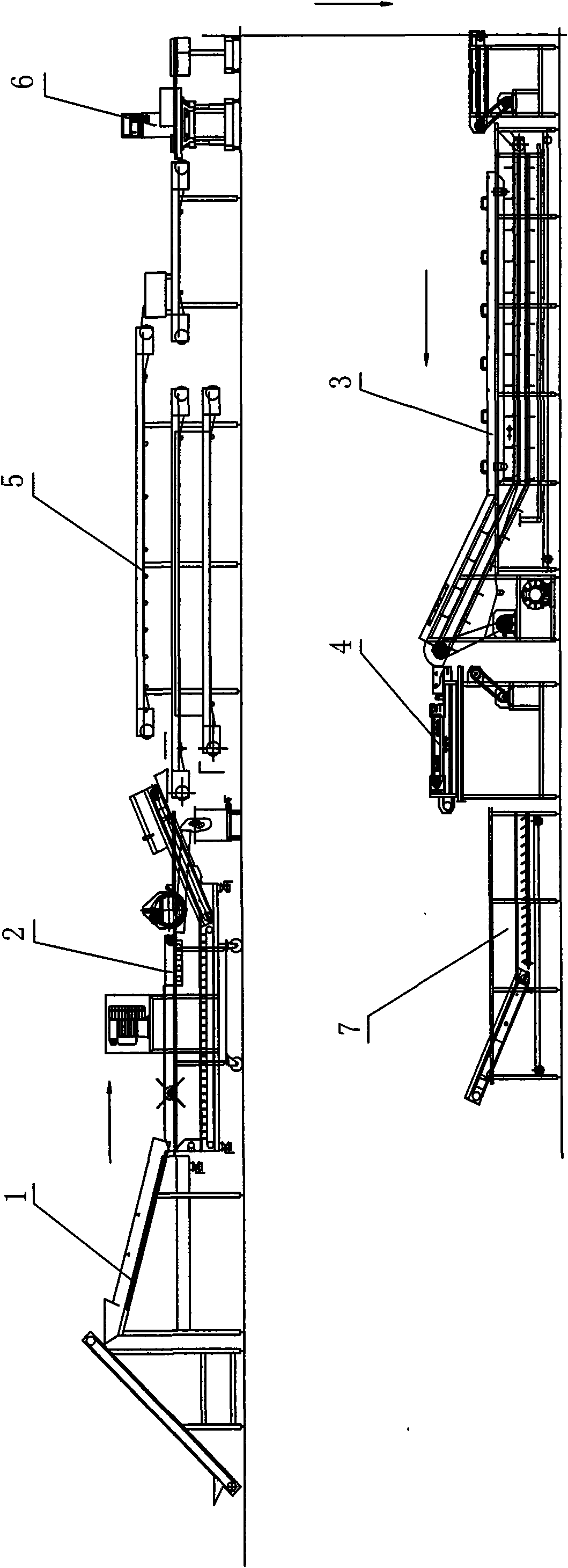

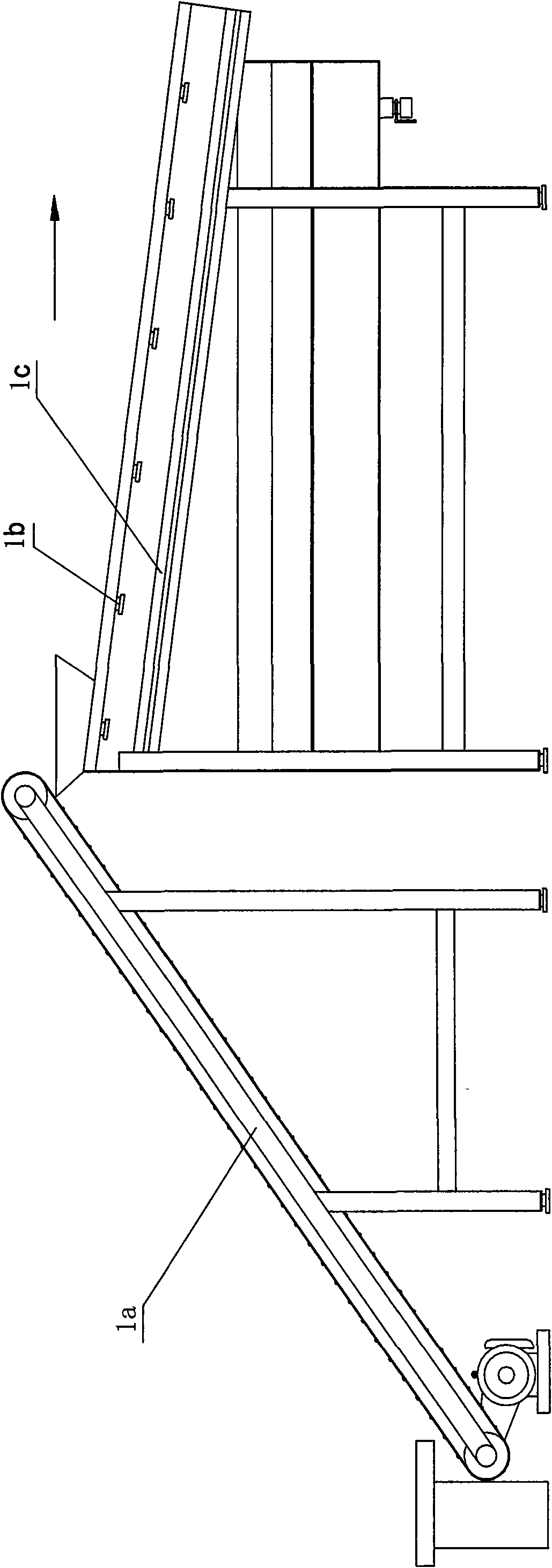

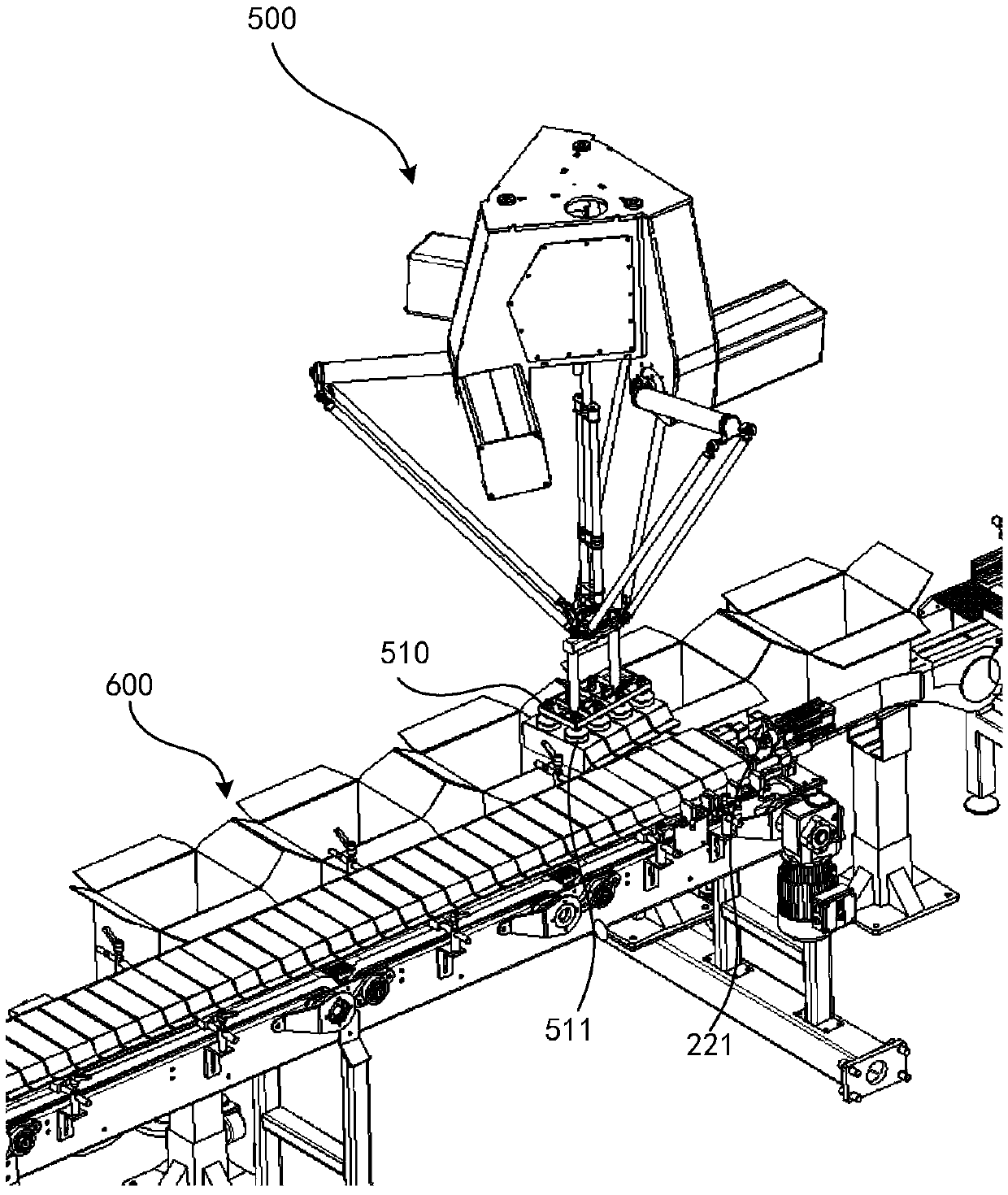

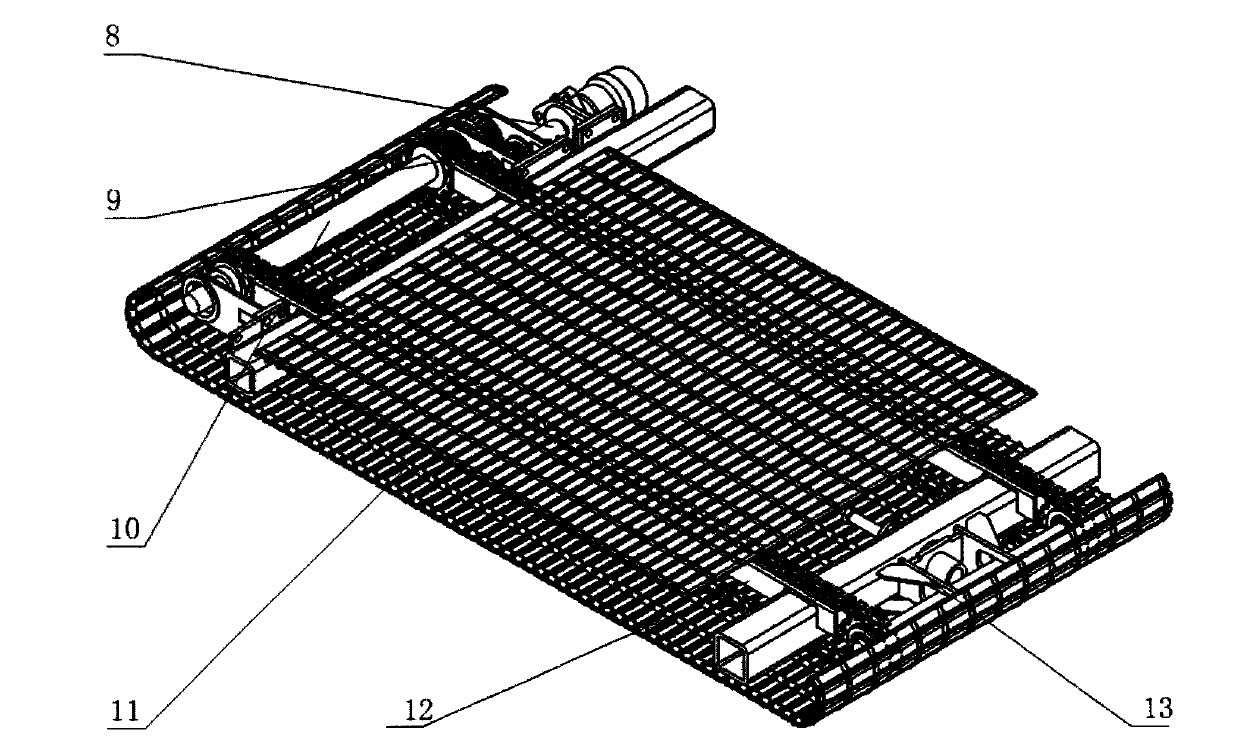

Bagged material car-loading system and method

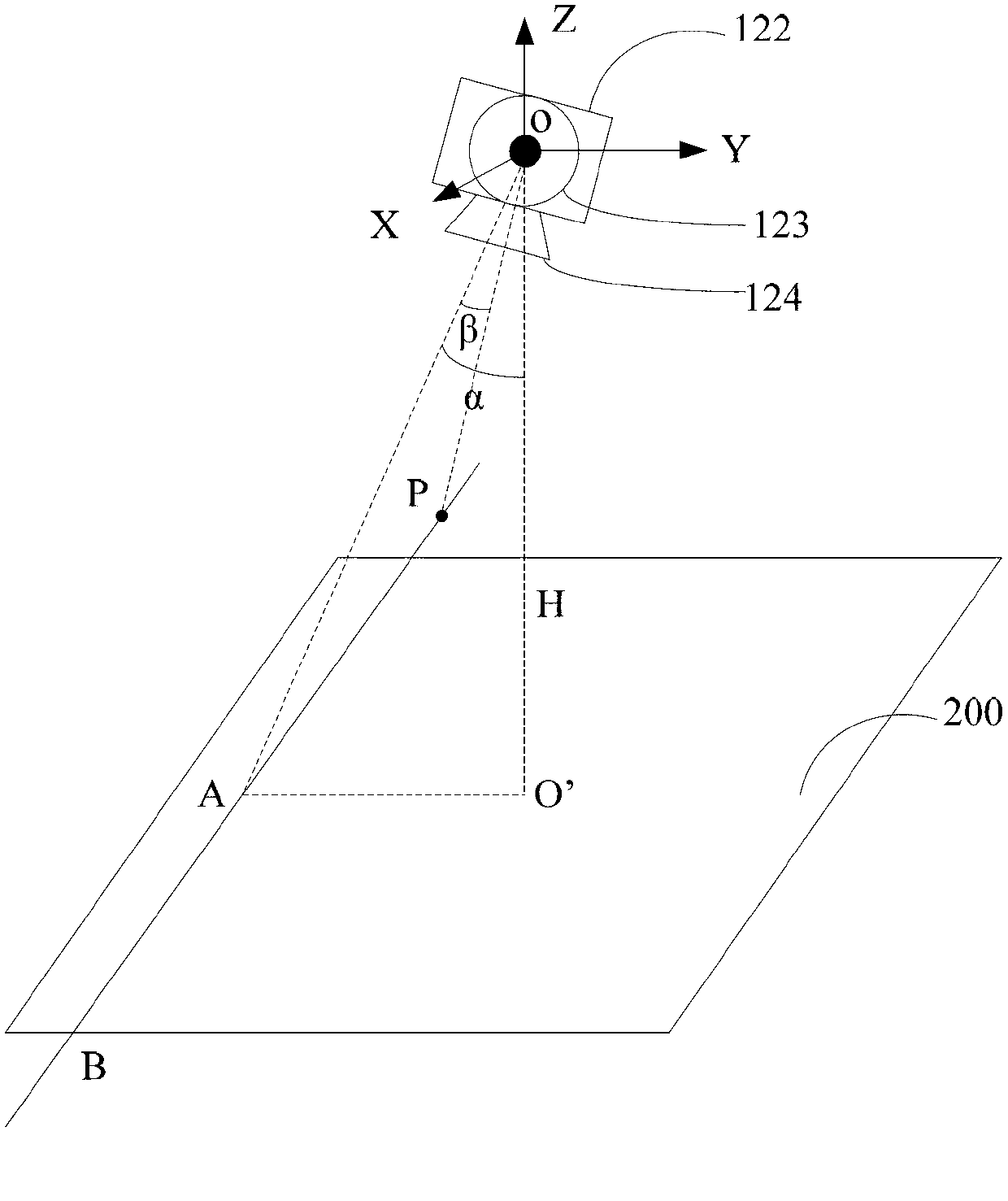

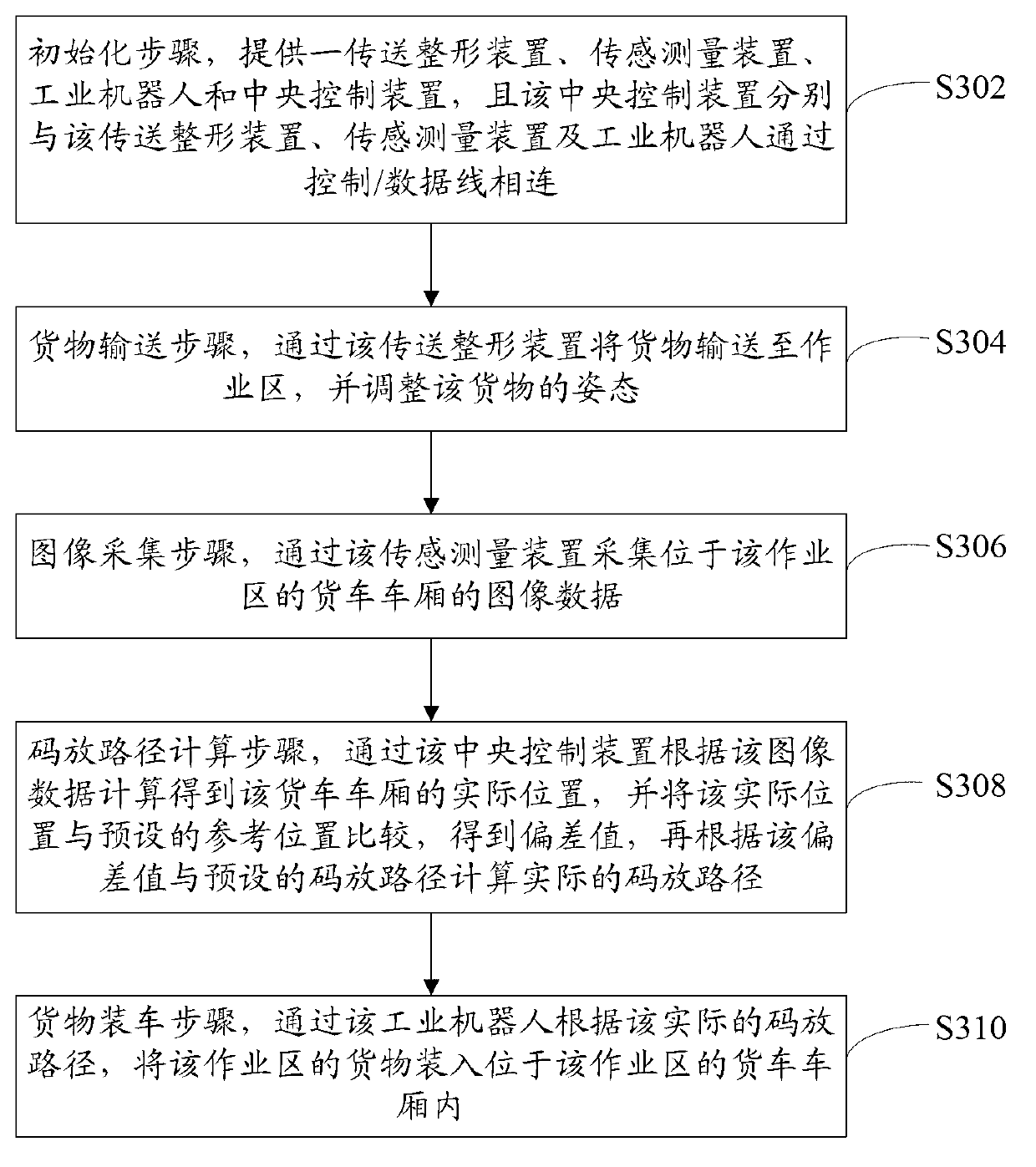

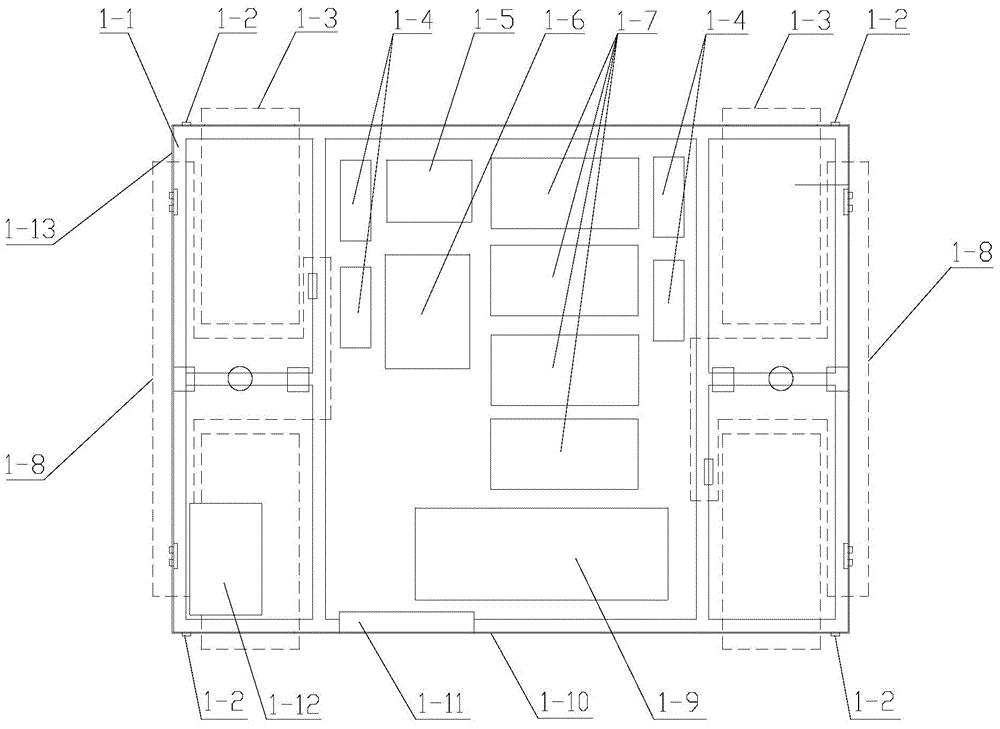

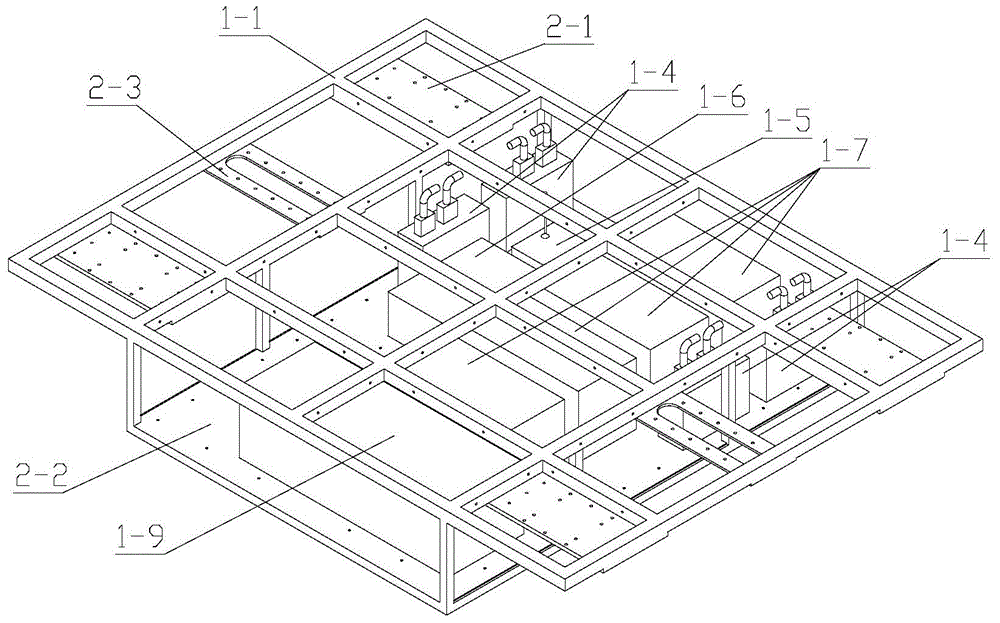

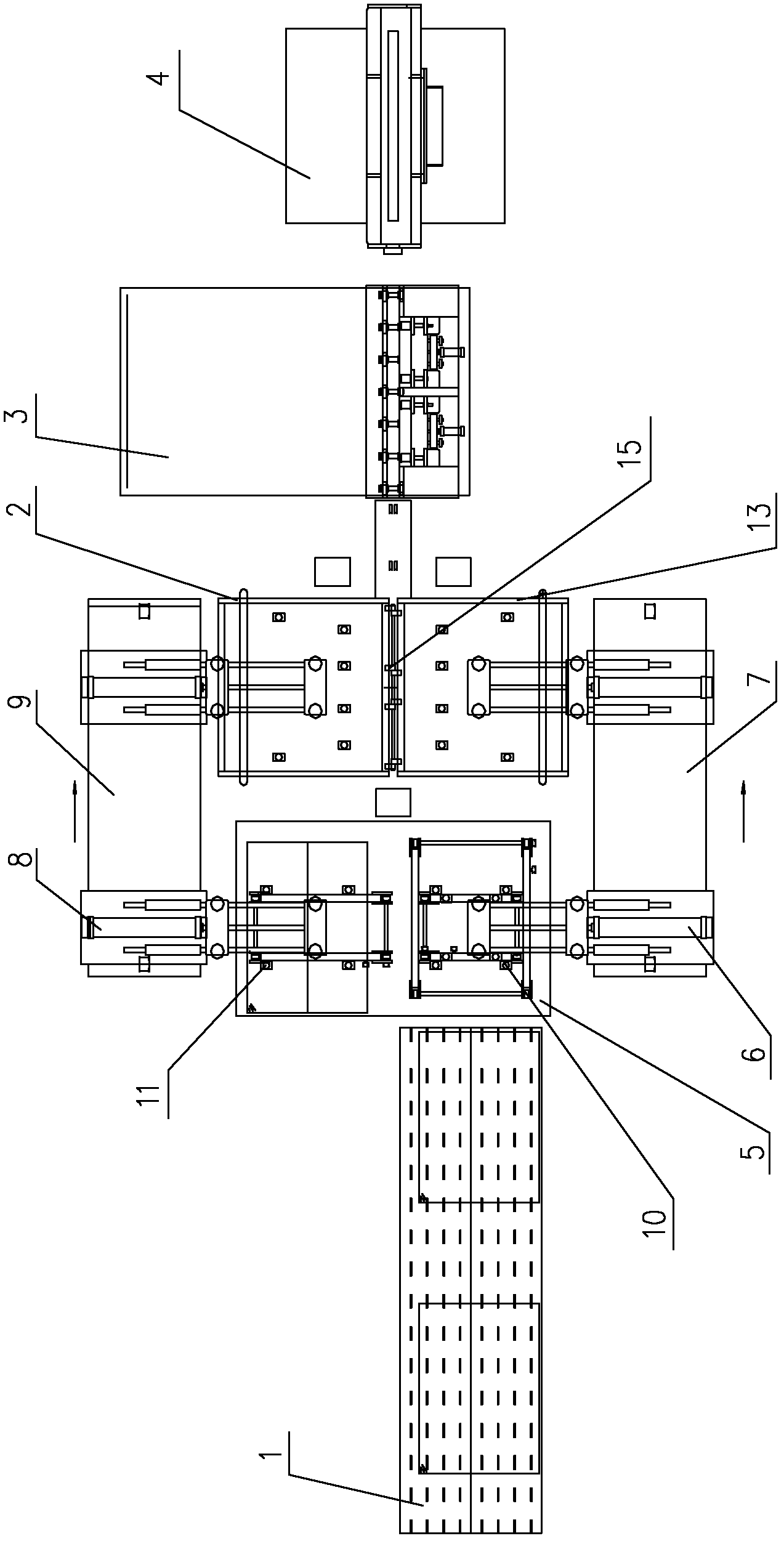

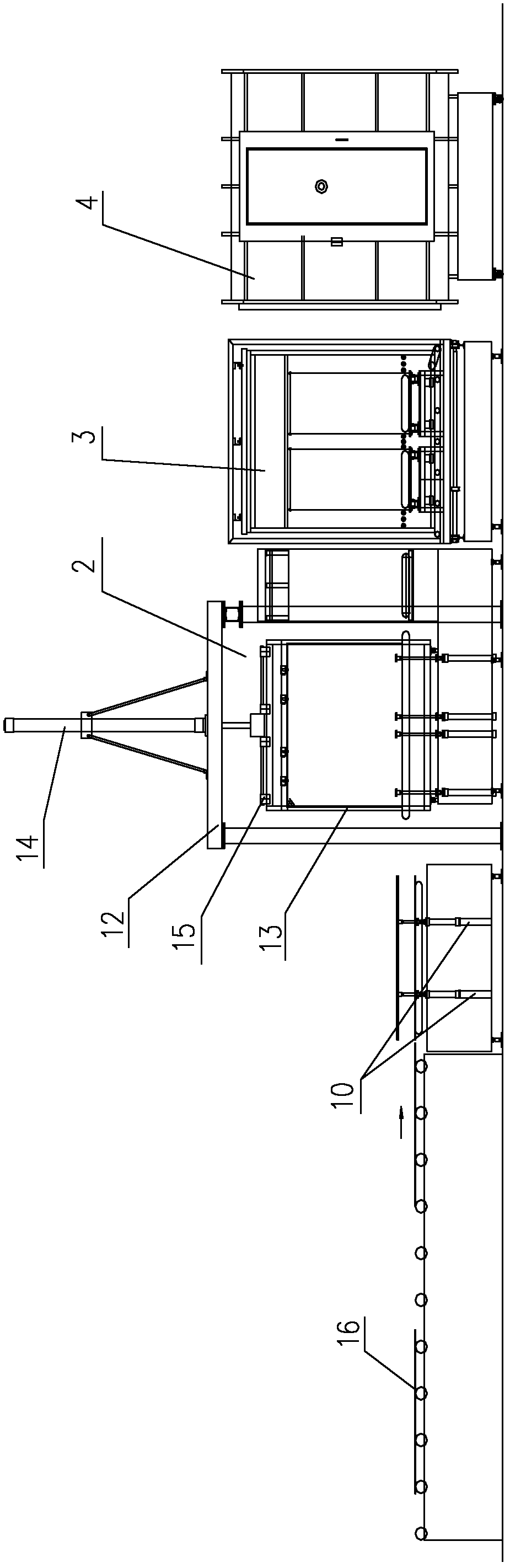

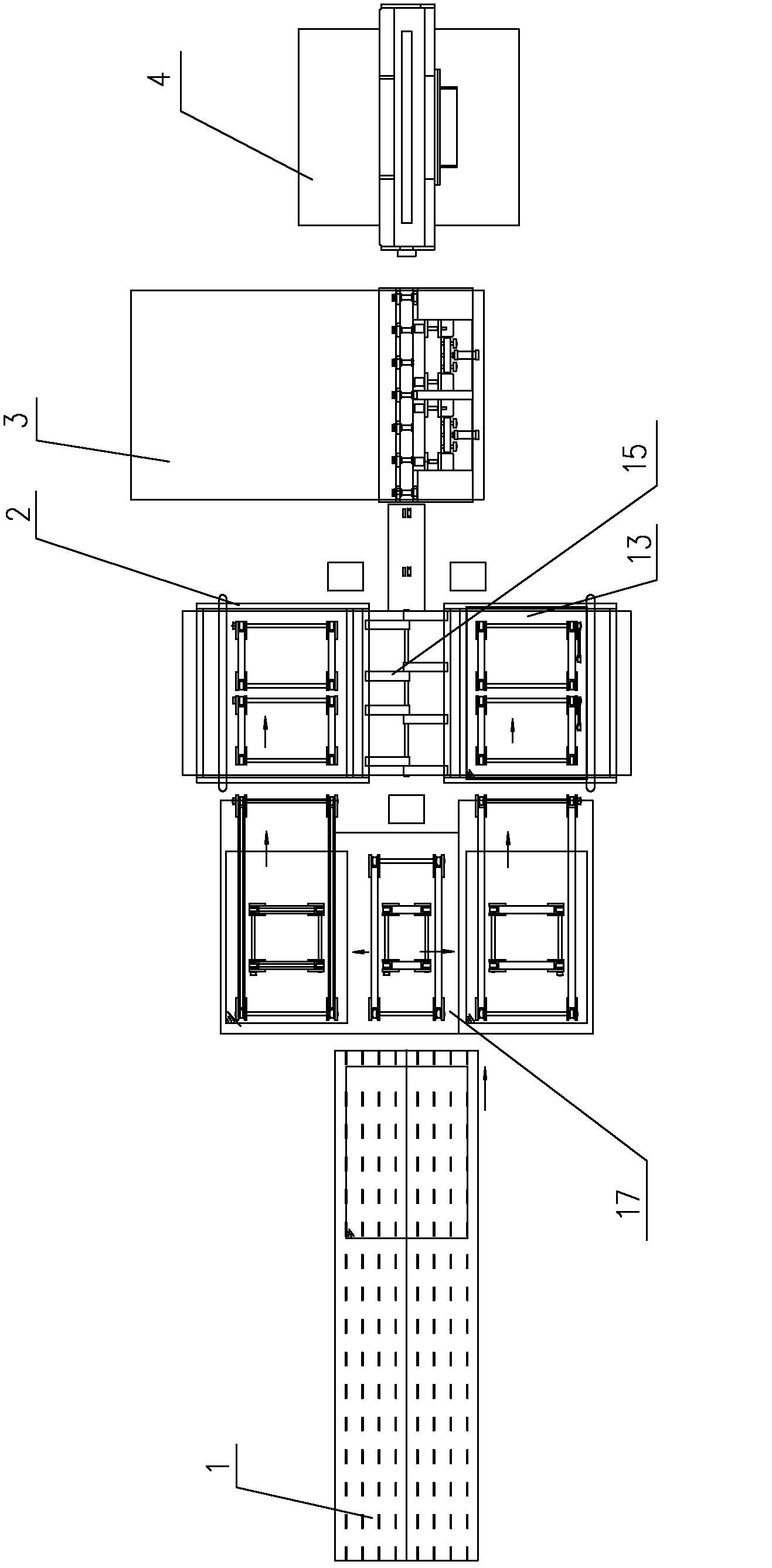

The invention relates to a bagged material car-loading system and method. The system comprises a conveying and shaping device, a sensing measuring device, a central control device and an industrial robot, wherein the conveying and shaping device is used for conveying goods to a work zone and adjusting the postures of the goods; the sensing measuring device is installed on the top or one side face of the work zone and used for collecting image data of a freight car located in the work zone; the central control device is used for obtaining the actual position of the freight car through calculation according to the detected image data of the freight car, comparing the actual position with a preset reference position to obtain a deviation value, and calculating the actual stacking path according to the deviation value and a preset stacking path; the industrial robot is used for loading the goods in the work zone into the freight car located in the work zone according to the actual stacking path. The central control device is respectively connected with the conveying and shaping device, the sensing measuring device and the industrial robot through control / data lines. The bagged material car-loading system and method improves operation efficiency, eliminates dust hazards and promotes safety.

Owner:SHENZHEN INST OF ADVANCED TECH

Omnidirectional mobile platform vehicle with automatic line patrolling and obstacle avoiding functions

InactiveCN106325267AReduce picking timeImprove efficiency and accuracyInstruments for road network navigationElectromagnetic wave reradiationMecanum wheelEngineering

The invention discloses an omnidirectional mobile platform vehicle with automatic line patrolling and obstacle avoiding functions for a factor area indoor space. The omnidirectional mobile platform vehicle comprises a main frame, a vehicle-borne computer, a storage battery group, a motor driver, and a Mecanum wheel component. The automatic line patrolling is realized through the combined working of a magnetic navigation sensor and a digital camera, the magnetic navigation sensor detects a vehicle offset through the position of an induction sensor relative to the a magnetic strip, the digital camera collects a navigation magnetic strip sideline in real time, the offset of the sideline to a theoretical calibration line is calculated, the numerical value returned by the sensors are integrated to adjust a vehicle body direction in real time, and thus the platform vehicle can move forward along a preset magnetic strip. According to the omnidirectional mobile platform vehicle, with an omnidirectional mobile vehicle as a basis, the multiple sensor integrated function modules of automatic line patrolling and automatic obstacle avoiding are developed, the vehicle can carry out transverse movement and oblique movement and rotate for any angle on a spot in a mode of zero gyration radius, point-action position fine adjustment is achieved, the automatic line patrolling is realized, the material delivery time can be reduced, and the working efficiency is improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

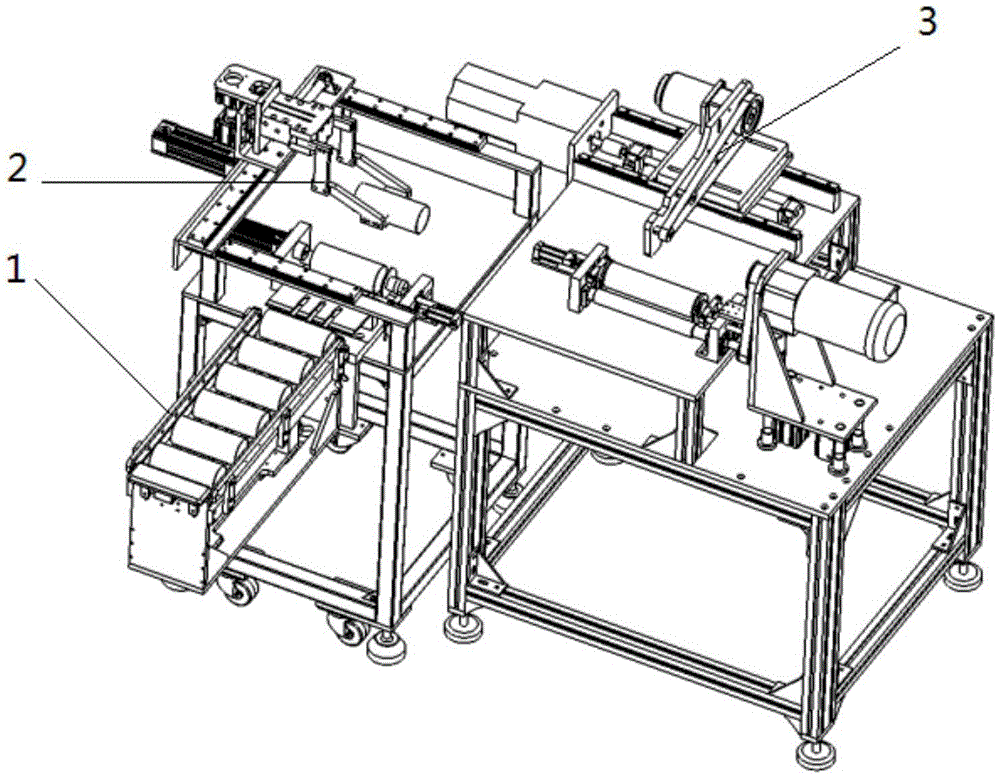

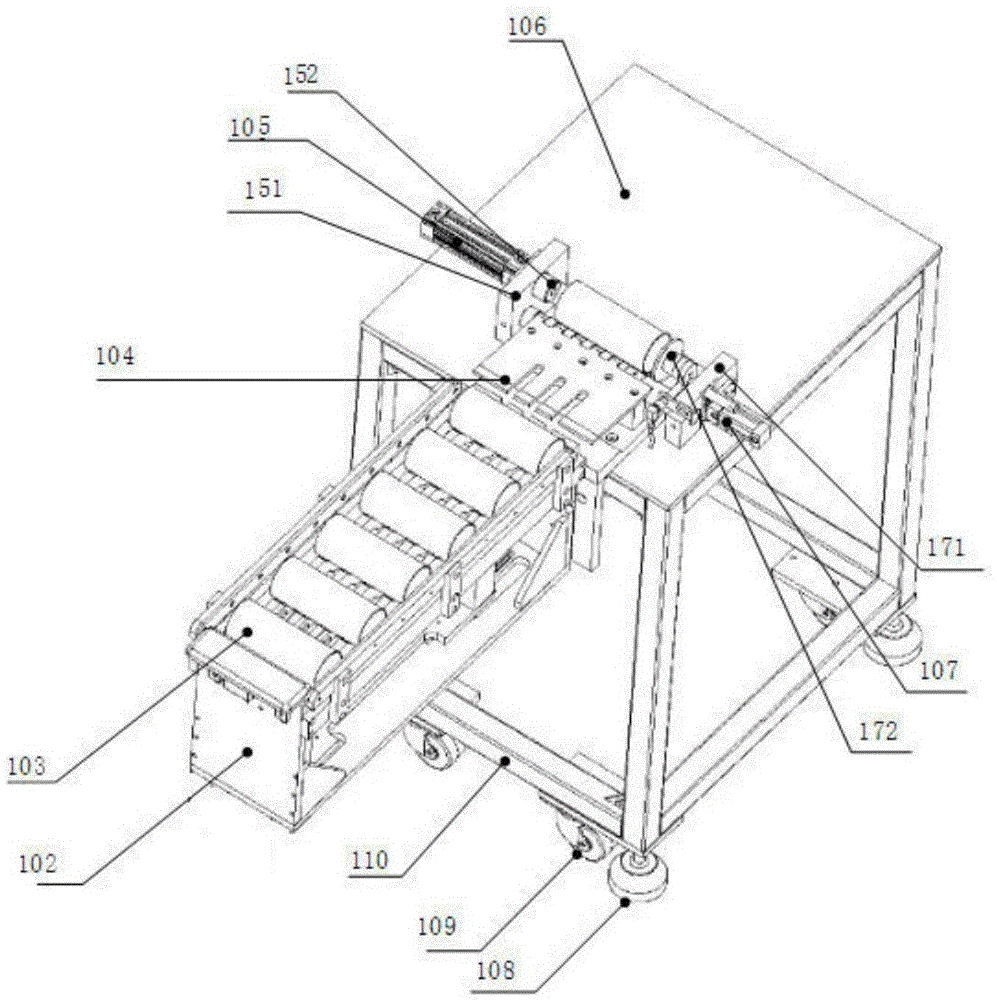

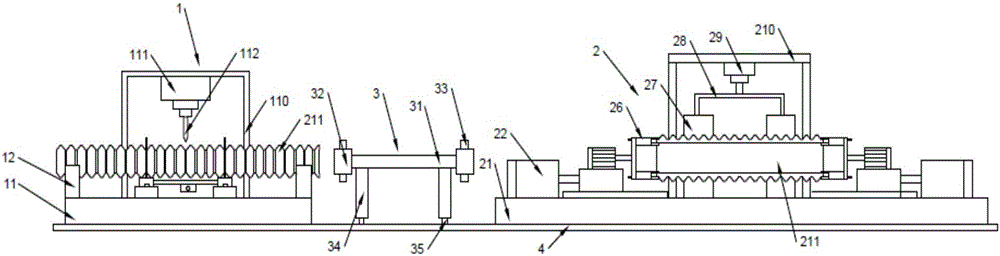

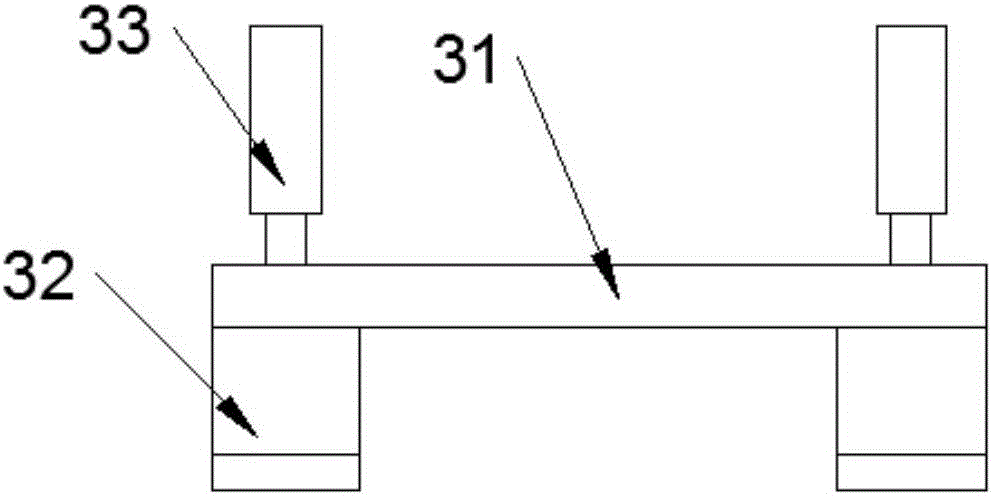

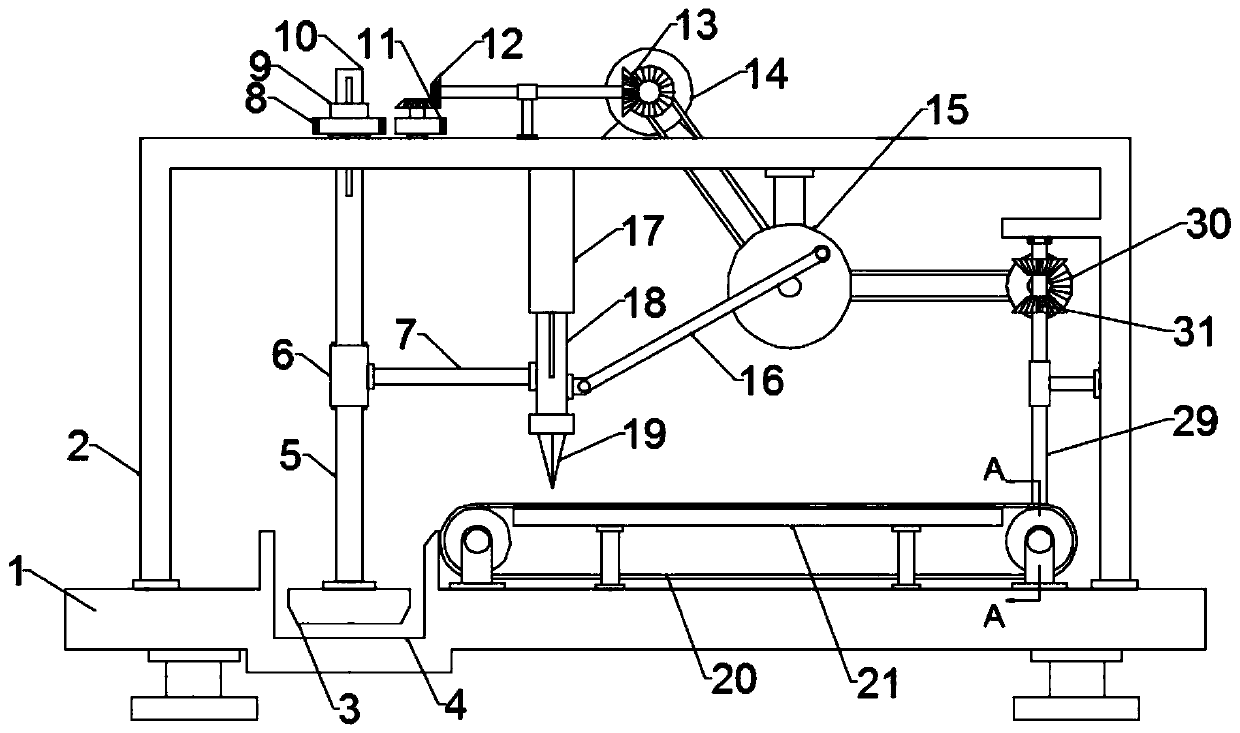

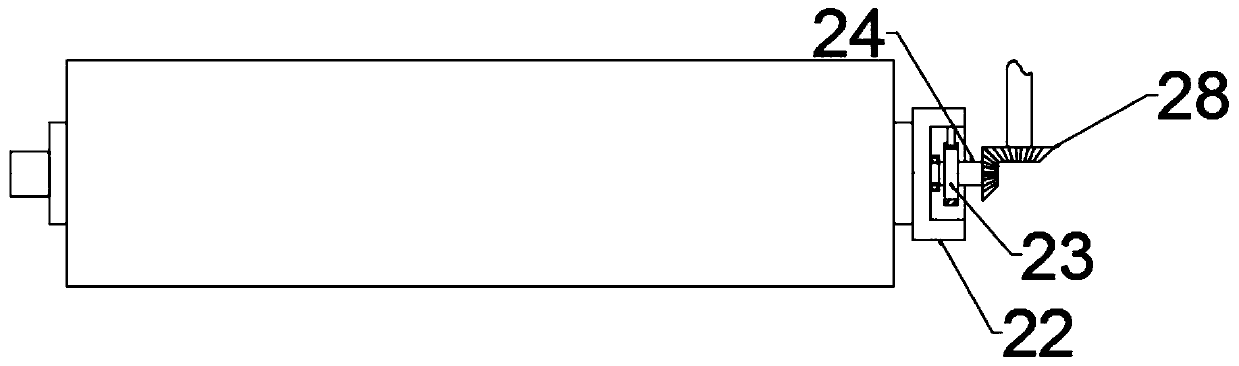

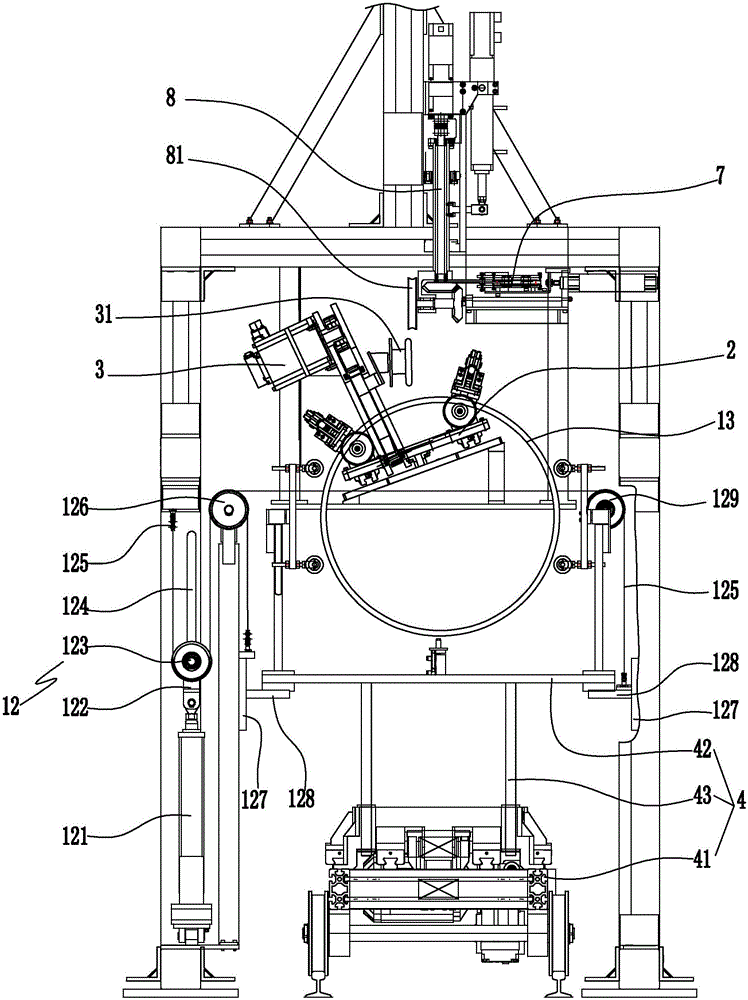

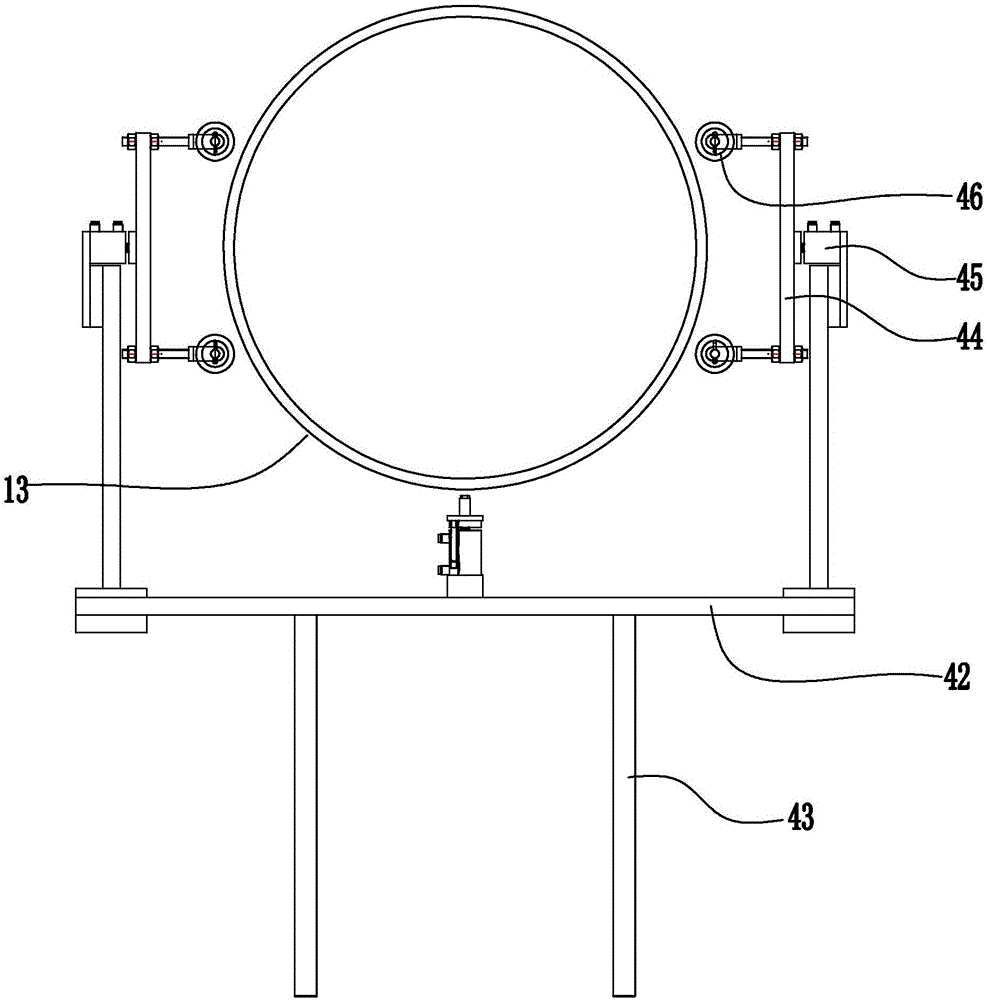

Automatic polishing system for cylindrical workpiece

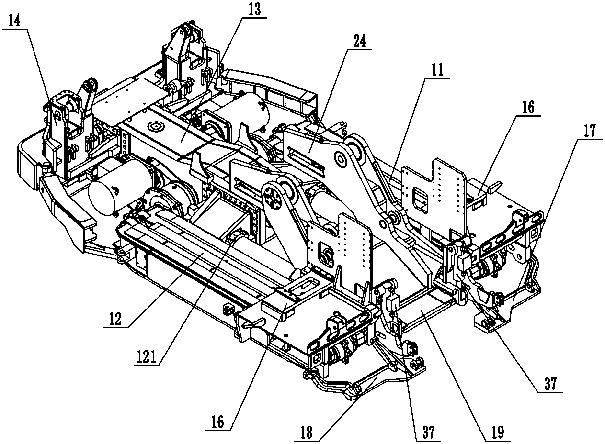

ActiveCN105619213ARealize automatic deliveryIncrease the level of automationGrinding drivesBelt grinding machinesDrive wheelElectric machinery

The invention provides an automatic polishing system for a cylindrical workpiece. The automatic polishing system comprises a feeding mechanism, a feed mechanism and an outer circle polishing mechanism. The feeding mechanism comprises a feeding rack, a conveying table unit and a pressing unit, and the conveying table unit and the pressing unit are mounted on the feeding rack. The feed mechanism is mounted on a support face plate of the feeding mechanism and comprises a feed rack and a motion control unit mounted on the feed rack. The outer circle polishing mechanism comprises a polishing rack, a motion unit and a polishing unit, and the motion unit and the polishing unit are mounted on the polishing rack. The polishing unit comprises linear guide rails, a sliding base, a stepping motor support, a driving wheel, a lead screw, a servo motor, a sanding belt, a tensioning wheel, a driven wheel and a stepping motor. The automatic polishing system can completely replace manual operation, work efficiency is remarkably improved, manpower cost is reduced, and the automation level of an enterprise is improved; and all polishing parameters are precisely controlled, and the more stable and better polishing quality can be achieved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

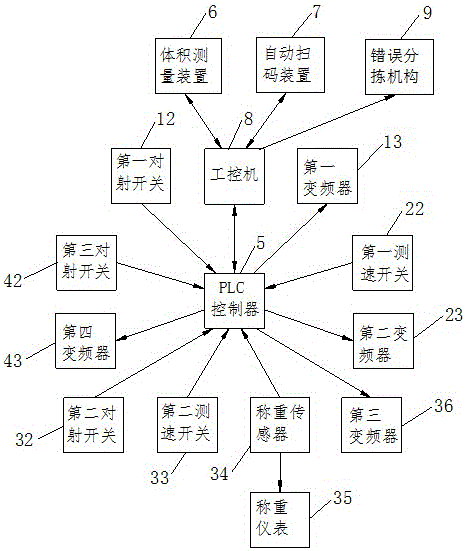

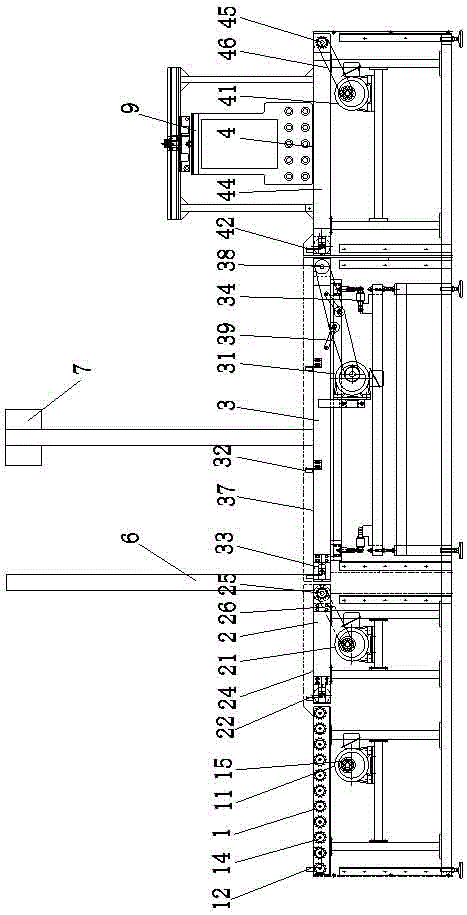

Weighing, scanning and body measuring trinity machine

InactiveCN106000893AEven by forceConvenient automatic deliveryWeighing apparatus detailsSortingLogistics managementIndustrial engineering

The invention relates to a weighing, scanning and body measuring trinity machine. The weighing, scanning and body measuring trinity machine comprises a goods feeding roller line. The goods feeding roller line, a goods entering belt line, a weighing belt line and a goods discharging belt line are sequentially fixed to a same base through a rack according to the packet passing sequence; a volume measuring device is fixed to the position of a gap between the goods entering belt line and the weighing belt line; an automatic code scanning device is fixed over the weighing belt line through a first support; an error sorting mechanism is fixed to the ground and installed over the goods discharging belt line; a PLC is in two-way communication with an industrial personal computer; the industrial personal computer is in two-way communication with the volume measuring device and the automatic code scanning device; and the output end of the industrial personal computer is connected with the input end of the error sorting machine. The weighing, scanning and body measuring trinity machine integrates bar code scanning, volume measuring and goods weighing on one belt conveyor, the using space is greatly saved, the weighing, scanning and body measuring trinity machine can be in perfect butt joint with an express unit better, and automatic logistics conveying can be achieved without changing an existing device.

Owner:HEFEI HAIMING SCI & TECH CO LTD

Corrugated pipe machining device

InactiveCN106271946AGuaranteed stabilitySimple structureEdge grinding machinesGrinding carriagesEngineeringMachining system

The invention provides a corrugated pipe machining device. Each adjustment sliding rail is provided with a first adjustment sliding block and a second adjustment sliding block, positioning parts are fixedly connected to the opposite side faces of the first adjustment sliding block and the second adjustment sliding block on the same adjustment sliding rail respectively, a first connecting rod is connected between every two adjacent first adjustment sliding blocks, a second connecting rod is connected between every two adjacent second adjustment sliding blocks, a first nut is connected to the first connecting rod between any two first adjustment sliding blocks, and a second nut is connected to the second connecting rod corresponding to the first connecting rod. The corrugated pipe machining system can conduct cutting and grinding on a corrugated pipe, positioning and fixing on the corrugated pipe are enhanced, the corrugated pipe machining device is suitable for clamping and positioning the corrugated pipes with different sizes, the application range is wide, and the machining precision and the uniformity of standards of machined products are guaranteed.

Owner:南昌迪亚汽车波纹管有限公司

Double-plate or double-side film coating system

ActiveCN102534539AEasy to installIncrease productivityVacuum evaporation coatingSputtering coatingProduction lineAgricultural engineering

The invention discloses a double-plate or double-side film coating system comprising a plurality of vacuum chambers in linear arrangement, wherein a through hole is formed between any two adjacent vacuum chambers; the first vacuum chamber is a plate inlet chamber; the last vacuum chamber is a plate outlet chamber; at least one film coating chamber is arranged between the plate inlet chamber and the plate outlet chamber; chamber doors are arranged on chamber walls on two sides of the film coating chamber in the workpiece conveying direction; and a magnetron sputtering target is arranged on each chamber door. The double-plate or double-side film coating system adopts the vacuum chambers in linear arrangement, and the magnetron sputtering targets are arranged on the chamber doors on two sides of each film coating chamber, so that film coating on two sides of a workpiece or on two workpieces can be realized at the same time, which effectively improves the production efficiency of a film coating production line; meanwhile, the magnetron sputtering targets are arranged on the chamber doors respectively, so that the equipment maintenance is facilitated, and the magnetron sputtering targets are simple to mount.

Owner:广东腾胜科技创新有限公司

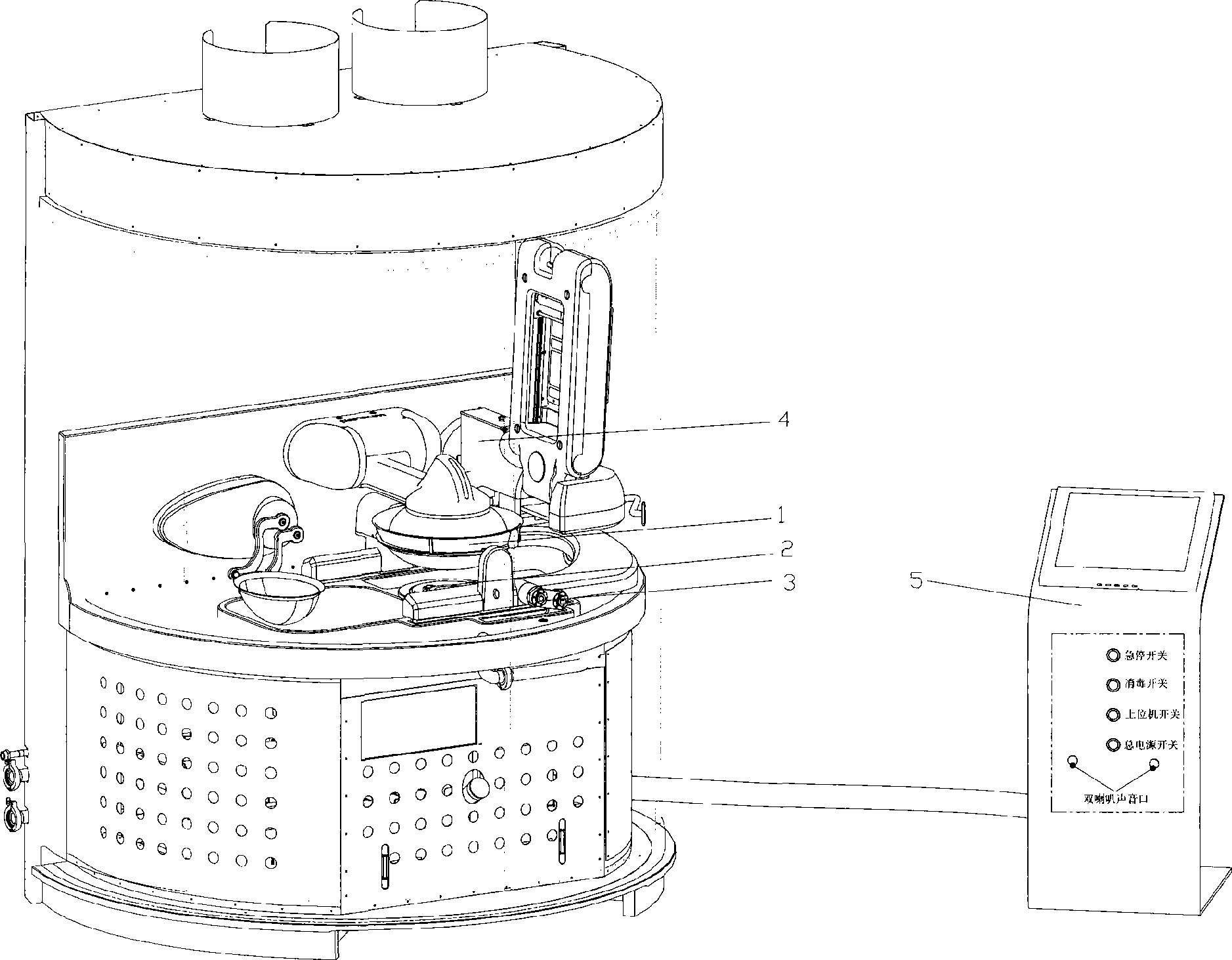

Device for automatically delivering fluid material and automatic/semiautomatic cooking device

InactiveCN101461652ARealize automatic deliveryImprove efficiencyCooking vesselsElectric controllersSolid componentSolid mass

The invention discloses a fluid material automatic delivering device for automatic / semi-automatic cooking equipment including a cooking container, a heating device, a material turning device and an overhead control system, wherein, the fluid material automatic delivering device includes a controller, implementation components, a material distribution mechanism for distributing the fluid material in the cooking container and a material storage device for storing the fluid material for delivery. The invention also discloses an automatic / semi-automatic cooking equipment provided with the fluid material automatic delivering device. The inventive fluid material automatic delivering device may realize the automatic delivery of the fluid material; and the fluid material can not only be equably distributed in the required scope, but also the solid component in the solid-liquid mixture is not easy to deposit on the material output position.

Owner:AIC ROBOTICS TECH

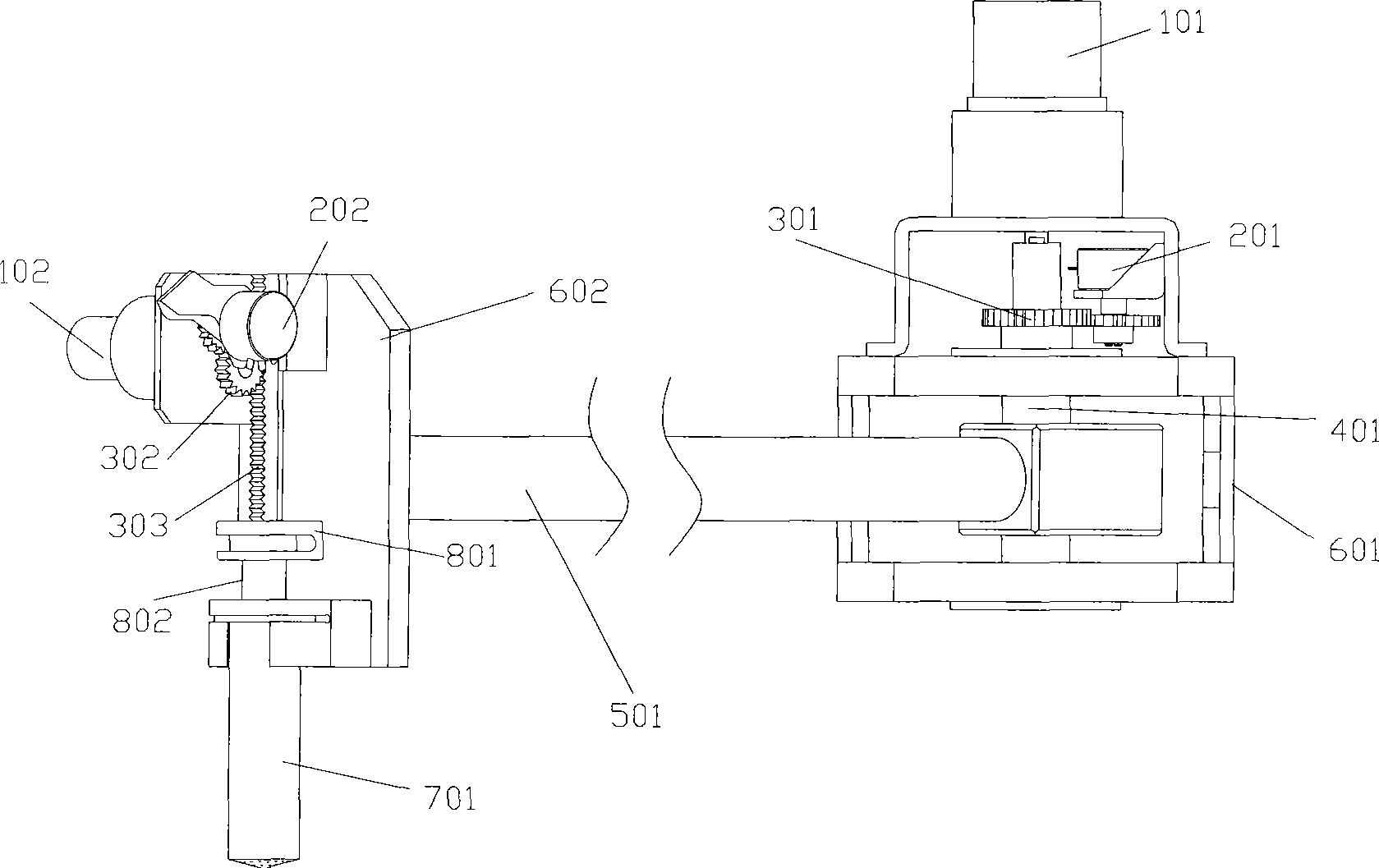

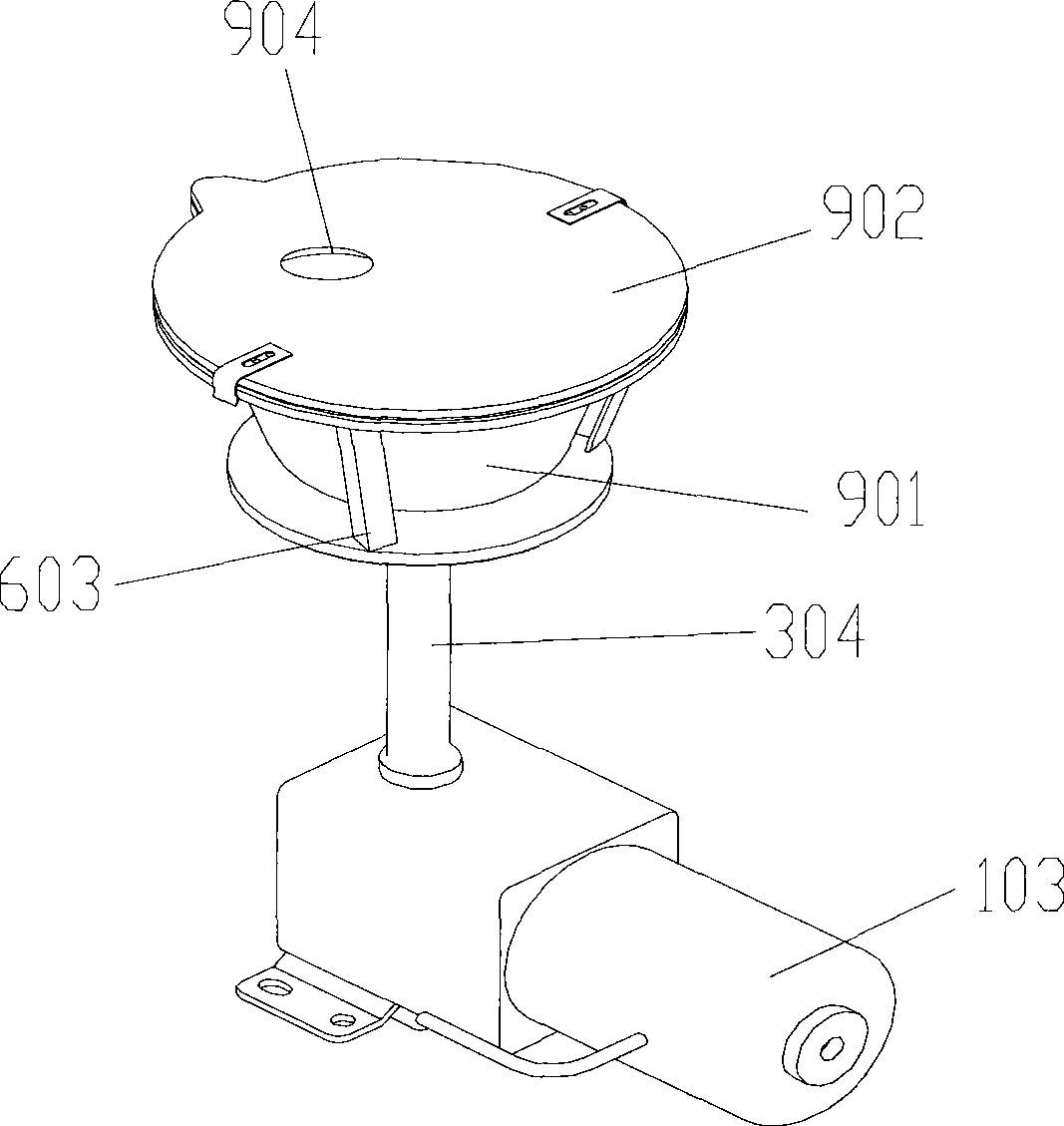

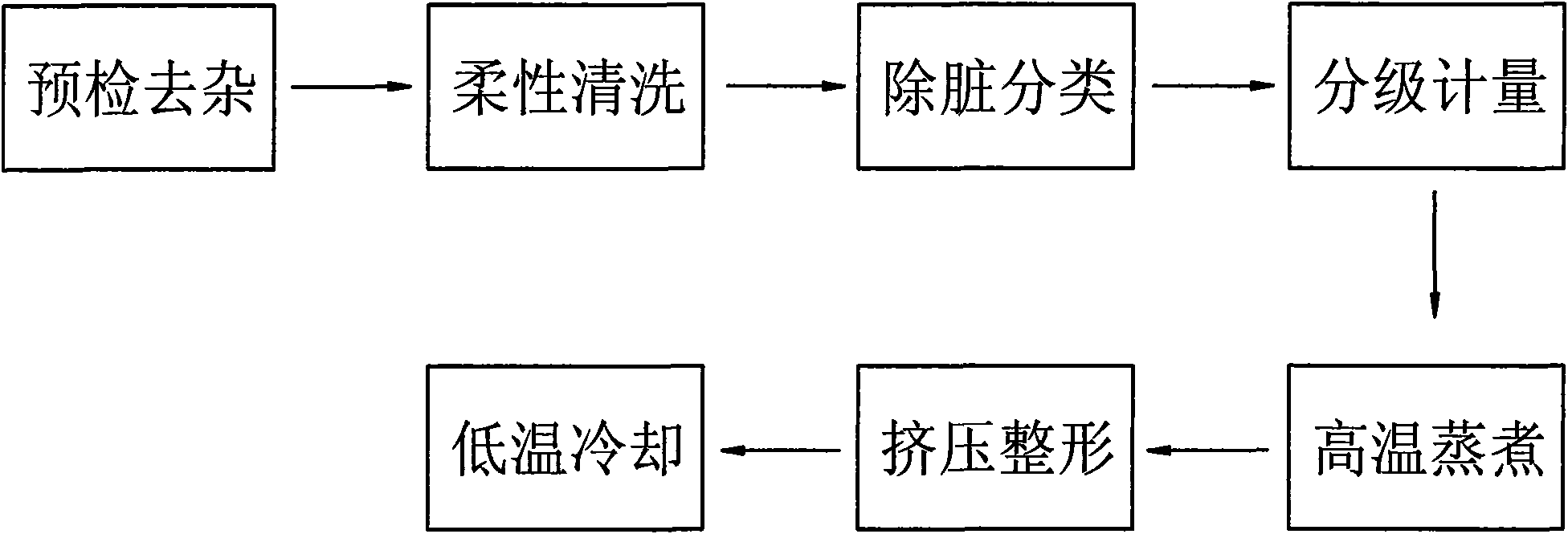

Sea cucumber pretreatment technology for mechanically processing and corresponding equipment thereof

InactiveCN101617837AQuality improvementEasy to mechanize sievingFish washing/descalingMeat/fish preservation by heatingWater storageWater flow

The invention relates to a sea cucumber pretreatment technology for mechanically processing and equipment thereof. The sea cucumber pretreatment technology for mechanically processing comprises the working procedures of pre-inspection impurity removal, flexible cleaning, dirty removal classification, grading measurement, high-temperature stewing, extrusion molding and low-temperature cooling; in the working procedure of the pre-inspection impurity removal, a sea cucumber is sprayed, wetted and washed by purified water and screened by taking a hole and a seam with a certain geometric dimension as boundaries; in the cleaning working procedure, the sea cucumber is placed into a water storage container of which the bottom is input with pressure gas from bottom to top and transported by pressure water flow; in the working procedure of the high-temperature stewing, the sea cucumber is advanced at a certain speed in the boiling water of a stewing groove, and after being gathered, the scum of the water surface is dispelled out of the stewing groove in a guide gathering and / or draining way; and in the working procedure of the extrusion molding, the sea cucumber is sprayed and cooled by low-temperature water and extruded by elastic flexible force during drainage. A pre-inspection device, a cleaning device, a stewing device and a molding device are manufactured and provided according to the sea cucumber pretreatment technology for mechanically processing, thereby the high working efficiency is achieved and the high quality of a finished product is ensured.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

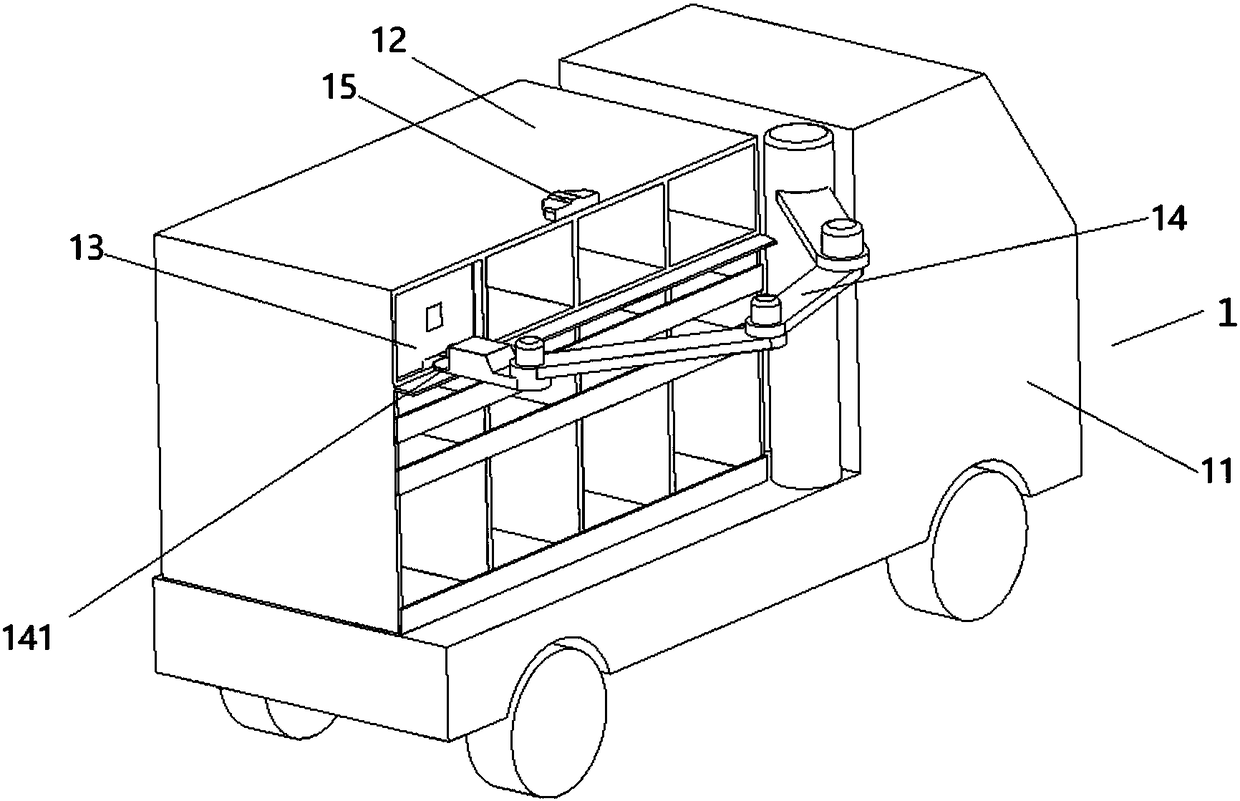

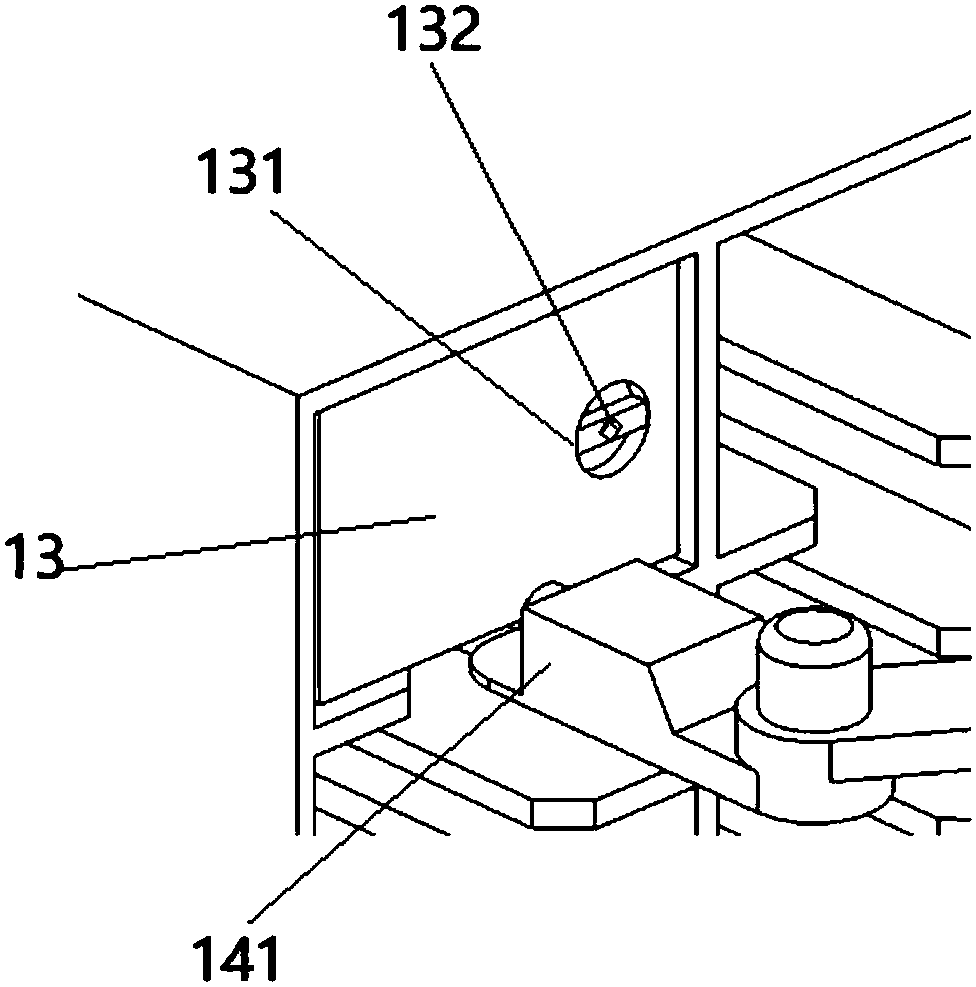

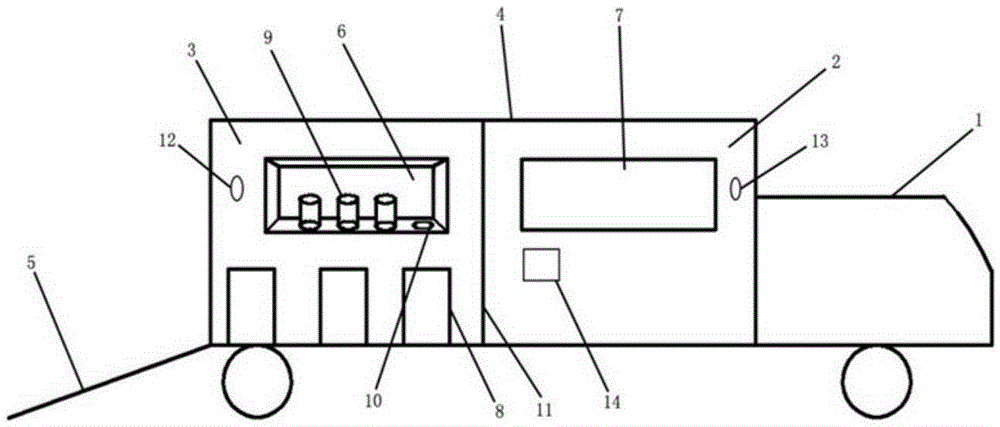

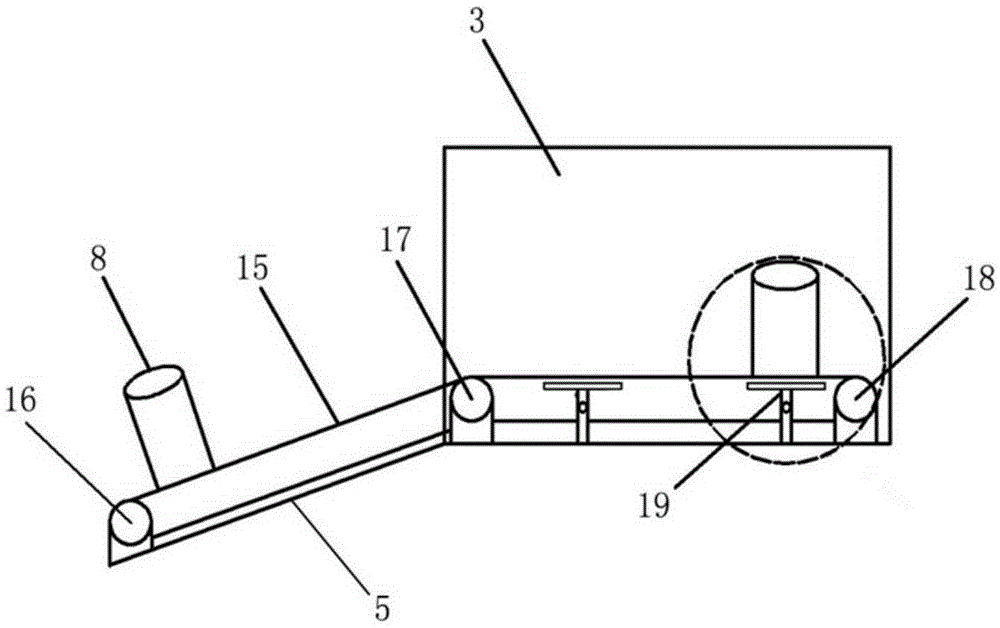

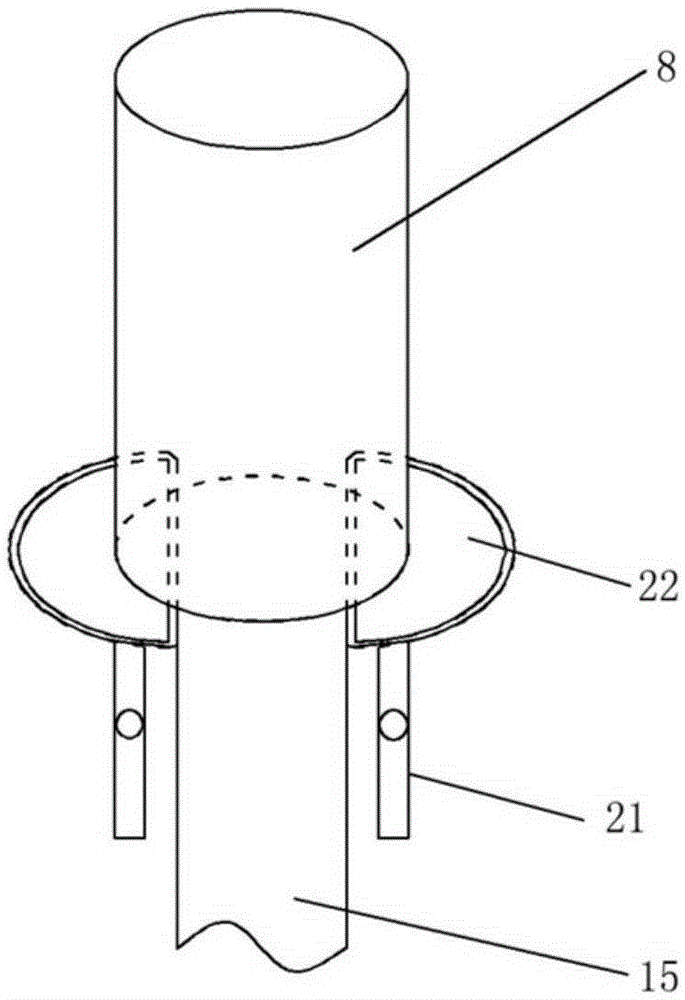

Unmanned express vehicle, unmanned express distribution system and automatic distribution method of unmanned express distribution system

ActiveCN108422918AEfficient handlingLow costData processing applicationsItem transportation vehiclesElectricityCommunication unit

The invention provides an unmanned express distribution vehicle, an unmanned express distribution system and an automatic distribution method of the unmanned express distribution system. The unmannedexpress vehicle comprises an unmanned vehicle body, wherein the unmanned vehicle body is provided with express shelves, the express shelves are internally provided with circulation boxes with identification tags, and express items are loaded in different circulation boxes; the express shelves are provided with a mechanical arm for taking out the circulation boxes from the express shelves, and thetop of the unmanned vehicle body or / and the top of the express shelves are provided with a three-dimensional space measuring sensor; the mechanical arm is provided with a visual sensor; the unmanned vehicle body is provided with a control unit, a communication unit and a storage unit, the communication unit and the storage unit are respectively connected with the control unit, and the control unitis electrically connected to the control circuit of the mechanical arm and the three-dimensional space measuring sensor. By adoption of the technical scheme of the invention, a fast, efficient and cheap unmanned distribution system is realized, the goods distribution efficiency is improved and the labor cost is reduced.

Owner:江门市腾米机器人技术有限公司

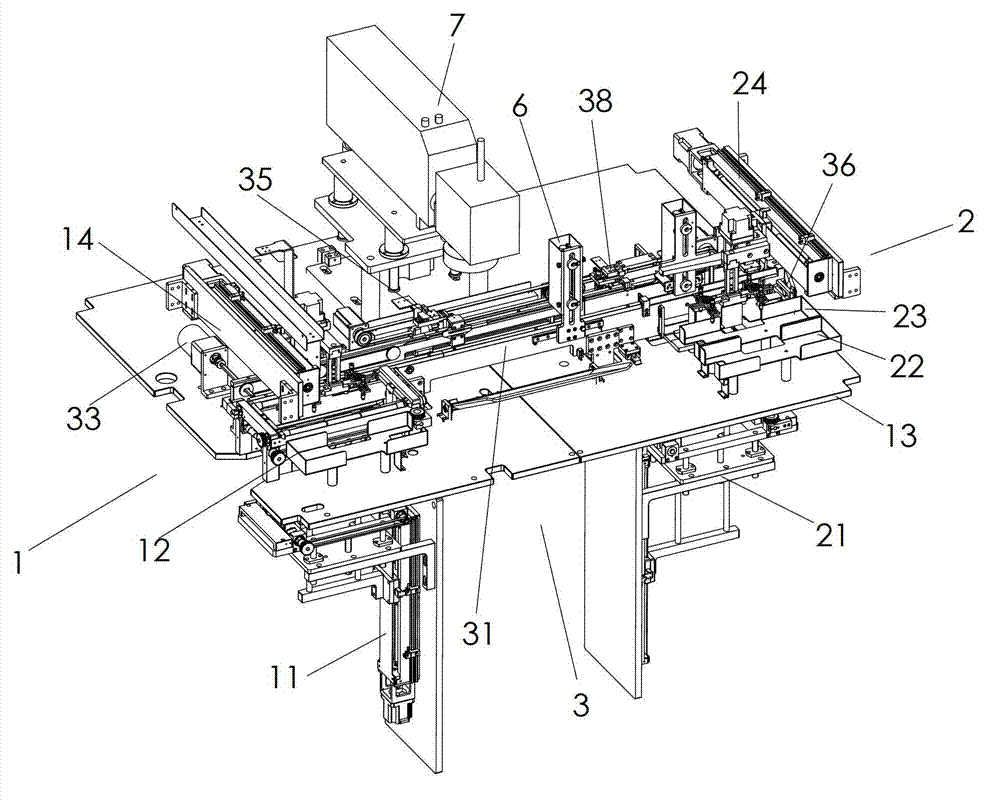

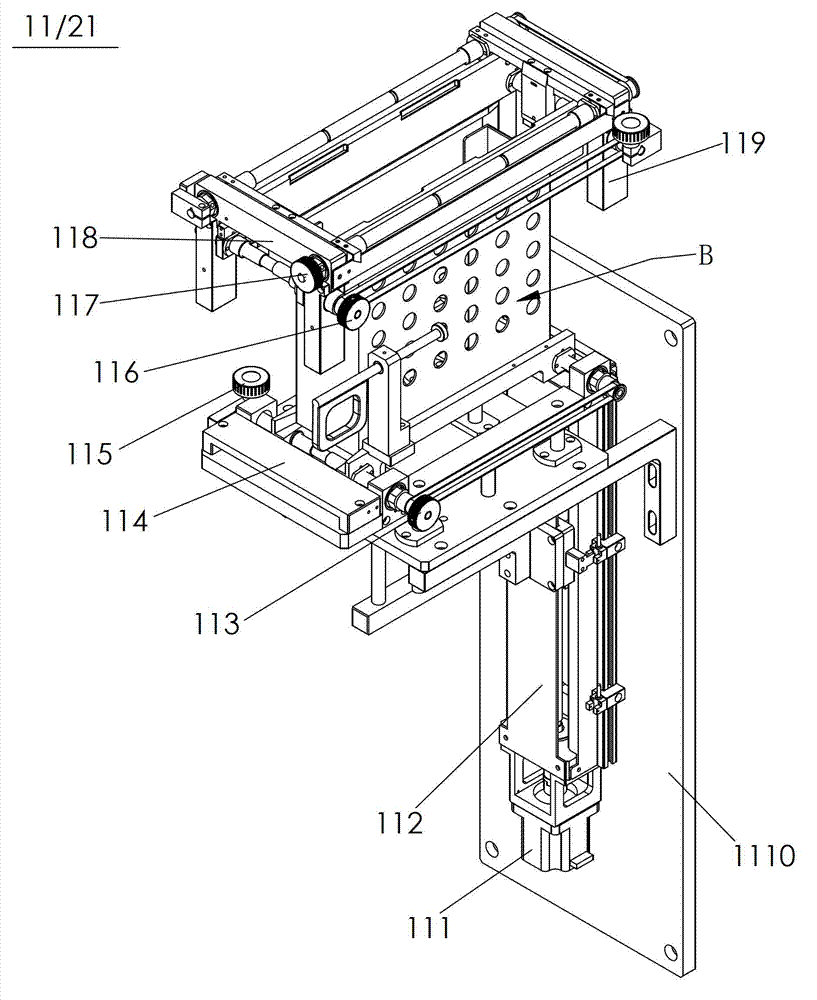

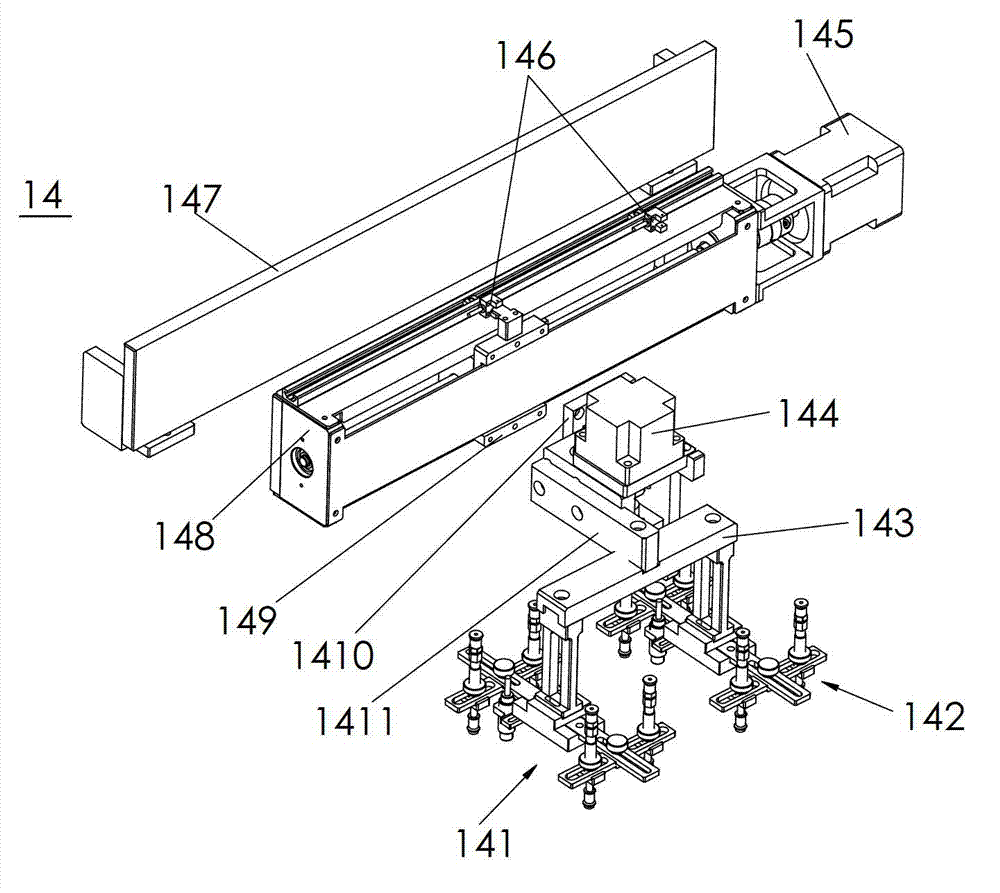

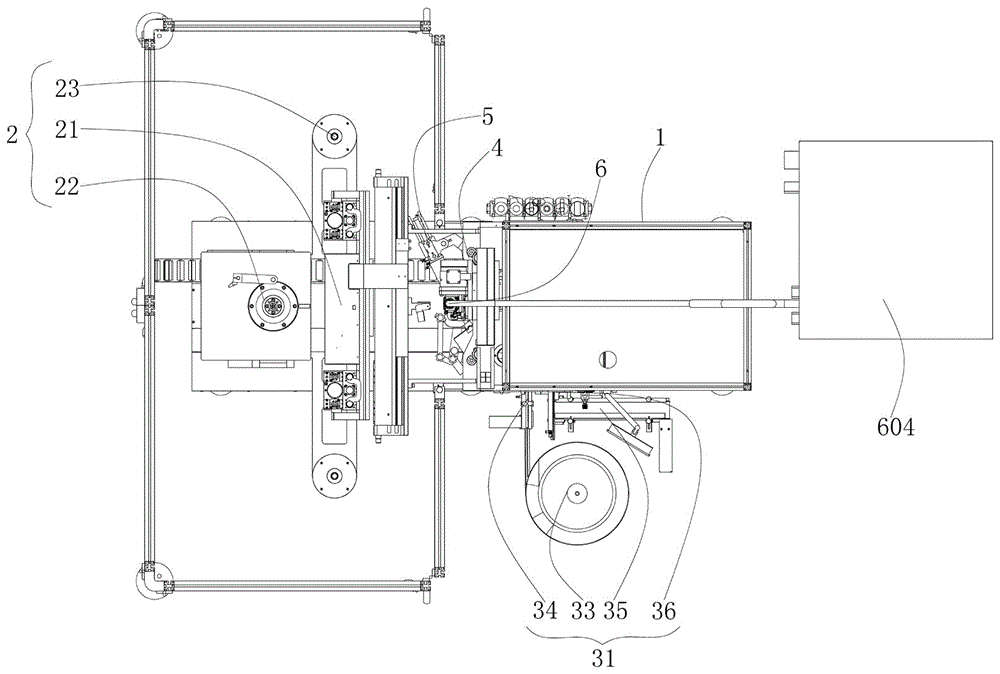

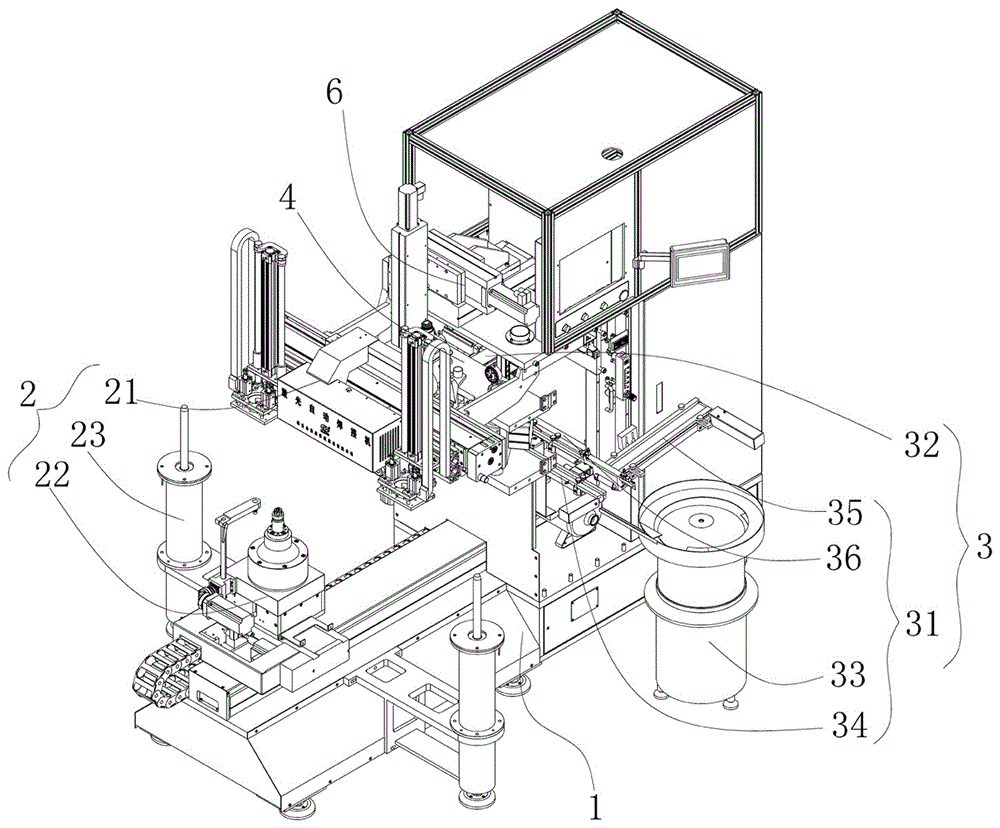

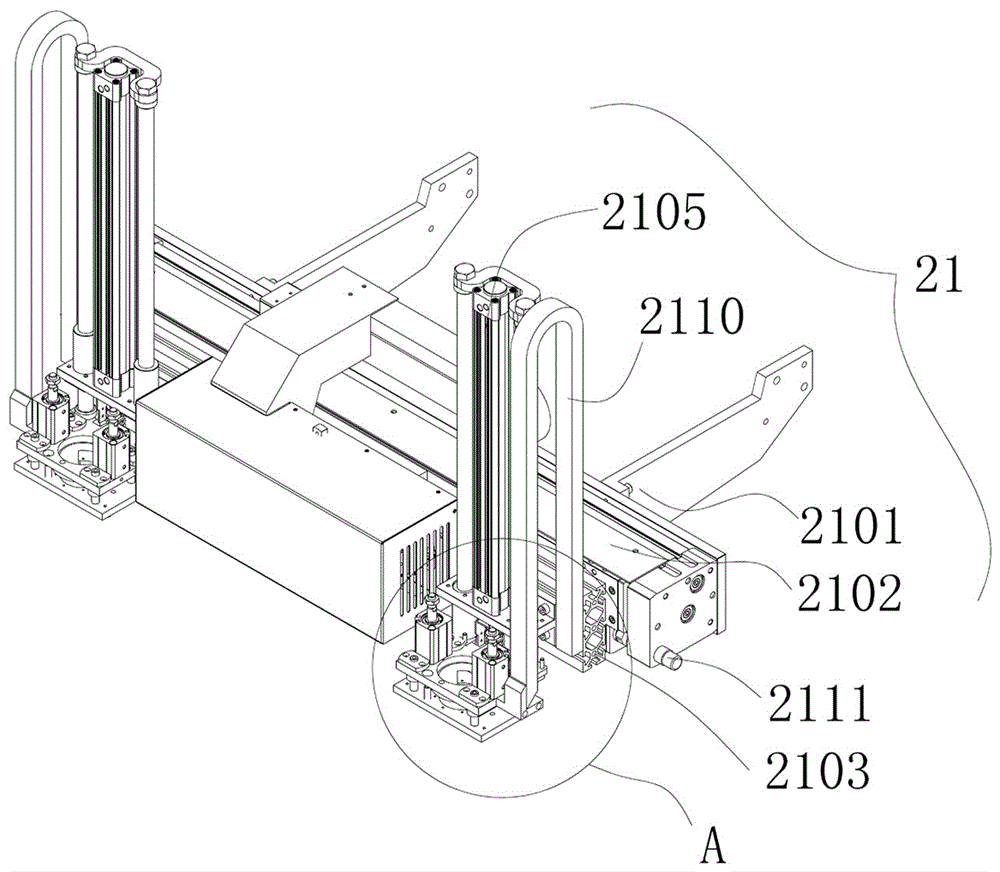

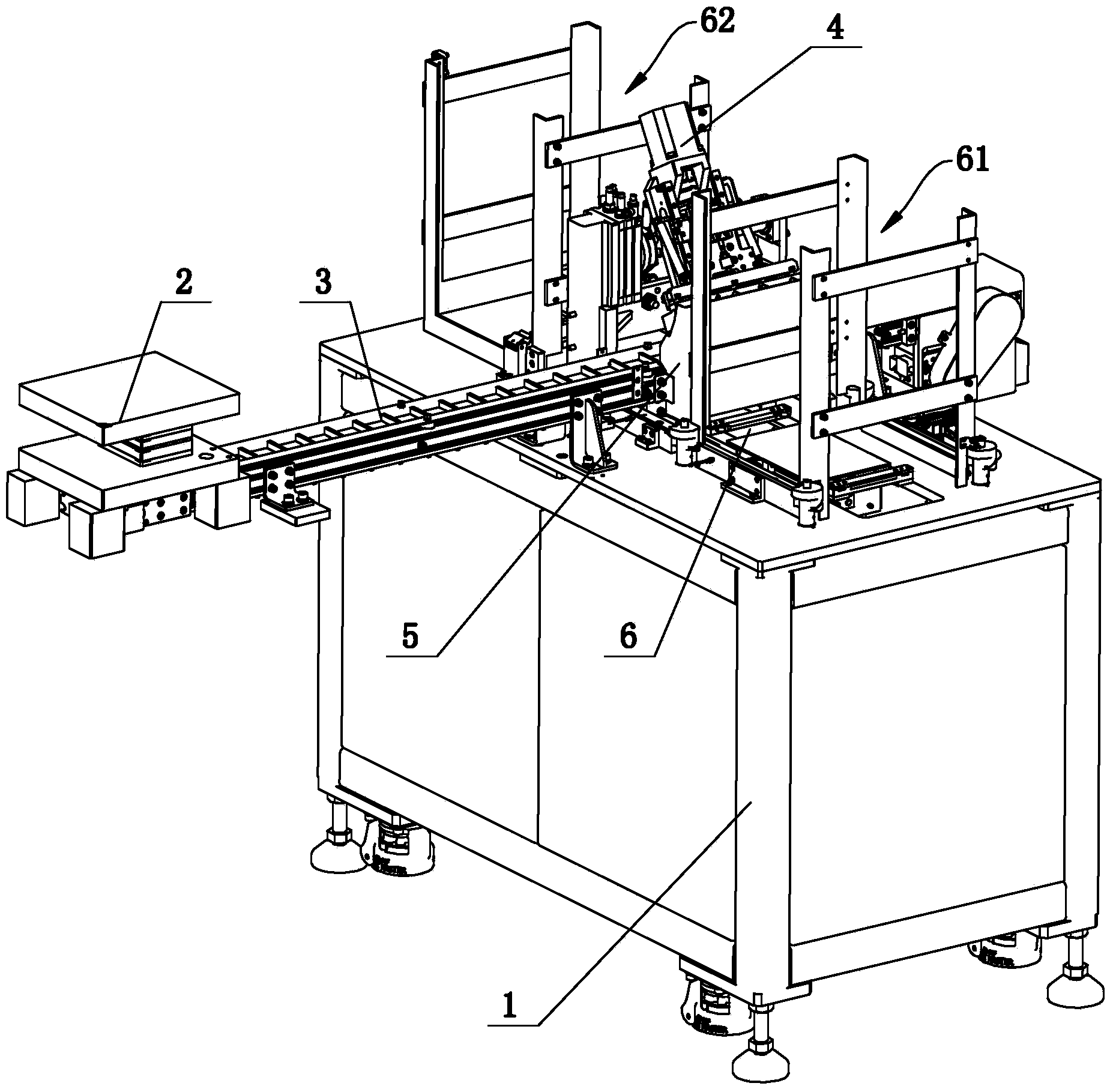

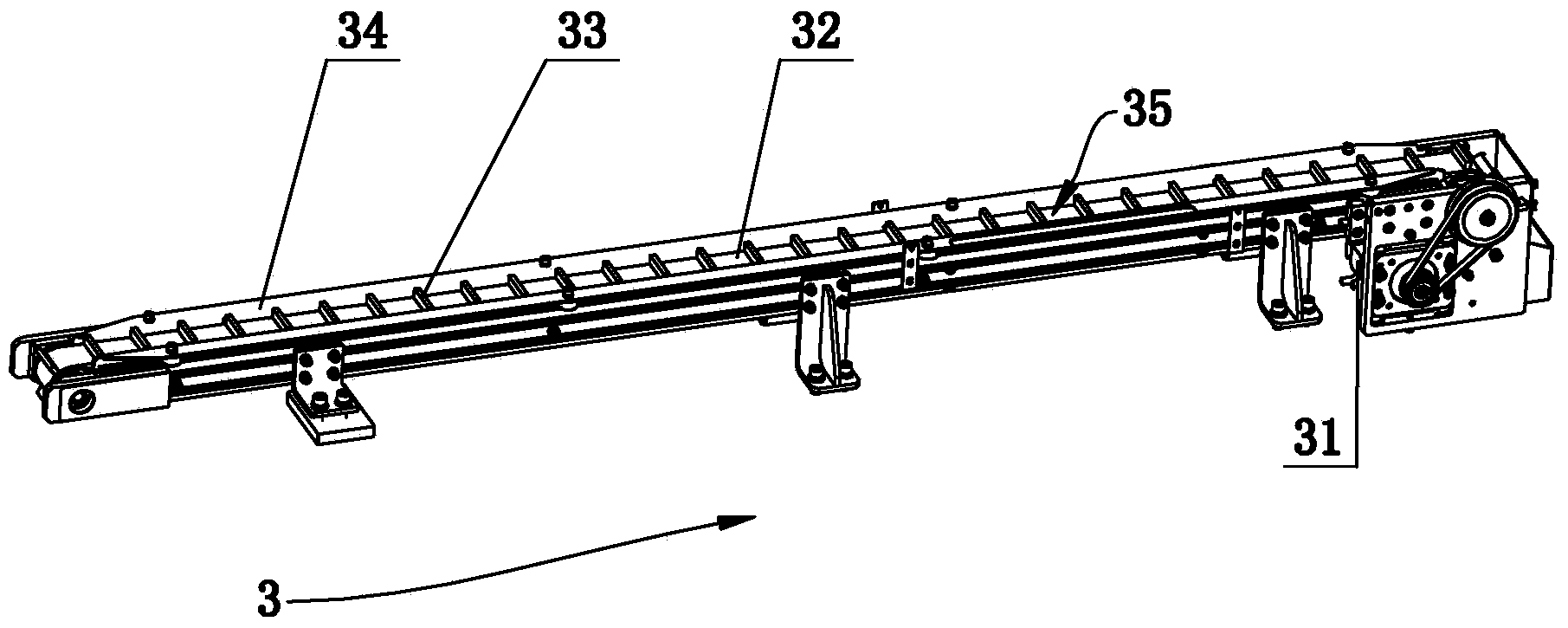

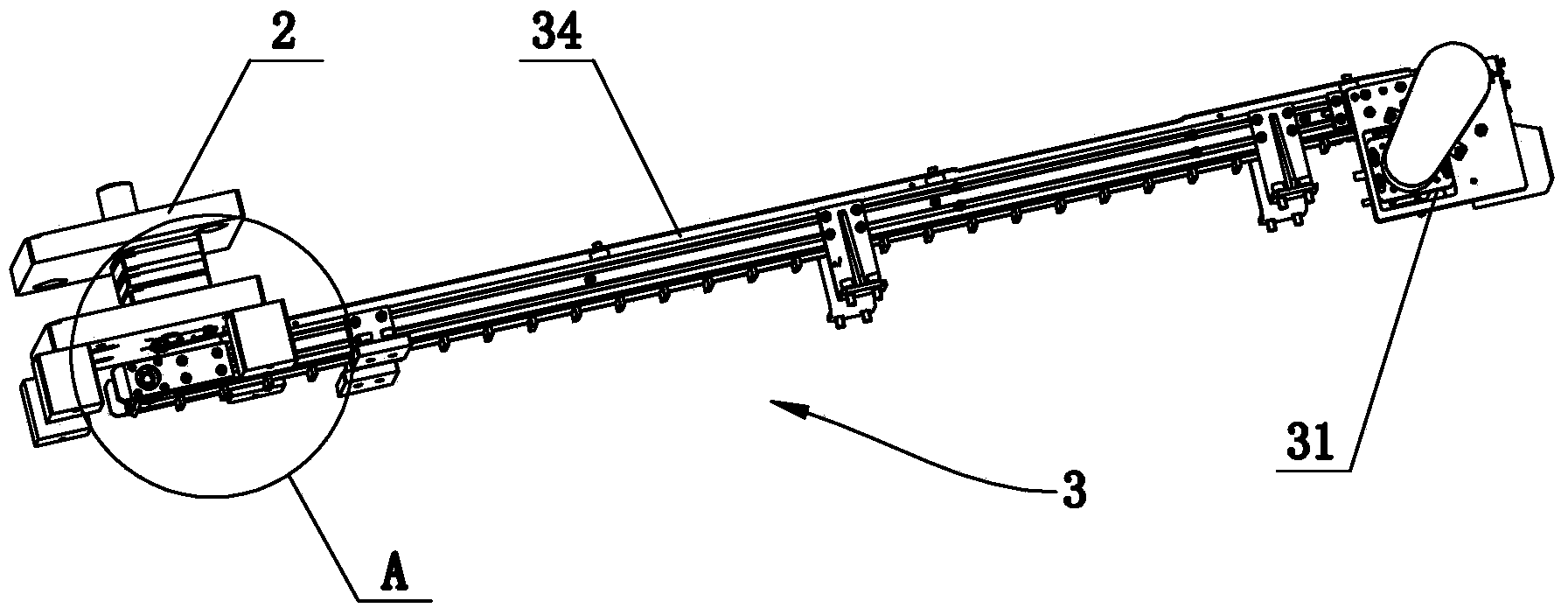

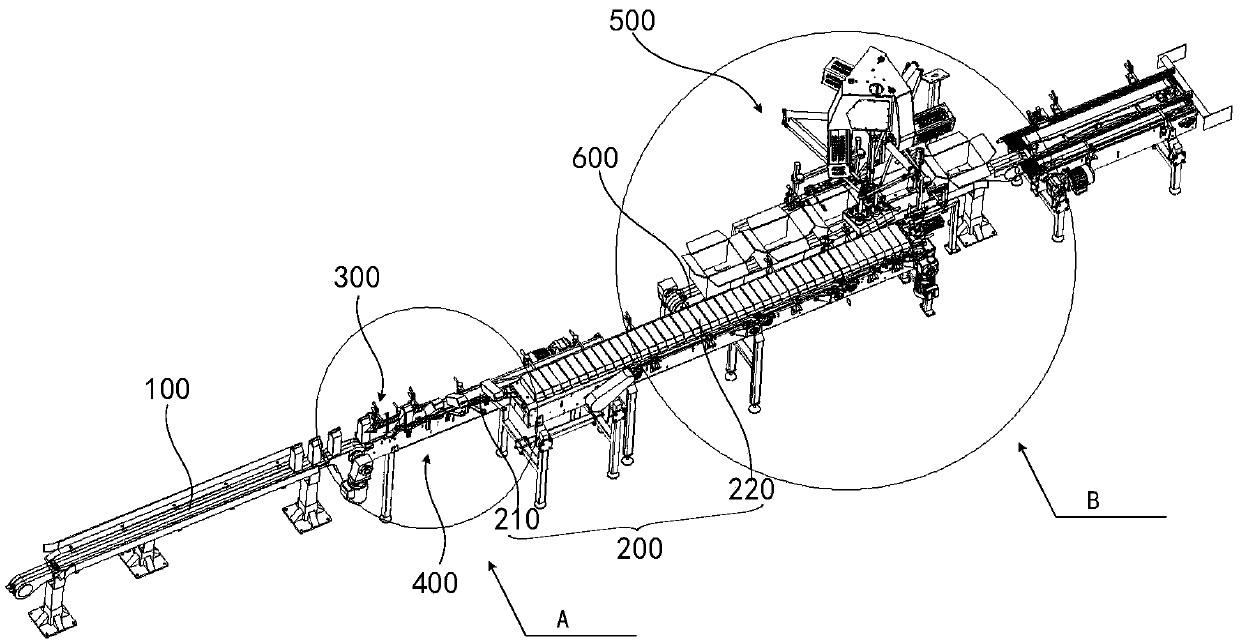

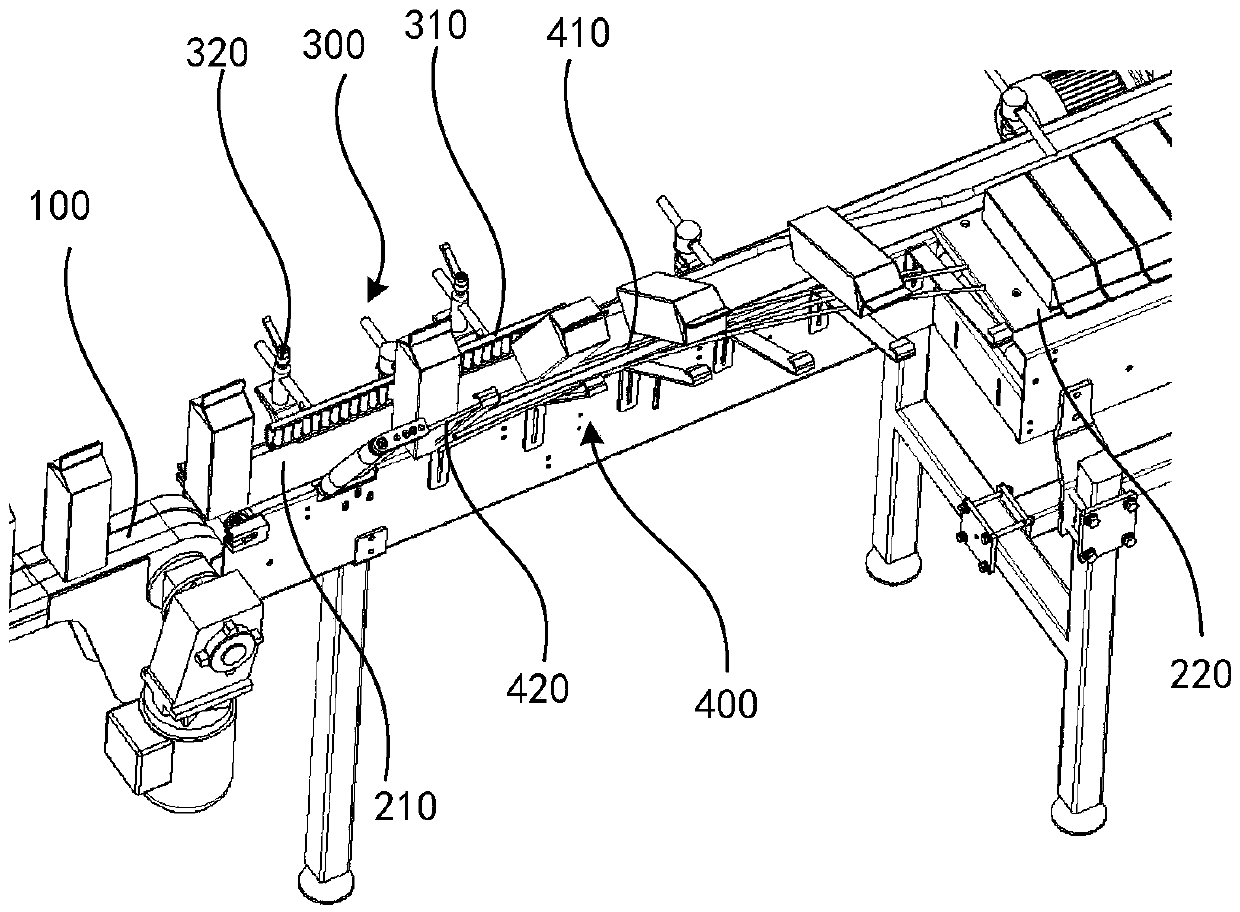

Two-dimensional code marking machine of lead frame and working method of two-dimensional code marking machine

ActiveCN102922882AEasy to detectRealize automatic deliveryTypewritersDimensional modelingEngineering

The invention discloses a two-dimensional code marking machine of a lead frame and a working method of the two-dimensional code marking machine. The marking machine comprises a lead frame conveyer, a direction detection device, a marking device and a lead frame blanking device; the lead frame conveyer comprises lead rails, a feeding conveying module, a middle material push and clamp module, a discharging pushing hand module and an oscillating blanking module; the feeding conveying module conveys the lead frame to be processed to the middle material push and clamp module; the middle material push and clamp module conveys the lead frame to be processed to a direction detection bit to detect the direction and mark; the discharging pushing hand module pushes the processed lead frame to the position of the oscillating blanking module, and the oscillating blanking module puts the qualified lead frame into a stack blanking box between the front lead rail and the rear lead rail. According to the two-dimensional code marking machine and the working method of the two-dimensional code marking machine disclosed by the invention, automatic conveying and automatic direction detection and marking of the lead frame to be processed can be achieved, and detection and location of the processed lead frame are achieved after automatically marking.

Owner:SHENZHEN GRAND INNOSYS CORP

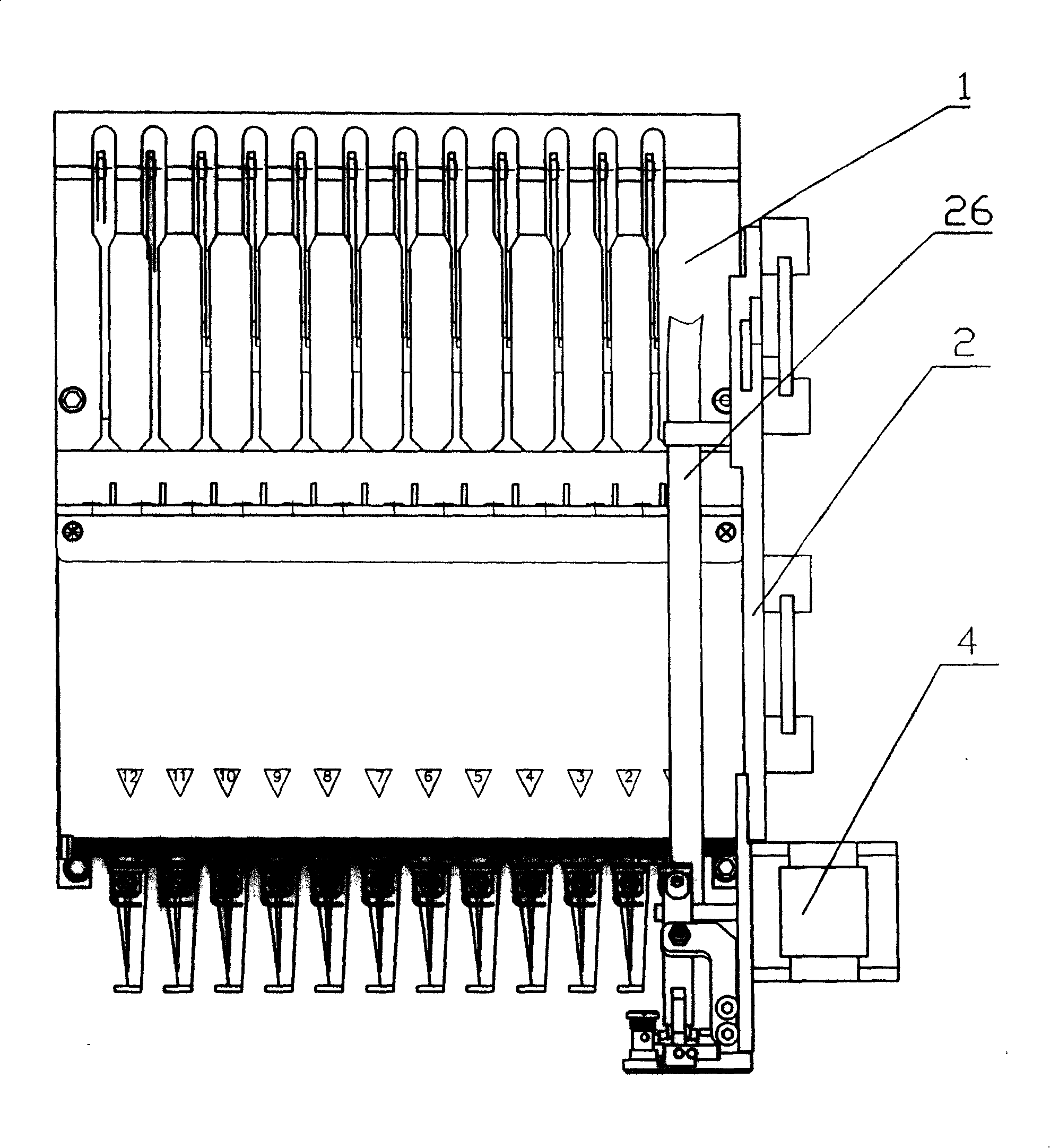

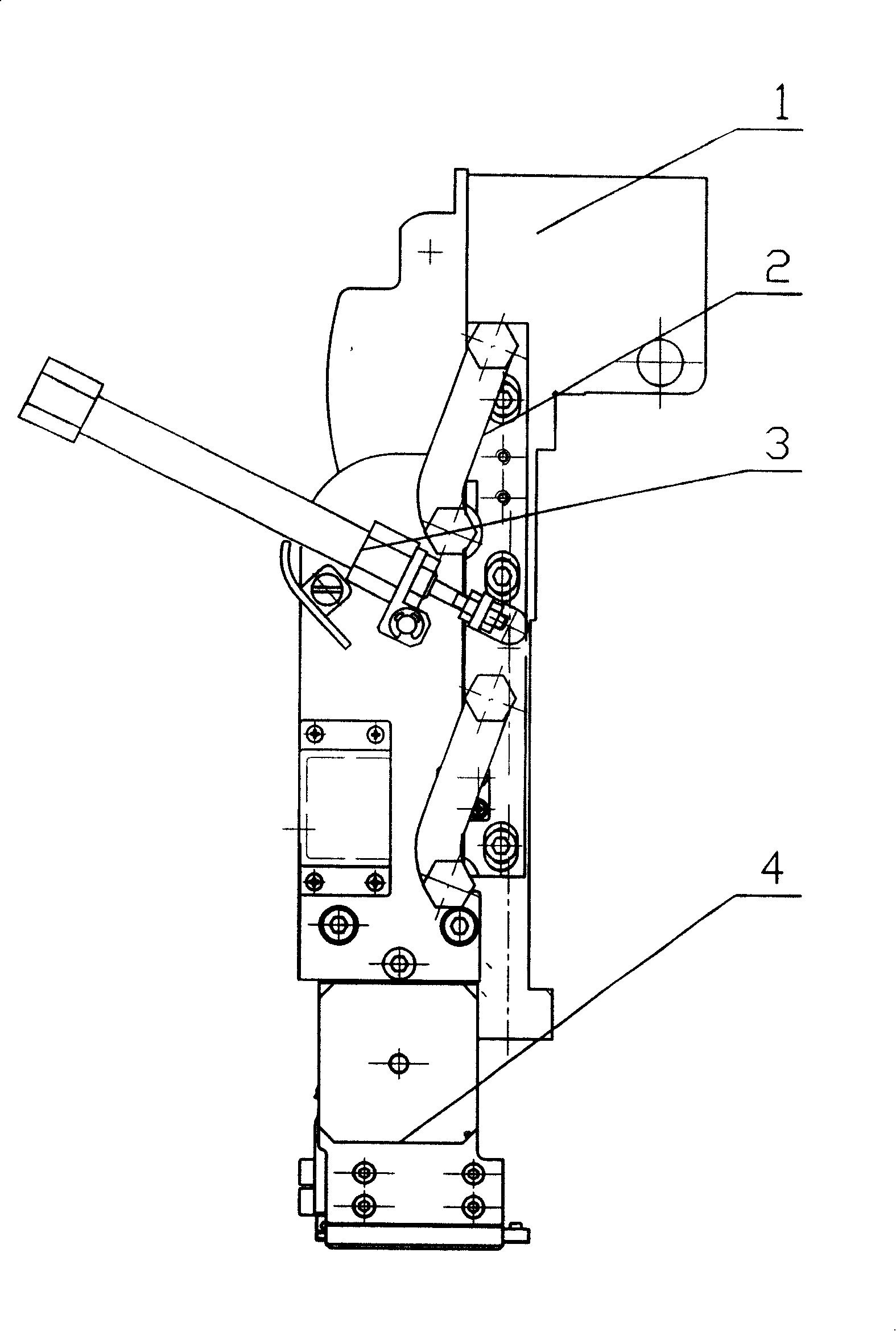

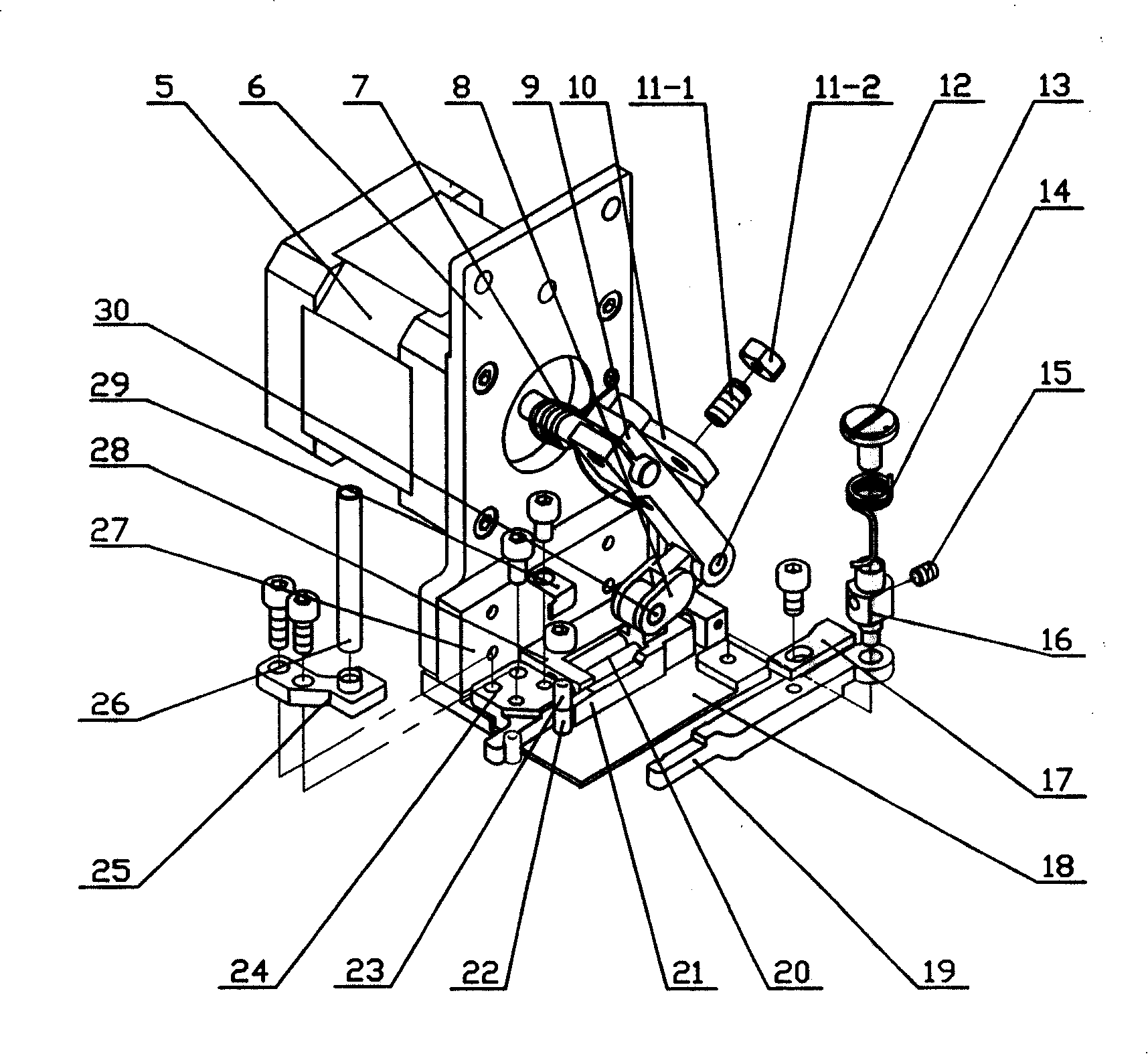

Bead embroidering mechanism for computer embroidering machine

InactiveCN101235583ARealize automatic deliveryIncrease productivityAutomatic machinesFeedersElectric machineryEngineering

The invention relates to a beads enchasing mechanism of a computerized embroidery machine, which is characterized in that a stepping motor which is only controlled by a computer is installed on frame work which is composed of a bottom board and a motor plate, a motor connecting bar is installed on a shaft of the motor, the other end of the motor connecting bar is hinged with an actuation link, the other end of the actuation link is hinged with a bead push-rod, a fixed lever component is installed on the bottom board on one side of the push-rod, a rotatable lever component is installed on the other side, and a connecting base which is provided with a discharge port and is connected with a material feeding pipe is arranged on the fixed lever, The mechanism can be installed on a needle bar frame of the computerized embroidery machine in match with various lifting devices and can realize automatic enchasing of the beads on various embroideries.

Owner:浙江珠光集团临海电脑刺绣设备有限公司

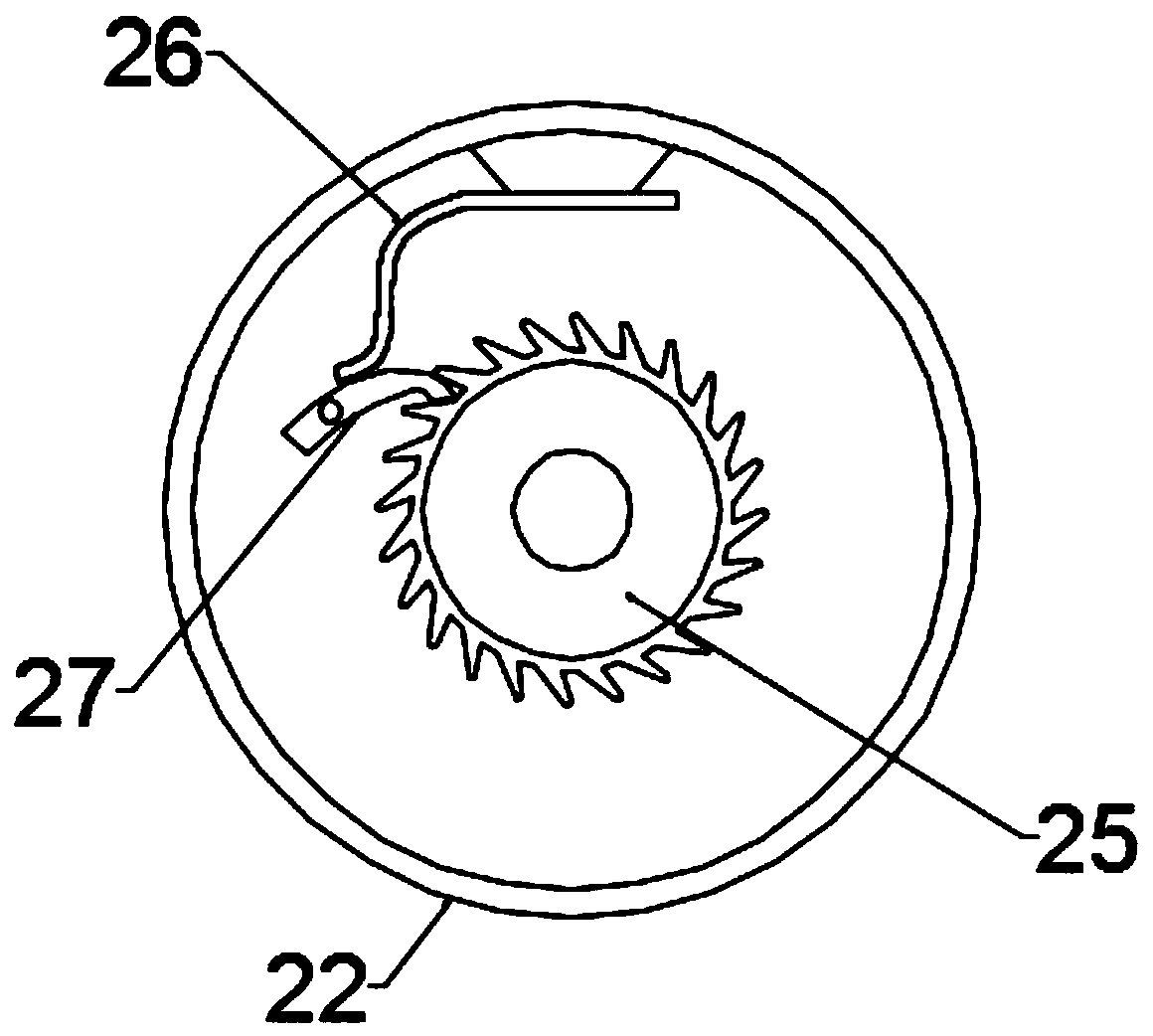

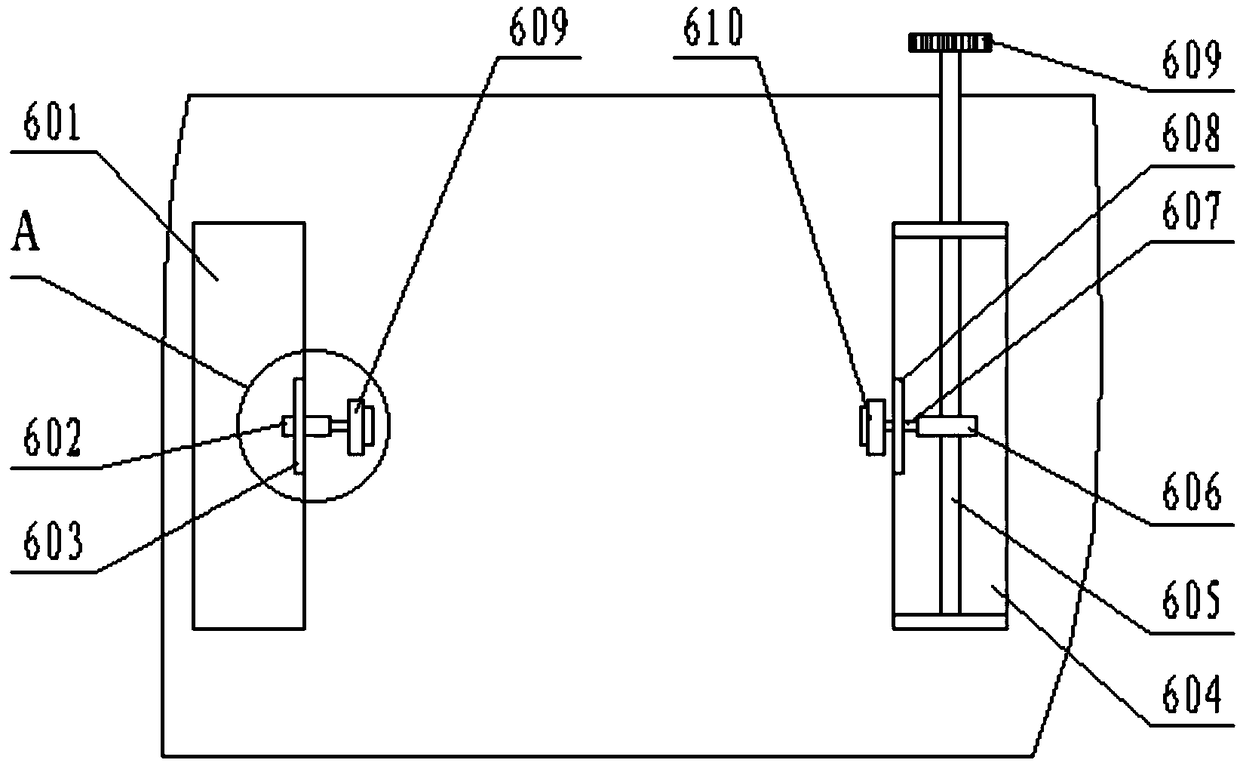

Mechanical vegetable and vine plant chopping machine

InactiveCN109732658ARealize intermittent deliveryRealize automatic deliveryMetal working apparatusMotor driveTransmission belt

The invention relates to a chopping device, in particular to a mechanical vegetable and vine plant chopping machine. The machine comprises a worktable, a bracket, an up-down cutting mechanism, and a conveying belt for intermittently conveying vegetables or vine plants; the bracket is fixed on the worktable, and is used for fixing the up-down cutting mechanism; the up-down cutting mechanism is arranged above the conveying belt on the worktable; the up-down cutting mechanism is driven to work through a motor mounted on the bracket; and an output shaft of the motor is rotationally connected witha connecting rod mechanism of an intermittent driving mechanism connected to a belt wheel on one side of the conveying belt through multiple sections of transmission belts. The machine is novel in design; and when the motor drives the up-down cutting mechanism to work, the multiple sections of transmission belts and the connecting rod mechanism drive a first transmission rod to perform a forward-reverse reciprocating motion, so that the conveying belt is intermittently driven to rotate under the effect of a ratchet mechanism to realize intermittent conveying of the vegetables or vine plants and to realize automatic conveying and cutting treatment.

Owner:WEIFANG UNIV OF SCI & TECH

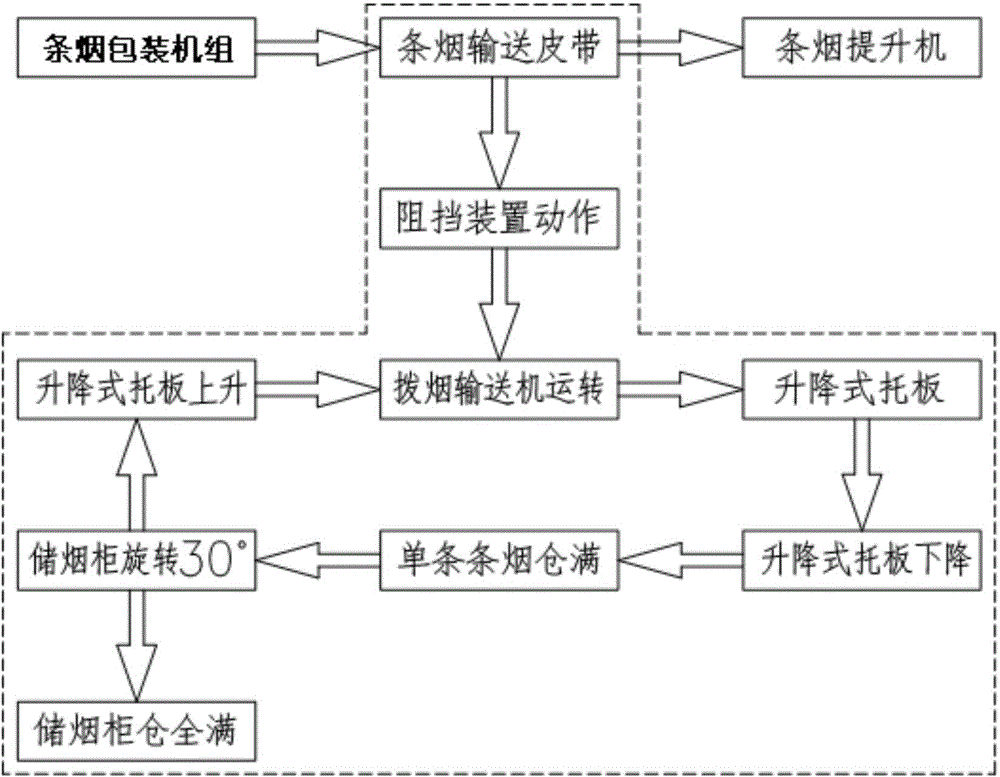

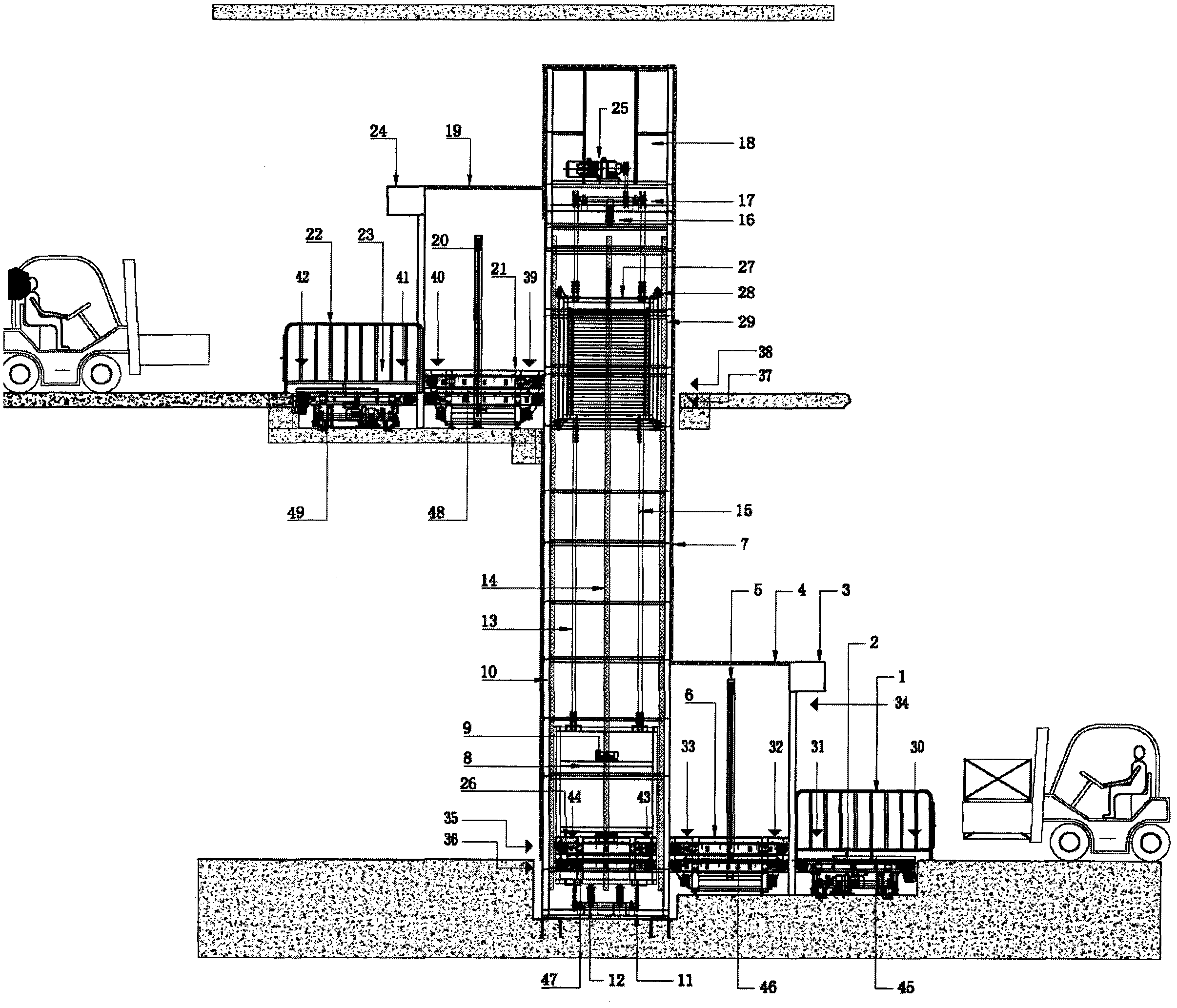

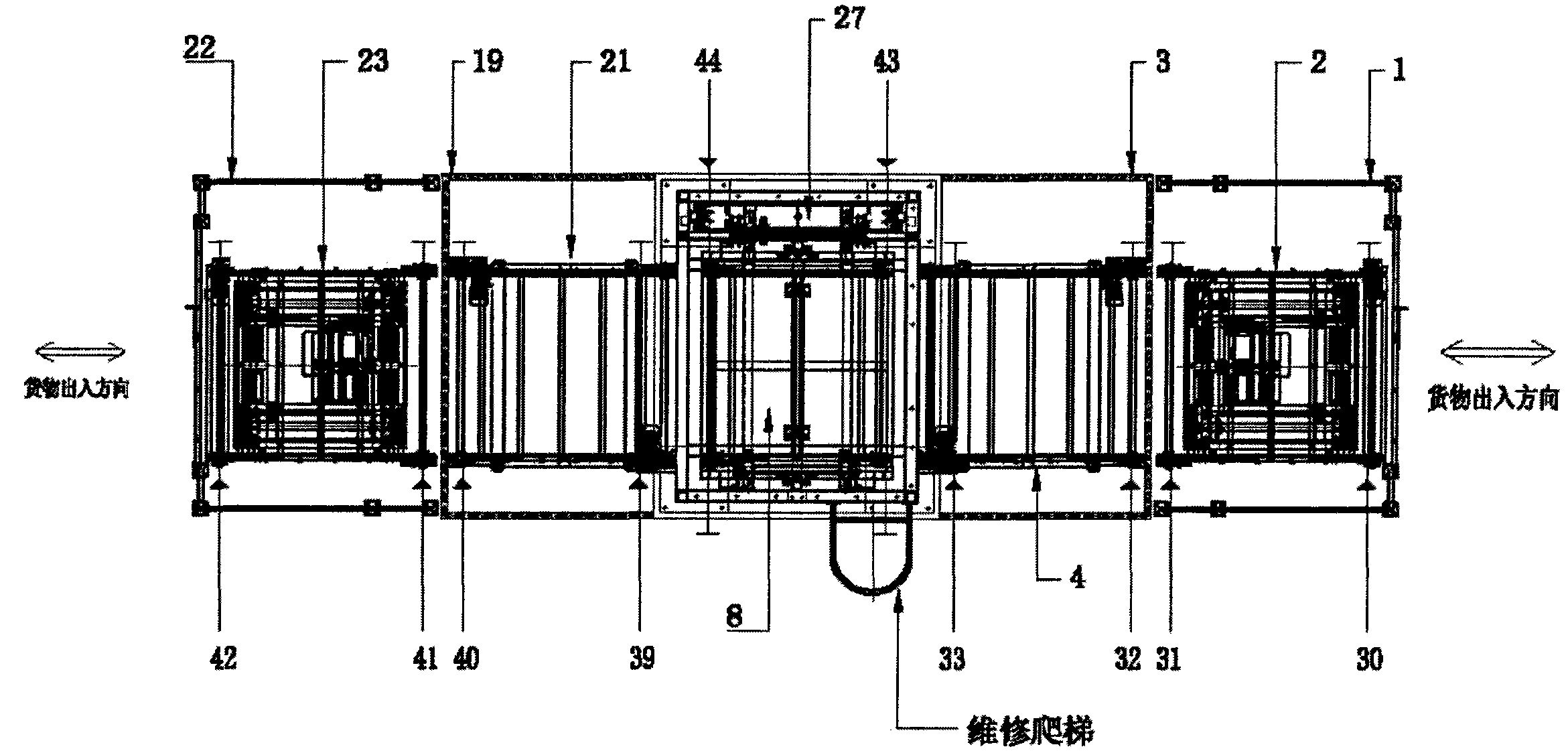

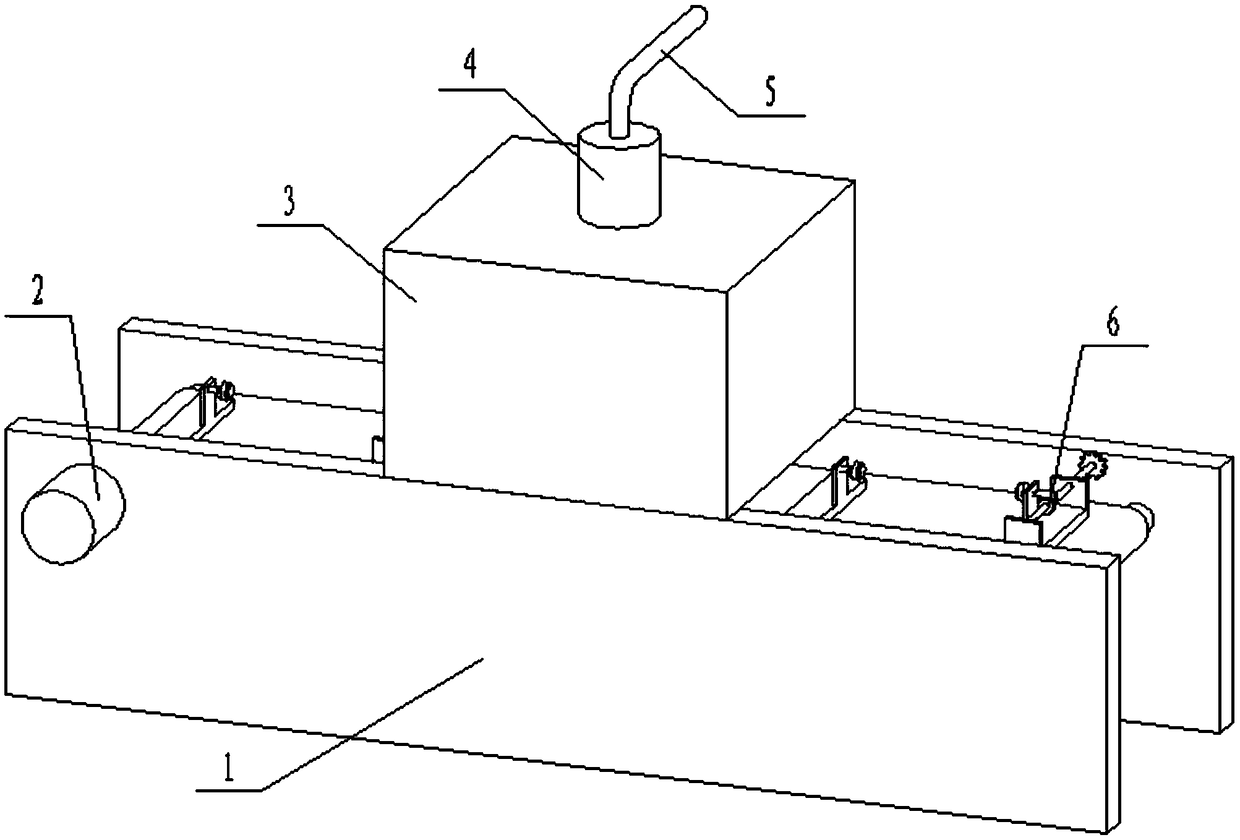

Turntable type cigarette storing device

InactiveCN103818720ARealize automatic deliveryLarge capacityConveyor partsAutomatic steeringEngineering

A turntable type cigarette storing device is mounted between a cigarette packaging unit and a cigarette lift and is a cylindrical storing bin. A conveying belt is mounted between the cigarette packaging unit and the cigarette lift. A limit device is mounted on the conveying belt. The cylindrical cigarette storing cabinet is arranged on one side of the conveying belt. A cigarette conveyor is mounted above the conveying belt and integrates the conveying belt and the cylindrical cigarette storing cabinet. The turntable type cigarette storing device has the advantages of accurate control, high action speed, high efficiency, and capability of a conveying mode of automatic control, conveying and storing and turntable rotation and displacement. An automatic steering, collecting and storing technology is adopted, cigarette conveying and packaging efficiency is improved, a rotatable turntable type storing mechanism is created, fast cigarette conveying and storing is realized, cigarette packaging efficiency and sliding groove collecting capability are improved, the problems with cigarette package online collection and storage are solved, and the turntable type cigarette storing device is an ideal matching device for cigarette conveying and packaging.

Owner:ETABONG QINGDAO TOBACCO MACHINERY +1

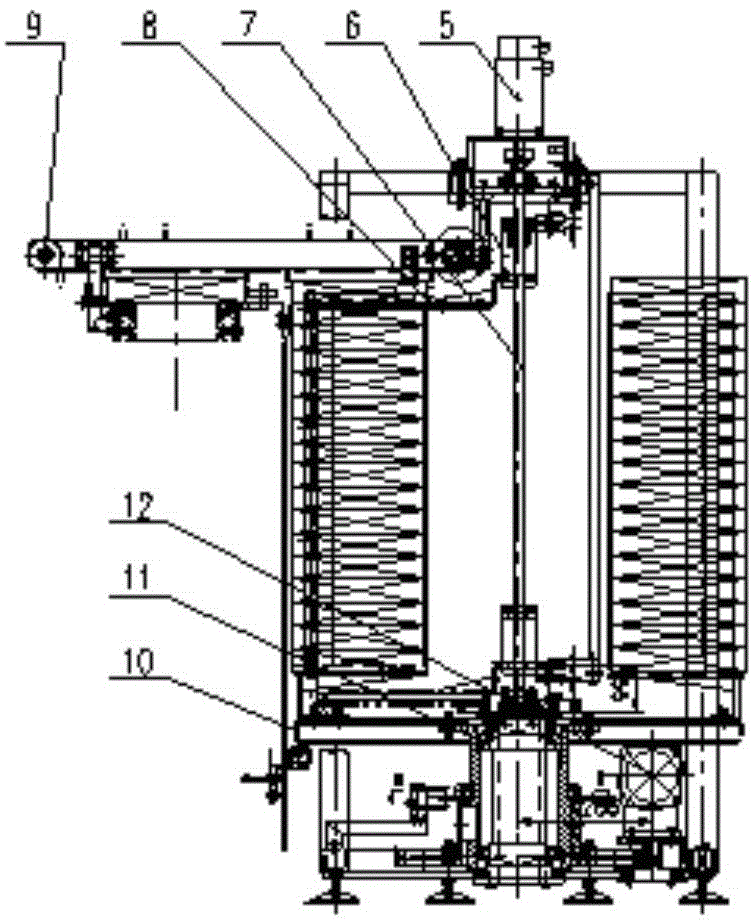

Horizontal automatic cycle tooling plate vertical conveyor

A horizontal automatic cycle tooling plate vertical conveyor comprises two groups of single chain tooling plate lifting conveying sections, two groups of fireproofing devices, two groups of double chain tooling plate lifting conveying sections, a lift car, a lift car guide wheel assembly, a machine frame, a bottom driven sprocket, a bottom anti-collision device, two groups of vertical conveying drive chains, lift car guide rails, a top anti-collision device, a top drive sprocket, a main drive motor, a double chain tooling plate lifting conveying section in the lift car, a photoelectric detection group and a tooling plate group. The horizontal automatic cycle tooling plate vertical conveyor improves the warehouse fireproofing safety and reduces the fire damage to devices and goods effectively; can achieve automatic goods conveying and automatic management of the conveying process; omits a carrying device in the goods conveying process to reduce conveying cost; reduces labors in the conveying process; improves the efficiency and the safety, and reduces the damage to goods; has a compact structure, occupies small areas, and improves the land utilization rate; and achieves vertical conveying of a variety of goods, and solves the problem of three-dimensional storing of certain goods.

Owner:谢刚

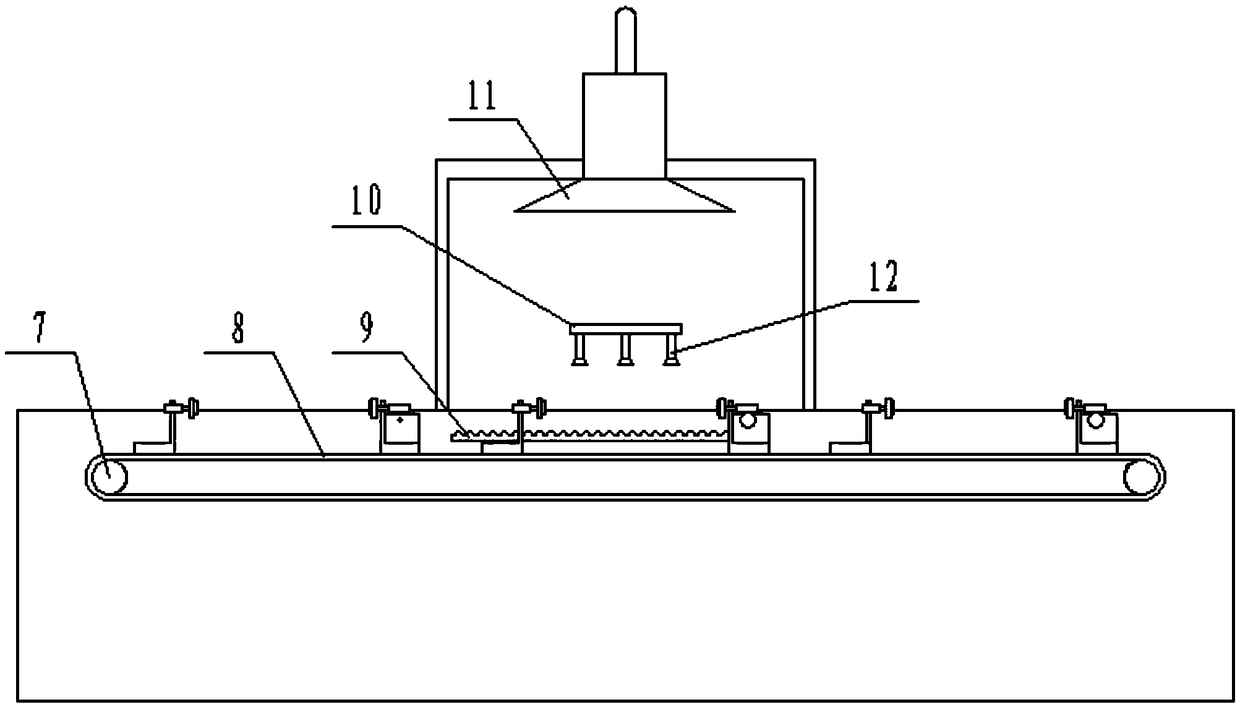

Environment-friendly building pipe paint spraying device

ActiveCN108654877ARealize automatic deliveryRealize automatic paintingSpraying apparatusEngineeringExhaust pipe

The invention discloses an environment-friendly building pipe paint spraying device. The environment-friendly building pipe paint spraying device comprises a rack, a conveying motor is arranged on oneside of the rack, a toothed bar is arranged on one side of the inner wall of the rack, a conveying roller is arranged in the rack, the conveying roller is fixedly connected with the conveying motor,a conveying belt is arranged on the outer side of the conveying roller, a clamping mechanism is arranged on the surface of the conveying belt, a box body is arranged at the upper end of the rack, an air suction pump is arranged at the upper end of the box body, the air suction pump communicates with the box body, the exhaust end of the air suction pump is provided with an exhaust pipe connected with a water box, a bearing plate is arranged in the box body, and a nozzle is arranged at the bottom of the bearing plate. The device has the beneficial effects that automatic conveying and automatic paint spraying of pipes can be achieved, the paint spraying effect is good, the efficiency is high, in the paint spraying process, paint mist generated by paint spraying can be absorbed, and the phenomenon that due to paint mist drifting, the health of an operator is affected is avoided.

Owner:杨智萍

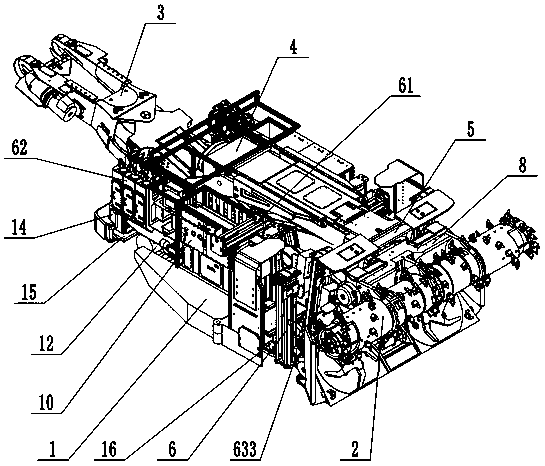

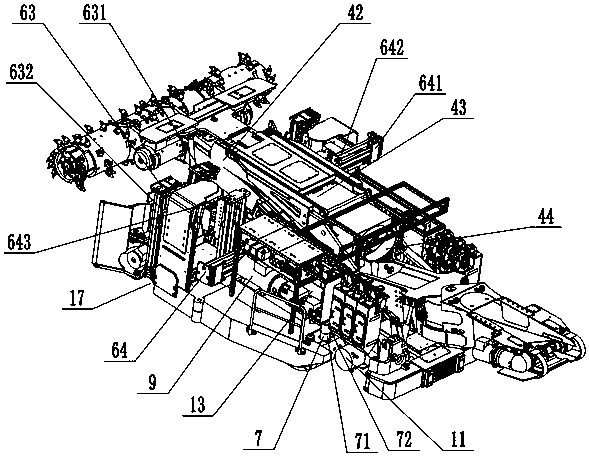

High-adaptability digging and anchoring integrated machine with dual-mode anchor drilling system

PendingCN111075444AAchieving parallel operation of anchor diggingFully automatedPropulsionAnchoring boltsSupporting systemElectric control

The invention provides a high-adaptability digging and anchoring integrated machine with a dual-mode anchor drilling system, and belongs to the technical field of underground coal mining equipment. The high-adaptability digging and anchoring integrated machine comprises a frame main body, a cutting system, a conveying system, a dust removing system, a multifunctional temporary supporting system, the dry-wet dual-mode anchor drilling system, an automatic lubricating system, a water-cooling spraying system, a hydraulic system and an electric control system, wherein a traveling mechanism adopts awide crawler design, so that the adaptability of the digging and anchoring integrated machine to a muddy bottom plate is improved; and the dry-wet dual-mode anchor drilling system has two functions of dry dust removal and wet dust removal, and real-time switching selection is carried out according to the geological conditions of the roadway bottom plate without replacing a drill box. By means ofthe high-adaptability digging and anchoring integrated machine, the problems of muddy of the bottom plate, poor stability of a top side wall and low tunneling efficiency in the rapid coal roadway tunneling under the complex geological conditions are solved; the integrated parallel operation of tunneling, anchor protection, transportation, dust removal and the like of a roadway tunneling working surface is realized; and the efficiency and safety of coal mining and transportation are improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

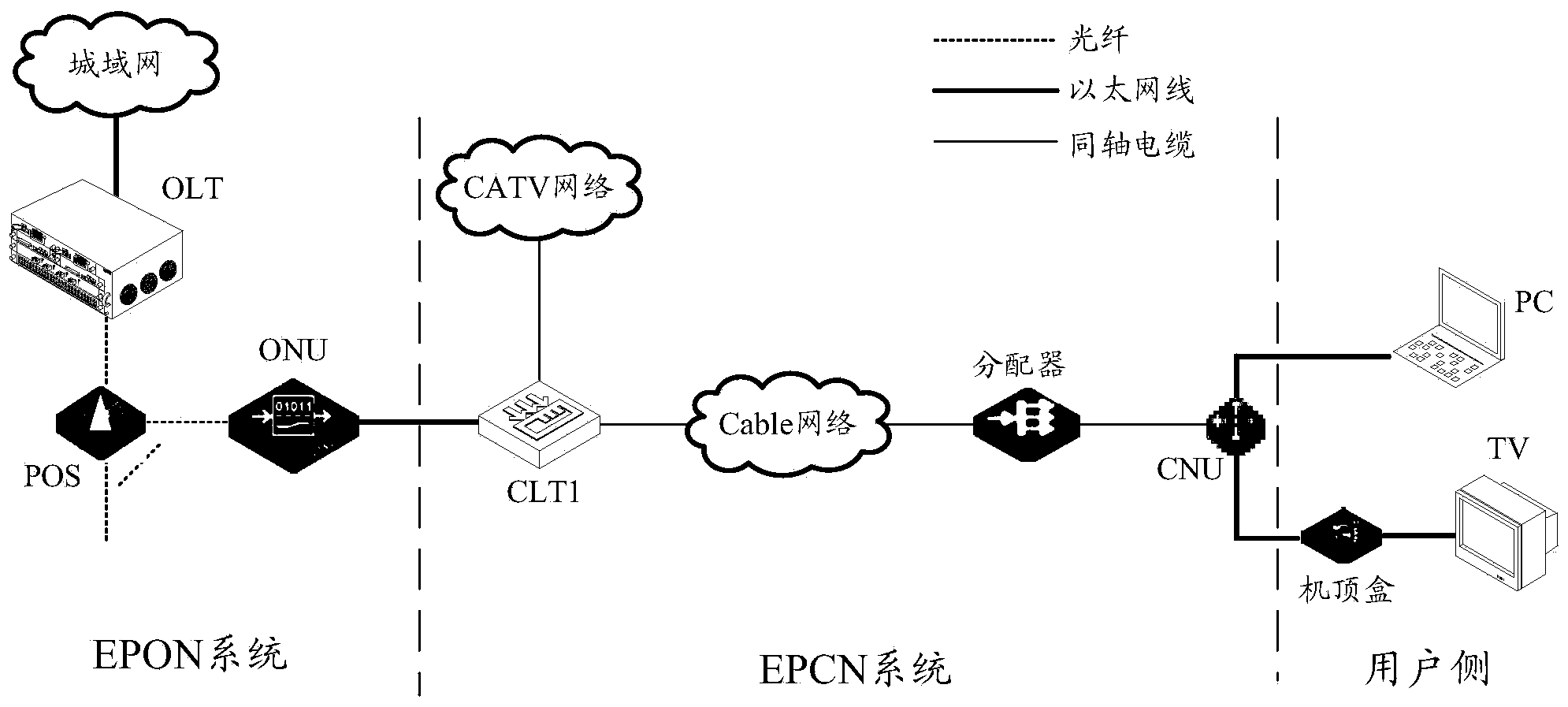

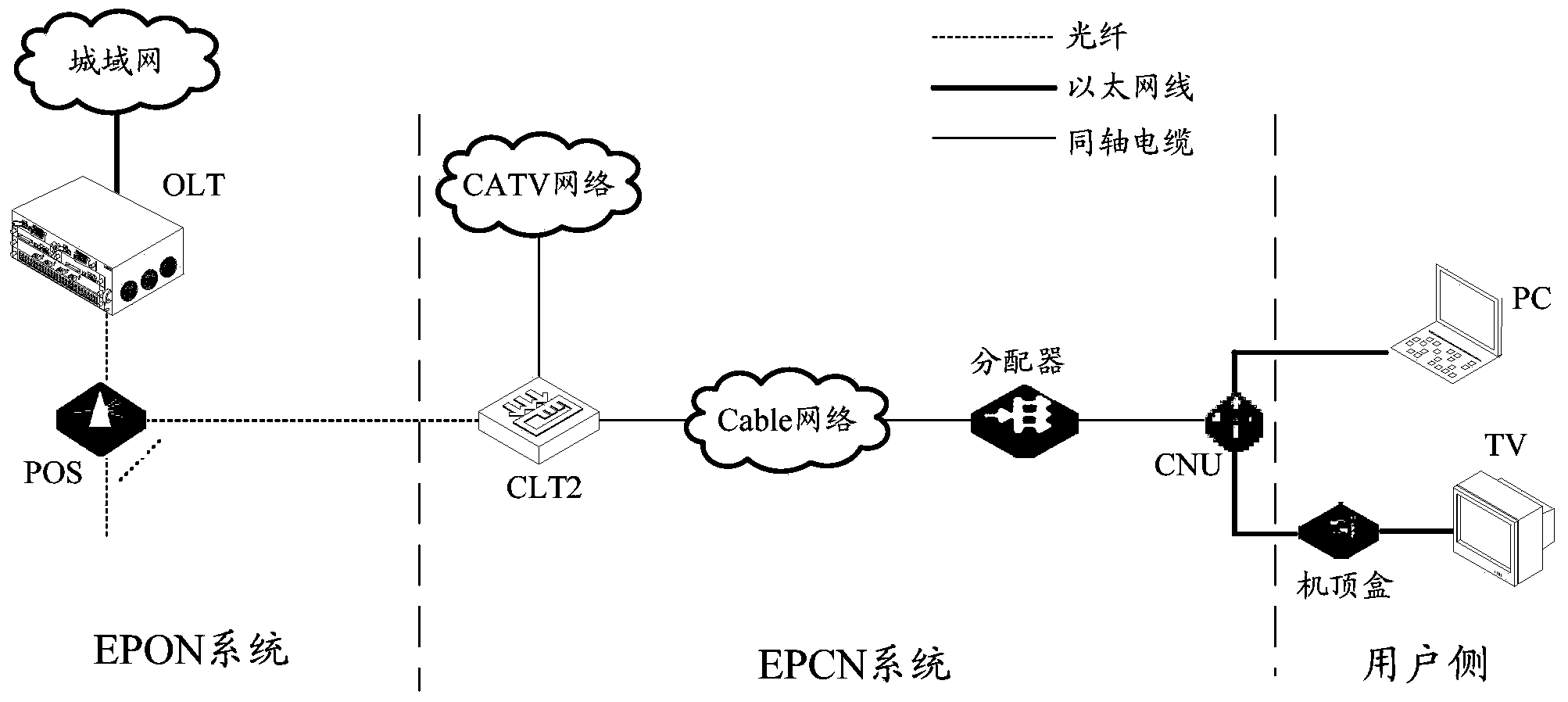

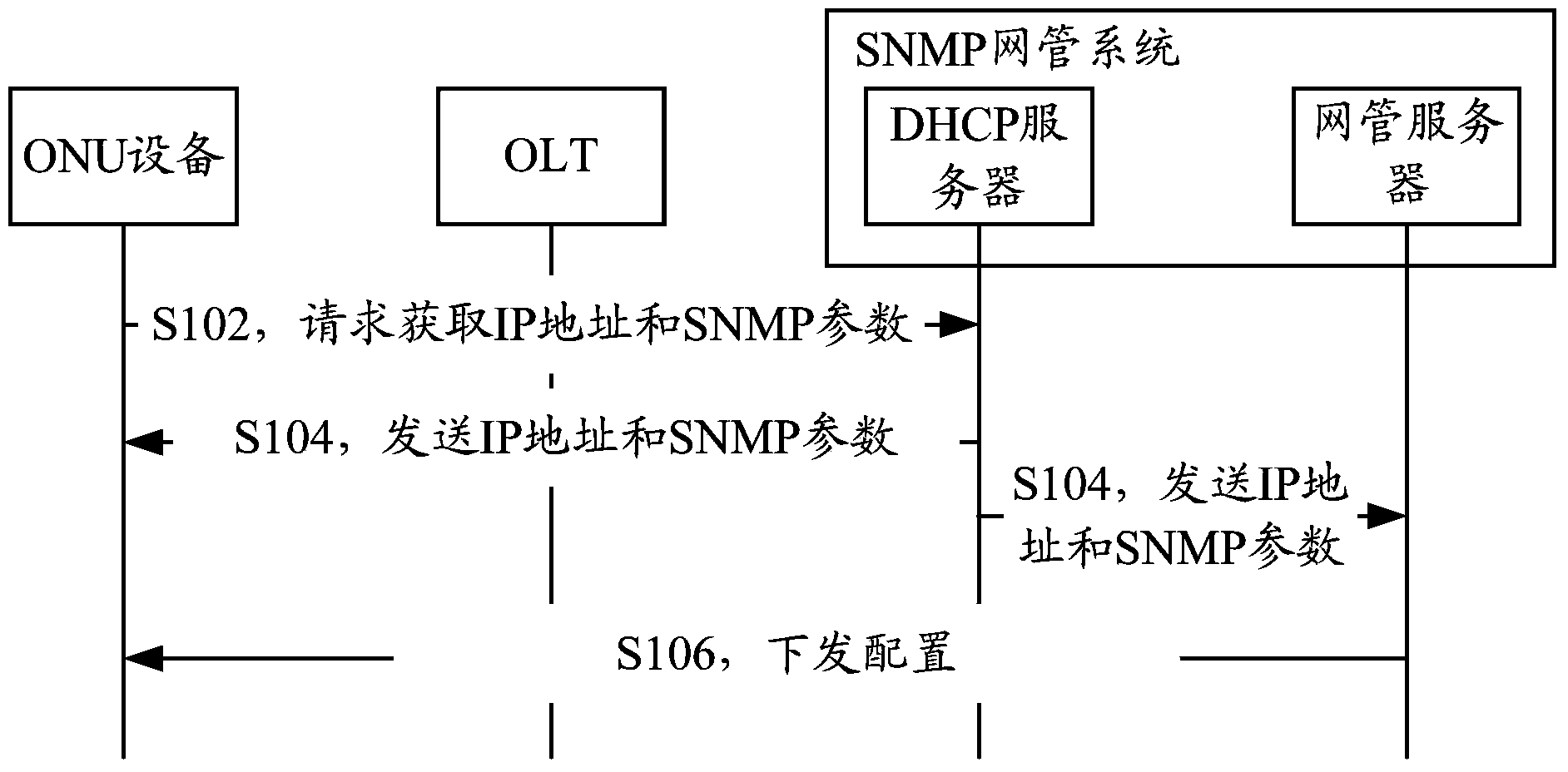

Method and device for automatically issuing ONU device configuration

ActiveCN104080020ARealize automatic deliveryShorten the timeMultiplex system selection arrangementsData switching networksDevice typeComputer science

The invention discloses a method and device for automatically issuing ONU device configuration. The method includes the steps that according to the device type of an ONU device, a corresponding configuration template file is determined, wherein the configuration template file comprises the device type, complete configuration information needing to be loaded by the ONU device of the device type, an ONU device system software version number list compatible with the complete configuration information and a version number of the configuration template file; if the version number of the current configuration file of the ONU device is different from the version number of the determined configuration template file, the current system software version number of the ONU device is in the system software version number list in the determined configuration template file, and the determined configuration template file is sent to the ONU device.

Owner:NEW H3C TECH CO LTD

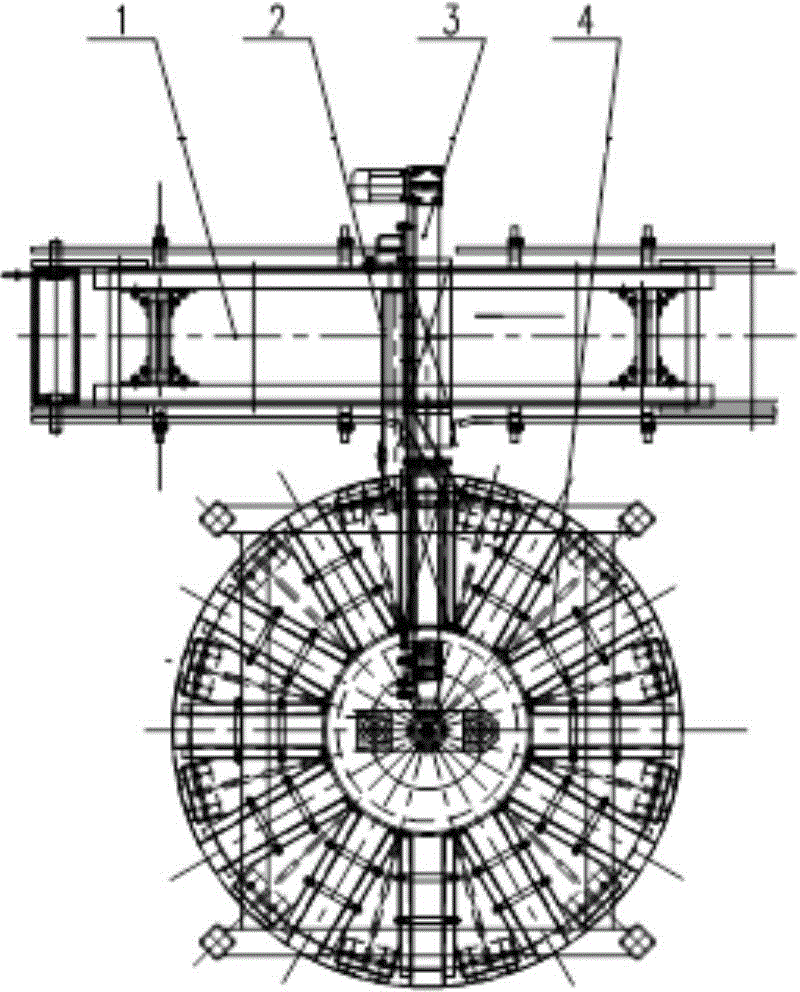

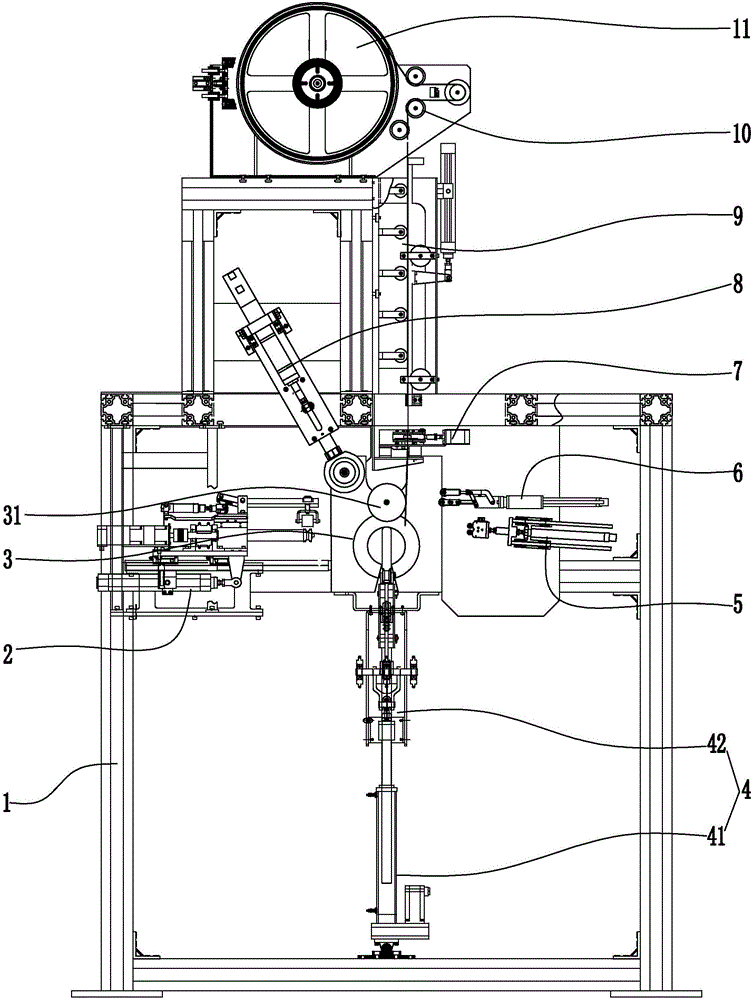

Laser automatic welding machine for diamond saw blades

ActiveCN106425095AHigh degree of mechanizationReduce manufacturing costLaser beam welding apparatusHigh volume manufacturingEngineering

The invention belongs to the technical field of diamond saw blade welding, and particularly relates to a laser automatic welding machine for diamond saw blades. The machine comprises a machine body, a saw blade absorbing grabbing system, a base body rotary indexing system, a tool bit conveying grabbing system, a welding clamping assembling system and a laser welding light path system; saw blade base bodies and tool bits are grabbed and subject to alignment pairing through the saw blade absorbing grabbing system and the tool bit conveying grabbing system, clamping positioning is completed through the welding clamping assembling system, and welding is carried out through the laser welding light path system; after the tool bits are welded, the saw blade base bodies are rotated to the next welding station through the base body rotating indexing system until the tool bits on the saw blade base bodies are welded, and the finished product saw blades are conveyed and discharged to the storing position through the saw blade absorbing grabbing system. The machine is a producing machining device which is high in speed, free of contact and small in deformation, large-batch production can be achieved, the welding strength is high, in the cutting and using process, the tooth disengaging phenomenon is avoided, and use safety of the machine is greatly improved.

Owner:郑州金海威科技实业有限公司

Automatic bead flipping machine

ActiveCN106079504ARealize automatic deliveryReduce labor intensityTyresEngineeringMechanical engineering

The invention discloses an automatic bead flipping machine. According to the automatic bead flipping machine, automatic bead conveying, feeding and discharging and bead flipping can be achieved, so that labor intensity is greatly relieved, and the working efficiency is improved. The automatic bead flipping machine comprises a machine frame, a bead rotation driving device, a bead flipping mechanism and a bead conveying device, wherein the bead rotation driving device, the bead flipping mechanism and the bead conveying device are arranged on the machine frame. The bead conveying device comprises a conveying rail, a conveying trolley, a bead storage device and a bead lifting mechanism, wherein the conveying trolley can move along the conveying rail, the bead storage device is arranged on the conveying trolley, and the bead lifting mechanism is arranged on the machine frame and used for lifting the bead storage device. Vertical installation holes are formed in the conveying trolley. The bead storage device comprises a storage rack, vertical guide columns, a left bead clamping mechanism and a right bead clamping mechanism, wherein the vertical guide columns are arranged on the storage rack and matched with the vertical installation holes, and the left bead clamping mechanism and the right bead clamping mechanism are arranged on the storage rack.

Owner:机械科学研究院浙江分院有限公司

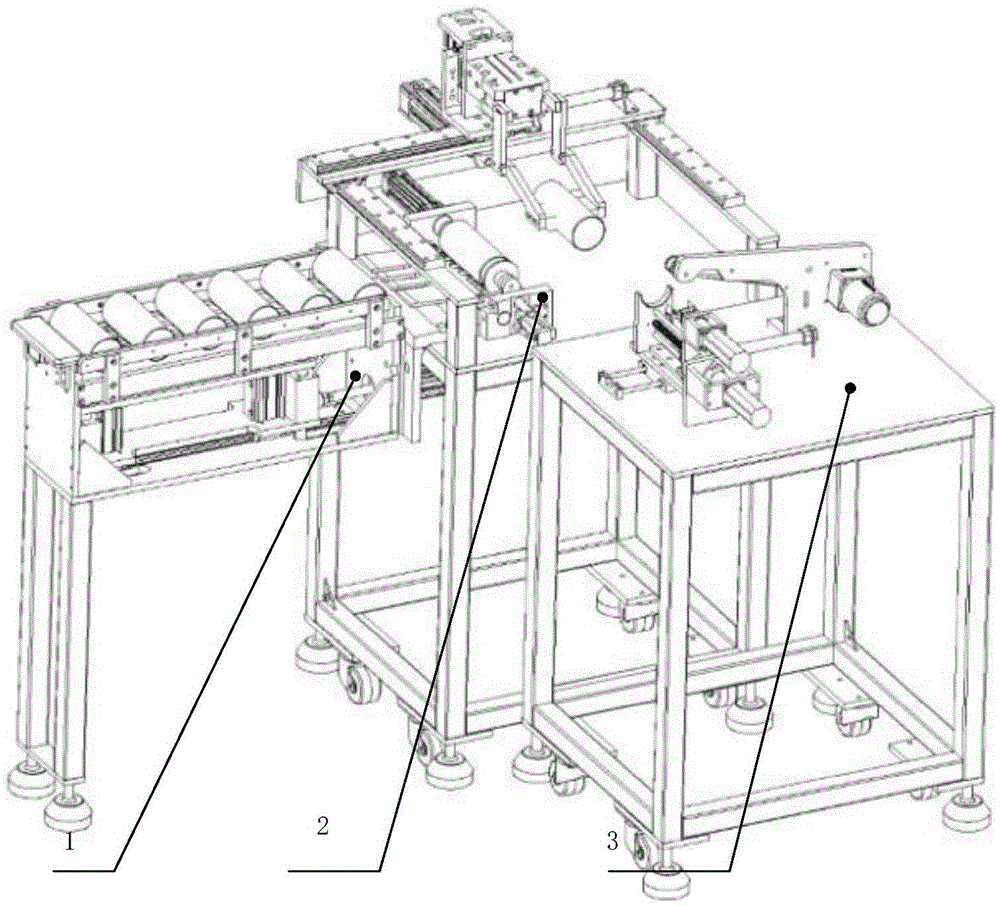

Automatic polishing system for stainless-steel cups

InactiveCN105619212ARealize automatic deliveryRealize automatic clampingGrinding drivesBelt grinding machinesEngineeringMotion control

The invention provides an automatic polishing system for stainless-steel cups, which comprises a conveying mechanism, a feeding mechanism and an external polishing mechanism, wherein the conveying mechanism comprises a conveying frame, a conveying table unit and a pressing unit; the conveying table unit and the pressing unit are mounted on the conveying frame; the feeding mechanism is mounted on a bracket faceplate of the conveying mechanism and comprises a feeding frame and a motion control unit mounted on the feeding frame; the external polishing mechanism comprises a polishing frame, an abrasive belt control unit and a part motion control unit; and the abrasive belt control unit and the part motion control unit are mounted on the polishing frame. The automatic polishing system for the stainless-steel cups can completely replace manual operation, remarkably improves the working efficiency, lowers the labor cost and increases the automation level of enterprises. Meanwhile, the automatic polishing system for the stainless-steel cups realize accurate control of polishing parameters and can achieve more stable and favorable polishing quality.

Owner:望江县雷创科技有限公司

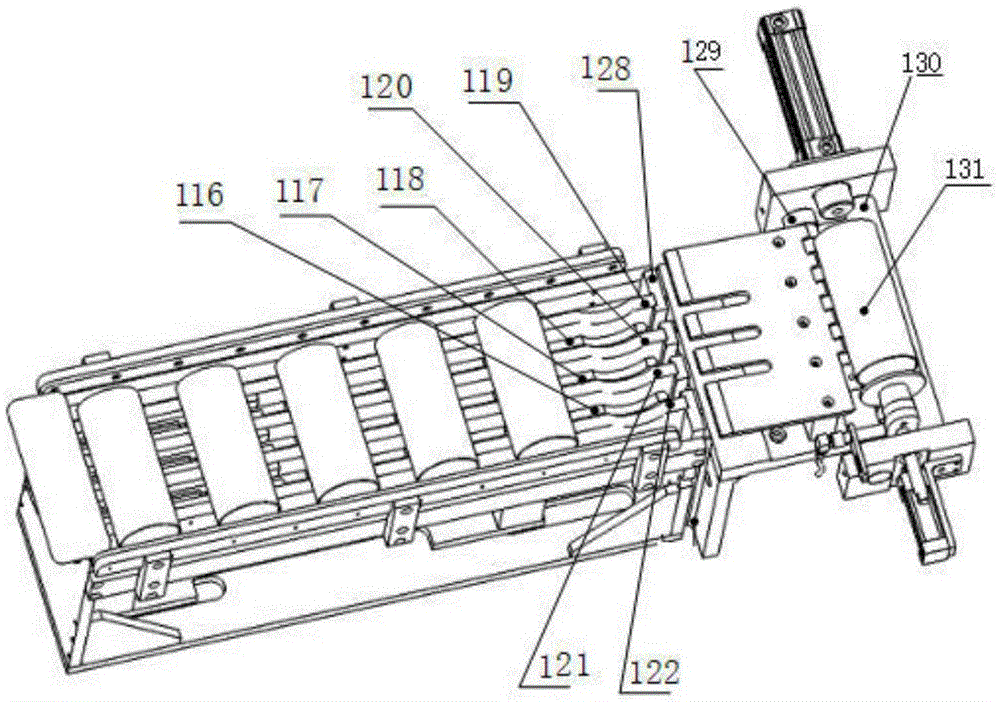

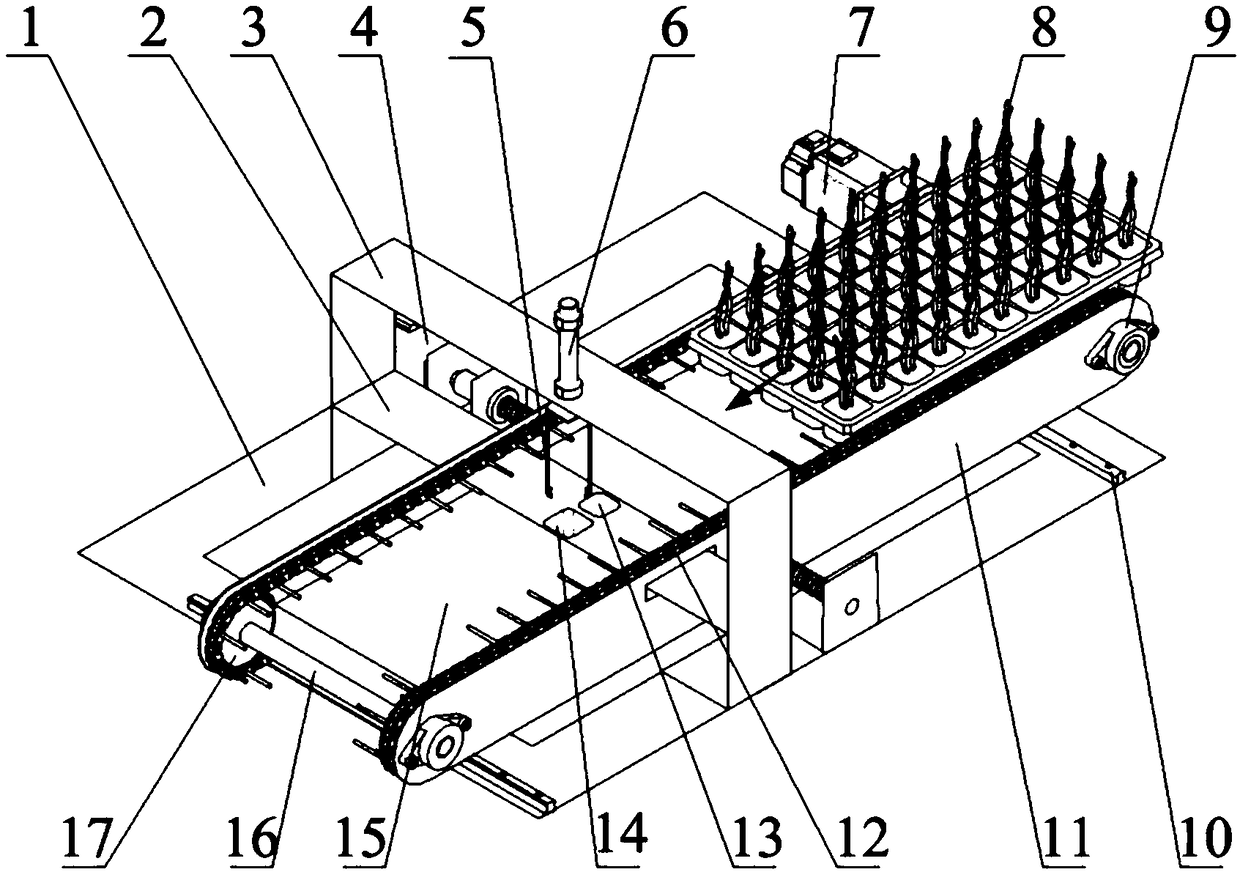

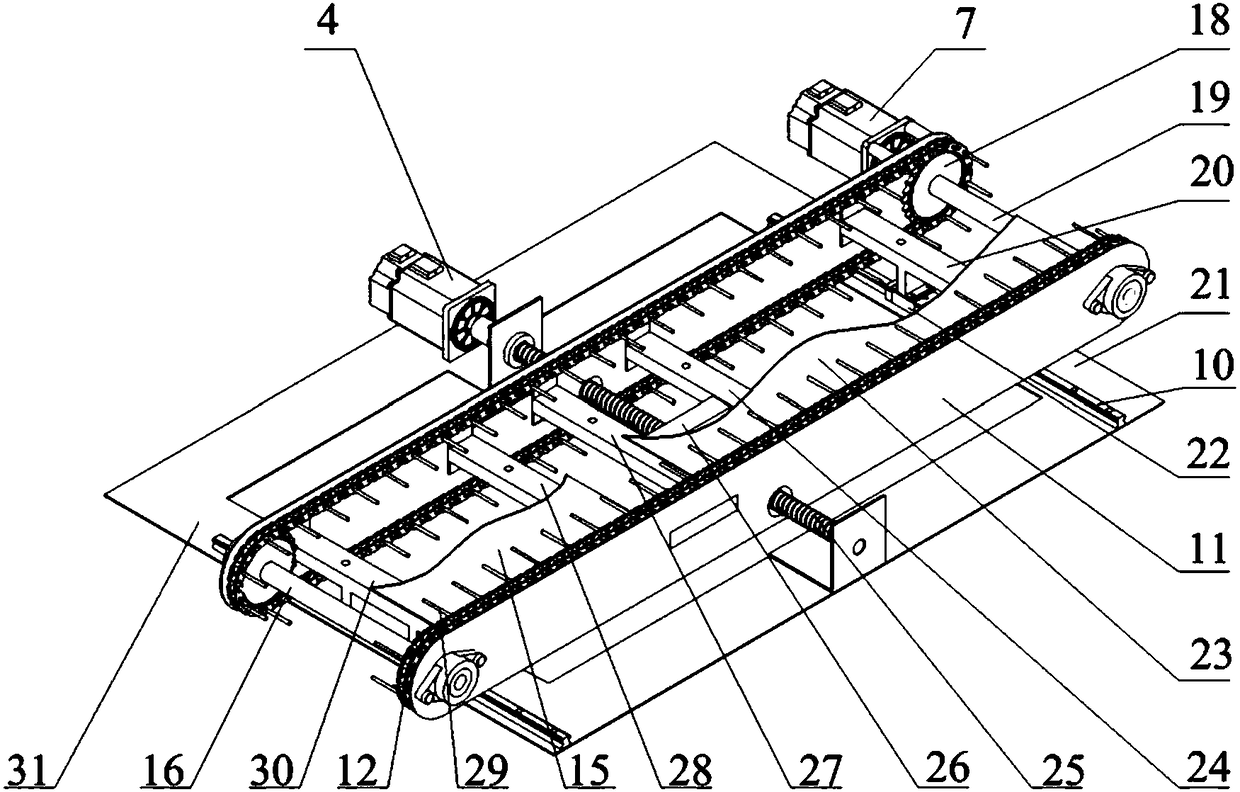

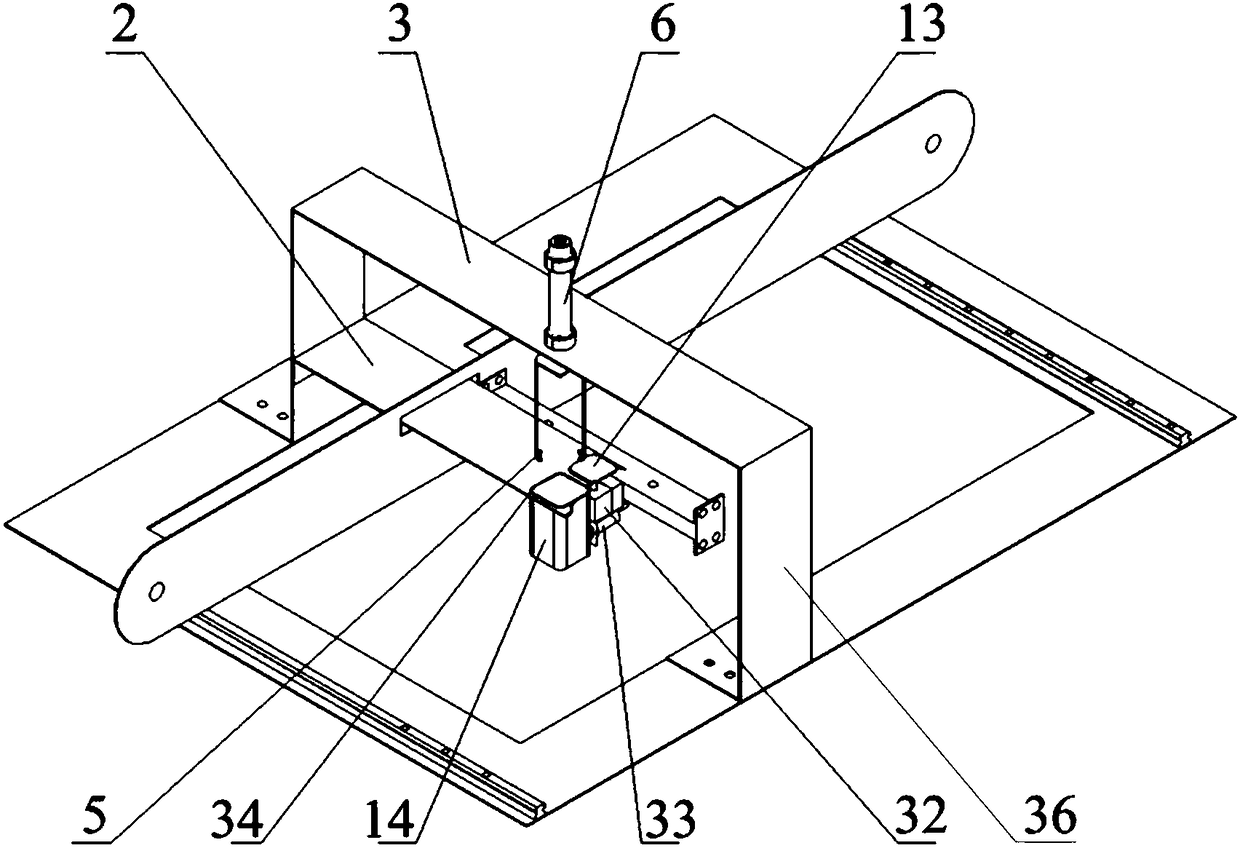

Seedling sending, taking and delivering device for pressing type seedling taking full-automatic seed tray seedling transplanter

InactiveCN108391491AEasy to get seedlingsImprove seedling efficiencyTransplantingEngineeringSeedling

The invention belongs to the technical field of agricultural mechanized transplantation, and particularly relates to a seedling sending, taking and delivering device for a pressing type seedling taking full-automatic seed tray seedling transplanter. The device comprises a rack, a seedling sending mechanism and a seedling taking and delivering mechanism; the seedling sending mechanism comprises a lead screw driving motor, a chain driving motor, a sliding rail, a side plate, a chain, a front bottom plate, a driven shaft, a driving shaft, a rear sliding rail support, a sliding rail sliding block,a rear bottom plate, a first connecting beam, a ball lead screw, a lead screw sliding block, a second connecting beam, a third connecting beam and a front sliding rail support; the seedling taking and delivering mechanism comprises a seedling taking plate, a cylinder mounting plate, a seedling pressing rod, a seedling pressing cylinder and a seedling guide tube. Accordingly, pot seedlings are taken out from the lower portion of a seedling tray, seedling delivering is conducted directly, and the seedling taking process and the seedling delivering process are combined into a whole, and the efficiency is higher.

Owner:CHINA AGRI UNIV

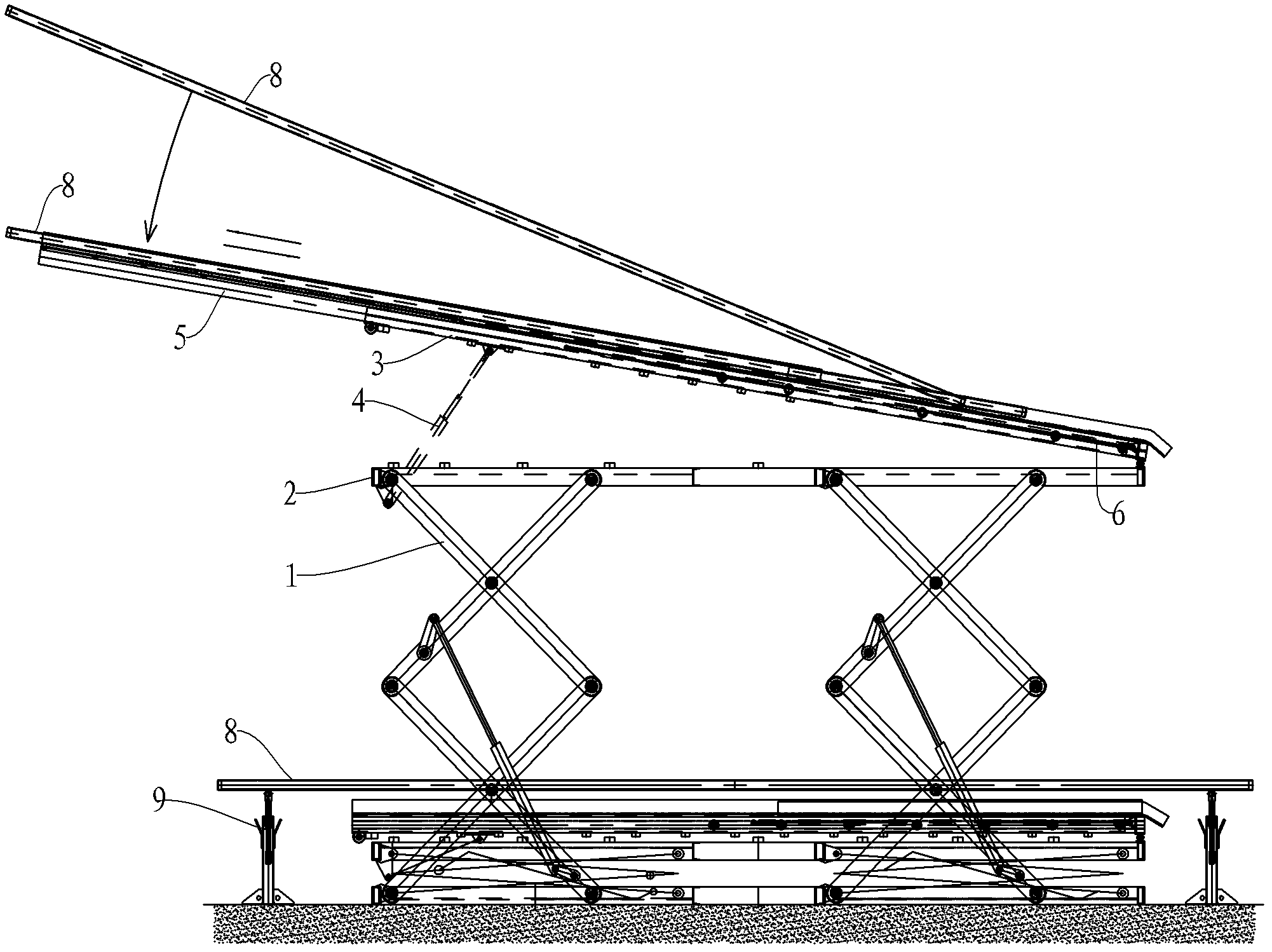

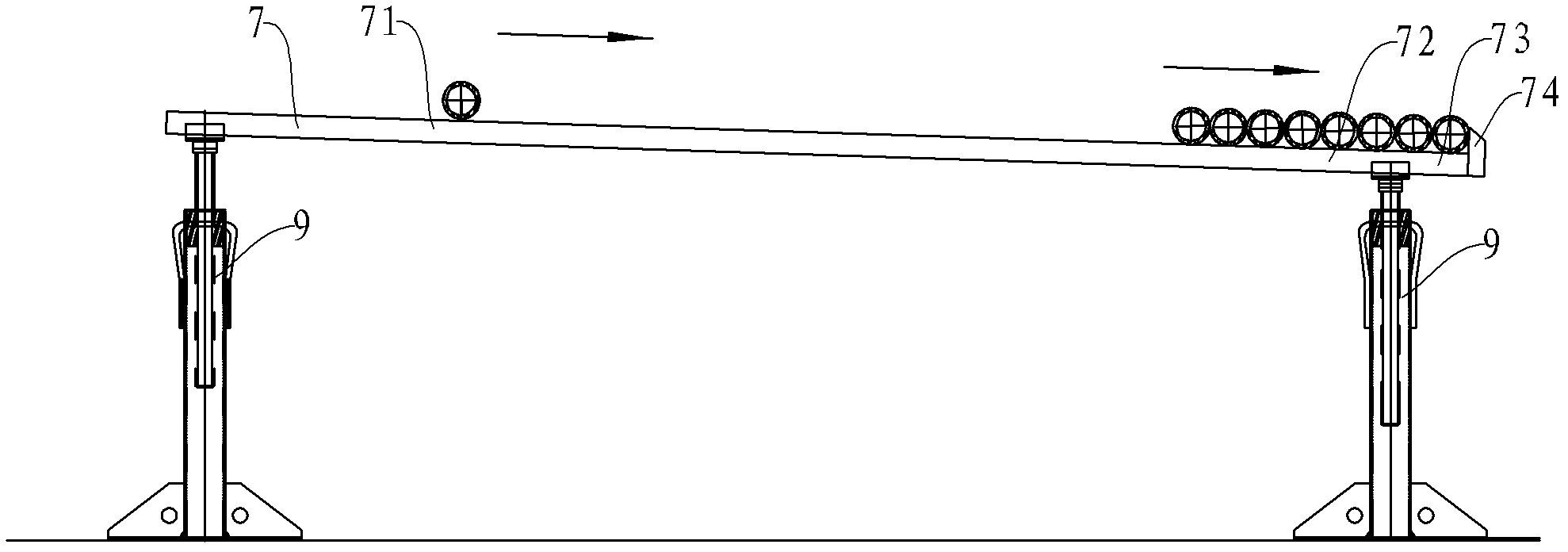

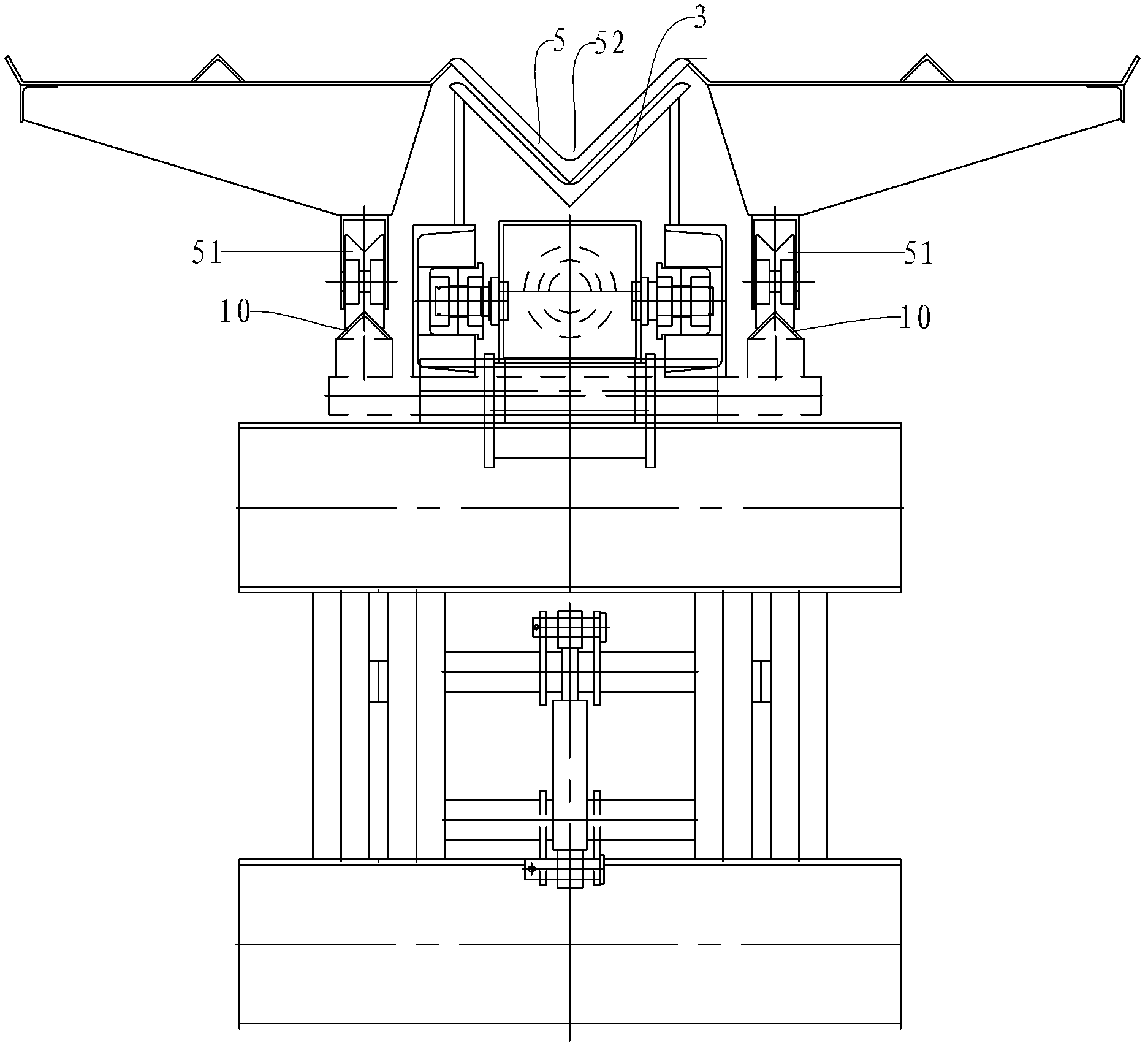

Oilfield drill stem conveying device

InactiveCN102561960ARealize automatic deliveryImprove work efficiencyDrilling rodsDrilling casingsEngineeringUltimate tensile strength

An oilfield drill stem conveying device is characterized by comprising a scissors type horizontal lifting mechanism and an oblique lifting mechanism, wherein the scissors type horizontal lifting mechanism comprises an upper rack combination which is horizontally arranged at the top end of the scissors type horizontal lifting mechanism, the oblique lifting mechanism comprises an oblique lifting bracket combination and an oblique lifting cylinder, the oblique lifting bracket combination is disposed above the upper rack combination, after an oilfield drill stem is placed on the oblique lifting bracket combination, the end, along the axial direction of the oilfield drill stem, of the oblique lifting bracket combination is a rear end, the rear end of the oblique lifting bracket combination is hinged with the rear end of the upper rack combination, and the oblique lifting cylinder is located in front of a hinge position and disposed between the upper rack combination and the oblique lifting bracket combination. The oilfield drill stem conveying device automatically conveys oilfield drill stems, improves work efficiency, saves labor, and reduces labor intensity.

Owner:济南金力液压机械有限公司

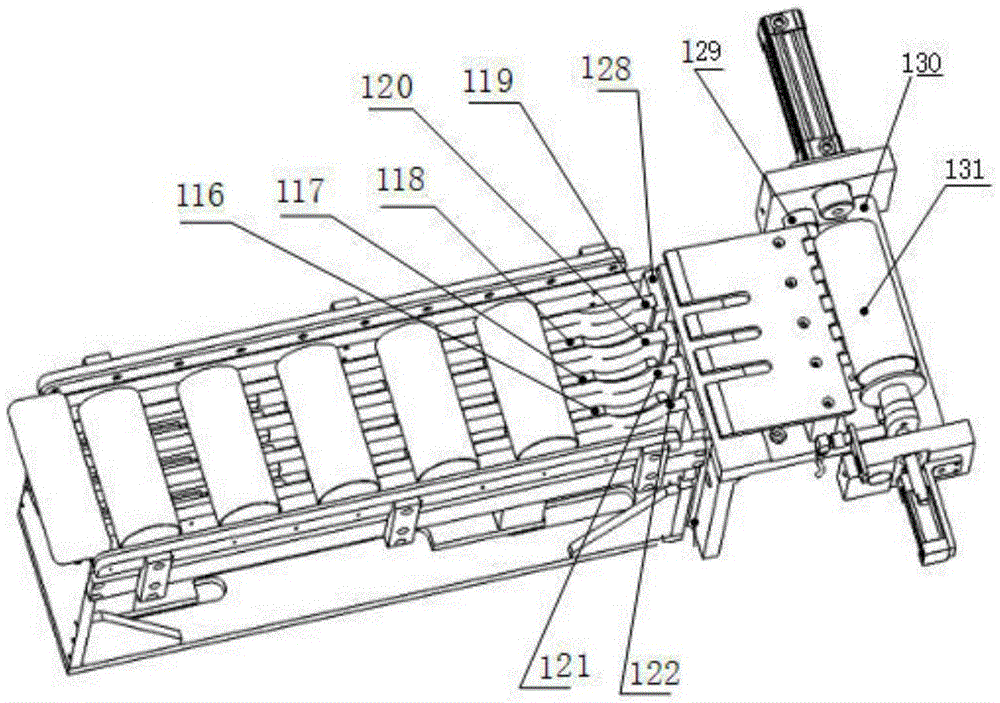

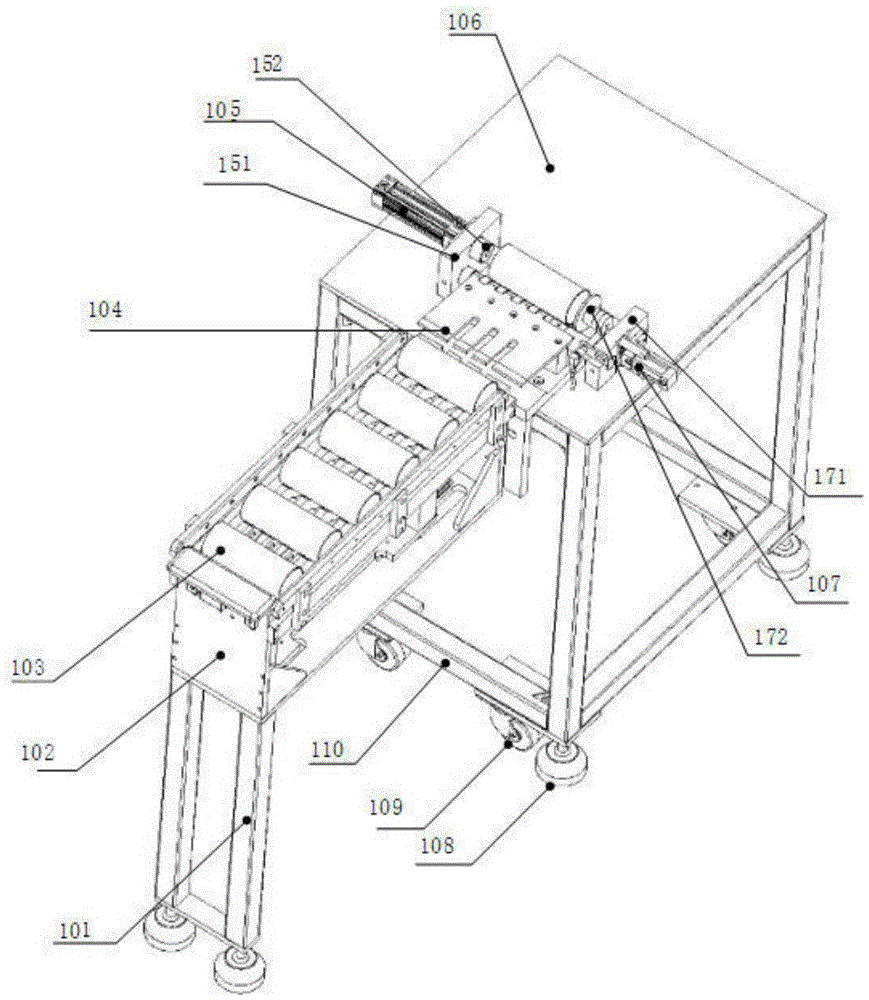

Punching material collecting and disc arranging machine

The invention discloses a punching material collecting and disc arranging machine, which belongs to the technical field of element production equipment and comprises a machine frame, a material collecting and conveying mechanism, a suction and turning mechanism, a material guide mechanism and a material disc conveying mechanism, wherein the material collecting and conveying mechanism is used for receiving materials falling down from a material falling opening part of a punching mold and realizing the automatic material partition and conveyance, the suction and turning mechanism is used for sucking the materials conveyed by the material collecting and conveying mechanism and realizing the material turning, the material guiding mechanism is used for guiding the materials turned by the suction and turning mechanism into a material disc, the material disc conveying mechanism is used for conveying the material disc under the material guide mechanism, and the material disc conveying direction of the material disc conveying mechanism is vertical to the material conveying direction of the material collecting and conveying mechanism. The punching material collecting and disc arranging machine has the advantages that the structure is compact, the high-speed automatic material collection and the automatic disc arranging can be realized, the automatic material collecting and disc arranging is realized on the premise of not influencing the original efficiency of a punching machine, the production efficiency can also be improved, the labor is saved, and the cost is reduced.

Owner:GOERTEK INC

Packing box casing machine

The invention discloses a packing box casing machine which comprises a material taking mechanism, an overturn mechanism, a first product conveying belt and a second product conveying belt, wherein the first product conveying belt is sequentially connected with the second product conveying belt; the first product conveying belt is used for conveying vertical packing boxes; the second product conveying belt is used for conveying horizontal packing boxes; the overturn mechanism is positioned above one end, close to the first product conveying belt, of the second product conveying belt; and the material taking mechanism is related to an output end of the second product conveying belt. With the adoption of the packing box casing machine, the packing boxes can be changed from a vertical state to a horizontal state, and then are clamped and cased, so that the possibility of shaking of the packing boxes easily caused in a clamping process is reduced, the casing safety and an casing accuracy rate of the packing boxes are ensured, and the casing speed is increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Movable power transmission network transformer maintenance station

InactiveCN105291940APrecise positioningRealize automatic deliveryItem transportation vehiclesVehicle with endless chains/beltsTransformerDiesel generator

A movable power transmission network transformer maintenance station comprises a traction part, an overhaul tool and instrument compartment and an oil tank compartment, wherein an oil tank conveying and positioning device is arranged in the oil tank compartment and can achieve automatic conveying and accurate positioning of an oil tank. In addition, the space utilization rate of the compartments can be maximized while necessary tools and instruments for maintenance of a power transmission network transformer are provided by reasonably arranging the positions and structures of a hydraulic oil station, a diesel generator, a storage battery, a special tool stepped cabinet, a common tool cabinet and an elevator for aerial operation. Multi-functionalization of the maintenance station is achieved by applying a fingerprint identifier, an electronic cipherer, a solar thermal collector and other modernized means. The novel movable power transmission network transformer maintenance station can meet the demand for remote transformer maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

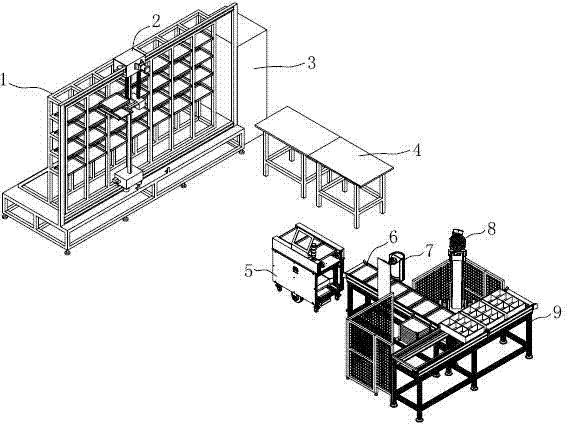

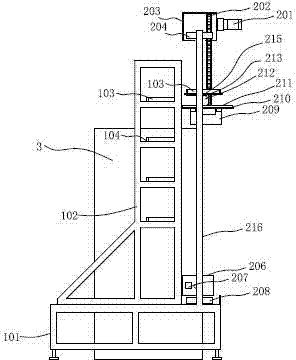

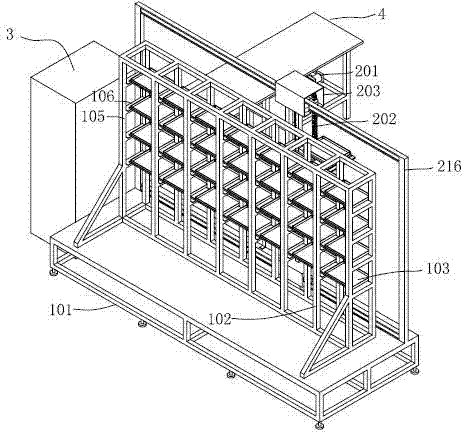

Practical training system of industrial robot technology

The invention relates to a practical training system of an industrial robot technology. The practical training system comprises a stereoscopic warehouse system, a control cabinet and a worktable, wherein a stacker crane capable of moving in an X axis and a Y axis and storing and fetching trays is arranged on the stereoscopic warehouse system; the practical training system further comprises a first conveying mechanism and a second conveying mechanism; the first conveying mechanism travels to and fro between the stereoscopic warehouse system and the second conveying mechanism through a guide rail; a mechanical arm and a camera are arranged on the two sides of the second conveying mechanism respectively; a third conveying mechanism is further arranged at the end part of the second conveying mechanism. A tray frame of the practical training system can accommodate a plurality of trays; meanwhile, a tray positioning block is arranged on the tray frame and used for preventing the trays from dropping out of the tray frame in storage; by setting the stacker crane on a sliding framework and by using an X axis or Y axis code reader, the accurate positioning and storing and fetching of each tray on the tray frame are realized; the product identification is realized by the camera; the articles are grabbed by the mechanical arm; therefore, the practical training system of the industrial robot technology is high in automation; the working efficiency of the practical training system is greatly improved.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

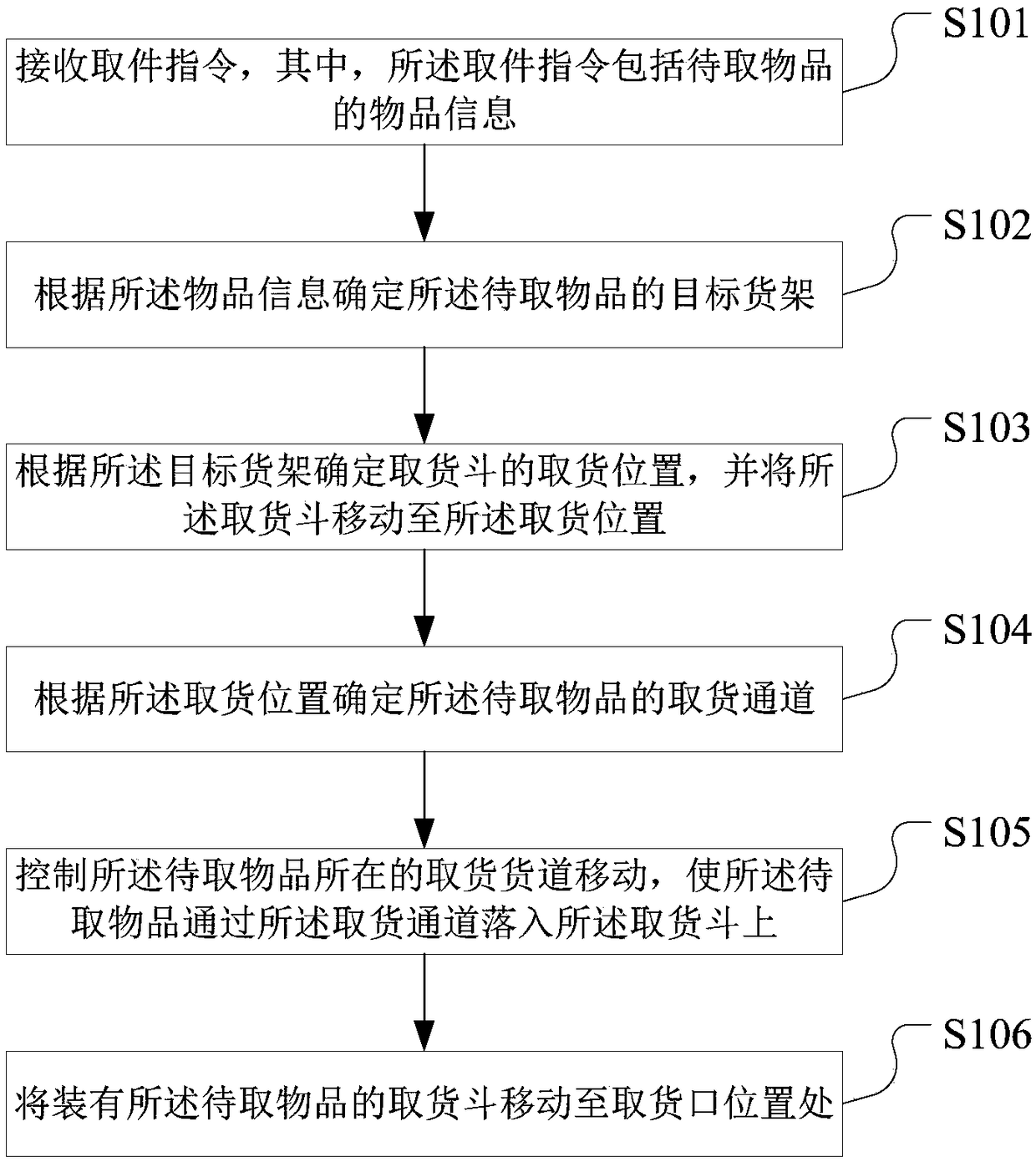

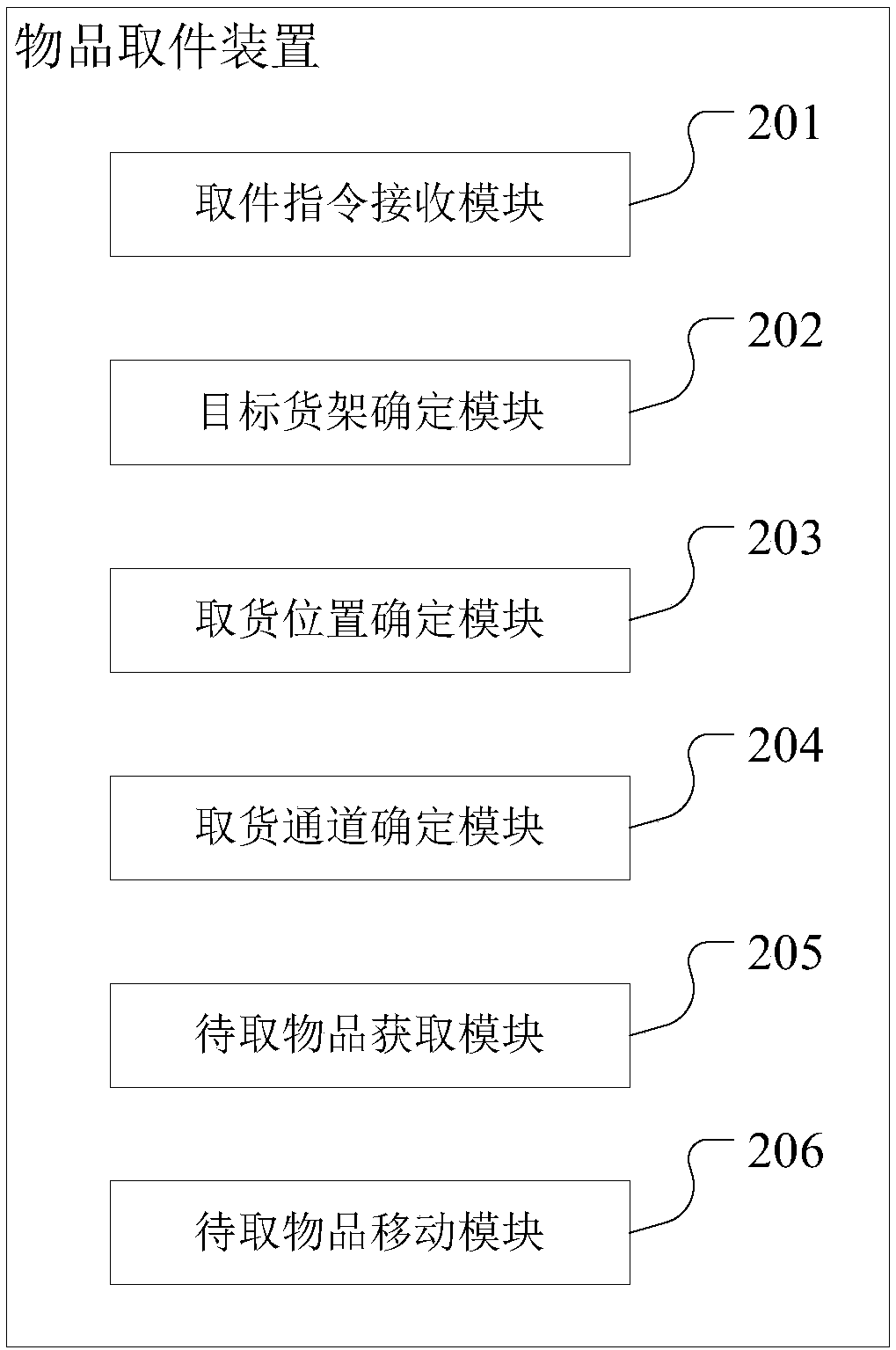

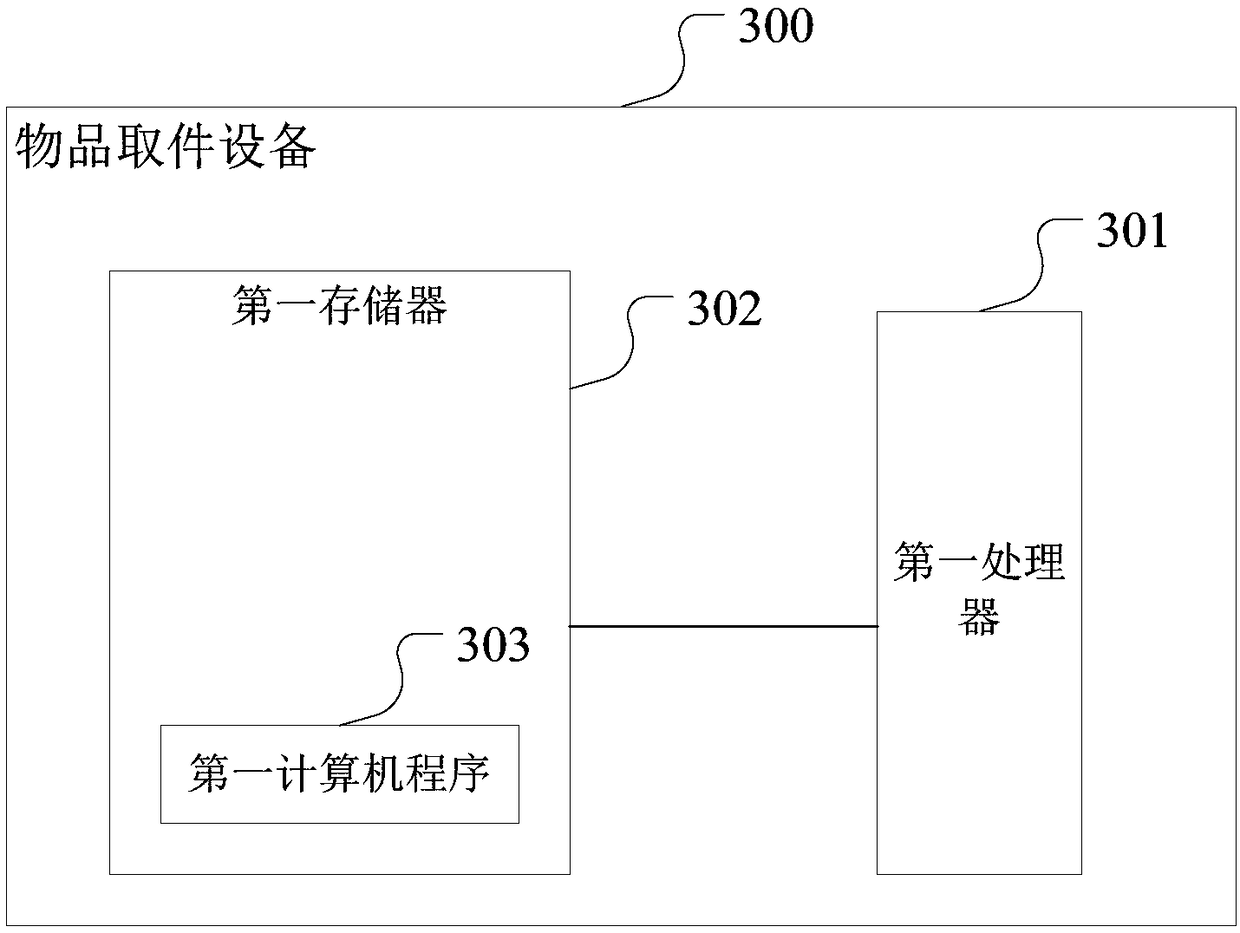

Article collecting method, delivery method, article storing and collecting method and storage medium

ActiveCN108382783AEasy to useImprove delivery operationsStorage devicesComputer scienceDelivery methods

Owner:深圳志合天成科技有限公司

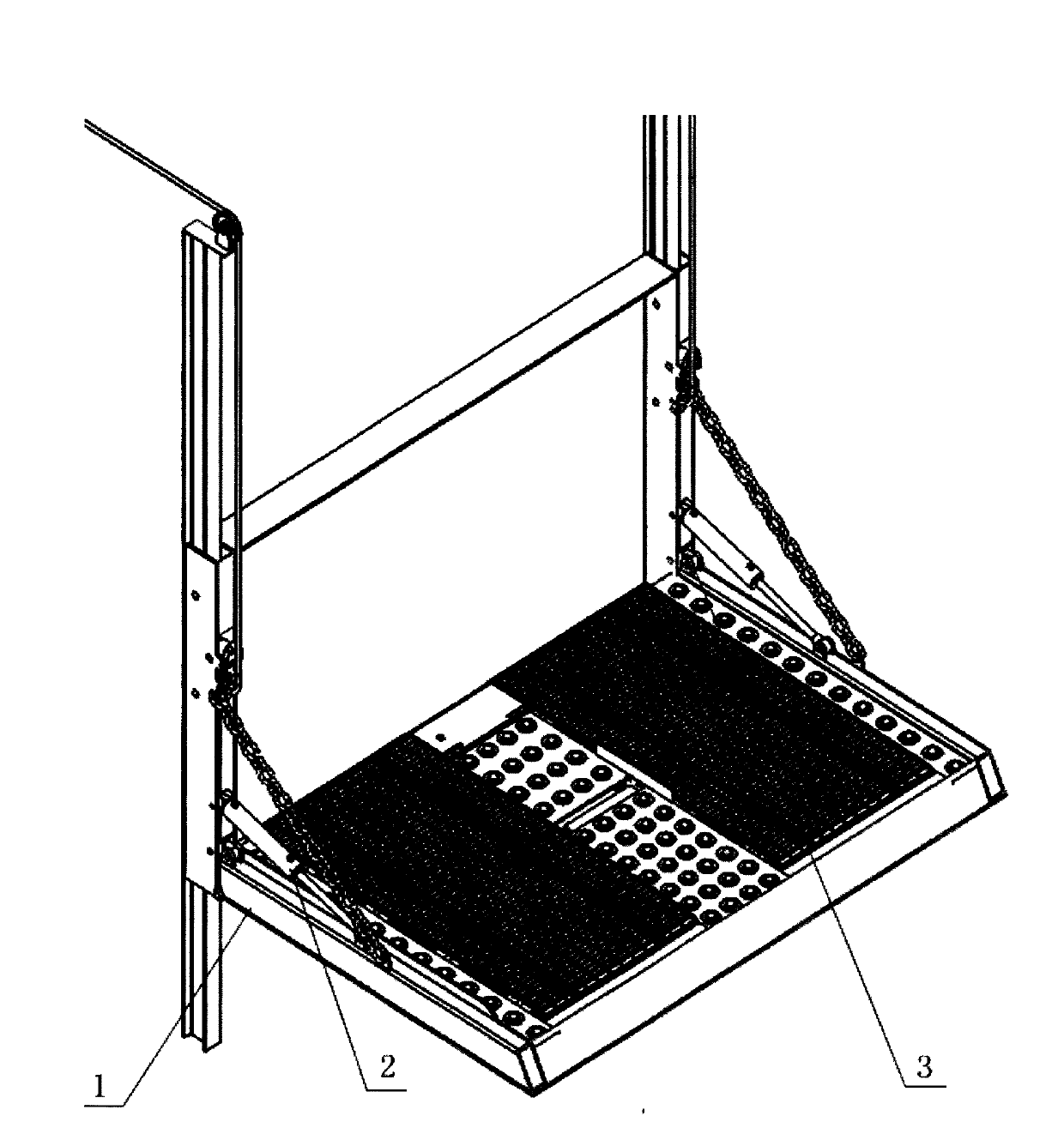

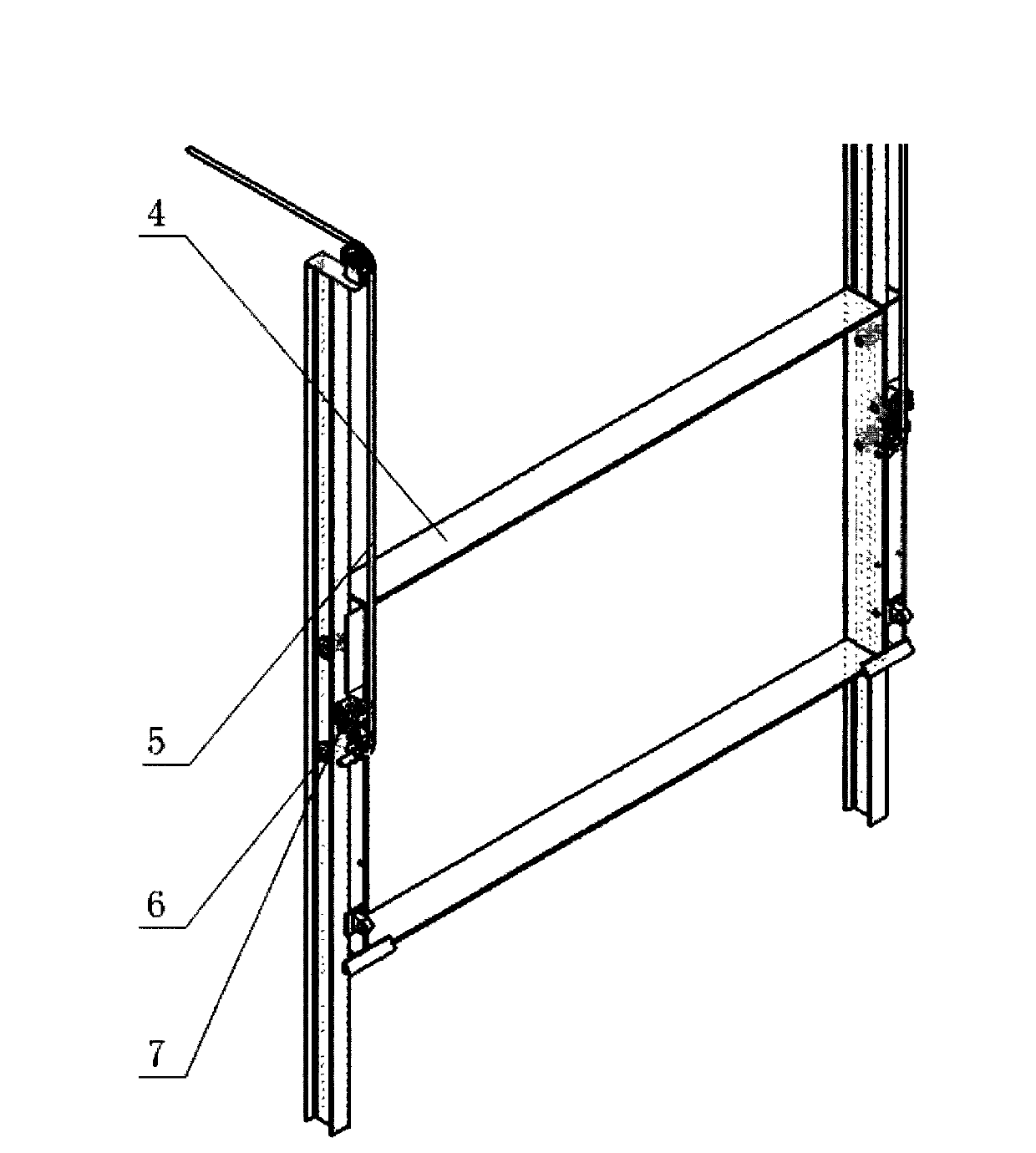

Perpendicularly-lifting tail plate capable of carrying out loading and unloading automatically

ActiveCN103661065ARealize automatic deliveryRealize automatic positioningVehicle with raised loading platformVehicle with tipping movementLogistics managementEngineering

Provided is a perpendicularly-lifting tail plate capable of carrying out loading and unloading automatically. The perpendicularly-lifting tail plate comprises a tail plate system, a perpendicularly-lifting system, an automatic conveying system, an automatic locating device, a protection device and a hydraulic control system. The tail plate system is composed of a tail plate framework, an overturn oil cylinder and hinges. The perpendicularly-lifting system is composed of a guide rail framework, a steel wire rope, rollers on the back side, rollers on the front side and a lifting drive device. The automatic conveying system is arranged on the tail plate, and automatic loading and unloading of goods can be achieved through the automatic conveying system and a transmission system (see the patent 201210437463.5, an automatic loading and unloading logistics vehicle) inside a vehicle compartment; automatic locating of the tray goods can be achieved by installing the automatic locating device, through the installation of the protection device, the tail plate can be locked when accidents happen, and therefore the accidents can be avoided; the hydraulic control system supplies power to the tail plate. The automation degree of the logistics vehicle in the process of loading and unloading of the goods can be improved by adding the automatic conveying system, the automatic locating device and the protection device through cooperation with the automatic loading and unloading logistics vehicle (the patent number is 201210437463.5) on the basis of an existing perpendicularly-lifting tail plate, and the perpendicularly-lifting tail plate has the advantages of being compact in structure, high in automation degree, safe and reliable, and suitable for the field of logistics.

Owner:CHONGQING SHENGHE LOGISTICS

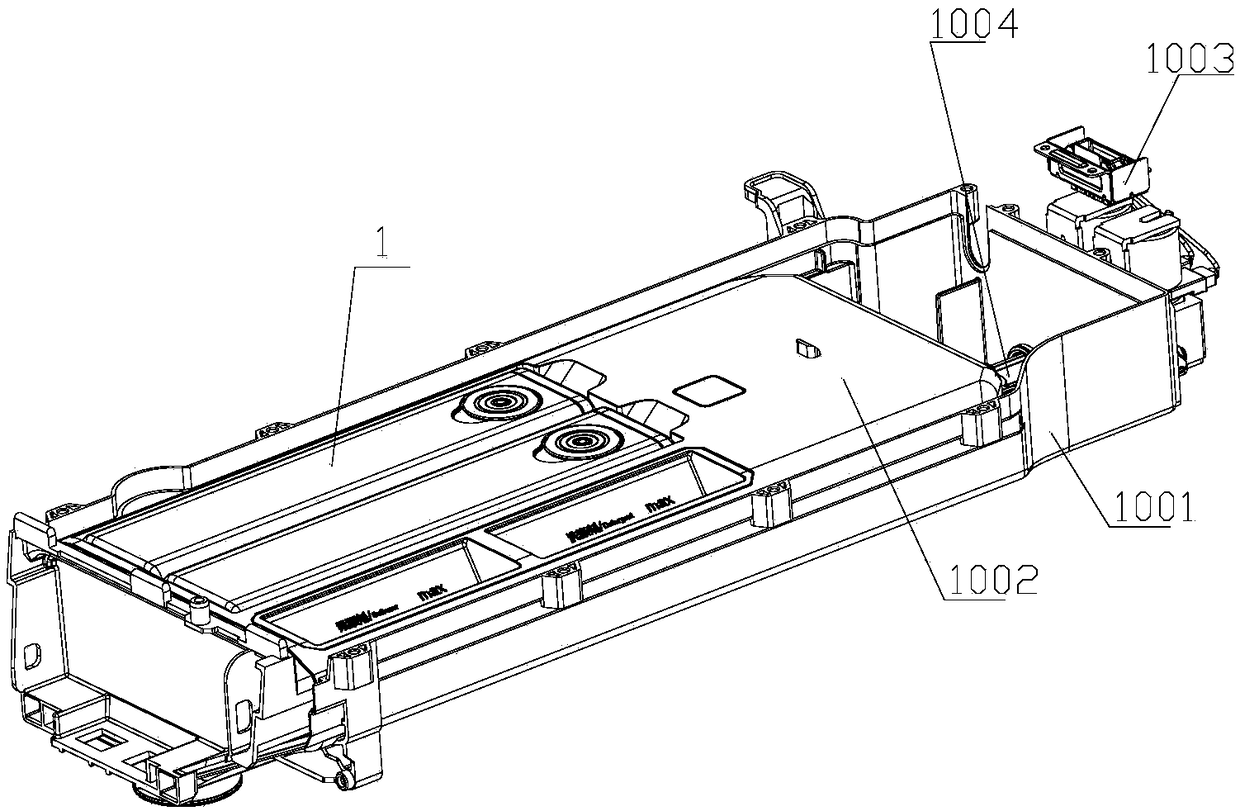

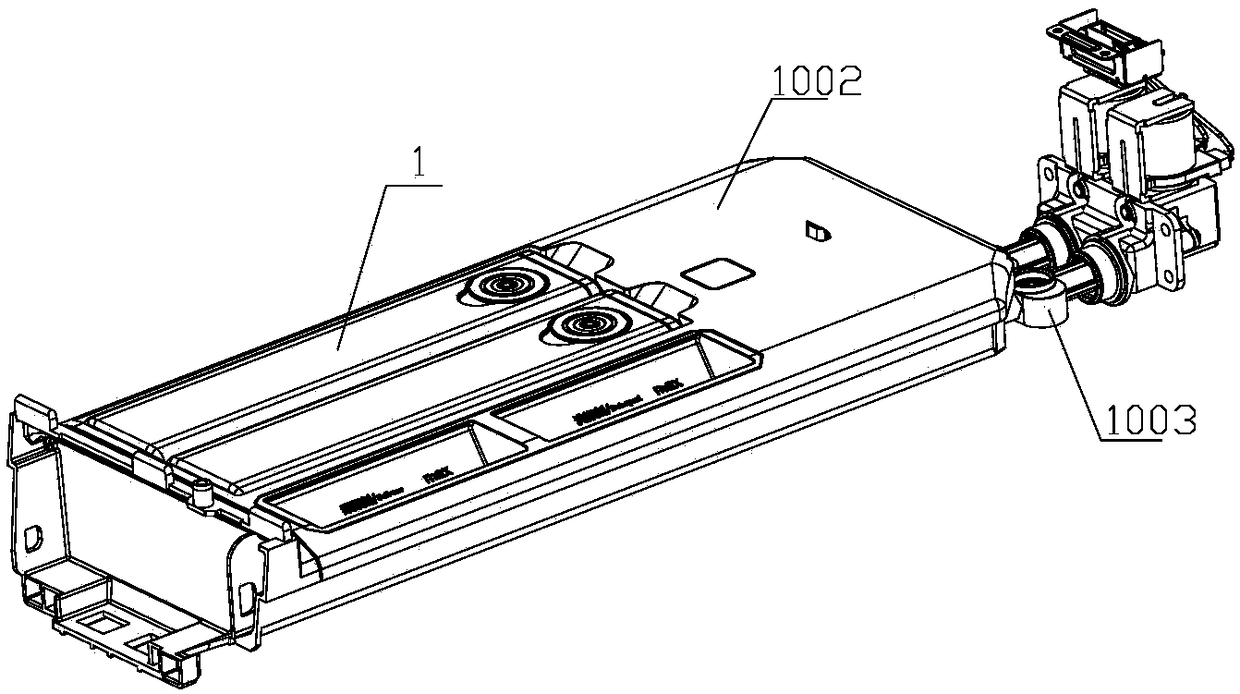

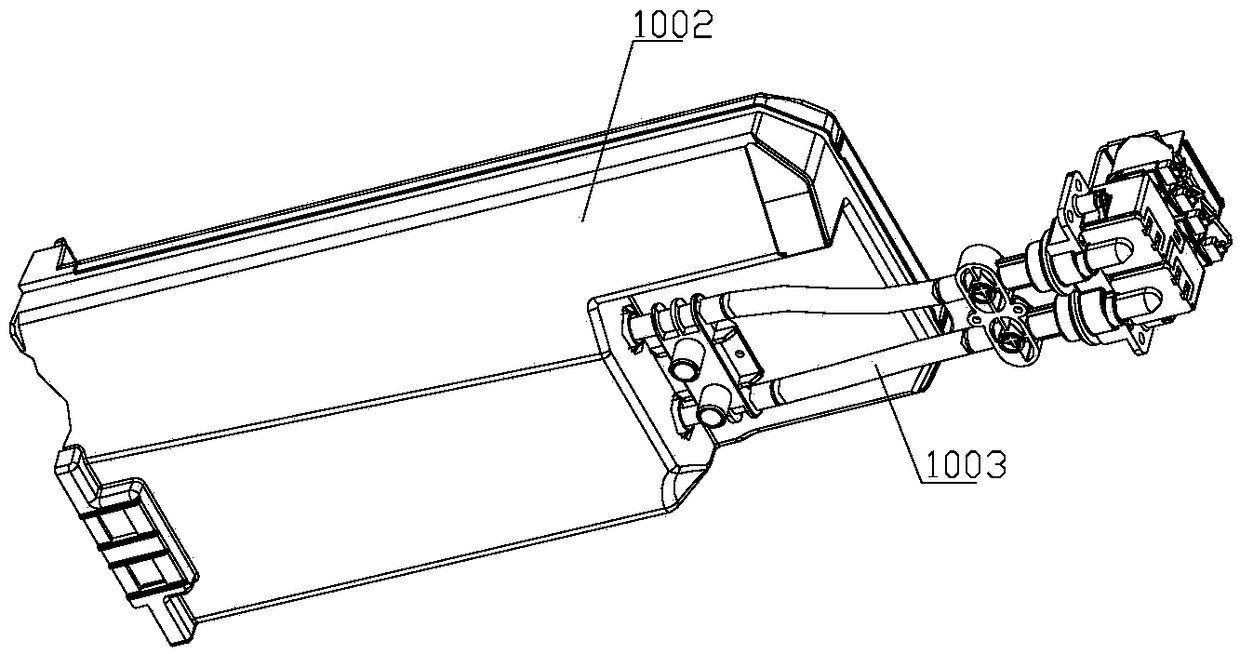

Automatic putting system of washer and washer

ActiveCN108729130ASave internal spaceSolve the burdenOther washing machinesTextiles and paperWater flowWaste management

The invention discloses an automatic putting system of a washer and the washer. The automatic putting system of the washer comprises a water box, a distribution box, washing addictive boxes, a negative pressure extraction mechanism and disposable putting boxes. A main water inlet pipe and washing addictive putting pipes are integrated on the water box, the distribution box is arranged in the waterbox, and a first installation part which is provided with one or more installation cavities and a second installation part which is provided with one or more installation cavities are arranged in thedistribution box; unilateral breathable structures and liquid outlets are formed in the washing addictive boxes, the washing addictive boxes are mounted in the installation cavities, when the washingaddictive boxes are communicated with the washing addictive putting pipes, the liquid outlets are opened, and when the washing addictive boxes are disconnected with the washing addictive putting pipes, the liquid outlets are closed; the negative pressure extraction mechanism comprises a Venturi tube which is arranged in the main water inlet pipe, and liquid in the washing addictive boxes is drawnout and put in a washing barrel through the washing addictive putting pipes under the negative pressure which is generated when water flows through an outlet of the Venturi tube; the disposable putting boxes are arranged in the second installation part. A user can replace the washing addictive boxes randomly and adopt different kinds of washing addictive aiming at different clothes each time, andthus the washing experience and efficiency are improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com