Patents

Literature

444 results about "Goods distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DISTRIBUTION is a step in the economic process which brings goods and services from those who make them to those who use them. The making of such goods and services is called PRODUCTION. The use of the goods is called CONSUMPTION. DISTRIBUTION includes all methods by which the goods are sent from producers to consumers.

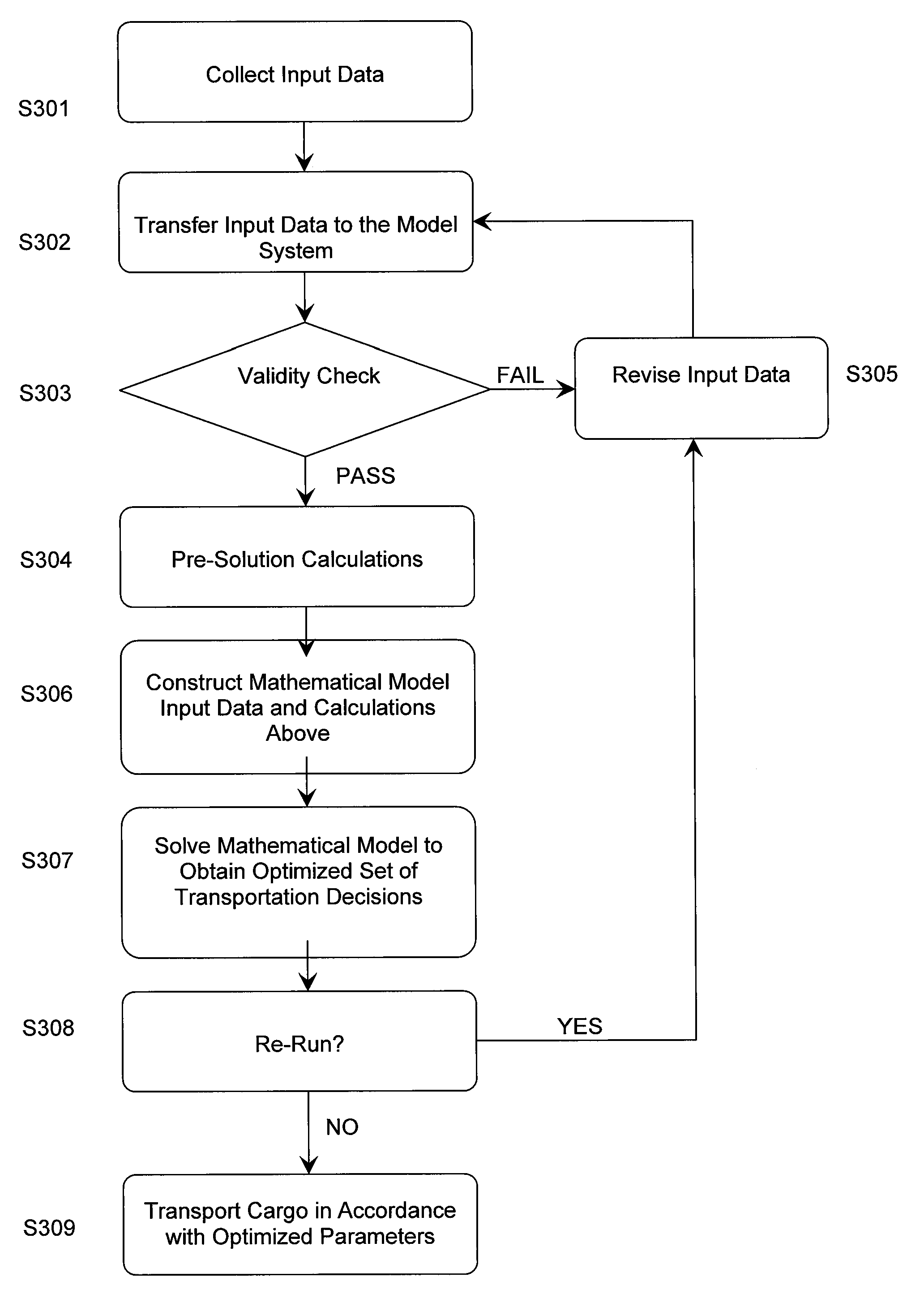

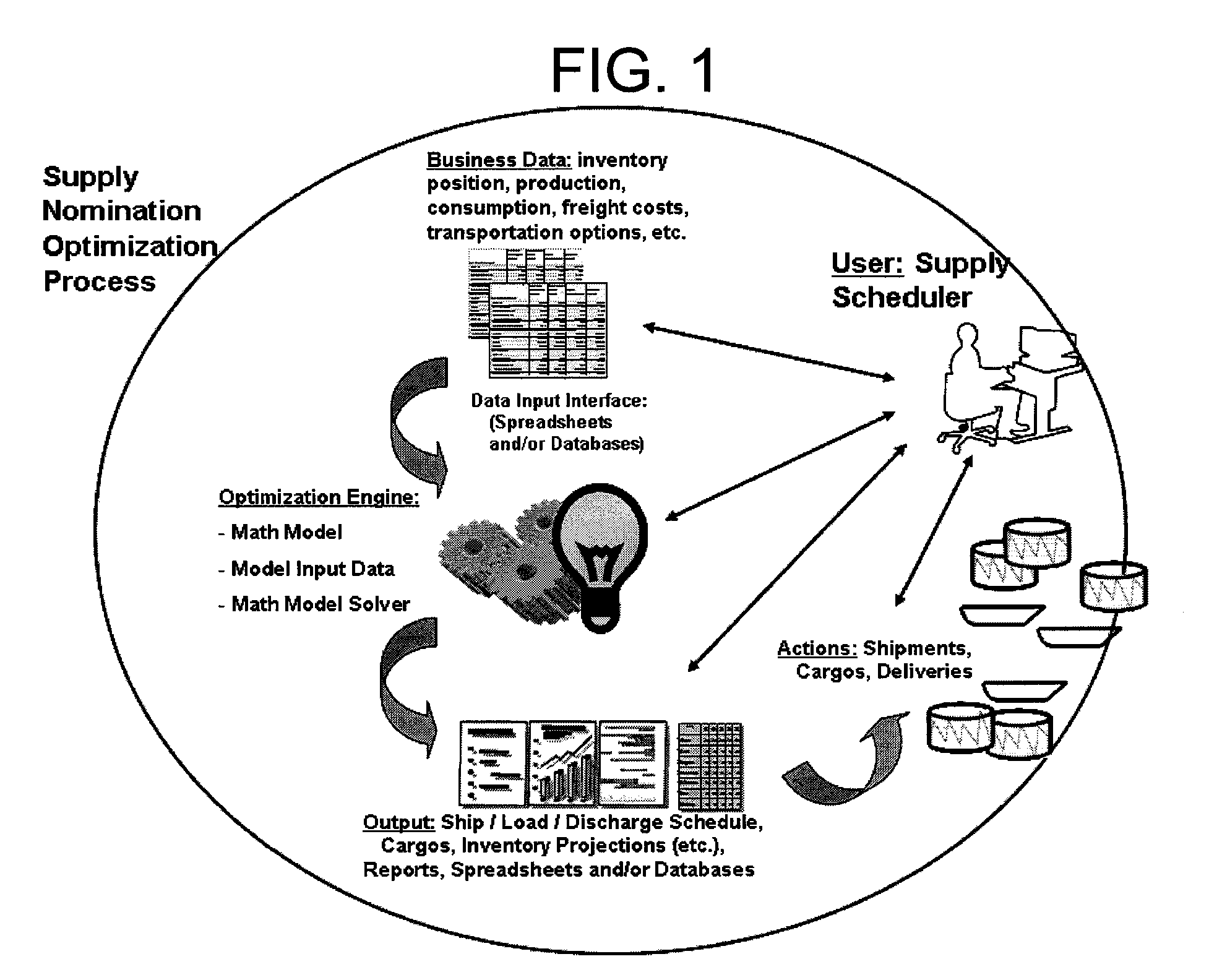

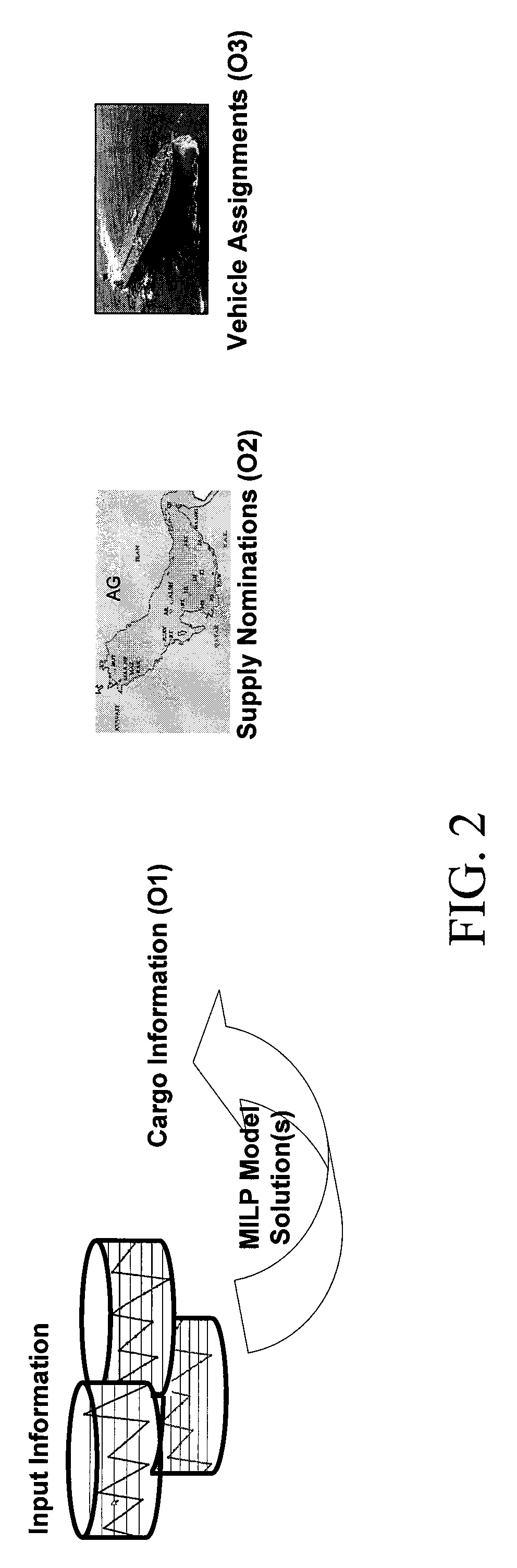

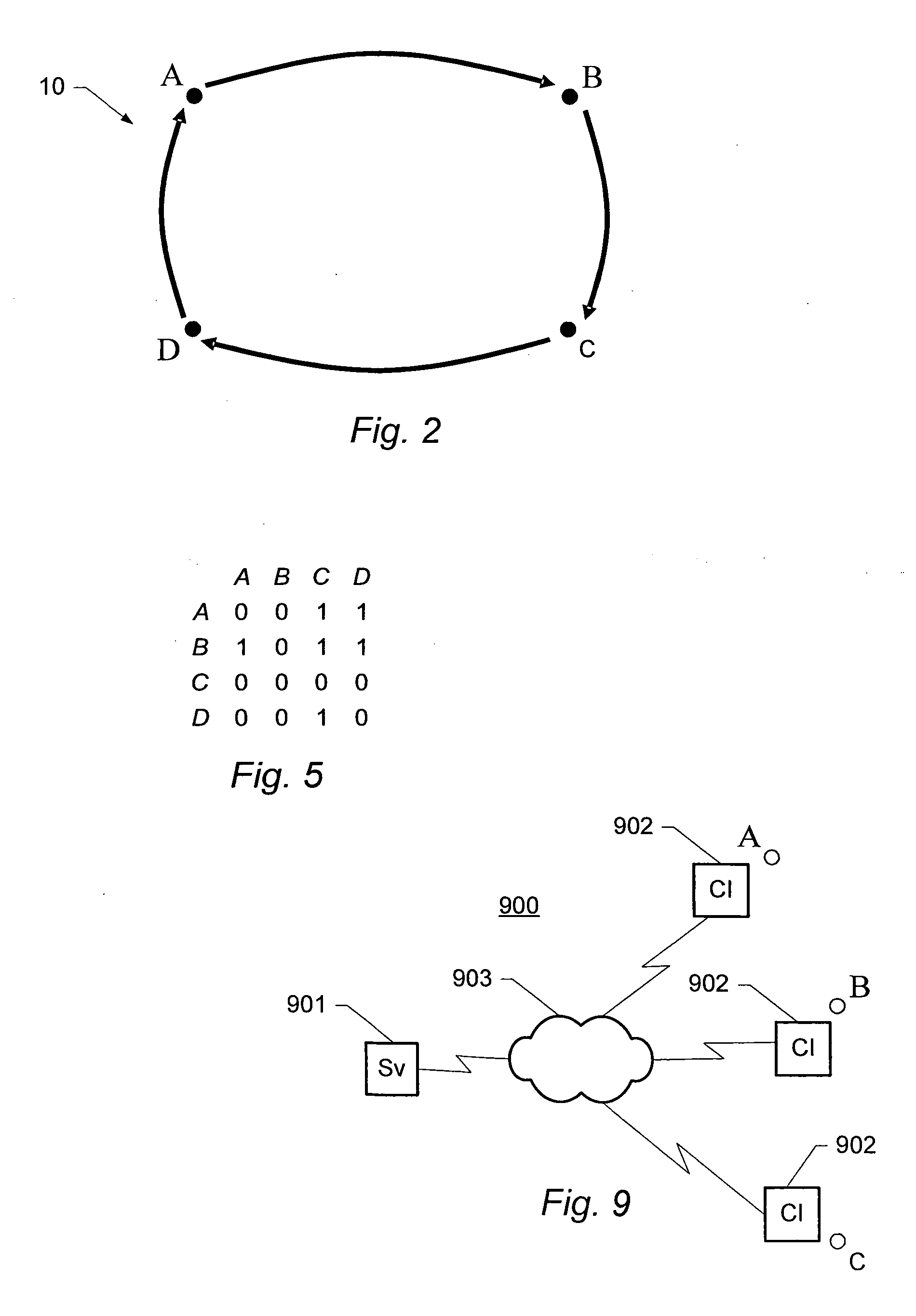

Method for optimizing a transportation scheme

InactiveUS20100287073A1Maximize total net marginIncurring costForecastingCommerceInteger linear programming modelTransport engineering

A method and apparatus for optimal transporting of cargo is provided. The method includes optimizing a plurality of transportation decisions and mechanically transporting cargo through movement of a plurality of vehicles in accordance with a set of optimized transportation decisions. The decisions include transportation routes and schedules for the transportation vehicles, allocation of cargo to be transported to one or more demand locations by the transportation vehicles, nomination of cargo pickup by the transportation vehicles from the one or more supply locations, the use of specialized transportation locations, and vehicle assignments for each of the transportation vehicles. The set of decisions is optimized by collecting data relating to the various transportation decisions, using the data collected as part of a mixed integer linear programming model, and obtaining a solution to the model to arrive at a set of optimized transportation decisions.

Owner:EXXON RES & ENG CO

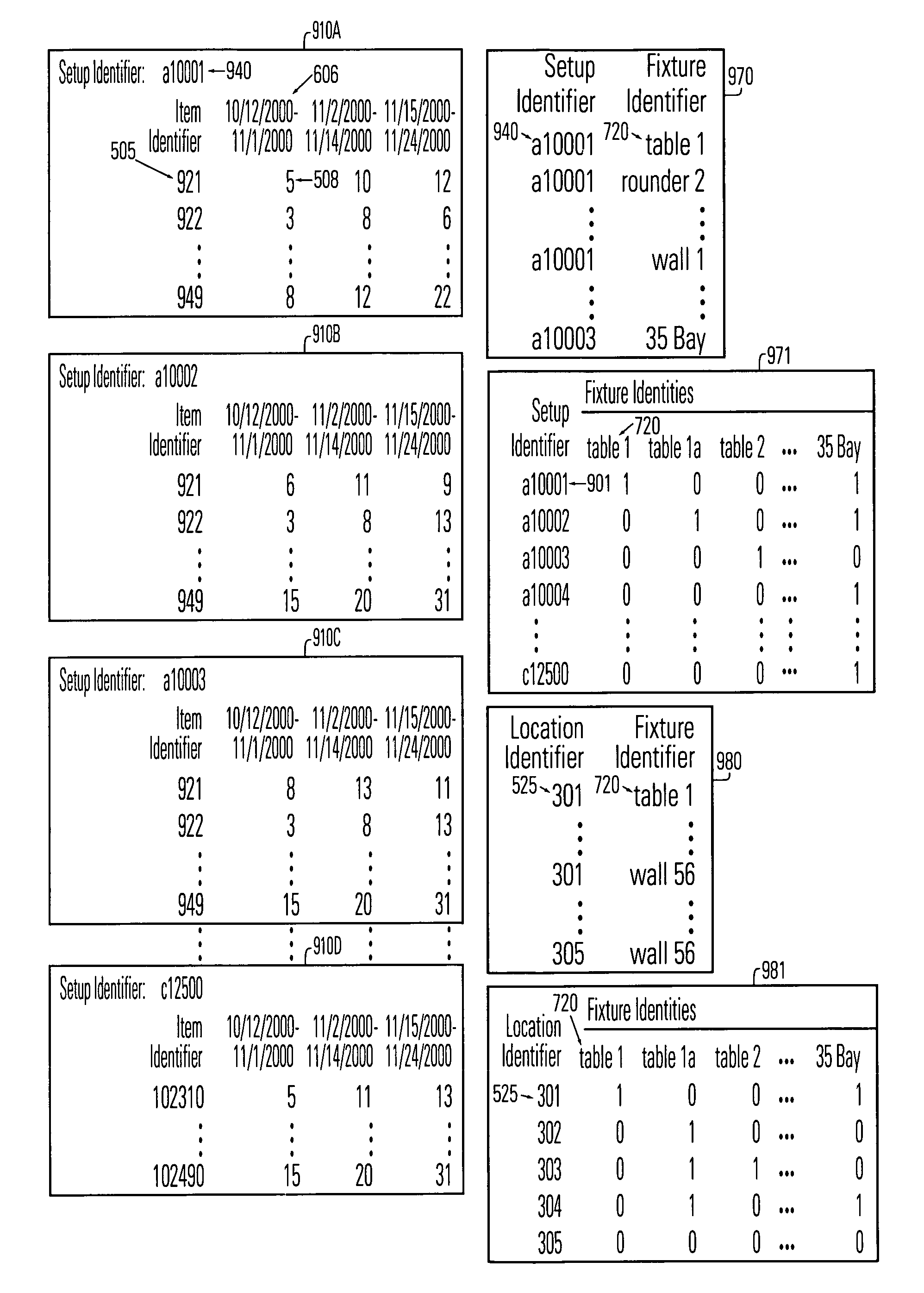

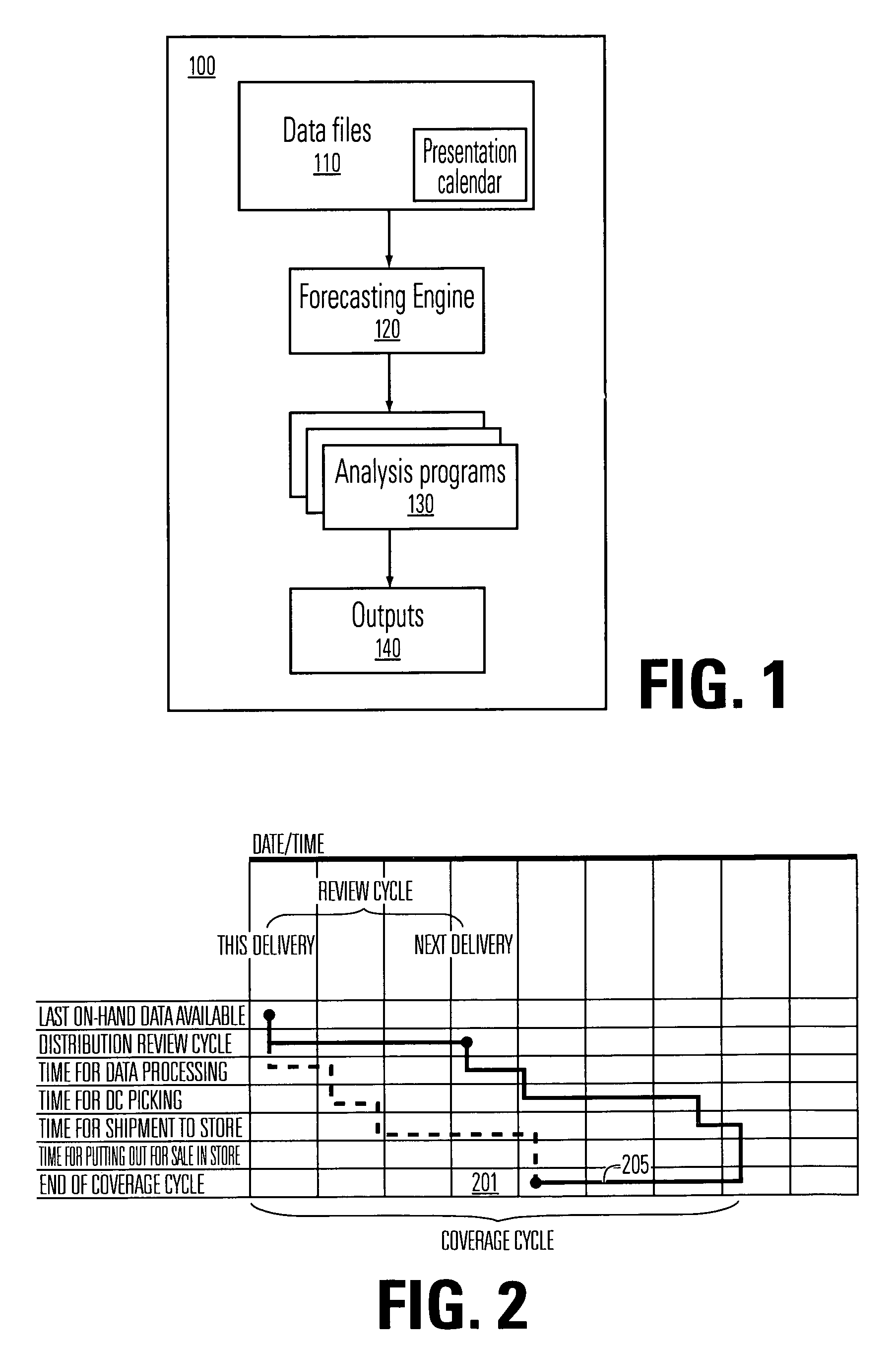

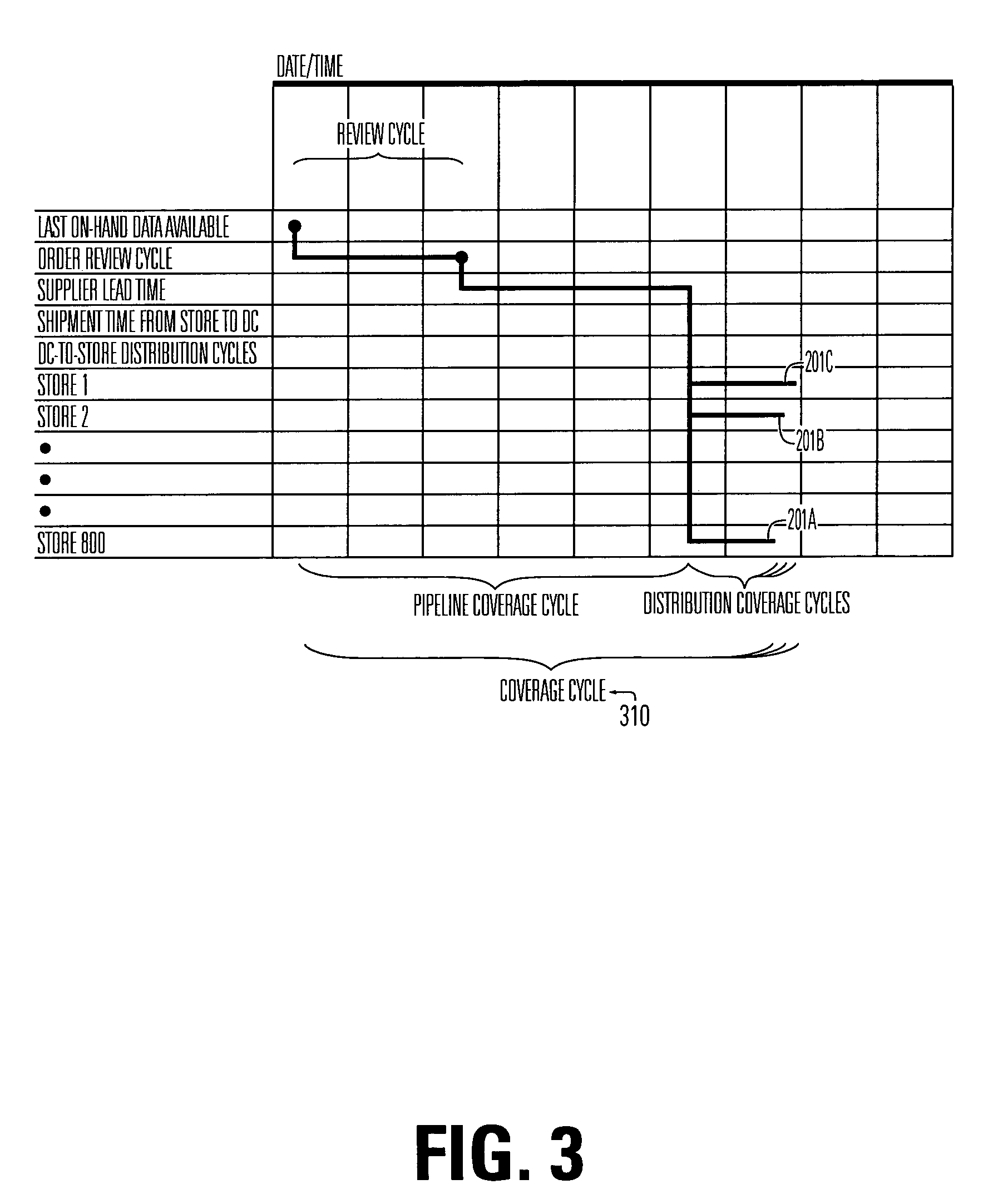

Multipurpose presentation demand calendar for integrated management decision support

Aspects of the present invention include improvements to a management decision support system. Before improvement, the system includes a computer system having memory and resources, a retail demand forecasting program applying one or more forecasting approaches, running on the computer system and utilizing the output, said analysis programs generating at least one of (a) order of goods from a supplier-related data, (b) allocation of the goods to be shipped by the supplier-related data, or (c) distribution of goods to selling locations-related data. The improvements, according to one aspect of the invention, include a causal calendar utilized by the forecasting program to generate the output, the calendar including certain attributes for a plurality of events, and an analysis program to generate open to buy reports. Other aspects of the present invention are described in the specification, drawing and claims.

Owner:BLUEFIRE SYST

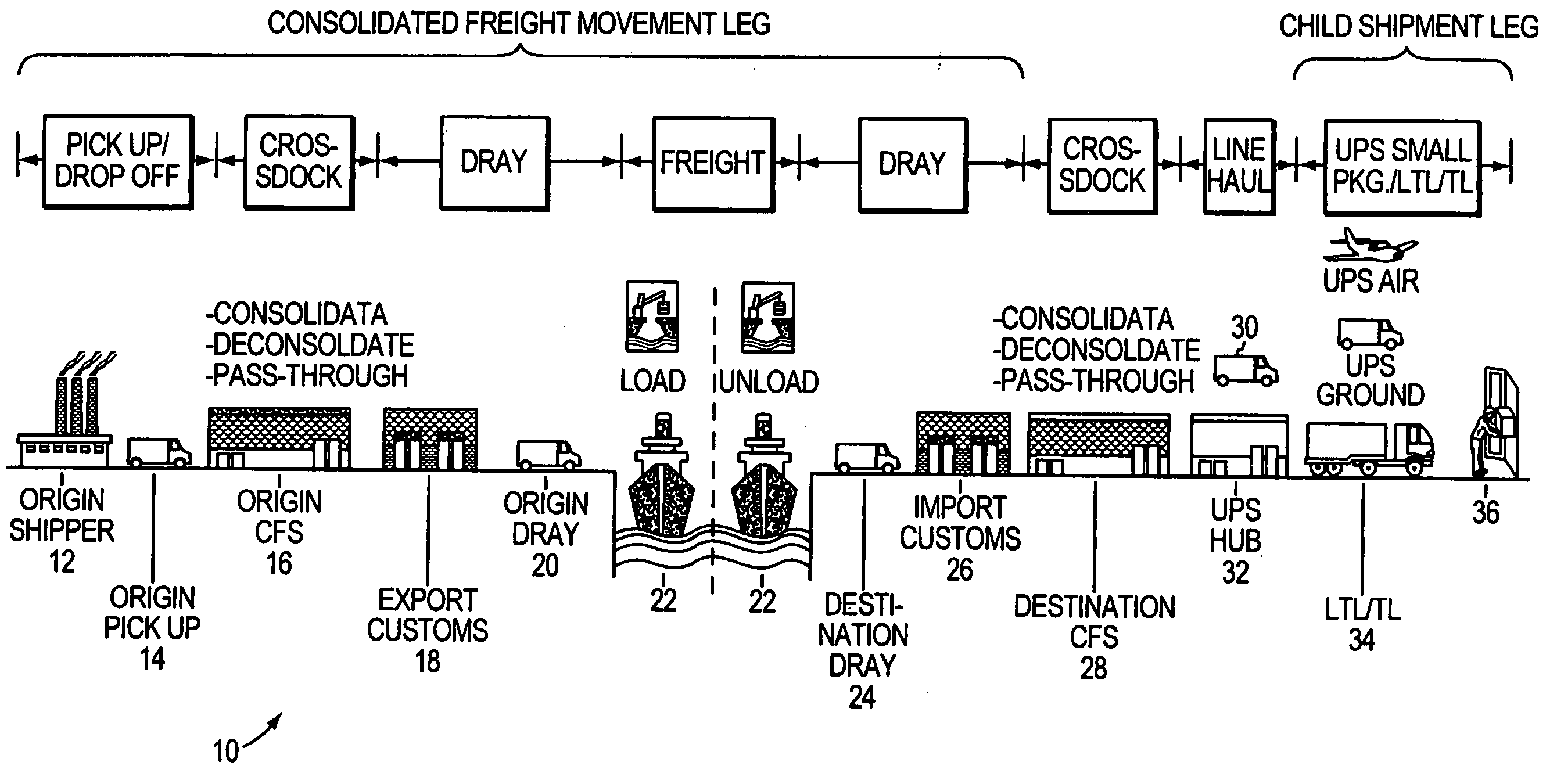

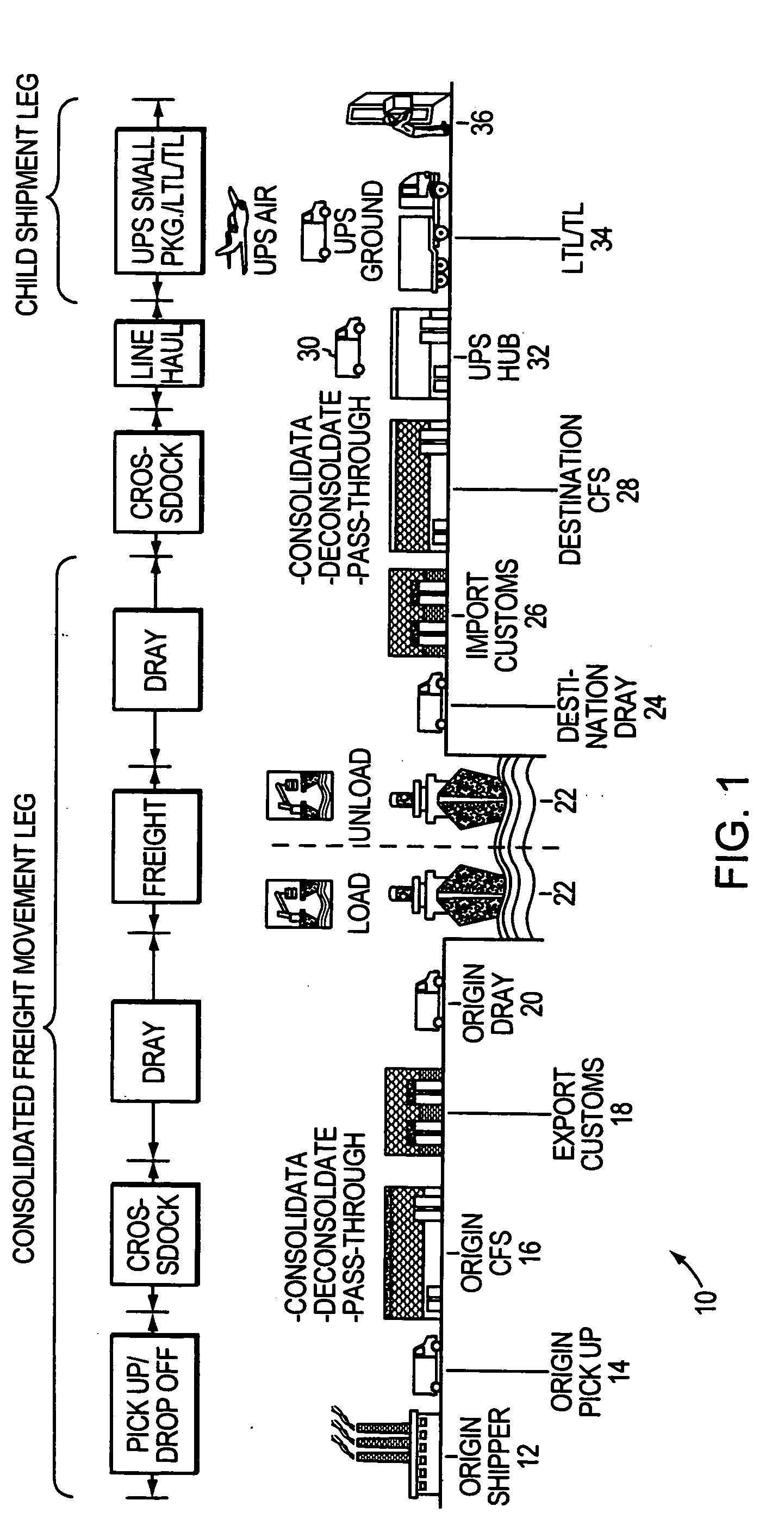

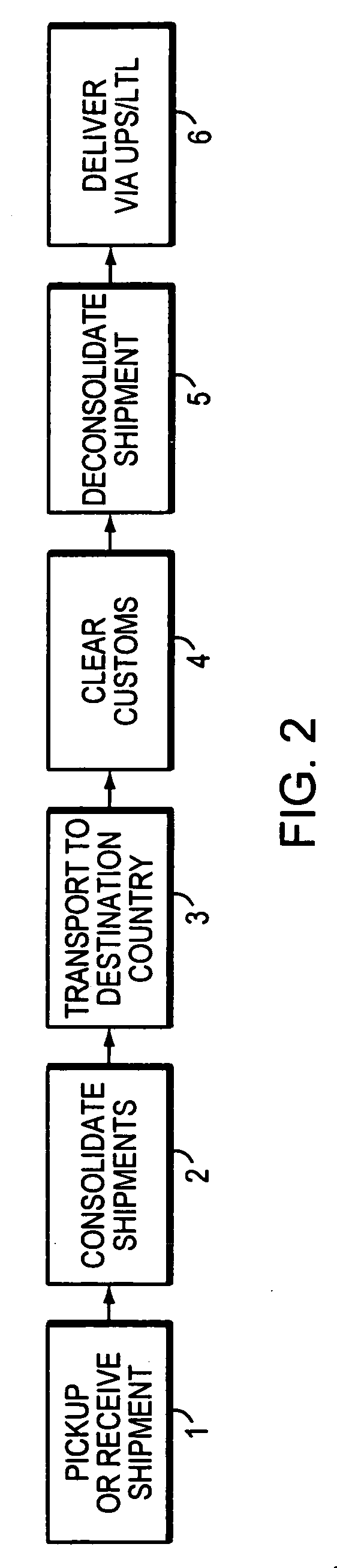

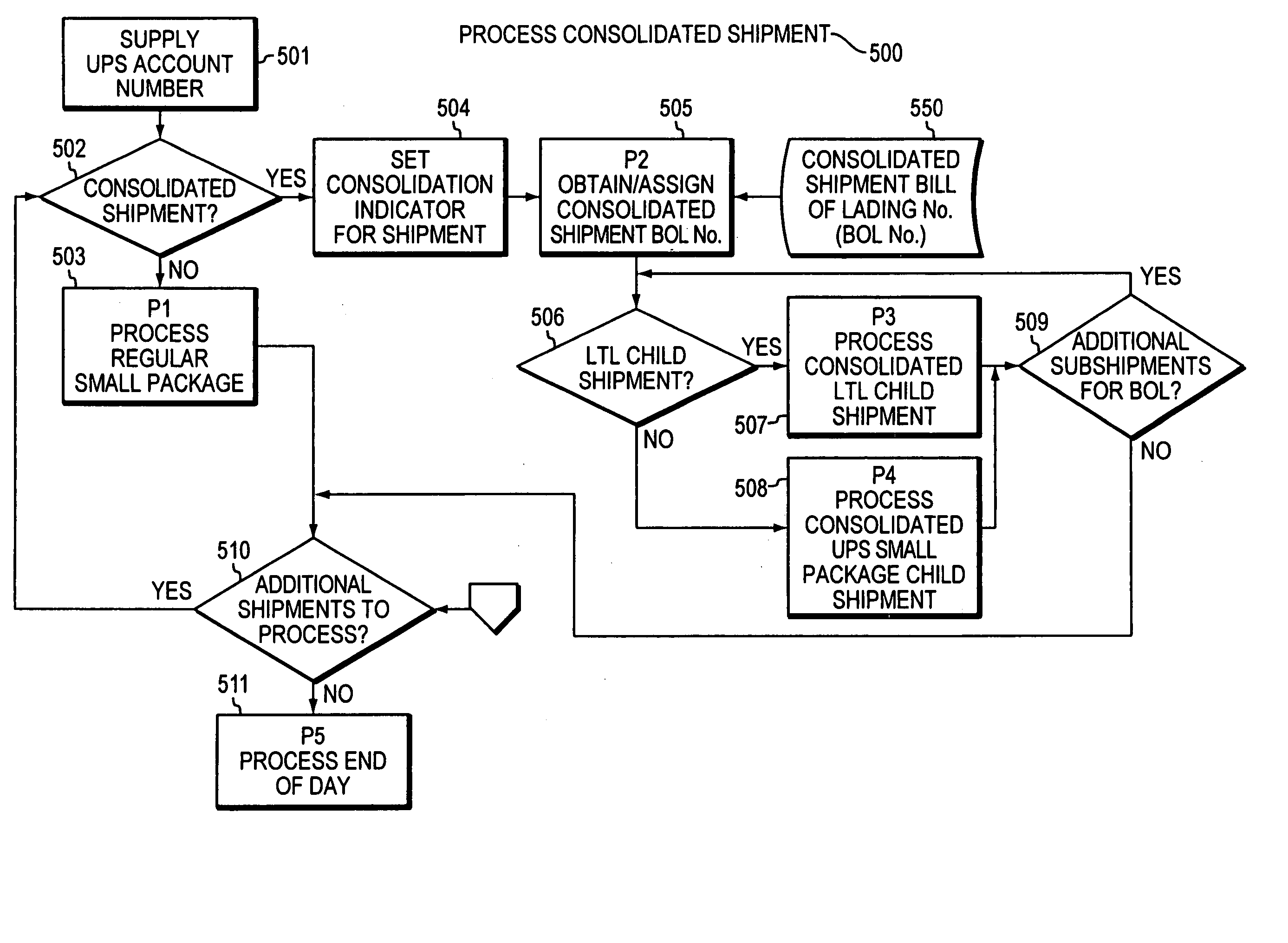

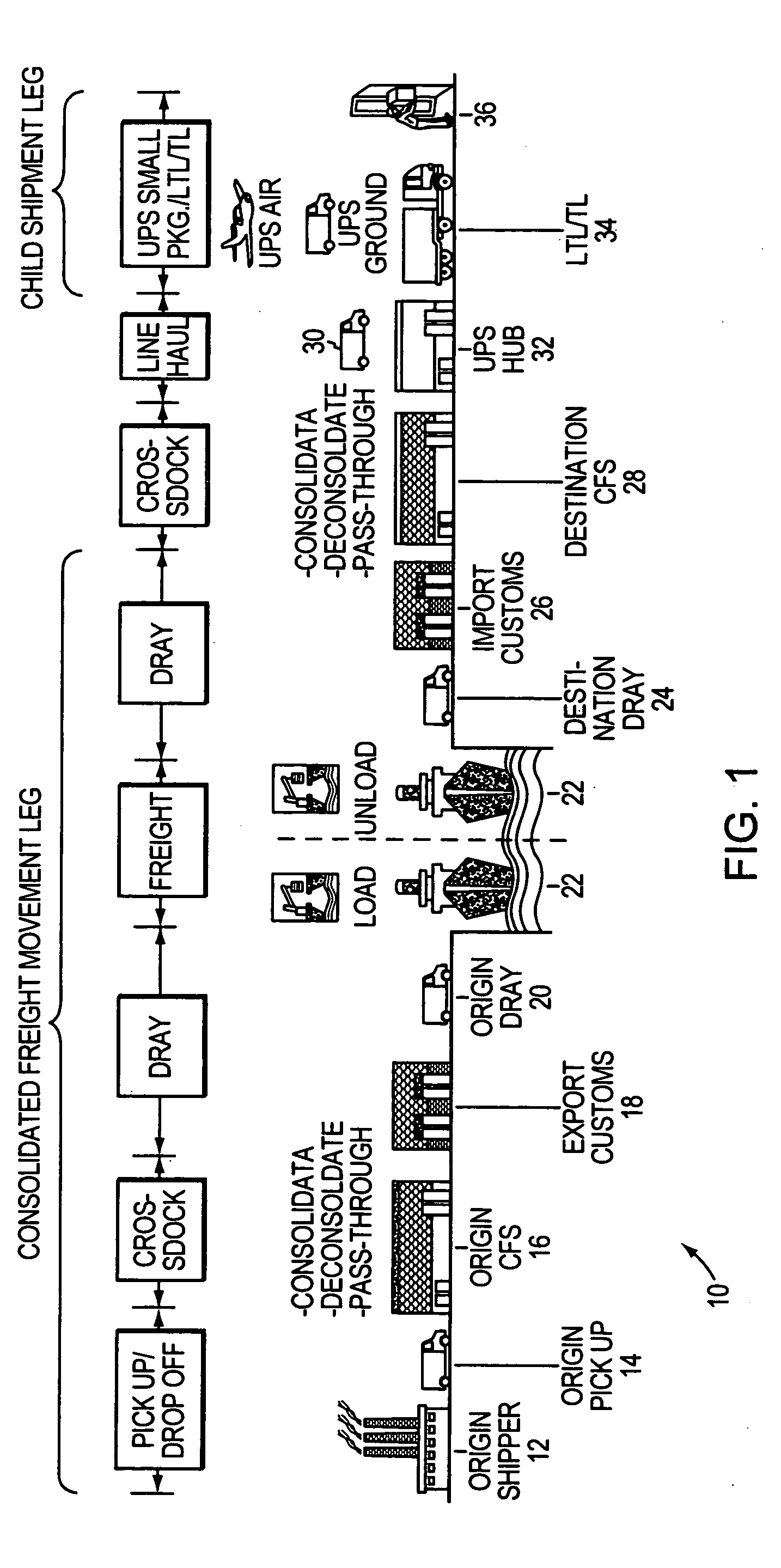

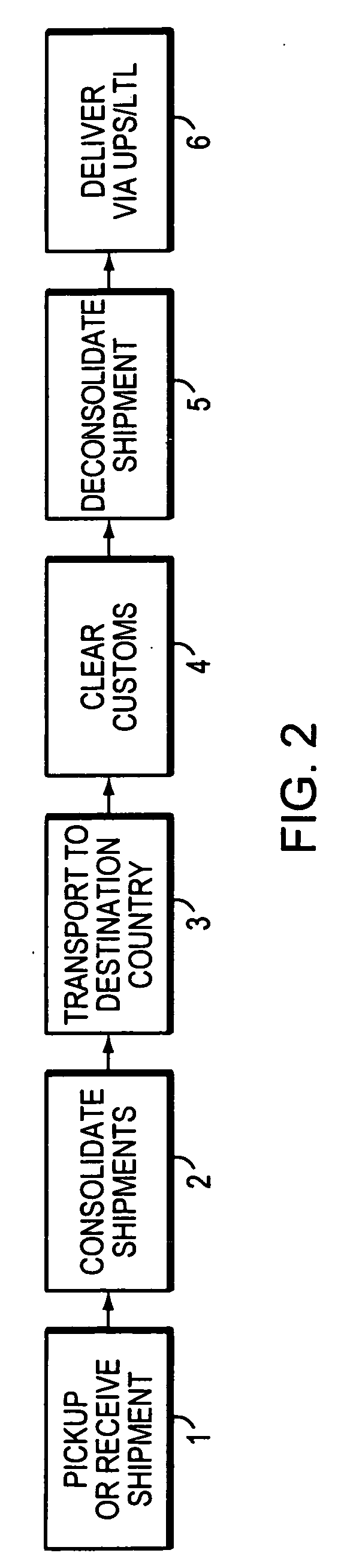

Systems and methods for consolidated global shipping

ActiveUS20050149373A1Promote sportsEasy to managePackaging vehiclesContainers for machinesVisibilityInventory management

Disclosed is an integrated global shipment system that provides end-to-end visibility of the movement of a package. The integrated global shipment system employs a shipment consolidating application for integrating one or more freight tracking systems with one or more end-delivery systems. As a result, shippers are provided with complete visibility of the movement of their shipments of goods from an origin country to a destination country and till the final consignees. In addition, the integrated shipment system significantly decreases the cost of managing inventories by providing a virtual inventory solution. Under this virtual inventory solution, suppliers are able to bypass distribution centers and delay allocation of goods until after the importation of goods into a destination country.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Systems and methods for integrated global shipping and visibility

InactiveUS20050149453A1Promote sportsEnhanced inventory managementPackaging vehiclesContainers for machinesInventory managementDelivery system

Disclosed is an integrated global shipment system that provides end-to-end visibility of the movement of a package. The integrated global shipment system employs a shipment consolidating application for integrating one or more freight tracking systems with one or more end-delivery systems. As a result, shippers are provided with complete visibility of the movement of their shipments of goods from an origin country to a destination country and till the final consignees. In addition, the integrated shipment system significantly decreases the cost of managing inventories by providing a virtual inventory solution. Under this virtual inventory solution, suppliers are able to bypass distribution centers and delay allocation of goods until after the importation of goods into a destination country.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

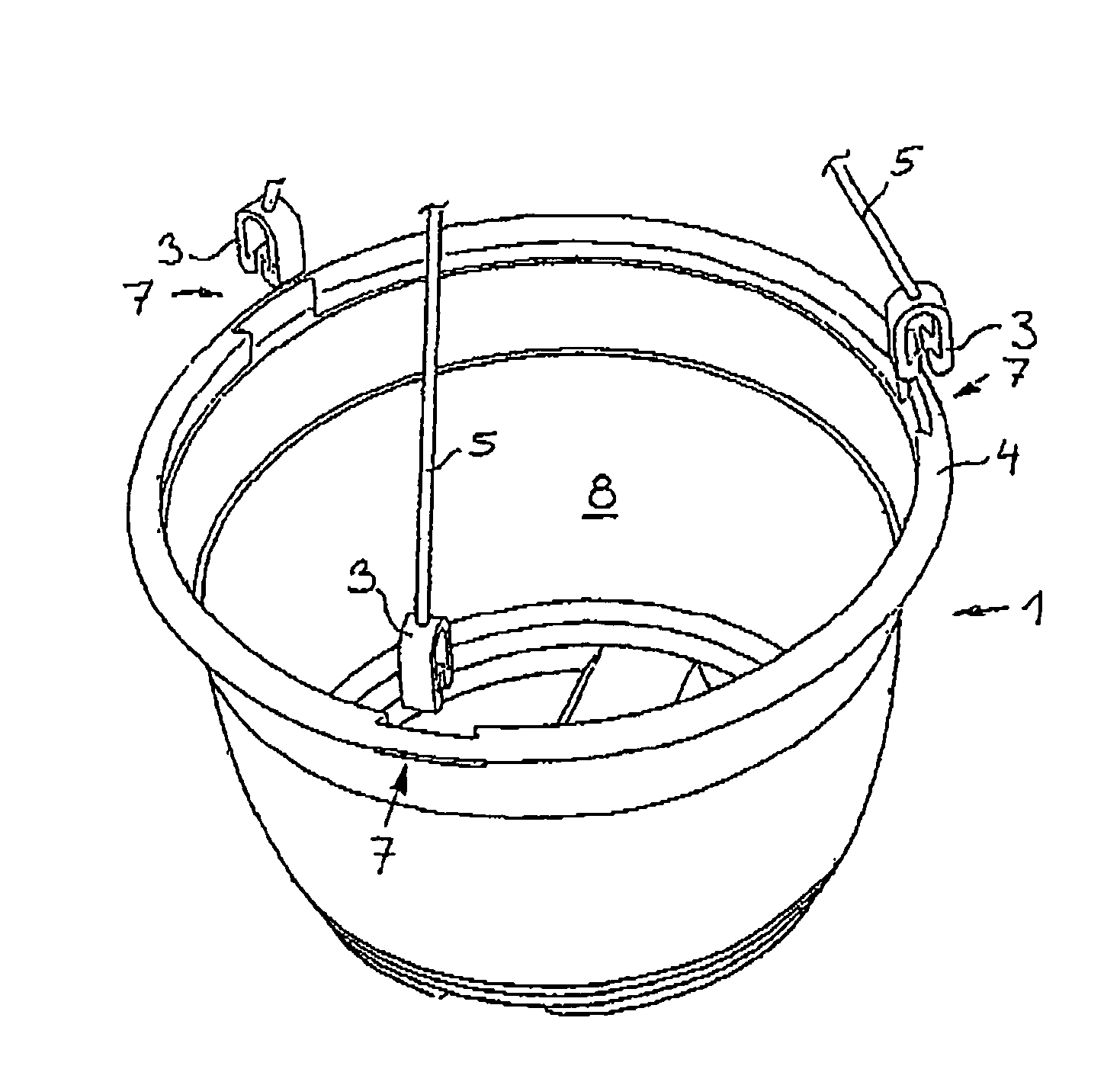

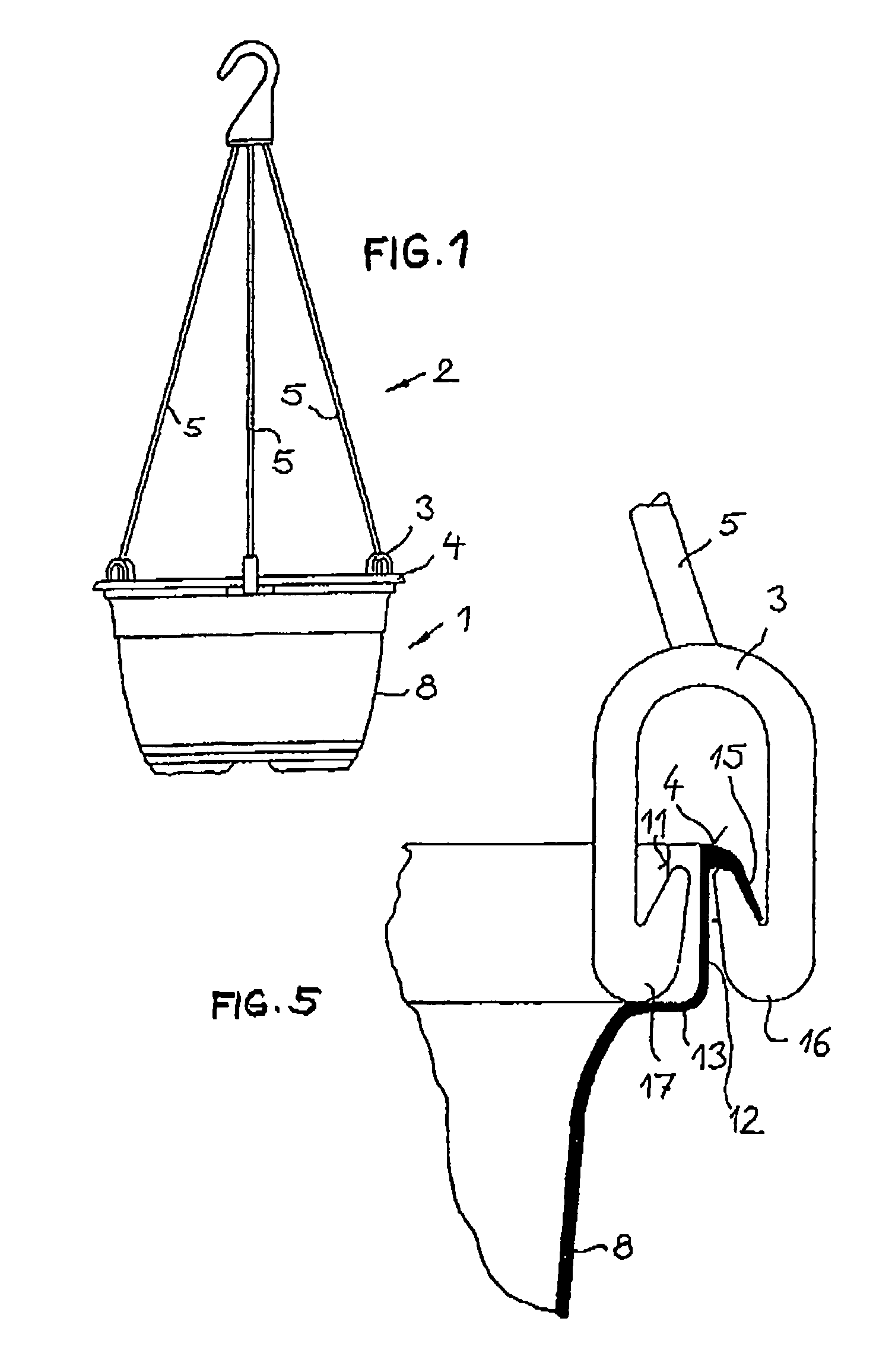

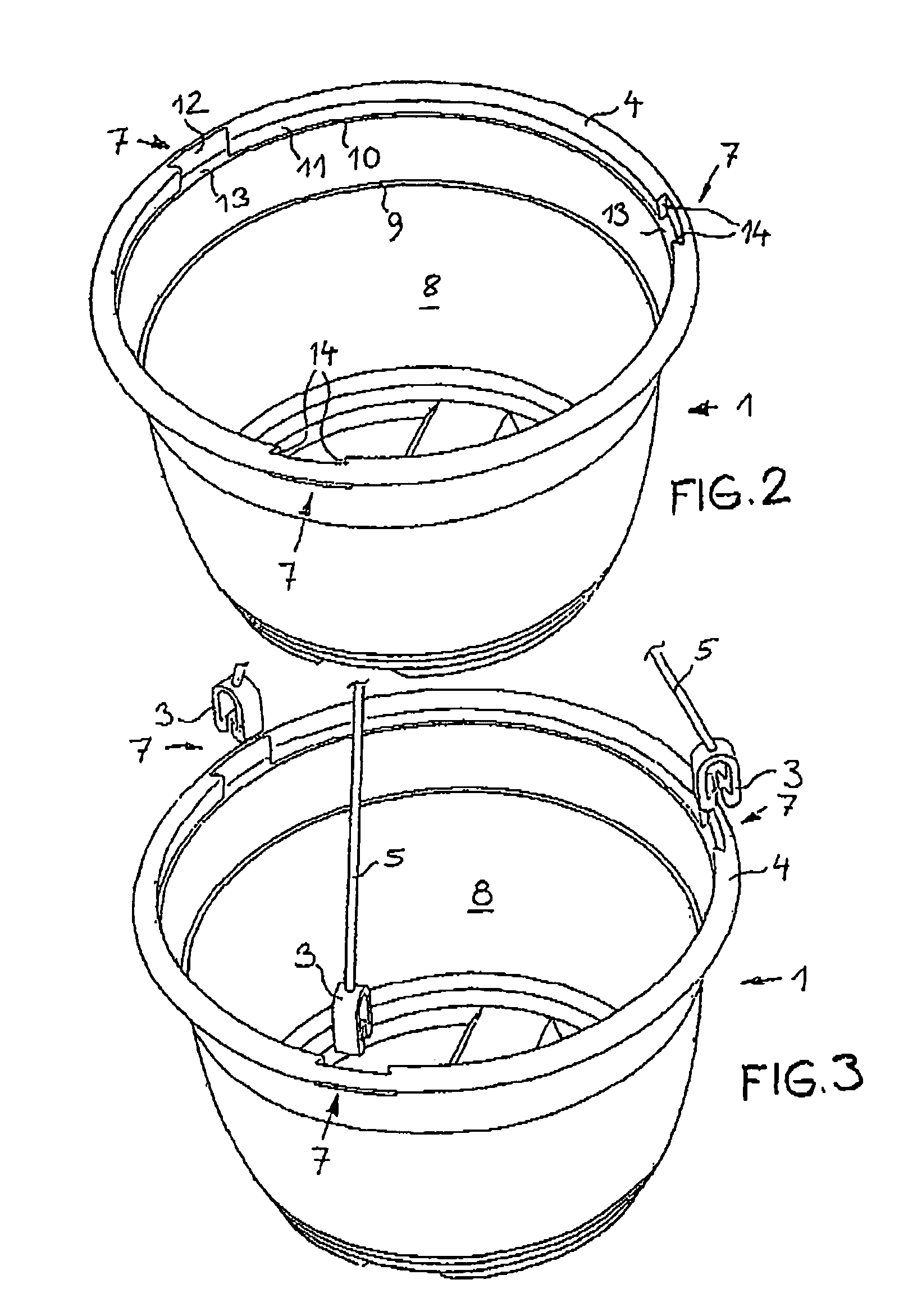

Flower pot

InactiveUS7610717B2Easy transferEasy to handleSnap fastenersStands/trestlesPlastic materialsEngineering

The invention relates to a flower pot (1) made of deep drawn plastic material and provided for a hanging flower pot wherein a suspension part (2) comprises a plurality of strands (5) that are linked via hook clips (3) with the pot rim (4) that has an outer continuous contour. The aim of the invention is to provide a flower pot that, in accordance with the special technical conditions during the deep drawing, is provided with a fixation of the seat (7) of the hook clips (3), while maintaining a good distribution of suspension loads between the pot and the hook clips and safeguarding an appealing yet easy to handle shape. To achieve this aim, the pot rim (4) has tapered sections extending inwards towards a wall contiguous with the bottom. These tapered sections form a seat (7) for the hook clips (3).

Owner:GEBR POPPELMANN KUNSTSTOFFWERK WERKZEUGBAU

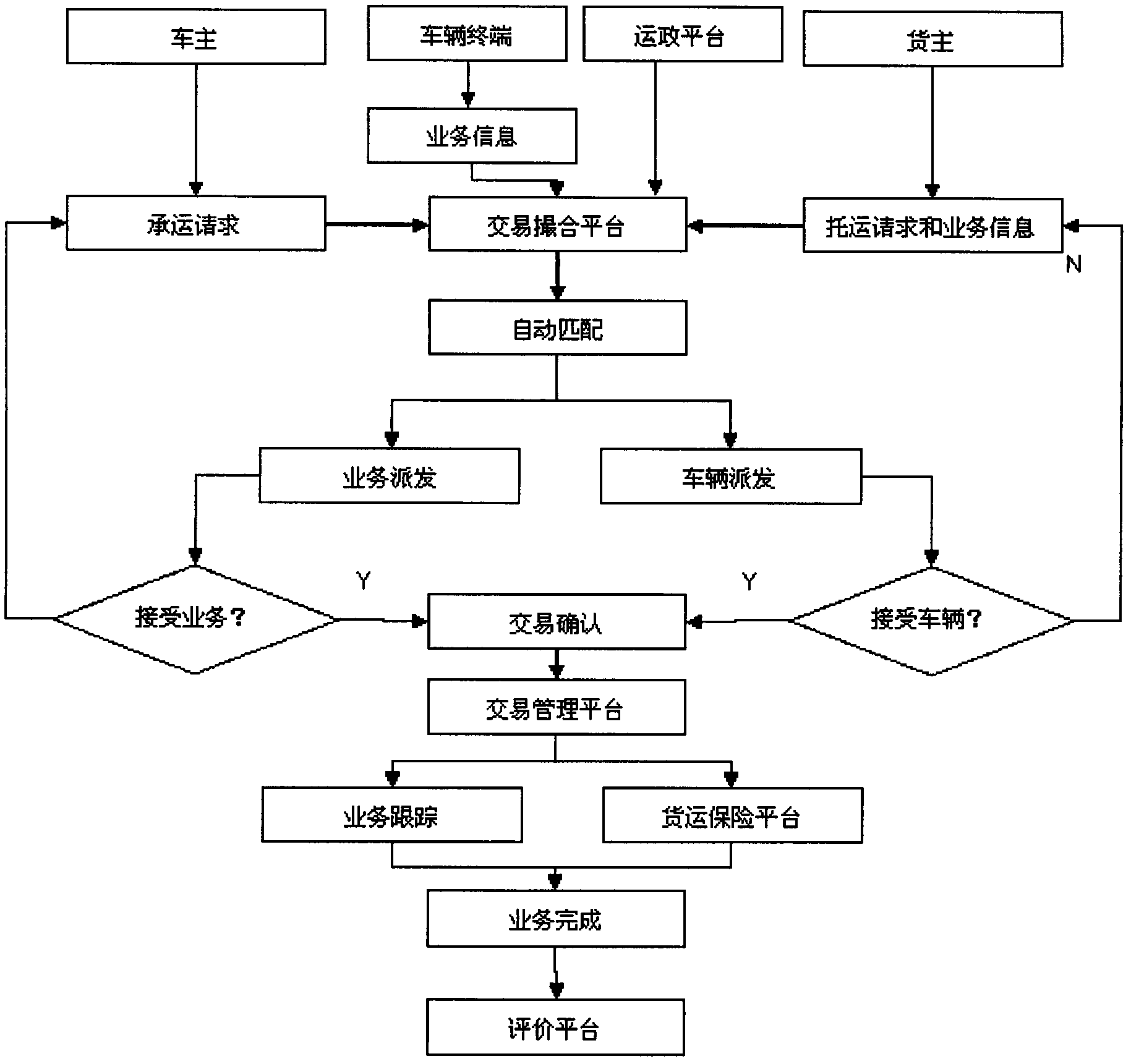

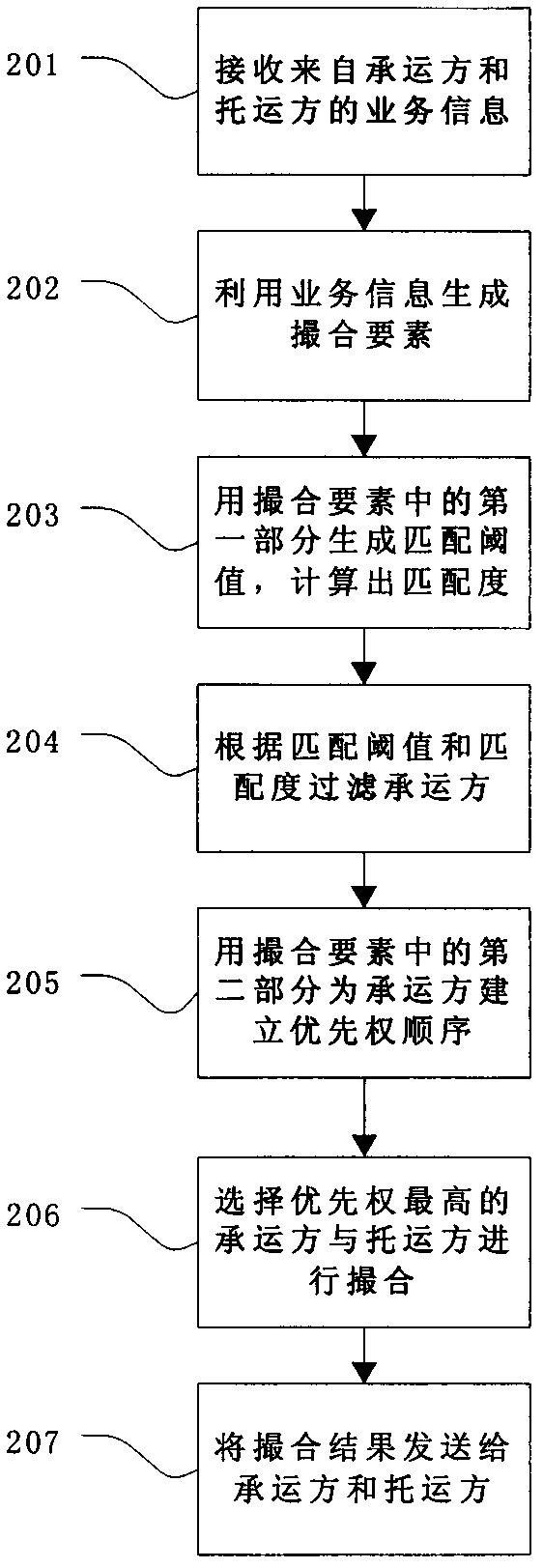

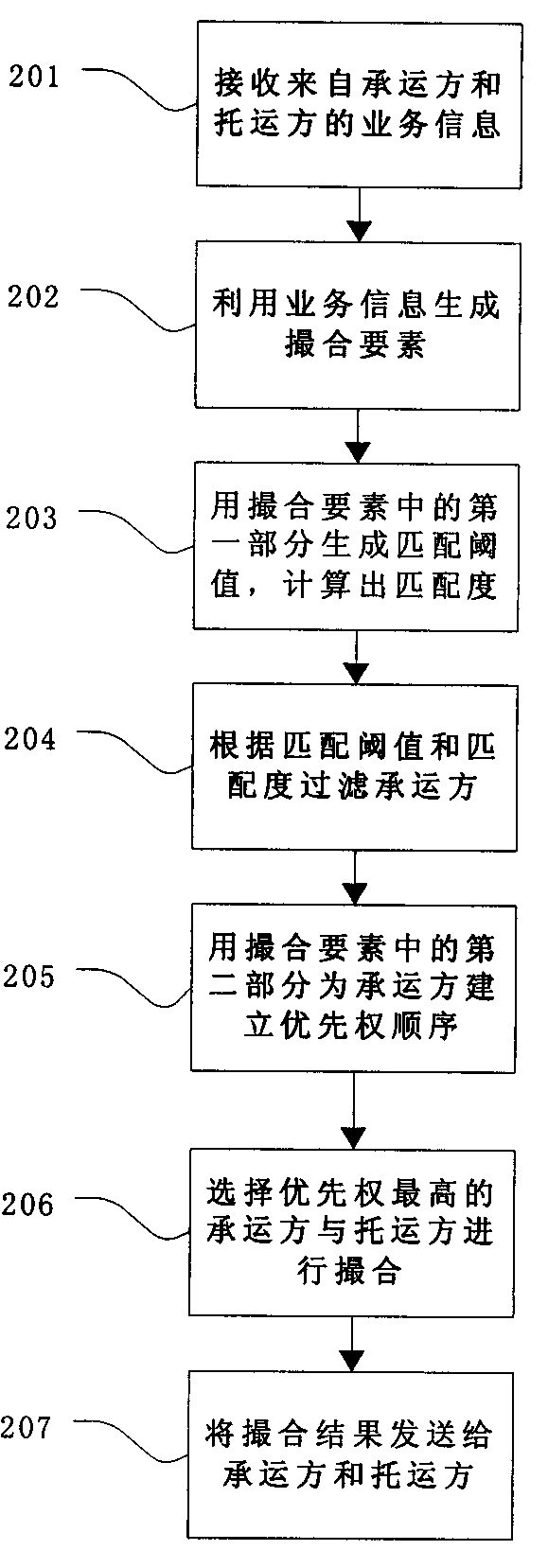

Method and system for matching freight transaction

InactiveCN101930580AObvious drawingsObvious requirementBuying/selling/leasing transactionsData miningDatabase

The invention relates to a method and a system for matching freight transaction, which are used for matching transaction for carriers and shippers. The method comprises the following steps: receiving business information coming from the carriers and the shippers; using the business information to generate matching factors; using the first part in the matching factors to filter the carriers; using the second part in the matching elements to sequence the priority of the filtered carriers; selecting the carrier with the highest priority to match with the corresponding shipper; and respectively sending the matching result to the carrier and the corresponding shipper. In the invention, the preferable matching between two parties of freight transaction is realized through matching the business information of the two parties of the freight transaction and filtering and sequencing transaction select objects, thus greatly improving efficiency, security and reliability of goods distribution.

Owner:BEIJING TRANWISEWAY INFORMATION TECH +2

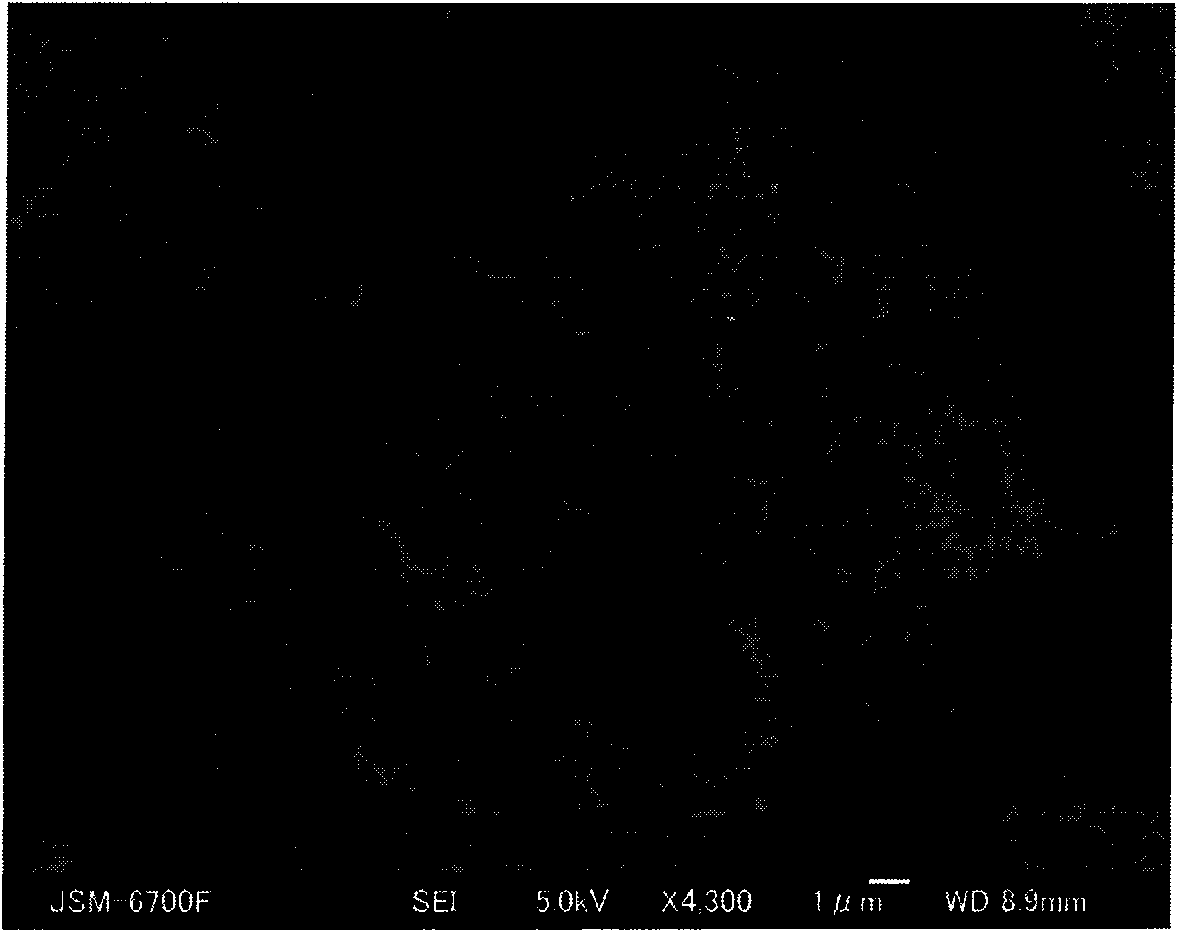

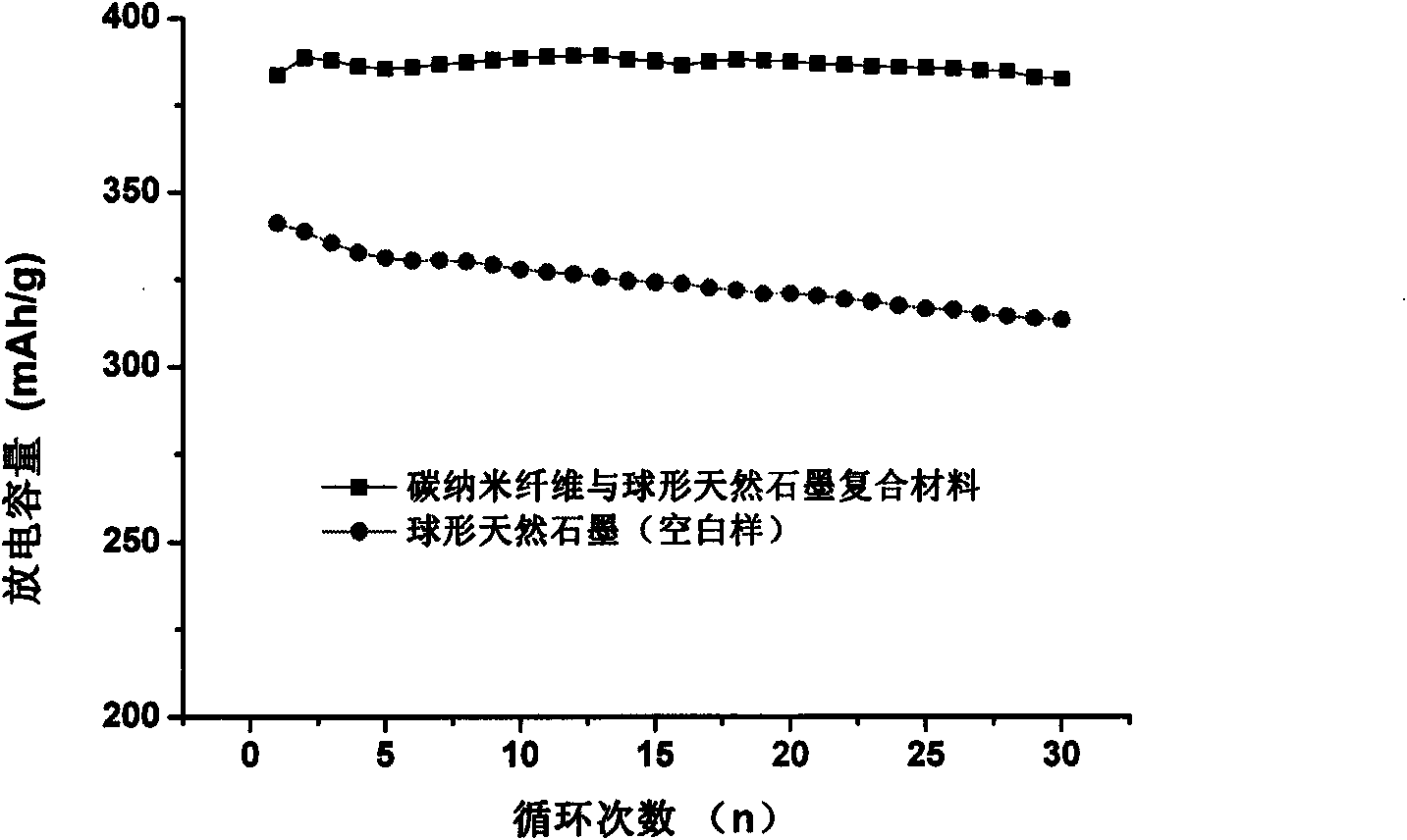

Composite cathode material of lithium ion battery and preparation method thereof

ActiveCN101540390ASolving Dispersion ProblemsChange the combinationElectrode manufacturing processesActive material electrodesFiberGas phase

The invention discloses a composite cathode material of a lithium ion battery and a preparation method thereof, and pertains to the technical field of nano-materials and chemical power source. The material is a composite of cathode material and a carbon nanotube or carbon nanofiber; the method of the invention comprises the step of adopting a chemical vapor deposition process for the in-situ growth of the carbon nanotube or the carbon nanofiber on the surface of the cathode material; the invention has simple process, energy conservation and consumption reduction and low production cost; and the composite cathode material is prepared by the steps that the carbon nanotube or the carbon nanofiber are directly erected on the surface of the cathode material to form a sea urchin type structure, and the carbon nanotube or the carbon nanofiber has good distribution uniformity, concentration degree and crystallinity on the surface of the cathode material; and the invention is characterized by high conductivity, high capacity, capability of rapid charge and discharge and the like in performance. The materials prepared by adopting the method of the invention can be widely applied in the new energy devices including lithium ion batteries, supercapacitors and the like, and can also be applied to catalyst carrier, absorbing materials, conductive materials and heat conducting materials and the like.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD

Site selection and transportation optimization method for super-large scale logistics distribution

ActiveCN103473612AReduce computing requirementsGreat innovationForecastingLogisticsDistractionCluster algorithm

The invention provides a site selection and transportation optimization method for super-large scale logistics distribution. The method comprises the steps of clustering, side selection planning and route planning, specially, the method comprises the steps that computing is carried out with a method combined by a from-bottom-to-top clustering method and a designating-based clustering algorithm; a given distribution center number is p, the best site selection scheme is computed with minimum total cost as a target; site selection schemes with different distribution center numbers are compared, administration cost is integrated, an ideal site selection scheme is selected; according to the requirements of distraction point numbers in each cluster and geographic information, the time requirement of distribution connecting of each distribution point and the traffic time requirement between points are computed; an ant colony algorithm is used, and the best distribution route is obtained by computing. According to the site selection and transportation optimization method for super-large scale logistics distribution, the problem that computing amount is large caused by the fact that distribution points are increased greatly is effectively solved, compared with existing site selection-route planning, computing expenditure is greatly lowered, and efficiency is obviously improved.

Owner:周伟华

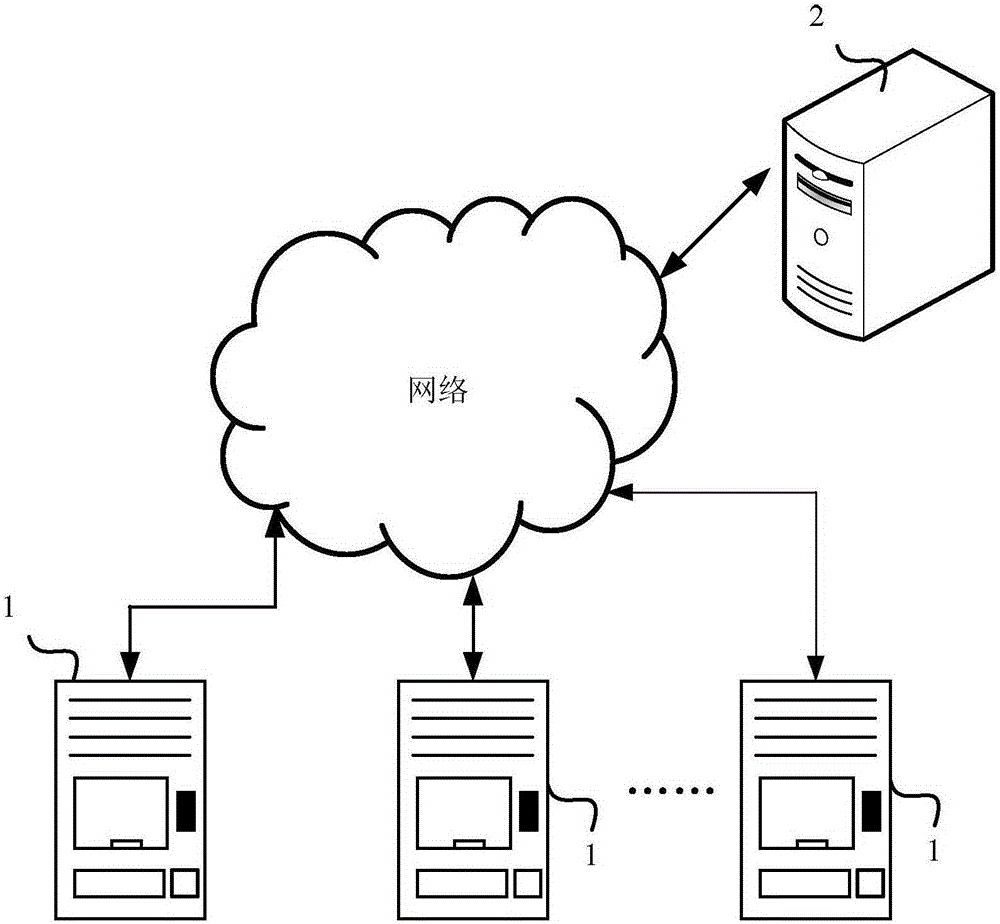

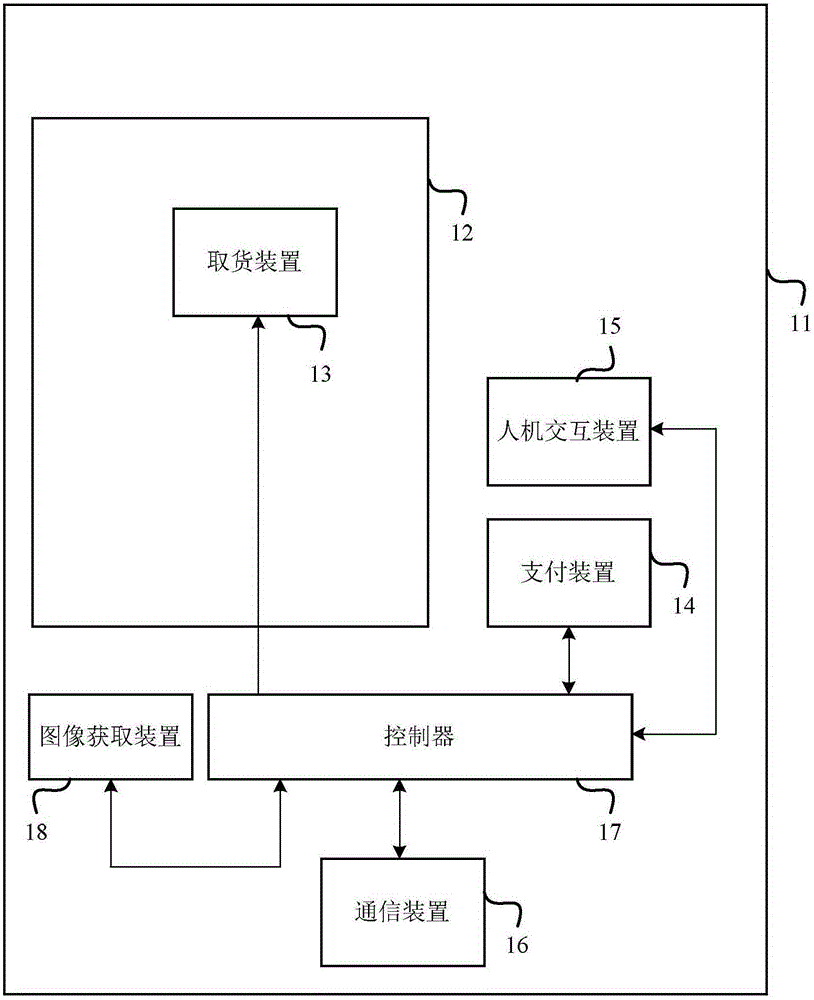

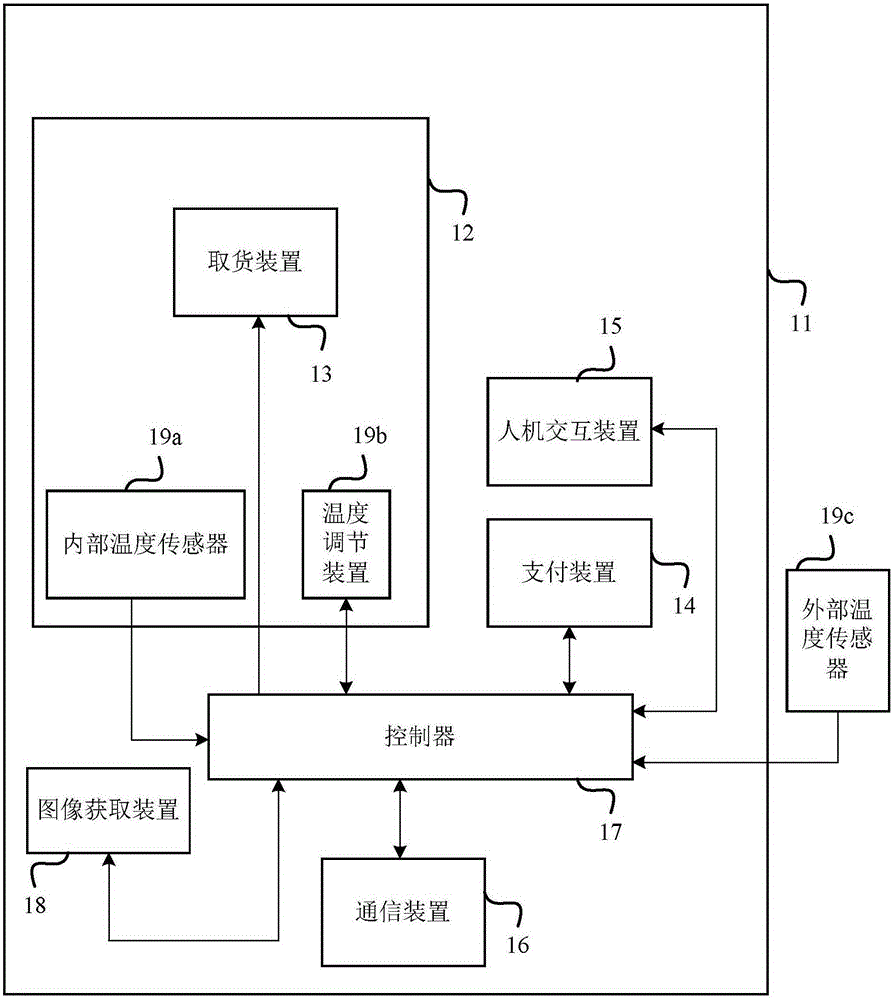

Management system and management method for vending machine

InactiveCN105184975ARealize precise managementImprove experienceCoin-freed apparatus detailsMarketingData miningManagement system

The invention discloses a management system and a management method for a vending machine. The management system and the management method are characterized in that: when the vending machine sells goods, a person image is obtained at the same time; attribute information including gender, age, identity or degree of satisfaction is confirmed based on the obtained person image; corresponding statistical information is generated based on the attribute information and information of the sold goods; optimization information of goods distribution or device parameters of each vending machine is obtained based on the analysis of the statistical information, so as to achieve precise management for the vending machine and improve the user experience.

Owner:WEIDIAN BEIJING CULTURAL MEDIA

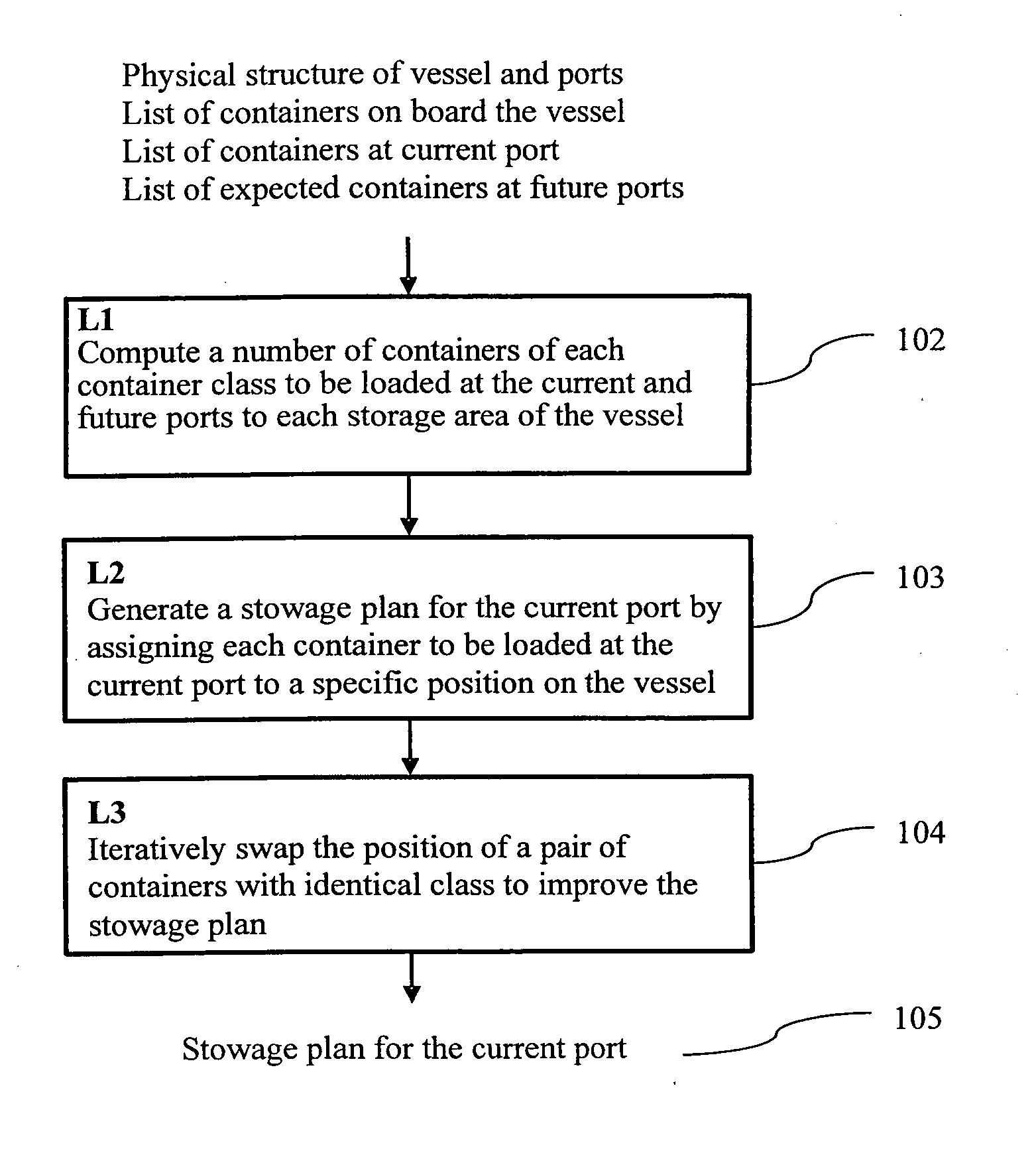

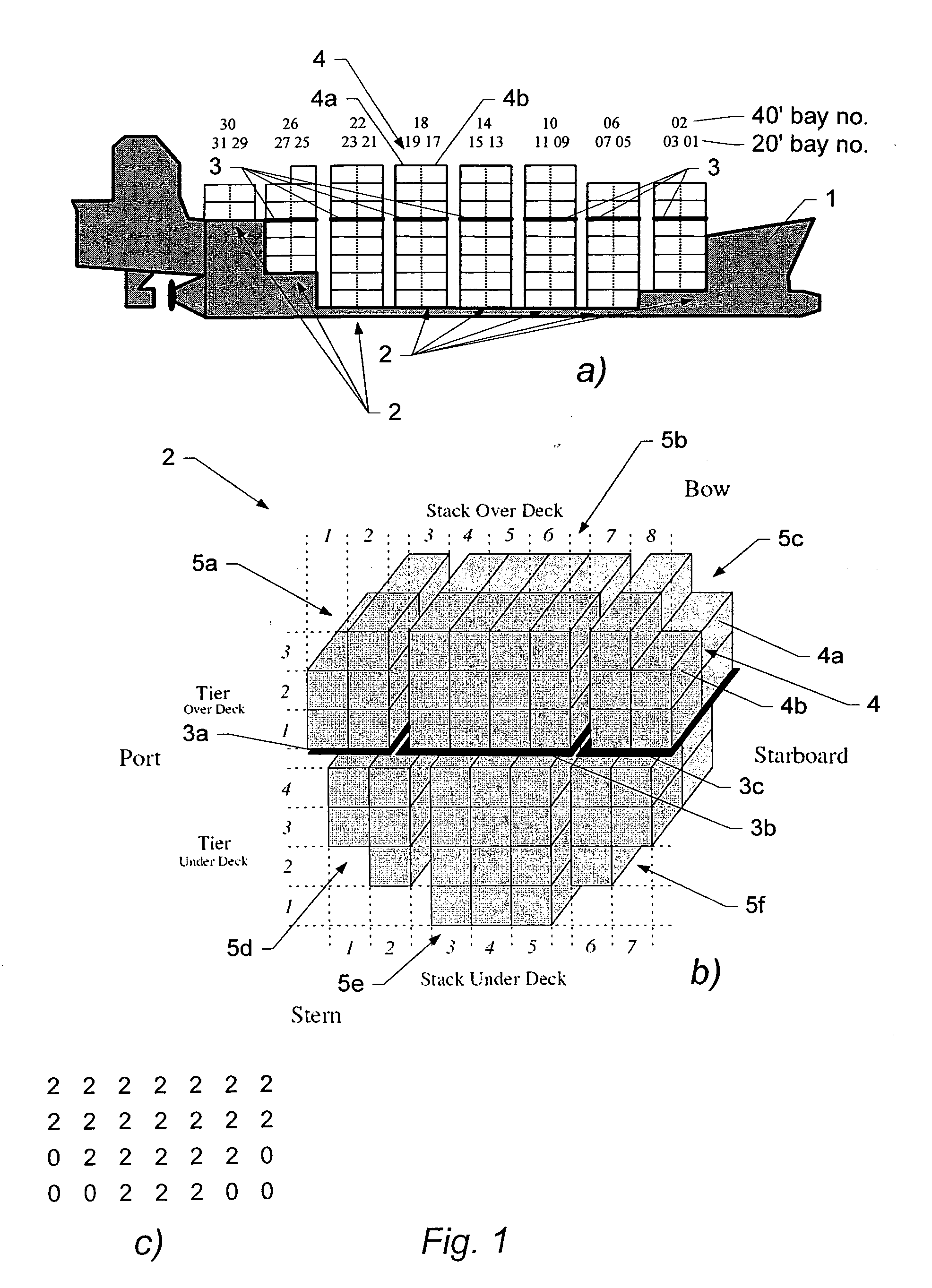

Container vessel stowage planning

InactiveUS20100145501A1Reduce computational complexityQuality improvementDigital data processing detailsKnowledge representationEngineeringStowage

A computer-implemented method of determining an allocation plan for a cargo stowage problem of allocating a set of cargo items to a set of cargo item positions of a vessel, each cargo item position being suitable for receiving a cargo item. The method comprises constructing an expression indicative of one or more constraints to be satisfied by said allocation plan, constructing a cost function indicative of a cost of an updated allocation plan relative to a current allocation plan of said cargo stowage problem, iteratively updating a current allocation plan from an initial allocation plan to an updated allocation plan so as to decrease said cost function under said one or more constraints.

Owner:A P MOLLER AS

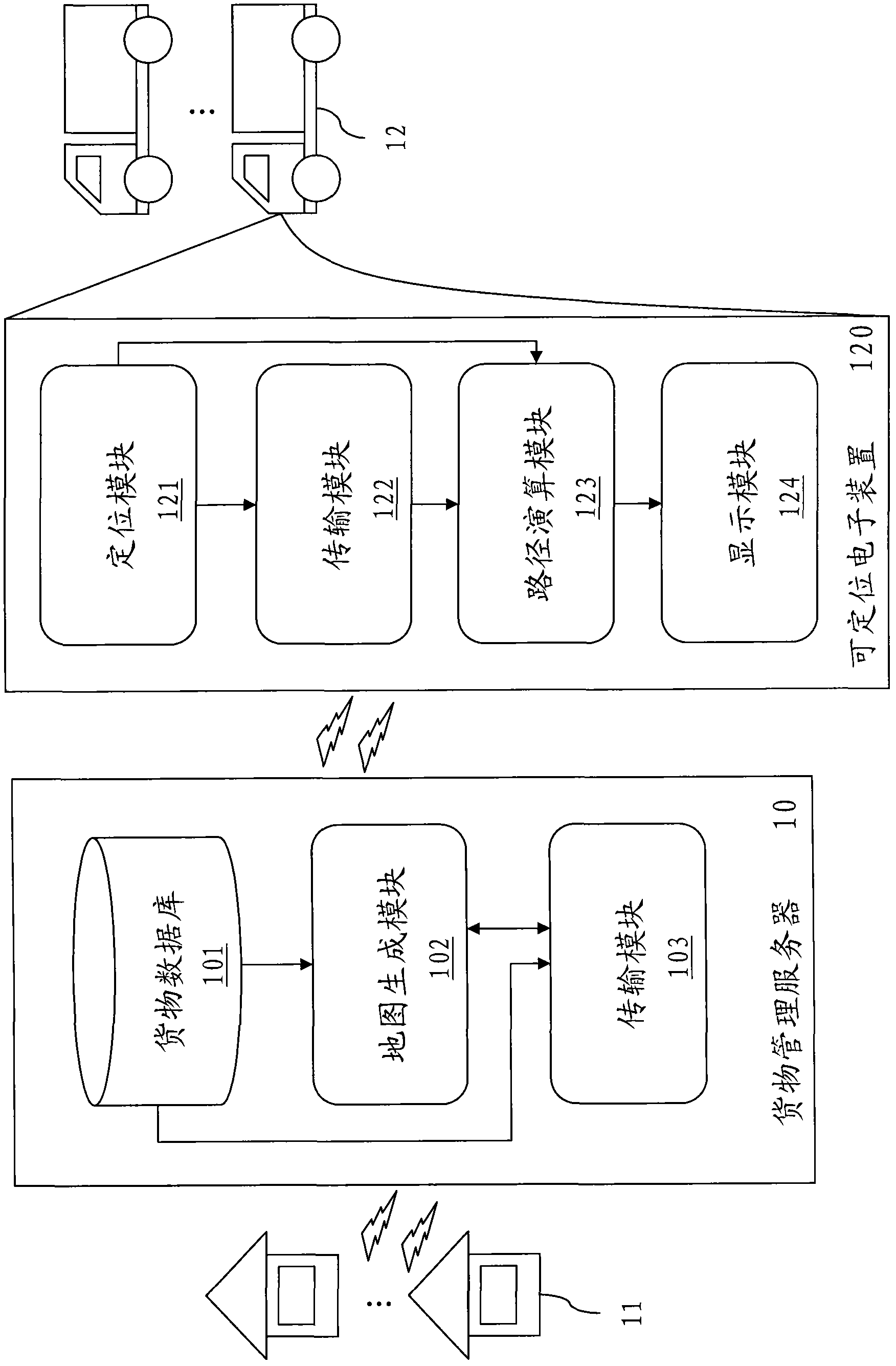

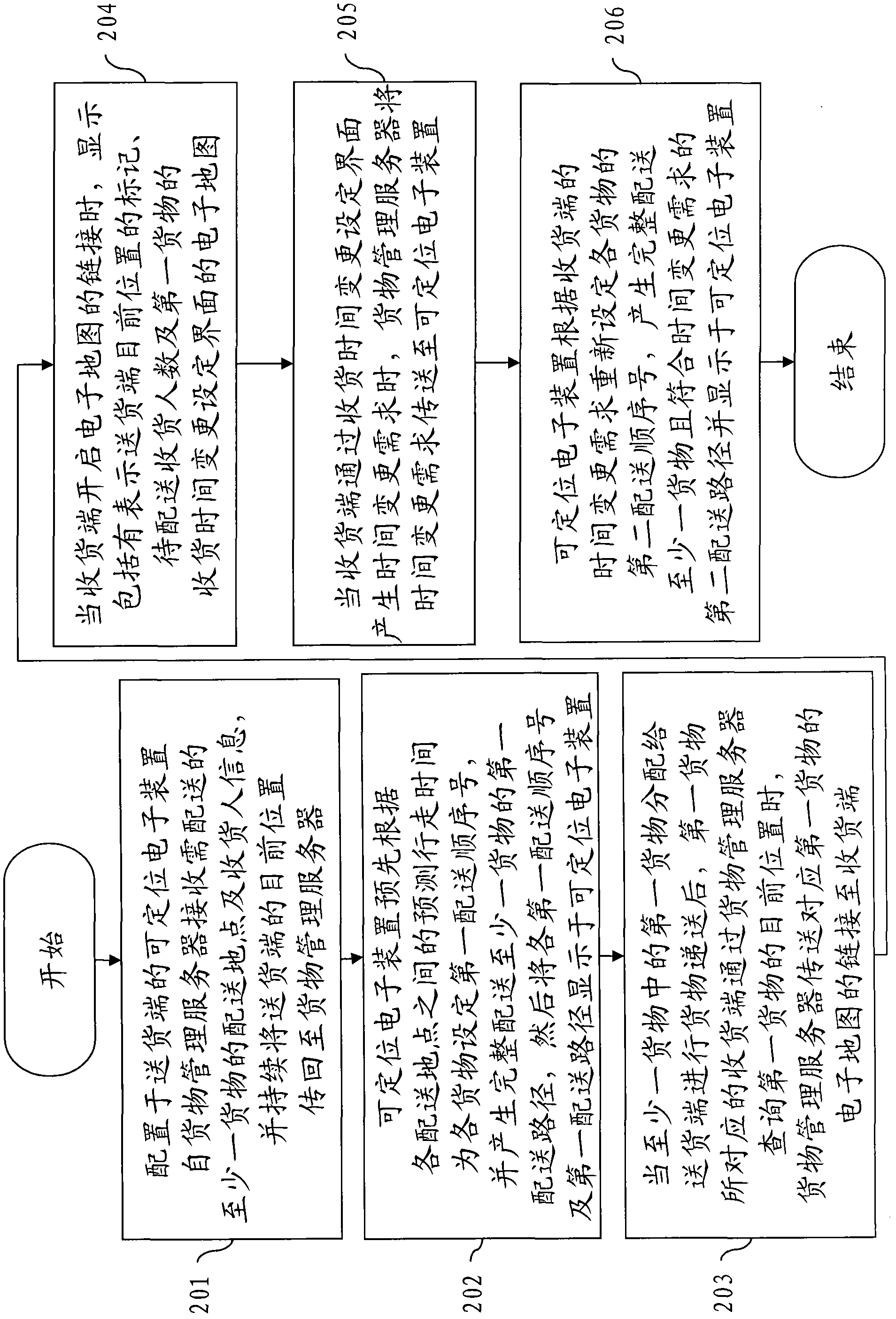

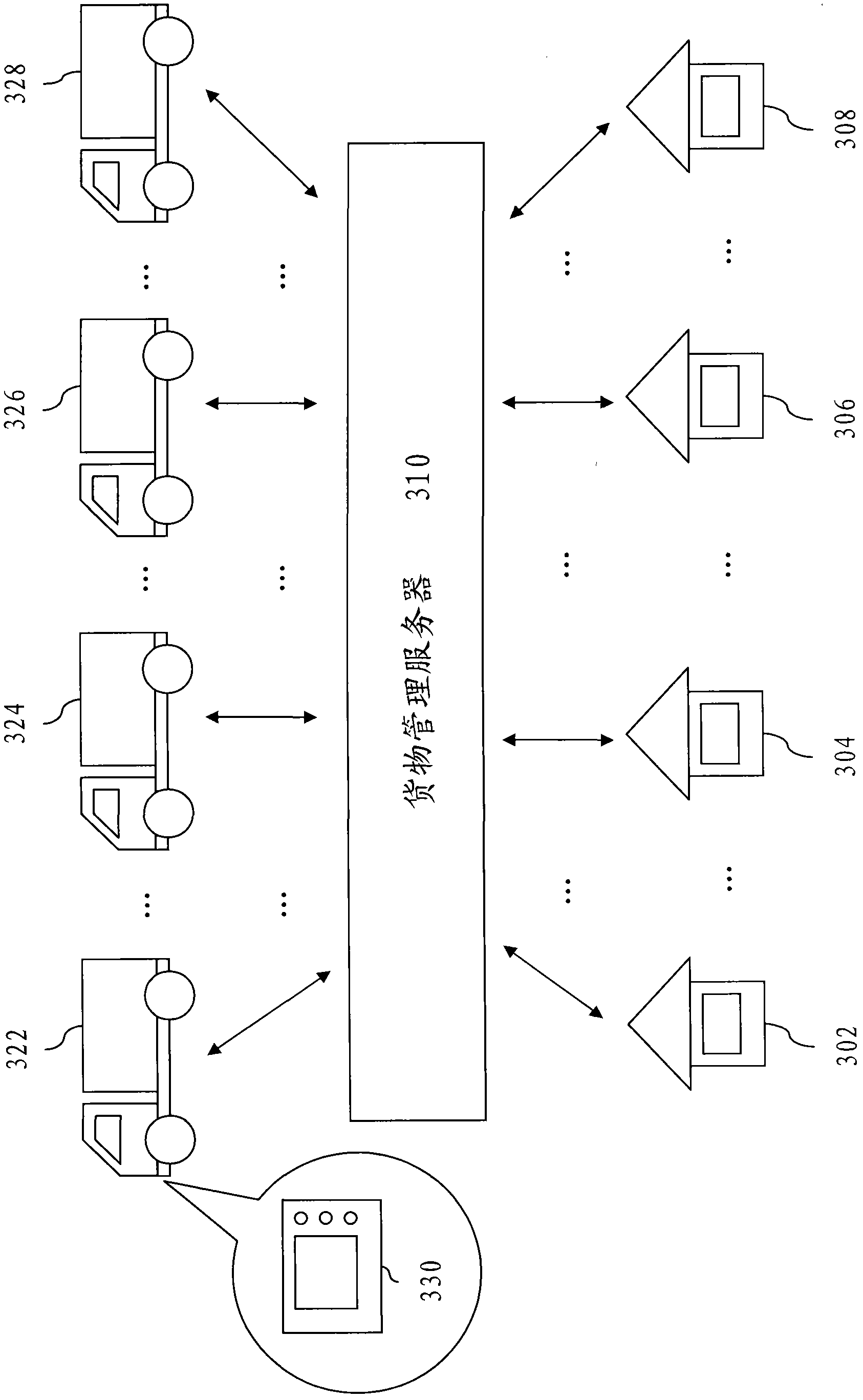

Goods distribution interaction system and method thereof

Disclosed are a goods distribution interaction system and a method thereof. Goods distribution routes are planned by positioning electronic devices configured at goods distribution ends when goods are distributed to the goods distribution ends, current positions of the goods distribution ends and number of goods deliverers of the goods distributed are displayed via electronic maps when receiving ends inquire current positions of the goods via a goods management server, and the goods distribution routes are replanned by the positioning electronic devices of the goods distribution ends when the receiving ends transmit time change demands to the goods distribution ends via a receiving time changing and setting interface, so that technical effect in scheduling efficiency of both the distributing part and the receiving part of goods distribution can be improved.

Owner:INVENTEC CORP +1

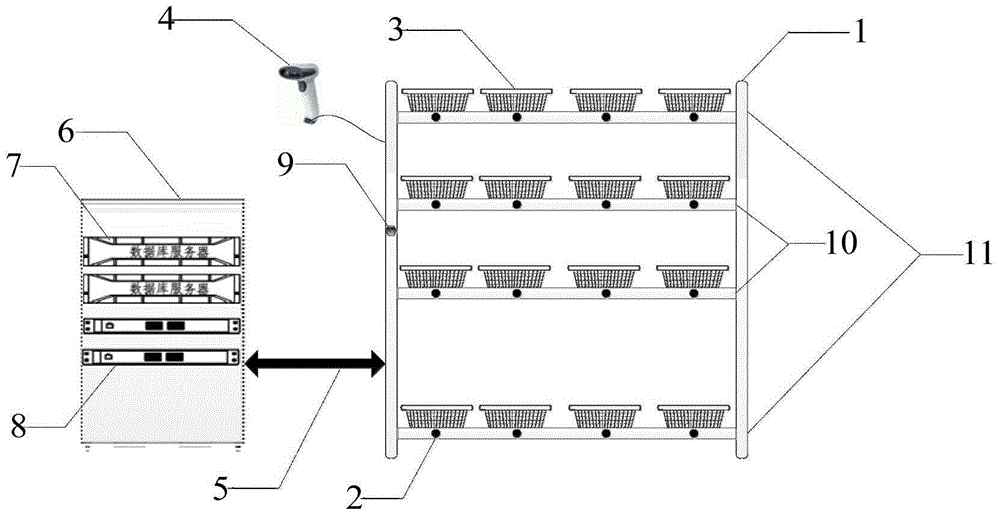

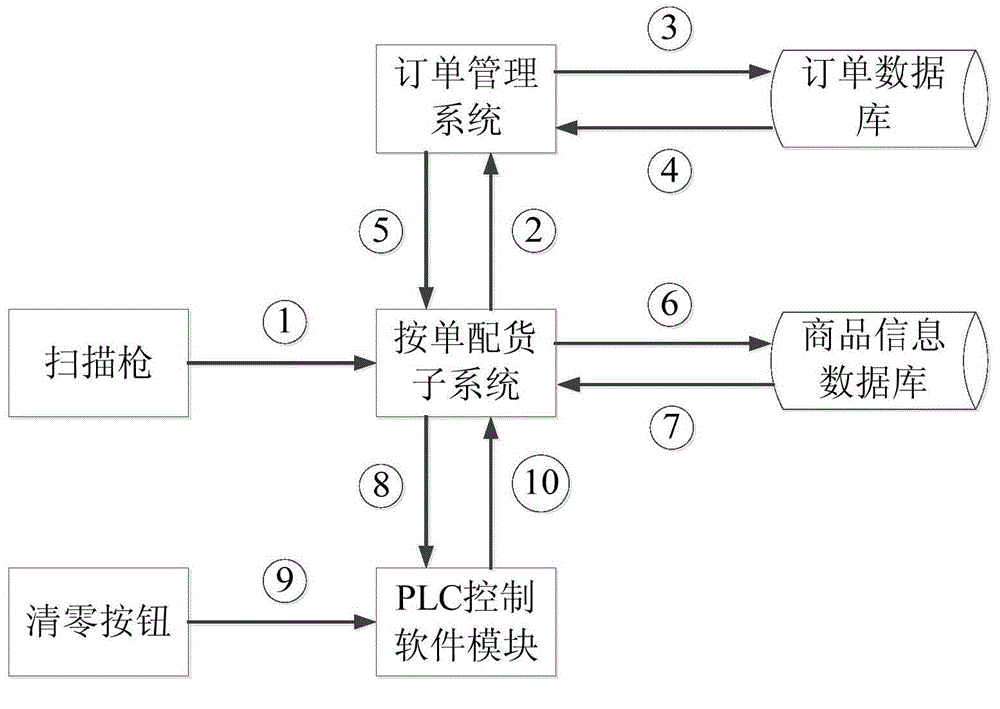

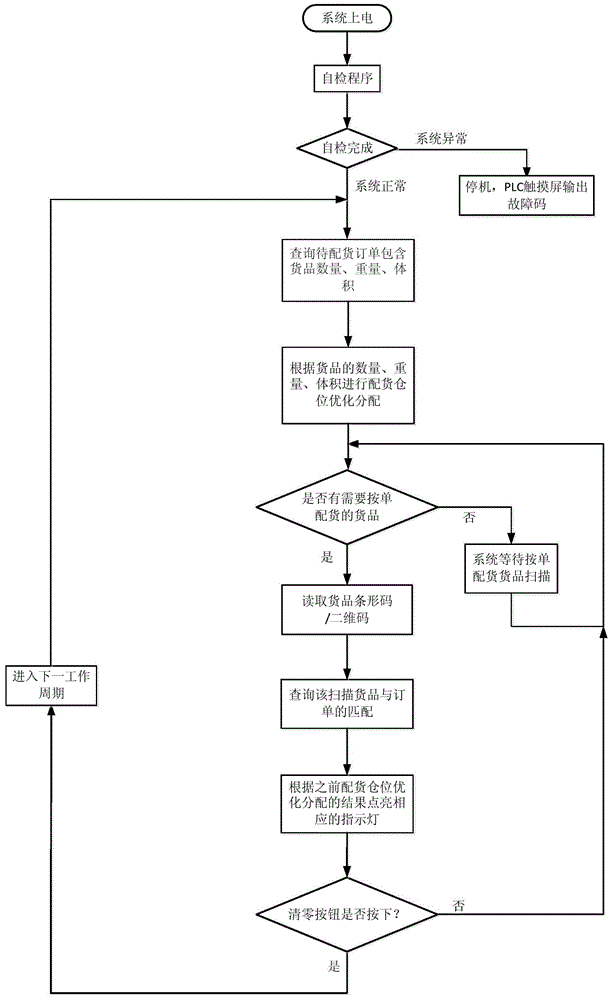

Intelligent goods distribution system and method

Owner:杭州翱度信息科技有限公司

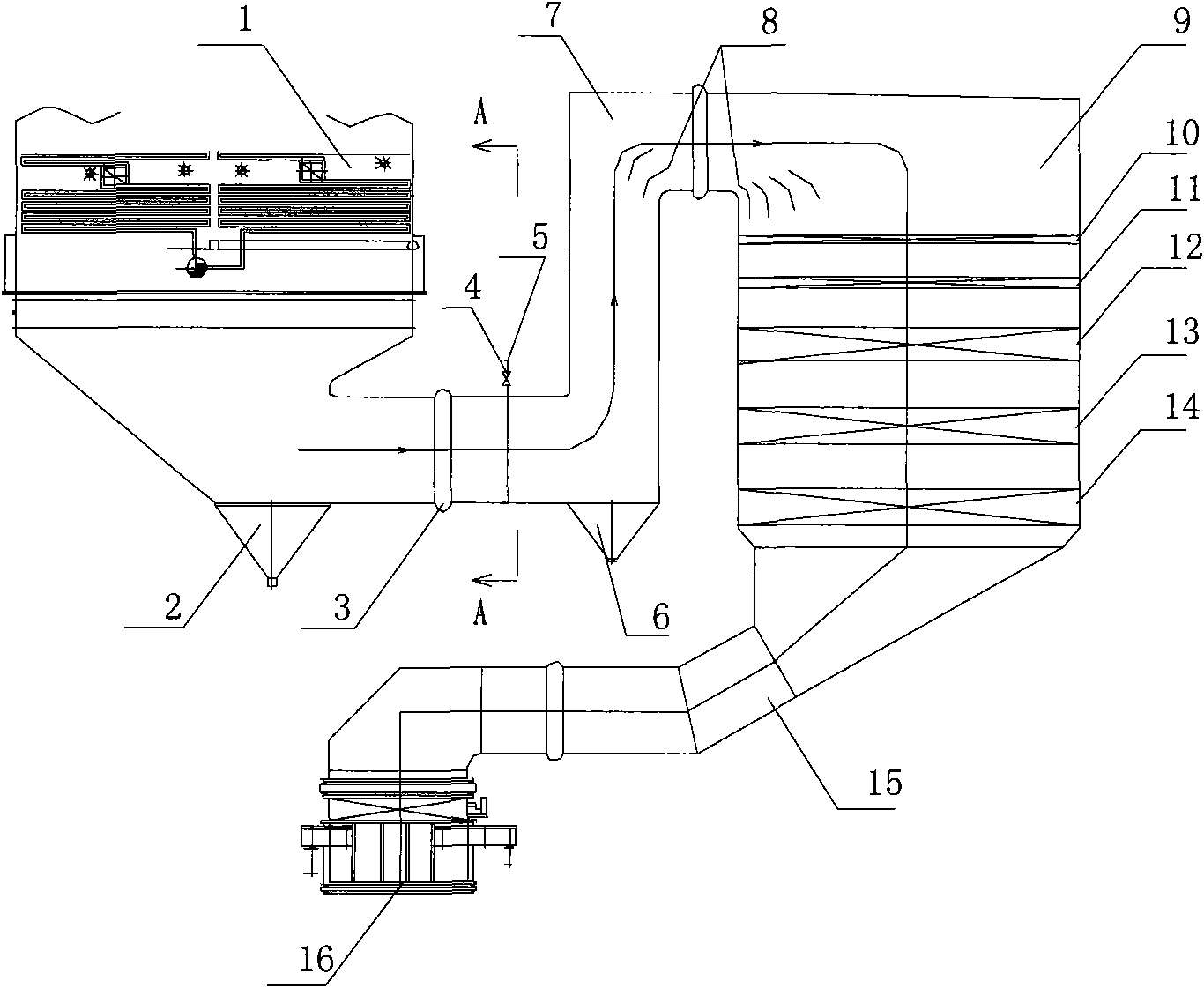

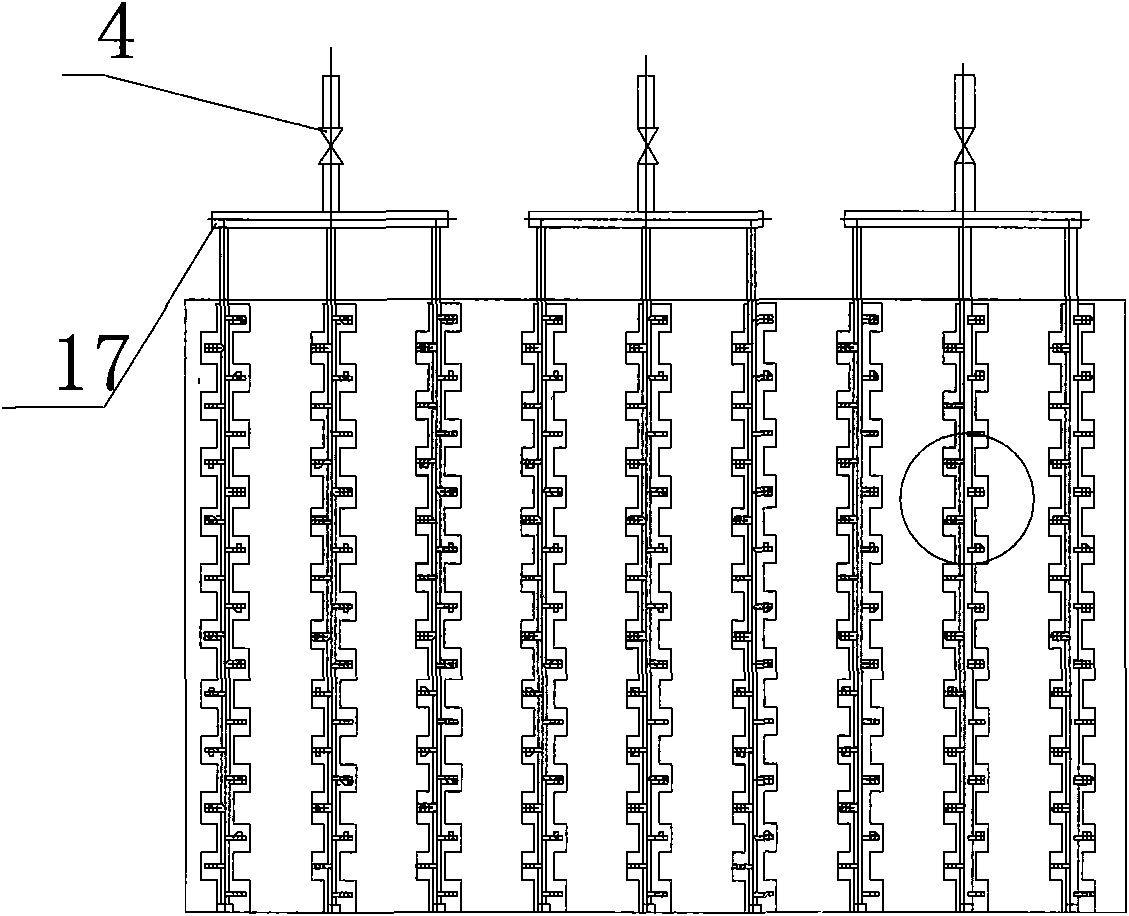

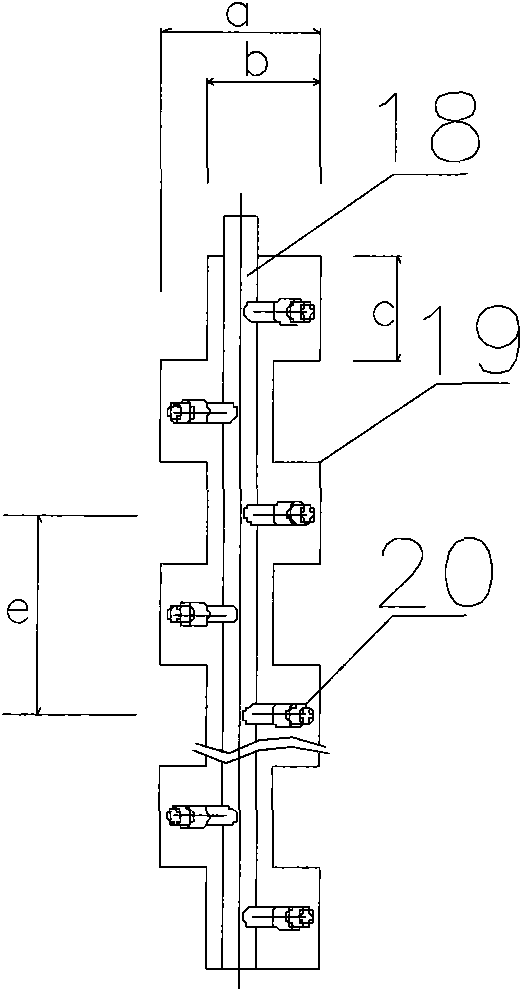

Ammonia-spraying grid device for SCR-method flue gas denitrification, and SCR-method flue gas denitrification process

ActiveCN101601965ASolve the resistanceReduce resistanceNitrous oxide captureDispersed particle separationFlue gasProduct gas

The invention discloses an ammonia-spraying grid device for SCR-method flue gas denitrification, which comprises an ammonia-spraying grid consisting of bundles of metal pipes, wherein each metal pipe is provided with a nozzle in the radial direction; the nozzle is communicated with the metal pipe; and the included angle between the opening direction of the nozzle and the flow direction of flue gas is between 0 and 90 degrees. The invention also discloses an SCR-method flue gas denitrification process adopting the ammonia-spraying grid device. The process adopts the ammonia-spraying grid to distribute ammonia / air gas mixture sprayed into an inlet flue of a denitrification reactor, and adjusts ammonia spray distribution according to the concentration of NOx in the inlet flue of the reactor so as to mix the NOx in the flue gas with NH3 sprayed in well, thus the mixing effect of the NH3 and the flue gas as well as denitrification efficiency can be effectively improved. A grid-type ammonia spraying-distributing-mixing device of the invention has the advantages of simple structure, low mixture resistance, good distribution effect, insusceptibility to ash deposition, capability of effectively protecting ammonia-spraying grid nozzles from wear, reducing the mixture distance of ammonia and the flue gas in an inlet of the denitrification reactor, improving the utilization rate of denitrification catalysts, reducing the height of the denitrification reactor and reducing the resistance of a flue gas denitrification system, thereby greatly reducing the unit cost of flue gas denitrification.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH

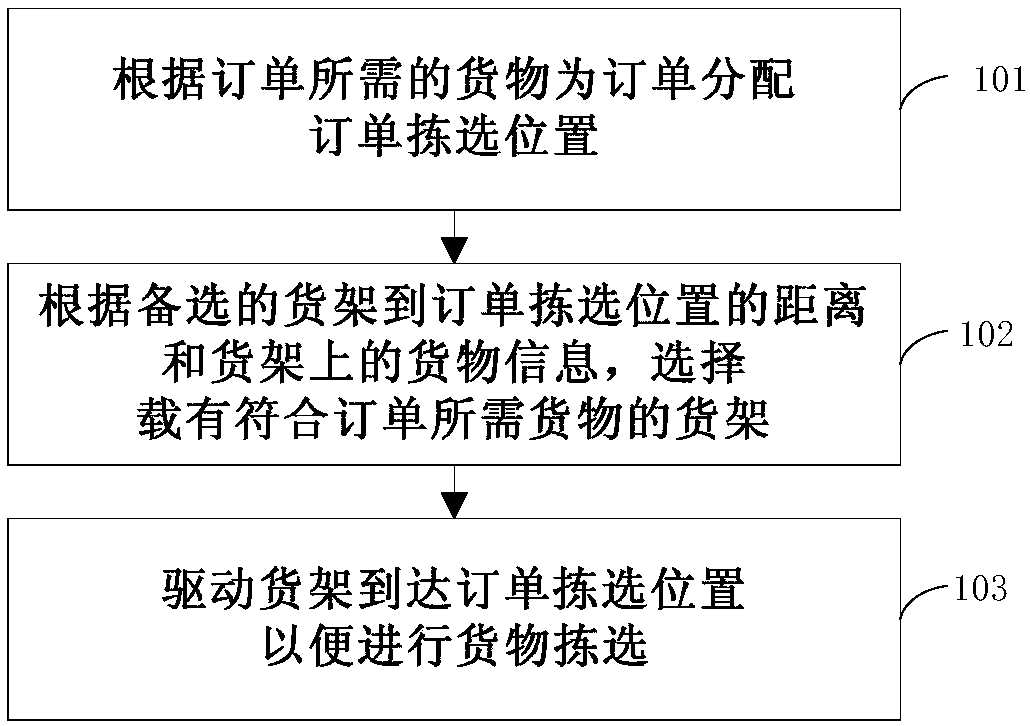

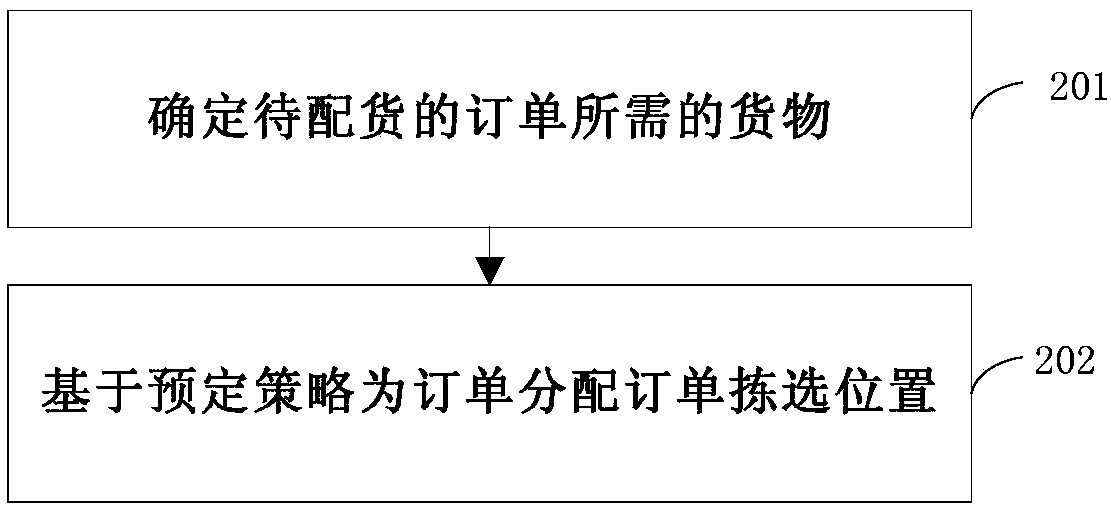

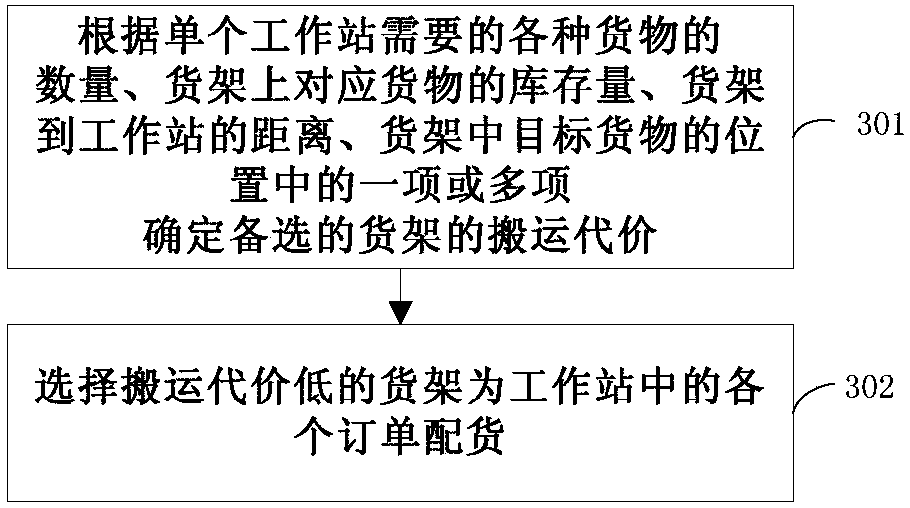

Cargo sorting method, server and system

ActiveCN109835651AImprove efficiencyImprove accuracyProgramme controlLogisticsIndustrial engineeringGoods distribution

The invention provides a cargo sorting method, server and system, and relates to the technical field intelligent warehousing. The cargo sorting method comprises the steps: the order picking position is assigned for an order according to cargoes needed by the order; according to the distance between alternative shelves and the order picking position and information of the cargoes on the shelves, the shelf carried with the cargoes needed by the order is selected; and the shelf is driven to reach the order picking position so as to conduct cargo picking. Through the method, the order picking position can be assigned according to the cargoes needed in the order, then according to the cargoes on the shelves and the positions of the shelves, the shelf is selected to reach the order picking position to conduct cargo picking, thus the order picking mode of driving the shelf to the order picking position is achieved, and the order picking efficiency and accuracy are improved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

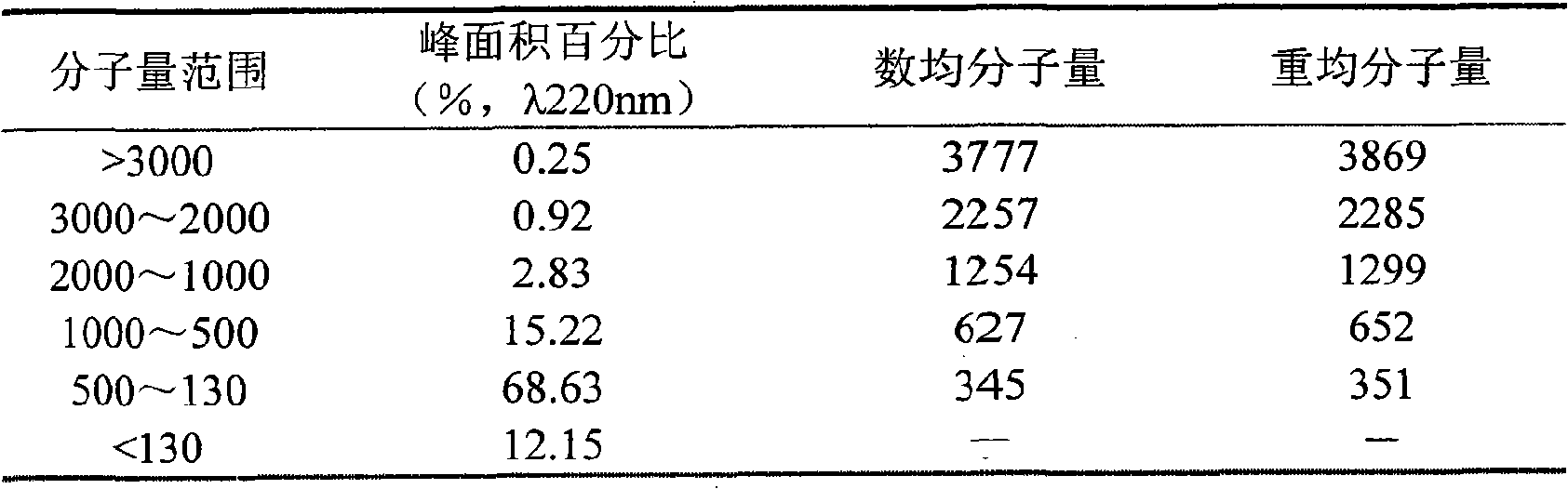

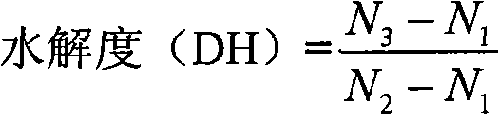

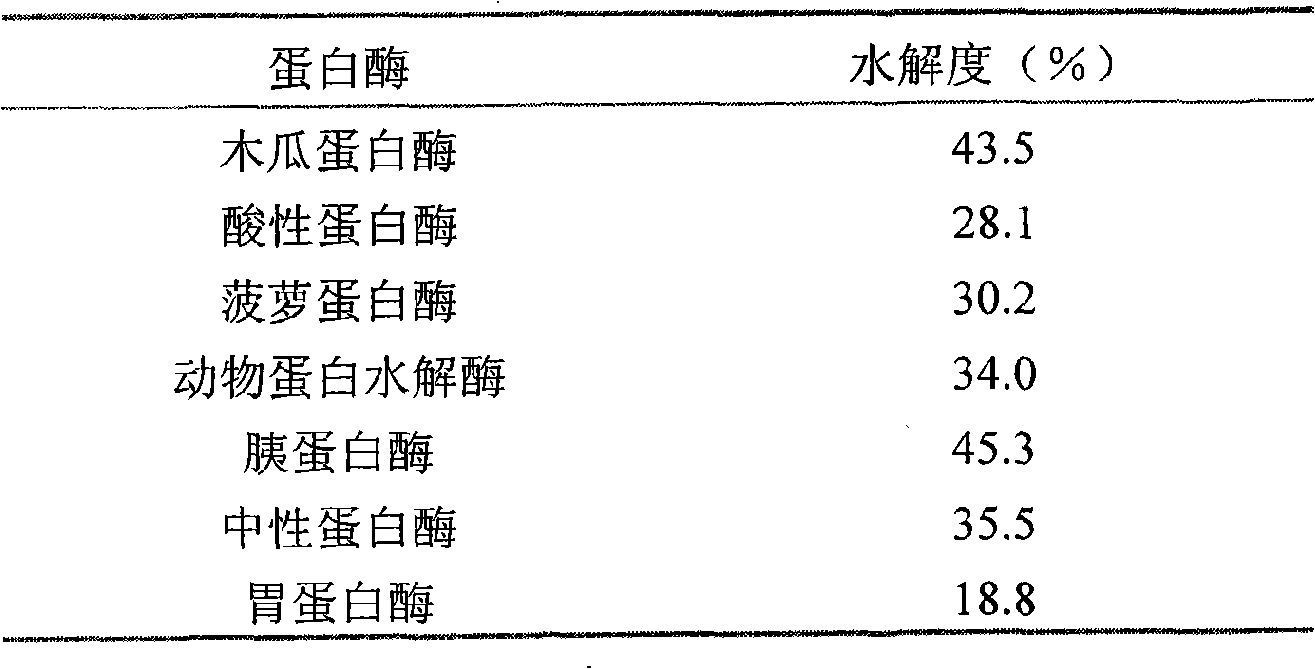

Method for preparing whey protein peptide by composite protease hydrolysis

InactiveCN101260421AIncrease profitExcellent molecular weight distribution rangeFermentationLactalbuminChemistry

The invention discloses a method for preparing lactalbumin peptides, comprising the following steps: (1) adding compound protease into lactalbumin solution to carry out enzymatic hydrolysis; (2) inactivating the compound protease; (3) depositing the enzyme solution and selecting supernatant fluid to carry out centrifugation; (4) carrying out decoloring processing on the centrifugalized supernatant fluid and then carrying out desalting processing; (5) carrying out nanofiltration on the desalted enzyme solution; (6)concentrating; (7) embedding the concentrated product into wall material; (8) spray drying, then the product is obtained. By applying compound protease in the invention, the lactalbumin is zymohydrolyzed with effectively improving enzyme hydrolysis degree, prominently improving usage factor of the lactalbumin, high product yield, good distribution range of molecular weight of the lactalbumin peptides, high peptide content and good product quality. By detecting, the content (counted by dry basis) of the lactalbumin peptides prepared by the method in the invention is up to 75.15 percent, the molecular weight distribution range of the peptide smaller than 2258 dalton can reach 98.83 percent.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

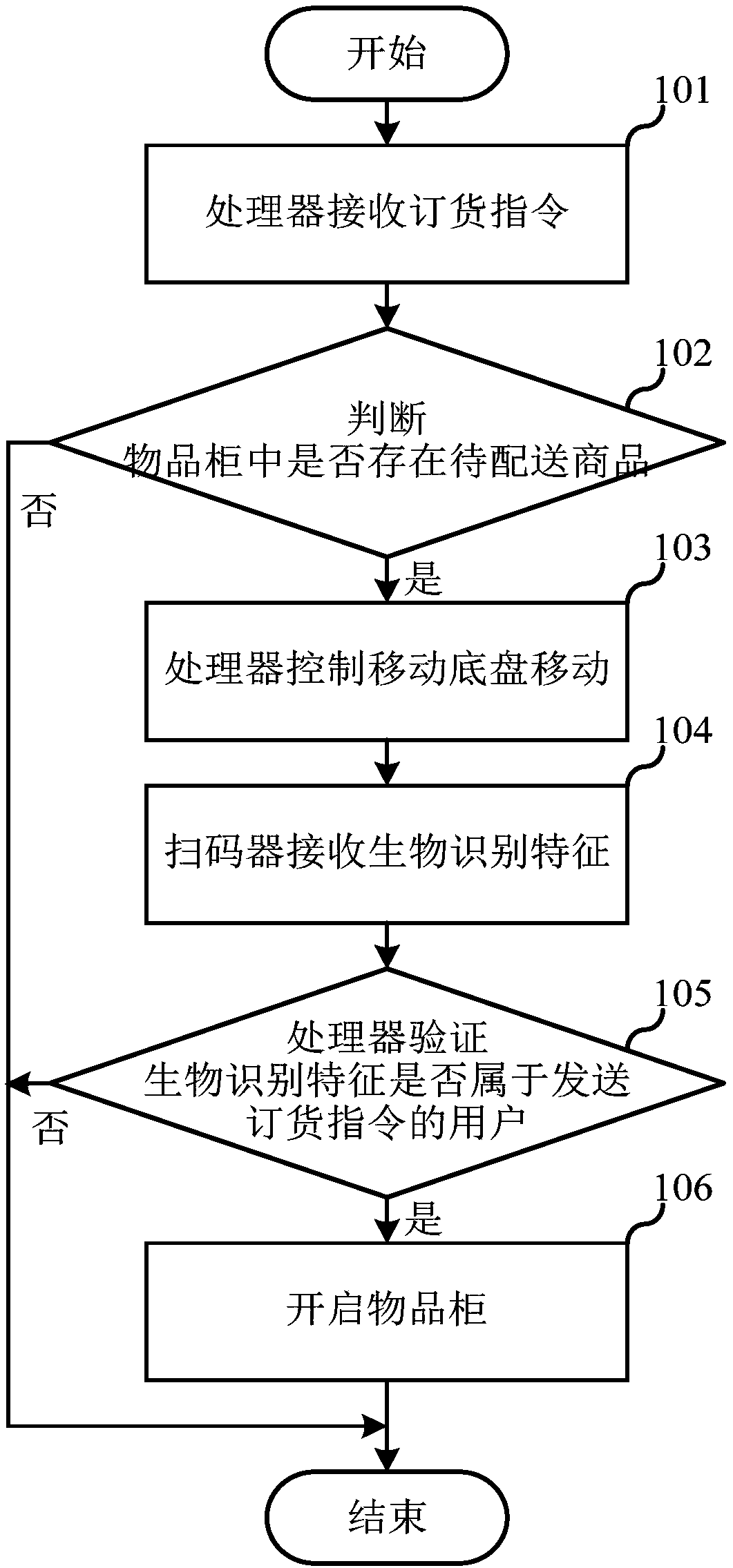

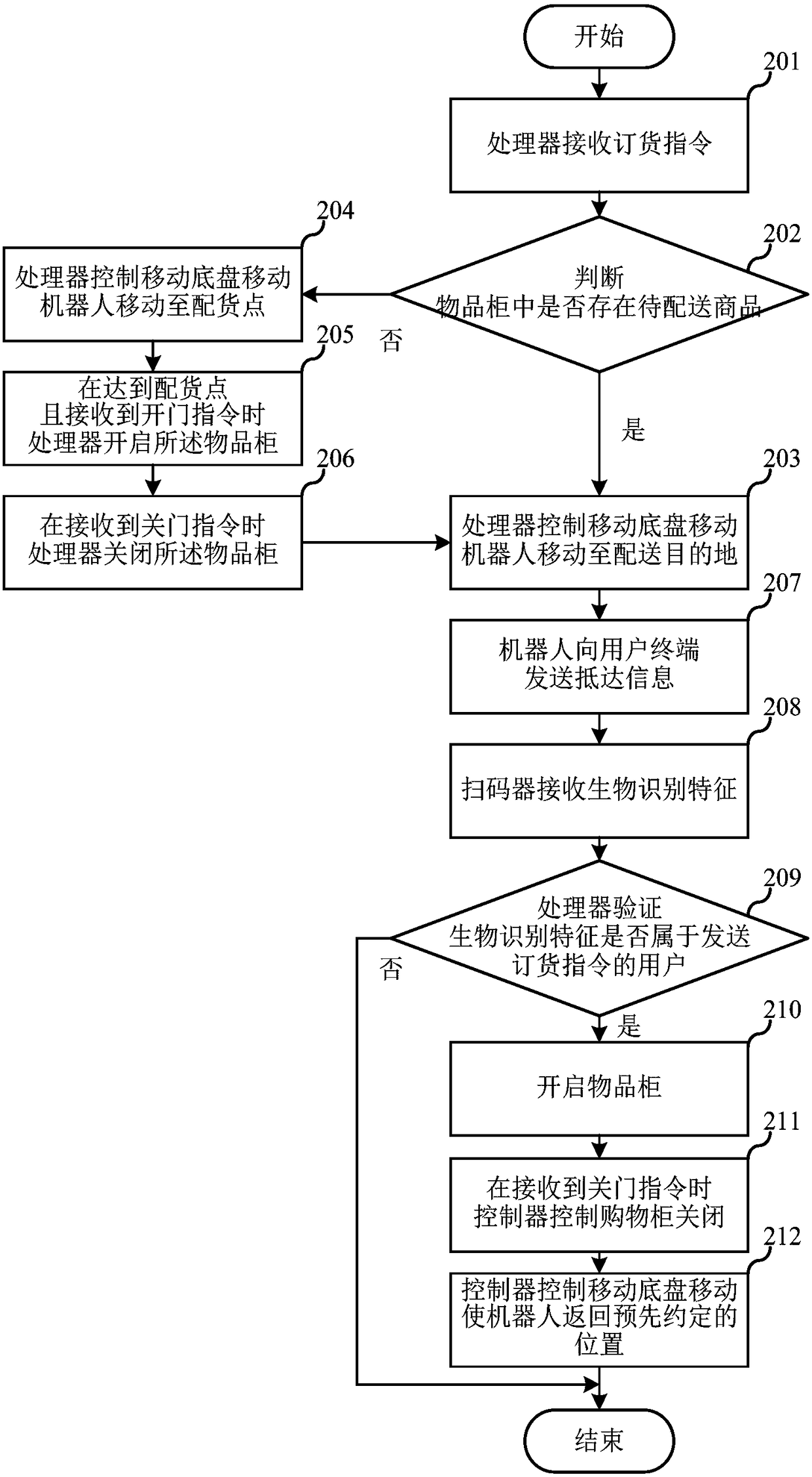

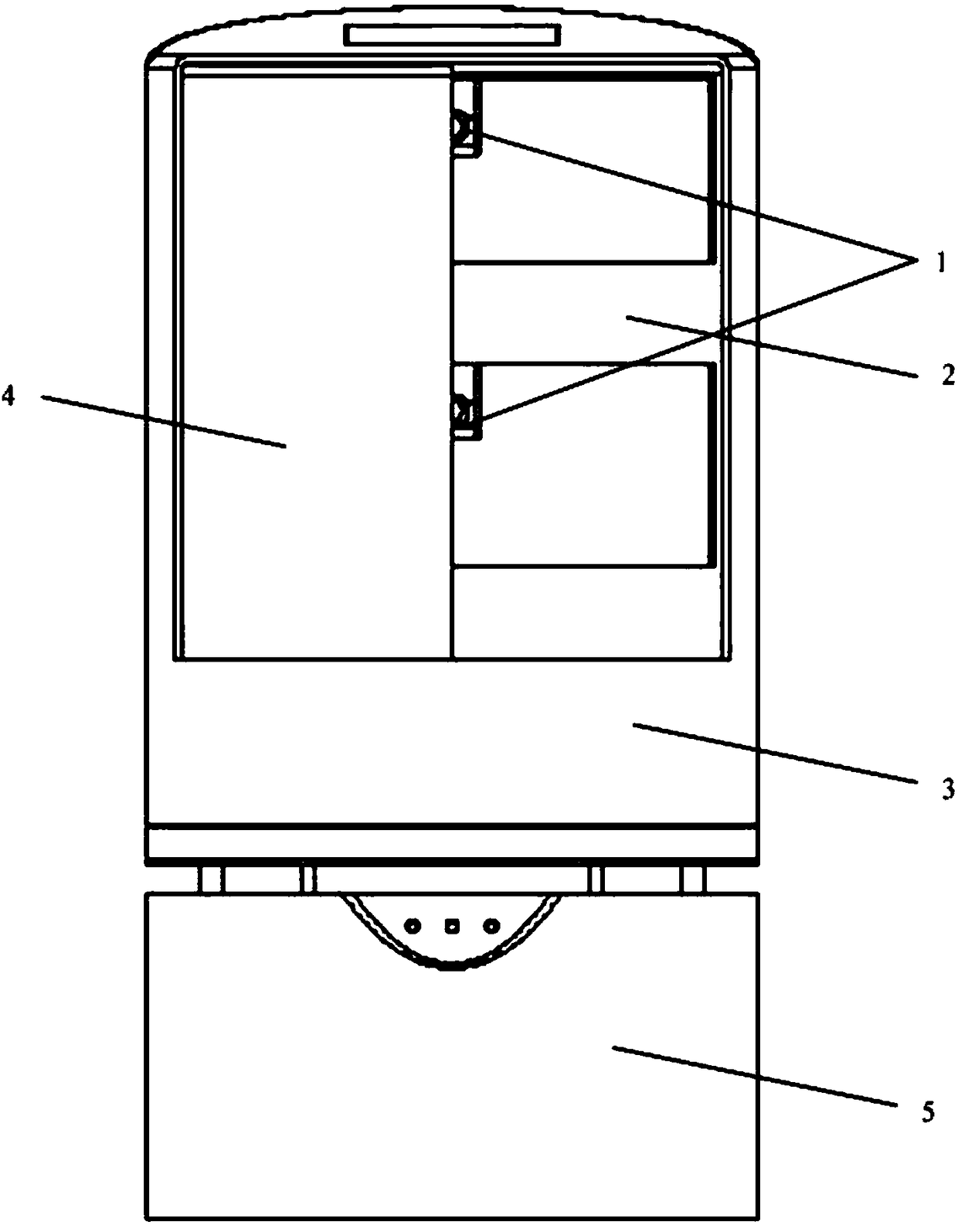

Intelligent goods distribution and delivery method and robot

ActiveCN108171875ASave time and costSave shopping time and costCoin-freed apparatus detailsManipulatorElectricityTime cost

The embodiment of the invention relates to the field of intelligent terminals and discloses an intelligent goods distribution and delivery method and a robot. The intelligent goods distribution and delivery method is applied to the robot. The robot comprises a movable bottom plate, a goods cabinet, a recognizer and a processor. The goods cabinet and the processor are arranged in a housing. The movable bottom plate is positioned below the housing. The recognizer, the movable bottom plate and the processor are electrically connected. The intelligent goods distribution and delivery method comprises following steps: the processor receives goods-ordering instructions containing distribution and delivery destinations and to-be-distributed and delivered goods and determines whether the to-be-distributed and delivered goods exist in the goods cabinet or not; the movable bottom plate is controlled to move when the processor determines that the to-be-distributed and delivered goods exist in thegoods cabinet; and the processor verifies whether received user recognition information comes from users who send ordering instructions or not, then, the goods cabinet is opened after verification passes so that users can take and pick distributed and delivered goods. The invention further provides the robot. When the users want to buy goods, shopping time cost of the users is saved. Meanwhile, safety of delivered goods is ensured.

Owner:深兰机器人产业发展(河南)有限公司

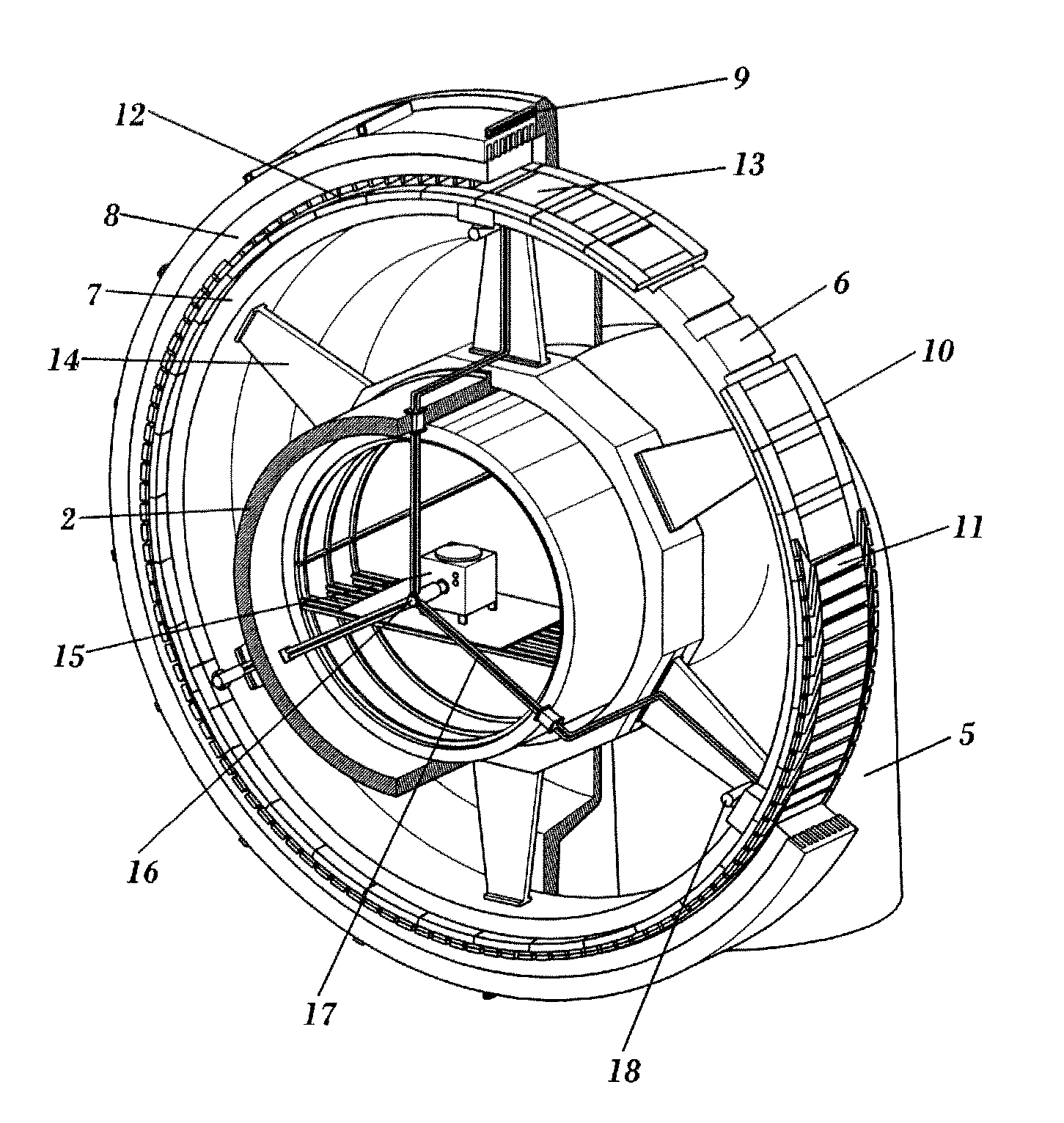

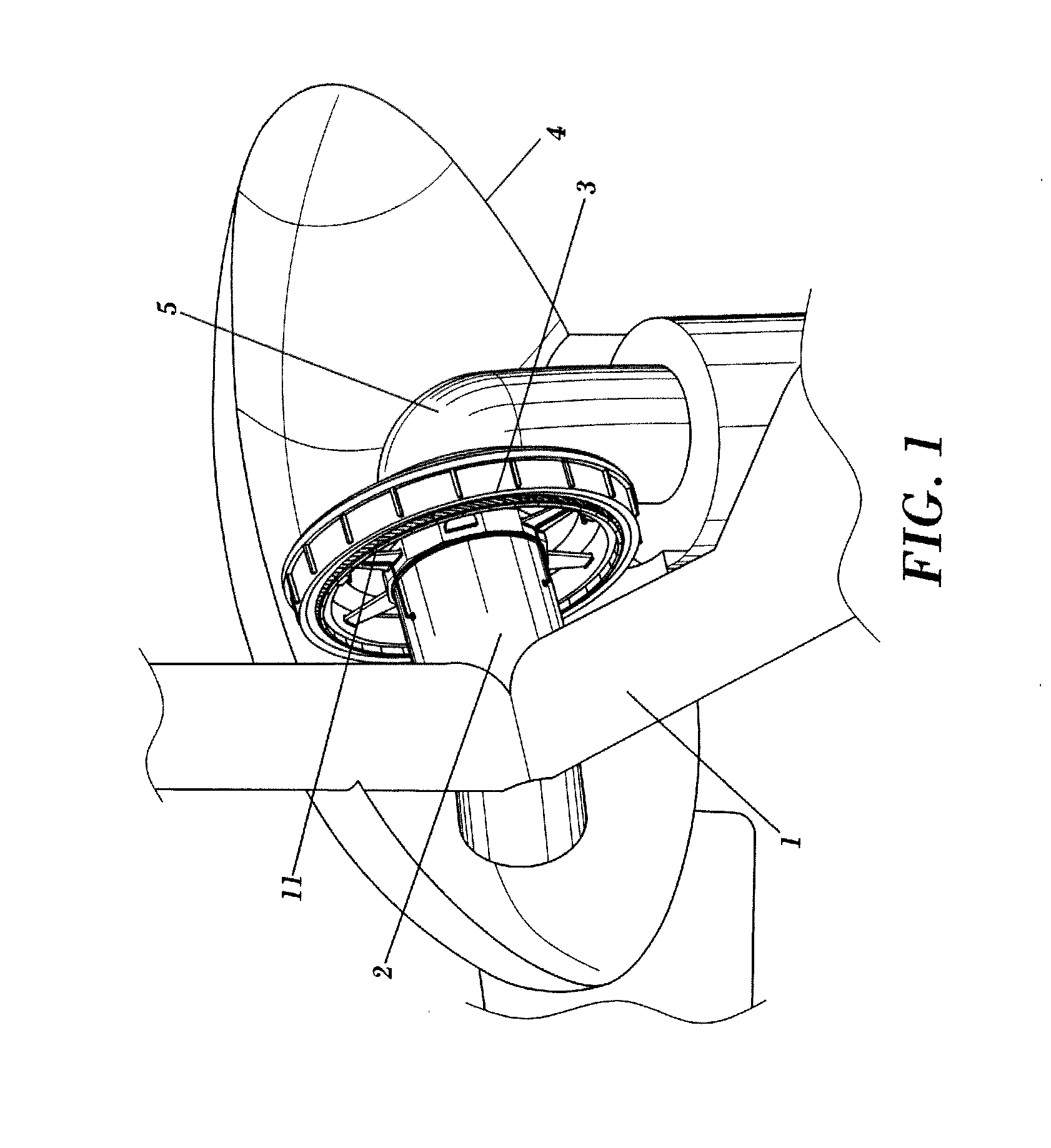

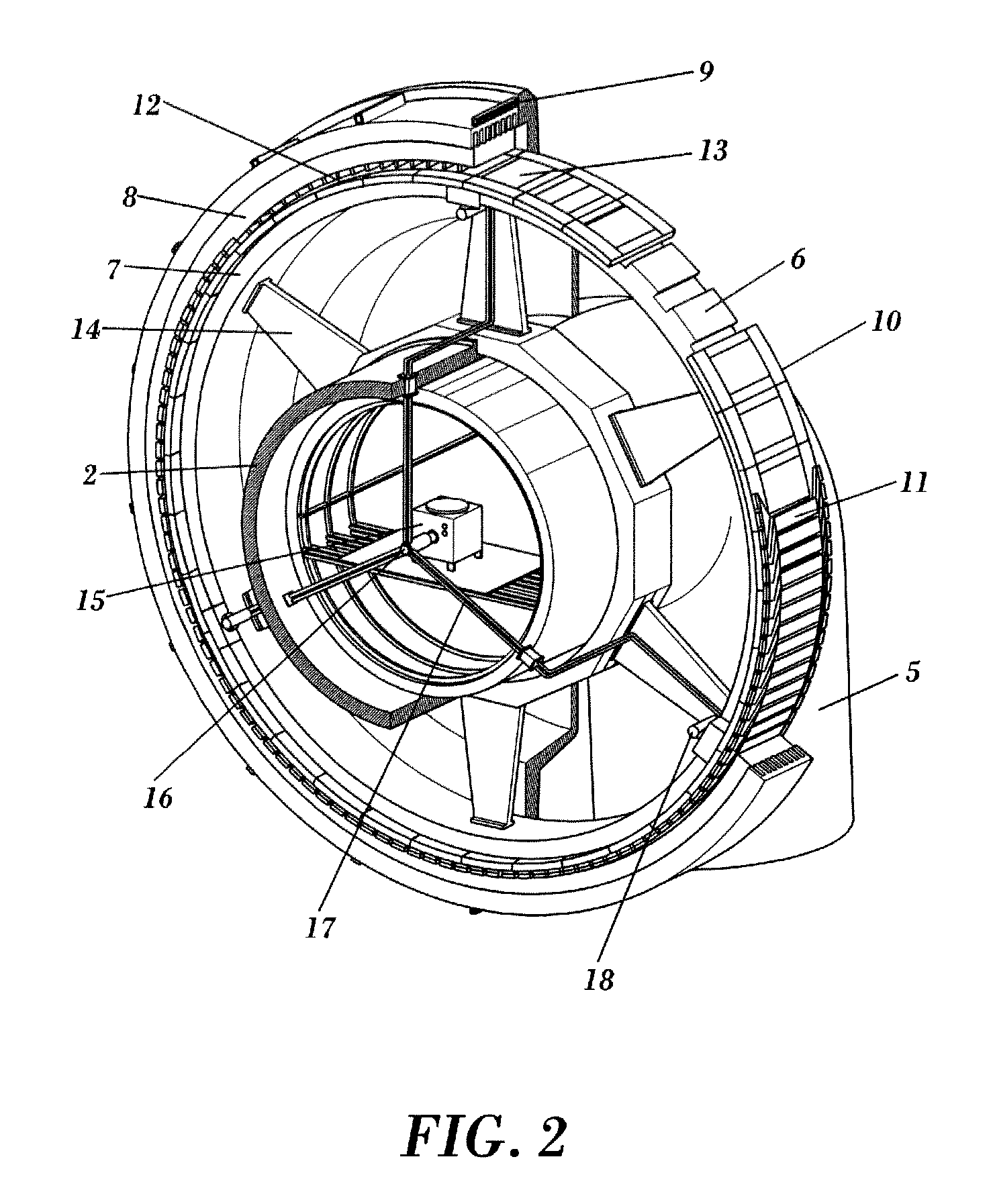

Direct-action superconducting synchronous generator for a wind turbine

InactiveUS20120306212A1Shorten the timeReduce frictionEngine fuctionsMachines/enginesThermal insulationEngineering

The invention refers to a direct drive electric generator for a wind turbine provided with rotor salient poles and a ladder-like cryostat for housing superconductive coils and keeping them at a cryogenic temperature while the interior of the cryostat is kept free of coolant.The invention achieves optimal thermal insulation of the coils without the need of a continuous re-filling of the cryostat and ensuring a good distribution of the magnetic field avoiding the use of expensive materials.

Owner:FUNDACION TECNALIA RES & INNOVATION

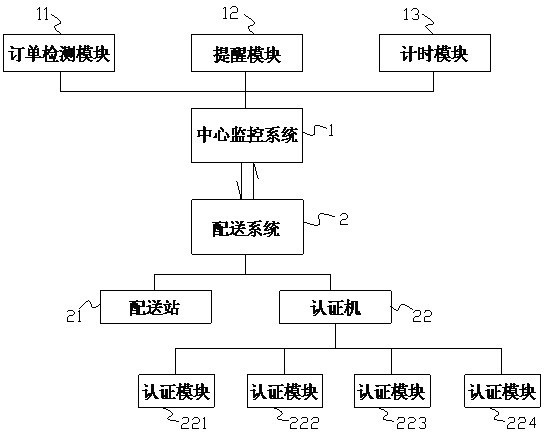

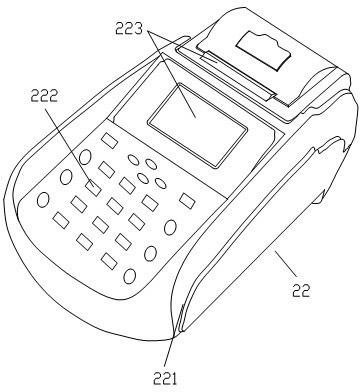

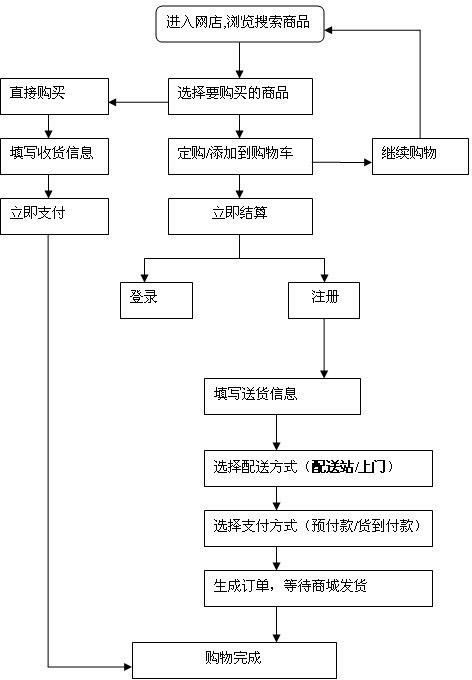

On-line shopping distribution station management system

InactiveCN102194193AImprove scientificImprove intelligenceCommerceLogistics managementDistribution system

The invention relates to an on-line shopping distribution station management system. The system comprises a central monitoring system and a distribution system; the central monitoring system consists of a service program running on a server and a central database, and can monitor the running state of the management system and the goods distribution condition in real time; the distribution system comprises a distribution station and an authentication machine arranged at the distribution station; and the authentication machine has identification and data transmission functions. The system is convenient, fast and quick for taking goods; idle resources of the conventional sites of community merchants or properties are fully integrated, and the problem of high cost in last mile distribution in the on-line shopping logistic distribution process is effectively solved; and the system becomes a logistic distribution system with high reproducibility, high portability and quick deployment.

Owner:深圳市智胜达科技有限公司

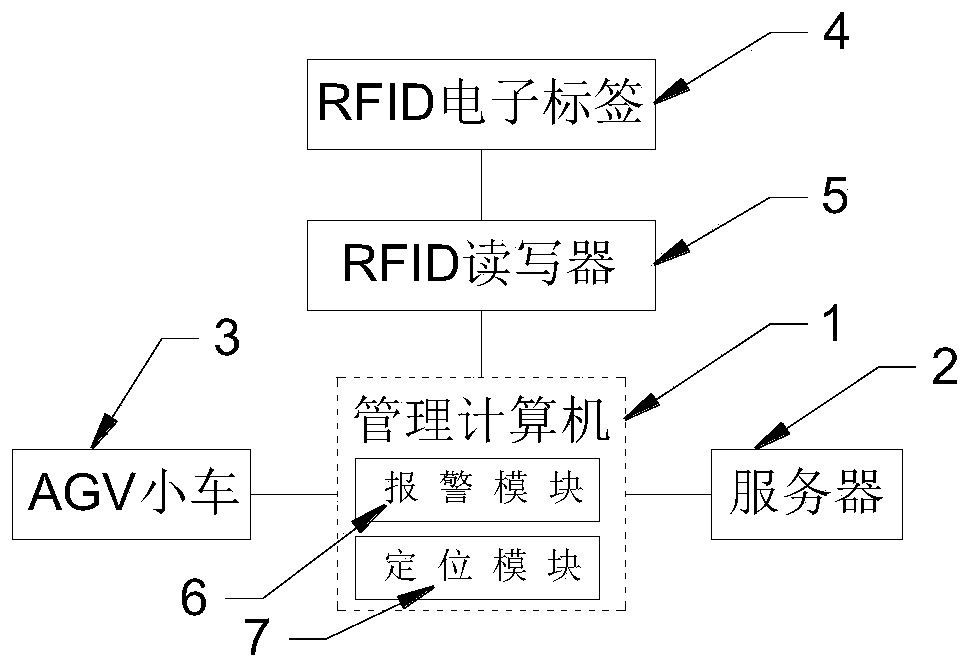

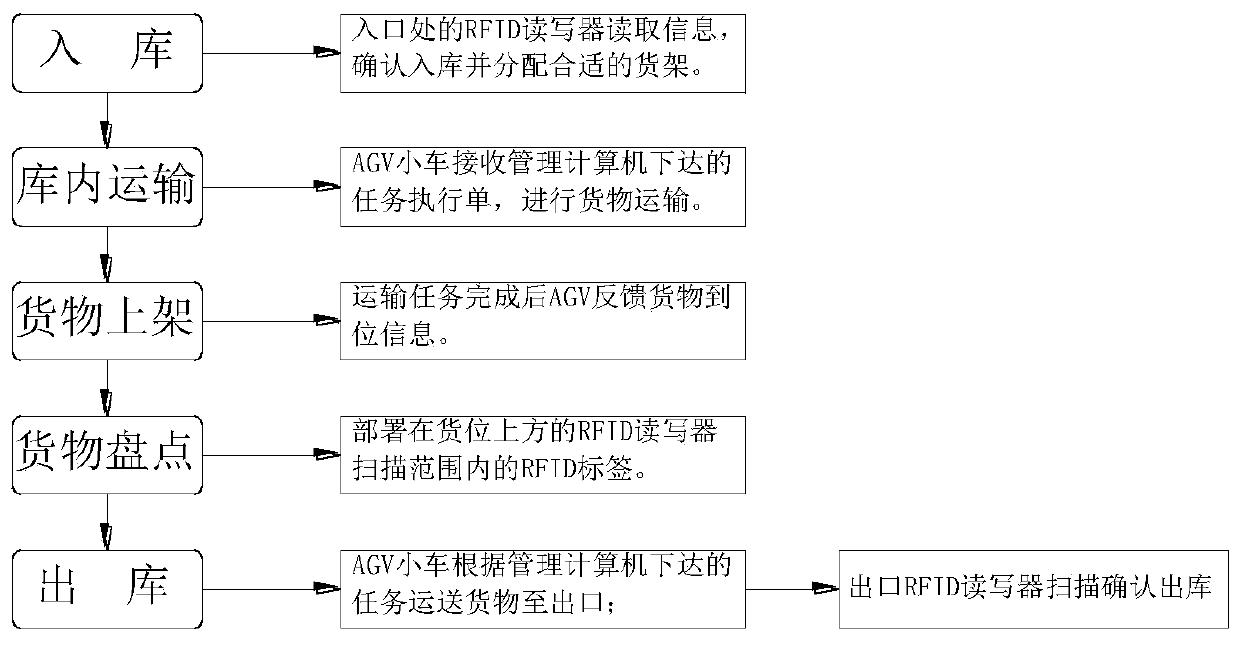

Three-dimensional warehouse management system and method based on RFID

ActiveCN110414638AImprove turnover rateHigh transparencyCo-operative working arrangementsElectric/hybrid propulsionStorage managementReader writer

The invention relates to the technical field of warehouse management, and discloses a three-dimensional warehouse management system and method based on RFID, and the system comprises a management computer, a server, an AGV, an RFID electronic tag which can be pasted on a cargo, and an RFID reader-writer. The RFID reader-writer and the AGV are in communication connection with the management computer, the management computer is in communication connection with the server, and an alarm module is arranged in the management computer. According to the invention, the RFID electronic tag containing the cargo identifier is pasted on the surface of the cargo, and the RFID reader-writer is adopted to complete the input work of a large number of cargos, so that the warehouse-in and warehouse-out efficiency is greatly improved, and the labor cost is saved. Proper goods allocations are distributed to warehoused goods, so that the turnover rate of warehousing is greatly increased; and for intelligentalarming of abnormal conditions, occurred errors can be handled in time, so that the management cost of storage is reduced, and further improvement of storage management is facilitated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

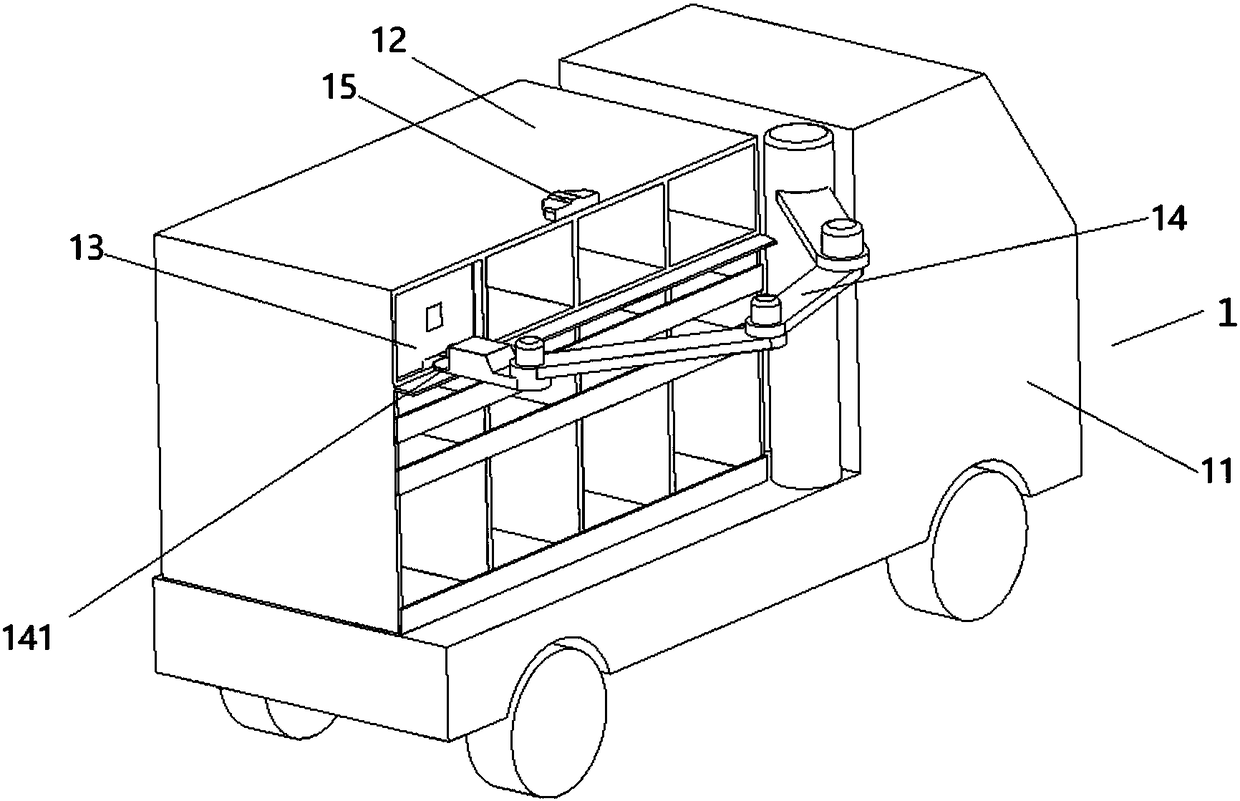

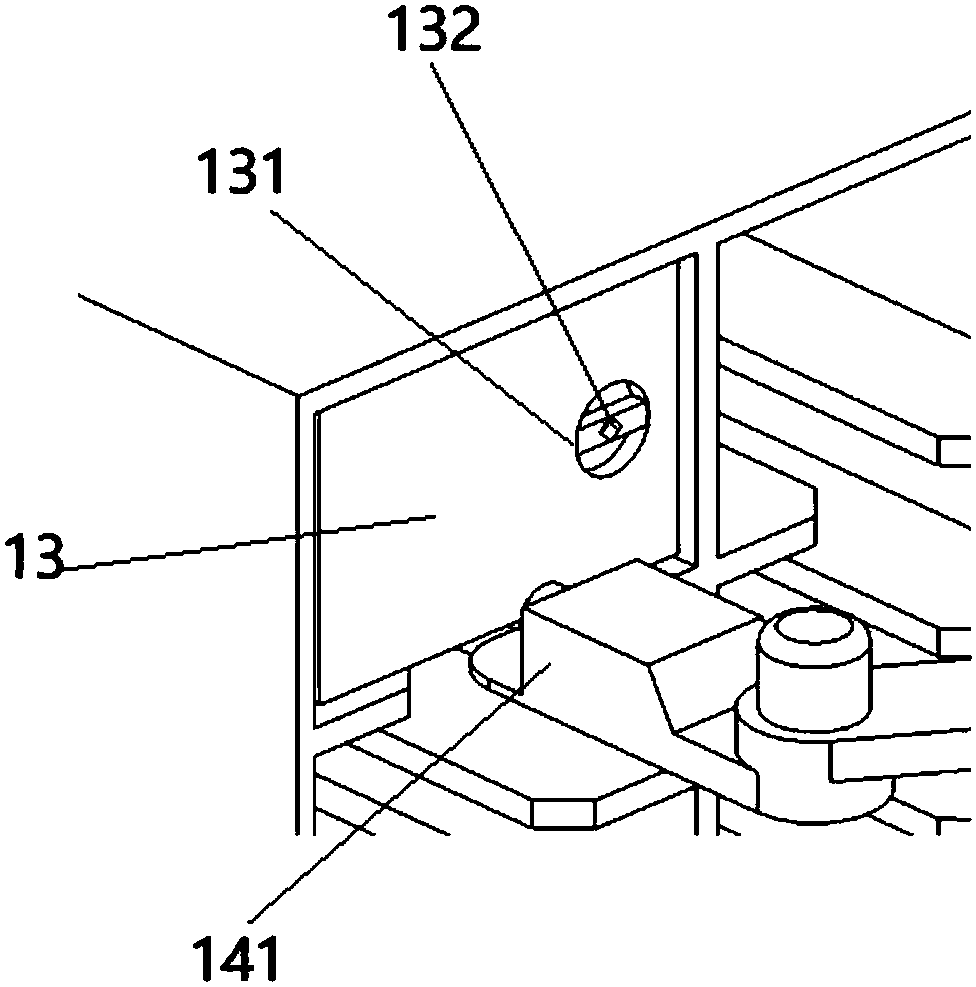

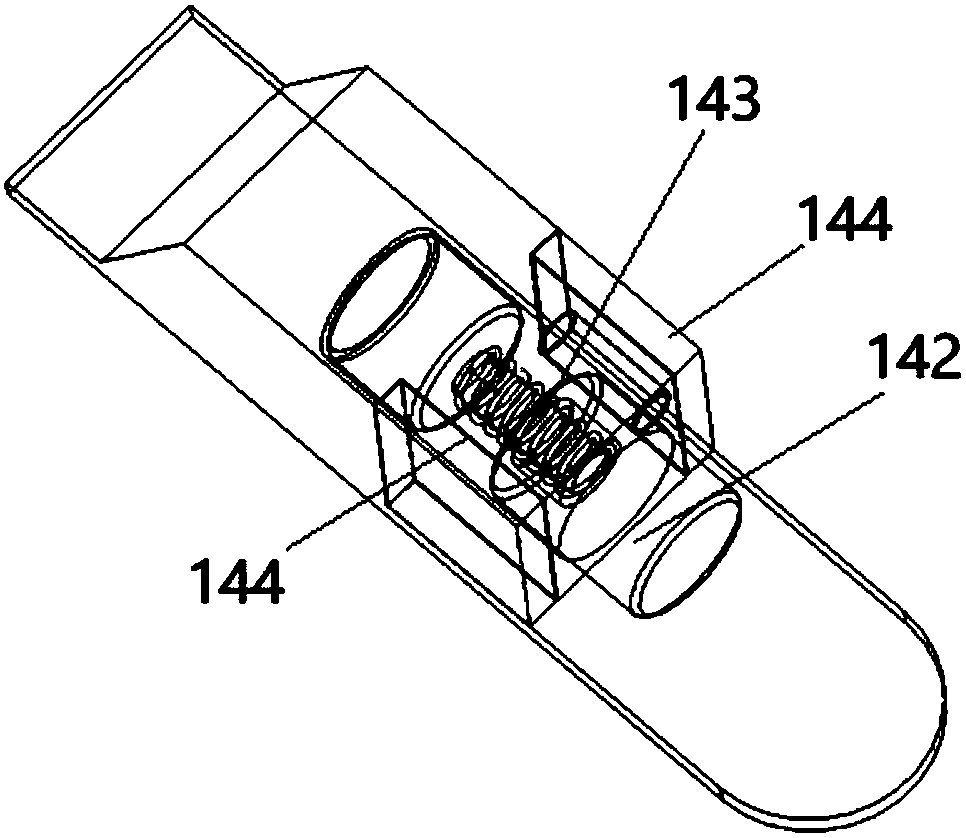

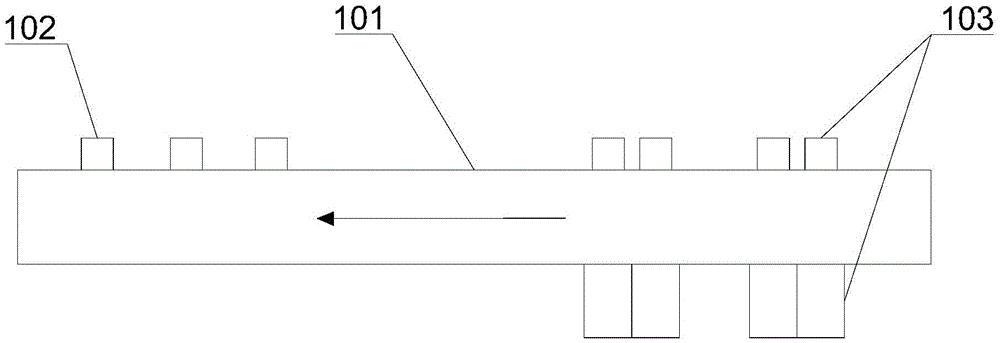

Unmanned express vehicle, unmanned express distribution system and automatic distribution method of unmanned express distribution system

ActiveCN108422918AEfficient handlingLow costData processing applicationsItem transportation vehiclesElectricityCommunication unit

The invention provides an unmanned express distribution vehicle, an unmanned express distribution system and an automatic distribution method of the unmanned express distribution system. The unmannedexpress vehicle comprises an unmanned vehicle body, wherein the unmanned vehicle body is provided with express shelves, the express shelves are internally provided with circulation boxes with identification tags, and express items are loaded in different circulation boxes; the express shelves are provided with a mechanical arm for taking out the circulation boxes from the express shelves, and thetop of the unmanned vehicle body or / and the top of the express shelves are provided with a three-dimensional space measuring sensor; the mechanical arm is provided with a visual sensor; the unmanned vehicle body is provided with a control unit, a communication unit and a storage unit, the communication unit and the storage unit are respectively connected with the control unit, and the control unitis electrically connected to the control circuit of the mechanical arm and the three-dimensional space measuring sensor. By adoption of the technical scheme of the invention, a fast, efficient and cheap unmanned distribution system is realized, the goods distribution efficiency is improved and the labor cost is reduced.

Owner:江门市腾米机器人技术有限公司

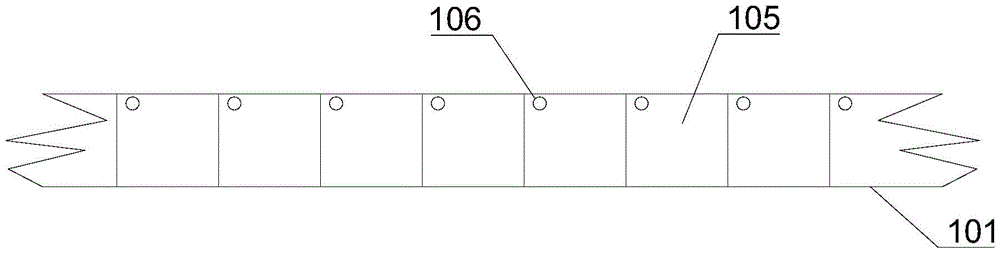

Goods sorting system and goods sorting method

InactiveCN105562354AReduce engagementSave human resourcesSortingLogistics managementTransport engineering

The embodiment of the invention provides a goods sorting system and a goods sorting method and relates to the field of express and logistics. A main conveying belt for conveying goods is divided into a plurality of goods locations differentiated by information identifiers. When goods are sorted, the goods locations are allocated to the goods automatically, the goods to be sorted are fed onto the goods locations of the main conveying belt by scanning the information identifiers, the goods are then conveyed out from corresponding outlets, and thus automatic sorting of the goods is achieved. The whole sorting process is automatically completed by equipment, so that manpower resources are saved. Meanwhile, since the participation degree of sorting personnel is low in the sorting process, the sorting mistake probability is reduced.

Owner:唐长春 +1

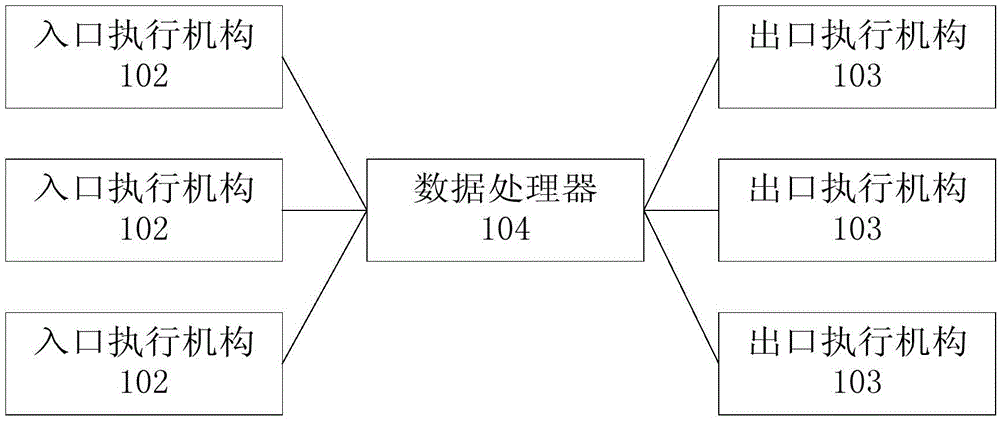

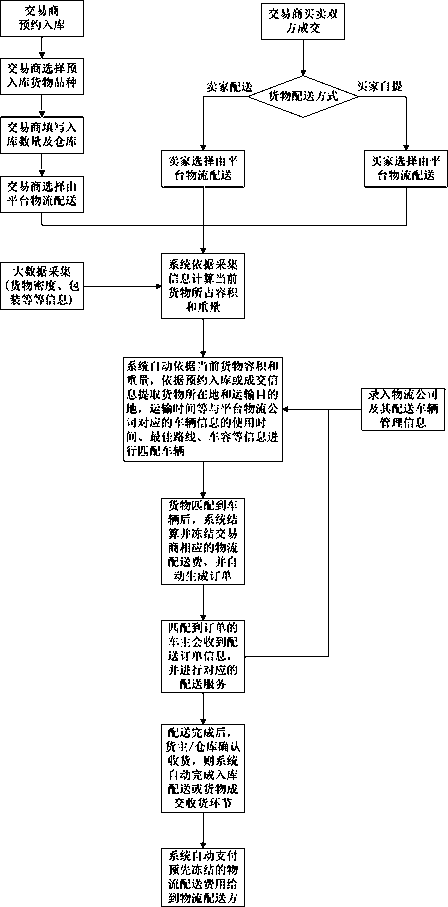

Intelligent logistics distribution method

PendingCN107844941AReduce shipping costsAchieve optimal utilizationLogisticsPaymentLogistics management

The invention relates to the technical field of intelligent logistics, and specifically discloses an intelligent logistics distribution method. The method comprises the steps: obtaining the information of logistics vehicles and carrying out the real-time updating; obtaining the demand information of goods delivery, and carrying out the real-time updating; carrying out the matching of the information of logistics vehicles with the demand information of goods delivery, and generating a goods distribution order; and carrying out the automatic settlement and payment of delivery cost after the delivery is completed and goods is received. The method provided by the invention can achieve the automatic optimal matching according to the actual demands of the goods delivery and the existing logistics vehicle resources. Because the information of logistics vehicles are updated in real time, the logistics transportation mode provided by the invention is effective and quick, and the method can provide an optimal logistics transportation mode for a logistics demand side, and can effectively reduce the transportation cost.

Owner:东莞市大易产业链服务有限公司

Intelligent logistics distribution information processing system and method

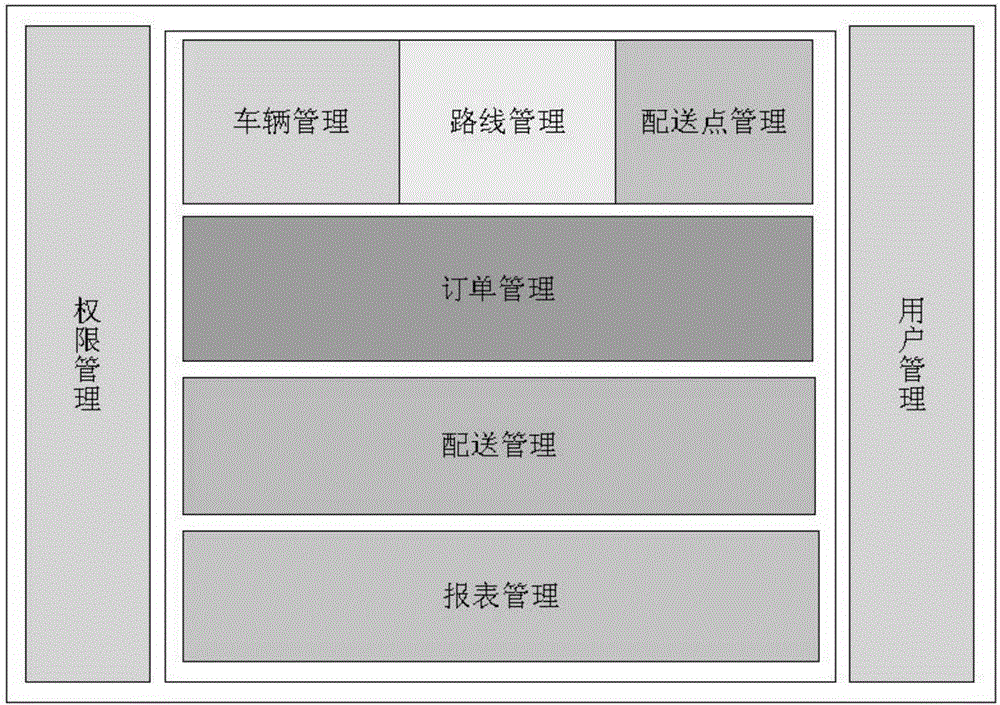

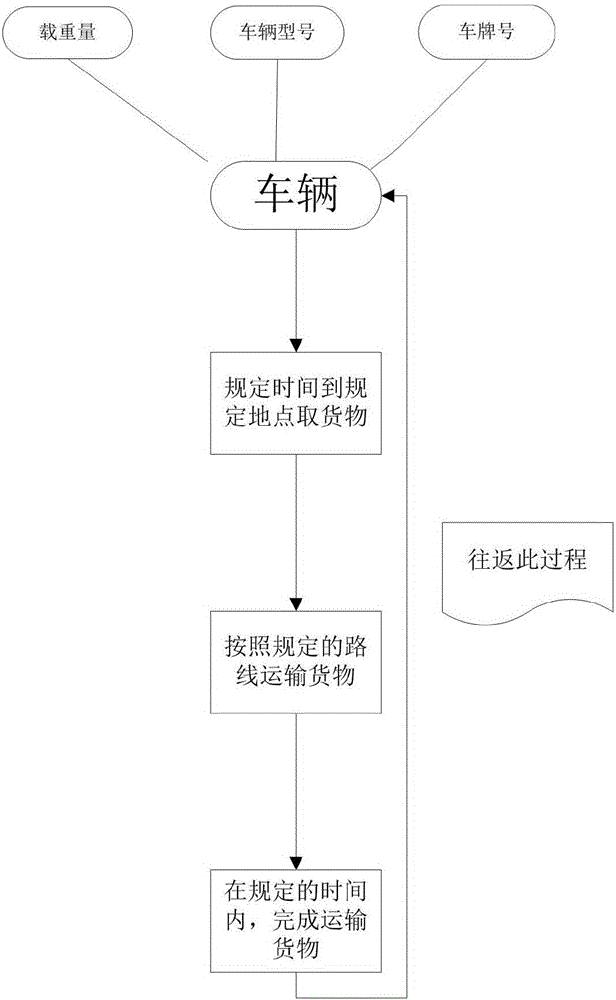

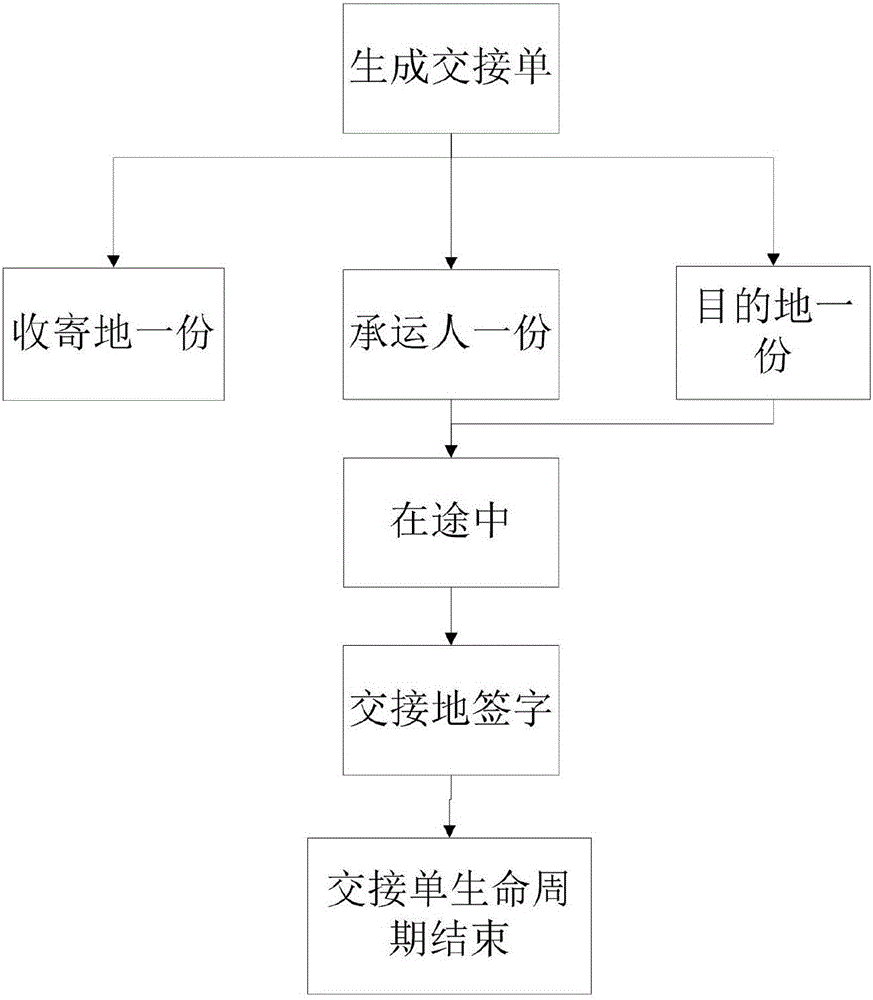

InactiveCN106779548ARealize standardized managementEasy to manageLogisticsInformation processingSystems management

The invention relates to a distribution system and method, belongs to the field of information management, and particularly relates to an intelligent logistics distribution information processing system and method. According to the logistics distribution management system capable of being applied to goods distribution of a company, standardized management of logistics distribution is realized, system management of goods orders and distribution is realized, vehicle management and route management are facilitated, resource conflicts are avoided, and the usage rate is increased; and systematized personnel management distribution and a perfect permission management mechanism effectively control responsibility distribution in a goods distribution process.

Owner:WUHAN ZHONGHAN TECH CO LTD

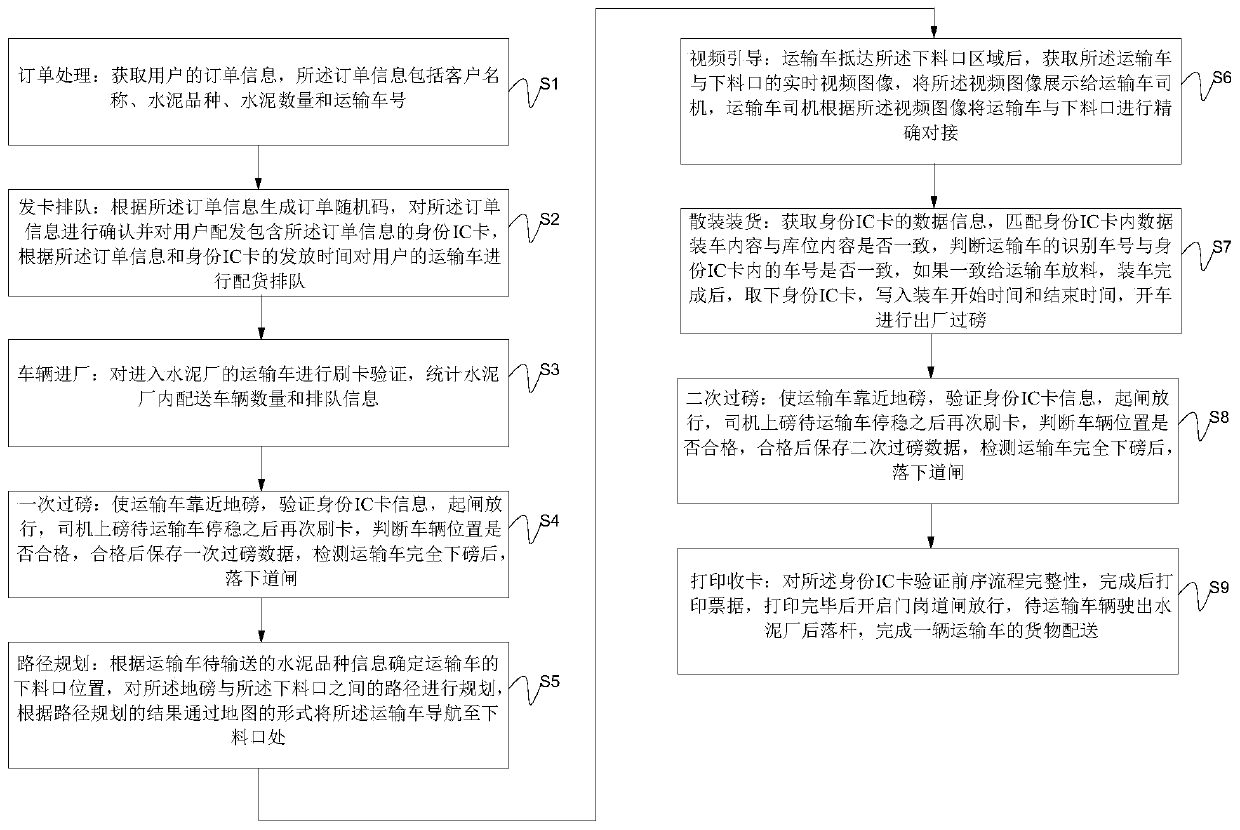

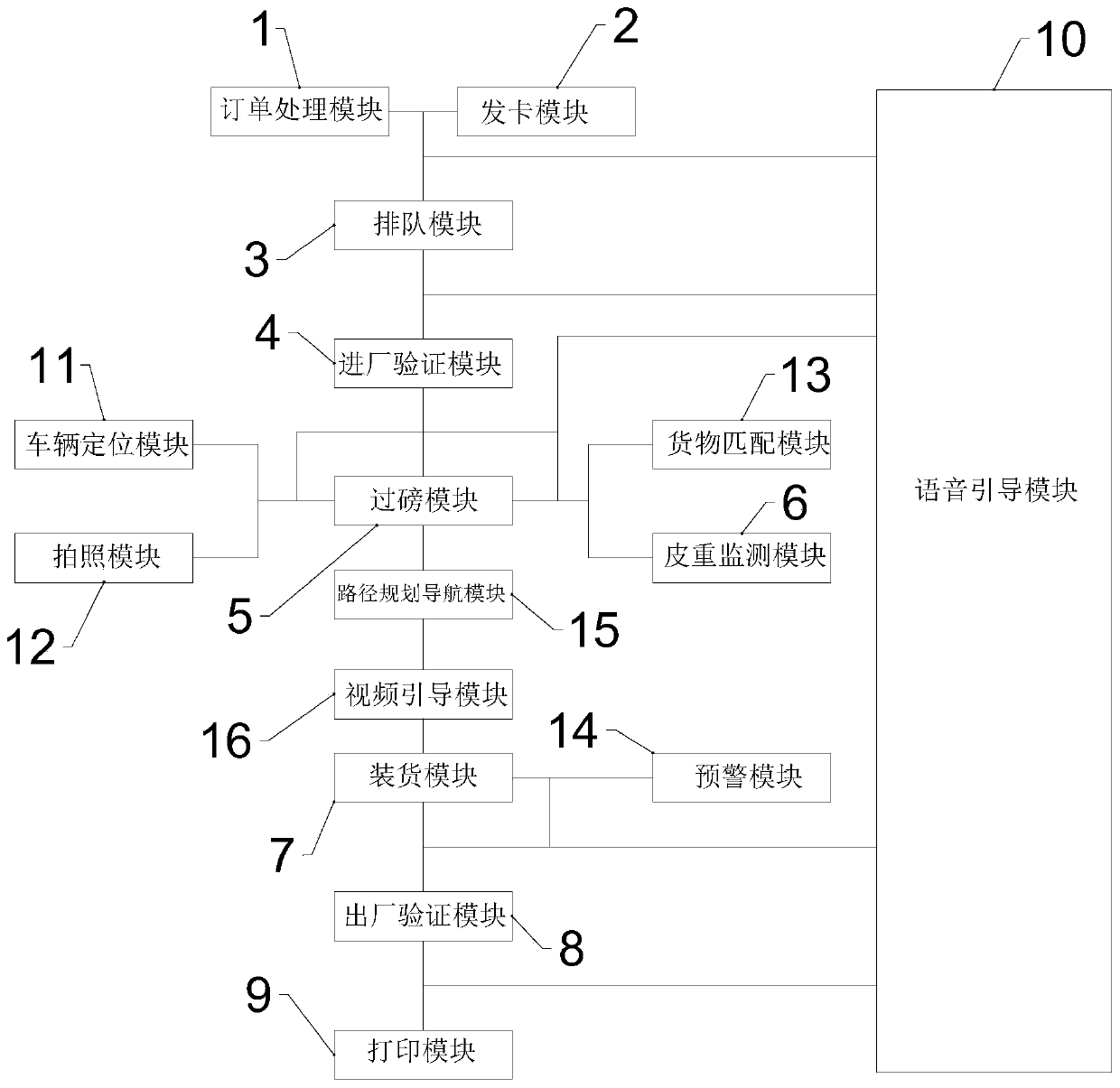

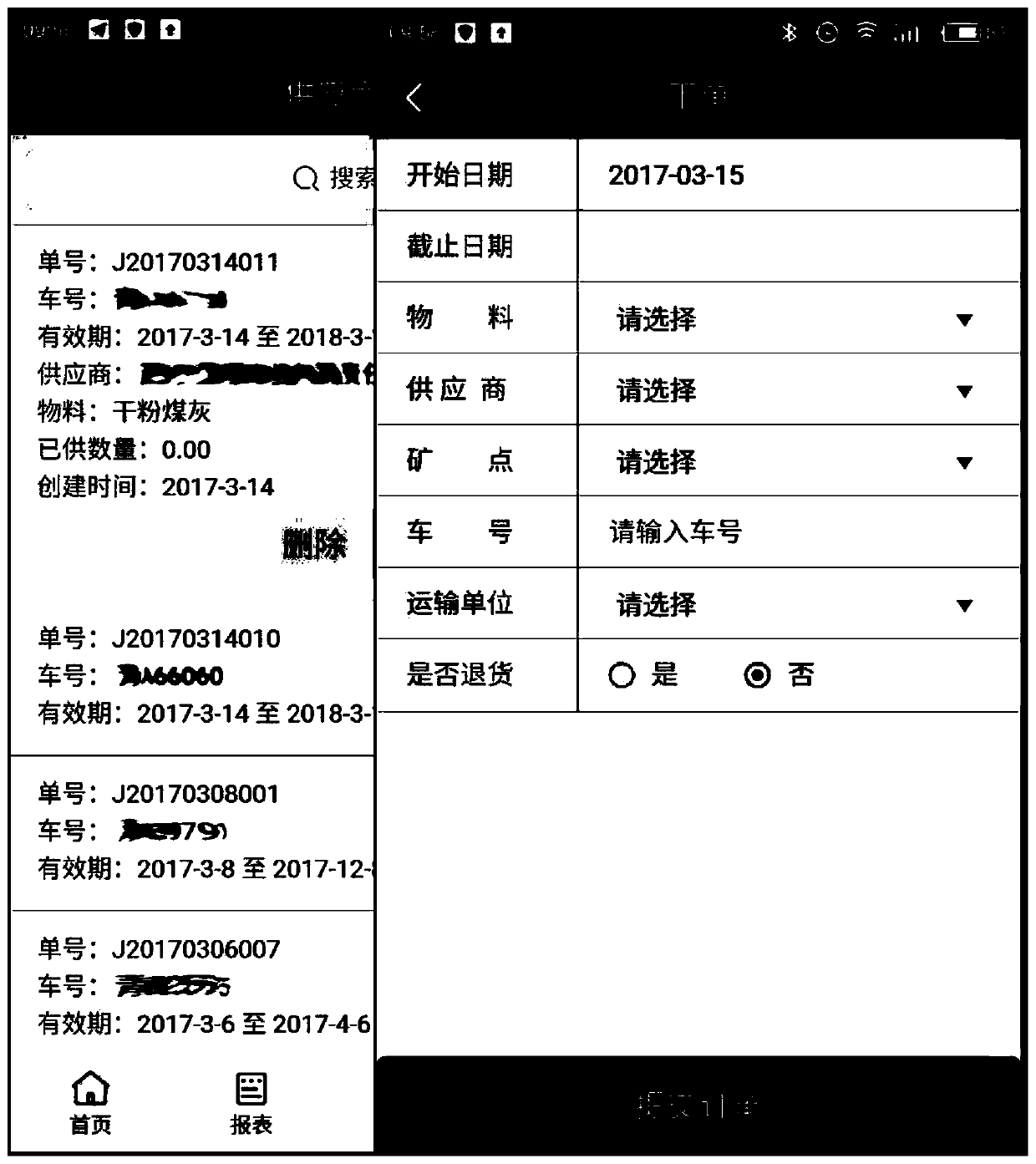

Cement plant cargo distribution method and system

InactiveCN110472917AQuickly complete the weighingAccurately complete the weighingIndividual entry/exit registersLogisticsDistribution methodVideo image

The invention discloses a cement plant cargo distribution method and system, and the method comprises the steps: generating an order random code according to order information, confirming the order information, distributing an identity IC card comprising the order information to a user, and carrying out the cargo distribution queuing of a transport vehicle of the user according to the order information and the distribution time of the identity IC card; conducting card swiping verification on the transport vehicles entering the cement plant, and counting the number of distribution vehicles in the cement plant and queuing information; verifying the identity IC card information, and judging whether the vehicle position is qualified or not; planning a path between the weighbridge and the discharge port, and navigating the transport vehicle to the discharge port in a map form according to a path planning result; acquiring real-time video images of the transport vehicle and the discharge port, enabling a driver of the transport vehicle to accurately connect the transport vehicle with the discharge port according to the video images, and matching whether data loading content in the identity IC card is consistent with storage location content or not. Economic losses of enterprises caused by human factors are reduced, and the goods distribution efficiency and quality of cement plants are improved.

Owner:北京坚构创新科技有限公司

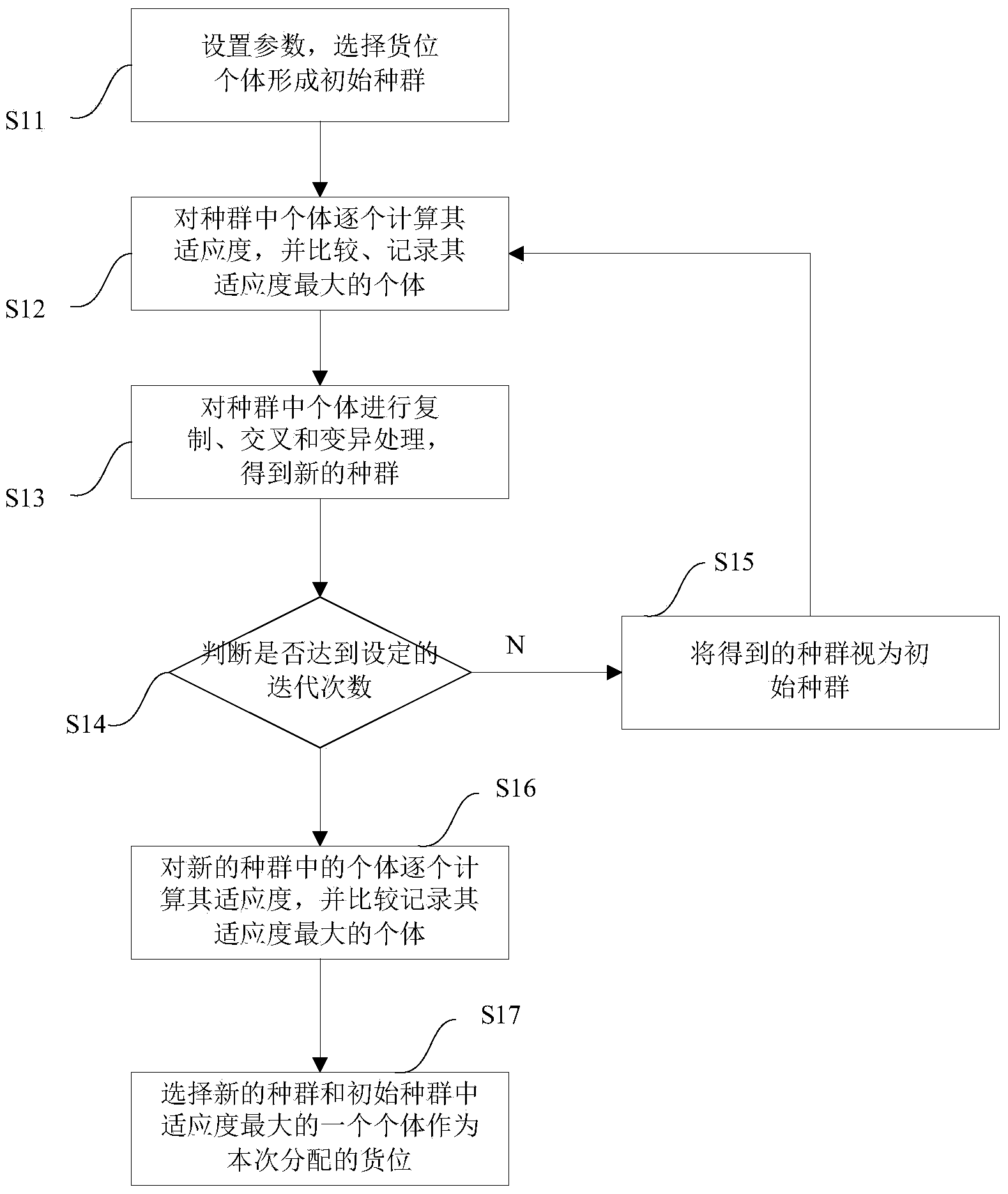

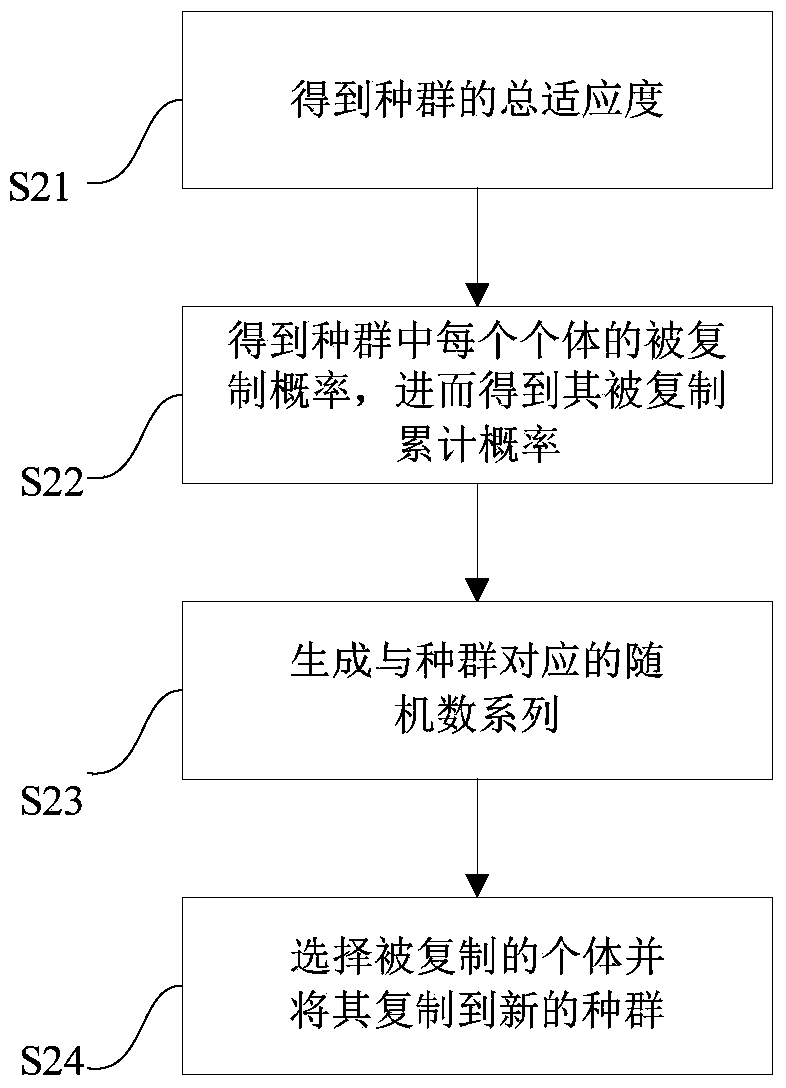

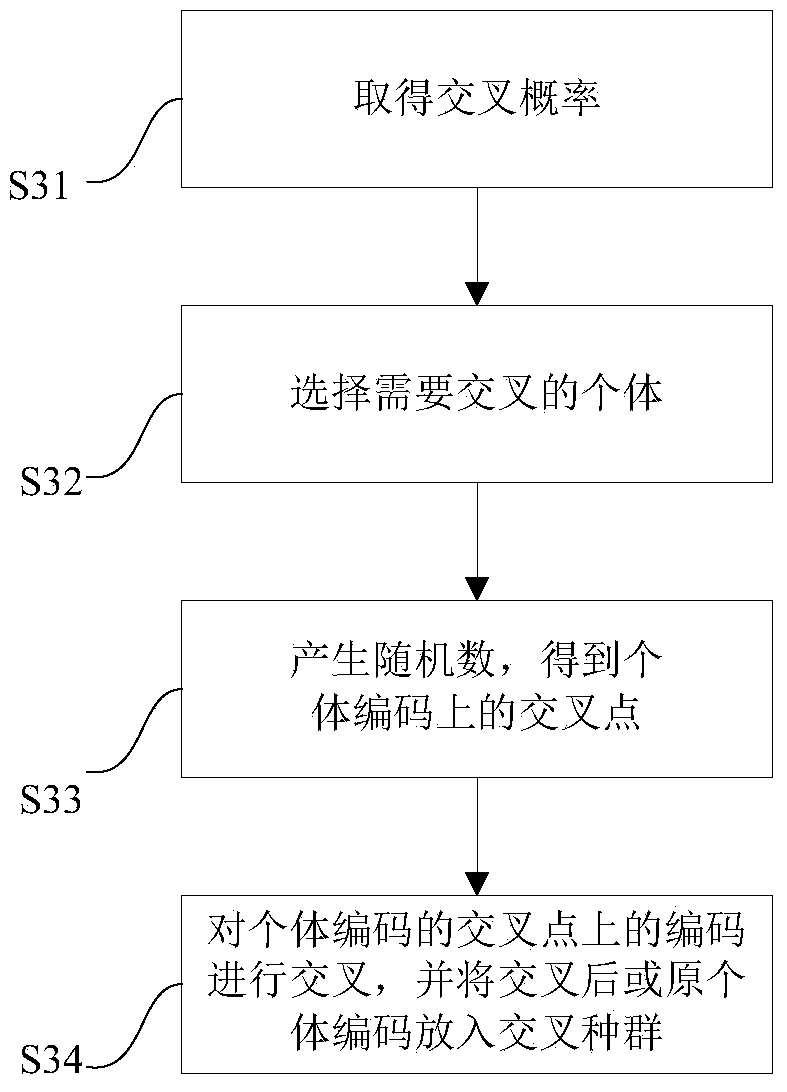

Method for allocating cargo positions for cargoes in three-dimensional warehouse

The invention relates to a method for allocating cargo positions for cargoes in a three-dimensional warehouse. The method comprises the following steps that an original group is obtained; the weighted average method is used for calculating the individual fitness of each cargo position represented with position coordinates; comparing is carried out, and the individual with the highest fitness is recorded; the genetic algorithm is adopted to carry out individual copy, cross, variation and individual variation on the individuals in the original group, and a new group is obtained; whether the set number of iterations is achieved or not is judged, if yes, the weighted average algorithm is used for calculating the individual fitness for the new group; comparing is carried out, and the individual with the highest fitness is recorded; the highest fitness of the new group and the highest fitness of the original group are compared, the individual with the highest fitness is selected, and the cargo position represented by the individual is obtained; or otherwise, the obtained new group serves as the original group, and processing is carried out again. The method for allocating the cargo positions for the cargoes in the three-dimensional warehouse has the advantages that the time for searching for the warehouse is shortened, and cost is low.

Owner:INVENGO INFORMATION TECH

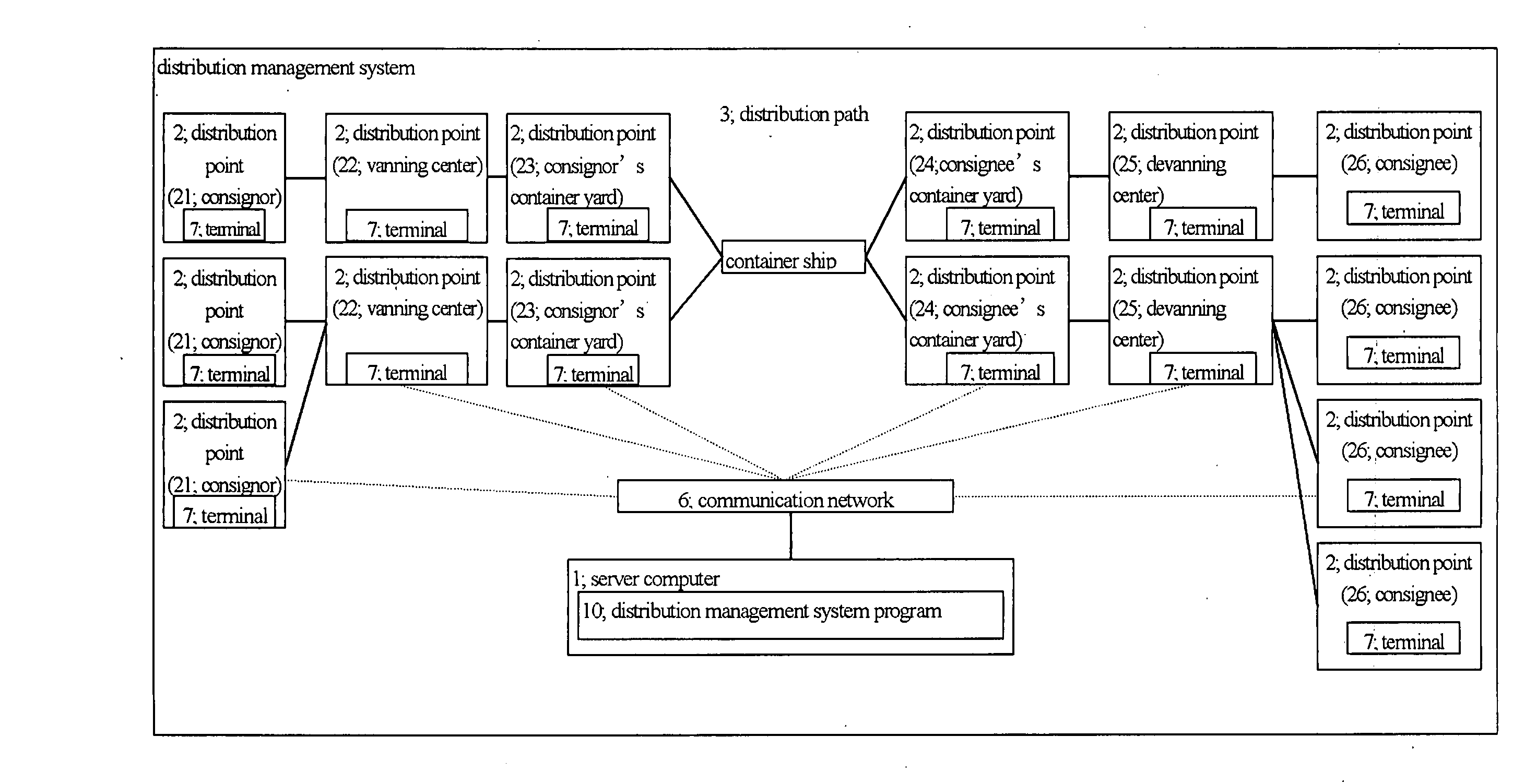

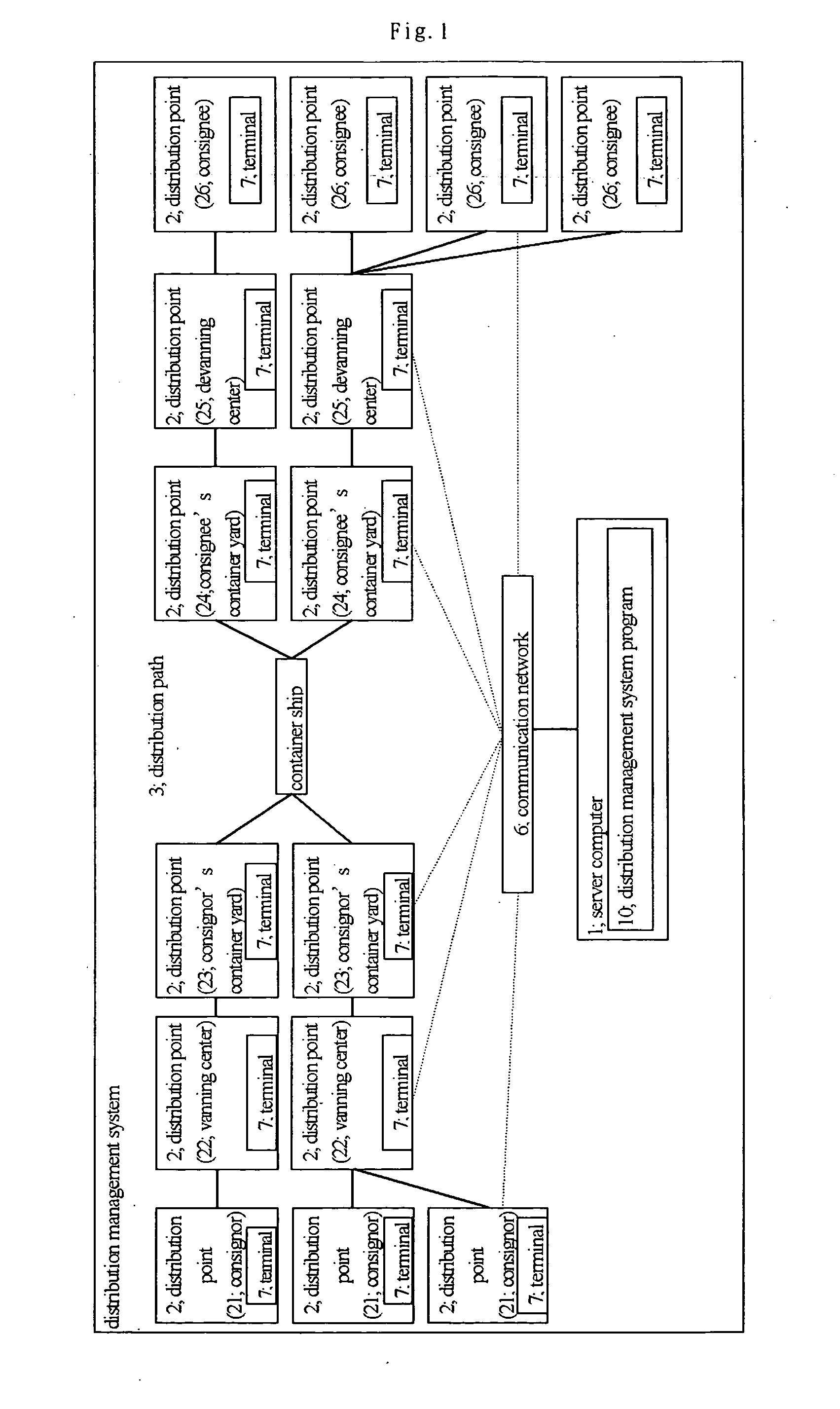

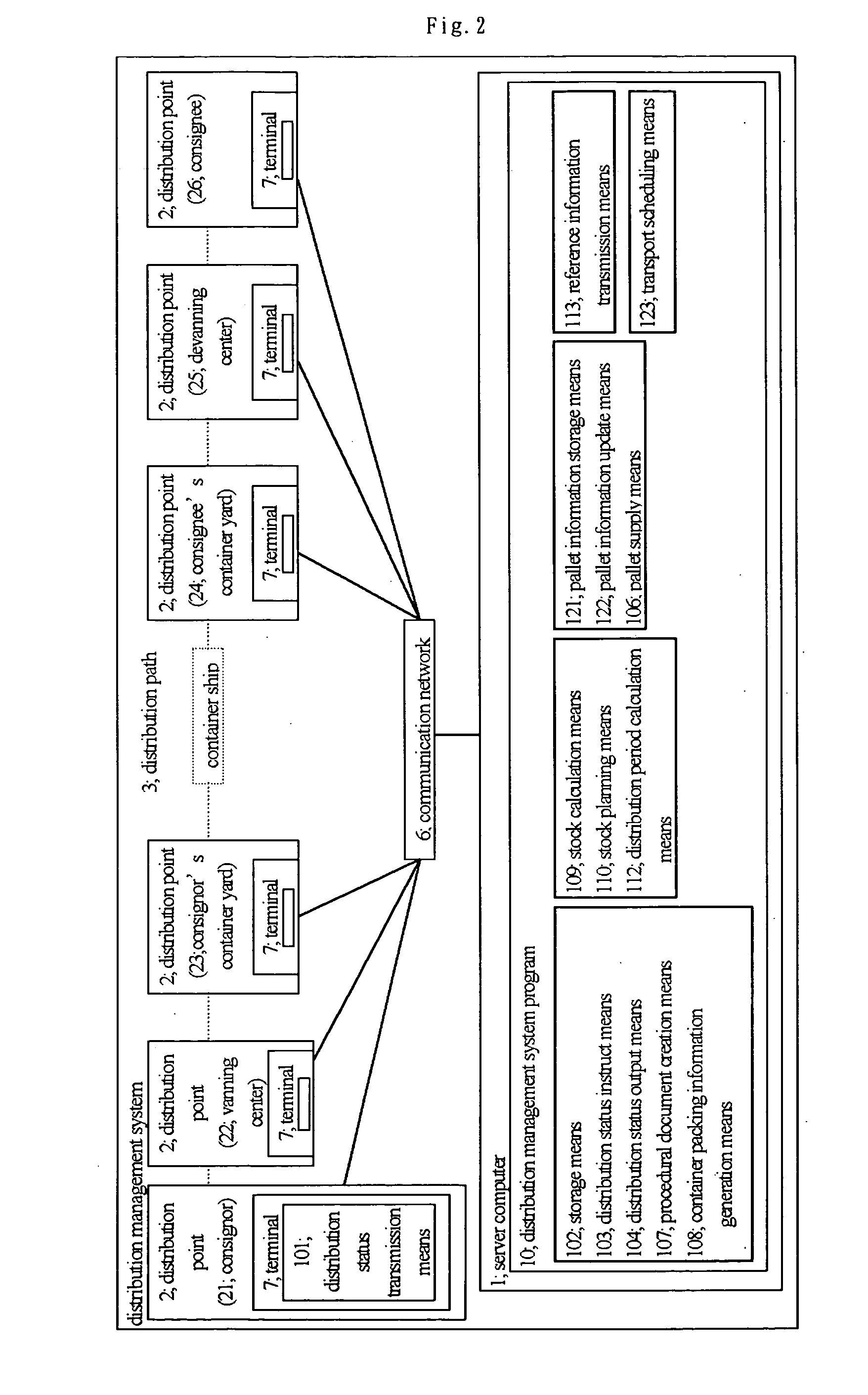

Cargo distribution management system, palette management system, and computer-readable storage medium and program used for them

InactiveUS20060106684A1Reduce distribution costsShorten the timeLarge containersLogisticsInformation transmissionComputer science

This invention provides a cargo distribution management system, a pallet management system, and a computer readable recording medium capable of facilitating reducing time required for distribution using containers by marine transport or the like, acquiring information for time reduction, and decreasing distribution cost. A cargo distribution management system program executed by a server computer 1 of the system includes storage means 102, distribution status instruct means 103, distribution status output means 104, procedural document creation means 107, container packing information generation means 108, stock calculation means 109, stock planning means 110, distribution period calculation means 112, pallet information storage means 121, pallet information update means 122, transport scheduling means 123, and reference information transmission means 113.

Owner:TOYOTA STEEL CENT CO LTD

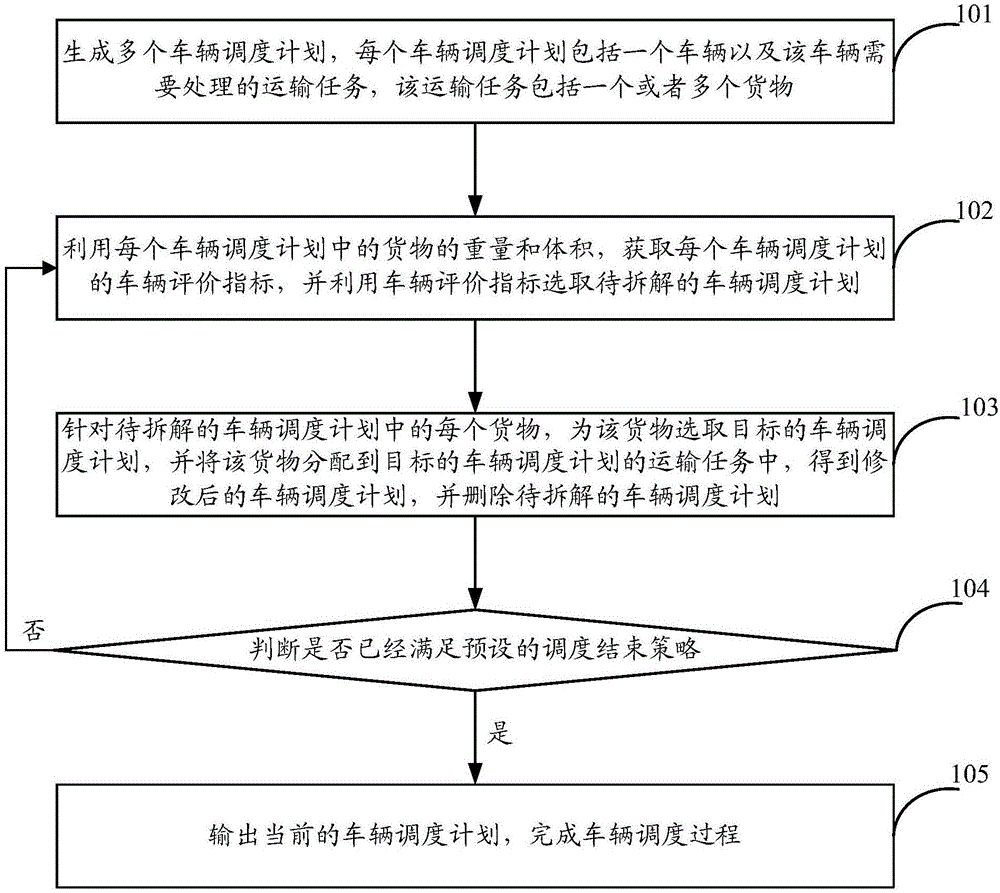

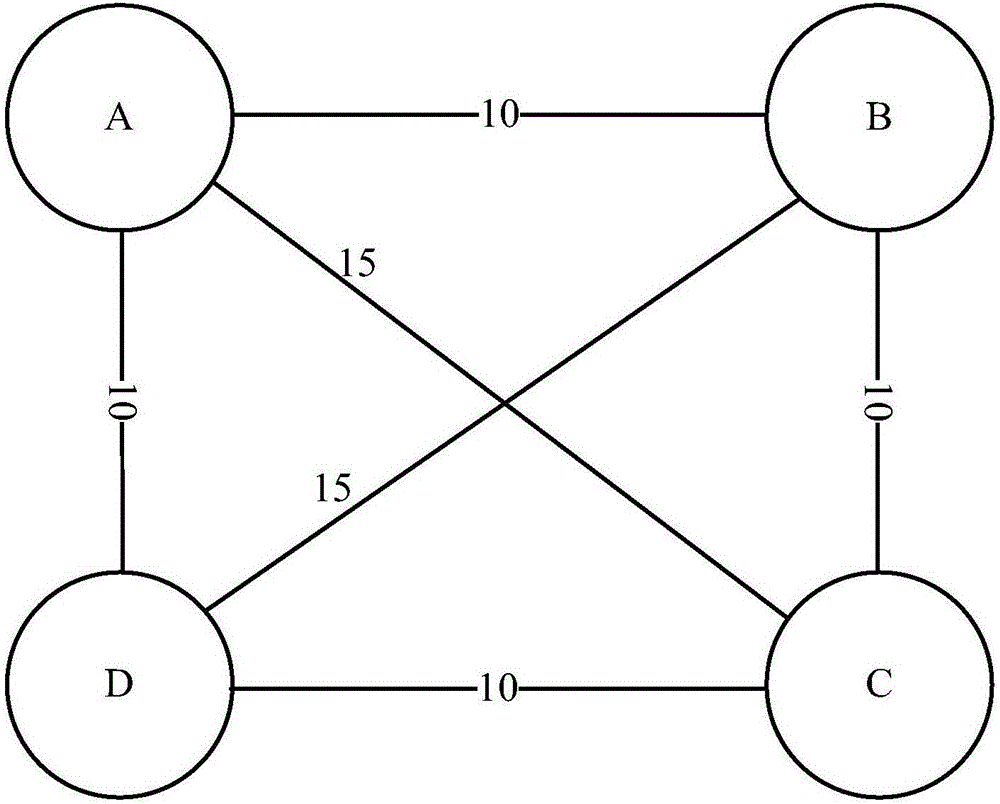

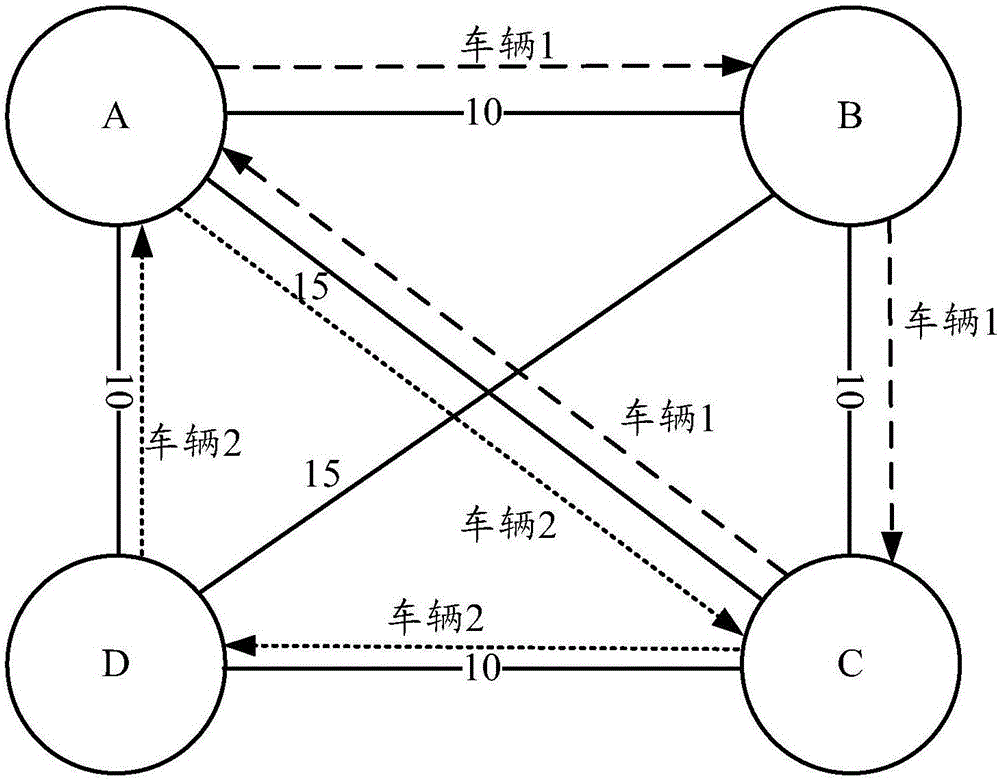

Vehicle dispatching method and device

ActiveCN106156961ASolve the path problemFast convergenceResourcesProgram planningRate of convergence

The invention provides a vehicle dispatching method and device. The method comprises the steps that multiple vehicle dispatching plans are generated, each vehicle dispatching plan comprises a vehicle and a transport task which the vehicle needs to process, and each transport task comprises one or more cargos; according to the weight and size of the cargos in each vehicle dispatching plan, a vehicle evaluation index of each vehicle dispatching plan is acquired, and the vehicle dispatching plan to be detached is selected according to the vehicle evaluation indexes; according to each cargo in the vehicle dispatching plan to be detached, a target vehicle dispatching plan is selected for the cargo, the cargo is distributed to the transport task of the target vehicle dispatching plan, a modified vehicle dispatching plan is obtained, and the vehicle dispatching plan to be detached is deleted; whether a preset dispatching ending strategy is met or not is judged, and if yes, the current vehicle dispatching plan is output. Through the technical scheme, the rate of convergence is higher, and a large quantity of computing resources are saved.

Owner:HANGZHOU DT DREAM TECH

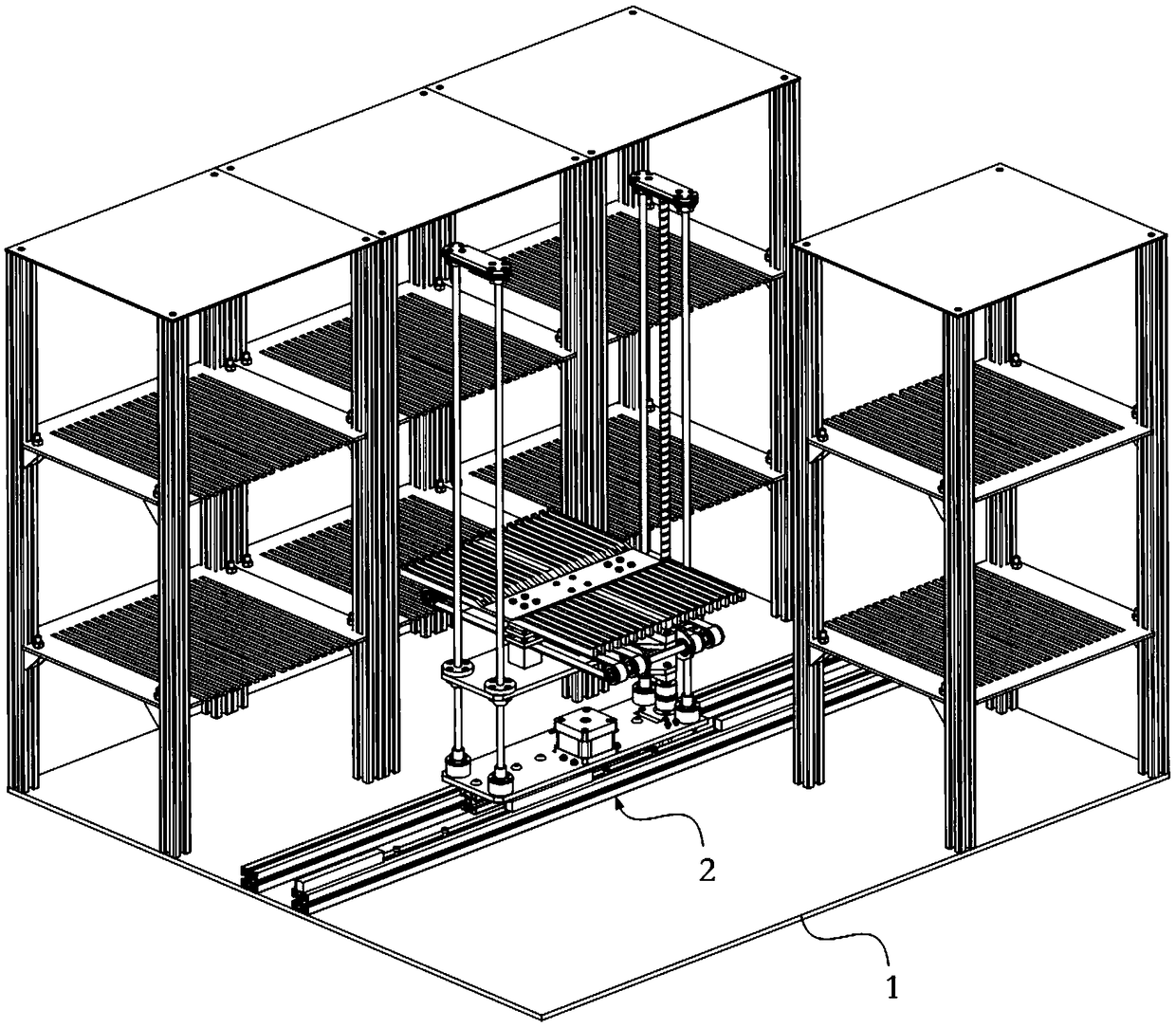

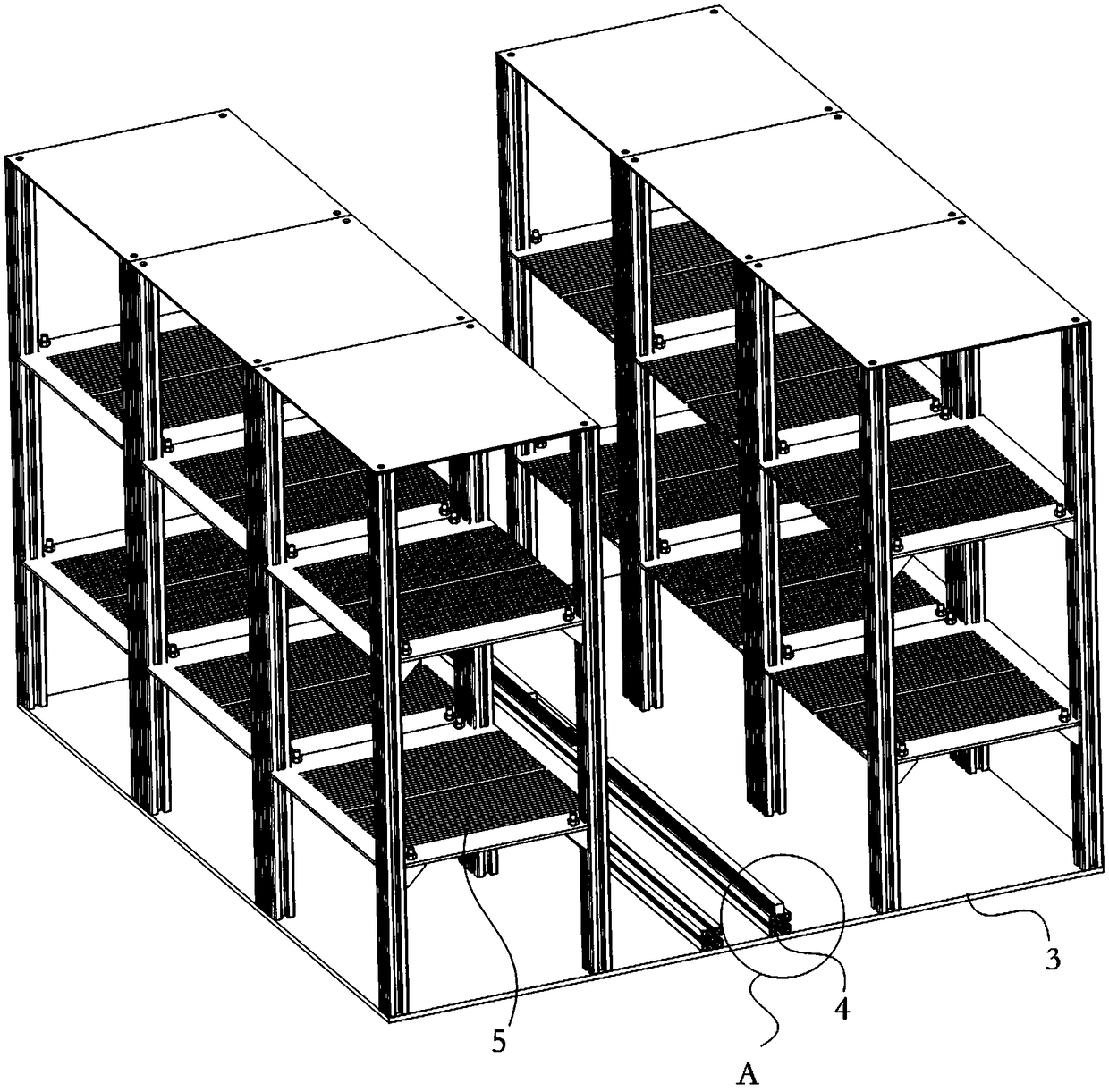

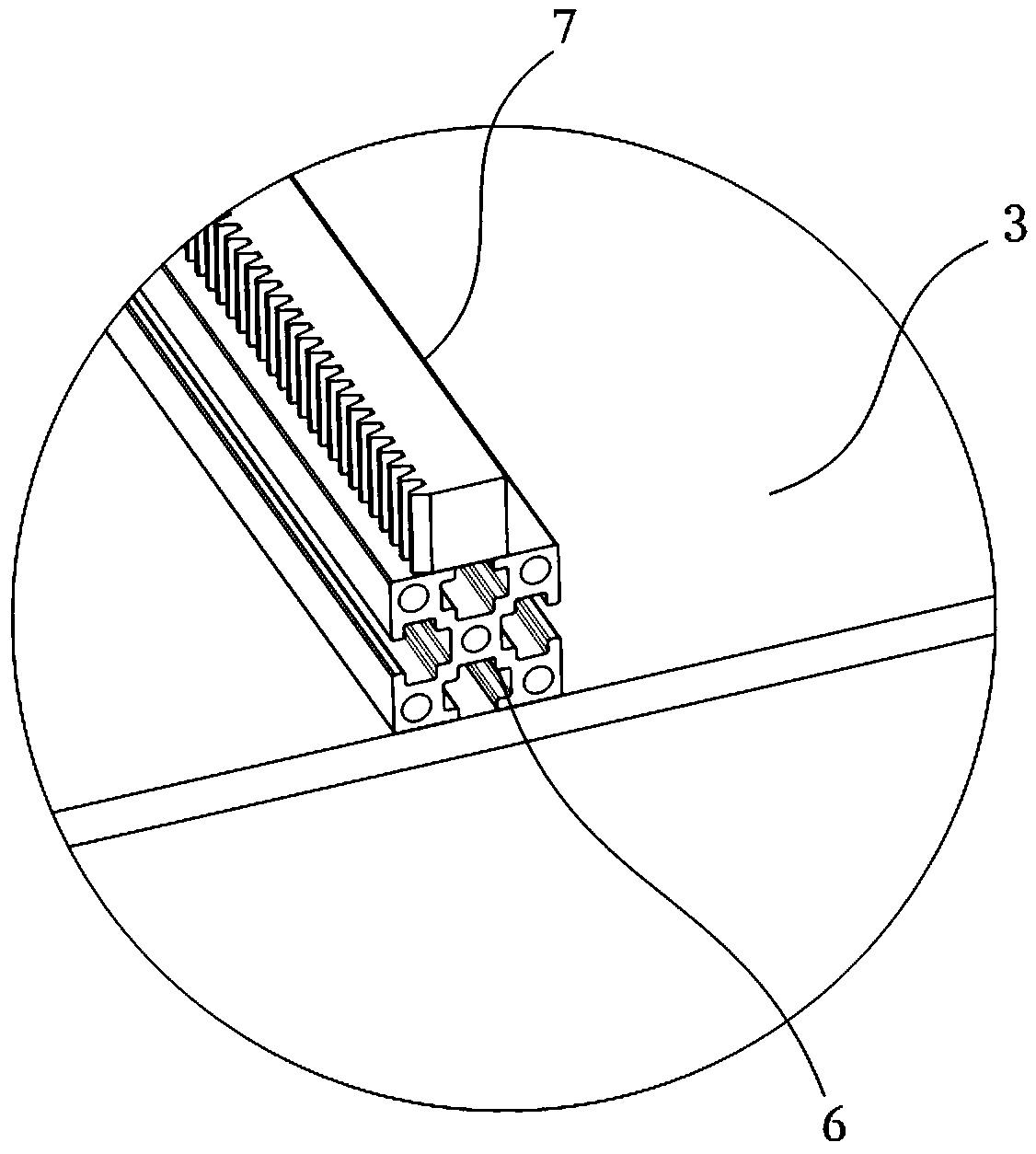

Vehicle-mounted automatic three-dimensional storage mechanism for express robot

The embodiment of the invention discloses a vehicle-mounted automatic three-dimensional storage mechanism for an express robot. The vehicle-mounted automatic three-dimensional storage mechanism comprises a goods shelf assembly and a guide rail mechanical arm assembly, wherein goods shelves are separately arranged at the two sides of guide rails; and the guide rail mechanical arm assembly can horizontally move on the guide rails, and can take out goods from any positions of the goods shelves or can place the goods onto any positions of the goods shelves. Compared with the prior art, the vehicle-mounted automatic three-dimensional storage mechanism is novel in form, is strong in universality and is high in feasibility; moreover, a goods supporting structure of the vehicle-mounted automatic three-dimensional storage mechanism is simple and light, and is suitable for express goods in three packaging forms of file pockets, cartons and plastic bags which are common on the market;and the keypoint is that the whole storage mechanism only needs to equipment with one or a few guide rail mechanical arm assemblies, so that in-vehicle quick storage and transportation for all express goods canbe realized, and therefore, a highly-automatic, high-efficiency and high-benefit express goods distribution task is realized.

Owner:SHANTOU UNIV

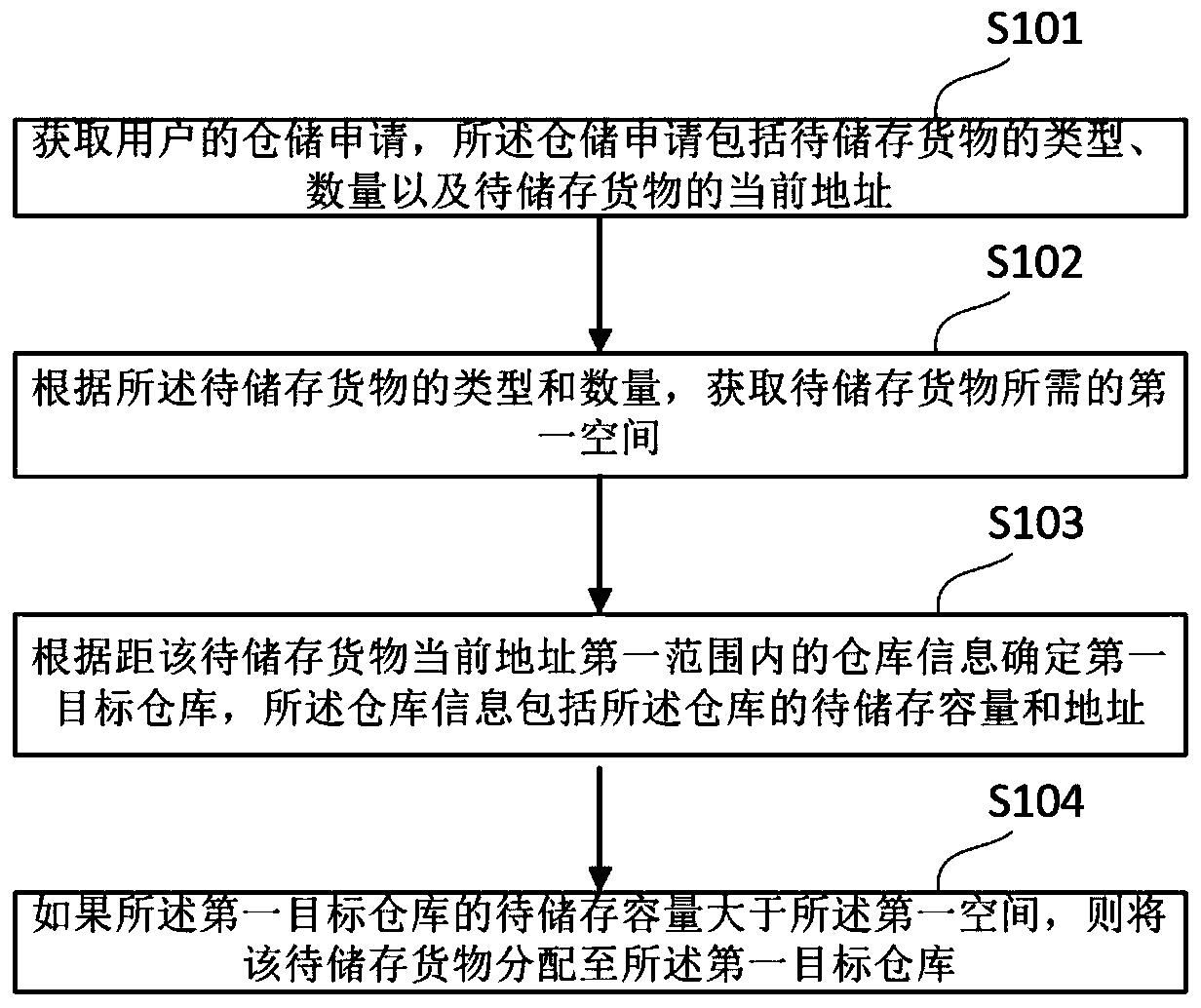

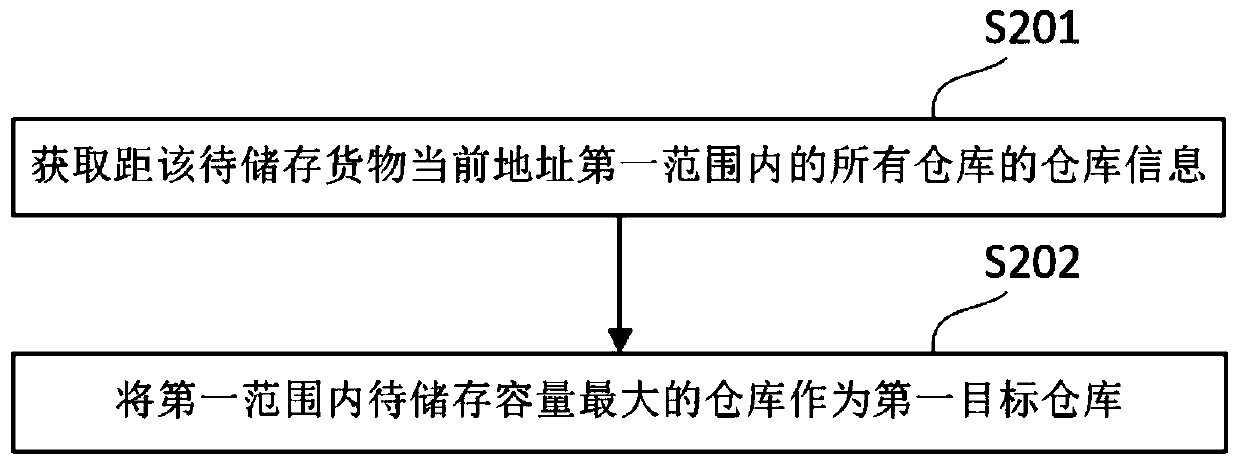

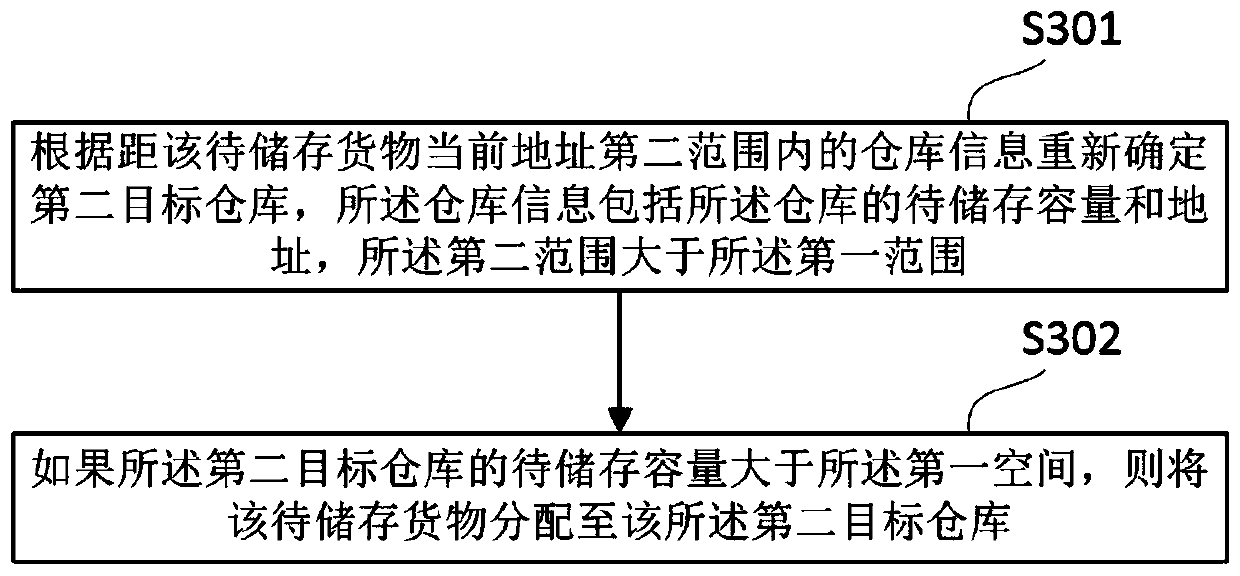

Storage scheduling method and system, storage medium and electronic device

InactiveCN109978444AReasonable automatic allocationImprove distribution efficiencyLogisticsData warehouseOperating system

The invention relates to a warehouse scheduling method and system, a storage medium and an electronic device. The storage scheduling method comprises the following steps: obtaining a storage application of a user, wherein the storage application comprises the type and quantity of to-be-stored cargos and the current address of the to-be-stored cargos; obtaining a first space required by the to-be-stored goods according to the type and the number of the to-be-stored goods; determining a first target warehouse according to warehouse information within a first distance range from the current address of the to-be-stored cargo, wherein the warehouse information comprises to-be-stored capacity and address of the warehouse; and if the to-be-stored capacity of the target warehouse is greater than the first space, allocating the to-be-stored goods to the first target warehouse. According to the warehouse scheduling method, warehouse resources can be distributed more reasonably, and the distribution efficiency can be improved.

Owner:东莞市大易产业链服务有限公司

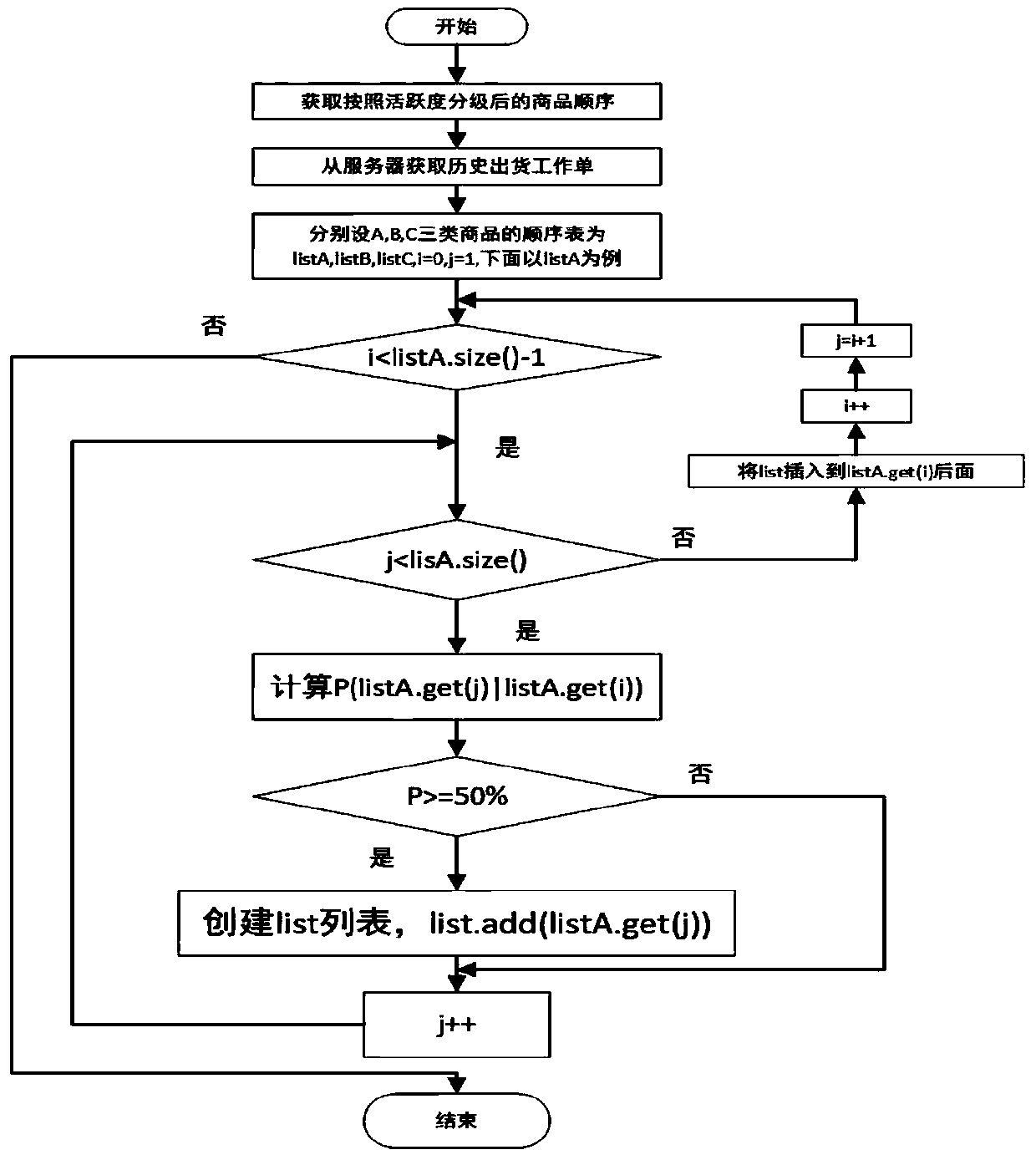

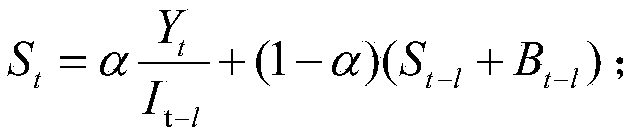

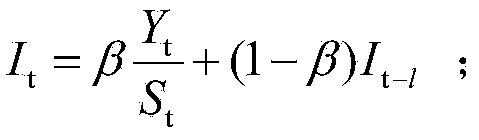

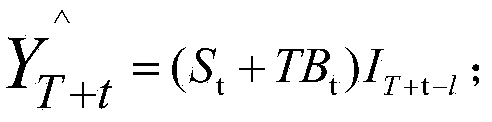

Sale forecasting method based on big data mining of cloud service platform

InactiveCN103984998ASimple methodImprove efficiencyForecastingCommerceData predictionComputer science

The invention discloses a sale forecasting method based on big data mining of a cloud service platform. The method specifically includes the step of conducting data mining analysis according to data of historical successful goods distribution of a warehouse, forecasting a prospective sale condition and forecasting the sale quantity and the growth rate according to historical sale data of the goods. According to the sale forecasting method based on the big data mining of the cloud service platform, sale data of existing orders and goods distribution data of the warehouse are analyzed and forecasted; the method is simple, efficient and capable of meeting actual demands.

Owner:CHENGDU DMI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com