Method for preparing whey protein peptide by composite protease hydrolysis

A compound protease and whey protein peptide technology, which is applied in the field of preparation of biologically active short peptides, can solve the problems of immature detection methods and technologies, difficulty in separation and purification, and difficulty in industrial production, and achieve excellent molecular weight distribution range, peptide High content, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

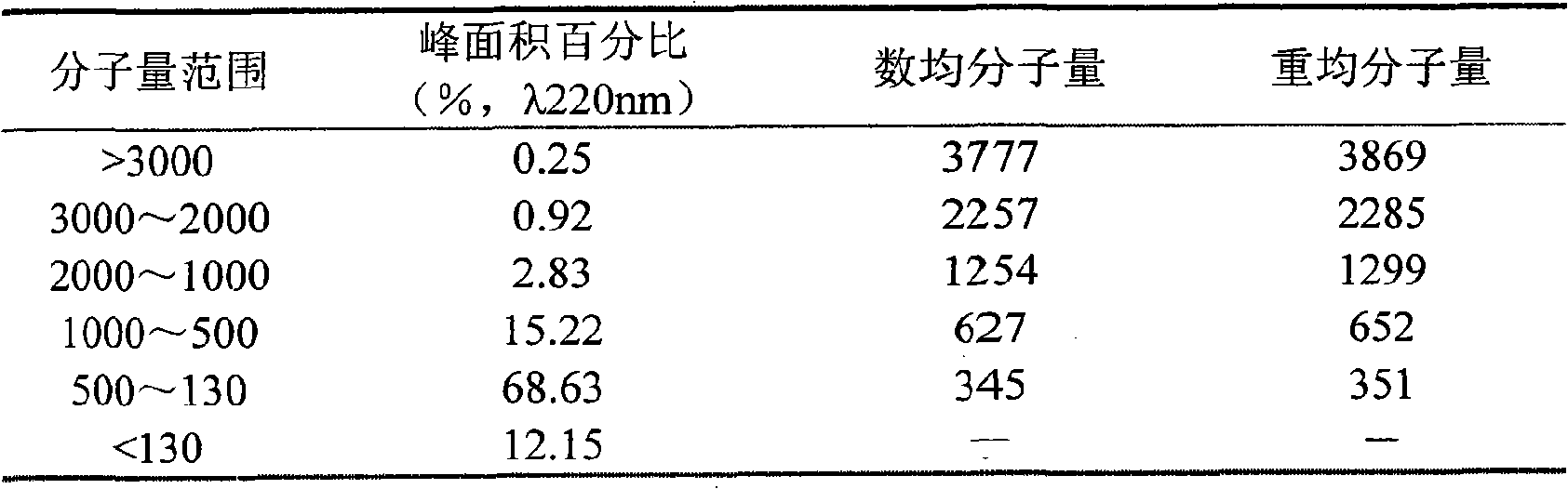

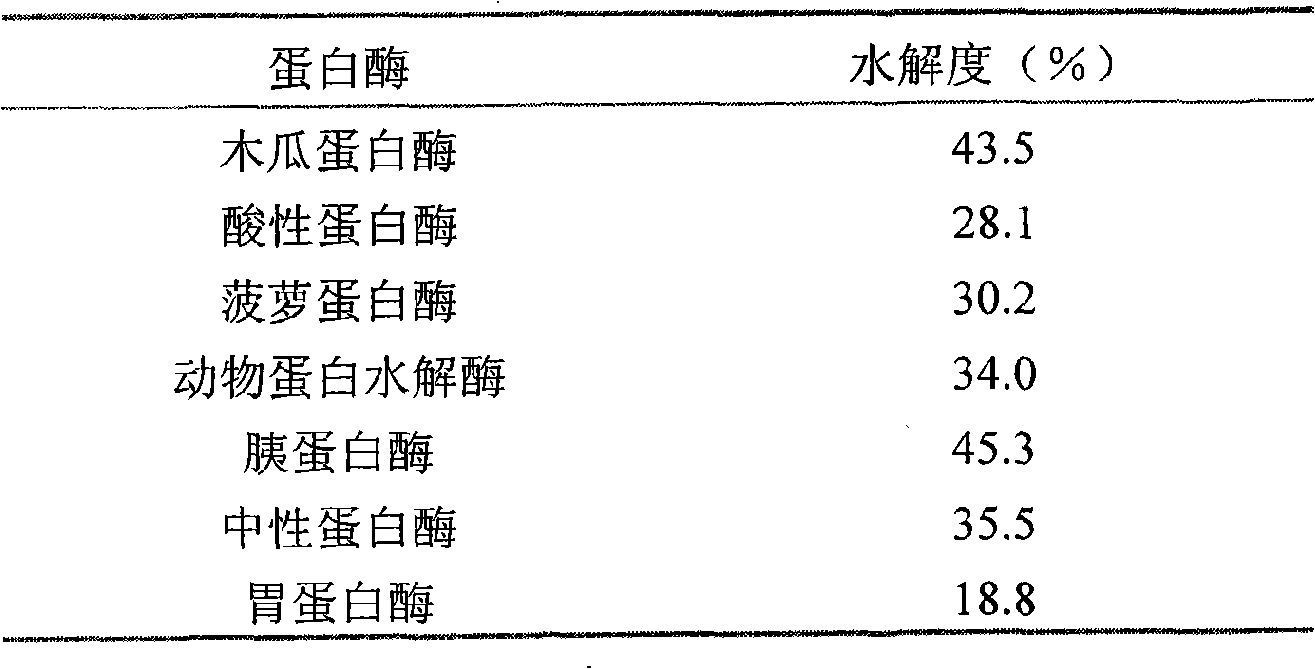

Embodiment 1

[0079] Weigh quantitative whey protein, hydrate it, prepare 6.0wt% whey protein solution, heat at 85℃ for 15min, cool to 45℃, adjust the pH to 7.5; add compound protease (the compound protease is composed of trypsin and papain according to 2:1 weight ratio), the compound protease dosage is 4.0% of the quality of whey protein, hydrolyzed in a thermostatic enzymolysis tank (enzyme reaction device) at a constant temperature of 45°C; pH regulators are continuously added during the hydrolysis process, Keep the pH constant at 7.5; after 7 hours of enzymatic hydrolysis, the degree of hydrolysis of whey protein is determined to be 46.5%; the whey protease hydrolysate of the reaction system is quickly heated to 90°C and kept for 20 minutes to inactivate the enzyme and control the degree of hydrolysis ; Add HCl solution to the enzyme hydrolysate, adjust the pH to 4.3-4.7, heat for 15-20 minutes to precipitate the incompletely hydrolyzed whey protein macromolecules; take the enzyme hydrolysi...

Embodiment 2

[0082] Weigh quantitative whey protein, hydrate it, prepare a 4.0wt% whey protein solution, heat at 85°C for 15 minutes, cool to 56°C, and adjust the pH to 6.0; add compound protease (the compound protease is composed of trypsin and papain according to 3:1 weight ratio), the compound protease dosage is 8.0% of the weight of whey protein, hydrolyzed in a thermostatic enzymatic hydrolysis tank (enzyme reaction device) at a constant temperature of 35°C; pH regulator is continuously added during the hydrolysis process , Keep the pH constant at 6.0; 10 hours after enzymatic hydrolysis, the degree of hydrolysis of whey protein is 42.5% after testing; the reaction system whey protease hydrolysate is quickly heated to 85°C and kept for 20 minutes to inactivate the enzyme and control the hydrolysis Degree; add HCl solution to the enzymatic hydrolysis solution, adjust the pH to 4.3-4.7, heat for 15-20min, and precipitate the incompletely enzymatically hydrolyzed whey protein macromolecules;...

Embodiment 3

[0085]Weigh quantitative whey protein, hydrate and prepare a 2.0% whey protein solution, heat at 100°C for 10 minutes, cool to 30°C, and adjust the pH to 5.0; add compound protease (the compound protease is composed of trypsin and papain according to 1 :1 weight ratio), the added amount of composite protease is 2.0% of the mass of whey protein, hydrolyzed in a thermostatic enzymolysis tank (enzyme reaction device) at a constant temperature of 60°C; pH regulators are continuously added during the hydrolysis process , Keep the pH constant at 5.0; after 10 hours of enzymatic hydrolysis, the degree of hydrolysis of whey protein is detected to be 41.2%; the reaction system whey protease hydrolyzate is quickly heated to 88°C and kept for 20 minutes to inactivate the enzyme and control the hydrolysis Degree; add HCl solution to the enzyme hydrolyzate, adjust the pH to 4.3-4.7, heat for 15-20min to precipitate the incompletely hydrolyzed whey protein macromolecules; take the enzymatic hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com