Patents

Literature

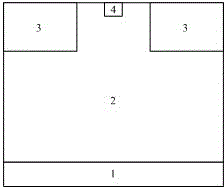

48results about How to "Solve the resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

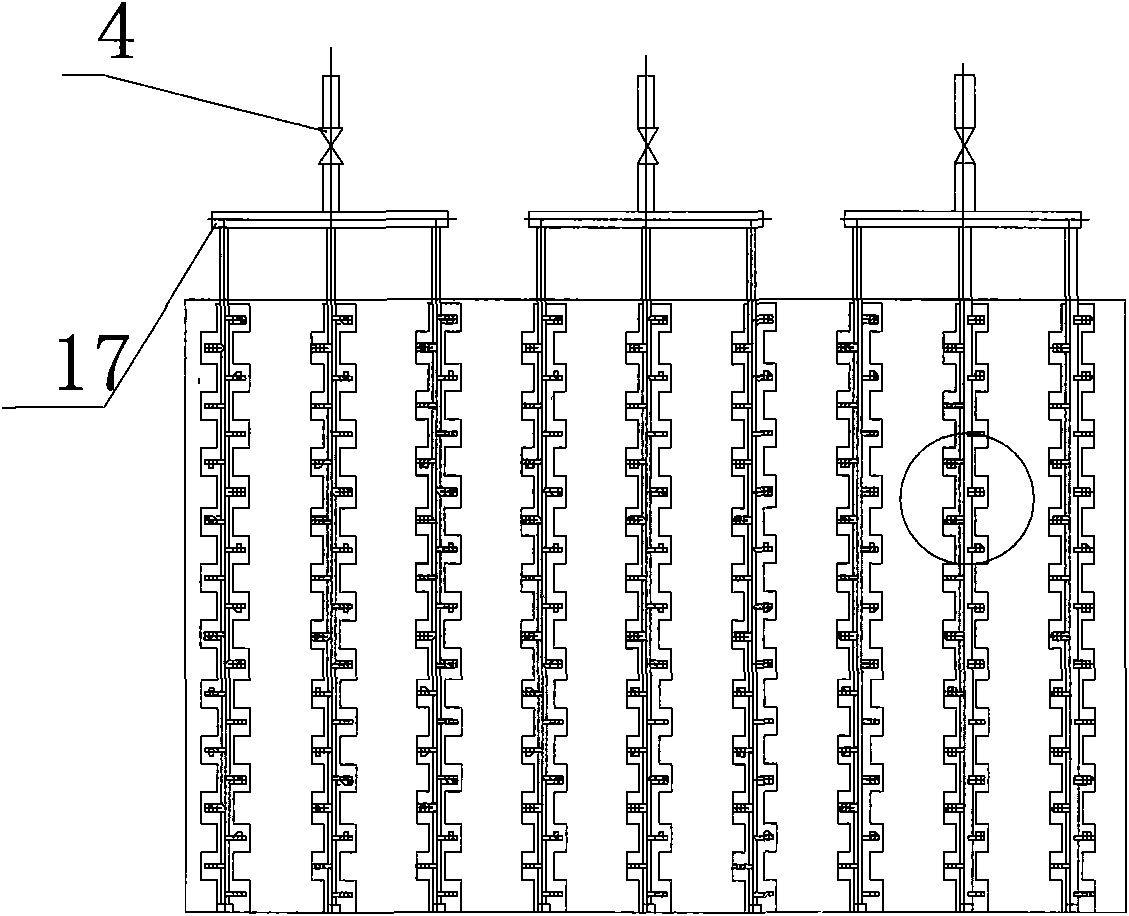

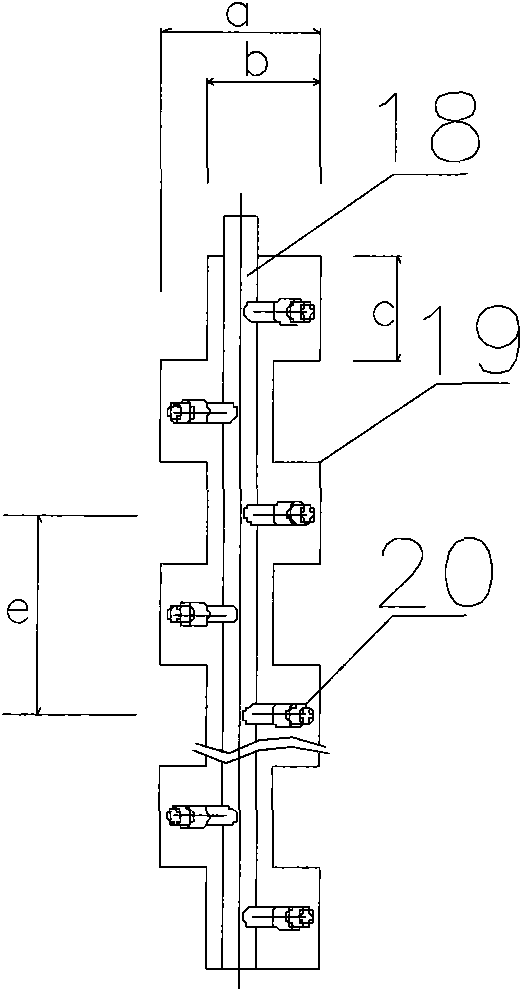

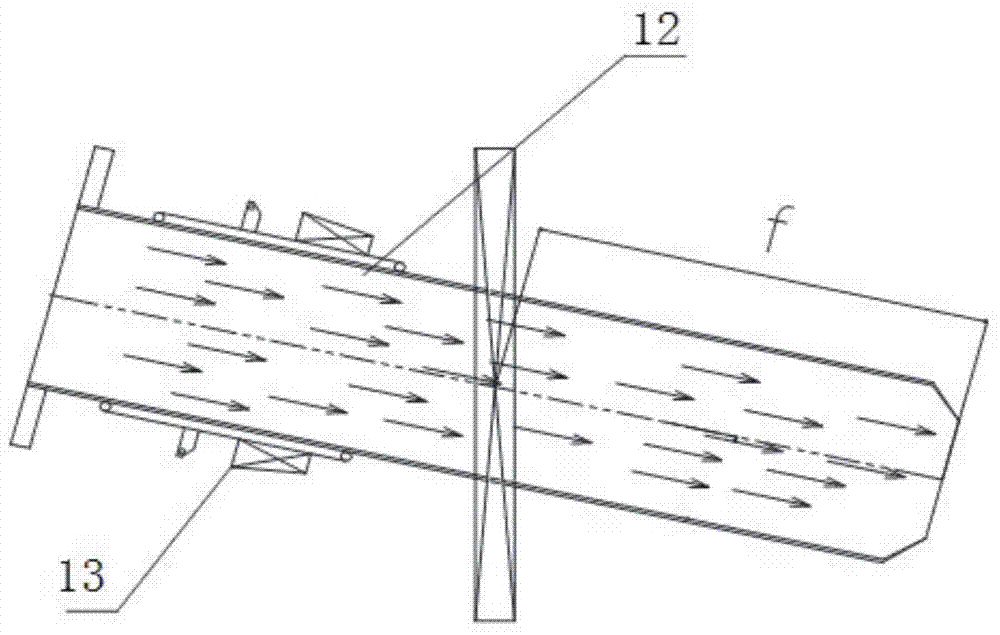

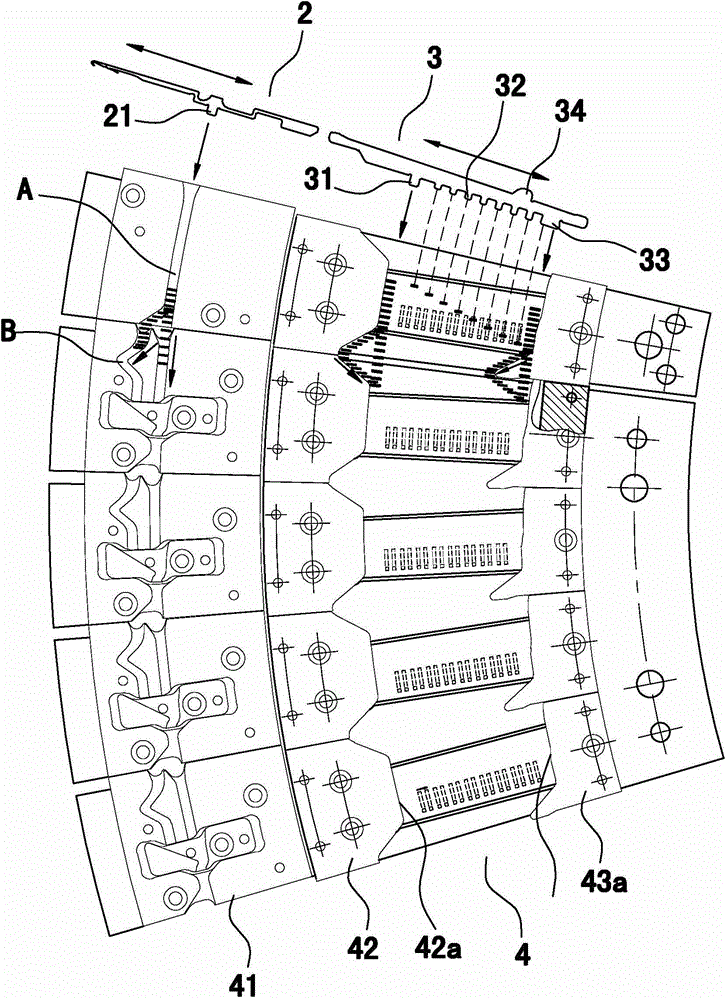

Ammonia-spraying grid device for SCR-method flue gas denitrification, and SCR-method flue gas denitrification process

ActiveCN101601965ASolve the resistanceReduce resistanceNitrous oxide captureDispersed particle separationFlue gasProduct gas

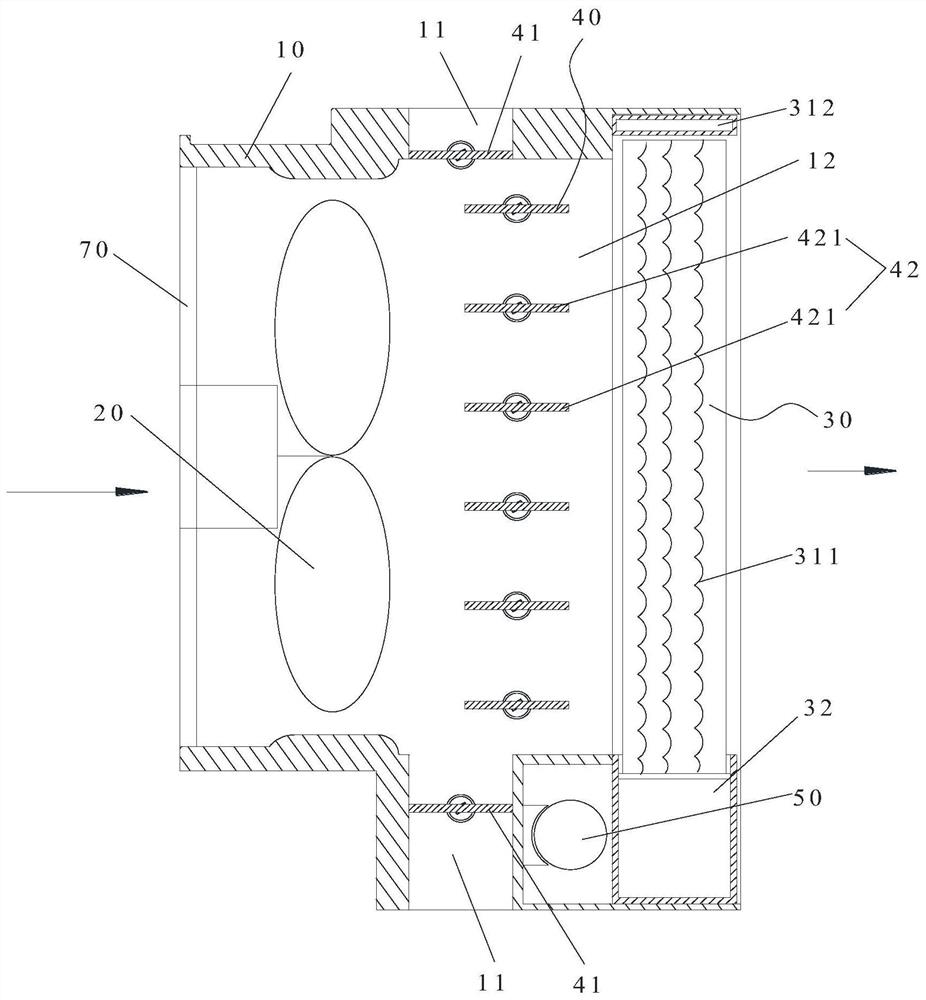

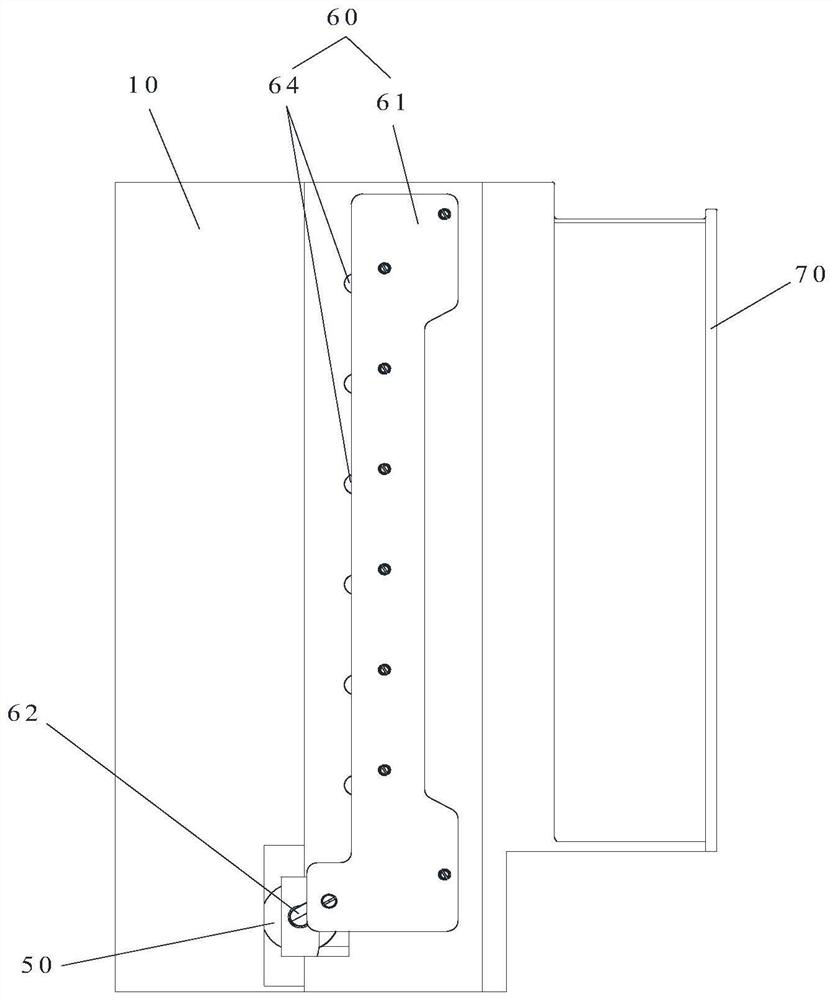

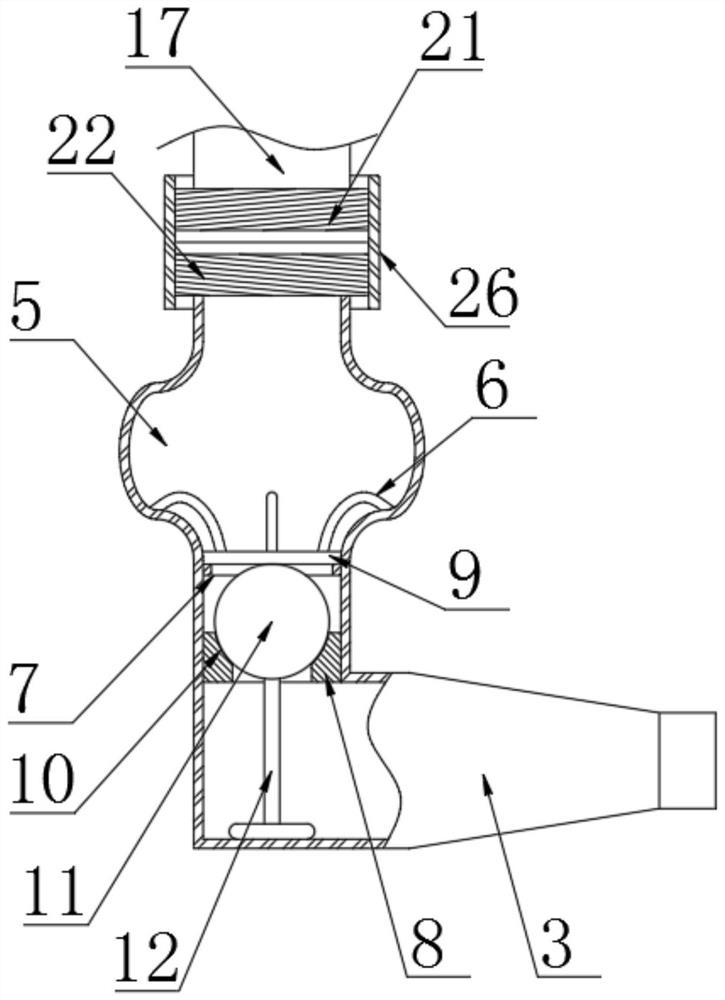

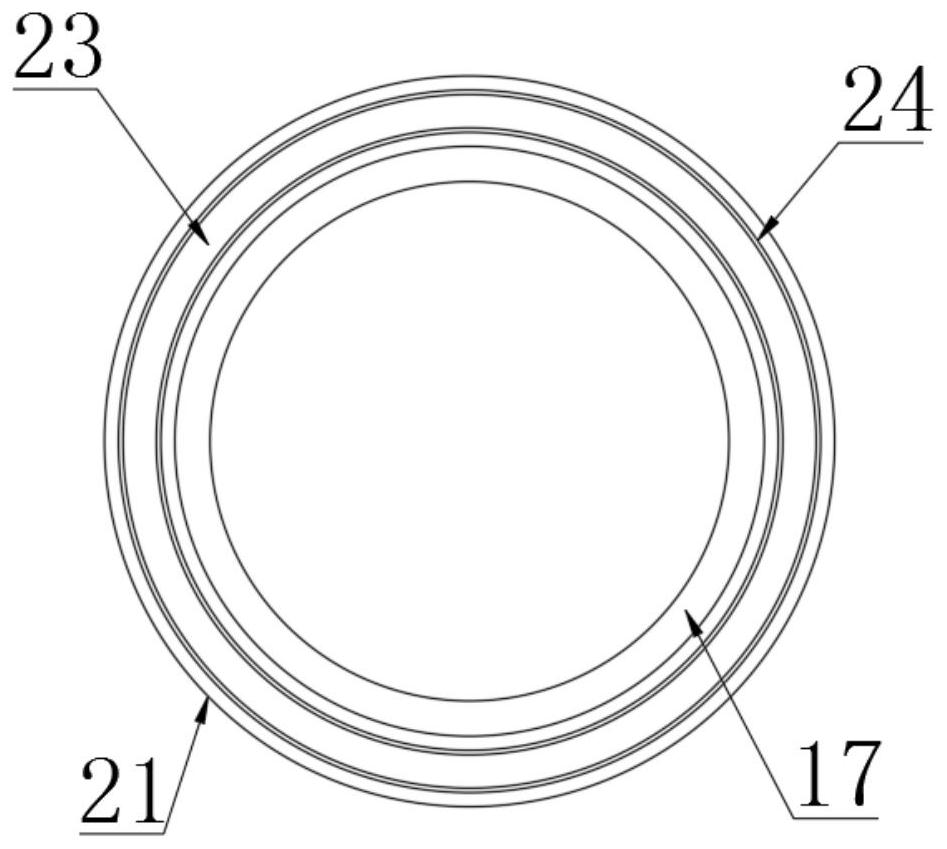

The invention discloses an ammonia-spraying grid device for SCR-method flue gas denitrification, which comprises an ammonia-spraying grid consisting of bundles of metal pipes, wherein each metal pipe is provided with a nozzle in the radial direction; the nozzle is communicated with the metal pipe; and the included angle between the opening direction of the nozzle and the flow direction of flue gas is between 0 and 90 degrees. The invention also discloses an SCR-method flue gas denitrification process adopting the ammonia-spraying grid device. The process adopts the ammonia-spraying grid to distribute ammonia / air gas mixture sprayed into an inlet flue of a denitrification reactor, and adjusts ammonia spray distribution according to the concentration of NOx in the inlet flue of the reactor so as to mix the NOx in the flue gas with NH3 sprayed in well, thus the mixing effect of the NH3 and the flue gas as well as denitrification efficiency can be effectively improved. A grid-type ammonia spraying-distributing-mixing device of the invention has the advantages of simple structure, low mixture resistance, good distribution effect, insusceptibility to ash deposition, capability of effectively protecting ammonia-spraying grid nozzles from wear, reducing the mixture distance of ammonia and the flue gas in an inlet of the denitrification reactor, improving the utilization rate of denitrification catalysts, reducing the height of the denitrification reactor and reducing the resistance of a flue gas denitrification system, thereby greatly reducing the unit cost of flue gas denitrification.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH

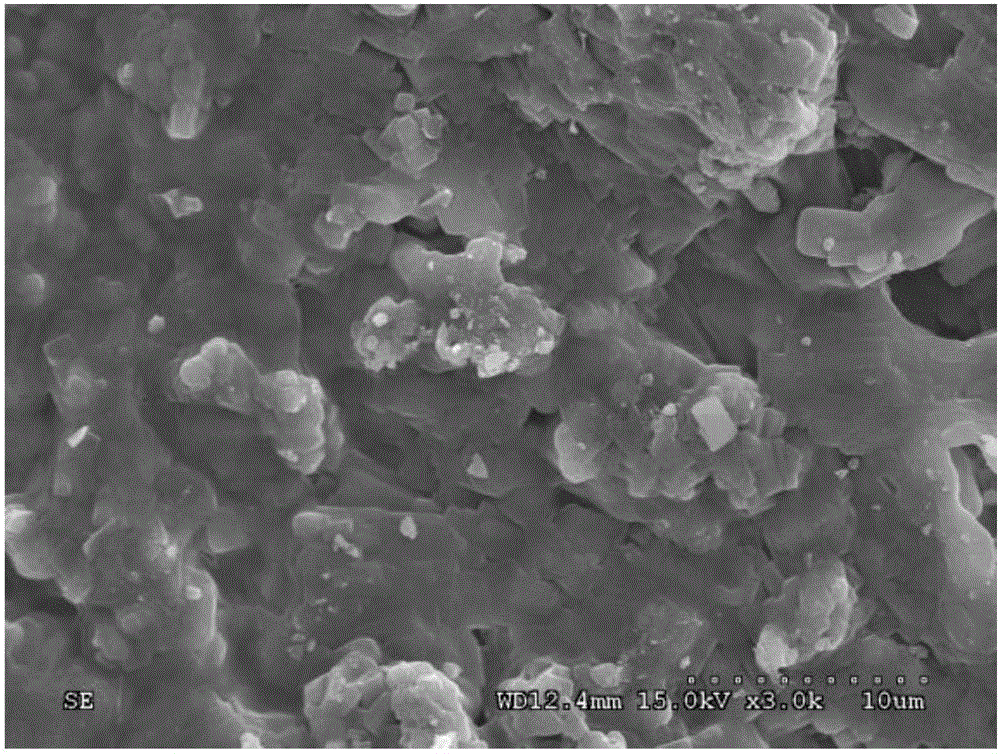

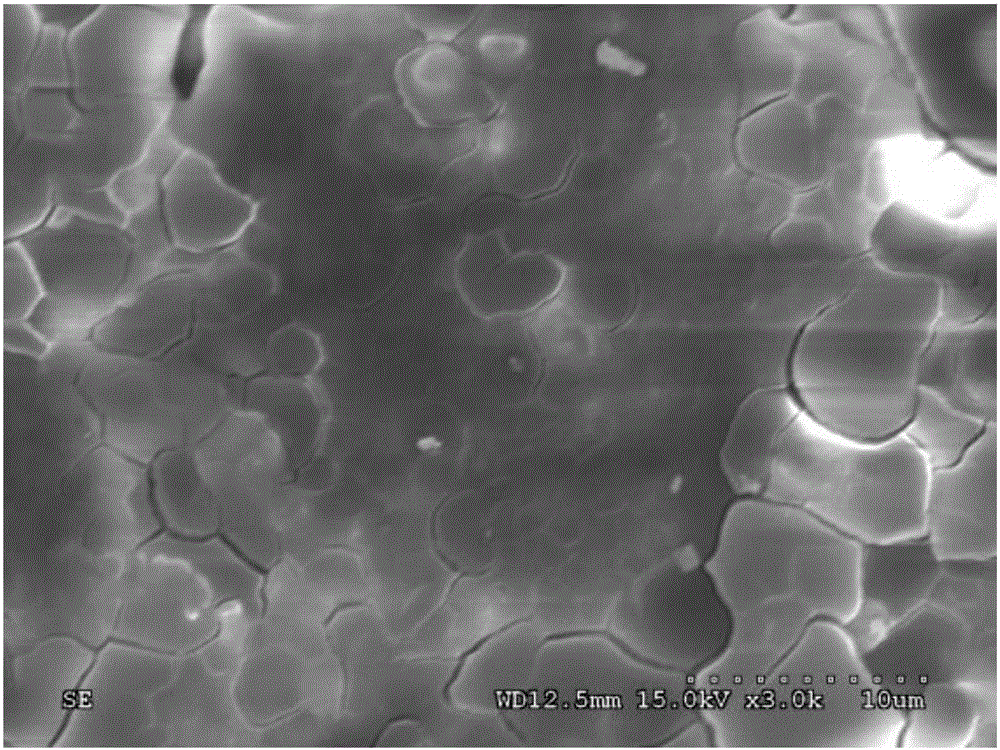

Industrial organic waste gas catalytic degradation catalyst cooperated with low-temperature plasma, and preparation method and application of catalyst

ActiveCN105478136APromote degradationSolve the real problemHeterogenous catalyst chemical elementsDispersed particle separationRare earthRoom temperature

The invention discloses an industrial organic waste gas catalytic degradation catalyst cooperated with low-temperature plasma, and a preparation method and application of the catalyst. The catalyst comprises a carrier, a main active ingredient and a catalyst promotion ingredient, wherein the carrier is SiC; the main active ingredient is a mixture of at least one kind of noble metal and at least one of transition metal oxide or at least one kind of noble metal or at least one kind of transition metal oxide; the catalyst promotion ingredient is a mixture of at least one kind of rare-earth oxide and alkaline earth oxide or at least one kind of rare-earth oxide or at least one kind of alkaline earth oxide; the main active ingredient accounts for 0.1 to 5 percent of the total mass of the catalyst; the catalyst promotion ingredient accounts for 0.1 to 5 percent of the total mass of the catalyst. The catalyst provided by the invention has the advantages that the preparation is simple; the price is low; the service life is long; the performance is good; the catalyst can be used for high-efficiency removal of industrial VOCs waste gas at room temperature after being combined with plasma; in addition, the discharge of low byproducts is guaranteed.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

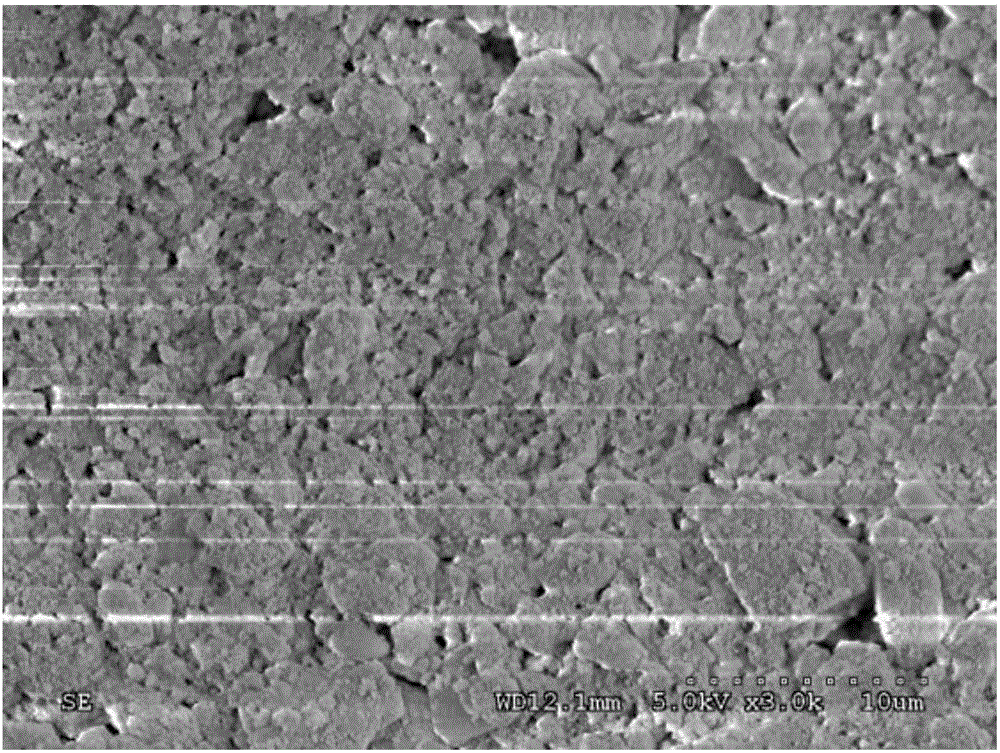

Double-metal integral type plasma catalyst as well as preparation method and application of double-metal integral type plasma catalyst

InactiveCN106693955AGood for degradation efficiencySolve the resistanceGas treatmentDispersed particle separationSolventMetal

The invention provides a double-metal integral type plasma catalyst as well as a preparation method and application of the double-metal integral type plasma catalyst and belongs to the technical field of plasma catalysts. The catalyst is prepared by adopting an excessive immersion method; the catalyst is prepared through the following steps: pre-treating a carrier, and drying and roasting; taking water as a solvent and adding gamma-Al2O3 powder and active components; ultrasonically stirring; putting pre-treated cordierite honeycomb ceramic into slurry and carrying out ultrasonic treatment; drying and roasting to obtain the double-metal integral type plasma catalyst. According to the double-metal integral type plasma catalyst, the water is used as the solvent in a preparation process, so that no environment pollution is caused; a silica sol solution is used as a bonding agent and a dispersant, and the excessive immersion method is adopted, so that the active components can be relatively uniformly dispersed on the surface of the carrier, and furthermore, the degradation efficiency of volatile pollutants is easy to improve. The technology provided by the invention is simple to operate, the raw materials are cheap, preparation conditions are moderate and no pollution is caused in the process, so that the technology is a novel environment-friendly technology capable of easily popularizing industrialization and marketization.

Owner:BEIJING UNIV OF TECH

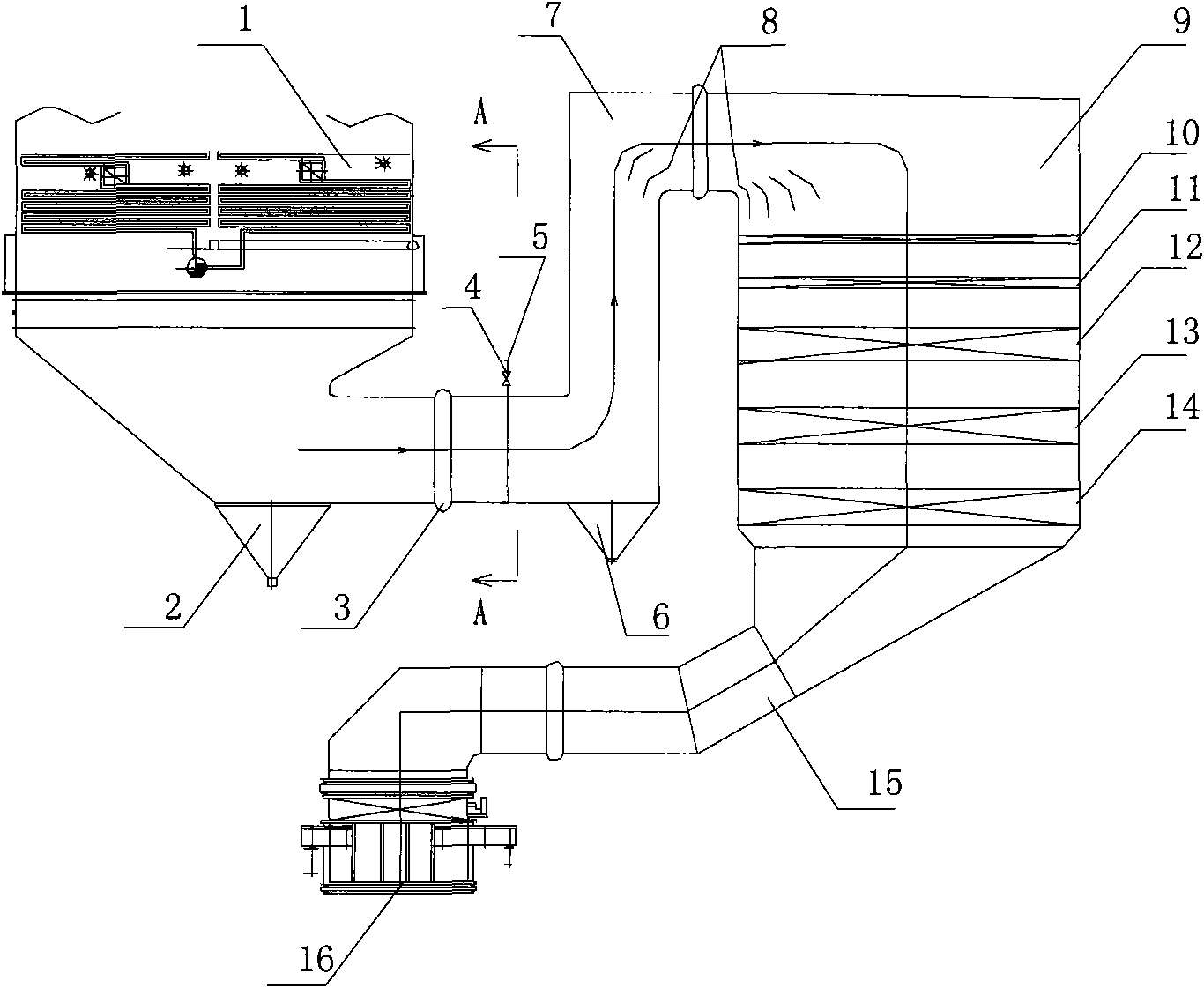

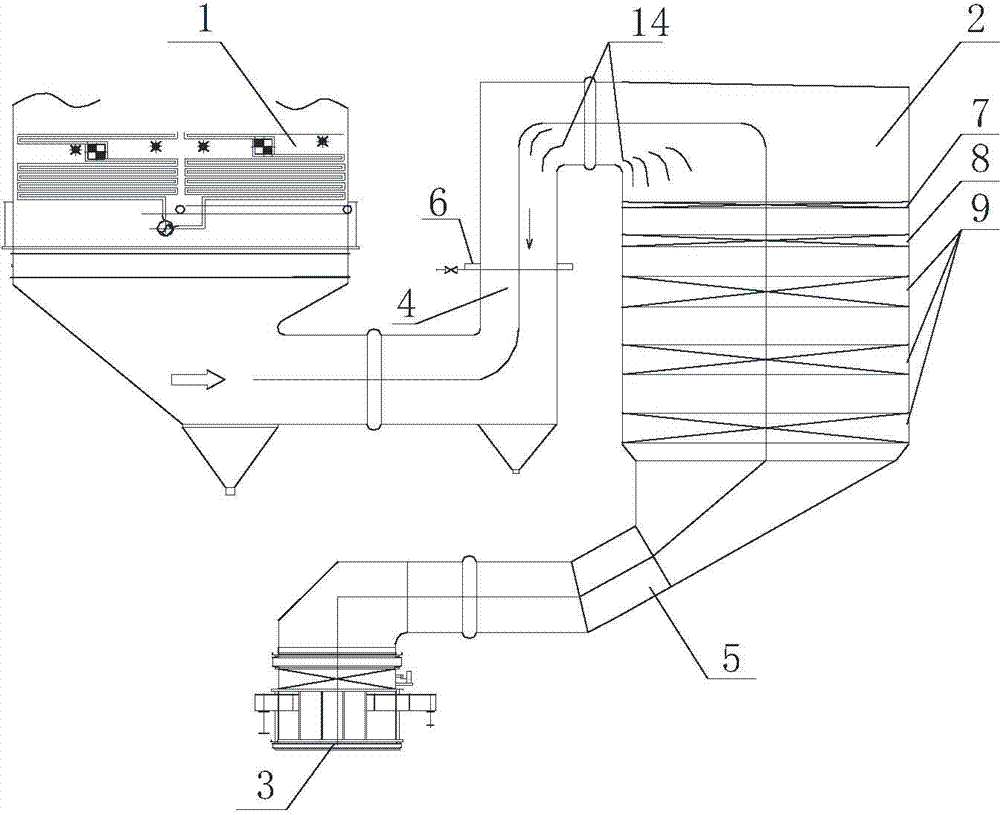

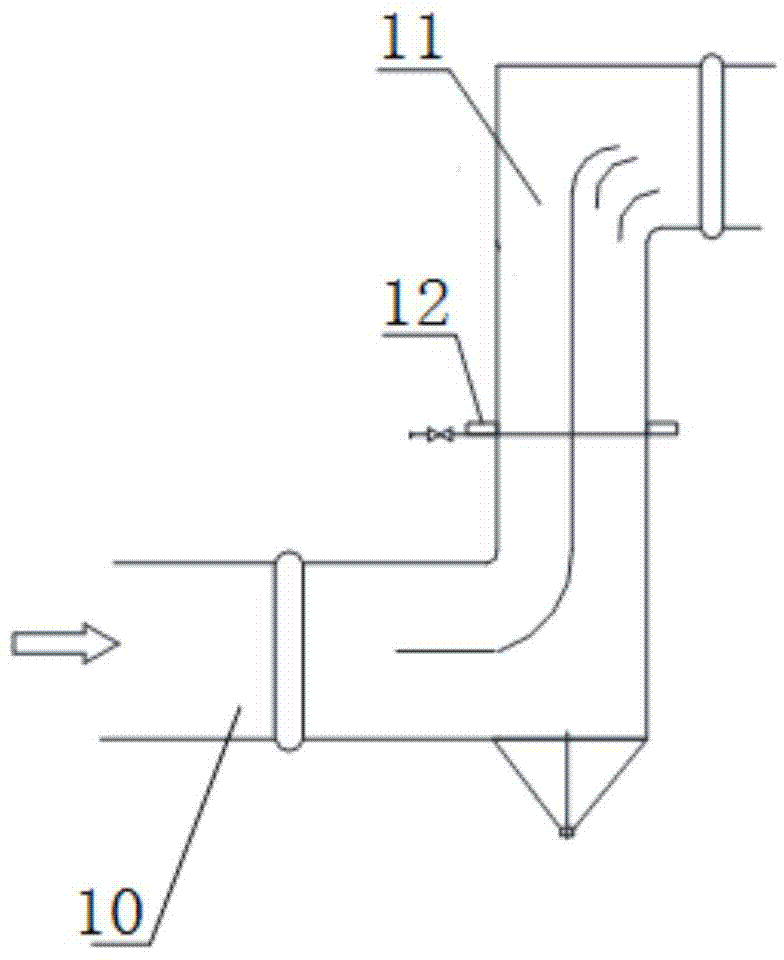

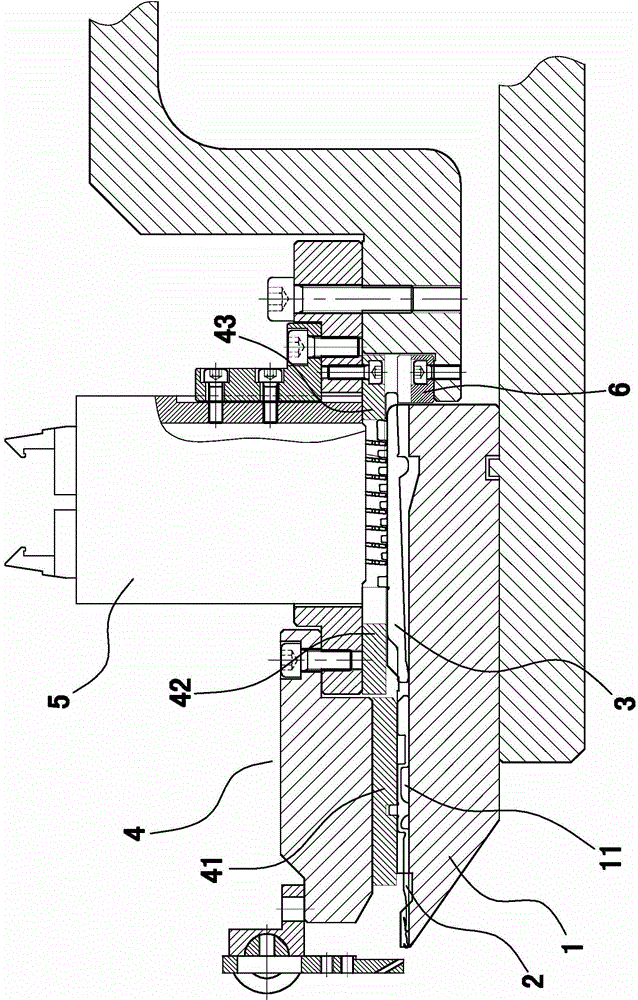

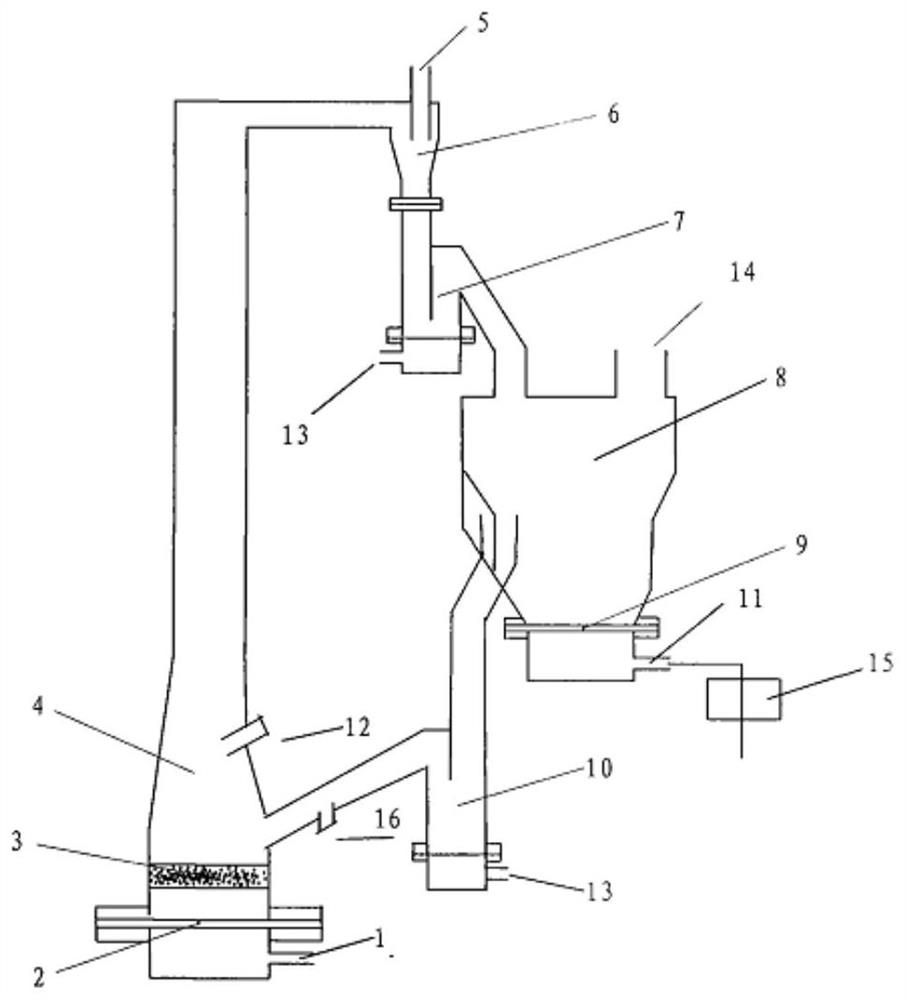

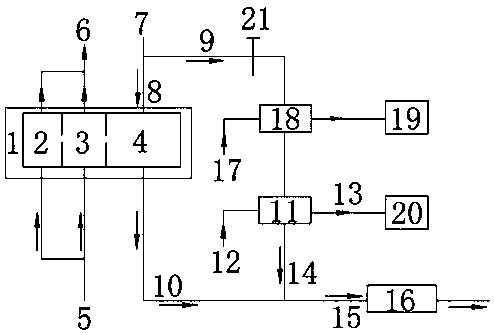

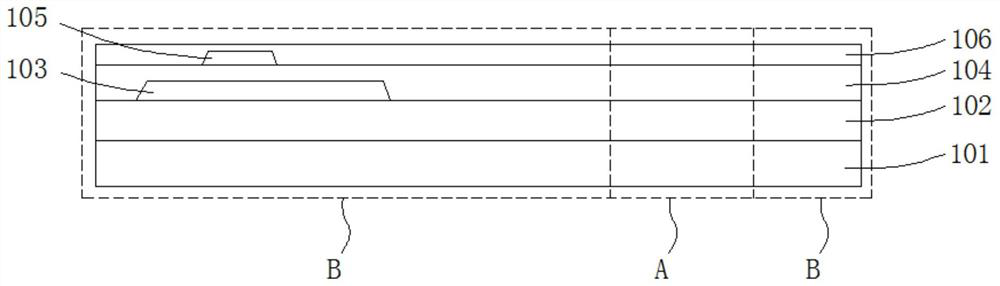

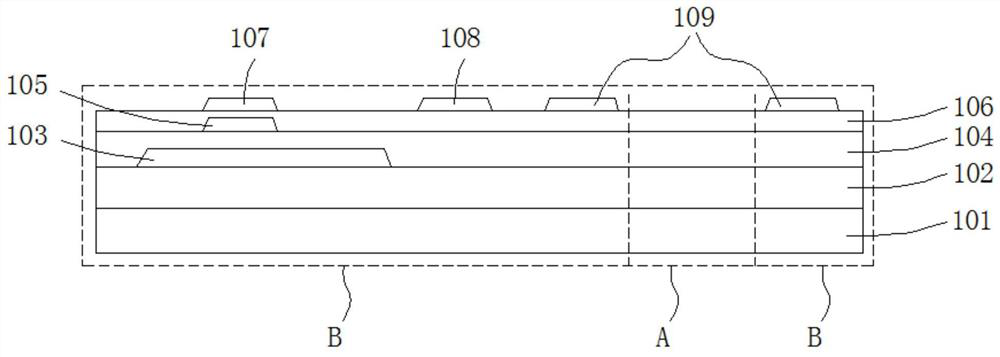

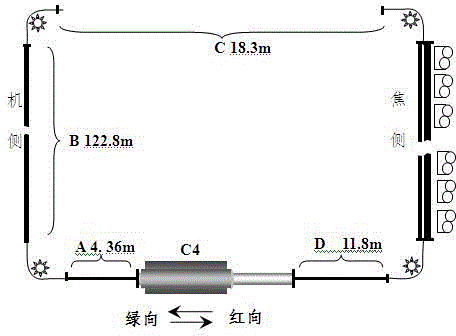

SCR (Selective Catalytic Reduction) flue gas denitration device and flue gas denitration method

InactiveCN104741001ASolve the resistanceReduce resistanceLighting and heating apparatusDispersed particle separationAir preheaterFlue gas

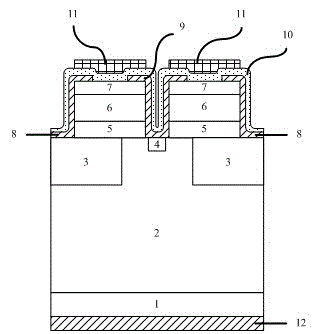

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration device and a flue gas denitration method. The SCR flue gas denitration device comprises a coal economizer (1), a denitration reactor (2) and an air preheater (3), wherein the bottom of the coal economizer (1) is connected with the top of the denitration reactor (2) by an inlet flue (4), the bottom of the denitration reactor (2) is connected with the air preheater (3) by an outlet flue (5), an ammonia spraying device (6) is arranged in the inlet flue (4), and an ash crushing device (7), a rectifying layer (8) and a catalyst layer (9) are sequentially arranged in the denitration reactor (2) from top to bottom. The denitration method comprises the steps of ammonia gas mixture preparation, ammonia spraying, denitration and exhausting. According to the invention, through the reasonable setting of a nozzle, an effect of mixing sprayed ammonia with flue gas is better, and the uniformity of a temperature field in a flue can be effectively guaranteed, thereby improving the denitration efficiency.

Owner:CHINA HUADIAN ENG +1

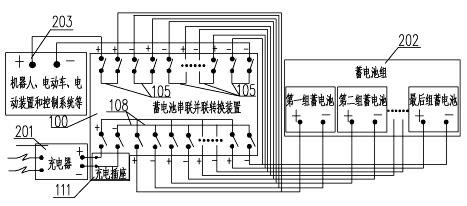

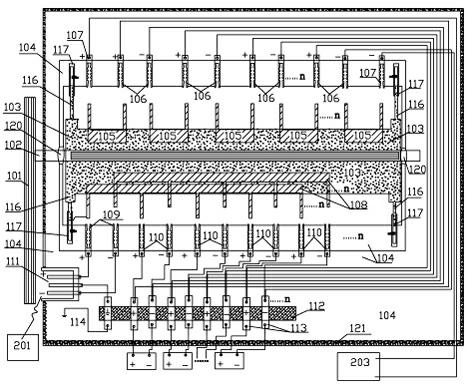

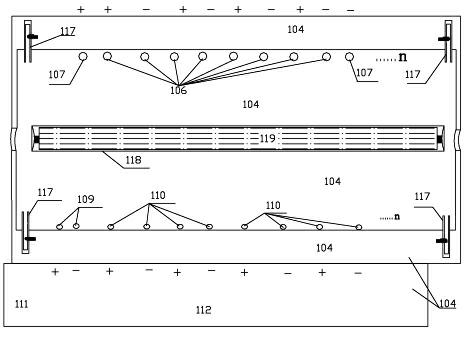

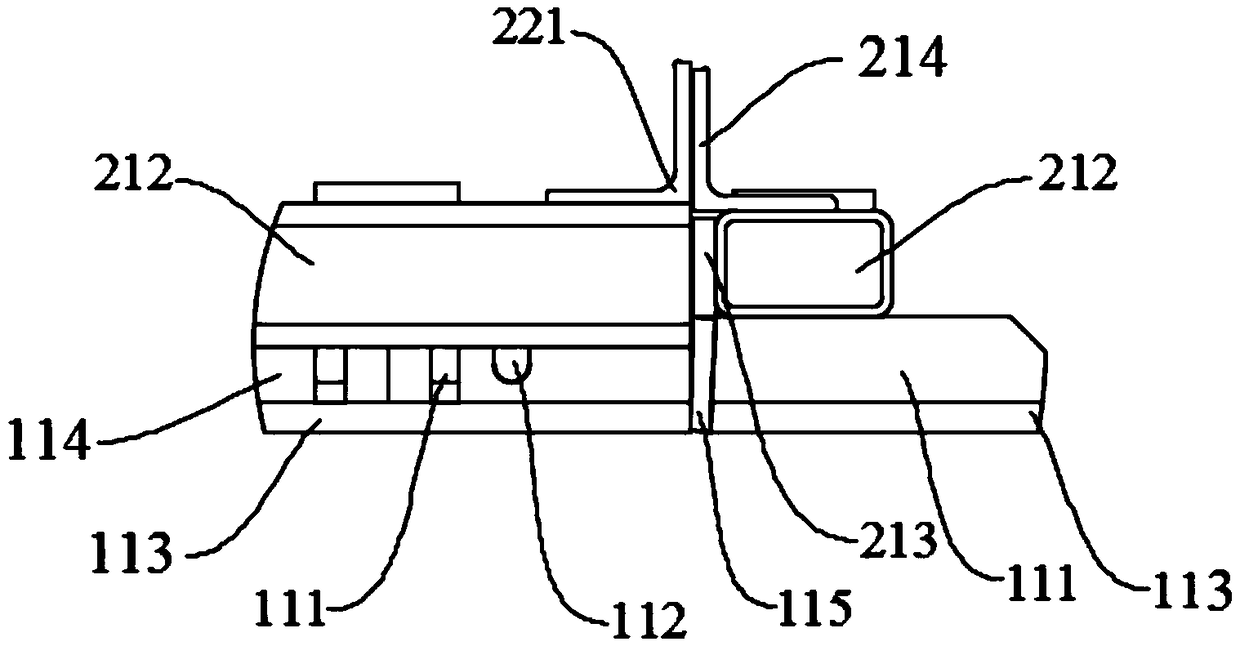

Device allowing battery packs to switch between series connection and parallel connection

InactiveCN102624052ASolve internal frictionSolve the resistanceBatteries circuit arrangementsElectric powerSystem safetyElectric devices

The invention provides a device allowing battery packs which are connected in series and applied to robots, electric motor cars, electric devices, control systems and the like to accurately and conveniently switch between series connection and parallel connection. The device provide by the invention is arranged on a charging socket, a charging socket door, actually a master trigger, is opened to link with an upper main drive gear shaft, a jumper wire movable plate slides, a series circuit and a series discharge end socket are disconnected, a parallel jumper wire plug is connected with a parallel end socket and a parallel charging end socket, and a positioner is locked, as a result, the series connection is switched into the parallel connection, so that the charging current charges the batteries at the same time, both the energy and time are saved, the use frequency is increased and the system safety is improved; and when the charging socket door covers the charging socket to link with the upper main drive gear shaft, the jumper wire movable plate slides, the parallel circuit and a charging end socket are disconnected, a series jumper wire plug is inserted into a series end socket and a series discharge end socket, and the positioner is locked, as a result, the parallel connection is switched into the series connection, so that the purposes of cleaning the charging socket and ensuring the safety of the function system are achieved.

Owner:陈小林 +1

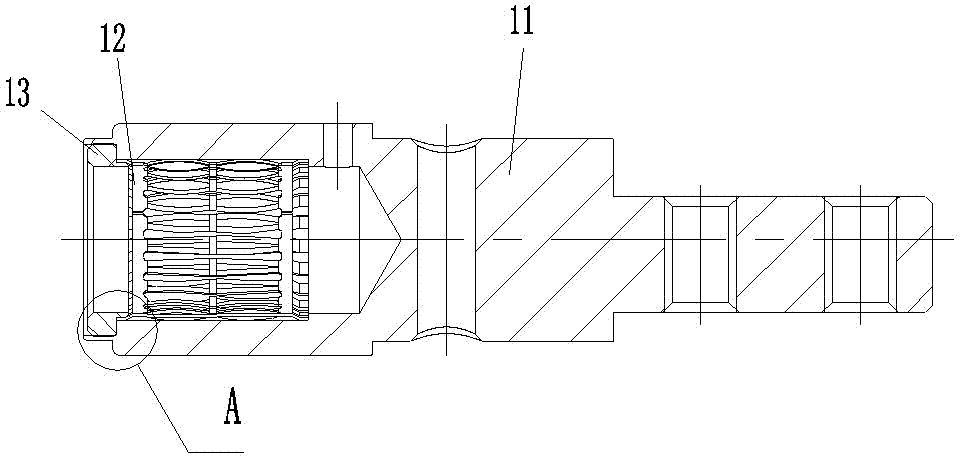

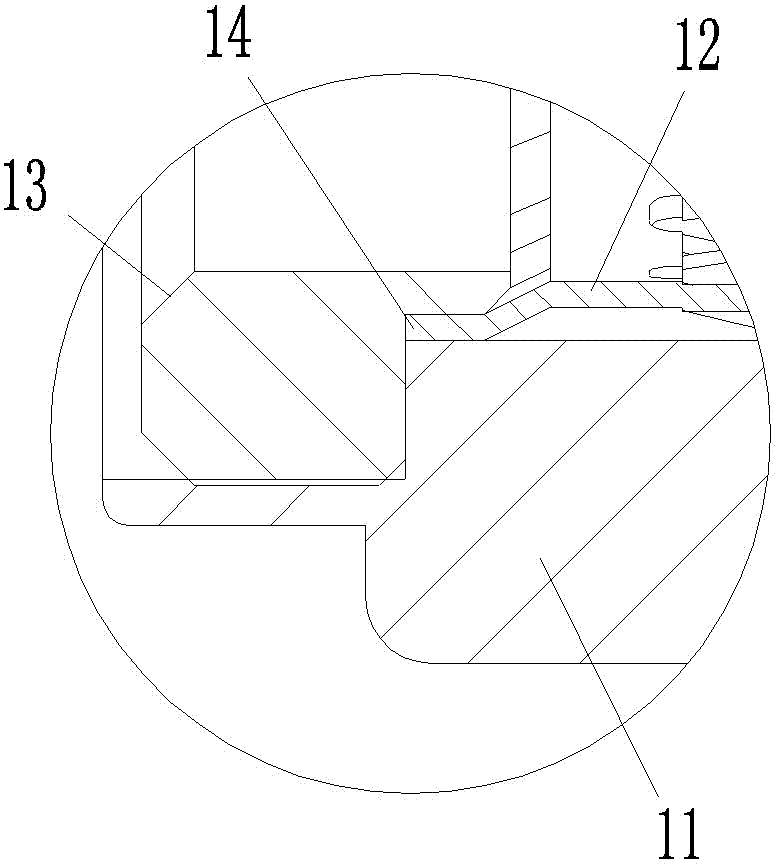

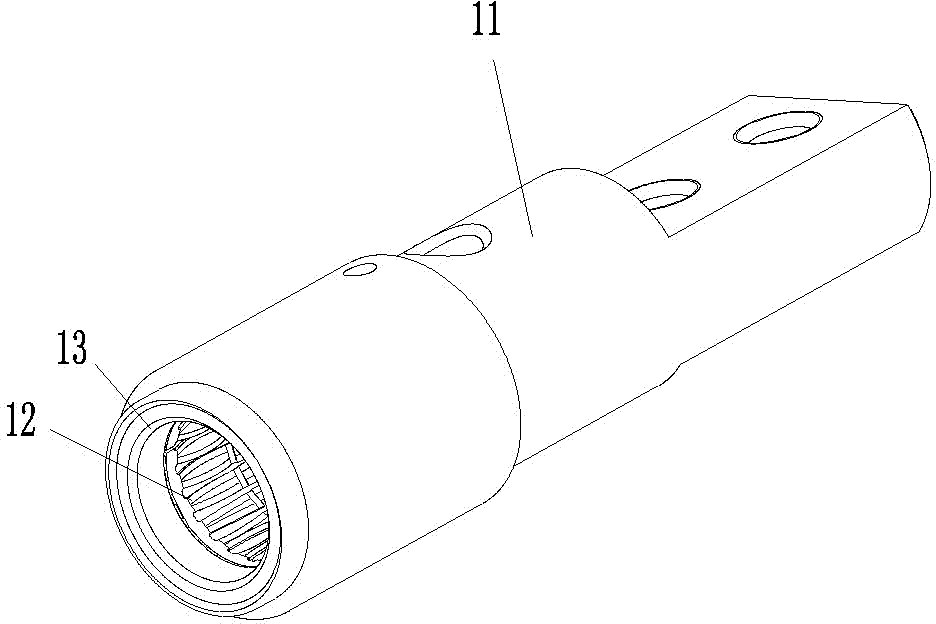

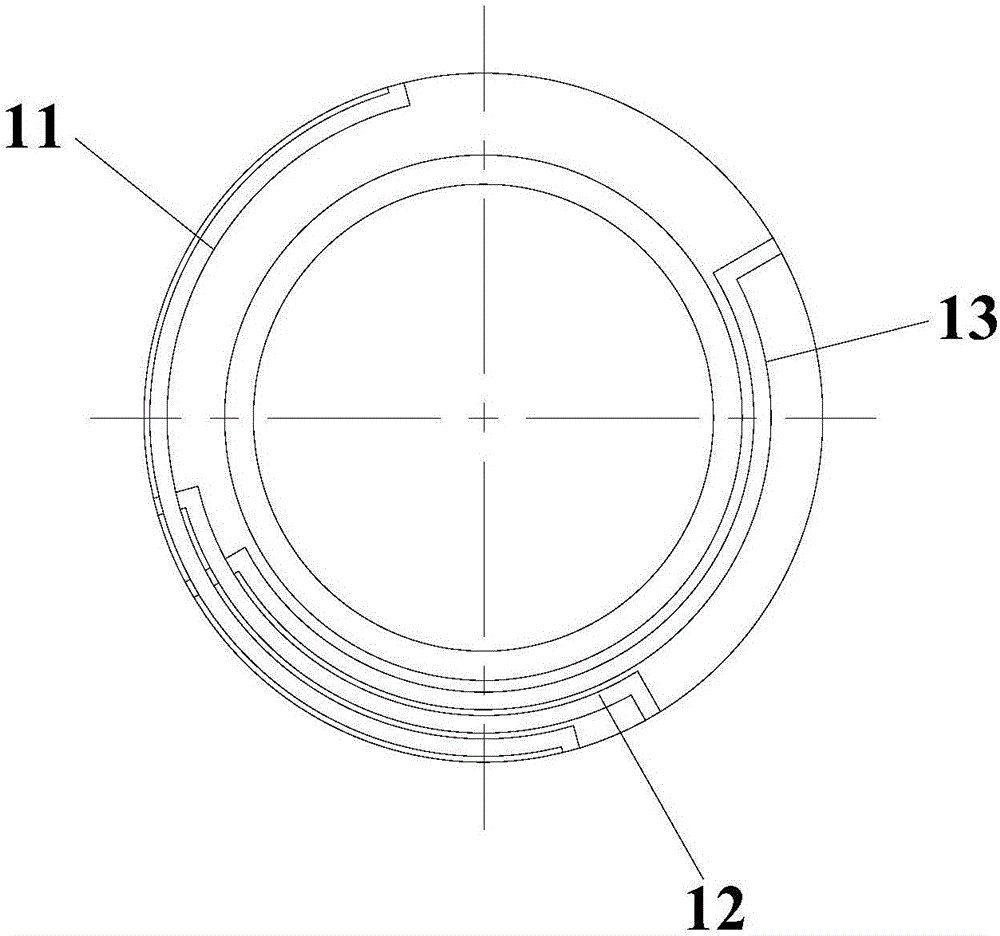

High-current jack contact

InactiveCN104505620ALower resistanceAddress reliabilityCouplings bases/casesInterference fitElectricity

The invention relates to the field of an electric connector, in particular to a high-current jack contact. The high-current jack contact comprises a jack rear sleeve and a core sleeve assembled in the jack rear sleeve, wherein the core sleeve is a crown belt or a torsional spring; a cylindrical structure which is connected end to end is formed by the core sleeve in the jack rear sleeve along the circumferential direction of the jack rear sleeve; the core sleeve is in interference fit with the jack rear sleeve. Due to the fact that when the high-current jack contact is matched with an adaptive contact pin, the high-current jack contact does not leave a space for the deflection of the contact pin, so the reliability of matching with the contact pin can be greatly improved; furthermore, due to the fact that the core sleeve is in interference fit with the jack rear sleeve, the pressure between the core sleeve and the jack rear sleeve can be greatly increased, and the whole resistance of the contact is reduced. In conclusion, according to the high-current jack contact provided by the invention, the problem that the existing contact used for transmitting high current is not reliably in contact with the adaptive contact pin and is high in resistance is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

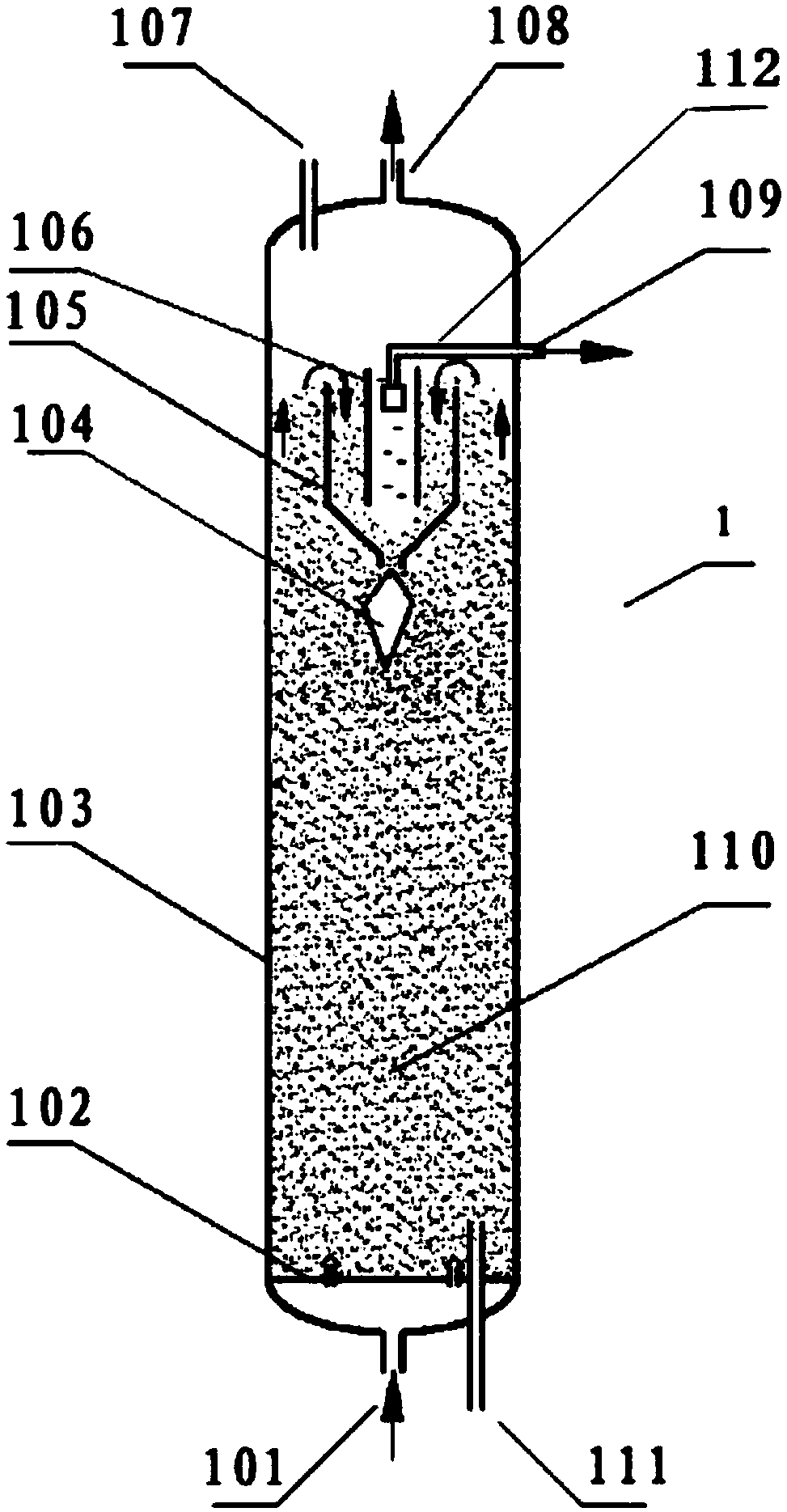

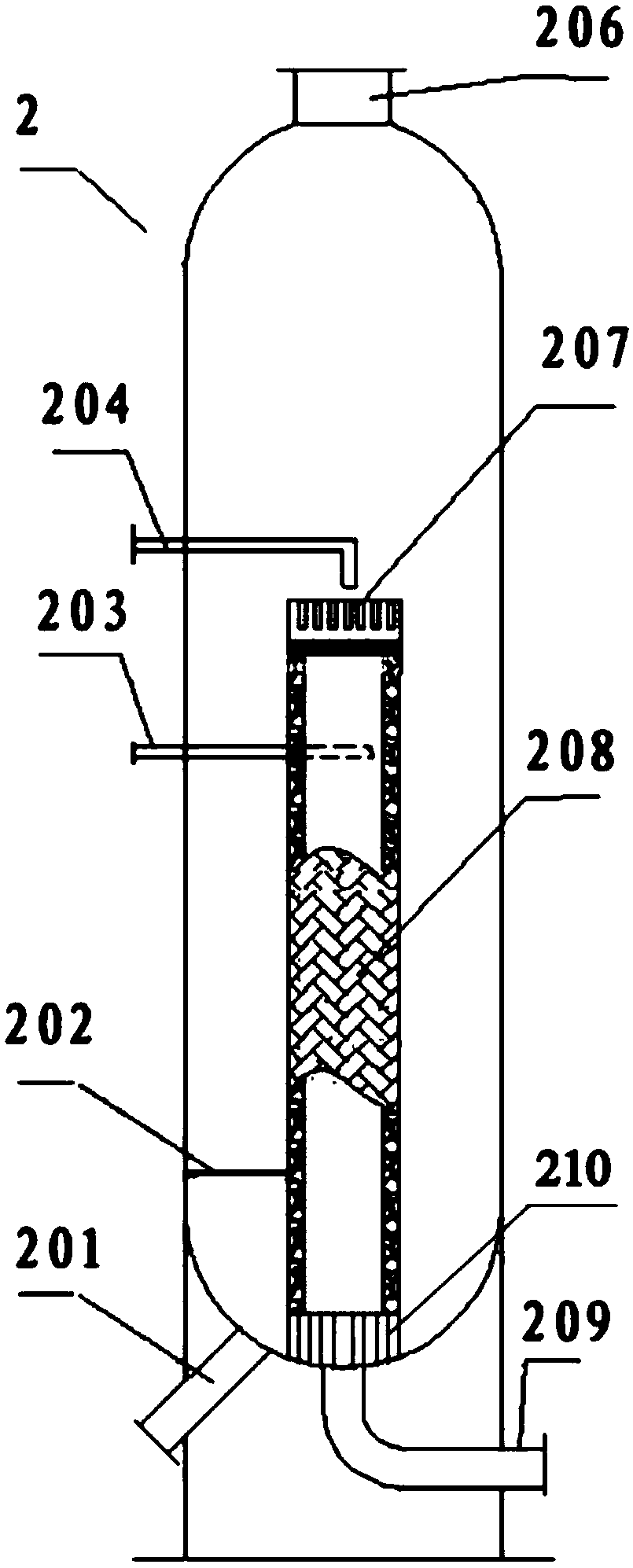

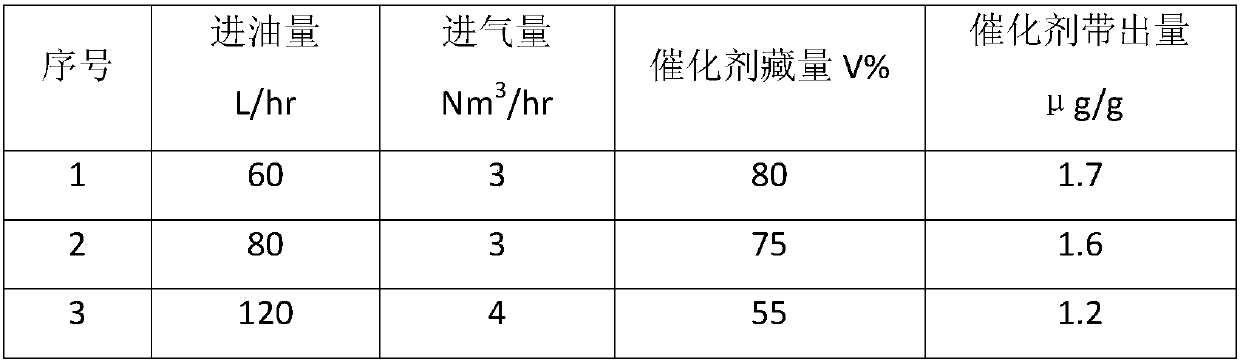

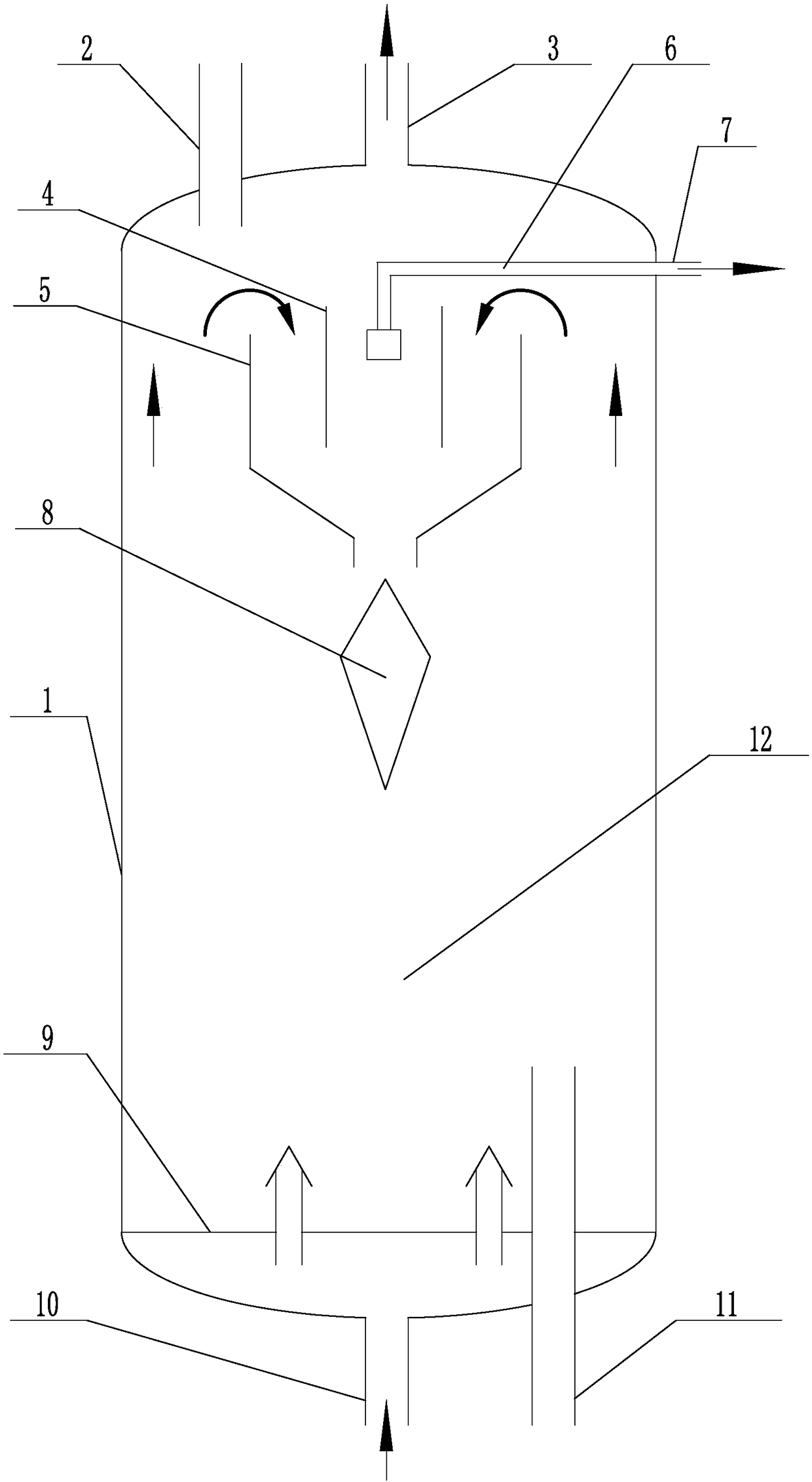

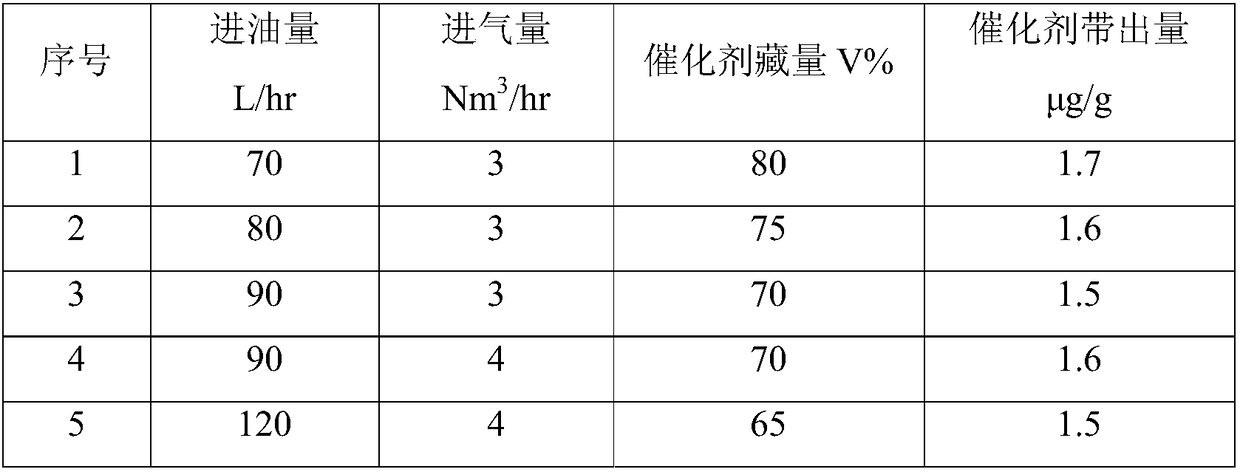

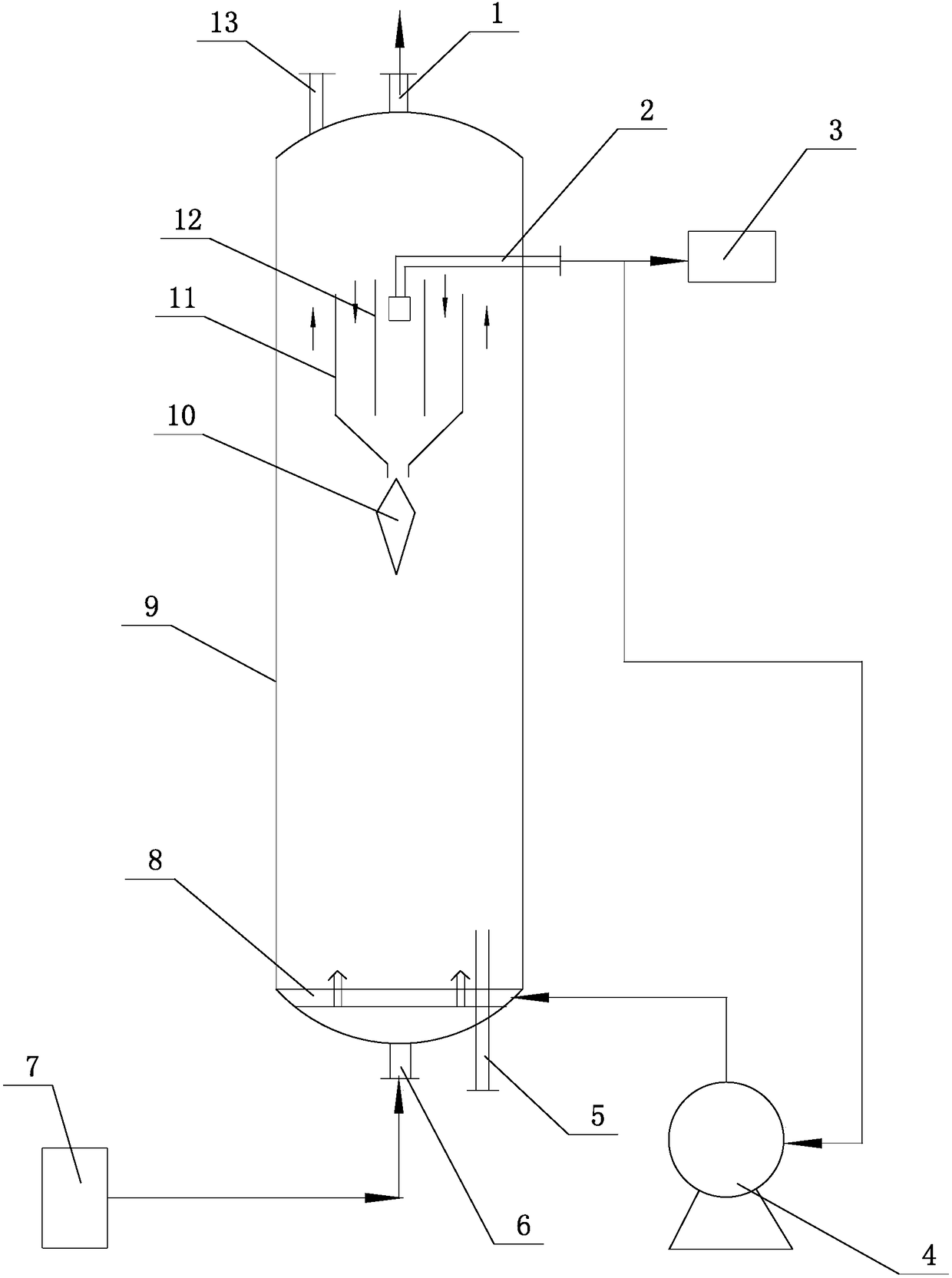

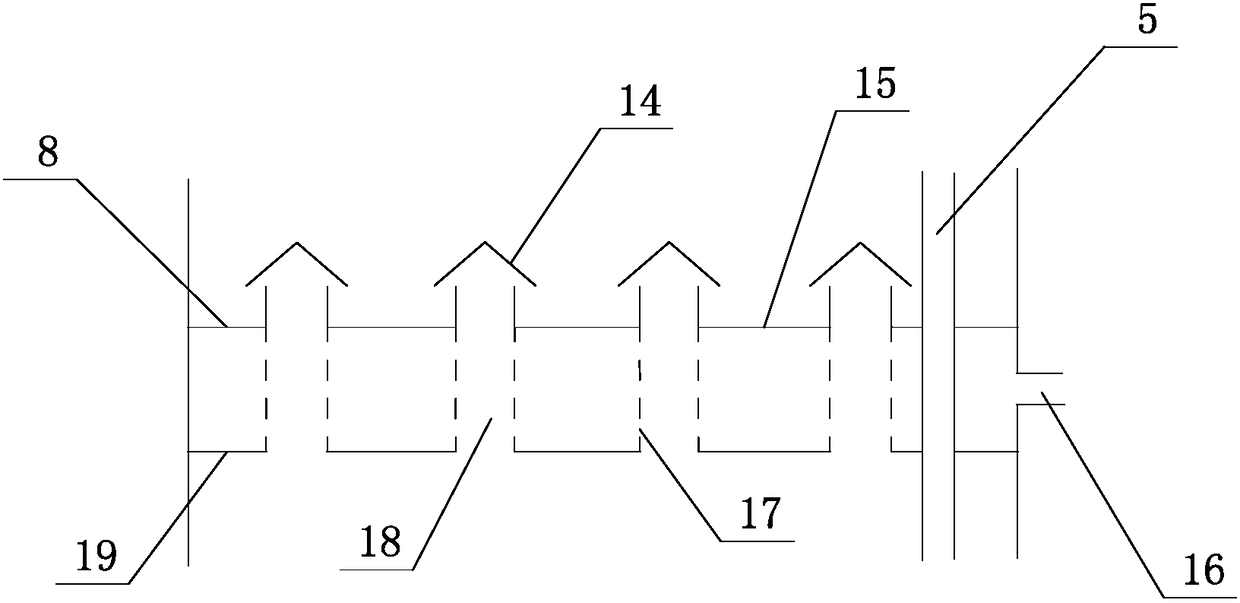

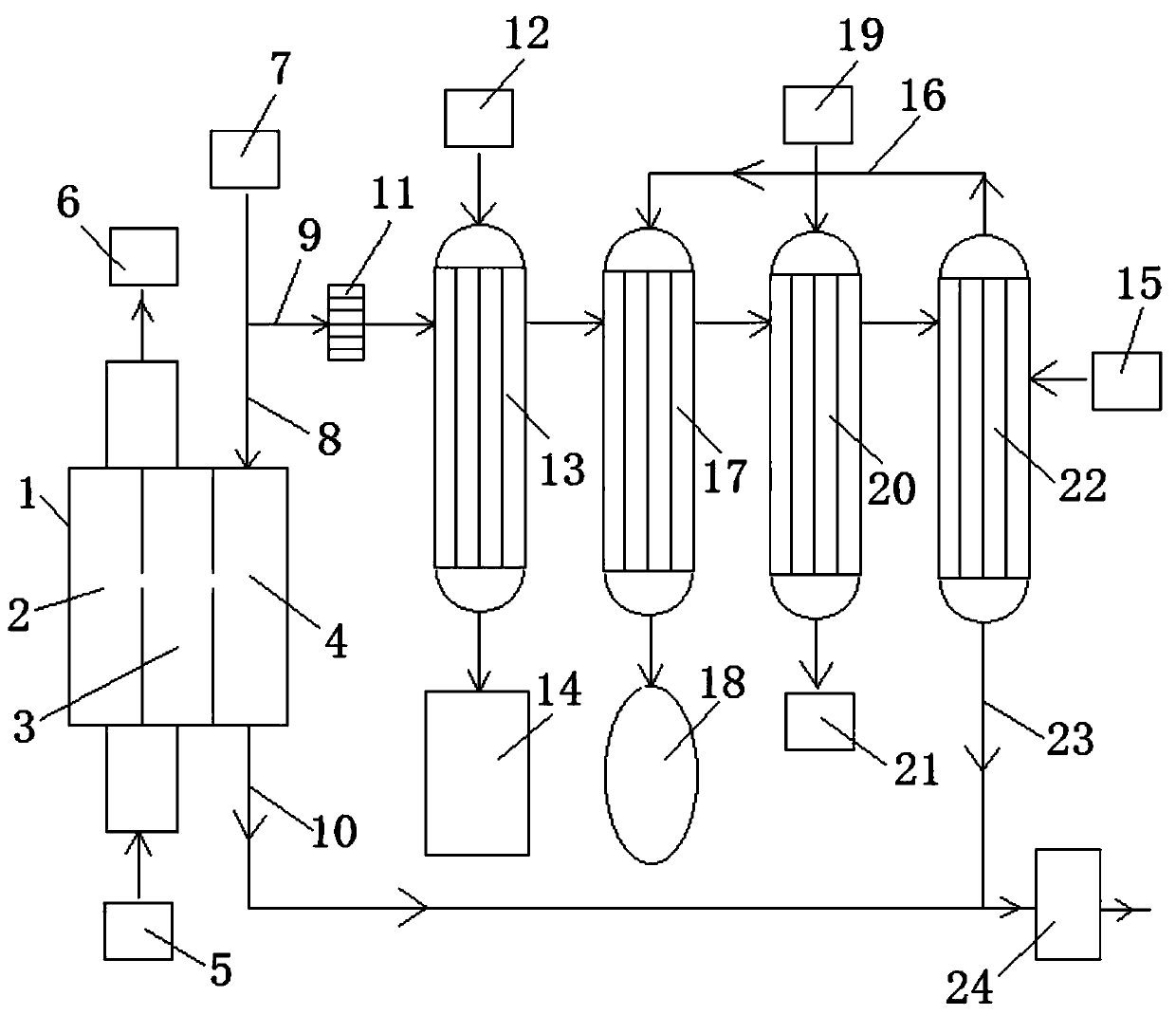

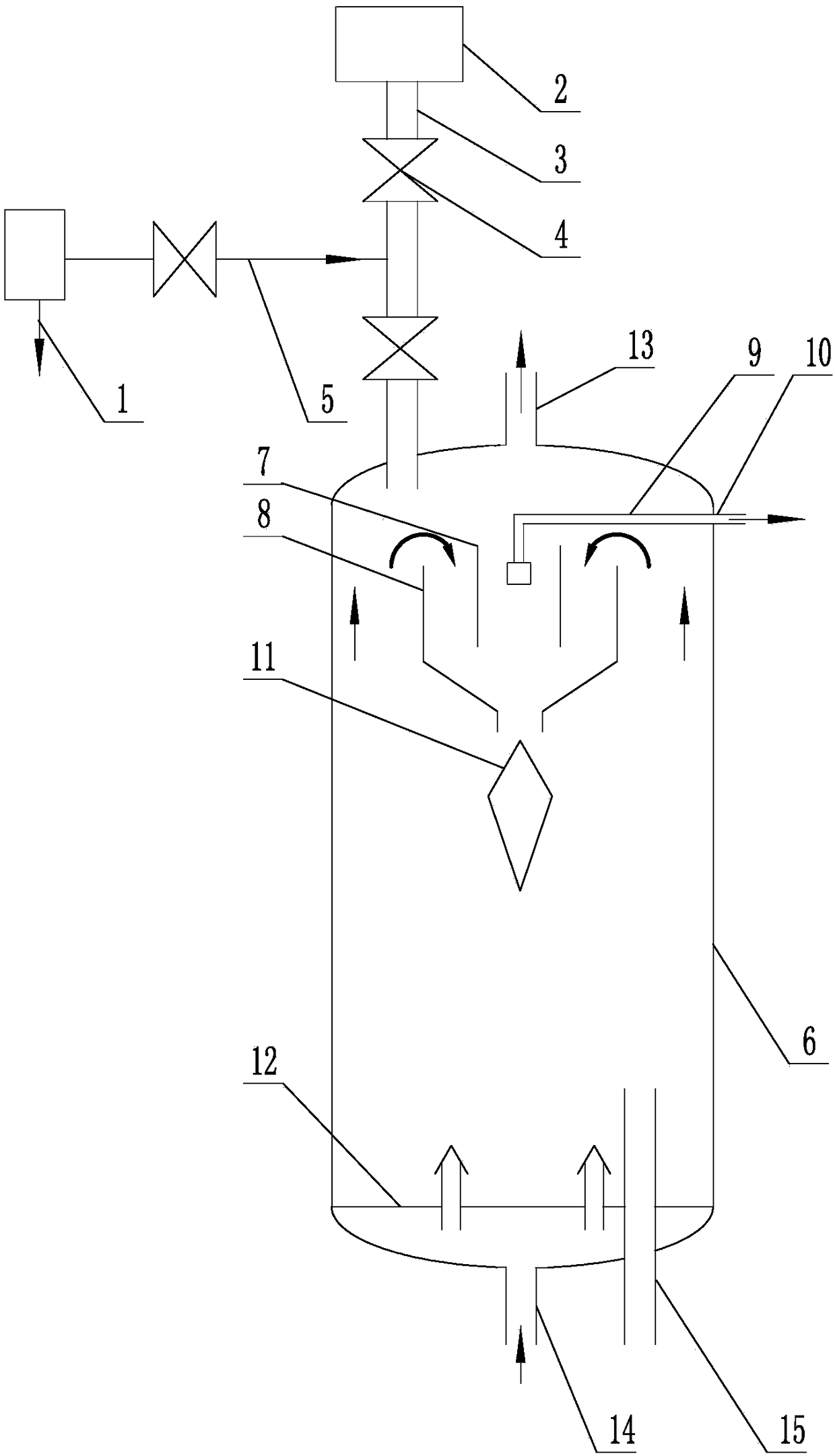

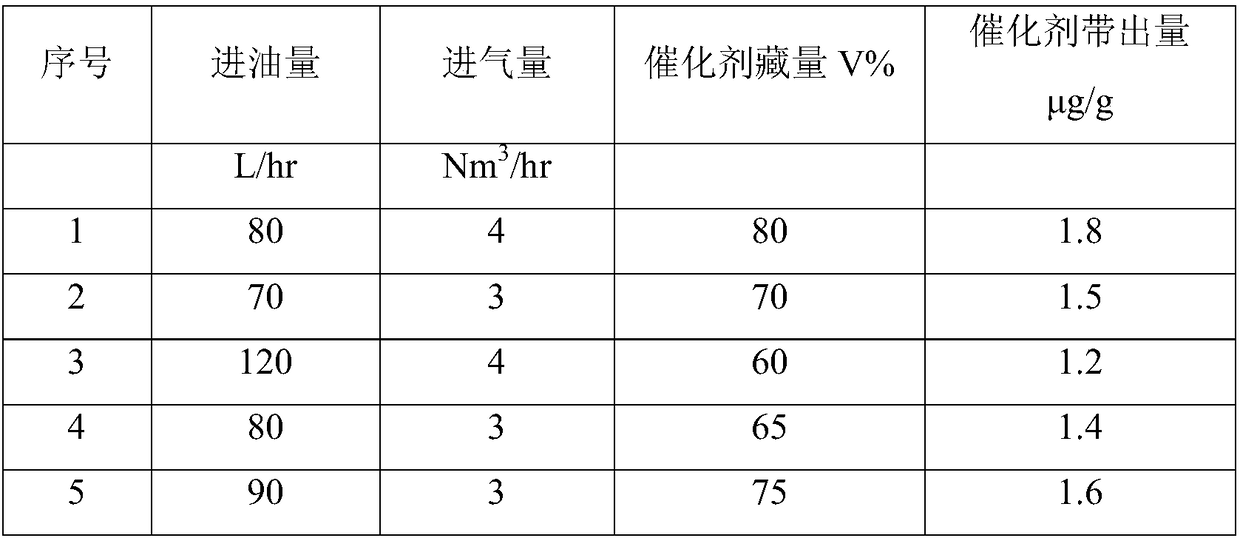

A kind of fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186BEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

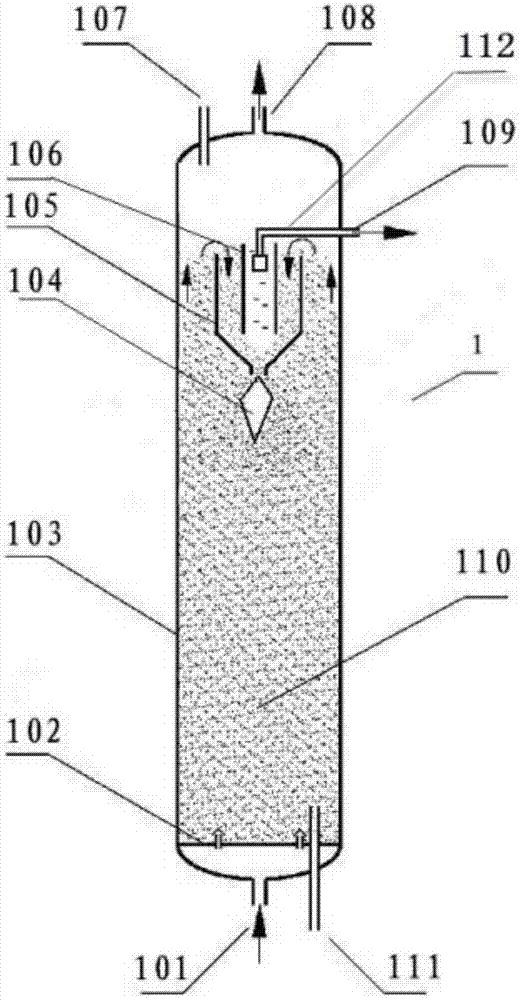

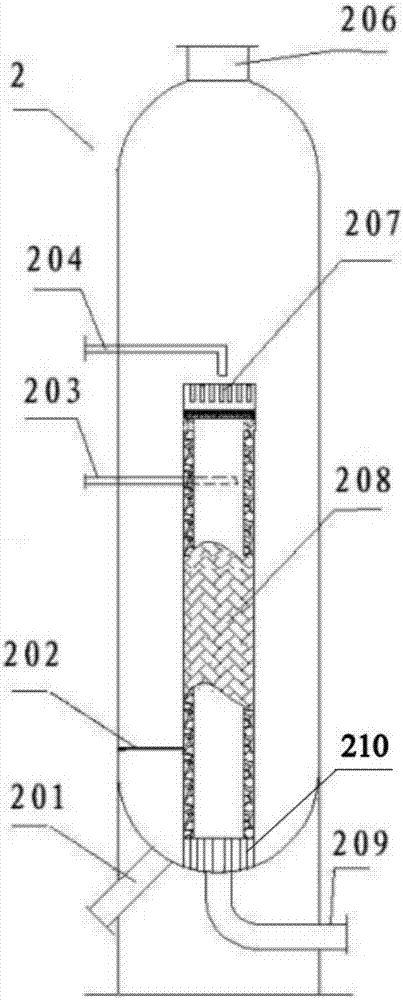

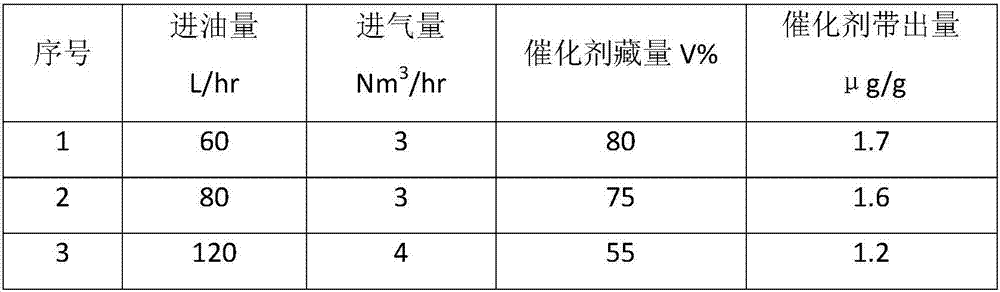

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

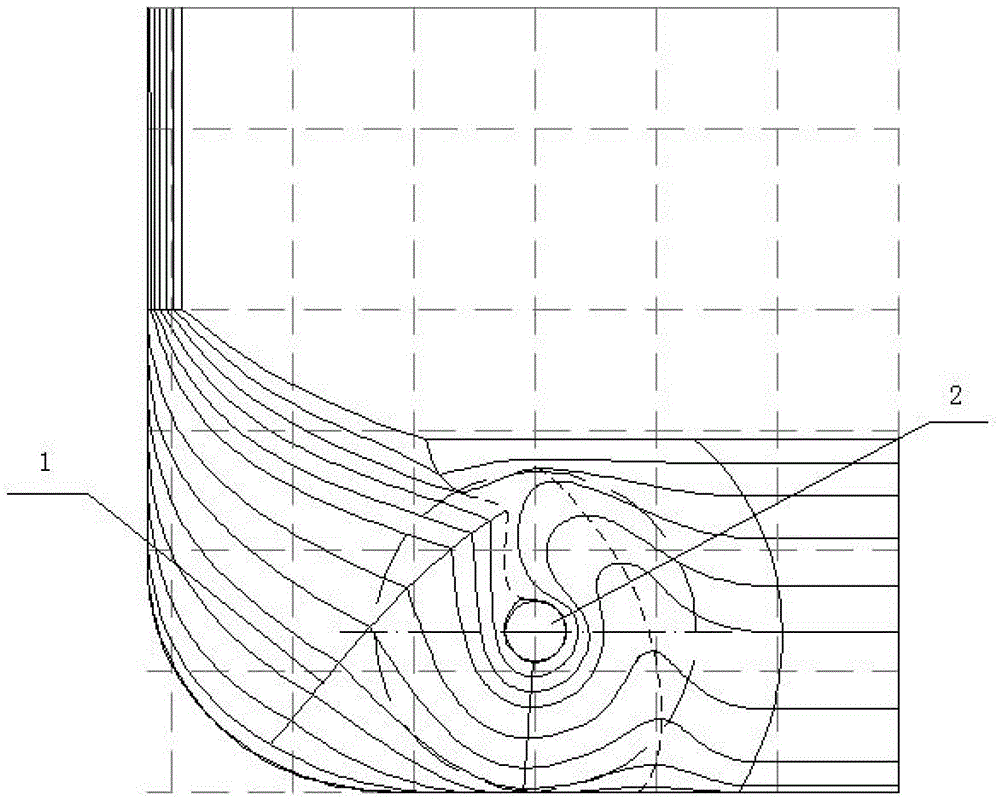

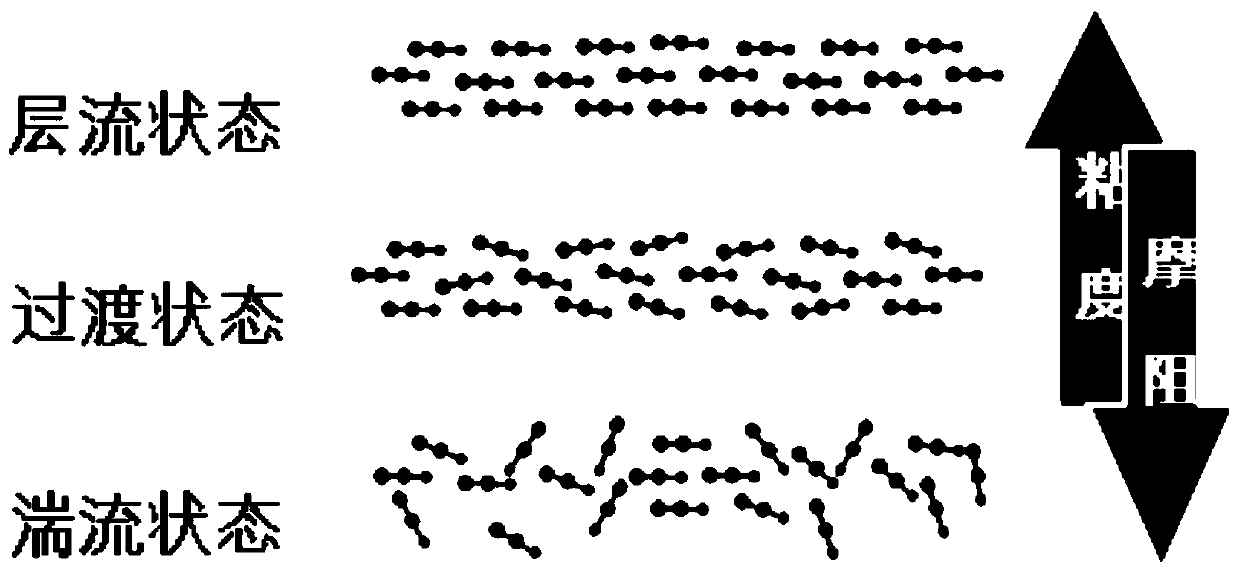

Ship with knuckle line and internal rotational fin tail

InactiveCN102745304AReduce resistanceSolve the resistanceWatercraft hull designStern postsPropellerInternal rotation

The invention discloses a ship with a knuckle line and an internal rotational fin tail, and belongs to the technical field of ships. The ship comprises a propeller, and the knuckle line is arranged on the basis of a ship with an internal rotation fin tail and positioned on the outer side of a shaft of the propeller along the length direction of the ship. The ship has the advantages that longitudinal flow and lateral flow can be guided, and a flow regulating effect can be achieved.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

Needle bed jacquard mechanism on knitting circular weft machine

The invention discloses a needle bed jacquard mechanism on a knitting circular weft machine, and relates to the field of knitting circular weft machine mechanical structures, in particular to the needle bed jacquard mechanism on the knitting circular weft machine. The needle bed jacquard mechanism comprises a dial, a knitting needle, a jacquard piece, a cam unit, a needle selection device and a reset cam. The tail end of the knitting needle is not connected with the head end of the jacquard piece. A lower presser foot, jacquard teeth and a needle jack foot are sequentially arranged on the jacquard piece at intervals. The cam unit comprises a knitting cam arranged corresponding to the knitting needle, a needle pressing cam arranged corresponding to the lower presser foot of the jacquard piece and an elevating cam arranged corresponding to the needle jack foot of the jacquard piece. The needle pressing cam and the elevating cam are respectively provided with a waveform side face, so that the waveform side face of the needle pressing cam and the waveform side face of the elevating cam can make contact with the lower presser foot and the needle jack foot in a motion mode to form the motion guidance trajectory of the jacquard piece. By means of the jacquard mechanism, the resistance generated in the jacquard action of the knitting needle and the jacquard piece is reduced, and service life of machine parts is prolonged.

Owner:HUIAN KING TANSO PRECISION MACHINERY

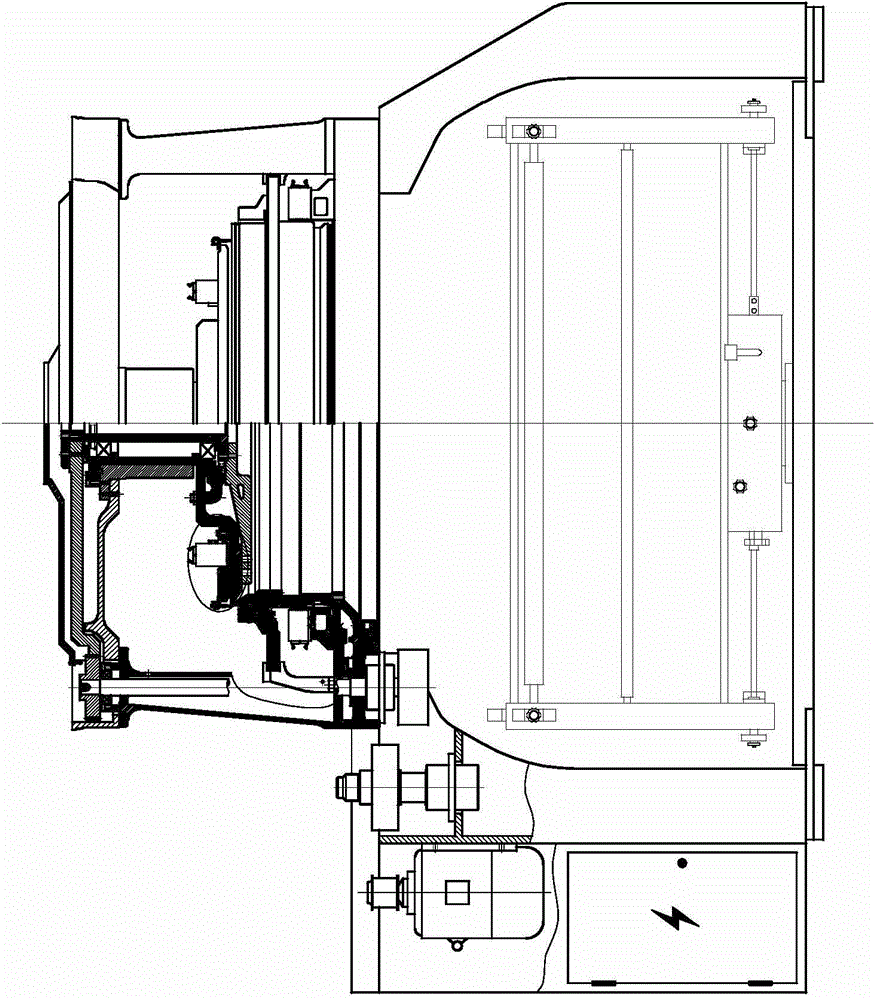

Fluidized bed hydrogenated reactor and fluidized bed hydrogenating method

InactiveCN108148621AEasy to separateSolve the resistanceTreatment with moving solid particlesEarth's rotationHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to a fluidized bed hydrogenated reactor and a fluidized bed hydrogenating method. The fluidized bed hydrogenatedreactor comprises a shell, wherein a catalyst adding opening and a gas outlet are formed in the top of the shell; a three-phase separator is arranged on the upper portion of the inside of the shell and comprises two concentric barrels with different inner diameters, namely an inner barrel and an outer barrel; a flow guiding body is arranged below an opening of the lower end of the outer barrel; the shape of the flow guiding body is in the shape of a spindle with the small upper and lower ends and the large middle; a distributing plate is arranged on the lower portion of the inside of the shell; and a material inlet and a catalyst discharging opening are formed in the bottom of the shell. While the capacity utilization ratio of the reactor is improved, a catalyst lean-phase zone is reducedor cancelled, the hydrogenation reaction effect is improved, and the problem that the reaction effect is affected due to uneven distribution of catalysts caused by earth rotation is solved.

Owner:上海竣铭化工工程设计有限公司

Fluidized bed hydrogenation reaction system and fluidized bed hydrogenation method

ActiveCN107297186AEasy to separateSolve the resistanceChemical/physical processesHydrogenation reactionFluidized bed

The invention relates to a fluidized bed hydrogenation reaction system, which comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor barrel; a three-phase separator is arranged at the upper part of the reactor barrel and comprises an inner barrel and an outer barrel; openings are formed in the upper ends and the lower ends of the inner barrel and the outer barrel; the opening in the upper end of the outer barrel is lower than that of the inner barrel and the opening in the lower end of the outer barrel is lower than that of the inner barrel; the inner barrel is a straight barrel segment; the straight barrel segment is arranged at the upper part of the outer barrel and a frustum-shaped contraction segment is arranged at the lower part; the opening in the lower end of the contraction segment is the opening in the lower end of the outer barrel; and a gap is arranged between the opening in the lower end of the inner barrel and the outer barrel contraction segment, so that a material passes through the gap. The fluidized bed hydrogenation reaction system is adopted by the fluidized bed hydrogenation method, so that the utilization rate (namely the catalyst inventory in the reactor) of the reactor is further improved, and the hydrogenation reaction effect can be further improved.

Owner:上海竣铭化工工程设计有限公司

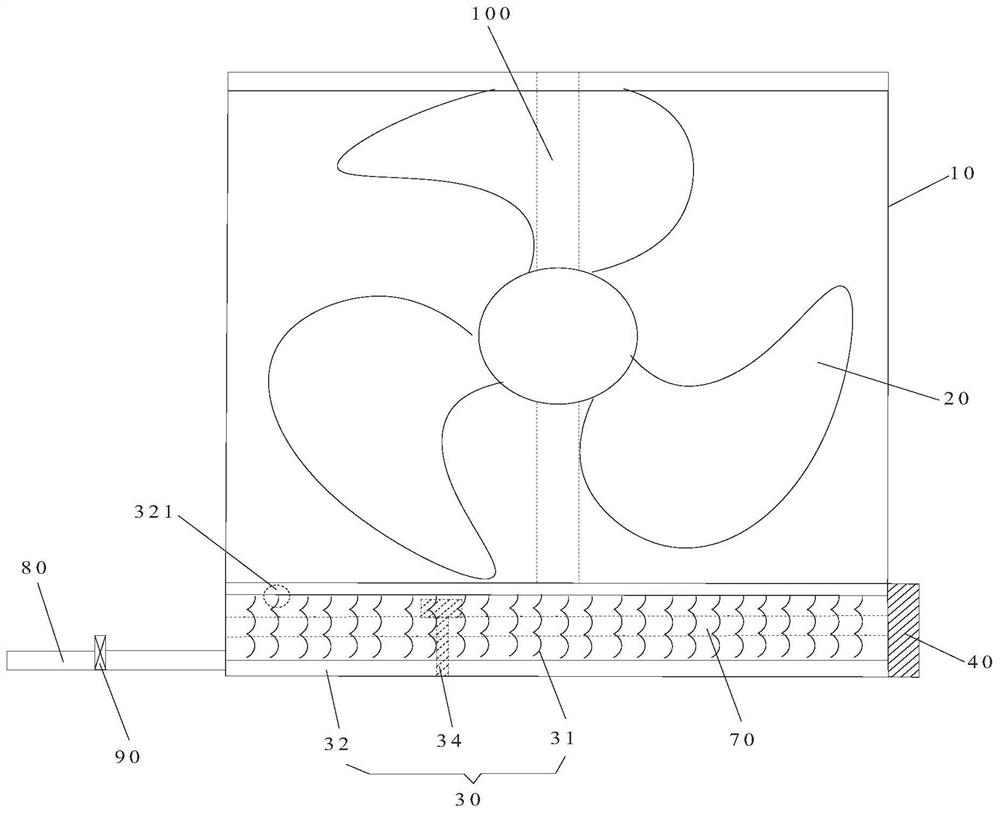

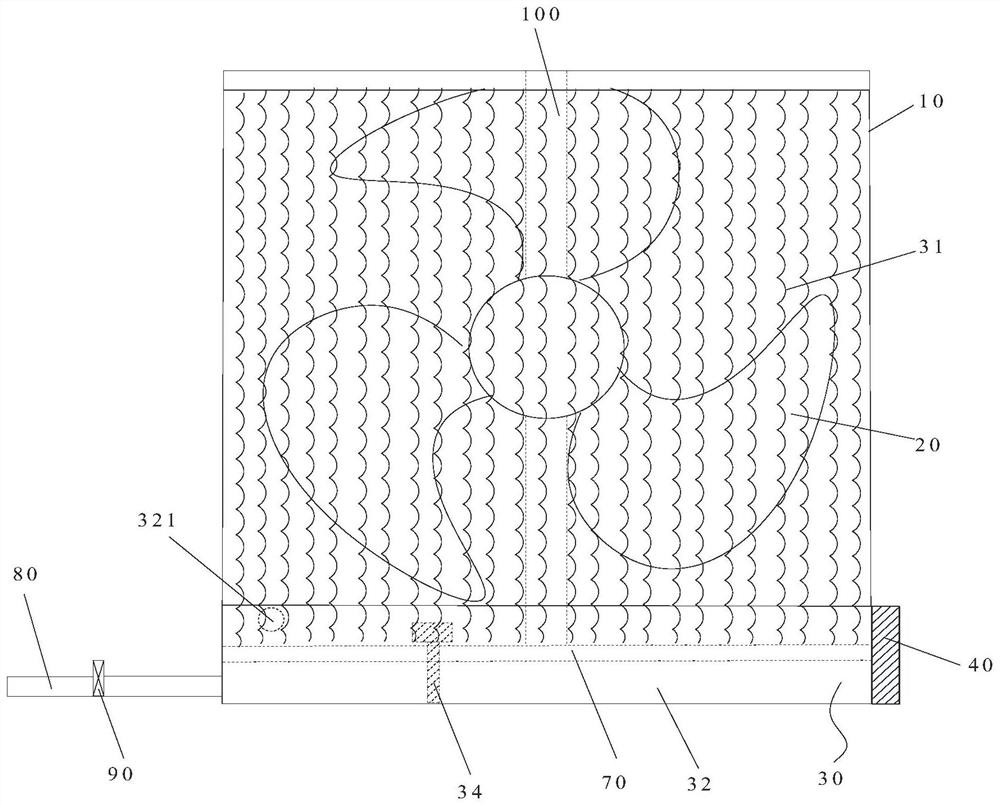

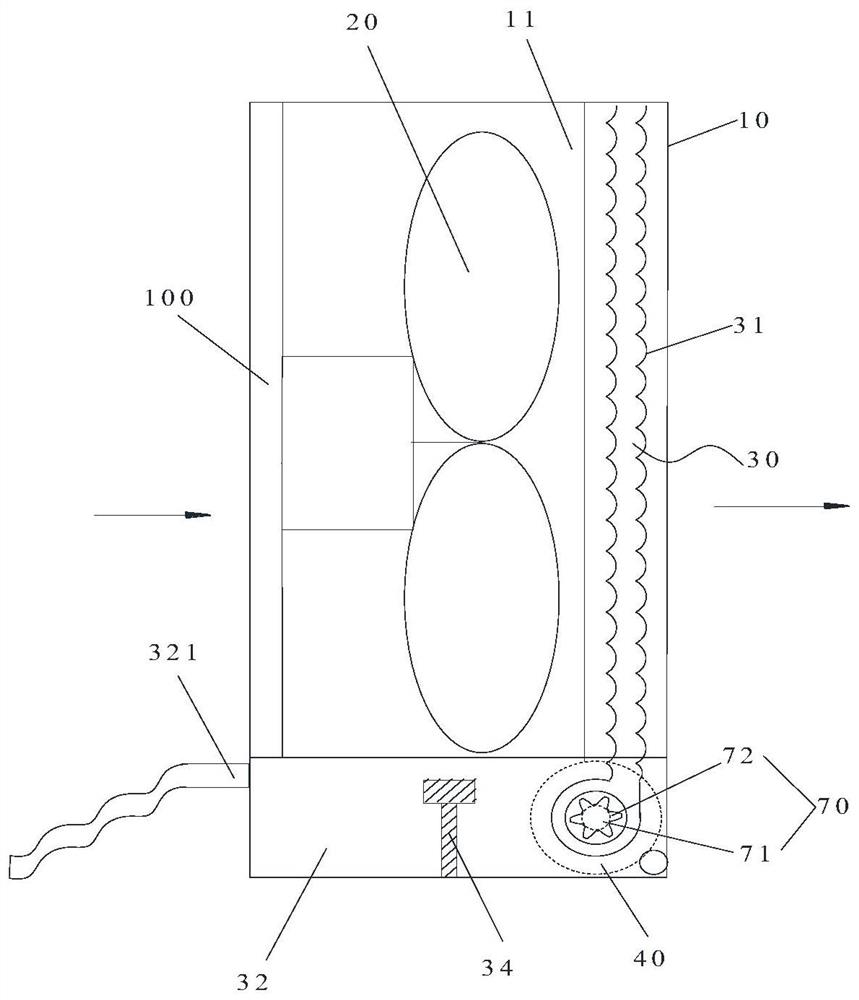

Ventilation and humidification system, air conditioner system, and air conditioner system control method

PendingCN111811038AImprove fresh air efficiencySolve the resistanceMechanical apparatusCondensate preventionThermodynamicsFresh air

The invention provides a ventilation and humidification system, an air conditioner system, and an air conditioner system control method. The ventilation and humidification system comprises a ventilation and humidification device and a shielding structure. The ventilation and humidification device comprises a shell, a fan and a humidification assembly. The shell is provided with a first air outletand a second air outlet. The fan is arranged in the shell. An air inlet of the fan communicates with the outdoors. The humidification assembly is arranged at the second air outlet and is opposite to an exhaust port of the fan so as to humidify outdoor fresh air discharged from the exhaust port. The shielding structure has a first shielding state for shielding the first air outlet and a second shielding state for shielding the second air outlet. When the shielding structure is in the first shielding state, the outdoor fresh air goes into the fan and is humidified through the humidification assembly and blown to the indoors. When the shielding structure is in the second shielding state, the outdoor fresh air goes into the fan and is blown to the indoors through the first air outlet. Throughthe ventilation and humidification system, the problem that the resistance of a wet film to the outdoor fresh air is large in the prior art is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

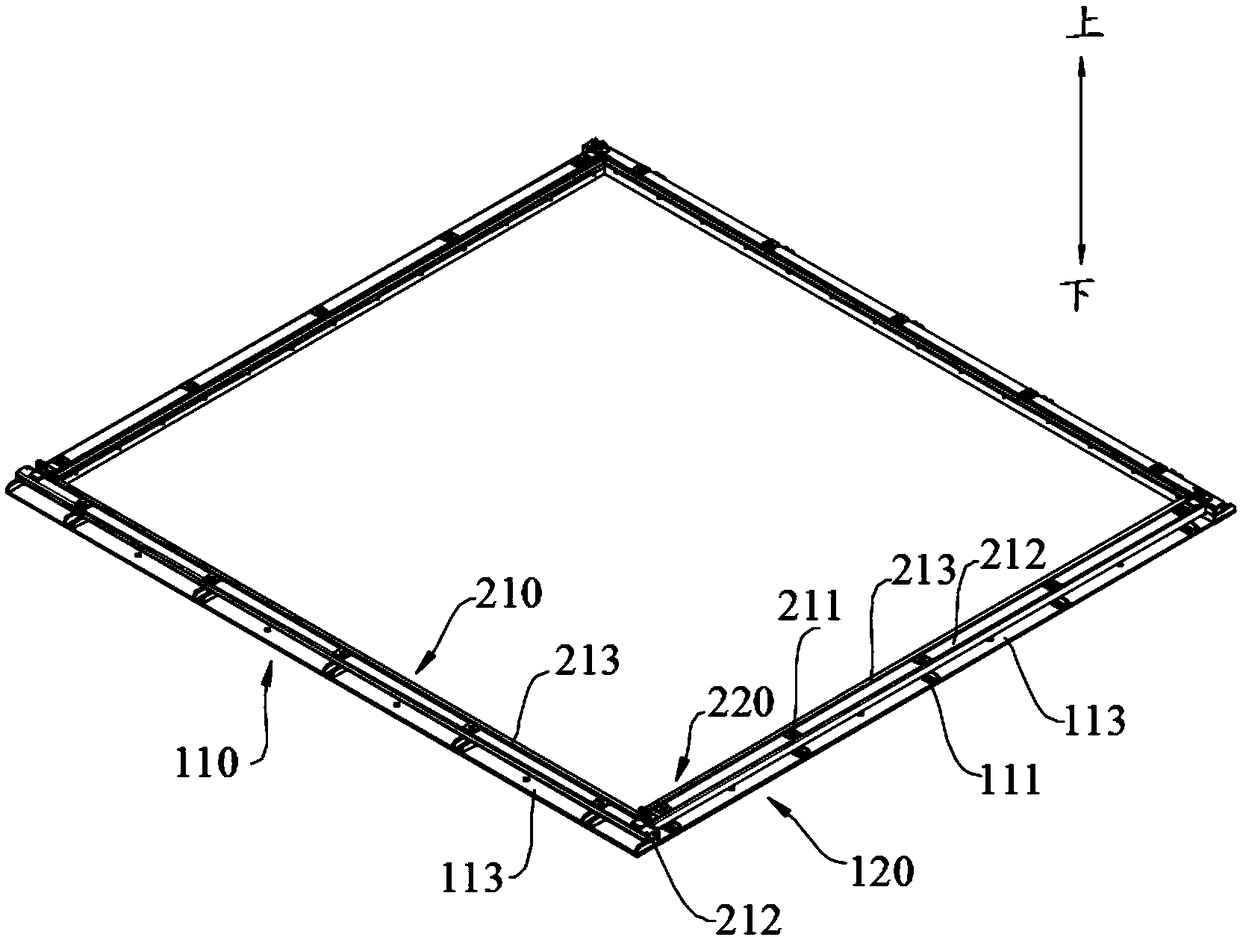

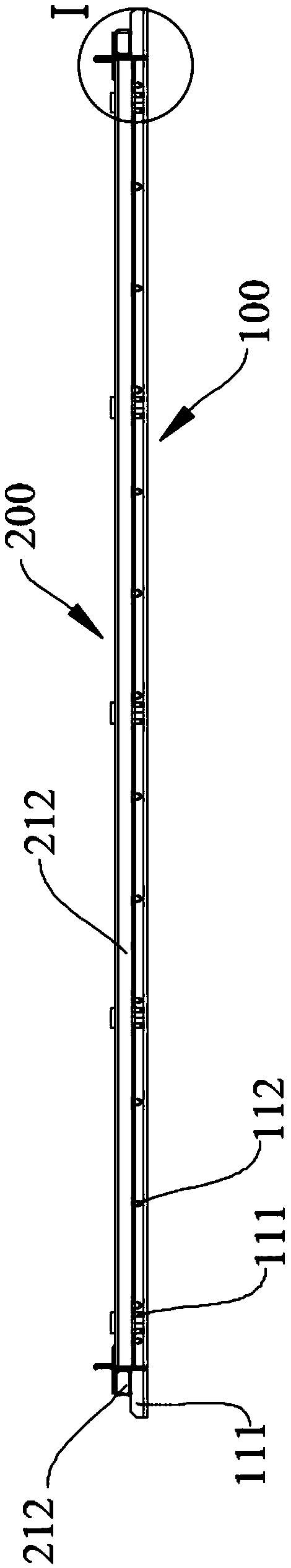

Production mold of prefabricated stacking floor slab

The invention provides a production mold of a prefabricated stacking floor slab. The production mold includes a lower-layer mold body and an upper-layer mold body. The lower-layer mold body can be fixed to a mold platform, the procedures of dismantling the lower-layer mold body before pouring every time and installing the lower-layer mold body after pouring every time are omitted, only the upper-layer mold body needs to be dismantled and installed, and the problem that large resistance is generated during dismantling of the mold after pouring is solved. The upper-layer mold body can shield a rib output groove or is provided with a groove matched with the rib output groove, and the slurry leakage amount of the rib output groove is reduced; a square pipe and a second side plate connected with the square pipe are arranged on the upper-layer mold body, and the square pipe can not only prevent the second side plate from causing a mold expansion problem during pouring but also provide convenience for positioning the upper-layer mold body since the square pipe is placed on a bearing part. The whole side face of the square pipe is connected with the second side plate, and compared with a welding baseplate and a reinforced rib, the production mold has the advantage of high machining efficiency.

Owner:长沙英平机械制造有限责任公司

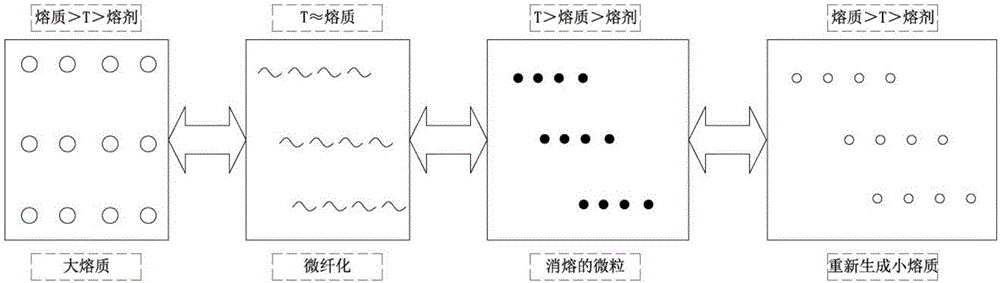

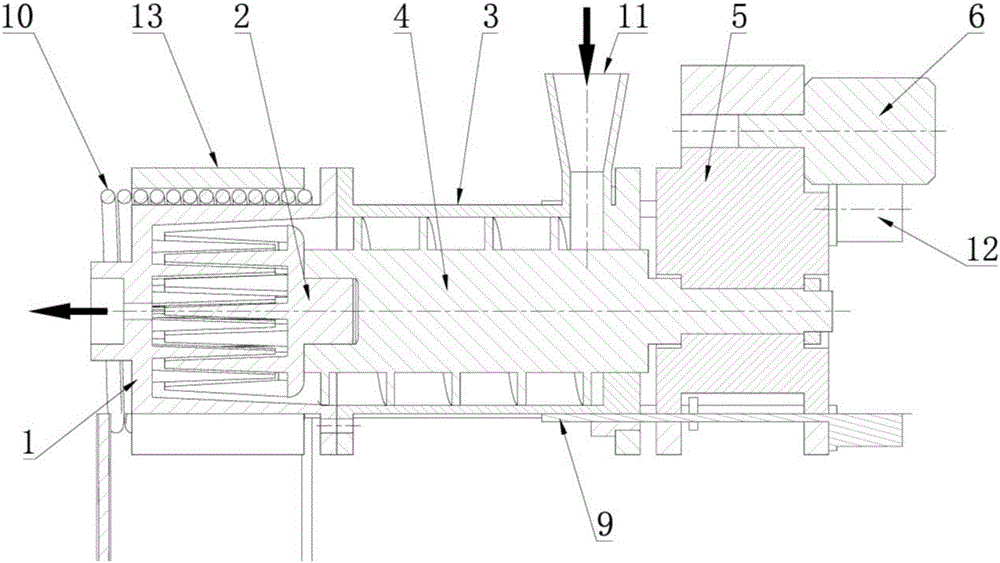

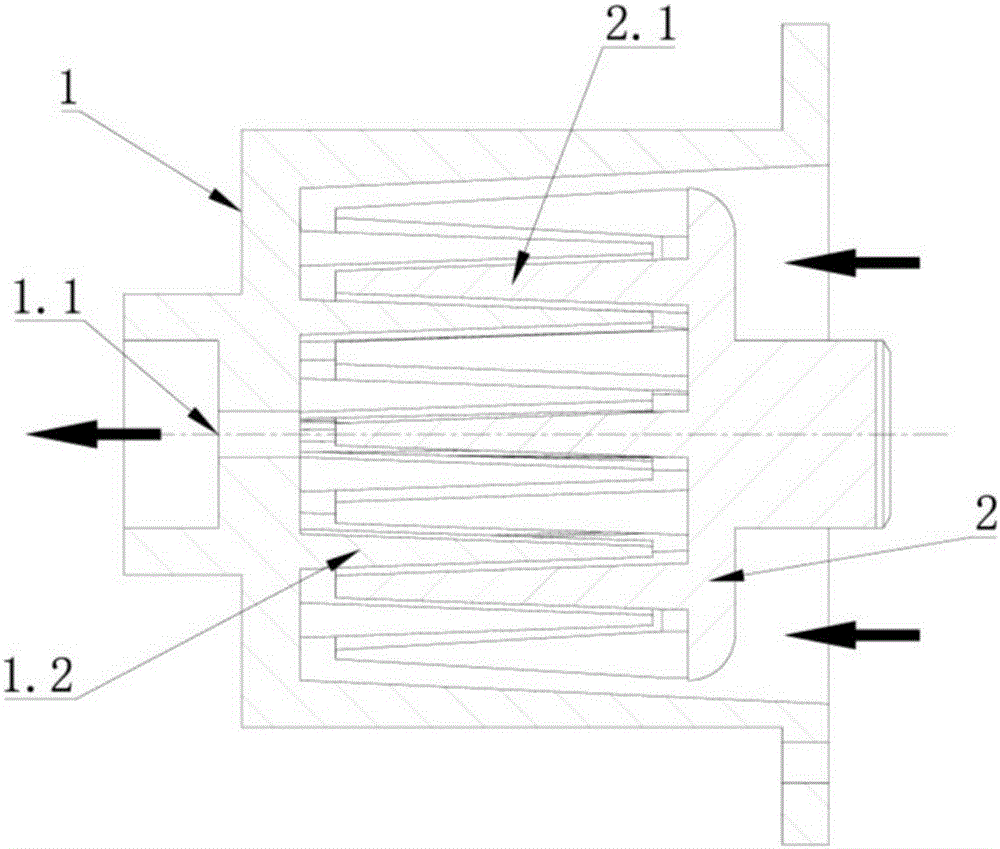

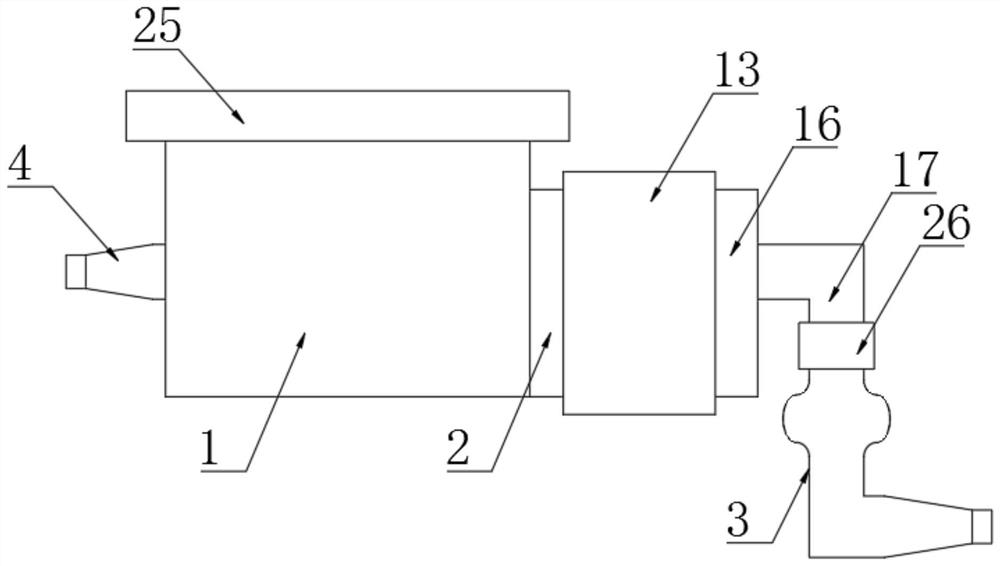

Temperature-dependent phase alternation surface shear plasticization method

InactiveCN106808667AImprove plasticizing effectIncrease the degree of mixingMolten stateTemperature control

The invention discloses a temperature-dependent phase alternation surface shear plasticization method. According to the method, a surface shear grinding device is formed by connecting an inner sleeve with annular comb teeth and an outer sleeve with annular comb teeth in a butt-joint manner, and in combination with the fast heating and fast refrigeration of materials, materials with different melting points or softening points in at least two components are treated through a mixing plasticization method; the materials with the low melting point or the low softening point in the components are always in the molten state in the plasticization process, the materials with the high melting point or the high softening point are subjected to fast temperature control, the phase state of the materials with the high melting point or the high softening point is alternately changed among the solid state, the semi-solid state and the molten state, in cooperation with the mechanical grinding function of the full plane shear, solid particles and melt fragments of the materials are refined, homogenized, micro-fibered and plasticized under the function of repeatedly and alternately conducting fracture, fragmentation, friction and the like, the plasticization effect can be improved greatly, and the mixed materials are dispersed to the great extent.

Owner:HUBEI UNIV OF TECH

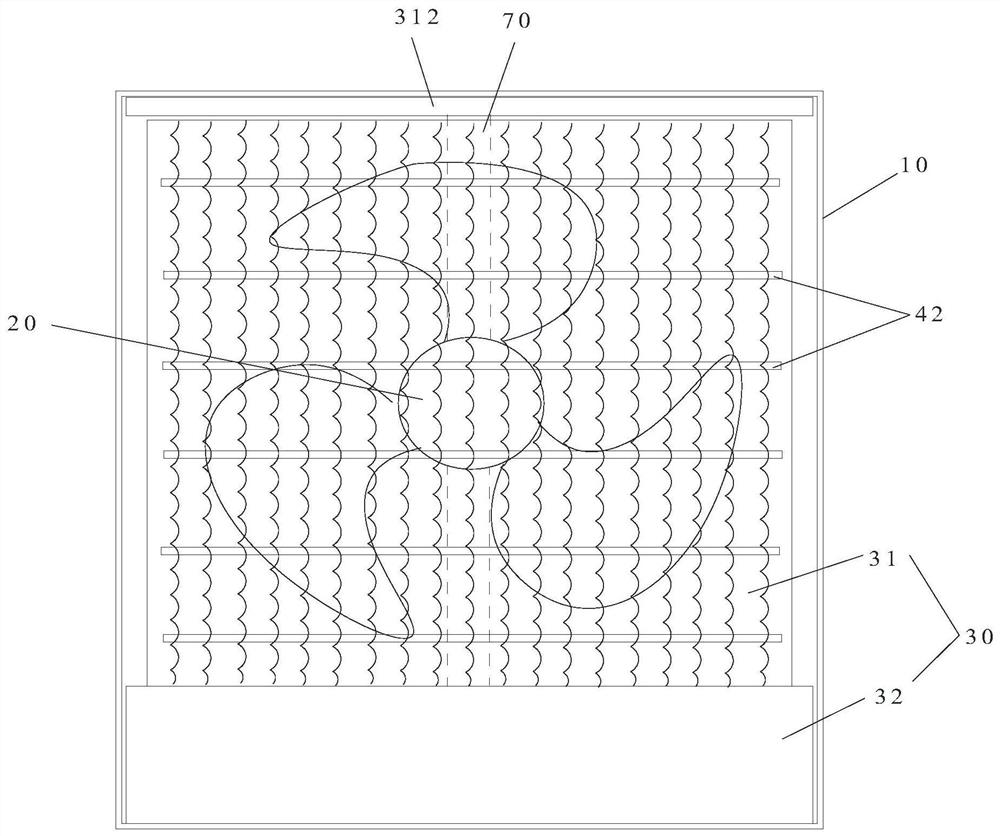

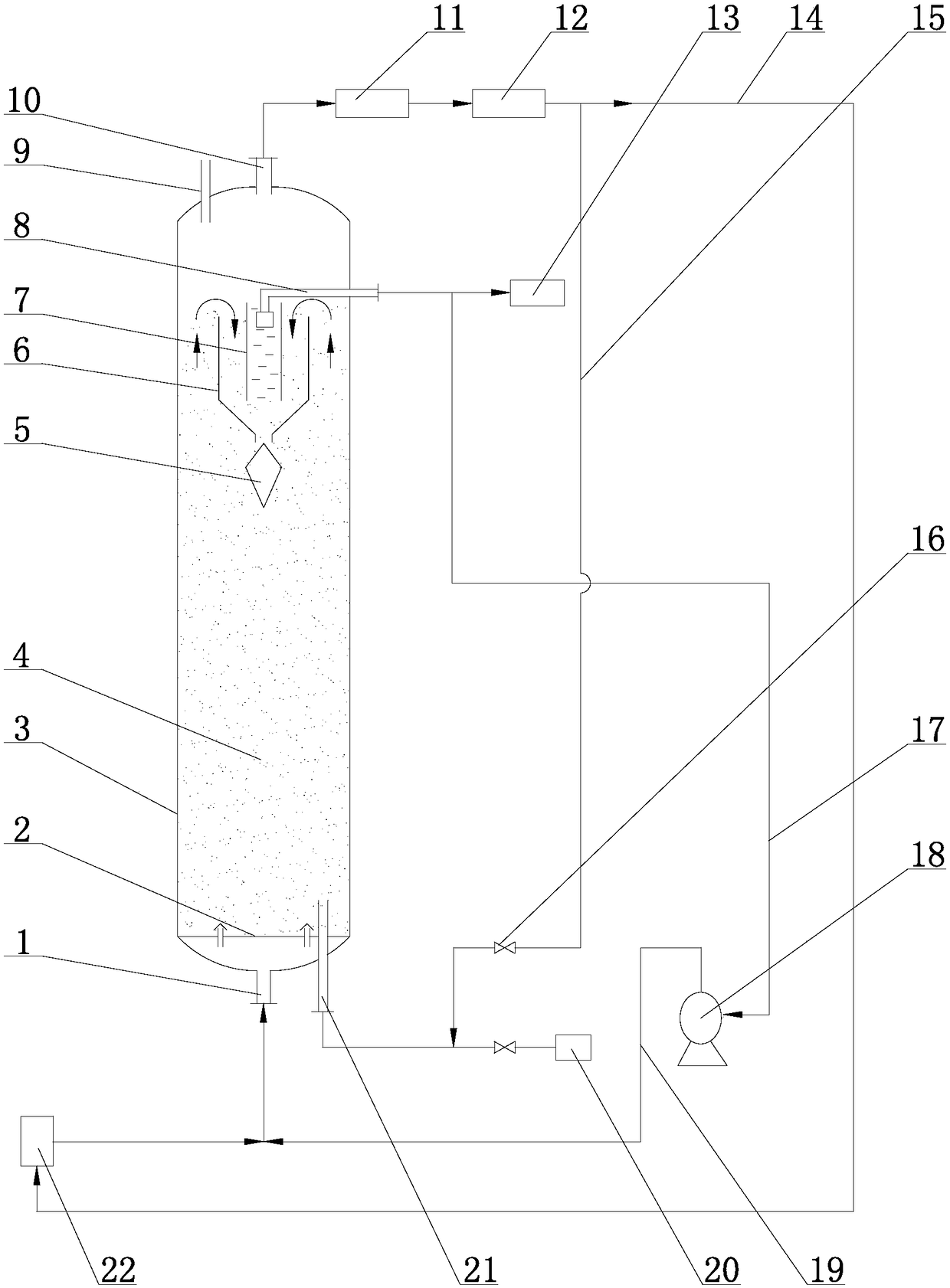

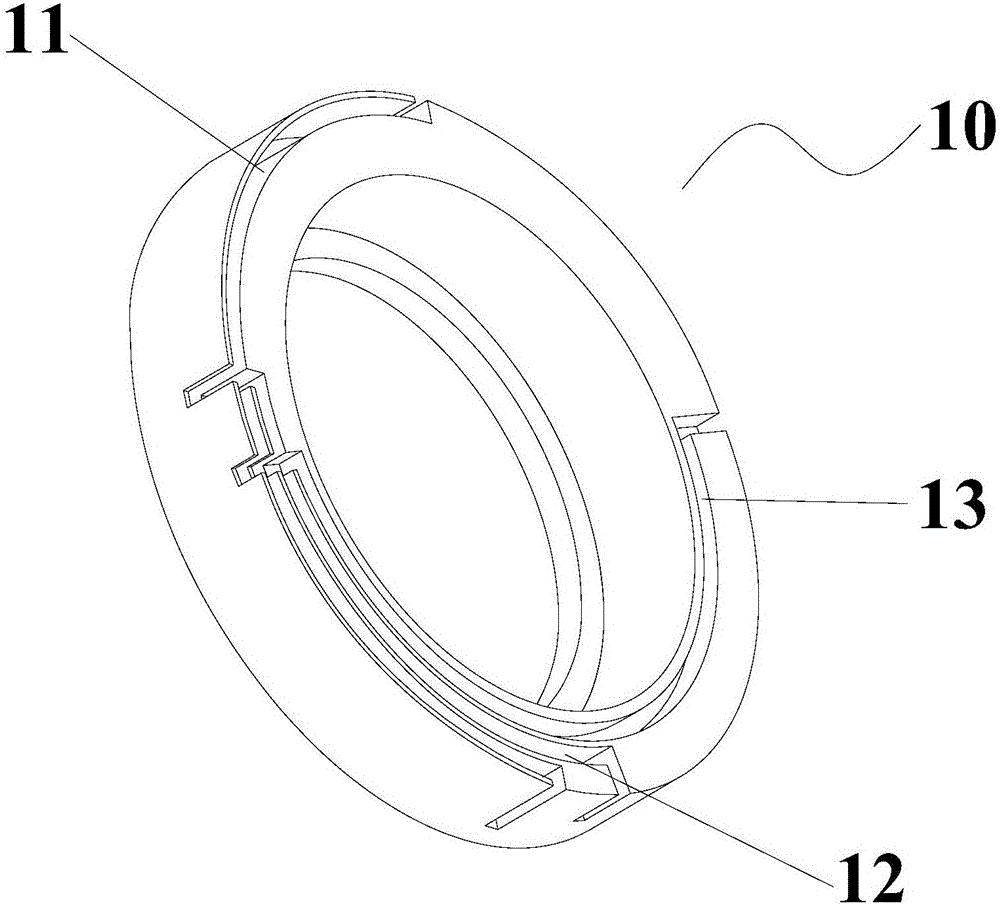

Boiling bed reactor

ActiveCN108067169AEasy to separateSolve the resistanceHydrocarbon oils refiningChemical/physical processesThree-phaseEngineering

The invention relates to the technical field of boiling beds, in particular to a boiling bed reactor. The boiling bed reactor comprises a reactor cylinder, a three-phase separator is arranged at the upper side inside the reactor cylinder, a gas-liquid distributor is arranged at the lower side inside the reactor cylinder and comprises a material distributing pipe, an upper tray and a lower tray, the upper tray and the lower tray form a dual-layer tray structure, gaps are formed by the upper tray and the lower tray, the material distributing pipe penetrates through the upper tray and the lower tray, a hood is arranged at an upper end opening of the material distributing pipe, a pipe wall opened hole is formed in the portion, between the upper tray and the lower tray, of the material distributing pipe, and a circulating oil reactor inlet is further formed between the upper tray and the lower tray. By means of the boiling bed reactor, a solid catalyst which is separated from the three-phase separator is settled in the radial center area of the reactor and flows back into the reactor, the problem that when the three-phase separator is filled with a large dosage of catalyst, the settlingand backflow resistance of the catalyst is large is solved, and it is guaranteed that the three-phase separator still has a good separating effect when filled with a large dosage of catalyst.

Owner:上海竣铭化工工程设计有限公司

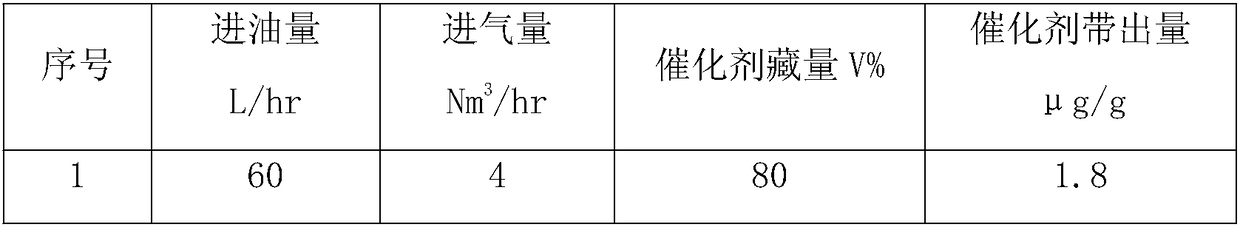

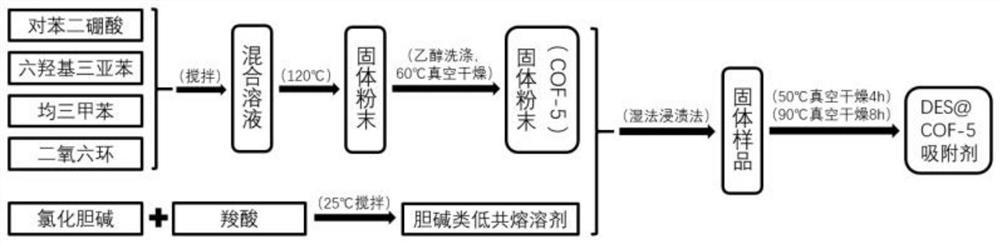

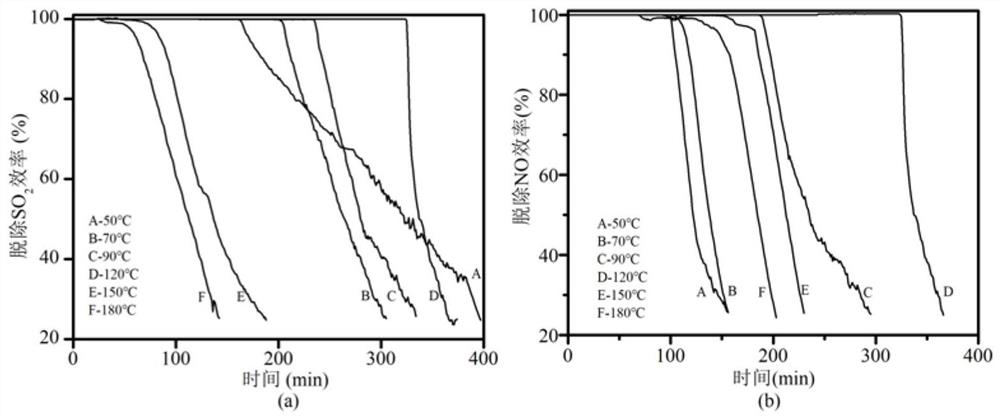

Preparation, use and regeneration methods of green adsorbent for flue gas desulfurization and denitrification

PendingCN112076728AEnhance interactionGood regeneration effectNitrous oxide captureGas treatmentBoronic acidMesitylene

The invention discloses preparation, use and regeneration methods of a green adsorbent for flue gas desulfurization and denitrification. The preparation method comprises the following steps: (1) uniformly mixing 95-105 mg of 1,4-benzenediboronic acid (BDBA), 9-11 ml of mesitylene, 9-11 ml of 1,4-dioxane and 145-155 mg of 2,3,6,7,10,11-hexahydroxy triphenylene (HHTP) under normal temperature and pressure, and performing heating to prepare a covalent organic framework material (COF-5); (2) uniformly mixing choline chloride serving as a hydrogen bond receptor and acetic acid serving as a hydrogenbond donor in a molar ratio of (1:2) to (1:5) at a room temperature to obtain a choline deep eutectic solvent; and (3) mixing the organic covalent framework material with the choline eutectic solventaccording to an impregnation ratio of 0.08-0.38 to prepare a covalent organic framework material-loaded deep eutectic solvent (DES@COF-5), namely the flue gas desulfurization and denitrification adsorbent. Meanwhile, the invention discloses a use method and a regeneration method of the adsorbent. The removal efficiency of the adsorbent on SO2 and NOx in flue gas is greater than 95%, and the adsorbent is simple in preparation process, low in cost, easy to regenerate and capable of being recycled for multiple times.

Owner:UNIV OF SCI & TECH LIAONING

Ventilation and humidification device, air conditioner system and air conditioner system control method

PendingCN111811044ASolve the resistanceImprove fresh air efficiencyMechanical apparatusSpace heating and ventilation safety systemsEngineeringFresh air

The invention provides a ventilation and humidification device, an air conditioner system and an air conditioner system control method. The ventilation and humidification device comprises a shell, a fan and a humidification assembly, wherein the shell is provided with an air outlet; the fan is arranged in the shell, and an air inlet of the fan communicates with the outdoors; the humidification assembly is opposite to an exhaust port of the fan; outdoor fresh air goes into the fan through the air inlet and is humidified through the humidification assembly and then blown into a room; the humidification assembly comprises a humidification structure movably arranged at the air outlet; and the humidification structure has a humidification state for closing the air outlet and an avoiding state for avoiding at least part of the air outlet. Through the ventilation and humidification device, the problem that a wet film has large resistance to outdoor fresh air in the prior art is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Flue gas bypass heat primary air and fed water heating method for trisection air preheater

PendingCN107654995AIncrease profitReduce air leakage rateCombustion processIndirect carbon-dioxide mitigationProcess engineeringFlue gas

The invention discloses a flue gas bypass heat primary air and fed water feeding method for a trisection air preheater. The primary air and fed water heating method includes the following steps that cold secondary air enters a primary air chamber and a secondary air chamber of the trisection air preheater to be heated through a cold secondary air inlet, and heated cold secondary air is converged and then flows out through a hot secondary air outlet; boiler hot flue gas enters a hot flue gas main way and a hot flue gas bypass through a boiler hot flue gas inlet; the boiler hot flue gas enters afed water heat exchanger and a tube-shell type primary air heat exchanger in sequence through a flue gas bypass to be subjected to heat releasing, and the boiler hot flue gas enters a cold flue gas bypass to become bypass cold flue gas after heat releasing; and fed water flows a water heat exchanger to absorb heat through a water feeding opening and then enters a boiler economizer. By means of the flue gas bypass heat primary air and fed water heating method for the trisection air preheater, cold primary air, cold secondary air and fed water can be heated at the same time, the flue gas heat utilization rate is high, and the problem that the resistance of the trisection air preheater is large is solved.

Owner:北京慧峰仁和科技股份有限公司

System and method for heating primary air and condensation water by using bypass heat

PendingCN110726150AIncrease profitImprove qualityCombustion processSteam/vapor condensersAir preheaterFlue gas

The invention discloses a system and a method for heating primary air and condensation water by using bypass heat. The system for heating primary air and condensation water by using bypass heat comprises a tri-sectional air preheater which comprises a primary air cabin, a secondary air cabin and a flue gas cabin communicating to each other. A hot flue gas inlet of a boiler is separately connectedto a hot flue gas main road and a hot flue gas bypass. According to the method for heating primary air and condensation water by using bypass heat, the hot flue gas of the boiler entering into the hotflue gas bypass flows through a baffle door of a bypass flue, a water supplying heat exchanger, a high temperature tube shell type primary air heater, a condensation water heat exchanger and a low temperature tube shell type primary air heater successively to release heat and is converted into bypass cold flue gas, and the bypass cold flue gas flows out through a cold flue gas bypass. The systemand method can be used for heating cold primary and secondary air simultaneously. The condensation water heat exchanger heats the condensation water, so that the utilization ratio of flue gas heat isrelatively high, and the problem that the tri-sectional air preheater is large in resistance is solved.

Owner:江苏慧峰仁和环保科技有限公司 +1

Boiling bed hydrogenation reaction system and boiling bed hydrogenation process method

PendingCN108144556ASolve easy cokingEasy to operateHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionHydrogenation process

The invention belongs to the technical field of hydrogenation, and particularly relates to a boiling bed hydrogenation reaction system and a boiling bed hydrogenation process method. On one hand, theproblem of coking of parts of pipelines caused by intermittent operation of a catalyst discharge system can be effectively solved. On the other hand, the use ratio of a reactor can be further increased (namely, reserve of catalysts in the reactor is improved), hydrogenation reaction effects are further improved, operating stability of the system is improved, and particularly, stable boiling stateof the catalysts can be maintained in start, in stop and under unusual service conditions.

Owner:上海竣铭化工工程设计有限公司

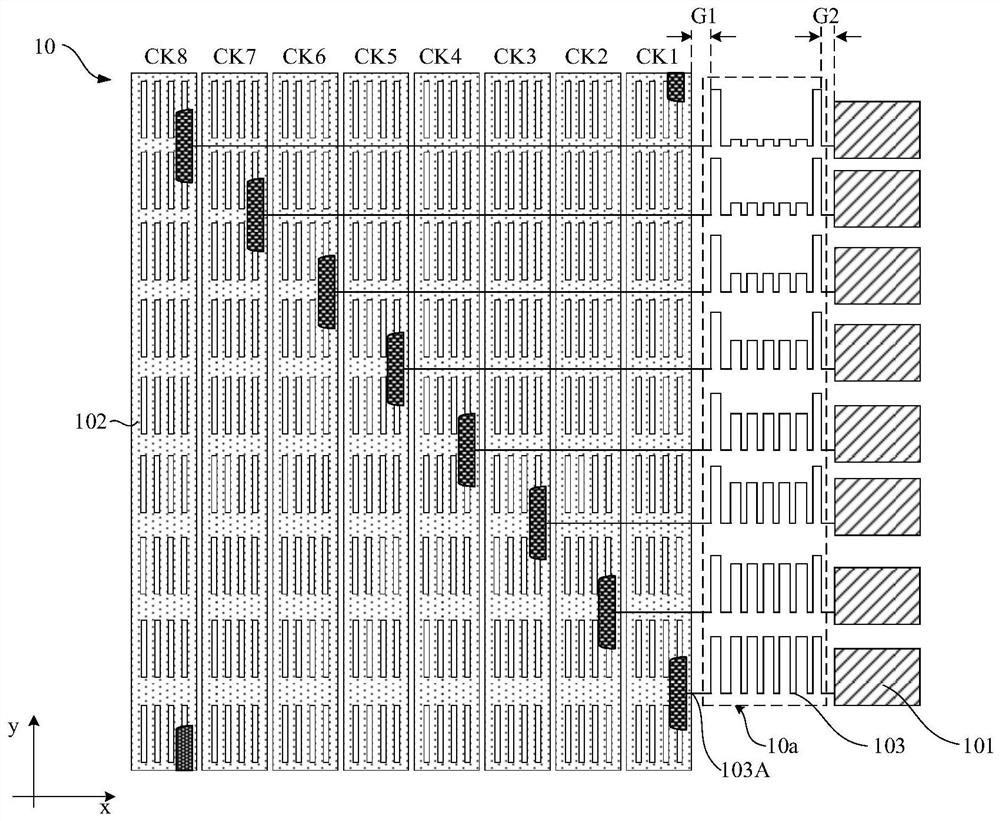

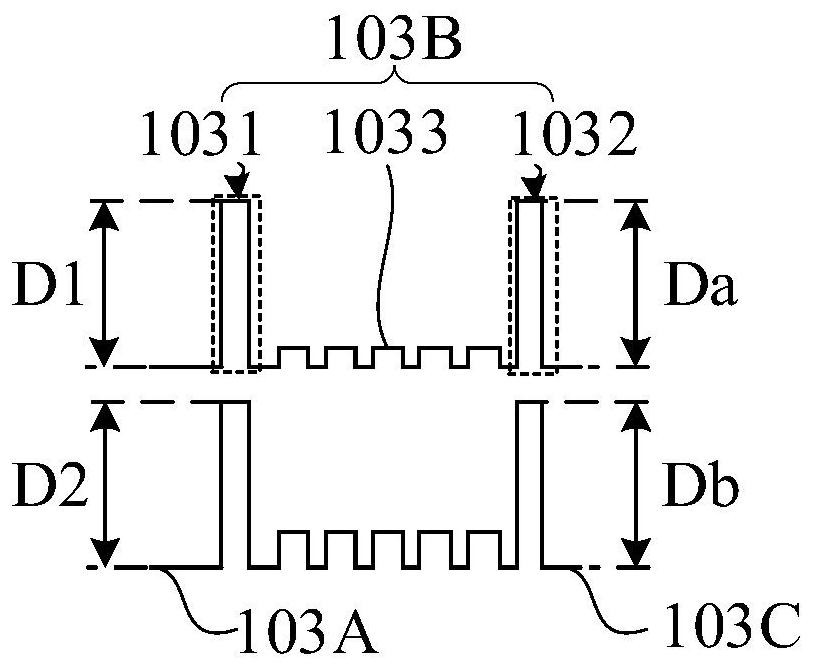

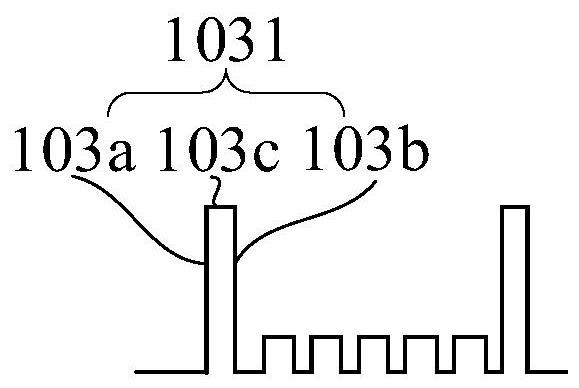

Array substrate and display panel

ActiveCN113964136AImprove the problem of light and dark linesConsistent overall lengthSolid-state devicesSemiconductor devicesCapacitanceTelecommunications

Embodiments of the invention disclose an array substrate and a display panel. The array substrate provided by one embodiment of the invention comprises a plurality of GOA units, a plurality of clock signal lines and a plurality of communication lines, wherein the lengths of the plurality of communication lines are the same; a winding area is arranged between the clock signal lines and the GOA units; the communication lines are bent in the winding area; and in the winding area, the lateral capacitance of the communication lines close to the clock signal lines or close to at least one sides of the GOA units is the same. Through the above winding design, lateral capacitance matching of the communication line on the same side can be consistent. Therefore, the problem that lateral capacitance generated by communication lines in different rows and surrounding wires is different is solved. Besides, the communication lines are subjected to winding design in the winding area, so the total lengths of the communication lines in different rows are consistent, the problem that the resistance and capacitance of the communication lines in different rows are inconsistent is solved, and the problem of light and dark lines of a panel can be solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

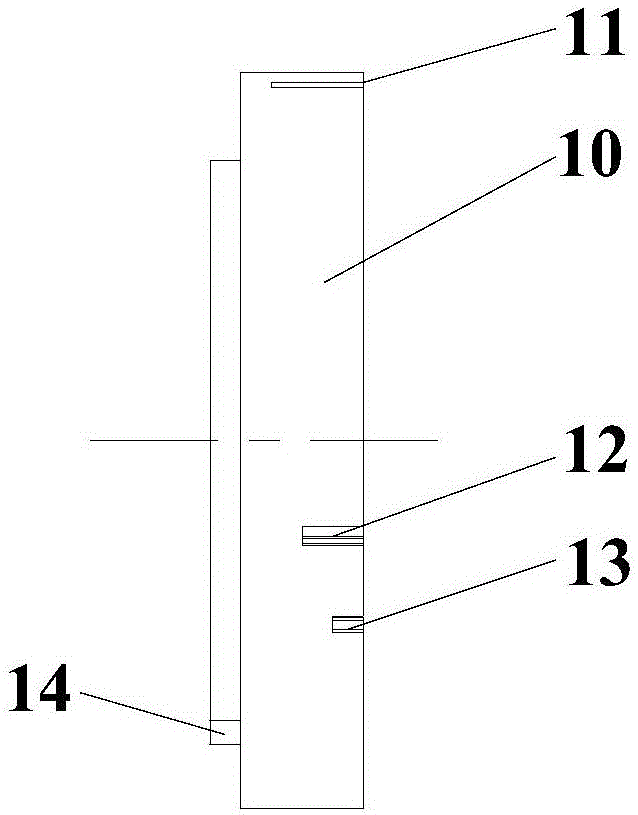

Resistance measurement method for transmission pull strip of coke oven reversing machine

ActiveCN103292937AAvoid failureEasy to operateForce measurement by elastic gauge deformationPull forceCoke oven

The invention relates to a resistance measurement method for a transmission pull strip of a coke oven reversing machine and belongs to a coke oven process. The resistance measurement method comprises a first step of measuring deformation delta L of the transmission pull strip in a stressed state and a second step of calculating pulling force F of the transmission pull strip according to the equation that F=E*S*delta L / L, wherein E is elasticity modulus; S is the sectional area of the transmission pull strip; the unit is mm2; delta L is the deformation of the transmission pull strip in the stressed state; and L is an original length of the transmission pull strip. According to the resistance measurement method, faults of an exchange transmission system can be avoided. The resistance measurement method is simple to operate and easy to popularize, and only a ruler or a measuring tape is required.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

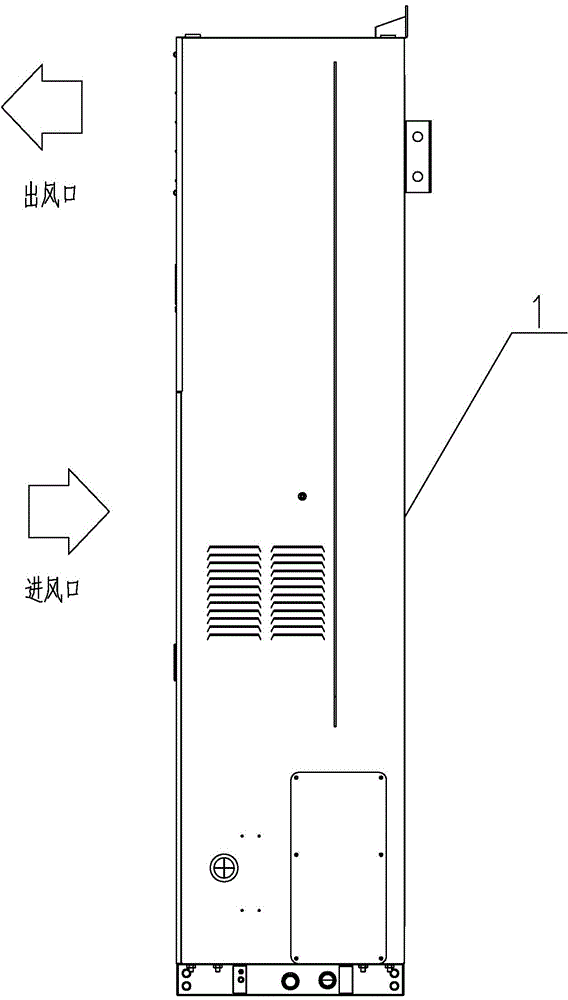

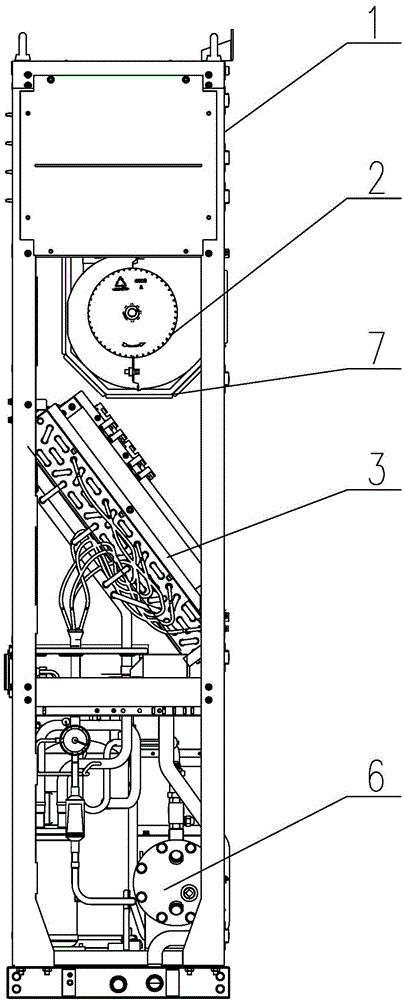

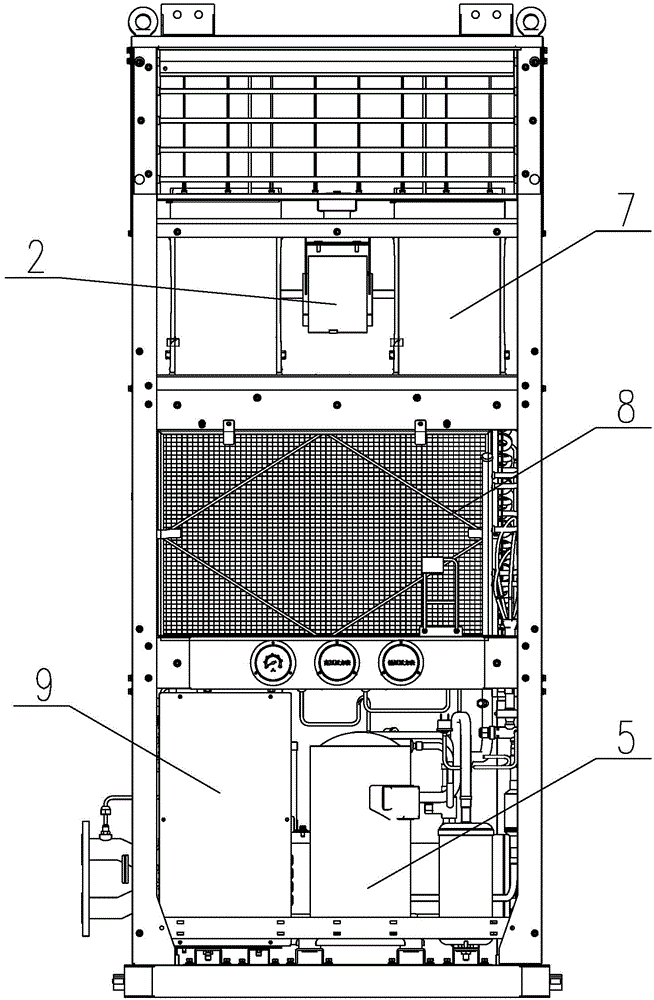

Ship water cooling cabinet unit

InactiveCN104648648ASolve the noiseSolve environmental problemsAuxillariesPump componentsImpellerPlate heat exchanger

The invention relates to the field of ship refrigerating, in particular to a ship water cooling cabinet unit, which comprises a casing, a fan and a heat exchanger, wherein the fan and the heat exchanger are arranged in the casing, the heat exchanger is positioned at the air intake side of the fan, a front panel of the casing is provided with at least one air outlet and at least one air inlet, the position of the air inlet corresponds to the position of the heat exchanger, the fan comprises a volute casing, a motor and an impeller, the volute casing is provided with a flow inlet and a flow outlet, the impeller is positioned in the volute casing, and is driven by the motor to rotate in the volute casing, and the volute casing and the impeller are made of ABS (acrylonitrile-butadiene-styrene) materials. The ship water cooling cabinet unit can solve the problems of large noise and easiness in rusting of the fan under the ship environment of the ship water cooling cabinet unit.

Owner:GREE ELECTRIC APPLIANCES INC

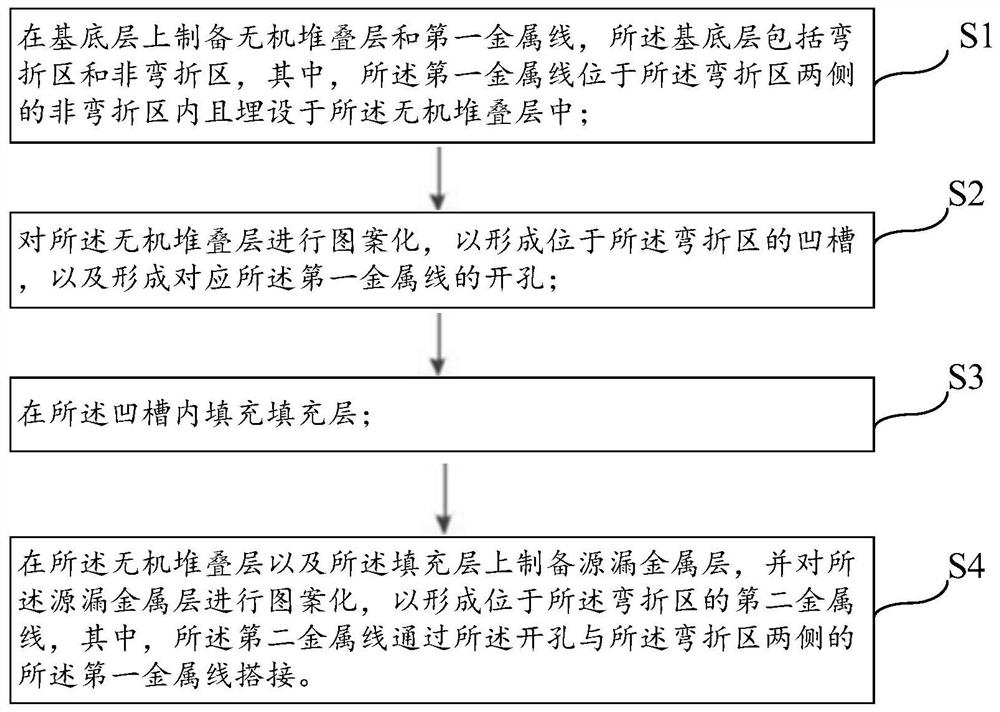

Array substrate and preparation method thereof and display panel

PendingCN112259555ASolve the problem of high line resistanceSolve the poor contact of the transferSolid-state devicesSemiconductor/solid-state device manufacturingSignal onEngineering

The invention provides an array substrate and a preparation method thereof, and a display panel. The array substrate comprises a bending region and non-bending regions, and also comprises: a substratelayer; an inorganic stacking layer arranged on the substrate layer, wherein a groove is formed in the bending region of the inorganic stacking layer, first metal wires are arranged in the inorganic stacking layer, and are located in the non-bending regions on the two sides of the bending region; a filling layer filled in the groove; and a second metal wire arranged on the inorganic stacking layerand the filling layer, wherein the first metal wires on the two sides of the bending region are in lap joint through the second metal wire. According to the array substrate, only one layer of patch cord is adopted in the bending region to achieve conduction of signals on the two sides of the bending region, so that the problems that according to a traditional structure, due to the fact that multiple layers of patch cords are needed to achieve conduction of signals on the two sides of the bending region, the circuit resistance of the bending region is large, and switching contact is poor are solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

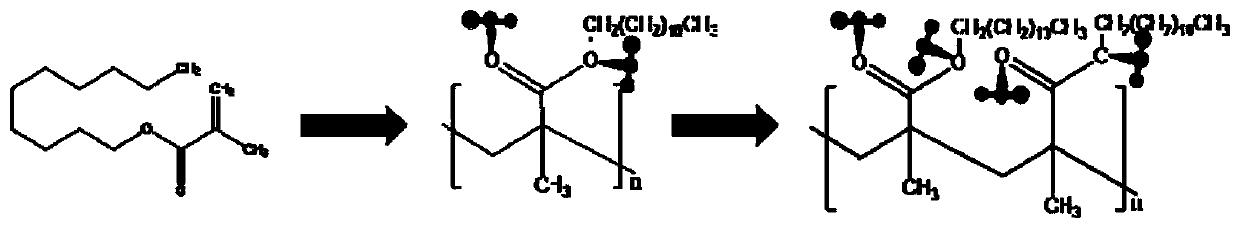

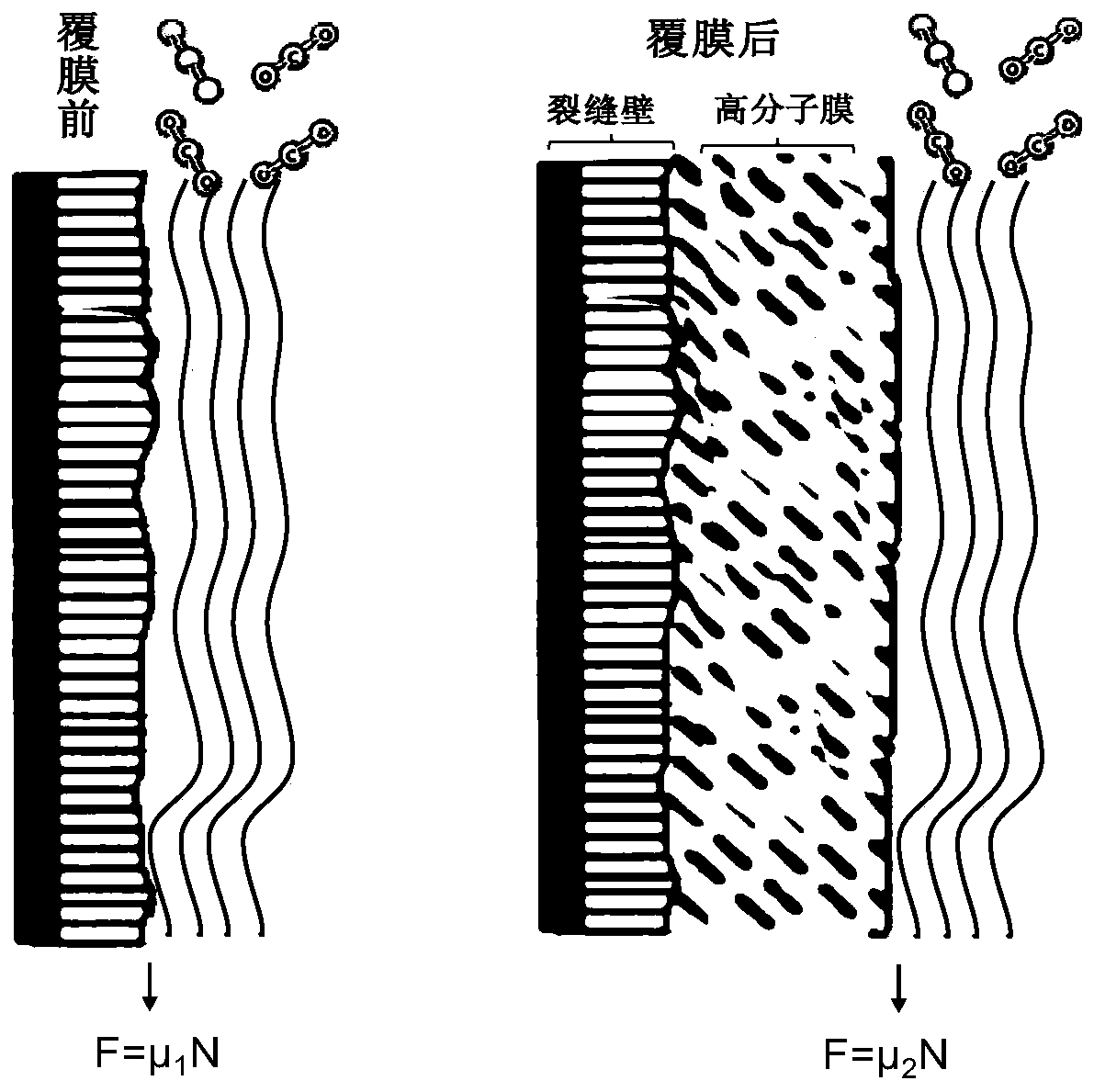

Drag reducer as well as preparation method and application thereof

ActiveCN111019627AReduce resistanceImprove solubilityDrilling compositionBulk chemical productionMethacrylatePolymer science

The invention provides a drag reducer as well as a preparation method and an application thereof. The drag reducer is prepared from the following raw materials: polyether polyol, polydimethylsiloxaneand lauryl polymethacrylate. The mass ratio of the polyether polyol to the polylauryl methacrylate is 1:1-6: 1, and the volume ratio of the solution of the polyether polyol containing the polylauryl methacrylate to the polydimethylsiloxane is 2:1-4:1. The drag reducer provided by the invention can effectively solve the problem of large resistance in a supercritical carbon dioxide fracturing process under the condition that the viscosity of supercritical carbon dioxide is not obviously increased.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP +1

Fluidized bed hydrogenation reaction equipment and fluidized bed hydrogenation method

ActiveCN108148620AEasy to separateSolve the resistanceChemical/physical processesHydrocarbon oils treatmentFluidized bedHydrogenation reaction

The invention belongs to the technical field of hydrogenation, and particularly relates to fluidized bed hydrogenation reaction equipment and a fluidized bed hydrogenation method. The fluidized bed hydrogenation reaction equipment comprises a fluidized bed hydrogenation reactor, a catalyst adding system and a catalyst adding pipeline, wherein the catalyst adding system comprises a catalyst storagetank and a catalyst delivering pipeline; the catalyst delivering pipeline communicates with the catalyst storage tank and inner space of the fluidized bed hydrogenation reactor; at least two valves are arranged on the catalyst delivering pipeline; the catalyst delivering pipeline between the two valves communicates with the catalyst adding pipeline by a hydrogen sulfide leakage prevention pipeline; and at least one valve is arranged on the hydrogen sulfide leakage prevention pipeline. By the fluidized bed hydrogenation reaction equipment, potential safety hazards caused by internal leakage due to frequent operation under special working conditions when a catalyst is added in a system are solved; the utilization rate of the reactor is further increased, the hydrogenation reaction effect isimproved, and the stability of operation of the device is improved; and the fluidized bed hydrogenation method is scientific and reasonable, and simple and practicable.

Owner:上海竣铭化工工程设计有限公司

Winding framework and outer rotor motor having same

The invention discloses a winding frame and an outer rotor motor provided with the winding frame. More than two winding slots are arranged on the upper surface of the winding frame, and the openings at both ends of each winding slot are located at the center of the winding frame. on the side wall. Applying the technical solution of the present invention, two or more winding slots are provided on the winding frame, so that the winding wires of each phase pass through the winding frame, avoiding the wires from the teeth, and can effectively solve the problem of winding overshoot. The problem of wires can be solved, and the problem of increased motor resistance and copper loss can be solved, the efficiency of the motor can be effectively improved, and the cost of the motor can be reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Resistance measurement method for transmission pull strip of coke oven reversing machine

ActiveCN103292937BSolve the resistanceEliminate downtimeForce measurement by elastic gauge deformationPull forceCoke oven

The invention relates to a resistance measurement method for a transmission pull strip of a coke oven reversing machine and belongs to a coke oven process. The resistance measurement method comprises a first step of measuring deformation delta L of the transmission pull strip in a stressed state and a second step of calculating pulling force F of the transmission pull strip according to the equation that F=E*S*delta L / L, wherein E is elasticity modulus; S is the sectional area of the transmission pull strip; the unit is mm2; delta L is the deformation of the transmission pull strip in the stressed state; and L is an original length of the transmission pull strip. According to the resistance measurement method, faults of an exchange transmission system can be avoided. The resistance measurement method is simple to operate and easy to popularize, and only a ruler or a measuring tape is required.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A stainless steel water meter housing and its processing method

The invention discloses a stainless steel water meter casing and a processing method thereof, comprising a main casing, an auxiliary casing, a water inlet pipe and a water outlet pipe, the inner cavity of the main casing communicates with the inner cavity of the auxiliary casing, the inlet The inner cavity of the water pipe is provided with an expansion cavity, and the inner cavity of the expansion cavity is fixedly connected with a first pull rope. The present invention relates to the technical field of water meters. In the stainless steel water meter casing and its processing method, when the water flow enters the inside of the water meter casing through the water inlet pipe, the floating ball drives the sealing plate to move upward under the buoyancy of the water, the sealing plate is separated from the fixed ring plate, and the floating ball passes through the fixed ring. The sealing plate and the sealing plate are located in the expansion chamber under the action of the first pull rope, which reduces the resistance of the water flow. When the water flow reverses, the sealing plate is tightly pressed on the fixed ring plate, and the floating ball is pressed on the ball groove to ensure the water flow. Unable to reverse flow, which solves the problem that the common water meter shell itself cannot realize the function of preventing water reverse flow, and the one-way valve has a large resistance to water flow.

Owner:山东华美精密铸业有限公司

Mixed-structure field effect transistor and manufacturing method thereof

ActiveCN102881721BDoes not cause punch-through problemsSolve the resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETEngineering

The invention discloses a mixed-structure field effect transistor and a manufacturing method thereof. According to the transistor, a device is controlled to switch on and off by the voltage withstanding of SiC and a heterostructure layer grown epitaxially on a SiC epitaxial layer. According to the mixed-structure field effect transistor, the current collapse effect of the conventional HFET (Heterojunction Field Effect Transistor) is avoided, a device of which the voltage withstanding capacity is better than that of AlGaN / GaN HFET can be manufactured, a threshold voltage is easy to adjust, and a normally off device and a longitudinal device are realized. Simultaneously, compared with a SiC MOS (Metal Oxide Semiconductor) channel, a two-dimensional electron gas channel in the position of the interface of the heterostructure layer has high electronic mobility inside and small channel resistance, so that the advantages of the AlGaN / GaN HFET and the SiC MOSFET (Metal-Oxide -Semiconductor Field Effect Transistor) are combined, and a high-performance power semiconductor switching device is realized.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com