Patents

Literature

103results about How to "Eliminate downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

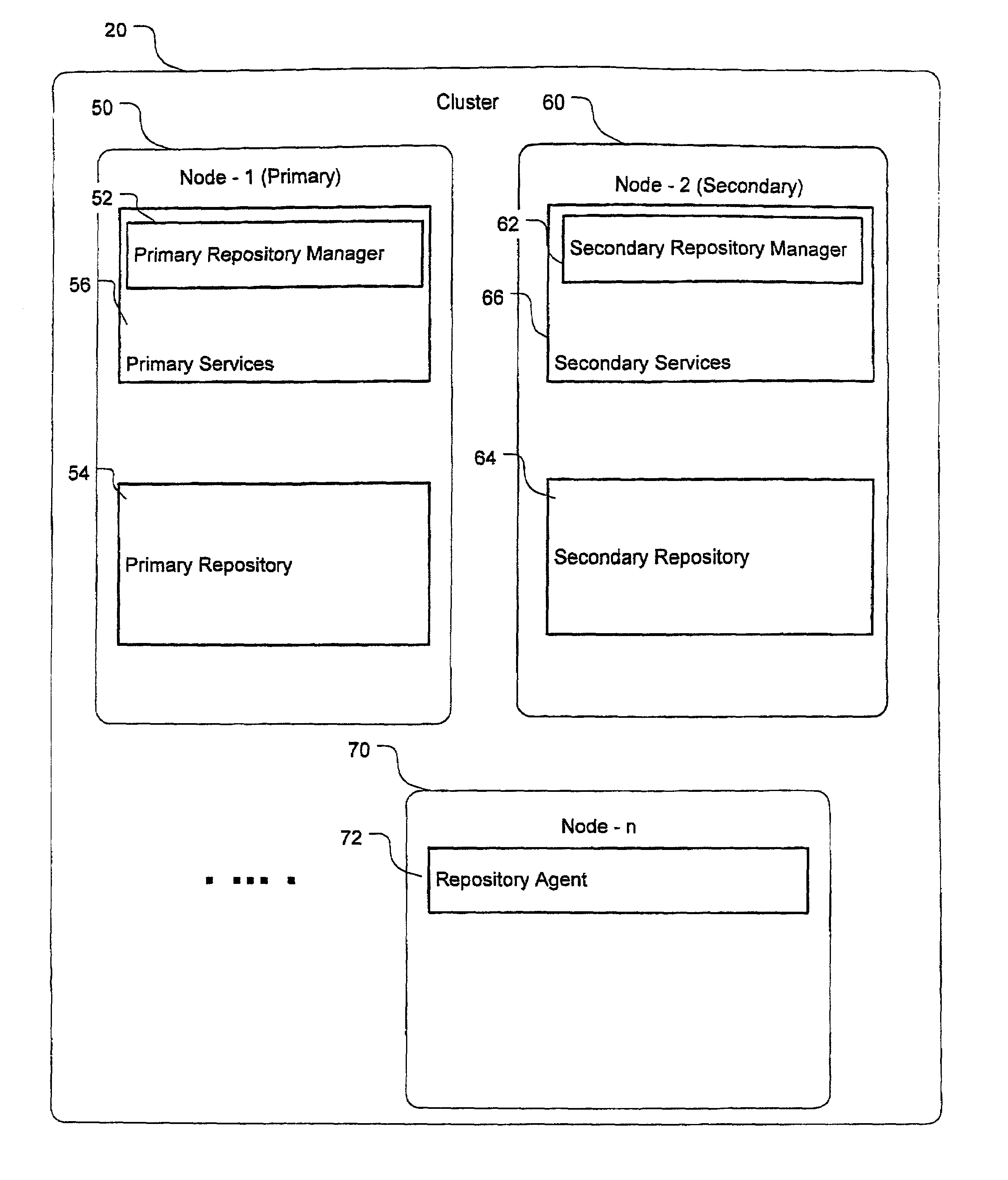

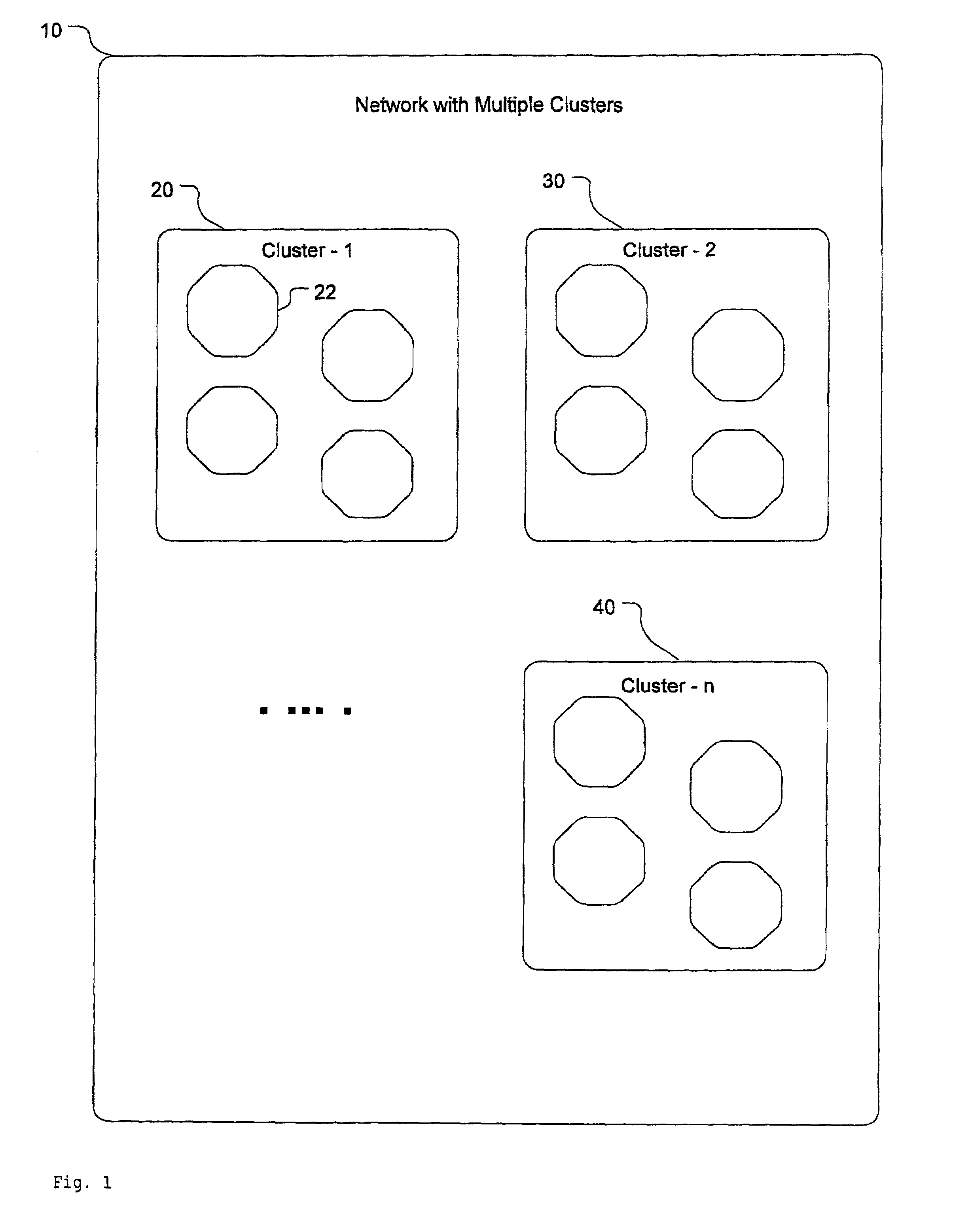

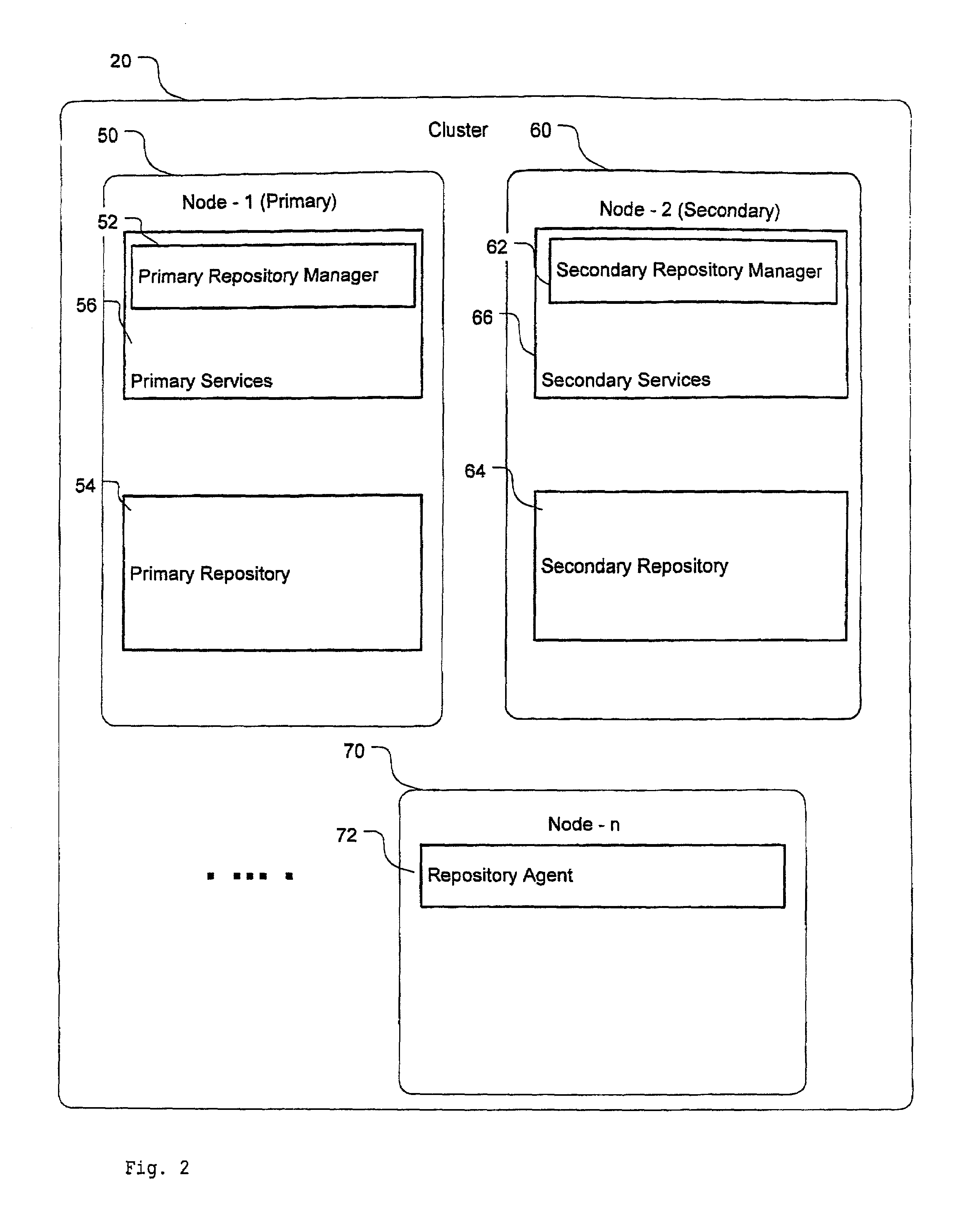

Cluster configuration repository

ActiveUS7010617B2Eliminate downtimeMultiple digital computer combinationsData switching networksData miningTime clustering

A system for providing real-time cluster configuration data within a clustered computer network including a plurality of clusters, including a primary node in each cluster wherein the primary node includes a primary repository manager, a secondary node in each cluster wherein the secondary node includes a secondary repository manager, and wherein the secondary repository manager cooperates with the primary repository manager to maintain information at the secondary node consistent with information maintained at the primary node.

Owner:ORACLE INT CORP

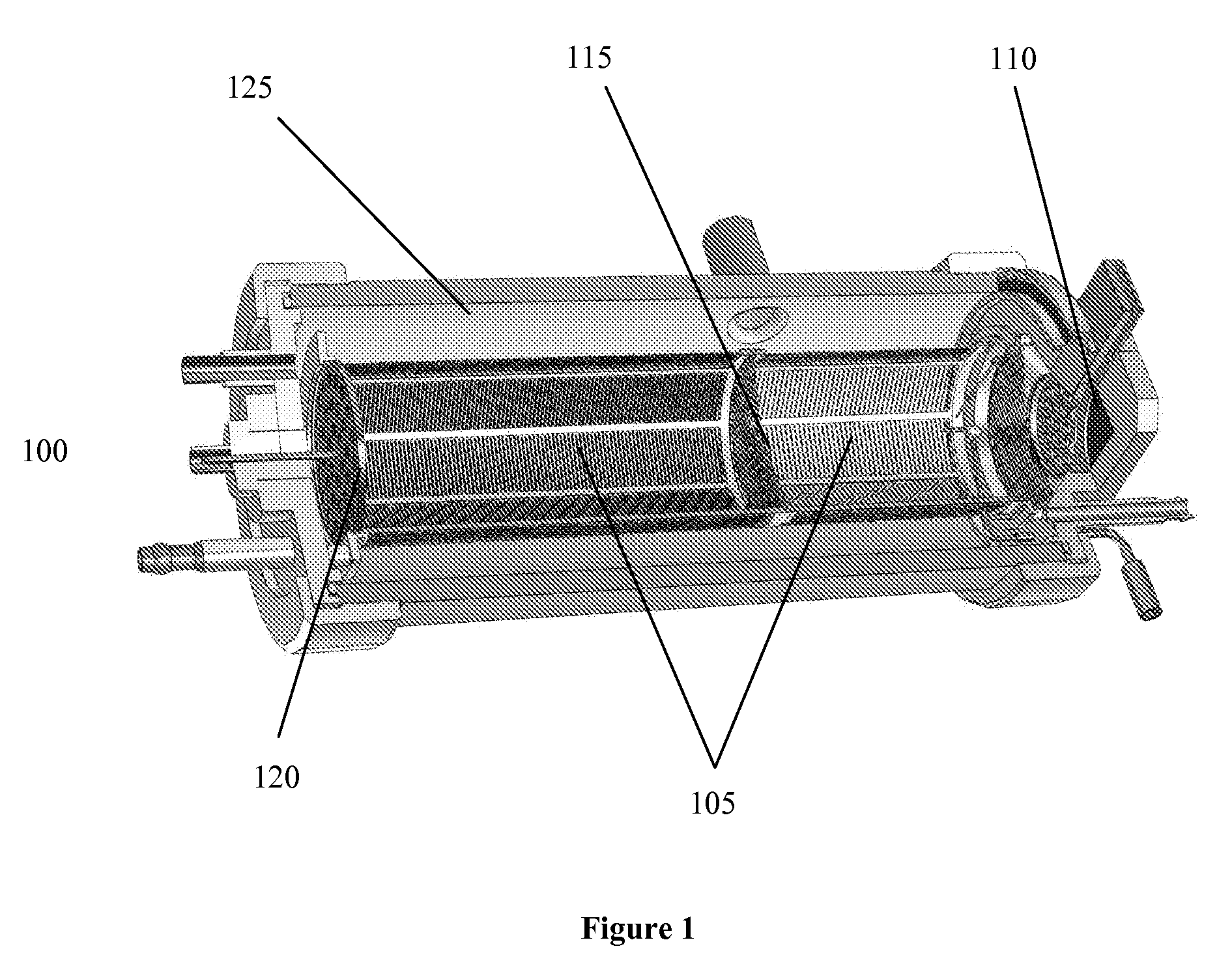

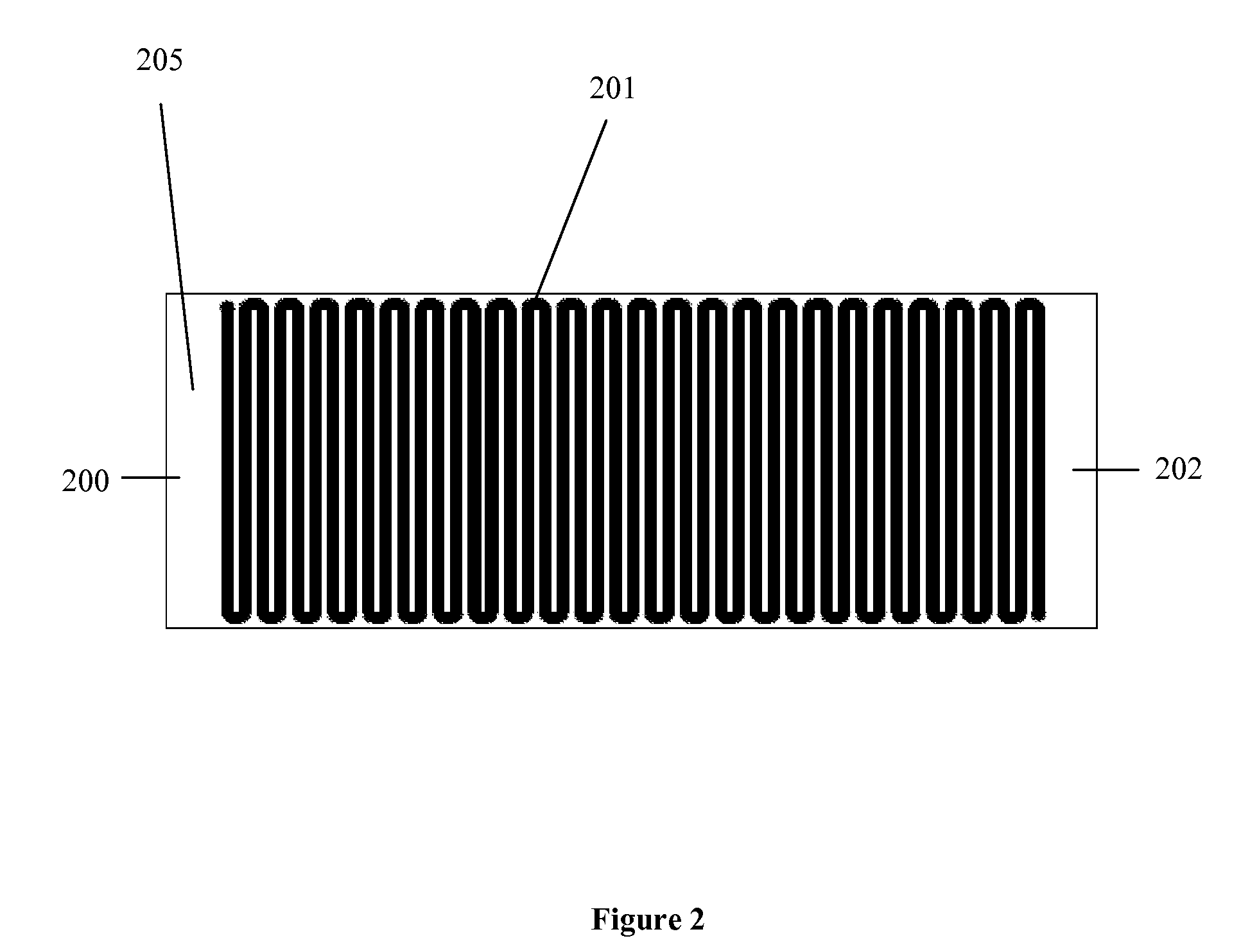

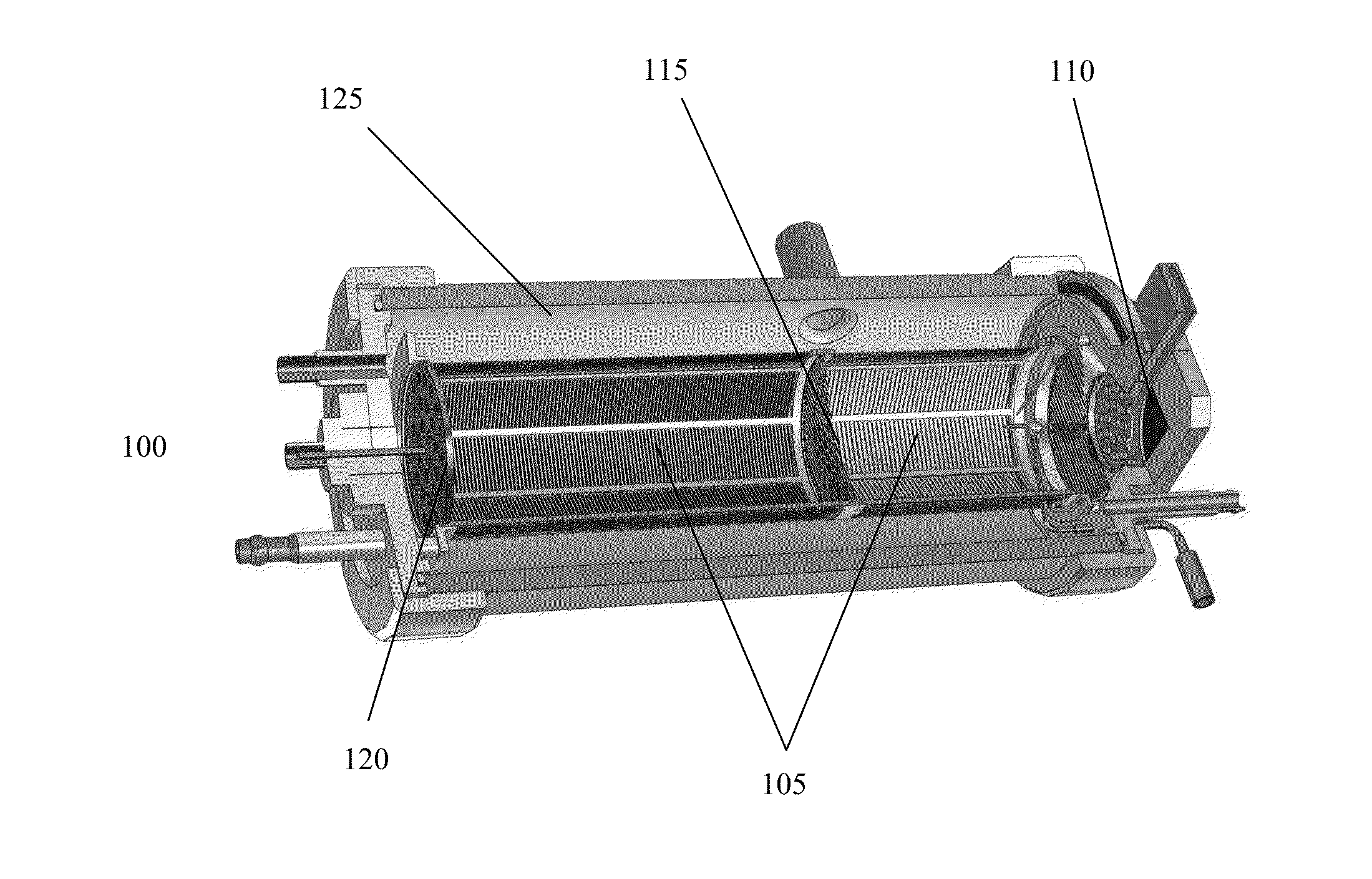

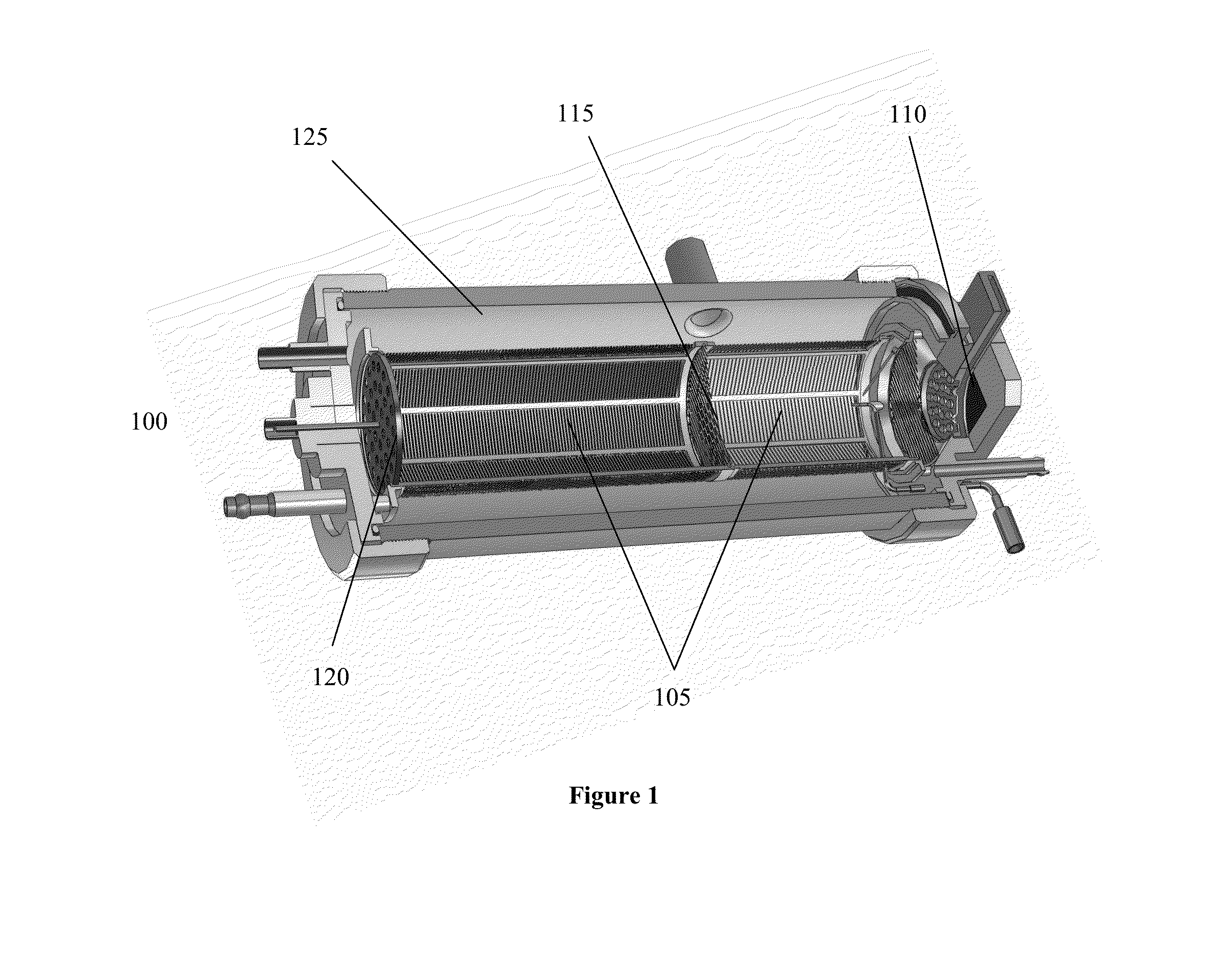

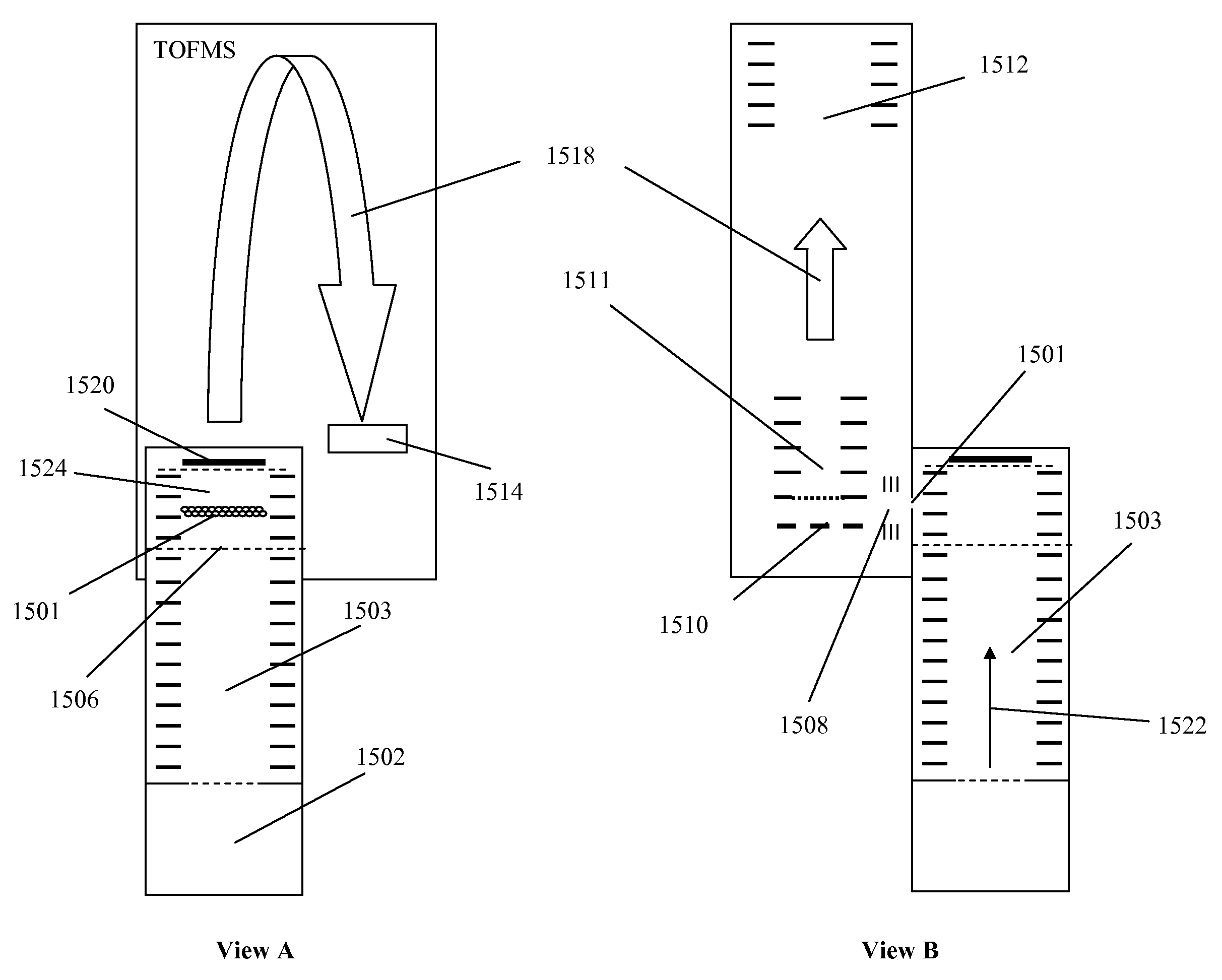

Practical ion mobility spectrometer apparatus and methods for chemical and/or biological detection

ActiveUS20080121797A1High sensitivity and selectivityIncrease capacityTime-of-flight spectrometersSamples introduction/extractionIonizationMass spectrometric

This invention describes an ion mobility spectrometer system for chemical detection in the field. The system allows: a high throughput operation, an interface to new ionization methods, and an interface to a mass spectrometer.

Owner:EXCELLIMS CORP

Practical ion mobility spectrometer apparatus and methods for chemical and/or biological detection

ActiveUS20130009053A1Enhancing and enabling fieldabilityHigh sensitivity and selectivitySamples introduction/extractionMaterial analysis by electric/magnetic meansTemperature controlIon-mobility spectrometry

This invention describes an ion mobility spectrometer and operational methods for chemical analysis. The ion mobility spectrometer allows for continuous operation and rapid temperature control to reach designed operational conditions, as well as analysis under a temperature gradient.

Owner:EXCELLIMS CORP

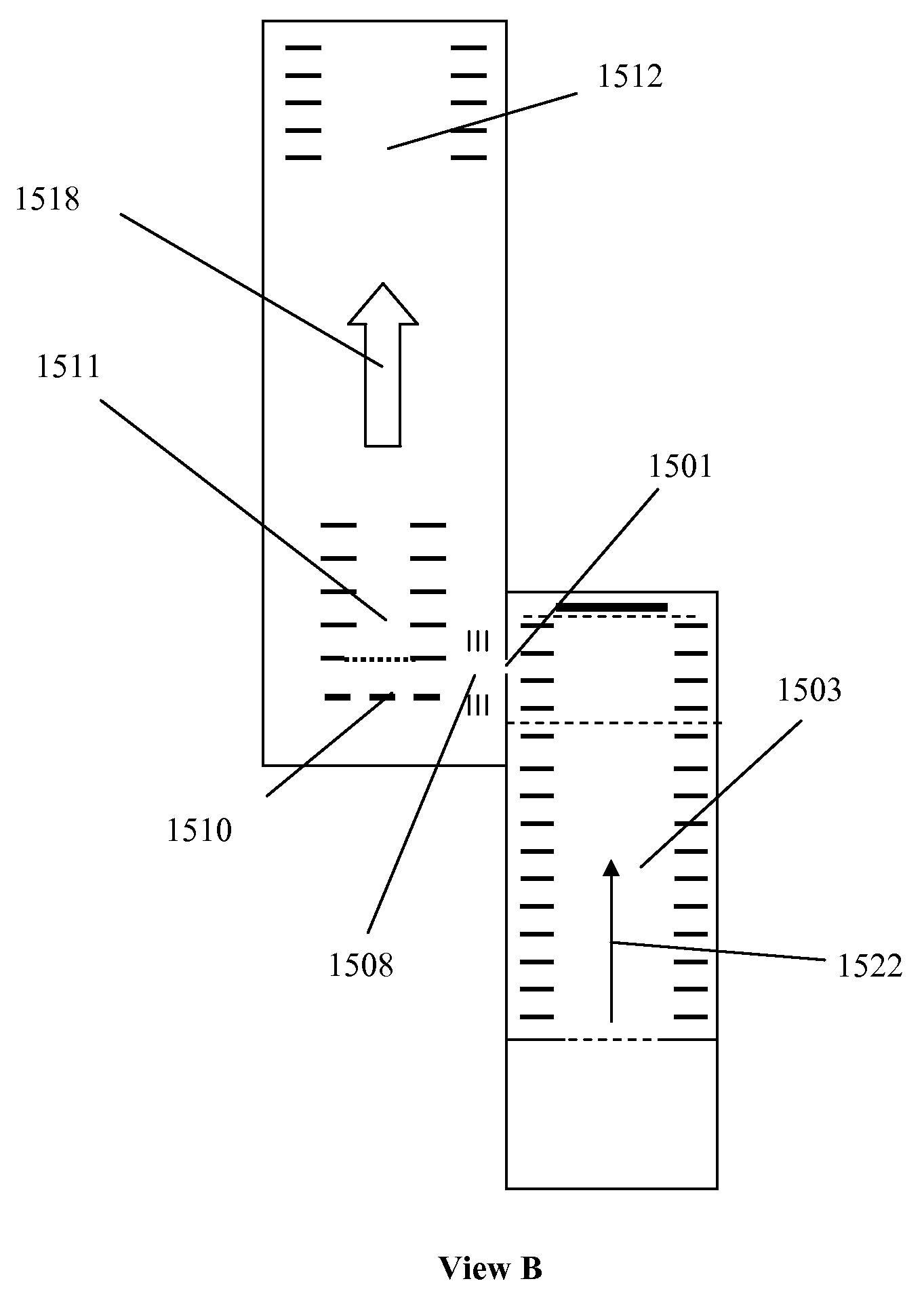

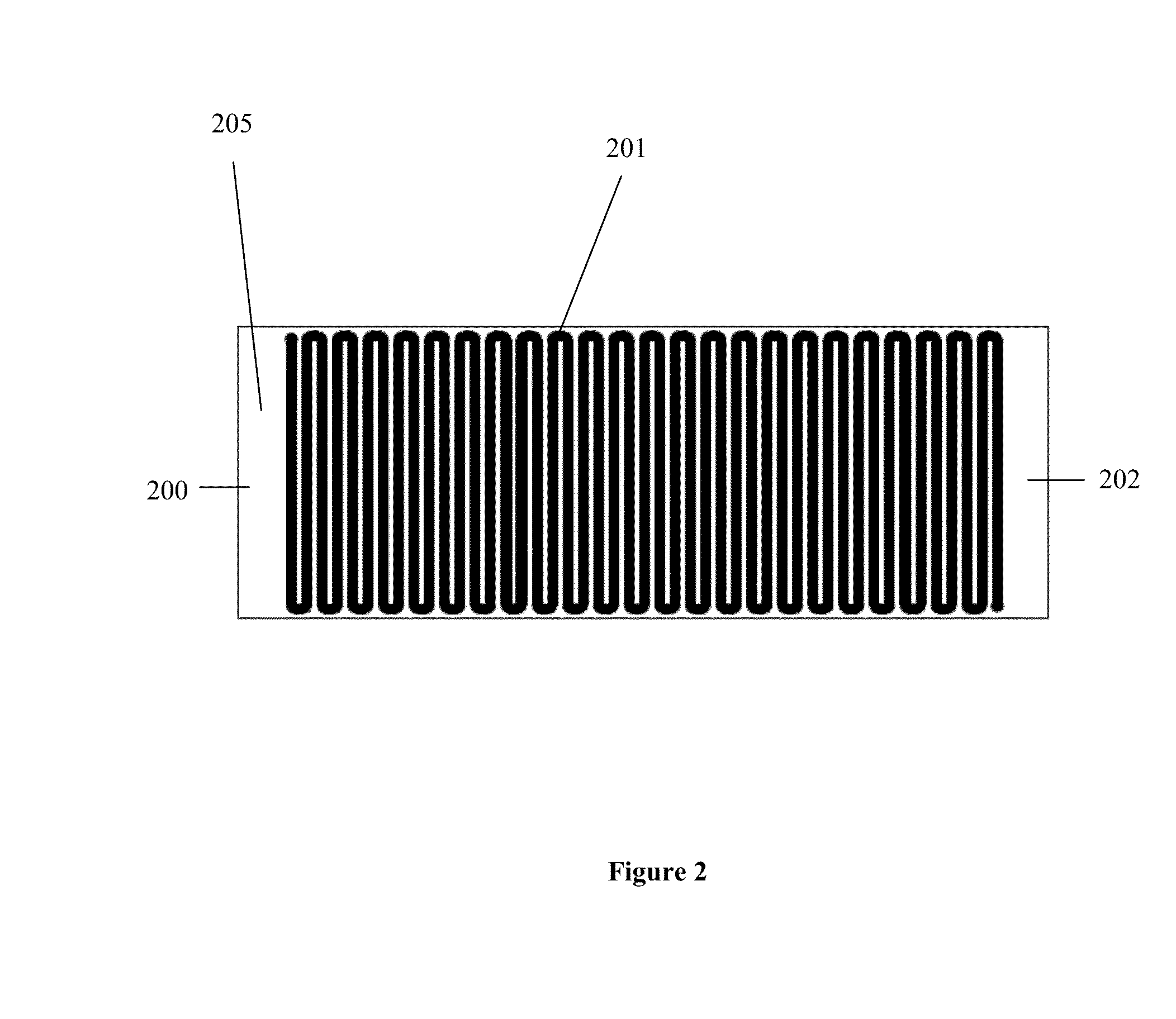

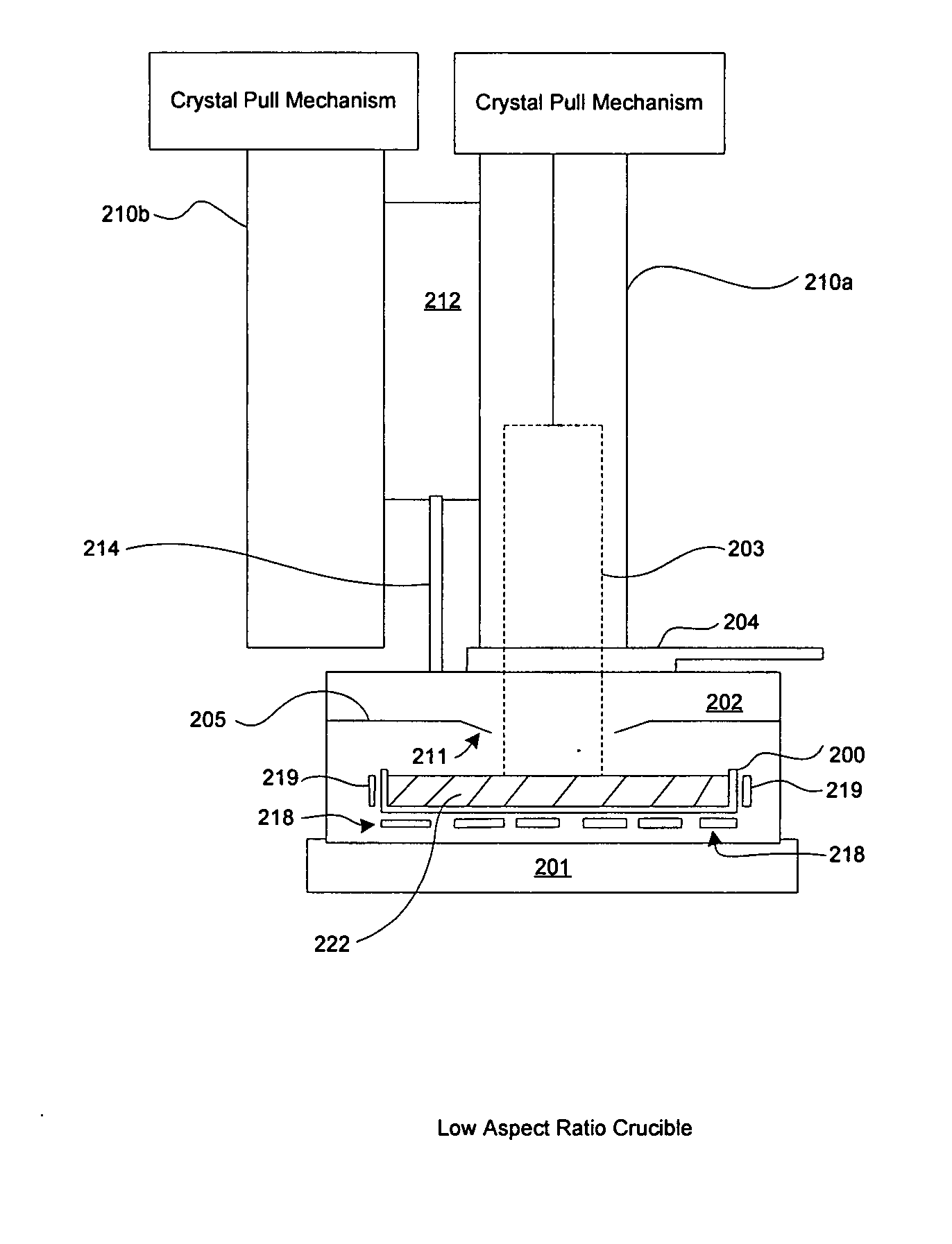

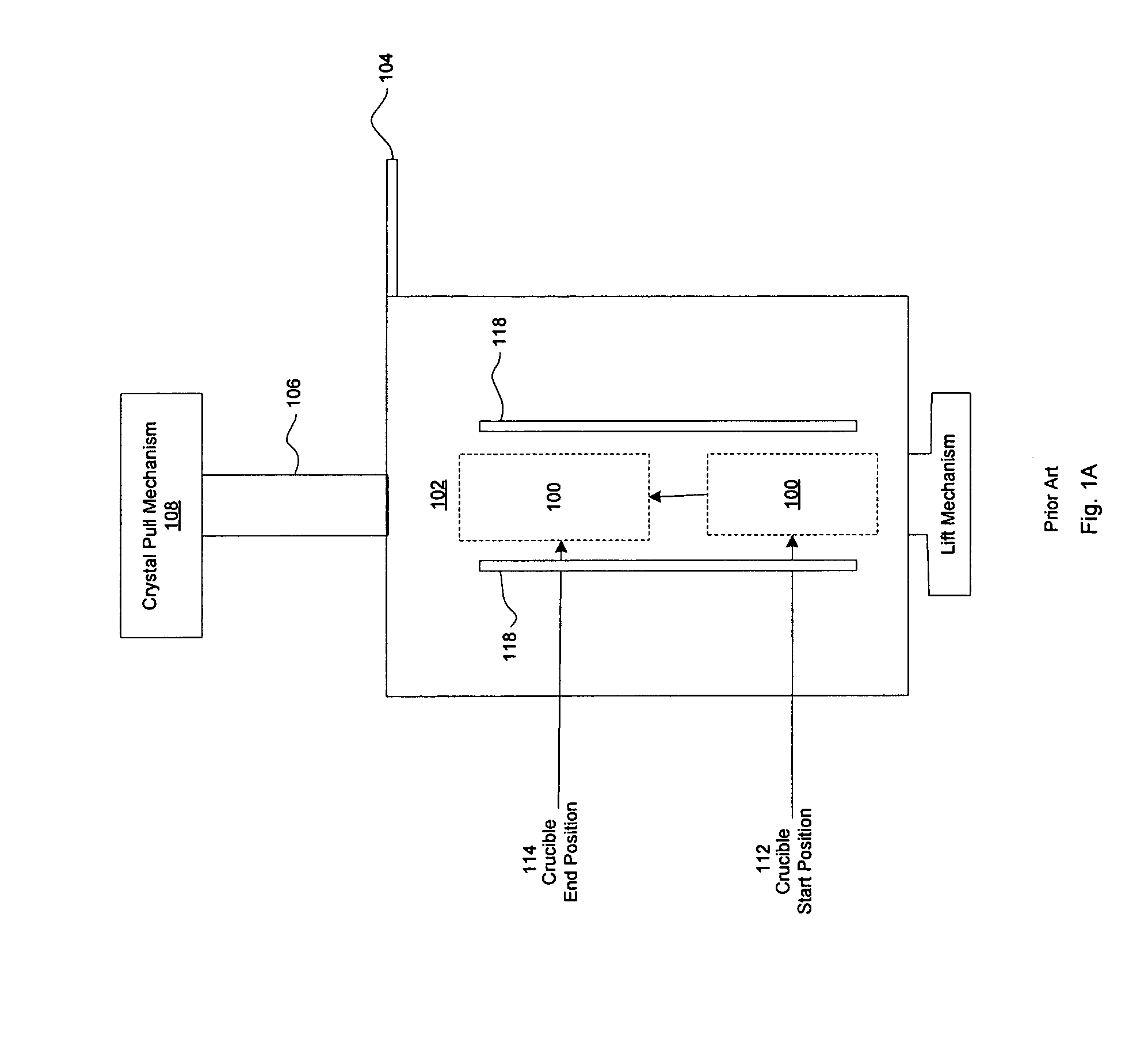

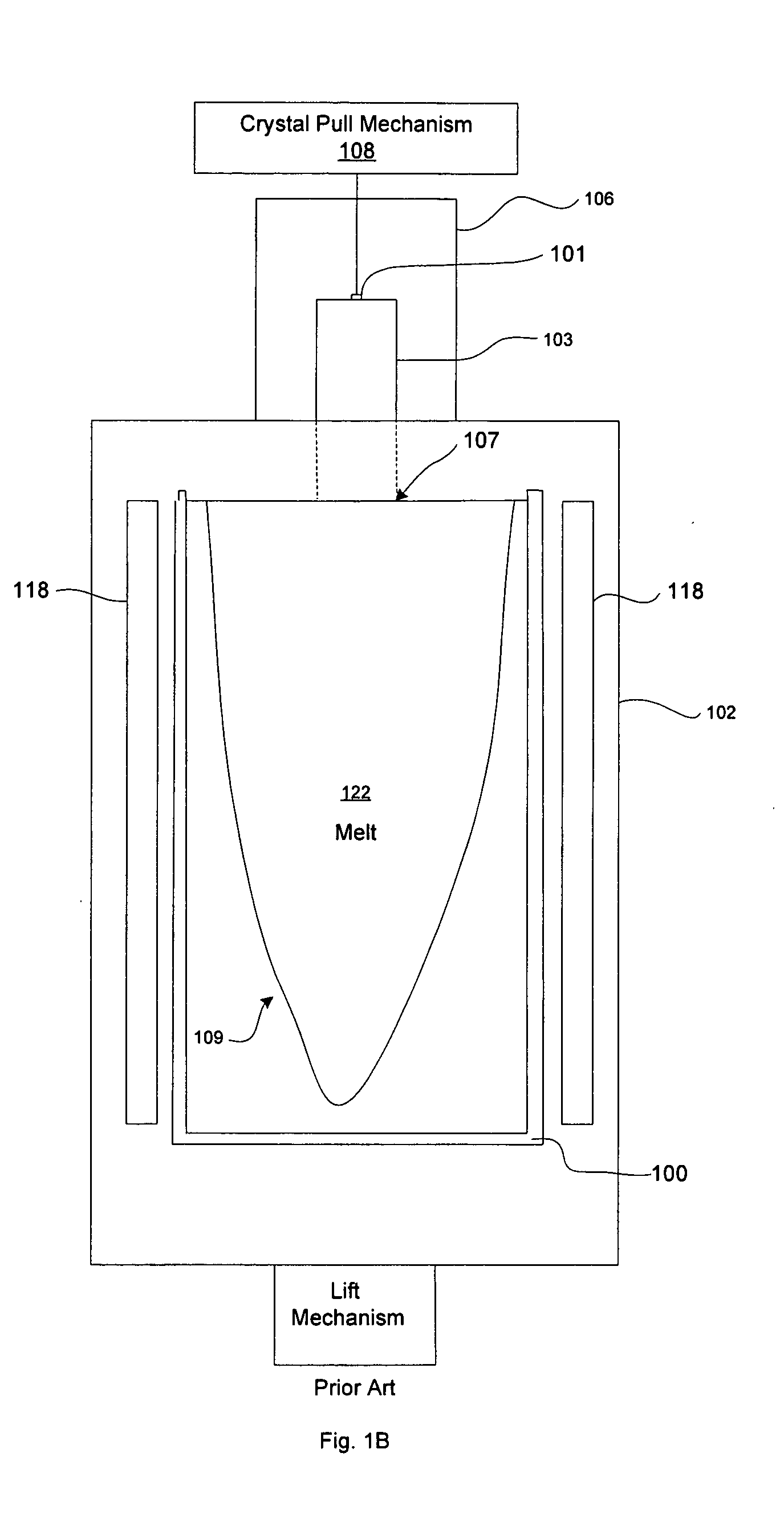

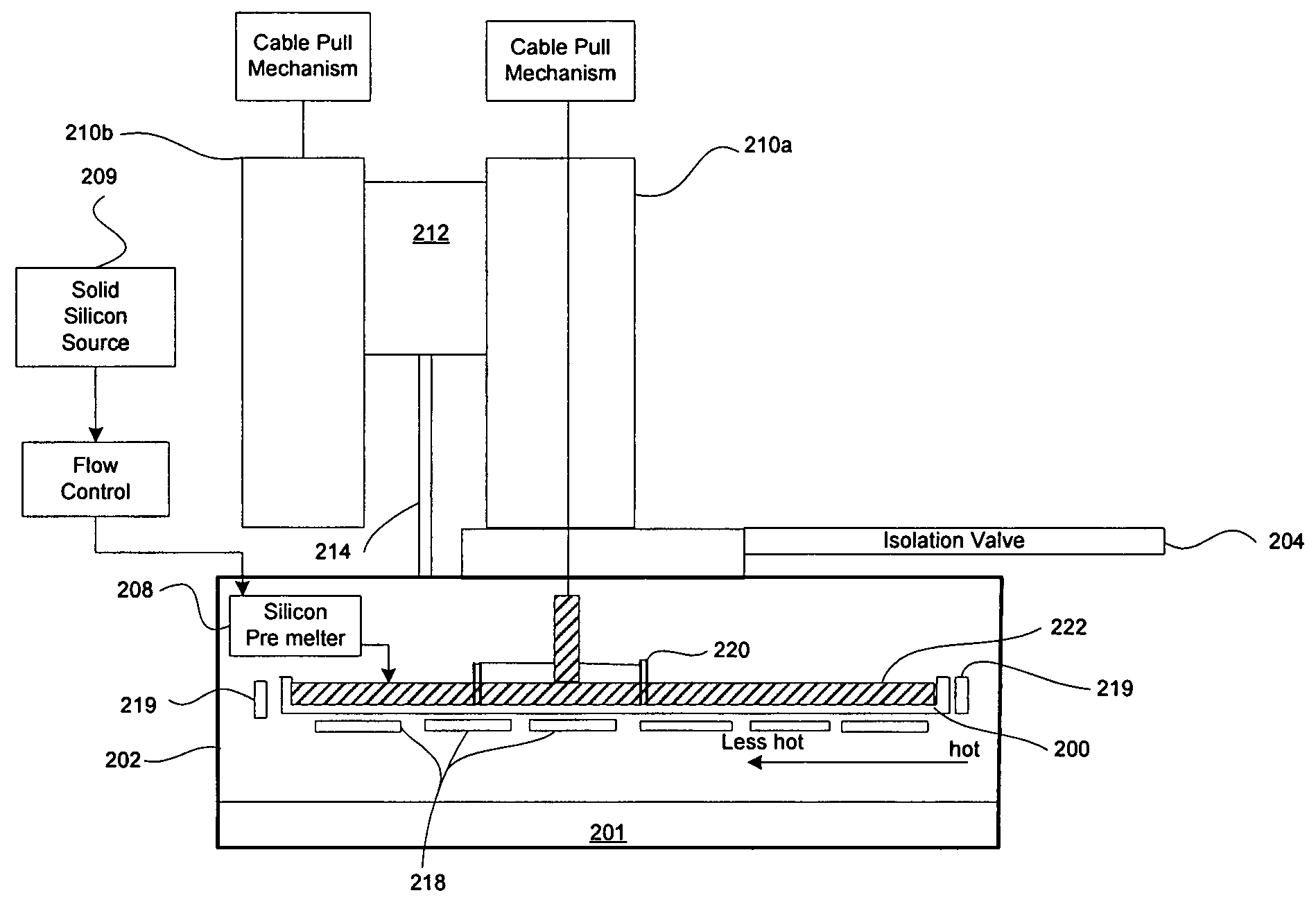

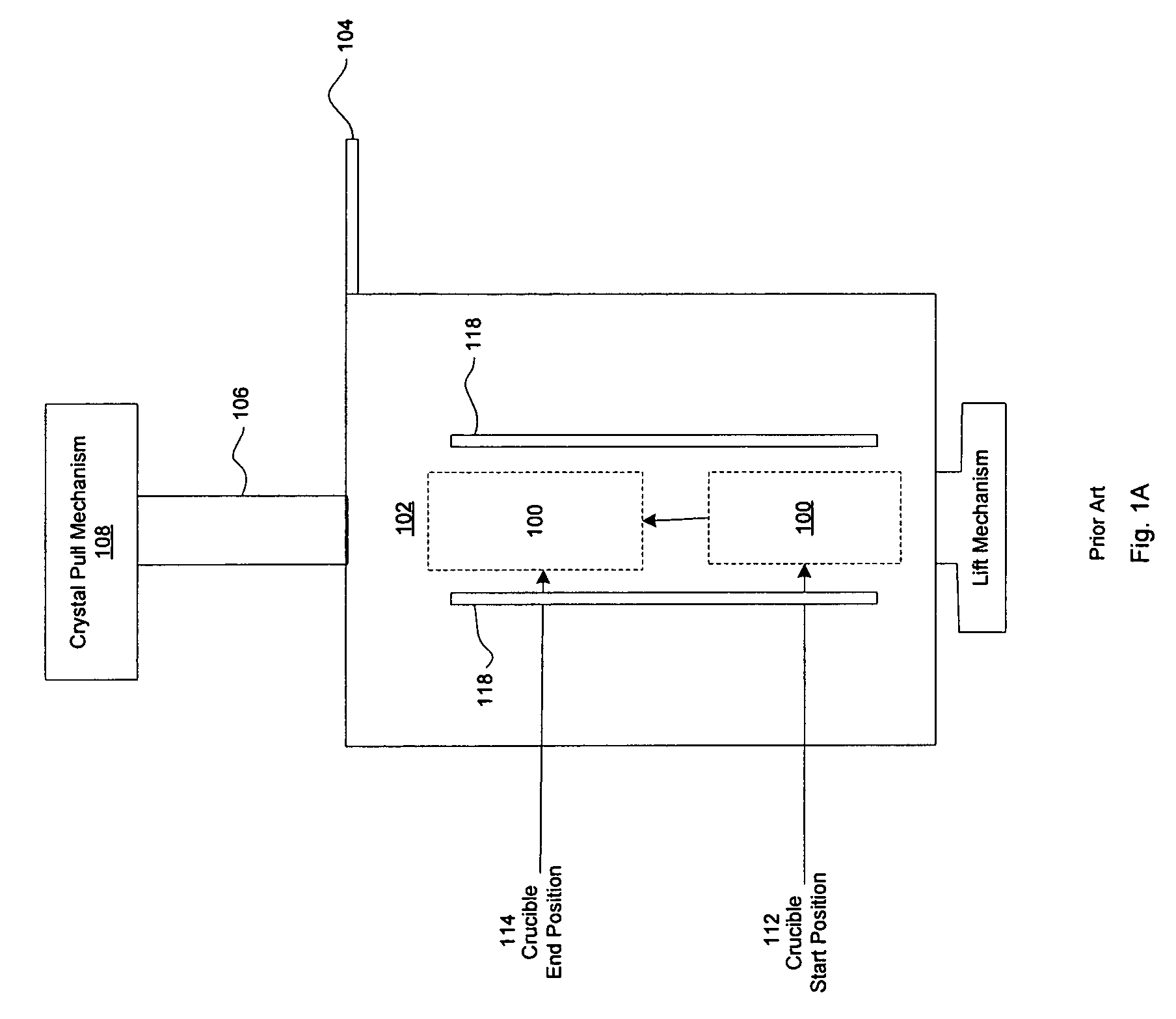

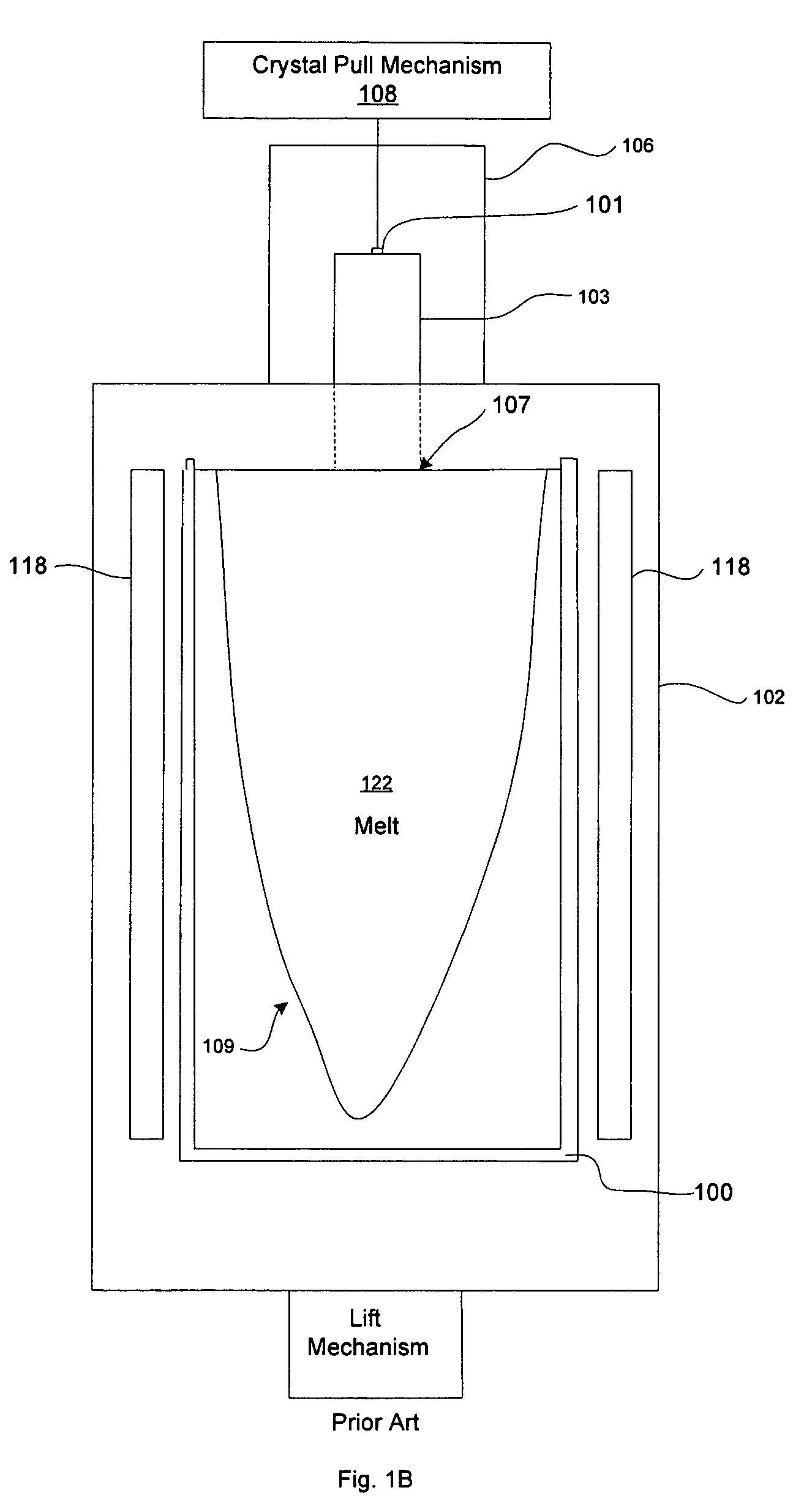

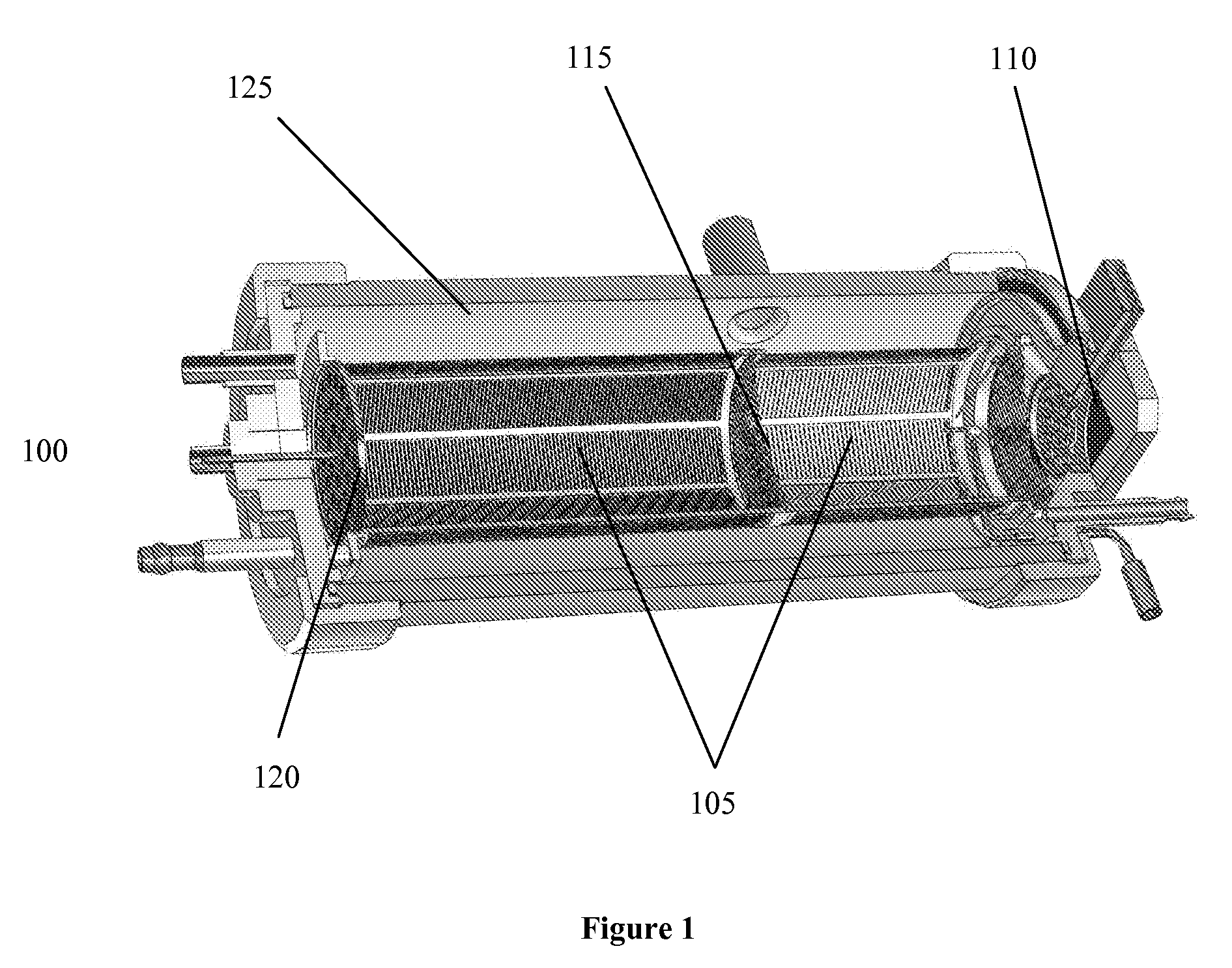

System for continuous growing of monocrystalline silicon

ActiveUS20050092236A1Easy temperature controlAccelerated crystal growthAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

Switchover method and terminal

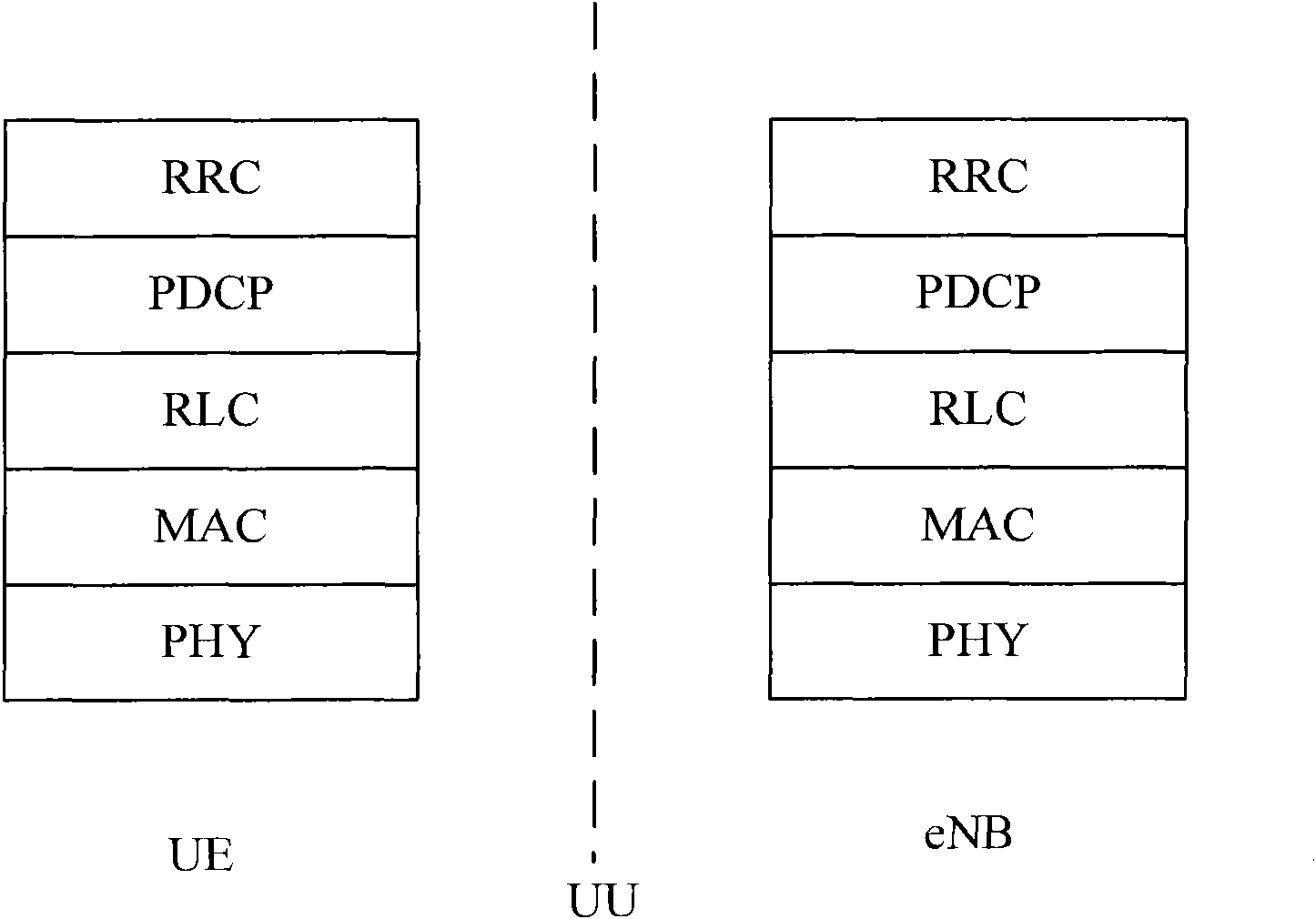

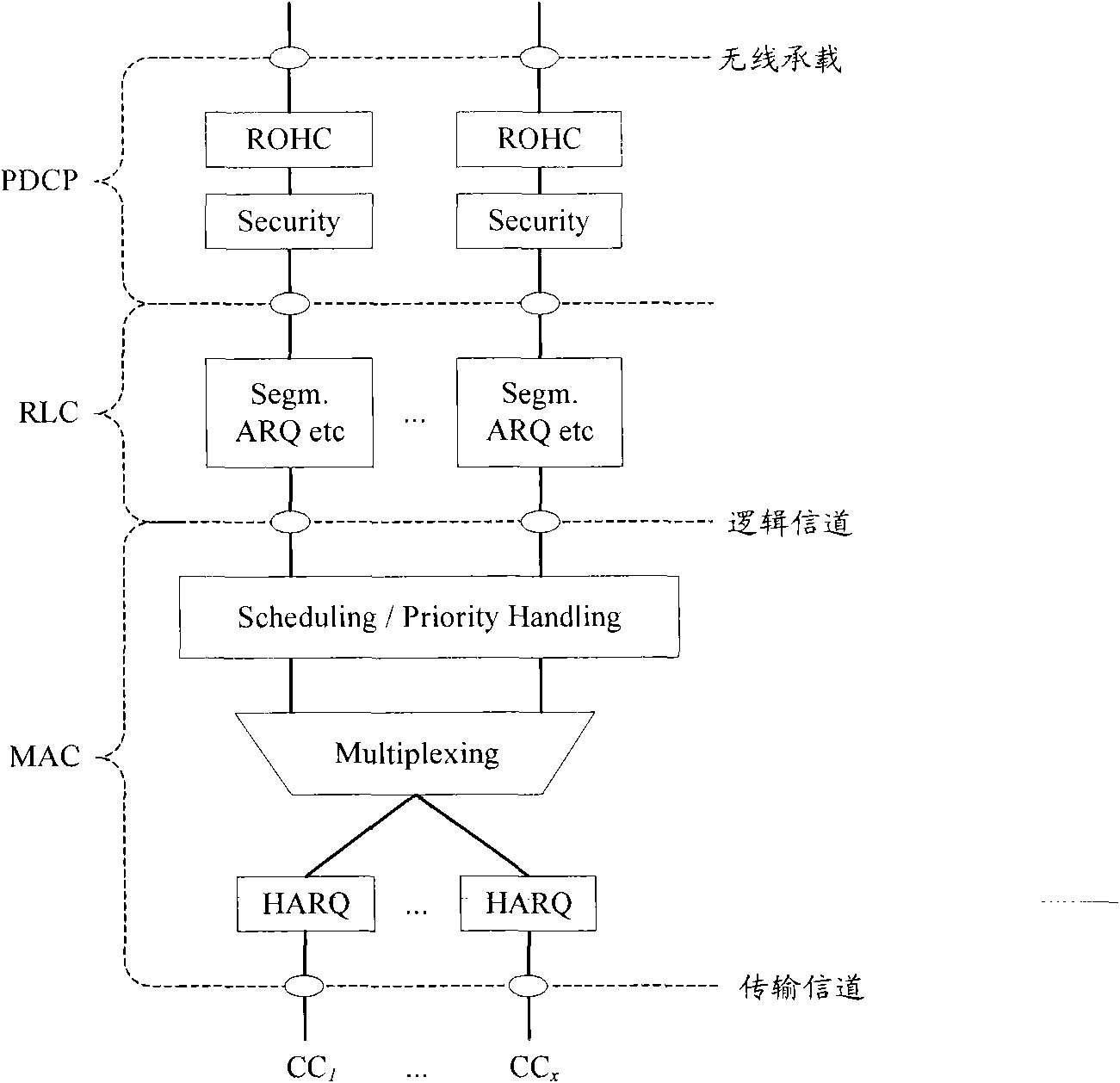

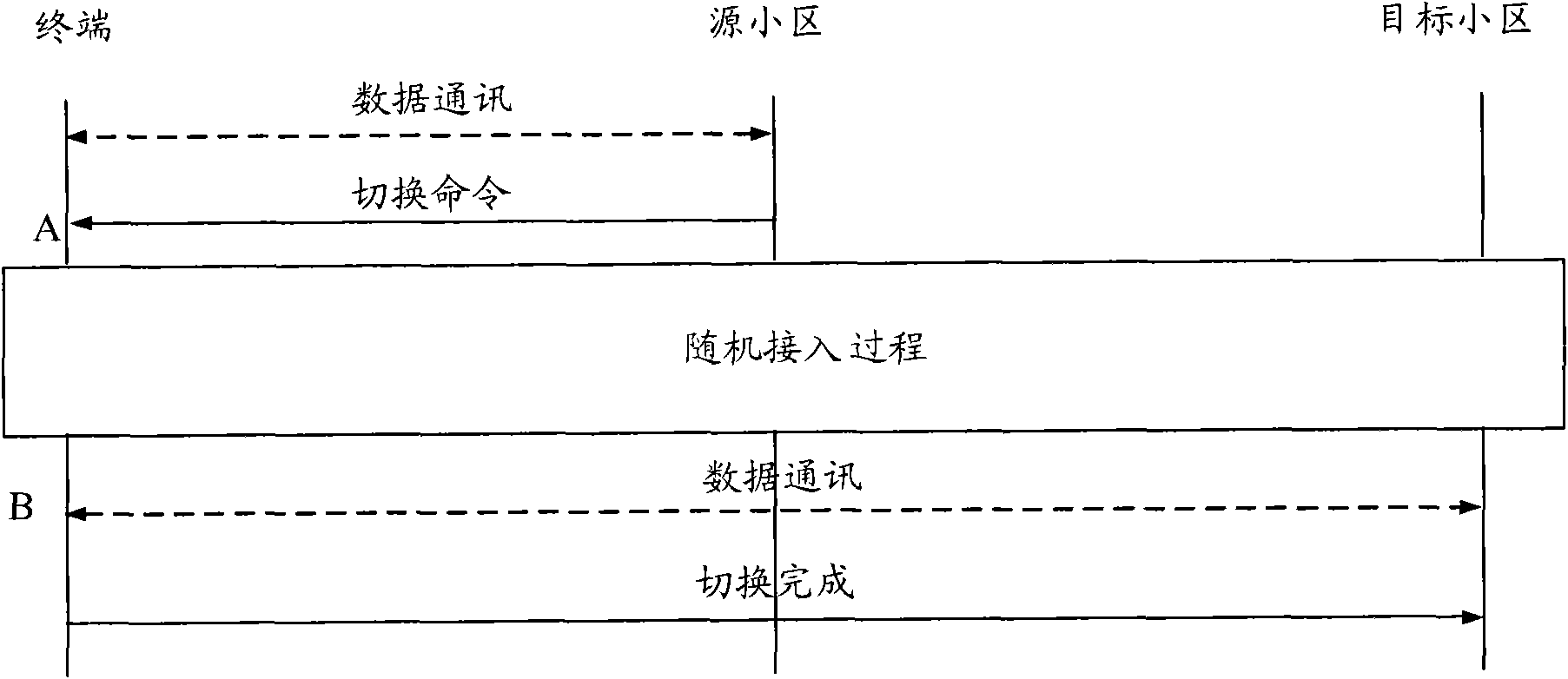

ActiveCN102123457AReduce downtimeReduce or even eliminate downtimeNetwork traffic/resource managementService experienceMobility management

The invention discloses a switchover method and a terminal. The switchover method comprises the steps: the terminal receives a switchover command, wherein the switchover command is used for indicating the terminal to be switched to a target cell; and the terminal executes a switchover process to the target cell and maintains data communication with a source cell till the switchover process is confirmed to be successful. The switchover method and the terminal, provided by the invention, can be used for shortening and even eliminating interruption time of switchover in mobile management to achieve the purpose of seamless switchover and improve the service experience of a user.

Owner:ZTE CORP

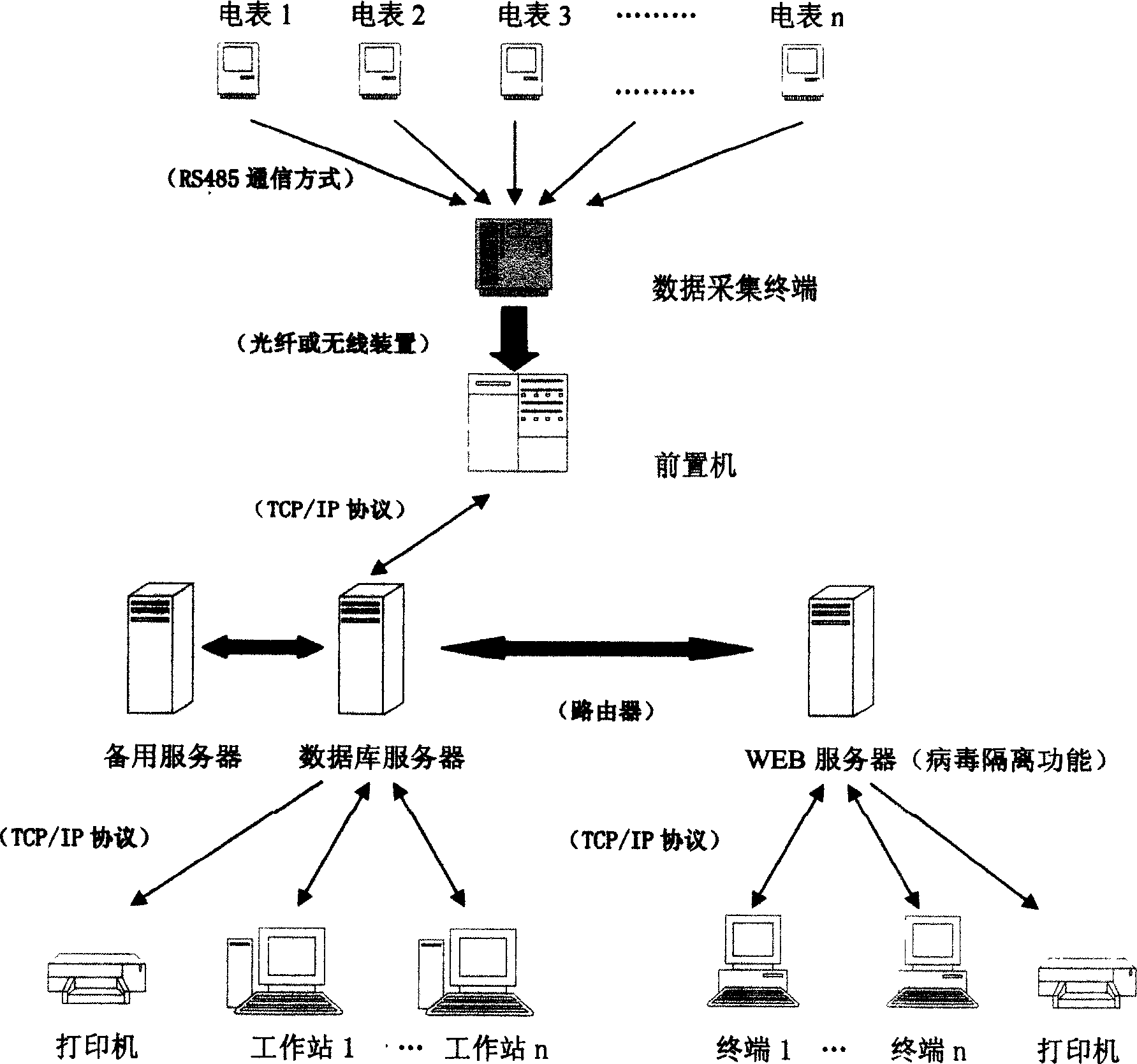

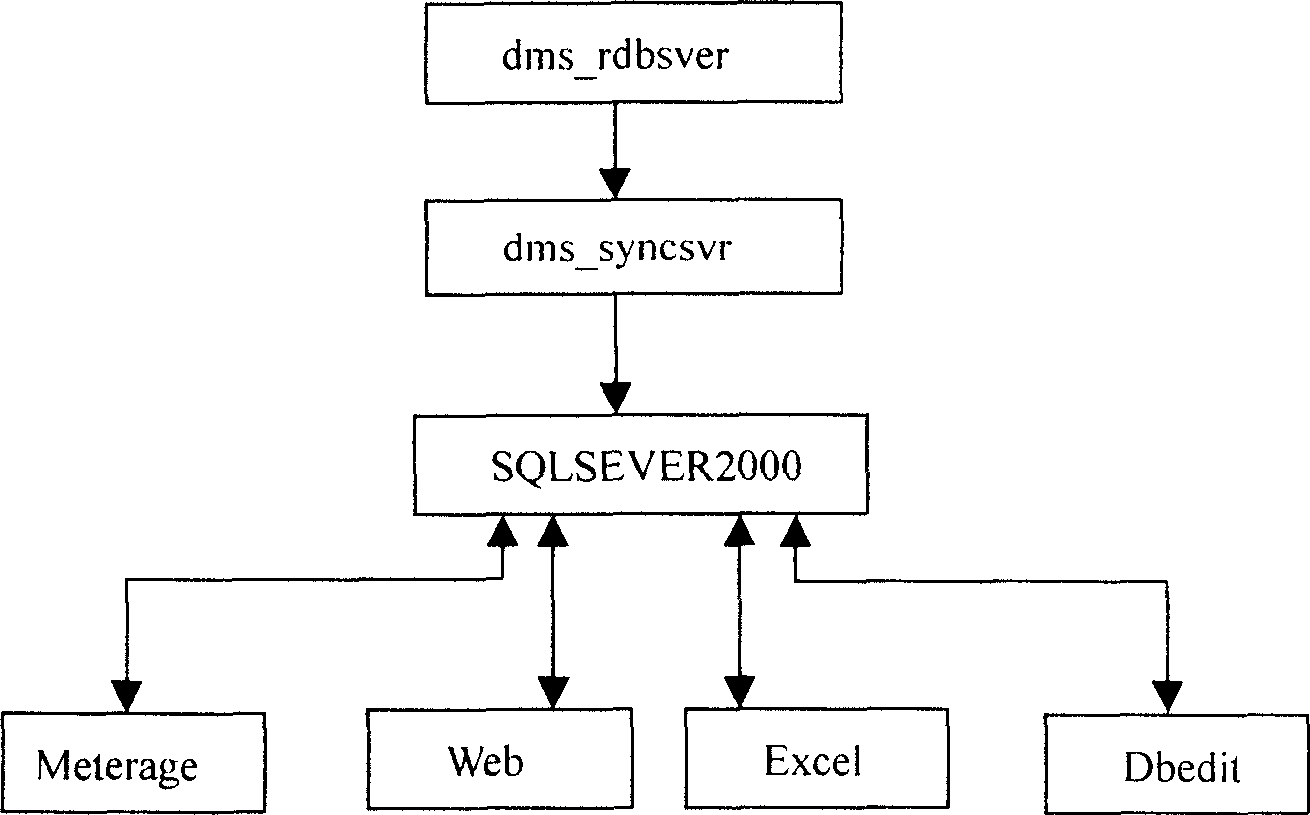

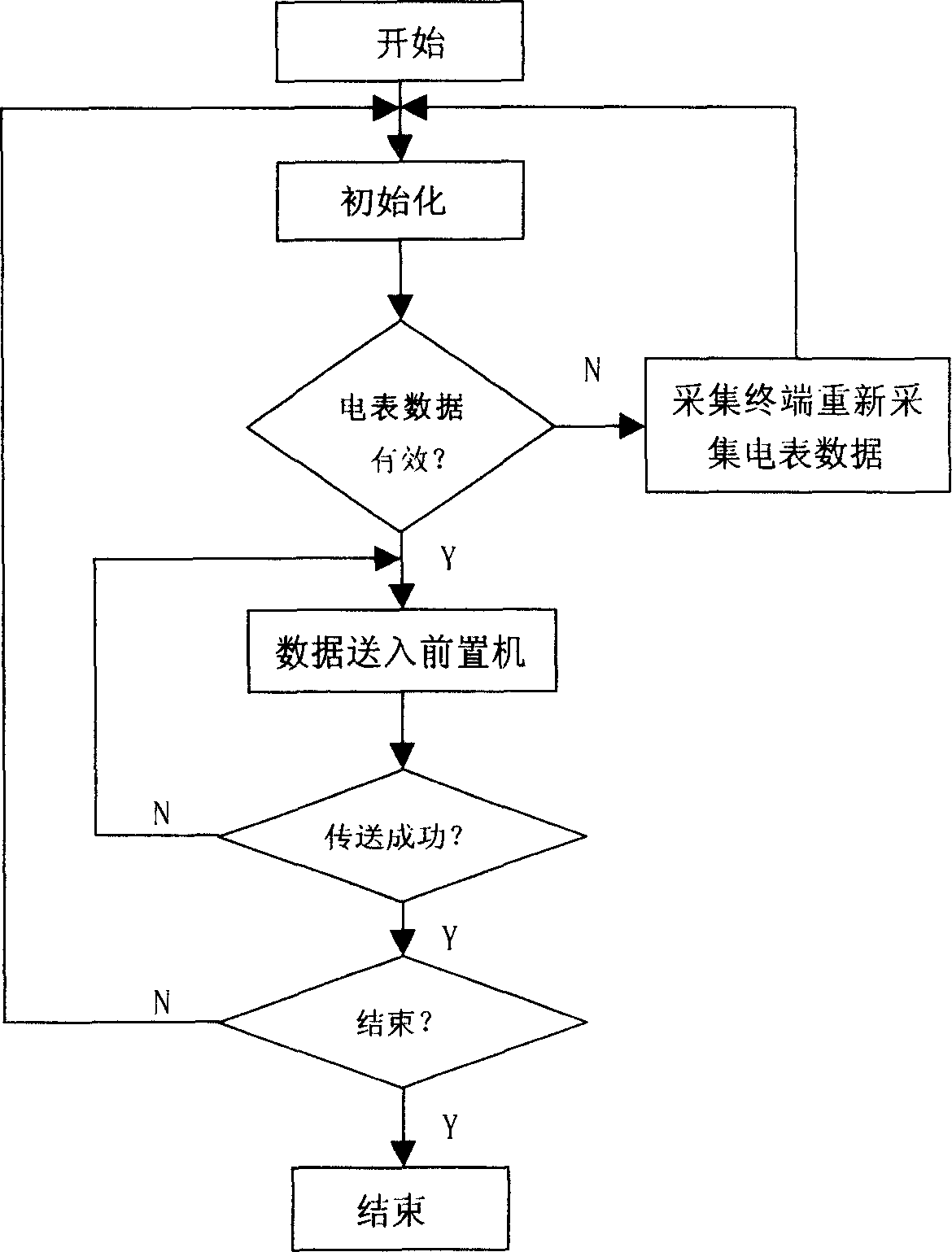

Metering and charging system of electric energy amount

InactiveCN1680817AUniqueness guaranteedIntegrity guaranteedElectric signal transmission systemsTariff metering apparatusData platformData acquisition

A metering and charging system of electric energy consists of four parts of data collection, data management, network browse and electronic report. It is featured as using data collection unit and data management unit to form databank for application, using network browse unit to browse data in databank and using electronic report unit to print out required data. The system has unified data platform being able to obtain remote electric energy data and it can ensure uniqueness, completeness and correctness of the data.

Owner:南京迪玛斯电气有限公司

System for continuous growing of monocrystalline silicon

ActiveUS7635414B2Low oxygenEliminate downtimeAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

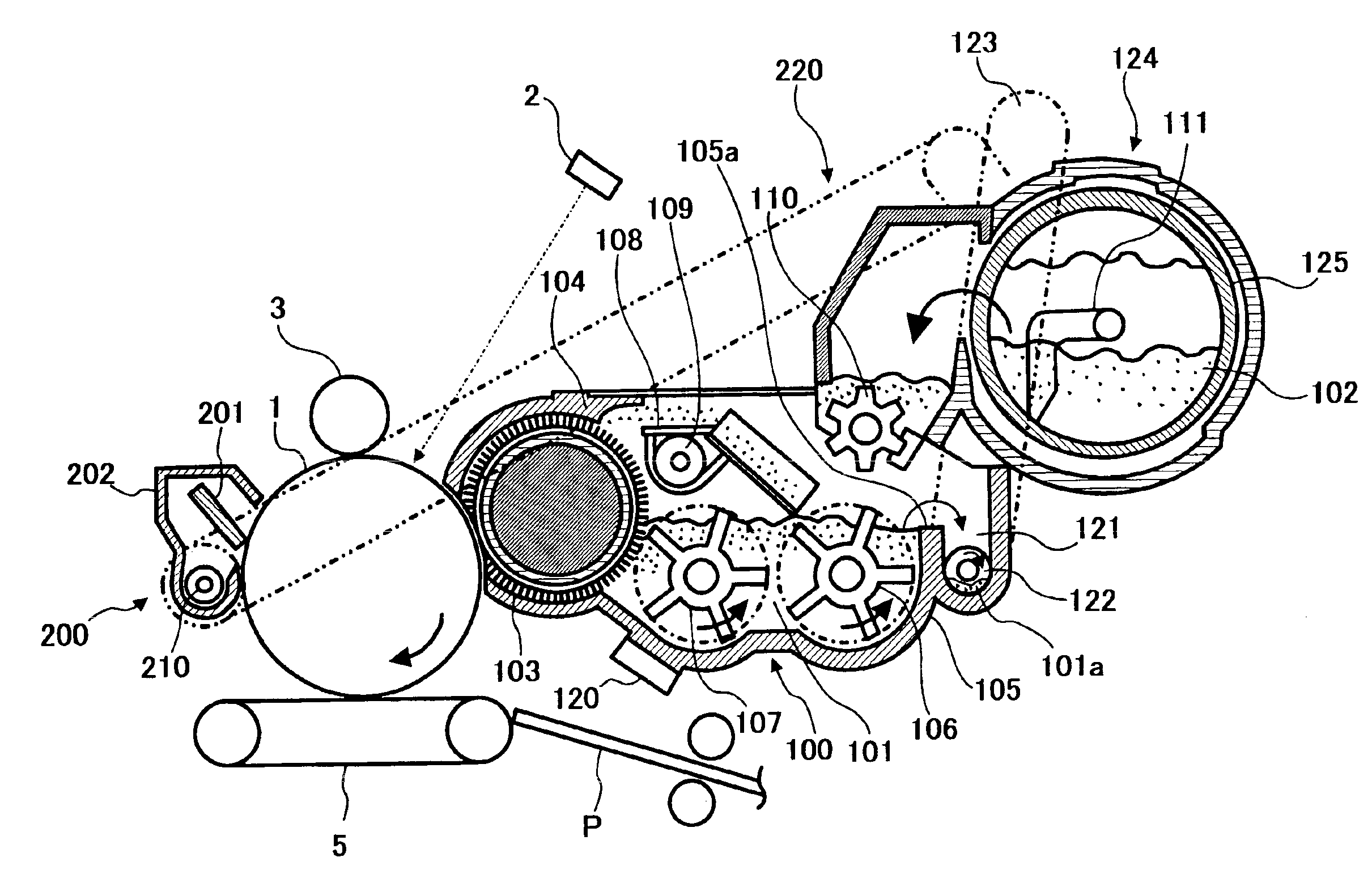

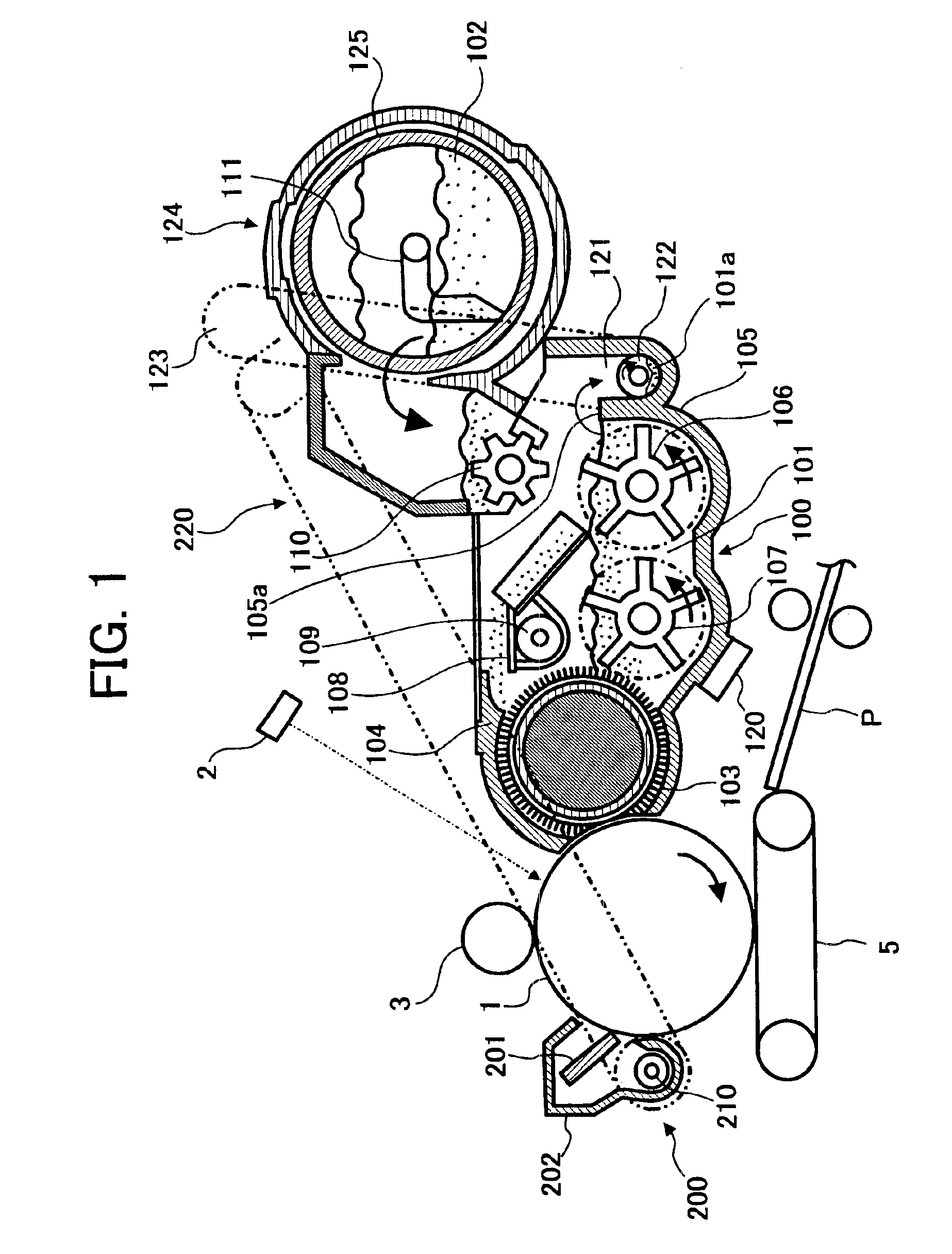

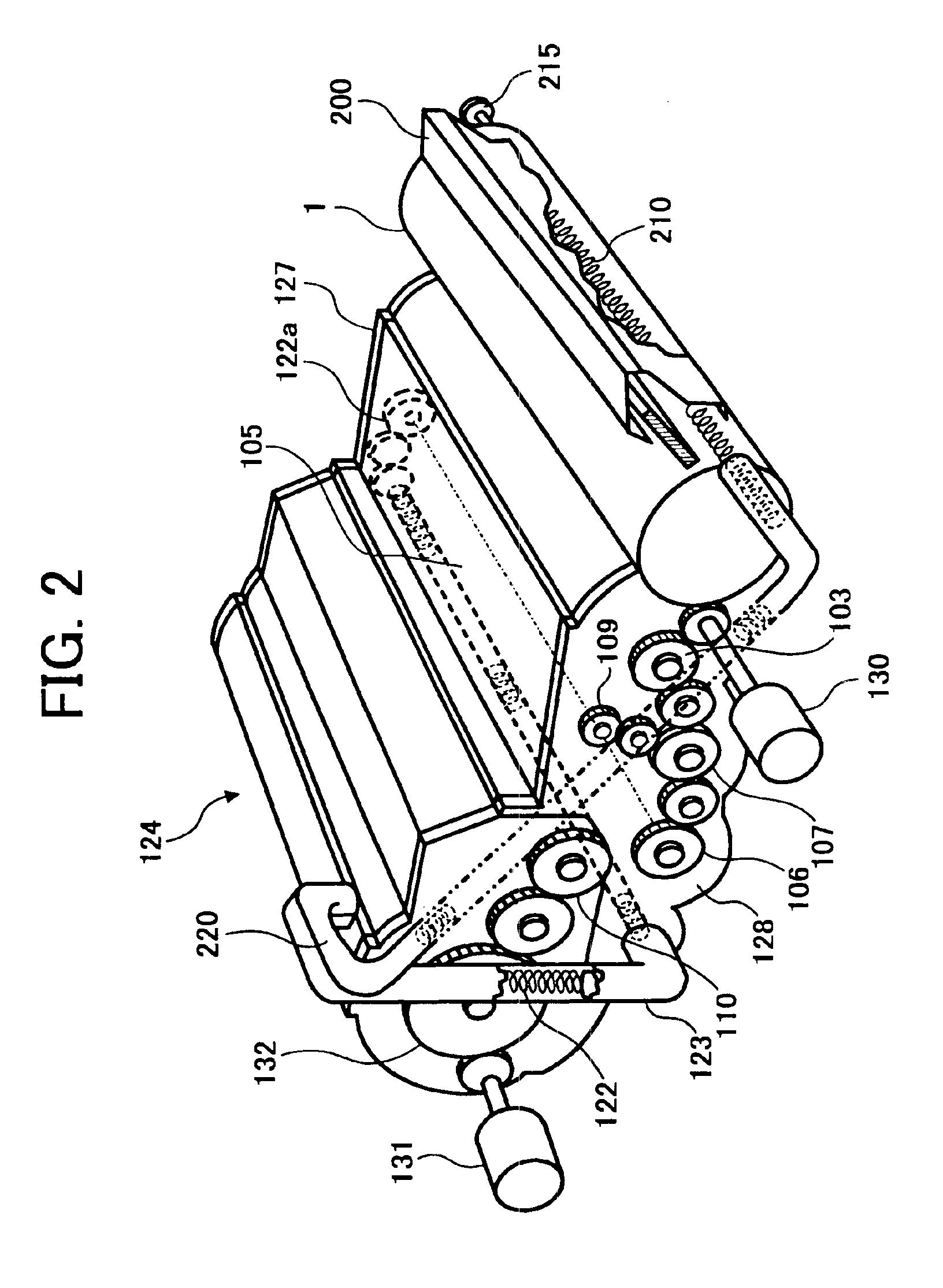

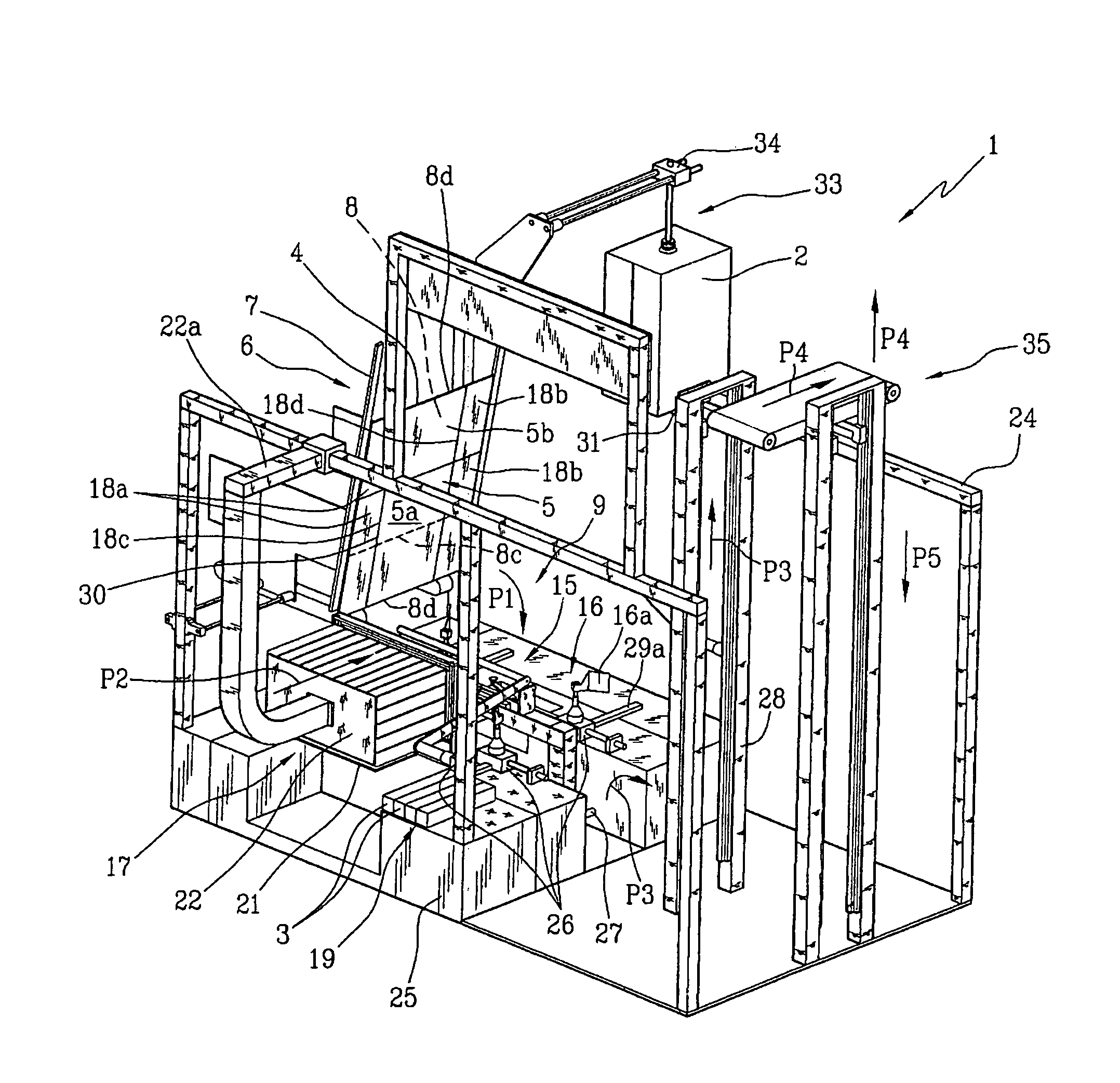

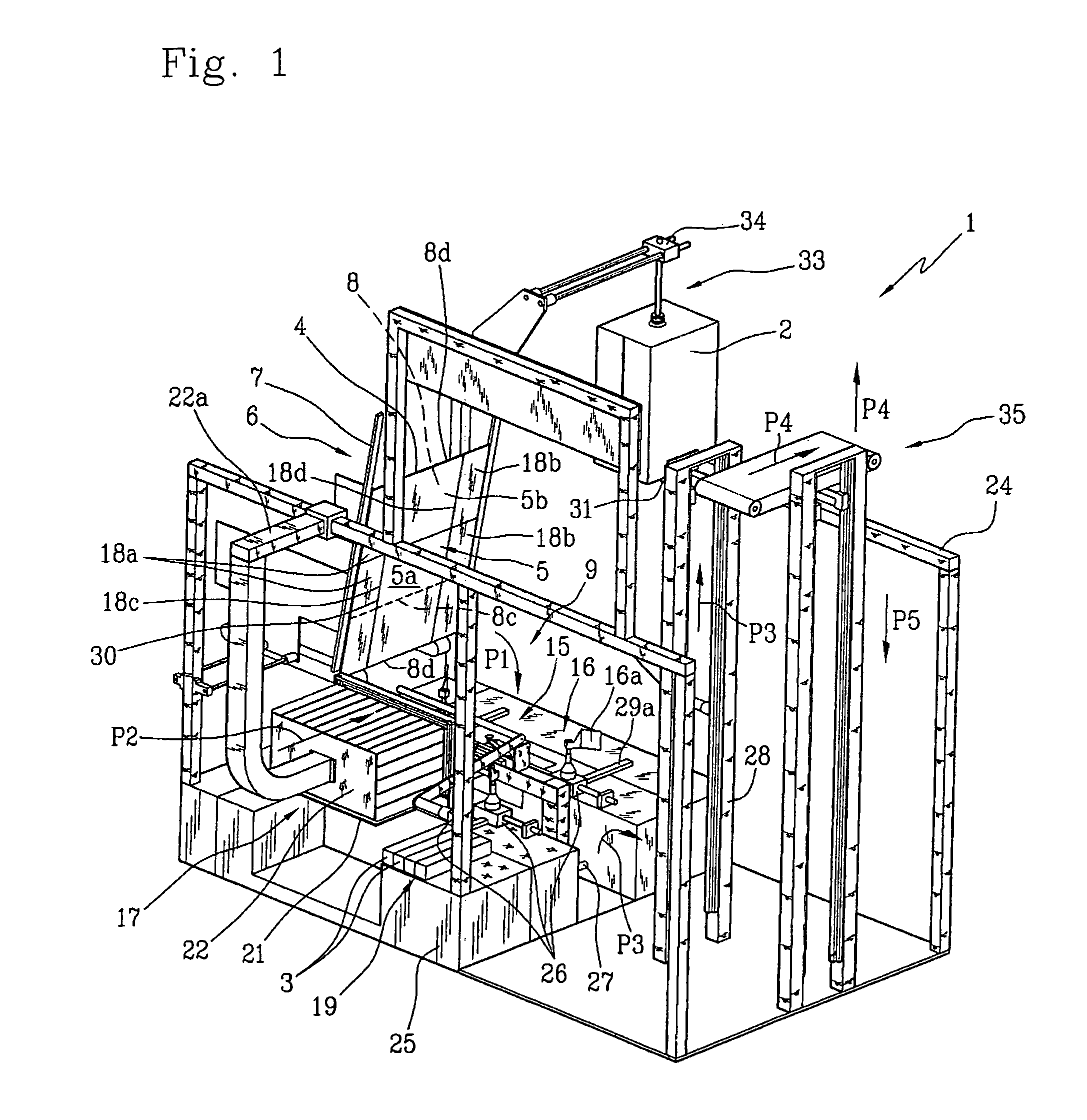

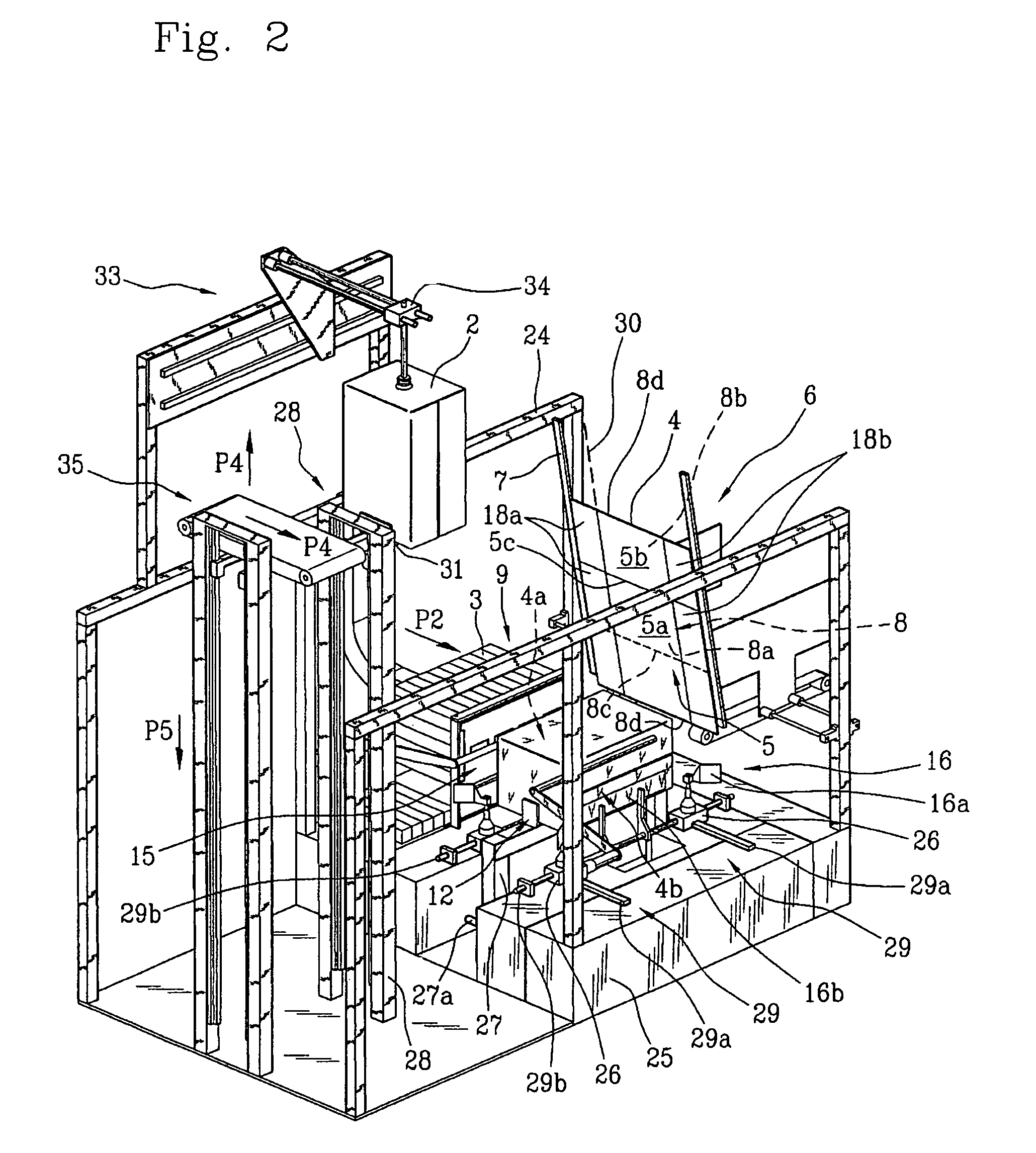

Image forming apparatus including developing device and developer containing device

InactiveUS6882812B2Eliminate downtimeElectrographic process apparatusImage formationImaging equipment

Owner:RICOH KK

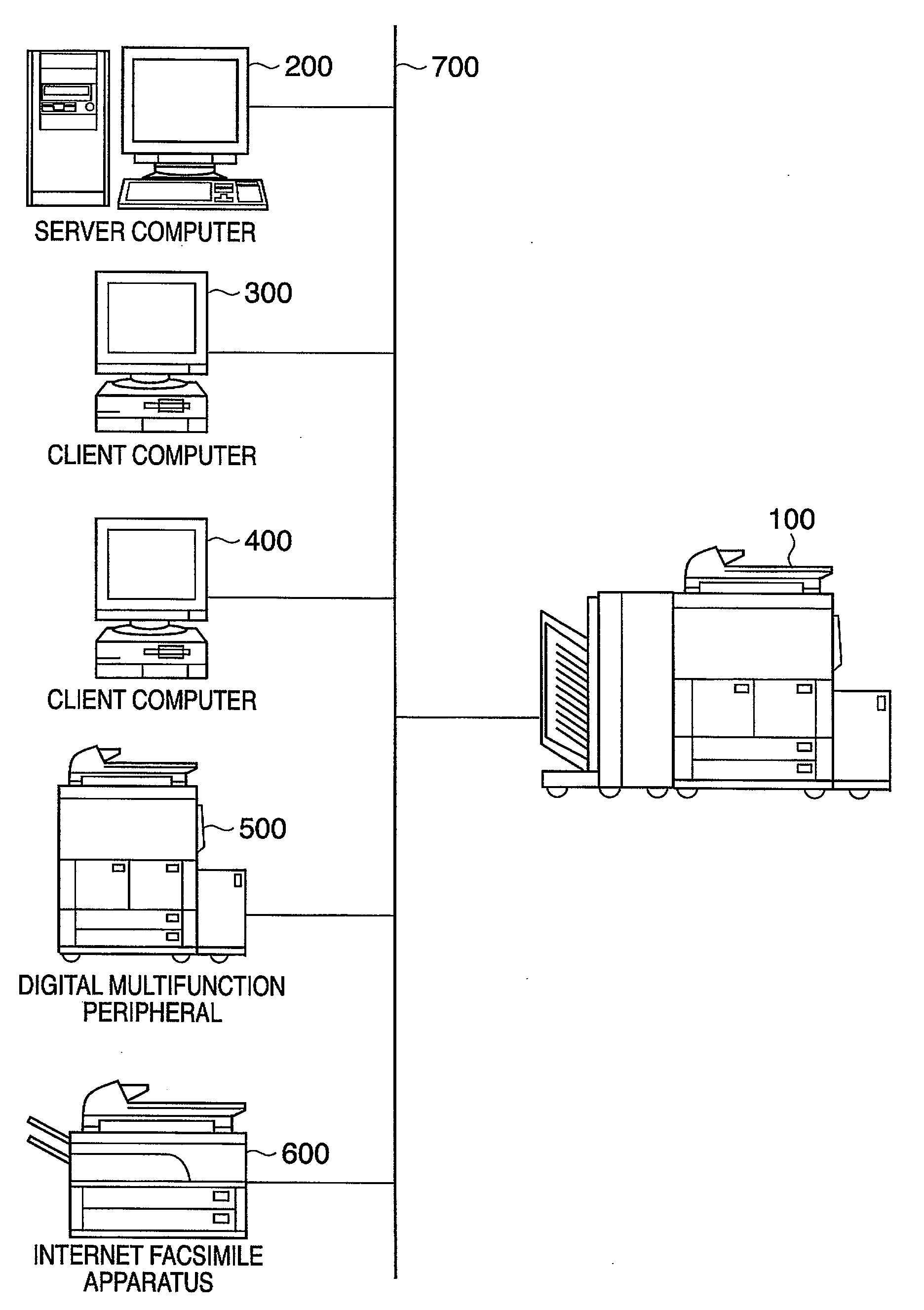

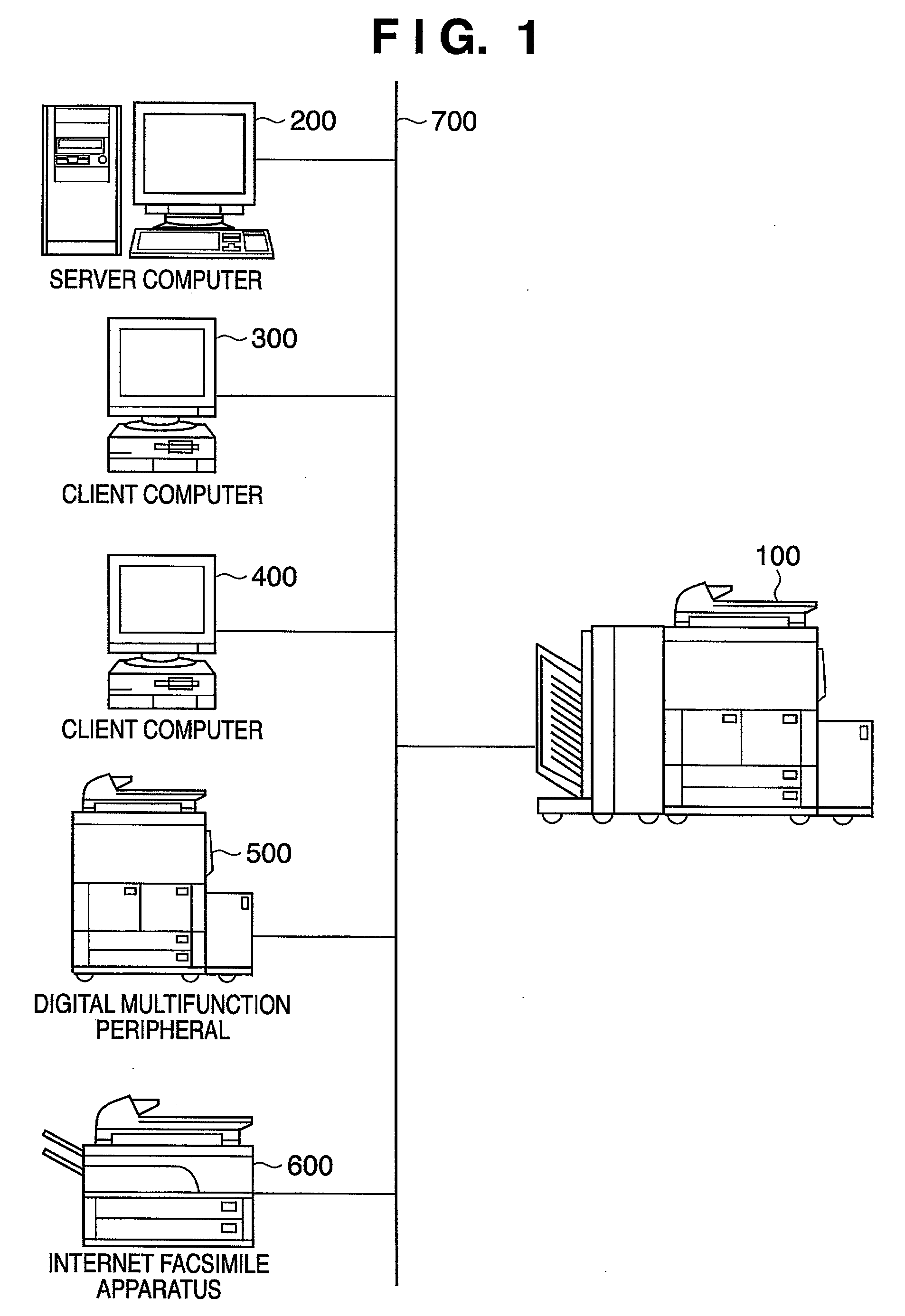

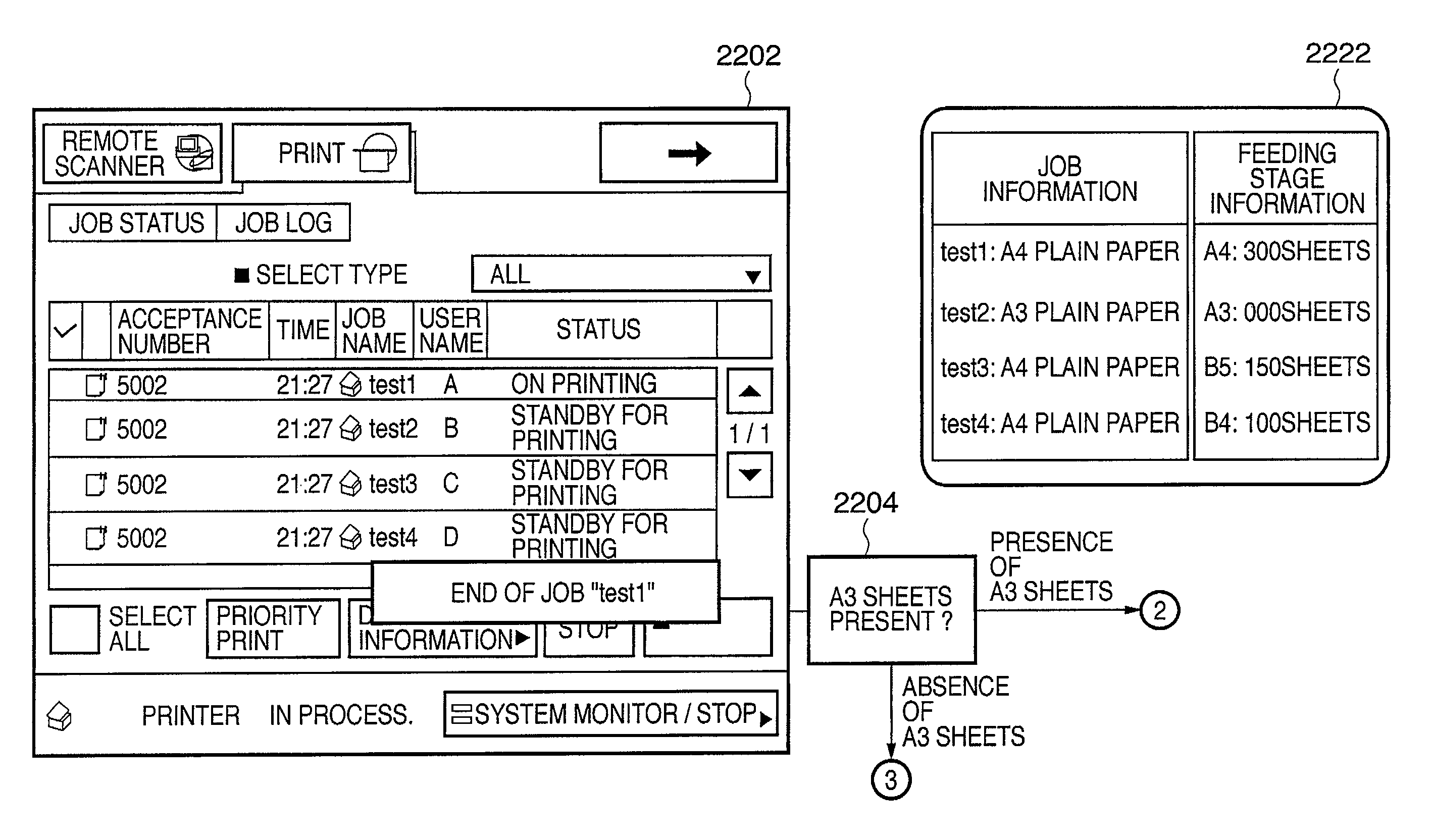

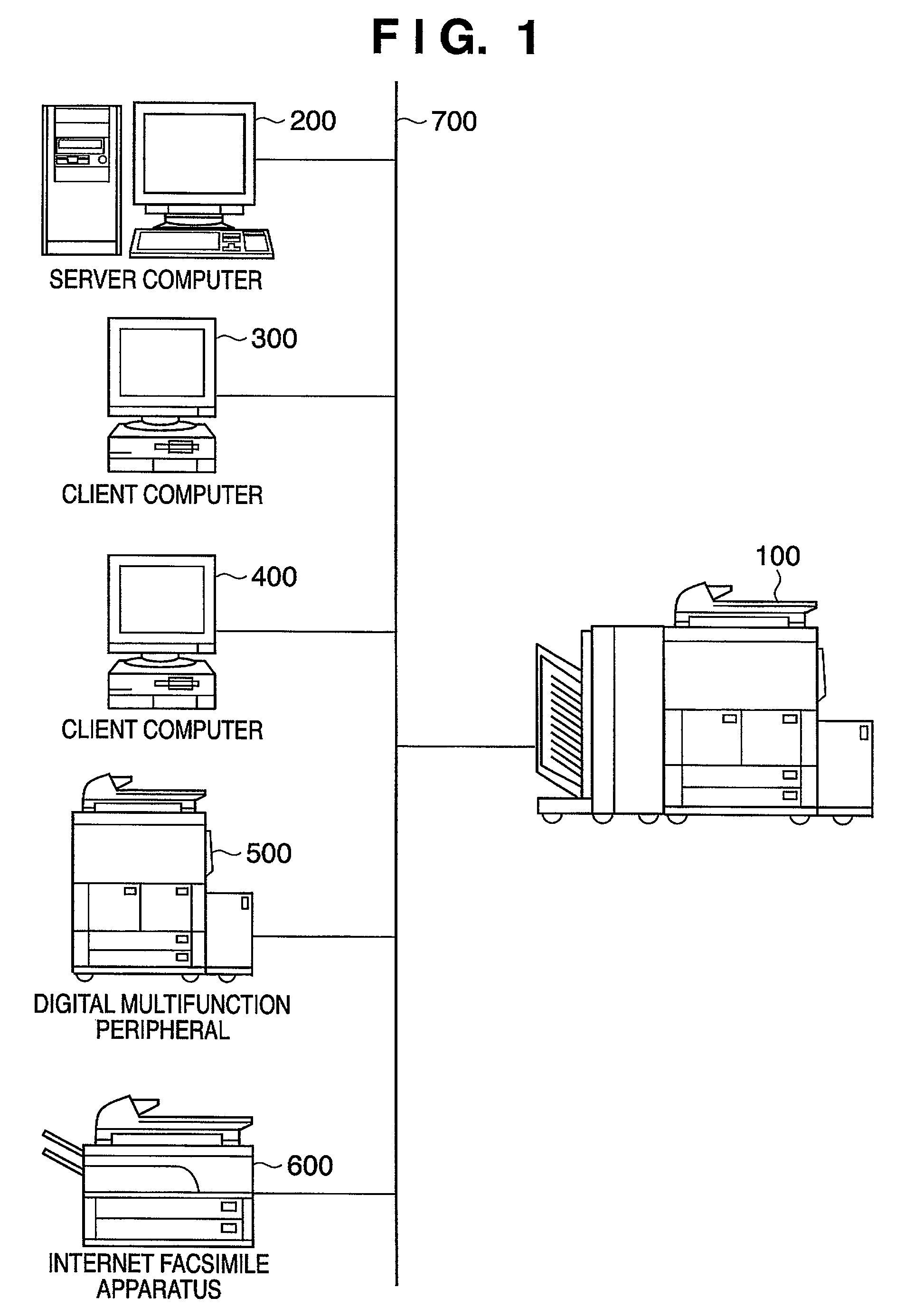

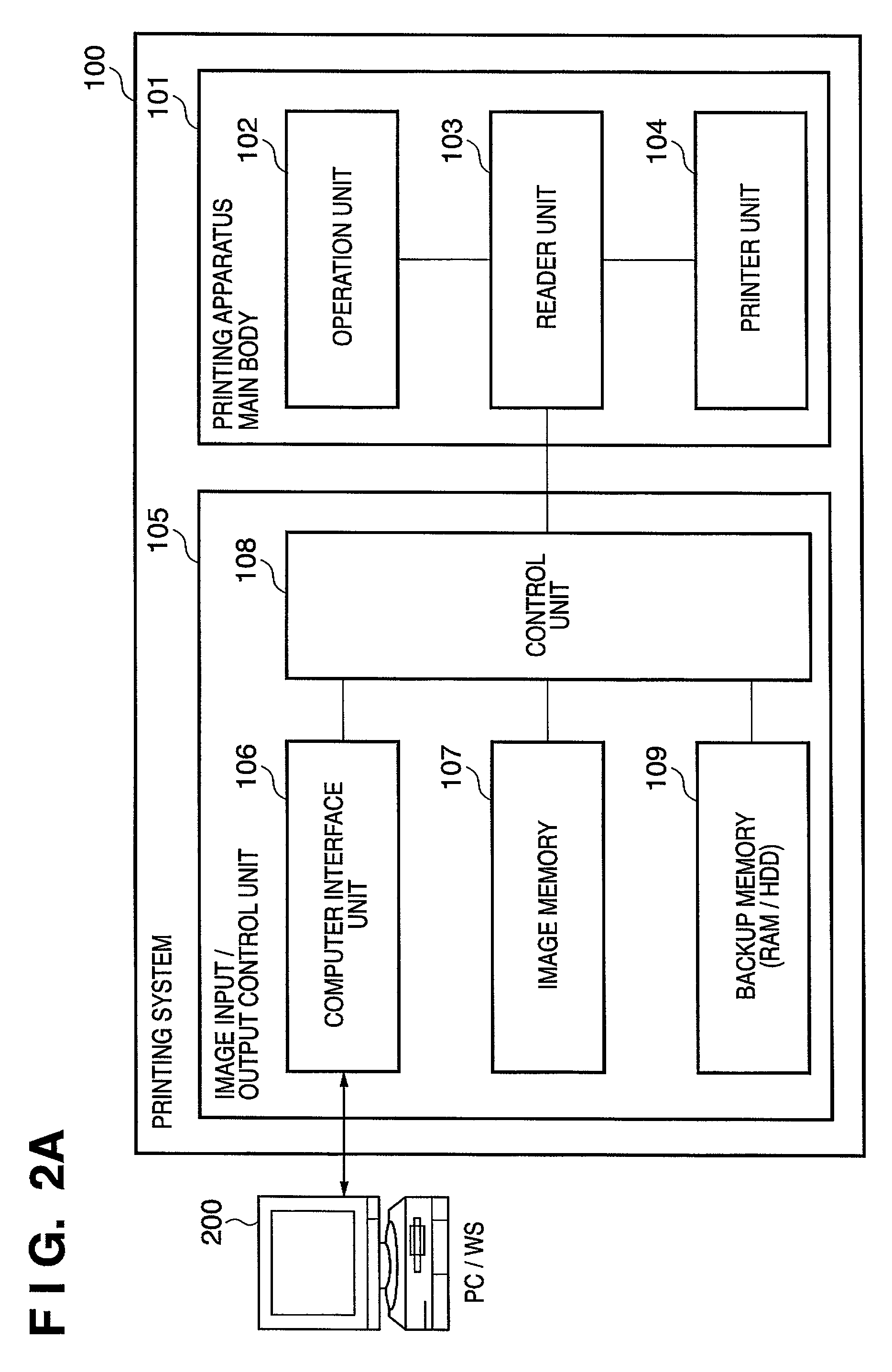

Print job management method and image forming apparatus

ActiveUS20080180742A1Simple replenishment of consumablesEliminate downtimeDigitally marking record carriersDigital computer detailsImage formationComputer science

In a system configured to enable a printing unit to execute another job preferentially to a job not prepared for printing, when no predetermined time has elasped from a timing in which it has been determined that the job was not prepared for printing, it is inhibited to execute the other job preferentially to the job. When the predetermined time has elapsed from the timing, it is permitted to execute the other job preferentially to the job. This configuration can prevent unconditionally executing the another job preferentially to the job not prepared for printing.

Owner:CANON KK

Practical ion mobility spectrometer apparatus and methods for chemical and/or biological detection

ActiveUS7943901B2High sensitivity and selectivityIncrease capacityTime-of-flight spectrometersSamples introduction/extractionIon-mobility spectrometryIonization

This invention describes an ion mobility spectrometer system for chemical detection in the field. The system allows: a high throughput operation, an interface to new ionization methods, and an interface to a mass spectrometer.

Owner:EXCELLIMS CORP

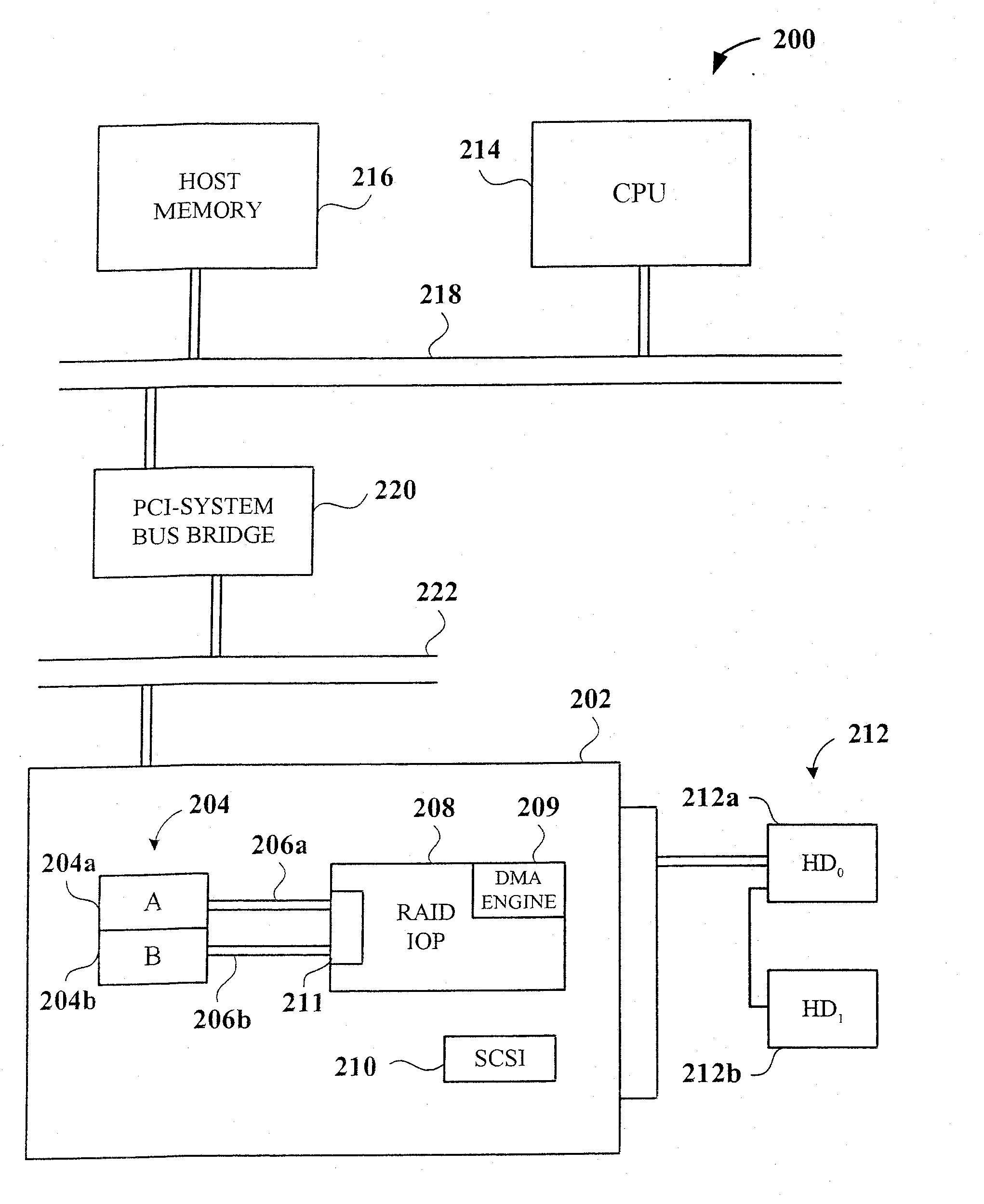

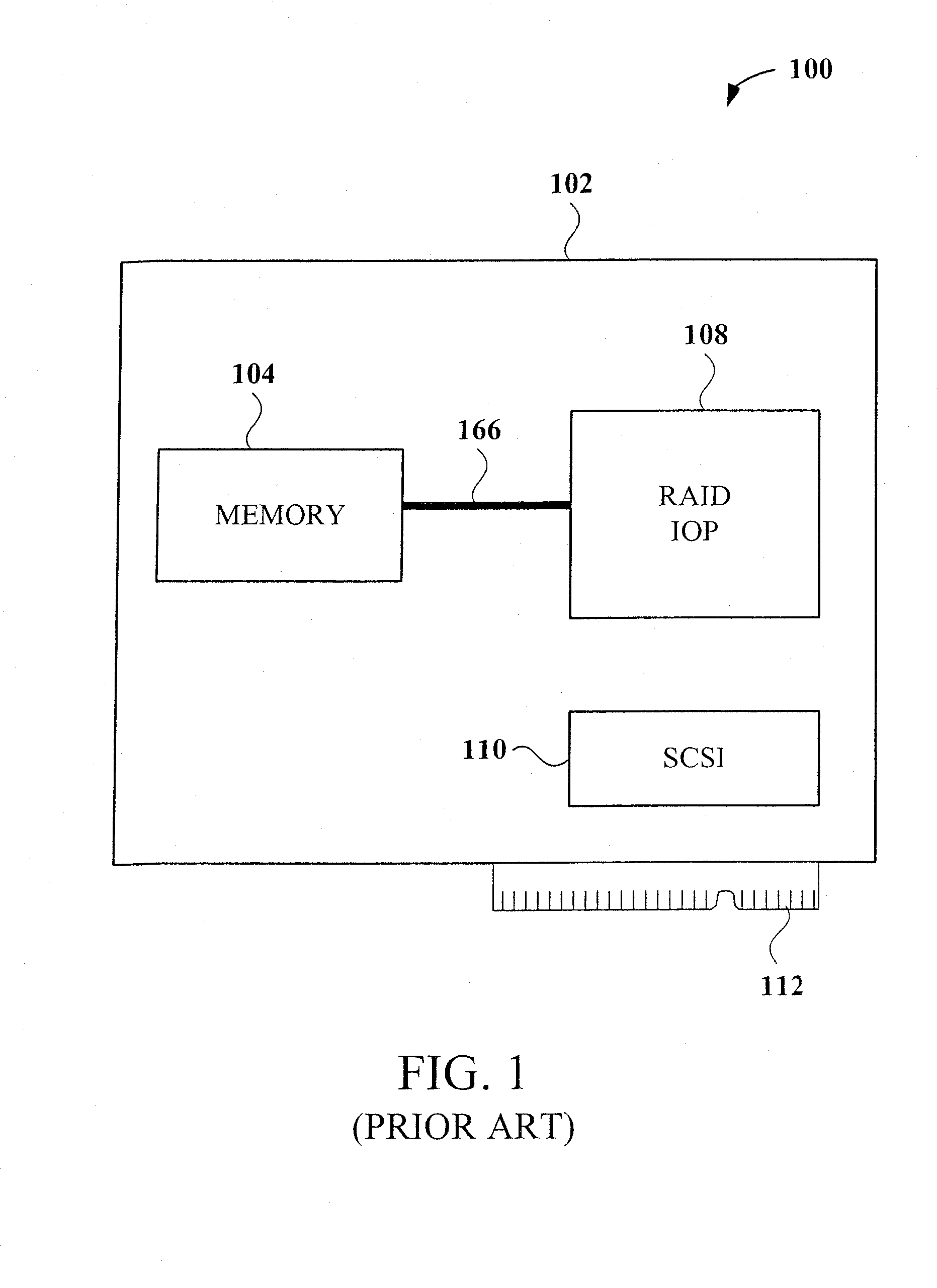

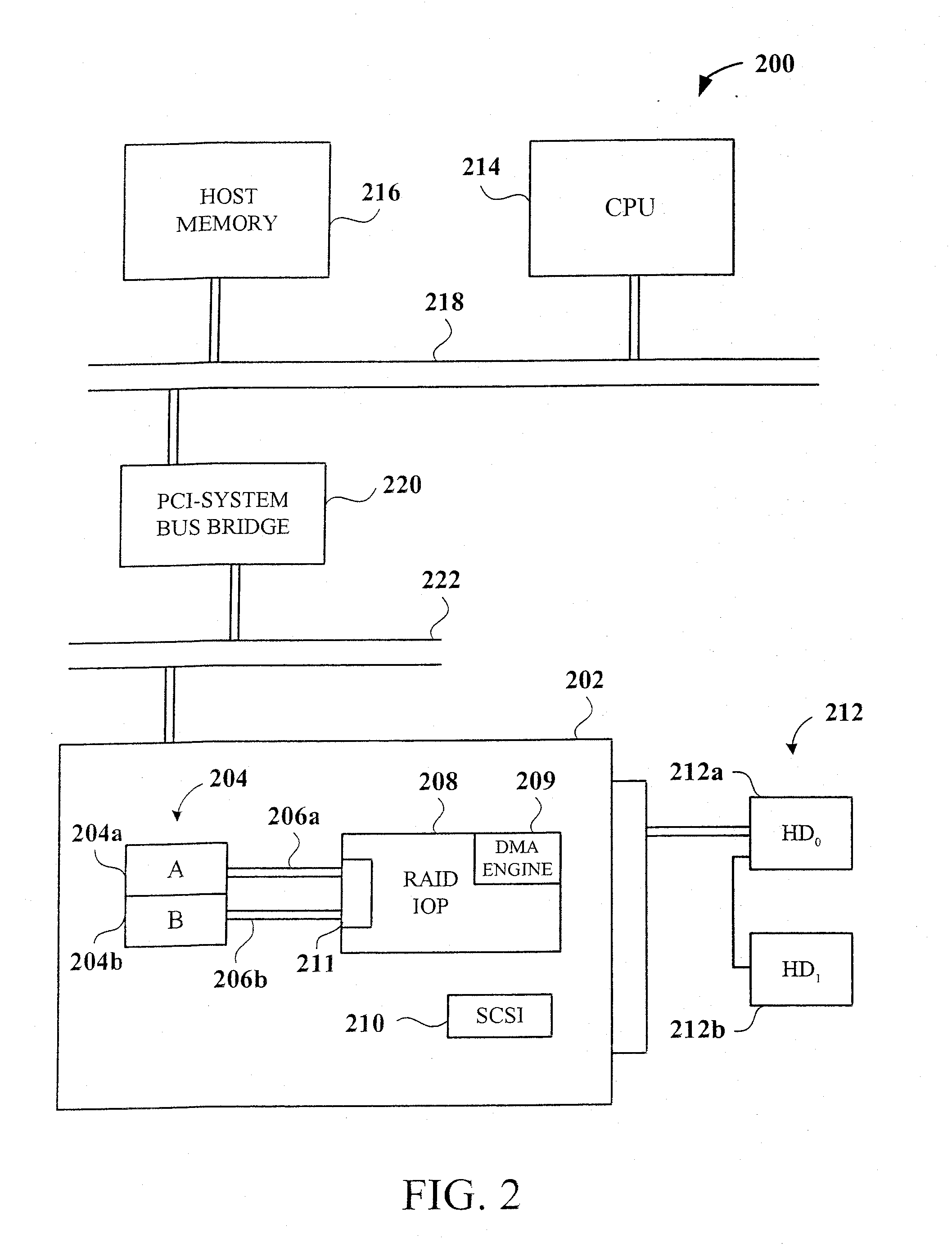

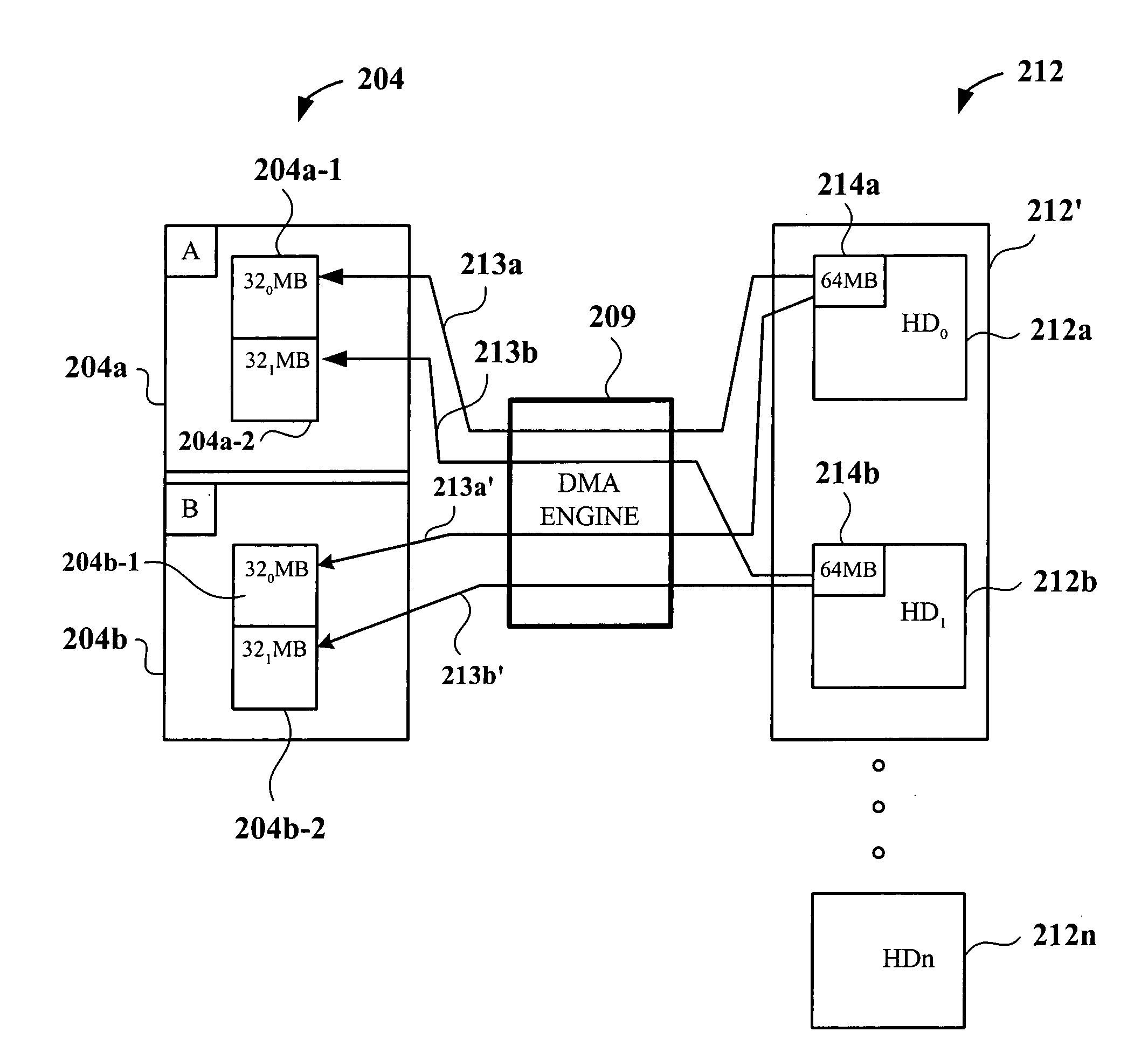

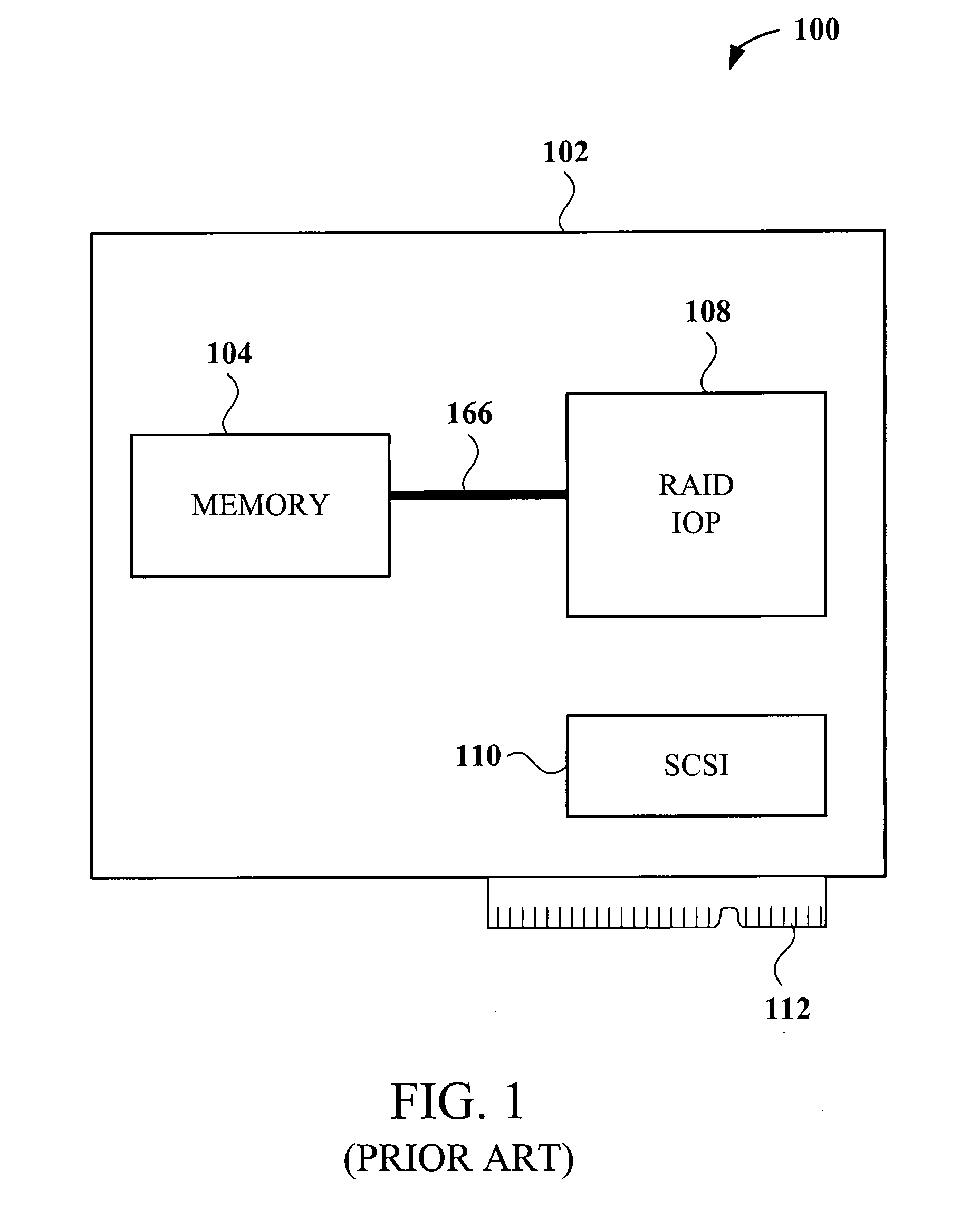

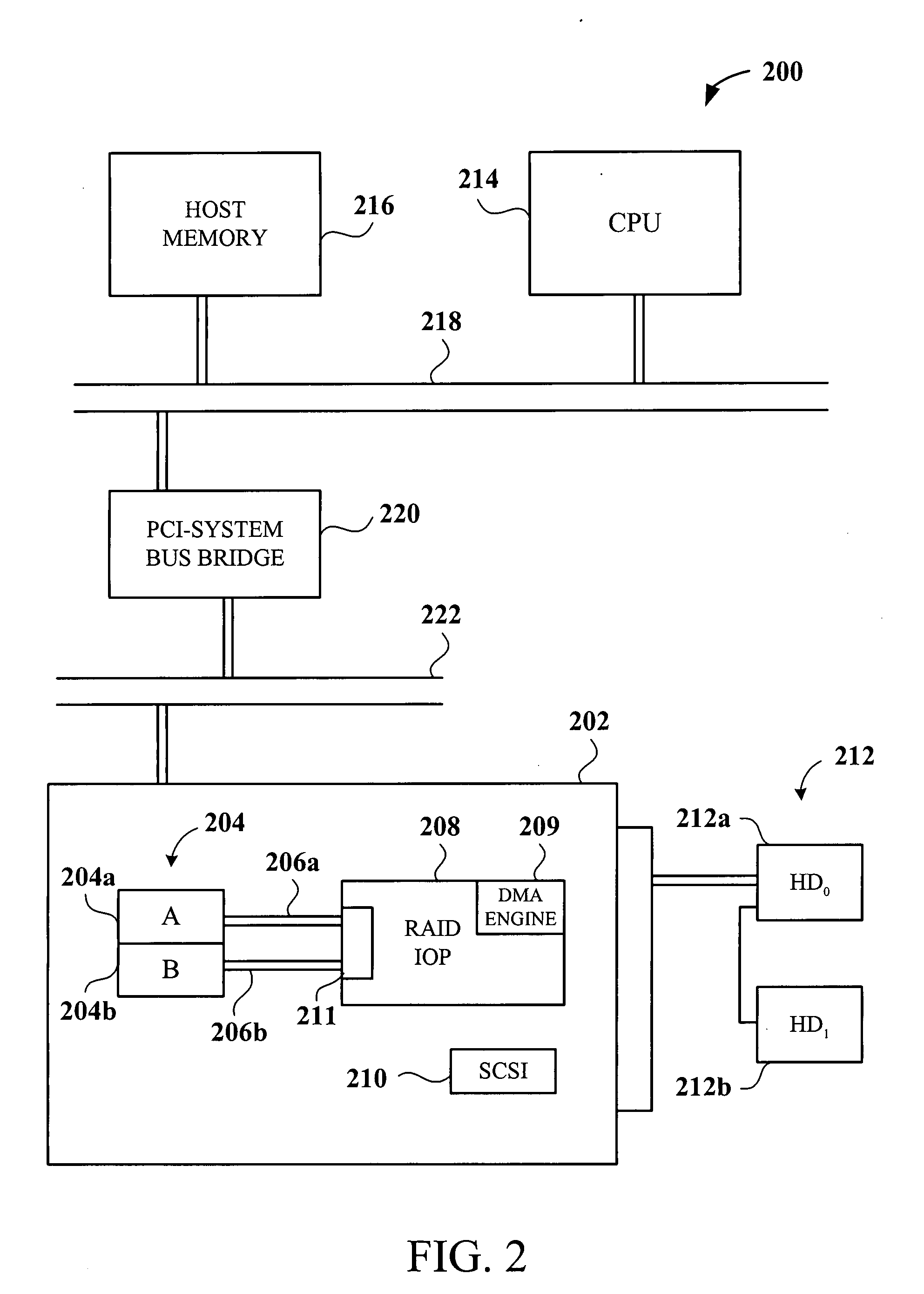

Method and apparatus for raid on memory

InactiveUS20080163385A1Improve performanceImprove reliabilityVolume/mass flow measurementPower supply for data processingRAID

Owner:PMC-SIERRA

Method and apparatus for raid on memory

InactiveUS7293138B1Improve performanceImprove reliabilityMemory loss protectionRedundant hardware error correctionRAID

Owner:PMC-SIERRA

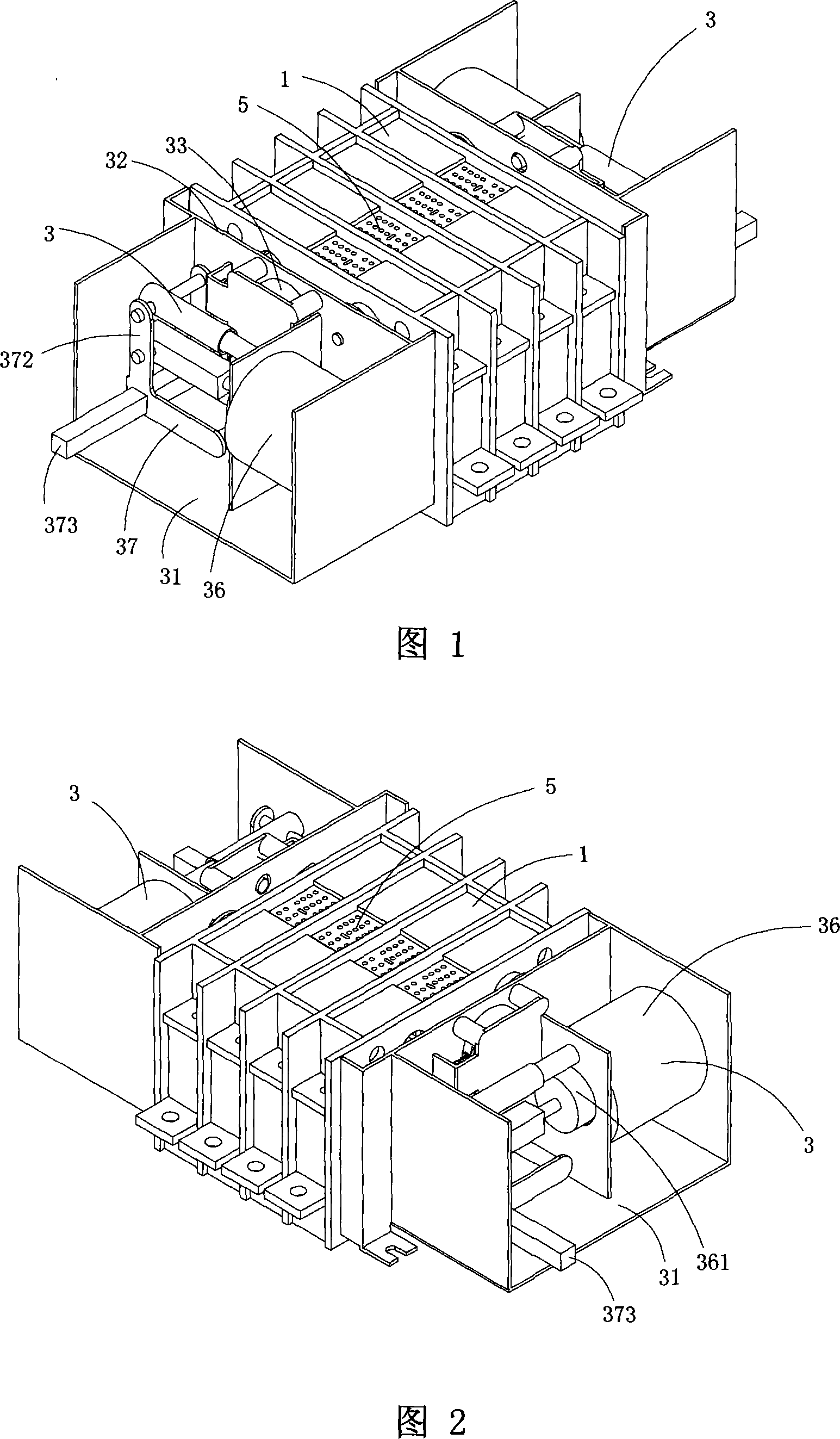

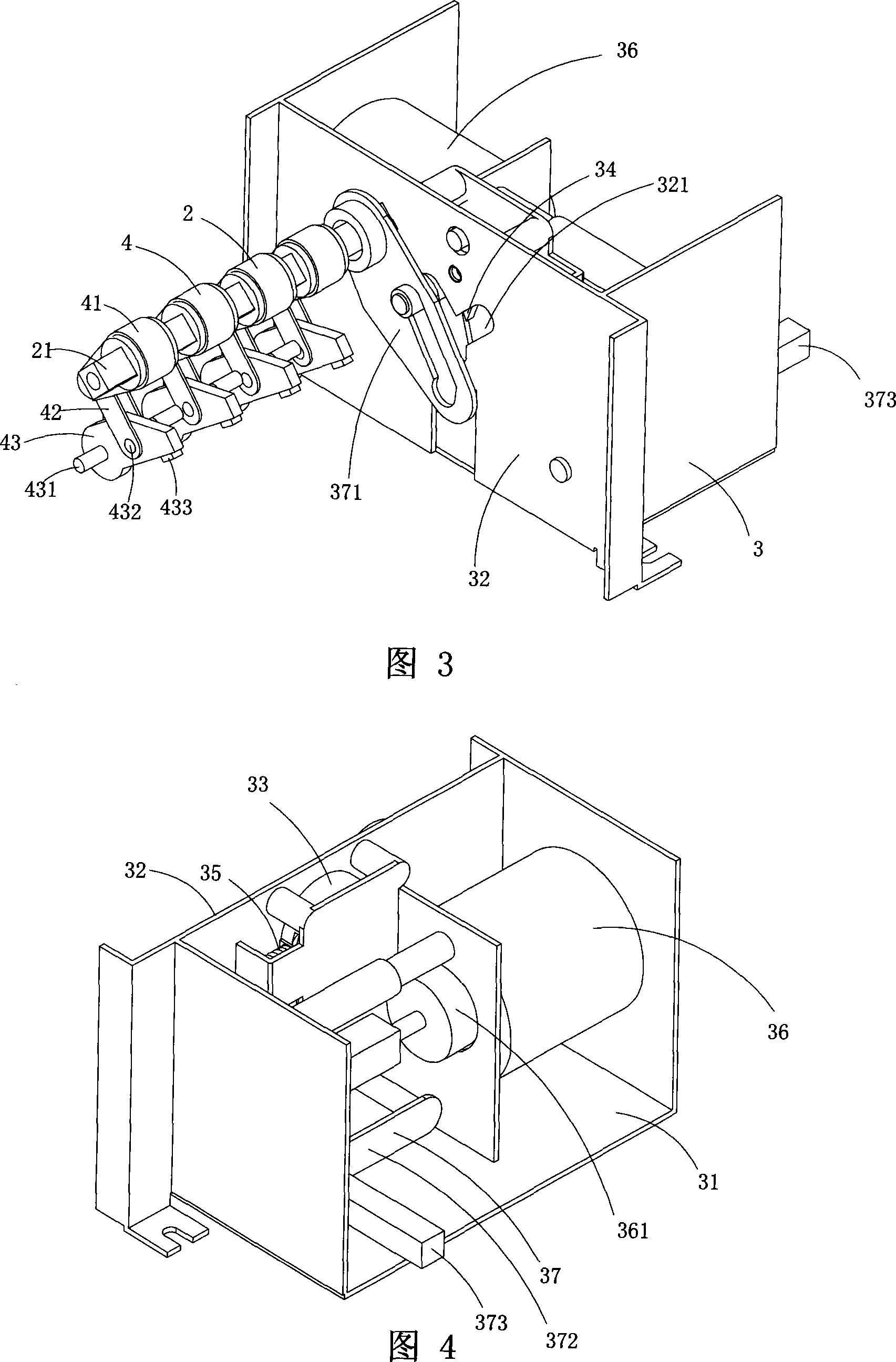

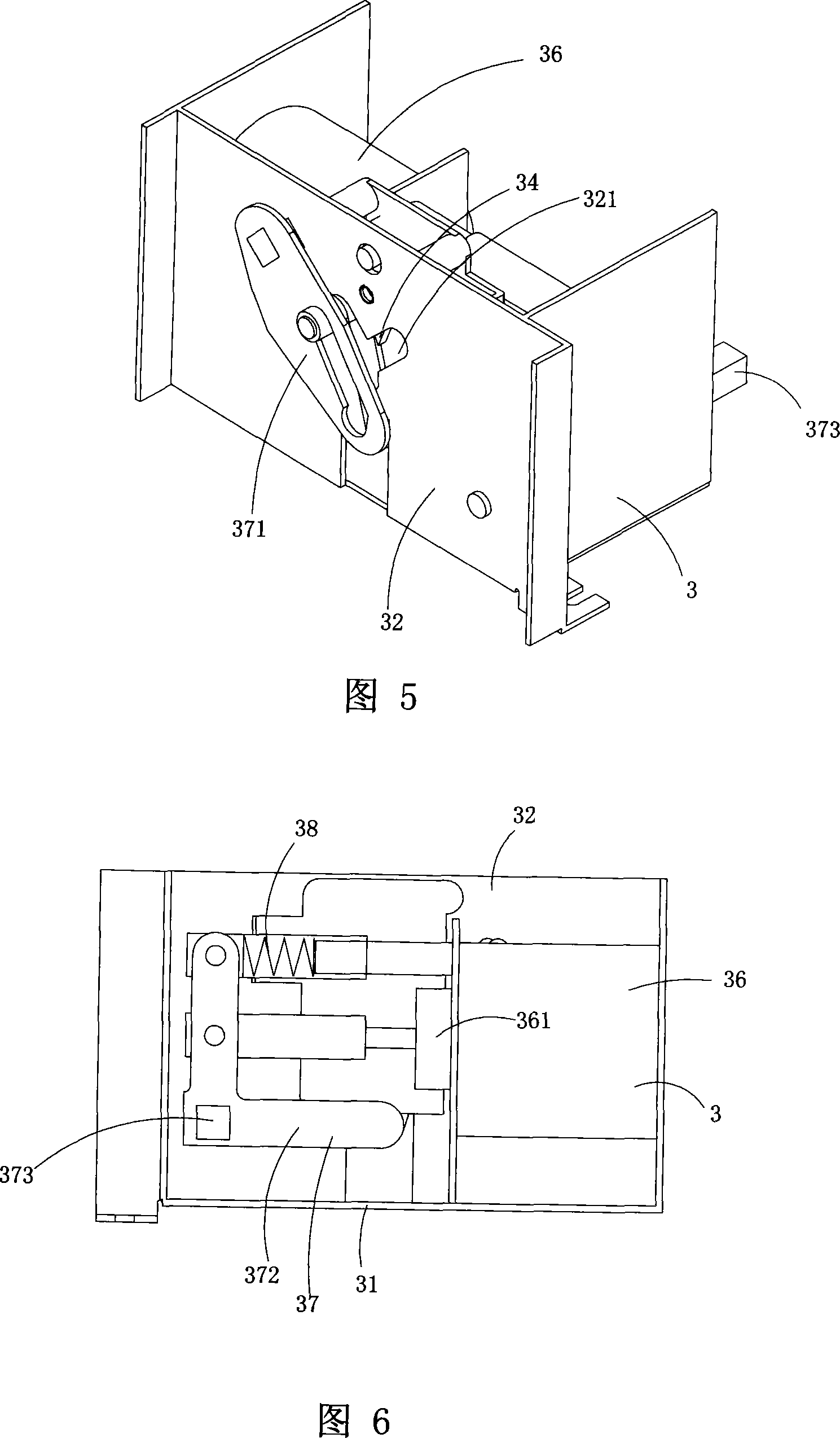

Double power change-over switch without intermittence

InactiveCN101231915AEliminate downtimeAny interruption timeSwitch power arrangementsChangeoverMechanical transmission

The invention discloses an uninterrupted dual power supply changeover switch, which comprises an encloser, a contact on-off system and a mechanical transmission system. The invention is structurally characterized in that the uninterrupted dual power supply changeover switch comprises two mechanical transmission systems which are independent of each other and two contact on-off systems which are independent of each other; each of the mechanical transmission systems drives one contact on-off system matched with the mechanical transmission system. The invention has the advantages of compact structure and small volume. In addition, the invention can eliminate power interruption, thus achieving uninterrupted conversion of dual power supply.

Owner:黄勤飞

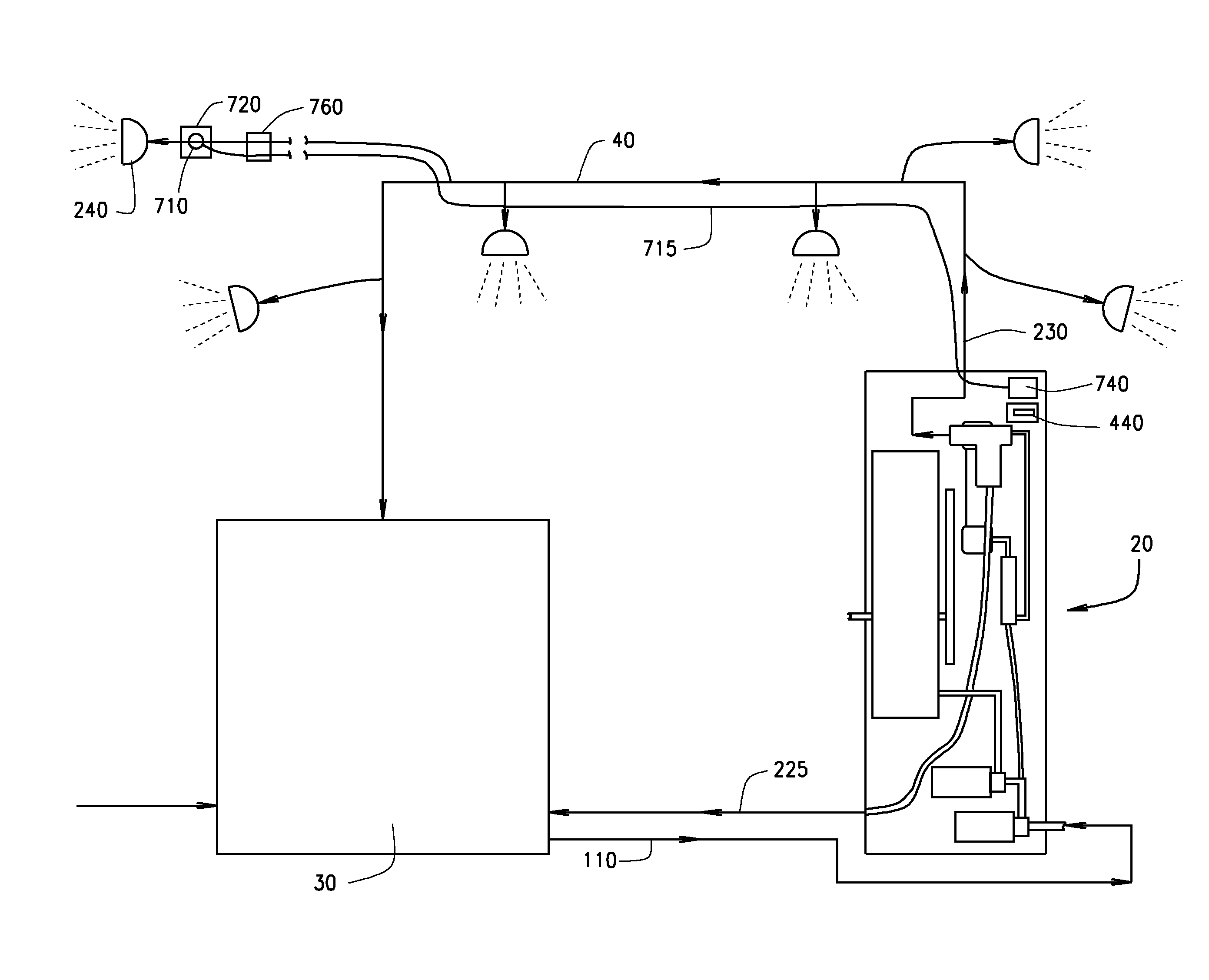

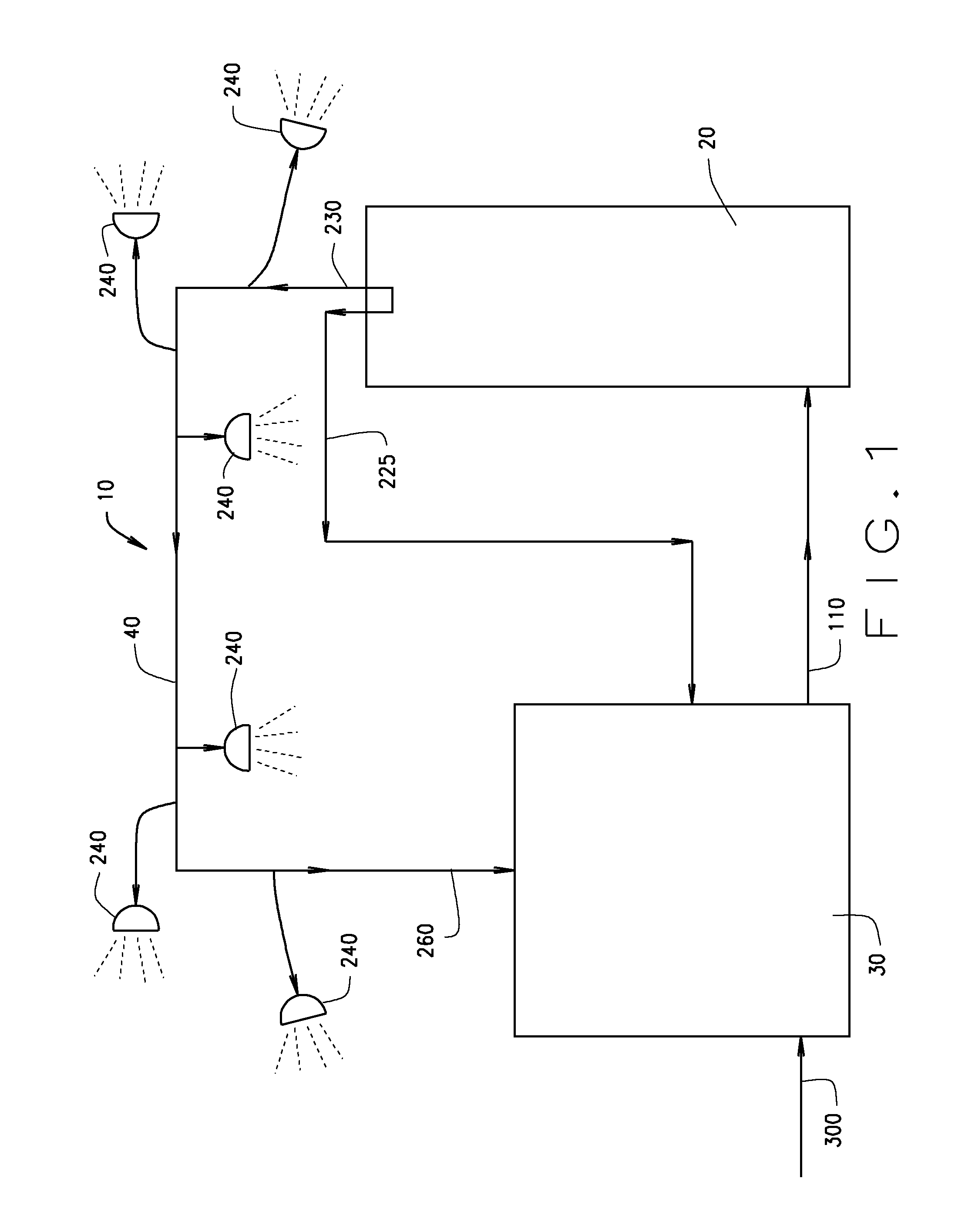

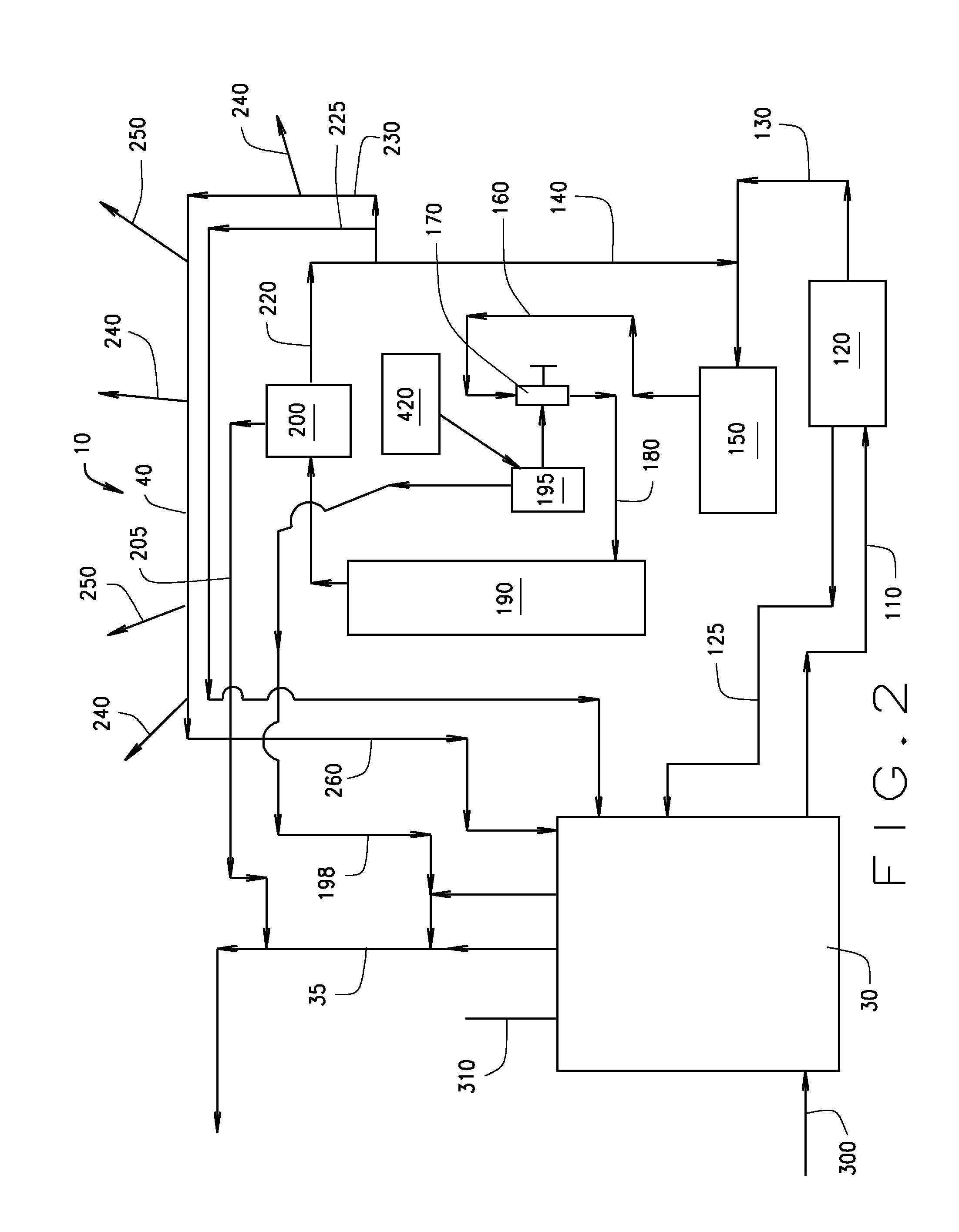

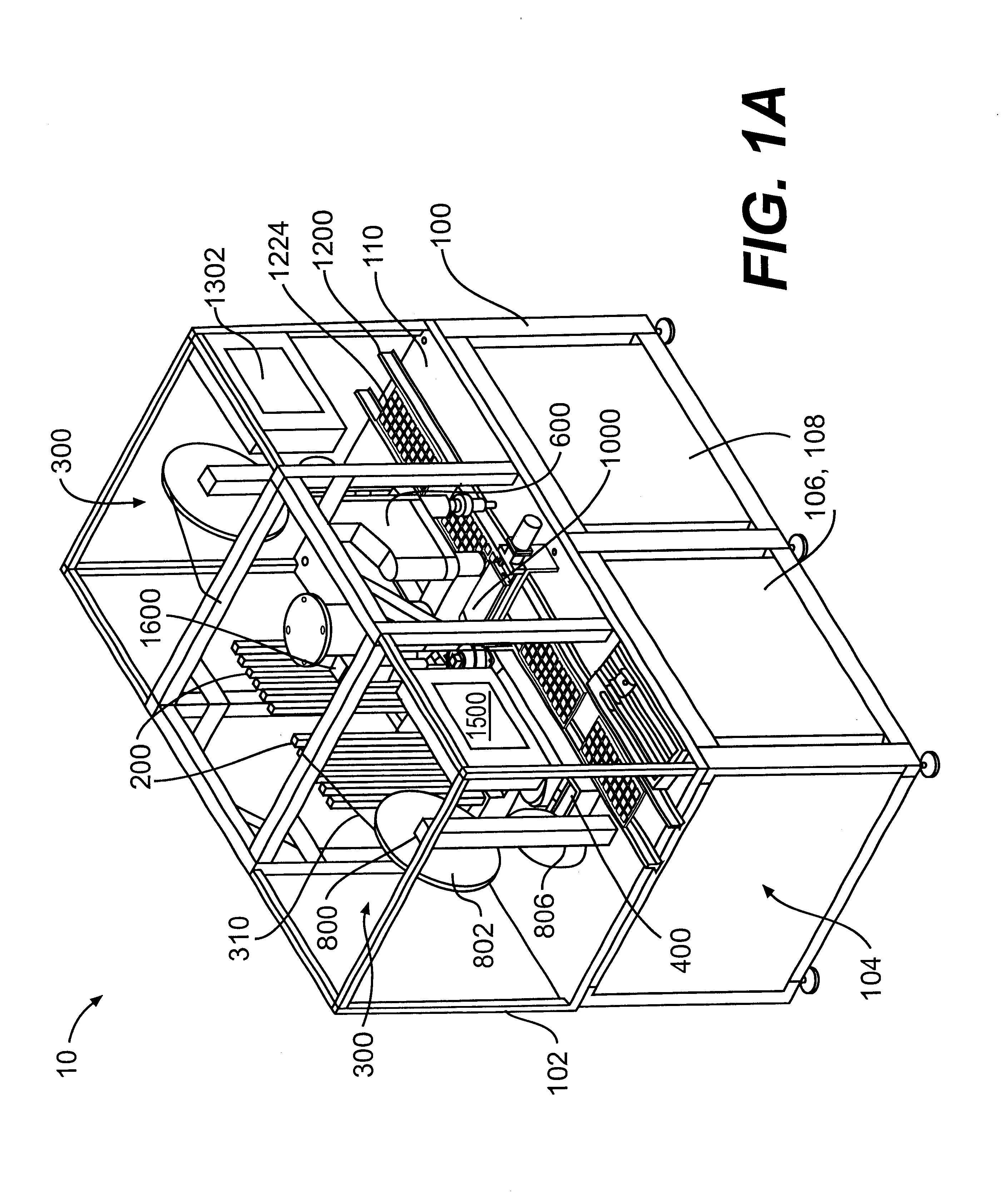

System for producing and distributing an ozonated fluid

InactiveUS20110030730A1Reduce hydraulic loadEliminate damageFlow mixersTransportation and packagingOzone generatorFuel tank

A system for producing and distributing an ozonated fluid is described. The system includes a tank for a fluid. A skid is in fluidic communication with the tank to receive the fluid from the tank. The skid includes an ozone generator to generate ozone gas and an injector to inject the fluid with the ozone gas to produce an ozonated fluid. A distribution network distributes the ozonated fluid for application. The distribution network is in fluid communication with the tank to return unapplied ozonated fluid to the tank.

Owner:FOOD SAFETY TECH

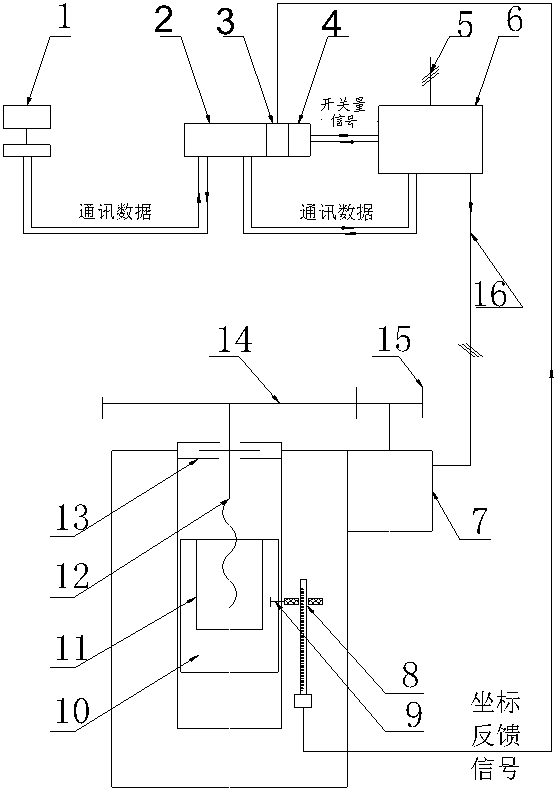

Electric screw press control system and electric screw press control method

InactiveCN103008518AImprove use reliabilityExtended service lifeForging press drivesPressesLinear motionControl system

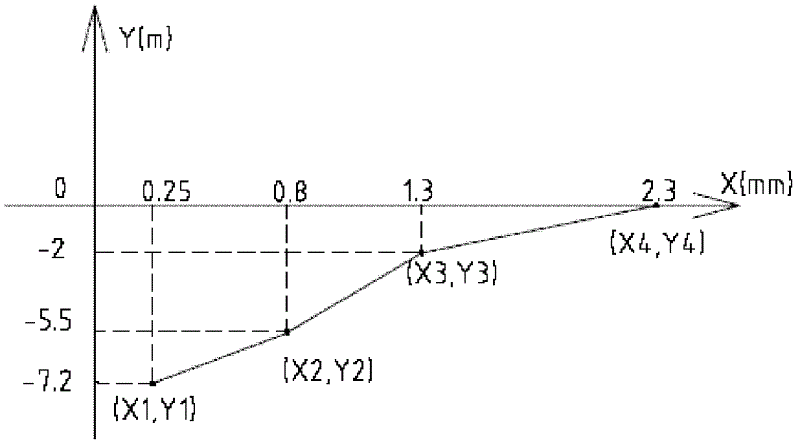

The invention discloses an electric screw press control system and an electric screw press control method. The electric screw press control system comprises a main motor, a programmable logic controller (PLC), a motor driver, an upper computer and a sliding block position detection device, wherein the main motor drives a sliding block of an electric screw press to do linear motion and is not provided with a shaft end position sensor; the PLC and the motor driver control the operation of the main motor; the upper computer is connected with the PLC and used for setting and acquiring data; the sliding block position detection device is used for detecting the current coordinate position of the sliding block; the sliding block position detection device is connected with the PLC through an analog quantity module; and the motor driver is connected with the PLC through a data bus and a switch quantity signal. The current coordinate position of the sliding block is detected by the sliding block position detection device and fed back to the PLC, so that the state switching of the main motor can be controlled, the shut-down phenomenon caused by failure of the shaft end sensor is eliminated, the using reliability of the whole electric screw press is improved, and the service life of a die is prolonged.

Owner:青岛宏达锻压机械有限公司

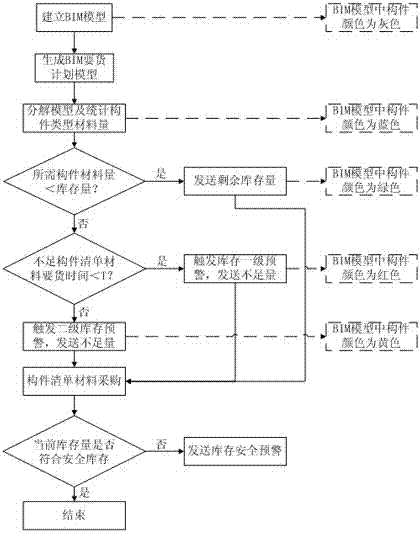

Intelligent inventory early warning and management system based on BIM (Building Information Modeling) model

PendingCN107133769AReduce inventory levelsPrecision productionForecastingLogisticsInformatizationInventory management

The invention relates to an intelligent inventory early warning and management system based on a BIM (Building Information Modeling) model. The method comprises the following steps: 1, a BIM model is imported to the system; 2, a cargo requirement task plan based on the BIM model is generated in the system, and the cargo requirement task plan is sent to a factory; 3, the BIM cargo requirement plan is subjected to model decomposition, and the material amount for needed component types is counted; 4, the system judges the current inventory; 5, the system judges an insufficient component material amount, if the cargo requirement plan time is smaller than needed time T, first-level inventory early warning is triggered, or otherwise, second-level inventory early warning is triggered; 6, coordinated purchasing is carried out on component list materials; and 7, the system detects whether the current inventory meets enterprise safety inventory. The informatization operation level of inventory management of a construction enterprise is enhanced.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

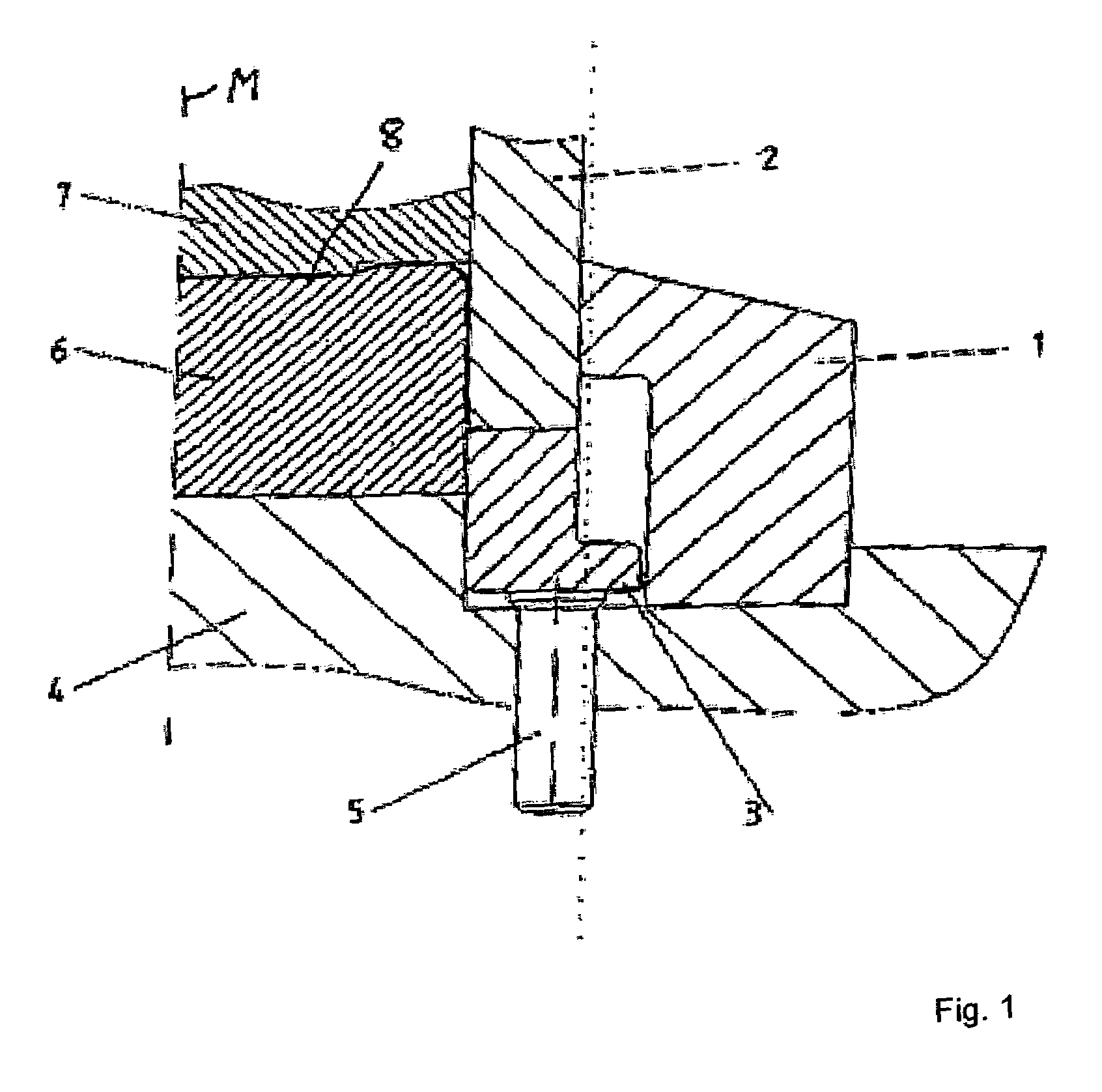

Method for producing a cup-shaped object

A method for the production of a cup-shaped article, in particular a blank of a screw cap for glass bottles or the like, from an enameled metal sheet, using two tools in a stepwise manner: 1) the blank is stamped from the metal sheet in a first tool by the relative motion between a cutting bell cooperating with a blank holder and a drawing block, and the blank is drawn around the drawing block, the width of a flange forming between the cutting bell and the blank holder being continuously reduced with a progressive degree of deformation until the flange reaches a defined width (R-r), and 2) the blank is deformed in a second tool such that the radially outwardly directed flange is deflected toward a profiling introduced in a wall of the blank.

Owner:MAIKO ENG

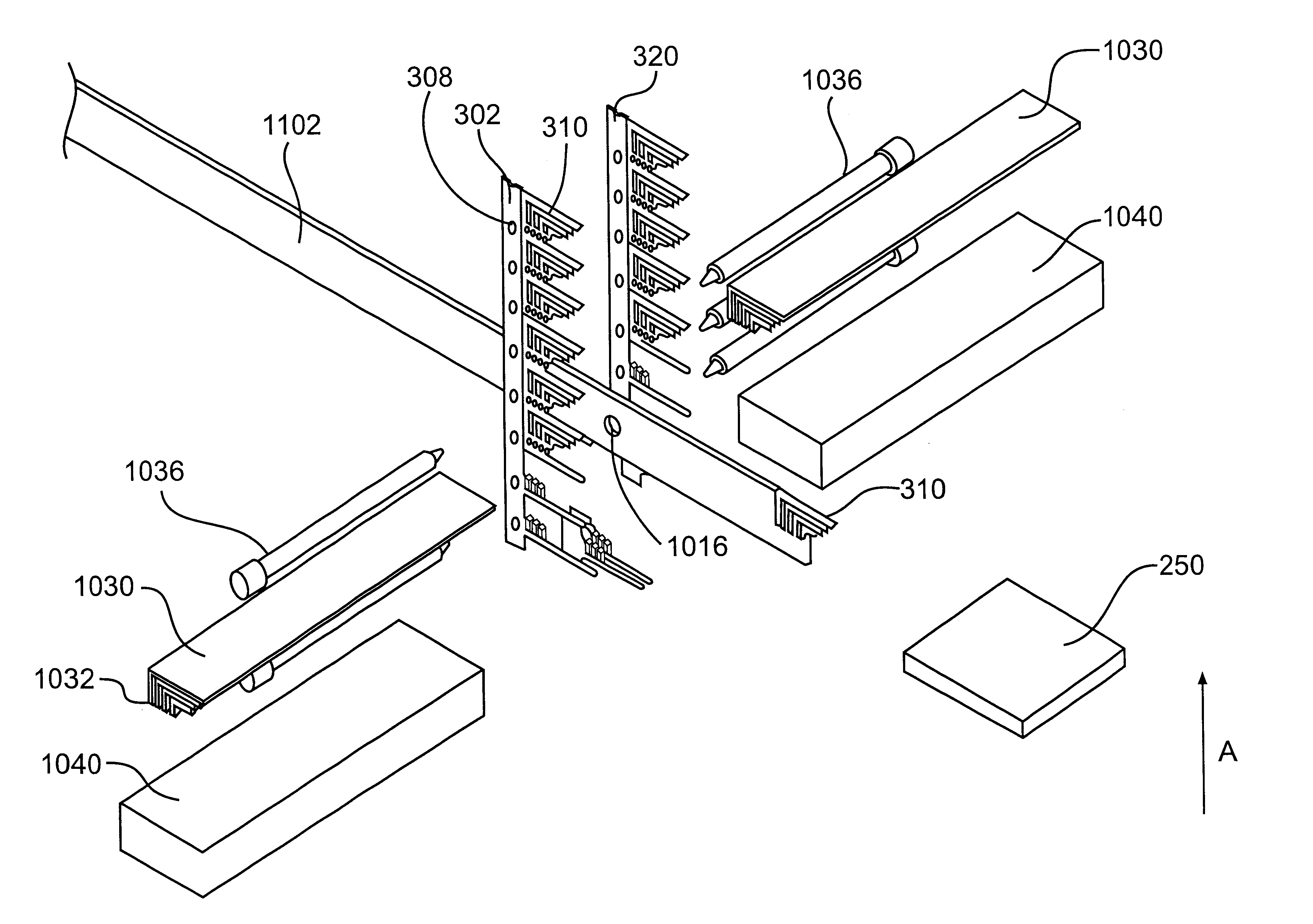

Apparatus for and method of manufacturing a semiconductor die carrier

InactiveUS6857173B1Accurate insertionEliminate downtimePrinted circuit assemblingLine/current collector detailsSemiconductorEngineering

A lead insertion machine includes a substrate supply, a conductive lead supply, and an lead insertion mechanism. The conductive leads are inserted into lead passages formed in side walls of the substrate. Also disclosed is a method of manufacturing a semiconductor die carrier including the steps of forming a plurality of conductive leads, forming a substrate for holding a semiconductor die, the substrate having a plurality of insulative side walls defining an exterior surface of the substrate, each of the side walls having a plurality of lead passages formed therethrough, and simultaneously inserting at least one of the conductive leads into the lead passage of one of the side walls for retention therein and at least one other of the conductive leads into the lead passage of another of the side walls for retention therein.

Owner:IQLP

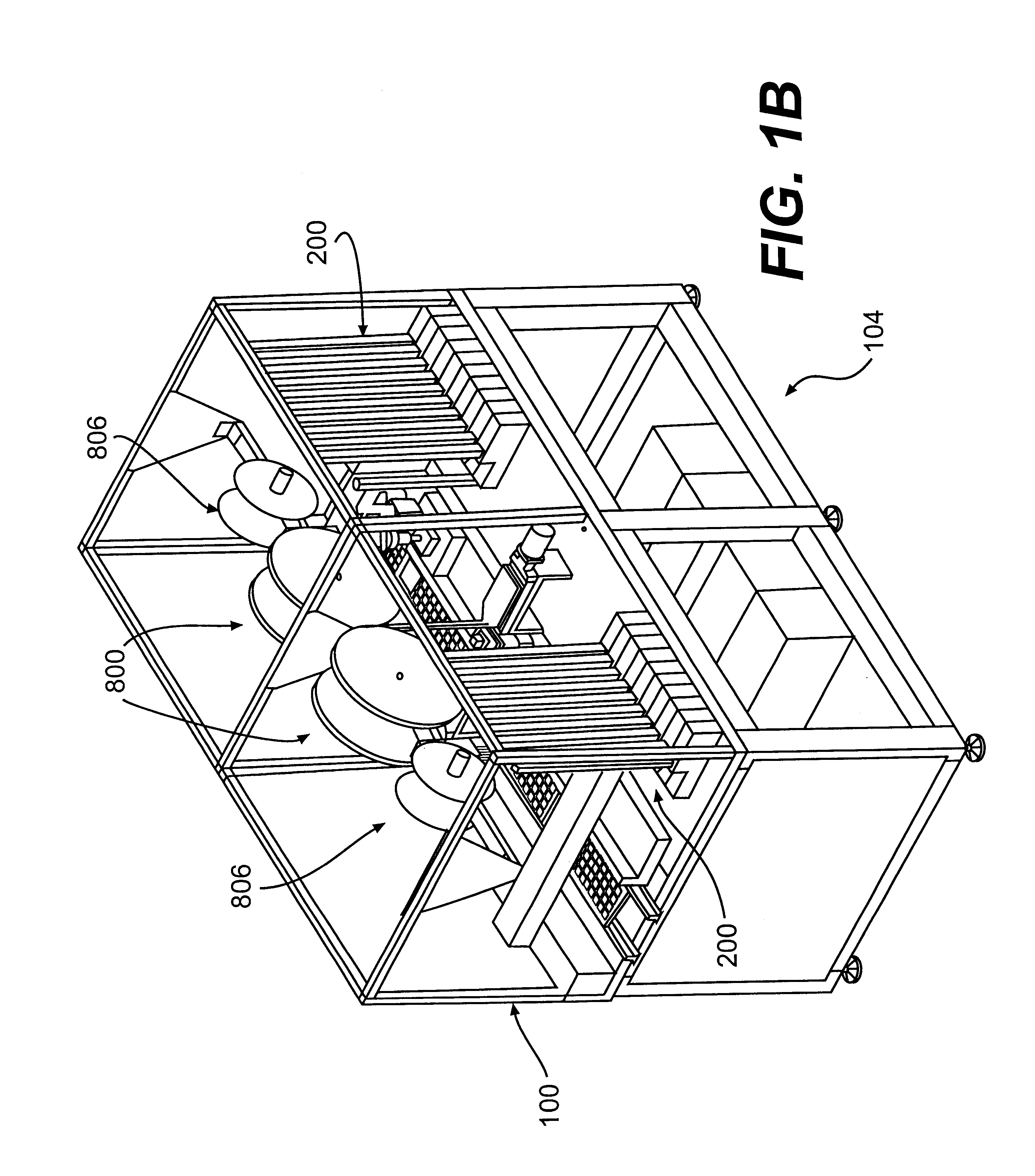

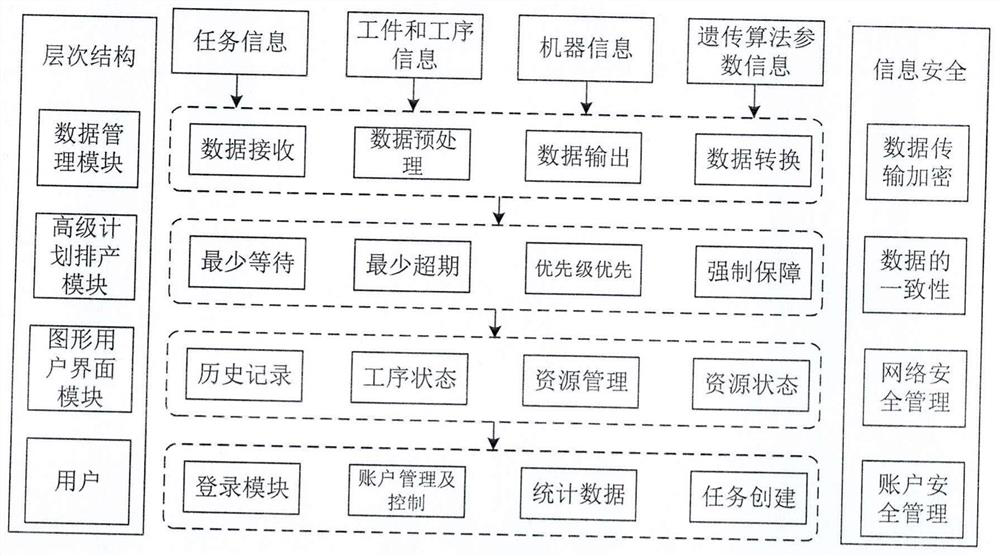

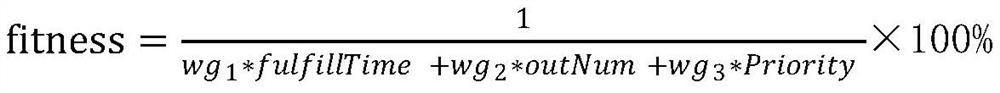

Workshop resource scheduling method based on heuristic optimization algorithm

PendingCN112990515AIncrease productivityReduce consumptionForecastingArtificial lifeLocal optimumAlgorithm

The invention relates to a workshop resource scheduling method based on a heuristic optimization algorithm, which comprises the following production scheduling steps: receiving input data, and inputting the data into the algorithm; setting constraint conditions for screening output results; the method also includes that the algorithm calculates the received data and outputs a result; the algorithm supports input of various constraint conditions, and the constraint conditions comprise minimum waiting time, minimum overdue tasks, priority priority and forced guarantee priority, wherein the constraint condition is a digital quantity, the value range is 1-5, and the default value is 3. According to the method, submitted data are processed by using a genetic algorithm, and a group of locally optimal solutions are obtained under certain constraint conditions; the delivery time accuracy is improved, the consumed resources are reduced, the time required by an enterprise to specify a production plan is reduced, and the production efficiency of the enterprise is improved.

Owner:中船重工信息科技有限公司

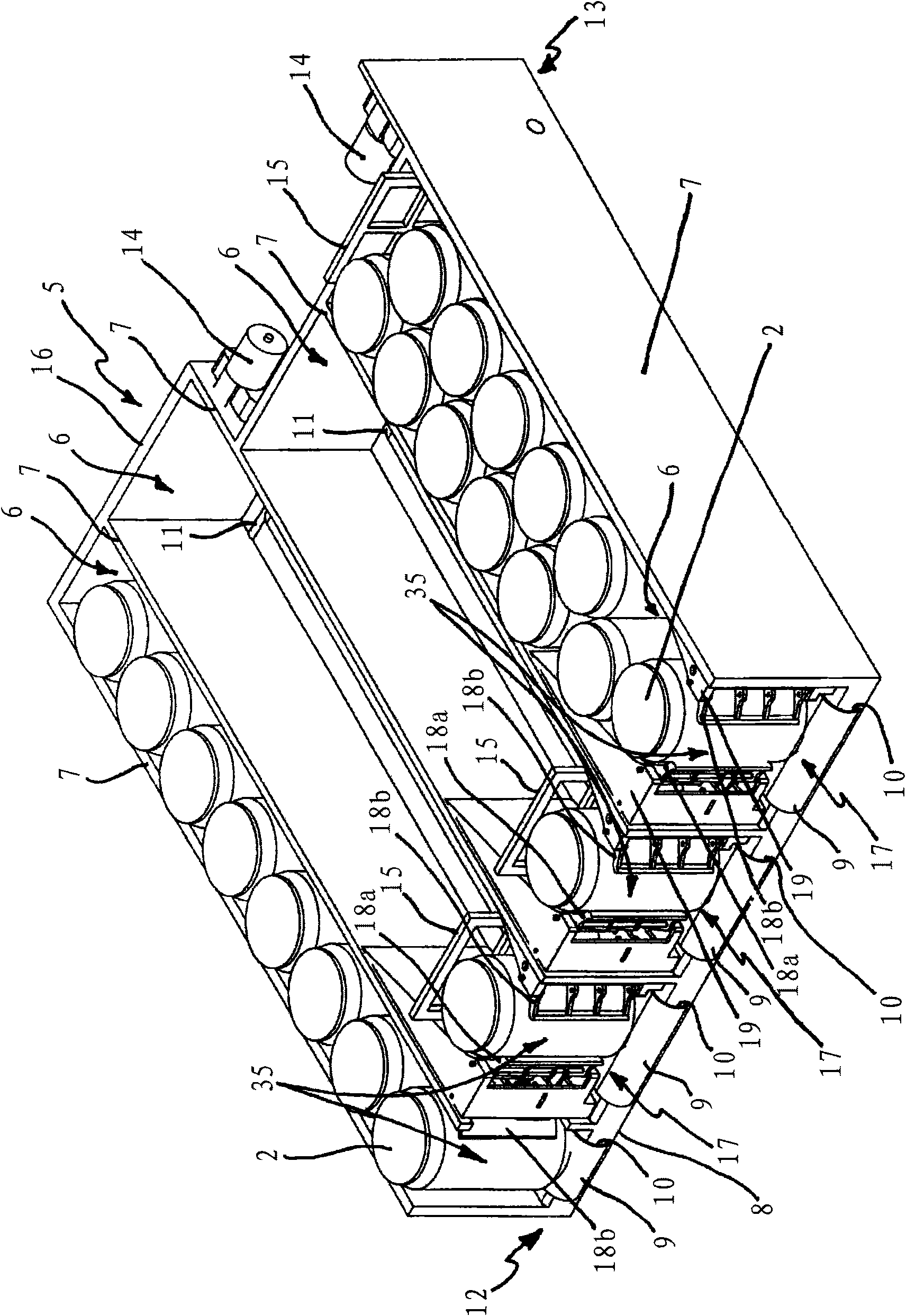

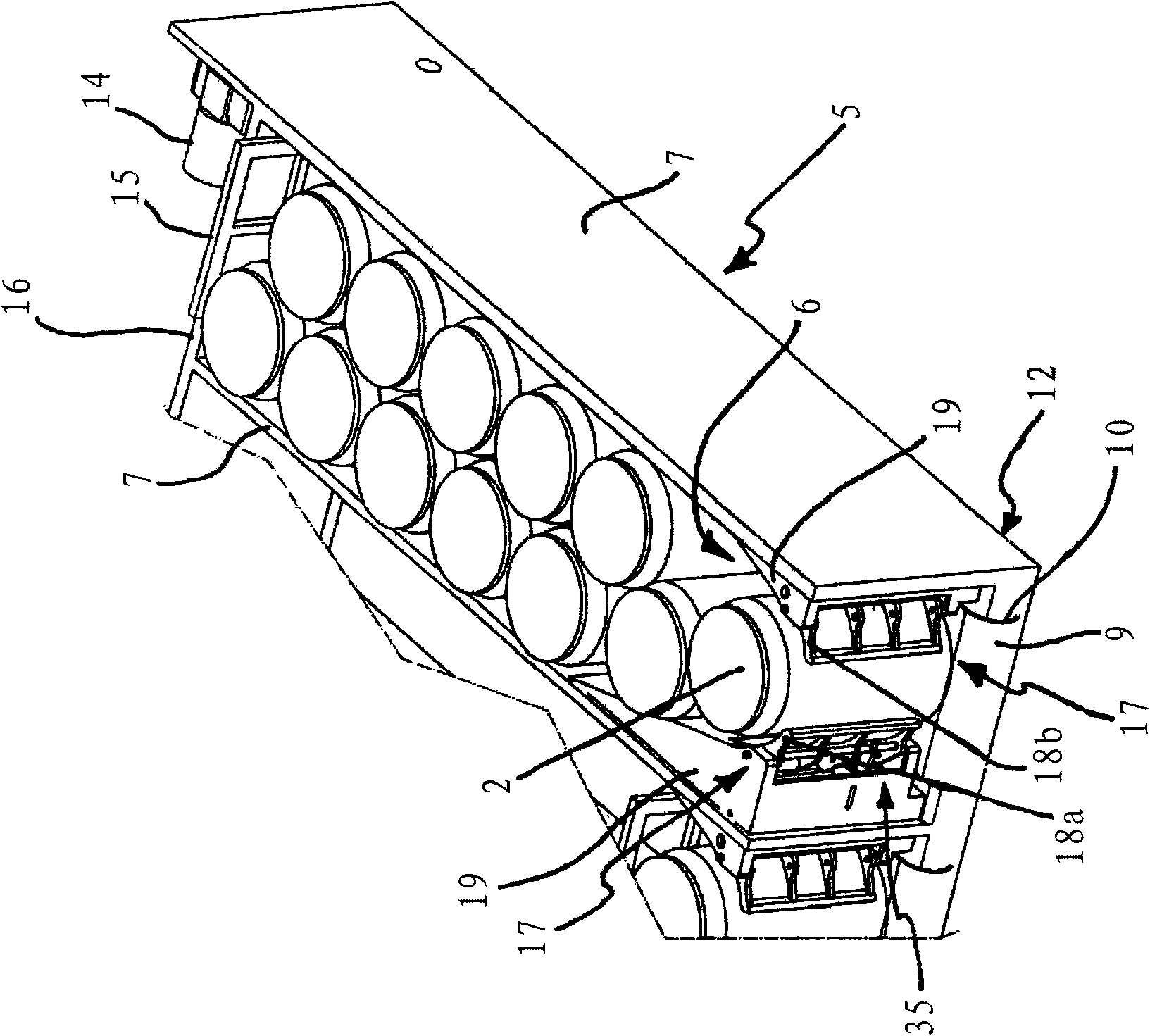

Case packer

InactiveUS8015782B2Simple and compact designEliminate downtimePackaging cigarettePackaging automatic controlCartoning machineEngineering

Owner:GD SPA

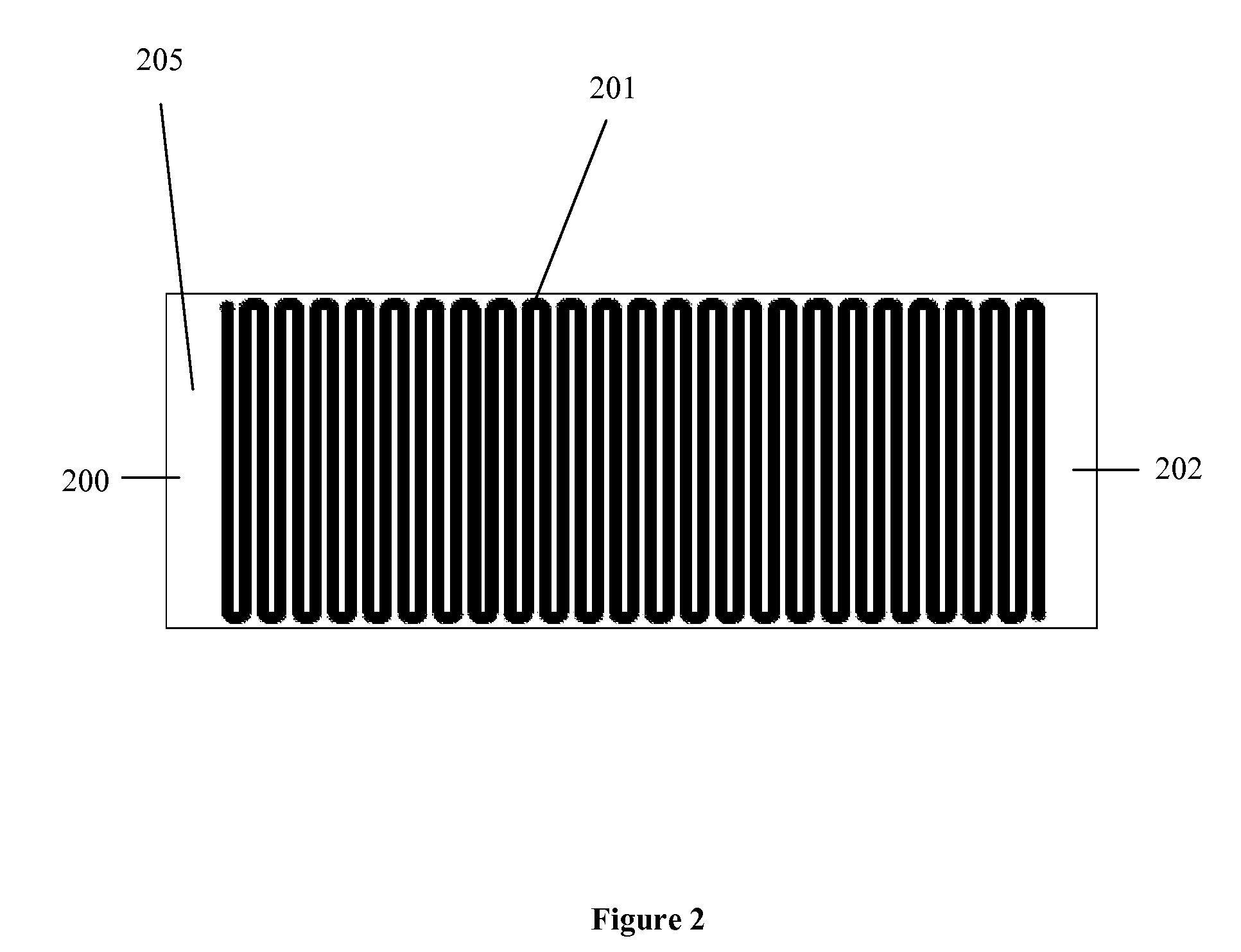

Practical ion mobility spectrometer apparatus and methods for chemical and/or biological detection

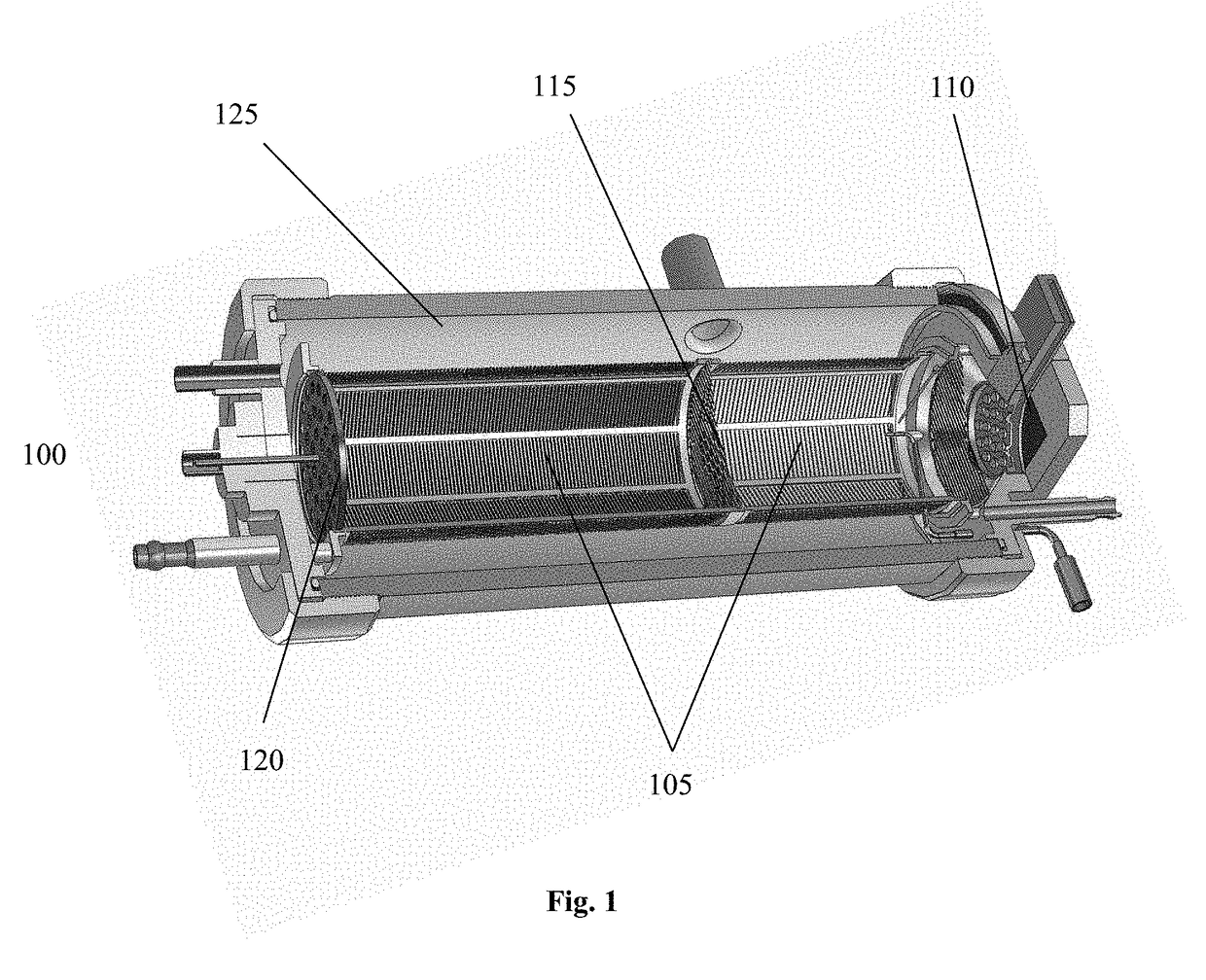

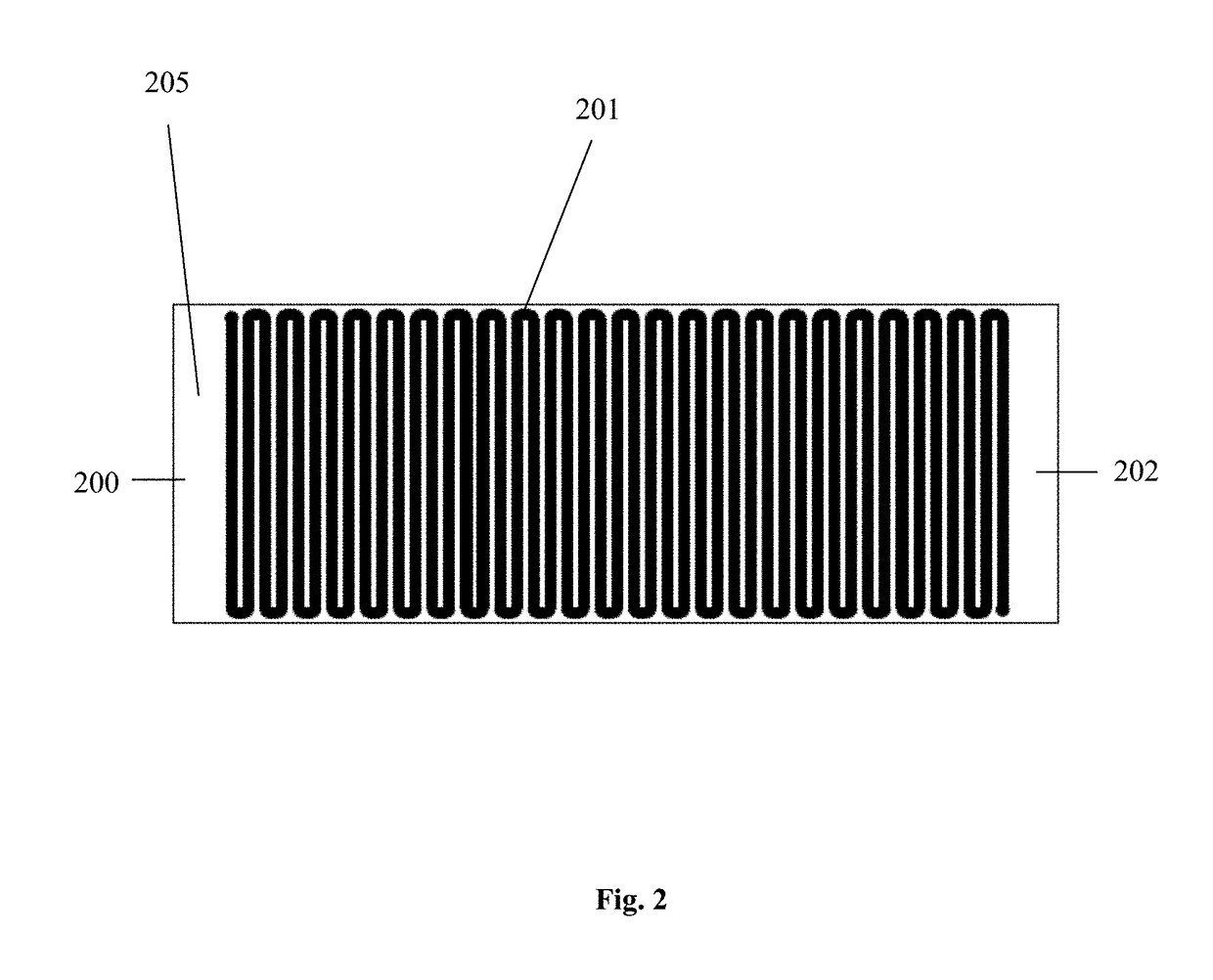

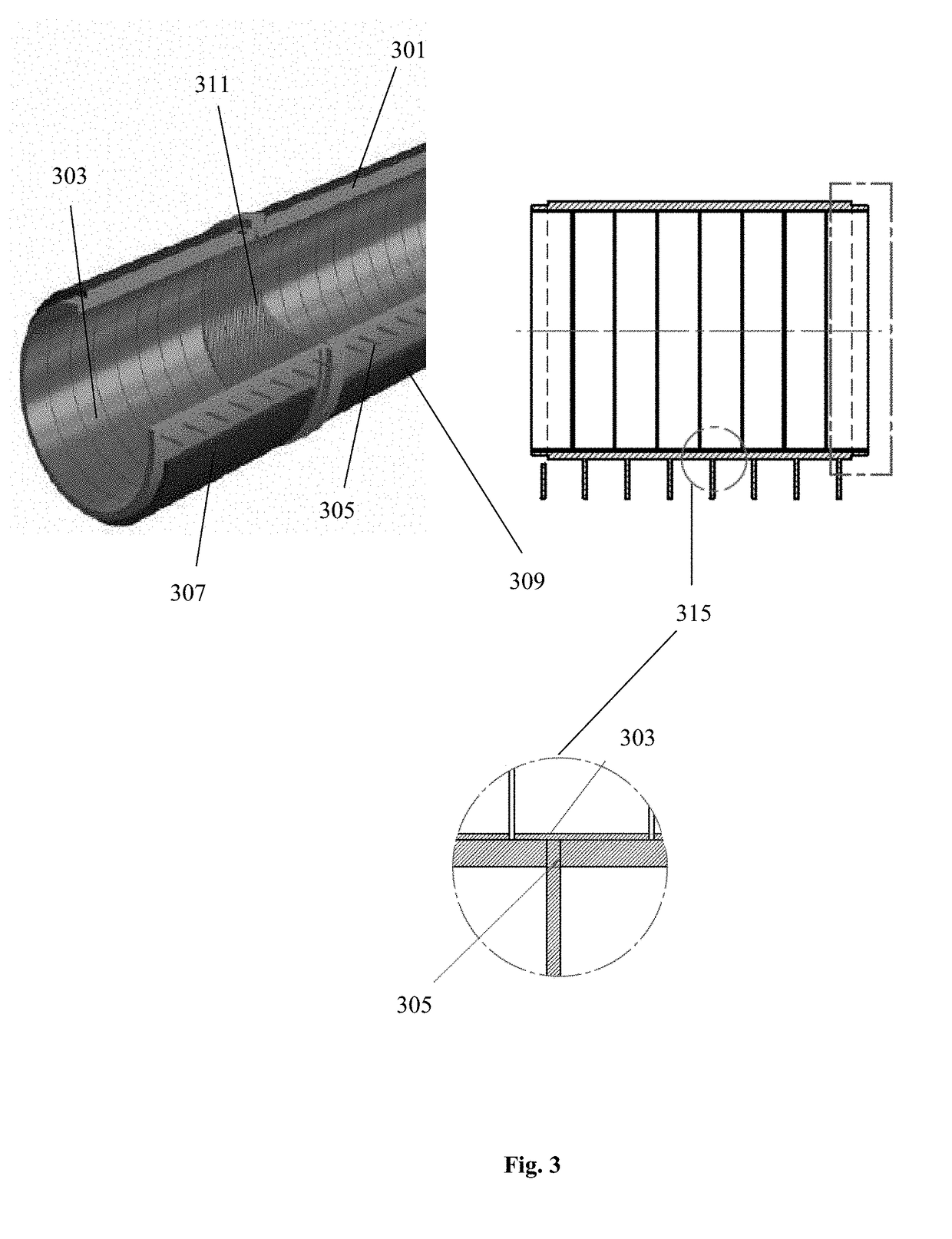

ActiveUS20180372684A1Increase temperatureEasy to buildSamples introduction/extractionElectron/ion optical arrangementsElectrical resistance and conductanceDrift tube

The present invention relates to drift tubes for ion mobility spectrometers. In one embodiment, the drift tube of the present invention uses a simplified design having helical resistive material to form substantially constant electric fields that guide ion movements. The drift tube for ion mobility spectrometers described herein is constructed with a non-conductive structure. This configuration provides a robust ion mobility spectrometer that is simple to build. One feature of the present invention is that the drift tube design described herein enables the ion mobility spectrometer to be built with a lower weight, lower power consumption, lower manufacturing cost, and free of sealants.

Owner:EXCELLIMS CORP

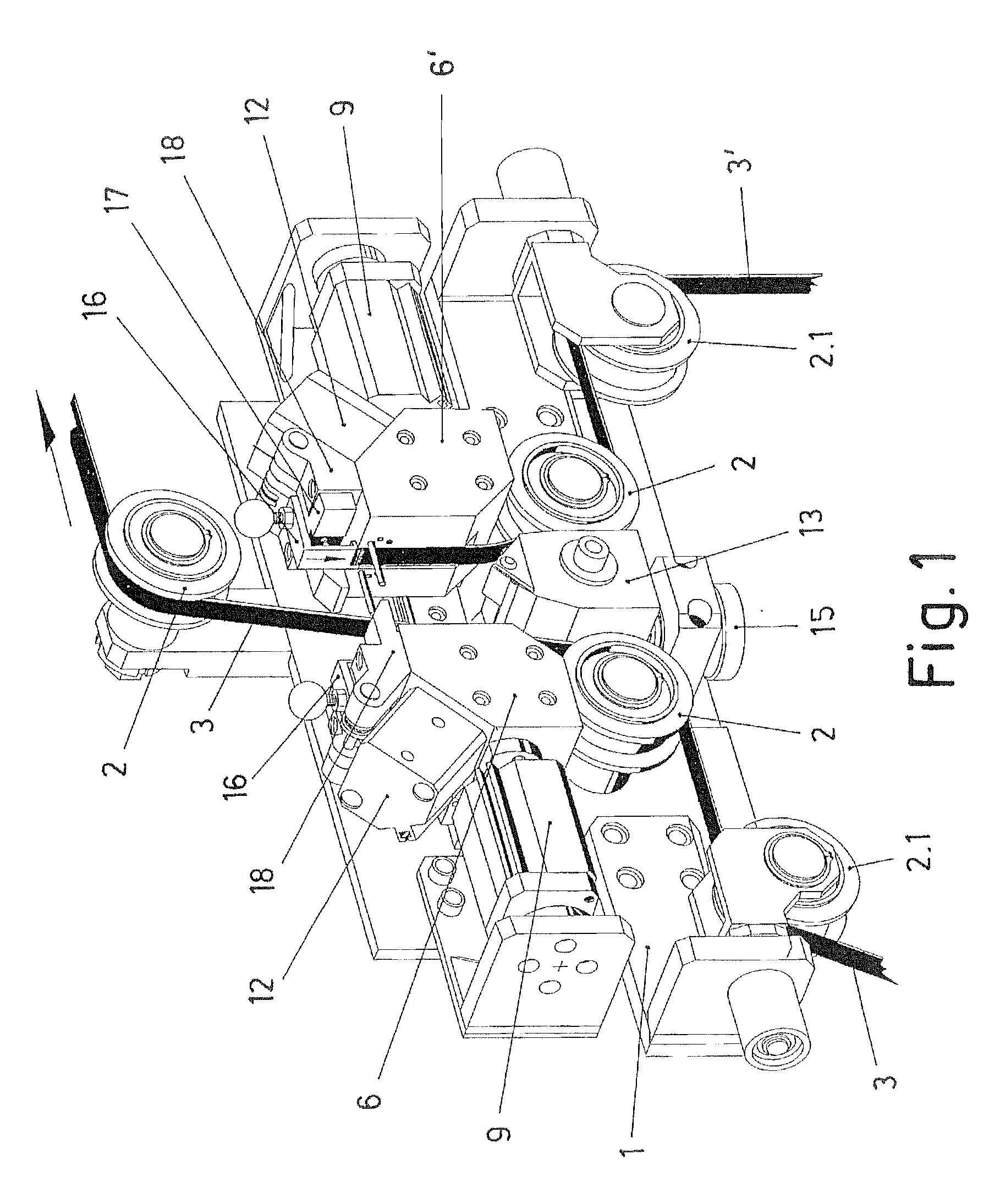

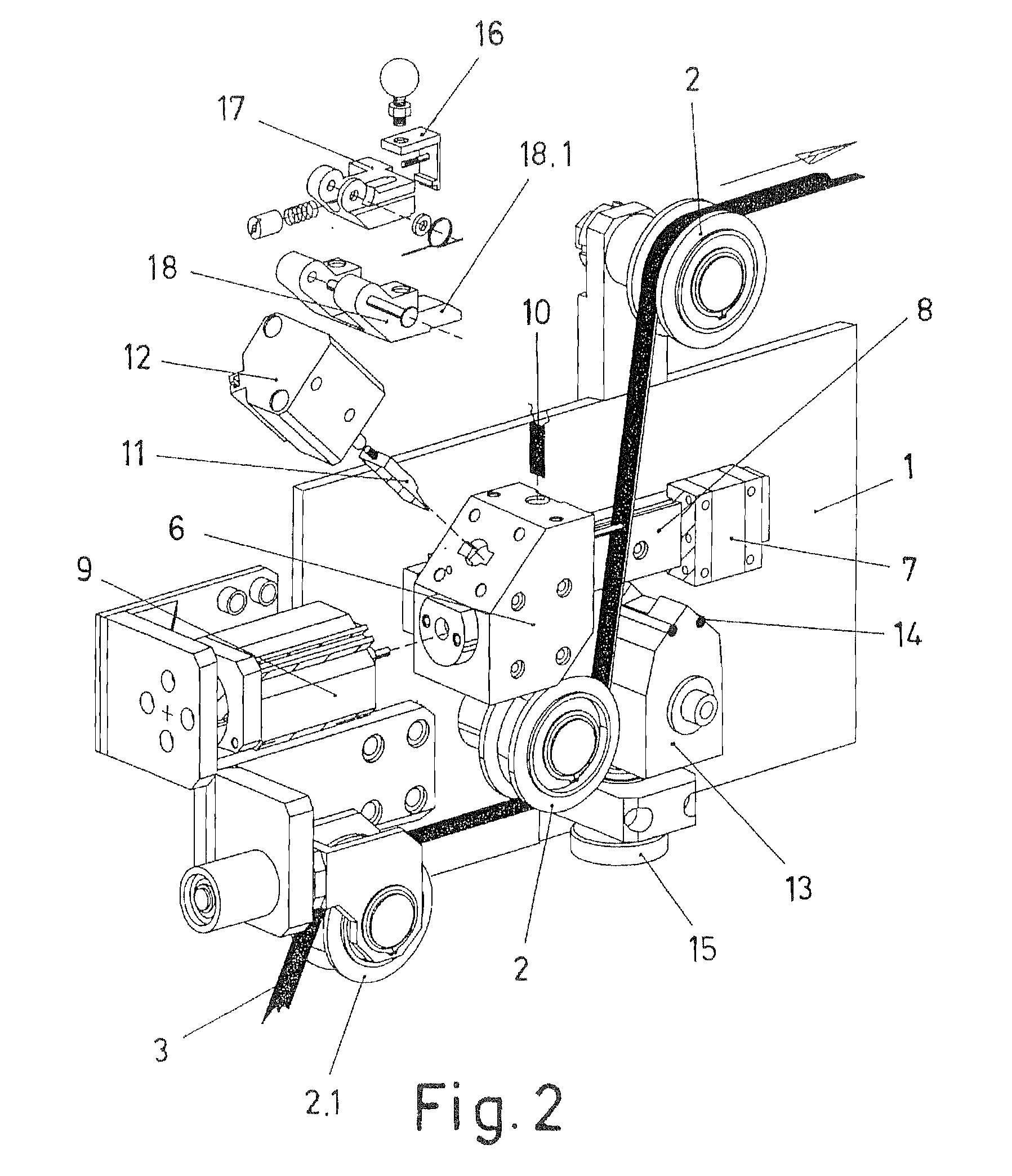

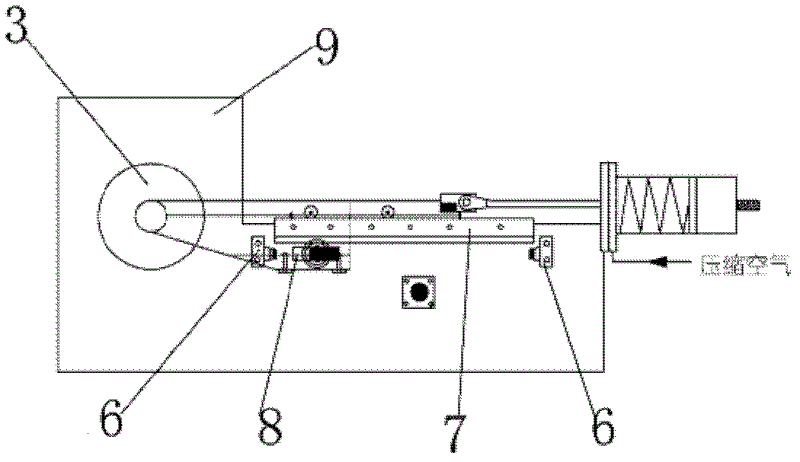

Fiber strip splicer for taping machines

InactiveUS20080202693A1Eliminate downtimeUniform widthMechanical working/deformationFilament handlingFiberEngineering

The invention relates to a fiber strip splicer for taping machines, formed by two mobile assemblies comprising respective modules (6, 6′) between which the capture for joining the fiber strip (3) that is being fed to the application process and a strip (3′) intended to continue with the supply when the first strip ends is possible, the modules (6, 6′) incorporating heating means (10) to activate the fiber strips in the joining, a blade for cutting the excess of the finished fiber strip (3) after the joint, and a catch (16) for securing the end of the new fiber strip (3′) on standby for the joining.

Owner:TORRES MARTINEZ MANUEL

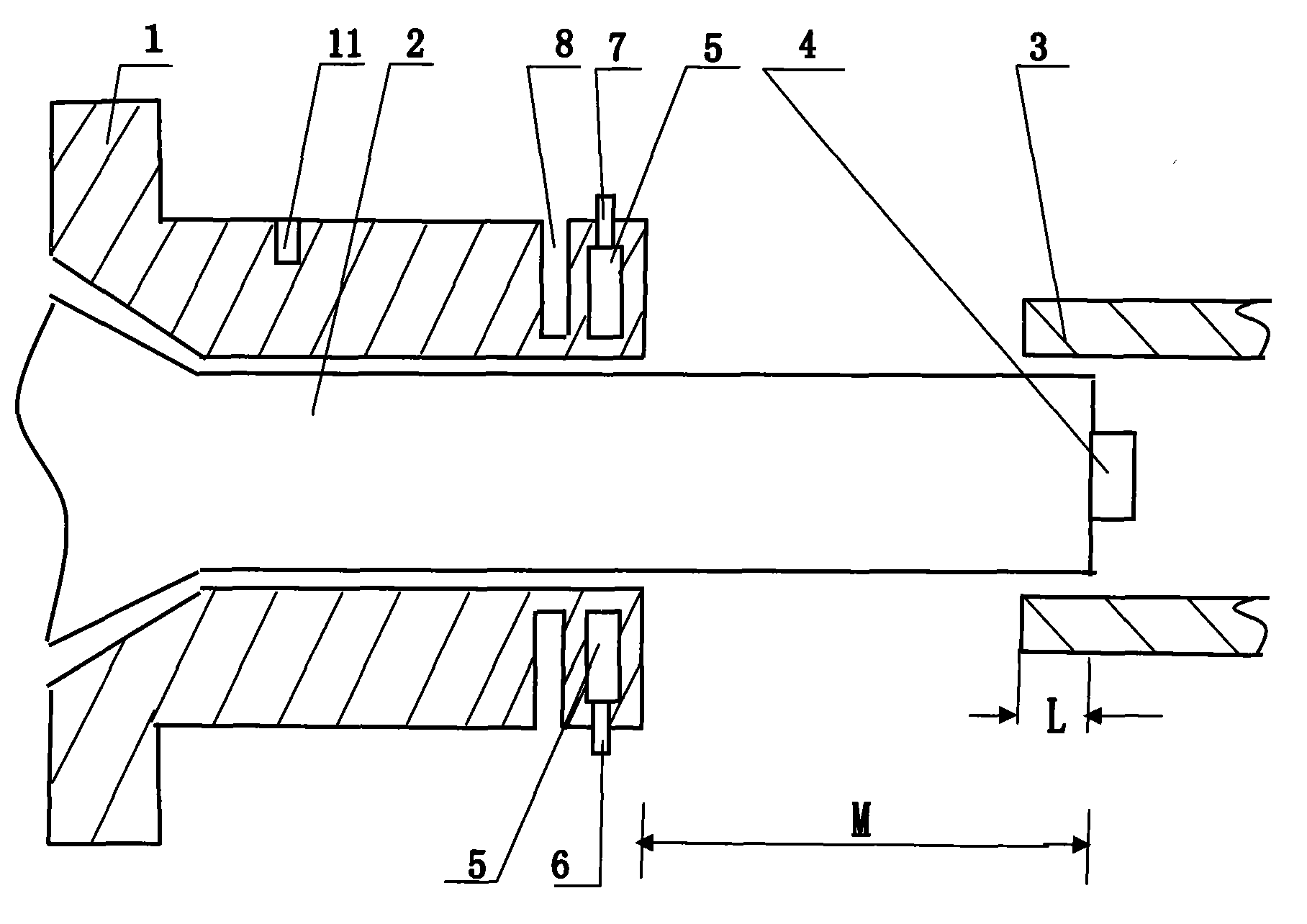

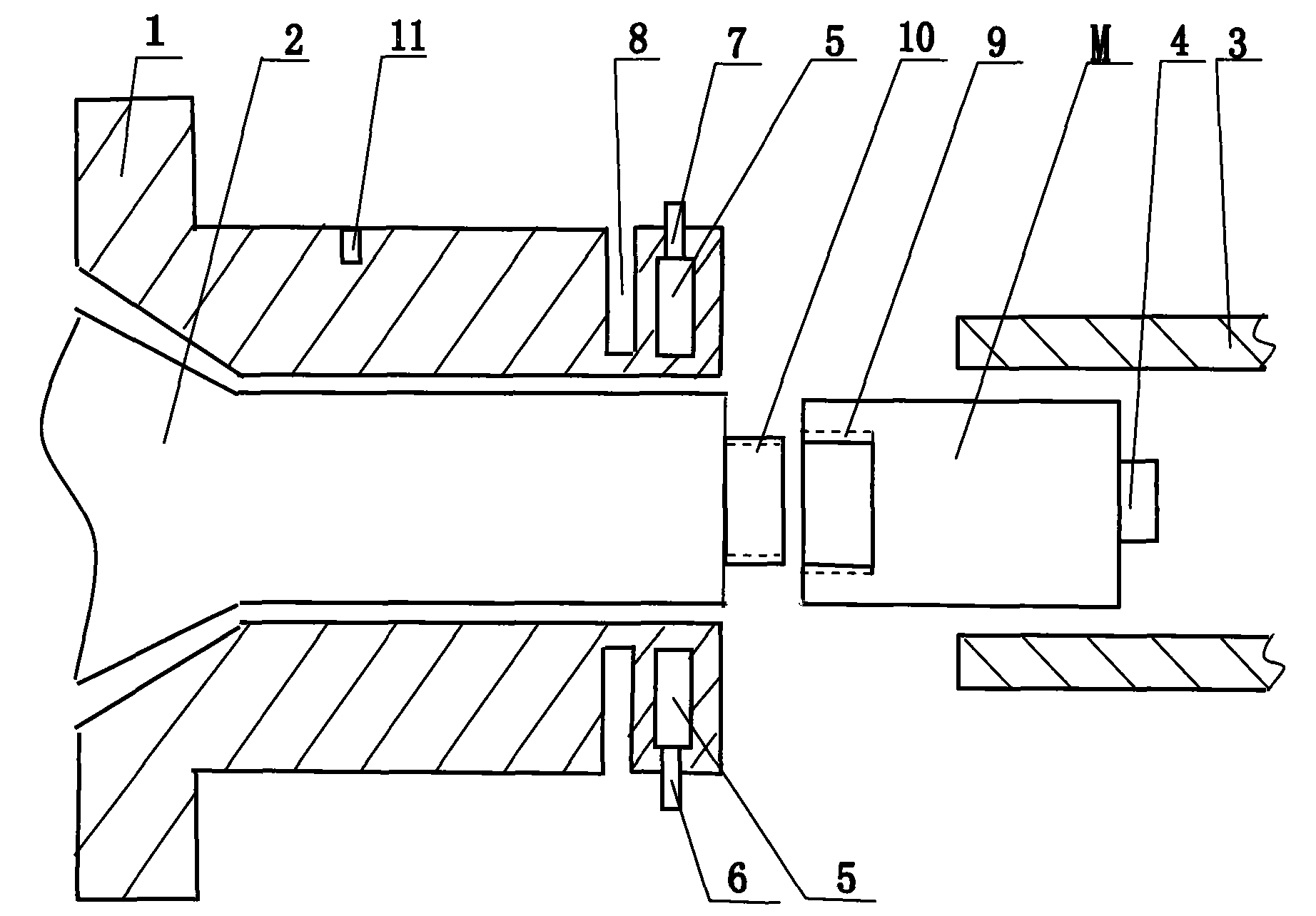

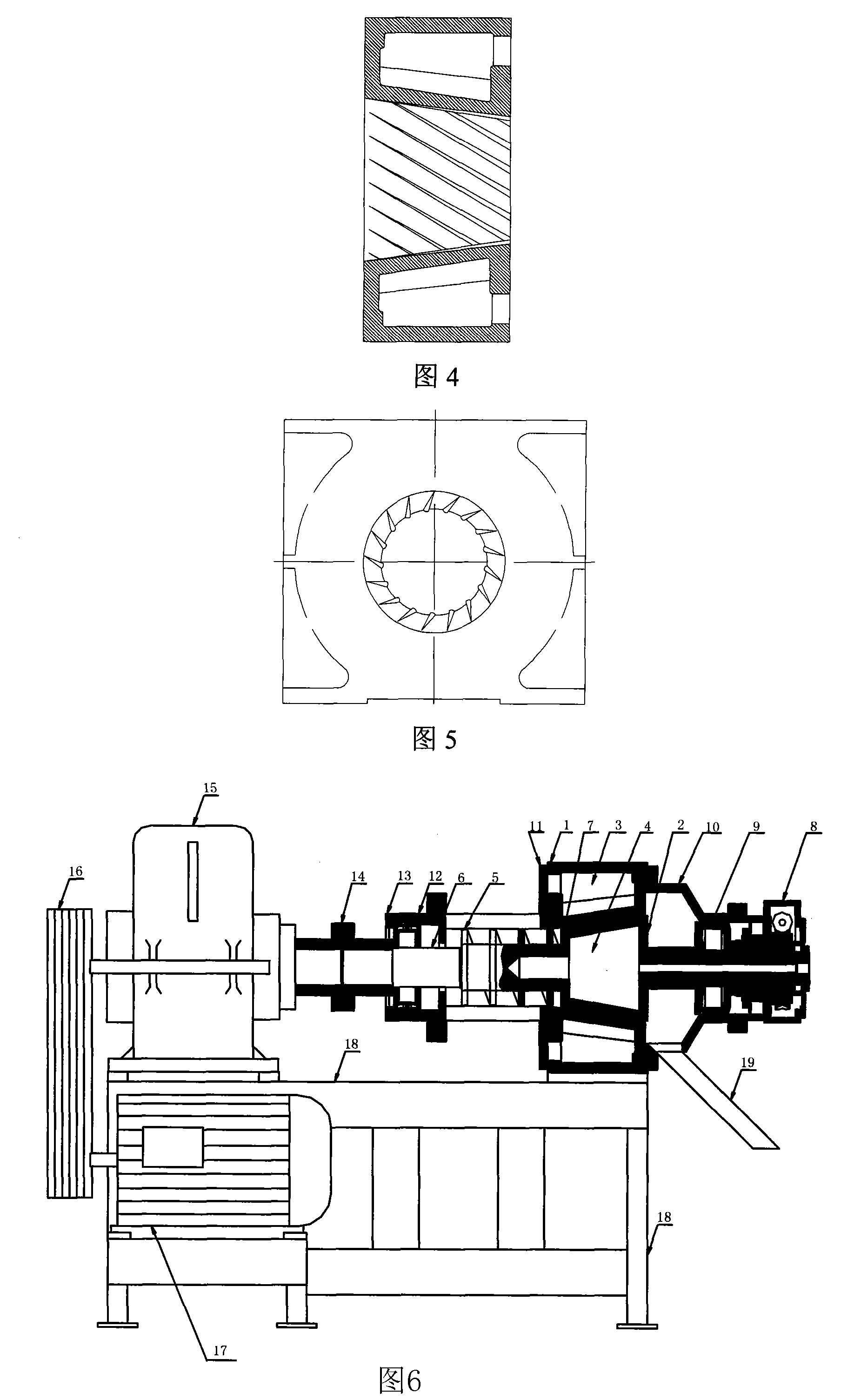

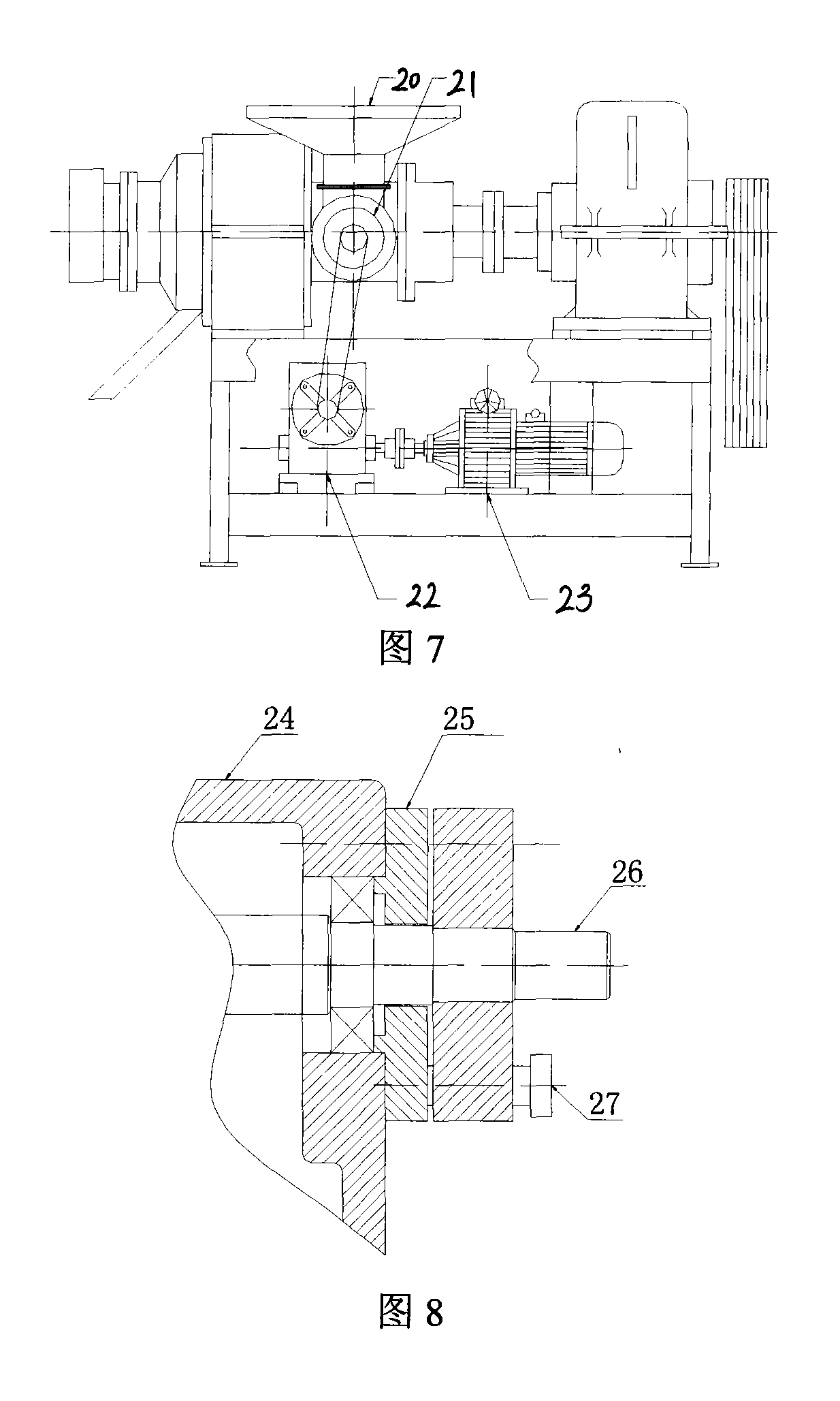

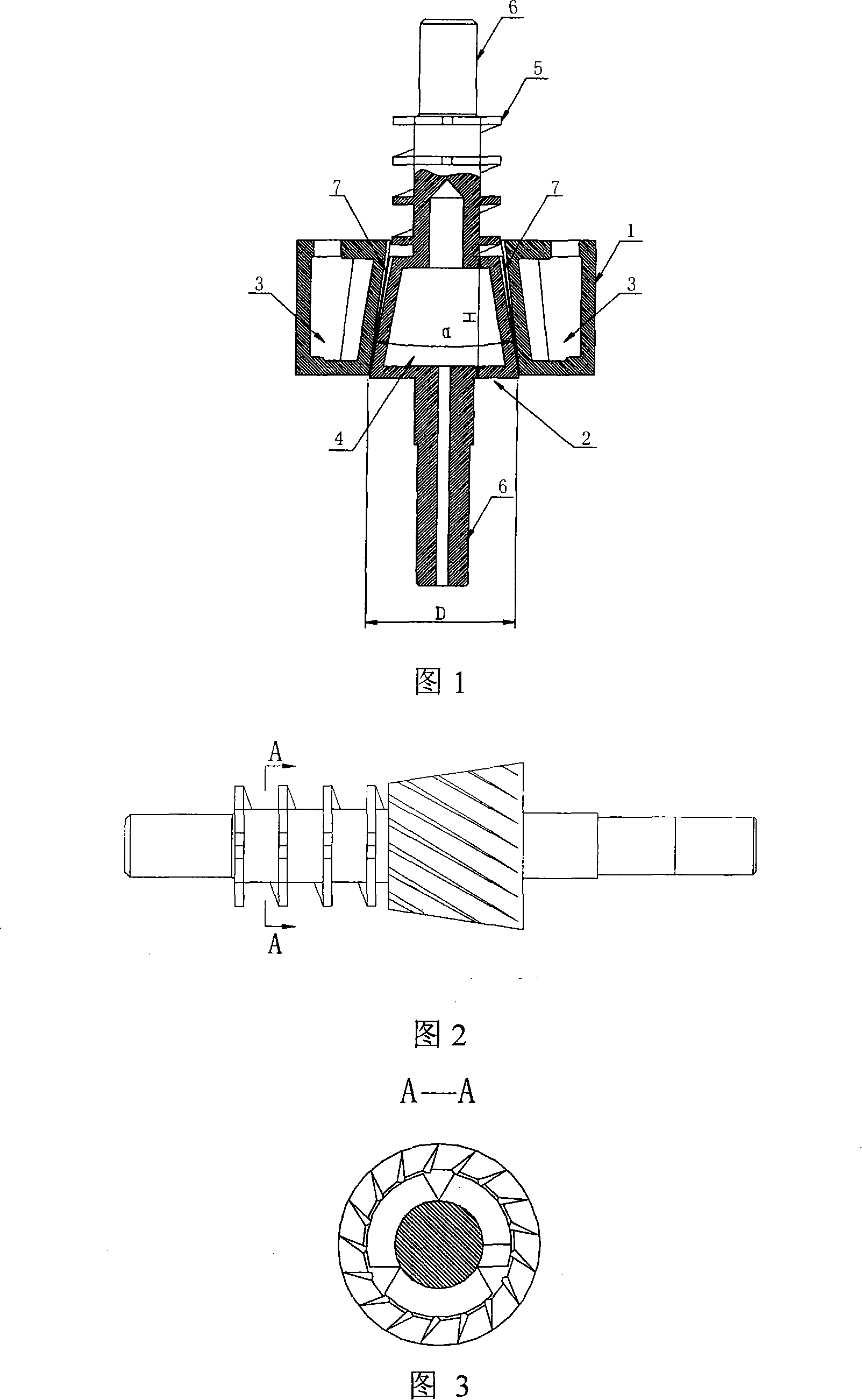

Pre-setting supporting assembling die for plastic extruder

The invention belongs to plastic extruders for producing plastic pipes, in particular to a pre-setting supporting assembling die for a plastic extruder. The die comprises a neck ring mold and a core rod and is characterized in that the outlet end face of the core rod is longer than the outlet end face of the neck ring mold, and a supporting section M is formed between the outlet end face of the neck ring mold and a calibrating sheath; the outlet end face of the core rod is arranged in the calibrating sheath, and the core rod forms a coincidence section with the calibrating sheath; and the outlet end face of the neck ring mold is provided with a cooling medium cavity as well as a medium inlet and a medium outlet which are communicated with the cooling medium cavity. The invention can be used for producing various plastic pipes made of PVC, PE, PPR, and the like. The invention has the advantage that the production rate is obviously enhanced and the yield is greatly enhanced without changing the original production technology, equipment and material formulation; in addition, produced products have good flexibility and high pressive strength and do not have fluff and protuberance, and the outer walls of the products are smooth and have good brightness.

Owner:GANSU BIGAO PLASTIC ELECTRIC

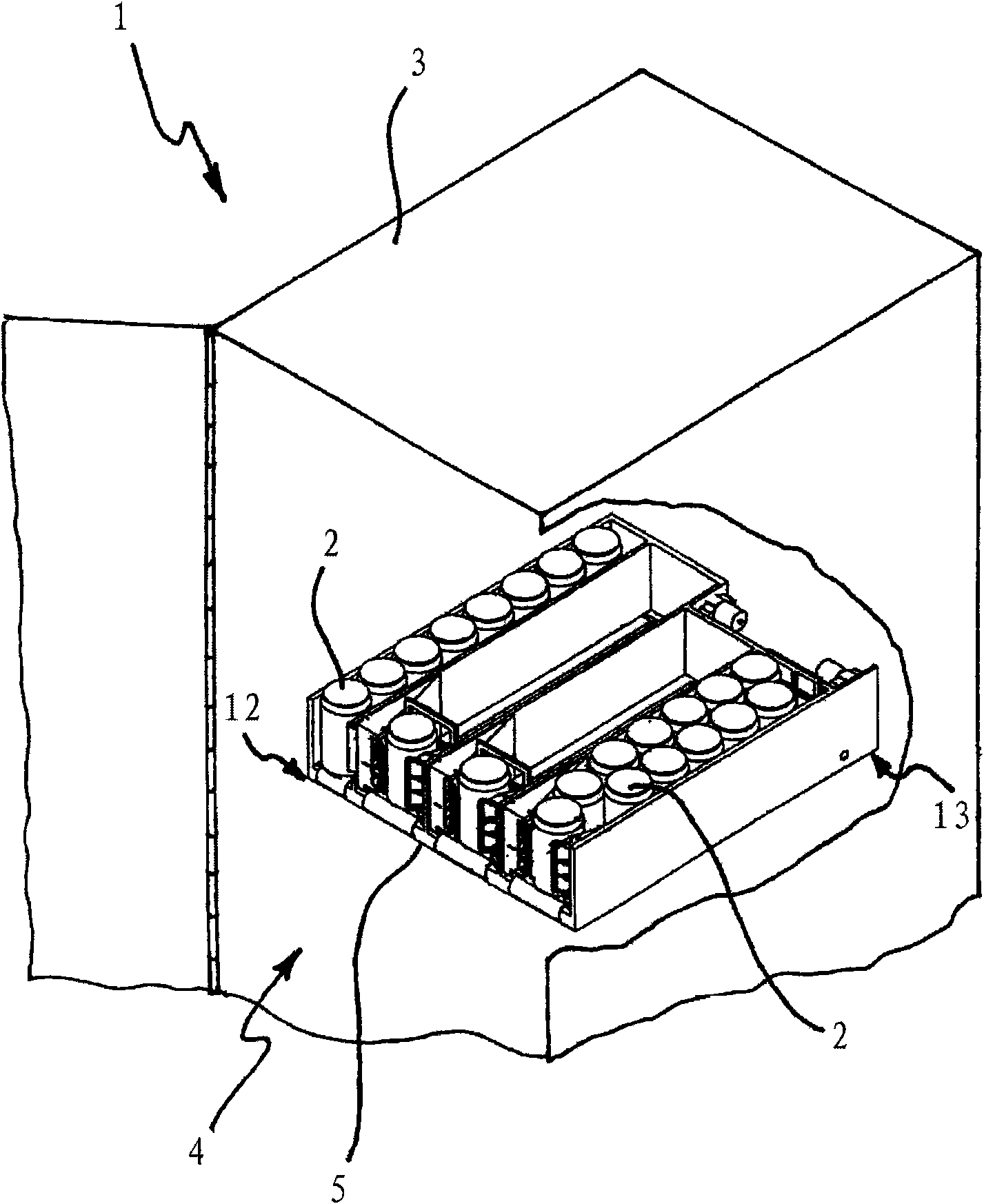

Automatic product vending machine

InactiveCN101578638AReduce defectsEliminate deficienciesCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringSingle row

The present invention relates to an automatic product dispenser, i.e. vending machine featuring improved product delivery ability. The vending machine according to the present invention comprises at least one tray (5) for supporting the products (2) to be dispensed, which is arranged in a substantially horizontal manner and is subdivided into a plurality of compartments (6), at least a conveyor belt (9) for handling the products (2) within the compartments (6) and conveying the products (2) towards a release section (35); the inventive vending machine further comprises delivery means (17) provided close to the release section (35). The inventive vending machine is characterized in that at least one of the compartments (6) is so configured as to be able to receive products (2) arranged along two rows, and in that it comprises selection means (19) adapted to arrange the products (2) into a single row in proximity of the release section (35).

Owner:N& W GLOBAL VENDING

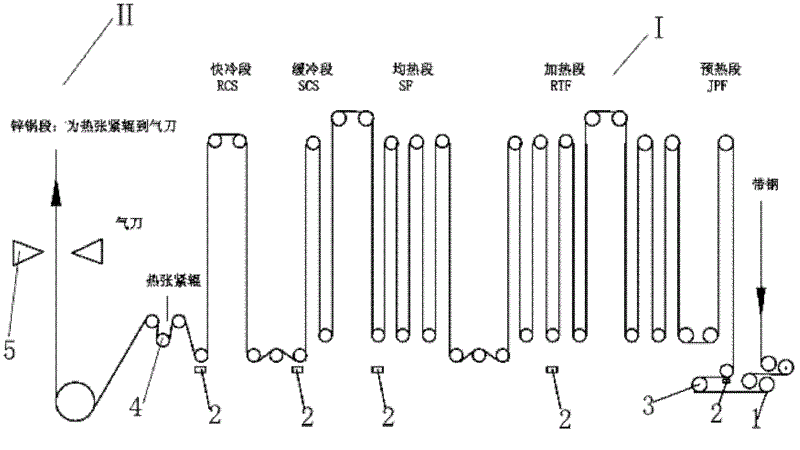

Method for tracking and controlling weld joints of band steel of continuous processing production line

ActiveCN102618813AEliminate downtimeReduce labor intensityHot-dipping/immersion processesProduction lineStrip steel

A method for tracking and controlling weld joints of band steel of a continuous processing production line is characterized in that the method is a control method combining dynamically compensating the length of band steel of a jumping roller in a furnace section with building a band steel expansion model in a zinc pot section to realize tracking and controlling welding joints in a process section. The length of the band steel of the jumping roller in the furnace section is dynamically compensated by means of adding the length, which is measured by a position sensor, of the band steel into the physical length of a preheating section (JPF) so that the weld joints are tracked and controlled; and an output factor is built according to the thickness of the band steel and a hot galvanizing process curve and is used as a variation value of the length of the band steel, and the variation value is added to the physical length of the zinc pot section so that the weld joints are tracked and controlled. Optimal tension switching moments of various sections of the furnace section are realized, proper tension is provided for the band steel, and accordingly a unit can produce qualified galvanized products. In addition, weld joint tracking control precision of the process section is greatly improved, the problem that the unit stops and is failed due to the fact that the band steel is collided with a baffle plate at the edge of an air knife when the weld joints pass through the air knife is completely avoided, and accordingly labor intensity of operators is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

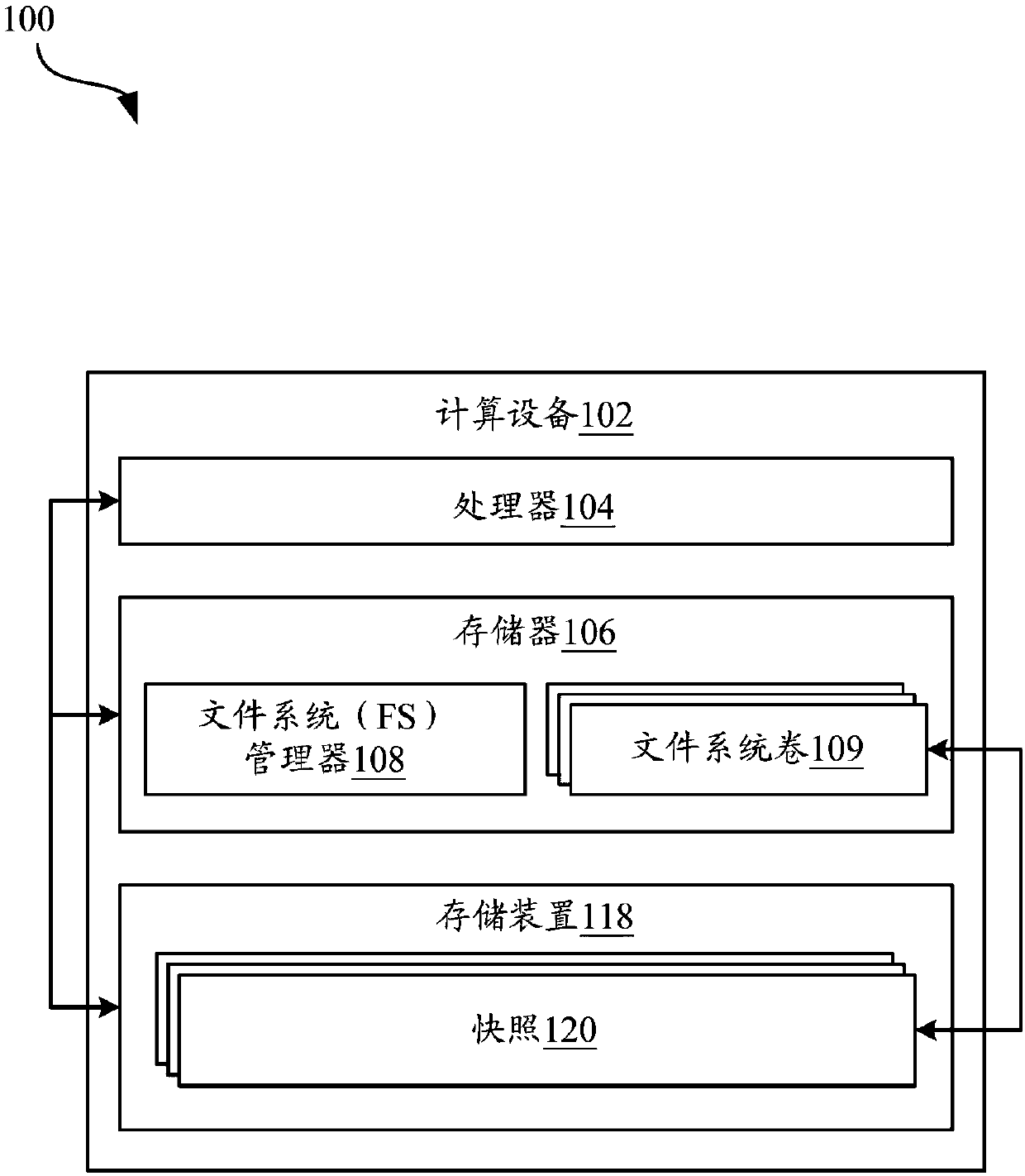

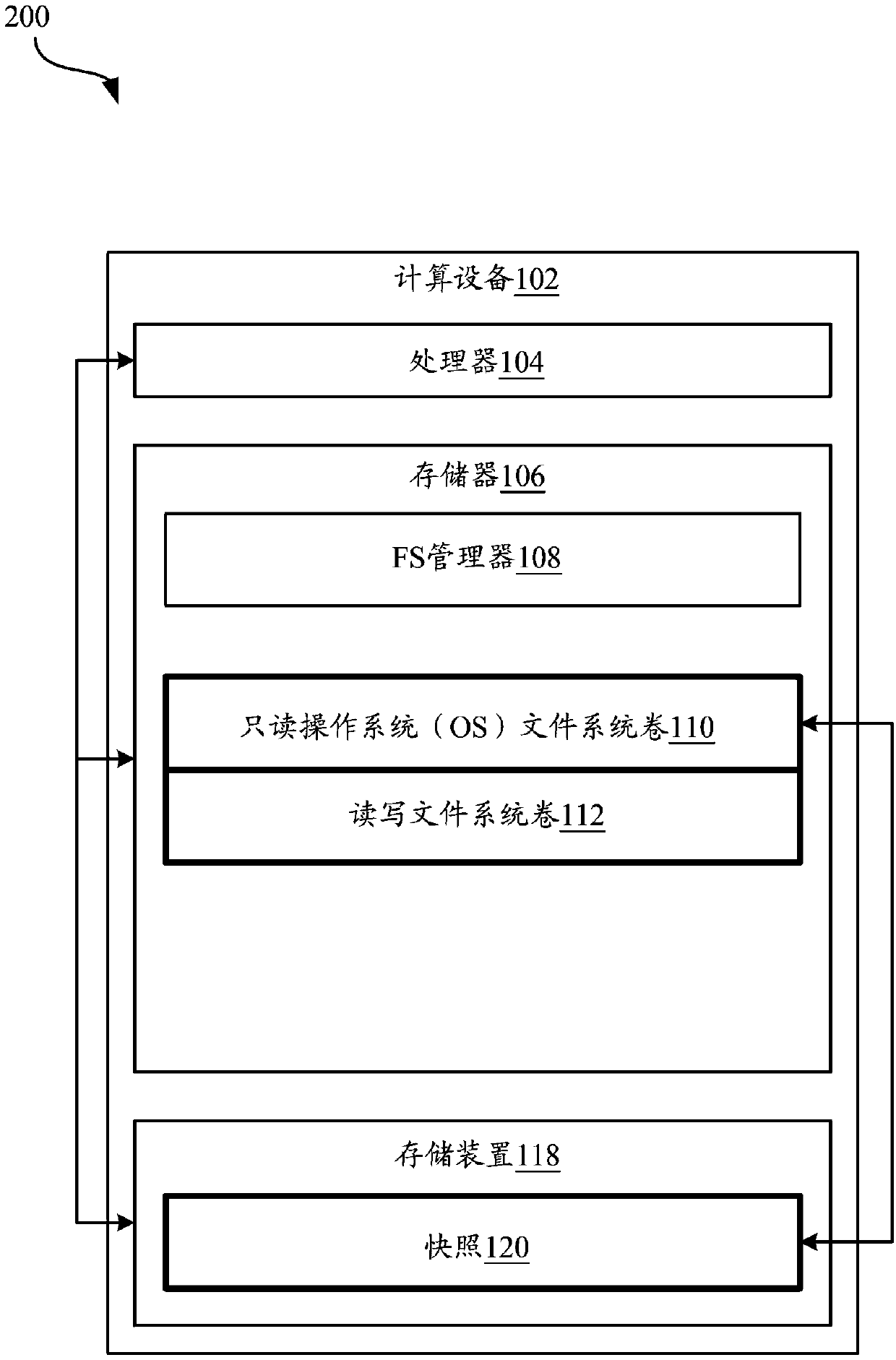

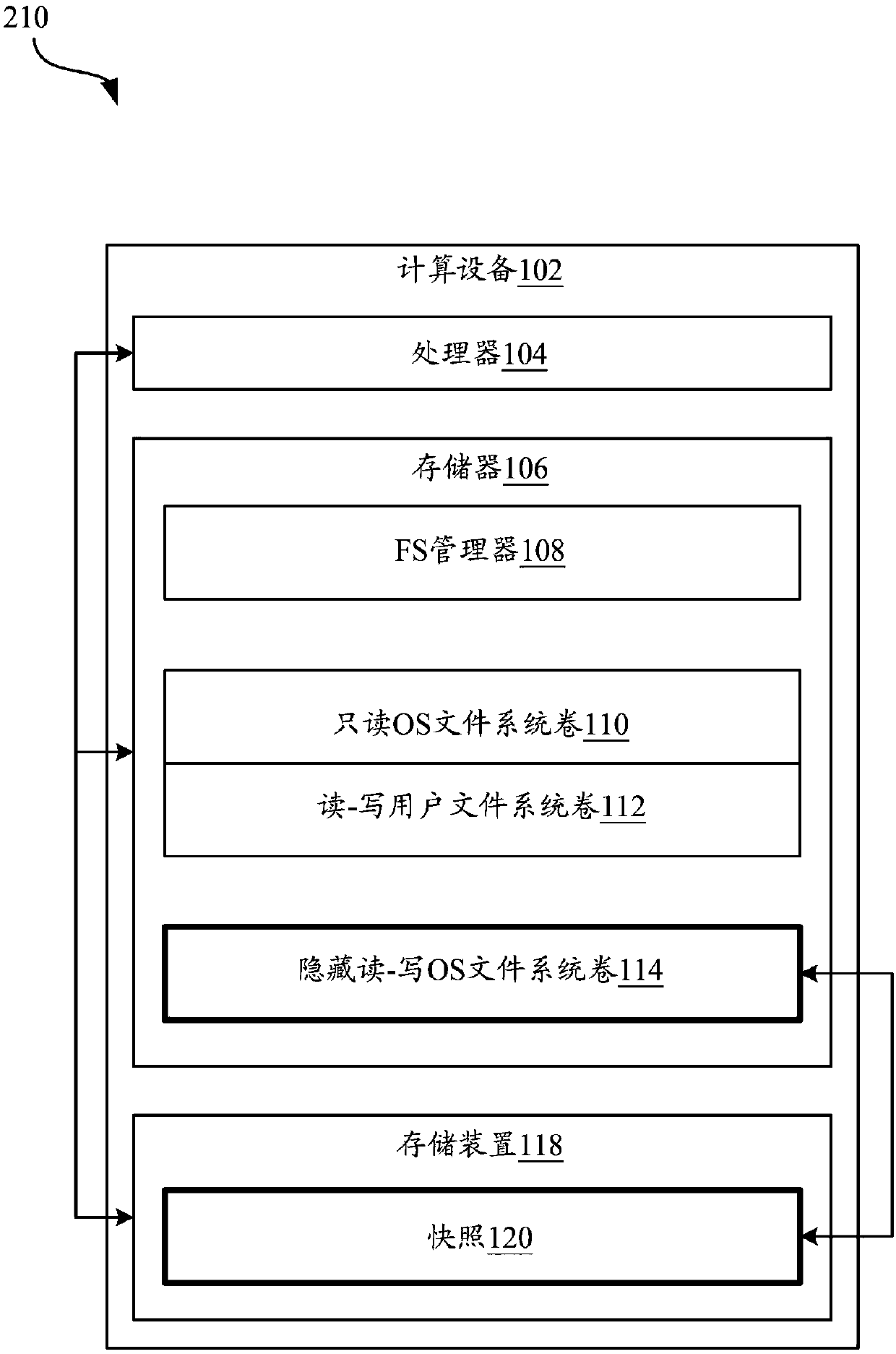

Performing live updates to file system volumes

ActiveCN107870968AReduce the amount of timeEliminate downtimeSoftware engineeringRedundant operation error correctionOperational systemFile system

The present invention provides 'performing live updates to file system volumes'. The described embodiments set forth techniques for performing live updates to file system volumes (e.g., operating system (OS) file system volumes) of computing devices through the utilization of snapshots. In particular, the techniques enable a computing device to remain active while a majority of an update process is performed, which eliminates the considerable functional downtime that is normally imposed when implementing conventional update techniques. Moreover, the overall robustness of the update process isenhanced as the techniques described herein reduce the amount of time that is required for the computing device to remain in the above-described specialized update mode.

Owner:APPLE INC

Elastic body coarse and intermediate crushing crusher

InactiveCN101209430AAvoid the disadvantages of large mechanical noiseEliminate self-phase wearPlastic recyclingGrain treatmentsElastomerSurface stiffness

The invention relates to an elastomer rough and medium grinder with a cone grinding disc. A shell of the cone grinding disc is provided with a limit mechanism for the axial movement limit of a main bearing of a conehead of a control table so as to guarantee that no zero clearance appears in the clearance of a working face of the cone grinding disc. The grinder is also characterized in that the relative rotate speeds of the dynamic grinding working shell face and the static grinding working shell face are in the range of 10 to 200 R / M, and the surface stiffness of a dynamic grinding working shell face and a static grinding working shell face is set at HIC 55-64 DEG C so as to ensure that the crusher has longer service life.

Owner:费建祖

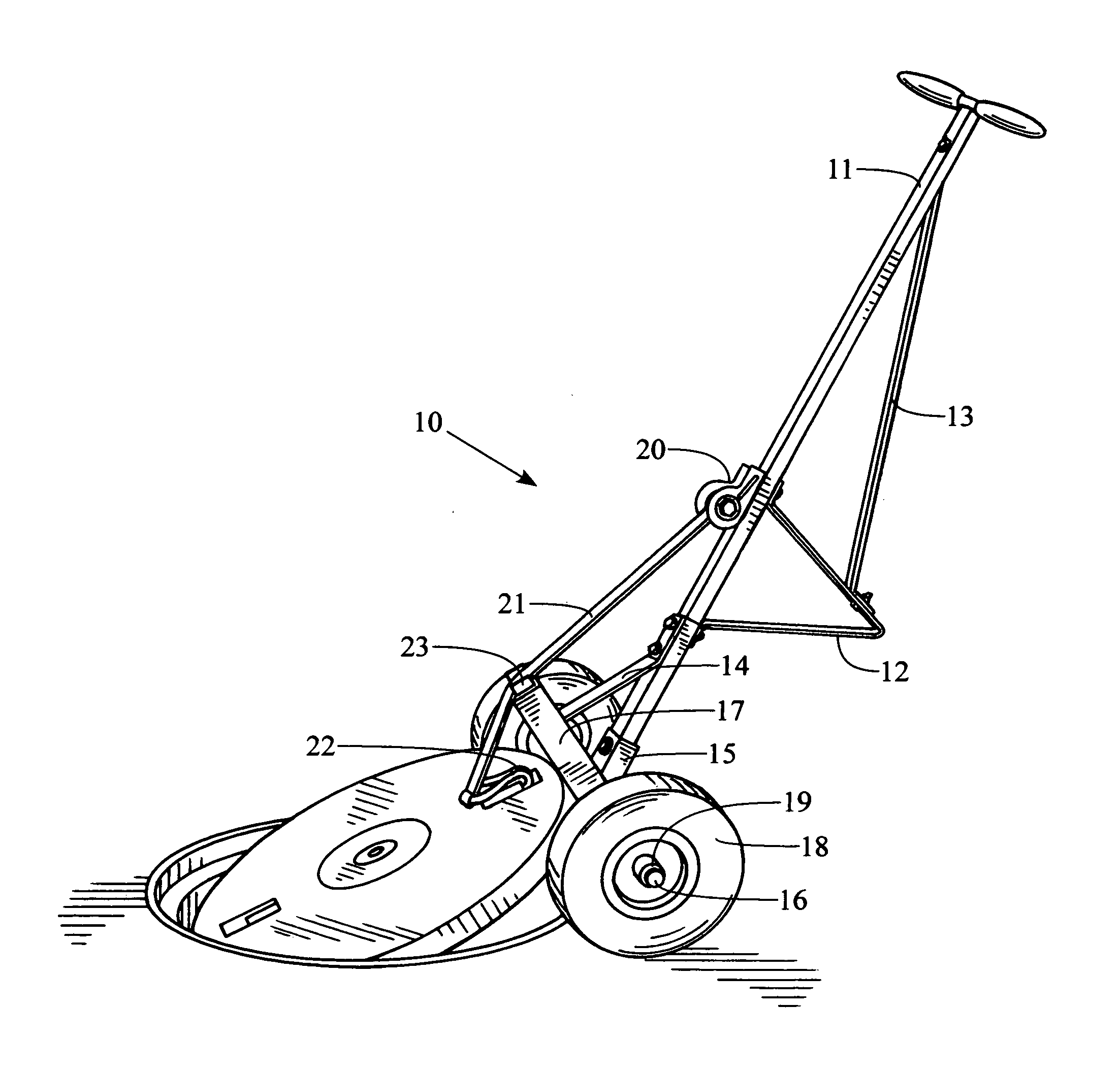

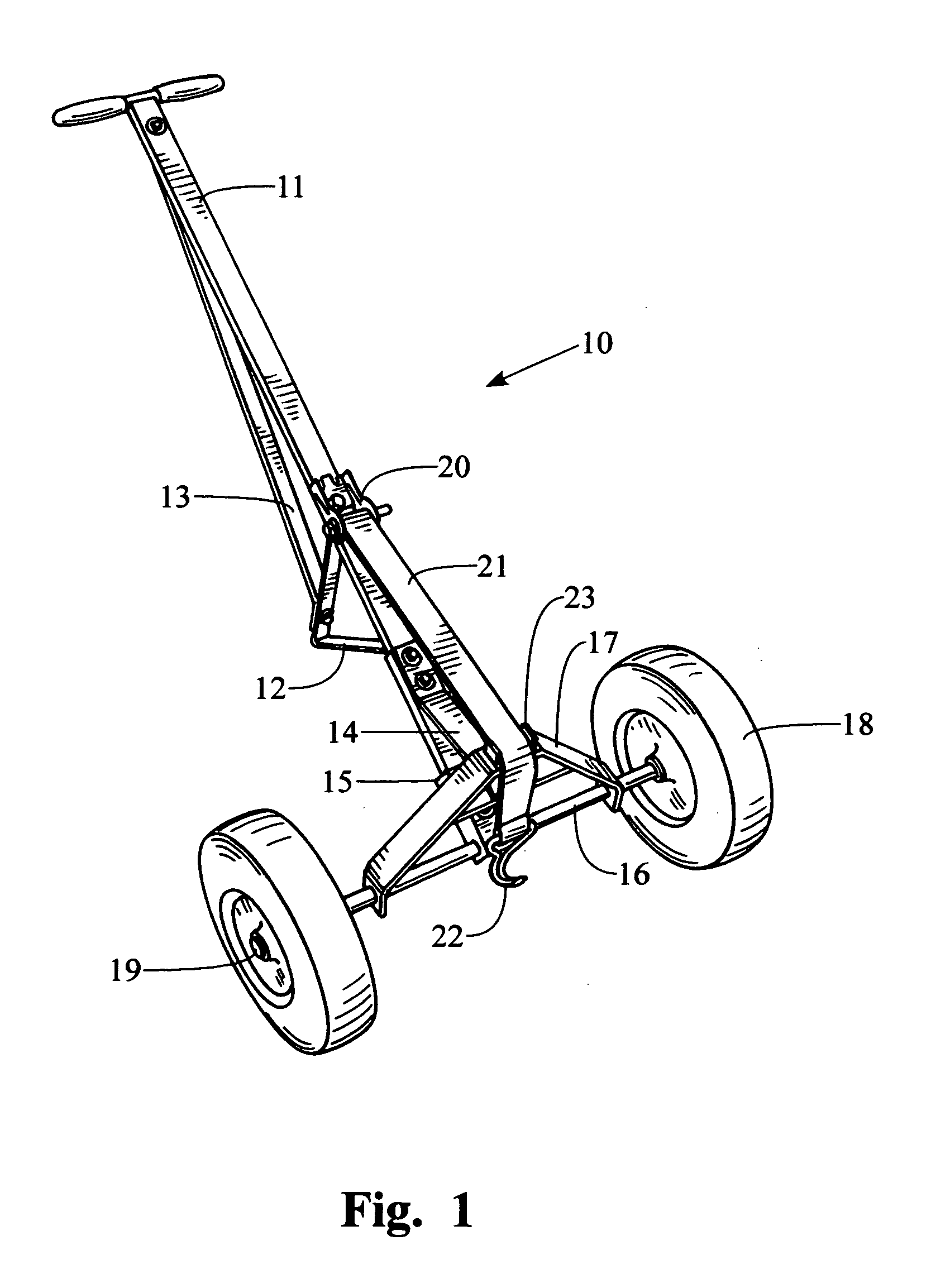

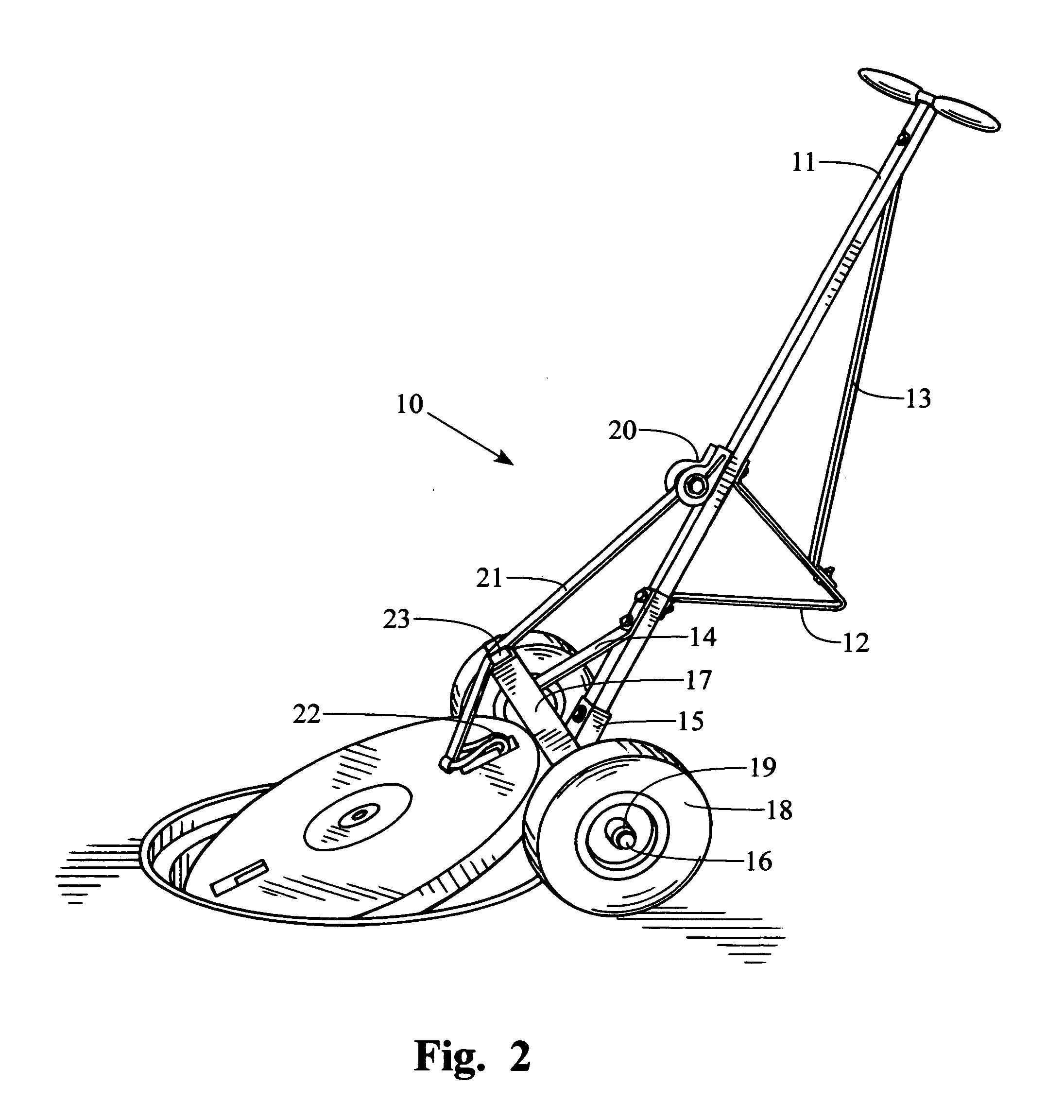

Manhole cover extractor

InactiveUS20110133140A1Eliminate downtimeLifting devicesHand wheelsEngineeringMechanical engineering

A manhole cover extractor that pulls and lifts weighty horizontal items such as manhole covers and handhold enclosure covers that are lifted perpendicular from one side and pulled from the original position, removed and on same plane able to lift and move cover back to the original setting or simply move cover as to not create a tripping hazard; the tool consists of a T-bar which gives the necessary fulcrum for effortless removal and management of cumbersome manhole covers, the T-bar is comprised with handles to control the load. A polypropylene strap which is doubled back with reinforced cross stitching and J-hook which engages the object(s) listed and the aforementioned polypropylene strap is docked to the T-bar handle. Pneumatic all-terrain tires that are attached to an axle that is secured to the T-bar handle through the A-frame of the dolly.

Owner:SHEPHERD ALAN BYRON

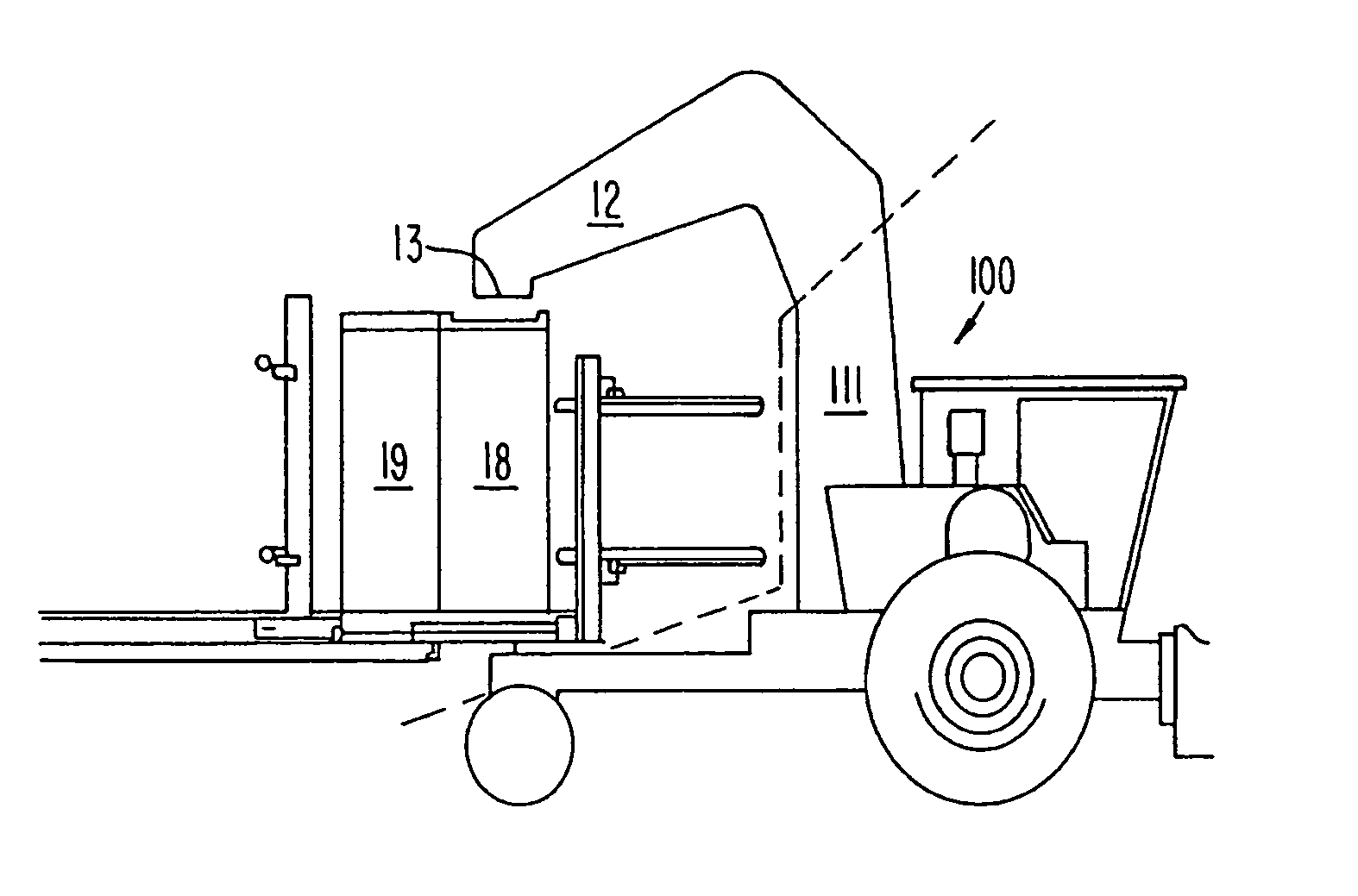

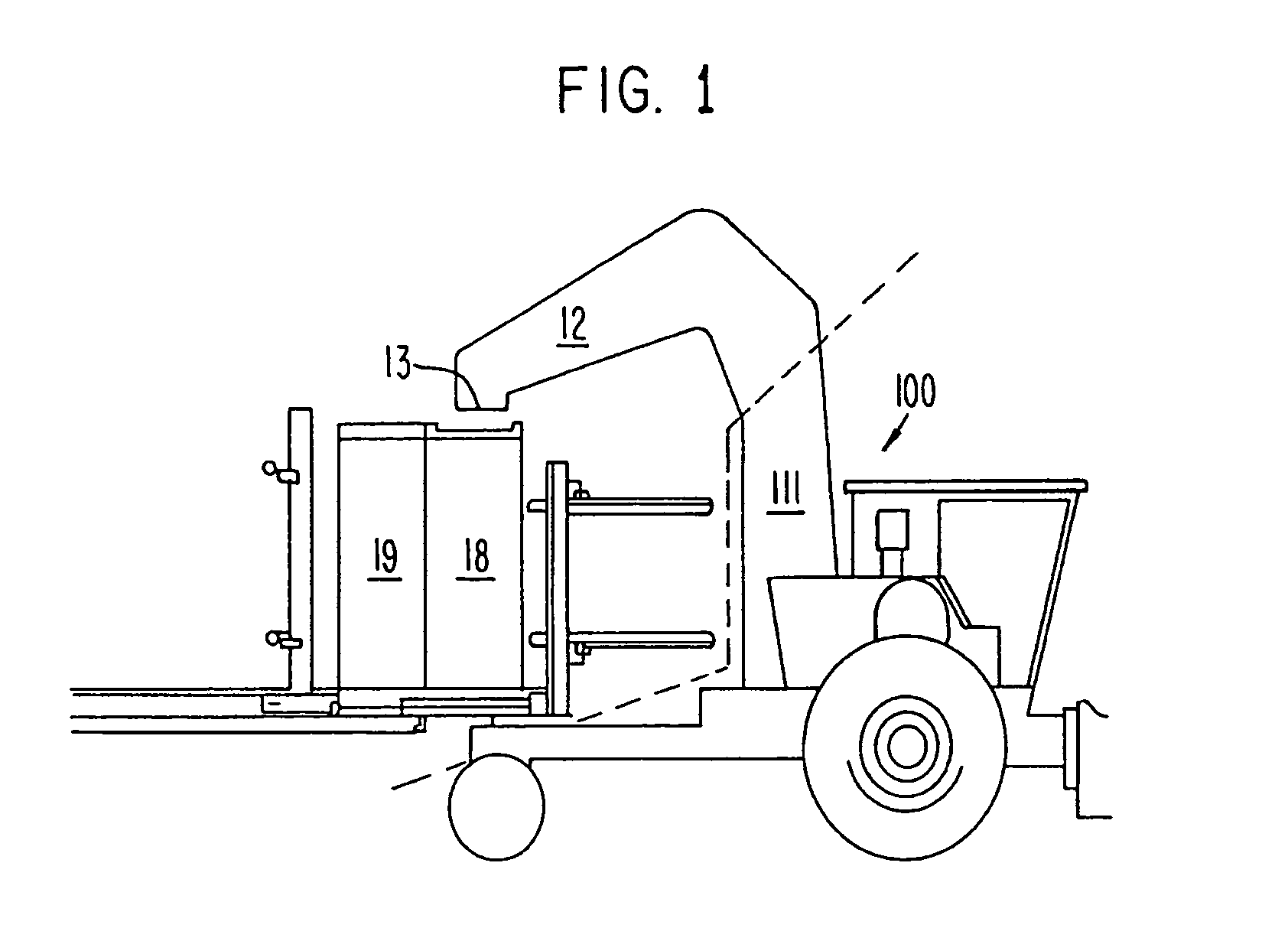

Method and apparatus for forming modules from harvested crops

Module builder including holding chamber, wheeled frame towable behind a harvester; compaction chamber, compaction device, forming chamber, door assembly. The compaction chamber having compaction surface oriented between and substantially perpendicular to compaction chamber sidewalls. Compaction surface is nominally vertical and translatable through the compaction chamber at vertical and near-vertical. The compaction chamber is situated to receive material from the holding chamber. Compaction device are coupled to the compaction surface, and operative to translate it in a substantially horizontal direction through the compaction chamber at vertical and near vertical. The forming chamber is aligned with the compaction chamber trailing edge. The forming chamber door assembly includes a substantially vertical door frame at least spanning the forming chamber trailing edge, and is movable toward and away from the forming chamber along the wheeled frame. The door assembly also includes two doors mounted on the frame and movable between open and closed states.

Owner:LACKEY WELDON LEROY

Print job management method and image forming apparatus

ActiveUS8441657B2Simple replenishment of consumablesEliminate downtimeDigitally marking record carriersDigital computer detailsImage formationComputer science

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com