Workshop resource scheduling method based on heuristic optimization algorithm

A heuristic optimization and resource scheduling technology, applied in resources, computing, computing models, etc., can solve problems such as inability to effectively obtain better feasible solutions, complex production scheduling tasks beyond imagination, etc., to improve return on investment, increase Quick response ability, the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

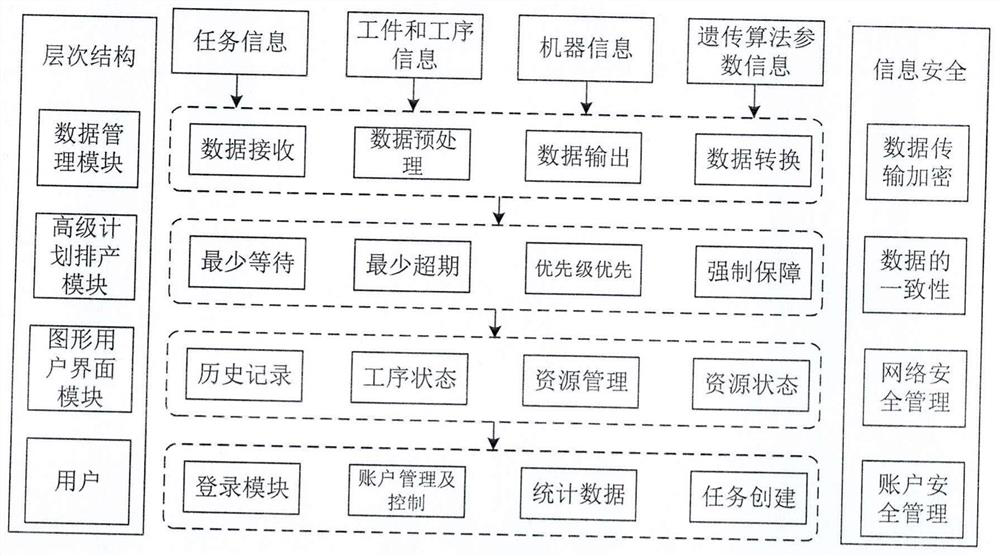

[0039] The workshop resource scheduling method based on the heuristic optimization algorithm, its structure diagram is as follows figure 1 As shown, it includes three parts: input operation data, operation and output result.

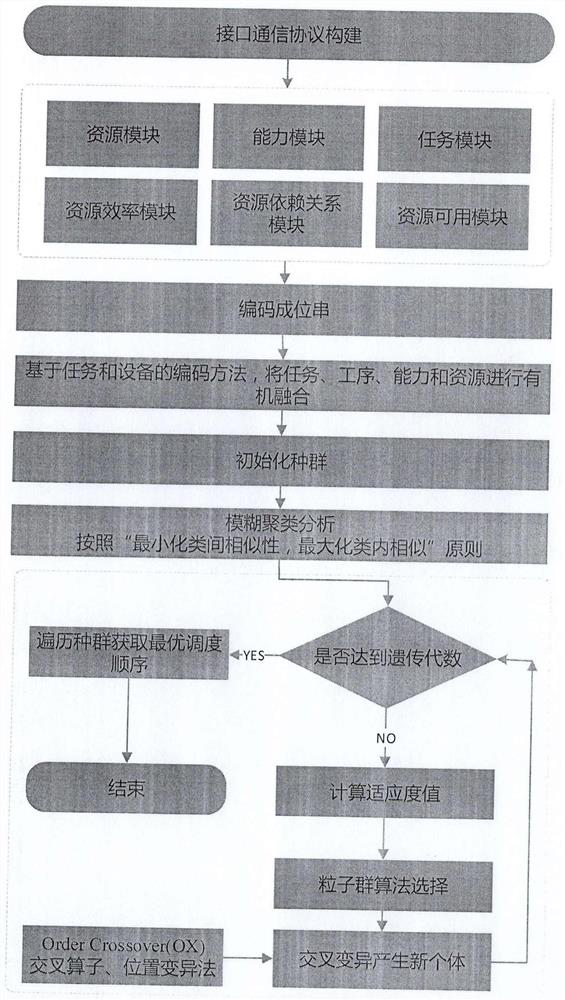

[0040] In order to overcome the complex situation existing in the actual task process, the inventor uses the heuristic optimization algorithm combined with the greedy algorithm to select the optimal task, so as to achieve the purpose of outputting a solution that meets the constraint conditions, and implements the scheduling of workshop resources by adopting the following steps:

[0041] Step 01. Receive the input data and feed the data into the algorithm.

[0042] Step 02. Set the constraints to filter the output results.

[0043] Step 03. The algorithm operates on the received data and outputs the result.

[0044] The step 02 is specifically described as follows:

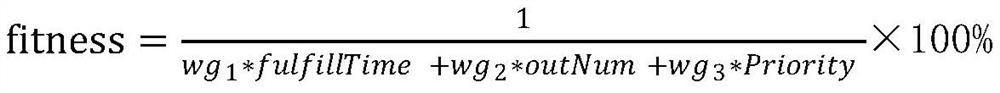

[0045] The algorithm supports the input of various constraint conditions. Constraint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com