Patents

Literature

1398 results about "Production planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

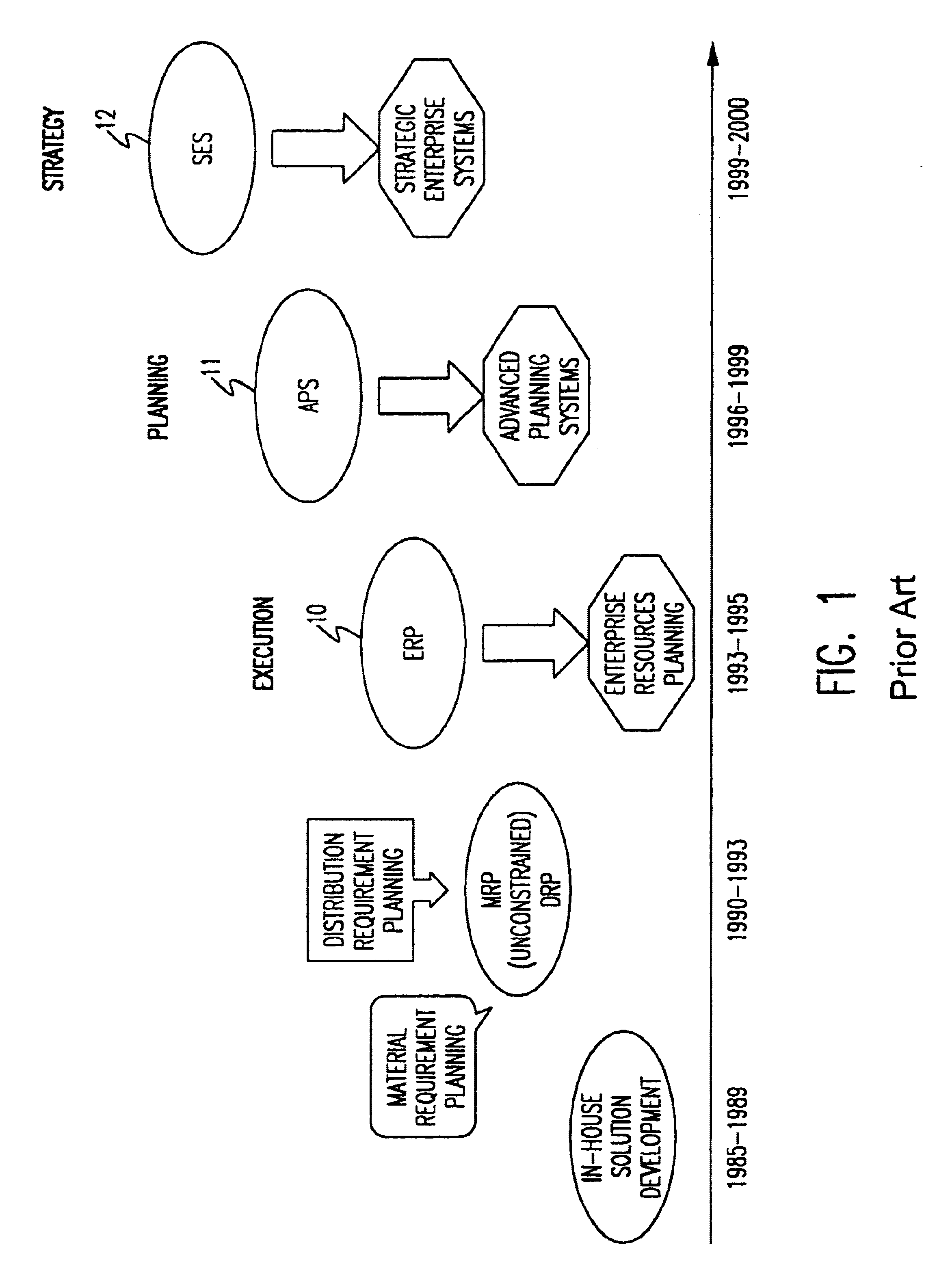

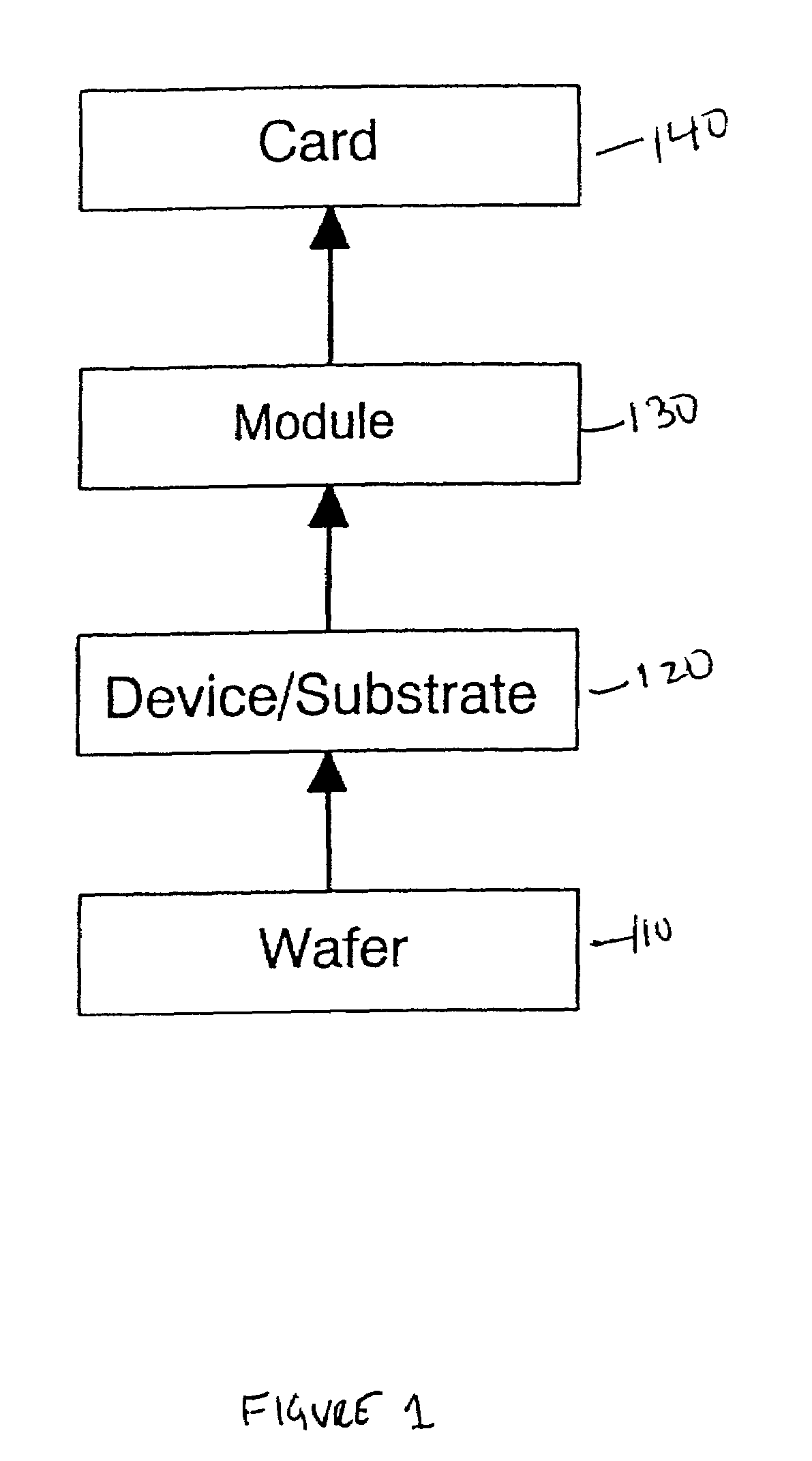

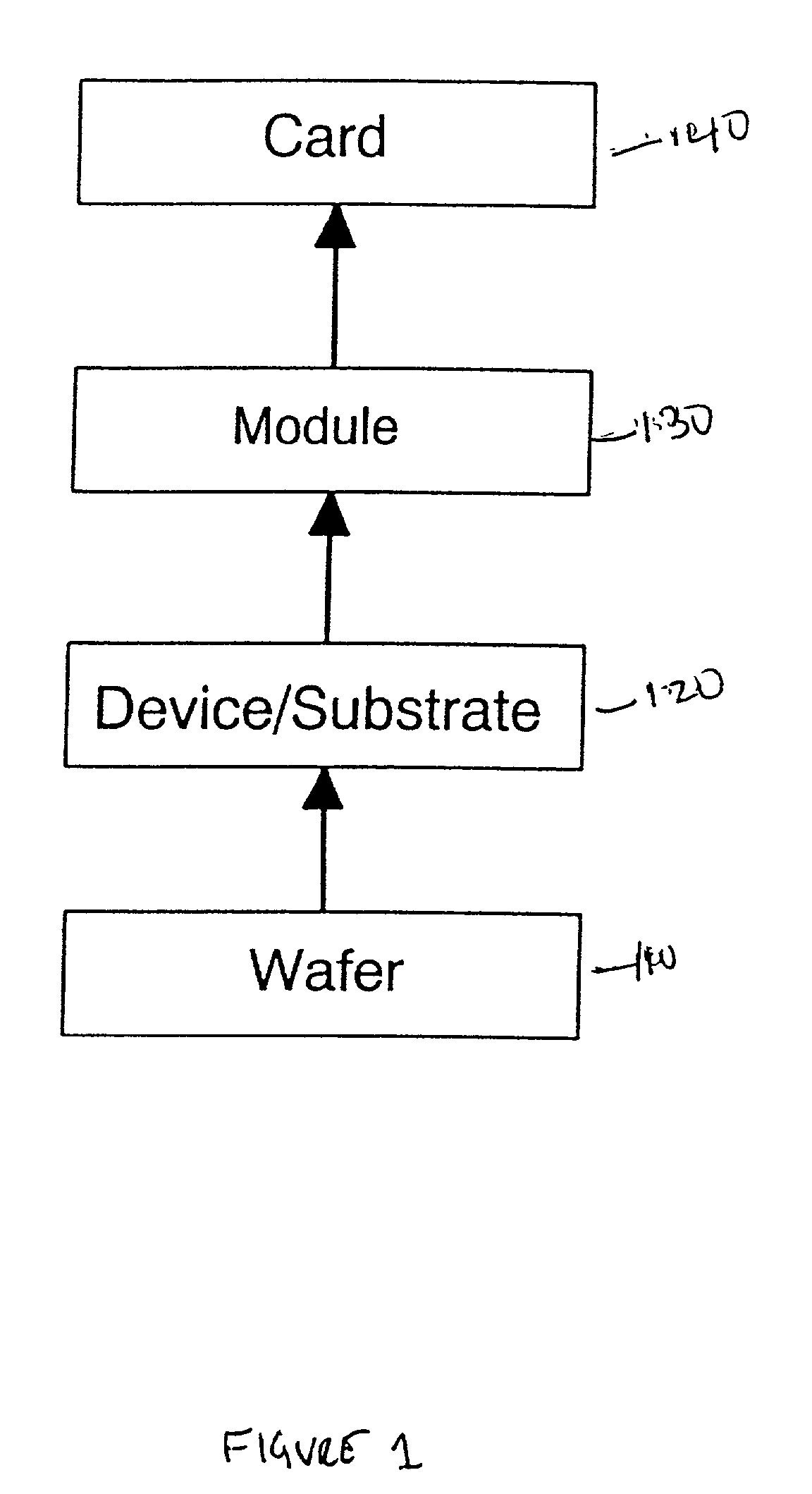

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.

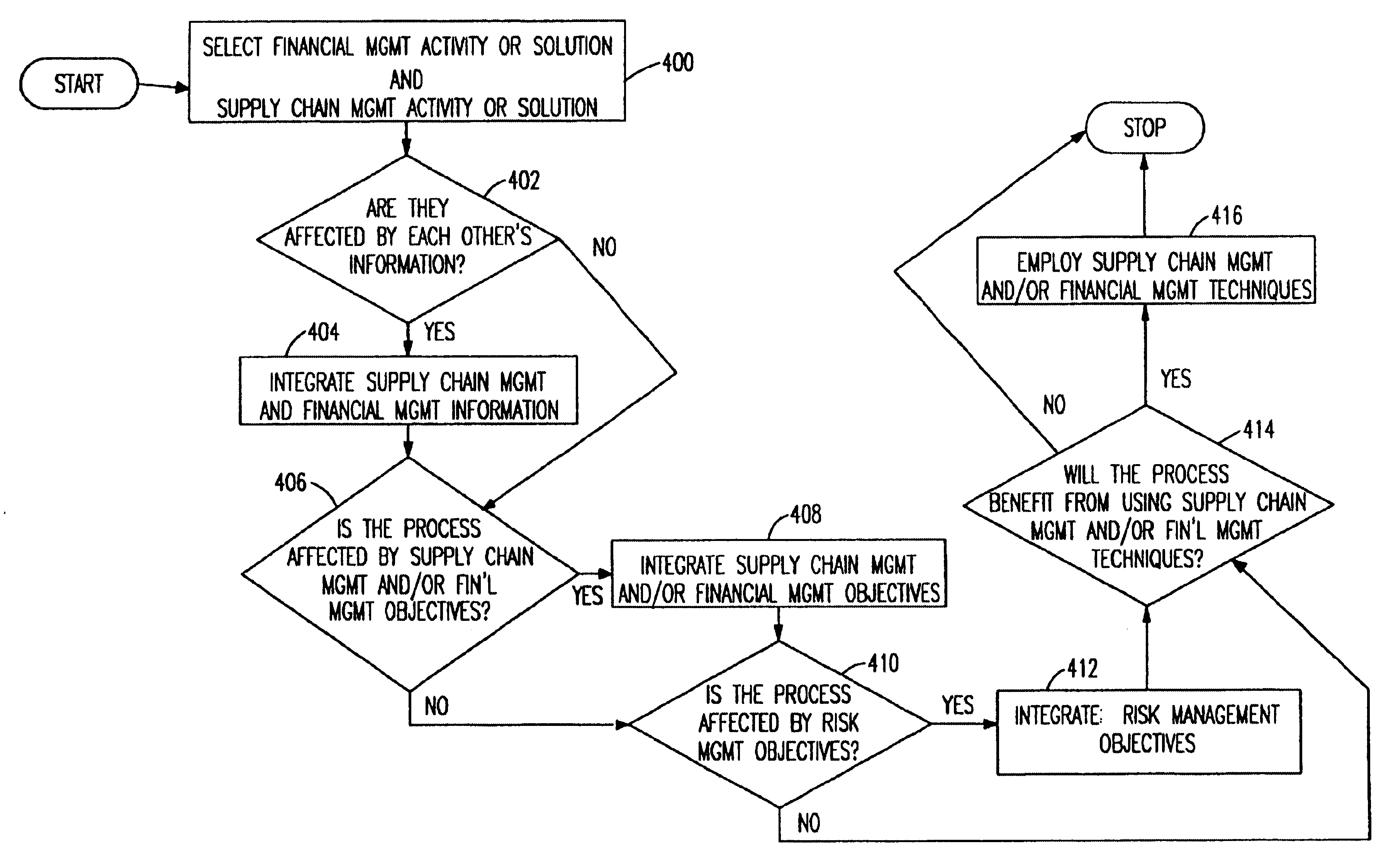

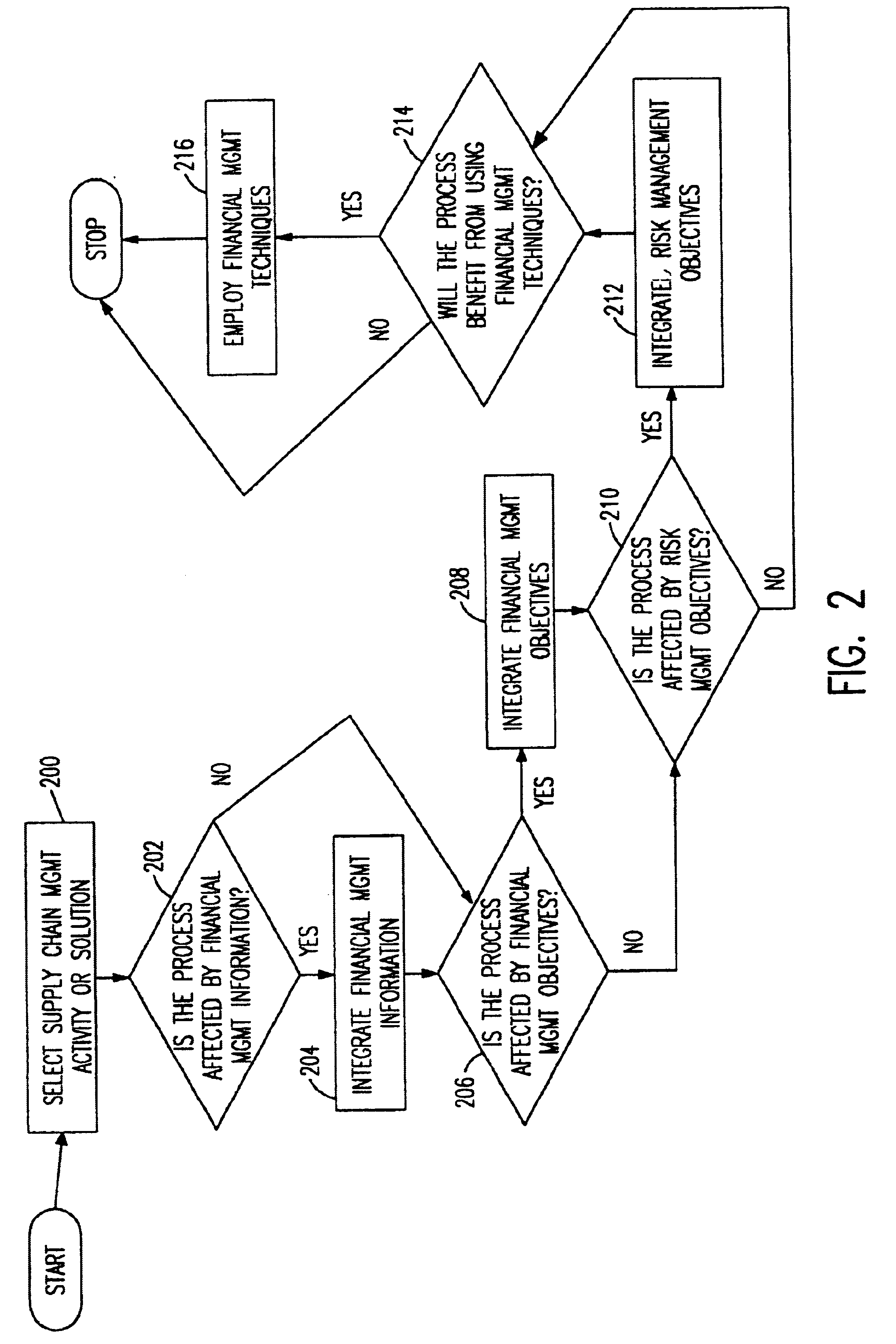

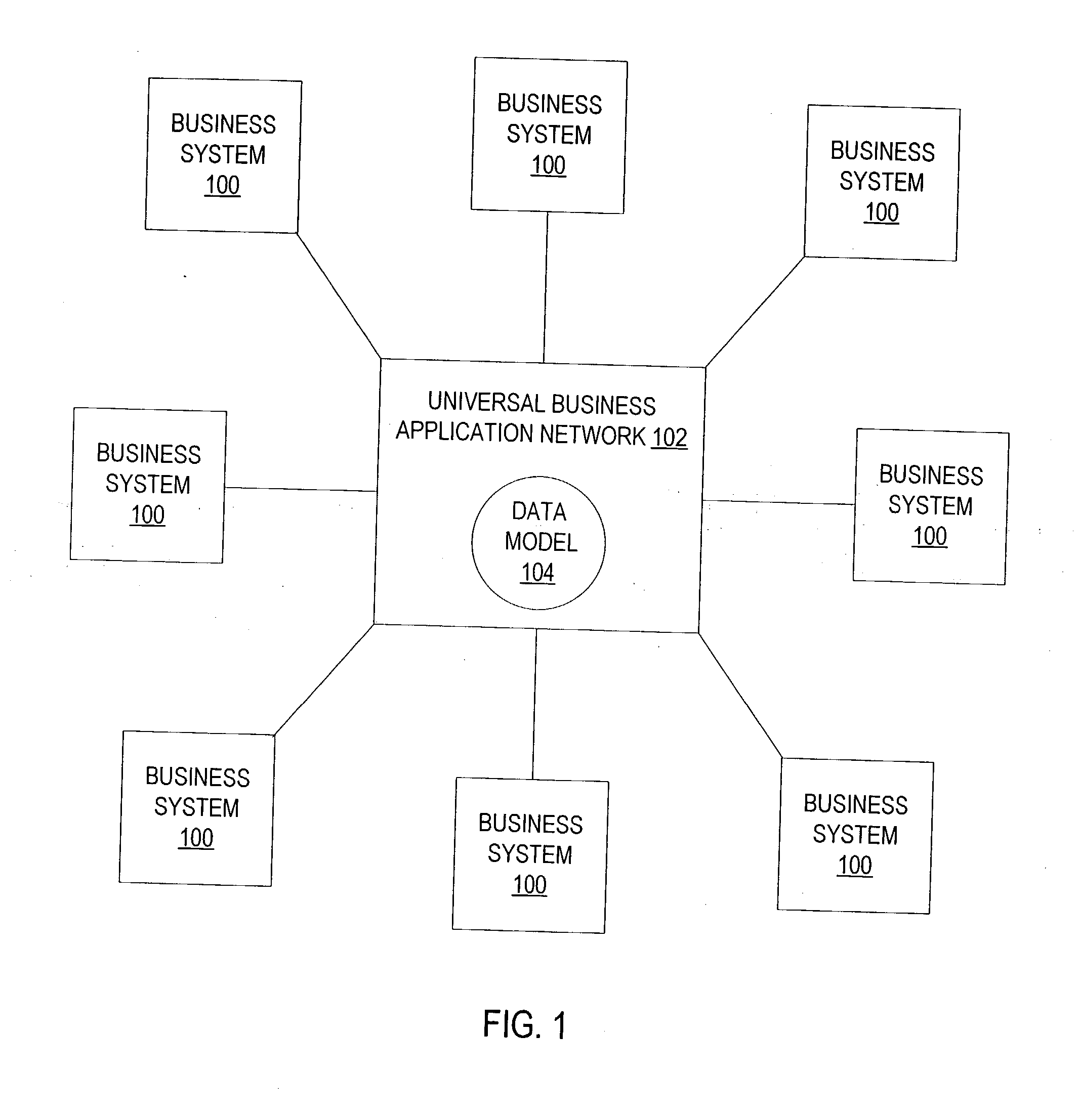

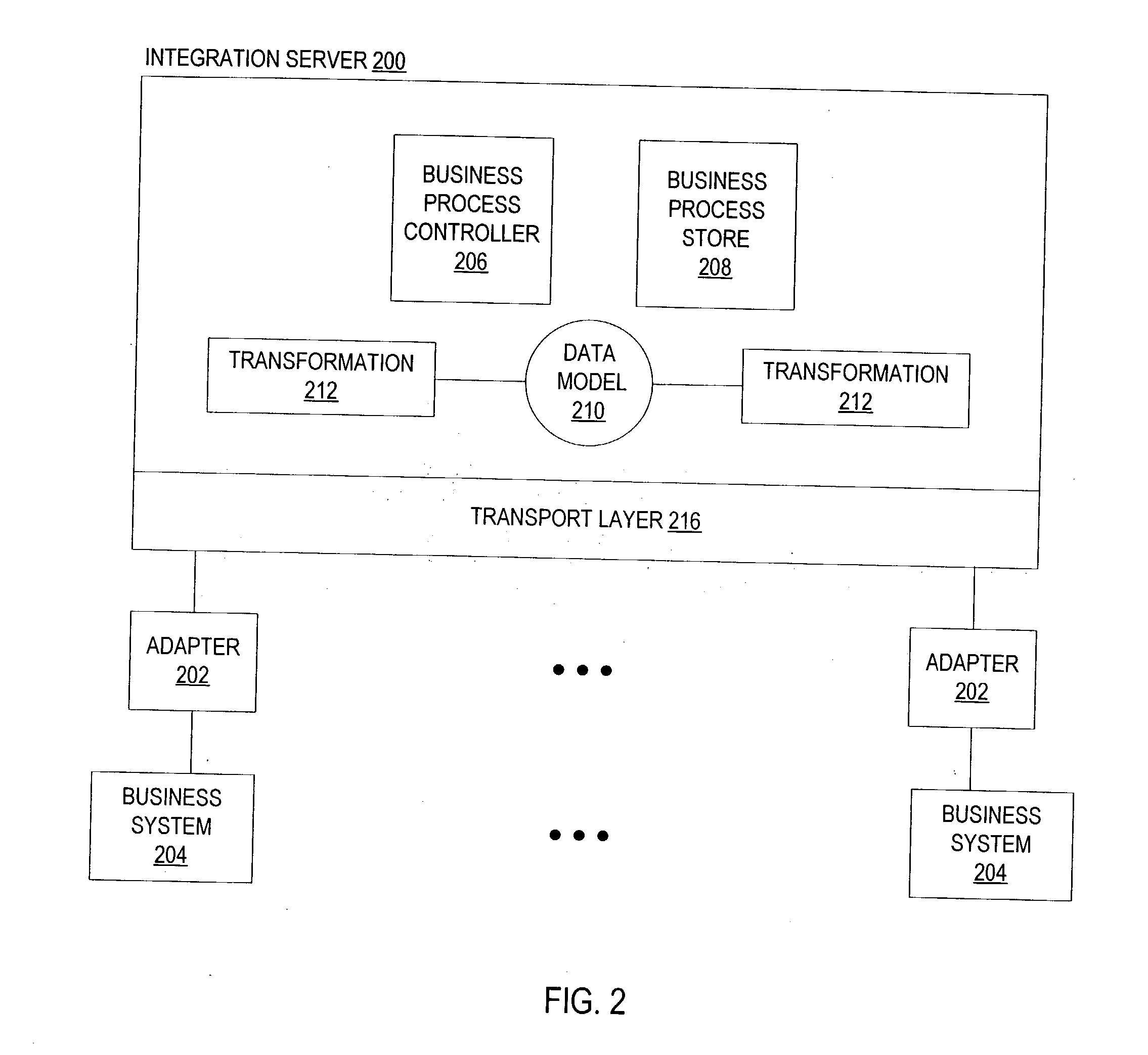

Method for integrated supply chain and financial management

A method to generate a strategic business plan to improve operations, and to closely monitor various performance measures of an enterprise. This is accomplished employing a more comprehensive approach to maximizing profitability, increasing revenue, and explicitly considering risk. In particular, the method extends supply chain management using financial management considerations, extends financial management using supply chain management considerations, employs supply chain management techniques to improve financial management, and employs financial management techniques to improve supply chain management. The method uses information and models derived from at least one of the following business processes: accounting; cash management; funds management, financing, profitability analysis, risk management, loan management, treasury management, investments management, business development, order management, demand planning and forecasting, procurement, production planning, inventory management, transportation and distribution, and supply chain design.

Owner:IBM CORP

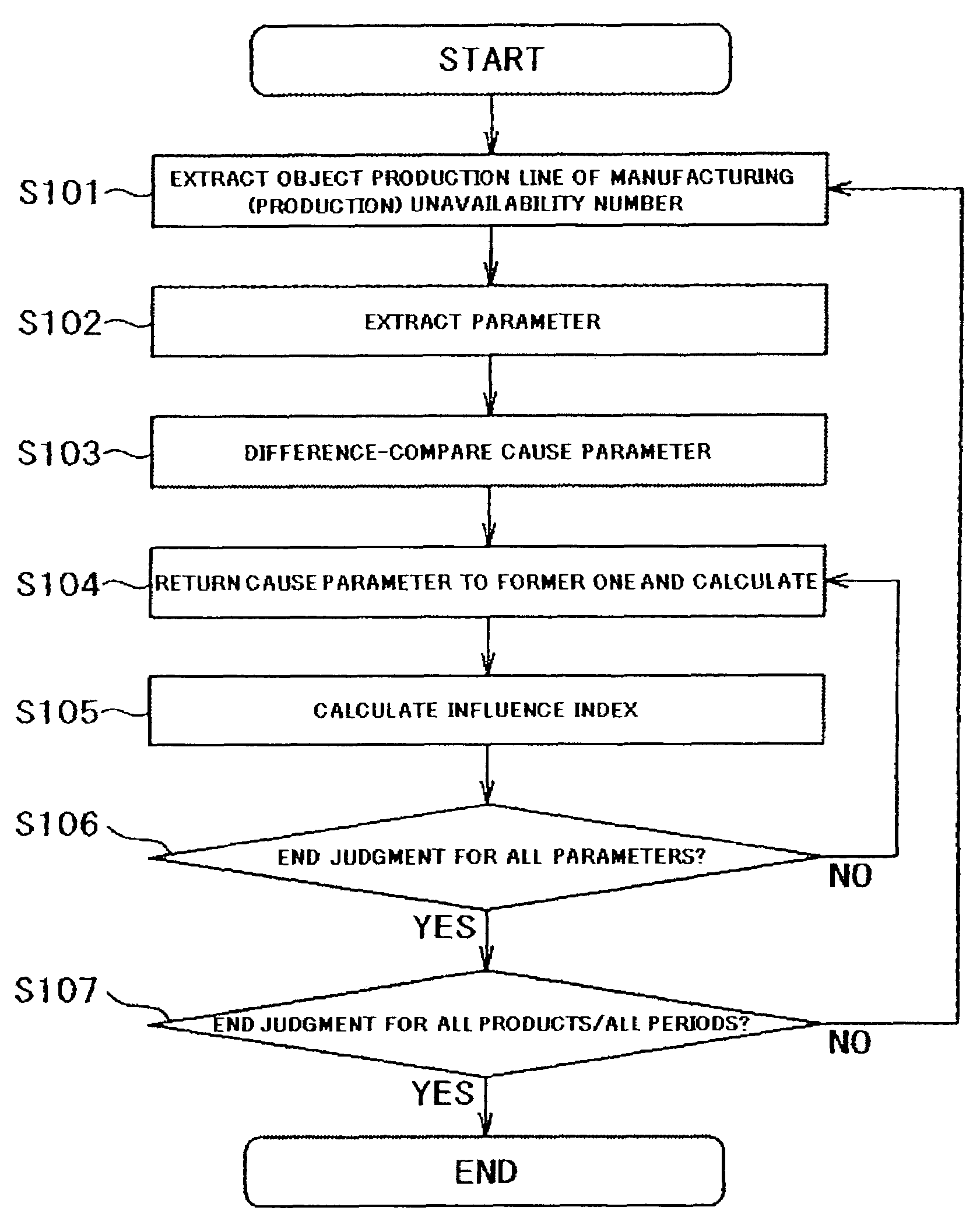

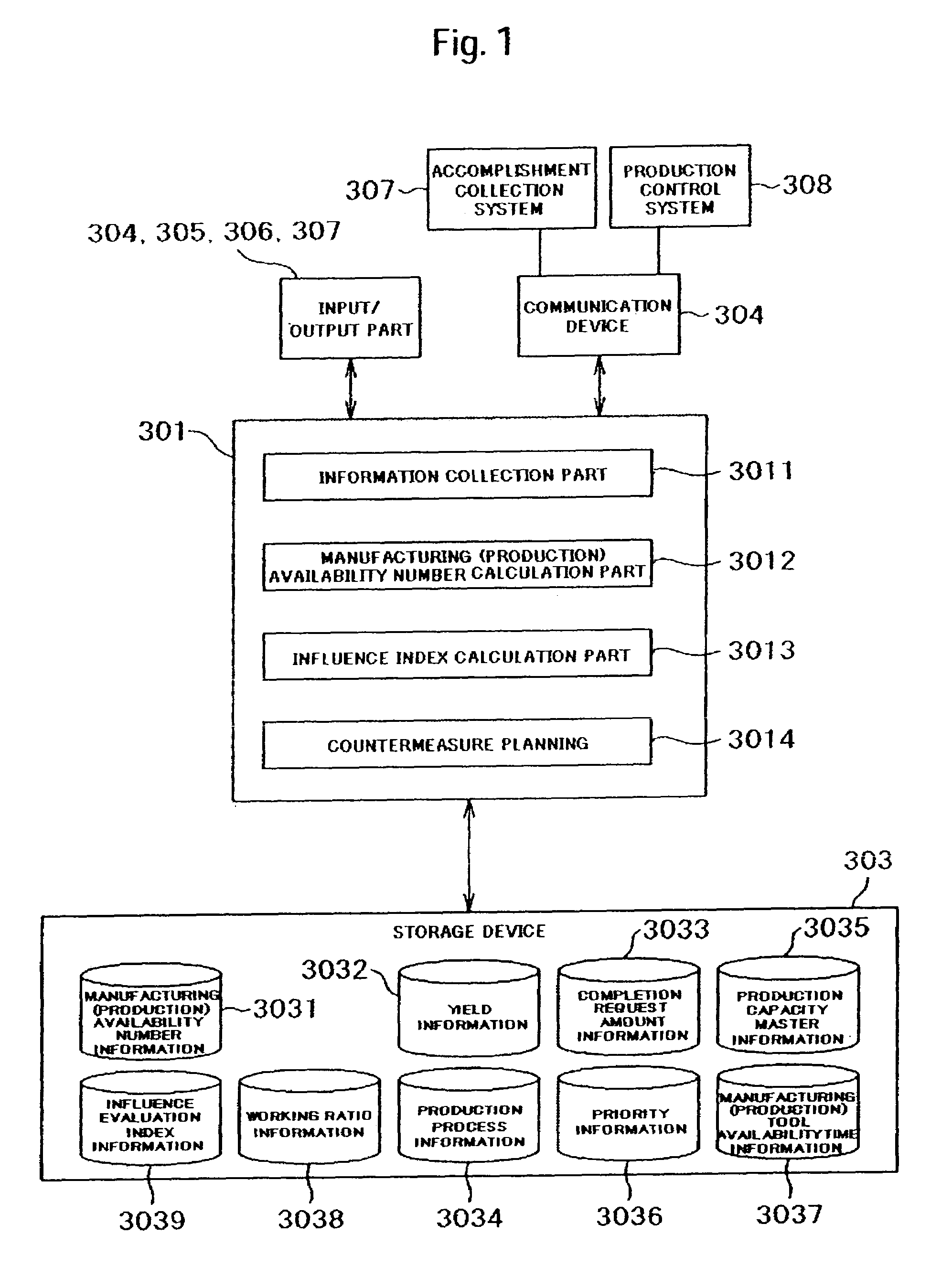

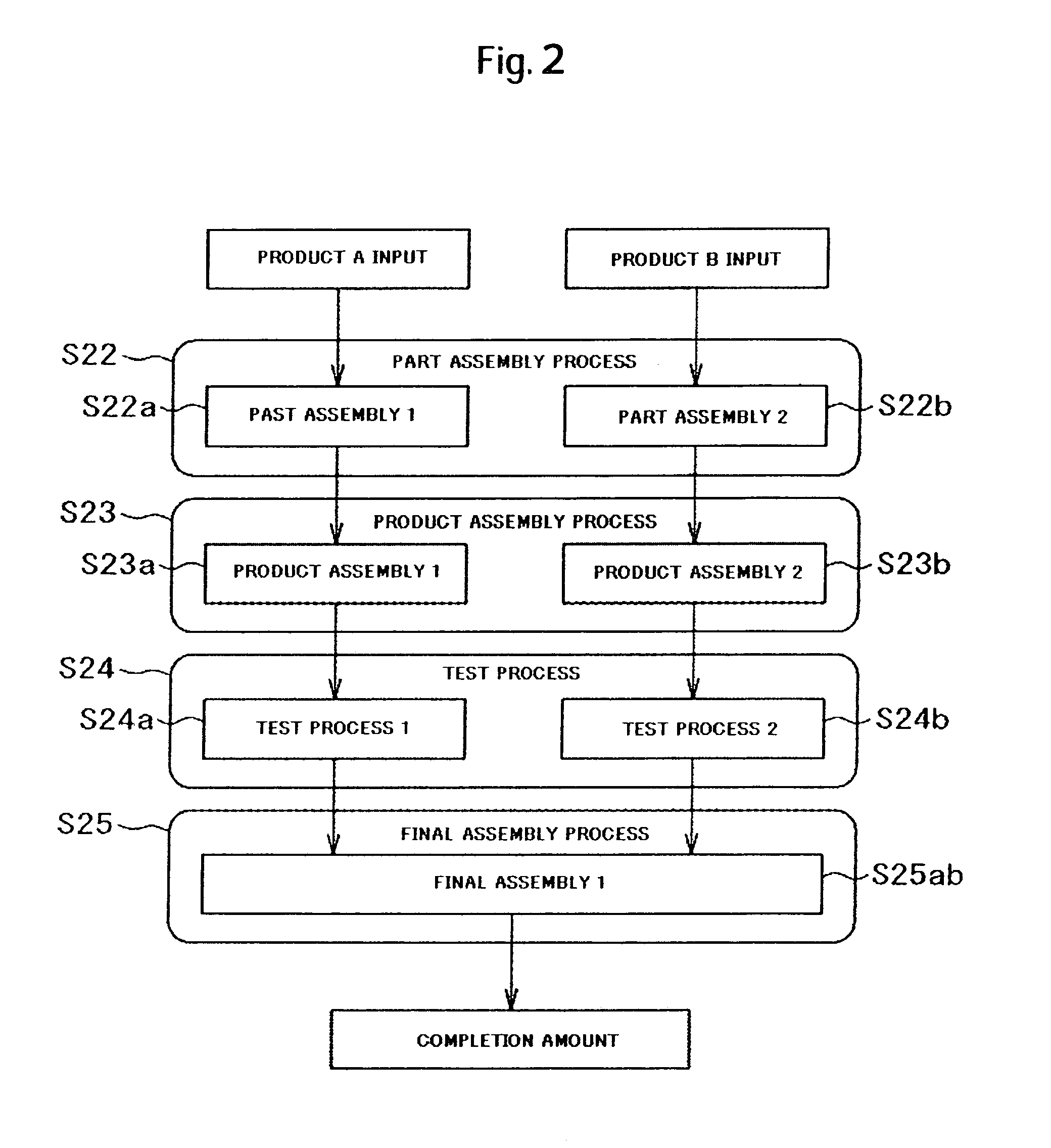

Production planning method and production planning system

InactiveUS7693593B2Change in yield of the production line is vigorousComplicated processingForecastingResourcesProduction lineUnavailability

Embodiments of the present invention provide a production planning method and system. Where a manufacturing apparatus is shared by a plurality of products in a production line, if a manufacturing (production) availability number is changed, a cause parameter is automatically investigated so that a production plan with high precision can be prepared in a short time. With respect to a production plan as the previous / current comparison objects, a production process used in the production plan in which a change occurs, is extracted. From the production process, a parameter item to be used in the production capacity evaluation is extracted for all products, a difference comparison is made between the value of the previous parameter and the value of the current parameter, so that the parameter item as the cause is specified. The combination of the cause parameter items is calculated, and a cause parameter list is prepared. Next, from the specified parameter list, the parameter item is sequentially changed, and the manufacturing (production) availability number is recalculated. An influence index given to the manufacturing (production) unavailability number by the cause parameter, is calculated.

Owner:WESTERN DIGITAL TECH INC

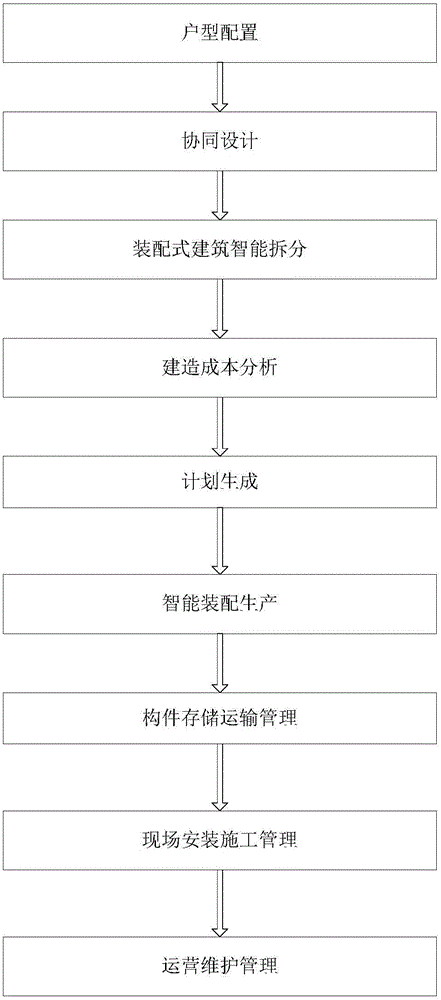

Assembled building detailed design and construction method based on BIM (Building Information Modeling) and large data

ActiveCN105023201AReduce difficultyEasy extractionData processing applicationsThe InternetTransportation management system

The present invention relates to an assembled building detailed design and construction method based on BIM (Building Information Modeling) and large data. The method comprises the following steps of: a user-defined house type based on the BIM; multi-specialty cooperative design based on the BIM; intelligent assembled building splitting based on the BIM; construction cost analysis based on the large data; auto-generation of a production plan, a construction plan and a raw material purchase plan based on the large data; intelligent factory assembling production based on the BIM; a storage, transportation and management system based on the internet of things; on-site installation and construction management based on the BIM; and assembled building operation and maintenance management based on the BIM. By adopting the scheme provided by the present invention, the management and control of the whole assembled building design and production process are improved, the working efficiency is improved, the project quality is ensured, and the development of an assembled building can be effectively promoted.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +2

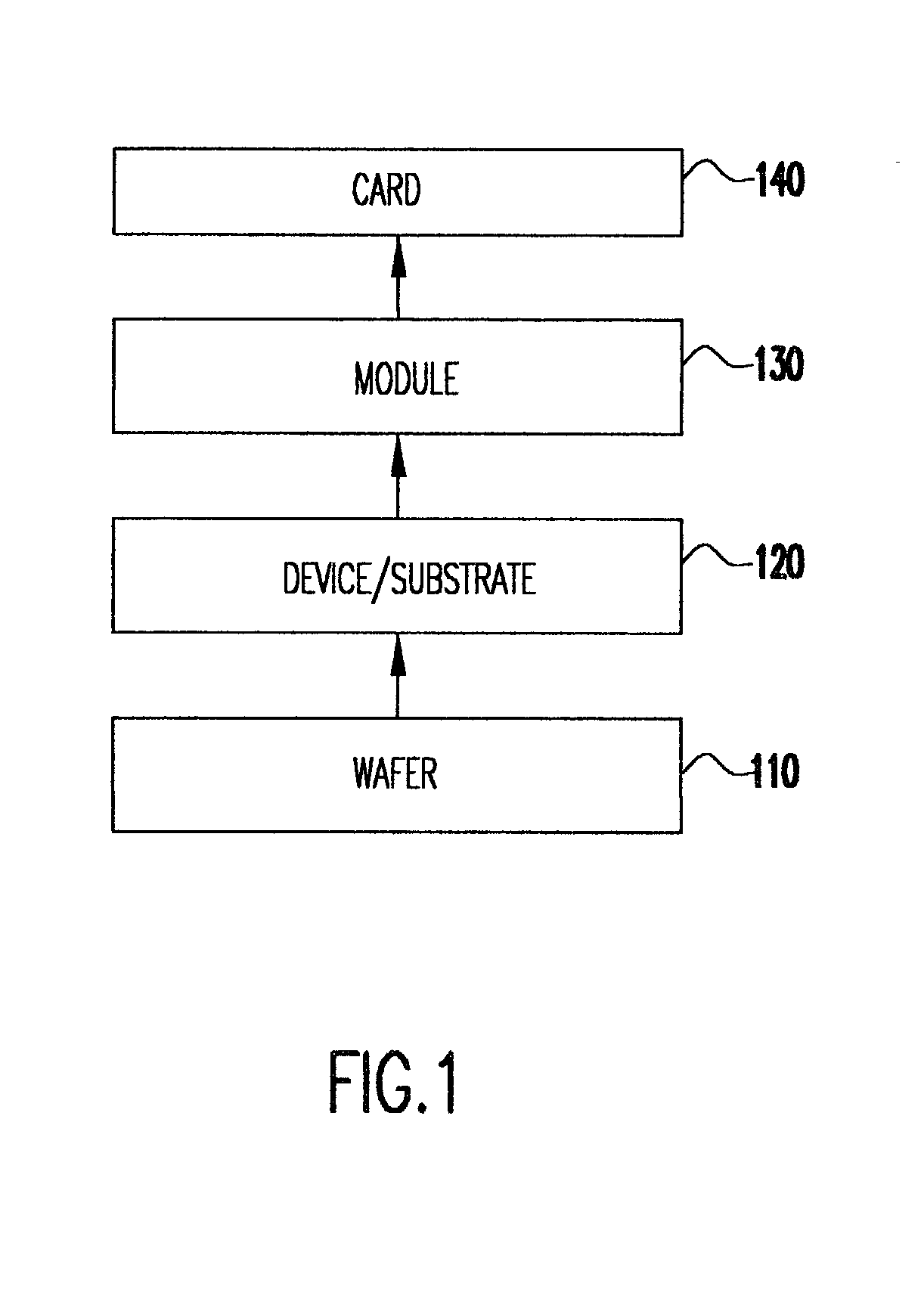

Decomposition system and method for solving a large-scale semiconductor production planning problem

Owner:INT BUSINESS MASCH CORP

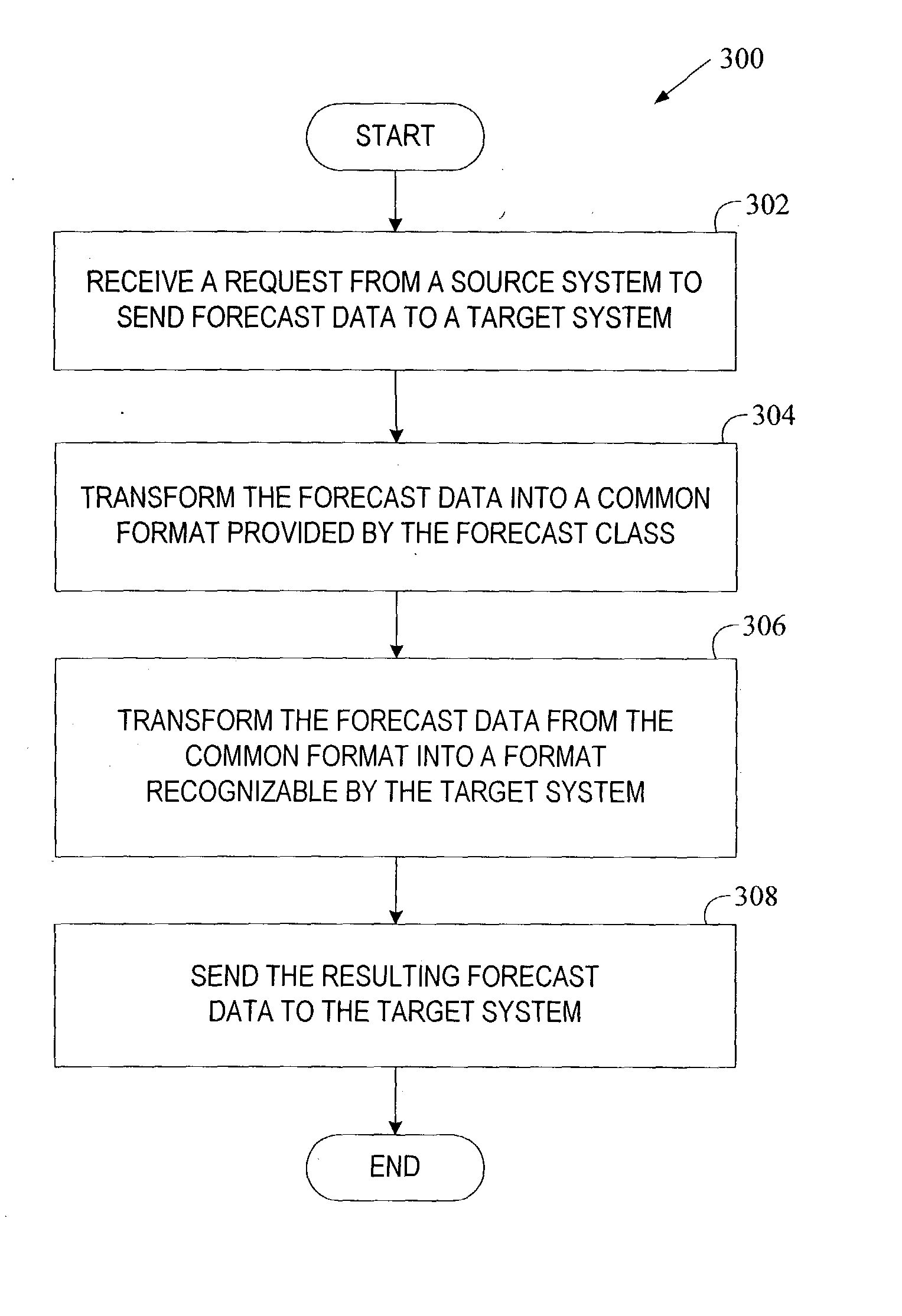

Modeling of forecasting and production planning data

ActiveUS20070225949A1ForecastingComputation using non-denominational number representationProgram planningBusiness forecasting

Owner:ORACLE INT CORP

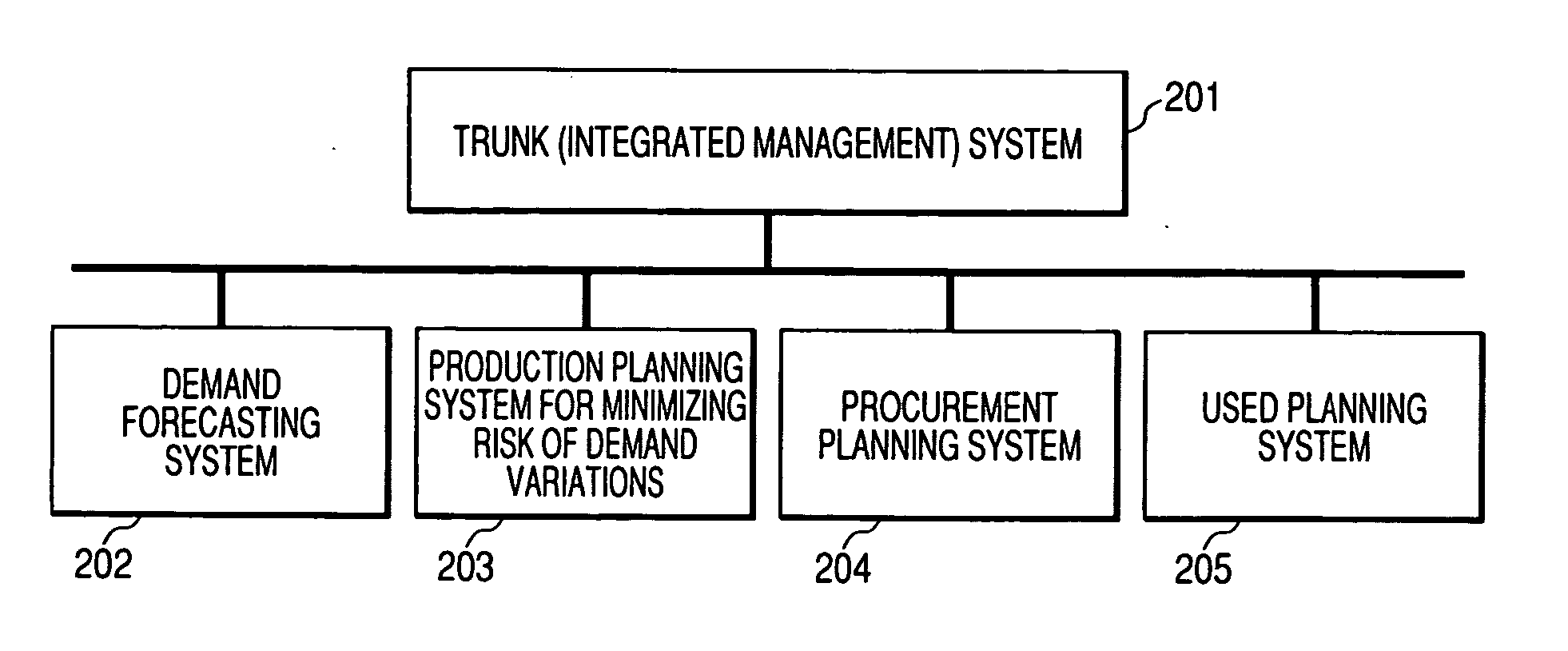

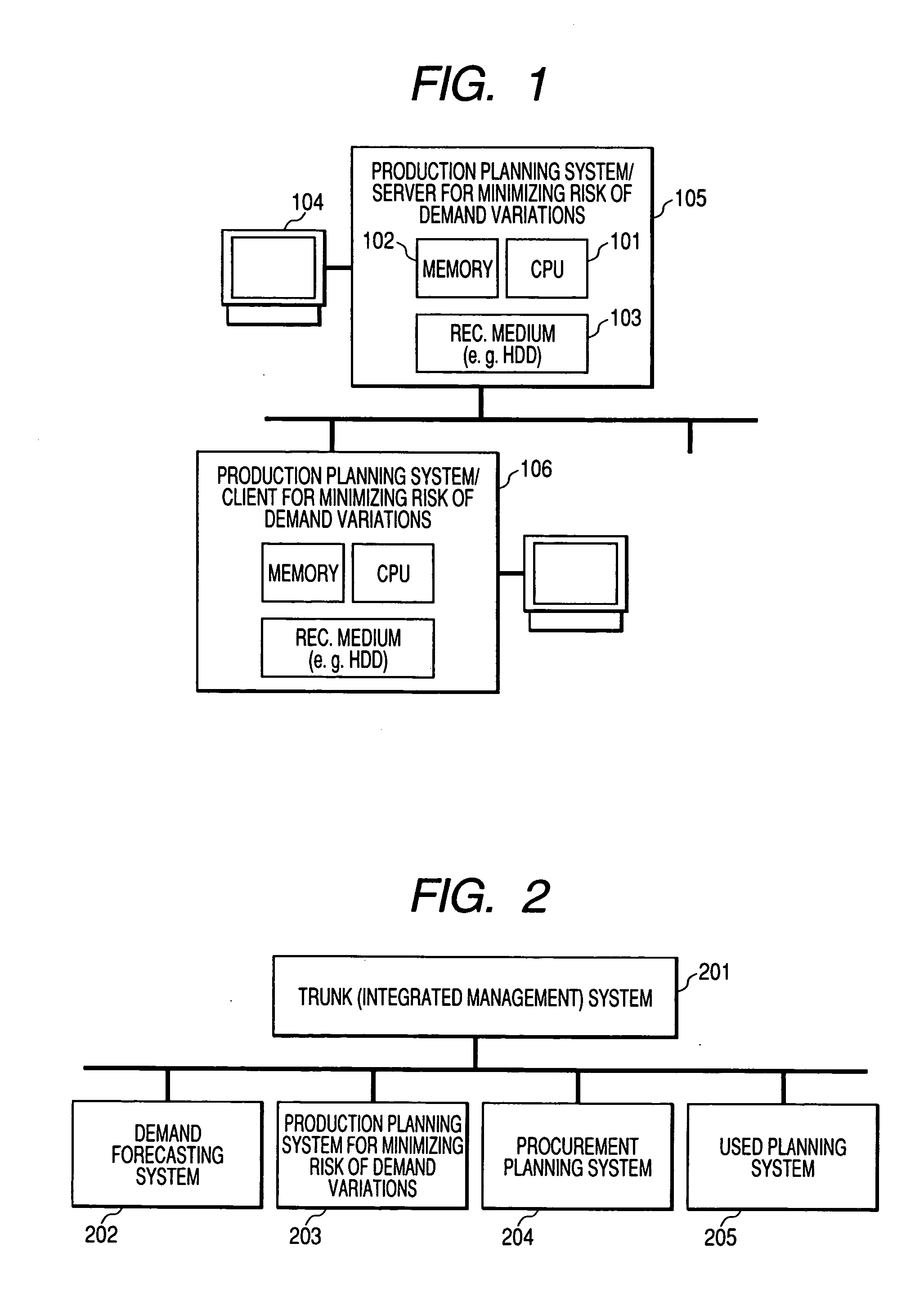

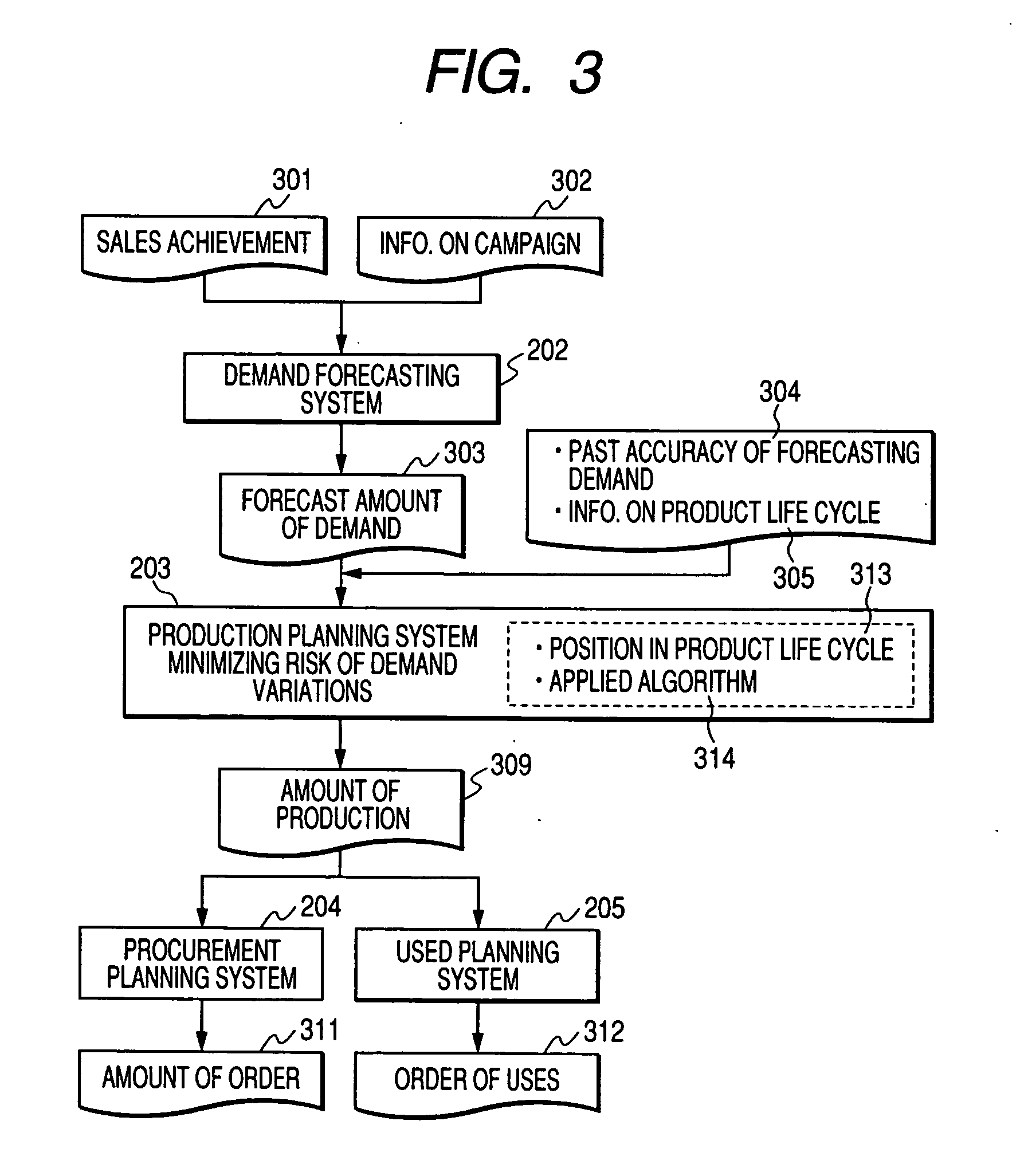

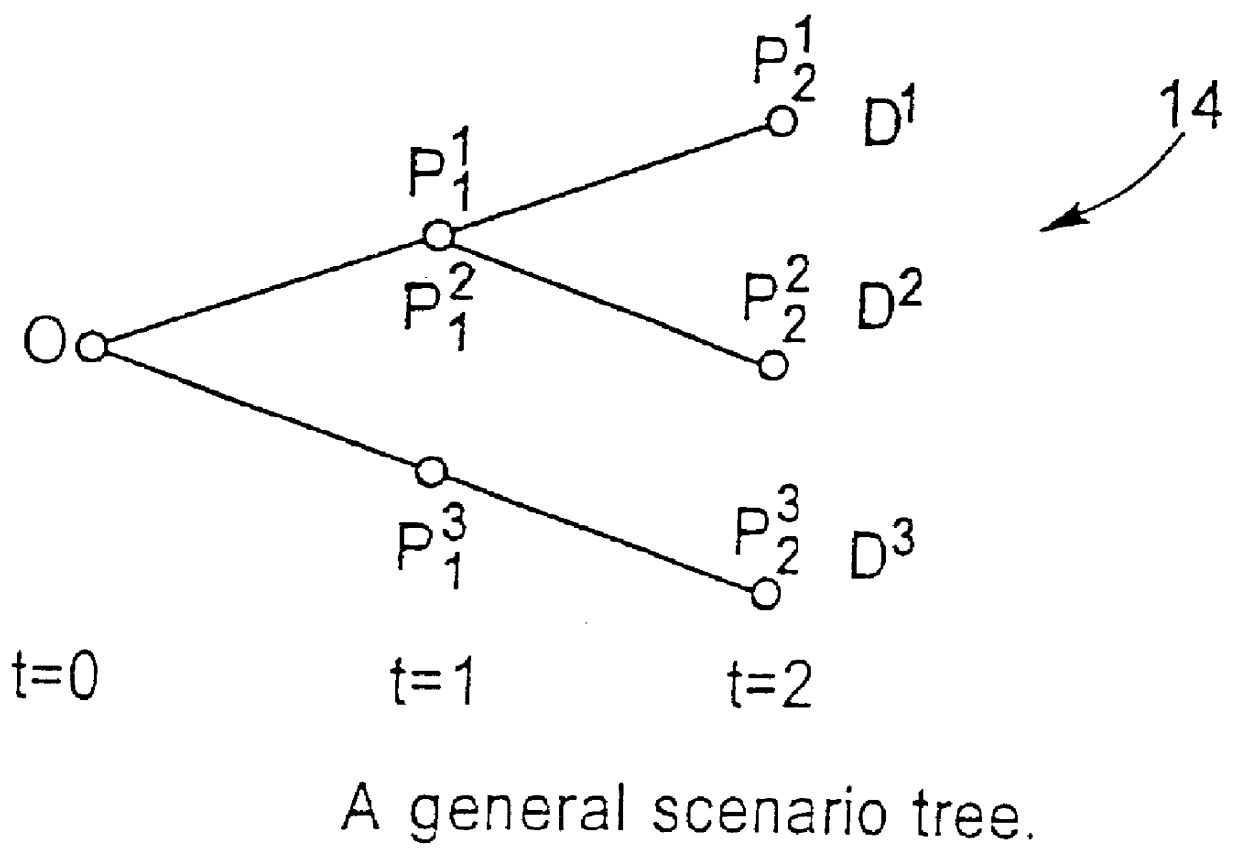

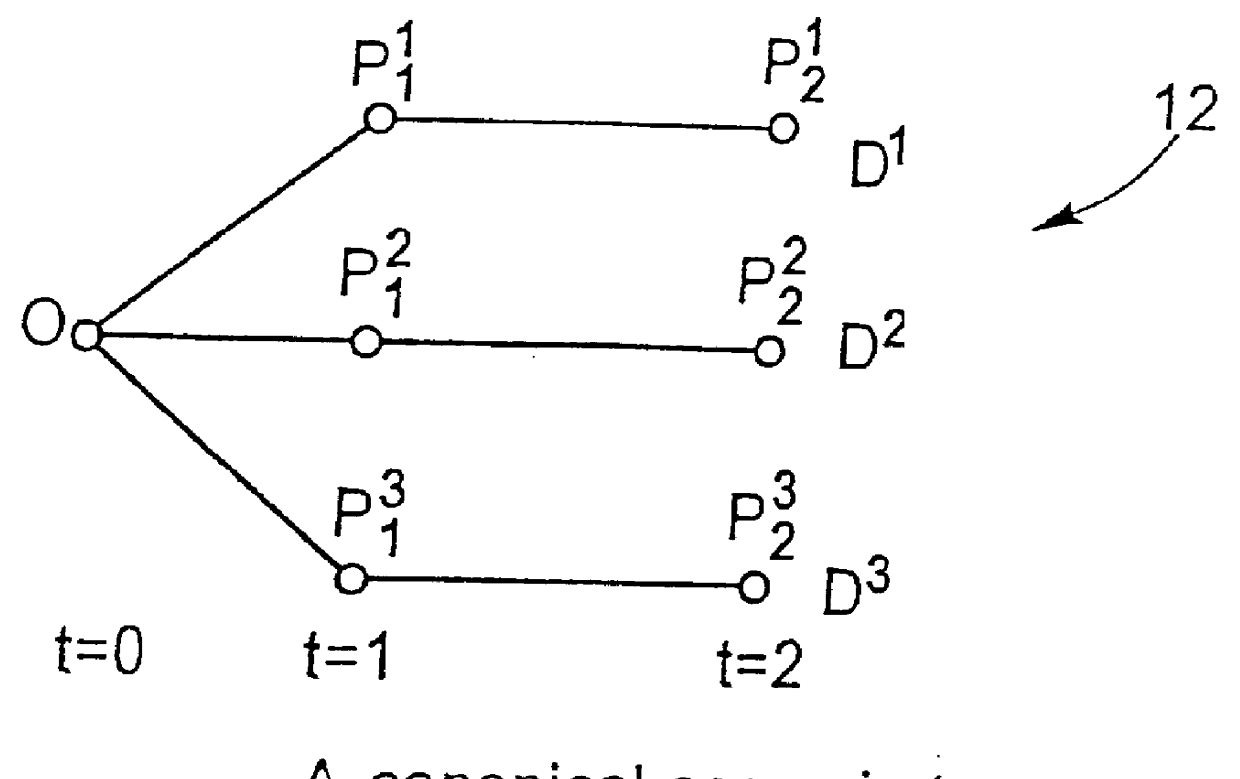

Method of creating production plan of demand variation input type and method of creating production plan minimizing risk of demand variations

InactiveUS20050222888A1Avoid adjustmentMaximizes achievement ratioCommerceSpecial data processing applicationsStockoutRate ratio

A production plan is created so as to minimize risk of demand variations. Forecasted values of amounts of requests are entered for each different item of products, markets, dates, past accuracy of demand forecasts, and order achievements at the time when the plan is created. Scenario information is created in which assumable amounts of request for each different item of the products, markets, and dates and probabilities at which the amounts of requests agree with actual amounts of requests are defined. Management indexes are found from the amount of stockout and amount of stock calculated in each different scenario, based on the scenario information, target values of the management indexes, and information on strongpoints. An amount of production that maximizes the achievement ratios of the management ratios to their targets within the ranges of supplied materials and within the range of the production capacity is calculated by an optimization algorithm.

Owner:HITACHI LTD

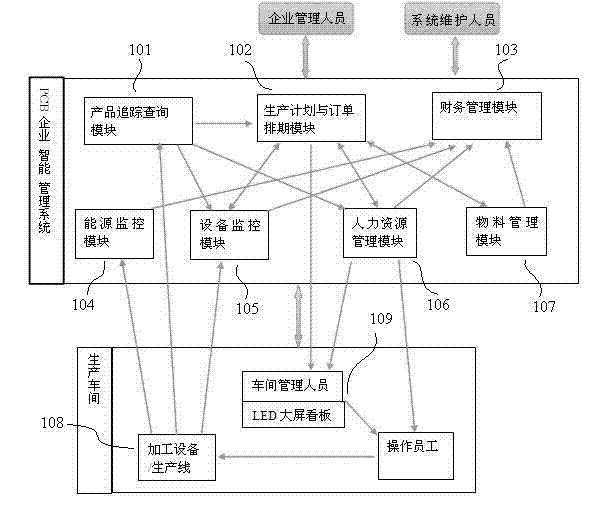

Intelligent management system of flexible production enterprise

InactiveCN104331770AReduce manufacturing costMonitor usage in real timeTechnology managementResourcesHuman resource managementProgram planning

The invention provides an intelligent management system of a flexible production enterprise. The system comprises a product tracing inquiry module, an order management and production planning module, an equipment monitoring module, a material management module, an energy monitoring module, a human resource management module, a financial management module and an information exchange platform, wherein the product tracing inquiry module is used as a basis and the order management and production planning module is a core to intelligently realize automatic generation of a production plan, whole-course on-line tracing recording of a processing process, monitoring of equipment and hydroelectric energy and plan management of human, material and money. By using the intelligent management system of the flexible production enterprise, the flexible production enterprise can perform true product quality tracing, master the use conditions of the equipment and the hydroelectric energy in real time and fully utilize the capacities of the equipment, the human, the energy and the like of the enterprise, so that the production cost of the enterprise is reduced.

Owner:叶校然

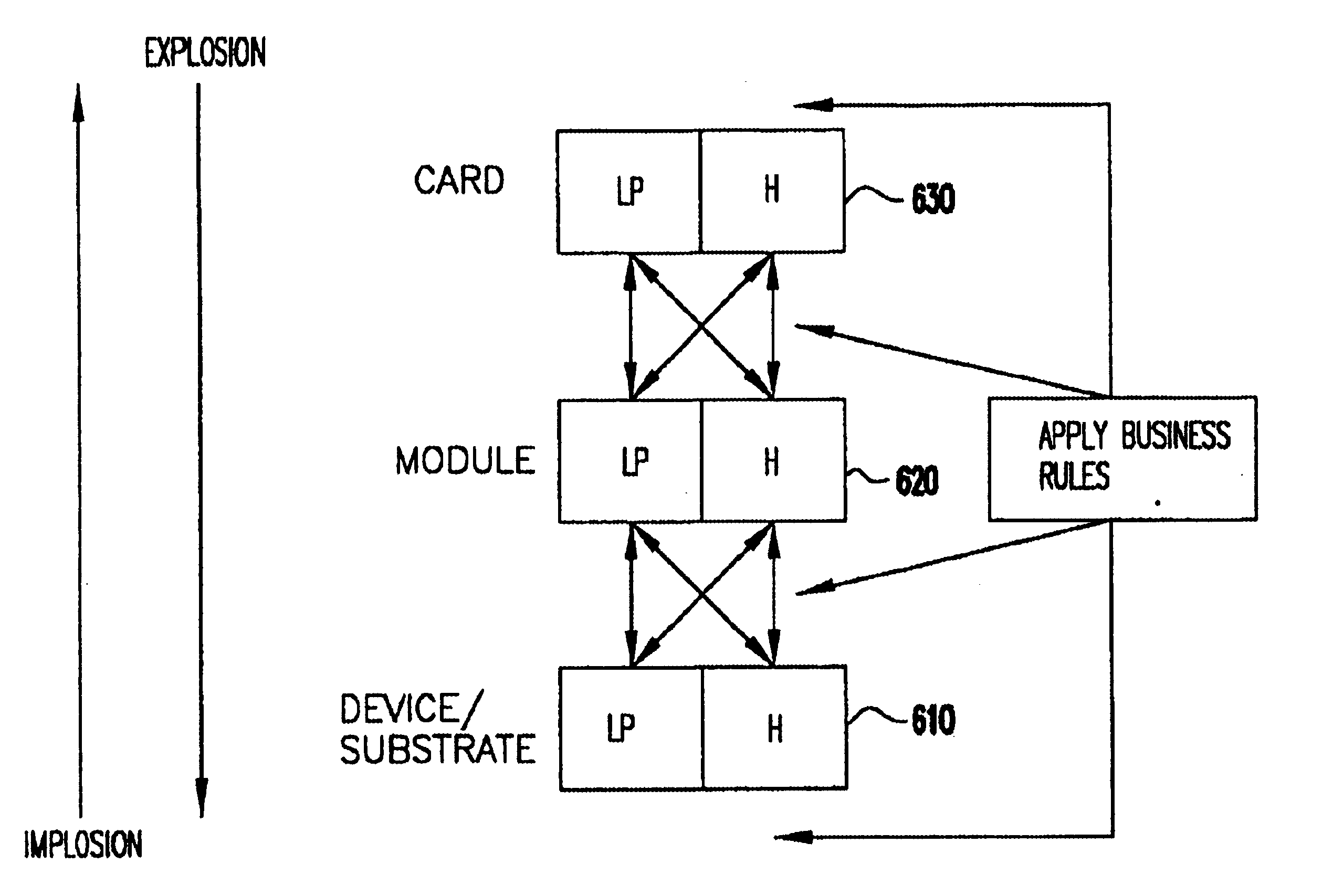

Decomposition system and method for solving a large-scale semiconductor production Planning problem

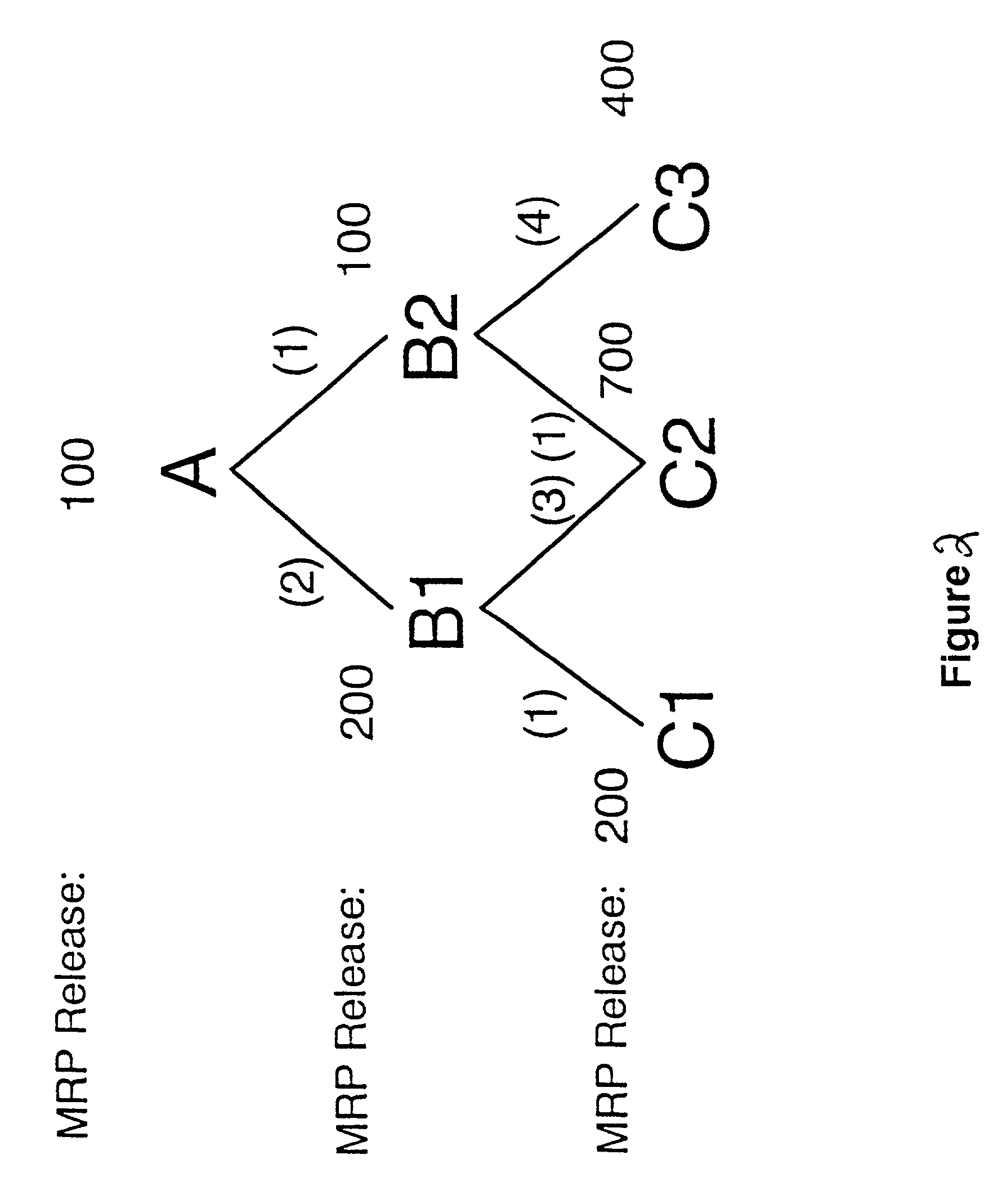

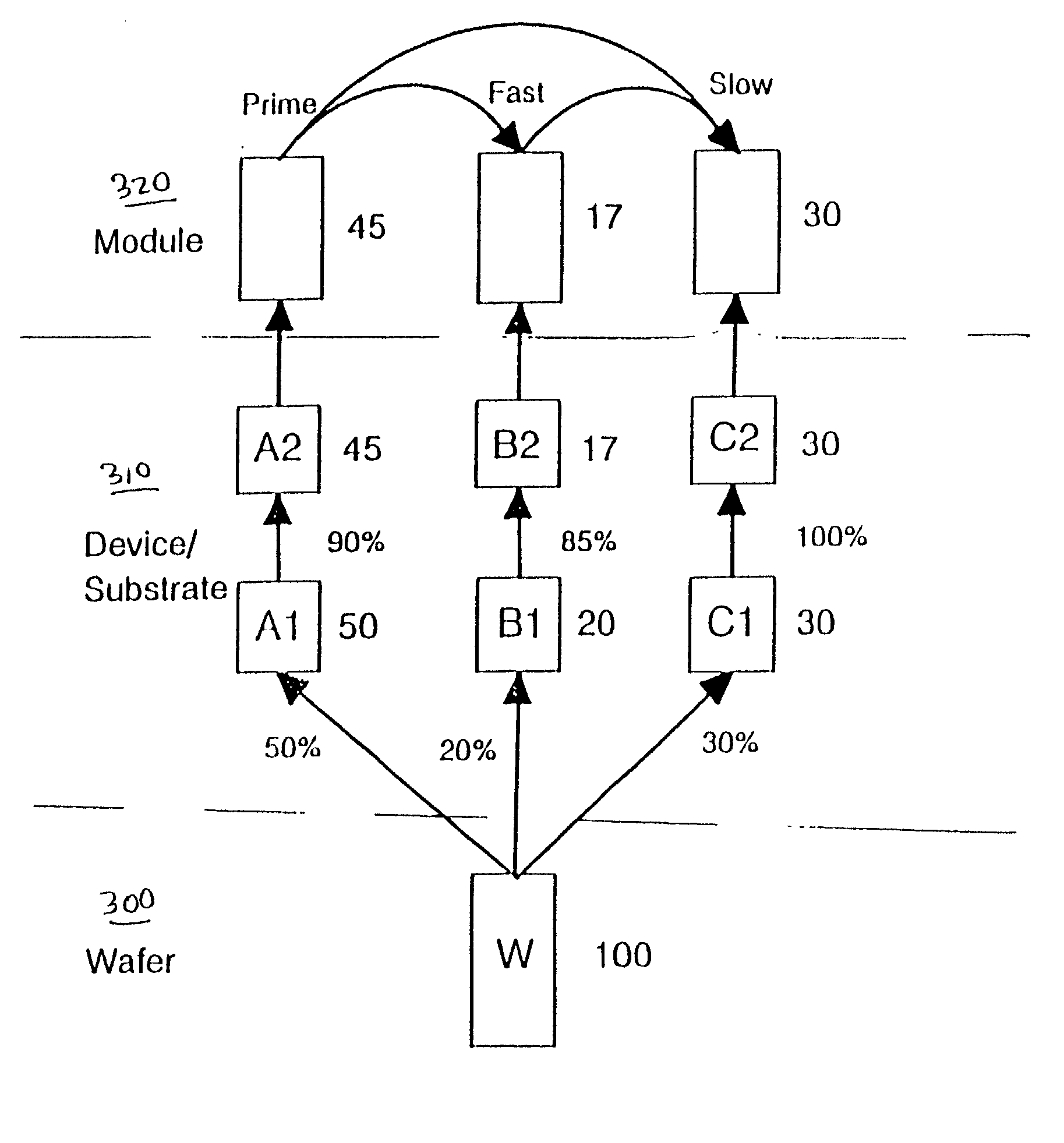

A method and system for efficient allocation of limited manufacturing resources over time to meet customer demand. At the enterprise planning level this typically requires determination of a feasible production schedule for an extended supply chain. The method and system utilizes a new and unique type of systematic decomposition based on both product and process considerations. This approach simultaneously reduces the model size (and therefore computation time) and increases modeling flexibility from strictly linear programming based decision making to include more general nonlinear programming characteristics.

Owner:IBM CORP

Vehicle assembly line control system and method

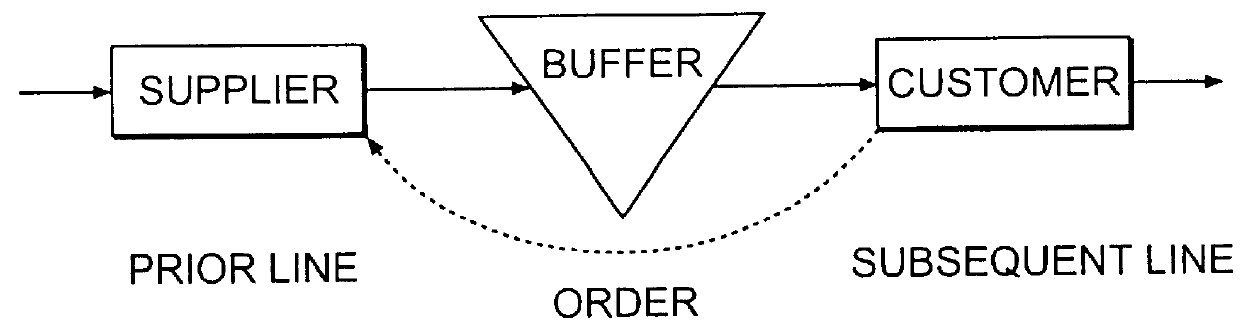

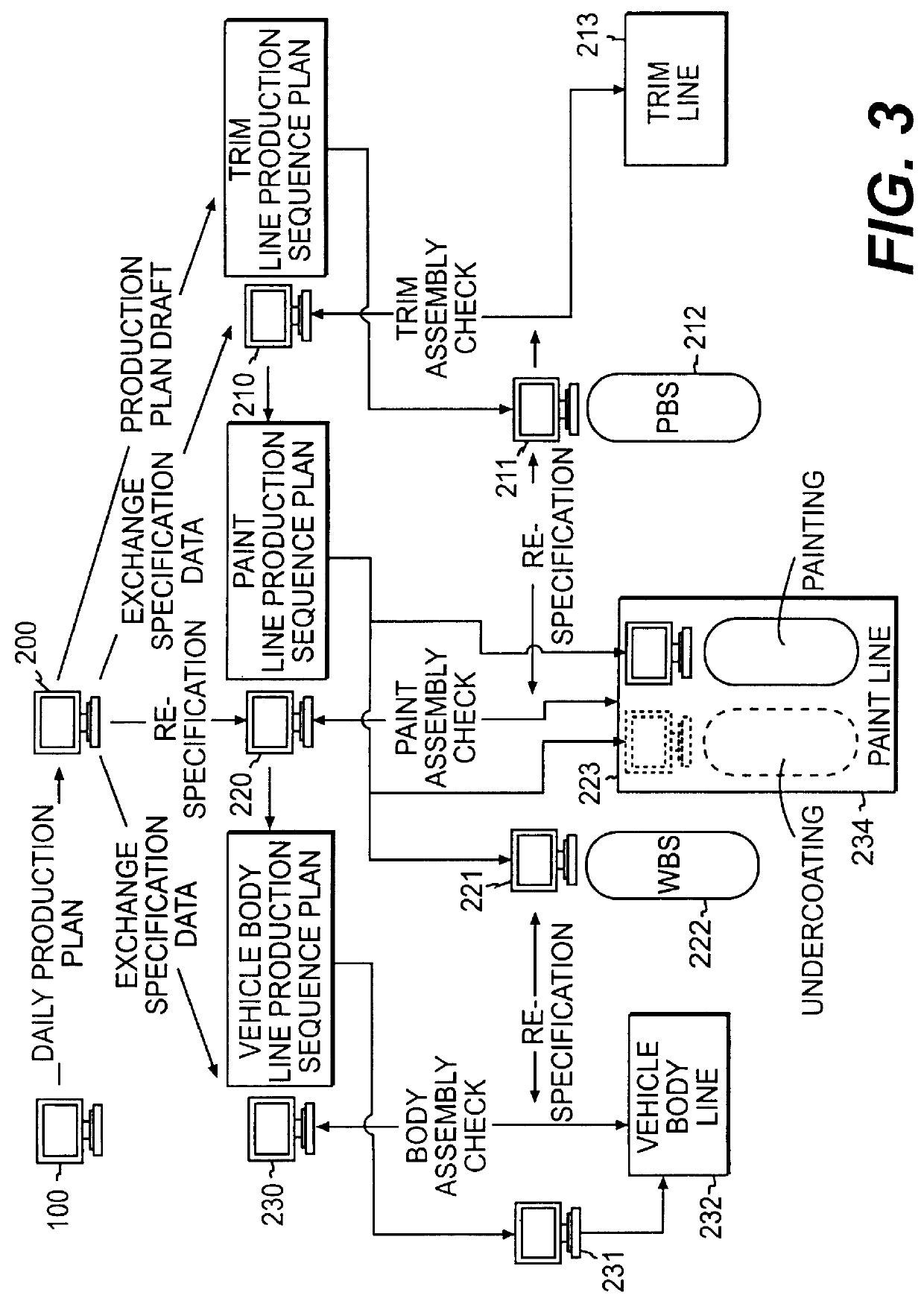

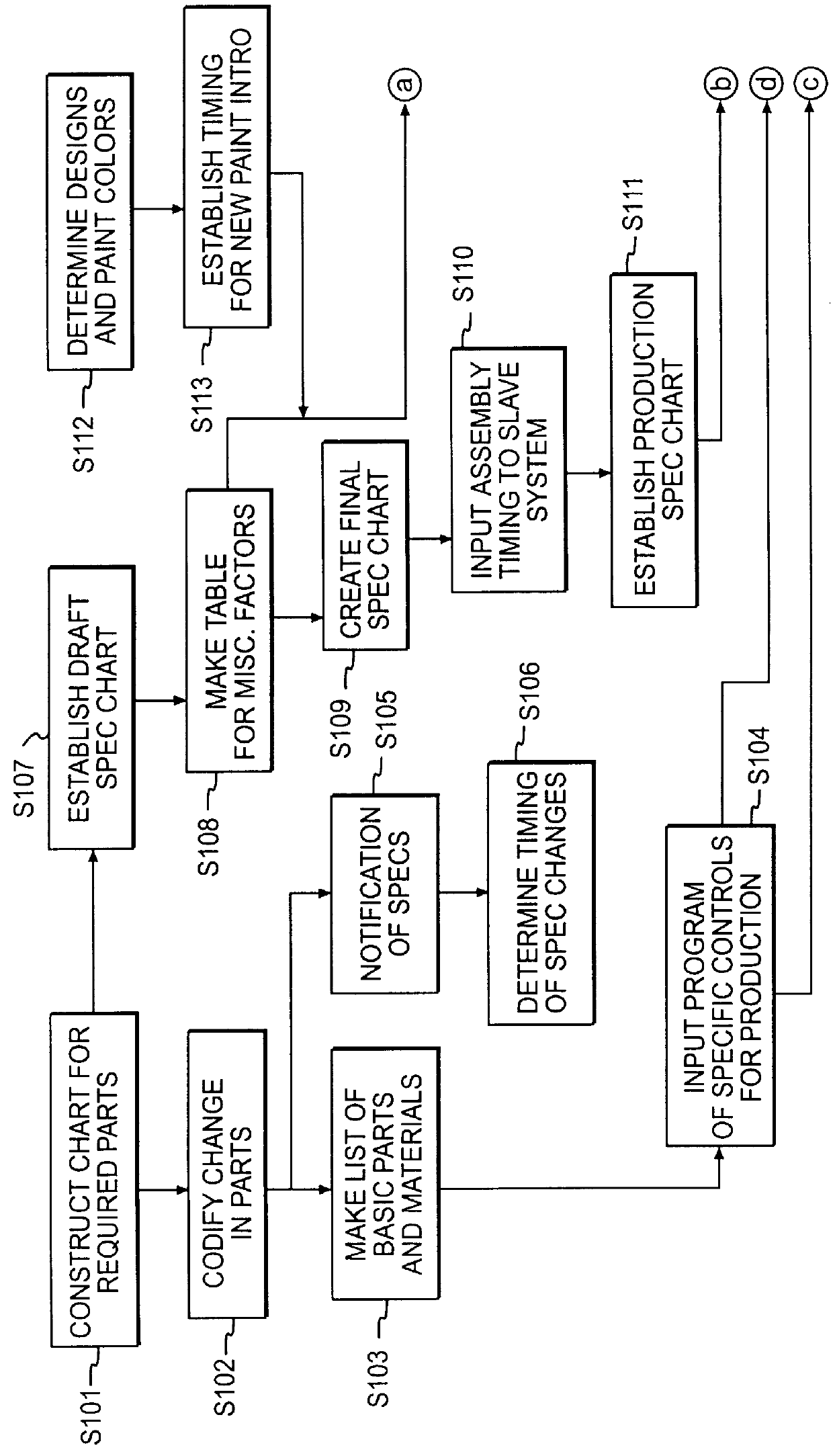

InactiveUS6141598AImprove productivityEasy to returnComputer controlAssembly machinesControl systemAssembly line

Disclosed is a pull-type vehicle assembly line control system and method in which a production plan for a final assembly process, or a trim process, is established first, and, using this as a basis, a production plan for a paint process then that for a vehicle body assembly process are set up. Further, in the present invention, information on the progress for the three main assembly processes--the vehicle body assembly process, paint process, and trim process--is mutually exchanged such that a dynamic re-specification assembly process is utilized in which operational sequences for each of the process are continuously readjusted to adapt to the overall assembly process.

Owner:HYUNDAI MOTOR CO LTD

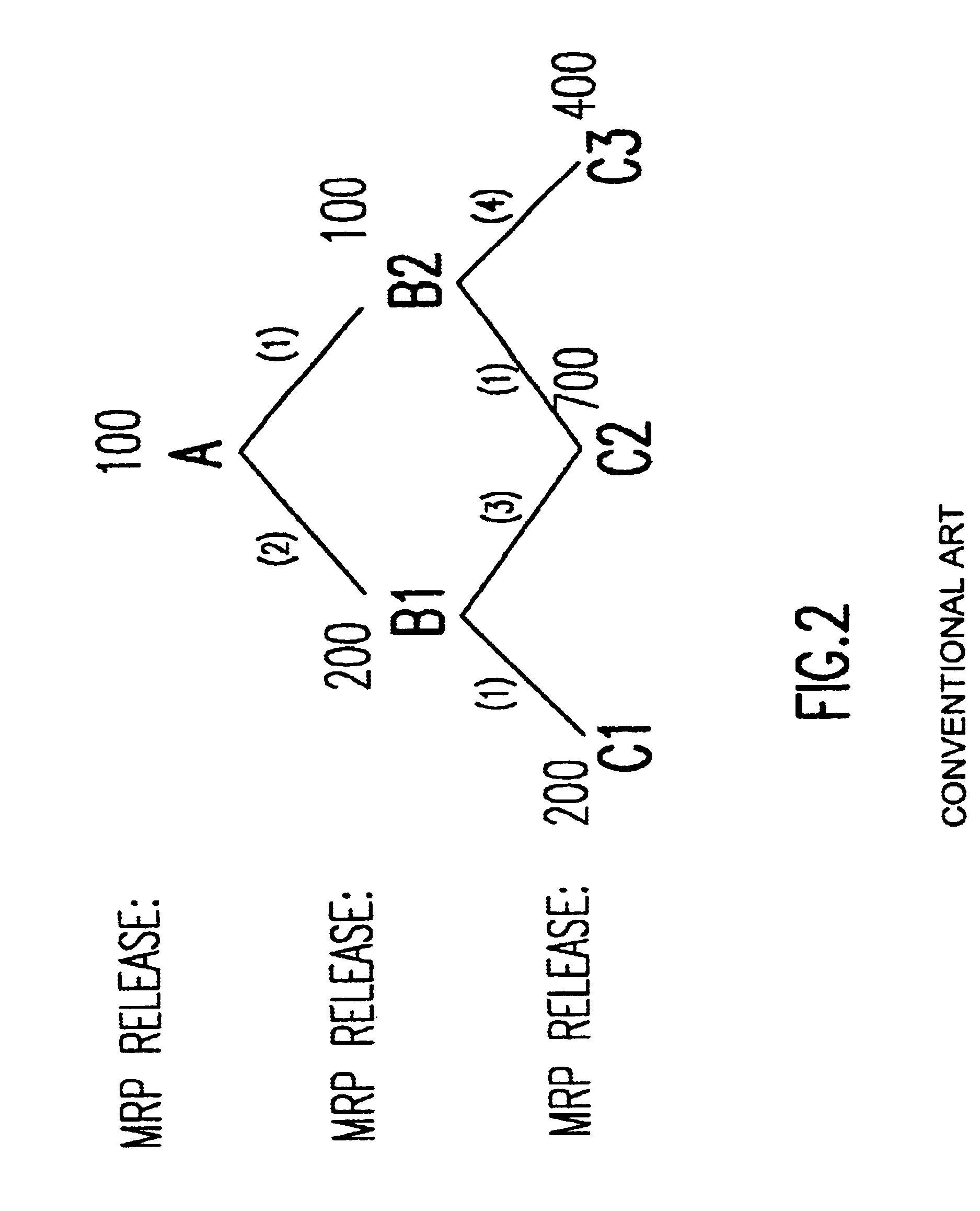

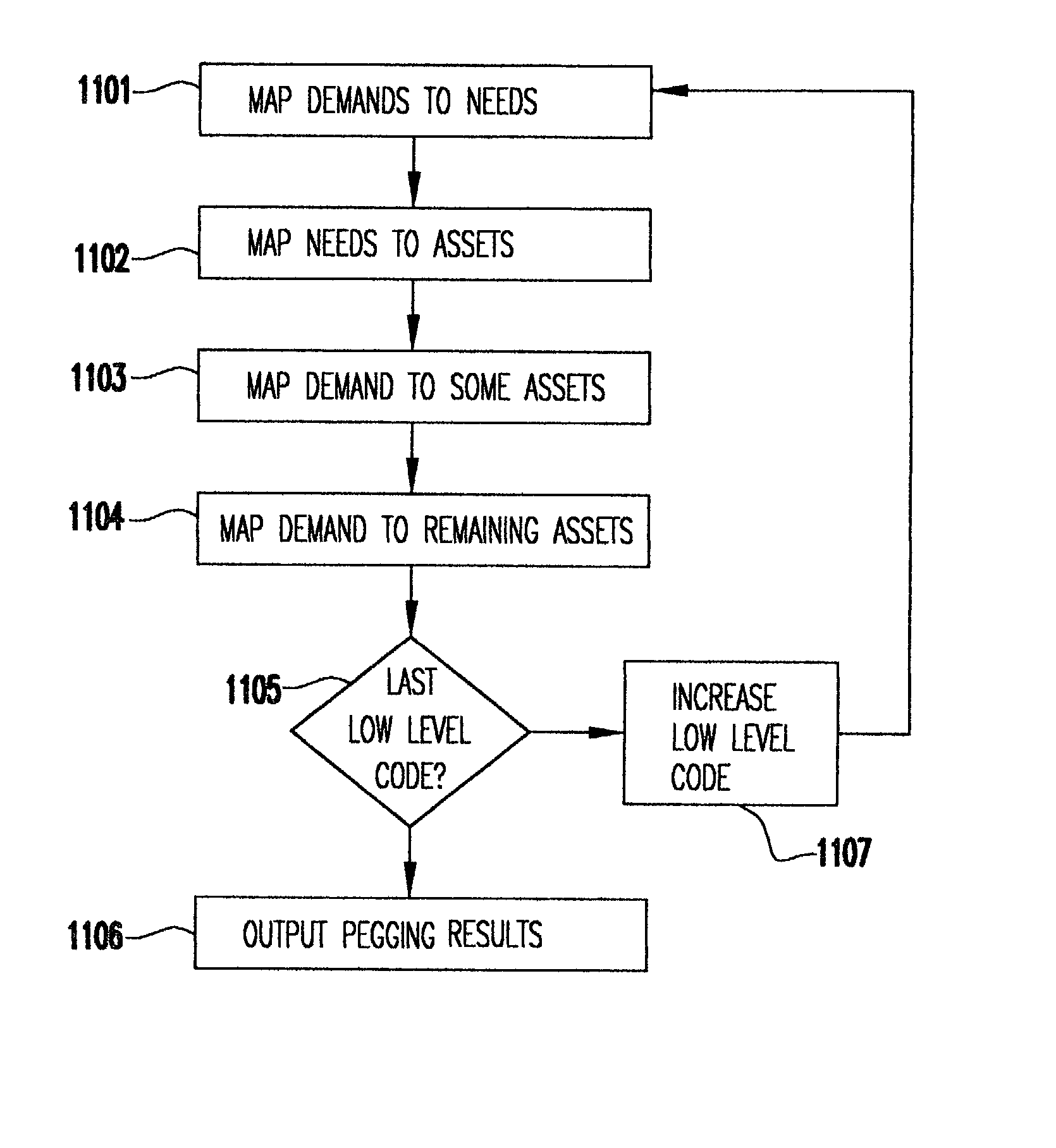

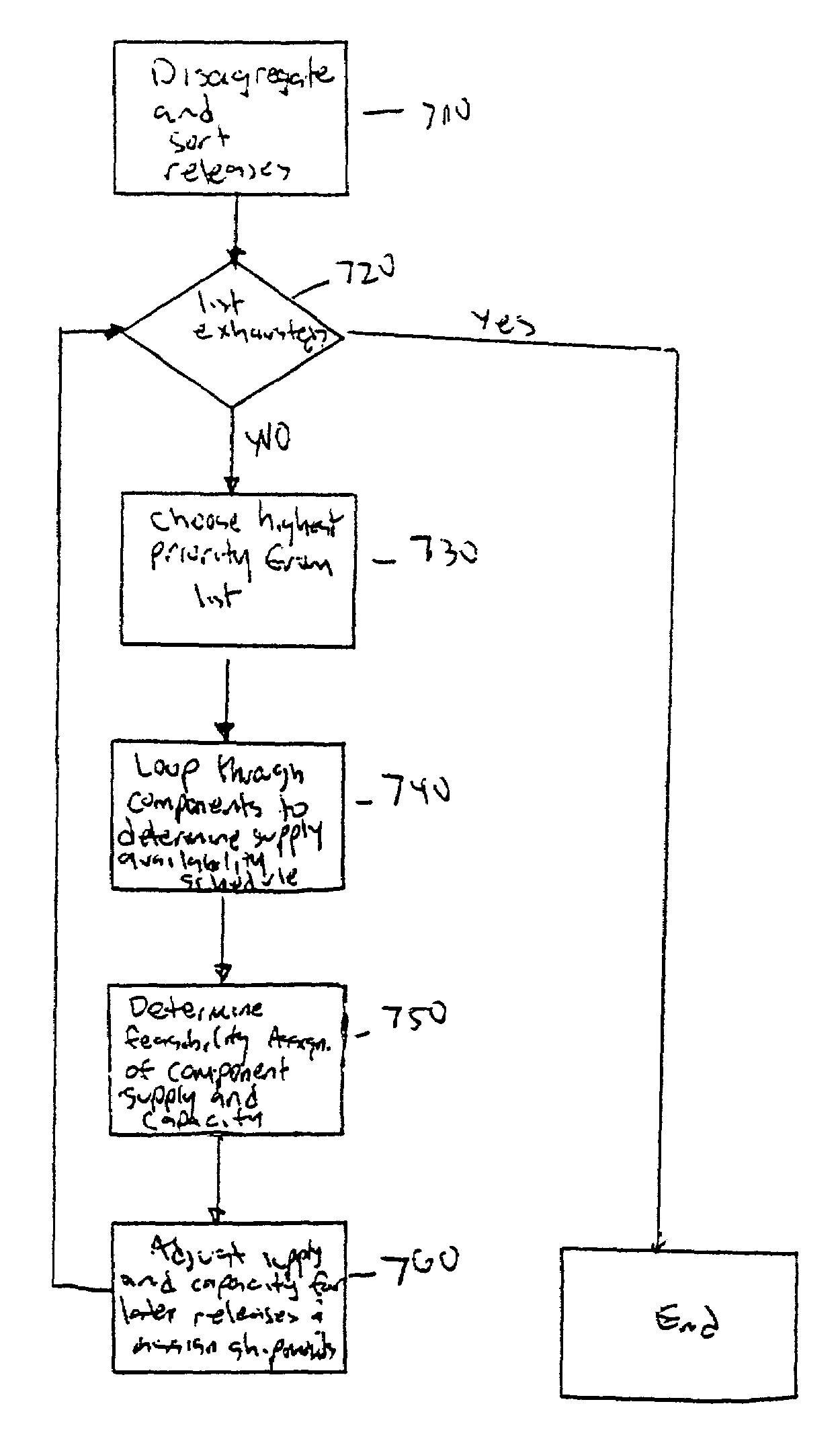

Method for allocating limited component supply and capacity to optimize production scheduling

ActiveUS7197469B2Efficient rateTechnology managementMultiprogramming arrangementsMaterial requirements planningLimited component

Owner:RAKUTEN GRP INC

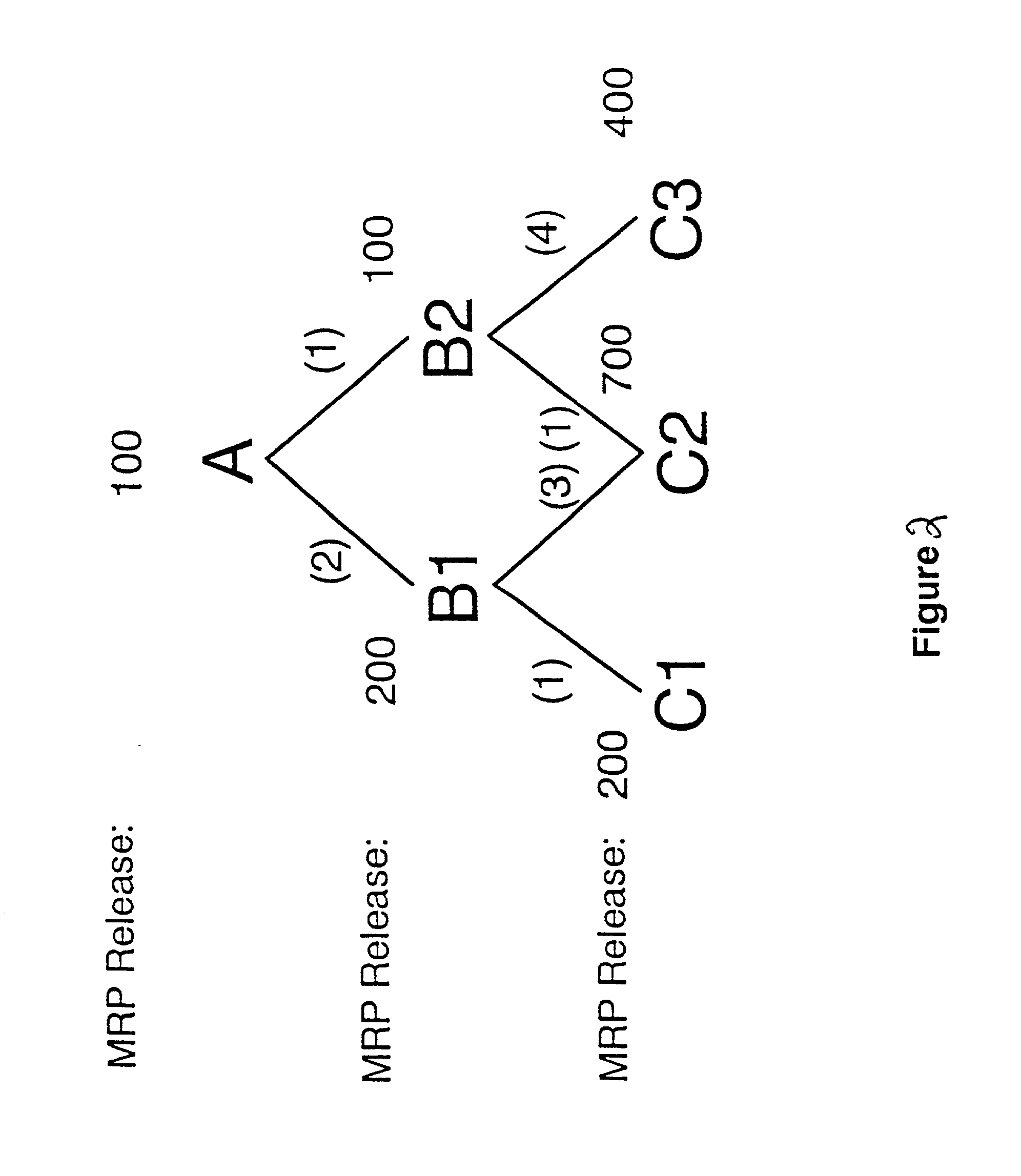

Method for allocating limited component supply and capacity to optimize production scheduling

ActiveUS20020198757A1Technology managementResourcesProduction planningMaterial requirements planning

A method and system for resource rationing which employs decision rules for the optimal allocation of supply and capacity over time that satisfy two key requirements (a) being consistent with accepted operational objectives (e.g. low inventory, short lead times, prioritized allocation of supply and capacity) and (b) allowing for the timely computation of a feasible production schedule. The method and system is generally characterized in that it is able to divide each of the priority ranked scheduled releases (Material Requirements Planning (MRP)) into "N" separate and smaller sized scheduled releases where the priority of each of the "N" releases may be equal to the priority of the original release. The "N" separate and smaller sized scheduled releases are sorted according to priority and then used to determine an optimal supply schedule for allocating resources including component supply and assembly capacity.

Owner:RAKUTEN GRP INC

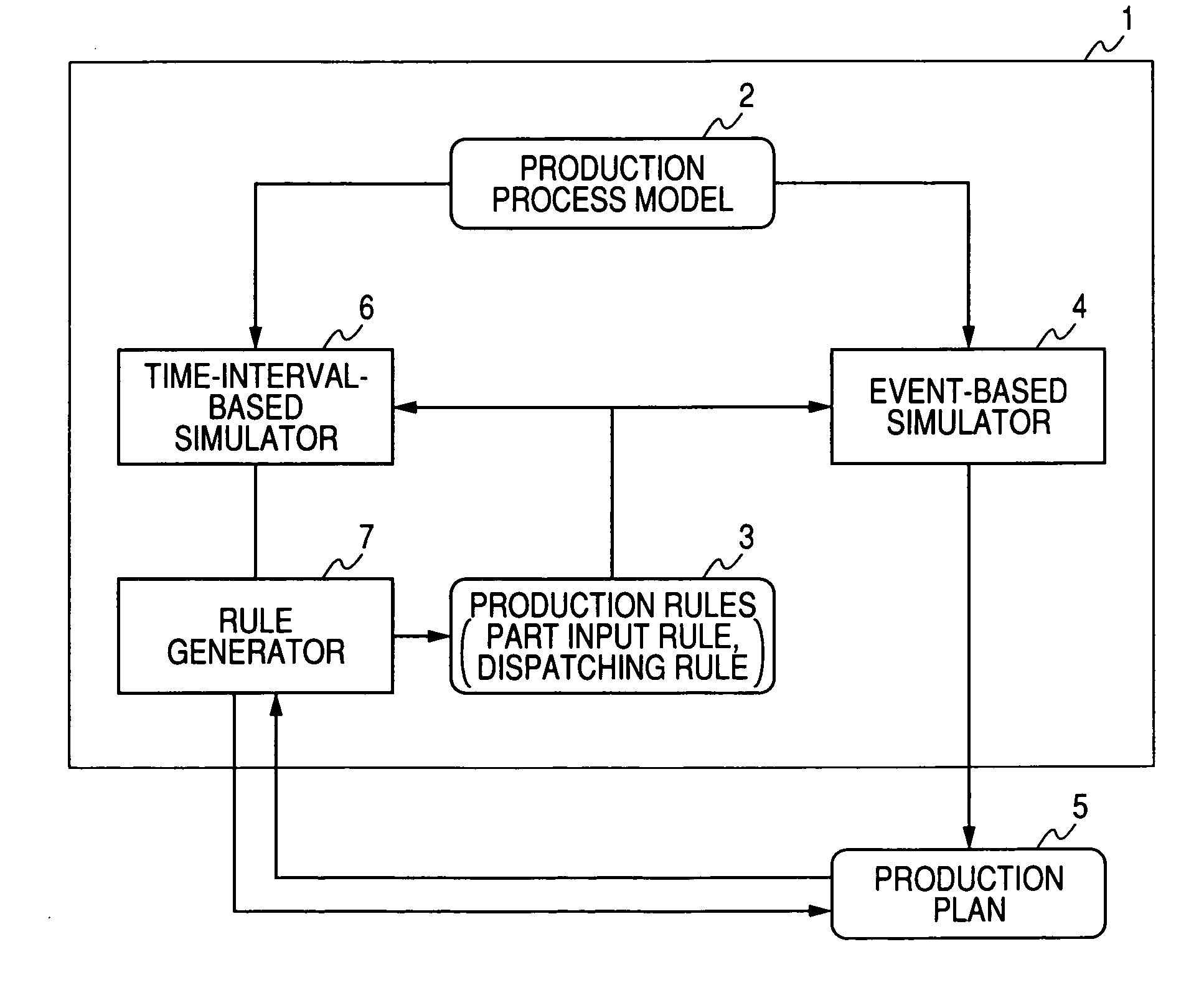

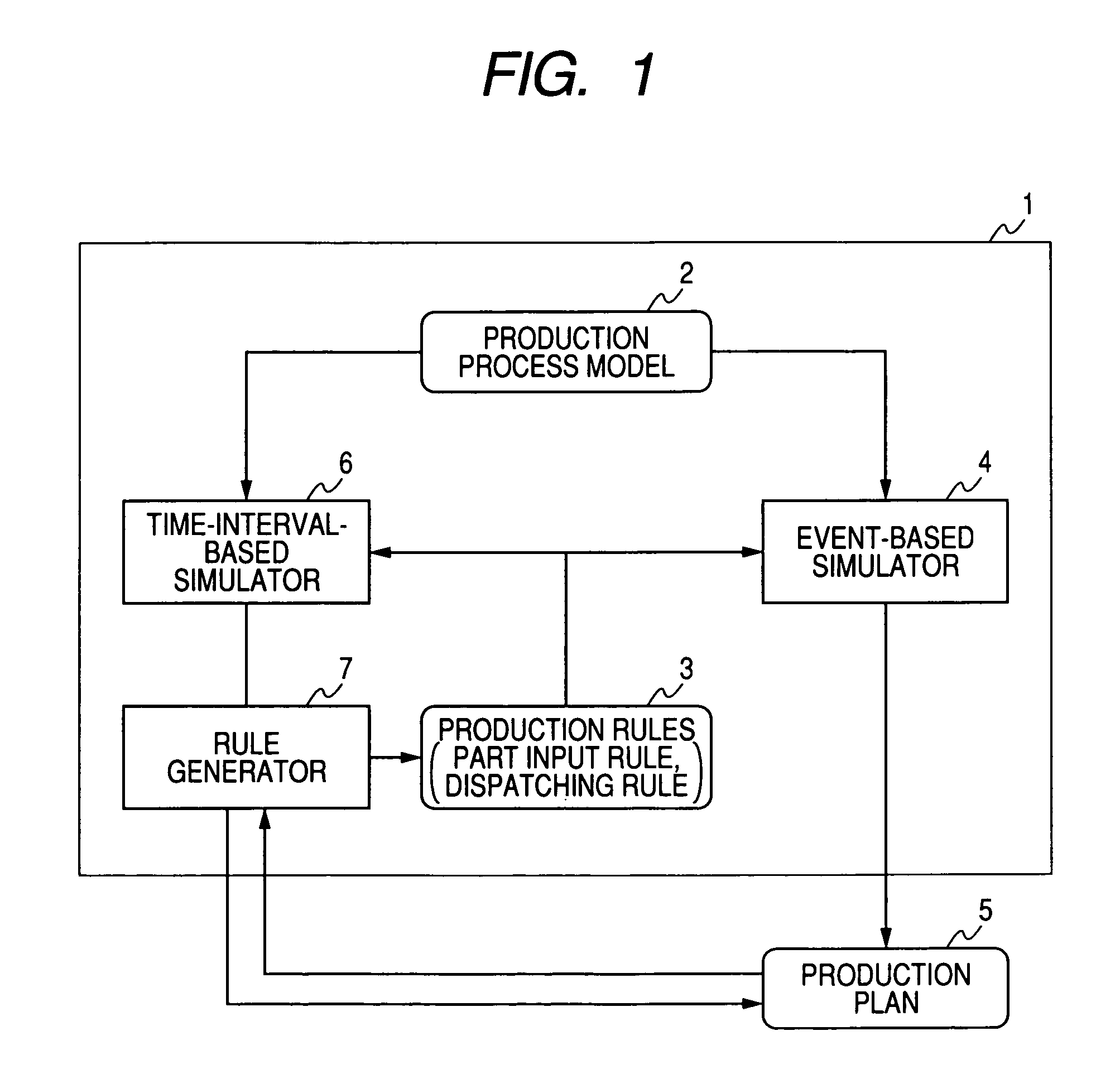

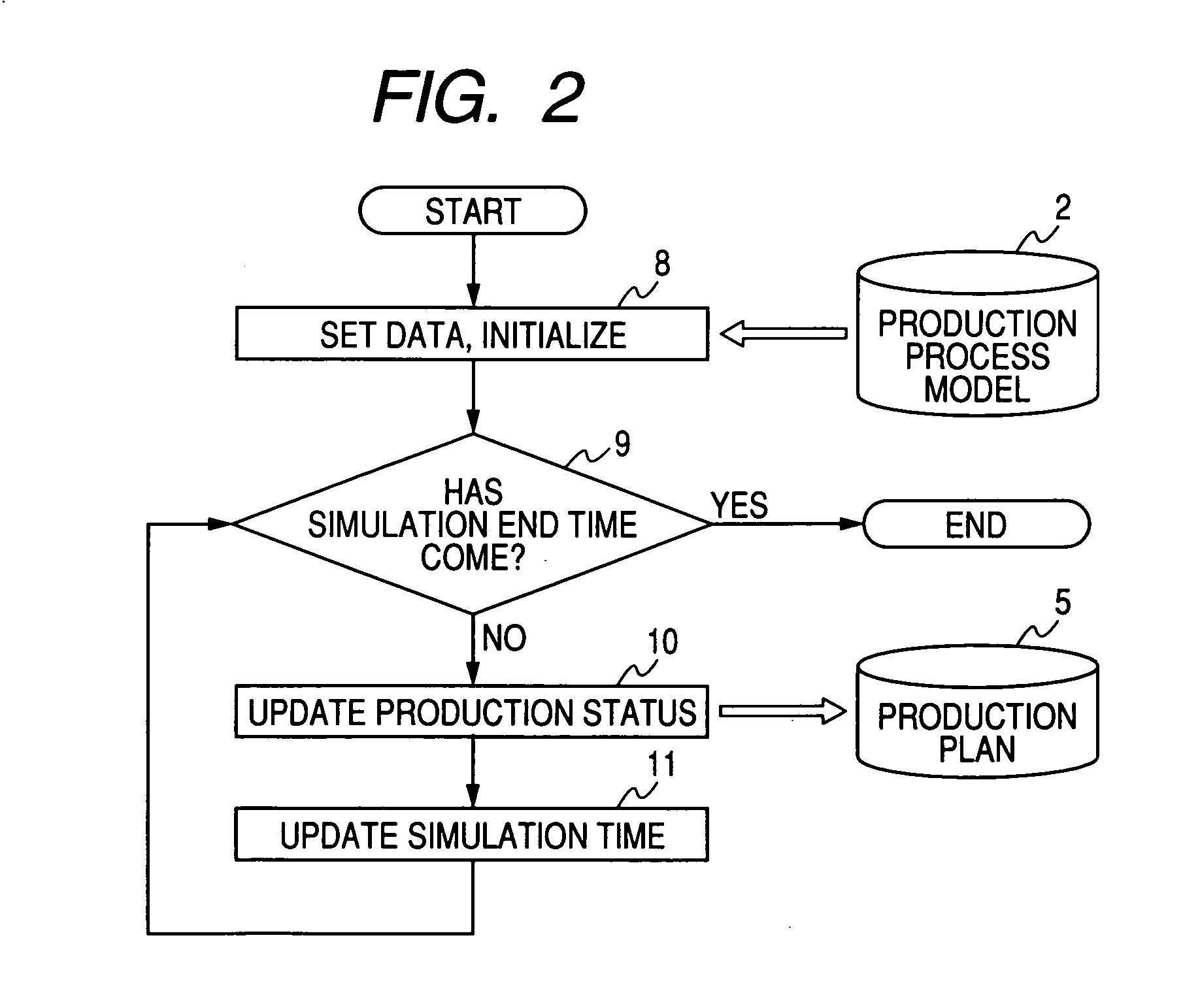

Production plan creation system, method, and program

InactiveUS20060106477A1Increase productivityIncrease speedResourcesTotal factory controlContinuous optimizationEvent based

The present invention is to formulate a production plan 5 by means of an event-based simulator 4 simulating movement of products within a factory through use of a production process model 2 and a production rule 3. There are provided a time-interval-based simulator 6 for computing the statuses of production processes at given time intervals, and a rule generator 7 for automatically deriving the production rule 3 through use of the time-interval-based simulator 6. As a result of a production plan being repeatedly formulated at high speed through use of the time-interval-based simulator 6, the rule generator 7 can automatically, efficiently formulate the production rule 3 by application of machine learning based on a consecutive optimization method. An event-based simulator 4 devises a high-quality production plan 5 using the generated production rule 3.

Owner:NAT INST OF ADVANCED IND SCI & TECH

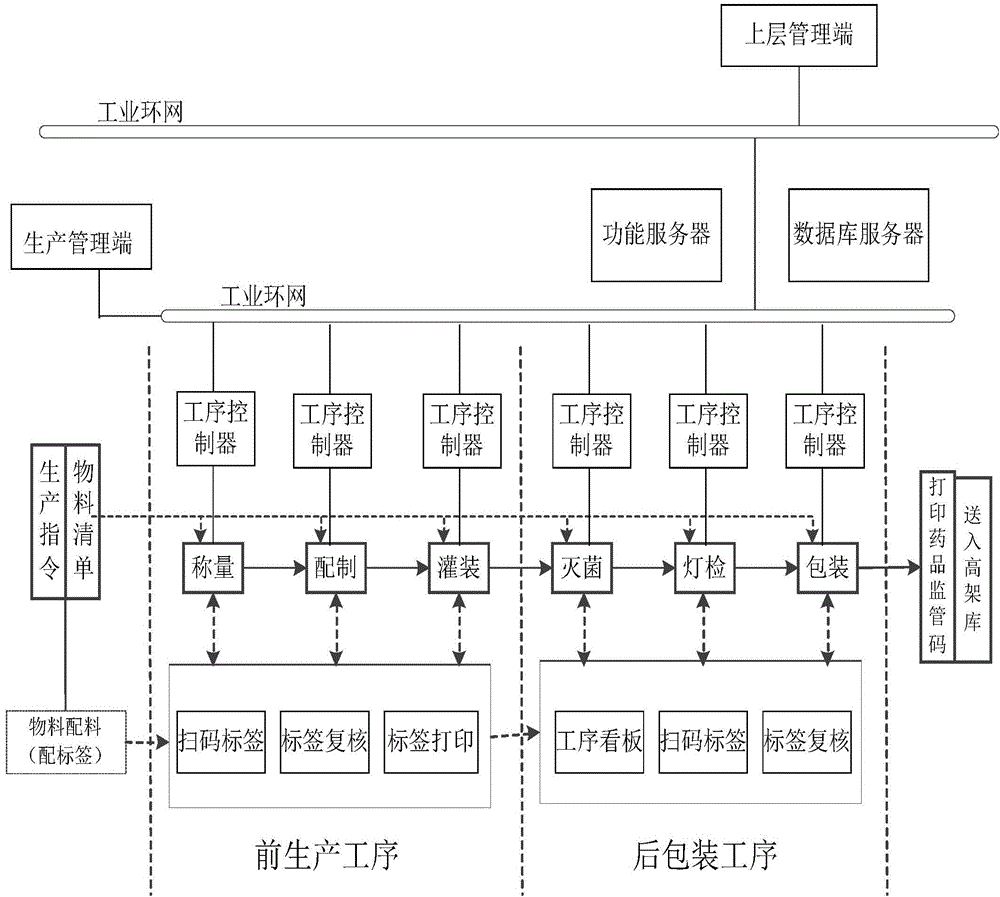

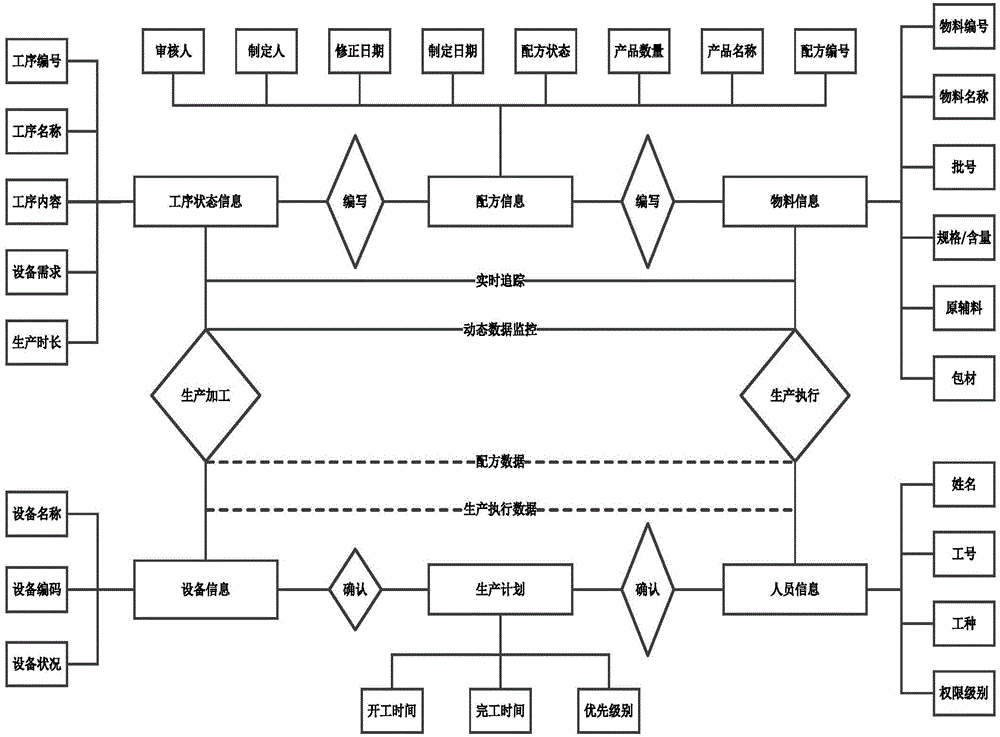

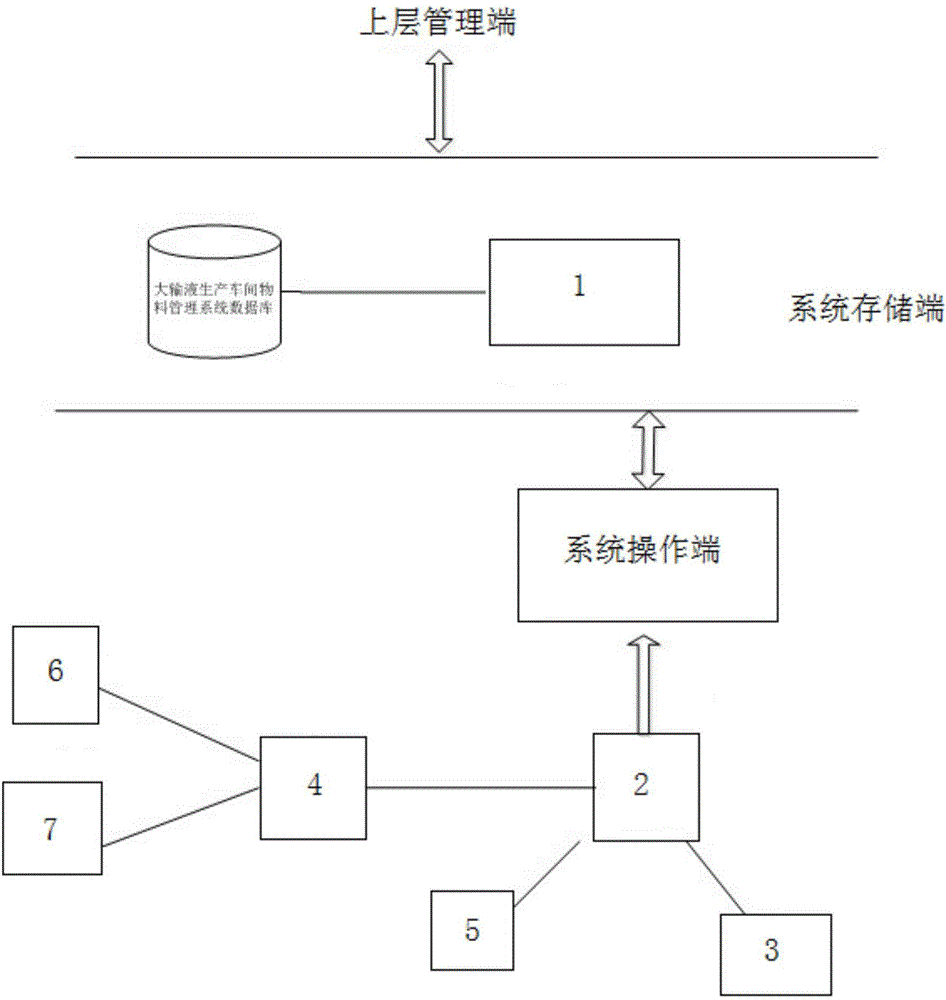

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

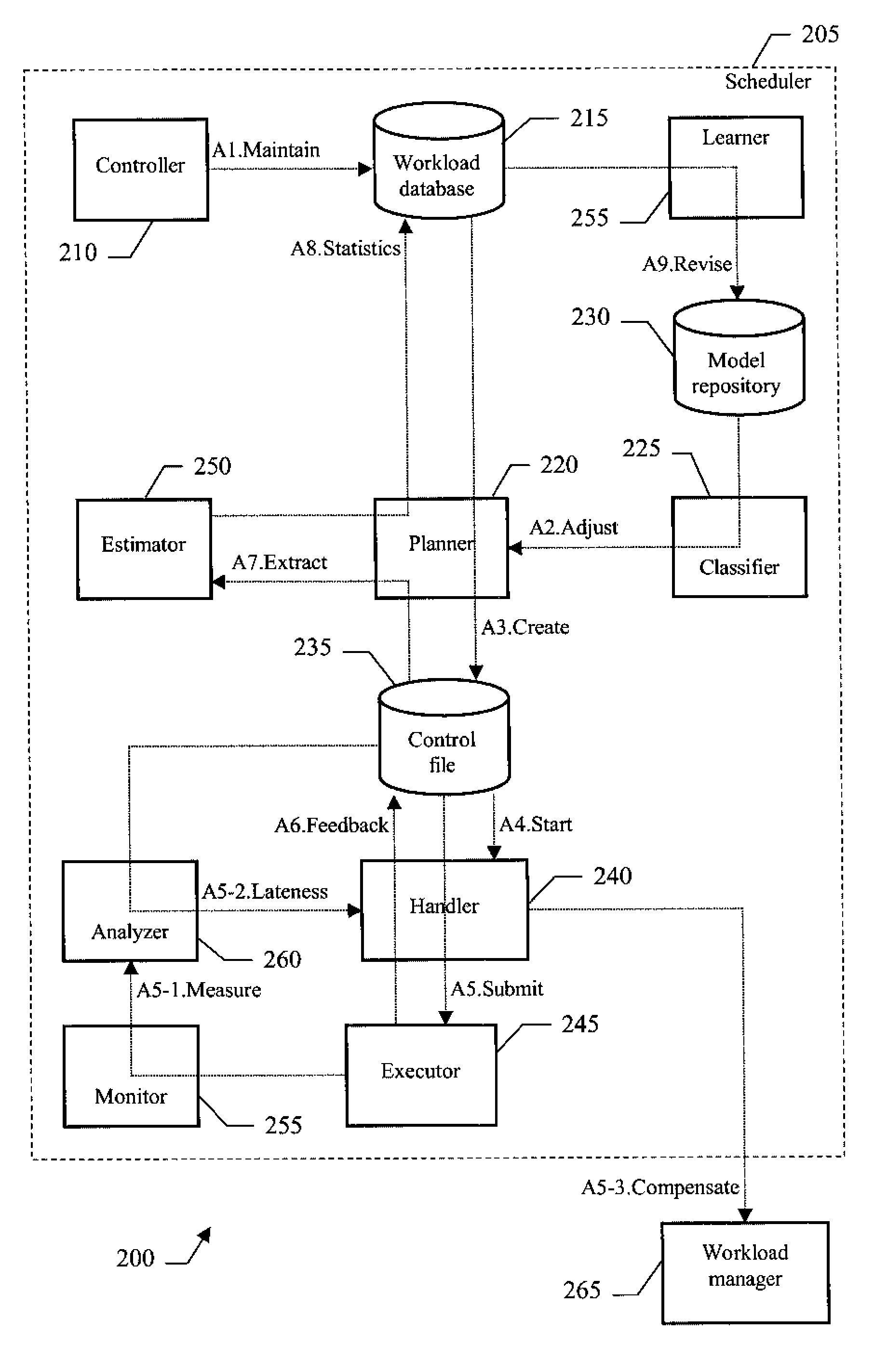

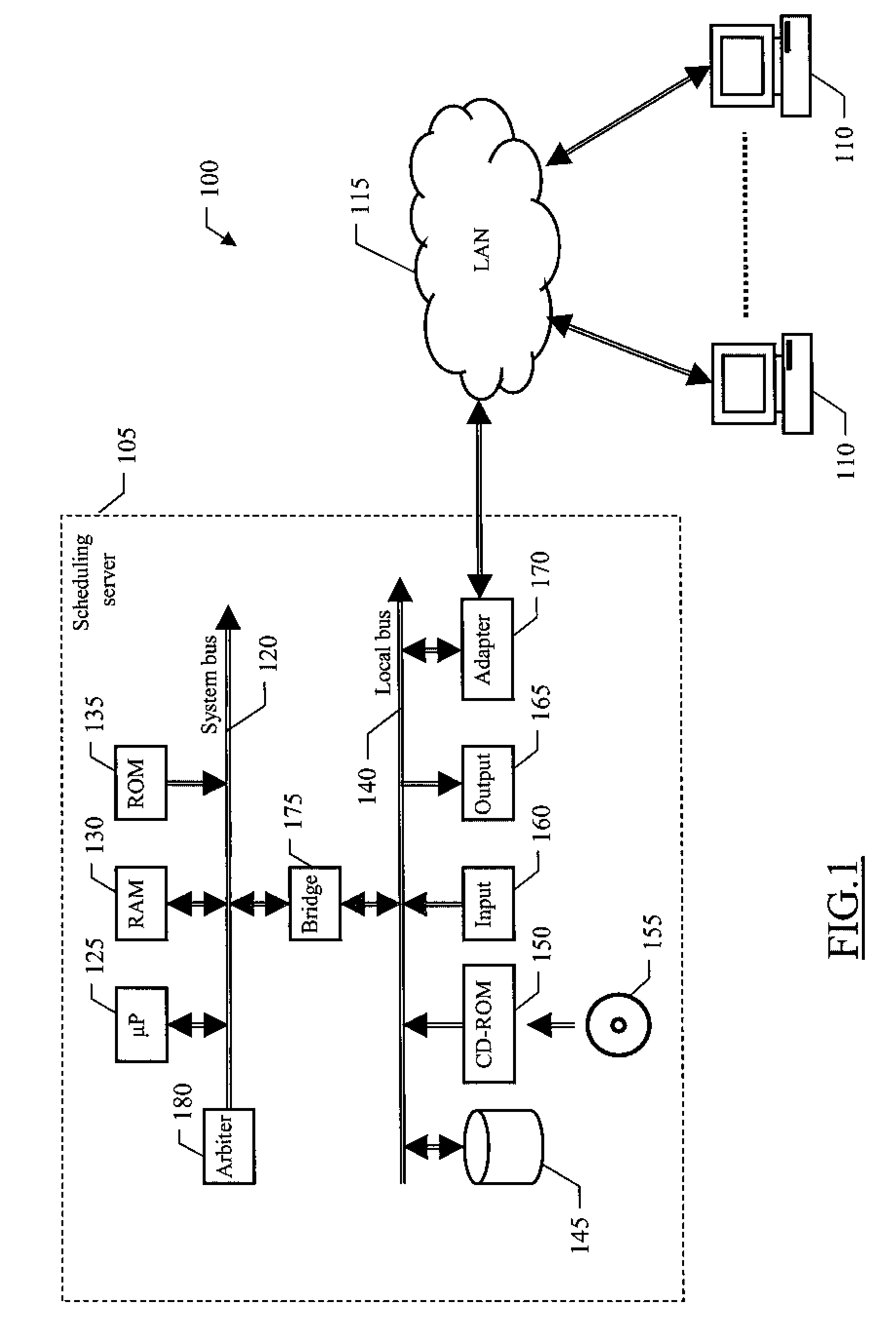

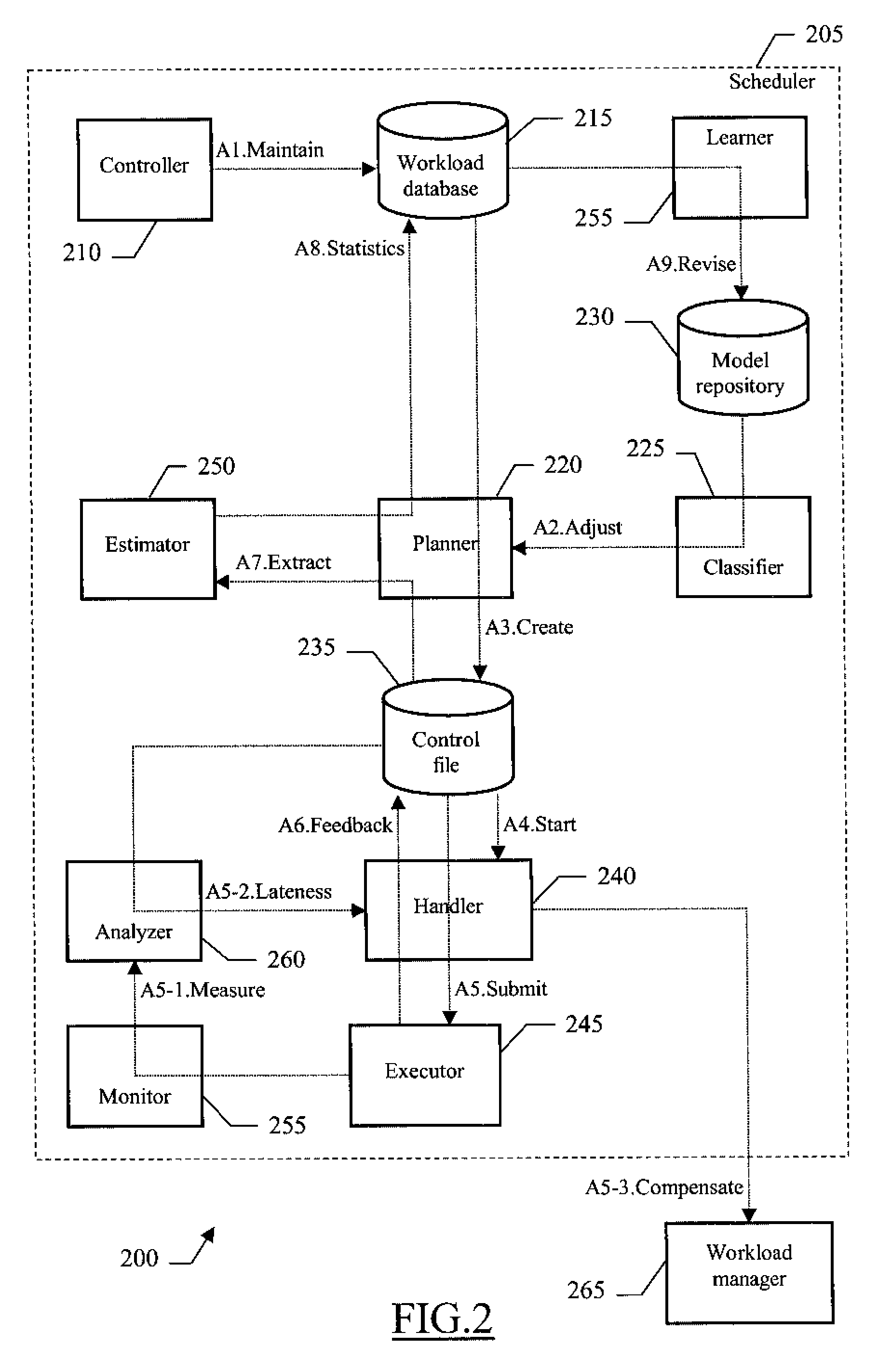

Method, system and computer program for scheduling execution of work units with monitoring of progress thereof

A solution (400) for scheduling execution of jobs is proposed. The submission of the jobs is generally controlled according to a production plan (406), which specifies a required finish time of critical jobs. In the proposed solution, a current progress of each critical job is monitored (427-430)—such as comparing a (measured) number of processor cycles dedicated to the critical job with an estimated total number thereof (required to complete the critical job, as inferred from previous executions thereof). At the same time, an expected progress of each critical job is estimated (433)—such as by the ratio between a time elapsed from an actual start time of the critical job and an allowable duration thereof (from the actual start time to the required finish time). The current progress of each critical job is then compared with its expected progress, so as to identify (436) the critical jobs that are late in their execution. Additional execution resources can then be assigned to each late critical job only when it is necessary to bring back the critical job on schedule.

Owner:IBM CORP

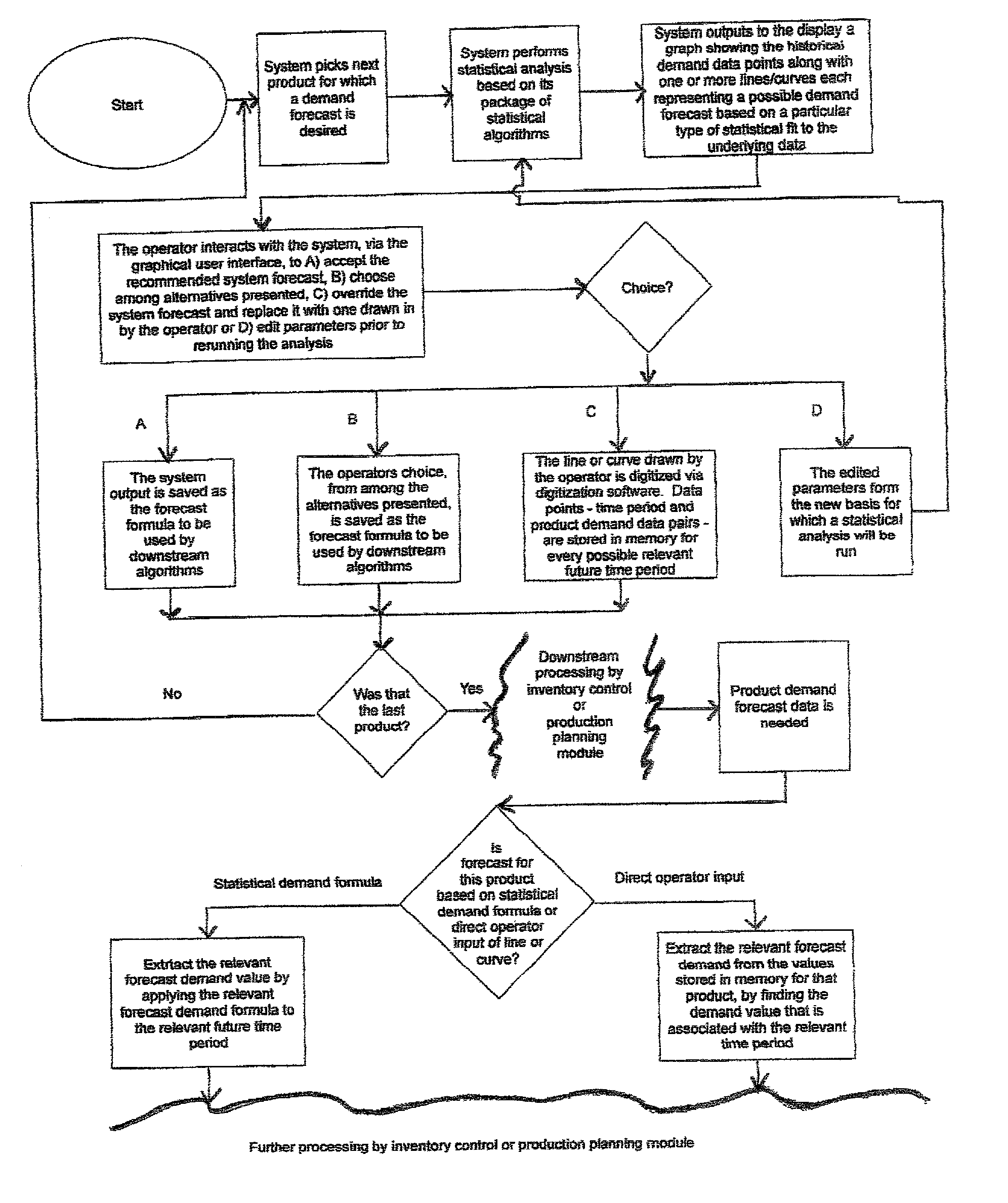

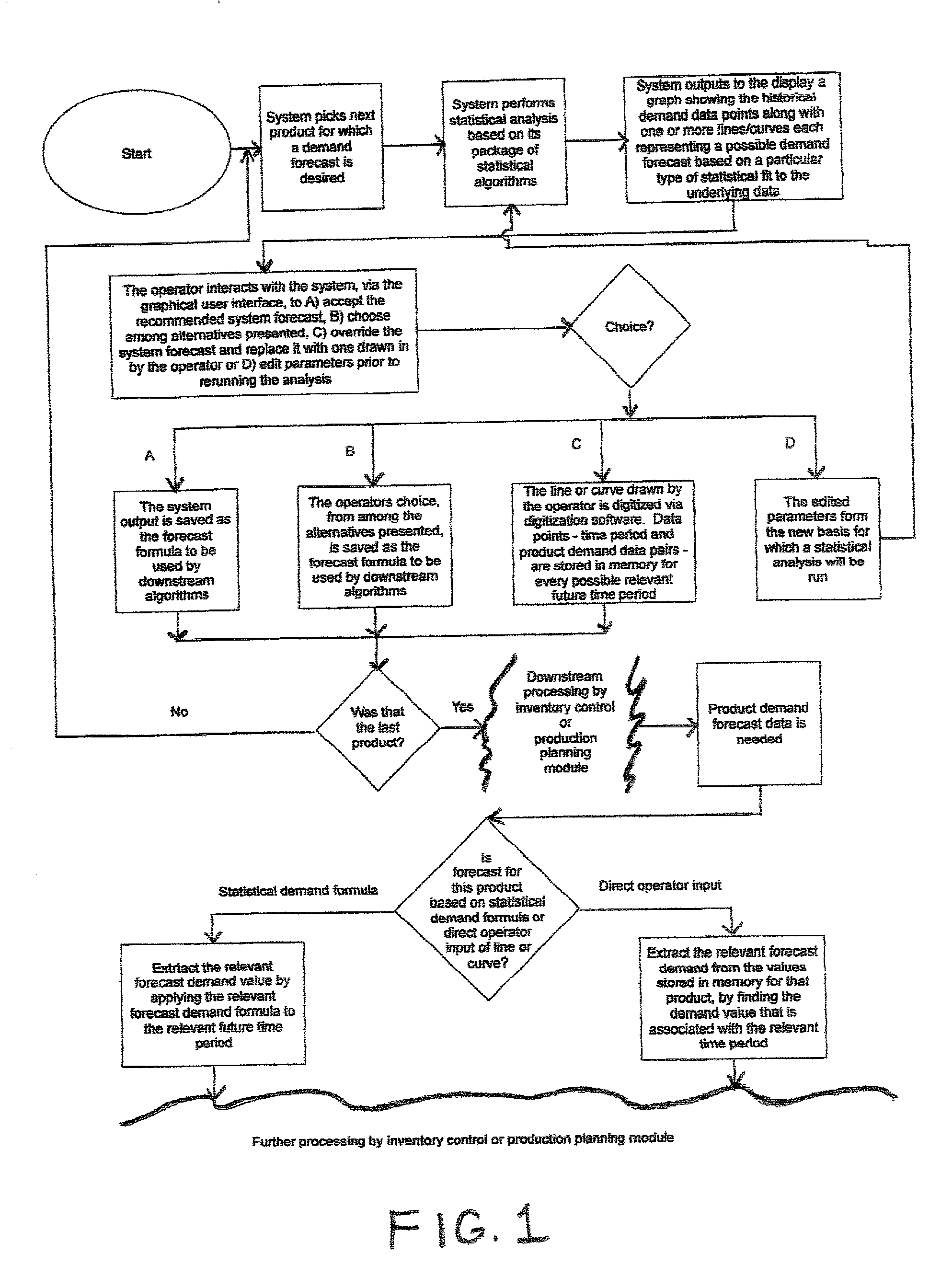

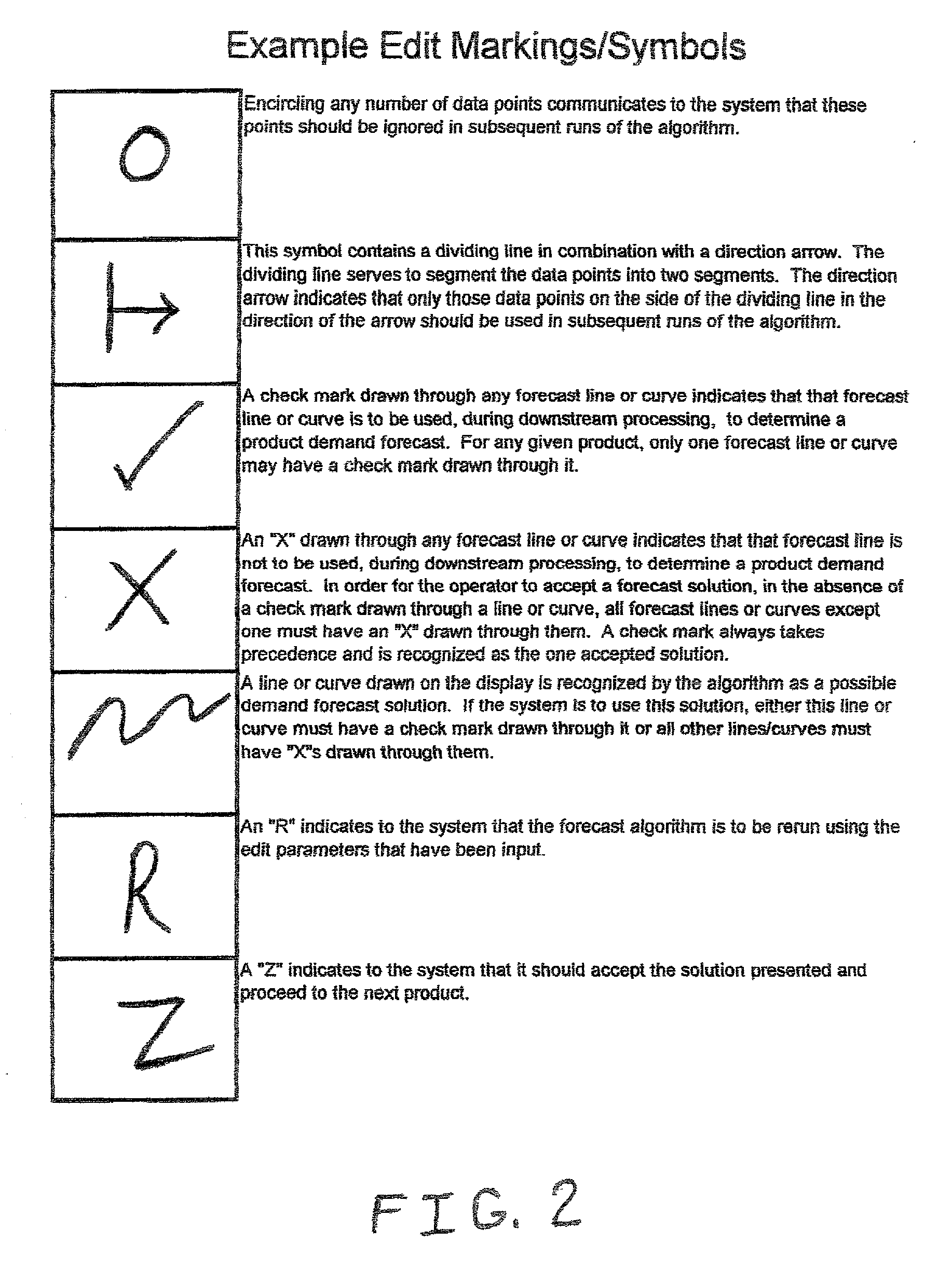

Process for forecasting product demand

InactiveUS20030212590A1LogisticsSpecial data processing applicationsGraphicsGraphical user interface

An improved process for forecasting product demand to be used within inventory management and / or production planning systems. This improved process overcomes the limitations of the prior art by providing an optimal combination of automated statistical data processing and human intelligence, in one interactive system. The new method provides an efficient means for an operator to incorporate much information, known to the operator, that would otherwise be missed by the systems of the prior art. It allows the operator to analyze information very quickly by viewing graphs drawn on a graphical user interface and to make changes very quickly using that same graphical user interface. The method relies on the use of edit markings / symbols drawn on the display portion of the graphical user interface. These edit markings / symbols are used to make changes to the parameters forming the basis for a product demand forecast. The markings / symbols are recognized by the forecast software algorithm and a new forecast is generated based on the revised parameters.

Owner:KLINGLER GREGORY L

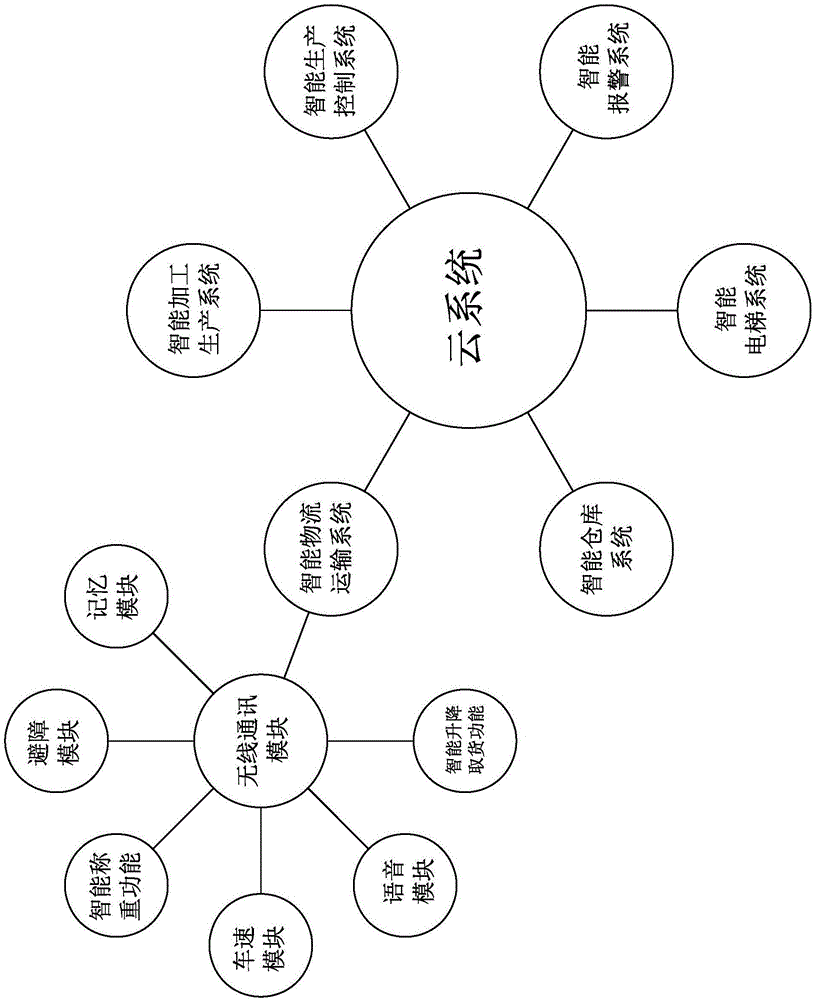

Factory intelligent workshop real-time scheduling system

ActiveCN106056298AIntelligent Management ScienceManagement scienceResourcesProduction control systemStorage garage

The invention relates to a factory intelligent workshop real-time scheduling system, and is designed to solve the technical problem that a management system of an existing factory intelligent workshop needs further improvement. The system is mainly characterized in that an intelligent processing production line of the scheduling system finishes research and purchase as well as installation and debugging of workshop machining equipment; an intelligent warehouse and logistics transportation system carries out scientific classification, storage and transportation on raw materials and substances, management of finished and semi-finished products, and analysis and management on storage data of the raw materials, the semi-finished products and the finished products; an intelligent production control system, by fully utilizing information technology, carries out control in multiple dimensions of production plan issuing, material delivery, production scheduling, completion confirmation, standard operation guidance, quality control and finished product bar code acquisition, and accurately conveys on-site information to a production manager and a decision maker in real time through a network; and an intelligent alarm system is used for monitoring environment and temperature and reminding a transfer robot to return, avoid obstacles and charge.

Owner:宁波赛夫科技有限公司

Method for production planning in an uncertain demand environment

A decision-making method suitable for production planning in an uncertain demand environment. To this end, the method comprises combining an implosion technology with a scenario-based analysis, thus manifesting, a sui generis capability which preserves the advantages and benefits of each of its subsumed aspects.

Owner:IBM CORP

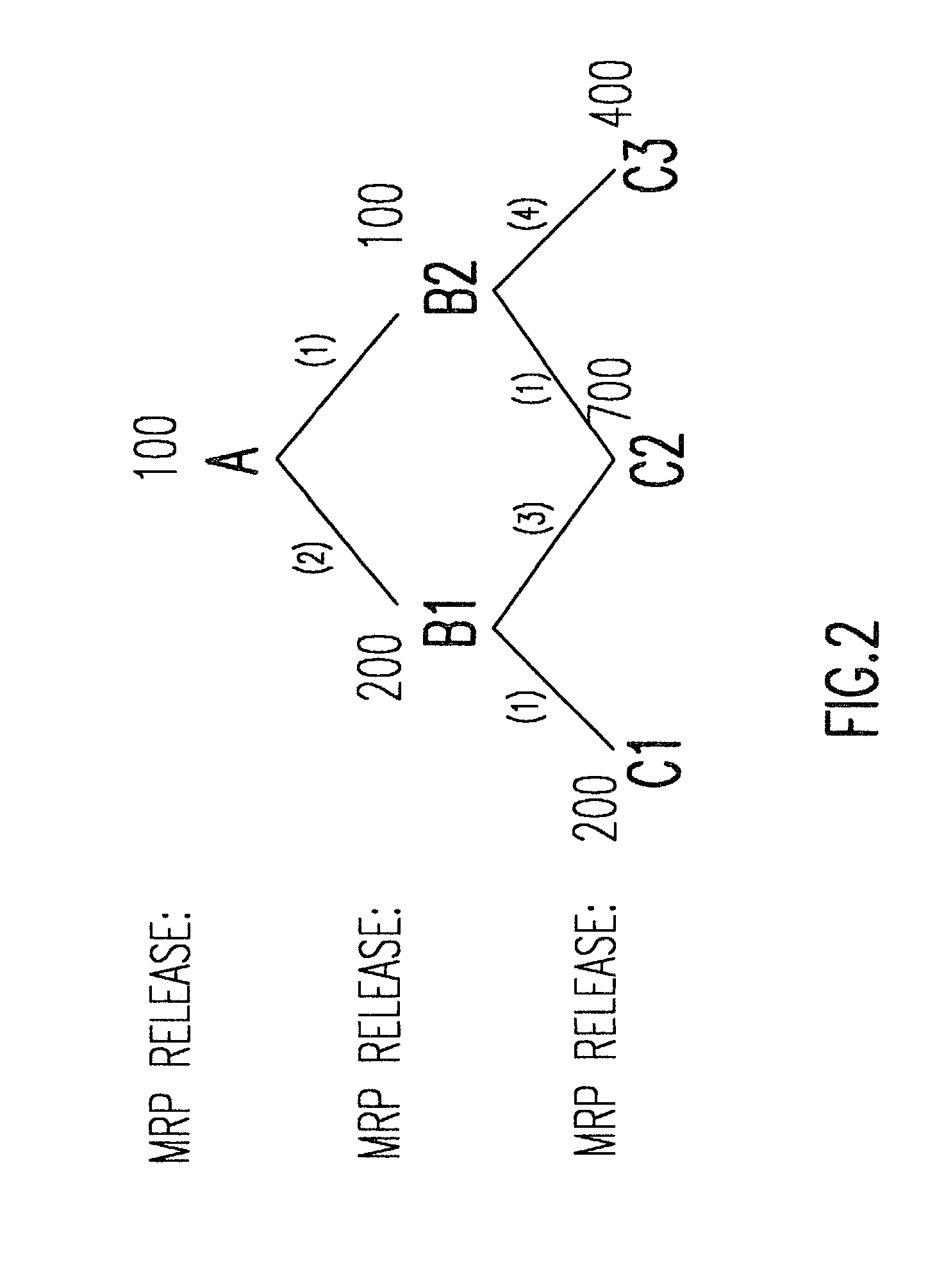

Production scheduling system

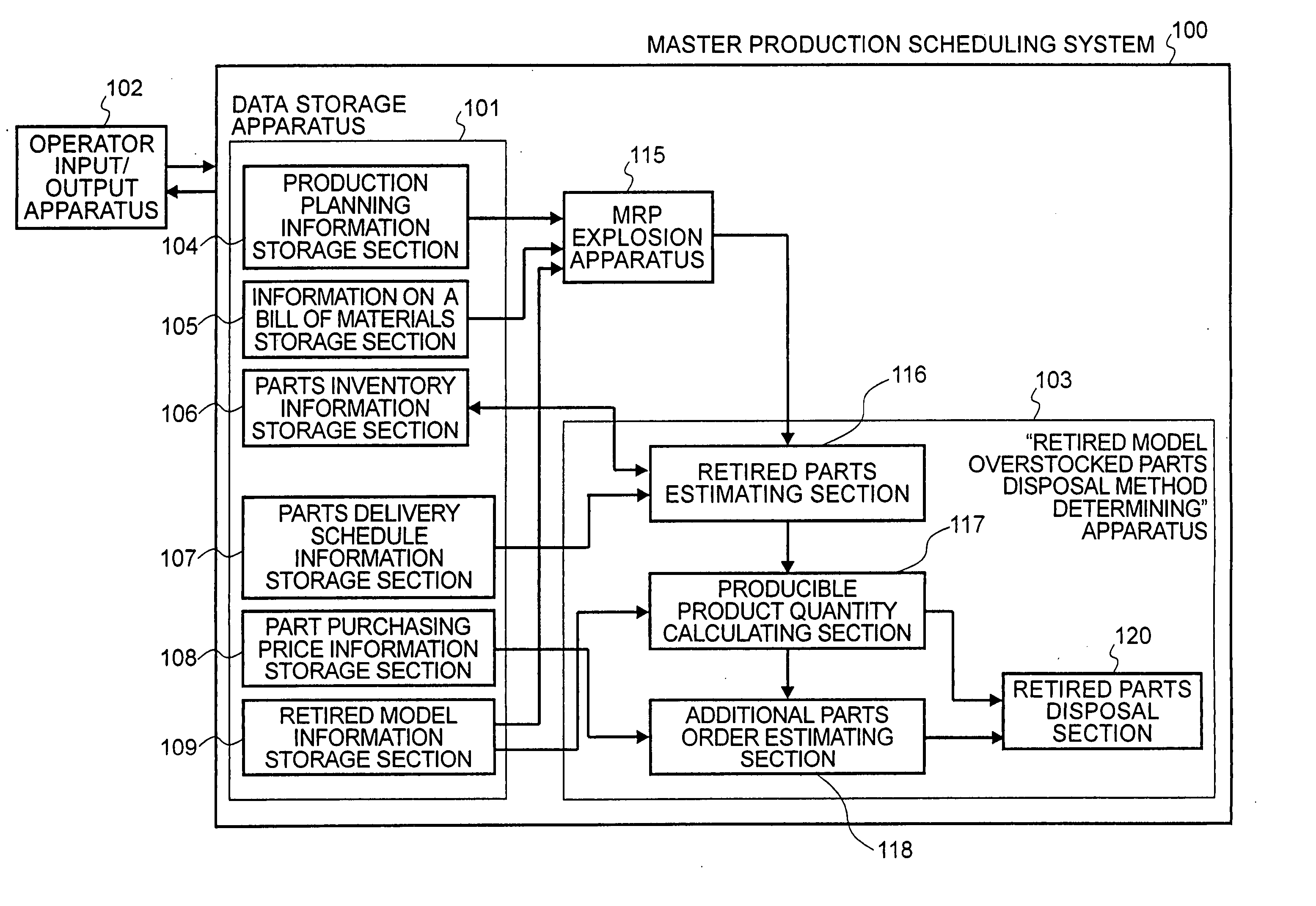

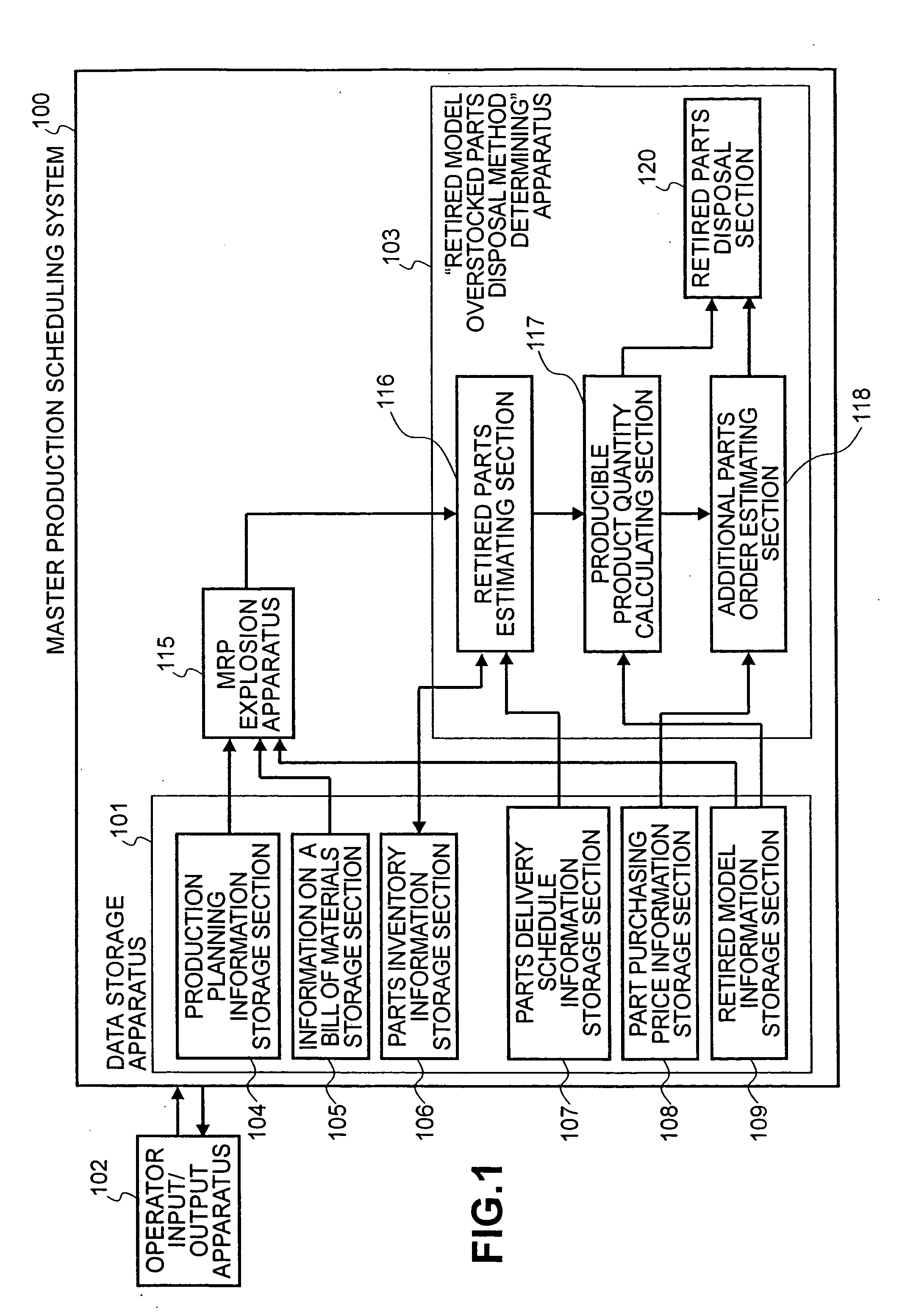

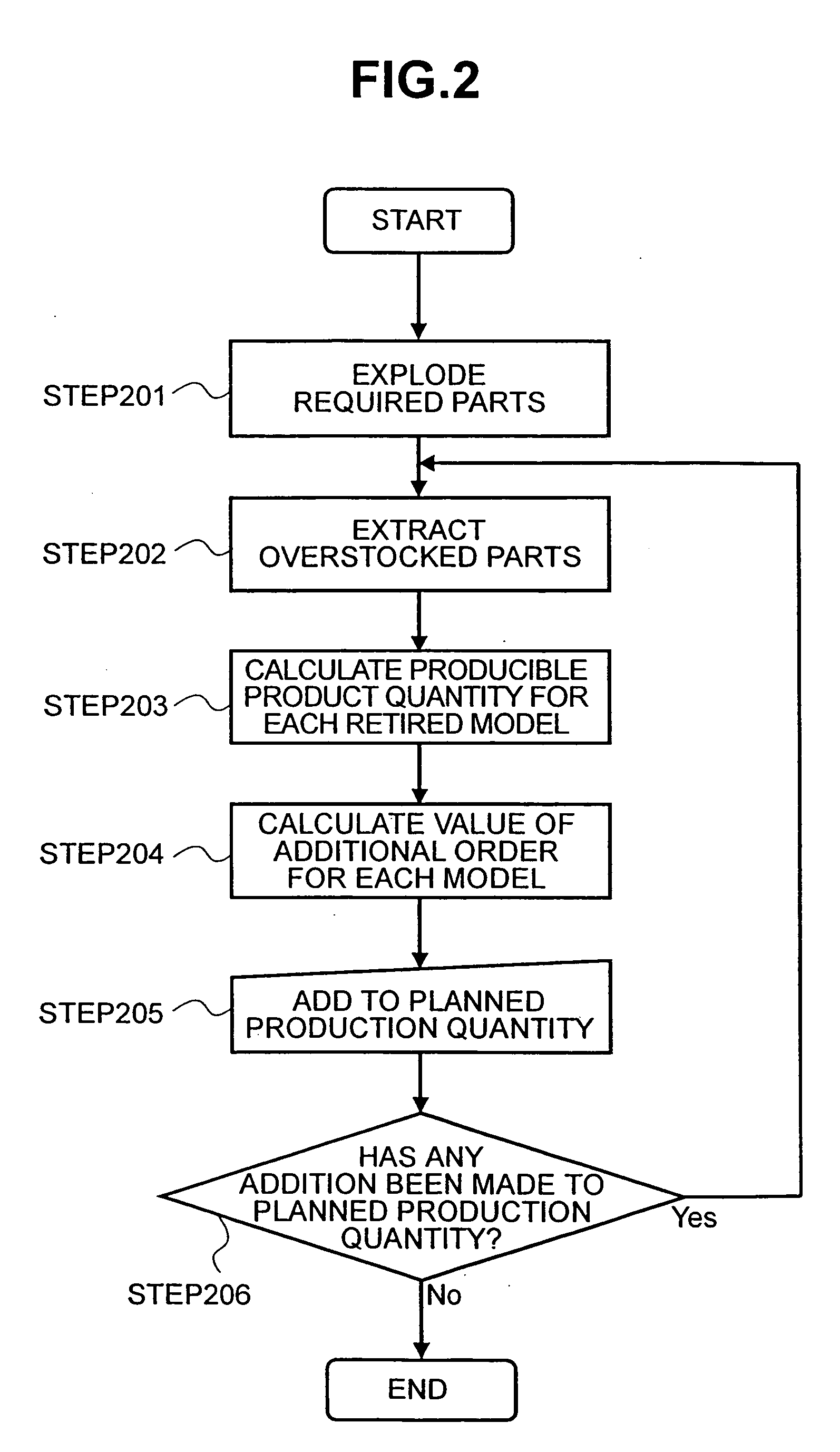

InactiveUS20050131779A1Minimizes valueIncrease salesAnimal feeding devicesResourcesData storingIndustrial engineering

The present invention provides a master production scheduling system in which overstocked parts are disposed of with minimum loss. The master production scheduling system refers to data stored in a data storage apparatus 101 and performs the following processing: an MRP explosion apparatus 115 explodes a product listed in a production plan into gross requirements; a retired parts estimating section 116 specifies overstocked parts based on the explosion results; a producible product quantity calculating section 117 calculates a producible product quantity for a retired model which can be produced using the overstocked parts; an additional parts order estimating section 118 calculates the value of an additional parts order (which is an amount of money to be paid for parts to be additionally ordered) for each quantity of retired model products to be produced; and a retired parts disposal section 120 drafts a production plan for the retired model in which the value of the additional parts order is minimized based on the producible product quantity and the value of the additional parts order.

Owner:HITACHI LTD

Method and system for resource requirement planning and generating a production schedule using a uniform data model

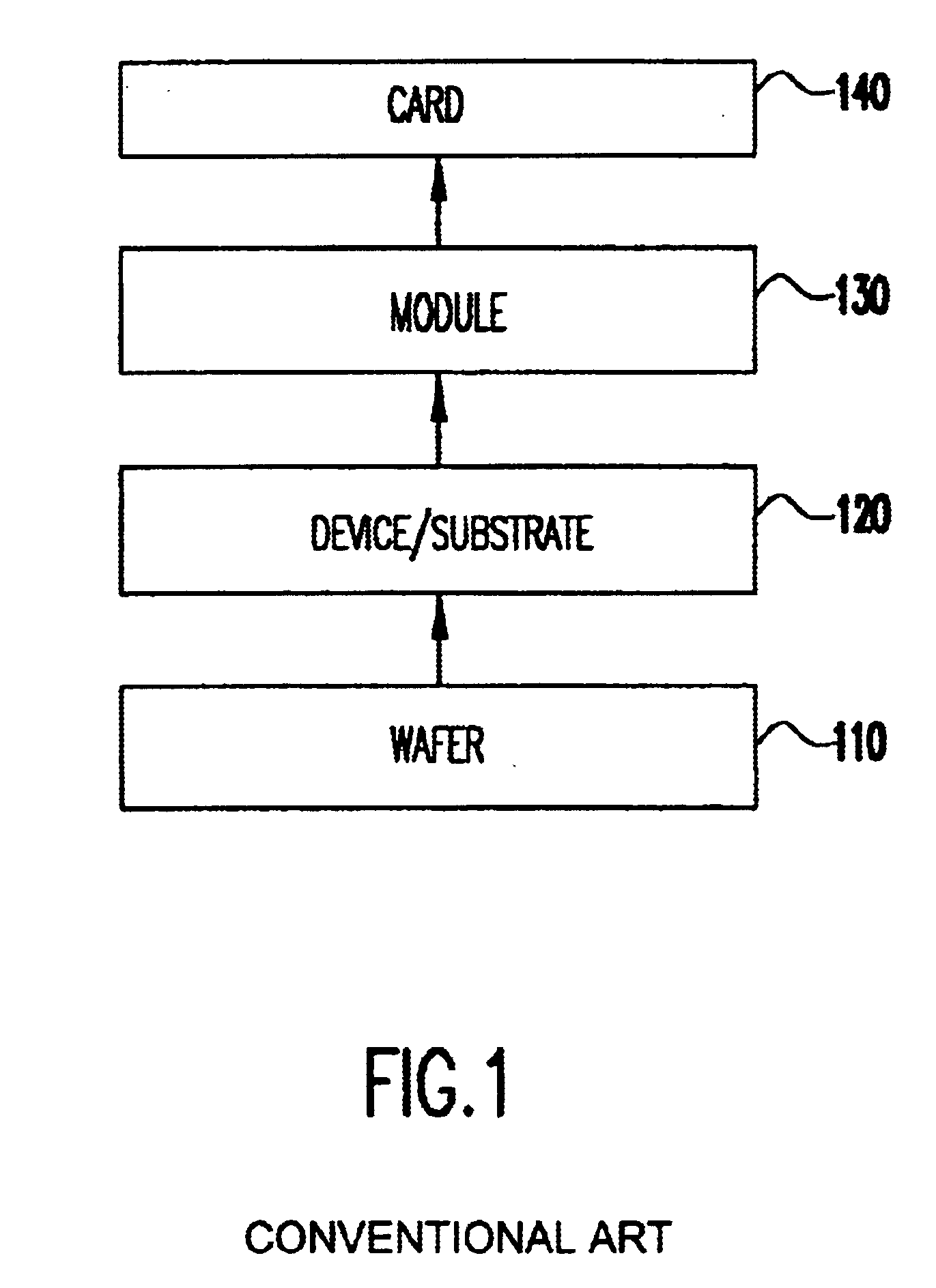

InactiveUS7209869B1Avoid exponential growthEasy to understandAnimal feeding devicesResourcesDocumentation procedureBill of materials

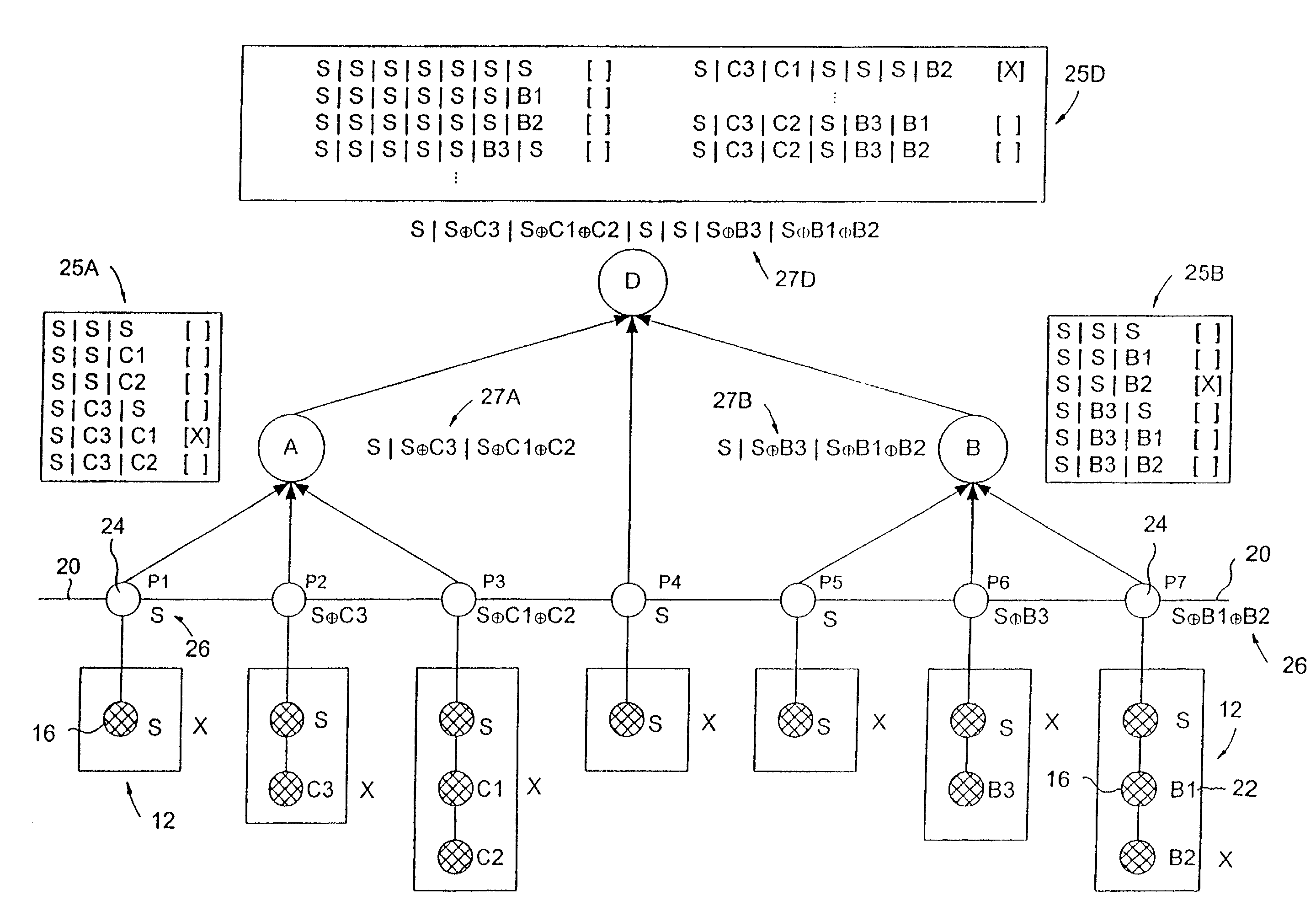

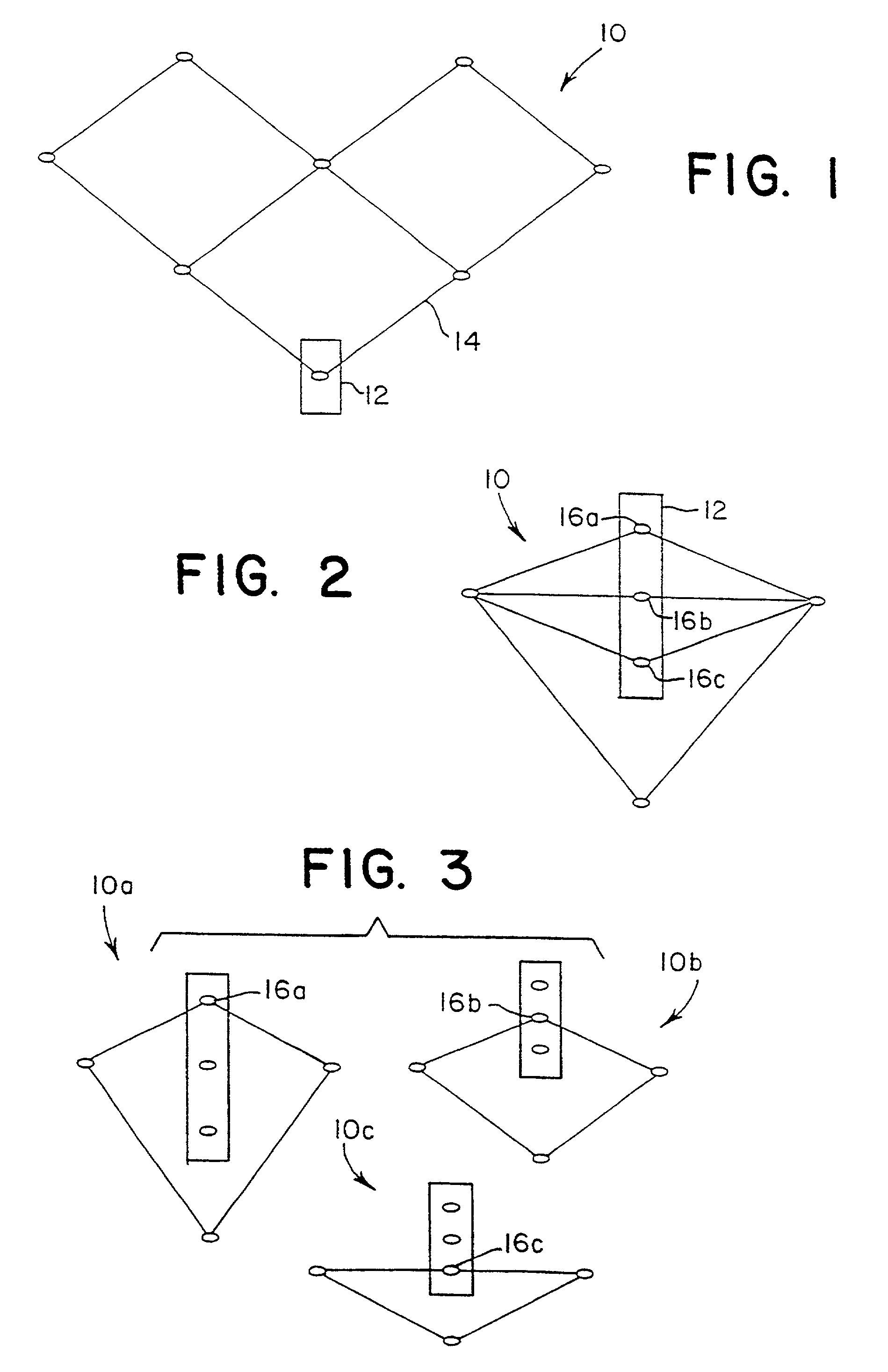

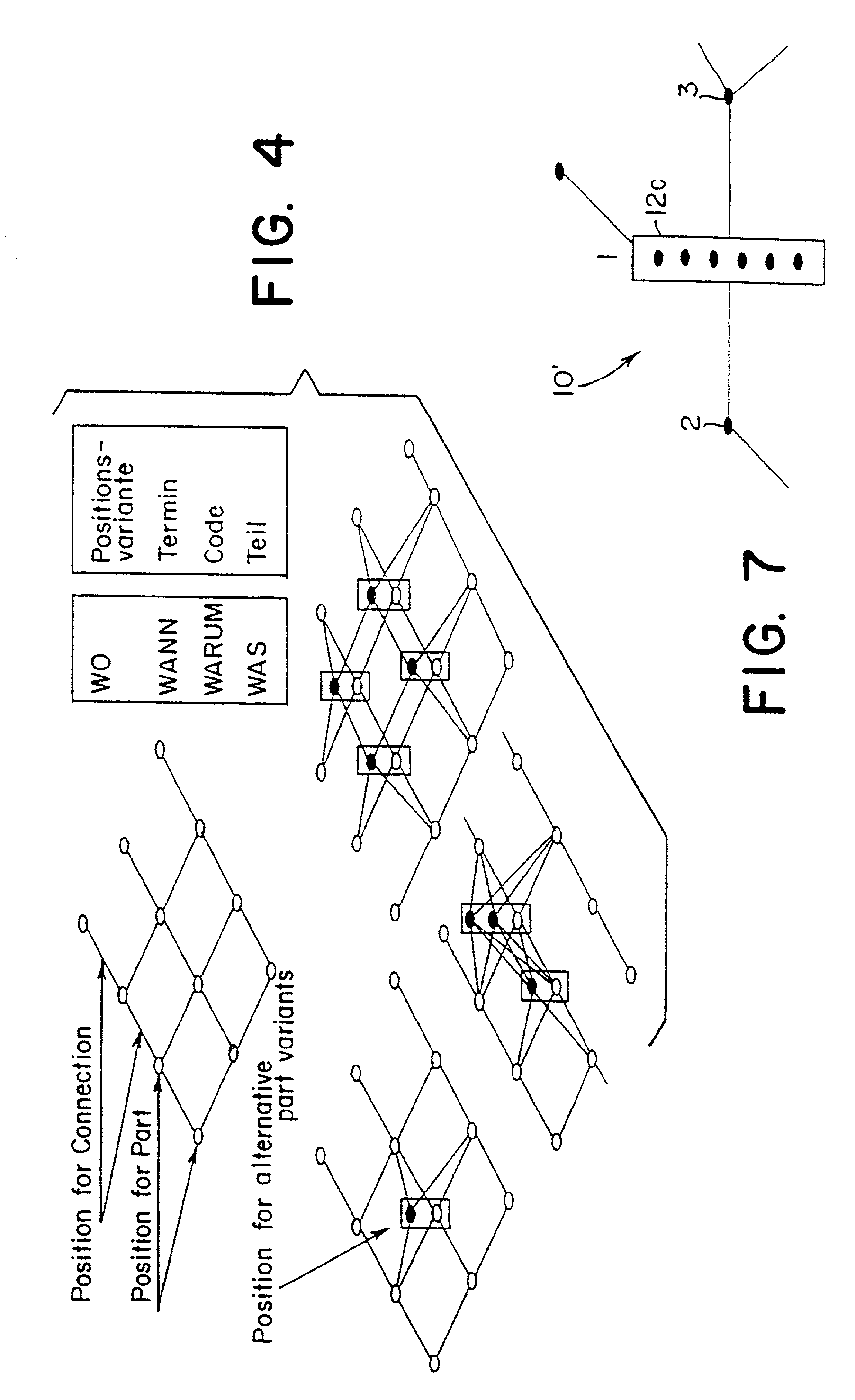

A method for representing the structure of an article of manufacture having a plurality of design variants includes defining a plurality of positions corresponding to different predefined locations on the article of manufacture and assigning at least one variant to each position. Each variant identifies a specific part that may be used in the respective position or a specific type of connection between a pair of parts. In any given position, at most one part or connection variant can be selected. Code rules are defined for each variant which indicate when a particular variant should be used in accordance with specified design options. The position and variant representation can be implemented as part of a bill of materials used for manufacturing resource planning. Improved methods for defining the code rules, for evaluating the code rules in the bill of materials to determine manufacturing parts requirements for a plurality of orders, and for generating documentation for manufactured variants of the article are also disclosed.

Owner:MONKE ECKHARD +1

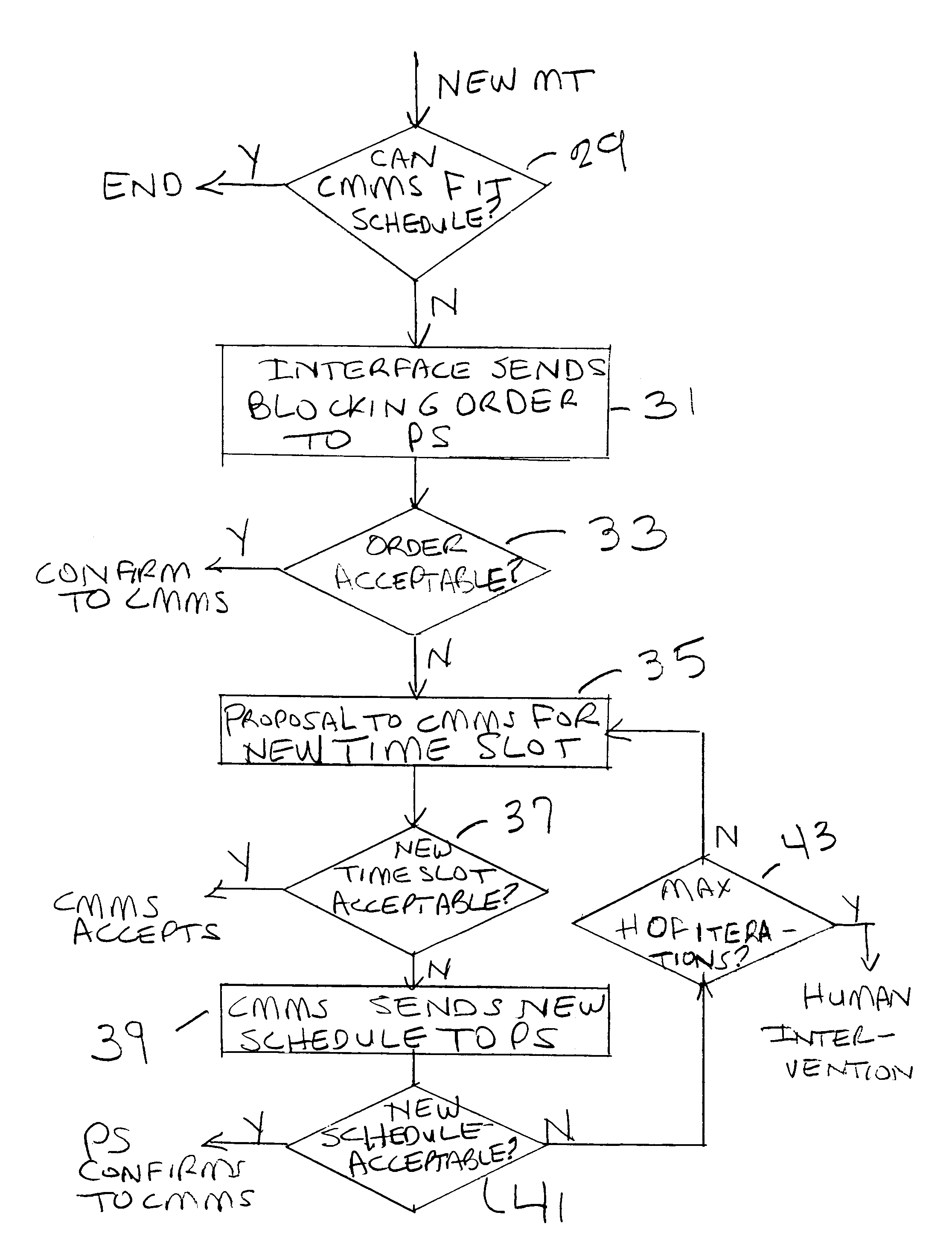

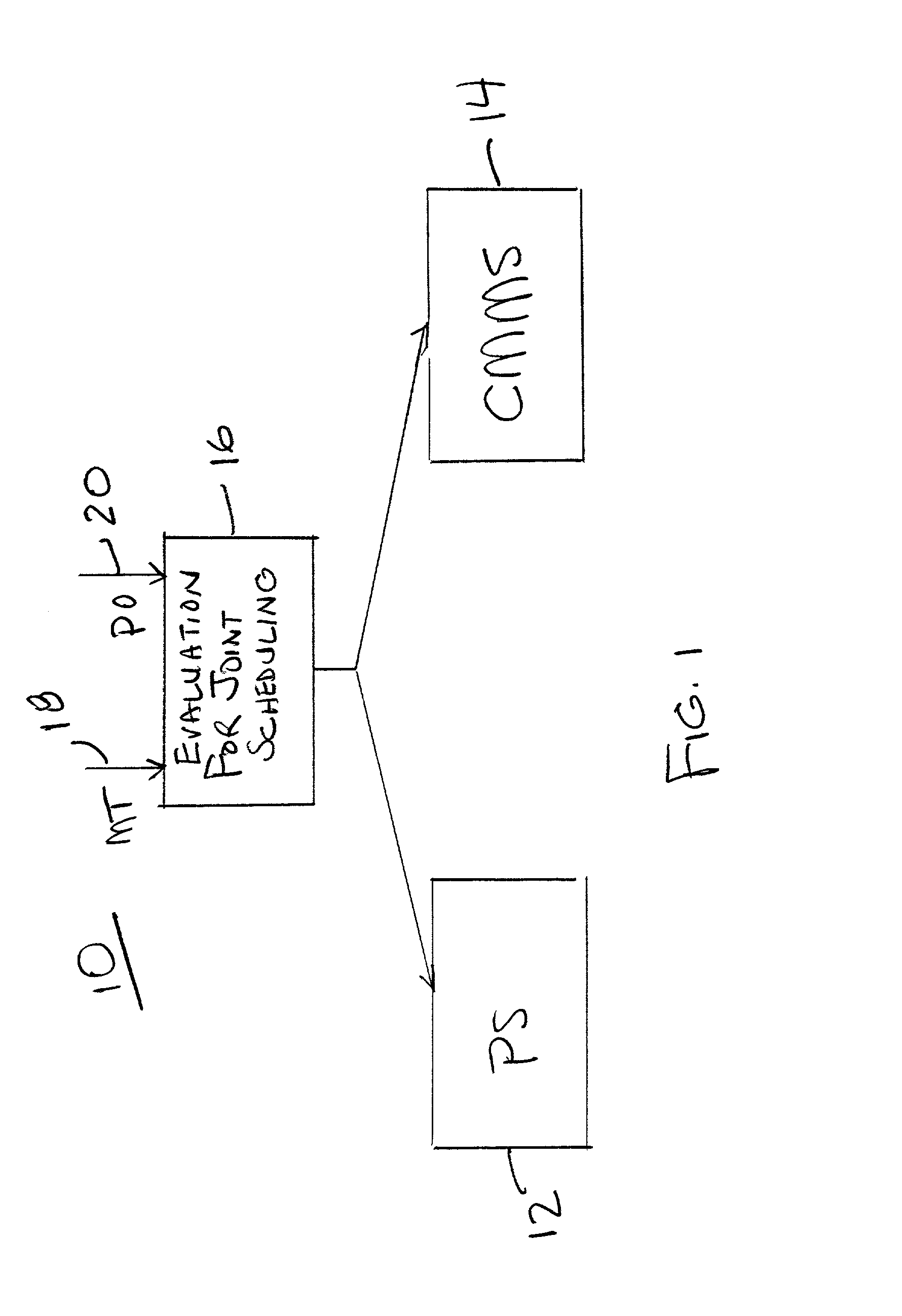

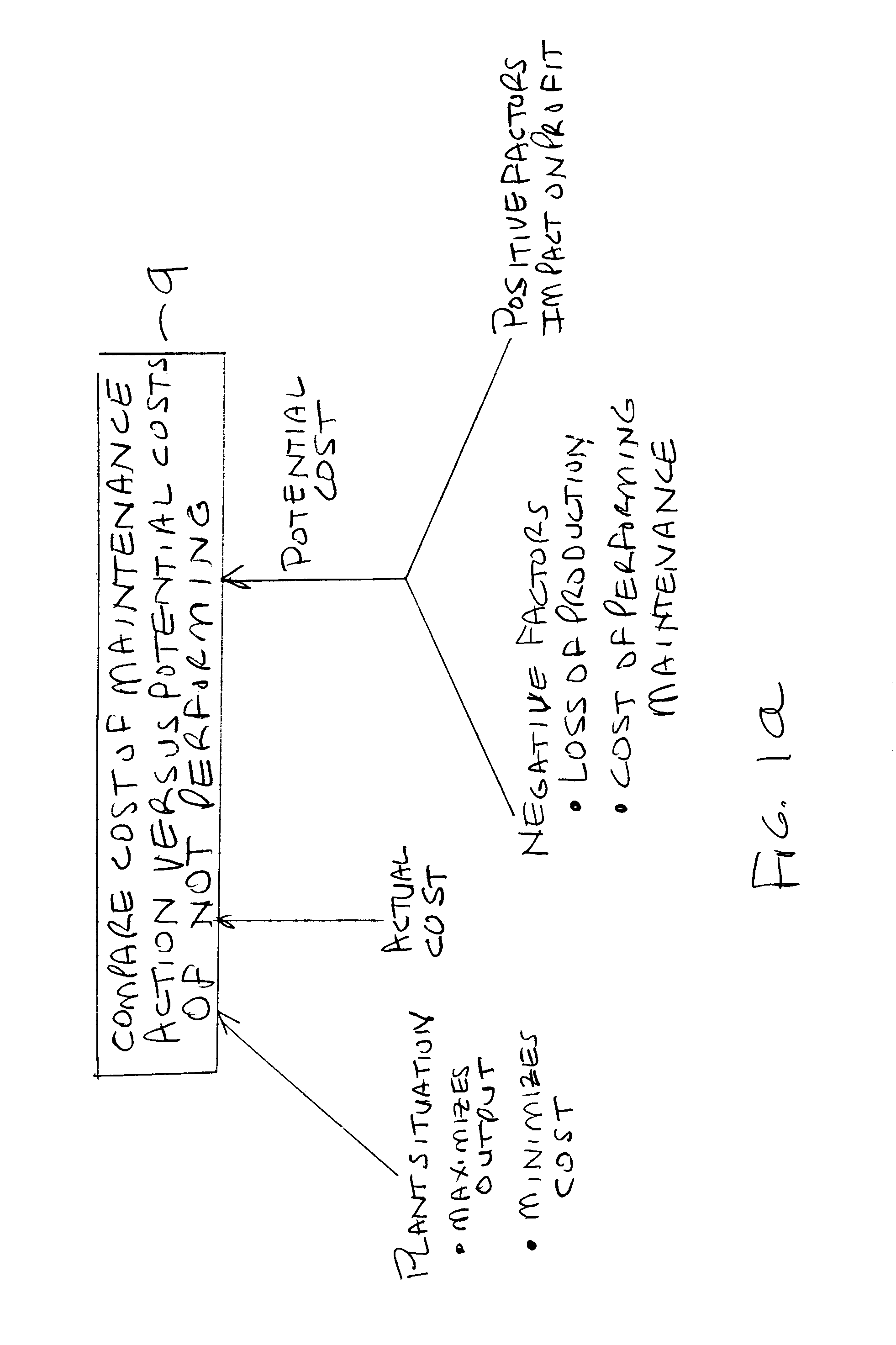

Real time asset optimization

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

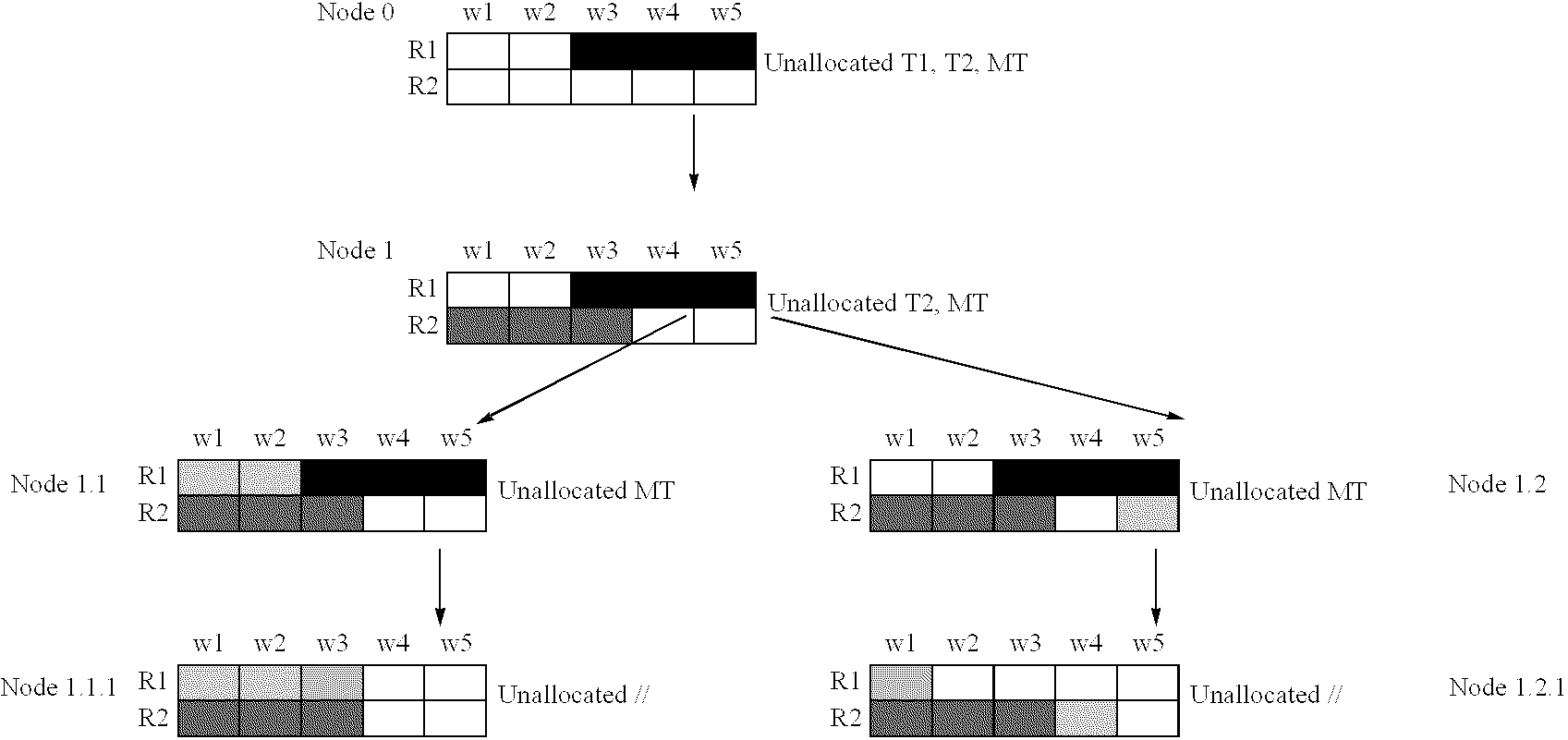

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

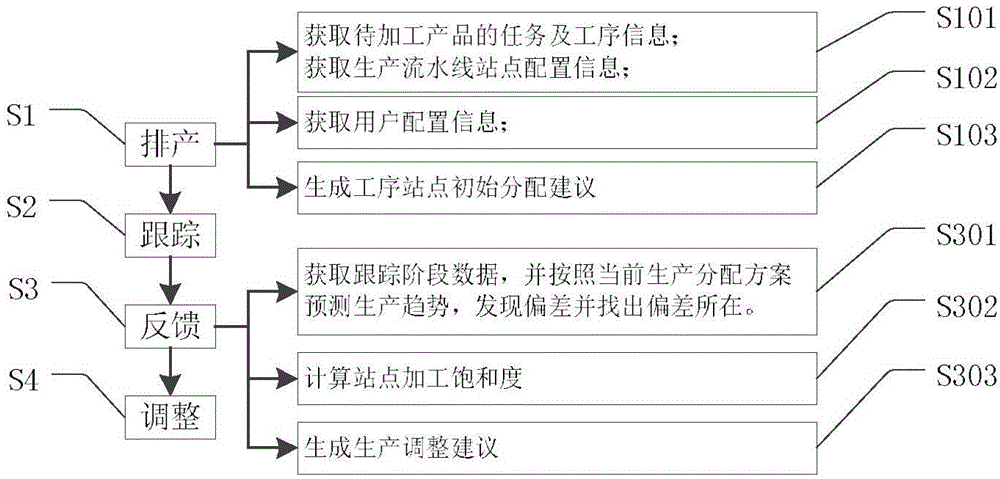

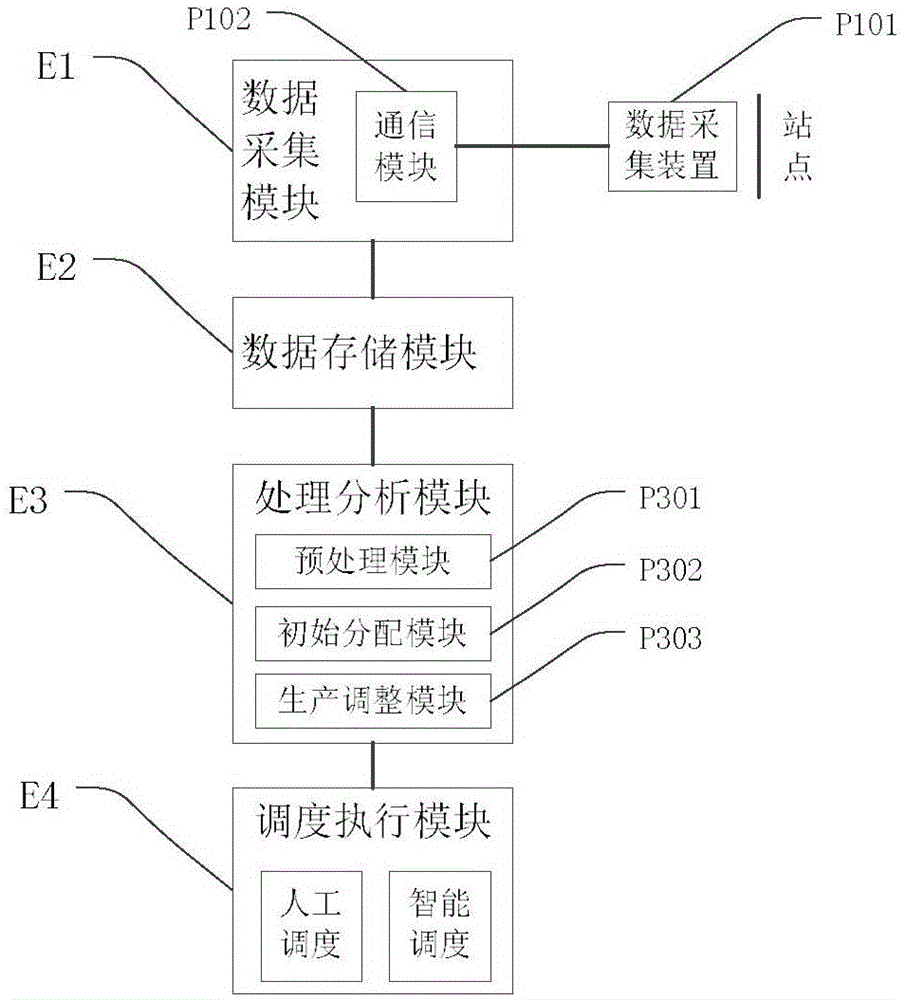

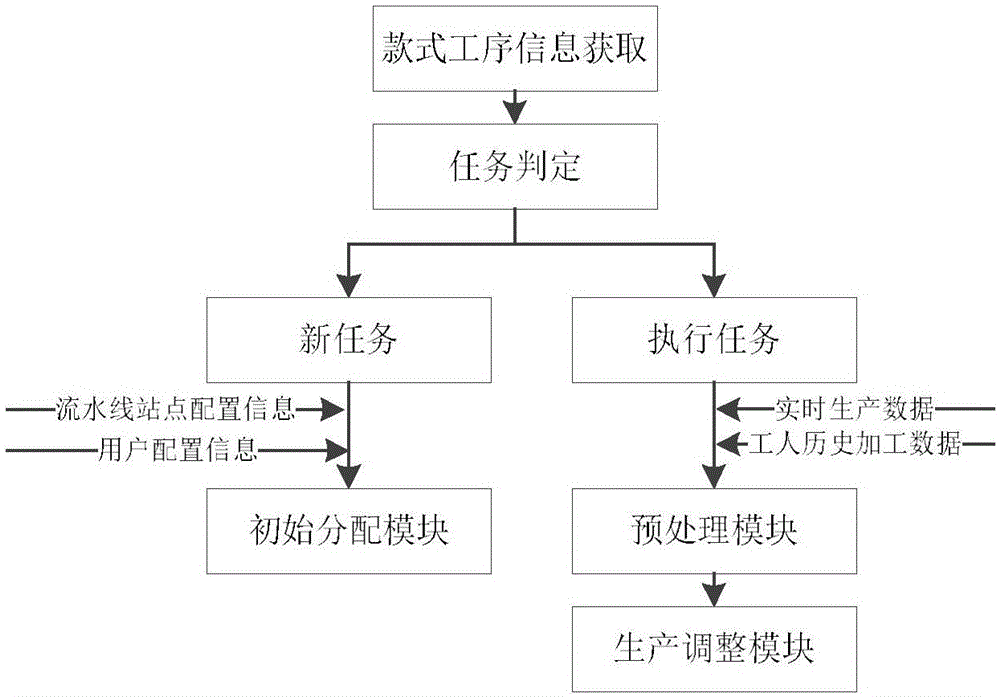

Assembly line production scheduling method and system

ActiveCN105045236AAvoidance of productivityAvoid balanceTotal factory controlProgramme total factory controlProduction lineAssembly line

The invention discloses an assembly line production scheduling method and system. The method comprises the steps of production scheduling, tracking, feedback and adjustment. According to production scheduling, site configuration and production process information of a product production assembly line is acquired to form an initial allocation recommendation. According to tracking, the production data of the assembly line is acquired in real time, and the processing capacity of each site on the assembly line is analyzed and measured based on dependency. According to feedback, based on the analysis of the processing capacity of each site, specified deliveries completed within specified delivery expectation according to the current production allocation scheme is predicted; a site processing task is coordinated through a feedback control method; a production adjustment recommendation is generated; and feedback control is carried out on assembly line resources and site configuration. According to adjustment, the allocation of production line material flow and process sites is adjusted according to the production adjustment recommendation acquired in the step of feedback. According to the invention, production planning is scientific, and production resource configuration scheduling ensures balance between internal processes and processes.

Owner:江苏云道信息技术有限公司

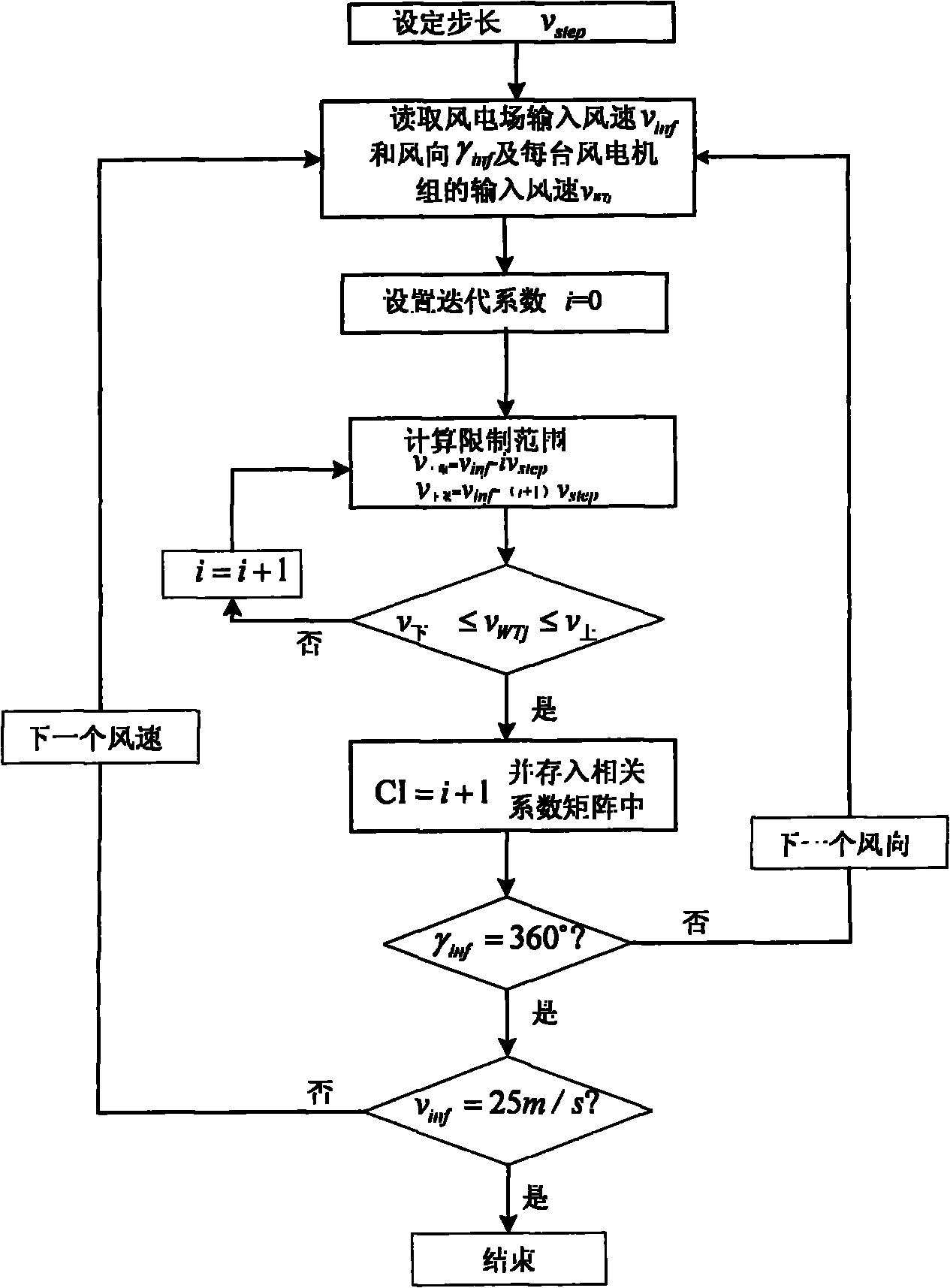

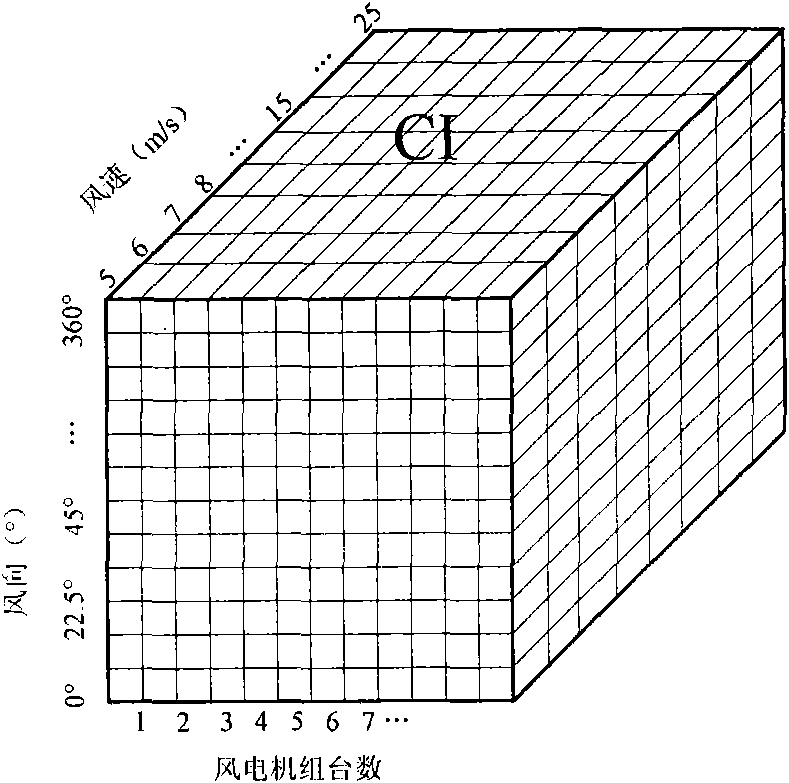

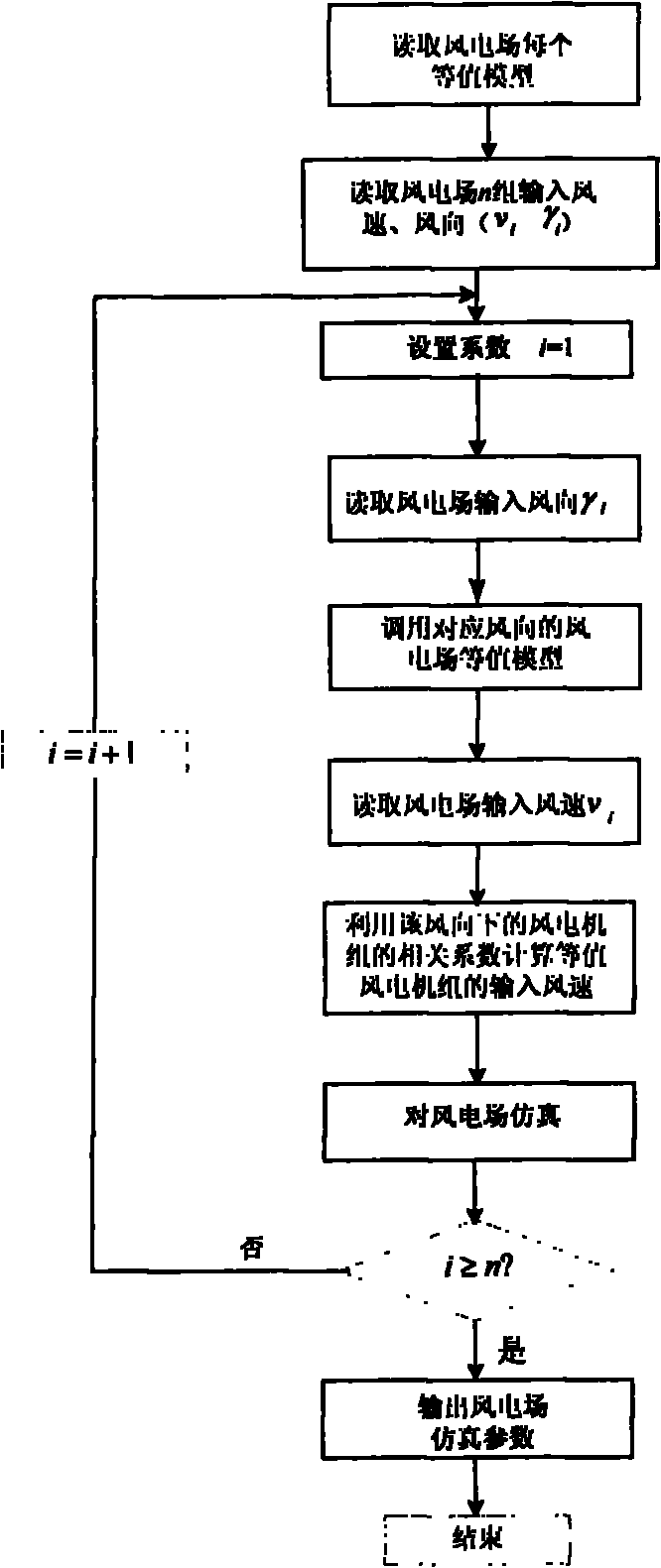

Wind farm equivalent method based on wind farm input wind speed and wind direction chance fluctuation

ActiveCN102012956AImprove accuracySpecial data processing applicationsInformation technology support systemConstant powerModel parameters

The invention discloses a method for establishing a wind farm random model based on factors such as wind farm input wind speed and wind direction chance fluctuation, wake flow effect between wind generating sets, an electric network in a wind farm and the like. The technical scheme comprises the following steps of: grouping the wind generating sets based on the wind farm wind speed and wind direction chance fluctuation; equating wind farm power according to a constant power exchange principle between the wind farm and a power grid before and after the equating; equating model parameters such as a generator of a wind generating set, a shaft system, a control system and the like according to a principle that the dynamic characteristic of the wind farm is constant before and after the equating; and keeping the detailed degree of an equivalent wind generating set model the same as that of a single wind generating set by rationally selecting an equivalent wind generating set reference value. When wind farm interconnecting analysis is performed by the model established by the method, the defects brought on the basis of the absence of the factors such as the wind farm input wind speed and wind direction chance fluctuation, the wake flow effect between the wind generating sets, the electric network and the like are overcome, and more accurate wind power data is provided for power grid dispatching and reasonable production plan arrangement.

Owner:SHANDONG UNIV OF SCI & TECH

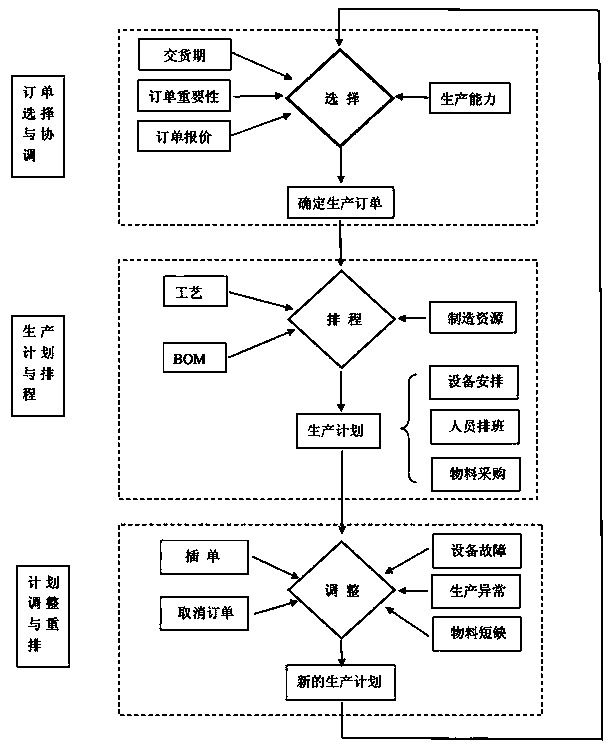

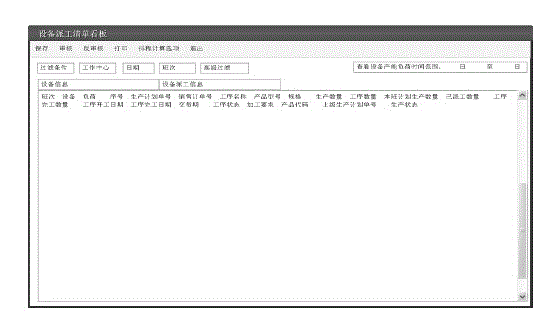

PCB enterprise order management and production planning system

InactiveCN104299107AReduce manufacturing costTake advantage ofResourcesProgram planningEnterprise data management

The invention provides a PCB enterprise order management and production planning system. According to the system, a production schedule in a period of time is automatically generated according to the production capacity of existing equipment, and the equipment, personnel and materials are arranged. The system is operated in coordination with a PCB enterprise product tracking query system and can master the processing progress of each order and the equipment utilization condition. If abnormal situations such as equipment failure and material shortage occur, or a customer inserts an order or withdraws an order, deviation between the actual production situation and the scheduled production plan occurs, the system can conduct calculation again and generates a new production plan and an order schedule according to the situations, and a new estimated product delivery time is provided.

Owner:叶校然

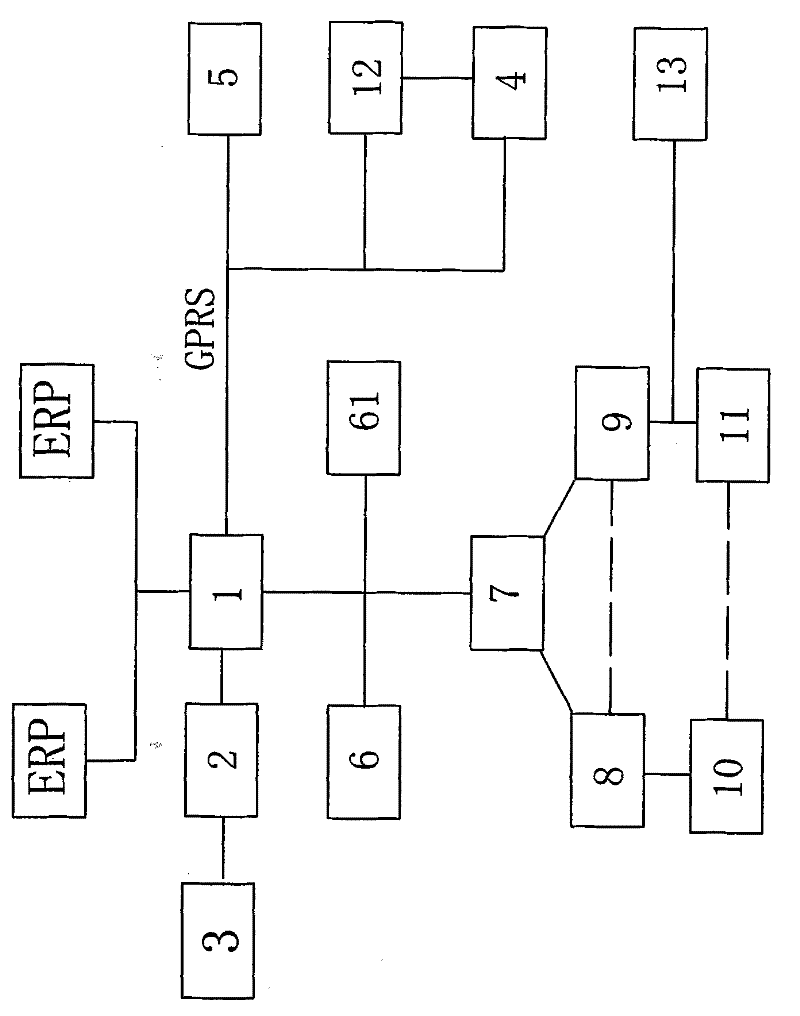

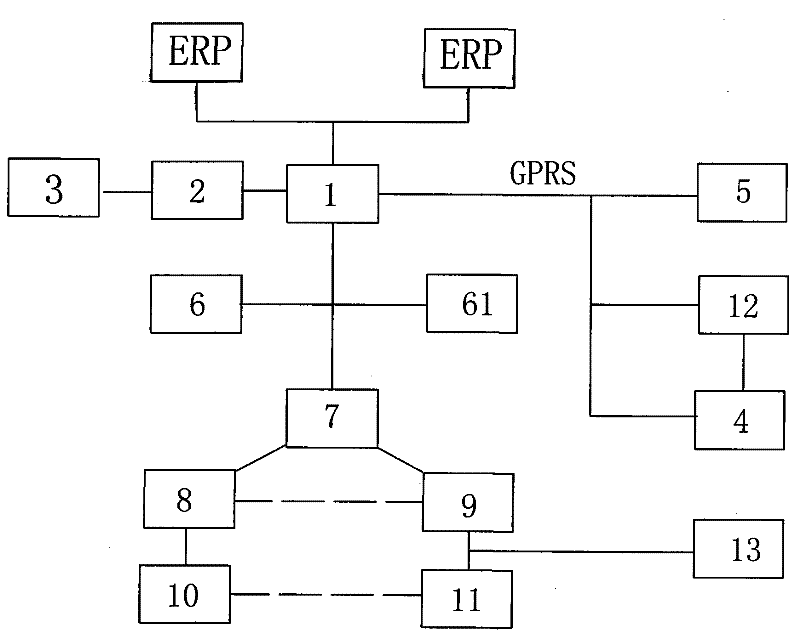

aps/mes lean manufacturing management system

InactiveCN102262757AImprove reaction speedImprove reaction efficiencyInstrumentsSoftware systemHand held

APS / MES lean manufacturing management system, including system hardware and system software, the software in the hardware is integrated in the main system software, and is seamlessly connected with the main system; the system hardware includes: industrial touch all-in-one machine connected to the host server and LED electronic kanban and The RFID card reader used to read the RFID card, the wireless receiving and transmitting device is connected with the host server, the handheld terminal and the terminal touch screen through the sensor, and the host server is also connected with the host of the logistics distribution center and the host of the delivery center; the system software includes: Supply chain management, sales management, procurement management, warehouse management, subcontract processing, production order, process route, workshop scheduling plan, handheld terminal module, terminal touch screen, material distribution, LED electronic kanban control system software module; system software The management module is divided into: basic data module, supply chain management module, equipment management module, production management module, and handheld terminal module; each module is composed of its corresponding sub-modules.

Owner:王圣亮

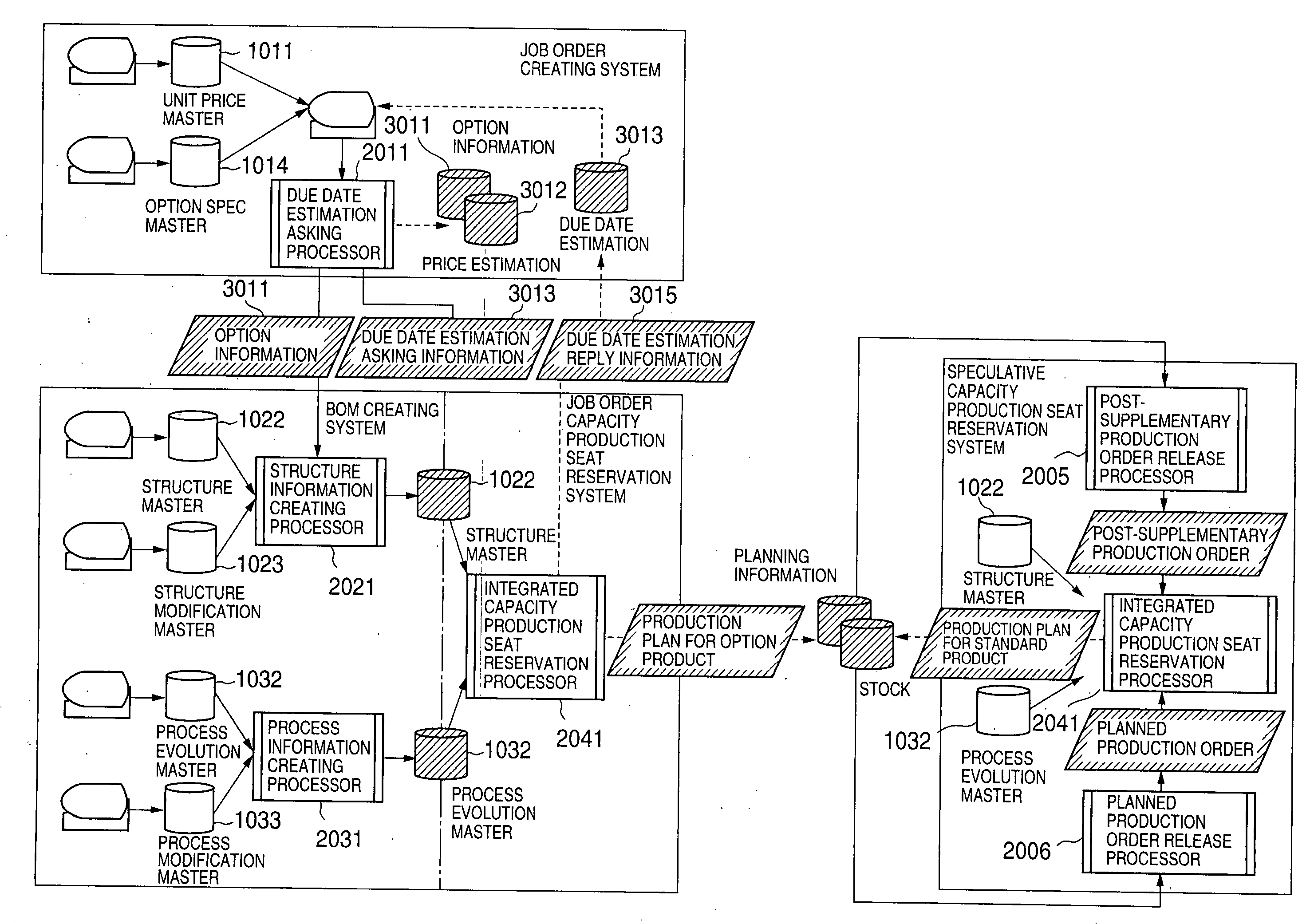

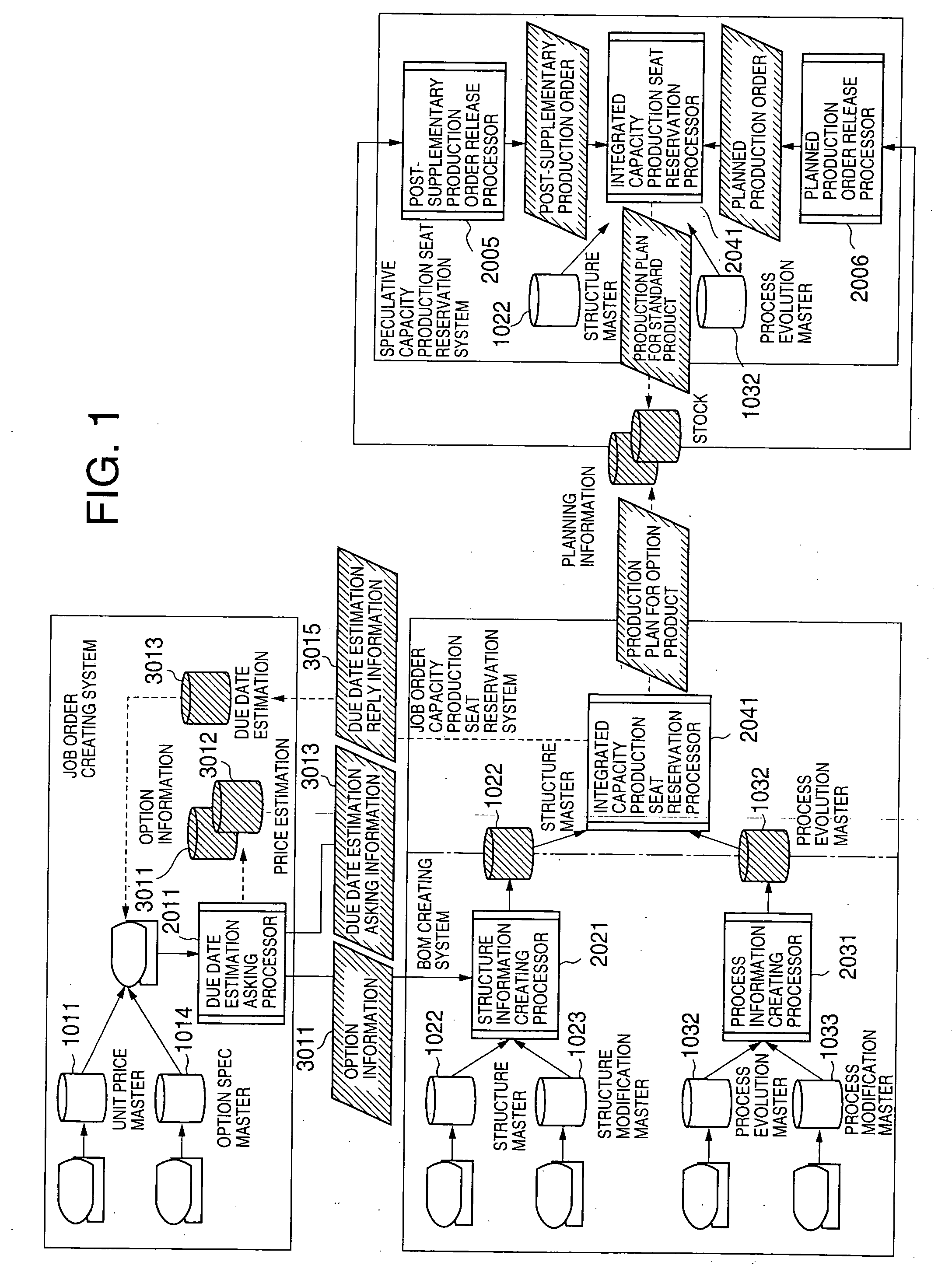

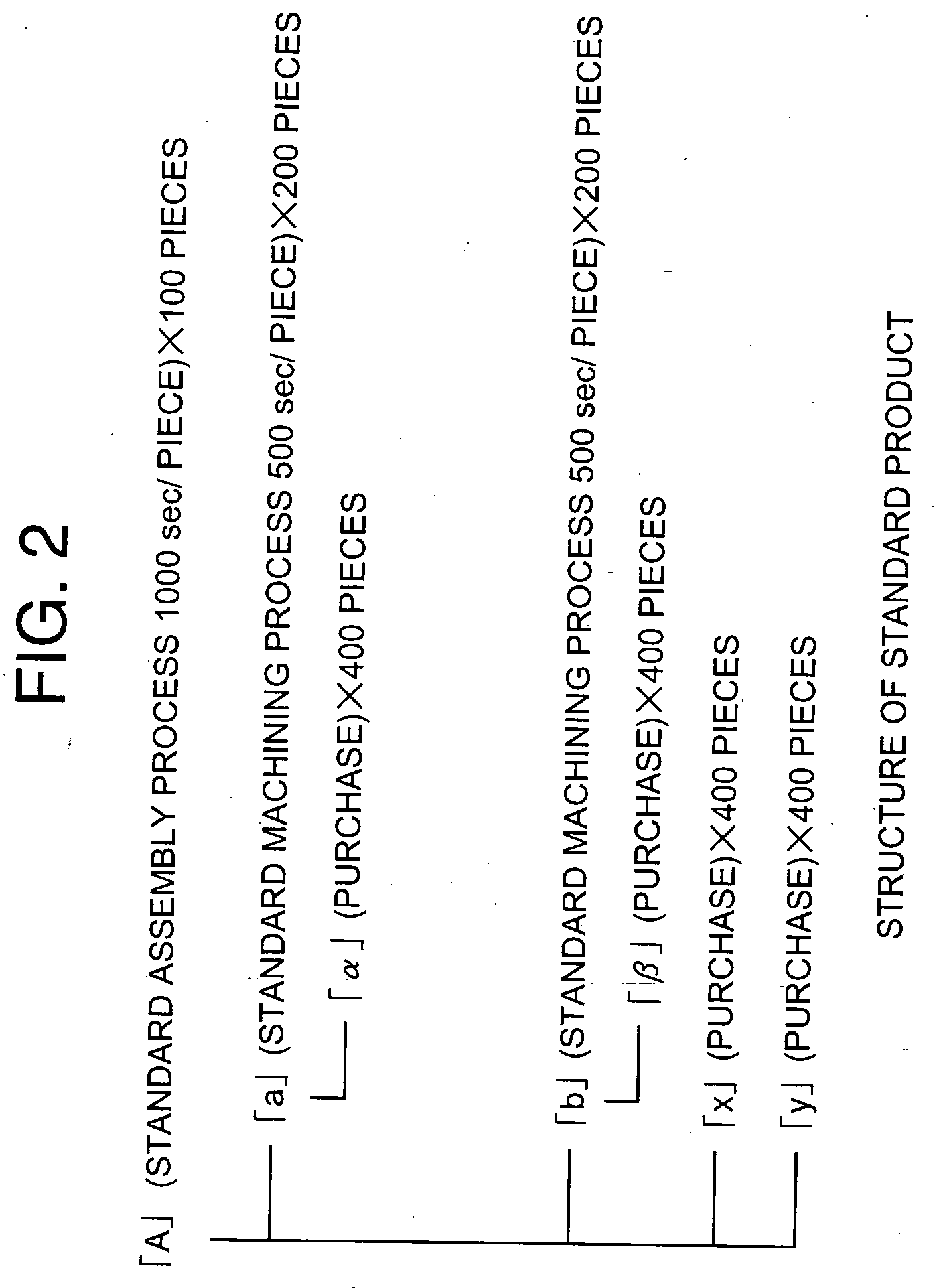

Production management system production management method

InactiveUS20040210467A1Buying/selling/leasing transactionsResourcesProgram planningProcess information

Here is disclosed a system and a method for production management. In response to a job order created by a job order creating system, which indicates option to be applied to parts and processes associated with a standard specification product, a structure information creating processor creates, with reference to a structure modification master recording option applicable to the parts, a second structure master by applying the parts of an option specification product to a first structure master while a process information creating processor creates, with reference to a process modification master recording the option applicable to the process, a second process evolution master by applying processes for the option specification product to a first process evolution master. Then a capacity production seat reservation processor applies the parts of the option specification product and processes for the option specification product to a production planning for the standard specification product in order to create a production planning for the option specification product and stores the production planning for the option specification product created in this manner.

Owner:YOKOYAMA HIROSHI

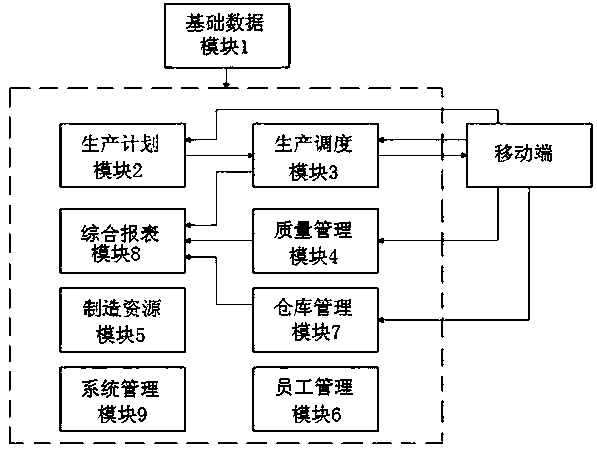

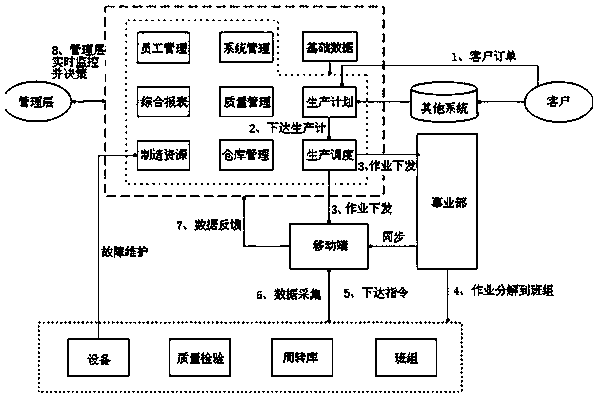

IMES intelligent manufacturing execution system

PendingCN107831750ASolve the problem of missing ringsResolving conflicts in using different information systemsTotal factory controlProgramme total factory controlUser needsIslanding

An IMES intelligent manufacturing execution system is featured by comprising a basic data module, a production planning module, a production scheduling module, a qualify management module, a manufacturing resource management module, an employee management module, a warehouse management module, an integral report module, a system management module and an equipped mobile terminal system; the advantages are that the system can solve the information isolated island problems existing in MES and the defect ring problems formed between a MRP layer and a DCS layer; novel modules are developed according to user demands and used by a plurality of departments in the same time, thus solving the contradictions of different departments using different information systems, and improving the working efficiency; the IMES intelligent manufacturing execution system can monitor the factory flow data, thus enabling the management layer to make rapid decisions aiming at problems.

Owner:QINGDAO PENGHAI SOFT CO LTD

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

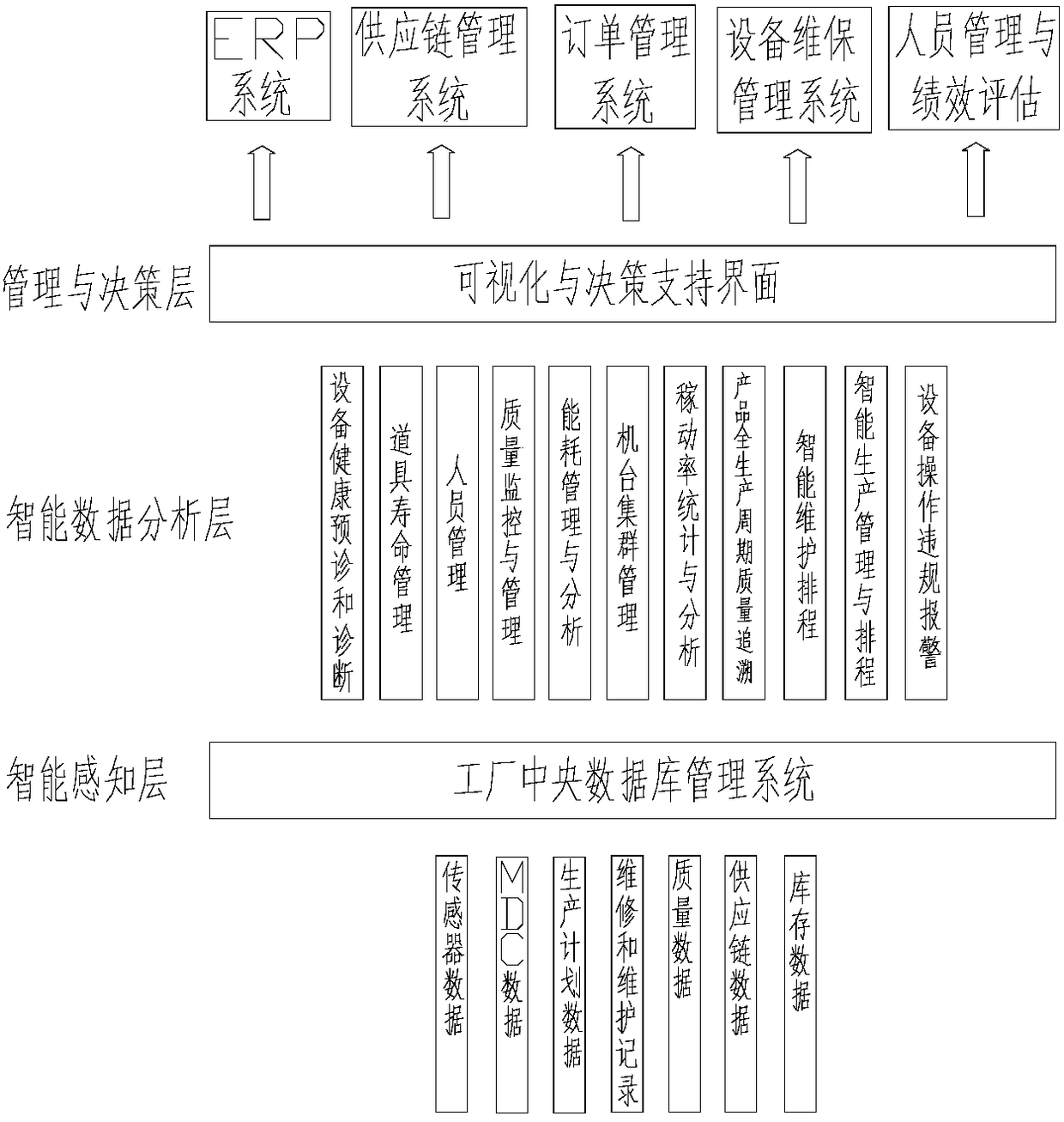

Smart factory management platform system

InactiveCN108241343AAvoid failureReduce operation and maintenance costsTechnology managementTotal factory controlReal time analysisInteraction interface

The invention relates to a smart factory management platform system comprising an intelligent sensing layer for collecting, arranging and storing data of all information sources during a production process, an intelligent data analysis layer for carrying real-time analyses on various collected data, monitoring, evaluating, and predicting healthy states of equipment and product quality states, displaying analysis results at a visual human-computer interaction interface, and generating corresponding decision-making support suggestions, and a management and decision-making layer for pushing the analysis results and decision-making suggestions to all departments under jurisdiction of a company and providing a decision-making and planning basis for a superior information system. According to the invention, historical and real-time monitoring data and production data are dug fully and health states of the equipment are analyzed and controlled precisely and quantitatively; a reasonable production plan and a reasonable maintenance plan are made based on the predictive analysis of the states of the equipment; failures of the equipment and products due to faults can be prevented; the operation and maintenance costs are lowered effectively; the production efficiency is improved; the product quality is guaranteed; and the comprehensive competitiveness of the market is strengthened.

Owner:QINGDAO HAIER MOLDS

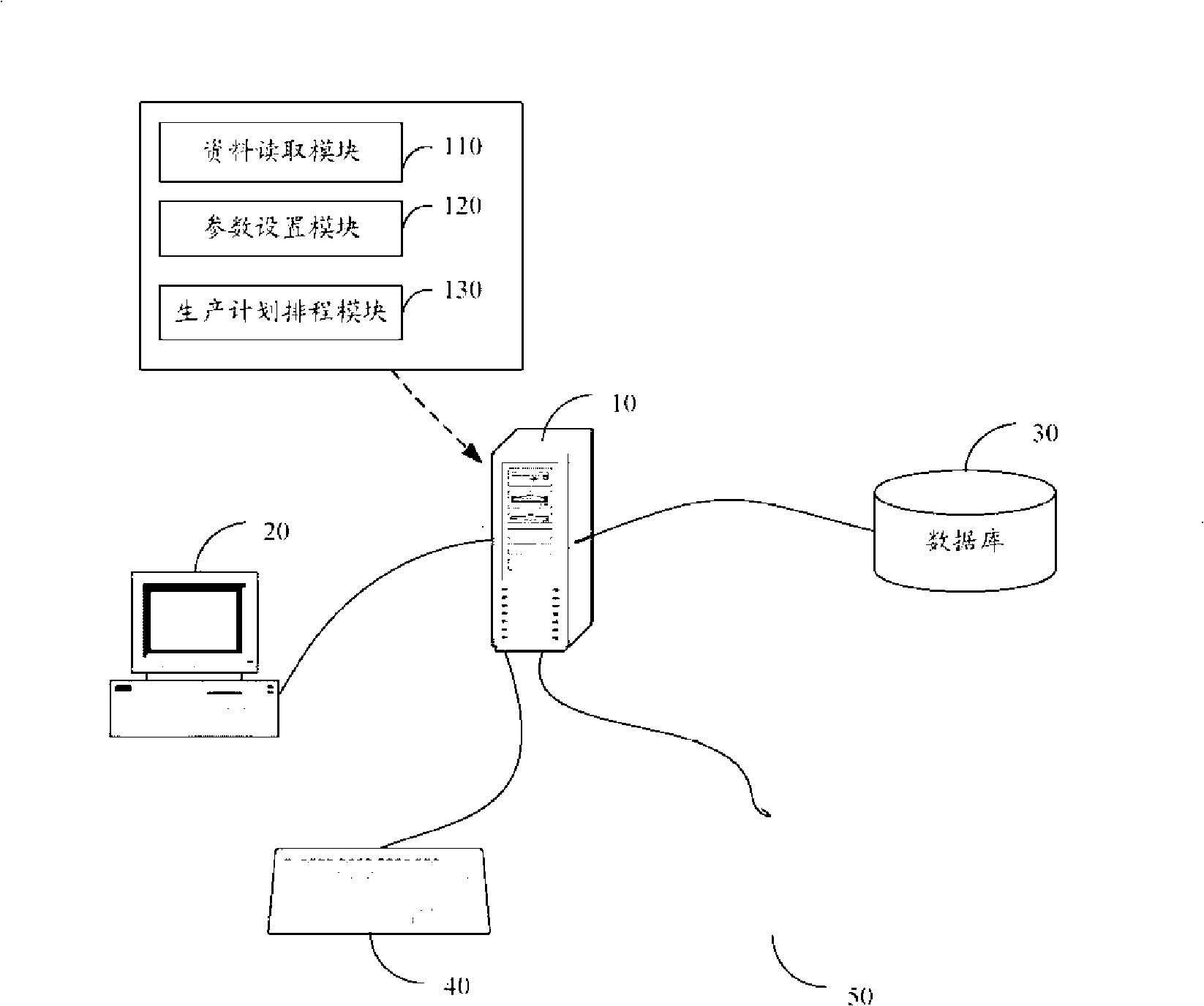

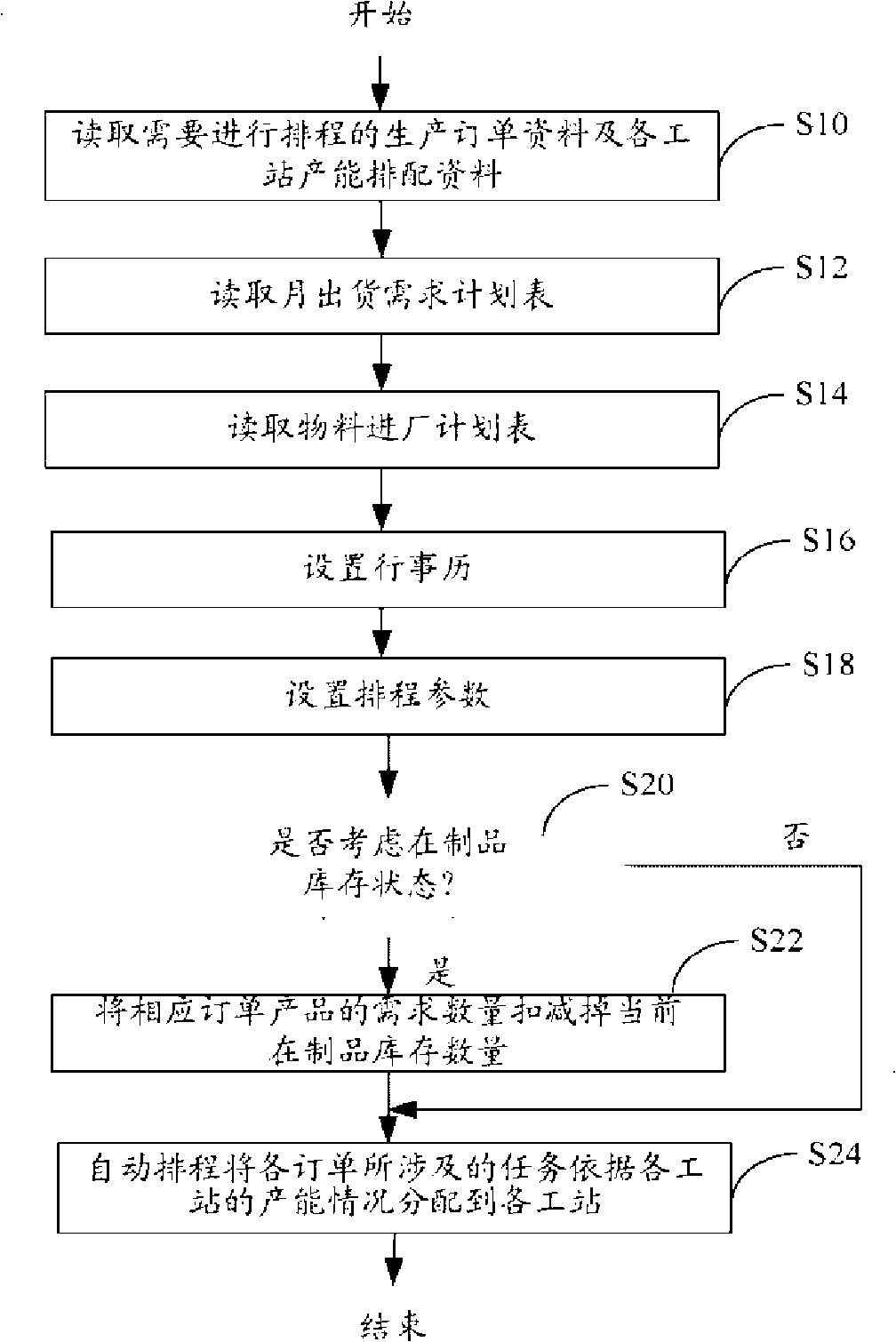

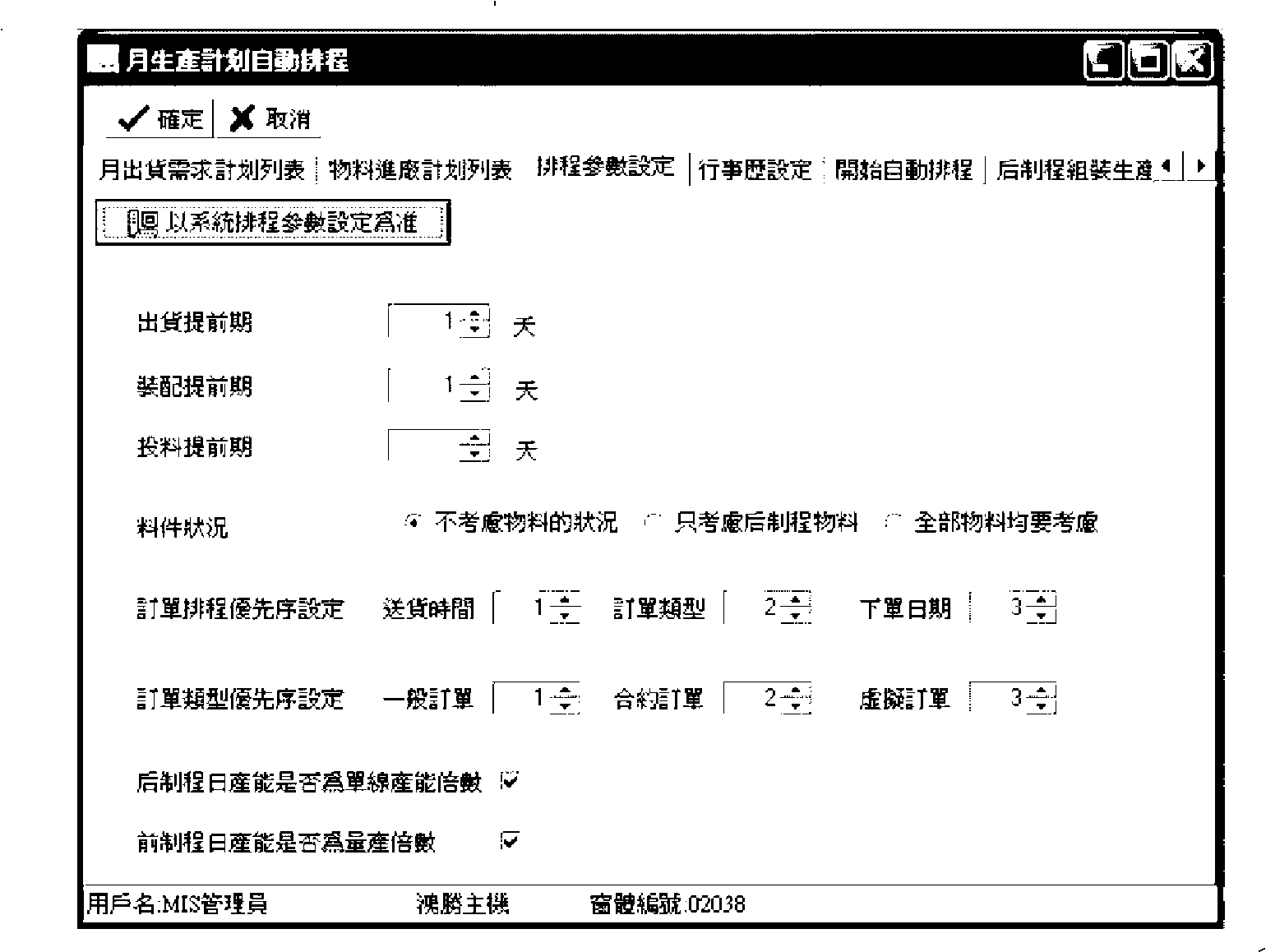

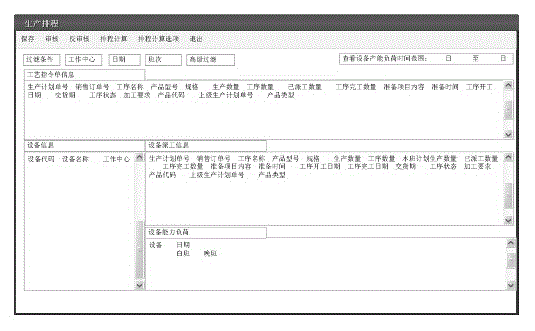

System and method for automatically arranging production plan

The invention provides an automatic production plan scheduling system which comprises a host computer and a database. The database is stored with order information, production capacity scheduling and distributing information for various working stations on a production line, monthly delivery demand plan information and material incoming plan information in an enterprise. The host computer is used for reading information from the database, setting up working schedule and scheduling parameters, and automatically carrying out the scheduling of production plans according to multiple limit conditions such as the monthly delivery demand information, the material incoming plan information and the set priority sequence of the order arrangement, and distributing commissions involved with different orders to different working stations according to the production capacity conditions of each working station. The invention also provides an automatic production plan scheduling method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

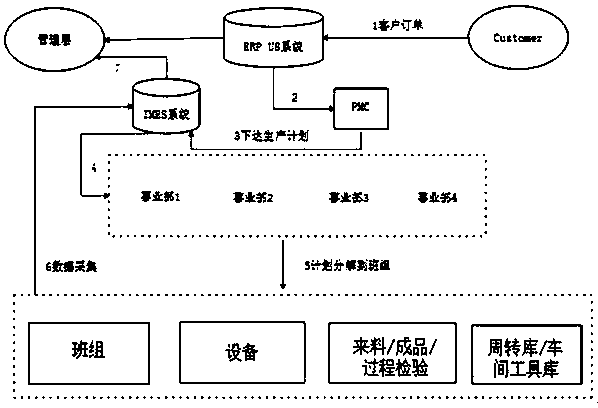

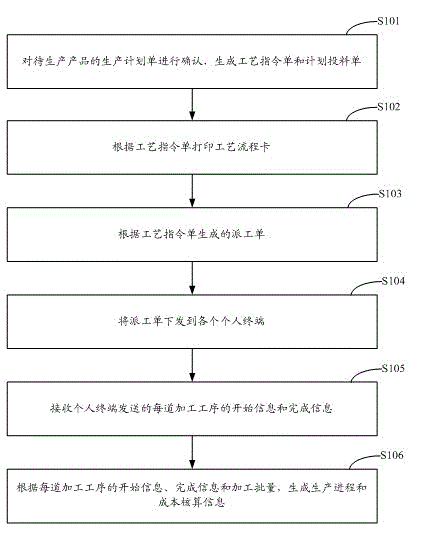

Workshop operation management method, system and server

The invention belongs to the technical field of production control, and provides a workshop operation management method, a workshop operation management system and a server. The method comprises the following steps of: determining a production plan list of a product to be produced, and generating a process command list and a plan feeding list; printing a process flow card according to the process command list, wherein the process flow card at least comprises two bar codes, respectively a bar code of the product to be produced and the bar code of each processing procedure; generating a dispatch list according to the process command list; transmitting the dispatch list to each personal terminal; receiving the start information and the completion information of each processing procedure transmitted by the personal terminal; and generating production process and cost accounting information according to the start information, the completion information and the processing batch quantity of each processing procedure. Therefore, the production management controlled by the bar codes on the process flow card is realized; the production process is managed and controlled effectively; the on-time delivery rate of orders is improved; quota material reception is realized; and simultaneously, the product quality is ensured.

Owner:ANHUI KING LAN INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com