IMES intelligent manufacturing execution system

An execution system and intelligent manufacturing technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of MRP and DCS two-layer defects in information islands, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

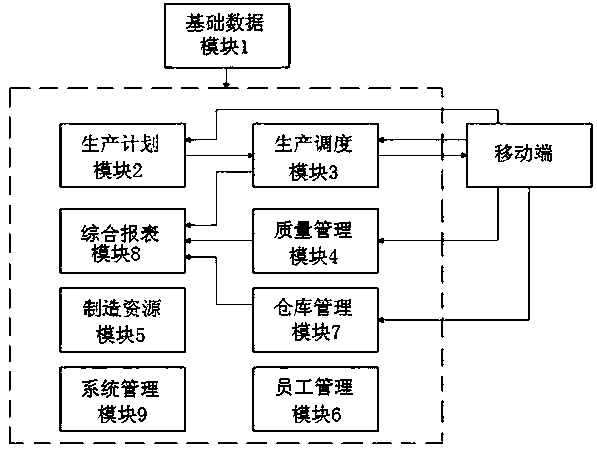

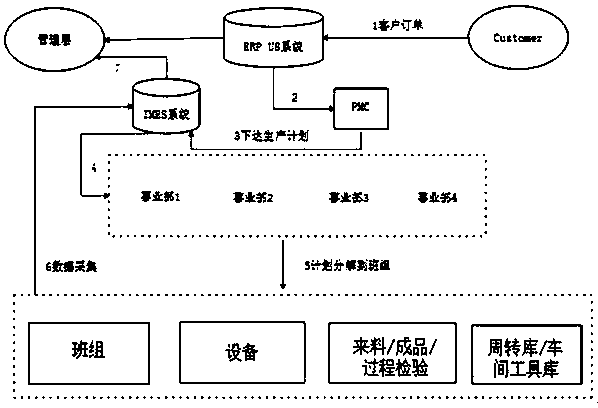

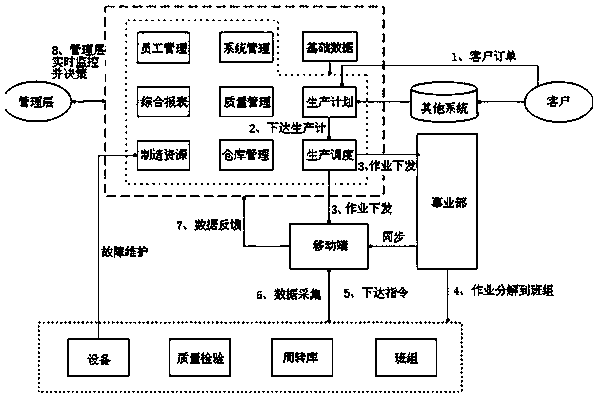

[0023] see Figure 1-Figure 16 , an IMES intelligent manufacturing execution system of the present invention, including a basic data module 1, a production planning module 2, a production scheduling module 3, a quality management module 4, a manufacturing resource management module 5, an employee management module 6, a warehouse management module 7, and a comprehensive report Module 8, system management module 9, can be connected with ERP (Enterprise Resource Planning) and PMC (Production and Material Control). It is also equipped with a mobile terminal system 10 . Each module in the above system constitutes a complete computer program, which runs on a computer network system composed of multiple computer terminals and servers. The composition and flow of the system of the present invention are described in detail as follows.

[0024] Basic data module 1: public data management 11, manufacturing resource management 12, material data management 13, product data management 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com