Patents

Literature

676 results about "Performance control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

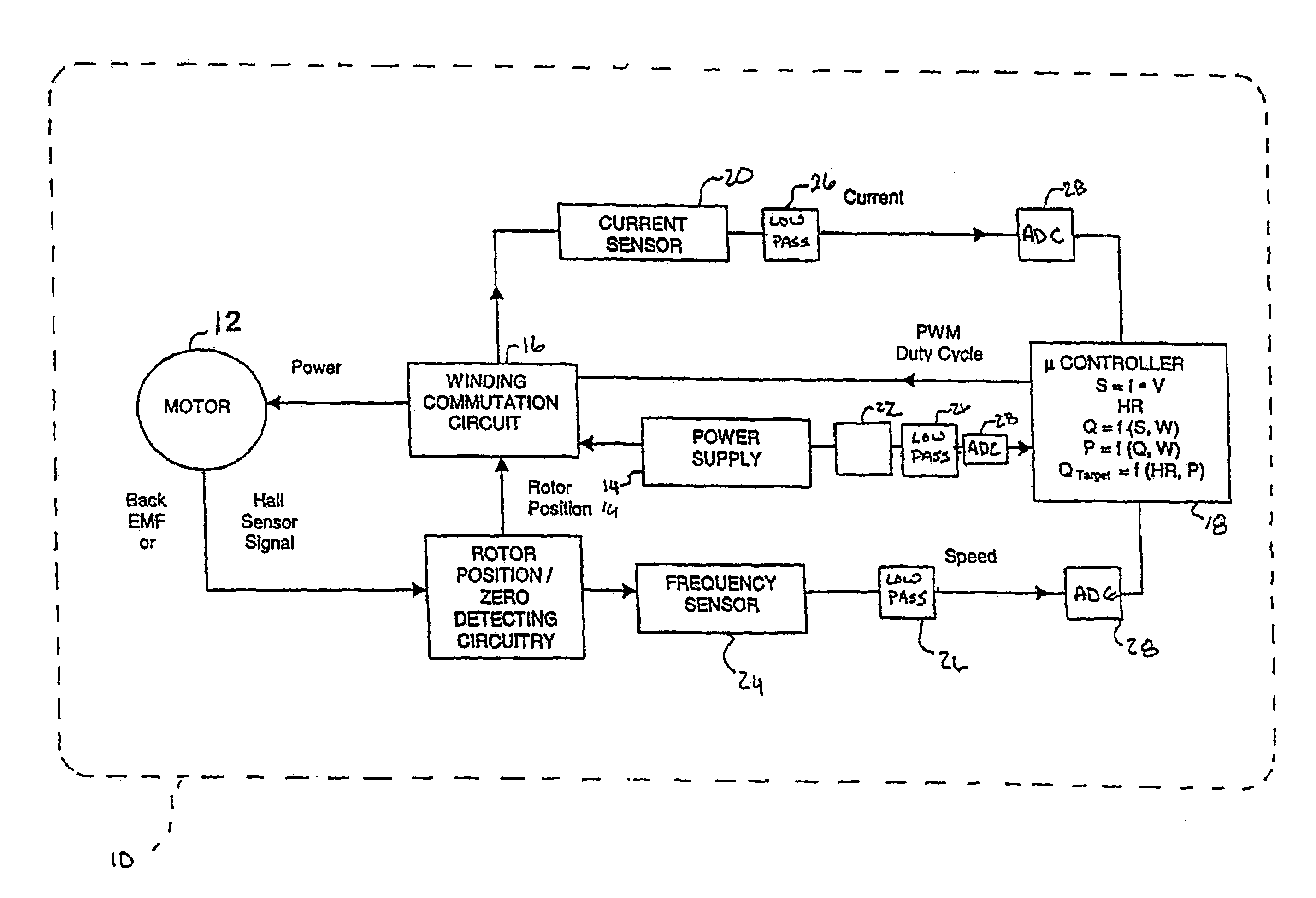

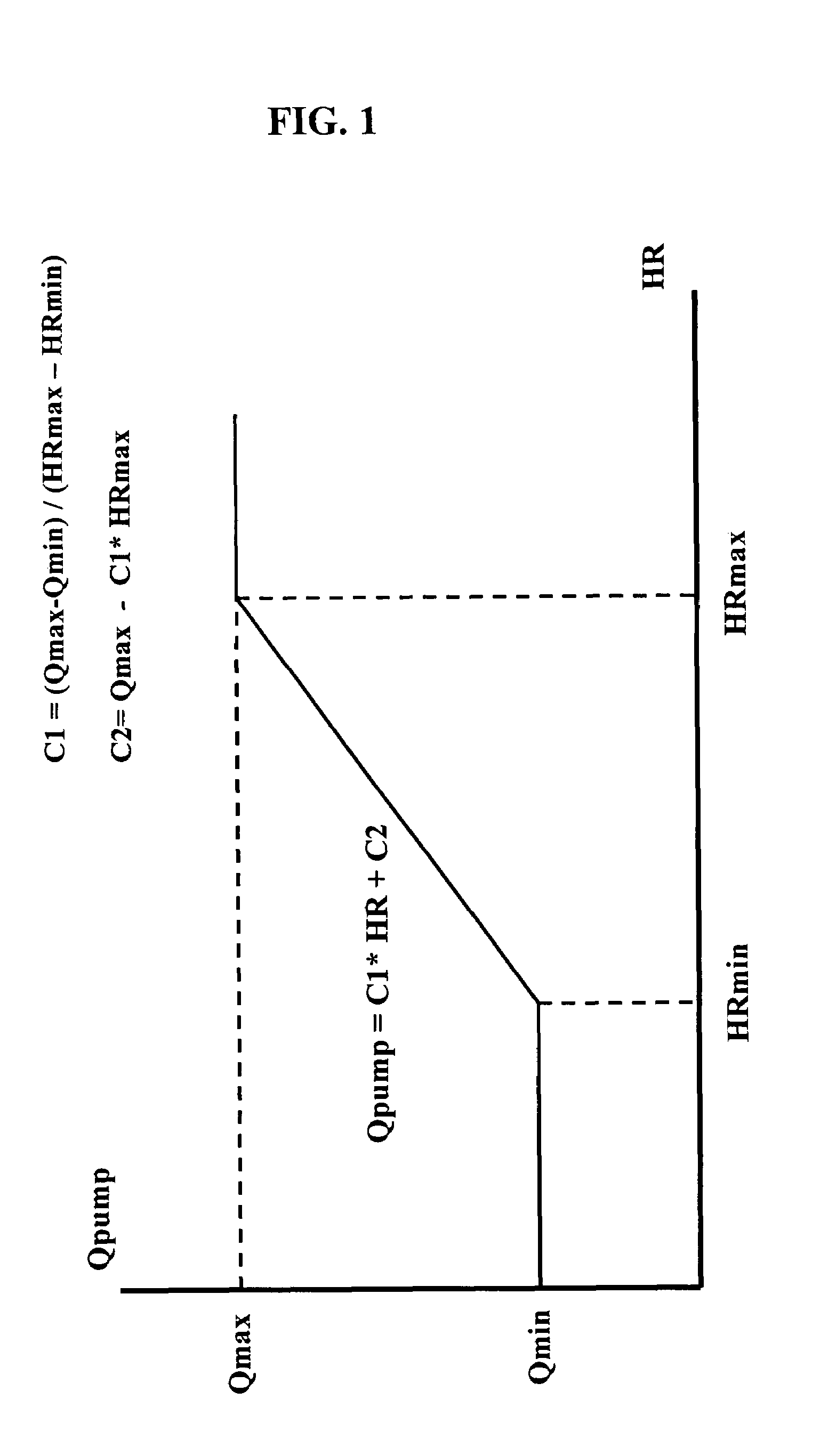

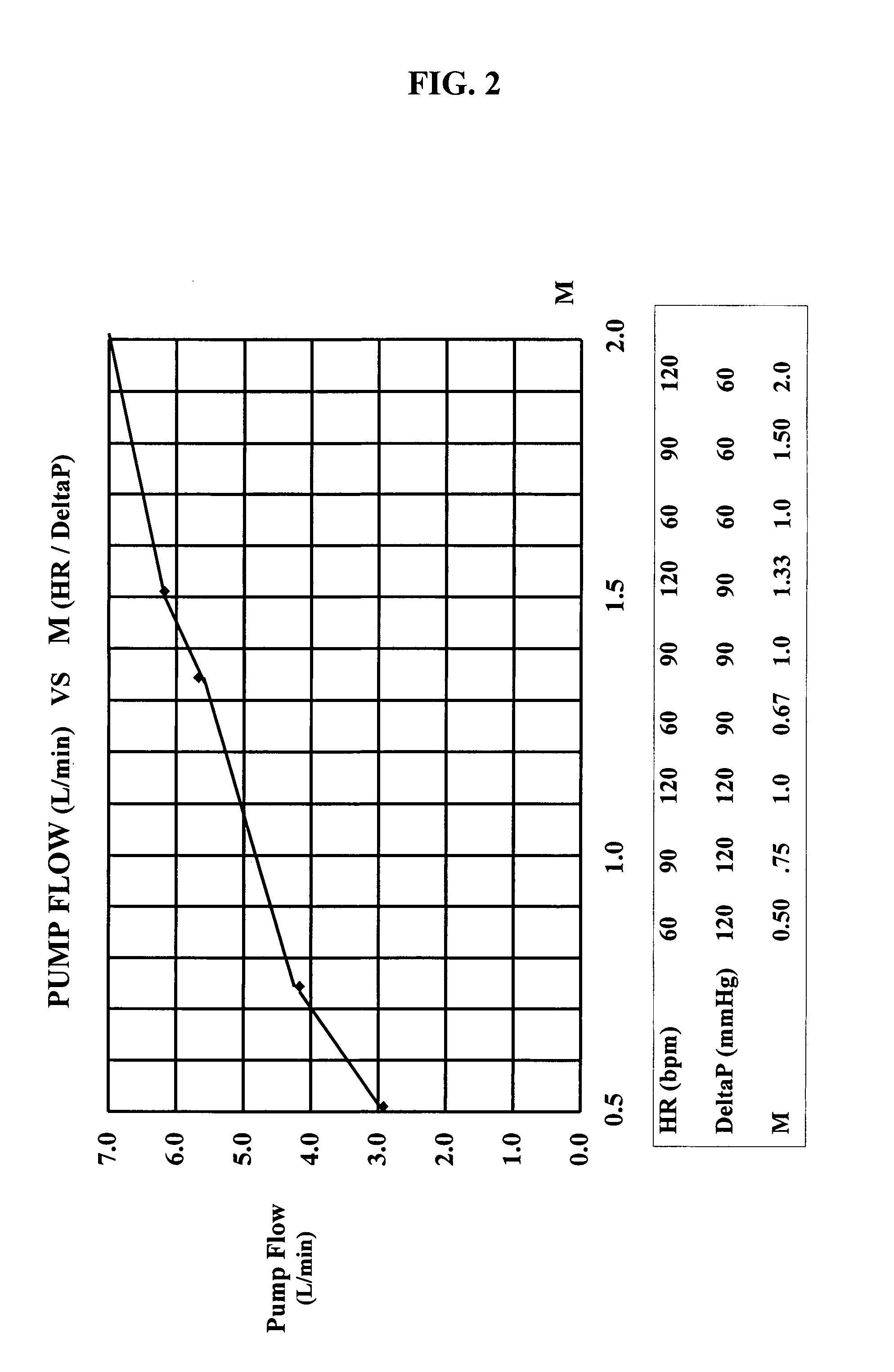

Chronic performance control system for rotodynamic blood pumps

InactiveUS7645225B2Simple control circuitIncrease control flexibilityDC motor speed/torque controlAC motor controlMicrocontrollerMotor speed

In a left ventricular assist device (LVAD) a rotodynamic blood pump (10) is powered by a brushless DC motor (12). A power supply (14) supplies power to the motor (12). Three feedback channels, one for each of voltage, current, and motor speed lead to a microcontroller or microprocessor (18). The three feedback waveforms are analyzed, and from these waveforms, motor input power, patient heart rate, current pump flow rate, and systemic pressure are determined. The microprocessor (18) then calculates a desired flow rate proportional to the patient heart rate. The microprocessor communicates a new power output to a commutation circuit (16), which regulates power to the motor (12). The pump (10) also includes safety checks that are prioritized over desired pump flow. These include prevention of ventricular suction, low pulsatility, minimum and maximum pump speed, minimum speed-relative pump flow, minimum absolute pump flow, minimum and maximum motor input power.

Owner:MEDVEDEV ALEXANDER +2

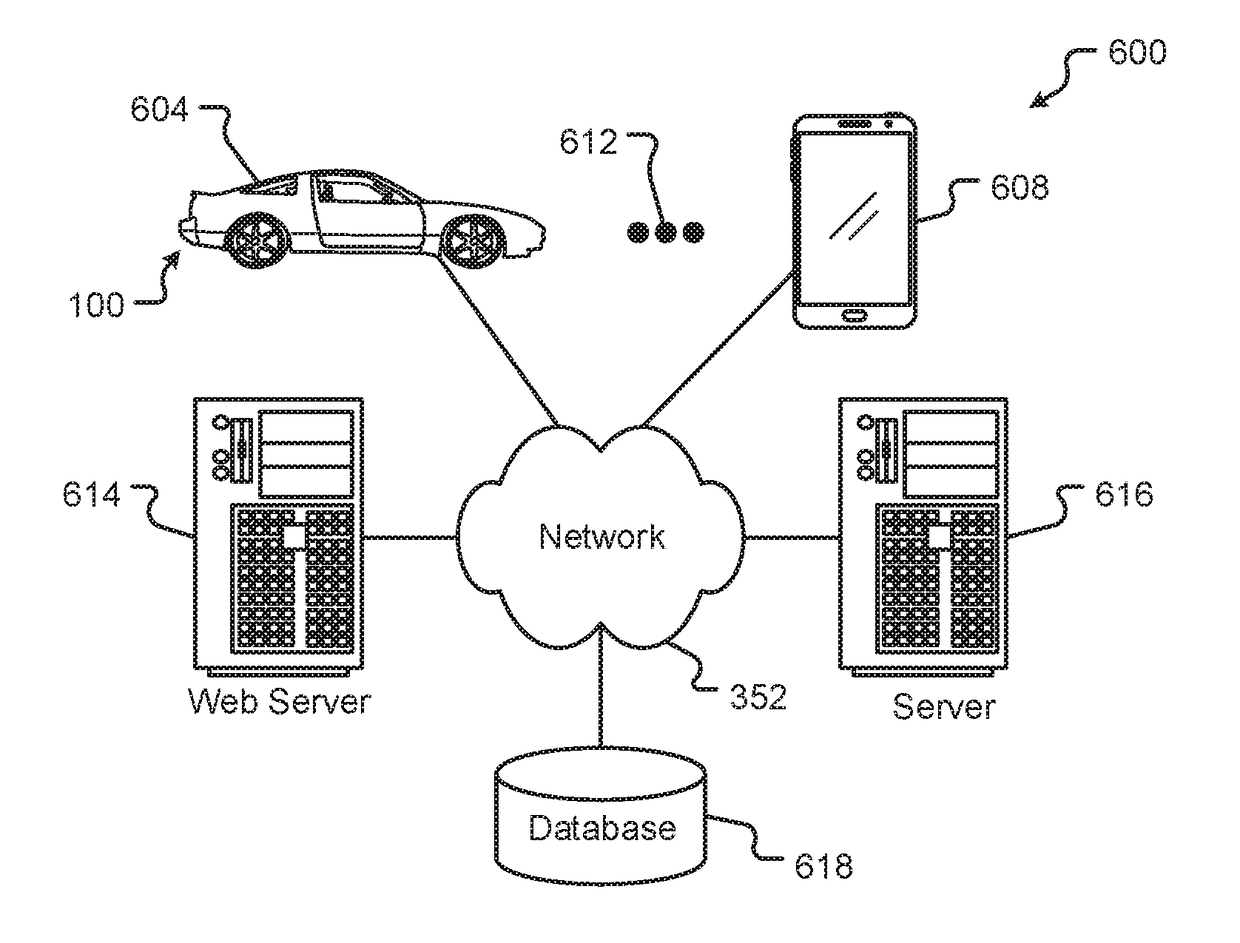

Feedback Performance Control and Tracking

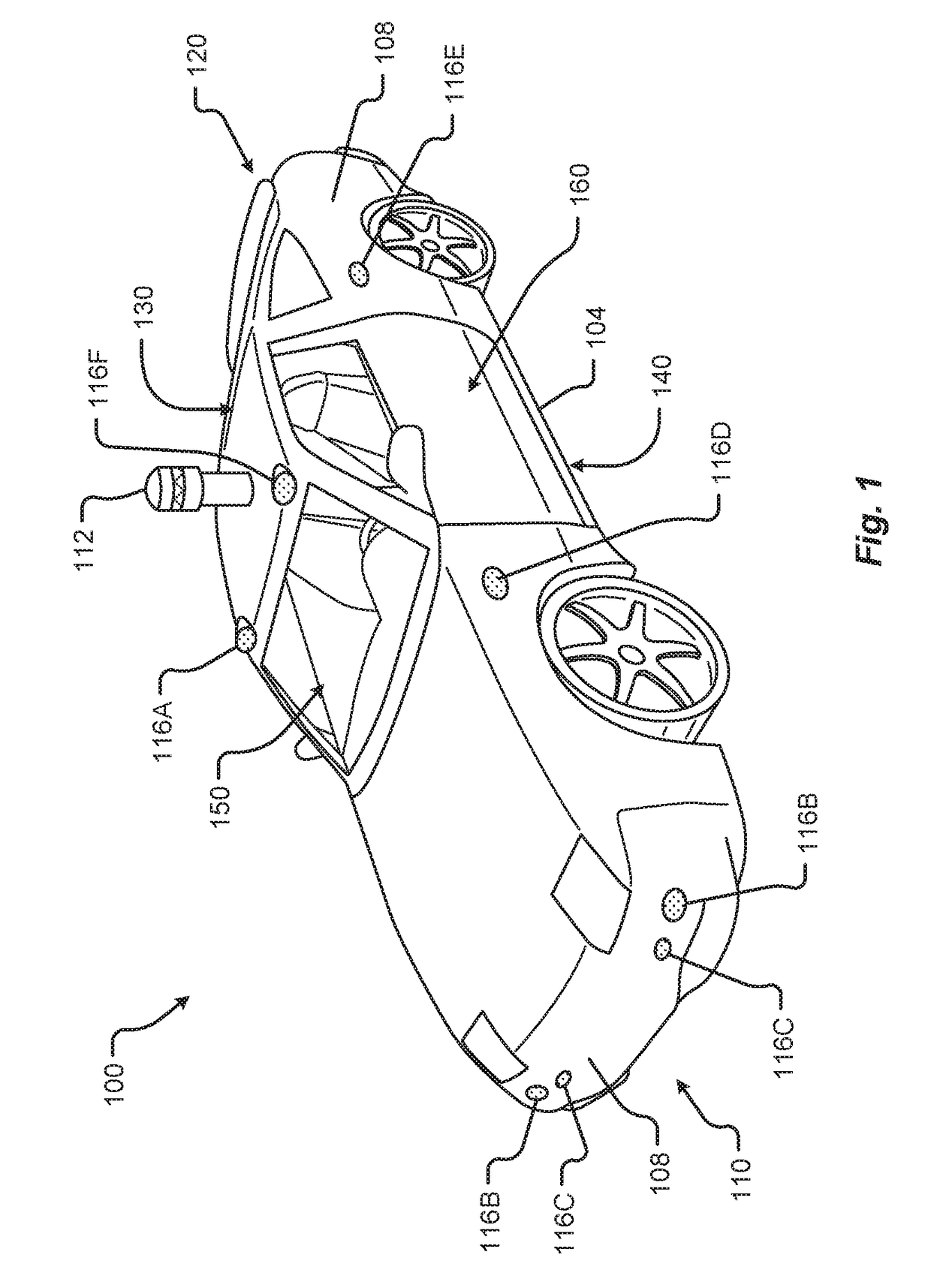

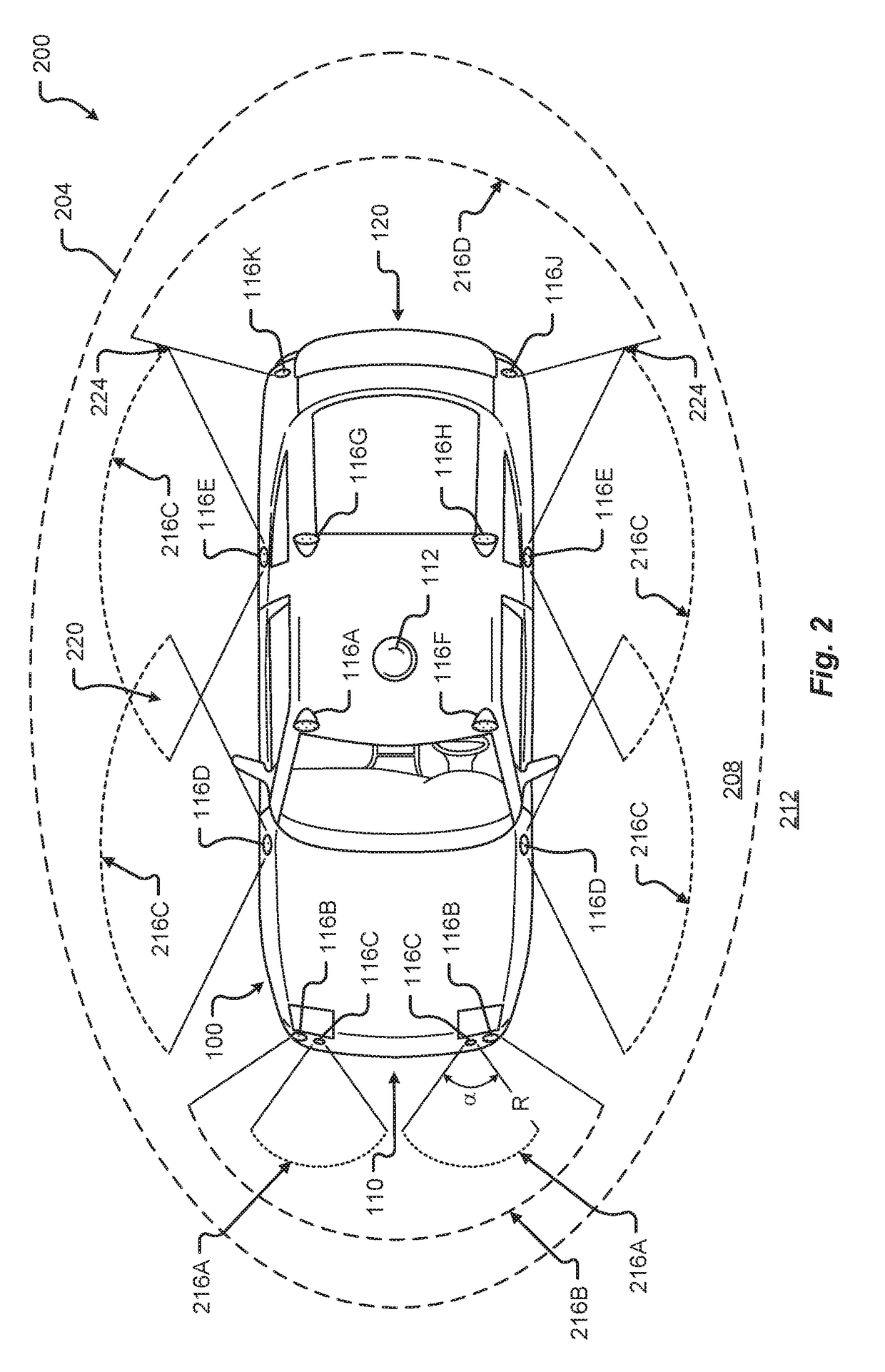

ActiveUS20180127001A1Instruments for road network navigationAutonomous decision making processDriver/operatorEngineering

A method is provided for optimizing the use of autonomous features of advanced driver assistance systems and the tracking thereof. For example, a vehicle may be equipped with several driver assistance systems in which a driver of the vehicle may be assisted. The vehicle may automatically change the number of active assistance systems or suggest to the driver one or more assistance systems to activate based on several factors, including poor driving on behalf of the driver or poor driving conditions due to weather or road quality. Statistics regarding the use of such advanced driver assistance systems may be monitored and tracked and stored on an onboard database or transmitted continuously or periodically to various entities. For example, the system may operate to allow an insurance company to track the driving performance and the use of the advanced driver assistance systems to update actuarial models to more accurately adjust rates.

Owner:NIO TECH ANHUI CO LTD

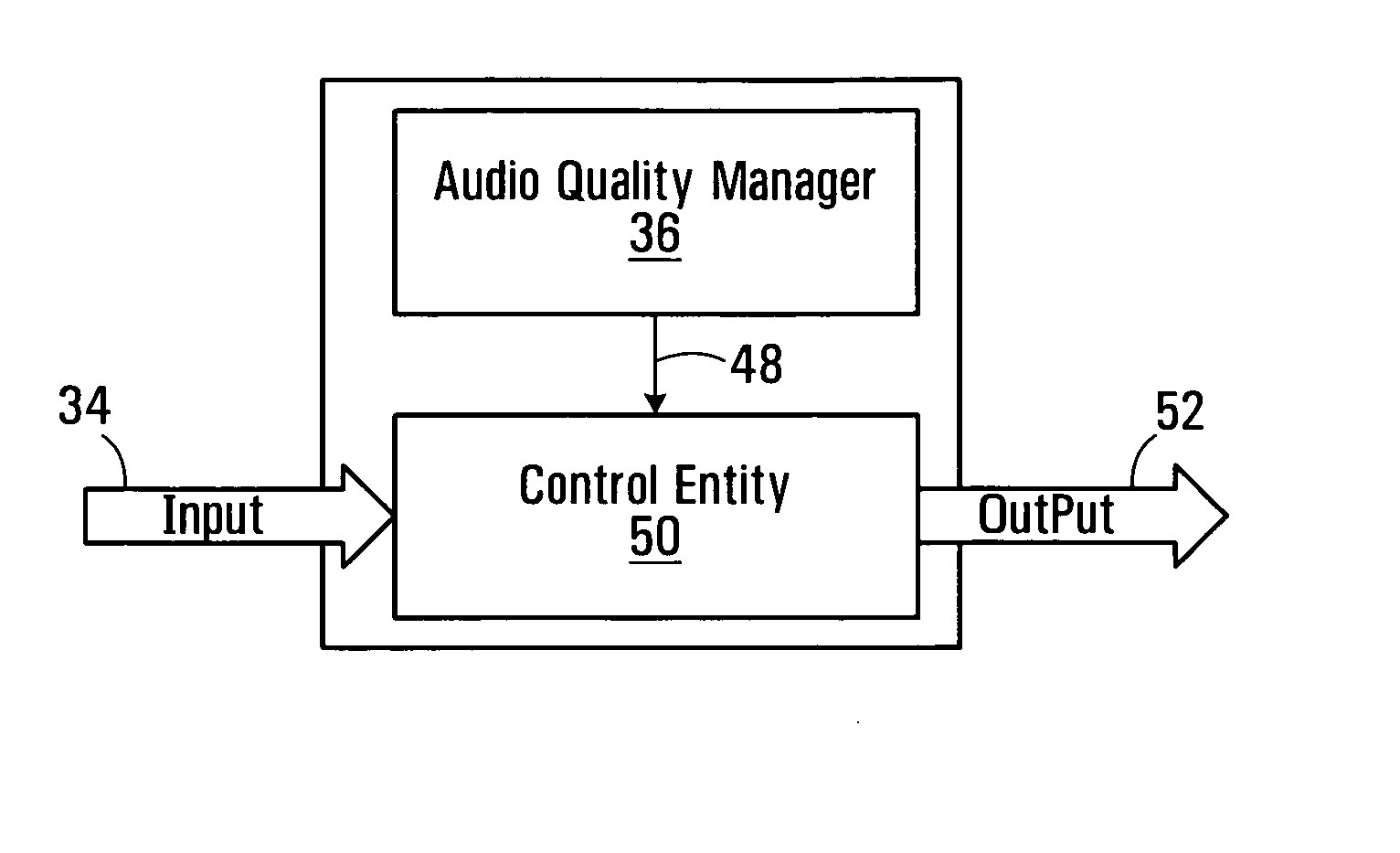

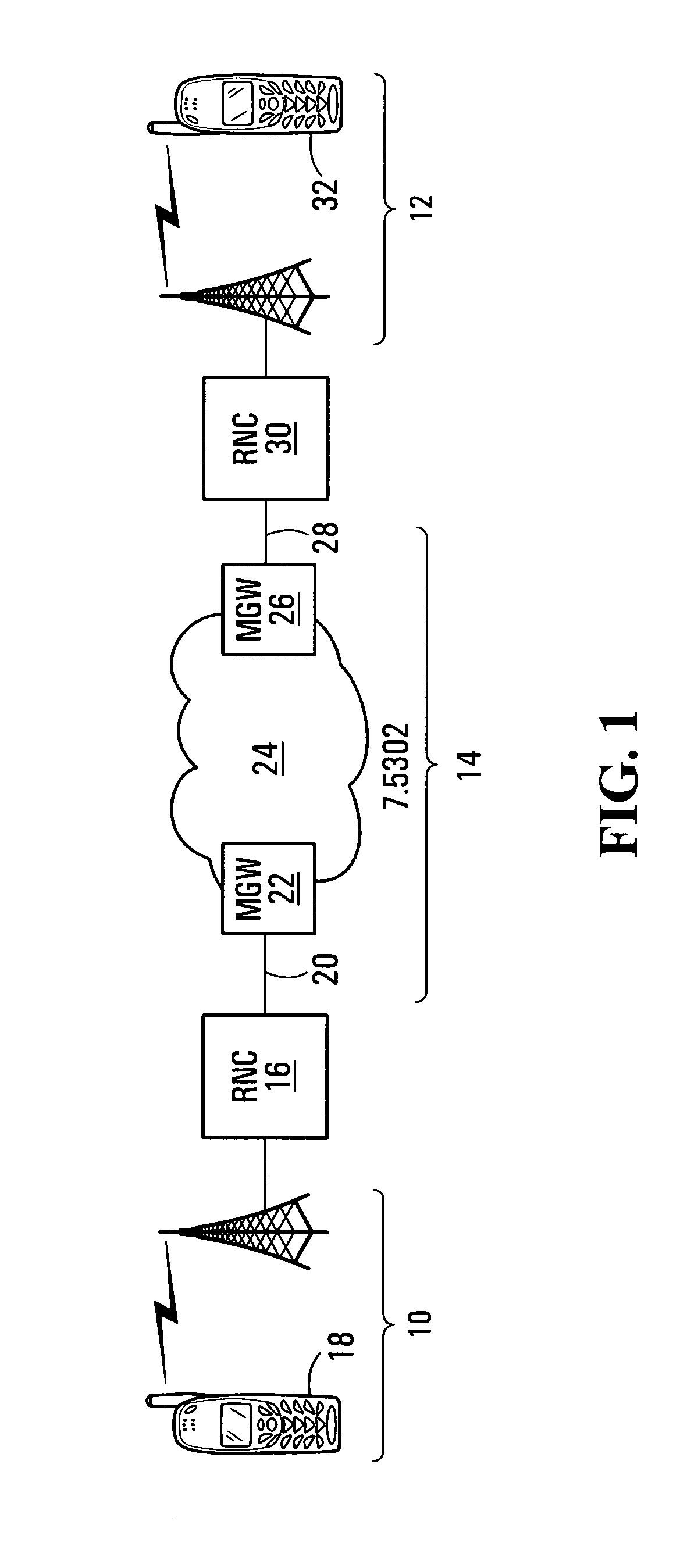

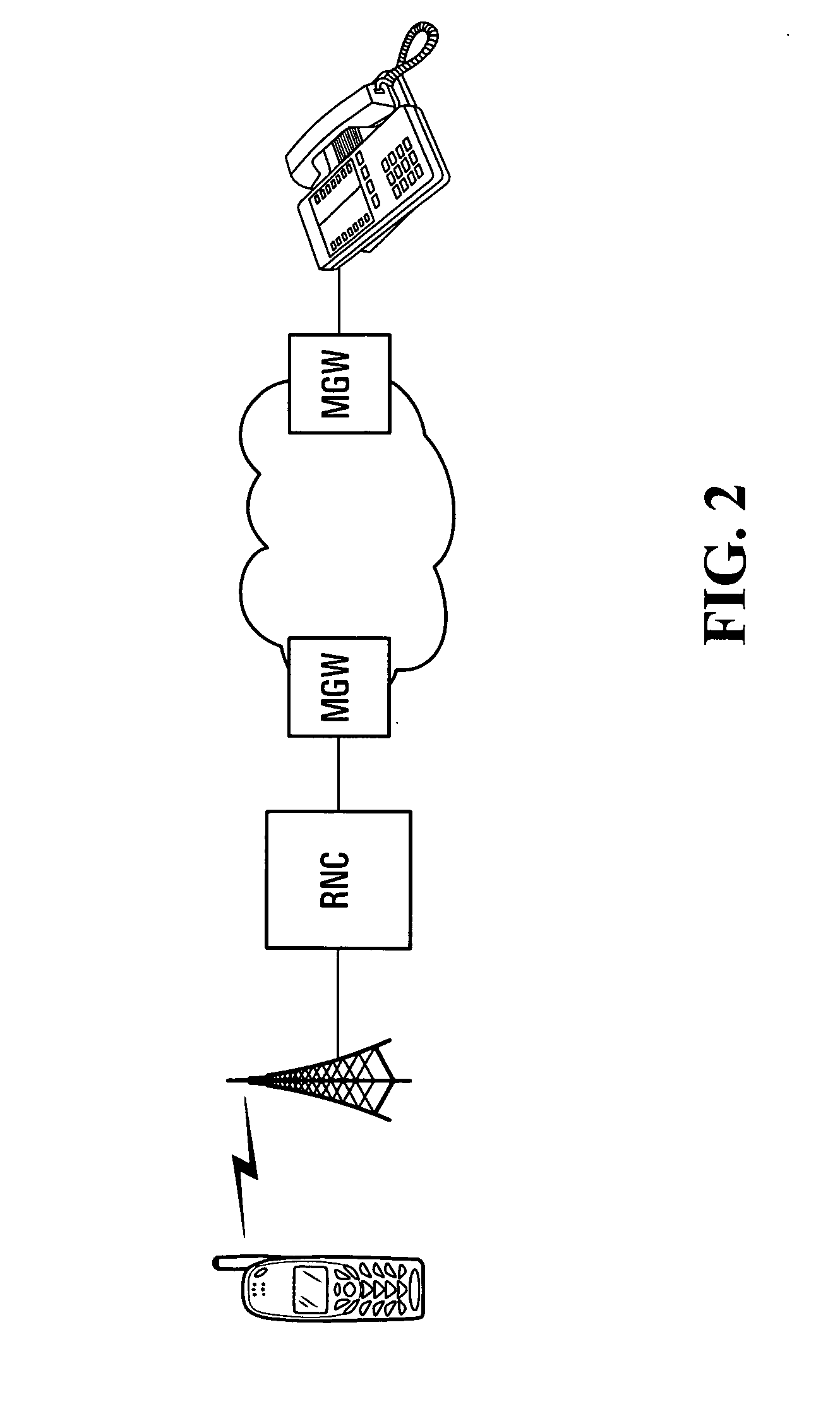

Method and communication network components for managing media signal quality

ActiveUS20070201485A1Reduce degradationInfluences the audio quality of the callNetwork traffic/resource managementData switching by path configurationSignal qualityAudio signal

A media signal quality manager for controlling one or more parameters of a network node through which passes a media signal. The audio signal quality manager has an input for receiving information conveying a characteristic of the media signal and a processor that generates performance control information in response to the characteristic of the media signal. The performance control information can be conveyed to the network node for allowing the network node to adjust at least one parameter of the media signal that can influence the quality of the media signal as perceived by a user.

Owner:GENBAND US LLC

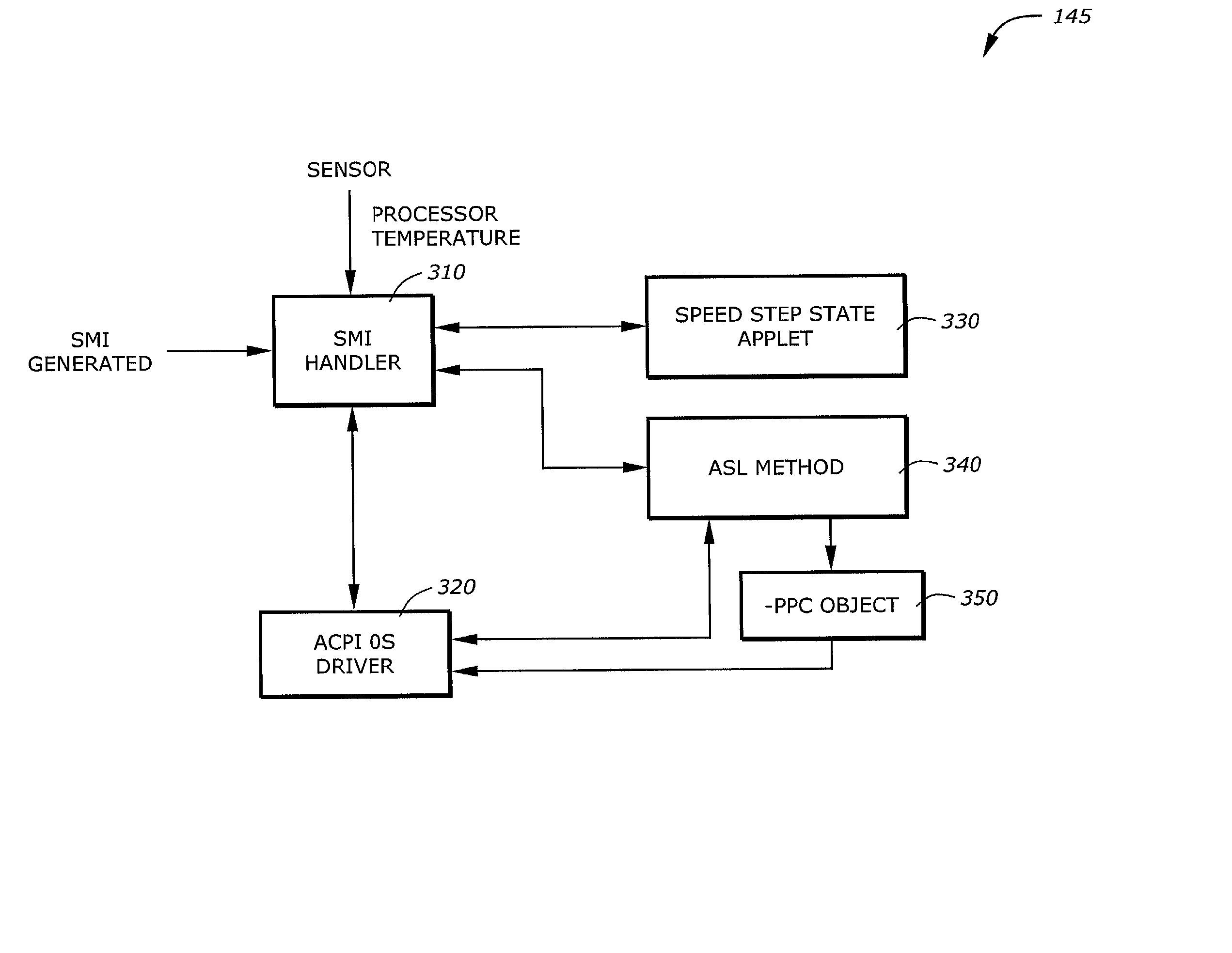

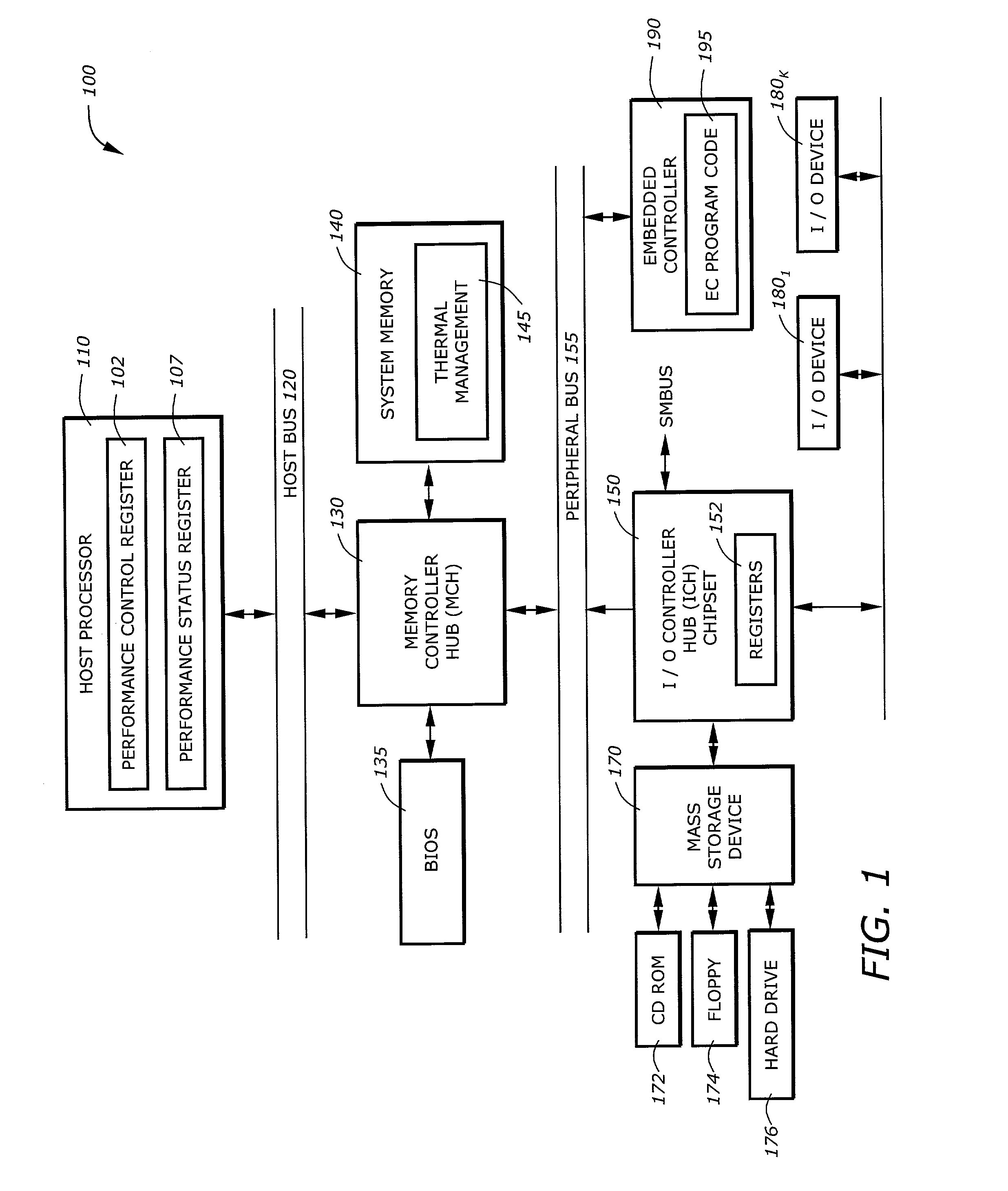

Universal thermal management by interacting with speed step technology applet and operating system having native performance control

InactiveUS20030117759A1Energy efficient ICTVolume/mass flow measurementThermal stateOperational system

In one embodiment of the invention, a system management interrupt (SMI) handler is invoked in response to an SMI. The SMI handler determines a thermal state of a processor. The SMI handler interacts with one of a speed step technology applet and a thermal driver in a thermal management operating system to transition the processor to one of a low power state and a high power state based on the thermal state according to a native performance control status.

Owner:INTEL CORP

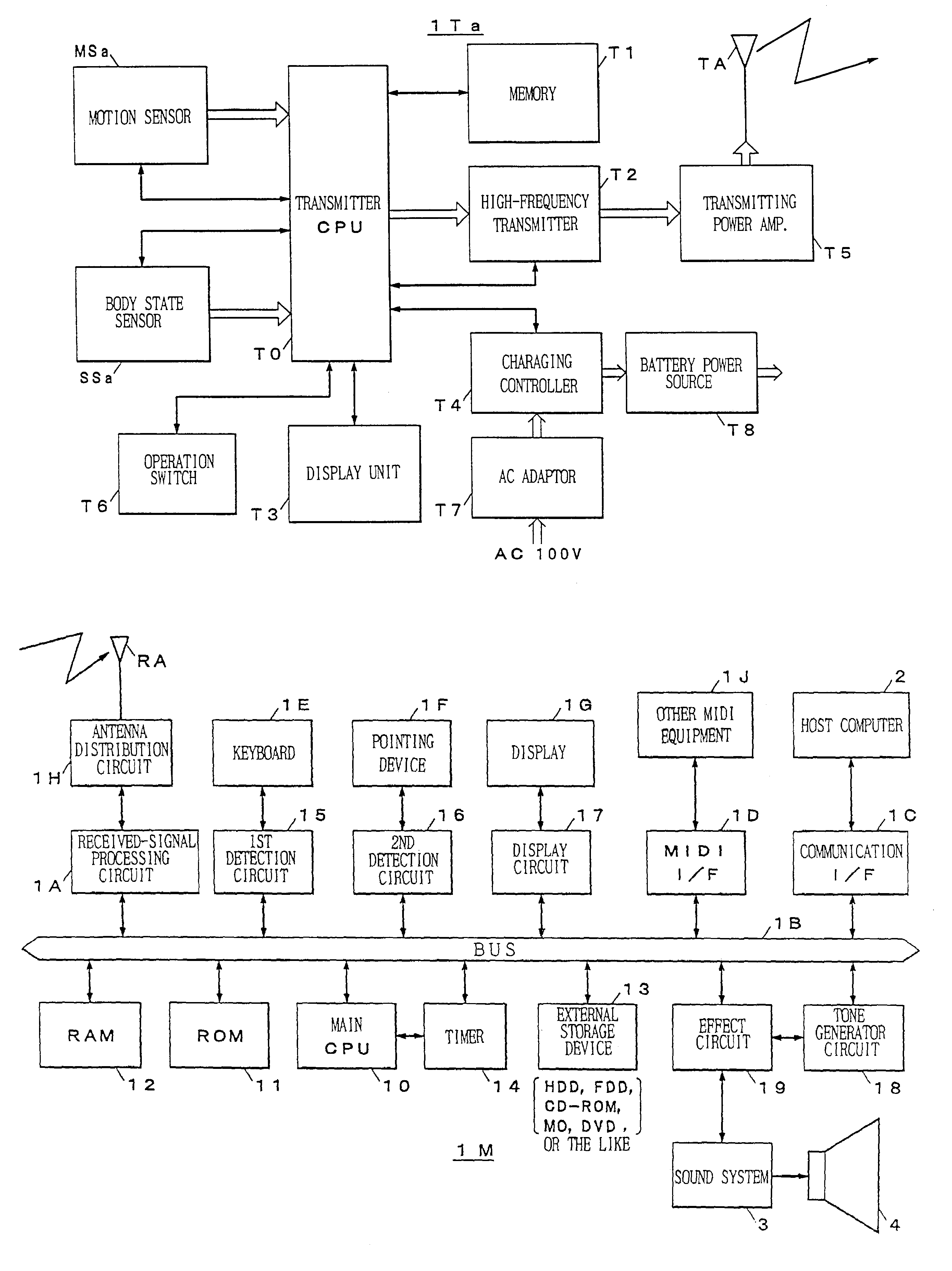

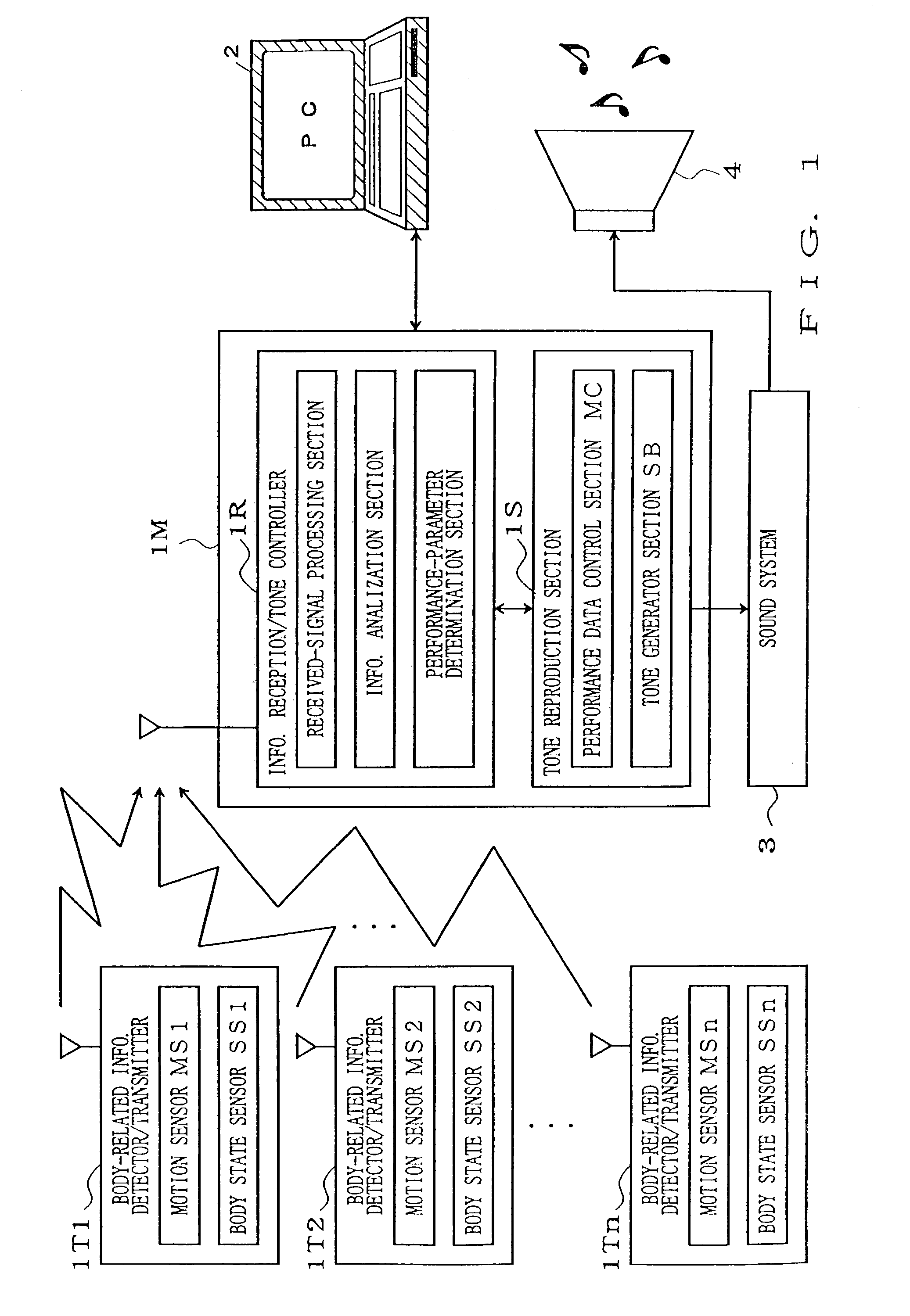

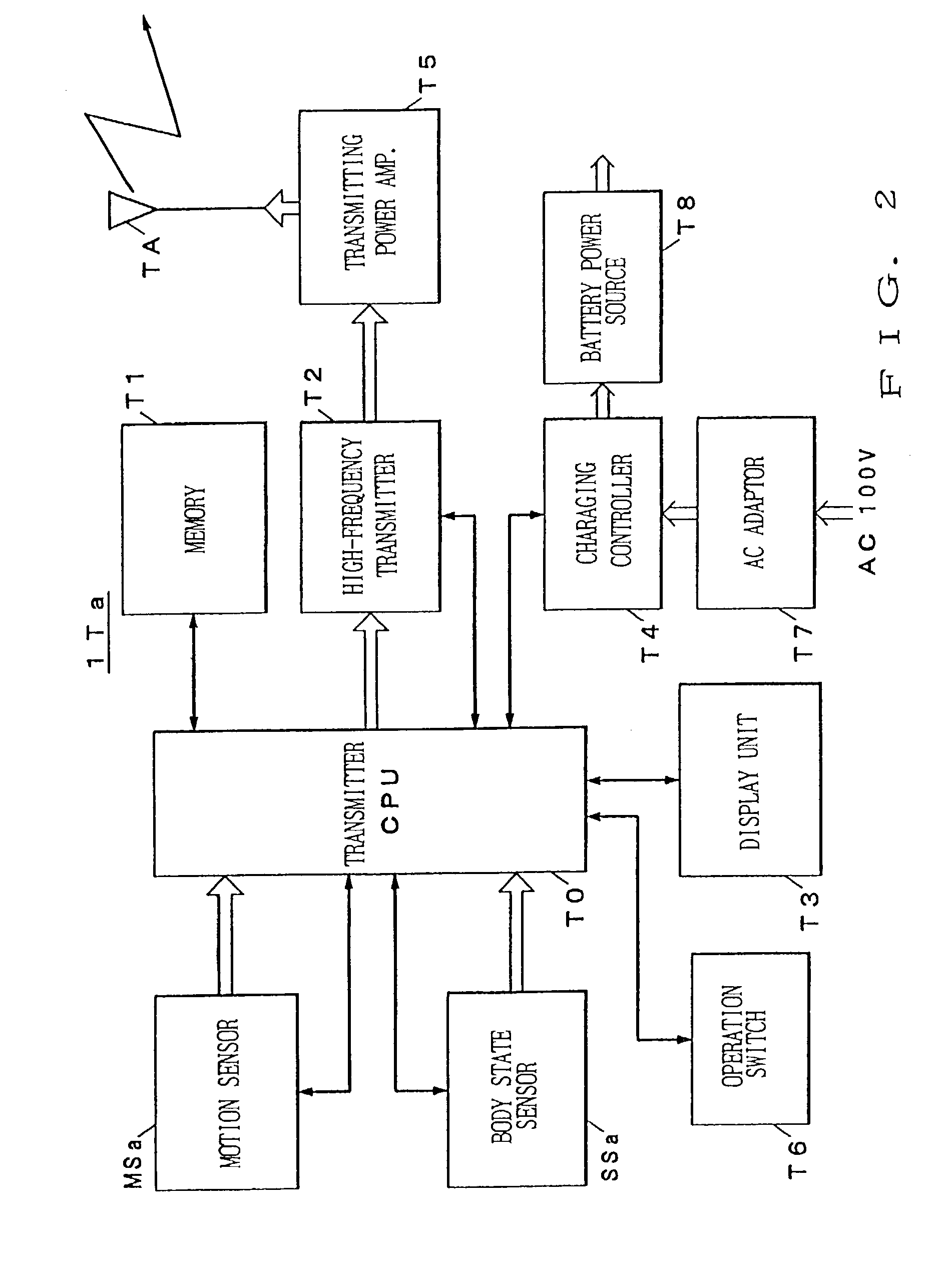

Apparatus and method for detecting performer's motion to interactively control performance of music or the like

Performance interface system includes a motion detector provided for movement with a performer, and a control system for receiving detection data transmitted from the motion detector and controlling a performance of a tone in response to the received detection data. State of a performer's motion is detected via a sensor of the motion detector, and detection data representative of the detected motion state is transmitted to the control system. The control system receives the detection data from the motion detector, analyzes the performer's motion on the basis of the detection data, and then controls a tone performance in accordance with the analyzed data. With this arrangement, the performer can readily take part in the tone performance in the control system. For example, as the performer moves his or her hand, leg or trunk while listening to a manual or automatic performance of a music piece being carried out by a performance apparatus of the control system, the motion detector detects the performer's motion and transmits corresponding detection data to the control system, which in turn variably controls a predetermined one of tonal factors in the music piece performance. This arrangement can readily provide interactive performance control and thereby allows an inexperienced or unskilled performer to take part in a performance with enjoyment.

Owner:YAMAHA CORP

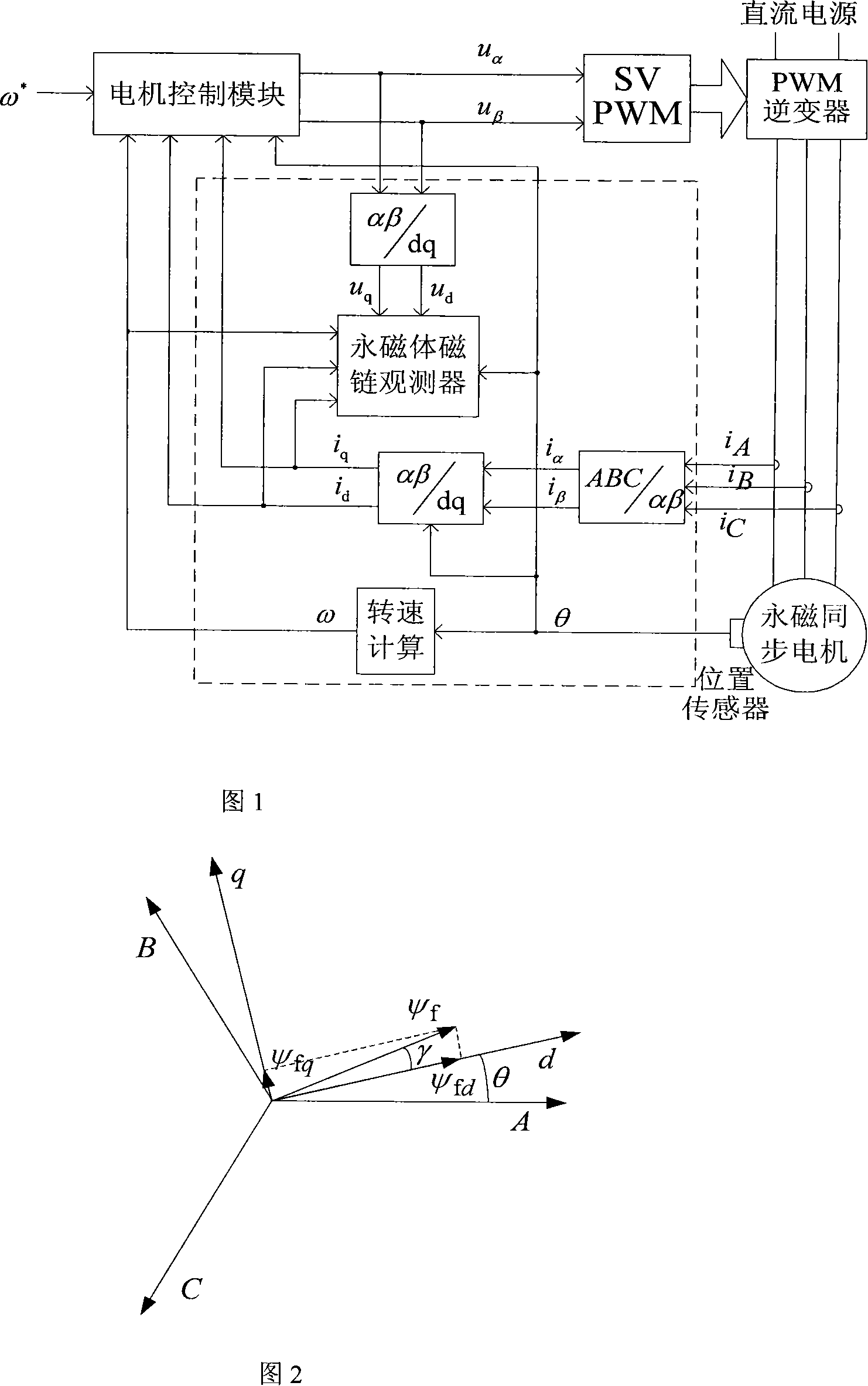

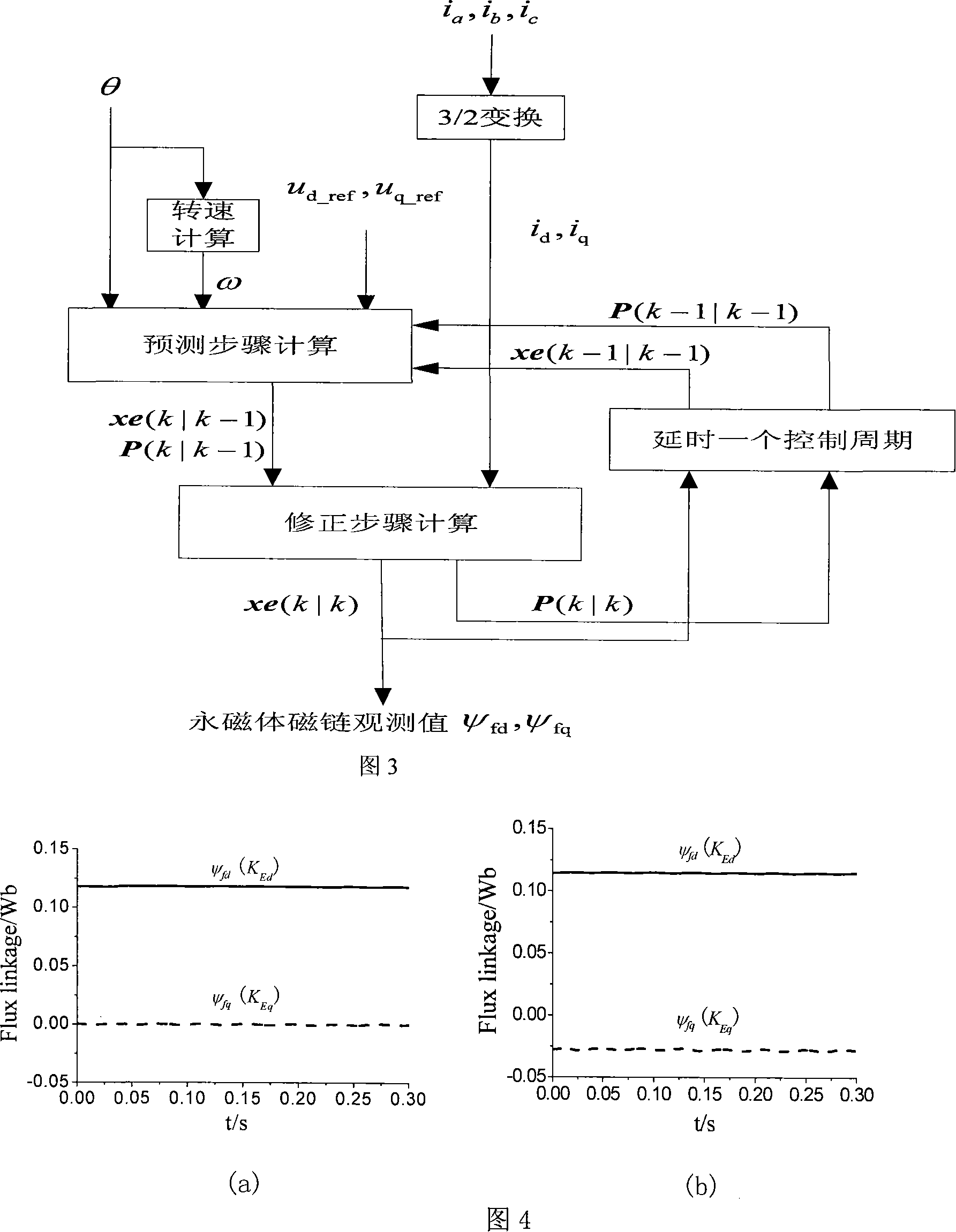

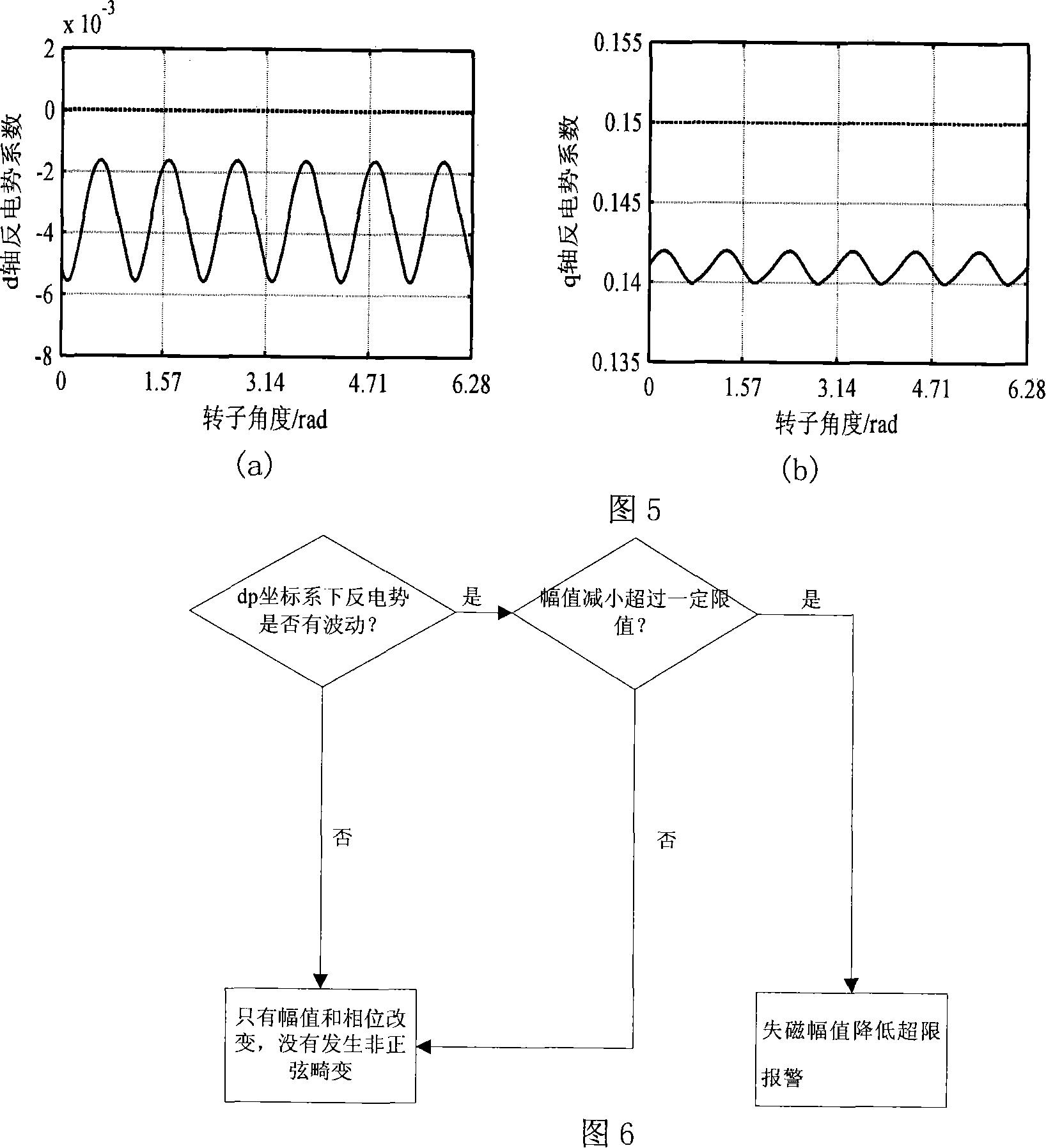

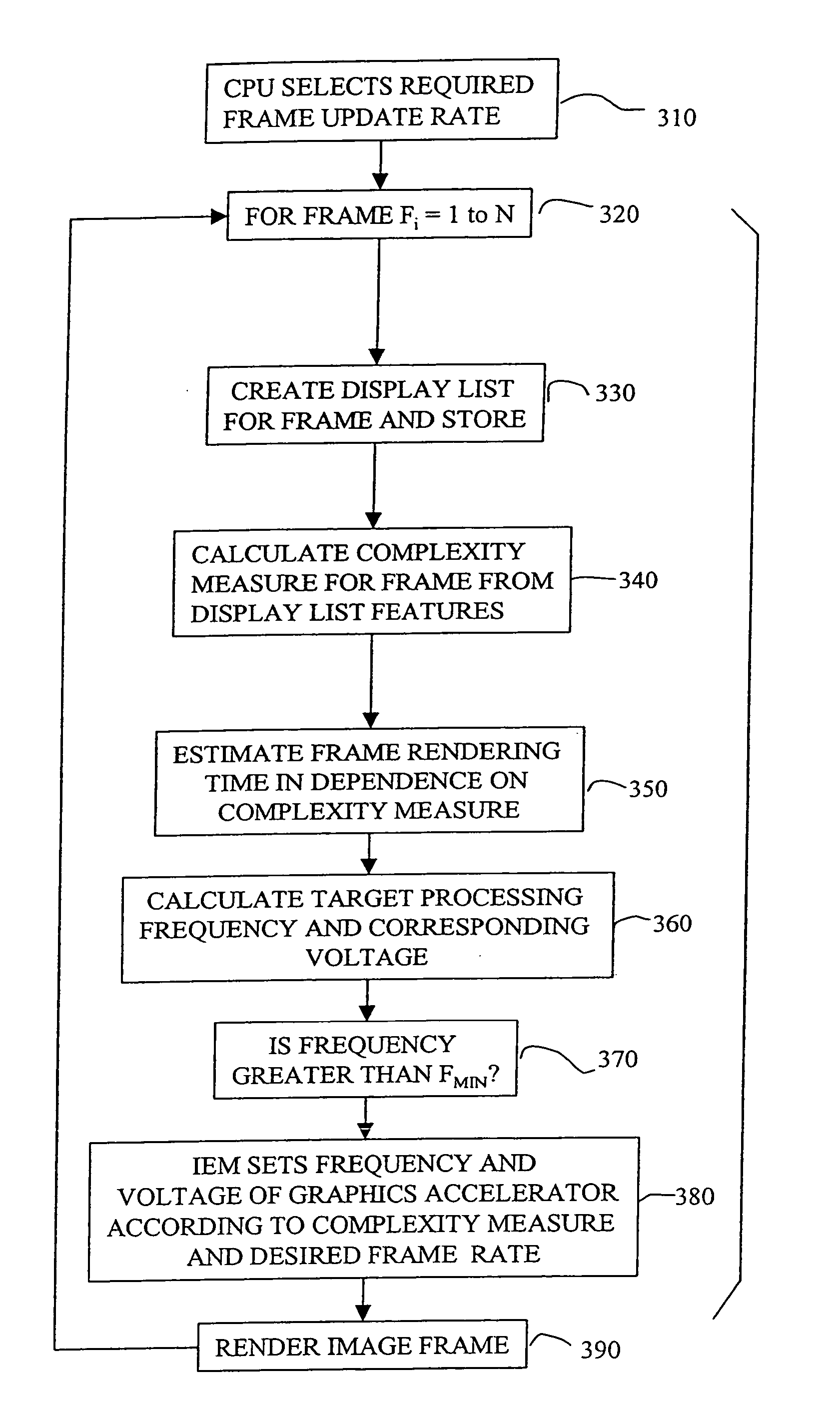

Permanent-magnetism synchronous motor permanent magnetic field aberration real-time detection and analysis method and device

InactiveCN101149423AImprove reliabilityImprove controllabilitySpectral/fourier analysisTorque ripple controlSynchronous motorElectric machine

This invention relates to detecting, analyzing method and devices of permanent magnetic field deformation in permasyn motor. It is in the electric machine control technique field. This method is based on signals which are easy to detect such as voltage, current, electric engine rotate speed, location of the rotor, and so on. To get a real-time observation to the changing state of permasyn motor permanent magnetic field and calculate the back electromotive force coefficient, the permanent magnetic flux linkage on magnetic field synchronous revolution dq coordinate system of permasyn motor. Then the harmonic component in permanent magnetic waveform reflected motor phase winding back electromotive force coefficient by analyzing the back electromotive force. According as those methods, the optimizing control can be applied to forecast and prevent status of excitation losing in permasyn motor. The outcome has already reached can apply to excitation losing online detecting and high performance control of electric engines.

Owner:TSINGHUA UNIV

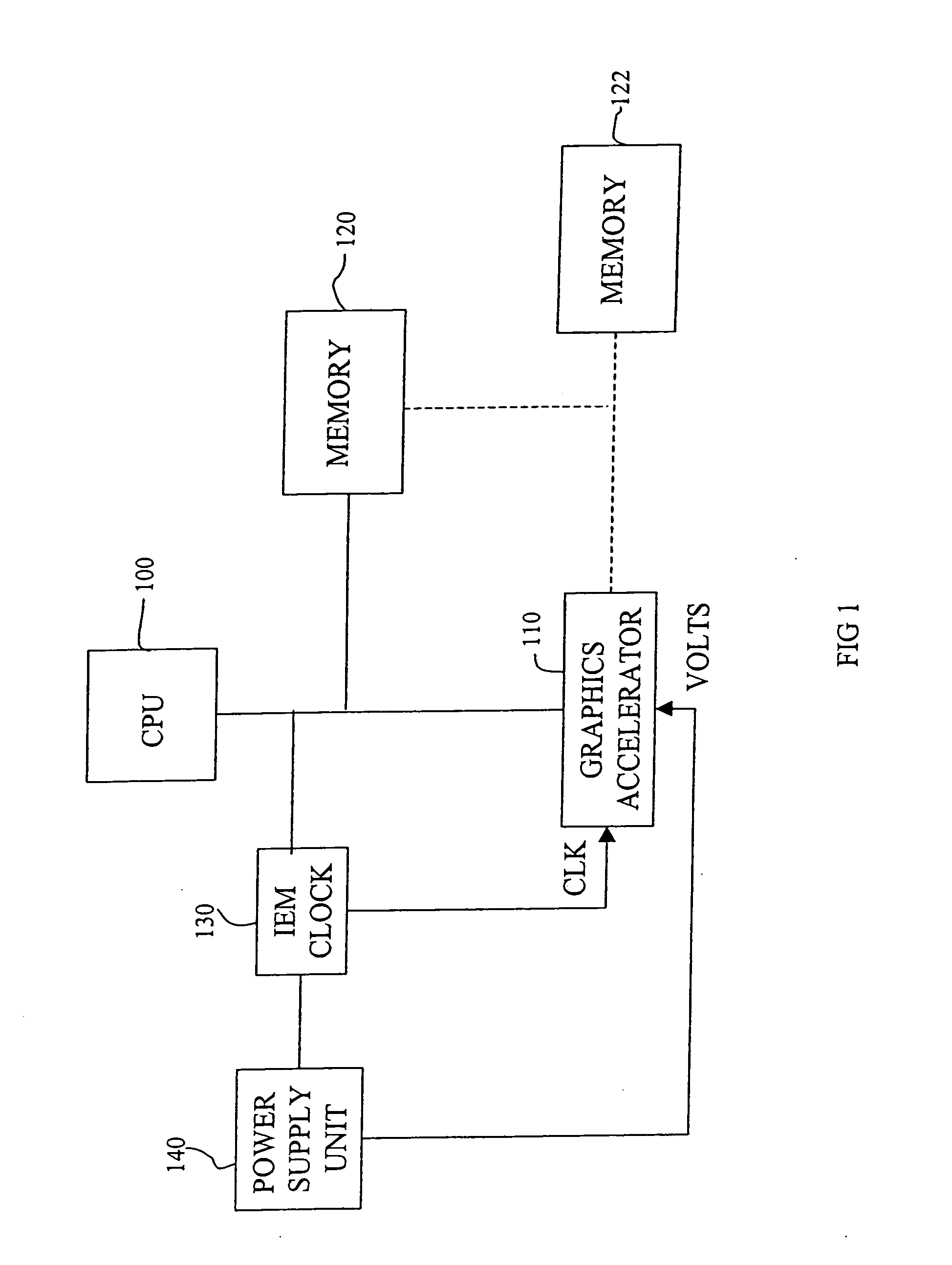

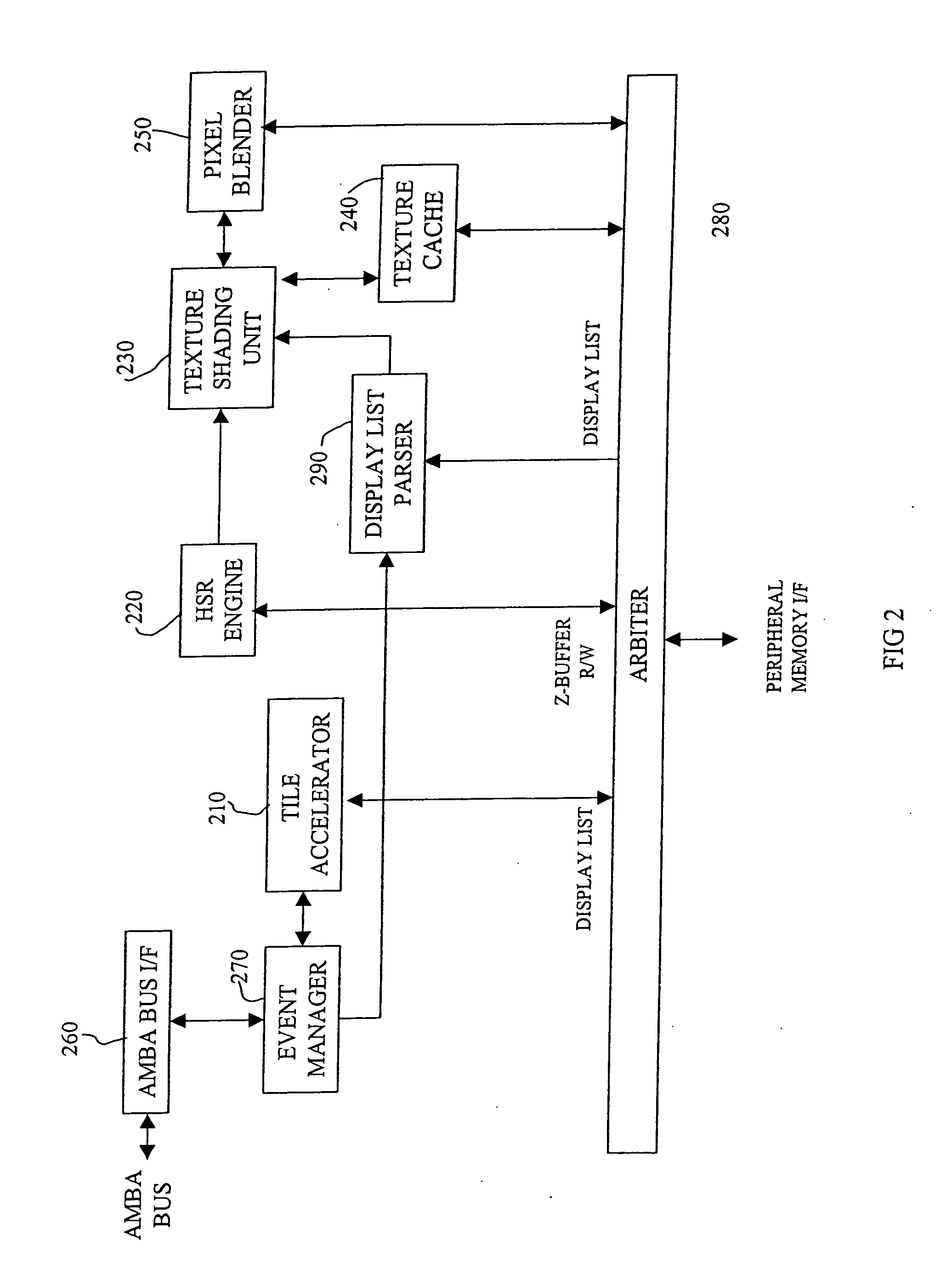

Data processing system

ActiveUS20050057571A1Reliable estimateEasy to predictDigital computer detailsNuclear monitoringData processing systemData stream

A data processing system is provided for setting a value of a performance controlling parameter during processing of a data stream comprising a plurality of data blocks. The performance controlling parameter is set by deriving a complexity measure for at least one data block by performing an initial processing stage on the at least one data block. The performance controlling parameter is set to a predicted value in dependence upon the complexity measure and at least one further processing stage is performed on the at least one data block at the predicted value of the performance controlling parameter.

Owner:ARM LTD

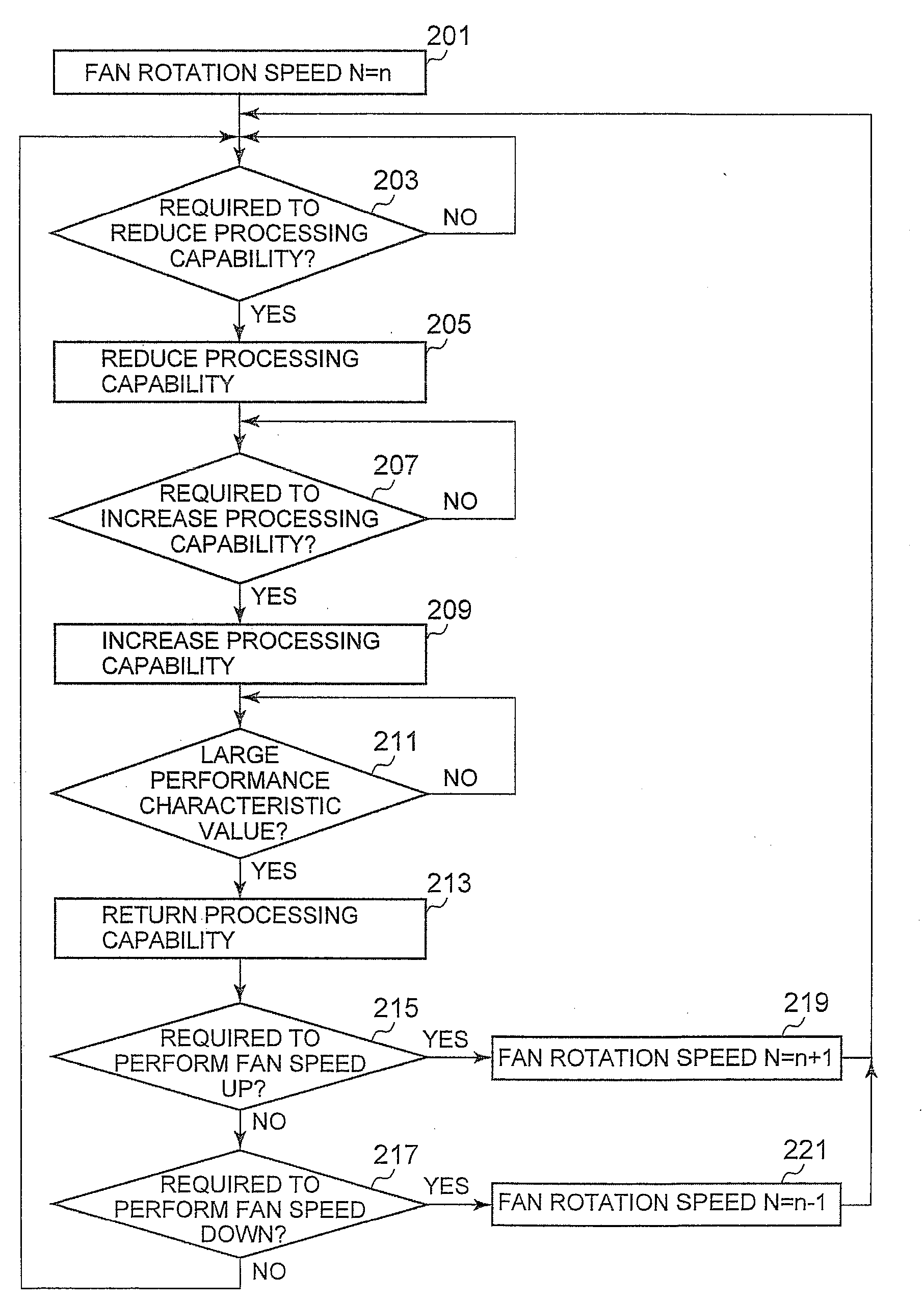

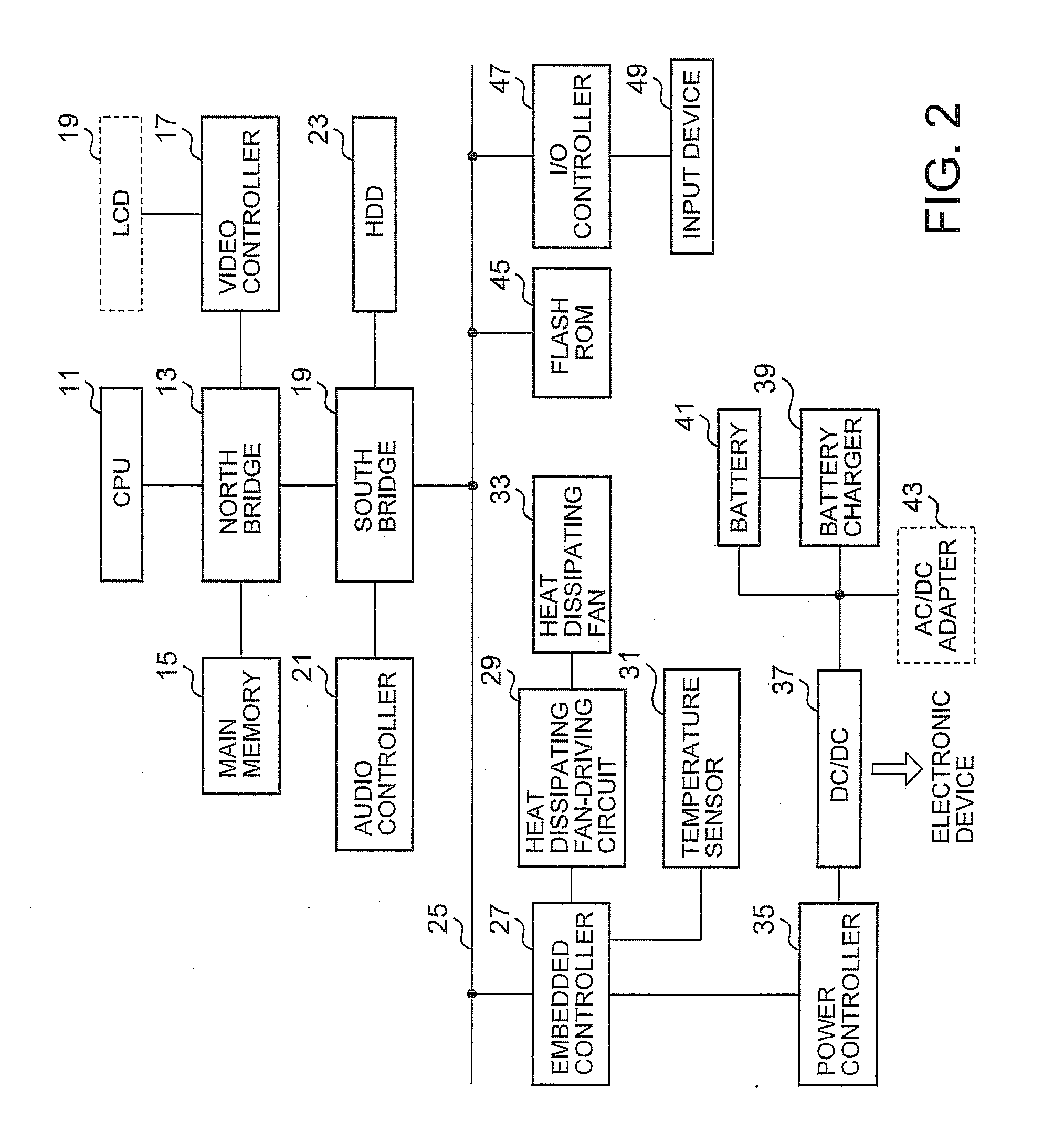

Heat Dissipation System for Computers

ActiveUS20100030395A1Maximizing levelEasy to handleThermometer detailsEnergy efficient ICTEngineeringThreshold temperature

A heat dissipation system within a housing of a computer is disclosed. The heat dissipation system includes a heat dissipating fan, a temperature sensor, a rotation speed setting portion, and a performance control portion. The rotation speed setting portion is configured to change a rotation speed of the heat dissipating fan in a stepwise manner based on a threshold temperature and a measurement temperature measured by the temperature sensor. The performance control portion is configured to temporarily reduce the processing capability of a processor within the computer in response to a determination that the measurement temperature has exceeded the threshold temperature during a predetermined period of time.

Owner:LENOVO PC INT

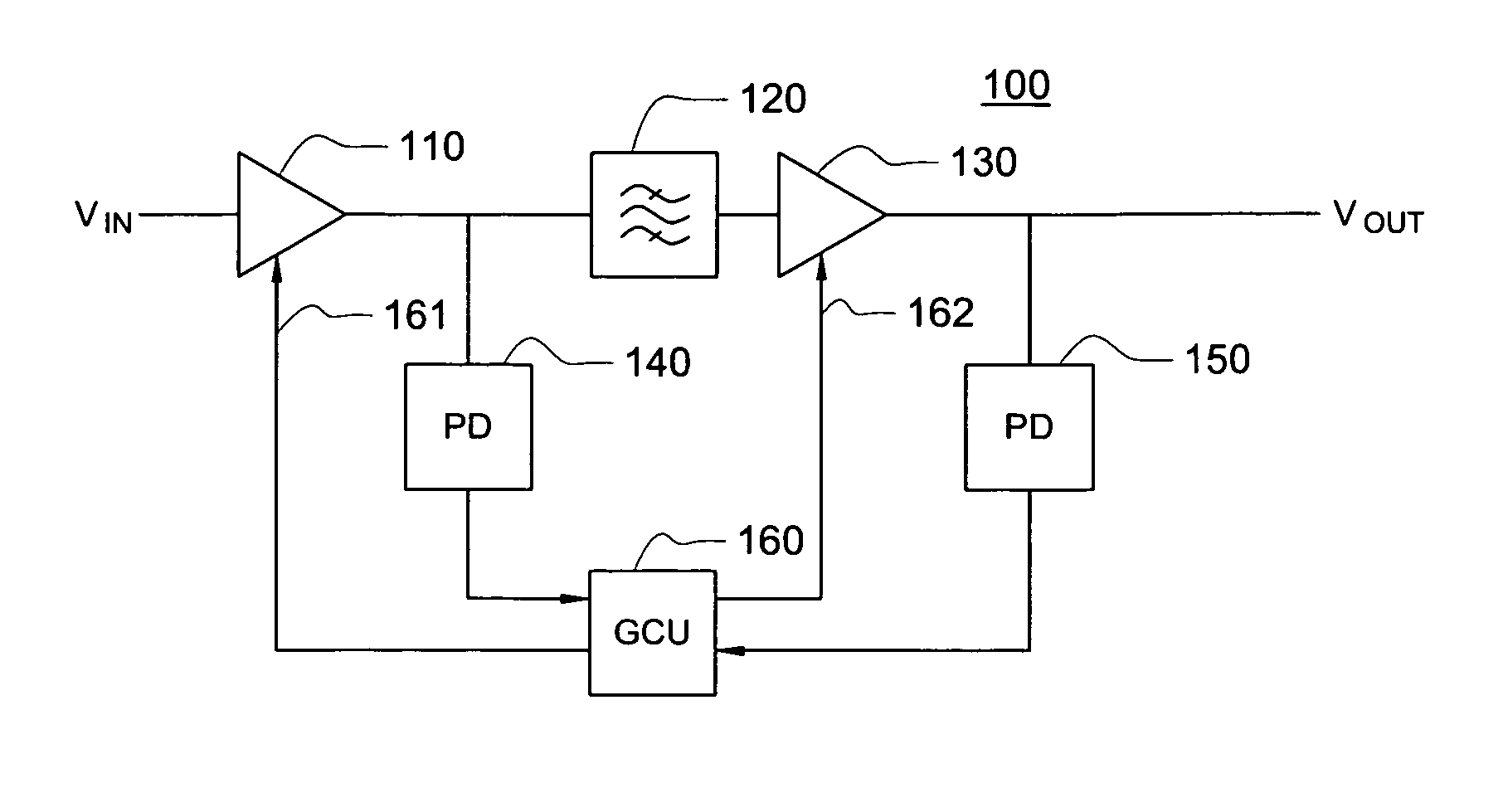

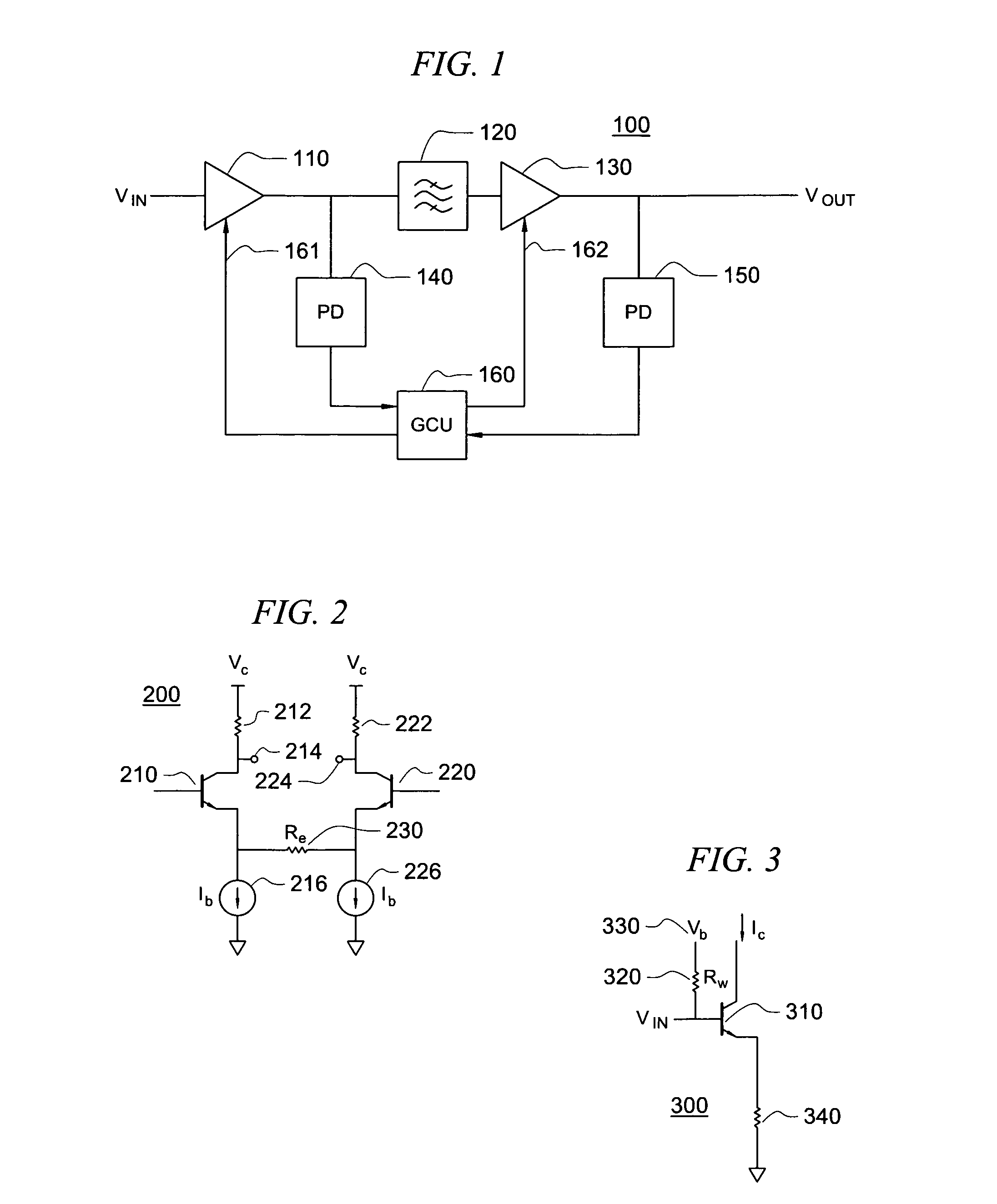

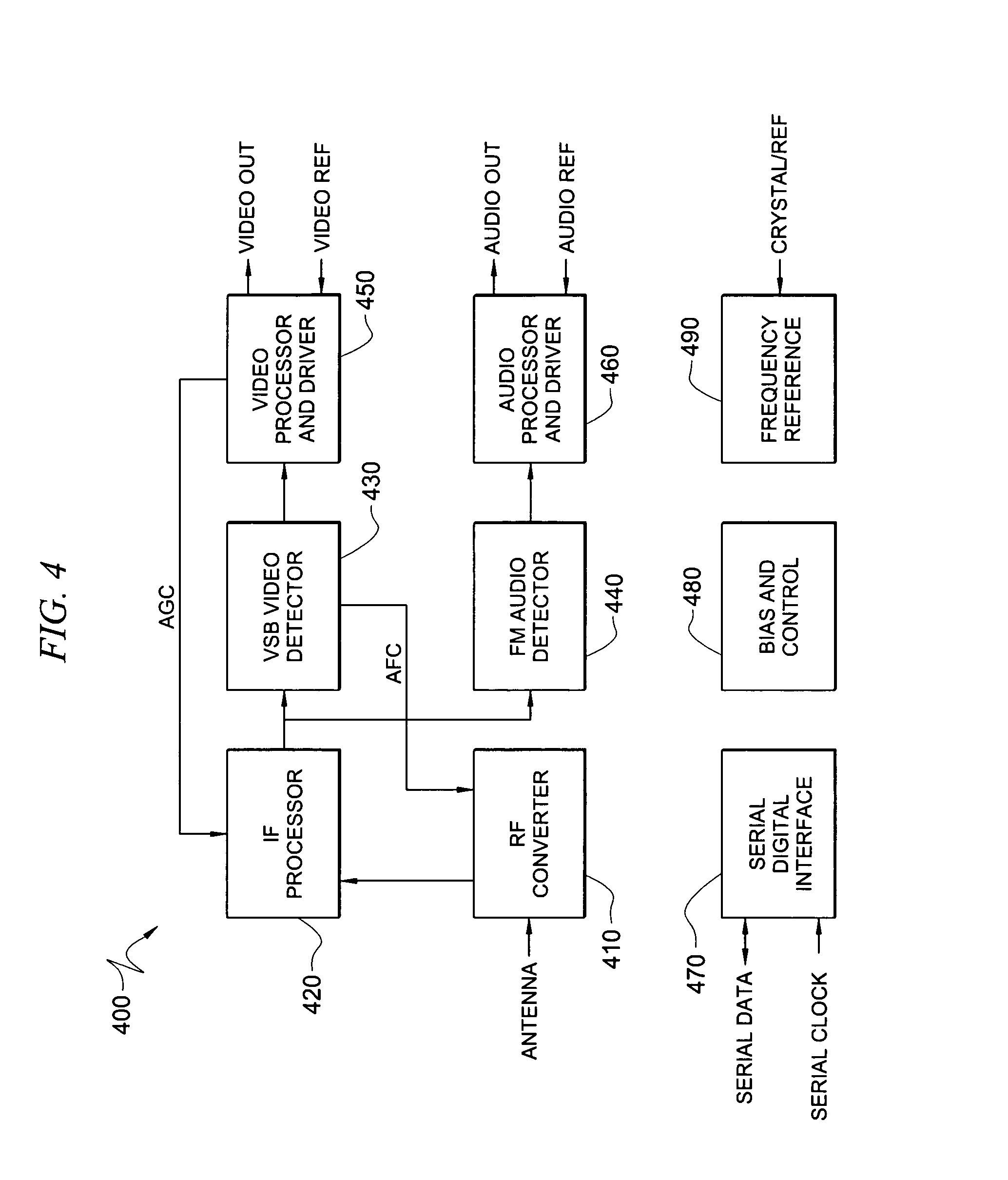

Dynamic performance control of broadband tuner

ActiveUS7783272B2Reduce signalingMinimum level of performanceTelevision system detailsResonant long antennasAudio power amplifierControl signal

A broadband signal amplifier includes one of more broadband amplifier circuits, each dynamically controlled in response to a total power level of signals applied thereto to reduce linearity in response to a reduction of input signal strength. A filter may couple the output of the broadband amplifier circuits to each other to form a tandem arrangement. Power detectors are connected to detect and provide outputs indicative of the total power levels of the signals applied to respective broadband amplifiers. A control unit is connected to and receives the output from the power detectors and, in response, provides a control signals to the broadband amplifier circuit so as to operate each over portions of their operating characteristic curves that provide only that degree of linearity necessary to limit distortion to a predetermined or dynamically adjustable maximum acceptable level.

Owner:CSR TECH INC

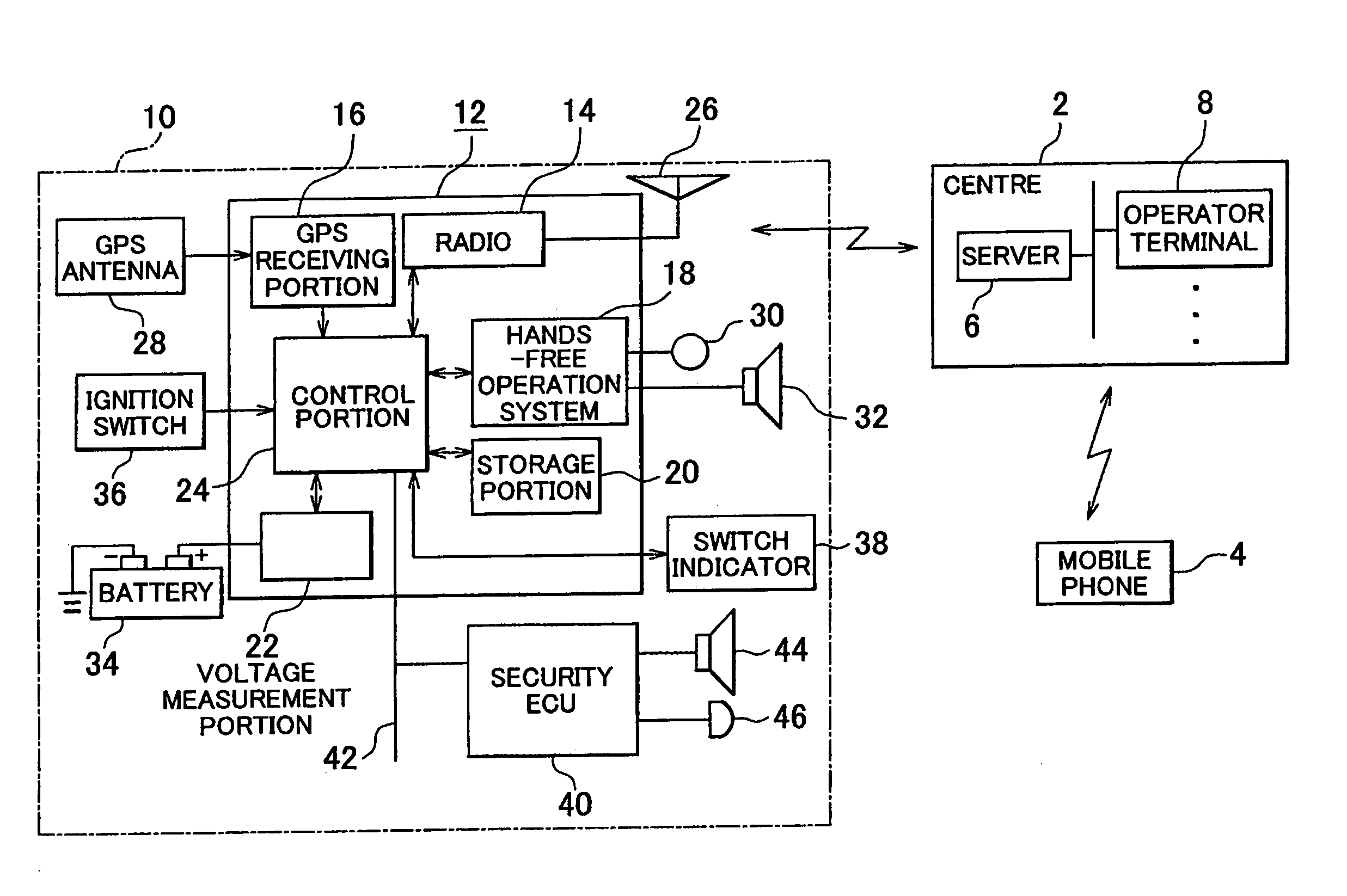

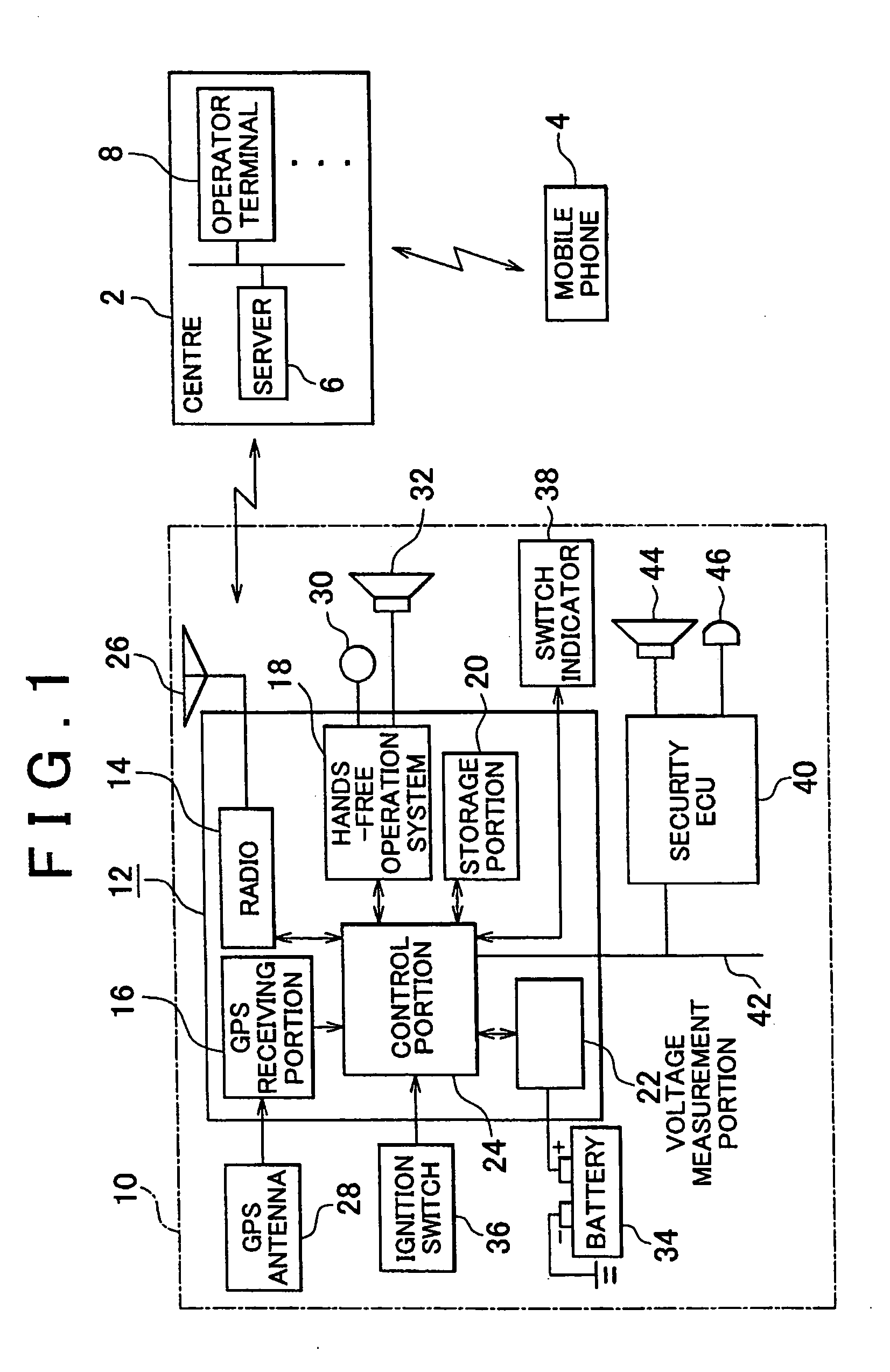

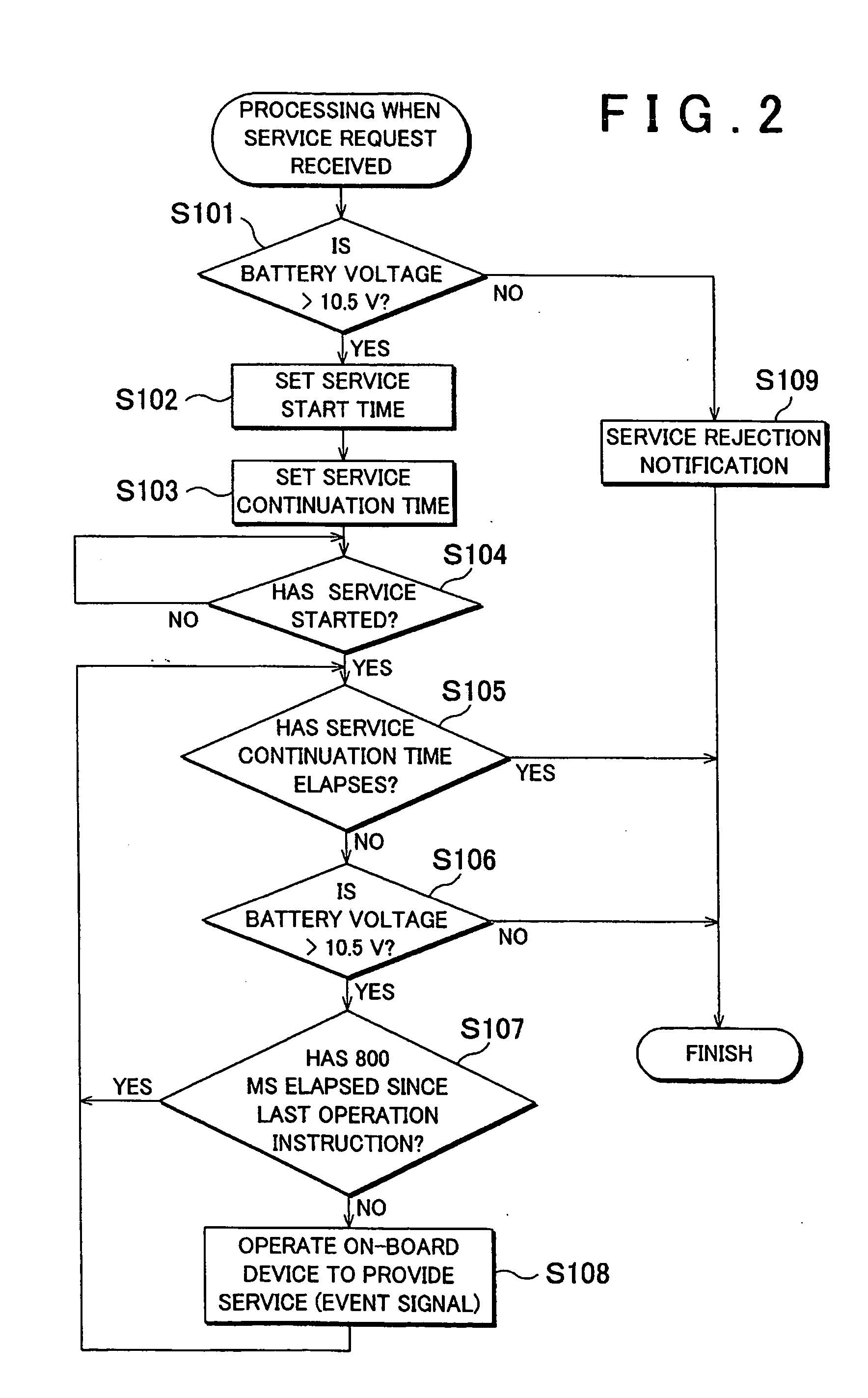

Apparatus for performance control of remote control operation service, and system and method for provision of same

InactiveUS20050060067A1Service is limitedAvoid problemsTelemetry/telecontrol selection arrangementsDigital data processing detailsStart timeRemote control

If a control portion determines, upon receipt of the service request information, that a battery does not have enough remaining voltage to start an engine, the control portion notifies the driver by sending a service rejection notification via the center. However, if the battery has sufficient remaining charge, when the operation start time is reached, the control portion performs the remote control operation service by causing the light to flash. Further, if the control portion detects that the voltage of the battery has reduced during the performance of the remote control operation service to a level at which starting the engine will be difficult, the control portion compulsorily terminates the remote control operation service that is being performed in order to make sure that the engine can be started.

Owner:TOYOTA JIDOSHA KK

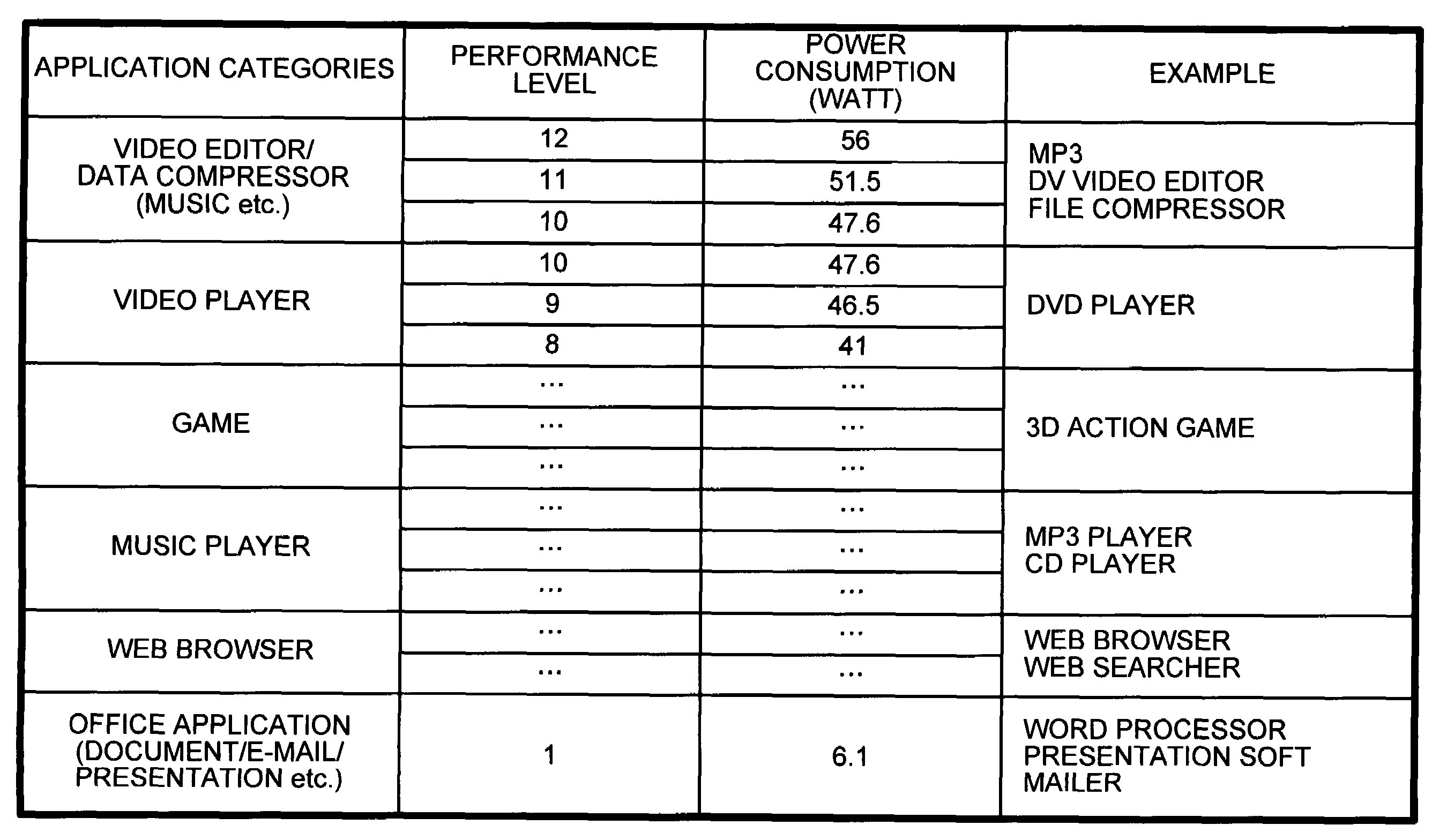

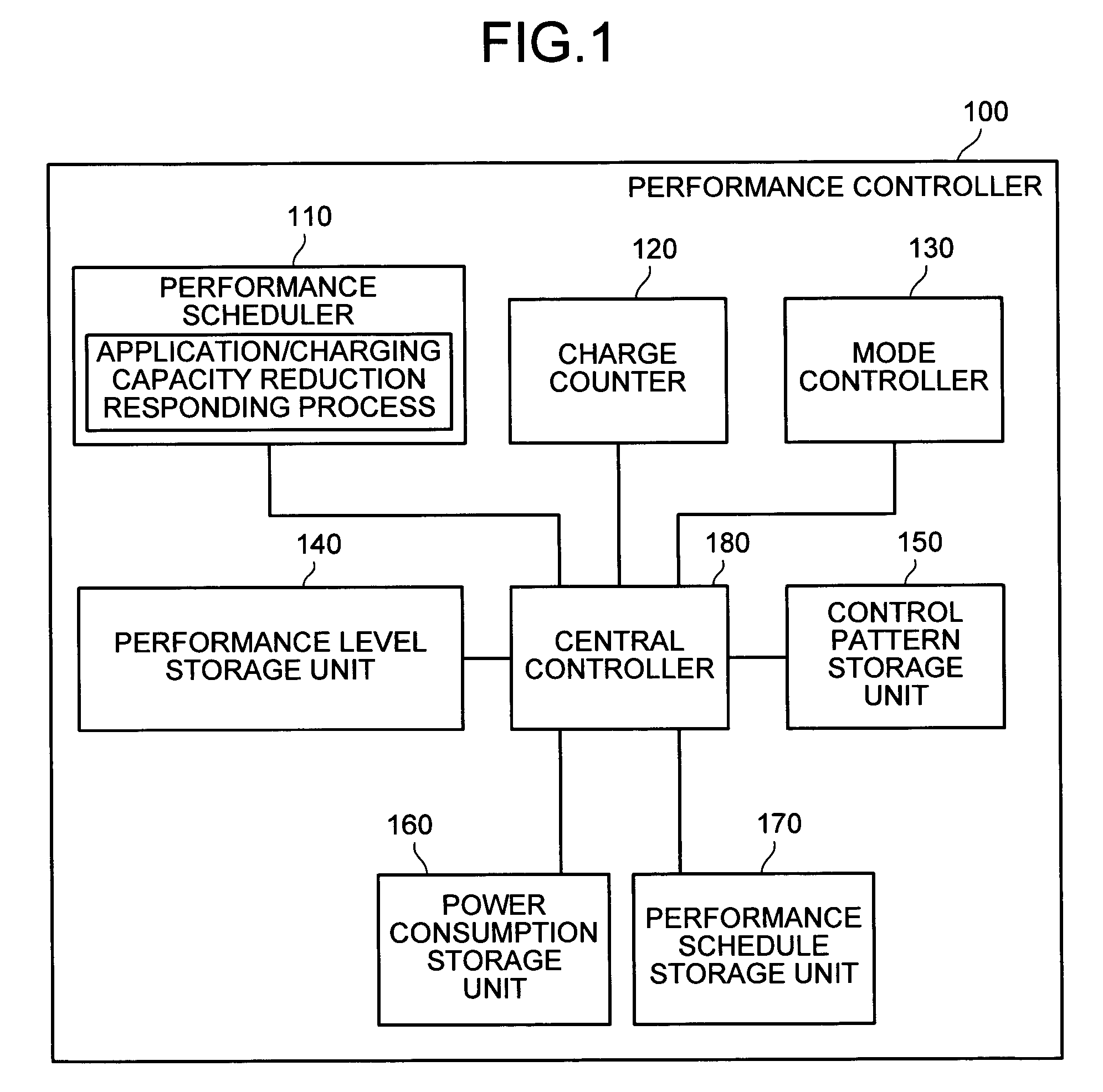

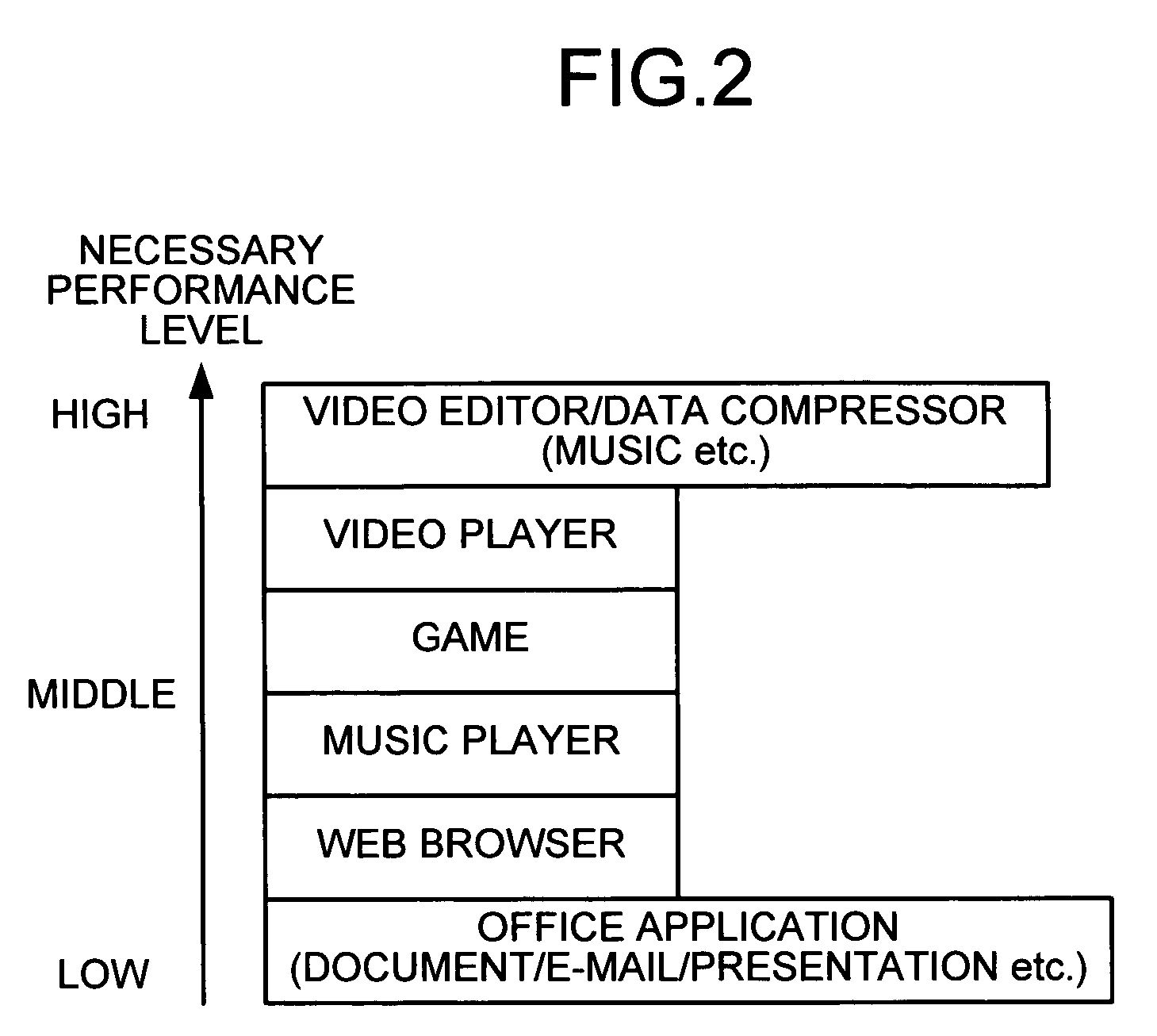

Performance controller of electronic device, performance controlling method and computer program product

A performance scheduler creates performance schedule of a battery based on use schedule of applications and residual charge level. A mode controller monitors and controls performance levels of a laptop personal computer according to the performance schedule. Further, when a charge counter counts a number of charge cycles of the battery and estimates residual charge level, a reduction in a charging capacity is taken into consideration based on the number of the charging times.

Owner:FUJITSU LTD

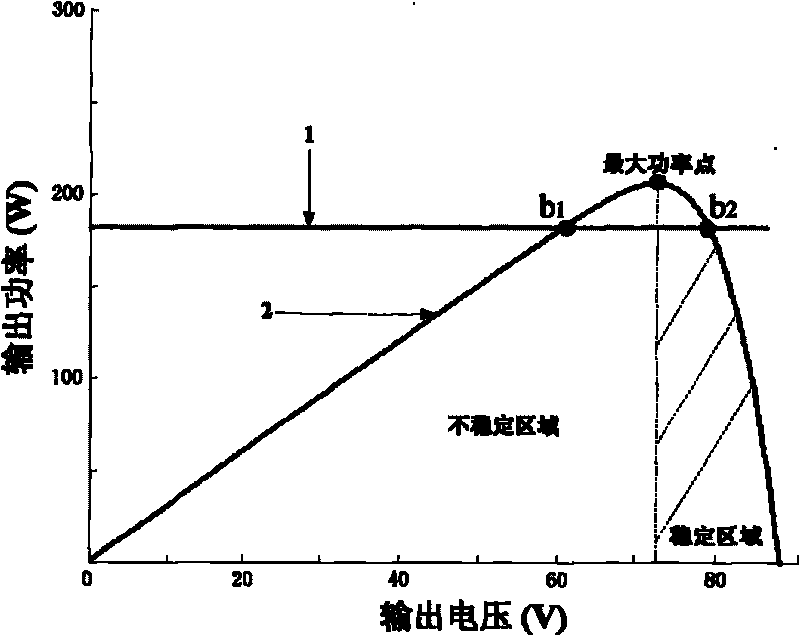

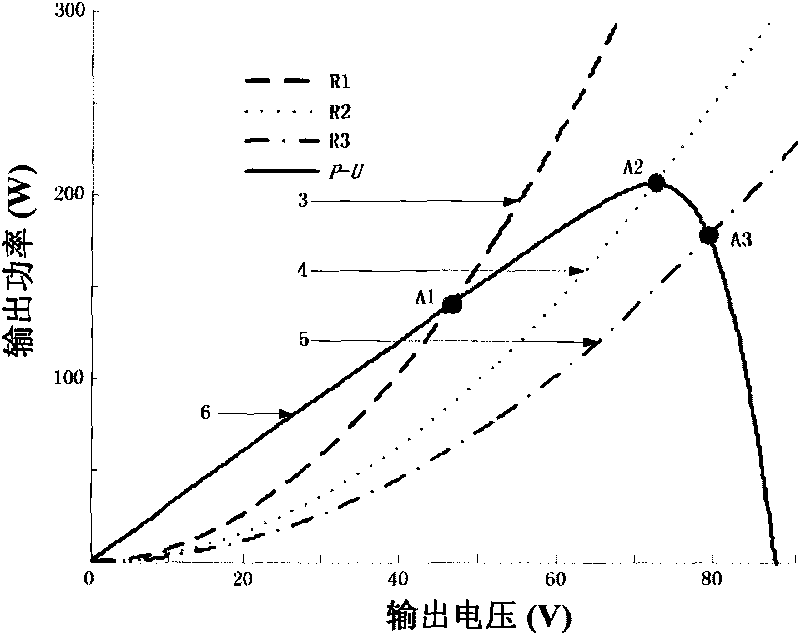

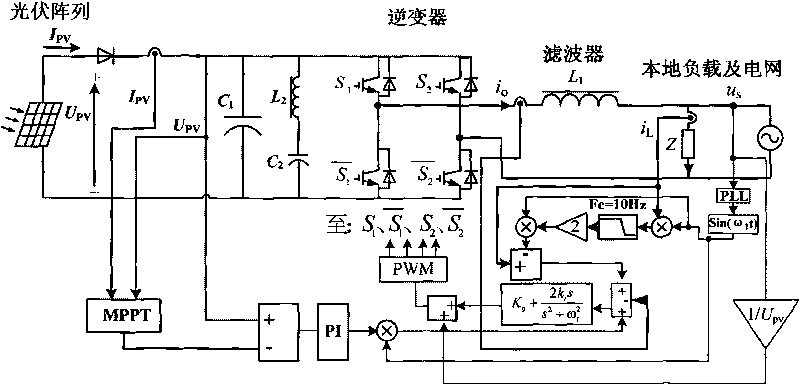

High-efficiency stable multifunctional single-stage photovoltaic single-phase grid-connected control method

InactiveCN101714763AReduce Harmonic Distortion RateImprove power qualitySingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationPower factorClosed loop

The invention discloses a high-efficiency stable multifunctional single-stage photovoltaic single-phase grid-connected control method, and belongs to the technical field of photovoltaic power generation control. The method is characterized in that: the method adopts a high-speed digital signal processor and applies a C language dynamic fixed-point algorithm to form a high-performance control algorithm of a whole grid-connected control system; the method adopts a single-stage grid-connected control structure and a quick smooth maximum power point tracking method to directly transmit the maximum energy sent by a photovoltaic array to a local urban power grid through first-stage DC / AC transformation; the harmonic and idle work produced by a local load can be compensated by adopting an FBD method, so the method is favorable for improving the electrical energy quality of the local power grid; and a proportional resonant converter is used to implement precise closed-loop control for the grid-connected current so that the photovoltaic grid-connected current and the commercial single-phase voltage are totally synchronous while implementing maximum power point tracking of the photovoltaic array. The power factor is high, the system efficiency is high, the operation of the whole system is safe and reliable, and the aberration rate of the grid-connected current harmonic is lower than 3 percent.

Owner:WUXI SLD POWER TECH

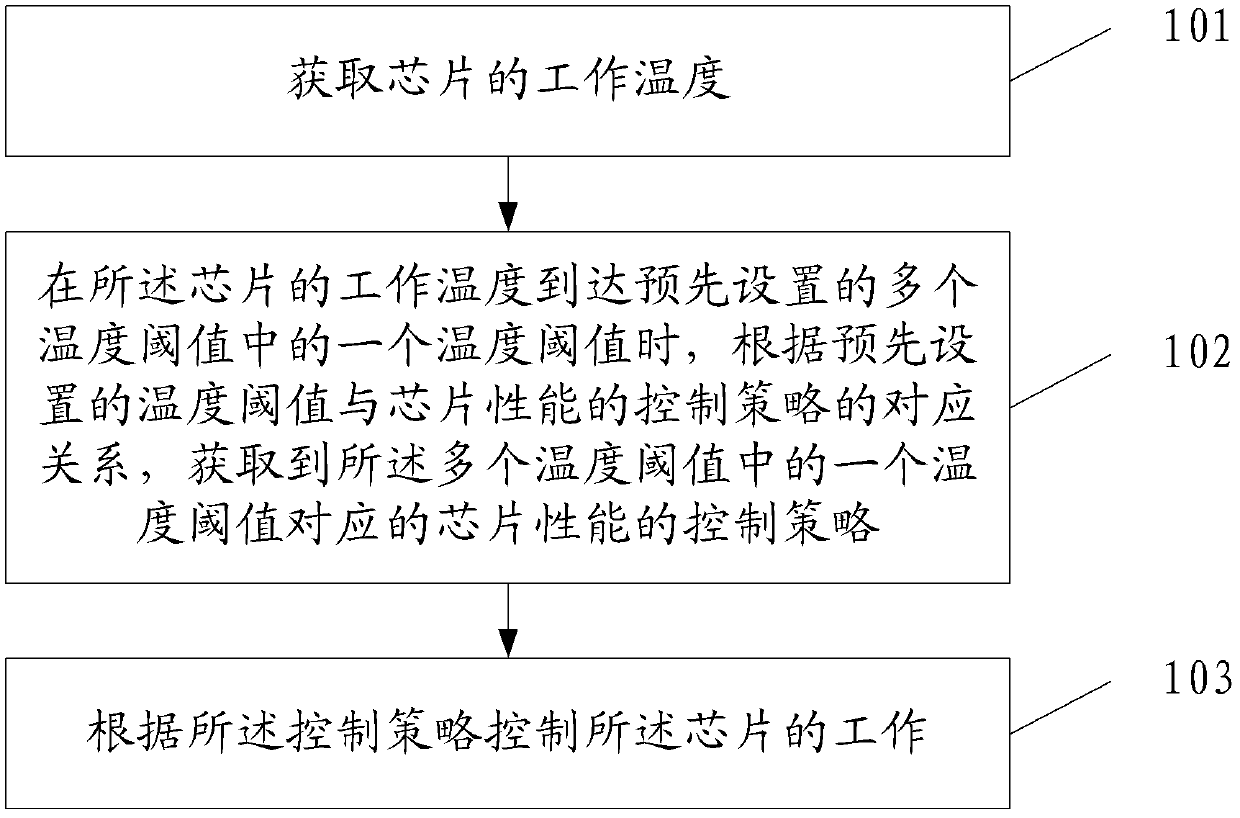

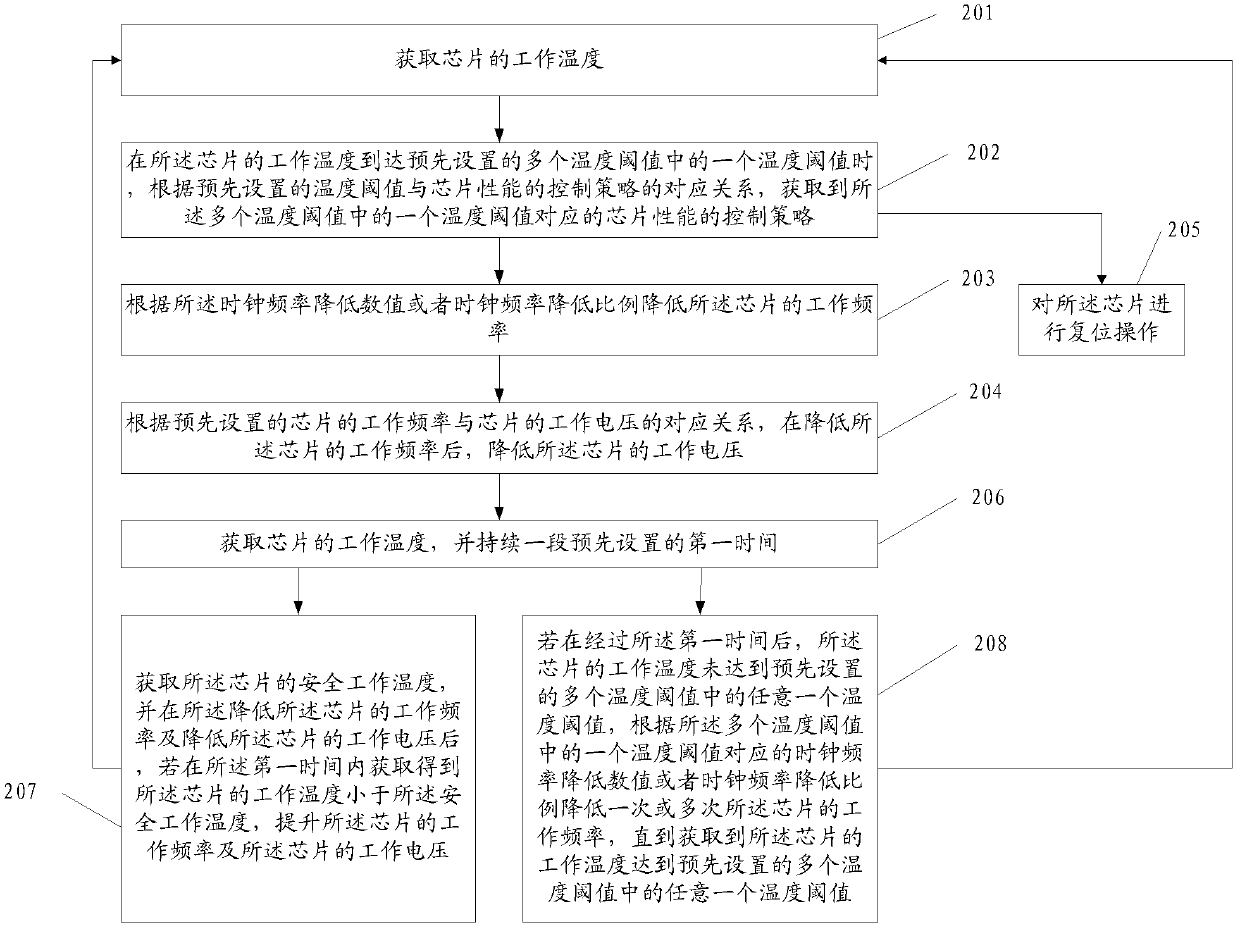

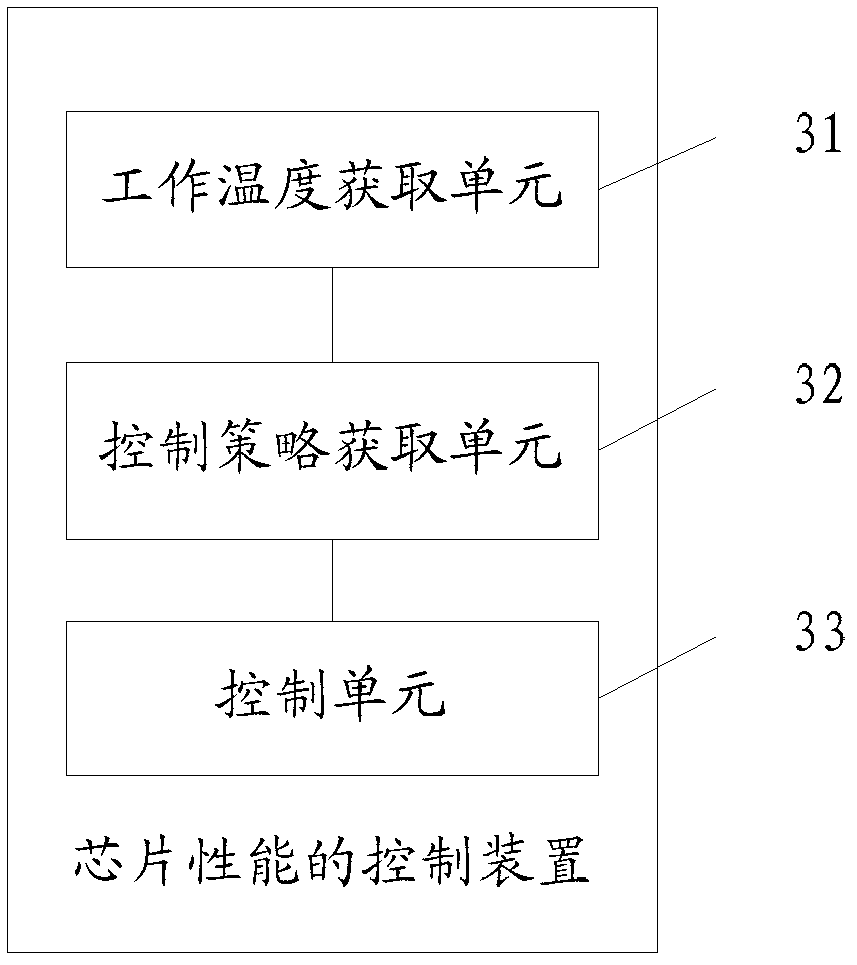

Chip performance control method and device

ActiveCN103376859AAvoid the problem of large performance degradationDigital data processing detailsEnergy efficient computingWorking temperatureThermal threshold

Embodiments of the present invention disclose a method and an apparatus for controlling chip performance, and relate to the field of communications technologies, which solves a problem in the prior art that a chip is reset or performance is greatly decreased as long as a temperature of the chip is higher than a preset threshold. The method includes: obtaining a working temperature of a chip; when the working temperature of the chip reaches one of multiple preset temperature thresholds, obtaining, according to preset correspondence between a temperature threshold and a chip performance control policy, a chip performance control policy that corresponds to the one of the multiple temperature thresholds; and controlling working of the chip according to the control policy. The present invention is applicable to an electronic device to which a chip is applied, such as a desktop computer or a notebook computer.

Owner:HUAWEI TECH CO LTD

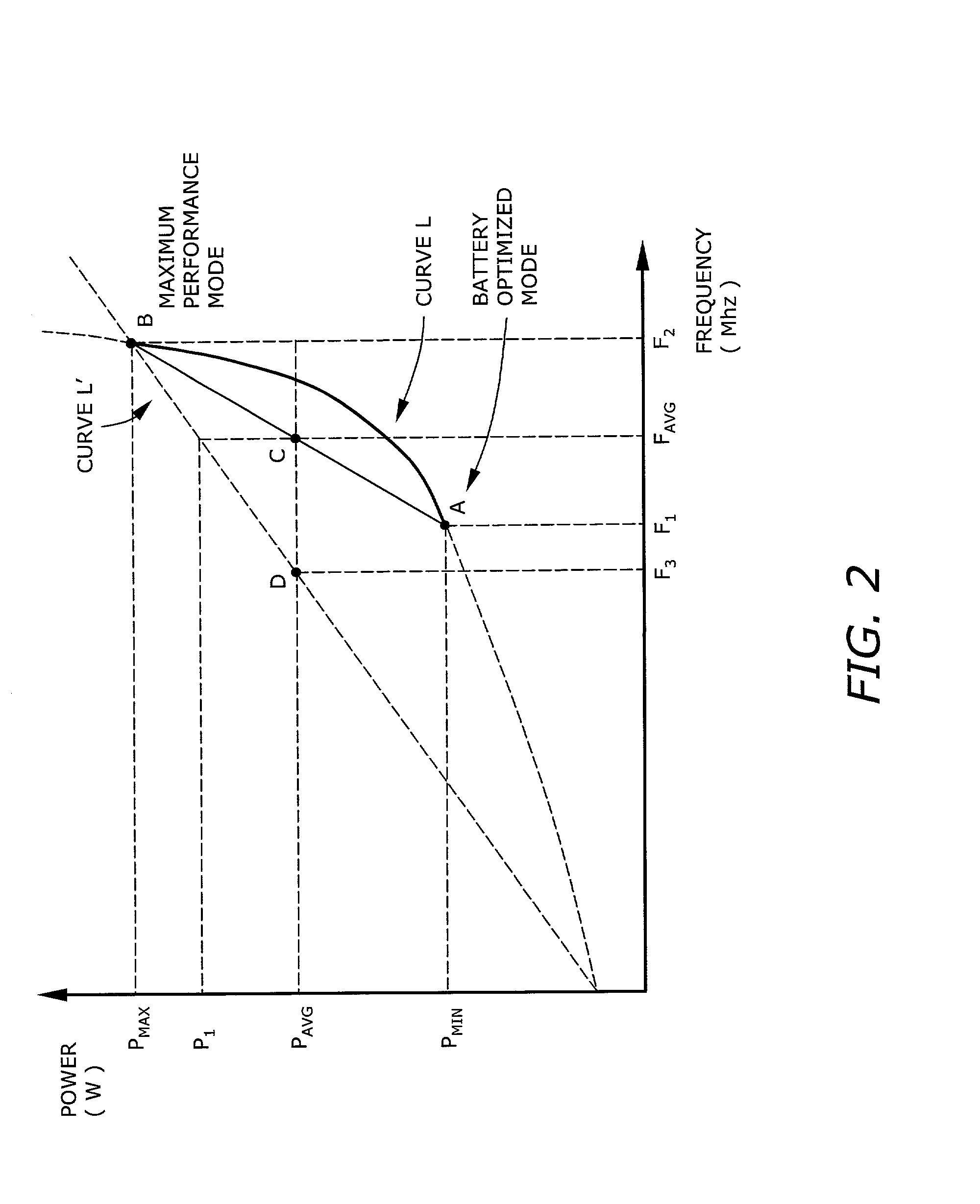

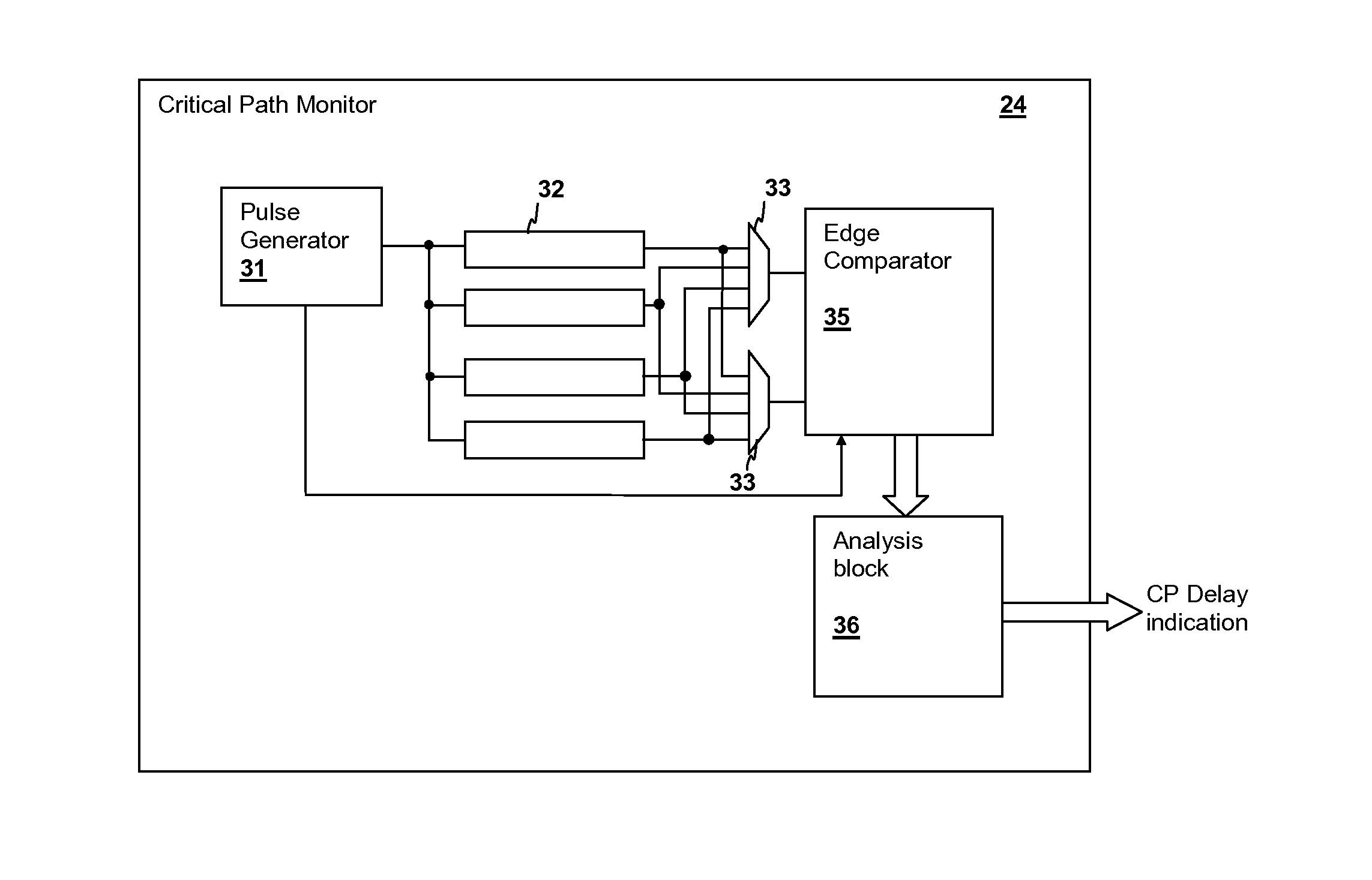

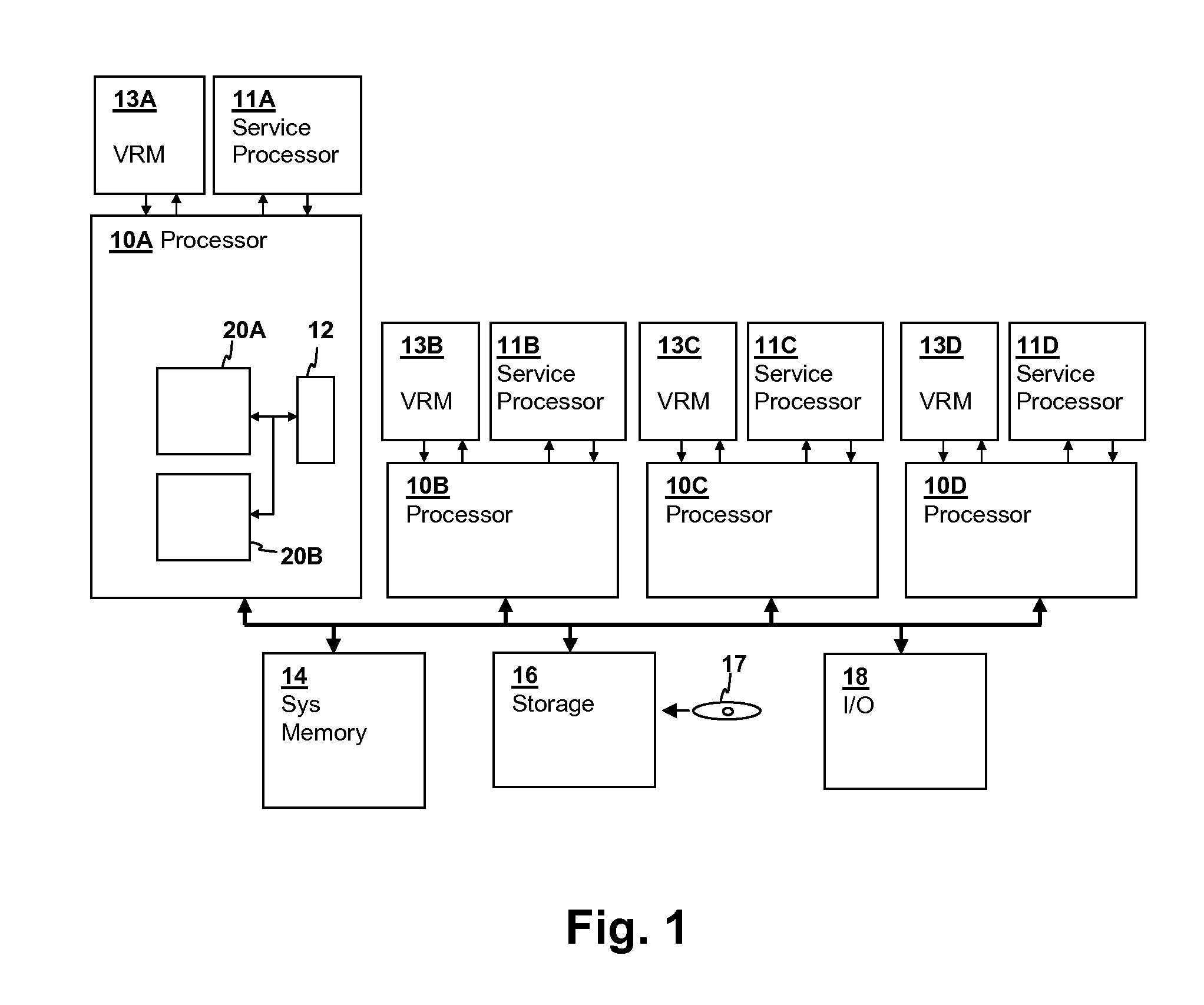

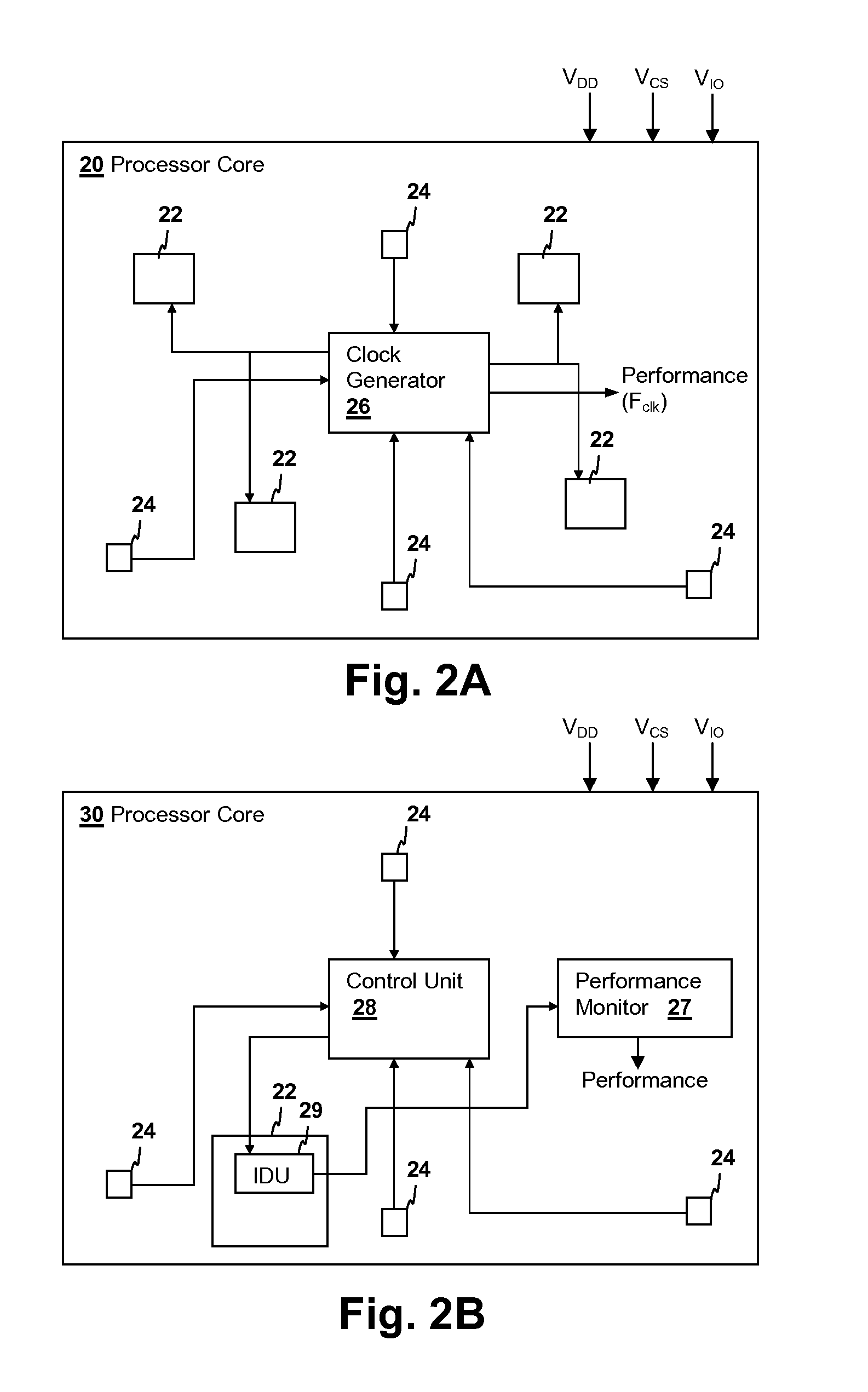

Performance control of frequency-adapting processors by voltage domain adjustment

InactiveUS20120005513A1Performance maximizationMaintain securityEnergy efficient ICTElectric devicesSelf adaptiveMargin of safety

A performance control technique for a processing system that includes one or more adaptively-clocked processor cores provides improved performance / power characteristics. An outer feedback loop adjusts the power supply voltage(s) provided to the power supply voltage domain(s) powering the core(s), which may be on a per-core basis or include multiple cores per voltage domain. The outer feedback loop operates to ensure that each core is meeting specified performance, while the cores also include an inner feedback loop that adjusts their processor clock or other performance control mechanism to maximize performance under present operating conditions and within a margin of safety. The performance of each core is measured and compared to a target performance. If the target performance is not met for each core in a voltage domain, the voltage is raised for the voltage domain until all cores meet the target performance.

Owner:IBM CORP

Hot isostatic pressing three-control method suitable for additive manufacturing parts

ActiveCN105562694AAvoid deformationGuaranteed shape accuracyAdditive manufacturing apparatusPhase controlHigh pressure

The invention belongs to the technical field of additive manufacturing, and relates to a hot isostatic pressing three-control method suitable for additive manufacturing parts. The method comprises the steps that design of the hot isostatic pressing treatment technology is firstly carried out according to the materials and defect conditions of parts, in order to prevent deformation of the parts in complex shapes, the low-temperature and high-pressure treatment technology is selected, and auxiliary tools are matched to guarantee the shapes and size precision of the parts. In addition, in the hot isostatic pressing treatment process, according to the requirement of the phase control technology of the parts, heat treatment is selected to be carried out while hot isostatic pressing high-temperature treatment is carried out, or heat treatment is carried out in the cooling process after hot isostatic pressing treatment is finished, phases and structures are regulated and controlled, and the additive manufacturing parts with the needed performance are obtained. Control over the shapes of the additive manufacturing parts, improving of the performance of the additive manufacturing parts and phase control of the additive manufacturing parts are combined, shape control, performance control and phase control are achieved in the short procedure in the hot isostatic pressing technology process, cost can be better reduced, and industrial production can be achieved.

Owner:CHINA IRON & STEEL RES INST GRP +1

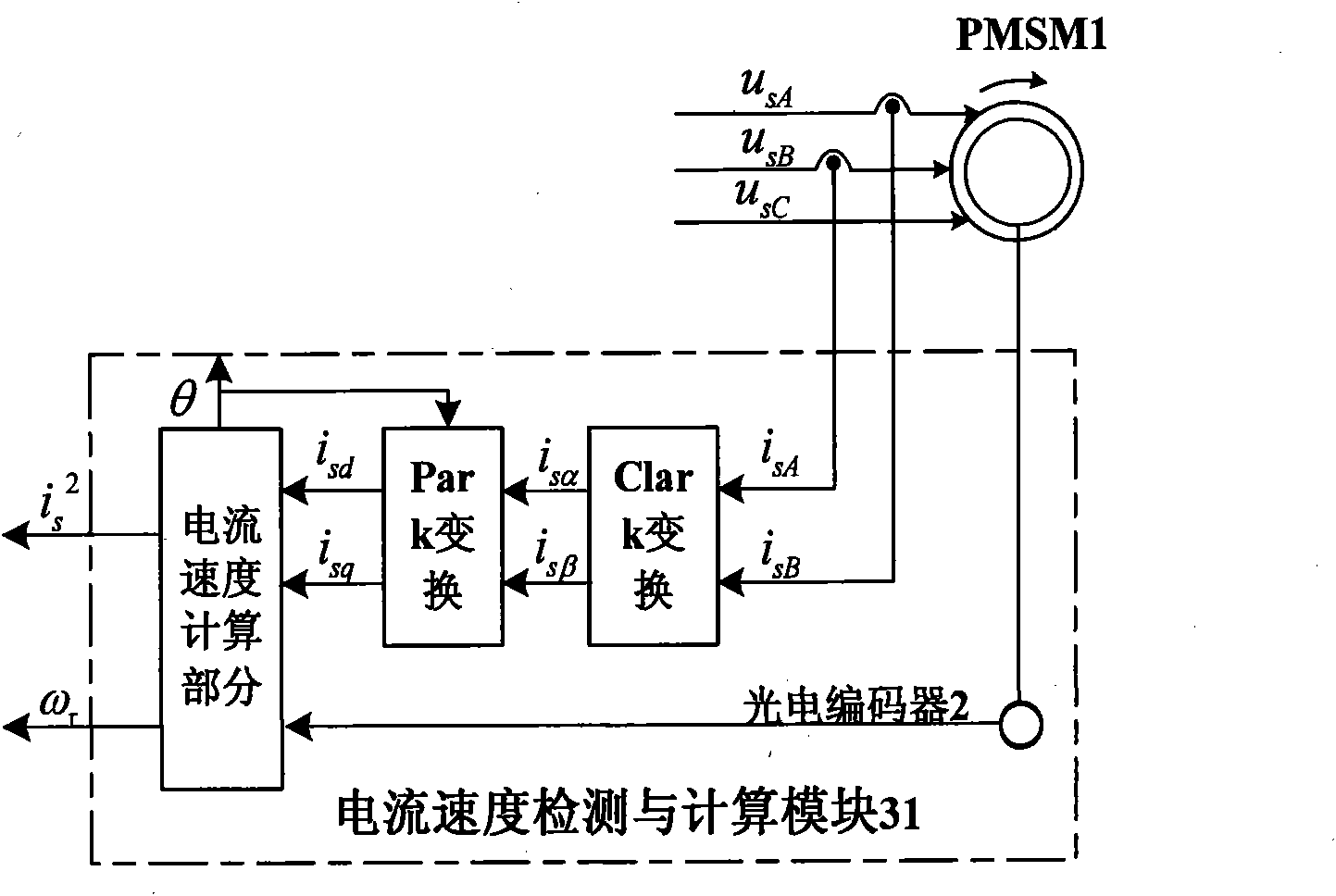

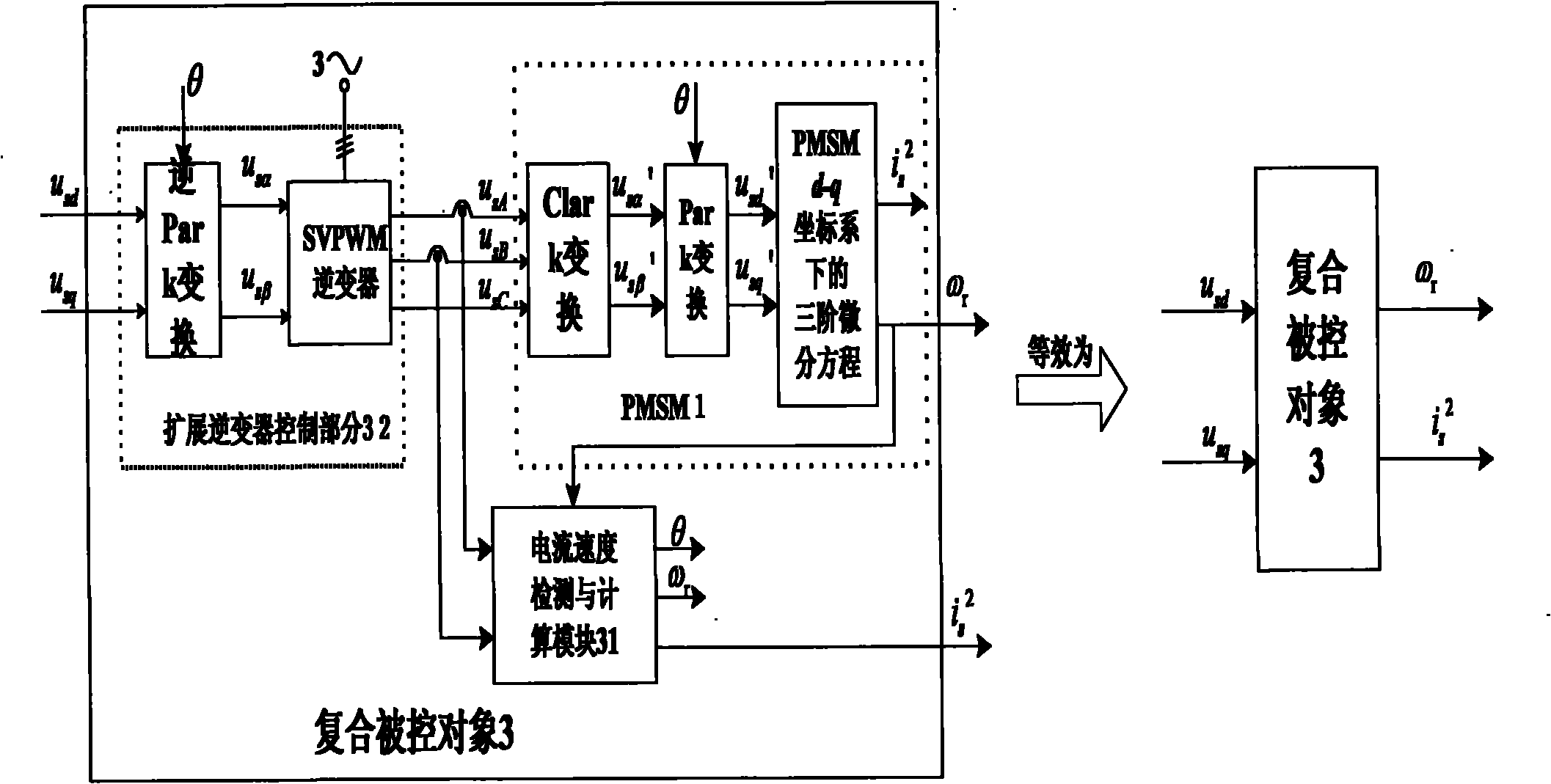

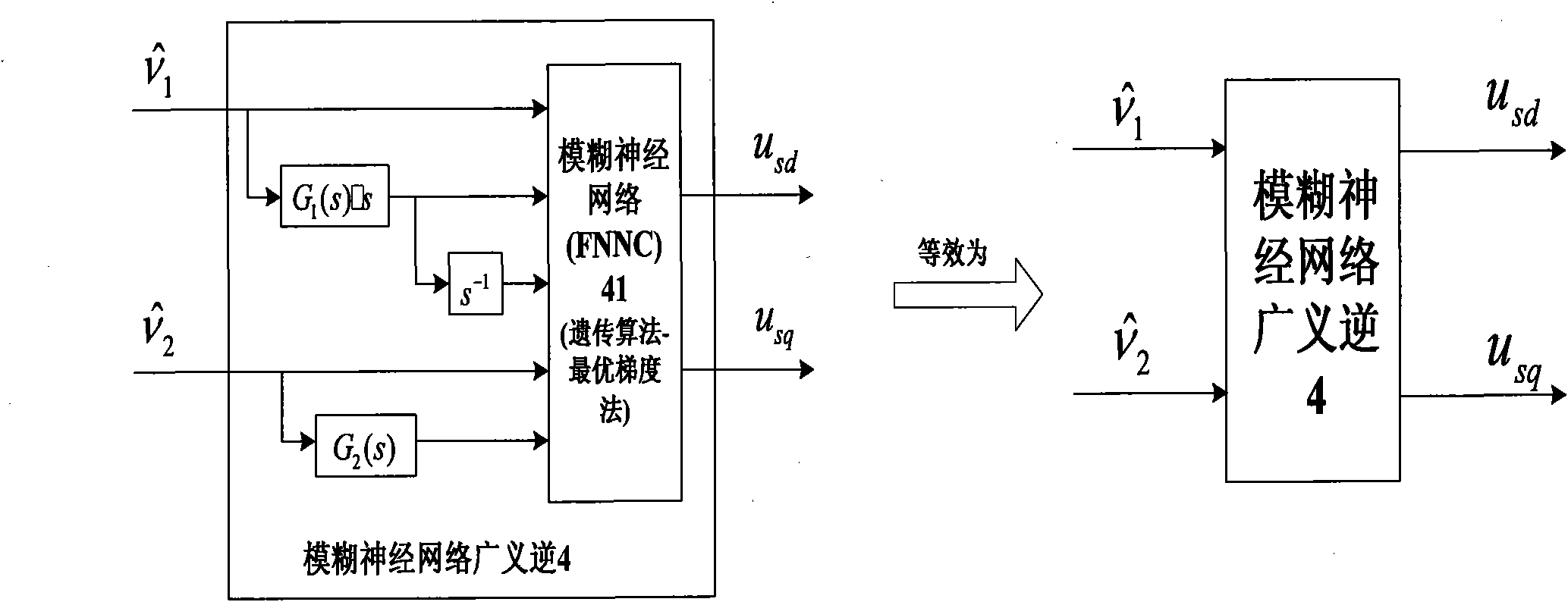

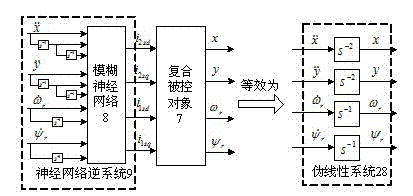

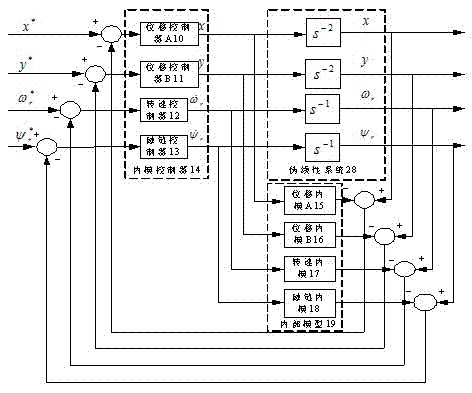

Robust controller of permanent magnet synchronous motor based on fuzzy-neural network generalized inverse and construction method thereof

ActiveCN101917150AStrong self-learning abilityImprove self-learning abilityVector control systemsSingle motor speed/torque controlIntegratorWeight coefficient

The invention discloses a robust controller of a permanent magnet synchronous motor based on a fuzzy-neural network generalized inverse and a construction method thereof. The construction method of the invention comprises the following steps of: combining an internal model controller and a fuzzy-neural network generalized inverse to form a compound controlled object; serially connecting two linear transfer functions and one integrator with the fuzzy-neural network with determined parameters and weight coefficients to form the fuzzy-neural network generalized inverse, serially connecting the fuzzy-neural network generalized inverse and the compound controlled object to form a generalized pseudo-linear system, linearizing a PMSM (permanent magnet synchronous motor), and decoupling and equalizing the linearized PMSM into a second-order speed pseudo-linear subsystem and a first-order current pseudo-linear subsystem; and respectively introducing an internal-model control method in the two pseudo-linear subsystems to construct the internal model controller. The robust controller of the invention has the advantages of overcoming the dependence and local convergence of the optimal gradient method on initial values and solving the problems of randomness and probability caused by using the simple genetic algorithm, obtaining the high performance control, anti-disturbance performance and adaptability of the motor and simplifying the control difficulty, along with simple structure and high system robustness.

Owner:UONONE GRP JIANGSU ELECTRICAL CO LTD

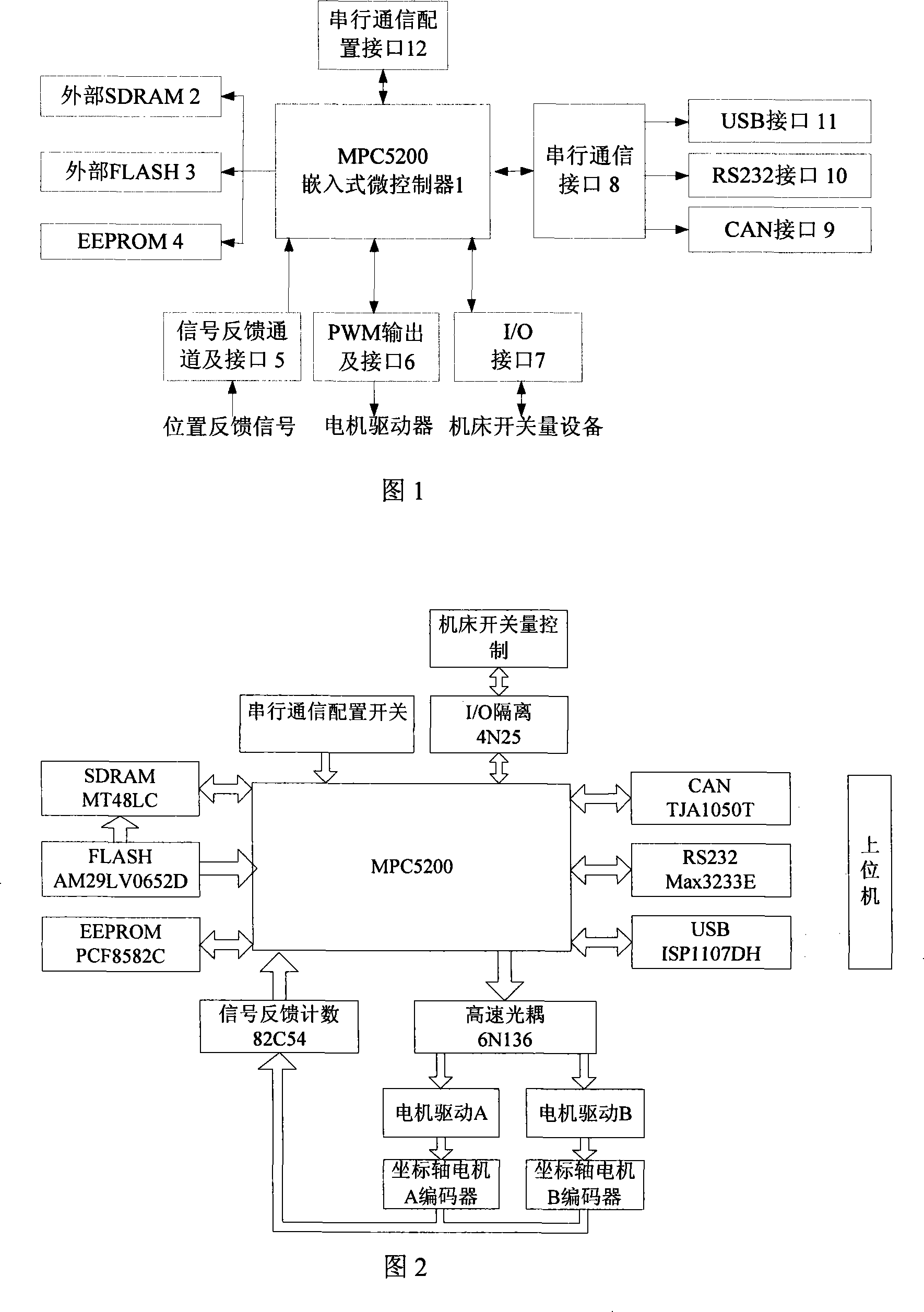

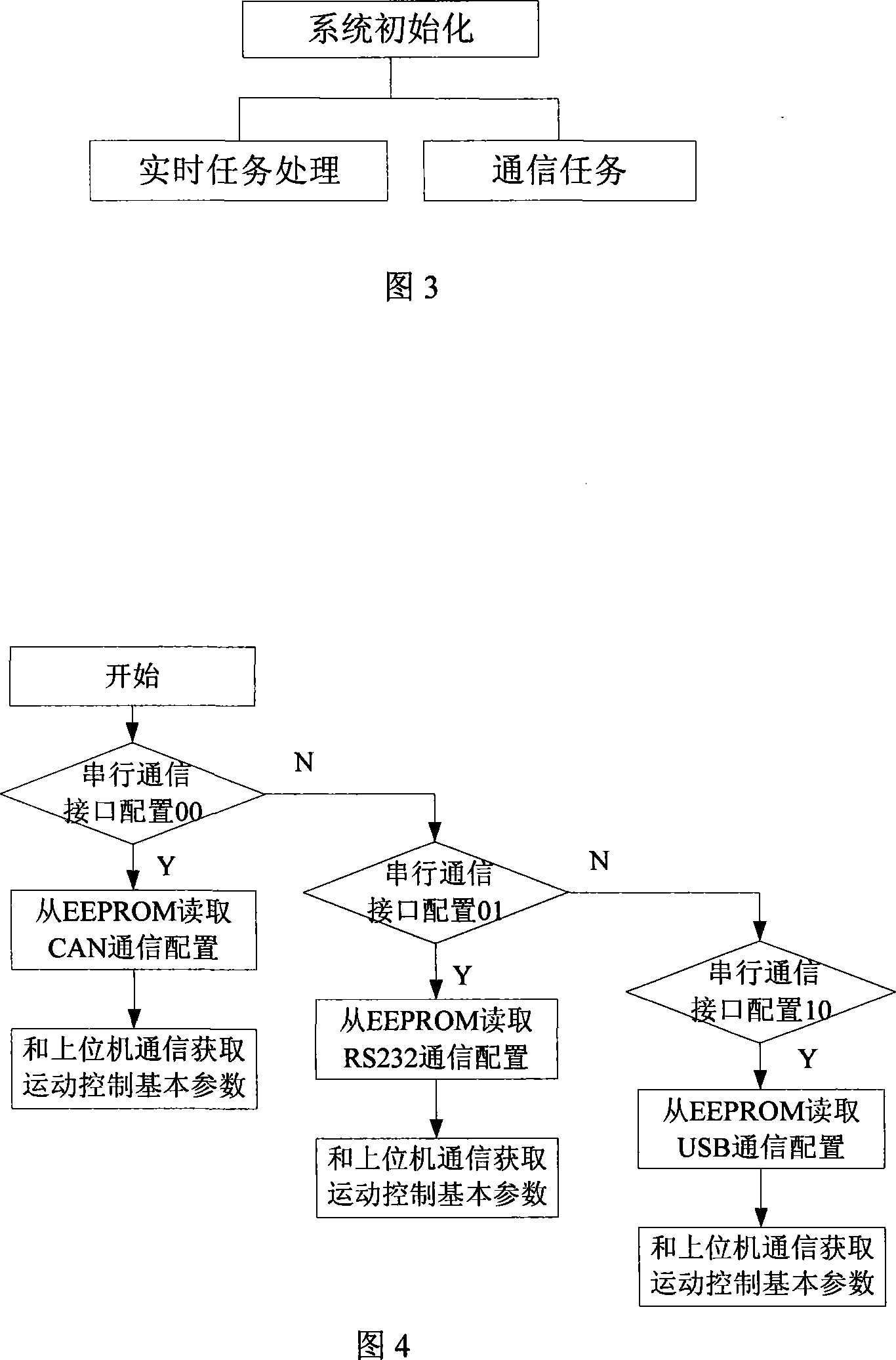

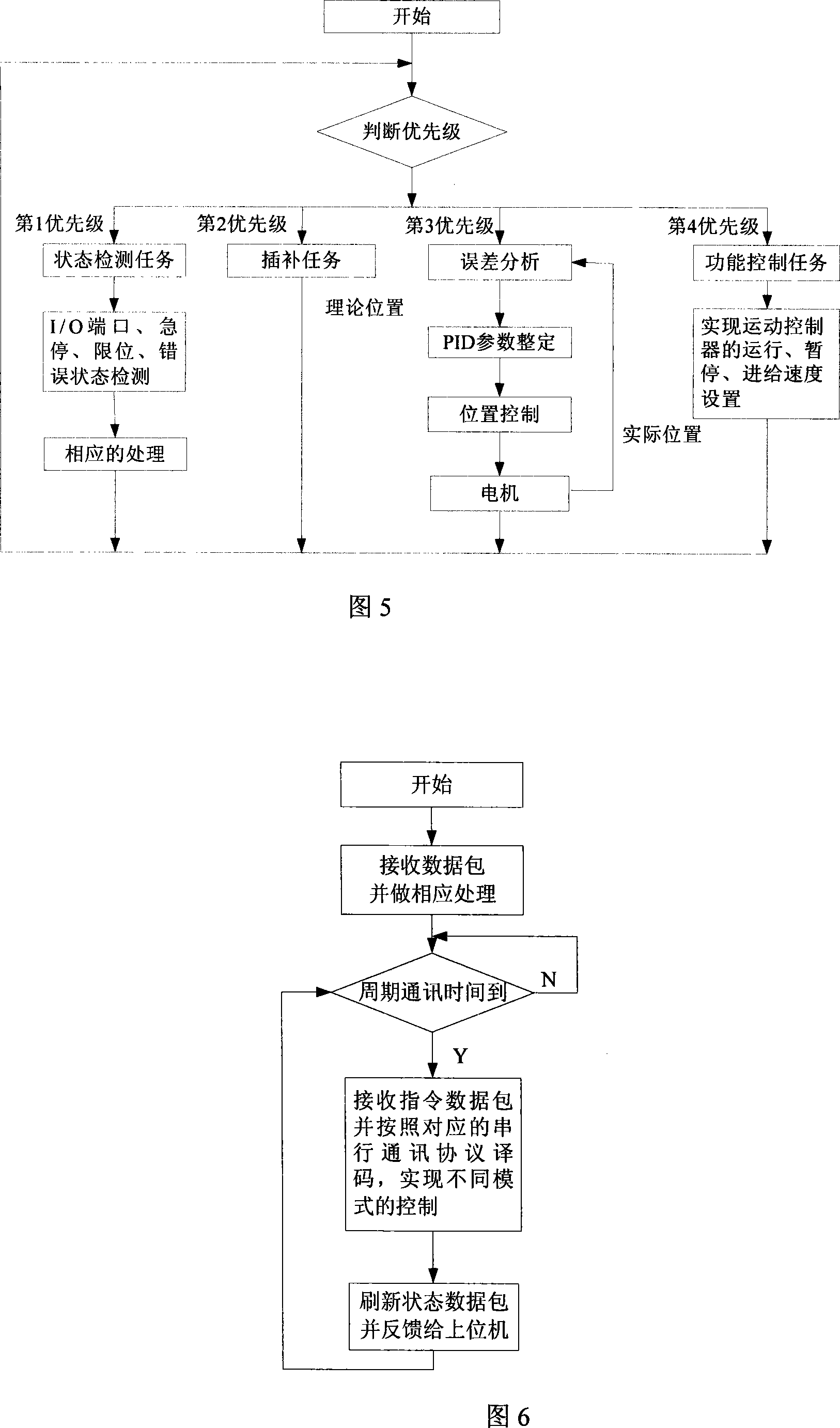

Multiple axle movement controller based on MPC5200 and its operation method

InactiveCN101086664AReduce in quantityImprove reliabilityNumerical controlRs 232 interfaceDrive motor

The invention relates to a multi-axial movement controller and its operation based on MPC5200.The movement controller comprises the outside SDRAM, outside FLASH, ERPROM and MPC5200 micro controller connected movement controller critical module, providing the basic environment for software running of the movement controller, going through serial communication interface configuration and top position specific serial communication protocol, connecting it with the top position machine through CAN, RS232, or USB interface for digital controlled data processing and instruction transmission, separating the controller with the top position machine, easy for distributional high performance control, through signal feedback channel and interface to make rectification, counting of the feedback signal of the motor coder, inputting to the MPC5200 micro controller for computation and sending out the result to the pulse driven motor driver through the PWM output interface.

Owner:SHANGHAI UNIV

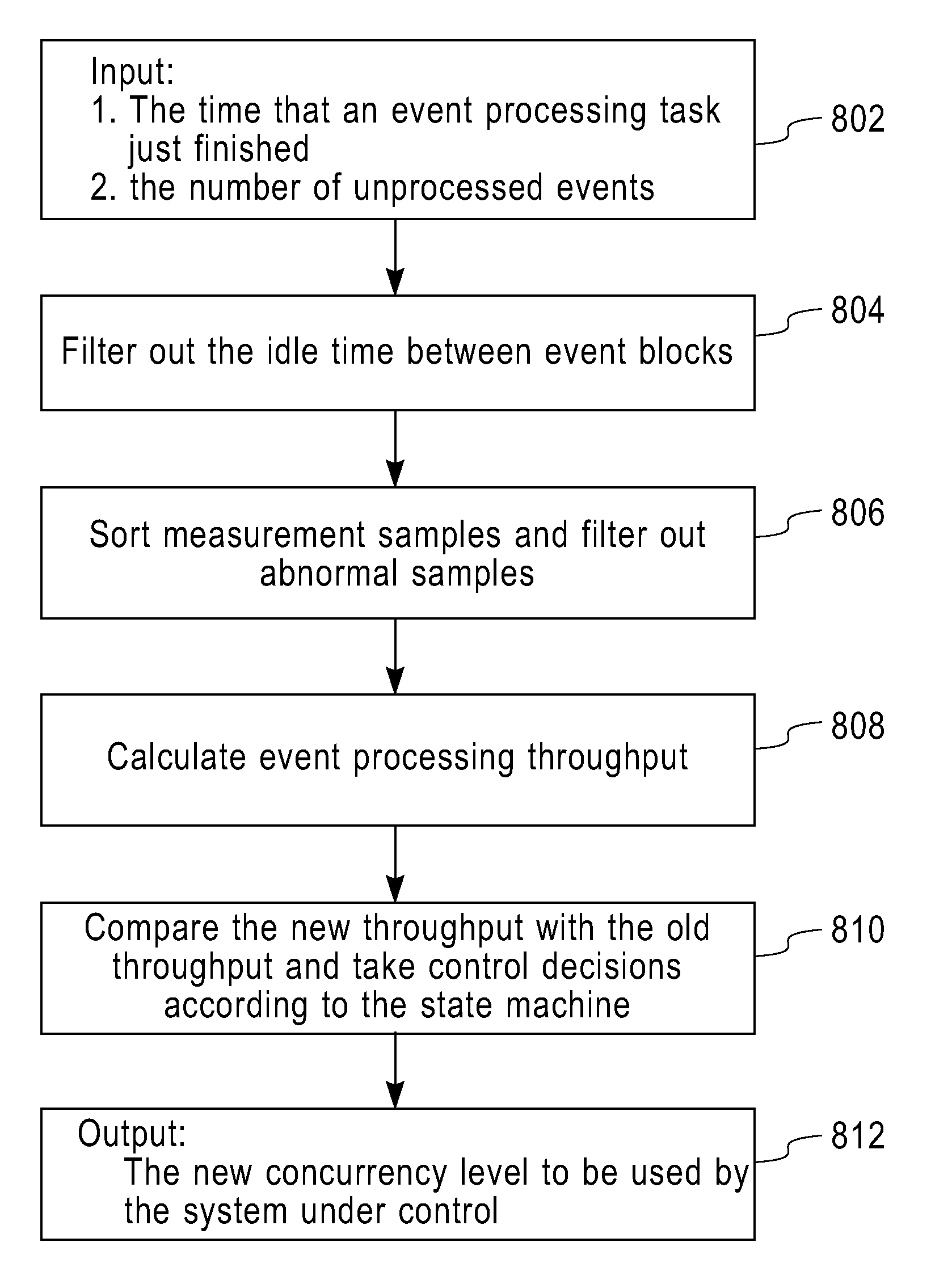

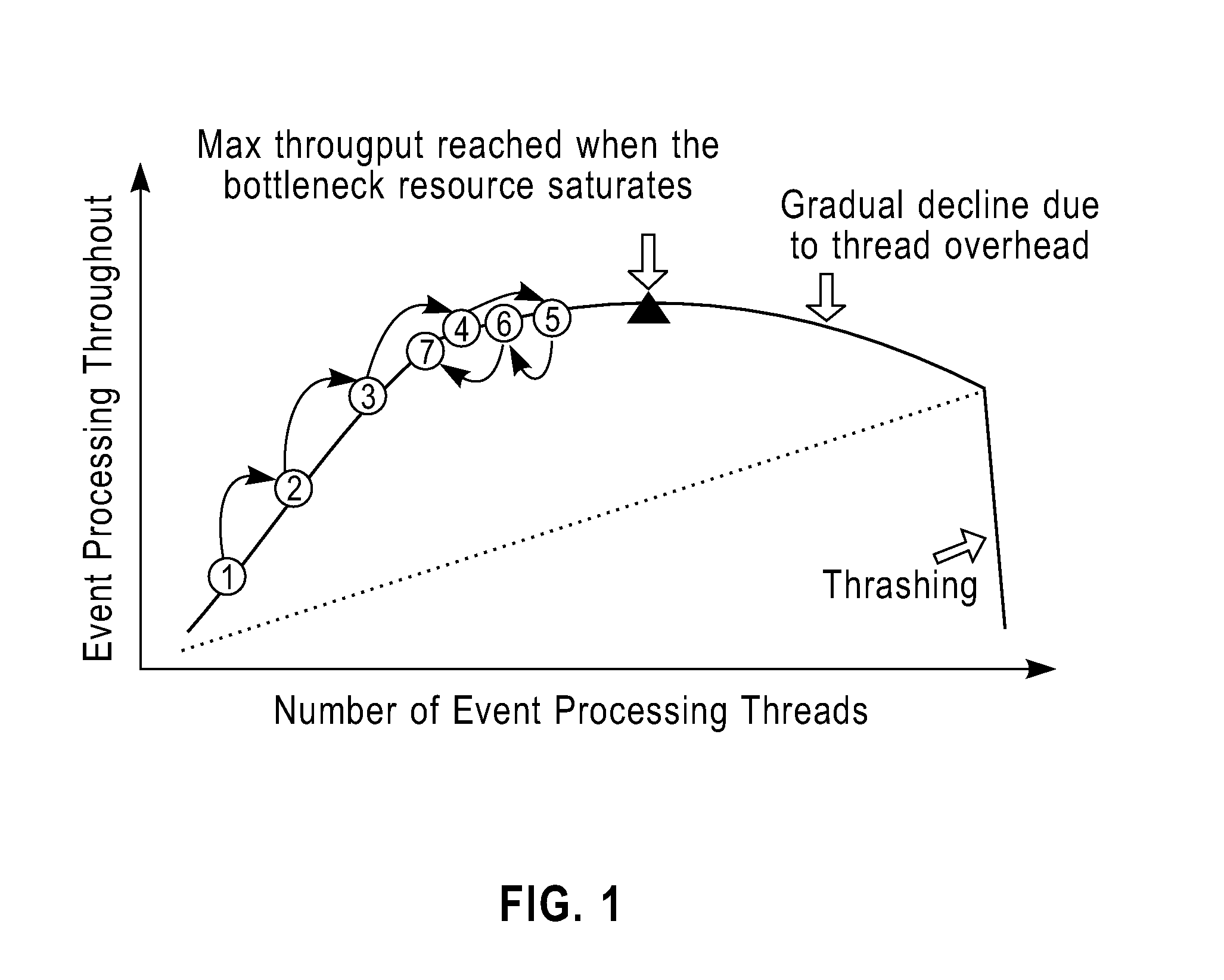

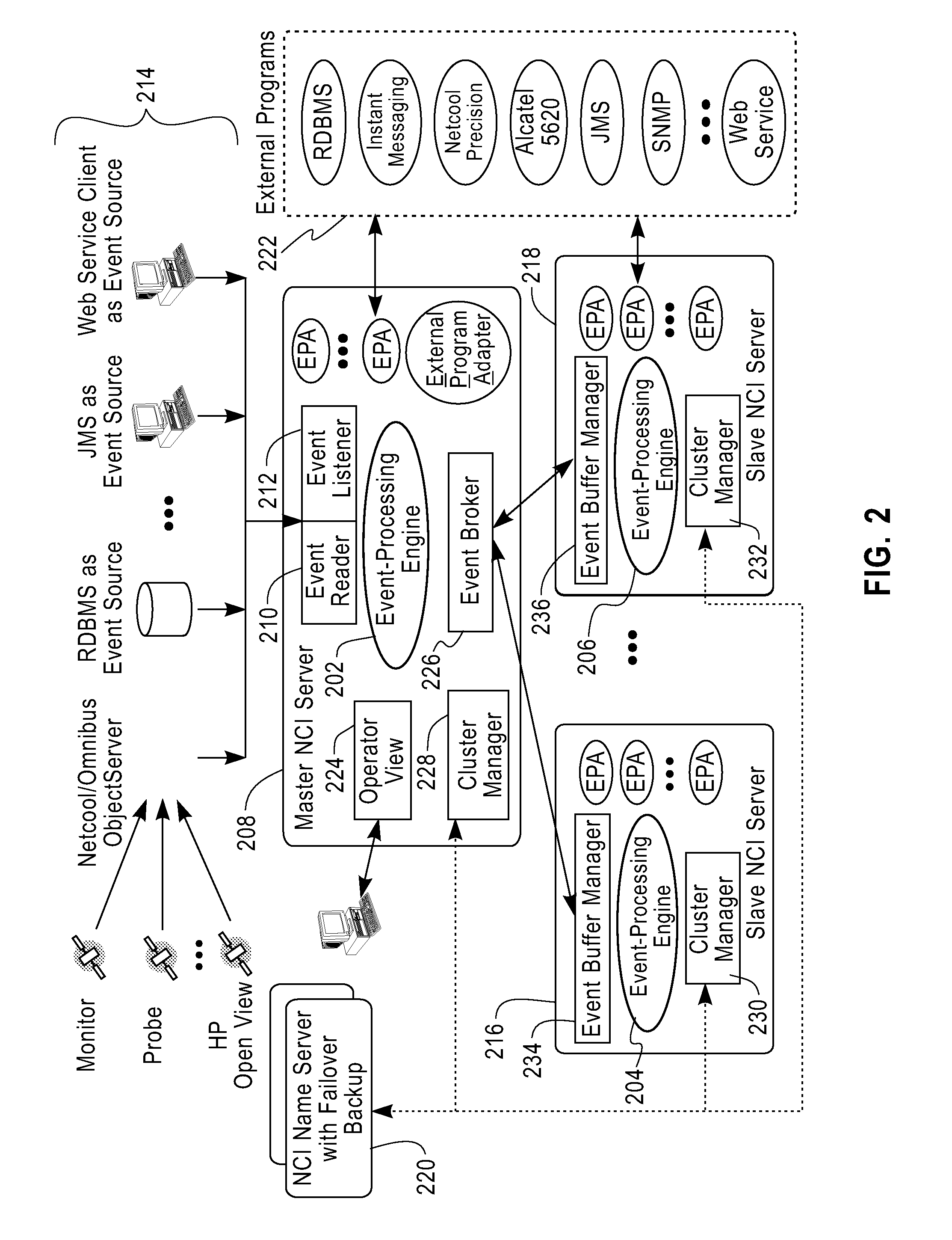

Black-box performance control for high-volume throughput-centric systems

InactiveUS20100005468A1Minimize the numberIncrease adjustable stepError detection/correctionMultiprogramming arrangementsComputerized systemHandling system

Throughput of a high-volume throughput-centric computer system is controlled by dynamically adjusting a concurrency level of a plurality of events being processed in a computer system to meet a predetermined target for utilization of one or more resources of a computer system. The predetermined target is less than 100% utilization of said one or more resources. The adjusted concurrency level is validated using one or more queuing models to check that said predetermined target is being met. Parameters are configured for adjusting the concurrency level. The parameters are configured so that said one or more resources are shared with one or more external programs. A statistical algorithm is established that minimizes total number of samples collected. The samples may be used to measure performance used to further dynamically adjust the concurrency level. A dynamic thread sleeping method is designed to handle systems that need only a very small number of threads to saturate bottleneck resources and hence are sensitive to concurrency level changes.

Owner:IBM CORP

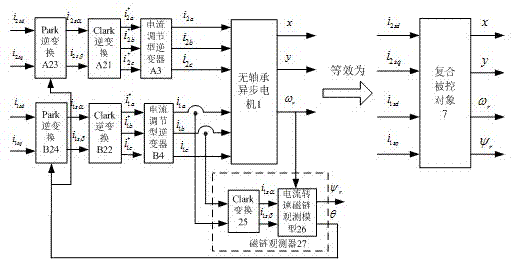

Bearing-free asynchronous motor control method based on neural network inverse system theory

InactiveCN102361429ASelf-learningWith adaptive functionElectronic commutation motor controlVector control systemsLoop controlIntegrator

The invention discloses a bearing-free asynchronous motor control method based on a neural network inverse system theory. A composite controlled object is composed of two sets of Park inverse transformation, two sets of Clark inverse transformation, two sets of current regulating inverters, a flux linkage observer, and a bearing-free asynchronous motor; a fuzzy neural network and integrators form a fuzzy neural network inverse system; and the fuzzy neural network inverse system is in series connection with the composite controlled object; besides, the bearing-free asynchronous motor is decoupled into a pseudo linear system comprising two displacement subsystems, a rotating speed subsystem and a rotor flux linkage subsystem; and the obtained pseudo linear system is introduced into internal model control to form closed-loop control. According to the invention, the control precision is high and there is high robustness on an external disturbance, a parameter change and a modeling error, thereby realizing high-performance control on a bearing-free asynchronous motor.

Owner:JIANGSU UNIV

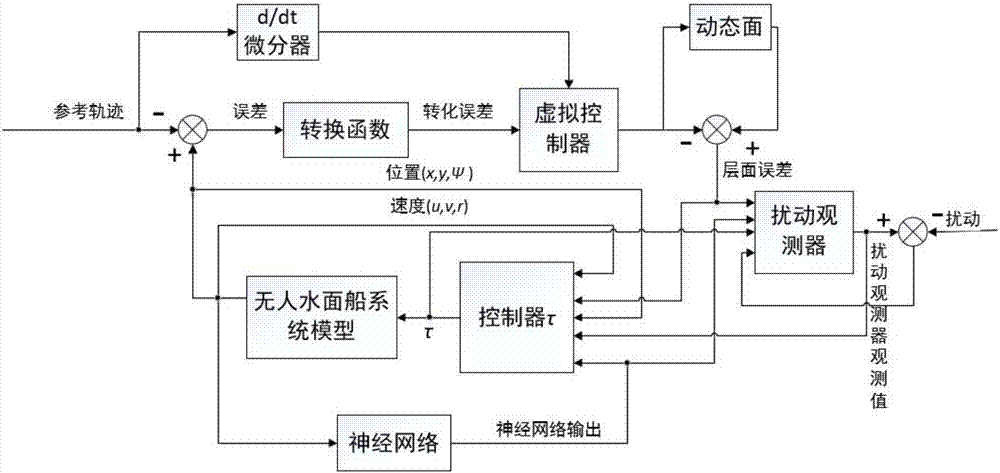

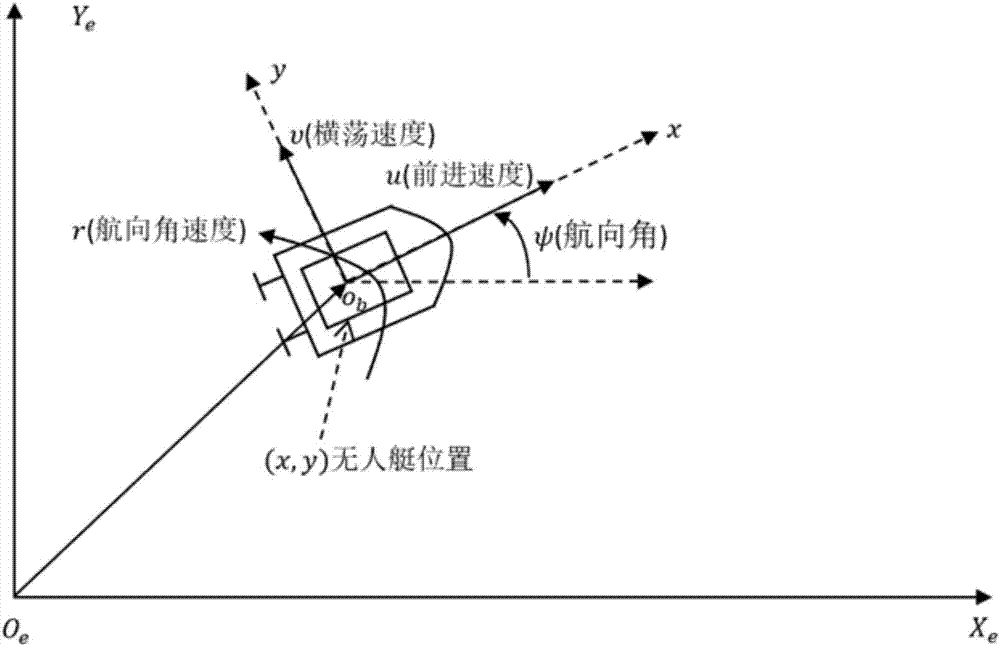

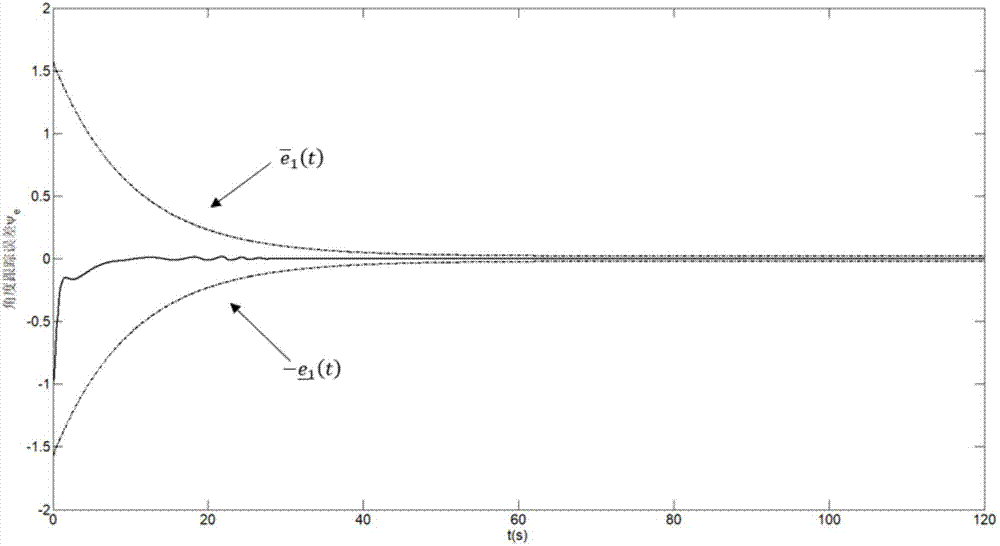

Preset performance control method for uncertain under-actuated unmanned surface vehicle (USV) system

ActiveCN108008628AAvoid design odditiesImprove tracking speedAdaptive controlLyapunov stabilityDynamic models

The invention discloses a preset performance control method for an uncertain under-actuated unmanned surface vehicle (USV) system. The preset performance control method specifically comprises the steps of establishing a USV dynamic model, including kinematics and dynamics models; processing tracking error constraints by proposing a preset performance control method; processing a virtual controllerby applying the dynamic surface control technology; learning the uncertain dynamics of the system online by using the neural network technology; and designing a tracking controller that meets the requirements by applying the Lyapunov stability theory. The preset performance control method of the invention can avoid the singular problem of controller design and can satisfy the pre-specified tracking error transient and steady state performance. The uncertain dynamics of the system are learned online by applying the adaptive neural network control technology and the controller is designed to complete the trajectory tracking control objective and the practicality of the control method is improved.

Owner:SOUTH CHINA UNIV OF TECH

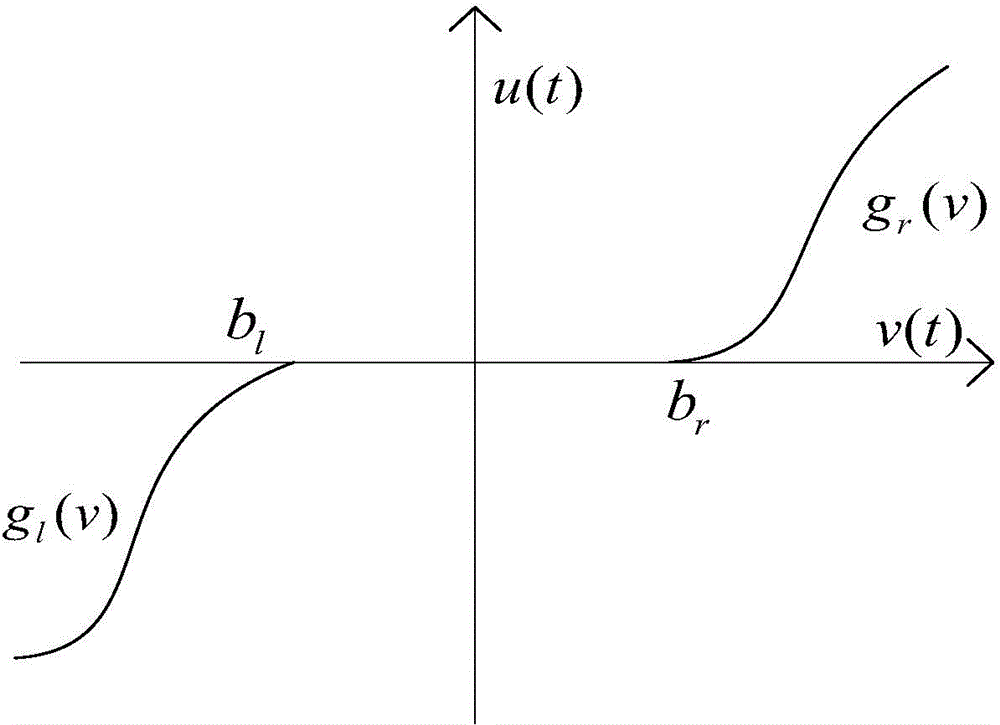

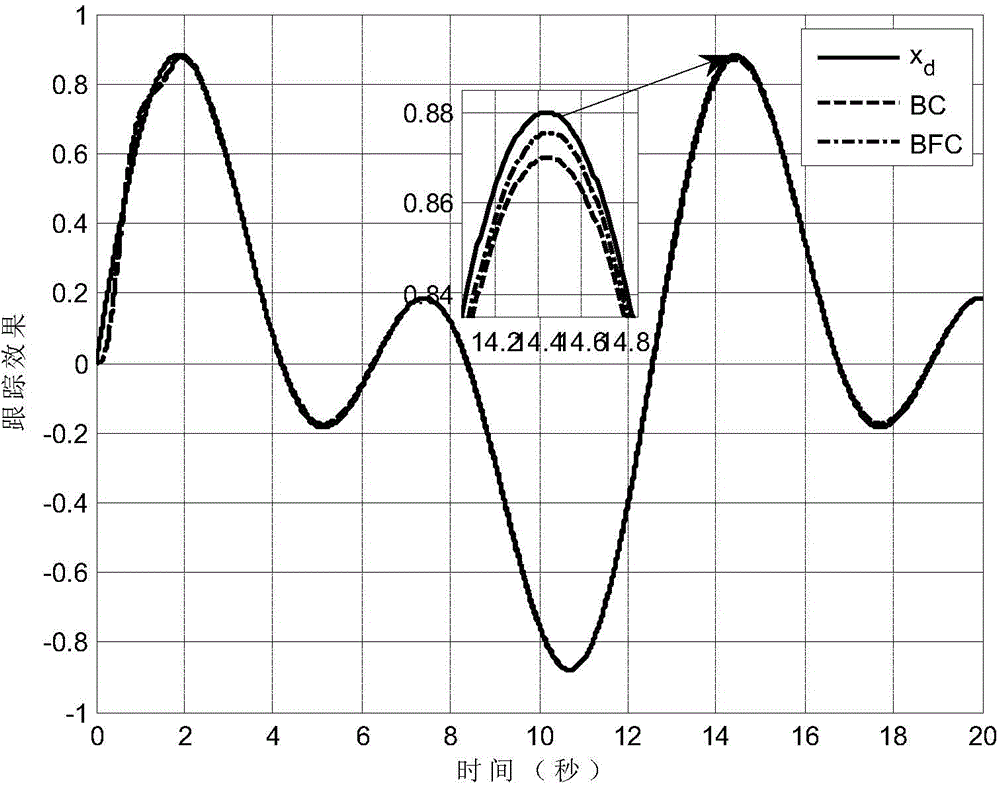

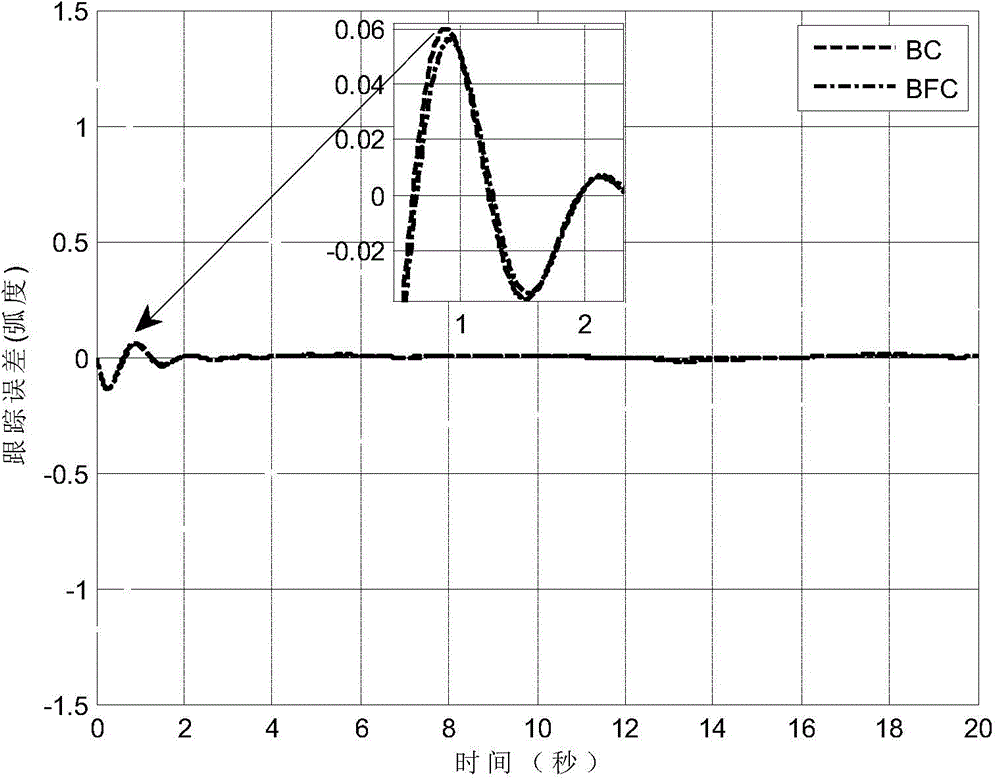

Specified performance back-stepping control method of mechanical arm servo system

ActiveCN104698846AAvoid dead zone with additional compensationAvoid buffetingAdaptive controlDynamic modelsTime-variant system

The invention provides a specified performance back-stepping control method of a mechanical arm servo system. The method comprises the steps of constructing a dynamic model of the mechanical arm servo system; initializing the system state, sampling time and control parameters; linearly approximating a nonlinear input dead area of the system as a simple time varying system according to the differential mean value theorem; deviating a mechanical arm servo system model with the unknown dead area; calculating the tracking error of the control system, FC (funnel control) error variation and differential. With the adoption of the method, the problem of control buffeting of a sliding die can be reduced, the system of the dead area input on the system can be effectively avoided, and the specified performance control of the mechanical arm control system can be achieved.

Owner:ZHEJIANG UNIV OF TECH

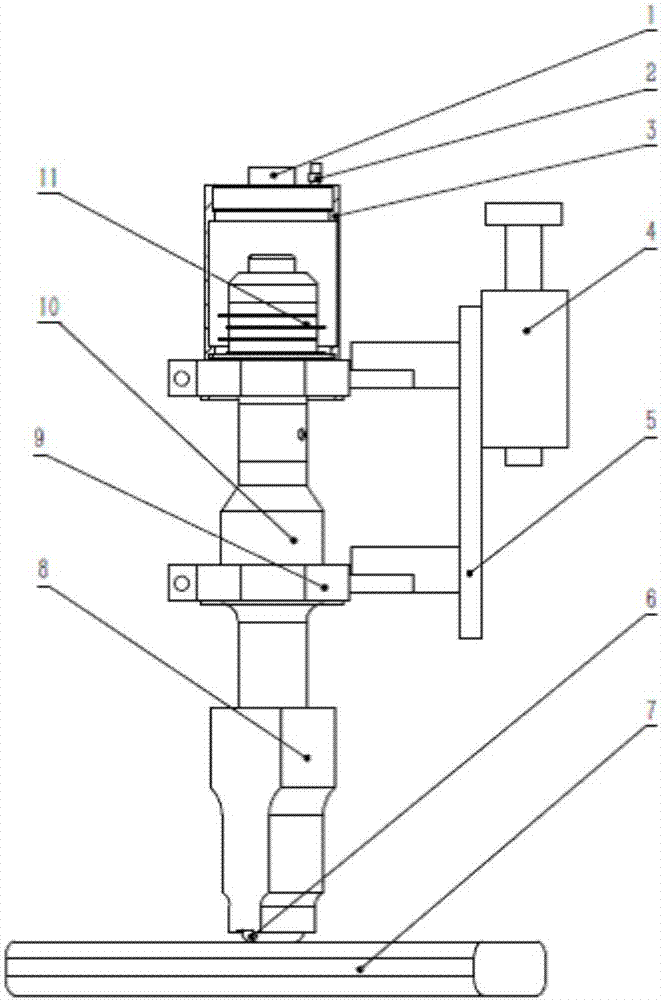

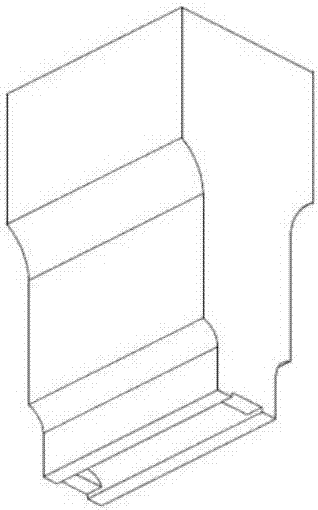

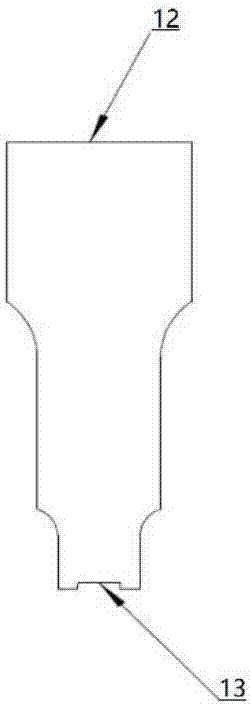

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

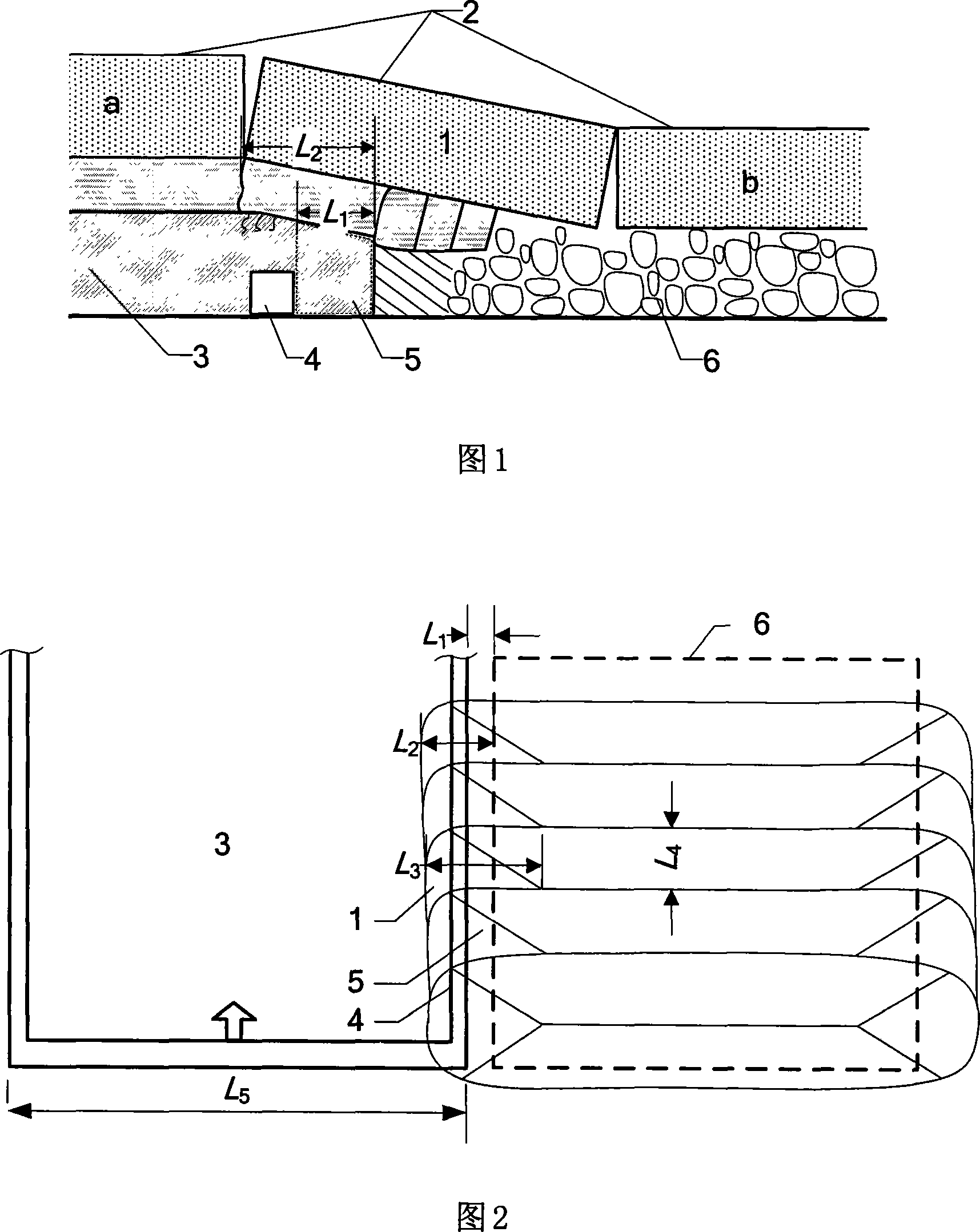

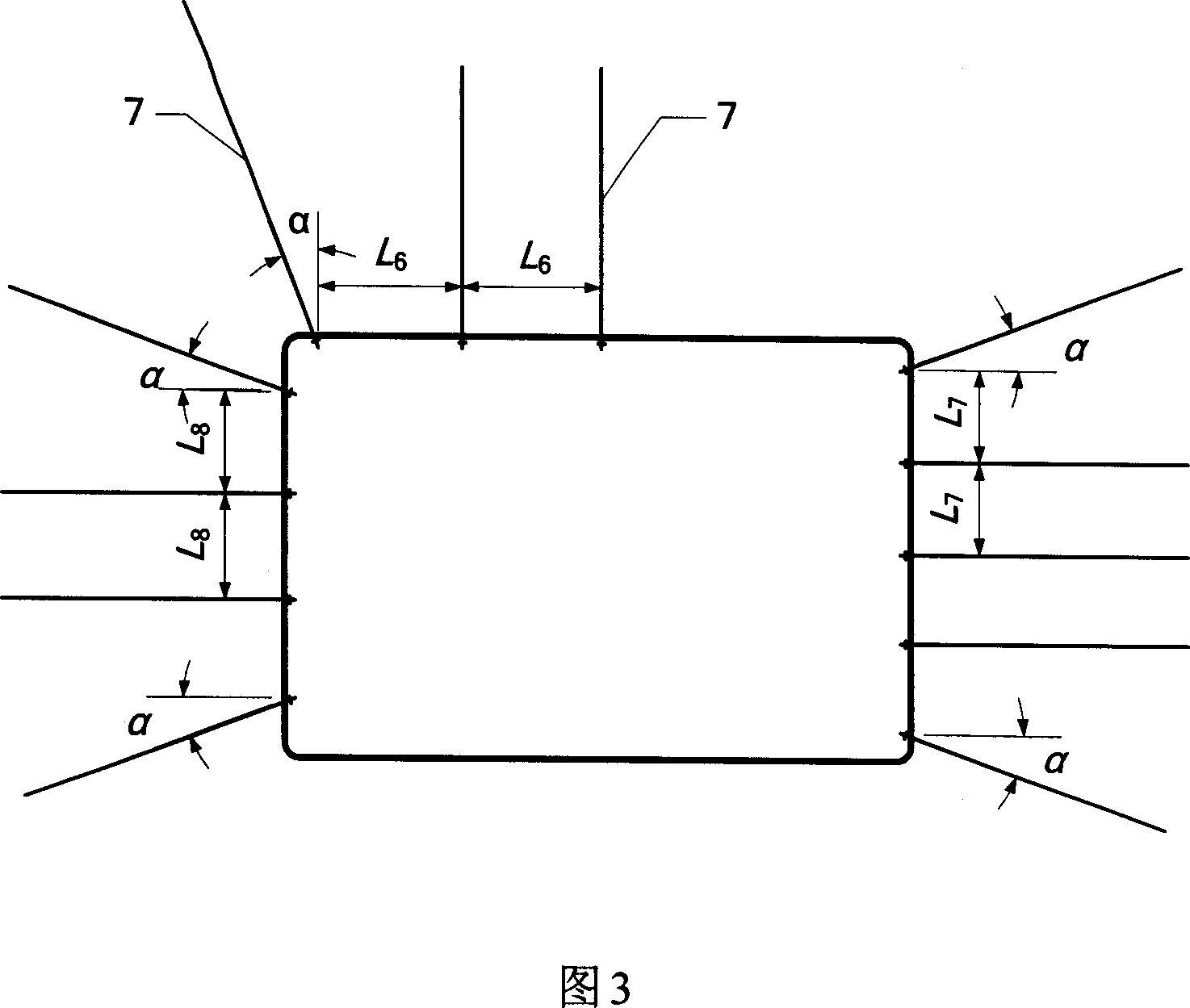

Method for controlling wall rock of fully mechanized coal face goaf side coalbed laneway

A method for controlling the surrounding rock of the side coal seam roadway in the goaf of the fully-mechanized caving face. According to the geology of the fully-mechanized caving face measured on site and the mine pressure data of the adjacent mining face, the stability of the large structure of the overlying rock mass on the roadway is analyzed. Determine the width of the narrow coal pillar reserved on the side of the goaf, so that the roadway is located in the area of relatively low vertical stress in the coal body, and the high-performance bolt support that controls the surrounding rock of the roadway forms a small load-bearing structure in the surrounding rock in the anchorage area . The small structure can make full use of the surrounding rock's own bearing capacity, and has strong adaptability to the deformation of the surrounding rock, ensuring smooth roadway support without repair, low bolt support cost, fast speed, and low labor intensity; it is compatible with large coal pillar roadway protection Compared with the narrow coal pillar protection roadway, the method reduces the loss of coal resources, improves the recovery rate of fully mechanized caving mining, and has good economic and social benefits.

Owner:CHINA UNIV OF MINING & TECH

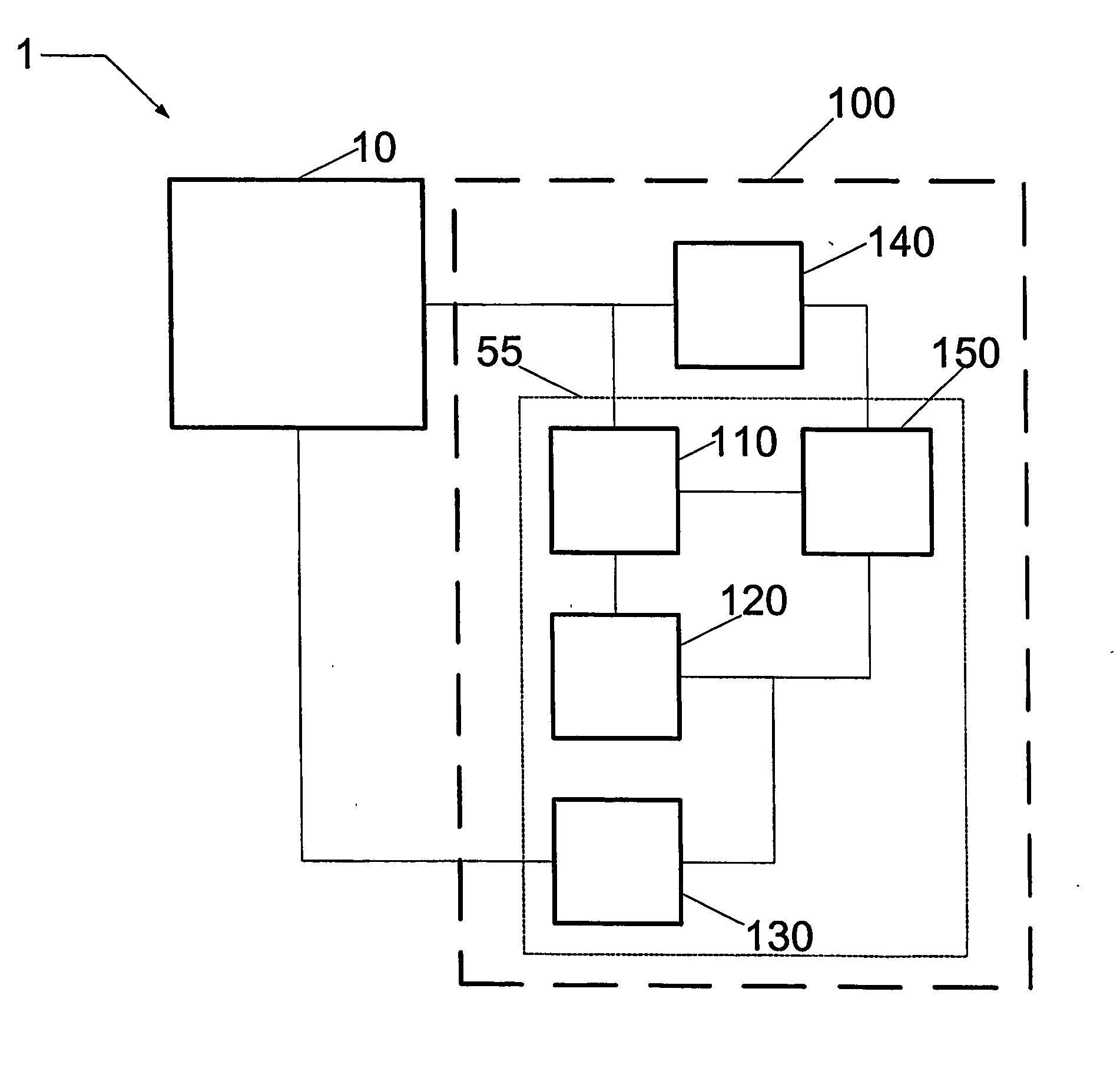

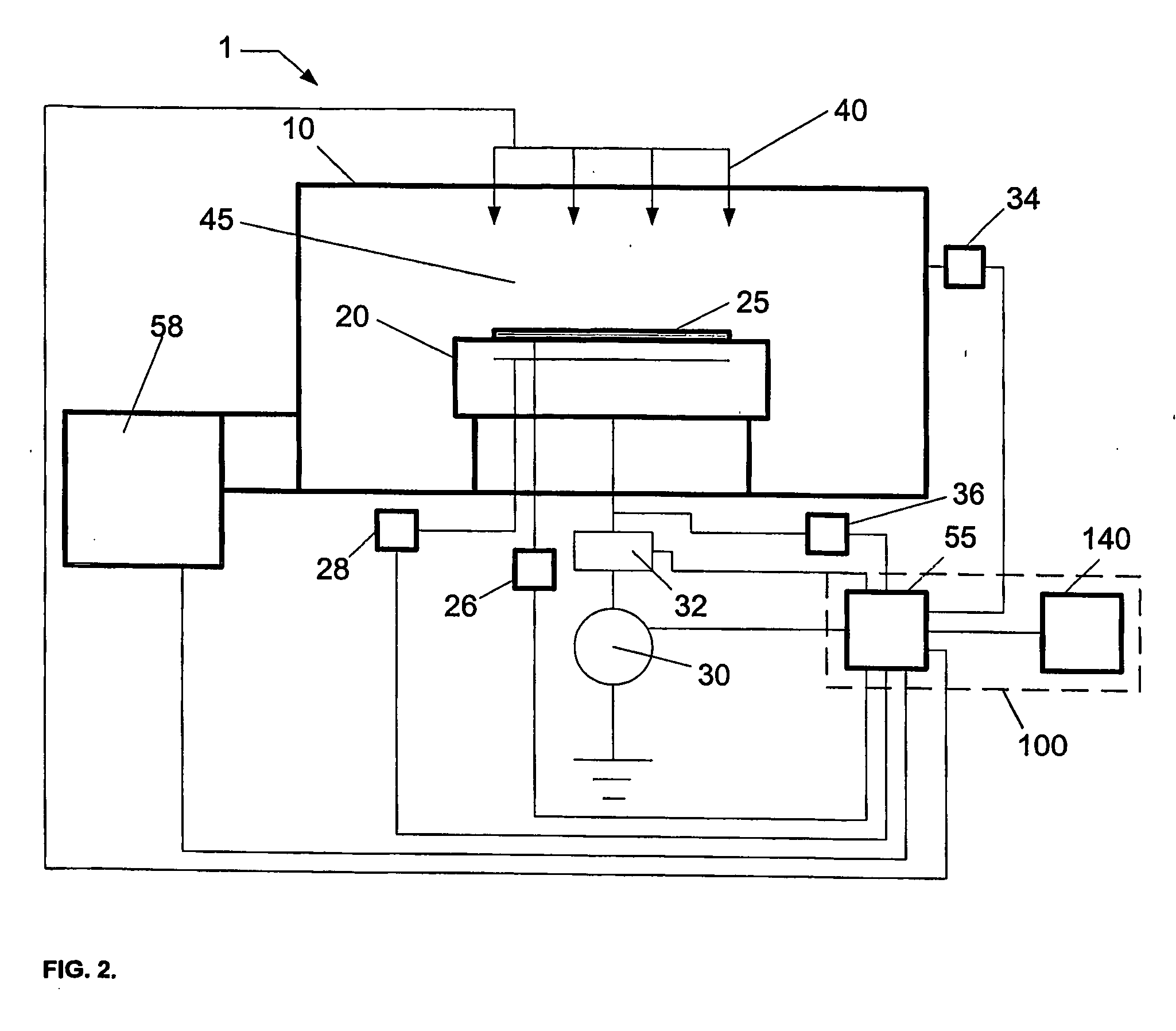

Controlling a material processing tool and performance data

InactiveUS20050234574A1Easy to controlDigital computer detailsNuclear monitoringCorrection algorithmControl system

According to an embodiment of the present invention, a material processing systeme (1) including a process tool (10) and a process performance control system (100). The process performance control system (100) includes a process performance controller (55) coupled to the process tool (10), where the process performance controller (55) includes a process performance prediction model (110), a process recipe correction filter (120), a process controller (130), and process performance model correction algorithm (150). The process performance prediction model (110) is configured to receive tool data from a plurality of sensors coupled to process tool (10) and to predict process performance data. The process recipe correction filter (120) is coupled to the process performance prediction model (110) and configured to receive predicted process performance data and generate a process recipe correction for run-to-run process control. The process controller (130) is coupled to the process recipe correction filter (120) and is configured to update a process recipe according to the process recipe correction.

Owner:TOKYO ELECTRON LTD

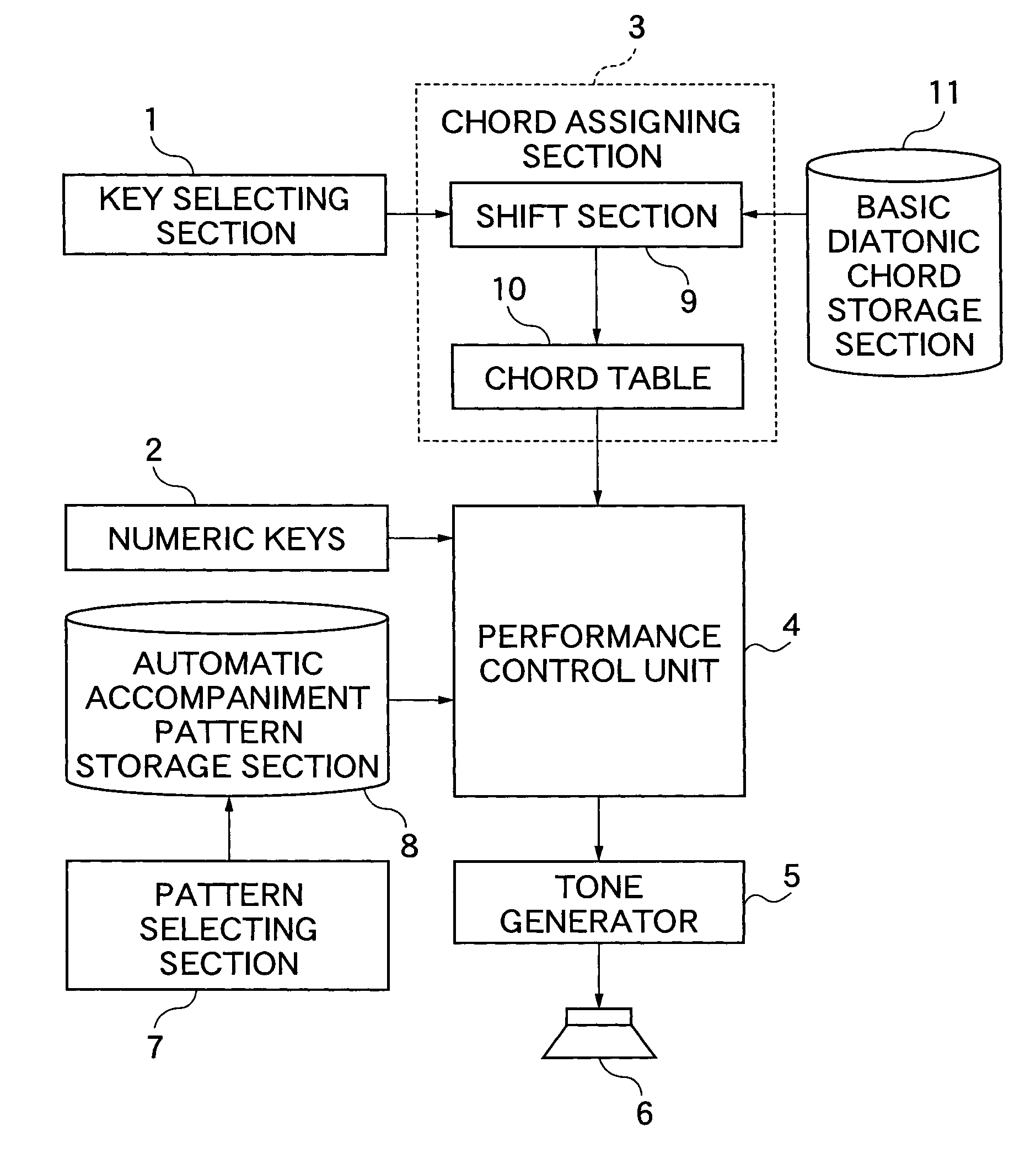

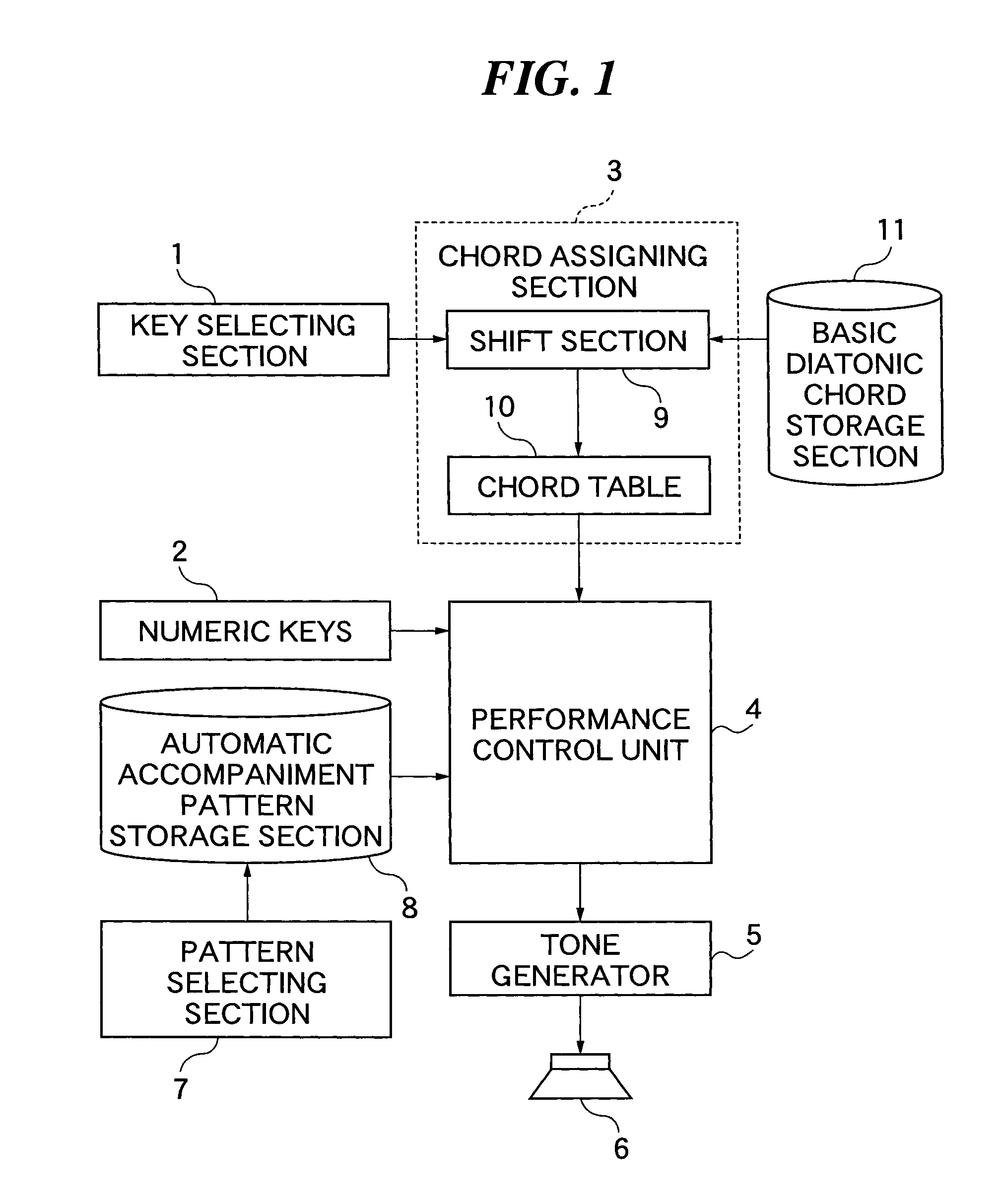

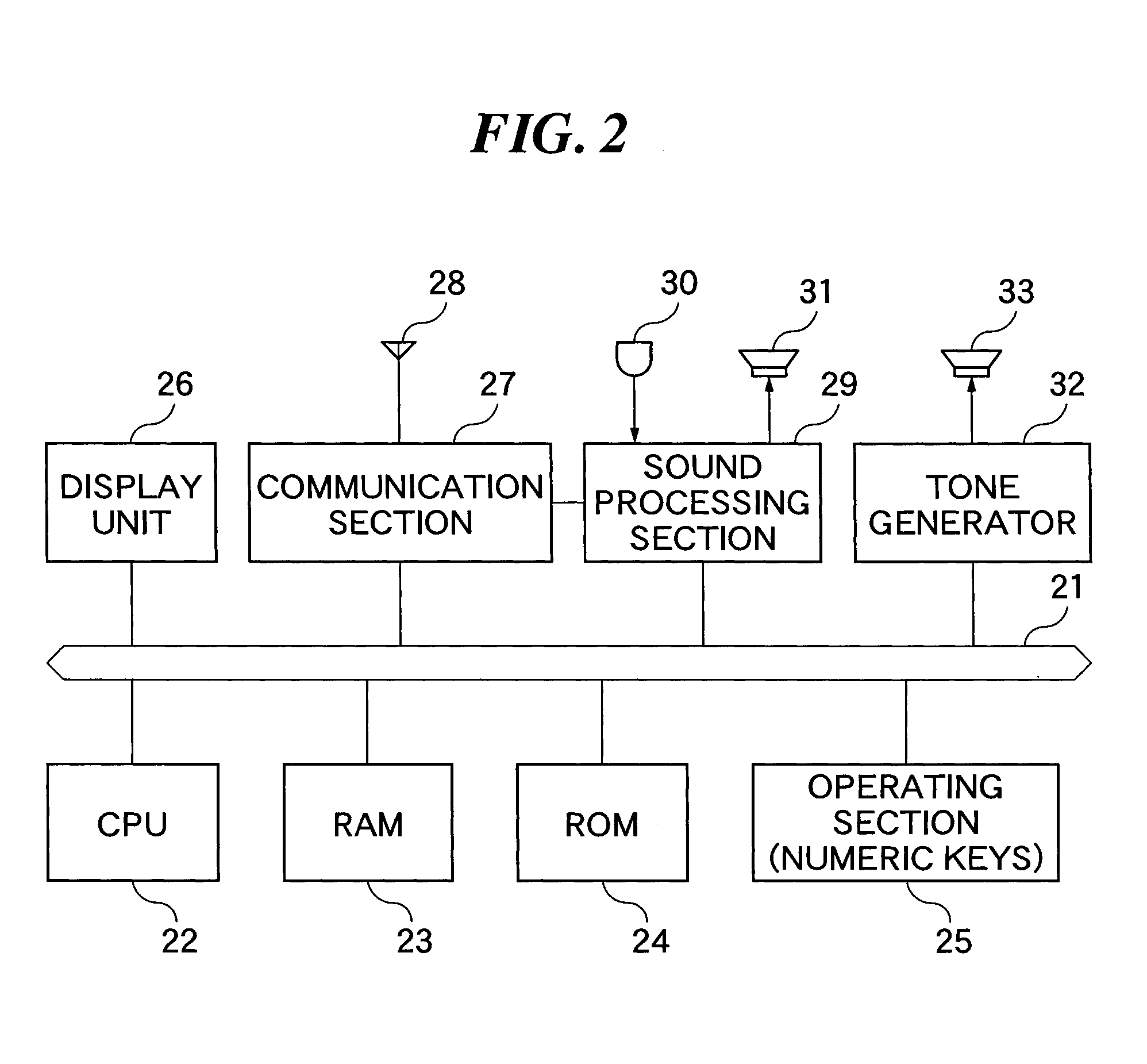

Musical tone signal generating apparatus

InactiveUS20070240559A1Easy to operateElectrophonic musical instrumentsSound producing devicesLoudspeakerComputer science

A musical tone signal generating apparatus enabling a user to designate a desired chord in a selected key of a piece of music with a simple operation such as operating a numeric key. A chord assigning section assigns numeric keys with respective ones of numeric keys in a key of a piece of music selected by a key selecting section. When any of the numeric keys is operated, a performance control unit reads out, from a chord table, note numbers of chord tones constituting the diatonic chord assigned to the operated numeric key, and outputs sounding instruction data including tone pitch data. In timing in which the sounding instruction data is inputted, a tone generator generates musical tone signals according to the tone pitch data, and causes via a sound system a speaker to sound musical tones.

Owner:YAMAHA CORP

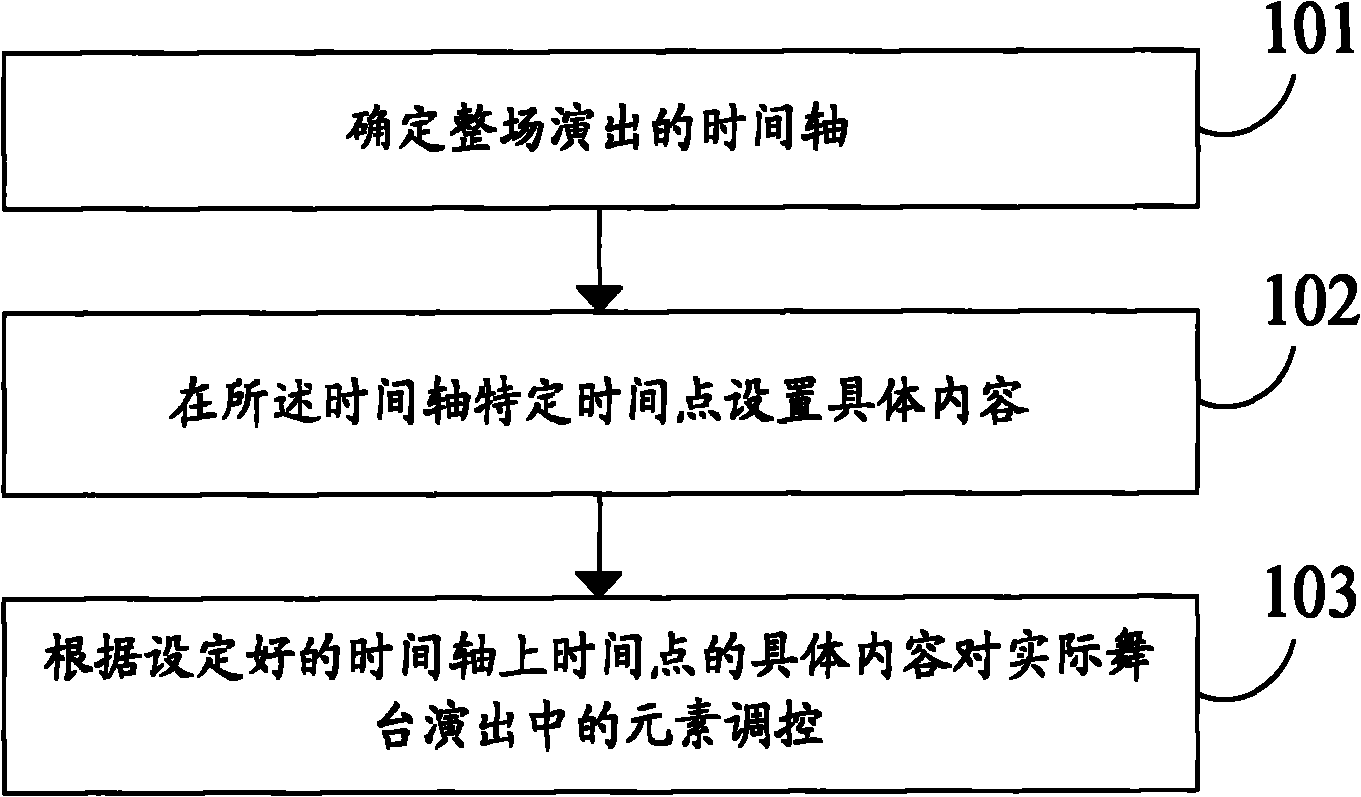

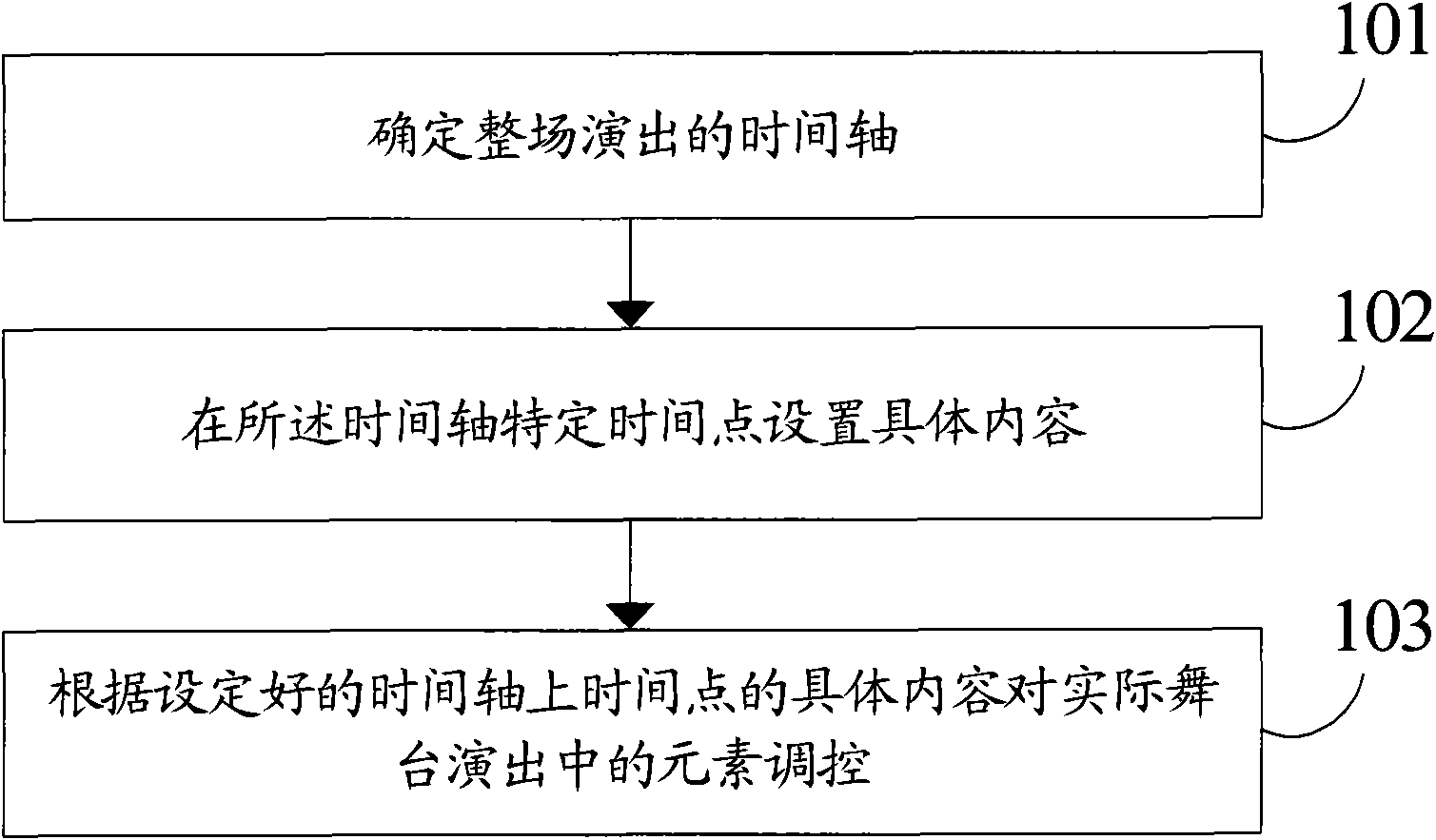

Rehearsal performance control method

InactiveCN101916095ASave manpower and material resourcesTotal factory controlProgramme total factory controlSpecific timePerformance control

The invention relates to a rehearsal performance control method which is characterized by comprising the following steps of: determining the time axis of the entire performance; setting particular contents at specific time points on the time axis; and controlling elements in the actual stage performance according to the set particular contents at the specific time points on the time axis.

Owner:BEIJING CRYSTAL TECH TRAINING LTD

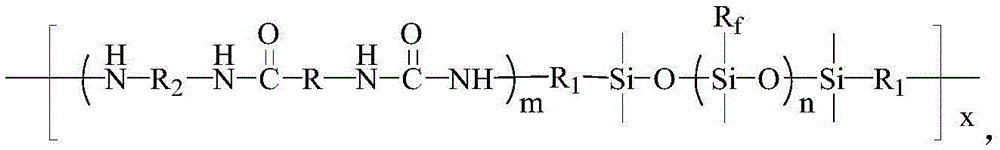

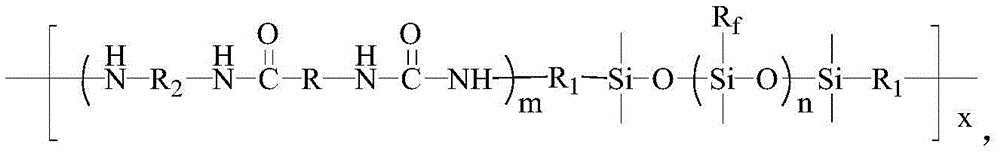

Organic fluorine-silicone-polyurethane block copolymer synthesizing method

The invention relates to an organic fluorine-silicone-polyurethane block copolymer synthesizing method. The method includes prepolymerizing alpha, omega-amino-hydrocarbon poly-fluorosilicone and diisocyanate in solvent, adding chain extender into prepolymer for extending chain, and removing the solvent to obtain the organic fluorine-silicone-polyurethane block copolymer. With the organic fluorine-silicone-polyurethane block copolymer, molecular structure design and performance control can be realized according to chain length of the poly-fluorosilicone and the structure of the diisocyanate, and chain segments of the poly-fluorosilicone have the features of excellent water resistance, low surface performance and others. The polyurethane chain segments are excellent in thermal stability and wear resistance. The organic fluorine-silicone-polyurethane block copolymer synthesizing method has great application potential in antifouling coatings, leather, textiles, papermaking and modification of fiber surfaces.

Owner:QINGDAO UNIV OF SCI & TECH

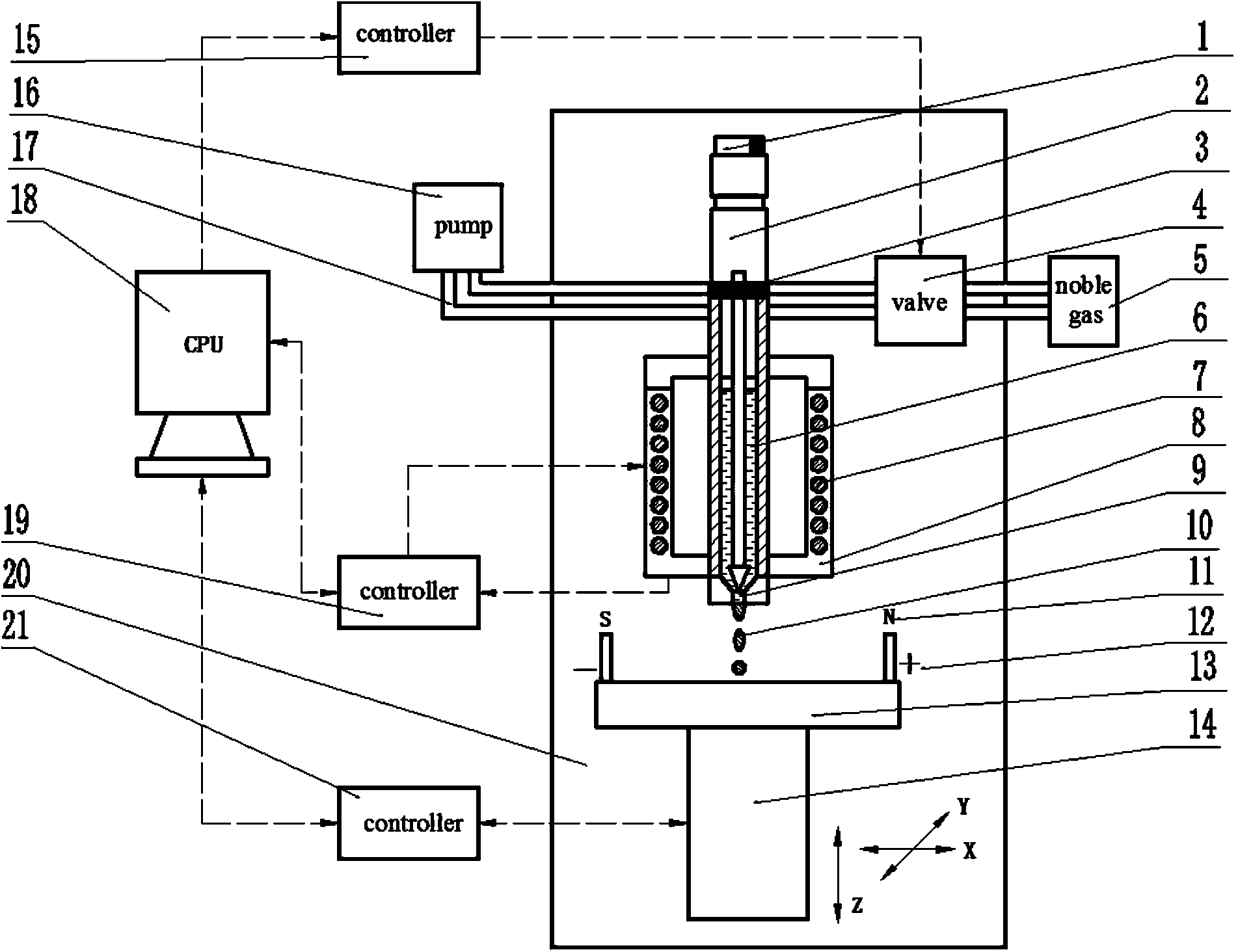

Metal micro-spraying molten drop electromagnetic restraint deposition modeling system

InactiveCN104028761AHigh forming precisionImprove molding efficiencyVolumetric Mass DensityElectromagnetic field

The invention discloses a metal micro-spraying molten drop electromagnetic restraint deposition modeling system. By using the system, a metal molten drop deposition modeling technology, a micro-spraying technology and a metal solidification modeling theory under effects of an electromagnetic field are integrated, expanded and contracted pulse pressure is generated in a cavity of a crucible by using pressure pulses, metal molten drops are uniformly sprayed controllably through a gap-adjustable nozzle as needed by controlling change of the pulse pressure, and the metal micro molten drops are supplied as needed in a molecule manner by adjusting driving control parameters and relative positions of the gap-adjustable nozzle and a substrate. The metal micro molten drops are subjected to accurate deposition modeling in a shape-controlled and performance-controlled manner after the metal micro molten drops flow and are quickly solidified by a restraint effect of an electromagnetic field in environments of small space, high field intensity and high time and temperature gradient by applying the external electromagnetic field to a position nearby a micro molten drop deposition area. The modeling precision and the modeling efficiency of metal composite components are improved; crystalline grains are refined; the density of a microstructure is improved; and the modeling quality is also improved.

Owner:XI AN JIAOTONG UNIV +1

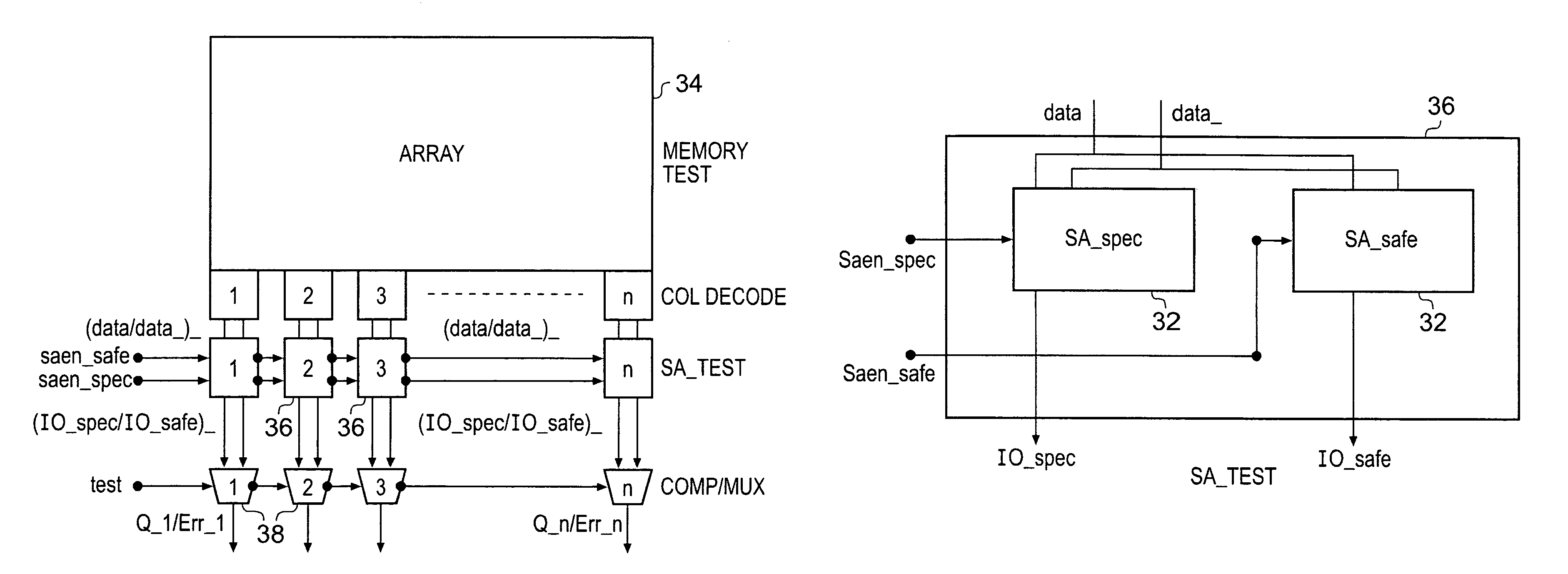

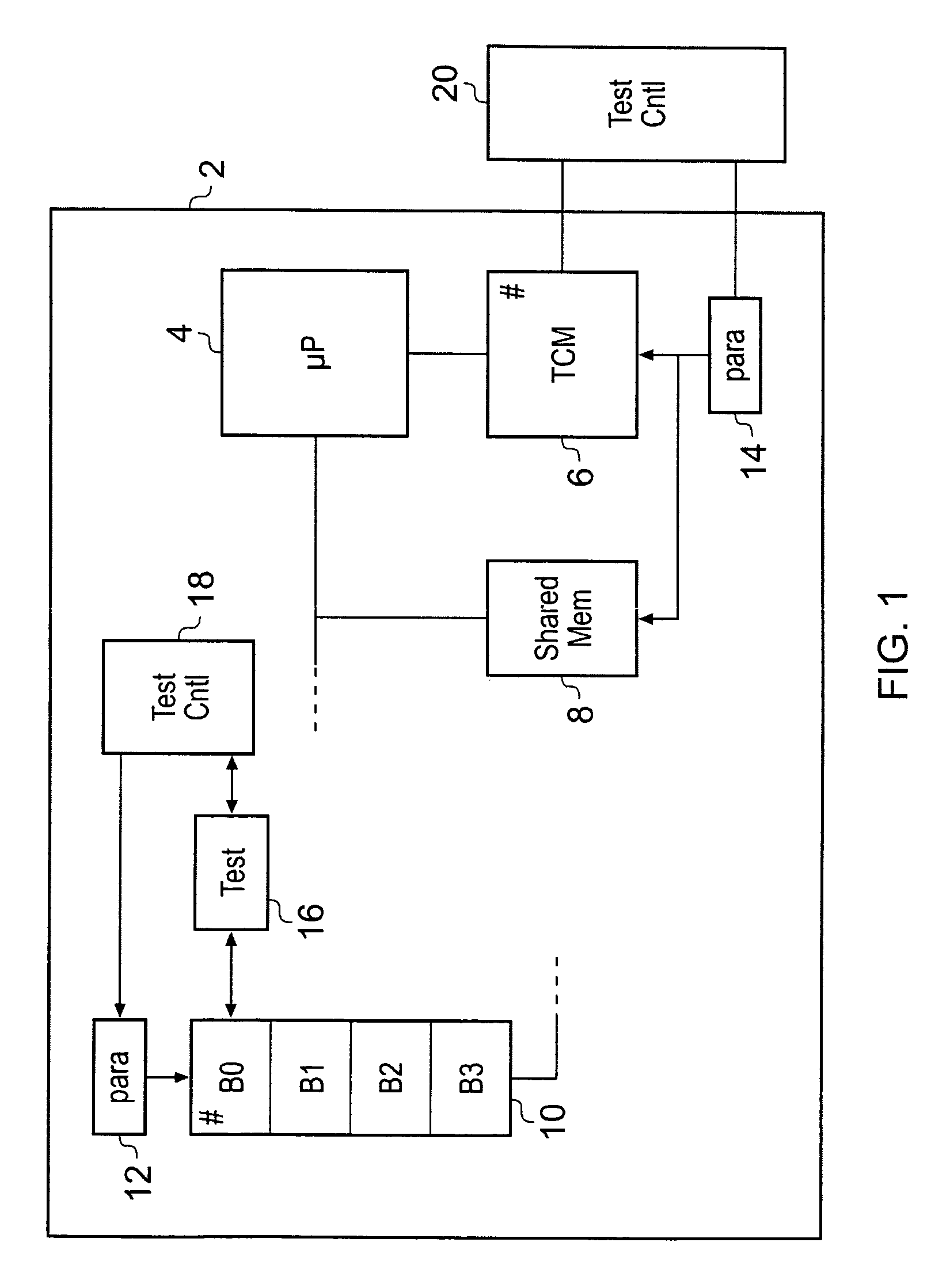

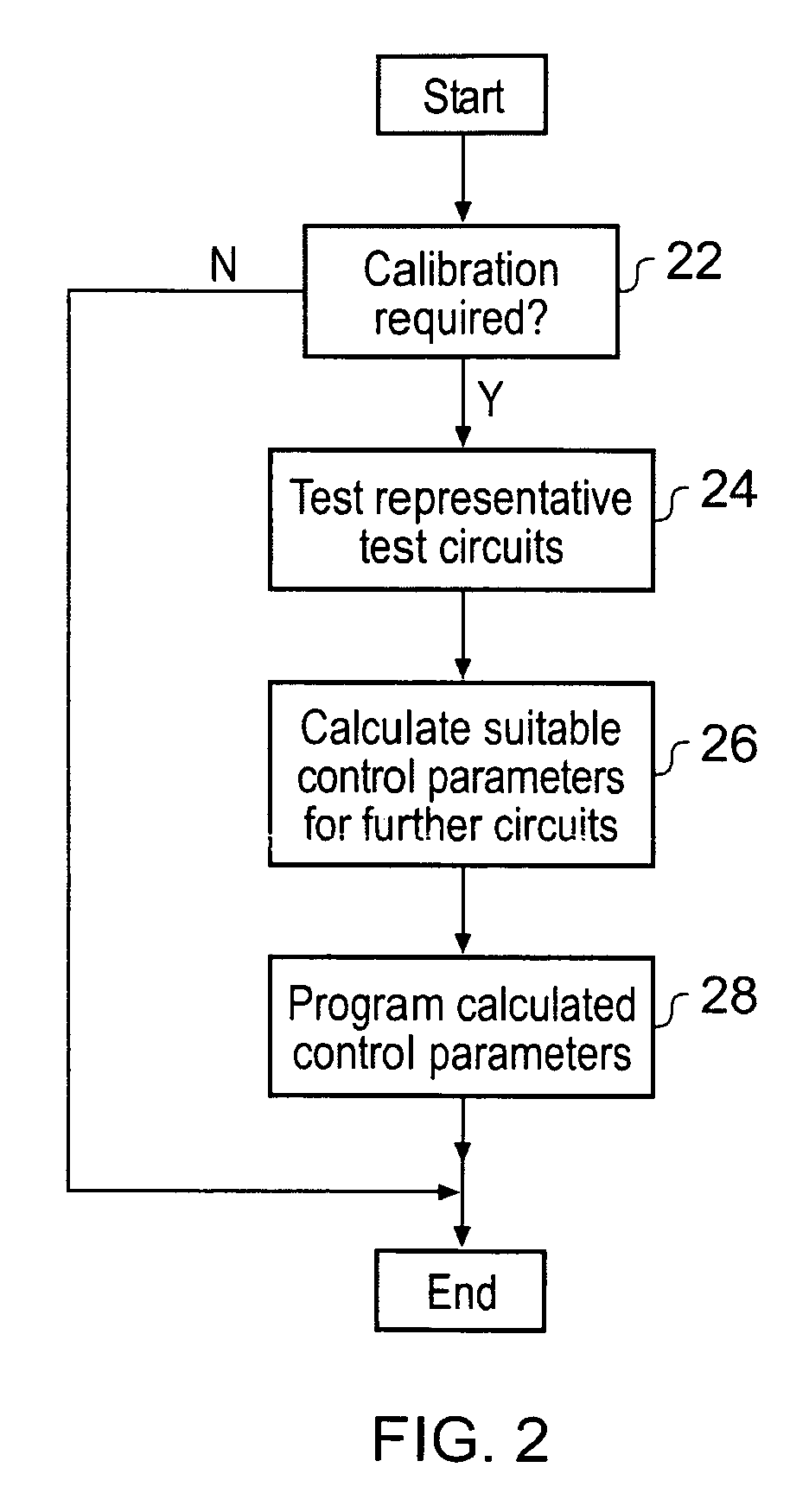

Performance control of an integrated circuit

ActiveUS7603605B2Reduce overheadHigh degreeError detection/correctionElectrical testingMemory bankControl engineering

An integrated circuit is provided with a test circuit element and one or more further circuit elements. The performance of the test circuit element at various settings of a performance controlling parameter is determined. That performance controlling parameter is then applied across the one or more further circuit elements. The integrated circuit may include memory banks and the performance controlling parameter can be sense amplifier timing, delay line length or another parameter such as operating voltage, operating frequency and circuit timing in general.

Owner:ARM LTD

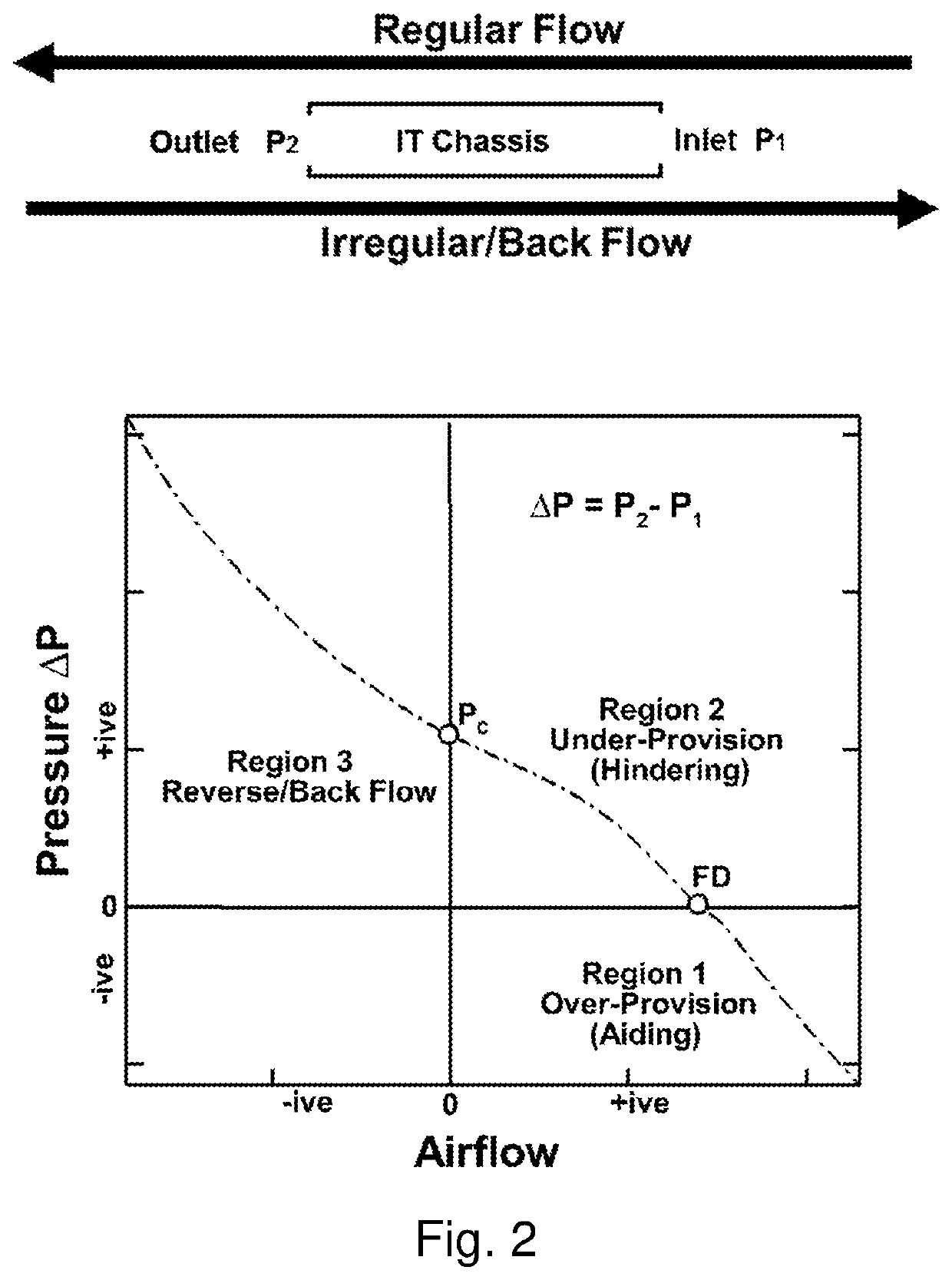

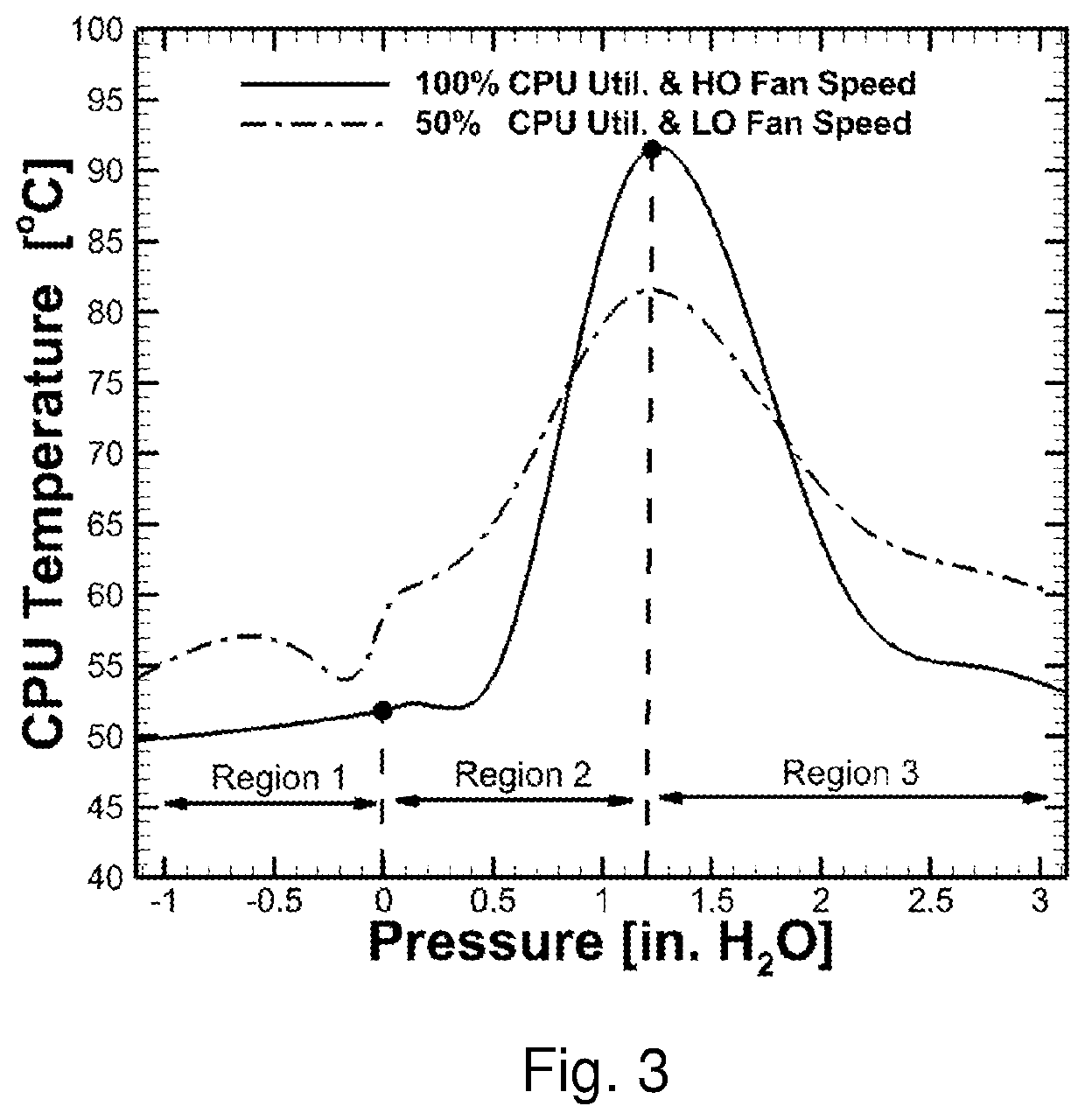

Control systems and prediction methods for it cooling performance in containment

ActiveUS11076509B2Avoiding CPU thermal throttlingReduce deliveryCooling/ventilation/heating modificationsAdaptive controlCold airData center

A method of controlling a data center having a cold air cooling system, and at least one containment structure, comprising: determining a minimum performance constraint; determining optimum states of the cold air cooling system, a controlled leakage of air across the containment structure between a hot region and a cold air region, and information technology equipment for performing tasks to meet the minimum performance constraint, to minimize operating cost; and generating control signals to the cold air cooling system, a controlled leakage device, and the information technology equipment in accordance with the determined optimum states.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com