Method for controlling wall rock of fully mechanized coal face goaf side coalbed laneway

A technology for gobs and fully-mechanized caving faces, which is applied to mining equipment, earthwork drilling, and installation of bolts, etc., and can solve the problem that the mining of fully-mechanized caving faces hinders the ability of fully-mechanized caving equipment, reduces the recovery rate of fully-mechanized caving mining, and wastes coal resources. and other problems, to achieve the effect of reducing the cost of roadway support, reducing the labor intensity of workers, and improving the efficiency of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

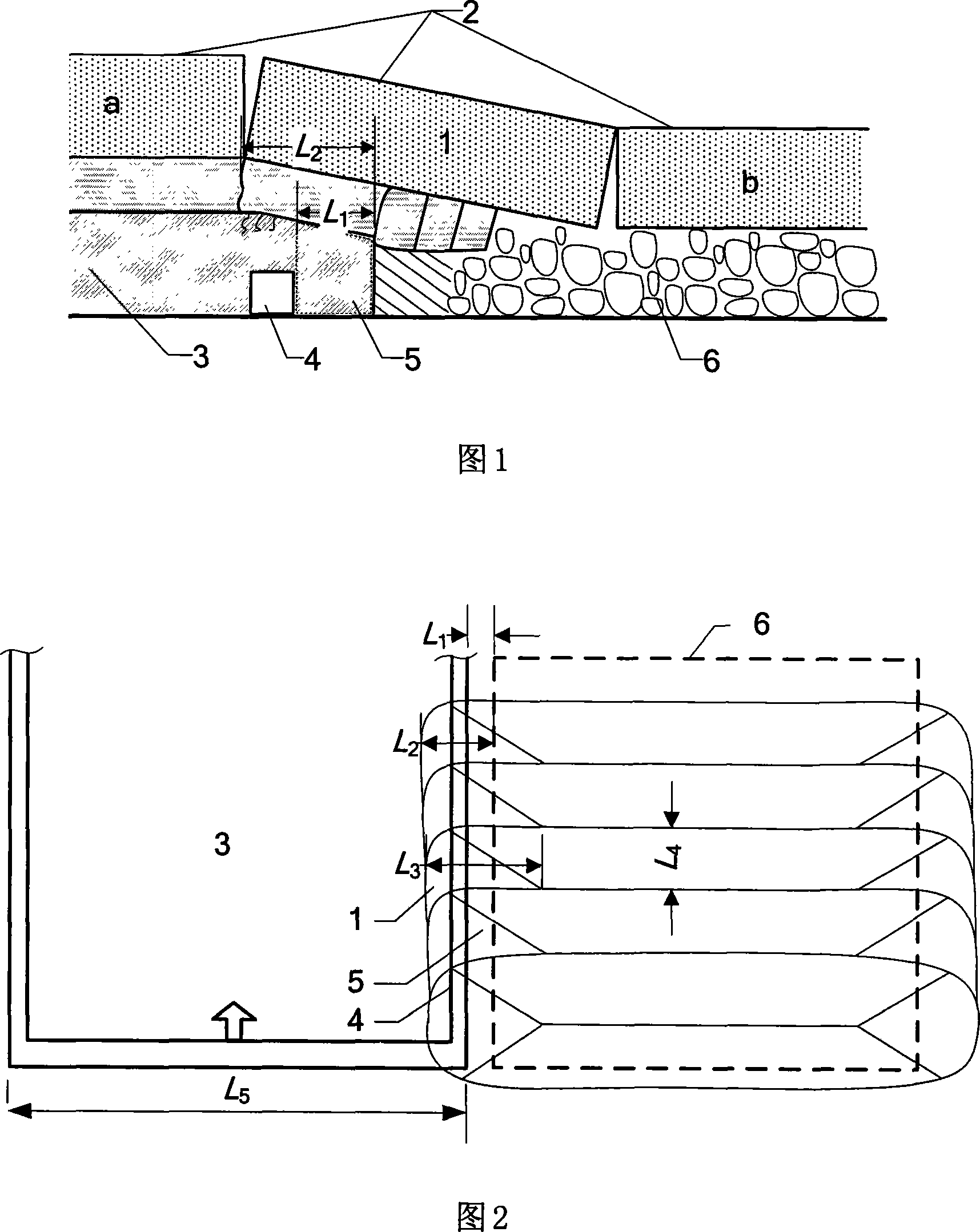

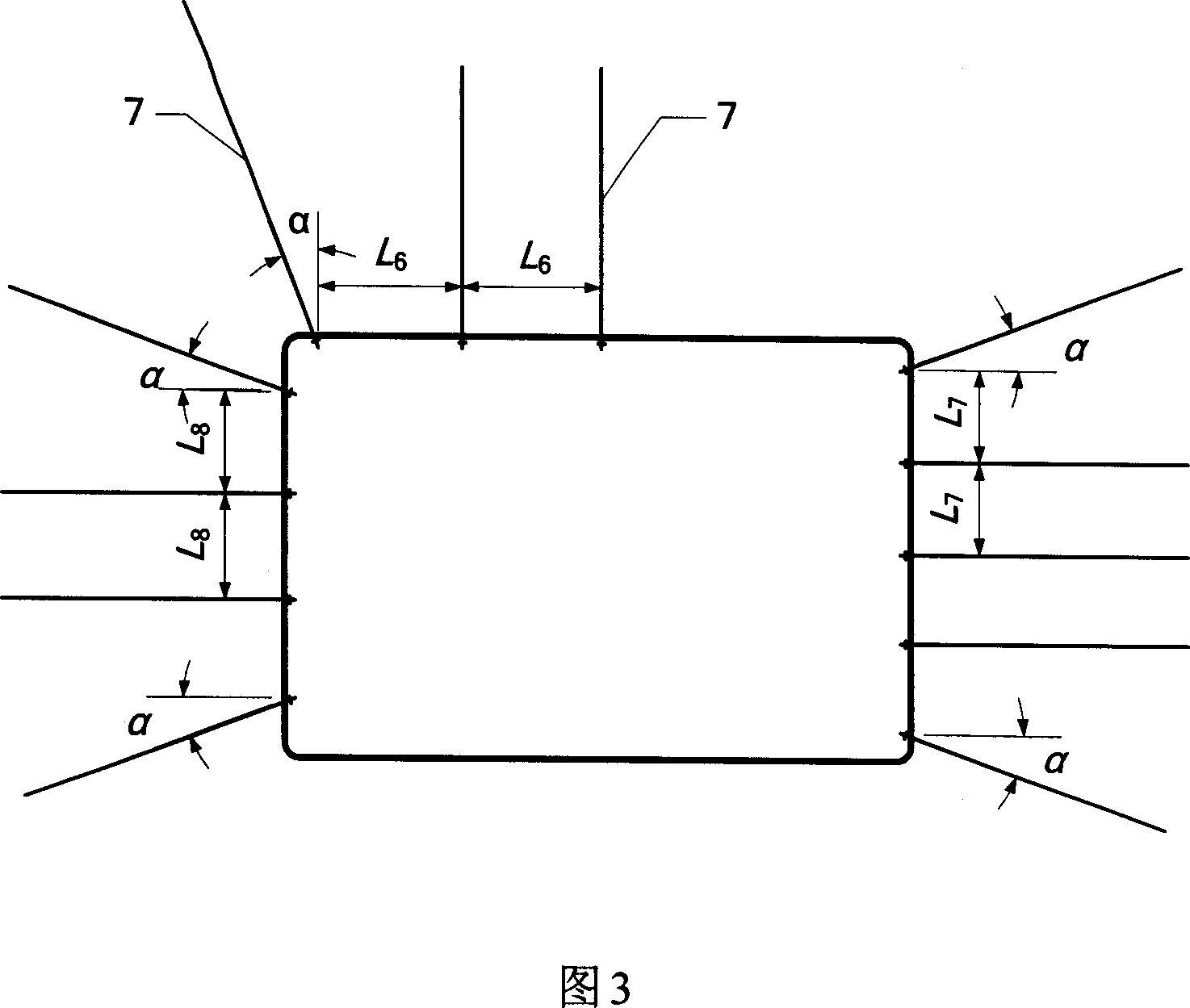

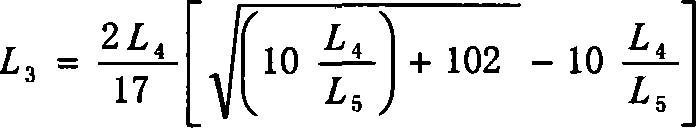

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0015] The method for surrounding rock of the present invention to control the side coal seam roadway in the goaf of fully mechanized caving face is as follows:

[0016] 1. Stability analysis of large structure of overlying rock mass

[0017] 1. Taking a coal mine as an example, according to the geological data of the fully-mechanized caving face measured in the coal mine and the mine pressure data of the adjacent mining face, it is known that the average buried depth of roadway 4 is 500m, the average coal thickness is 8.28m, and the coal seam dip angle is 3 ~7°, the joints and fissures of the coal seam are developed, which belongs to the weak and broken coal seam. The cohesion of the coal seam is 2.2Mpa, the internal friction angle is 20°, and the density is 1.5g / cm 3 . The top of the coal seam is 0.2m thick gray mudstone, 2.06m thick gray black siltston...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com