Patents

Literature

363 results about "Spelunking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caving – also known as spelunking in the United States and Canada and potholing in the United Kingdom and Ireland – is the recreational pastime of exploring wild (generally non-commercial) cave systems. In contrast, speleology is the scientific study of caves and the cave environment.

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

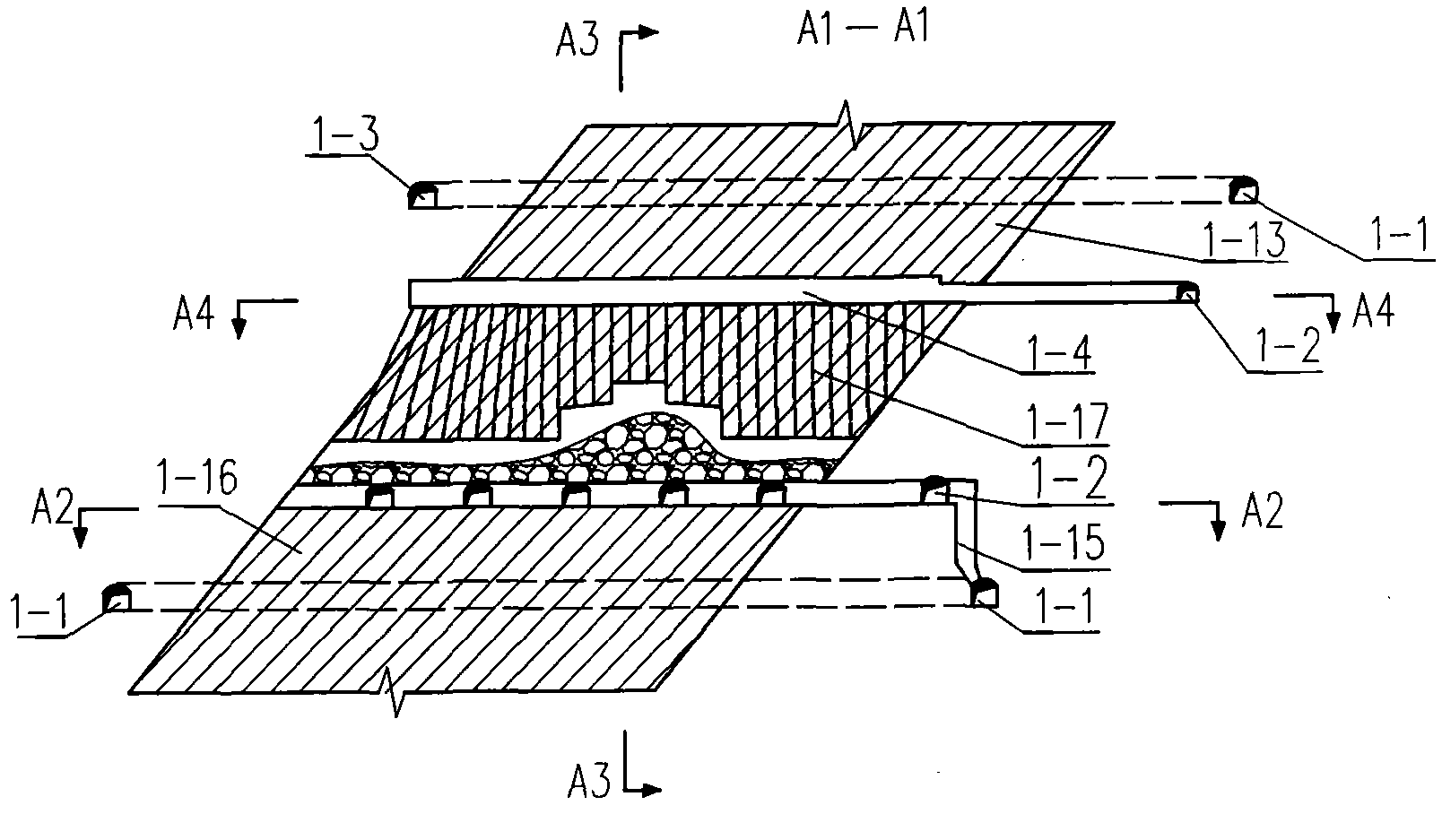

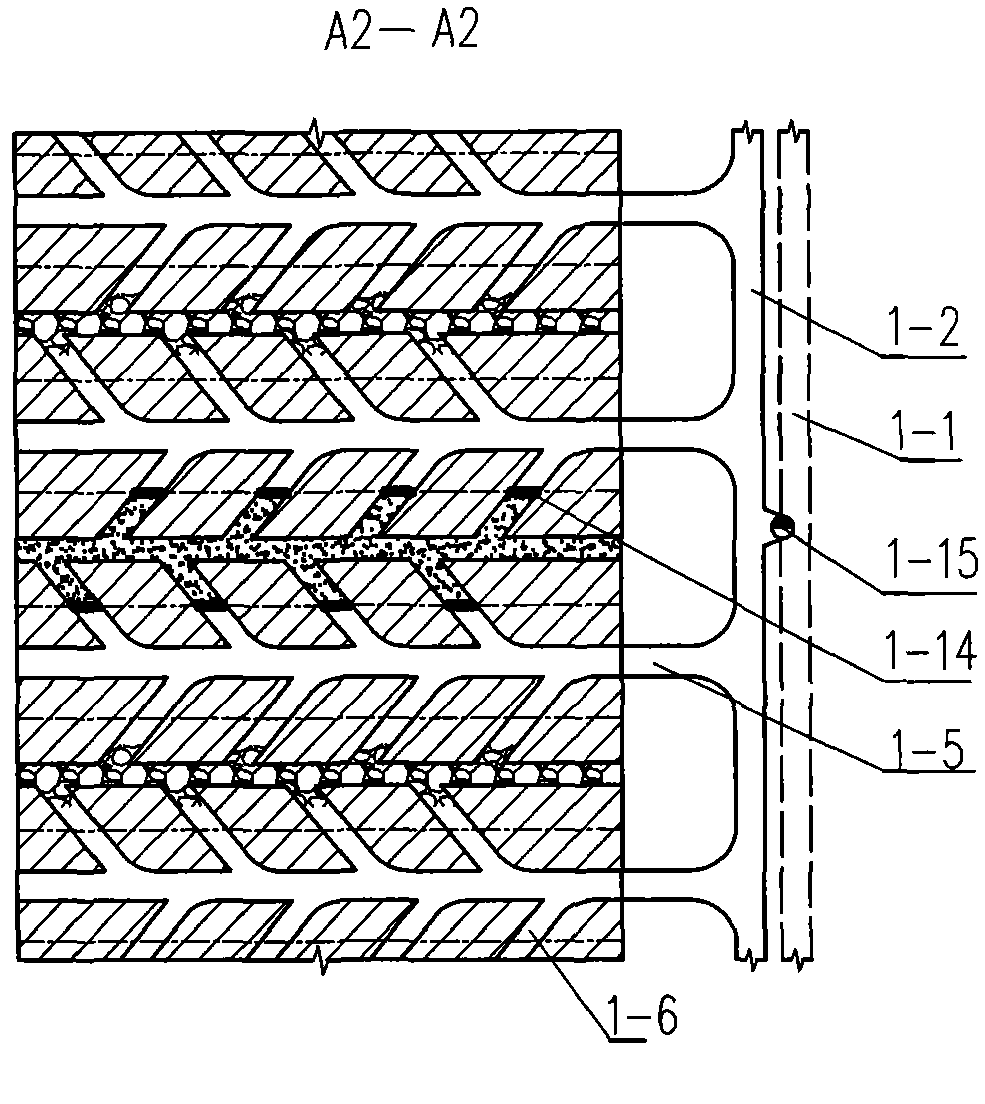

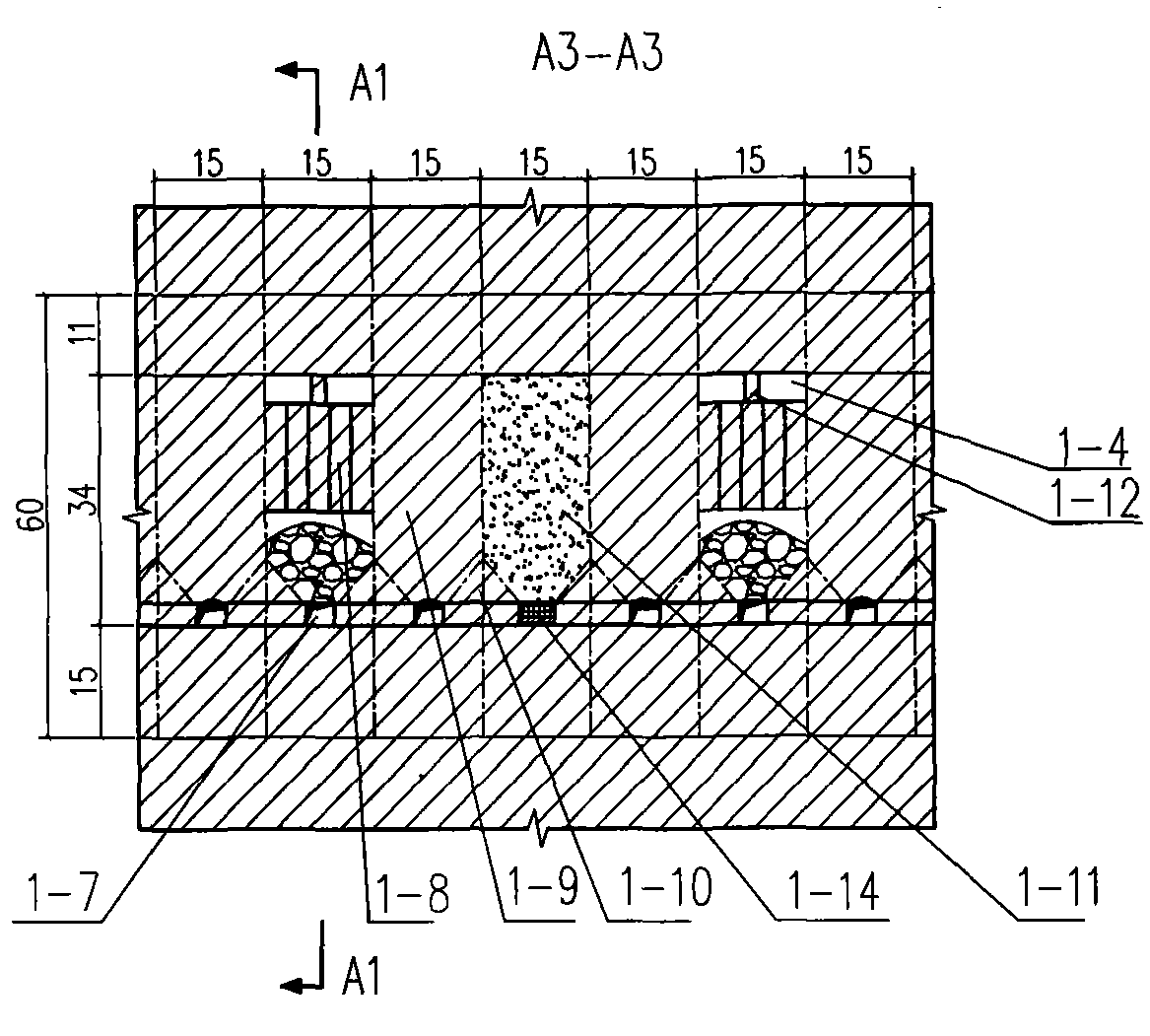

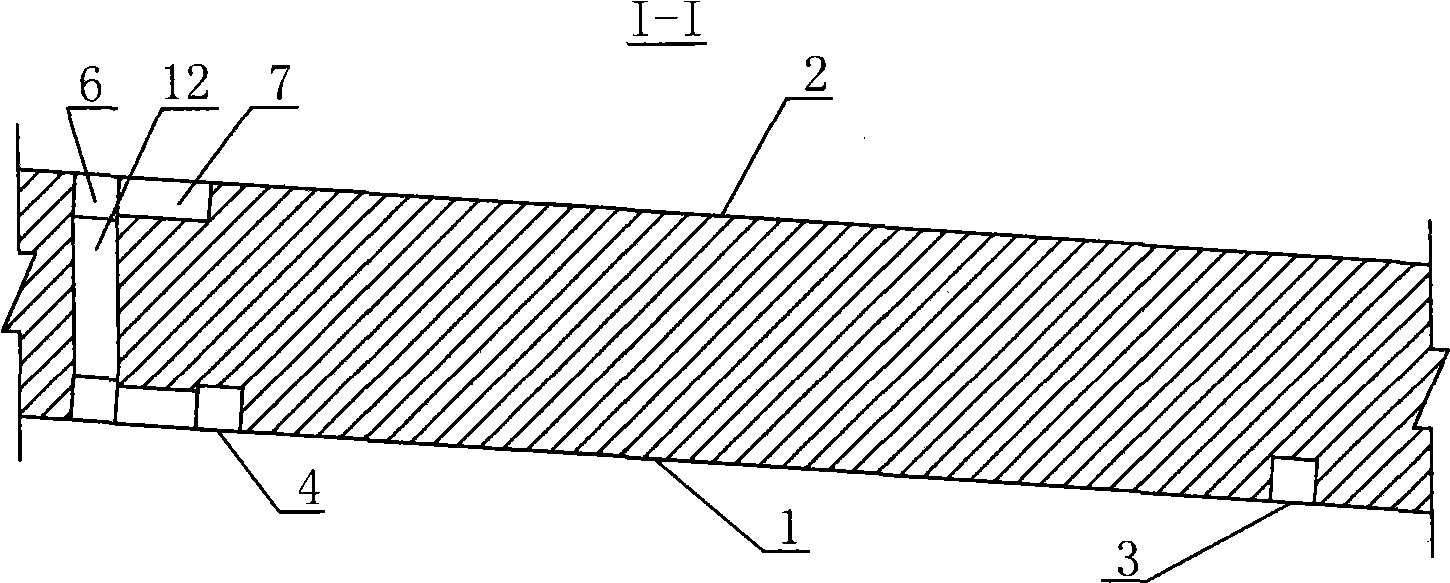

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

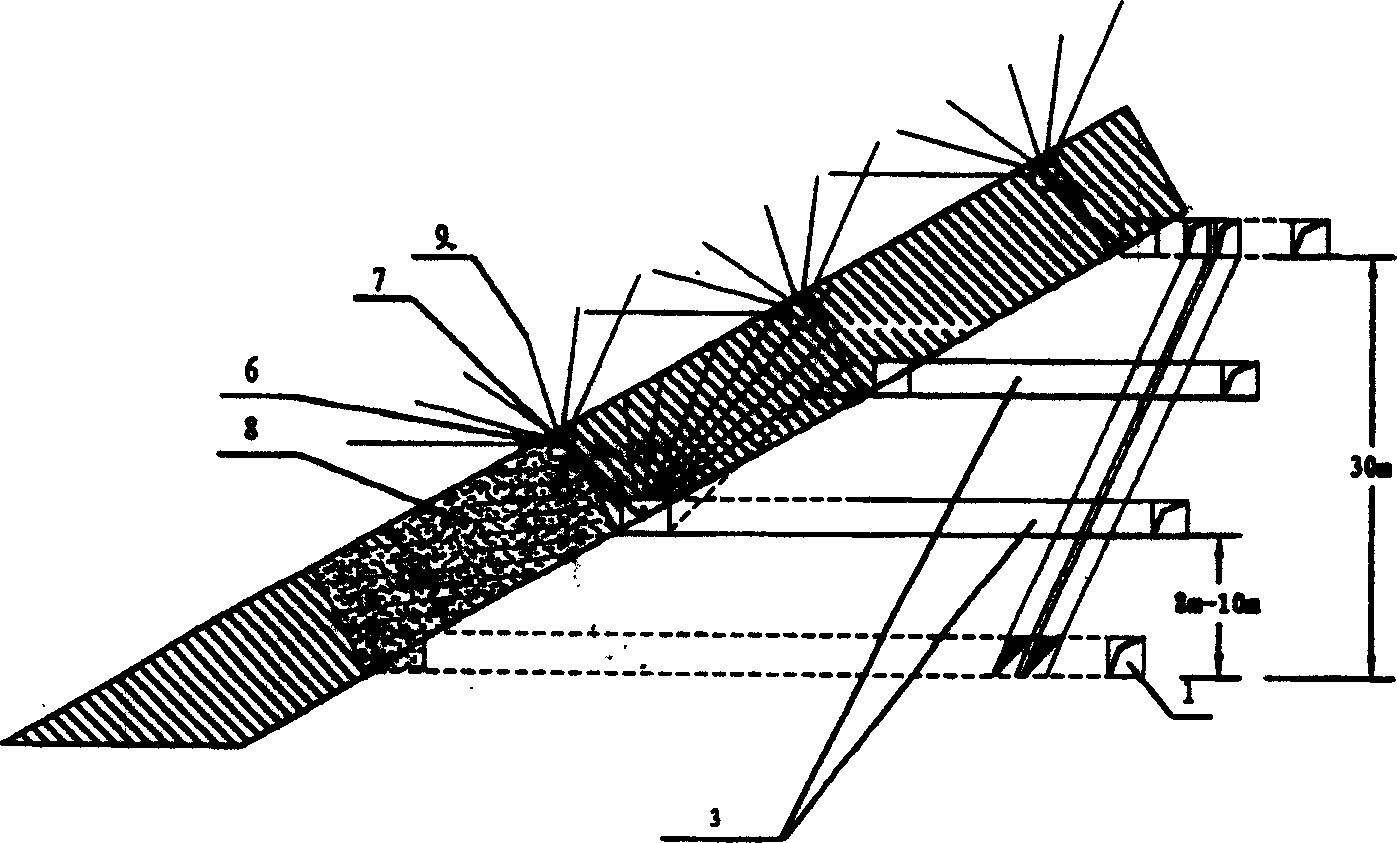

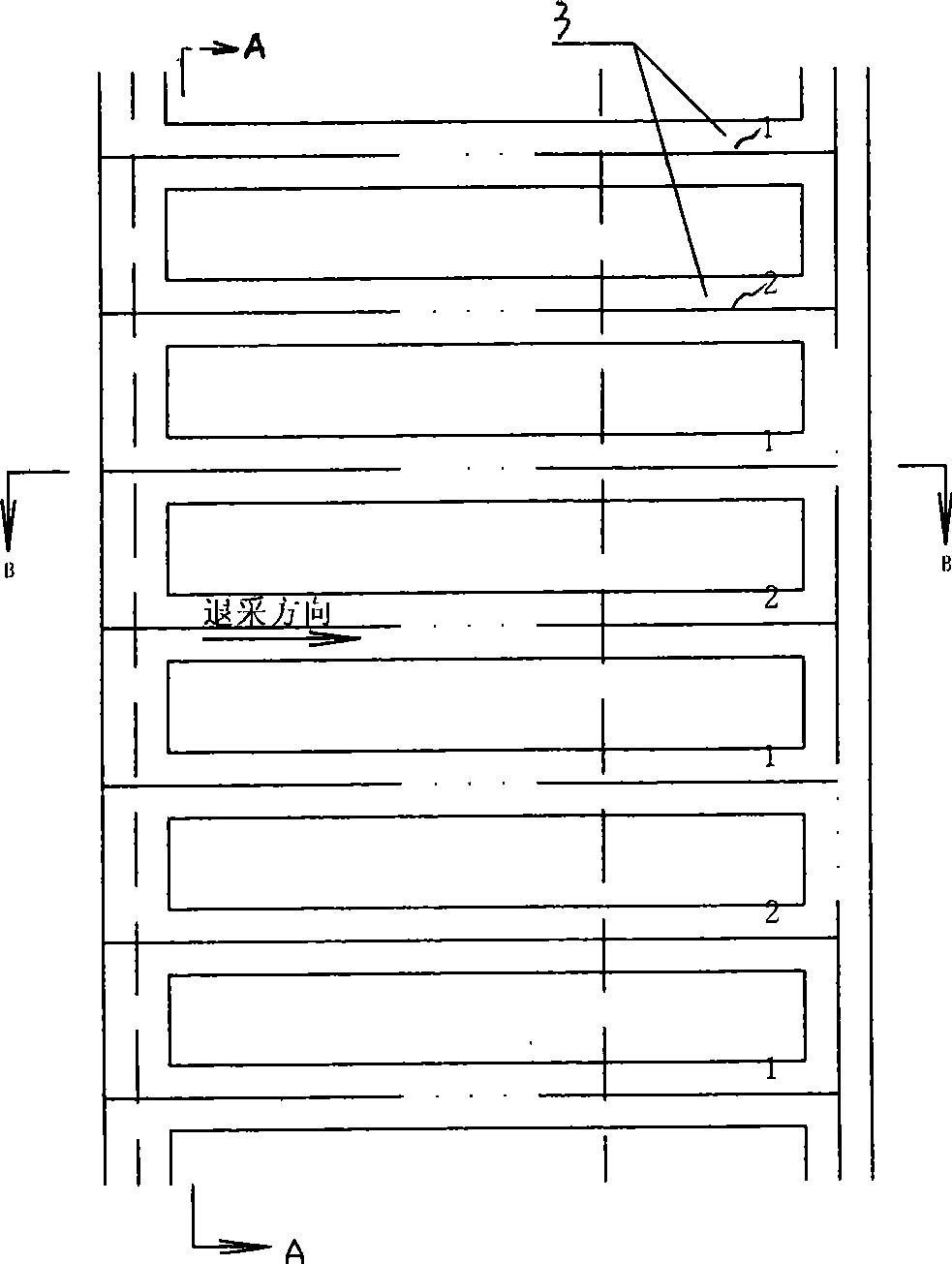

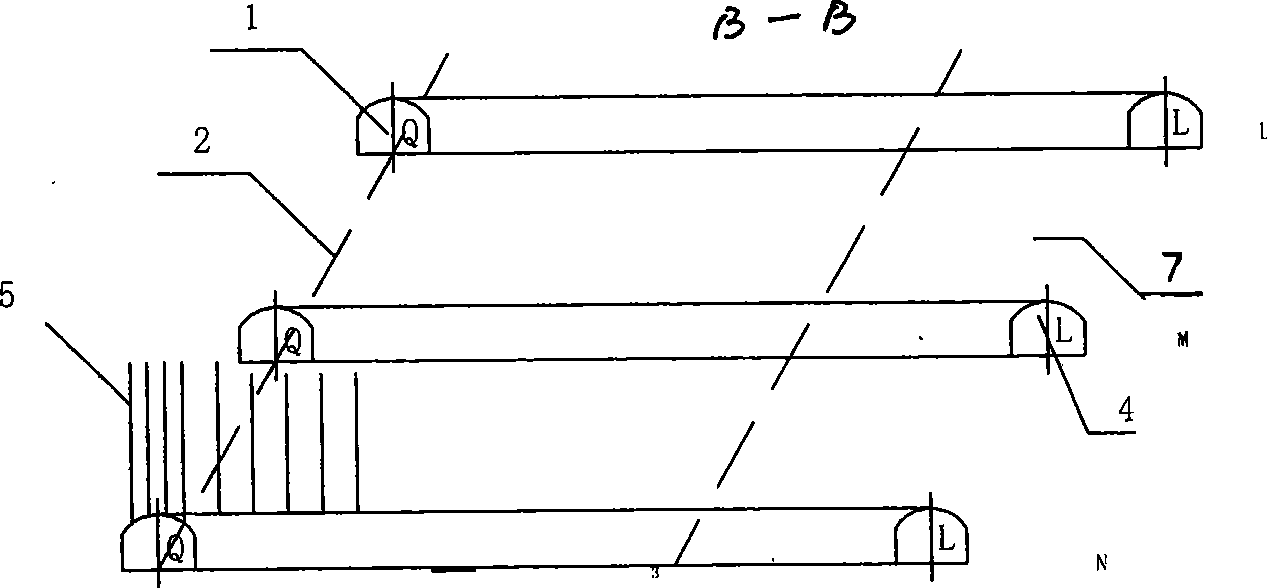

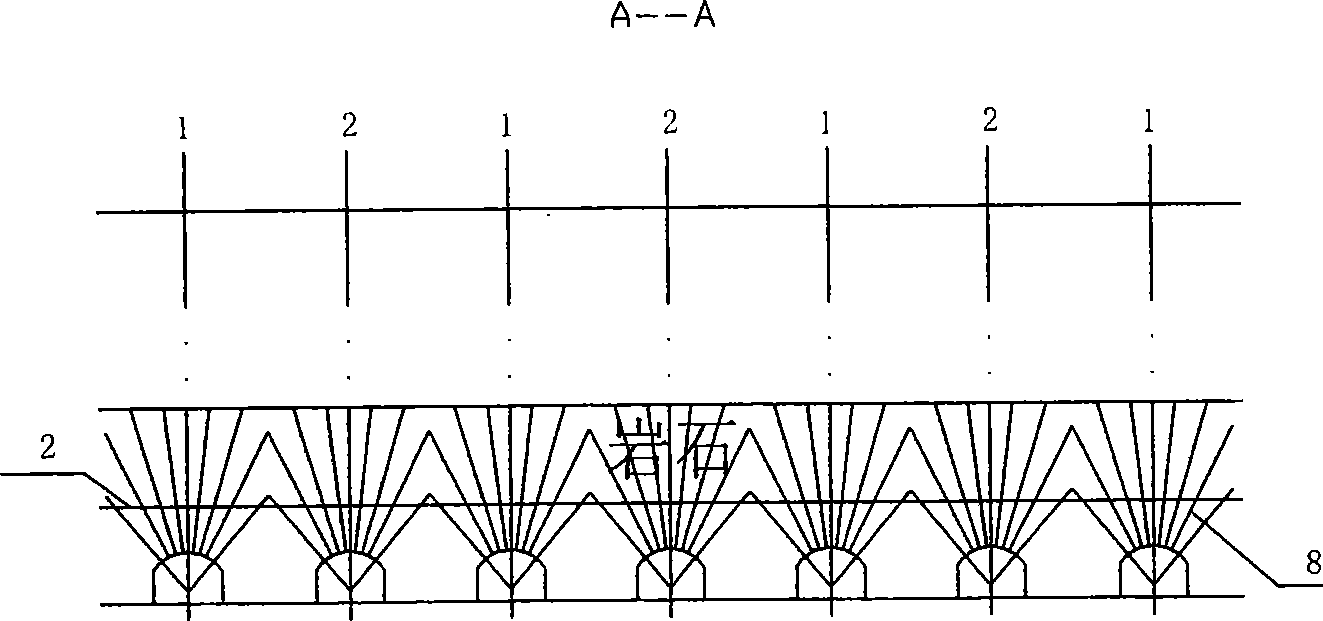

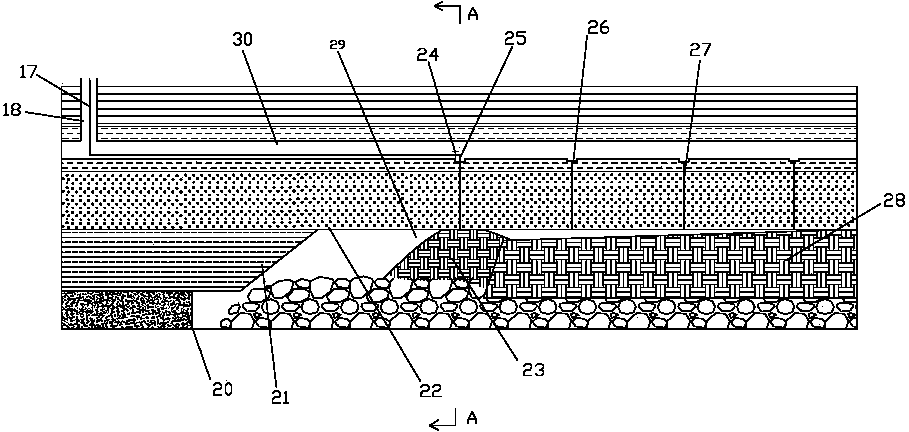

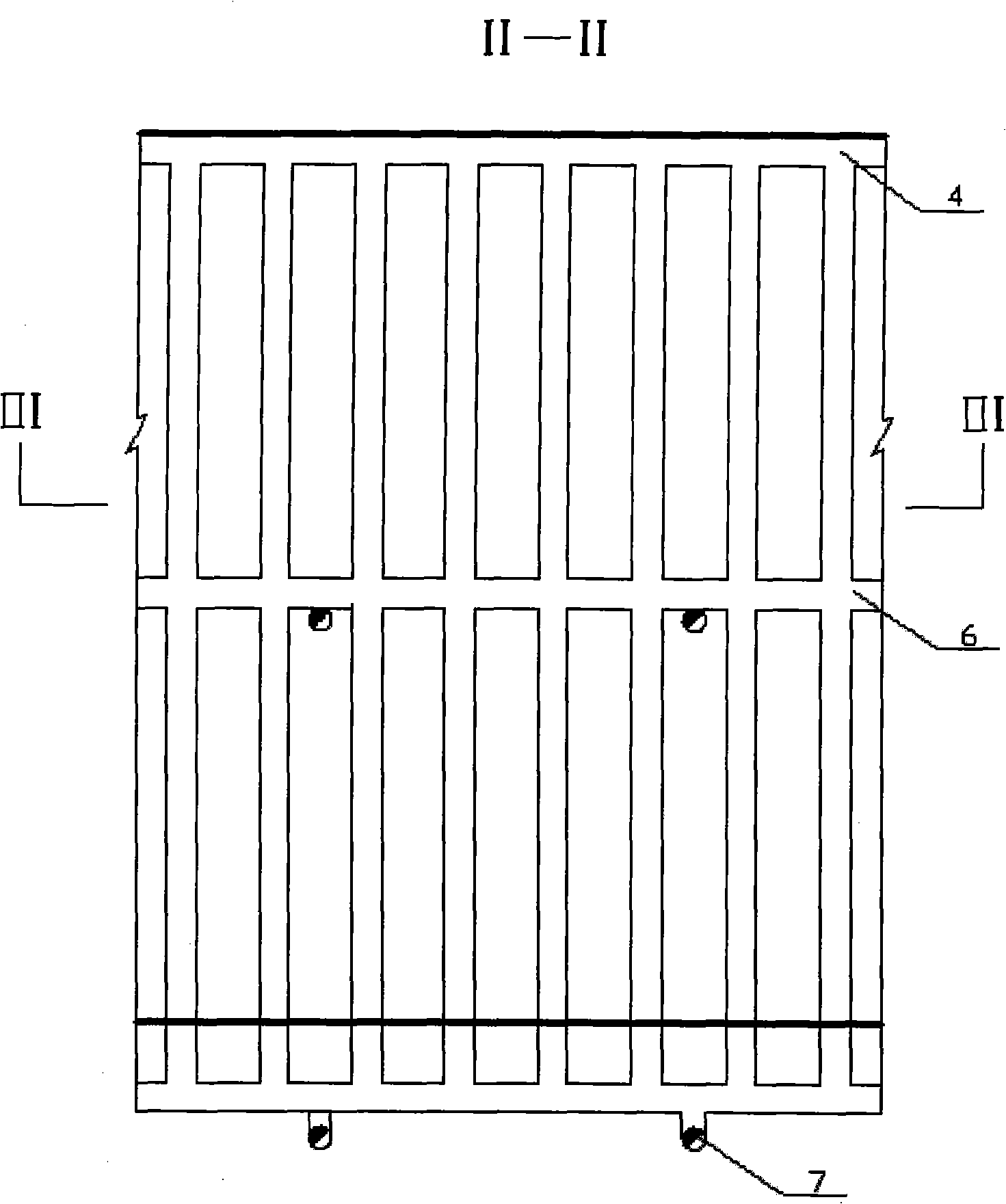

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

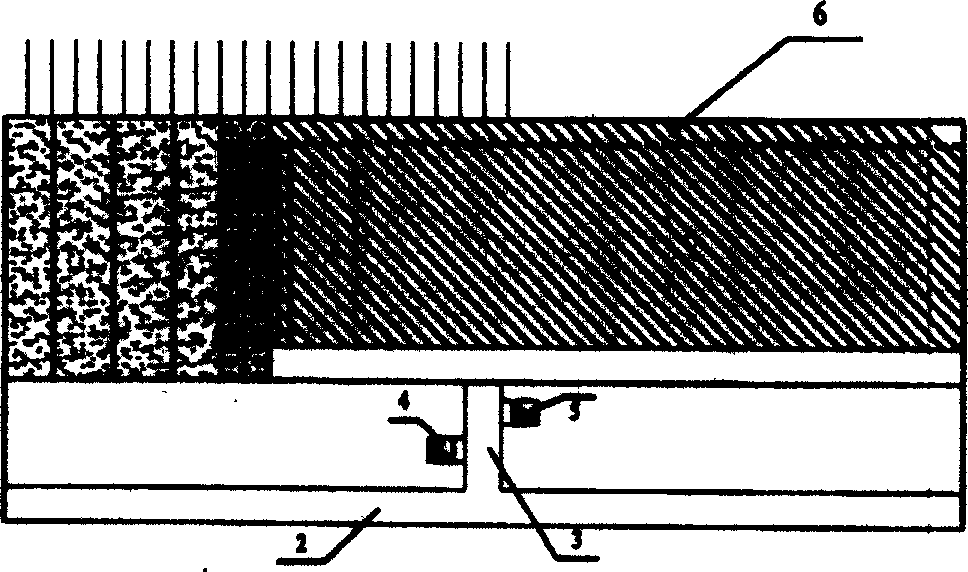

Method for weakening coal-rock mass by hydraulic blasting and fracturing

ActiveCN101644156AImprove fraudIncreased range of cracking fissuresDisloding machinesFluid removalSpelunkingHydraulic fracturing

The invention discloses a method for weakening coal-rock mass by hydraulic blasting and fracturing. The structure of coal-rock mass can be changed by adopting hydraulic blasting and fracturing. The method comprises the following steps: drilling a hole in a coal layer, and placing water-gel explosive in the hole; and then sealing the hole and injecting water into the hole to a set pressure; stopping water injection based on the standard that no hydraulic fracture is generated; detonating the explosive and carrying out hydraulic blasting to lead the wall rock of the drilling hole to burst; generating a great number of fractures on the periphery of the drilling hole; and then carrying out hydraulic fracturing; expanding along exploding fracture under the action of hydraulic pressure of the fracture, and forming a great number of hydraulic pressure fractures. The method of the invention not only can effectively weaken the strength of the coal-rock mass, can reduce wall rock stress of the weakening area, but also can improve ventilation property of the coal layer; is an effective technical way of improving the top coal caving, preventing impact mine pressure, preventing coal and gas burst, and improving efficiency of gas extraction in coal mine. The method has simple process, convenient construction, reliable safety, easy operation and good control.

Owner:CHINA UNIV OF MINING & TECH

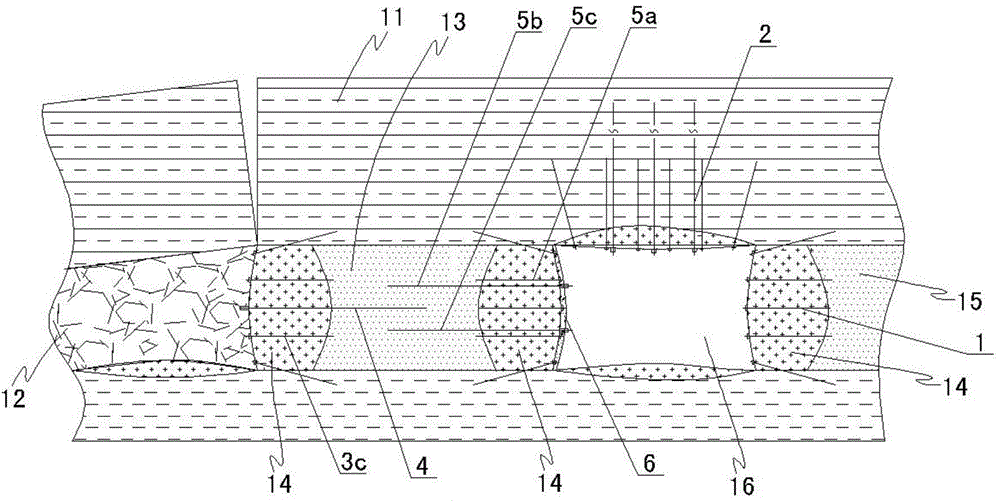

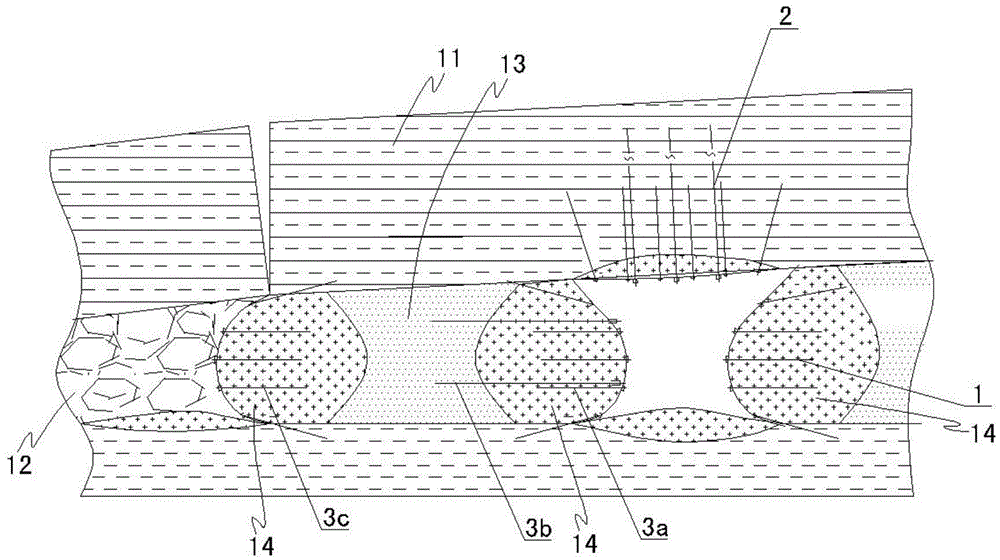

Sublevel fill-mining method

The invention discloses a sublevel fill-mining method. By utilizing the natural angle of repose characteristics of caving ores and dry mine fill and according to medium hole drilling device-adapted height and the ore-permitted exposed area, space and time at present, sublevel mining is carried out from the bottom to the top in the open-field state and the dry mine fill is adopted for filling in time. The sublevel fill-mining method has the advantages of an open-field method and a dry fill and sublevel caving method without sill pillar, thereby forming a novel sublevel dry fill-mining method without sill pillar, and is particularly applied to ore mines with large-scale ore body and high yield requirement. The top filling of a filling body is realized by the self-weight of the filling body; a vibratory roller or a device special for underground tamping is adopted to apply pressure to the filling body through a lane top plate to tamp the filling body in a vibration mode, so that the filling body generates a certain bearing force to the above ore body or the rock mass. The sublevel fill-mining method is a mining method which has the advantages of safety, high efficiency, high mining capacity, low loss and dilution, and low production cost.

Owner:HEBEI HAN XING INST OF MINE & METALLURGY DESIGN

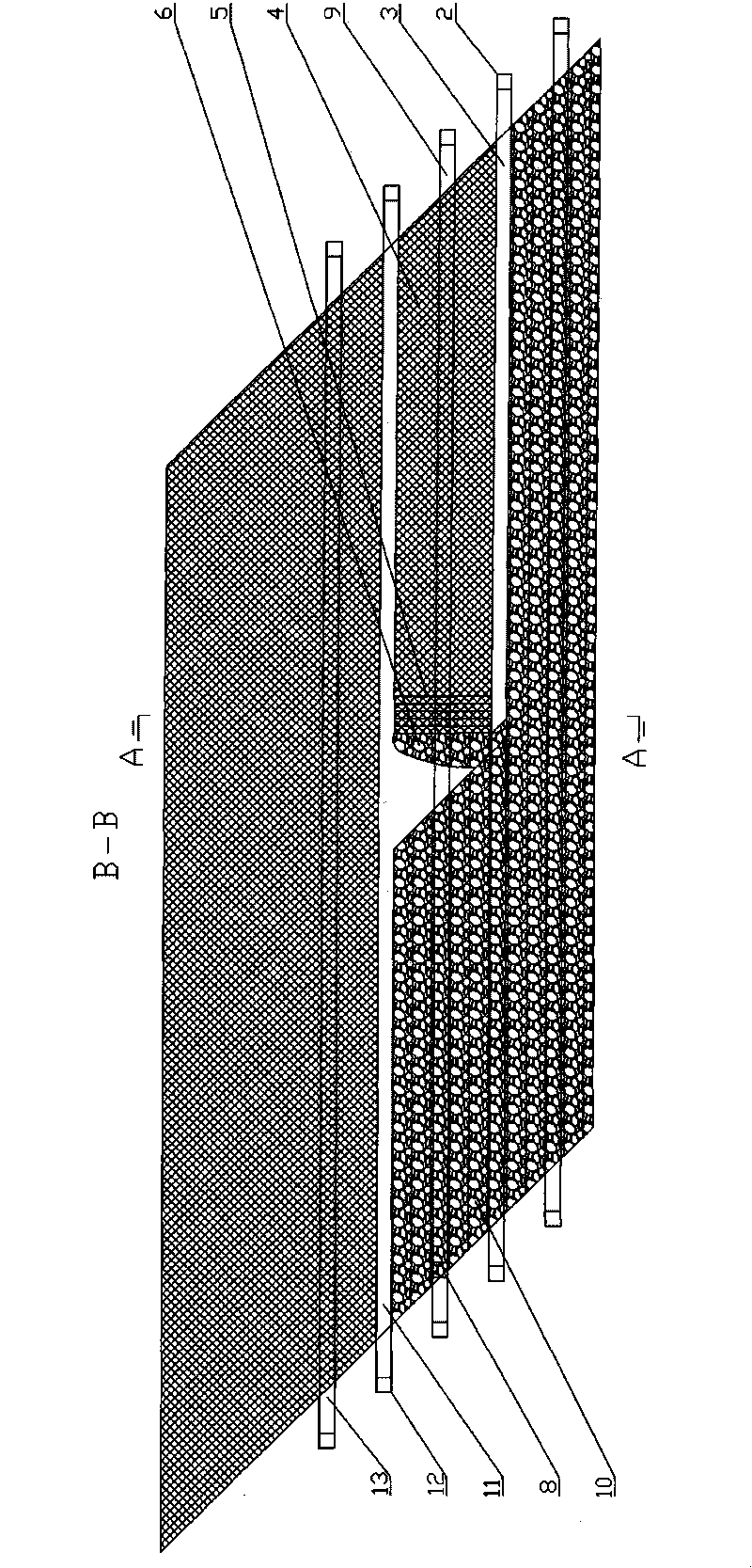

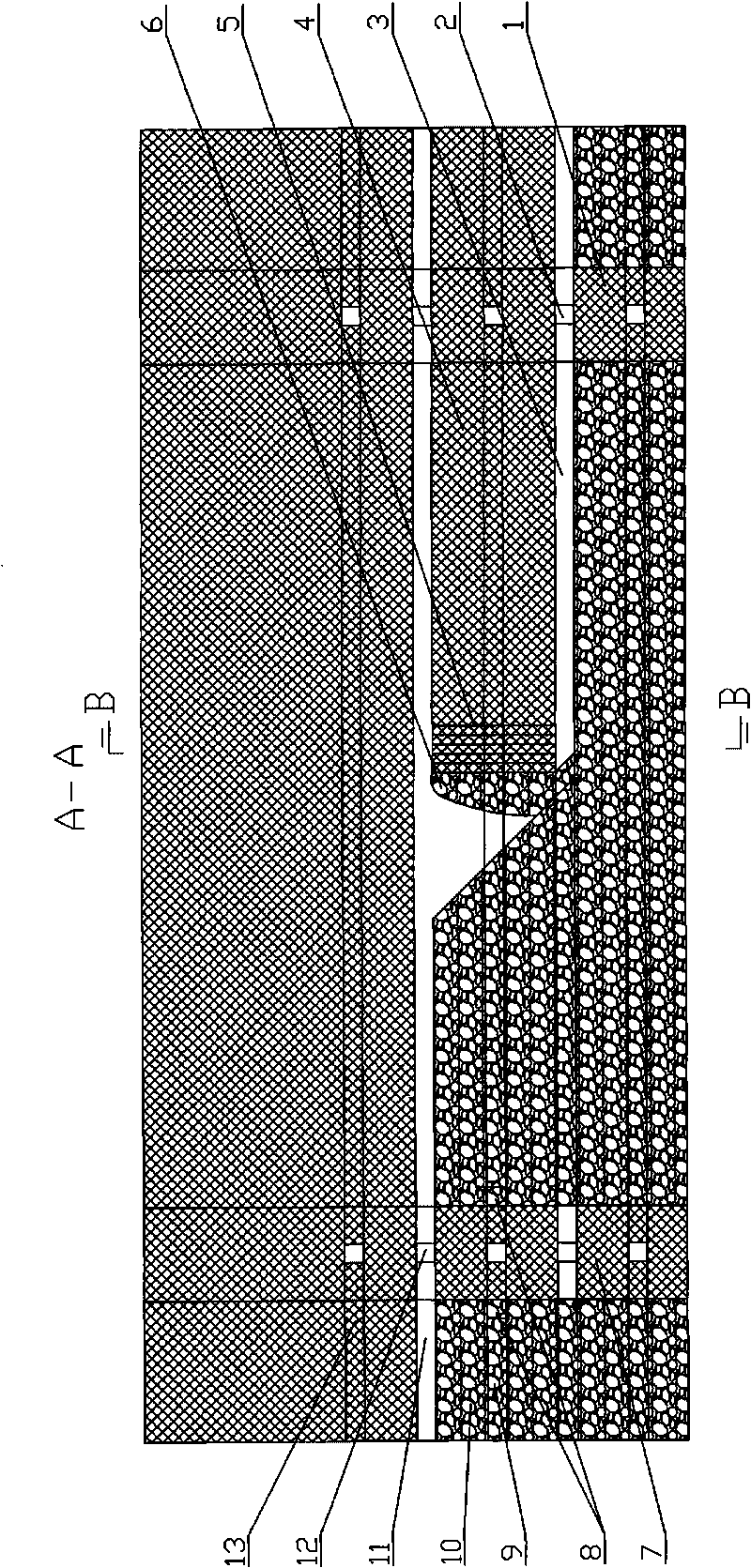

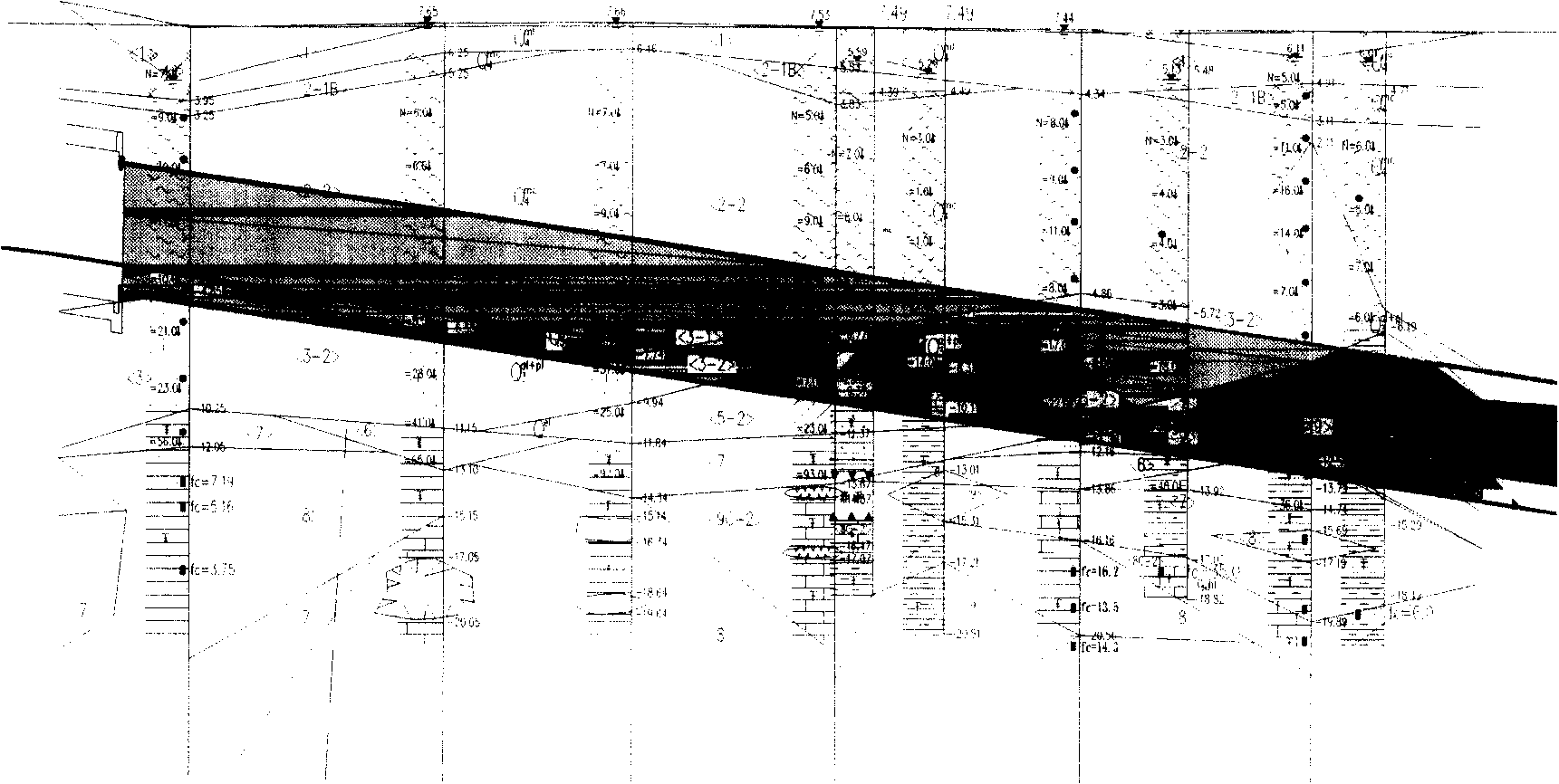

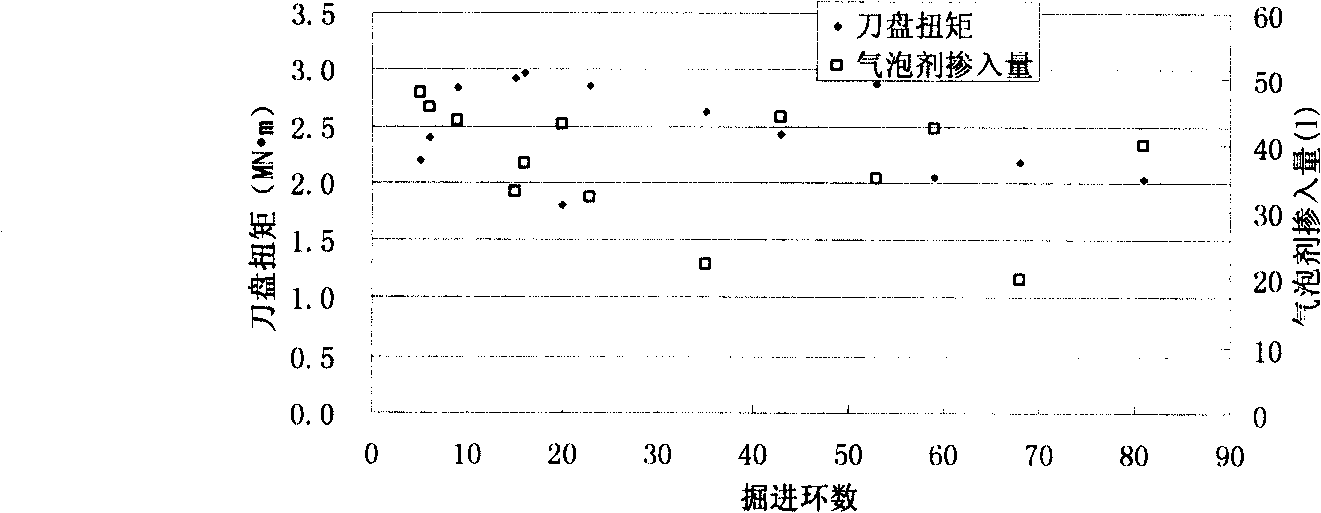

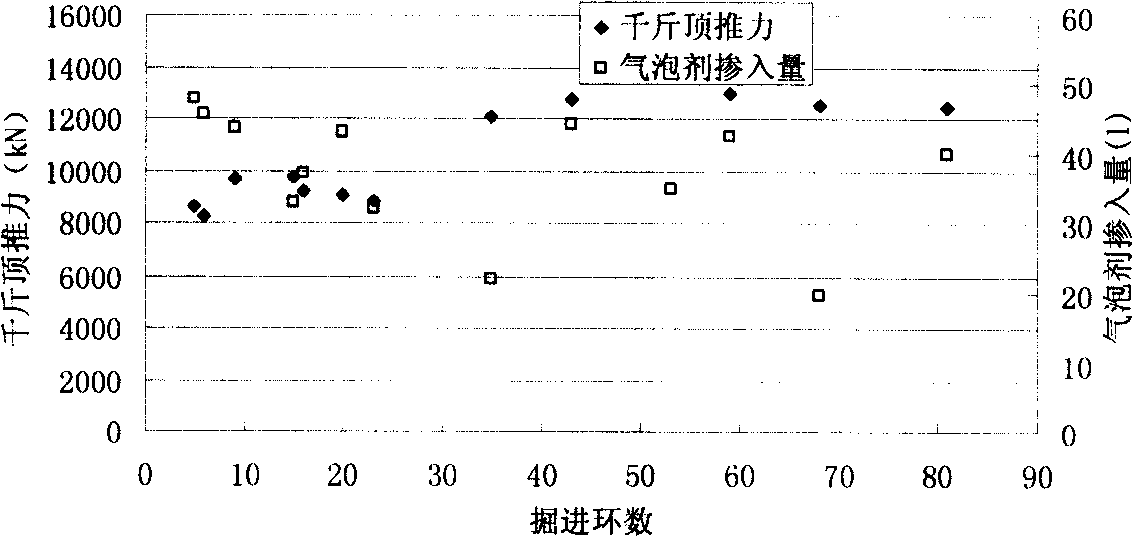

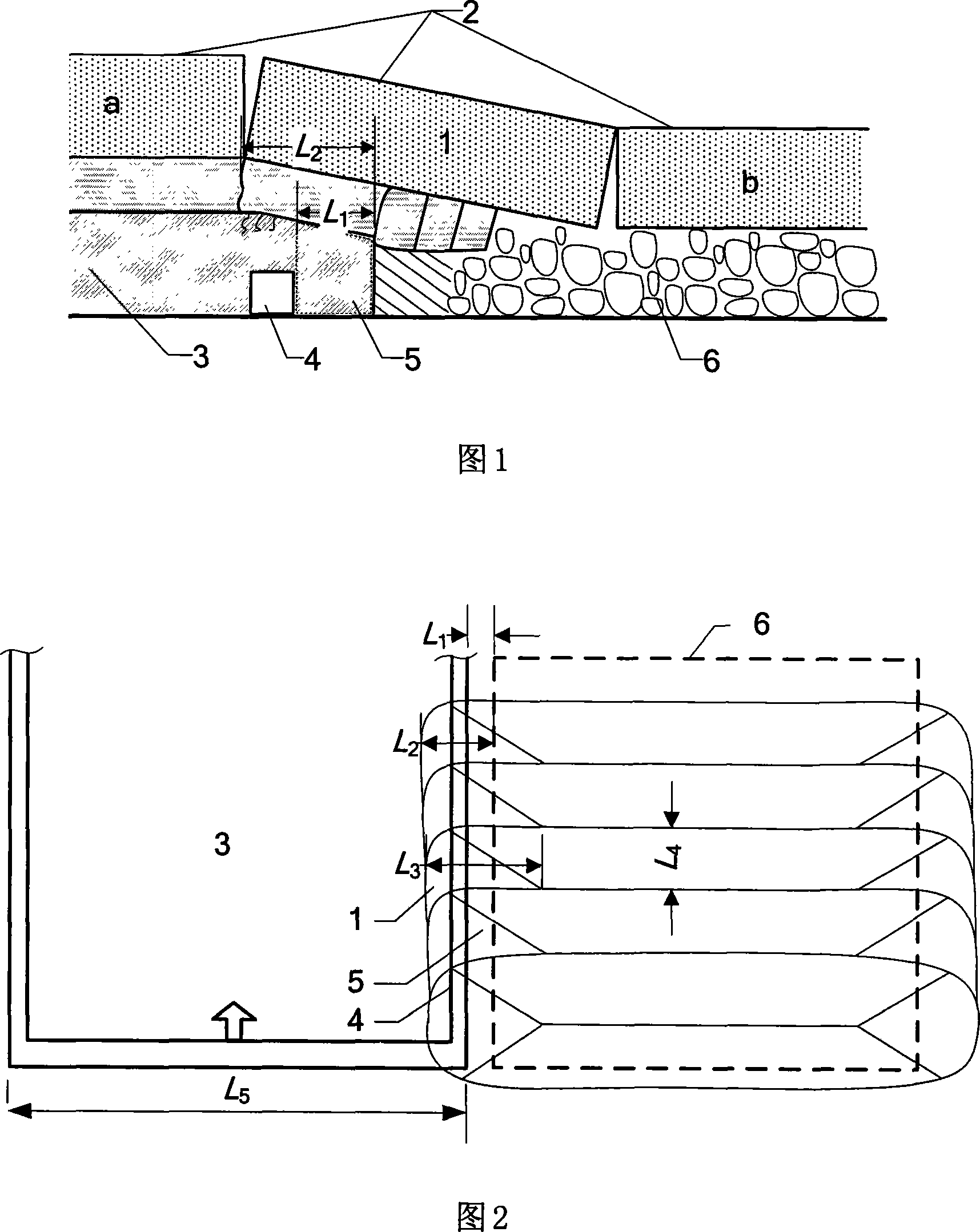

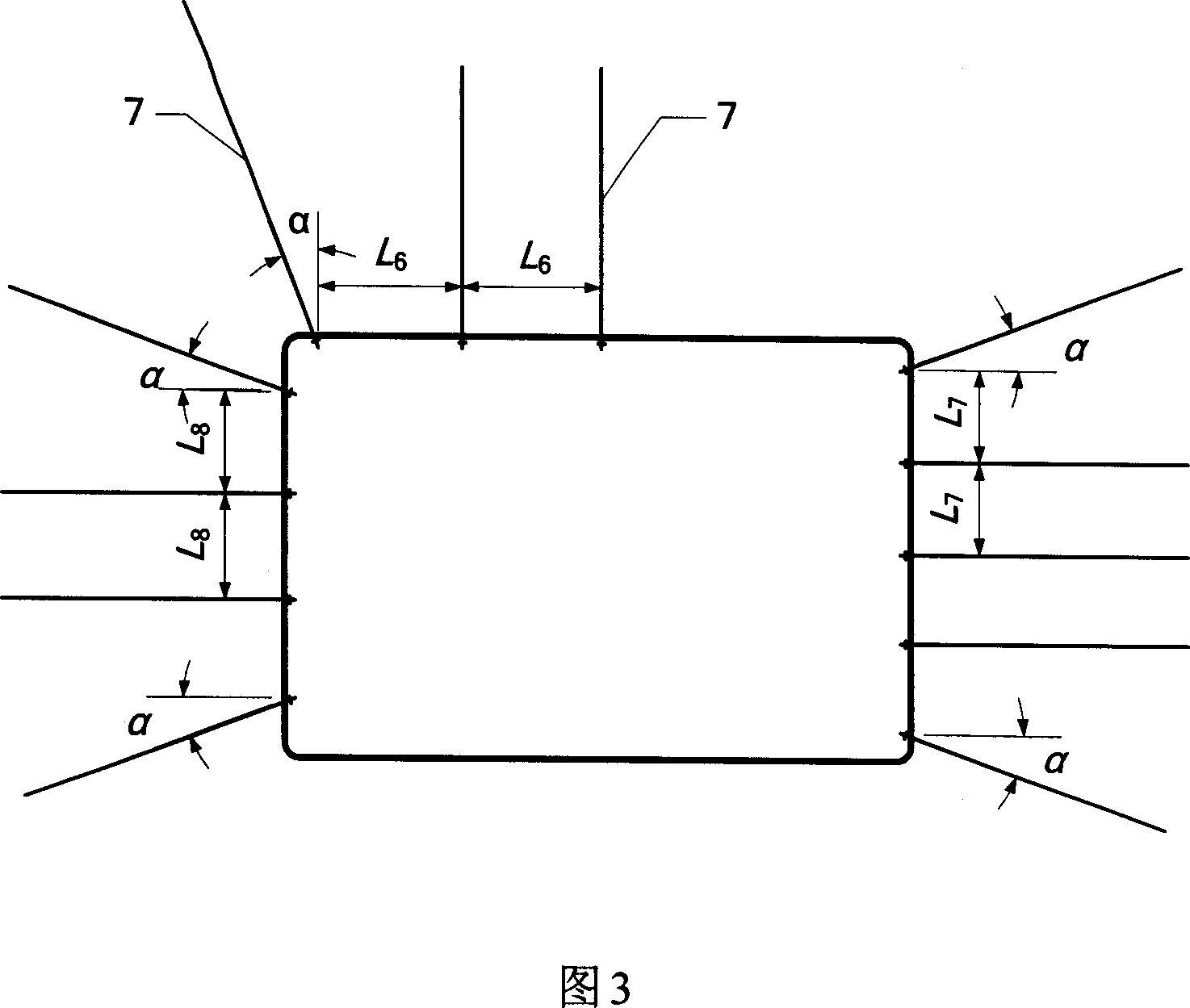

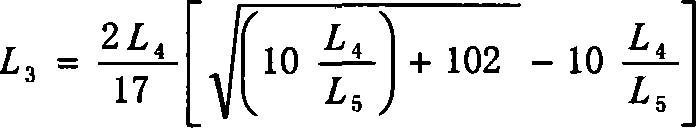

Construction method of composite soil pressure balance tunnel shielding machine for traversing shallow-buried water-rich sand layer

ActiveCN101403307AScientific and reasonable technical solutionsEasy to implementTunnelsEngineeringPressure balance

The invention discloses a construction method that a composite soil pressure balanced shield machine passes through a shallow sand layer rich in water, pertaining to the technical field of tunnel construction. When the composite soil pressure balanced shield machine passes through the shallow sand layer rich in water, an injecting system is arranged at the position of a pressure plate and a cutter head of the shield machine so as to inject a matter-a foaming agent, or bentonite, or a macromoleclar polymer, or the mixture of the three, which has the performances of rapid volume expansion and viscosity increase after absorbing water, into the front shallow sand layer rich in water; the shallow sand layer rich in water is rapidly expanded, soil entering an integral pressure cabin is caused to form plastic flow state, and the soil is caused to reach the permeability coefficient of lower than the magnitude of 10<-5>cm / s which is needed by the construction and the caving degree of 10 to 15cm. The technical proposal is scientific and reasonable, simple and easy to implement, can acquire obvious technique effect, adopts the composite soil pressure balanced shield machine for passing through the shallow sand layer rich in water successfully and acquires satisfactory construction quality as well as guarantees the construction period.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

Method for controlling wall rock of fully mechanized coal face goaf side coalbed laneway

A method for controlling the surrounding rock of the side coal seam roadway in the goaf of the fully-mechanized caving face. According to the geology of the fully-mechanized caving face measured on site and the mine pressure data of the adjacent mining face, the stability of the large structure of the overlying rock mass on the roadway is analyzed. Determine the width of the narrow coal pillar reserved on the side of the goaf, so that the roadway is located in the area of relatively low vertical stress in the coal body, and the high-performance bolt support that controls the surrounding rock of the roadway forms a small load-bearing structure in the surrounding rock in the anchorage area . The small structure can make full use of the surrounding rock's own bearing capacity, and has strong adaptability to the deformation of the surrounding rock, ensuring smooth roadway support without repair, low bolt support cost, fast speed, and low labor intensity; it is compatible with large coal pillar roadway protection Compared with the narrow coal pillar protection roadway, the method reduces the loss of coal resources, improves the recovery rate of fully mechanized caving mining, and has good economic and social benefits.

Owner:CHINA UNIV OF MINING & TECH

Method for determining load of multiple-arch tunnel

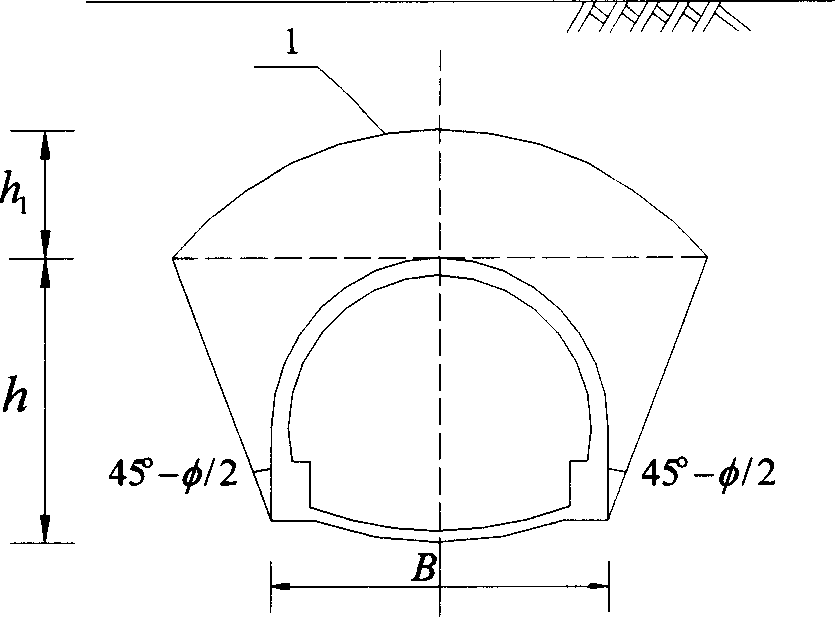

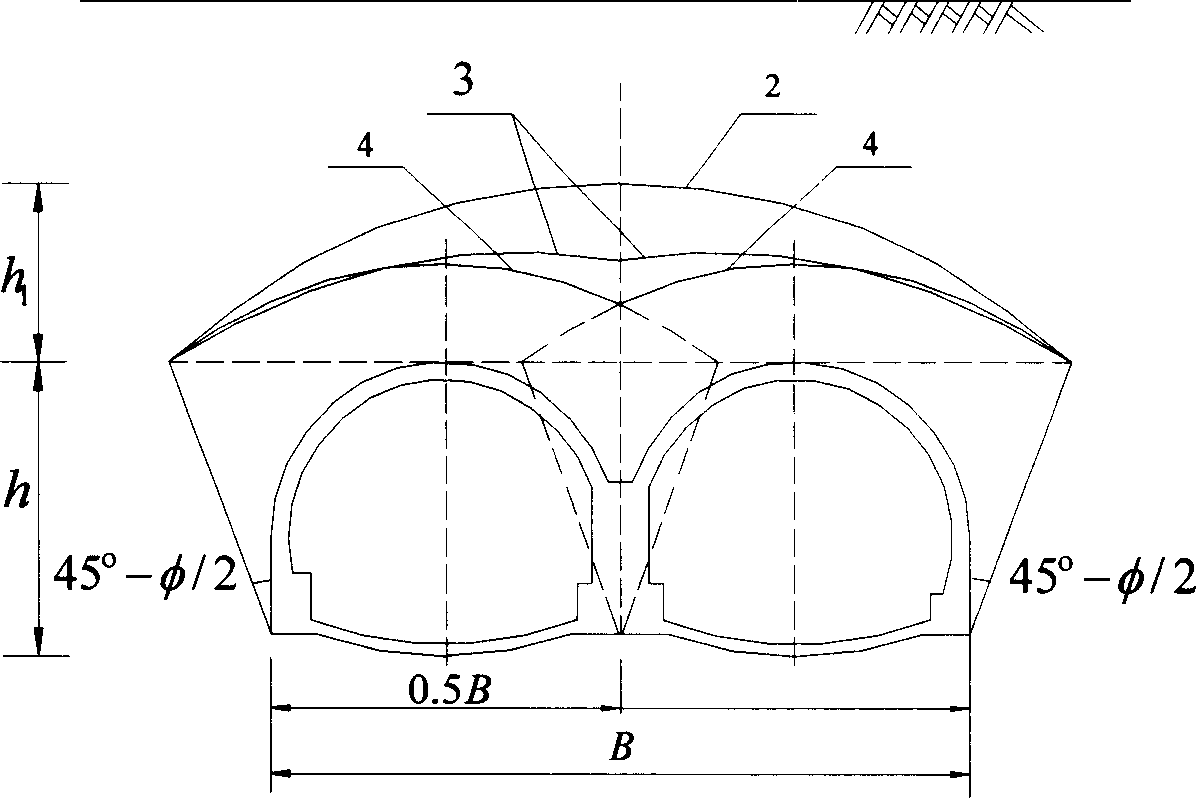

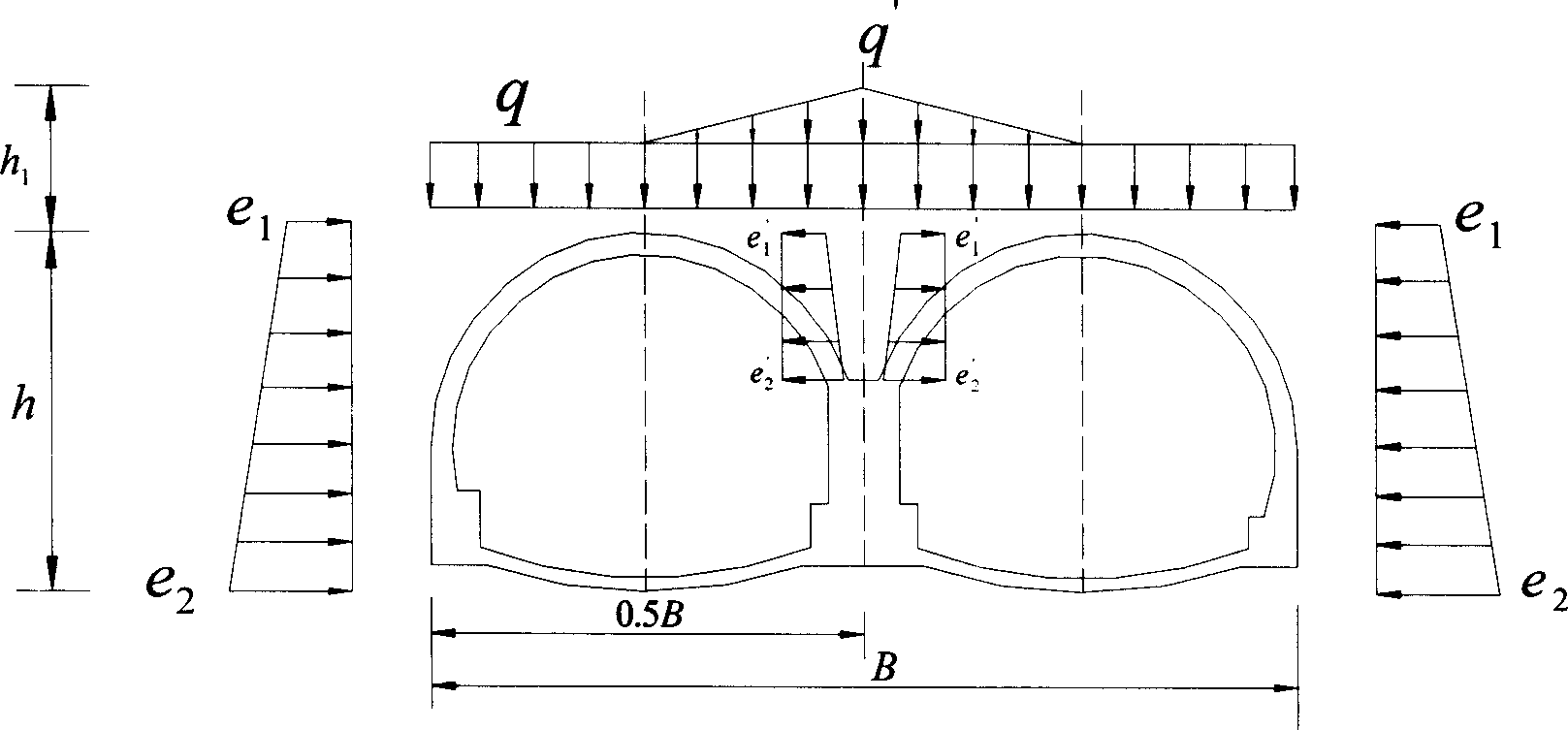

A method for confirming load of multi-arch tunnel includes confirming load mode of deep buried multi-arch tunnel based on suppose of double caving arch, confirming deep-shallow buried boundary of multi-arch tunnel according to deep-shallow burying boundary dividing manner in JTGD70-2004 specification for single hole tunnel and confirming load mode of shallow buried multi-arch tunnel by considering dead weight of triangle block at wall top in multi-arch tunnel.

Owner:TONGJI UNIV

U+I type ventilating system for top-coal caving face

InactiveCN101498225AEfficient dischargeEliminate buildupUnderground miningSurface miningSpelunkingCoal dust

The invention provides a U+I type ventilation system for a work surface of top coal caving, which is an improvement of the arrangement of the U type, the U+L type and the E type or B type laneways and the ventilation systems in the prior art. An air intake way and an air return way of the work surface of top coal caving are arranged along a bottom board of a coal bed, and a regulation air door is arranged on the part of the air return way close to a big air return lane to control the reasonable ventilating parameter of the U+I type ventilating system. The invention is mainly characterized in that air exhausting lanes of top boards are arranged in parallel along the air return way with the parallel outward-staggered distance of 0 m to 5 m from the air return way to form the U+I type ventilating system of a one-intake and two-return mode. The invention fundamentally solves the problem of the accumulation of gas and coal dust on the upper section, the upper spatial angle and the gob area of the work surface of top coal caving, in particular the problem of the accumulation of the gas and the coal dust of the upper space of the upper gob area, provides a safe and high-effect ventilating system, and creates an excellent mechanical environment for realizing the exploitation of the top coal caving of small coal pillars and increasing the recovery rate of coal.

Owner:TAIYUAN UNIV OF TECH

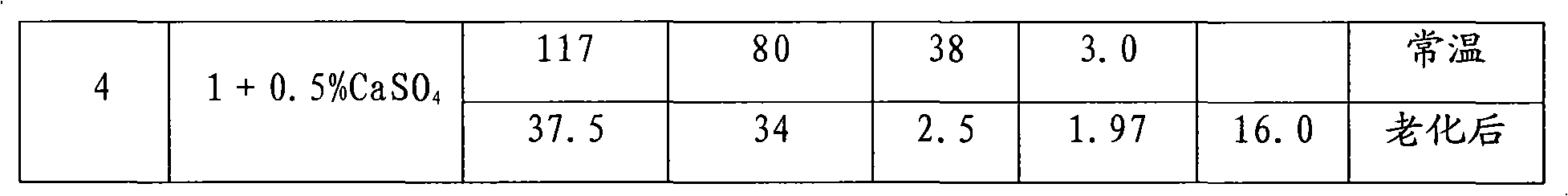

Method for baking ceramsite by using town sludge, river mud and bentonite

InactiveCN102173746ASolving difficult and costly problemsIncrease productionCeramic materials productionClaywaresSodium BentoniteSludge

The invention discloses a method for baking ceramsite by using town sludge, river mud and bentonite. The method comprises the following steps of: milling 30 to 35 weight percent of original sludge, 45 to 50 weight percent of river sludge, and 17 to 23 weight percent of bentonite by wheels, mixing and stirring to homogenize the materials; and aging, pelleting, screening, sintering and expanding, and performing air cooling. The bulk density of the obtained ceramsite is 400 to 500Kg / m<3>, the compression strength is 1 to 3.5Mpa, one-hour water absorption is 8 to 10 percent, and the grain size of the product is 1 to 26mm; and the original sludge, the river sludge and the bentonite are used as the raw materials, the ceramsite is directly baked by taking cavings as fuel, the treatment capacity of the sludge is large, the production cost is low, secondary pollution in the production process is avoided, and the performance of the obtained ceramsite product meets the standard requirement of GB / T17431.1-1998.

Owner:常州市金坛博大陶粒制品有限公司

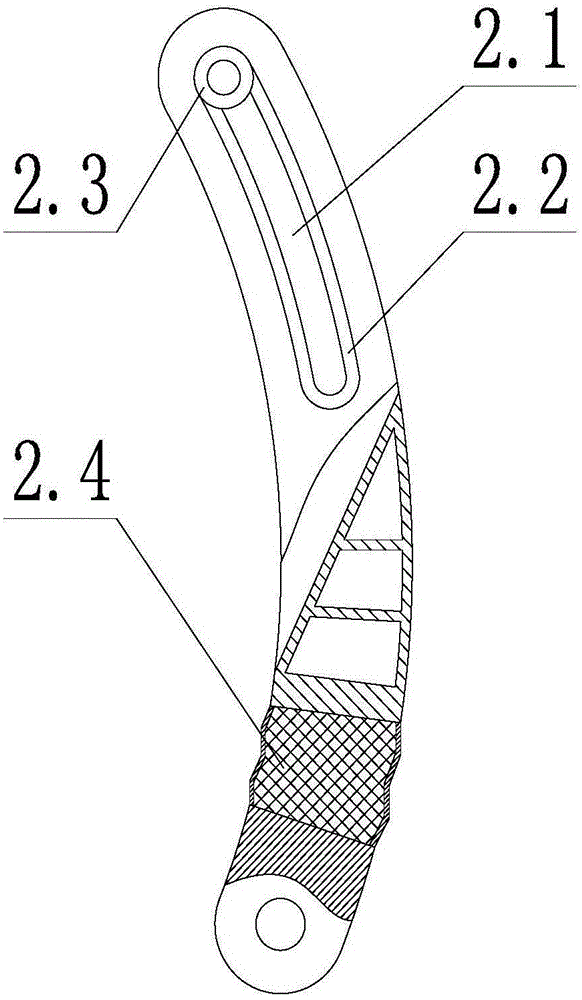

Hydraulic support for large-mining height caving coal

InactiveCN101463729AImprove stabilityReasonable sampling ratioMine roof supportsSpelunkingProtection mechanism

The invention discloses a large mining height top coal caving hydraulic support and relates to the technical field of colliery coal mining supporting equipment and support equipment for large mining height top coal caving working face. The support comprises a pillar, a top beam and a base that the two ends thereof are articulated respectively, a front beam that is articulated to the front end of the top beam, a telescopic beam in the front beam, a side wall protection mechanism that is articulated with the telescopic beam, a shield beam that is articulated with the rear end of the top beam, a caving mechanism that is arranged at the rear the shield beam, a connecting-rod mechanism that is articulated between the rear of the base and the rear of the shield beam and four pillars which are articulated between the base and the top beam and can lead the maximum of the height of the support to be 4.0-5.2 meters, wherein the connecting-rod mechanism is provided with two front connecting rods and two rear connecting rods and has good stability, and a pedestrian passageway is formed between the two front connecting rods and the two rear connecting rods. The support has the characteristics of a top coal caving hydraulic support and a large mining hydraulic support, thus beneficial for safely and efficiently caving thick and super-thick coal seams, rationalizing the caving ratio, and ensuring gas dilution near a working face coal caving mouth.

Owner:TIANDI SCI & TECH CO LTD

Method for recovering disc ore on incline ore block

InactiveCN101424186ASimple methodFlexible and convenient constructionUnderground miningSurface miningSpelunkingBody height

The invention relates to a method for recovering hanging wall ores of a slant ore body, which mainly solves the technical problems of low ore recovery rate, large mining difficulty, low production efficiency and the like existing in the process of recovering the hanging wall ores of the prior slant ore body. When the slant ore body is exploited, an extracting drift is arranged according to the construction layout of a hanging wall prospecting drift, an ore rock boundary line and a hanging wall cutting tunnel, wherein the prospecting drift is dug out 1.5 to 3 meters from the ore rock boundary line, and the hanging wall cutting tunnel is arranged within the ore rock boundary line; the ore body height above the position of the hanging wall cutting tunnel is taken as a subsection, and a vertical upward cutting blast hole is arranged along the direction of the hanging wall cutting tunnel; and vertical or pitching upward back production fan-pattern holes are arranged according to ore caving step pitch and rock drilling row space in the back production direction. The method is suitable for the prior sublevel caving method without sill pillar and a novel technology of large space mining without the sill pillar.

Owner:宝钢集团上海梅山有限公司

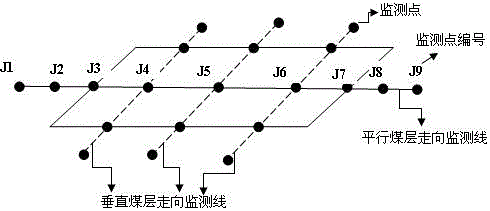

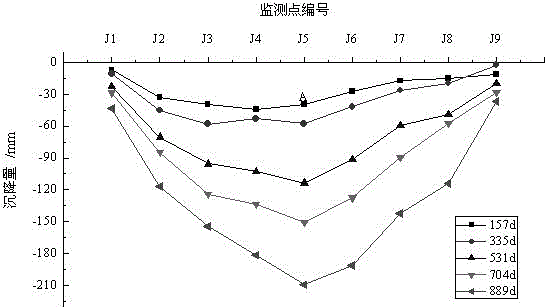

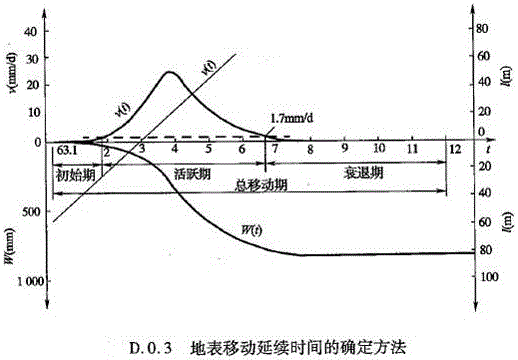

Method for quantitatively evaluating site stability of old goaf in coalmine based on settlement monitoring data

InactiveCN105926569AConvenient quantitative evaluation of stabilitySimple and fast operationIn situ soil foundationSpelunkingTime effect

The invention discloses a method for quantitatively evaluating the site stability of an old goaf in a coalmine based on settlement monitoring data. The method is applicable to a site where the old goaf is exploited according to a caving method and main settlement is finished, and comprises the following steps: (1) arranging monitoring lines on the ground surface of the old goaf in the coalmine and acquiring the ground surface settlement monitoring data; (2) preliminarily analyzing the ground surface deformation characteristics according to the monitoring data; (3) calculating deformation of the ground surface of the old goaf in the coalmine; and (4) evaluating the site stability of the old goaf. According to the method provided by the invention, a probability integral method with consideration of a time effect can be utilized; when parameters are confirmed, the following relation is met: an increment in the actually monitored settlement is equal to a decrement in the calculated residual settlement; and accordingly, the evaluating work can be carried out by adopting the monitoring data of two years or longer, the operation is simple, convenient and easy to perform, the evaluation is in accordance with industrial standards and regulations, the evaluating effect is good, and the quantitative evaluation of the site stability of the old goaf in the coalmine is greatly facilitated.

Owner:河北地质大学

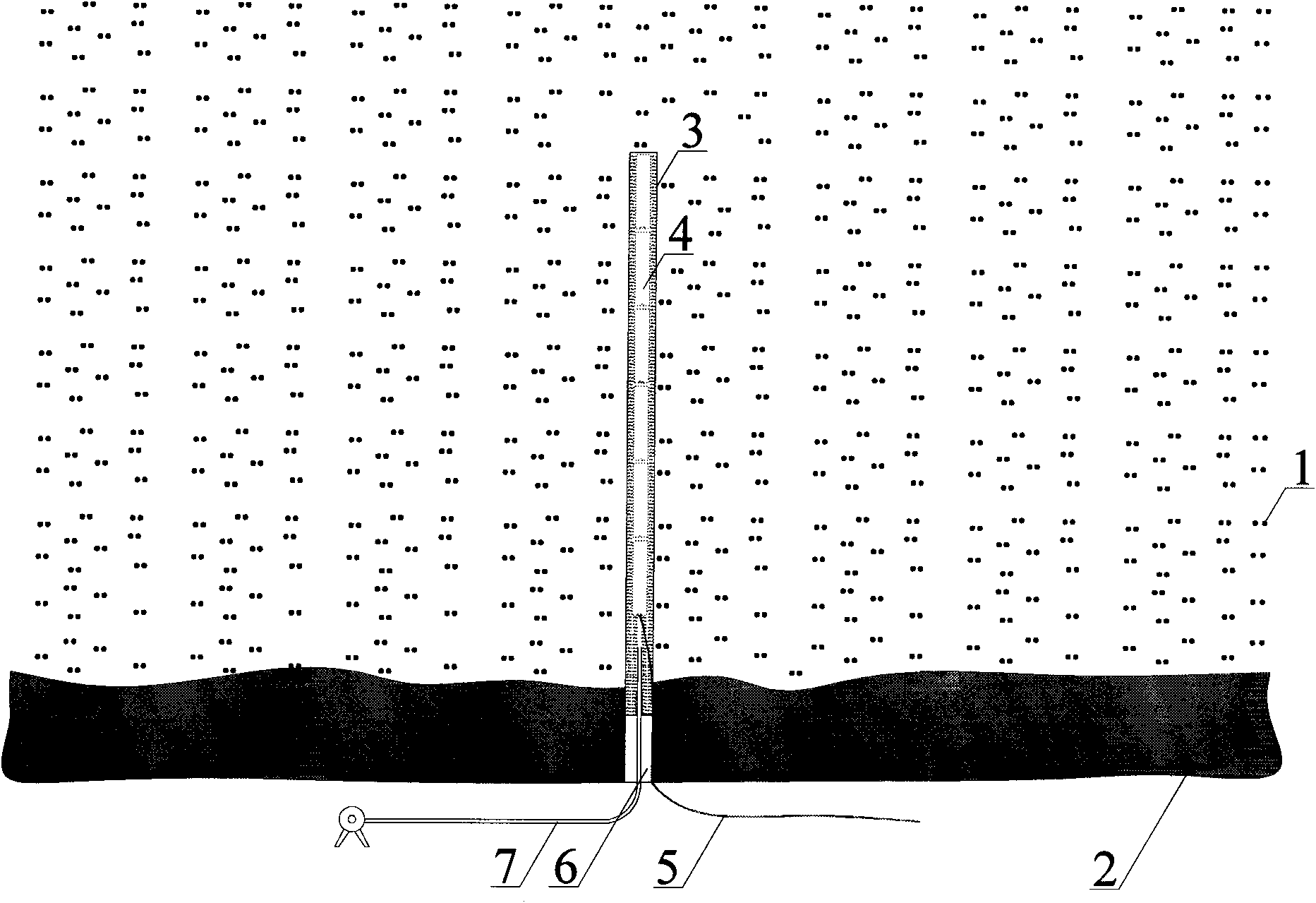

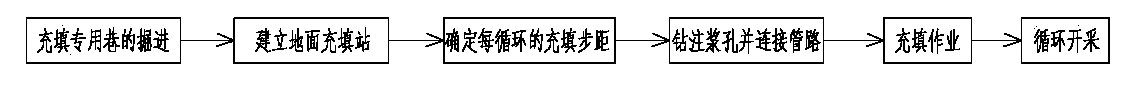

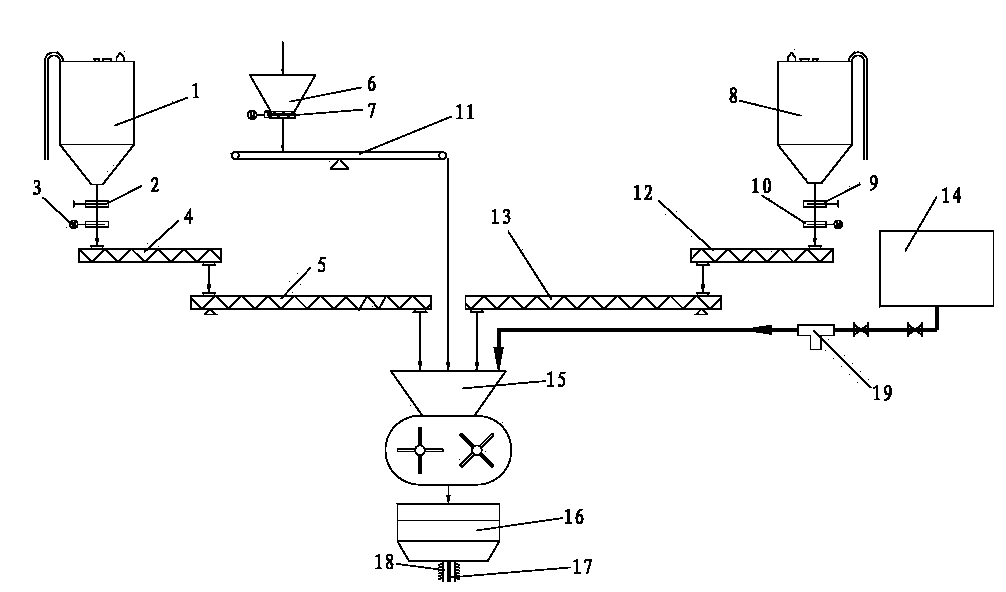

Filling mining method for caving zone on coal face

InactiveCN104251139AEasy to achieve high production efficiencyOvercome the disadvantage of low yieldUnderground miningSurface miningSpelunkingMining engineering

The invention relates to a filling mining method for a caving zone on a coal face and the method can effectively solve the problems that coal filling mining is greatly limited by space of the coal face, time and floor space, and the coal mining efficiency on the coal face is low. The invention adopts the technical scheme that the method comprises the following steps: (1) excavating a special filling roadway; (2) establishing ground filling stations; (3) determining the filling interval of each cycle; (4) drilling grouting holes and connecting pipelines; (5) conducting filling operation; and (6) conducting cycle mining. Compared with other filling methods, the method provided by the invention is free from limits of space of the coal face, time and floor space, can be matched with any coal mining technology under appropriate conditions, can easily achieve high yield and high efficiency on a filling face through the combination with a fully mechanized top coal caving mining method, overcomes the defect of low yield of the conventional filling face, and has favorable social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

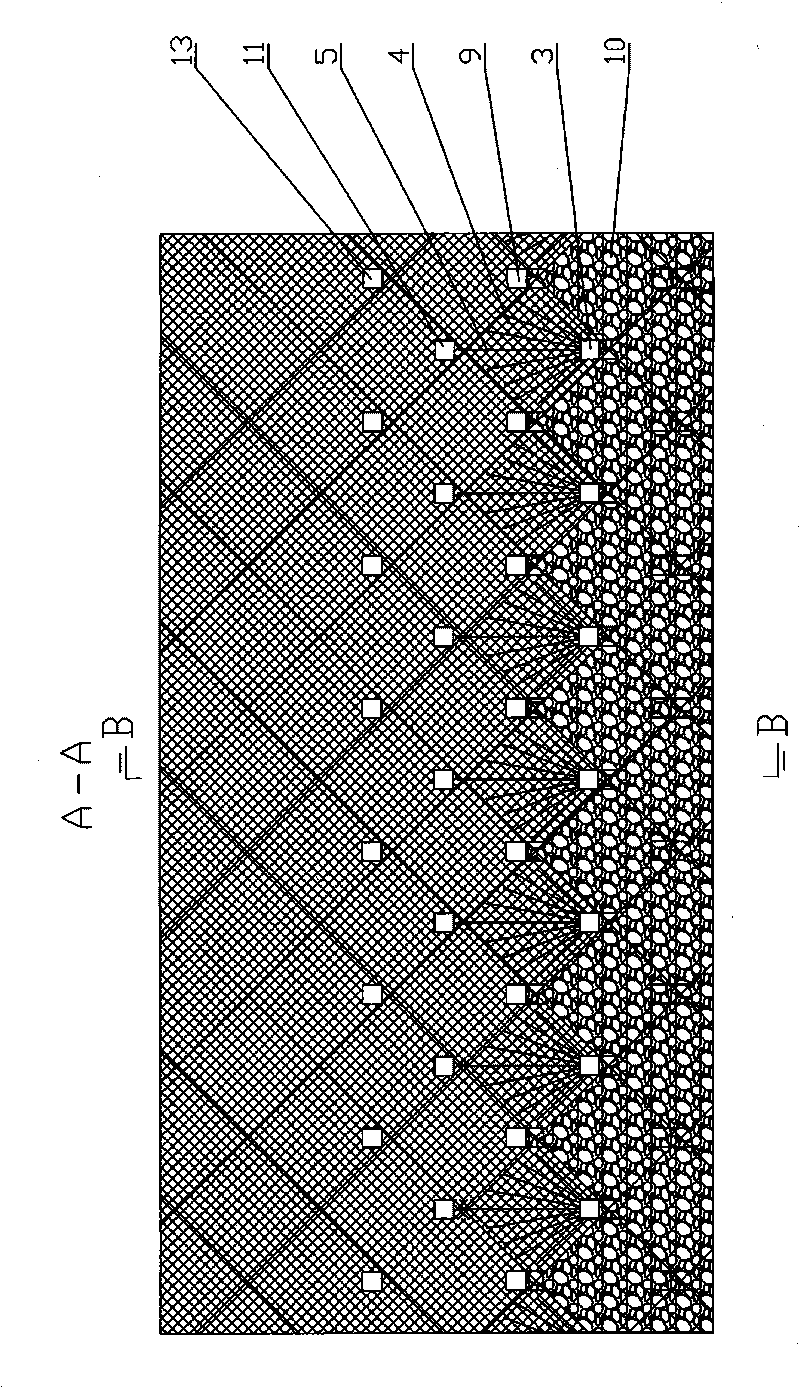

Reinforcing method for improving stability of gob-side entry driving small coal pillar

ActiveCN104533482AEnsure stabilityHigh strengthUnderground chambersTunnel liningSpelunkingCement slurry

The invention discloses a reinforcing method for improving the stability of a gob-side entry driving small coal pillar. The reinforcing method is characterized in that roadway-side pre-reinforcing anchor ropes are pre-arranged in an upper zone section stoping roadway close to a lower zone section lateral wall and located on the upper zone section wall of the small coal pillar before upper zone section working face stoping; multiple small coal pillar wall anchor rods and multiple small coal pillar wall portion reinforcing anchor ropes are arranged at the small coal pillar wall position in the lower zone section gob-side entry driving process, wherein the small coal pillar wall portion reinforcing anchor ropes include small coal pillar wall portion hollow grouting reinforcement anchor ropes and conventional reinforcement anchor ropes; small coal pillar wall concrete spraying layer is arranged on the small coal pillar wall when the lag distance of a gob-side entry driving head does not exceed 100 m; cement slurry reinforcement is performed on the hollow grouting reinforcement anchor ropes on the small coal pillar wall portion when the lag distance of the gob-side entry driving head does not exceed 200 m. The reinforcing method can prevent gob-side entry driving small coal pillar wall caving, improve the stability of the small coal pillar and reduce gob-side entry driving surrounding rock deformation amount.

Owner:淮浙煤电有限责任公司顾北煤矿 +1

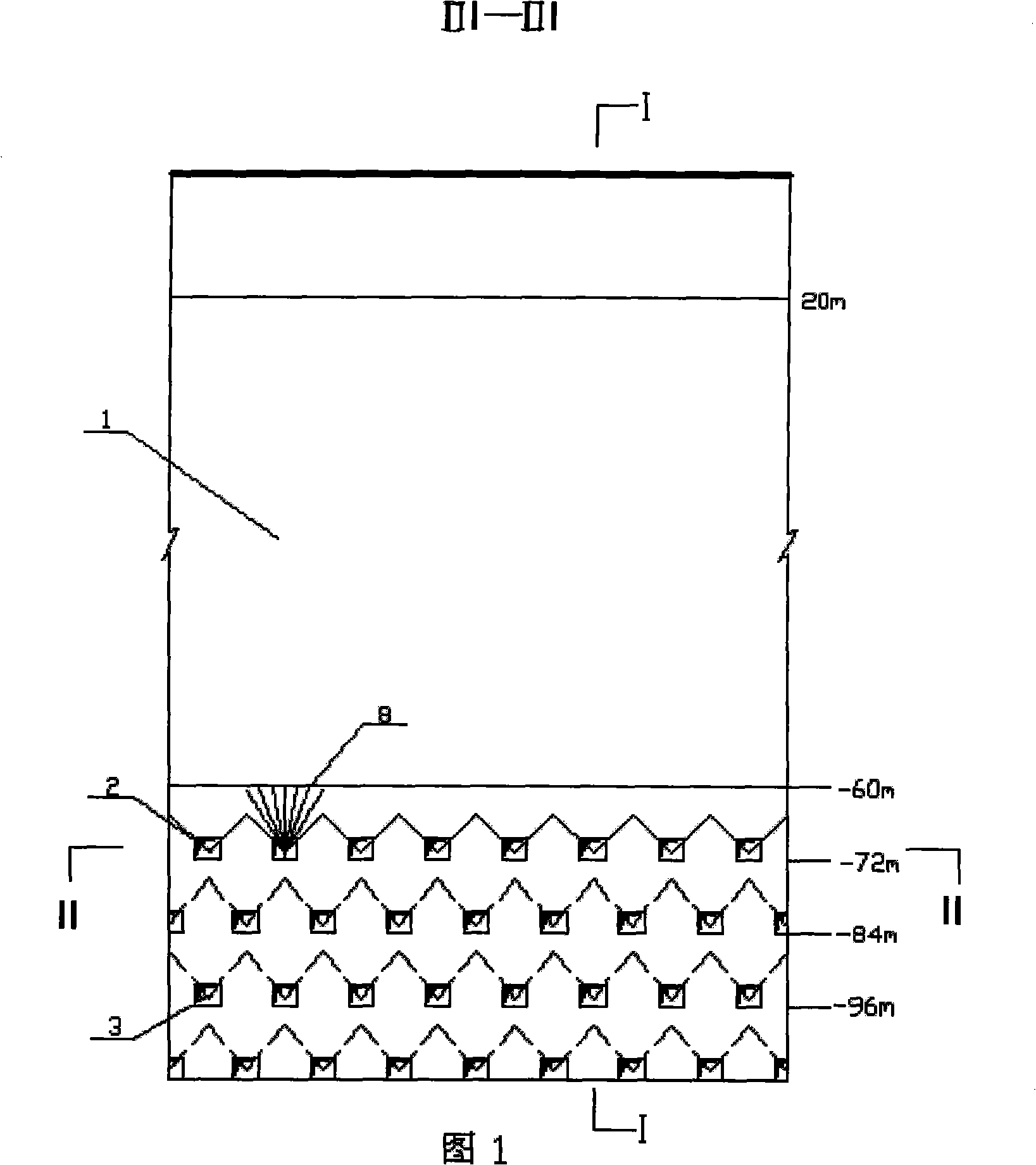

Large dead zone residual ore recovery method

InactiveCN101403304AHigh recovery rateImprove safety conditionsUnderground miningBlastingSpelunkingRecovery method

The invention relates to a recovery method of residual ores in a large mined out space. The method comprises the steps of sublevel caving method without sill pillar, rock drilling and blasting in an inlet passage and ore removal; and is characterized in that: forced caving and induced inbreak are adopted by ore break down, a recycling inlet passage is arranged at the bottom of the mined out space, residual orebody inside and at the periphery of the mined out space to be recycled is divided into an induced inbreak area and a forced caving area from top to bottom, the continuous mined out space formed after the blasting is utilized to induce the inbreak of the ore at the upper part, and the recycling inlet passage is arranged in the ore body at the lower part of the mined out space. The method solves the problems of poor safety condition and low recovery rate and the like of the traditional residual ore recovery in the mined out space, realizes high degree of safety, low production cost and high recovery rate and the like of the residual ore recovery, and improves the production efficiency and economic efficiency of mines.

Owner:KUNMING UNIV OF SCI & TECH

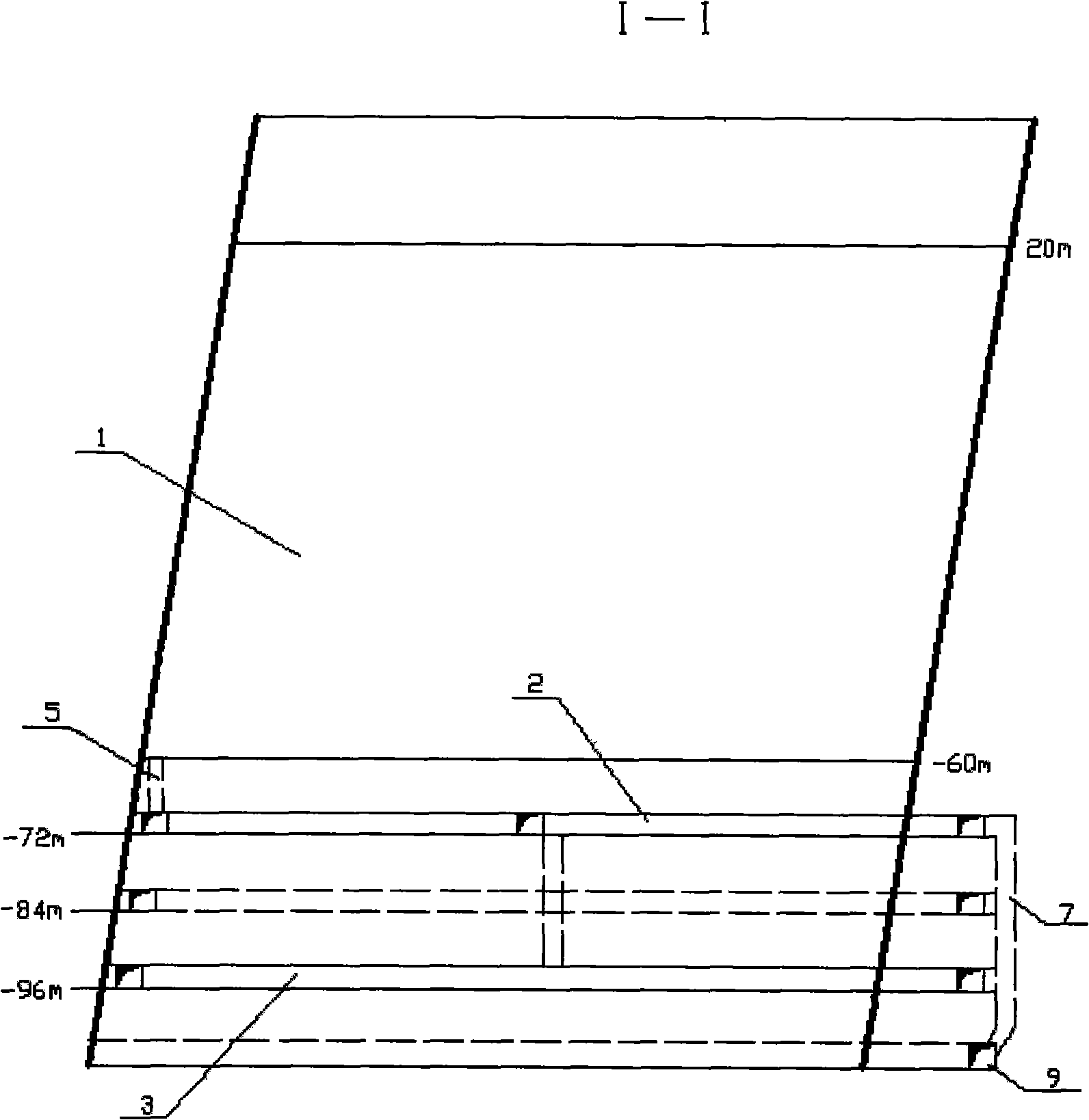

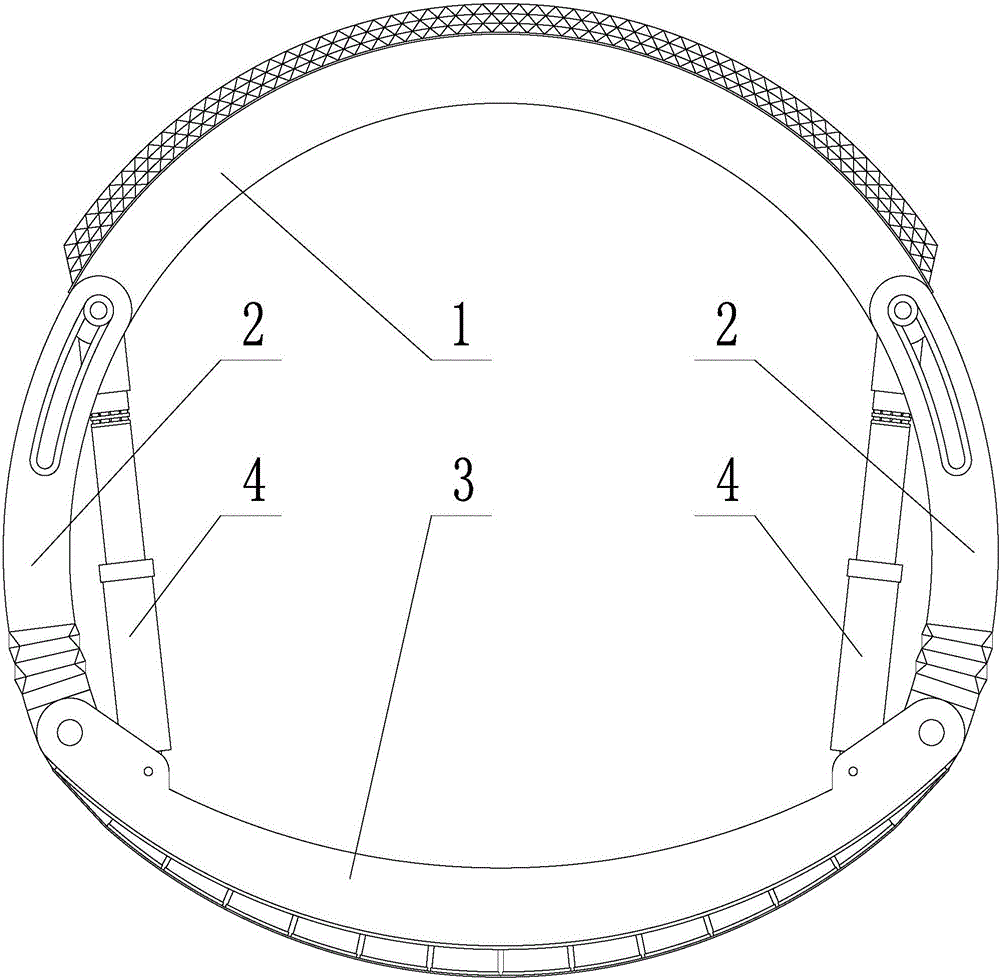

Energy-absorption type impact-resistant tunnel cross-section hydraulic support

ActiveCN104989436AImprove impact resistanceImprove securityMine roof capsProps/chocksSpelunkingFiber

An energy-absorption type impact-resistant tunnel cross-section hydraulic support comprises an energy-absorption impact-resistant top beam, side protection side beams, an energy-absorption impact-resistant floor-heave-resistant bottom beam and anchoring force energy-absorption impact-resistant hydraulic supporting columns. Energy-absorption impact-resistant back plates with interlayer structures are distributed on the upper surface of the energy-absorption impact-resistant top beam, and therefore the local or large-area rock impact effect borne by the top beam can be relieved; the rising, falling and overall deforming of the support top beam are reasonably guided by the side protection side beams, the support top beam is prevented from collapse caused by unbalance loading or the thrust effect in the third direction, wall caving can be prevented, and the hydraulic supporting columns inside the support are protected; buffering time is provided for opening of a safety valve through the anchoring force energy-absorption impact-resistant hydraulic supporting columns, the safety valve is prevented from instant impact damage, and the impact resistance and the safety coefficient of the hydraulic supporting columns are increased; under the common effect of carbon fiber fabric and impact blocks of the energy-absorption impact-resistant floor-heave-resistant bottom beam, energy-absorption blocks are damaged and deformed to recede, and therefore the impact kinetic energy of the bottom plate surrounding rock is rapidly absorbed, and the impact effect borne by a bottom beam body is relieved.

Owner:LIAONING TECHNICAL UNIVERSITY

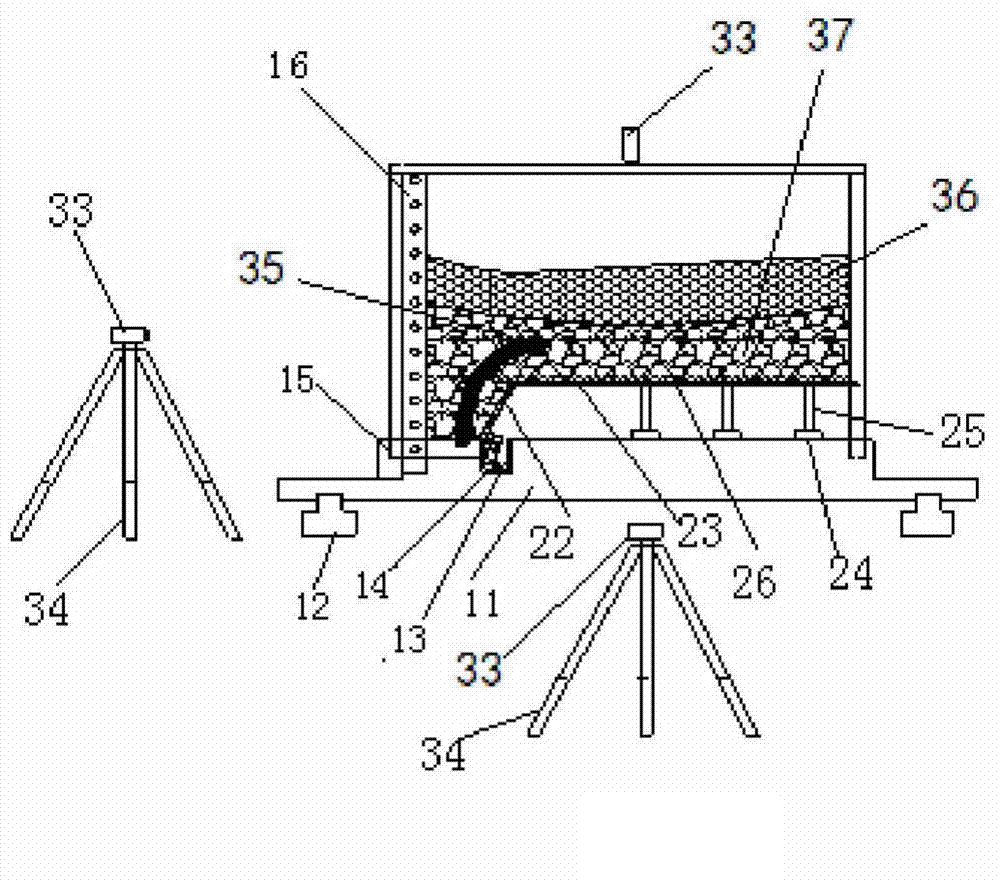

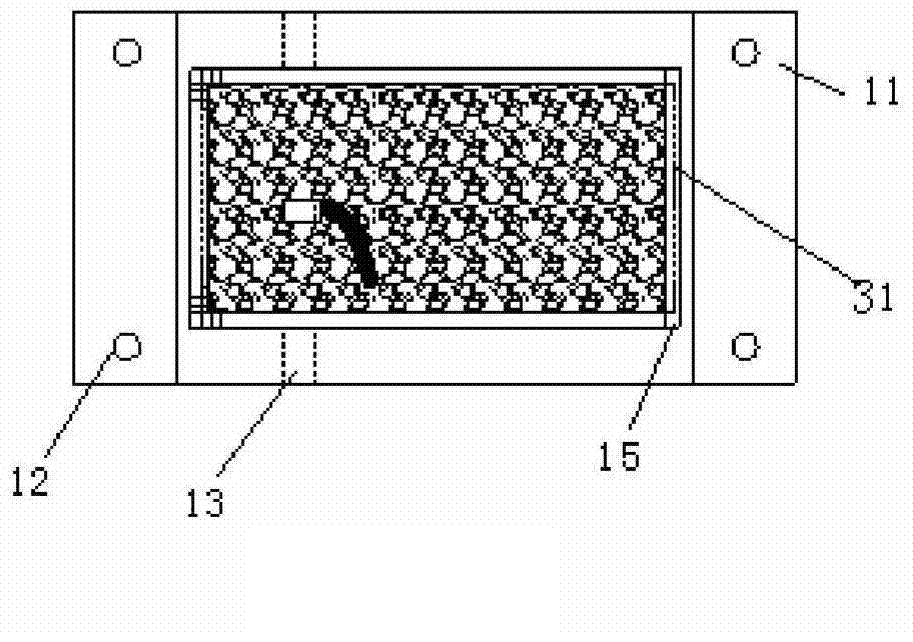

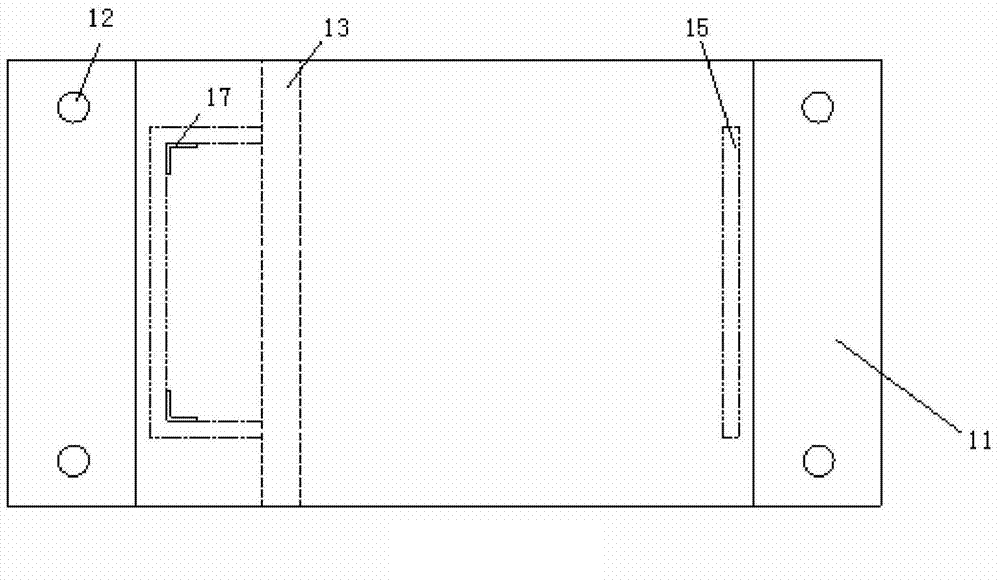

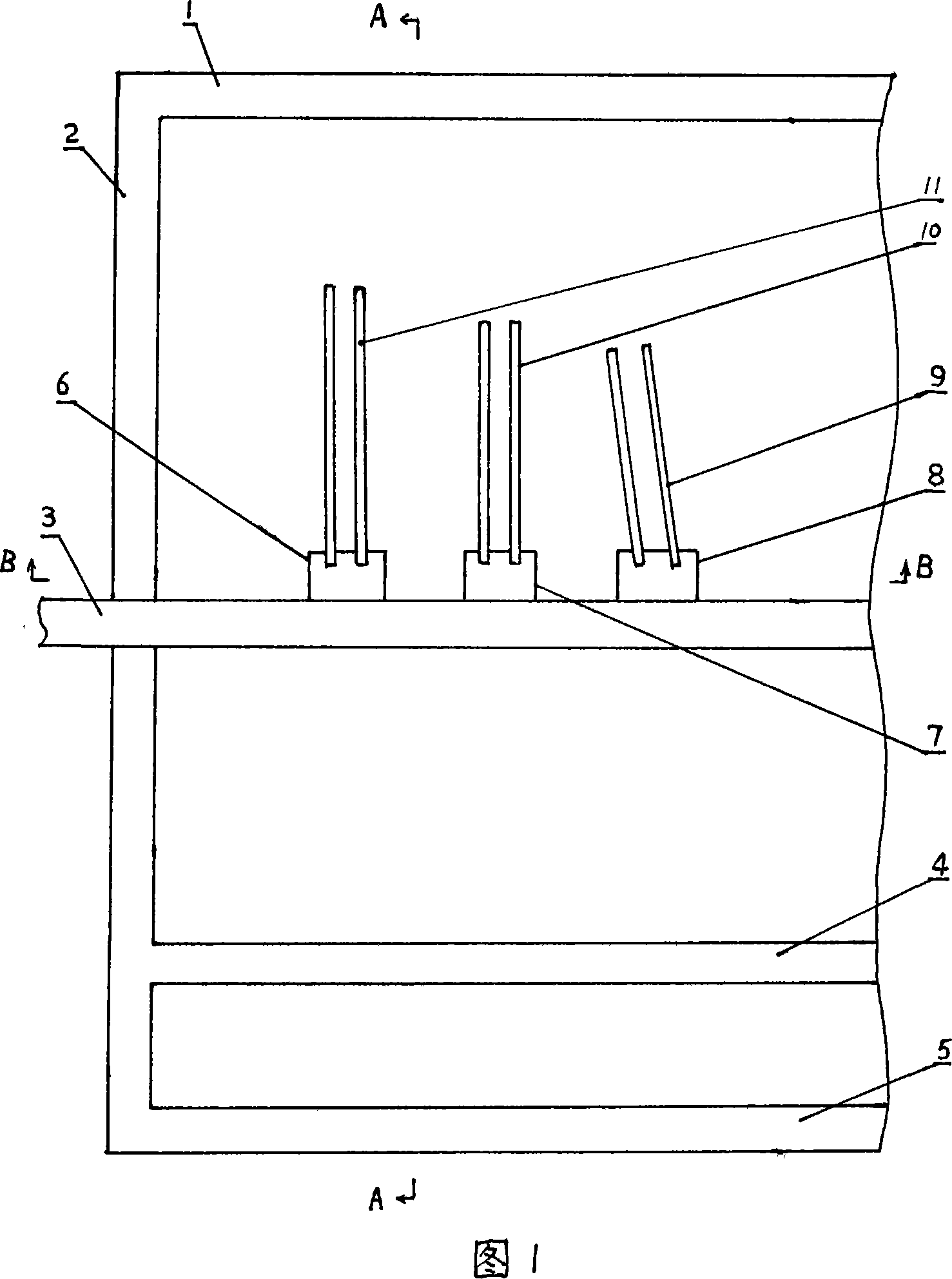

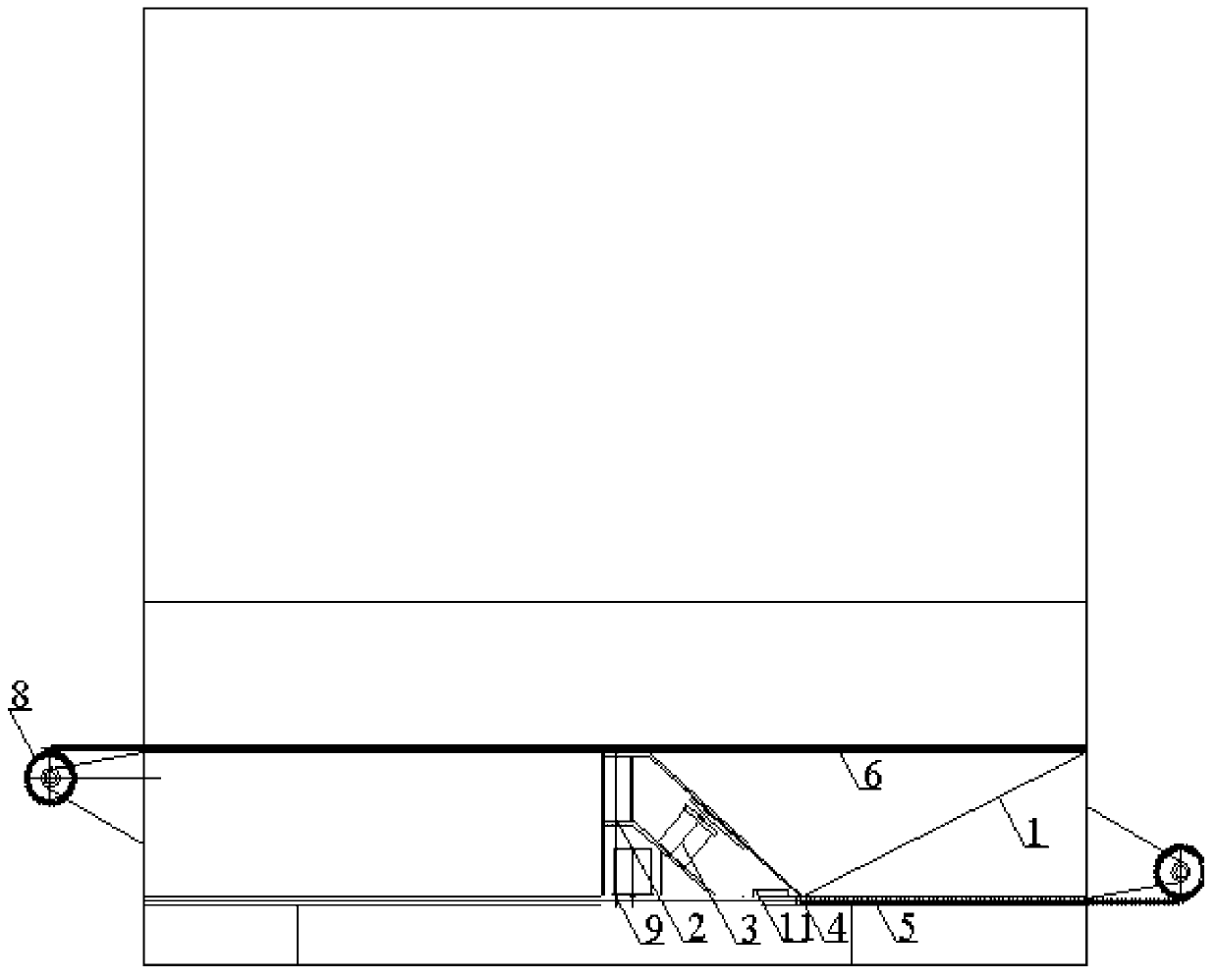

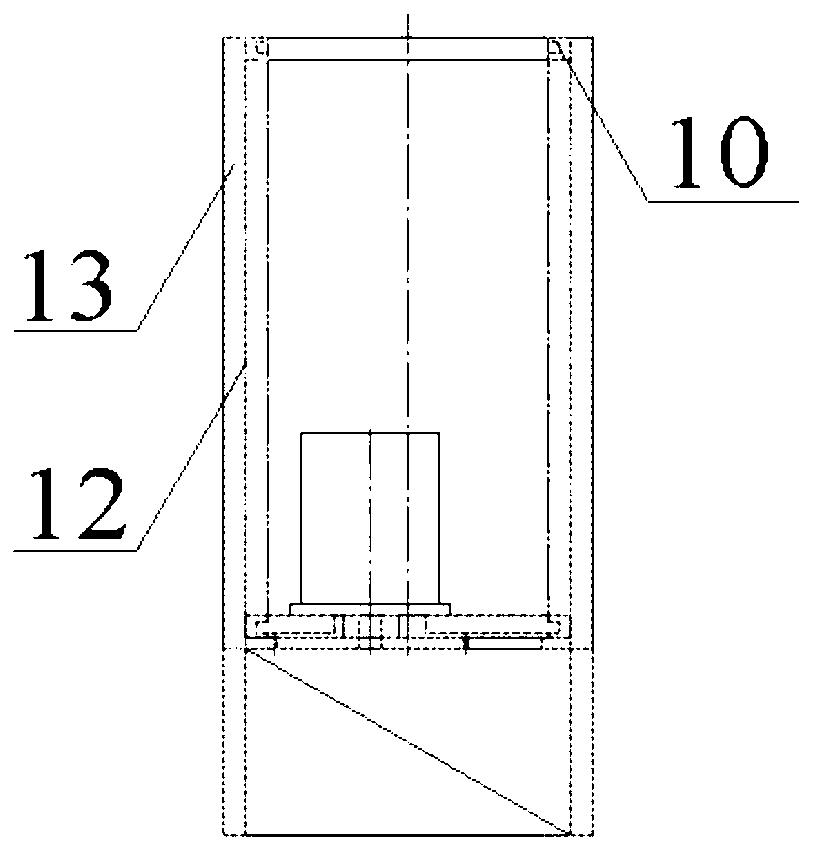

Four-dimensional transparent visual experiment table and method for simulating top coal drawing

InactiveCN104504988ACompact and efficientReasonable optimization of coal discharge parametersEducational modelsSpelunkingThree-dimensional space

The invention relates to a four-dimensional transparent visual experiment table and method for simulating top coal drawing and belongs to the technical field of mine engineering. Hydraulic jacks are respectively disposed at four corners under a base, a transparent organic glass cover is inserted into organic glass cover slots in the front and rear ends of the base, the front end of the transparent organic glass cover is fixed on fixing angle bars located at the front end of the base by the aid of anchoring screws through anchoring screw holes and anchoring eyelets, a transport box is disposed in a transport box groove in the middle of the base, and a coal caving supporter is arranged on the upper portion of the transport box at the lower end of the transparent organic glass cover through top beam support pillars and top beam support bases so as to be connected with the base; a transparent gangue simulation medium, a transparent top coal simulation medium and luminous mark point particles are arranged in an enclosed space encircled by the coal caving supporter and the transparent organic glass cover, and high definition cameras and camera stands are connectedly disposed in three pairwise orthogonal space ranges on the front side, lateral side and upper side of the transparent organic glass cover. The conditions that the top coal positions and velocity fields in a three-dimensional space change with time under the circumstance of any coal seam dip angle can be measured accurately.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

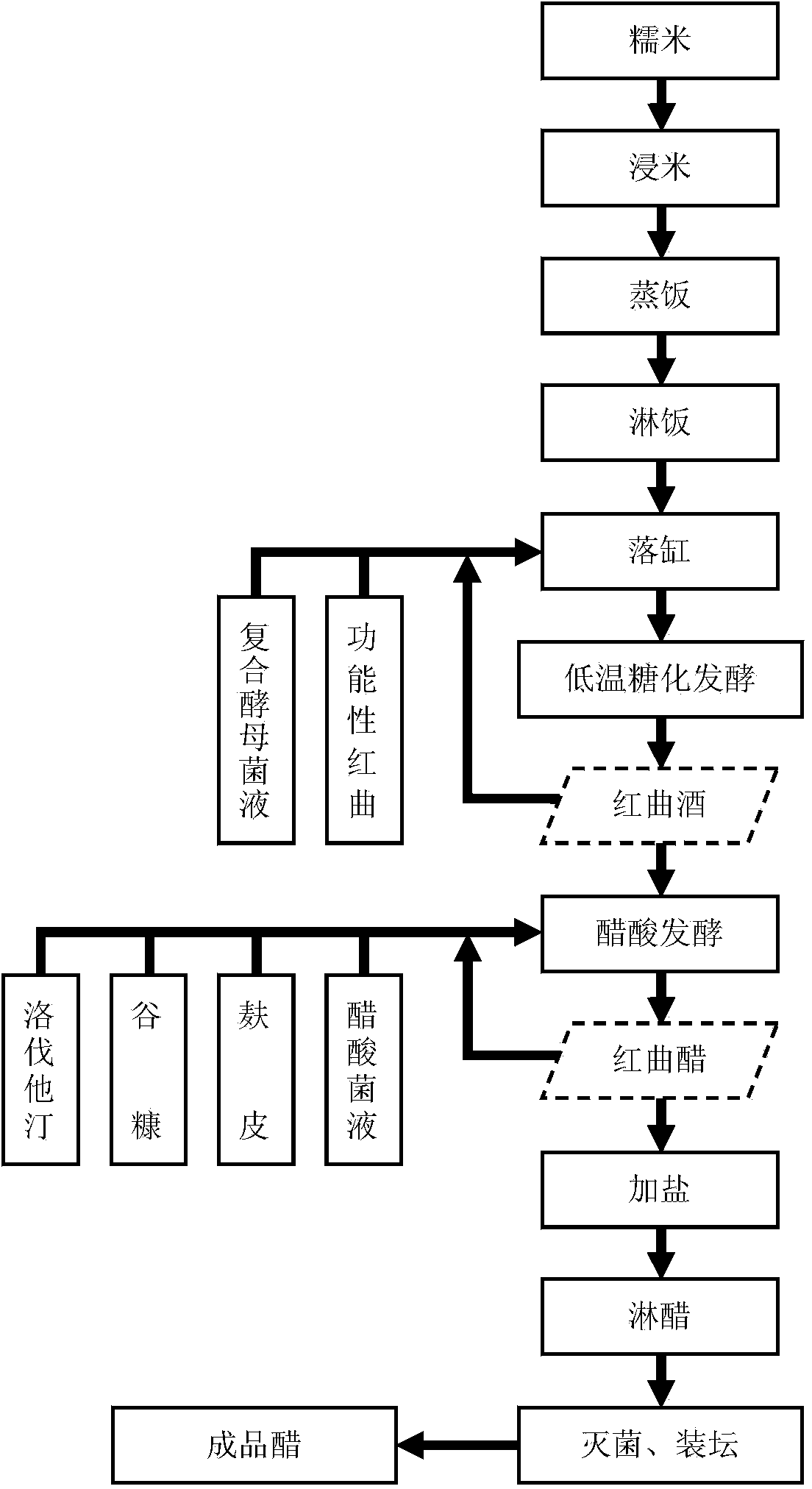

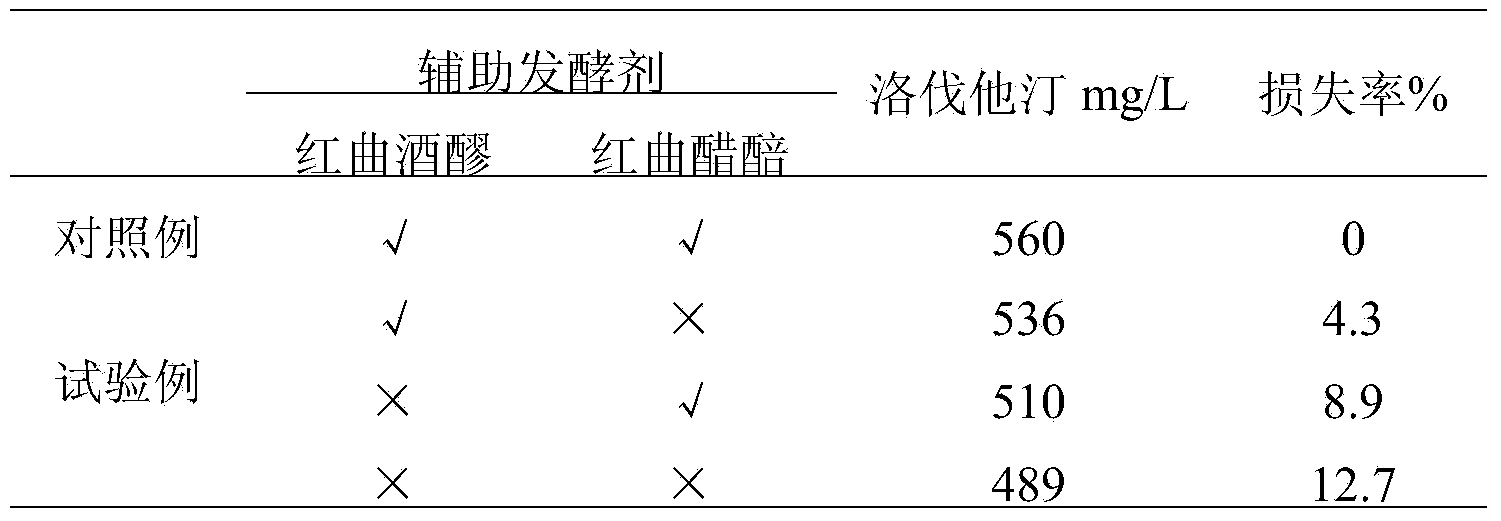

Production method of monascus vinegar rich in lovastatin

ActiveCN103865747AIncrease concentrationReduce water consumptionVinegar preparationRed yeast riceSpelunking

The invention relates to a production method of a monascus vinegar rich in lovastatin. The production method comprises the following steps: soaking, steaming and sprinkling cold water on high-quality glutinous rice, mixing the rice with a composite yeast solution, a former batch of fermented red yeast rice wine mash and functional red yeast, then carrying out diastatic fermentation at a low temperature to obtain mature red yeast rice wine mash; mixing bran, cavings, the former batch of fermented monascus vinegar culture and acetic acid bacteria liquid into the wine mash to perform solid-state acetic fermentation, adding lovastatin in a later period of fermentation with an adding amount being 0.03-0.05% of mass of a raw material, and fermenting for a total of 28-30 days to obtain mature monascus vinegar culture; and adding salt in the vinegar culture, pouring vinegar in the vinegar culture, sterilizing the vinegar culture, clarifying the and then filling the vinegar culture in jars and sealing to obtain the finished product, namely the monascus vinegar rich in lovastatin. The production method of the monascus vinegar rich in the lovastatin has the characteristics that the obtained monascus vinegar is rich in fragrance, mellow in taste and excellent in color and luster, and has a content of the lovastatin being 560-600mg / L.

Owner:JIANGNAN UNIV

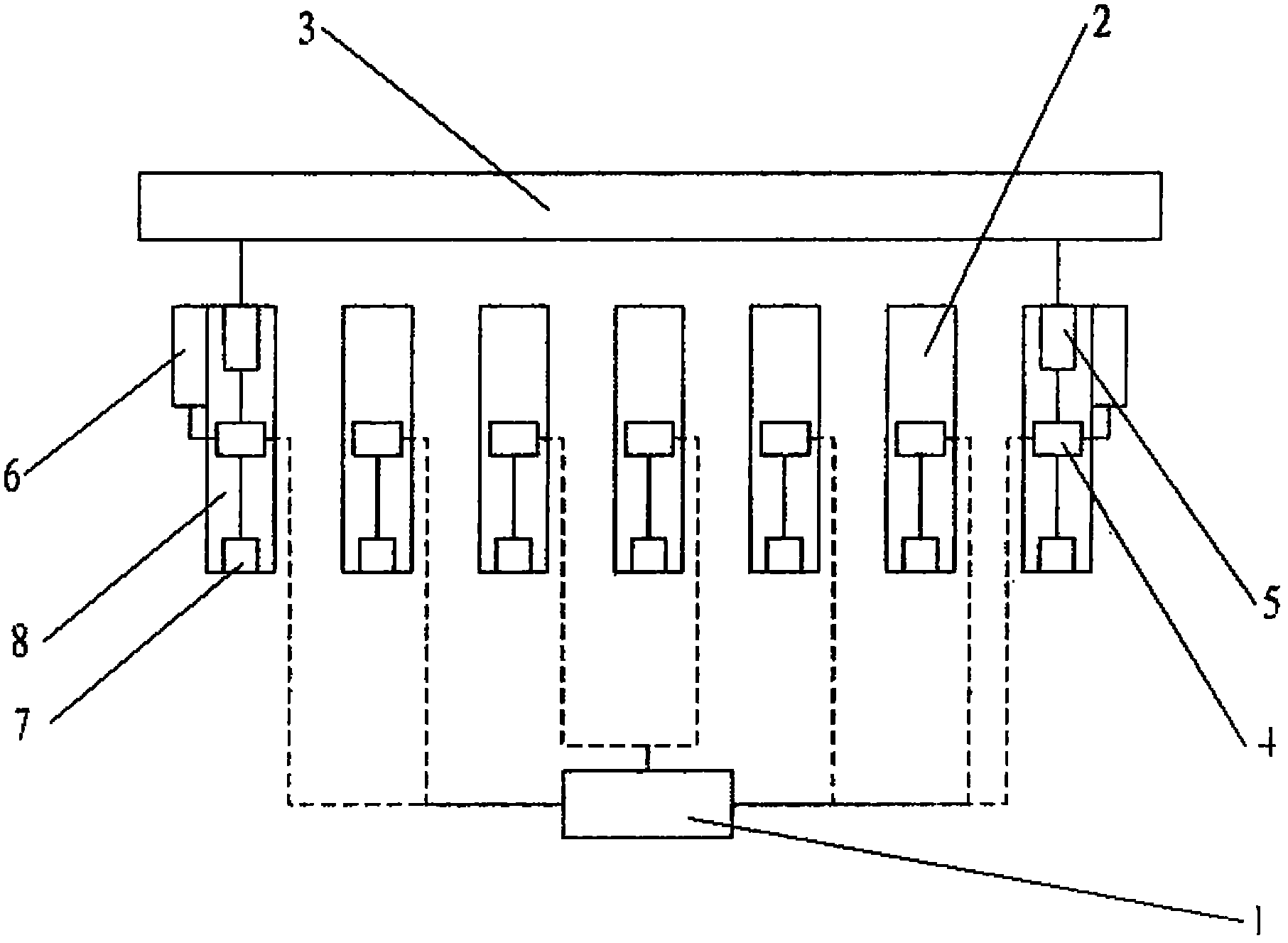

Automatic coal caving system on top coal caving working face and coal caving method thereof

ActiveCN102493827ARealize automatic coal dischargeNo human intervention requiredMine roof supportsSpelunkingControl system

The invention relates to an automatic coal caving system on a top coal caving working face and a coal caving method thereof. The automatic coal caving system comprises a monitoring host, support controllers, inclination angle sensors, distance measuring instruments and data acquisition devices, wherein the distance measuring instruments and the data acquisition devices are mounted on end hydraulic supports in top coal caving supports, and the data acquisition devices are connected with a scraper conveyor of the top coal caving working face; the support controllers are in the same number with the top coal caving supports, and each top coal caving support is provided with the support controller; the inclination angle sensors are in the same number with the top coal caving supports, and the inclination sensor is arranged on a tail beam of each top coal caving support; the monitoring host is mounted in an underground road and in wireless connection with all the support controllers; each distance measuring distance and the corresponding data acquisition device are electrically connected with the support controller on the same top coal caving support; and each inclination angle sensor is electrically connected with the support controller on the same top coal caving support through a connector.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

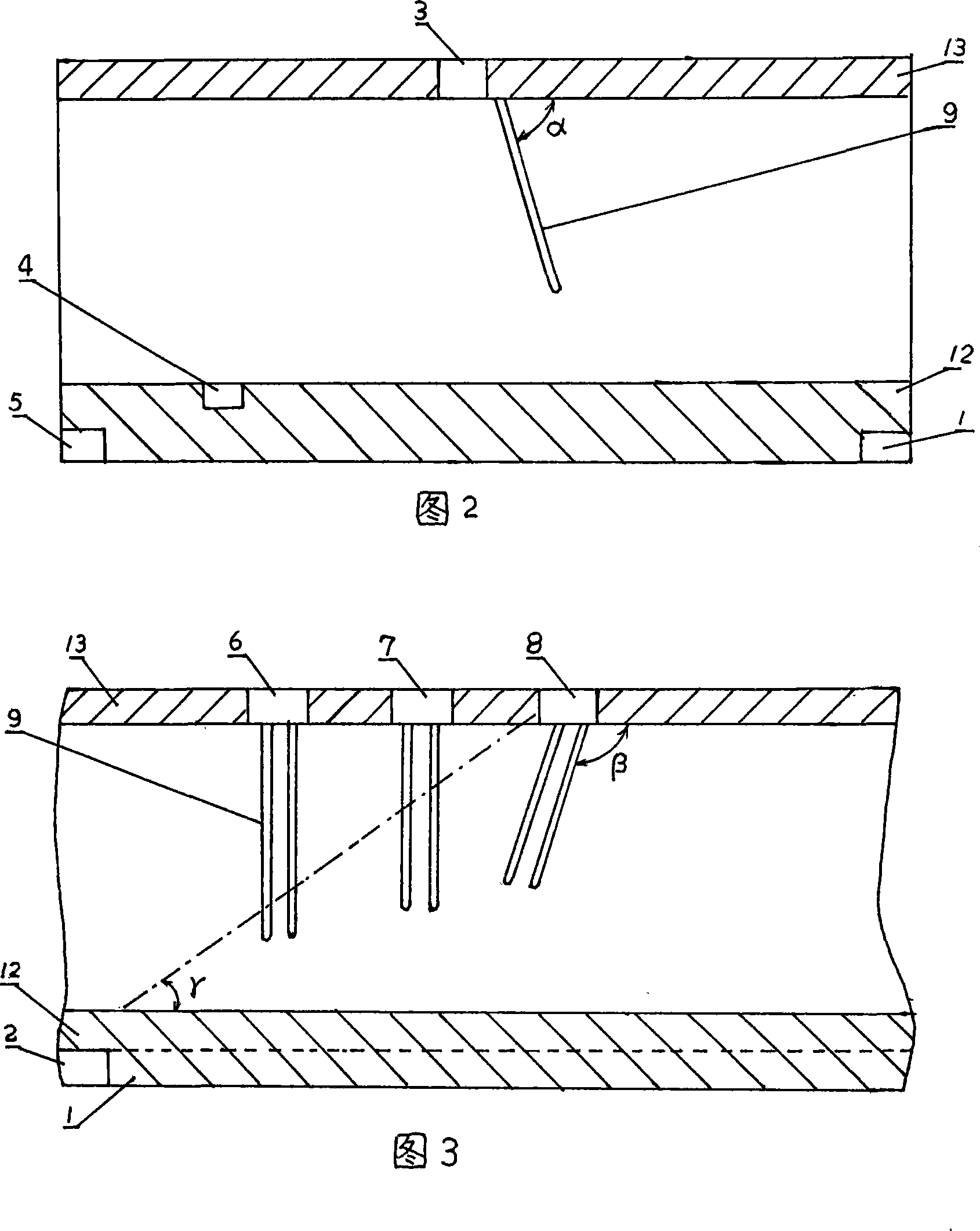

Fully mechanized coal face high suction tunnel lower-returning drilling primary mining gas drainage method

The present invention relates to a gas pumping and exchanging method of downward drilling hole high pumping lane with a comprehensive caving face used in gas initial pumping and exchanging, and aims to create a safe and simple working condition, to improve pumping and exchanging efficiency and to reduce the gas consistency of the working face efficiently; the present invention is to dig two or three drilling fields being suitable for drilling machine working at the place that the inner bottom plate of a trending high pumping lane is horizontally 0 to 50 meters being far away from the cutting lane; and two or three drilling holes are also need to be drilled; besides, towards the working face, the drilling machine can be used to drill downwards drilling holes which can replace the high pumping lane; the drilling holes can be drilled from the high pumping lane to reach the loading belt which is positioned above the working face and is newly developed during the initial mining period. The final drilling hole can be positioned in the angle of 70 degrees formed by the working face roof of the cutting lane and the roof of the coal seam and also can be positioned in the stratum as far as four and five times away from the working face; during the initial mining period, the trending high pumping lane is sealed in wall and pressed with iron tubes to connect with the main pumping and exchanging system; under the condition of high subpressure and through downward drilling holes, the gas lifted to the slit belt is pumped to the trending high pumping lane to enter into the pumping and exchanging system to reach the ground.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

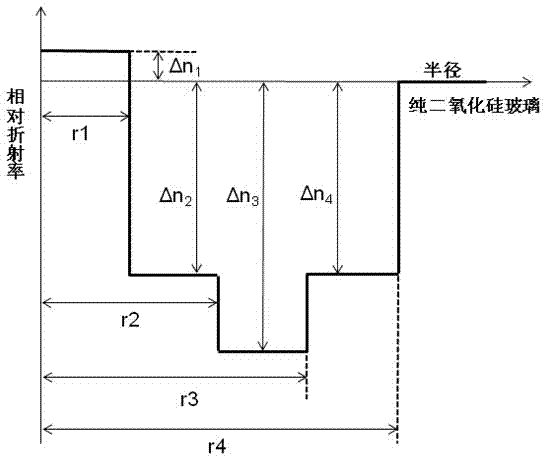

Ultralow attenuation single mode fiber

ActiveCN104777553AReduce defectsDecrease the attenuation parameterOptical fibre with multilayer core/claddingSpelunkingUltrasound attenuation

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

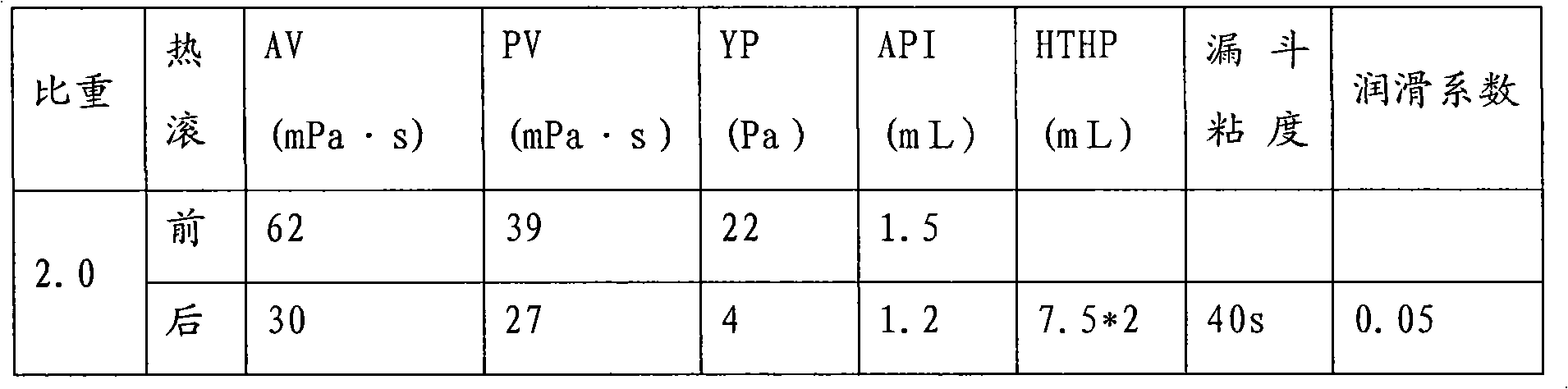

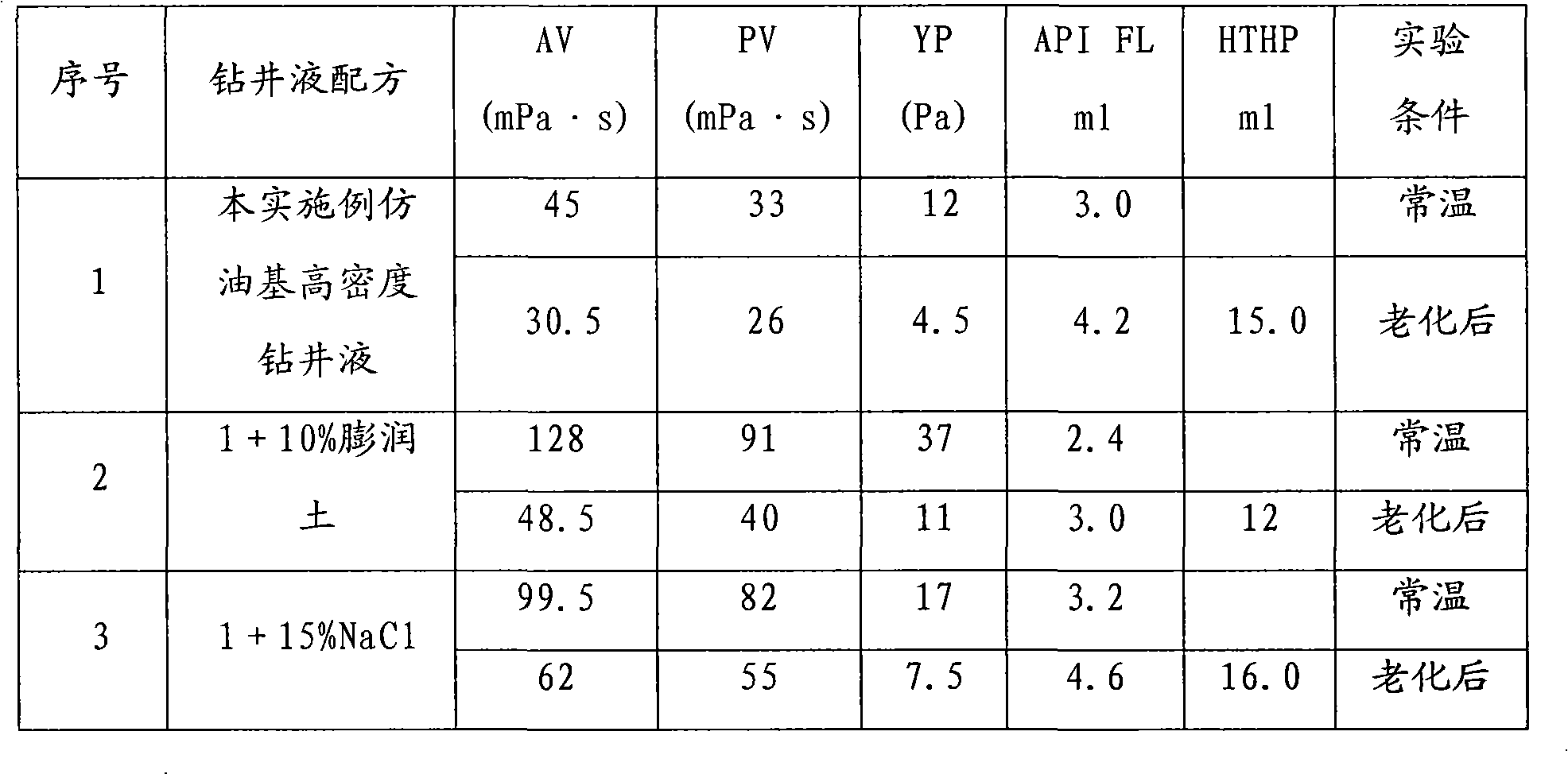

Imitated oil base high-density drilling fluid

ActiveCN101955761AMeet development requirementsSolve drilling complex problemsDrilling compositionSlurryPollution

The invention relates to an imitated oil base high-density drilling fluid which is characterized by comprising 2-4% fresh water bentonite slurry, a tackifier, a high temperature resistant filtrate loss reducer, a lubricant, a shielding plugging agent, an anti-caving agent and inorganic salt. The 2-4% fresh water bentonite slurry is base slurry formed by adding 2-4 g of sodium base bentonite to each 100 ml of water. In every 100 ml of 2-4% fresh water bentonite slurry, the drilling fluid comprises 0.2-0.5 g of tackifier, 3-6 g of high temperature resistant filtrate loss reducer, 3-10 g of lubricant, 1-3 g of shielding plugging agent, 2-4 g of anti-caving agent and 5-8 g of inorganic salt. The imitated oil base high-density drilling fluid resists high temperature, salts and pollution, the comprehensive properties of the imitated oil base high-density drilling fluid are equivalent to those of an oil base high-density drilling fluid, and the defects of environmental pollution, influence on the display of an oil-gas layer and high cost of the oil base high-density drilling fluid are overcome.

Owner:北京奥凯立科技发展股份有限公司

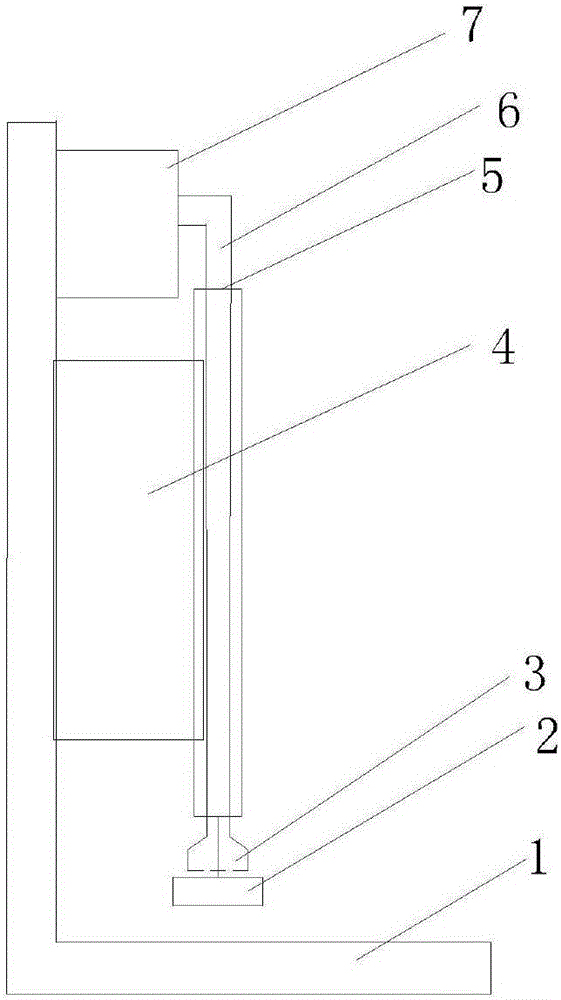

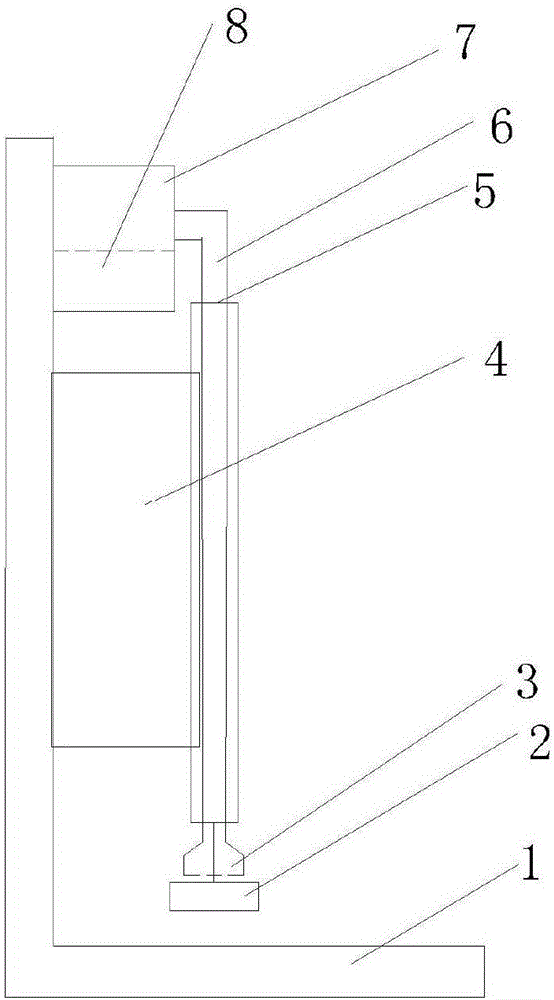

Caving cleaning device

The invention relates to a caving cleaning device which comprises a bracket, a lifting mechanism I, a drill rod and a recycling device, wherein the lifting mechanism I is cooperatively mounted with the bracket; the drill rod is cooperatively mounted with the lifting mechanism I; the recycling device is cooperatively mounted with the lifting mechanism I; the recycling device comprises an air channel and a ventilation device; the ventilation device is cooperatively connected with the air channel; and an air inlet of the air channel is positioned at the rear part of a drill bit and goes up and down along with the drill bit. The caving cleaning device provided by the invention offers a mechanical caving cleaning device and can improve the working efficiency of caving cleaning.

Owner:李 俊杰

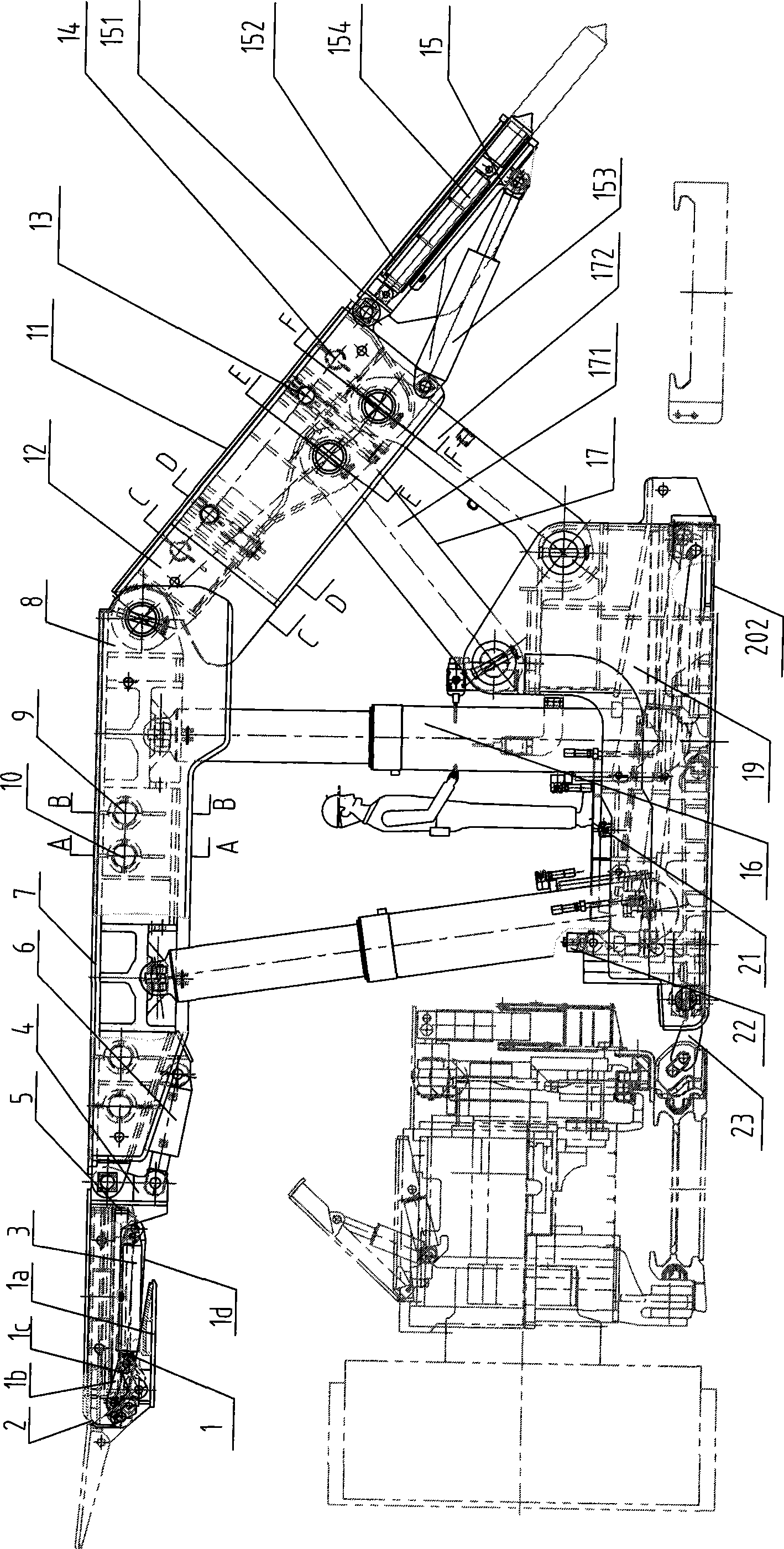

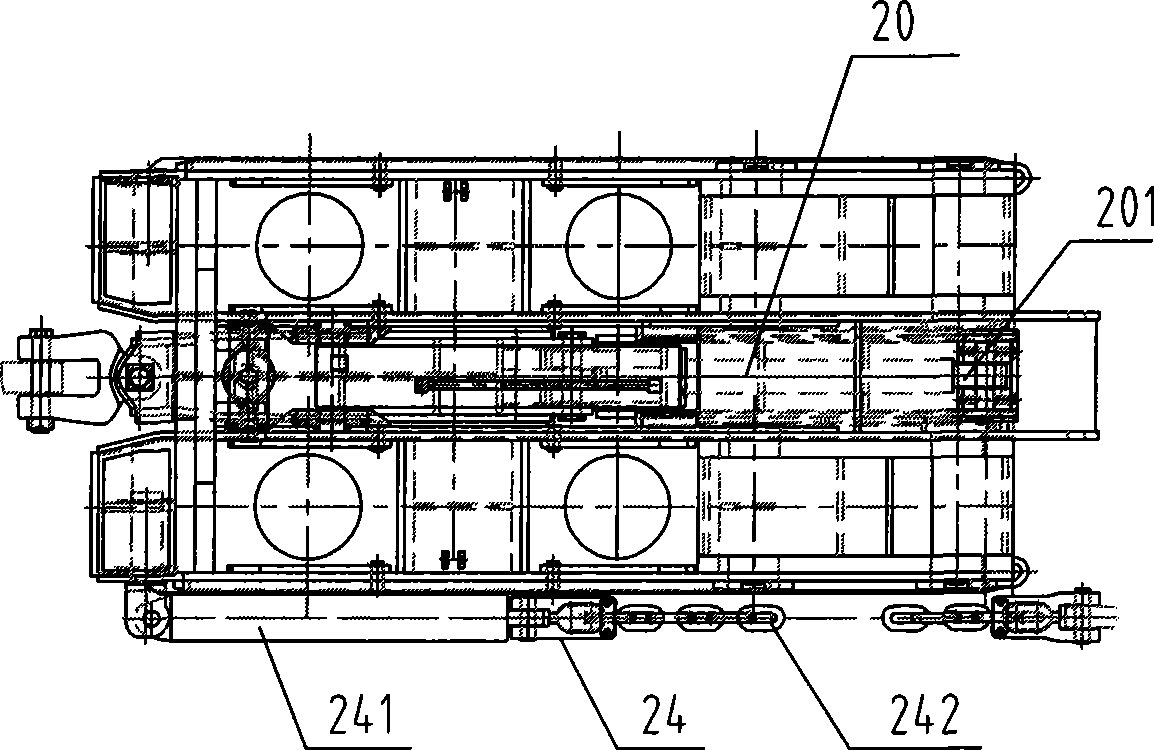

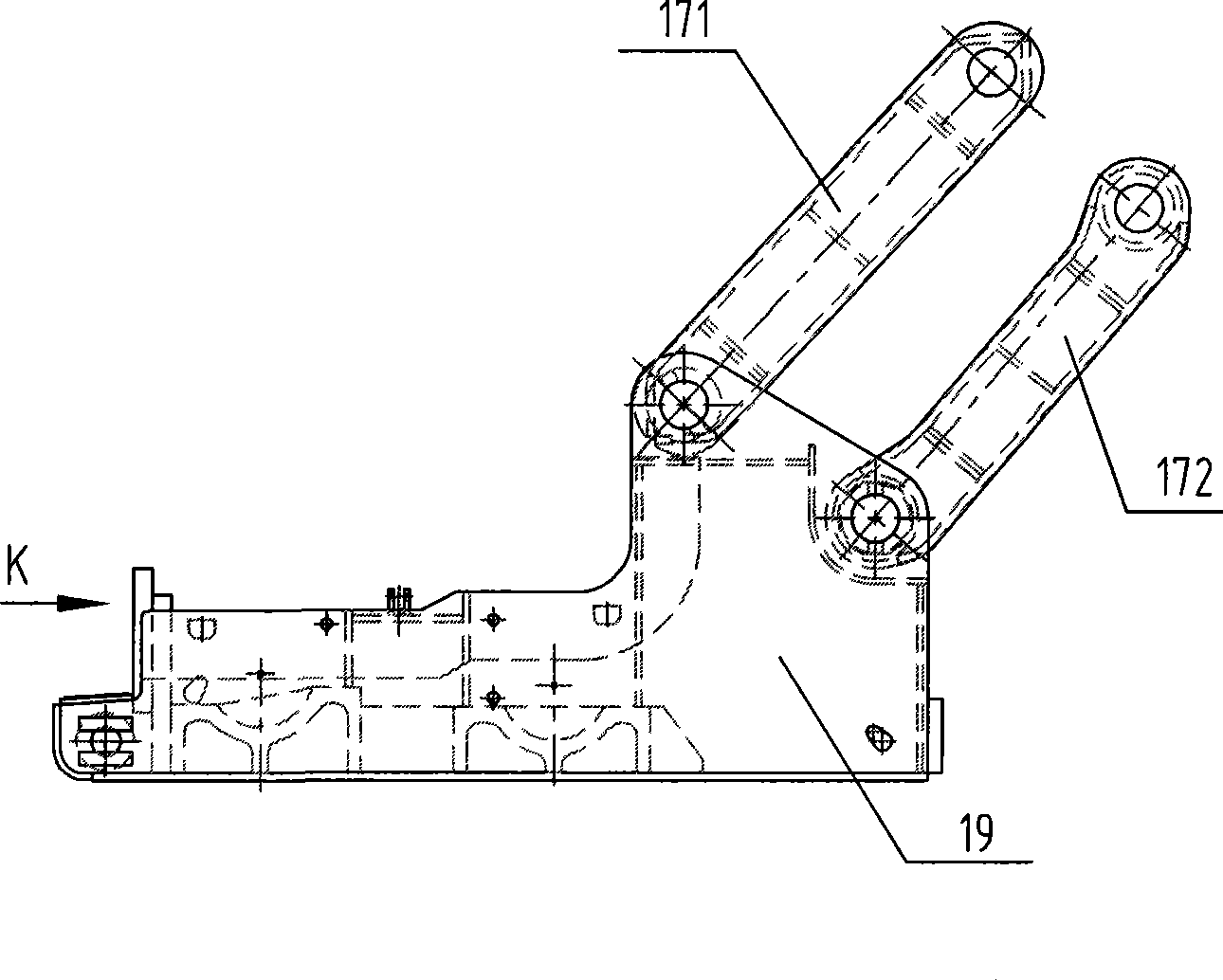

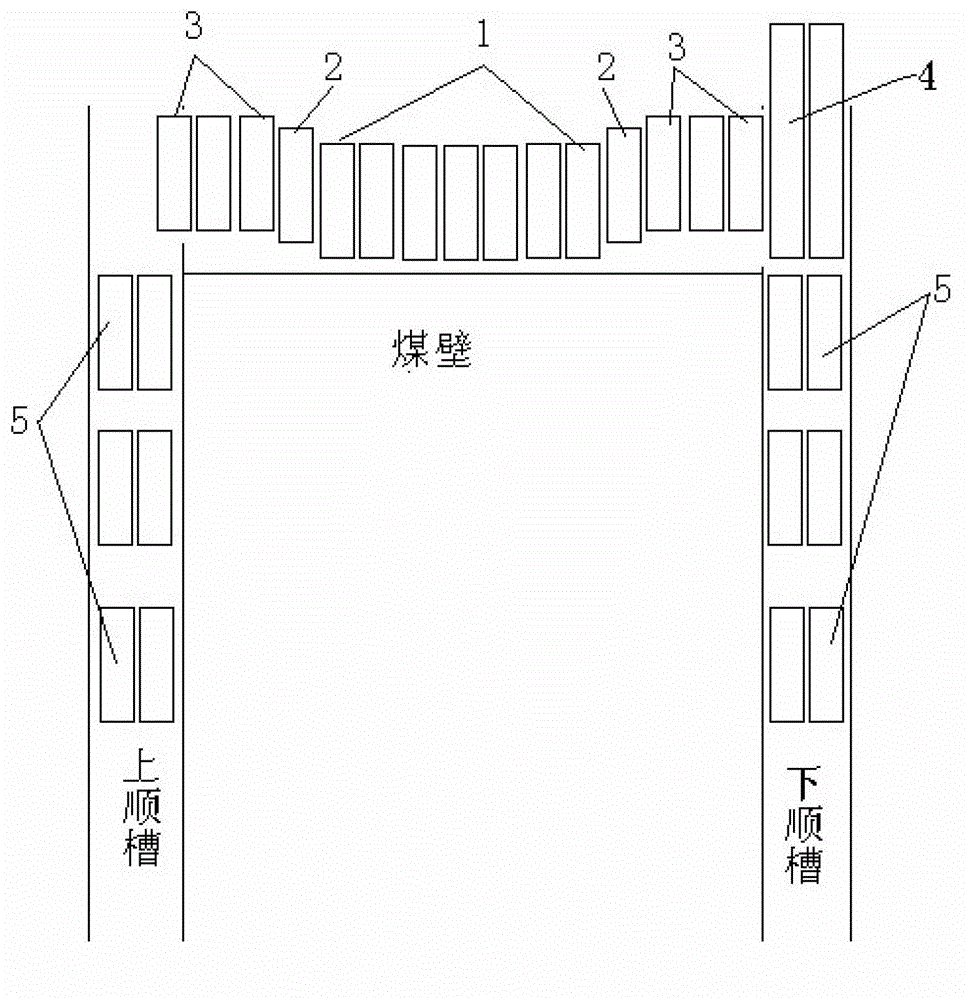

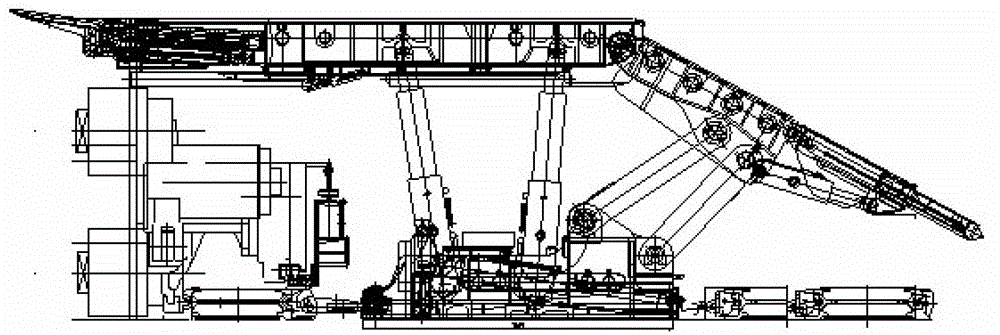

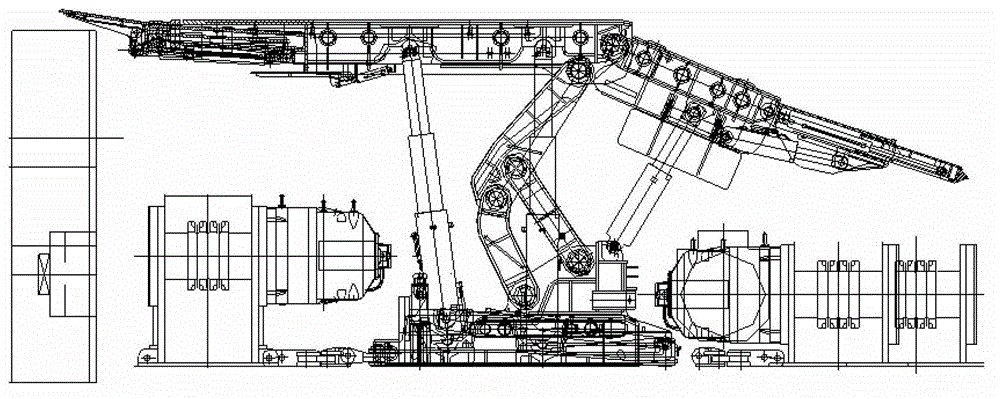

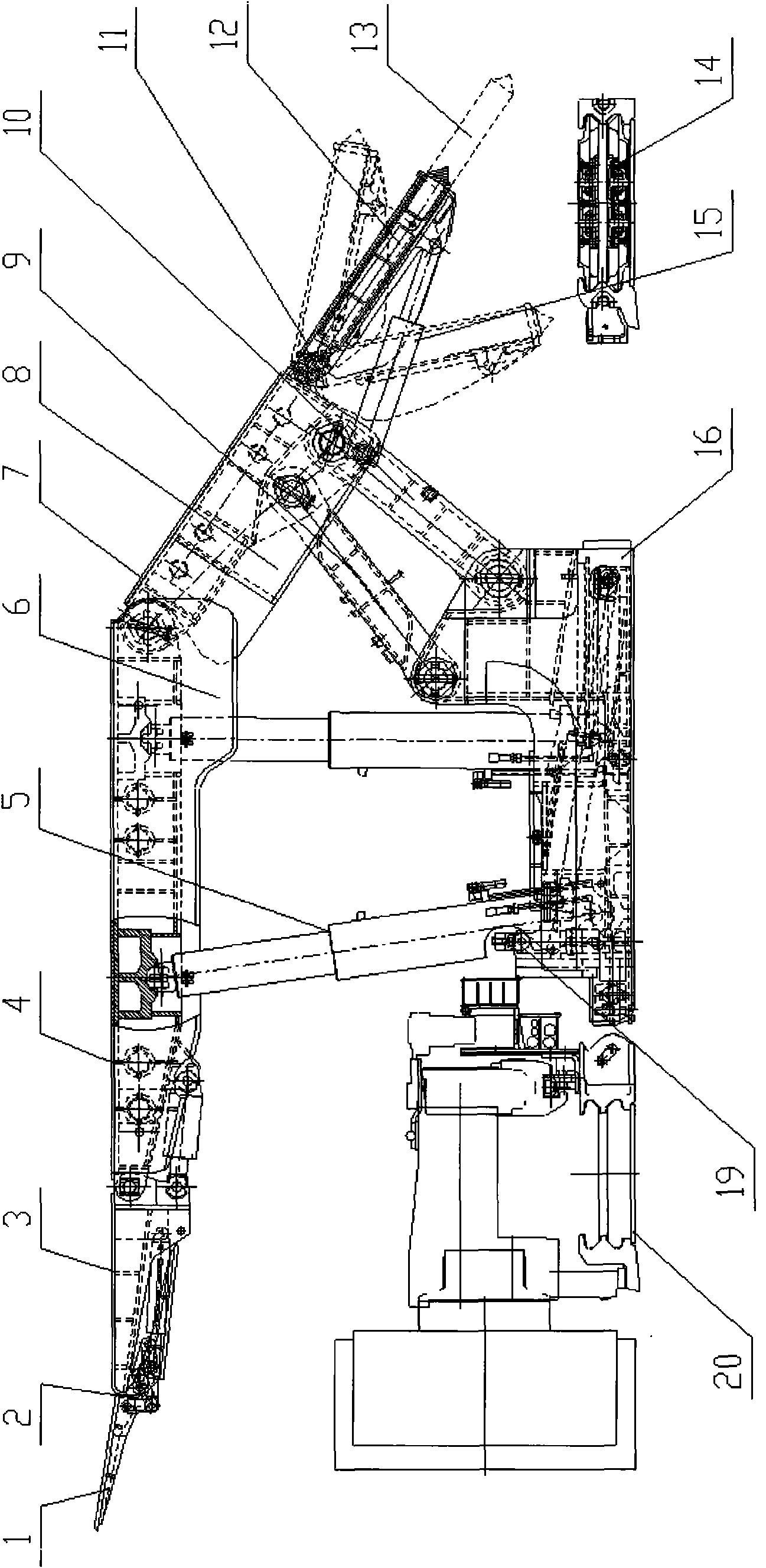

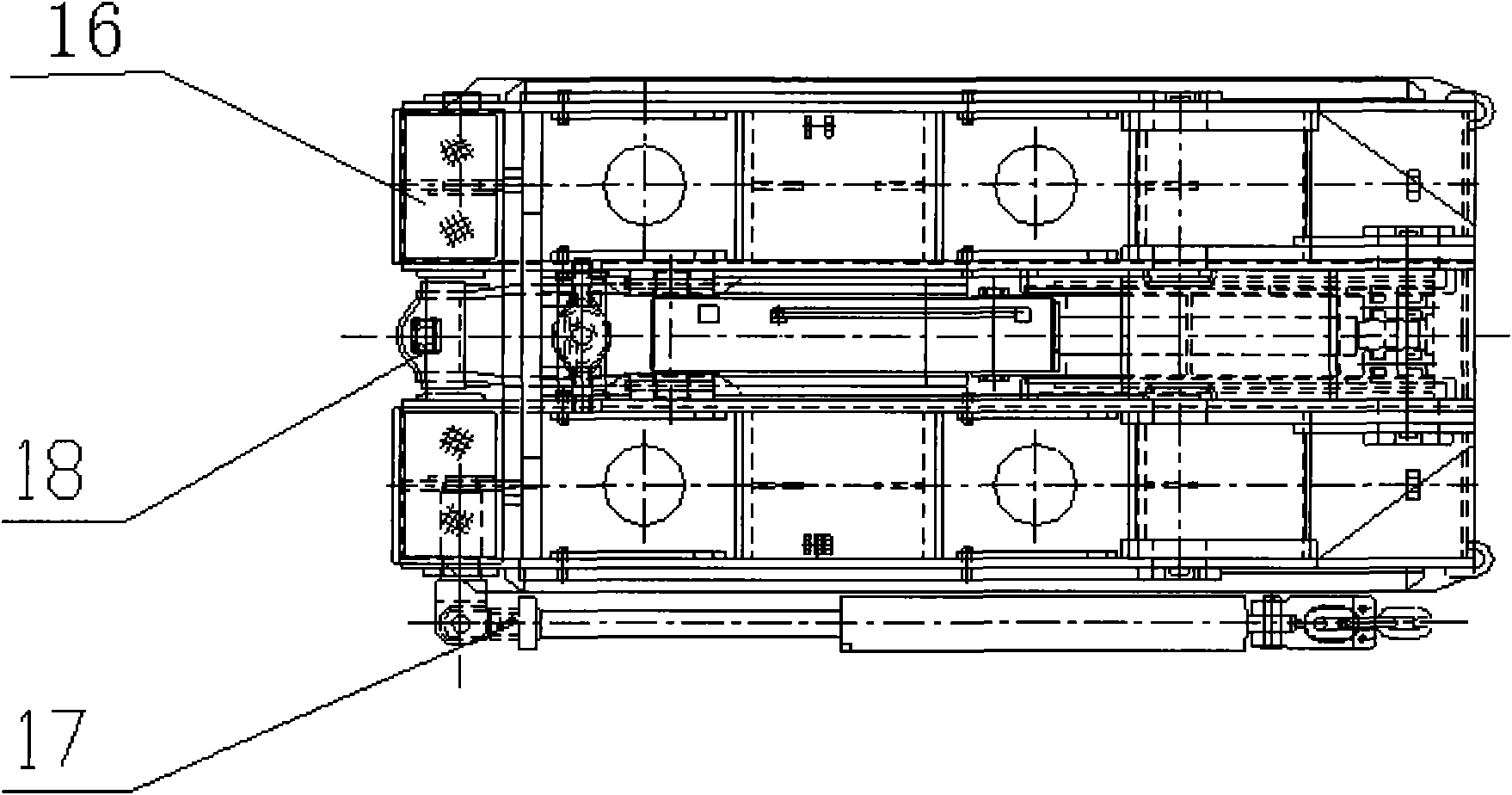

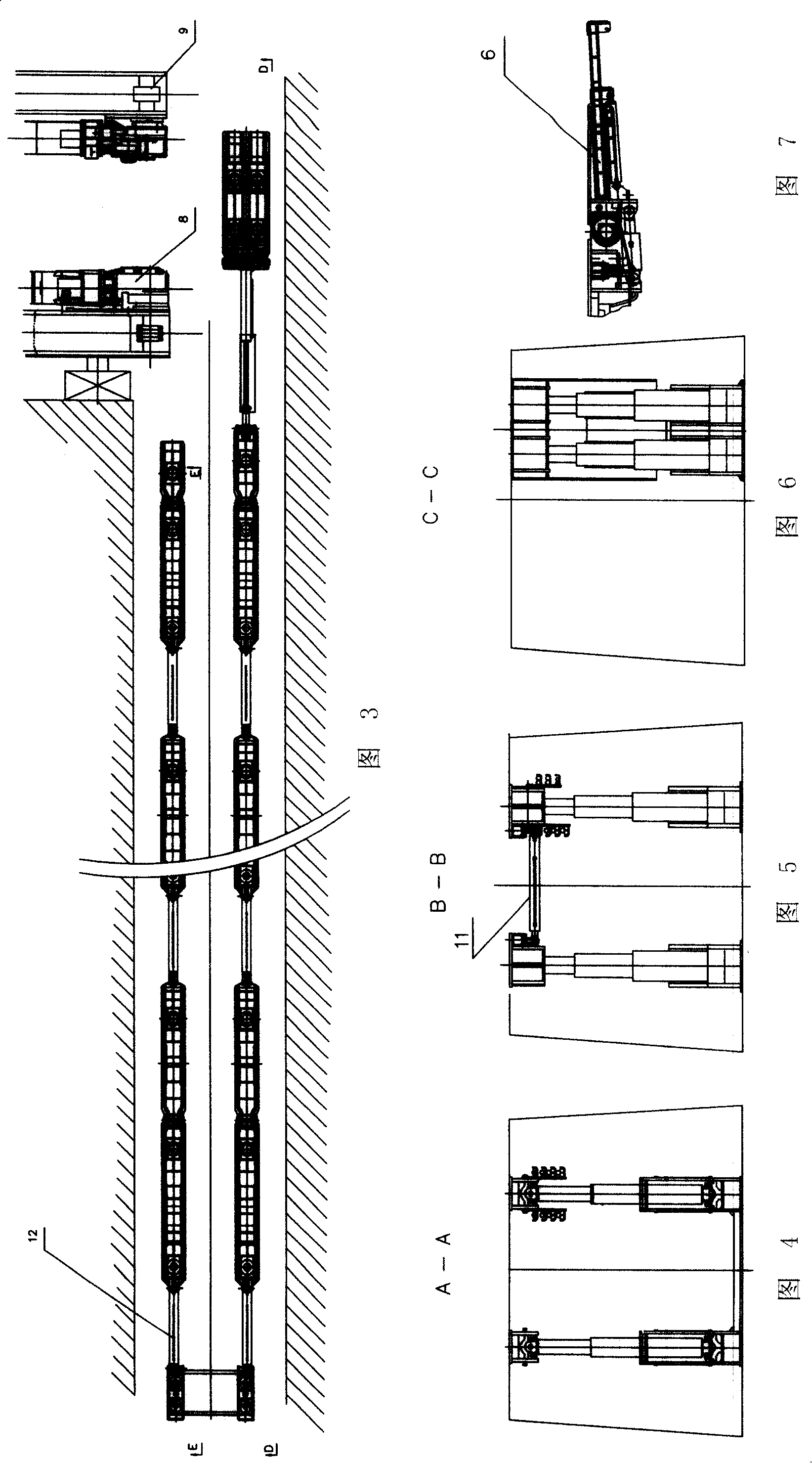

Heavy large-mining-height full-protection large-dip-angle long-wall fully mechanized caving face automatic control supporting equipment

The invention discloses heavy large-mining-height full-protection large-dip-angle long-wall fully mechanized caving face automatic control supporting equipment. A plurality of middle brackets are arranged on a caving face; transition brackets and leader brackets are respectively and sequentially arranged at the both sides of the middle brackets; look-ahead brackets are respectively arranged inside an upper gateway and a lower gateway; a group of end head brackets are arranged at the part, which is transversely aligned to the leader brackets, of the lower gateway; an anti-falling device is connected between top beams of the two adjacent brackets; bracket turning devices are respectively connected between the front ends and back ends of bases of the two adjacent brackets; an inclined-draw anti-falling device is connected between the top beam of the bracket at the lower side and the base of the bracket at the upper side; a front roller anti-sliding device and a back roller anti-sliding device are respectively connected between the front ends and back ends of the bases of the brackets, and a front roller and a back roller; auxiliary pushing mechanisms are respectively arranged at one sides of the leader brackets and the bases of the end head brackets; rigid handrail and stepping boards among the brackets are arranged at the both sides of a side pavement inside the brackets; and a stretchable protection network is arranged between every two front stand posts of the brackets. According to the large-mining-height full-protection large-dip-angle long-wall fully mechanized caving face, the working resistance of the bracket is more than 7000 KN; the length applicable to the caving surface is more than 200 m; the inclination angle is more than 50 degree; and the thickness of a coal layer is more than 1.8 m.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

Production method for oat health-care vinegar by fermenting oat raw materials

InactiveCN102559471AReduce pollutionSave energyMicroorganism based processesVinegar preparationSpelunkingBran

The invention discloses a production method for oat health-care vinegar by fermenting oat raw materials, which includes the following steps of A1 smashing and sieving processes; A2 saccharifying and alcoholizing processes; A3 an acetic fermentation process: leading acetic acid bacteria culture solution is in mature wine mash according to 8-10% of the weight of naked oat powder, adding auxiliary materials, wherein the auxiliary materials are cavings and bran, and the weight proportion of the cavings and the bran is 1:1, stirring evenly, controlling product temperature at 35 to 40 DEG C, turning over one time everyday, performing solid-state acetic fermentation, and fermenting for 7 to 10 days; A4 a postprocessing process; A5 a vinegar pouring process; and A6 a blending sterilization process. The production method uses oats as raw materials, and adopts a raw material vinegar producing process to make oat health-care vinegar. The method adopts the raw materials to make the vinegar. Compared with other processes, the process using the raw materials to make the vinegar has the advantages of saving energy and time. The saccharifying, alcoholic fermentation and acetic fermentation are conducted simultaneously, and the process can omit stewing of main materials, saves energy, and reduces pollution to the environment.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

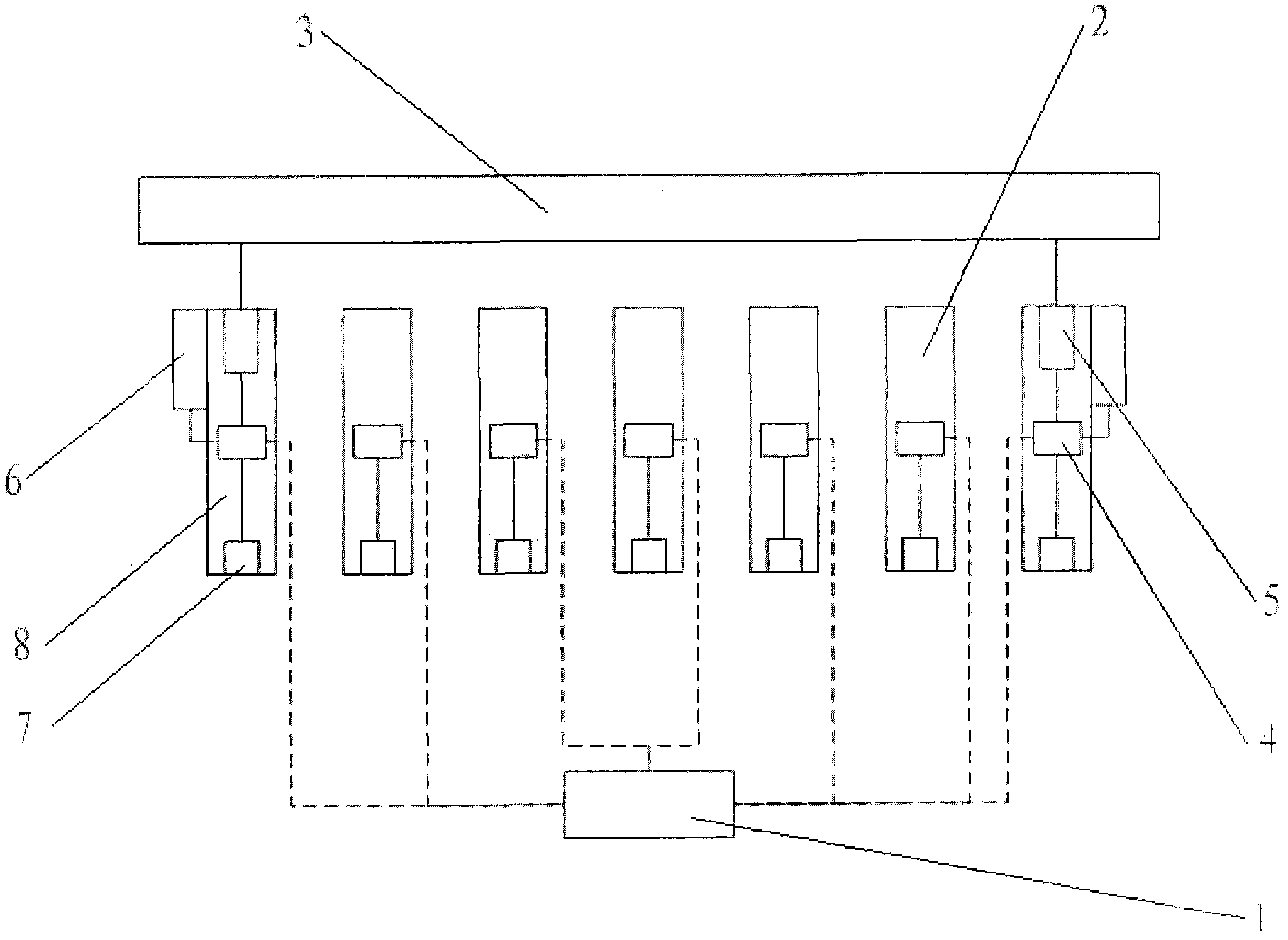

Automatically controlled full-mechanized caving mining loose visual simulation experiment table

InactiveCN103216235ARealize visual simulationRealize automatic controlUnderground miningSurface miningSpelunkingAutomatic control

The invention provides an automatically controlled full-mechanized caving mining loose visual simulation experiment table. The invention comprises a experiment table framework, a visual portion, a remote control apparatus, a top coal support grid and moving system, a support moving system and an angle adjusting system; The main body of the experiment table employs a frame-type structure, and the side surface of the experiment table framework employs a transparent plastic plate, and the remote control apparatus controls the simulation experiment table system, and experiment table system control parameters are set by the remote control apparatus, and an initial goaf is simulated on the experiment table frame, and a spoil baffle plate is disposed behind the initial goaf, thereby the simulation is directly in a normal top coal case; the top coal support grid is temporarily supported by top coal and the top board, and the support employs a simple top coal support, and support is provided with a gear which moves on a self-moving track, and the support gear is driven by a stepping motor, and a tooth bar which is engaged with the support gear is fixed on a experiment table framework base plate, and the top coal support grid moves on the self-moving rack by the support which is remotely controlled by a stepping motor.

Owner:CHINA UNIV OF MINING & TECH

Large mining height shield type low caving coal hydraulic support

The invention discloses a large mining height shield type low caving coal hydraulic support. The support comprises a base, a top beam and a shielding beam, wherein an upright post is arranged between the top beam and the base; the upright post is a double telescopic upright post; the inner diameter of the large cylinder body of the upright post is more than or equal to 500mm; and the expanded height of the upright post is more than or equal to 4m. A push device is arranged in the middle of the base, the front end of the push device is connected with a front scraper conveyor; a pull back sliding device is arranged outside the base; and the rear end of the pull back sliding device is connected with a back scraper conveyor. A coal feed mechanism comprises a tail beam and a tail beam jack; a flashboard and a flashboard jack are arranged in the tail beam, and the end part of the flashboard is provided with a conical tooth for crushing range coal; and the upper oscillation angle of the tail beam is between 10 and 15 degrees, while the lower oscillation angle is between 40 and 45 degrees. The support can be applied to primary top-coal caving mining for super high coal seam with support height of over 4 meters, thickness of a coal placement layer of over 16 meters and good top-coal caving performance, and improve the production efficiency of a sub-level caving working face and the resource recovery rate.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

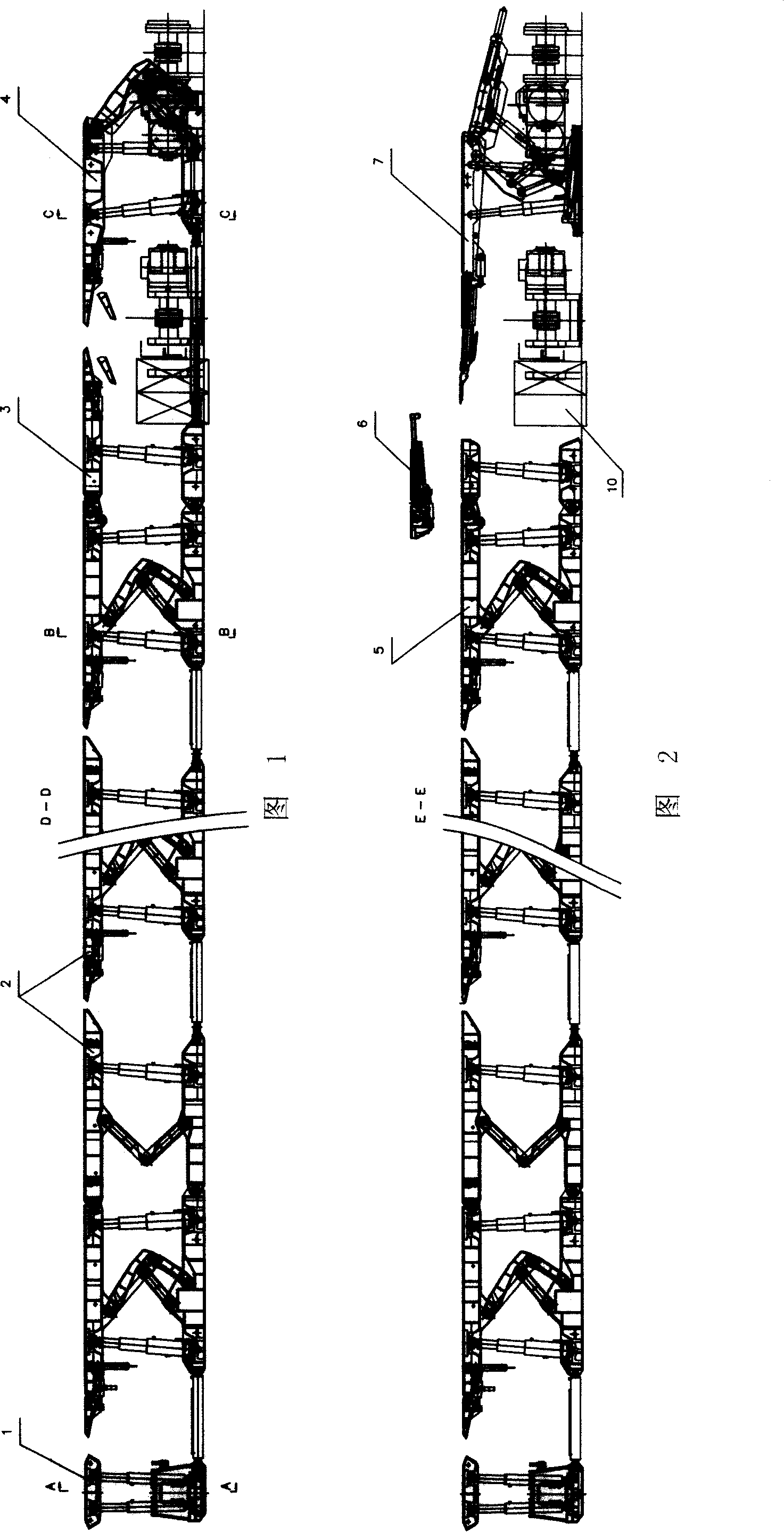

Fully mechanized working faces track along end head bracket

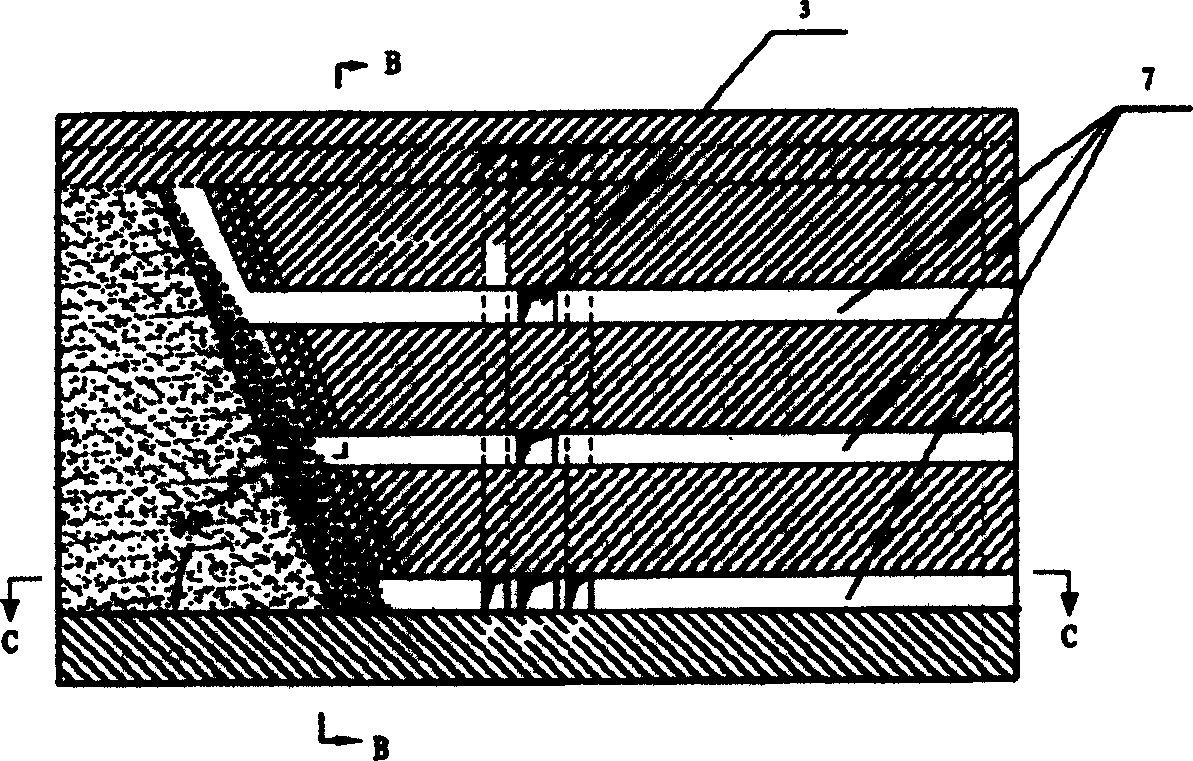

ActiveCN101191419AReduce labor intensityReduce the number of repetitionsMine roof supportsSpelunkingSelf motion

The invention provides a comprehensive caving working face along-rail face-end support, mainly comprising a face-end support(4), 3 to 6 groups of forepolings and an anchor support(1), wherein the face-end support(4) is the chock-shield support; each group of forepoling comprises two racks, that is, formed by the inner and the outer side racks arranged on both sides of the along-rail and the rack adjusting lifting jack(11) arranged between top beams of the inner and the outer side racks; the inner and the outer side racks of the forepolings both comprise articulated roof bars, articulated bases, upright columns, four-bar linkage mechanisms and front beams, etc. The anchor support, which is arranged in front of the forepolings, has the structure of integrated base and split top beam; the upright columns are the four-upright columns which are sleeved by elastic rings and rigid guide holders. The anchor support, the forepolings and the face-end support are orderly connected by pull-move lifting jacks arranged between bases of the anchor support, the forepolings and the face-end support. The invention has the advantages of realizing the advance support of the along-rail face end in self-motion mode, lowering labor intensity, improving working efficiency and safety; the stepping-type forward lead of the invention makes relative small area of empty support and little roof convergence, thereby the invention is particularly suitable for the big deformation of the gob-side entry driving rail sublevel.

Owner:兖矿能源集团股份有限公司

Medicinal preparation for treating acnes, whelks and folliculitis and preparation method thereof

InactiveCN101637578AHyperinhibitionInhibition of anti-sebaceous keratosisDermatological disorderPlant ingredientsAntibiosisSpelunking

The invention discloses a medicinal preparation for treating acnes, whelks and folliculitis and a preparation method thereof. The medicinal preparation is mainly prepared from fructus forsythiae, honeysuckle, scutellaria baicalensis, radix sophorae flavescentis, spina gleditsiae, isatis roots, Paris polyphylla, loquat leaves, angelica sinensis, radix salviae miltiorrhizae, amur corktree barks, rhizoma coptidis, flos chrysanthemi indici, dark plum fruit, mint, sticky rice and cavings by adopting a conventional fermentation process of adding Chinese yeast, lump mold cultures and yeast. The medicinal preparation has the effects of oil control, antibiosis and inflammation diminishing, and proved by clinical experiments, the medicinal preparation has unique curative effect on the acnes, the whelks and the folliculitis. Generally, the medicinal preparation can get effective after being taken for three days and has no side effect after long-term use. The medicinal preparation has wide medicine source, simple preparation, remarkable curative effect and worthy popularization.

Owner:朱建华

Fortified collapse proof well drilling liquid

InactiveCN1903973AImprove rheologyEnhanced inhibitory effectFlushingDrilling compositionSodium BentonitePolyacrylamide

The present invention relates to an enhanced anti-caving drilling fluid for safely drilling in saline bed and caving ground. Said drilling fluid composition includes (by weight portion) 4-6 portions of bentonite, 0.3-0.4 portion of hydrolyzed polyacrylamide potassium salt, 1-1.2 portions of methyl polyacrylamide calcium salt; 1.5-2 portions of valchovite, 2-3 portions of sulfonated lignite, 2-4 portions of asphalt blocking agent, 6-8 portions of Kcl, 0.4 portion of CaO, 1-1.2 portions of organosilicon alcohol and 100 portions of water.

Owner:西部钻探吐哈钻井公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com