Patents

Literature

419results about "Mine roof caps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick seam large mining height working face gob-side entry retaining method

InactiveCN101725368APrevent overflowAvoid enteringMaterial fill-upMine roof capsSpontaneous combustionEngineering

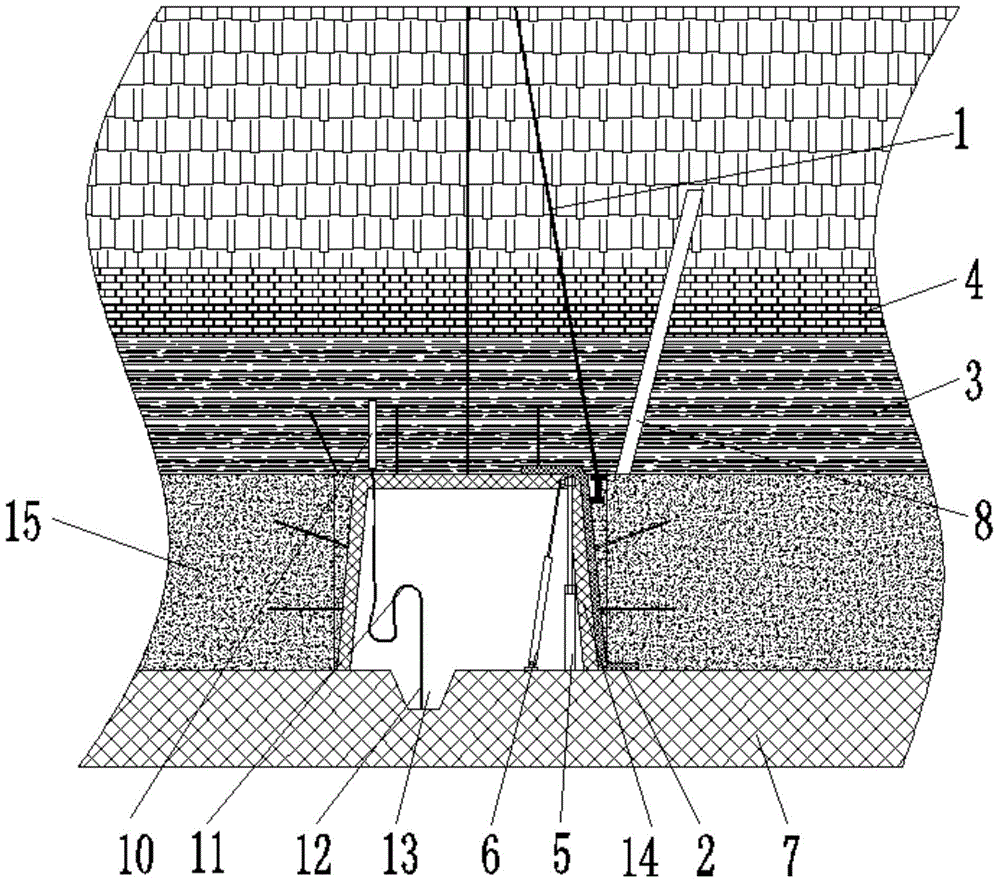

The invention discloses a thick seam large mining height working face gob-side entry retaining method, wherein a flexible yield airbag is installed on the deformed space retained on the top part of the filling body besides the lane; the height of the filled airbag is equal to the prediction value of the sinking quantity of the top plate; the airbag is filled with air, the inflation pressure is 3MPa; a one-way decompression valve is installed on the bag body and the decompression pressure is 4MPa. The flexible yield airbag is arranged, thus on the one hand, effectively protecting the filling body besides the lane and achieving the purpose of gob-side entry retaining, and on the other hand, preventing the coal in the gob from spontaneous combustion, ensuring safe production and simultaneously improving the mining coefficient of the coal.

Owner:SHANDONG UNIV OF SCI & TECH

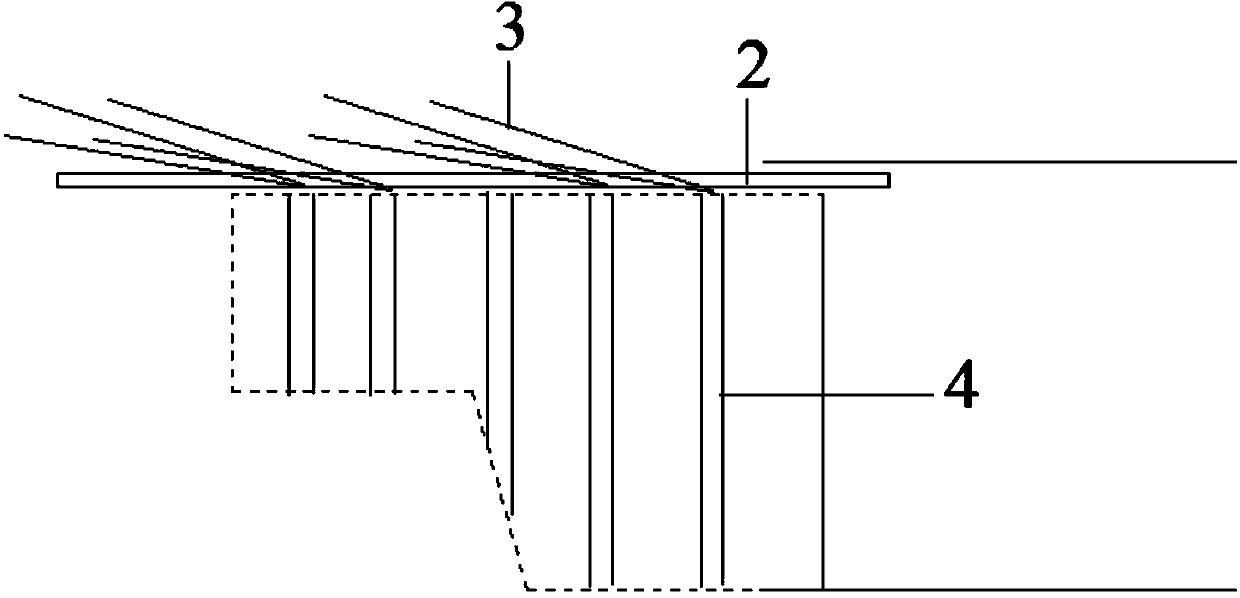

Top breaking gob-side entry retaining method for tender roofs

InactiveCN104929666ACollapse accident preventionAvoid damageUnderground chambersMine roof capsShotcreteStone wall

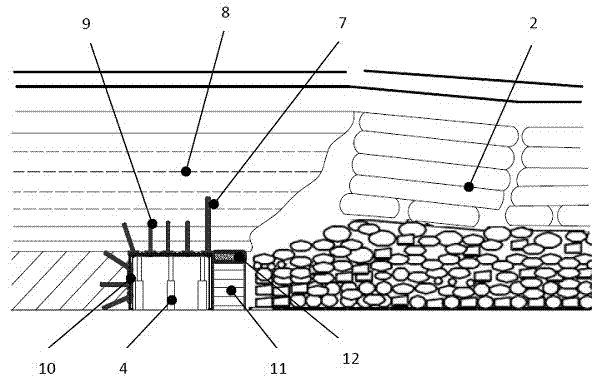

The invention discloses a top breaking gob-side entry retaining method for tender roofs. The top breaking gob-side entry retaining method includes steps of firstly, reinforcing and supporting the tender roofs of roadways jointly supported by original anchor meshes and cables or supported by sheds; secondly, laying wire meshes on gob sides; thirdly, preliminarily breaking the roofs of the roadways on the gob sides; fourthly, piling up preliminarily broken caved gangue until the caved gangue reaches rock of upper-end hard roofs to form gangue piled walls; fifthly, burying perforated grouting pipes in the formed gangue walls, spraying concrete on the surfaces of the wire meshes and the surfaces of the gangue walls to form concrete sprayed supporting layers; sixthly, injecting concrete grout in each preliminarily buried grouting steel pipe by the aid of a grouting pump after the concrete sprayed supporting layers are solidified; seventhly, sequentially detaching falling preventing devices and dense reinforcing columns along with advancing of working faces; eighthly, reinforcing and supporting the roofs under special conditions. The top breaking gob-side entry retaining method has the advantages that active bearing supporting effects can be realized for inherent characteristics of the tender roofs, supporting forms are simple, the cost is low, and entry retaining effects can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

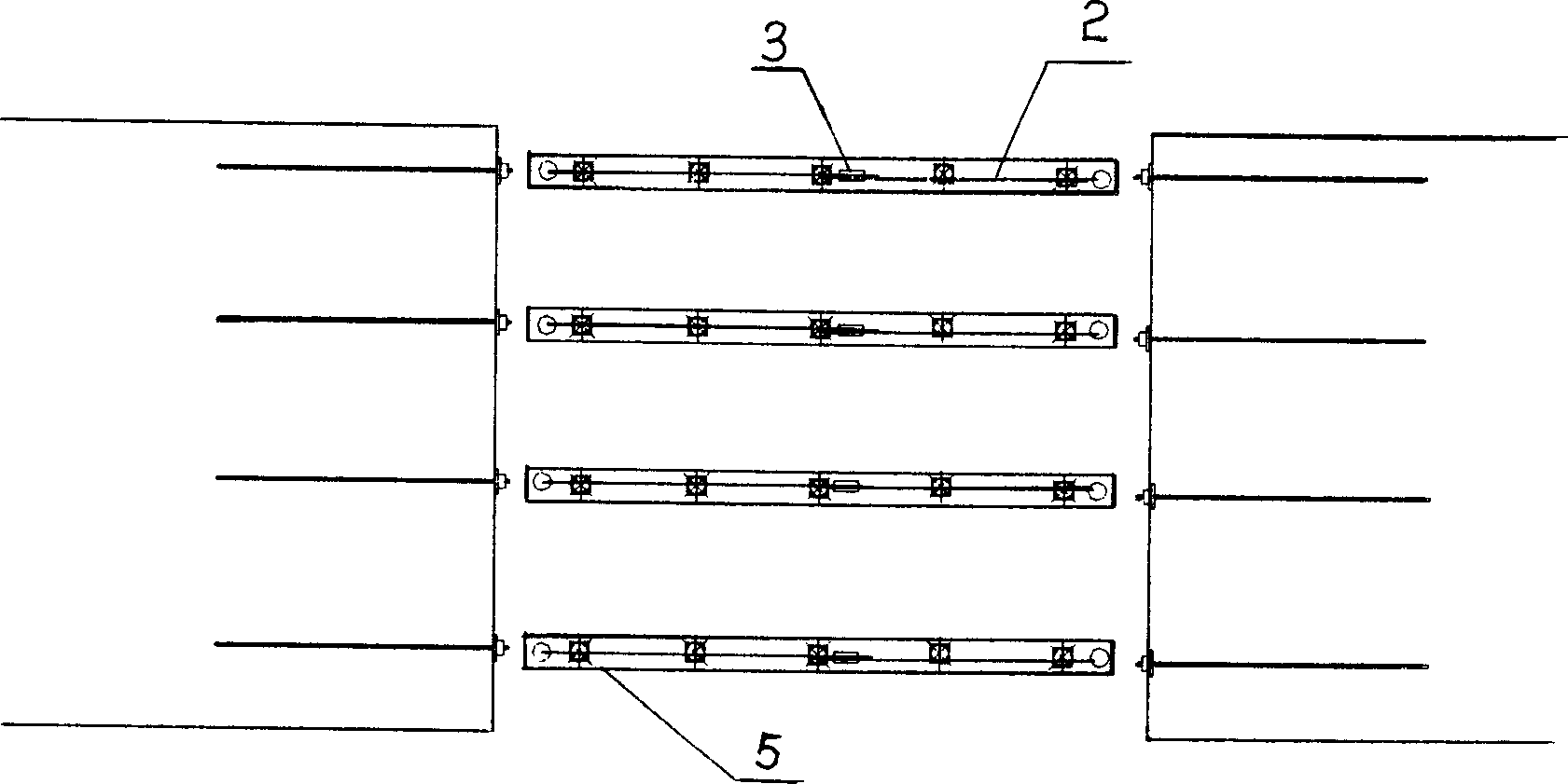

Truss supporting technology for ingredient top slope deformation control

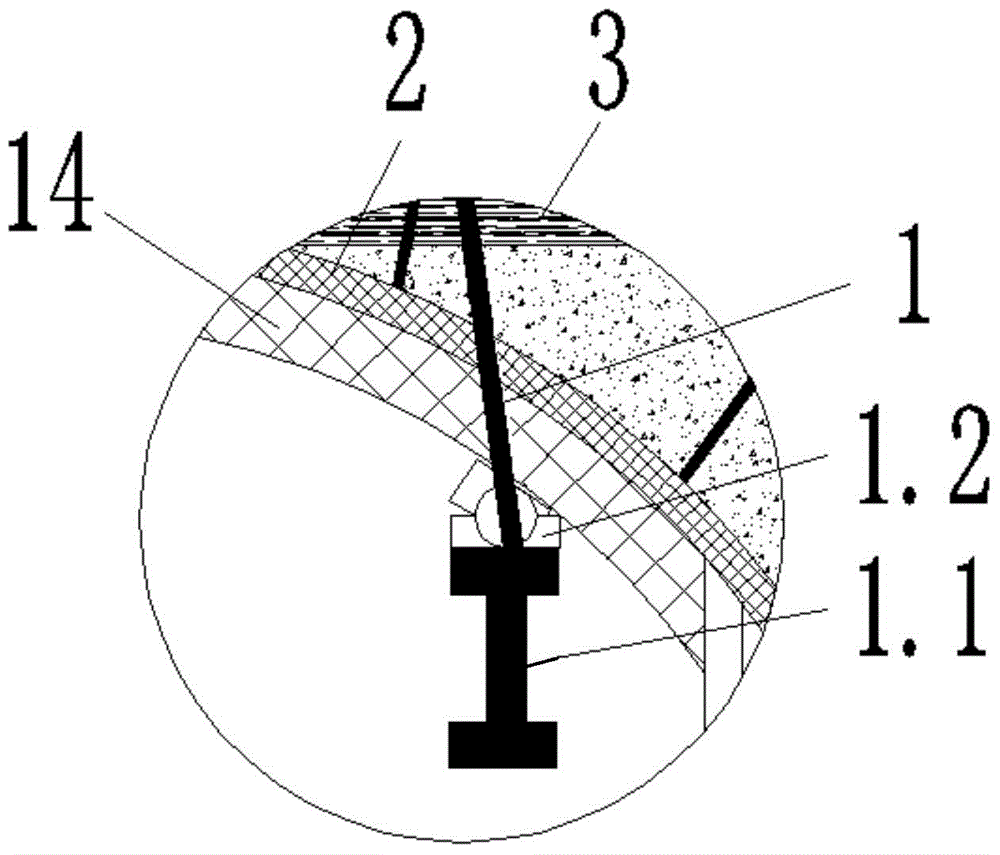

InactiveCN1594834AReduce distortionSolve the problem of shear slip and cavingMine roof capsAnchoring boltsPull forceWhole body

A truss supporting technology for controlling ingredient top slope deformation is adapted for controlling the sinkage of wide span alley way top board separation layer, the top board and alley slope shear-slip breakaway or controlling the deformation of alley slope part. When using an anchor rod anchorage cable support for ingredient top board or alley slope part, plural trusses composed of two steel twist lines and double hole steel bushing coupler is set on the ingredient top board or alley slope part with spaces for support, each truss is shielded under the anchor solid, two steel twist lines are connected and locked by the coupler to form expansion and pull force to generate extrusion and protection function for the ally way top board or slope part. Not only the problem that the sinkage of the wide span alley way top board separation layer and the top board and alley slope shear-slip breakaway is solved, the top board is supported effectively, but also the displacement of the alley slope towards to alley inside is controlled, thereby the deformation of the alley slope is reduced, so the alley way can satisfy production requirement. In addition, the connection of the support whole body between the steel twist lines is adopted to change the limit of single anchorage cable support. The structure is simple, convenient in use and has broad practicability.

Owner:CHINA UNIV OF MINING & TECH

Method for actively supporting lane side filling gob-side entry retaining

InactiveCN103161480AEnhanced CapabilityReduce initial sinkageMaterial fill-upMine roof capsEngineeringActive support

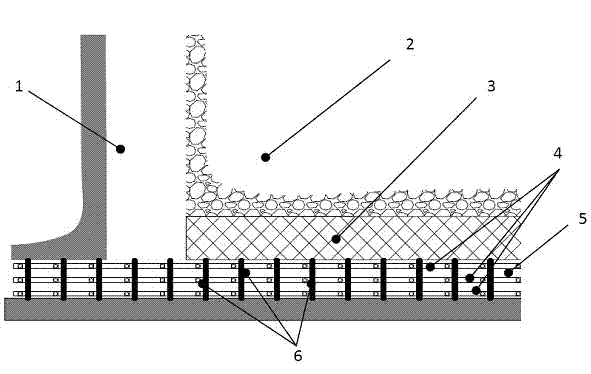

The invention discloses a method for actively supporting a lane side filling gob-side entry retraining. Firstly, a lane interior support and an enforcing support are built on a reserved lane according to a sounding rock condition and a working face. On the back of the working face, nogs, gangues or blockworks and the like are adopted to build a lane side filling wall along the edge of a gob. High-strength and sealed filling bags are paved on the filling wall, and high-expanding materials or cement coagulation serous fluid added with a rapid hardening early strength agent is filled into the filling bags through a grouting pump. The enforcing support is dismounted after a top plate behind the working face is movably stabilized, the high-strength and sealed filling bags are enabled to be contacted tightly with the top plate, and active support force is formed to be exerted on the top plate. By means of the active support force provided for the lane side filing wall, the top cutting capacity of a lane side filling body is enhanced, initial deflection of the entry retaining top plate is reduced, the stability of the top plate is improved, the quality of the gob-side entry retaining is improved, and repair rate of the gob-side entry retaining is reduced. The method is simple, convenient to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Semi-rigid abnormal beam anchor cable truss roadway supporting system

InactiveCN102182483AGuaranteed integrityEfficient deliveryMine roof capsAnchoring boltsSupporting systemRock bolt

The invention relates to a semi-rigid abnormal beam anchor cable truss roadway supporting system. A metal net is paved on the surface of a roadway, a semi-rigid abnormal beam anchor cable truss is arranged at a coal-rock roof or a roadway side, the semi-rigid abnormal beam anchor cable truss is formed by abnormal beams with semi-rigid nodes and anchor cables or anchor rods, and each abnormal beam is provided with a plurality of anchor cables or anchor rods; the anchor cables and anchor rods are anchored into a rock layer by passing through the abnormal beams and the metal net and apply a prestress to form an extrusion and annular protection function on surrounding rocks; and outer anchor ends of the anchor cables and anchor rods are provided with trays and locks, the trays and the locks make the end heads of the anchor cables or anchor rods tightly matched with the abnormal beams. The invention has the advantages that: (1), the protective surface area is large, the rigidity is high, stability is not easy to loss, and the integrality of the supporting system is ensured; (2), a steel material is saved, the cost is reduced, and the efficiency is increased; (3), the strength is high, and the regulation space of the whole supporting performance is large; and (4) the semi-rigid nodes can play a role of better flexible yield, and the stability and the safety of the whole supporting system are ensured.

Owner:SHANDONG UNIV

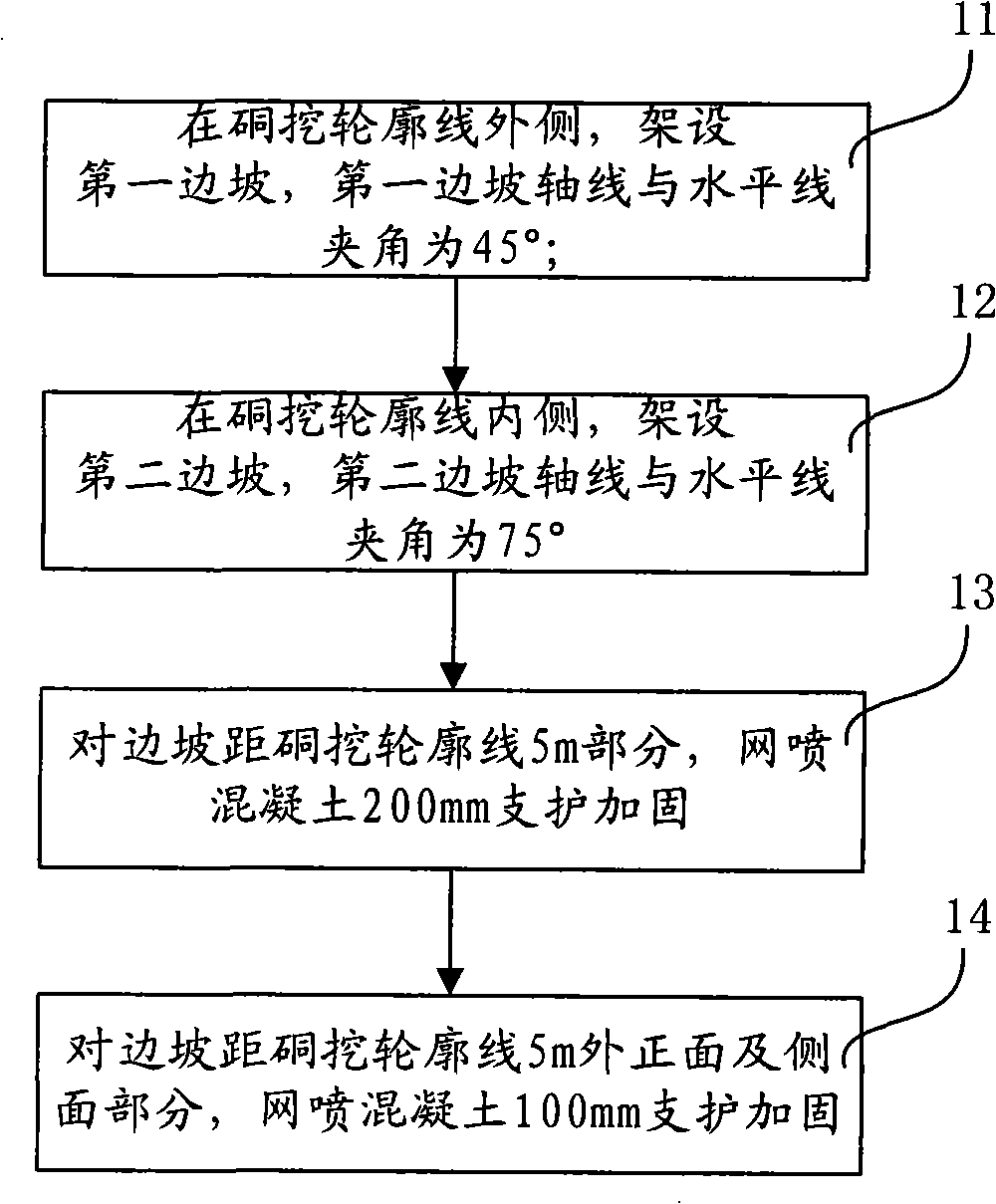

Supporting method for soft broken nonuniform stratum tunnel construction

InactiveCN103993892AImprove self-stabilityReduce construction difficultyUnderground chambersMine roof capsEngineeringSelf-stabilization

The invention discloses a supporting method for soft broken nonuniform stratum tunnel construction. The supporting method includes the steps that firstly, an arch support is erected in a bottom layer tunnel through steel pipes, and the portion, on the top of the arch support, of the bottom layer tunnel is drilled; secondly, a small pipe roof is constructed on the drilled portion of the arch crown of the arch support; thirdly, during construction of the small pipe roof for supporting, advanced reinforcement treatment is conducted on a top arch of the tunnel through advanced small pipes in a floor staggered mode; fourthly, the tunnel is excavated; fifthly, after the tunnel is excavated, preliminary supporting construction is conducted in time each cycle; sixthly, after excavation and supporting of a tunnel trunk of the tunnel, an inverted arch is constructed and sealed into a loop; and then secondary lining following operation is conducted. The method has the advantages that deformation of tunnel surrounding rocks can be effectively reduced, self-stabilization and seepage prevention capacity of the tunnel is permanently improved, a multifunctional surrounding rock reinforcement region is formed, and safety of tunnel constructors and equipment is guaranteed.

Owner:SHANDONG UNIV

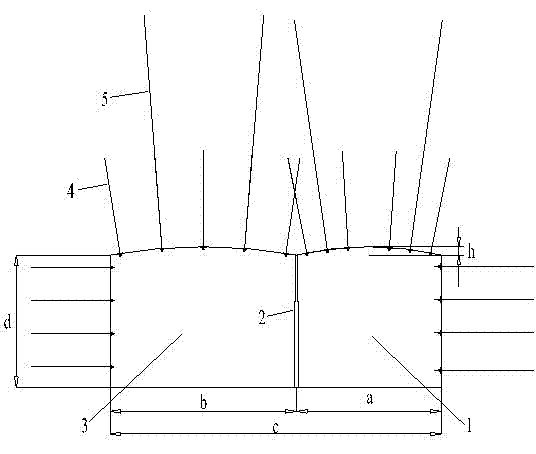

Support method for span reduction with double micro-arches in large-span cut-outs

InactiveCN102268998ASolve the problem of difficult to control the stability of the roofImprove top control effectTunnelsMine roof capsLong spanMonomer

The invention discloses a span-reducing support method with double micro-arches for large-span cutouts, which is suitable for span-reduction support in areas with complex structures and deep composite roofs with large-span cutouts. The secondary roadway is used instead of the first roadway, and the double micro-arch cutout is used to replace the traditional one-time long-span rectangular cutout, and the prestressed anchor / cable is used to strengthen the surrounding rock of the cutout. The distribution law of the plastic zone of the surrounding rock of the micro-arch cutout, select reasonable support parameters, give full play to the support function of the prestressed anchor rod / cable, add a row of single pillars and top beams to reduce the span support in the double micro-arch cutout protection, the top control effect is obvious. For large-span cutouts, the span reduction support method of secondary roadway formation + double micro-arch sections + anchor net cables + single pillars and hinged roof beams was adopted to solve the problem of difficult control of the roof of long-span rectangular cutouts and realize The large-span cutting eye is fast, safe and economical to construct, and its method is simple and easy to implement, with low support cost and good support effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

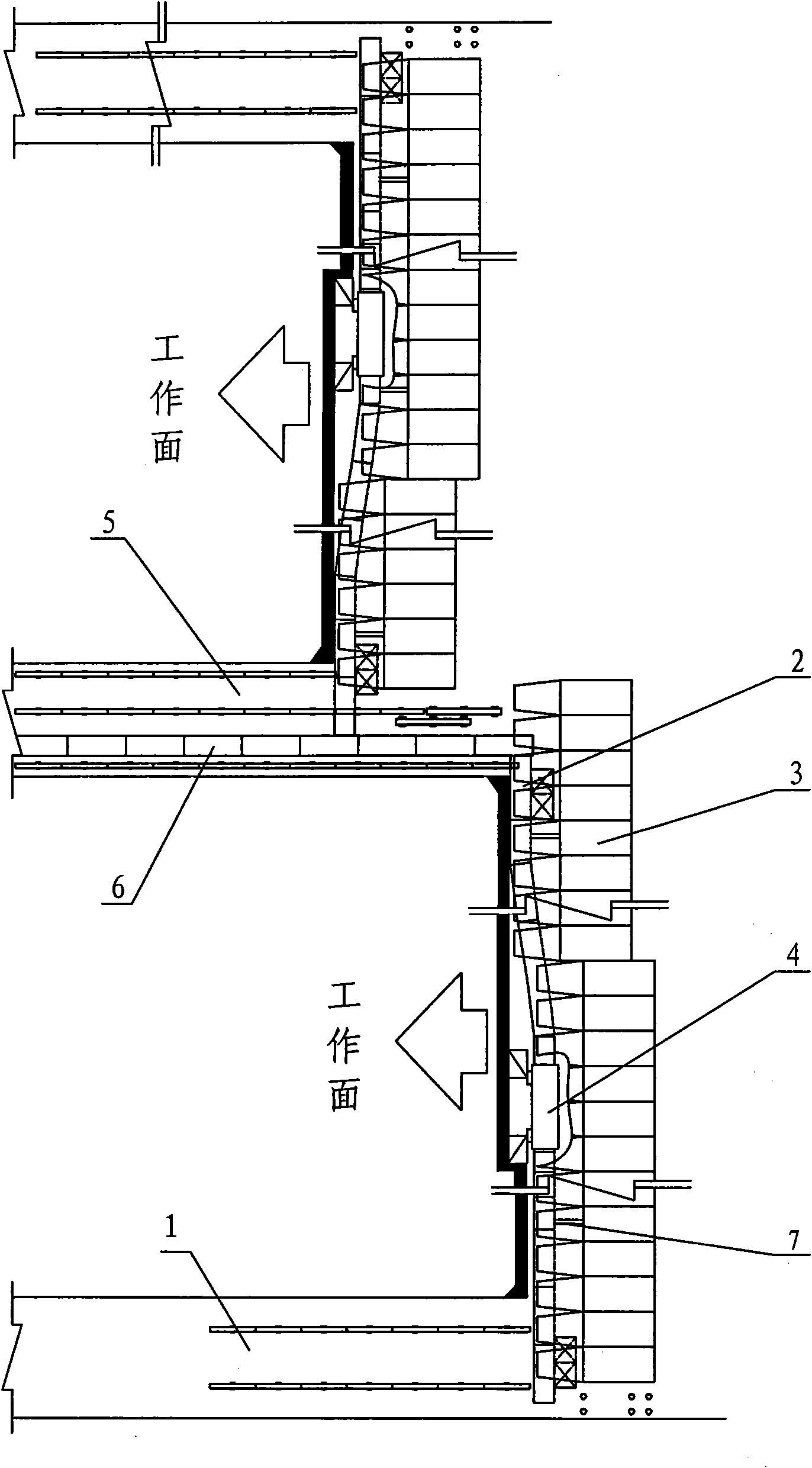

Comprehensive mining opposite-pull working face coal excavating process for thin coal bed

InactiveCN101526001AReduce the tunneling rate of 10,000 tonsReduce storage rateUnderground miningSurface miningCoal pillarIndustrial engineering

The invention relates to a comprehensive mining opposite-pull working face coal excavating process for a thin coal bed, comprising the following steps: 1, two working face material lanes and a working face common transporting lane are arranged in parallel, wherein part between two adjacent lanes is a working face, and the middle working face common transporting lane is selected as a common lane; 2, each working face is provided with a working face coal mining machine, a working face scraper transporter and a hydraulic bracket, and two working faces simultaneously carry out comprehensive mining in parallel. In order to leave a channel of the common transporting lane for passing in and out for workers between the hydraulic brackets of the two working faces, the two working faces are staggered with a certain distance. The invention reduces the ten-thousand-ton drivage ratio of a mine, saves the cost, realizes non-coal pole exploitation between the working faces, improves the recovery ratio of resources and increases the yield of the same unit workers by almost one time.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

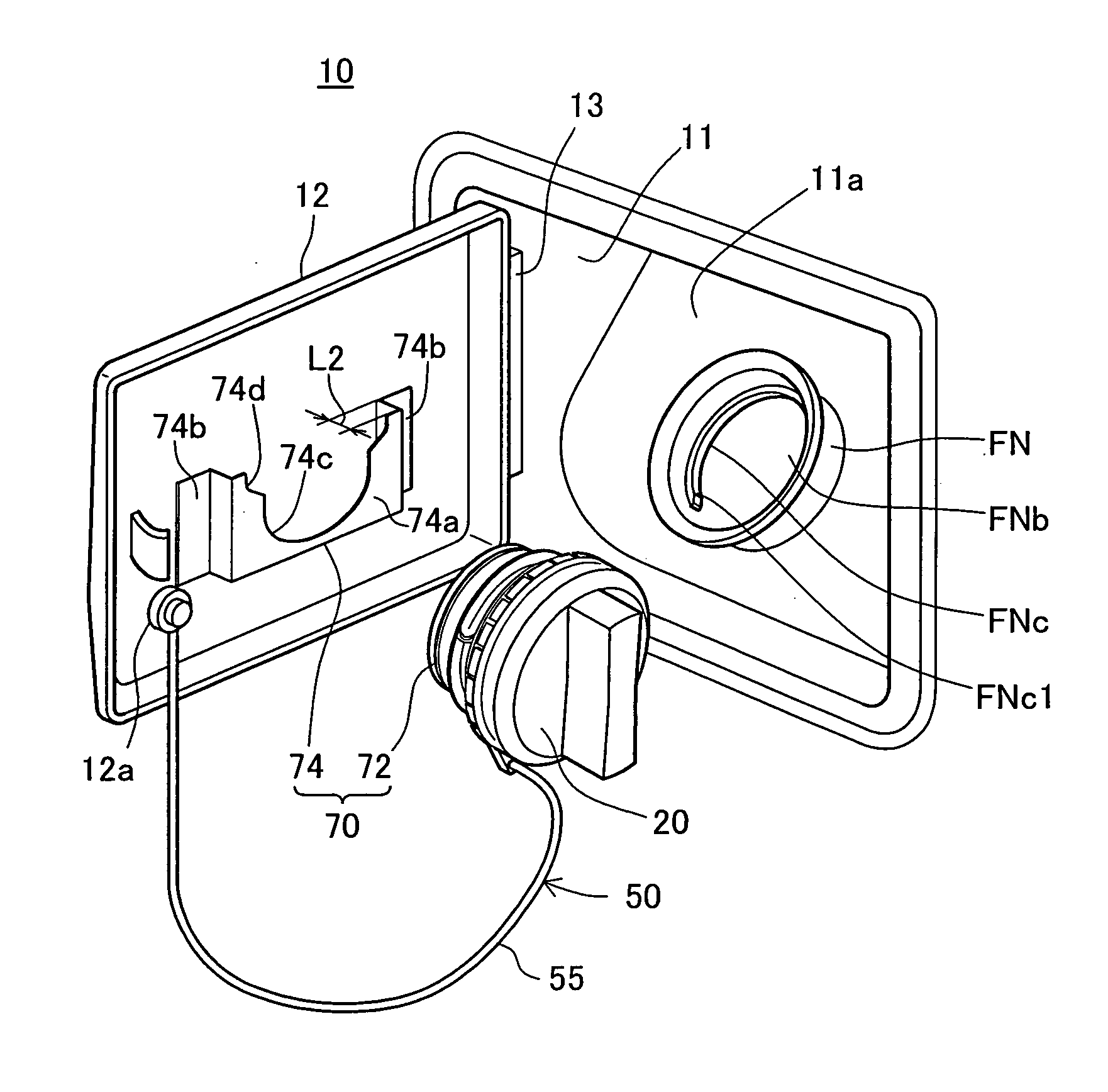

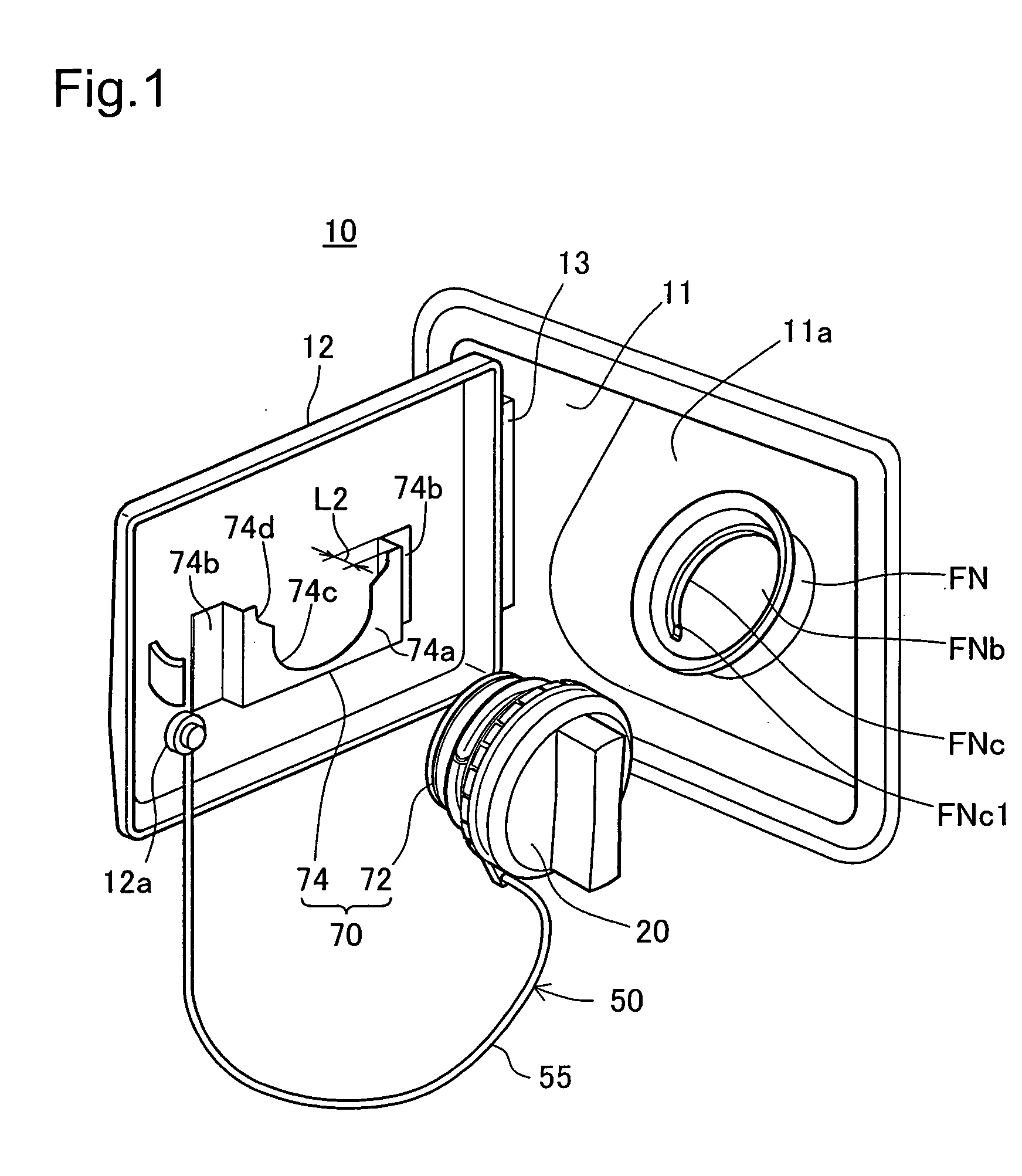

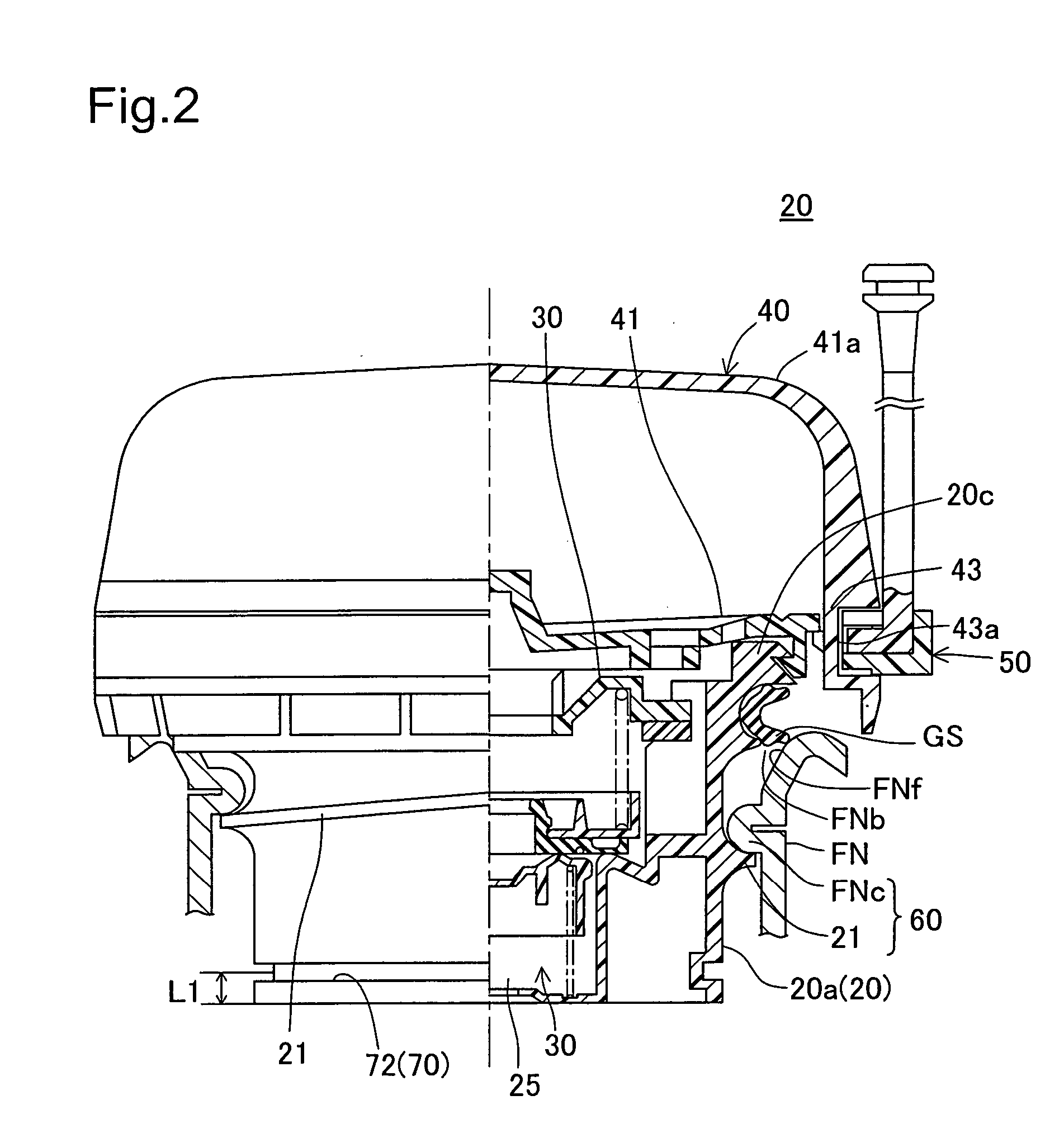

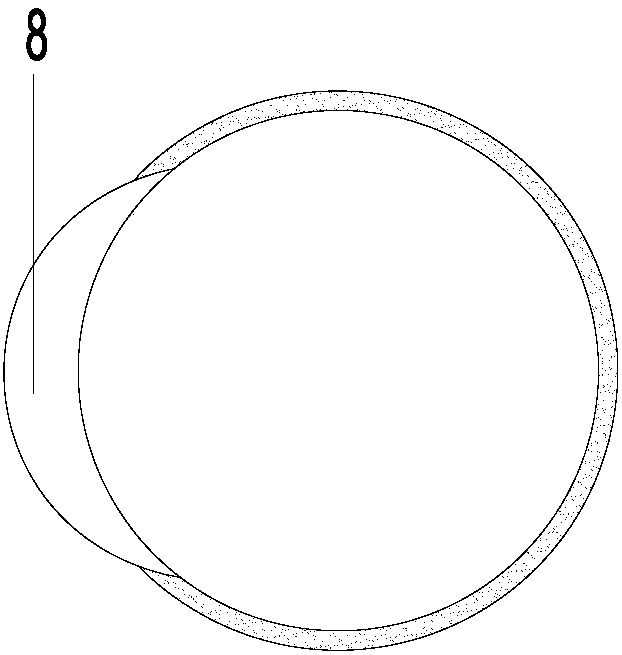

Cap device

Owner:TOYODA GOSEI CO LTD

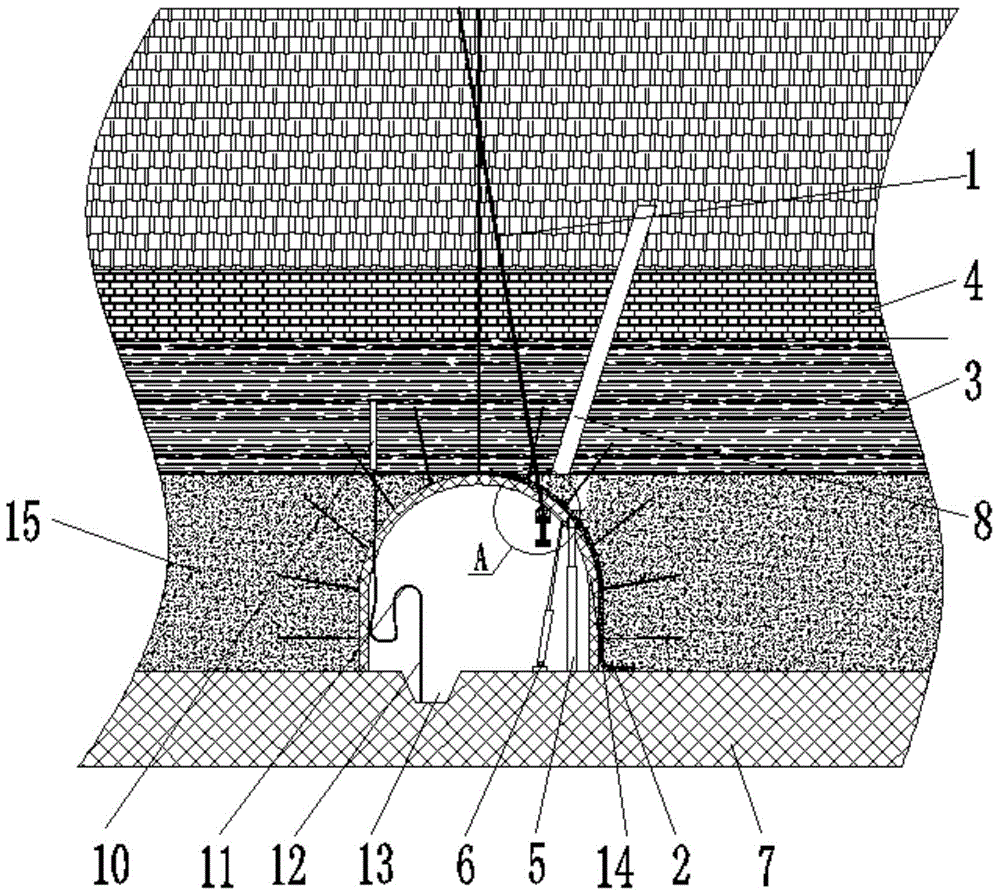

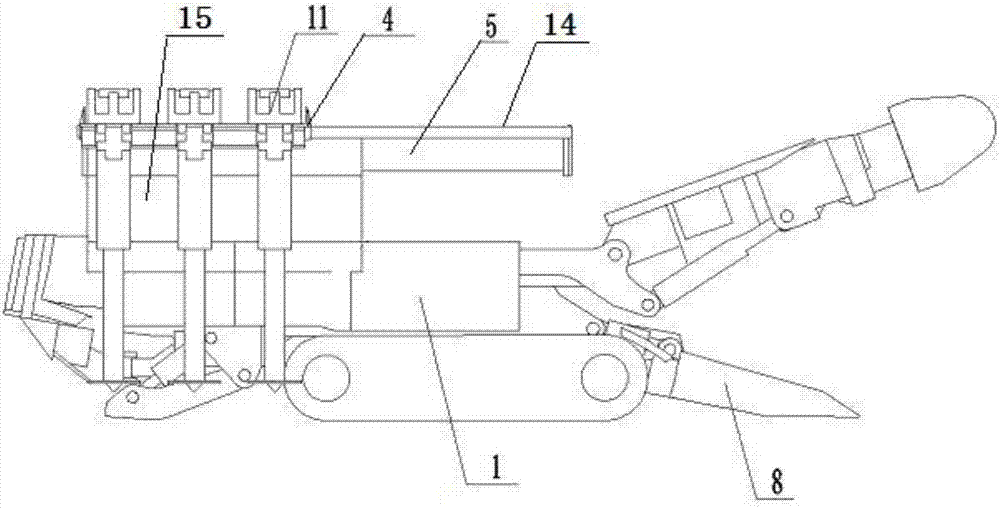

Down-dip mining method of shaped hydraulic bracket on long-wall working surface in direction of large dip angle coal bed

InactiveCN102061921AReasonable designMining method is simpleUnderground miningSurface miningInstabilityAbnormal shaped

The invention discloses a down-dip mining method of a shaped hydraulic bracket on a long-wall working surface in the direction of a large dip angle coal bed, comprising the following steps of: firstly, determining a false down-dip working surface: selecting a false down-dip working surface as the actual mining working surface of a large dip angle coal bed; and secondly, mining the coal bed: usingthe determined false down-dip working surface as the actual mining working surface and the large dip angle coal bed direction as the propelling direction to mine the large dip angle coal bed by usinga regular coal bed mining method, and synchronously supporting the actual mining working surface by using the shaped hydraulic bracket in the actual mining process, wherein the shaped hydraulic bracket comprises a top beam, a bottom plate and a plurality of support pillars, the top beam is in the shape of a parallelogram. The invention has reasonable design and simple mining method, adopts the shaped hydraulic bracket which has reasonable structure, convenience of operation and good using effect, and solves the problems of instability, low safety coefficient and large mining difficulty of a bracket-wall rock system existing in the mining process of the long-wall working surface in the direction of large dip angle coal bed.

Owner:XIAN UNIV OF SCI & TECH +1

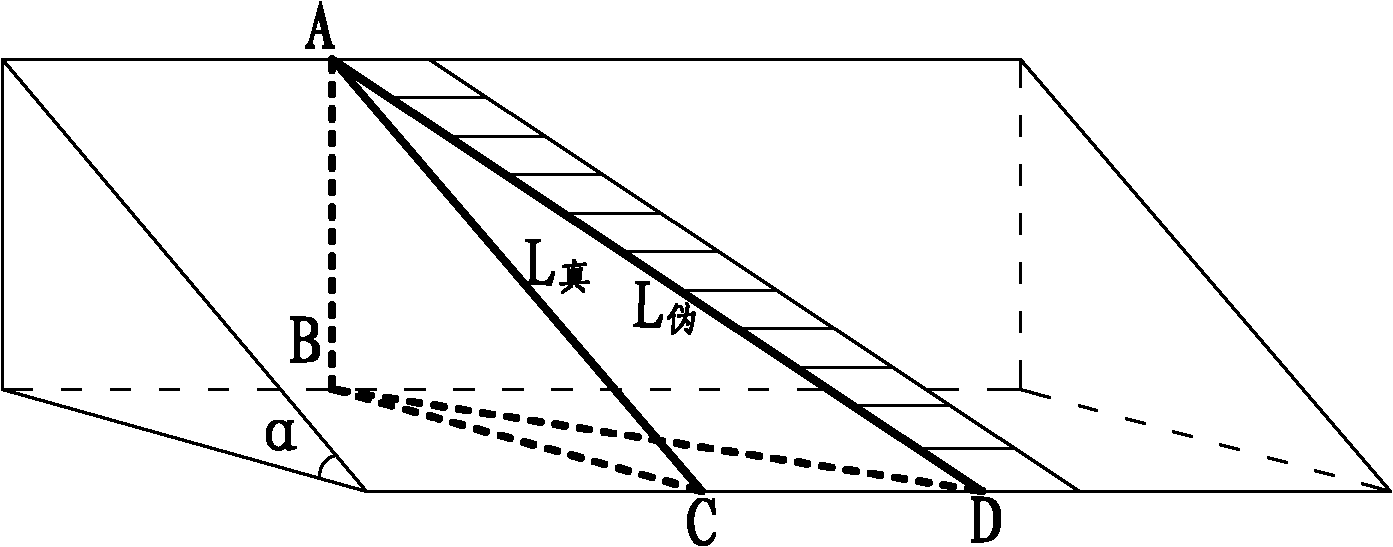

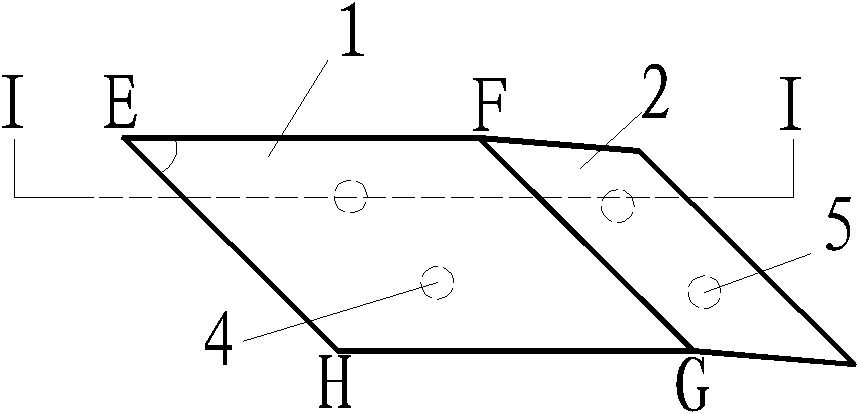

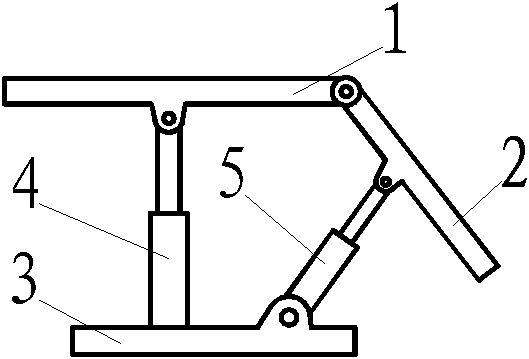

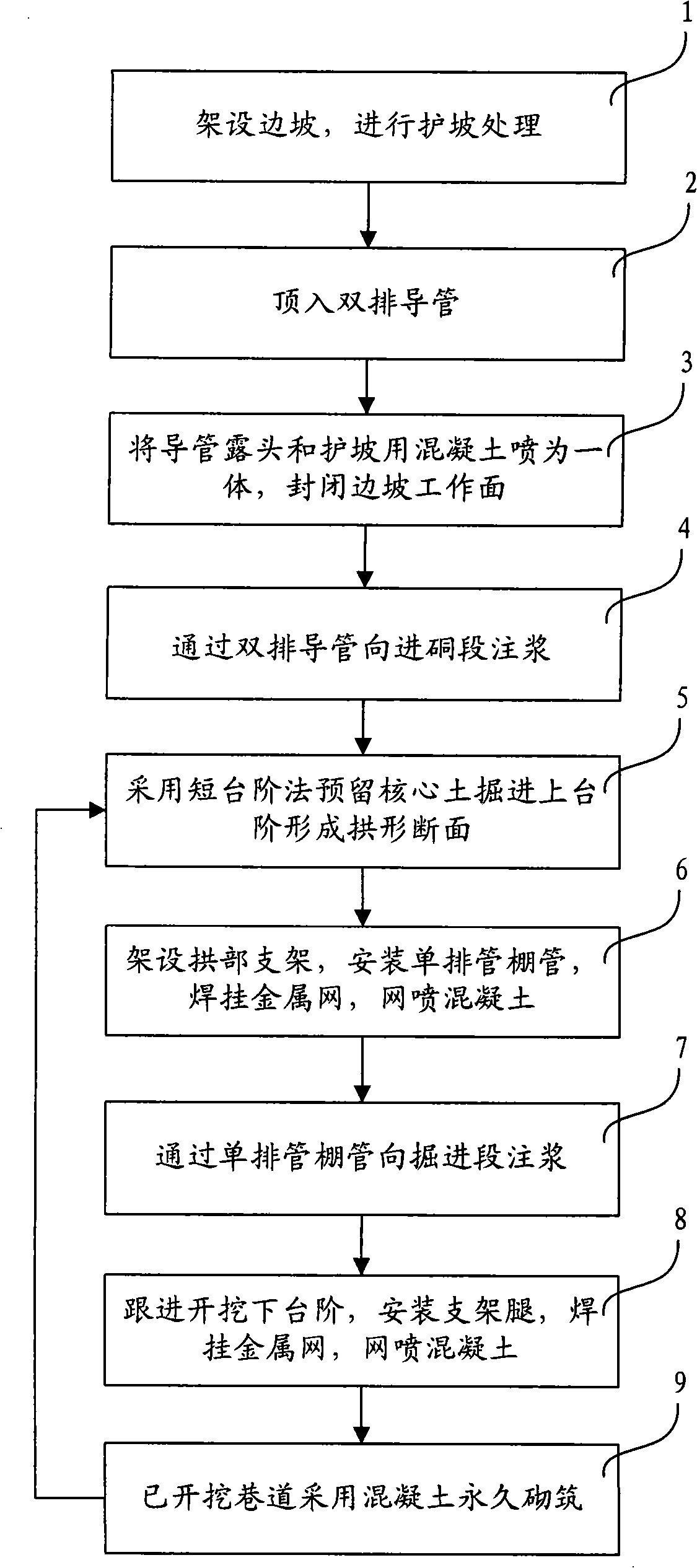

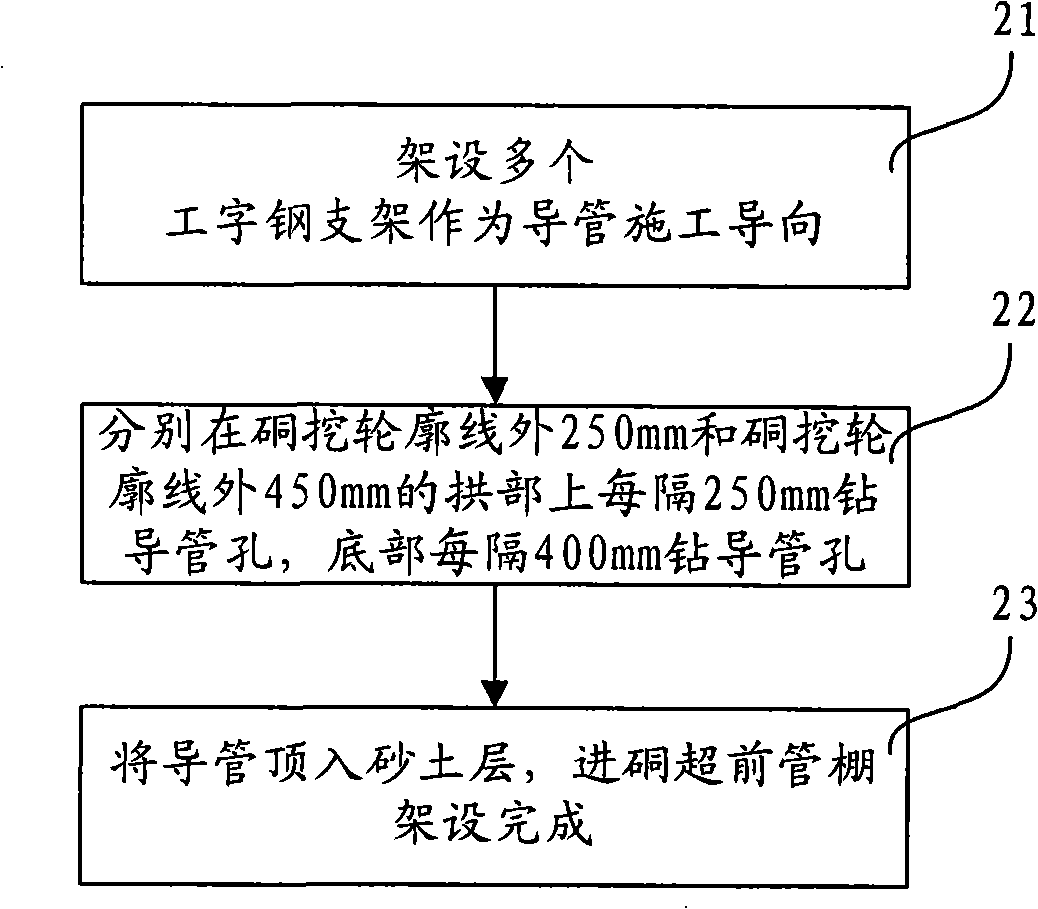

Small tube shed pre-grouting method

InactiveCN101408106AImprove adhesionStable supportUnderground chambersMine roof capsGuide tubeMetal mesh

The invention relates to an advanced grouting method of a small pipe roofing, comprising the following steps of: slope protection processing; inserting a double guide pipe; closing the working surface of a side slope; grouting to adit section through the double guide pipe; preserving core soil for driving by a short step method; mounting an arch part bracket, mounting a single row pipe roofing pipe on the arch part bracket, welding and hanging a metal mesh on the arch part bracket and mesh-spurting concrete so as to form an arch part support; grouting to a driving section through the single row pipe roofing pipe; continuing to excavate a lower step, mounting bracket legs of the arch part bracket and mesh-spurting the concrete so as to form a wall part support; and adopting the concrete to carry out permanent masonry for the excavated laneway, adopting the method to continue digging at the front and masonry at the back until the engineering of the driving section is completed. The method carries out advanced grouting through the small guide pipe and increases the adhesion of a loose layer; an outer support formed by a metal mesh-spurting concrete and the pipe roofing ensures the stability and the safety of the excavated laneway before the permanent support is carried out; the cost of the engineering is low; the construction speed is fast; the safe effect is good; and the construction quality can be ensured.

Owner:CHINA COAL NO 3 CONSTR GRP

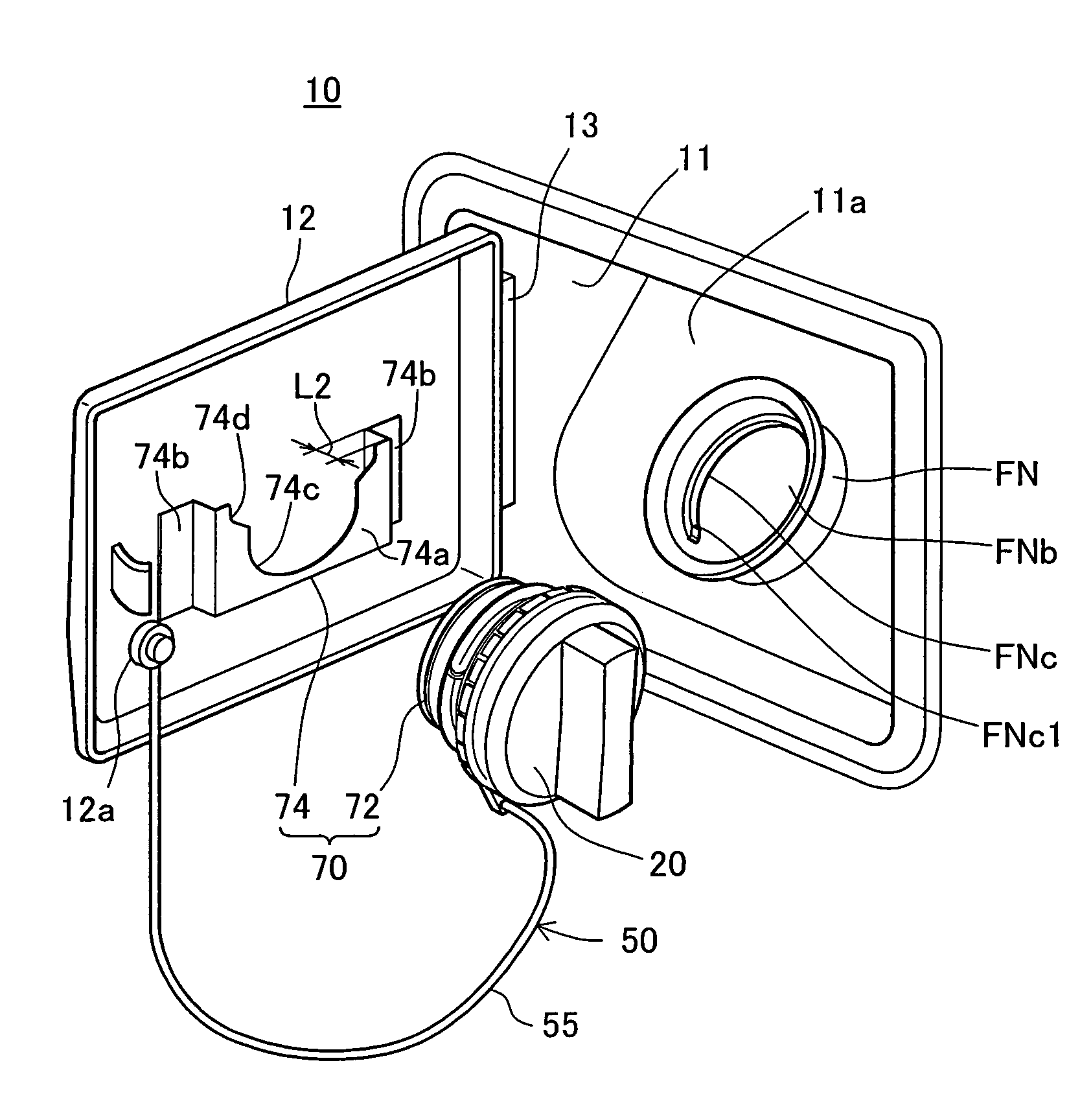

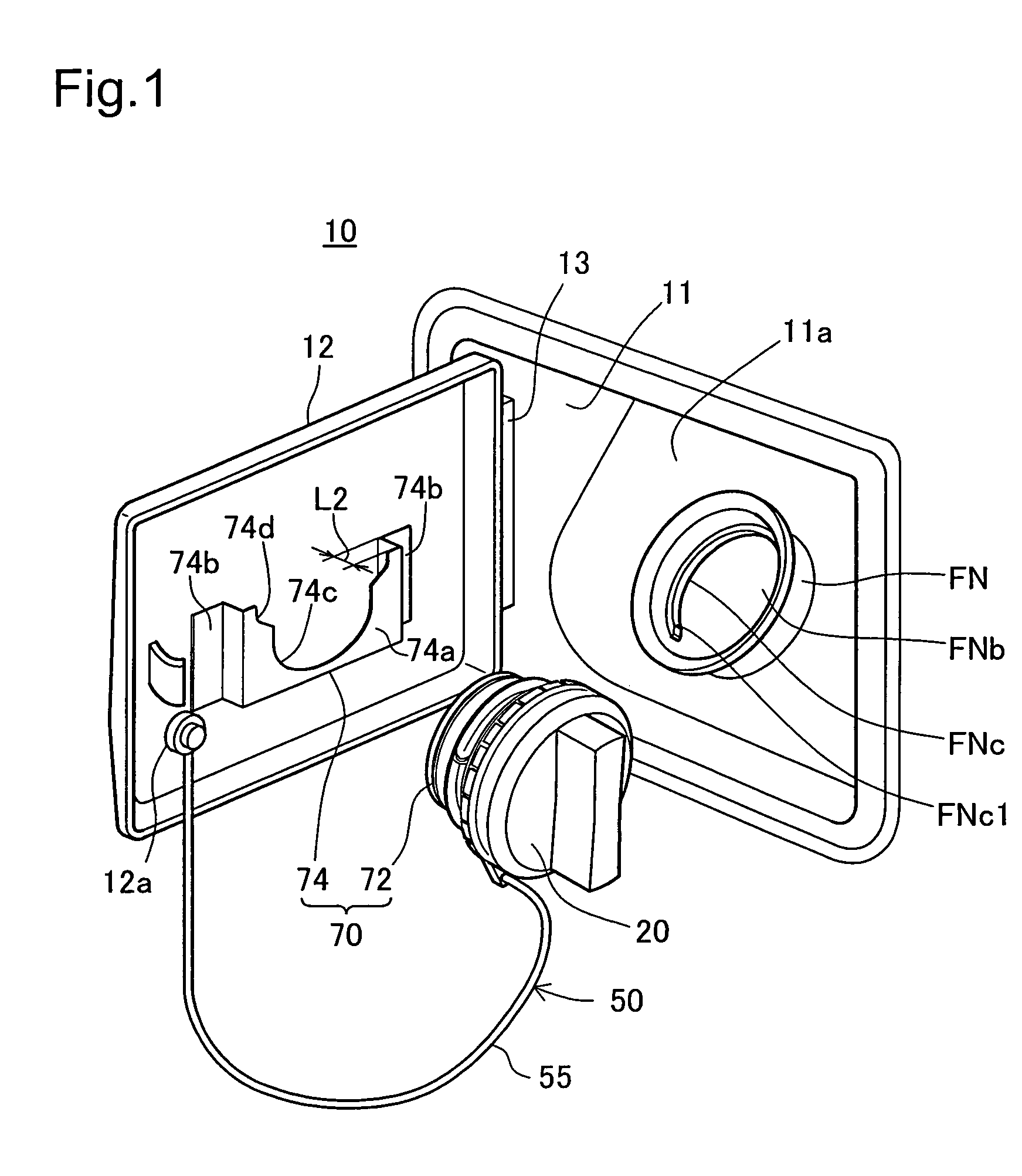

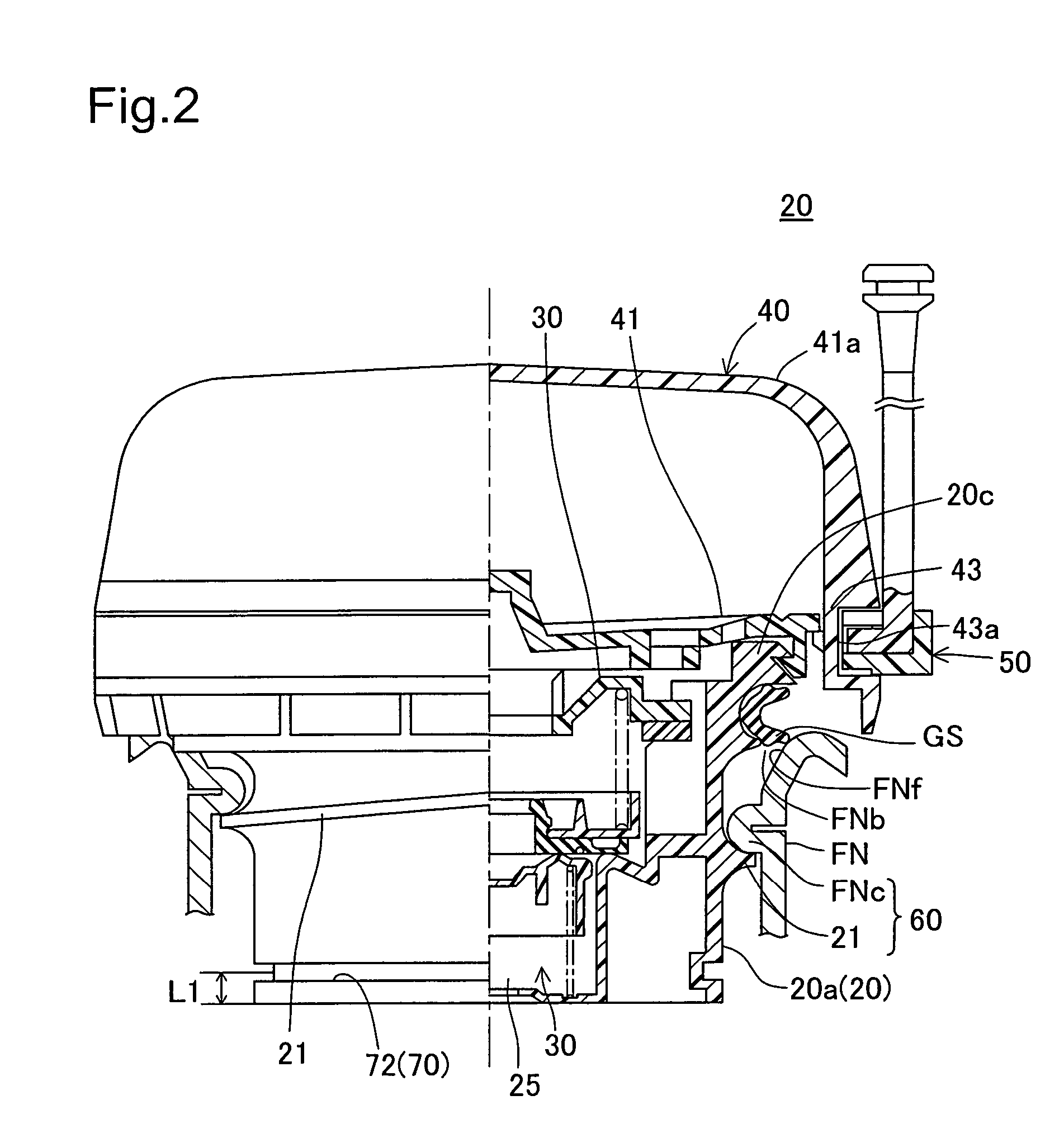

Cap device

A cap device of the invention has a tether mechanism, which is used to link a fuel cap to a fueling lid. The tether mechanism includes a cord-like flexible linkage body having one end as a first support end, which is fit in a support member of a rotating ring. The first support end is inserted from inside of the rotating ring through an insertion opening into a support recess. This fits the first support end in the support recess, while allowing the linkage body to be led through a lead opening. The first support end is accordingly fixed to the support member. The rotating ring is then attached to a circular groove formed on the fuel cap. The tether mechanism of this simple structure is readily fixed and thereby ensures easy attachment to the fuel cap.

Owner:TOYODA GOSEI CO LTD

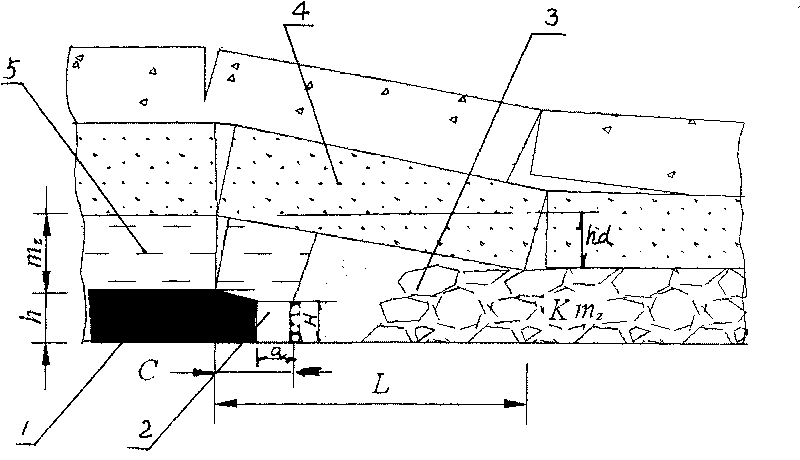

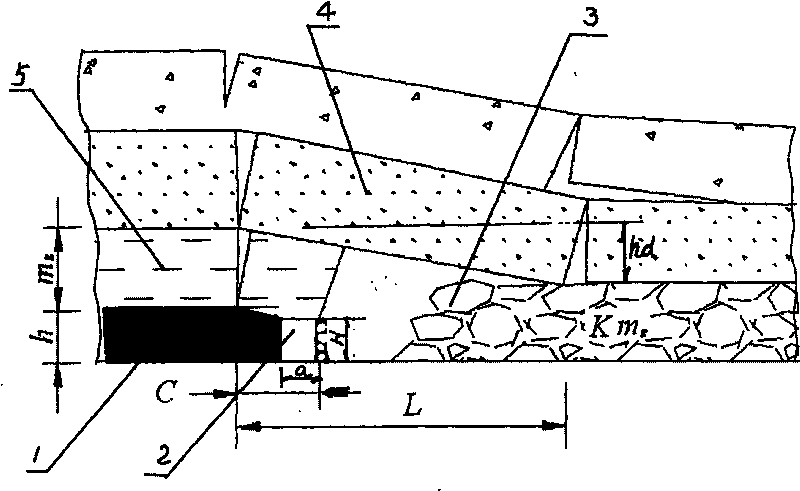

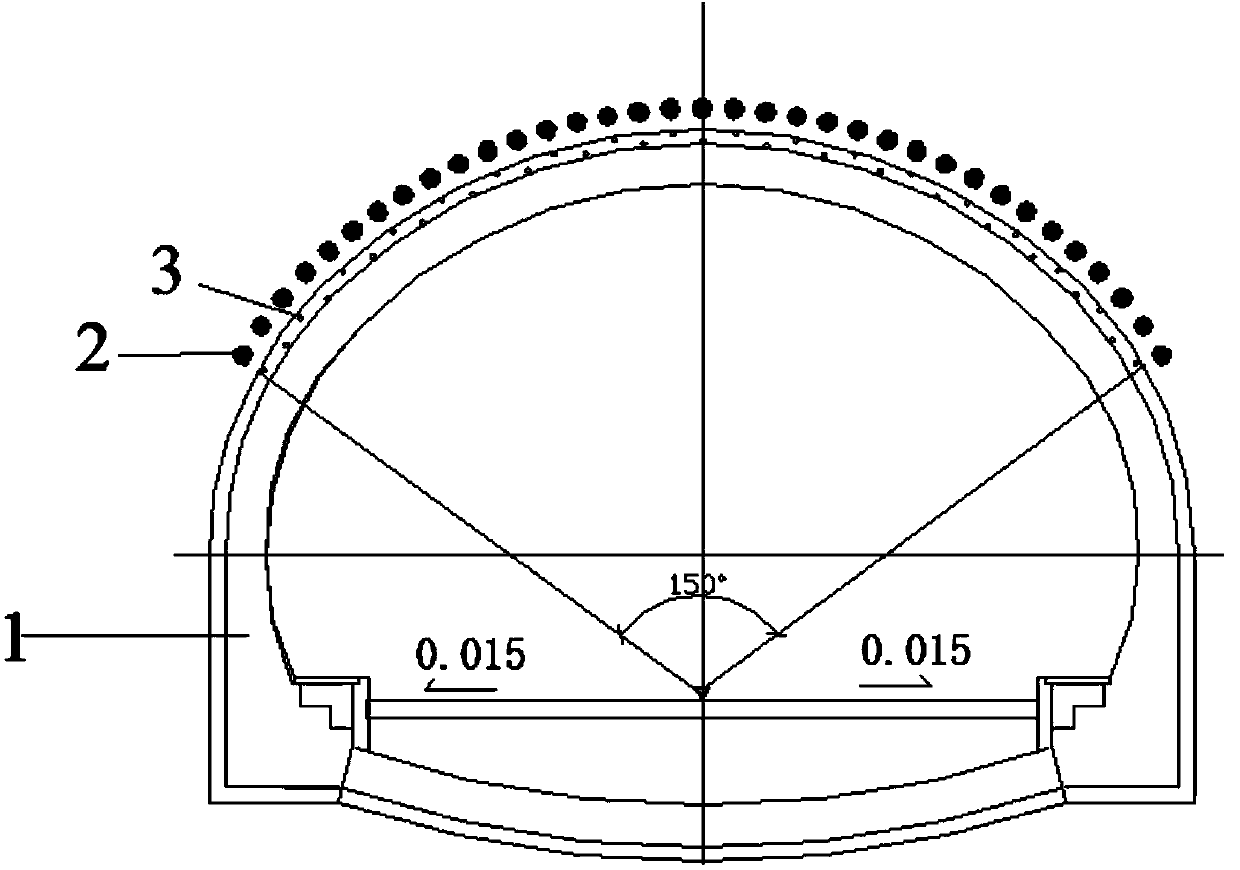

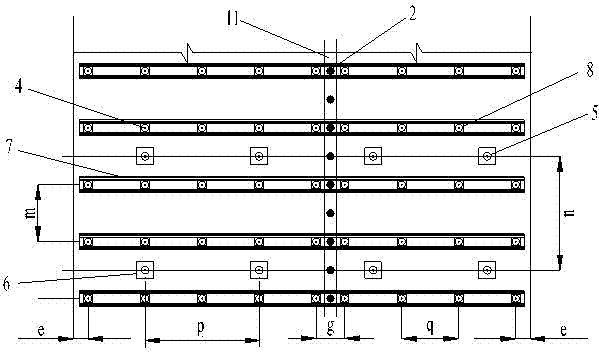

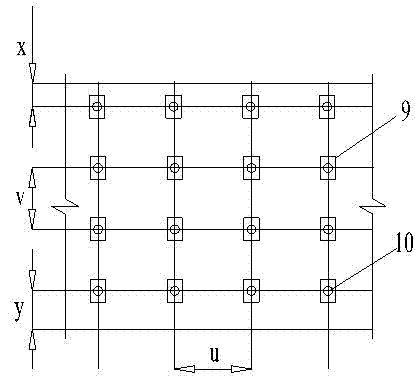

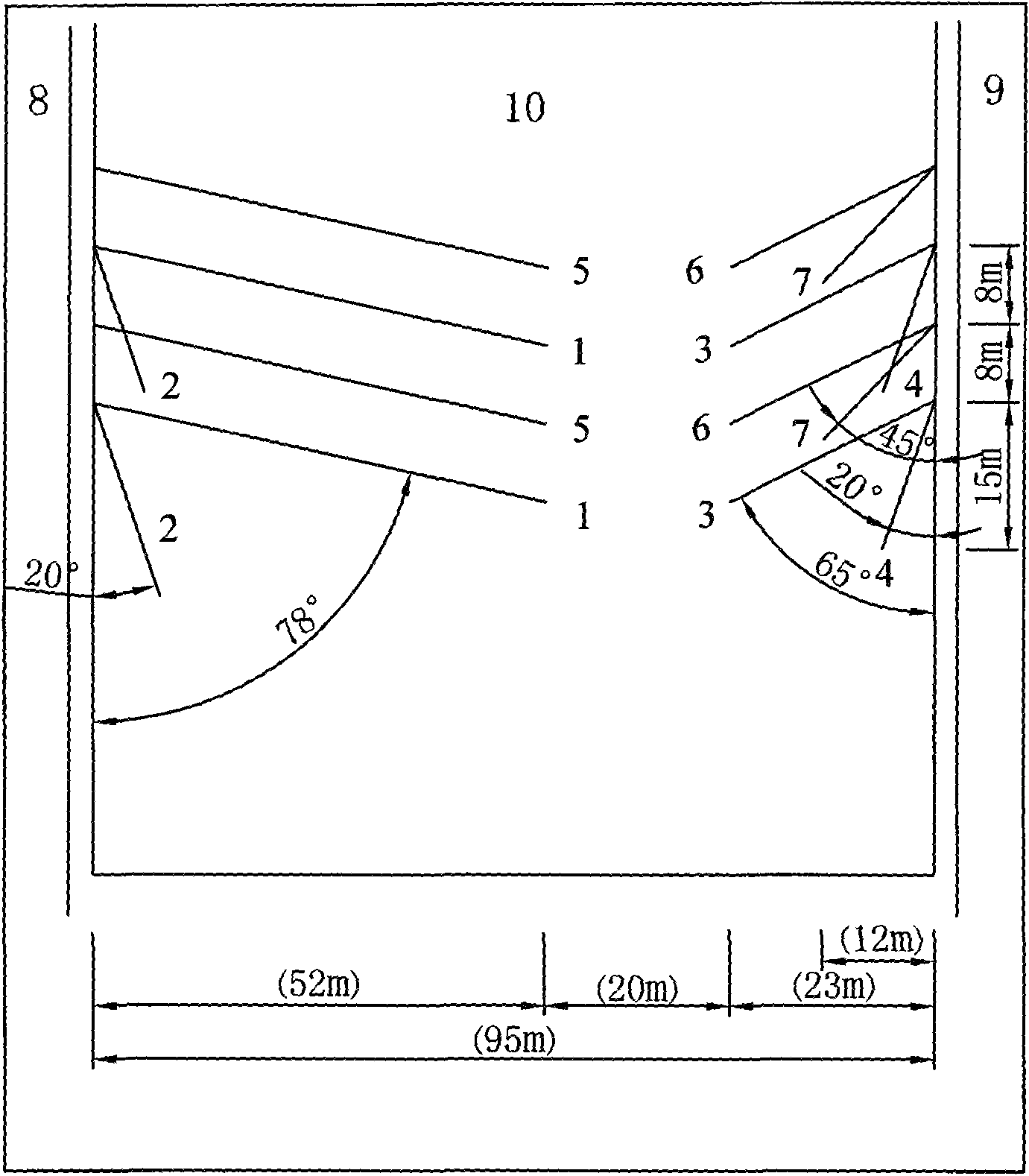

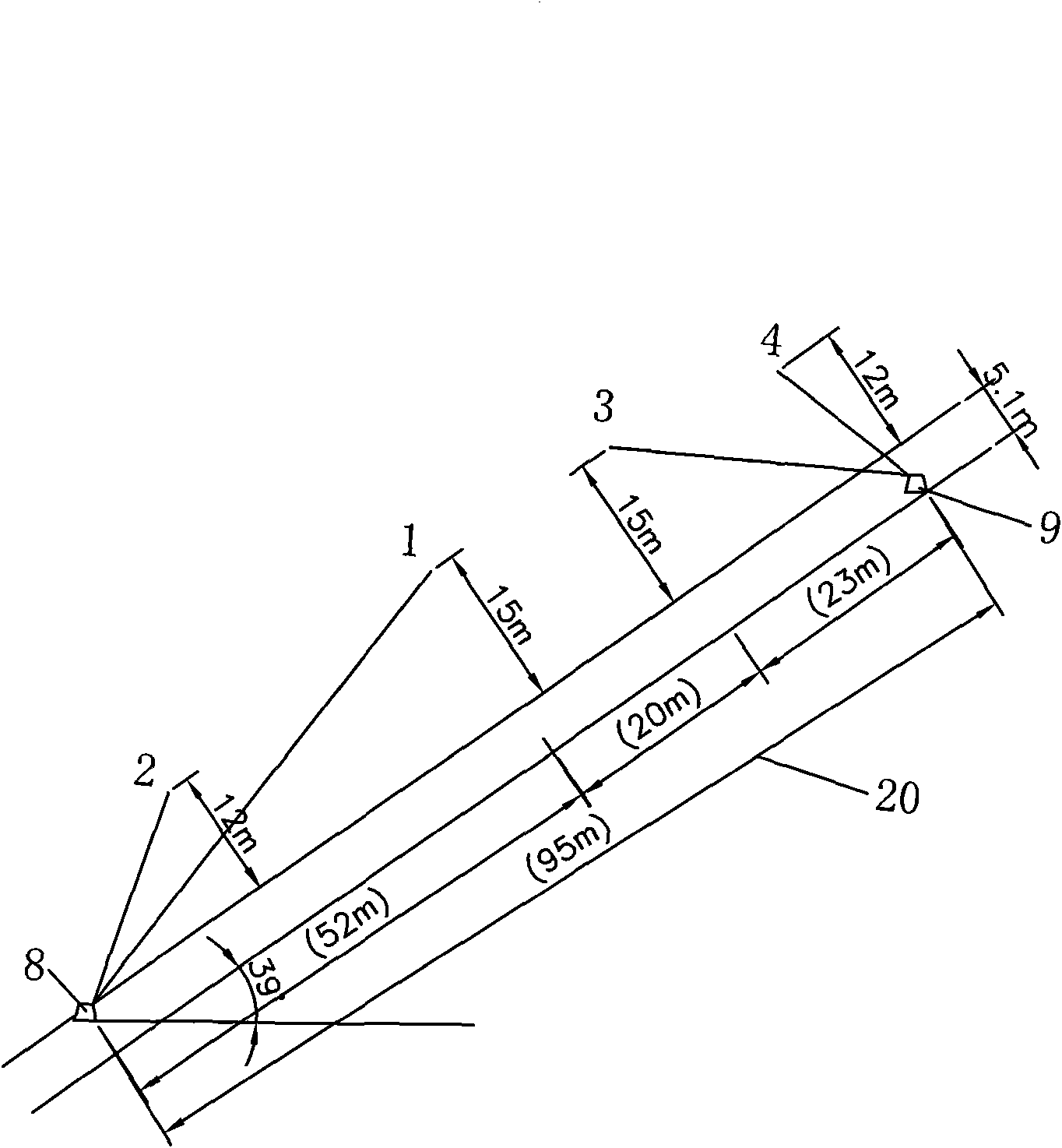

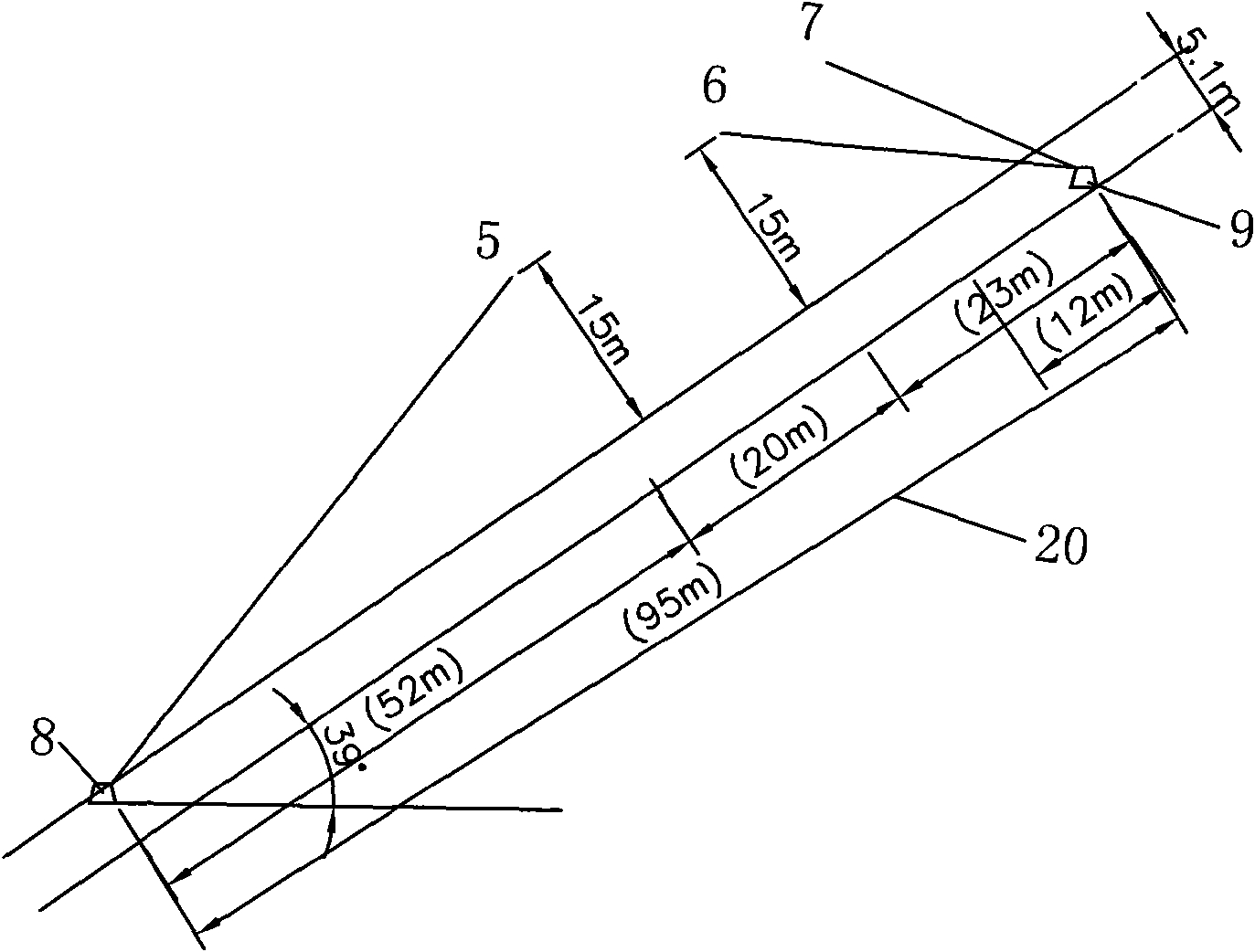

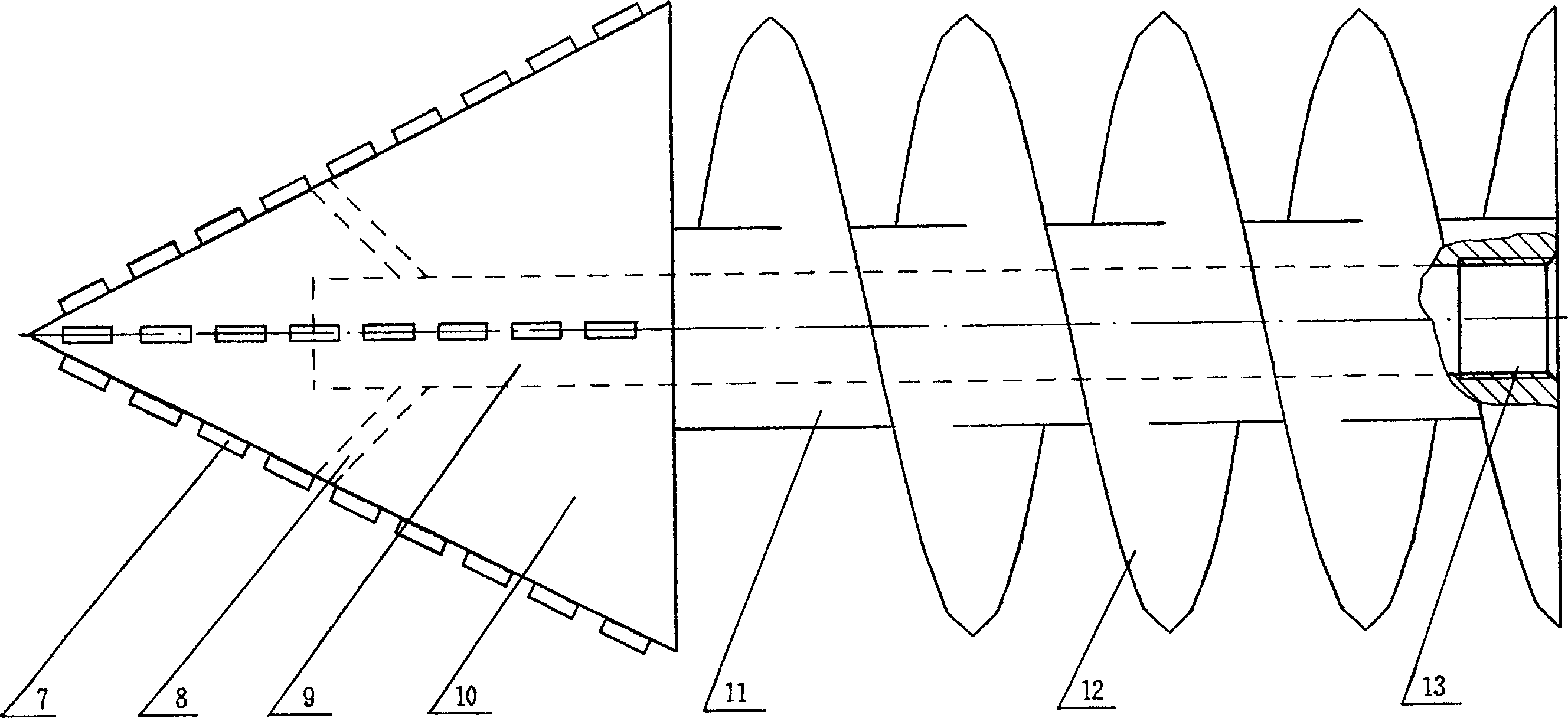

Segment pre-blasting technology for steeply dipping hard coal seam roof

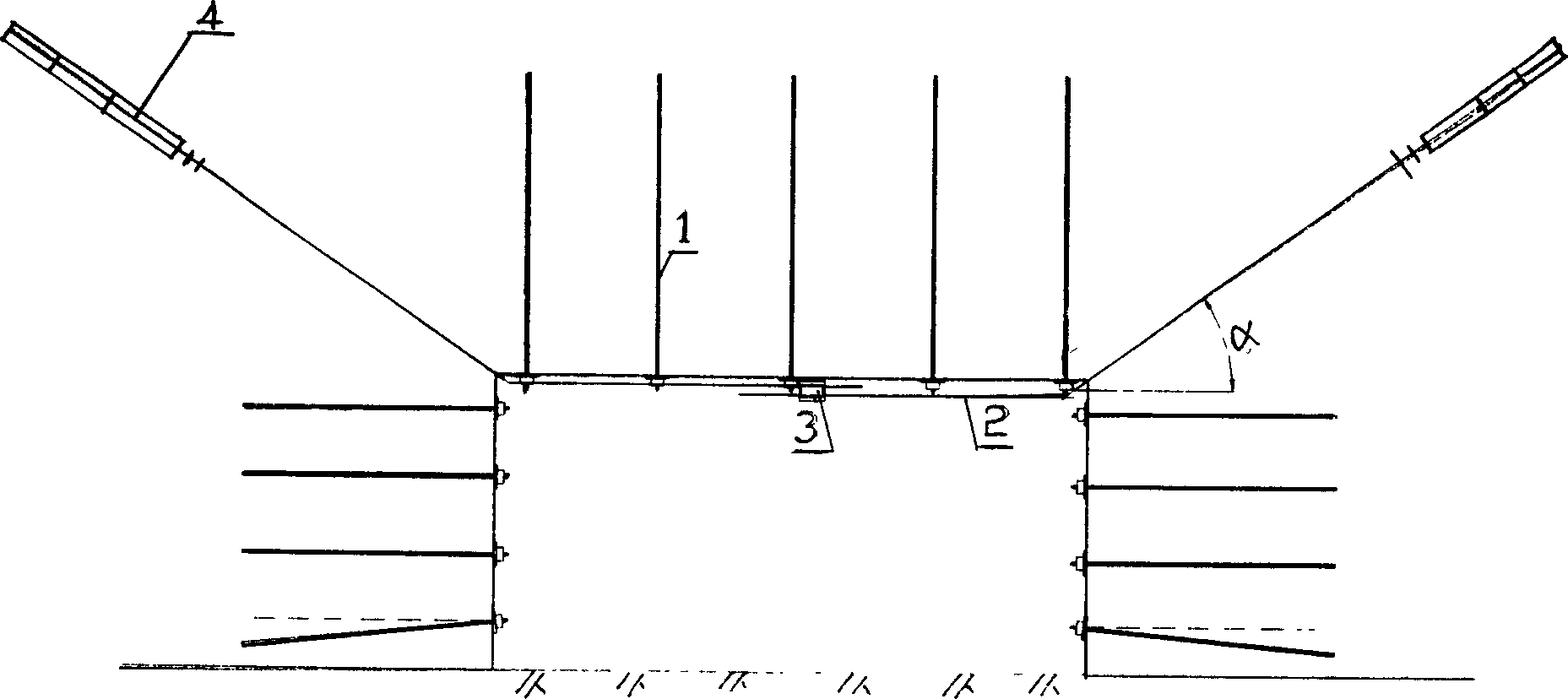

InactiveCN101876520ADecrease the caving stepReduce cavingBlastingMine roof capsEngineeringMechanical engineering

The invention discloses a segment pre-blasting technology for a steeply dipping hard coal seam roof. Blast holes with different angles and length are distributed in gate roads of air return and transportation roadways in front of a working surface towards a roof rock in front of the working surface; and the blast holes are charged in an uneven way with large charge mass, which has controlled fracturing action on the hard roof.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

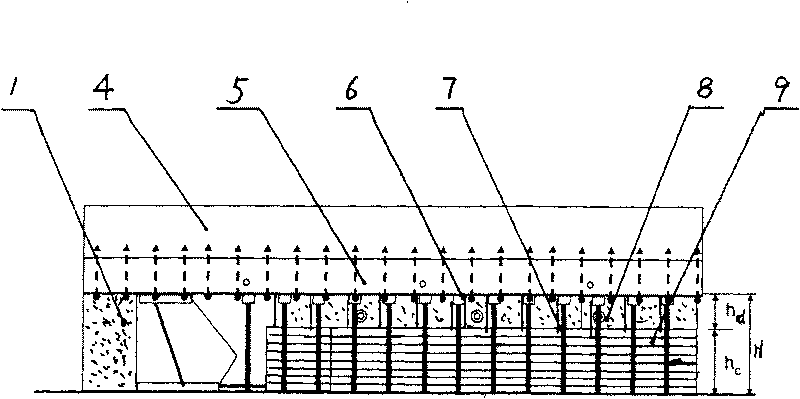

Energy-absorption type impact-resistant tunnel cross-section hydraulic support

ActiveCN104989436AImprove impact resistanceImprove securityMine roof capsProps/chocksSpelunkingFiber

An energy-absorption type impact-resistant tunnel cross-section hydraulic support comprises an energy-absorption impact-resistant top beam, side protection side beams, an energy-absorption impact-resistant floor-heave-resistant bottom beam and anchoring force energy-absorption impact-resistant hydraulic supporting columns. Energy-absorption impact-resistant back plates with interlayer structures are distributed on the upper surface of the energy-absorption impact-resistant top beam, and therefore the local or large-area rock impact effect borne by the top beam can be relieved; the rising, falling and overall deforming of the support top beam are reasonably guided by the side protection side beams, the support top beam is prevented from collapse caused by unbalance loading or the thrust effect in the third direction, wall caving can be prevented, and the hydraulic supporting columns inside the support are protected; buffering time is provided for opening of a safety valve through the anchoring force energy-absorption impact-resistant hydraulic supporting columns, the safety valve is prevented from instant impact damage, and the impact resistance and the safety coefficient of the hydraulic supporting columns are increased; under the common effect of carbon fiber fabric and impact blocks of the energy-absorption impact-resistant floor-heave-resistant bottom beam, energy-absorption blocks are damaged and deformed to recede, and therefore the impact kinetic energy of the bottom plate surrounding rock is rapidly absorbed, and the impact effect borne by a bottom beam body is relieved.

Owner:LIAONING TECHNICAL UNIVERSITY

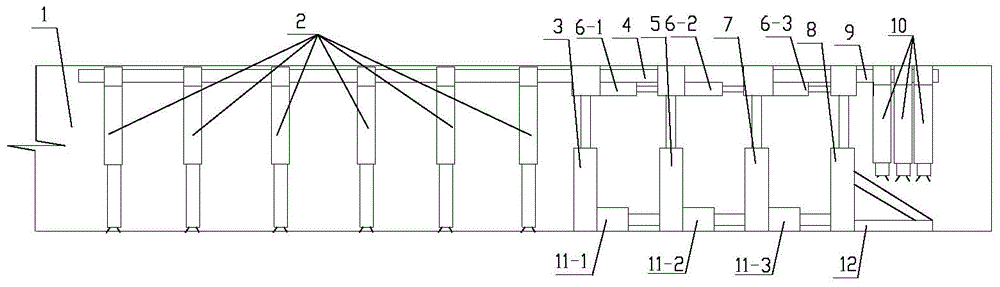

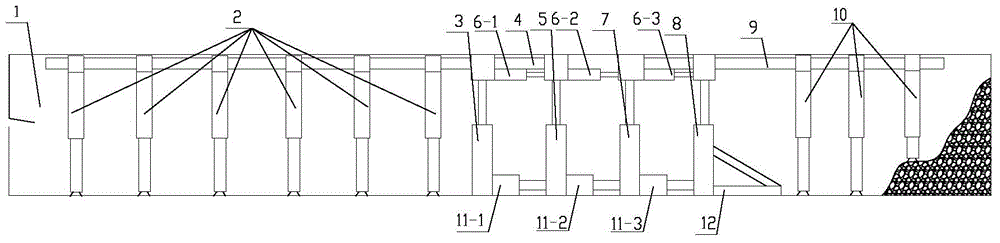

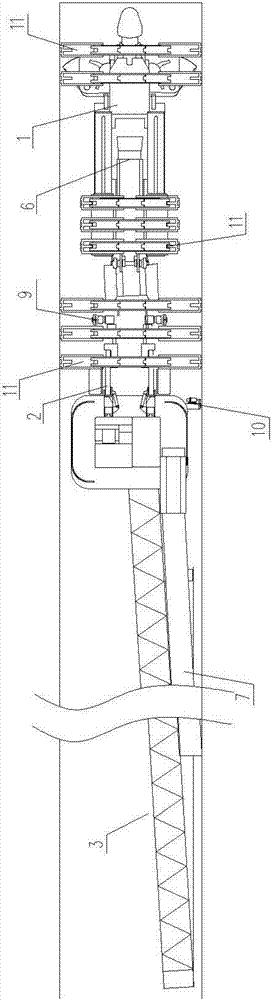

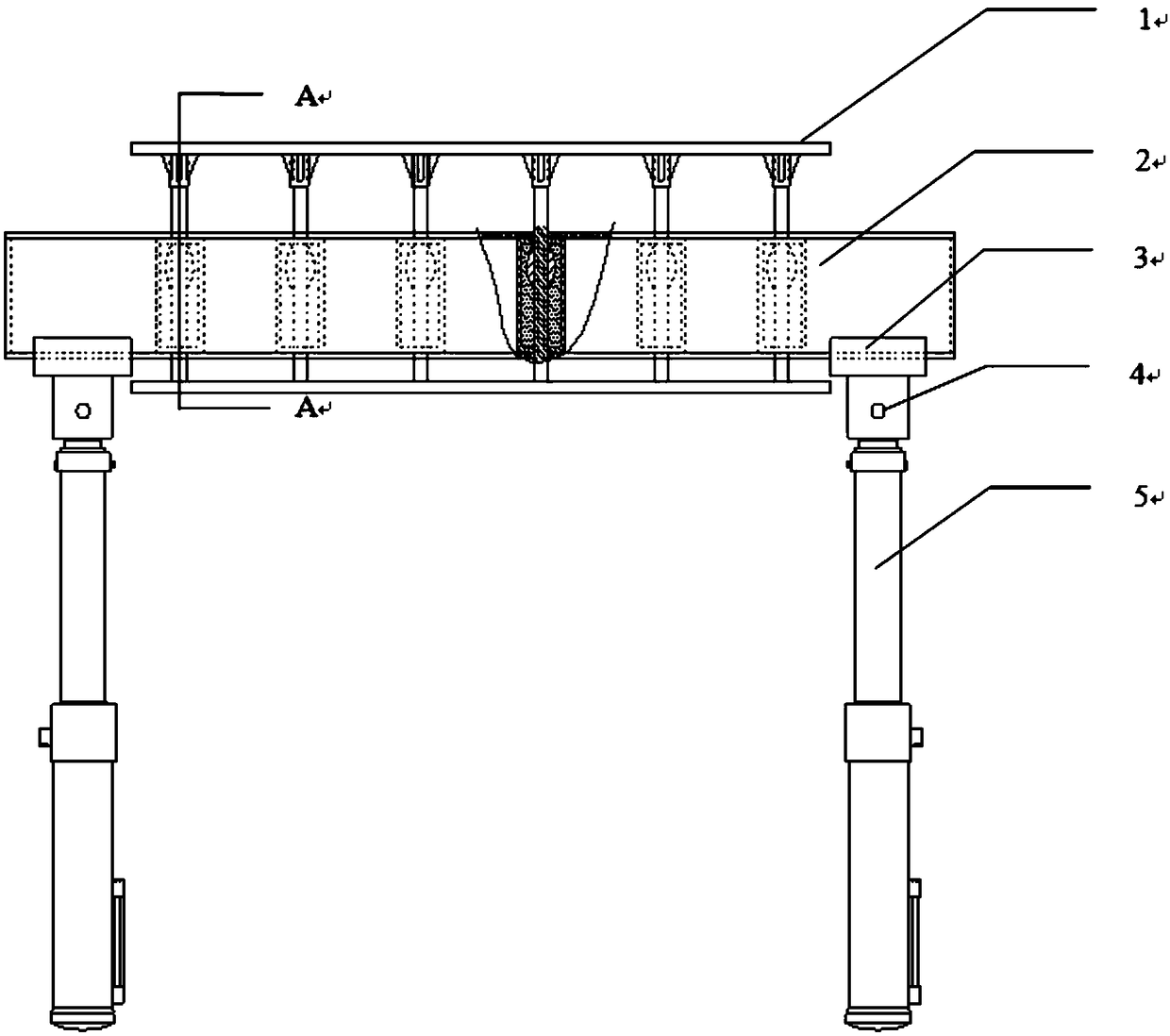

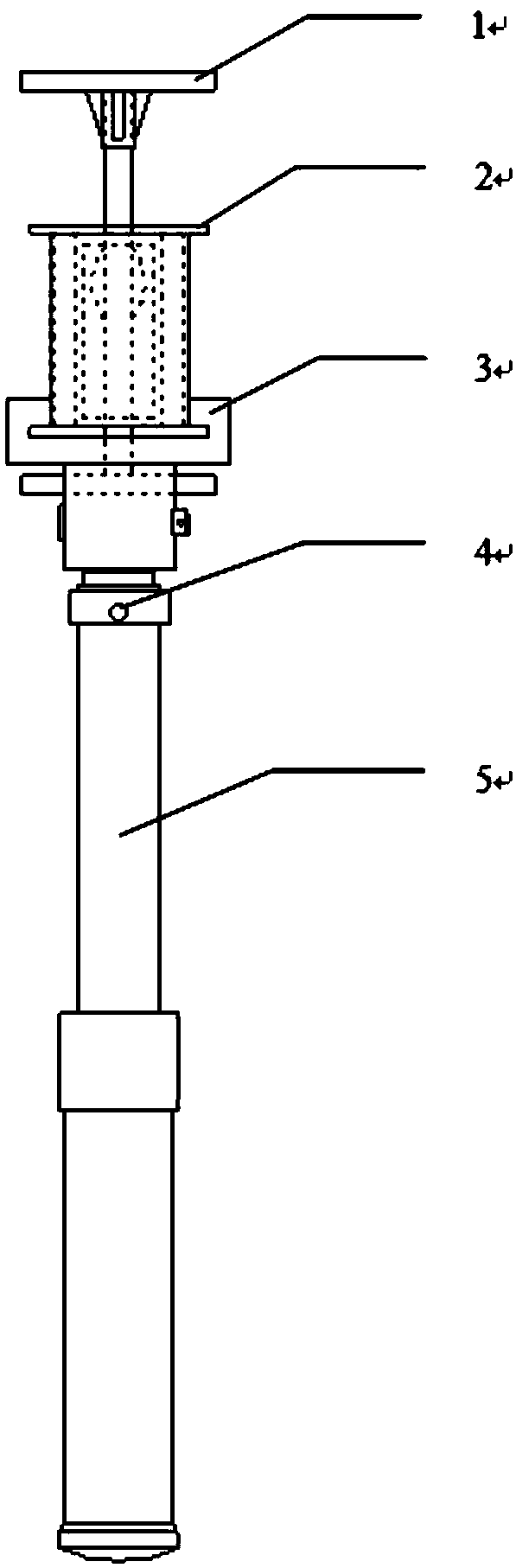

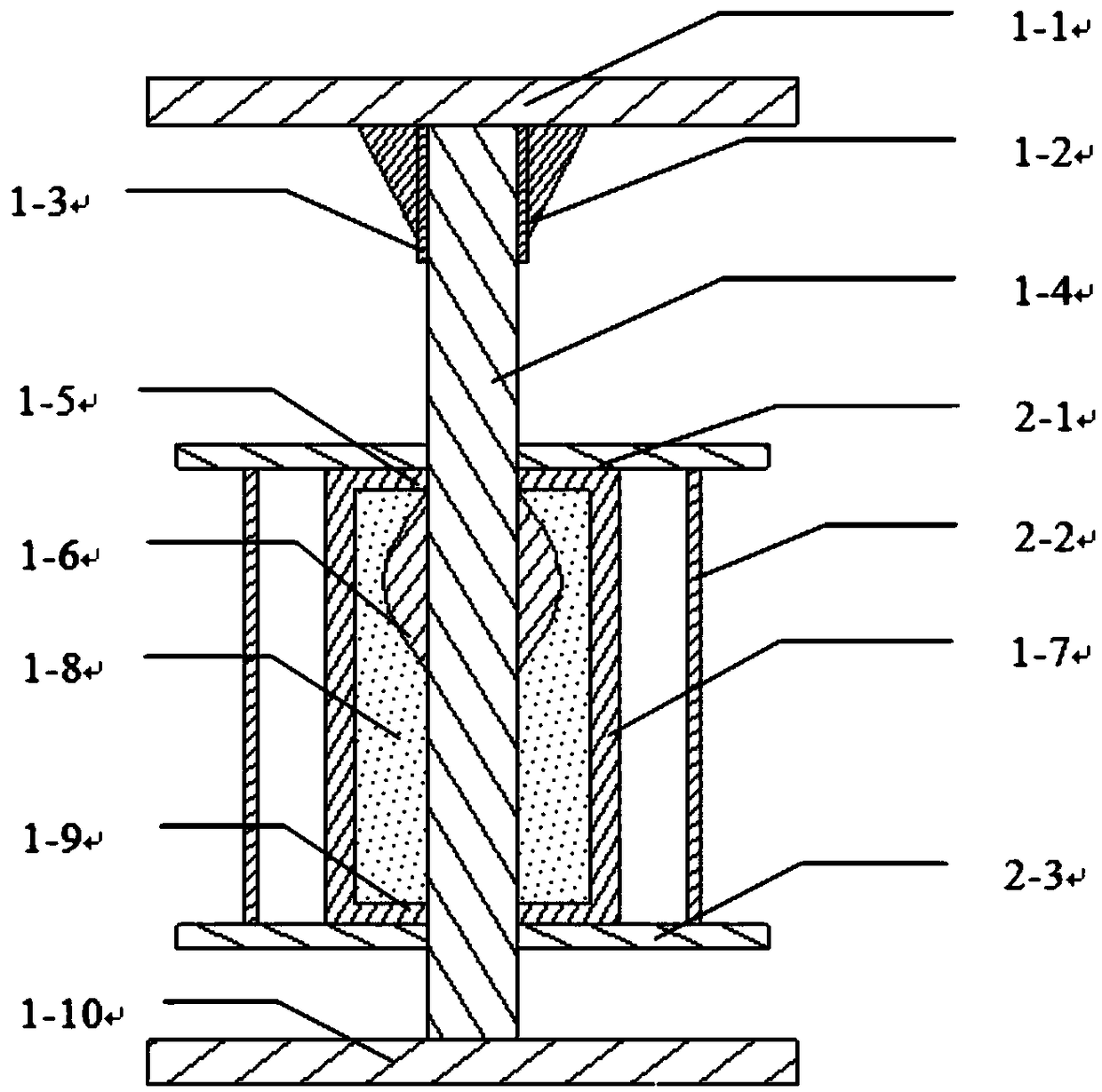

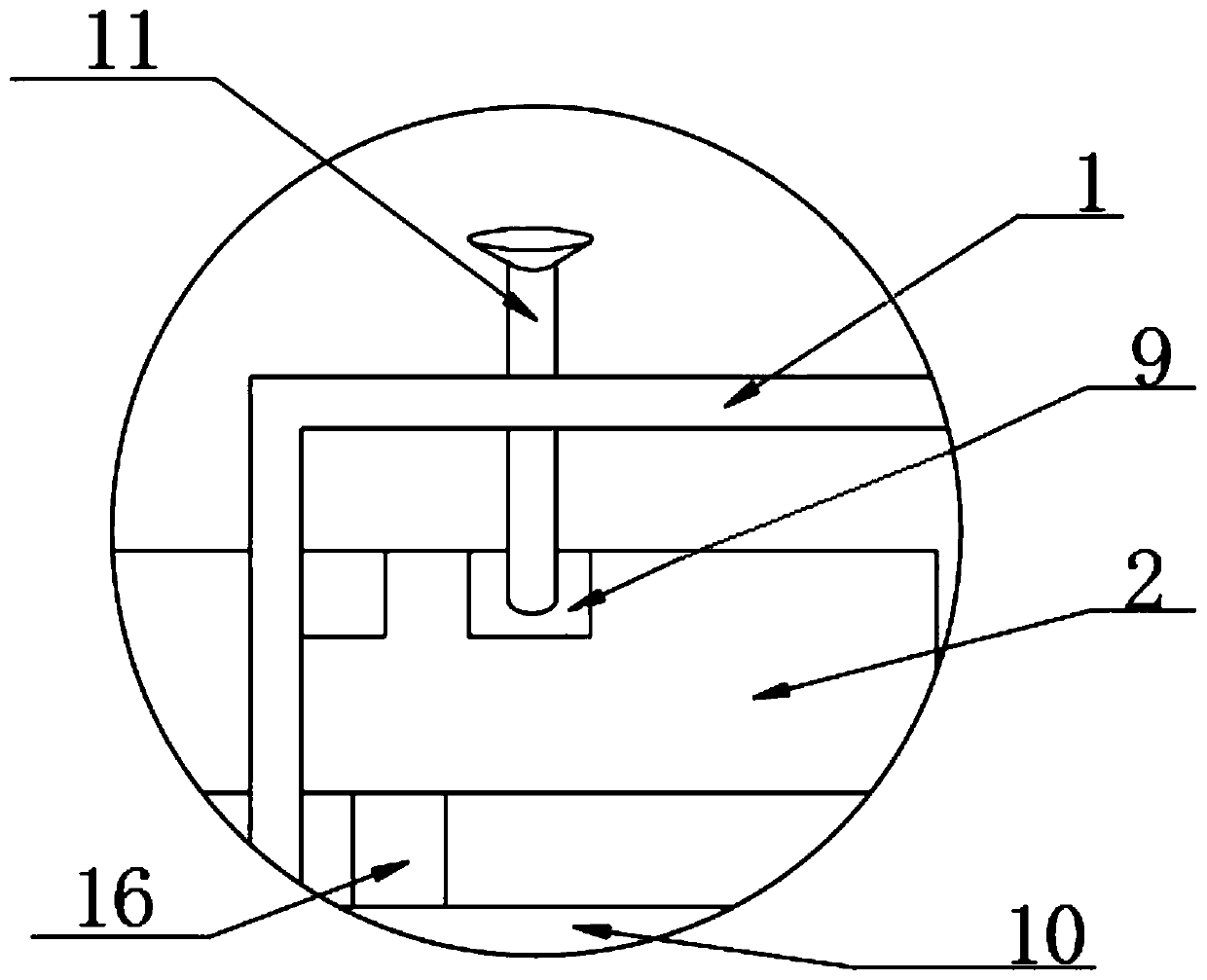

Mine roadway excavation working face temporary support hydraulic device

InactiveCN104675422AReduce labor intensityImprove securityMine roof supportsMine roof capsSupporting systemEngineering

The invention discloses a mine roadway excavation working face temporary support hydraulic device comprising a hydraulic combined support, four graded telescopic jacks, a head temporary support and a tail temporary support. The hydraulic combined support comprises four sets of hydraulic supports composed of top beams, lifting jacks and longitudinal-moving jacks; the graded telescopic jacks are installed on the upper portions of the top beams of the hydraulic combined support; the tail temporary support supporting range serves as the roadway supporting operation space, the head temporary support provides the operation space for muck loading, rock drilling and one-step supporting, and the hydraulic combined support is used for implementing the entire moving of a roadway excavation temporary supporting system; each temporary support comprises a top beam and two hydraulic jacks, the top beams of the temporary supports are fixed to the graded telescopic jacks, the two hydraulic jacks are suspended freely to serve as support legs, and the top beams and the hydraulic jacks are connected through pins. The roadway construction empty roof operation is avoided, surrounding rock can be supported timely, and roadway excavation and supporting parallel operation is implemented.

Owner:徐州赛特机械制造有限公司

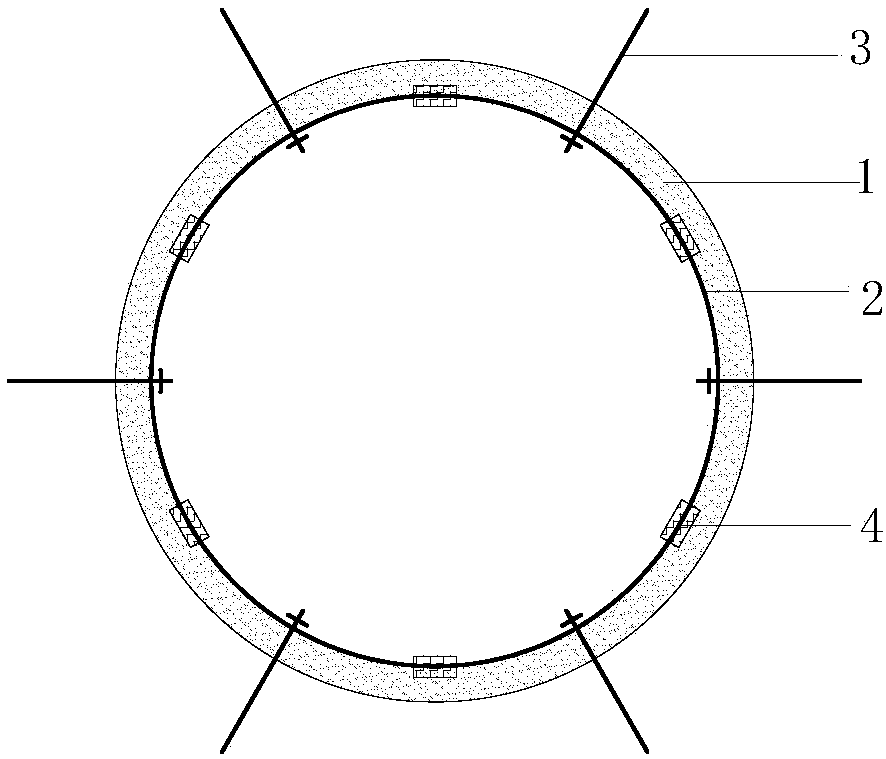

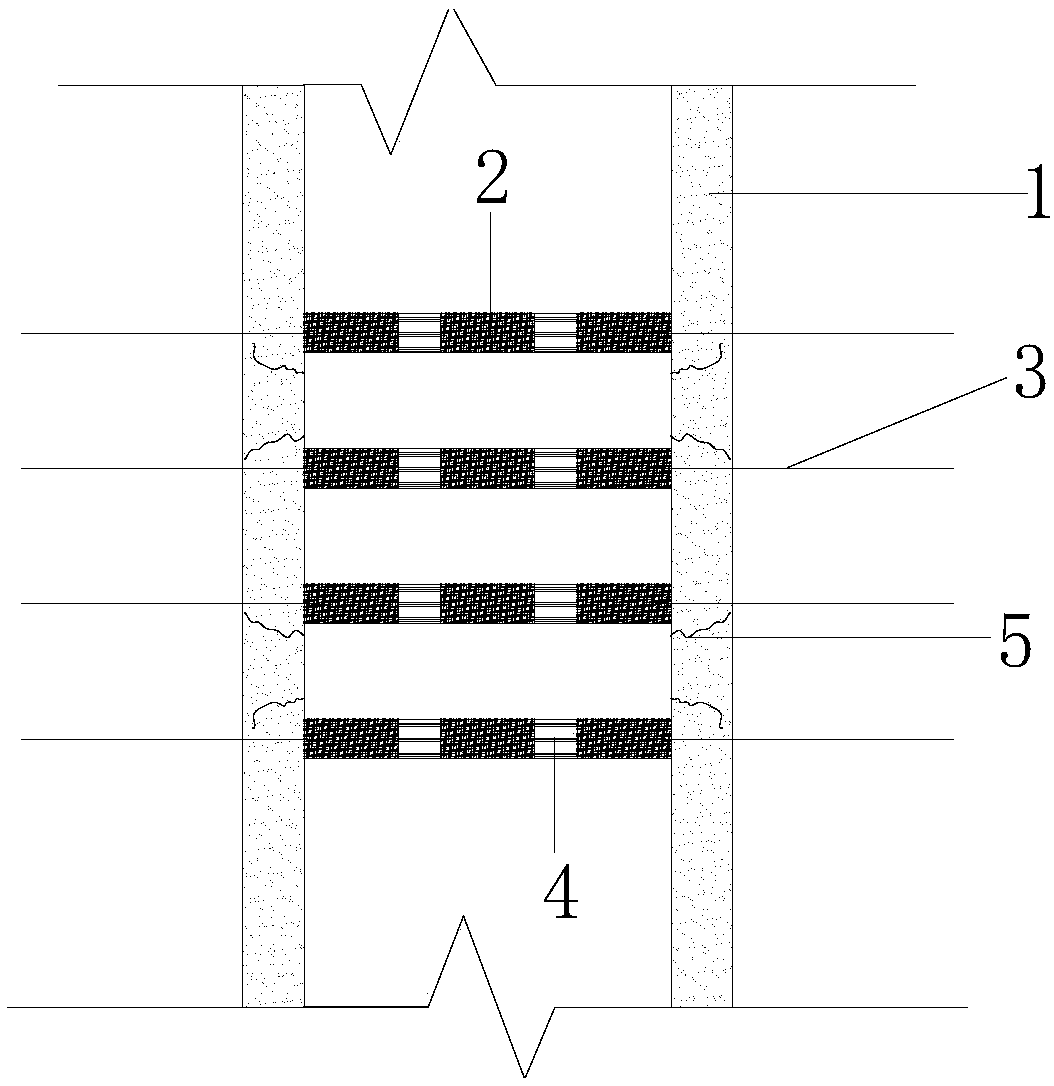

Different repair and reinforcement method based on classification of well wall rupture degree

ActiveCN108119144ABreak through limitationsShort construction periodMine roof capsAnchoring boltsEngineeringTreatment plan

The invention discloses a different repair and reinforcement method based on classification of a well wall rupture degree. The method comprises the steps of classifying the rupture degree of the wellwall according to the rupture range and the rupture depth of the well wall; and then adopting a corresponding repair and reinforcement method according to different well wall rupture degrees. According to the method, the different repair and reinforcement method covers repairing construction methods of different crack degrees and depths of the well wall from surface cracks to the deep hollowing, the limitation of a single well wall construction repairing process is broken through, and the urgent need for a sudden comprehensive treatment plan in the field of vertical shaft repairing is met. Themethod has the advantages of safety and reliability, short construction period, practicality and high efficiency.

Owner:HUNAN UNIV OF SCI & TECH

Material for reinforcement of coal and rock and preparation process and application thereof

InactiveCN101747524ADoes not affect admissibilityImprove adhesionMine roof capsCeramicwareOrganic acidPlasticizer

The invention relates to a material for reinforcement of coal and rock and a preparation process and application thereof. In the technical scheme, resol, a plasticizer, fire-resistance polyether and methanol are used as raw materials and are heated under alkaline conditions to form modified phenolic resin with an inter-penetrating structure through copolymerization and condensation, the modified phenolic resin is then mixed with an organic acid catalyst system by a pump, and the mixture is then poured into a broken coal and rock to be cured and to be closely combined with the coal and rock. The preparation process comprises preparation of the modified phenolic and preparation of the coal and rock curing material. The modified phenolic resin has low viscosity and can infiltrate into tiny cracks. The cured phenolic material has excellent bounding capacity and can achieve strong viscosity with the formation. Due to the excellent flexibility properties, the material can withstand the subsequent formation movement without retardant fire, thereby improving the safety of underground operation. Moreover, the material can not affect the mineability of coal, and can be easily planed and cut, thereby realizing the easy breakage of large coal lumps bonded together.

Owner:滕州市华海新型保温材料有限公司

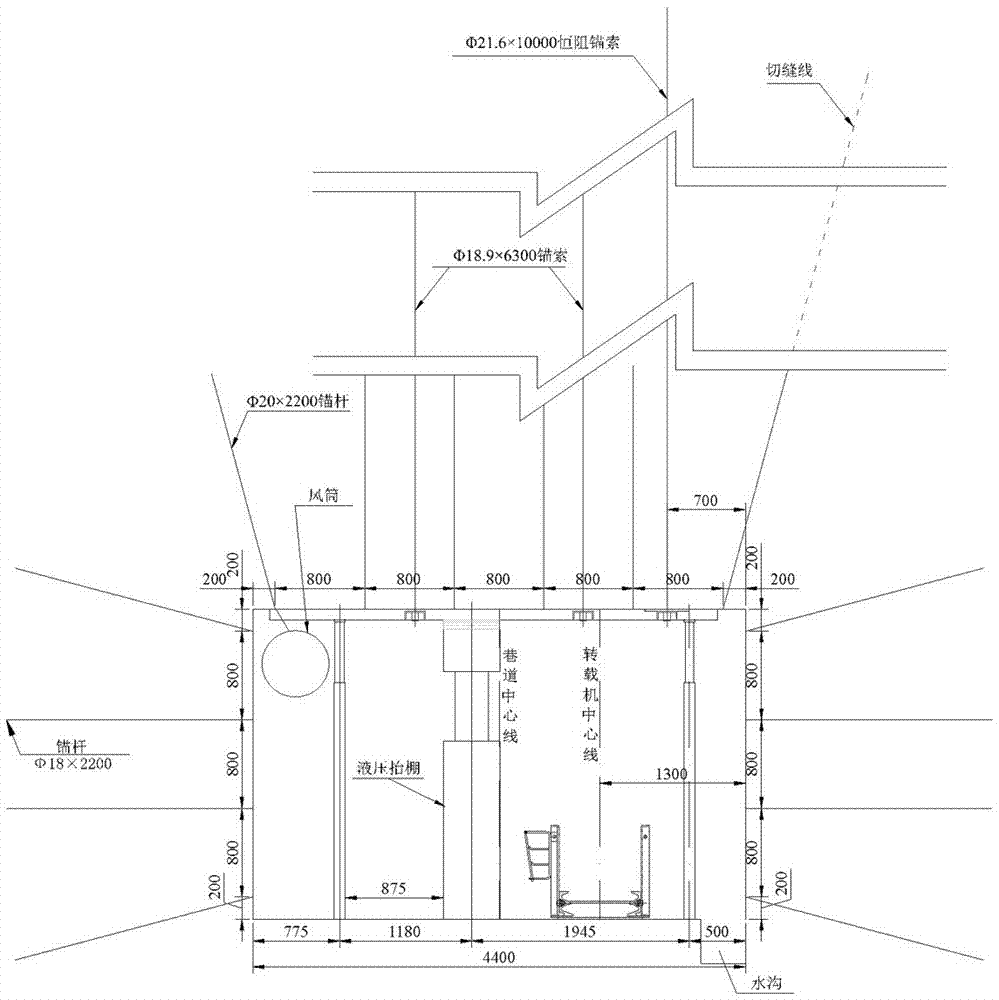

Construction method of large-diameter coal bunker flat-topping lid

InactiveCN101586465AImprove ergonomicsShorten the construction periodUnderground chambersMine roof capsSupporting systemSheet steel

The present invention discloses a construction method of a large-diameter coal bunker flat-topping lid, which comprises the following technical processes: 1. confirming the positions of the H-shape steel and the slip-form platform, 2. pre-embedding a steel plate in the inner bulkhead of the coal bunker, 3. pre-embedding the steel lattice structural column on the bulkhead ring beam of the coal bunker, 4. lowering the slip-form platform; 5. fixing the slip-form platform; 6. welding and fixing the steel corbel of the H-shape steel, 7. fixing the H-shape steel in position; 8. reinforcing the H-shape steel; 9. installing a bunker top main-beam formwork; 10. binding the main-beam reinforcement steel bars; 11. pouring the main-beam concrete; 12. constructing the secondary beam and the roof plate; and 13. detaching the formwork and the supporting system. The construction method of the large-diameter coal bunker flat-topping lid according to the invention has the advantages of no requirement for building full hall scaffold in the bunker, high work efficiency, short construction period, low construction cost, reliably safety and remarkable economic benefit.

Owner:CHINA COAL BUILDING & INSTALLATION ENG GRP

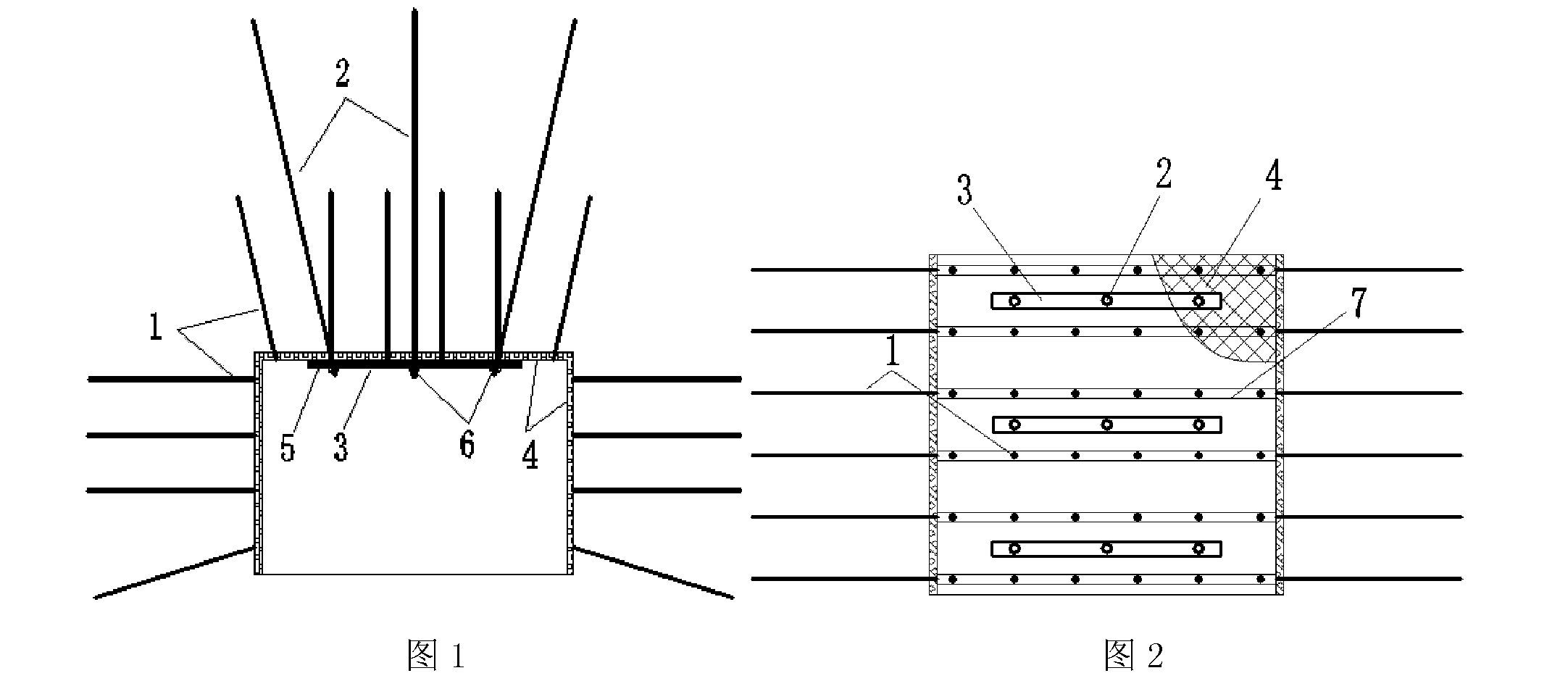

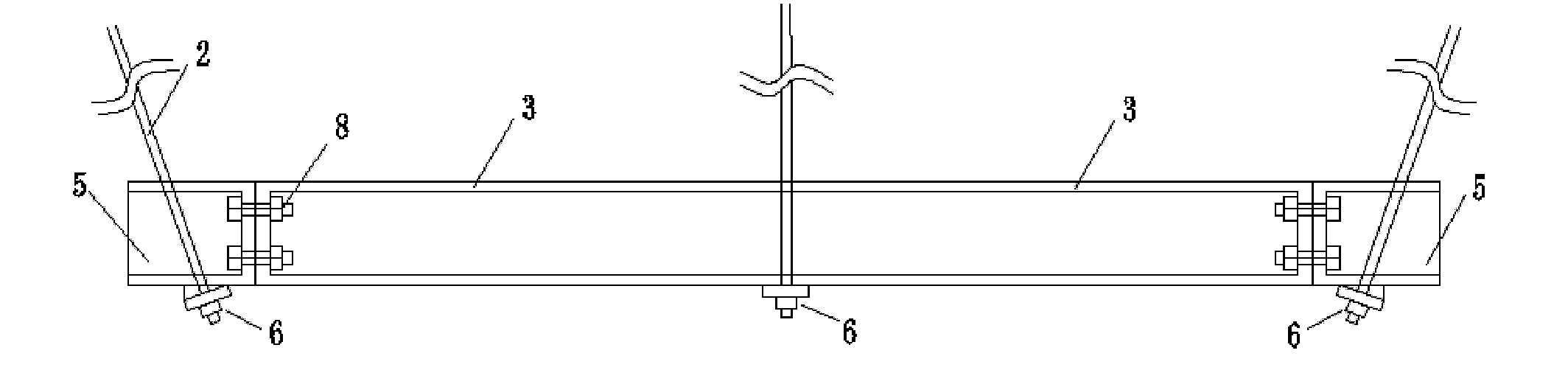

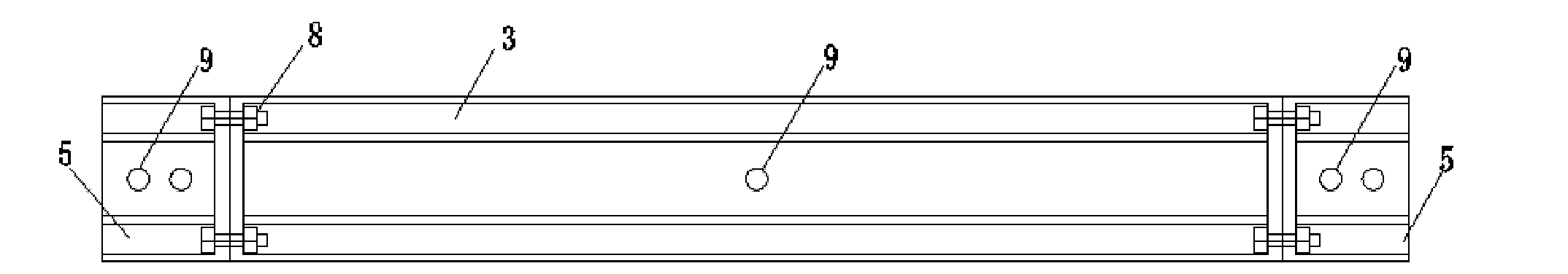

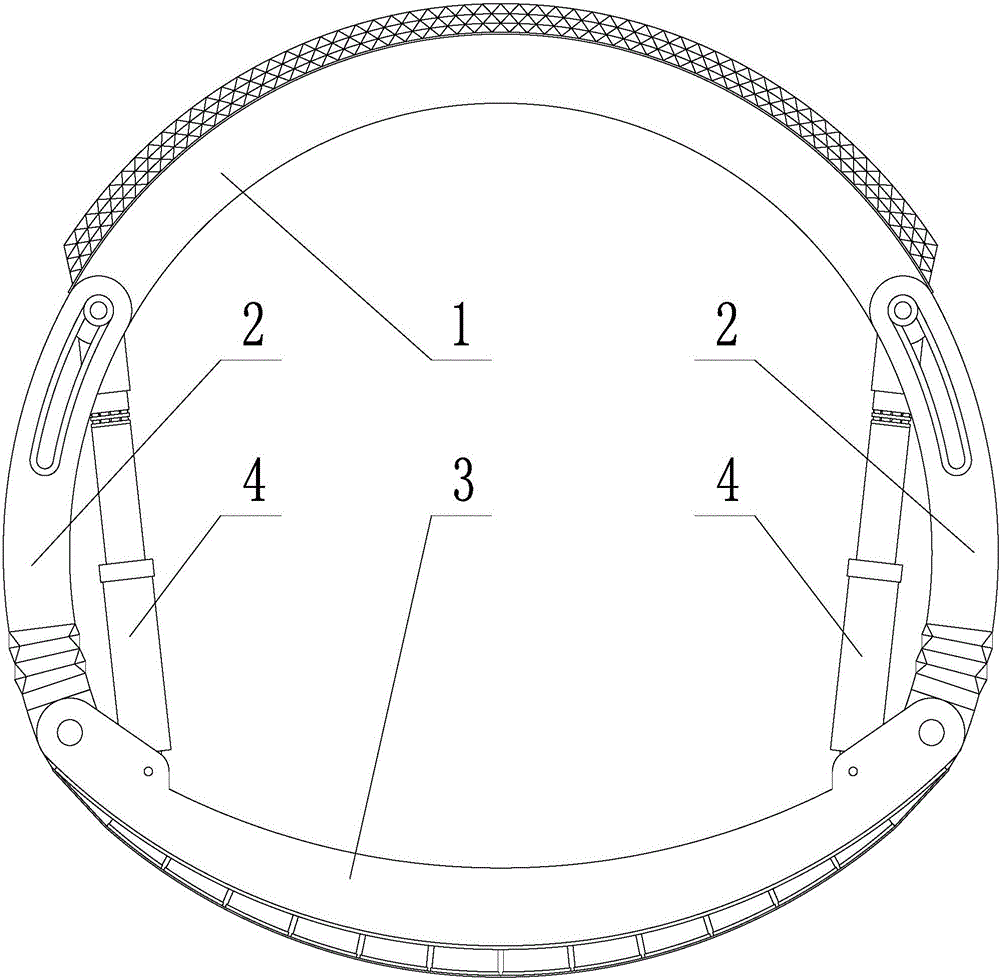

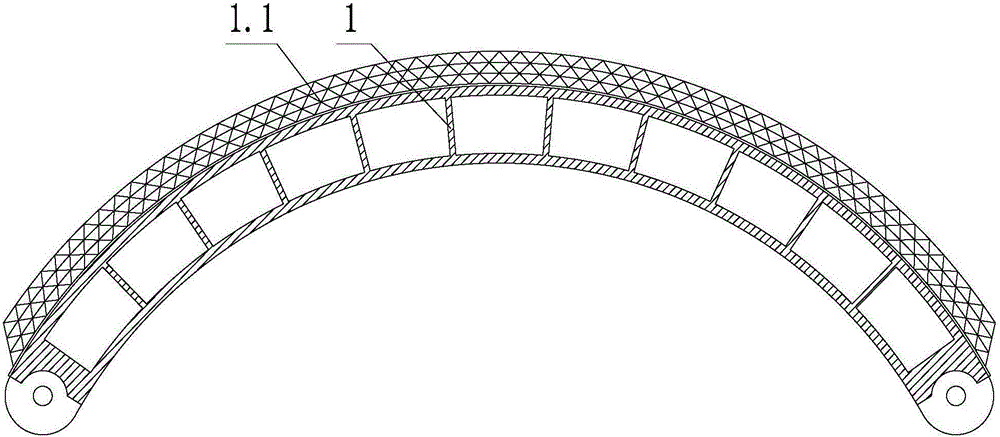

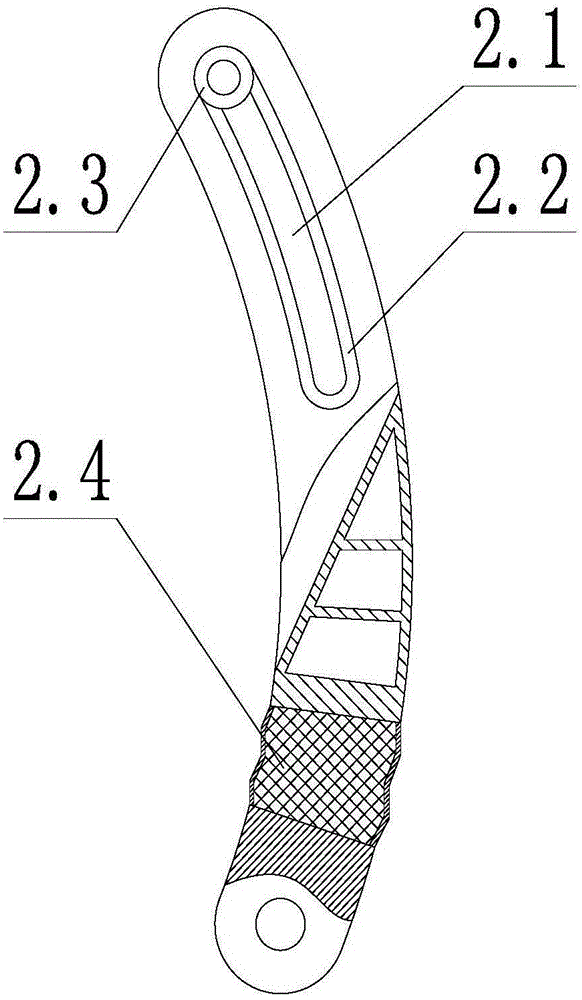

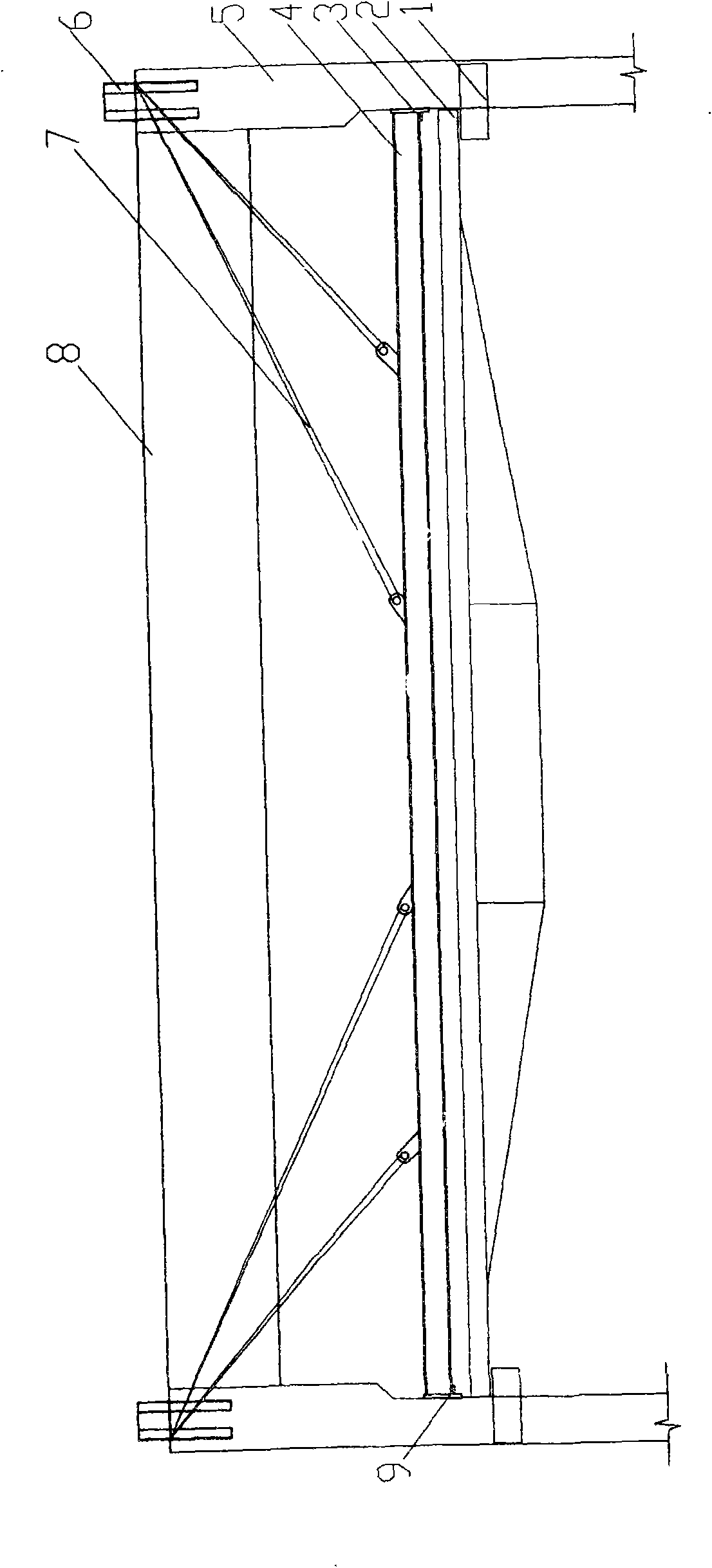

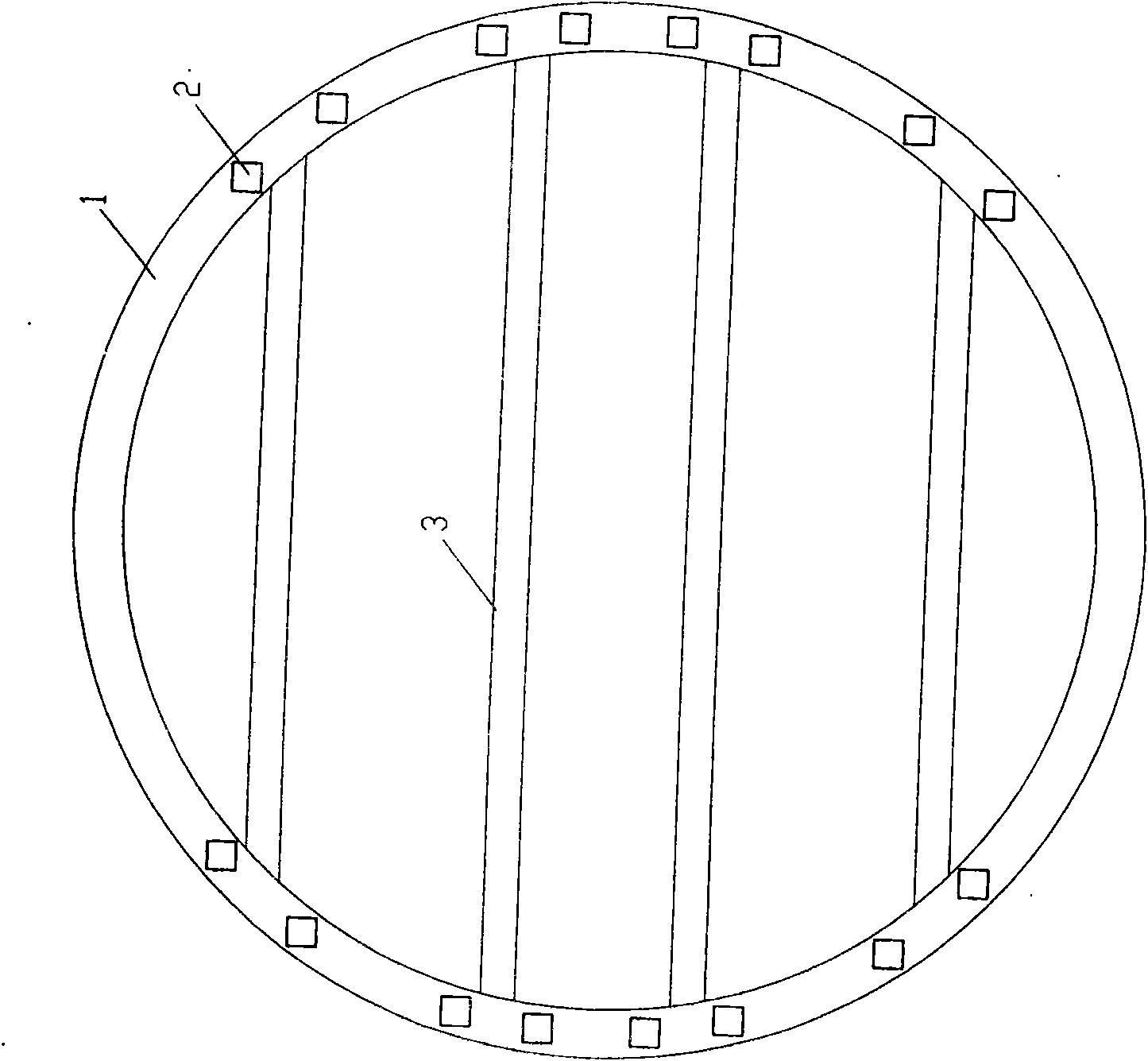

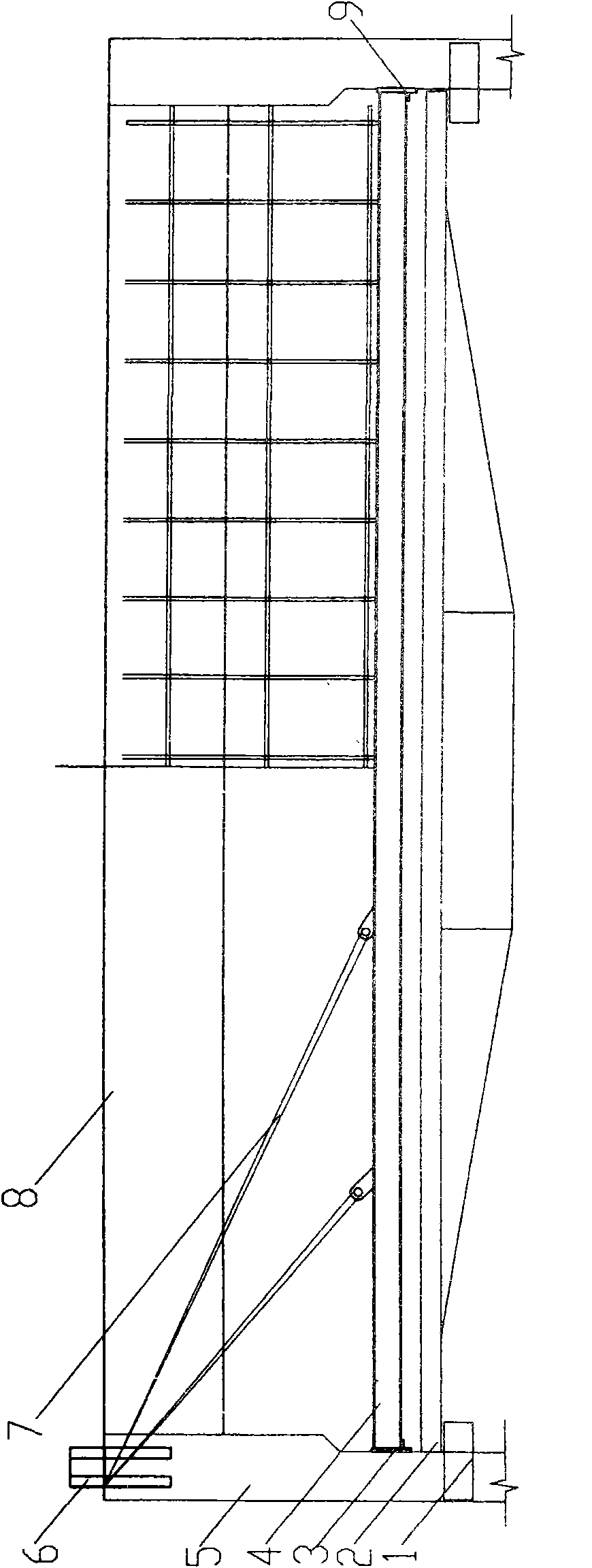

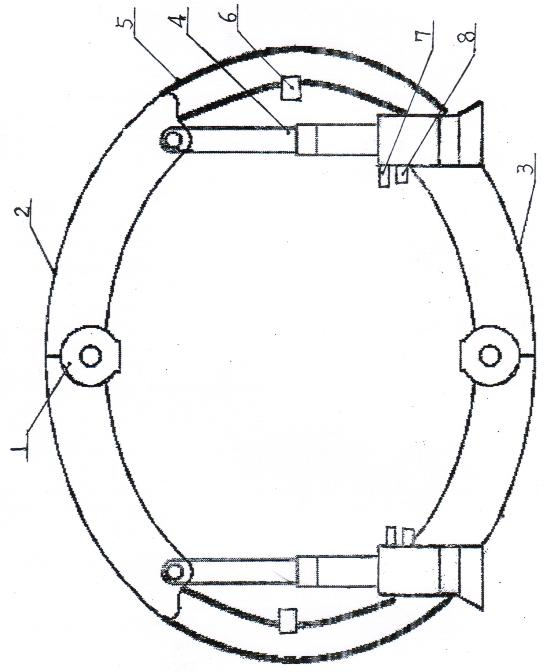

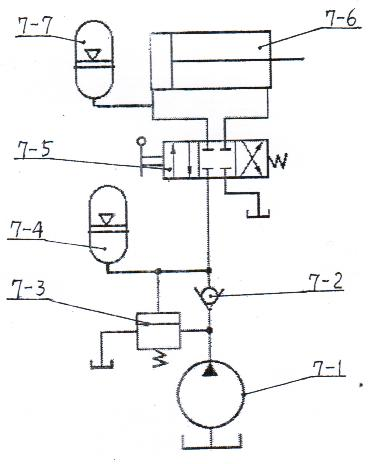

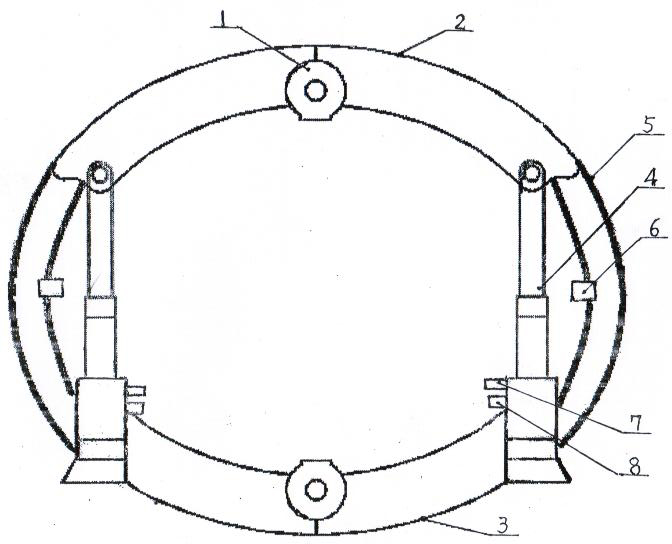

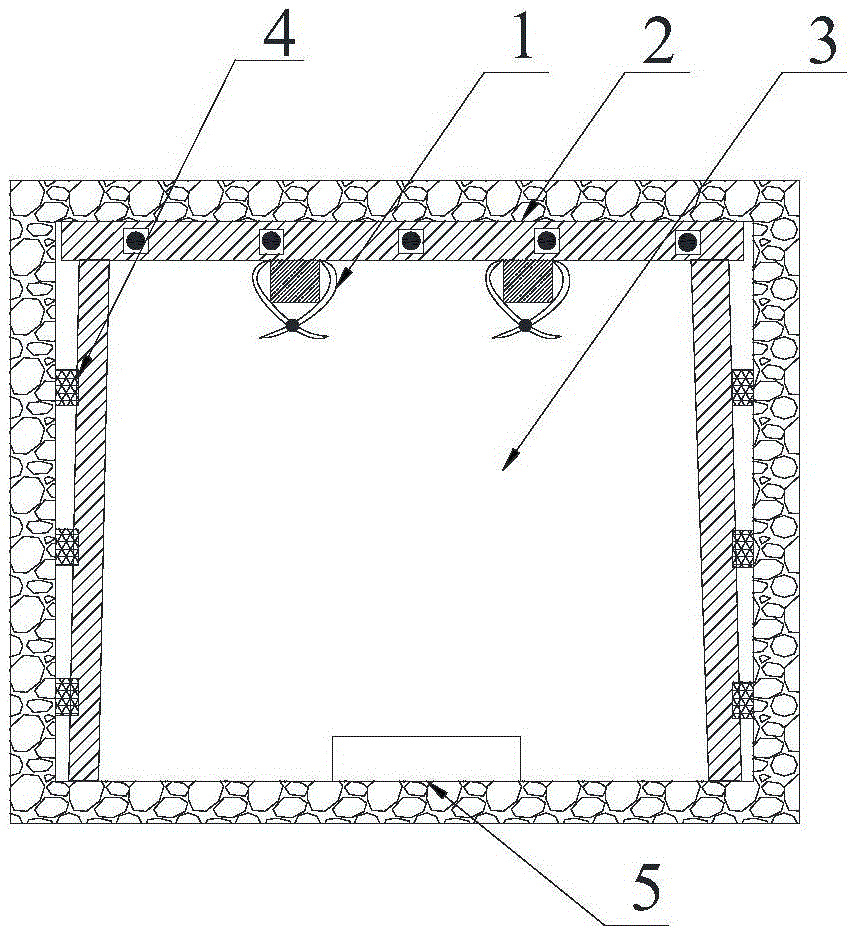

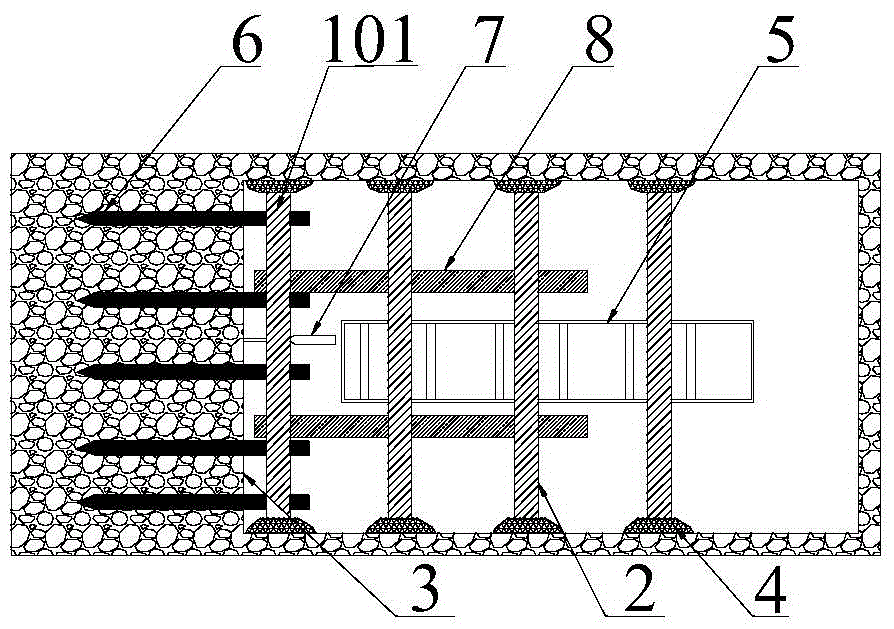

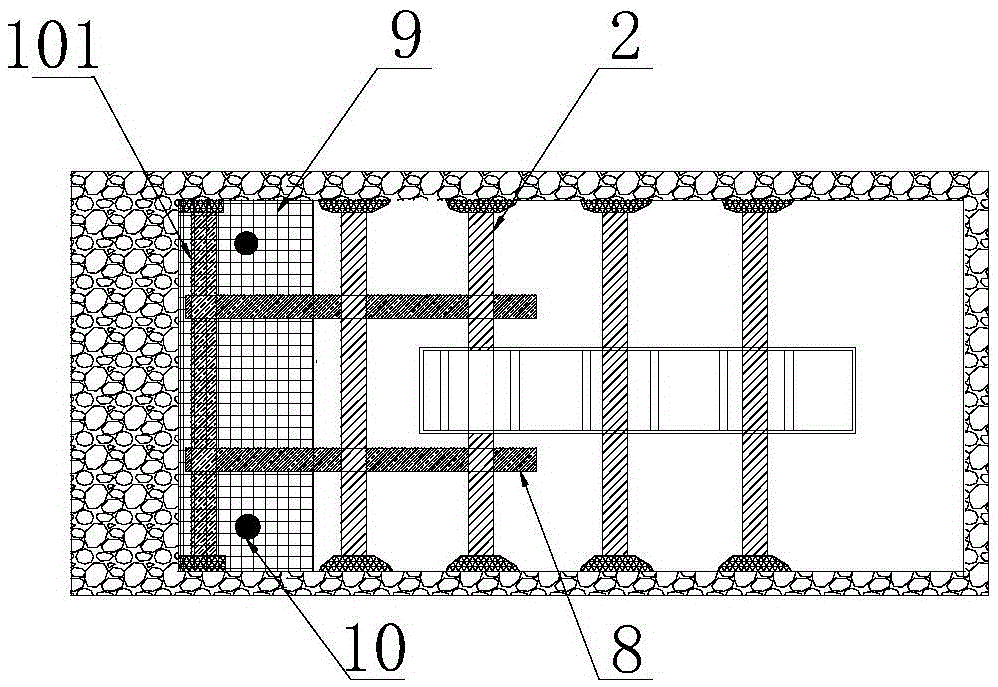

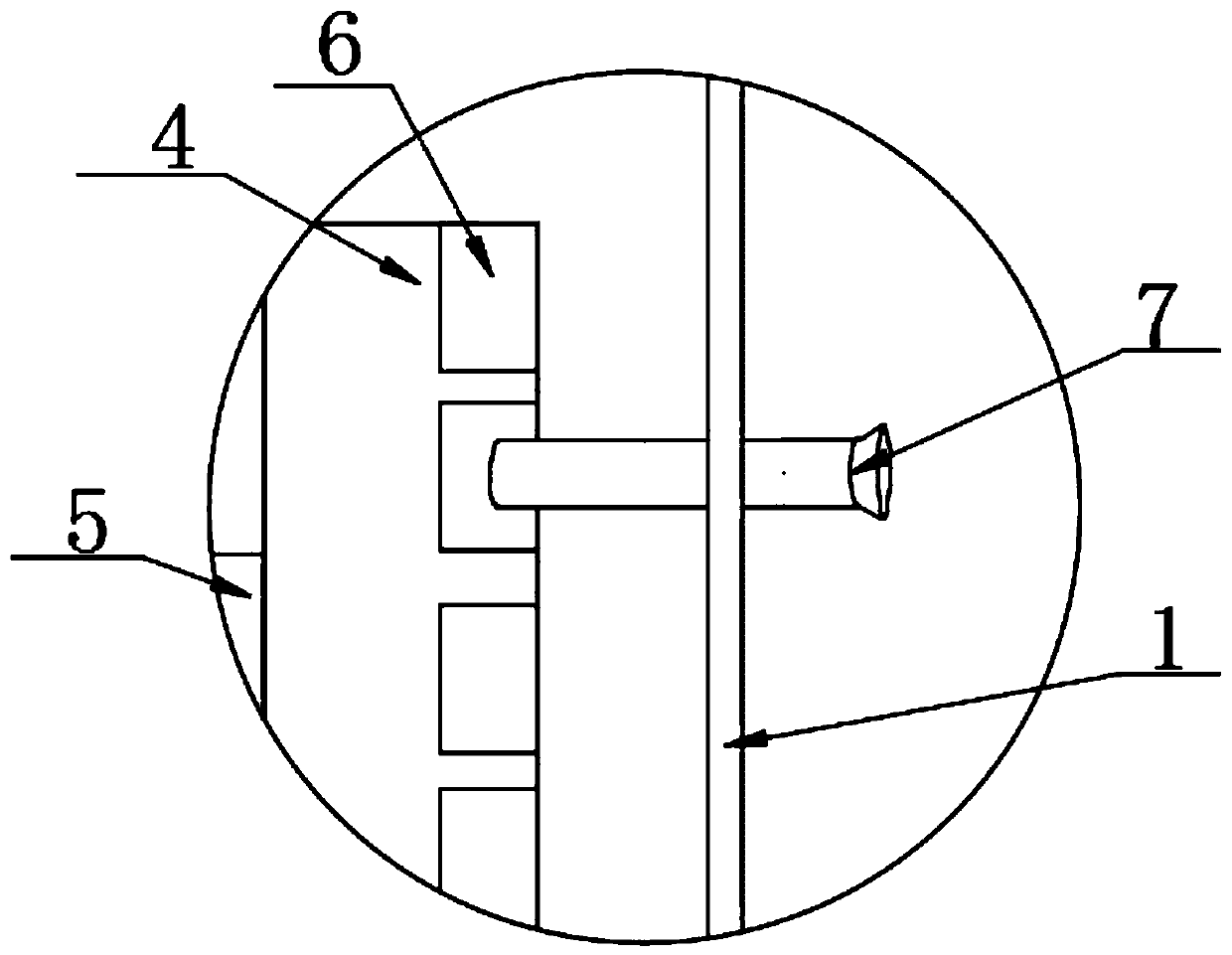

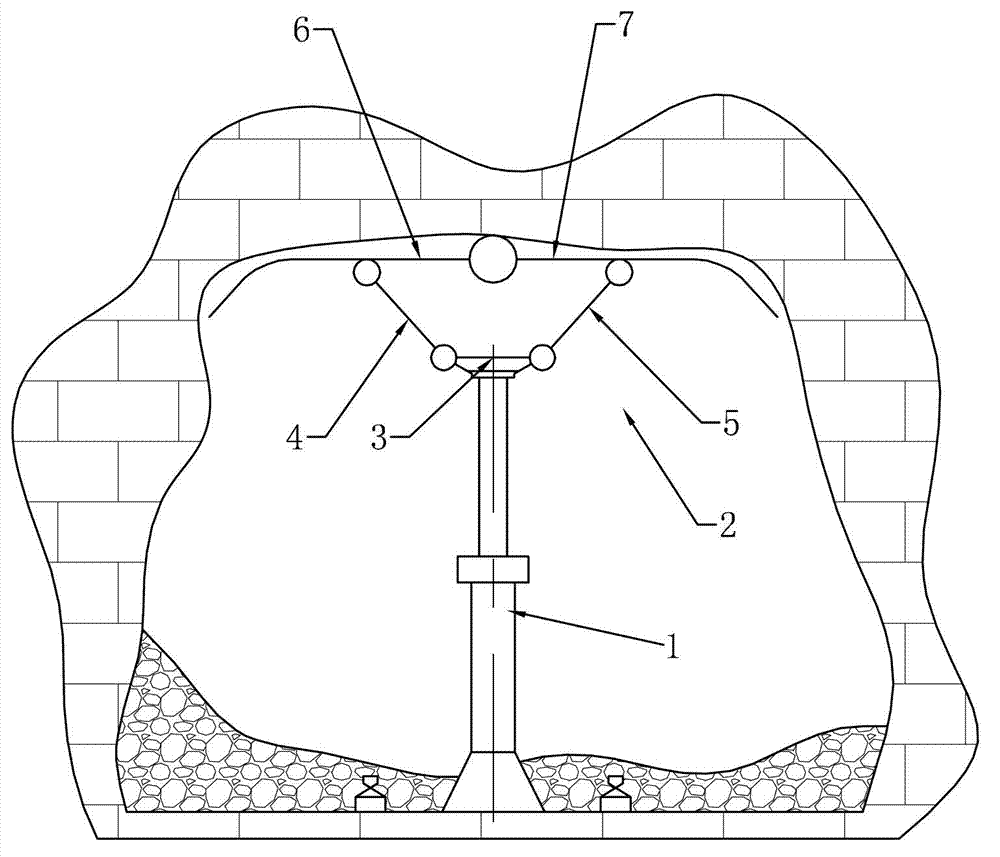

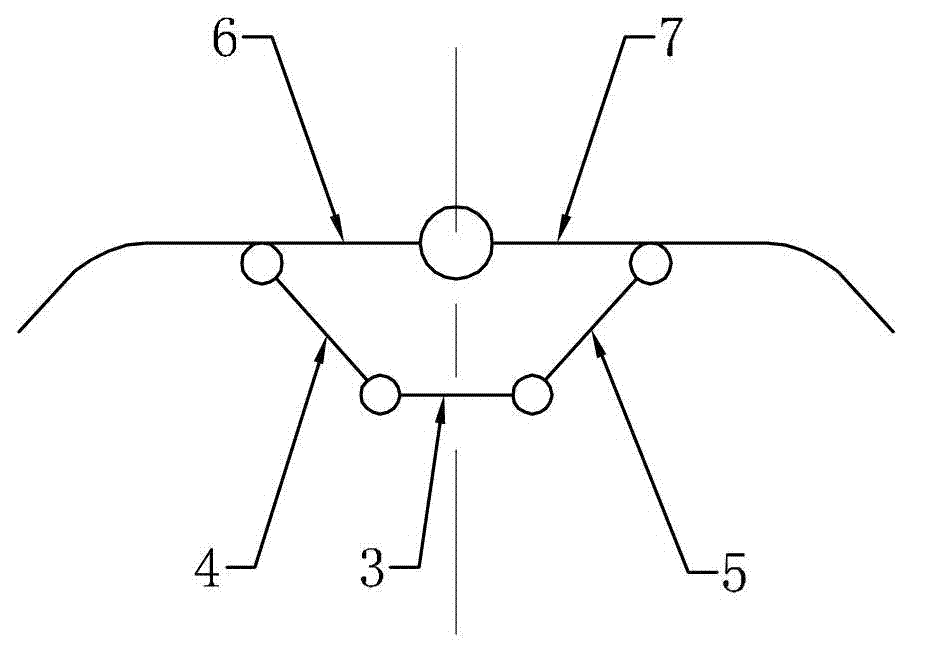

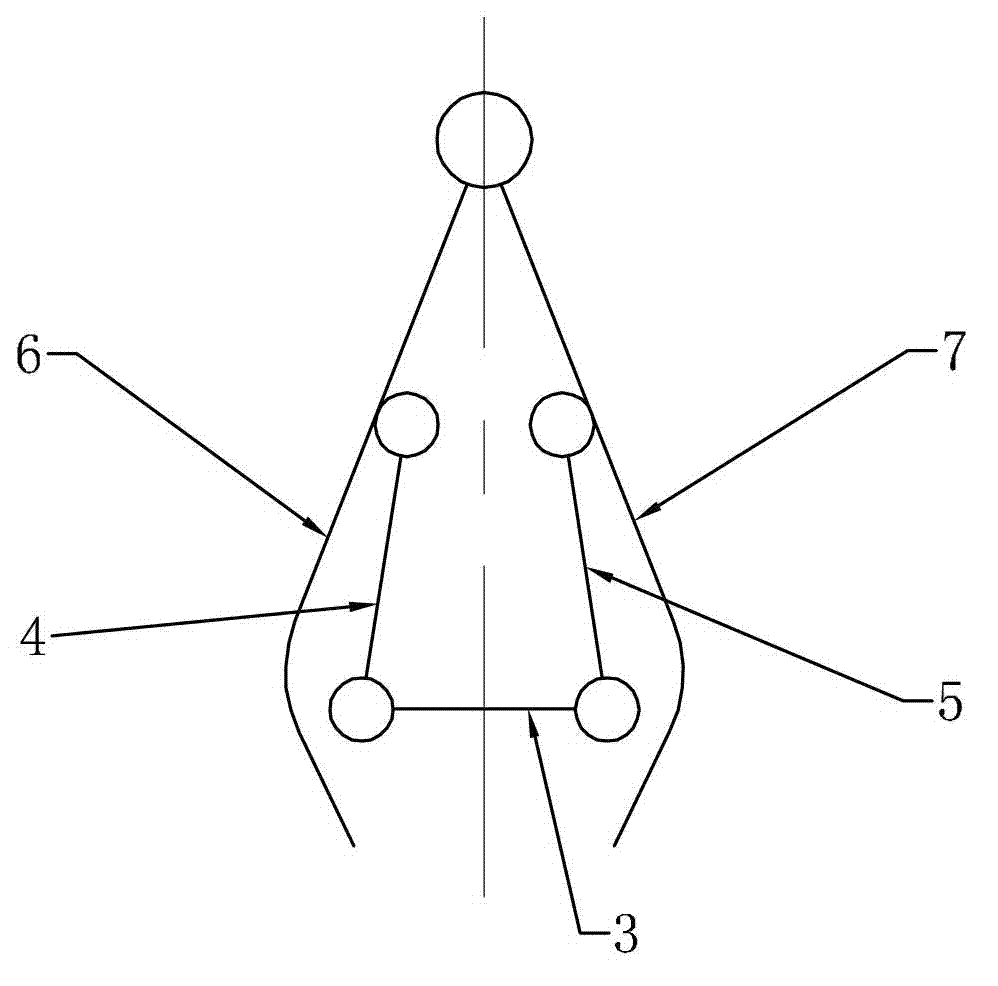

Intelligent anti-impact bracket device

InactiveCN102400695AImprove impact resistanceEnhance load resistanceMine roof capsProps/chocksEngineeringStress sensor

The invention belongs to underground coal mining equipment and in particular relates to an intelligent anti-impact bracket device. The intelligent anti-impact bracket device comprises a top beam (2), a bottom beam (3), dowels (1), a hydraulic bracket (4), a baffle (5), a stress sensor (6) and a displacement sensor (8), wherein the top beam (2) and the bottom beam (3) are divided into two half parts from the middle position; two half top beams (2) and two half bottom beams (3) are in pin connection at the dividing position through the dowels (1); the upper end of the hydraulic bracket (4) is connected with the top beam (2); the lower end of the hydraulic bracket (4) is connected with the bottom beam (3); the baffle (5) is arranged between the top beam (2) and the bottom beam (3); the stress sensor (6) is arranged on the middle part of the baffle (5); and the displacement sensor (8) and an anti-impact component (7) are arranged on the side of the lower part of the hydraulic bracket (4). The elasticity and anti-impact capacity of the hydraulic bracket are enhanced, and the intelligent anti-impact bracket device has high overall structural stability, can be folded, and is convenient to carry and mount.

Owner:LIAONING TECHNICAL UNIVERSITY

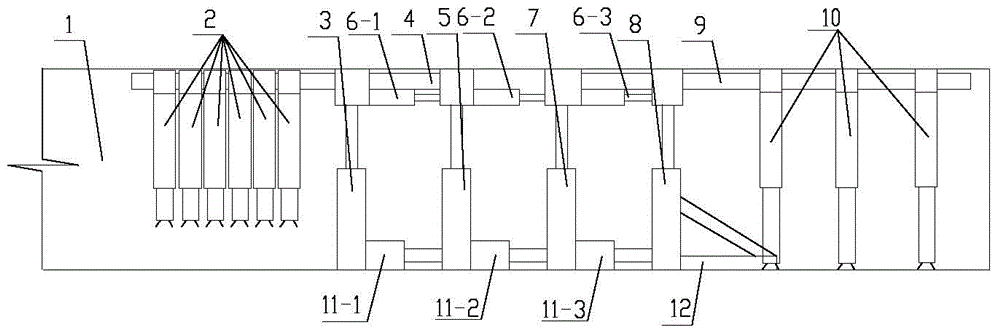

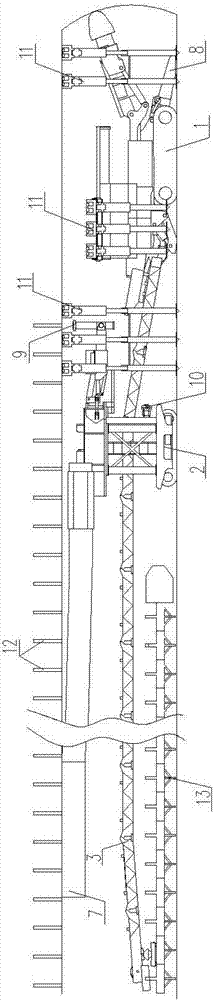

Roadway rapid integrated tunneling system

PendingCN108005665AMechanizationAchieve recyclingDust removalFire preventionWorking environmentCoal mining

The invention relates to a roadway rapid integrated tunneling system, and belongs to the technical field of roadway tunneling, anchoring and transportation devices. The roadway rapid integrated tunneling system comprises multiple top plate support devices, a heading machine located below the top plate support devices, an anchor rod operating vehicle located at the rear portion of the heading machine, and a dedusting air supply system arranged along the roadway; a support conveying device used for conveying the anchor rod support area top plate support devices to an empty-support area to support is arranged on the heading machine; the tail portion of the heading machine is provided with a second conveying machine for conveying materials; and the anchor rod operating vehicle spans the secondconveying machine. The roadway rapid integrated tunneling system can realize comprehensive mechanized operation of roadway tunneling, support, anchoring and transportation, solves the problems of lowefficiency, dispersed equipment and high labor intensity of traditional tunneling methods, and can provide a good safe working environment for workers, and the labor intensity is reduced. The roadwayrapid integrated tunneling system can improve the tunneling efficiency and is beneficial to the coal mining, downsizing and increasing efficiency, and creates conditions for the mechanized and intensive production mode for the mine.

Owner:SHIJIAZHUANG COAL MINING MACHINERY

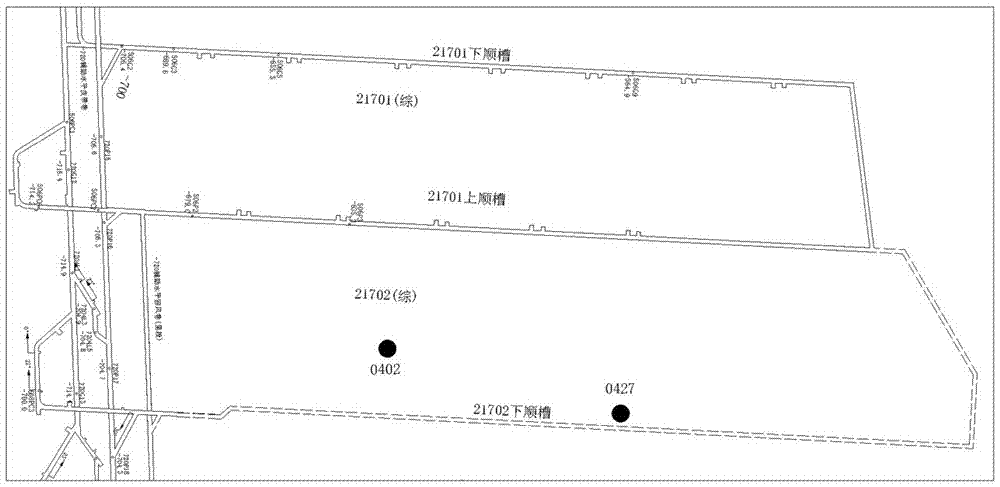

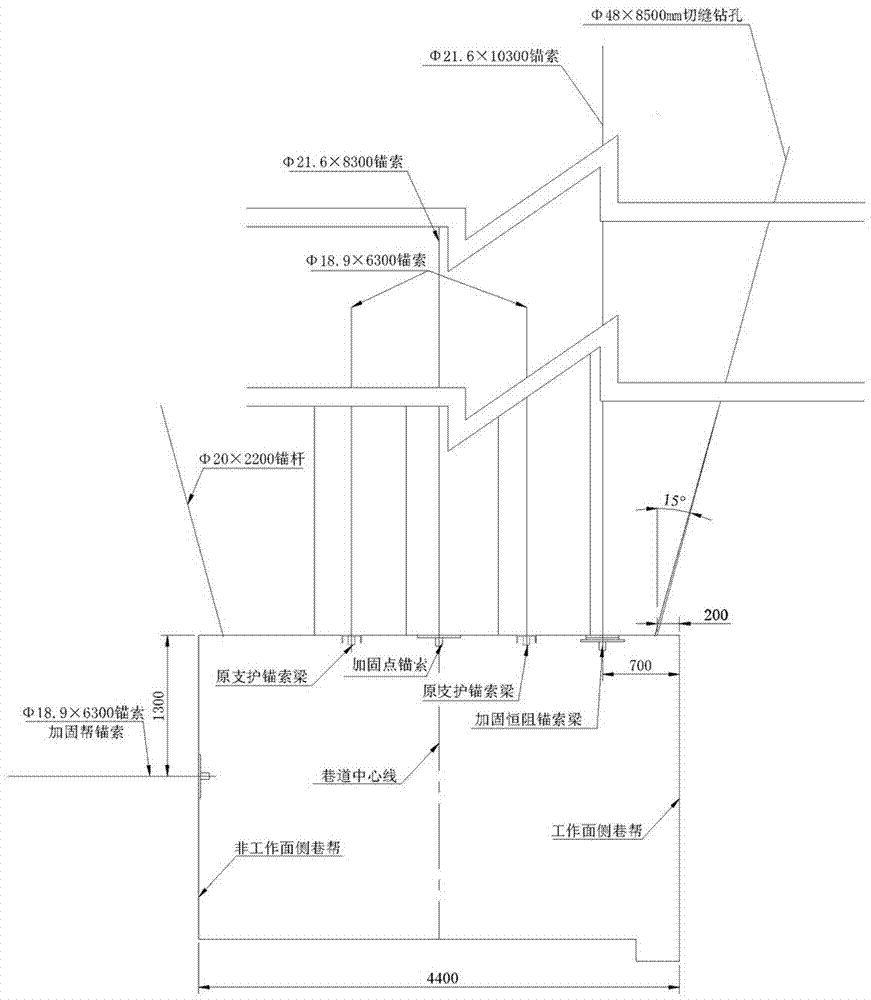

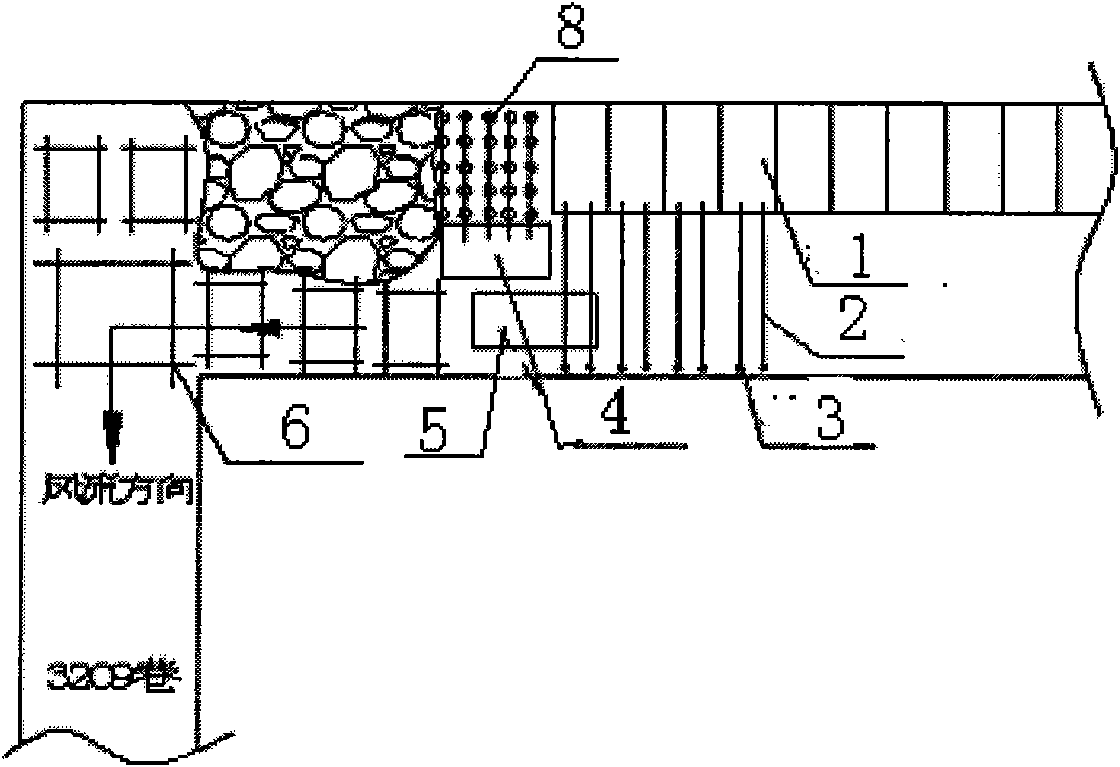

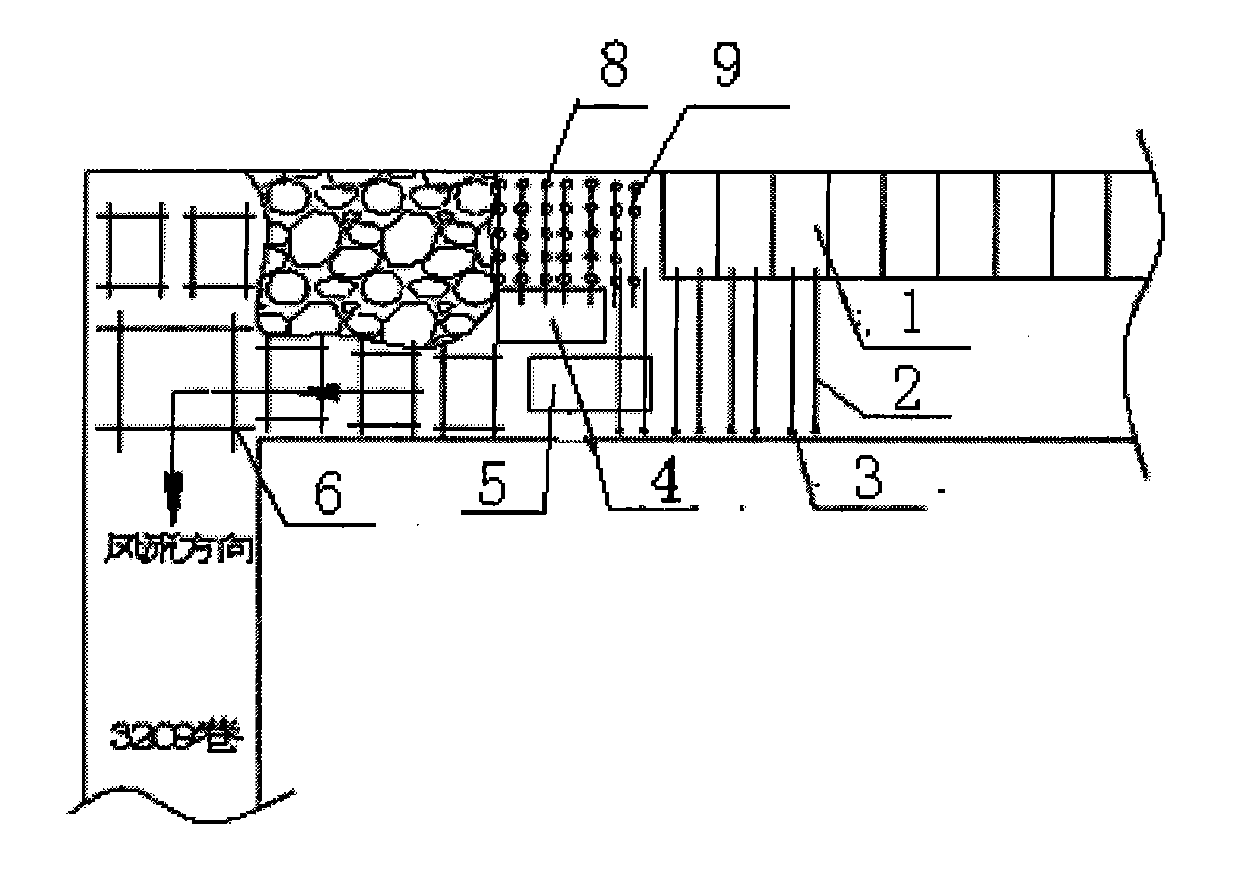

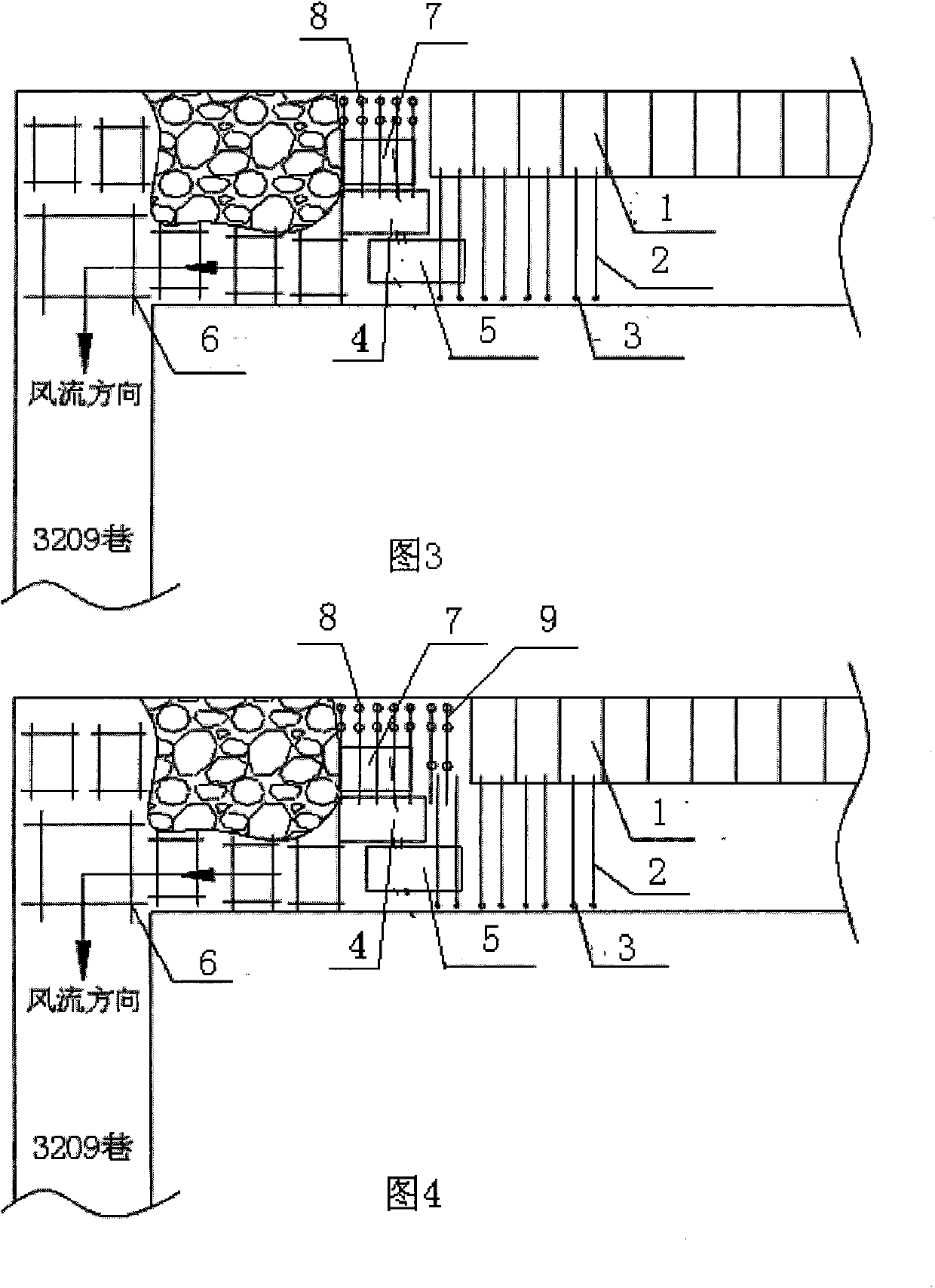

Gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method

ActiveCN107191208AImprove resource recoveryHigh recovery rateMine roof supportsMine roof capsResource recoveryStructural engineering

The invention relates to a gob-side-entry-retaining supporting method, in particular to a gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method. The method comprises the steps that a row of point-anchor rope reinforced roadway top plates are arranged in a roadway in the tunneling period, a row of point-anchor rope reinforced roadway ribs are arranged in the side roadway rib of the non-working surface, and a row of constant-resistance anchor rope beam reinforced roadway top plates are arranged on the position a certain distance away from the side roadway rib of the working surface; and according to the data changing situation of the mine pressure in a retained roadway in the period of backstopping of the working surface and the showing situation of the roadway mine pressure, an entry-in supporting area in the retained roadway is divided into an advance supporting area, a lagging supporting area, a roadway-forming to-be-stable area and a roadway-forming stable area. According to the gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method, through the successful practice of cross heading under the 21702 working surface, an excessive coal safety pillar with the width of 5 m is recycled compared with tunneling of an original gob-side entry driving, the coal resource recovery rate is improved, a solid foundation is laid for popularization of the gob-side entry retaining technology in other mining-area working surfaces of the whole mine, and a brand-new thinking is provided for the excavation-replacement layout of the whole mine.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

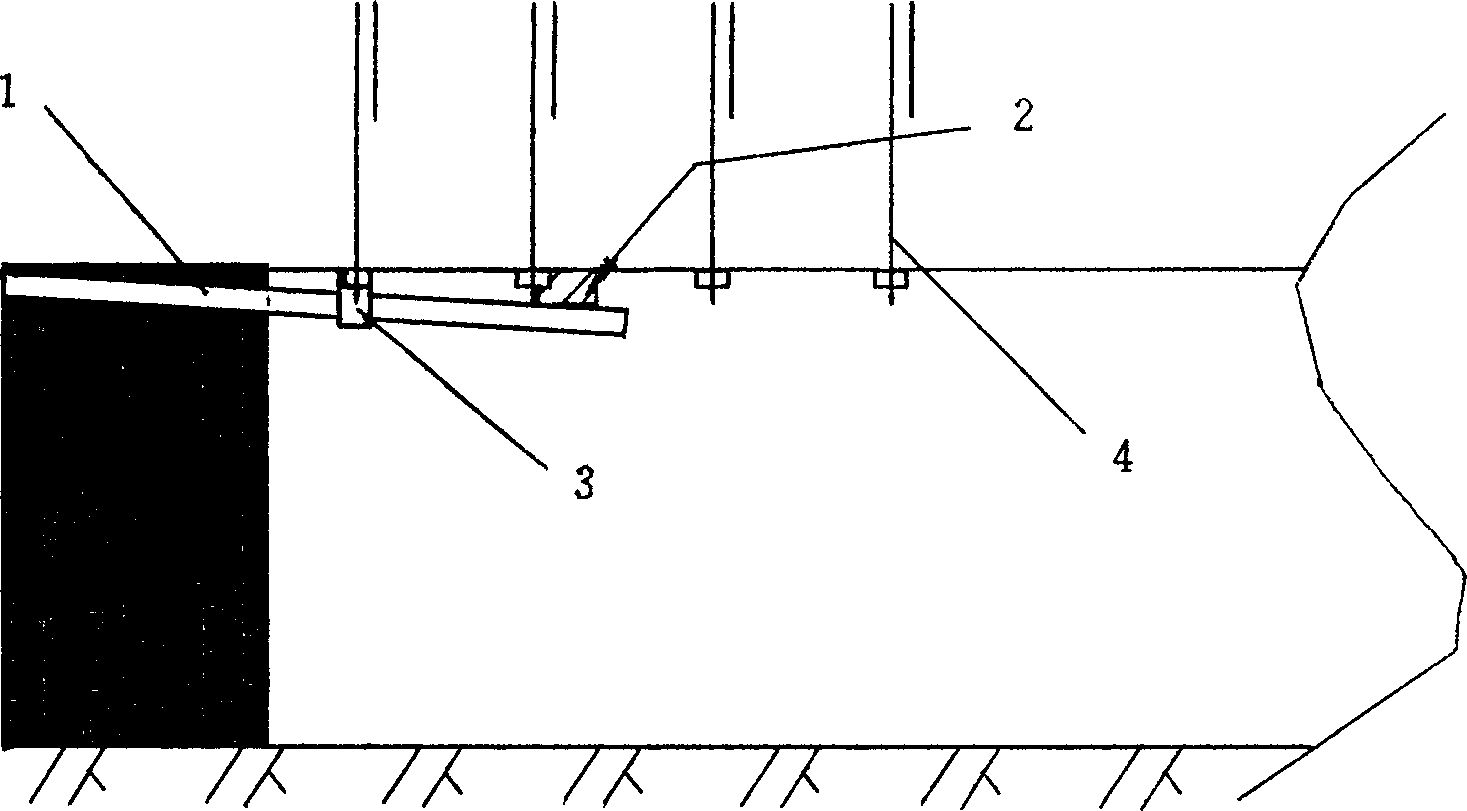

Method for tunneling coal bed repeated mining roadway in goaf

InactiveCN105649635ARealize advanced supportSolve the technical problems of effective supportUnderground chambersMine roof capsEngineeringCoal

The invention discloses a method for tunneling a coal bed repeated mining roadway in a goaf. The method is characterized in that on the basis of performing roadway roof support by adopting steel sheds, the steel sheds, a pre-drilling beam and a pre-drilling steel chisel are organically combined for realization; in the tunneling process, a roadway roof is subjected to advance support; in the construction process, the pre-drilling steel chisel is matched with the hanging type pre-drilling beam to perform temporary roof support. According to the method disclosed by the invention, the technical difficulty of the effective roadway roof support when the repeated mining roadway in the goaf is tunneled and blasted is solved; the integrity of the tunneling working surface roof is ensured, the rapidity and the safety of coal bed repeated mining roadway tunneling in the goaf are realized, and the tunneling cost of the repeated mining roadway is reduced. A combined tool used in the invention is simple in structure, simple and convenient to disassemble and assemble, easy to process and manufacture and good in practicability. The method disclosed by the invention has the advantages of being low in running cost, good in safety and good in market promotion and application prospect.

Owner:SHANDONG UNIV OF SCI & TECH

Repeatable energy absorption roadway anti-impacting hydraulic supporting frame and anti-impacting method thereof

ActiveCN108708759AImproving the method of prevention and control of rock burstImprove technical levelMine roof supportsMine roof capsEnergy absorptionEngineering

The invention discloses a repeatable energy absorption roadway anti-impacting hydraulic supporting frame and an anti-impacting method thereof. A repeatable energy absorption device is arranged in a box-type top beam, and the repeatable energy absorption device is composed of a cylinder body containing a lead body and a sliding rod with a damping block. During the supporting protection of a roadway, when the roadway is under the impacting of a top plate, the sliding rod along with the damping block and the lead body move to each other in the cylinder body to rapidly absorb and consume impactingenergy, the impacting on a whole supporting frame structure generated by the top plate is weakened, the destruction of the supporting frame and the failure of the supporting protection of a whole supporting protection system are prevented, and after energy is absorbed through deformation, the top beam can be turned for 180 degrees, assembled and repeatedly used. According to the above structuraldesign and using method, the anti-impacting hydraulic supporting frame which can repeatedly absorb energy is provided, and the technical problems of inconvenient replacement, high using cost and largeenergy absorption limitation due to the fact that an energy absorbing device can only absorb energy for once are solved.

Owner:LIAONING UNIVERSITY +2

Roadway safety protection support

PendingCN110017158ASolve the problem of prone to collapseImprove work efficiencyMine roof capsProps/chocksEngineering

The invention relates to a roadway safety protection support, comprising a cross beam and two supporting legs which are used for supporting the left end and the right end of the cross beam respectively and are independently adjustable in height. The cross beam is fixedly connected with the supporting legs; a vault plate assembly is mounted on the cross beam; each supporting leg comprises a base, astand column, a fixed box and a first limiting column, the stand column is vertically and fixedly installed on the base, the stand column is upwards inserted into the fixed box and is in up-down sliding connection with the fixed box, a plurality of first limiting holes are vertically formed in the upper portion of the stand column at intervals, in the installation state, and the first limiting column penetrates through one side wall of the fixed box and is inserted into one first limiting hole to achieve relative fixation of the stand column and the fixed box; and the supporting legs are fixedly connected with the left end and the right end of the cross beam through the fixed box. The roadway safety protection support can adapt to the installation environment with the uneven ground in a mine and cannot collapse due to the uneven ground.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

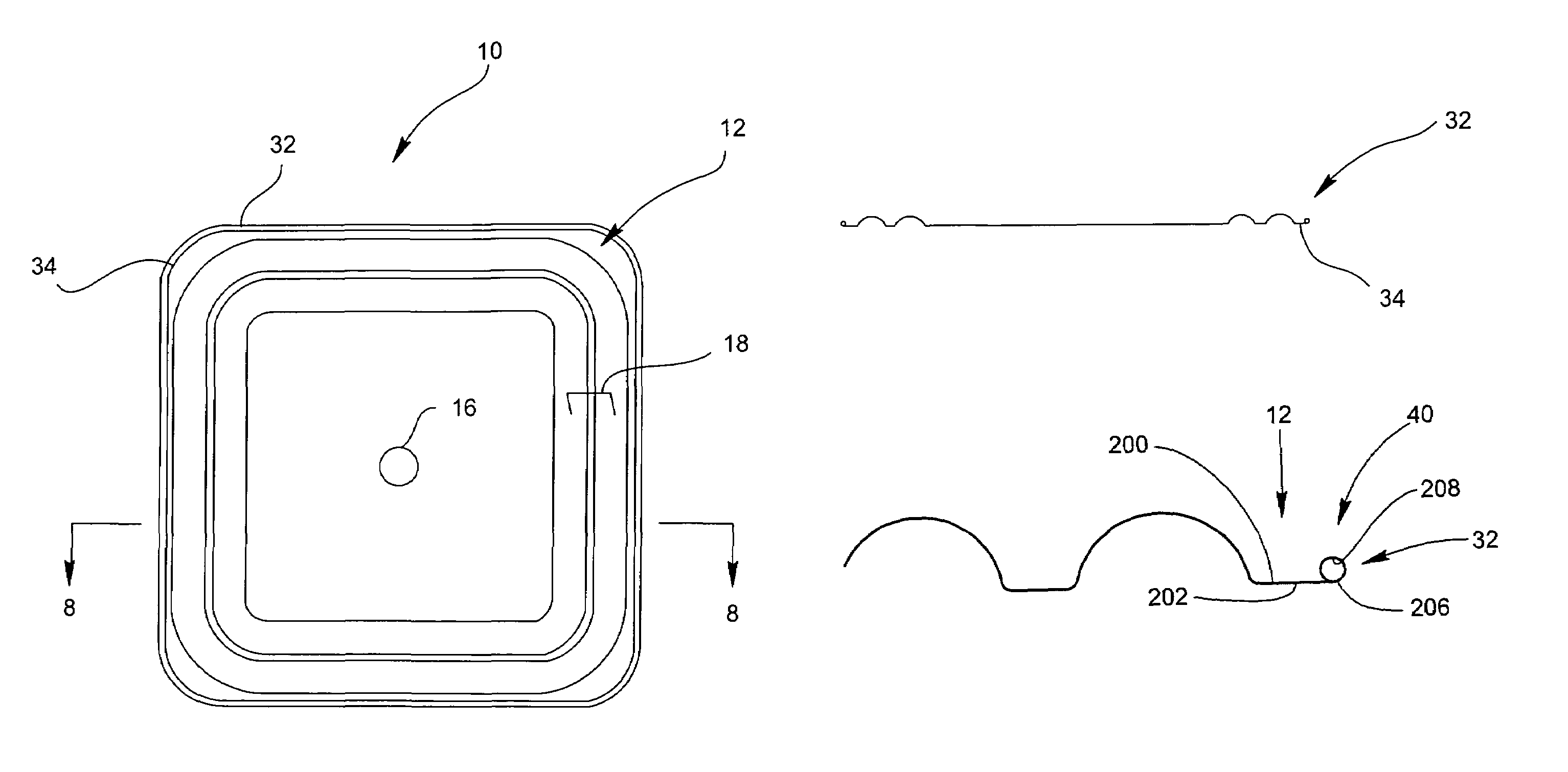

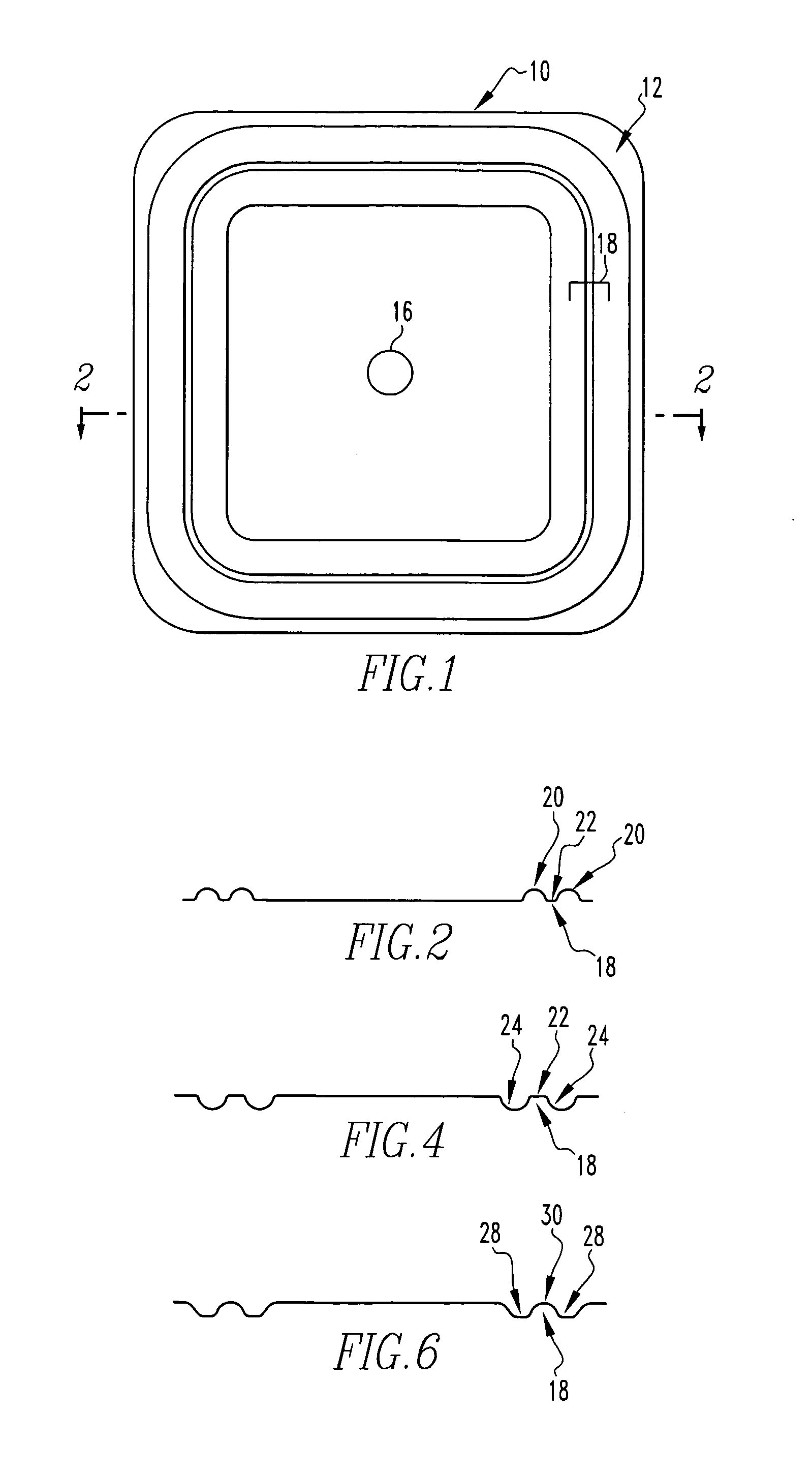

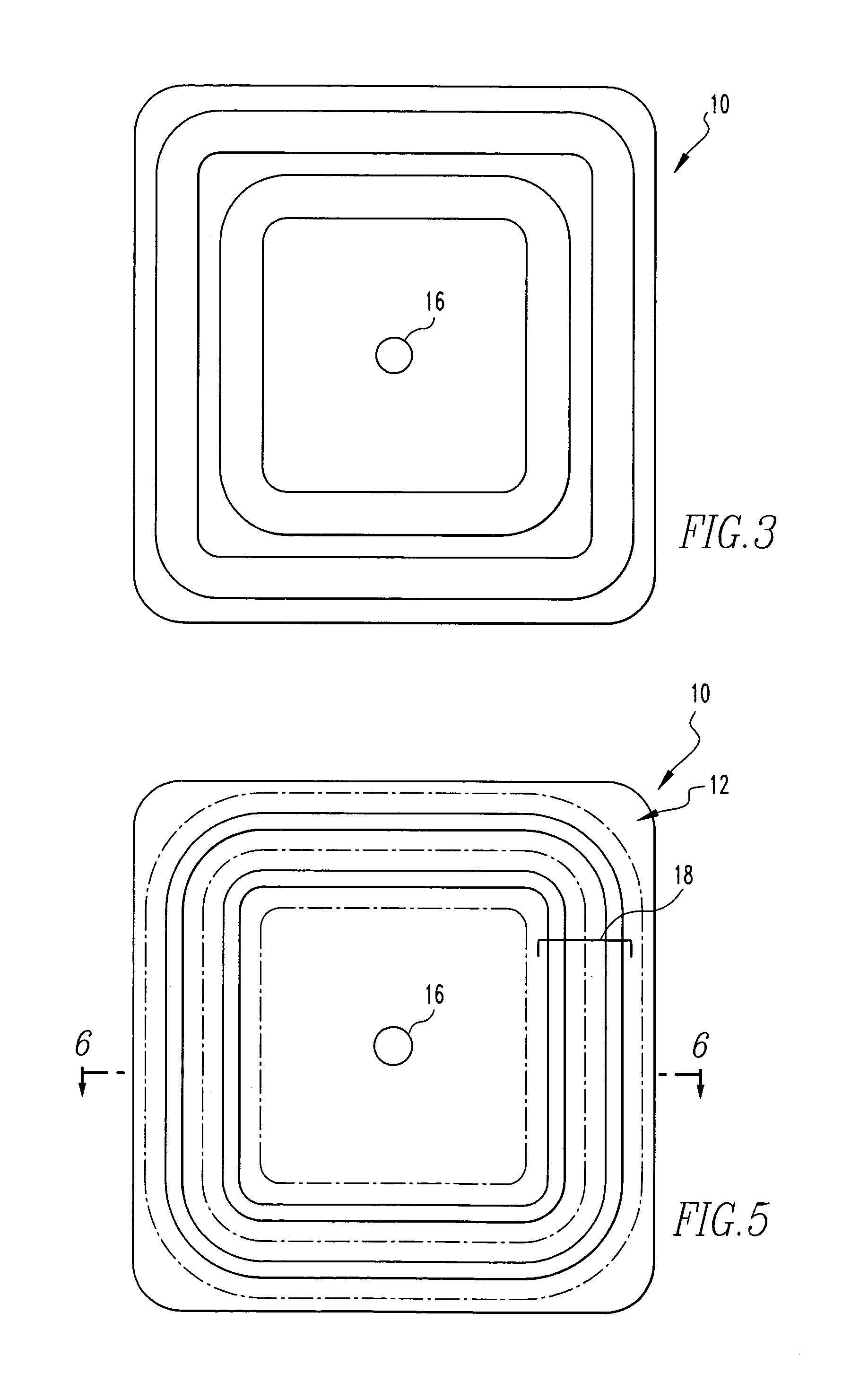

Square embossed roof and rib plate

Disclosed is a mine roof and rib support system generally including a square bearing plate. A through hole is positioned near a center portion of the square bearing plate. A peripheral section at least partially circumscribes the bearing plate. In between the through hole and the peripheral section is a rib member area. The rib member area may include two rib members with a convex cross-section connected by a substantially linear surface member disposed between the two rib members, two or more concave ribs with a substantially linear surface member disposed between the two rib members, or two substantially linear surfaces connected by a convex rib member. A safety edge surrounds the square bearing plate. The safety edge may be a rolled edge, a looped edge, a folded edge, or another comparable edge. Also disclosed is a method for making the mine roof and rib support system.

Owner:FCI HLDG DELAWARE

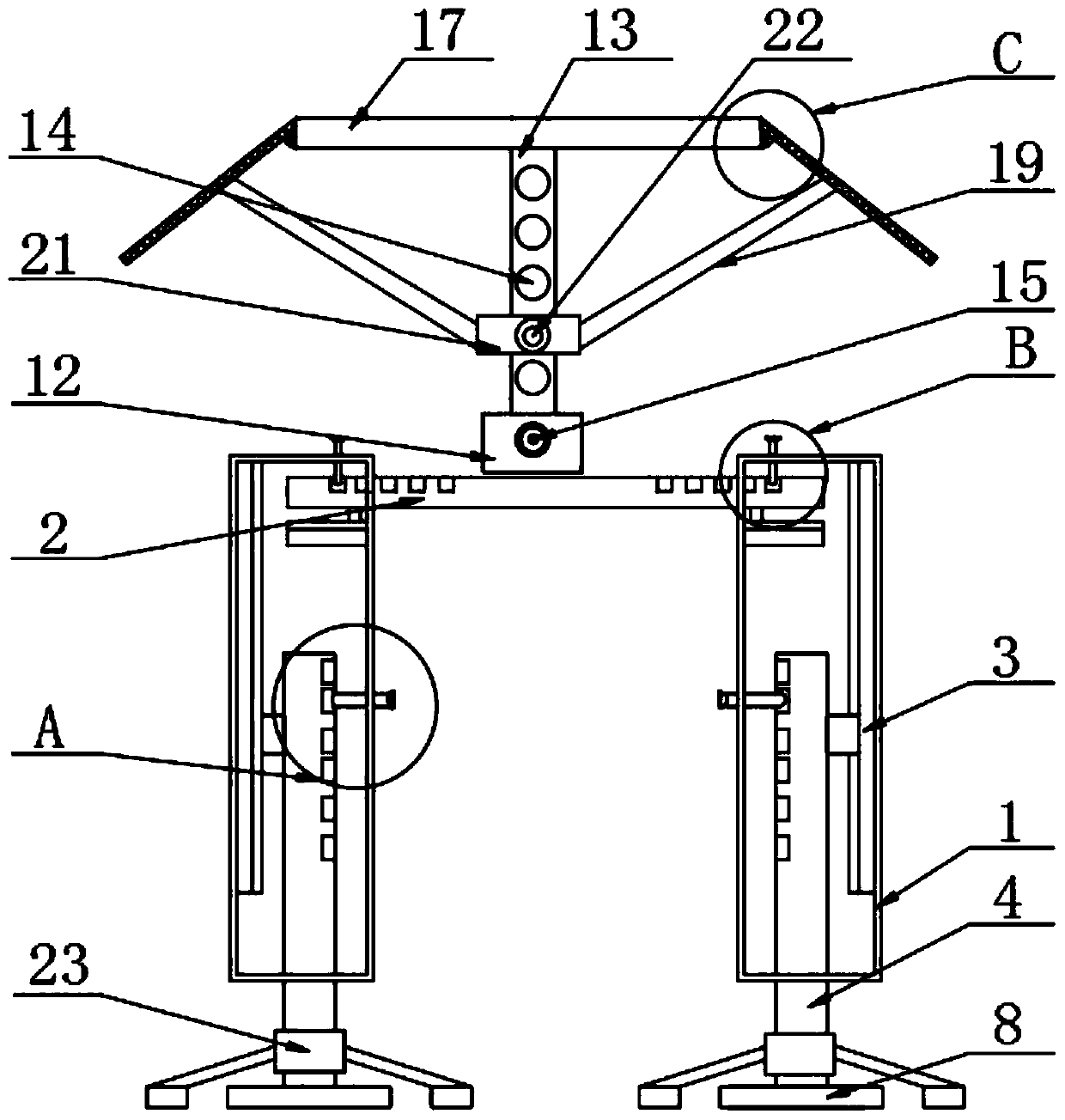

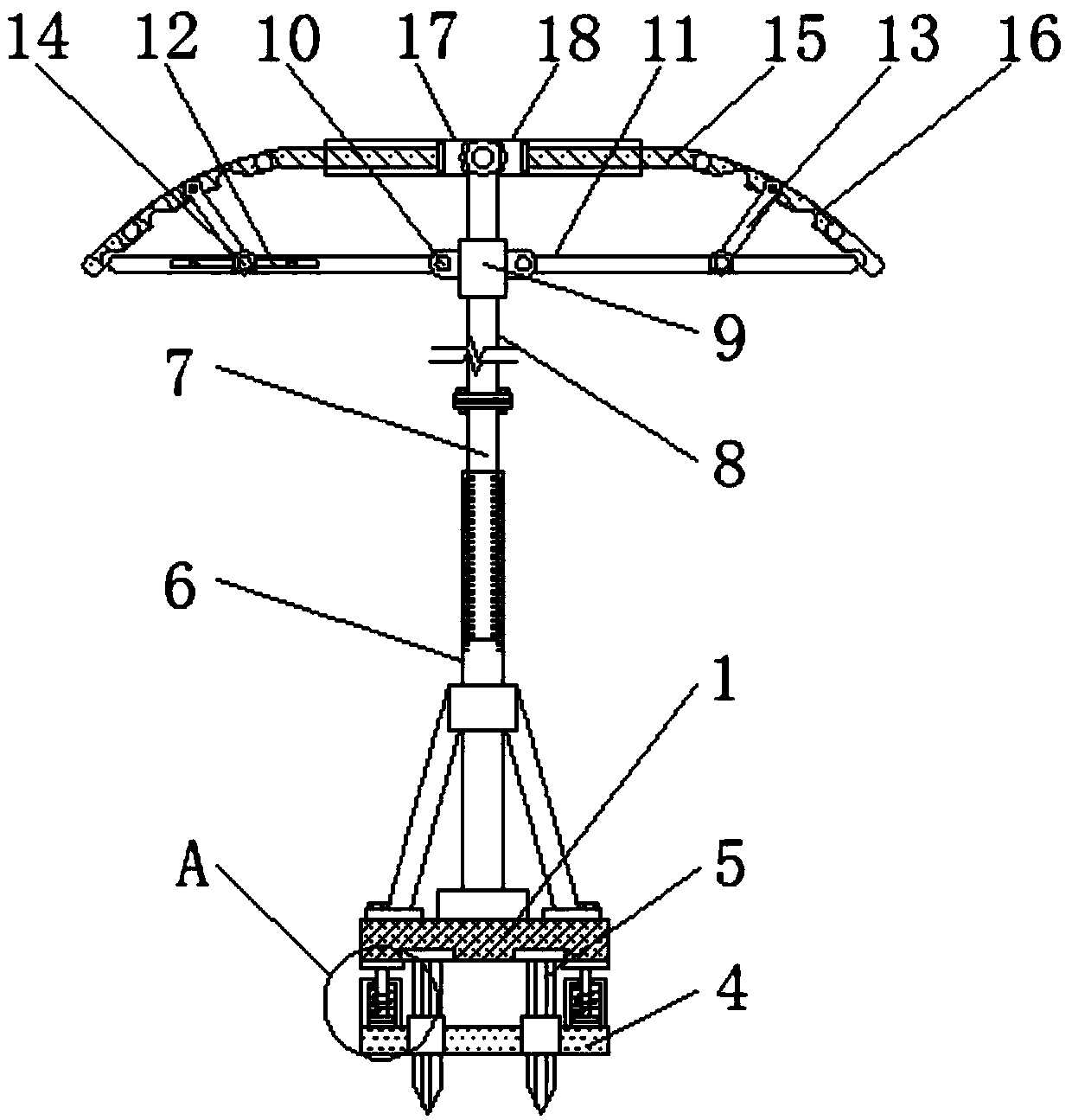

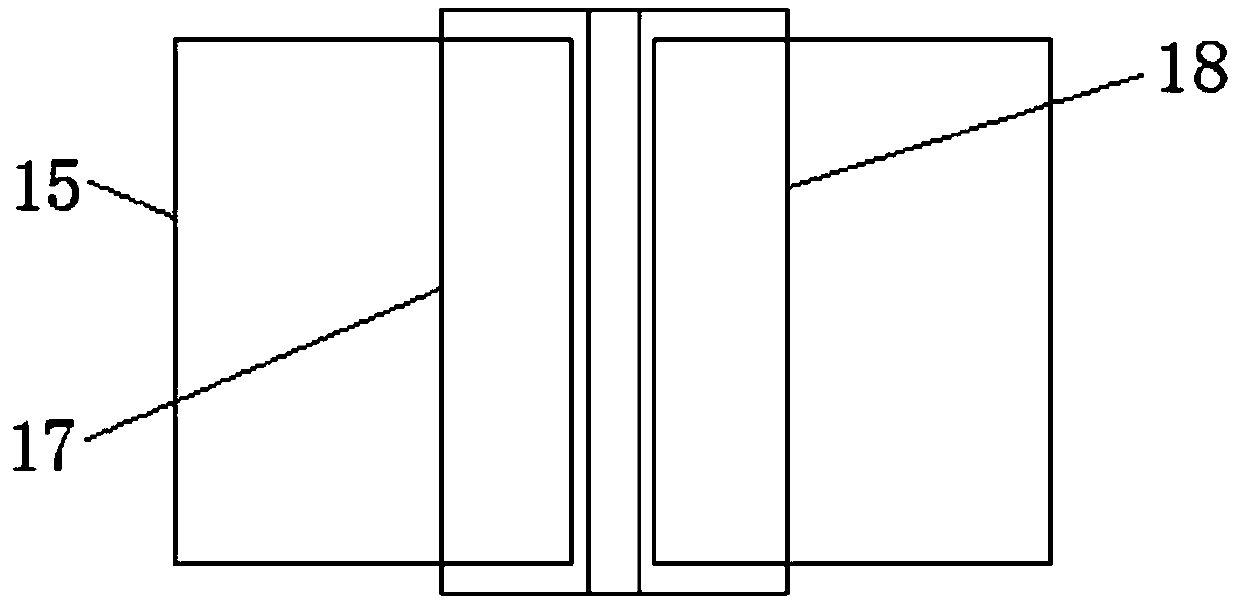

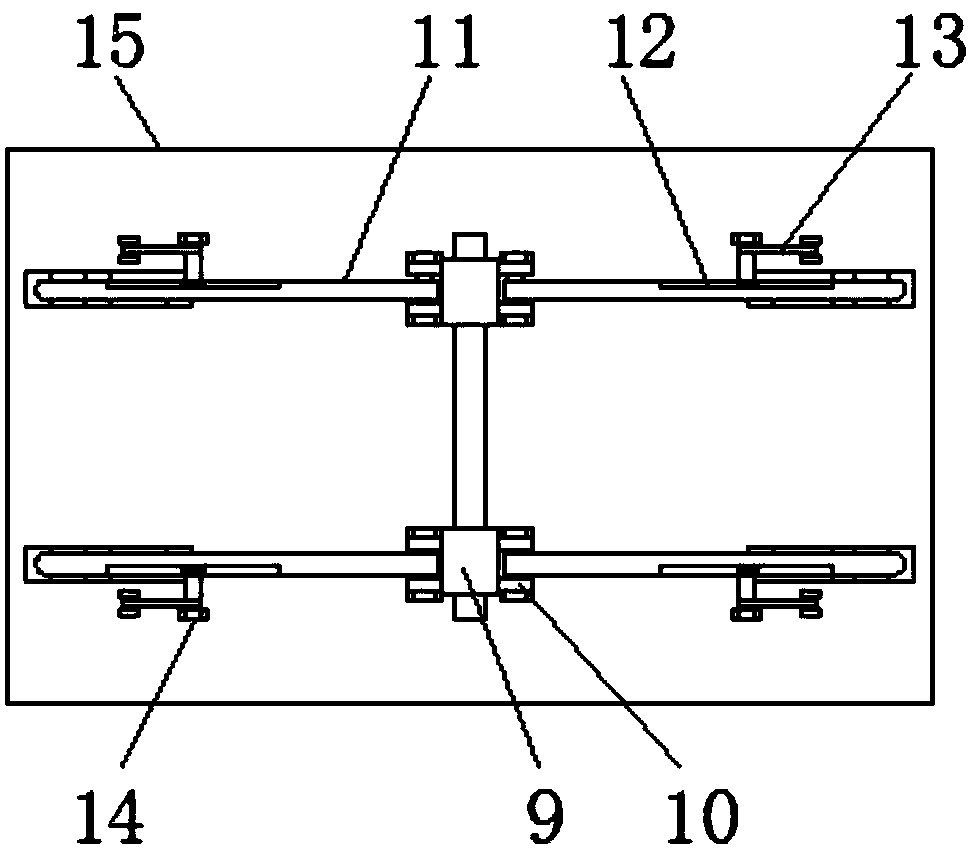

Umbrella-shaped point pillar type temporary support for coal mine roadway

The invention discloses an umbrella-shaped point pillar type temporary support for a coal mine roadway. The umbrella-shaped point pillar type temporary support comprises a base, first buffer rods arefixed to the bottom of the base, and fixed panels are fixed to the bottoms of adjusting blocks; a fixed rod is fixed to the upper portion of the base, a second connection rod is connected with the upper portion of a first connection rod, and connection blocks are fixed to the outer side of a nested block; adjusting rods are connected with the interiors of the connection blocks, sliding grooves areformed in the outer sides of the adjusting rods, and fastening blocks are connected with the bottoms of limit rods; a supporting groove is formed in an umbrella-shaped supporting panel, a first connection panel is connected with the right side of the umbrella-shaped supporting panel, and a second connection panel is connected with the right side of the first connection panel. The umbrella-shapedpoint pillar type temporary support for the coal mine roadway is convenient to mount and fix, the supporting area can be effectively adjusted, and the temporary support can be effectively and stably fixed at a suitable position.

Owner:GUIZHOU UNIV

Method for supporting tunnel roof below mined-out area

InactiveCN102155249AIncrease the areaStrong watch protectionMine roof capsAnchoring boltsShortest distanceHigh pressure water

The invention relates to a method for supporting a tunnel roof below a mined-out area. In the method, steel belt combination hydraulic power expansion anchor rods are used for supporting the tunnel roof below the mined-out area. The method comprises the following steps of: erecting temporary supports for the tunnel roof dug out below the mined-out area and at both sides of the tunnel roof, laying a metal net and a steel belt on the roof so as to lead the steel belt to push down the metal net, using a single prop to support the steel belt, and punching holes and drilling holes on the tunnel roof through orifices of the steel belt; then sequentially placing the hydraulic power expansion anchor rods in boreholes, leading the steel belt to be clung to a top plate by a tray, injecting high pressure water with the pressure of 20 to 22MPa into the hydraulic power expansion anchor rods one by one, wherein the liquid injection time for each steel belt combination hydraulic power expansion anchor rod is not less than 2min; and repeating the steps till finishing the support of the tunnel roof below the mined-out area. The method solves the difficult problem that a traditional resin anchoring anchor rod can not be anchored in the mined-out area and can not effectively support the top plate of the tunnel roof below the mined-out area at a very short distance; and the method has simple process and is convenient to operate.

Owner:CHINA UNIV OF MINING & TECH

Single-column type advance support device of blasting work surface

Owner:徐州徐工精密工业科技有限公司

Advanced supporting and protecting technology for cracked top plate of digging operation face

InactiveCN1580491AImprove support strengthImprove securityMine roof capsEngineeringUltimate tensile strength

An early support and protect technology for a dug-working-face broken-head plate includes the following steps: 1. closing to the head plate to determine the drilling position avoiding normal support, 2. carrying out wet drilling with large diameter cone driller driven by electric coal or wind coal drillers before exposing the head plate, its diameter is greater than the outward diameter of the from beam cross section and hole depth is larger than the cyclic length. 3. plugging the steels making the front beam or hinged bar into the front holes, 4. supporting or fixing the end outside of the hole of the front beam and fastening it with die square wood or wedges, which turns the early support from passive to active and increases the support strength, stability and reliability.

Owner:新汶矿业集团汶南煤矿有限责任公司

Method for supporting triangular area in coal mine support-dismantling process

ActiveCN102003188AReduce physical exertionGood effectUnderground chambersMine roof capsRecovery methodEngineering

The invention relates to a moving and recycling method of comprehensive collecting equipment, in particular to a method for supporting a triangular area in a coal mine support-dismantling process and solves the problem of low efficiency of a maintenance method of a support-dismantling space top plate in a support-dismantling process of the traditional comprehensive collecting working face. Three shielding frames are arranged at the original triangular area; after a support is dismantled, two frame canopies are arranged at the place of the original support in a direction vertical to the shielding frames; three columns are used for supporting; plate beams are used for supporting above a single column, and then the shielding frames are drawn, wherein the drawing sequence of the shielding frames is that: the shielding frame close to a coal upper side is drawn firstly to bear the plate beams on the front ends of the supports to be dismantled, after chocks are piled behind the shielding frame and the shielding frame is returned to the back of a coal upper column, the middle shielding frame is drawn secondly to make the ends of the beams bear the plate beams in the triangular area, and the shielding frame close to an old pond side is drawn finally to bear the plate beams; and after an old pond and the single column affecting the dismantling of the support are returned back, the supporting and circulating process of shielding the support is finished. By the method, the working efficiency is improved and materials are saved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com