Truss supporting technology for ingredient top slope deformation control

A technology of coal rock and truss, which is applied to support the roof beam of the mine roof, mining equipment, earth square drilling and mining, etc., and can solve problems such as safety accidents, roof separation deformation, and roof shearing and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

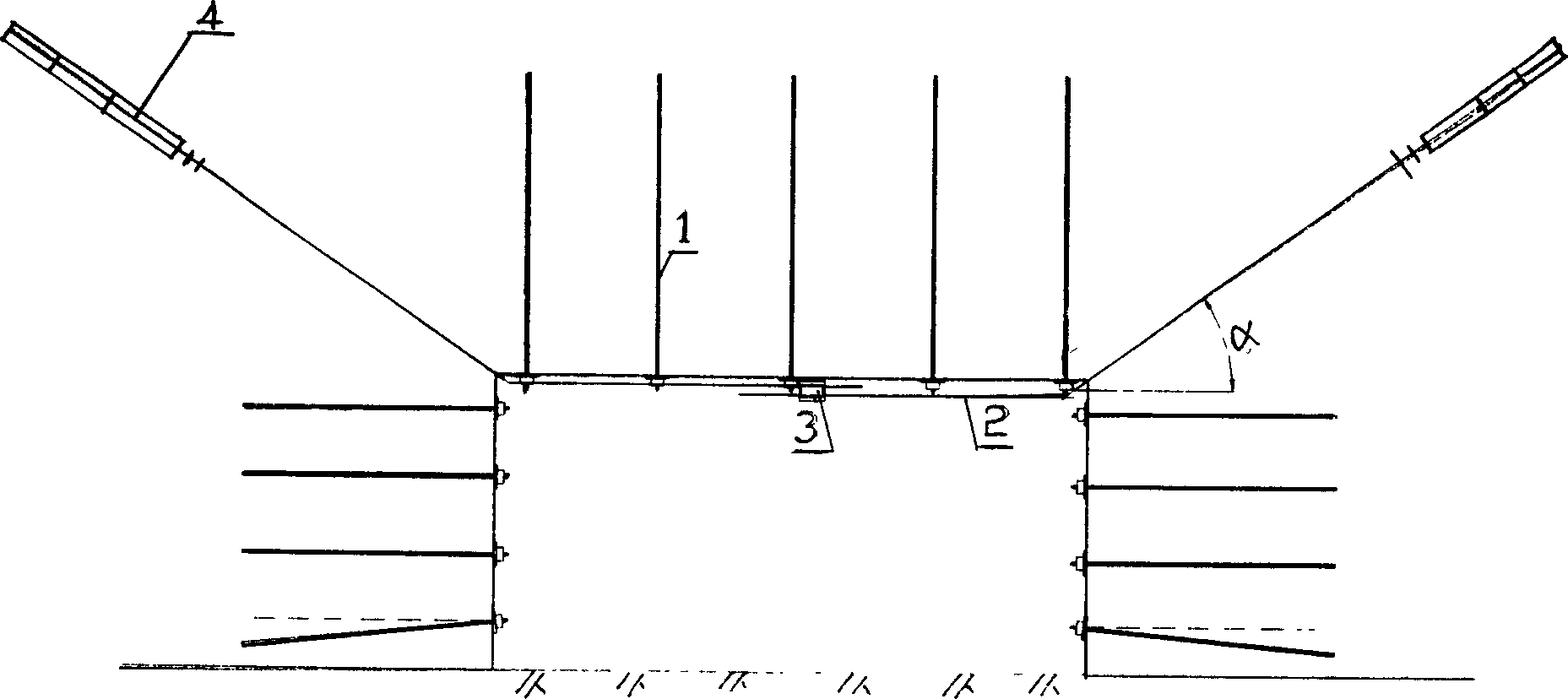

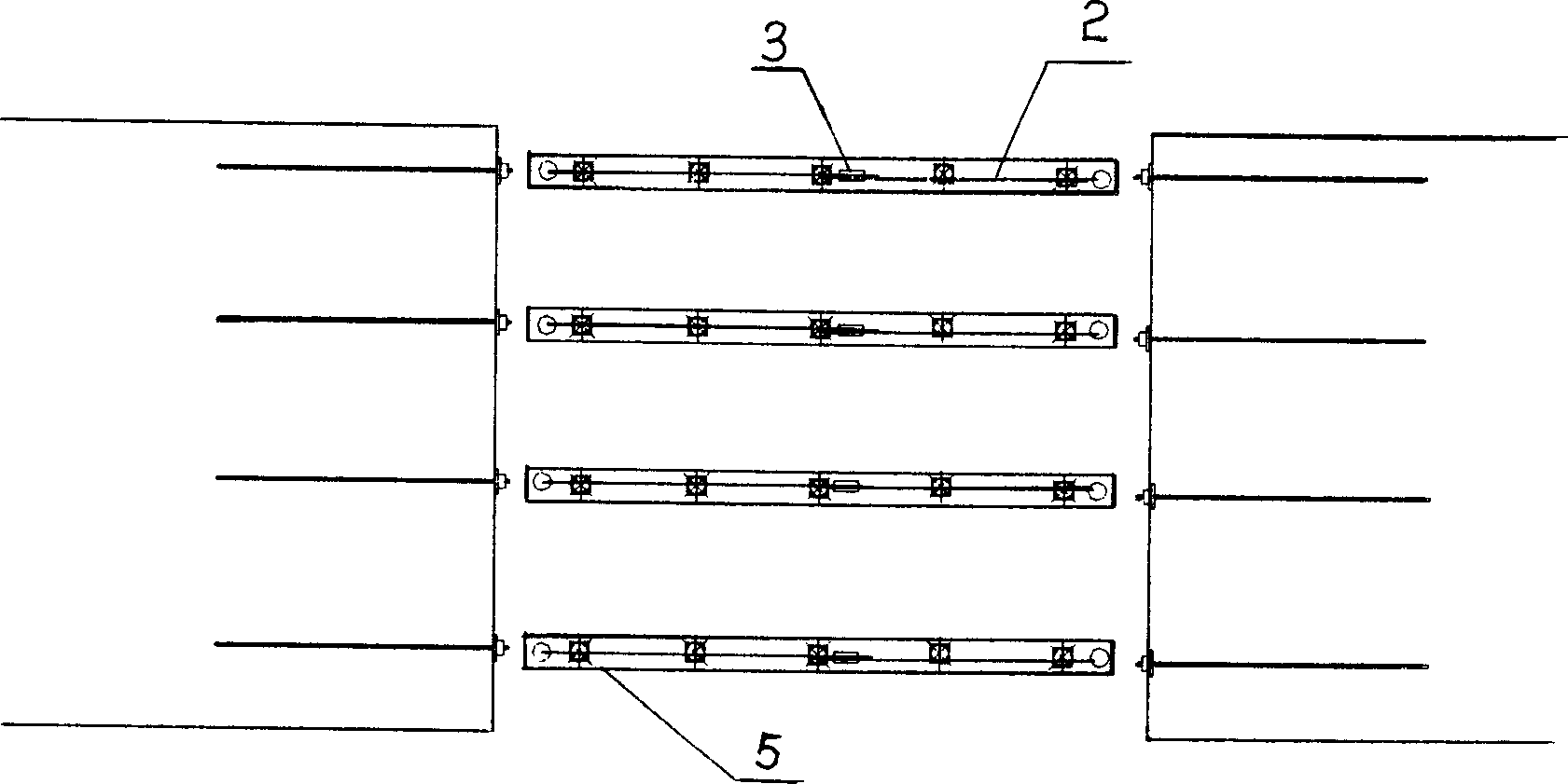

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

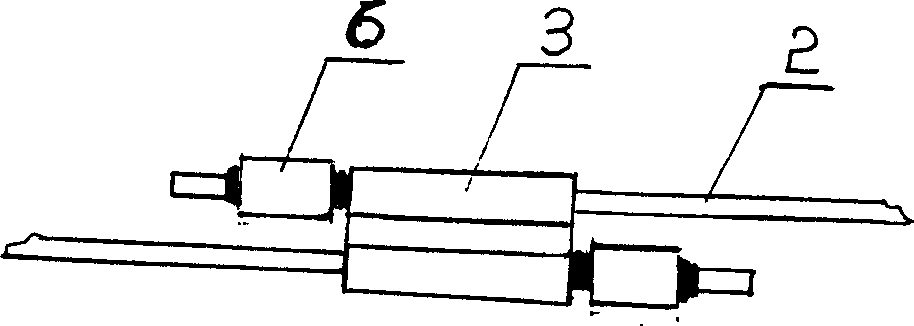

[0017] The present invention is a truss support technology for controlling the deformation of the coal-rock roof. While using bolts and cables to support the coal-rock roof or the roadway side, a plurality of two A truss composed of a steel hinge wire 2 and a double-hole steel sleeve connector 3 is used for support, and each truss is protected under an anchor body anchored by a steel belt 5 and an anchor rod 1, and the steel strand 2 passes through the anchor body steel The holes on both sides of belt 5 extend into the deep part of the coal rock roof or the side of the road to form prestress. Less than 3m, the tails of the two prestressed steel strands 2 are staggered through the double-hole connector 3 in reverse. The 6 tensions are fastened to form a squeeze protection effect on the coal rock roof or the side of the roadway, to control the roof separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com