Patents

Literature

4069results about How to "Meet production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

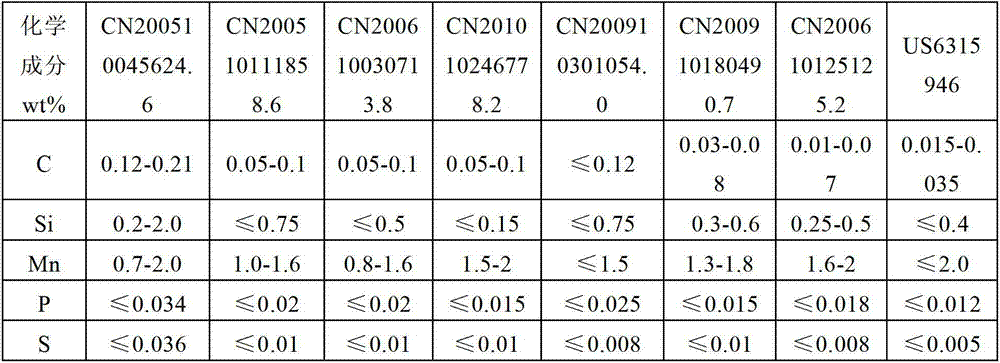

Hot galvanizing steel plate for car and production method thereof

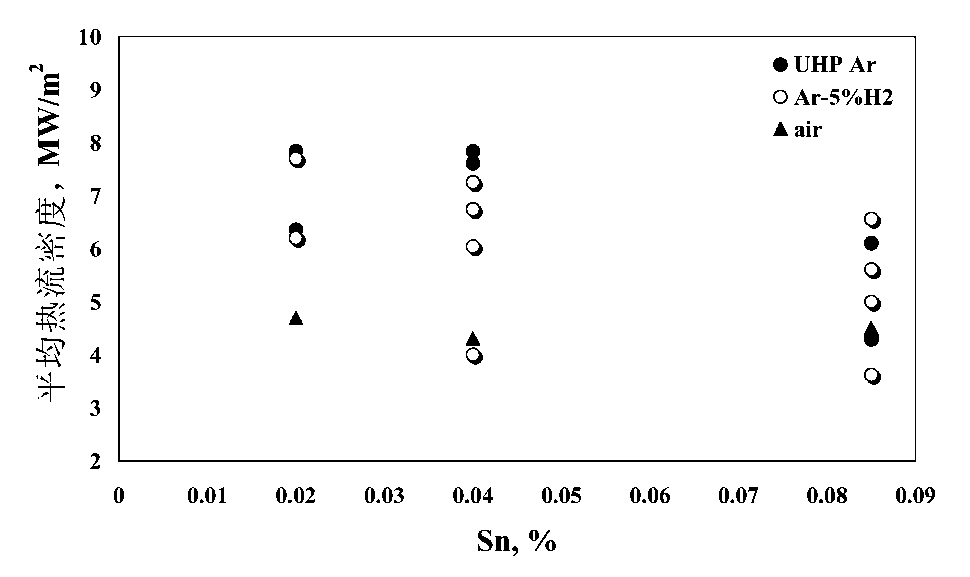

InactiveCN102839322AHigh work hardening indexHigh work hardening index n90 valueMetal rolling arrangementsSheet steelTrace element

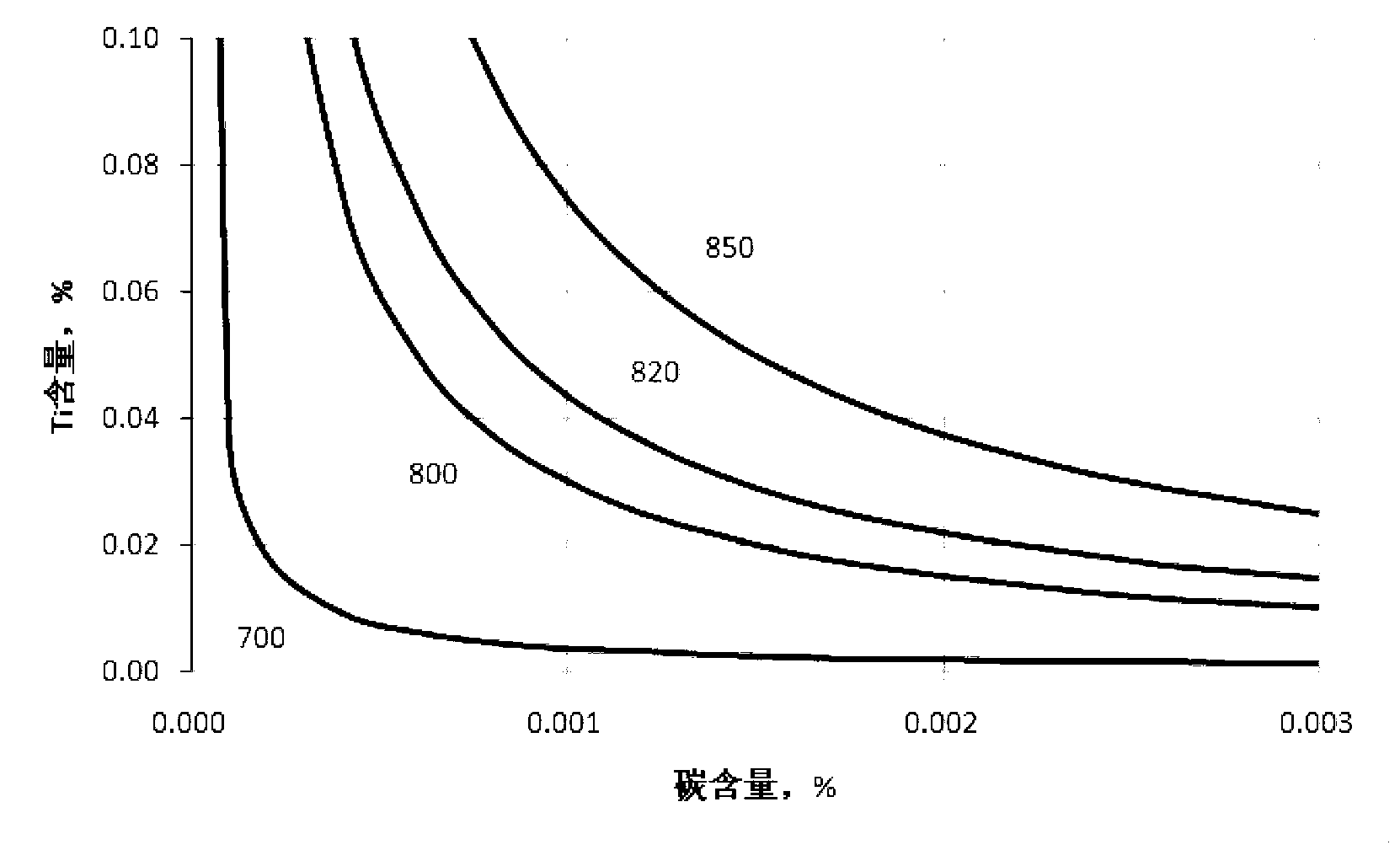

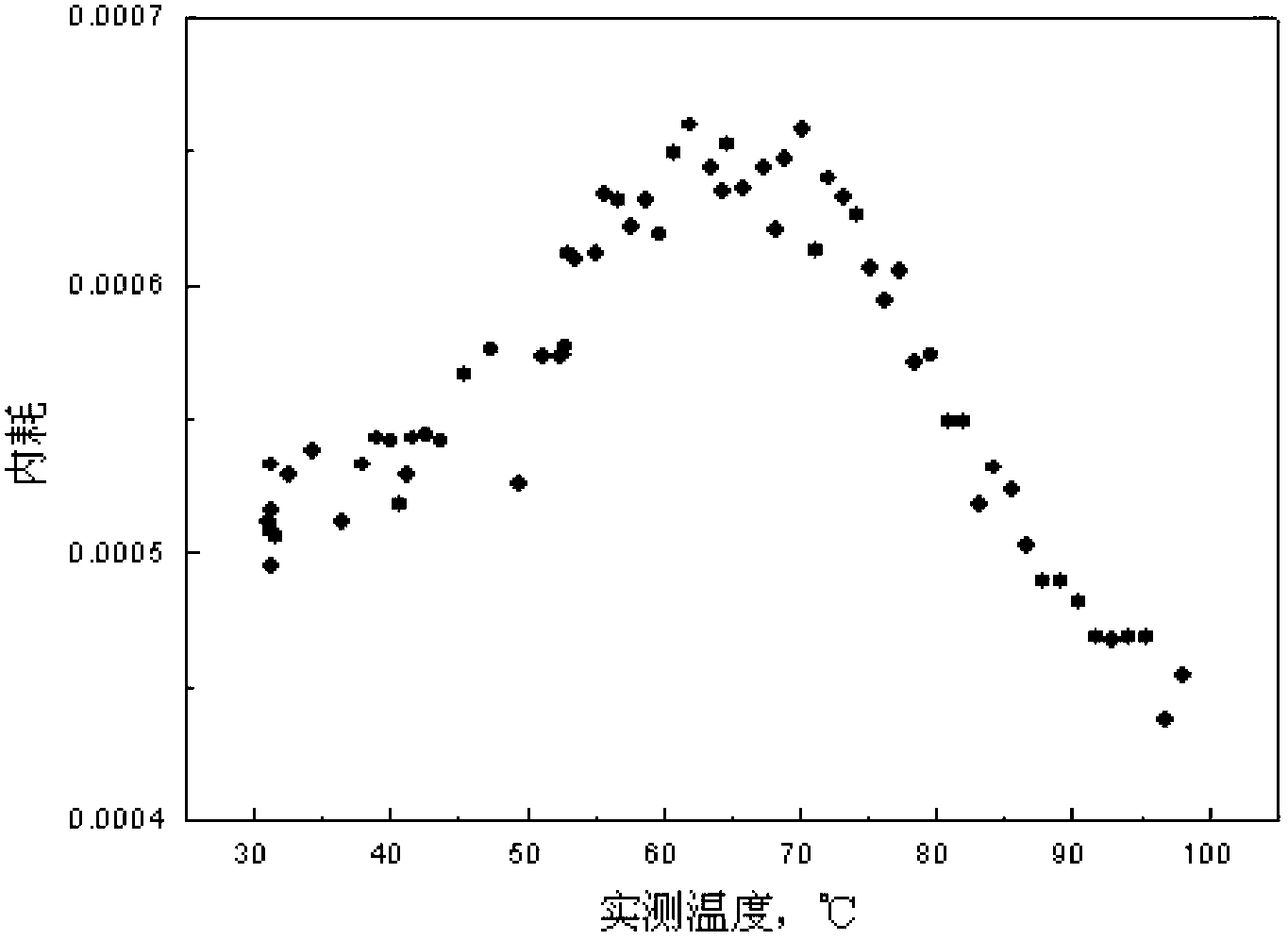

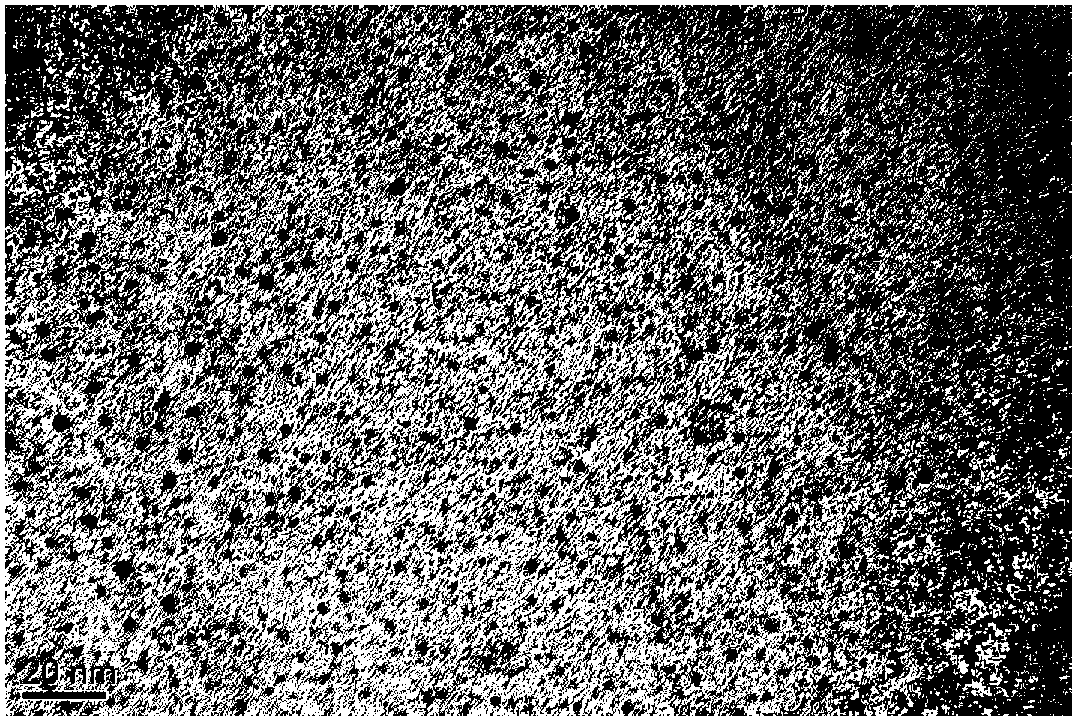

The invention discloses a hot galvanizing steel plate for a car. The hot galvanizing steel plate comprises the following chemical components by weight: C is more than or equal to 0.001% and is less than or equal to 0.003%, Mn is more than or equal to 0.05% and is less than or equal to 0. 15%, Si is less than or equal to 0.03%, P is less than or equal to 0.02%, S is more than or equal to 0.008% and is less than or equal to 0.015%, Alt is more than or equal to 0.02% and is less than or equal to 0.07%, Ti is more than or equal to 0.05% and is less than or equal to 0.09%, B is more than or equal to 0.0002% and is less than or equal to 0.010%, N is less than or equal to 0.004% and the balance of Fe and trace element. The invention also discloses a method for producing the hot galvanizing steel plate for the car; according to the hot galvanizing steel plate for the car and the production method of the hot galvanizing steel plate, the sulfur content in steel making can be adjusted based on the mixture ratio of components, and the technology of hot rolling, continuous annealing, hot galvanizing steel and finishing are optimized, thus producing the continuous annealing hot galvanizing steel, so that the steel plate has the characteristics of high processing hardening index of n90 value, and the requirements on demand of expanding-formed car plate are satisfied.

Owner:SHOUGANG CORPORATION

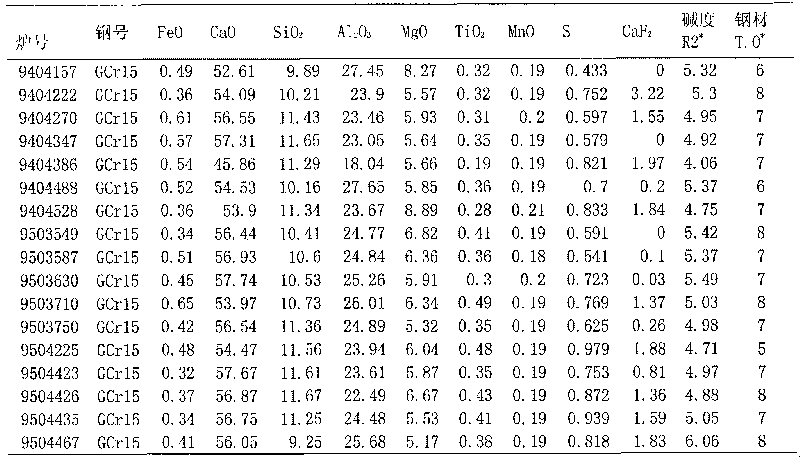

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

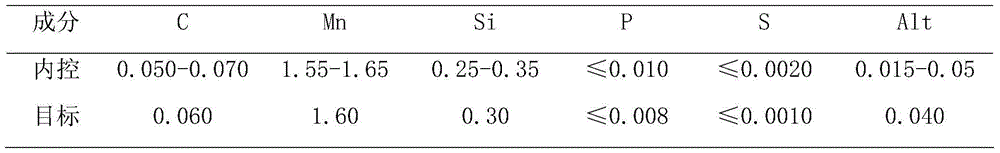

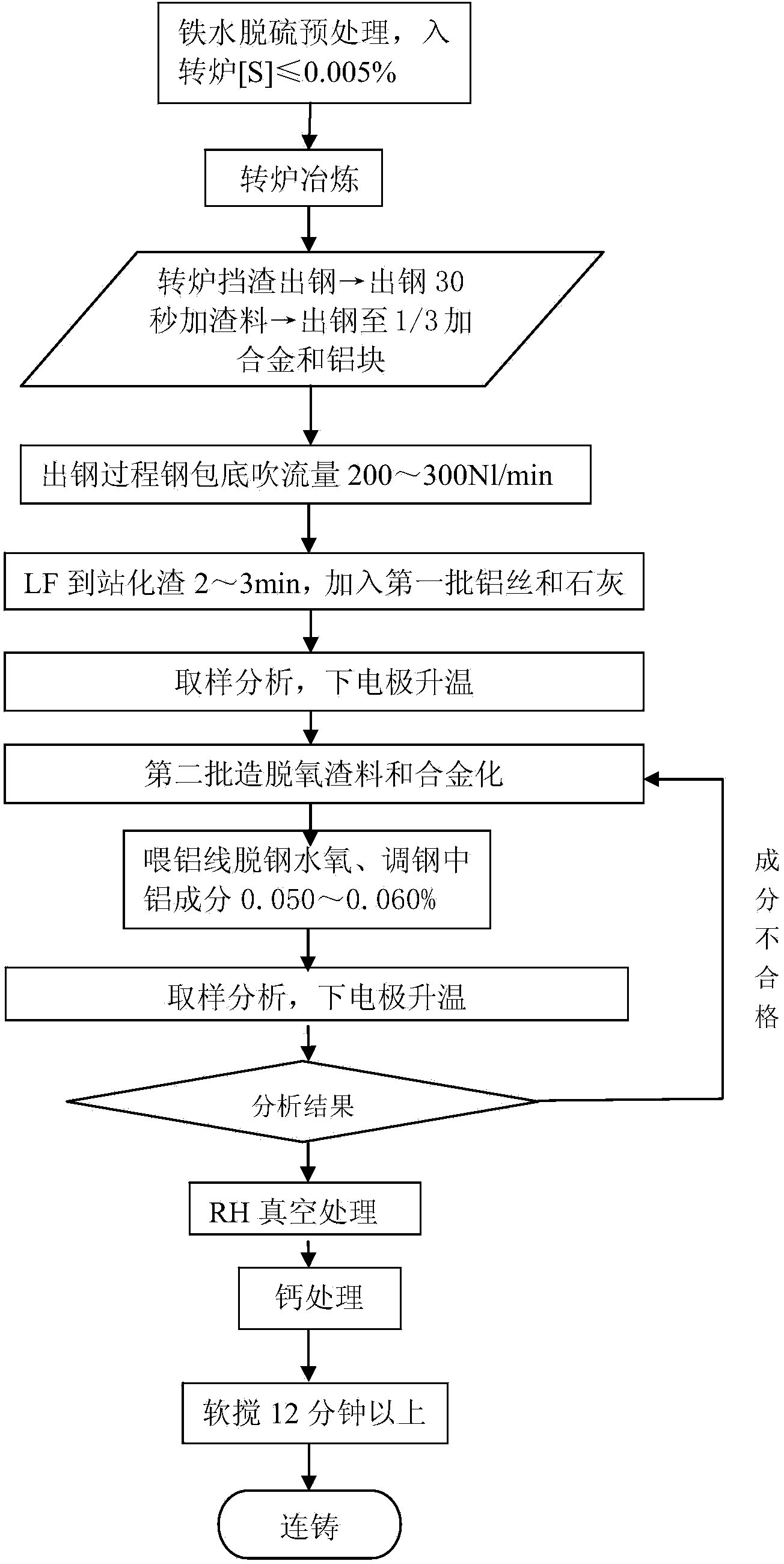

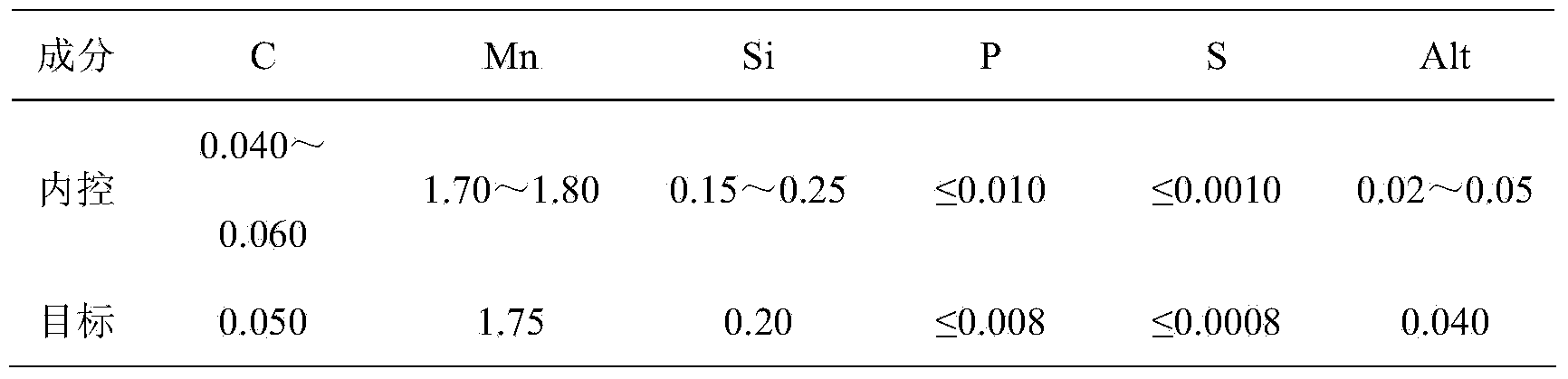

High-cleanliness pipeline steel smelting process

ActiveCN104630418ASolve the difficulty of cleanliness controlQuality improvementManufacturing convertersSulfurNon-metallic inclusions

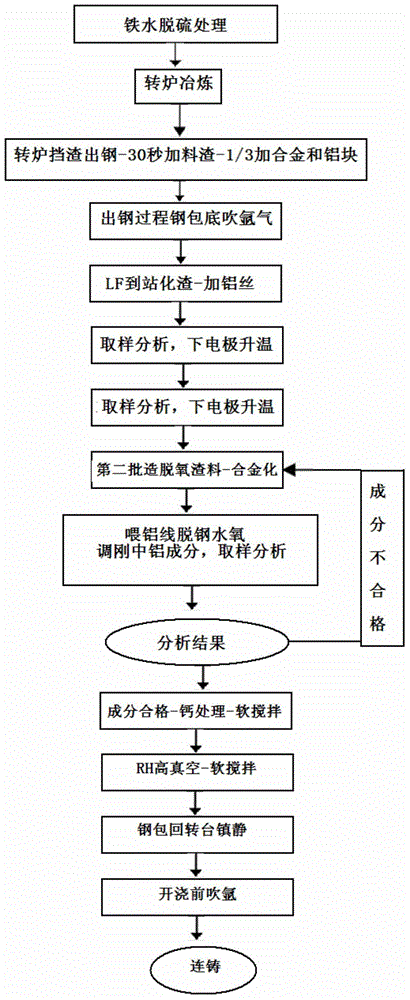

The invention discloses a high-cleanliness pipeline steel smelting process. The process route comprises molten iron pouring, molten iron pretreatment, converter smelting, tapping, deoxidizing, alloying, LF refining furnace, treating with calcium, RH vacuum furnace and continuous casting and is characterized by comprising the following specific steps: firstly, converter smelting process; secondly, refining furnace smelting process; and thirdly, continuous casting process. The invention belongs to a steel-making process in the field of metallurgy and relates to a method for smelting and controlling a high-cleanliness pipeline steel. By molten iron desulphurization pretreatment, optimizing a converter tapping and deoxidizing system and a slagging system, LF refining furnace deep deoxygenation and reducing slag manufacturing processes, RH high-vacuum-degree degassing and inclusion removal process, the pouring is protected by the continuous casting in the whole process so that the composition of a casting billet is uniform, the contents of harmful elements such as S, P, O, N and H are low, the non-metallic inclusions are effectively controlled, the casting billet is good in internal quality and the production of high value-added ultra-low sulfur steel is ensured.

Owner:NANJING IRON & STEEL CO LTD

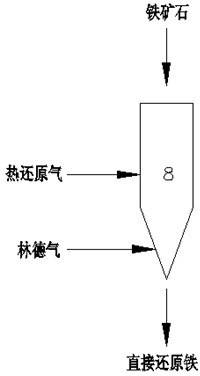

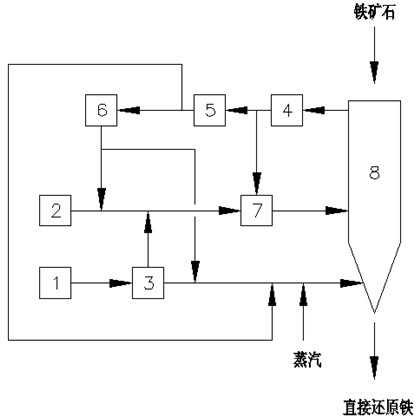

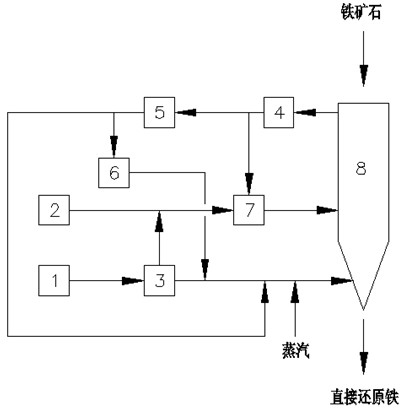

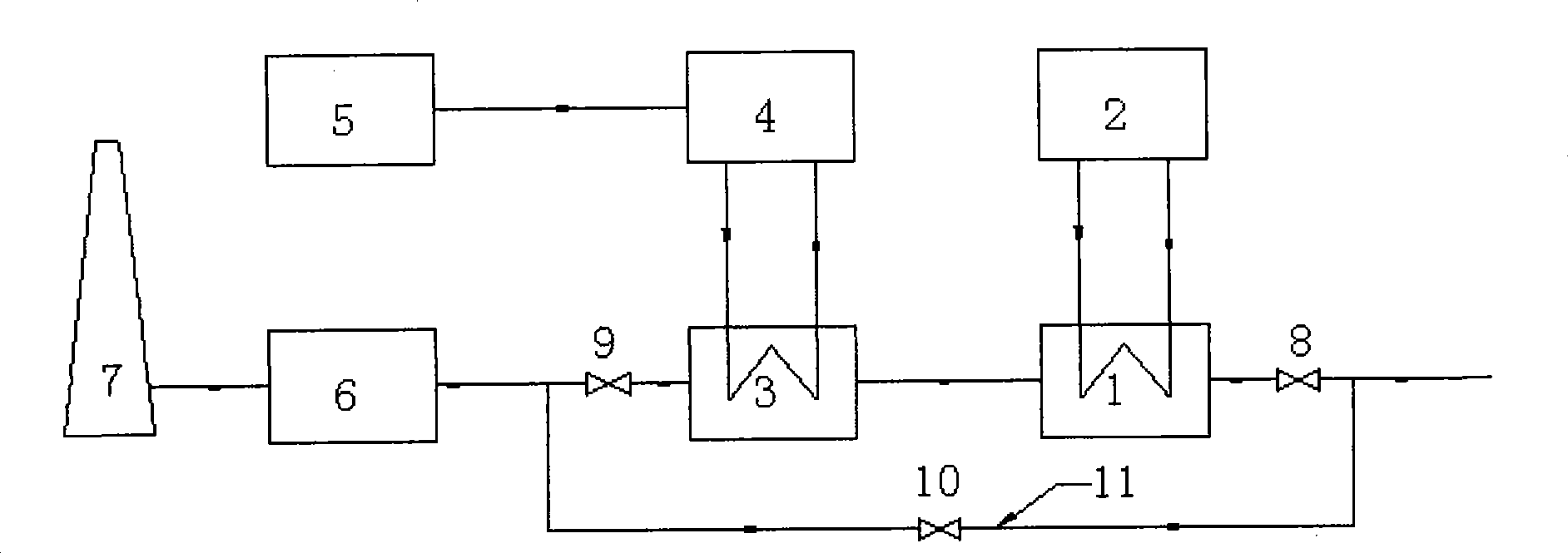

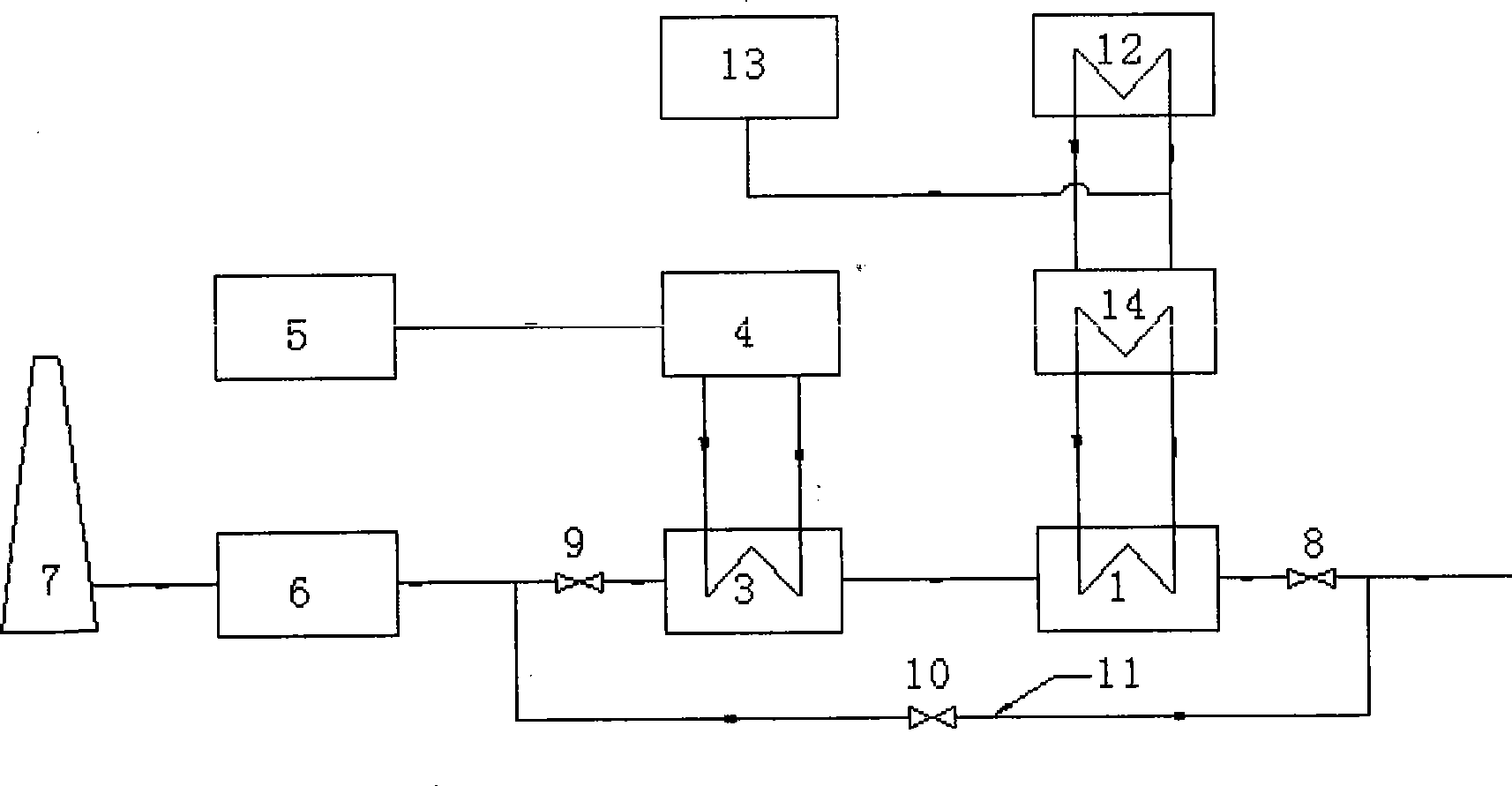

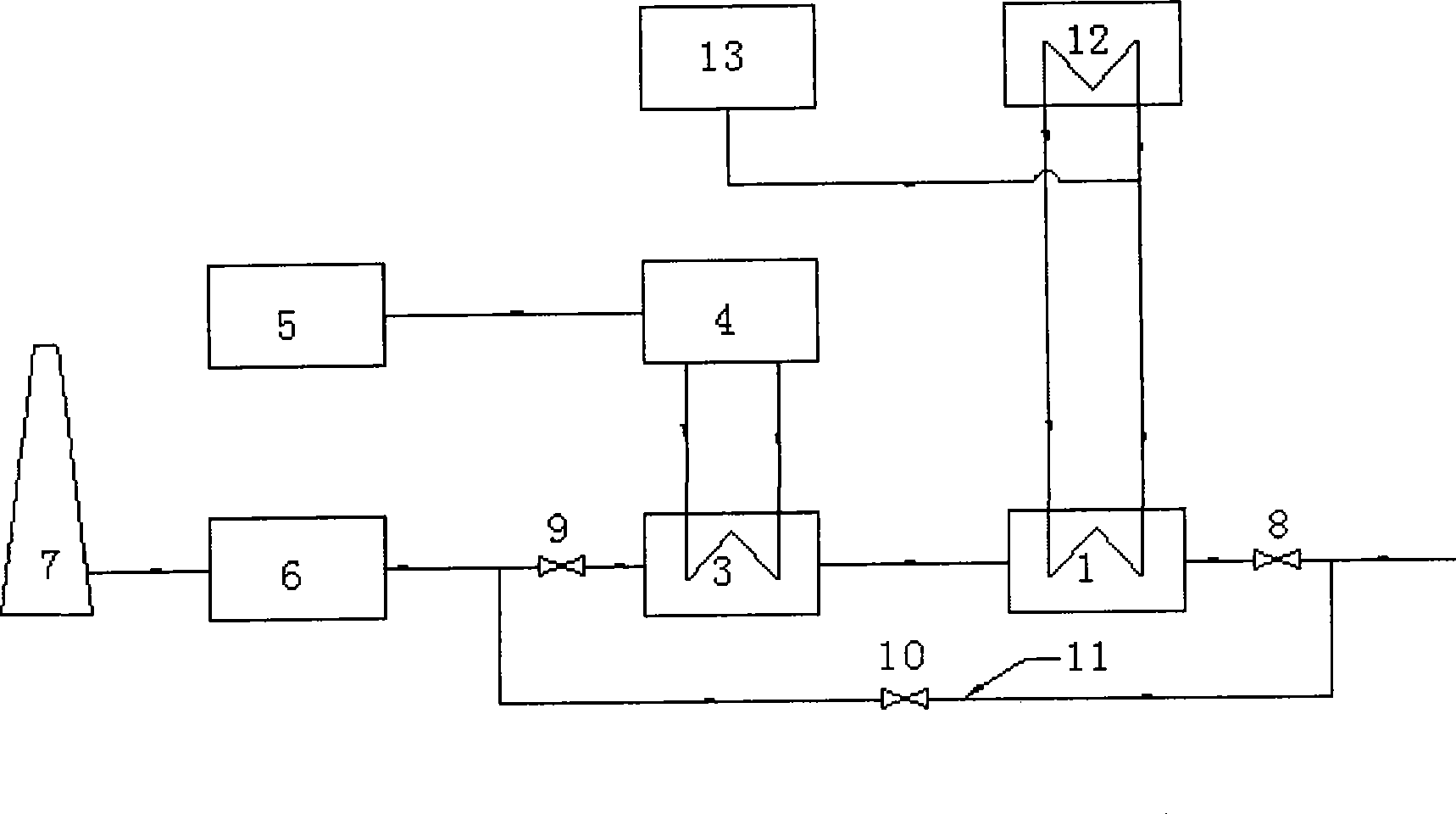

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

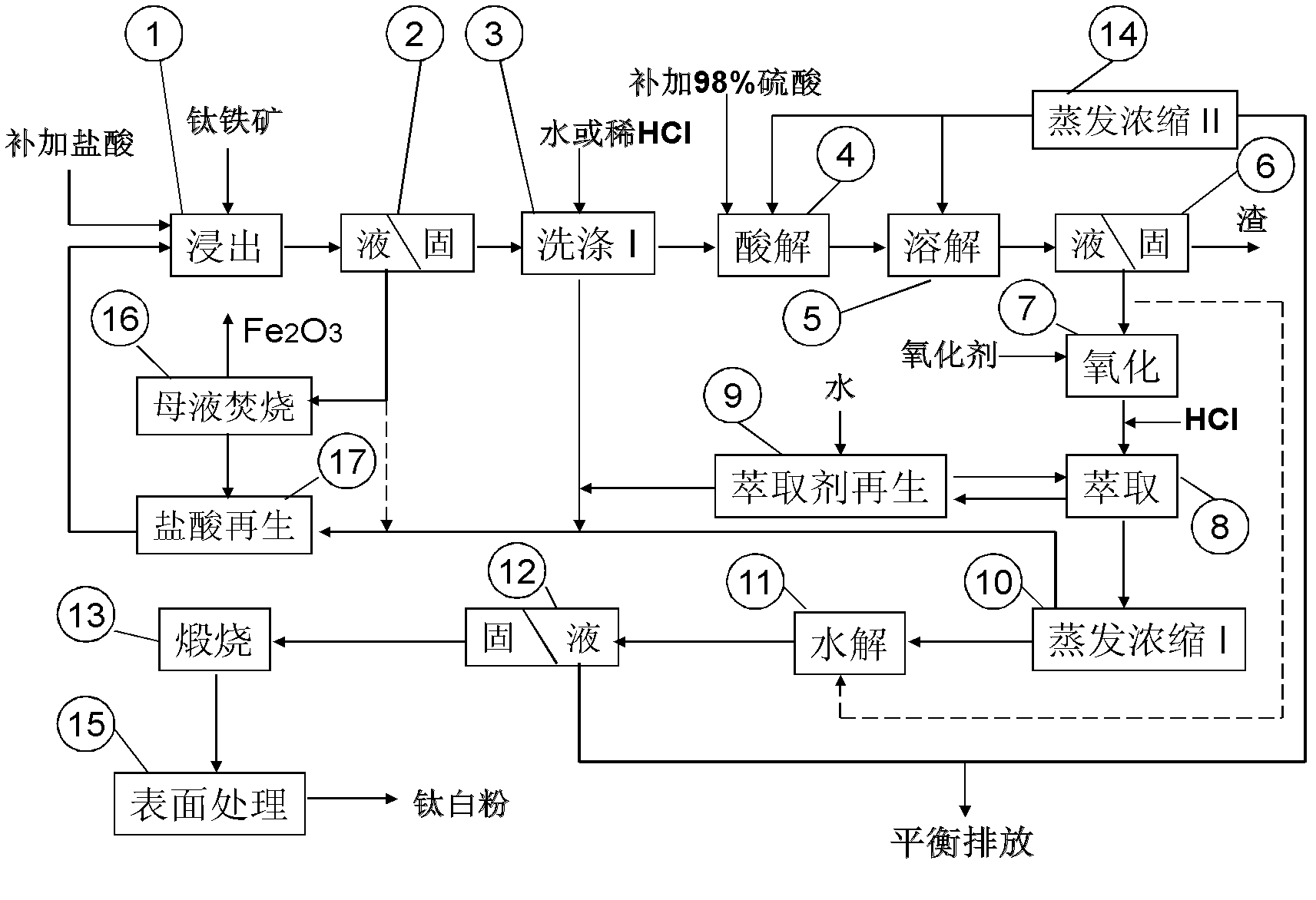

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

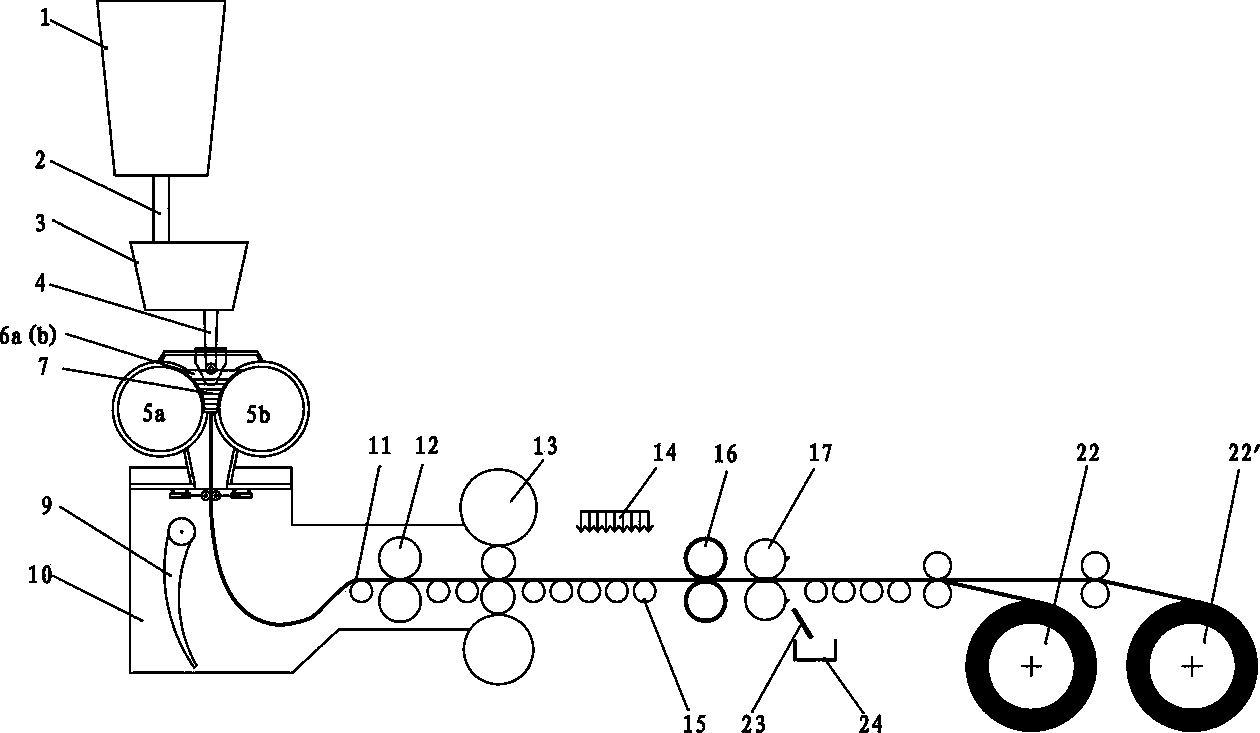

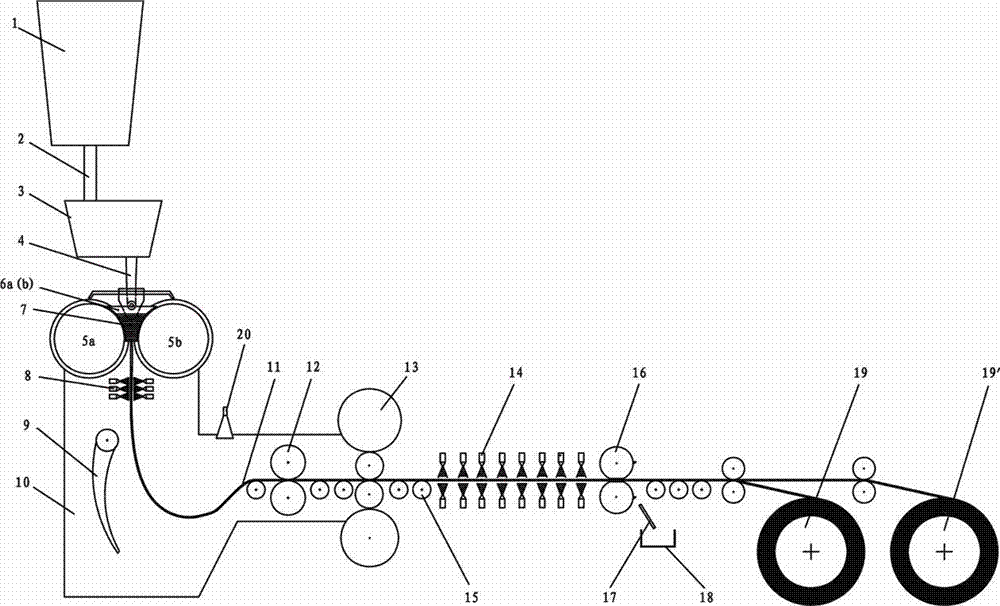

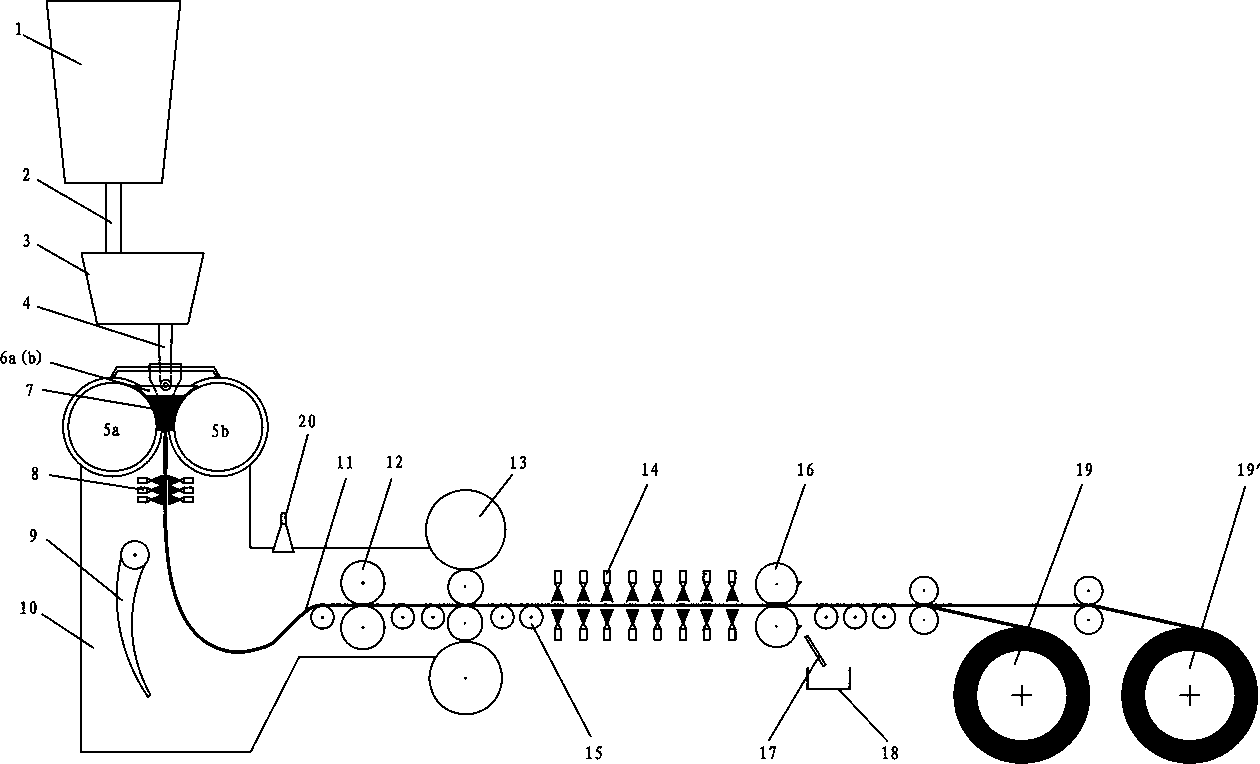

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

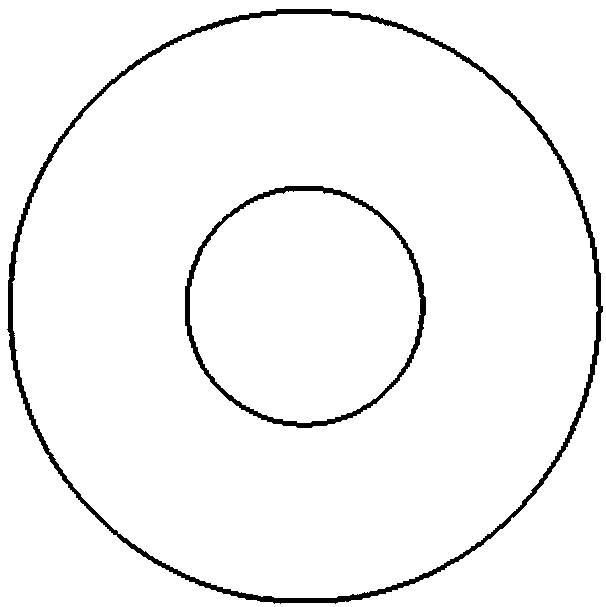

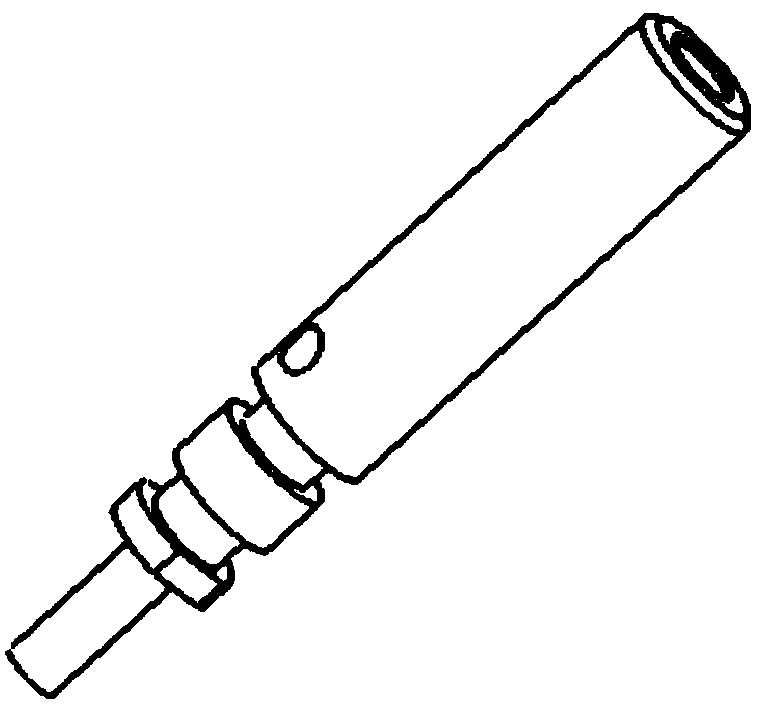

O-shaped sealing ring automatic assembly device and method

InactiveCN108655689AAssembly precisionAccurate assembly tasksMetal working apparatusEngineeringMechanical engineering

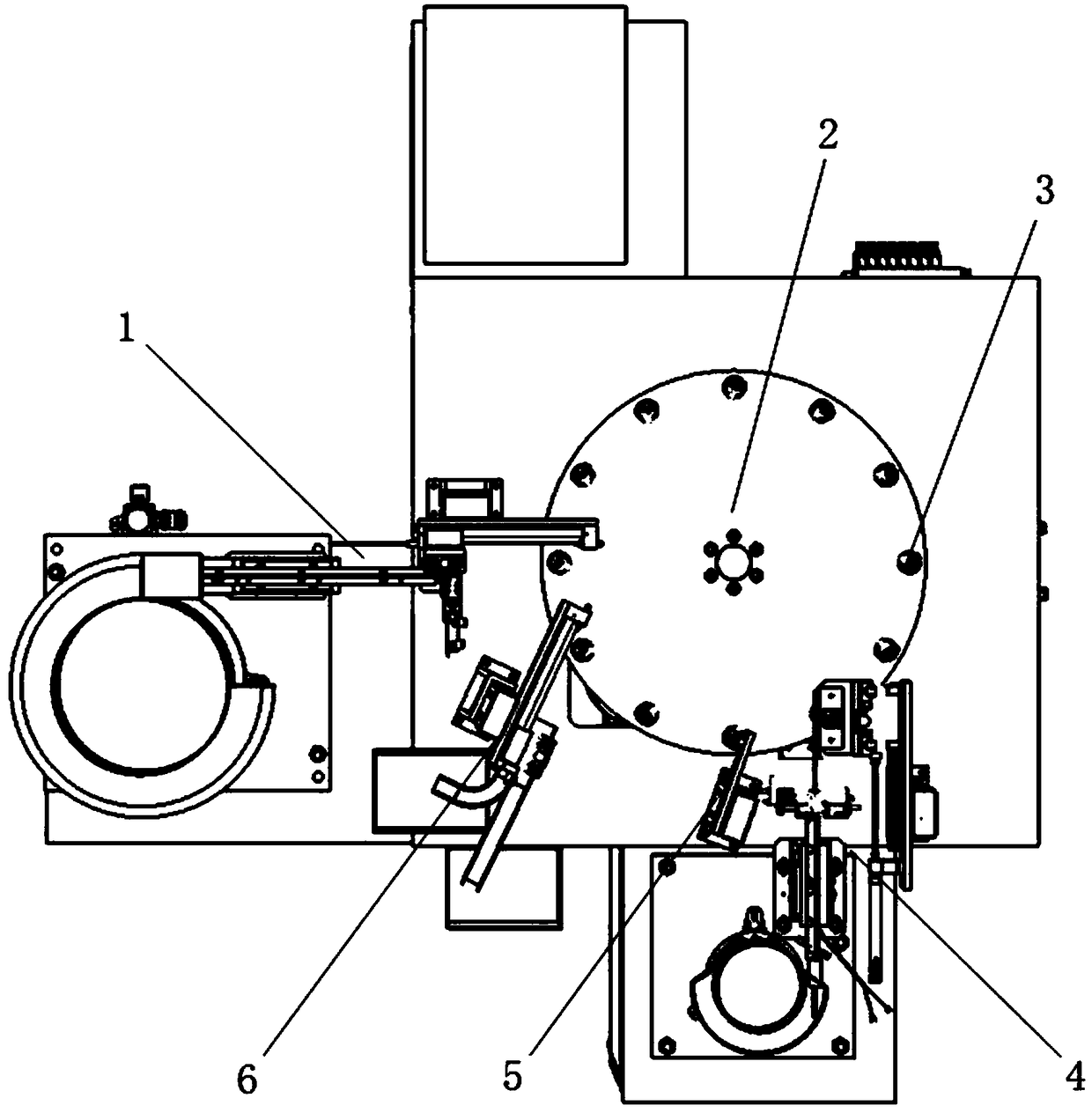

The invention discloses an O-shaped sealing ring automatic assembly device and method. The device comprises a sleeve automatic loading module, an O-shaped sealing ring automatic loading module, an automatic detecting module, a finished product sorting module, all of which are arranged on the outer side of a revolving worktable module in the peripheral direction in sequence; the sleeve automatic loading module and the O-shaped sealing ring automatic loading module are in supply connection with the revolving worktable module; the automatic detecting module detects the assembly effect of O-shapedrings on the revolving worktable module in real time; and the finished product sorting module is used for realizing sorting of qualified and unqualified products through chutes according to the detecting result of the automatic detecting module. The device is simple in structure and convenient to use; and through motions of three arc plates on clamping jaws of a three-jaw cylinder and pressing plates with the same apertures as the diameters of sleeves, the clamping and assembly of the O-shaped sealing rings are achieved, the automatic assembly task of the O-shaped sealing rings can be finished with high quality, a lot of manpower and costs are saved, the assembly efficiency is quickly accelerated, and the production demands are met.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD +1

Laser outer diameter detecting instrument

InactiveCN101013026AMeet production needsDetection speedUsing optical meansLaser transmitterEconomic benefits

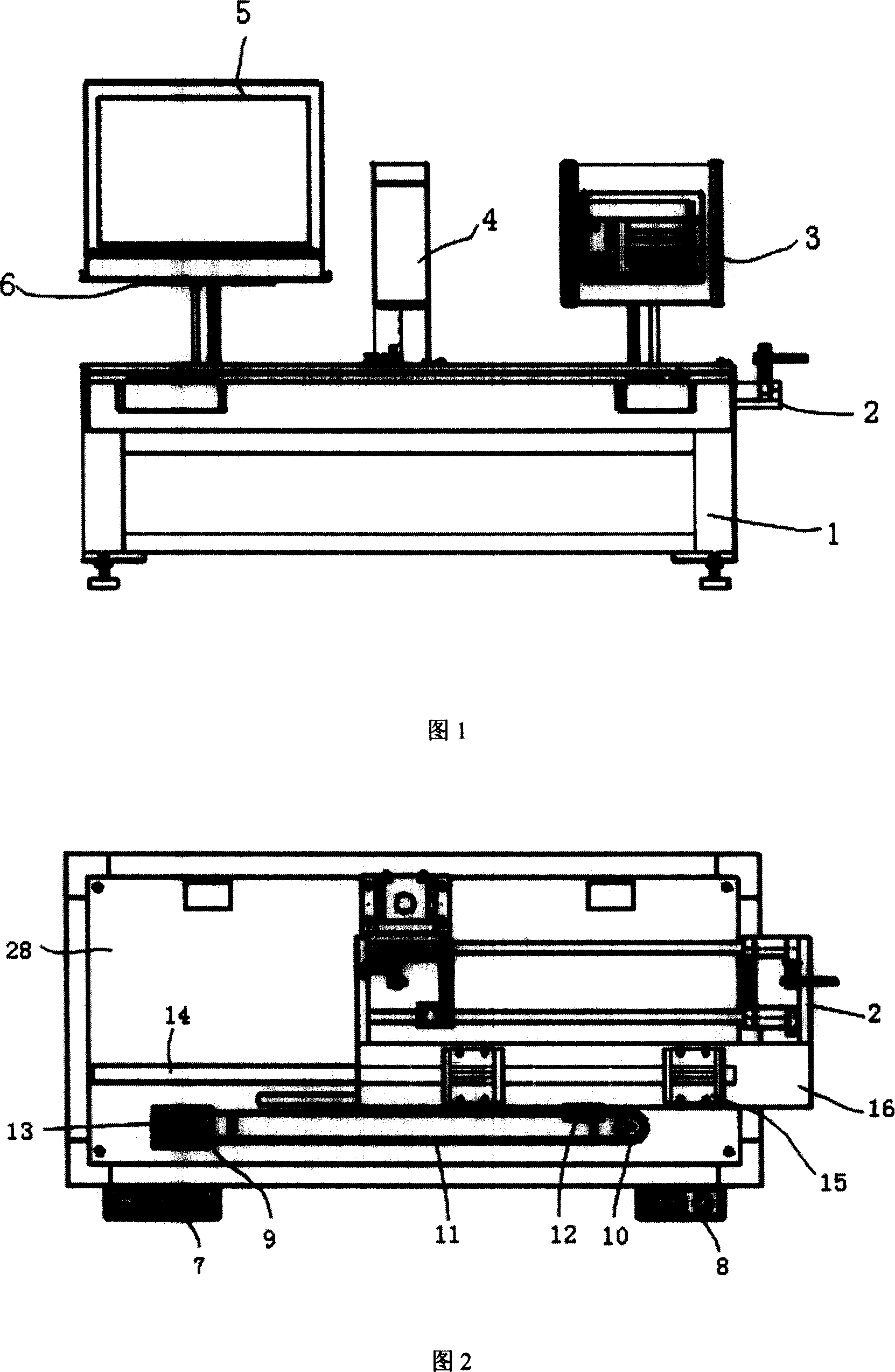

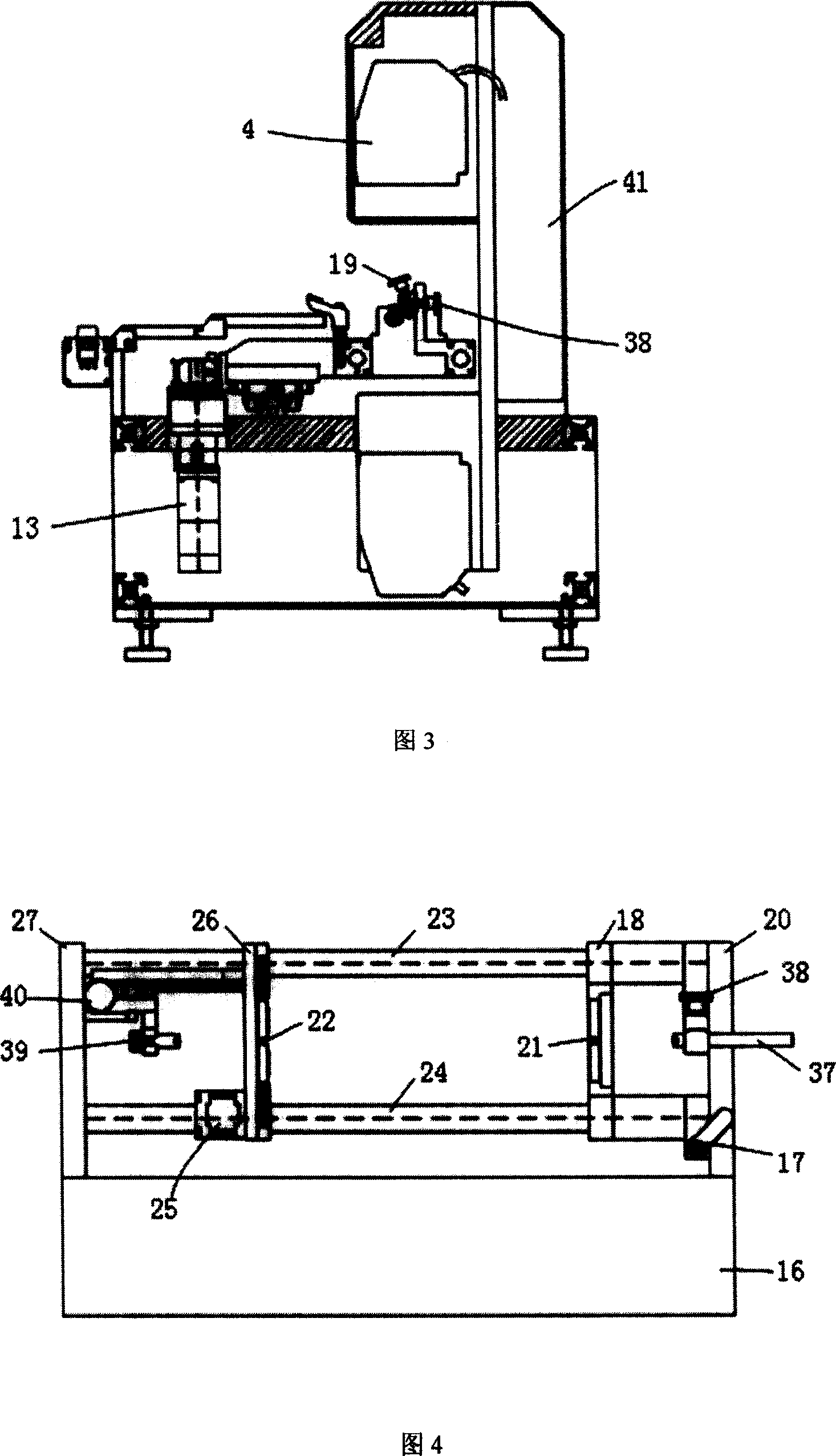

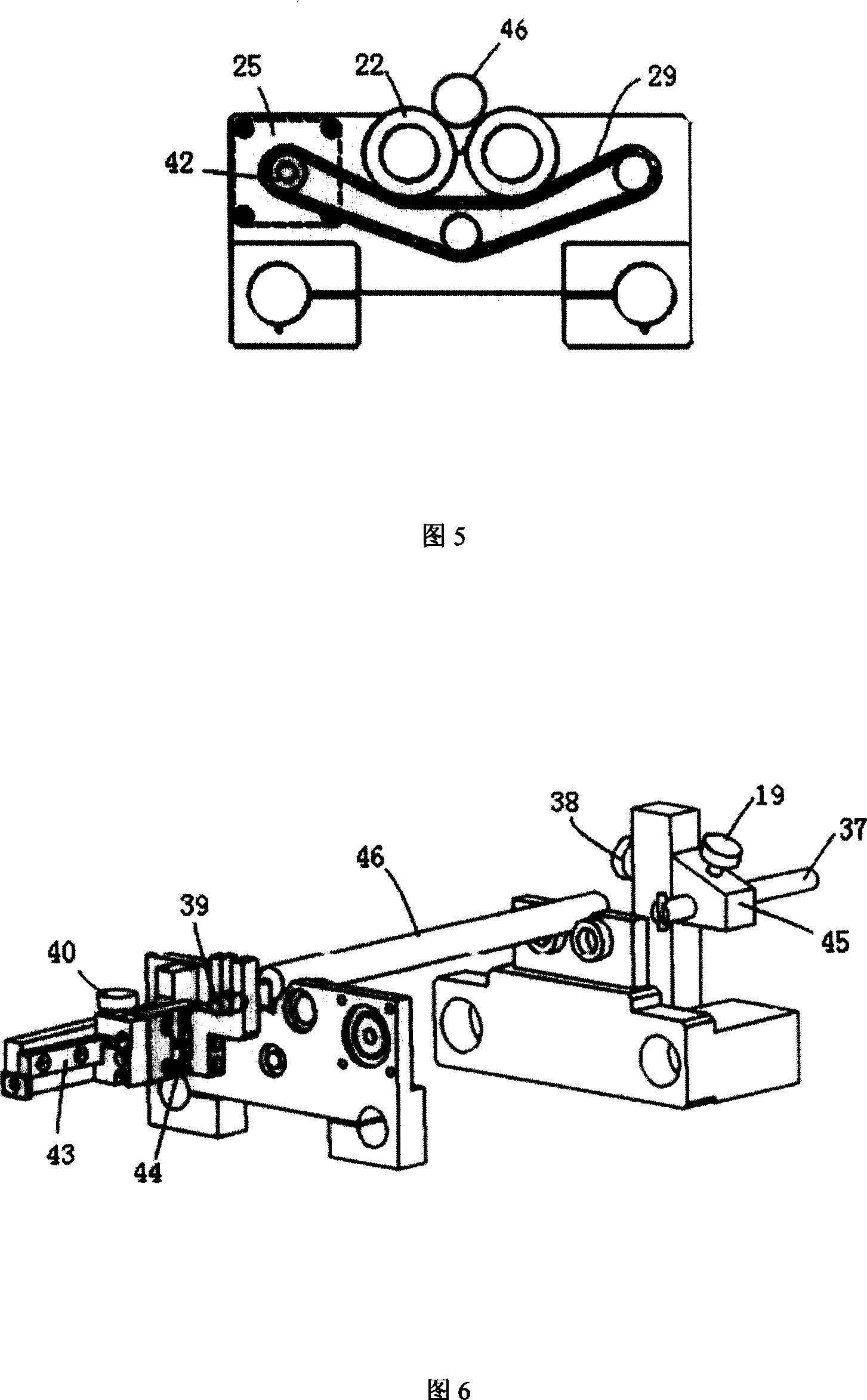

The invention discloses a laser detector, including the machine body, the laser detection head, the laser controller, the level mobile device, and the fixture part, and the said laser detection head and the laser controller are installed in the machine body, the level mobile device installed between the laser transmitter and the laser receiver on the main supporting board of the machine body, and the fixture part connecting with the level mobile device, which can left and right move with the driven of the level mobile device, and the fixture part has the rotating pair rotors, the groove formed between the rotors is used to place the detected products. The laser diameter detector also includes the control device to control the said laser detection head, the laser controller, the level mobile device, and movement of the fixture part. The invention can detect the diameter and beating value of the shaft units, with high detection speed and accuracy, to solve the difficulty the traditional manual detection, which is slow and low accuracy, and it has the multi-function detection, flexible parameter setting, easy and convenient operation, and this invention can meet the great demand for OA production industry, with the broad market and higher economic benefit.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

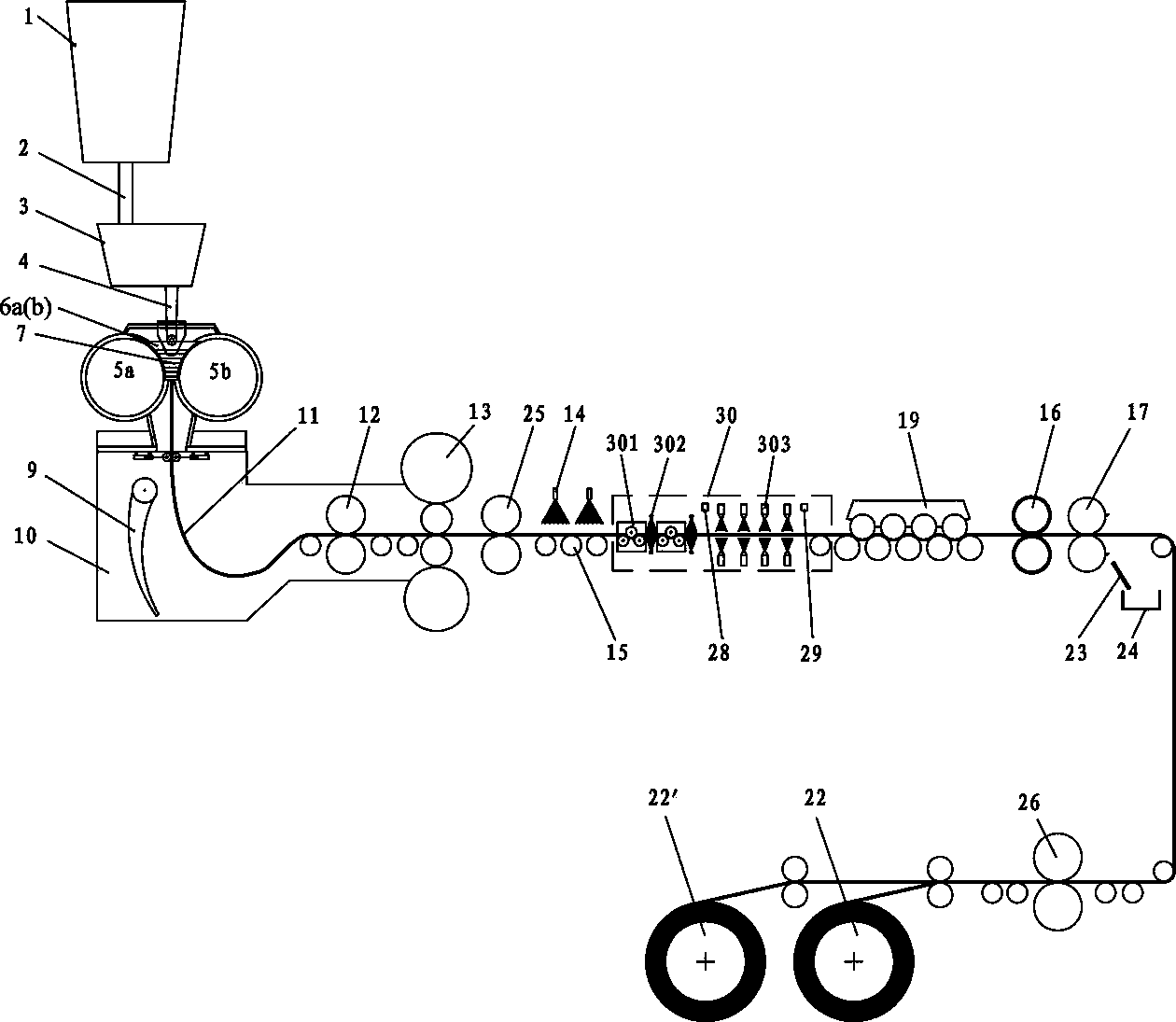

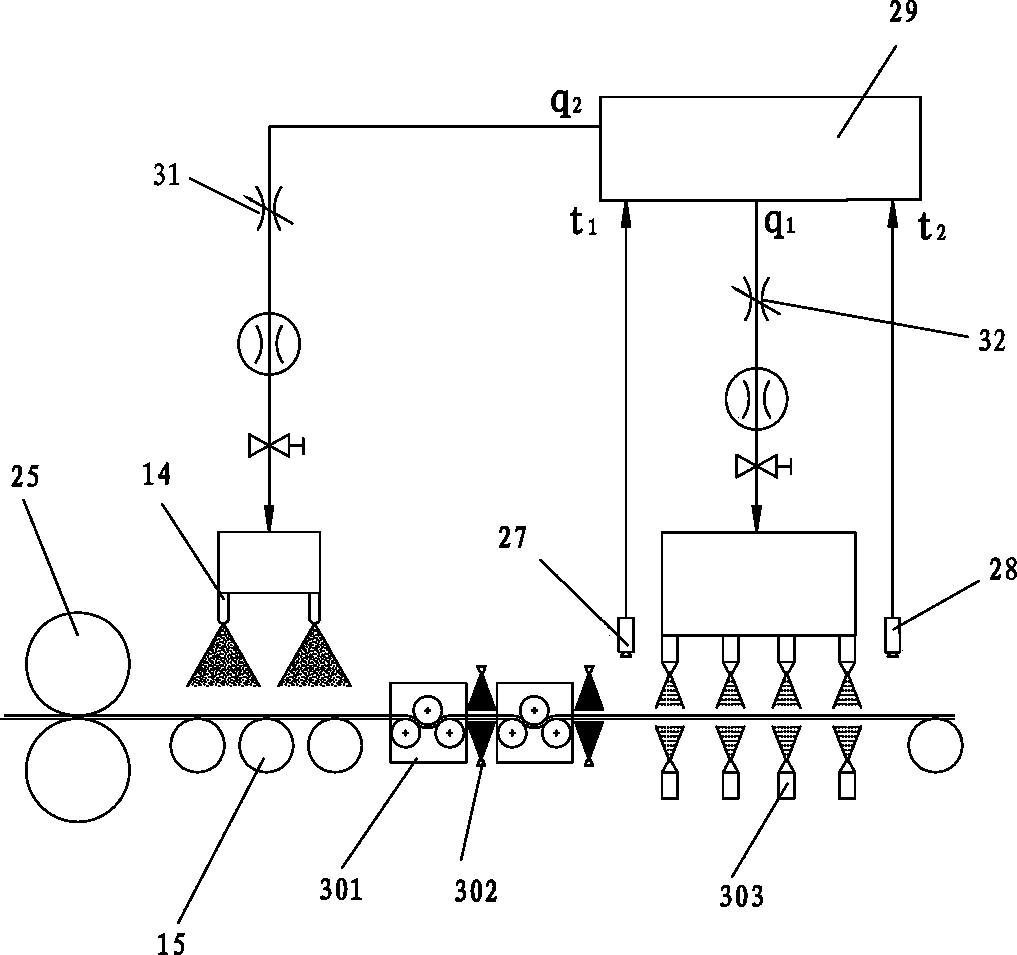

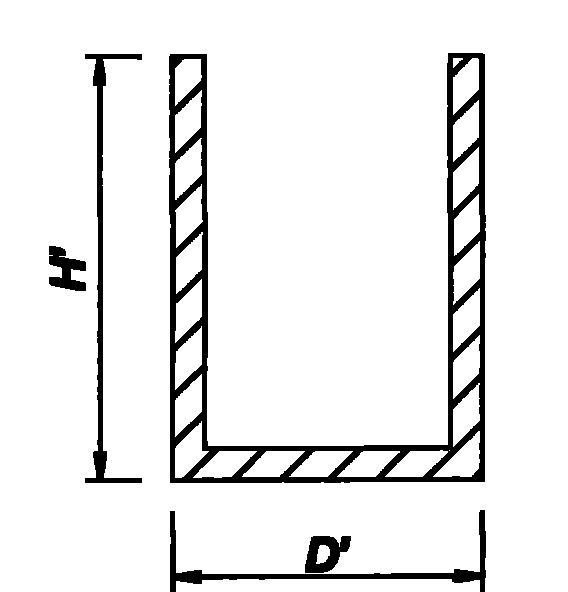

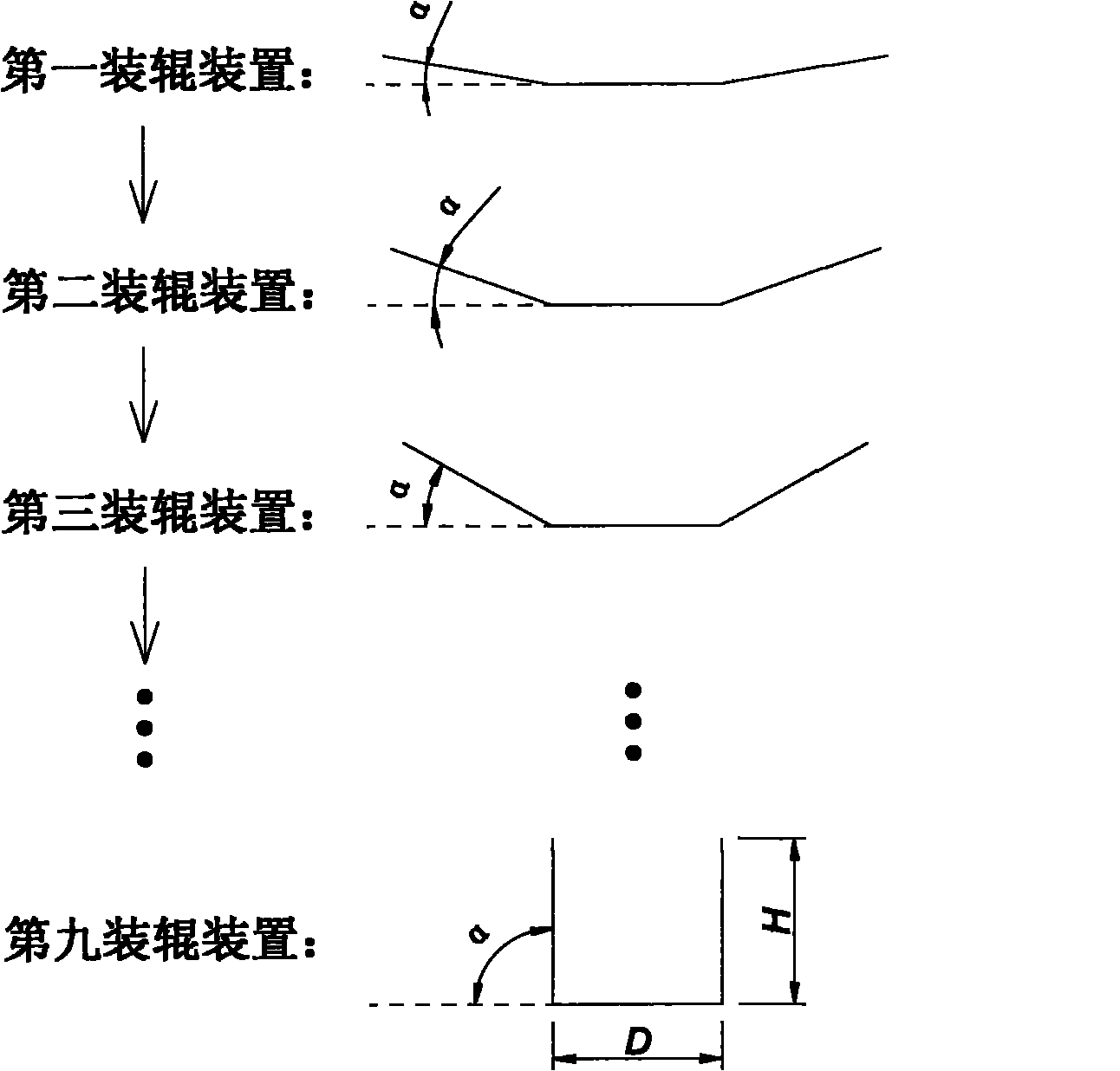

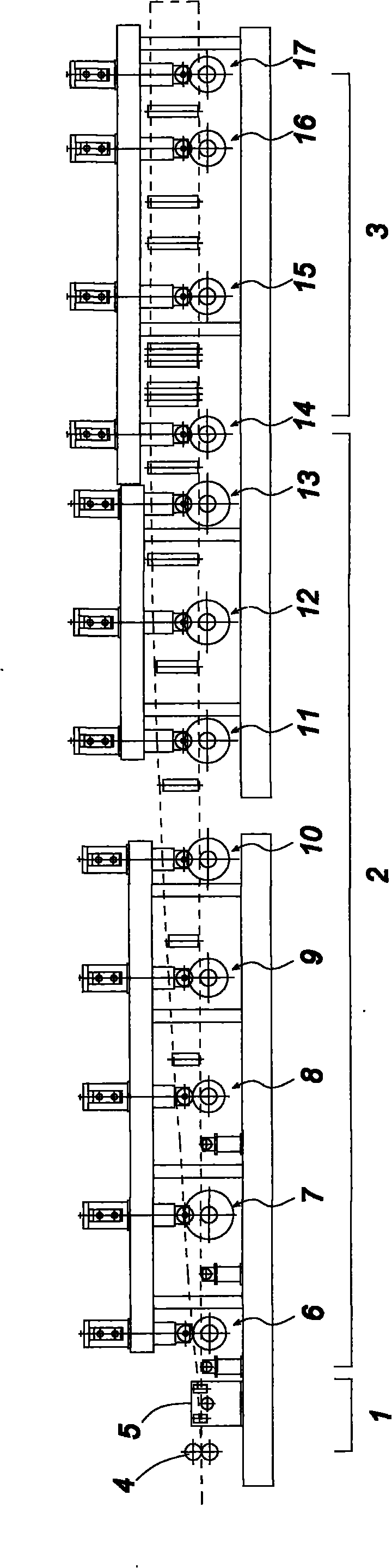

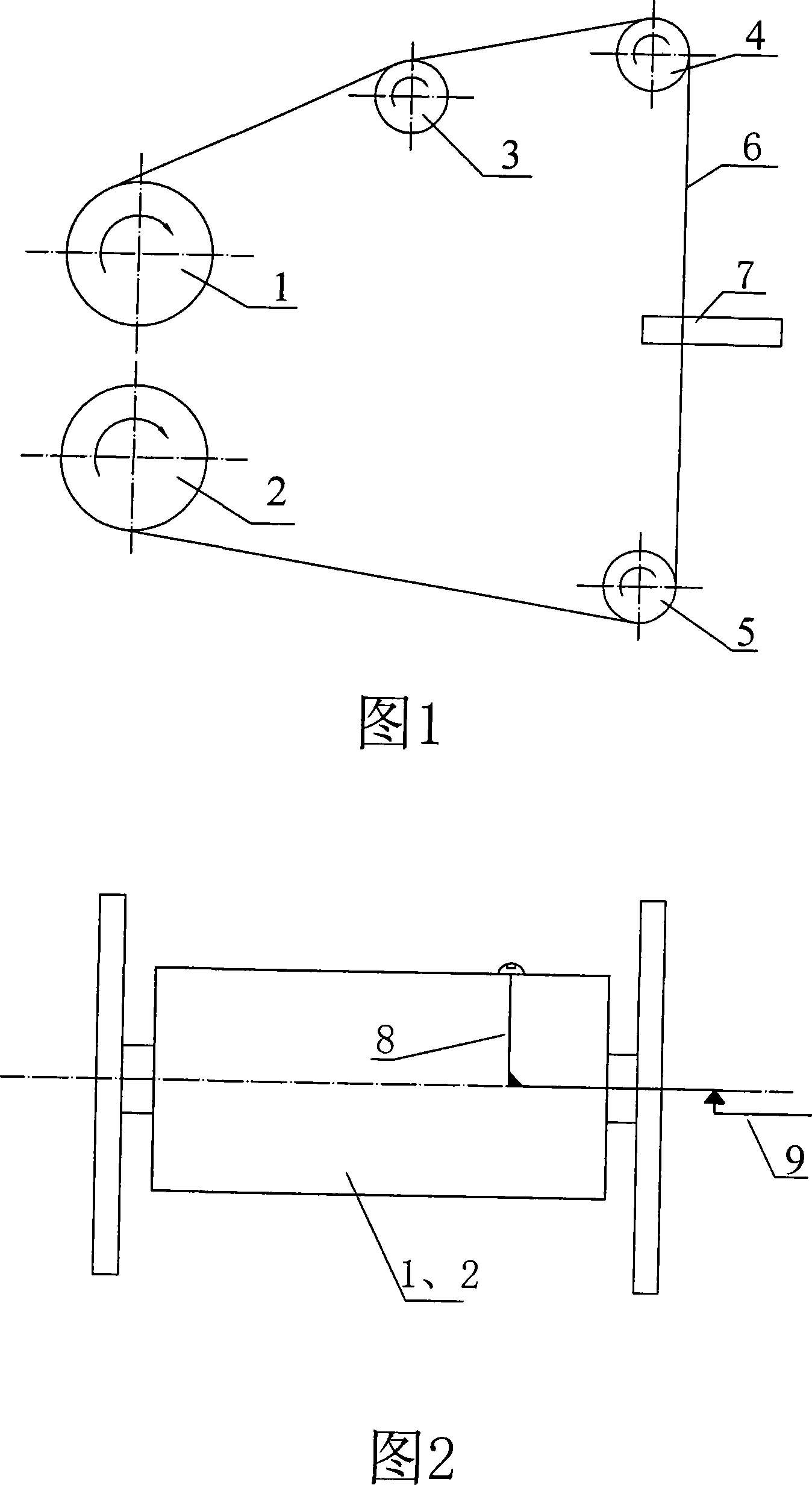

Cold-bending molding technology and production line for producing broad width U-shaped channel steel

The invention provides a cold-bending molding technology and a production line for producing a broad width U-shaped channel steel. The technology comprises the following steps: 1) sheets are pinched synchronously; 2) the sheets pass through a plurality of roll loading devices, the roll loading devices bend both sides of the sheet so as to make both sides of the sheet produce a bending angle alpha, and in the moving direction of the sheet, the rear roll loading device makes the bending angle alpha increased gradually to 90 degrees, so a U-shaped channel steel is initially molded; and 3) the side surface of the U-shaped channel steel initially molded is rectified. With the technology, the flat sheet can be relatively and continuously molded into the integral U-shaped broad width channel steel without welding. The production line of the technology has the advantages of no limit on the total length of the channel steel, high production efficiency, stable production quality, stable operation, low noise and the like.

Owner:山东力丰重型机床有限公司

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

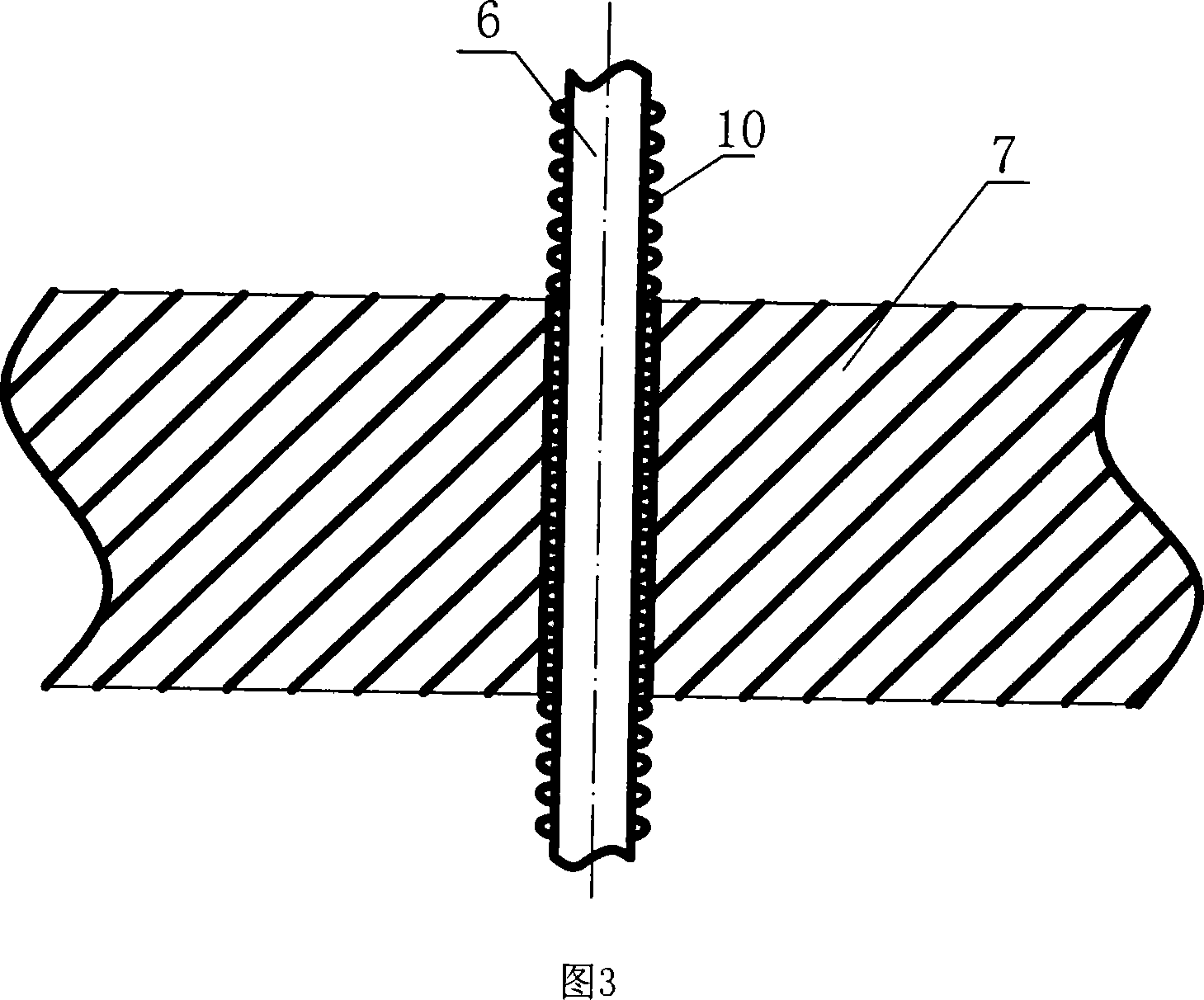

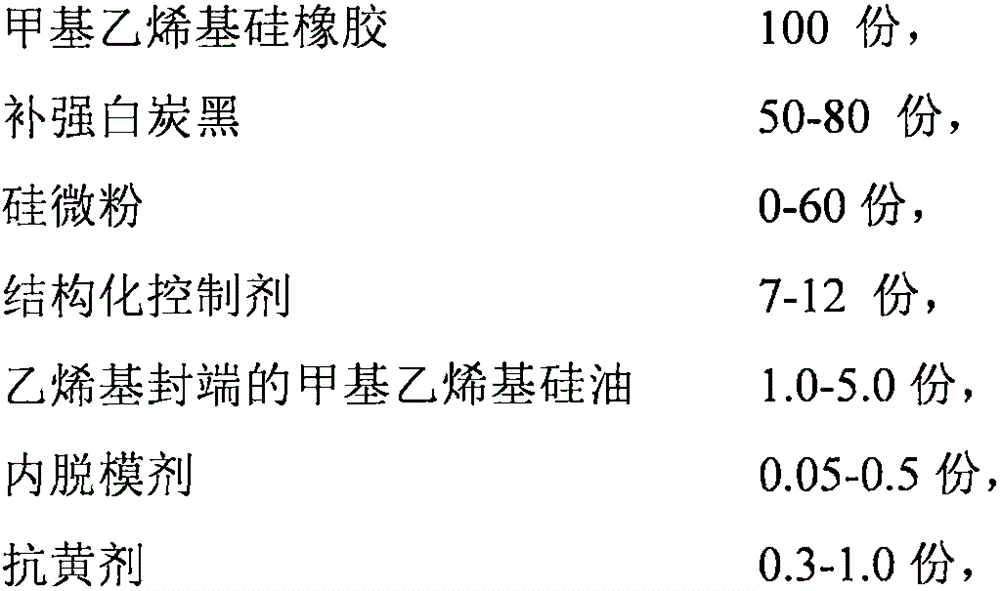

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

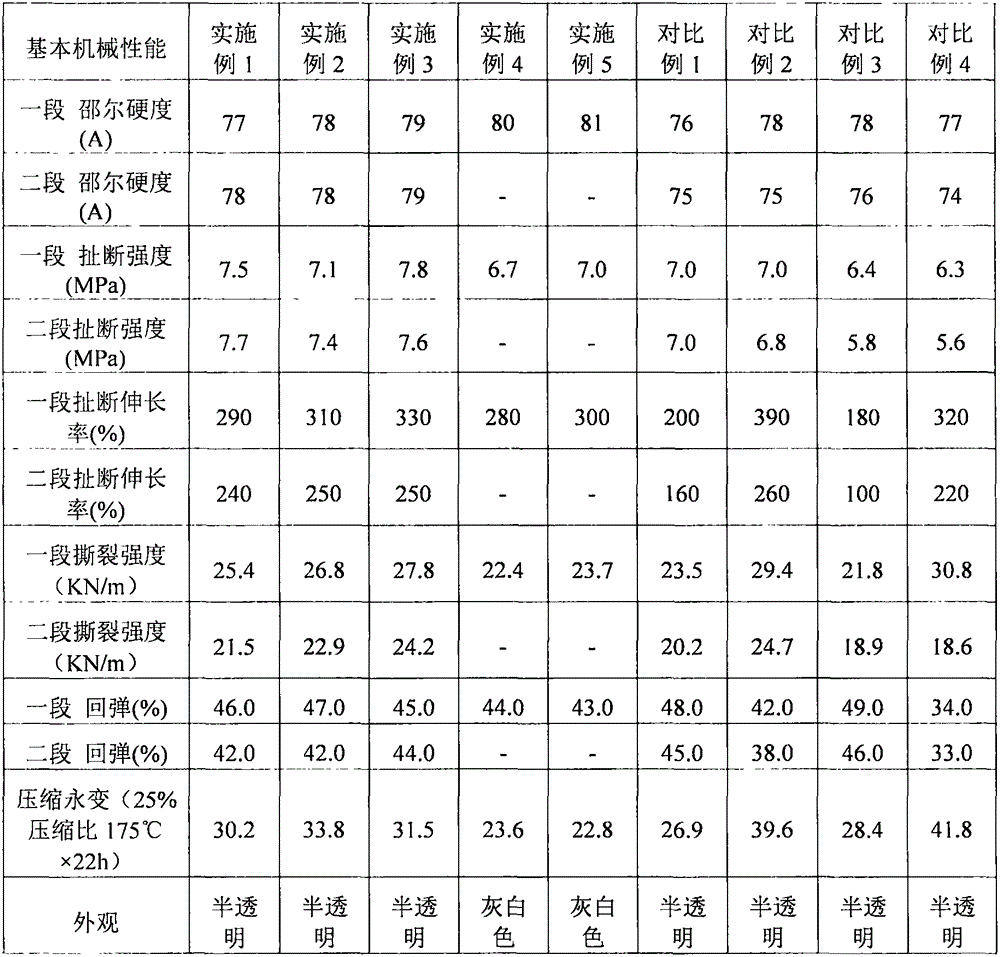

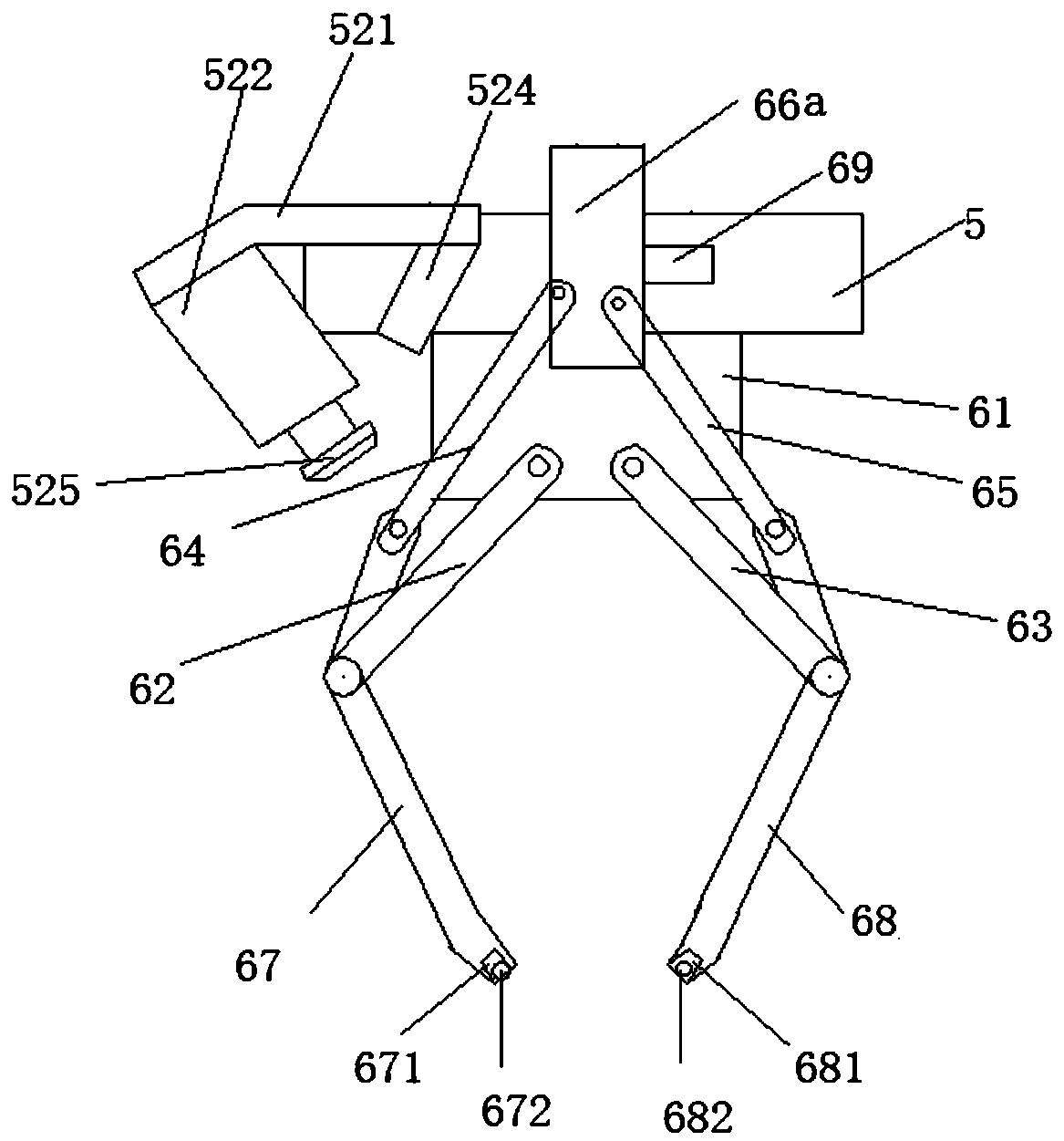

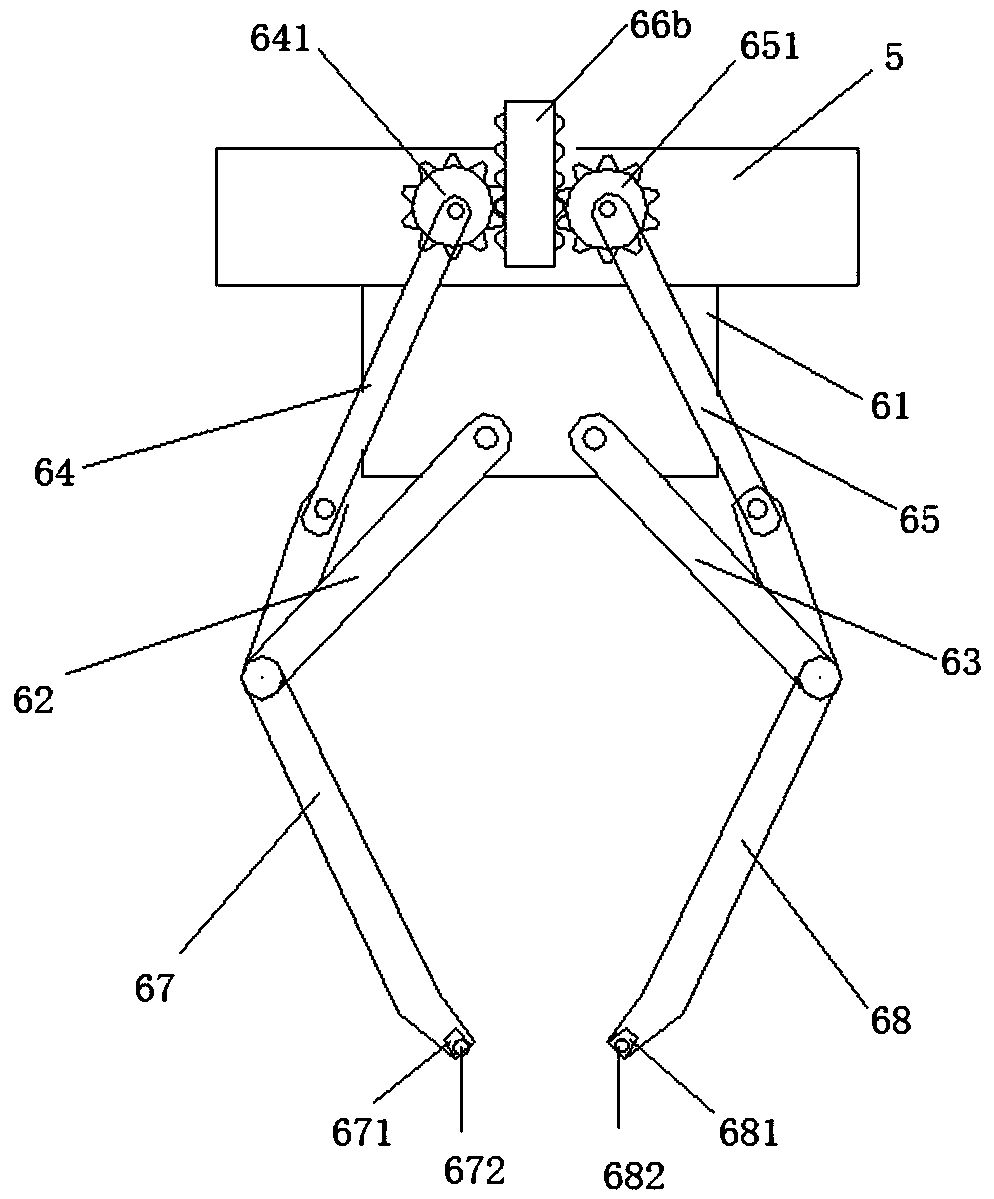

Multifunctional rotary displacement conveying mechanical arm capable of taking materials in branched mode

The invention discloses a multifunctional rotary displacement conveying mechanical arm capable of taking materials in a branched mode. The multifunctional rotary displacement conveying mechanical armcomprises a base, a lifting stand column, a transverse moving mechanism, a mechanical arm body, a connecting piece and a mechanical claw; the lifting stand column is fixed on the base through a rotarydisc, the transverse moving mechanism is arranged on the lifting stand column, the lifting stand column comprises a lifting air cylinder and a supporting stand column, and the bottom of the lifting air cylinder is arranged on the rotary disc; a plurality of spherical ring holes are formed in the mechanical arm body, spherical fixing rings are installed in the spherical ring holes, a branch mechanical arm body penetrates through the spherical annular holes of the mechanical arm body and is fixed on the mechanical arm body, two symmetric arc-shaped notches are formed in each spherical ring hole, the width of the arc-shaped notches is smaller than the width of the spherical fixing rings, and a hook or a vacuum sucking disc is arranged on the branch mechanical arm body. According to the mechanical arm, the branch mechanical arm body is fixed on the mechanical arm body through spherical positioning rings, multi-direction and multi-angle position adjustment of the branch mechanical arm bodyis realized along with the rotation of the spherical positioning rings, and the production requirements of multi-variety small-batch production are met.

Owner:薛敏强

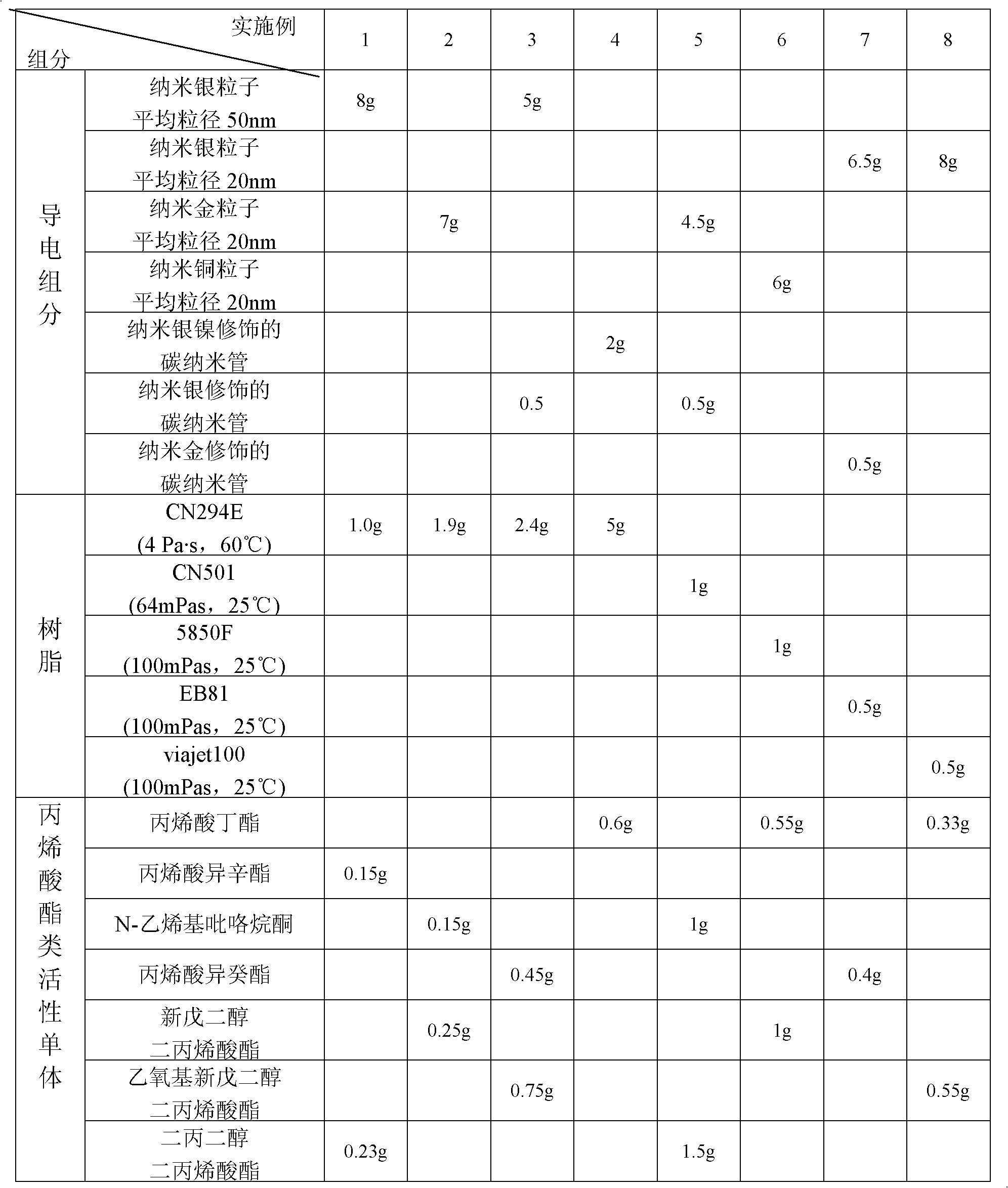

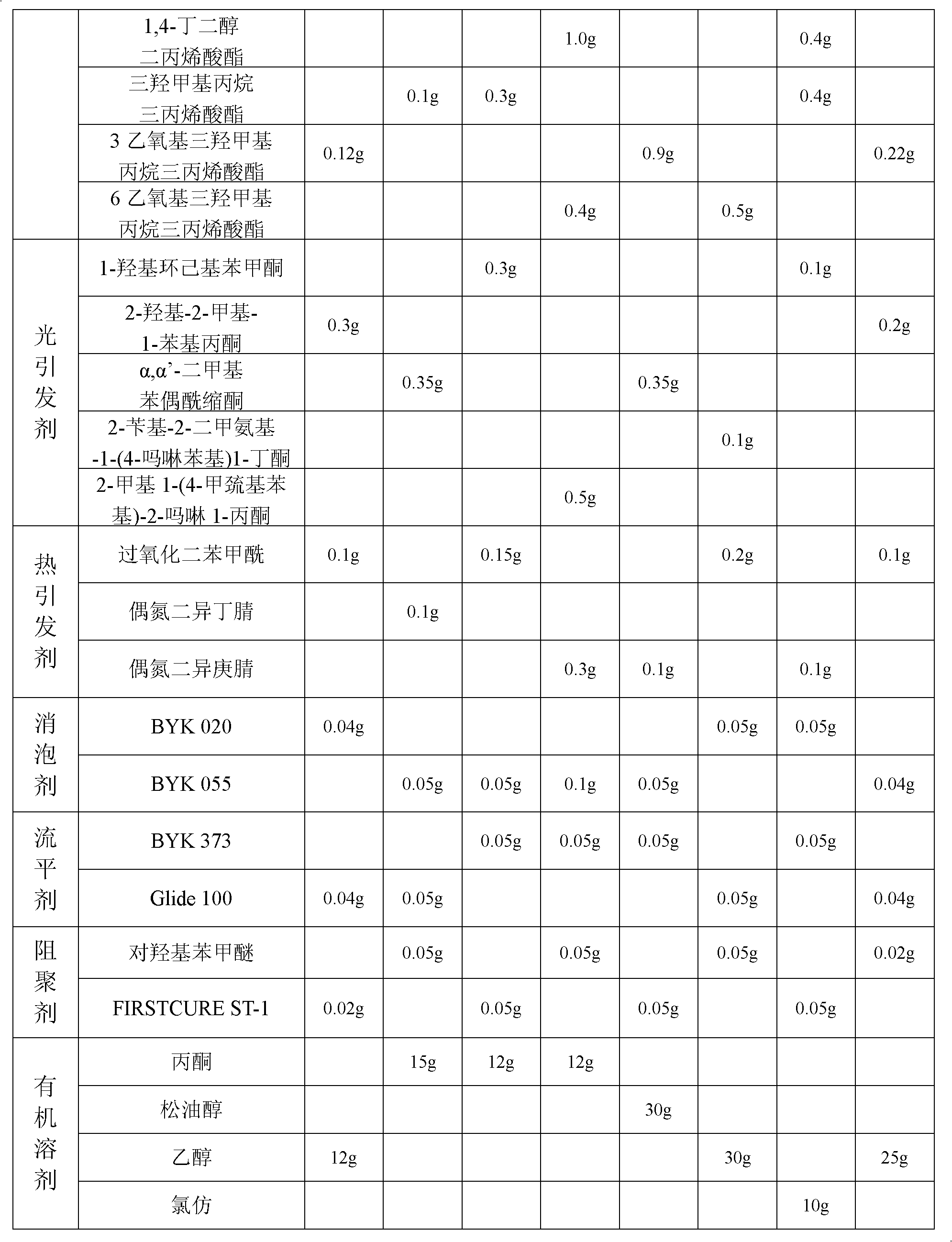

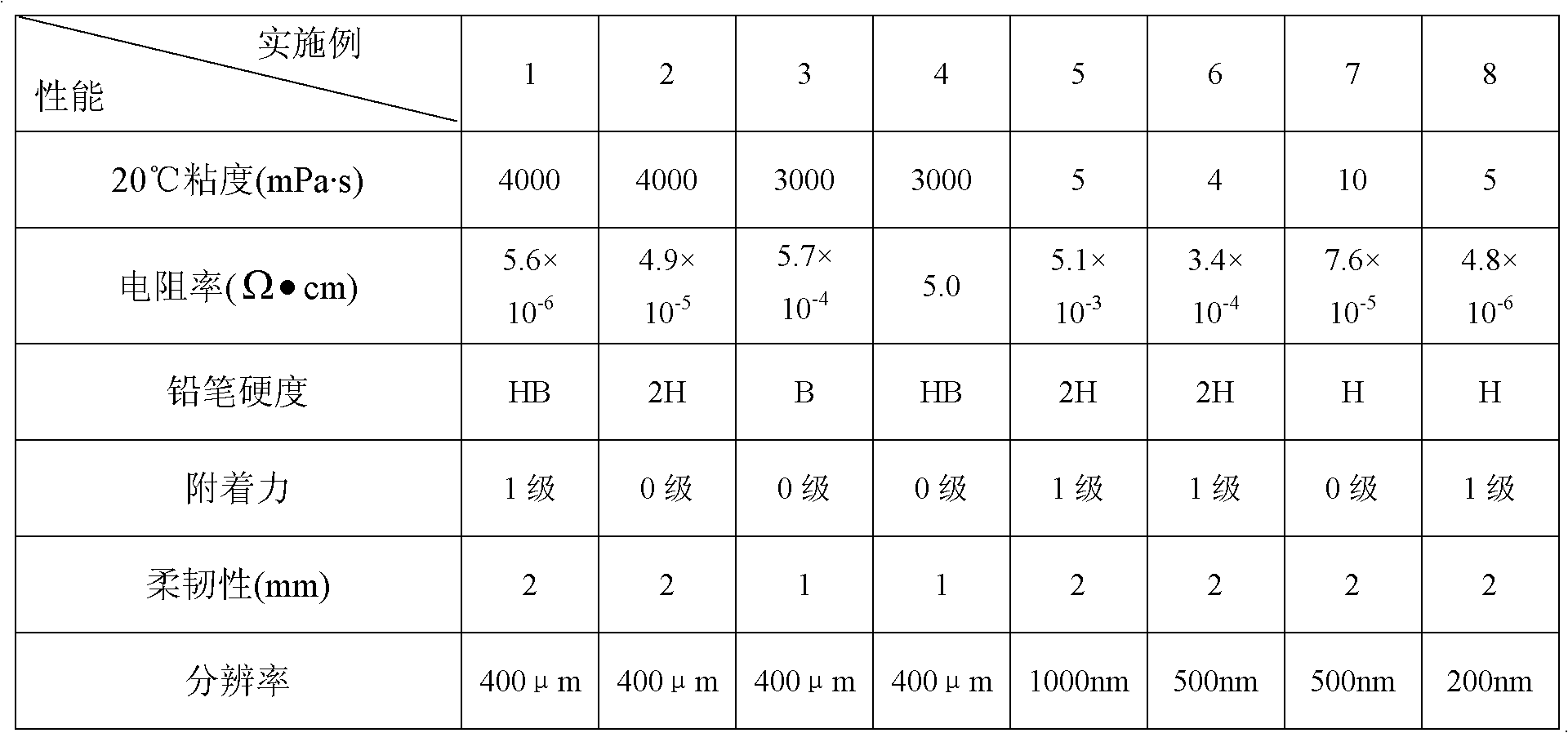

Flexible circuit conductive composition, preparation method and using method thereof

ActiveCN102212304AGuaranteed resistivityGuaranteed adhesionPhotomechanical apparatusPolyurea/polyurethane coatingsFlexible circuitsFlexible electronics

The invention relates to a flexible circuit conductive composition for a flexible printed circuit board (FPC), a preparation method and a using method thereof. The preparation method comprises the following steps of: adding photocurable resin and an optical activity monomer into a conductive nanometer material dispersion liquid and then preparing the composition by adopting a double-curing mode such as firstly photocuring and then thermal treatment. The photocuring leads the surface coating to be rapidly cured so as to achieve good mechanical property; and the thermal curing leads the coatingto be cured completely so as to reach the deep curing requirements. The thermal treatment leads nanometer metals to be sintered together so as to achieve good conductive performance. The prepared conductive system obtains a predesigned pattern in the specific area of a base material in a screen printing or nanometer impressing mode; the conductive pathway is obtained after the double curing and has the advantages of short curing time, low curing temperature, good electrical conductivity, high resolution ratio; and the prepared conductive film has the advantages of good adhesiveness, high hardness and good flexibility.

Owner:BEIJING UNIV OF CHEM TECH

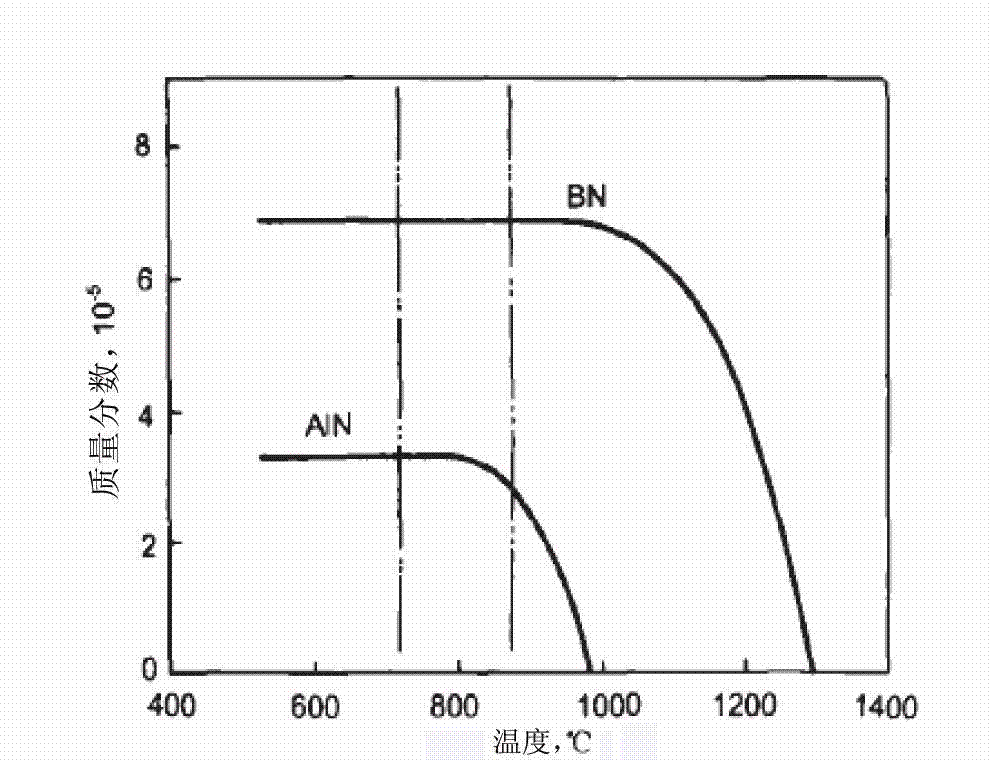

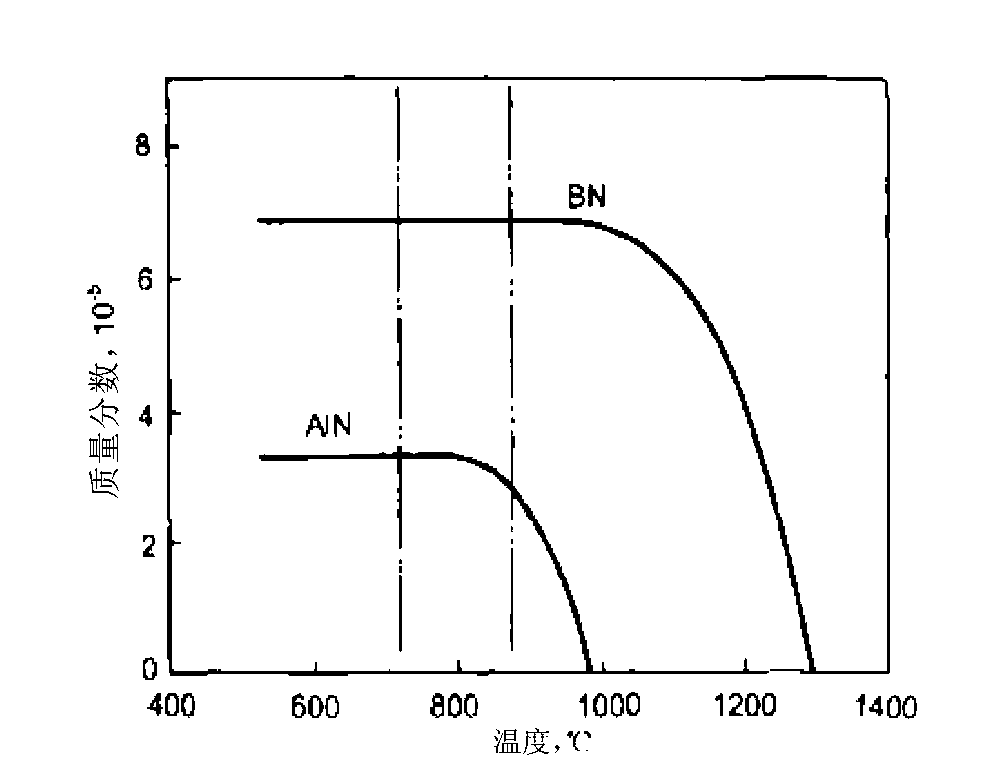

Boron-containing weather-proof thin strip steel and manufacturing method thereof

Provided are boron-containing weather-proof thin strip steel and a manufacturing method thereof. The manufacturing method comprises performing double roller thin strip continuous casting to produce boron-containing weather-proof steel; after a cast strip is processed through a crystallizing roller, adopting a mode of spraying dry ice to perform uniform strengthened cooling on the cast strip, rapidly cooling the cast strip to below 1,280 DEG C, and enabling the cooling speed to be 200-300 DEG C / s, so that precipitation of thick and large BN in the cooling mode is promoted, emergency of low-melting-point-phase B203 and precipitation of tiny AlN are avoided, and the aims of homogenizing austenite grains and reducing yield ratio are achieved; then performing austenite on-line recrystallization rolling; then performing anti-oxidizing rapid cooling to cool the strip steel undergoing hot rolling, and enabling the cooling temperature to be 80-200 DEG C / s; and enabling coiling temperature to be 500-600 DEG C. Steel with low yield ratio can be obtained through the manufacturing method, and the problems that steel produced by thin strip continuous casting are universally uneven in structure, high in yield ratio and difficult to form and cannot meet the requirements for cold rolling materials are effectively solved.

Owner:BAOSHAN IRON & STEEL CO LTD

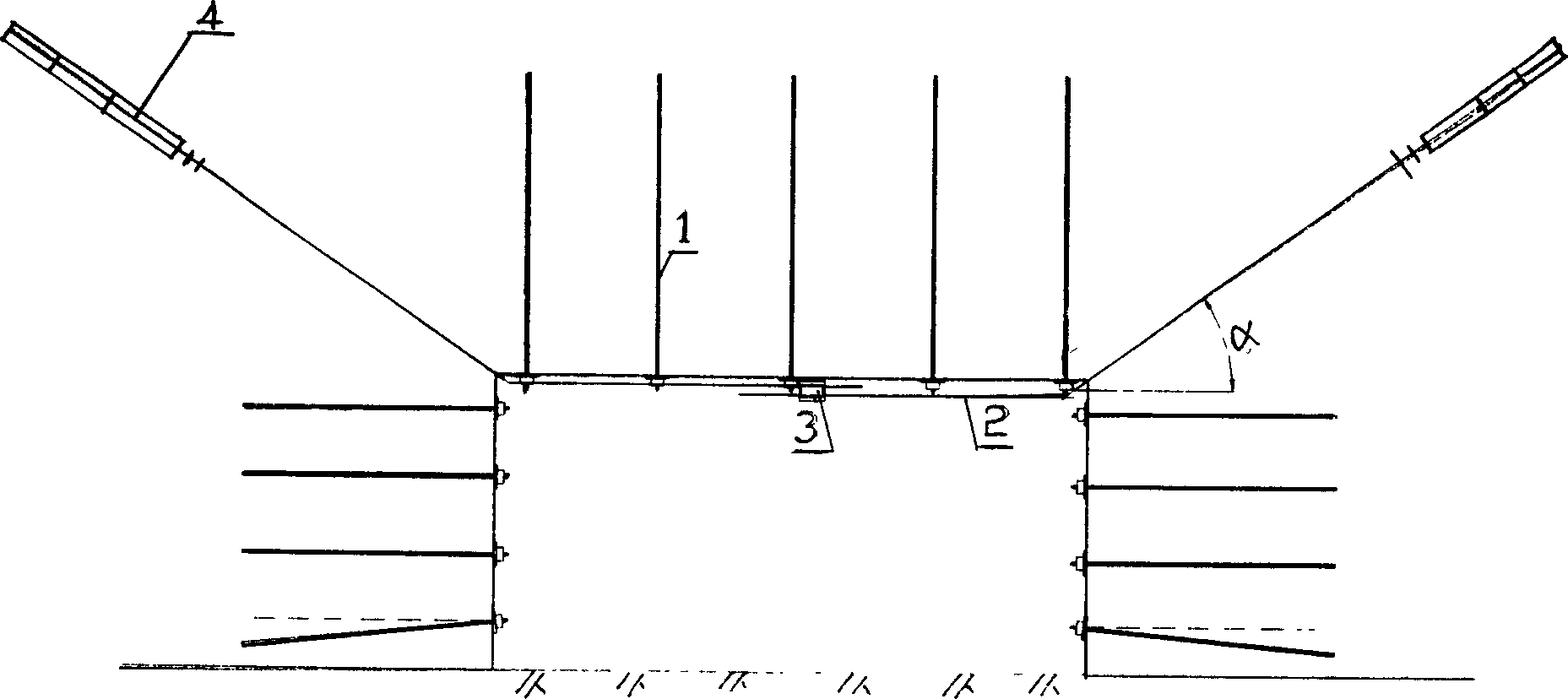

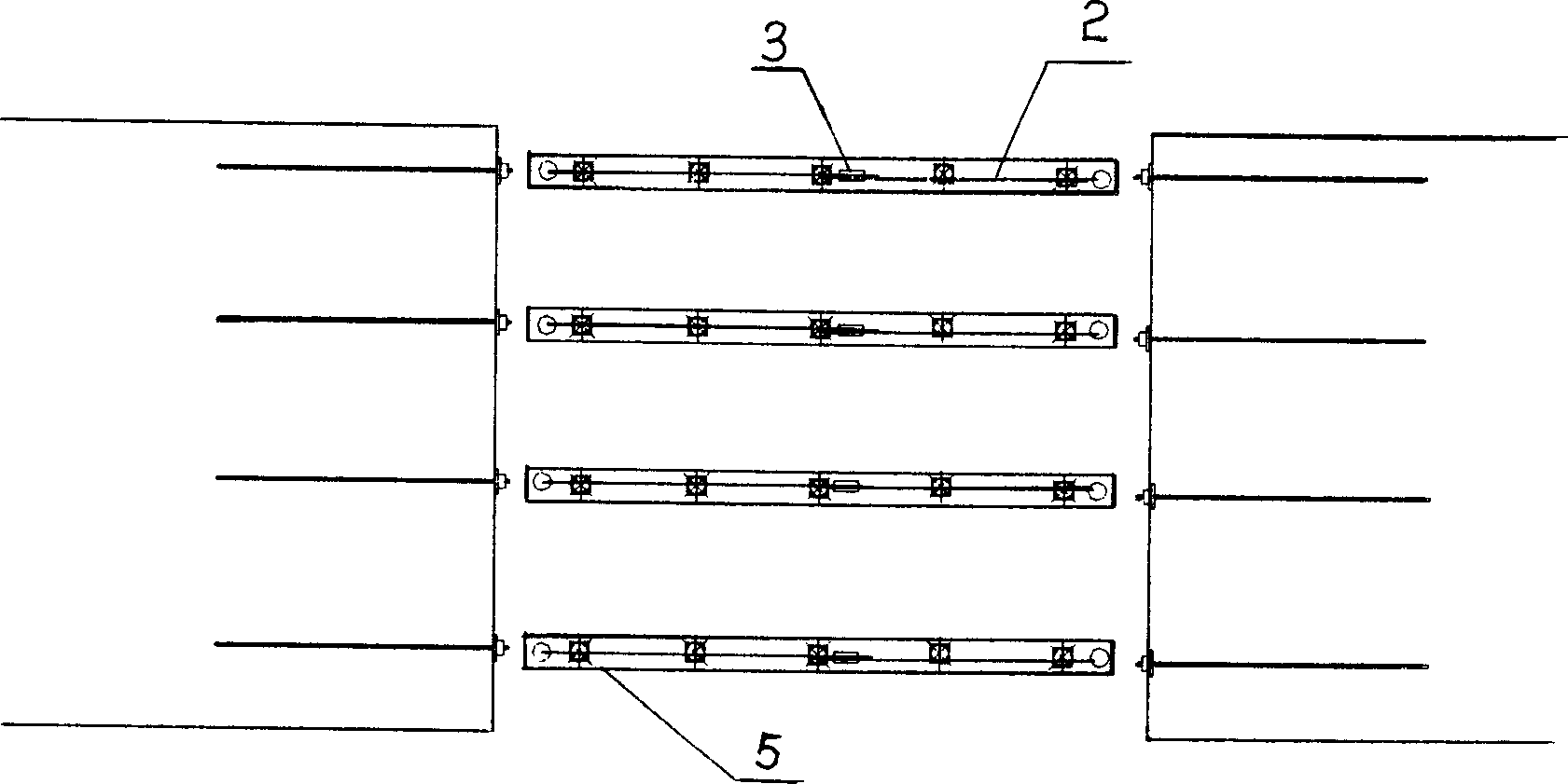

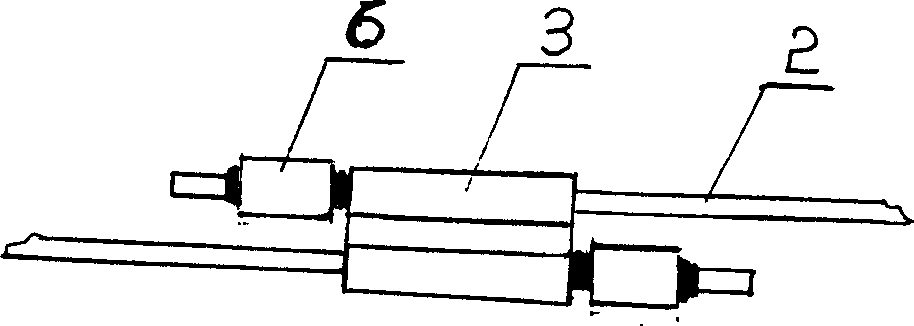

Truss supporting technology for ingredient top slope deformation control

InactiveCN1594834AReduce distortionSolve the problem of shear slip and cavingMine roof capsAnchoring boltsPull forceWhole body

A truss supporting technology for controlling ingredient top slope deformation is adapted for controlling the sinkage of wide span alley way top board separation layer, the top board and alley slope shear-slip breakaway or controlling the deformation of alley slope part. When using an anchor rod anchorage cable support for ingredient top board or alley slope part, plural trusses composed of two steel twist lines and double hole steel bushing coupler is set on the ingredient top board or alley slope part with spaces for support, each truss is shielded under the anchor solid, two steel twist lines are connected and locked by the coupler to form expansion and pull force to generate extrusion and protection function for the ally way top board or slope part. Not only the problem that the sinkage of the wide span alley way top board separation layer and the top board and alley slope shear-slip breakaway is solved, the top board is supported effectively, but also the displacement of the alley slope towards to alley inside is controlled, thereby the deformation of the alley slope is reduced, so the alley way can satisfy production requirement. In addition, the connection of the support whole body between the steel twist lines is adopted to change the limit of single anchorage cable support. The structure is simple, convenient in use and has broad practicability.

Owner:CHINA UNIV OF MINING & TECH

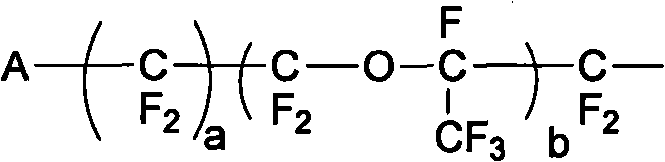

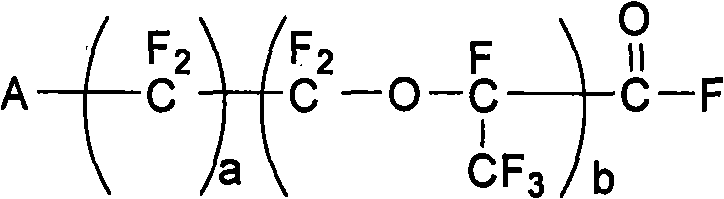

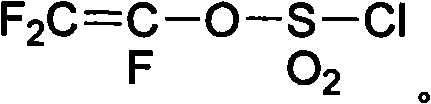

Method for preparing functional fluorine-bearing monomer by vertical-tube type catalytic reaction

ActiveCN101712639AHigh purityFast addition reactionGroup 5/15 element organic compoundsSulfonic acid preparationLiquid productVertical tube

The invention discloses a preparation method of a functional fluorine-containing monomer. The method comprises the following steps of: uniformly mixing a perfluoro-linear chain or branched chain acyl fluoride compound, trifluoroethylene sulfuric ester and anhydrous hydrogen fluoride liquid in the mole ratio of 1:1:(1-20); passing from bottom to top through a vertical-tube type reactor which is filled with a catalyst; finishing addition reaction in a short time under the action of the high specific surface area catalyst inside the reactor; and setting apart a reaction liquid product from the upper part of the vertical-tube type reactor to form a product with a general formula in formula (I). In the invention, the functional fluorine-containing monomer can be prepared continuously and efficiently with easily operated reaction equipment, conveniently controlled reaction temperature and no use of any organic solvent, and a high-purity monomer can be obtained through simple rectification. The catalyst filling in the tubular reactor is one or a mixture of active carbon, macro-porousmolecular sieve and porous aluminum oxide. The reaction can be carried out continuously inside the reactor and satisfies industrialization requirements. CF2=CF-O-Rf(I).

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

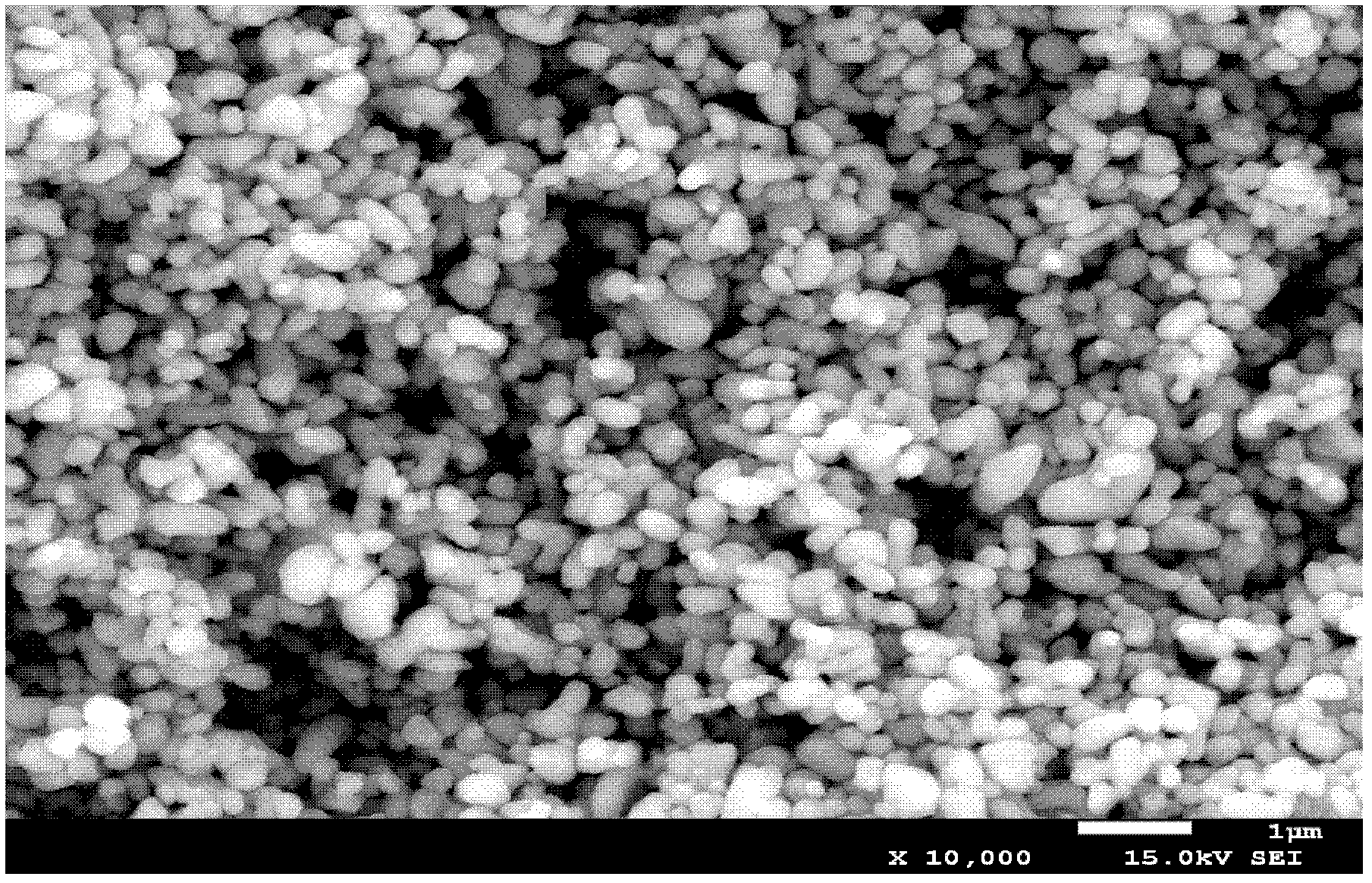

High-dispersity acidic copper plating additive as well as preparation method and application thereof

InactiveCN105734623AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of highly dispersive all-bright acidic copper plating of printed circuit boards, in particular to a highly dispersive acidic copper plating additive and its preparation method and application. A highly dispersed acidic copper plating additive: at least one divalent sulfide main brightener, at least one polyethylene glycol or polypropylene glycol or both block copolymer polymer inhibitors, at least one alkyl quaternary ammonium salt Type cationic surfactant, 5‑50ml / L sulfuric acid, 0.1‑4ml / L formaldehyde. Its preparation method is to slowly add a specified amount of concentrated sulfuric acid into water, stir evenly and cool to room temperature, then sequentially add the inhibitor, surfactant, main brightener and formaldehyde into the sulfuric acid aqueous solution, stir until completely dissolved Concentrate to the final volume to obtain the highly dispersed acidic copper plating additive of the present invention. The high-dispersion acidic copper plating additive of the invention is especially suitable for electroplating through-holes with high thickness-to-diameter ratio of printed circuit boards, and can obviously improve the dispersion ability of the plating solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

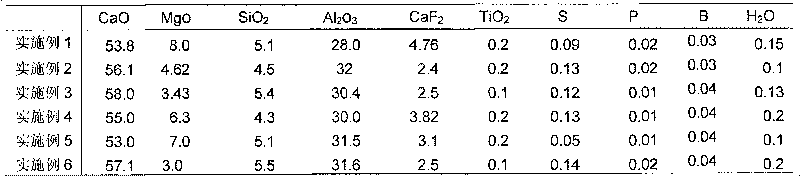

Premelted refining slag for refining low-oxygen steel by converter

InactiveCN101701281AImprove reducibilityMeet production needsManufacturing convertersProcess efficiency improvementChemical compositionSteelmaking

The invention discloses a premelted refining slag for refining low-oxygen steel by a converter, belonging to the technical field of metallurgy and steelmaking. The invention is characterized in that the premelted refining slag comprises the following chemical compositions in percentage by weight: 53.0-58.0% of CaO, 28.0-32.0% of Al2O3, 3.0-8.0% of MgO, less than or equal to 6.0% of SiO2, less than or equal to 5.0% of CaF2, less than or equal to 0.3% of TiO2, less than or equal to 0.05% of B, less than or equal to 0.03% of P and less than or equal to 0.2% of S. According to the aim and the function of the CaO-Al2O3 slag system, the invention designs premelted refining slag chemical composition proportioning; the premelted refining slag can be used for quickly forming refining slag with favourable mobility and reducibility as well as high alkalinity in the LF refining process so as to cause LF to adapt to the technical characteristics of the converter, thus efficiently finishing desulfuration and deoxidation, removing impurities and refining; the invention satisfies the production requirements of low-oxygen high-quality converter steel and realizes the aim of low-oxygen steel.

Owner:SHIJIAZHUANG IRON & STEEL

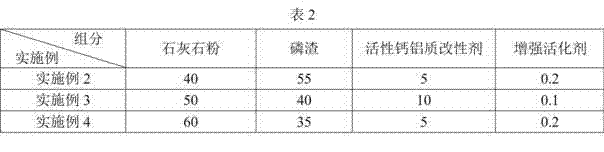

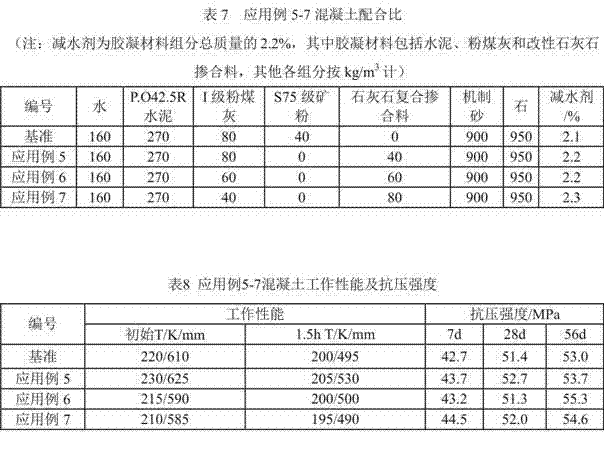

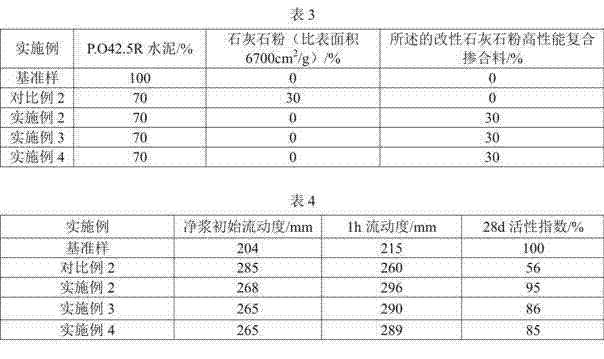

Modified limestone powder high-performance mineral admixture and preparation method thereof

The invention relates to a modified limestone powder high-performance mineral admixture and a preparation method thereof. The invention is characterized in that the modified limestone powder high-performance mineral admixture is prepared by mixing and grinding the following raw materials in parts by mass: 40-60 parts of limestone powder, 35-55 parts of phosphorus slag, 5-10 parts of active calcium aluminum modifier and 0.1-0.2 part of reinforced activator. The concrete mineral admixture prepared by the method solves the problems of high loss of concrete workability, low strength and the like in the common limestone powder admixture; when substituting 50-100% of I-grade fly ash or 20-50% of I-grade fly ash and 100% of S75-grade mineral powder in concrete by equal quality, the concrete mineral admixture can improve the concrete workability, and has the characteristics of quick development of early strength and stable later strength.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

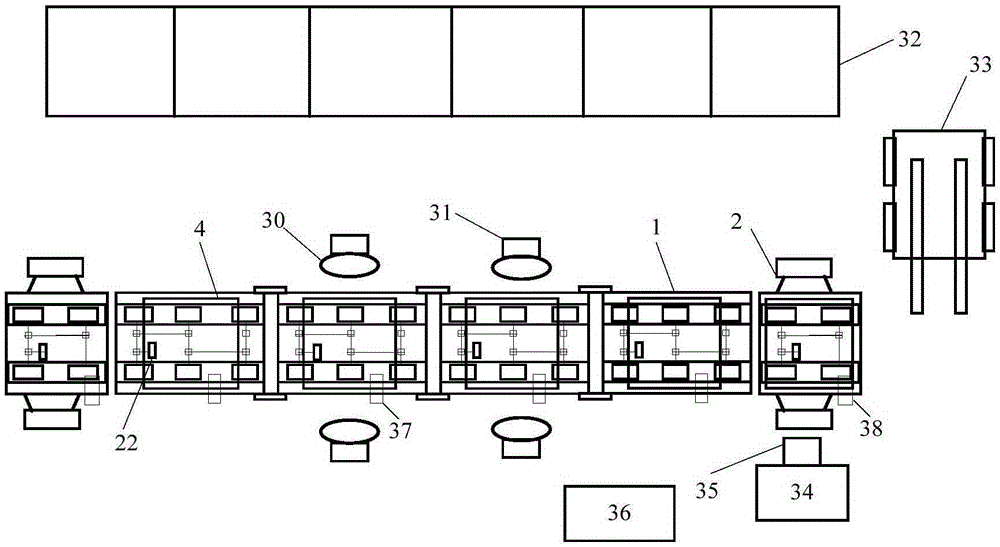

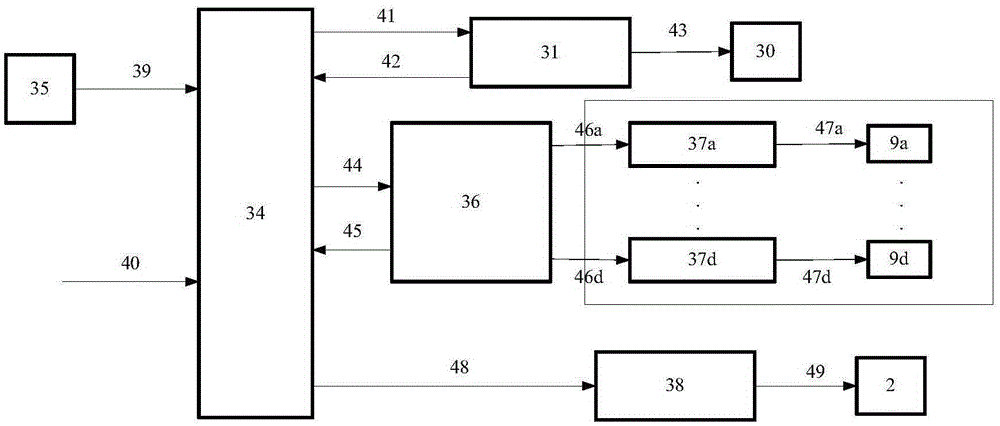

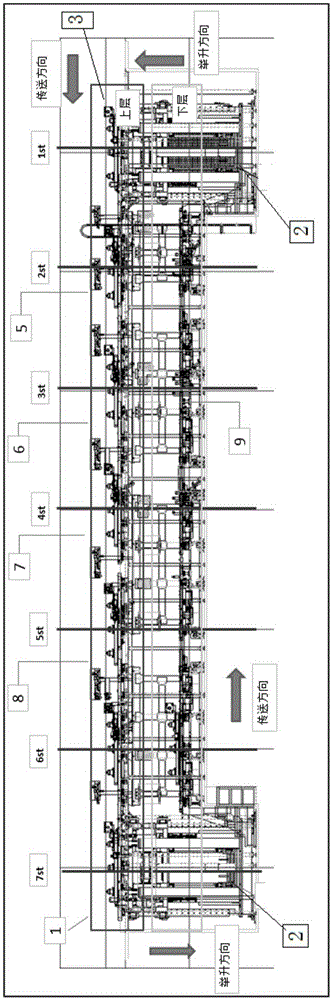

Reconfigurable automatic flexible welding production platform and operation method thereof

ActiveCN105252180ATo achieve high flexibility requirementsProduction task production capacity coordinationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRe design

The invention discloses a reconfigurable automatic flexible welding production platform and an operation method thereof. The reconfigurable automatic flexible welding production platform comprises a production line main body, an accompanying platform, an accompanying fixture, a lifting mechanism, welding robots, a welding robot control center, a fixture transfer trolley, a fixture base and a production platform control center, wherein the accompanying platform can move on a line body; the accompanying clamp is positioned on the accompanying platform; the lifting mechanism is positioned on two sections of the line body; the welding robots are positioned at the two sides of a line body welding station; the welding robot control center controls movement of the welding robots and welding action of a fixed welding gun; the transfer trolley is responsible for replacing a fixture; the fixture base stores fixtures for producing different kinds of assemblies; the production platform control center controls movement of the whole production platform, wherein the movement comprises operation of a welding production line main body and operation of the lifting mechanism, so that high-flexibility requirements of automatic welding production for various small assembly components are reached, and production capacity is re-designed for realizing coordination of production tasks and production capacity.

Owner:YANGZHOU XINLIAN AUTO PARTS +1

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Mold powder for continuous casting of high aluminium-titanium-rare earth steel

The invention discloses a mold powder for continuous casting of high aluminium-titanium-rare earth steel, which comprises the following compositions in percentage by weight: 20 to 40 percent of CaO, 30 to 50 percent of SiO2, 3 to 8 percent of F, 5 to 9 percent of Na2O, 0 to 5 percent of Li, 0.5 to 5 percent of C, less than 8 percent of Al2O3, less than 5 percent of MgO and the balance of inevitable impurities; and the alkalinity range of CaO / SiO2 is R+ / -0.05, wherein R is alkalinity and is equal to between 0.917 and 0.333M; and M is the sum of mass percent of Al, Ti and rare earth elements in molten steel. The mold powder improves the performance, can meet the requirement of the continuous casting of steel types such as Al, Ti, rare earth and the like, fully guarantees the thickness, lubrication and consumption of a melt cinder layer, avoids causing surface defects of casting blanks such as cinder inclusion, cracks and the like or causing steel leakage due to too big withdrawal resistance, and effectively guarantees smooth continuous casting process and the surface quality of the casting blanks so as to produce high-quality casting blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing sheet-like microcrystal cellulose and modification processing method

InactiveCN101070352AMaintain physical propertiesMaintain mechanical propertiesAcetic acidDispersed media

This invention relates to preparation method of a flakiness microcrystalline cellulose, as well as its surface reshaping method. The process: in water disperse medium, take reaction with sulfuric acid to gain flakiness microcrystalline cellulose, then surface by acetic acid esterification or SAA absorption modifing, repass wash, filter , dryness, gain the product. The mass ratio of water and cellulose is 3 to 25:1, sulfuric acid volumetric concentration for 30 to 80%, temperature for 10 - to 85 deg, time for 5 to 120 minutes. The mass ratio of acetic ester modifier or SAA and microcrystalline cellulose is 0.1 to 5: 100. The modifier not only keep the favorable physics and mechanical property of cellulose, but also improve dispersibility, greatly advance consistency with high molecular material, broaden the application area.

Owner:LUDONG UNIVERSITY +1

Method for sprouting and rapidly seedling maolai seed

InactiveCN102630470AImprove germination rateRaise the ratioSeed and root treatmentHorticultureAcid etchingCold storage

The invention provides a method for sprouting and rapidly seedling a maolai seed, comprising the following steps of: seed collection; seed meat and oil removal; acid etching treatment; hormone treatment; sand mixing and cold storage; sowing; sprout transplantation; and seedling management. By using the method for sprouting and rapidly seedling the maolai seed, provided by the invention, the annual germination rate and planting percent of seeds can be remarkably increased, the seed culturing period can be shortened, and the production cost can be reduced.

Owner:JIANGSU ACAD OF FORESTRY

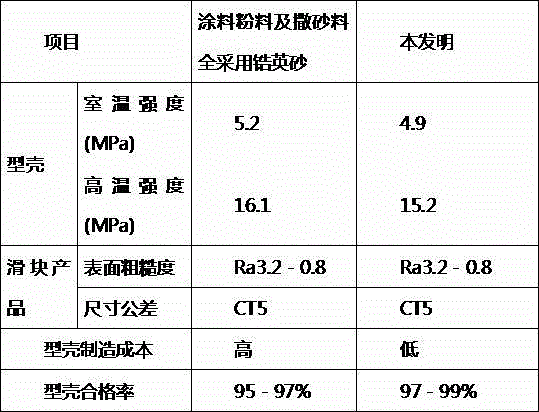

Preparation method of heat-resisting alloy sliding-block shell by investment casting

InactiveCN103600030AImprove room temperature strengthImprove pass rateFoundry mouldsFoundry coresAlloySurface coating

The invention discloses a preparation method of a heat-resisting alloy sliding-block shell by investment casting. The preparation method is characterized in that: the method comprises a first step of preparing coating, wherein surface coating comprises silica sol and a refractory powder material is fused alumina; and transition layer coating and back layer coating comprise the silica sol and a refractory powder material is one selected from the fused quartz, kaolin clinker and bauxite clinker; a second step of coating a wax mould with the surface coating, scattering the sand material of the fused alumina, drying and repeating for 2 times; coating the surface layer with the transistion layer coating, scattering one of the fused quartz, the kaolin clinker and the bauxite clinker, drying, and repeating for 5 times; and finally coating with a back layer coating, scattering one of the fused alumina, the kaolin clinker and the bauxite clinker and drying; and a third step of dewaxing and calcinating; and the shell produced by the method has advantages of high room-temperature strength and high-temperature strength, good internal surface quality, high percent of pass, low production cost and good economic benefit.

Owner:泰州枫叶冶金设备有限公司

Method for pellet formation using steel-making slurry

InactiveCN1594607ARaw material balling performance improvementReduce the requirement of raw material particle sizePellet FormationWater content

The invention relates to a pelletizing method using sludge of steel production and belongs to pelletizing technology in metallurgy field. The method comprises: adjusting sludge concentration to 10-40%, adding 3-10% (weight percentage) sludge in mixture of iron ore powder and bentonite, continuously spraying it in palletizing disk, The advantage of the method : material sphericity is improved greatly. Bentonite usage can reduce greatly in mixture, which promote the pelletizing quality. Pelletizing disk don't take on sandification. Aqueous sludge can minimize the extra water. The enterprise has electric furnace, open-hearth furnace, revolving furnace and pelletizing line can use the method.

Owner:攀钢集团成都钢铁有限责任公司

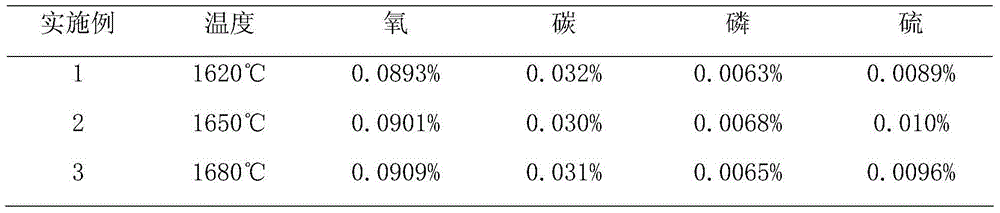

Ultralow sulfur steel quick smelting method

ActiveCN103898269AObvious slag desulfurization effectStable controlManufacturing convertersSmelting processMolten steel

The invention discloses an ultralow sulfur steel quick smelting method. The difficult points of slagging, deoxidizing and desulfurating in the smelting process of the ultralow sulfur steel ([S] is not more than 0.0010%) are successfully solved. The method comprises the following steps: pretreating molten steel to desulfurate and remove slag, deeply deoxidizing tapping aluminum block through a converter, modifying composite refined top slag, deoxidizing aluminum wire through a LF refining furnace, slagging through lime and feeding aluminum wire to trimming aluminum molten steel, combining the whole reasonable argon bottom blowing control in the smelting process of the LF furnace, fully playing the metallurgical thermodynamics and thermodynamics and kinetics of desulfuration, organically combining the diffusion deoxidization and sediment deoxidization, sufficiently evacuating deoxidization and desulfuration potential of the slag so that the sulfur content in the molten steel within 40min can be reduced to within 0.0010% through the LF refining furnace and the full oxygen content of casting blank is controlled within 0.0010%. The sulfur content control of the molten steel is stable, the casting blank is good in quality, the steel plate flaw detection yield can achieve above 99%, the ultralow sulfur steel production requirement is completely satisfied, and the smelting production rhythm and the continuous casting pouring furnace are guaranteed.

Owner:NANJING IRON & STEEL CO LTD

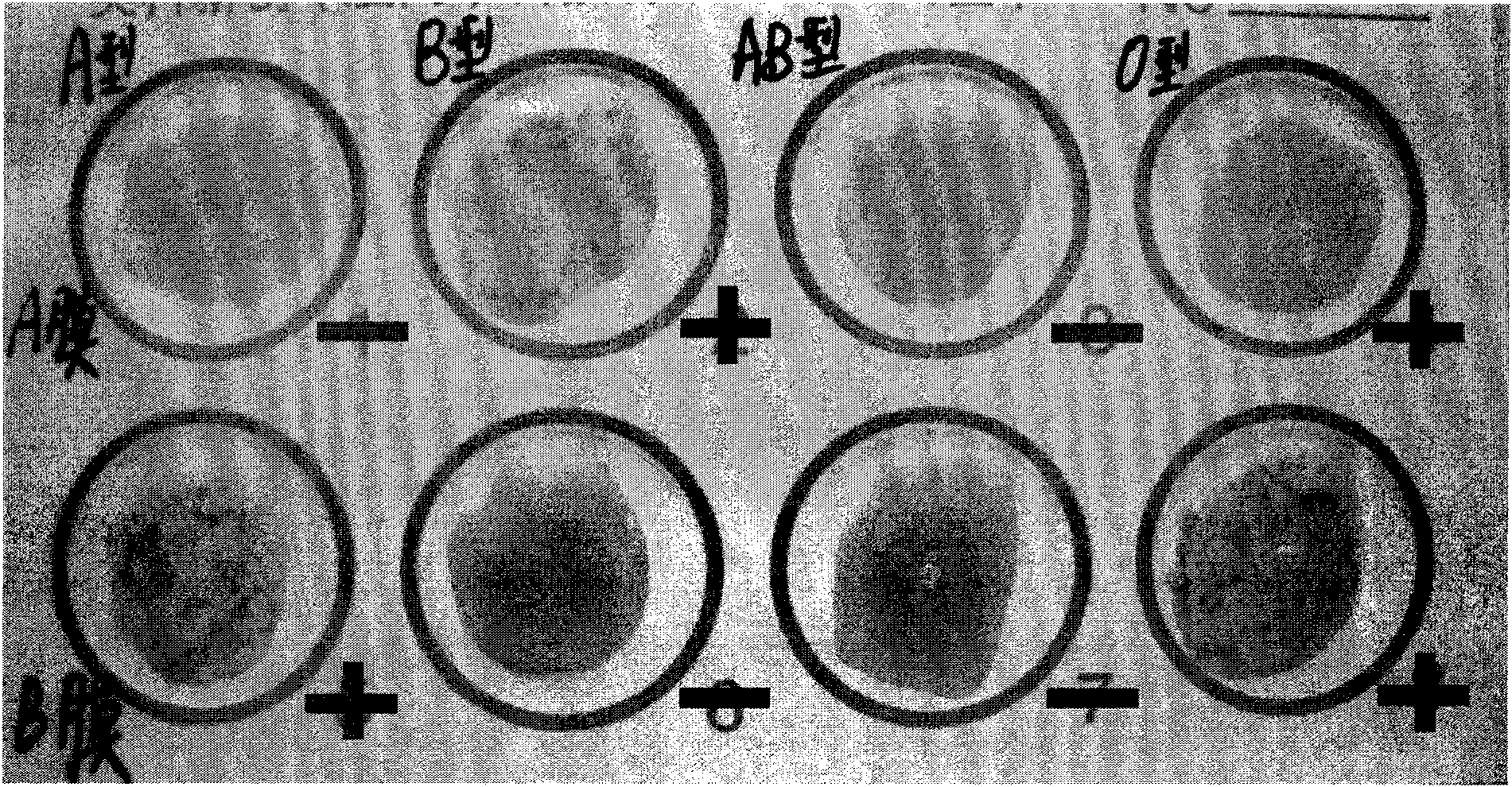

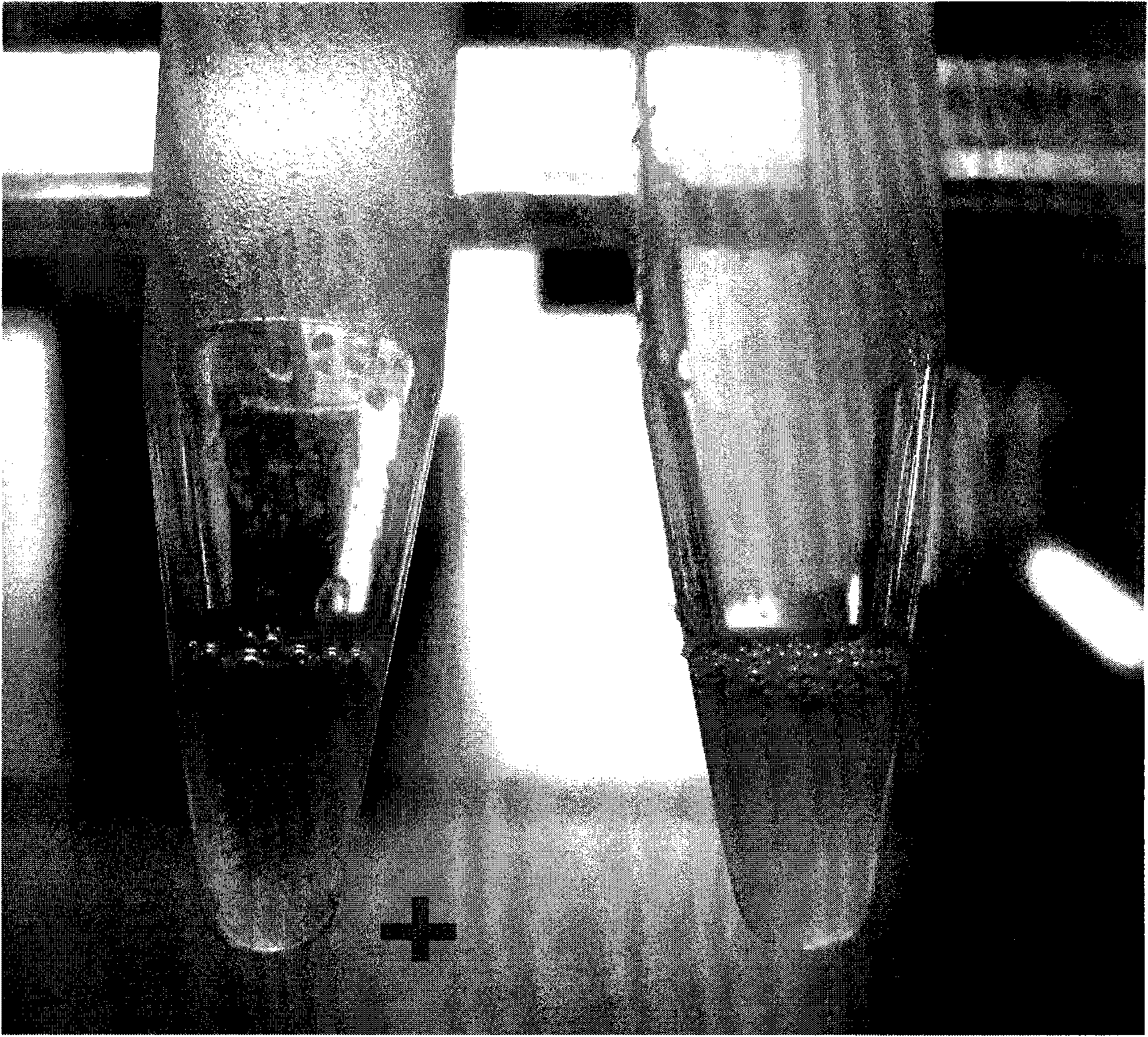

Human erythrocyte membrane antigen coated microsphere and application thereof

InactiveCN101957366AMaintain and preserve antigenic activityLong validity periodBiological testingAntiendomysial antibodiesMicrosphere

The invention provides a method for preserving the activity of a human cell membrane blood group antigen, which comprises the steps of: preparing an erythrocyte membrane blood group antigen extract, and then coating the prepared erythrocyte membrane blood group antigen on a solid microsphere so as to replace a fresh erythrocyte to be used for detecting a blood group antibody in a sample.

Owner:INTEC PROD INC

System and method for utilizing residual heat of electrolyzer low temperature flue gas

ActiveCN101435089AImprove work efficiencyMeet different needsHeat recovery systemsIncreasing energy efficiencySocial benefitsElectrolysis

The invention discloses a system and a method for utilizing low-temperature flue gas afterheat of an electrolytic bath. The system mainly comprises a heating system, a cooling system, a dust collecting device and a fume extractor, and utilizes energy cascade utilization, low-temperature afterheat recovery and a heat exchanger to absorb heat by classification from low-grade flue gas for cooling, heating and heat using of technological process. The method includes the following steps: when the low-temperature flue gas afterheat of the electrolytic bath passes through the heat exchanger, the heat exchanger is used for absorbing the heat in the flue gas, and converting the absorbed heat into liquid or steam to utilize, the dust collecting device is used for collecting dust in the flue gas after heat release and temperature reduction, and then the flue gas after dust collection is exhausted by the fume extractor. The invention solves the problem of utilization of the low-temperature flue gas afterheat of the electrolytic bath, realizes continuous supply of cooling and heating, can improve the dust collecting system efficiency of the electrolytic bath, save energy, lower consumption, reduce pollutants discharge, expand utilization ways of afterheat and reduce the production cost of enterprises, and has remarkable economic, environmental and social benefits.

Owner:北京佰能电气技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com