Premelted refining slag for refining low-oxygen steel by converter

A converter refining and refining slag technology, which is applied in the field of refining slag for converter steelmaking and its preparation, as well as premelted refining slag for converter refining of low-oxygen steel, which can solve the problems of increased difficulty in rhythm removal and refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

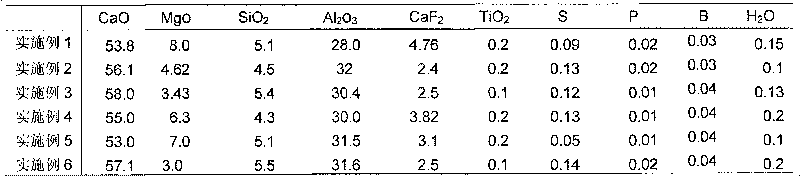

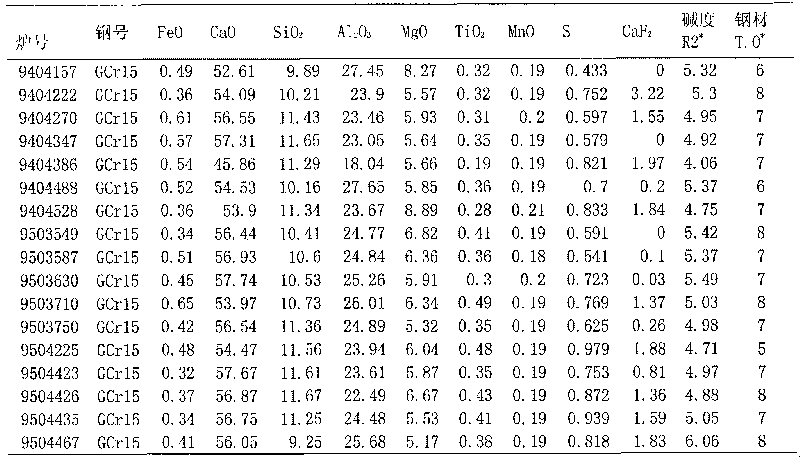

Examples

Embodiment Construction

[0009] LF refining slag is the most critical factor for LF to realize the refining task. Through refining slag, the desulfurization, deoxidation, and inclusion removal effects of refining can be realized. In long-term research and practice, LF refining slag mainly forms CaO-CaF 2 Slag system, CaO-Al 2 o 3 Slag system, CaO-Al 2 o 3 -CaF 2 Slag system, etc., in which CaO-Al 2 o 3 The slag system has many excellent metallurgical characteristics, such as high alkalinity, strong desulfurization ability, low oxygen potential, which can play a role in diffusion deoxidation, good fluidity, strong ability to absorb inclusions, fluorine-free or low-fluorine, and reduce the impact on the furnace lining. erosion, etc., due to its effect on CaO and Al 2 o 3 It has a strong holding capacity, so a large amount of lime, foaming agent, etc. can be added to form LF refining slag with strong desulfurization and deoxidation capabilities.

[0010] The present invention is based on CaO-Al ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com