Environment-friendly diatom ooze composite and preparation method thereof

A composite material and diatom mud technology, applied in the field of composite materials for construction, can solve the problems of construction, water absorption, reducibility, adsorption, decorative pulverization degree defects, etc., and achieve easy construction and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

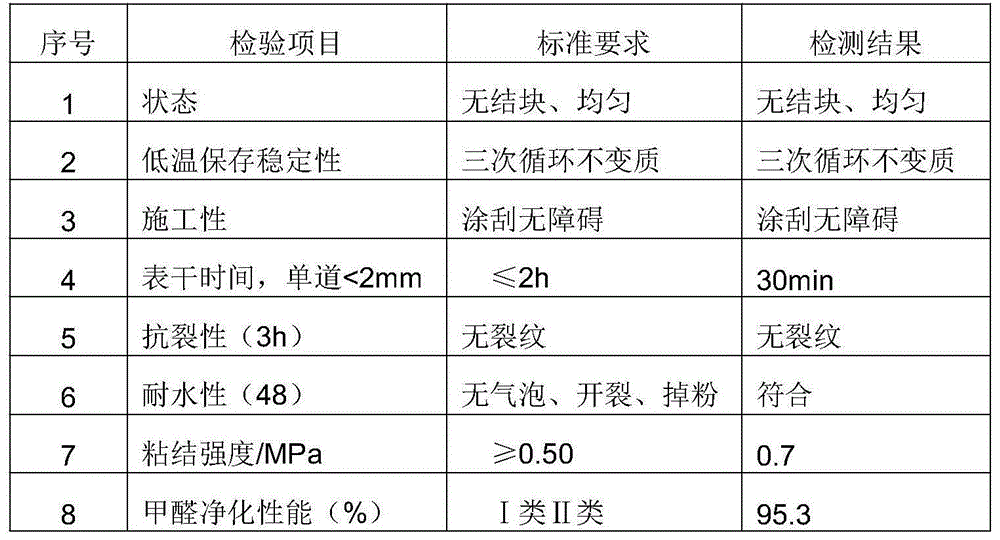

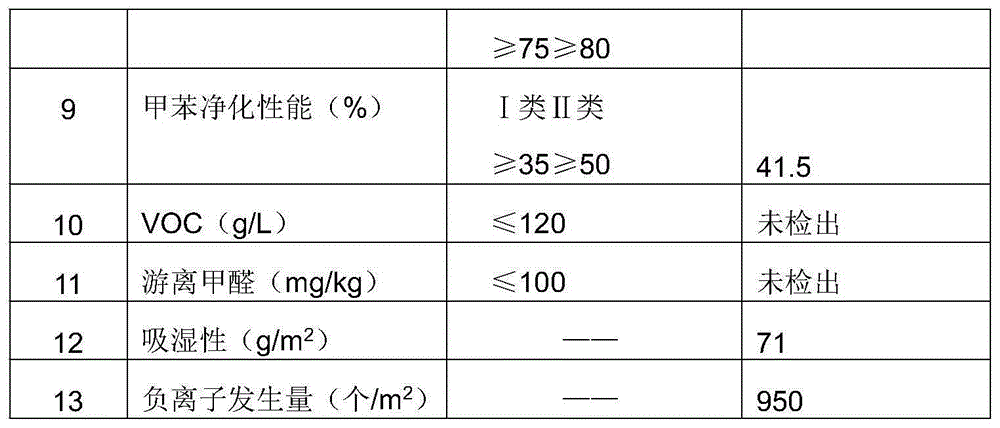

Image

Examples

Embodiment 1

[0024] A new type of environmentally friendly diatom mud composite material and its preparation method, the invention is composed of the following raw materials (total mass 100kg): diatomite 32%, heavy calcium powder 10%, quartz sand 10%, sodium bisulfate 10% %, calcined kaolin 9%, talc 8%, sepiolite 5.5%, iron oxide 4%, pregelatinized starch 2%, hydroxypropyl methylcellulose 3%, dispersible latex 2%, starch ether 2 %, sodium tripolyphosphate 0.5%, sodium hexametaphosphate 0.5%, polyvinyl alcohol 1%, guar gum 0.3%, nano titanium dioxide 0.2%.

[0025] The diatomaceous earth described in this embodiment is 400 mesh, and the whiteness is 90%.

[0026] The heavy calcium powder described in this embodiment is 800 meshes, the whiteness is 95%, and the calcium carbonate content is greater than 95%.

[0027] The quartz sand described in this embodiment is 80 mesh, SiO 2 The content is 98%, Fe 2 o 3 The content is 0.02%, and the refractoriness is 1750°C.

[0028] The calcined kao...

Embodiment 2

[0035] A new type of environmentally friendly diatom mud composite material and its preparation method, the invention is composed of the following raw materials in mass ratio (total mass 100kg): diatomite 35%, heavy calcium powder 12%, quartz sand 12%, sodium bisulfate 8 %, calcined kaolin 8%, talc 6%, sepiolite 5%, iron oxide 4%, pregelatinized starch 0.8%, hydroxypropyl methylcellulose 2%, dispersible latex 2%, starch ether 1.5 %, sodium tripolyphosphate 0.5%, sodium hexametaphosphate 0.5%, polyvinyl alcohol 2%, guar gum 0.5%, nano titanium dioxide 0.2%. Compared with Example 1, the workability of Example 2 is equivalent, the difference in drying time is not large, and it is slightly sticky when scraped.

[0036] The diatomaceous earth described in the present invention is 400 mesh, and the whiteness is 90%.

[0037] The heavy calcium powder described in the present invention is 800 meshes, the whiteness is 95%, and the calcium carbonate content is greater than 95%.

[003...

Embodiment 3

[0046] A new type of environmentally friendly diatom mud composite material and its preparation method, the invention is composed of the following raw materials (total mass 100kg): 37% of diatomite, 11% of heavy calcium powder, 15% of quartz sand, 6% of sodium bisulfate %, calcined kaolin 3%, talc 12%, sepiolite 6%, iron oxide 4%, pregelatinized starch 0.5%, hydroxypropyl methylcellulose 0.8%, dispersible latex 0.8%, starch ether 1 %, sodium tripolyphosphate 0.5%, sodium hexametaphosphate 0.5%, polyvinyl alcohol 0.8%, guar gum 0.6%, nano titanium dioxide 0.5%. Compared with Example 1, the workability of Example 3 is equivalent, the difference in surface dry time is increased by 5 minutes, sticky when applied and scratched, and water absorption is increased.

[0047] The diatomaceous earth described in the present invention is 400 mesh, and the whiteness is 90%.

[0048] The heavy calcium powder described in the present invention is 800 meshes, the whiteness is 95%, and the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com