Preparation method of polyester acrylate hybrid aqueous dispersion

A technology of polyester acrylate and acrylate, which is applied in the field of preparation of new polyester acrylate hybrid water dispersions, can solve the problems of high solvent content of dispersions, low gloss of coatings, poor water resistance, etc., and achieve dispersion process Simple and environmentally friendly, good water resistance, and the effect of improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

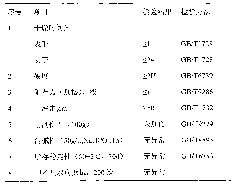

Image

Examples

Embodiment 1

[0042] (1) Preparation of hydroxyacrylate resin

[0043] First add 280g of propylene glycol methyl ether acetate into the reaction kettle with a condensing device and a stirring rod, and raise the temperature to the reflux temperature of 130°C while feeding nitrogen gas; after constant temperature, start to drop 200g of methyl methacrylate, hydroxypropyl acrylate A mixed solution of ester 300g and tert-amyl peroxyacetate 13.5g. Control the dropping speed, add the monomer mixture within 2 to 3 hours, keep it for 0.5 to 1 hour, then add a mixed solution of 1.5g initiator and 15g propylene glycol methyl ether acetate, keep warm for 2 to 3 hours, and measure the hydroxyl The conversion rate of the acrylate resin reaches more than 98%, and then drops to room temperature.

[0044] The obtained hydroxyacrylate resin is characterized by the following methods:

[0045] Acrylic resin molecular weight test: adopt the Waters 515 gel chromatograph of American Waters company to measure; ...

Embodiment 2

[0074] Embodiment 2: the preparation of polyester acrylate hybrid aqueous dispersion

[0075] First drop into the hydroxyacrylic acid ester resin 138g of the step (1) of embodiment 1 in the reactor that has condensing device and stirring bar, 1,4-butanediol 221g, adipic acid 320g, trimethylol propane 18g, 168g of the intermediate in step (2) of Example 1, control the heating rate for about 30 minutes and raise the temperature to 160°C while blowing nitrogen gas. After 1 hour of heat preservation, the temperature rises to 220°C. Continue to keep heat for 2 hours, then cool down to 140°C, and then add hydroxyl Take 262g of acrylic resin prepolymer, raise the temperature to 220°C, and continue to react for 1h until the acid value of the resin is ≤15mgKOH / g. Cool the resin solution to about 70°C, pour it into a container, then slowly add 780g of deionized water dropwise, stir and disperse for 40min at 2500 rpm under a high-speed disc disperser to obtain the product. Product techn...

Embodiment 3

[0078] Embodiment 3: the preparation of polyester acrylate hybrid aqueous dispersion

[0079] First drop into the hydroxyacrylate resin 148g of the step (1) of embodiment 1 in the reactor that has condensing device and stirring bar, diethylene glycol 245g, adipic acid 320g, trimethylolpropane 18g, embodiment 1 168g of the intermediate in step (2), control the heating rate for about 30 minutes and raise the temperature to 160°C while blowing nitrogen gas. After 1 hour of heat preservation, the temperature rises to 220°C. Continue to keep heat for 2 hours, then lower the temperature to 140°C, and then add hydroxyacrylic resin for pretreatment Polymer 252g, heat up to 220°C, continue to react for 1h until the acid value of the resin is ≤15mgKOH / g. Cool the resin solution to about 70°C, pour it into a container, then slowly add 790g of deionized water dropwise, stir and disperse for 50min at 2500 rpm under a high-speed disperser to obtain the product. Product technical indicators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com