Patents

Literature

51results about How to "Achieving water-based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

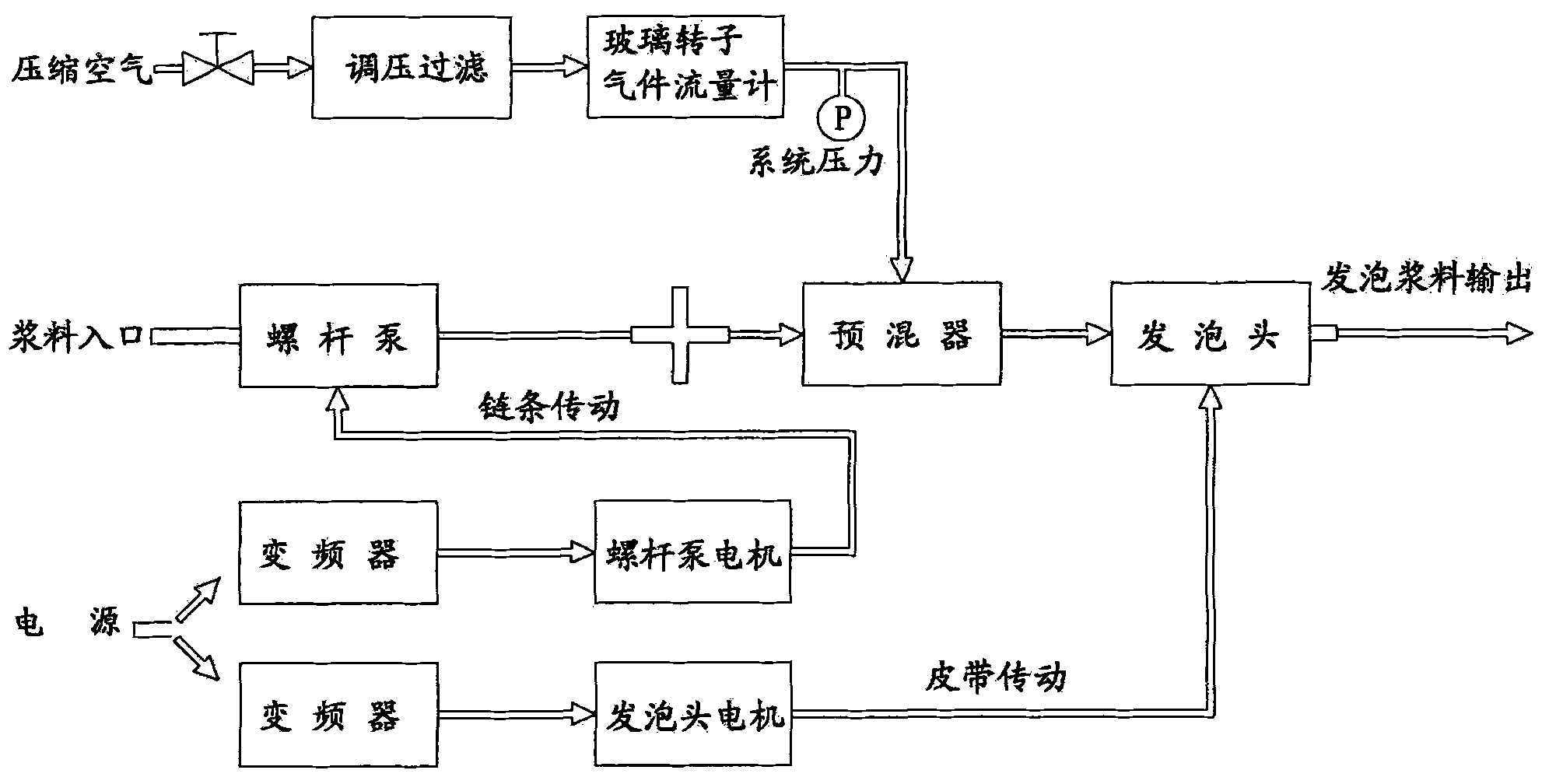

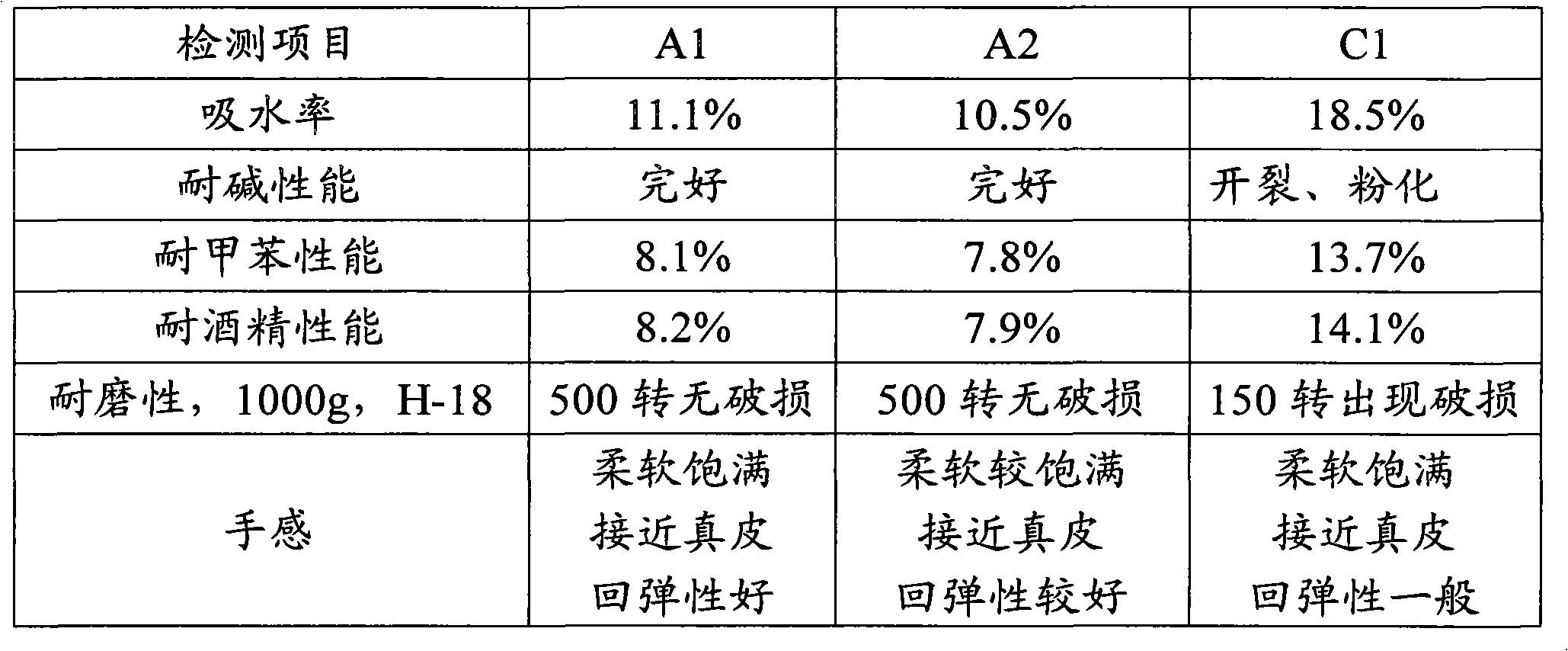

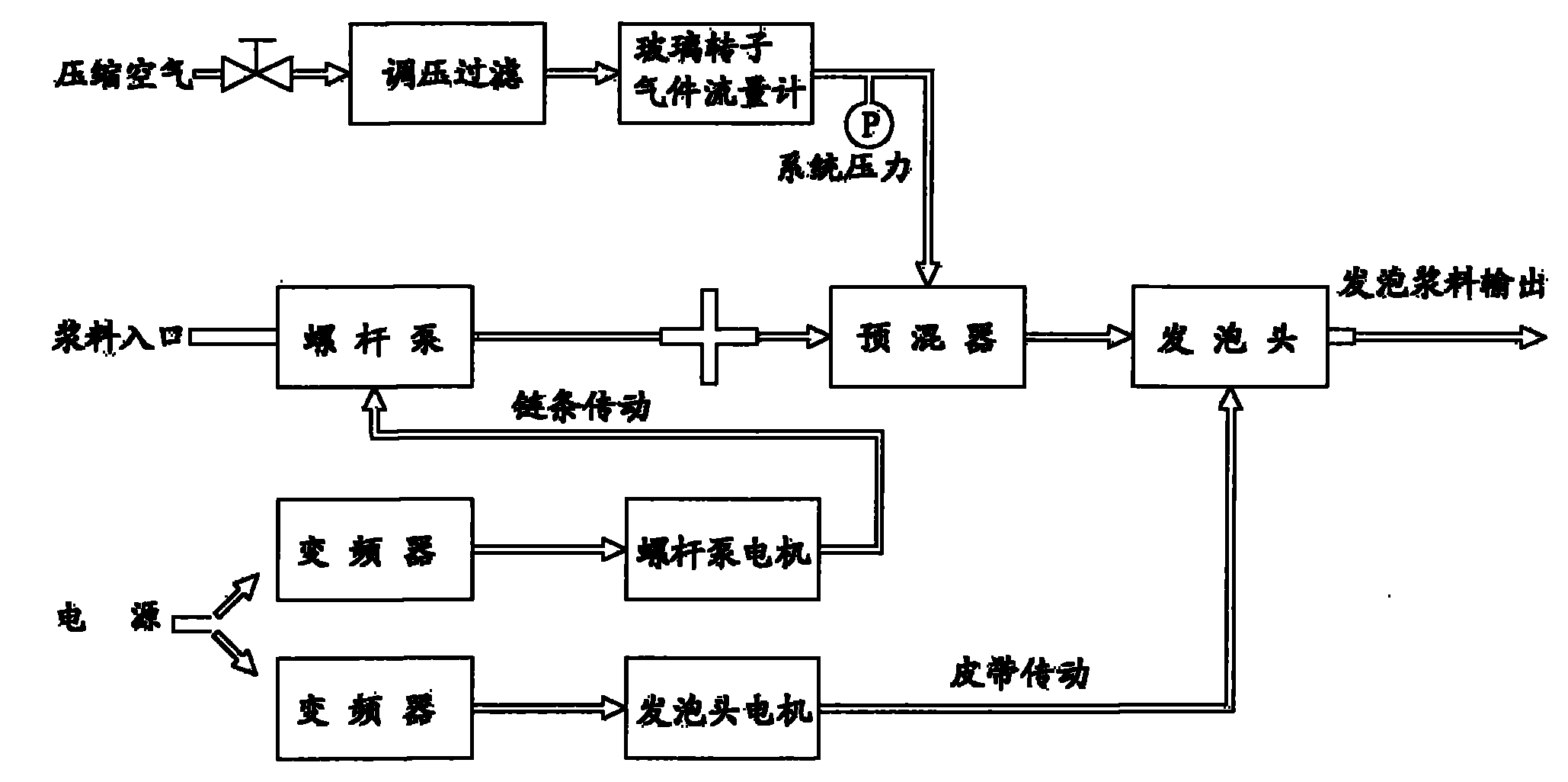

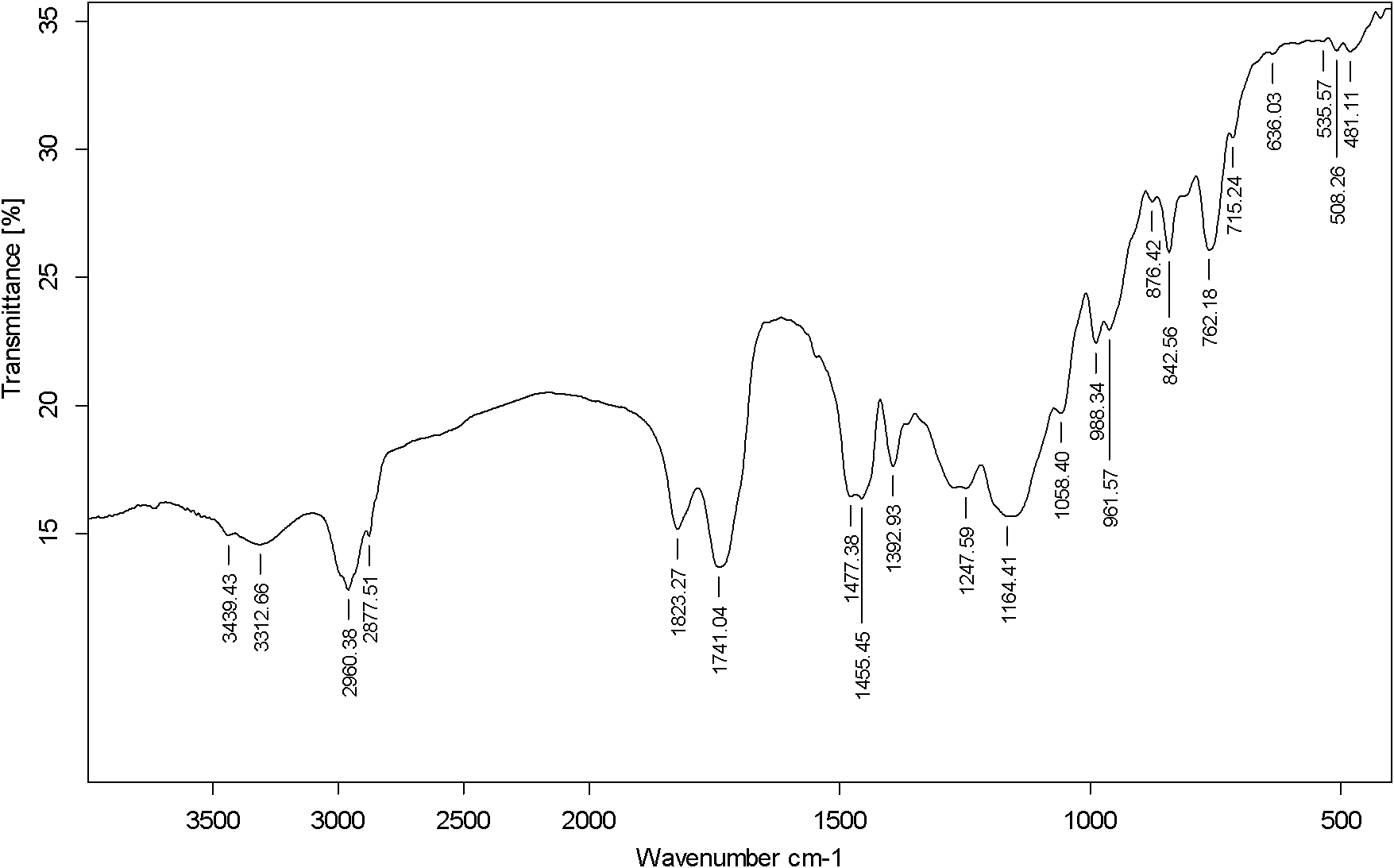

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

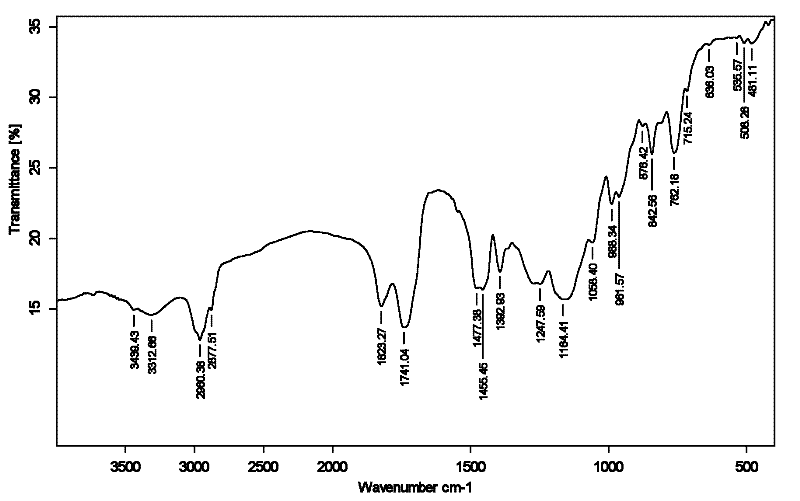

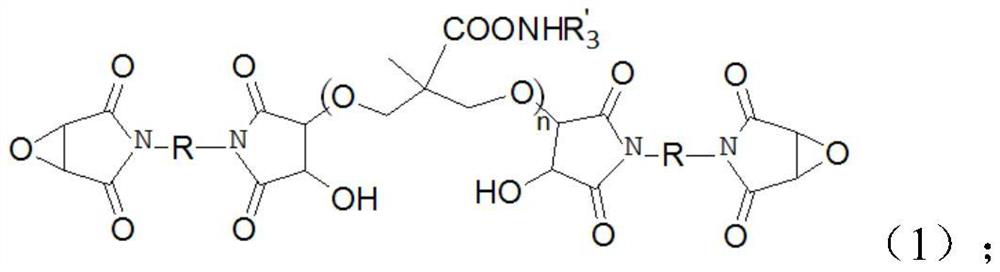

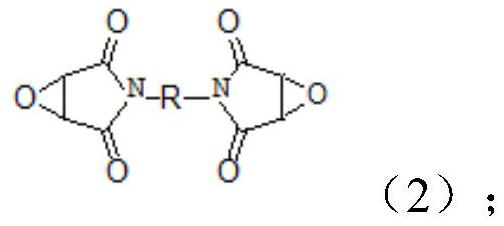

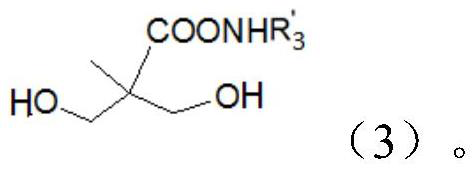

Water-based non-isocyanate polyurethane and preparation method thereof

The invention provides water-based non-isocyanate polyurethane (NIPU) and a preparation method thereof. The water-based non-isocyanate polyurethane provided by the invention is water-dispersed or water-soluble resin prepared with cyclic carbonate functionalized prepolymer and dual or multi-element amino compounds. Compared with the traditional polyurethane, the water-based non-isocyanate polyurethane contains no isocyanate and thus has no toxicity. Therefore, the water-based non-isocyanate polyurethane can be used as film-forming resin for a water-based coating. The preparation method comprises the following steps: polymerization of one or a plurality of unsaturated monomer(s) containing cyclic carbonate groups and a hydrophilic unsaturated monomer through free radical solution, neutralization and emulsification for preparation of a water dispersion of cyclic carbonate functionalized prepolymer, and reaction of the water-dispersed cyclic carbonate functionalized prepolymer and a dual amino compound or a multi-element amino compound, thereby preparing the dispersion of the water-based non-isocyanate polyurethane (NIPU).

Owner:HUAZHONG UNIV OF SCI & TECH

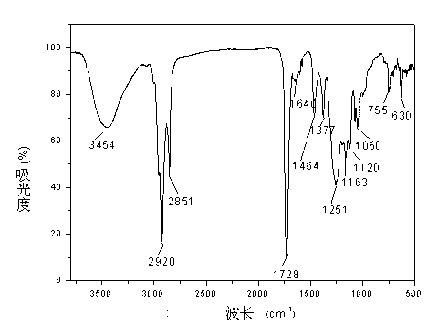

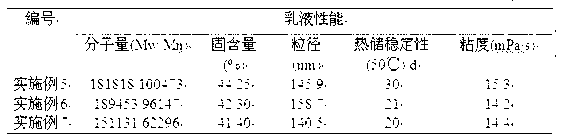

Silicone modified acrylic ester emulsion and preparation method thereof

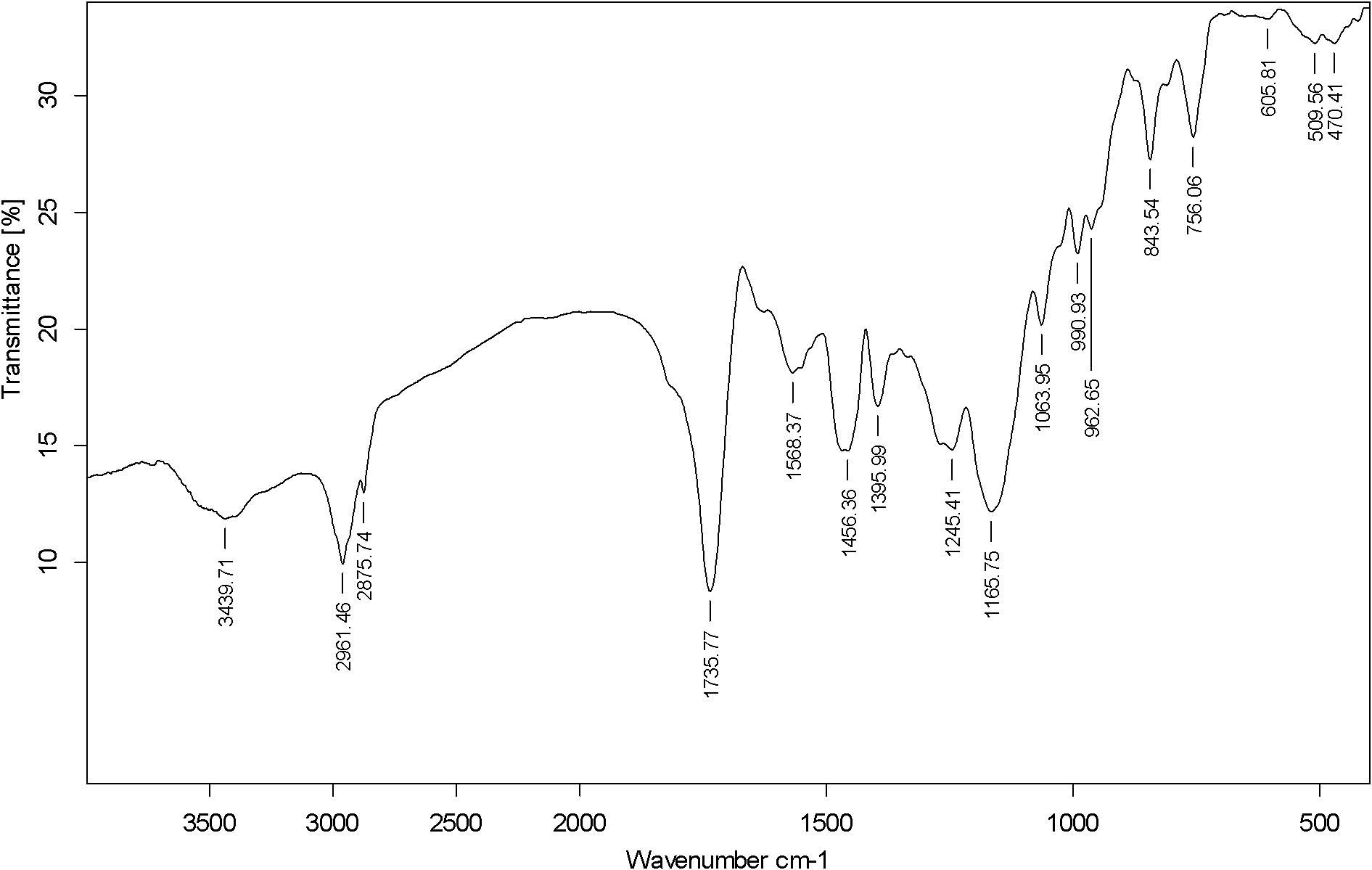

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Preparation method of polyester acrylate hybrid aqueous dispersion

InactiveCN101824209AAchieve chemical modificationImprove stabilityPolyurea/polyurethane coatingsPolyesterOrganic solvent

The invention relates to a preparation method of polyester acrylate hybrid aqueous dispersion, which belongs to the field of chemical coatings, and the preparation method comprises four steps of synthesizing hydroxyl acrylate resin, preparing an intermediate, preparing polyester acrylate resin and dispersing with deionized water. The preparation method effectively combines the advantages of polyester and acrylic resin, the prepared stable dispersion can be used as the hydroxyl resin component of a dual-component polyurethane coating for preparing a high-performance waterborne dual-component polyurethane coating with hydrophilic polyisocyanate, and a coating film has excellent performance; in addition, the preparation of the dispersion does not use amine as a neutralizer, thereby avoiding the smell caused by the amine and simplifying the process; and only a small amount of cosolvent is adopted in the dispersion, and the content of an organic solvent in the coating is low.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

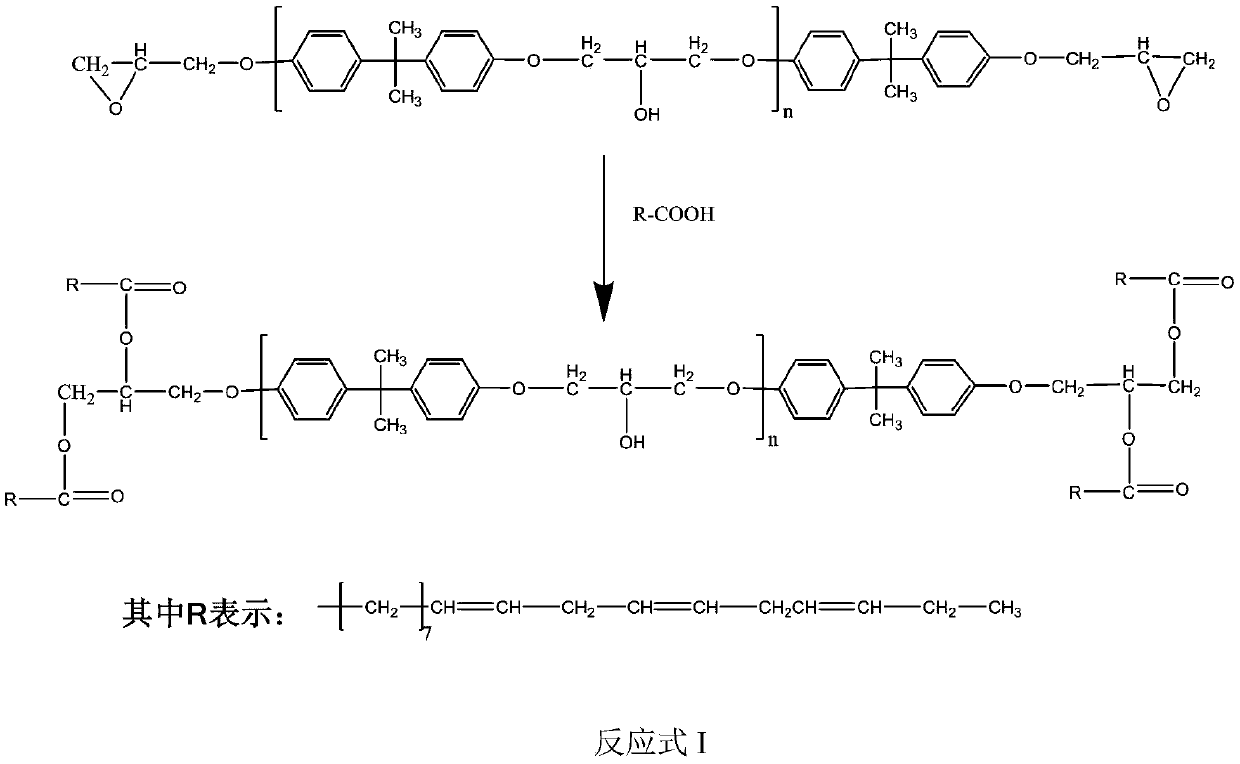

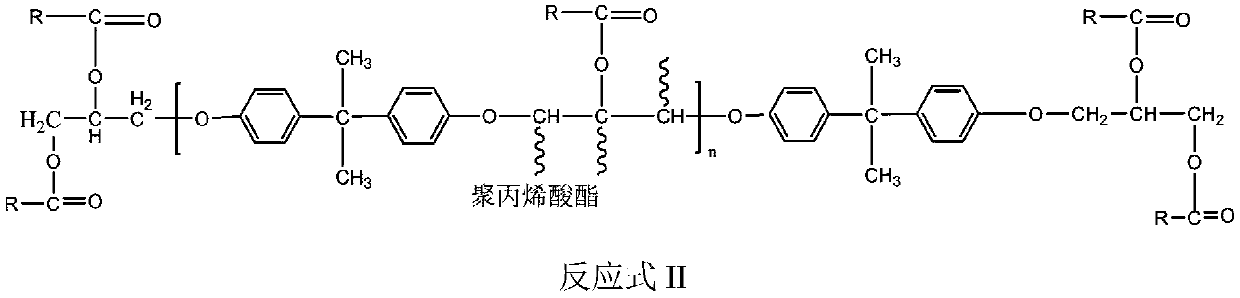

Process for preparing water soluble epoxy resin grouting agent

The invention relates to a process for preparing water soluble epoxy resin grouting agent which consists of, introducing carboxyl radicals onto the molecular matrix of the epoxy resin, preparing water-based epoxy resin by neutralizing with neutralization agent, introducing double bonds to both ends of the molecular chain, employing water-soluble redox initiation system to produce water non-soluble gel through radical polymerization reaction. The invention can be applied to realize epoxide aquosity.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

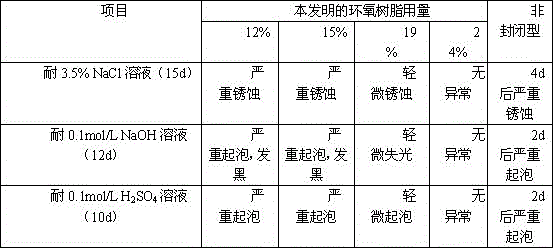

High-performance easy-construction two-component aqueous epoxy zinc-rich coating and preparation method thereof

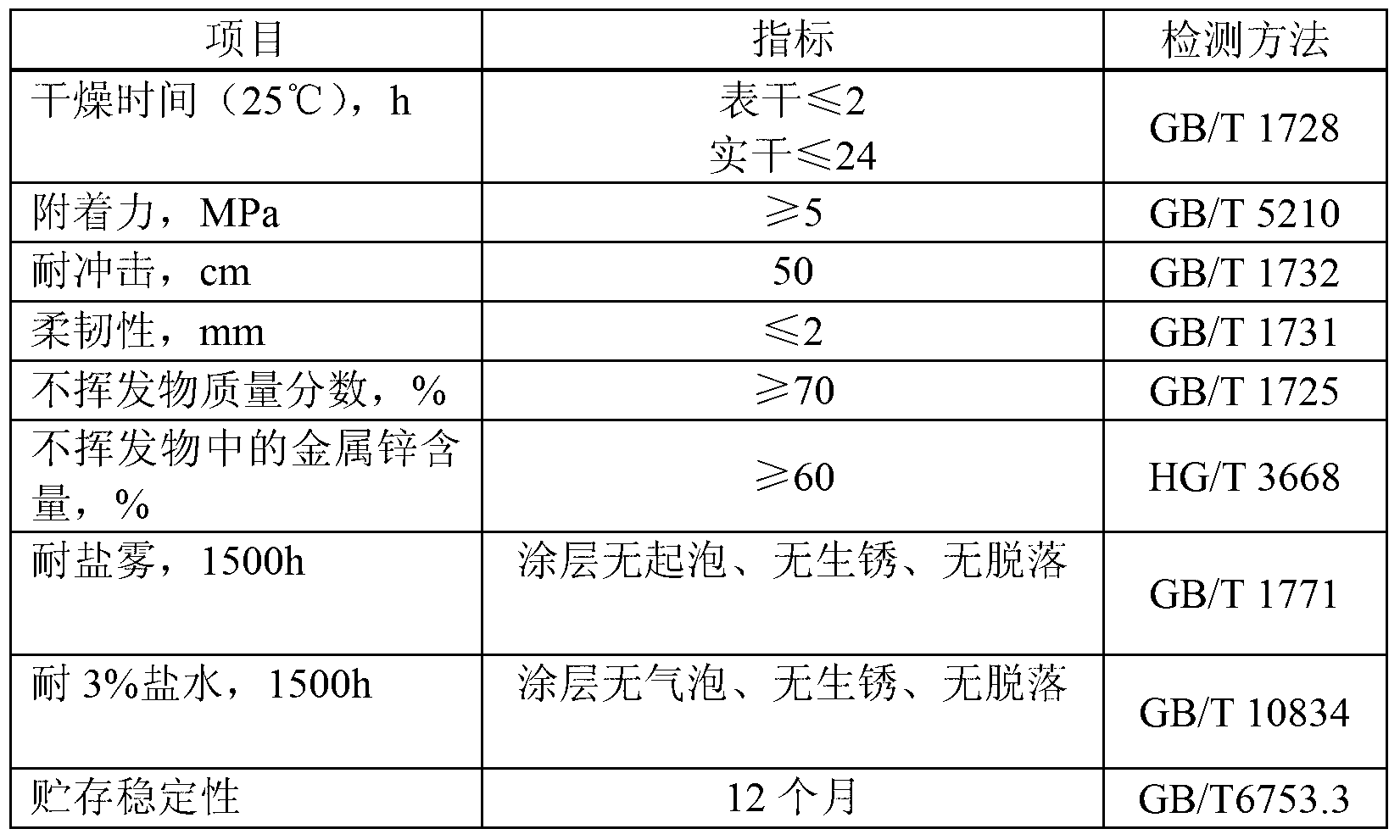

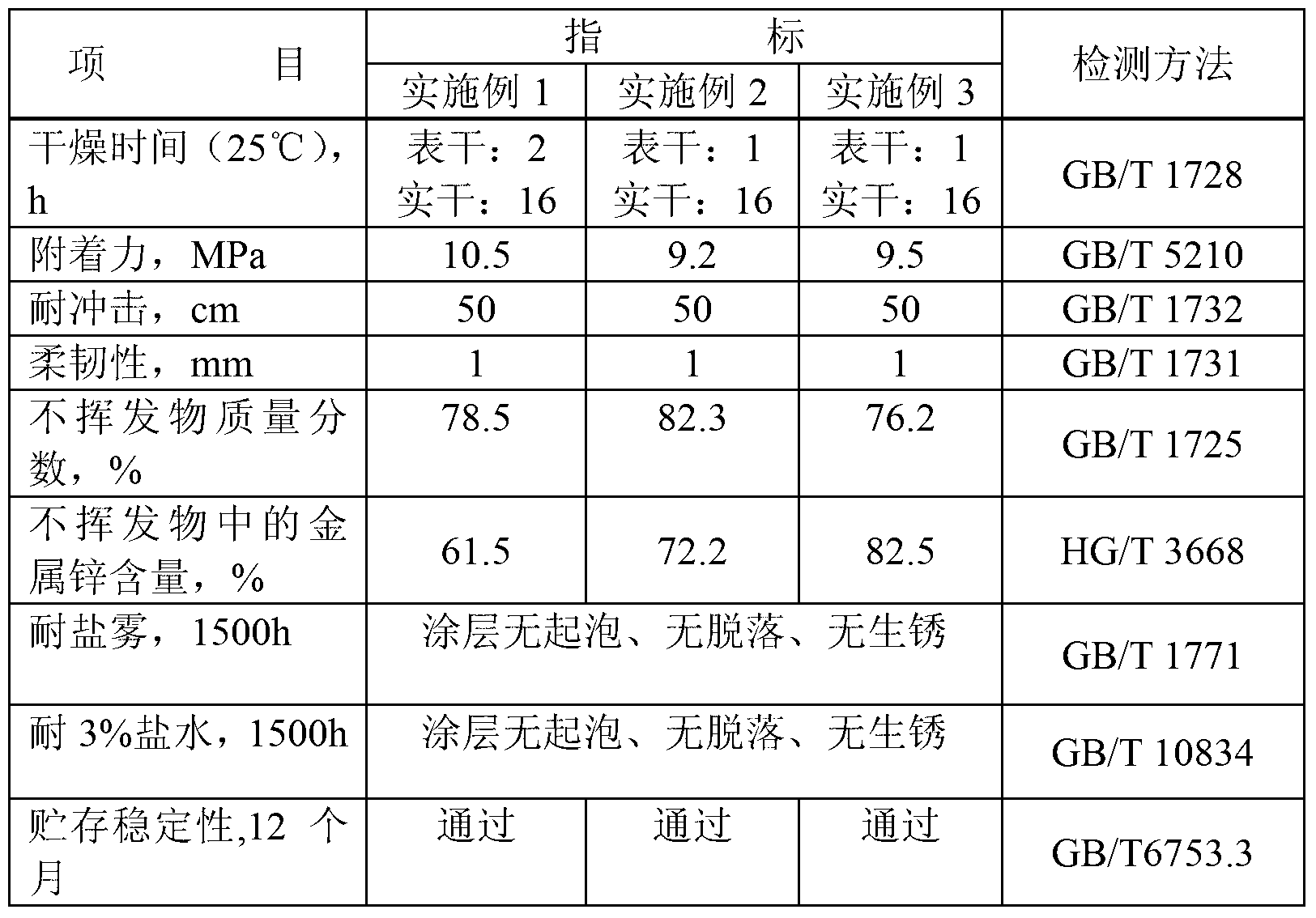

ActiveCN103319981AModerate viscosityEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

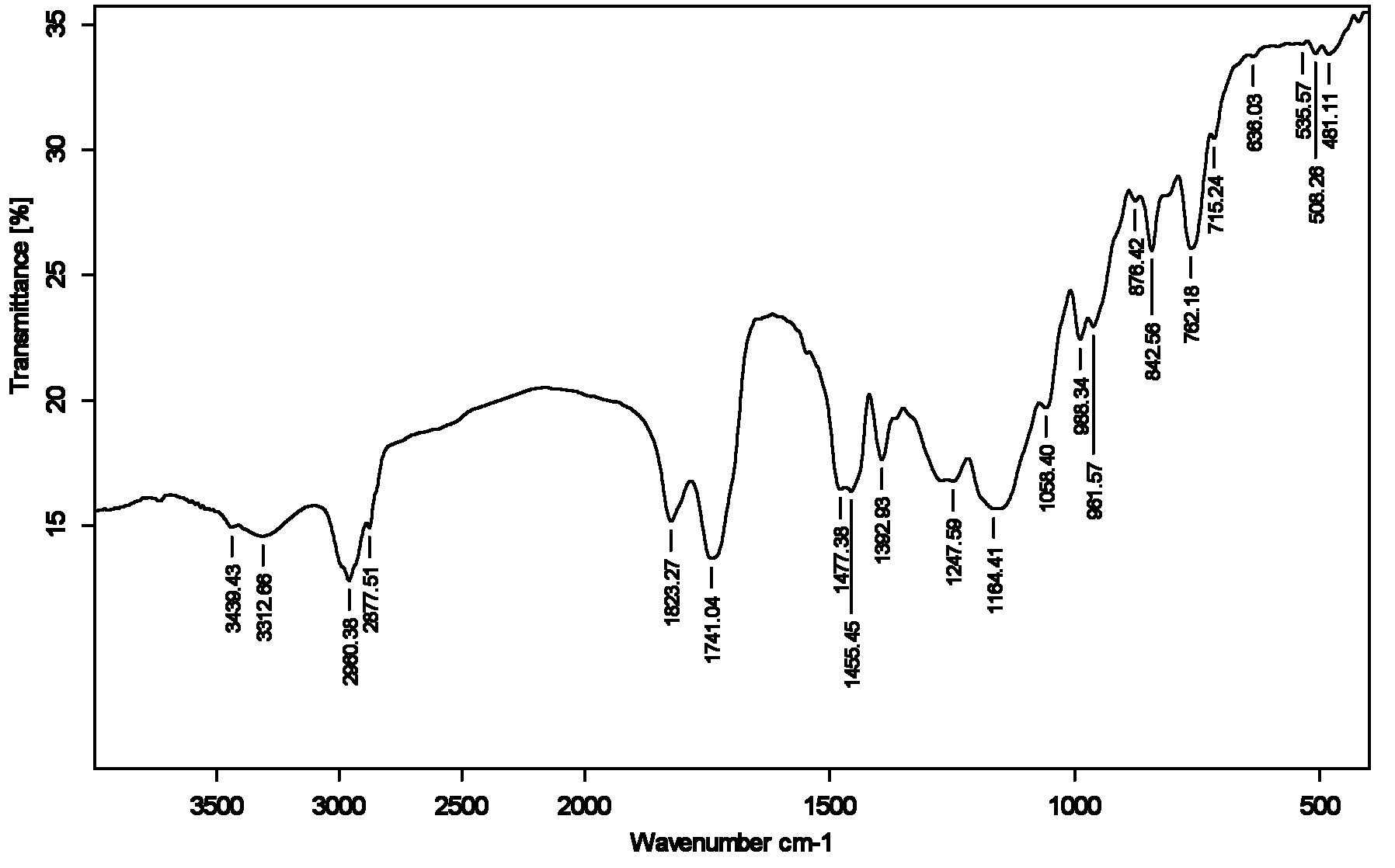

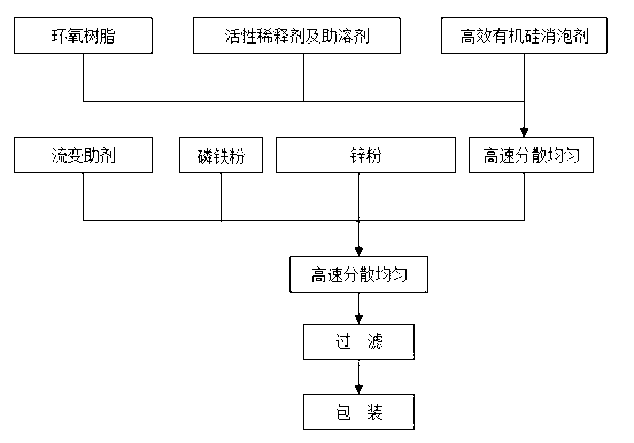

The invention relates to an easy-construction two-component packaging aqueous epoxy zinc-rich coating. The coating selects a low-molecular-weight epoxy resin, an active diluent, a high-efficiency antifoaming agent, a wetting dispersant, ultrafine zinc powder, a self-emulsifying aqueous epoxy hardener, a cosolvent and water as raw materials. The aqueous epoxy zinc-rich coating has the advantages of good corrosion resistance, realization of resisting salt spray for 1500h, no foaming, rust or shredding of the coat of the coating, according with requirements of HG / T3668-2009 Zinc Rich Primer, good application performance, convenient onsite use, realization of the thickness of the once-formed coat of above 80mum, 1h surface drying and 16h hard drying at 25DEG C, and satisfying of the steel structure anticorrosion construction requirement. The aqueous epoxy zinc-rich coating can be applied to the anticorrosion of steel structures comprising ships, bridges, sea engineering apparatuses and the like, and can also be applied to the steel plate pretreatment streamline as a workshop primer.

Owner:XIAMEN SUNRUI SHIP COATING

Preparation method of acrylic-modified water-based tall oil alkyd resin emulsion

ActiveCN102796228AEasy to reuseIn line with the national policy of developing circular economyPolyesterPolymer science

The invention relates to a preparation method of an acrylic-modified water-based tall oil alkyd resin emulsion, which comprises the following steps: (1) reacting dibasic acid with -SO3M group with dibasic alcohol to prepare a polyester intermediate; (2) reacting the polyester intermediate, vegetable oil fatty acid, polybasic alcohol and polybasic acid, and dispersing with deionized water to prepare an alkyd resin water dispersion; and (3) reacting an acrylic monomer and the alkyd resin water dispersion to prepare the acrylic-modified water-based tall oil alkyd resin. The acrylic-modified water-based tall oil alkyd resin prepared by the method has the advantages of no emulsifier, almost zero VOC (volatile organic compound) content, low viscosity, high storage stability, high solid content, high drying and curing rate and high hardness, does not need an amine neutralizer for neutralization, and can be used in metal anticorrosive paint, woodware paint and the like. The coated film has the advantages of quick drying, high hardness, favorable mechanical properties and high corrosion resistance.

Owner:HUNAN UNIV

Chromium-free passivation solution and preparation method thereof

InactiveCN103866304AImprove corrosion resistanceImprove stabilityMetallic material coating processesEpoxyChromium free

The invention discloses a chromium-free passivation solution comprising 15-60% of modified waterborne epoxy resin, 2-5% of silica sol and additives. The chromium-free passivation solution has the beneficial effects that 1, embossed aluminum plates having required high corrosion, acid and alkali resistance and hardness can be produced by directly applying the chromium-free passivation solution onto the embossed aluminum plate in a roller coating manner; 2, the chromium-free passivation solution has strong stability and good self-crosslinking properties, so that the coating having excellent overall performance can be obtained; 3, water-based modification of epoxy can be achieved, and good self-crosslinking properties are realized by introducing a variety of functional groups into grafting monomers of the modified waterborne epoxy resin, so that corrosion resistance is improved and the salt spray resistance can be improved by more than 100 hours; 4, the amino modified silane is used for chain extension of the grafted epoxy resin in the chromium-free passivation solution instead of the anodizing solution disclosed by the invention, and the adhesion between the coating and embossed aluminum plate is greatly improved by introducing siloxane groups; 5, the hardness of the film is greatly improved by adding silica sol in the formula, and the hardness of the coated embossed aluminum plate reaches 6H above.

Owner:WENZHOU WANZHONG SURFACE TREATMENT TECH CO LTD

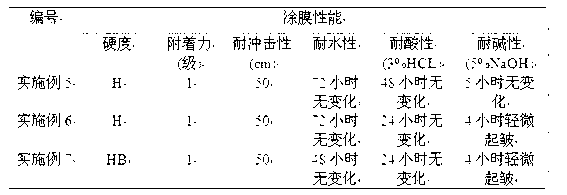

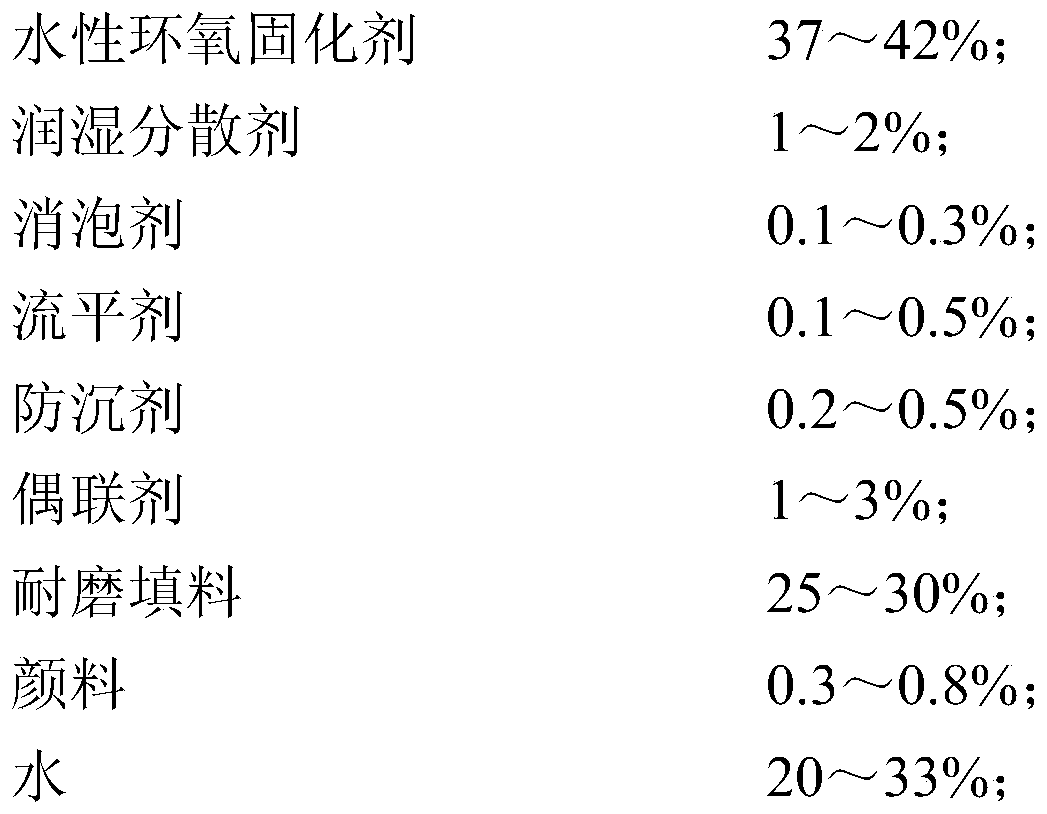

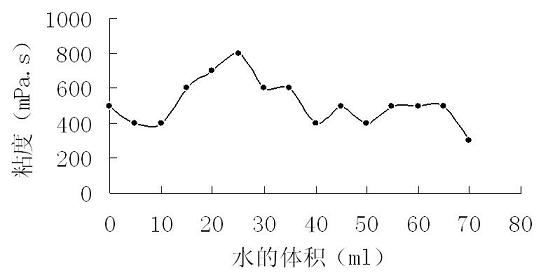

Water-based epoxy wear-resistant floor coating and preparation method and application thereof

InactiveCN109796842AImprove bindingImprove adhesionEpoxy resin coatingsFlooringEnvironmental resistanceWater based

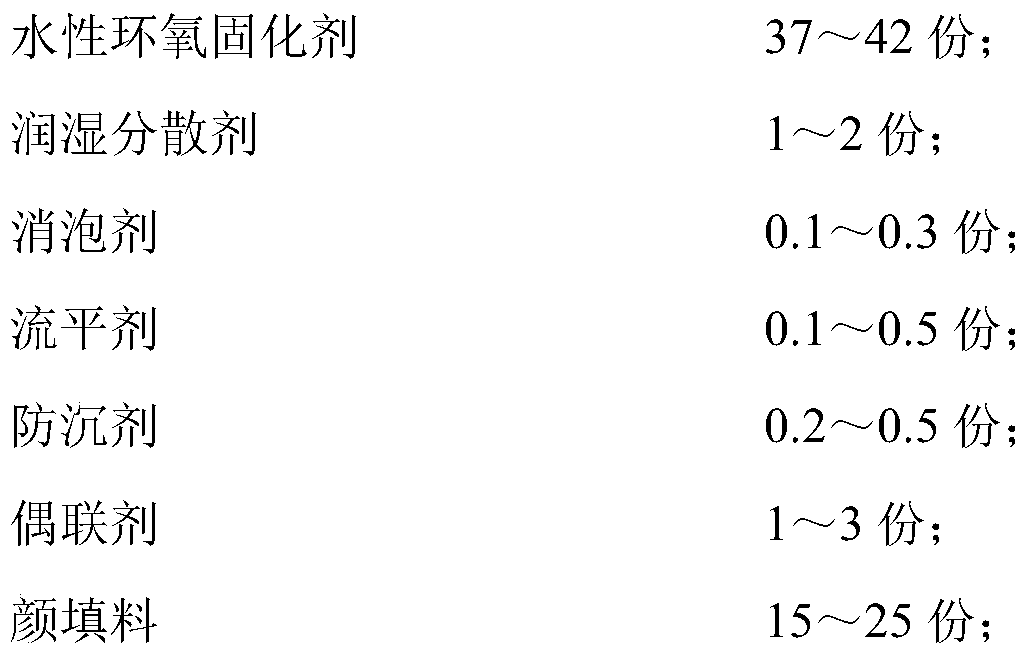

The invention relates to the technical field of environment-friendly coatings, in particular to a water-based epoxy wear-resistant floor coating and a preparation method and application thereof. The water-based epoxy wear-resistant floor coating comprises a composition A and a composition B, wherein the mass ratio of the composition A to the composition B is 1:(3.8-4.6); the composition B is a water-based epoxy emulsion; the composition A is prepared from, by mass, 37-42% of a water-based epoxy curing agent, 1-2% of a wetting dispersant, 0.1-0.3% of a defoaming agent, 0.1-0.5% of a leveling agent, 0.2-0.5% of an anti-settling agent, 1-3% of a coupling agent, 25-30% of a wear-resistant filler, 0.3-0.8% of pigments and 20-33% of water. The coating has excellent physical properties and greatwear resistance, can be applied to ground with a large pressure load and is long in service life.

Owner:洛阳双瑞防腐工程技术有限公司

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108AGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxySynthesis methods

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparing antiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

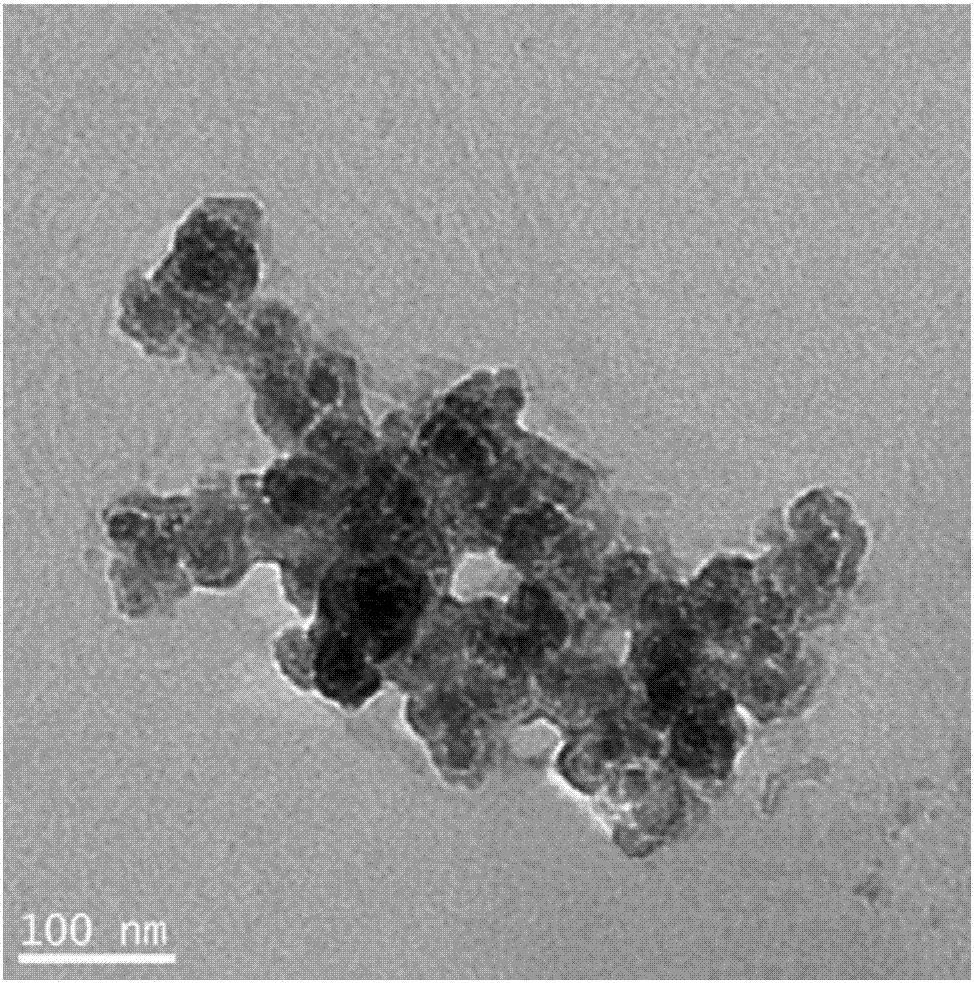

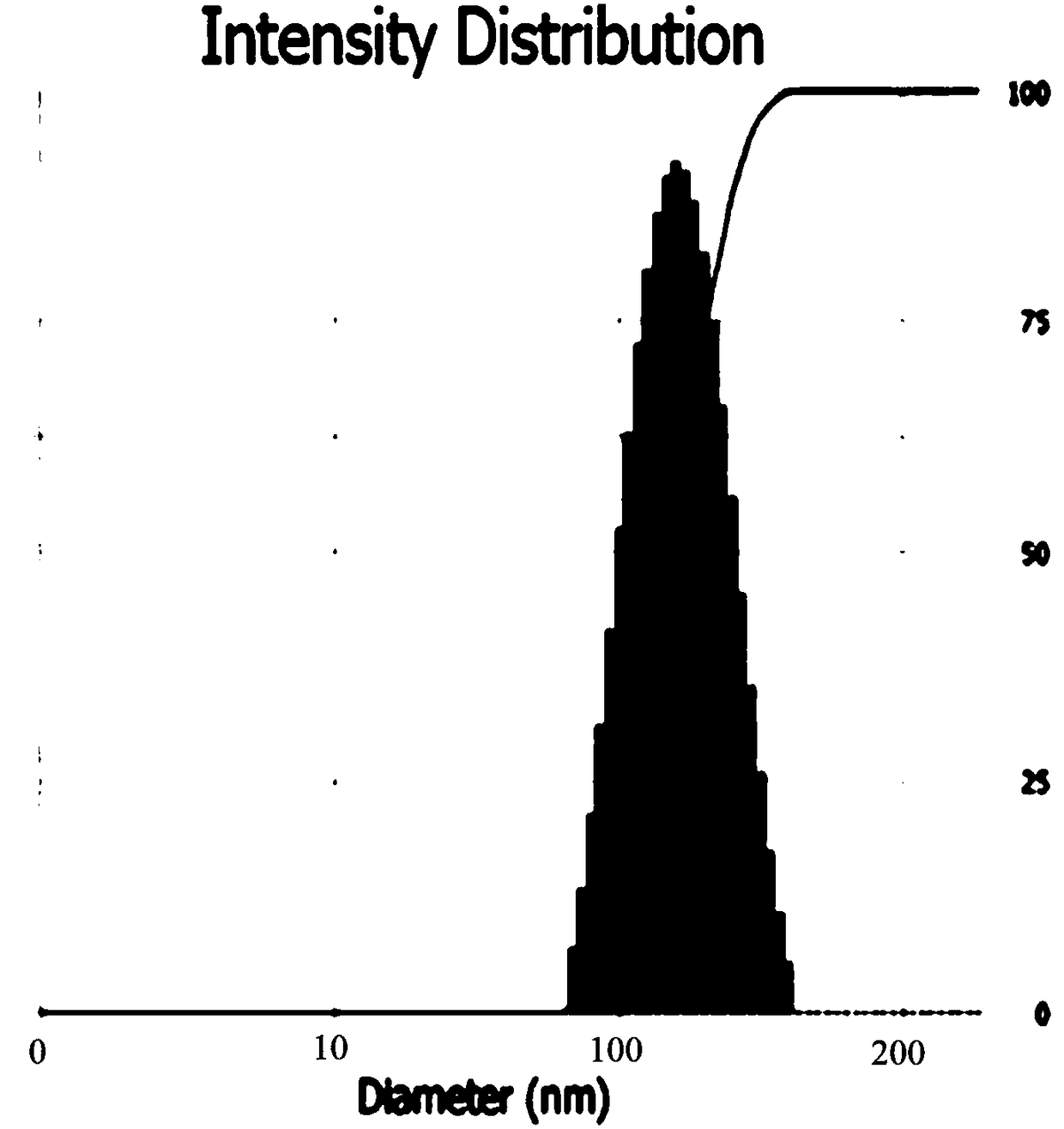

Aqueous nano polyaniline-epoxy acrylic resin conductive anticorrosion primer base

InactiveCN107286777AOvercoming dispersionOvercoming the problem that nanoparticles are easy to agglomerateAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention relates to an aqueous nano polyaniline-epoxy acrylic resin conductive anticorrosion primer base, which is prepared by mixing and stirring a nano polyaniline-epoxy acrylic resin mixture, aqueous acrylic acid anticorrosion emulsion, pigment-filler, and auxiliary agents. An in-situ emulsion polymerization method is adopted to make aniline carry out polymerization in epoxy acrylic resin to form resin wrapped nano polyaniline particles, which are evenly dispersed in resin, and then the particles are mixed with aqueous acrylic acid anticorrosion emulsion and pigment-filler to prepare the primer base. The anticorrosion primer base is enable to have an aqueous property, an in-situ emulsion polymerization technology and a nano technology are well combined, nano polyaniline particles are well dispersed in paint, the coating has a good conductive property and anticorrosion performance therefore, on the other hand, the oil-water layering is avoided because no solvent is added, and thus the primer base can be well stored.

Owner:HUBEI QILI NEW MATERIAL CO LTD

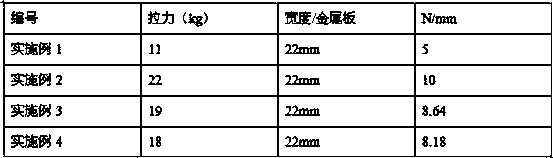

Preparation of water-based adhesive and preparation method of metal/polypropylene composite material

ActiveCN103396750AIncrease production capacityEasy to useMacromolecular adhesive additivesMetal layered productsBonding strengthMetal

The invention discloses a preparation of a water-based adhesive and a preparation method of a metal / polypropylene composite material. The preparation of the water-based adhesive is characterized in that the preparation steps are as follows: a, grafting and copolymerizing chlorinated polypropylene; and b, preparing the adhesive, wherein the adhesive is uniformly coated on the upper part of a metal sample strip; a polypropylene sheet is adhered on the metal sample strip by the adhesive; the metal and the polypropylene sheet are clamped on an injection molding machine, and placed in an oven with the temperature of 100 DEG C-150 DEG C for 15-60 minutes after the clamping. Compared with the prior art, the preparation of the water-based adhesive and the reparation method of metal / polypropylene composite material have the advantages that the adhesive is better in bonding strength and good in environment friendliness; and the composite material is simple to prepare and capable of being produced in mass.

Owner:JIANGSU STERRIC CHEM IND

Preparation method of polyether polyol-unsaturated polyester modified hydroxyl acrylic dispersion

The invention relates to a preparation method of a polyether polyol-unsaturated polyester modified hydroxyl acrylic dispersion. The preparation method comprises the following steps: (1) mixing organicepoxide, a compound containing activated hydrogen groups, a solvent, a catalyst and unsaturated polyester, rising the temperature to 140 to 145 DEG C, and stirring and reacting for 0.5 to 1 hour, thus obtaining a reaction mixture; (2) dropwise adding an initiator and an acrylate monomer in the reaction mixture obtained in step (1) by two steps, keeping warm for 1 to 2 hours after completing dropwise adding, cooling to 75 to 80 DEG C, adding a neutralizer, adding deionized water, and stirring and dispersing for 1 to 2 hours, thus obtaining the polyether polyol-unsaturated polyester modified hydroxyl acrylic dispersion.

Owner:江苏天问新材料科技有限公司

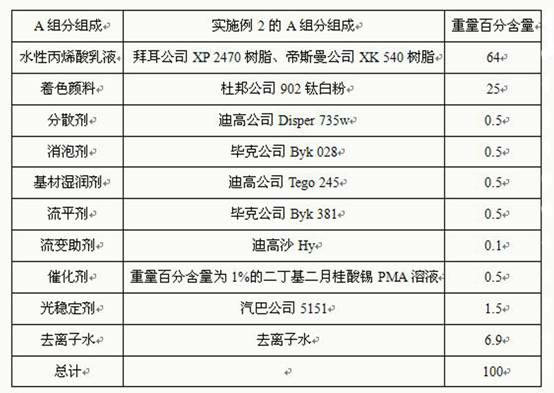

Aqueous finishing coat

ActiveCN102220059AReduce pollutionImprove working environmentCoatingsVolatile organic compoundChemistry

The invention discloses an aqueous finishing coat. The aqueous finishing coat is composed of a component A and a component B, wherein the component A is composed of the following components by weight percent: 55-85% of aqueous acrylic emulsion, 5-25% of tinting color, 0.5-2.5% of dispersant, 0.5-2% of defoaming agent, 0.5-2% of base material humectant. 0.5-1% of flatting agent, 0.1-0.5% of rheological additive, 0.1-0.5% of catalyst, 0.5-1.5% of light stabilizer and the balance of deionized water; the component B is an aqueous firming agent; and the weight ratio of the component A to the component B is (2-6) to 1. The aqueous finishing coat provided by the invention realizes the aquosity of the finishing cost for a car coating and the amount of the contained harmful substances is obviously reduced; the harmful substances, such as benzene, toluene, dimethylbenzene, ethylbenzene and the like, are not detected; and the content of VOC (Volatile Organic Compounds) is greatly reduced and the content of the free formaldehyde is obviously reduced. The aqueous finishing coat provided by the invention has the advantages of reducing the pollution on the environment and also improving the work environment of the coating operating personnel.

Owner:时锋林 +1

Method for preparing blocked polyurethane-epoxy resin composite emulsifier

InactiveCN106317374AAchieving water-basedSolve the problem of insufficient modified dosagePolyurea/polyurethane coatingsEpoxyEpoxy resin composite

The invention discloses a method for preparing blocked polyurethane-epoxy resin composite emulsifier. The method includes the steps of ring opening of epoxy resin and synthesis of the blocked polyurethane-epoxy resin composite emulsifier. The use amount of epoxy resin is increased, so corrosion resistance of the emulsifier is greatly improved, and accordingly the composite emulsifier with good stability and excellent corrosion resistance is prepared.

Owner:上海闵轩钢结构工程有限公司

A kind of preparation method of polyether polyol-unsaturated polyester modified hydroxyl acrylic acid dispersion

The present invention relates to a kind of preparation method of polyether polyol unsaturated polyester modified hydroxyacrylic acid dispersion, comprising the following steps: (1) organic epoxide, compound containing active hydrogen group, solvent, catalyst and Mix the unsaturated polyester, raise the temperature to 140-145°C, stir and react for 0.5-1h to obtain the reaction mixture; (2) add the initiator and acrylate monomer in two steps to the reaction mixture obtained in step (1), drop After heat preservation for 1-2 hours, cool down to 75-80°C, add a neutralizer, add deionized water to stir and disperse for 1-2 hours, and then obtain the polyether polyol-unsaturated polyester modified hydroxyl acrylic acid dispersion body.

Owner:江苏天问新材料科技有限公司

Preparation method of epoxy modified thermosetting acrylic waterborne resin

The invention discloses a preparation method of epoxy modified thermosetting acrylic waterborne resin. The method includes: dissolving epoxy resin in an alcohol ether solvent to obtain a material A, and mixing a reaction monomer with an initiator to obtain a material B; dissolving the initiator in the alcohol ether solvent to obtain a material C; feeding the material A into a four-mouth flask andconducting heating reflux; feeding the material C into a beaker, stirring the substances evenly, dripping the mixture into the four-mouth flask for 3h, conducting heating reflux and heat preservationfor 2h; replenishing the material C under reflux within 30min, and conducting reflux and heat preservation for 3h; and performing cooling and discharging, thus obtaining the epoxy modified thermosetting acrylic waterborne resin. By grafting the epoxy resin to thermosetting waterborne resin molecules, the method can well overcome the shortcomings of poor fullness and chemical resistance, and then improves the product performance and increase the product competitiveness.

Owner:鹤山市肇能新材料有限公司

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108BGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxyDistilled water

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparingantiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

Waterborne alkyd resin emulsion for interior wall water-based paint and preparation method thereof

ActiveCN106866950AAchieving water-basedImprove water resistancePolyester coatingsWater basedEmulsion

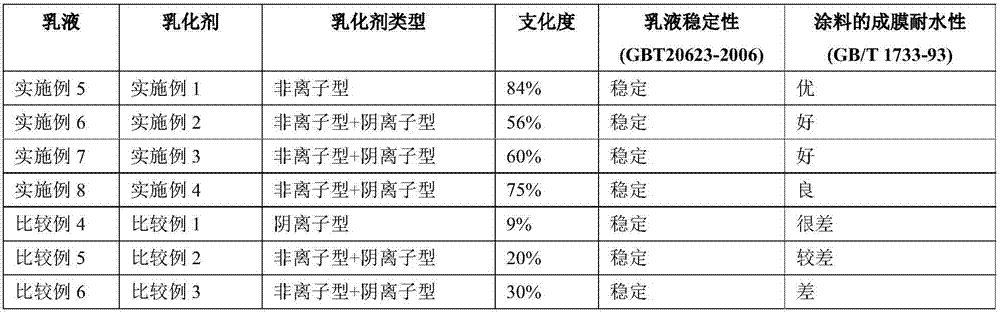

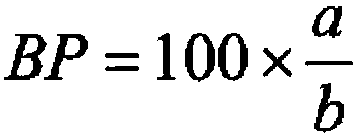

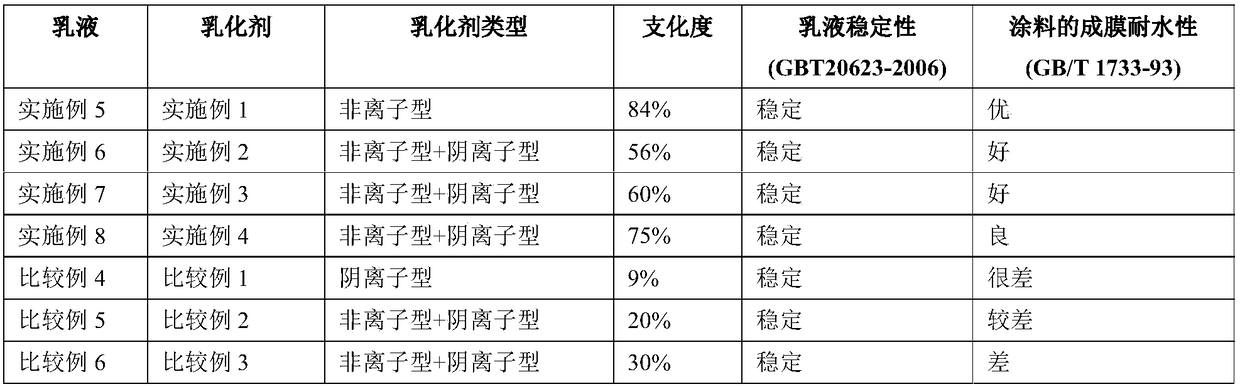

The invention provides waterborne alkyd resin emulsion for interior wall water-based paint and a preparation method thereof. The method comprises the following steps: carrying out esterification reaction on 30 weight percent to 60 weight percent of unsaturated fatty acid, 5 weight percent to 10 weight percent of polyatomic alcohol, 10 weight percent to 15 weight percent of trimethylol propane and 15 weight percent to 20 weight percent of binary acid until the acid value is reduced to be less than or equal to 10mgKOH / g; adding trimellitic anhydride at 175 DEG C to 180 DEG C until the acid value is 60mgKOH / g to 75mgKOH / g; adding dimethylethanolamine, an emulsifier and water at 80 DEG C to 90 DEG C and mixing, wherein the emulsifier is an anion emulsifier and / or a non-ionic emulsifier and the branching degree of the emulsifier is 50 percent to 90 percent or lower. The waterborne alkyd resin emulsion for the interior wall water-based paint, provided by the invention, has excellent stability; meanwhile, a film of the paint prepared from the waterborne alkyd resin emulsion has excellent water resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

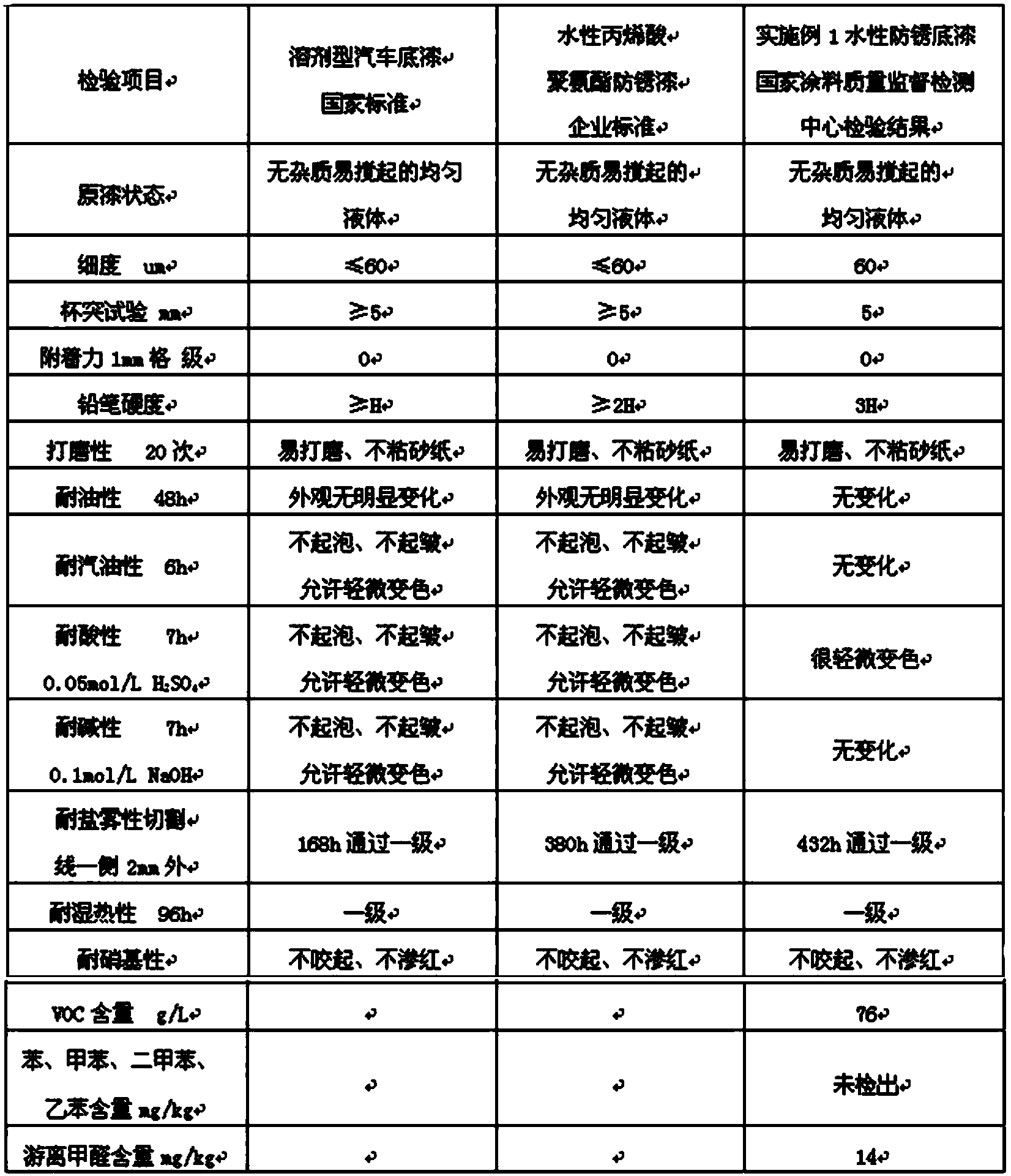

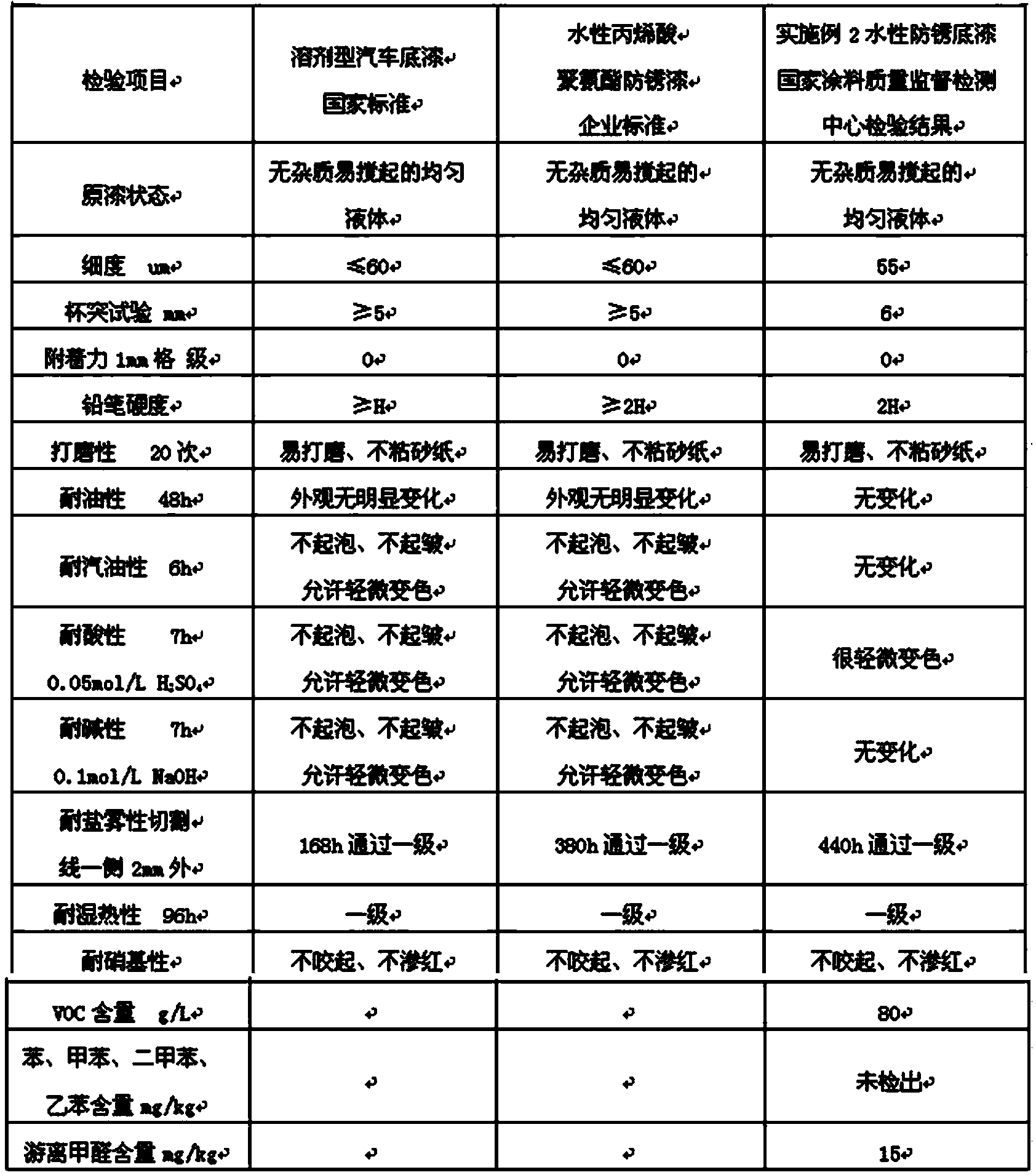

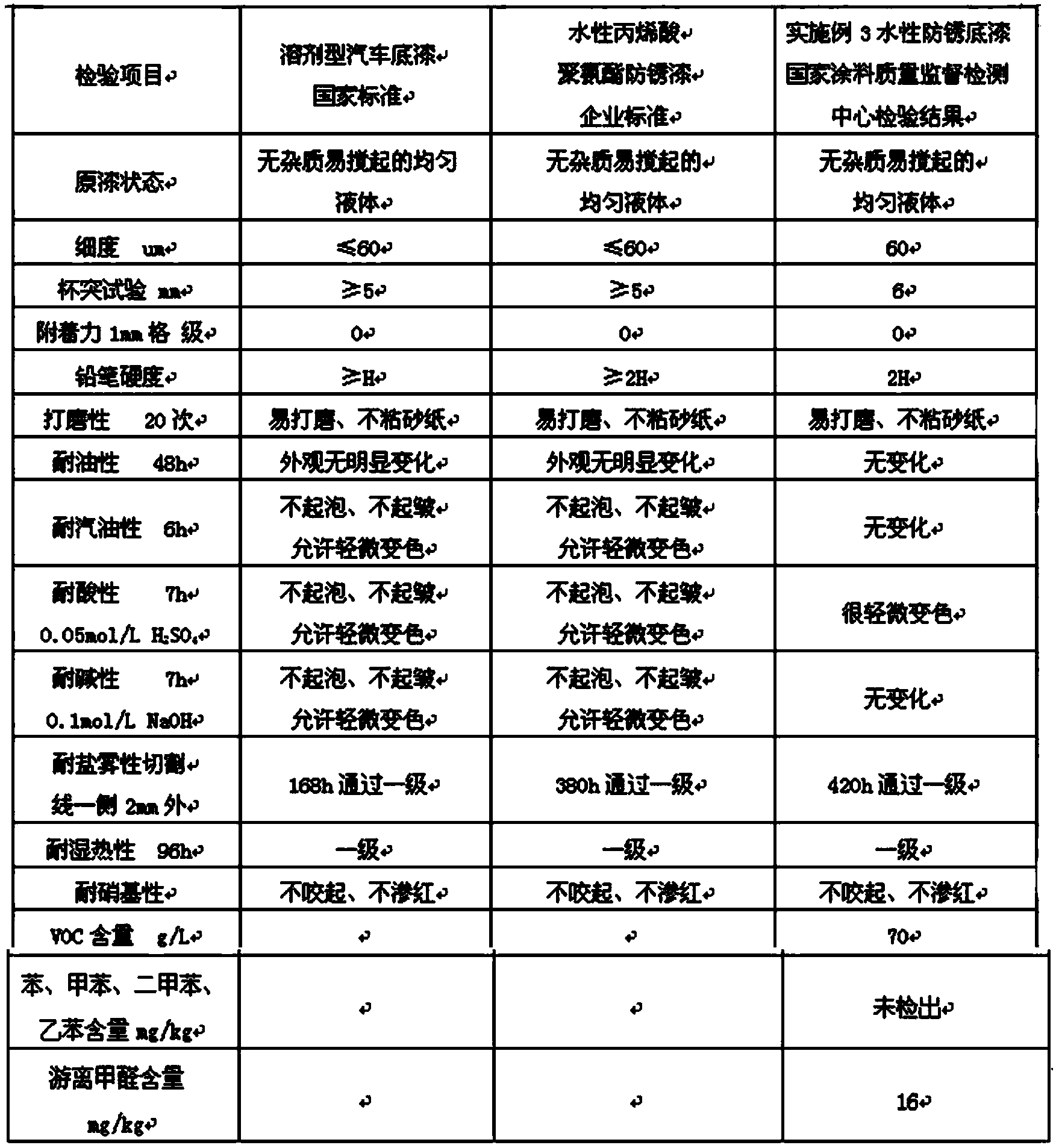

Water-based anti-rust primer

ActiveCN102250540BAchieving water-basedReduce contentAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEmulsion

The invention discloses a water-based anti-rust primer, which is composed of a component A and a component B, wherein the component A consists of the following components by weight percent: 40-55% of water-based acrylic emulsion, 10-20% of anti-rust pigment, 15-30% of extender pigment, 0.5-1% of defoamer, 0.5-1.5% of dispersant, 0.1-0.5% of leveling agent, 0.5-1.5% of substrate wetting agent, 0.1-0.5% of rheological additive, 0.5-2% of anti-flash-rust agent and the balance of deionized water; and the component B is a water-based curing agent. According to the invention, the water-based anti-rust primer for an automobile paint is provided; harmful substances in the water-based anti-rust primer are significantly reduced; benzene, toluene, xylene, ethyl benzene and other harmful substances are not detected in the water-based anti-rust primer; the content of a VOC (volatile organic compound) is significantly reduced and the highest content is only 80 g / L; and the content of free formaldehyde is significantly reduced and the highest content is only 16 mg / kg.

Owner:时锋林 +1

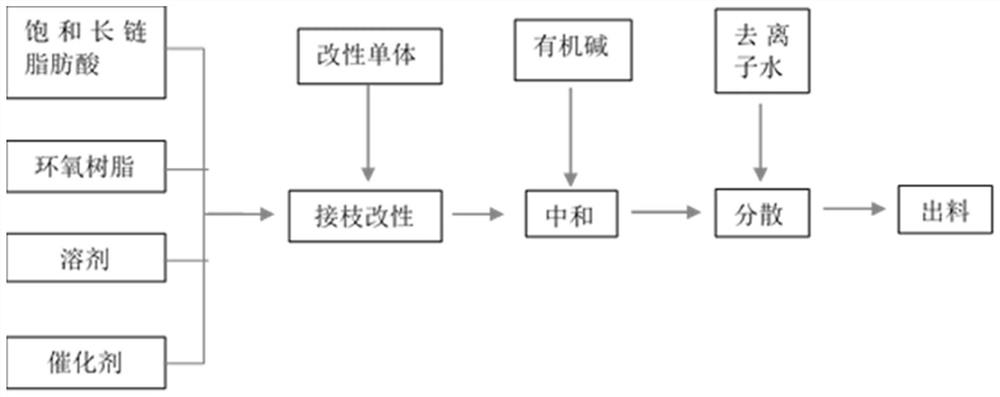

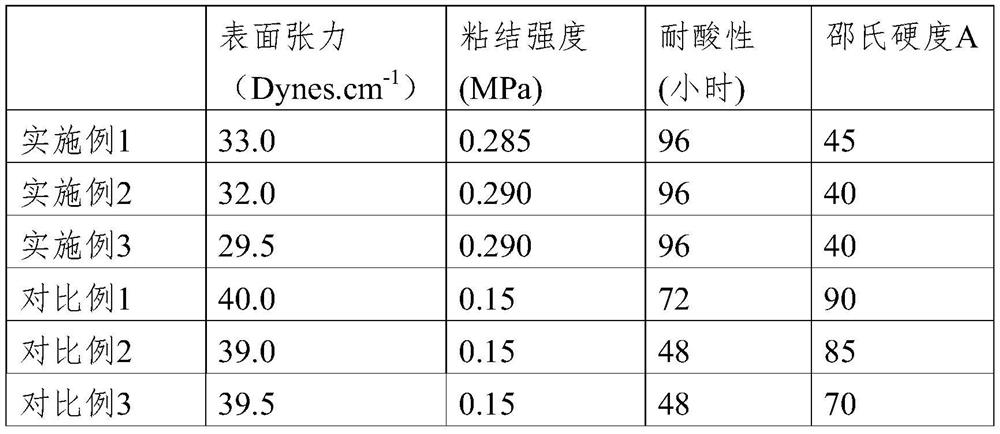

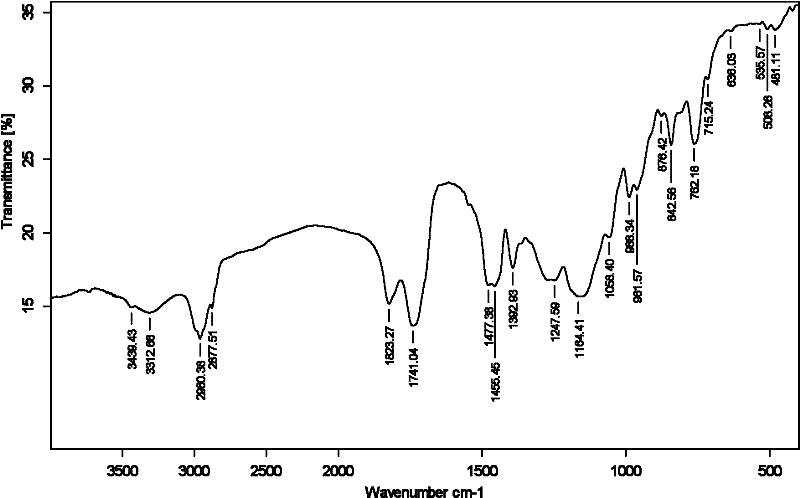

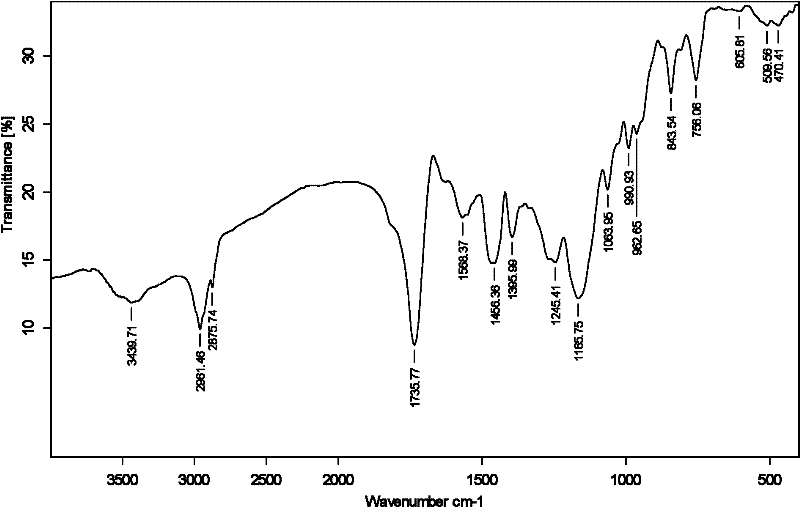

Preparation method of water-based glue for ultrahigh-modulus polyethylene fibers

The invention discloses a preparation method of a water-based glue for ultrahigh-modulus polyethylene fibers. The method comprises the following steps of: adding saturated long-chain fatty acid, epoxyresin, a solvent and a catalyst into a reaction kettle according to a formula ratio, introducing nitrogen for protection, performing heating to 100+ / -5DEG C, and keeping the temperature for 2h; raising the temperature to 110+ / -5DEG C, dropwise adding a mixture of single-ended vinyl-terminated silicone oil, butyl acrylate, an acrylic acid fluorine-containing monomer, a silane coupling agent and aninitiator according to a formula ratio at a constant speed within 3h; and adding an initiator, continuously carrying out reaction for 2h, performing cooling to 65+ / -5DEG C, dropwise adding organic alkali according to a formula amount for neutralizing, adding water according to a formula amount, performing dispersing at a high speed, and conducting discharging to obtain the water-based glue for ultrahigh-modulus polyethylene fibers. The water-based glue prepared by the invention has excellent wettability and adhesive property on ultrahigh-modulus polyethylene fibers, and has the characteristics of softness, environmental protection and no pollution.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

Water-based non-isocyanate polyurethane and preparation method thereof

The invention provides water-based non-isocyanate polyurethane (NIPU) and a preparation method thereof. The water-based non-isocyanate polyurethane provided by the invention is water-dispersed or water-soluble resin prepared with cyclic carbonate functionalized prepolymer and dual or multi-element amino compounds. Compared with the traditional polyurethane, the water-based non-isocyanate polyurethane contains no isocyanate and thus has no toxicity. Therefore, the water-based non-isocyanate polyurethane can be used as film-forming resin for a water-based coating. The preparation method comprises the following steps: polymerization of one or a plurality of unsaturated monomer(s) containing cyclic carbonate groups and a hydrophilic unsaturated monomer through free radical solution, neutralization and emulsification for preparation of a water dispersion of cyclic carbonate functionalized prepolymer, and reaction of the water-dispersed cyclic carbonate functionalized prepolymer and a dual amino compound or a multi-element amino compound, thereby preparing the dispersion of the water-based non-isocyanate polyurethane (NIPU).

Owner:HUAZHONG UNIV OF SCI & TECH

Waterborne polyurethane printing ink resin and production method thereof

The invention relates to waterborne polyurethane printing ink resin and a production method thereof. The production method of the waterborne polyurethane printing ink resin comprises the steps of according to weight parts, under a condition of protection of inert gas, taking 100-140 parts of cyclic isocyanate, 95-160 parts of polypropylene oxide glycol with a molecular weight of 2000, 40-70 partsof homemade polyester polyol with a molecular weight of 200-400 and 20-35 parts of hydrophilic groups, and placing the raw materials in a container; stirring a solution in the container, slowly elevating temperature, when the temperature reaches 80 DEG C, carrying out a heat preservation reaction for 5 hours, conducting sampling, detecting a NCO value, and when the NCO value is in a prescribed range, starting to conduct cooling to obtain a NCO-terminated prepolymer; and adding 10-20 parts of ethylenediamine and 600-650 parts of deionized water into the prepolymer, when the temperature is 30 DEG C, conducting high-speed stirring for two hours, conducting sampling, detecting the NCO value, when the NCO value is zero, conducting high-speed stirring continuously for 2 hours, and standing to obtain the waterborne polyurethane resin. According to the waterborne polyurethane printing ink resin and the production method thereof, waterborne polyurethane is produced by adopting an anion self-emulsifying technology, the tenacity and the rigidity of the anionic waterborne polyurethane are good, and the anionic waterborne polyurethane has good dispersity, water resistance and stability so thatthe waterborne polyurethane can conveniently form a film.

Owner:YELE XINXIANG CHEM IND MFG CO LTD

Water-based high-temperature-resistant epoxy resin and preparation method thereof

ActiveCN112457332AHigh heat distortion temperatureImprove solubilityOrganic chemistryComposite materialCarboxylate

The invention relates to the technical field of epoxy resin, and in particular, relates to water-based high-temperature-resistant epoxy resin and a preparation method thereof. The high-temperature-resistant epoxy resin is composed of the preparation raw materials: a diepoxy compound and dihydroxy ammonium carboxylate. According to the prepared polyfunctional glycidyl amine epoxy resin, a certain amount of hydrophilic groups are introduced, and then water is added for high-speed shearing to obtain the water-based high-temperature-resistant epoxy resin; the water-based high-temperature-resistantepoxy resin can be cured with an amine curing agent, the thermal deformation temperature is obviously increased, the solubility in water is improved, uniform dispersion is promoted, and a dispersionsystem with proper viscosity is formed; water-based treatment is realized, a uniform cross-linked network can be formed with an amine curing agent, increasingly strict environmental protection standards are met, and the constructability of imide is improved; the epoxy resin containing the epoxy group is directly prepared by utilizing the imide structure, so that the high temperature resistance isremarkably improved, and meanwhile, good tensile and bending strength and high temperature resistance stability are ensured.

Owner:深圳飞扬兴业科技有限公司

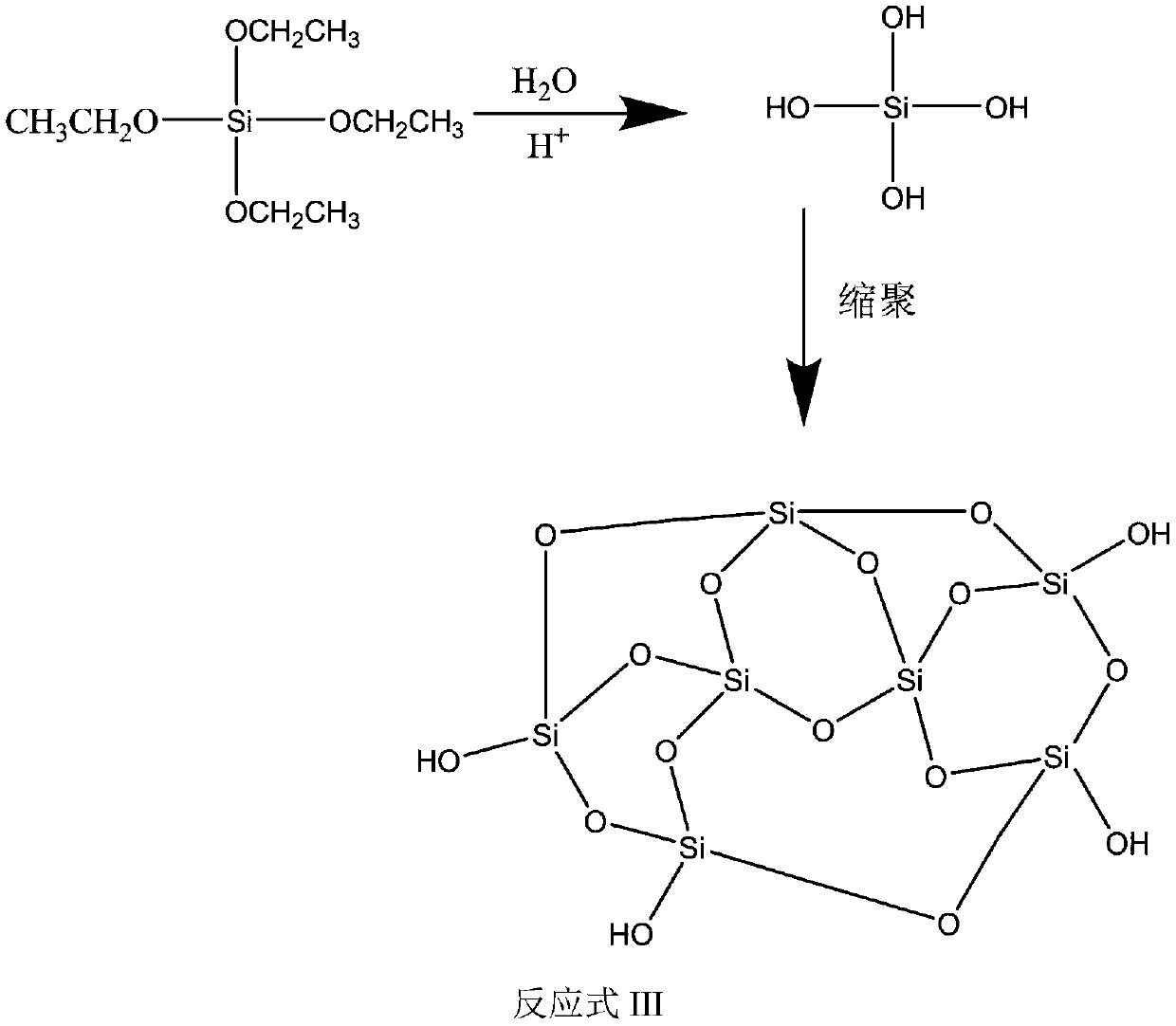

A kind of one-component normal temperature curing water-based anticorrosion resin and preparation method thereof

ActiveCN108586678BIncrease crosslink densityImprove self-drying at room temperatureAnti-corrosive paintsEpoxyPolymer science

The invention discloses one-component room-temperature curing water-based anticorrosive resin and a preparation method thereof, and relates to the technical field of anticorrosive coating. The anticorrosive resin comprises unsaturated fatty acid, epoxy resin, vinyl monomers, acrylic monomers, acrylate monomers, ethyl orthosilicate and perfluorosilane. The preparation method of the resin comprisesthe steps that unsaturated fatty acid and epoxy resin are subjected to an esterifying reaction to generate epoxy ester, the vinyl monomers, the acrylic monomers, the acrylate monomers and initiators are uniformly mixed and then added dropwise to epoxy ester for a reaction, heat preservation is conducted for a certain period of time, then ethyl orthosilicate is added for a reaction, a neutralization agent is adopted for neutralization, perfluorosilane is added, and finally water is added for high-speed dispersion. According to the resin, with ethyl orthosilicate and perfluorosilane as special functional cross-linking agents, the cross-linking agents are not simply self-polymerized, further cross-linking polymerization can be generated between ethyl orthosilicate and perfluorosilane after orbefore polycondensation, and the corrosion resistance, heat resistance, water whitening resistance and neutral salt spray resistance of coating film are improved.

Owner:优美特(北京)环境材料科技股份公司

Water-based alkyd resin emulsion for interior wall water paint and preparation method thereof

ActiveCN106866950BAchieving water-basedImprove water resistancePolyester coatingsWater basedEmulsion

The invention provides waterborne alkyd resin emulsion for interior wall water-based paint and a preparation method thereof. The method comprises the following steps: carrying out esterification reaction on 30 weight percent to 60 weight percent of unsaturated fatty acid, 5 weight percent to 10 weight percent of polyatomic alcohol, 10 weight percent to 15 weight percent of trimethylol propane and 15 weight percent to 20 weight percent of binary acid until the acid value is reduced to be less than or equal to 10mgKOH / g; adding trimellitic anhydride at 175 DEG C to 180 DEG C until the acid value is 60mgKOH / g to 75mgKOH / g; adding dimethylethanolamine, an emulsifier and water at 80 DEG C to 90 DEG C and mixing, wherein the emulsifier is an anion emulsifier and / or a non-ionic emulsifier and the branching degree of the emulsifier is 50 percent to 90 percent or lower. The waterborne alkyd resin emulsion for the interior wall water-based paint, provided by the invention, has excellent stability; meanwhile, a film of the paint prepared from the waterborne alkyd resin emulsion has excellent water resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

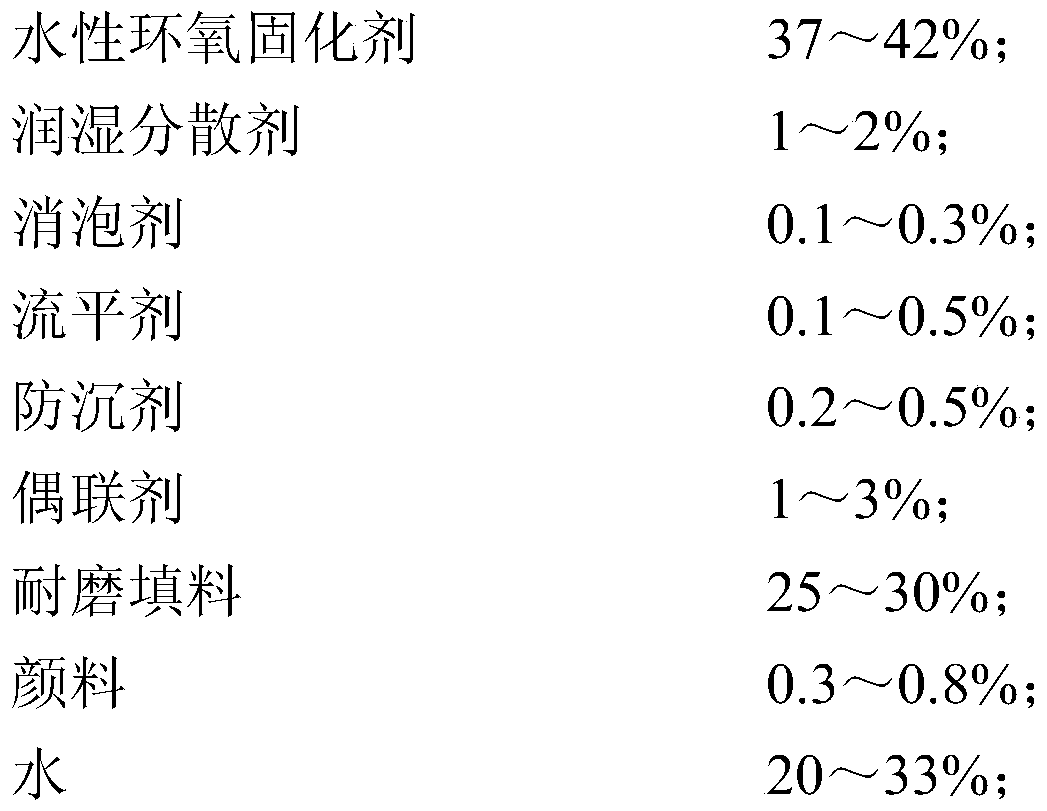

Water-based nano static conductive coating and preparation method thereof

InactiveCN111548702AImprove adhesionImprove impermeabilityAnti-corrosive paintsEpoxy resin coatingsFiberConductive coating

The invention relates to a water-based nano static conductive coating and a preparation method thereof, and belongs to the technical field of coatings, wherein the static conductive coating comprisesa component A and a component B with a mass ratio of 1:(4-5.5); the component B is a waterborne epoxy emulsion; the component A comprises the following components in parts by mass: 37-42 parts of a waterborne epoxy curing agent, 1-2 parts of a wetting dispersant, 0.1-0.3 part of an antifoaming agent, 0.1-0.5 part of a leveling agent, 0.2-0.5 part of an anti-settling agent, 1-3 parts of a couplingagent, 15-25 parts of a pigment filler, 10-15 parts of a static conductive filler and 20-33 parts of water; the static conductive filler is at least one of nano chromium fibers and nano nickel fibers.The coating has excellent corrosion resistance and excellent static electricity conduction performance, and can be applied to corrosion resistance and static electricity conduction requirements of the inner wall of an oil storage tank.

Owner:洛阳双瑞防腐工程技术有限公司

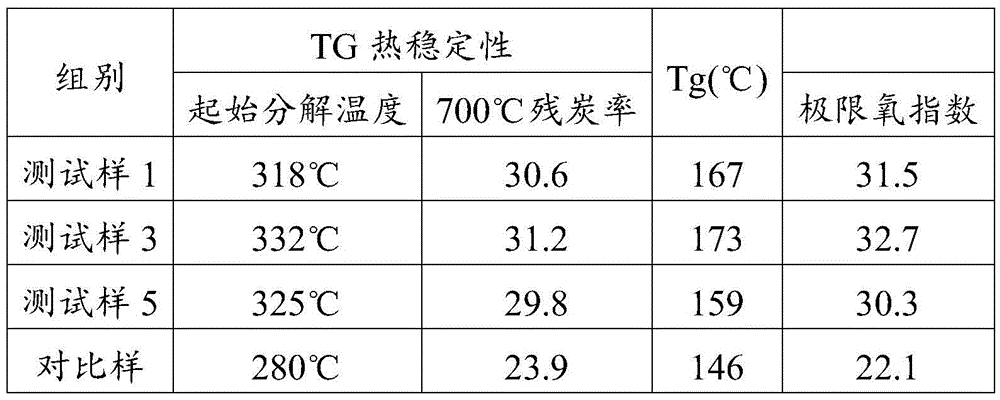

A kind of organosilicon-phosphorus hybrid flame-retardant water-based self-emulsifying epoxy resin curing agent and its preparation method and application

ActiveCN104098757BSimple processSuitable for industrial productionFireproof paintsEpoxy resin coatingsEpoxyWater based

Owner:天津道科包装材料有限公司

Preparation method of water-based radix asparagi polyurea resin and water-based radix asparagi polyurea resin

PendingCN113683775ASimple preparation processEase of industrial productionPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The invention relates to a preparation method of water-based radix asparagi polyurea resin, which comprises the following steps: in an inert gas atmosphere, dropwise adding unsaturated fatty acid diester into a glycidyl ether binary primary amine adduct, conducting reacting at 80-120 DEG C for 2-36 hours, and then conducting drying to obtain the water-soluble water-based radix asparagi polyurea resin. The resin has the advantages of high curing speed, water resistance, heat resistance and environment friendliness.

Owner:HUNAN TUOCHUANG POLYMERIC NEW MATERIAL CO LTD

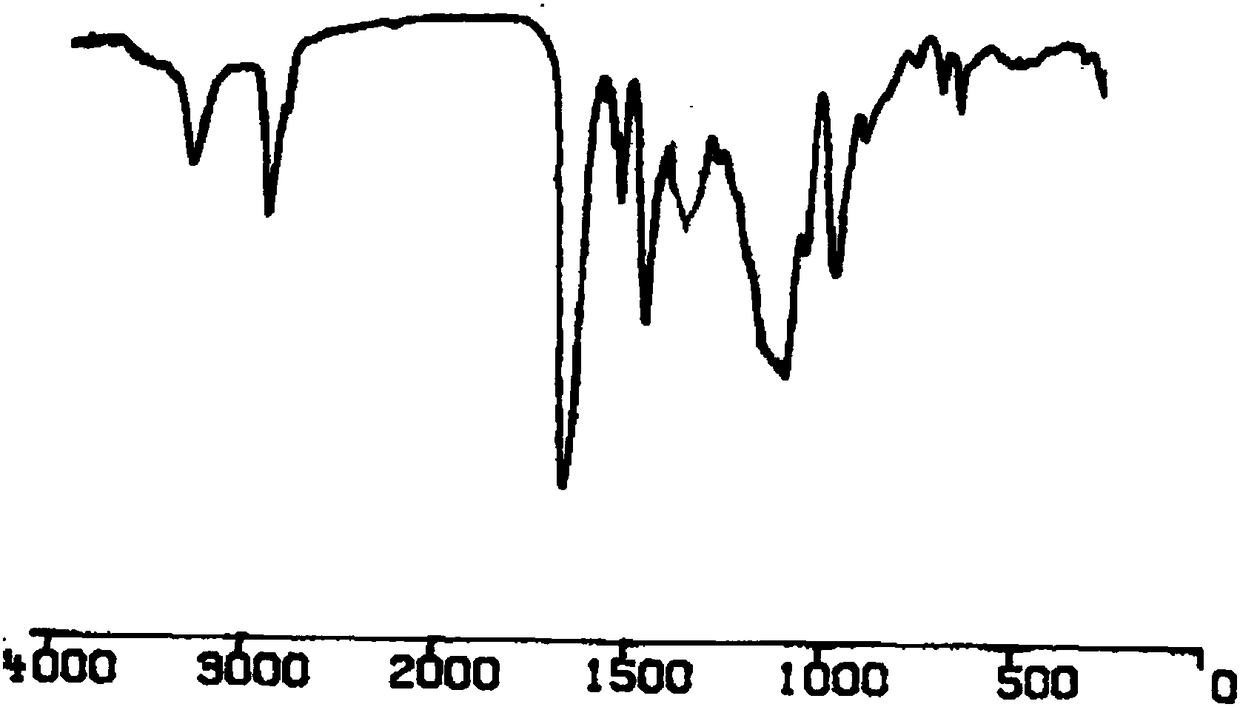

Preparation method of polyaniline dispersion

PendingCN113265197AImprove adhesionGood dispersion performanceAnti-corrosive paintsAmmonium sulfatePolymer chemistry

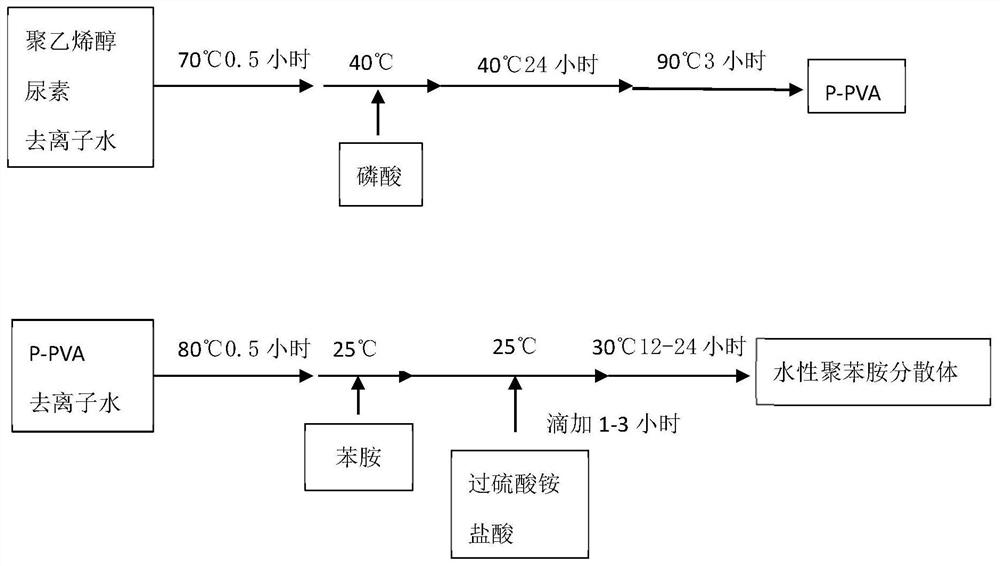

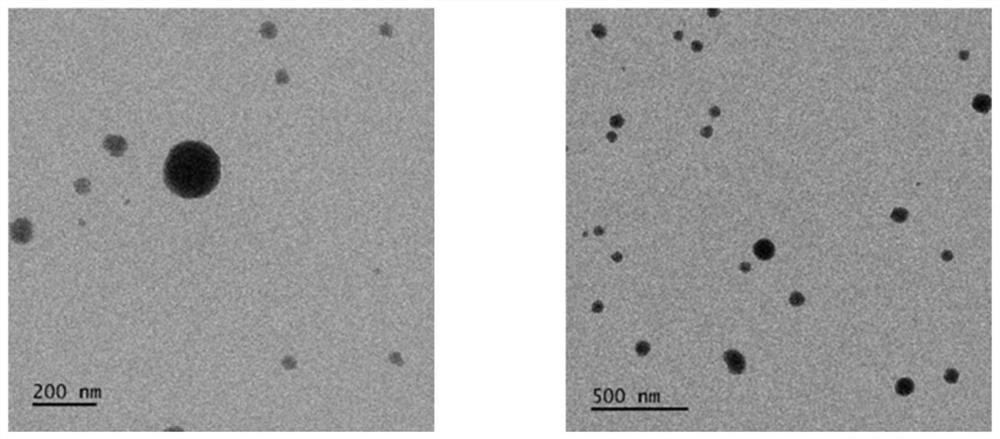

The invention relates to a preparation method of a polyaniline dispersion, which comprises the following steps: preparing an acidic doped emulsifier P-PVA by using phosphoric acid modified polyvinyl alcohol, weighing 4-6 parts by weight of P-PVA, adding into 100 parts by weight of deionized water, heating to 70-90 DEG C, stirring until P-PVA is completely dissolved, cooling to room temperature, adding 3-6 parts by weight of aniline at one time, and stirring for 0.5-1.5 hours; and weighing 3-6 parts by weight of ammonium persulfate, adding 100 parts by weight of hydrochloric acid, stirring and dissolving, transferring into a constant-pressure dropping funnel, dropwise adding into the step (2) for 1-3 hours, and stirring for 12-24 hours at the temperature of 25-30 DEG C to obtain the phosphorylated aqueous polyaniline dispersion. Phosphoric acid groups are introduced through a chemical method, acid modification and water treatment are achieved, and meanwhile the adhesive force and the anti-corrosion function of the coating are improved; the acid and the polyvinyl alcohol jointly realize the water-based property of the polyaniline, so that the excellent dispersion property of the polyaniline is realized; and acid modification under the normal temperature condition is realized, and the step of ice-water bath modification in the existing method is overcome.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com