Aqueous finishing coat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The water-based finish paint for automobile painting provided by this embodiment is composed of A component and B component, wherein the composition of A component is shown in Table 1, and B component is Bayer VPLS 2319, A component and B group The weight ratio of points is 4:1.

[0022] The composition of A component of table 1 embodiment 1

[0023]

[0024] The preparation method of the water-based topcoat in this example: according to the amount of titanium dioxide used in Example 1, add BYK 191 dispersant and part of Bayer 2470 resin, then add a certain amount of deionized water, and disperse and grind at high speed to obtain a white finish. Then add the remaining materials, disperse evenly at high speed, filter, and pack into component A for later use; in addition, mix the water-based curing agent Bayer VPLS2319 of component B with propylene glycol methyl ether acetate (PMA) evenly for later use; directly mix the two can be mixed. The weight ratio of Bayer VPL...

Embodiment 2

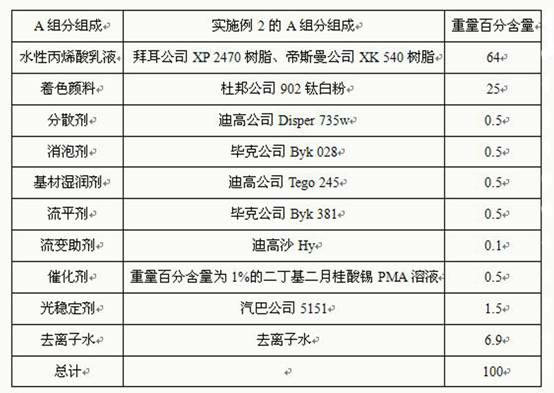

[0026] The water-based finish paint for automobile painting provided by this embodiment is composed of A component and B component, wherein the composition of A component is shown in Table 2, and B component is a mixture of Bayer VPLS 2319 and Bayer XP 2565 , The weight ratio of component A and component B is 2:1.

[0027] The composition of A component of table 2 embodiment 2

[0028]

[0029] The preparation method of the water-based topcoat in this example: according to the amount of titanium dioxide used in Example 2, add Tego735w dispersant from Tego Company, XK540 resin from DSM Company and part of 2470 resin from Bayer Company, then add a certain amount of deionized water, Disperse and grind to obtain a white color paste; then add the remaining materials, disperse evenly at high speed, filter, and pack into component A for later use; in addition, component B water-based curing agent Bayer VPLS2319, Bayer XP2565 and propylene glycol methyl ether acetate ( PMA) and mi...

Embodiment 3

[0031]The water-based finish paint for automobile painting provided by this embodiment is composed of A component and B component, wherein the composition of A component is shown in Table 3, and B component is the product of Bayer VPLS 2319 and Rhodia 803 Mixture, the weight ratio of A component and B component is 6:1.

[0032] The composition of the A component of table 3 embodiment 3

[0033]

[0034] The preparation method of the water-based topcoat of this embodiment: according to the amount of titanium dioxide used in Example 3, add Borchers Company Gen 0451 dispersant, Newpace Company SC 6516 resin and part of Bayer Company 2470 resin, then add a certain amount of deionized water, through high-speed Disperse and grind to obtain a white color paste; then add the remaining materials, disperse evenly at high speed, filter, and pack into component A for later use; in addition, component B water-based curing agent Bayer VPLS2319, Rhodia 803 and propylene glycol methyl ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com