Patents

Literature

30273results about How to "Reduce content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

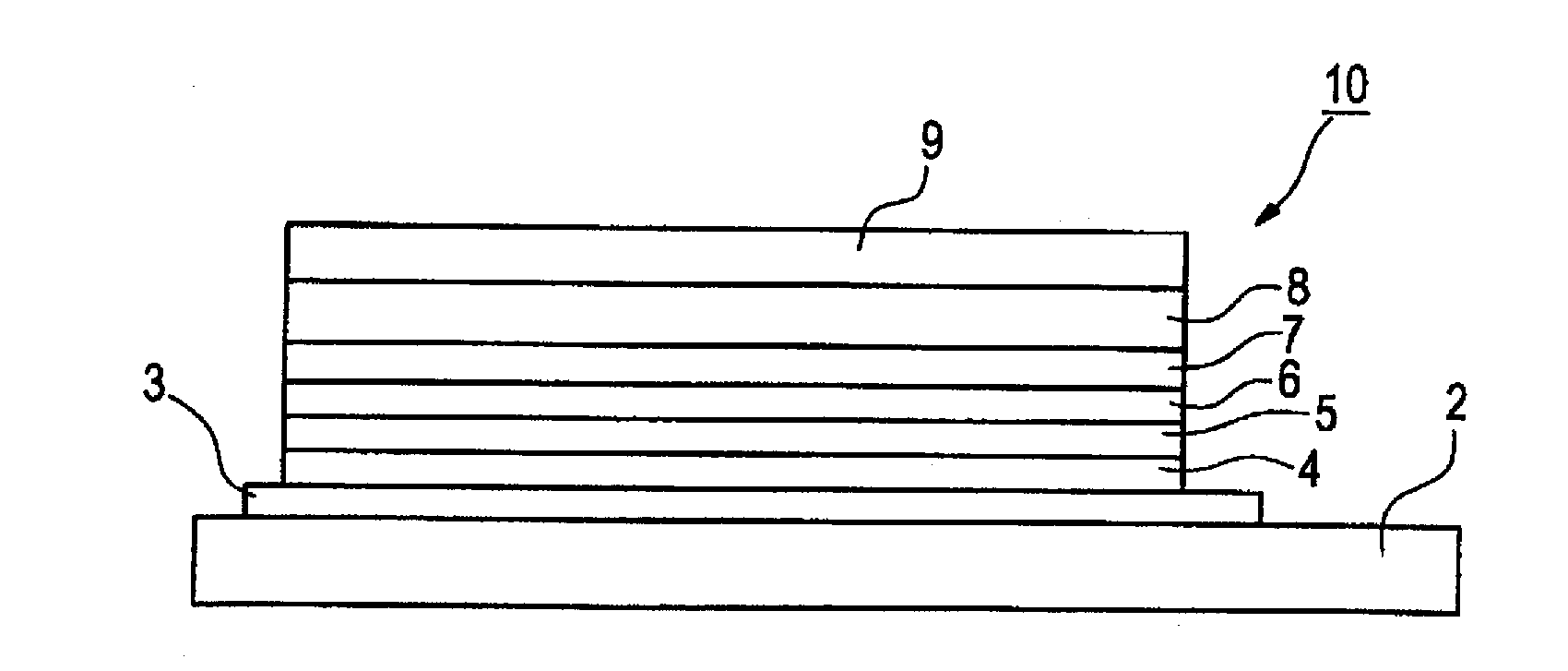

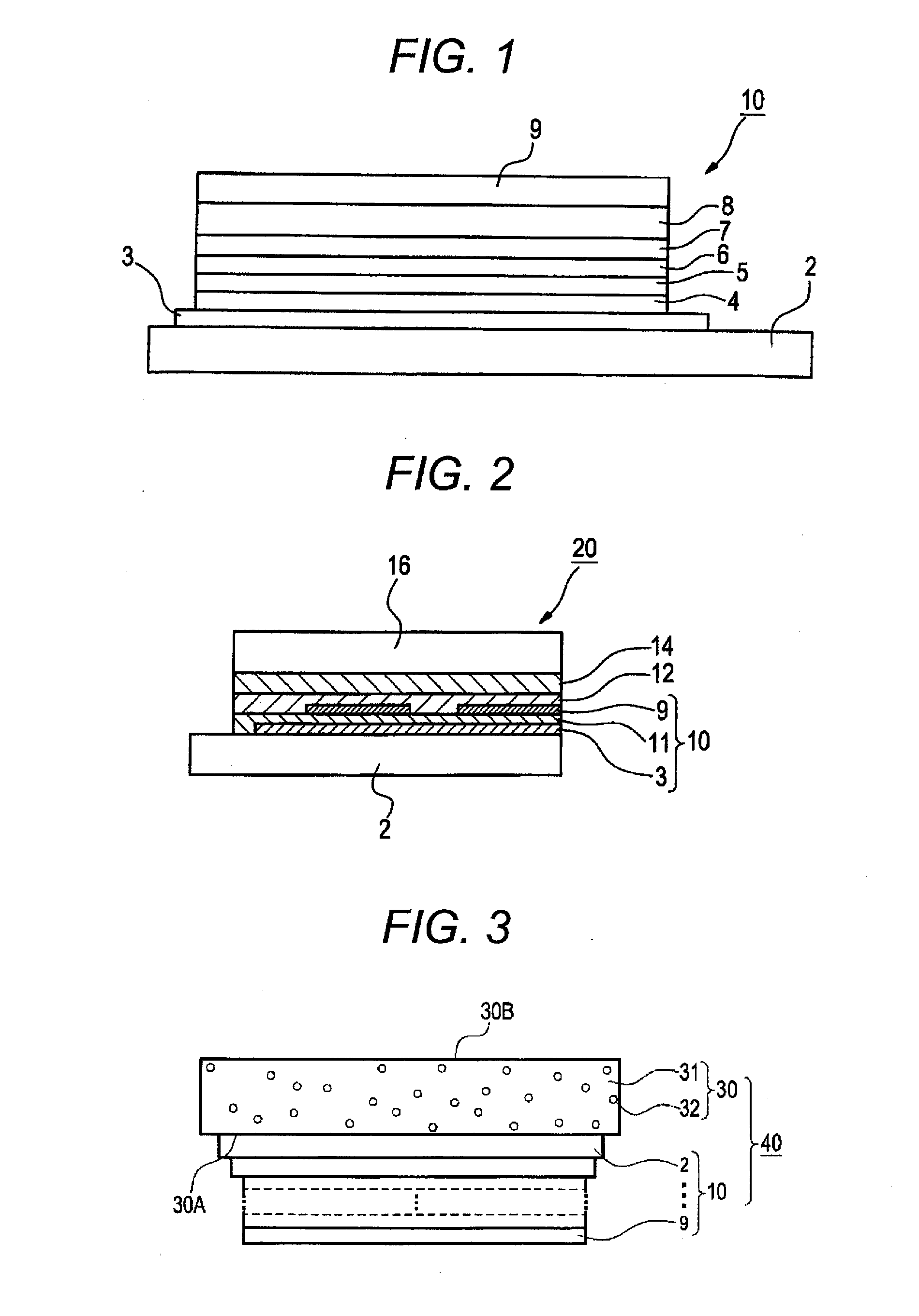

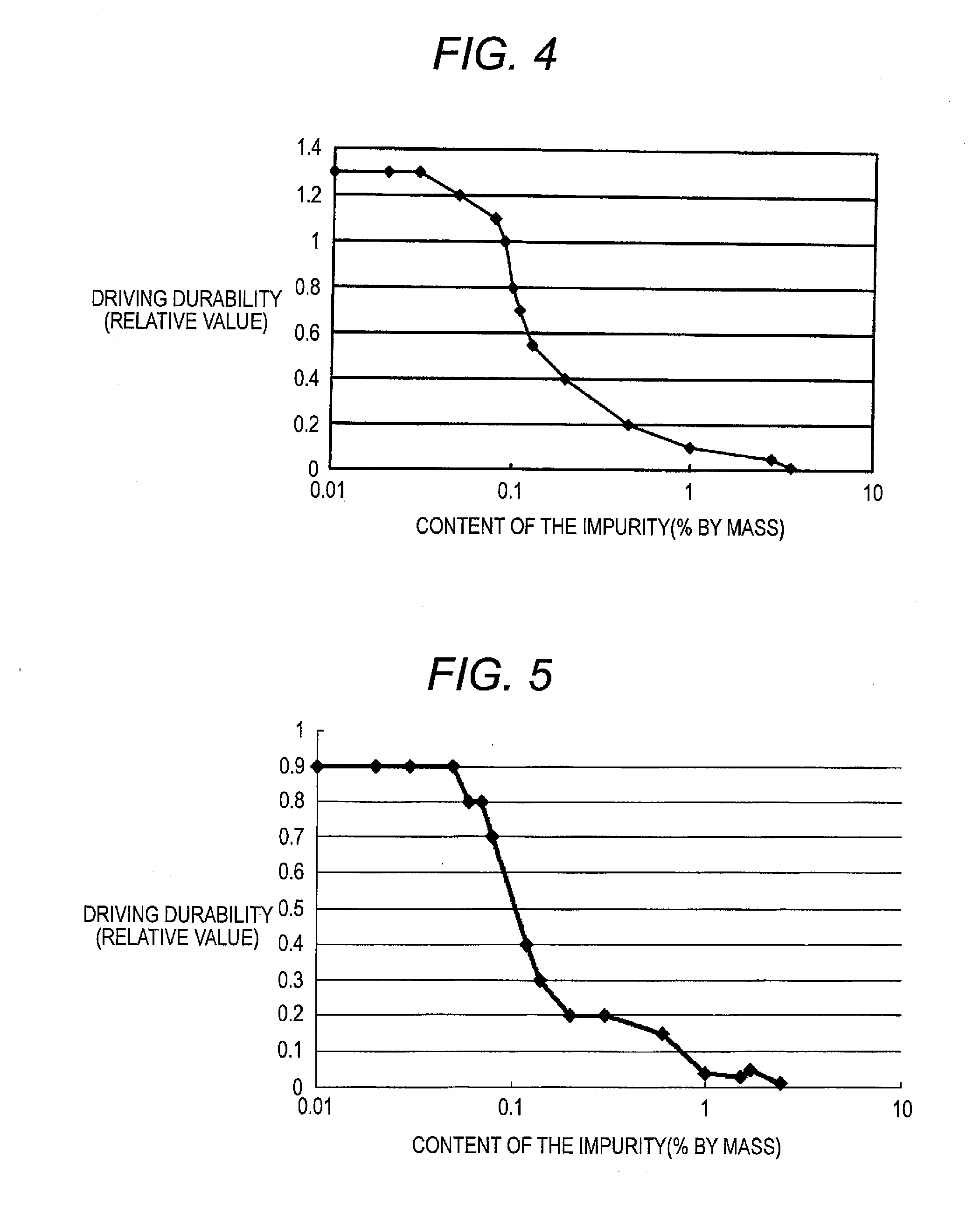

Charge-transporting material and organic electroluminescence device

InactiveUS20120126221A1Improve light emission efficiencyIncreased durabilitySilicon organic compoundsSolid-state devicesHalogenOrganic layer

A charge-transporting material contains a compound represented by the following formula (1) in an organic layer, in which the contents of specific halogen-containing compounds are 0.1% or less to the compound represented by formula (1). In formula (1), each of A1 and A2 independently represents N, —CH or —CR; R represents a substituent; L represents a single bond, an arylene group, a cycloalkylene group or an aromatic heterocyclic group; each of R1 to R5 independently represents a substituent; each of n1, n2 and n3 independently represents an integer of 0 to 4; each of n4 and n5 independently represents an integer of 0 to 5; and each of p and q independently represents an integer of 1 to 4.

Owner:UDC IRELAND

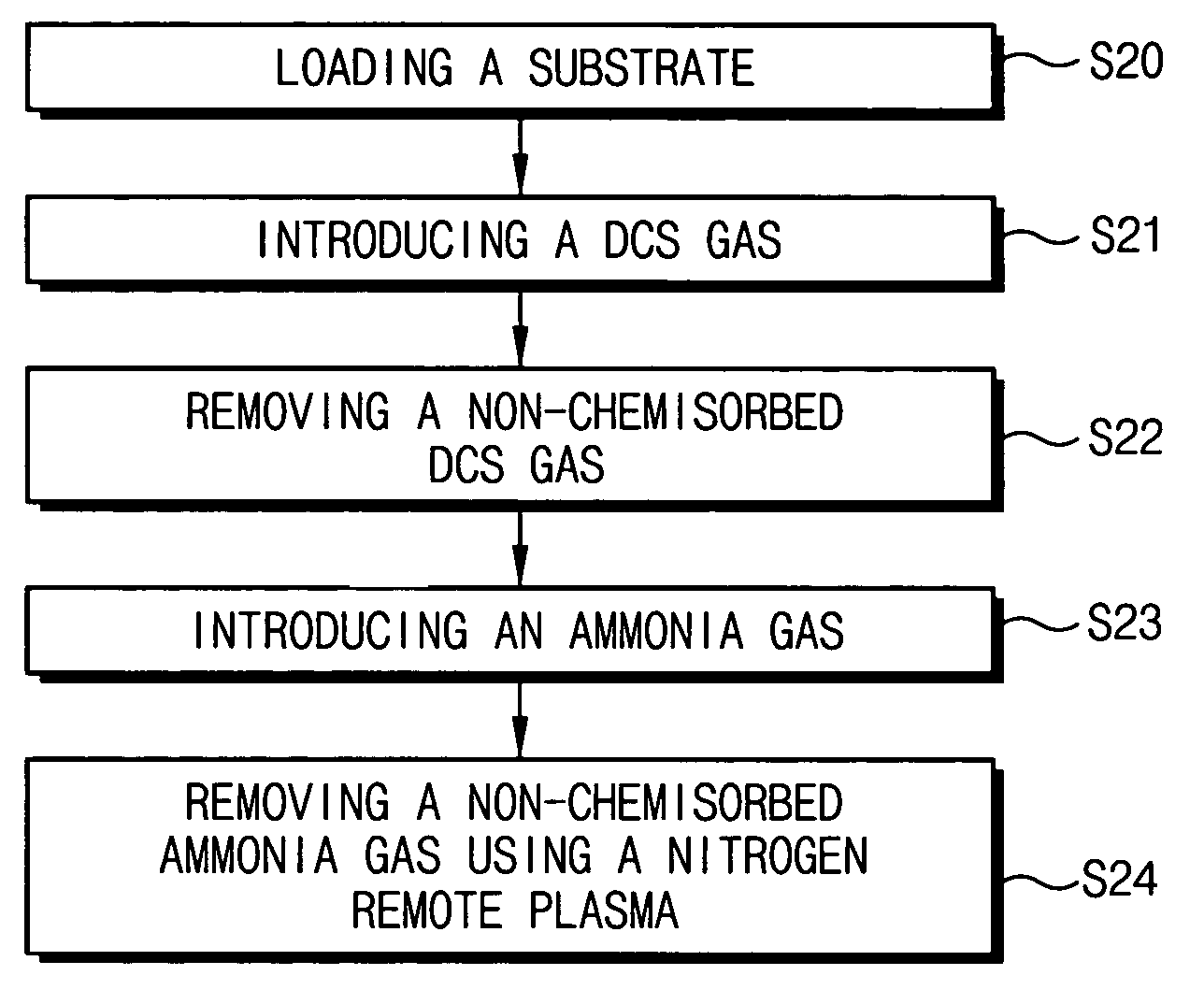

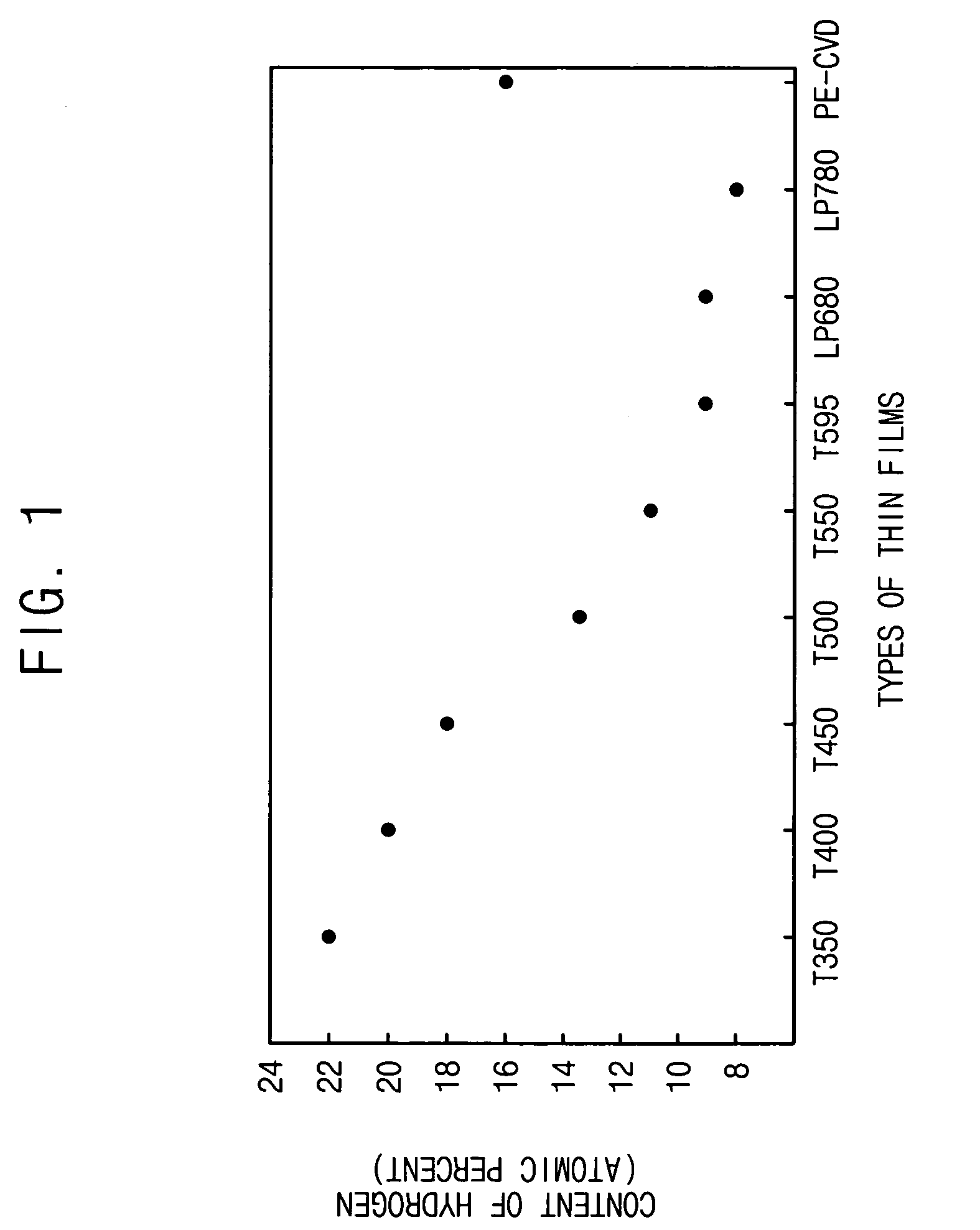

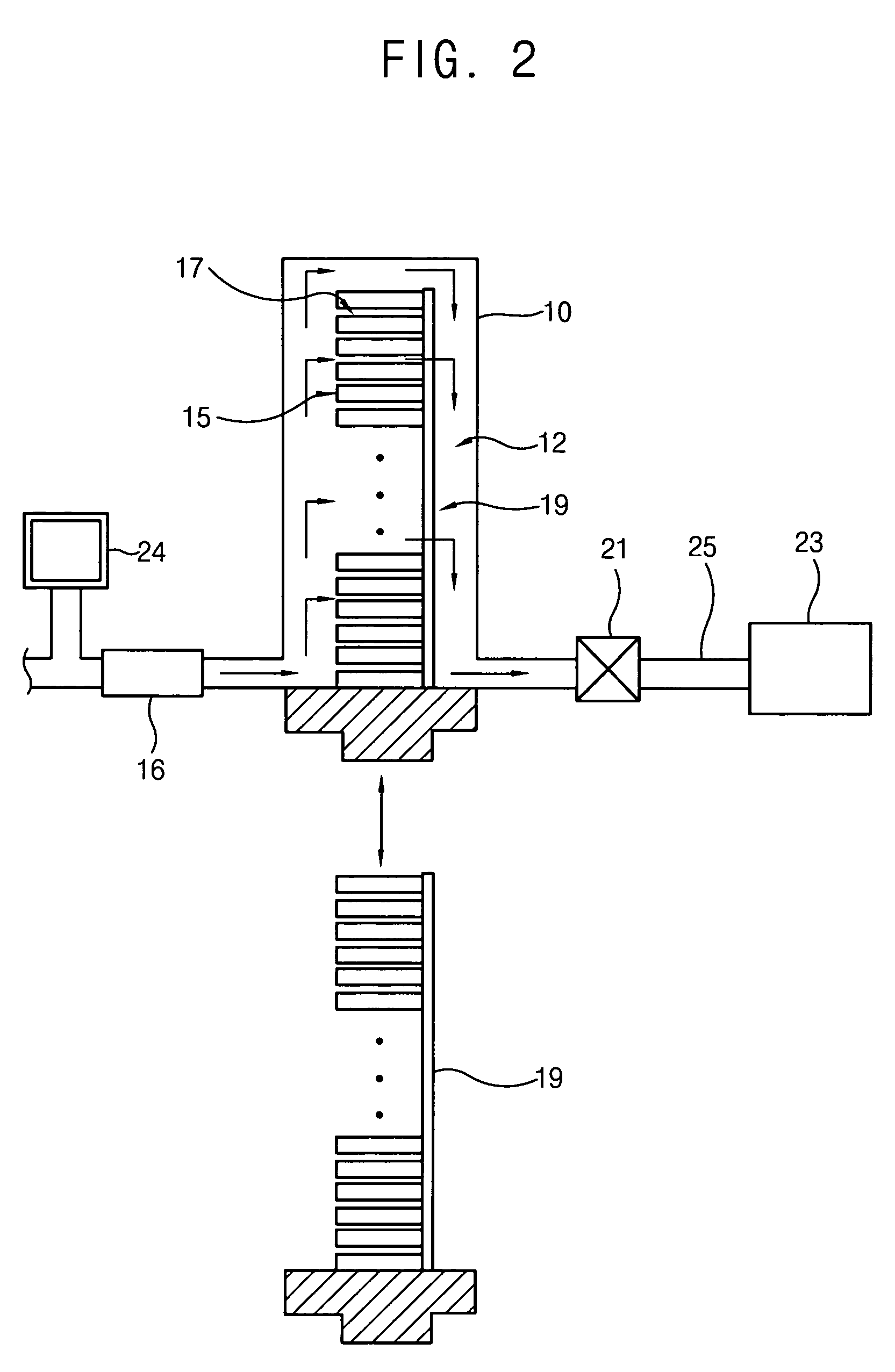

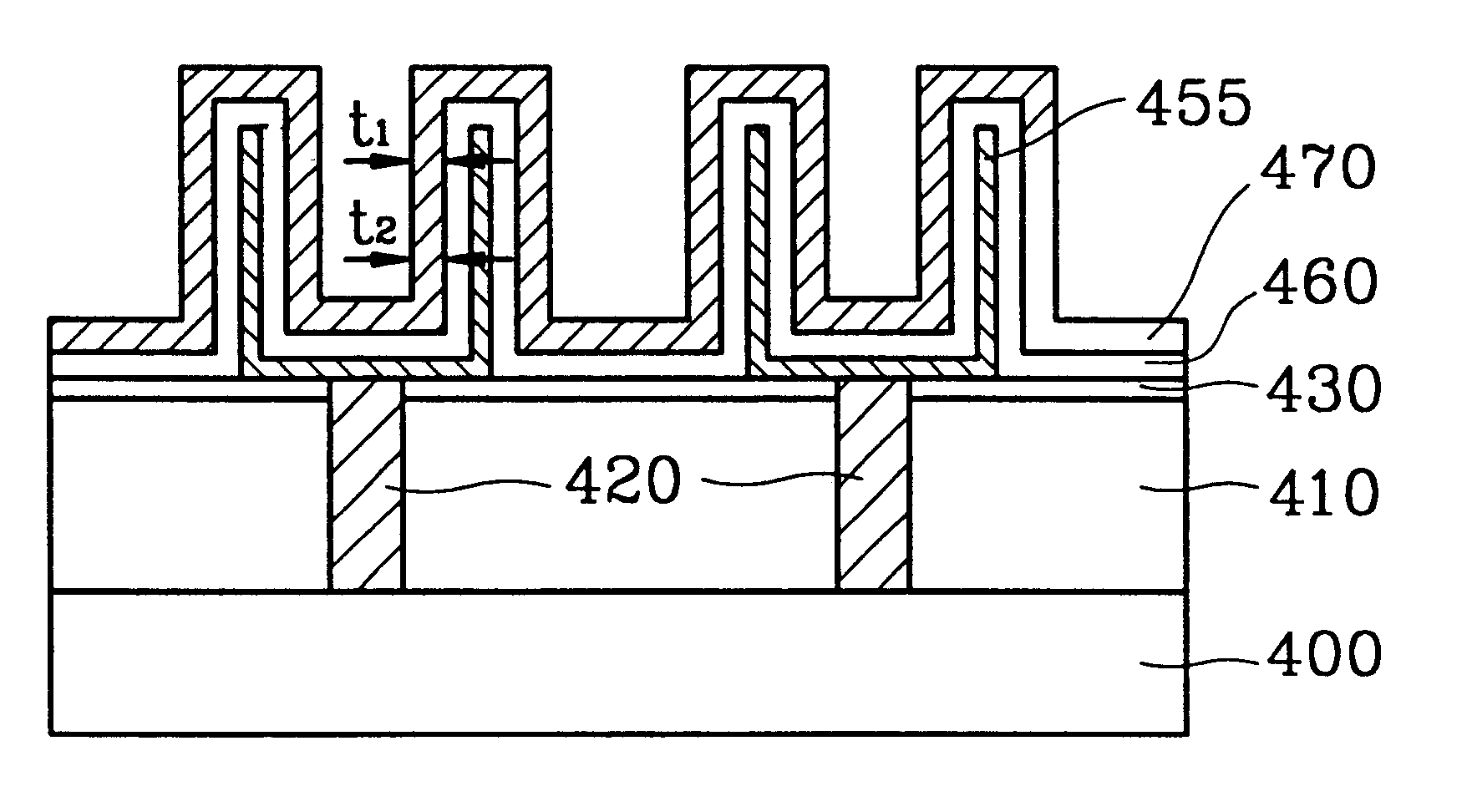

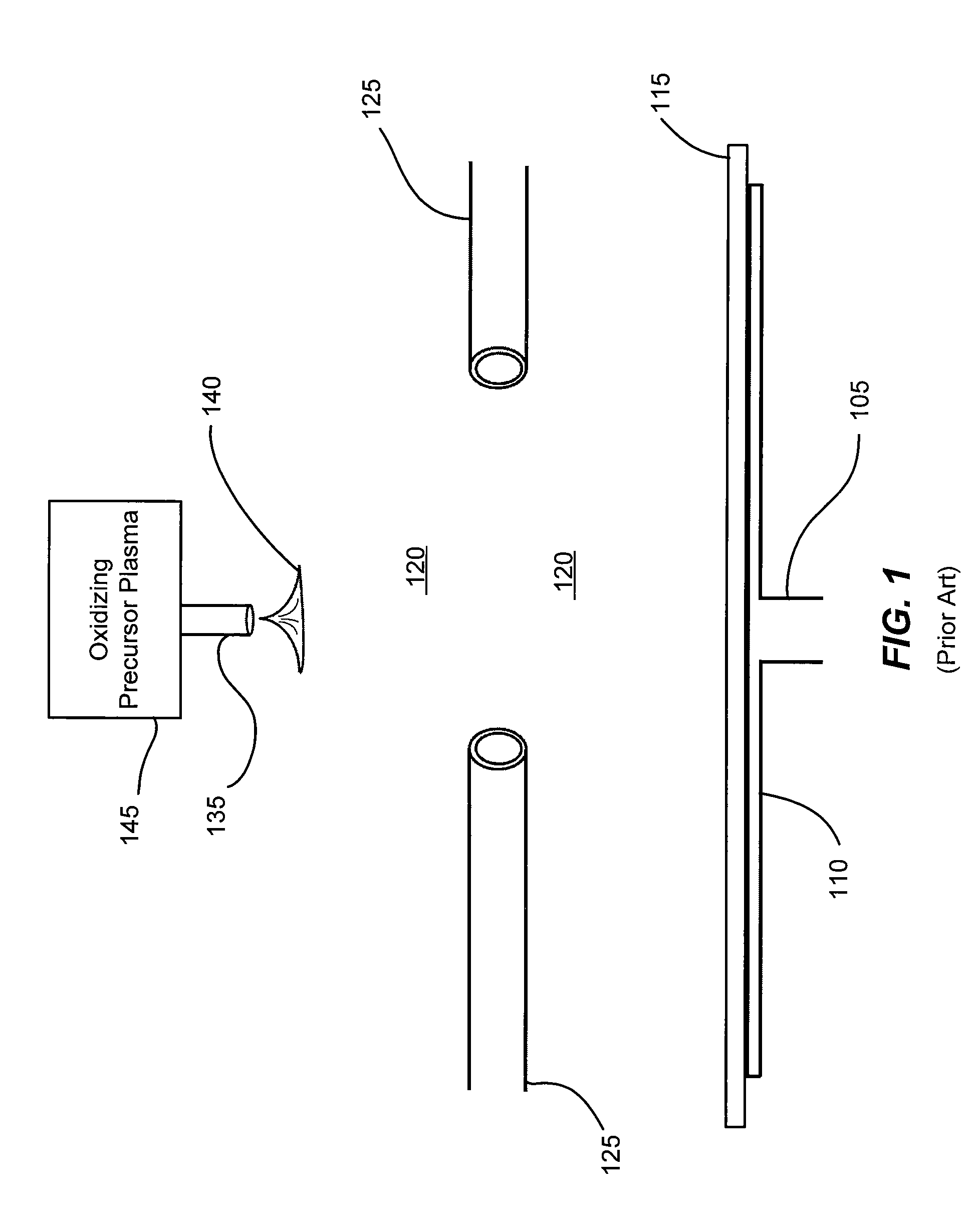

Method of forming a layer and forming a capacitor of a semiconductor device having the same layer

InactiveUS20060014384A1Low hydrogen contentReduce leakage currentSemiconductor/solid-state device manufacturingCapacitorsChemical reactionDevice material

In a method of forming a layer using an atomic layer deposition process, after a substrate is loaded into a chamber, a first reactant is provided onto the substrate. The first reactant is partially chemisorbed on the substrate. A second reactant is introduced into the chamber to form a preliminary layer on the substrate by chemically reacting the second reactant with the chemisorbed first reactant. Impurities in the preliminary layer and unreacted reactants are simultaneously removed using a plasma for removing impurities to thereby form the layer on the substrate. The impurities in the layer may be effectively removed so that the layer may have reduced leakage current.

Owner:SAMSUNG ELECTRONICS CO LTD

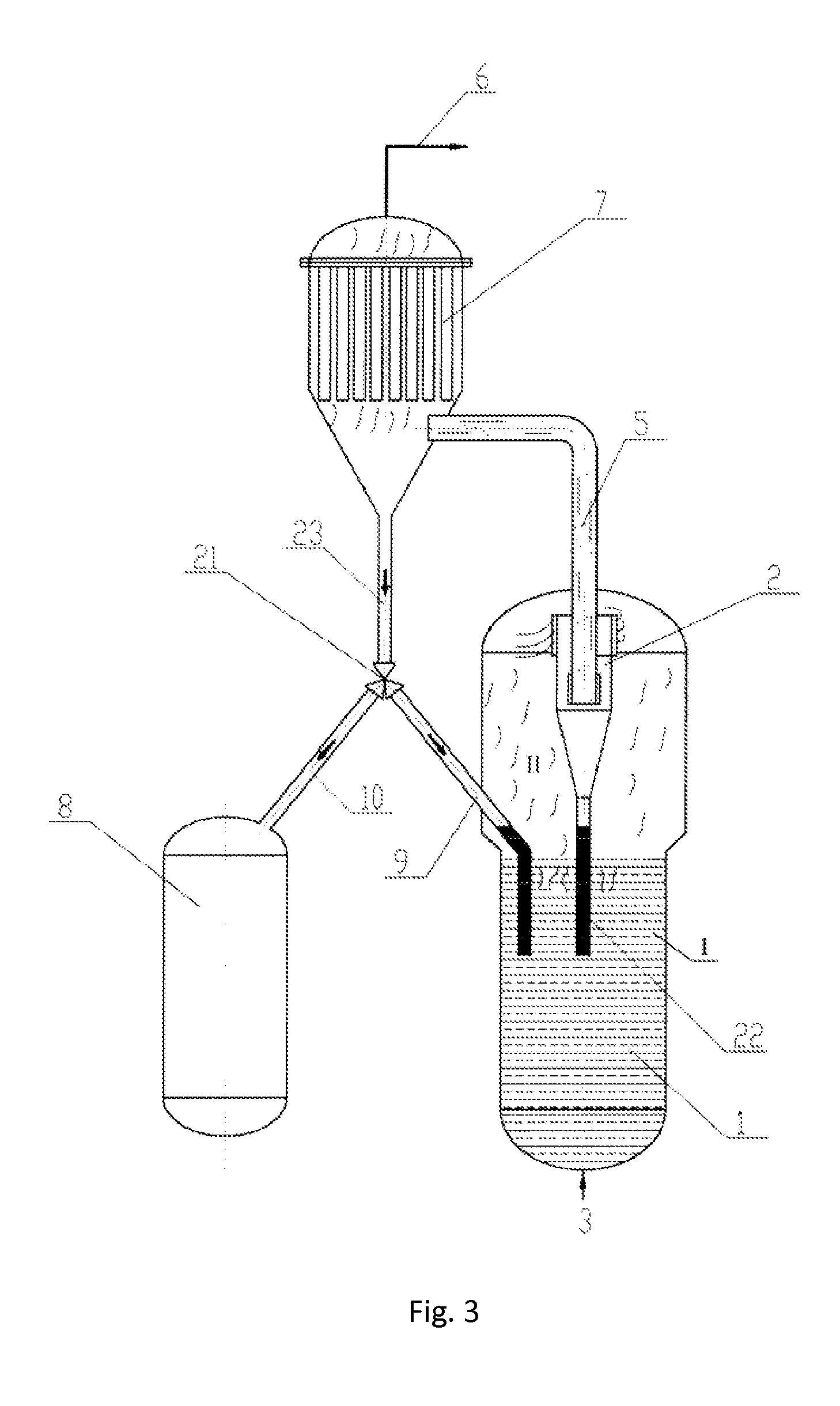

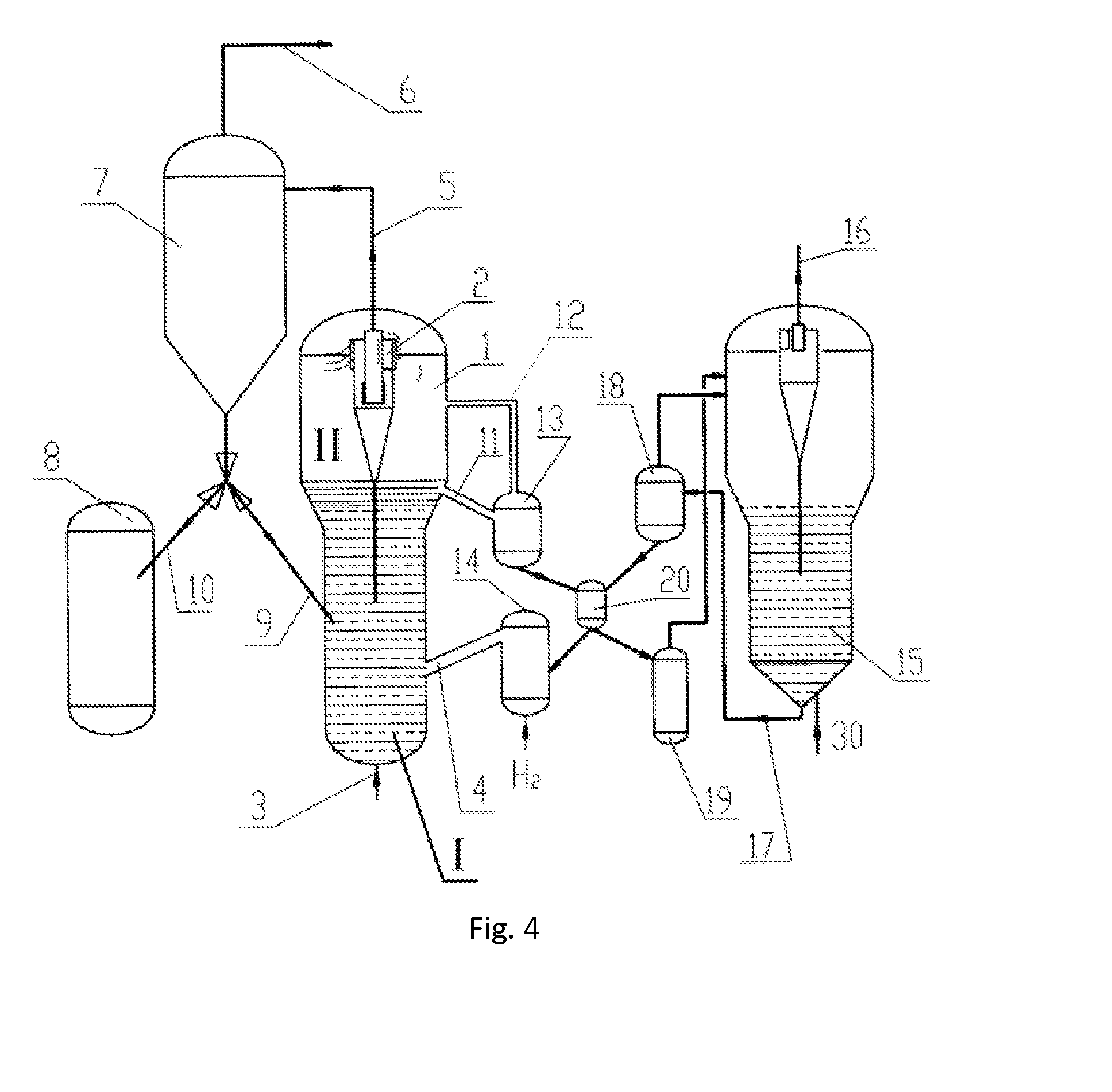

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

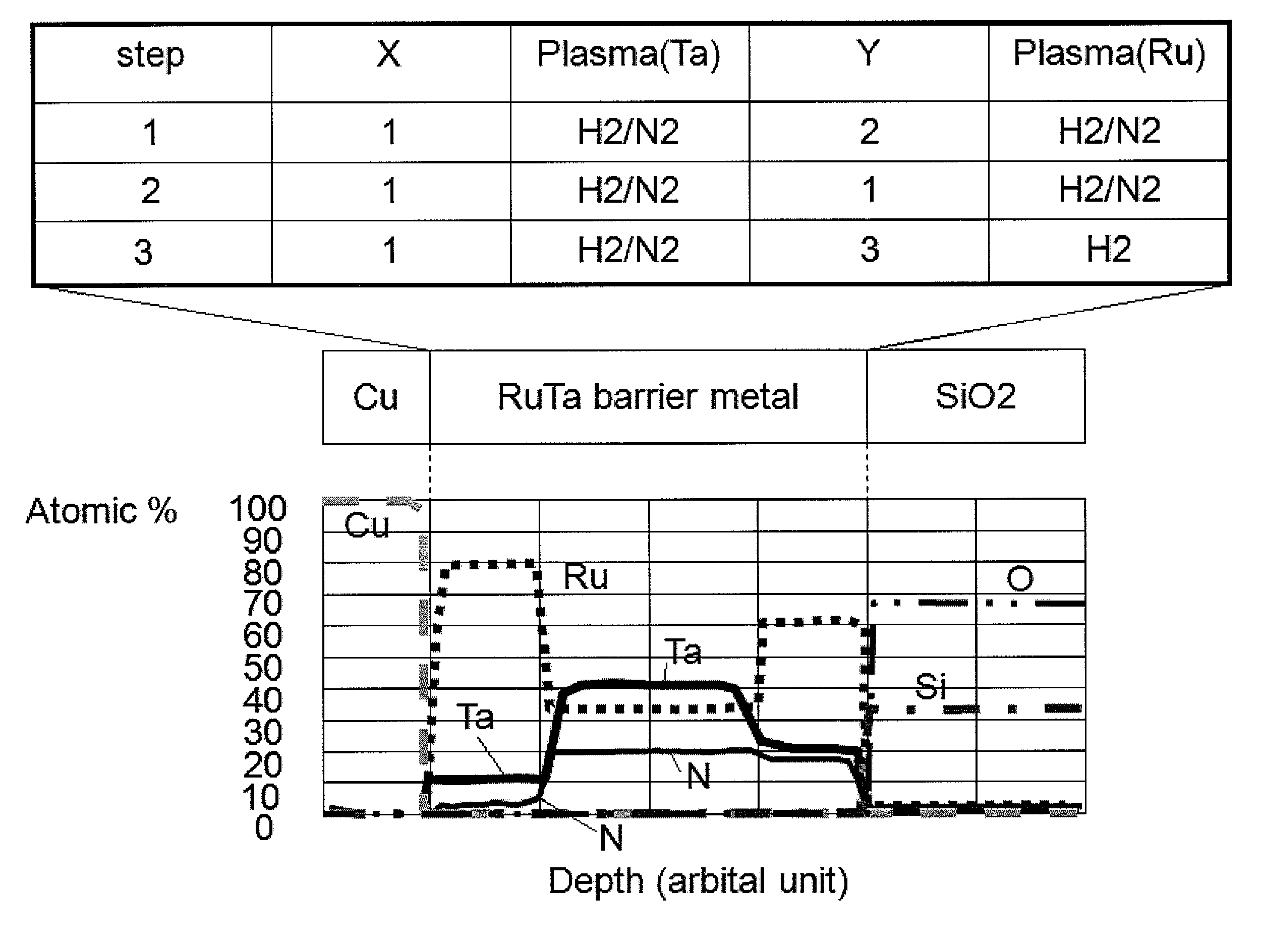

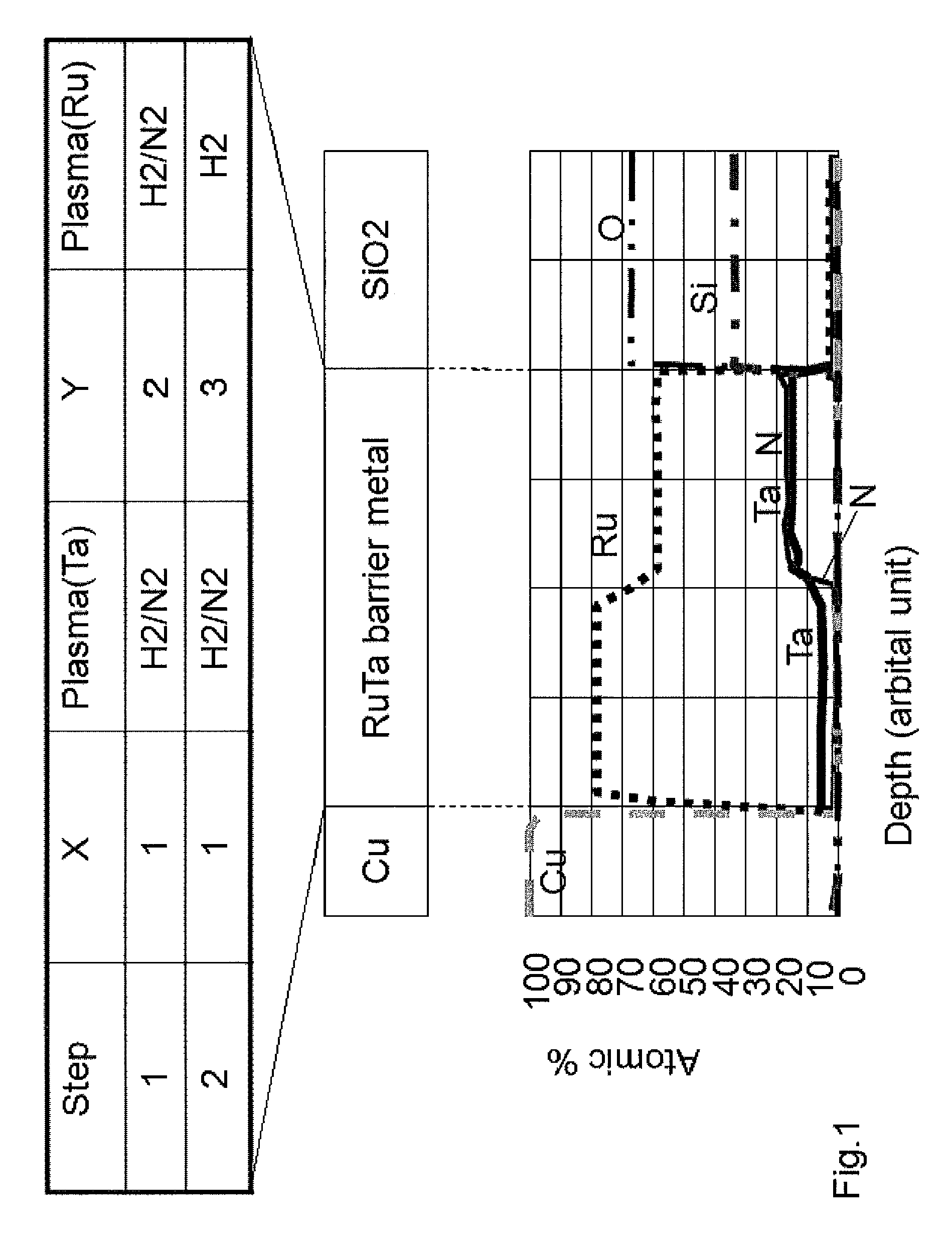

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

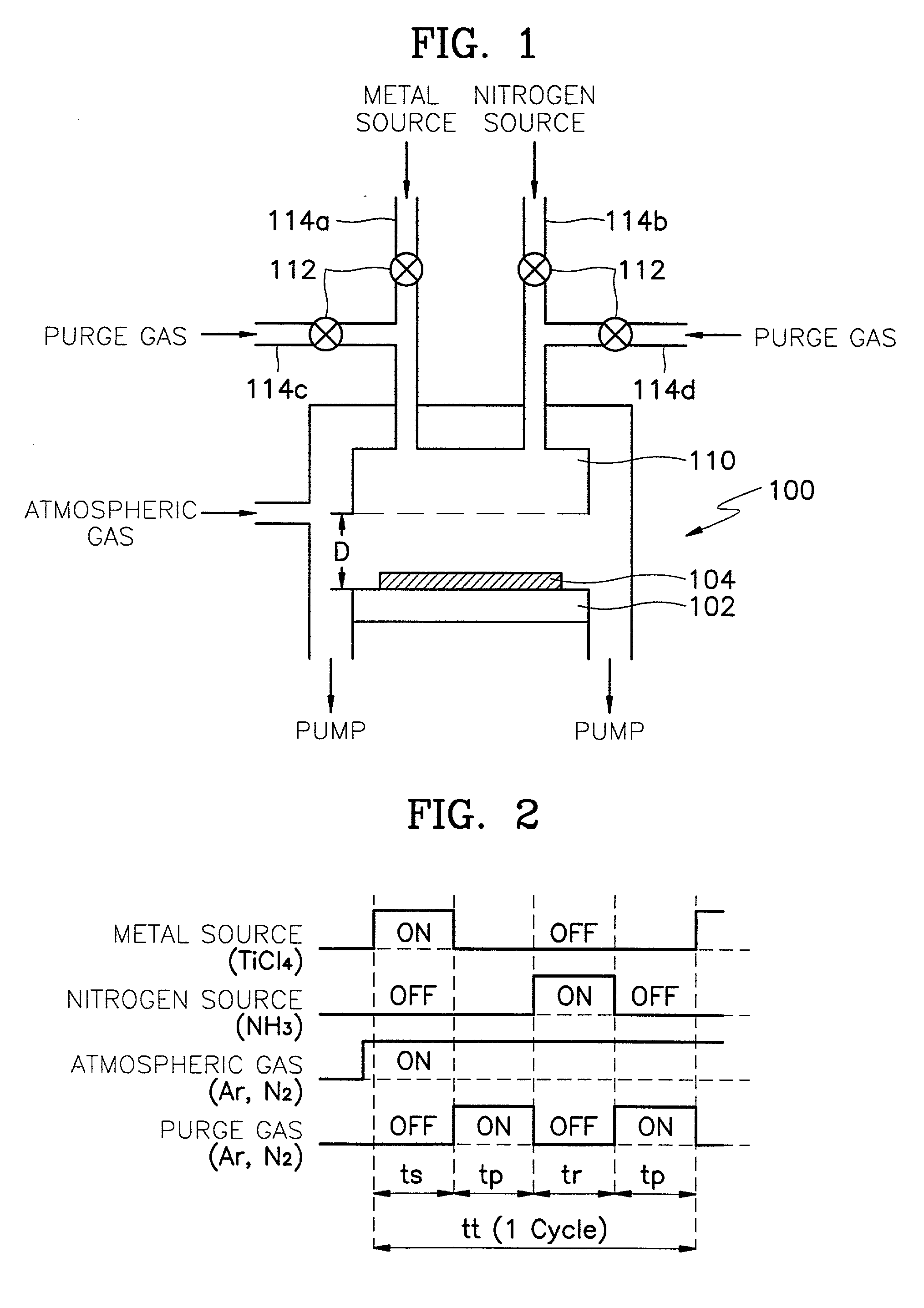

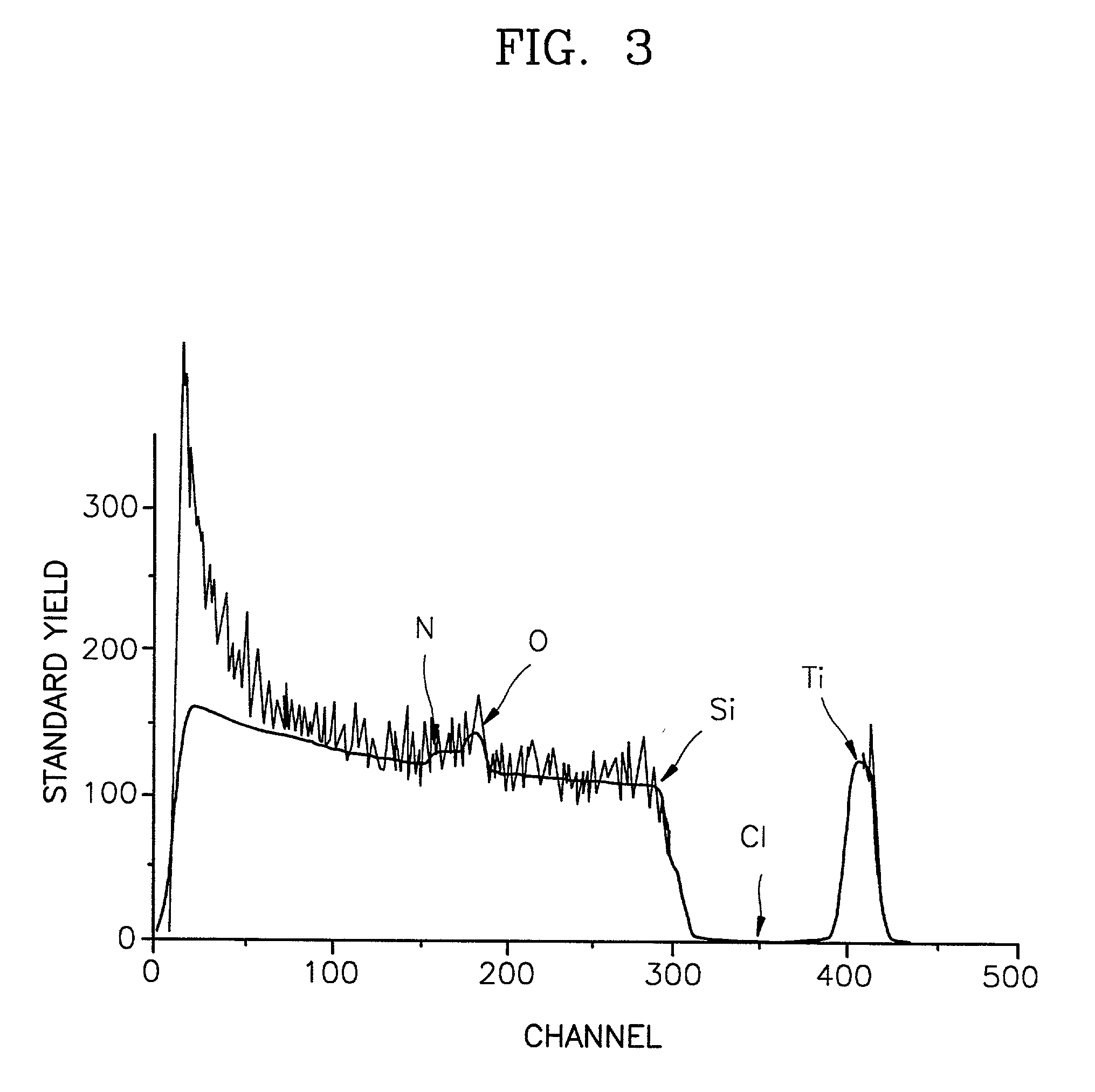

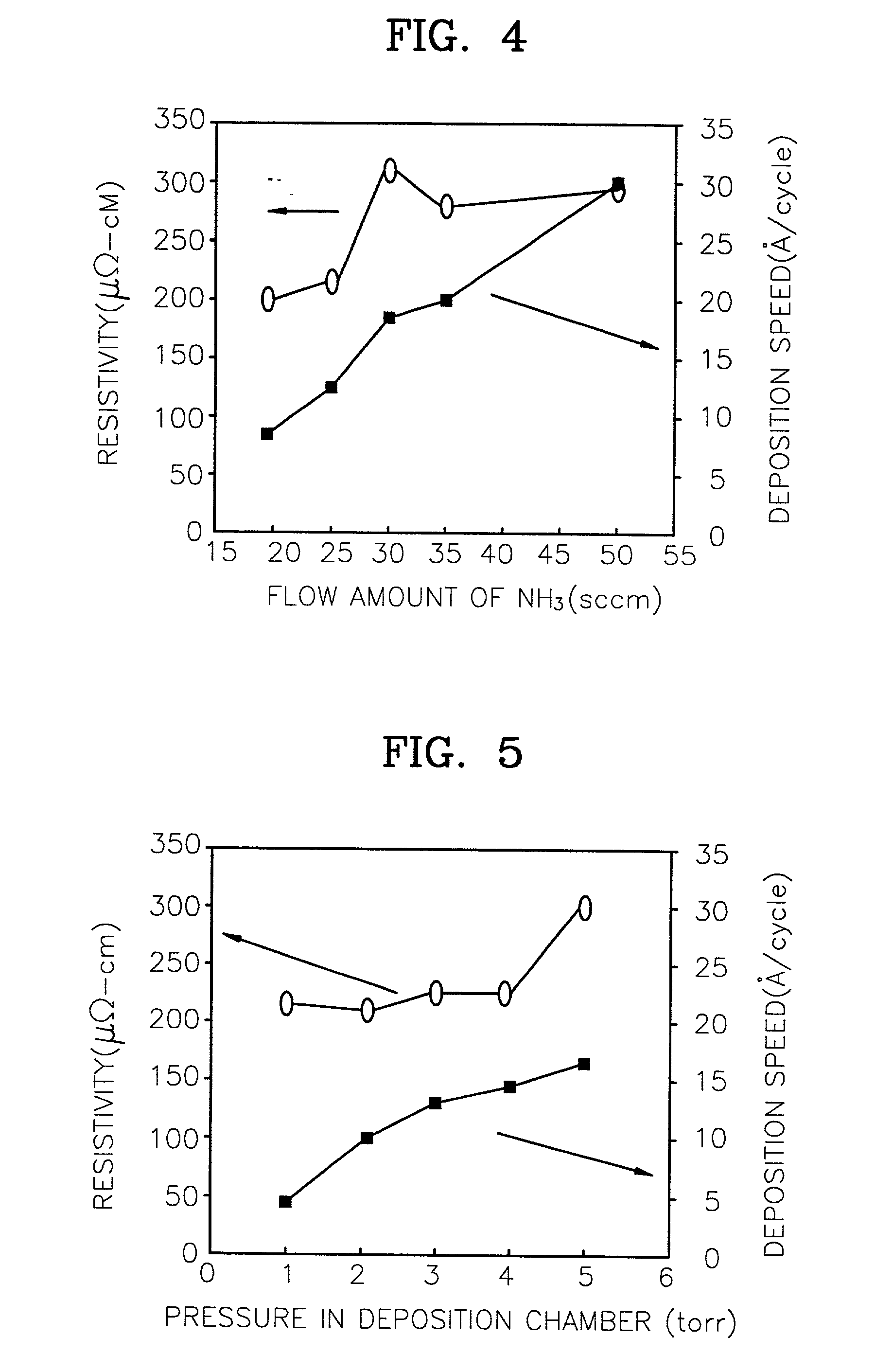

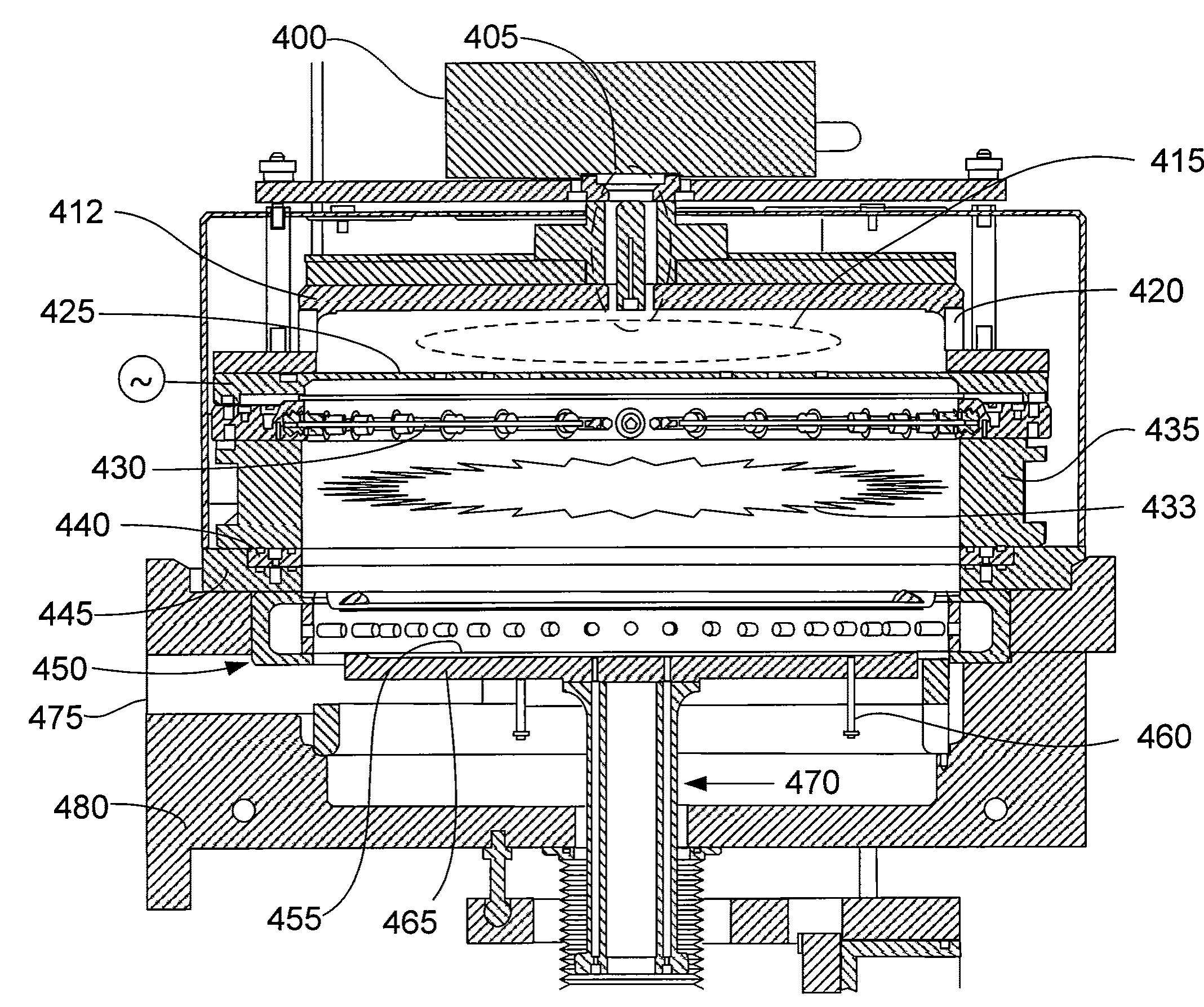

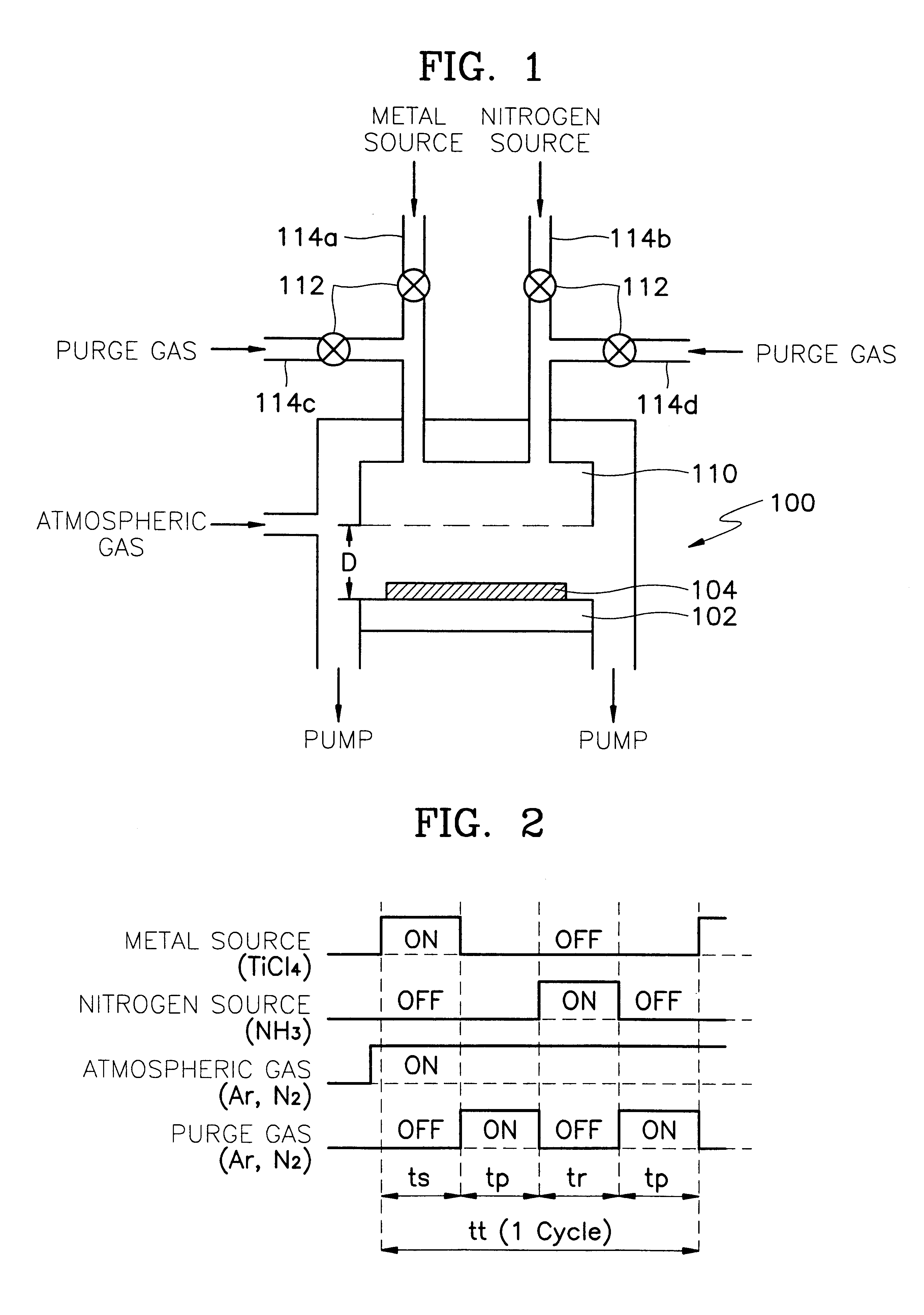

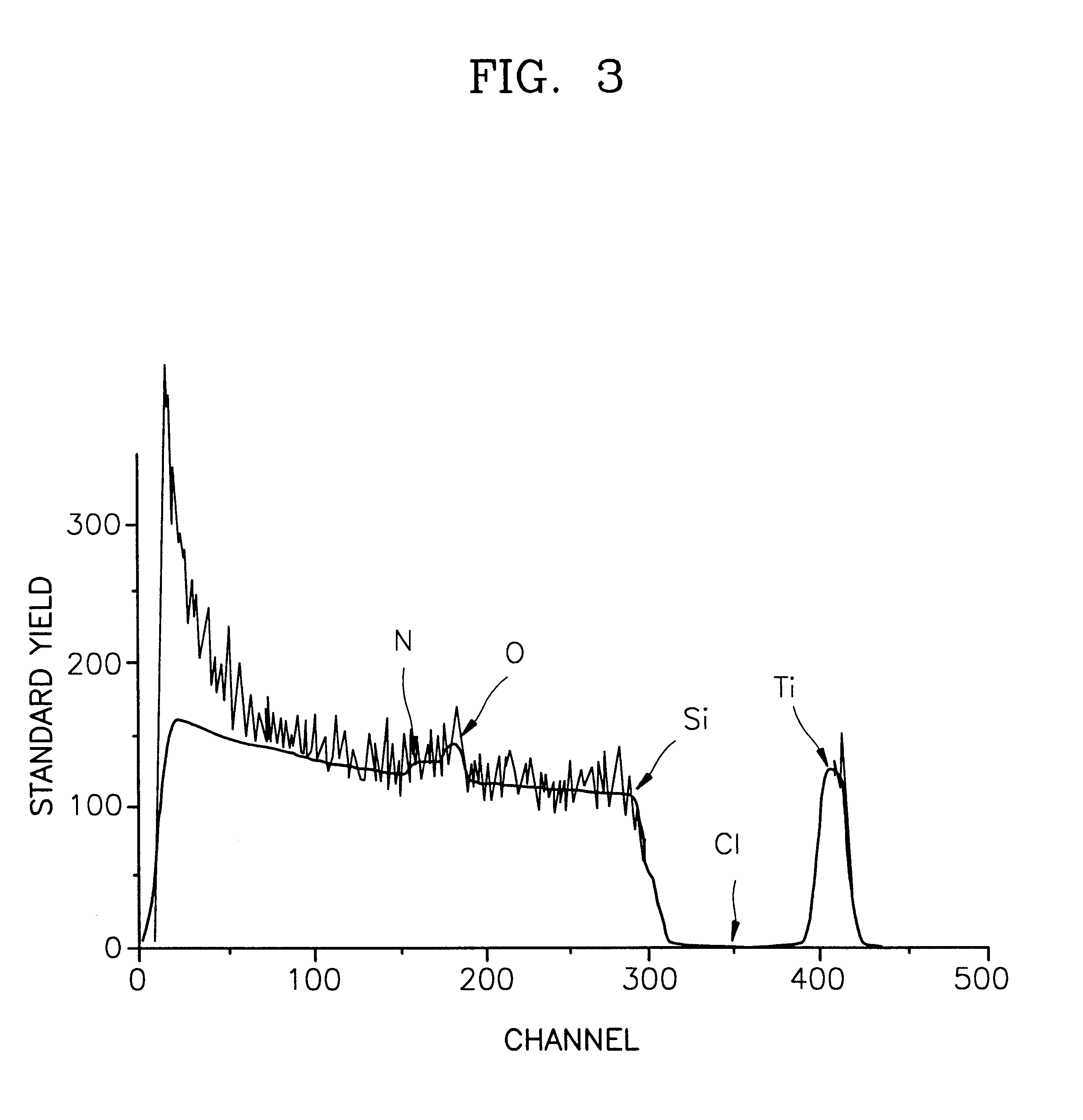

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS20010034097A1Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsChemical physicsDevice material

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

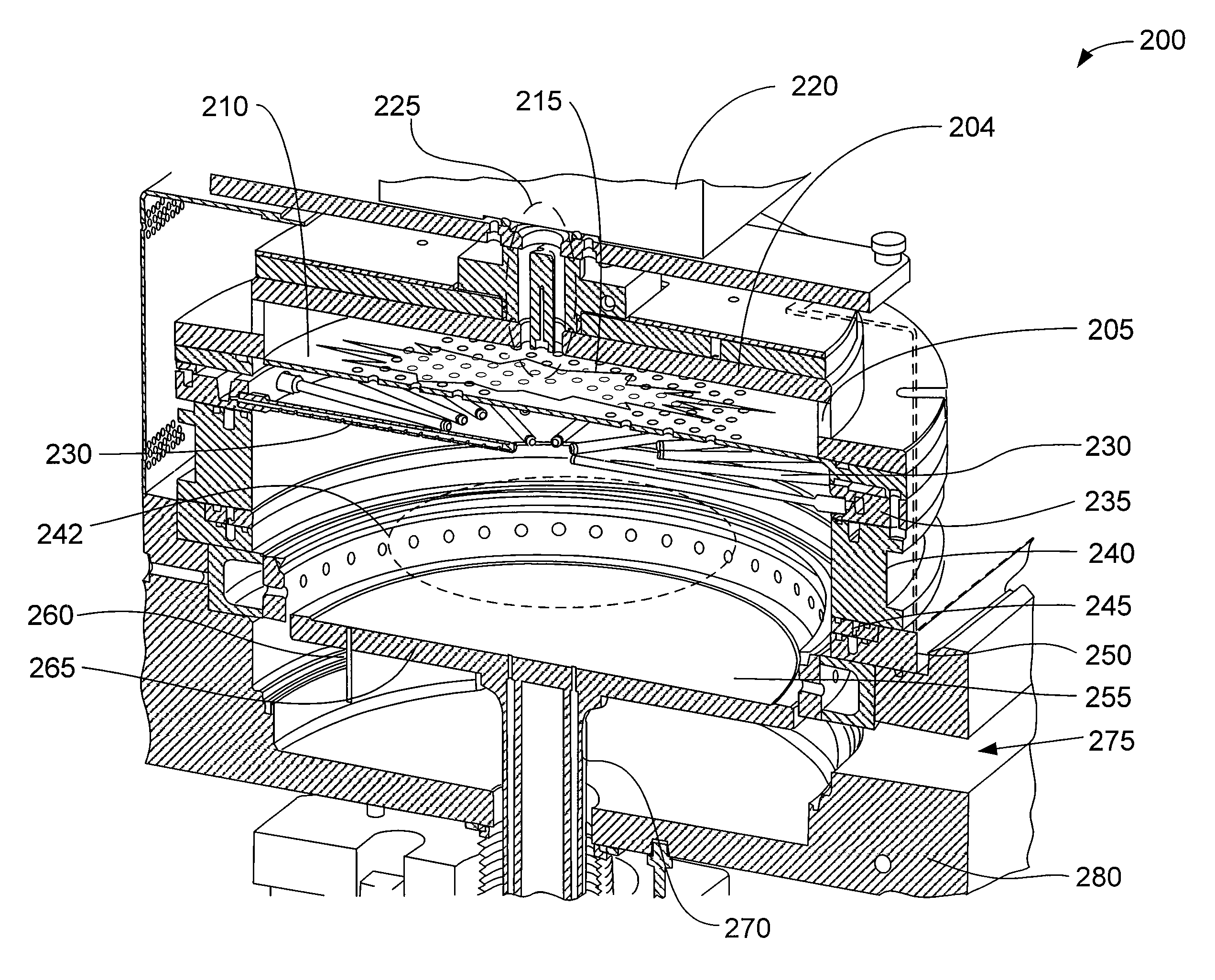

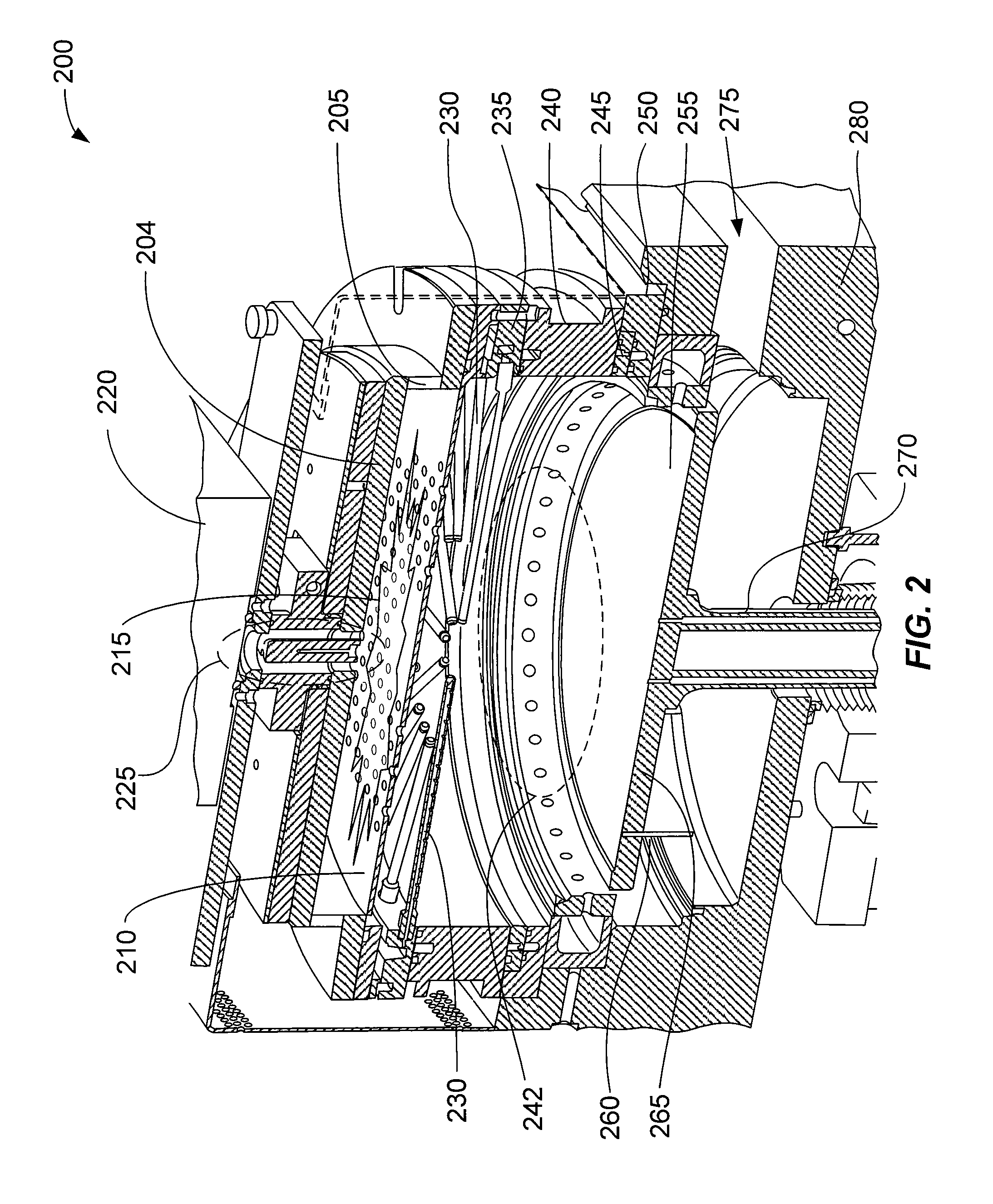

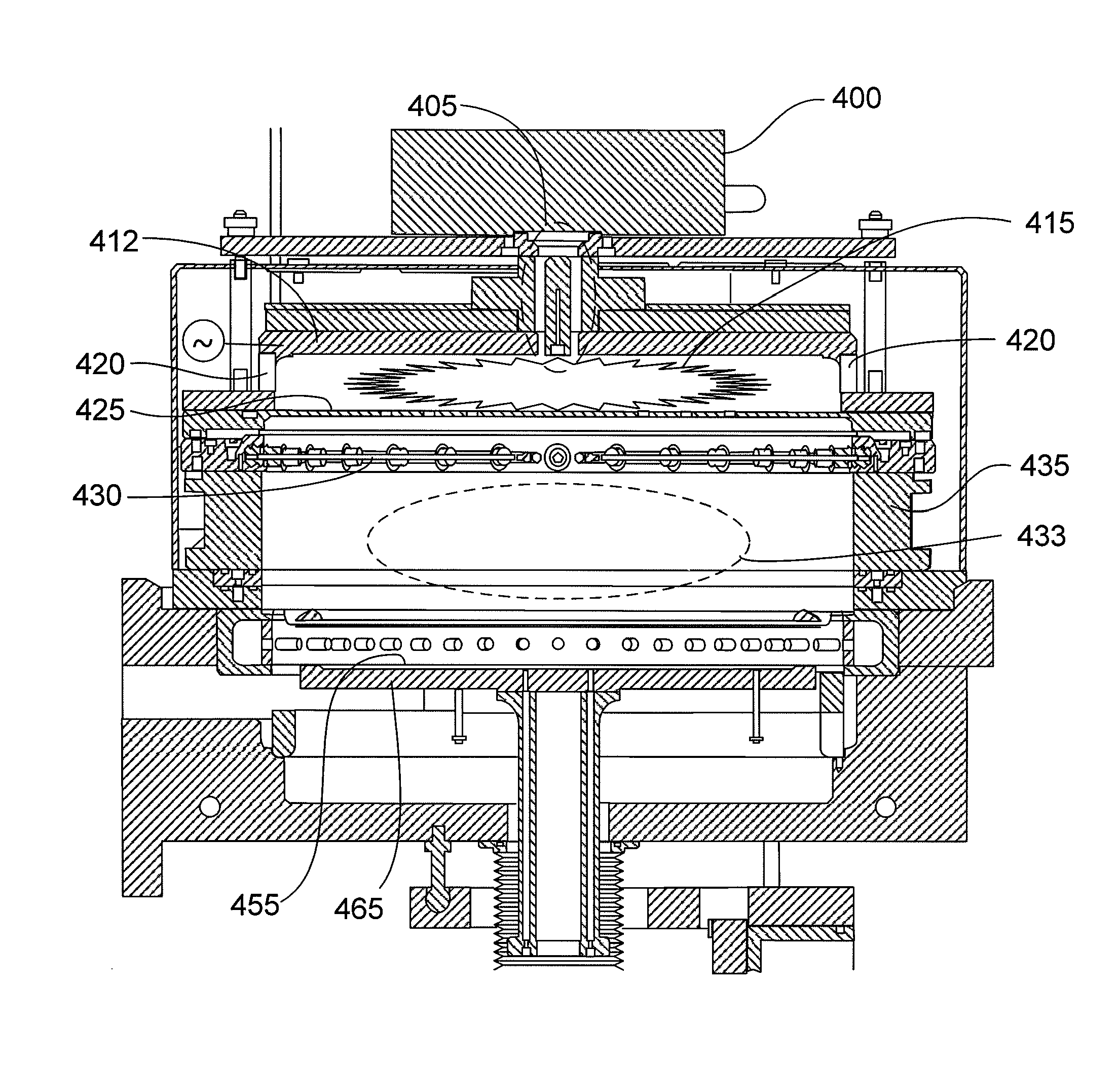

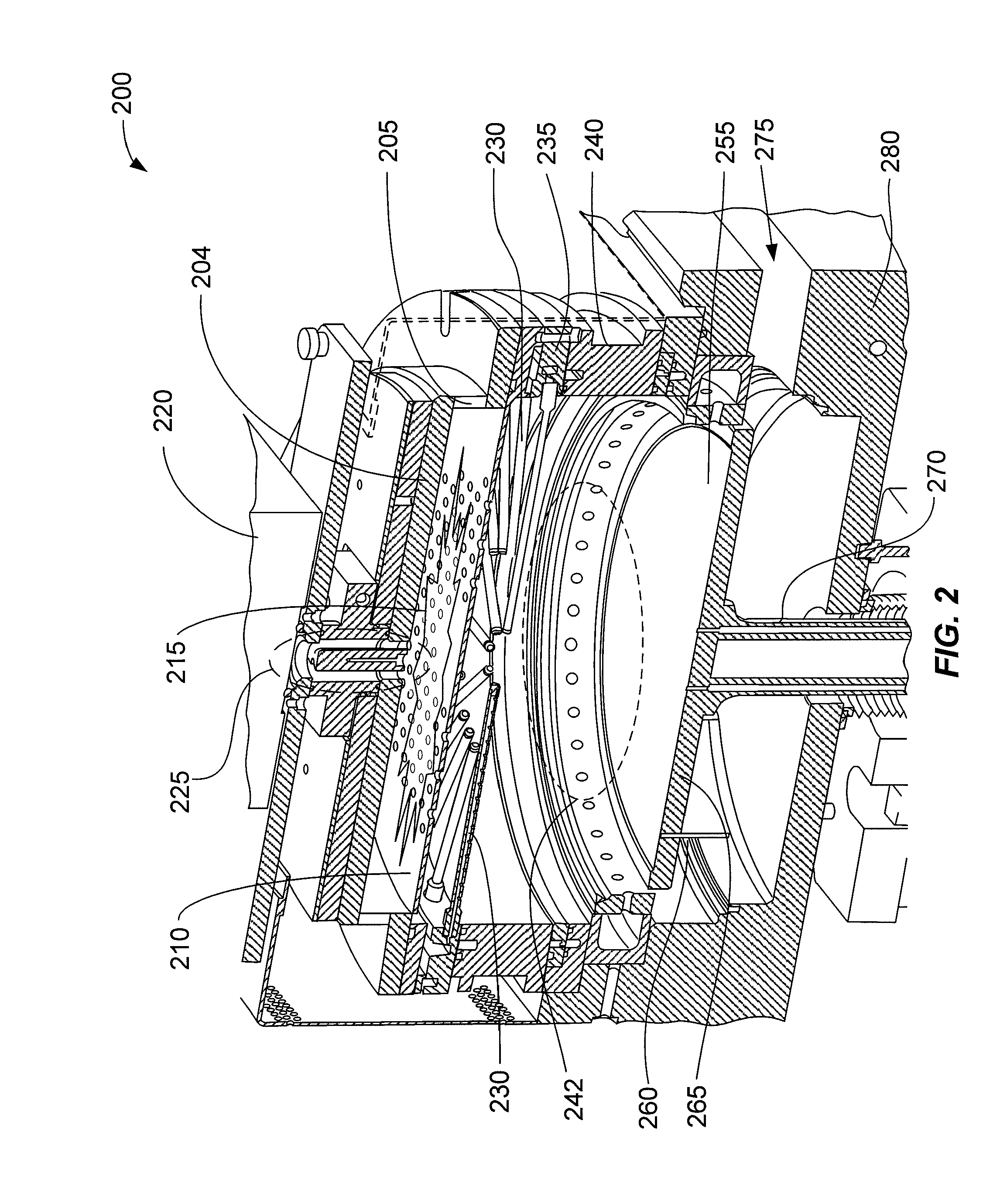

Flowable dielectric equipment and processes

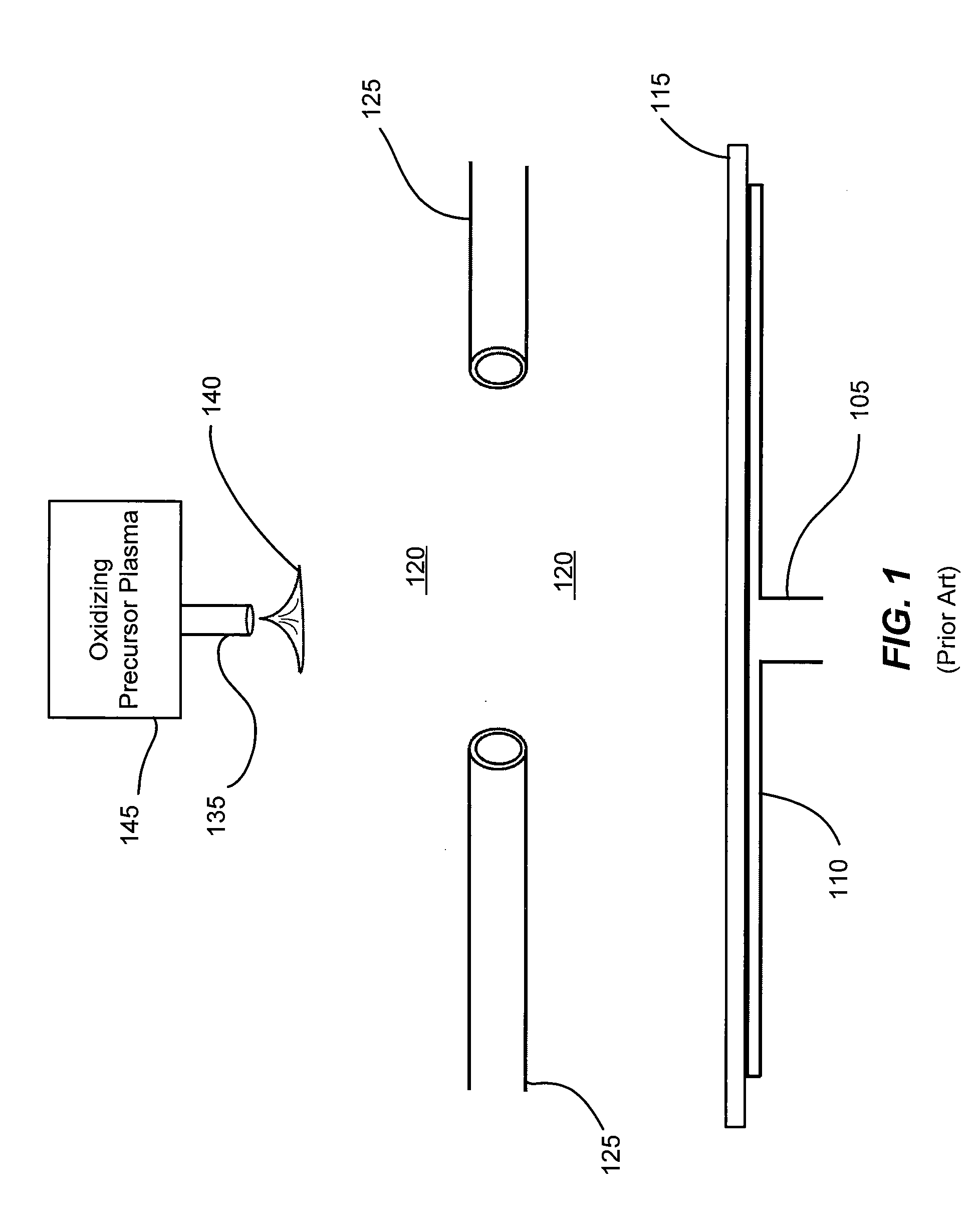

ActiveUS20090280650A1Reduce carbon contentReduce fluorine contentElectric discharge tubesDecorative surface effectsDielectric layerMaterials science

Methods of depositing and curing a dielectric material on a substrate are described. The methods may include the steps of providing a processing chamber partitioned into a first plasma region and a second plasma region, and delivering the substrate to the processing chamber, where the substrate occupies a portion of the second plasma region. The methods may further include forming a first plasma in the first plasma region, where the first plasma does not directly contact with the substrate, and depositing the dielectric material on the substrate to form a dielectric layer. One or more reactants excited by the first plasma are used in the deposition of the dielectric material. The methods may additional include curing the dielectric layer by forming a second plasma in the second plasma region, where one or more carbon-containing species is removed from the dielectric layer.

Owner:APPLIED MATERIALS INC

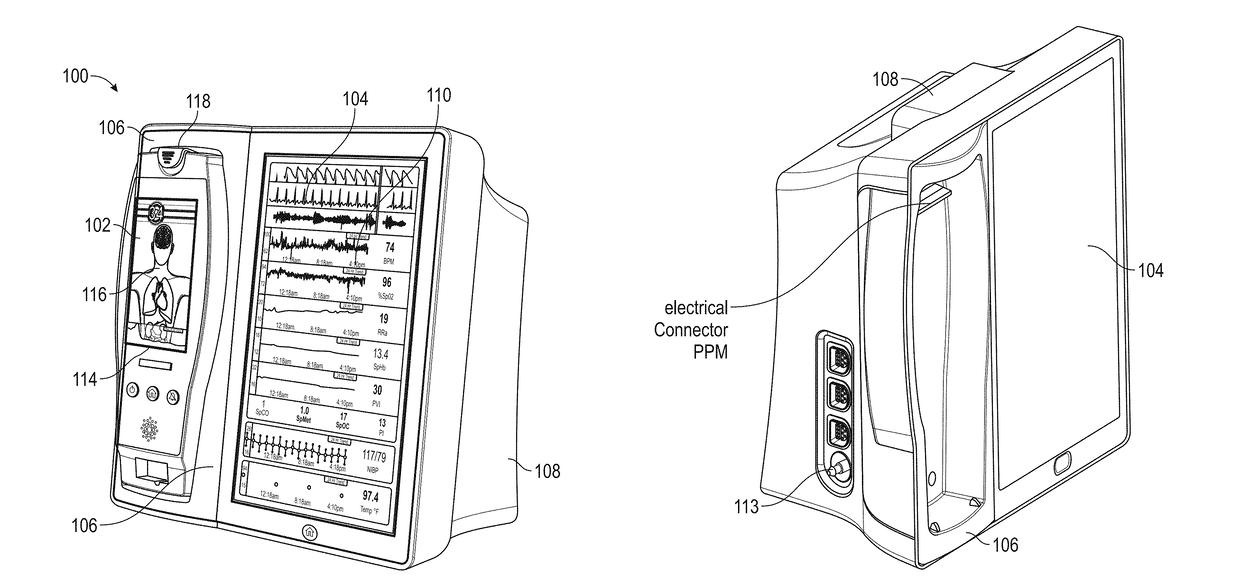

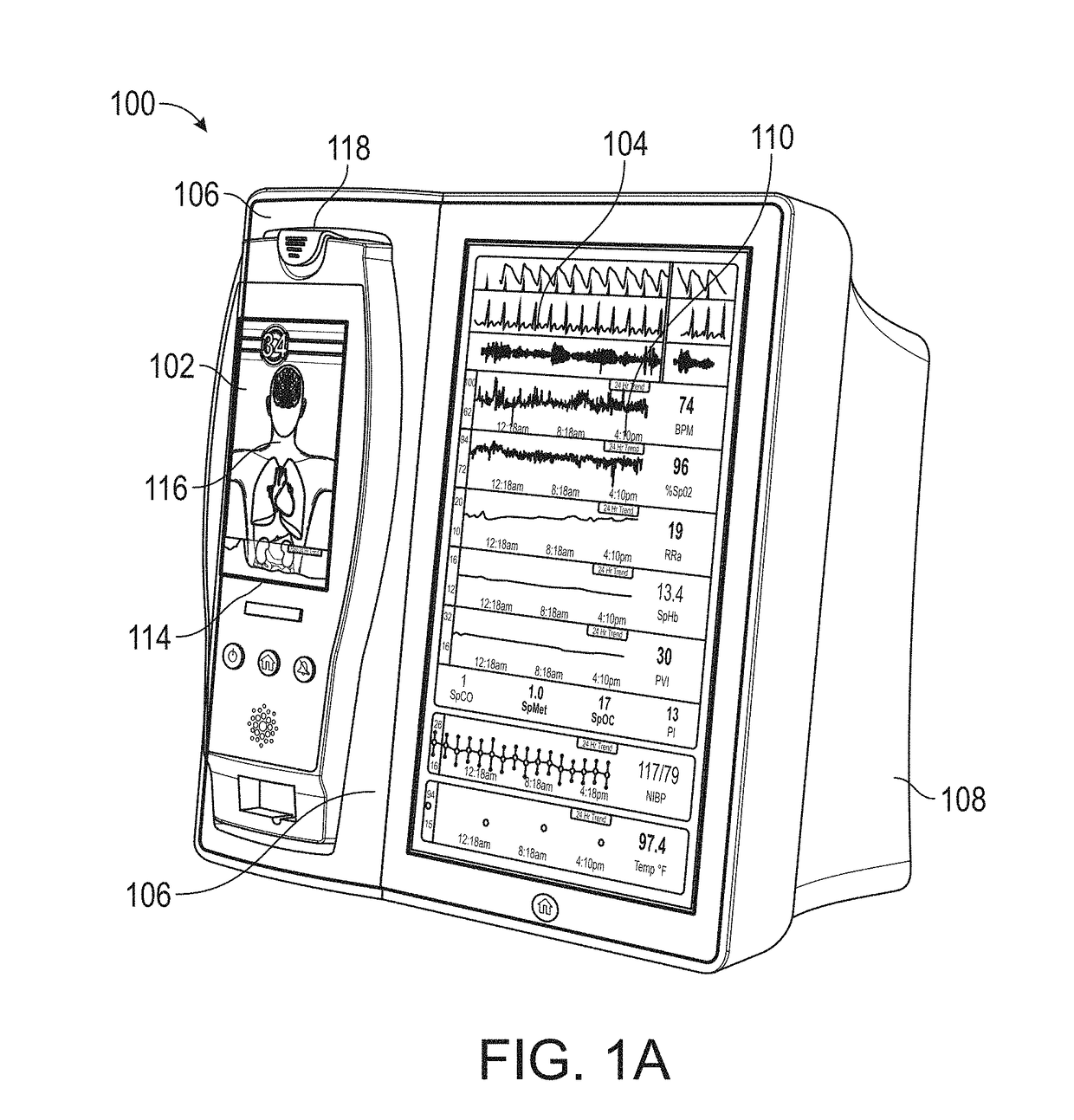

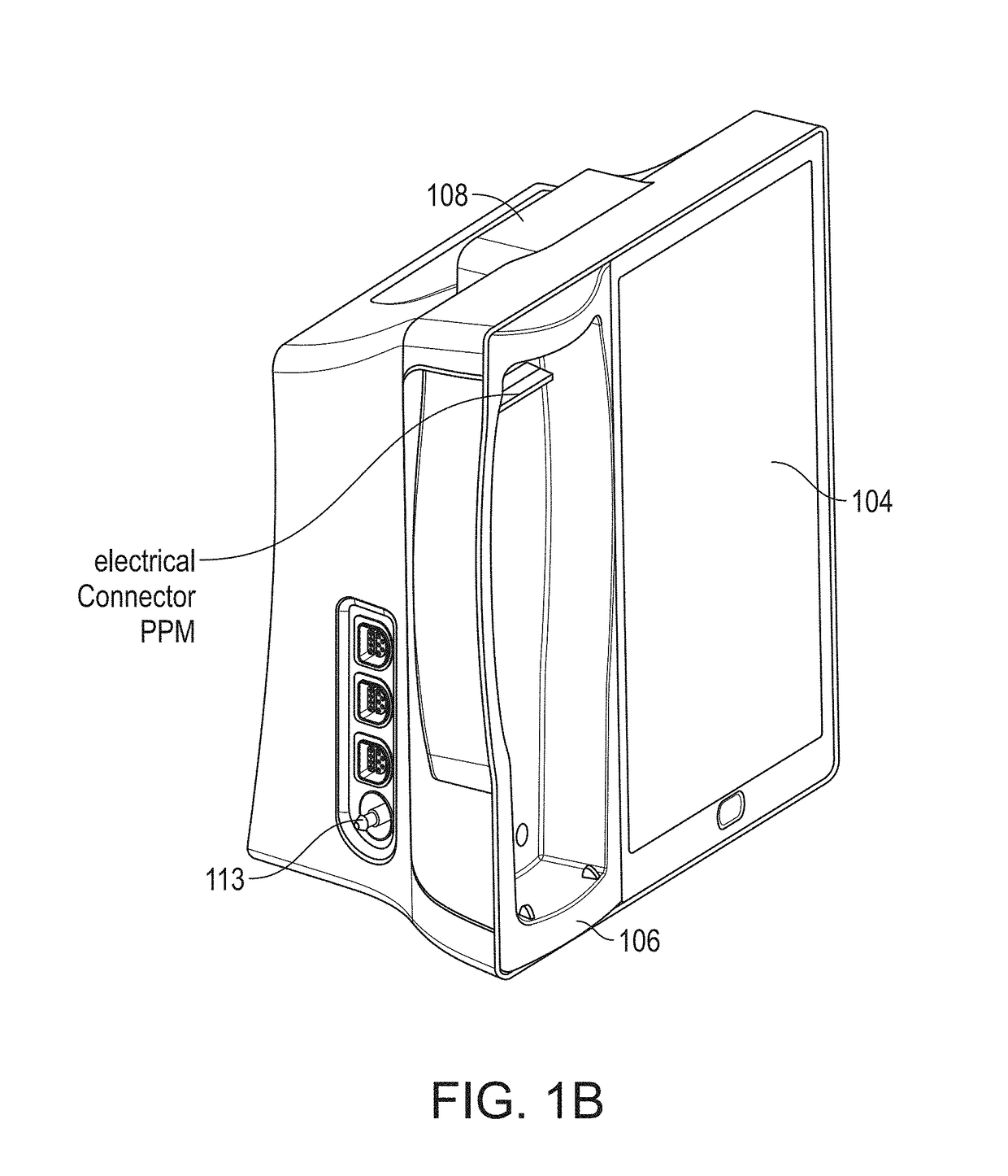

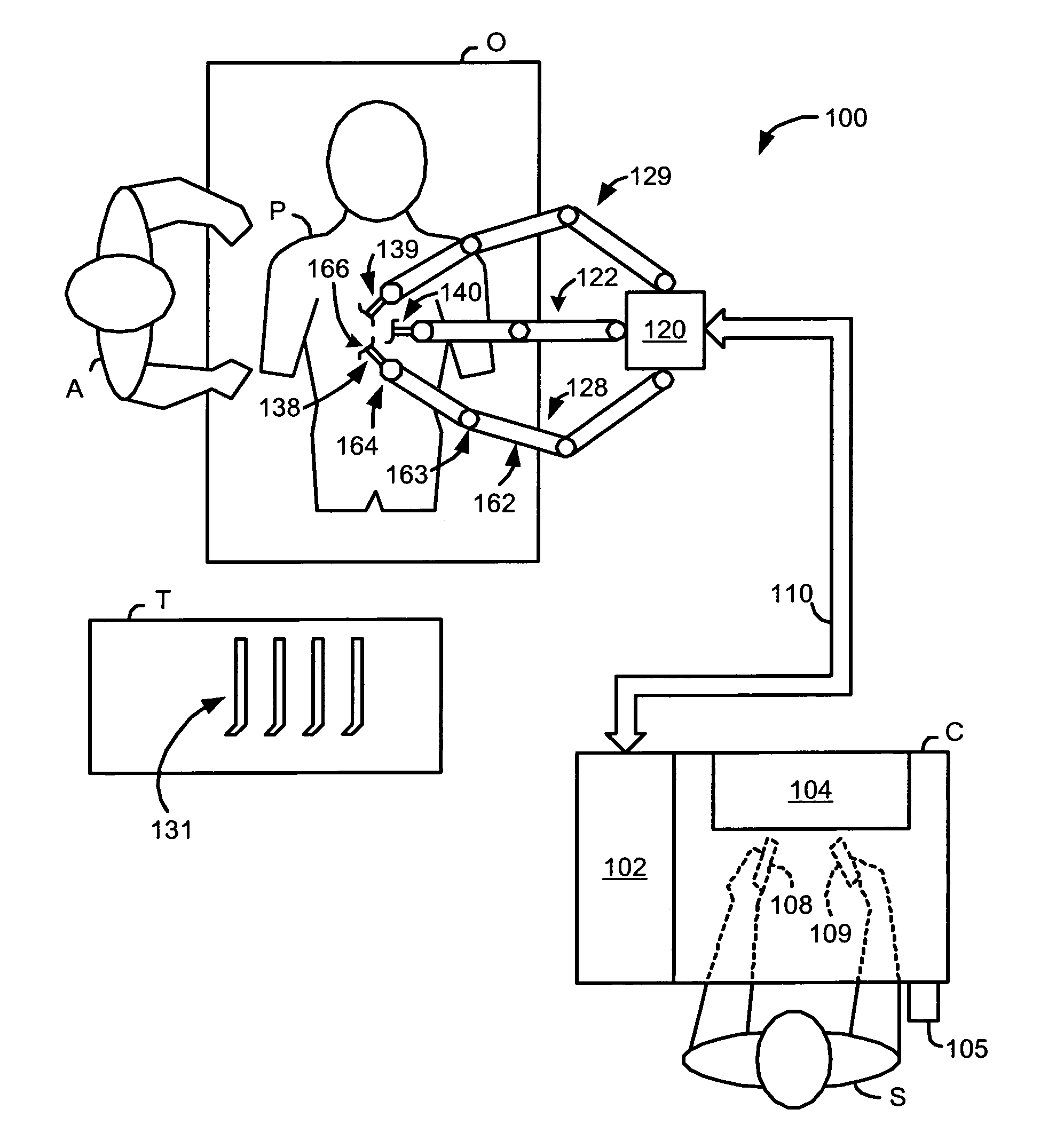

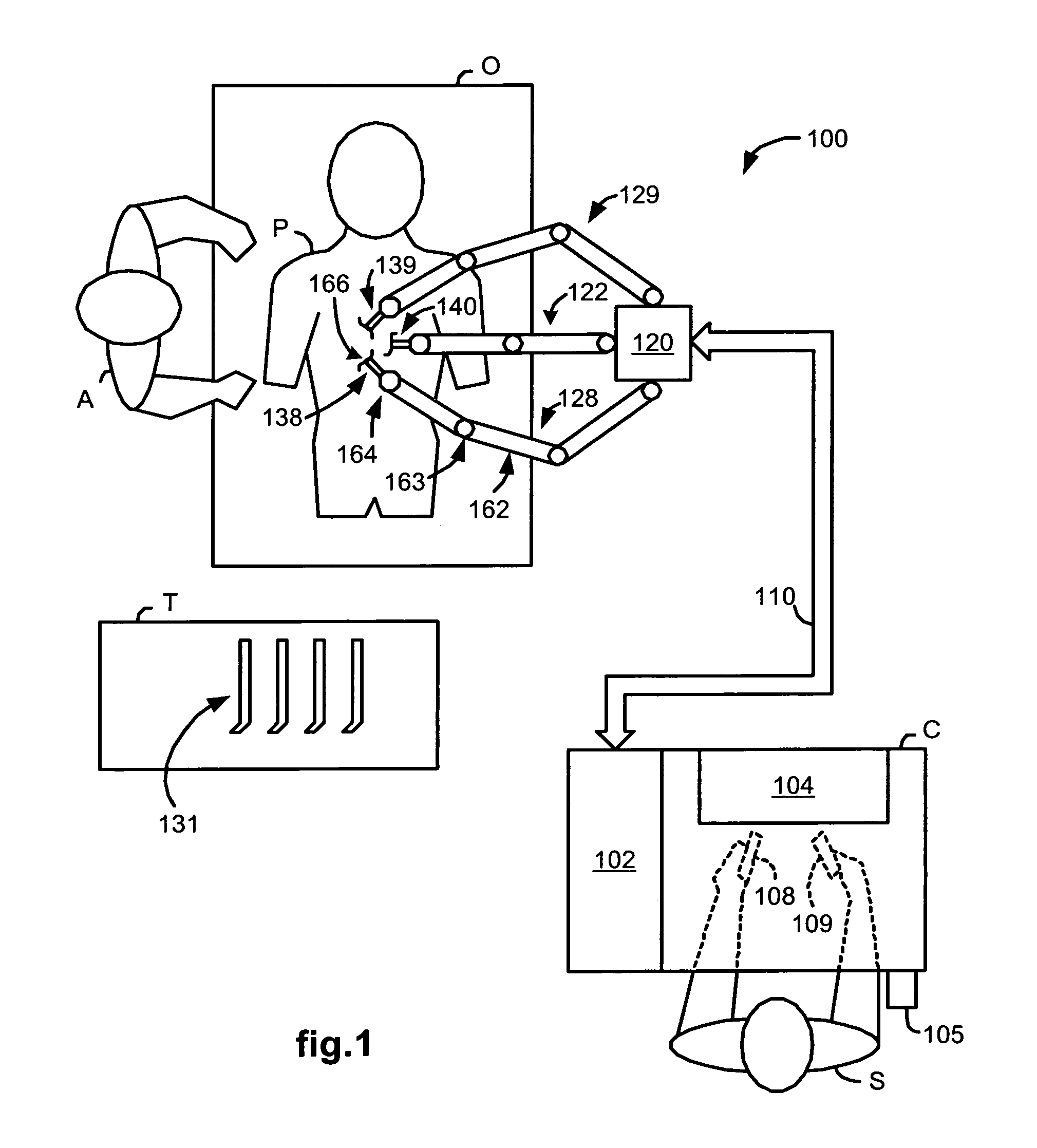

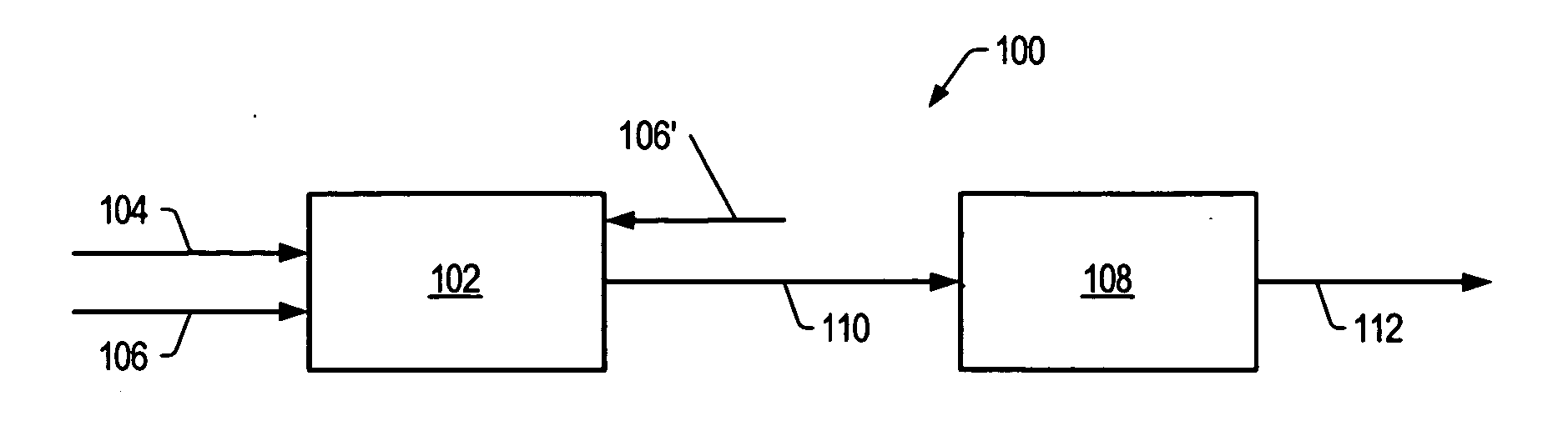

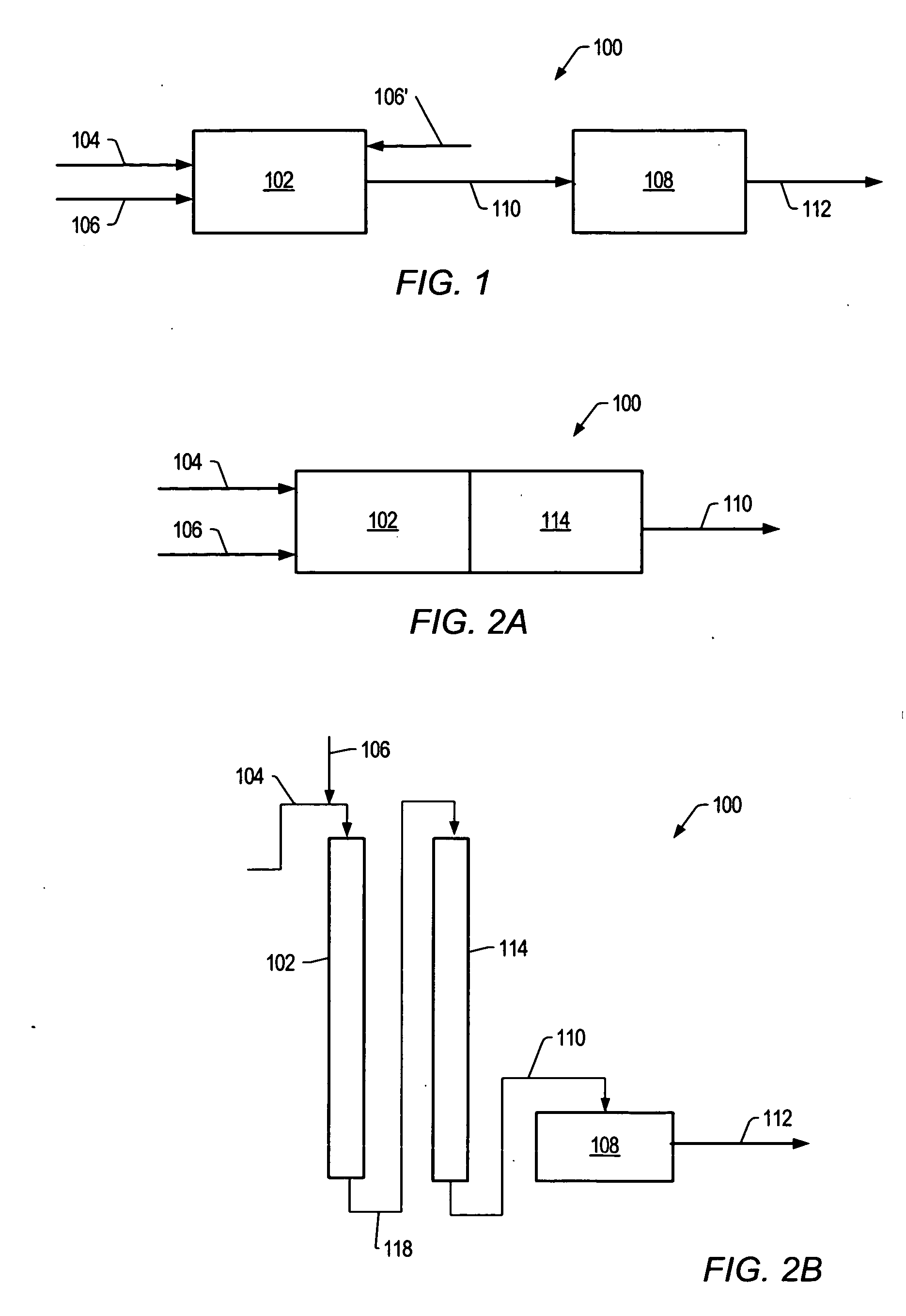

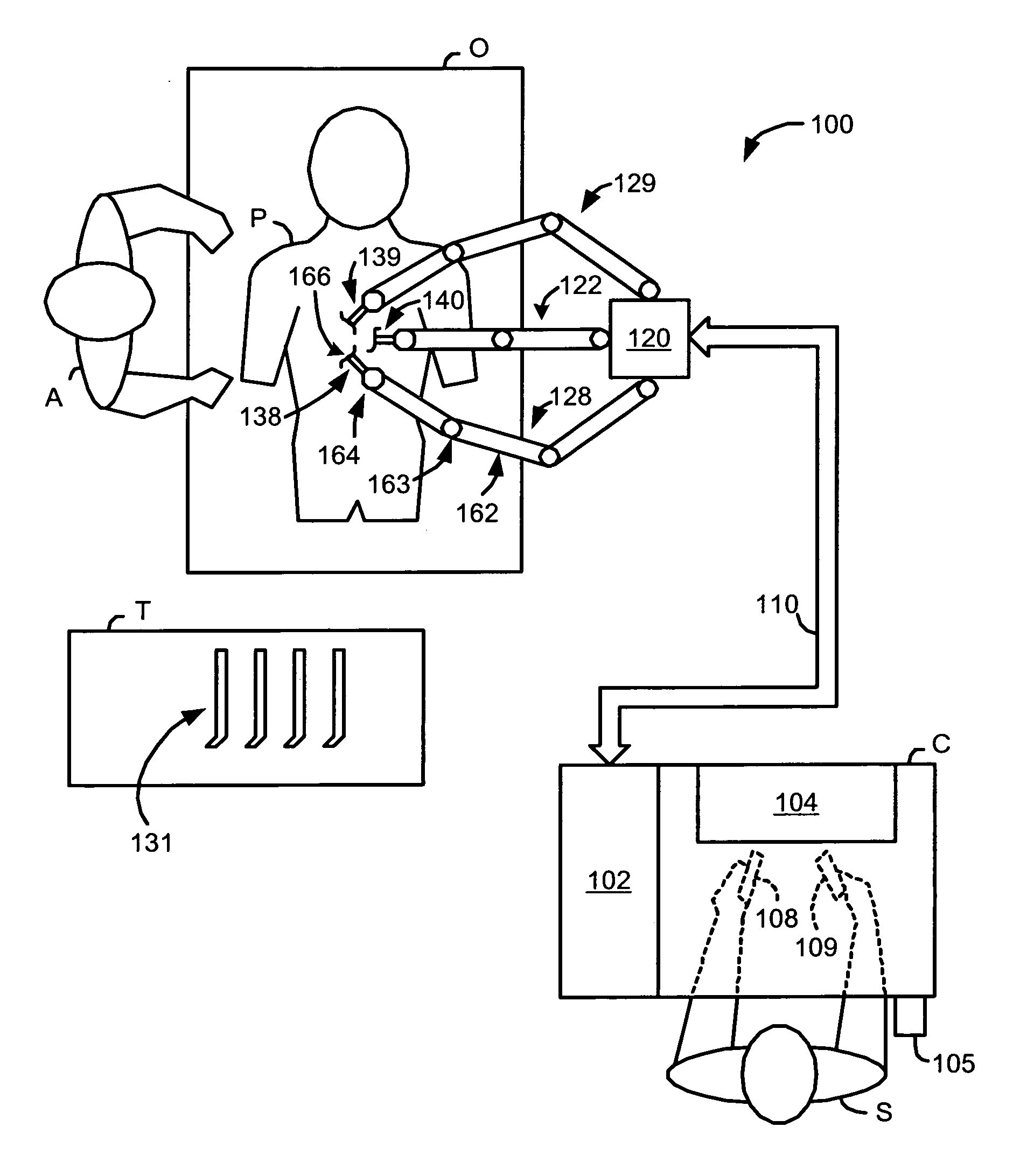

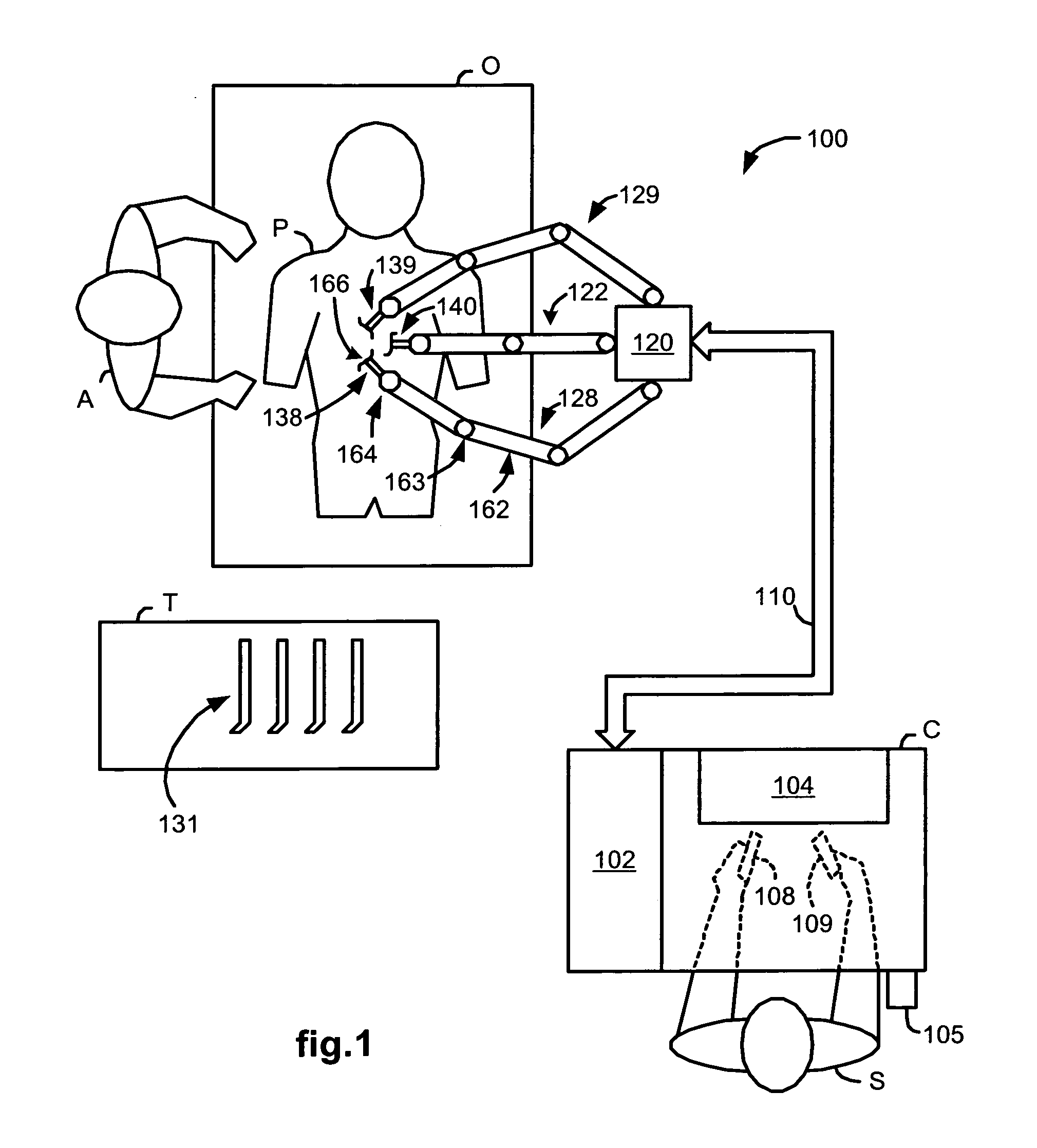

Augmented reality system for displaying patient data

ActiveUS20180300919A1Small sizeReduce contentMedical simulationImage enhancementAugmented reality systems

System and methods are provided for augmented reality displays for medical and physiological monitoring. Augmented reality user interfaces are virtually pinned to a physical device, a location, or to a patient. An augmented reality position determination process determines the presentation of user interfaces relative to reference positions and reference objects. Detection of gestures causes the augmented reality users interfaces to be updated, such as pinning a user interface to a device, location, or patient. Looking away from an augmented reality user interface causes the user interface to minimize or disappear in an augmented reality display. An augmented reality gesture detection process determines gestures based on captured image data and computer vision techniques performed on the image data.

Owner:MASIMO CORP

Method of forming metal nitride film by chemical vapor deposition and method of forming metal contact and capacitor of semiconductor device using the same

InactiveUS6348376B2Good step coverageLow resistivitySemiconductor/solid-state device manufacturingCapacitorsDevice materialNitrogen source

A method of forming a metal nitride film using chemical vapor deposition (CVD), and a method of forming a metal contact and a semiconductor capacitor of a semiconductor device using the same, are provided. The method of forming a metal nitride film using chemical vapor deposition (CVD) in which a metal source and a nitrogen source are used as a precursor, includes the steps of inserting a semiconductor substrate into a deposition chamber, flowing the metal source into the deposition chamber, removing the metal source remaining in the deposition chamber by cutting off the inflow of the metal source and flowing a purge gas into the deposition chamber, cutting off the purge gas and flowing the nitrogen source into the deposition chamber to react with the metal source adsorbed on the semiconductor substrate, and removing the nitrogen source remaining in the deposition chamber by cutting off the inflow of the nitrogen source and flowing the purge gas into the deposition chamber. Accordingly, the metal nitride film having low resistivity and a low content of Cl even with excellent step coverage can be formed at a temperature of 500° C. or lower, and a semiconductor capacitor having excellent leakage current characteristics can be manufactured. Also, a deposition speed, approximately 20 A / cycle, is suitable for mass production.

Owner:SAMSUNG ELECTRONICS CO LTD

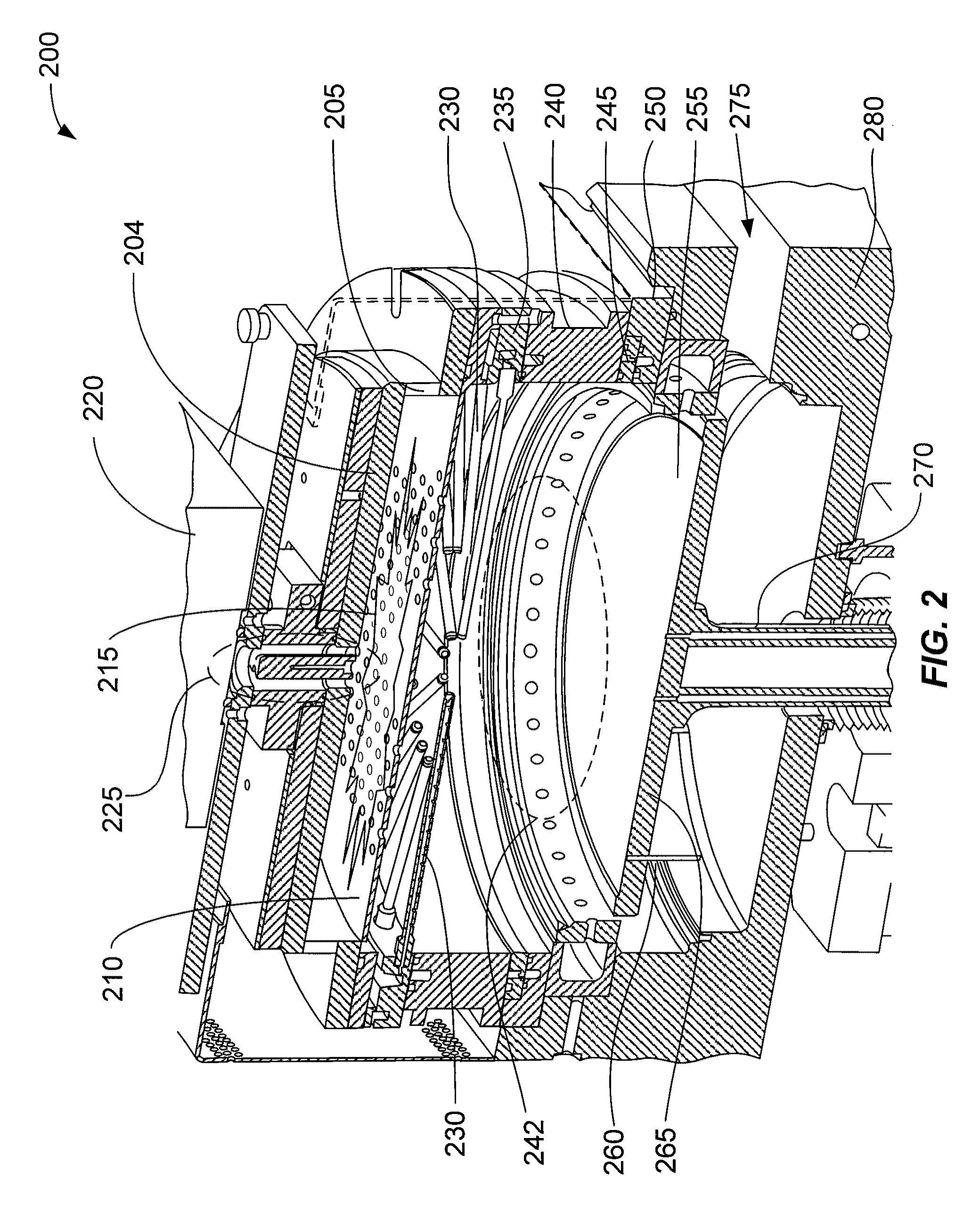

Flowable dielectric equipment and processes

InactiveUS20090277587A1Reduce carbon contentReduce fluorine contentElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaProcess engineering

Substrate processing systems are described that may include a processing chamber having an interior capable of holding an internal chamber pressure different from an external chamber pressure. The systems may also include a remote plasma system operable to generate a plasma outside the interior of the processing chamber. In addition, the systems may include a first process gas channel operable to transport a first process gas from the remote plasma system to the interior of the processing chamber, and a second process gas channel operable to transport a second process gas that is not treated by the remote plasma system. The second process gas channel has a distal end that opens into the interior of the processing chamber, and that is at least partially surrounded by the first process gas channel.

Owner:APPLIED MATERIALS INC

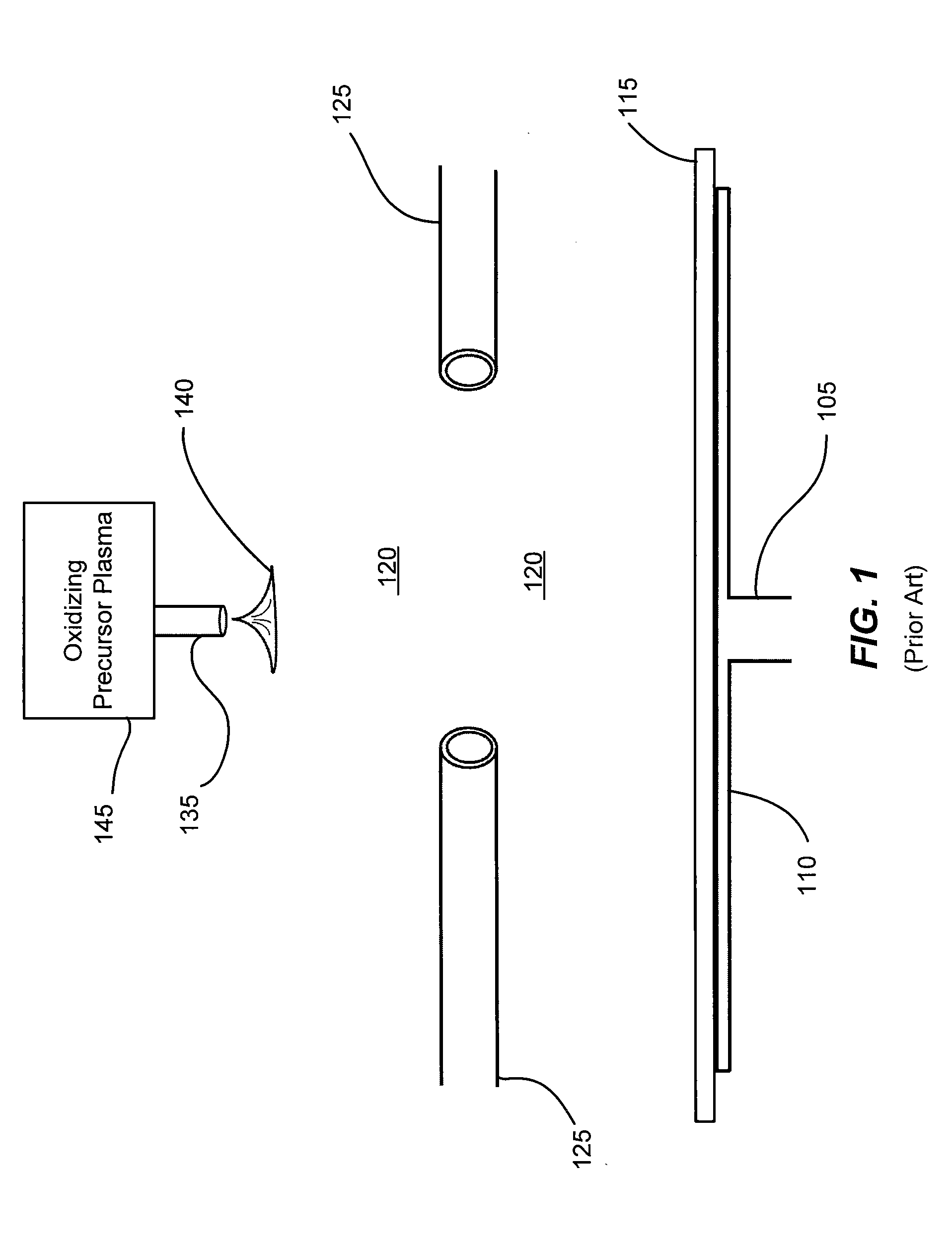

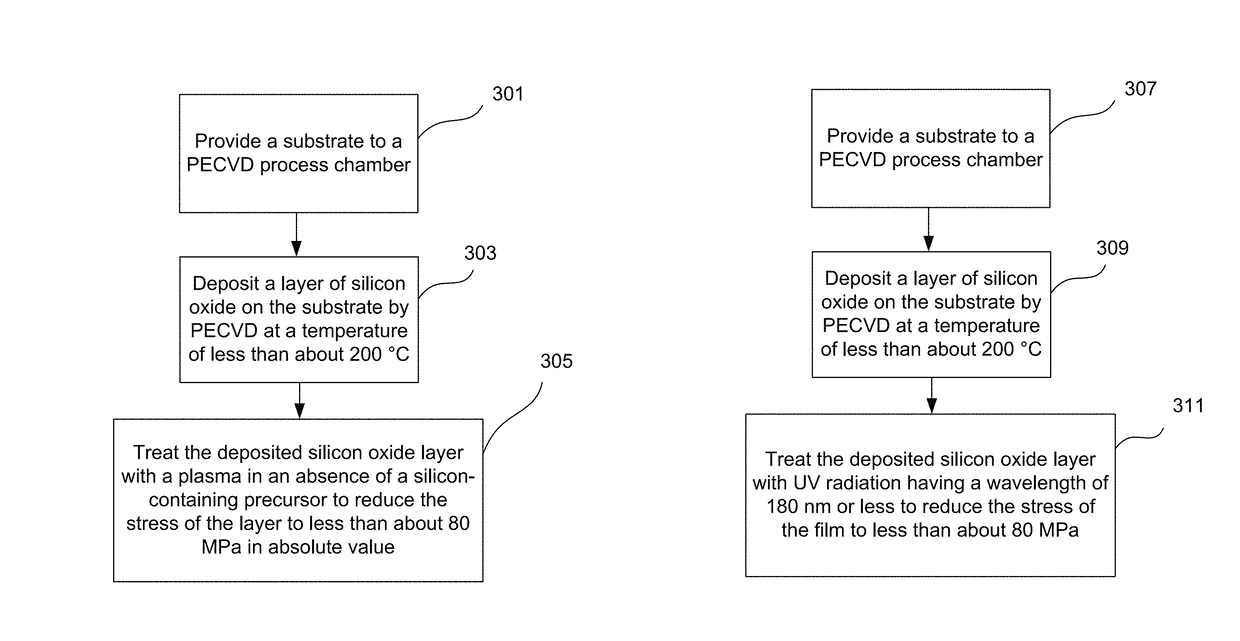

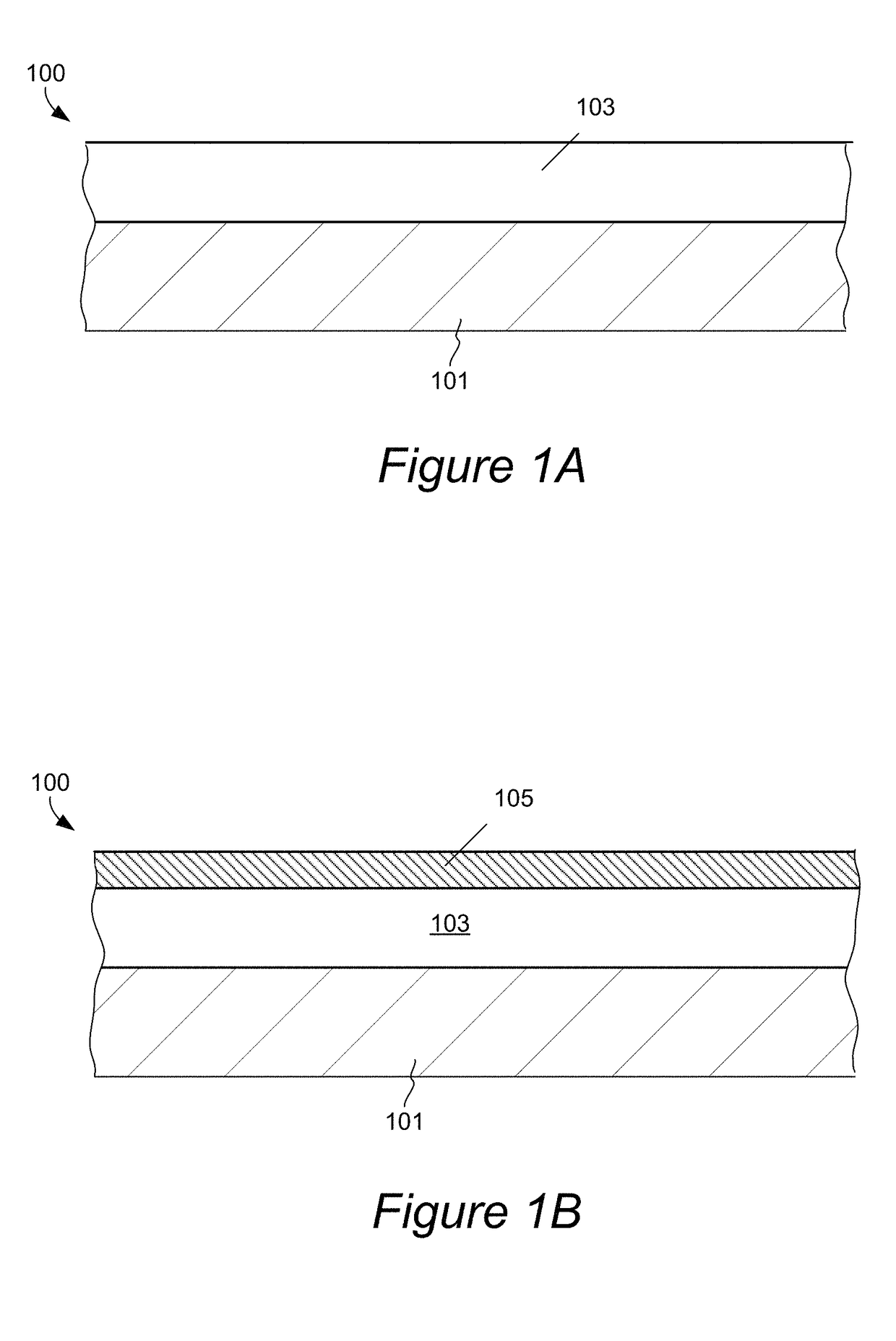

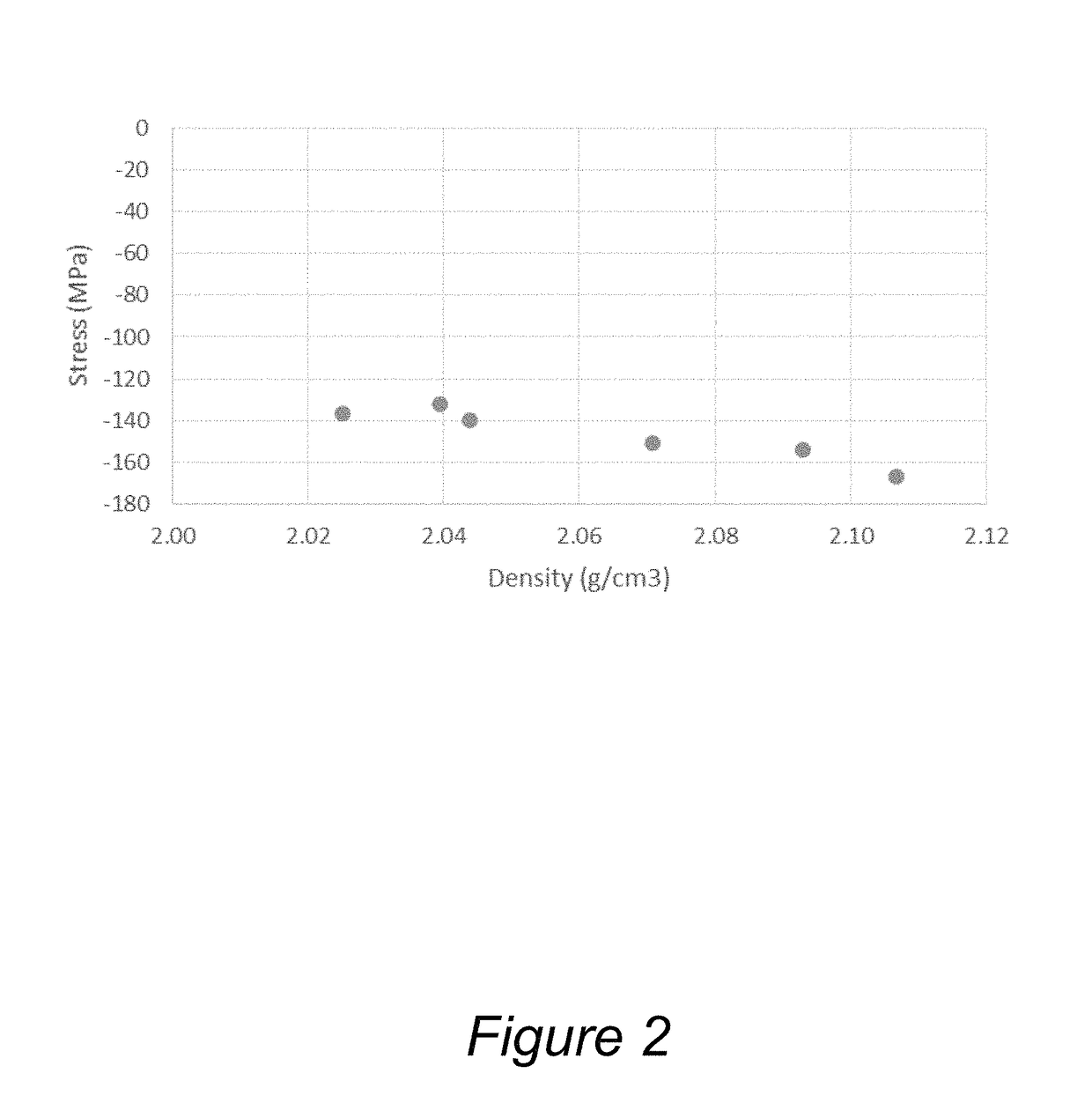

Low temperature formation of high quality silicon oxide films in semiconductor device manufacturing

ActiveUS9847221B1Relieve pressureReduce film stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricDevice material

Silicon oxide layer is deposited on a semiconductor substrate by PECVD at a temperature of less than about 200° C. and is treated with helium plasma to reduce stress of the deposited layer to an absolute value of less than about 80 MPa. Plasma treatment reduces hydrogen content in the silicon oxide layer, and leads to low stress films that can also have high density and low roughness. In some embodiments, the film is deposited on a semiconductor substrate that contains one or more temperature-sensitive layers, such as layers of organic material or spin-on dielectric that cannot withstand temperatures of greater than 250° C. In some embodiments the silicon oxide film is deposited to a thickness of between about 100-200 Å, and is used as a hardmask layer during etching of other layers on a semiconductor substrate.

Owner:LAM RES CORP

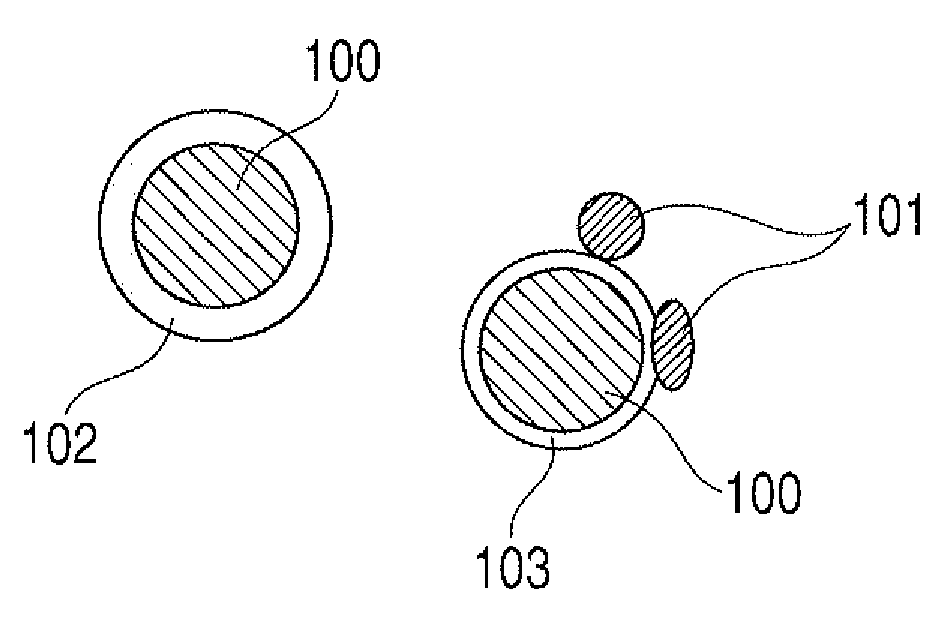

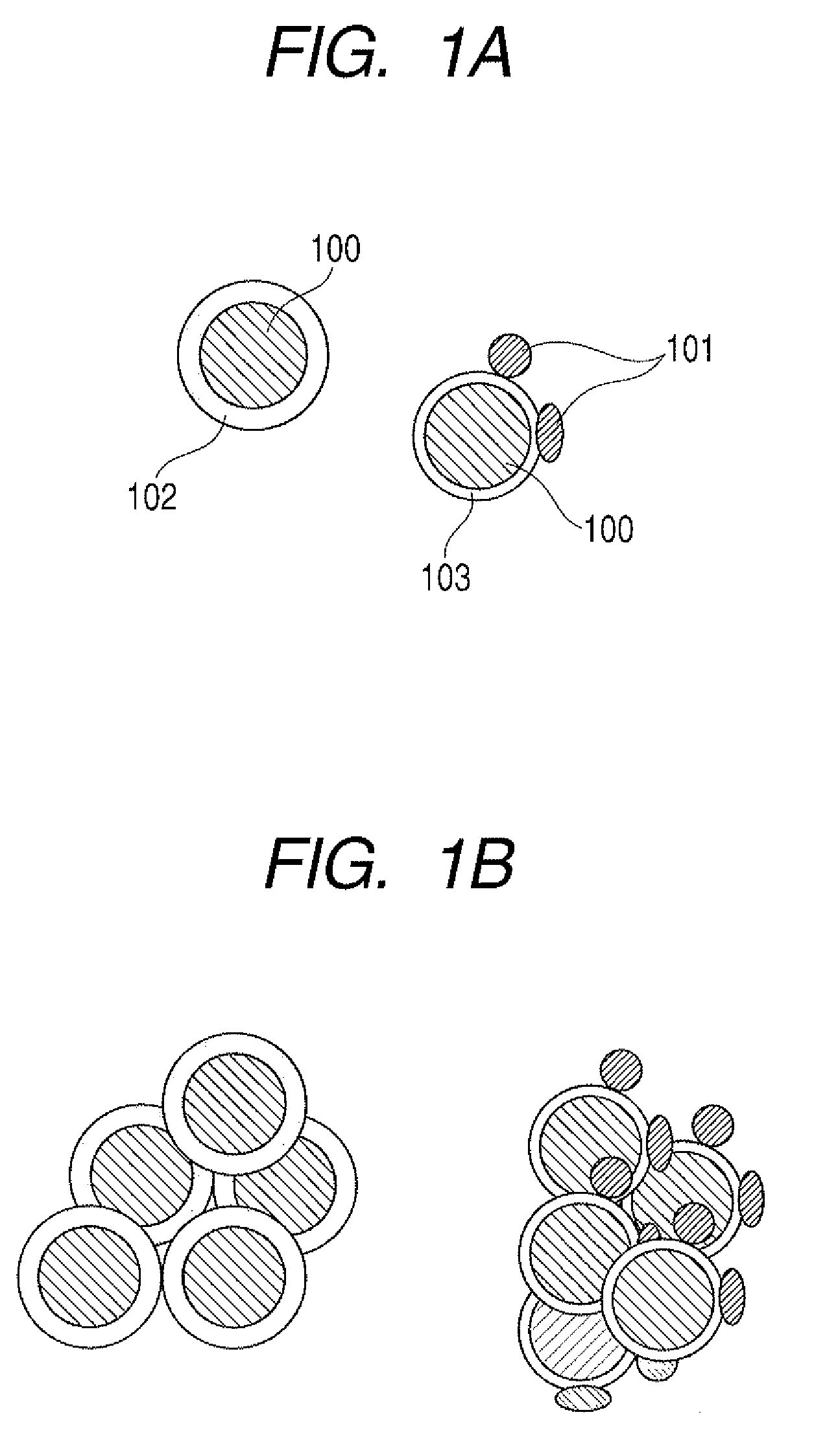

Method of producing lithium ion-storing/releasing material, lithium ion-storing/releasing material, and electrode structure and energy storage device using the material

InactiveUS20090162750A1Quickly chargeHigh charge and discharge efficiencyHybrid capacitor electrodesDouble layer capacitorsLithiumSilicon oxide

A method of producing a material capable of electrochemically storing and releasing a large amount of lithium ions is provided. The material is used as an electrode material for a negative electrode, and includes silicon or tin primary particles composed of crystal particles each having a specific diameter and an amorphous surface layer formed of at least a metal oxide, having a specific thickness. Gibbs free energy when the metal oxide is produced by oxidation of a metal is smaller than Gibbs free energy when silicon or tin is oxidized, and the metal oxide has higher thermodynamic stability than silicon oxide or tin oxide. The method of producing the electrode material includes reacting silicon or tin with a metal oxide, reacting a silicon oxide or a tin oxide with a metal, or reacting a silicon compound or a tin compound with a metal compound to react with each other.

Owner:CANON KK

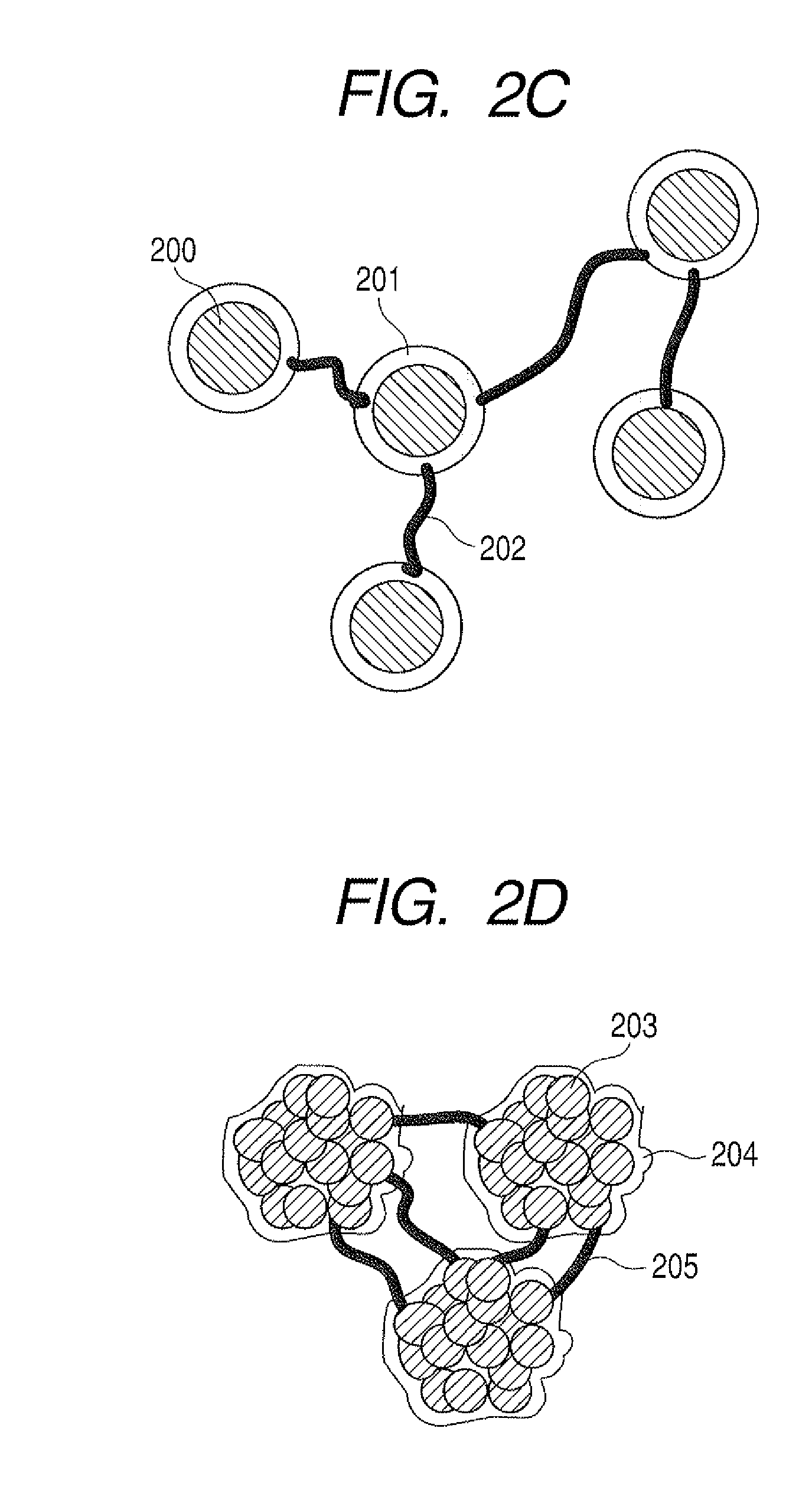

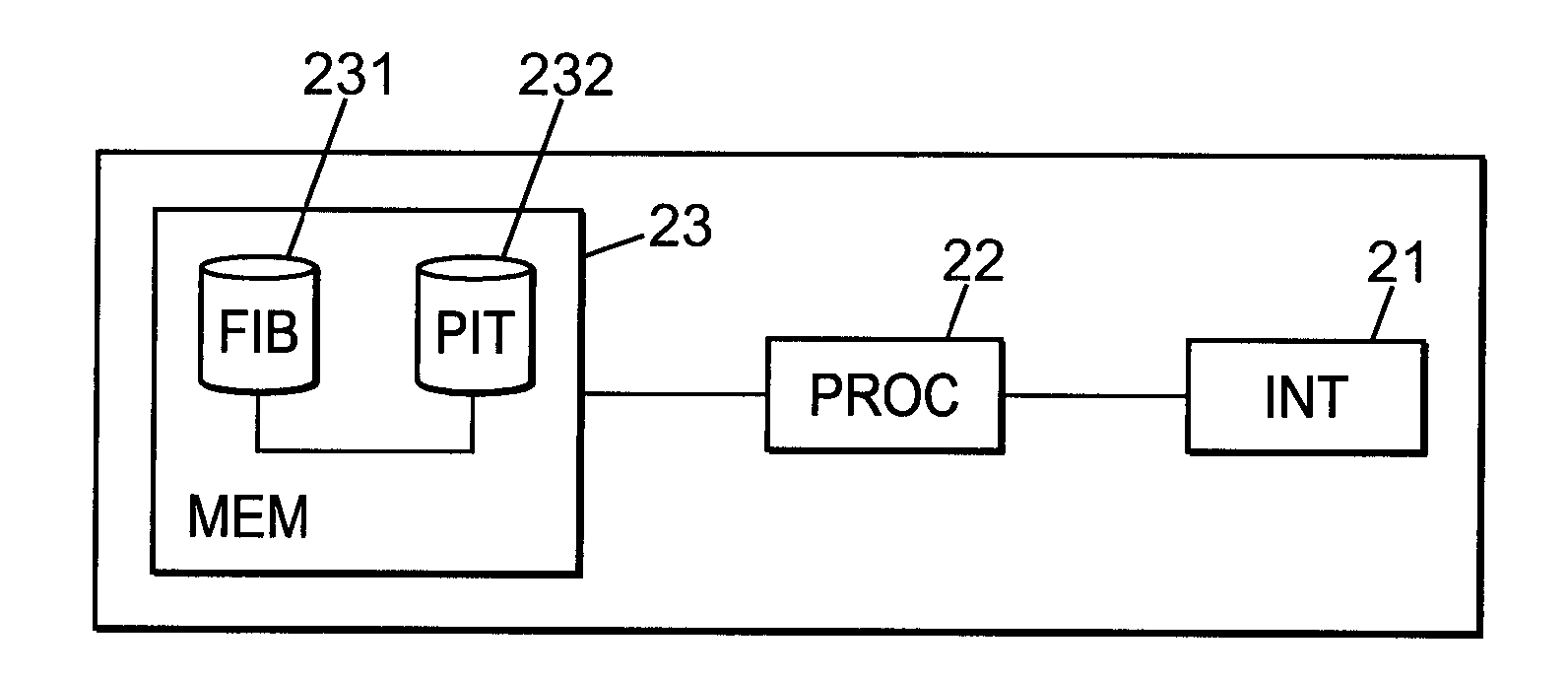

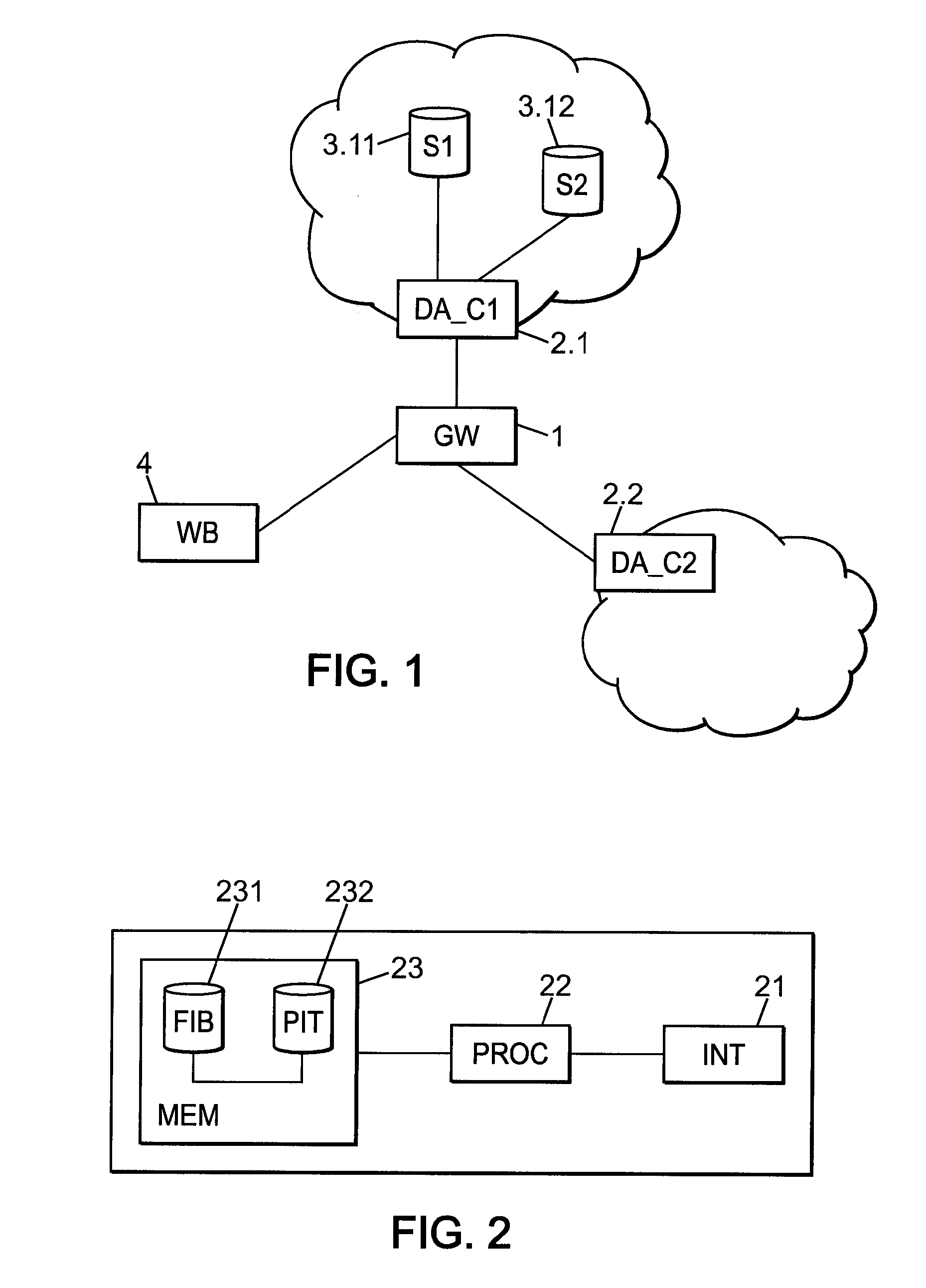

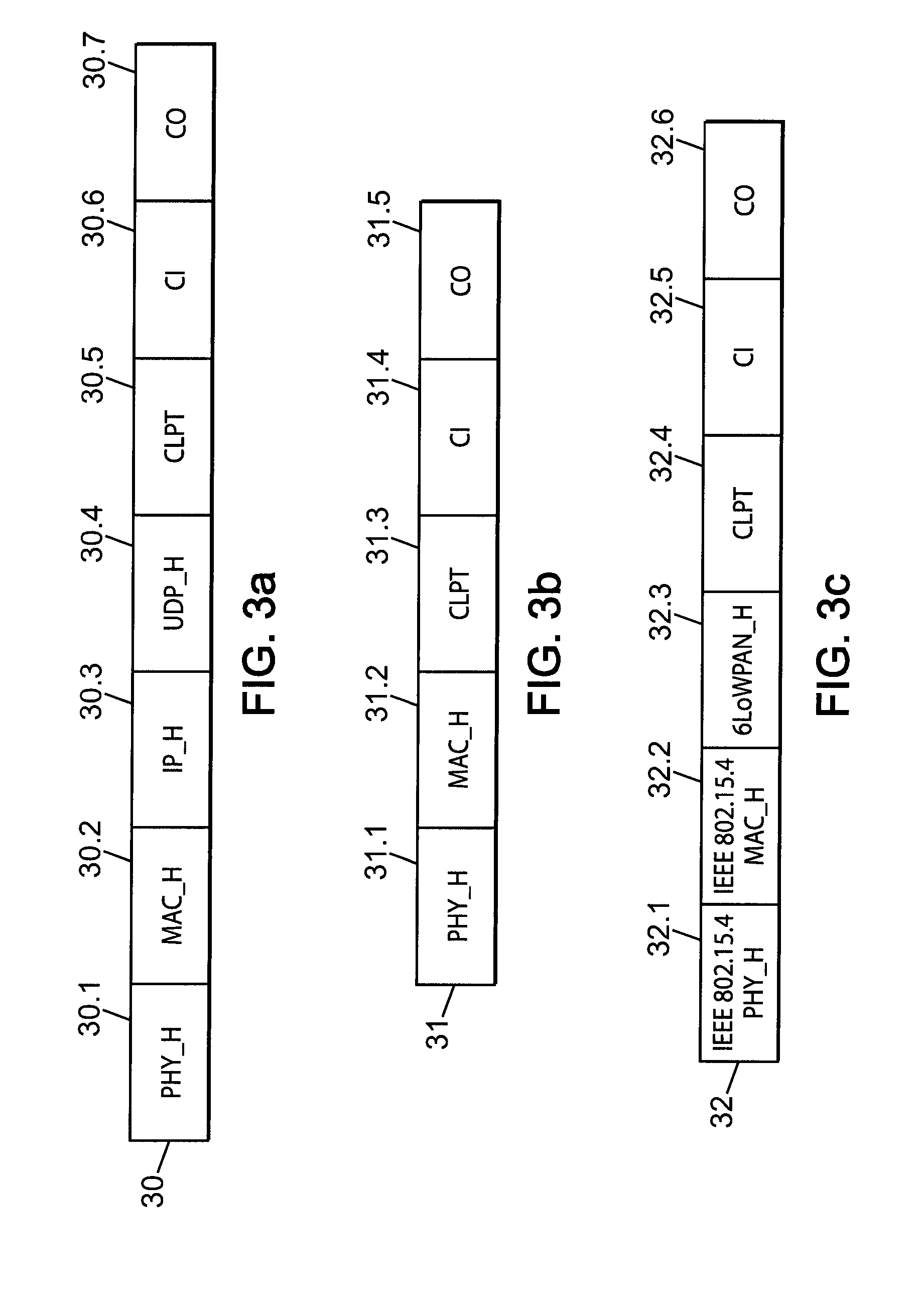

Content Centric M2M System

ActiveUS20150095514A1Reduce payloadReduce contentWeb data retrievalDigital computer detailsContent IdentifierContent centric

A method for routing data at a first node of a network including a second node. The method includes: providing the first node with a database storing an association between: an URL component identifying content at the first node, and a unique identifier associated to the second node, the unique identifier being specified by the second node; registering content locally stored in the second node by storing in the database an association between an URL component identifying the locally stored content and the unique identifier of the second node; and, upon reception from a requesting entity, by the first node, of a content request having a content identifier, the method includes: checking in the database whether the content identifier includes the URL component, and forwarding the content request to the second node if the content identifier includes the URL component associated with the unique identifier of the second node.

Owner:ORANGE SA (FR)

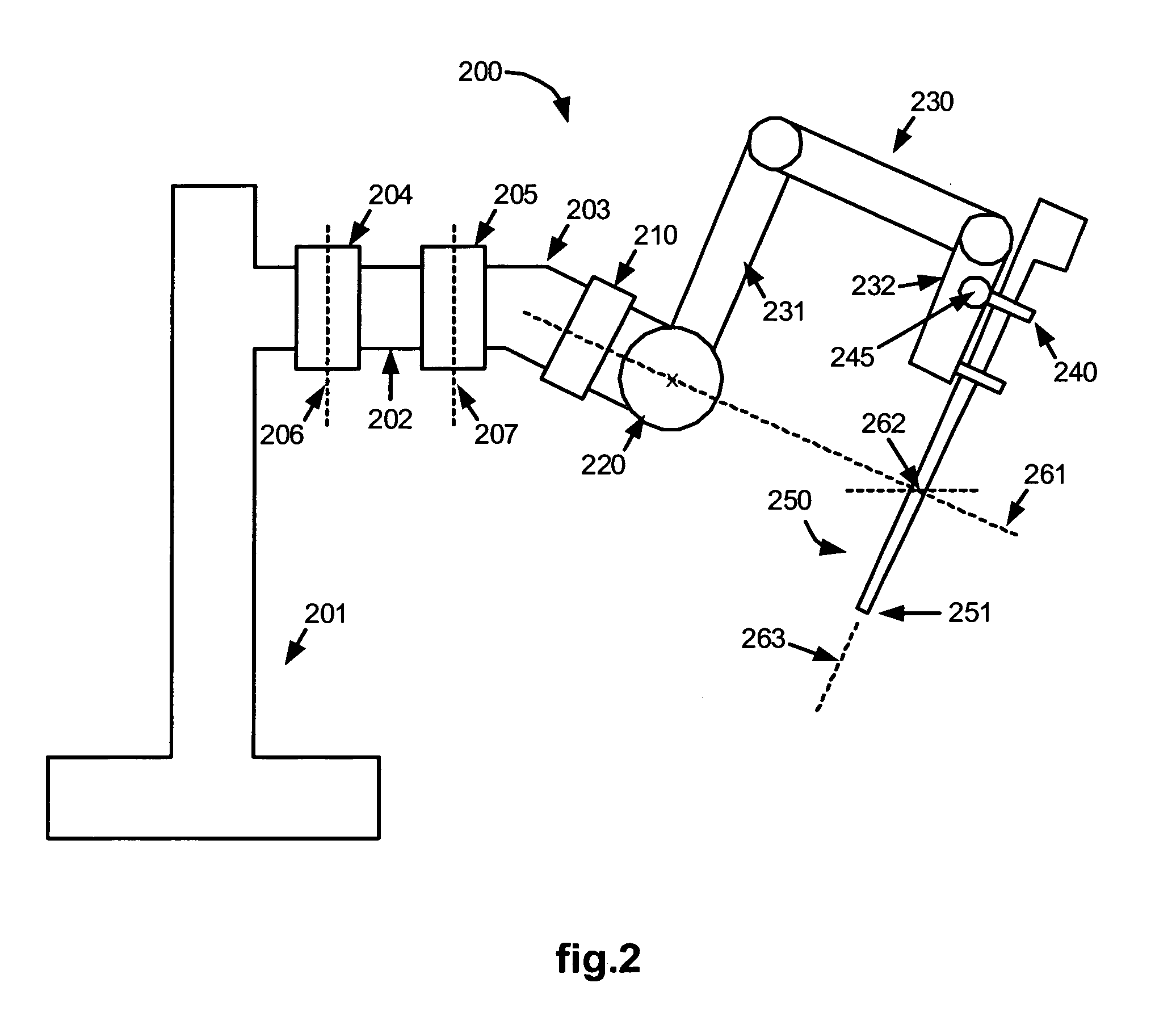

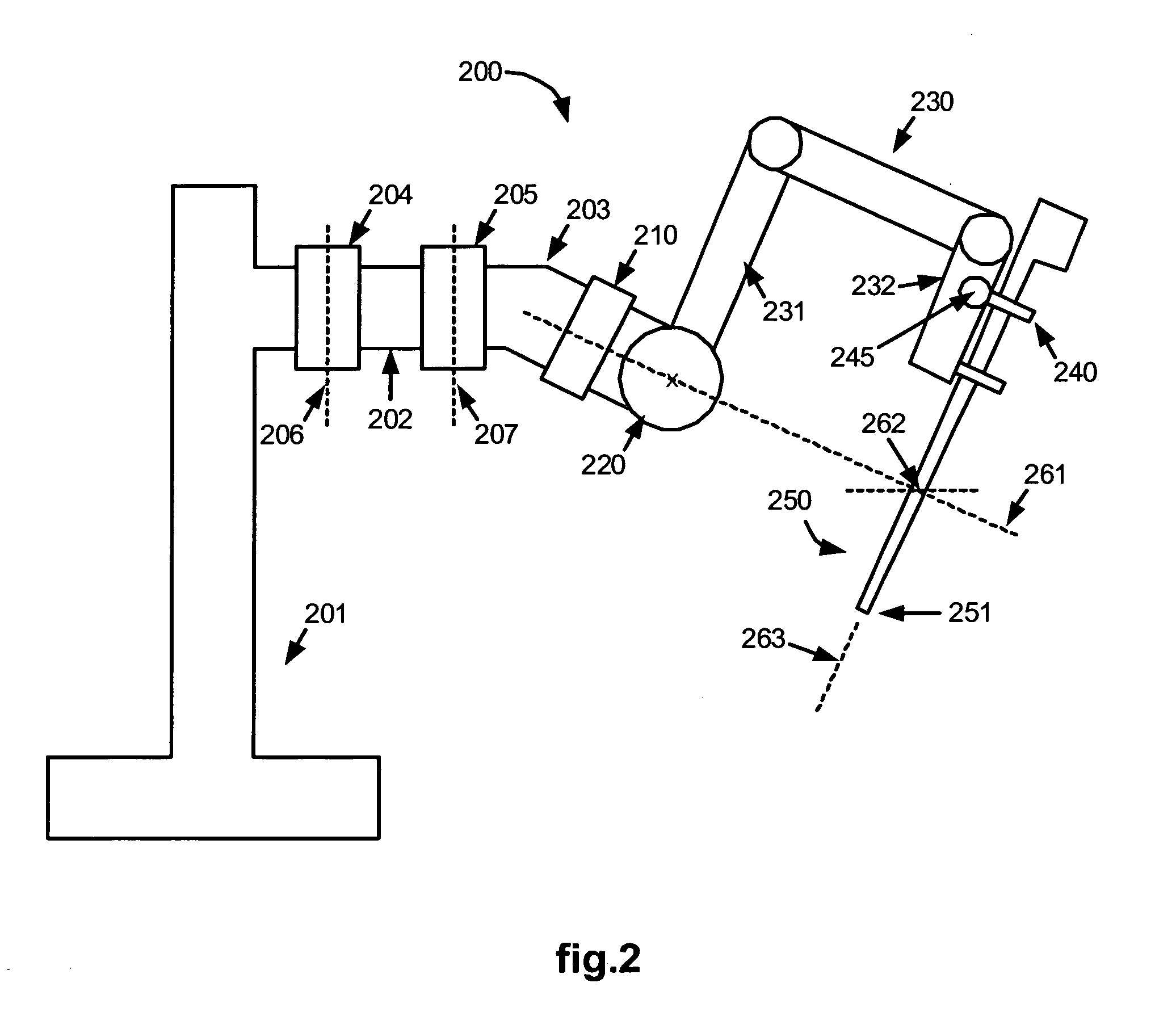

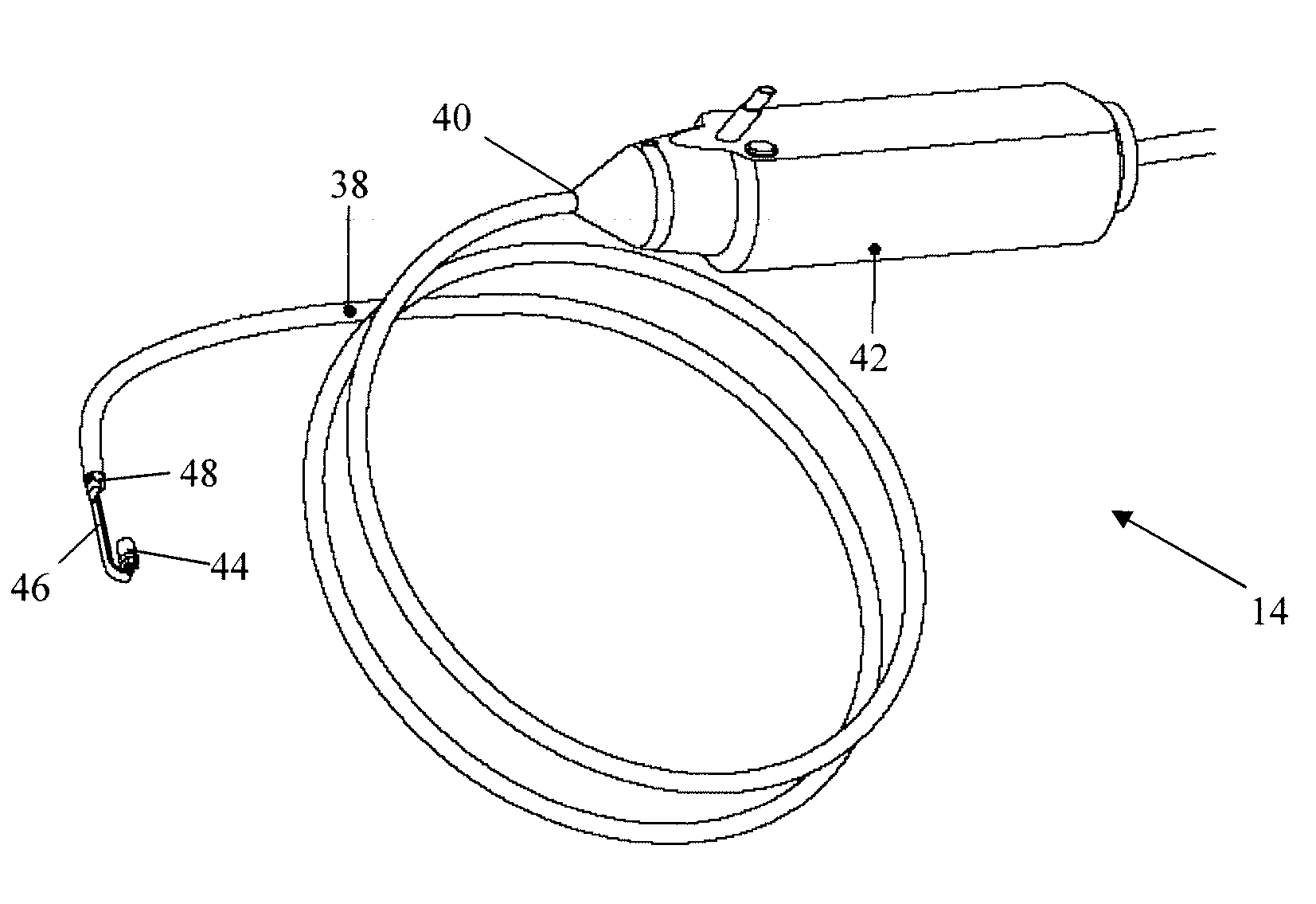

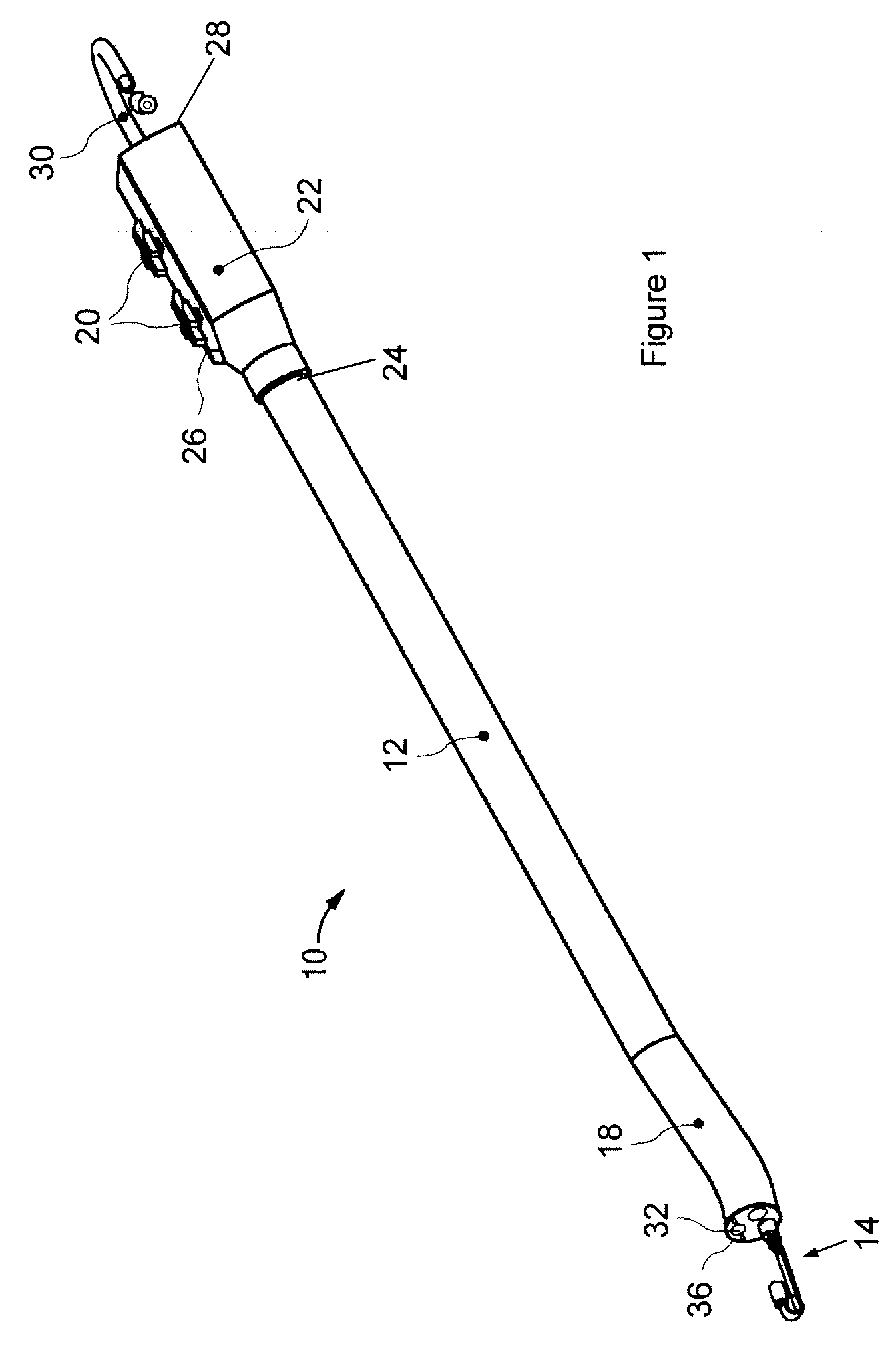

Robotic surgical system with joint motion controller adapted to reduce instrument tip vibrations

ActiveUS7689320B2Reduce vibrationWithout jeopardizing control system stabilityProgramme-controlled manipulatorMechanical/radiation/invasive therapiesControl systemJoints movement

A robotic surgical system has a robot arm holding an instrument for performing a surgical procedure, and a control system for controlling movement of the arm and its instrument according to user manipulation of a master manipulator. The control system includes a filter in its forward path to attenuate master input commands that may cause instrument tip vibrations, and an inverse filter in a feedback path to the master manipulator configured so as to compensate for delay introduced by the forward path filter. To enhance control, master command and slave joint observers are also inserted in the control system to estimate slave joint position, velocity and acceleration commands using received slave joint position commands and torque feedbacks, and estimate actual slave joint positions, velocities and accelerations using sensed slave joint positions and commanded slave joint motor torques.

Owner:INTUITIVE SURGICAL OPERATIONS INC

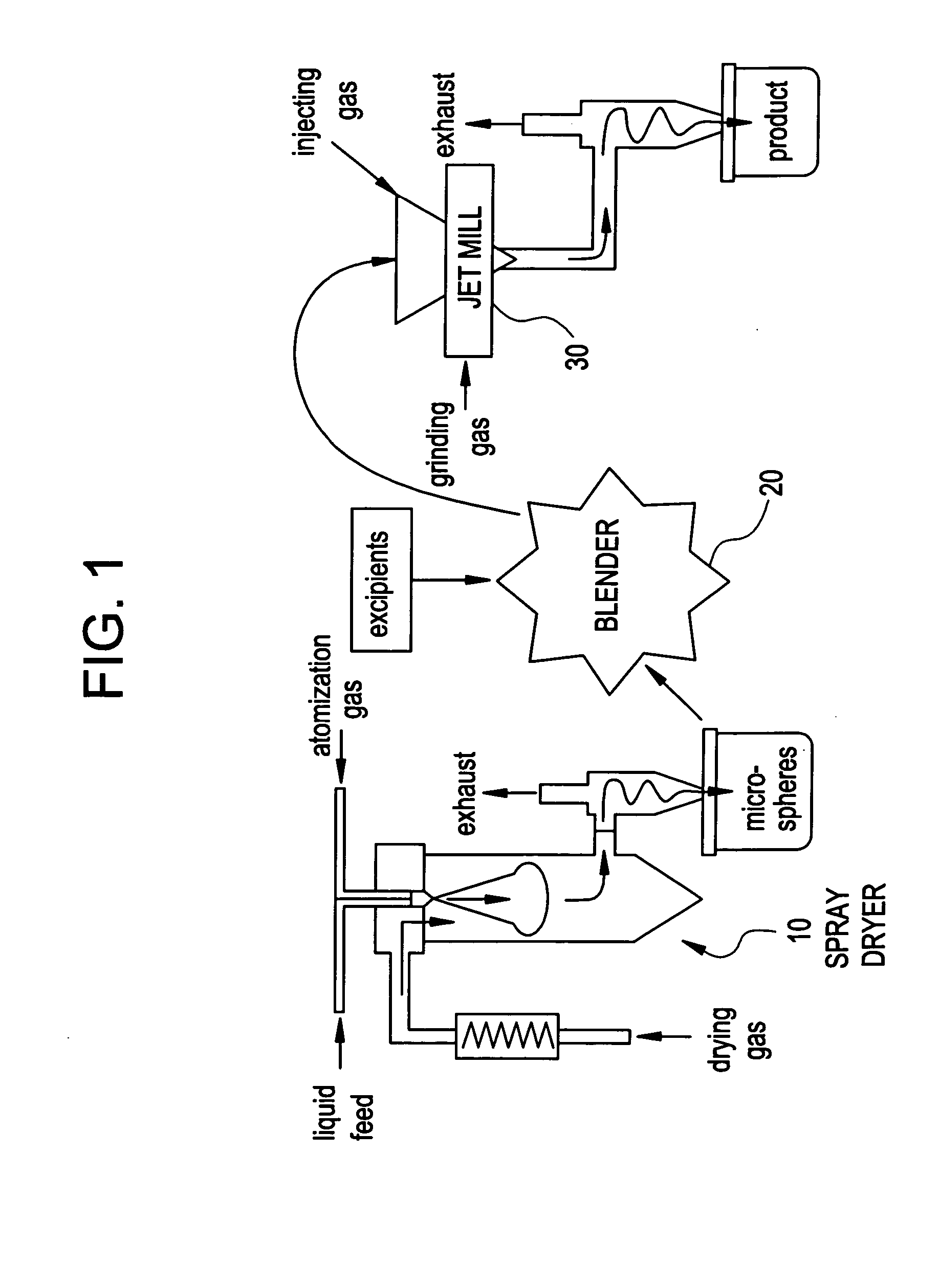

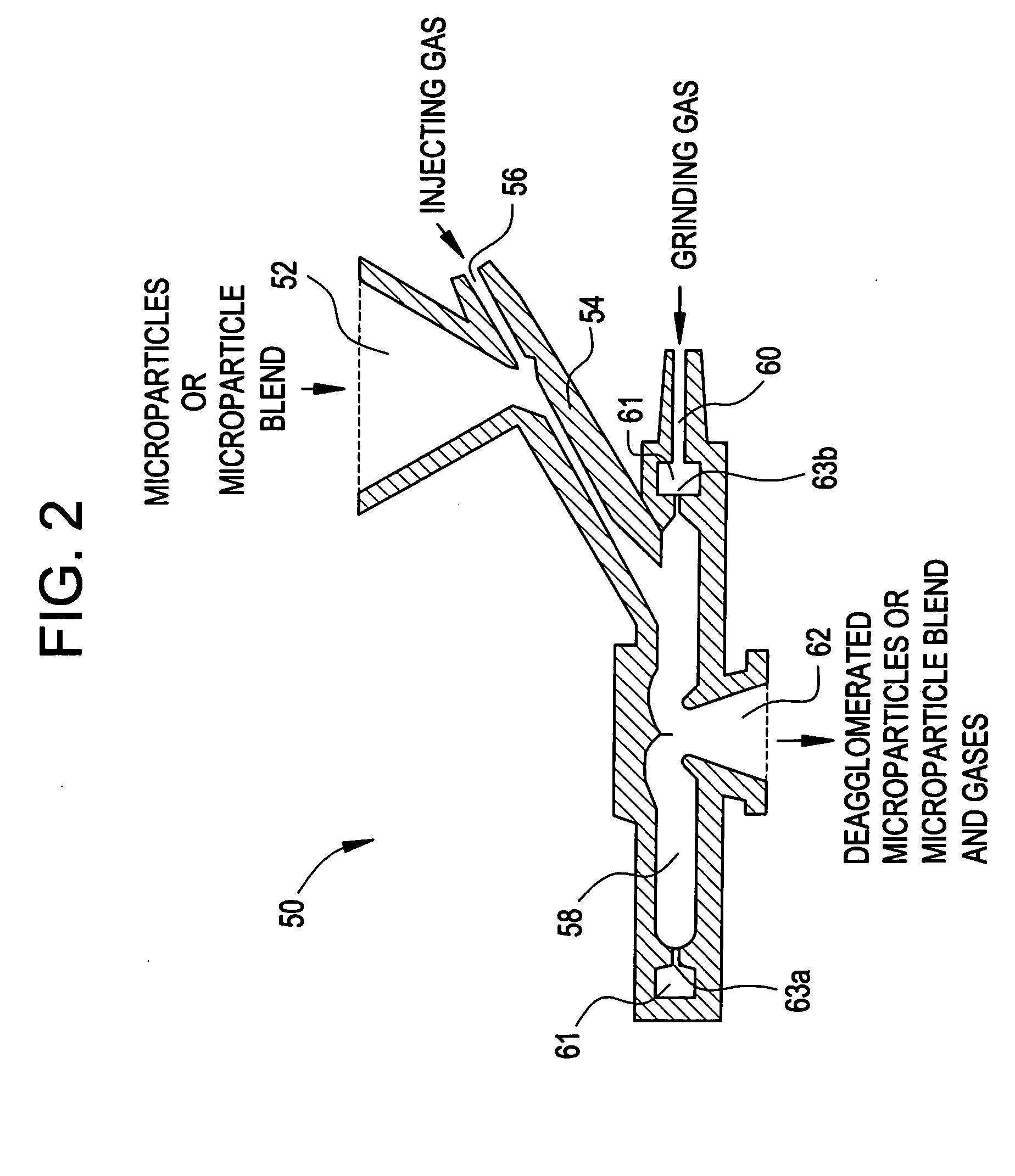

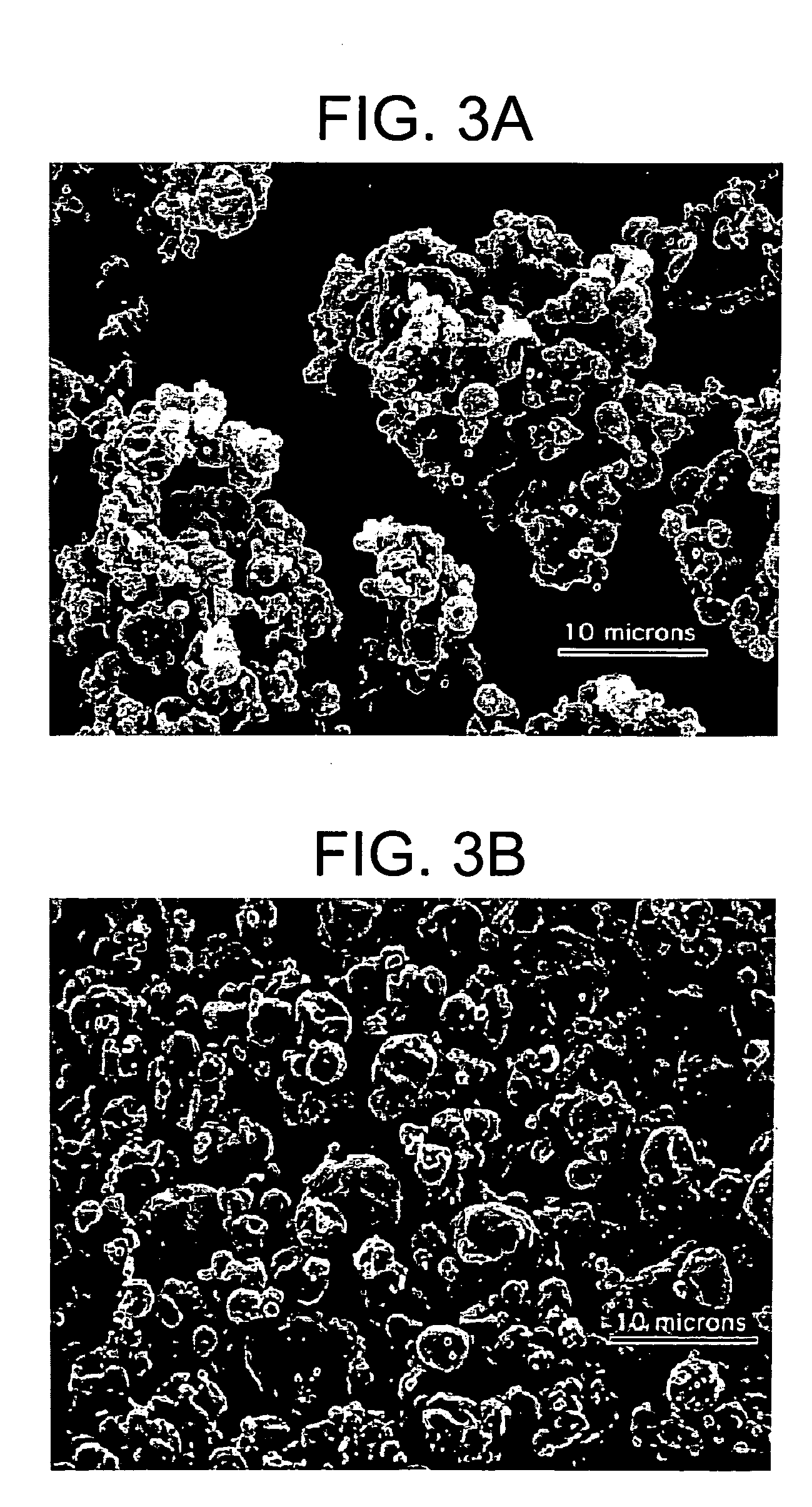

Methods for making pharmaceutical formulations comprising microparticles with improved dispersibility, suspendability or wettability

InactiveUS20050079138A1Good dispersibilityImproved suspendabilityPowder deliveryGranulation by liquid drop formationPowder mixtureMicroparticle

Methods are provided for making a dry powder blend pharmaceutical formulation, comprising the steps of: (a) providing microparticles which comprise a pharmaceutical agent; (b) blending the microparticles with at least one excipient in the form of particles to form a powder blend; and (c) jet milling the powder blend to form a dry powder blend pharmaceutical formulation having improved dispersibility, suspendability, or wettability as compared to the microparticles of step (a) or the powder blend of step (b). The method can further include dispersing the dry powder blend pharmaceutical formulation in a liquid pharmaceutically acceptable vehicle to make an formulation suitable for injection. Alternatively, the method can further include processing the dry powder blend pharmaceutical formulation into a solid oral dosage form. In one embodiment, the microparticles of step (a) are formed by a solvent precipitation or crystallization process.

Owner:ACUSPHERE INC

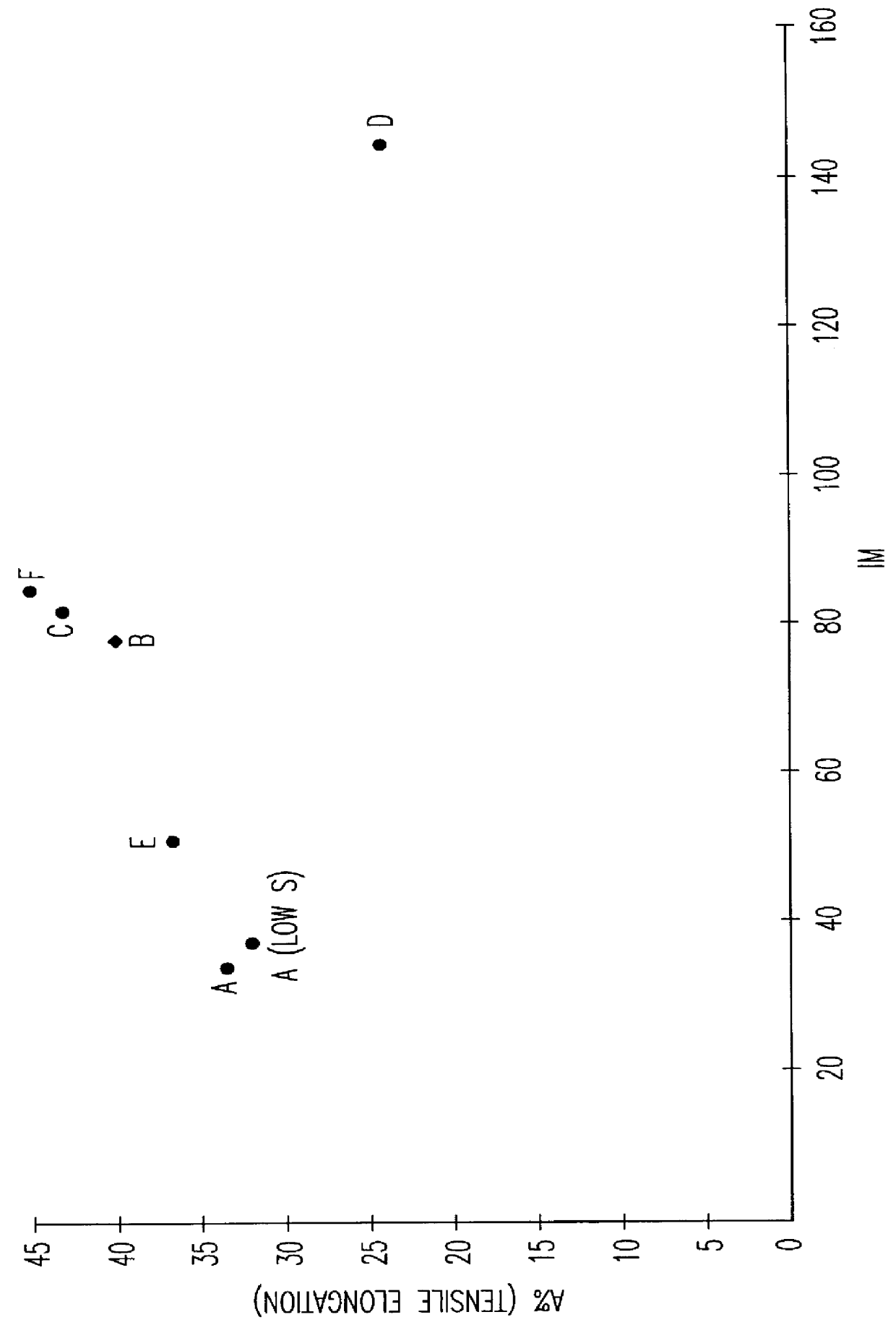

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

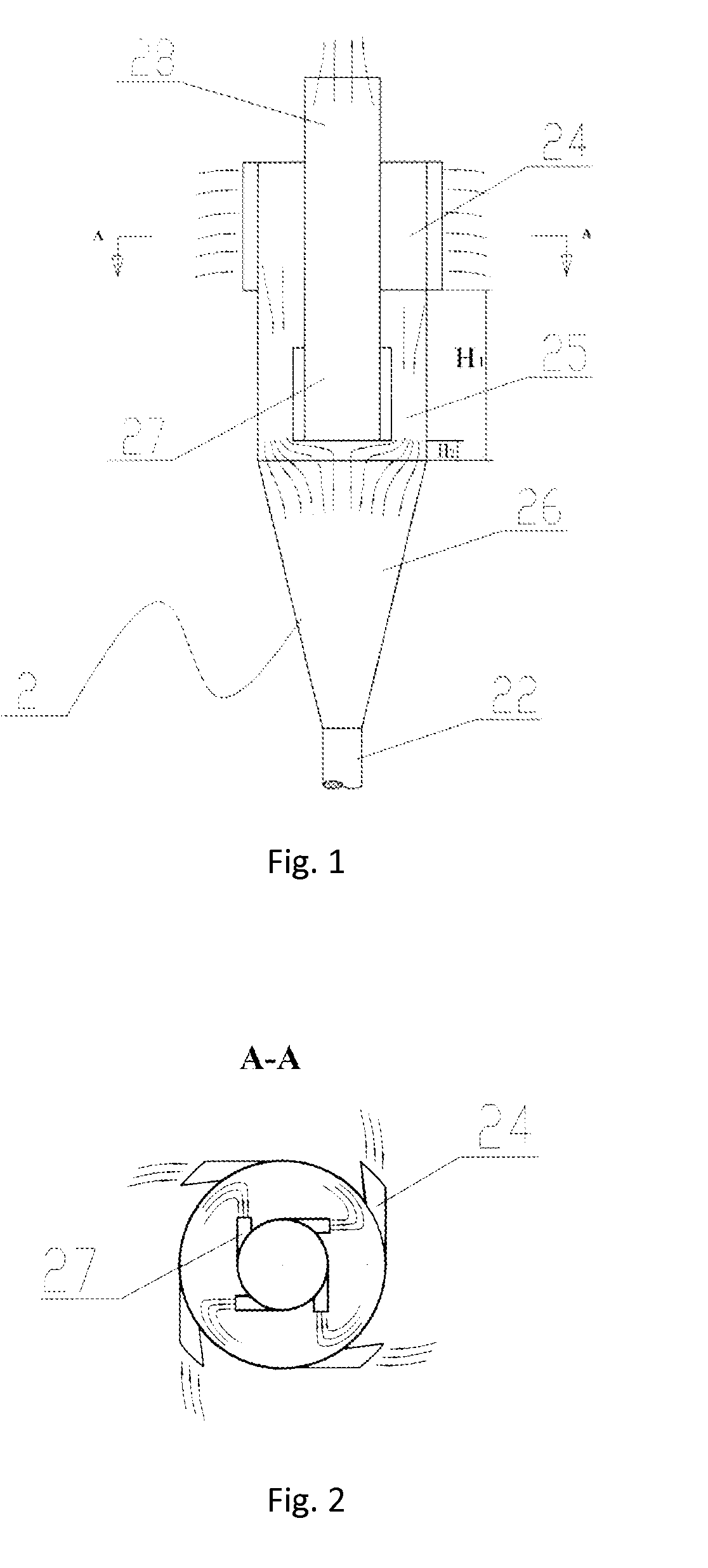

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

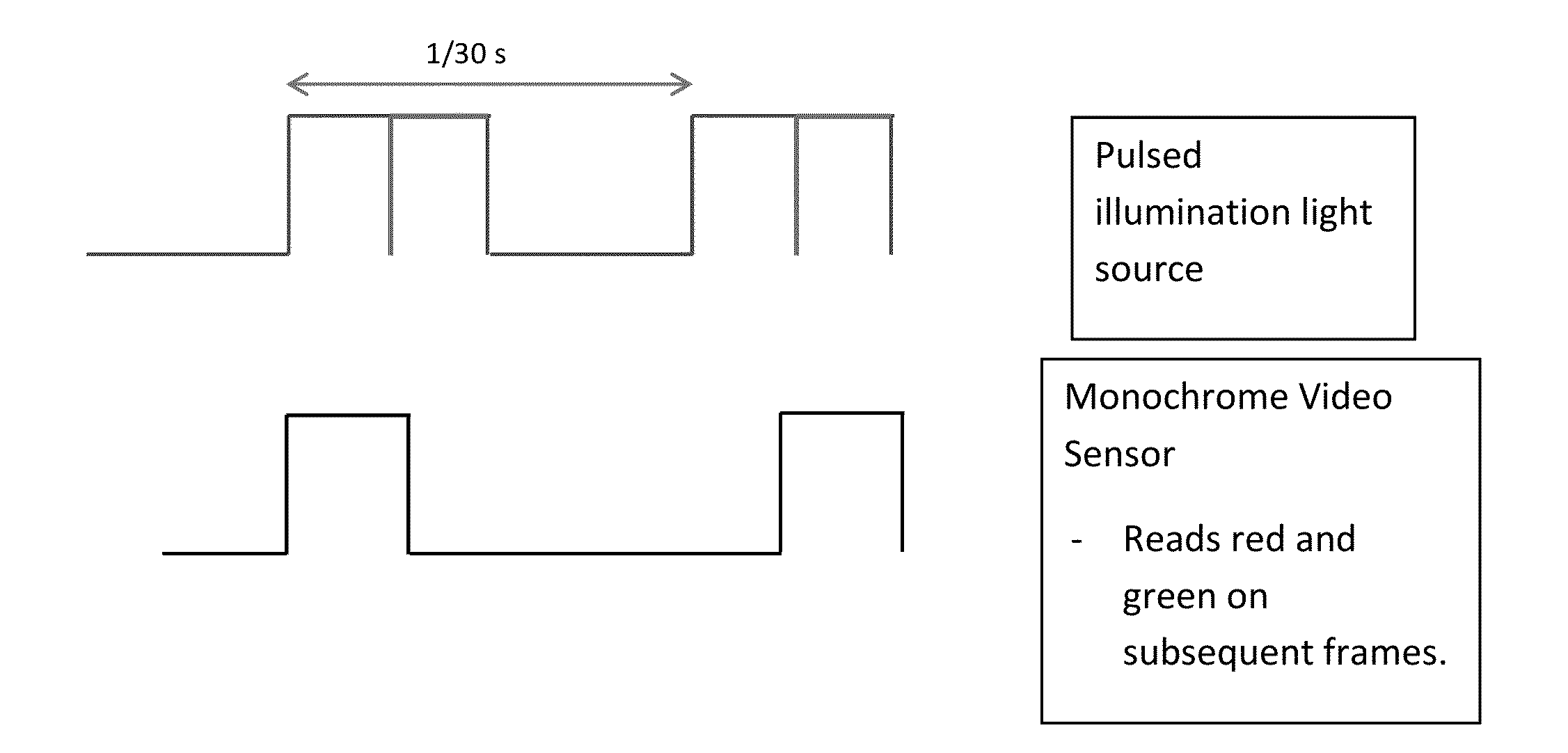

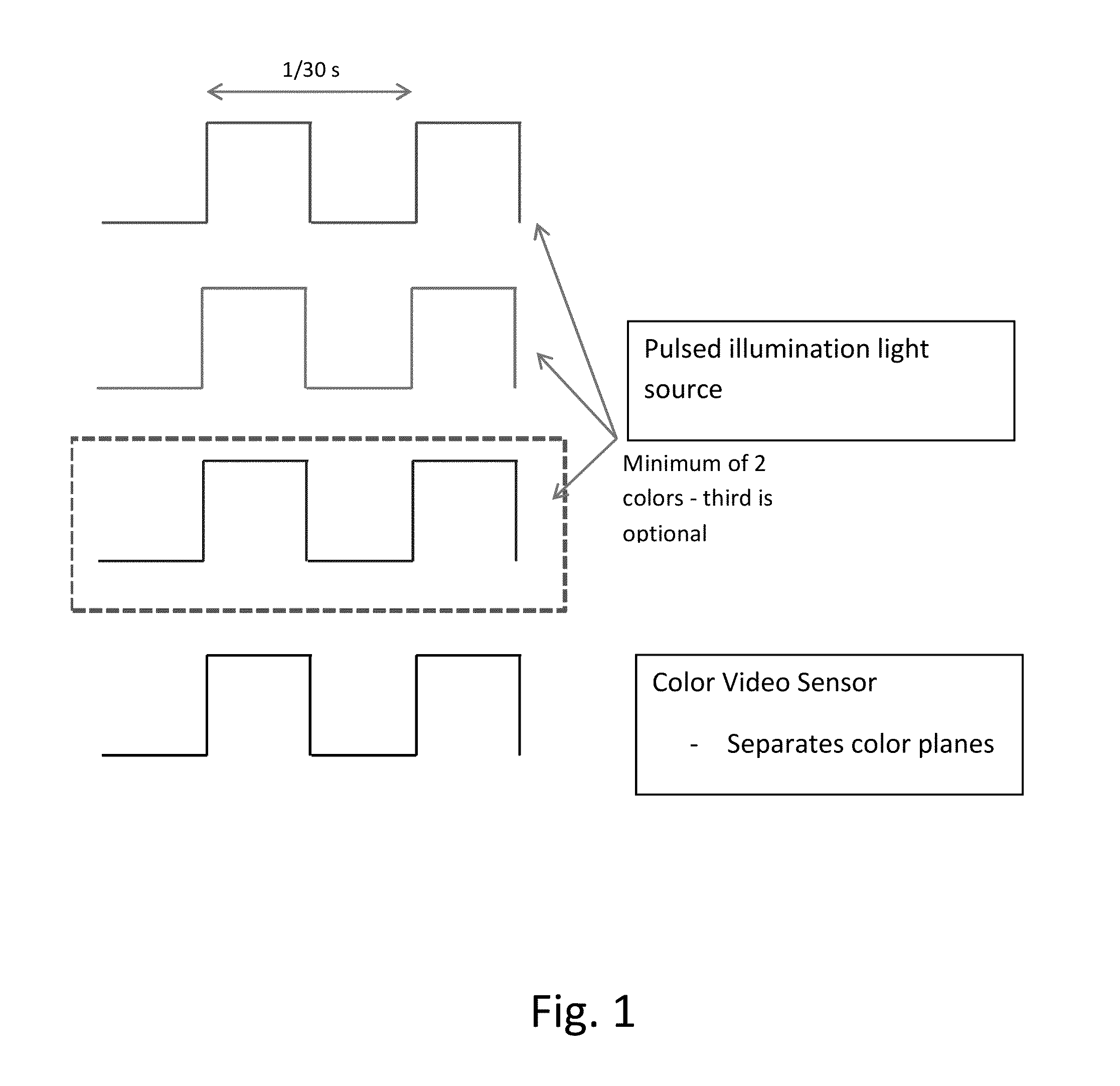

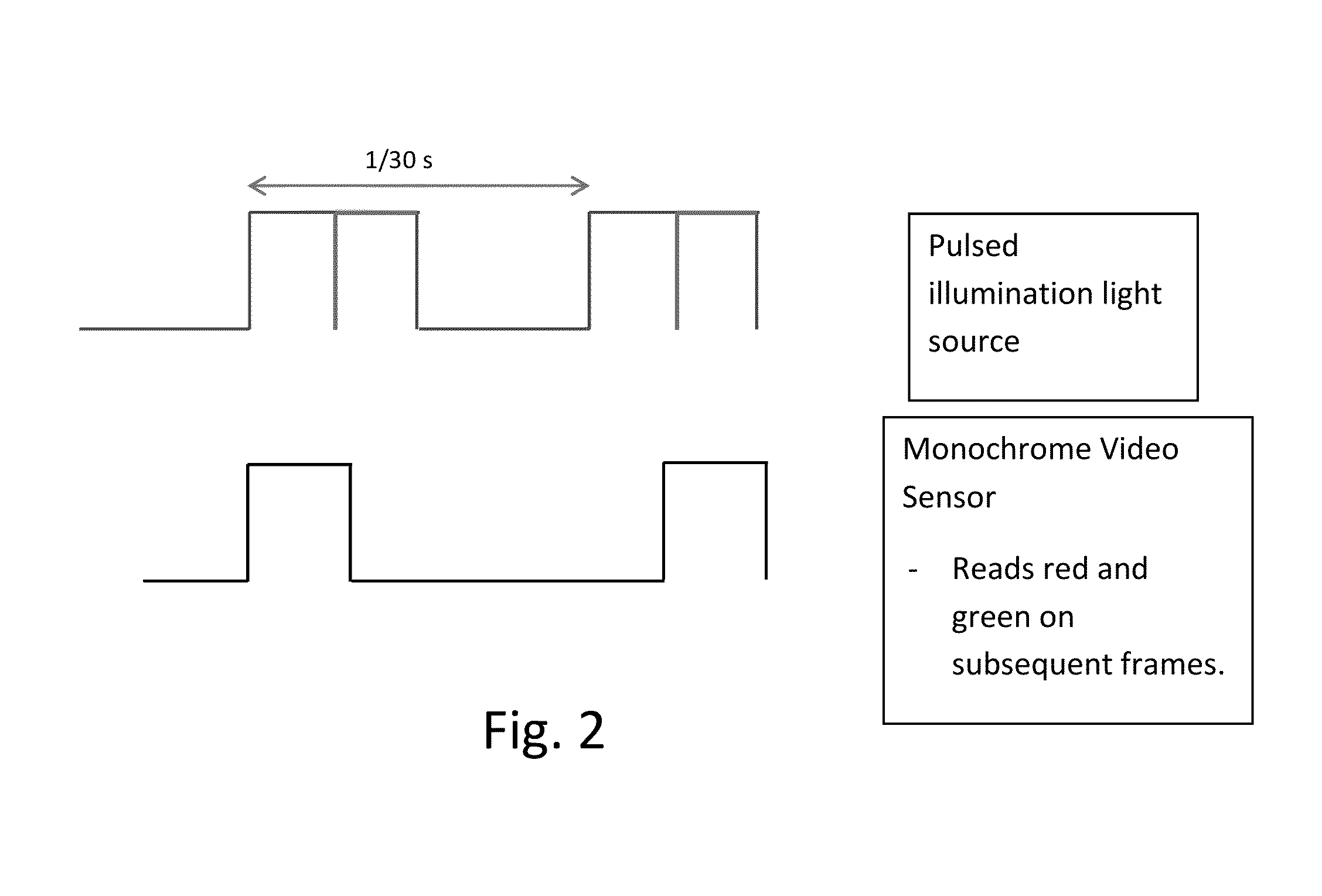

Coordinated illumination and image signal capture for enhanced signal detection

ActiveUS20130329006A1Low costLimited rangeTelevision system detailsColor signal processing circuitsPattern recognitionSignal-to-noise ratio (imaging)

Signal detection and recognition employees coordinated illumination and capture of images under to facilitate extraction of a signal of interest. Pulsed illumination of different colors facilitates extraction of signals from color channels, as well as improved signal to noise ratio by combining signals of different color channels. The successive pulsing of different color illumination appears white to the user, yet facilitates signal detection, even for lower cost monochrome sensors, as in barcode scanning and other automatic identification equipment.

Owner:DIGIMARC CORP

Systems, methods, and catalysts for producing a crude product

InactiveUS20060231465A1Reduce contentRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsChemistryCrude oil

Owner:SHELL OIL CO

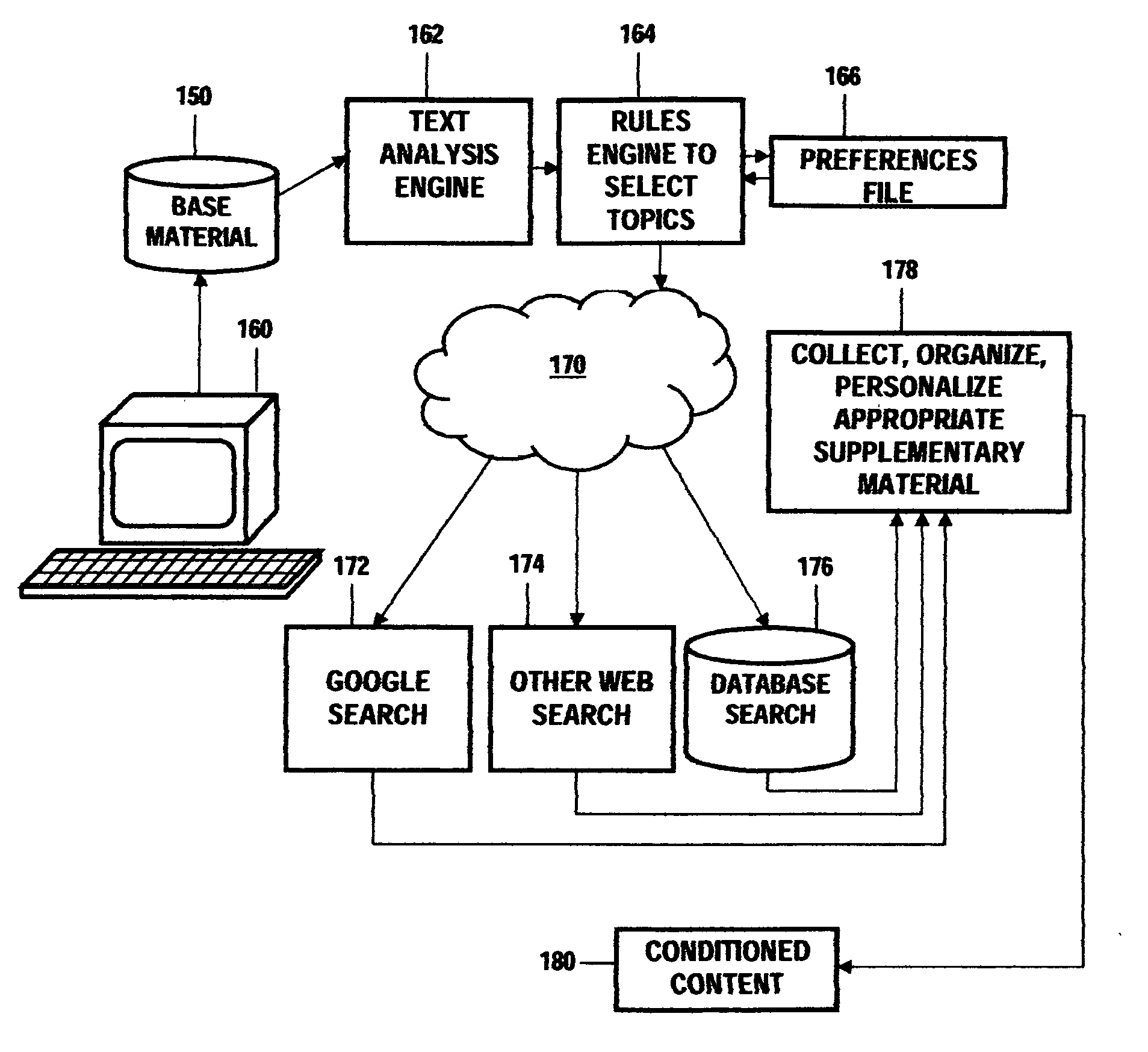

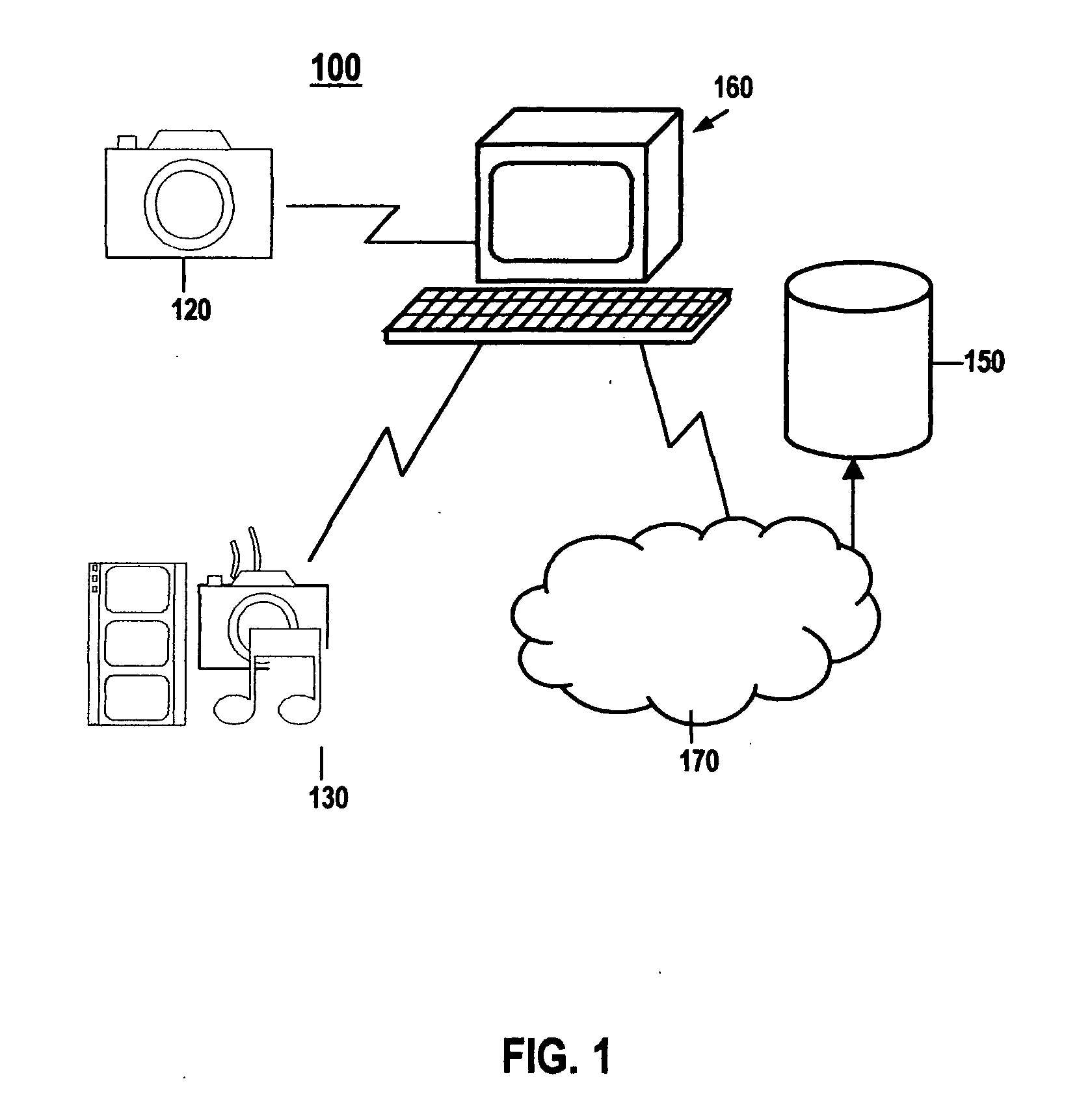

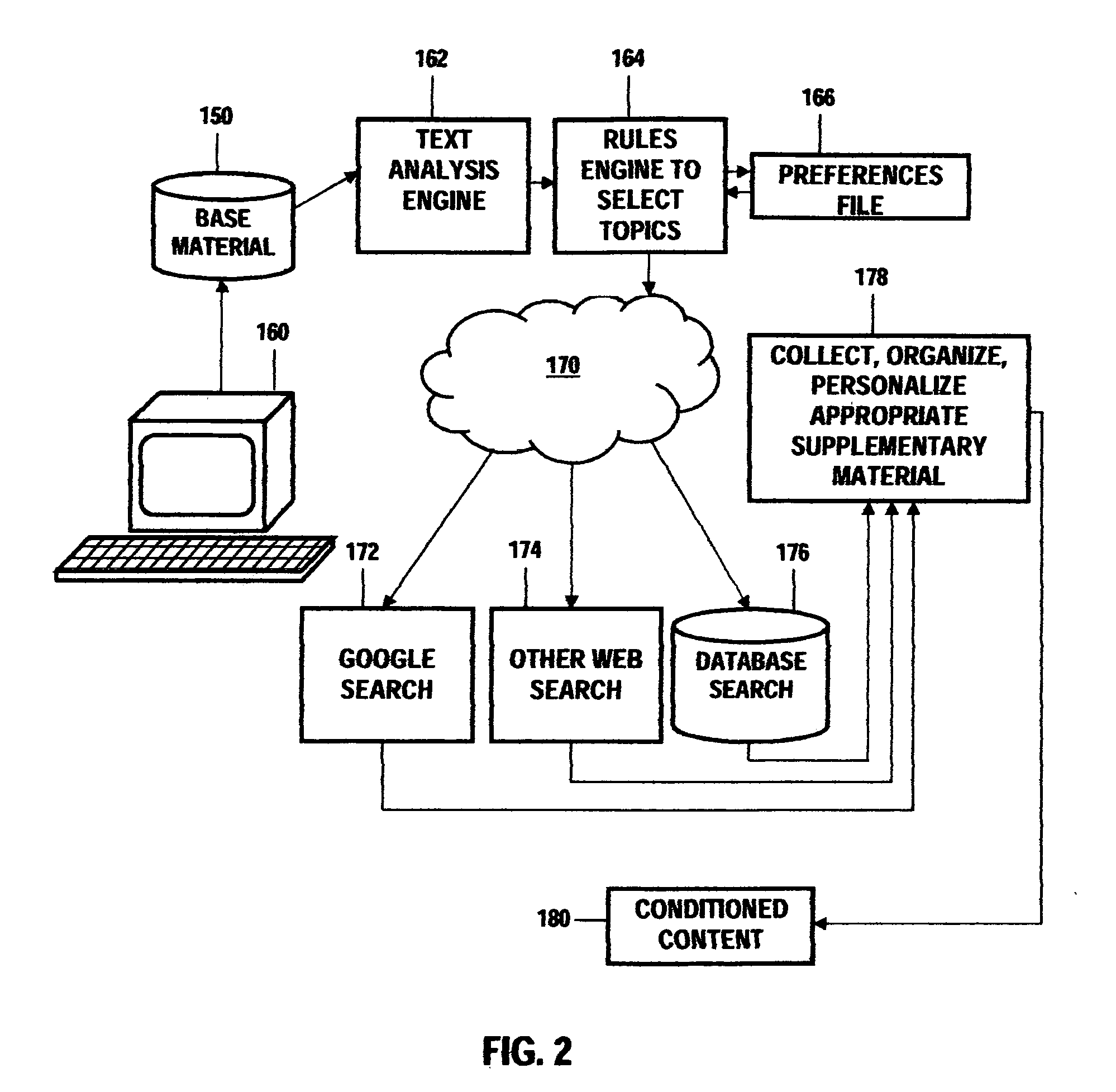

Method and system for personalized content conditioning

InactiveUS20050193335A1Improve learning experienceShorten study timeWebsite content managementSpecial data processing applicationsPersonalizationThe Internet

The present system and method provide an automated approach to conditioning of content. The content is scanned for topics for conditioning, then supplemental content is identified and selected using search tools such as general search engines searching the Internet and search tools for private databases. The conditioned content may be customized for a particular user or category of users, including different materials for different users, in different formats including multimedia, based on a profile for the user(s) for which the personalized content is being prepared. The topics for conditioning may be identified using a text analysis engine, either alone or in combination with a rules engine, in the preferred embodiment.

Owner:IBM CORP

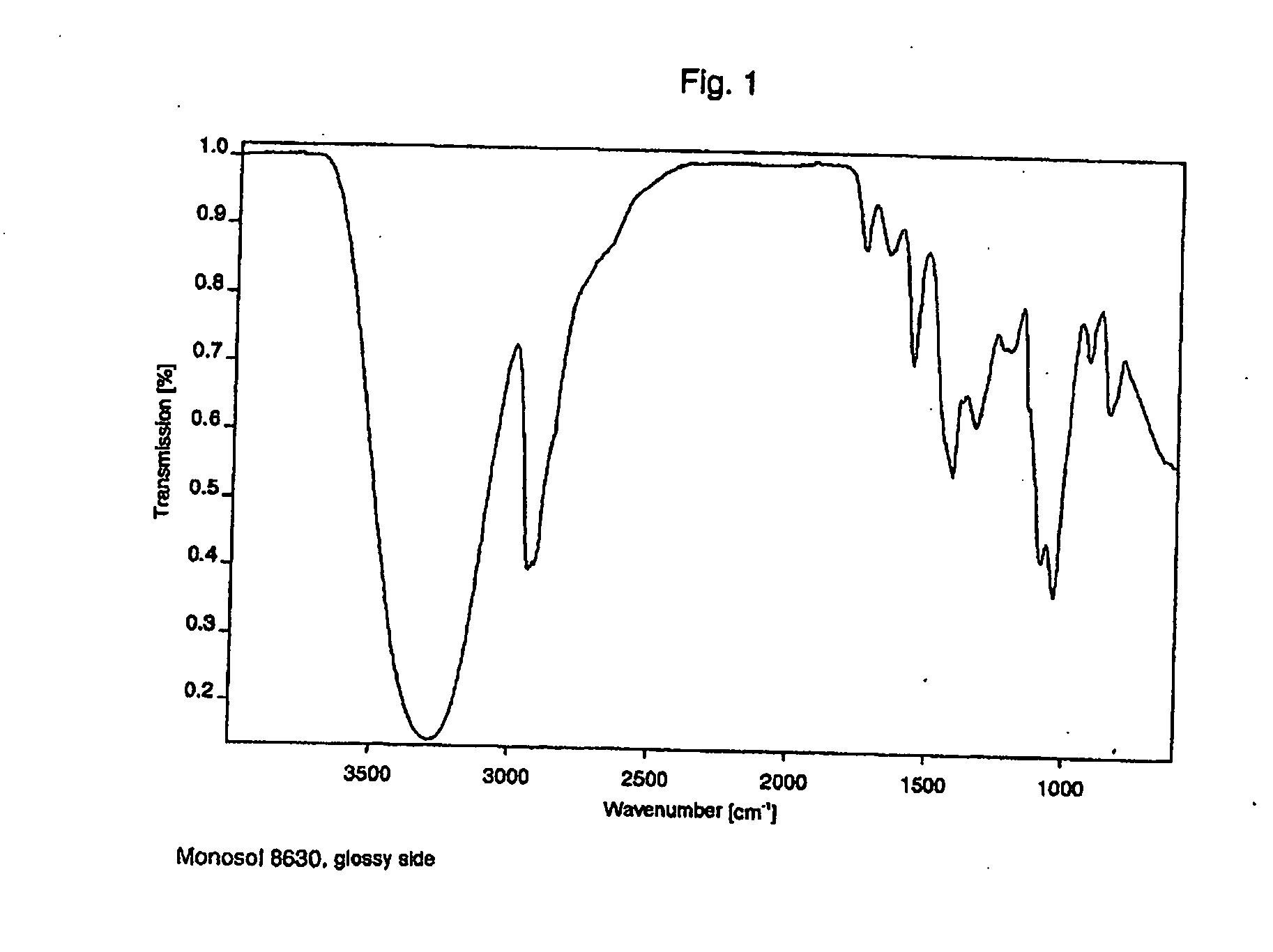

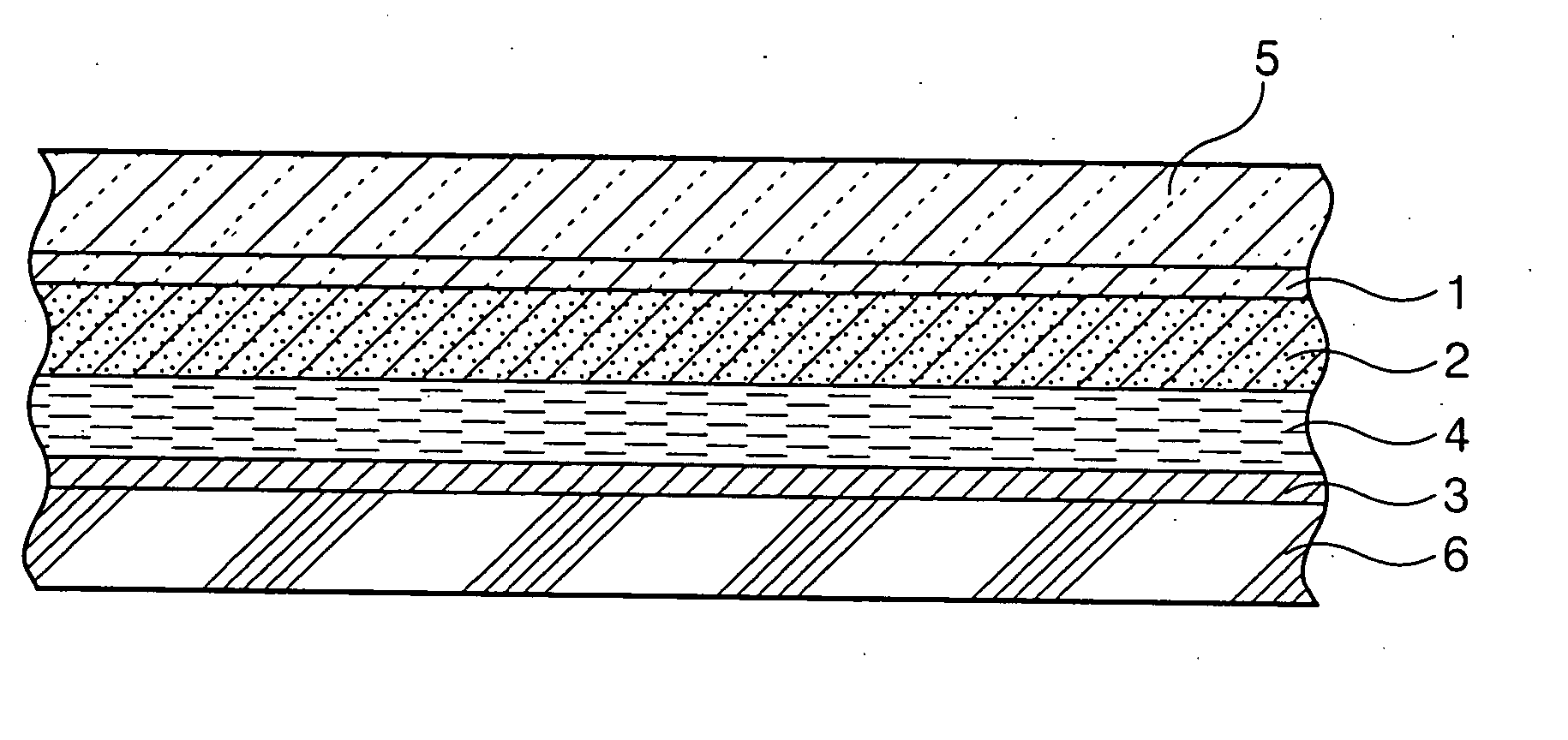

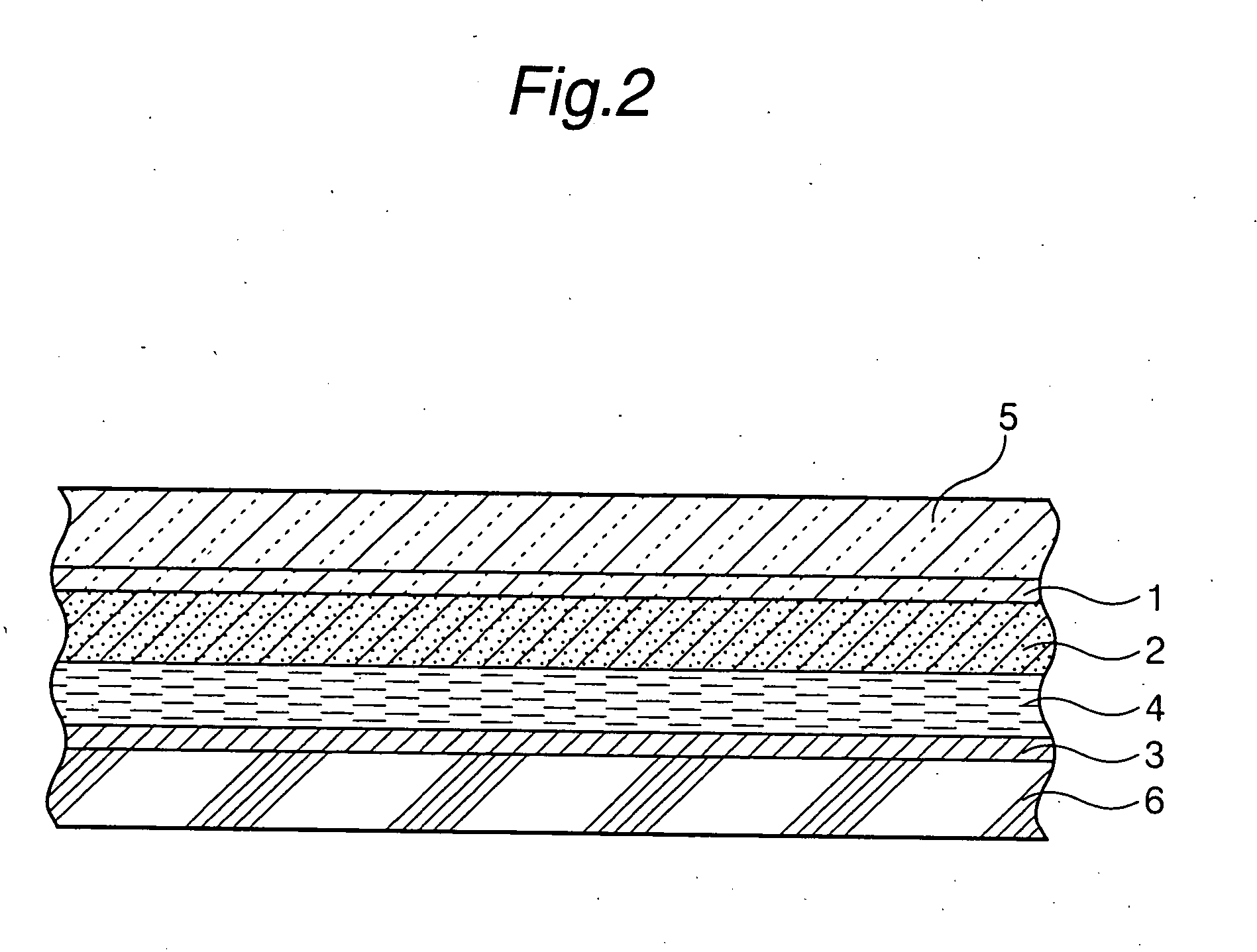

Film packaged product portion and method for producing the same

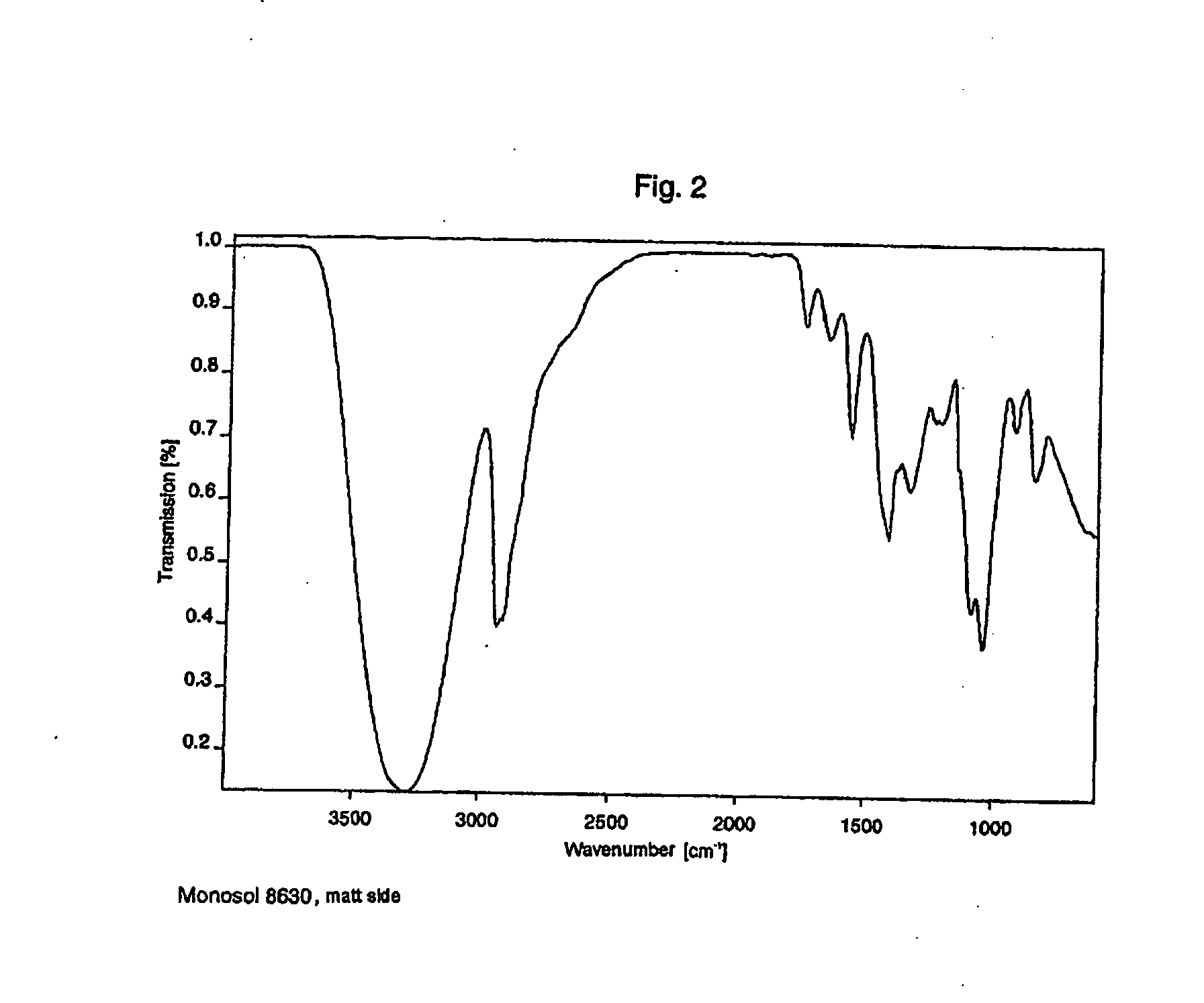

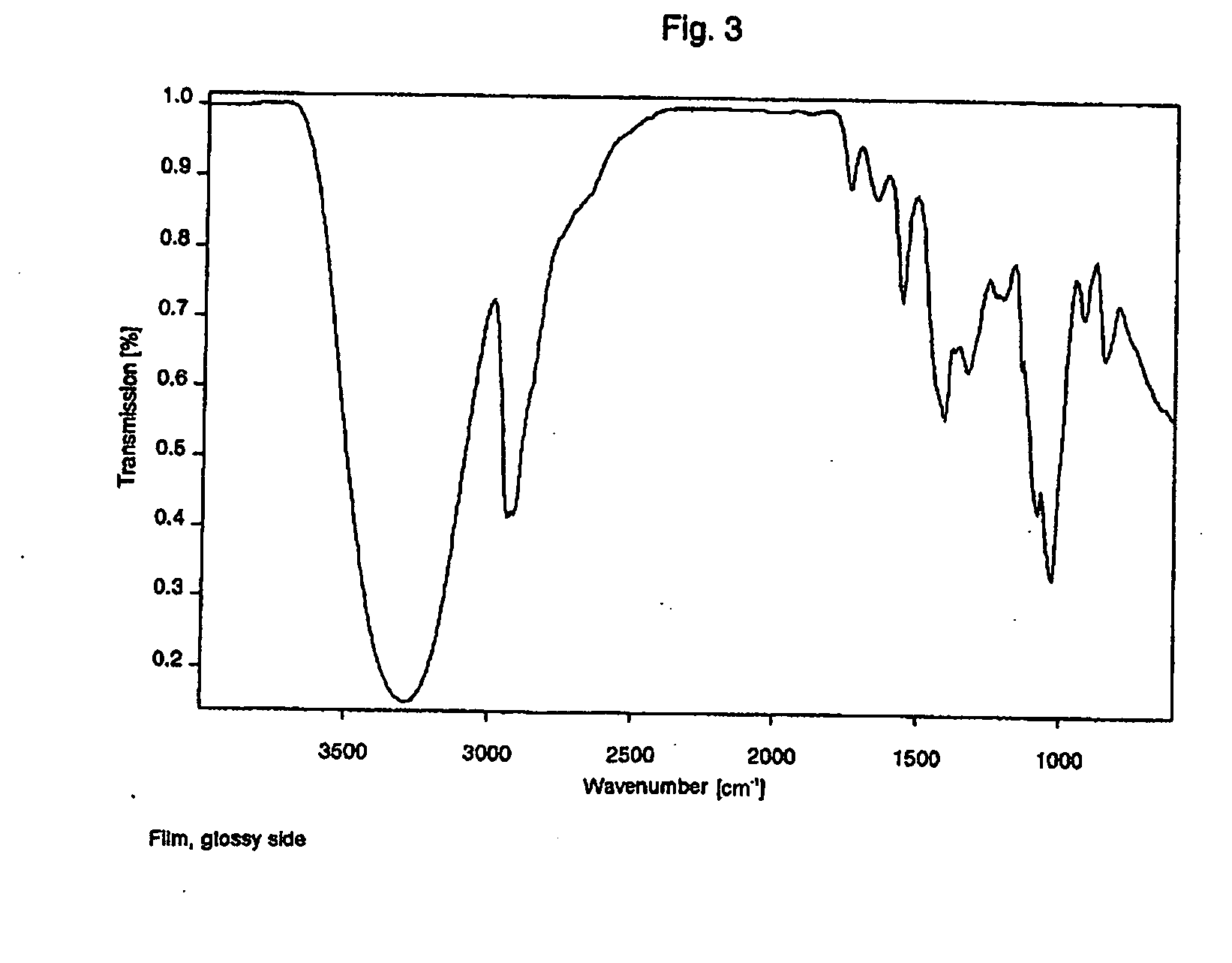

InactiveUS20060213801A1Improved film solubilityImprove dissolution rateSynthetic resin layered productsPackaging corrosive chemicalsEngineeringProduct Part

The invention relates to a package formed from at least two films, containing product portions, in particular washing, cleaning and / or care products, which are released when the package is opened, by dissolution or disintegration of at least one film. The package comprises at least one compartment for receiving the product. At least one film of the package is substantially plastically reshaped in order to provide a compartment to receive the product. The disintegration and / or dissolving times of the package measured in distilled water at a temperature of 10° C. are less than similar times for a conventional film package made, for example of a Mono-Sol-M-8630 or an equivalent film measured under the same conditions. The improved disintegration and / or dissolving time may be enhanced by providing a striated surface structure and / or small holes whose diameter ranges from 1 μm to 50 μm.

Owner:HENKEL KGAA

Robotic surgical system with joint motion controller adapted to reduce instrument tip vibrations

ActiveUS20070142968A1Reduce vibrationWithout jeopardizing control system stabilityProgramme-controlled manipulatorMechanical/radiation/invasive therapiesJoints movementInstrumentation

A robotic surgical system has a robot arm holding an instrument for performing a surgical procedure, and a control system for controlling movement of the arm and its instrument according to user manipulation of a master manipulator. The control system includes a filter in its forward path to attenuate master input commands that may cause instrument tip vibrations, and an inverse filter in a feedback path to the master manipulator configured so as to compensate for delay introduced by the forward path filter. To enhance control, master command and slave joint observers are also inserted in the control system to estimate slave joint position, velocity and acceleration commands using received slave joint position commands and torque feedbacks, and estimate actual slave joint positions, velocities and accelerations using sensed slave joint positions and commanded slave joint motor torques.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Flowable dielectric equipment and processes

ActiveUS8357435B2Reduce contentReduction in undesirable componentElectric discharge tubesDecorative surface effectsDielectric layerMaterials science

Methods of depositing and curing a dielectric material on a substrate are described. The methods may include the steps of providing a processing chamber partitioned into a first plasma region and a second plasma region, and delivering the substrate to the processing chamber, where the substrate occupies a portion of the second plasma region. The methods may further include forming a first plasma in the first plasma region, where the first plasma does not directly contact with the substrate, and depositing the dielectric material on the substrate to form a dielectric layer. One or more reactants excited by the first plasma are used in the deposition of the dielectric material. The methods may additional include curing the dielectric layer by forming a second plasma in the second plasma region, where one or more carbon-containing species is removed from the dielectric layer.

Owner:APPLIED MATERIALS INC

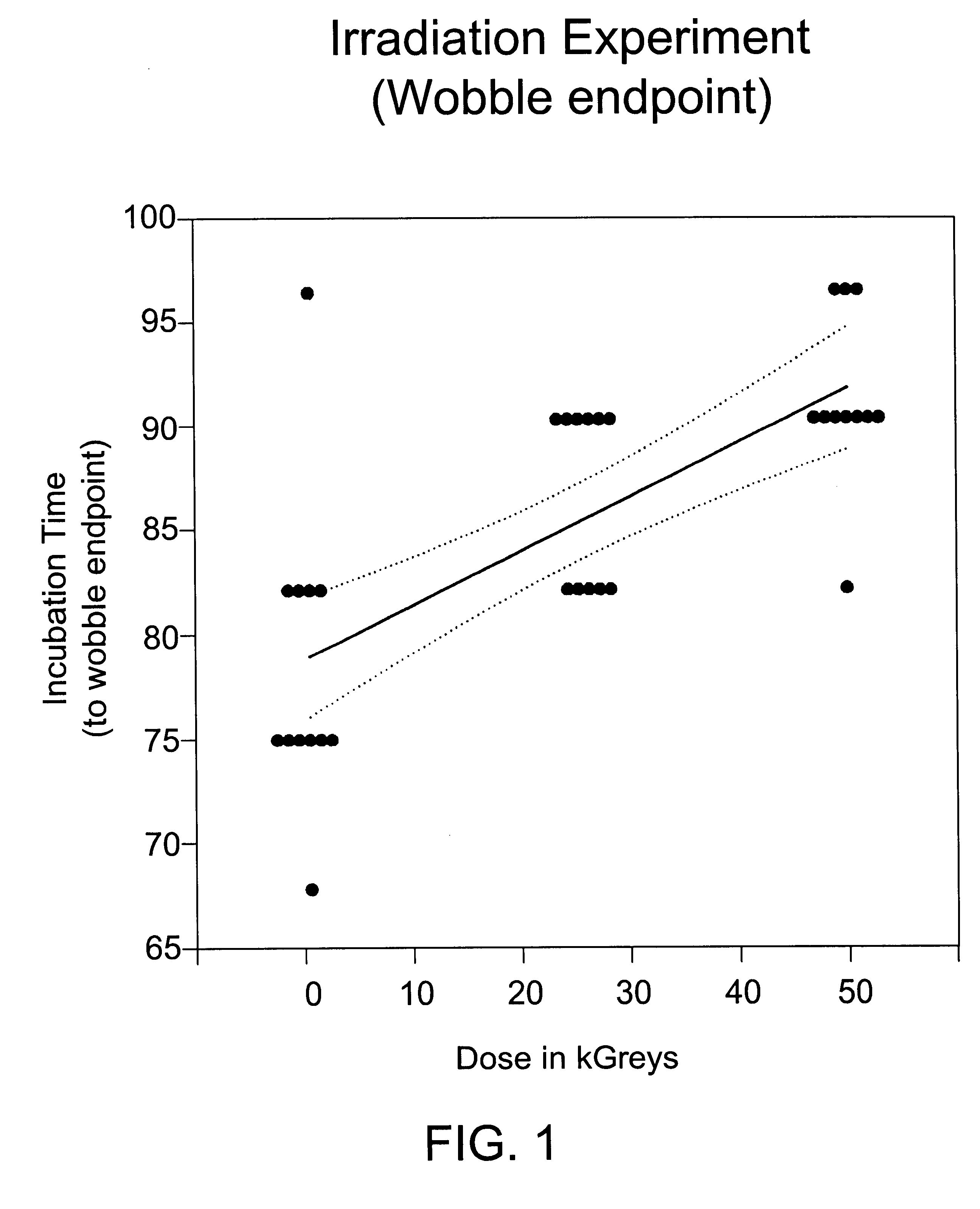

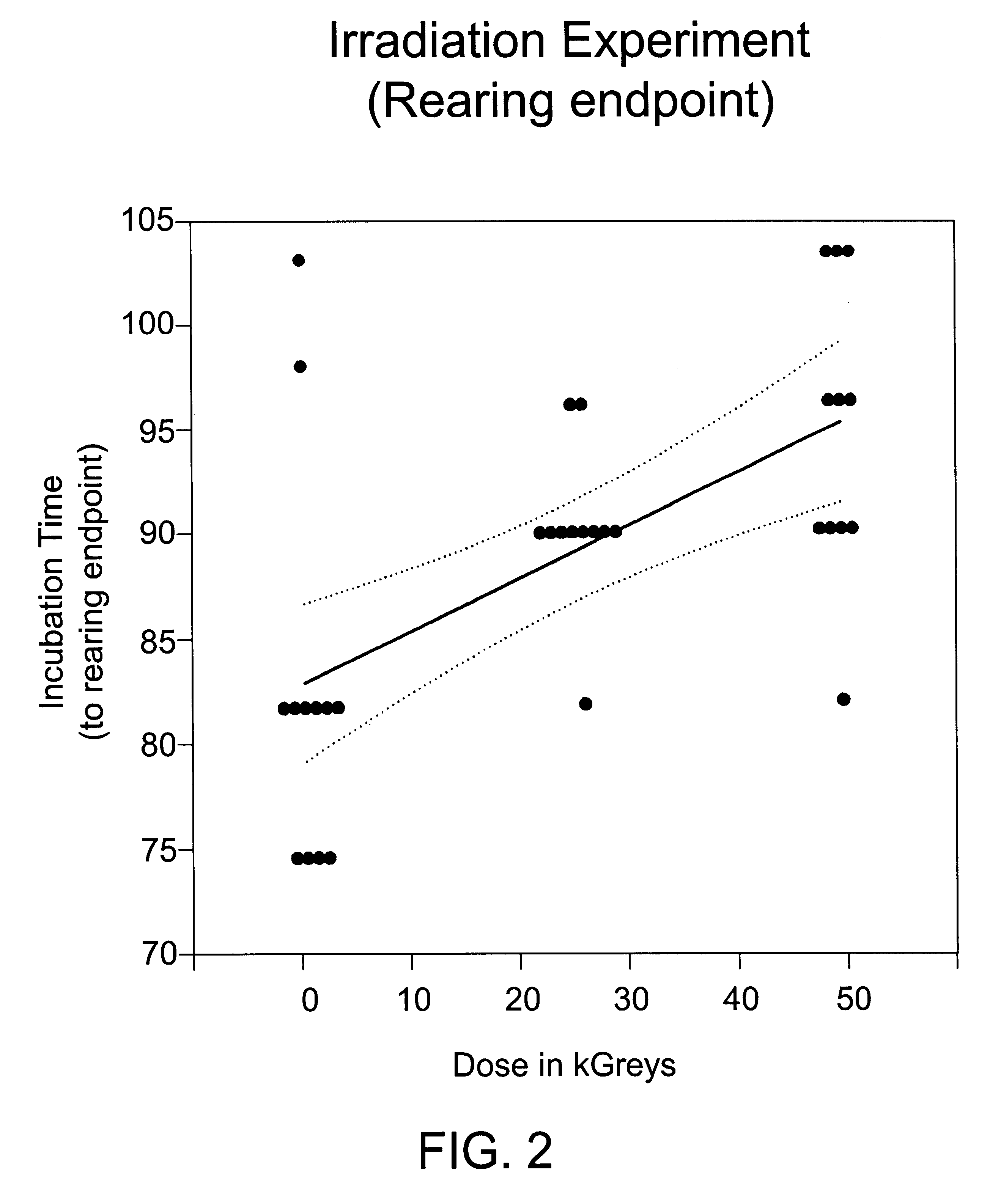

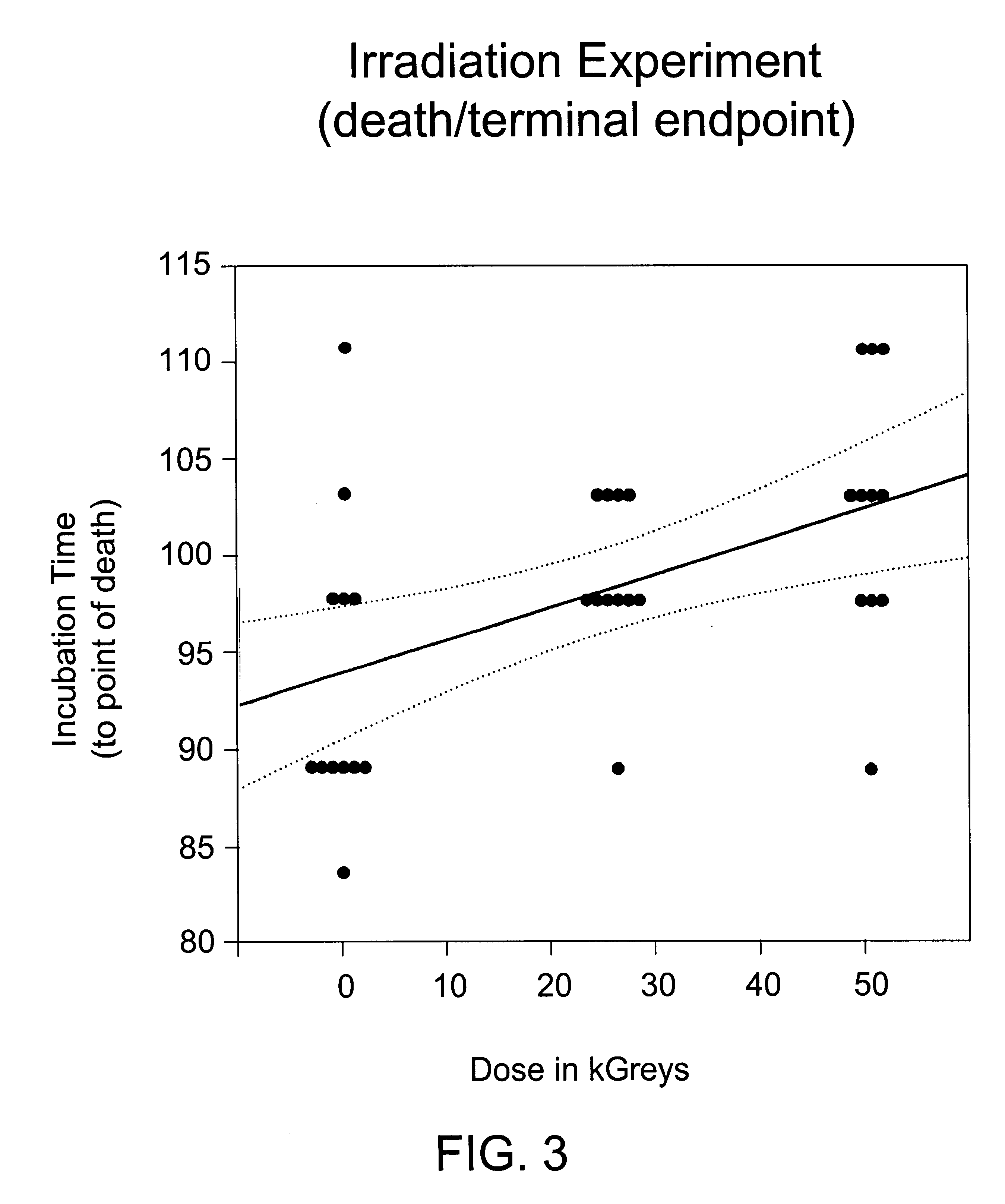

Methods for sterilizing biological materials

InactiveUS6946098B2Lowered residual solventReduce the temperatureOther blood circulation devicesFood preservationBiochemistryBiological materials

Methods are disclosed for sterilizing biological materials to reduce the level therein of one or more biological contaminants or pathogens, such as prions, responsible for the disease states known as transmissible spongiform encephalopathies (TSEs) in mammals. These methods involve sterilizing biological materials with irradiation.

Owner:CLEARANT

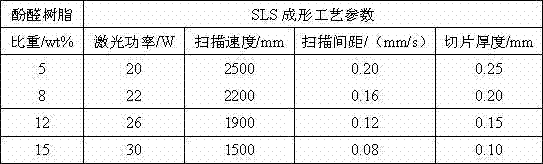

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

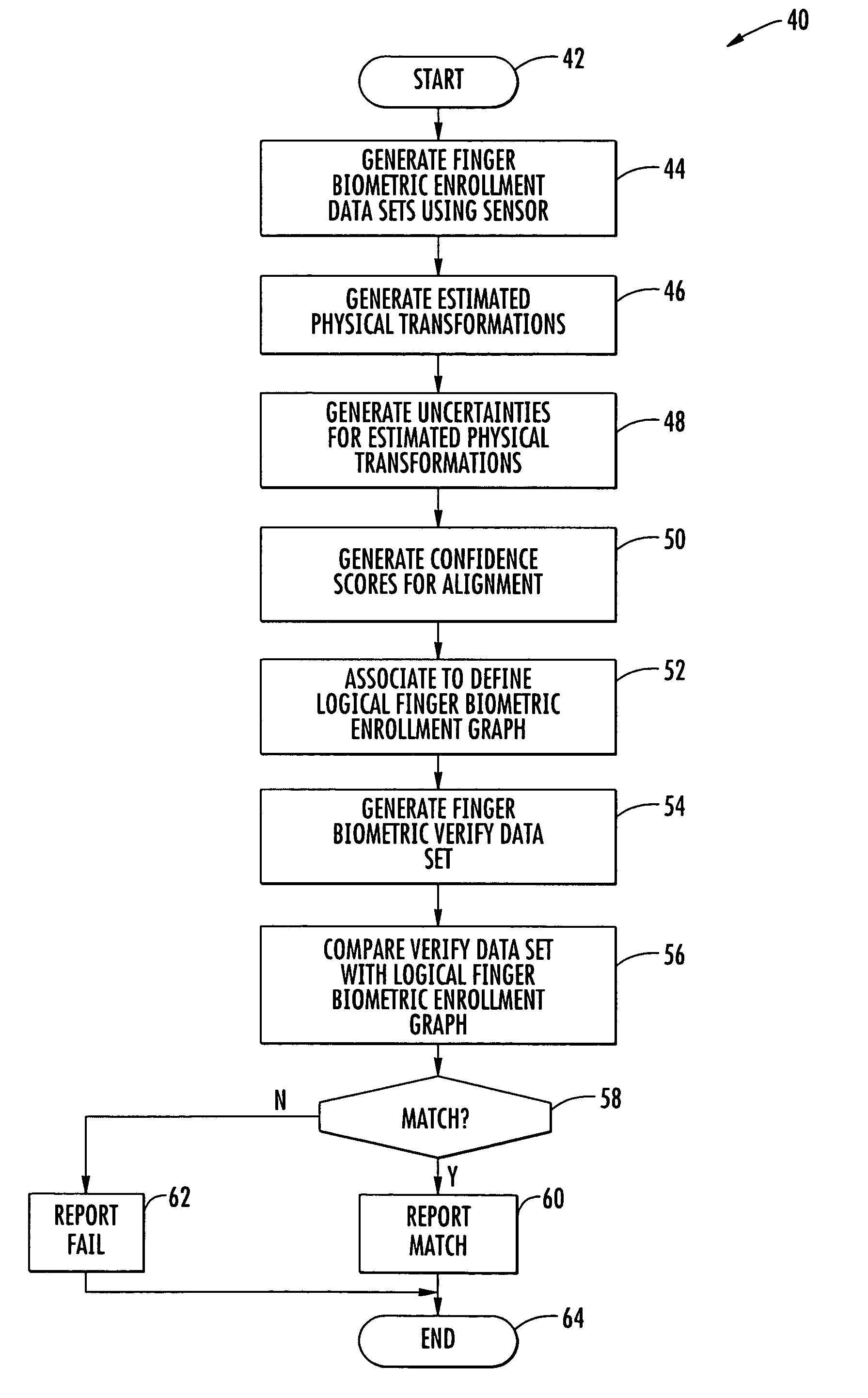

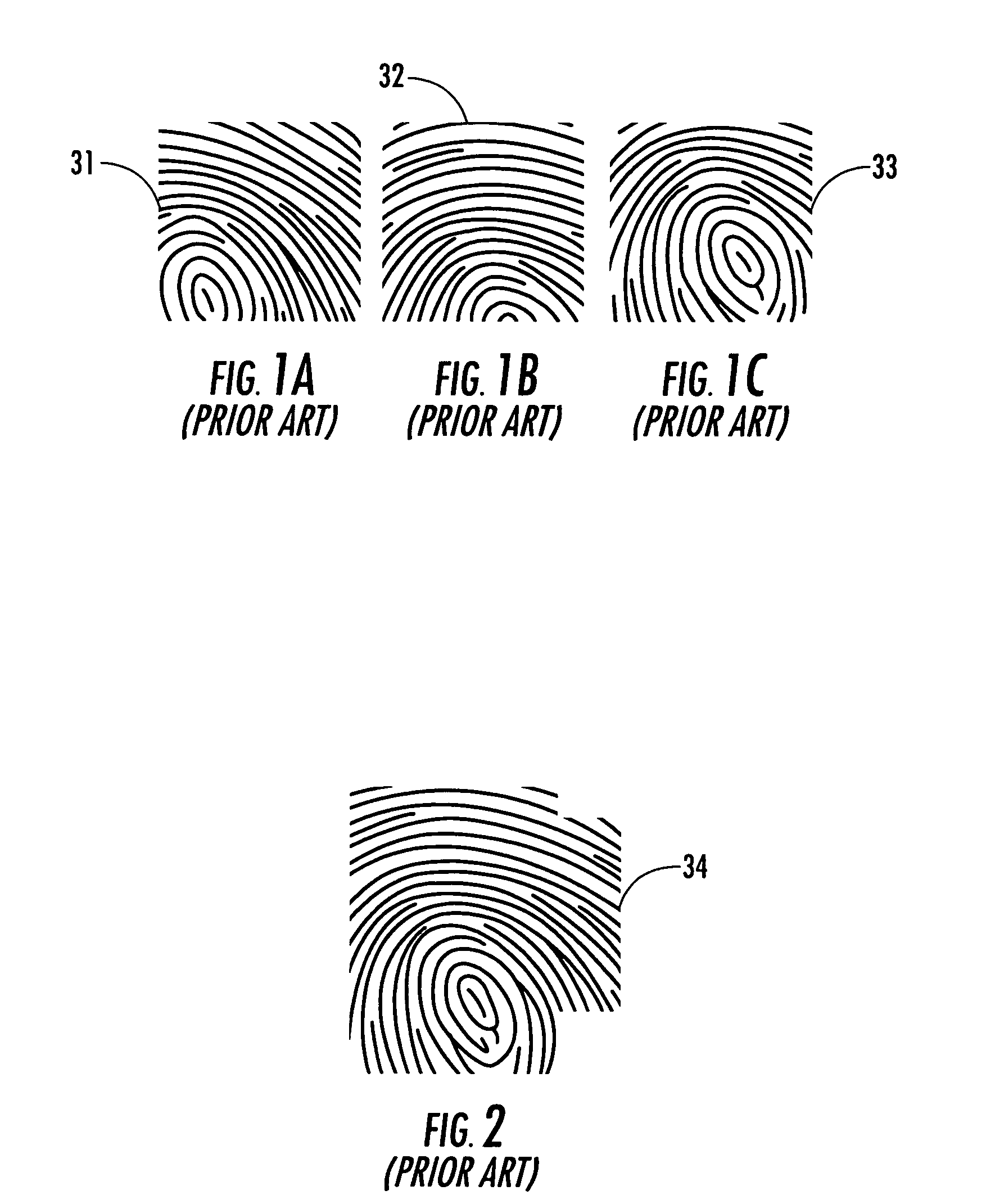

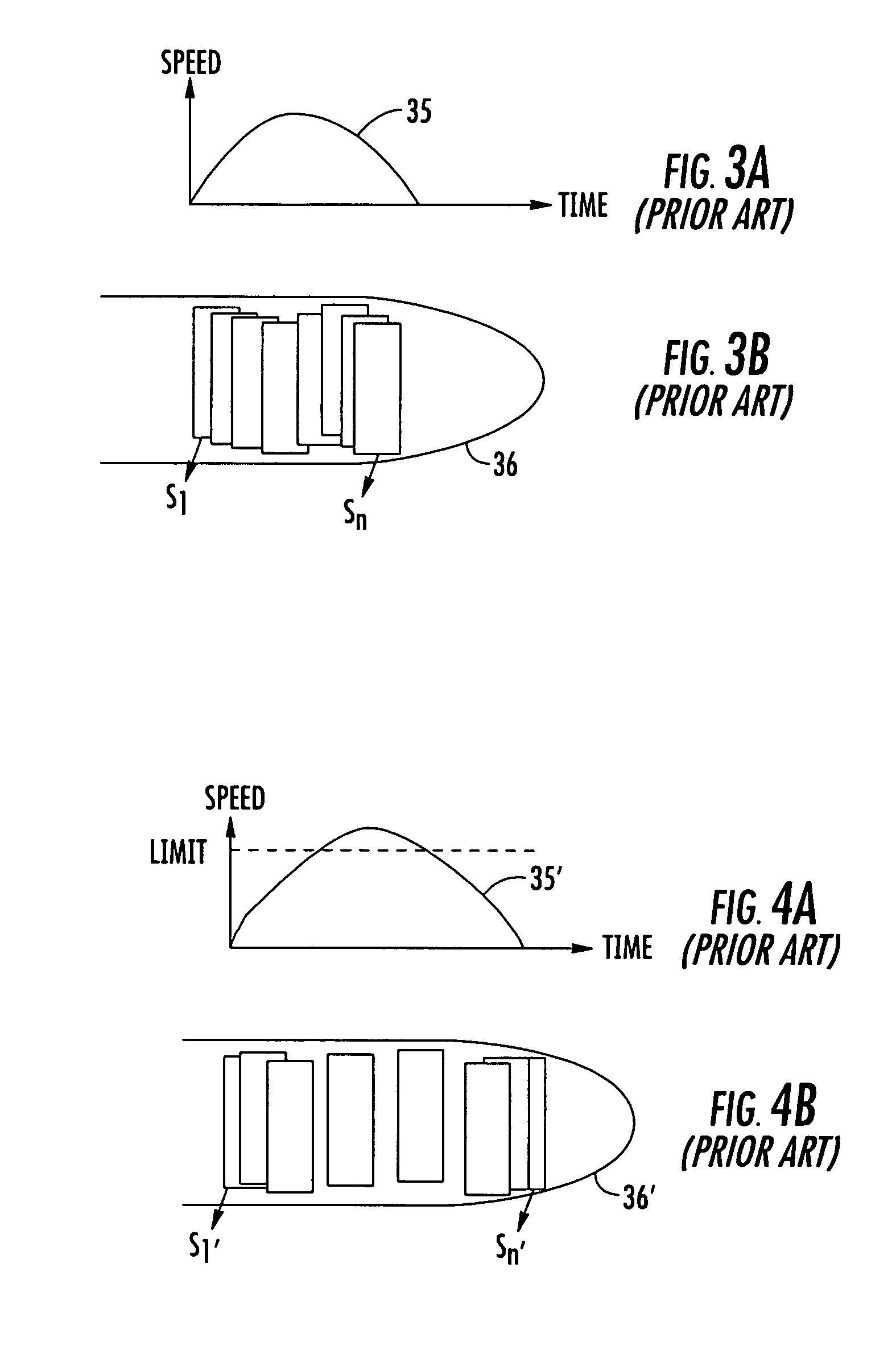

Methods for finger biometric processing and associated finger biometric sensors

InactiveUS20050129291A1Exact matchReduce contentCharacter and pattern recognitionPattern recognitionData set

A method is for processing a plurality of finger biometric enrollment data sets that accounts for uncertainty in alignment between finger biometric enrollment data sets. The method may include generating a respective estimated physical transformation between each pair of finger biometric enrollment data sets, and generating a respective uncertainty for each estimated physical transformation. The method may also include associating the respective estimated physical transformation and the uncertainty for each estimated physical transformation with each pair of finger biometric enrollment data sets to define a logical finger biometric enrollment graph. The logical finger biometric enrollment graph is readily used for subsequent accurate matching in either touch sensor applications or slide sensor applications.

Owner:APPLE INC

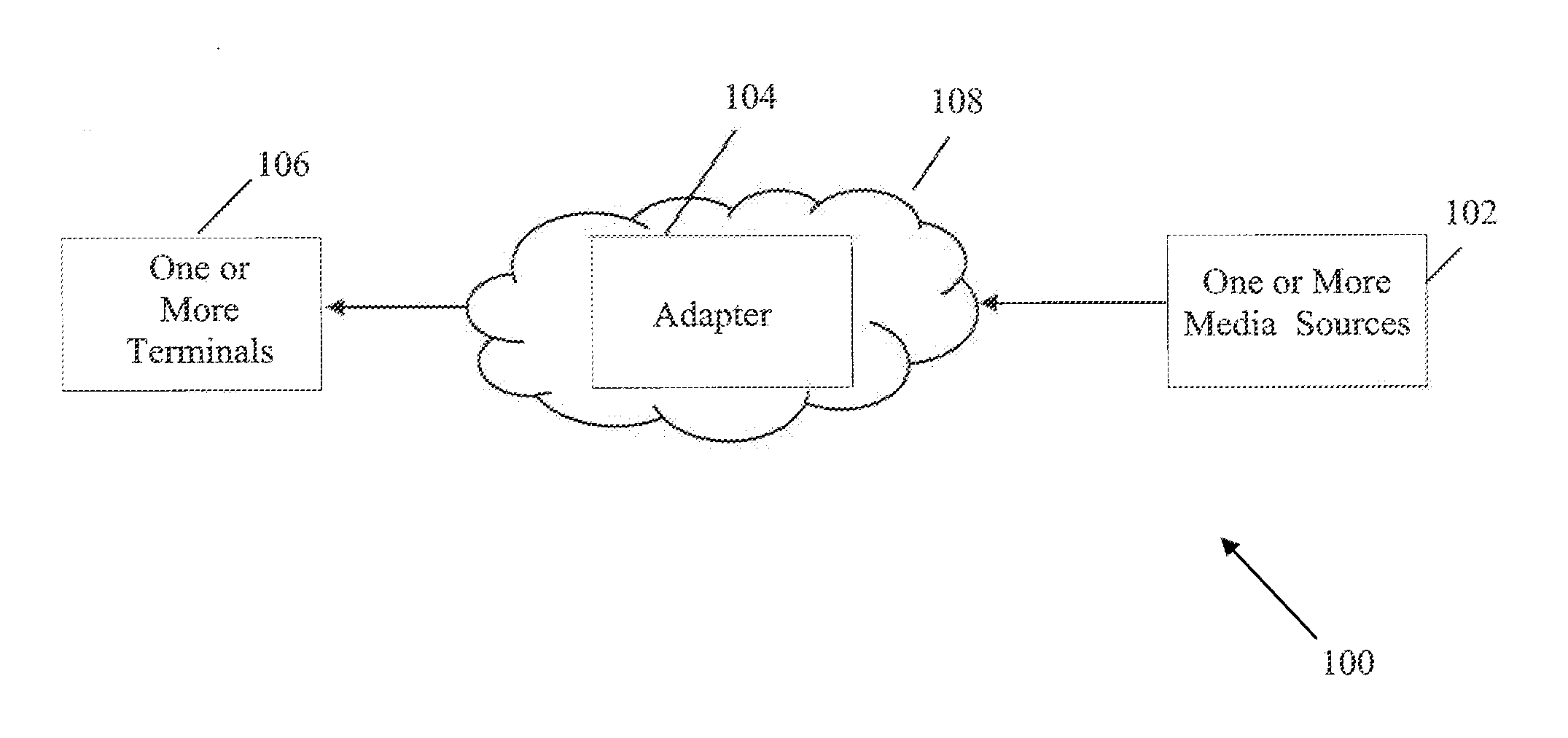

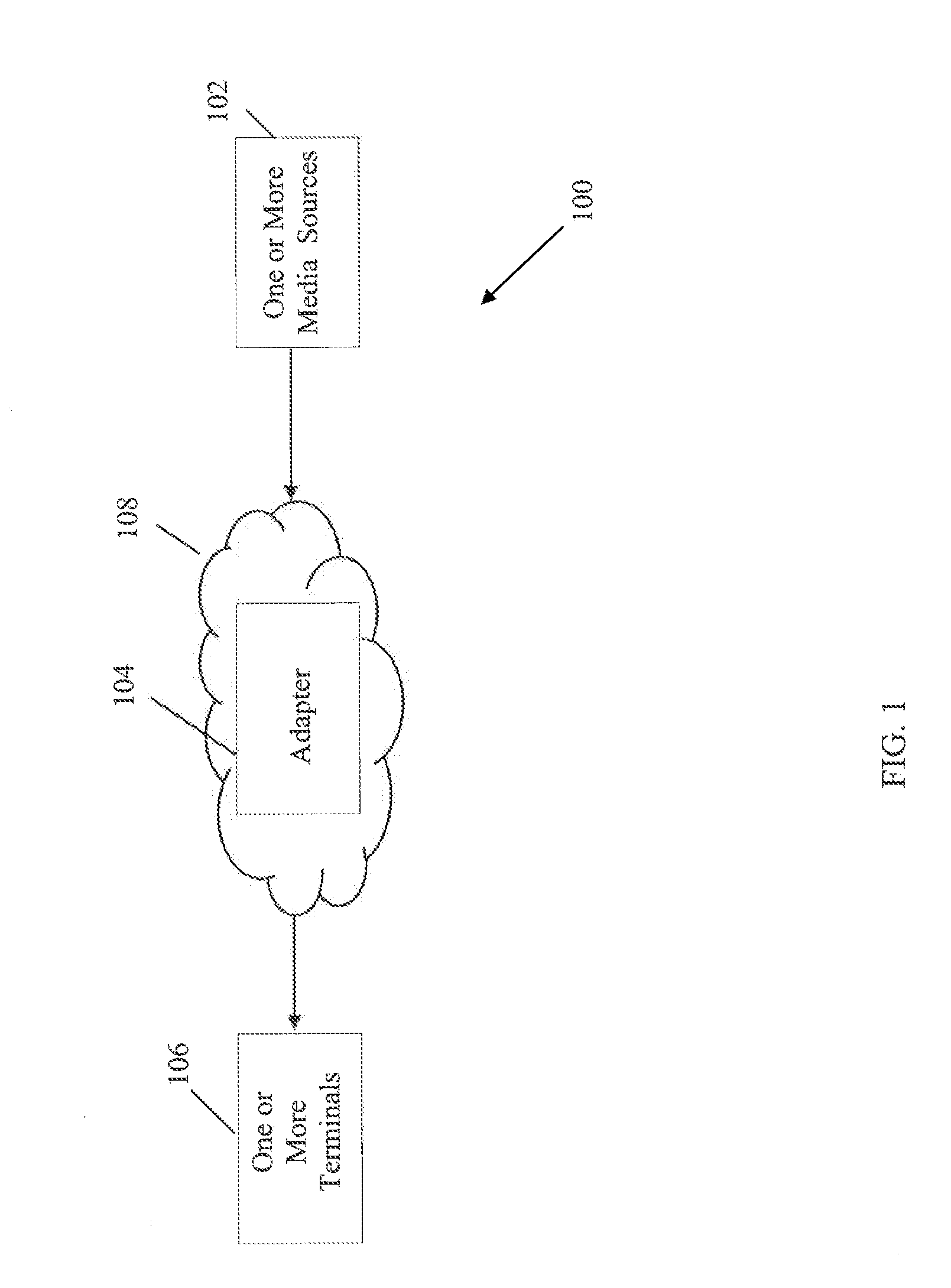

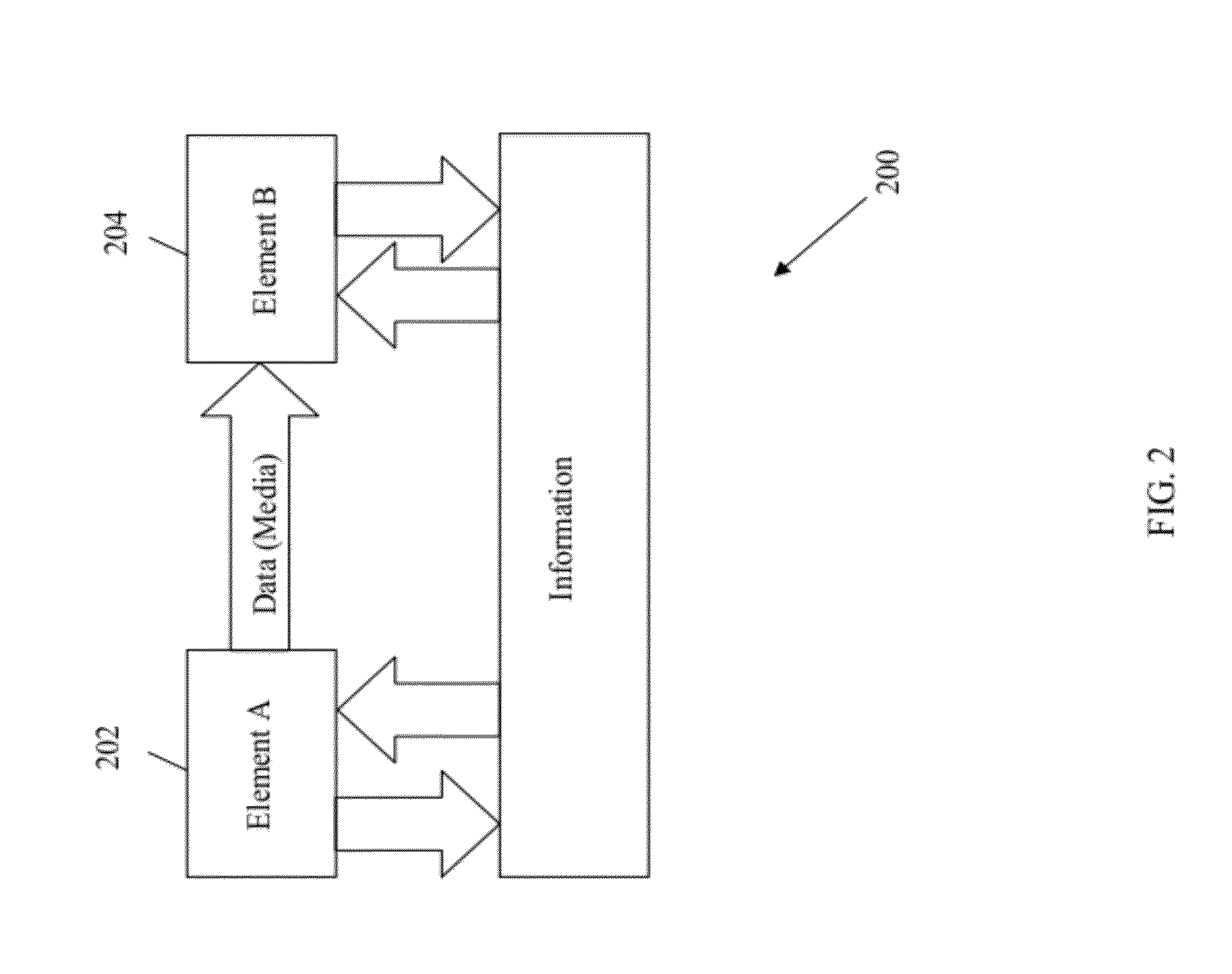

Method and apparatus for adapting media

InactiveUS20120179833A1Reduce processing costsReduce transmission costsMultiple digital computer combinationsDigital video signal modificationComputer networkProcessing element

A method and apparatus for adapting media is provided. The method includes receiving a request for a first media stream and a second media stream at different media times. The method further includes processing a source media stream to produce a first portion media stream and a second portion media stream using a media processing element. A method for processing media comprises creating a first media processing element and a second media processing element. The method further includes processing a first media stream using the first media processing element to produce assistance information. Further, the method includes processing a second media stream using the second media processing element wherein the second media processing element utilizes the assistance information.

Owner:ONMOBILE GLOBAL LTD

Tobacco having reduced nicotine and nitrosamines

InactiveUS20050072047A1Reduce the amount requiredImprove availabilityBiocideTobacco preparationNicotiana tabacumJasmonate

Aspects of the present invention concern tobacco having reduced nicotine and nitrosamines, which is used to manufacture consumer tobacco products, and methods to produce such tobacco. More specifically, embodiments include methods to reduce nicotine and nitrosamines in tobacco crops by applying auxin, auxin analogs, and jasmonate antagonists during the cultivation of such tobacco crops. Tobacco generated using said methods and consumer tobacco products obtained therefrom are also embodiments.

Owner:VECTOR TOBACCO LLC

Device and method for reducing effects of video artifacts

A method for reducing an effect of a video artifact includes adjusting a phase of a second imaging device's video clock signal so that a phase of the second imaging device's video synchronization signal matches a phase of a first imaging device's video synchronization signal. An endoscopic system includes a first imaging device, a second imaging device, a light source, and a controller that reduces an artifact in an image produced by the first imaging device. In some embodiments, the first imaging device faces the light source.

Owner:PSIP LLC

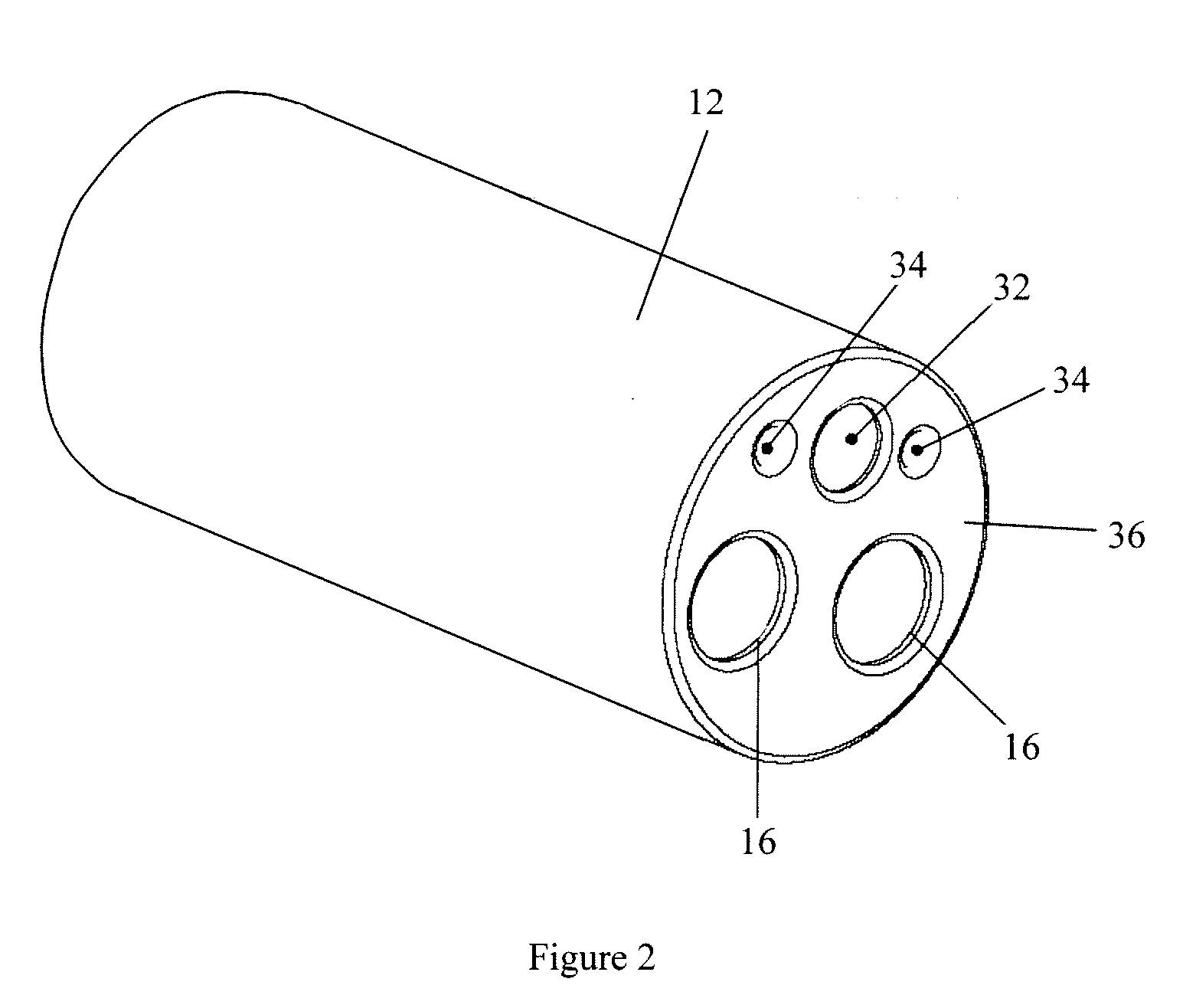

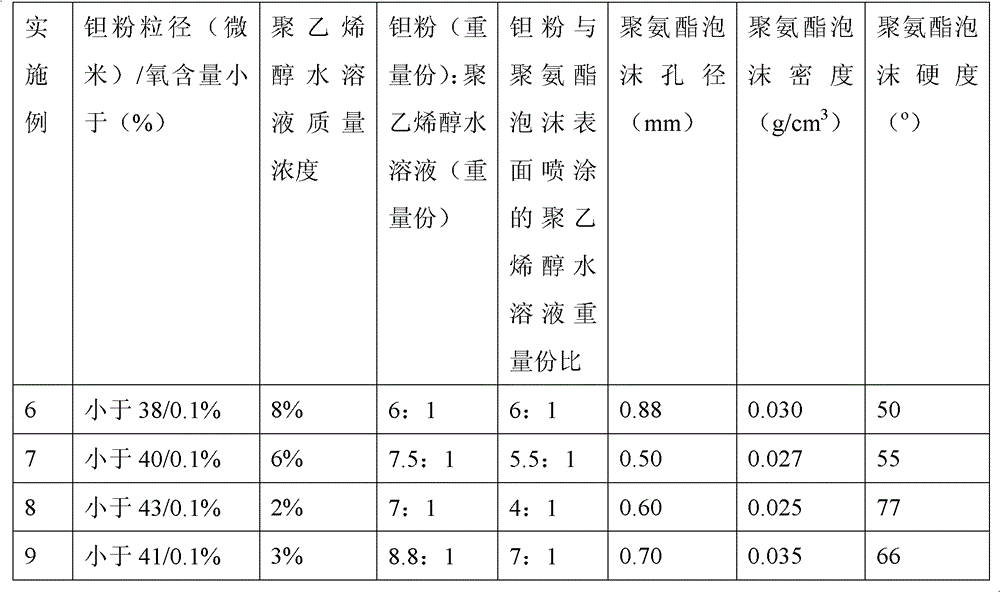

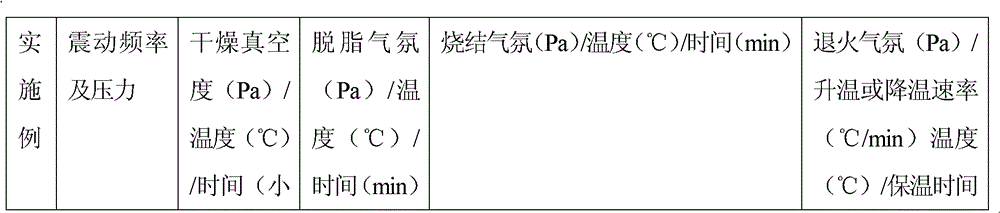

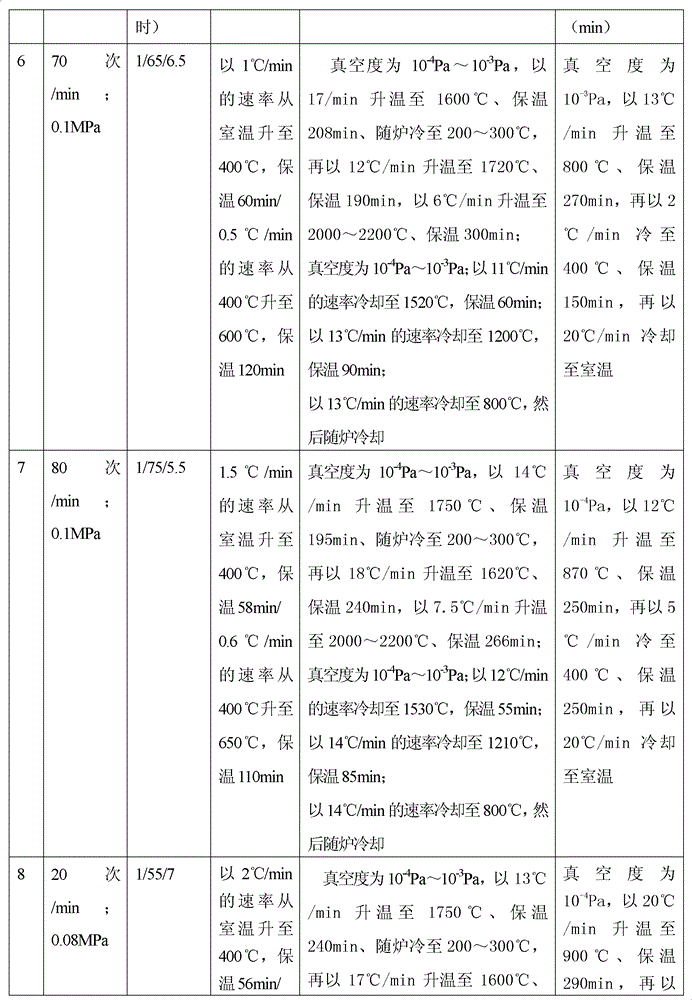

Method for preparing medical porous tantalum implant material

ActiveCN102796894AReduce contentImprove mechanical propertiesProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention discloses a method for preparing a medical porous tantalum material. The method comprises the following steps of: mixing a poly ethanol aqueous solution and tantalum powder to obtain slurry, wherein the mass concentration of the poly ethanol aqueous solution is 2 to 8 percent; injecting the slurry into an organic foam by vibrating and pressurizing, wherein the vibrating frequency is 20 to 80 times / min; drying; degreasing; sintering, namely raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3>Pa, preserving heat for 120 to 240 minutes, cooling to 200 to 300 DEG C along with a furnace, raising temperature to 1,500 to 1,800 DEG C at the speed of 10 to 20 DEG C / min again, preserving heat for 180 to 240 minutes, raising temperature to 2,000 to 2,200 DEG C at the speed of 5 to 10 DEG C / min, and preserving heat for 120 to 360 minutes; cooling; and performing thermal treatment, namely raising temperature to 800 to 900 DEG C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DGE C at the speed of 2 to 5 DGE C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with the furnace. The porous tantalum prepared by the method is very suitable to be used for the medical implant material for replacing bearing bone tissues, and biocompatibility and the mechanical property can be guaranteed simultaneously.

Owner:CHONGQING RUNZE PHARM CO LTD

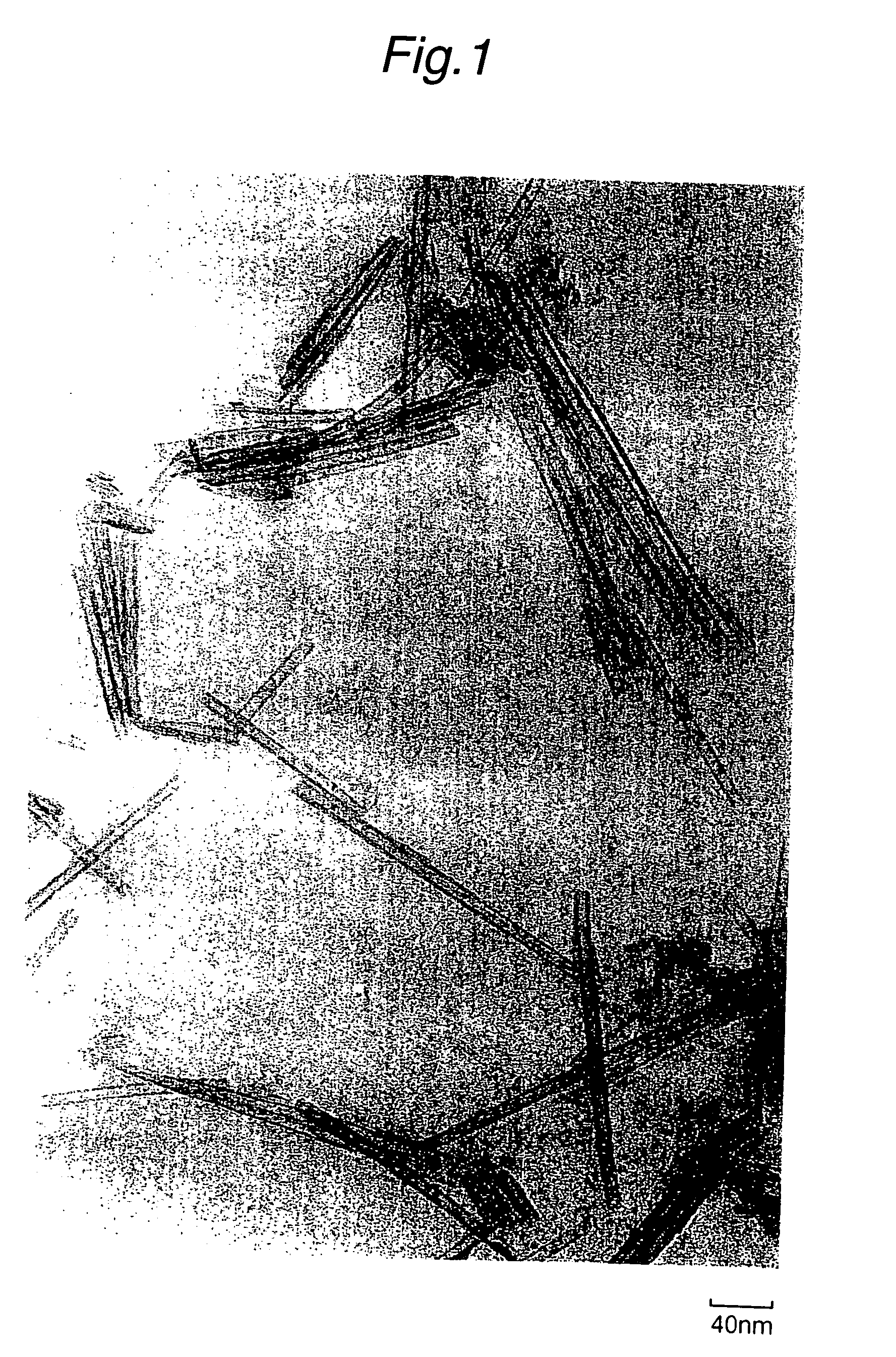

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com