Patents

Literature

84results about How to "Stable resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

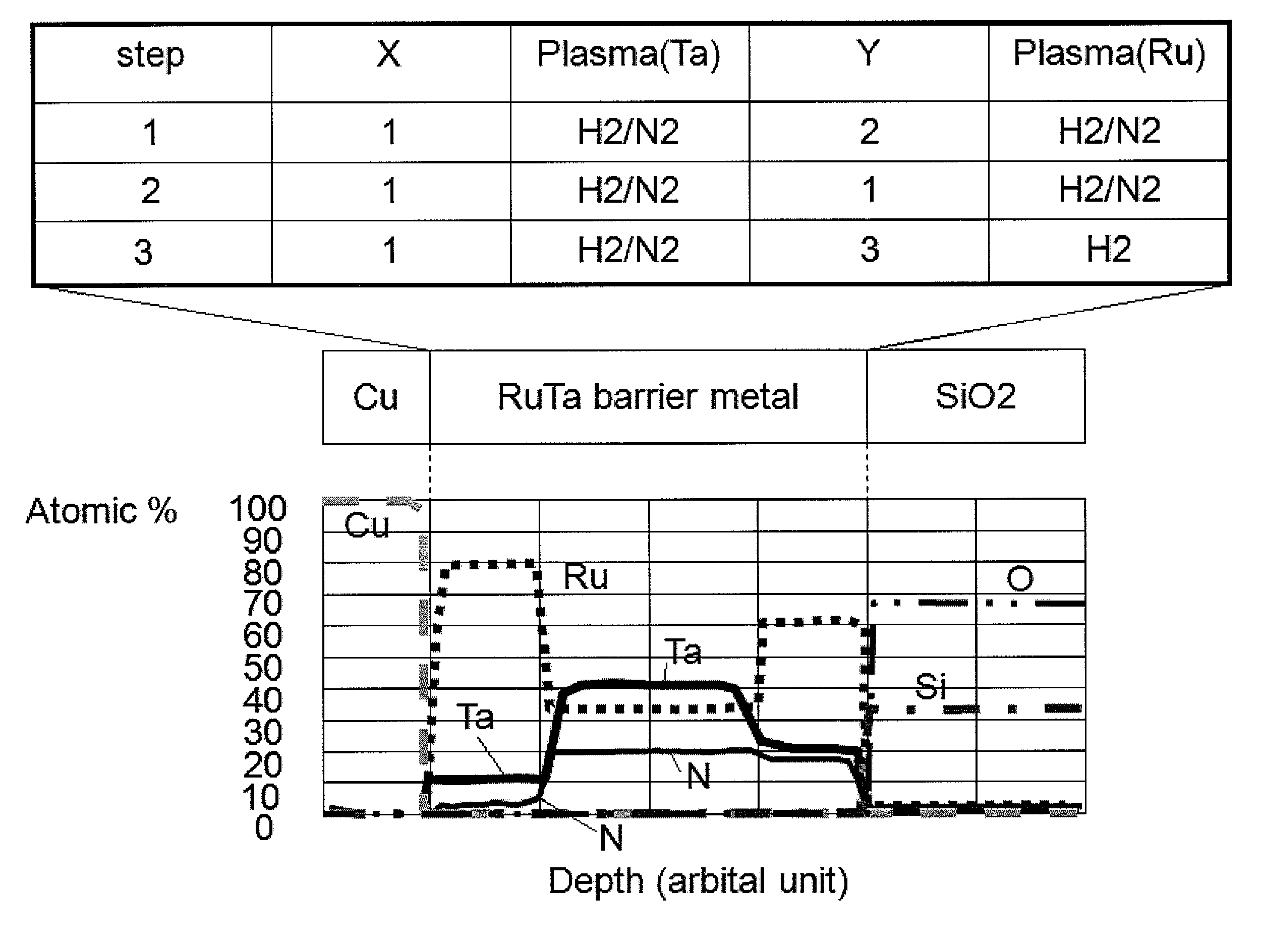

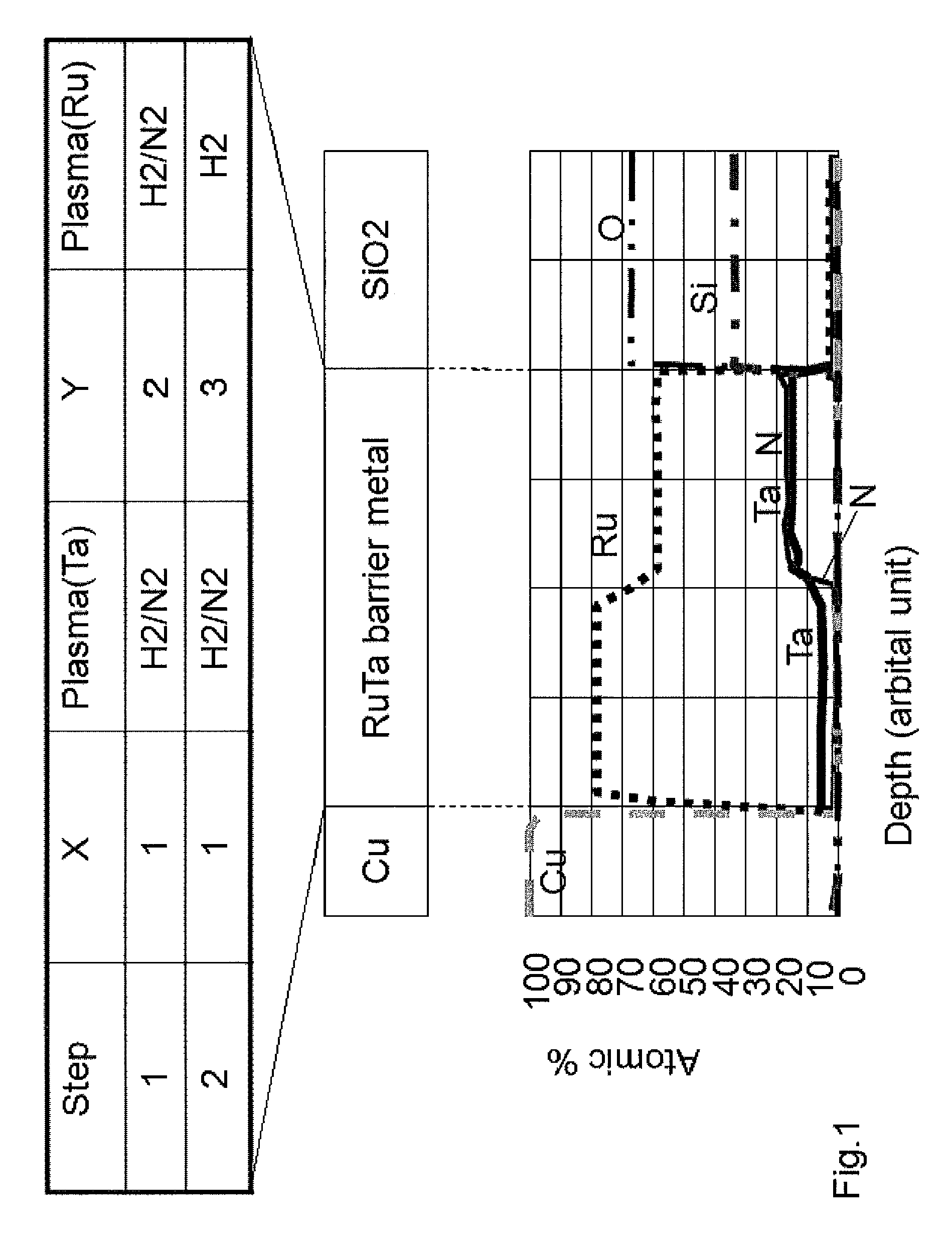

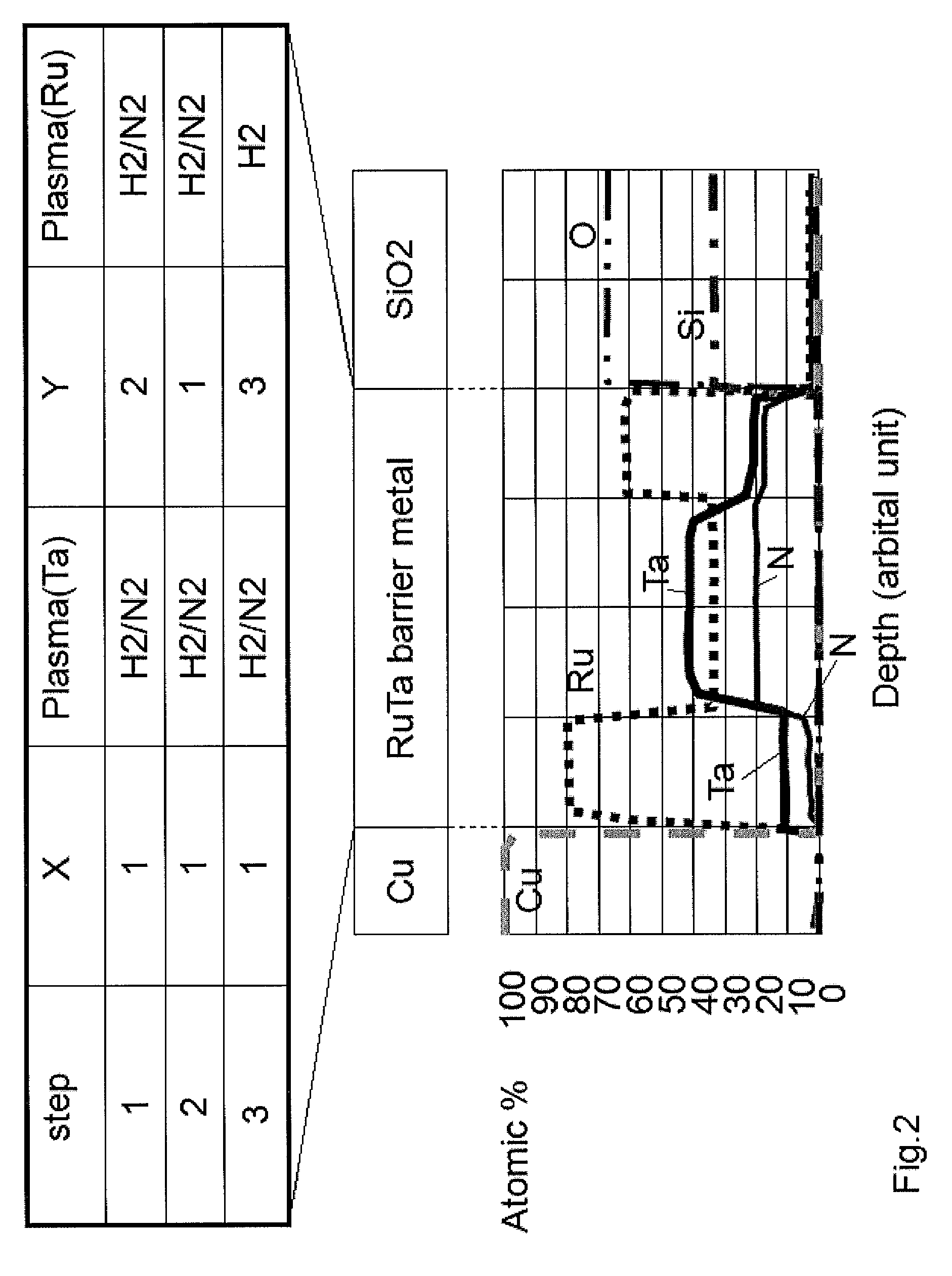

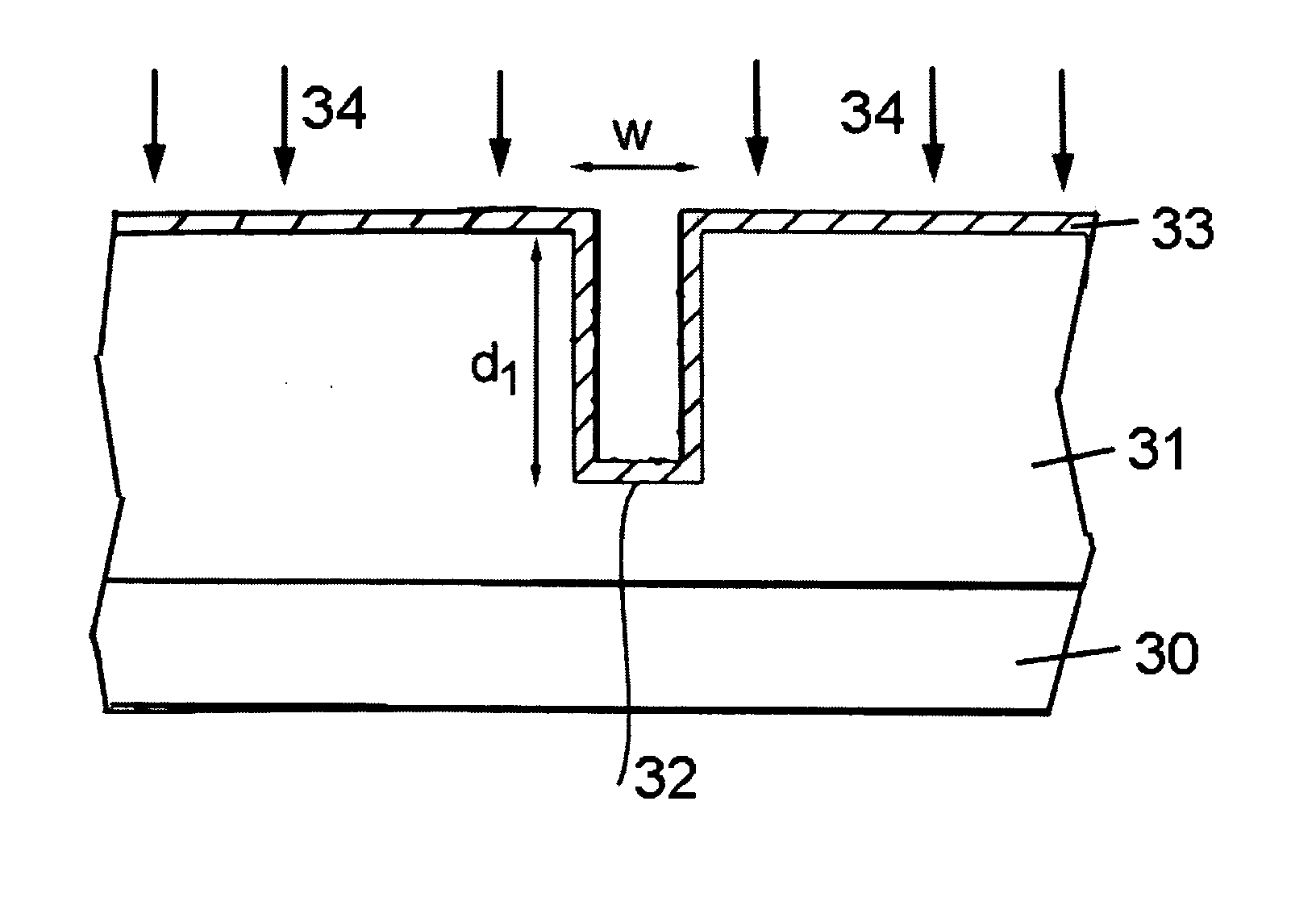

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

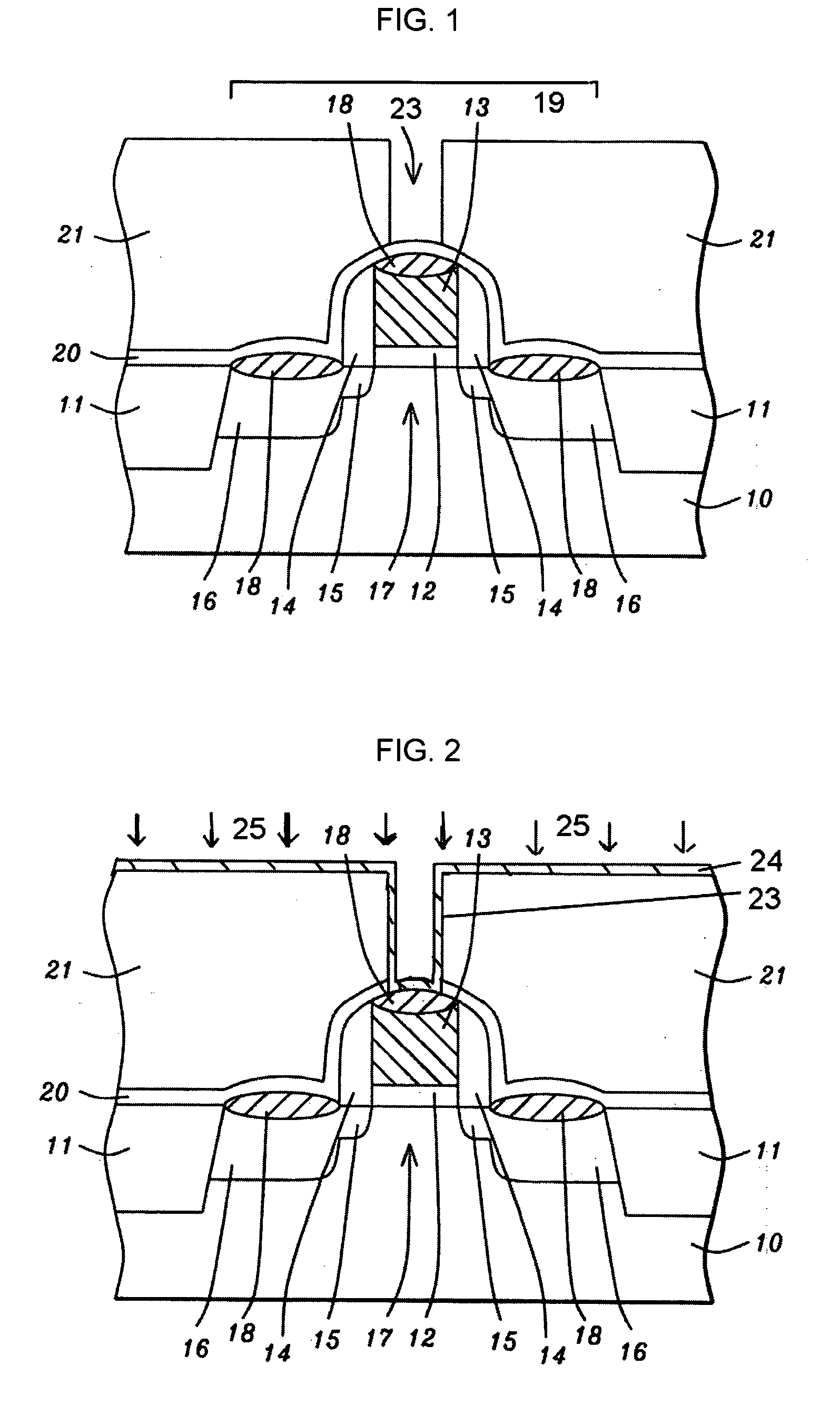

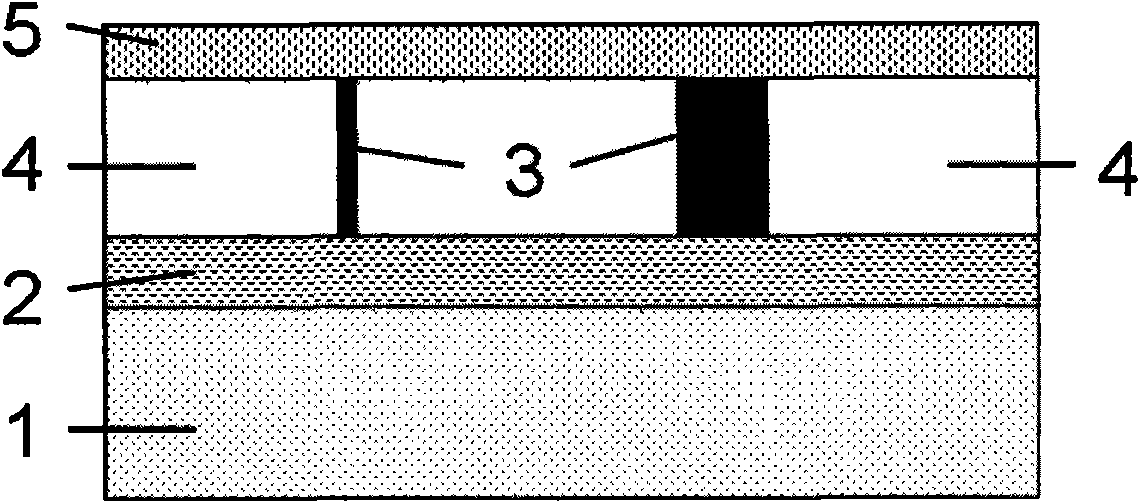

Method to form a robust TiCI4 based CVD TiN film

InactiveUS20050112876A1Low resistivityReduce stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorideLow leakage

A method is described for a plasma treatment of a TiCl4 based CVD deposited TiN layer that reduces stress, lowers resistivity, and improves film stability. Resistivity is stable in an air ambient for up to 48 hours after the plasma treatment. A TiN layer is treated with a N-containing plasma that includes N2, NH3, or N2H4 at a temperature between 500° C. and 700° C. Optionally, H2 may be added to N2 in the plasma step which removes chloride impurities and densifies the TiN layer. The TiN layer may serve as a barrier layer, an ARC layer, or as a bottom electrode in a MIM capacitor. An improved resistance of the treated TiN layer to oxidation during formation of an oxide based insulator layer and a lower leakage current in the MIM capacitor is also achieved.

Owner:TAIWAN SEMICON MFG CO LTD

High polymer-based graphene composite material with positive resistance temperature coefficient and preparation method

InactiveCN102532669AReduce dosageImprove conductivityState of artElectrical resistance and conductance

The invention relates to a high polymer-based graphene composite material with positive resistance temperature coefficient, and a preparation method of the material. The composite material comprises a base body and conductive filler; the content of conductive material is 0.01-10wt%; all components are mixed uniformly and are formed through mold-pressing or extrusion / injection molding; and the formed material is irradiated after being dried, so that the high polymer-based graphene composite material with positive resistance temperature coefficient can be obtained. Compared with the prior art, the graphene composite material and the preparation method have the advantages that the manufacturing process is simple, less influence is caused to the performance of base material, oxidation is unlikely to occur, the resistivity is more stable, the circulation stability of the material is better, and NTC (Negative Temperature Coefficient) effect is not generated easily.

Owner:SHANGHAI JIAO TONG UNIV

Conductive silicone rubber composition and low-resistance connector

InactiveUS6309563B1Stable resistivityInhibition of agglomerationLayered productsConductive materialPolymer scienceSpherical form

A conductive silicone rubber composition comprising (A) an organopolysiloxane having at least two aliphatic unsaturated groups, (B) a conductive powder comprising a silver powder premixed with 0.2-5% by weight of fine powder selected from the group consisting of inorganic fillers and spherical organic resins, and (C) a curing agent has a stable volume resistivity.

Owner:SHIN ETSU CHEM IND CO LTD +1

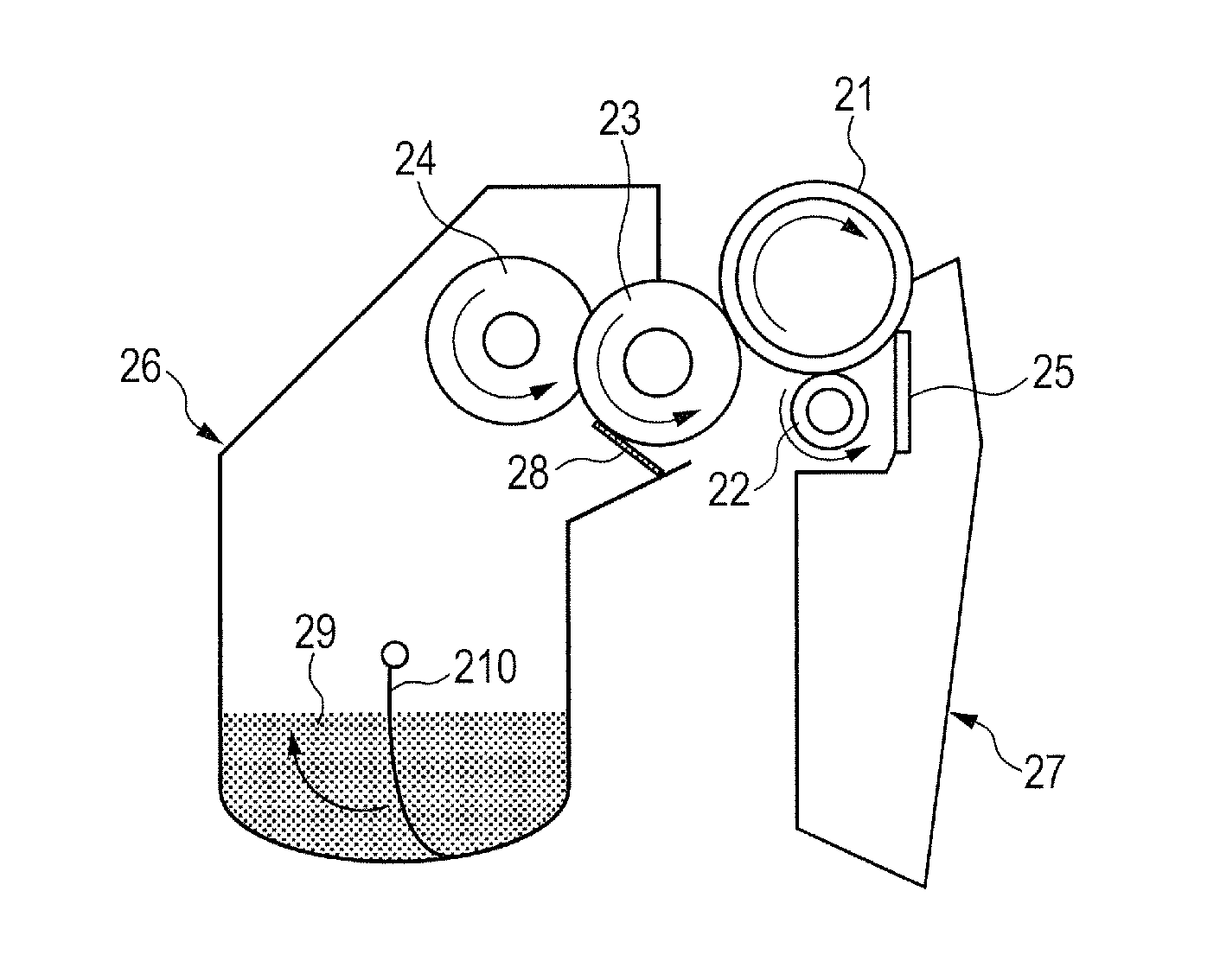

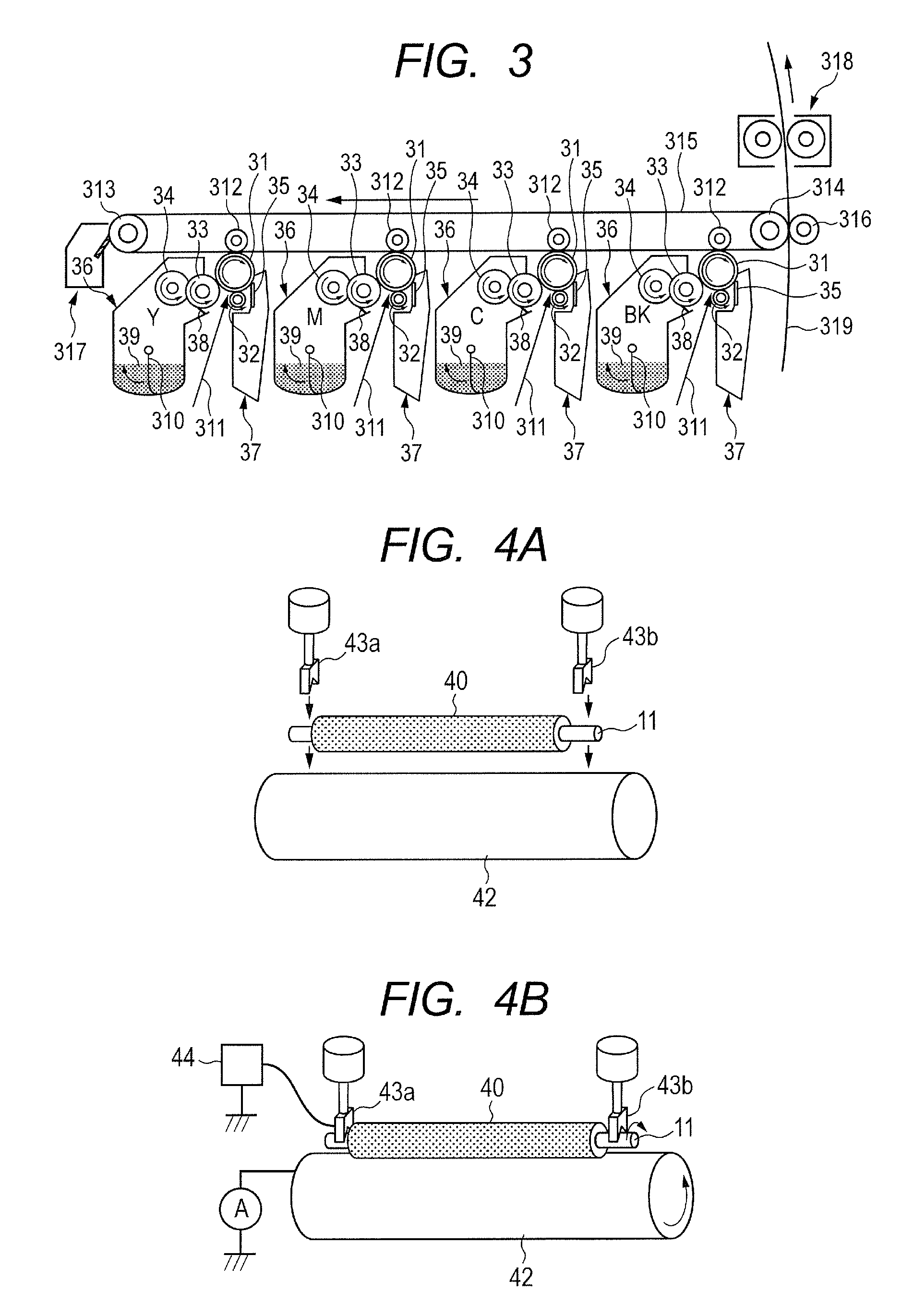

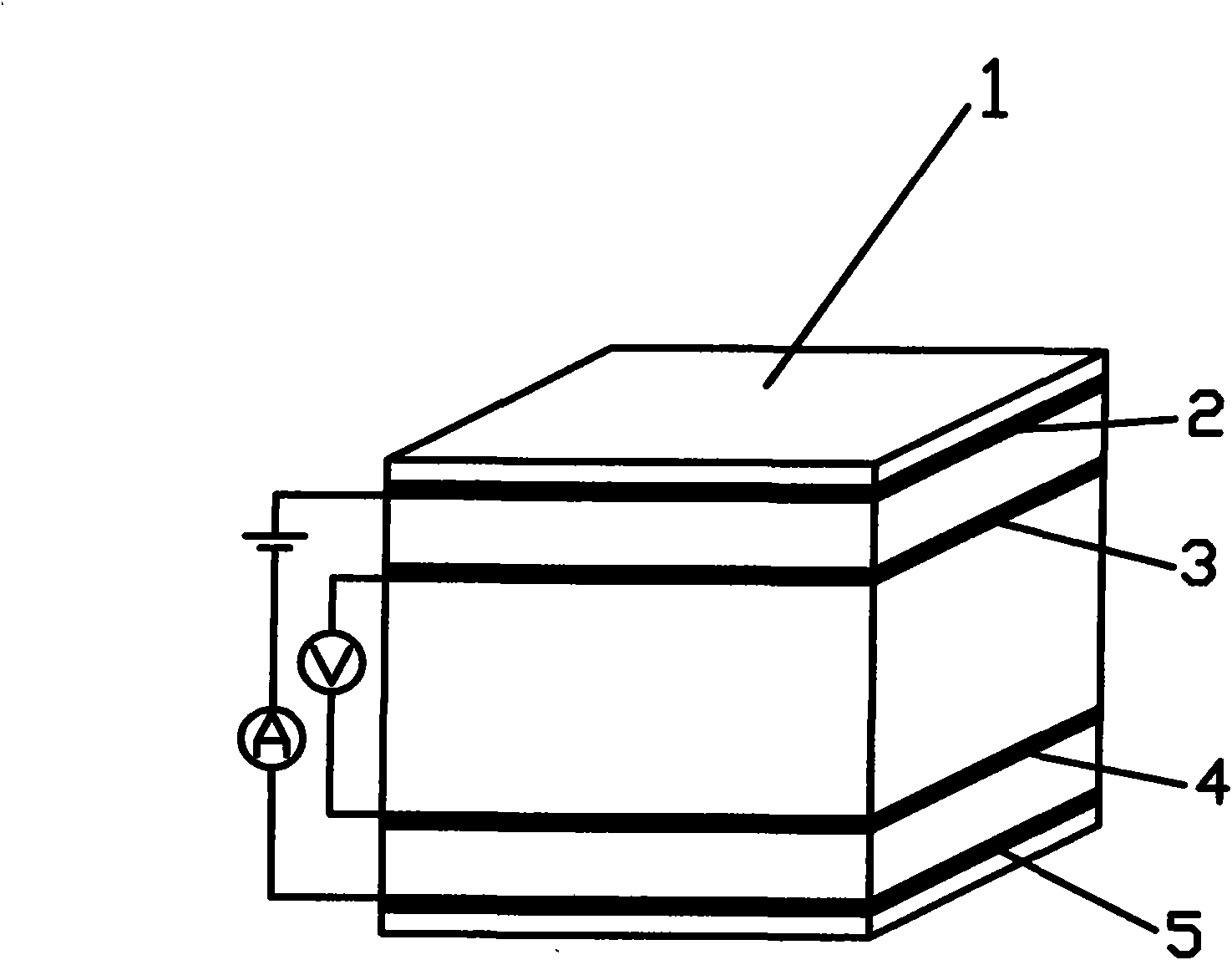

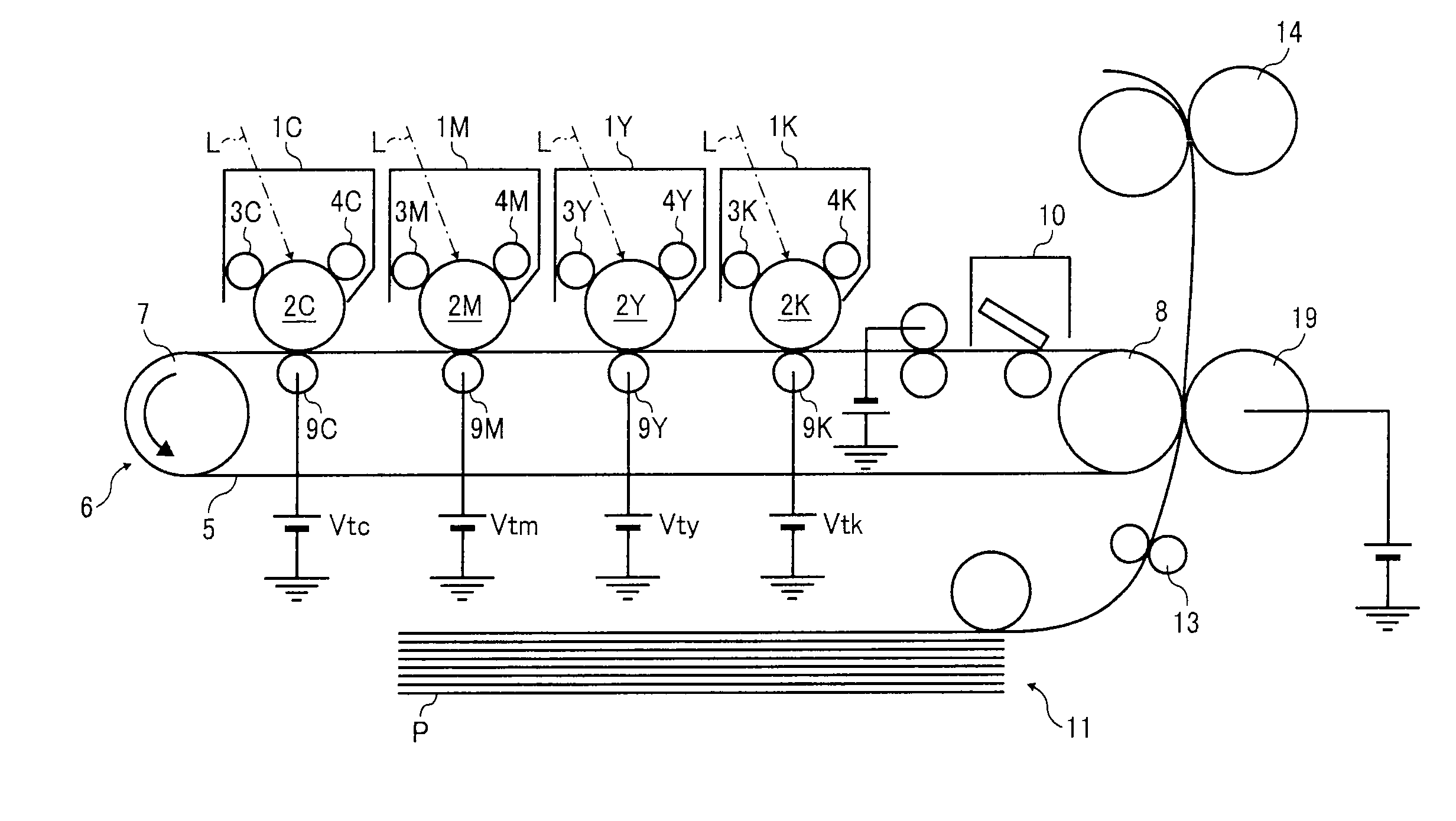

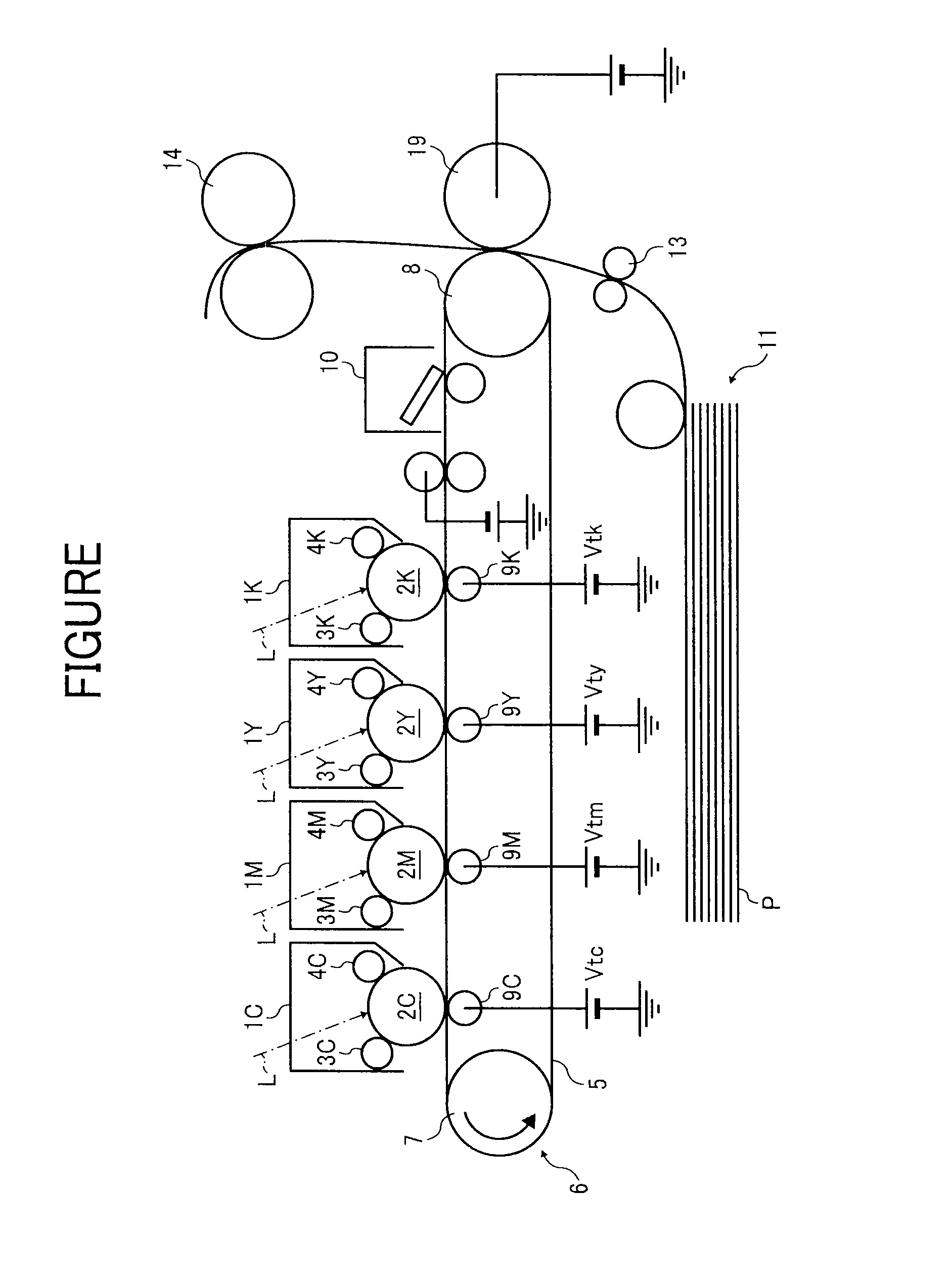

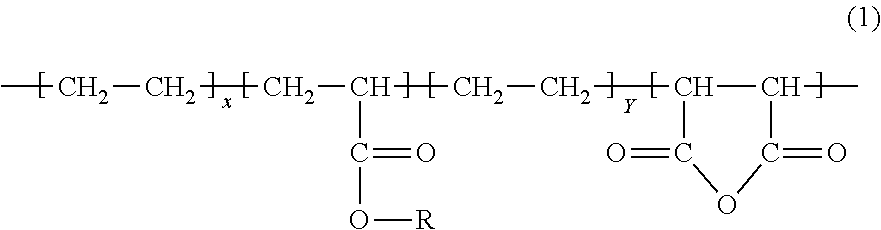

Electro-conductive member for electrophotography, process cartridge, and electrophotographic apparatus

ActiveUS8852743B2Improve the immunityMore resistantSynthetic resin layered productsElectrographic process apparatusIon exchangeAmmonium

An electro-conductive member for electrophotography, including an electro-conductive mandrel and an electro-conductive layer; and a process cartridge and an electrophotographic apparatus using the same. The layer contains a binder resin having a sulfo or a quaternary ammonium group as an ion exchange group, and an ion opposite in polarity to the ion exchange group. The resin has any one of structures represented by formulas (1)-1 and (1)-2, and any one of structures represented by formulas (2)-1 to (2)-3; and the resin has a molecular structure preventing occurrence of a matrix-domain structure. M represents an integer of 2-20, n represents an integer of 5-50, p represents an integer of 1-25, q represents an integer of 1-15, and r represents an integer of 1-12.—(CF2)m— Formula (1)-1—(CF2—CF2—O)n— Formula (1)-2—(CH2—CH2—O)p— Formula (2)-1—(CH2—CHCH3—O)q— Formula (2)-2—(CH2—CH2—CH2—CH2—O)r— Formula (2)-3

Owner:CANON KK

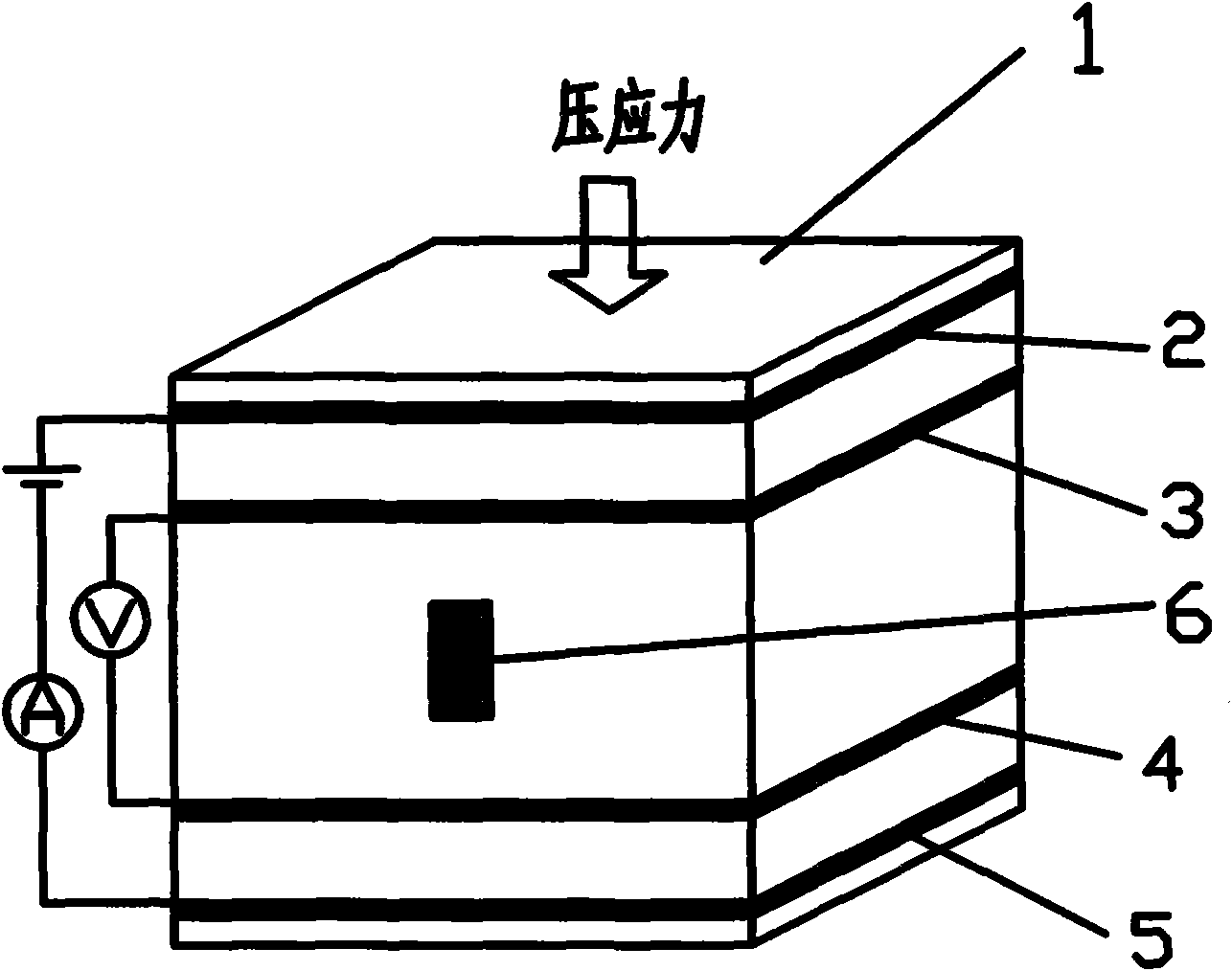

CCCW-mixing carbon fiber graphite smart concrete and application thereof

InactiveCN101602590AImprove performanceLow conductivityWeighing apparatus using elastically-deformable membersForce measurementFiberCarbon fibers

The invention relates to smart concrete, in particular to carbon fiber graphite smart concrete formed by adding CCCW concrete mixture and carbon-fiber-graphite mixing electric conduction phase into base materials comprising silicate cement and sand, wherein the mass ratio of cement to sand is 1 to 1; and the percentage of other components corresponding to the total mass of the cement and the sand: 1 to 2 percent of CCCW concrete mixture, 0.3 to 0.5 percent of carbon fiber, 5 to 25 percent of graphite, 0.1 to 0.2 percent of dispersing agent and 0.01 to 0.015 percent of antifoaming agent. By utilizing the tunneling conducting effect between the contact electric conduction of chopped carbon fiber and graphite and the electric conduction phase, the invention forms the electrically conductive concrete with smart property, and has the advantages of favorable electric conduction, high mechanical property, stable electrical conductivity and pressure-sensitivity, simple preparation, lower price, and the like; and the material can be utilized for manufacturing a concrete structure sensor element, can be used for the effective execution of the health supervision of the concrete structure and can be used for weighing cars, etc.

Owner:WUHAN UNIV OF TECH

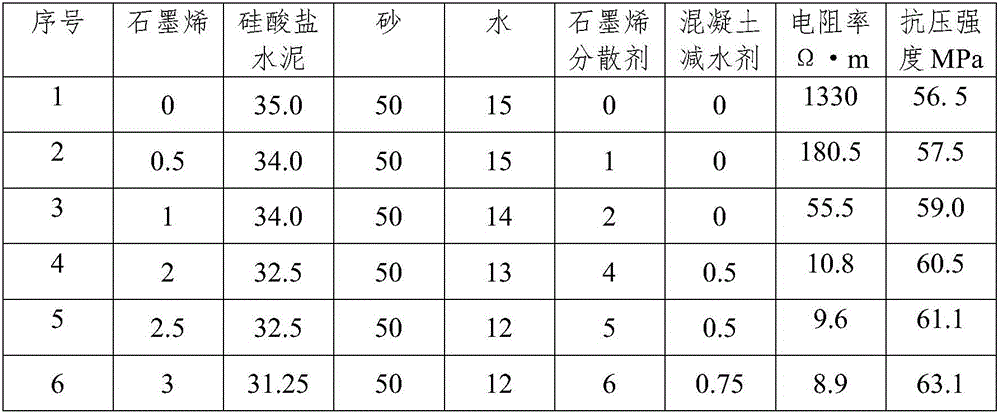

Graphene electric-conduction concrete

Provided graphene electric-conduction concrete comprises silicate cement and sand, and is characterized in that the graphene electric-conduction concrete is formed by adding graphene as an electric conduction phase, and the compositions comprise, relative to the total mass of cement and sand, 0.05-3 parts of graphene, 0.5-6 parts of a graphene dispersant, and 0-0.75 part of a water reducer for concrete. The graphene electric-conduction concrete possesses characteristics of good electric conductivity, high mechanical strength, stable electrical resistivity and good durability, and is applicable to electric heating ground surfaces, floors, and snow and ice thawing and the like.

Owner:GUANGZHOU UNIVERSITY

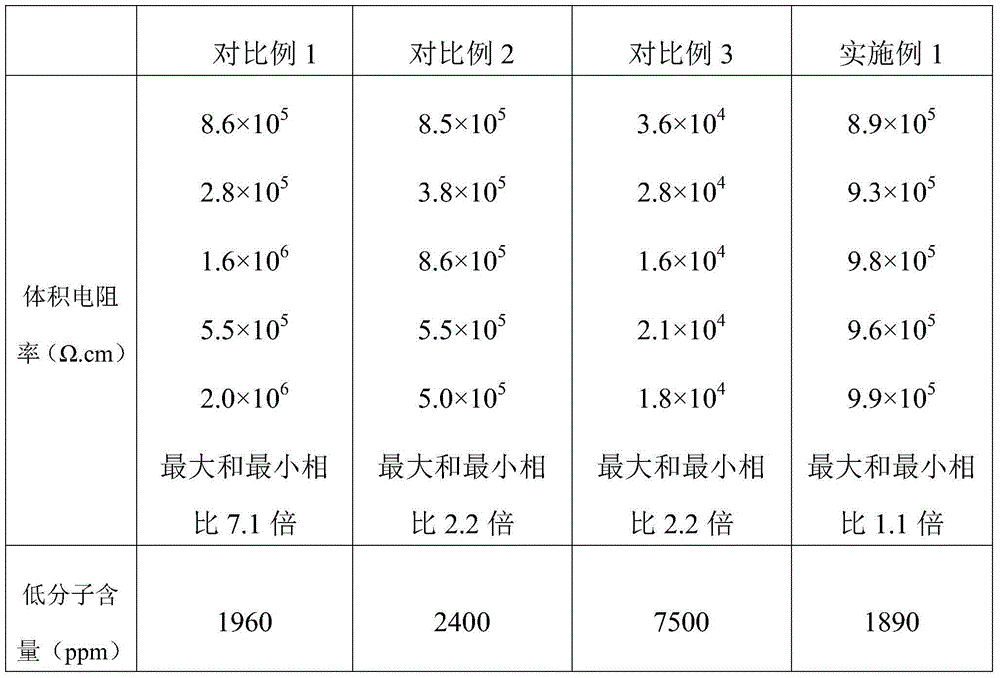

Preparation method of liquid silicone rubber composition

The invention relates to a preparation method of a liquid silicone rubber composition. The preparation method includes mixing polydimethylsiloxane, silica powder, magnesium carbonate, silane modificated conductive carbon black, fumed silica and treating agent to obtain a mixture, subjecting the mixture to heat treatment at 100-150 degrees for 0.5-5h, heating the mixture to 120-160 DEG C, evacuating the mixture under vacuum of -0.04--0.1MPa for 2-6hs, and grinding the mixture 2-4 times to obtain base gum after cooling the same to the indoor temperature; adding and mixing polydimethylsiloxane attenuation and platinum catalyst in the base gum at the normal temperature to obtain material A; adding and mixing polydimethylsiloxane attenuation, cross-linking agent and negative catalyst in the base gum at the normal temperature to obtain material B; mixing the material A and the material B, by weight, in the proportion of 1:1, subjecting the mixture to solidification at 100-200 DEG C for 0.1-50h to obtain the liquid silicone rubber composition. The preparation method is simple, and the liquid silicone rubber contains ultra-low low-molecular-weight content and is high in compression permanent deformation rate.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

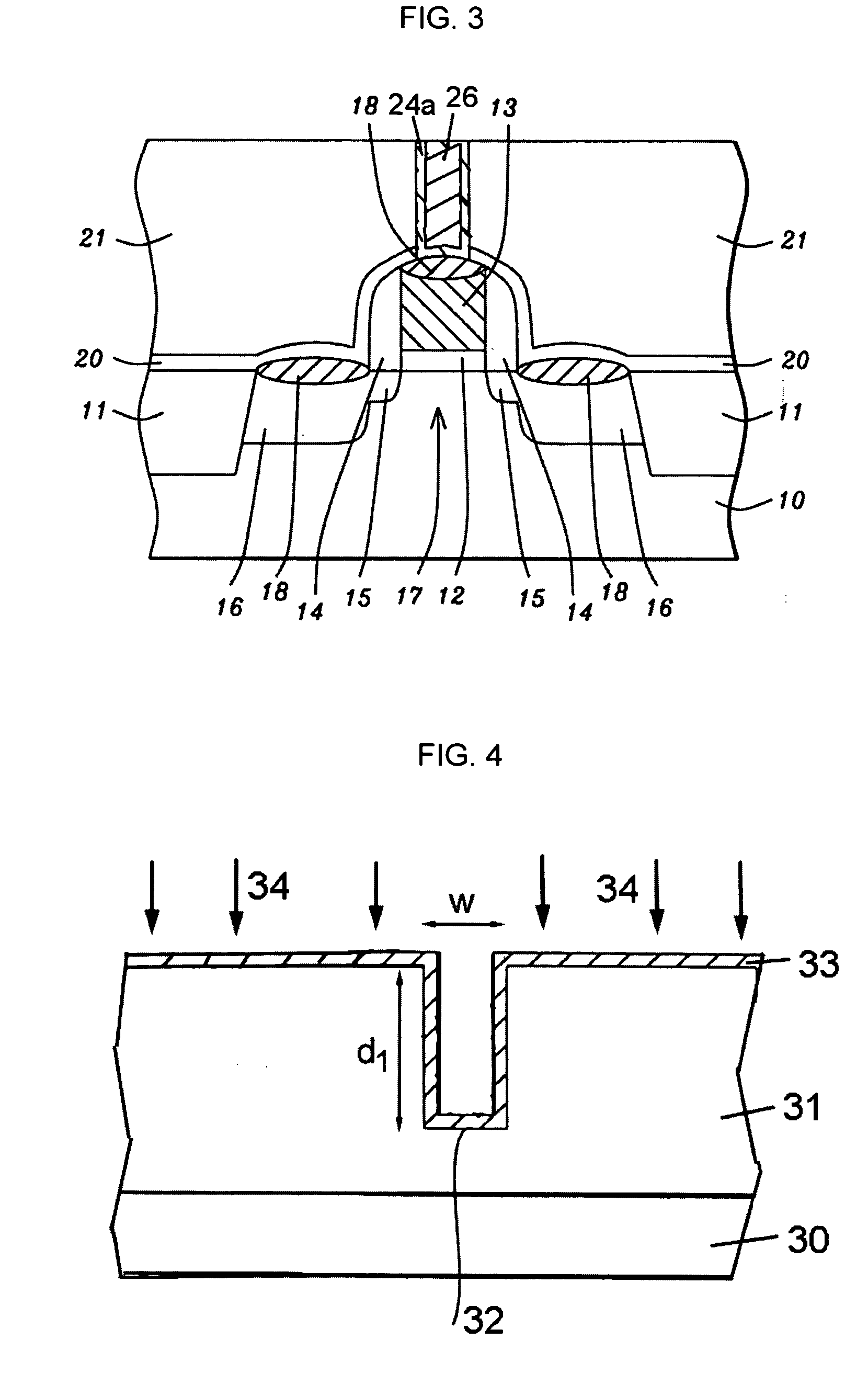

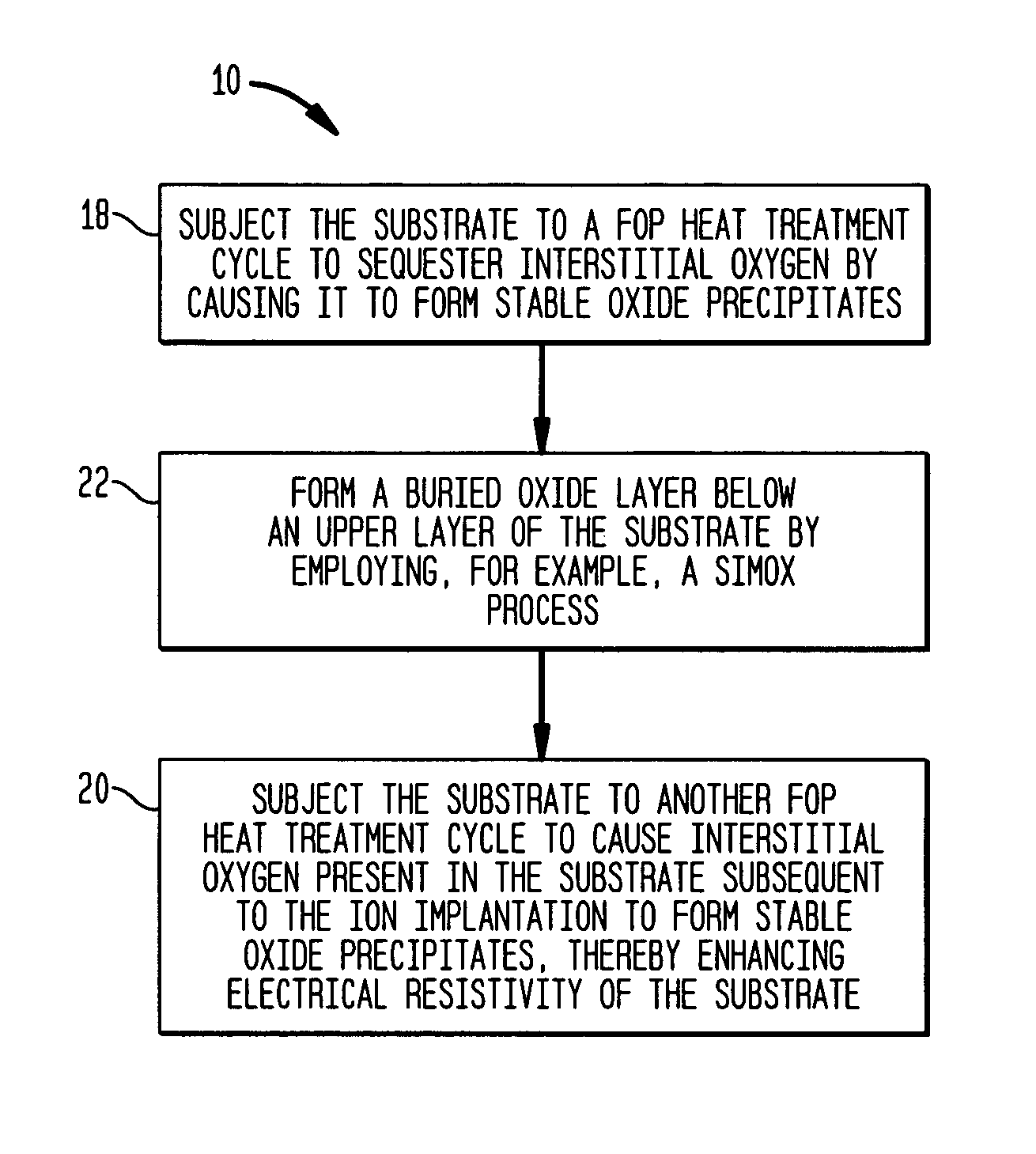

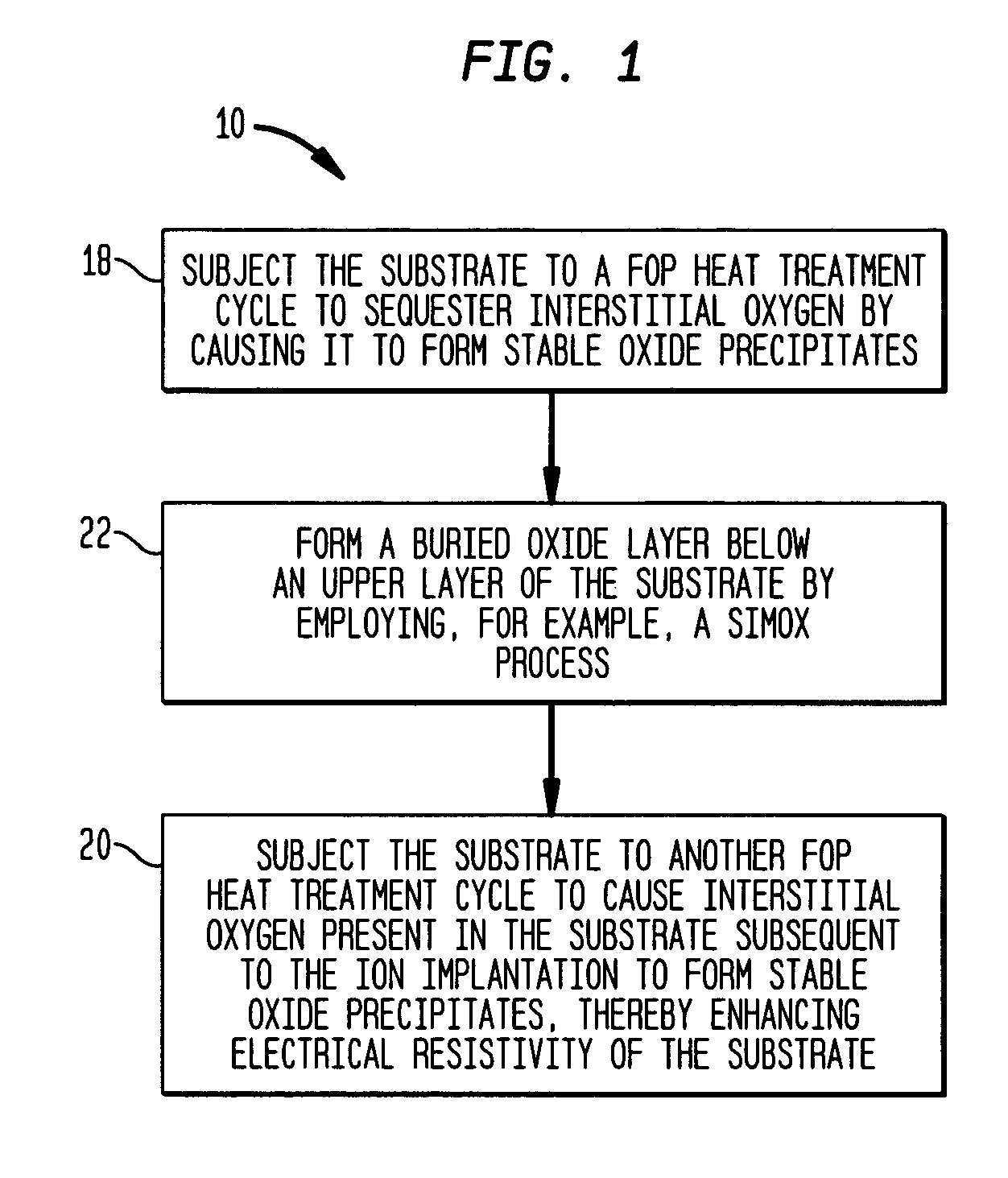

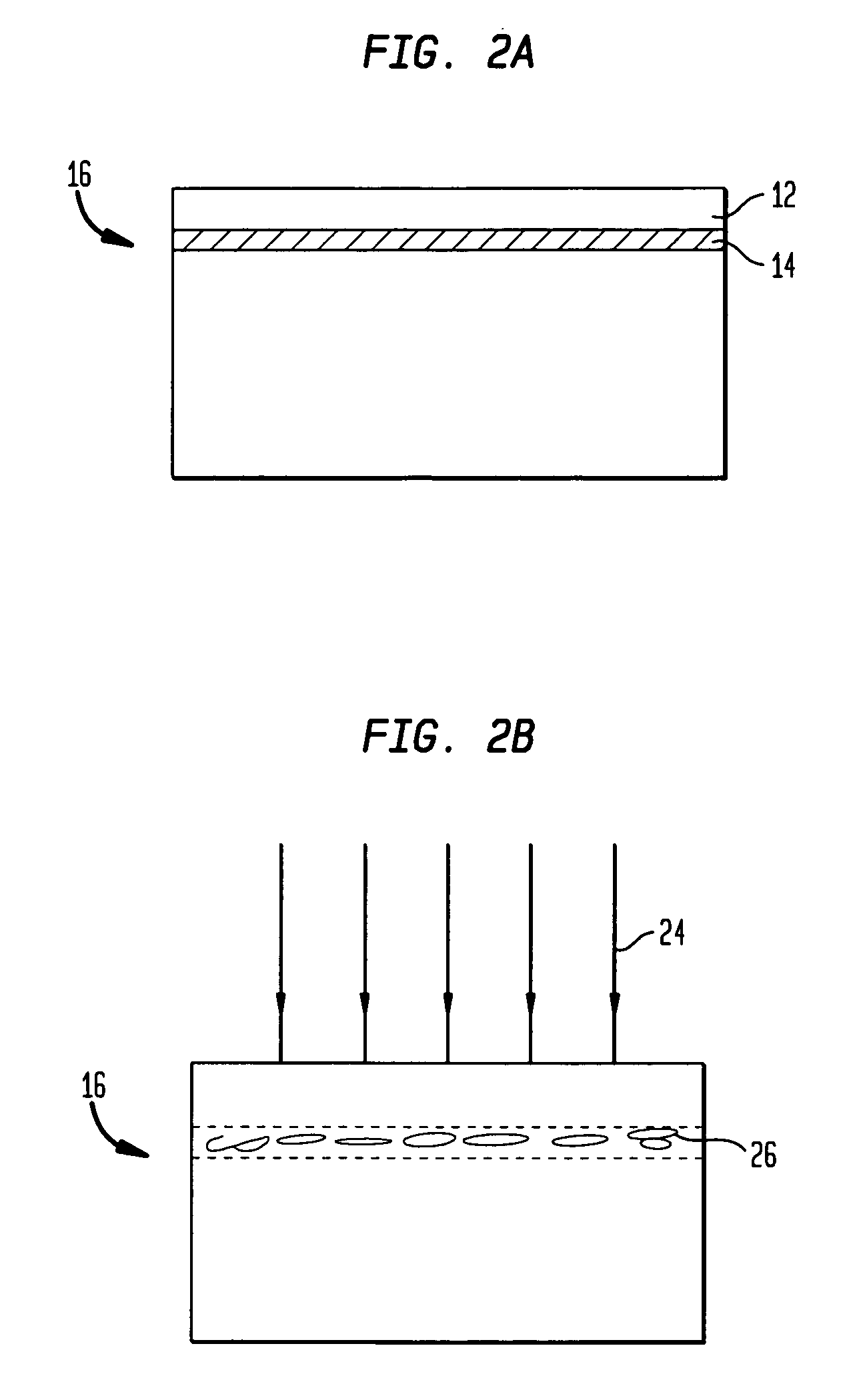

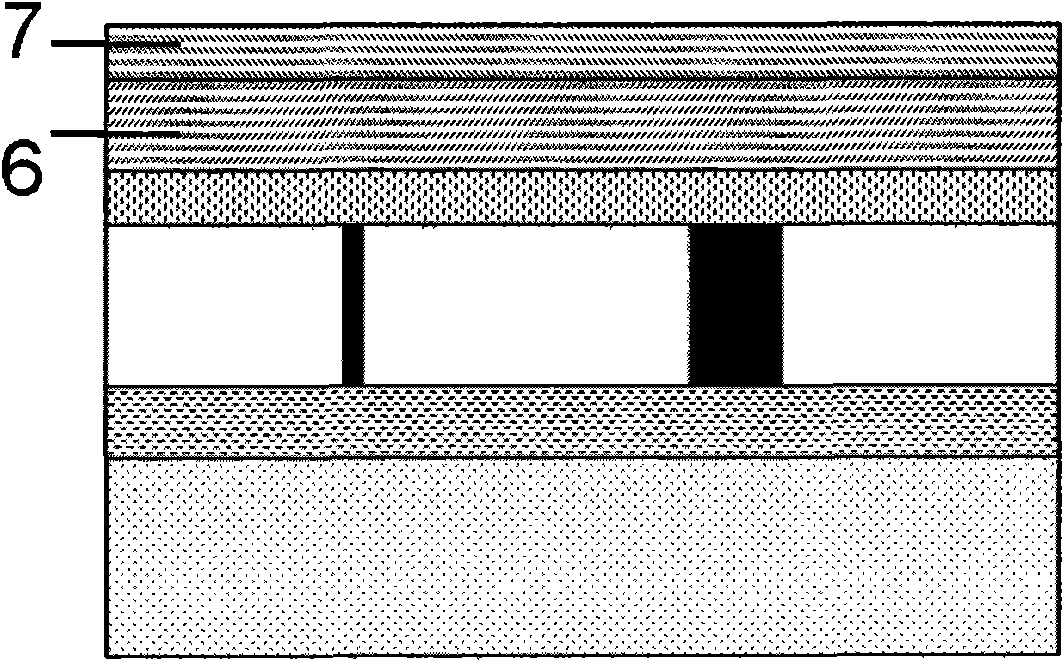

Method of producing a high resistivity SIMOX silicon substrate

InactiveUS7112509B2High resistivityStable resistivitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsHigh resistivity

The present invention provides a method for generating silicon-on-insulator (SOI) wafers that exhibit a high electrical resistivity. In one embodiment of a method according to the teachings of the invention, a SIMOX process is sandwiched between two Full Oxygen Precipitation (FOP) cycles that sequester interstitial oxygen present in the substrate in the form of oxide precipitates, thereby enhancing the electrical resistivity of the susbtrate.

Owner:IBIS TECH +1

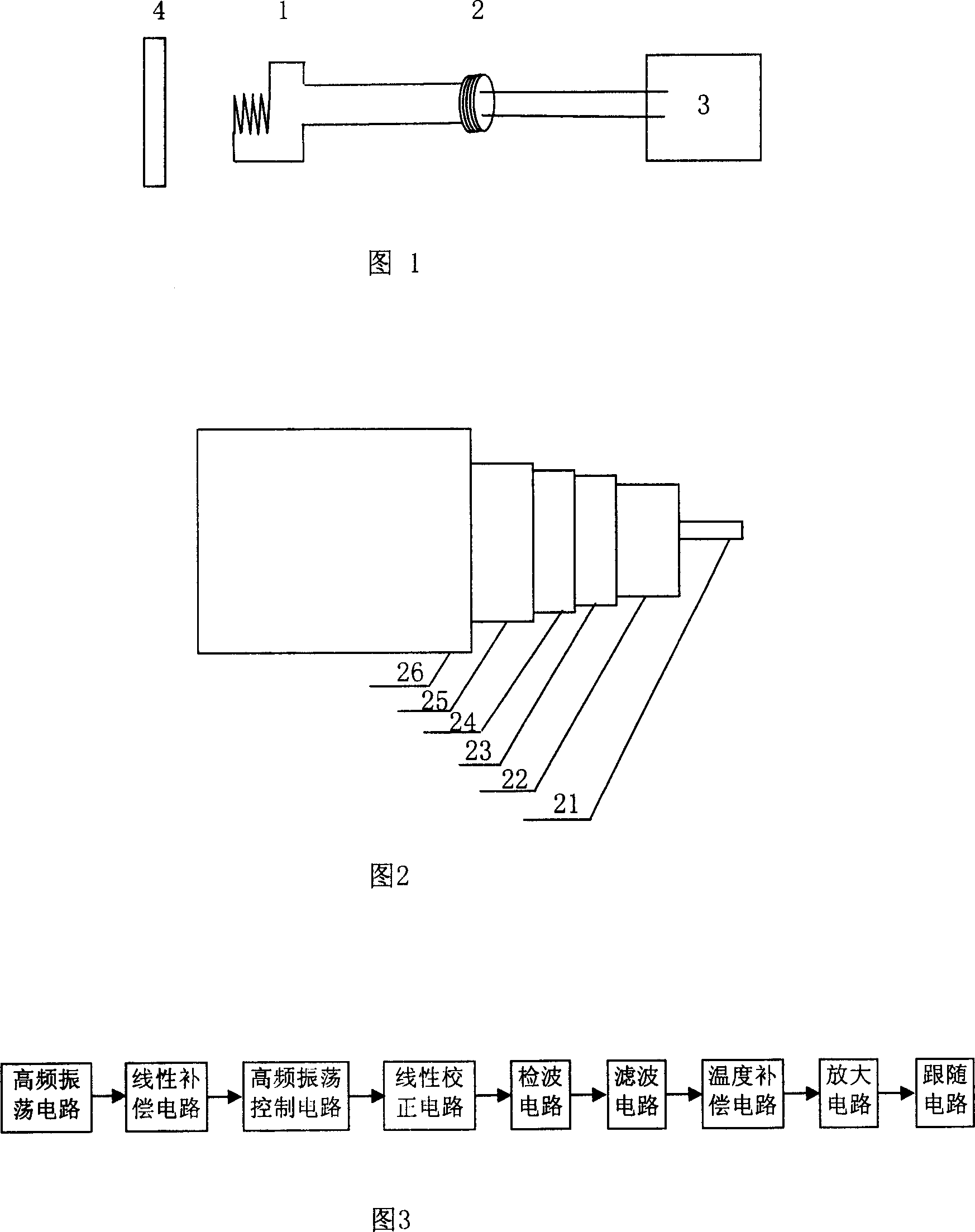

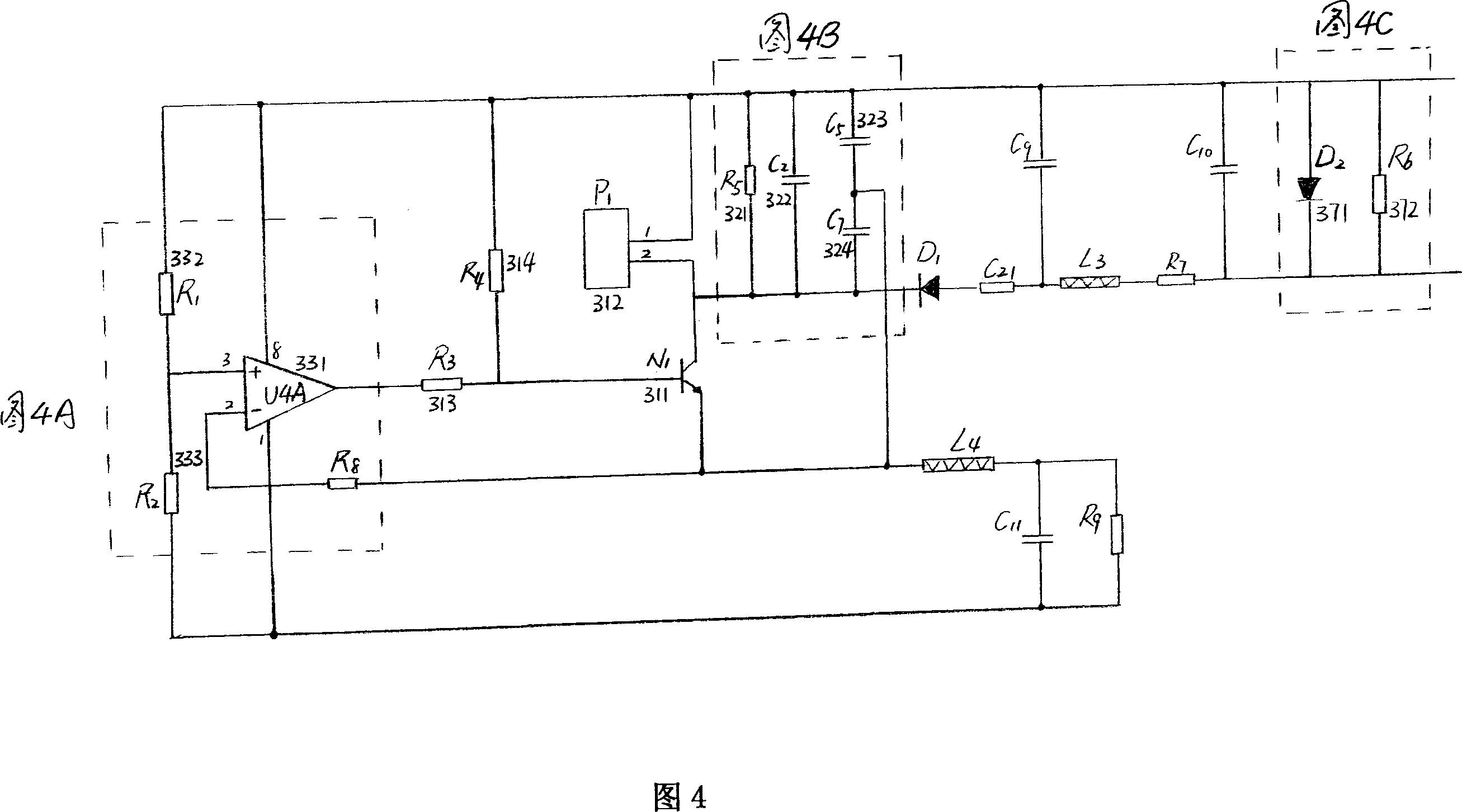

Fixed-frequency AM electric vortex displacement sensor of linear automatic compensation

InactiveCN101000229AAutomatic Compensation for Resistivity VariationsReduce the impactCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsFixed frequencyHigh frequency

The invention relates to linearity auto-compensation fixed frequency amplitude modulation electrical eddy current displacement transducer. It includes probe, coaxial cable, and preamplifier circuit. The coil of the probe adopts palladium-silver enameled wire. The coaxial cable structure includes inner conductor, inner insulating layer, inner shielding layer, isolating layer, outer shielding layer and isolating protective sleeve. The inner conductor is formed by many Mn, Cu, and Ag alloy wires. Inner and outer shielding layers are formed by gold-plate copper wire net. The others are made by polytetrafluoroethylene. The preamplifier circuit includes high frequency oscillating circuit, linearity compensation circuit, high frequency oscillating control circuit, linearity correcting circuit, detection circuit, filter circuit, temperature compensation circuit, amplification circuit, and follower. The invention has outstanding temperature compensation character, can ensure transducer precision in big temperature difference range by stabilizing its non-linear degree in small area.

Owner:SHANGHAI CHIJIE ELECTRONICS

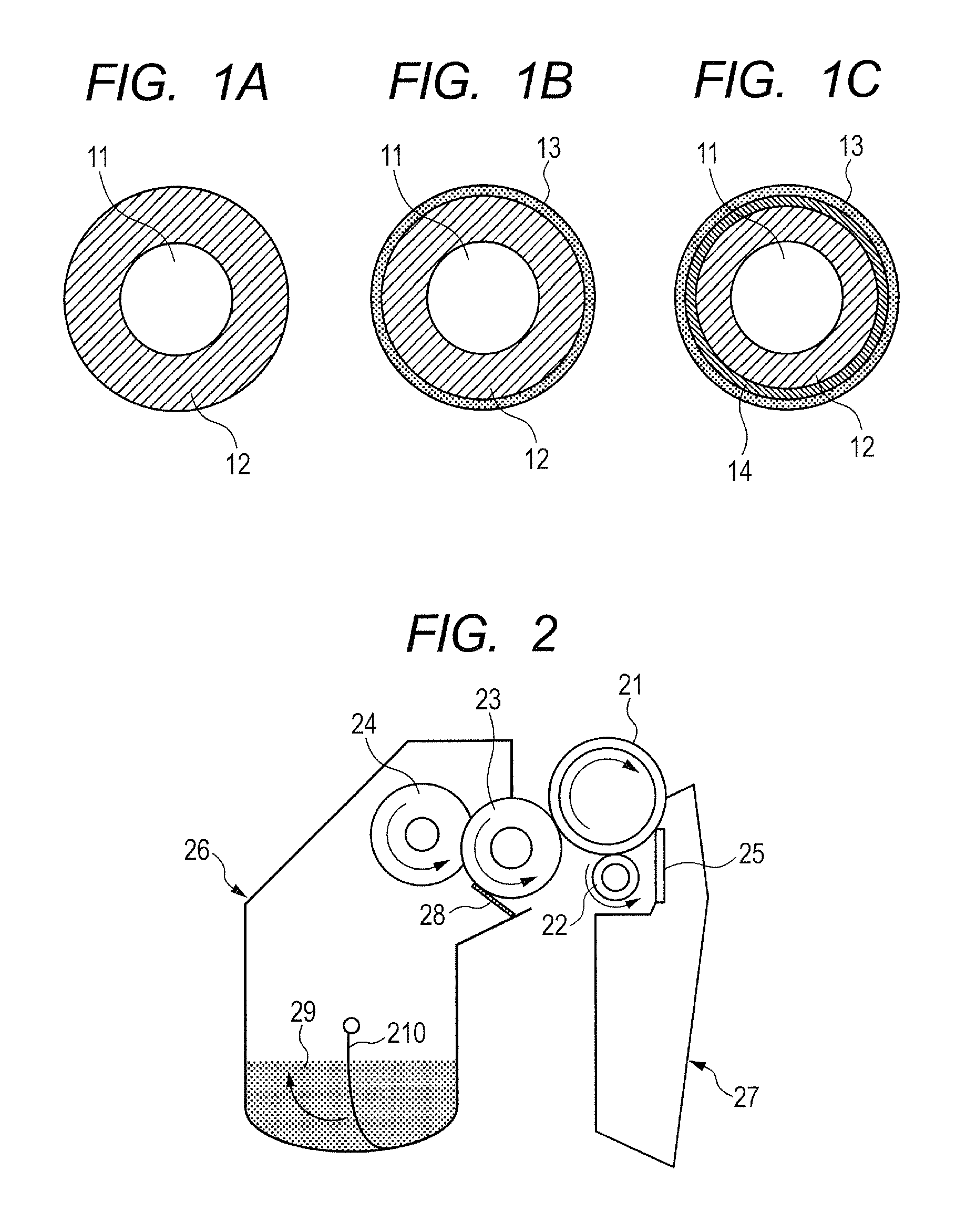

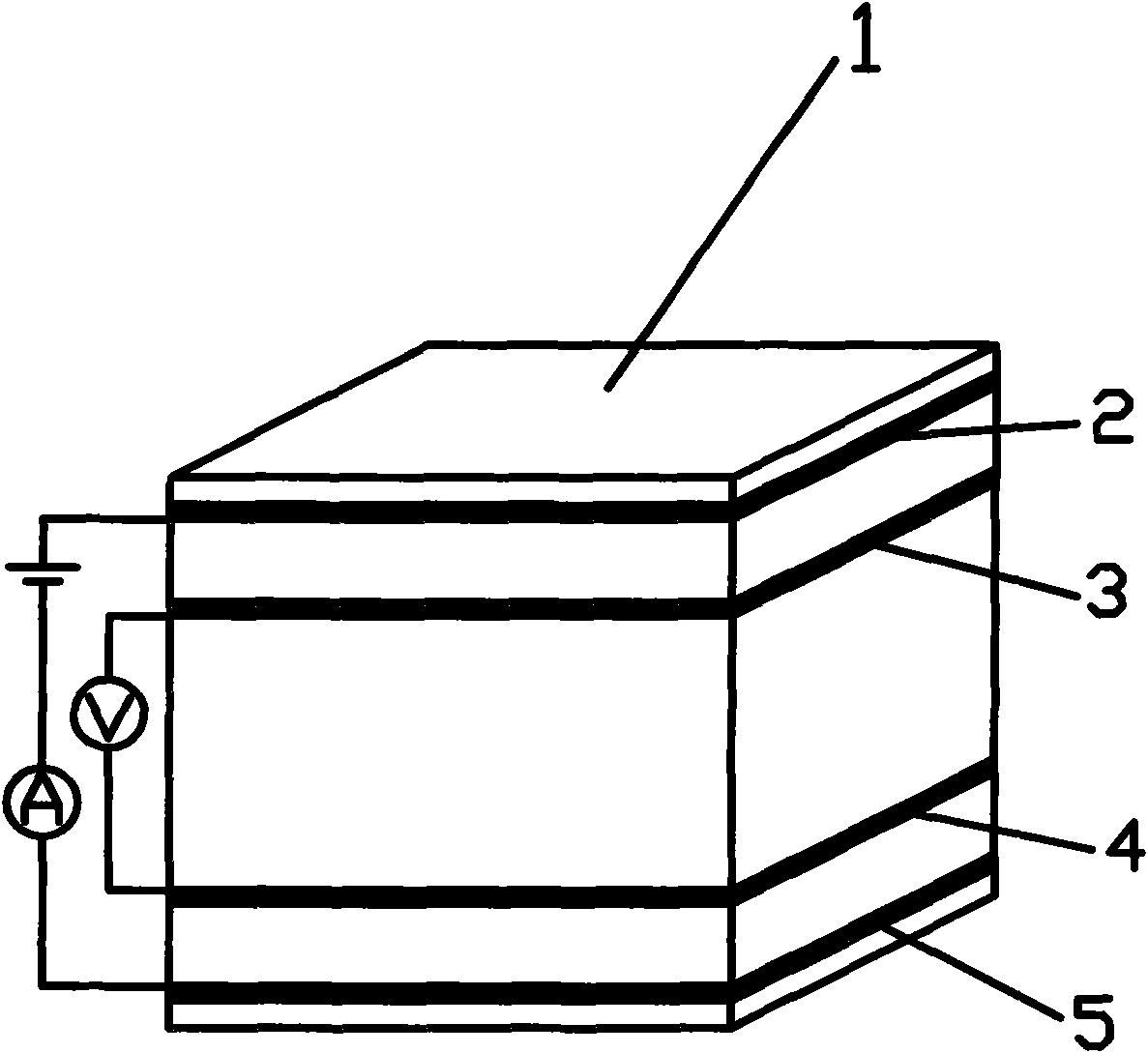

Conductive composition, electrophotographic belt, image forming apparatus, and method of manufacturing conductive composition

ActiveUS20110249994A1Extend your lifeStable resistivityNon-metal conductorsConductive materialCarboxylic acidImaging equipment

A conductive composition including a matrix resin comprising a thermoplastic resin, a conductive agent comprising a carbon black having an amine value of 1 to 100 mgKOH / g, and a stiffening agent comprising an acid anhydride, a carboxylic acid, or a compound having an epoxy group.

Owner:RICOH KK

CCCW-mixing graphite smart concrete and application thereof

InactiveCN101602591AImprove performanceImprove mechanical propertiesWeighing apparatus using elastically-deformable membersForce measurementMass ratioGraphite

The invention relates to smart concrete, in particular to CCCW-mixing graphite smart concrete formed by adding CCCW concrete mixture and graphite into base materials comprising silicate cement and sand, wherein the mass ratio of cement to sand is 1 to 1; and other components in percentage by weight to the total mass of the cement and the sand are as follows: 1 to 2 percent of CCCW concrete mixture and 5 to 25 percent of graphite. By utilizing the tunneling conducting effect between the contact electric conduction of the graphite and the electric conduction phase, the invention forms the graphite electrical conduction concrete with smart property, and has the advantages of favorable electric conduction, high mechanical property, stable electrical conductivity and pressure-sensitivity, simple preparation, lower price, and the like; and the material can be utilized for manufacturing a concrete structure sensor element, can be used for the effective execution of the health supervision of the concrete structure and can also be used as an industrial anti-static material, an electrical engineering material and an electrothermal material.

Owner:WUHAN UNIV OF TECH

Preparation method of large-size silicon nitride crucible

The invention discloses a preparation method of a large-size silicon nitride crucible. According to the method, (1) silicon nitride powder, a dispersing agent, sintering aids, a binding agent and a solvent are well mixed, such that a slurry is obtained; (2) the slurry is added into a mold cavity of a gypsum mold under stirring; the mold is placed in an environment with constant temperature and constant humidity, such that the mold can absorb and discharge water; and a molded cured blank is obtained; (3) a mold core and side molds of the mold are removed, and the molded cured blank is placed in a curing furnace, such that the product is cured and dried, and a green body is obtained; (4) the green body is placed in a gas pressure sintering furnace, and is subjected to segmented sintering; when sintering is finished, the temperature is reduced, the pressure is released and the product is fetched from the furnace, such that the silicon nitride crucible is obtained. According to the invention, silicon dioxide and magnesium silicon nitride are adopted as sintering aids, such that the prepared silicon nitride crucible has low oxygen impurity and metal impurity contents, large bulk density, high high-temperature strength, and large size. The crucible can be widely applied in various non-ferrous metal smelting and silicon crystal ingot casting. The preparation method is simple to operate, and is easy to popularize.

Owner:烟台同立高科新材料股份有限公司

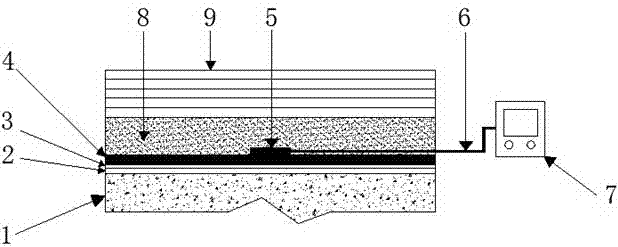

Carbon fiber floor heating device

InactiveCN104748200AStable chemical propertiesHigh tensile strengthLighting and heating apparatusElectric heating systemFiberTemperature control

The invention discloses a carbon fiber floor heating device. The device comprises an insulation reflecting layer arranged on a floor surface slab, wherein the insulation reflecting layer consists of a floor heating reflecting film and an insulation layer; a carbon fiber floor heating film is arranged at the upper part of an insulation layer of the insulation reflecting layer; a temperature sensor probe is arranged in the middle of the upper part of the carbon fiber floor heating film and communicates with a temperature control instrument through a temperature sensor conductor; the carbon fiber floor heating film is provided with a copper coil tape; the conductor externally connected to the copper foil tape is connected with one output voltage end of a transformer; the input voltage at the other end of the transformer is connected with a temperature control instrument inserting hole; a temperature control instrument socket is arranged at an external power supply. According to the device adopting the structure above, a carbon fiber cloth strip can be applied to an indoor floor heating device; good heating effect can be achieved; the operation is convenient and quick; the green and cleanness are achieved; the features of high energy consumption and low efficiency of the traditional heating manner can be overcome; in addition, indoor temperature can be preset under the control of the temperature control instrument; therefore, a user can use comfortable, and meanwhile, the energy waste can be reduced, and as a result, the energy consumption is reduced.

Owner:山东天意高科技有限公司

Conductive oxide transition layer and phase-changing memory unit with same

ActiveCN101615655AImprove operational reliabilityImprove reliabilityElectrical apparatusDigital storagePhase-change materialHeating efficiency

The invention provides a conductive oxide transition layer and a phase-changing memory unit with same and the phase-changing memory unit comprises a conductive oxide transition layer between a bottom electrode and a chalcogenide film with the thickness controlled to 2-10nm. The conductive oxide transition layer of the invention has good thermal stability, has good adhesivity to medium material, chalcogenide and W electrode, has lower thermal conductivity so that the heat efficiency of devices can be effectively improved and has better electroconductibility so that a big capacitor can be avoided to introduce. By planting the new conductive oxide transition layer material, the heating efficiency of devices can be improved effectively so that the operative voltage can be reduced, the diffusion of Sb and Te elements to the direction of the bottom W electrode in the phase-changing material can be avoided, and the chemical reaction between the transition layer and the bottom W electrode and the phase-changing material can not be performed, thus ensuring the consistency of the operation in the duty-cycle operation of devices and increasing the device life of devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Semiconductive resin composition

InactiveUS20100173108A1Large energyEasily raveledLayered productsConductive materialFiberPolymer science

The invention relates to a semiconductive resin composition containing at least two kinds of conductive fillers, wherein the difference in threshold values of percolation between at least two kinds of the conductive fillers is within a range of 10 to 50 mass %. The semiconductive resin composition of the present invention can be used widely in various form of molded products, such as component used for transport in a clean room, spin chuck, IC test socket, various rollers installed in copier, seamless belt, bearing, antistatic fiber, member for electrostatic coating, fuel tube, part around fuel or chemical tube.

Owner:SHOWA DENKO KK

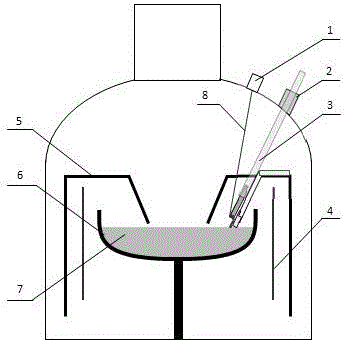

Manufacturing method of N type/P type monocrystalline silicon crystal ingot

InactiveCN105951172ASolve the problem of rapid decline in resistivity at the end of growthReduce the fluctuation range of axial resistivityPolycrystalline material growthBy pulling from meltLaser arrayOptoelectronics

The invention provides a manufacturing method of an N type / P type monocrystalline silicon crystal ingot. During the lifting growth of the crystal ingot, monocrystalline silicon strips containing uniform distribution opposite type conducting elements (sub doping elements) are molten through laser arrays; the sub doping elements are added into the flux in a continuous and adjustable way; carriers increased in the crystal ingot due to the fast rise of the concentration of main doping elements in flux caused by dephlegmation are counteracted, so that the problem of fast reduction of the electrical resistivity in a late growth stage of the crystal ingot growth is solved. By precisely controlling the addition quantity and the addition speed of the sub doping elements, the carrier density in the crystal ingot in a new crystallization region is stabilized, so that the electrical resistivity of the new crystallization region is stabilized; the fluctuation amplitude of the axial electrical resistivity of the whole crystal ingot is reduced; the utilization rate of the crystal ingot and the electric performance of wafers are improved.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

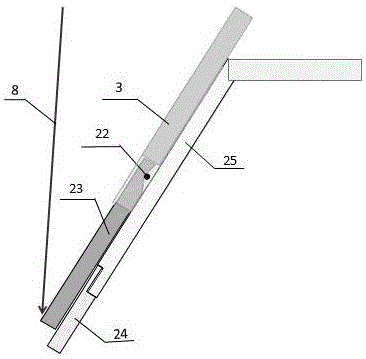

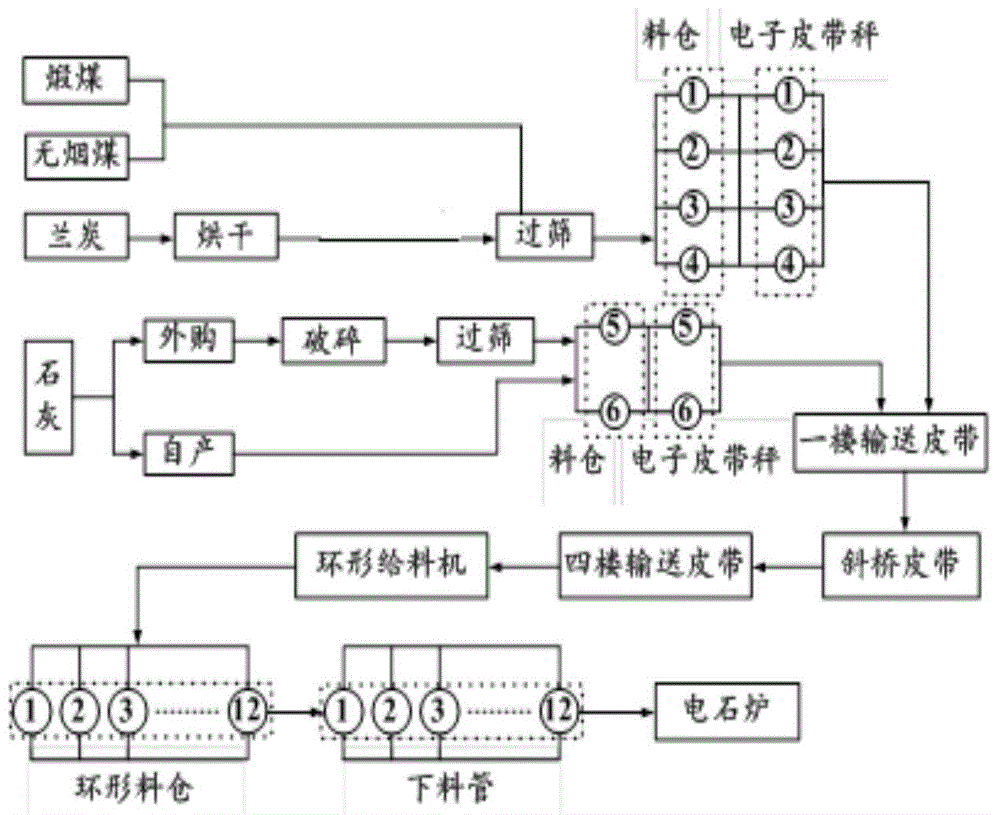

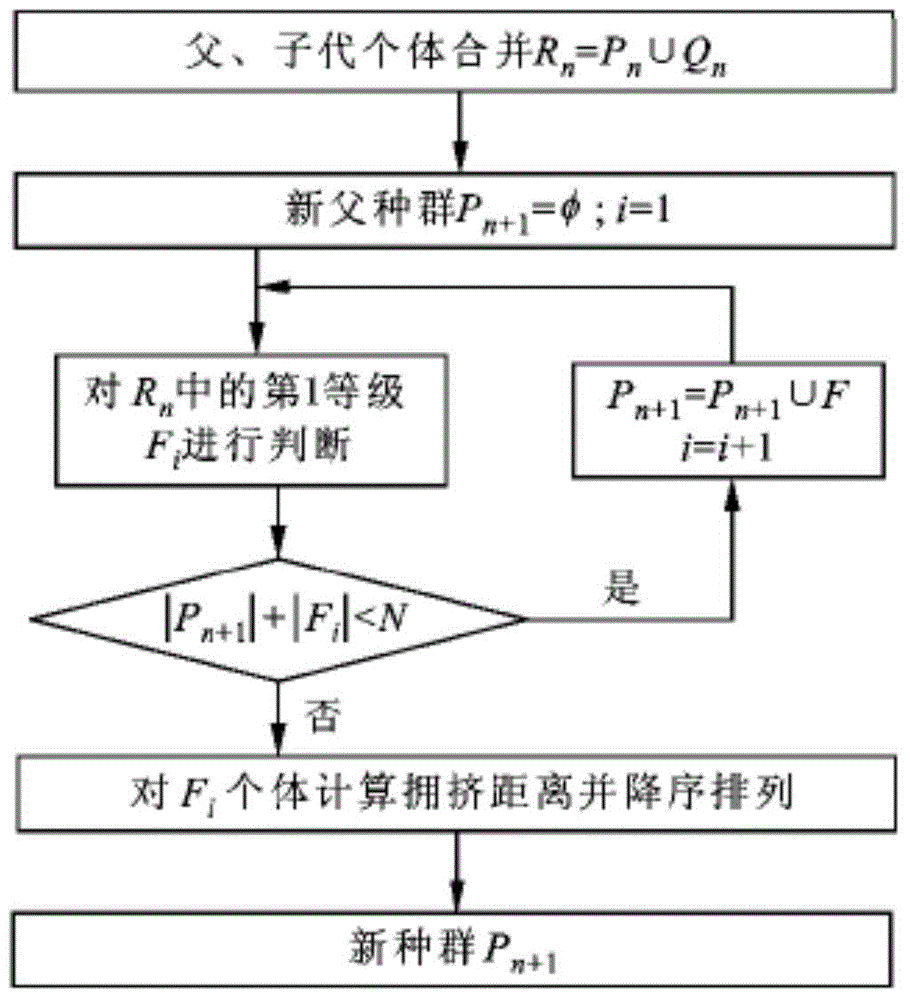

Controlling method for burdening of calcium carbide production

InactiveCN103950930AGuaranteed tasteImprove furnace conditionCalcium carbideChemical compositionMathematical model

The invention relates to a controlling method for burdening of calcium carbide production, and belongs to the technical field of calcium carbide production. According to the influences of resistivity and permeability of material on smelting and with the maximum permeability and resistivity as optimization objectives, a mathematical model for optimization burdening is established; and through the calculation of optimization burdening, the optimum charging burden is obtained; chemical composition of the charging burden is controlled, so that the chemical composition of the charging burden can meet the quality requirements for calcium carbide production, and stability of chemical composition of the charging burden is maintained; and on the promise of ensuring quality of calcium carbide, optimization calculation of resistivity and permeability of the charging burden are conducted, and influence of other constraints are fully considered, so as to improve the furnace condition for calcium carbide production.

Owner:STATE GRID CORP OF CHINA +2

Waterborne epoxy static-conducting oil-resistant anticorrosive paint and preparation method thereof

ActiveCN114181586AImprove conductivityStable resistivityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEmulsion

The invention relates to a waterborne epoxy static-conducting oil-resistant anticorrosive paint and a preparation method thereof. The paint is composed of a component A and a component B, the component A is prepared from the following components in parts by mass: 50 to 80 parts of water-based nano-silver modified epoxy emulsion, 10 to 20 parts of water-based cosolvent, 2 to 5 parts of water-based elastic carbon nanotube composite conductive mica powder, 1.5 to 5 parts of water-based dispersing agent, 0.4 to 1.2 parts of water-based defoaming agent, 20 to 35 parts of water-based antirust pigment and filler, 0.2 to 0.5 part of water-based thixotropic agent and 10 to 15 parts of deionized water; the component B is a water-based epoxy curing agent and comprises the following components in parts by mass: 50-80 parts of a water-based modified amine curing agent and 2-5 parts of a water-based adhesion promoter; the component A and the component B are uniformly mixed according to the mass ratio of (5-10): 1; the preparation method of the coating comprises the following steps: respectively preparing the component A and the component B, and uniformly mixing the two components according to the ratio. The coating has the characteristics of stable conductivity of an intrinsic conductive coating and excellent conductivity of a doped conductive coating, and the flexibility and corrosion resistance of a paint film on a metal surface and the conductivity of the paint film are improved.

Owner:洛阳双瑞防腐工程技术有限公司

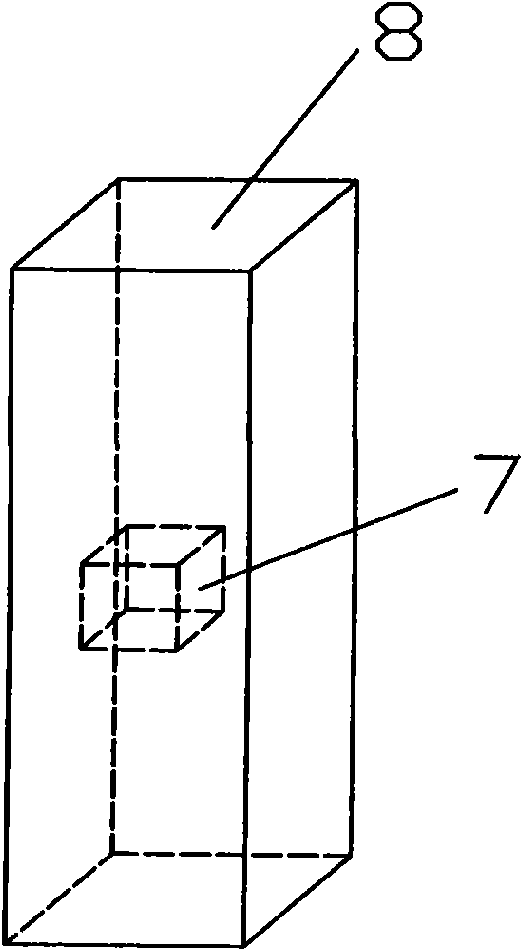

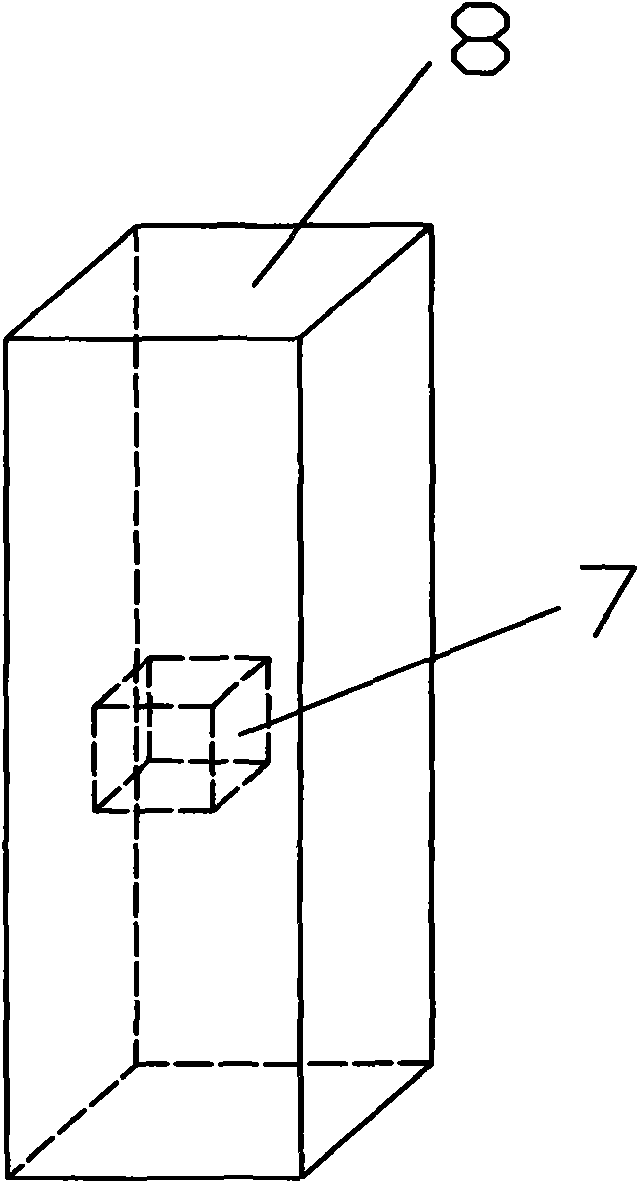

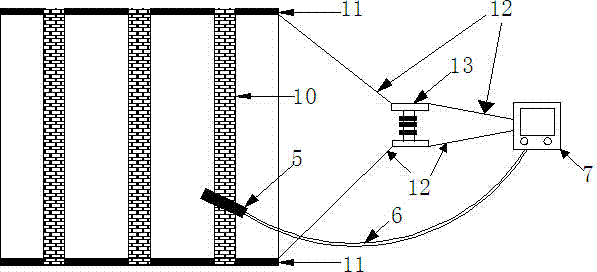

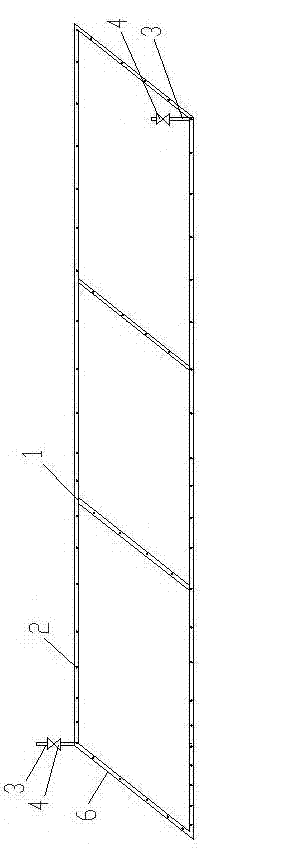

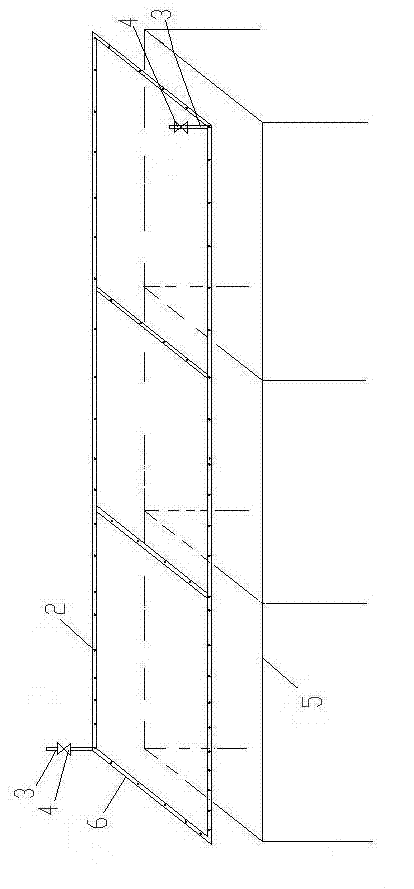

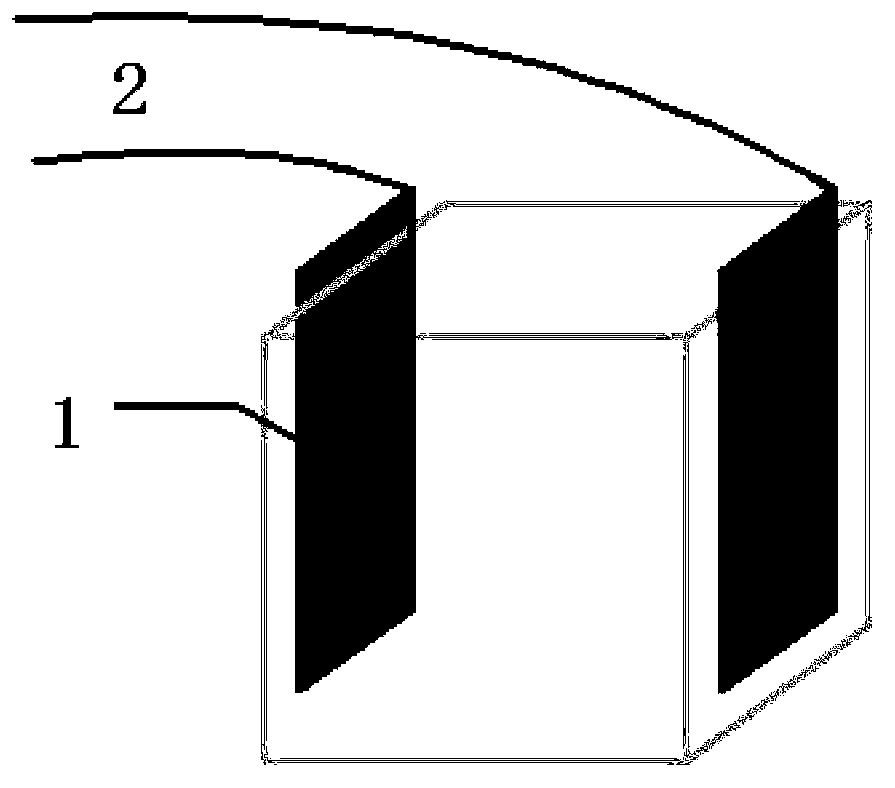

Resistance reducing device for ground grid

InactiveCN102904141AReduce ground resistanceLow resistivityLine/current collector detailsConnection contact member materialGrounding gridSoil resistivity

The invention discloses a resistance reducing device for a ground grid. The resistance reducing device is characterized by comprising a hollow pipe network (1), wherein a water injection port (3) is arranged in the hollow pipe network (1), a valve (4) is arranged on the water injection port (3), the hollow pipe network (1) is formed by connecting hollow pipes (6), and uniformly-distributed pores (2) are arranged at the periphery of the pipe wall of each hollow pipe (6). According to the resistance reducing device, liquid (such as water or resistance reducing agent) is injected to the hollow pipe network through the water injection port, and the soil around the ground grid is wetted, so that the soil resistivity is reduced, and the purpose of reducing the ground resistance is realized.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +3

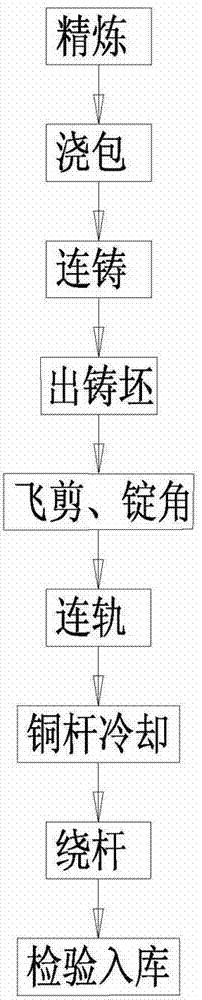

Continuous casting and rolling production technique for copper rods

The invention discloses a continuous casting and rolling production technique for copper rods. The production technique comprises the following steps: A) a plurality of pieces of waste red copper are added in an open hearth for refining; B) qualified copper liquid after refining is discharged out, and flows in a casting ladle through a flowing groove; in the casting process, the temperature of copper water in the casting ladle is 1,110-1,130 DEG C, and the oxygen content is 140-160 PPM; C) the copper liquid in the casting ladle passes through a gate; a stainless steel casting nozzle is continuously and evenly introduced in a crystallization recess of a casting wheel, and is strongly cooled by cooling water for crystallizing; crystals are increased continuously along with the rotation of the casting wheel; D) casting blanks are separated from the casting wheel; E) the unqualified casting blanks are cut off by flying scissors; two acute angles at the upper parts of the casting blanks are removed; F) the casting blocks enter a rolling machine to be rolled into the copper rods; G) oxidization layers on the surfaces of the rolled copper rods are removed through a cleaning and cooling pipe; the temperature is reduced below 80 DEG C; H) the cleaning and cooling pipe is dried through a compressed air spray nozzle, and is conveyed to a rod winder by a clamping roller for rod winding . The production technique can produce the copper rods by using the plurality of pieces of waste copper; the produced copper rods have good quality.

Owner:肇庆市弘达实业有限公司

Method for preparing prebaked anode with high-sulfur coke

InactiveCN103031573AHigh bulk densityEliminate defects with high porosityVolumetric Mass DensityCalcination

The present invention discloses a method for preparing a prebaked anode with high-sulfur coke. The high-sulfur coke is calcinated independently and grinded into powder in the prebaked anode formulation. The method comprises the following steps: A, calcinating the high sulfur coke with a sulfur content of 3-5% at 1250-1350 DEG C in a rotary kiln independently, then storing in a high-sulfur coke dedicated rear-calcination cabin; B, preparing the high-sulfur coke after calcination into powder; and C, dosing the powder with a sulfur content of 3-5% according to a normal production process, wherein the weight ratio of S / Ca in the raw material is (36-62):1. An embodiment of the invention can solve the problems that the molding raw block is low in density and the products are easy to crack in calcinations through calcinating the high sulfur coke independently, storing independently and making into the powder as an anode material; and can improve the oxidation resistance of the anode and reduce the environmental pollution caused by the high sulfur coke in the prior art.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

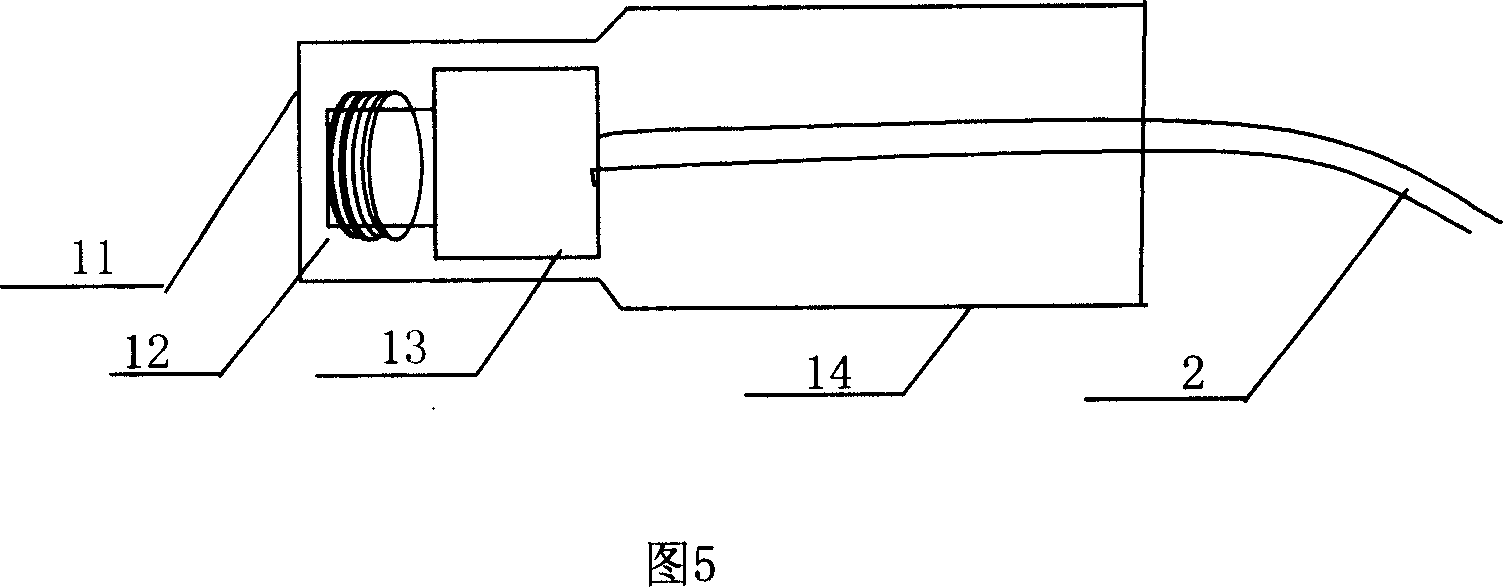

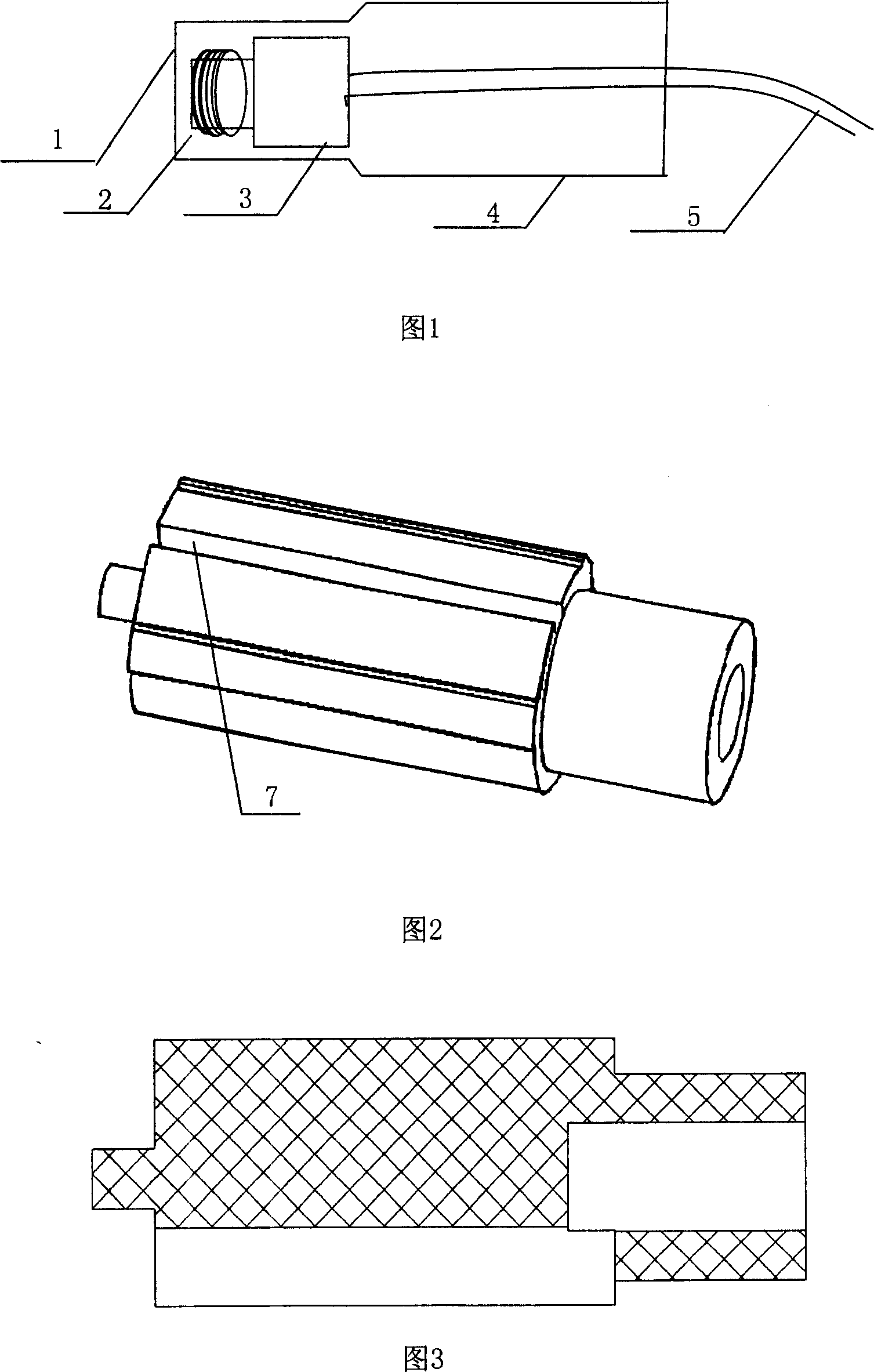

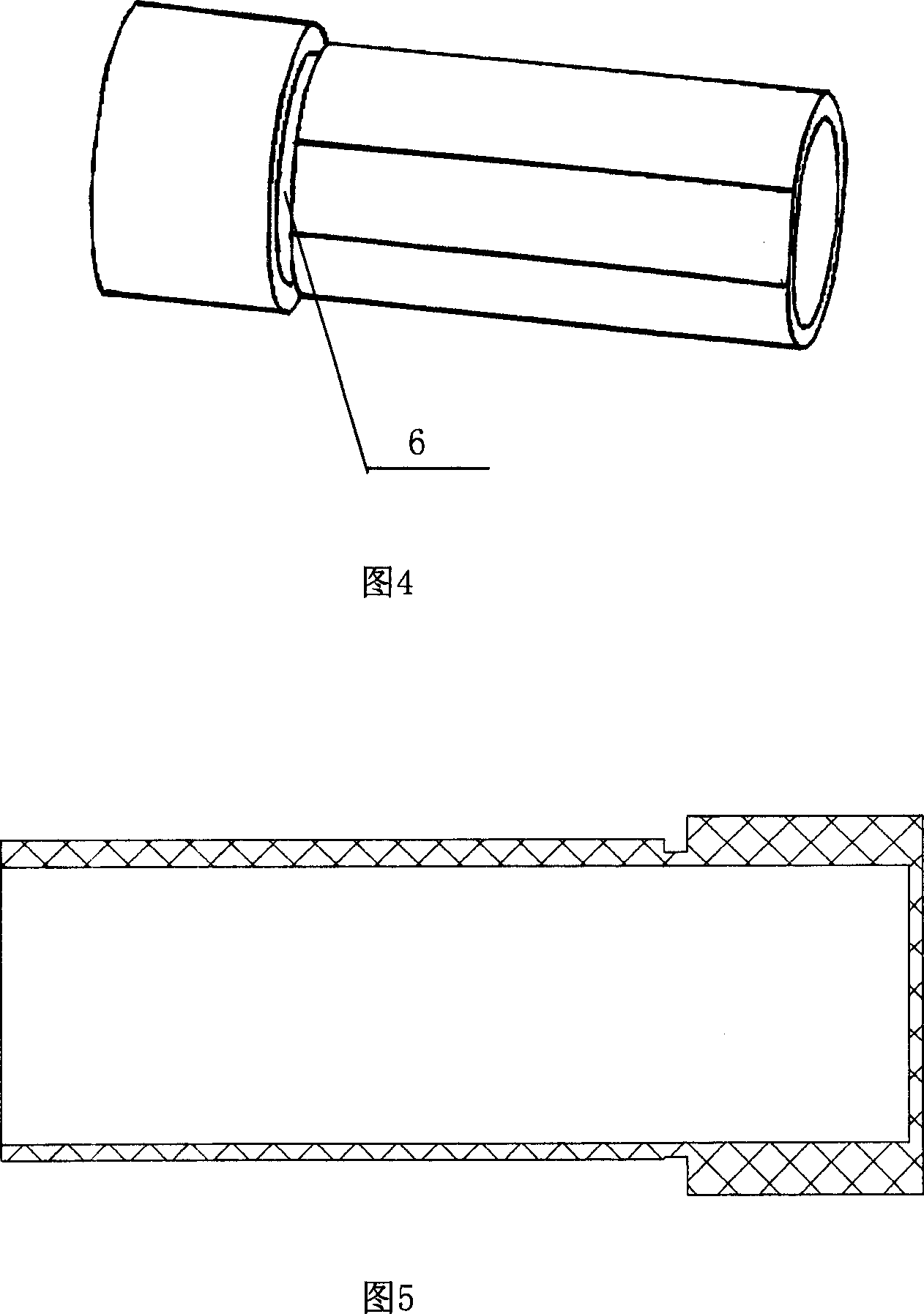

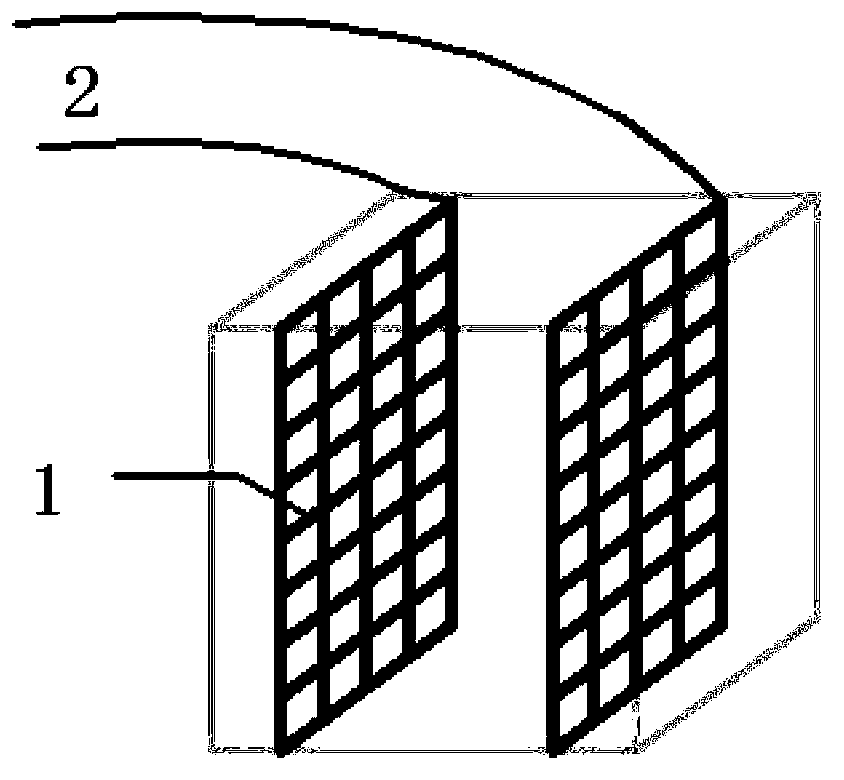

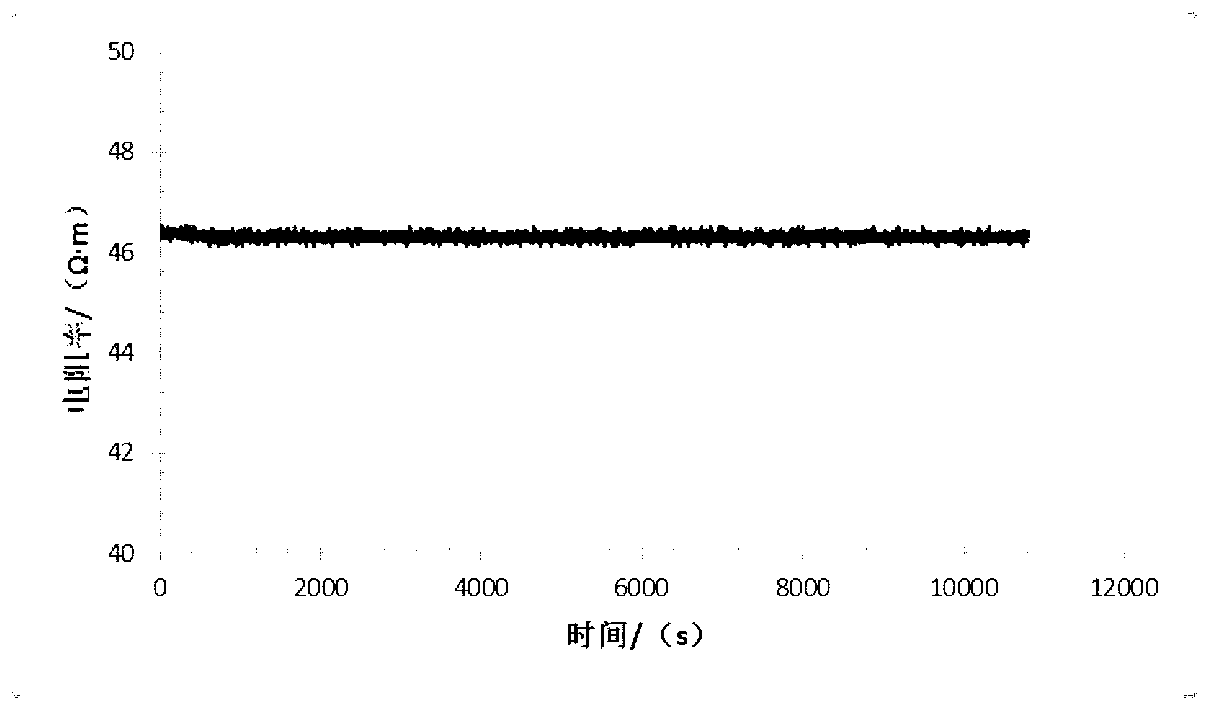

Fixed-frequency AM electric vortex displacement sensor probe of linear automatic compensation

InactiveCN101000230AStable resistivityAutomatic Compensation for Resistivity VariationsCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsElectricityCoaxial cable

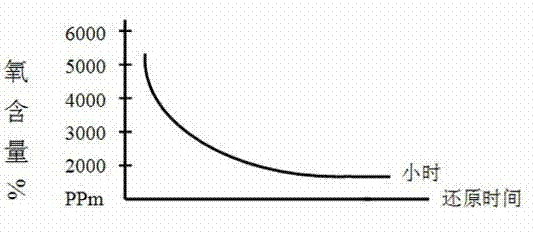

The invention relates to linear auto-compensation fixed frequency amplitude modulation electrical eddy current displacement transducer probe. It includes framework, coil, protecting case, shell, and coaxial cable. The coil is formed by palladium-silver wire with 75-85% palladium and 15-25% silver which are melted at 800 degree centigrade, take shape by cold drawing, has 0.11-0.34mmlinear diameter, 0.6-3.5ohm / m resistivity, 50ppm / degree centigrade resistivity temperature coefficient. The palladium-silver wire has stable resistivity, thus the quality factor Q of the probe can keep stable in big temperature difference range. The linear diameter is confirmed according to skin effect which can automatically compensate its resistivity change caused by temperature.

Owner:SHANGHAI CHIJIE ELECTRONICS

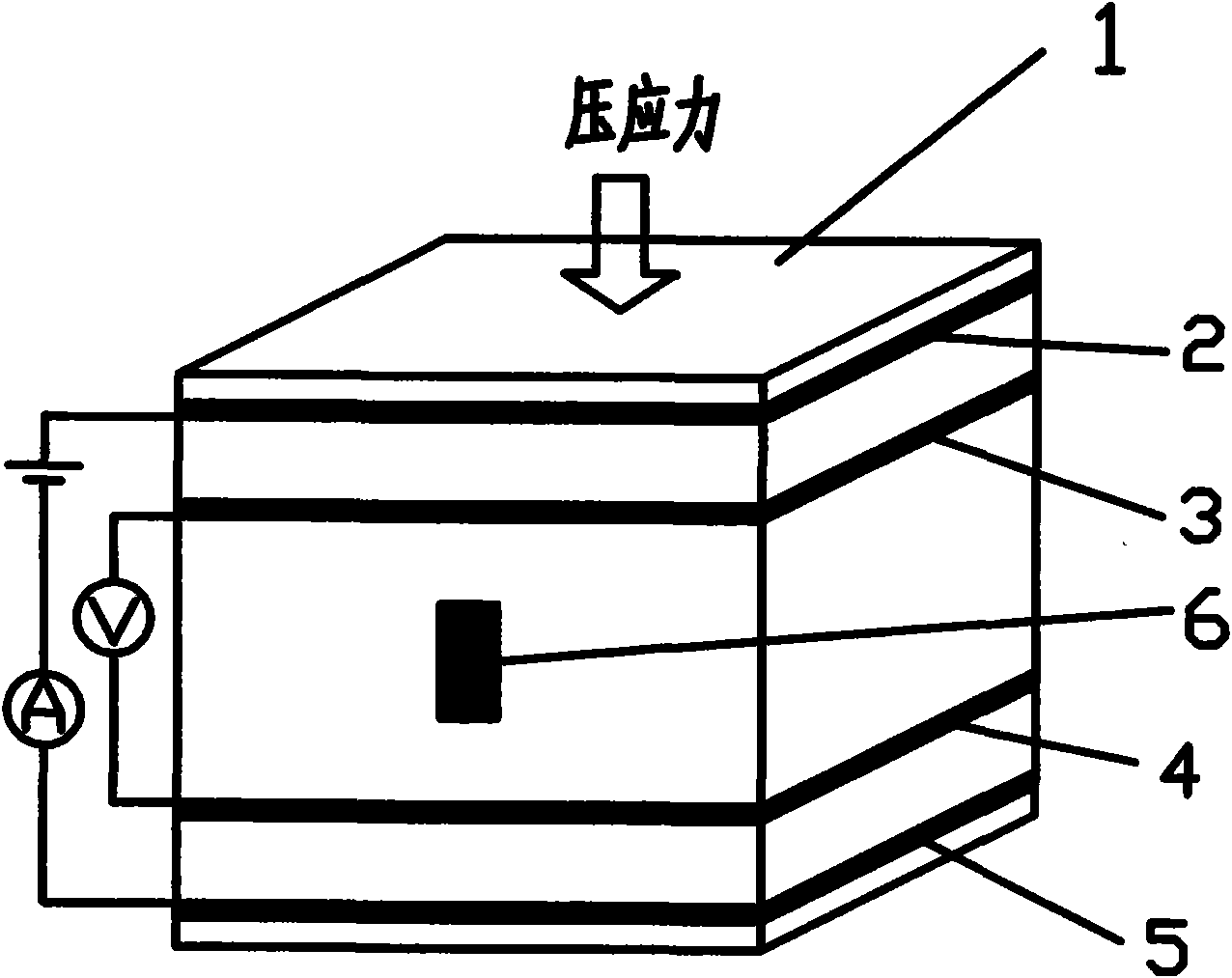

Polyethylene terephthalate (PET)-based composite material capable of sensing stress variation and preparation method thereof

The invention discloses a polyethylene terephthalate (PET)-based composite material capable of sensing stress variation. The composite material comprises a conductive phase functional component and a PET-based material, wherein the conductive phase functional component accounts for 6 to 80 percent of the mass of the PET-based material. The invention also discloses a preparation method of the material. The composite material has the advantages of good deformation coordination performance, high compatibility with a bituminous mixture, stable electrical resistivity, high force-electricity coupling effect sensitivity, strong reversibility and low moisture influence, and the electrical signal test is hardly affected by substrate polarization. The composite material can be applied to stress / strain monitoring of bituminous concrete structures such as road pavements, bridge deck pavements and airport runways, and can also be applied to monitoring of stress / strain in other fields.

Owner:SHANDONG UNIV

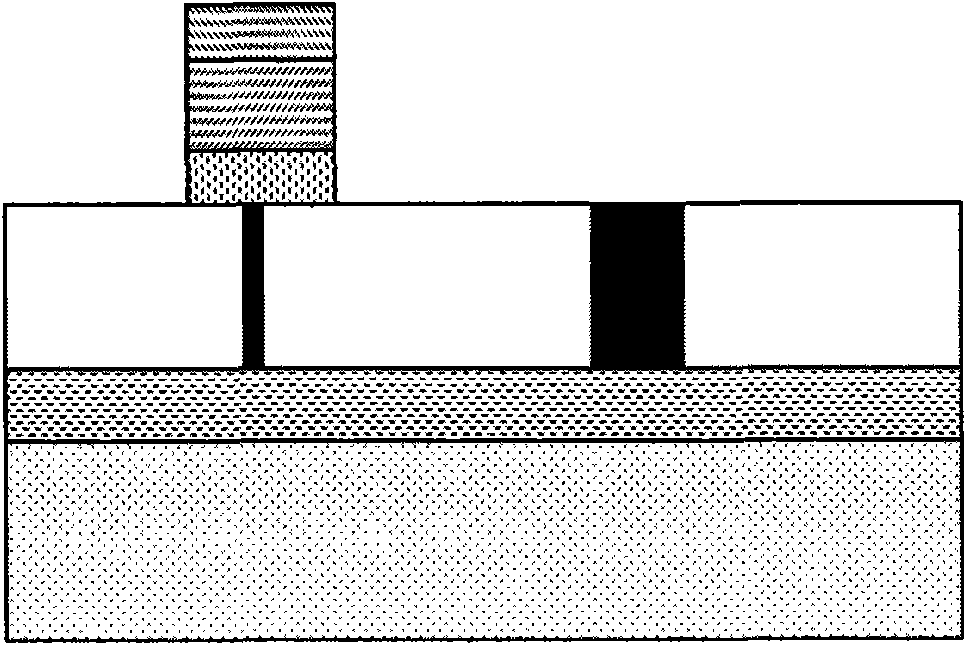

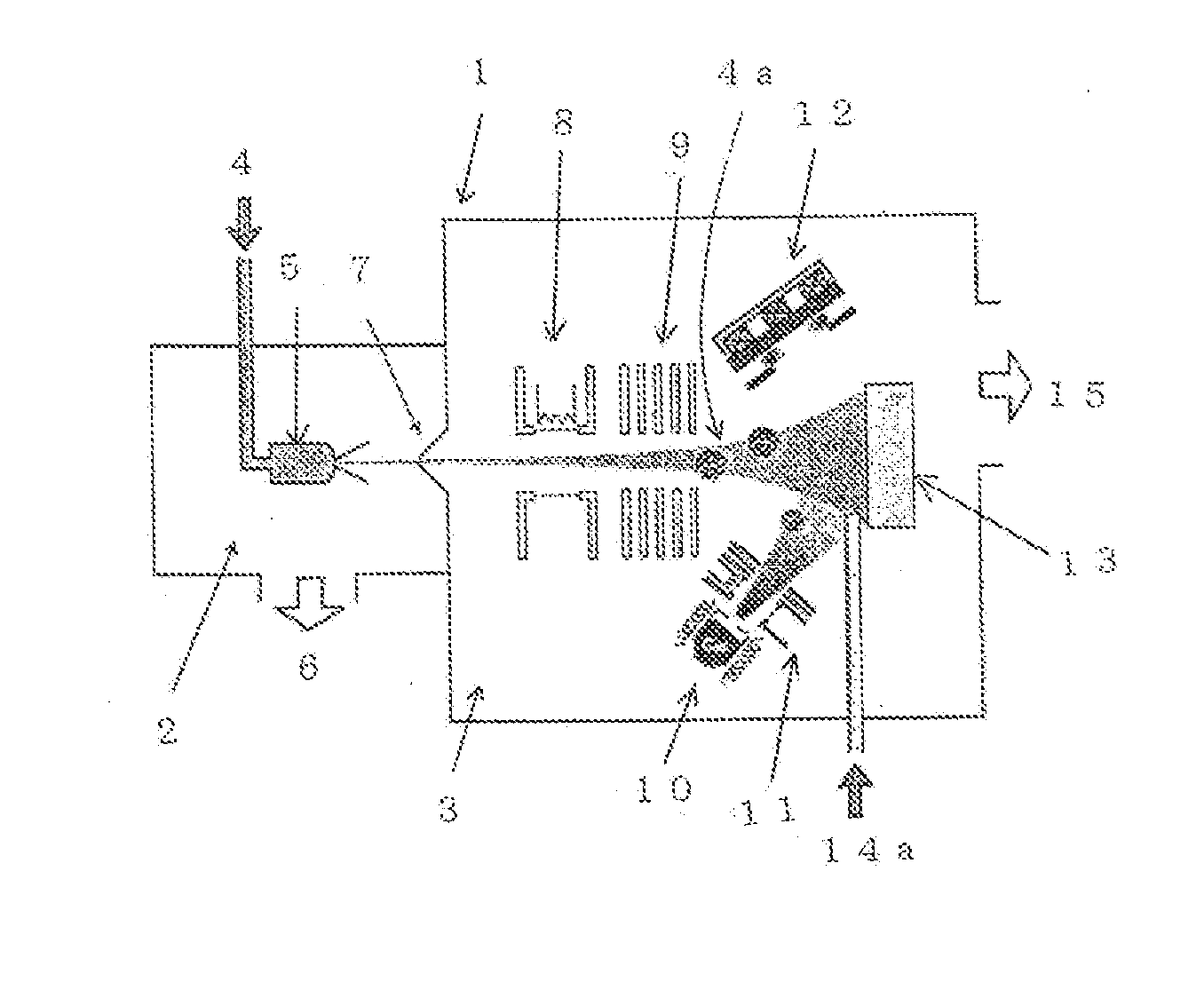

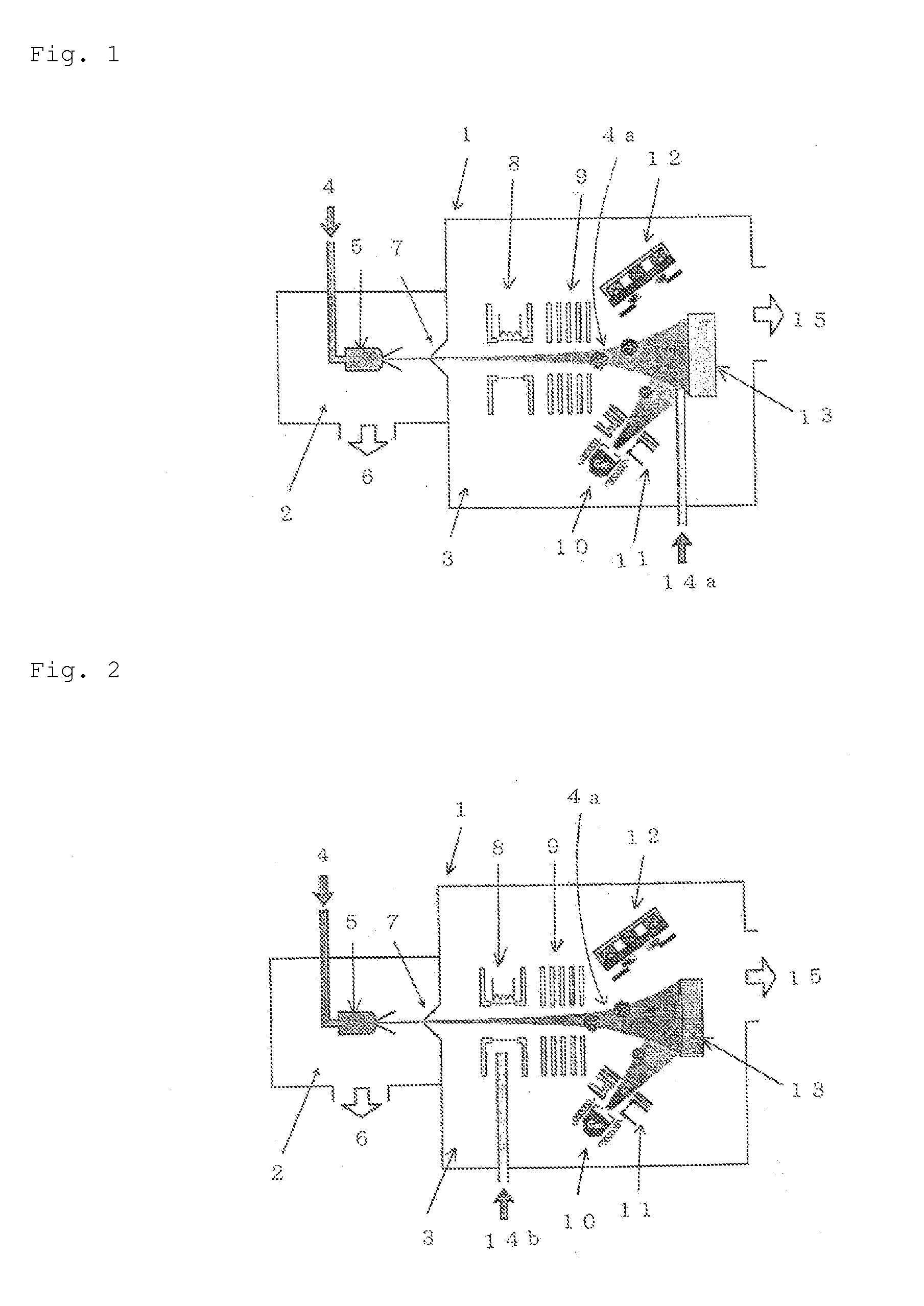

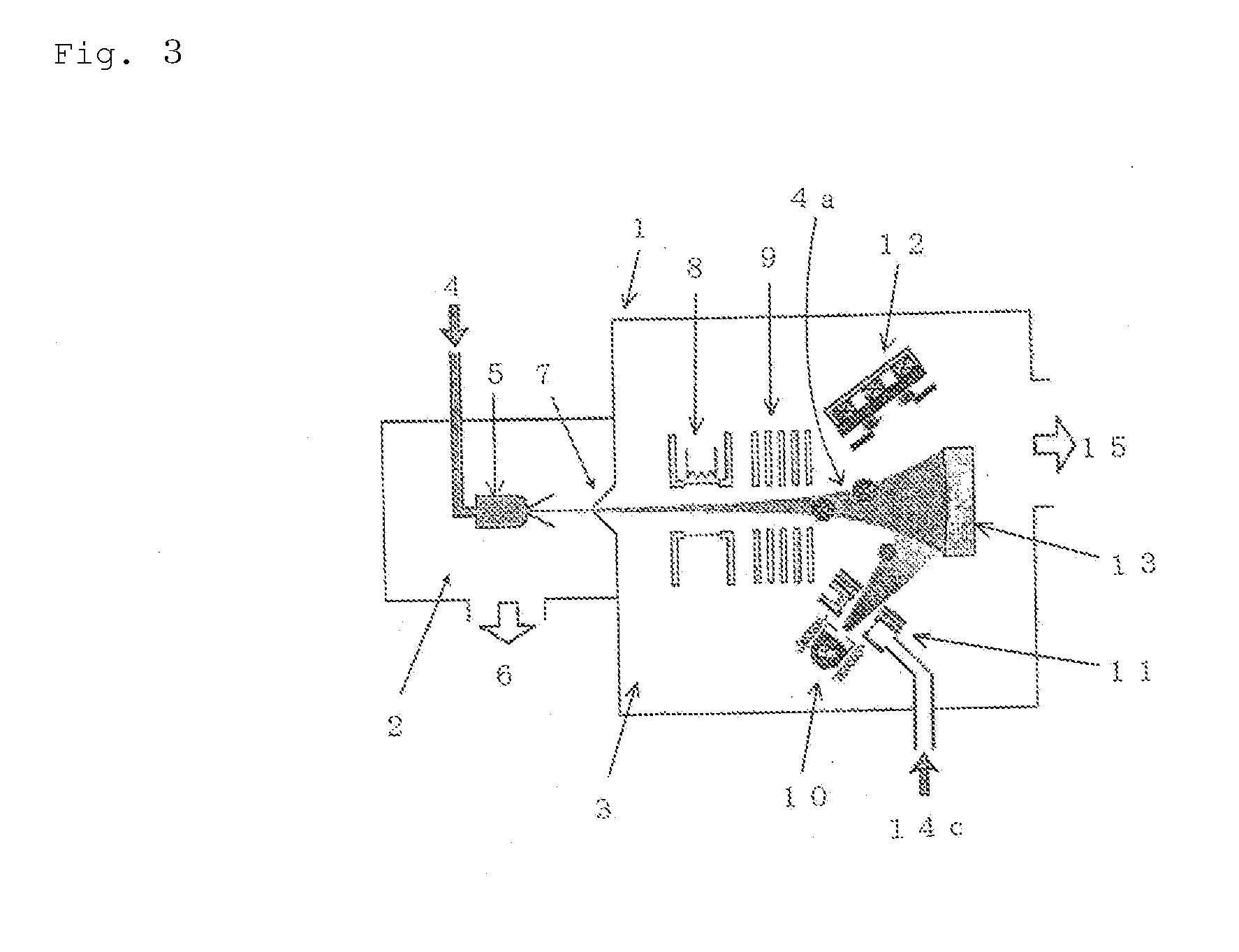

Conductive Hard Carbon Film and Method for Forming the Same

ActiveUS20150037568A1Stable hardnessStable resistivityConductive materialVacuum evaporation coatingCarbon filmHydrogen

A film is formed under vacuum by a step of purifying and / or flattening the base material (13) by irradiating the base material (13) with a gas cluster ion beam (4a); by a step of forming an intermediate layer film by evaporating / vaporizing an intermediate layer film forming material, allowing the evaporated / vaporized material to adhere to the surface of the base material (13), and irradiating the intermediate layer film forming material with a gas cluster ion beam (4a); and by evaporating / vaporizing a carbon film forming material containing a carbonaceous material containing substantially no hydrogen, and a boron material, allowing the evaporated / vaporized material to adhere to the surface of the intermediate layer film, and irradiating the carbon film forming material with a gas cluster ion beam (4a).

Owner:NOMURA PLATING CO LTD

Preparation of carbon / carbon composite material heating element for polysilicon furnace

Owner:CENT SOUTH UNIV +1

Preparation method of continuous SiC fiber having surface carbon-rich structure

ActiveCN103160955BReduce manufacturing costSimple processFibre chemical featuresCarbon layerAviation

The invention relates to a preparation method of a continuous SiC fiber having a surface carbon-rich structure, which comprises the following steps: continuously drawing a polycarbosilane (PCS) unmelted fiber at a traveling speed of 0.5-3 m / min to pass through a high-temperature pipe furnace of 1300-1400 DEG C, and firing, wherein inert atmosphere is used at both ends of the high-temperature pipe furnace to perform gas seal; gas mixture of alkane and the inert atmosphere is introduced into the inner side of the air seal at the inlet end; and the PCS unmelted fiber is converted through pyrolysis, thus preparing the continuous SiC fiber. According to the invention, the process is simple and convenient to operate; the manufacturing cost is low; and the prepared SiC fiber has the advantages of stable surface carbon layer structure, low and adjustable resistivity, high temperature resistance and favorable mechanical property, can suitably serve as a high-performance wave-absorbing structural composite material having integrated functional requirements for wave absorption and load bearing, and is especially applicable to the fields of high-performance weaponry, aviation, aerospace, nuclear industry and the like.

Owner:NAT UNIV OF DEFENSE TECH

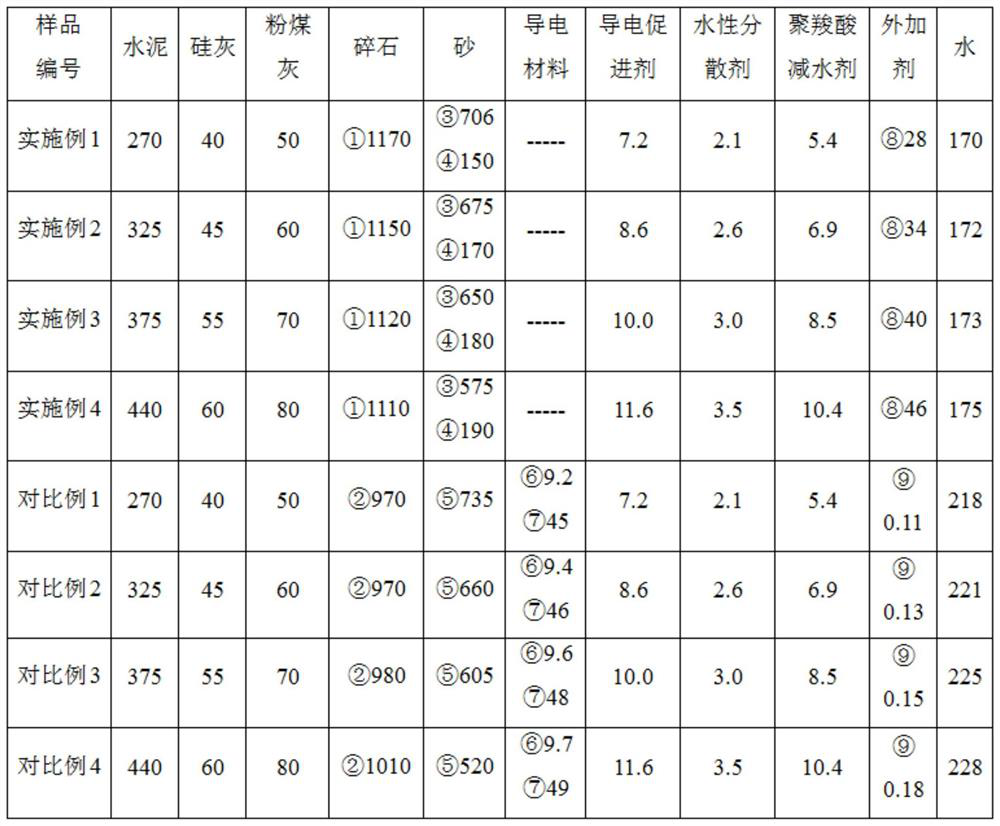

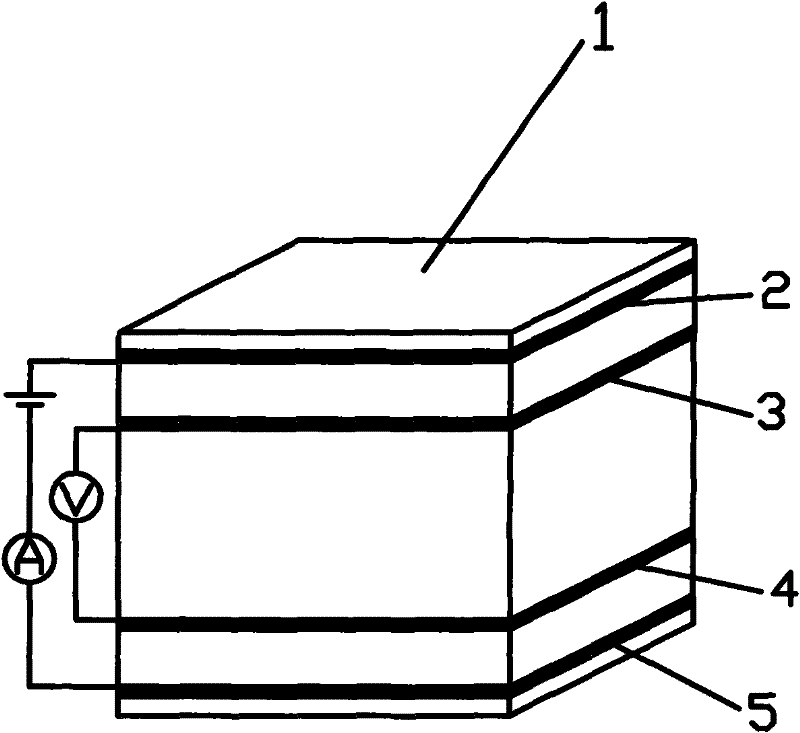

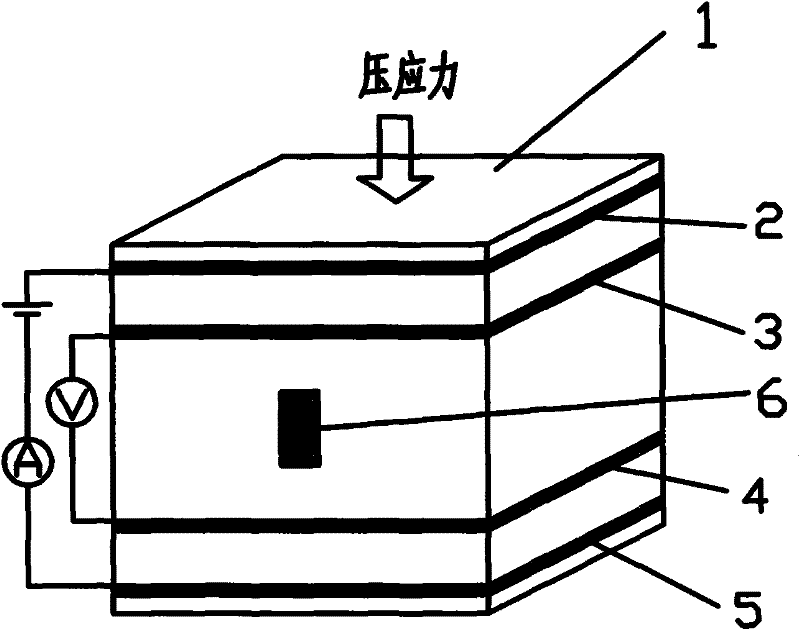

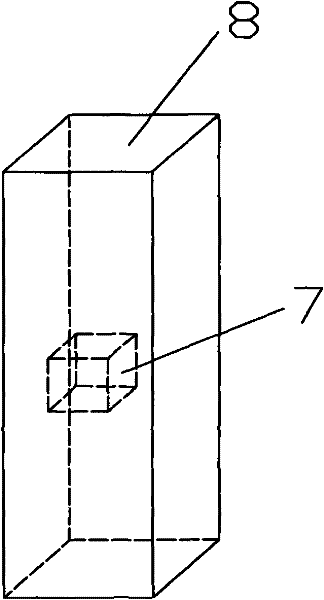

Iron tailing large-slump high-strength conductive concrete and preparation method thereof

ActiveCN112521076AIncrease slumpAvoid the effects of intensitySolid waste managementSuperplasticizerCarboxylic acid

The invention discloses iron tailing large-slump high-strength conductive concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The conductive concrete comprises the following components in parts by weight: 250-450 parts of cement, 1050-1180 parts of coarse aggregate, 720-960 parts of fine aggregate, 70-150 parts of admixture, 25.6-60.0 partsof expanding agent, 1.6-6.0 parts of water-based dispersing agent, 4.8-10.8 parts of polycarboxylate superplasticizer and 170-175 parts of water, wherein the unit is kg / m3. By adopting the technical scheme provided by the invention, the requirements of mechanical properties, working properties and conductivity of the conductive concrete can be effectively met.

Owner:CHINA MCC17 GRP

CCCW-mixing graphite smart concrete and application thereof

InactiveCN101602591BImprove performanceImprove mechanical propertiesWeighing apparatus using elastically-deformable membersForce measurementMass ratioGraphite

The invention relates to smart concrete, in particular to CCCW-mixing graphite smart concrete formed by adding CCCW concrete mixture and graphite into base materials comprising silicate cement and sand, wherein the mass ratio of cement to sand is 1 to 1; and other components in percentage by weight to the total mass of the cement and the sand are as follows: 1 to 2 percent of CCCW concrete mixture and 5 to 25 percent of graphite. By utilizing the tunneling conducting effect between the contact electric conduction of the graphite and the electric conduction phase, the invention forms the graphite electrical conduction concrete with smart property, and has the advantages of favorable electric conduction, high mechanical property, stable electrical conductivity and pressure-sensitivity, simple preparation, lower price, and the like; and the material can be utilized for manufacturing a concrete structure sensor element, can be used for the effective execution of the health supervision of the concrete structure and can also be used as an industrial anti-static material, an electrical engineering material and an electrothermal material.

Owner:WUHAN UNIV OF TECH

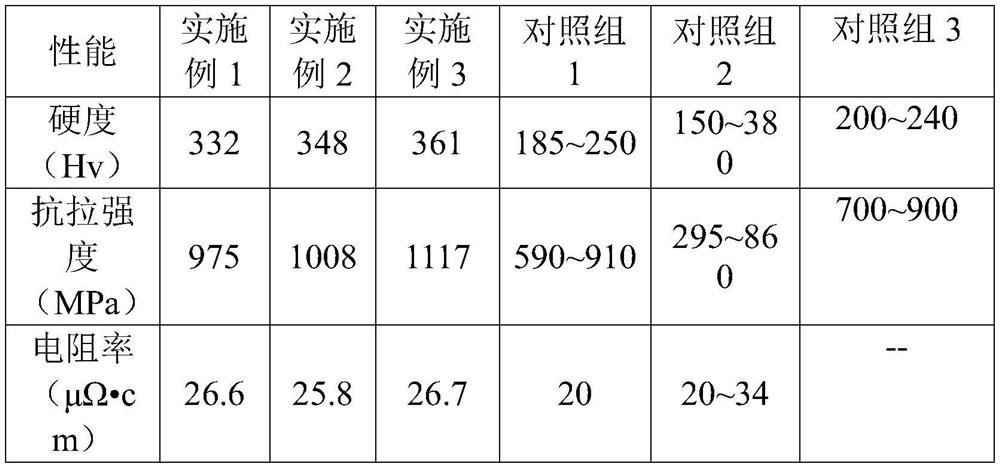

High-strength platinum-based electric contact material and preparation method thereof

The invention discloses a high-strength platinum-based electric contact material and a preparation method thereof. The high-strength platinum-based electric contact material comprises the following components in percentage by mass: 1 to 5 percent of Au; 1 to 5 percent of Ni; and the balance of Pt. According to the high-strength platinum-based electric contact material and the preparation method thereof provided by the invention, the tensile strength of a platinum-based alloy wire ranges from 900 MPa to 1150 MPa, the Vickers hardness ranges from 300 HV to 360 HV, the resistivity ranges from 25 mu omega.cm to 27 mu omega.cm, the comprehensive performance is improved, the machining performance is excellent, the yield is high, and the corrosion resistance is good.

Owner:YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com