Patents

Literature

41results about How to "Avoid the effects of intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

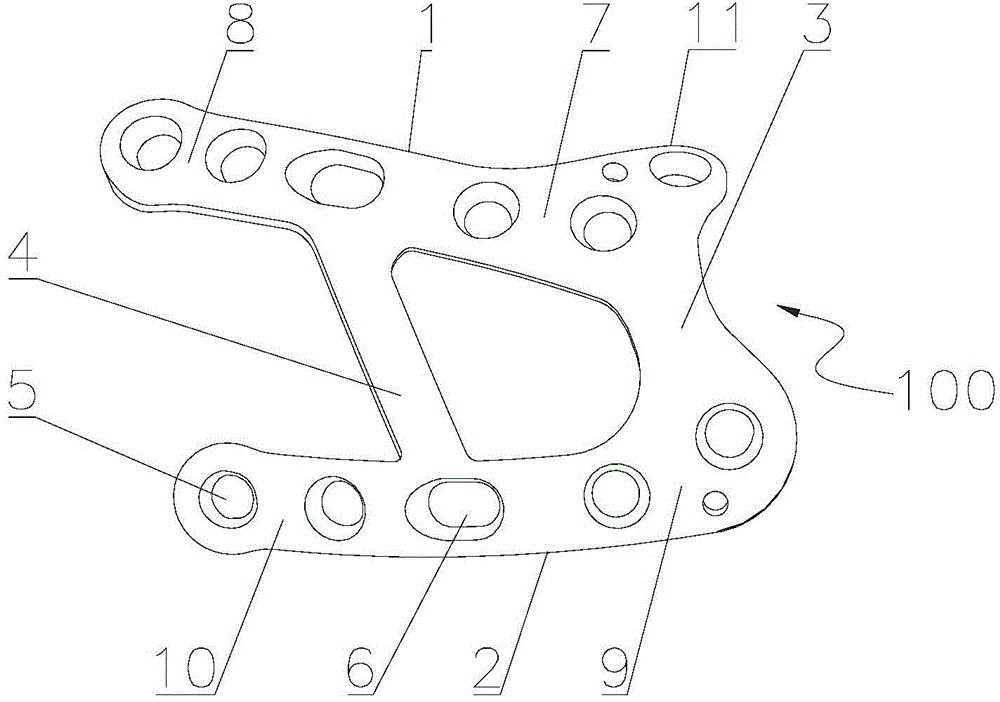

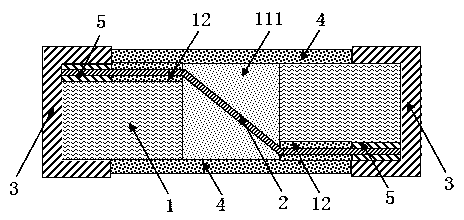

Lisfrance joint injury fusion plate

The invention relates to the field of medical devices, in particular a Lisfrance joint injury fusion plate. The fusion plate comprises a first tarsometatarsal joint plate, a second tarsometatarsal joint plate and a first transition plate for connecting the first tarsometatarsal joint plate and second tarsometatarsal joint plate; and the fusion plate provided with a plurality of fixing holes for fixing the fusion plate on a first metatarsal bone, an inner cuneiform bone, a second metatarsal bone and an intermediate cuneiform bone. The Lisfrance joint injury fusion plate has dissection-type design; in an operation, the fusion plate is not required to be pre-bent, the operation time is saved, and the bending influence on the plate strength; the close-end fixing holes of the first tarsometatarsal joint plate and the second tarsometatarsal joint plate have strong holding force for the inner cuneiform bone and the intermediate cuneiform bone; the curvature of human anatomy of Asian people is fully taken in to consideration of the design of the plates and bolts; and the fusion of multiple joint surfaces is conductive to arch anatomy reconstruction, excellent stability for joint fusion is provided, and the fixing effect of the fusion plate is further improved.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

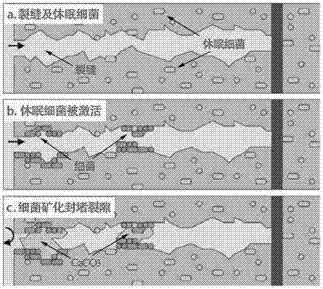

Microbial seal-healing capsule for coal mine air leakage plugging as well as preparation method and application of microbial seal-healing capsule

InactiveCN107973542AImplement automatic detectionAchieve automatic healingMicroparticleCalcium carbonate precipitation

The invention discloses a microbial seal-healing capsule for coal mine air leakage plugging as well as a preparation method and application of the microbial seal-healing capsule. Dry powder of bacterial spores is uniformly dispersed in water, a suitable substrate is selected according to the kinds of the bacterial spores, the substrate is added into a uniformly-dispersed mixed solution according to a certain ratio of the bacterial spores to the substrate and is uniformly stirred to be agglomerated, the agglomerated mixture is slowly added into a multifunctional granulator and is extruded, a cooling system is started, the temperature of the material is maintained, and the extruded strip-shaped substance is added into a rounder for rounding and is sieved and dried to obtain microparticles; and the microbial seal-healing capsule is prepared from the microparticles and a wall material by using a vacuum impregnation method or an interfacial polymerization method, the microbial seal-healingcapsule and a main material for air leakage plugging are mixed to be used, once concrete is cracked, the spores inside the material can be activated to normally metabolize, and calcium carbonate is continuously induced to be precipitated, so that the self-repair of cracks is realized.

Owner:SHANDONG UNIV OF SCI & TECH

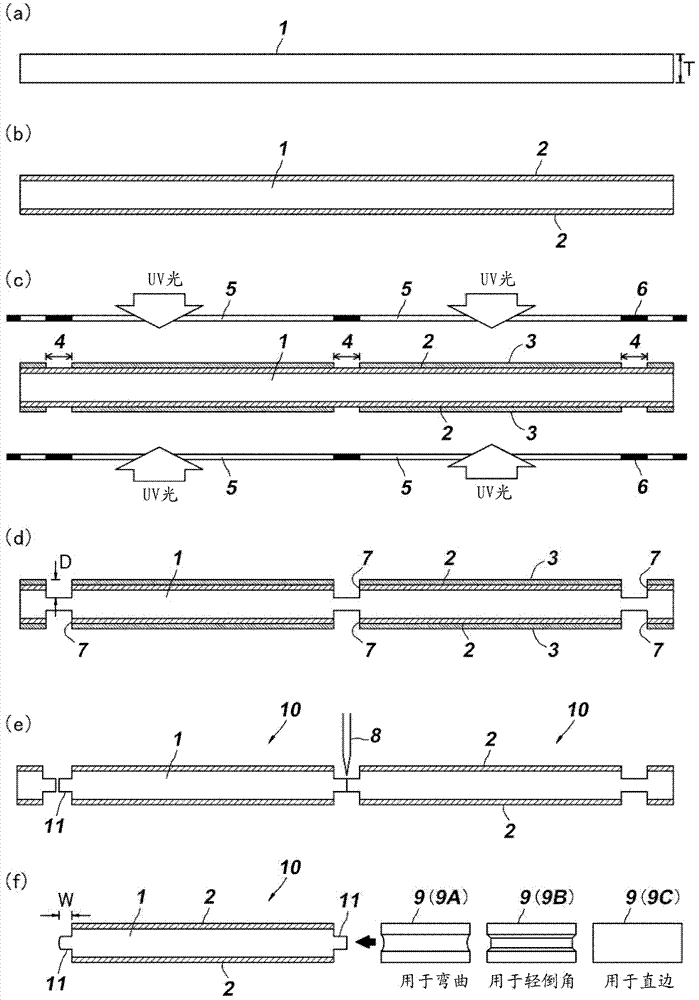

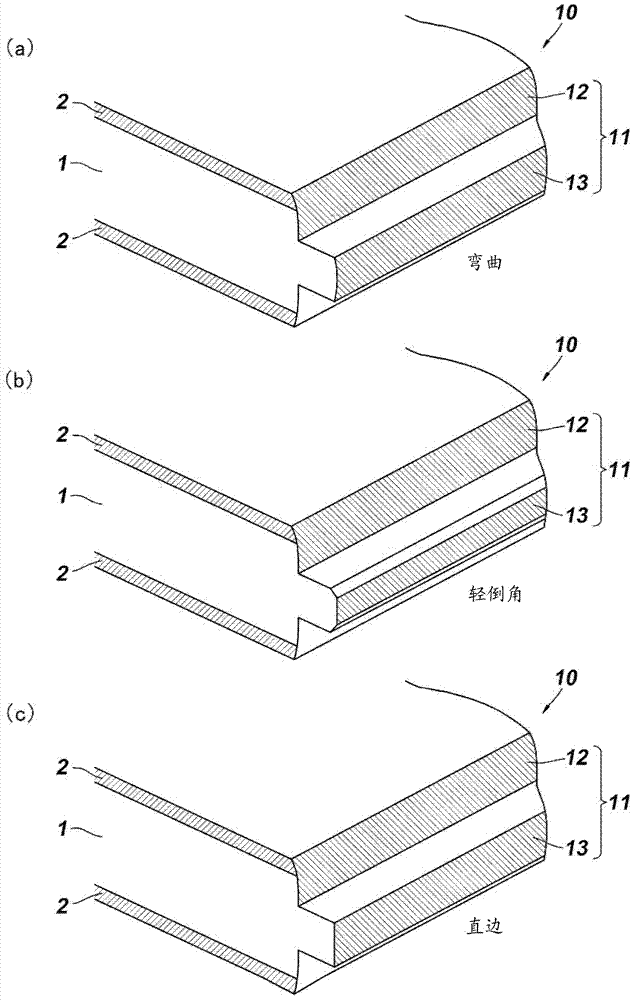

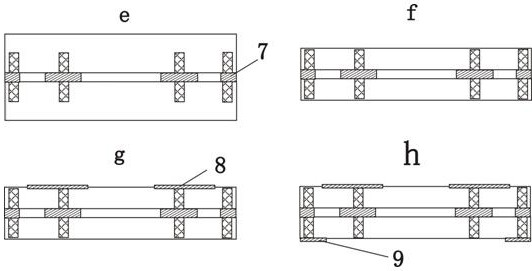

Strengthened glass, touch panel and method of manufacturing strengthened glass

InactiveCN103159411AAvoid it happening againAvoid breakingGlass severing apparatusCoatingsEdge surfaceCutting glass

There is provided a strengthened glass capable of shortening a process time for maintaining the strength to improve the production efficiency and forming an edge surface of the strengthened glass in any shape while preventing damage such as fracture due to micro-cracks or the like. Strengthening layers 2 are formed on both surfaces of the glass plate 1, and protection films 3 are formed in regions except for cutting portions 4. Subsequently, recessed portions 7 are formed by etching both surfaces of the glass plate at the cutting portions 4 of the glass plate 1 not covered by the protection films 3. Subsequently, the glass plate 1 is cut using a cutter 8 along the recessed portions 7 to form separated strengthened glass 10, and a stepped portion 11 having a protruding cutting surface and including an interior side surface 12 formed by etching a periphery of the glass plate 1 and an exterior side surface 13 formed by mechanical cutting is formed. Also, an edge portion of the stepped portion 11 may be formed in any shape by mechanical machining.

Owner:MICRO TECH CO LTD

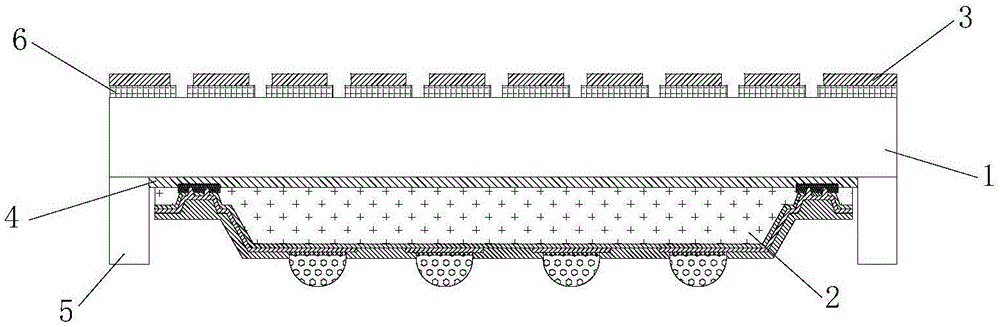

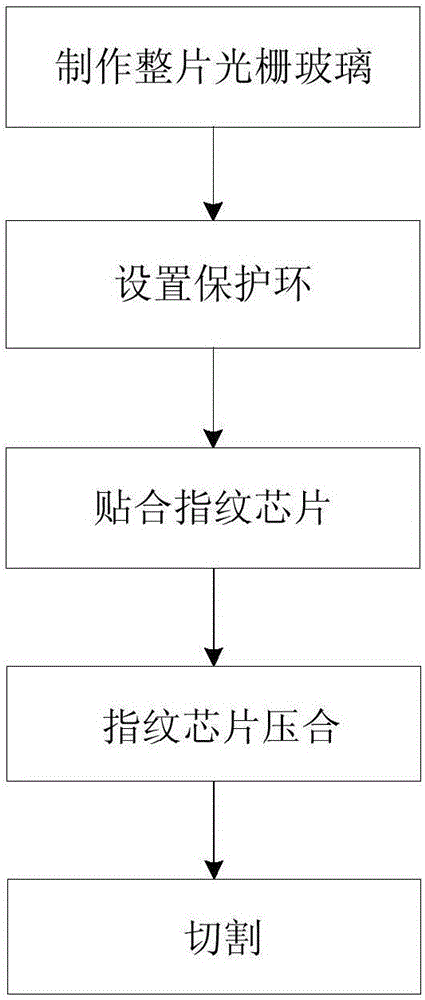

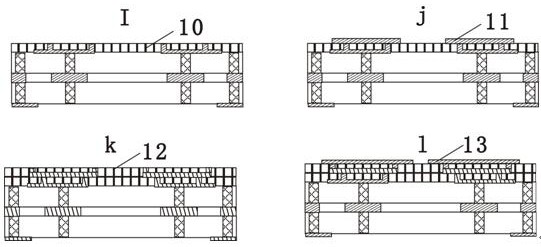

Fingerprint cover plate module and manufacturing method thereof

PendingCN106295534AWide range of color optionsImprove compatibilityCharacter and pattern recognitionAgricultural engineeringProtection ring

The invention discloses a fingerprint cover plate module, and relates to the technical field of semiconductor packaging. The fingerprint cover plate module comprises grating glass and a fingerprint chip, wherein the grating glass comprises a glass cover plate, one side of the glass cover plate is provided with a grating layer, the other side of the glass cover plate is provided with a protection ring, the protection ring is internally coated with a glue layer, and the fingerprint chip is glued to the internal part of the protection ring through the glue layer; and the grating layer comprises a light-proof nonmetal grating layer. Meanwhile, the invention discloses a manufacturing method of the fingerprint cover plate module. The manufacturing method comprises the steps of A, manufacturing a whole piece of grating glass; B, setting a protection ring; C, gluing the fingerprint chip; D, laminating the fingerprint chip; and E, cutting. The fingerprint cover plate and the manufacturing method thereof enrich the color selection space of the grating layer and effectively improve matching between the fingerprint cover plate module and a mobile phone panel on the one hand, and increase the size of a fingerprint module on the other hand, thereby enabling a fingerprint recognition operation of a user to be more accurate and more sensitive, and effectively improving the user experience in use.

Owner:苏州科阳半导体有限公司

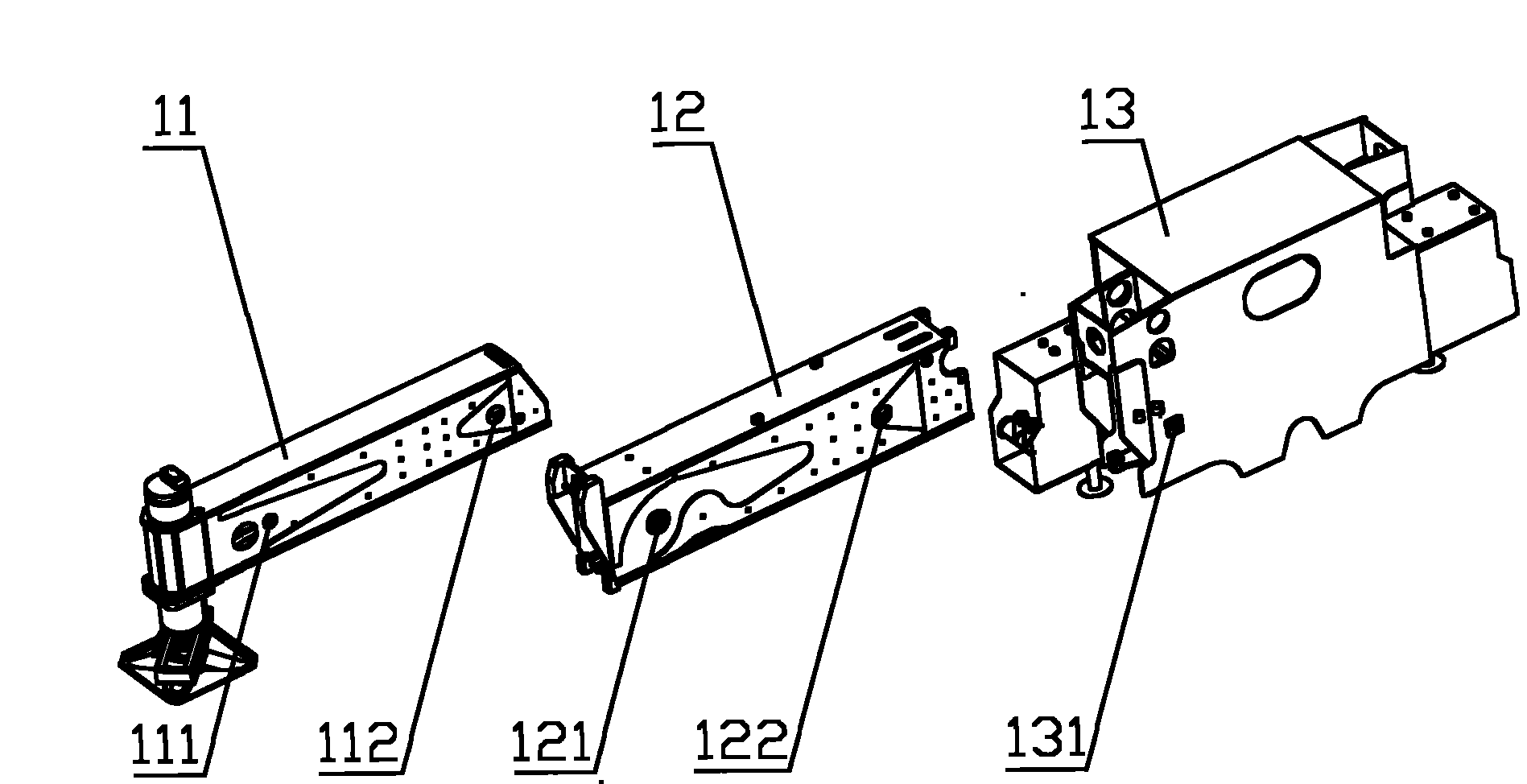

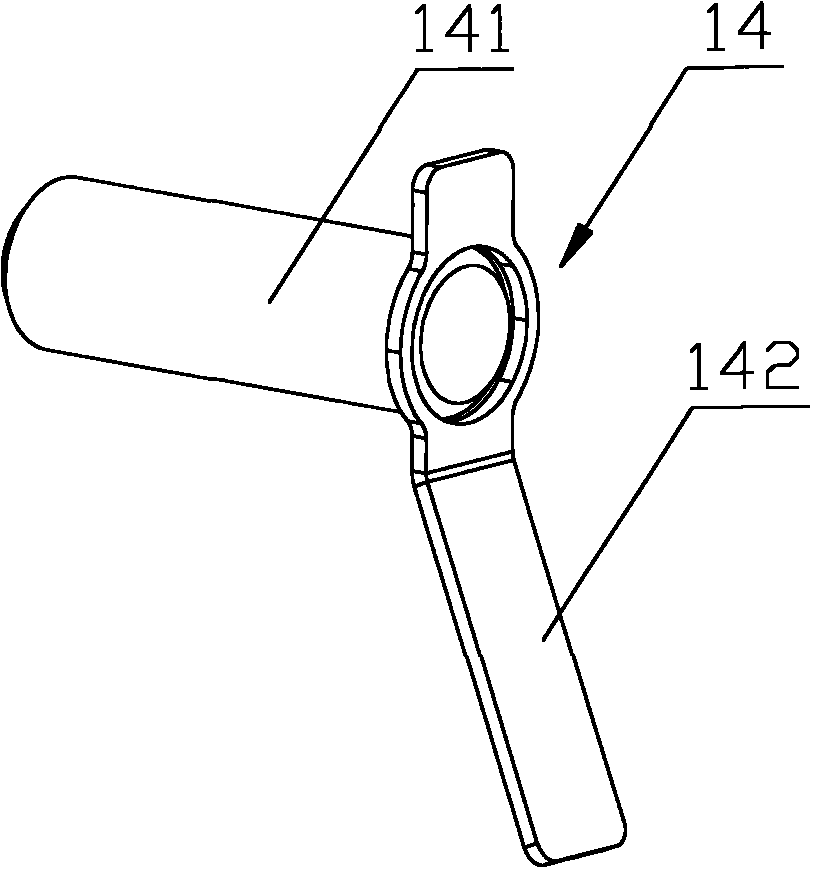

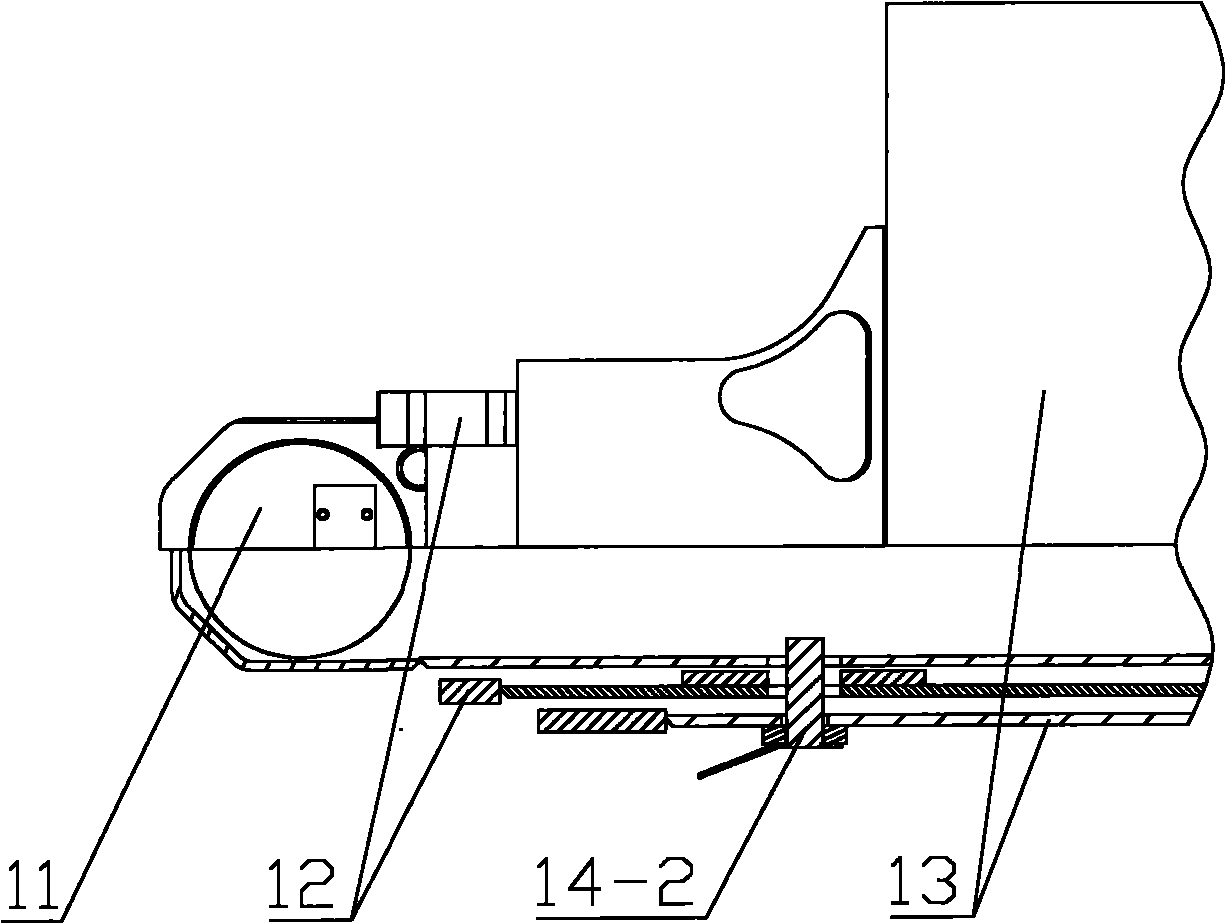

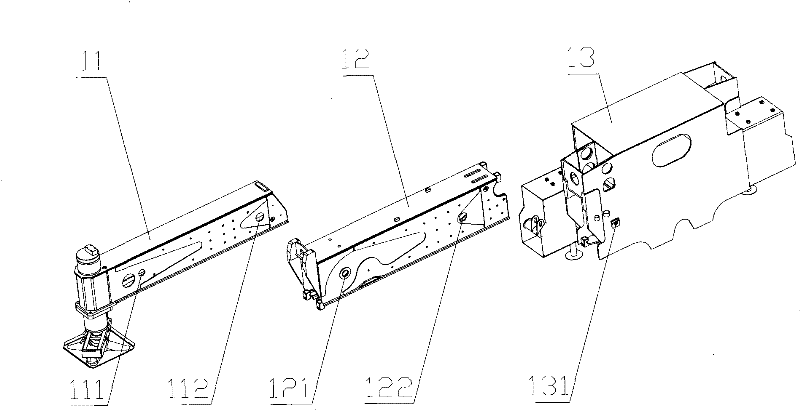

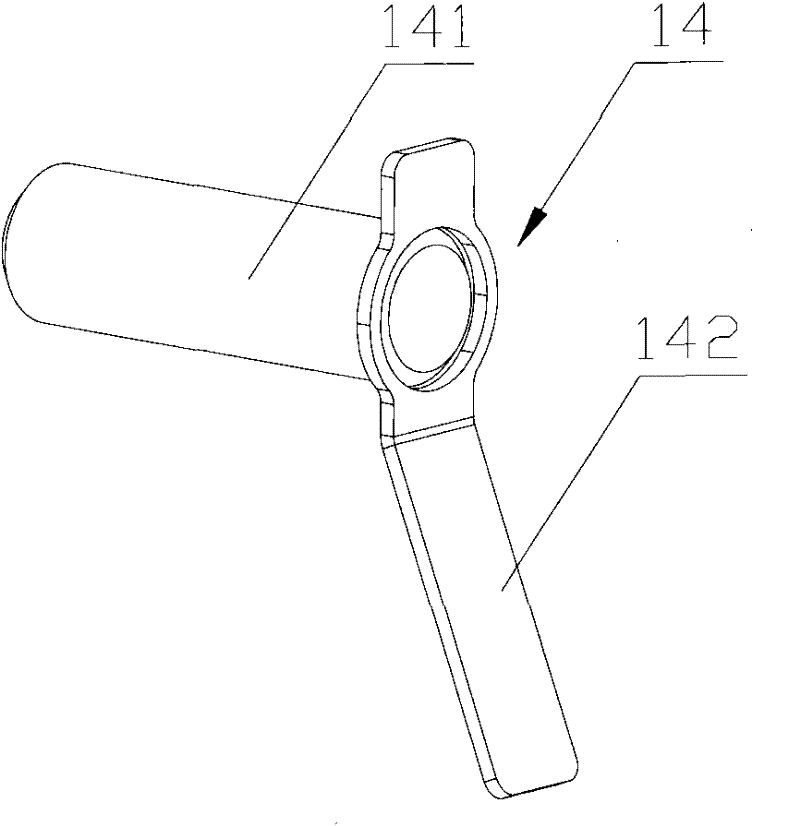

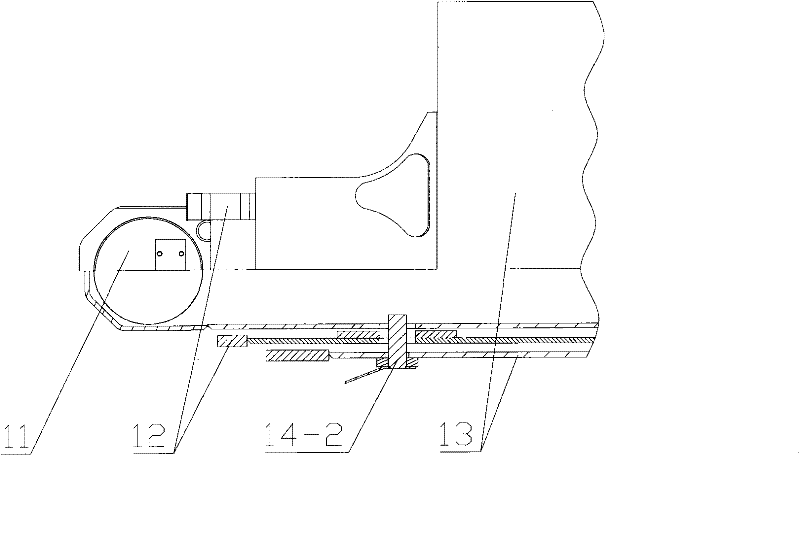

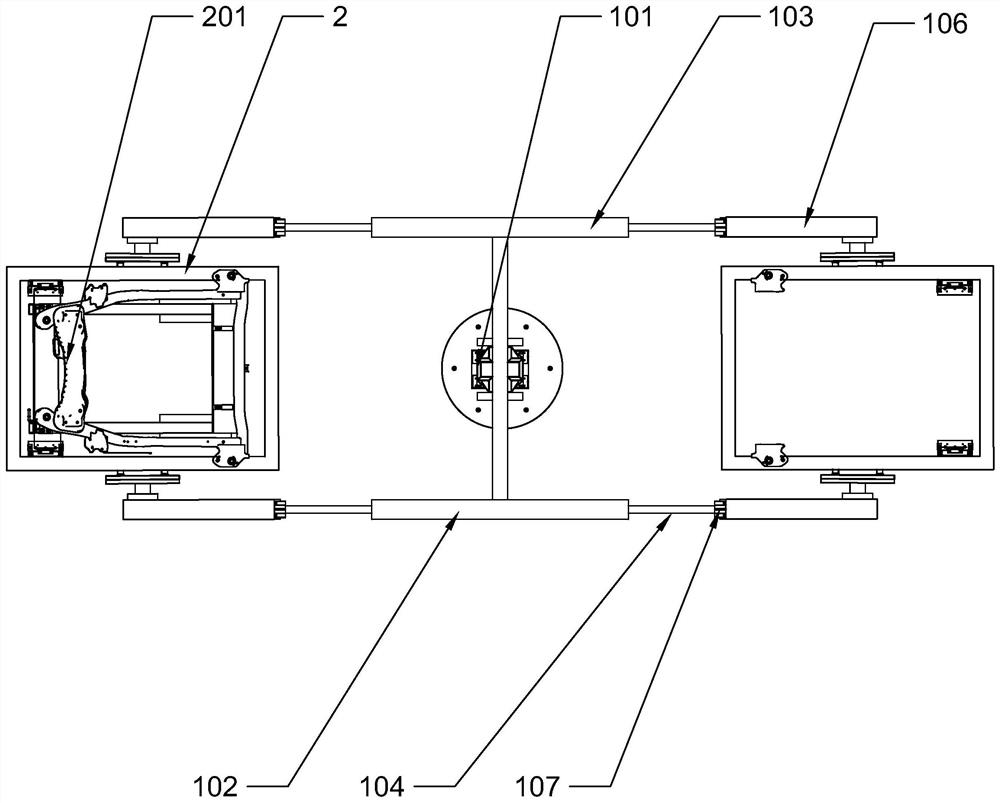

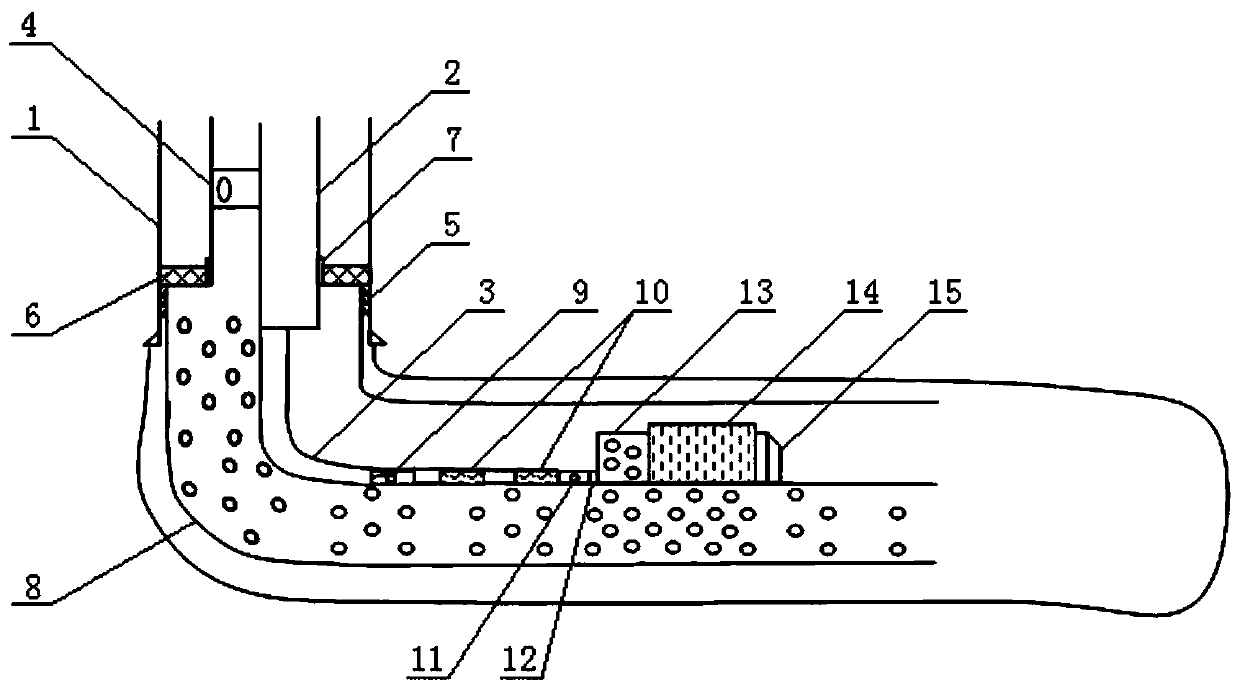

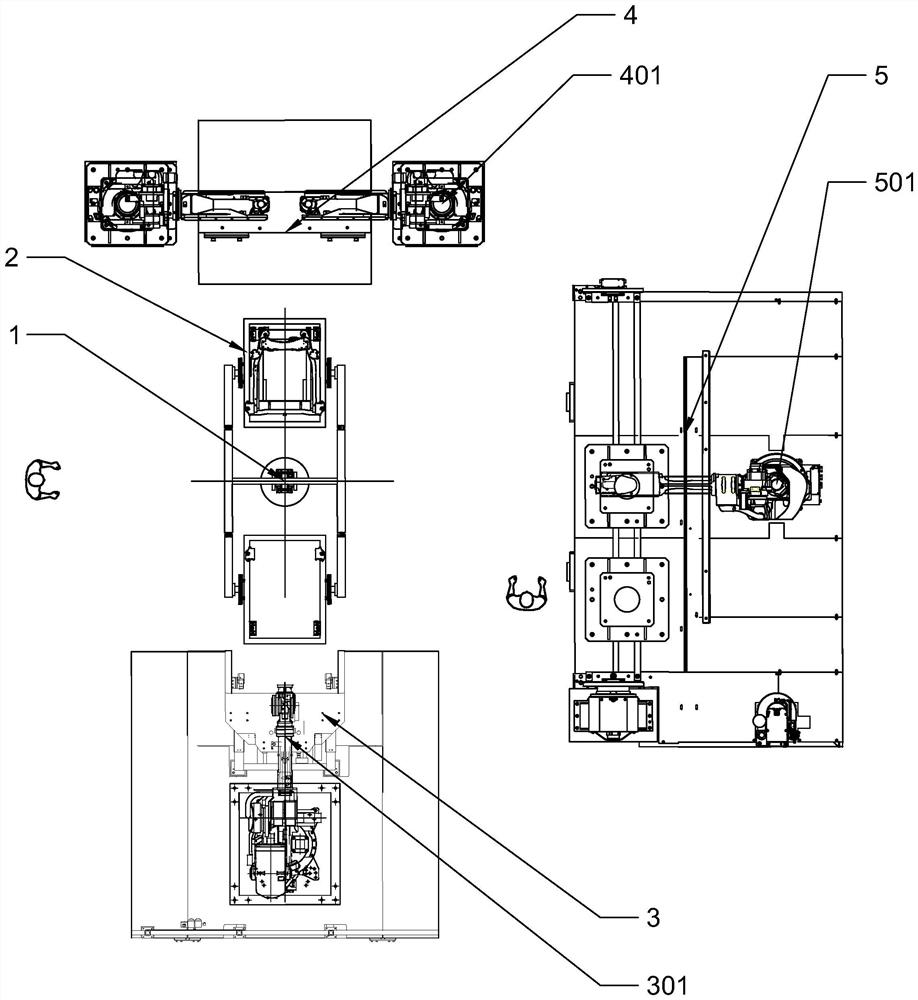

Mobile construction machinery and outrigger locking mechanism thereof

InactiveCN102079297AEffective lockingAchieve lockingVehicle fittings for liftingCranesEngineeringBuilding construction

The invention discloses an outrigger locking mechanism used for mobile construction machinery. In the invention, an outrigger of the mobile construction machinery comprises a first movable outrigger (2), a second movable outrigger (3) and a fixed outrigger (4); the outrigger locking mechanism comprises a locking part (6) and a first locking hole (21) which is matched with the locking part (6) and arranged at the outer end of the first movable outrigger (2); a first mounting hole (41) is arranged at the outer end of the fixed outrigger (4); and when both the first movable outrigger (2) and the second movable outrigger (3) are retracted into the fixed outrigger (4), the locking part (6) is inserted into the first locking hole (21) and the first mounting hole (41) and has a scheduled distance from the second movable outrigger (3). The outrigger locking mechanism is easy to operate and can effectively enhance locking efficiency. The invention also provides the mobile construction machinery comprising the outrigger locking mechanism and then the reliability is enhanced.

Owner:XUZHOU HEAVY MASCH CO LTD

Communication lumped parameter circulator based on MEMS technology and manufacturing method thereof

ActiveCN114156621AIncrease productivityImprove consistencyWaveguide type devicesHigh volume manufacturingHemt circuits

The invention discloses a lumped parameter circulator for communication based on an MEMS technology and a manufacturing method of the lumped parameter circulator, and belongs to the technical field of microwave components, the lumped parameter circulator comprises a silicon main substrate, a silicon auxiliary substrate is arranged below the silicon main substrate, and at least two layers of polyimide films are arranged above the silicon main substrate; circuit patterns are manufactured on the upper surfaces and the lower surfaces of the main silicon substrate and the auxiliary silicon substrate, and the main silicon substrate and the auxiliary silicon substrate are interconnected in a metal via hole and bonding mode; each layer of polyimide film is also provided with a circuit pattern, and is interconnected with a circuit at the lower layer through a metalized through hole in the polyimide film; the lumped parameter microstrip circulator manufactured by using the MEMS process technology has the size as small as 3 * 3mm, has the advantages of mature process, high speed, low cost, high efficiency, good consistency and the like, is suitable for mass production, can effectively reduce the sizes of ferrite and devices, and lays a process foundation for smaller devices such as 2 * 2mm and 1 * 1mm.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

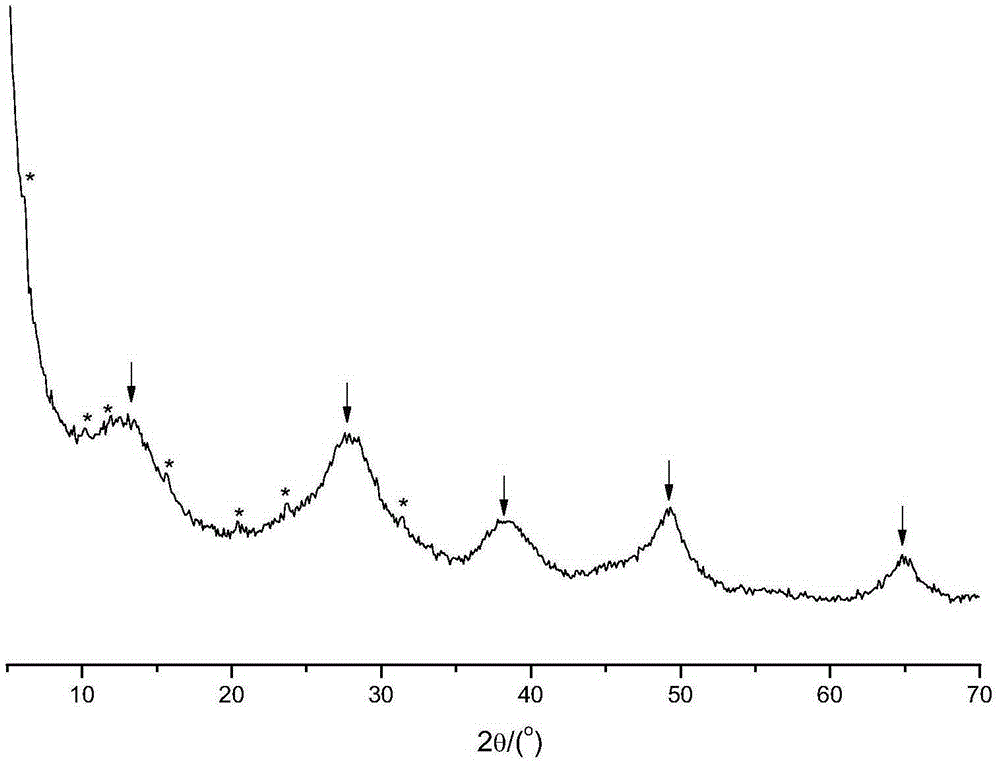

Preparation method of porous material

ActiveCN106809854ATypical Mesopore PropertiesStrong macromolecule cracking abilityFaujasite aluminosilicate zeoliteRoom temperatureSodium oxide

The invention provides a preparation method of a porous material, which is characterized in that an aluminium source, alkali solution, NaY crystallization mother liquor and / or washing filtrate are mixed in a parallel flow mode to form glue, the glue is aged to obtain solid precipitates, and then the solid precipitates are subjected to acid mixed exchange sodium removal until sodium oxide content being smaller than 0.3%; the step of mixing to form the glue is carried out at the temperature ranging from the room temperature to 85 DEG C; in a mixing glue forming system, a pH value is controlled within a range of 7 to 11, and a weight ratio of SiO2 to Al2O3 is controlled within a range of 1:(1 to 9). The porous material obtained by adopting the method provided by the invention has the characteristics of a mesoporous, and is small in particle size and better in cracking performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

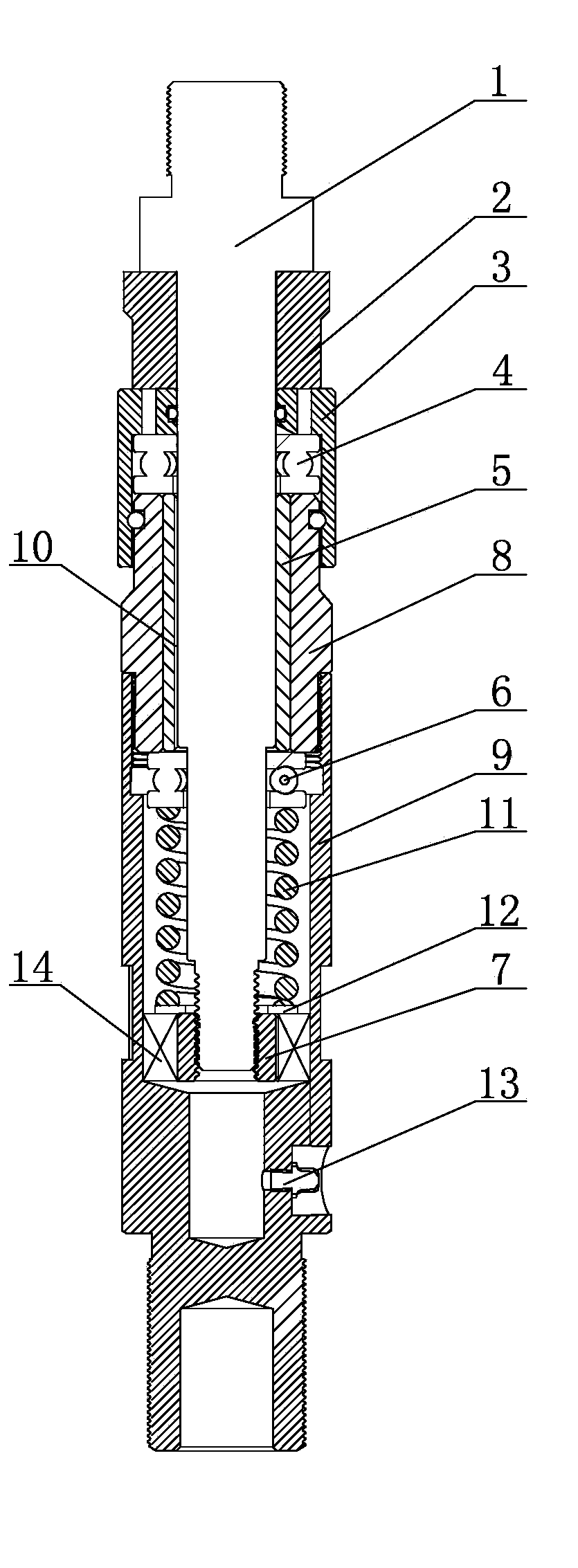

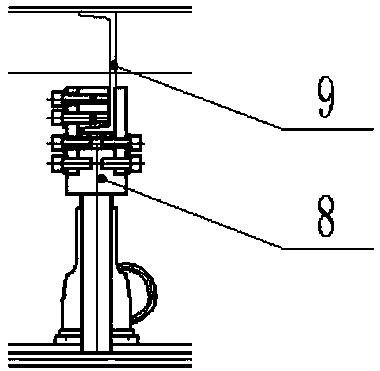

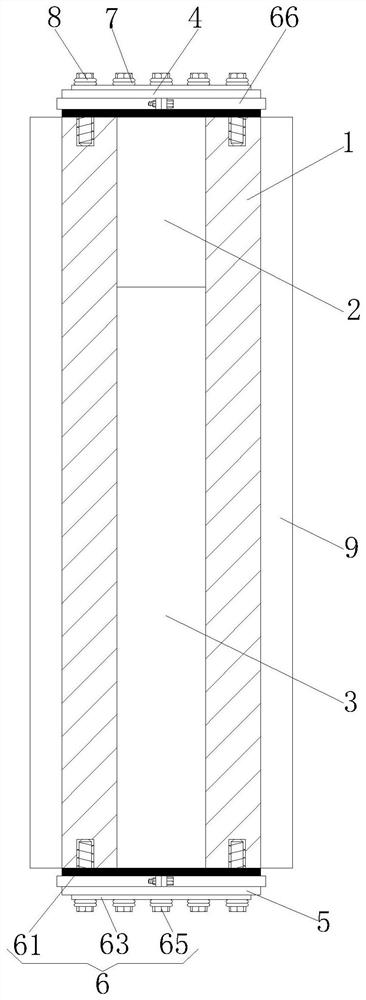

Novel internal single-action mechanism of drilling tool

The invention relates to a novel internal single-action mechanism of a drilling tool. The novel internal single-action mechanism comprises a shaft. A first connector, a bearing block, an upper bearing, a shaft sleeve, a lower bearing and a lock nut are sequentially connected to the peripheral surface of the shaft from top to bottom. The shaft sleeve is arranged in a second connector. One end of the second connector is in threaded connection with the bearing block. The other end of the second connector is in threaded connection with an inner tube. The lower bearing and the shaft section, below the lower bearing, of the shaft are both located in the inner tube. Oil grooves are evenly distributed in the inner wall of the shaft sleeve in the axial direction. The shaft section between the lower bearing and the lock nut is sleeved with a spring and a gasket. The inner tube is provided with a radial oil hole which is communicated with an inner cavity of the inner tube. A bearing is arranged at the bottom of the inner cavity. The lock nut is arranged in the bearing. A gap is formed between the gasket and the lock nut. The spring is in a compression state. Through the utilization of the novel single-action mechanism, single action of the drilling tool can be achieved, and meanwhile the shaft, the shaft sleeve and the bearings in the single-action mechanism can be effectively protected. The novel internal single-action mechanism is long in service life and stable in performance.

Owner:WUXI GEOTEC GEOLOGICAL EQUIP

Manufacturing method of magnesium alloy transmission box with ultrahigh corrosion resistance

ActiveCN104455349AAvoid the effects of intensitySolve the problem of insufficient anti-oxidation and corrosion resistanceAnodisationFoundry mouldsTectorial membraneMicro arc oxidation

The invention discloses a manufacturing method of a magnesium alloy transmission box with ultrahigh corrosion resistance. The manufacturing method comprises the following steps: performing foaming, forming a cluster structure, swabbing I, swabbing II, hardening, roasting, swabbing III, smelting and pouring, and micro-arc oxidation in sequence, and obtaining a casting of the magnesium alloy transmission box attached with a dense Al2O3 oxidation film on the surface layer. The manufacturing method disclosed by the invention has the following characteristics: during the formwork roasting process, the foamed plastic is burned up in advance to avoid the influence of high-temperature foam gasification to the quality of the casting during the pouring process, avoid the influence of carbon dust to the strength of the magnesium alloy, and ensure the purity of the magnesium alloy material; the nanometer powered aluminum dip-coated before pouring is molten and tightly attached to the surface of the casting at high temperature in the pouring process to form a complete aluminum protective film, and then form the dense Al2O3 oxidation film during the follow-up micro-arc oxidation process, so as to tightly coat the magnesium alloy, improve the oxidation resistance and the corrosion resistance of the magnesium alloy, and solve the problem that the oxidation resistance and the corrosion resistance of the magnesium alloy for the existing transmission box are insufficient.

Owner:山东蒙沃变速器有限公司

Loosening agent for regeneration of SCR denitration catalyst and preparation method of agent

InactiveCN103623876AAvoid damageAvoid physical damageCatalyst regeneration/reactivationEngineeringUltimate tensile strength

The invention discloses a loosening agent for regeneration of a SCR denitration catalyst and a preparation method of the agent. The loosening agent comprises the following components by mass: 0.5%-2% of a wetting agent, 1%-5% of a penetration enhancer, 1.5%-2.5% of a pH conditioning agent and 90.5%-97% of deionized water. The beneficial effects comprise that the loosening agent helps to shorten the immersing time of the catalyst in a cleaning fluid and avoid the influence on the catalyst strength caused by long-time immersing; the loosening agent is capable of replacing apparatuses for physical perforation and avoiding damage to the catalyst; and the loosening agent is beneficial for recovering the acid sites on the catalyst surface because of the weakly acidic system which is also beneficial for the cleaning of the catalyst surface. The loosening agent has relatively high practical value on improvement of catalyst regeneration effect and regenerated catalyst working efficiency and avoiding of physical damage during catalyst regeneration process.

Owner:SUZHOU HUALE AIR POLLUTION CONTROL TECH EXPAND CO LTD

Mobile construction machinery and outrigger locking mechanism thereof

InactiveCN102079297BEffective lockingAchieve lockingVehicle fittings for liftingCranesLocking mechanismBuilding construction

The invention discloses an outrigger locking mechanism used for mobile construction machinery. In the invention, an outrigger of the mobile construction machinery comprises a first movable outrigger (2), a second movable outrigger (3) and a fixed outrigger (4); the outrigger locking mechanism comprises a locking part (6) and a first locking hole (21) which is matched with the locking part (6) andarranged at the outer end of the first movable outrigger (2); a first mounting hole (41) is arranged at the outer end of the fixed outrigger (4); and when both the first movable outrigger (2) and thesecond movable outrigger (3) are retracted into the fixed outrigger (4), the locking part (6) is inserted into the first locking hole (21) and the first mounting hole (41) and has a scheduled distance from the second movable outrigger (3). The outrigger locking mechanism is easy to operate and can effectively enhance locking efficiency. The invention also provides the mobile construction machinery comprising the outrigger locking mechanism and then the reliability is enhanced.

Owner:XUZHOU HEAVY MASCH CO LTD

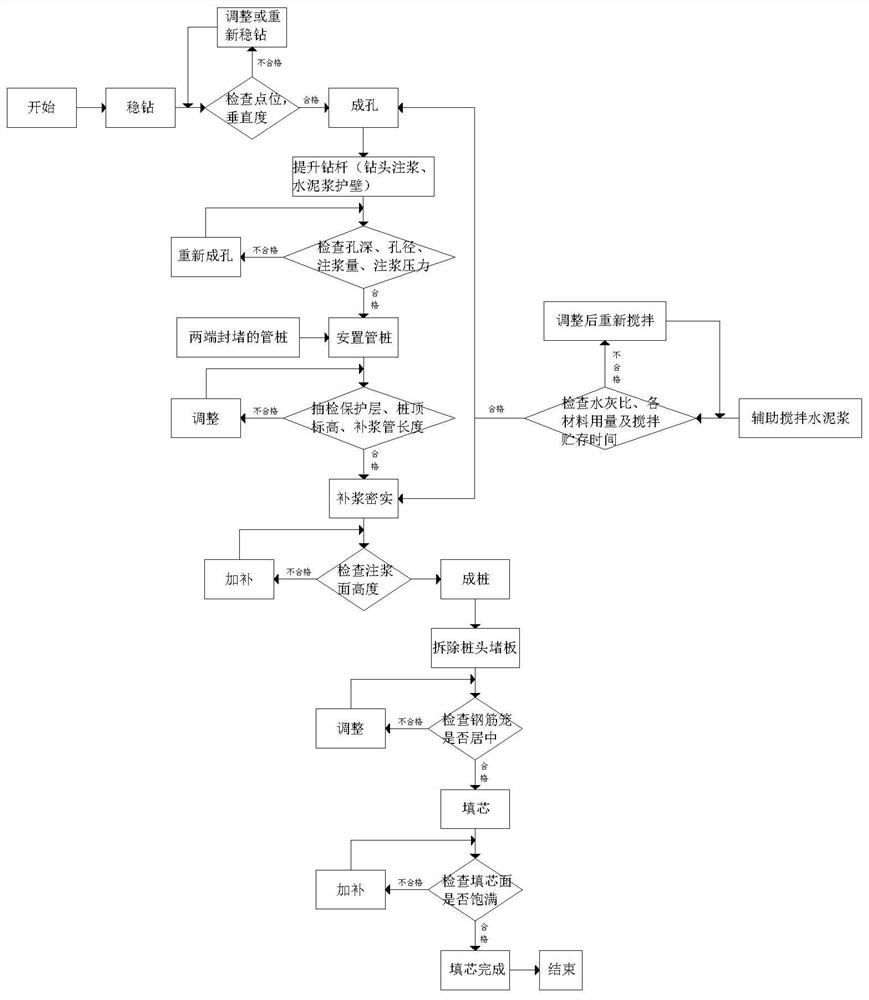

Construction method of premixing pouring soil cement pile used for strengthening ground and pile produced thereby

InactiveCN101487251AIncrease coarse particle contentLower plasticity indexBulkheads/pilesSoil mixingSoil cement

The invention discloses a construction method for pre-mixing pouring cement soil pipe used for reinforcing foundation and a pile formed by the construction method. Firstly, after the cement, soil, sand and the like are uniformly mixed with water by a forcible mixer, an internal pumping method is used for construction by a long spiral pipe; the problems that the pile-forming quality of the normal cement soil mixing pile is not easy to be controlled, the pile strength is low and the pile-forming depth is limited are thoroughly changed by ensuring the mixing uniformity, controlling the water-binder ratio, improving the soil quality and increasing the effective disposal depth and the like. Compared with the conventional cement soil mixing pile, the pile body strength can be improved by more than 3-5 times, the disposal depth can achieve 30m, and the CFG pile can be replaced for the engineering where the settlement is strictly controlled.

Owner:徐玉杰

Forming method for rzeppa constant-velocity universal joint finish forge piece

The invention relates to a forming method for a rzeppa constant-velocity universal joint finish forge piece. The forming method comprises the following steps that 1) material breaking is performed; 2)primary shot blasting is performed; 3) heating is performed; 4) warm forging forming is performed; 5) temperature control cooling is performed; 6) secondary shot blasting is performed; 7) oil spraying is performed; 8) cold finishing is performed; 9) cleaning is performed; and 10) rust-proof treatment is performed. The head section and the tail section of a round bar material are removed, the twoends of the round bar material is prone to be extruded and deformed by a clamp during clamping and mounting, the head section and tail section after being extruded and deformed are removed so that thestrength influence on the finish forge piece can be effectively avoided; meanwhile, the removed head section and the removed tail section are recovered to be re-melted, so that further waste of a rawmaterial is avoided; staged temperature control cooling is performed on the formed workpiece, and the influence of rapid cooling on the overall strength of the workpiece is avoided; through shot blasting and oil spraying treatment, an oxidation layer on the working surface can be effectively eliminated, and meanwhile, further cooling and lubricating treatment can be realized.

Owner:中科重工设备制造(江苏)有限公司

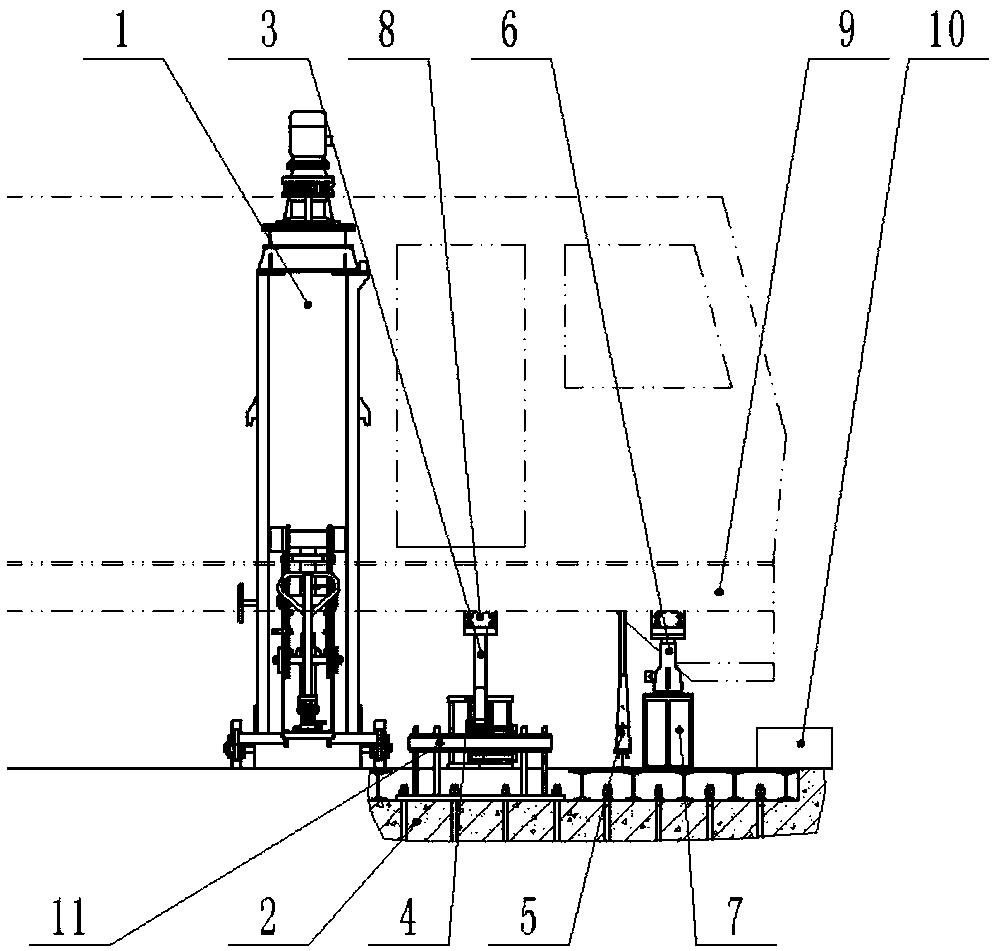

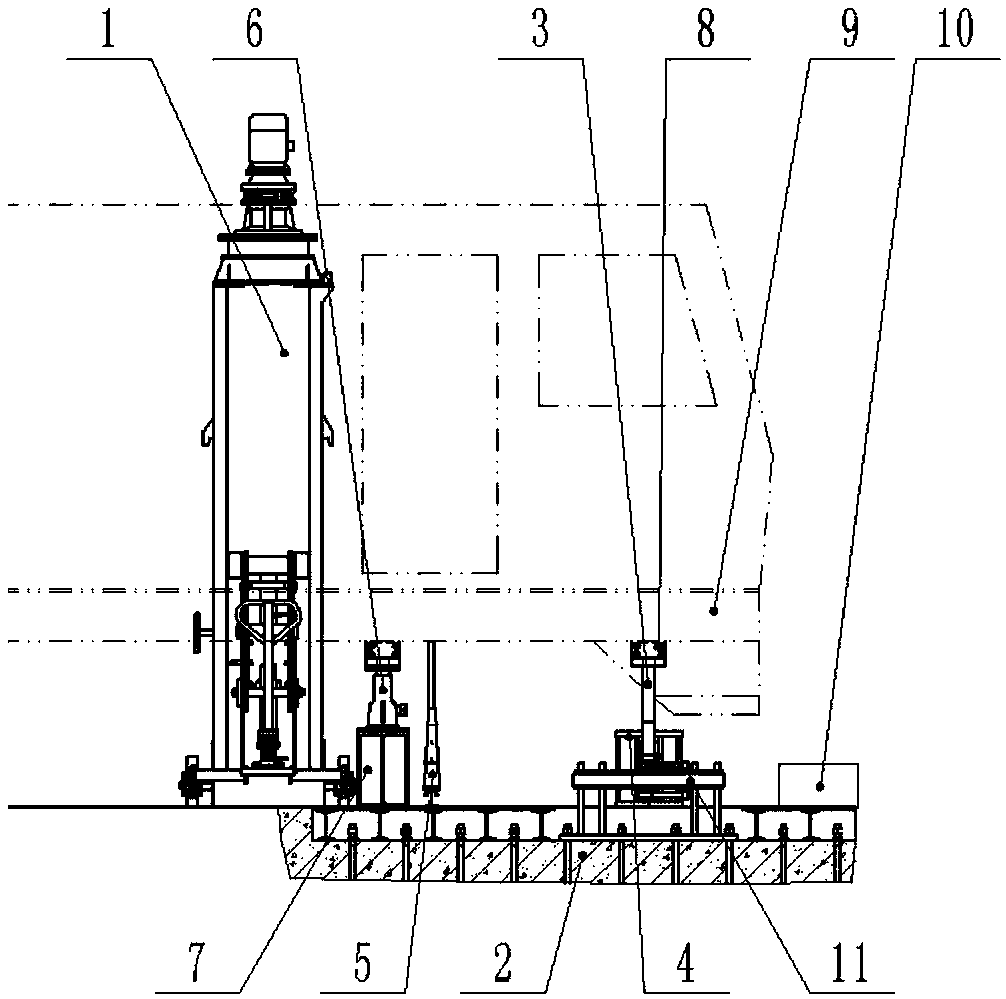

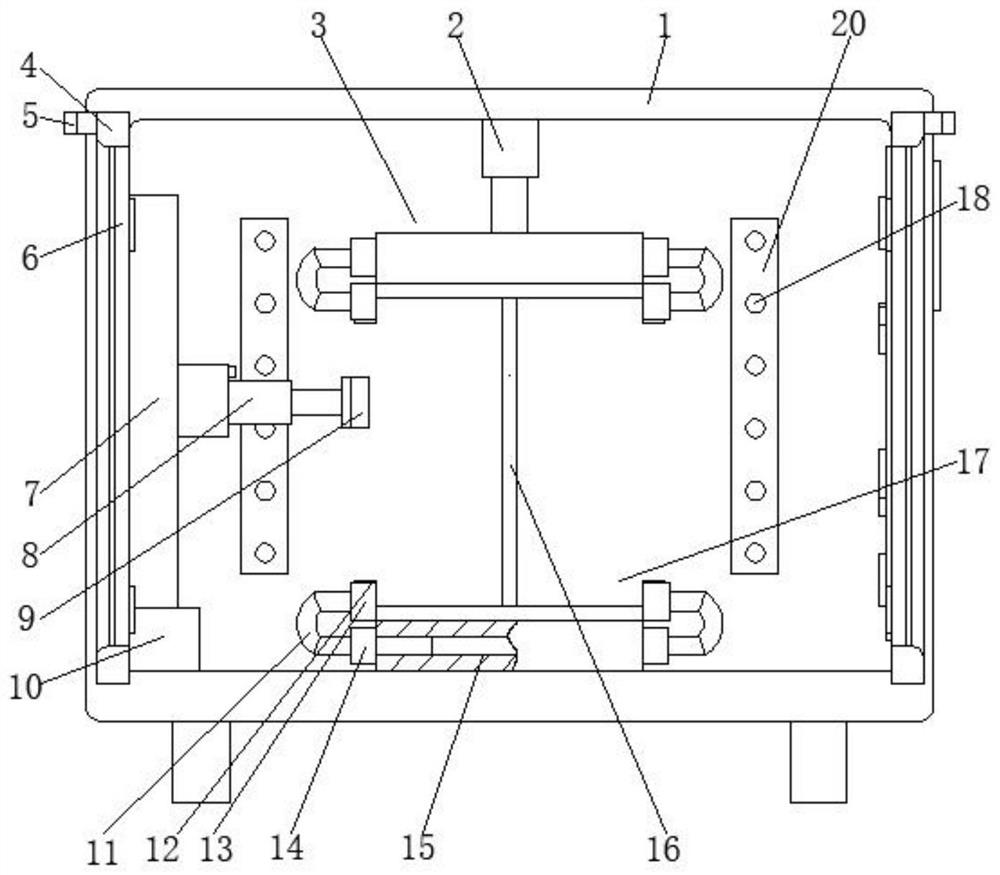

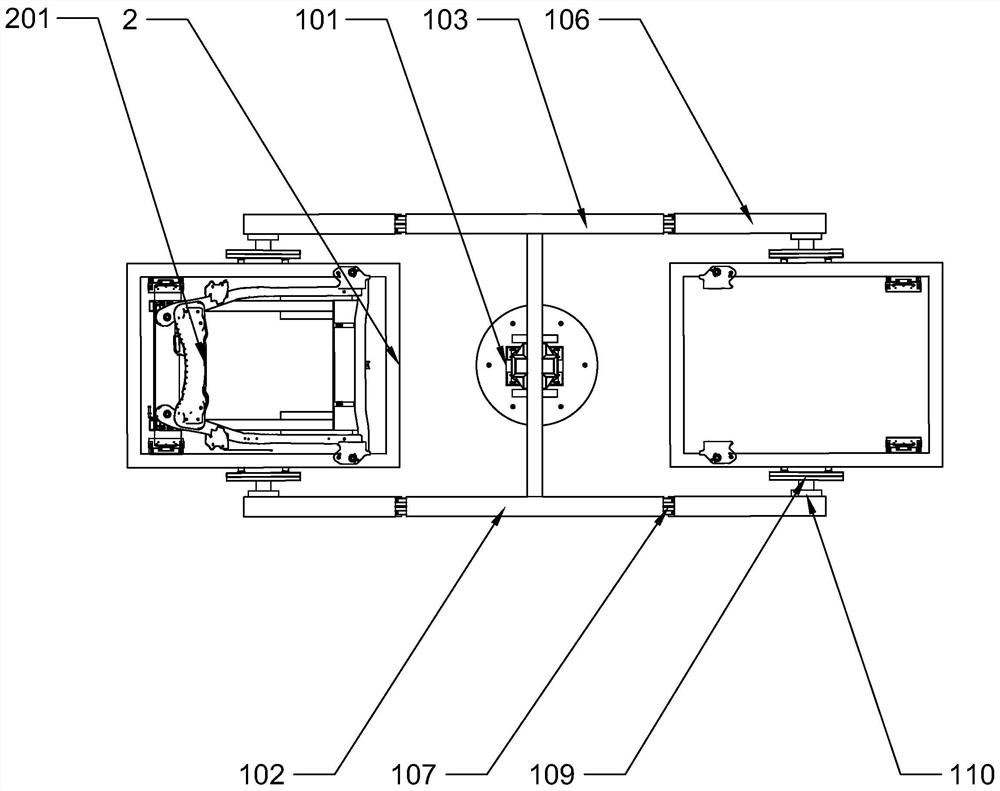

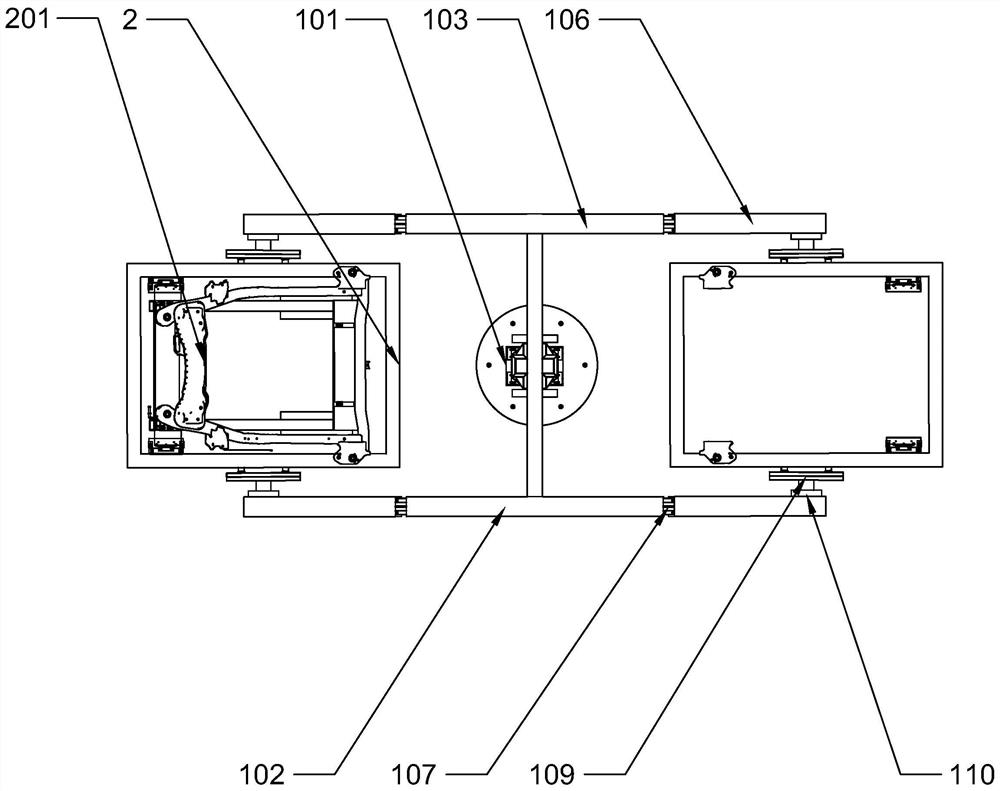

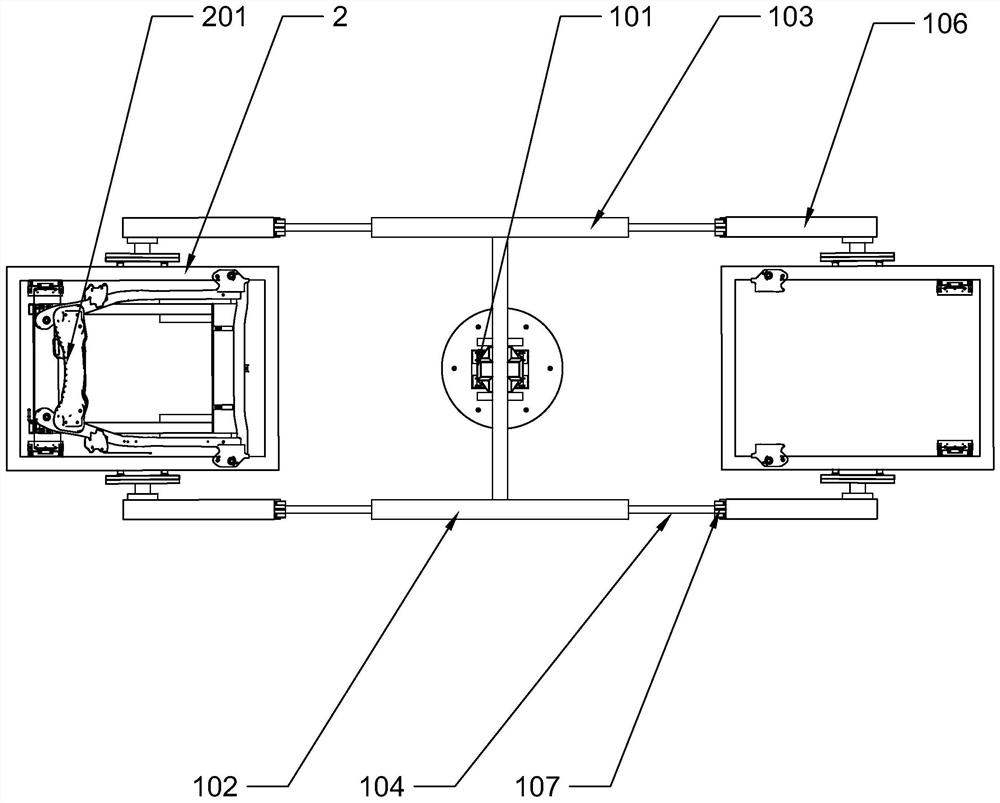

Railway vehicle side beam detection and self-adaption correction device and method

PendingCN107552603AAdaptive correction implementationAchieve correctionMetal working apparatusPull forceJackscrew

The invention discloses a railway vehicle side beam detection and self-adaption correction device. The railway vehicle side beam detection and self-adaption correction device comprises a fundamental component (2). An upper jacking mechanism, a lower pulling mechanism and a control mechanism are arranged between the fundamental component (2) and a side beam (9). The upper jacking mechanism comprises a component cross beam (7) and a hydraulic jack (6). The lower pulling mechanism comprises a combined cross beam (4) and an adjustable pull rod (3). The control mechanism comprises a measurement ruler (5) and a control cabinet (10). The invention further discloses a railway vehicle side beam detection and self-adaption correction method. According to the railway vehicle side beam detection and self-adaption correction device, the hydraulic jack conducts jacking, and meanwhile, and the combined cross beam generates counteractive pull force, so that deformation correction of the side beam is realized; the measurement ruler measures the deformation degree of the side beam in real time and transmits a feedback signal to the control cabinet; jacking force of the hydraulic jack is controlled through the control cabinet to realize self-adaption correction of upwarp and downwarp deformation of the front end of the side beam.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

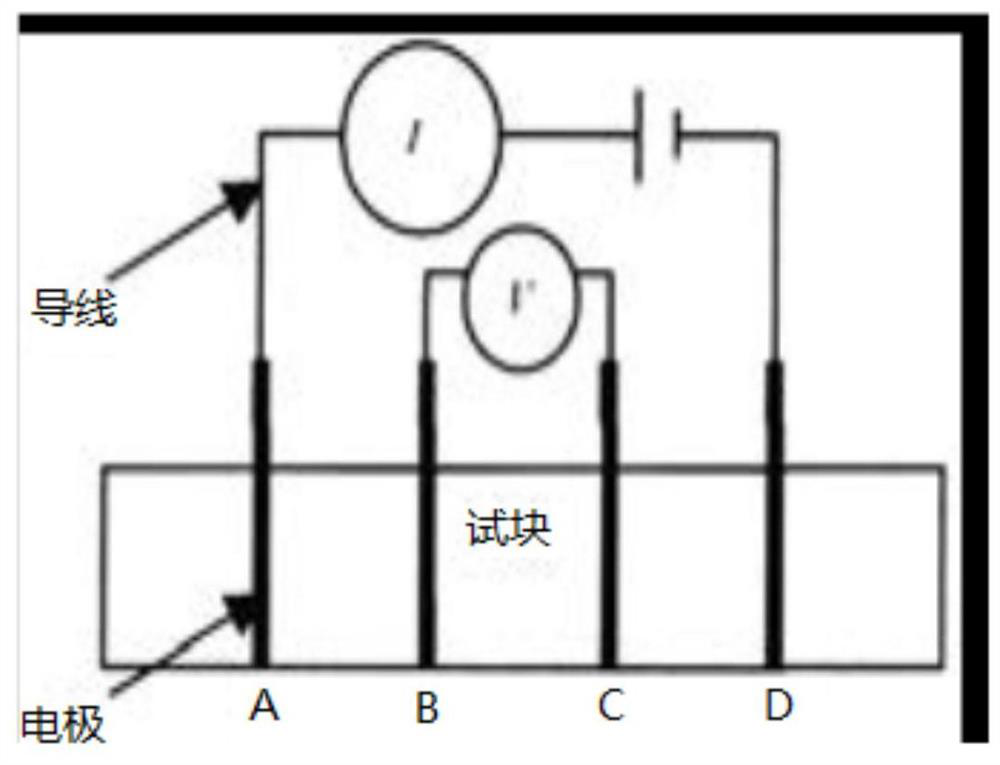

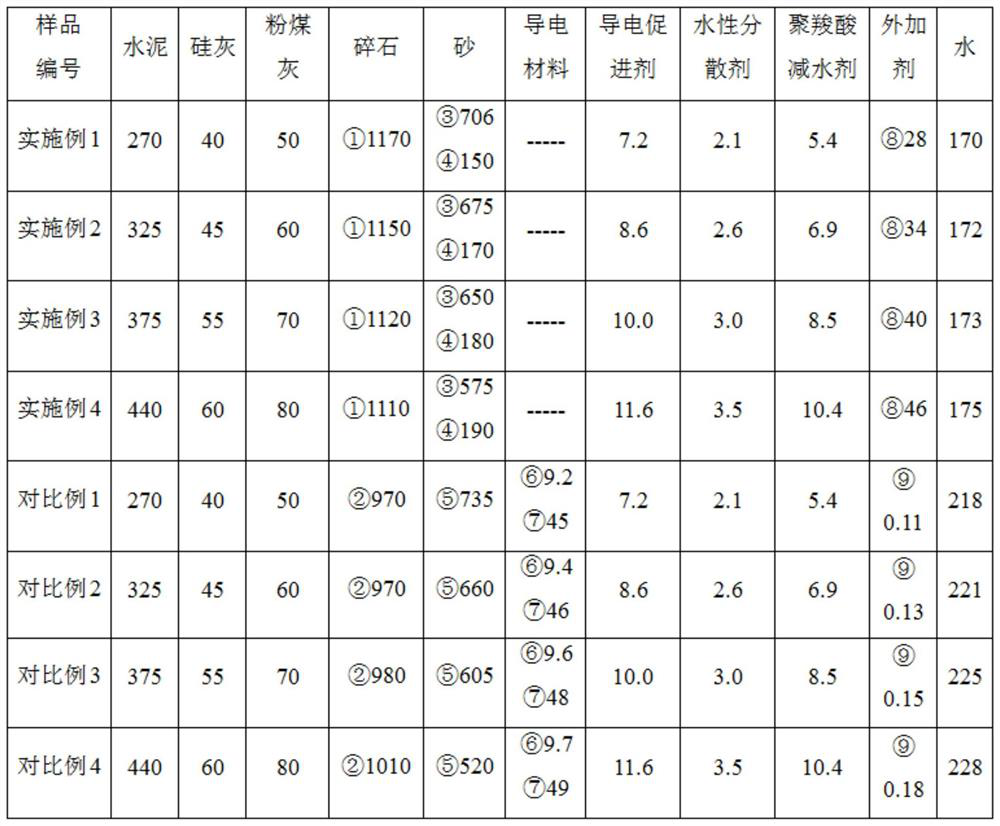

Iron tailing large-slump high-strength conductive concrete and preparation method thereof

ActiveCN112521076AIncrease slumpAvoid the effects of intensitySolid waste managementSuperplasticizerCarboxylic acid

The invention discloses iron tailing large-slump high-strength conductive concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The conductive concrete comprises the following components in parts by weight: 250-450 parts of cement, 1050-1180 parts of coarse aggregate, 720-960 parts of fine aggregate, 70-150 parts of admixture, 25.6-60.0 partsof expanding agent, 1.6-6.0 parts of water-based dispersing agent, 4.8-10.8 parts of polycarboxylate superplasticizer and 170-175 parts of water, wherein the unit is kg / m3. By adopting the technical scheme provided by the invention, the requirements of mechanical properties, working properties and conductivity of the conductive concrete can be effectively met.

Owner:CHINA MCC17 GRP

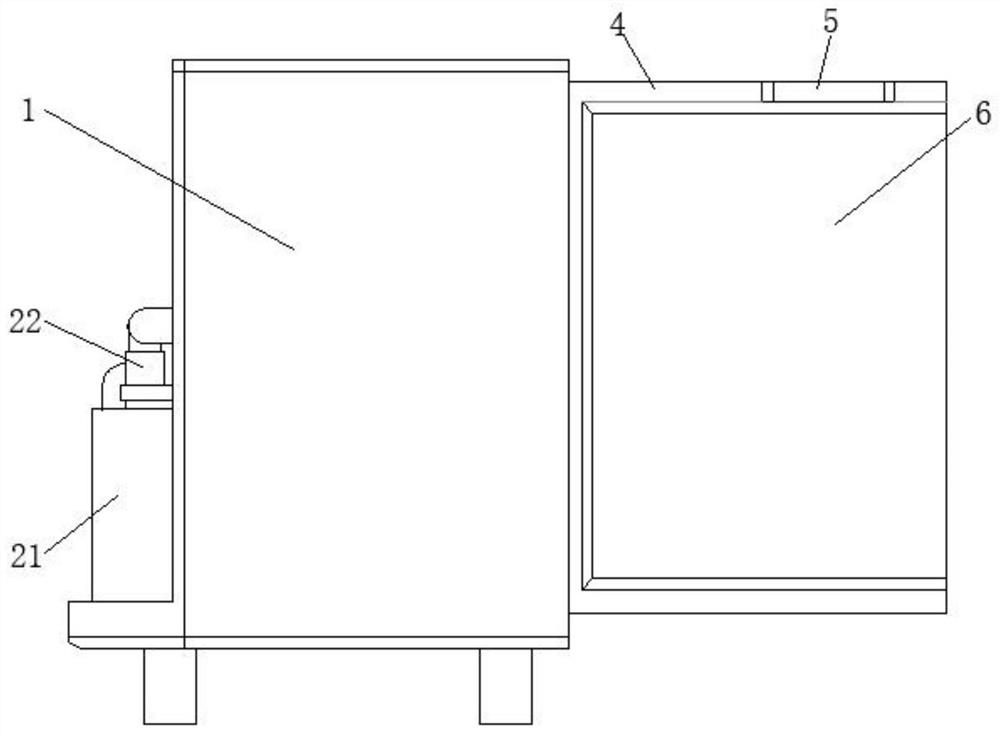

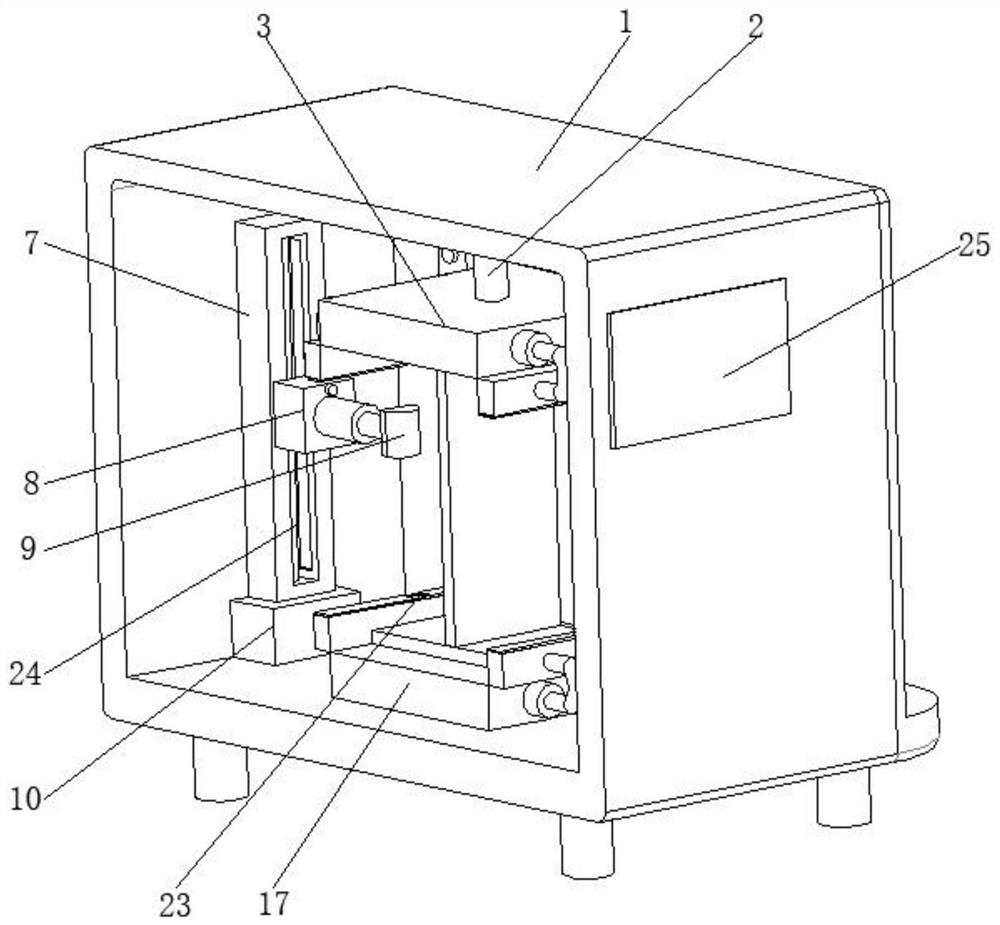

Strength detection device for weather-resistant anti-corrosion plywood

PendingCN113218854AEasy to operateReliable strength valueWeather/light/corrosion resistanceUsing mechanical meansCorrosion preventionEngineering

The invention provides a strength detection device for a weather-resistant anti-corrosion plywood, and relates to the technical field of board strength detection. The strength detection device for the weather-resistant anti-corrosion plywood comprises a box body, a lower clamp is arranged on the inner bottom surface of the box body, a hydraulic cylinder is arranged on the upper inner wall of the box body, an upper clamp is arranged at the output end of the hydraulic cylinder, and each of the upper clamp and the lower clamp comprises a workbench, an adjusting cap, a clamping block and a connecting rod. The adjusting caps are rotationally connected to the left side face and the right side face of the workbench respectively, the lower portions of the connecting rods are in threaded connection with the adjusting caps and are in sliding connection with the workbench, and the ends of the upper sides of the connecting rods are fixedly connected with the clamping blocks. Cold water in a cold water tank or hot water in an electric hot water tank is sprayed out through a nozzle of a spray head plate, so that an I-shaped weather-resistant anti-corrosion plywood is in a wet and cold or humid and hot environment, and a relatively reliable strength value of the weather-resistant anti-corrosion plywood can be obtained after the I-shaped weather-resistant anti-corrosion plywood is tested; in the testing process, the state of deformation or bonding stripping can be obtained according to a high-speed camera.

Owner:漳州市庆瑞工贸有限公司

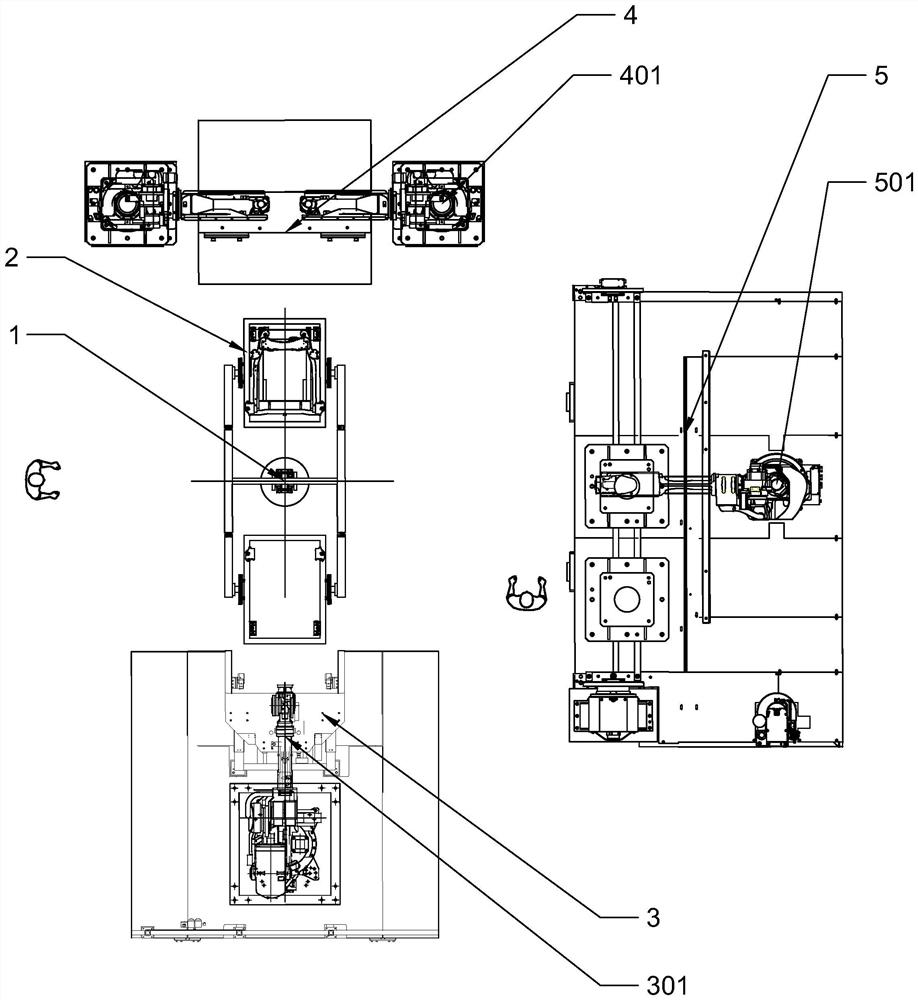

Multi-station robot production line and production method

ActiveCN111843256ARealize automatic flipAvoid the effects of intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProcess engineering

The invention discloses a multi-station robot production line, and aims to provide a multi-station robot production line which allows a frame to automatically move and turn in different welding stations. The multi-station robot production line of the technical scheme is characterized in that by arranging a rotating mechanism, the frame automatically moves among the different welding stations, by means of a turning device, the frame can turn, and by using a frame tool and the turning device in cooperation, not only is the problem that it is difficult to directly clamp the frame or to determinea turning center due to the irregular shape of the frame solved, but also the problem that deformation or strength reduction occurs near a welding spot due to residual welding heat when the frame moves among the different stations and needs to be clamped again is solved. The invention further provides a production method of the multi-station robot production line. Efficient machining of the frameis realized.

Owner:NINGBO DAHONGYING UNIV

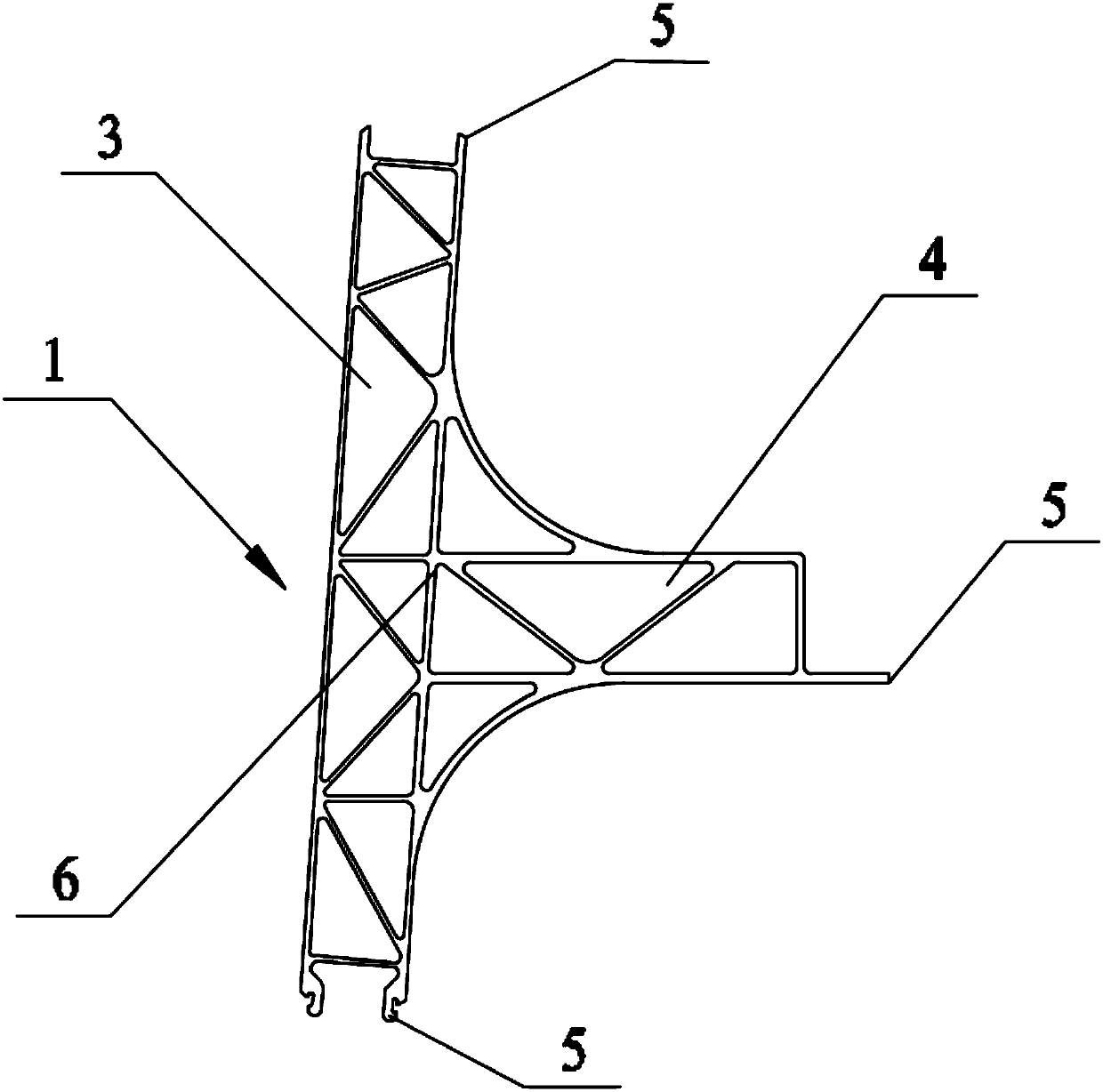

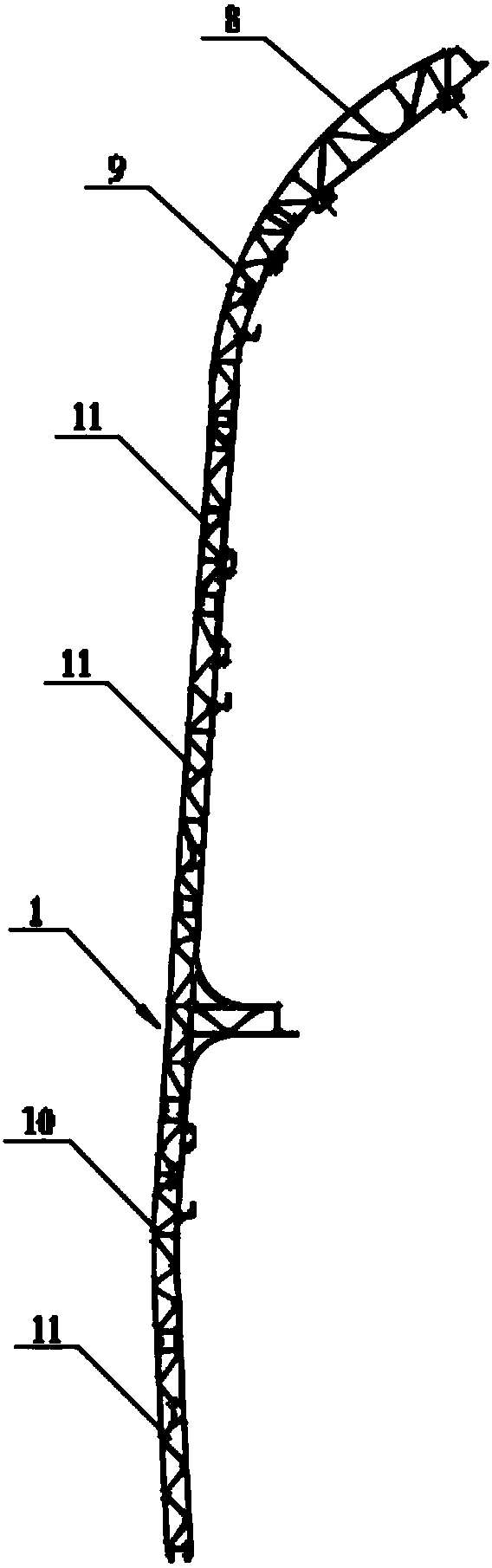

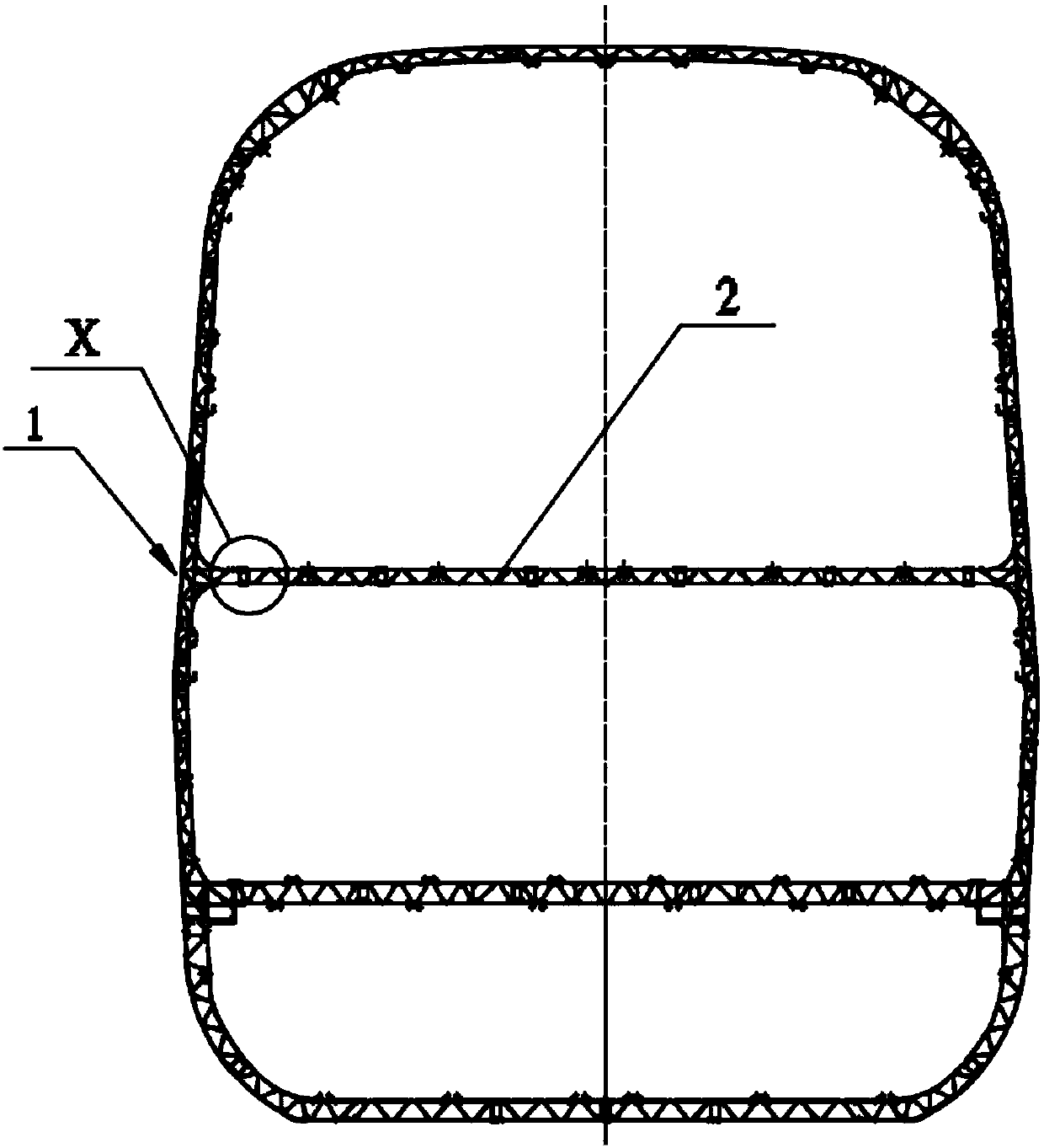

Double-layer train carriage

InactiveCN109808718AAvoid deformationAvoid local stressRailway transportAxle-box lubricationStress ProblemUltimate tensile strength

An embodiment of the invention provides a double-layer train carriage. The carriage comprises a roof, a bottom frame and a carriage space defined by side wall structures, wherein the carriage space isdivided into an upper carriage and a lower carriage by floor structures; each side wall structure comprises a roof connecting section for primary fixed connection, a load bearing section and a bottomframe linking section; each load bearing section comprises a switching structure for mounting and fixing the floor structure of the upper carriage. According to the technical scheme, adjustment transition is performed by the switching structure, the problem of fit tolerance accumulation caused in the side wall mounting process is solved, so that the floor structures of the two carriages can be fixedly connected with side walls smoothly, and meanwhile, local effects of local stress problems or welding processes in the direction connection process of the floor structures and the side walls on strength of the side walls are avoided.

Owner:CRRC TANGSHAN CO LTD

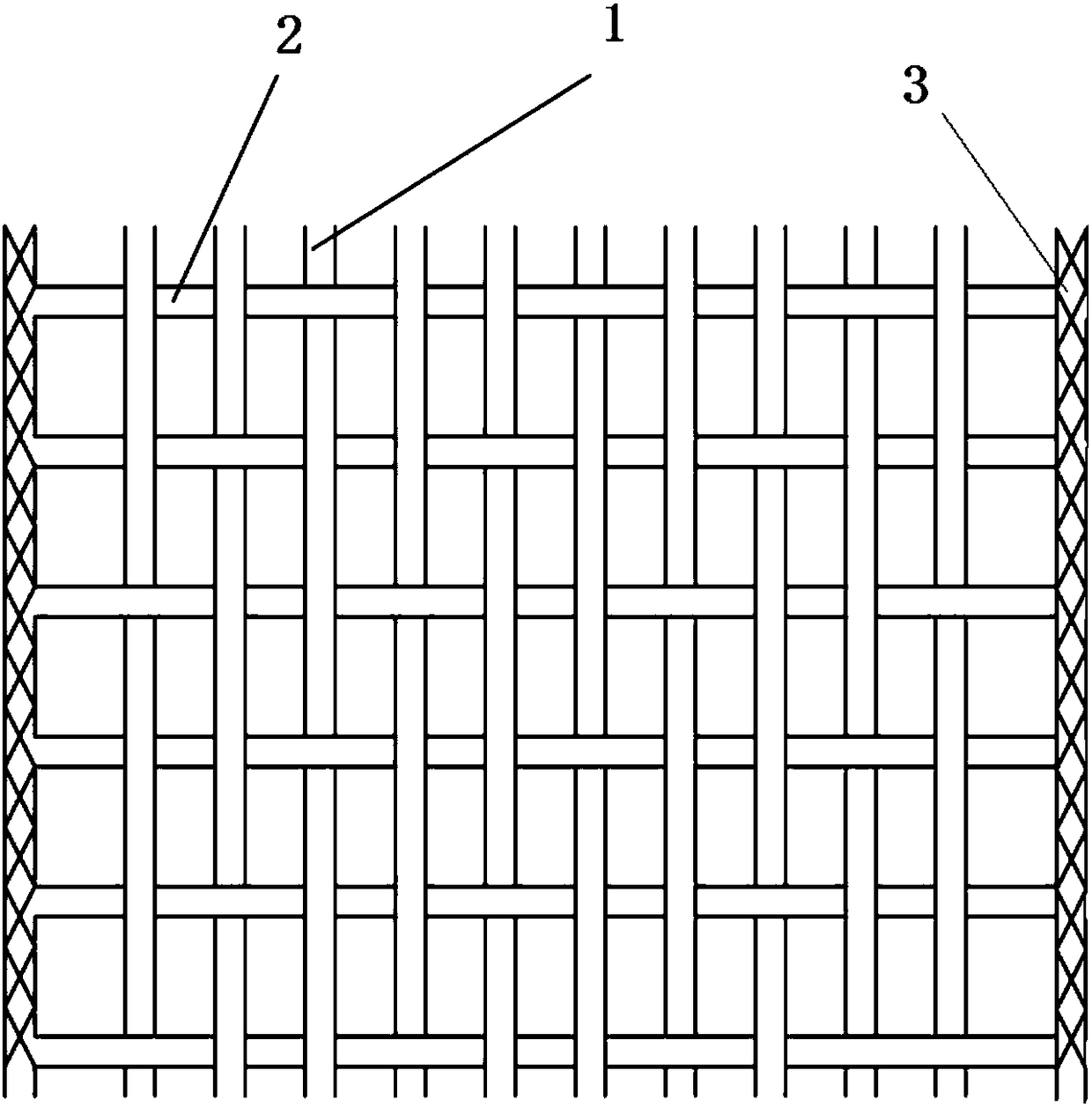

High-strength reinforced belt and manufacturing method thereof

PendingCN108086284ALow densityAvoid the effects of intensityArtificial islandsRoadwaysPulp and paper industryUltimate tensile strength

The invention relates to a high-strength reinforced belt and a manufacturing method thereof. The high-strength reinforced belt comprises multiple radial bundled rigid yarn, multiple weft polypropylenefilament yarn and radial side yarn; the radial bundled rigid yarn is arranged in parallel, the radial side yarn is arranged on the two sides of the radial bundled rigid yarn, during weaving, the radial bundled rigid yarn and the weft polypropylene filament yarn are Iinterspersed in a crisscross manner to form a reticulate body, two ends of the weft polypropylene filament yarn are fixedly connected with the radial side yarn, the radial bundled rigid yar comprises, by mass percent, 88 to 94% of polypropylene, 5 to 10% of polyethylene, 0.5 to 1% of a plastic antiaging agent and 0.5 to 1% of a plastic reinfocer. Through melting, stirring and extrusion forming, the radial bundled rigid yarn is obtained; the radial bundled rigid yarn is obtained through a mixture of polypropylene and polyethylene, the strength of the radial bundled rigid yarn can be effectively improved, and meanwhile, density of the radial bundled rigid yarn is reduced, and the proportion is low.

Owner:JIANGSU DINGTAI ENG MATERIAL

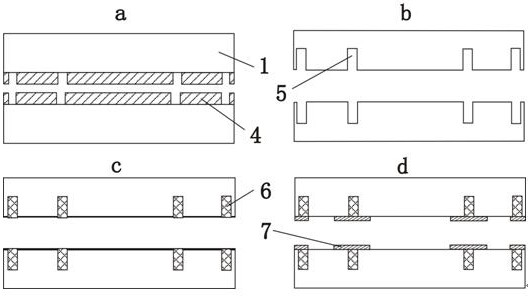

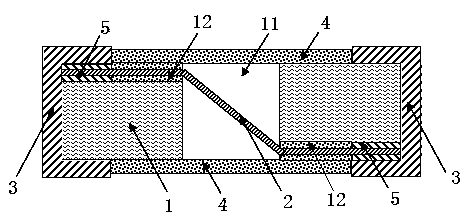

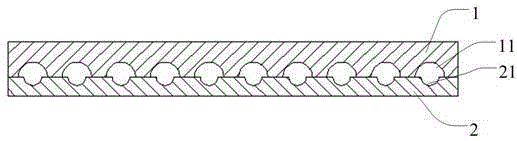

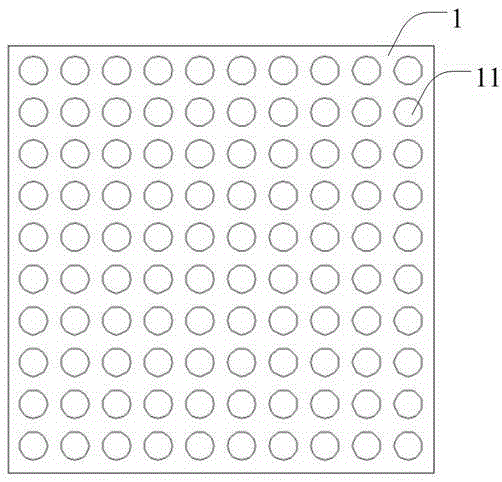

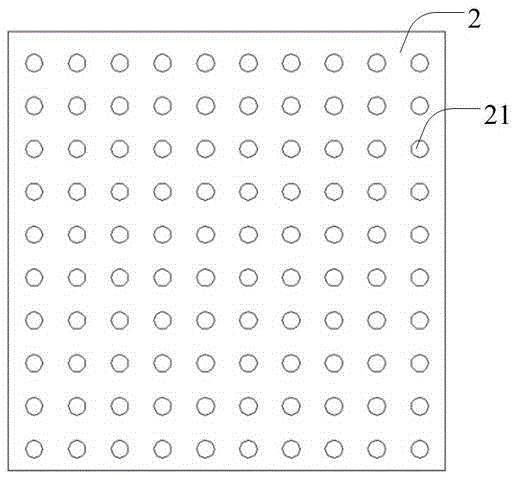

Chip type protecting element and batch manufacturing method thereof

ActiveCN103903929AImprove high voltage breaking capacityImprove breaking capacityFuse device manufactureEngineeringProtection layer

The invention discloses a chip type protecting element and a batch manufacturing method thereof. The element comprises an insulation base plate, a metal melt body, end electrodes and a protecting layer. A through hole is formed in the middle of the insulation base plate, and the opening direction of the through hole is perpendicular to the end electrodes. Grooves connected with the through hole are formed in the upper surface and the lower surface of the insulation base plate. The metal melt body penetrates in from a groove in one side of the insulation base plate, penetrates through the through hole in the opposite-angle direction and then penetrates out from a groove in the other side. The two ends of the metal melt body are fixed in the grooves through conducting resin and form electric connecting with the end electrodes at the two ends of the insulation base plate. The protecting layer is formed between the end electrodes. The design that the metal melt body forms a suspension melt wire structure by vertical opposite angle wire penetrating is used, the produced chip type protecting element has the advantages of being high in breaking capacity and high in reliability, two inherent defects of a traditional fuse structure are removed, structure design is simple, cost is low, and batch production can be achieved easily.

Owner:NANJING SART SCI & TECH DEV

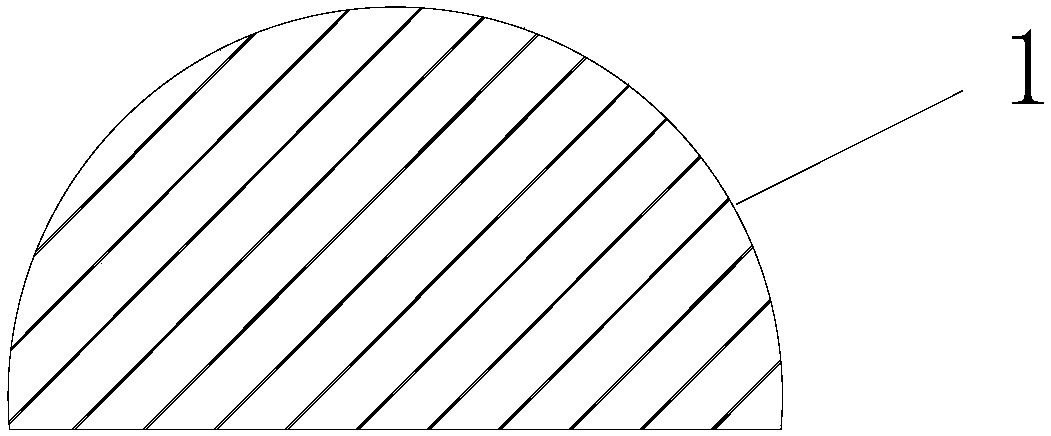

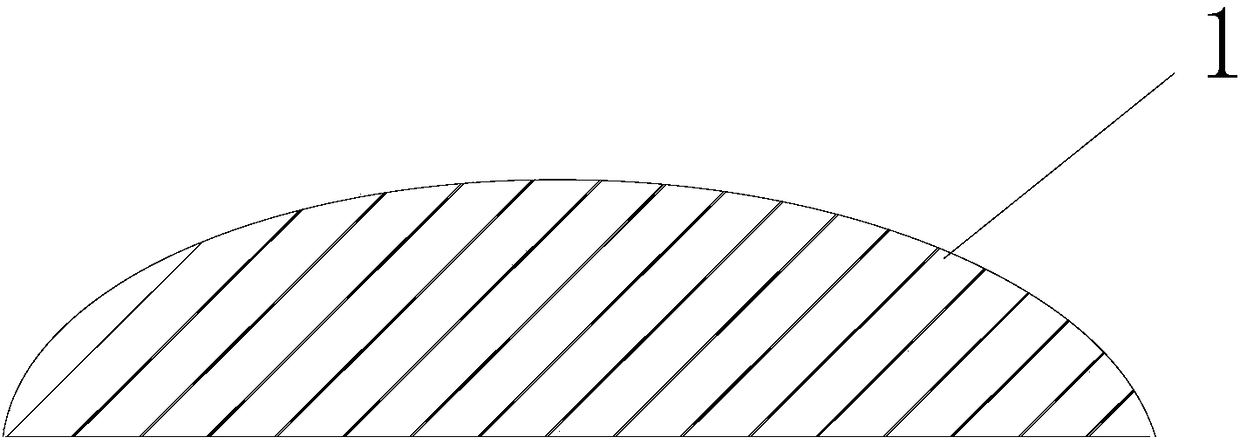

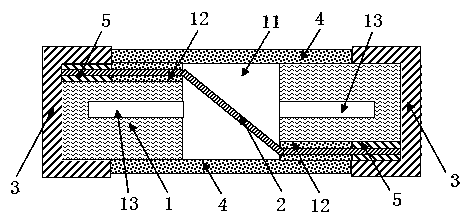

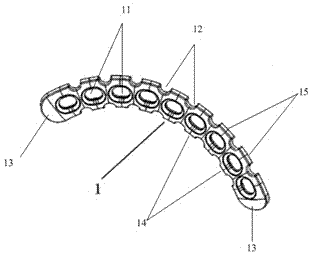

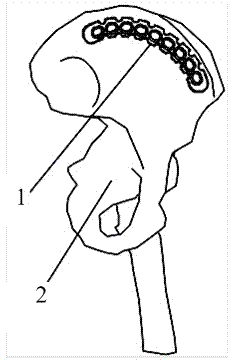

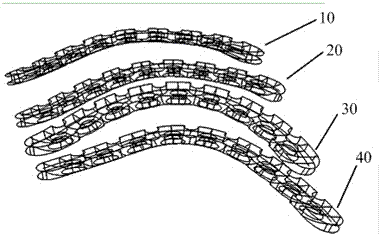

Pelvis ala ossis ilii dissection type bone plate

InactiveCN102499751BAvoid the effects of intensityRelieve painBone platesHuman bodyFracture reduction

The invention provides a pelvis ala ossis ilii dissection type bone plate which is used for fixing fractured ala ossis ilii on pelvis of a human body. The pelvis ala ossis ilii dissection type bone plate comprises an arc body, wherein the arc body is matched with the dissection shape of the pelvis ala ossis ilii, and the arc body is provided with a connection device which is used for connecting the pelvis ala ossis ilii. Compared with the prior art, the pelvis ala ossis ilii dissection type bone plate is well matched with the surface shape of the pelvis ala ossis ilii of a human body, four types of bone plates meet the requirements of all types of pelvis ala ossis ilii fracture, time consumed in shaping during operation is reduced due to the matched dissection shape of the bone plate, and the pelvis ala ossis ilii dissection type bone plates with different lengths and central arc space shapes can meet the fixation requirements of different types of pelvis ala ossis ilii, so that the influence of repeated shaping on the strength of the bone plate can be avoided, damage to the surrounding soft tissues in a mould testing process is reduced, fracture reduction loss is avoided, pains of a patient is reduced, and the effect and efficiency of treatment are improved.

Owner:SHANGHAI JIAOTONG UNIV

A sound-absorbing foam plastic board

InactiveCN103317807BEasy to processAvoid the effects of intensitySynthetic resin layered productsSound proofingEngineering

The invention discloses a sound-absorbing foam plastic board. The sound-absorbing foam plastic board at least comprises a first foam plastic board and a second foam plastic board, wherein the first foam plastic board and the second foam plastic board are bonded into whole; hemispherical grooves are uniformly distributed on the bonded surfaces of the first foam plastic board and the second foam plastic board respectively; and the ratio of the diameter of the hemispherical groove on the first foam plastic board to the diameter of the hemispherical groove on the second foam plastic board is 1:(0.5-0.7). According to the sound-absorbing foam plastic board disclosed by the invention, the hemispherical grooves are arranged on the foam plastic boards only, so that the processing is simple; and meanwhile, the influence of through hole foam plastic boards on the strength in the prior art can be avoided. The average sound absorption coefficient of the sound-absorbing foam plastic board in medium and low frequencies (100-1500Hz) is 0.59.

Owner:杨州富铭新材料有限公司

Novel glass fiber-reinforced plastic material

The invention discloses a novel glass fiber-reinforced plastic material. The novel glass fiber-reinforced plastic material comprises, by mass, 25-30 parts of epoxy resin, 15-25 parts of polyester resin, 42-55 parts of glass fiber, 3-5 parts of emulsified paraffin, 1-2 parts of polyamide, 6-8 parts of dibutyl phthalate, 4-6 parts of silicon carbide micropowder and 3-4 parts of a coupling agent. Thenovel glass fiber-reinforced plastic material of the invention is high in elastic modulus, good in rigidity, not prone to deformation and high in thermal endurance, prevents long period of high temperature from affecting strength, and has strong anti-aging ability and good shearing resistance.

Owner:刘学军

A method for manufacturing a corrosion-resistant magnesium alloy transmission case

ActiveCN104455349BAvoid the effects of intensitySolve the problem of insufficient anti-oxidation and corrosion resistanceAnodisationFoundry mouldsTectorial membraneMicro arc oxidation

The invention discloses a manufacturing method of a magnesium alloy transmission box with ultrahigh corrosion resistance. The manufacturing method comprises the following steps: performing foaming, forming a cluster structure, swabbing I, swabbing II, hardening, roasting, swabbing III, smelting and pouring, and micro-arc oxidation in sequence, and obtaining a casting of the magnesium alloy transmission box attached with a dense Al2O3 oxidation film on the surface layer. The manufacturing method disclosed by the invention has the following characteristics: during the formwork roasting process, the foamed plastic is burned up in advance to avoid the influence of high-temperature foam gasification to the quality of the casting during the pouring process, avoid the influence of carbon dust to the strength of the magnesium alloy, and ensure the purity of the magnesium alloy material; the nanometer powered aluminum dip-coated before pouring is molten and tightly attached to the surface of the casting at high temperature in the pouring process to form a complete aluminum protective film, and then form the dense Al2O3 oxidation film during the follow-up micro-arc oxidation process, so as to tightly coat the magnesium alloy, improve the oxidation resistance and the corrosion resistance of the magnesium alloy, and solve the problem that the oxidation resistance and the corrosion resistance of the magnesium alloy for the existing transmission box are insufficient.

Owner:山东蒙沃变速器有限公司

Stair cavity mold production process

InactiveCN110757114AImprove machining accuracyAvoid the effects of intensityFoundry mouldsFoundry coresManufacturing engineeringHeat treating

The invention discloses a stair cavity mold production process. The process comprises the steps of discharging fixed mold workblank and a movable mold workblank; rough machining, tempering, finish machining and obtaining a movable mold and a fixed mold; forming a main mold cavity in the middle of the fixed mold workblank, forming an auxiliary mold cavity in the middle of the movable mold workblank, and drilling multiple through holes in the auxiliary mold cavity; discharging multiple I columns, carrying out heat treatment on the I columns, and fixing the I columns after heat treatment in the through holes; performing discharging and rough machining to obtain a main mold core blank part, carrying out further heat treatment and finish machining on the main mold core blank part, and obtaininga main mold core; assembling and fixing the main mold core in a main mold cavity of the fixed mold; and assembling the fixed mold and the movable mold, and enabling the I columns to be in abut jointwith the main mold core. Through machining of the fixed mold, the movable mold, the main mold core and the I columns, the fixed mold, the movable mold, the main mold core and the I columns are high inmachining precision, after heat treatment of the main mold core and the I columns, hardness is uniform, forming and demolding effect is good, and the casting quality can be improved.

Owner:GUANGZHOU DIE & MOLD MFG

A horizontal open-hole well stimulation and completion string and its combined operation method

Owner:CHINA NAT OFFSHORE OIL CORP +1

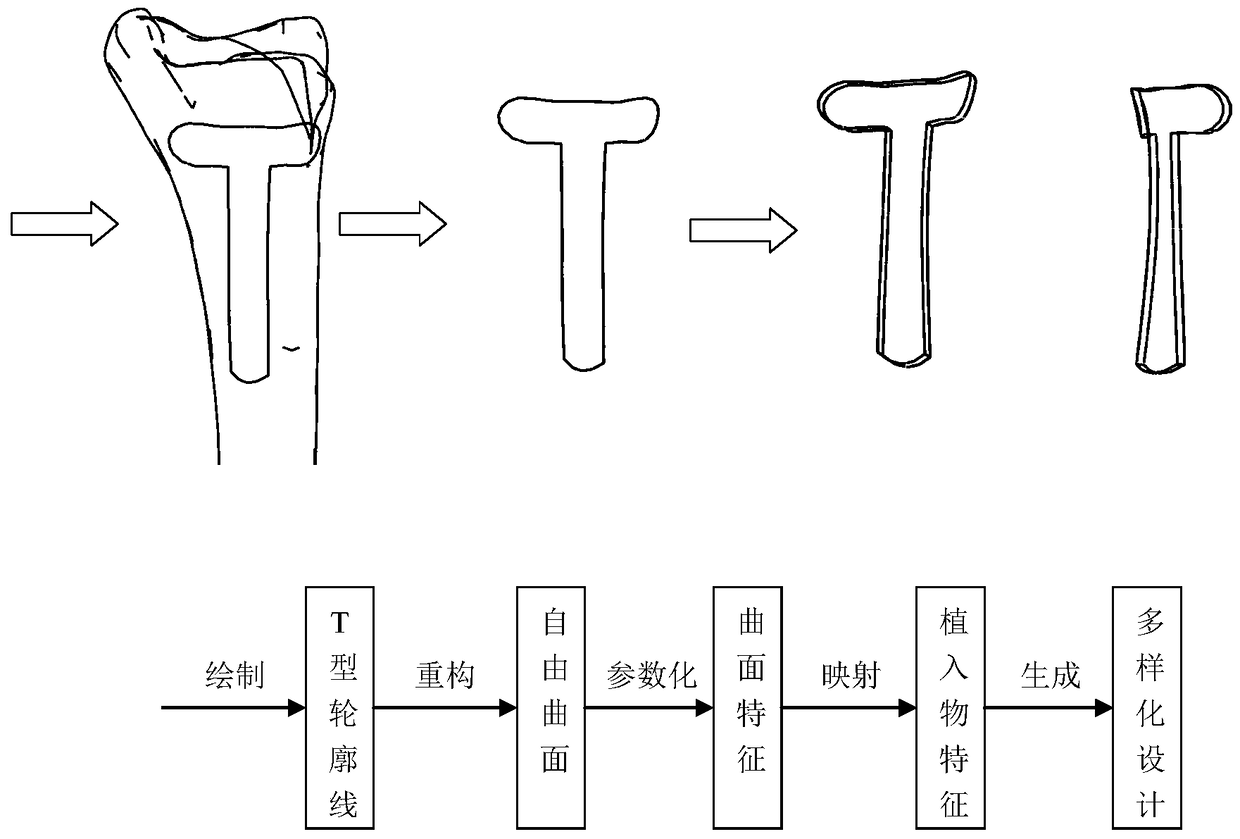

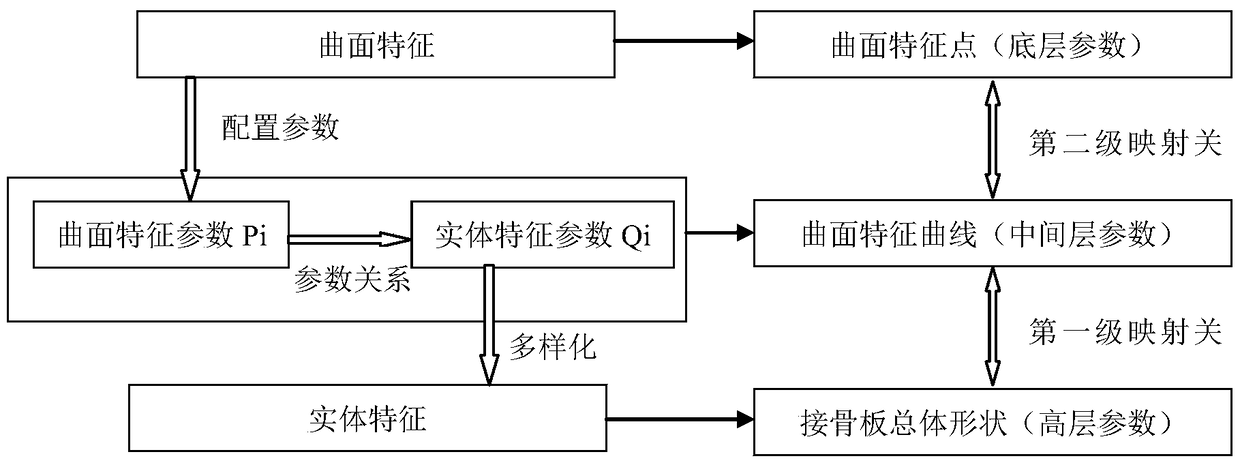

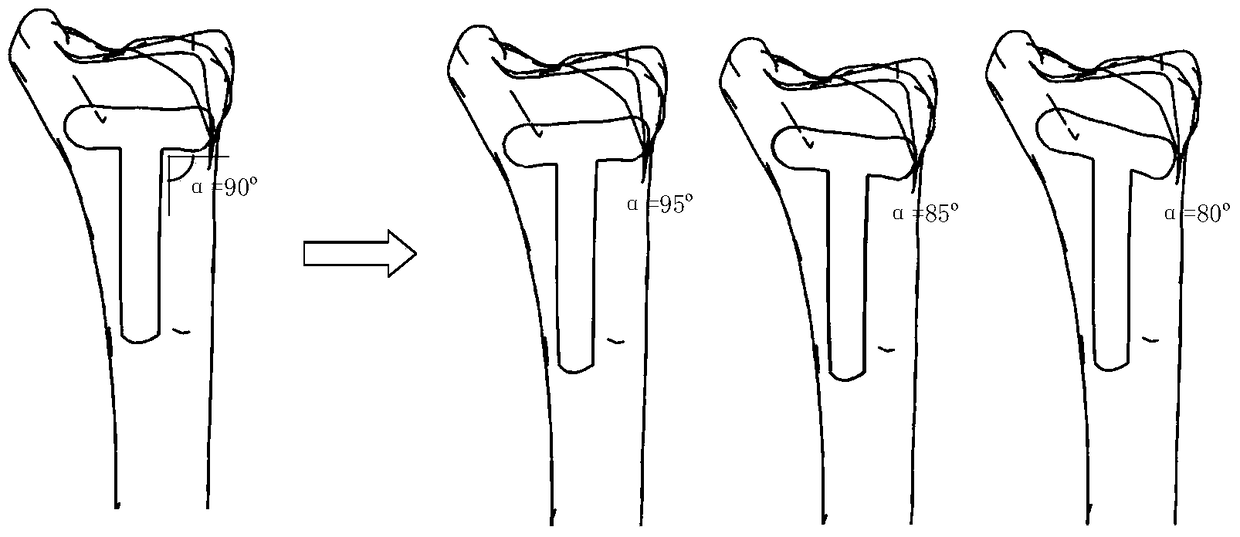

Diversified design method of tibial T-shaped bone plate based on parametric technology

ActiveCN105427367BAvoid the effects of intensityImprove design efficiencyImage rendering3D-image renderingComputer scienceSurface reconstruction

The invention discloses a parameterization technology based diversified design method for a T-shaped tibial connection plate. The method comprises the following steps: step 1, constructing the T-shaped tibial connection plate: drawing a boundary of the T-shaped tibial connection plate by utilizing a boundary line, and performing curved surface reconstruction on a region by constructing an internal constraint line; step 2, setting shape structure characteristics and parameters of the T-shaped tibial connection plate: defining characteristic points and characteristic lines on the reconstructed curved surface region to realize the setting of the characteristics and the related parameters; and step 3, performing diversified design on the T-shaped tibial connection plate: constructing a T-shaped tibial connection plate entity by utilizing a curved surface reconstructed in the step 1, and establishing a mapping relationship between a surface parameter and an entity thickness parameter, so that later fast editing and modification are facilitated for realizing diversified design. According to the method, the digitization, diversification and precision of tibial connection plate design can be realized through parameterization definition of the tibial connection plate; and the method has an important significance for improving the quality and efficiency of the tibial connection plate design.

Owner:HOHAI UNIV CHANGZHOU

A kind of loosening agent for regeneration process of SCR denitration catalyst and preparation method thereof

InactiveCN103623876BShorten the soaking timeAvoid the effects of intensityCatalyst regeneration/reactivationPenetration enhancerRelaxer

The invention discloses a loosening agent used in the regeneration process of an SCR denitration catalyst and a preparation method thereof. The loosening agent comprises the following components: 0.5% to 2% of a wetting agent, 1% to 5% of a penetration enhancer, 1.5% ~2.5% PH regulator, 90.5%~97% deionized water. The beneficial effects of the present invention are: it can shorten the immersion time of the catalyst in the cleaning solution, and avoid the influence of long-time immersion on the strength of the catalyst; it can replace the damage to the catalyst caused by the physical through-hole of the device; At the same time, it is beneficial to restore the acidic sites on the surface of the catalyst. The invention has high practical value for improving catalyst regeneration effect, catalyst regeneration work efficiency and avoiding physical damage in catalyst regeneration process.

Owner:SUZHOU HUALE AIR POLLUTION CONTROL TECH EXPAND CO LTD

A multi-station robot production line and production method

ActiveCN111843256BRealize automatic flipAvoid the effects of intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProcess engineering

The invention discloses a multi-station robot production line, aiming to provide a multi-station robot production line in which the vehicle frame can be automatically transferred and turned over in different welding stations. In the automatic transfer of different welding stations, the overturning device is used to realize the overturning of the frame, and the combined use of the frame tooling and the overturning device not only avoids the problem that it is difficult to directly clamp or determine the overturning center due to the irregular shape of the frame , It also solves the problem of deformation or strength weakening near the welding point caused by residual heat of welding when the frame is transferred at different stations and needs to be re-clamped. The invention also provides a production method of a multi-station robot production line, which realizes efficient processing of the vehicle frame.

Owner:NINGBO DAHONGYING UNIV

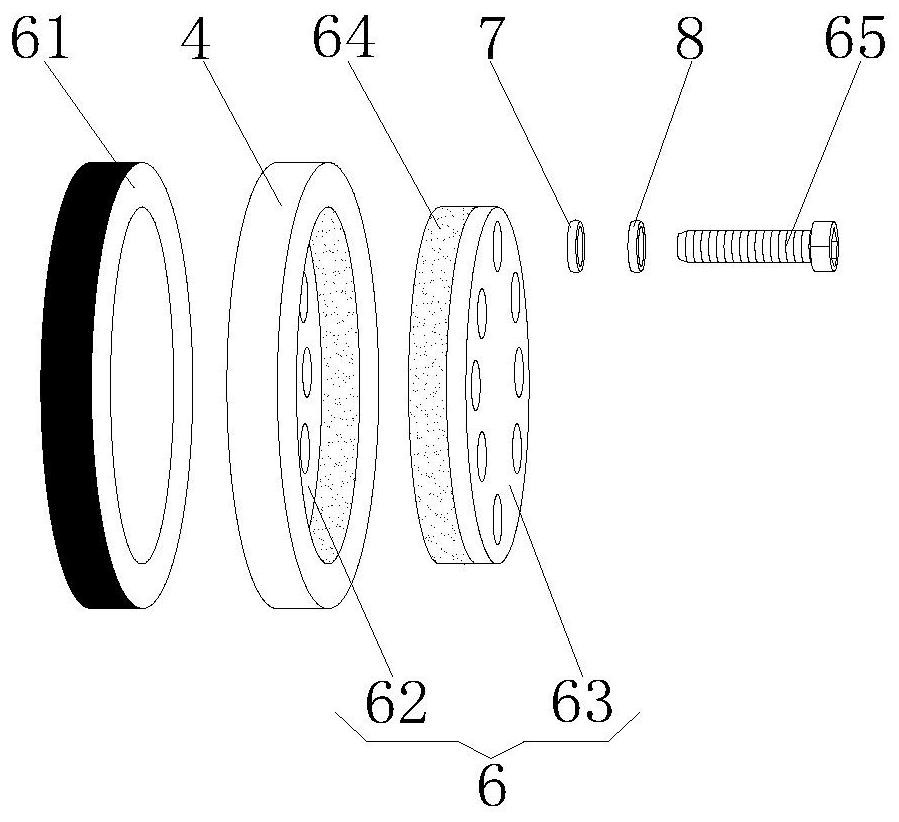

Tubular pile with good sealing effect and core filling method

PendingCN112575776AImprove sealingImprove stabilityProtective foundationBulkheads/pilesArchitectural engineeringSheet pile

The invention provides a tubular pile with a good sealing effect and a core filling method. The tubular pile comprises a tubular pile body, wherein a core filling part area is arranged at the top of an inner cavity of the tubular pile body, a sand filling and grouting part area is arranged at the bottom of the inner cavity of the tubular pile body, the top end of the tubular pile body is in bolt connection with a pile top end blocking plate, the bottom end of the tubular pile body is in bolt connection with a pile bottom end blocking plate, and threaded grooves are formed in the peripheries ofthe pile top end blocking plate, the pile bottom end blocking plate and the inner cavity of the tubular pile body. According to the tubular pile with the good sealing effect and the core filling method, through the cooperation of a sealing gasket, sealing treatment can be carried out between the tubular pile body and the pile top end blocking plate and between the tubular pile body and the pile bottom end blocking plate; through the cooperation of a limiting groove, a fastening disc, a water-swelling pad and a fastening bolt, overall fixed sealing can be carried out between the tubular pile body, the sealing gasket, the pile top end blocking plate and the pile bottom end blocking plate; and through the cooperation of a stainless steel hoop, auxiliary reinforced sealing treatment can be carried out on the outer side of the joint position of the sealing gasket, the pile top end blocking plate and the pile bottom end blocking plate, so that the overall sealing performance of the joint position of the tubular pile is directly enhanced.

Owner:JIANGXI THERMAL POWER CONSTR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com