A horizontal open-hole well stimulation and completion string and its combined operation method

A technology for horizontal open hole and completion strings, which is applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., to achieve the effect of improving operation effect, enhancing effective support, and reducing the risk of pipe sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

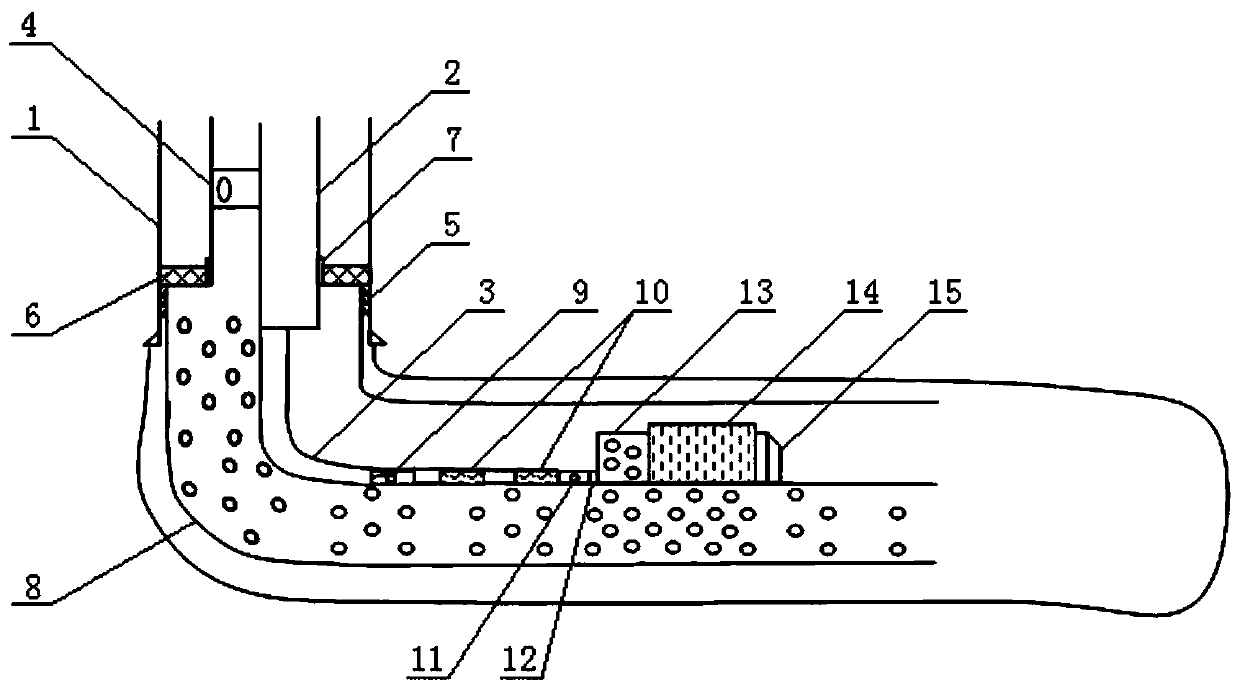

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] as attached figure 1 As shown, a horizontal open hole stimulation and completion string includes a large-size drill pipe 2 arranged in the upper casing 1, and a circulating sliding sleeve 4 is connected to the large-size drill pipe 2. The large-size drill pipe 2 The lower part of 2, located below the circulation sliding sleeve 4, is connected with a perforated tailpipe 8 sleeved outside the large-size drill pipe 2 through a hydraulic liner hanger; the end of the large-size drill pipe 2 is connected with a The small-sized drill pipe 3 in the pipe 8, the small-sized drill pipe 3 is connected with: check valve 9, shock absorber 10, pressure detonator 11, delay device 12, and bullet holes without bullets Gun 13, perforating gun 14 combined with deflagration fracturing, gun tail 15.

[0030] The perforated tailpipe 8 adopts the whole section to be perforated, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com