Wide-body double hull board side double bottom ship based on large openings of inner rib plates in ballast tank

A technology with large openings and ballast tanks, which is applied in the direction of hull, ship construction, and partial cabins in the hull, etc., can solve the problems of large empty ship weight, etc., and achieve the effects of increasing welding area, reducing empty ship weight, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

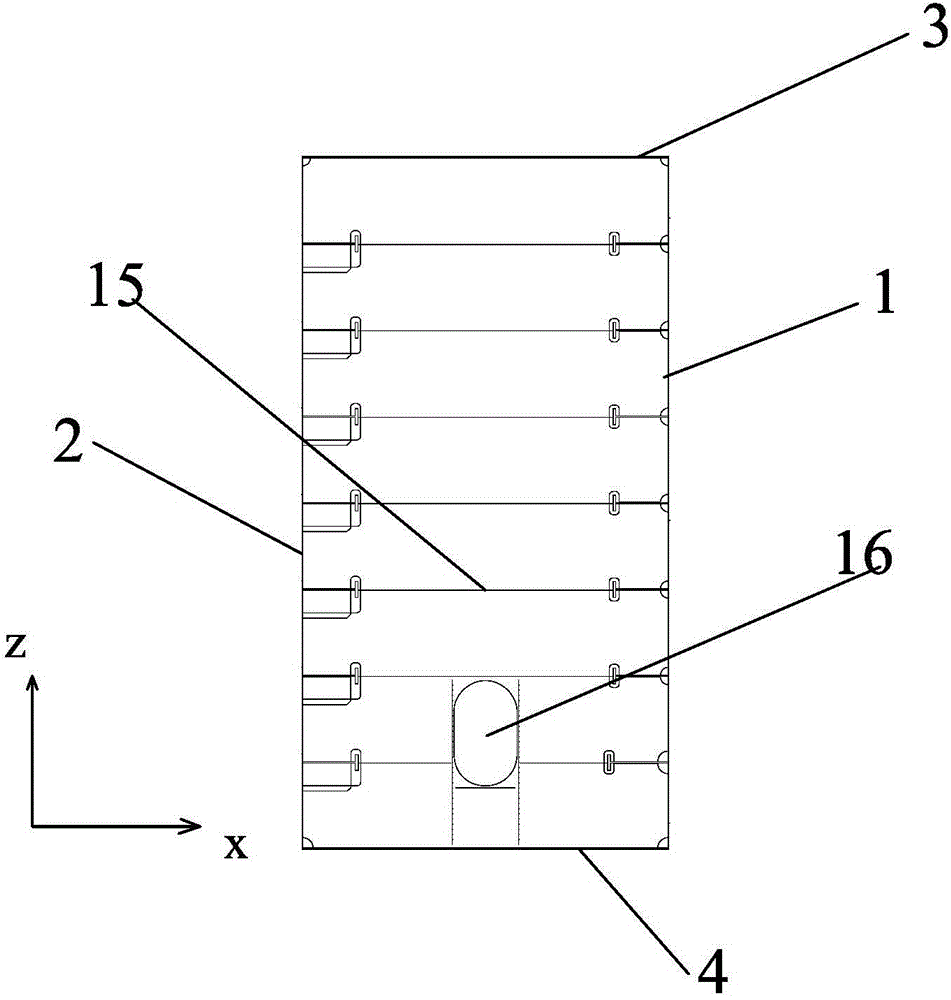

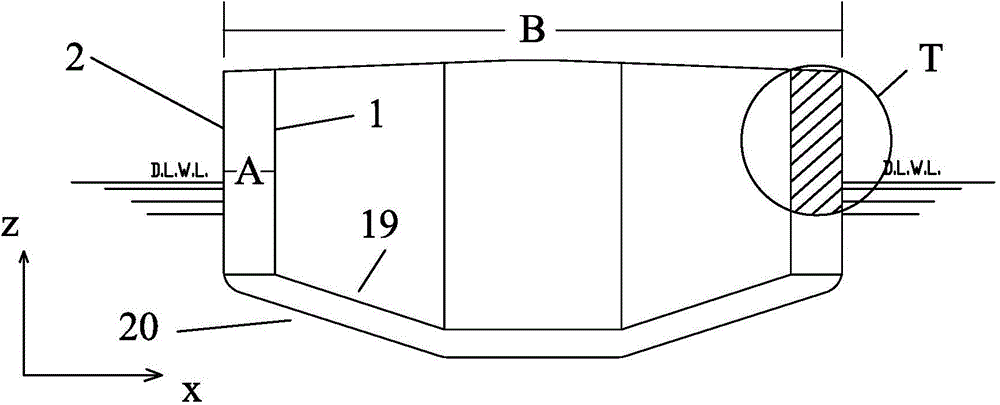

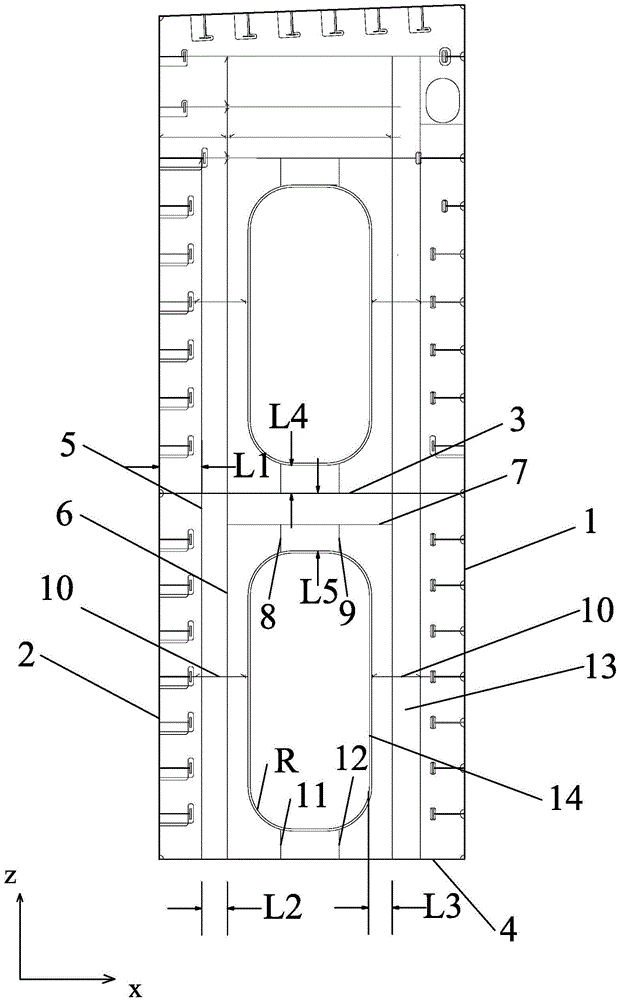

[0014] figure 2 The shaded area is image 3 Simplified schematic of the structure diagram. Such as image 3 The large opening design of the floor plate of the special wide-body double-side side ballast tank shown in the present invention mainly includes the form of vertical and horizontal connection arcs of the large opening in the figure; the layout spacing of vertical stiffeners; Oblique; the ratio of the area of large openings to the area of regions with strong structural boundaries.

[0015] Such as image 3 As shown, the opening of the floor plate of the double-side side ballast tank of the present invention is much larger than the traditional opening design; a panel is arranged at the large opening; two vertical stiffeners 5 and 6 are arranged between the large opening and the inner shell 1 and the outer shell 2; A horizontal stiffener 7 is arranged between the opening and the horizontal girder 3 above it, and two vertical stiffeners 8 and 9 are arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com