Patents

Literature

840results about "Hull interior subdivision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

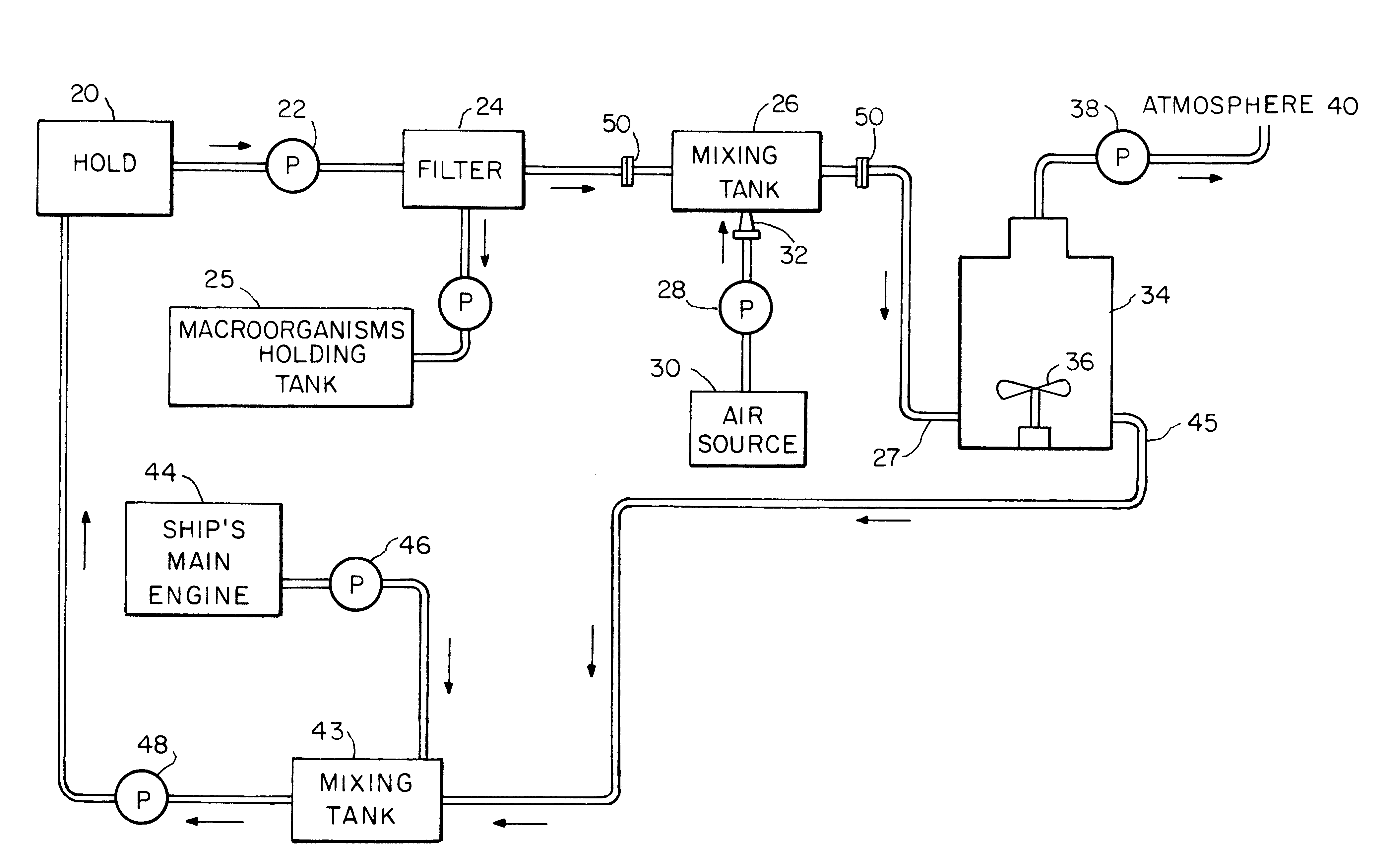

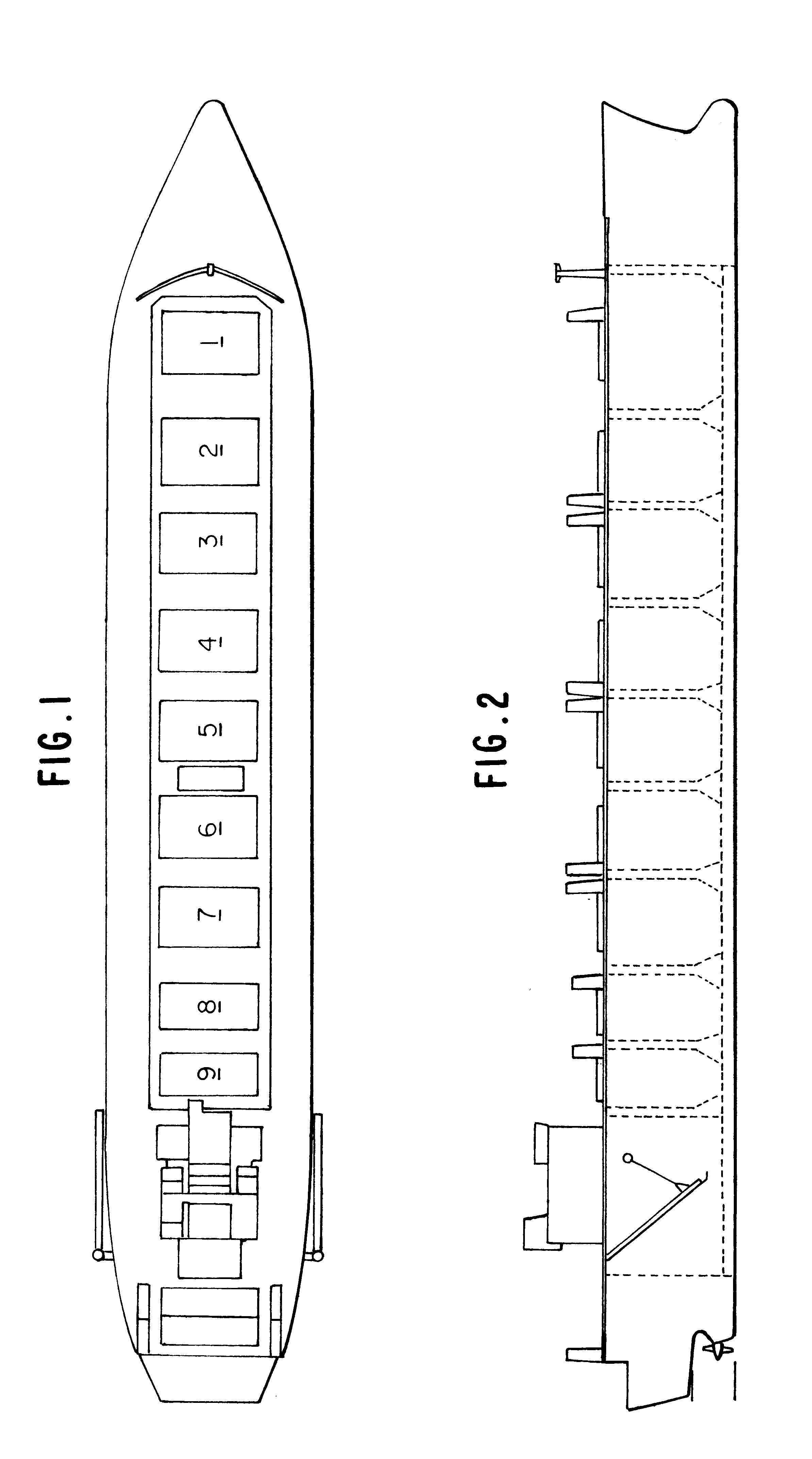

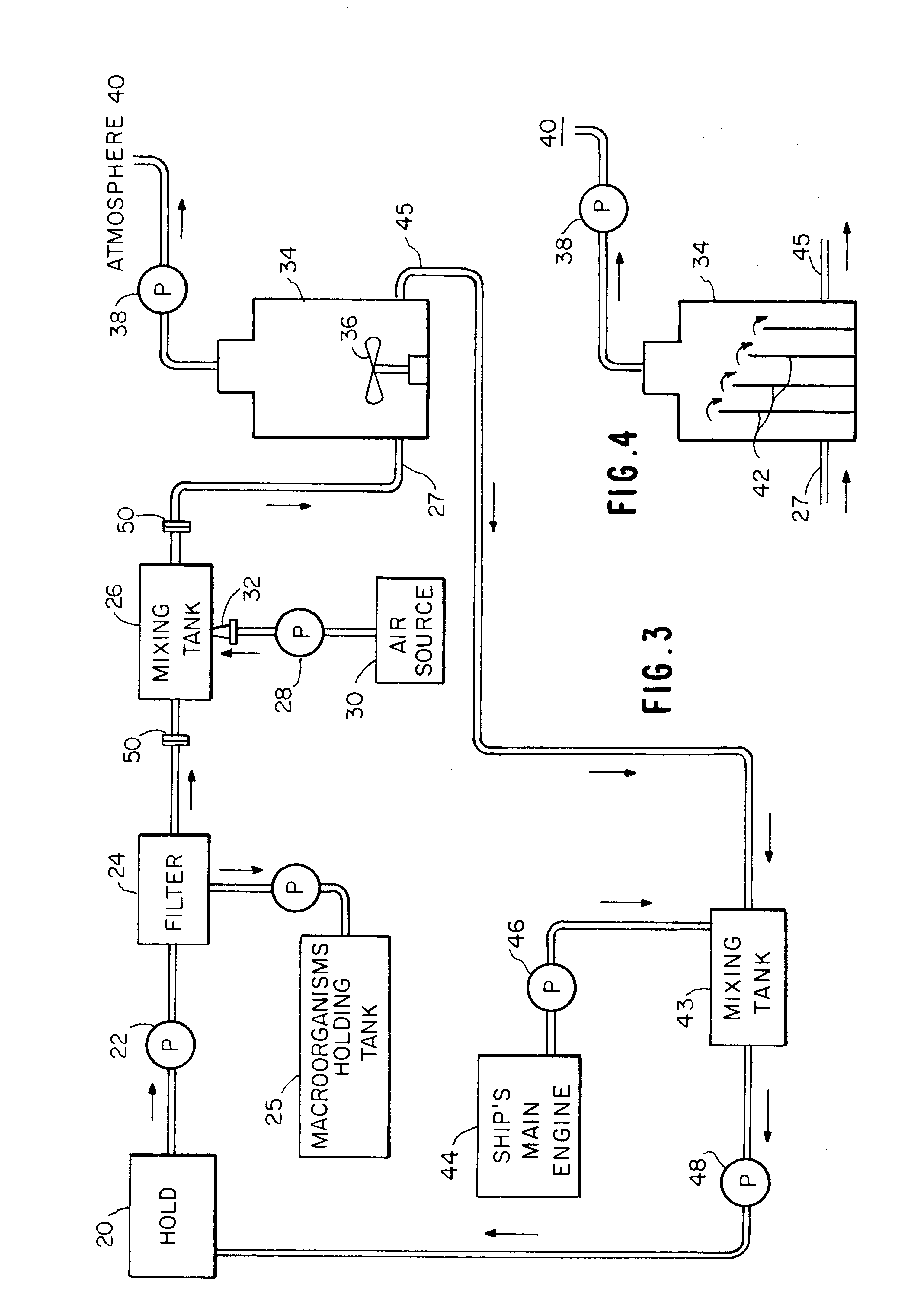

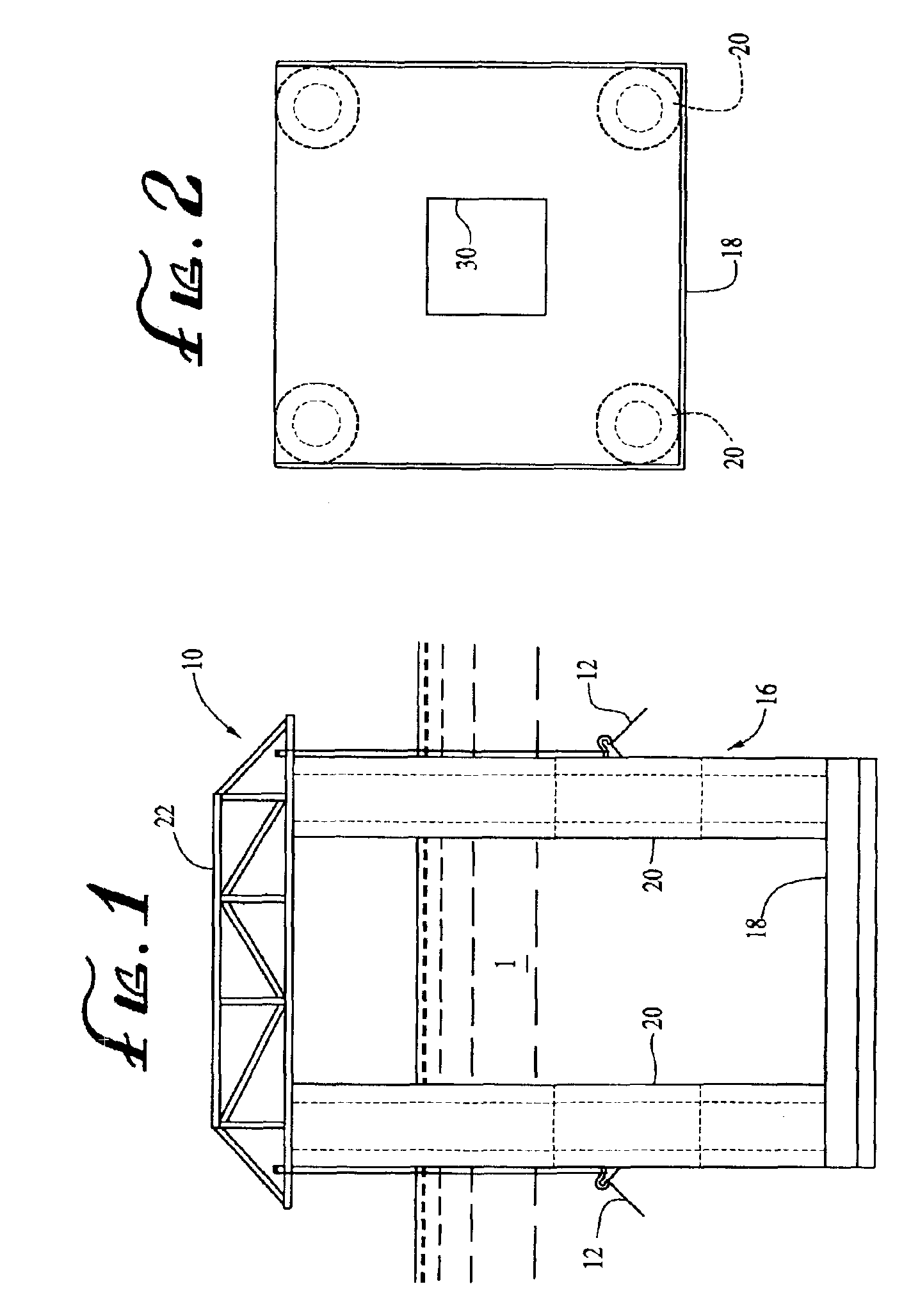

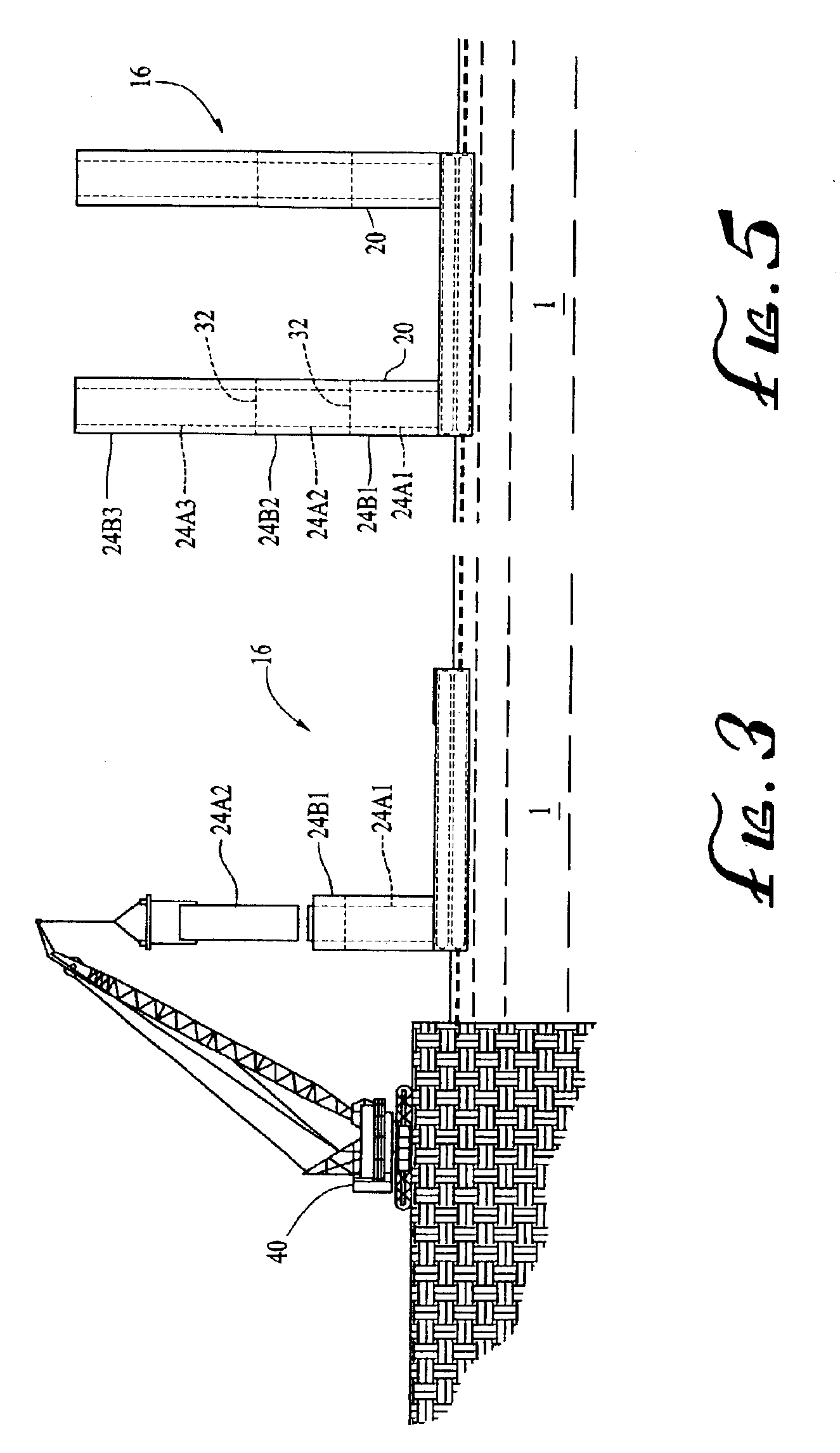

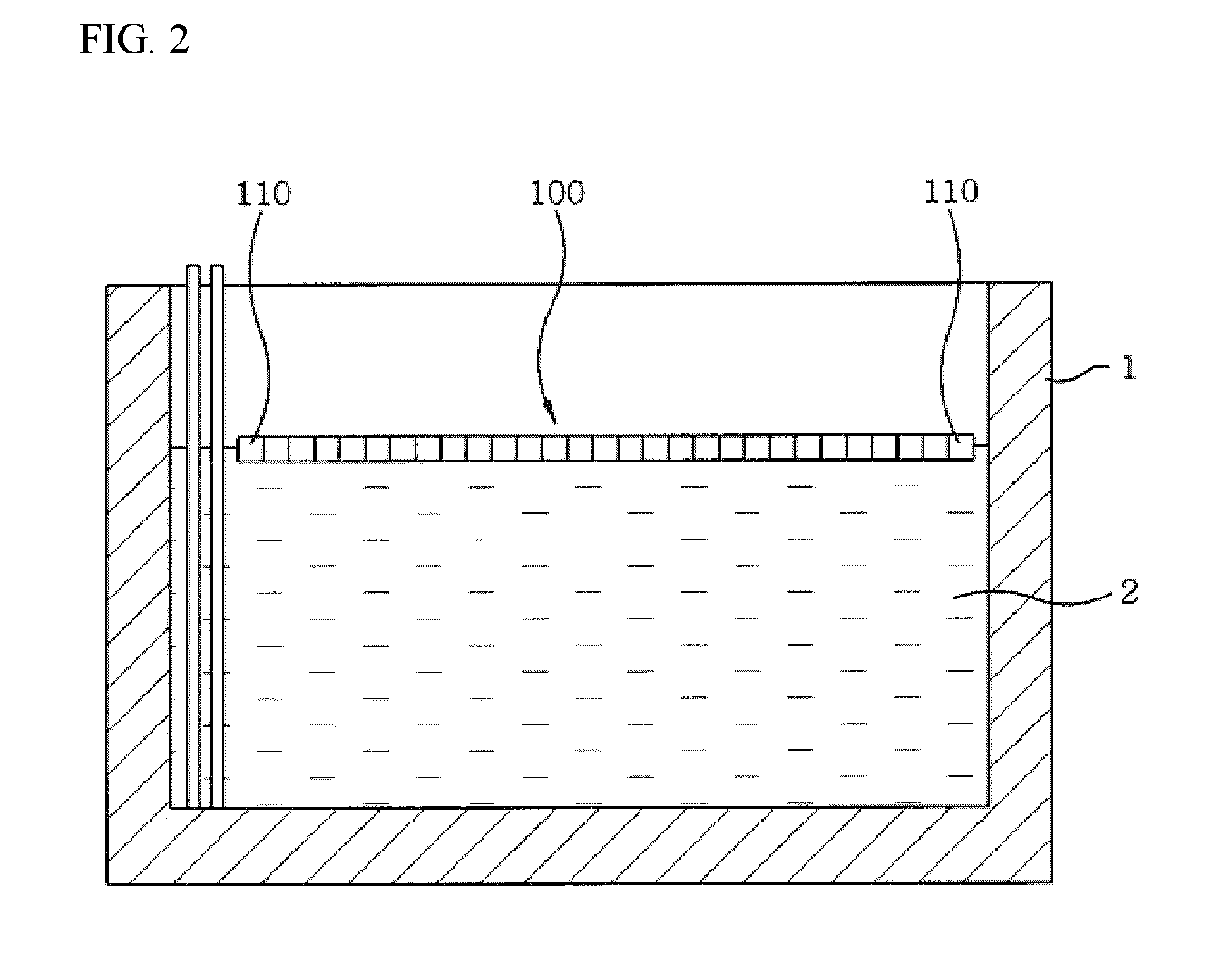

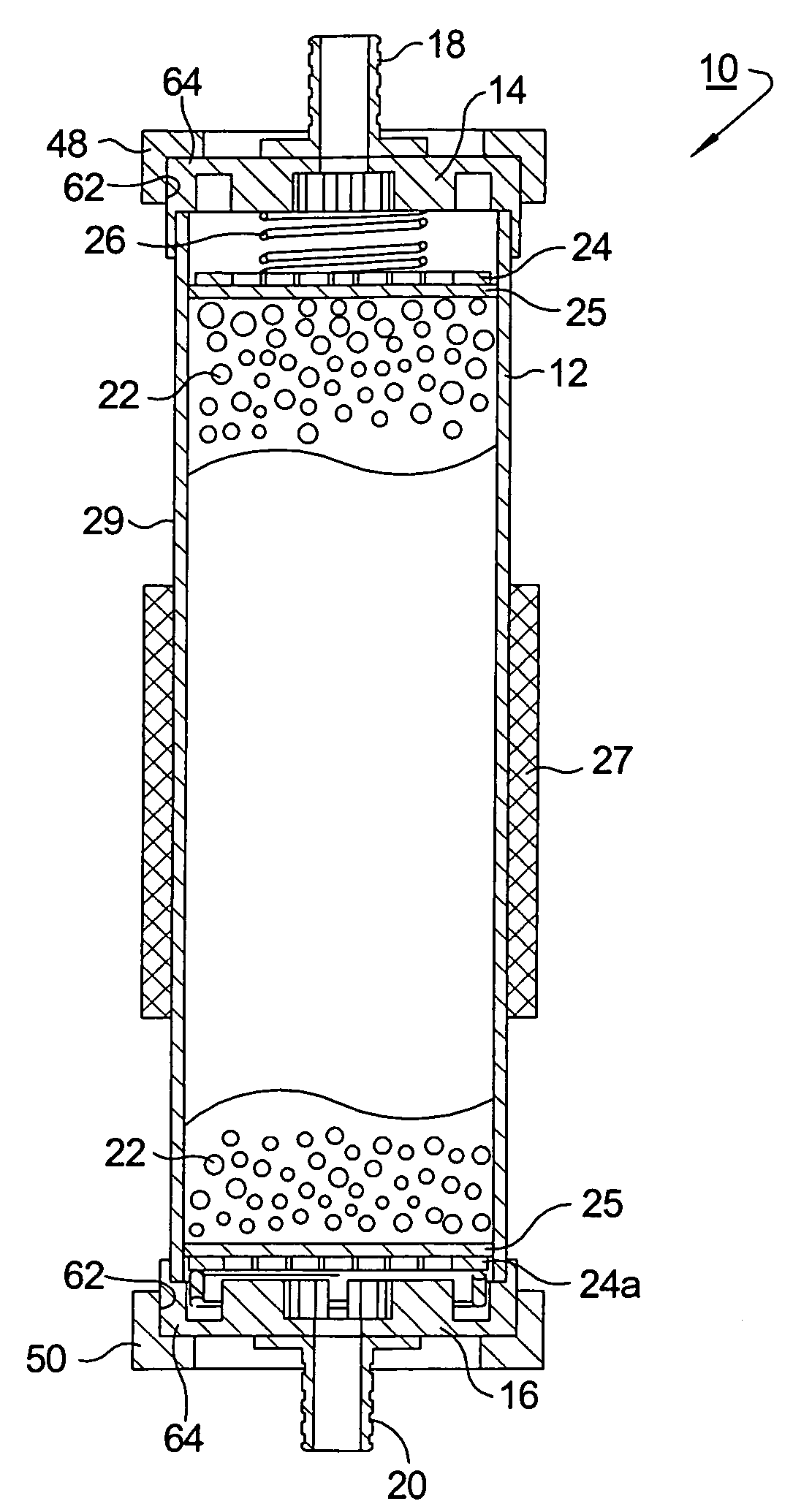

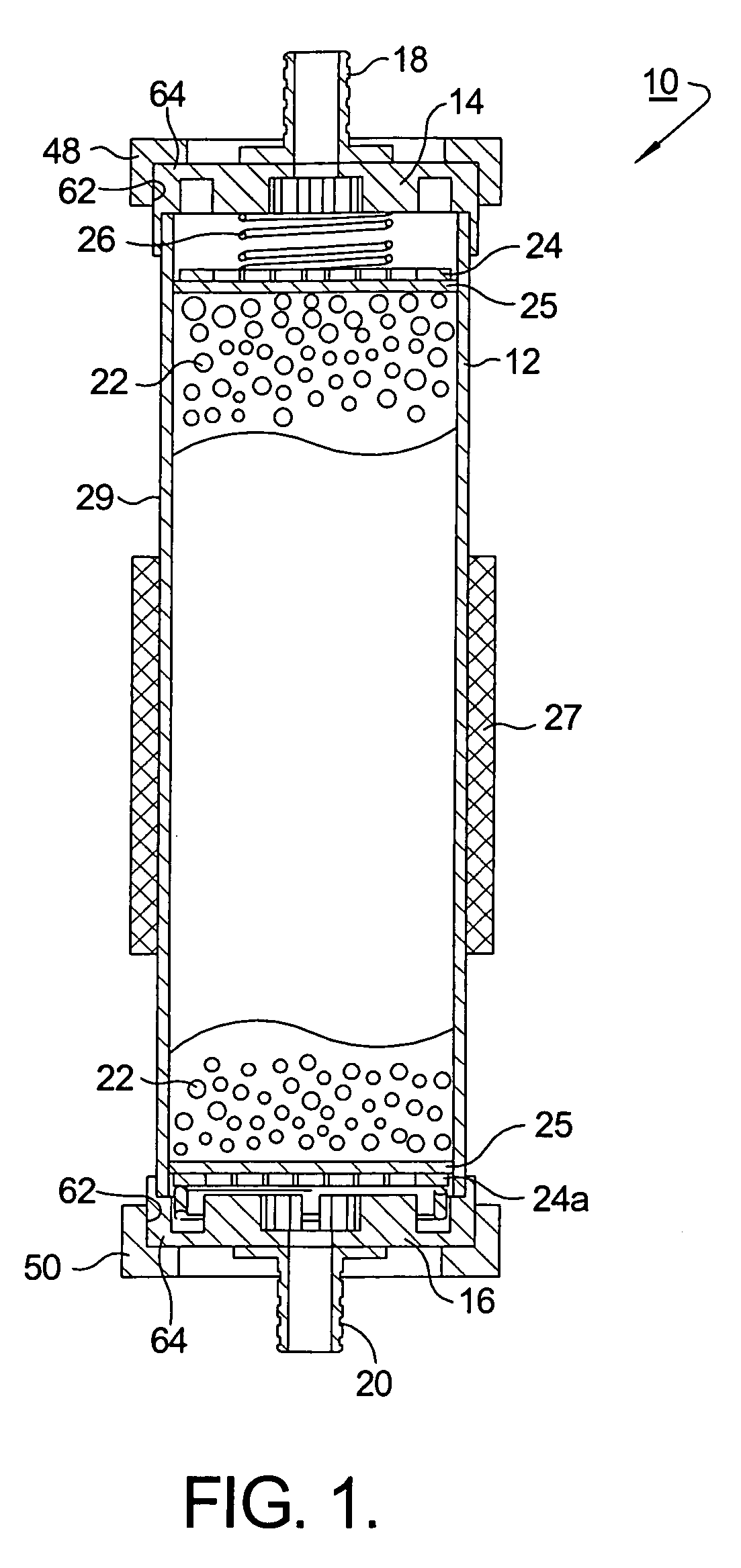

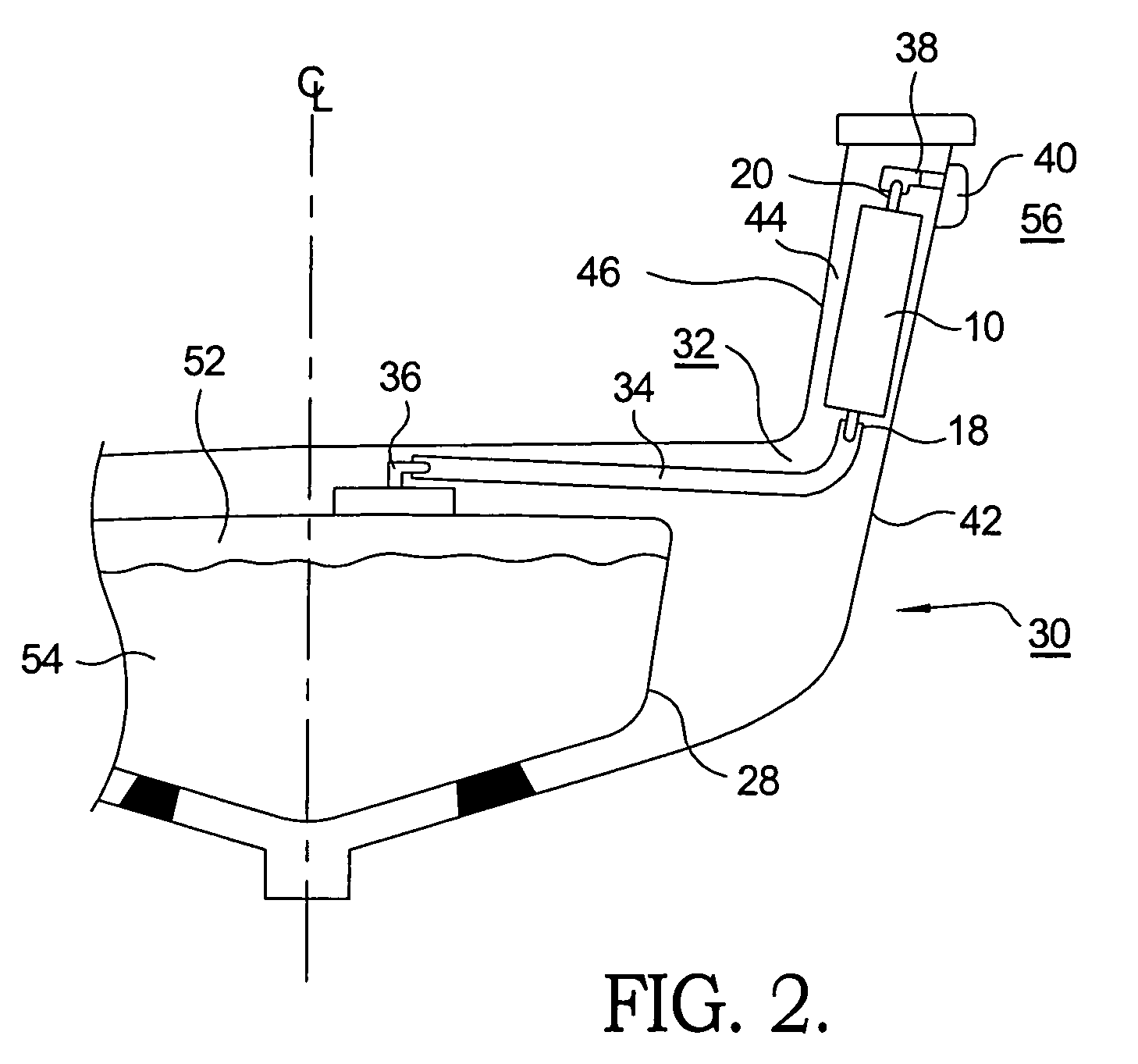

Method and apparatus for killing microorganisms in ship ballast water

InactiveUS6171508B1Rapidly reduce the DOTime requiredHull interior subdivisionWater treatment parameter controlOxygenAnaerobic microorganisms

A method and apparatus for treating ship ballast water before it is discharged into coastal waters. The ballast water may contain a generalized and diverse species population of harmful non-indigenous microorganisms. Before discharge, the ballast water is oxygenated and deoxygenated to reduce the populations of anaerobic and aerobic microorganisms, respectively. If anaerobic microorganisms are of no concern, the oxygenation step can be eliminated. Also, a method and apparatus for treating large volumes of any water, to reduce the population of a wide spectrum of diverse species of microorganisms wherein the water is deoxygenated, and then held in a sealed space for a period of time until the aerobic population has been reduced.

Owner:TIDEWATER BALLAST SOLUTIONS LLC

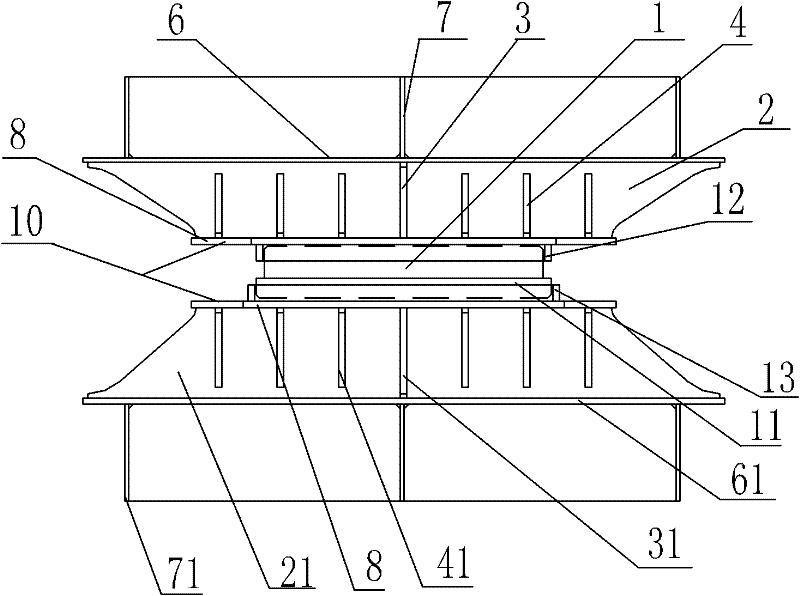

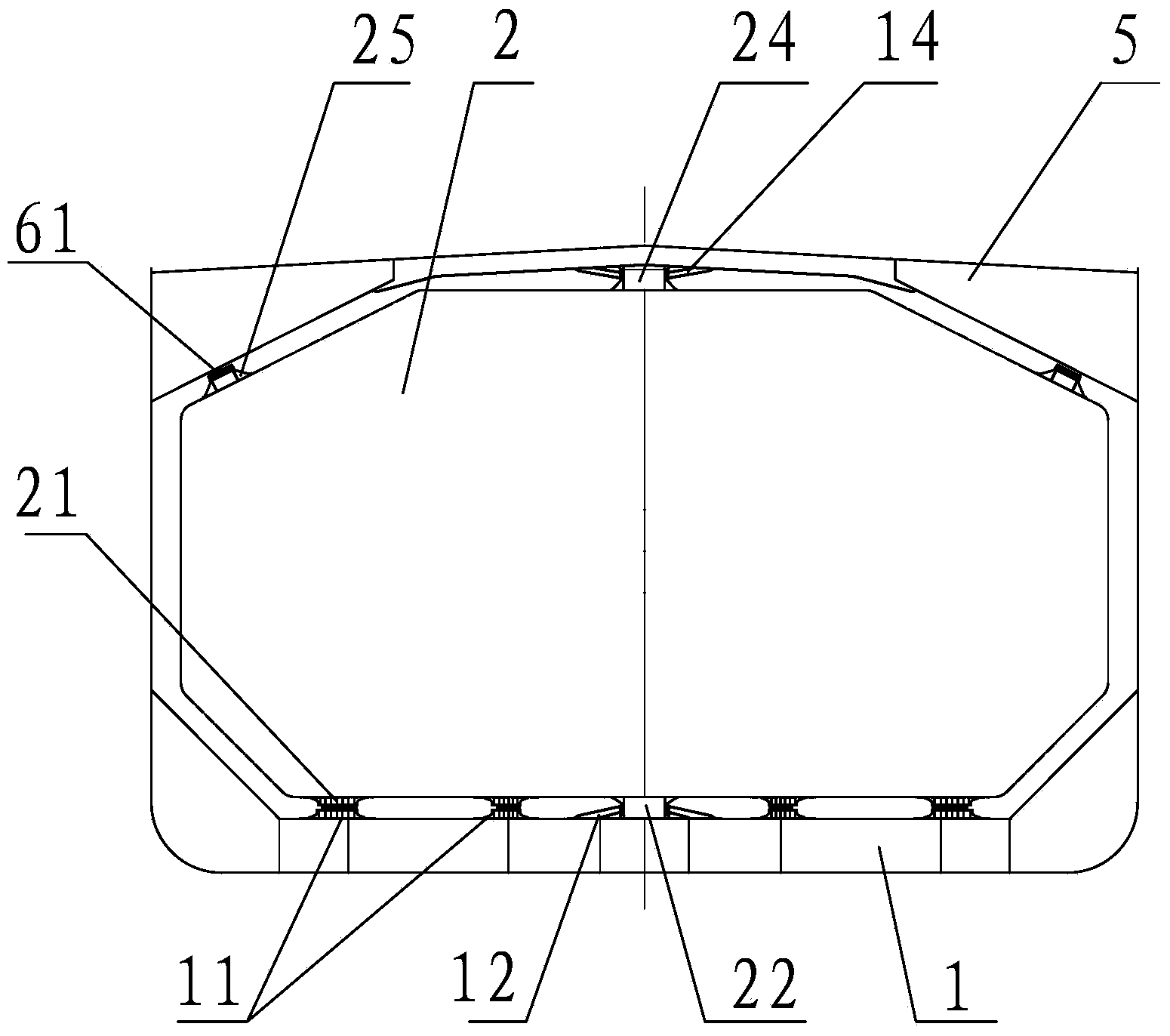

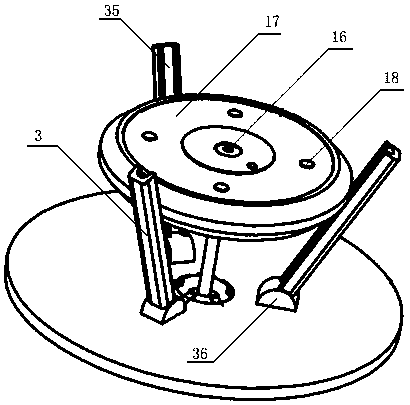

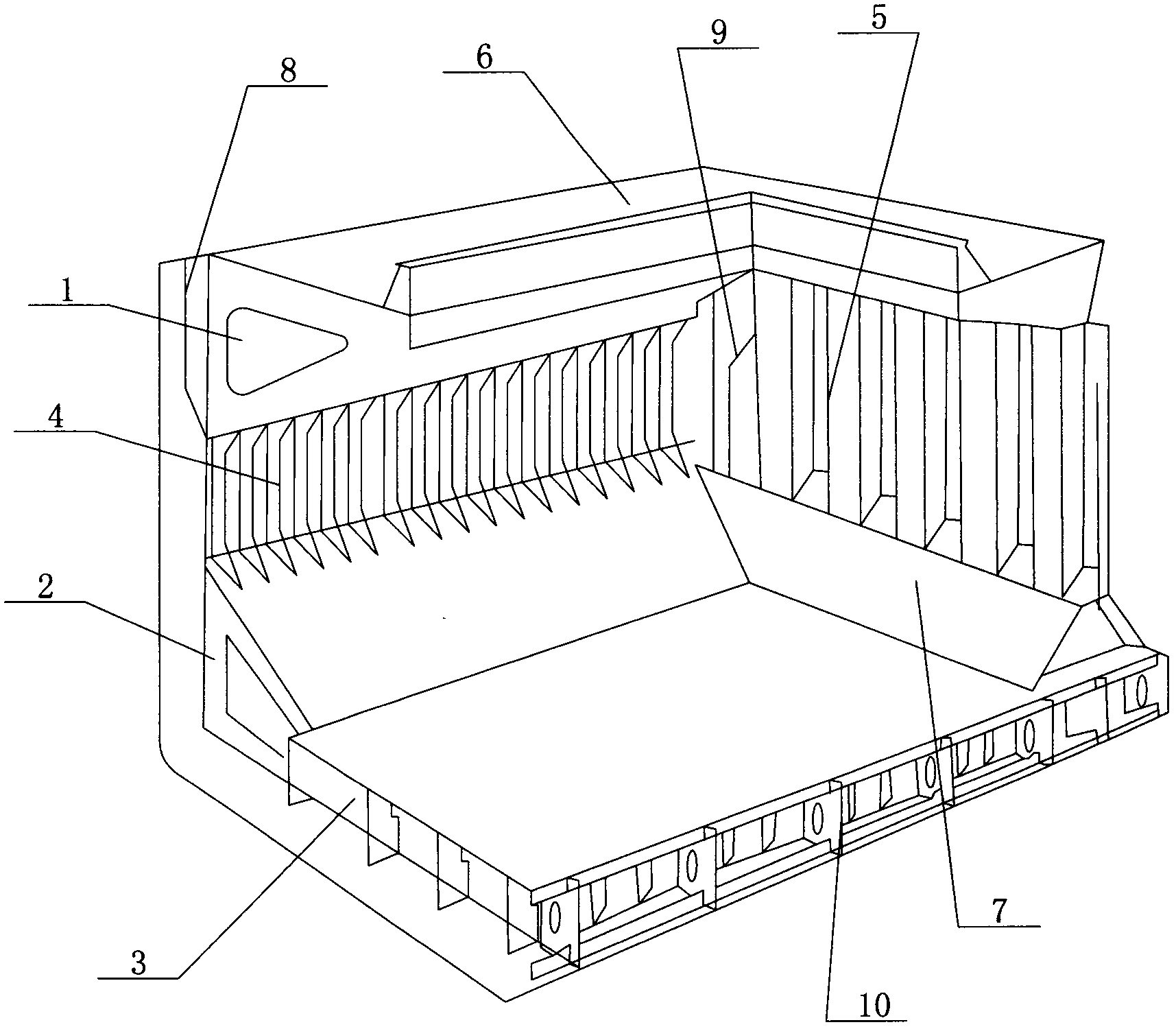

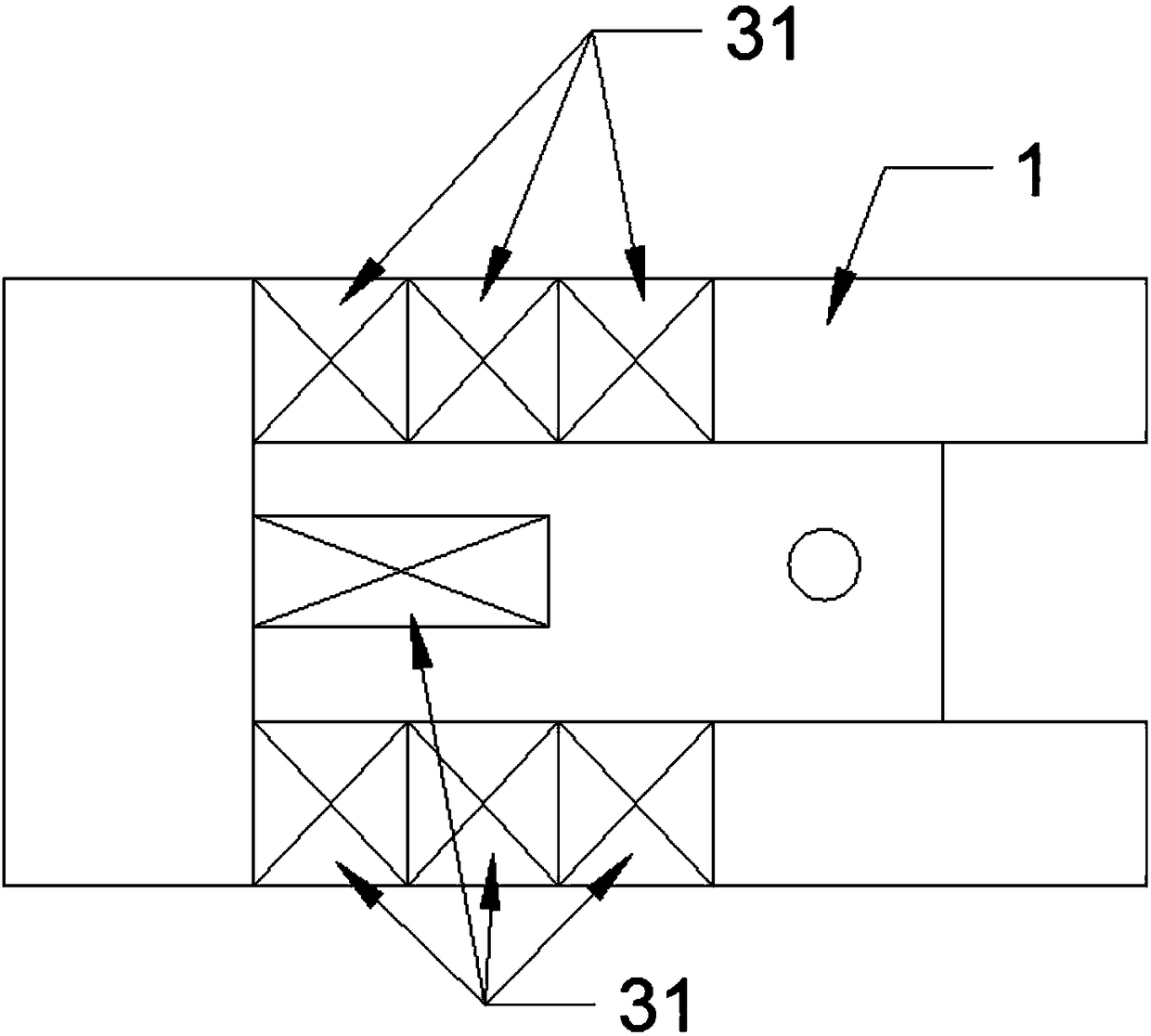

Vertical supporting structure for cargo tank and inboard bottom of full-refrigerated liquefied gas carrier and mounting method of vertical supporting structure

The invention provides a vertical supporting structure for a cargo tank and an inboard bottom of a full-refrigerated liquefied gas carrier. The vertical supporting structure comprises an upper support seat, a lower support seat, a first bed timber and a second bed timber, wherein the upper support seat is arranged on the cargo tank side of full-refrigerated liquefied gas carrier; the lower support seat is arranged on the inboard bottom side of full-refrigerated liquefied gas carrier; the upper and the lower support seats are the same in structure; each support seat comprises a baseplate and two panels on one side of the baseplate; a support toggle plate is arranged between the baseplate and the panels; a rib plate perpendicular to the baseplate is arranged on the other side of the baseplate; bed timber grooves are respectively arranged on the panels; a lifting jack supporting platform is arranged at two ends of each panel; the first bed timber is arranged in bed timber groove on the upper support seat; the second bed timber is arranged in a bed timber groove of the lower support seat; and the first bed timber is in contact with the second bed timber. The vertical supporting structure between the cargo tank and the inboard bottom provides convenience for mounting the cargo tank, and saves time and cost for mounting.

Owner:JIANGNAN SHIPYARD GRP CO LTD

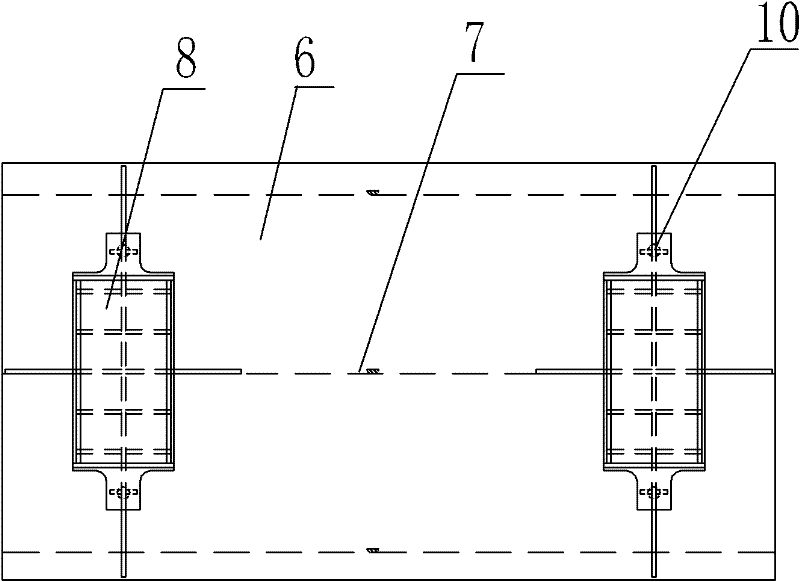

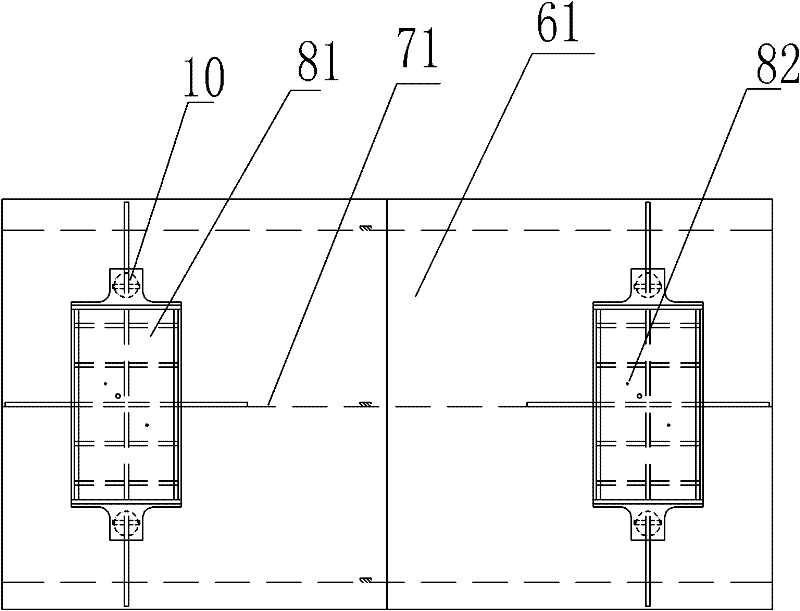

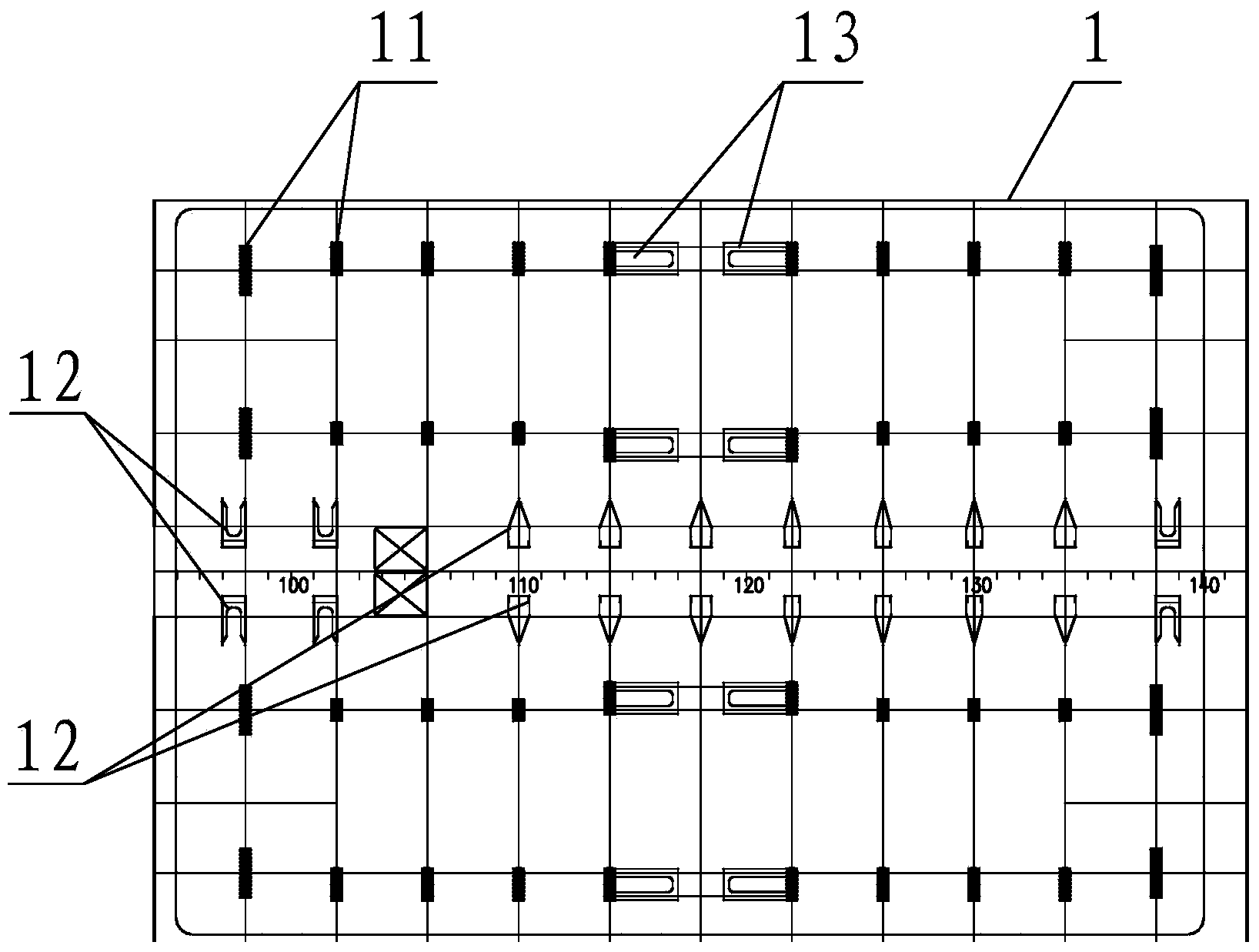

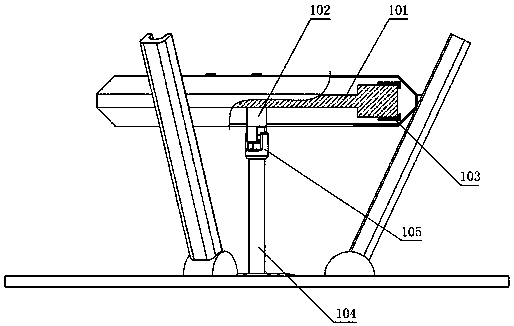

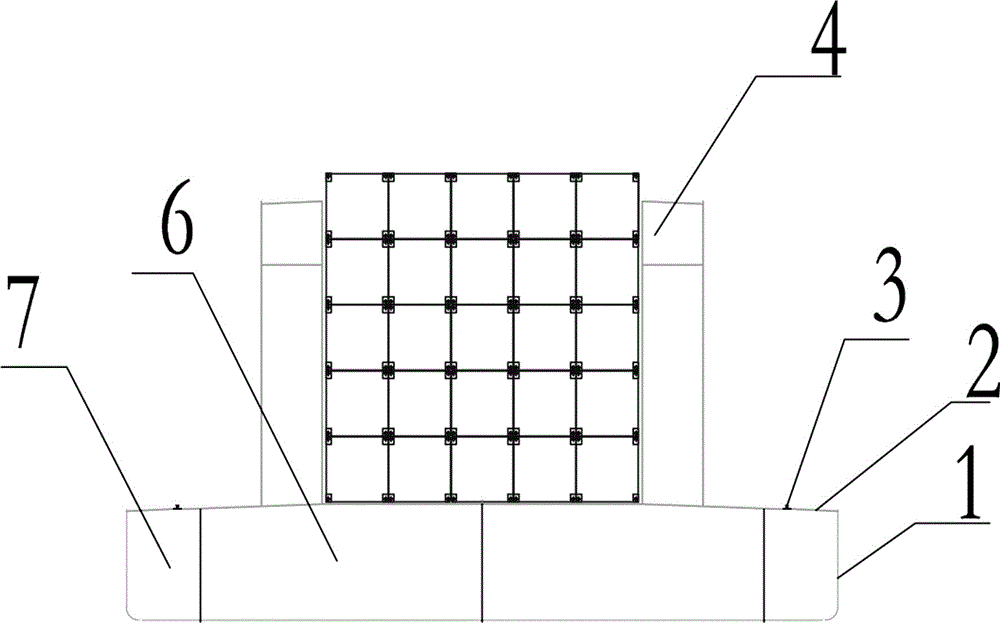

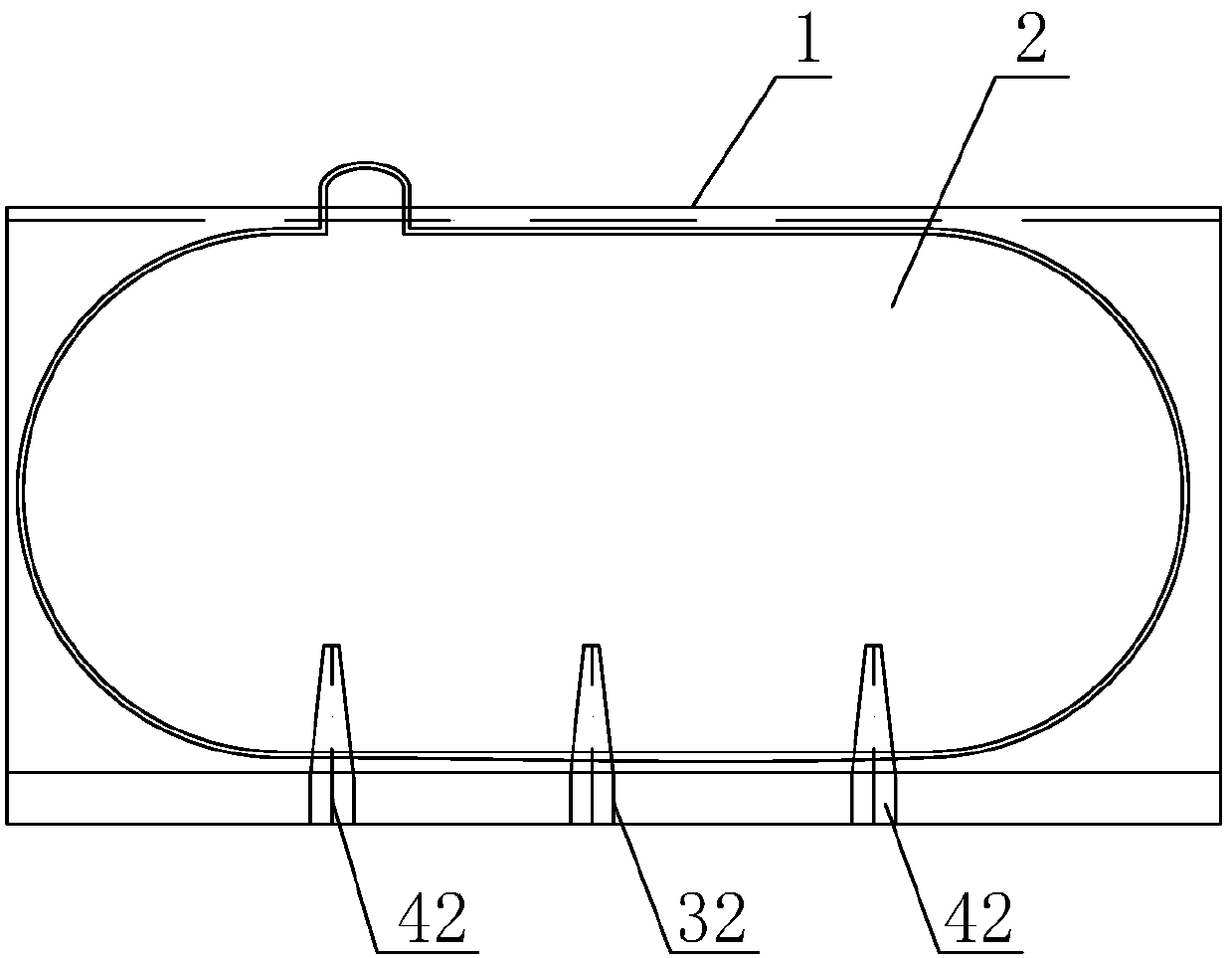

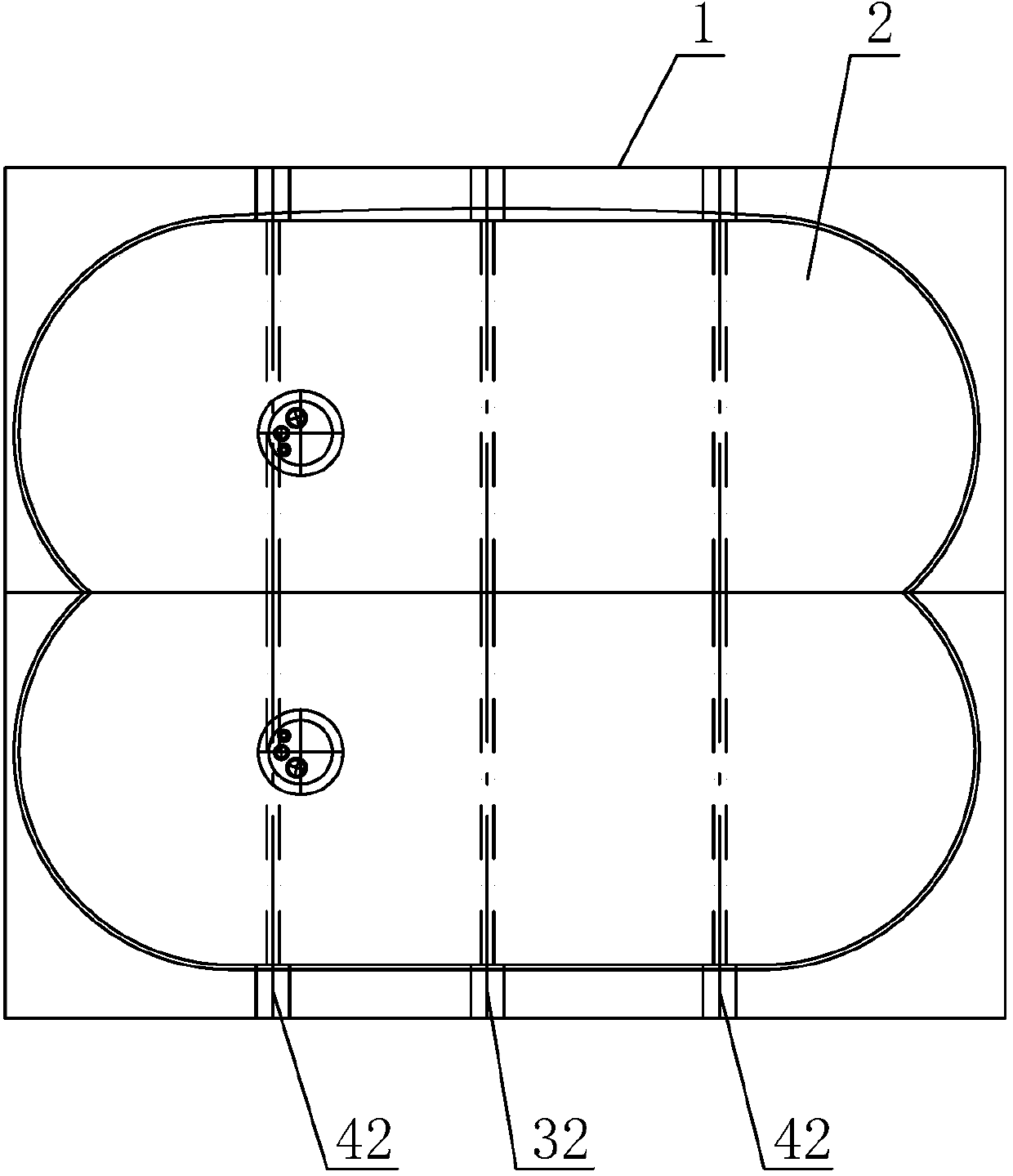

Installing structure of liquid tank of large liquefied gas carrier and installation locating method of liquid tank

ActiveCN103832543ALow equipment requirementsSimple and fast operationHull interior subdivisionLarge containersCollections dataLiquid tank

The invention provides an installing structure of a liquid tank of a large liquefied gas carrier and an installation locating method of the liquid tank. According to the installing structure of the liquid tank of the large liquefied gas carrier, a liquid tank cabin of the large liquefied gas carrier is mainly provided with a bottom perpendicular supporting base, a bottom transverse-shake preventing support, a top transverse-shake preventing support and a bottom longitudinal-shake preventing support, wherein the bottom perpendicular supporting base is used for supporting a whole liquid tank, the bottom transverse-shake preventing support and the top transverse-shake preventing support are used for preventing the liquid tank from transversely shaking relative to a hull, and the bottom longitudinal-shake preventing support is used for preventing the liquid tank from longitudinally shaking relative to the hull. In the actual working process of installing the liquid tank in the liquid tank cabin, according to the installation locating method of the liquid tank, the data collection step, the three-dimensional simulation step, the epoxy resin thickness calculation step, the locating datum line assignment step, the supporting positioning step and the like are carried out in sequence, and finally the liquid tank is installed in the liquid tank cabin. By the adoption of the installation locating method of the liquid tank, installation locating work of the liquid tank can be rapidly and accurately accomplished, the utilization rate of tools is high, the using time of a crane is short, and the construction cost of an enterprise is greatly reduced.

Owner:JIANGNAN SHIPYARD GRP CO LTD

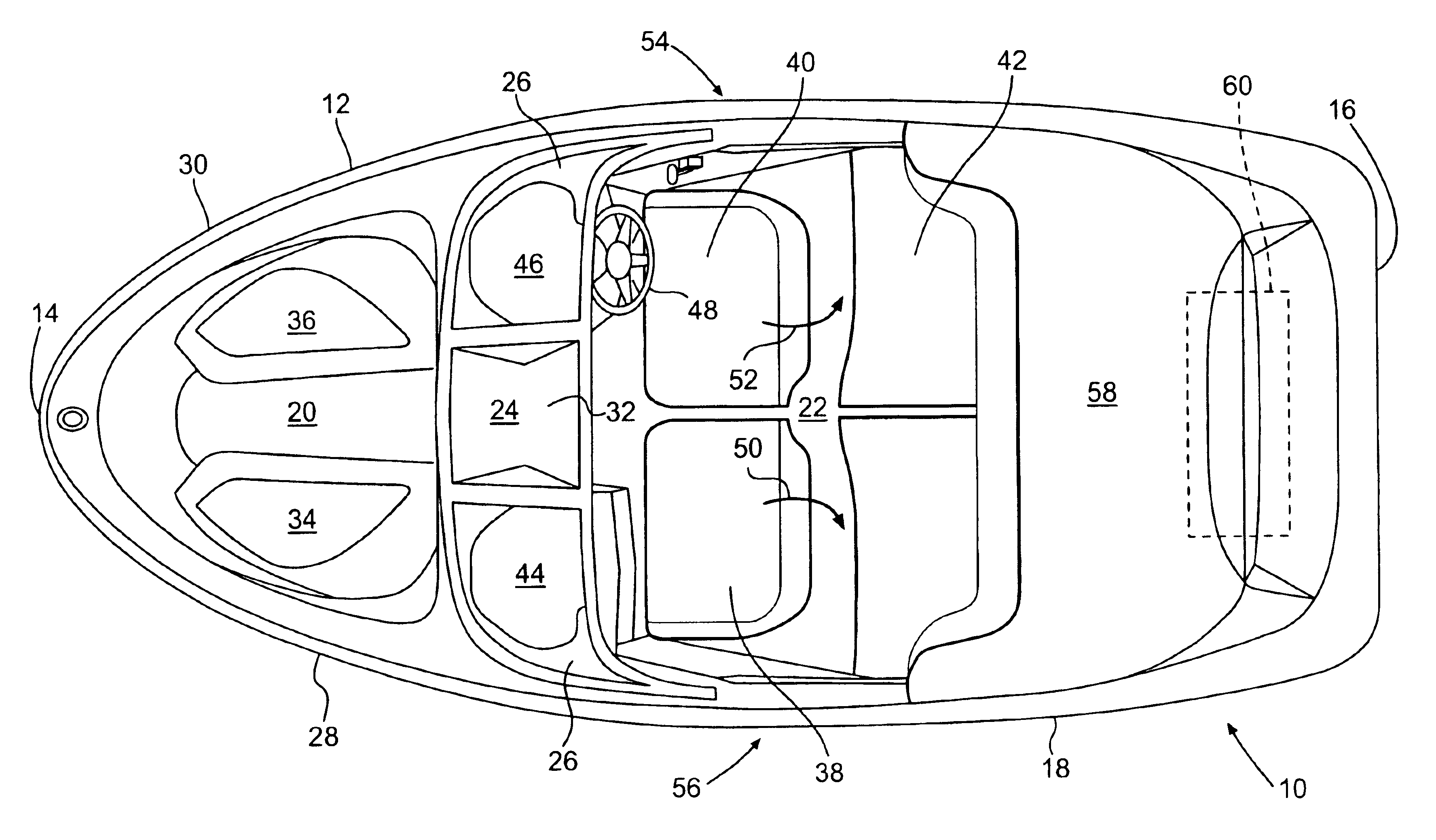

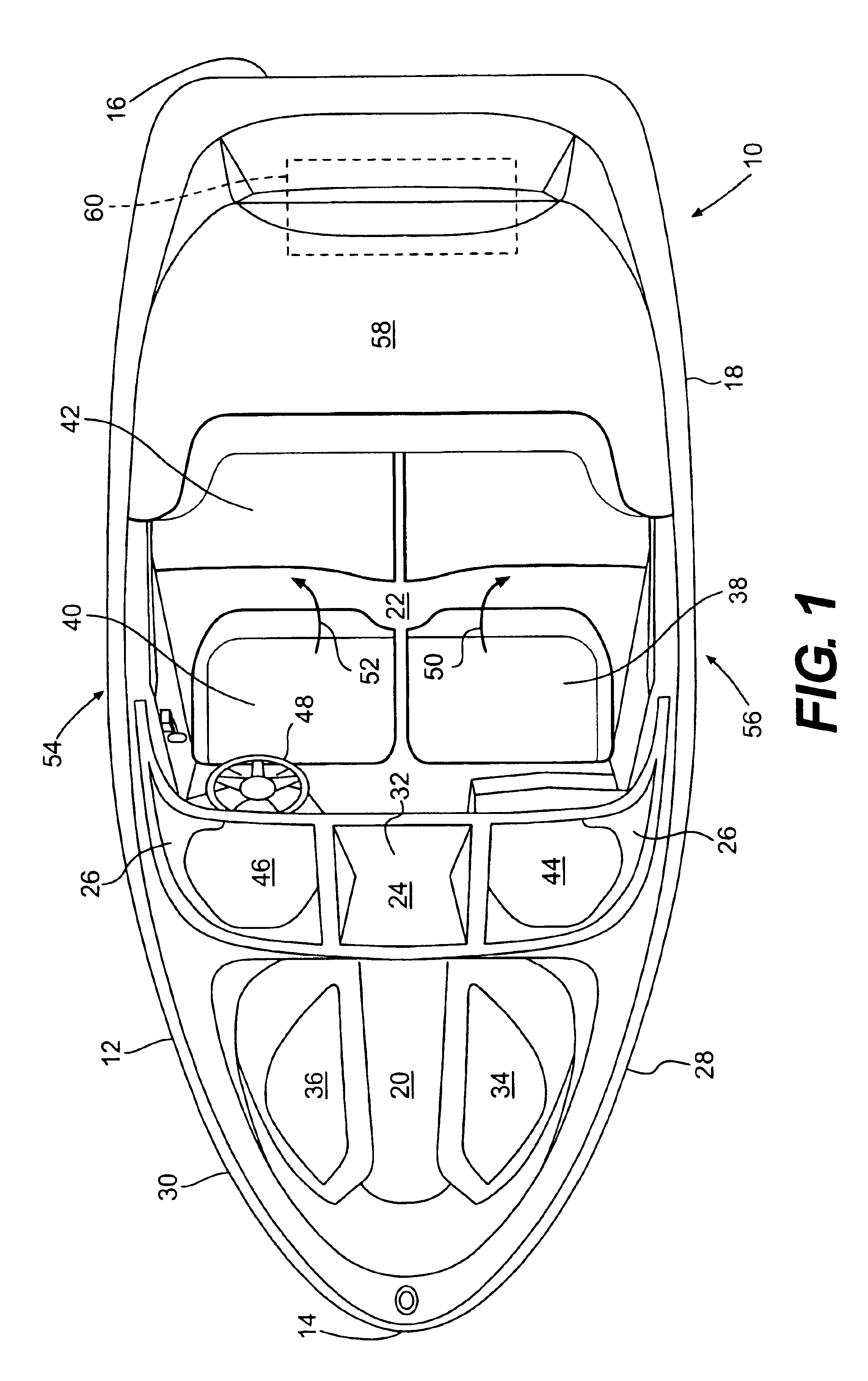

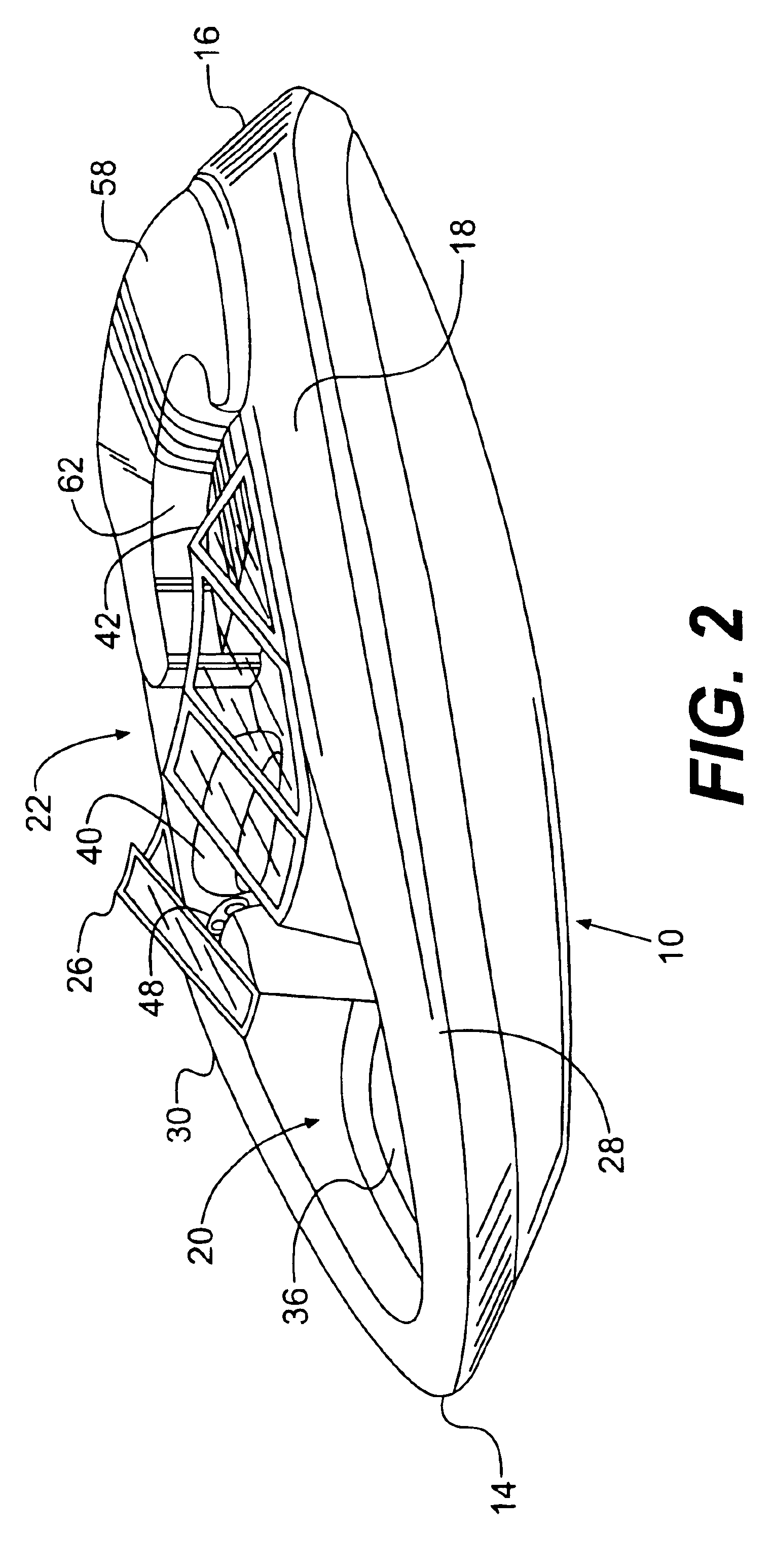

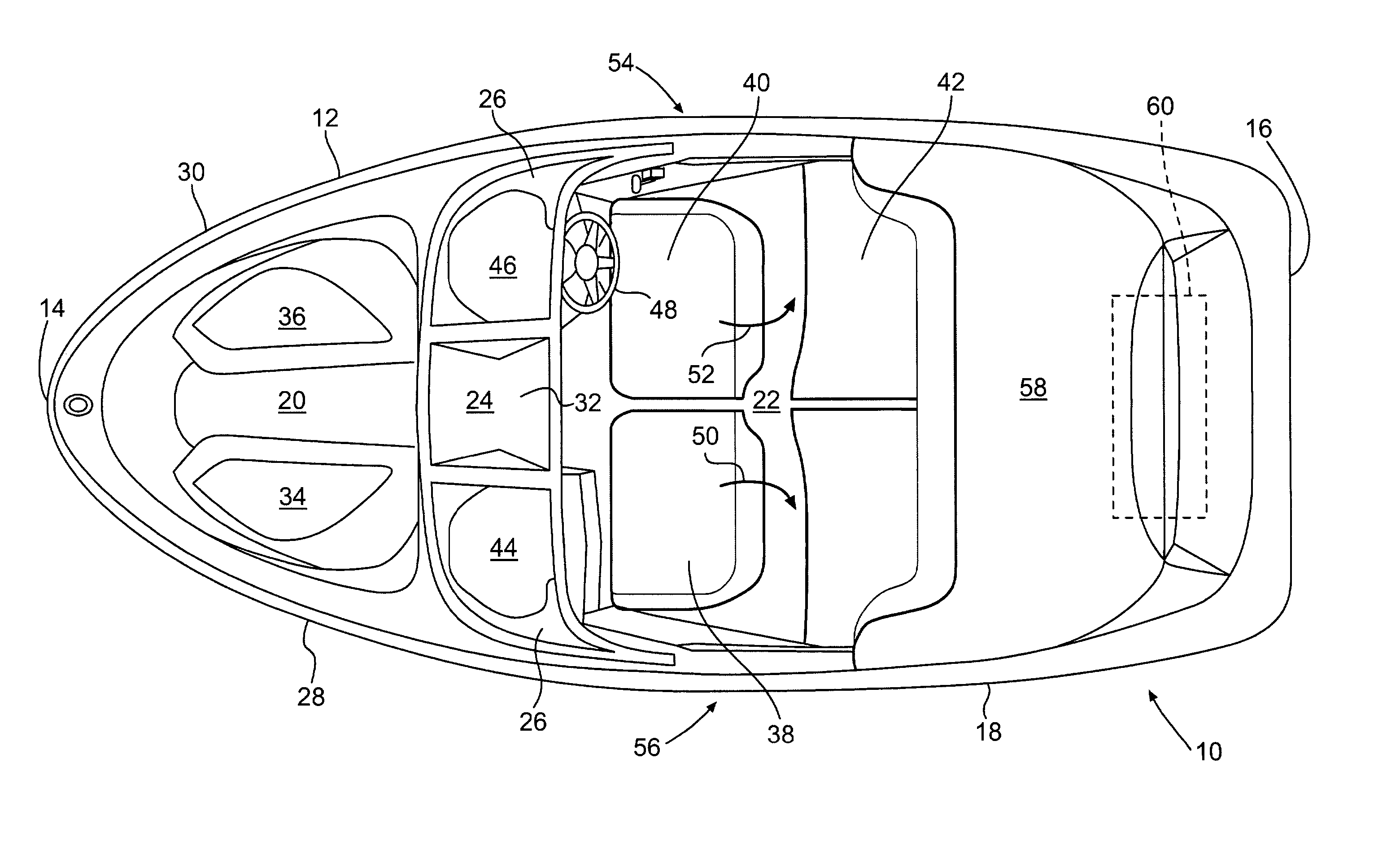

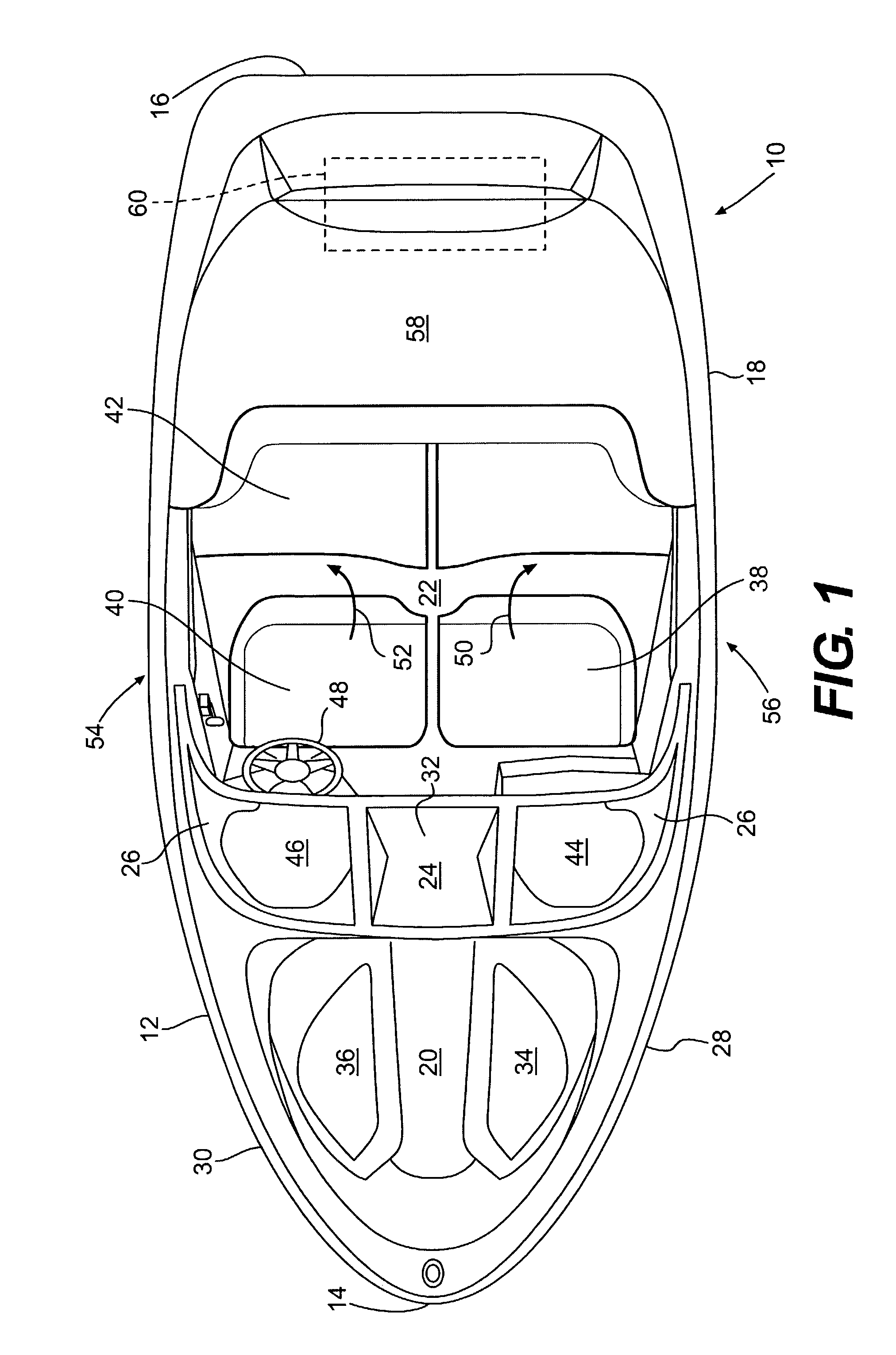

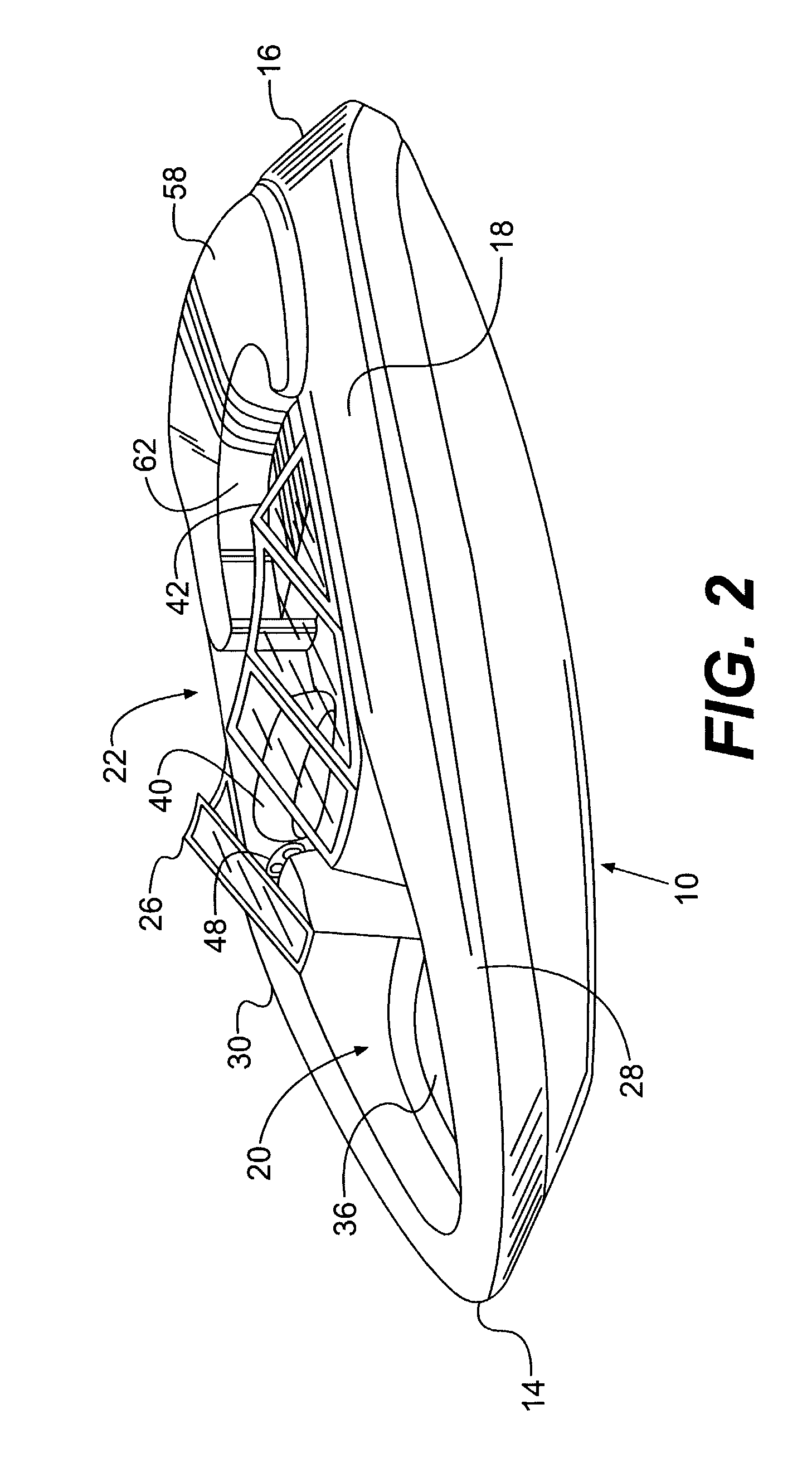

Watercraft

A watercraft is described with a powered hull and deck. The deck includes a forward passenger area and a rearward passenger area connected by a passageway. A windshield extends upwardly from the deck at a position forward of the rearward passenger area. An engine is positioned within the hull behind the rearward passenger area. An engine cover covers the engine and at least one compartment adjacent to the engine. The compartment is separated from the engine by a removable wall. The compartment houses at least a portion of a canopy system that may be erected over at least a portion of the rearward passenger area of the boat. The watercraft includes a rear bench that conceals a storage bucket thereunder. A console sits in front of a passenger seat with a console cover, which is hingedly mounted to the console to conceal a sound system.

Owner:BRP US

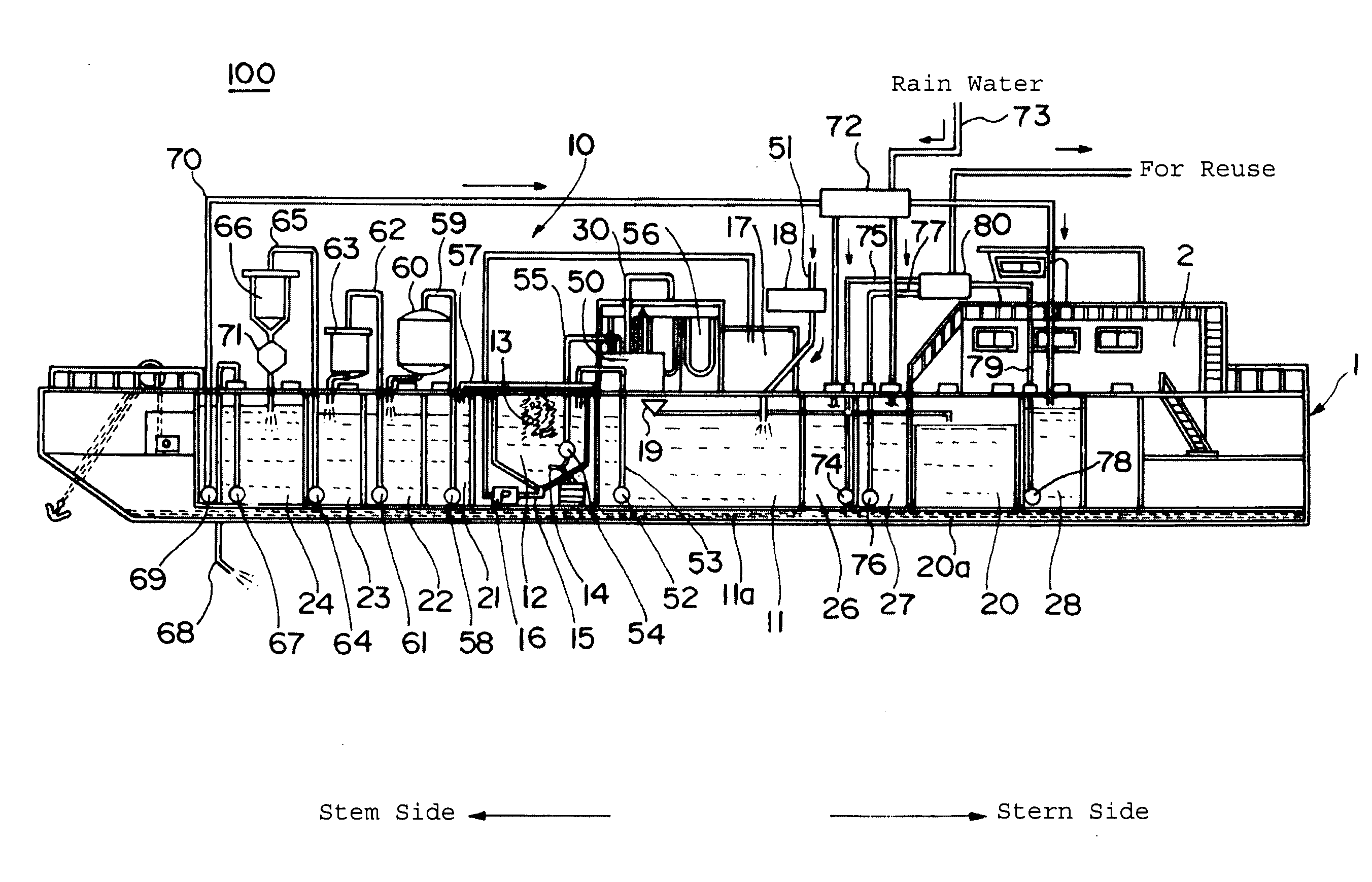

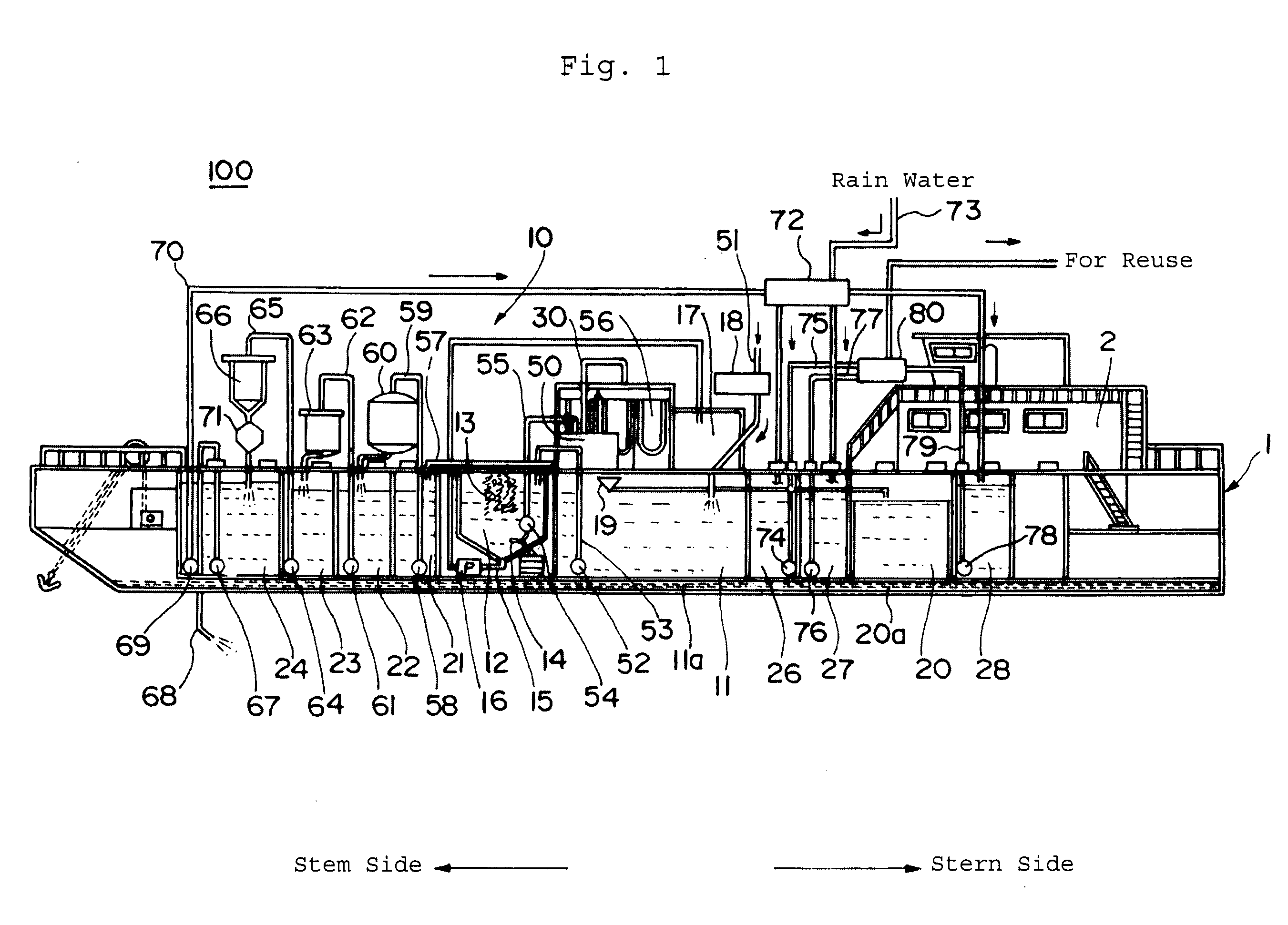

Wastewater treatment ship

ActiveUS20110147293A1Easy dischargeHull interior subdivisionAuxillariesSewage treatmentPurified water

A wastewater treatment ship is provided which is capable of purifying and treating oil bearing wastewater collected from a ship or the sea, wastewater such as domestic water and of reusing the purified water on the ship and easily discharging it. The wastewater treatment ship has a hull able to navigate by being towed or being self-propelled and a purification treatment unit disposed on the hull and configured to collect, purify, and treat wastewater. The purification treatment unit includes a floated oil collecting tank to collect floated oil collected from raw wastewater tank, a stirring tank having a cylindrical straight drum and a funnel-shaped bottom to stir wastewater taken out from the raw wastewater tank together with a coagulant and a collecting path to discharge precipitates, a plurality of filter treatment tanks to be used in multistage filtering treatment of wastewater in the stirring tank, and purified water tanks.

Owner:KANTO KOSAN

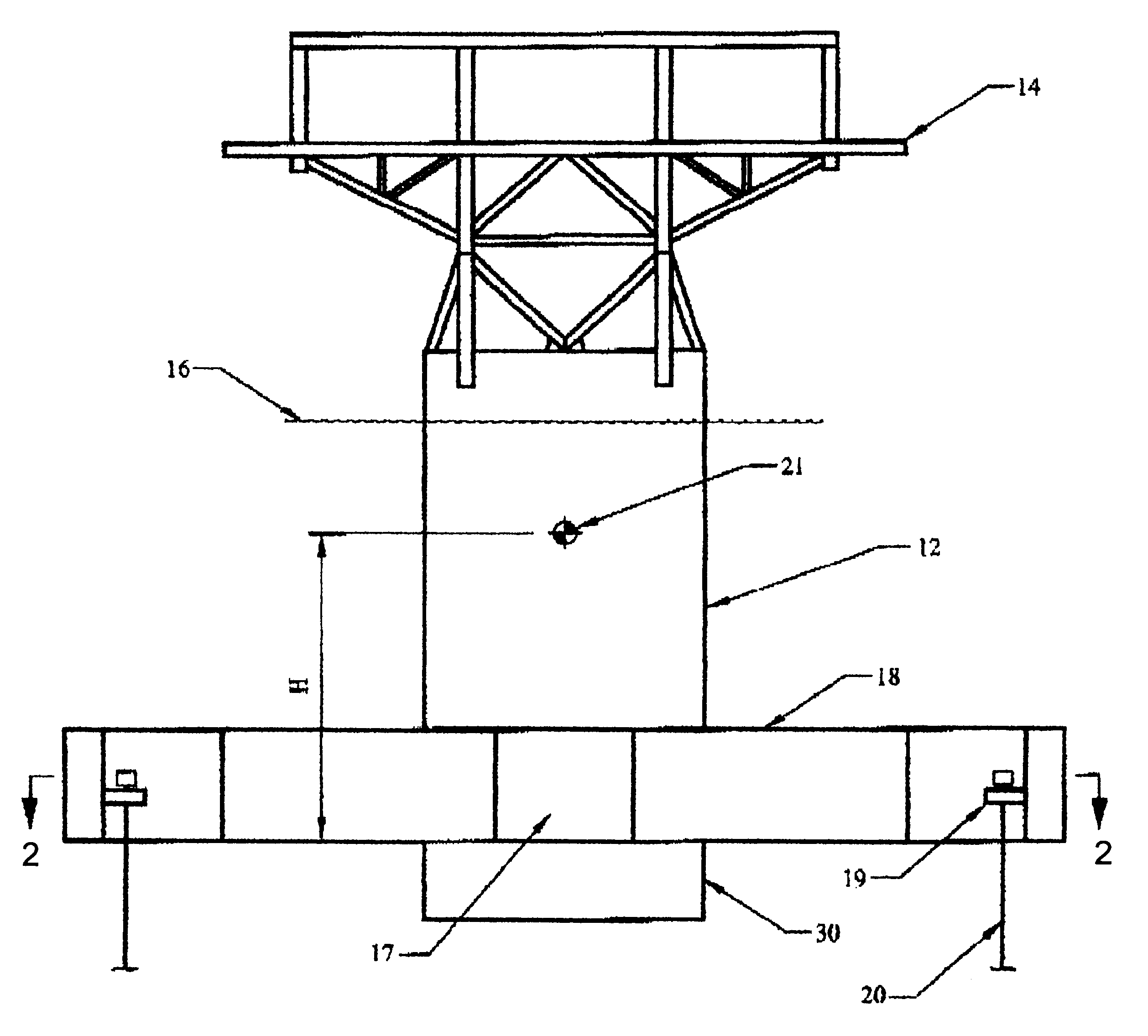

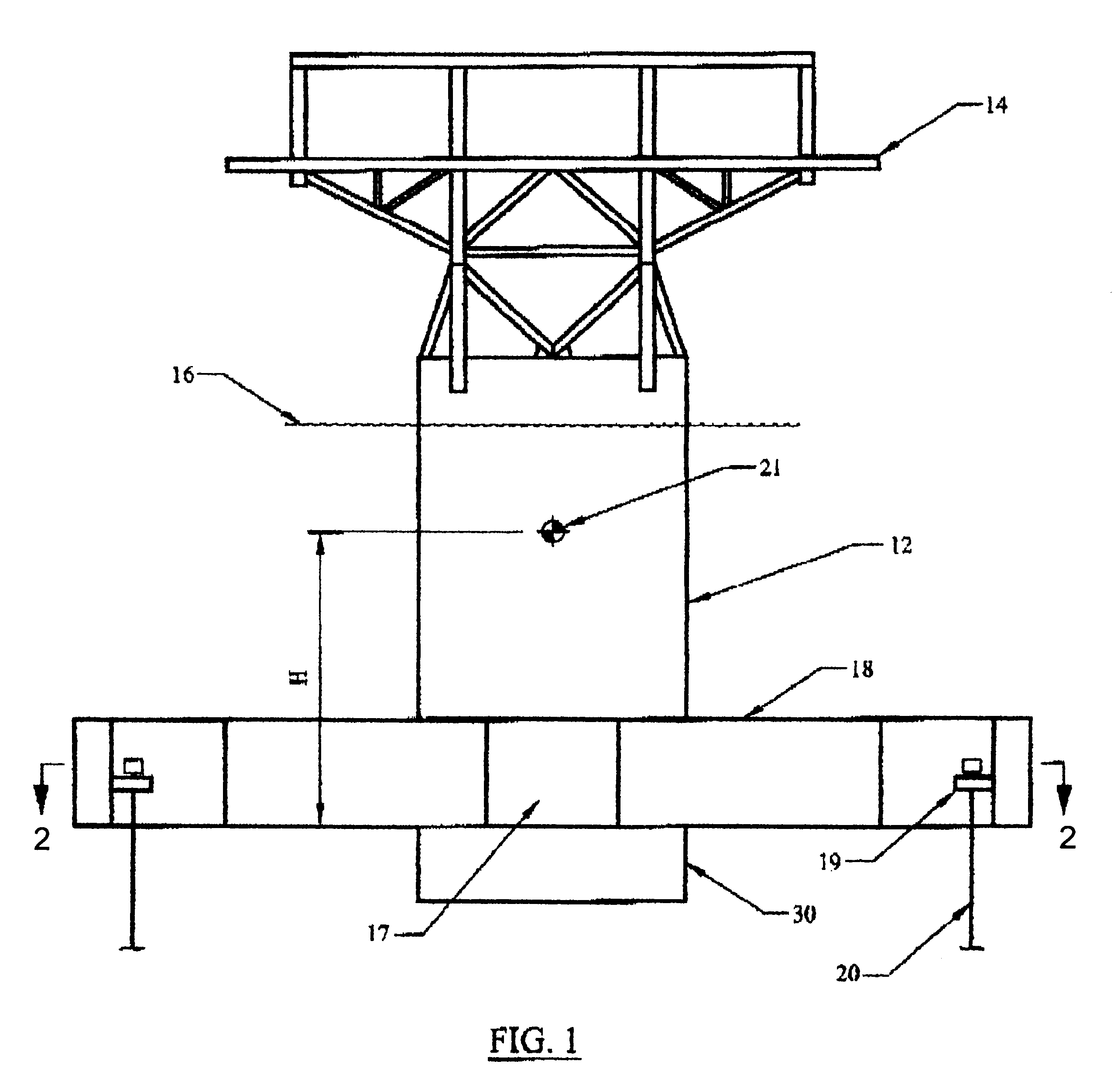

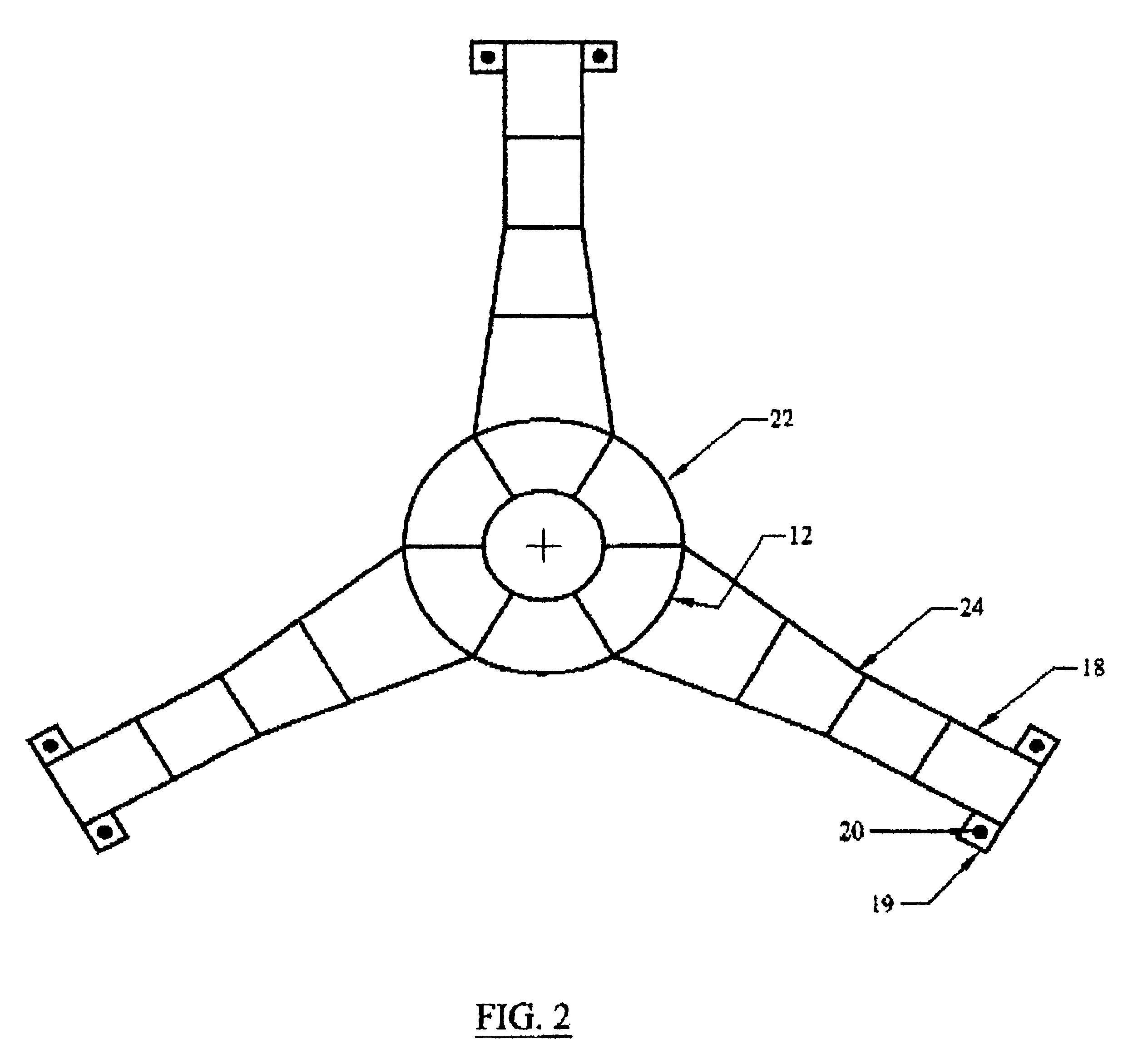

Semi-submersible multicolumn floating offshore platform

ActiveUS6935810B2Eliminate needHull interior subdivisionDrilling rodsMarine engineeringOffshore oil and gas

A semi-submersible, multicolumn, deep draft, floating offshore oil and gas drilling and production platform comprises a floating hull having an adjustably buoyant base, a plurality of columns vertically upstanding from the base, and an equipment deck that is supported atop the columns when the platform is operationally deployed. Each of the columns comprises a cellular structure that includes a plurality of elongated tubes having a variety of cross-sectional shapes extending from the base to the top of the column. Each of the tubes defines one or more closed compartments. At least one of the compartments has a buoyancy that is fixed, and at least another one of the compartments has a buoyancy that is adjustable. The buoyancy of the compartments and the base can be controllably adjusted with pressurized air to provide a safer and less costly method for deploying the platform for offshore operations.

Owner:HORTON WISON DEEPWATER

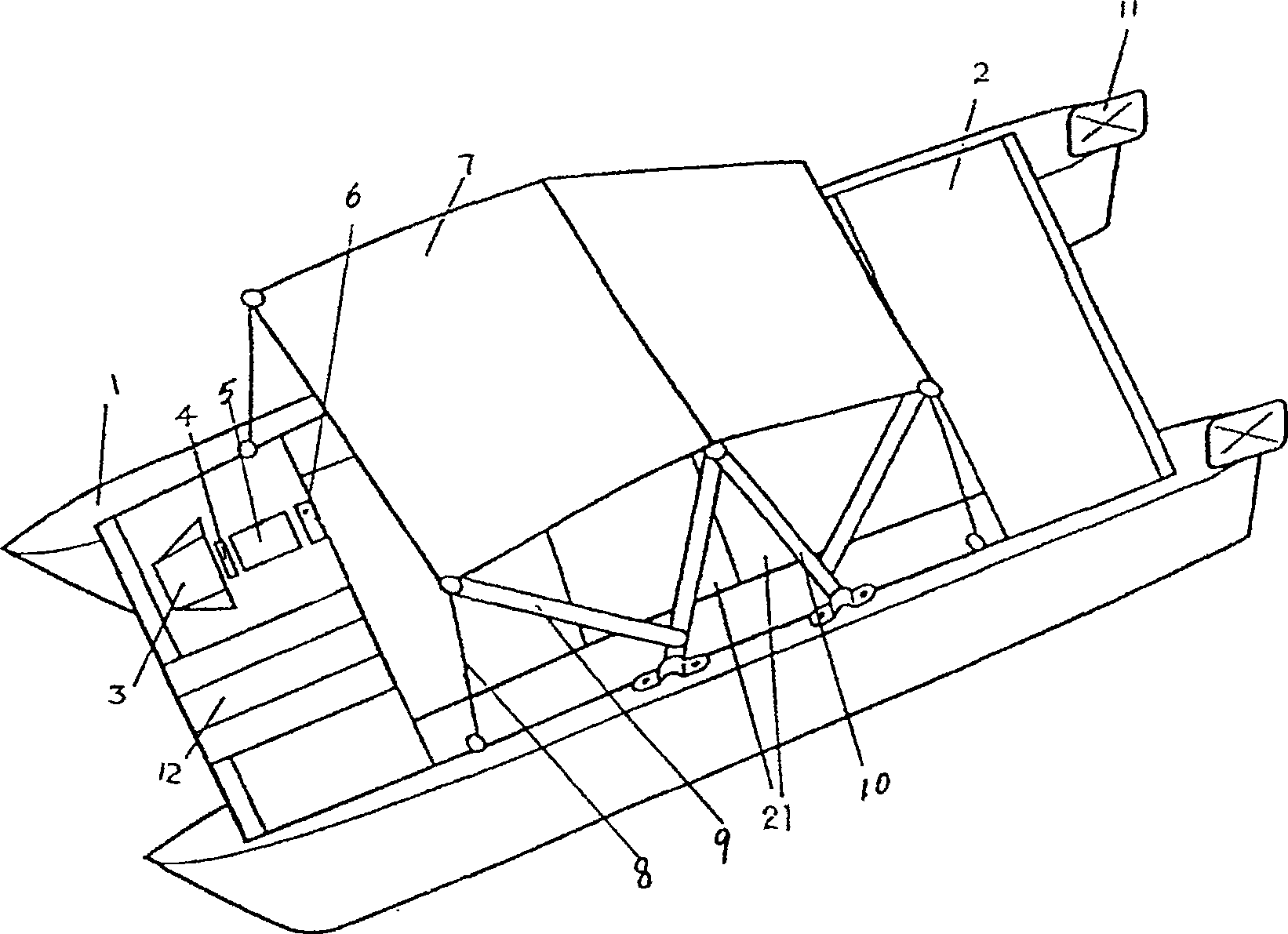

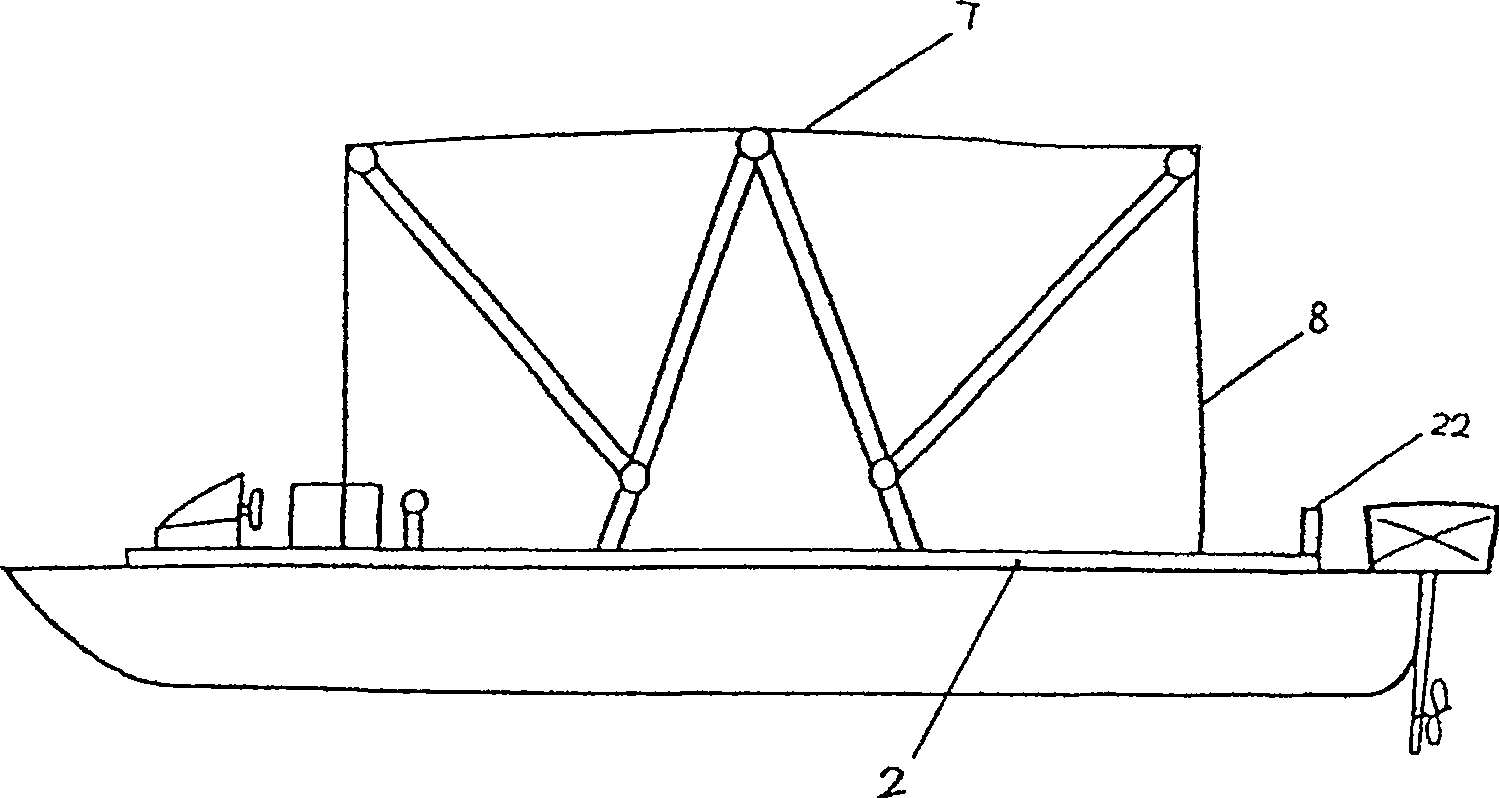

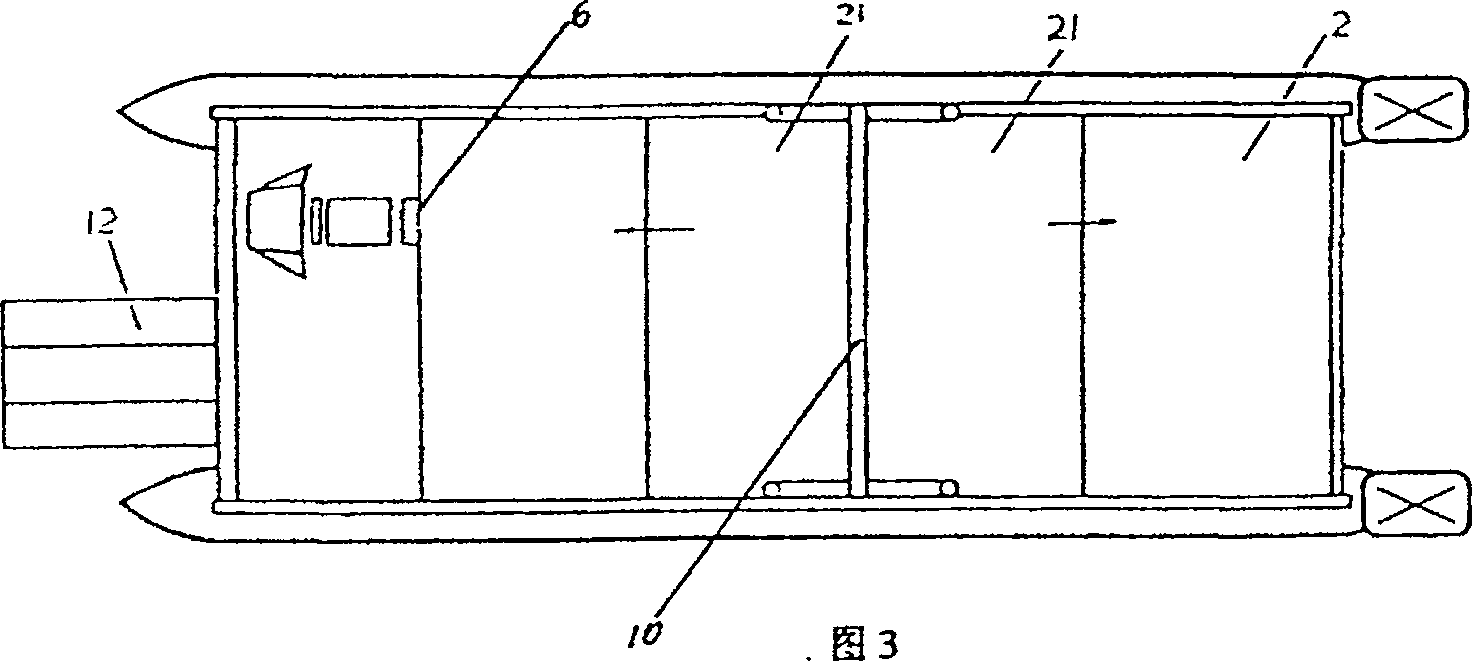

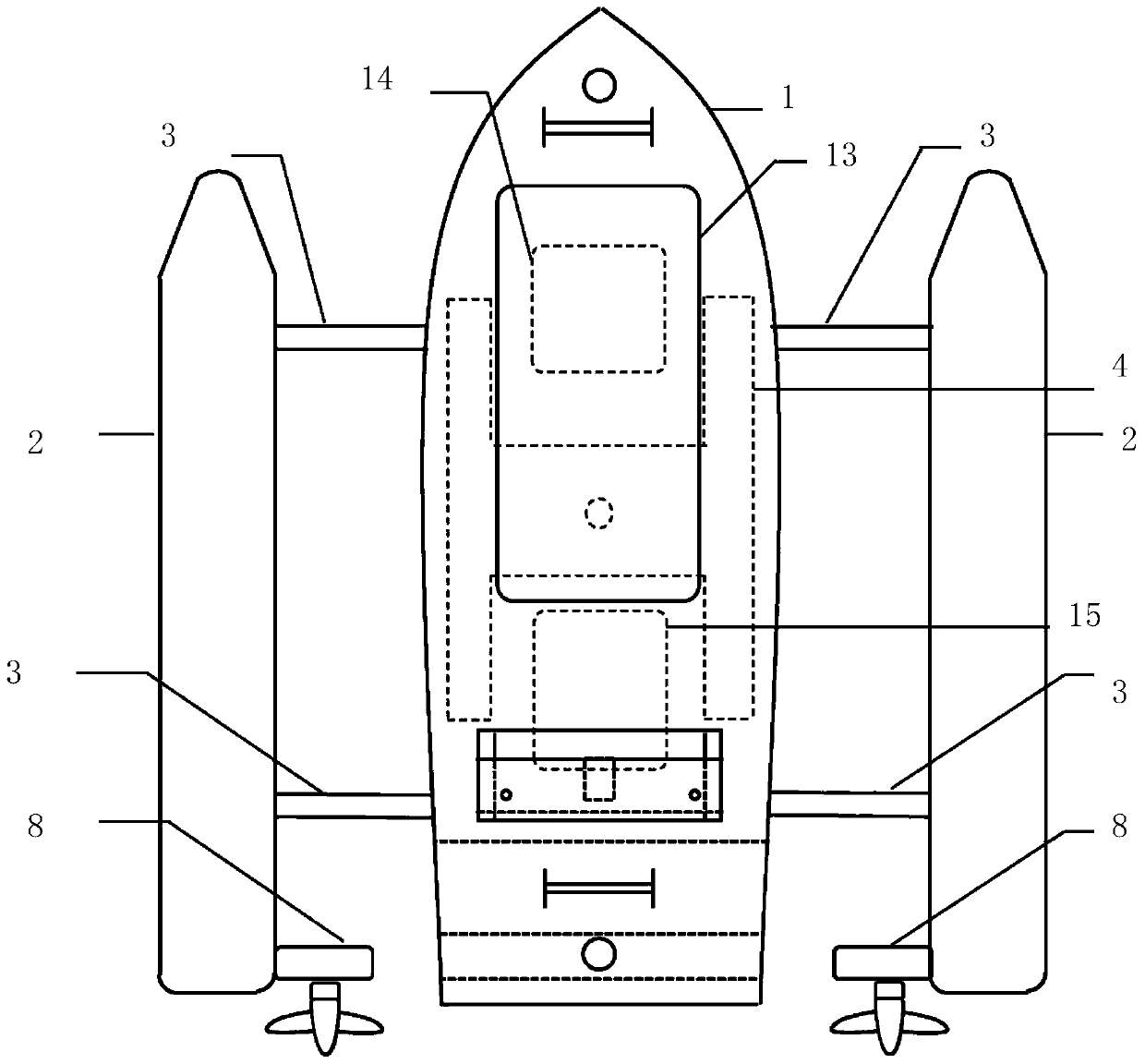

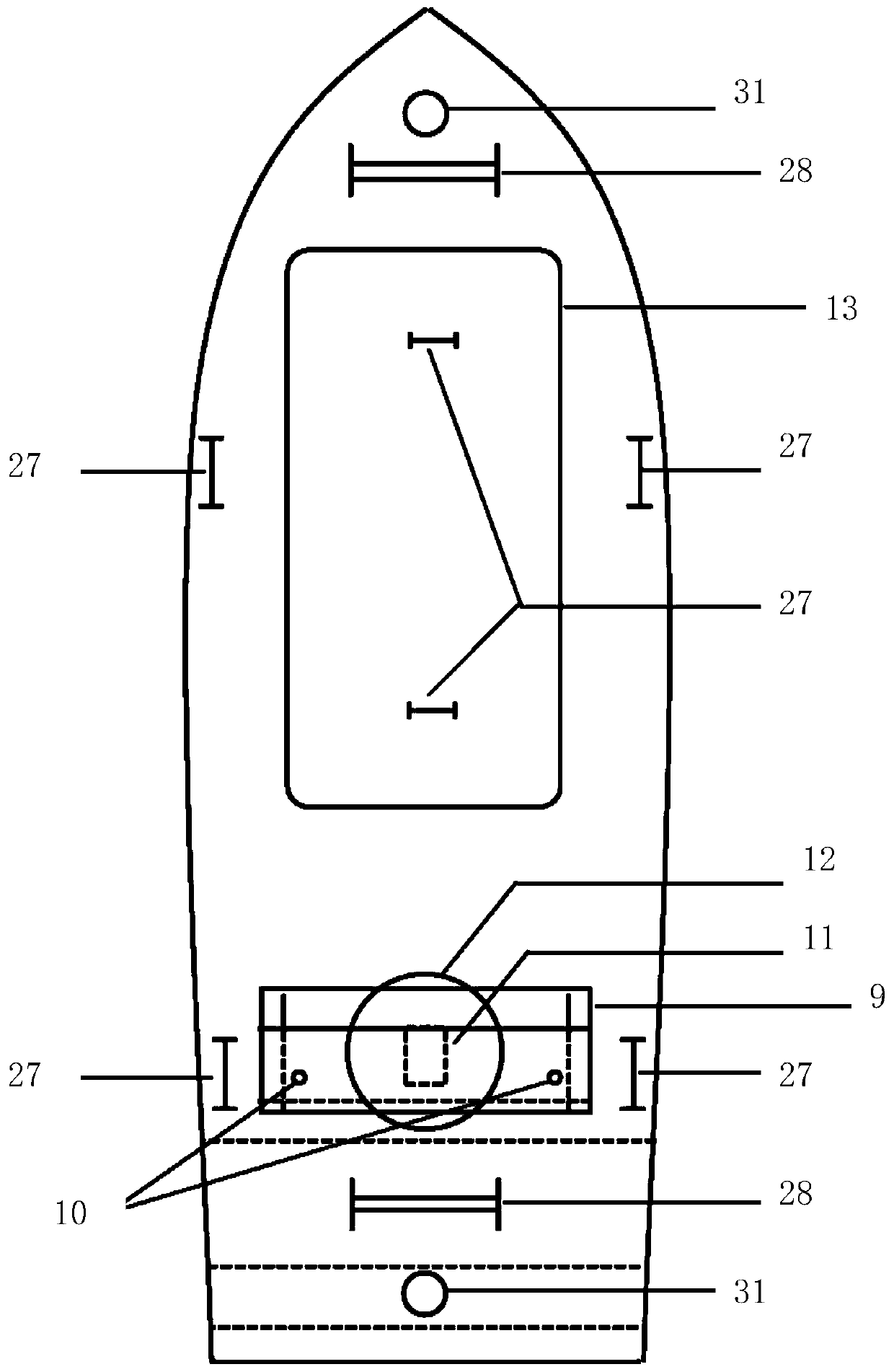

A multi-purpose catamaran and a method for building it using the means of tier

InactiveCN100491189CEasy to ship toLow costHull interior subdivisionNon-magnetic metal hullsAquatic productEngineering

A multi-purpose catamaran is disclosed in the present invention, comprising hulls and deck, wherein the hulls are two hulls, the central of the deck is arranged a movable deck, a detachable crane is set over the movable deck for hanging a fishing net or a fishing cage. The catamaran according invention can be easily disassembly and assembly, and expediently be carried and used. The fishing net or the fishing cage can be immerged in water for transiting live fish carried in it, can conveniently transfer to the deep water region for cultivating or to the shallow water region to disembark, removing the hoop can easily hoist it to the dock and can be easily transferred to a truck. The present invention has multi-purpose, except for using to retract and place fishing cage, to transfer aquatic products or personnel, or be as small-sized tow net, also can be used for selling, fishing etc. The present invention manufacturing method is simple, and can easily manufacture the catamaran without a model, suitable for fisherfolks to manufacture the catamaran by themselves, and the catamaran has lower cost.

Owner:徐汉杰

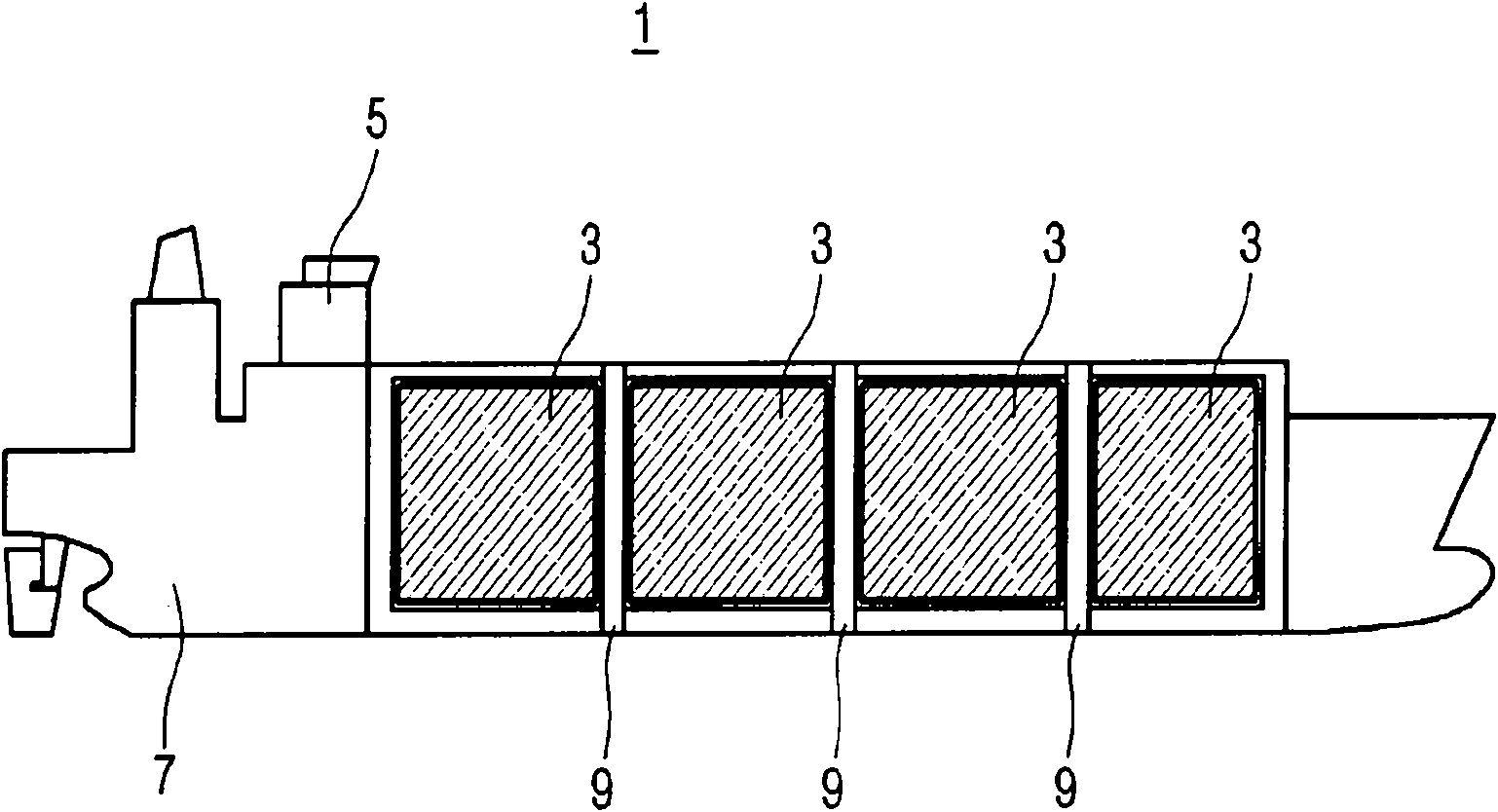

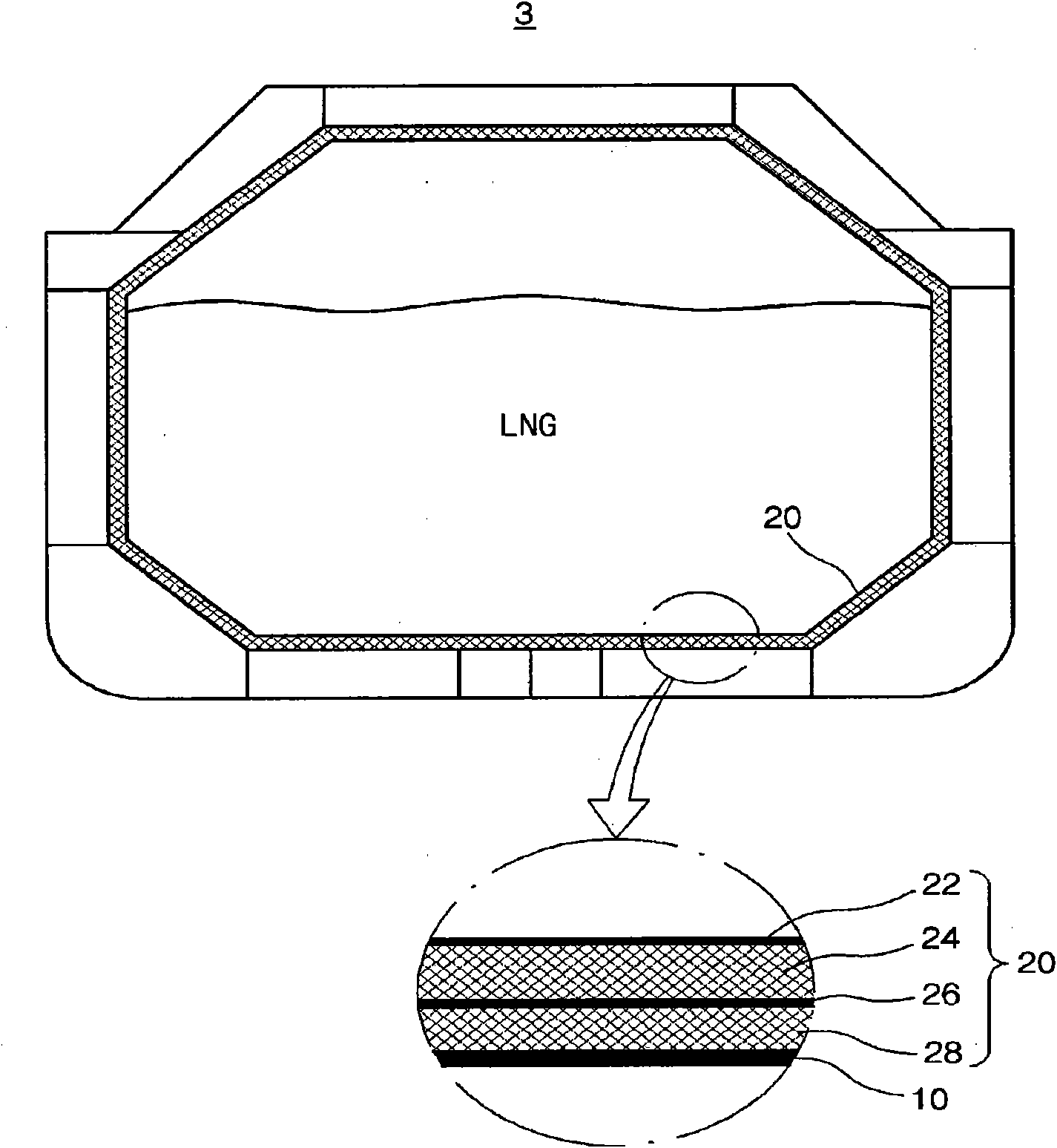

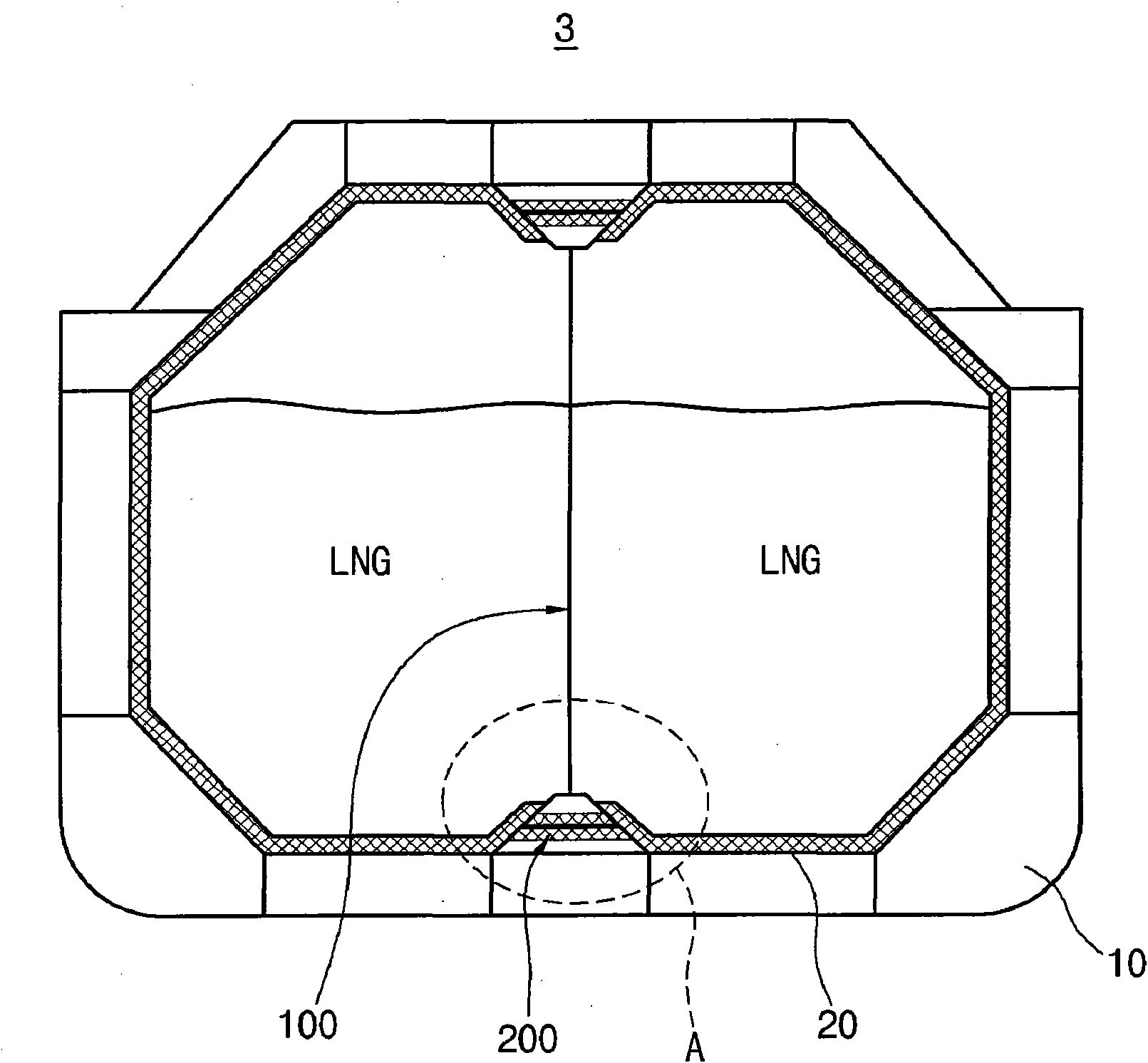

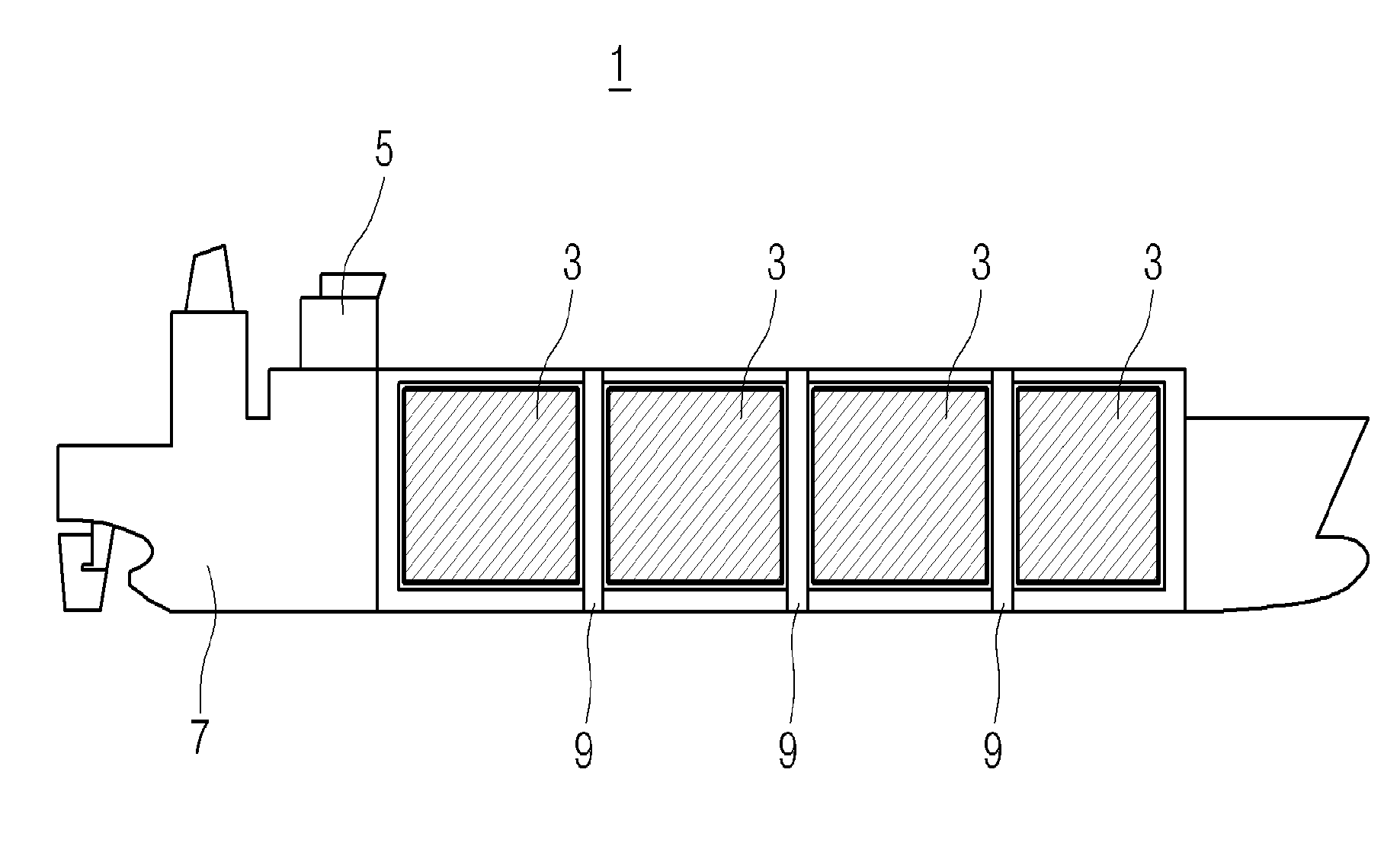

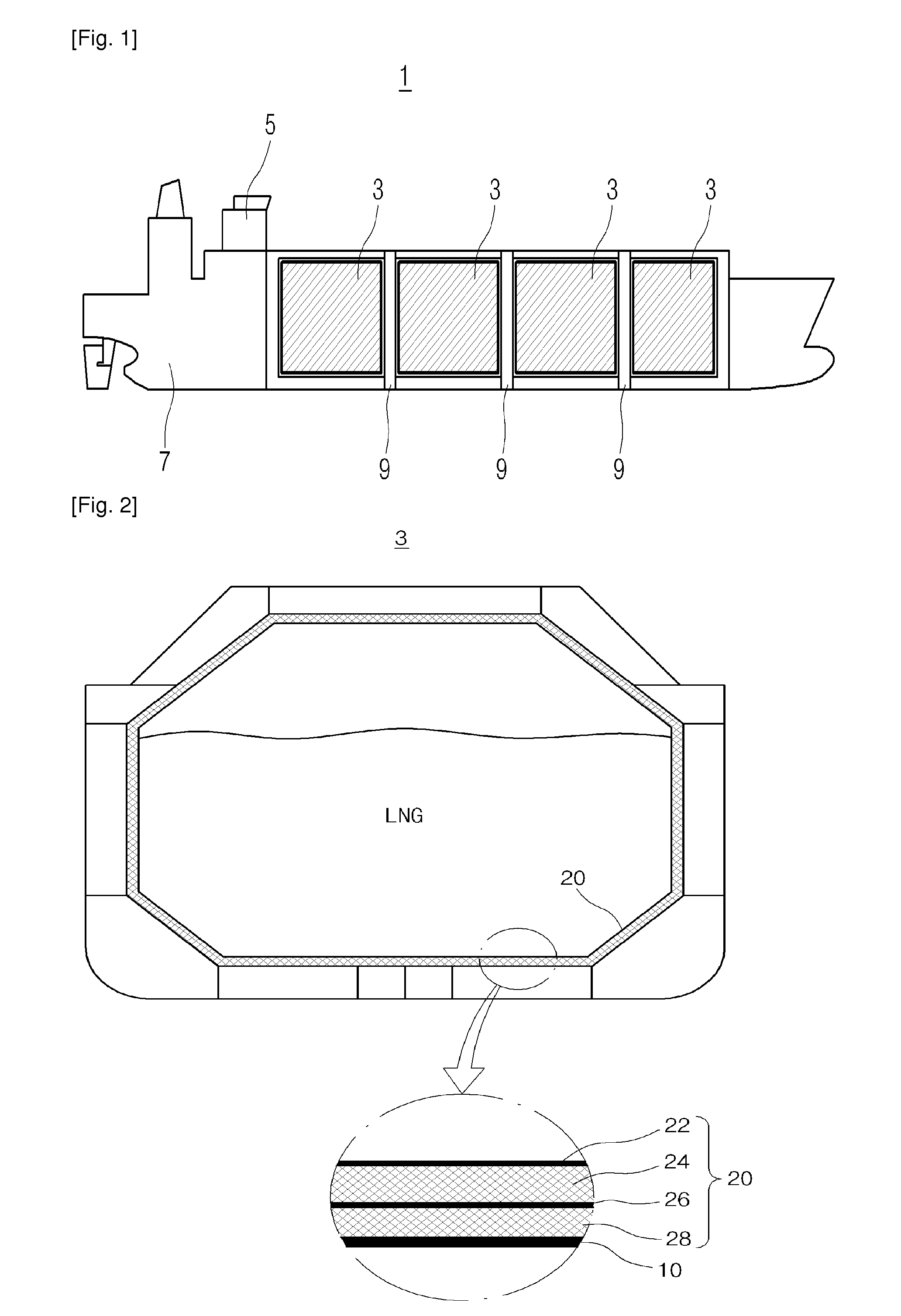

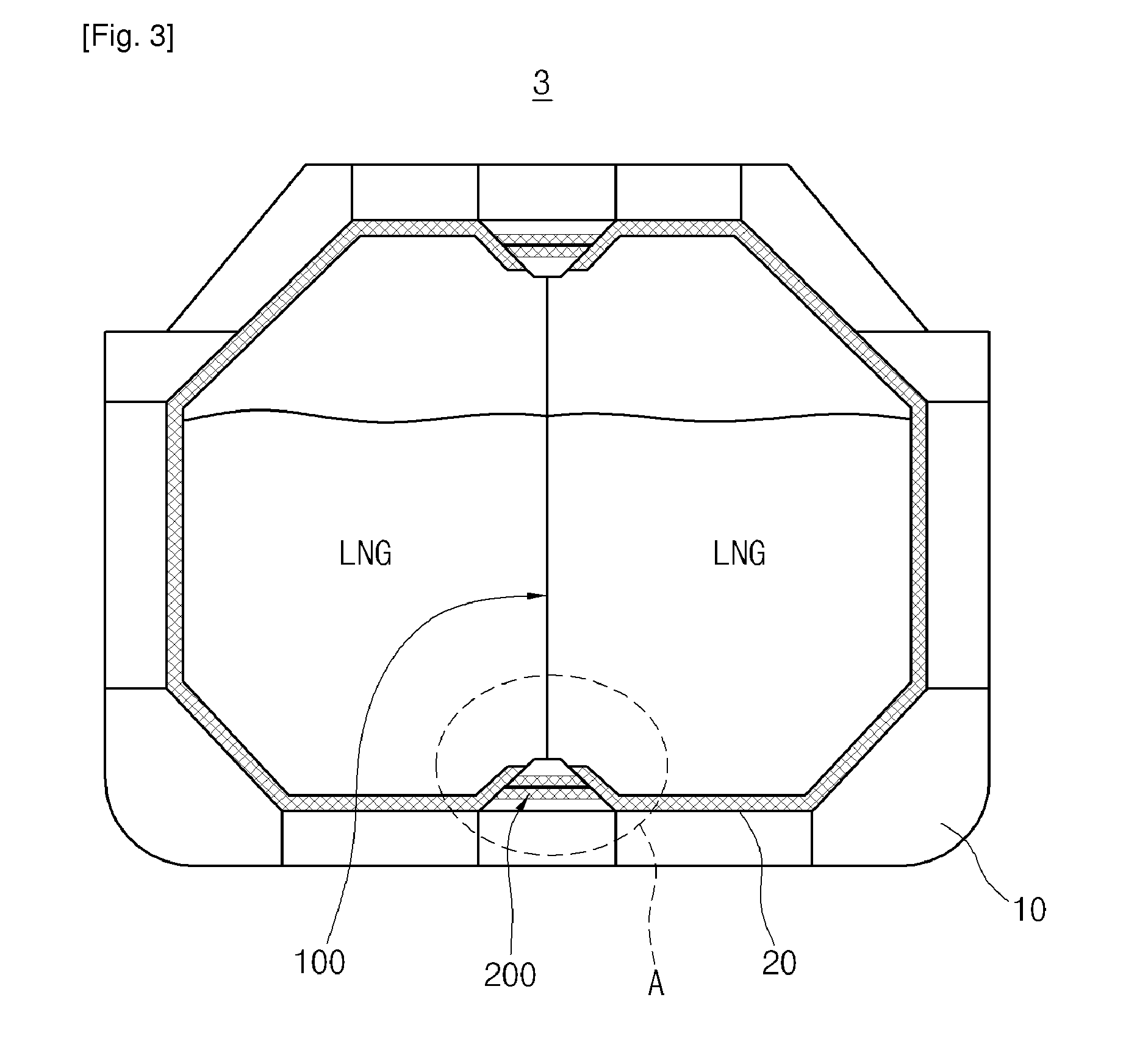

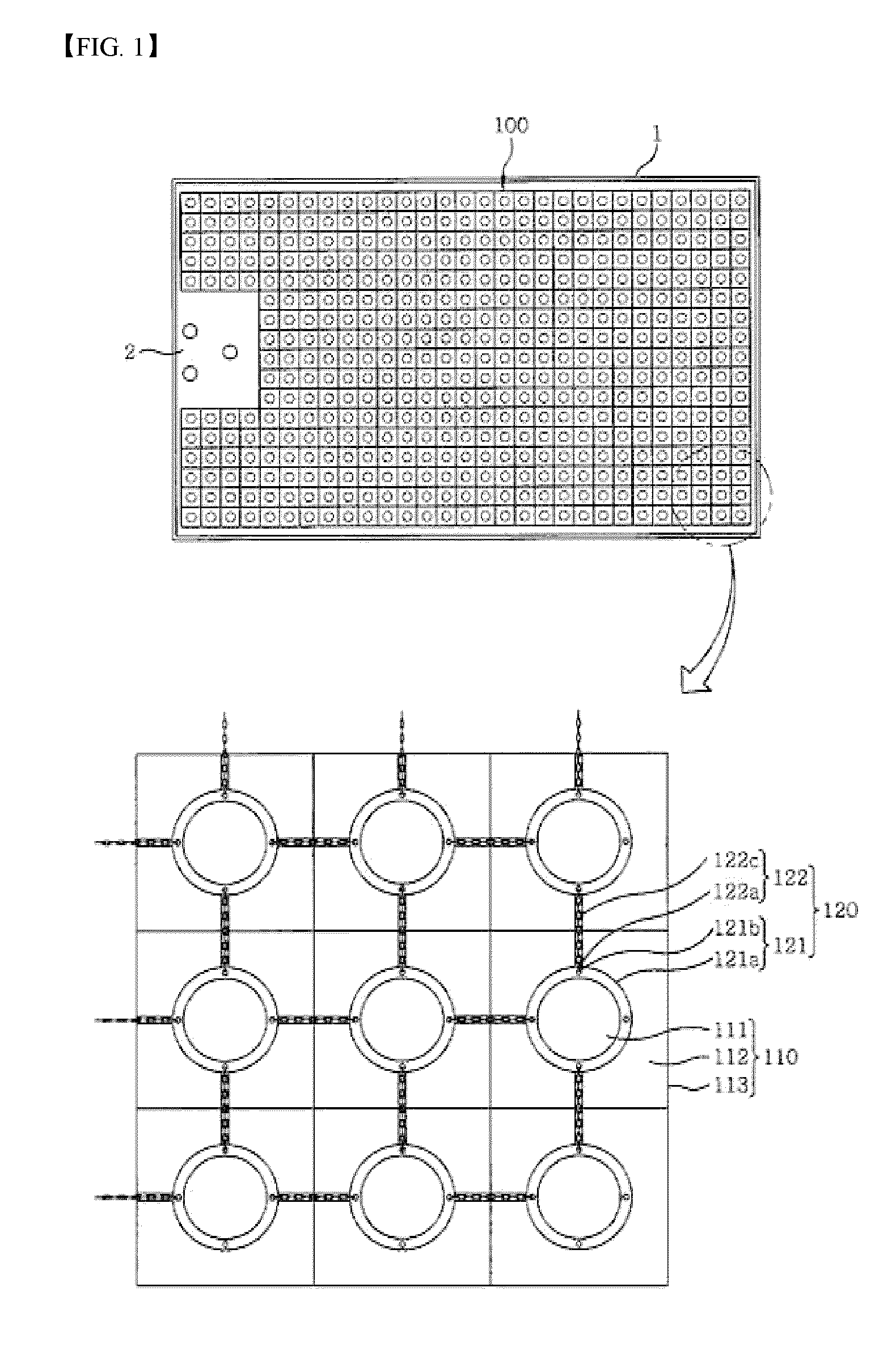

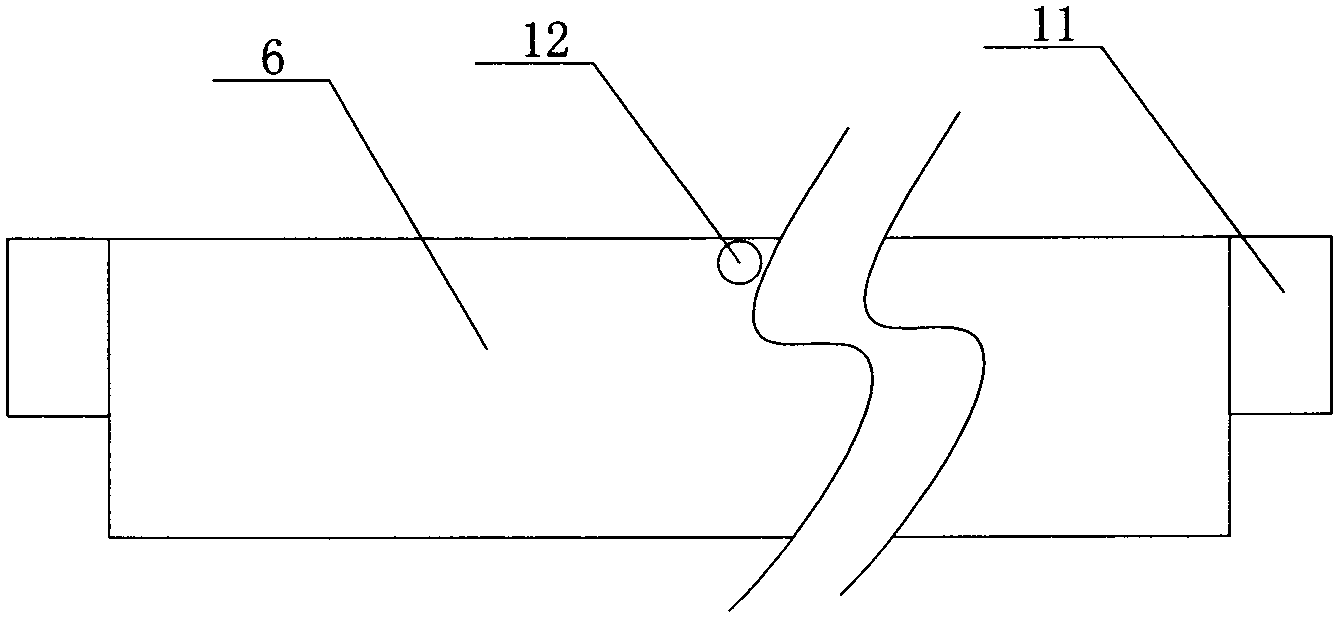

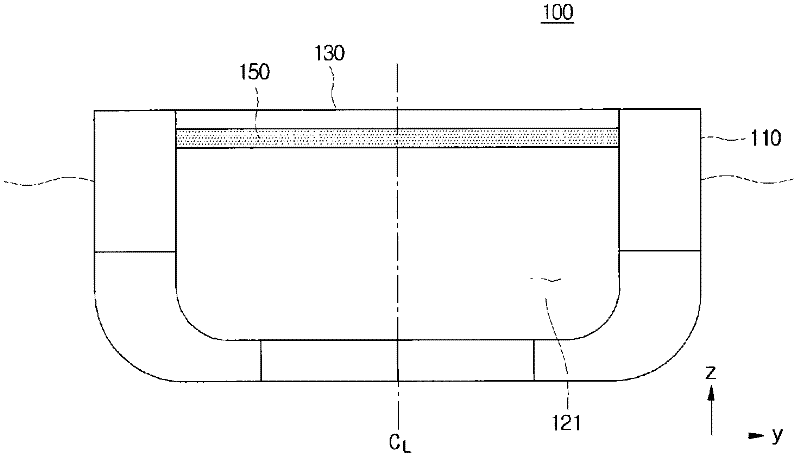

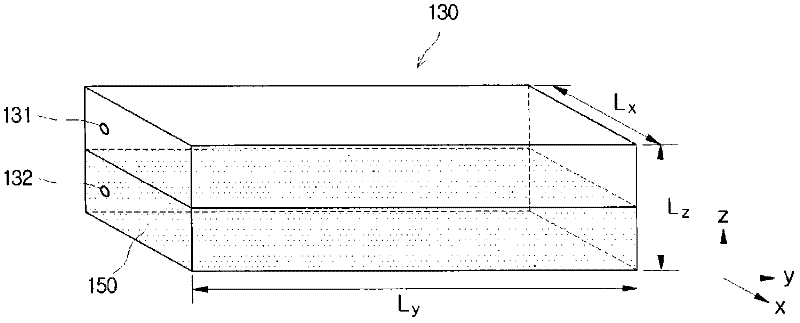

Anti-sloshing structure for lng cargo tank

ActiveCN101883715AReduce shakingSimple structureHull interior subdivisionFluid handledMechanical engineering

Owner:SAMSUNG HEAVY IND CO LTD

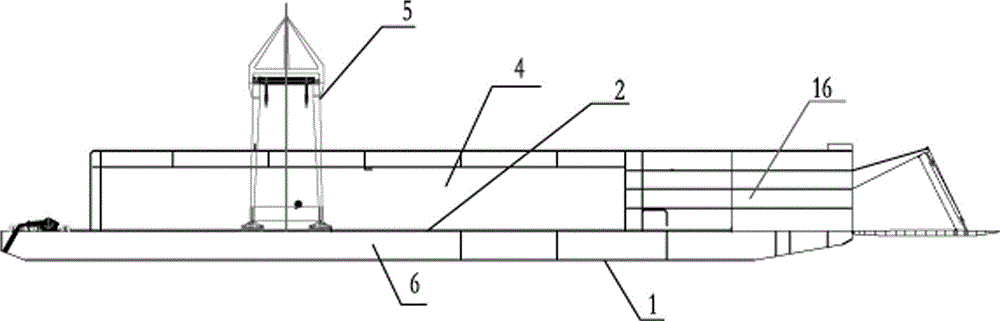

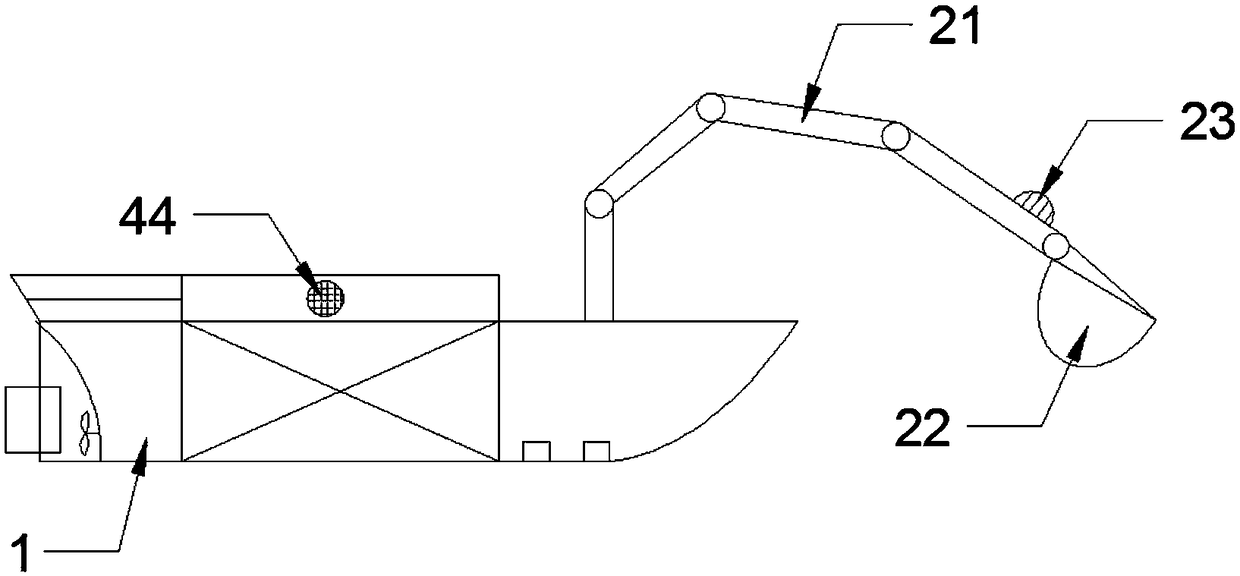

Full-automatic water floating garbage and aquatic plant salvage compression ship

InactiveCN104859808AIncrease loading capacityReduce unloading frequencyHull interior subdivisionSpecial purpose vesselsHydraulic cylinderCompression device

The invention provides a full-automatic water floating garbage and aquatic plant salvage compression ship. The head part of a fore peak is obliquely cut and opened to form two heads, a seaweed collection device is installed between the two heads, and a compression type storage transit cabin and a storage unloading cabin are sequentially arranged on a deck from the bow to the stern. A compression device is additionally arranged in the compression type storage transit cabin, a telescopic cylinder pushes a compression plate to the rear end of the transit cabin, to compress seaweeds and garbage in the cabin, when the seaweeds in the transit cabin is compressed to reach a certain pressure, a hydraulic cylinder controls a retaining door to be opened, and thus the seaweeds and garbage are sent to the storage unloading cabin to wait for unloading. By applying the full-automatic water floating garbage and aquatic plant salvage compression ship, the seaweeds in the storage transit cabin can be compressed, water is removed, the actual loading capacity of the storage transit cabin is improved, the unloading frequency is lowered, and extra fuel consumption caused by high-frequency returning and unloading is avoided, so that the work efficiency is greatly enhanced and the operation cost is reduced.

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

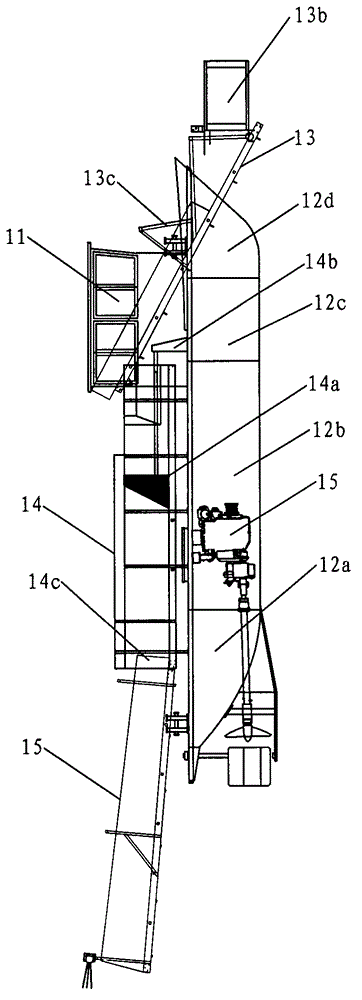

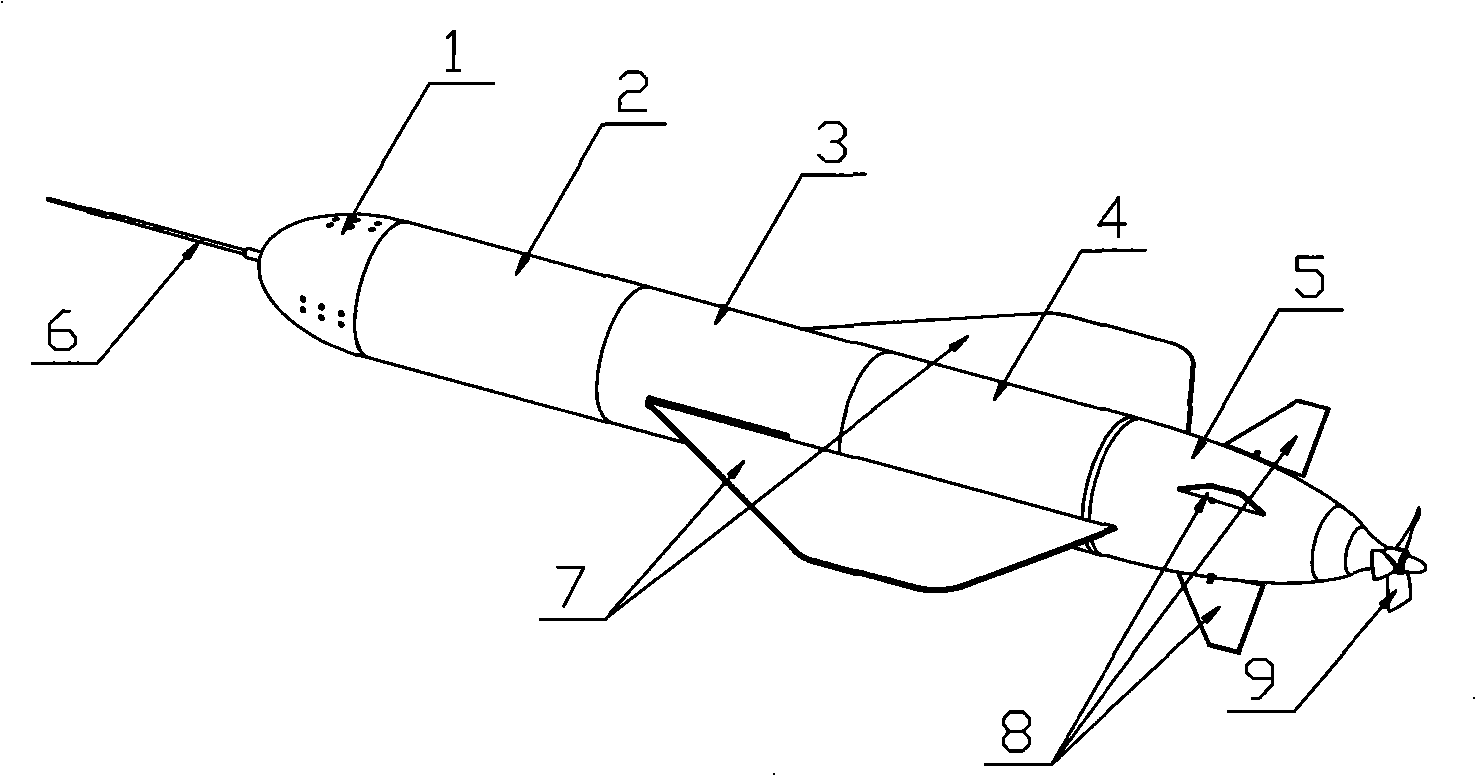

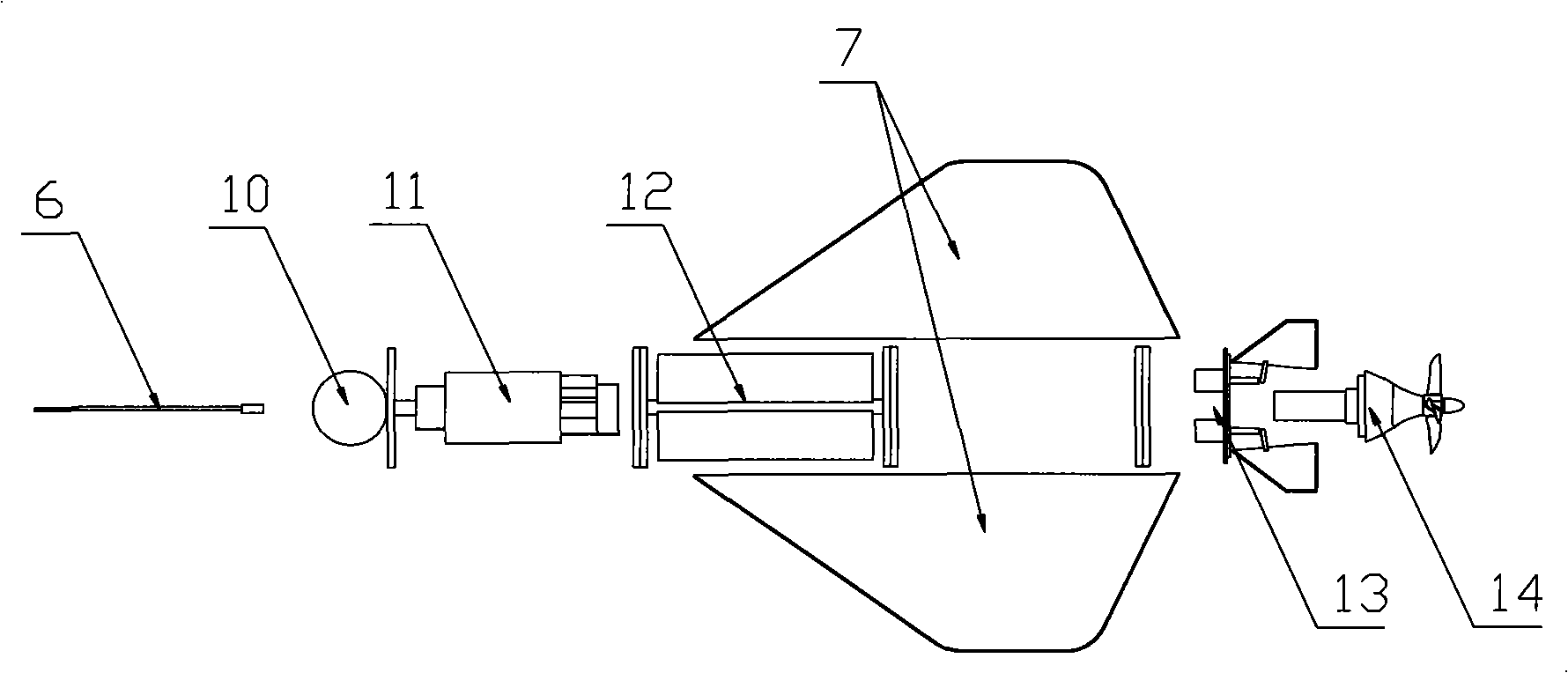

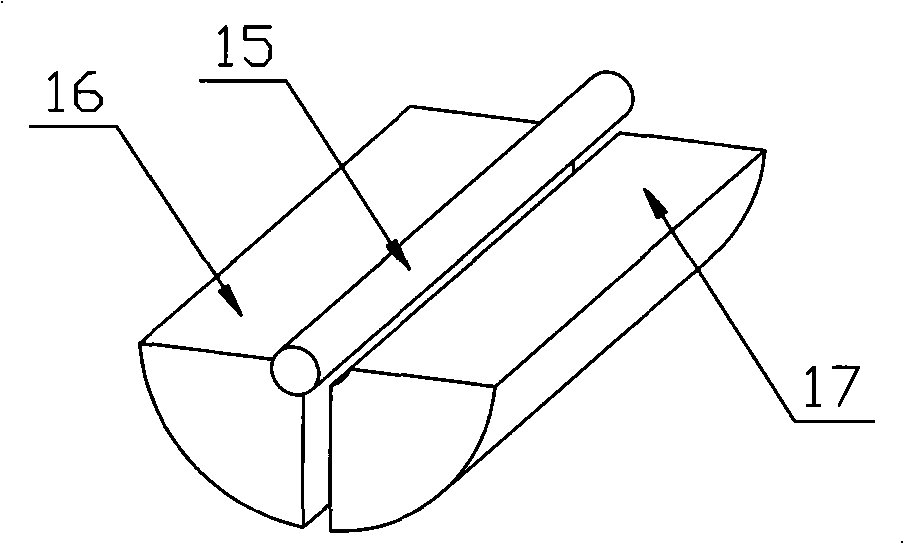

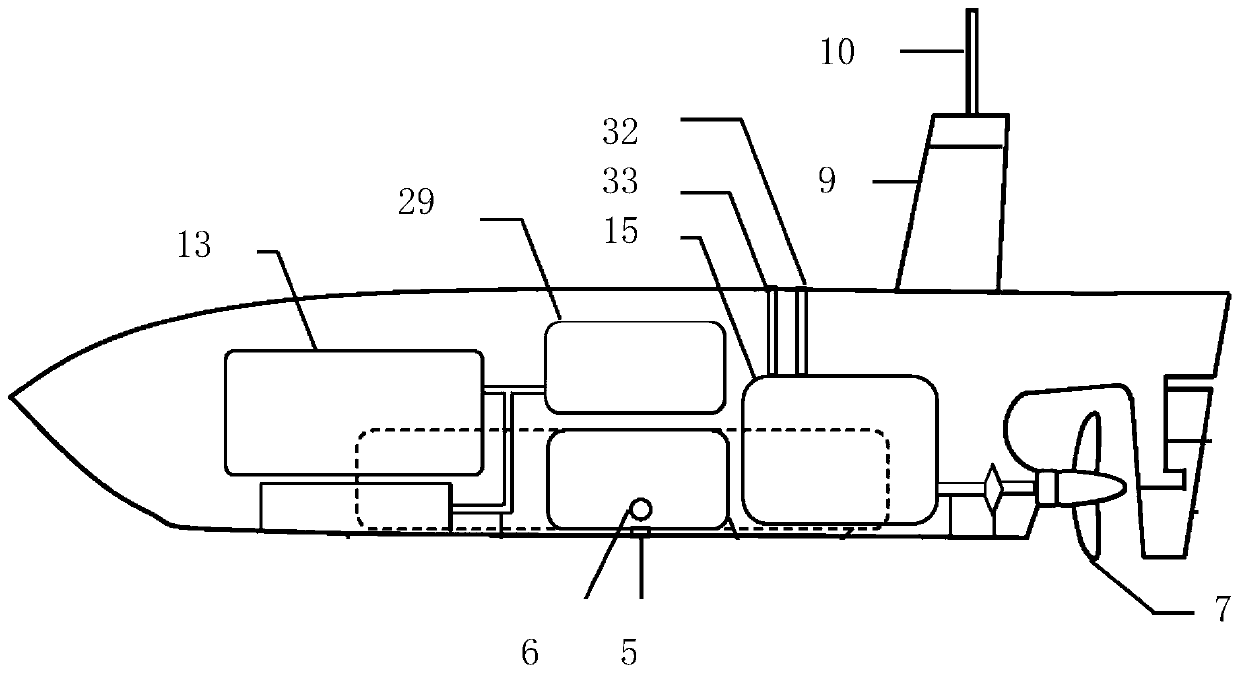

Hybrid multifunctional ocean monitoring independent platform

ActiveCN101549744AIncrease autonomySimple designHull interior subdivisionPropulsion power plantsHybrid typeGravity center

The present invention discloses a hybrid multifunctional ocean monitoring independent platform which comprises the following components: a body, two airfoils which are symmetrically installed on the body, four tail rudders which are installed with a shape like the Chinese character ''mi'', a communication antenna installed on the front end of body, and an airscrew at the bottom end of body. The body comprises a head cover, a floating power driving cabin section, a function broadening cabin section and an AUV function cabin section. The platform also comprises a gravity regulating cabin section. A gravity center regulating mechanism is installed in the gravity regulating cabin section. The gravity regulating cabin section is installed adjacent at the gravity center position of platform. The gravity center regulating mechanism comprises a central shaft and two rotatable battery packs installed on the central shaft. The central shaft and the gravity center regulating cabin section are connected through a rotating joint. Two battery packs have save shapes and same weight. The connecting line between the gravity center of battery pack and the gravity center of platform is perpendicular to the axis of platform. The gravity center of platform is the perpendicular foot of perpendicular line. The hybrid multifunctional ocean monitoring independent platform of the invention has the functions of four platforms of underwater independent vehicle, underwater independent glider, profiling float and neutral drifting float.

Owner:TIANJIN UNIV

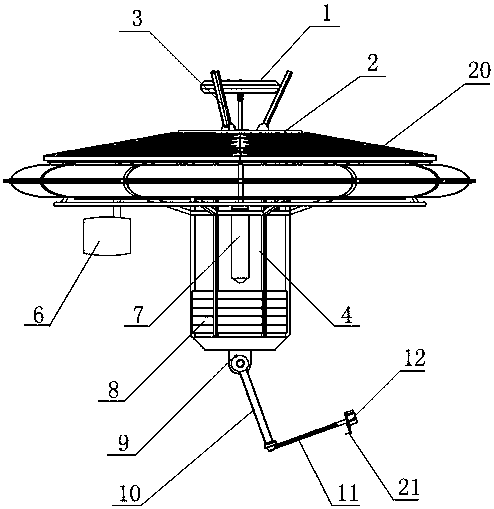

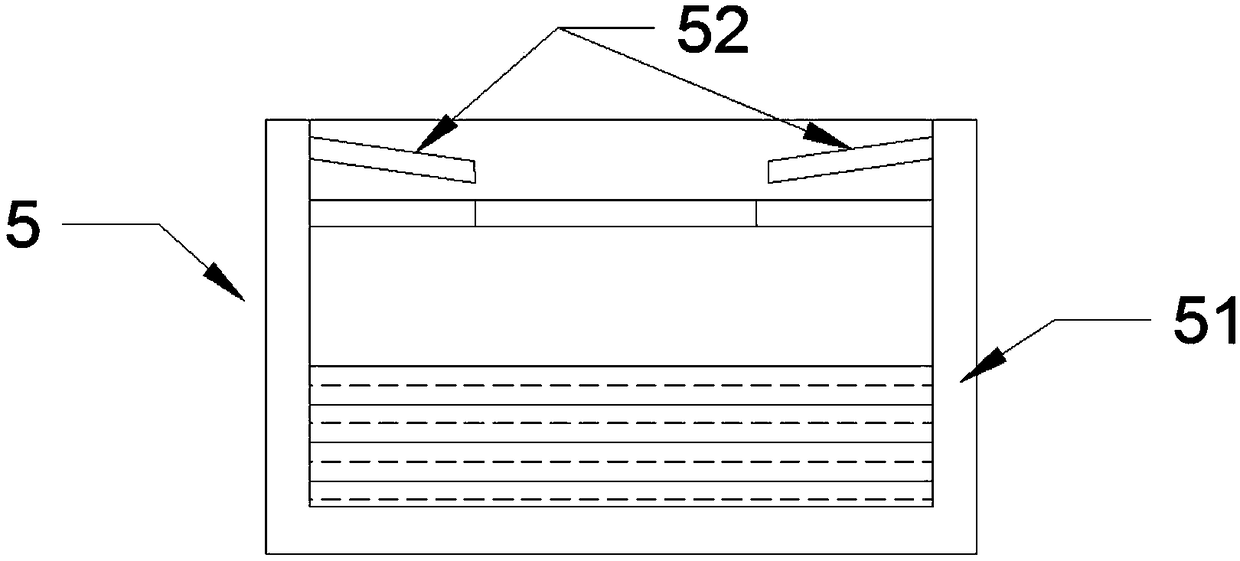

Multifunctional submerging and floating device with unmanned aerial vehicle taking-off and landing platform

PendingCN107672751AImprove battery lifePrecision landingHull interior subdivisionBatteries circuit arrangementsOcean bottomHigh pressure

The invention discloses a multifunctional submerging and floating device with an unmanned aerial vehicle taking-off and landing platform. The multifunctional submerging and floating device comprises afloating cabin, the unmanned aerial vehicle taking-off and landing platform, a high-pressure submersible pump, a balance weight cabin and a power drive device. Solar cell panels are arranged, so thatsolar energy serves as an energy source. The multifunctional submerging and floating device is provided with an energy storage device, and an unmanned aerial vehicle, all types of instruments and equipment carried on the multifunctional submerging and floating device and submarine electronic equipment can be charged. Through the maneuverability of the power drive device, the position of the multifunctional submerging and floating device can be adjusted or the multifunctional submerging and floating device can slowly move to the designated position. The multifunctional submerging and floatingdevice is simple in structure, flexible in loading and transporting and quick to arrange; and on the base of the platform, the functions of exploration, receiving, storage, launching, object transit shipment and the like can be expanded as well, and the device is extended to be the universal type multifunctional submerging and floating device which can process all types of information and integrate multiple functions.

Owner:余拓

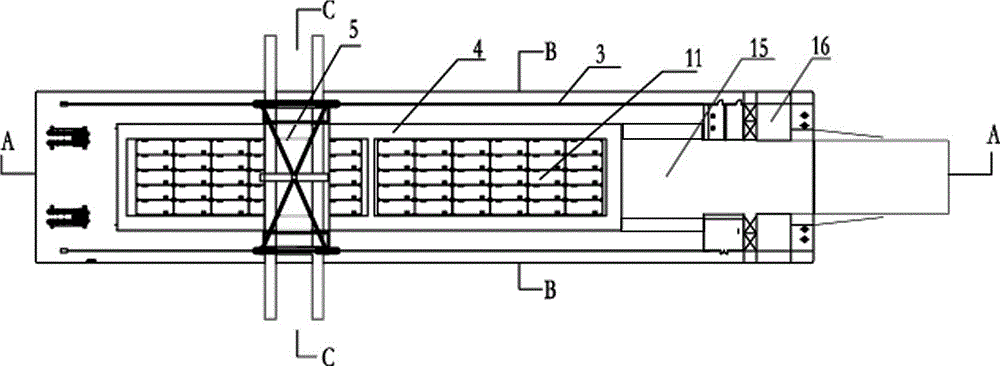

LNG tank container reloading ship

An LNG tank container reloading ship comprises a ship body, wherein a main deck is arranged on the upper surface of the ship body; two parallel tracks are arranged on the main deck; a portal bridge type special crane for LNG tank containers runs along the two tracks; an enclosed dock wall type protective wall is arranged between the two tracks; and a head springboard and a hoisting system for driving the head springboard to ascend and descend are arranged at the front end of the main deck. The LNG tank container reloading ship has the advantage that the seamless multimodal transportation water reloading new transportation mode for LNG tank containers of which tanks are not changed in the whole transportation process is implemented.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

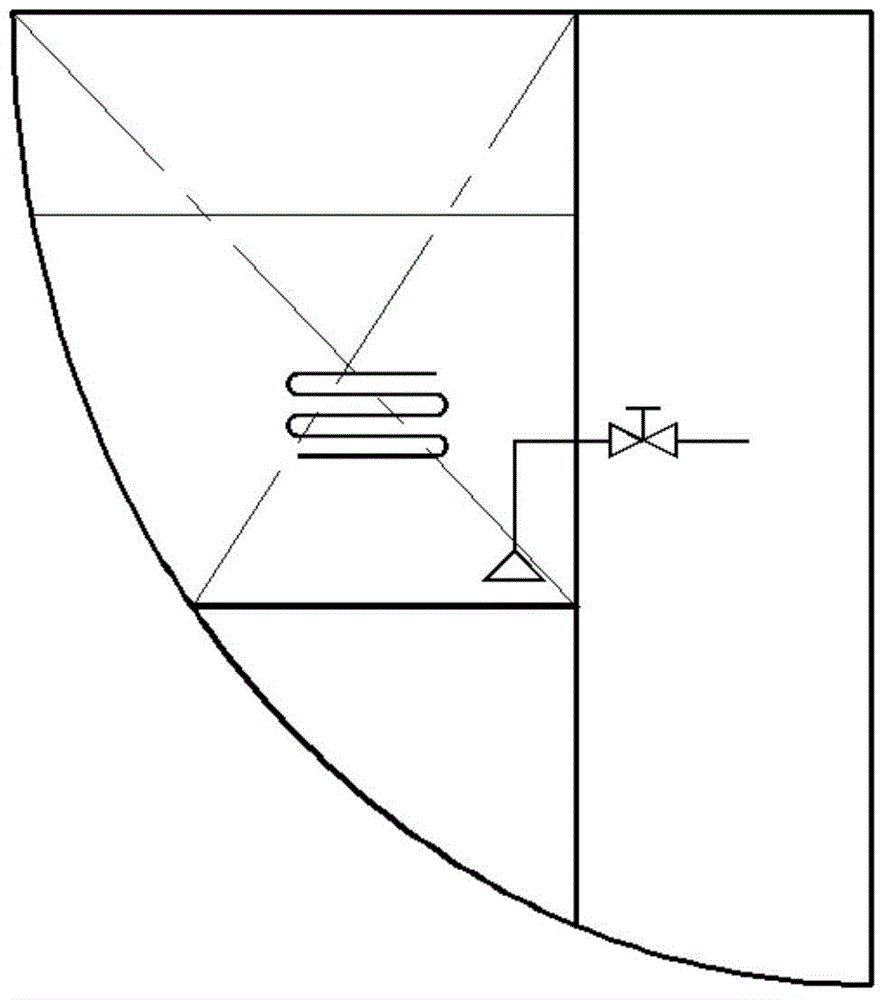

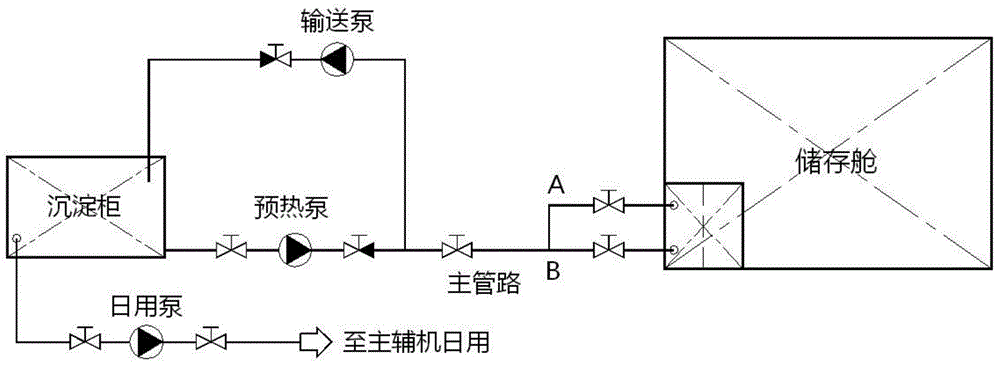

Ship fuel preheating system and preheating method

ActiveCN104819080AReduce operating costsEfficient use ofHull interior subdivisionElectrical controlFuel oilEngineering

The invention relates to a ship fuel preheating system. The ship fuel preheating system is characterized in that a fuel preheating branch pipeline and a fuel conveying branch pipeline are arranged between a storage bin and a sedimentation cabinet. A main pipeline is shared and is divided into two branches near the sedimentation cabinet, a preheating pump is arranged on one branch and provides high temperature fuel for the storage bin, a transfer pump is arranged on the other branch and conveys heated heavy oil to the sedimentation cabinet, and the two branches are provided with stop check valves in the corresponding directions so as to avoid pipeline direction malposition. A small compartment is arranged at one corner of the storage bin, and a first partition plate is arranged in the middle of the small compartment and divides the compartment into two parts in the X direction. A pipe A and a pipe B are arranged in a first sub-compartment, the upper right corner of the first partition plate is provided with a hole, the lower left corner of a second partition plate is provided with a hole, and the two holes are in opposite angle arrangement. Small holes are formed at the bottoms of partition plates to be used for sweeping. An upper plate of the compartment is provided with a plurality of air holes, so as to guarantee timely overflow of generated steam. The pipe A and the pipe B are communicated with the main pipeline and provided with regulating valves respectively.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

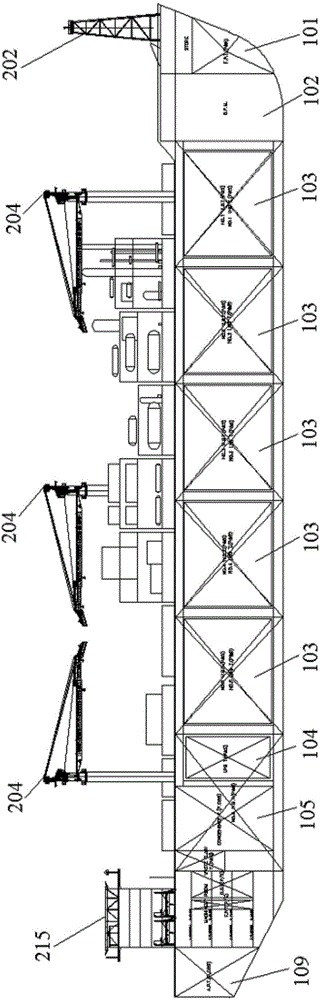

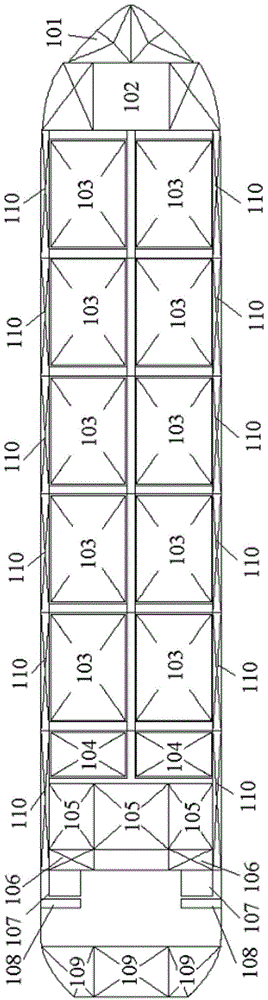

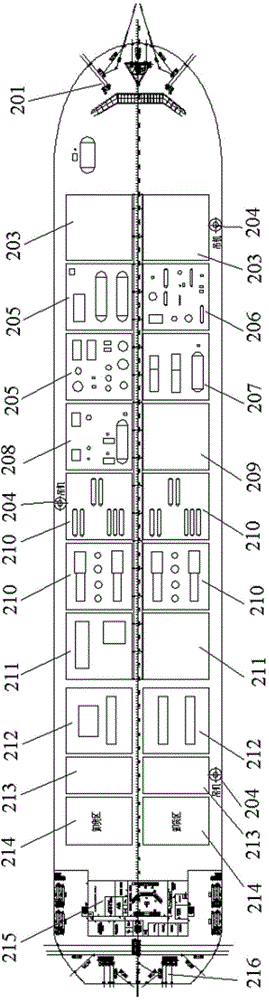

Large floating liquefied natural gas production, storage and unloading device

ActiveCN104608880AAchieve miningEnsure job safetyHull interior subdivisionFor bulk goodsPower stationTorch

The invention relates to a large floating liquefied natural gas production, storage and unloading device which comprises a ship and FLNG upper facilities arranged on a deck of the ship. The ship is sequentially provided with a fore peak tank, an inner rotary tower single-point bin, an LNG bin, an LPG bin, a gas condensate bin, an oily water bin, a fresh water bin, a diesel oil bin and an after peak tank from a ship bow to a stern. The FLNG upper facilities include a mooring device, a torch tower, an underwater production system control module, a preprocessing module, an LPG recycling module, a propane precooling module, a fuel gas compression module, an LNG output module, a liquefying and refrigerating module, a reservation module, a power station module, an electric room module, an unloading area, a living building and an LPG and gas condensate stern conveying device, wherein the mooring device and the torch tower are distributed on the ship bow, and the underwater production system control module, the preprocessing module, the LPG recycling module, the propane precooling module, the fuel gas compression module, the LNG output module, the liquefying and refrigerating module, the reservation module, the power station module, the electric room module, the unloading area, the living building and the LPG and gas condensate stern conveying device are distributed from the ship bow to the stern in a modular mode. The service life of the device can be 20 years in an in-water mode, the device can bear limiting typhoon and sea conditions with the recurrence interval of ten thousand years, and the device can be widely used for floating production, processing, liquefying, storage and output of natural gas in deep and high seas.

Owner:CHINA NAT OFFSHORE OIL CORP +1

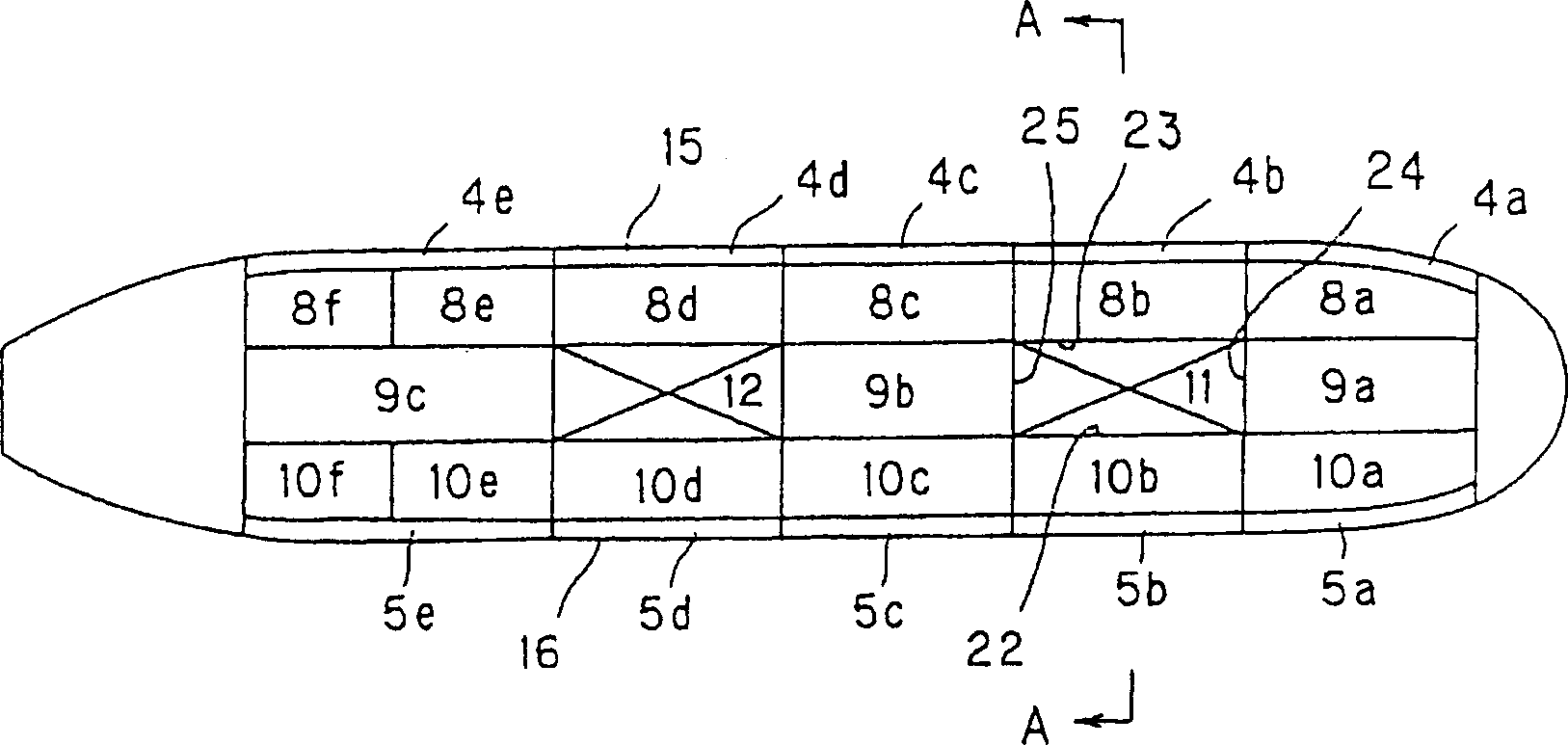

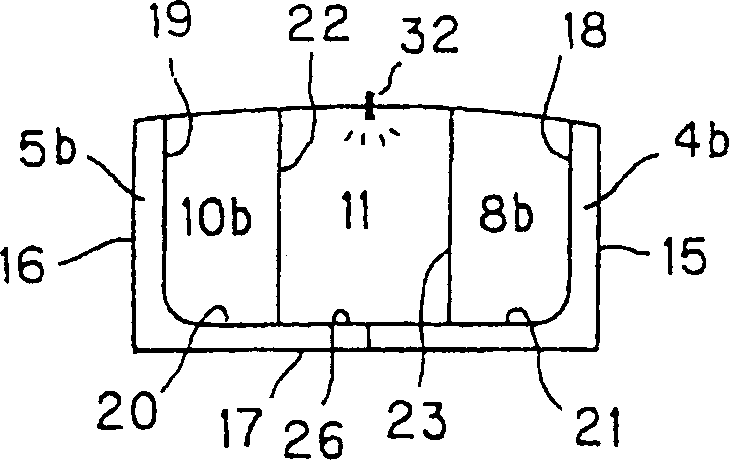

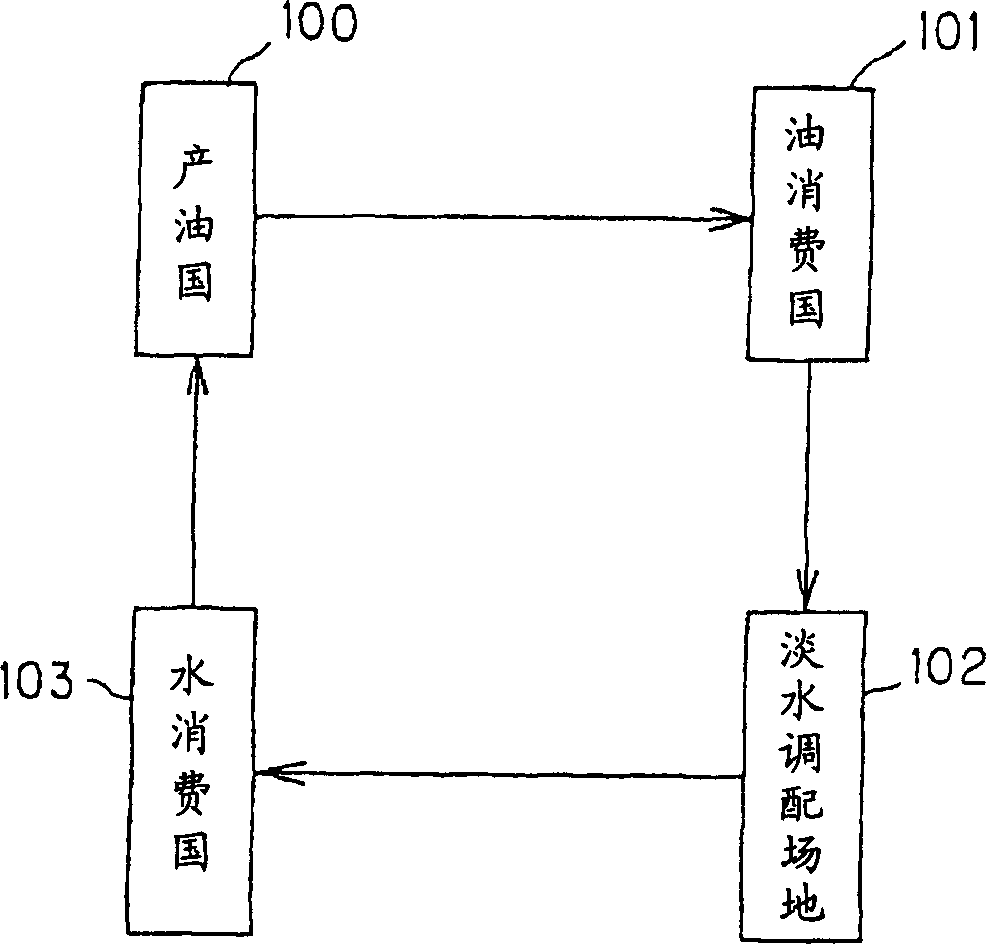

Ship structure for transporting oil and fresh water

InactiveCN1406812ANo empty sailingHull interior subdivisionSelf-bailing equipments/scuppersFresh waterBallast tank

The invention provides a hull construction of a oil tank for transporting oil and fresh water by using all ballast tanks formed in a double hull space as fresh water tanks 4a-4e and 5a-5e, and two combining tanks 11, 12 are provided at a central portion of a hull for combining a sea water ballast tank and a fresh water cargo tank. In this manner, non-wasteful sailing of an oil tanker can be realized by utilizing the tanker for transporting oil cargoes on a forward route and fresh water on a backward route.

Owner:约瑟夫·W·L·哈

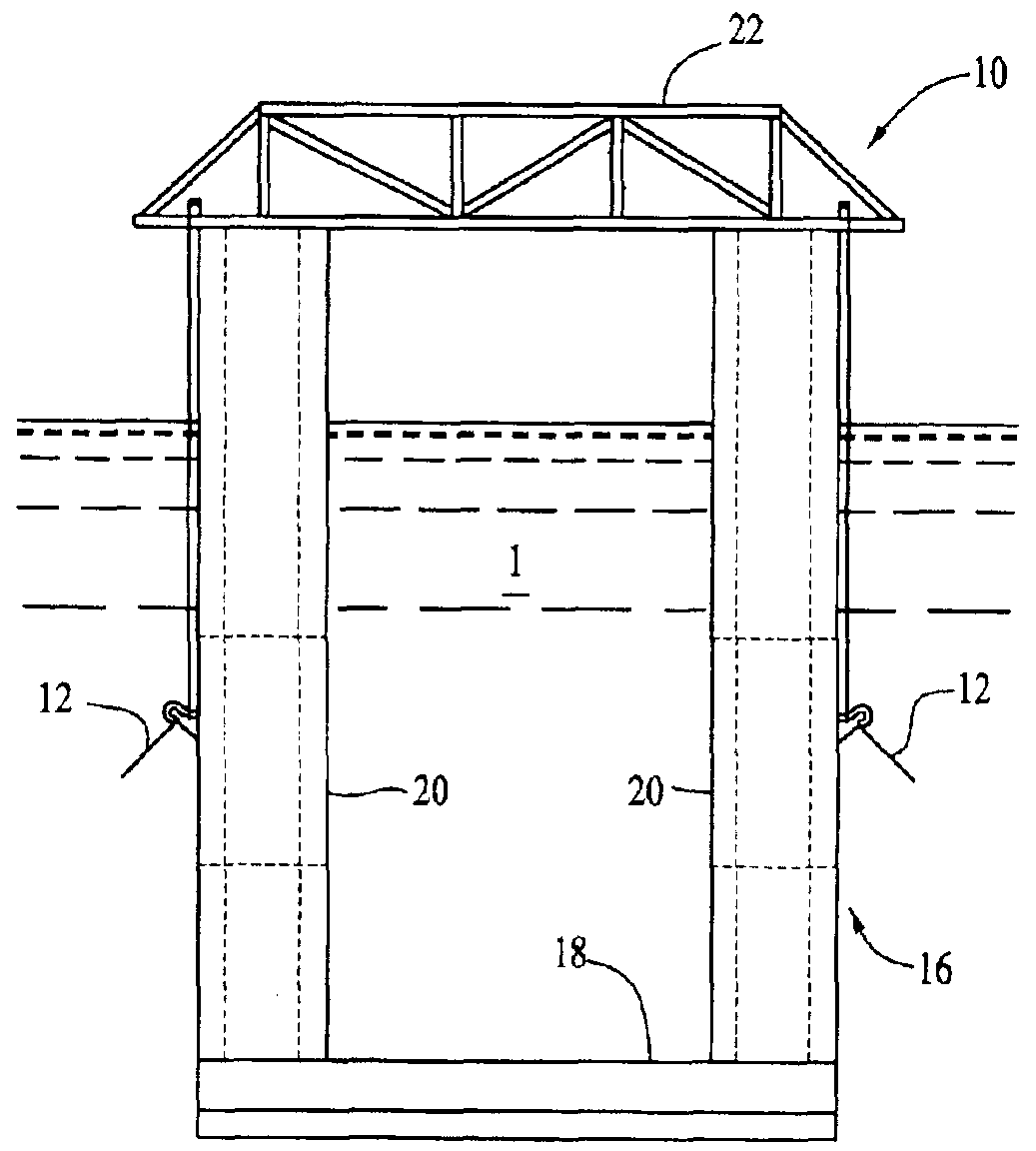

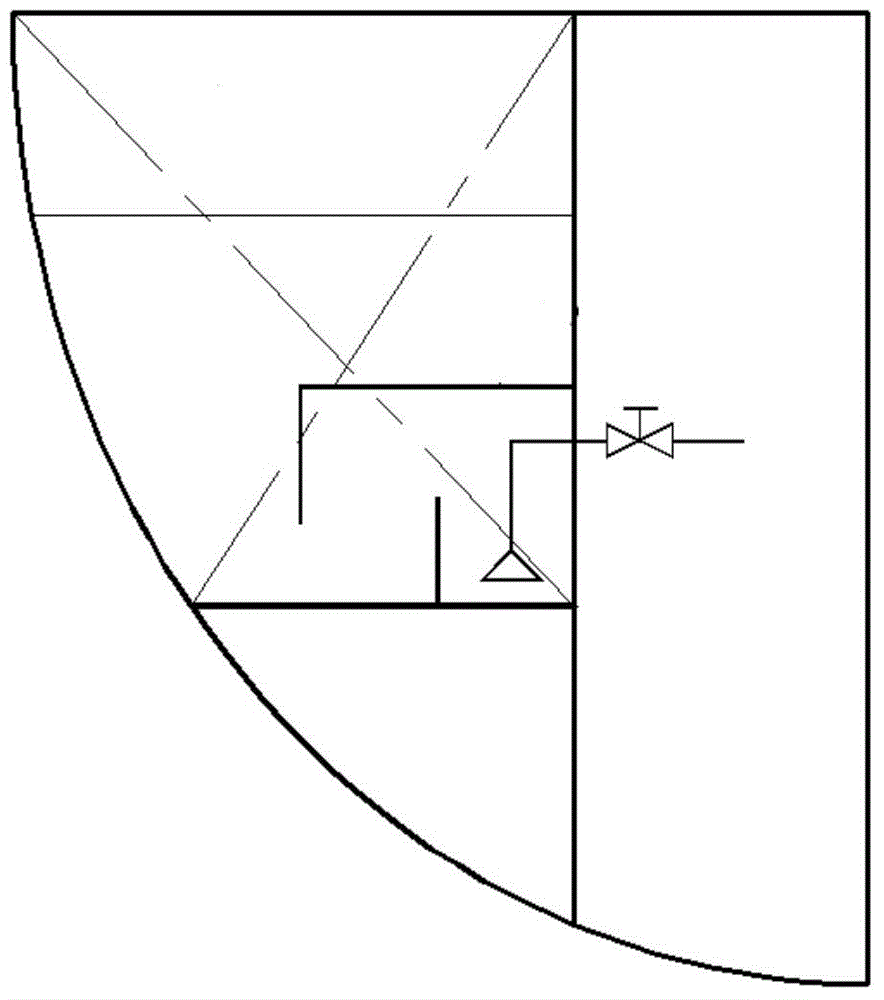

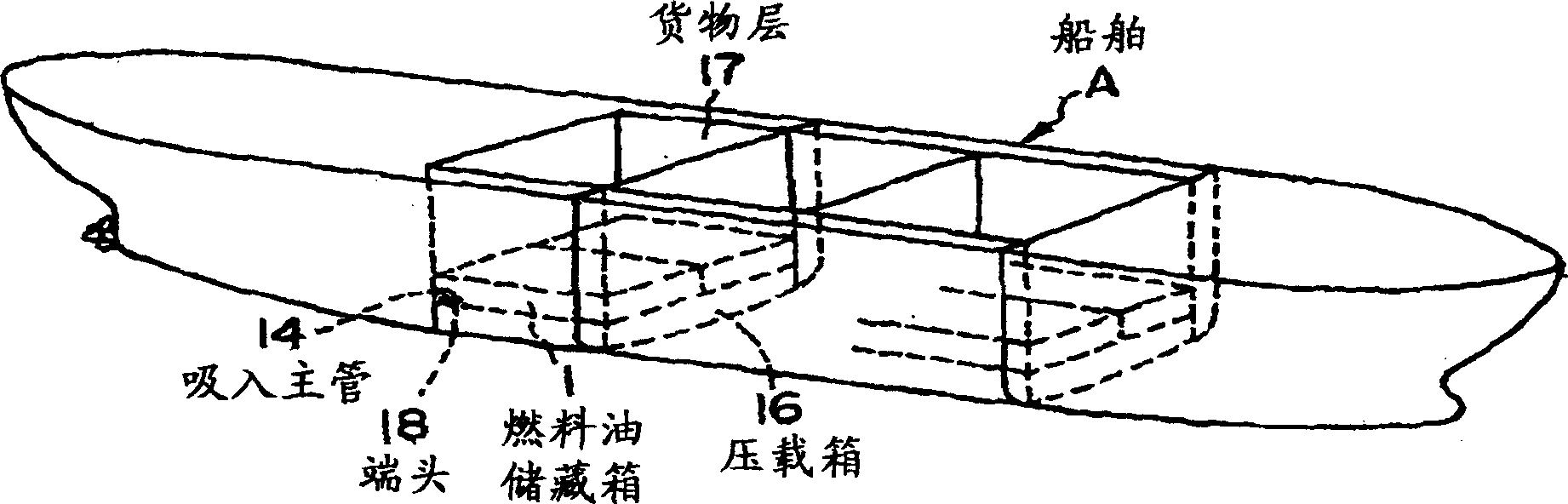

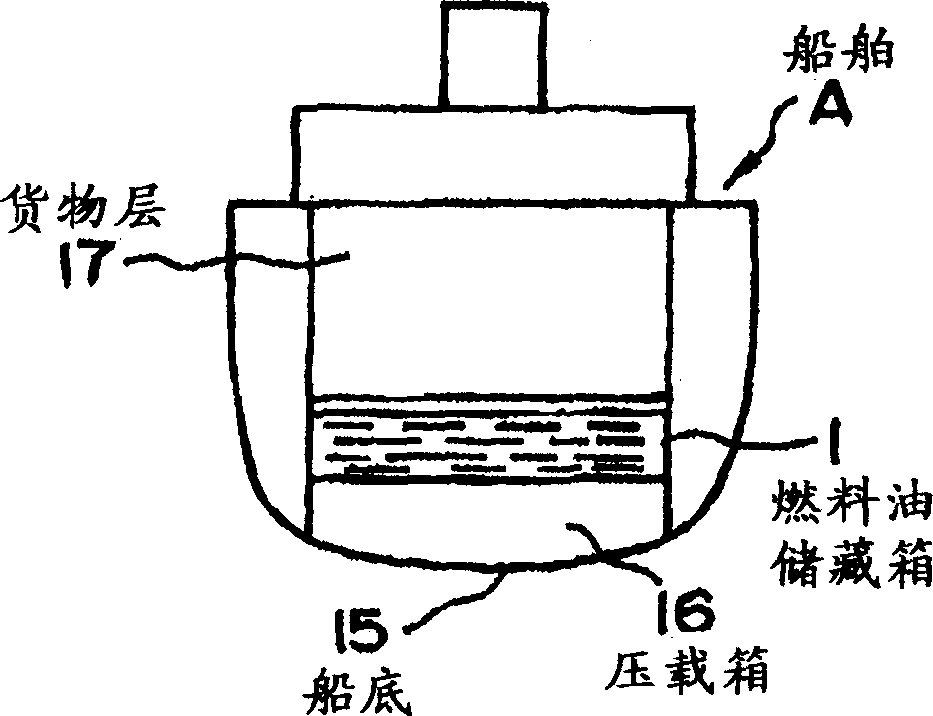

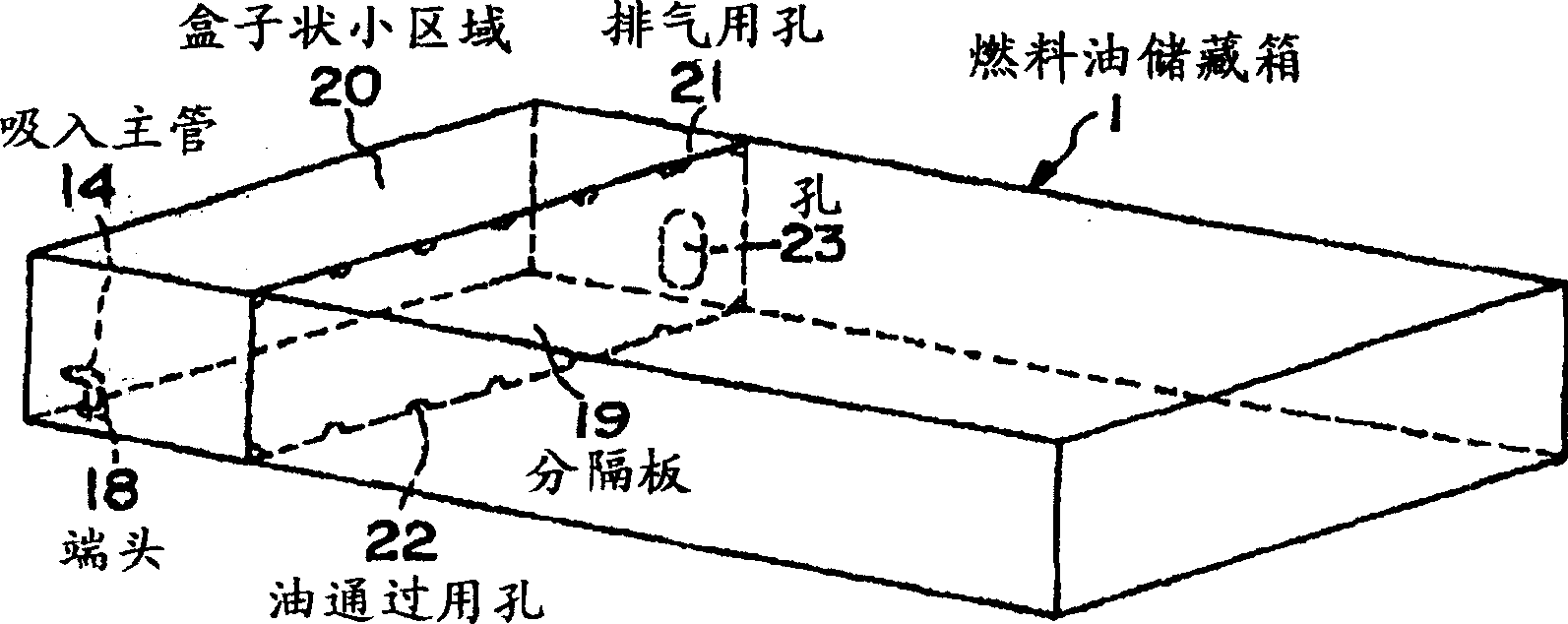

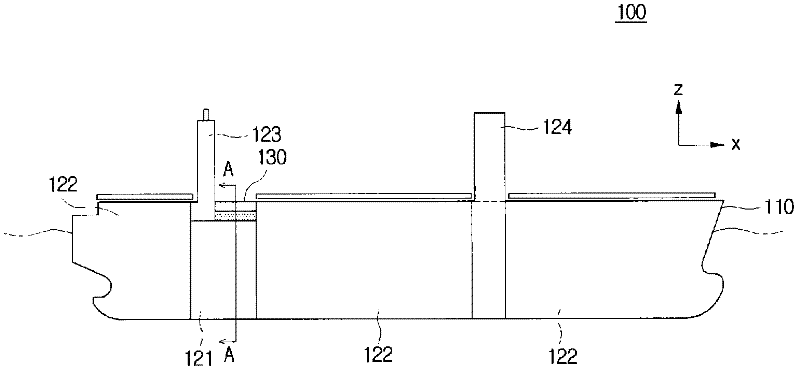

Heating method for fuel oil in fuel oil storage tank

ActiveCN1669873APrevent diffusion and heat dissipationEfficient heatingHull interior subdivisionPump componentsFuel tankFuel oil

This invention provides a method for heating fuel oil in a fuel oil storage tank to warm the fuel oil in the tank to intended temperature by flowing down heated fuel oil to the storage tank and mixing the heated fuel oil in the tank, and in particular, to partially improve warming efficiency for the fuel oil in the tank. In this method for heating fuel oil in the fuel oil storage tank, heated fuel oil is flowed down to and mixed with the fuel oil in the fuel oil storage tank 1 via a main intake pipe 14, to warm the fuel oil in the fuel oil storage tank 1. A box shape small division 20 is formed in the storage tank 1 by surrounding the perimeter of a tip 18 of the main intake pipe 14 by a partition plate. By preventing diffusion and heat release of the heated fuel oil flowed in through the tip 18, warming efficiency for the fuel oil is partially improved.

Owner:HOKUSHIN ENG

Anti-sloshing structure for LNG cargo tank

ActiveUS20100281887A1Easy constructionReduce shakingHull interior subdivisionLarge containersEngineeringMechanical engineering

Owner:SAMSUNG HEAVY IND CO LTD

Method and apparatus for reducing tension variations in mono-column TLP systems

A floating platform for recovery of oil and gas from offshore oil and gas fields supports one or more decks above the water surface to accommodate equipment for drilling and processing oil, gas and water recovered from the oil and gas field. The platform includes a central column having a portion substantially below the water surface, and including a portion which extends above the water surface. The central column includes a base node and a plurality of pontoons extending outwardly therefrom and is anchored to the seabed by one or more tendons secured to the pontoons and to the seabed. Ballast modules fixedly or removably secured to the base node and / or the pontoons accept solid or liquid ballast for lowering the vertical center of gravity of the platform.

Owner:SINGLE BUOY MOORINGS INC

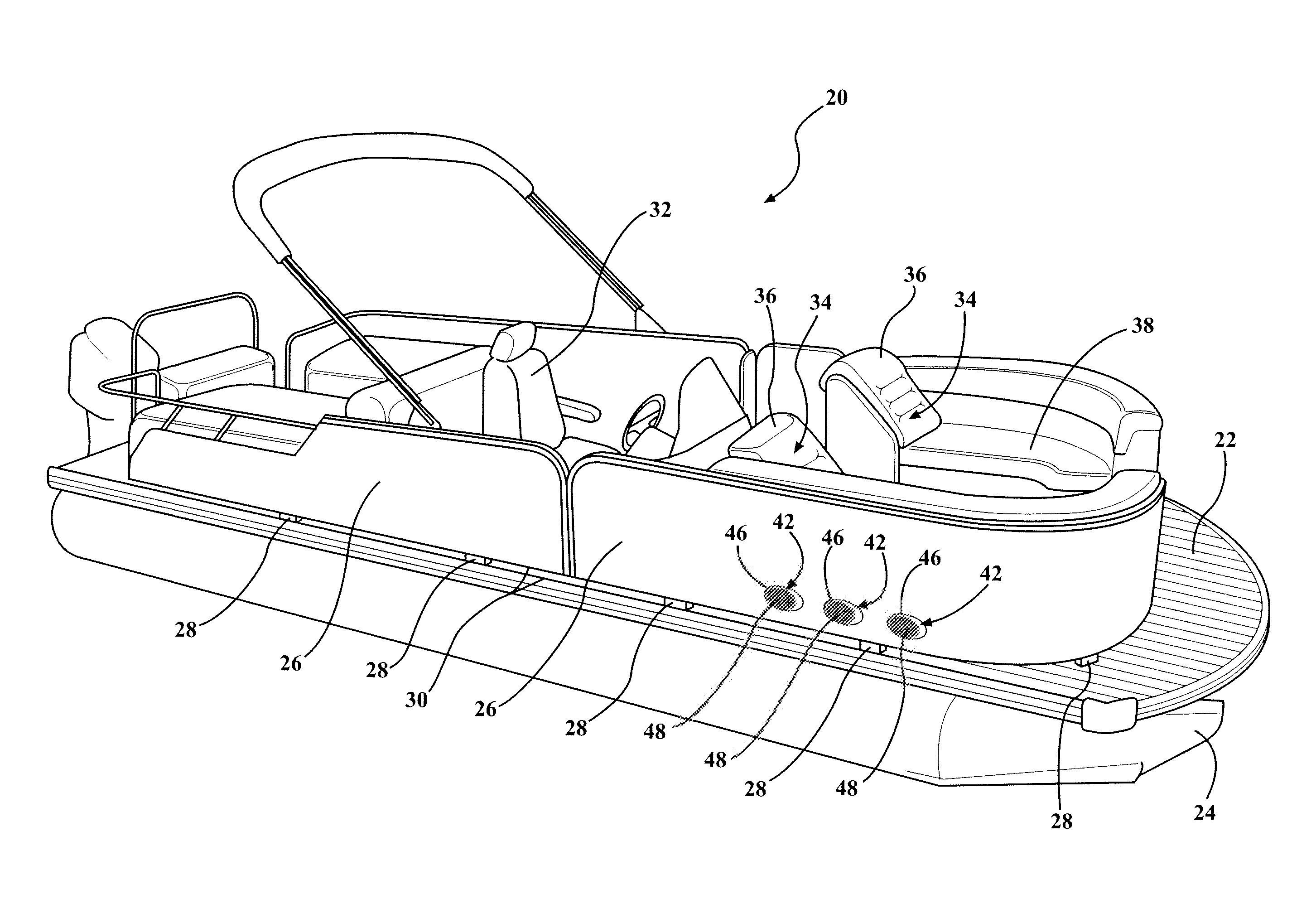

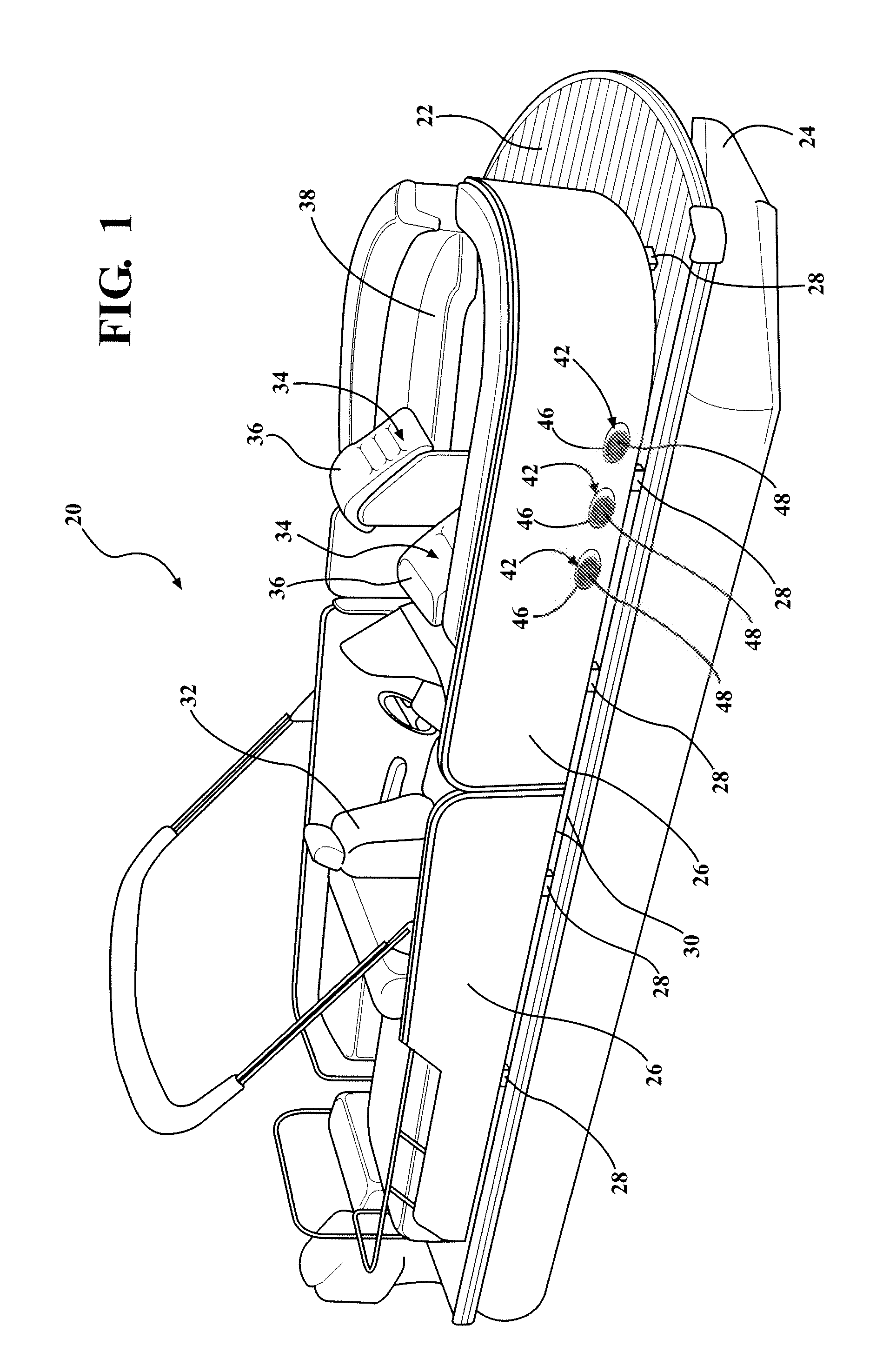

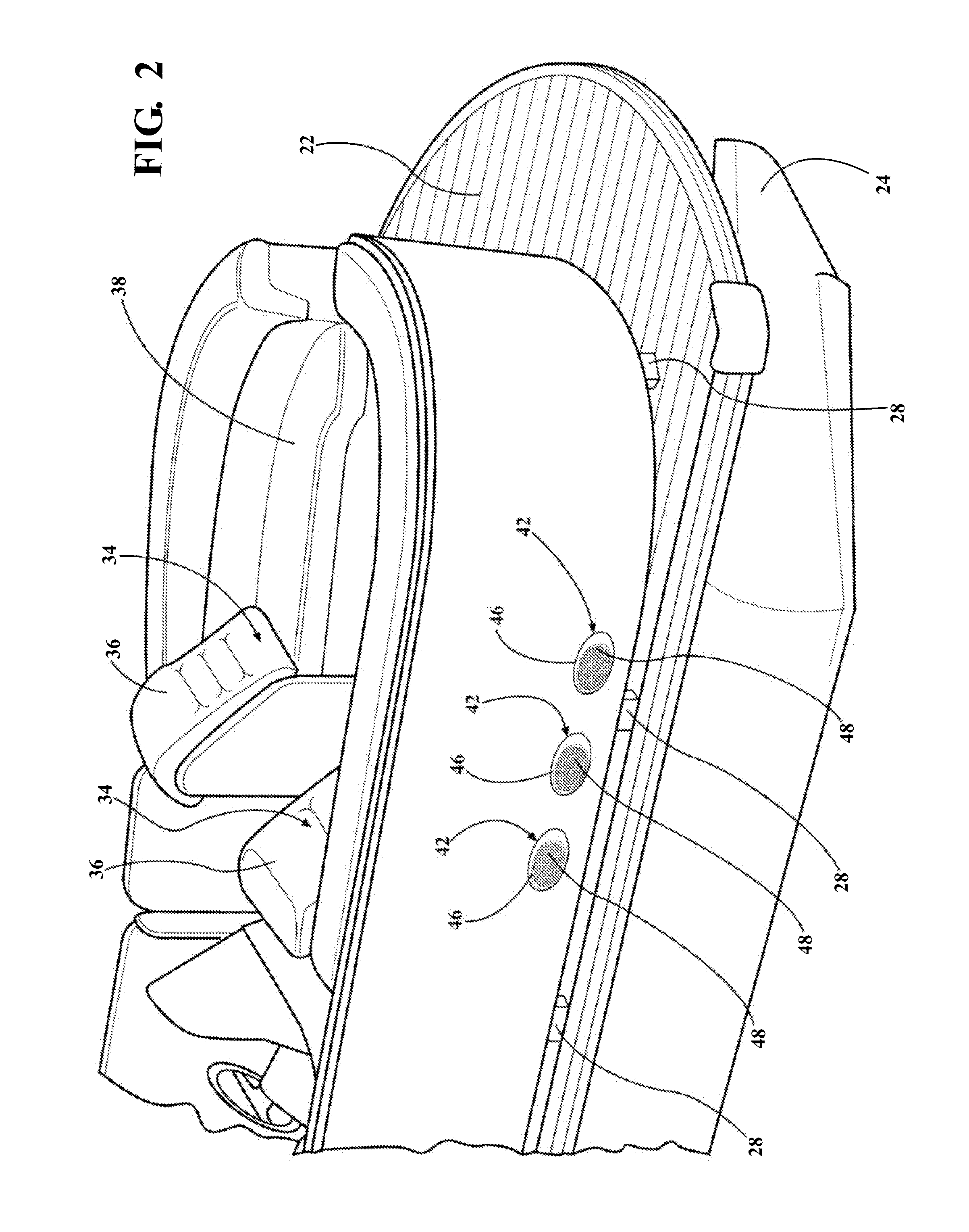

Vent for a pontoon boat storage space

InactiveUS20130025527A1Hull interior subdivisionNon-magnetic metal hullsInterior spaceOpen communication

A pontoon boat including a plurality of pontoons and a deck secured to the pontoons. A wall assembly is anchored to and extends upwardly from the deck to provide an interior space of the deck for accommodating passengers. The pontoon boat includes a substantially enclosed storage space defined at least in part by a portion of the deck and a portion of the wall assembly. The wall assembly has a bottom edge that is spaced off of the deck to provide a first air access opening into the storage space from beneath the wall. At least one vent is provided in the wall portion at a location spaced above the bottom edge and in open communication with the storage space. The vent enhances air flow and venting of the storage space.

Owner:AVALON PONTOONS

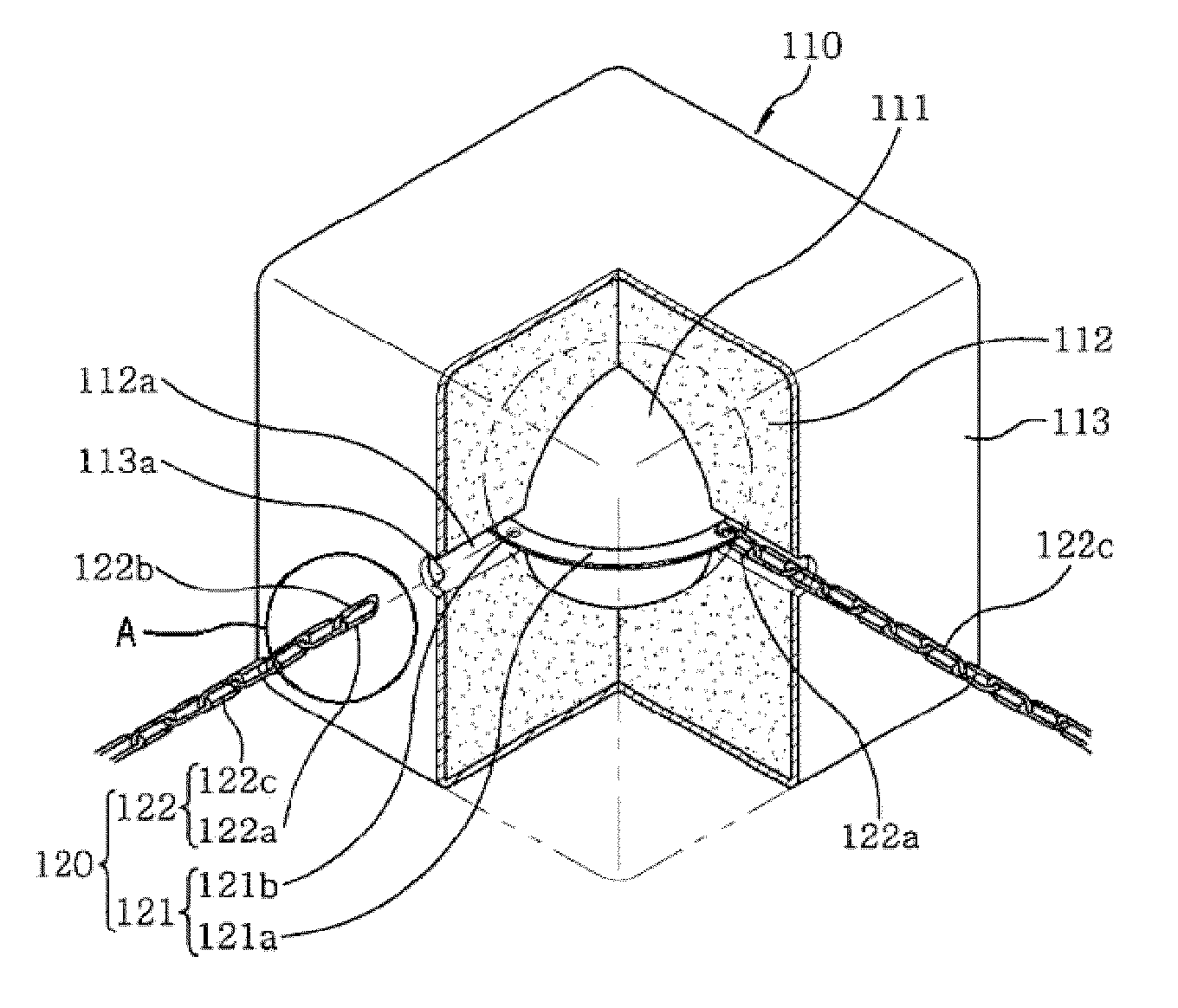

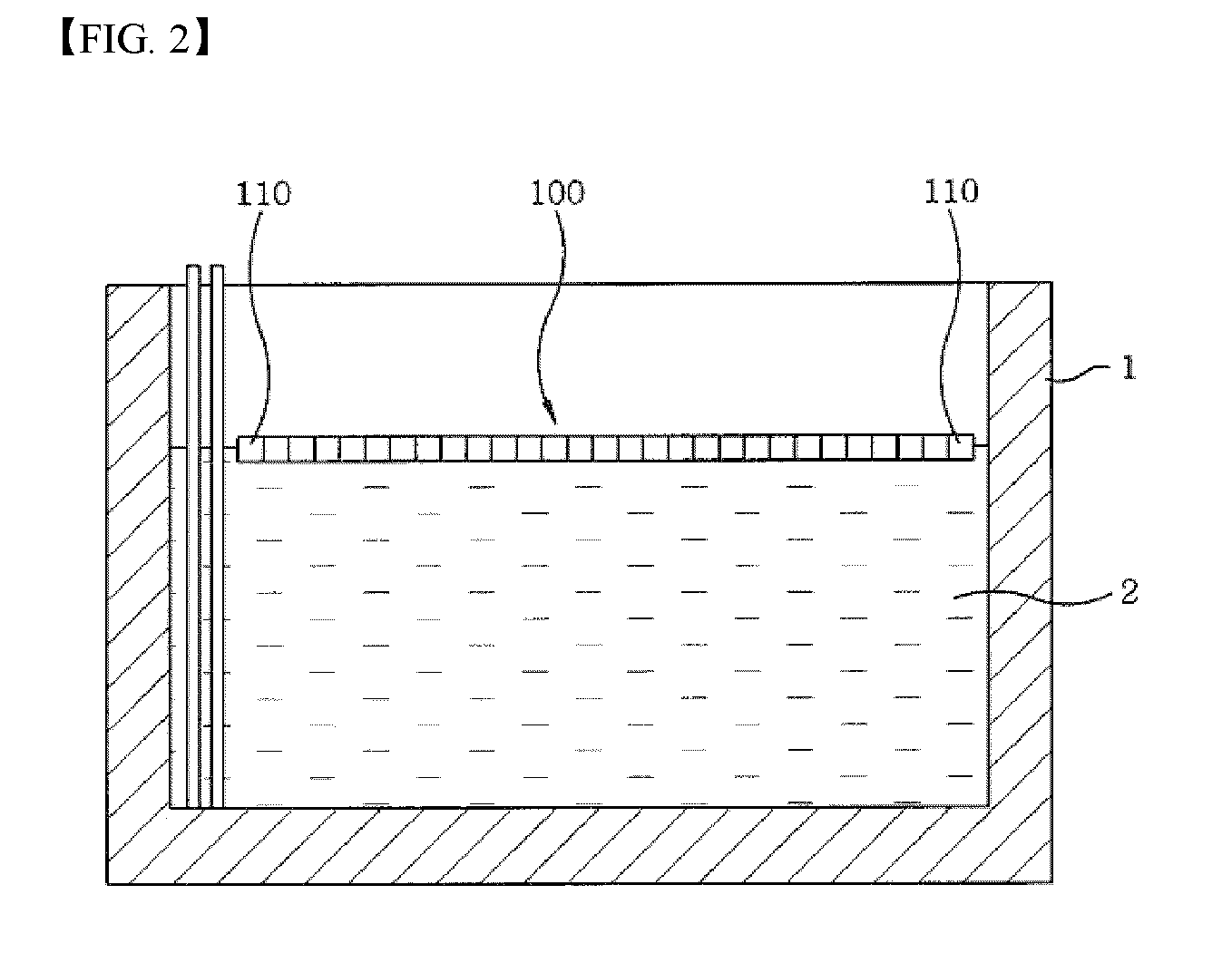

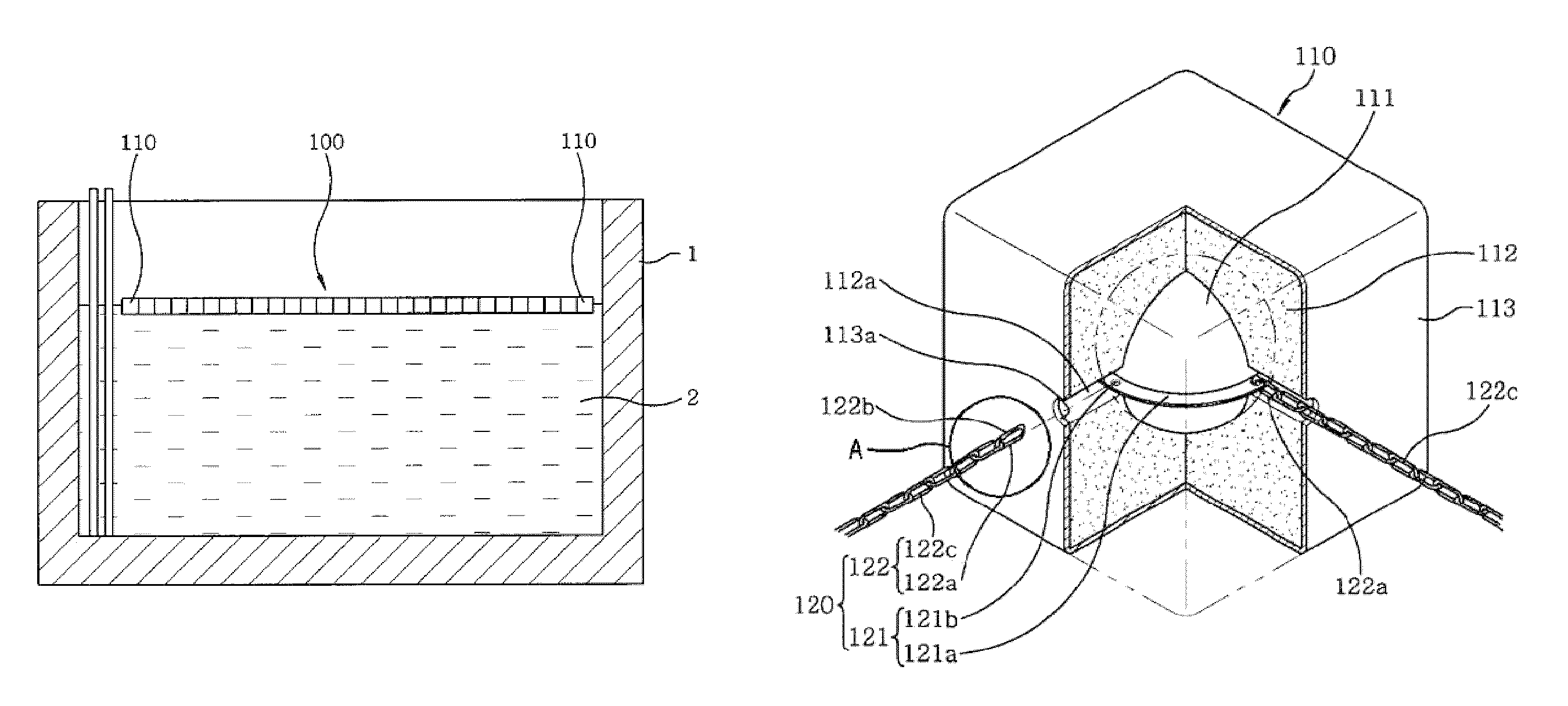

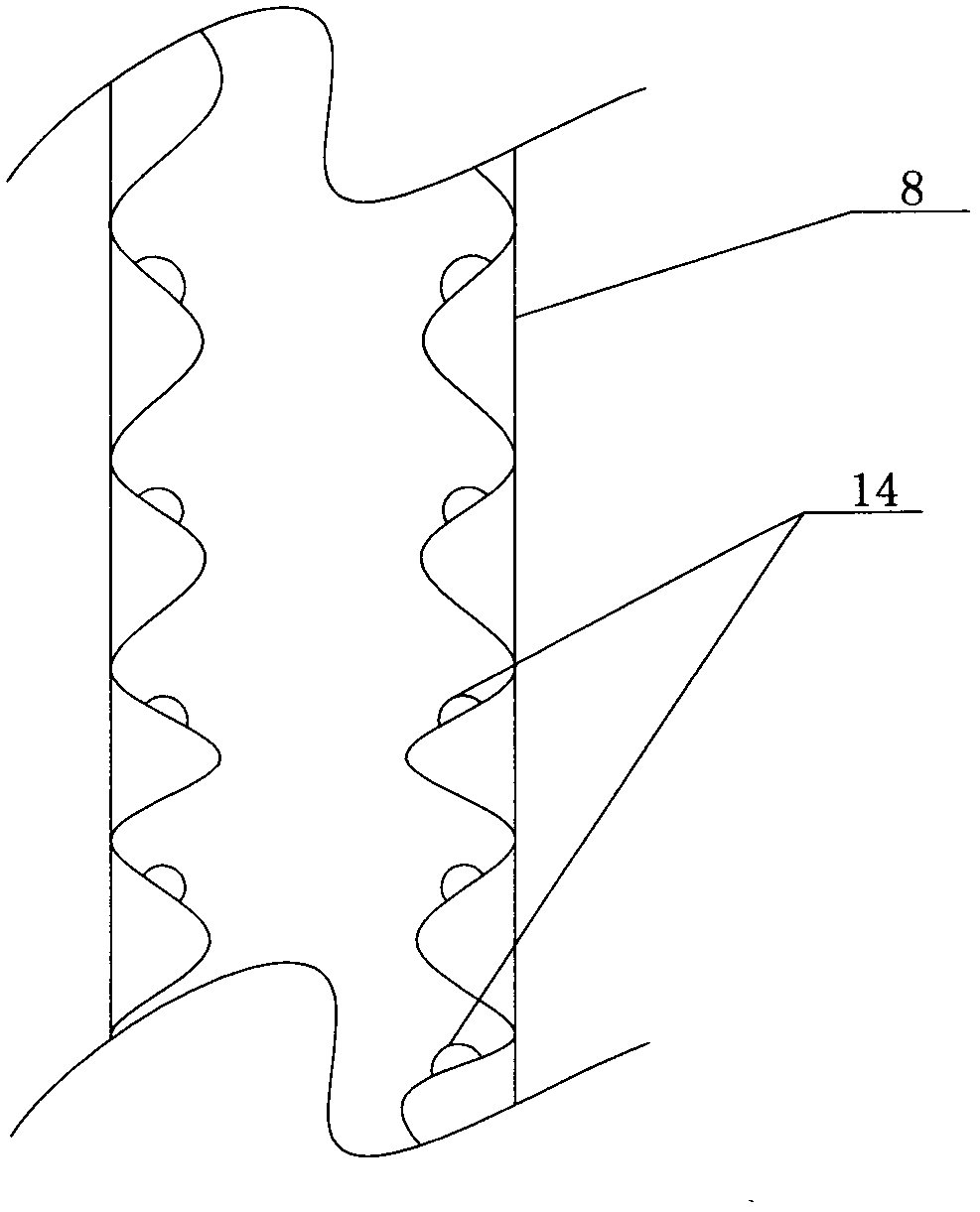

Anti-sloshing apparatus

ActiveUS20110278305A1Easy to disassembleInhibition is effectiveHull interior subdivisionVessel mounting detailsEngineeringBuoyancy

An anti-sloshing apparatus comprising: a plurality of buoyant members having buoyancy to be floated on the surface of liquid; a foam member having open cell structure to absorb the liquid and covering the buoyant member; and a connecting member to connect the adjacent buoyant members one another, allows effectively preventing liquid cargo sloshing.

Owner:SAMSUNG HEAVY IND CO LTD

Anti-sloshing apparatus

ActiveUS8708190B2Easy to disassembleInhibition is effectiveHull interior subdivisionAirbagsEngineeringOpen cell

An anti-sloshing apparatus comprising: a plurality of buoyant members having buoyancy to be floated on the surface of liquid; a foam member having open cell structure to absorb the liquid and covering the buoyant member; and a connecting member to connect the adjacent buoyant members one another, allows effectively preventing liquid cargo sloshing.

Owner:SAMSUNG HEAVY IND CO LTD

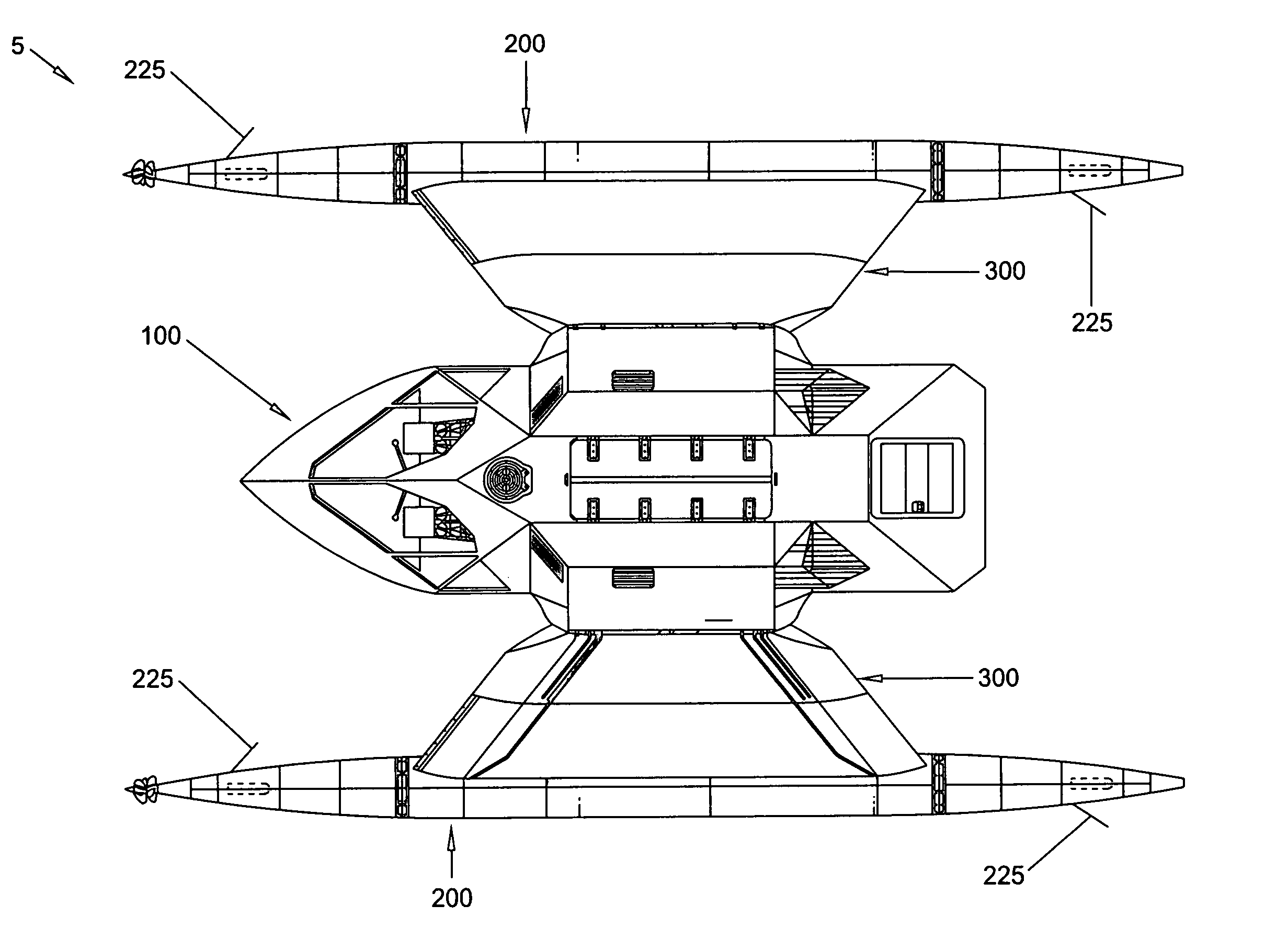

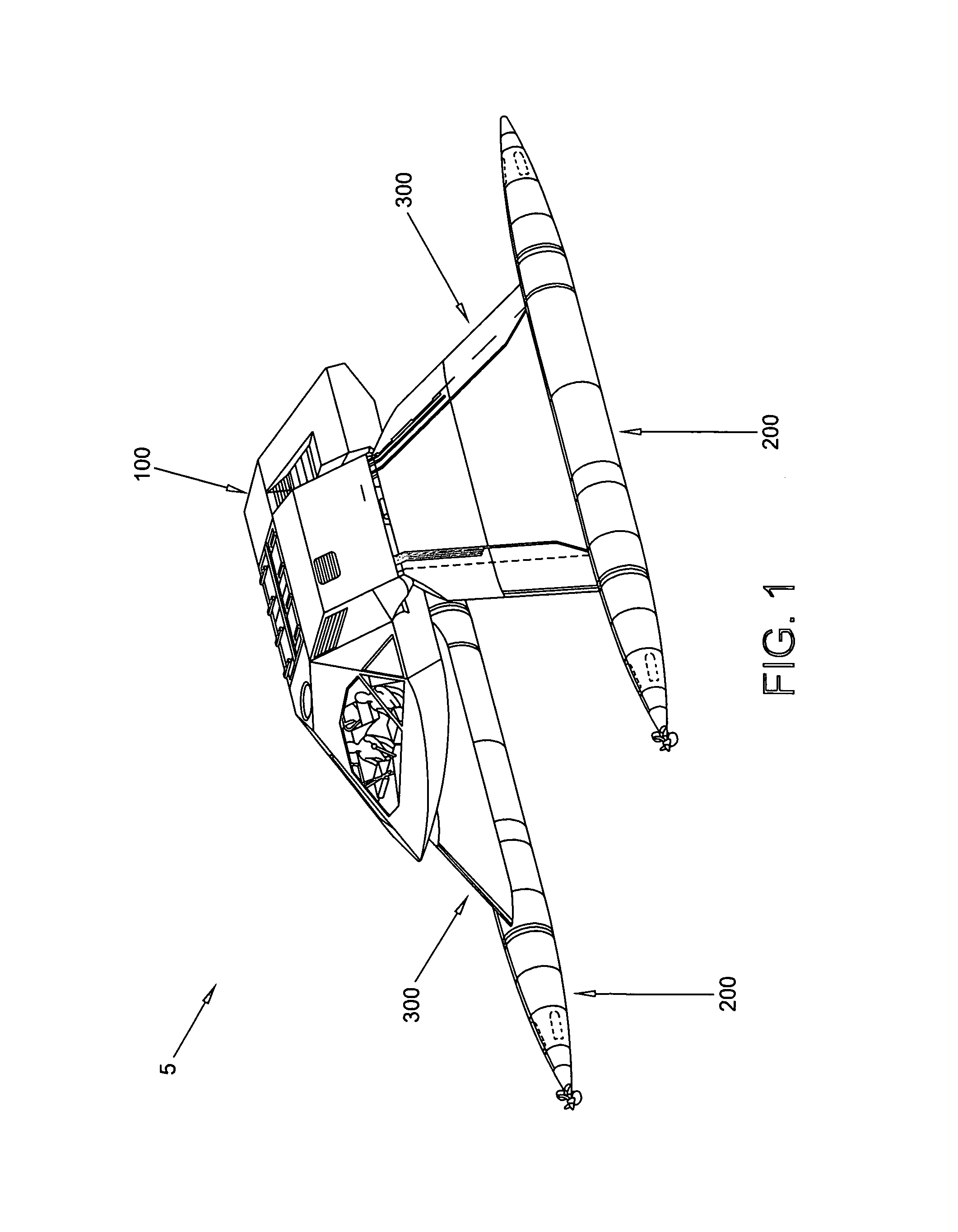

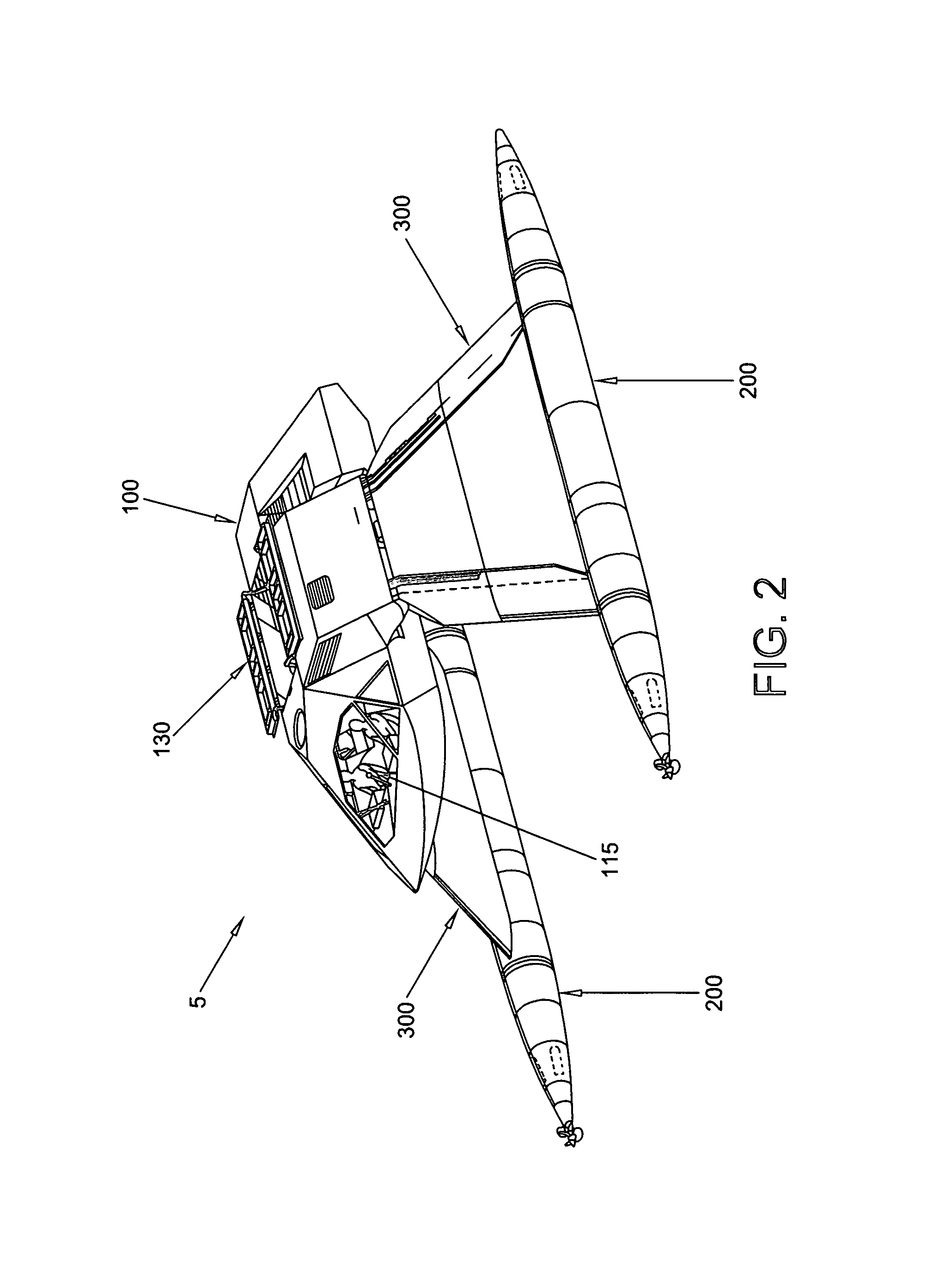

Fast disassembling and assembling semi-submersible three-body unmanned vehicle

InactiveCN110065588AGood anti-wave stabilityGood stealthHull interior subdivisionUnmanned surface vesselsFiberCarbon fibers

The invention relates to the technical field of unmanned vehicles, in particular to a fast disassembling and assembling semi-submersible three-body unmanned vehicle. The fast disassembling and assembling semi-submersible three-body unmanned vehicle include a main body and two auxiliary bodies, the main body is made from high-strength carbon fiber reinforced glass steel, the two auxiliary bodies adopt inflatable PVC buoys, and the auxiliary bodies and the main body are fixed through two high-strength carbon fiber connecting assemblies correspondingly; a plane groove type stabilization ballast tank is arranged in the center of the interior of the main body, a water inlet is formed in the bottom of the plane groove type stabilization ballast tank, a drainage port is formed in the side of theplane groove type stabilization ballast tank, and the water inlet and the drainage port are provided with electromagnetic valves; and oil-driven propeller is installed at the tail of the main body, and electric screw propellers are installed at the tails of the two auxiliary bodies. The unmanned vehicle adopts a three-body structure, has the better wave resistant stability, can effectively adjustthe draft and diving states, and provide the good working environment for carried acoustic instruments.

Owner:TIANJIN UNIV

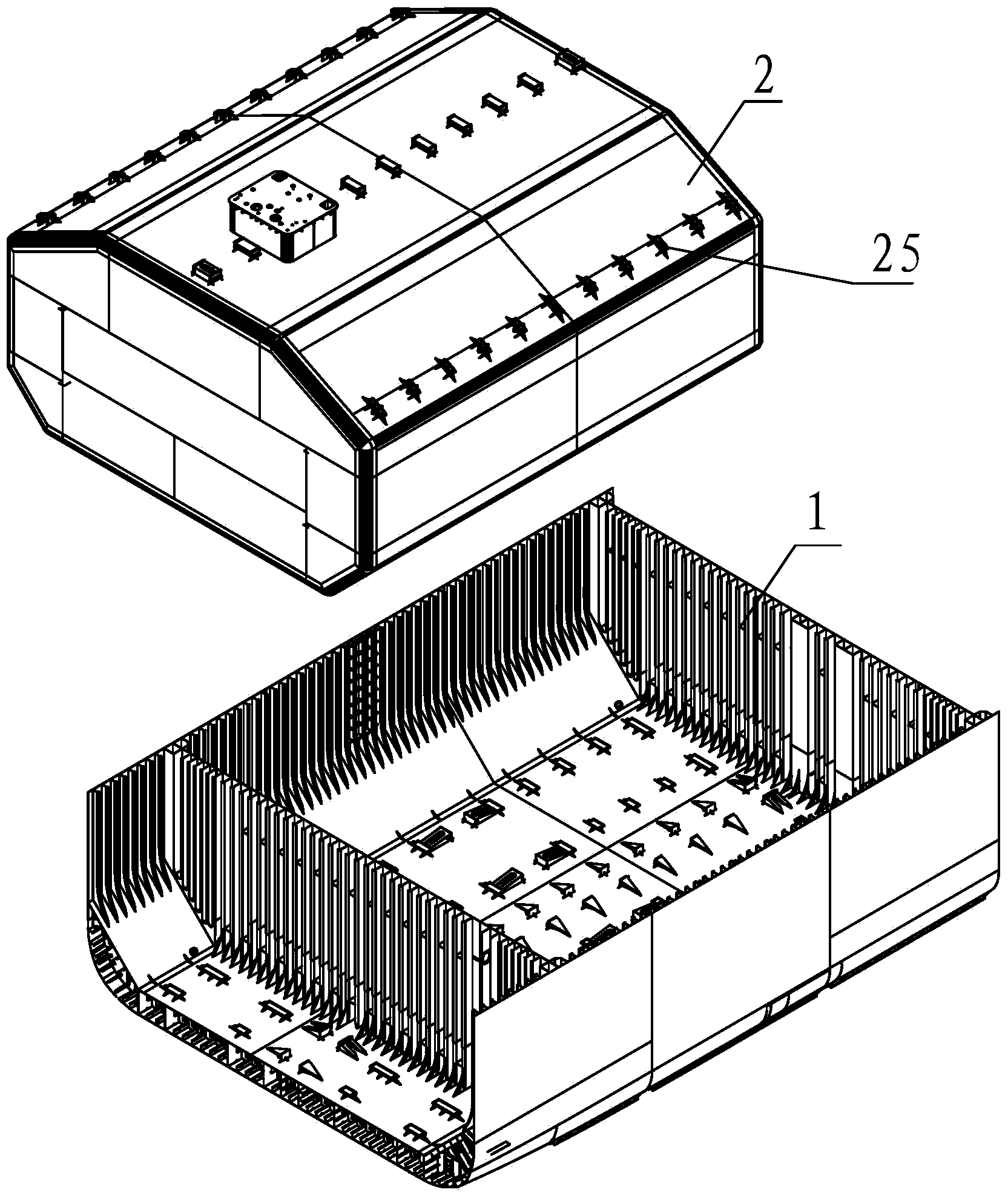

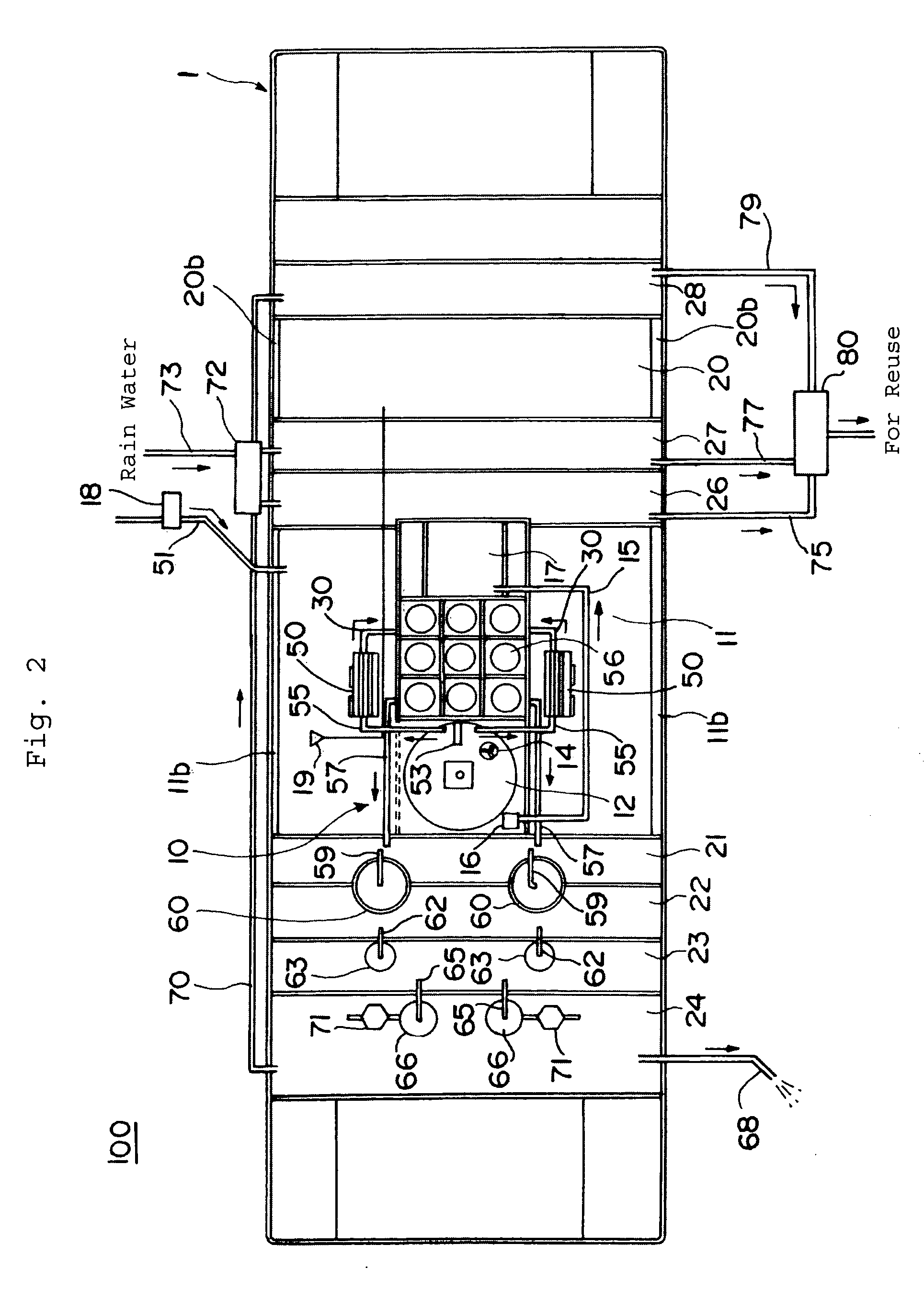

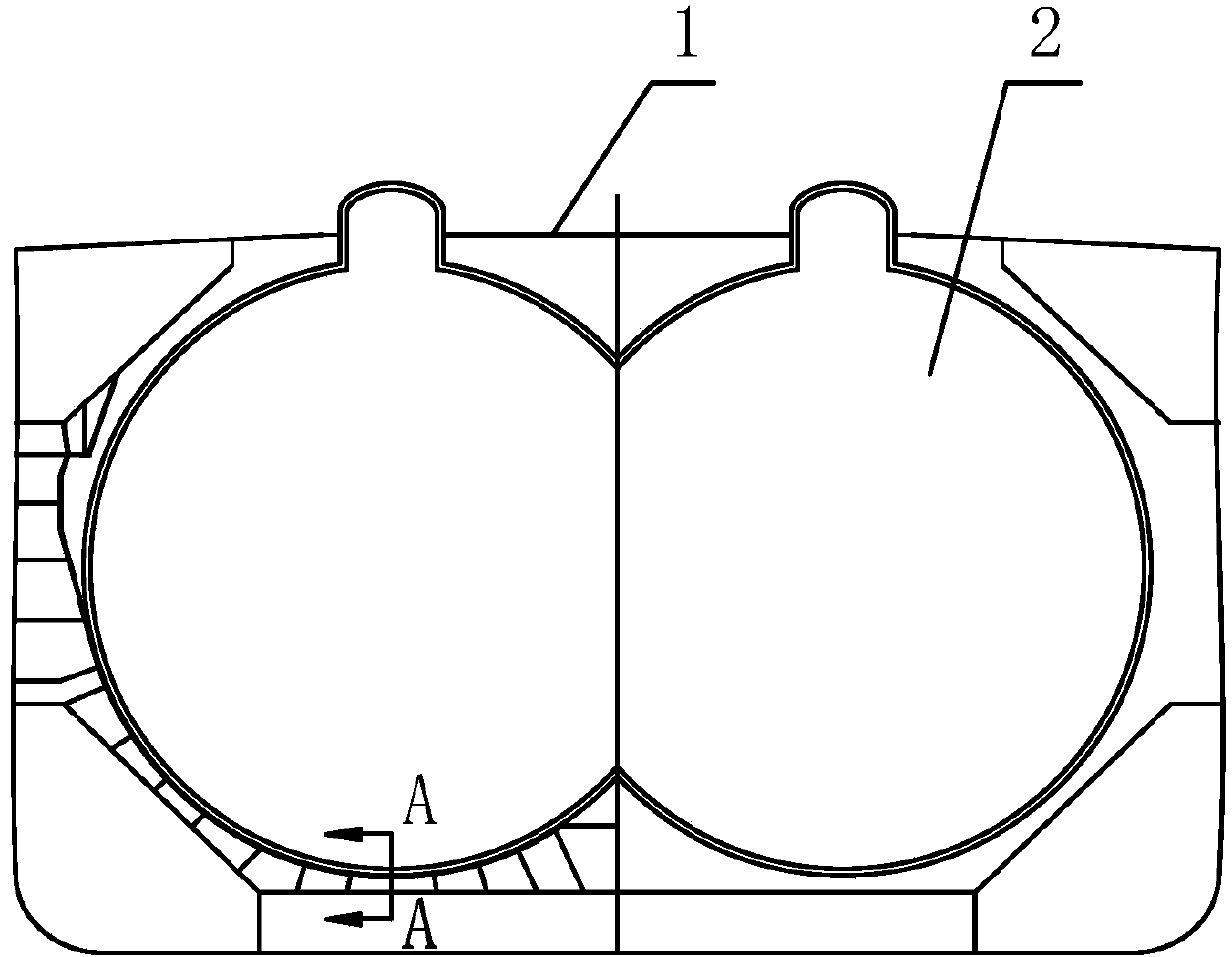

Support structure between C-shaped liquid cargo tank and inner bottom of hull and installation method thereof

ActiveCN105523140ASmall amount of shrinkageImprove stabilityHull interior subdivisionMarine engineeringSurface plate

The invention provides a support structure between a C-shaped liquid cargo tank and an inner bottom of a hull and an installation method thereof. The support structure comprises three groups of supporting bases, namely a fixed supporting base matched by a first upper supporting base and a first lower supporting base and two sliding supporting bases matched by second upper supporting bases and second lower supporting bases, and the fixed supporting base is arranged between the two sliding supporting bases; each crosser on the three groups of supporting bases is installed on the bottom surface of the liquid cargo tank in advance, and then the whole liquid cargo tank is hoisted in each crosser groove on the hull and the inner bottom of the hull by a portal crane so as to be supported in a matched mode; and each crosser groove is arranged on a panel of the inner bottom of the hull, and the panel is fixed on the inner bottom of the hull by a plurality of ribbed plates and support webs. According to the support structure and installation method thereof provided by the invention, the installation work of each crosser is finished before the liquid cargo tank is hoisted and installed on the hull, thereby shortening the adjusting time and positioning time of the liquid cargo tank with the first and second upper supporting bases, saving the cost and time for installation of the liquid cargo tank and improving the work efficiency.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Evaporative emissions canister suitable for marine use

ActiveUS7476269B2Hull interior subdivisionNon-fuel substance addition to fuelActivated carbonEngineering

An evaporative emissions control canister for adsorbing fuel vapors from a fuel tank on a marine vessel. The canister comprises a polymeric extruded housing that may be formed to any desired length or cut from extruded stock. Identical end caps having tubing connectors are bonded to opposite ends of the housing, defining an inlet and an outlet. Marine-grade pelletized activated carbon is disposed within the housing between porous slidable plates that are spring loaded against the end caps to pack the carbon tightly against the housing walls. Mounting brackets at each end are rotatably attached to the end caps so that opposite ends of the assembly may be attached to different surfaces of the vessel's hull, thus relieving stress which might be introduced into the assembly. Preferably, the assembly is wrapped in a fire retardant material.

Owner:DELPHI TECH IP LTD

Bilge mechanism of bulk cargo ship

InactiveCN104309761AImprove stabilityImprove space utilizationHull interior subdivisionFor bulk goodsBulk cargoBilge

The invention discloses a bilge mechanism of a bulk cargo ship and relates to the technical field of shipbuilding, wherein a top side tank and a bottom side tank are connected by a ship side frame, the bottom side tank is connected with a double-layer bilge, the middle part of the double-layer bilge is respectively provided with a plurality of rib plates, an upper stool is arranged on the top side tank, the upper stool is connected with the lower stool by a transverse bulkhead, the bottom of the upper stool is arranged in a bilge way, the top of the lower stool is arranged in a glide path, both sides of the upper and lower stools are respectively provided with a clamping block, and the middle parts of the upper and lower stools are respectively provided with a height detector; the bilge mechanism adopts the fixing rib plate so as to greatly increase bearing capacity of the bilge, the flexibility of the bilge is improved by the movable internal structure and the upper and lower stools and the triangular bottom side tank has the excellent steadiness.

Owner:JIANGSU ROKEE HEAVY IND TECH

Garbage clearing boat

ActiveCN108082405AEasy to organizeAvoid cross contaminationVessel cleaningHull interior subdivisionRefuse collectionLitter

The invention discloses a garbage clearing boat. The garbage collection boat comprises a hull, a garbage collection device, a garbage storage device, a garbage identification and classification device, a sounding device and a control panel. According to the garbage clearing boat, garbage in a water area in which the hull is running can be collected, classified and stored, so that river channel arrangement is greatly facilitated.

Owner:NANTONG INST OF TECH

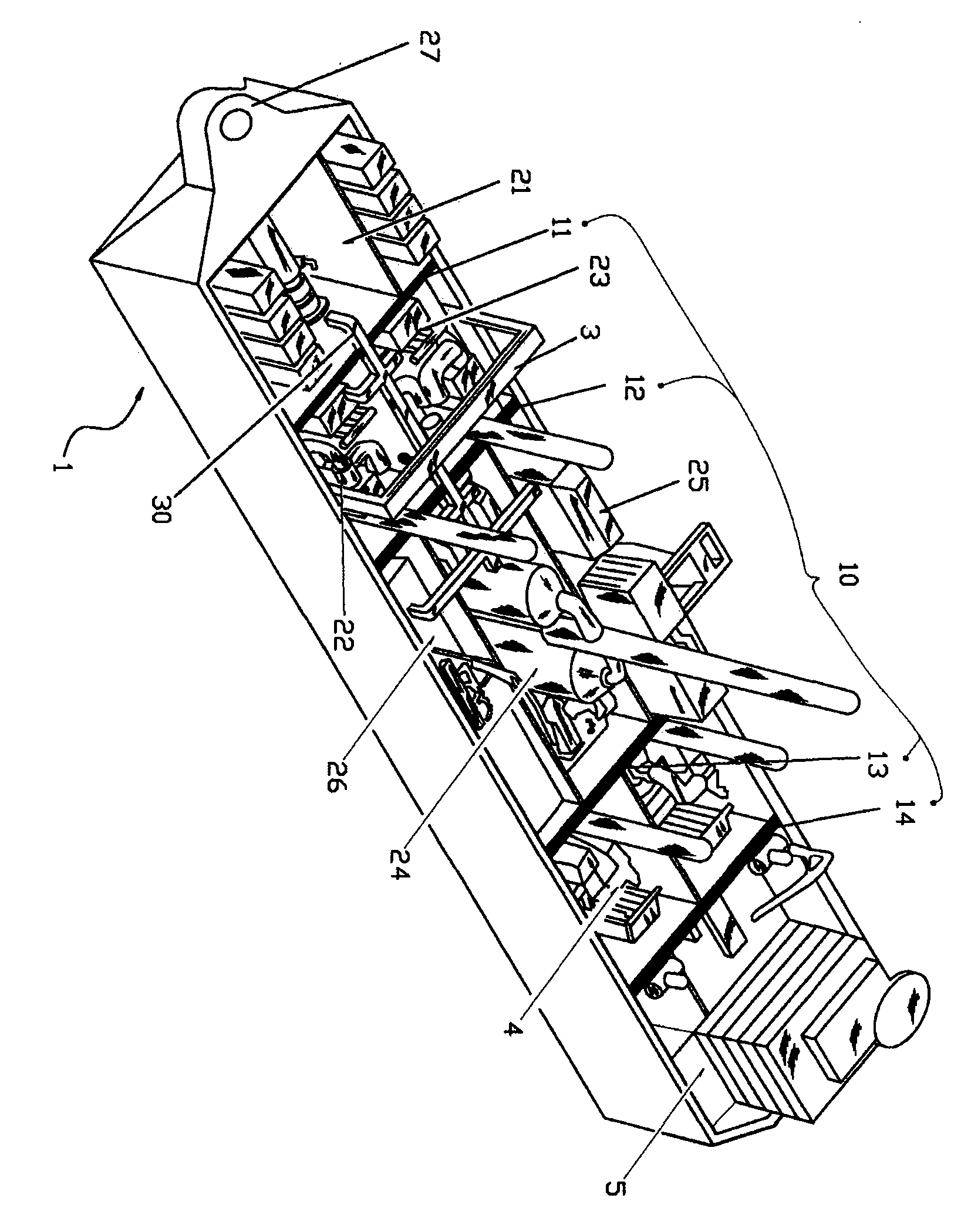

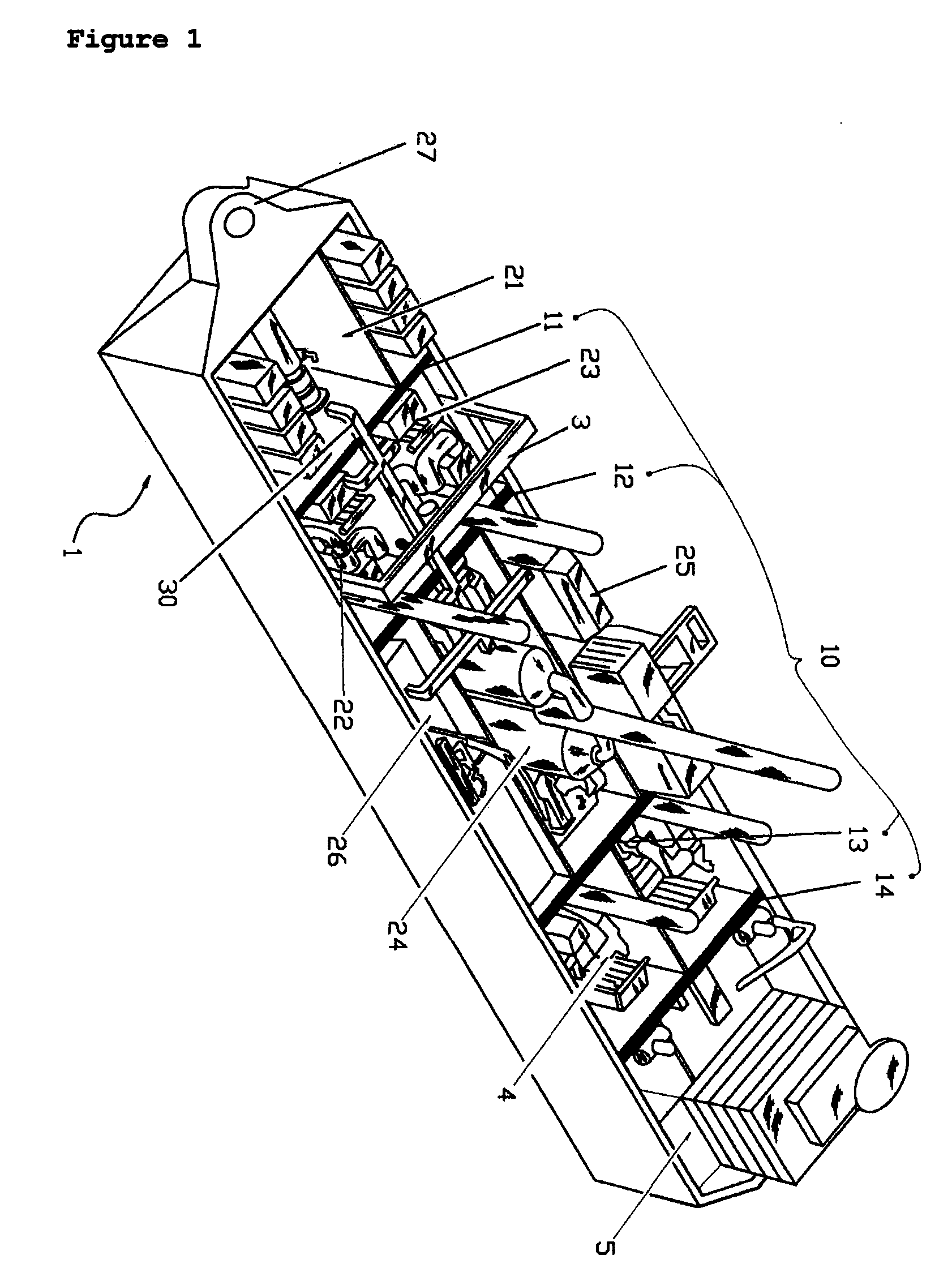

Fleet protection attack craft

ActiveUS8408155B2Stress minimizationStable weapons platformDefensive equipmentHull interior subdivisionMarine engineeringMechanical engineering

A marine vessel comprising:a command module;first and second buoyant tubular foils; andfirst and second struts for connecting the first and second buoyant tubular foils to the command module, respectively;wherein the first and second buoyant tubular foils provide substantially all of the buoyancy required for the marine vessel; andwherein the marine vessel further comprises first and second engines enclosed within the first and second buoyant tubular foils, respectively, and first and second propulsion units connected to the first and second engines, respectively, for moving the marine vessel through the water.

Owner:JULIET MARINE SYST

Anti-rolling ship

ActiveCN102574567AReduce rollingIncrease the use of spaceHull interior subdivisionVessel movement reduction by mass displacementMarine engineeringRolling moment

Disclosed is an anti-rolling ship. The anti-rolling ship comprises a hull having an engine room; and a tank which is mounted on the upper surface of the engine room, and which has an interior for partially containing a fluid therein. The fluid contained in the tank reciprocates when the vessel rolls, generating anti-rolling moment, and thus effectively reduces rolling of the ship. In addition, the space formed on the upper surface of the engine room of the ship is utilized as a tank accommodating portion to achieve improved space utilization.

Owner:SAMSUNG HEAVY IND CO LTD

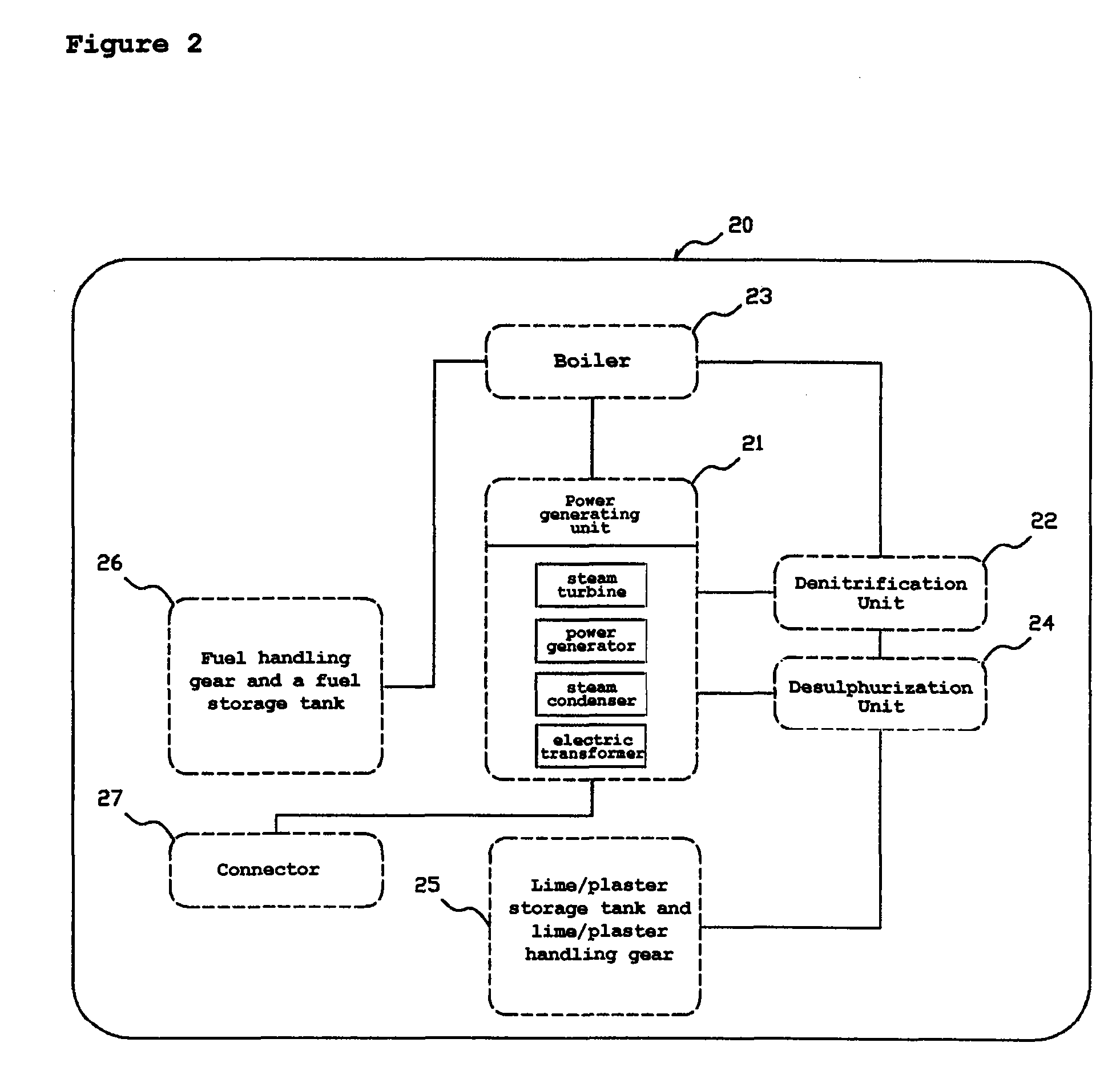

Floating power plant

InactiveUS20060243186A1Minimize limitationHull interior subdivisionBoiler cleaning apparatusElectricityPower station

Disclosed is a floating power plant. The floating power plant includes a hull having a structure suitable for being movable at sea; a plurality of watertight bulkheads placed in the hull to a height of a freeboard deck, thus partitioning the interior of the hull into a plurality of watertight chambers; a power generating means for generating electricity, the power generating means including a plurality of parts separately installed in the watertight chambers; and a duct arranged to pass over the freeboard deck to couple the parts of the power generating means installed in the watertight chambers to each other. Because the floating power plant, provided with the power generating means, is freely movable at sea, the floating power plant can economically supply electricity to a specific district or to a specific facility that temporarily uses electricity, and can minimize limitations caused by environmental regulations, and can be used as an emergency electric power source. Thus, the floating power plant remarkably increases the degree of freedom while forming and managing an energy policy. Furthermore, the present invention overcomes problems of conventional land power plants and, particularly, solves the problem of the waste of land caused by construction of power plants on land, and thus reduces environmental pollution.

Owner:KIM MI YEONG

Watercraft

A watercraft is described with a powered hull and deck. The deck includes a forward passenger area and a rearward passenger area connected by a passageway. A windshield extends upwardly from the deck at a position forward of the rearward passenger area. An engine is positioned within the hull behind the rearward passenger area. An engine cover covers the engine and at least one compartment adjacent to the engine. The compartment is separated from the engine by a removable wall. The compartment houses at least a portion of a canopy system that may be erected over at least a portion of the rearward passenger area of the boat. The watercraft includes a rear bench that conceals a storage bucket thereunder. A console sits in front of a passenger seat with a console cover, which is hingedly mounted to the console to conceal a sound system.

Owner:BRP US

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com