Vertical supporting structure for cargo tank and inboard bottom of full-refrigerated liquefied gas carrier and mounting method of vertical supporting structure

A support structure and cargo tank technology, applied in the support field between the cargo tank and the inner bottom of the ship, can solve the problems of high installation accuracy, long positioning time, and low efficiency, so as to save cost and time, reduce use time, and save The effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

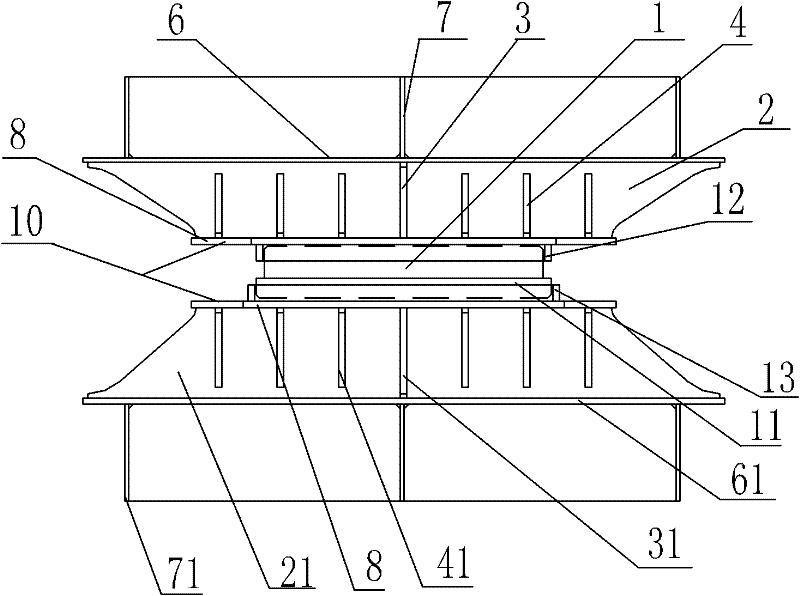

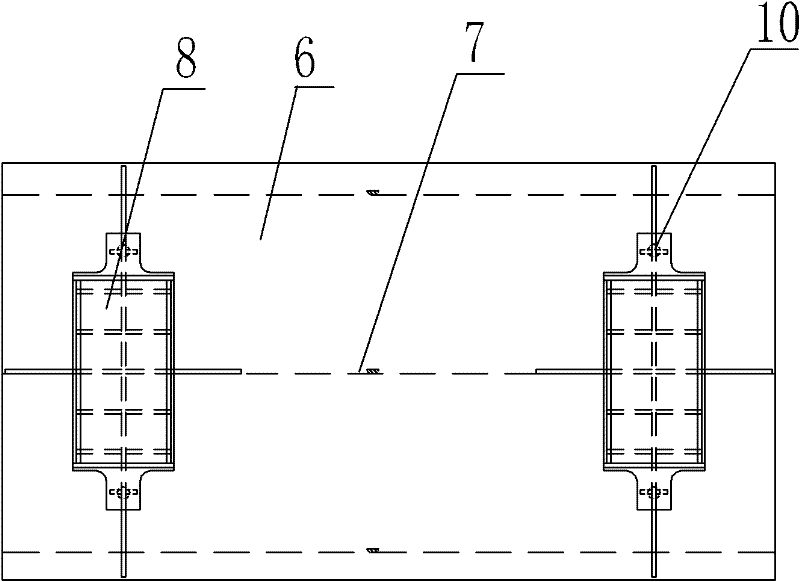

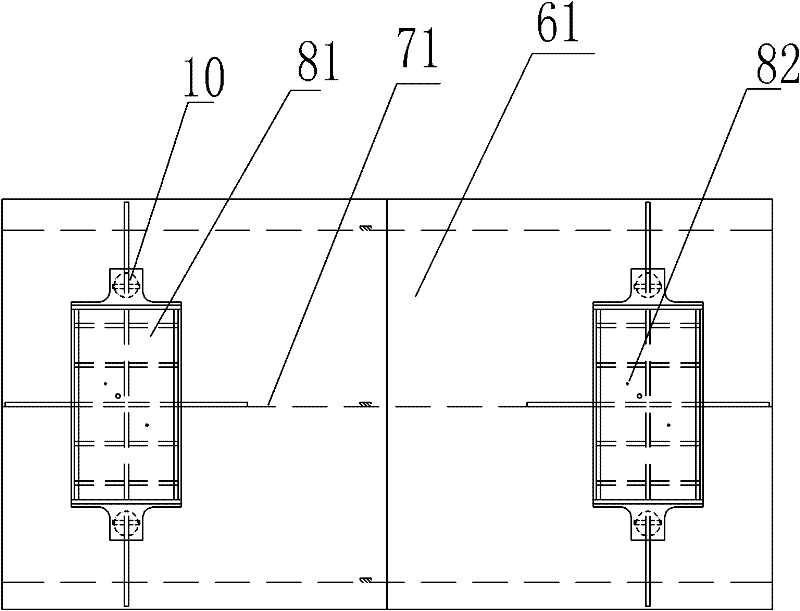

[0031] like figure 1 and Figure 4 As shown, the present invention is a vertical support structure used between the cargo tank and the inboard, including an upper support seat on one side of the cargo tank, a lower support seat on the inboard side, a first skid 1 and a second Skids 11, the upper support seat and the lower support seat are arranged symmetrically up and down, the first skid and the second skid are placed between the upper and lower support seats in contact, the upper support seat includes a bottom plate 6 and two panels 8, the two panels 8 is placed on one side of the bottom plate 6 and a supporting bracket is provided between the bottom plate 6 and the panel 8, and a rib 7 perpendicular to the bottom plate is provided on the other side of the bottom plate 6, and a wooden groove is provided on each of the two panels 8 12, and a jack support platform 10 is provided on the panels on both sides of the skid groove (see figure 2 ), the lower support seat includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com