Patents

Literature

121results about How to "Fully softened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft and strong webs from highly refined cellulosic fibres

InactiveUS20040144510A1Fully softenedNatural cellulose pulp/paperSpecial paperPolymer scienceWater soluble

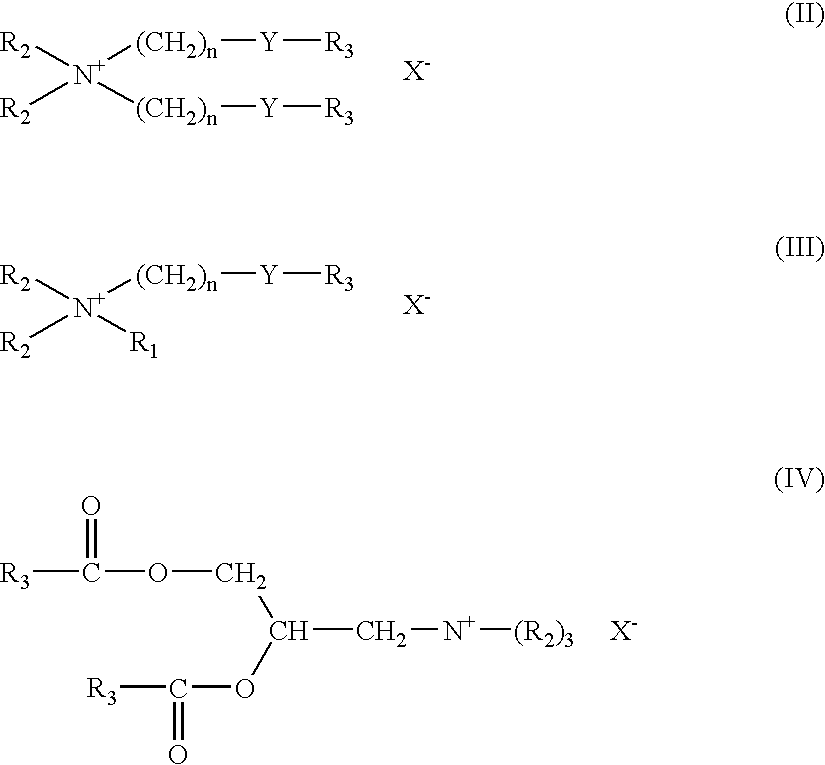

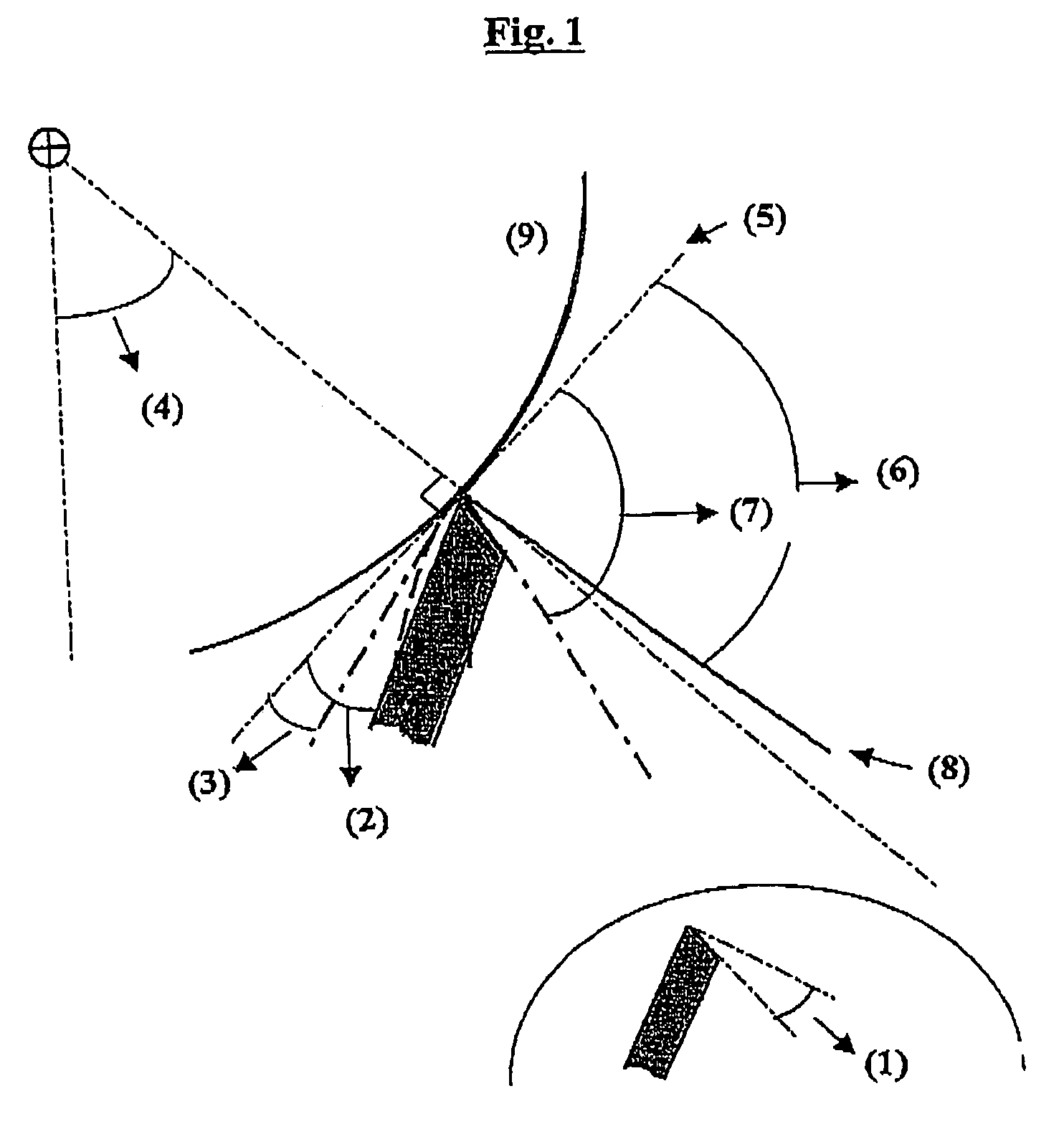

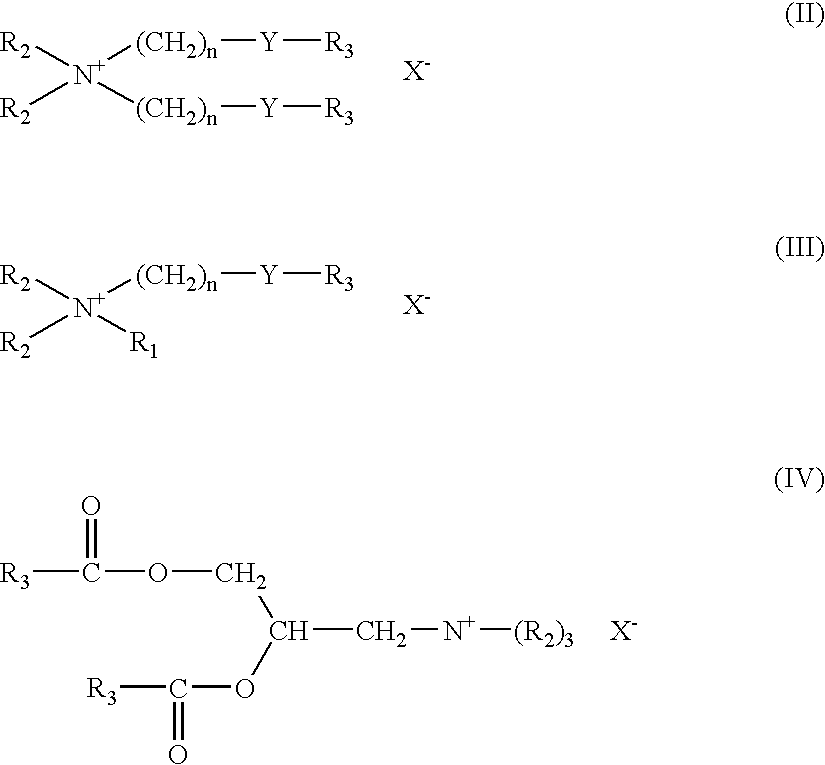

Soft and strong cellulose-based fibrous web, comprises a) cellulosic fibres having a freeness value of more than 26° SR measured according to DIN-ISO 5267 / 1 (March 1999), b) a water-soluble cationic polymer, c) a water-soluble anionic polymer, and d) a cationic surfactant-based softener. The webs are prepared by refining cellulosic fibres to a degree of freeness of more than 26° SR measured according to DIN-ISO 5267 / 1, adding at least one water-soluble anionic polymer and water-soluble cationic polymer to the refined cellulosic fibres, adding a cationic surfactant-based softener to the cellulosic fibres obtained thereby, and wet-laying and dewatering the celulosic fibres obtained thereby.

Owner:SCA HYGIENE PROD AB

Soft and strong webs from highly refined cellulosic fibres

InactiveUS7258764B2Fully softenedNatural cellulose pulp/paperSpecial paperCellulose fiberAnionic polymers

Soft and strong cellulose-based fibrous web, comprisesa) cellulosic fibres having a freeness value of more than 26° SR measured according to DIN-ISO 5267 / 1 (March 1999),b) a water-soluble cationic polymer,c) a water-soluble anionic polymer, andd) a cationic surfactant-based softener.The webs are prepared byrefining cellulosic fibres to a degree of freeness of more than 26° SR measured according to DIN-ISO 5267 / 1,adding at least one water-soluble anionic polymer and water-soluble cationic polymer to the refined cellulosic fibres,adding a cationic surfactant-based softener to the cellulosic fibres obtained thereby, andwet-laying and dewatering the celulosic fibres obtained thereby.

Owner:SCA HYGIENE PROD AB

Petroleum pitch-based carbon foam

InactiveUS6833012B2Useful and reliableImprove efficiencyPigmenting treatmentHarvestersLow densityNet shape

Petroleum or coal tar pitch-based cellular or porous products having a density of preferably between about 0.1 g / cm<3 >and about 0.8 g / cm<3 >are produced by the controlled heating of mesophase carbon materials derived from coal tar or petroleum pitch having a softening point in excess of about 300° C. and preferably between about 300 and about 400° C. in a "mold" and under a non-oxidizing atmosphere. The porous product thereby produced, preferably as a net shape or near net shape, can be machined, adhered and otherwise fabricated to produce a wide variety of low cost, low density products.

Owner:TOUCHSTONE RES LAB

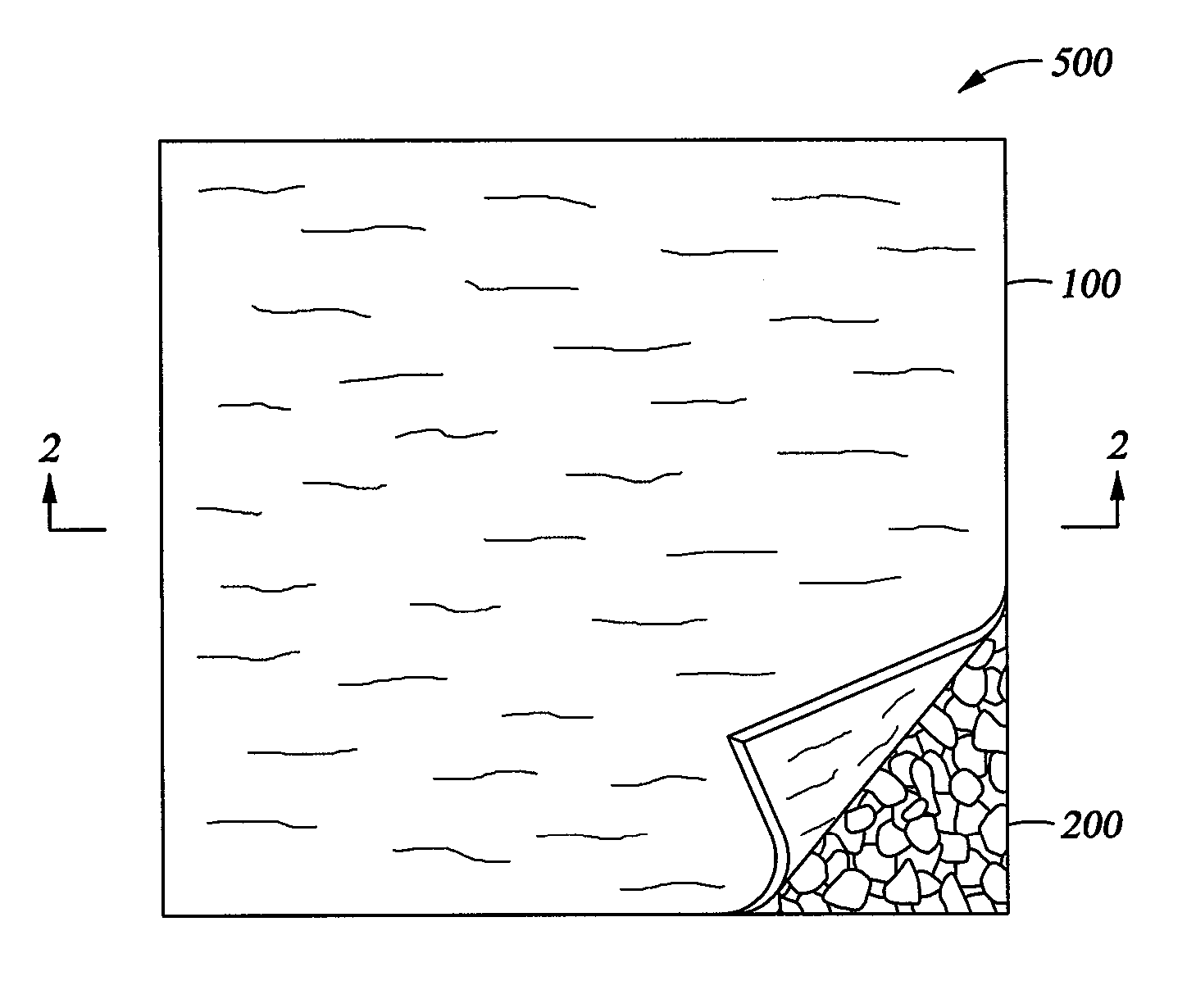

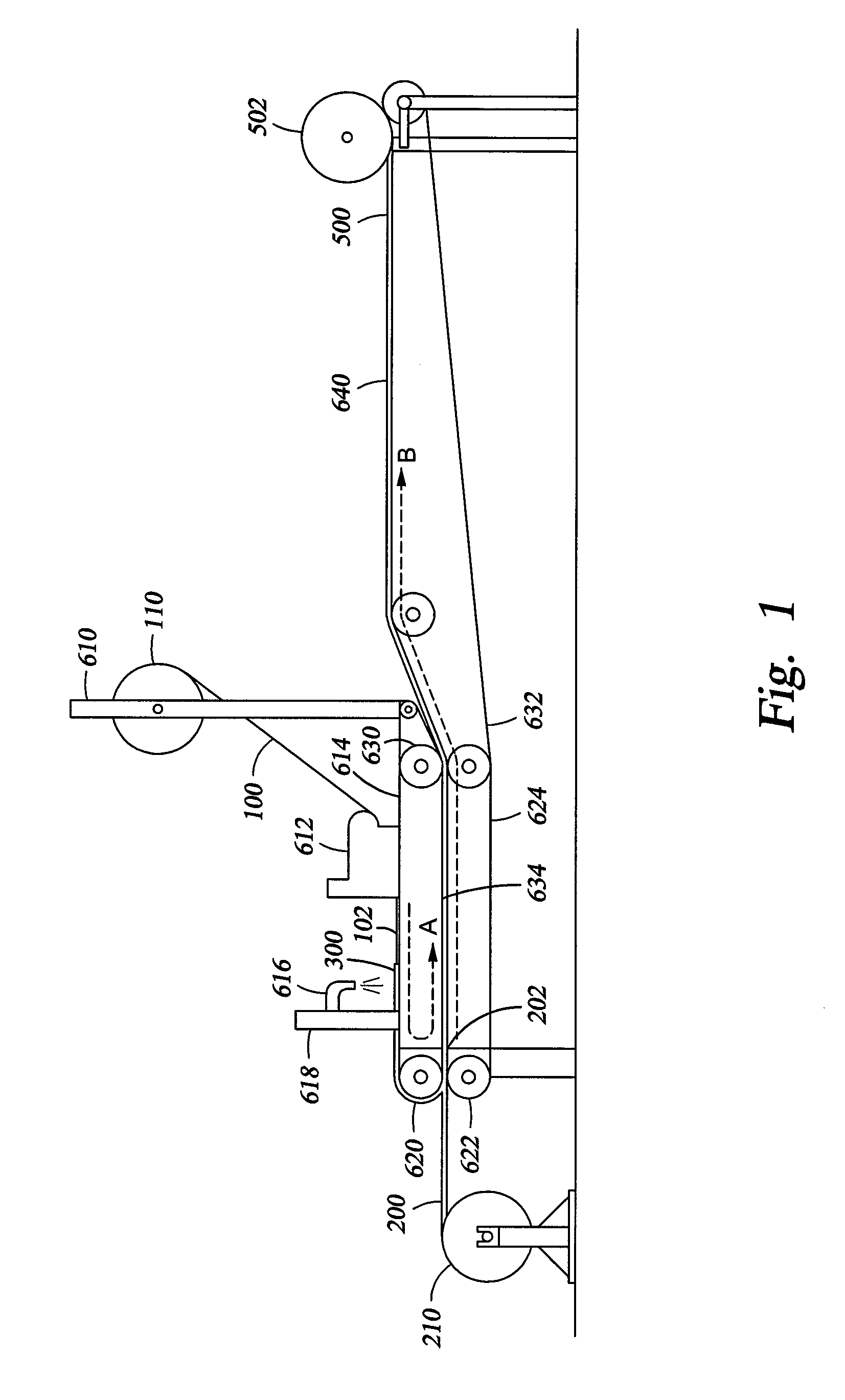

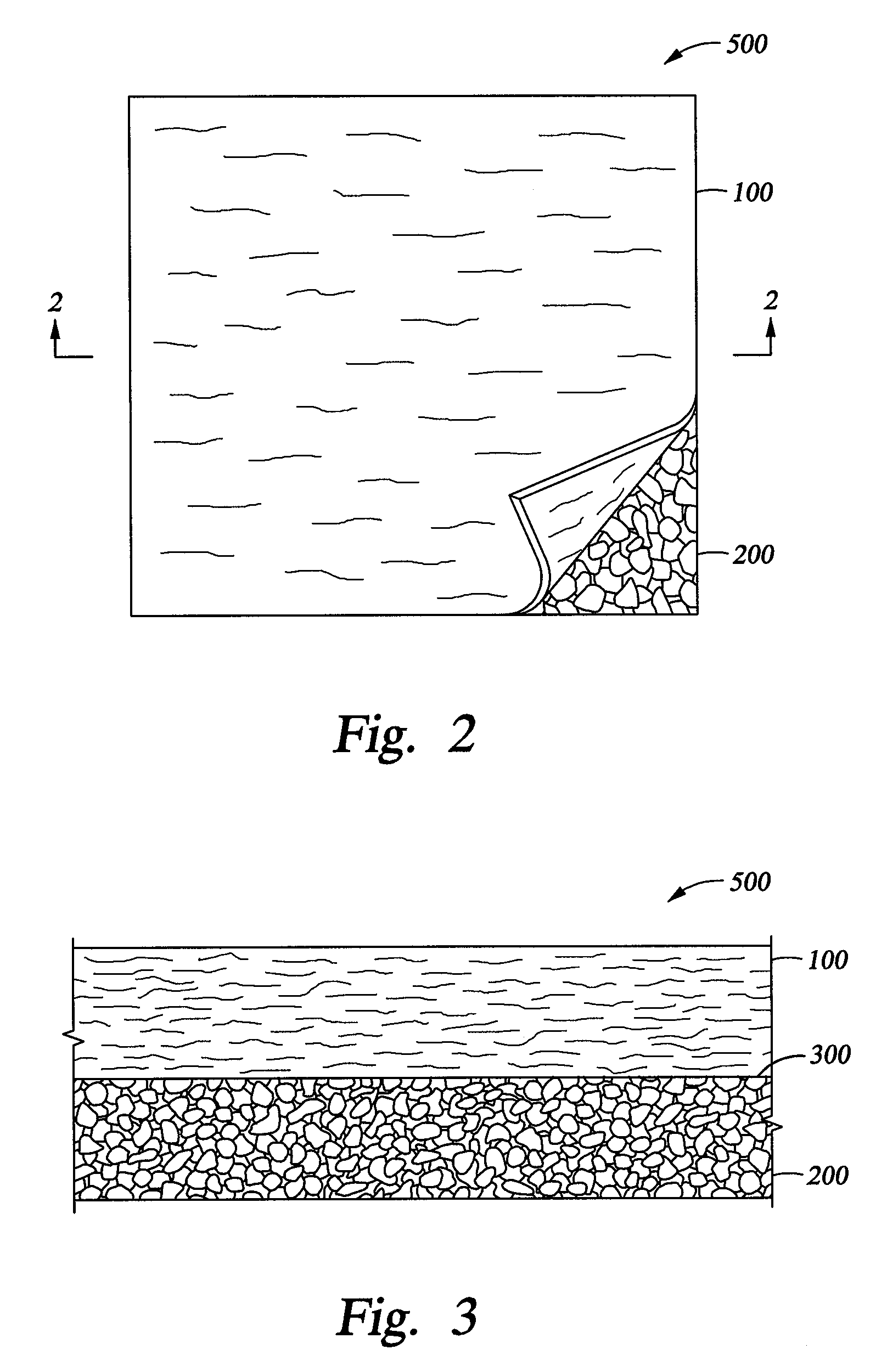

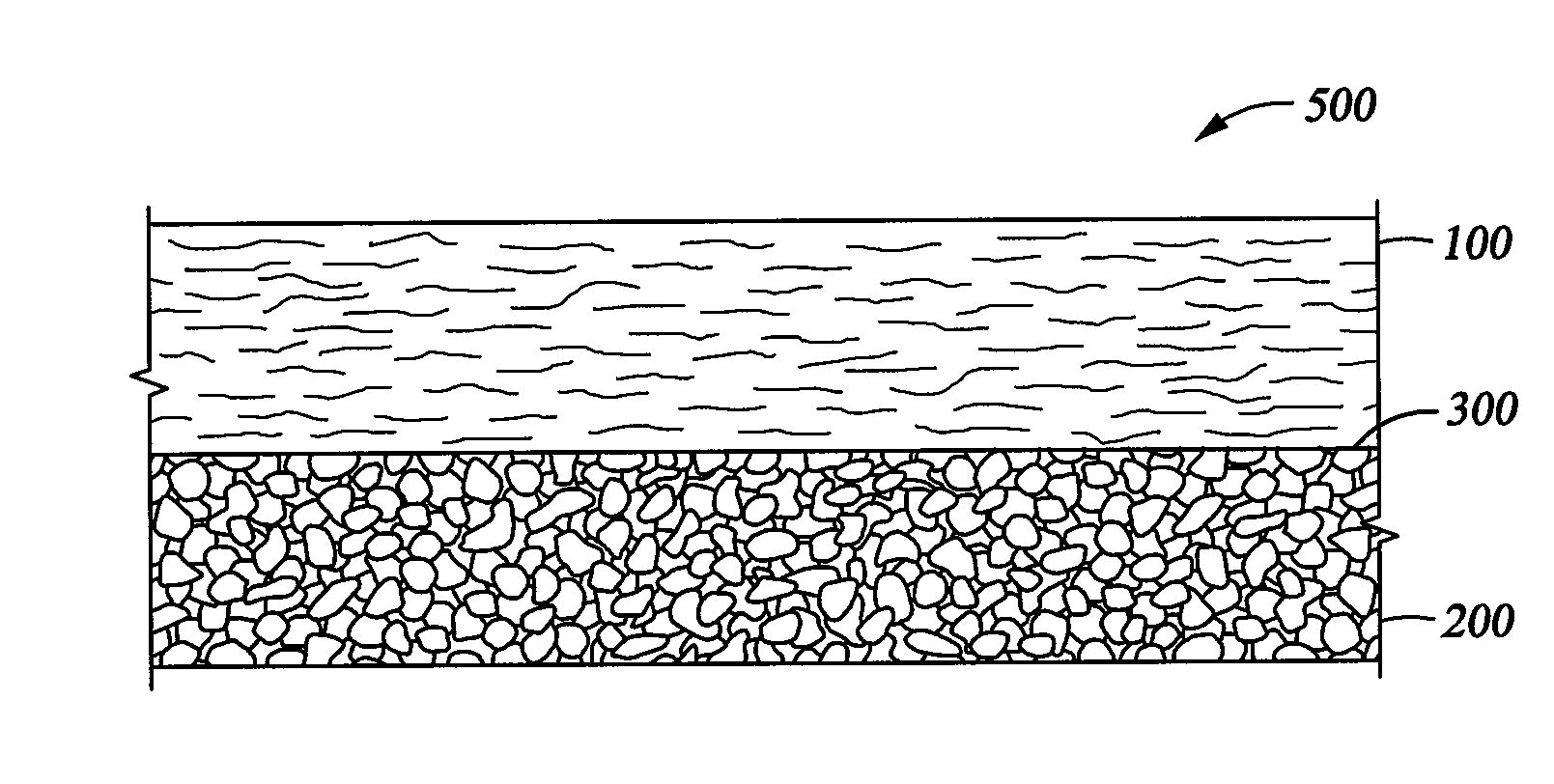

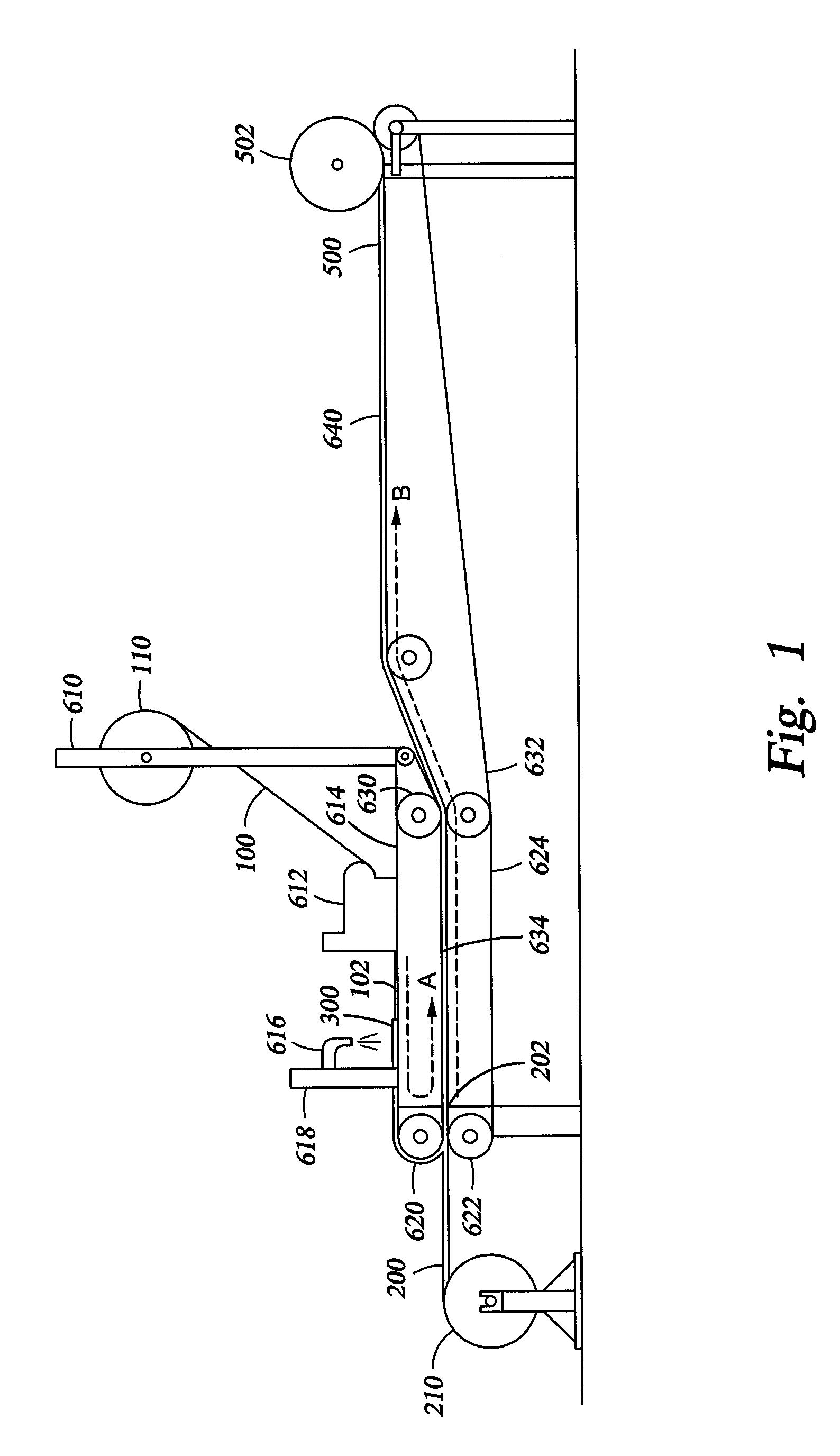

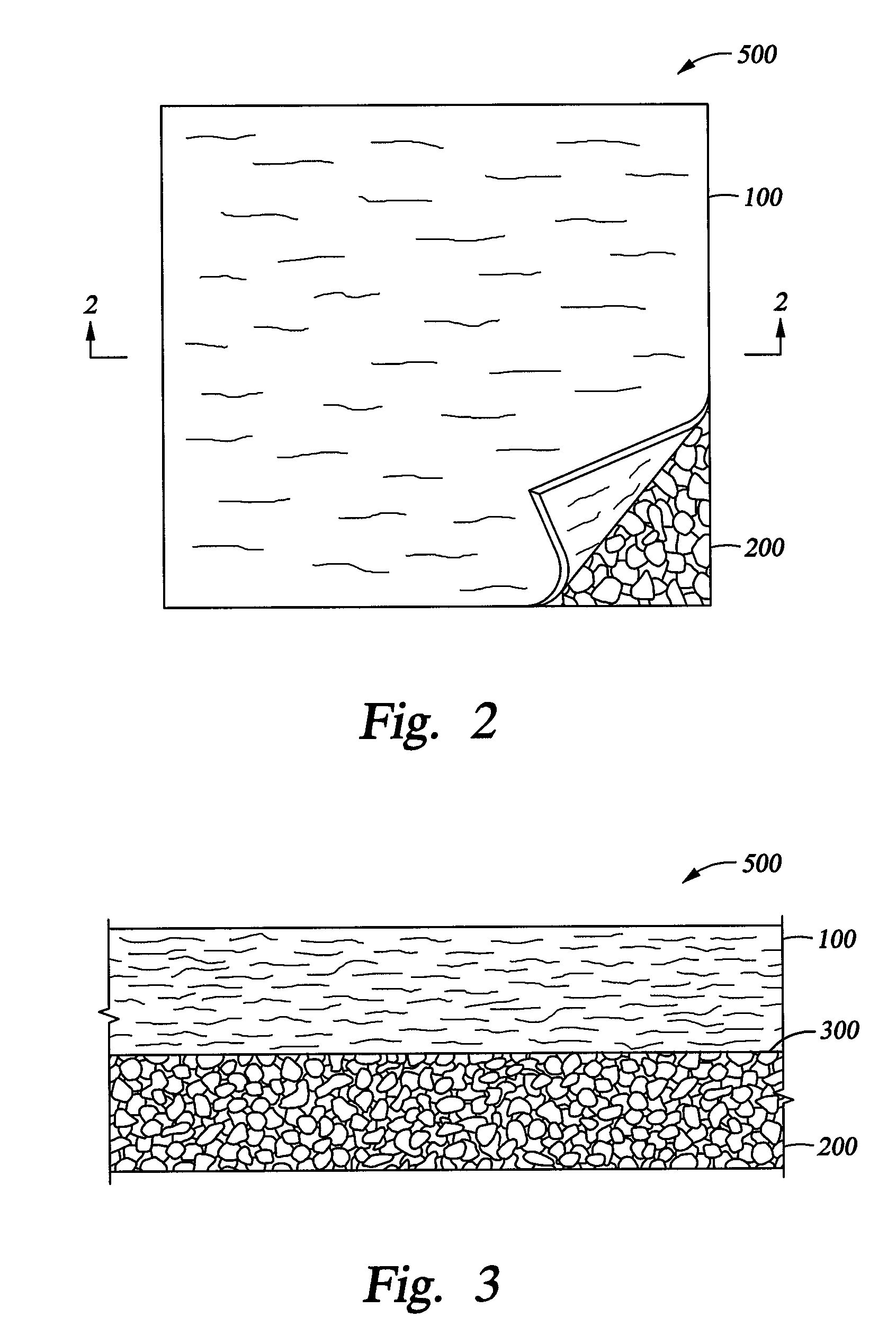

Method for forming bi-layered fiber and foam carpet underlay

InactiveUS20080008862A1Increased durabilityStay highSynthetic resin layered productsLaminationFiberCushioning

The present invention relates to a method for forming a bi-layered carpet underlay. More particularly, the method includes bonding a layer of non-woven fibers and a layer of re-bonded foam particles together to form the bi-layered carpet underlay. The layers of the carpet underlay can be bonded together with the use of adhesives, by heating a surface of one or both layers to a soft bondable state for lamination between the layers, by applying a film having adhesive surfaces between the layers, or by other suitable bonding means. The bi-layered carpet underlay combines the soft cushioning resilience of foam with the high durability bridging ability of fiber to provide a carpet underlay that maintains its height or thickness and firmness, while imparting softness and cushioning effects over an extended period of wear.

Owner:L & P PROPERTY MANAGEMENT CO

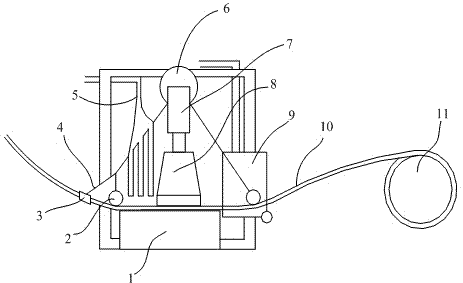

Cloth ironing device

InactiveCN104499259AAvoid wrinklesEasy to replaceIroning apparatusTextiles and paperEngineeringTextile

The invention relates to the field of spinning machinery equipment, in particular to a cloth ironing device. The cloth ironing device comprises a base platform, a support and an iron, wherein the iron is vertically connected on the support through an air cylinder, an ironing side of the iron is parallel to the base platform, the support is arranged on two sides of the base platform, a support cover is arranged around the iron, the bottom of the support cover is provided with a roller shaft spreading the cloth, the support cover is fixed on the support, a steam pipe is arranged on the inner side of the support cover, a smoothing mechanism is arranged at a cloth inlet end of the support cover and composed of a V-shaped plate and bristles, wherein the two sides of the V-shaped plate are fixed, and the bristles are fixed below the V-shaped plate. A drying tank is arranged at a cloth outlet end of the support cover. The cloth ironing device has the advantages that crinkled cloth can be effectively ironed, and crinkles generated during rolling the cloth are avoided.

Owner:桐梓县创兴自动化设备有限公司

Processing method of Chinese redwood barks

ActiveCN104441158AFully softenedImprove wooden structureCork treatment detailsMedicineRelative humidity

The invention relates to a processing method of Chinese redwood barks. The processing method comprises the following steps: (1) cleaning the Chinese redwood barks, mixing the Chinese redwood barks with a processing agent (1) at 40 DEG C for 10-15 minutes for treating; (2) processing the Chinese redwood barks processed in the step (1) at the temperature of 85 DEG C and the relative humidity of 75% for 3 hours; (3) soaking the Chinese redwood barks processed in the step (2) at 45 DEG C for 3-5 hours by virtue of a softener; and (4) processing the Chinese redwood barks processed in the step (3) at the temperature of 60 DEG C and the relative humidity of 45% for 2 hours, and airing until the water content is 55%-65%. By specially processing the Chinese redwood barks by virtue of the processing method, the softening effect of the Chinese redwood barks can be greatly improved, and the Chinese redwood barks are uniformly softened, so that situations of breakage, cracking and the like in a weaving process are prevented, and the yield of woven products is high after processing and reaches above 96.2%.

Owner:阜南佳利工艺品股份有限公司

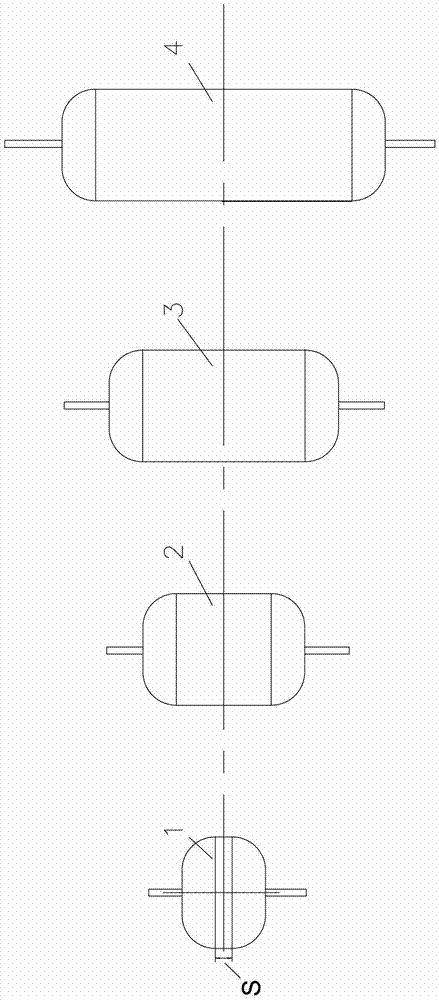

Preparation method for high-strength, high-plasticity and high-precision beta titanium alloy pipe

The invention discloses a preparation method for a high-strength, high-plasticity and high-precision beta titanium alloy pipe. The preparation method comprises the steps that firstly, raw materials are mixed and pressed into electrode blocks, the electrode blocks are welded into an electrode, and the electrode is smelted into a beta titanium alloy ingot; secondly, the beta titanium alloy ingot issubjected to beta phase region cogging forging and thus a square billet is formed, after upsetting and drawing are conducted for three or more times, rounding is conducted and thus a bar billet is formed, and the bar billet is machined into an extruded pipe billet; thirdly, the extruded pipe billet is extruded and then subjected to solution treatment, cogging rolling and finish rolling are conducted, and thus a semi-finished beta titanium alloy pipe is obtained; and fourthly, the semi-finished beta titanium alloy pipe in the third step is subjected to solution treatment and aging treatment, then precision machining is conducted, and thus the beta titanium alloy pipe is obtained. The beta titanium alloy pipe prepared through the preparation method is uniform in alloy structure, fine in grain size, uniform in wall thickness and good in straightness, and the results of the mechanical properties of the beta titanium alloy pipe show that the beta titanium alloy pipe has high strength and high plasticity and meanwhile also has better size precision.

Owner:西安秦钛智造科技有限公司

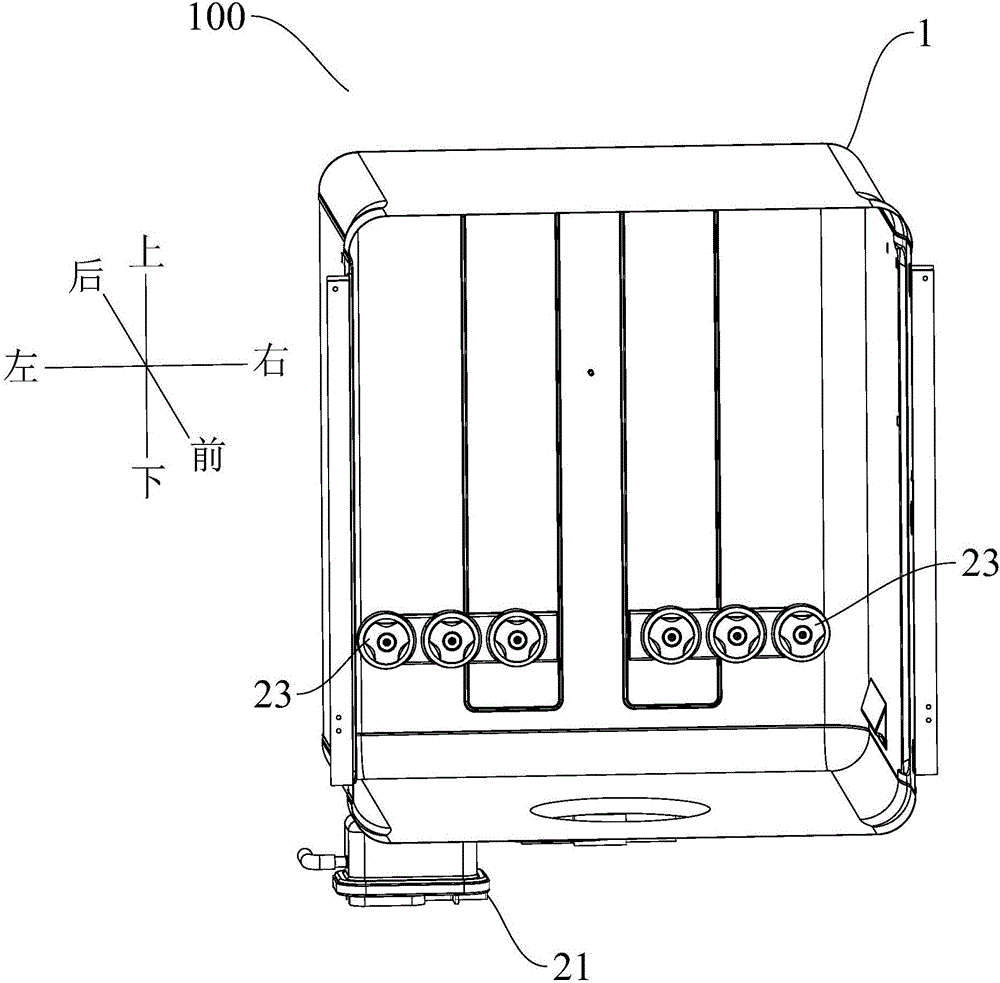

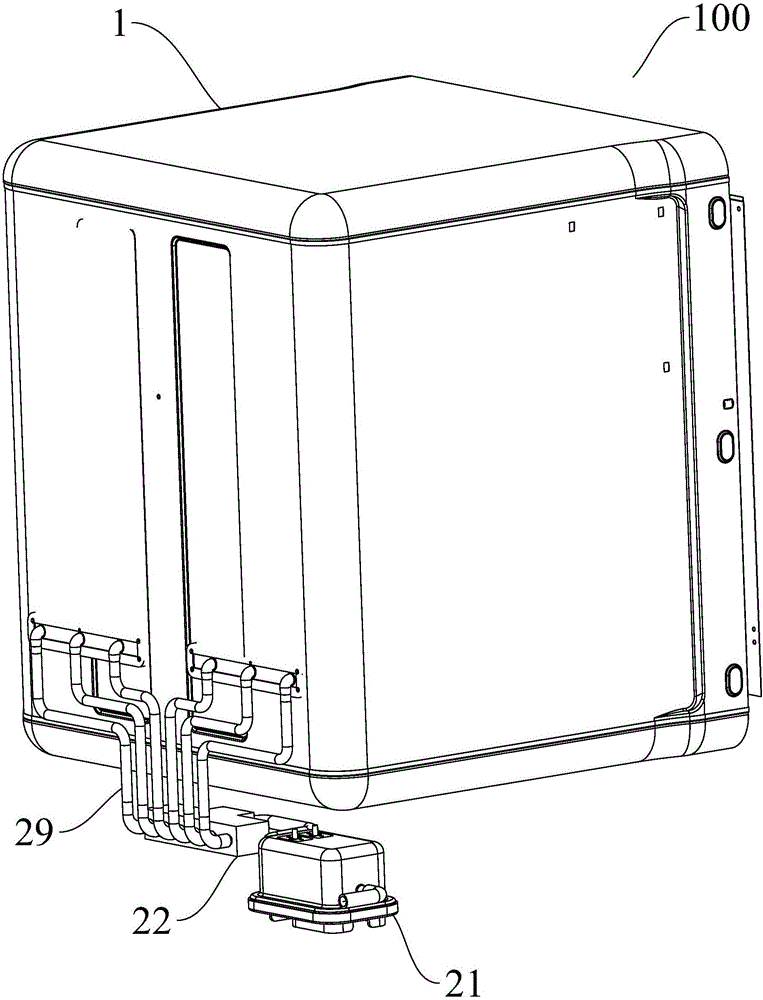

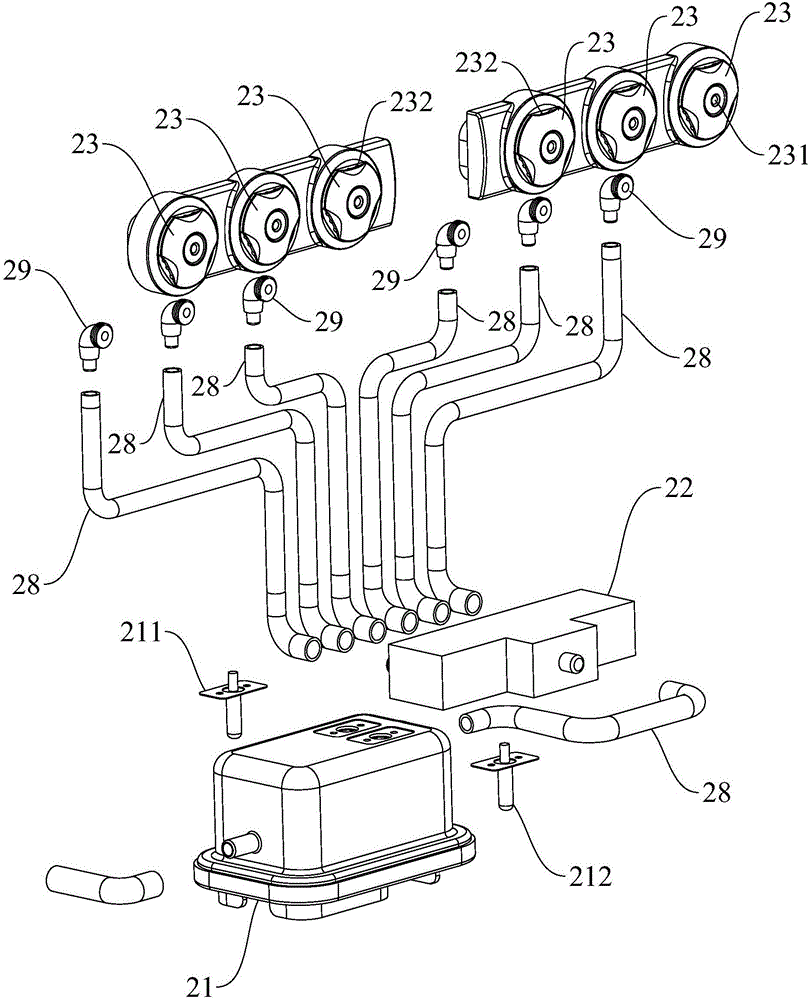

Dish washing machine

ActiveCN106510591AImprove cleanlinessFully softenedTableware washing/rinsing machine detailsCleaning equipmentSpray nozzleEngineering

The invention discloses a dish washing machine, which comprises an inner liner and a steam spraying device, wherein the steam spraying device comprises a steam generator, a steam rectifier and a plurality of steam spray nozzles; the plurality of steam spray nozzles are arranged in the inner liner; a steam inlet connected with the steam generator and a plurality of steam outlets respectively connected with the plurality of steam spray nozzles are formed in the steam rectifier; the steam rectifier is used for performing uniform pressure division and flow division on steam entering the steam rectifier from the steam inlet; and each steam spray nozzle is provided with a plurality of spray holes communicating with the corresponding steam outlets. The dish washing machine provided by the invention has the advantage that through the arrangement of the steam rectifier used for performing uniform pressure division and flow division on the steam entering the steam rectifier and the plurality of steam spray nozzles with the plurality of spray holes, contaminants such as stubborn oil stain on tableware put in the inner liner can be sufficiently softened, so that the clean washing effect of the dish washing machine is improved.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

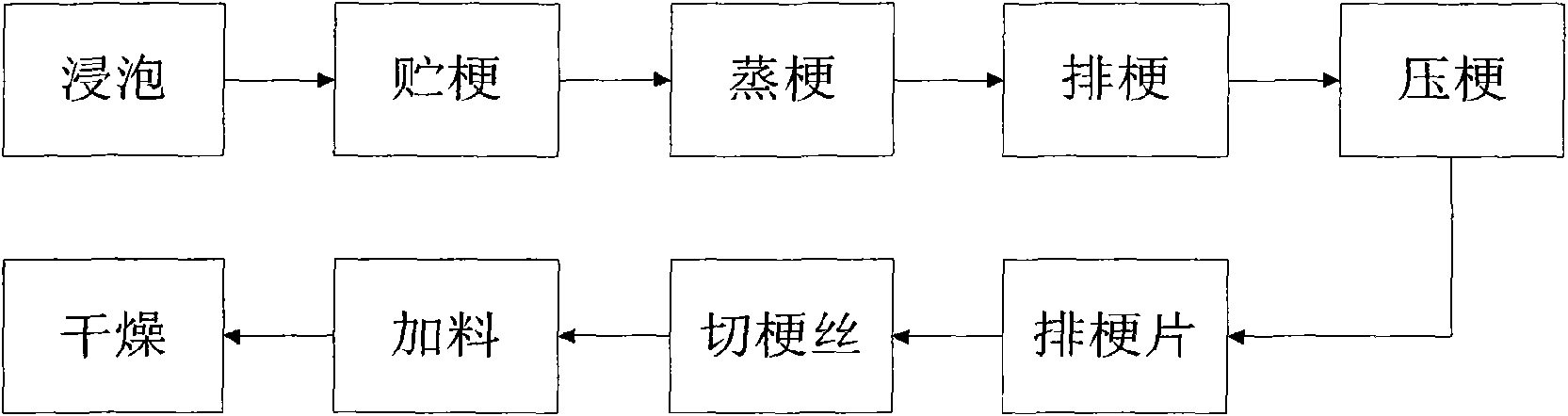

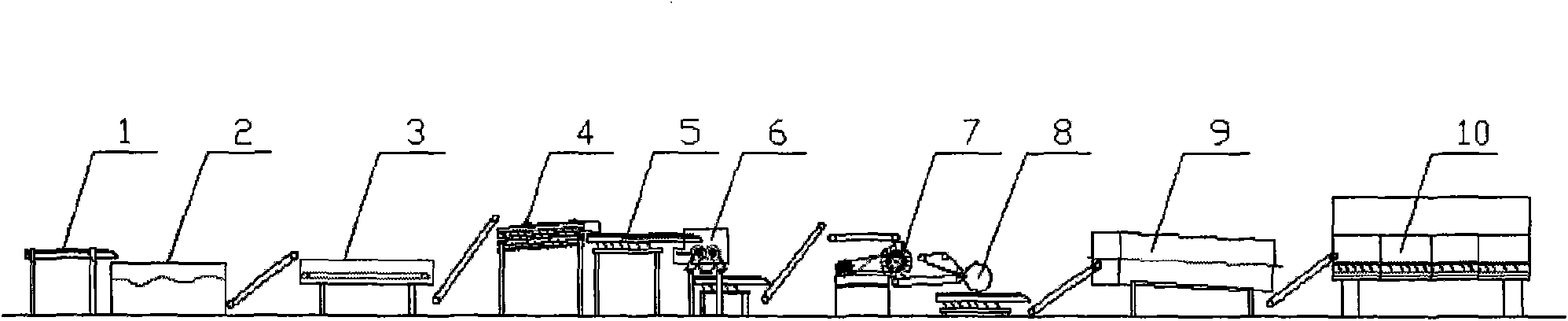

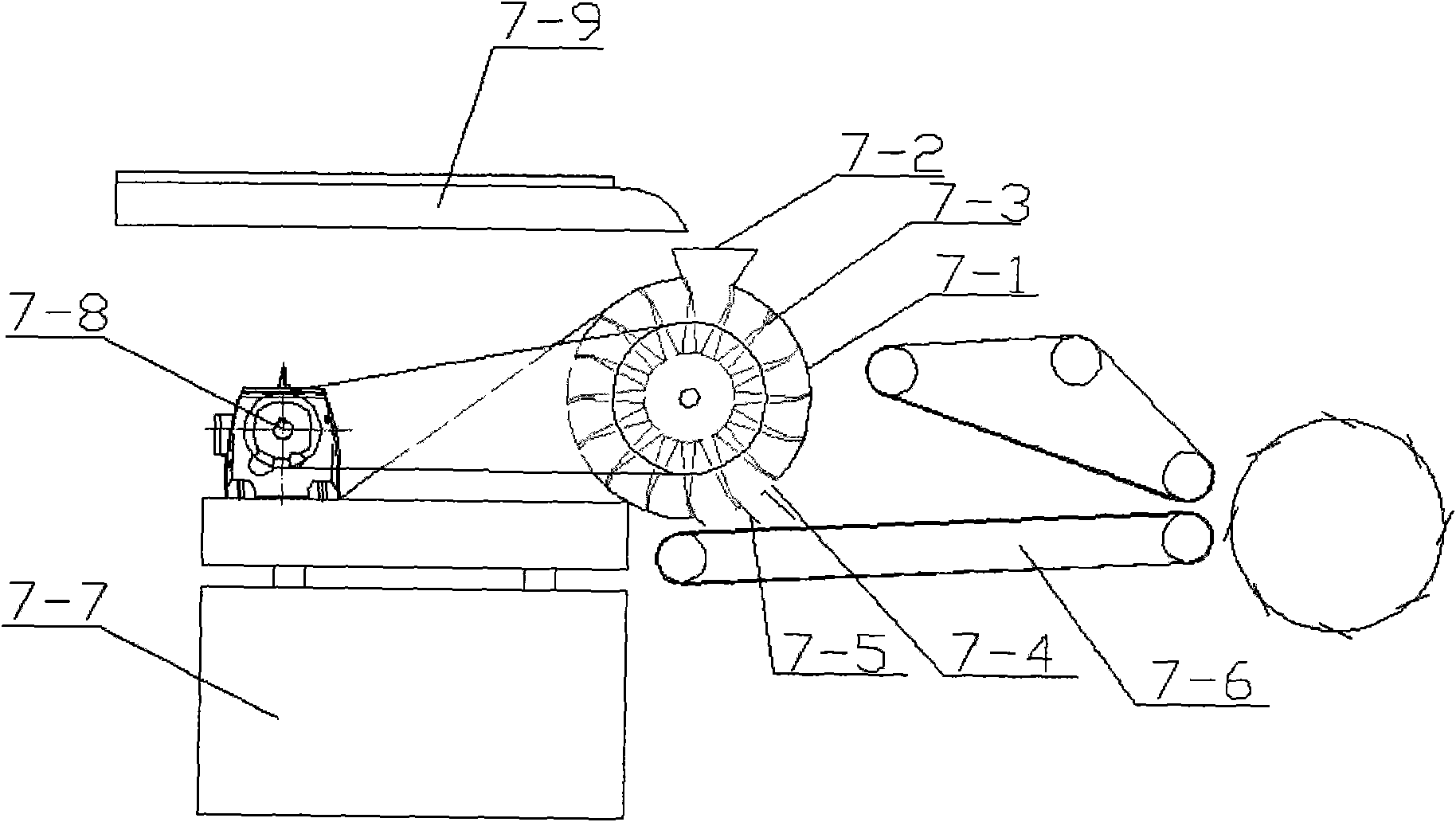

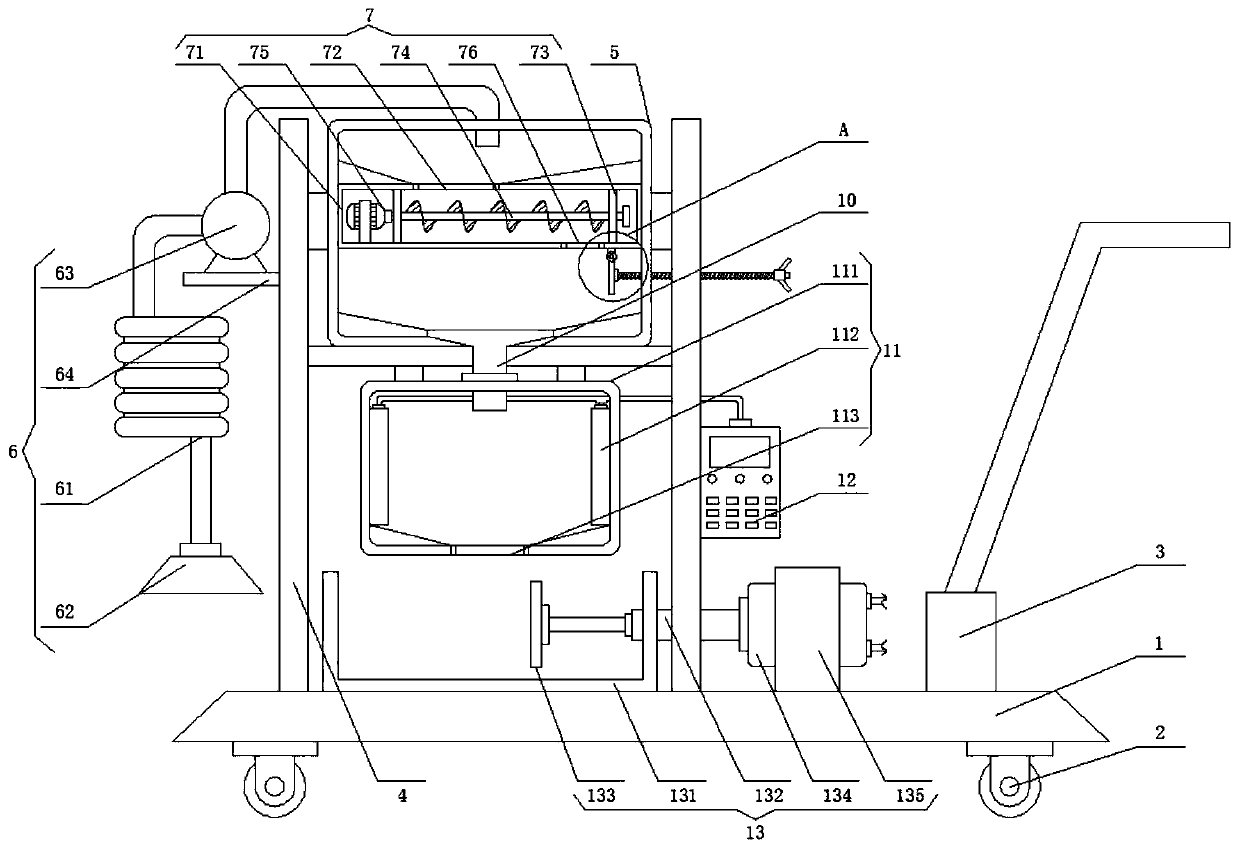

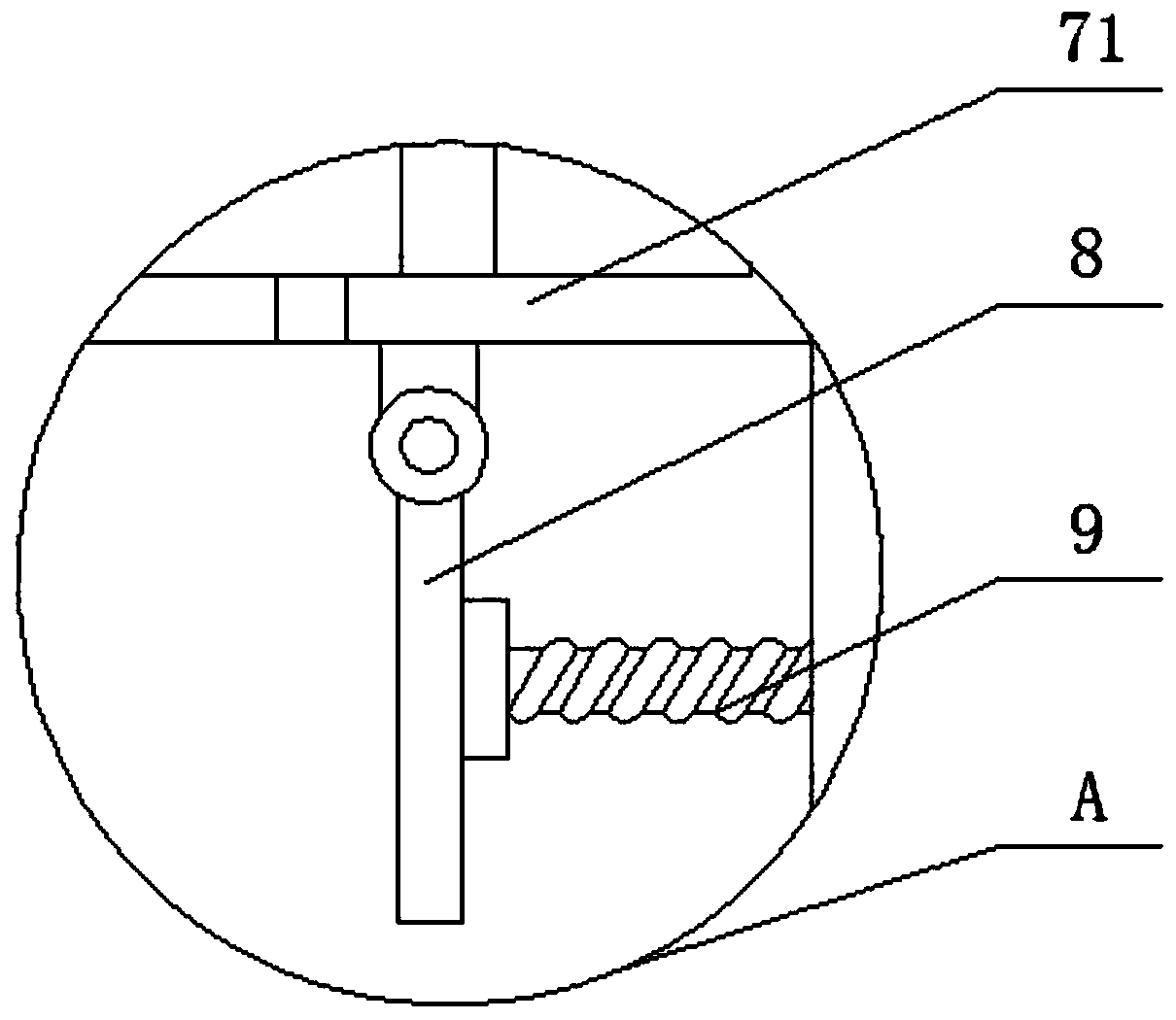

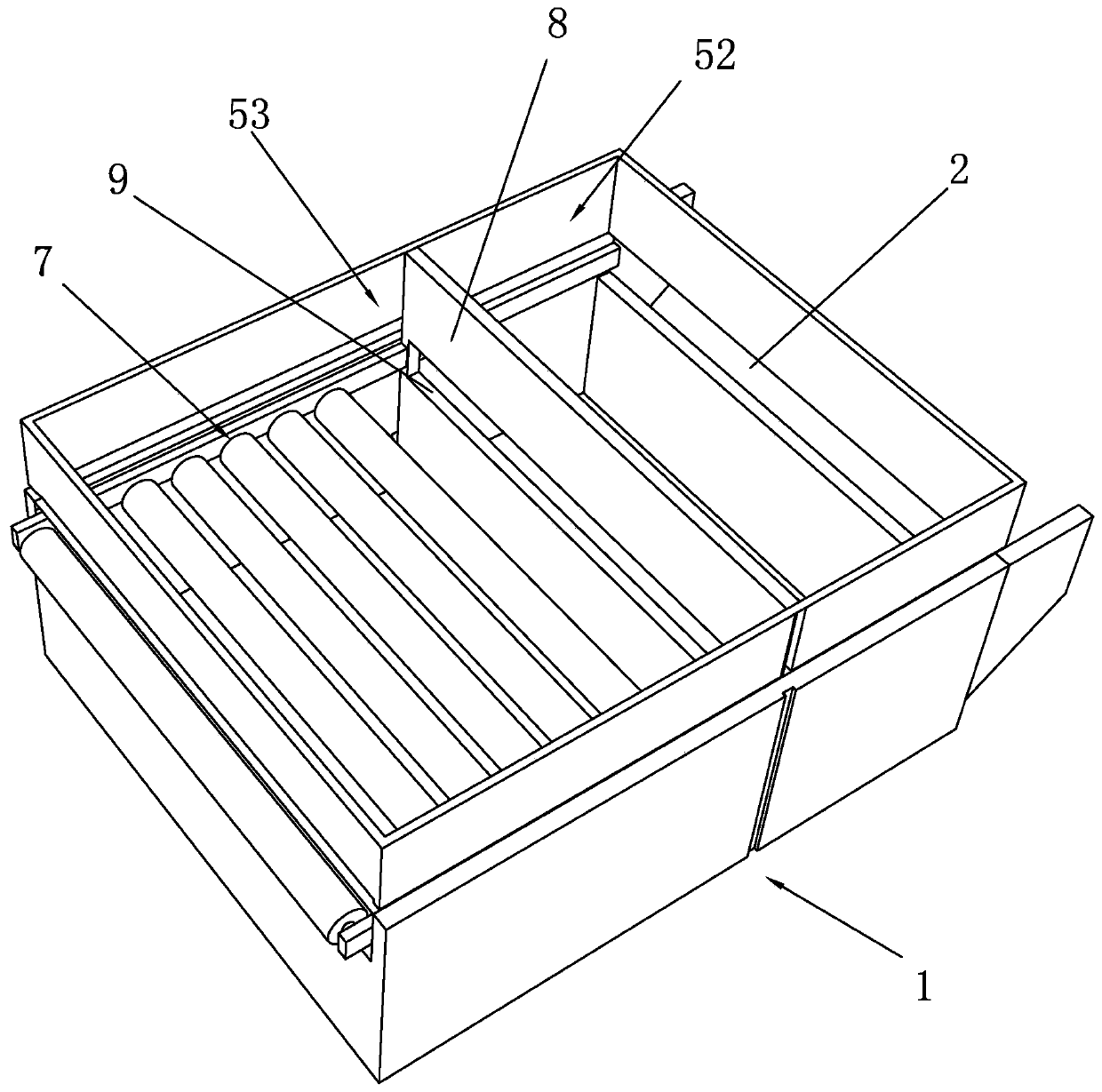

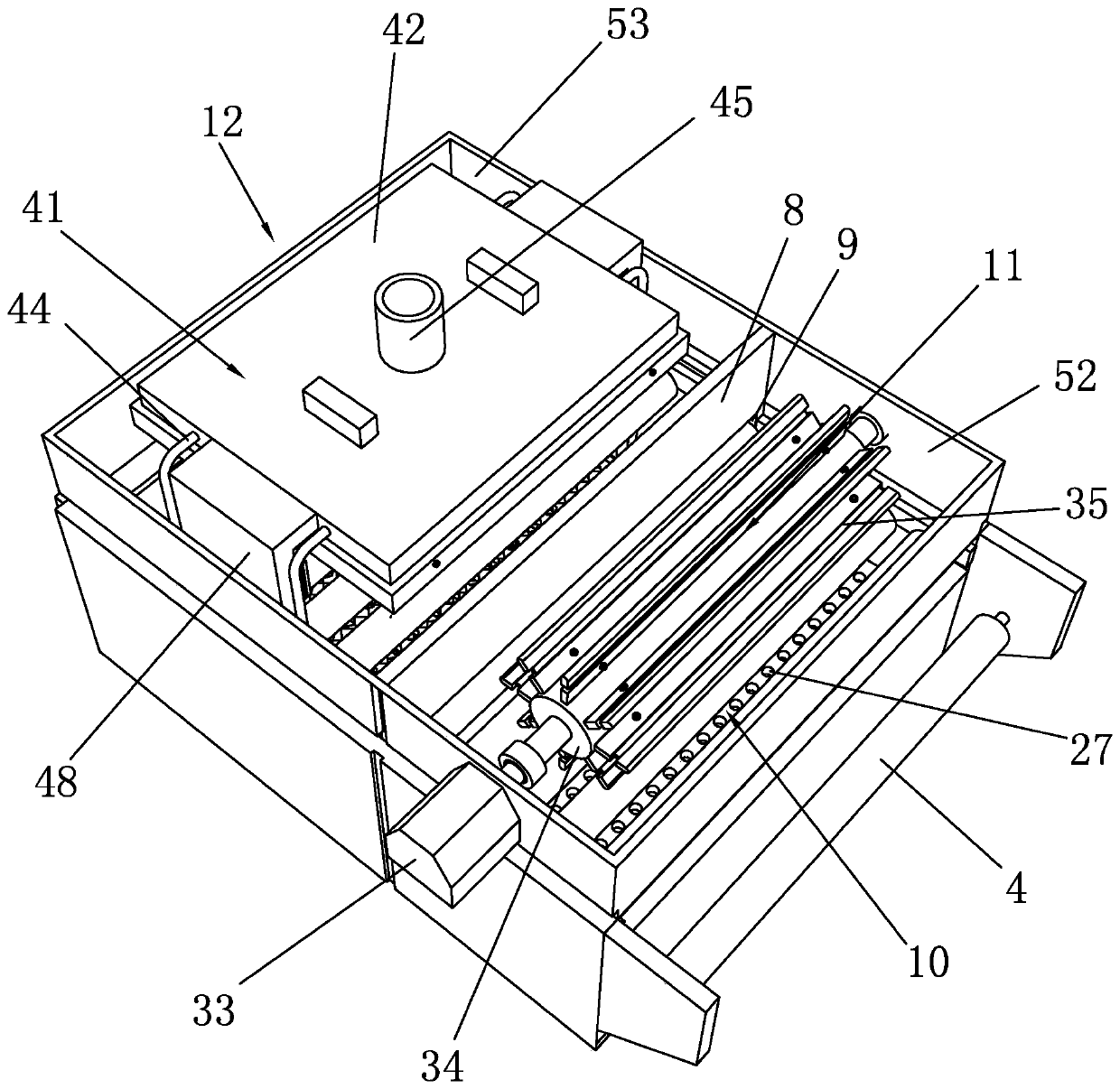

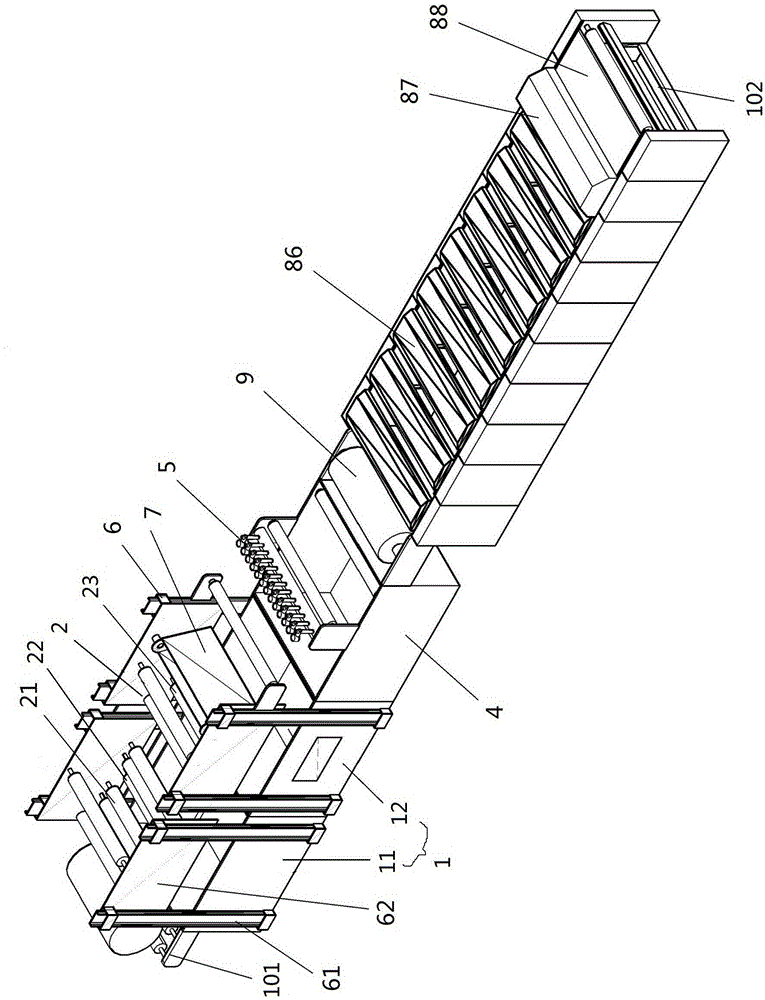

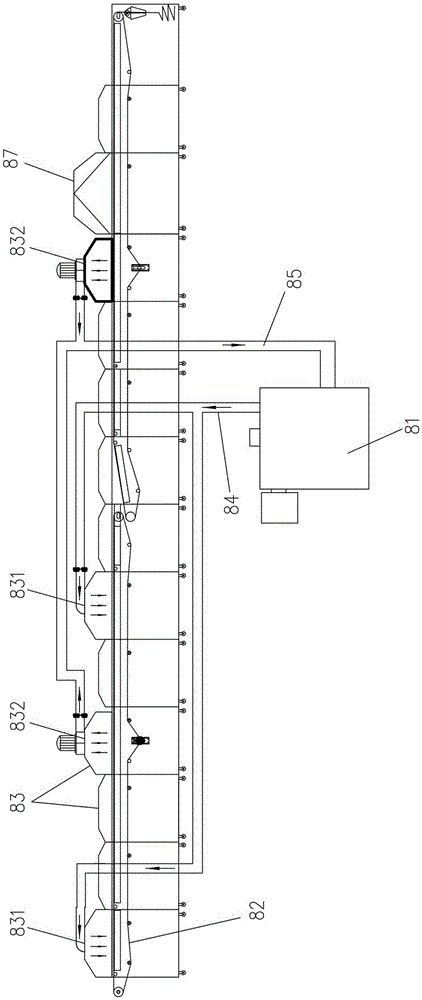

Cabo shredding process and equipment

ActiveCN101647600AFully softenedReduce overlapTobacco treatmentAgricultural engineeringMachining process

The invention relates to a cabo shredding process and equipment. The process comprises the following steps: soaking, cabo storing, cabo braizing, cabo arranging, cabo pressing, cabo slice arranging, cabo shredding, charging and drying. The equipment for realizing the process comprises a soaking device, a cabo storing cabinet, an HT cabo braizing machine, a cabo arranging device, a cabo pressing machine, a cabo slice arranging device, a shredder, a charging machine, a cabo drying machine and united conveyer equipment among the soaking device, the cabo storing cabinet, the HT cabo braizing machine, the cabo arranging device, the cabo pressing machine, the cabo slice arranging device, the cabo shredder, the charging machine and the cabo drying machine. The invention has the advantages that crumbling during the cabo machining process is lower, and the shape of the produced cabo shred is similar to leaf shed; moreover, the processability is good, and the invention can improve the quality and the stability of cigarette products and reduce the cigarette cost can be reduced.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

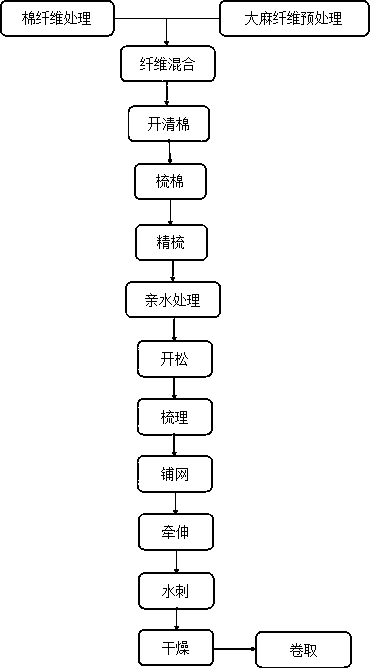

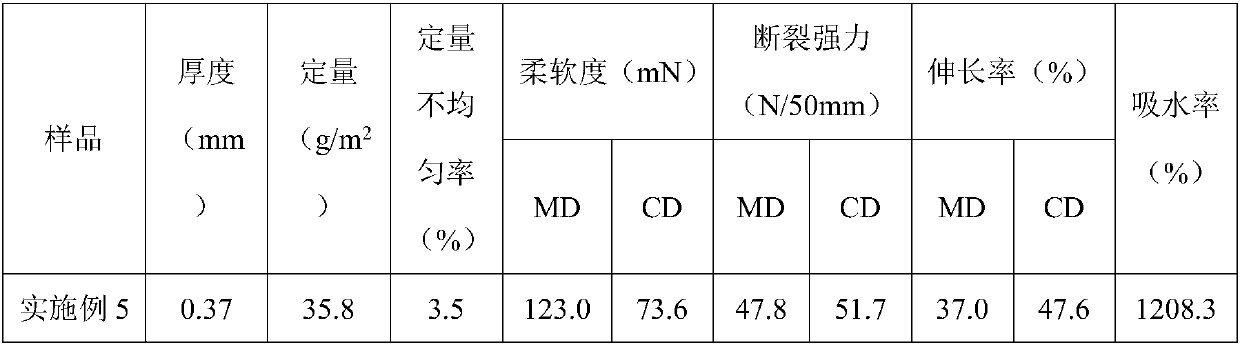

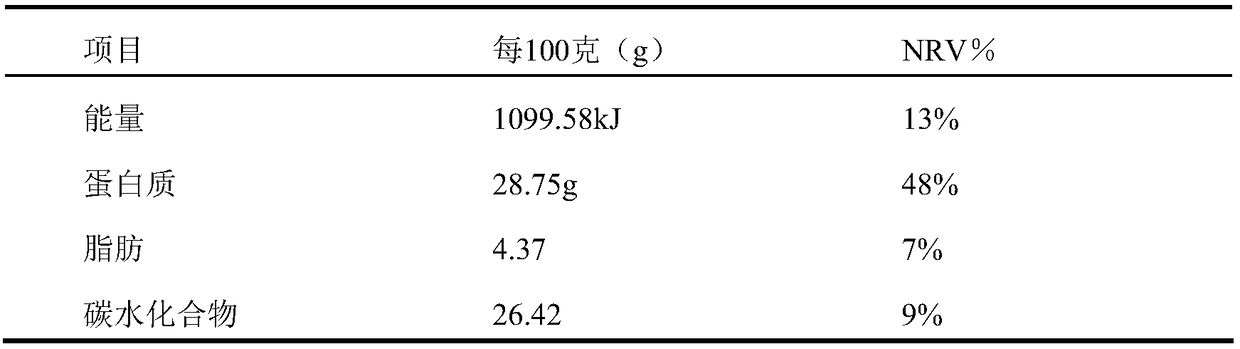

Natural antibacterial fiber spunlaced non-woven fabric and preparation method and application thereof

The invention relates to the field of sanitary articles, and provides a natural antibacterial fiber spunlaced non-woven fabric and a preparation method and application thereof. The natural antibacterial fiber spunlaced non-woven fabric comprises hemp fibers and cotton fibers. The preparation method includes the following steps that the hemp fibers and the cotton fibers are pretreated respectively;the pretreated hemp fibers and the pretreated cotton fibers are mixed; the mixed fibers are subjected to opening and picking, carding and combing in sequence to form fine silvers, the fine silvers are pull apart to form fine webs, and then hydrophilic treatment, opening, carding, lapping, drawing, spunlacing, drying and reeling are carried out to obtain the natural antibacterial fiber spunlaced non-woven fabric. According to the method, damage to the hemp fibers is small, the loss is low, and the antibacterial property of the hemp fibers is well retained; the natural antibacterial fiber spunlaced non-woven fabric is good in evenness and combines the advantages that the cotton fibers are soft and comfortable and the hemp fibers are natural antibacterial, dry and breathable; the fabric truly has the advantages of being good in evenness, soft and comfortable, natural antibacterial, dry and breathable, can be widely used in the fields of sanitary napkins, wet wipes, cotton wipes and the like, and has broad application prospects.

Owner:ZHUZHOU QIANJIN PHARMA +1

Pretreatment process of jute or red ramie

ActiveCN102086533AImprove spinnabilitySoft textureFibre treatment to obtain bast fibreSodium hypochlorite solutionTherapeutic effect

The invention discloses a pretreatment process of jute or red ramie, comprising the following steps: (1) stacking: staking jute or red ramie for 24-72 hours in a closed environment with steam kept at the temperature of 40-50 DEG C; (2) carding: carding the stacked jute or red ramie; (3) degumming: soaking the carded jute or red ramie in a treating solution to remove pectin and lignin of the jute or red ramie; (4) pickling: soaking the degummed jute or red ramie in an acid solution; (5) bleaching: treating the jute or the red ramie which are soaked in the acid solution with a sodium hypochlorite solution to remove the pigment of the jute or red ramie; (6) water washing: washing the bleached jute or red ramie with water; and (7) oil applying: applying oil to the jute or red ramie washed with water. The pretreatment process disclosed by the invention has good treatment effects on degumming the jute or red ramie and removing the lignin, thus ensuring that the treated jute or red ramie hasgood fiber spinnability and can be widely used for spinning and manufacturing refined fibrilia fabrics.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Preparation technology of Low-e bent laminated glass

ActiveCN106242259AIncrease bend radiusHigh impact strengthGlass reforming apparatusGlass tempering apparatusEngineeringUltimate tensile strength

The invention discloses a preparation technology of a Low-e bent laminated glass. The technology includes the steps of: a. employing a horizontal double-straight edge machine to conduct edging on Low-e glass substrates through a synchronous belt, then conducting cleaning in a cleaning machine; b. placing the cleaned glass horizontally on a roller way, sending the glass into a convection toughening furnace by the roller way and carrying out one-stage heating treatment; c. taking the heat treated glass out of the furnace and sending it into a bent wind grid, and letting the glass bend along with the bending of the conveying roller way and the wind grid by virtue of self weight; d. laminating the cleaned two or more bent steel glass in a dust-free airtight lamination chamber; e. reheating the bent glass obtained in step d and slowly prepressing the bent glass through a bent glass roller press to remove air; and f. putting the bent glass of step e into an autoclave to conduct heating and pressurization so as to remove residual air. The bent glass process is simple, the produced glass has high tensile strength, bending strength and impact strength and beautiful appearance, and is transparent.

Owner:浙江南晶玻璃科技股份有限公司

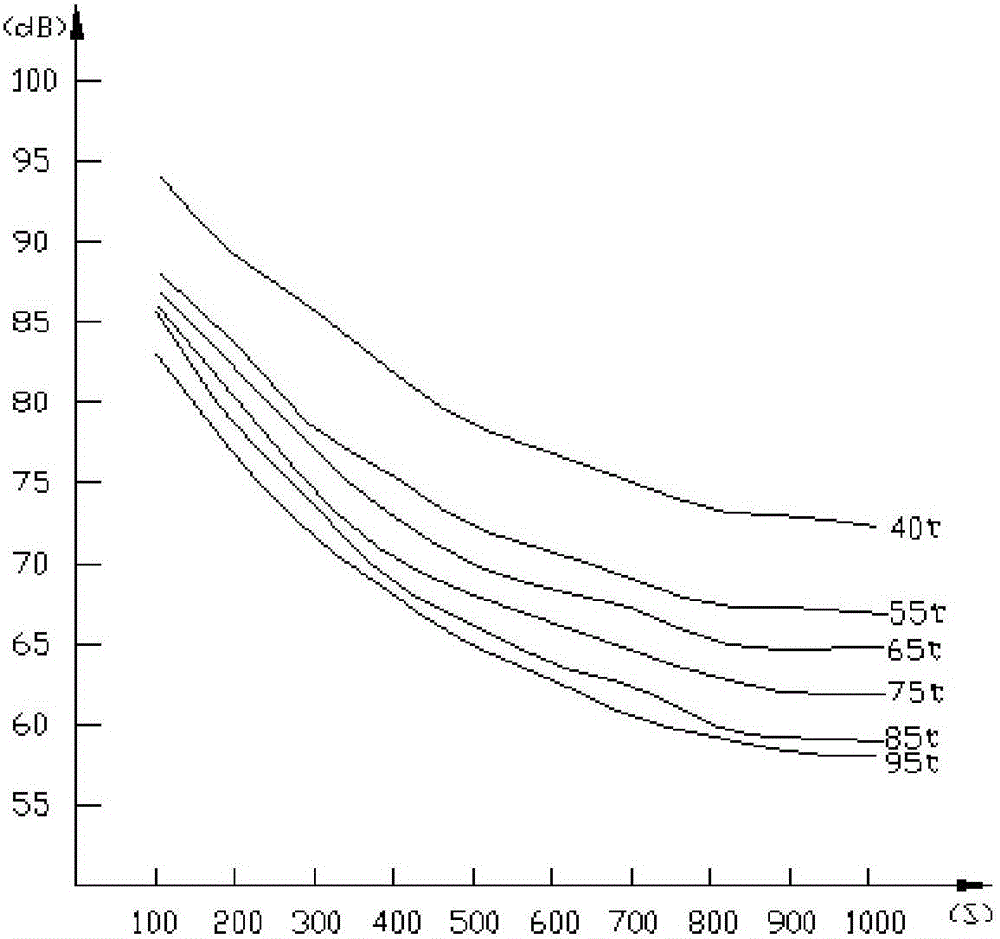

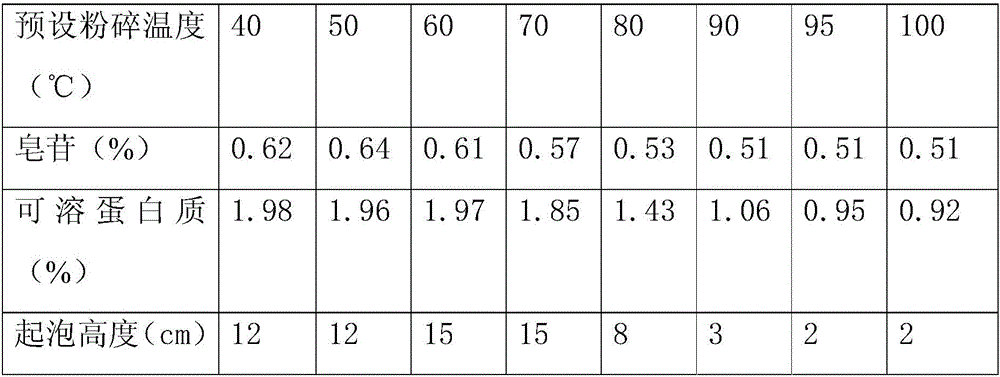

Low-noise milk-preparation method of soybean milk machine

InactiveCN105935247AReduce hardnessBad experienceBeverage vesselsDough shaping and cutting apparatusLow noiseElectricity

The invention relates to a low-noise milk-preparation method of soybean milk machine. A motor, a crushing cutter, a heating device and a cup body are provided. The control unit is electrically connected with the motor, and the heating device. The method at least comprises following phases: (1) a crushing stage: the motor drives the crushing cutter to rotate and crush water and material to milk and goes to the next phase; (2) a boiling phase: the heating device is used for heating milk till it is boiled. When the crushing phase begins, the temperature of liquid is larger than or equal to the pre-set crushing temperature. The pre-set crushing temperature is larger than or equal to 85 DEG C. Before the crushing phase, a heating pre-treatment phase is included. The heating pre-treatment phase lasts for 400 to 800 seconds. Therefore, noise can be effectively decreased and false boiling is avoided and reduced effectively.

Owner:JOYOUNG CO LTD

Waste recycling device and method for plastic product production

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

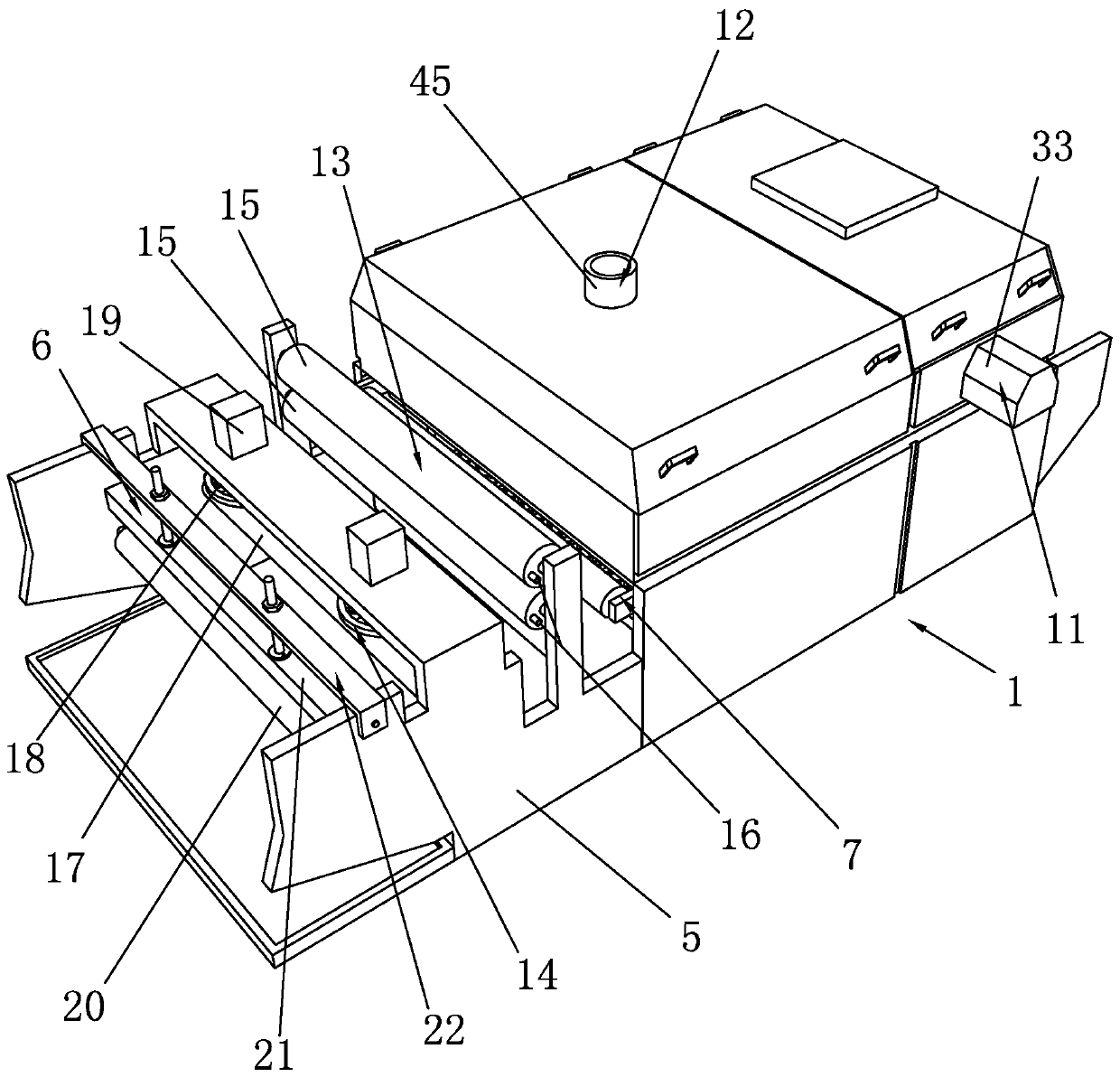

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

Method for forming bi-layered fiber and foam carpet underlay

InactiveUS7279065B1Increased durabilityStay highLamination ancillary operationsAdhesive processes with adhesive heatingCushioningFiber

The present invention relates to a method for forming a bi-layered carpet underlay. More particularly, the method includes bonding a layer of non-woven fibers and a layer of re-bonded foam particles together to form the bi-layered carpet underlay. The layers of the carpet underlay can be bonded together with the use of adhesives, by heating a surface of one or both layers to a soft bondable state for lamination between the layers, by applying a film having adhesive surfaces between the layers, or by other suitable bonding means. The bi-layered carpet underlay combines the soft cushioning resilience of foam with the high durability bridging ability of fiber to provide a carpet underlay that maintains its height or thickness and firmness, while imparting softness and cushioning effects over an extended period of wear.

Owner:L & P PROPERTY MANAGEMENT CO

Method for preparing sesame-flavored betel nut

InactiveCN108770982ARealize transformation and upgradingShorten production timeConfectionerySweetmeatsSesamumBetel

The invention discloses a method for preparing sesame-flavored betel nut, comprising the following steps: immersing and cleaning betel nut, carrying out physical pre-treatment by a steam blasting technology, fermenting, roasting seeds, cutting seeds and removing stones, adding bittern, airing, wrapping the bittern-added betel nut with sesame and packaging. The steam blasting technology is adoptedin fabric softening and sterilizing of the edible betel nut for the first time, and the use of a sweetener, flavours and fragrances and preservatives in the subsequent processing is minimized. By selecting the healthy food sesame, the image of edible betel nut in people's minds is corrected, the natural quality of the betel nut food is restored, the quality of betel nut is improved, the health ofconsumers is guaranteed, and the scientific consumption is guided. And a new expression of ''steam blasting + betel nut + sesame'' is created, and health value added and core competitiveness of the edible betel nut are enhanced.

Owner:湖南宾之郎实业集团有限公司

Slurrying method for fructus cannabis protein slurry

ActiveCN103445259AMeticulous and rigorous craftsmanshipSolve the precipitation problemFood scienceCannabisFlavor

The invention belongs to the technical field of beverages, and in particular relates to a slurrying method for fructus cannabis protein slurry. The slurrying method comprises specific slurrying technical steps of poaching, pulping or grinding to produce slurry, filtering and separating slurry residues and the like, particularly, adding the filtered residues into low-temperature alpha-amylase for enzymolysis, carrying out enzymolysis on a large quantity of starch in filtered residues to produce enzymatic hydrolysate containing maltose, glucose and fructus cannabis flavor substances, and mixing the enzymatic hydrolysate with fructus cannabis protein liquor so as to prepare the fructus cannabis albumen slurry. Resources are effectively and fully used; the problem of precipitates in the beverage caused by the starch is solved. According to the slurrying method provided by the invention, the defect of precipitation in a production technology for the fructus cannabis protein beverage can be solved, and various types of protein beverages can prepared by the fructus cannabis albumen slurry obtained by the slurrying method. The fructus cannabis protein slurry is milky-white, smooth, sweet, soft and rich in nutrition.

Owner:东台海滨科技创业园管理有限公司

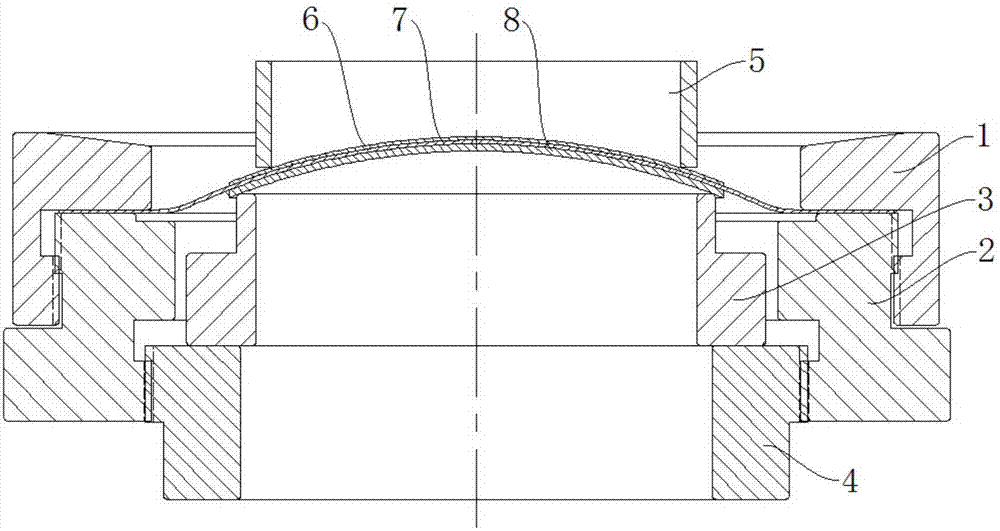

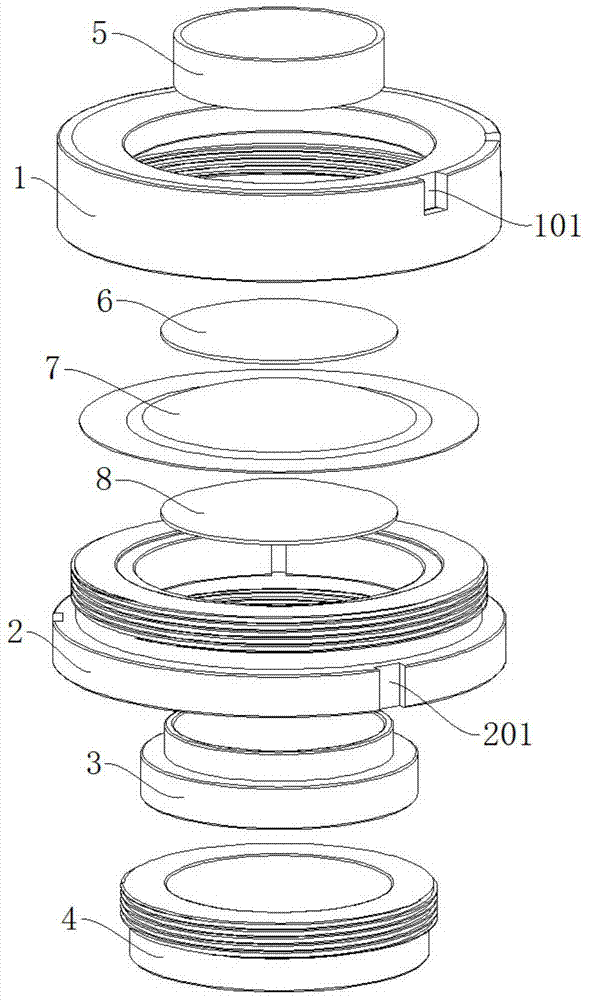

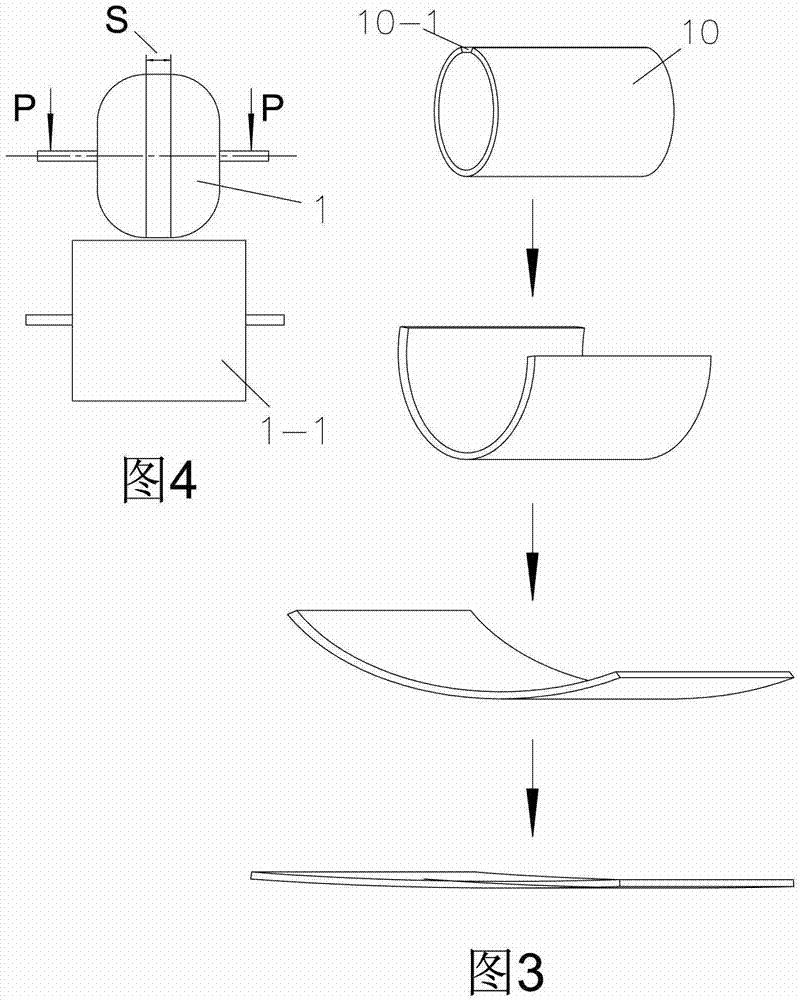

Method and die for manufacturing glass polarizing lens

ActiveCN103885113AReduce manufacturing costSimple molding processPolarising elementsEngineeringThin sheet

The invention discloses a method for manufacturing a glass polarizing light lens, and belongs to the field of lens manufacturing. The method comprises the first step of clamping a polarizing film and heating and humidifying the polarizing film until the polarizing film is softened, the second step of bonding the convex plane of a back glass thin sheet with one face of the polarizing film to enable the curve radian of the polarizing film to be consistent with the radian of the convex plane of the back glass thin sheet and removing dust on the surface of the polarizing film and bubbles between the polarizing film and the back glass thin sheet, the third step of bonding the concave plane of a front glass thin sheet with the other face of the polarizing film and removing the bubbles between the polarizing film and the front glass thin sheet, the fourth step of roasting and solidifying the glass polarizing lens, and the fifth step of cutting the unnecessary polarizing film and carrying out washing and testing. The invention further discloses a die for manufacturing the glass polarizing lens, the forming technology of the glass polarizing light lens is simplified, and the production efficiency and the finished product yield are improved; the special forming die is adopted, and the die is simple in structure, convenient to machine and manufacture and low in cost.

Owner:夏正华

Bleached needle wood fluff pulp board and manufacturing method thereof

ActiveCN102535235ALow water absorptionAdd lessNatural cellulose pulp/paperPulp beating methodsBursting strengthHigh concentration

The invention discloses a bleached needle wood fluff pulp board and a manufacturing method thereof. The method comprises the following steps of: adding the bleached needle wood fluff pulp board into a low-concentration hydrapulper for pulping to prepare pulp, removing impurities from the pulp by using a high-concentration slag separator, making the pulp enter a defibering machine for low-concentration thermal defibering, uniformly stirring the pulp, removing the impurities, making the pulp enter a machine chest, and manufacturing the fluff pulp board by using a pulp machine. The bursting strength of the pulp board can be remarkably reduced only by mechanical and physical functions, the pulp is mainly self-curled, fiber cutting and fibrillation are avoided as much as possible, and the strength loss of the fiber is low; when quantified to be 630 to 680g / m<2>, the fluff pulp board has an burst index lower than 0.75kPa. m>2> / g and the whiteness of 85 percent; a fluffed fluff pulp fiber has the fluff-specific volume of 24cm<3> / gm, water absorbing speed higher than 3.5mm / s and water absorbing capacity higher than 8.7g / g; and the quality of the bleached needle wood fluff pulp board meets quality requirements according to GB / T21331-2008, and is equivalent to that of an imported fluff pulp board.

Owner:SHAANXI UNIV OF SCI & TECH

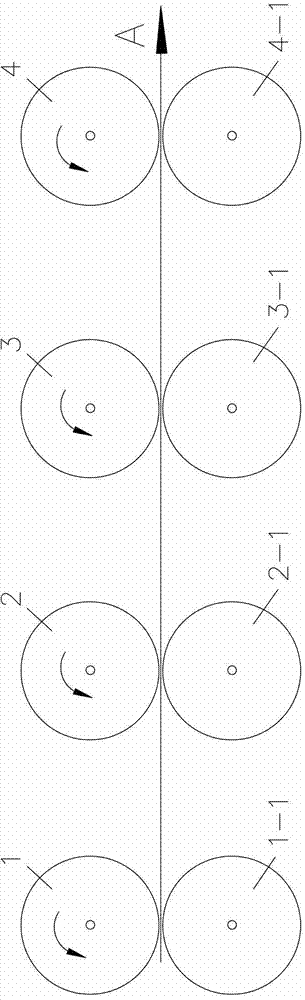

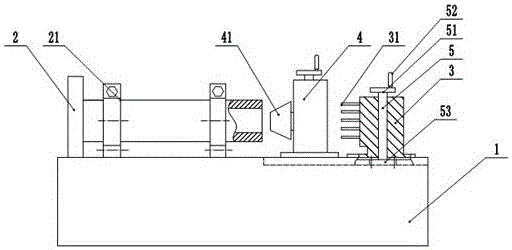

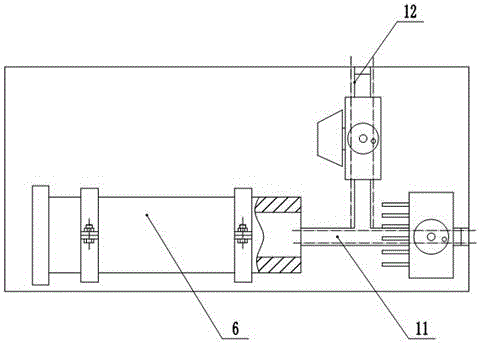

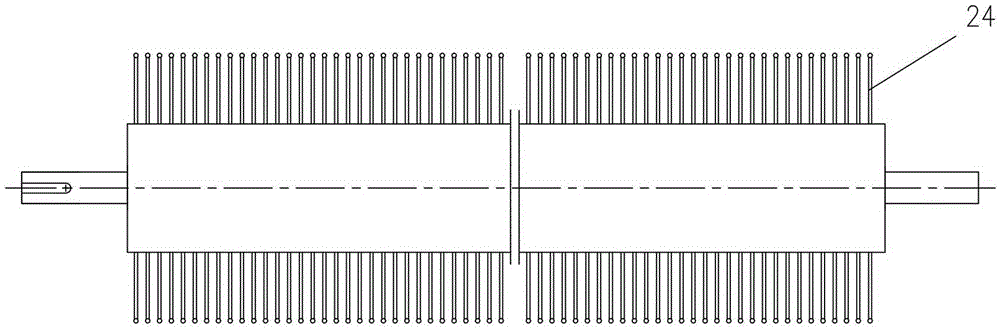

Manufacture method of bamboo plate

InactiveCN102848444AFully softenedNo crackingWood compressionWood treatment detailsProcessing costEngineering

The invention relates to a manufacture method of a bamboo plate. The manufacture method has the advantages of being simple in procedures, convenient to process and low in processing cost. The technical scheme is that the manufacture method of bamboo plates includes the following steps: (1) a bamboo is sawed into a bamboo tube with length larger than 0.3m; (2) an outer joint and an inner join of the bamboo tube are removed; (3) a longitudinally extending through groove is sawed on the wall portion of the bamboo tube; (4) the split bamboo tube is placed in a closed container to be softened for 0.5-3h at high temperature of 130-160 DEG C; and (5) the softened bamboo tube is placed in a press roller group of a flattening machine to be flattened to form the bamboo plate, wherein the press roller group comprises at least three pairs of horizontally arranged press rollers, each pair of press rollers is formed by a driving roller wheel and a driven roller wheel which are vertically correspondingly ranked, the upper driving roller wheel is driven by a power mechanism, and each pair of press rollers bears pressure exerted by a cylinder so that pressure for clamping and pressing the bamboo tube is generated between the driving roller wheel and the driven roller wheel.

Owner:ZHEJIANG TIANZHU IND & TRADE

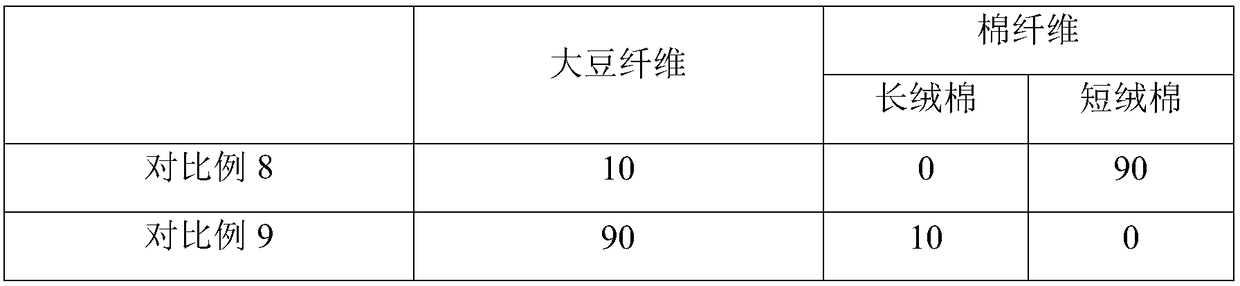

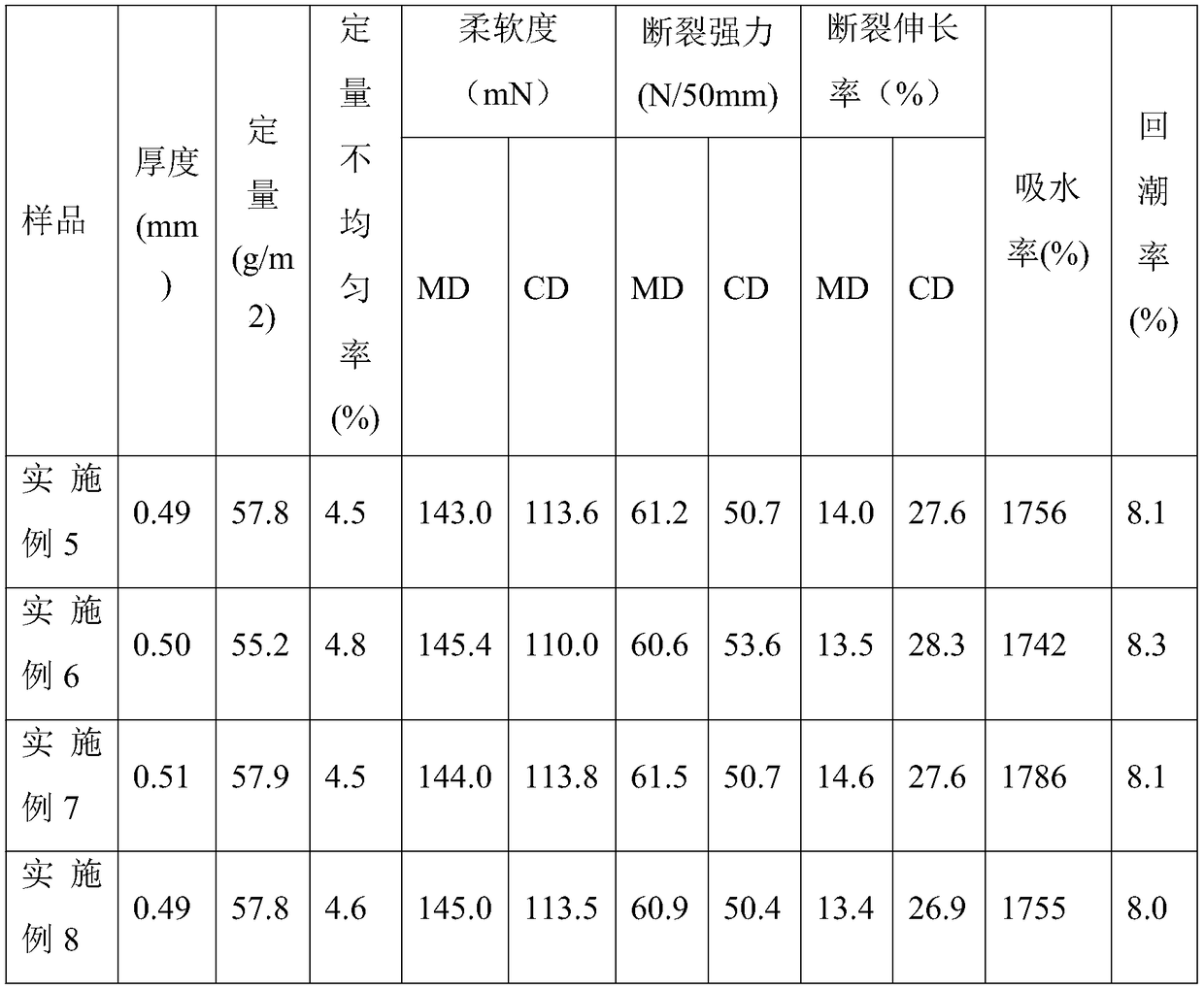

Preparation method of cotton soft towel and cotton soft towel

InactiveCN109457392AReduce static electricityImprove dispersion uniformityNon-woven fabricsVegetal fibresChemistryFiber strength

The invention discloses a preparation method of cotton soft towel and the cotton soft towel. The preparation raw materials of the cotton soft towel comprise pure cotton fiber and soybean fiber. The preparation method of the cotton soft towel and the cotton soft towel have the advantages that through scientific treatment, the technical problems that the soybean fiber and the cotton fiber are different in fiber strength, fineness and the like, and blending is difficult, the primary color of the soybean fiber is ensured after blending, the blending performance of the cotton fiber and soybean fiber is effectively improved, non-woven cloth is prepared from blend fiber, the disadvantages of the insufficient strength of the soybean fiber and poor air permeability of the cotton fiber are overcome,and the cotton soft towel prepared from the non-woven cloth has better soft and skin-friendly performance.

Owner:ZHUZHOU QIANJIN PHARMA +1

Application of efficient penetrating agent in high-yield pulp making

InactiveCN105178075AEasy to handleHigh degree of processingPretreatment with alkaline reacting compoundsPulp bleachingFiberWastewater

The invention discloses application of an efficient penetrating agent in high-yield pulp making. The application is mainly characterized in that in high-yield pulp making, the efficient penetrating agent which has alkali resistance and oxidative resistance, is easy to dissolve in water and has good emulsifying and penetrating properties is selected to accelerate penetration of pre-immersing chemical liquid and increase the treatment degree of wood chips, improve pulp grinding quality, reduce the wood chip fiber loss in pulp grinding, increase the yield of pulp grinding and improve physical strength of pulp grinding. According to the technological method, the efficient penetrating agent is pumped into an inlet of a chemical mixing tank pump through a metering pump to be mixed with sodium hydroxide, sodium silicate, chelating agents and other chemicals, the mixture is pumped to an MSD outlet expansion pup joint through the chemical mixing tank pump to be mixed with hydrogen peroxide, and then the new mixture enters an immerser to react with the wood chips. According to the quality of needed pulp, the usage amount of H2O2 and NaOH is optimized. The cost of producing the high-yield pulp is lower, the physical strength of the pulp is better, the pulp making yield is higher, and the content of COD in discharged waste water is lower.

Owner:YUEYANG FOREST & PAPER CO LTD

Fat emulsifier for feed use, preparation method and application thereof

ActiveCN103976150ALarge emulsification rangeReduce the cost of farmingAnimal feeding stuffAccessory food factorsMonoglycerideSucrose

The invention discloses a fat emulsifier for feed use. The fat emulsifier contains the following components, by weight, 200-300 parts of granulesten, 10-50 parts of sucrose ester, 10-50 parts of monoglyceride, 10-20 parts of taurine and 580-770 parts of an excipient. A preparation method of the fat emulsifier contains the following steps: mixing granulesten and monoglyceride in proportion, heating to 60 DEG C, spraying the mixture into the excipient, uniformly mixing and drying to prepare a mixture; adding components excluding granulesten, monoglyceride and the excipient into the mixture; placing the mixture obtained from the step (3) into an agitator, stirring for 1-2 hours, putting the mixture into a pulverizer for primary crushing, taking out the crushed mixture and putting the crushed mixture into a ultrafine grinder for secondary crushing so as to obtain fine particles, sieving through a 100-mesh sieve, sealing and packaging so as to obtain the fat emulsifier for feed use. The fat emulsifier can emulsify most mixed lipid and has a large emulsification range. Meanwhile, the emulsifier can be added in the most economic mode, thus remarkably reducing breeding cost.

Owner:WEIFANG KENENG BIOTECH CO LTD

Preparation method of sturgeon head seasoning

The invention discloses a preparation method of a sturgeon head seasoning. The specific steps are as follows: (1) preparation of fish head pulp; (2) enzymolysis of the fish head pulp: taking the fishhead pulp prepared in the step (1), adding papain with stirring for preliminary enzymolysis reaction, and then adding flavor enzyme for second enzymolysis reaction; (3) enzyme inactivation: carrying out enzyme inactivation after the enzymolysis is completed, and then filtering a enzymolysis product to obtain a fish head pulp filtrate; (4) maillard reaction: carrying out maillard reaction on the fish head pulp filtrate prepared by the step (3); (5) emulsification treatment: carrying out sufficient emulsification on the product of the maillard reaction in the step (4); and (6) sterilization andpackaging so as to obtain sturgeon head seasoning finished product. The preparation method of the invention is reasonable in process, simple to operate and capable of realizing industrial production easily, and has broad market prospect.

Owner:OCEAN UNIV OF CHINA

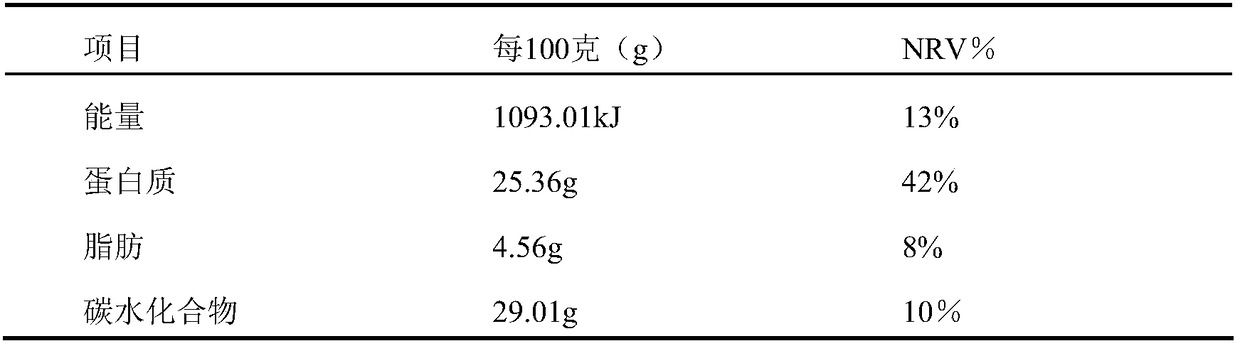

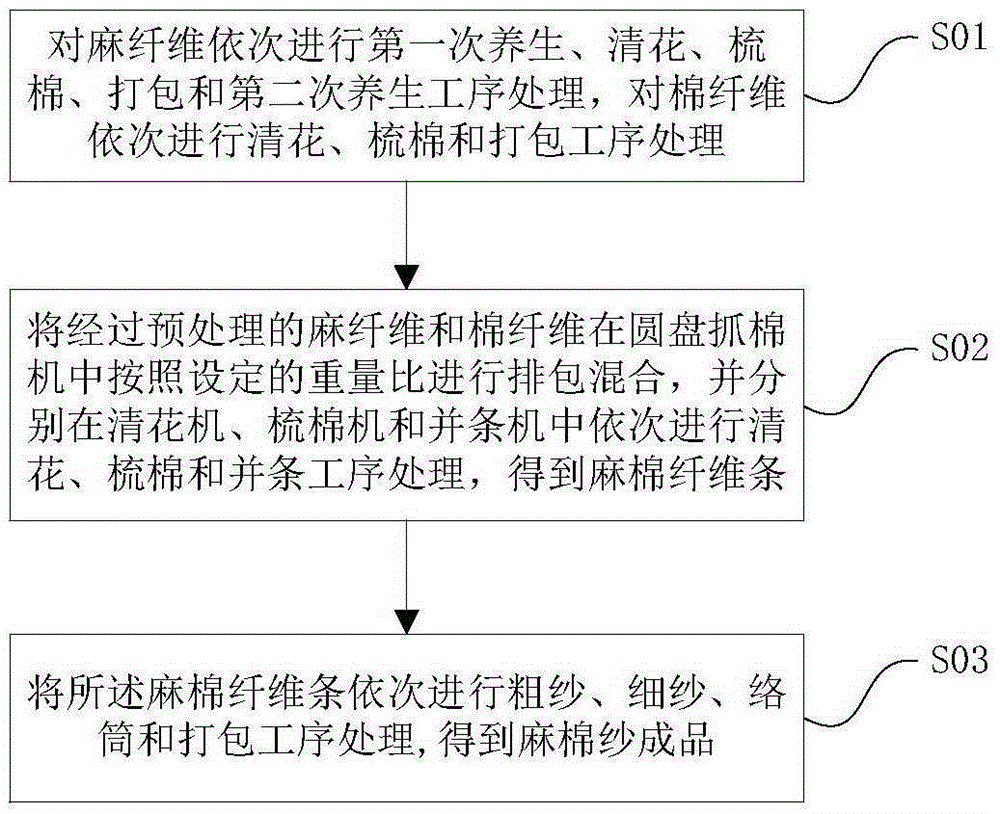

Novel manufacturing method for linen-cotton blended yarn

The invention relates to a novel manufacturing method for a linen-cotton blended yarn. The novel manufacturing method comprises raw material pretreatment, treatment before blending and treatment after bending. The raw material pretreatment comprises firstly softening a fibrilia, blowing, carding and packaging the fibrilia, secondly softening the fibrilia, and blowing, carding and packaging a cotton fiber. The treatment before blending comprises arranging and mixing packages of the fibrilia and the cotton fiber which have been pretreated respectively on a disc cotton picking according to a set weight ratio, and blowing, carding and drawing in order using a blowing machine, a carding machine and a drawing frame to obtain linen-cotton fiber strips. The treatment after bending comprises roving, spinning, winding and packing the linen-cotton fiber strips. According to the novel manufacturing method for the linen-cotton blended yarn, the fibrilia are softened twice, the spinnability of the fibrilia is improved, the work efficiency is raised, the cost of production is reduced, at the same time, the quality of the yarn is raised, the minimal brute force and the average brute force of the yarn can be increased, the uniformity of the yarn is improved, and the hairiness value, nep and other indexes are distinctly improved.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

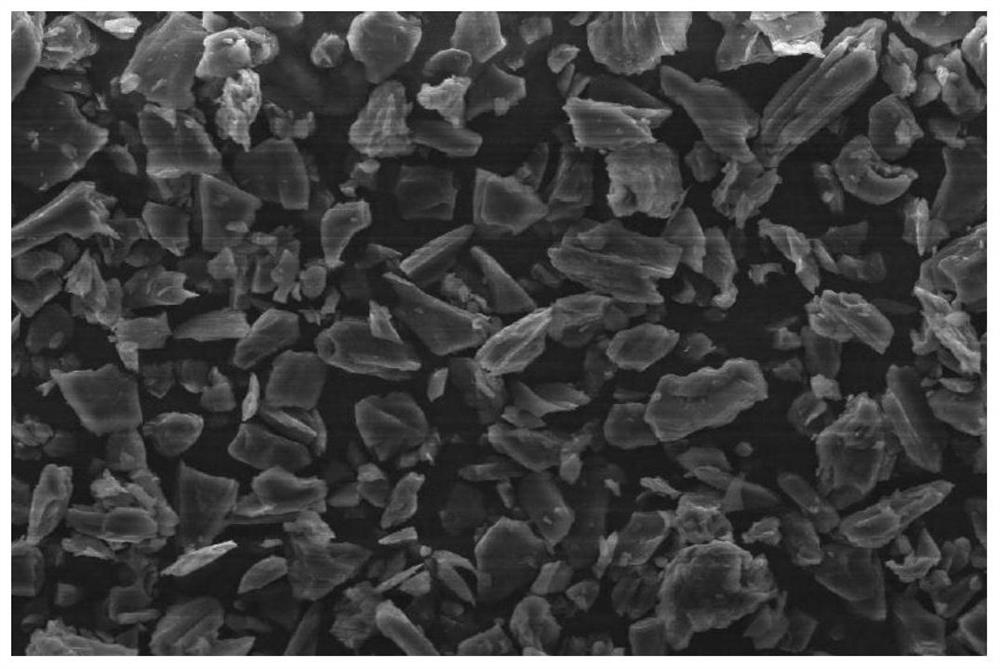

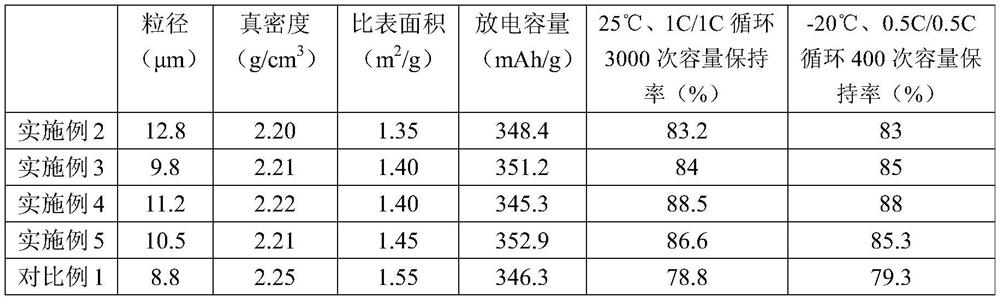

Preparation method of high-magnification quick-charging graphite negative electrode material

ActiveCN112289986AImprove defectsImprove the rate of fast charging performanceCell electrodesSecondary cellsGraphitePetroleum coke

The invention discloses a preparation method of a high-magnification quick-charging graphite negative electrode material. The method comprises the following steps: carrying out coarse crushing and fine grinding on one or more of needle coke, petroleum coke and pitch coke, carrying out spheroidizing shaping treatment, mixing with a first carbon source, heating to carry out surface coating, and carrying out high-temperature carbonization; then carrying out high-temperature graphitization treatment to obtain an artificial graphite powder; and mixing the obtained artificial graphite powder with asecond carbon source, heating for surface coating, and carbonizing at a high temperature to obtain the high-magnification quick-charging graphite negative electrode material. The graphite negative electrode material prepared by the invention has the advantages of a high charge-discharge rate, a large discharge gram capacity and good cycle performance, and a battery prepared from the graphite negative electrode material has excellent comprehensive performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Plastic pipe port flanging process

The invention relates to the technical field of pipe machining, and discloses a plastic pipe port flanging process. The plastic pipe port flanging process comprises the technological flows of: (S1) clamping of a plastic pipe; (S2) arrangement of the heating device; (S3) arrangement of the flanging device; (S4) heating of a pipe port; (S5) flanging molding; and (S6) cooling and surface treatment. Compared with the prior art, the plastic pipe port flanging process changes a heating mode to heating from internal of plastic, so that the heating becomes more uniform, the uniform heating of the inner wall and the outer wall of the pipe port is realized, the softening effect is better, and the breakage of the pipe port in reflanging is prevented.

Owner:ERA PIPELINE (CHONGQING) CO LTD

Washing preshrinking setting machine

ActiveCN105350276AImprove preshrinking effectSimple processingHeating/cooling textile fabricsDry-cleaning apparatus for textilesMegasonic cleaningWater tanks

The invention discloses a washing preshrinking setting machine. The washing preshrinking setting machine comprises a washing assembly and a drying assembly; the washing assembly comprises a scrubbing section and a clear water spraying section which are successively arranged according to procedures; the scrubbing section is provided with a scrubbing water tank and a fabric guide roller group; the fabric guide roller group at least comprises a desizing fabric guide roller, a gathering fabric guide roller and a flattening fabric guide roller, wherein the desizing fabric guide roller comprises a fabric guide roller body and desizing hairbrushes arranged on the circumferential surfaces of the fabric guide roller body, the gathering fabric guide roller and the flattening fabric guide roller both comprise a fabric guide roller body and two sections of screw threads encircling the fabric guide roller body, and the spiral directions of the two sections of screw threads are opposite; the scrubbing water tank is divided into a desizing zone and an ultrasonic cleaning zone according to procedures; the ultrasonic cleaning zone is provided with an ultrasonic cleaning apparatus; the clear water spraying section is provided with a water holding tank and a spray head assembly; the spray head assembly is used for flushing a fabric; and the water holding tank is used for water falling down during flushing of the fabric and is communicated with the scrubbing water tank. The washing preshrinking setting machine can simplify a preshrinking process for a fabric and reduces emission.

Owner:YILI (ZHAOQING) INTELLIGENT TECH CO LTD

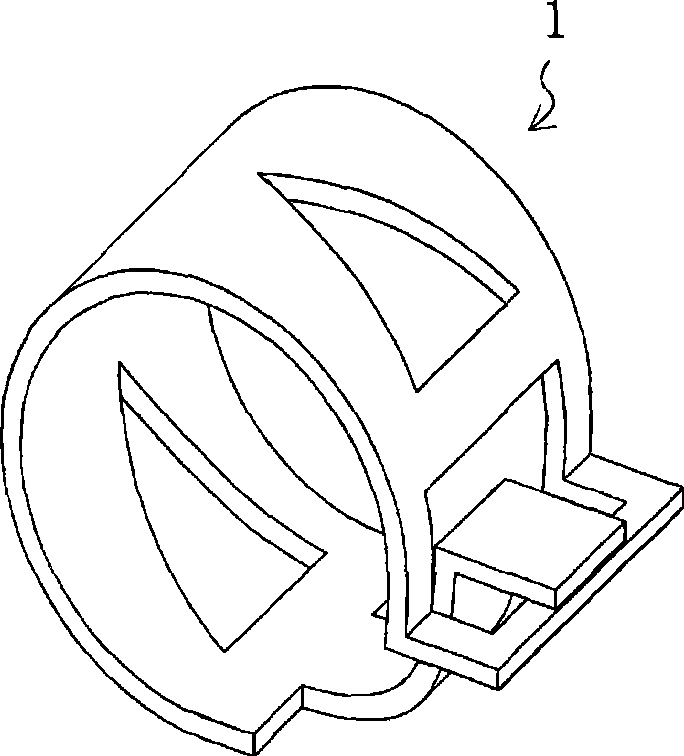

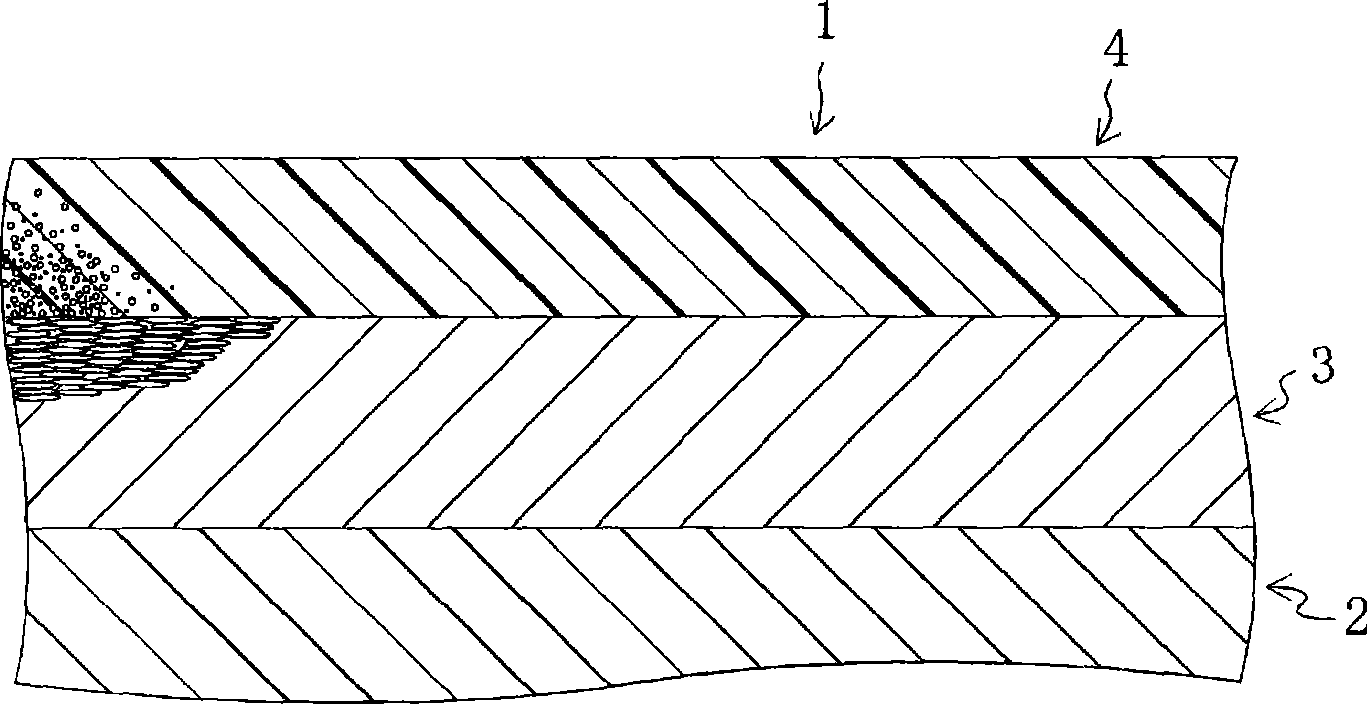

Metallic member being subjected to rust-preventive treatment and coating composition for the same

ActiveCN101381875AFully softenedPrevent peelingAnti-corrosive paintsEpoxy resin coatingsRubber materialOrganic solvent

The invention provides a metallic member subjected to rust-preventive treatment, which can thin a coat, can inhibit uncovering of the coat, and has excellent rust-preventive performance. The metallic member (1) subjected to rust-preventive treatment consists of a metallic member (2) with stated shape, a zinc composite protective film (3) formed on the upper layer of the metallic member (2), and a coat (4) coated on the upper layer of the zinc composite protective film (3) and formed by drying; a coating material as the material of the coat (4) comprises a coating substrate, a filler pigment (40) and a rust-preventive pigment (42); wherein the coating substrate comprises an organic solvent and a rubber material (41) dissolved in the organic solvent, and the filler pigment (40) and the rust-preventive pigment (42) keep scattered in the coating substrate.

Owner:TOGO SEISAKUSYO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com