Patents

Literature

232results about How to "Reduce static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne acrylate resin emulsion and synthetic method and application thereof

InactiveCN101565484AImprove performanceGood film formingFibre treatmentEster polymer adhesivesIsooctyl acrylateEmulsion

The invention pertains to the technical field of polymer materials and particularly relates to a waterborne resin emulsion for car cleaning cloth or common cleaning cloth and a textile finishing adhesive agent, a synthetic method and application of the waterborne resin emulsion. The resin emulsion consists of a waterborne resin polymer, an emulsifier, an evocating agent, a pH value modulator and water; the waterborne resin polymer is obtained by polymerization of 3-5 monomers such as butyl acrylate, ethyl hexyl acrylate and methyl methacrylate and the like. The synthesis comprises two steps of monomer pre-emulsion and polymerization by the evocating agent. The product of the invention has stable performance and good film formation performance, as well as soft hand feeling, good moisture permeability, long-term moisture and environment protection by absorbing fine dusts when used as cleaning cloth, and when used as a textile adhesive agent, the product can not only realize the characteristics and requirements above, but also decrease electrostatic interaction of the textile, thus having good and wide application in the textile field.

Owner:JILIN UNIV

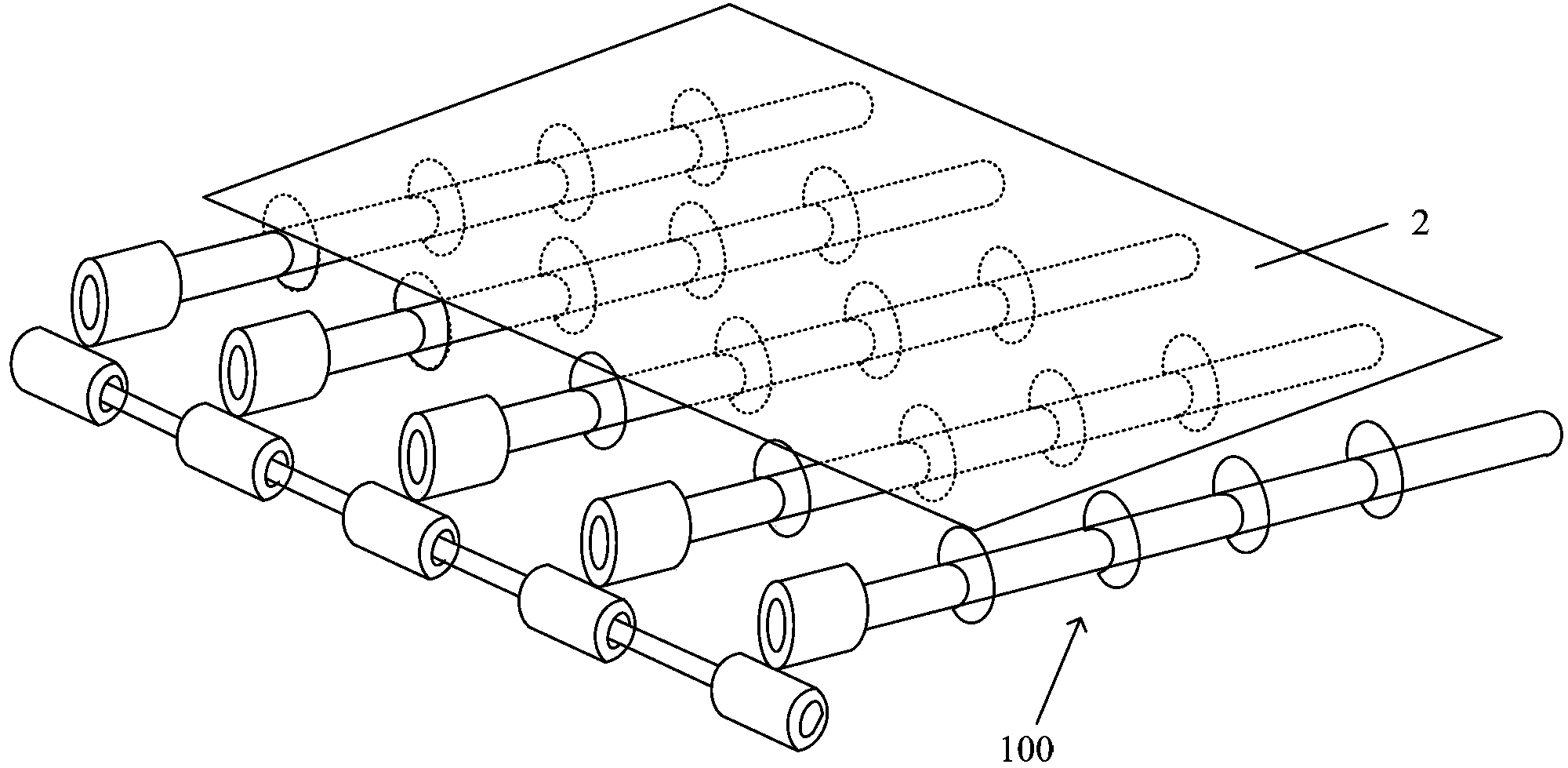

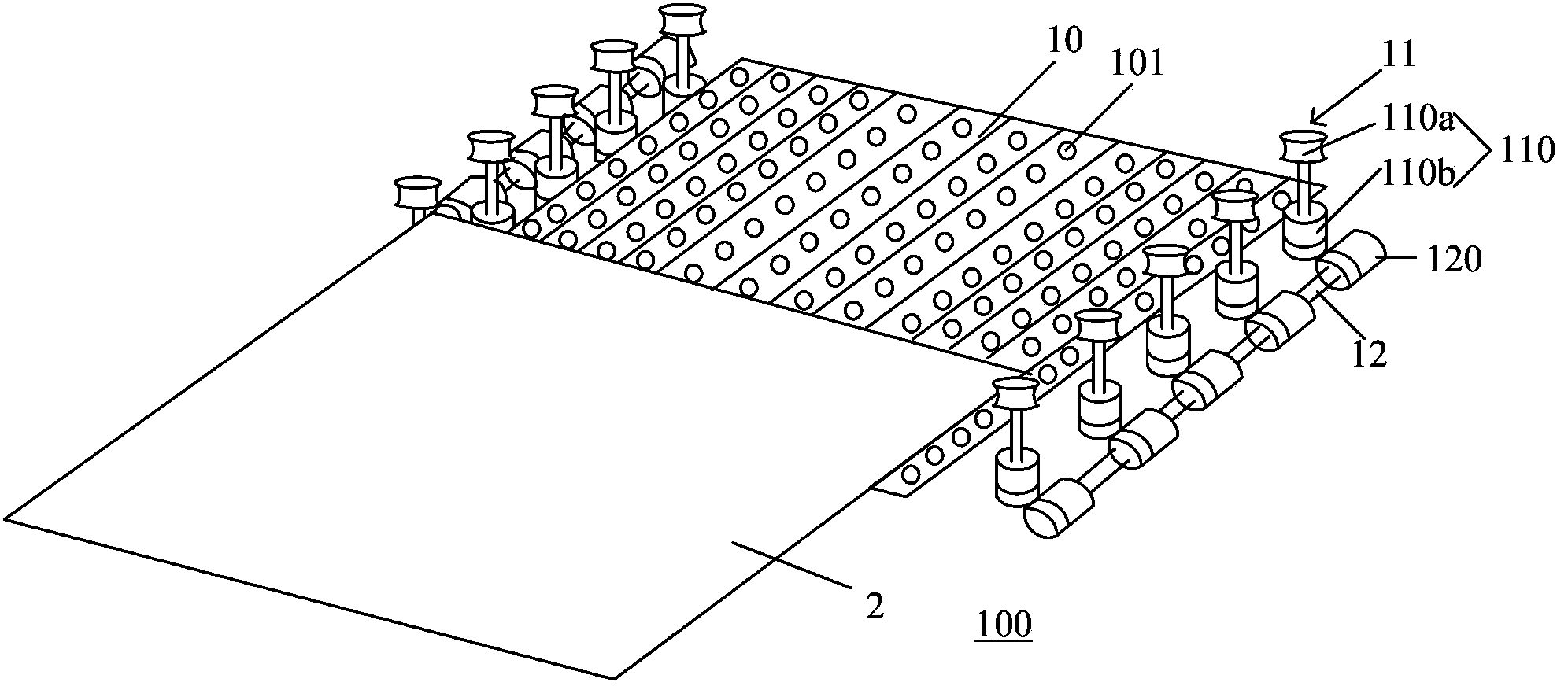

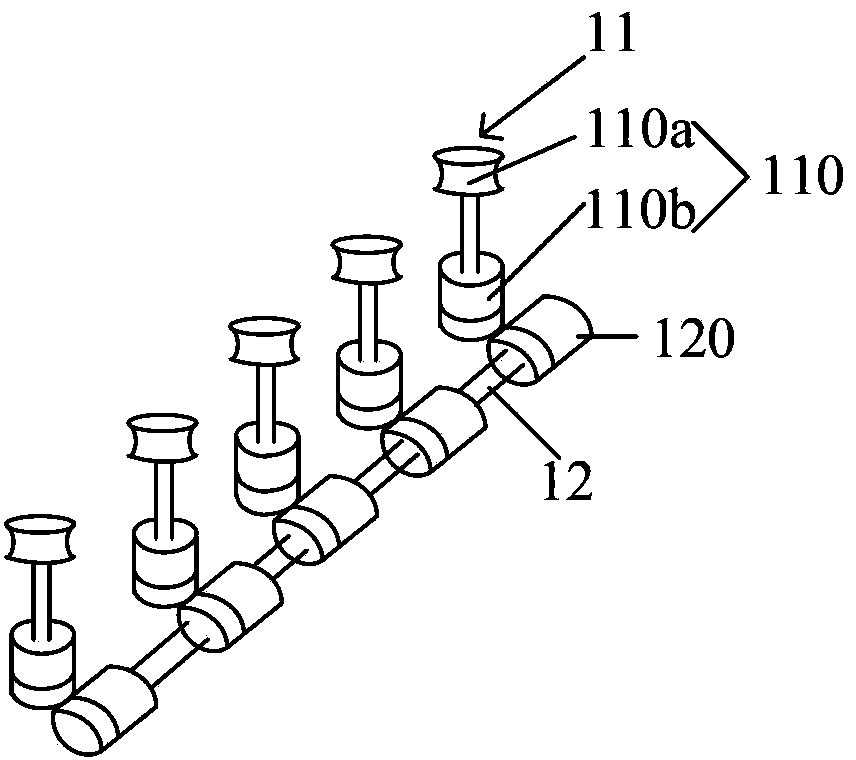

Air floating type guide wheel transmission device for liquid crystal panel

ActiveCN103381965AImprove yieldIncrease production capacitySemiconductor/solid-state device manufacturingCharge manipulationLiquid-crystal displayEngineering

The invention provides an air floating type guide wheel transmission device for a liquid crystal panel, which is used for guiding and transmitting the liquid crystal panel. The transmission device comprises an air floating type supporting platform, two guide wheel groups and a magnetic force wheel driving device, wherein a plurality of air holes are formed in the air floating type supporting platform; the two guide wheel groups are parallelly arranged on two sides of the air floating type supporting platform; the magnetic force wheel driving device is connected with guide wheels, and the guide wheel groups rotate under the driving of the magnetic force wheel driving device through rolling; air is blown through the air holes in the air floating type supporting platform, and the guide wheel groups are used for guiding and limiting the two sides of the liquid crystal panel, so as to ensure that the liquid crystal panel is transmitted in the rotation direction of the guide wheel groups.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Multipurpose magnetic couplings

InactiveUS20130048827A1Reduce static electricityPrevent noiseStampsStands/trestlesMagnetDrinking straw

The present invention includes a unique magnetic coupling that can be used as a drink identification system as well as a myriad of other useful purposes. In one embodiment, two magnets are connected by a connector. Each of the magnets have at least one surface with an opposite polarity from the other magnet to induce a magnetic attraction. When the magnets are close in proximity, they come together due to the polarity, and effectively produce a loop. The magnets can be attached to the rim of a cup. Decorative charms attached to a small ring or loop can be put onto the connector. Alternatively, the decorative charm can have a magnet attached to it. The charm can then be magnetically attached to the outer magnet of the coupling. A monogram or name tag can be substituted in lieu of a decorative charm. The magnetic coupling can be used for other purposes, such as securing objects in a drink (a decorative umbrella or drinking straw).

Owner:GLOBAL CONNECT TECH

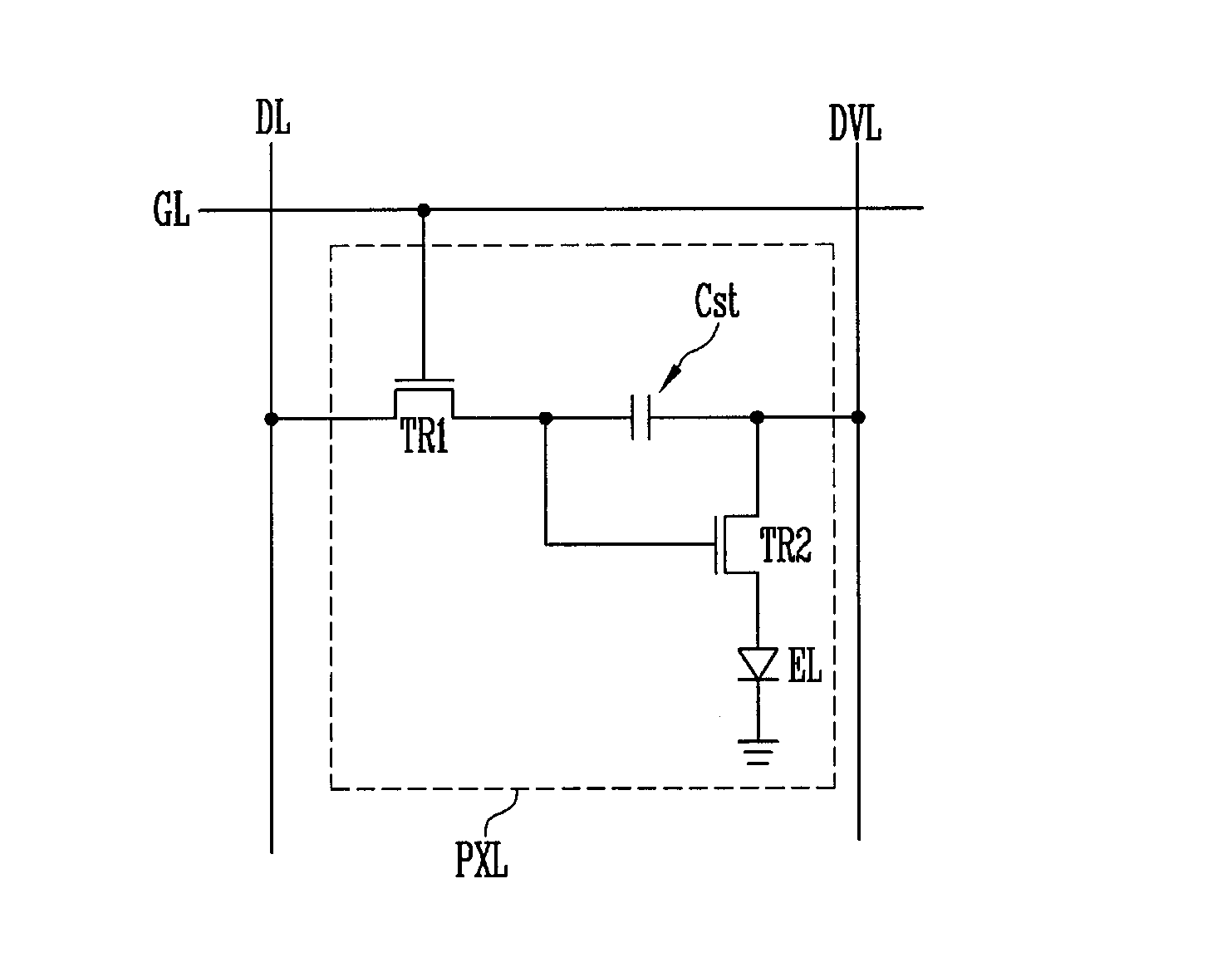

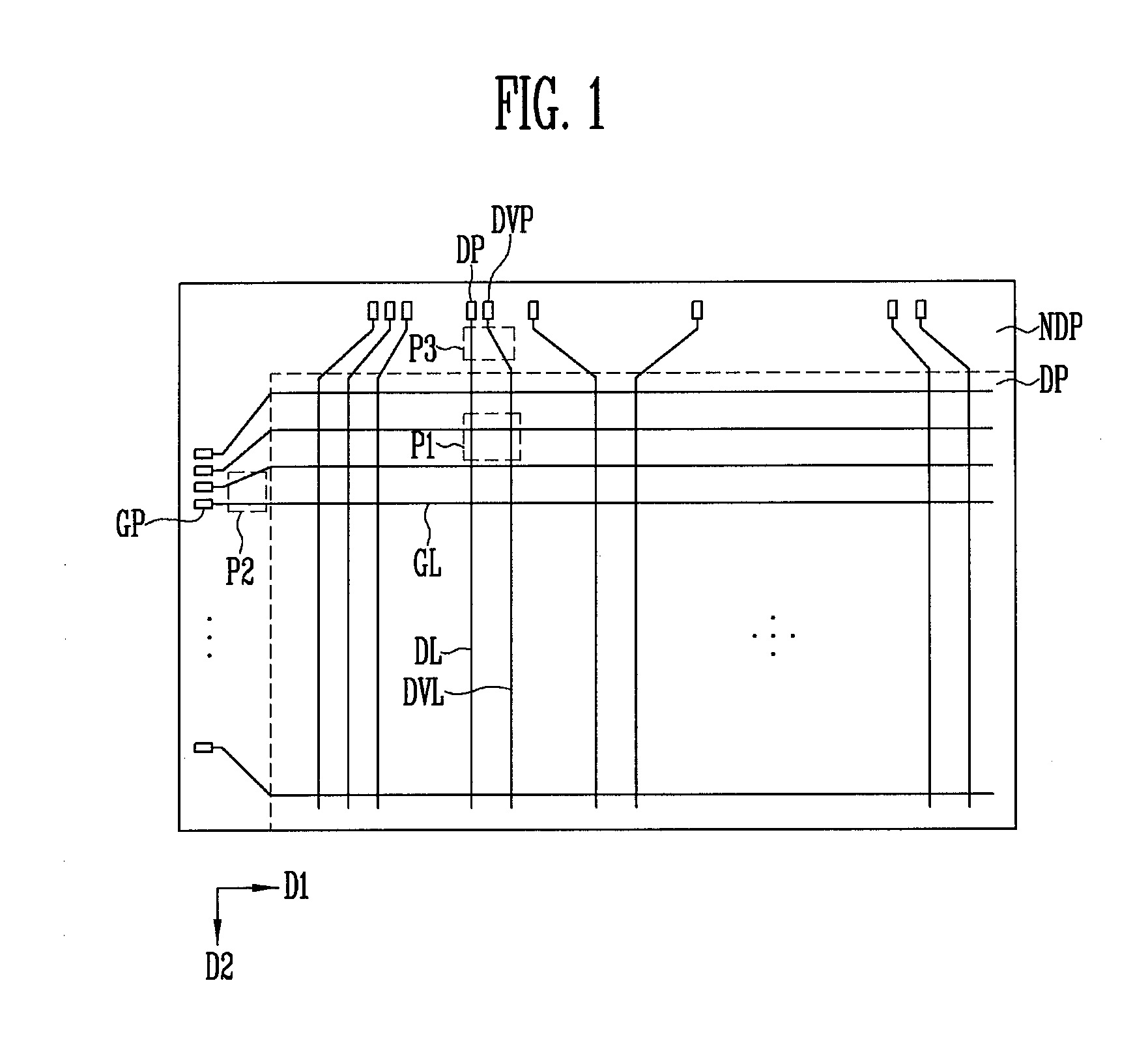

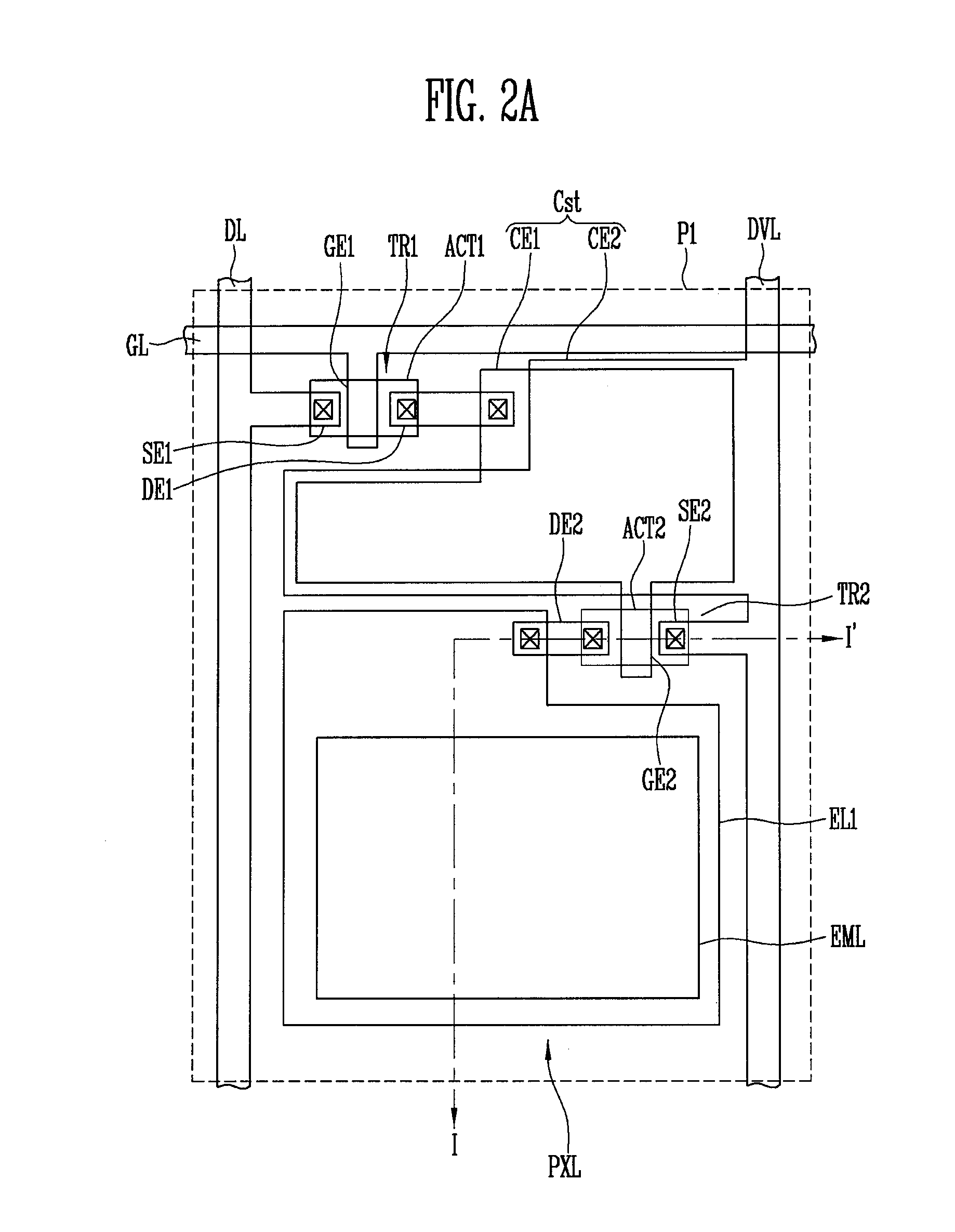

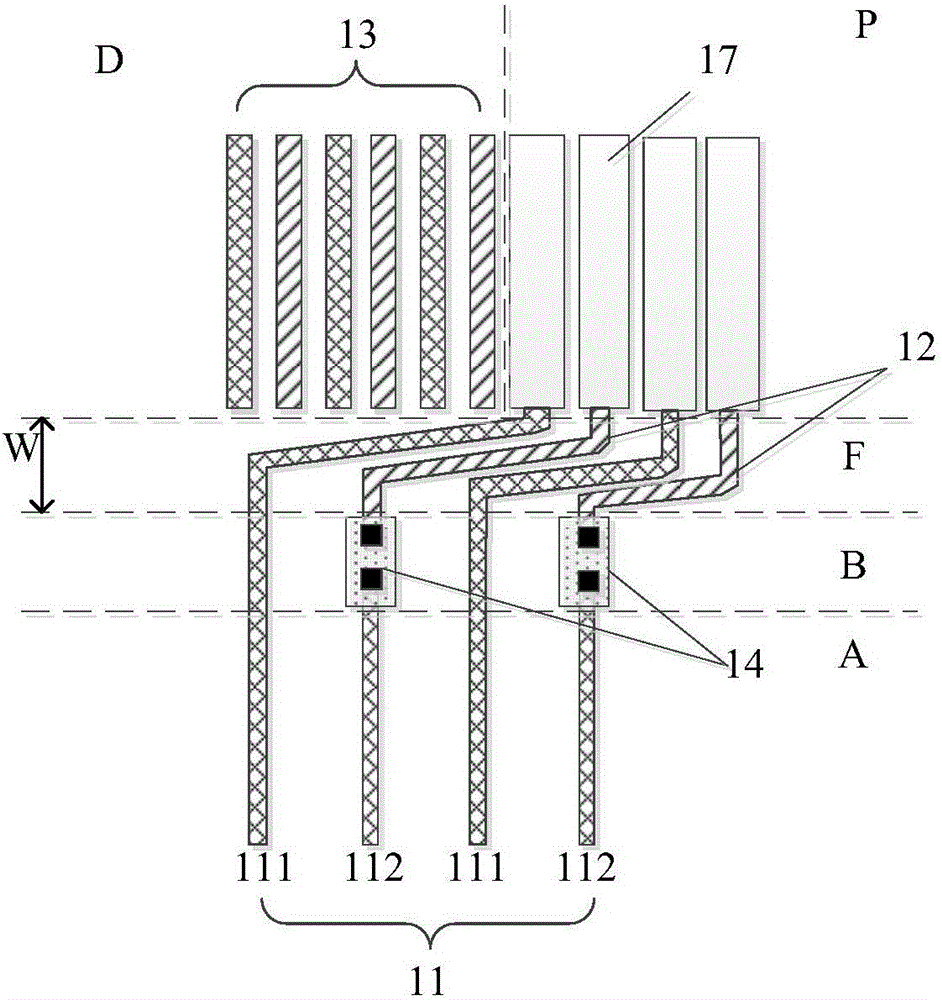

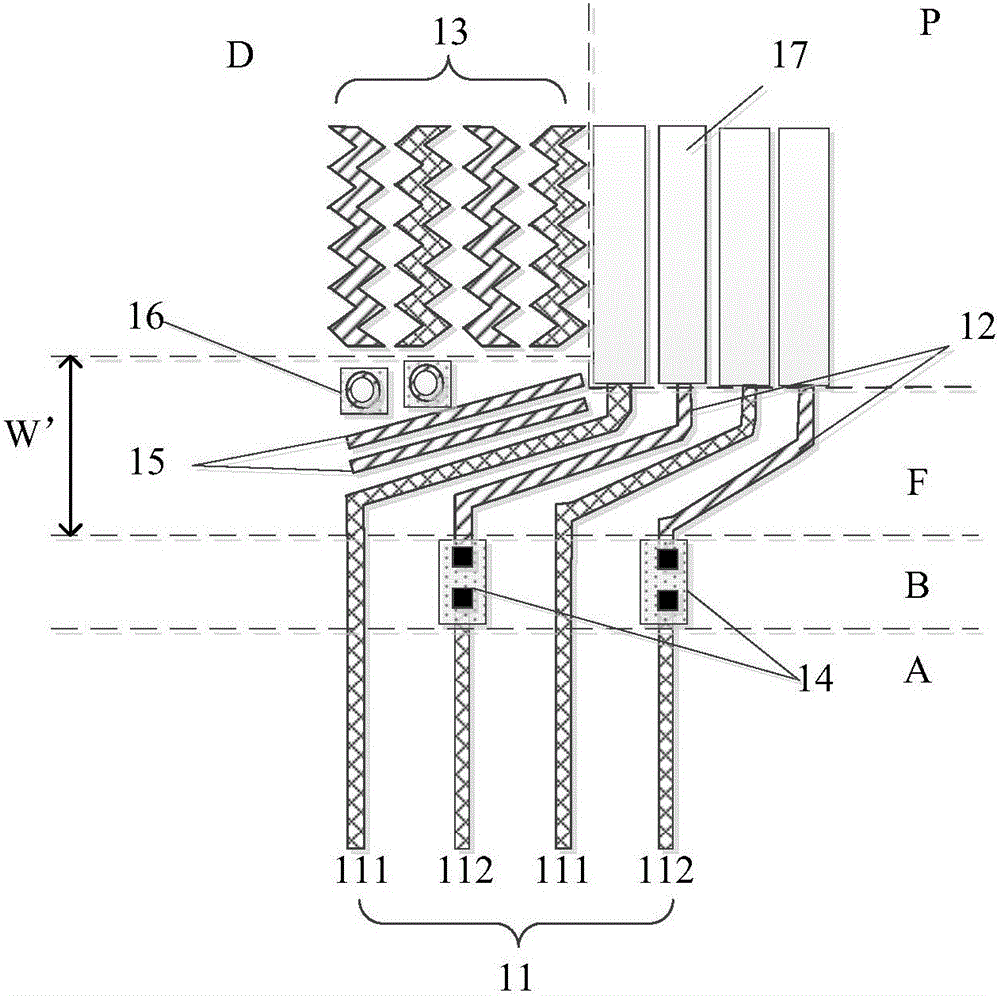

Display device and fabrication method thereof

ActiveUS20160358938A1Reduce static electricityAvoid defectsSolid-state devicesSemiconductor devicesDisplay deviceEngineering

A display device having a display area and a non-display area includes a substrate, a pixel at the display area, a signal line on the substrate and electrically connected to the pixel, and a static electricity prevention capacitor at the non-display area and including a lower pattern having a first region and a second region that have different electrical conductivities from each other, an insulating layer on the lower pattern, and an upper pattern including a portion of the signal line and overlapping the first region of the lower pattern in a plan view.

Owner:SAMSUNG DISPLAY CO LTD

Moisture-absorbing quick-drying yarn as well as production and manufacturing method thereof

The invention discloses a moisture-absorbing quick-drying yarn as well as a production and manufacturing method thereof. The yarn is manufactured by the blending of 65 to 80% of anti-pilling hollow highcount-type wool fiber and 20 to 35% of combed cotton or viscose in percentage by weight. By combining the high moisture thermal insulation of the Porel fiber and the hydrophilic moisture absorption of the cotton fiber and the viscose, the yarn of the invention can absorb the sweat completely and release the sweat to the air quickly to realize the dry and comfortable skin. The raw materials of the yarn are easy to obtain, the cost is low and the manufacture is convenient.

Owner:JIANGSU DASHENG GROUP

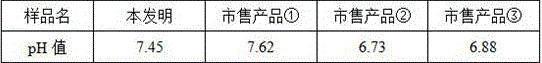

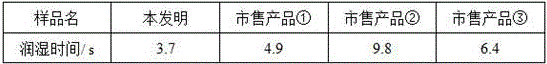

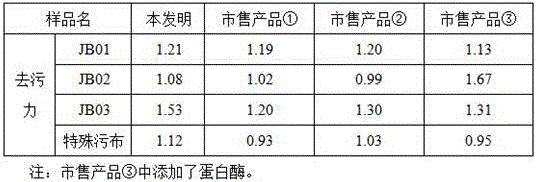

Sports wear detergent and preparation method thereof

InactiveCN106833932AEasy to decontaminateImprove wettabilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPolyesterLiquid product

The invention relates to a sports wear detergent and a preparation method thereof. The sports wear detergent is prepared from an anionic surfactant, a nonionic surfactant, a safe solvent, a dirt removing additive, a viscosity regulator, a chelating agent, a bacteriostatic agent, a deodorant, a conventional additive and deionized water. The sports wear detergent has the advantages that the sports wear detergent is a neutral moderate liquid product, the safe raw materials are adopted, the toxicity and irritation are avoided, and the green and environment-friendly effects are realized; multiple types of dirt, such as dust, grease, sebum and sweat stain, can be effectively removed, and the dirt on polyester and polyurethane fabrics can be washed away by a special hydrophilic modified polymer in a pertinent way; whitening and smoothing components are not contained, and the damage to a functional coating of the sports wear is avoided; the effects of inhibiting bacteria and deodorizing are realized, and health and cool cloth washing experience is provided for consumers.

Owner:于文 +1

Anti-static corrugated carton

InactiveCN105542593AHigh glossHigh transparencyEpoxy resin coatingsElectrically-conductive paintsEpoxyFiber

The invention discloses an anti-static corrugated carton which comprises a box body made from a corrugated board, wherein the surface of the corrugated board is coated with a layer of anti-static coating with thickness of 1-3mm; and the anti-static coating is prepared from the following raw materials in parts by weight: 100 parts of waterborne acrylic resin, 35-45 parts of epoxy resin, 20-30 parts of alkyd resin, 1-5 parts of carbon nanotube, 3-9 parts of carbon fiber, 10-15 parts of nano calcium carbonate, 1-2 parts of conductive carbon black, 2-8 parts of conductive graphite, 1-2 parts of antifoaming agent, 0.8-1.5 parts of thickening agent, 0.1-0.3 part of modifier, 0.2-0.5 part of dispersing agent, 1-3 parts of silane coupling agent and 50-80 parts of water. According to the invention, since the anti-static coating is added with the carbon nanotube and carbon fiber, the corrugated carton has high strength, the surface is delicate and smooth, the static effect is greatly reduced, thus the surface of the corrugated carton does not adsorb dust, the scratch caused by friction is reduced, and the printing speed and printing effect are improved; and moreover, due to the addition of nano calcium carbonate, the coating has good gloss, transparency and stability.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

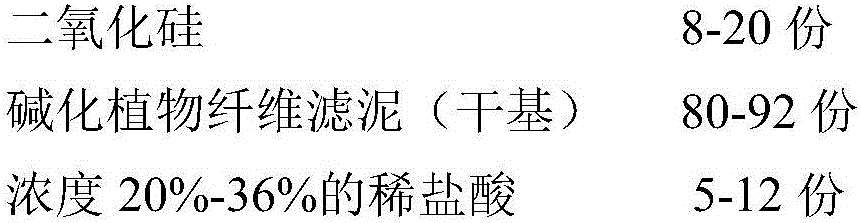

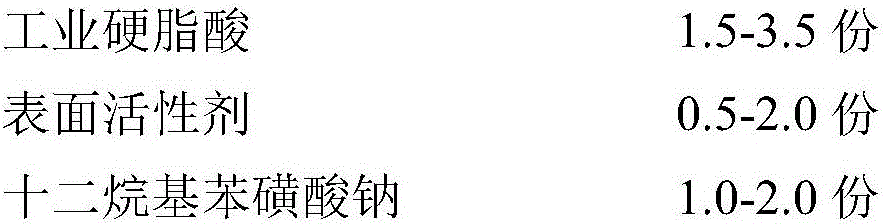

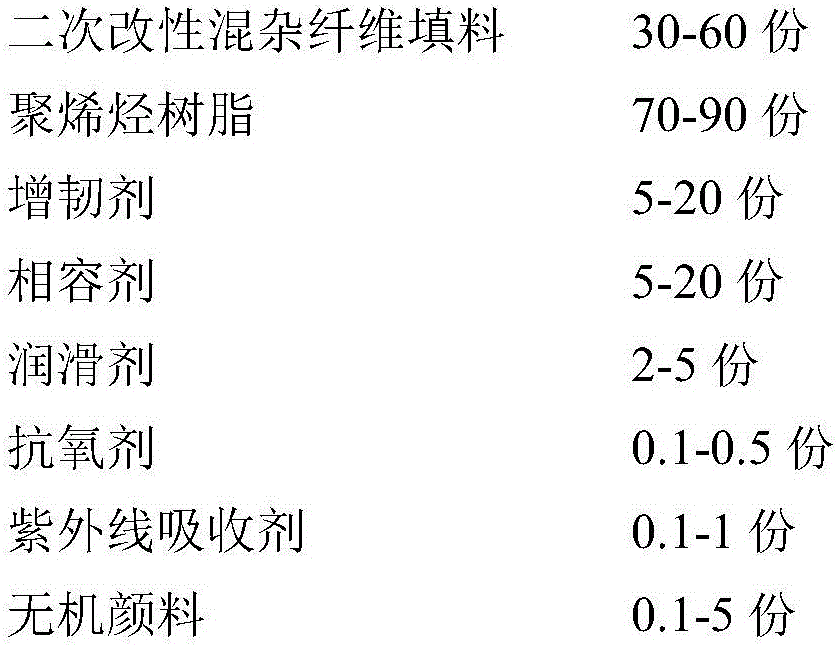

Degradable lightweight polyolefin composite for injection molding and preparation method of composite

The invention provides a degradable lightweight polyolefin composite for injection molding and a preparation method of the composite. The polyolefin composite is prepared from secondarily modified fiber mixed filler, polyolefin resin, a toughening agent, a compatilizer, a lubricant and the like through blending and extrusion granulation by a tri-screw extruders which are arranged triangularly and meshed in the same direction, wherein the modified fiber mixed filler is prepared as follows: a natural plant fiber material such as rice husks, chaff and the like are mixed with a nano-silica colloidal solution, a dispersant and a surfactant are added and a blending reaction, drying and other technologies processes are performed; then the modified mixed fiber filler is subjected to secondary surface coupling hydrophobic treatment and blended with polyolefin resin, the toughening agent, the compatilizer and the lubricant. The polyolefin composite has degradability specific to the natural plant fiber filler, has lower density than inorganic mineral filler and has excellent thermoplastic processing characteristics and mechanical properties in the injection molding process.

Owner:水发信达(山东)再生资源科技有限公司

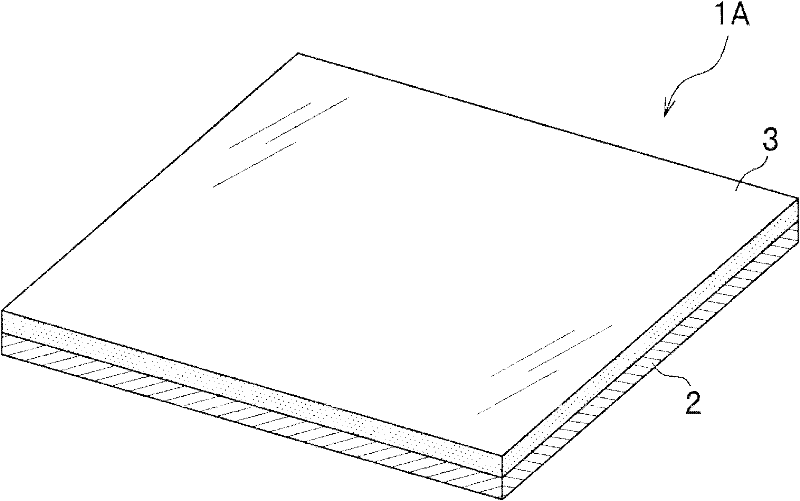

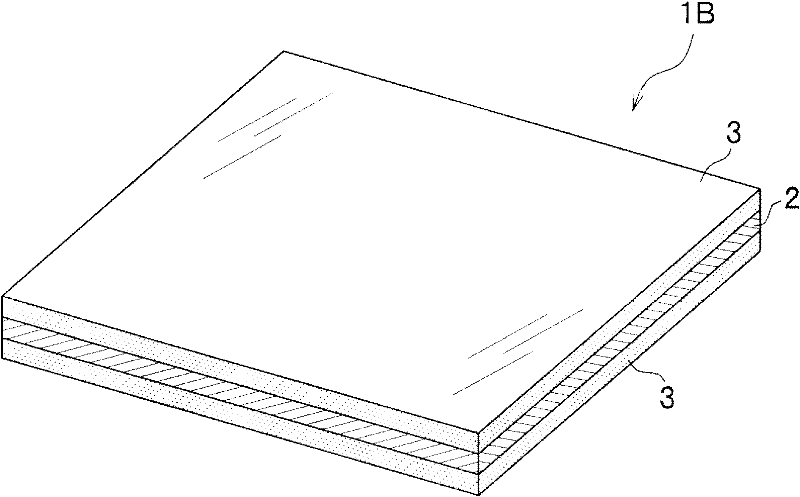

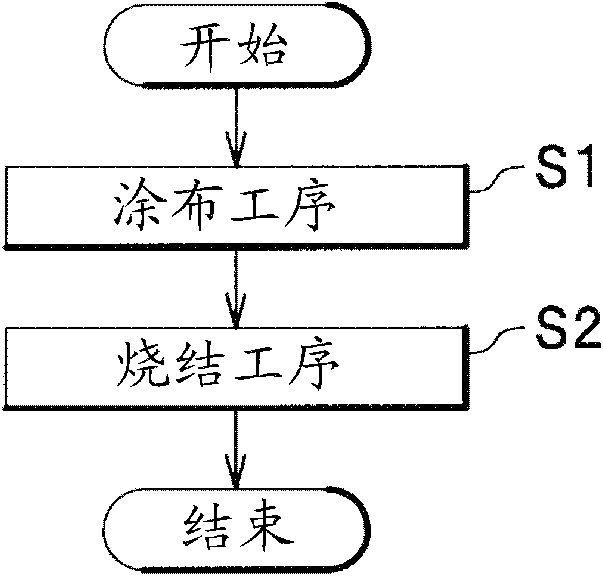

Demoulding material for resin matrix substrate and method for producing the same

InactiveCN102476484AImprove productivityReduce static electricitySynthetic resin layered productsSpecial surfacesAluminium foilResin matrix

The invention provides a demoulding material for resin matrix substrate and a method for making the same. When used for manufacturing the resin matrix substrate, the demoulding material is easier to be peeled off from the resin matrix substrate and has excellent stripping performance. The demoulding material for resin matrix substrate of the invention is used for producing the resin matrix substrate. The demoulding material is characterized in that: the demoulding material (1A) comprises an aluminium foil (2) and a resin film (3), with the resin film (3) formed upon one surface or double surfaces of the aluminum foil and composed of an epoxy series resin, a melamine series resin, and a silicone. The bonding strength of the resin film (3) to the resin matrix substrate is 1 to 200g / cm.

Owner:SUN ALUMINUM CORP

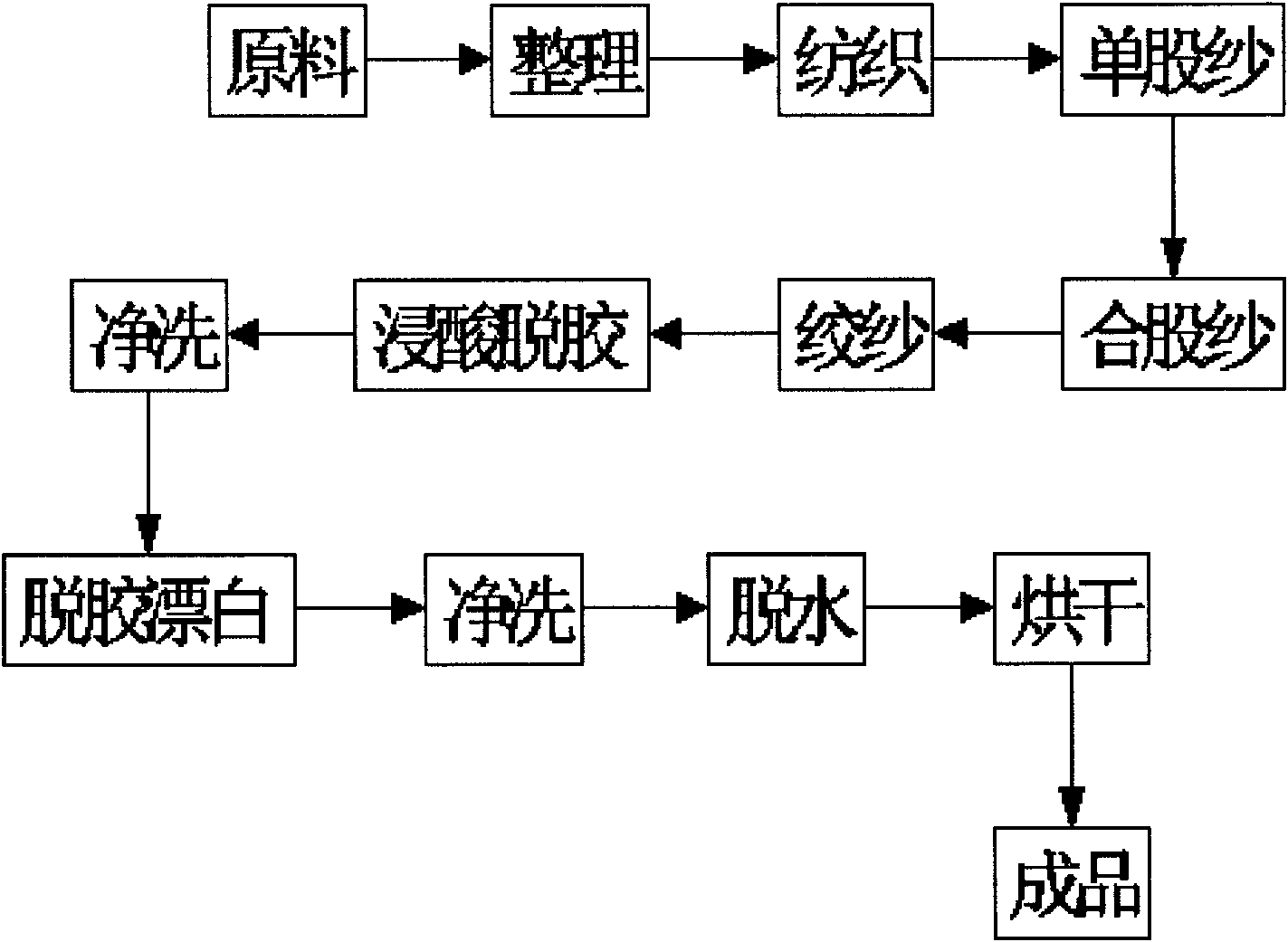

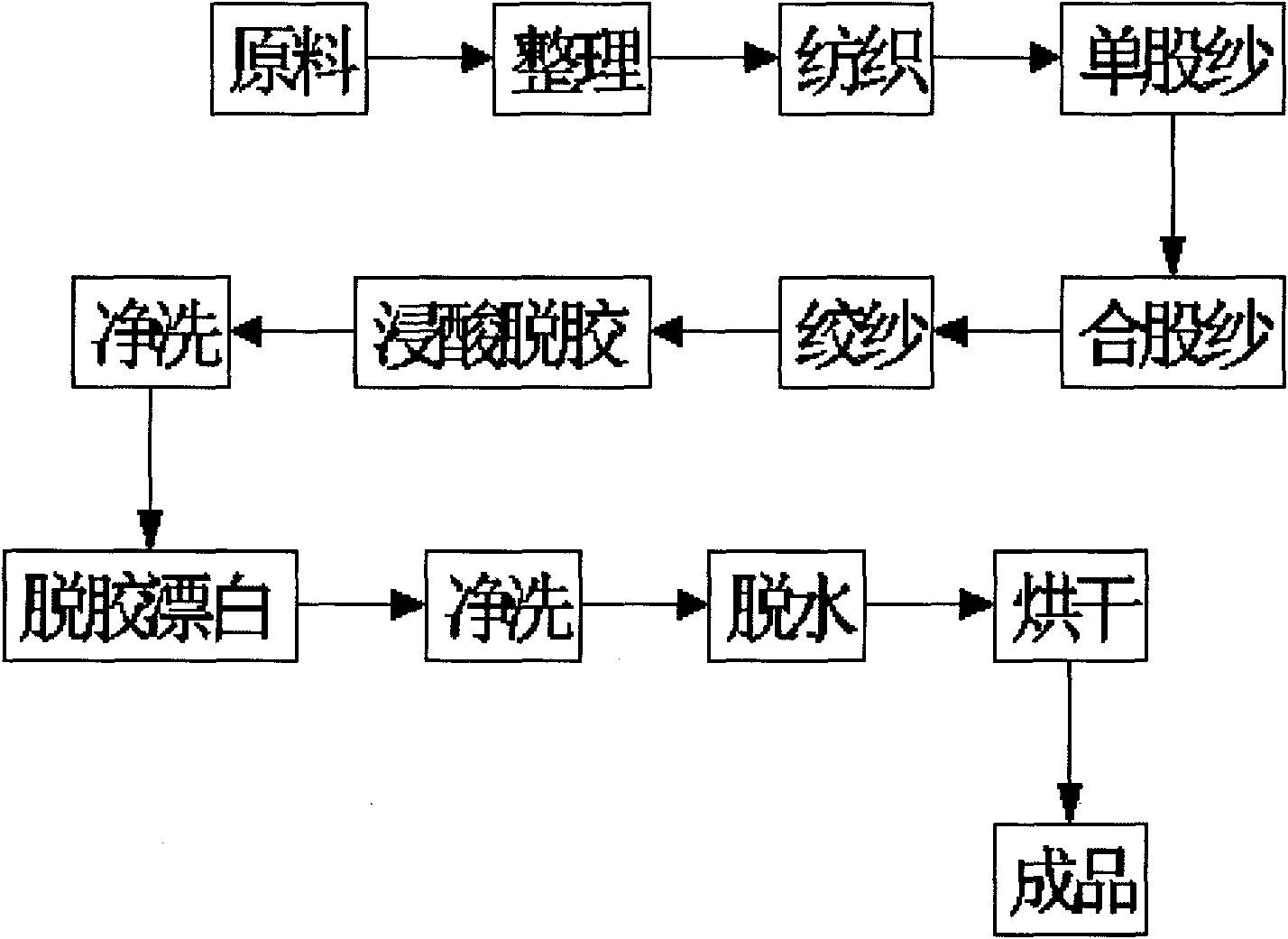

Hemp fibre filter wire and preparation method thereof

InactiveCN101884859AUnique anti-mold and bactericidal functionGood inhibition effectFiltration separationVegetable materialChemical industryYarn

The invention relates to a filter material for water treatment, in particular discloses a hemp fibre filter wire and a preparation method thereof. The hemp fibre filter wire is characterized by being prepared by using hemp fibres as raw materials, spinning the hemp fibres into yarns through hemp spinning equipment and then degumming, bleaching, drying and forming. The invention is mainly used for the purification and the filtering of various liquids; a wire-wound filter core prepared by the hemp fibre filter wire is used for the precise filtering of the liquids in a petroleum industry, a chemical industry, an electron industry, a pharmaceuticals industry, a food industry, a domestic water industry, and the like; and in addition, the invention can bring new vitality for the water treatment industry due to excellent performance and complete green environmentally-friendly quality.

Owner:郭淼

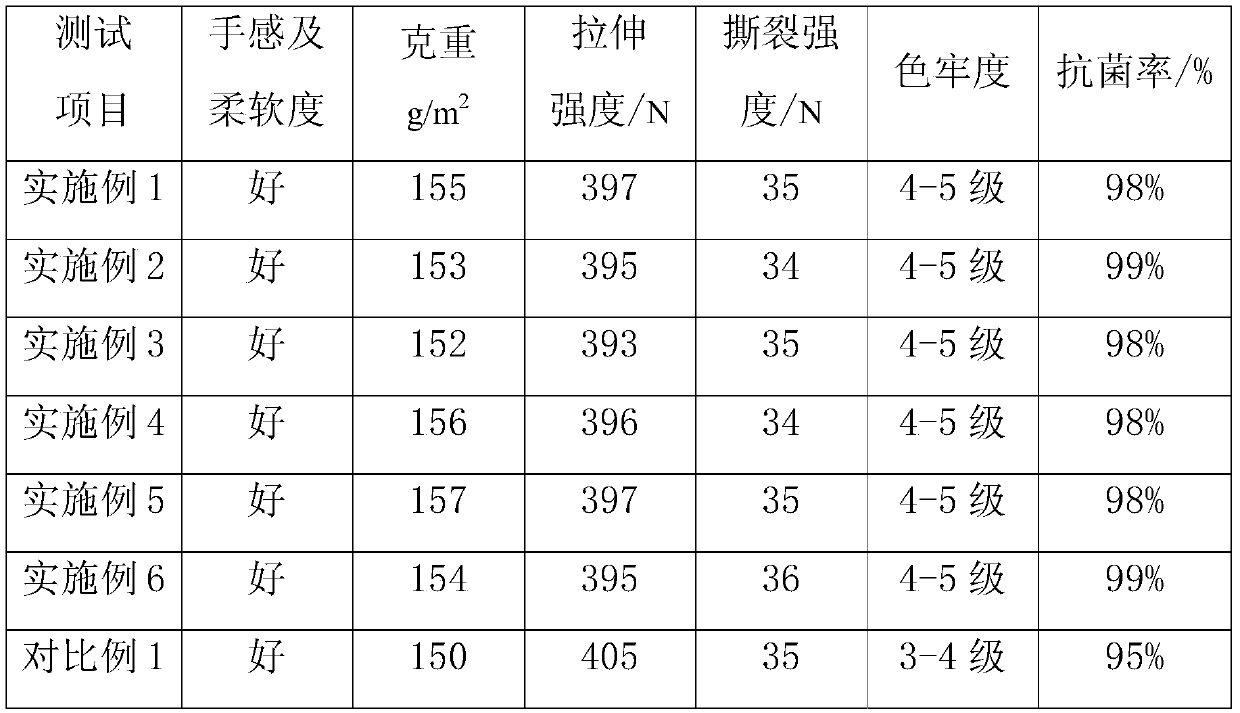

Antibacterial jeans-imitation fabric

InactiveCN109943953AImprove antistatic performanceReduce static electricityConjugated cellulose/protein artificial filamentsWoven fabricsOrganosiliconBamboo charcoal

The invention discloses an antibacterial jeans-imitation fabric. The fabric comprises, by weight, 200-320 parts of a mixed cellulose fiber, 50-80 parts of a bamboo carbon fiber, 60-90 parts of terylene, 5-10 parts of spandex, 35-60 parts of a conductive fiber, 25-35 parts of a copper ammonia fiber and 10-15 parts of an organosilicon quaternary ammonium salt antibacterial agent. The mixed cellulosefiber is formed by blending cotton and tencel with the mass ratio of 1:(1-2), a gray fabric is formed through the processes such as mixing of spinning color master batch and a fiber stock solution, high-temperature fusion extrusion spinning and fabric weaving, the color fastness of the fabric is improved, and through an antibacterial finishing process, the antibacterial performance of the fabricis further improved. The antibacterial jeans-imitation fabric has the advantages of being comfortable, soft, capable of achieving moisture absorption and air permeation, efficient and resistant to bacteria.

Owner:南通苏美纺织科技有限公司

Four sides elasticity chamois flannel

InactiveCN101191273AEasy to stretchEasy to replyMonocomponent polyurethanes artificial filamentWoven fabricsFiberExtensibility

The invention relates to a neoprene suede nap and belongs to the textile fabric technical field. The invention is mainly characterized in that: warp threads are wrapped yarns taking sea-island filament as urethane elastic fiber core yarns, and the sea-island filament is made to become elastic sea-island filament; weft yarns are wrapped yarns taking PTT polyester as urethane elastic fiber core yarns, thereby the PTT is made to have good tension and restoring force and advanced performances like softness, fluffiness, easy dyeing, easy washing and so on are fully displayed; because a little urethane elastic fiber is arranged inside the PTT, resilience of the PTT is strengthened. The invention utilizes stain resistance better than chinlon fiber, antistatic property better than nylon, fluffiness, resilience, chromaticity, good stain removal and antifouling properties, easy dyeing, soft hand feeling, abundance in elasticity, and extensibility same as urethane elastic fiber of the PTT fiber to prepare the suede nap through coating according to mixture ratio; advantages of the two fibers are given full play; due to addition of the PTT fiber, the cost of raw materials and processing costs like energy consumption and so on can be reduced; due to addition of the urethane elastic fiber, the resilience can be guaranteed; by weaving of the suede nap, disadvantages of thin fabrics are avoided.

Owner:YANGZHOU JIYUAN TEXTILE

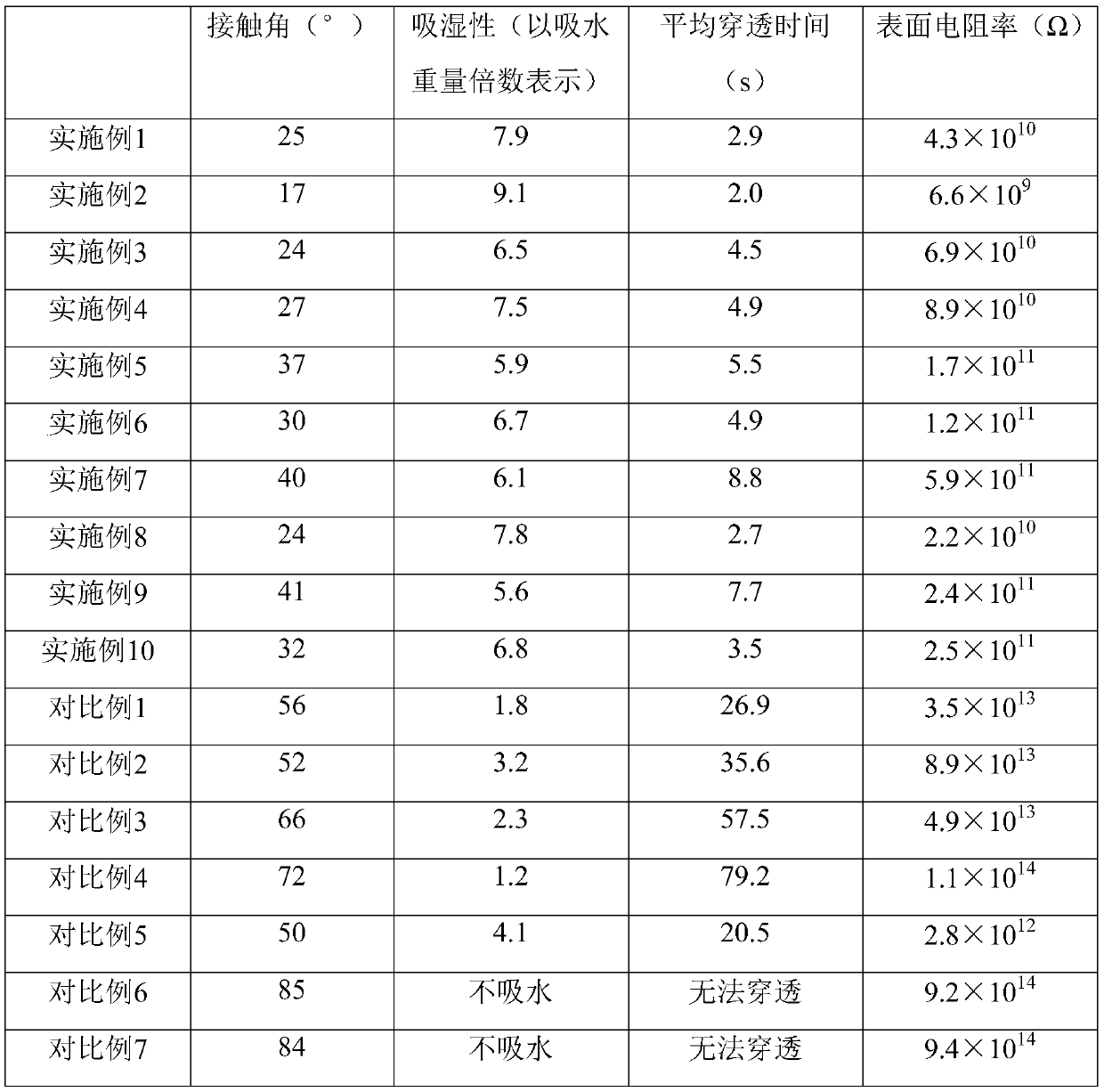

Hydrophilic antistatic polypropylene composition and preparation method and application thereof

ActiveCN111020870AImprove hydrophilicityShort penetration timeElectroconductive/antistatic filament manufactureNon-woven fabricsMasterbatchPolymer science

The invention discloses a hydrophilic antistatic polypropylene composition and a preparation method and application thereof. The composition is prepared from the following components in parts by weight: 30-75 parts of polypropylene, 0.5-15 parts of compatilizer, 2-25 parts of hydrophilic accelerant and 5-70 parts of hydrophilic agent, wherein the hydrophilic agent comprises a non-ionic surface active agent and an anionic surface active agent. The composition also includes optionally a dispersant, a lubricant, and an antioxidant. The obtained hydrophilic antistatic material can be used as a master batch to be directly added into polypropylene resin for melt spinning, the obtained polypropylene non-woven fabric is good in hydrophilic performance, capable of absorbing multiple times of wateramount of the non-woven fabric and short in penetration time, and good hydrophilicity can still be kept after multiple times of scouring, and the material has scouring resistance and durable hydrophilic effects. The product prepared by the method also has an excellent antistatic effect and is simple in preparation process and low in cost and is beneficial to large-scale commercial production.

Owner:联泓(江苏)新材料研究院有限公司 +1

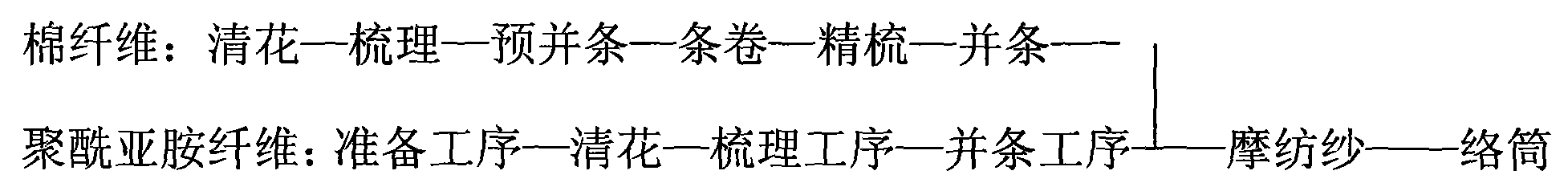

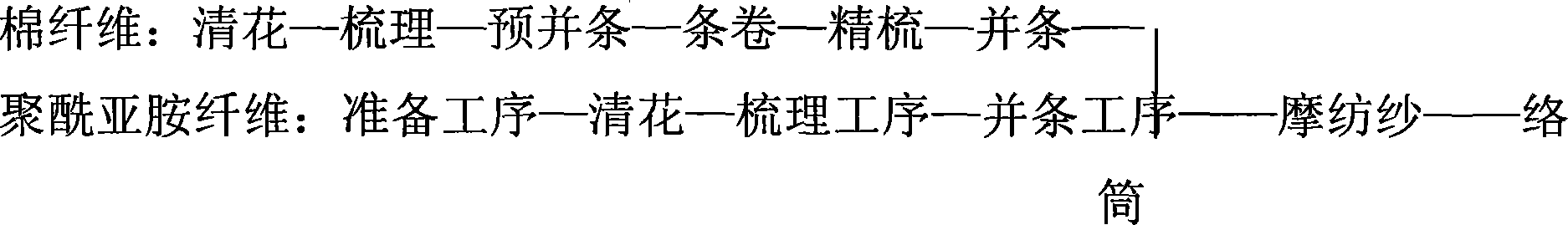

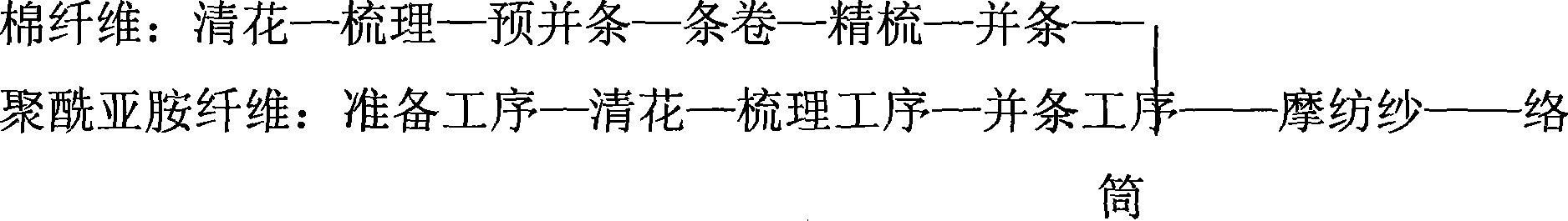

Weaving of core-spun yarn

The invention provides a brand novel weaving concept of the fabrics of polyimide and cotton fiber core-spun yarn variety; polyimide functional fiber and natural cotton fiber are used as raw material, and the process that leads the natural cotton fiber and the polyimide fiber into cleaning cotton, carding, pre-drawing, sliver lap, combing and drawing respectively is adopted. The spinning process is carried out on a friction spinning machine; polyimide fiber rod is put into the twisting area of a dust cage after being drafted, thus forming core yarns. Cotton fiber rod, after being drafted by a roller, is combed into single fiber condition by a combing roller and is coated outside the core yarns under the function of the dust cage, so as to form the structure of coating core yarns externally and shortening the technical process; meanwhile the adding of natural fiber improves the whole moisture regain of the yarns, reducing the electrostatic phenomena, improving the cloth performance and strengthening the dyeing ability of the yarns. The produced yarns can be used as clothing material, etc. for outdoor work, thus improving the producing value of the products.

Owner:SHENGHONG GRP CO LTD

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Health-care cloth

InactiveCN101343804AHigh far infrared emission effectOvercome limitationsWeft knittingWarp knittingEngineeringNatural fiber

Disclosed is a health care fabric, which relates to health care fabric which is manufactured by the industrial method and contains soybean fibers and bamboo charcoal fibers. The fabric on the market is mainly divided into natural fiber fabrics and artificial fiber fabrics. The costs of the natural fiber fabrics are high, the types of chemical fiber fabrics on the market are multiple, the functions are also various, but the wearing comfort is poor and the function is unitary, the chemical fiber fabrics can not reach the requirements of the customers in function, only the wearing purpose can be satisfied, and the health care and health building can not be achieved. The product can improve the defect of the products on the market. The product components comprise: 40 to 80 parts of soybean fibers by weight and 30 to 60 parts of bamboo charcoal fibers by weight. The product is the health care fabric which can be applied in various fields.

Owner:HEILONGJIANG HUASHEN SCI & TECH DEV

Cellulose nanocrystalline/polylactic acid composite material as well as preparation method and application thereof

The invention provides a cellulose nanocrystalline / polylactic acid composite material as well as a preparation method and application thereof, and belongs to the technical field of polylactic acid composite materials. The preparation method comprises the following steps: mixing a cellulose nanocrystalline aqueous dispersion with a salt modifier, and carrying out electrostatic adsorption modification to obtain a modified cellulose nanocrystalline aqueous dispersion; dropwise adding the modified cellulose nanocrystalline aqueous dispersion into a polylactic acid solution, carrying out coprecipitation reaction, and drying a solid obtained by the coprecipitation reaction to obtain the cellulose nanocrystalline / polylactic acid composite material; wherein a solvent of the polylactic acid solution is a water-soluble organic solvent. According to the method, negatively charged groups on the surface of cellulose nanocrystal are effectively utilized, the modifier is adsorbed to the surface of the cellulose nanocrystal through a simple water-based method, modification is completed, the preparation process is simple, only one-time drying is needed, used water and the solvent can be recycled, and the method is a green and environment-friendly process.

Owner:NORTHEAST FORESTRY UNIVERSITY

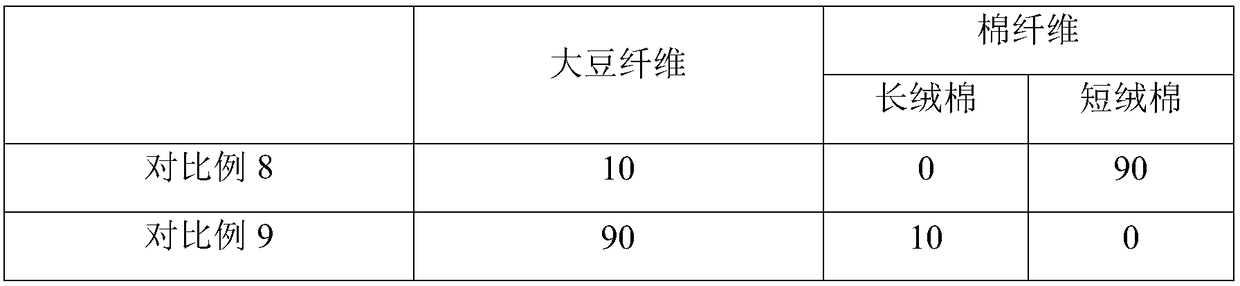

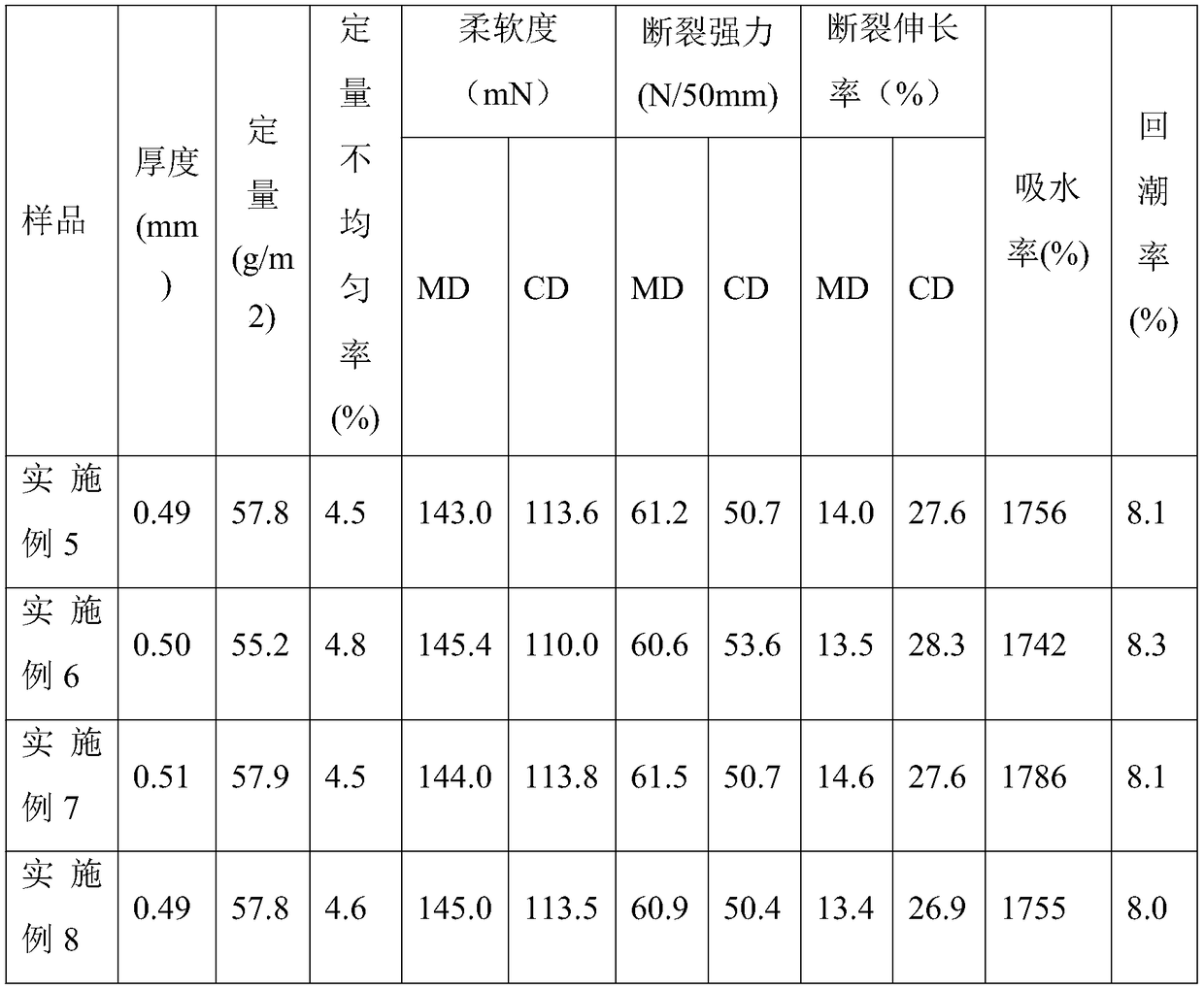

Preparation method of cotton soft towel and cotton soft towel

InactiveCN109457392AReduce static electricityImprove dispersion uniformityNon-woven fabricsVegetal fibresChemistryFiber strength

The invention discloses a preparation method of cotton soft towel and the cotton soft towel. The preparation raw materials of the cotton soft towel comprise pure cotton fiber and soybean fiber. The preparation method of the cotton soft towel and the cotton soft towel have the advantages that through scientific treatment, the technical problems that the soybean fiber and the cotton fiber are different in fiber strength, fineness and the like, and blending is difficult, the primary color of the soybean fiber is ensured after blending, the blending performance of the cotton fiber and soybean fiber is effectively improved, non-woven cloth is prepared from blend fiber, the disadvantages of the insufficient strength of the soybean fiber and poor air permeability of the cotton fiber are overcome,and the cotton soft towel prepared from the non-woven cloth has better soft and skin-friendly performance.

Owner:ZHUZHOU QIANJIN PHARMA +1

High-intensity-grade reflective film and preparation method thereof

ActiveCN110157347ASuper conductive propertiesReduce static electricityFilm/foil adhesivesCoatingsElectrostatic adsorptionSelf-assembly

The invention relates to a high-intensity-grade reflective film and a preparation method thereof, and particularly relates to a high-intensity-grade reflective film with carbon nano tube modified glass beads as reflective elements and a preparation method of the high-intensity-grade reflective film. The method comprises the following steps: firstly, modifying glass beads through an amino silane coupling agent, then carrying out self-assembly with carbon nano tubes through electrostatic adsorption to obtain carbon nano tube modified glass micro beads, and planting the glass micro beads for filmformation to obtain the high-intensity-grade light reflective film. The carbon nano tubes have excellent conductivity and strength performance, so that antistatic and anti-wear properties of the glass beads can be effectively improved. The oxidized carbon nano tubes have excellent visible fluorescence, and visual performance of the reflective film can be synergistically enhanced by the visible fluorescence of the oxidized carbon nano tubes and inverse reflection of the glass beads, so that safety of night driving is improved. The preparation method is simple and is easy to operate, and the obtained reflective film is high in visibility and good in quality.

Owner:ZHEJIANG YGM TECH CO LTD

Multicomponent hemp fiber blending antibacterial and deodorant healthcare yarn and preparation method thereof

The invention discloses multicomponent hemp fiber blending antibacterial and deodorant healthcare yarn. The multicomponent hemp fiber blending antibacterial and deodorant healthcare yarn comprises following raw materials, by weight, 15%-30% of hemp fiber, 20%-40% of aloe viscose, 30%-50% of wool fiber and 10%-35% of cashmere fiber. The performance indexes of the blending yarn is that the single-yarn breaking strength is 11.9-19.8 cN / tex, the variable coefficient Cv value of the single-yarn breaking strength is 8.3%-17.2%, and the variable coefficient Cv value of the yarn evenness is 13.9%-22.0%. The multicomponent hemp fiber blending antibacterial and deodorant healthcare yarn has the advantages that fabric made of the blending yarn has the anti-bacterial function, the anti-microbial function, the bacteriostat function, the antiphlogistic function, the skin protection and fitness function, the skin moisturizing function and the like, is high in strength, good in moisture absorption and breathability, lustrous, good in ultrasonic protection, anti-bacterial performance, mold prevention and non-corrosibility, and unique in appearance. In addition, the multicomponent hemp fiber blending antibacterial and deodorant healthcare yarn is wide in application and can be used for making various knitting or weaving healthcare textiles such as clothing and bedding articles.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Safe, environment-friendly and high-performance electrochromic film and preparation method thereof

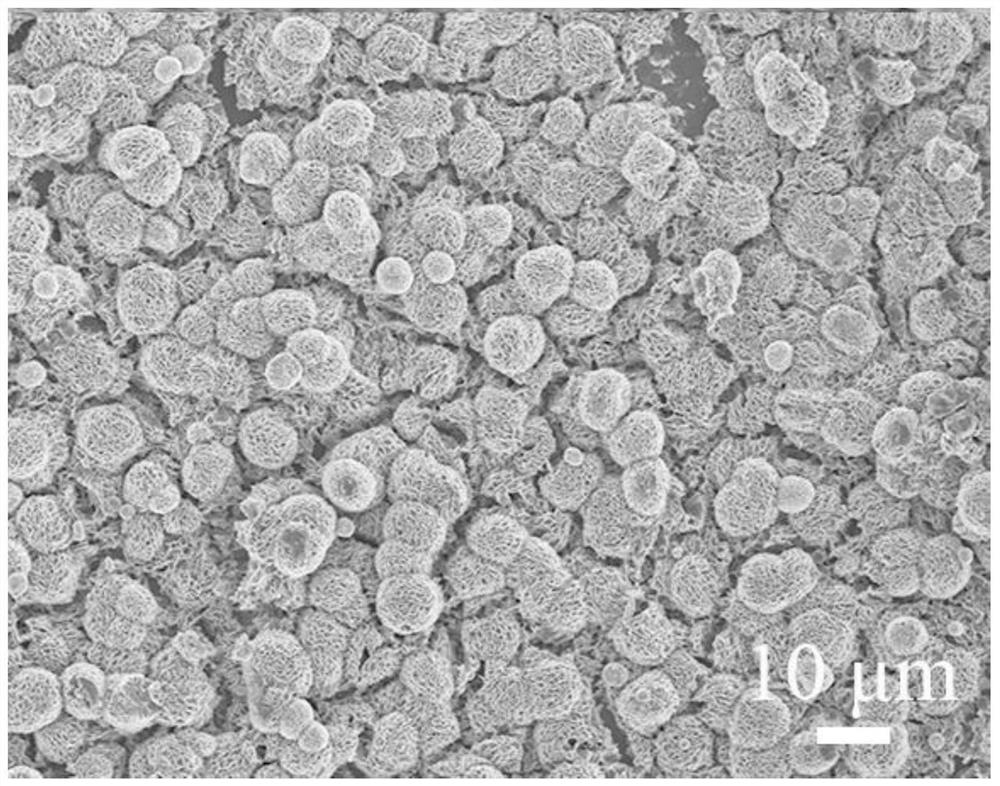

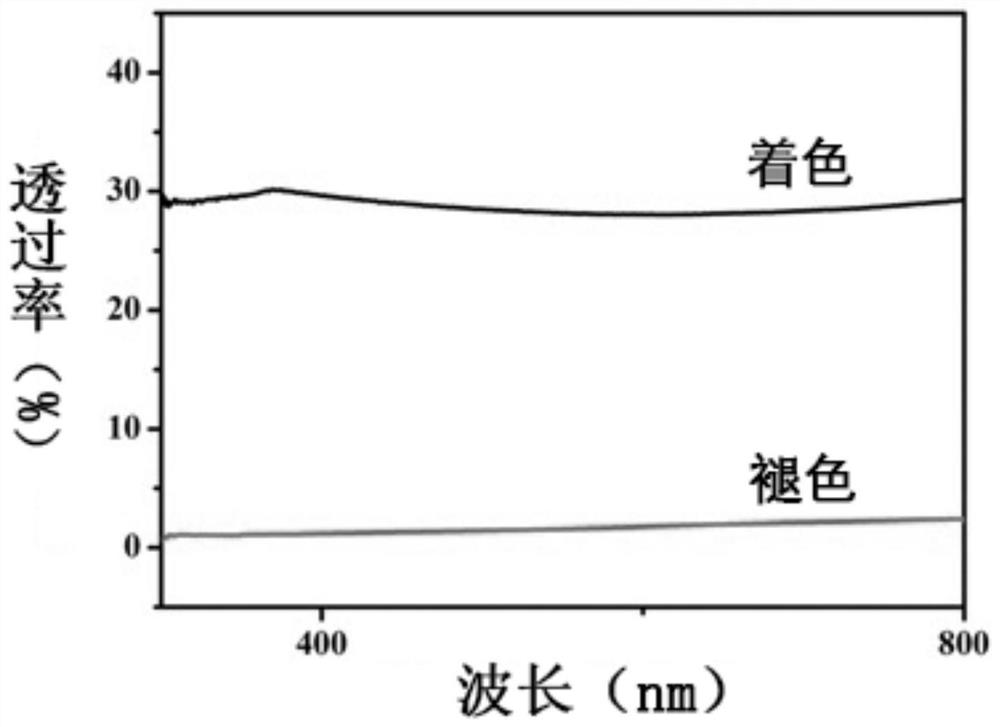

ActiveCN112255855ASimple preparation processLow equipment requirementsNon-linear opticsElectrolytic agentFilm base

The invention discloses a method for preparing and testing a safe, environment-friendly and high-performance electrochromic film capable of being applied to an aqueous electrolyte, and belongs to thefield of electrochromic materials. The electrochromic film is a NiO thin film based on Ni-MOF and is of a spherical structure formed by stacking porous nanosheets, a material can be deposited on an ITO substrate through a simple hydrothermal method and vertically grows on the ITO substrate, and the diameter of the electrochromic film is about 2-10 micrometers. An MOF derivative is used as an electrochromic material, the porous structure of the MOF derivative enables the MOF derivative to be applied to an aqueous electrolyte system, the requirement for equipment is low, raw materials are simpleand easy to obtain, and the manufacturing cost is low. The possibility is provided for preparing the water system electrochromic device with excellent performance, no toxicity, no pollution and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Substrate, manufacturing method thereof, and display device

ActiveCN105789184AReduce static electricityReduce the risk of electrostatic damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringDisplay device

The invention relates to a substrate, a manufacturing method thereof, and a display device. The substrate comprises at least one idle line, wherein the idle line comprises at least one tip, and the tip is suitable for discharging static electricity to the interior of an idle region. Therefore, the electrostatic charges generated at corresponding regions can be discharged to the idle region, thereby reducing static content discharged to a conductive connecting structure by the idle line, and reducing the risk that the conductive connecting structure is damaged by static electricity.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

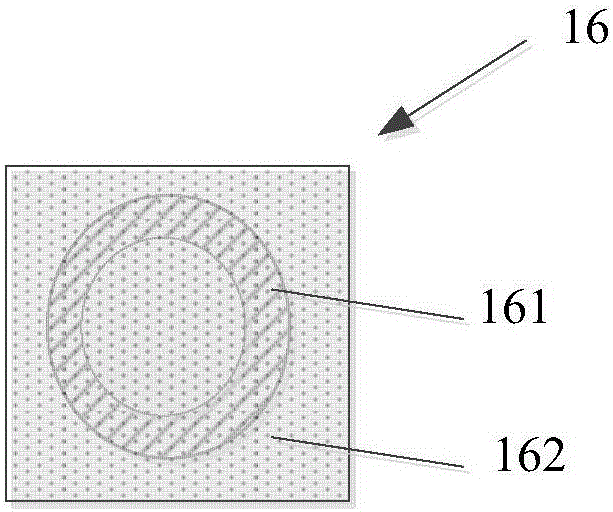

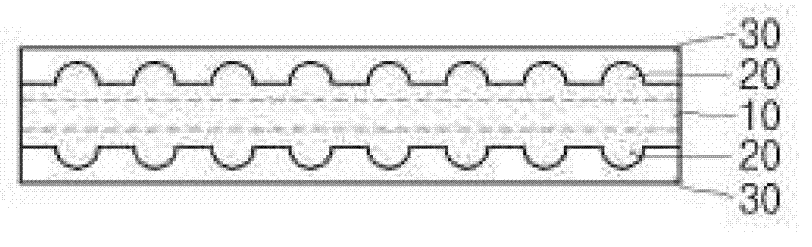

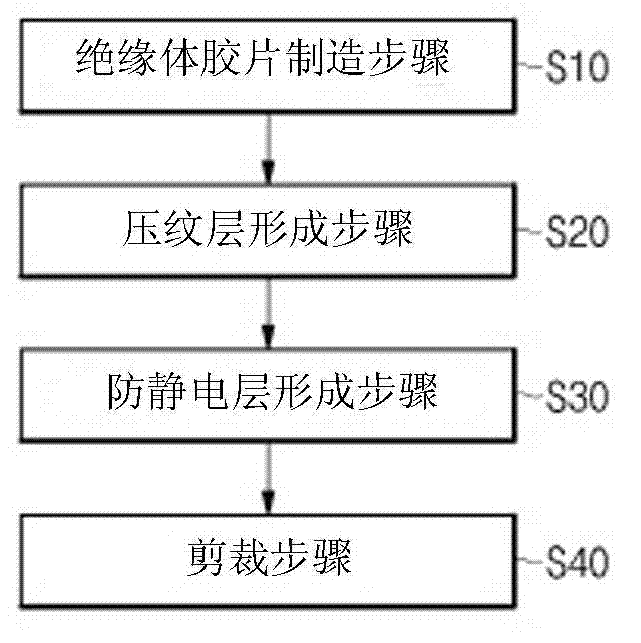

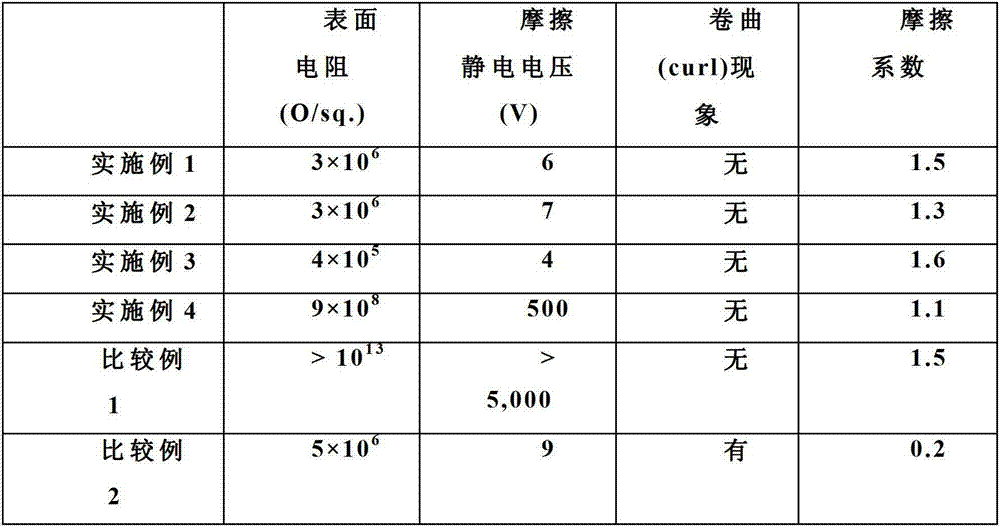

Anti-static gasket for stacking beverage and food containers and manufacturing method thereof

InactiveCN102806739AReduce sliding phenomenonZero curlSynthetic resin layered productsPackagingEngineeringForeign body

The invention relates to an anti-static gasket for stacking beverage and food containers and a manufacturing method thereof. The anti-static gasket comprises an insulator film, an embossed layer formed on at least one side surface of the insulator film, and an anti-static layer on the other side, opposite to the side connected with the embossed layer, of the insulator layer. The manufacturing method of the anti-static gasket for stacking beverage and food containers includes the steps of manufacturing the insulator film by extruding an ethylene series high polymer material; enabling the insulator film to pass through an embossed roll to form the embossed layer on at least one side surface of the insulator film; coating an anti-static material on the other side, opposite to the side connected with the embossed layer, of the insulator layer to form the anti-static layer. By the aid of the anti-static gasket, phenomena strikes among the containers, foreign material adhering caused by static, tiny dust pollution and surface scraping and the like can be effectively avoided, sliding phenomenon of the food containers can be reduced to the largest extend, and the stacked containers can be separated conveniently.

Owner:NANO CHEM TECH SUZHOUCO

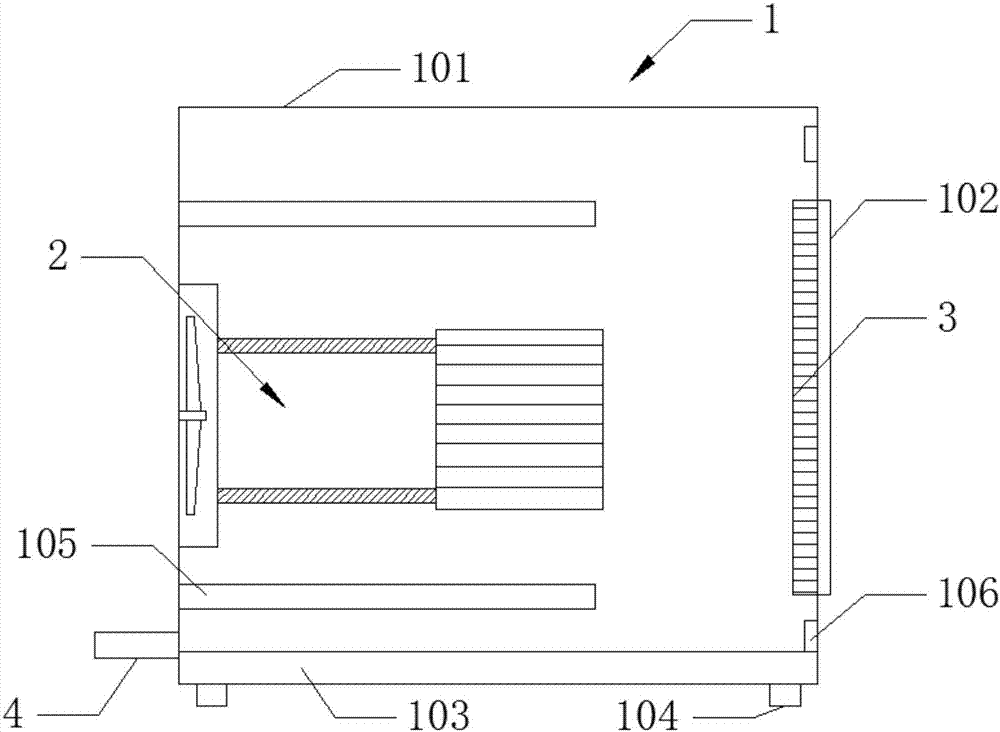

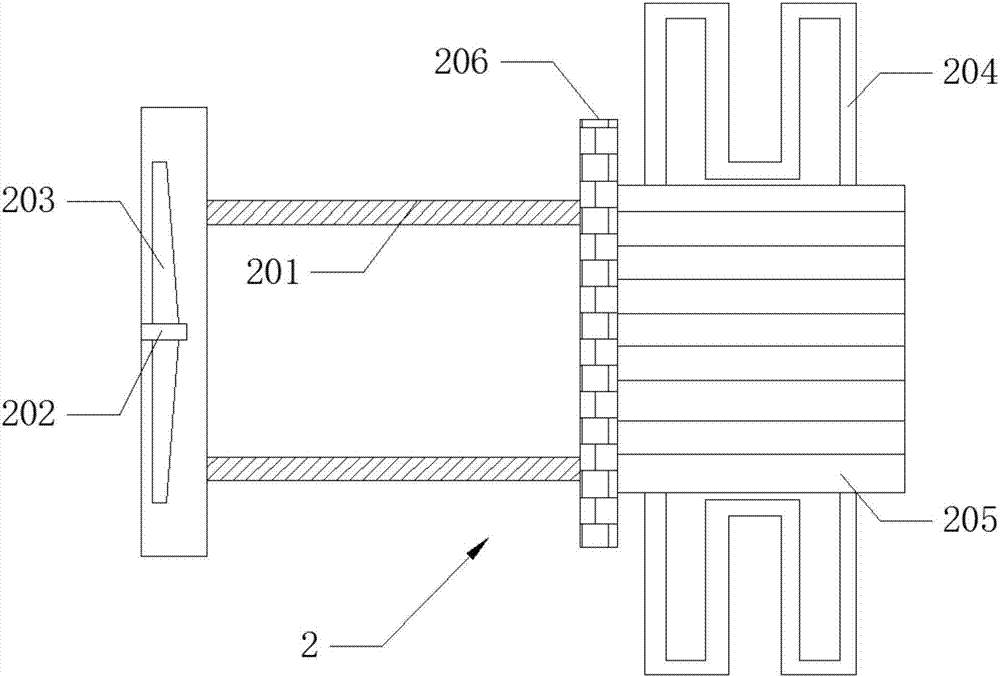

Radiatorfor server case

InactiveCN106886263AImprove cooling effectEasy maintenanceDigital processing power distributionHeat conductingComputer engineering

The invention discloses a radiatorfor a server case. The radiator includes a server case body and a radiating device, the server case body includes a case-body shell, a radiating window, a base, fixed support legs, a placement bracket andfixed buckles, the radiating window is fixed on the right side of the case-body shell, the inner side of the radiating window is provided with a ventilation net, the upper and lower sides of the radiating window are provided with the fixed buckles, the left side of the case-body shell is provided with a fixed clamping plate, the radiating device includes connection plates, an electric rotation shaft, radiating fan blades, heat-conducting copper pipes, a radiating sheet and a radiating-sheet base, two sides of the electric rotation shaft are welded with the radiating fan blades, the connection plates are arranged on the right of the radiating fan blades, the right sides of the connection plates are fixedly connected with the radiating-sheet base, the right side of the radiating-sheet base is fixedly connected with the radiating sheet, and the upper and lower sides of the radiating sheet are welded with the heat-conducting copper pipes. The radiatorfor the server case has the advantages of being convenient to use, good in radiating effect, convenient to maintain and the like, and the radiatorfor the server case can be widely popularized and utilized.

Owner:蒋宗霞

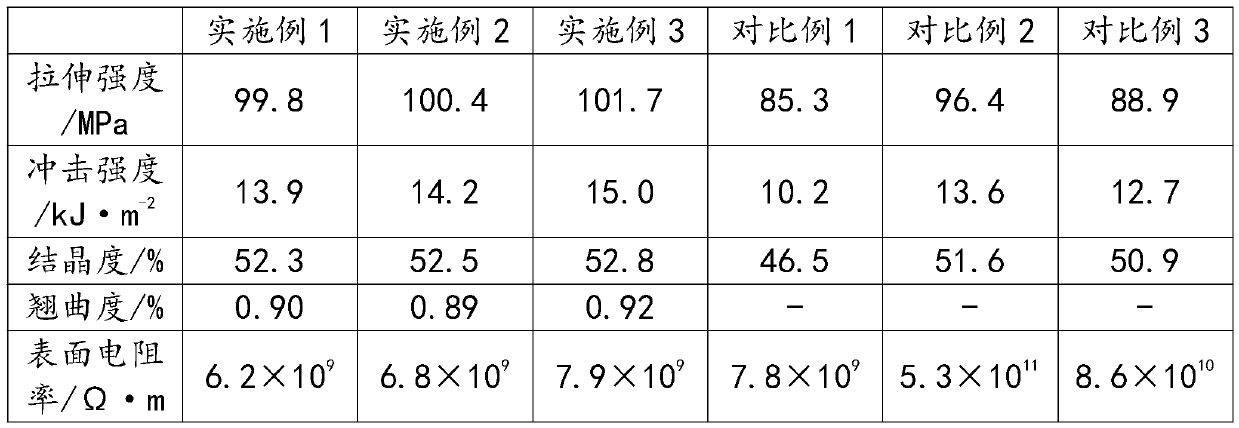

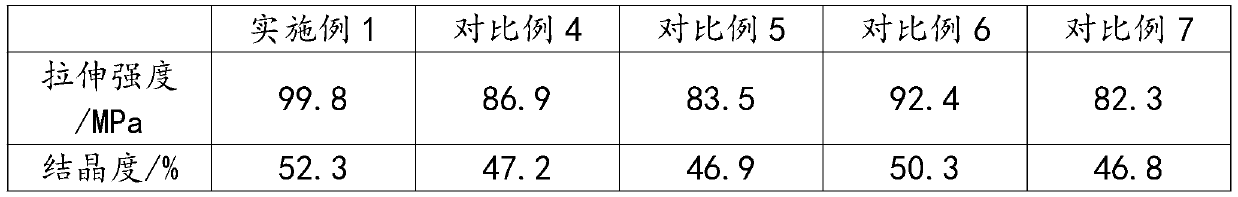

Fiber reinforced type PP (polypropylene) material and preparation method thereof

InactiveCN110591230APromote nucleation and crystallizationImprove mechanical propertiesElastomerUltraviolet

The invention discloses a fiber reinforced type PP (polypropylene) material which is prepared from the following raw materials in parts by weight: 65-75 parts of polypropylene, 26-32 parts of glass fiber, 4-5 parts of elastomer metallocene polyethylene, 0.8-1 part of modified nano titanium dioxide, 8-10 parts of modified conductive carbon black, 6-7 parts of a compatibilizer and 0.5-0.7 part of aplastic processing aid. The invention further discloses a preparation method of the PP material. As polypropylene is adopted as a substrate of the PP material, and the elastomer metallocene polyethylene is adopted as a toughening agent, high tension strength of the composite material can be maintained while the impact strength of the composite material is improved by using the substances; as the modified nano titanium dioxide is adopted as an anti-aging agent, not only are a great amount of ultraviolet rays shielded, but also the aging resistance of the material can be improved, and in addition, PP crystallization can be promoted; and as the modified conductive carbon black is adopted as an anti-electrostatic agent, an anti-electrostatic function can be brought into play sufficiently, andthus dust adherence on the surface of a PP material product can be remarkably reduced.

Owner:安徽强茗塑业科技有限公司

Long-acting barrier quality-guaranteeing food packaging material and manufacturing method thereof

InactiveCN101654165AReduce coefficient of frictionExtend shelf lifeFlexible coversWrappersFilm structureFood packaging

The invention provides a long-acting barrier quality-guaranteeing food packaging material, which has nine layers or seven layers; the change of the layers is required by customers; the first layer (outer layer) is a PE layer, the second layer is a paper layer, the third layer is an adhesive layer and the adhesive is polyurethane water-borne adhesive, the fourth layer is a PVDC coating layer, and the other five or three layers consist of a coextrusion film structure. The material has good long-acting performance on the basis of high barrier property.

Owner:王振光

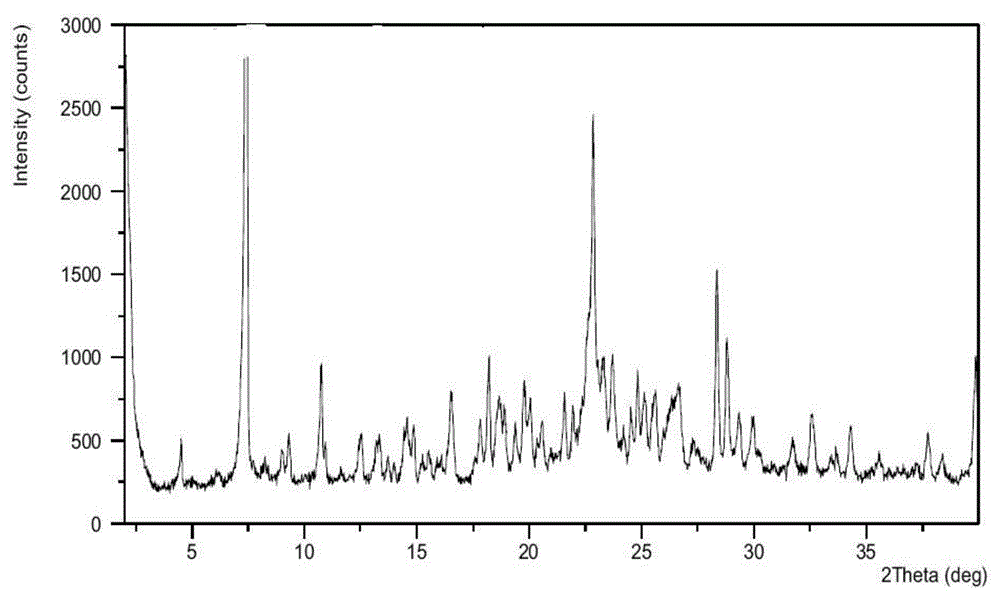

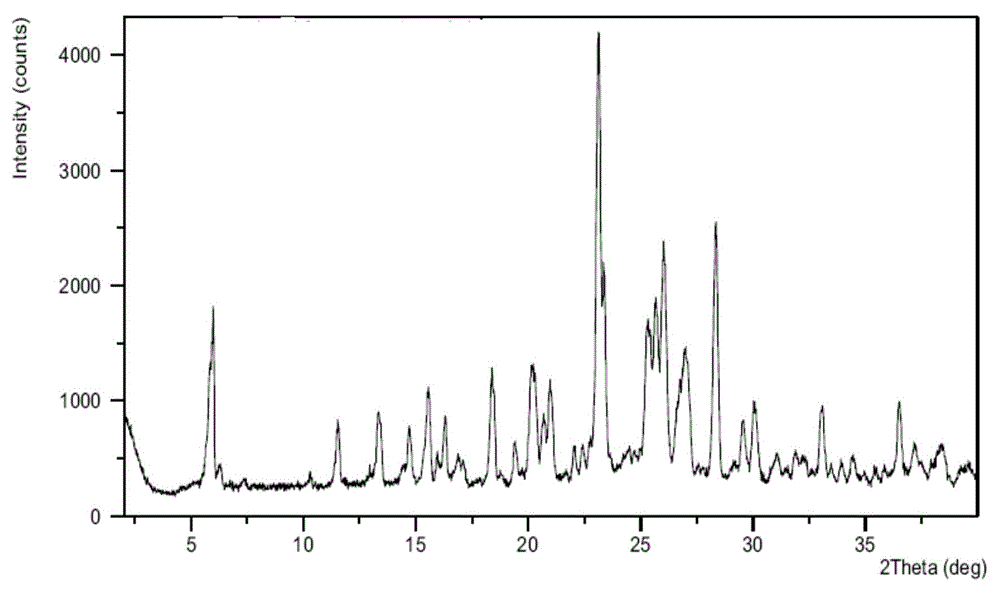

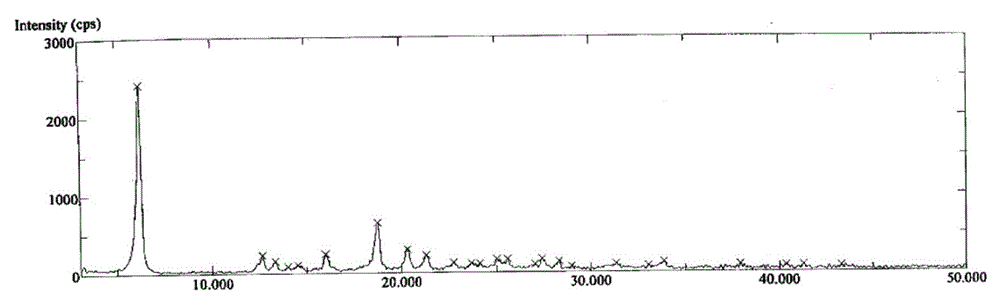

Crystalline forms of azilsartan medoxomil potassium and preparation and uses thereof

ActiveCN104039779AImprove performanceImprove oral bioavailabilityOrganic active ingredientsOrganic chemistrySolubilityAzilsartan Medoxomil

The present invention relates to the field of pharmaceutical chemistry. Disclosed herein is a crystalline form of azilsartan medoxomil potassium, which is substantially pure. The crystalline form is crystalline form A, form B, form C, form D, form E, form F, form G, form H, form I, form J, form K or form L. The substantially pure crystalline forms of azilsartan medoxomil potassium of the invention generally have good properties such as high solubility, high bioavailability, good stability, long shelf life and good antistatic property. The crystalline forms of azilsartan medoxomil potassium generally exhibit an excellent performance in reducing clinical systolic blood pressure (SBP) and average 24-hour SBP. Disclosed herein are methods of preparing the substantially pure crystalline forms of azilsartan medoxomil potassium, pharmaceutical compositions comprising the crystalline forms, and preparation methods and uses thereof.

Owner:RUYUAN HEC PHARM

Low-electrostatic sofa cushion fabric

InactiveCN108081712AStrong ability to store chargeStrong antistatic performanceElectroconductive/antistatic filament manufactureSynthetic resin layered productsElectrostatic dischargeYttrium

The invention relates to the technical field of sofa cushion fabrics and in particular to a low-electrostatic sofa cushion fabric which comprises cloth layers and an anti-electrostatic cloth layer, wherein the cloth layers are arranged on two sides; the anti-electrostatic cloth layer is arranged between the two cloth layers; the cloth layers are made of an anti-electrostatic modified polyamide fiber, a vinylon fiber, a ramine fiber, a jute fiber and a hibiscus syriacus fiber through blending; the anti-electrostatic cloth layer is made by coating two sides of an adhesive fabric by an anti-electrostatic liquid; the adhesive fabric is made of an adhesive fiber and a ramine fiber in a mass ratio of 2:1 through blending; the anti-electrostatic modified polyamide fiber comprises nano titanium dioxide, nano zirconium oxide, nano barium oxide, nano yttrium oxide, nano molybdenum oxide and nano carbon fiber powder. The sofa cushion fabric provided by the invention consists of the cloth layers on two sides and the anti-electrostatic cloth layer in the middle, the cloth layers have anti-electrostatic properties, the anti-electrostatic cloth layer is capable of dispersing and transferring electrostatic charges and plays a role of storing electrostatic charges, and due to synergism of the cloth layers and the anti-electrostatic cloth layer, the sofa cushion fabric does not easily generate electrostatic charges, has low electrostatic properties and is good in anti-electrostatic property.

Owner:HUZHOU KEBO INFORMATION TECH CO LTD

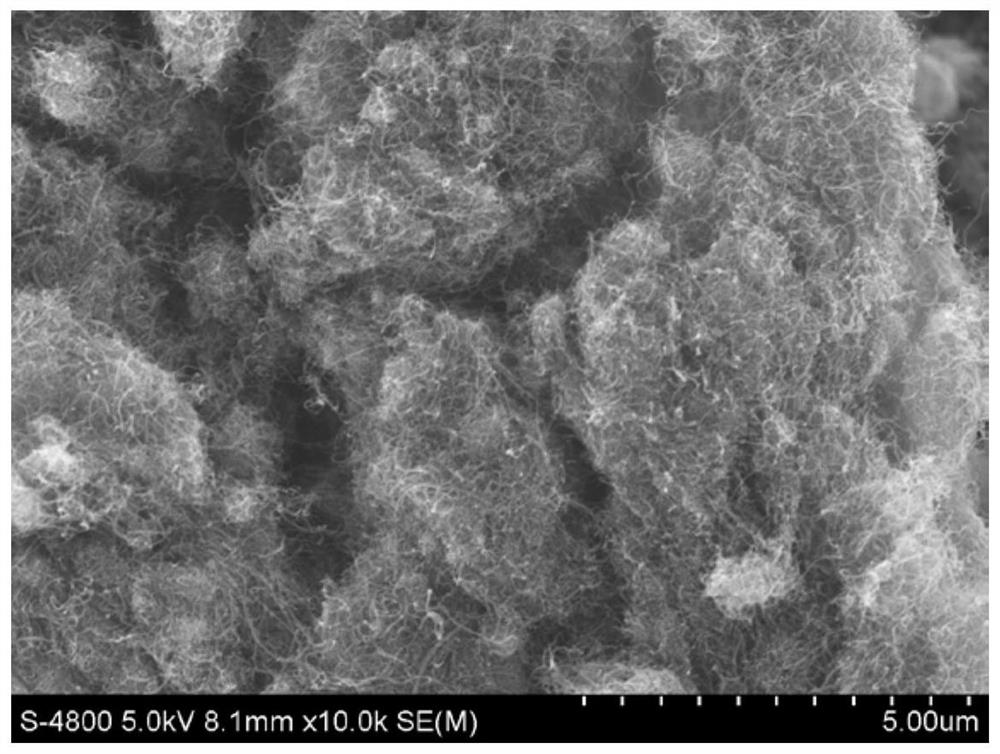

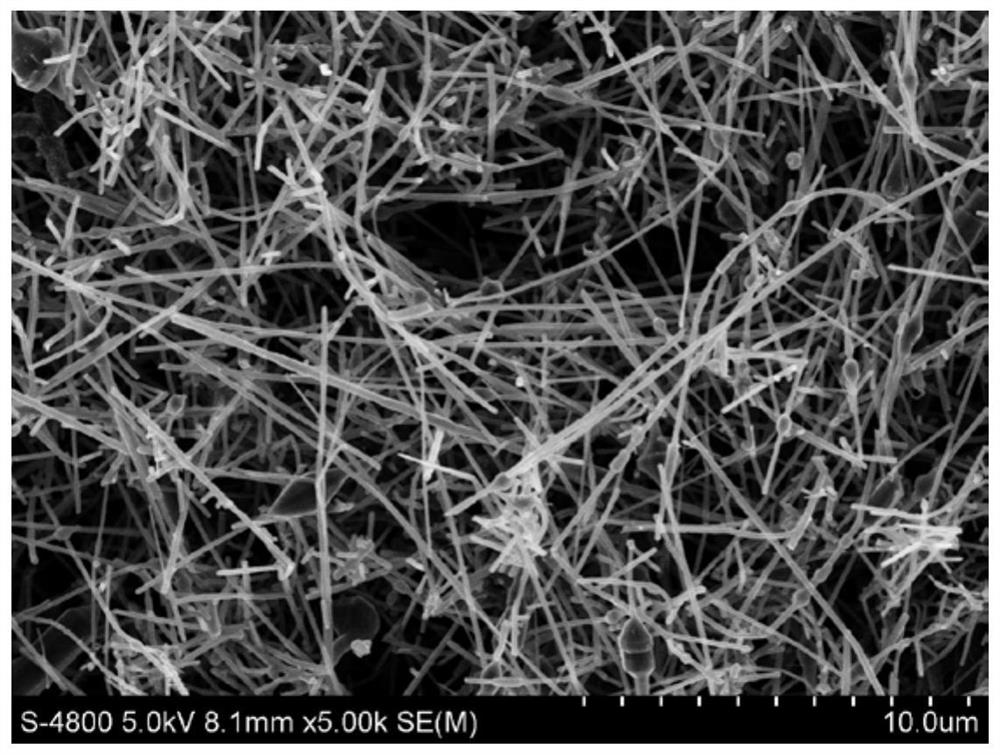

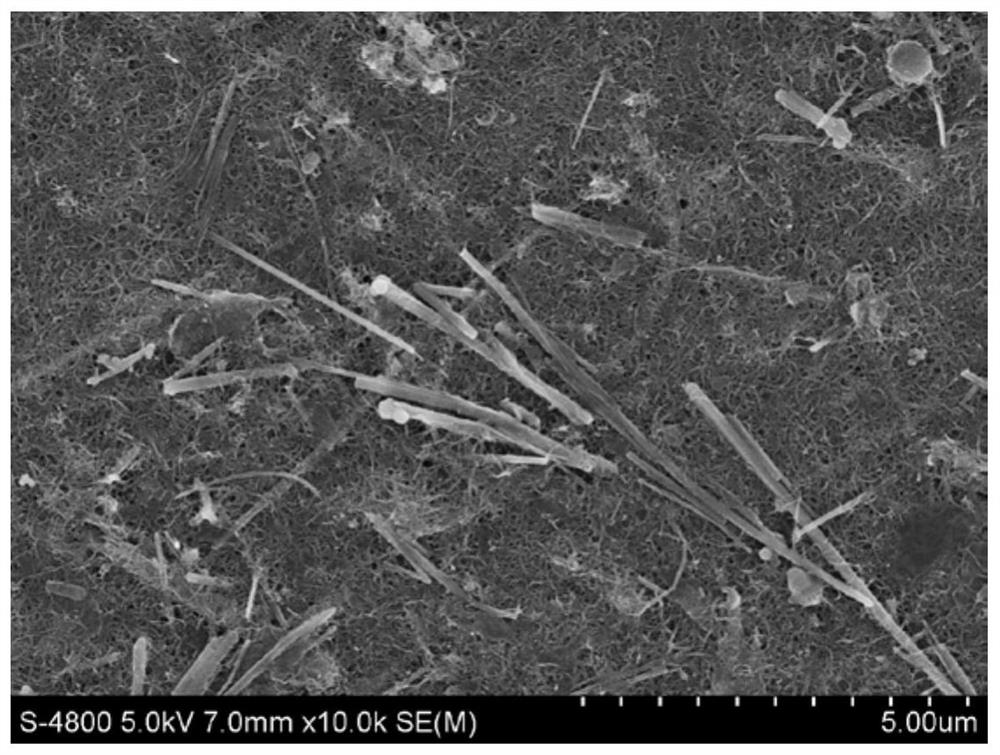

High-conductivity and high-stability carbon nanotube compound conductive paste for lithium ion battery and preparation method of high-conductivity and high-stability carbon nanotube compound conductive paste

PendingCN113035407AImprove performanceWeaken static electricityCell electrodesSecondary cellsElectrically conductivePolymer chemistry

The invention relates to high-conductivity and high-stability carbon nanotube compound conductive paste for a lithium ion battery and a preparation method of the high-conductivity and high-stability carbon nanotube compound conductive paste. The conductive paste is composed of the following raw materials: a conductive agent, a dispersant, a viscosity reducer and a solvent, wherein the conductive agent is composed of carbon nanotubes and carbon nanofibers, the total solid content of the carbon nanotubes and the carbon nanofibers is 2-15%, the weight ratio of the conductive agent to the dispersing agent to the viscosity reducer to the solvent in the conductive paste is (2-15):(0.75-4):(0.02-0.2):(80.8-97.23), the diameter of the carbon nanotube is 2-50 nm, the length is 5-300 [mu]m, the specific surface area is 50-800 m<2> / g, the diameter of the carbon nanofibers is 50-200 nm, the length is 5-50 microns, and the specific surface area is 10-100 m<2> / g. By utilizing the characteristics of the carbon nanotubes and the carbon nanofibers, the prepared paste is stable in viscosity, long in storage time and excellent in conductivity, is convenient to use in the homogenizing process of the lithium ion battery, and is beneficial to exerting the performance of the lithium ion battery in the later period.

Owner:河南克莱威纳米碳材料有限公司

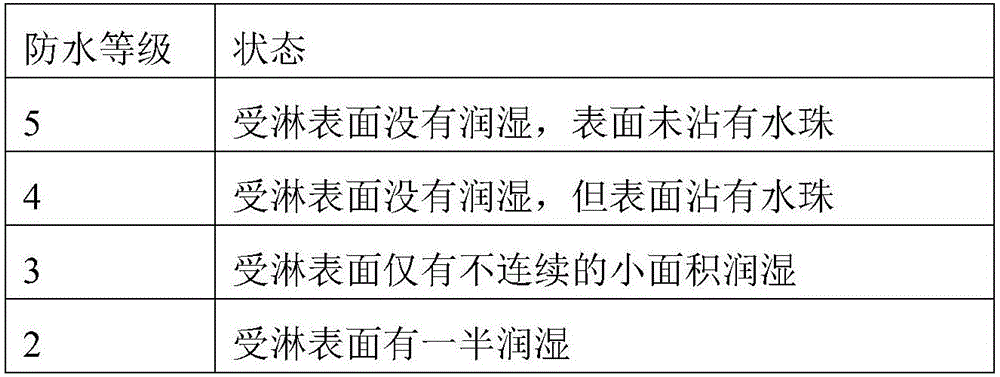

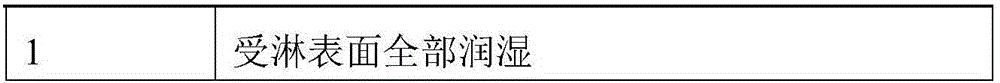

Fluorine-containing fabric waterproof agent and preparation method thereof

ActiveCN105777977AImprove waterproof performanceReduce frictionVegetal fibresCross-linkAcrylic resin

The invention discloses a fluorine-containing fabric waterproof agent. The fluorine-containing fabric waterproof agent is composed of, by mass, 6-14% of perfluoroalkylethyl acrylate, 9-17% of acrylic resin, 9-13% of octamethyl tetrasiloxane, 1-5% of carboxymethylcellulose, 5-13% of polyvinyl alcohol, 1-9% of cross-linked monomer, 0.2-0.5% of surfactant, 0.5-0.9% of initiator and 60-70% of deionized water. The invention further discloses a preparation method of the fluorine-containing fabric waterproof agent. The preparation method includes: mixing the surfactant with the deionized water to obtain obtain a surfactant water solution; adding perfluoroalkylethyl acrylate, the acrylic resin, octamethyl tetrasiloxane, carboxymethylcellulose and the cross-linked monomer into the surfactant water solution to form mixed liquid; mixing polyvinyl alcohol and the initiator with the mixed liquid, and filtering to obtain the waterproof agent. The fluorine-containing fabric waterproof agent is capable of making fabric soft, durable, waterproof and oil-proof.

Owner:GUANGZHOU HENGJIN CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com