High-conductivity and high-stability carbon nanotube compound conductive paste for lithium ion battery and preparation method of high-conductivity and high-stability carbon nanotube compound conductive paste

A technology of lithium-ion batteries and carbon nanotubes, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, battery electrodes, cables/conductors, etc., can solve the problems of easy rebound of the viscosity of carbon nanotube conductive paste, and achieve Reduce static electricity, improve performance and maintain stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 9 groups of experiments were designed to compare carbon nanofibers and carbon nanotubes with different addition ratios, different dispersant contents, different viscosity reducer contents, and nanocarbon fibers with different diameters, among which experiment 9 was a control group experiment;

[0034] Test 1:

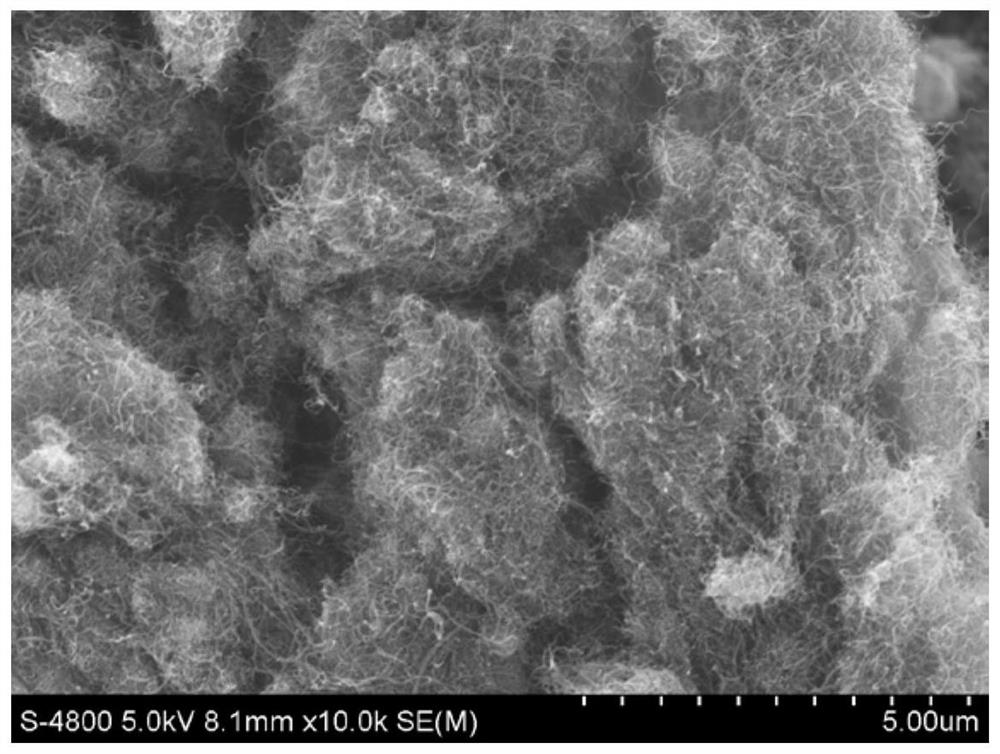

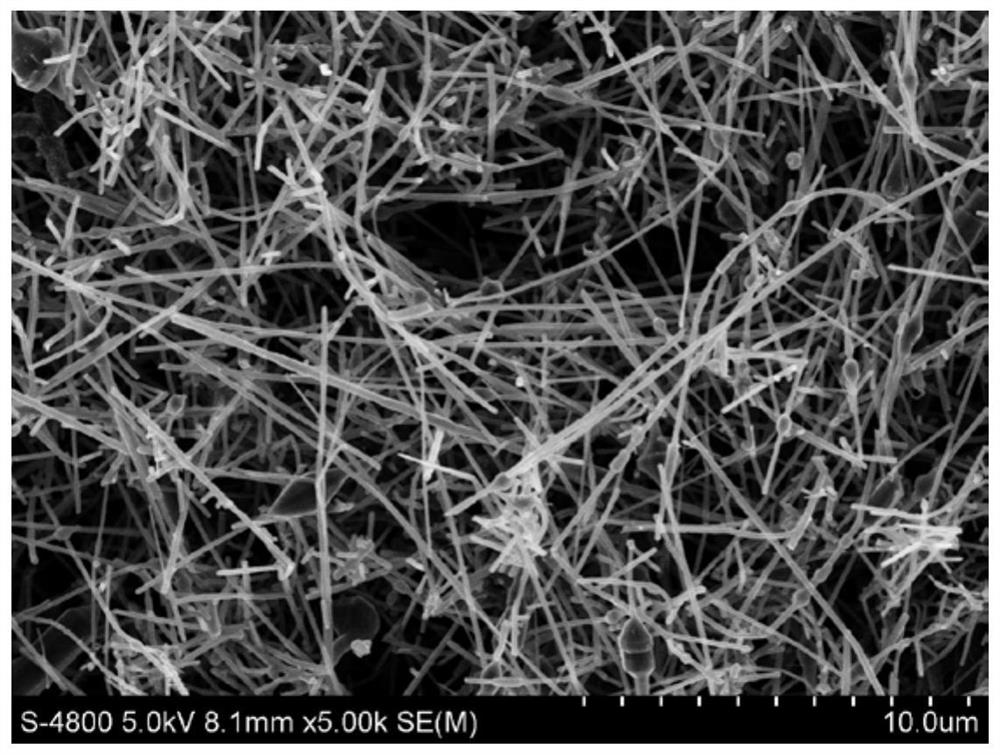

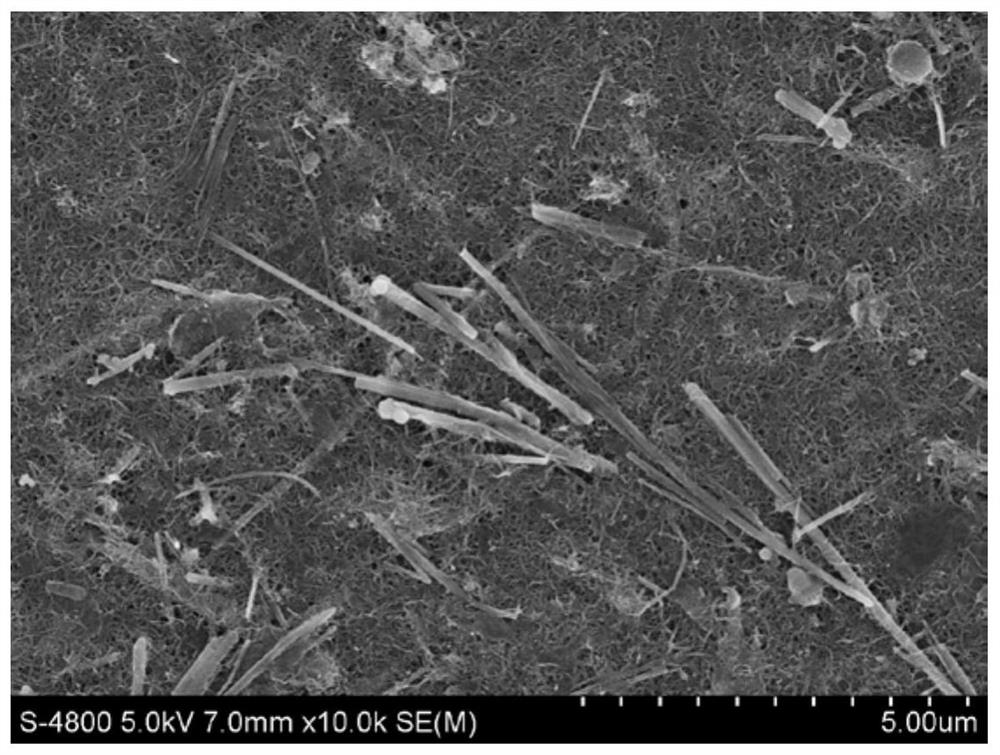

[0035] Dissolve 100g of PVPK30 in 11875g of NMP, the dispersion linear velocity is 4m / s, the dissolution time is 1.5h, add 12.5g of anhydrous piperazine, add 12.5g of sodium hydroxide, the dispersion linear velocity is 4m / s, the dissolution time For 1.5h, 375g of agglomerated carbon nanotubes with a diameter of 10-20nm were added, and the specific surface of the carbon nanotubes was 260m 2 / g, the length is 5~15μm (such as figure 1shown), the dispersion linear velocity is 8m / s, the viscosity after dispersion is 14542mpa s, the zirconium bead filling amount of the sand mill is 60%, the linear velocity is 11m / s, the zirconium bead size is 0.6~0.8μm, and the grindi...

Embodiment 2

[0050] Four sets of experiments were designed to compare the effects of different grinding times and different filling amounts of zirconium beads. The test results are shown in Table 3.

[0051] The difference between Test 10 and Test 1 is that the grinding time of the second grinding in Test 10 is 0.5h;

[0052] The difference between Test 11 and Test 1 is that the second grinding time of Test 11 is 3 hours;

[0053] The difference between Test 12 and Test 1 is that the filling amount of zirconium beads in the second grinding of Test 12 is 55%;

[0054] The difference between Experiment 13 and Experiment 1 is that the filling amount of zirconium beads in the second grinding of Experiment 13 is 75%.

[0055] The test result of test 10~13 in the embodiment 2 of table 3

[0056]

[0057]

[0058] By comparing tests 10, 11, 1 and 12, 13, 1, it is found that as the grinding time increases, the volume resistance of the pole piece first decreases and then increases; as the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com