Patents

Literature

639 results about "Total solid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier coating of a mixture of cured and uncured elastomeric polymers and a dispersed layered filler in a liquid carrier and coated articles

Barrier coating mixtures include (a) a mixture of pre-vulcanized and non-vulcanized elastomeric polymers; (b) an acid or base treated dispersed, substantially exfoliated silicate filler material that has not been functionalized with organic cations having an aspect ratio greater than 25; and (c) at least one additive, wherein the total solids content is less than 30% and the amount of filler is between 5% to about 60% of the total solids content. The coating retains its permeability properties under strain and has a strain to first damage of at least 10% biaxial elongation at 0% RH.Coated articles, free standing films and membranes, which are flexible and elastomeric, are produced using the barrier coating mixtures. Methods of manufacturing of such coated products are also encompassed.

Owner:INMAT INC

Barrier coating of a non-butyl elastomer and a dispersed layered filler in a liquid carrier and coated articles

InactiveUS7078453B1Reduce penetrationIncrease flexibilityPigmenting treatmentMaterial nanotechnologyElastomerTotal solid content

Barrier coating mixtures include (a) a non-butyl elastomeric polymer; (b) an acid or base treated dispersed, substantially exfoliated silicate filler material that has not been functionalized with organic cations having an aspect ratio greater than 25; and (c) at least one additive, wherein the total solids content is less than 30% and the amount of filler is between 5% to about 60% of the total solids content. The coating retains its permeability properties under strain and has a strain to first damage of at least 5% biaxial elongation at 0% RH.

Owner:IPL

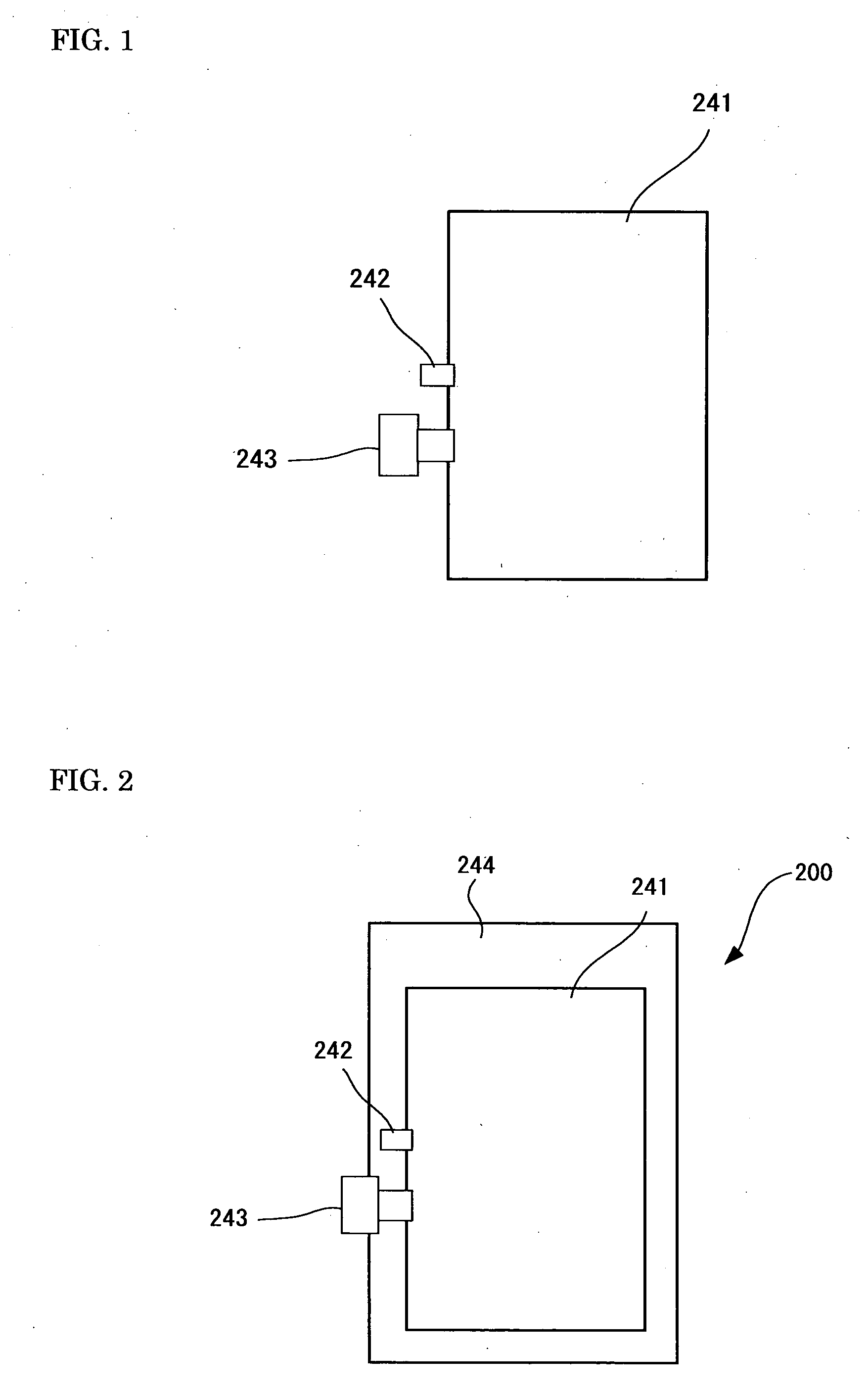

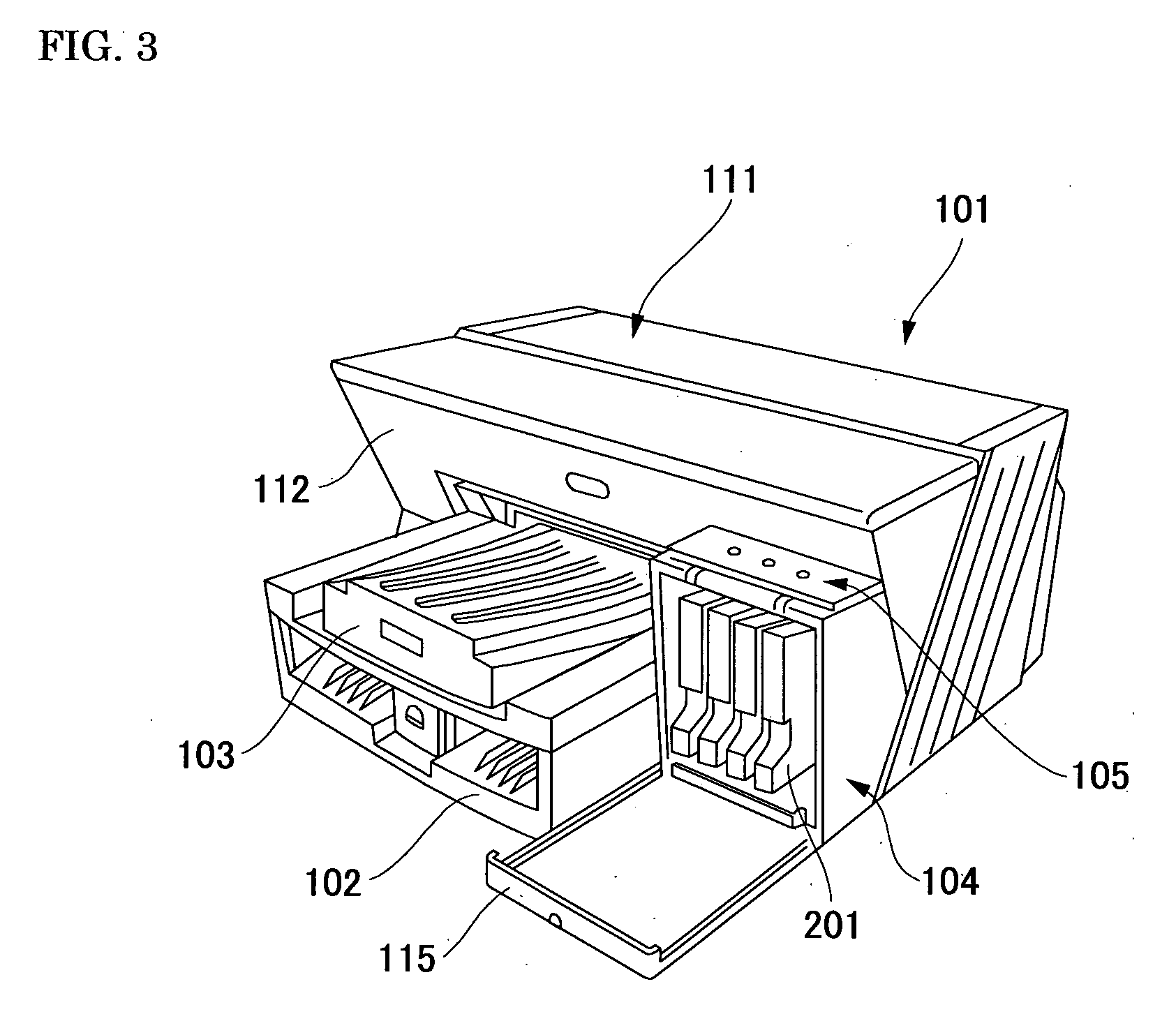

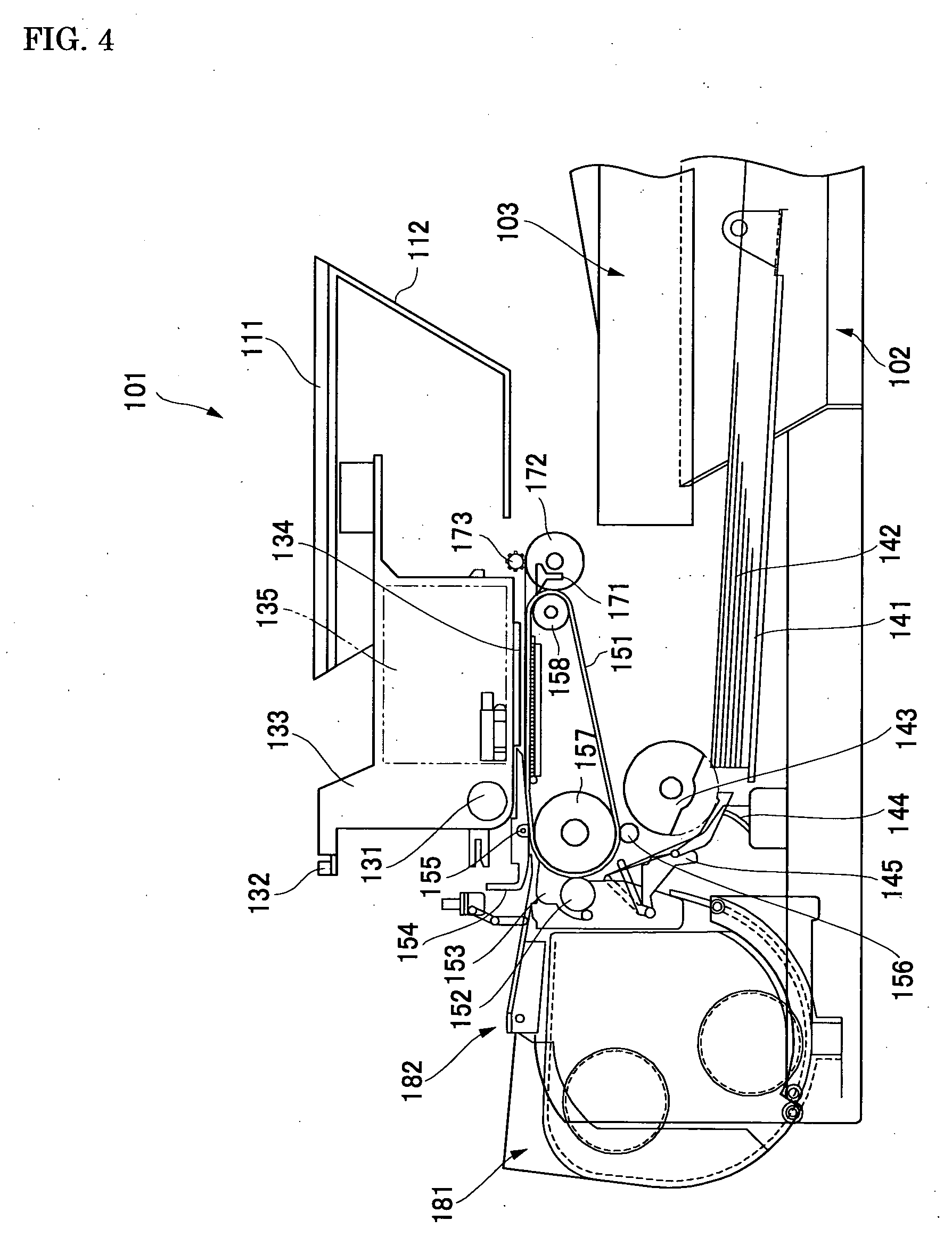

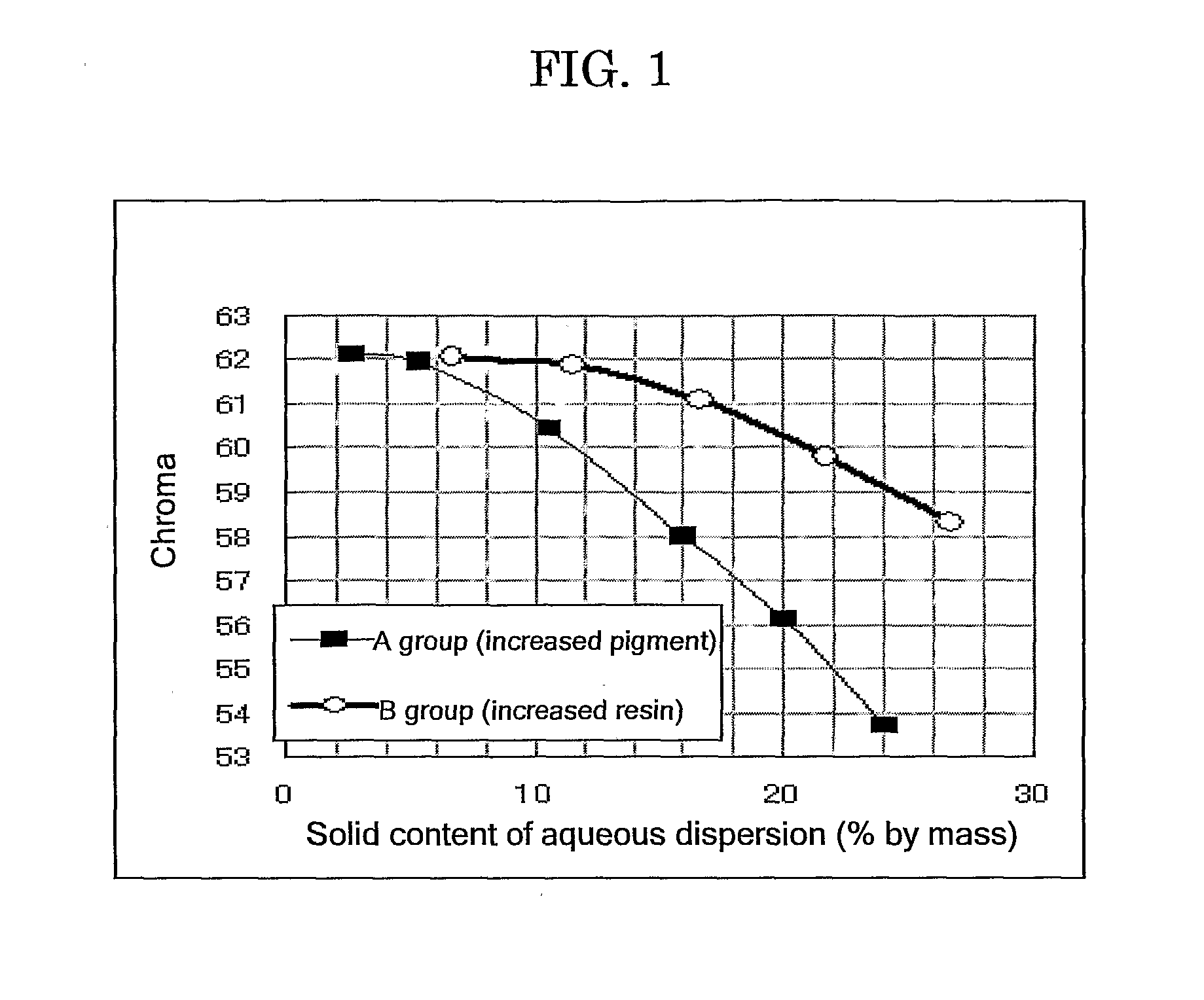

Recording Ink, Ink/Media Set, Ink Cartridge, Inkjet Recording Method and Inkjet Recording Apparatus

ActiveUS20080233363A1Avoid it happening againHigh image densityDecorative surface effectsLayered productsParticulatesWater dispersible

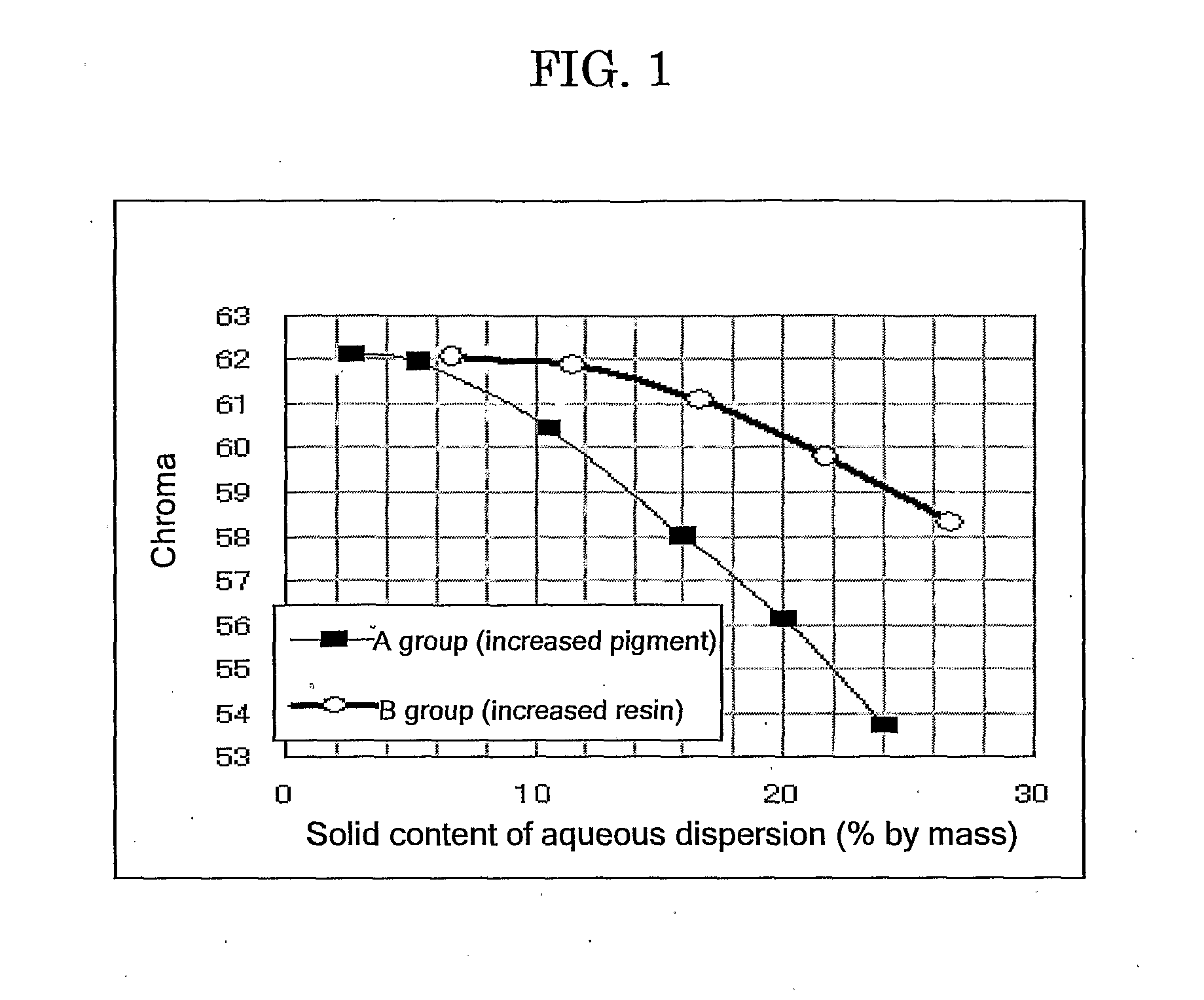

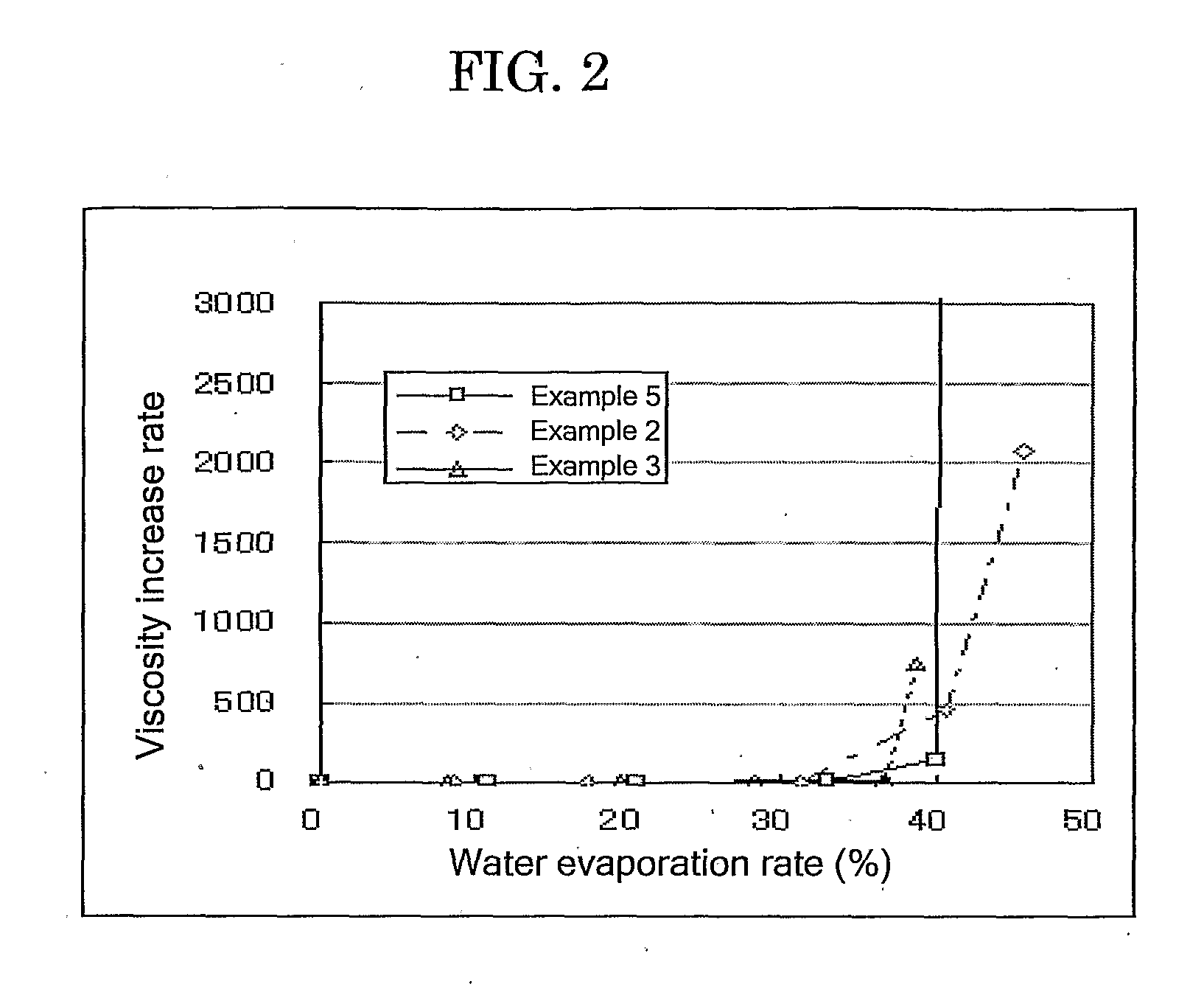

To provide a recording ink which contains at least a water-dispersible colorant, a water-dispersible resin, a wetting agent, a surfactant and water, wherein the content of the wetting agent in the recording ink is in the range of from 20% by mass to 35% by mass, the total solid content of the water-dispersible colorant and the water-dispersible resin in the recording ink is in the range of from 12% by mass to 40% by mass, the water-dispersible resin contains fluorine resin particulates, and the ratio A:B, where A is the solid content of the water-dispersible resin in the recording ink and B is the solid content of a pigment contained in the water-dispersible colorant in the recording ink, is in the range of 0.5 to 8.

Owner:RICOH KK

Natural liquid rubber slurry with added carbon nanotube and its prepn process

The present invention relates to composite polymer material performance improving technology. The liquid natural rubber slurry contains natural latex and carbon nanotube (CNT) and has total solid content of natural latex and CNT in 5-30 % and weight ratio between CNT and dry natural latex of 1-50 %. The liquid natural rubber slurry is prepared through surface treatment of CNT for hydrophilicity; mixing with dispersant and deionized water to obtain water suspension of CNT; regulating the pH value of the suspension to 9-12; and finally mixing with natural latex to obtain the liquid natural rubber slurry with added CNT. The liquid natural rubber slurry with homogeneously dispersed CNT is used in preparing CNT modified rubber powder and CNT modified sulfurized rubber products with greatly raised mechanical, electrically conducting, heat conducting, antistatic and other performance.

Owner:TSINGHUA UNIV

Polymer for Extending the Open Time of Waterborne Architectural Coatings

InactiveUS20120165428A1Extended opening timePolyurea/polyurethane coatingsTotal solid contentWater soluble

The present invention relates to water soluble open time extenders, which are mixed with an architectural coating, such as aqueous latex paints, to increase the coating's open time and crosslink to the architectural coating upon drying. The open time extender comprises neutralized water soluble polymers with hydrophobic, hydrophilic and cross-linkable monomers, and at least one crosslinking agent. The open time extender also comprises water and the total solid content of the open time extender is less than about 25% by weight.

Owner:COLUMBIA INSURANCE CO

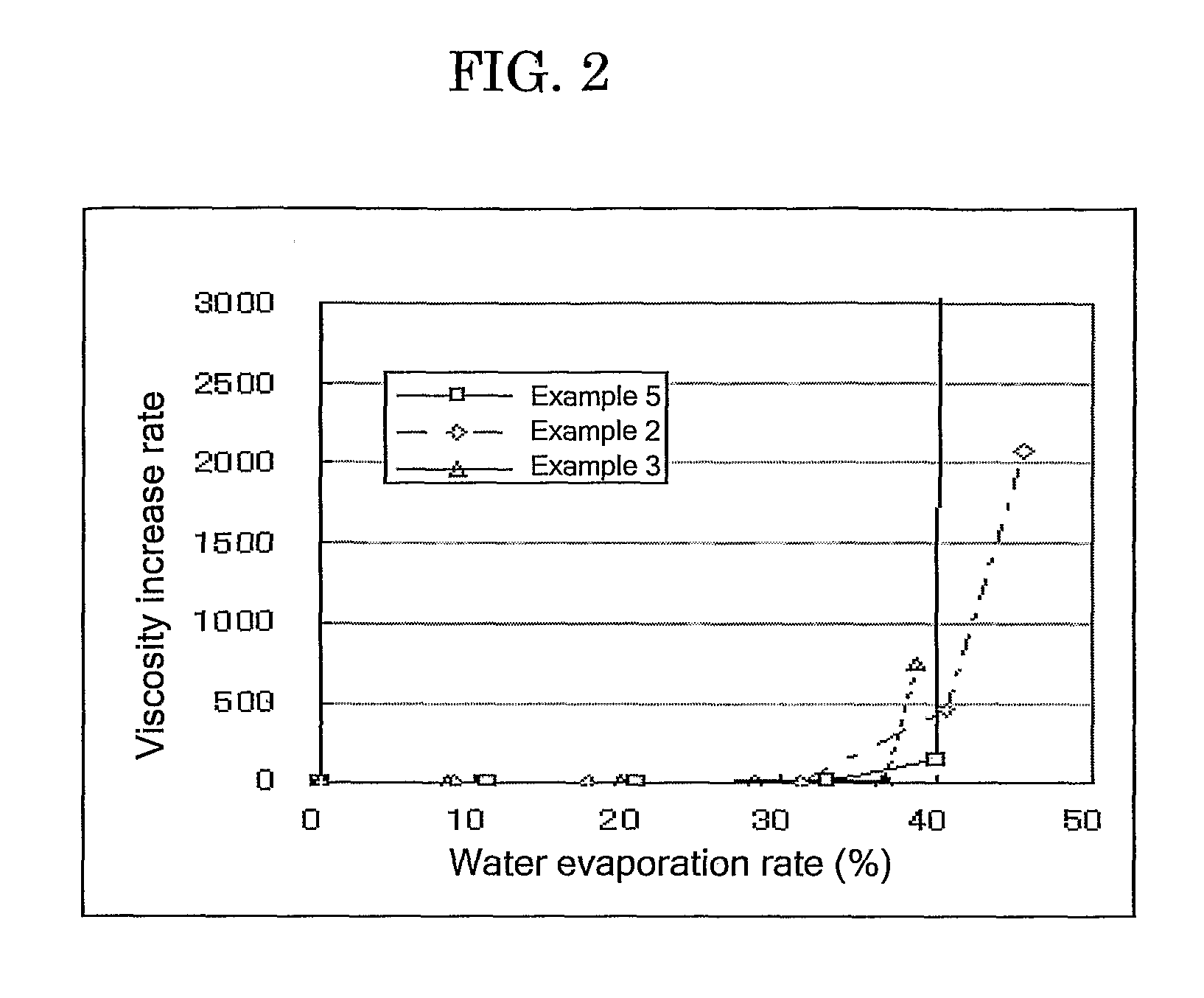

Ink for recording, and ink cartridge, ink recorded matter, inkjet recording apparatus and inkjet recording method using the same

ActiveUS20090239044A1Improve image qualityImprove reliabilityMeasurement apparatus componentsGroup 5/15 element organic compoundsTotal solid contentWater dispersible

There is provided an ink for recording, which contains: a coloring agent; a water-dispersible resin; a wetting agent; a surfactant; and water, wherein a total solid content of the coloring agent and the water-dispersible resin is 10% by mass to 30% with respect to a total mass of the ink, a ratio B / C is 0.1 to 1.6 where B is a solid content of the coloring agent in the ink, and C is a solid content of the water-dispersible resin in the ink, a viscosity of the ink is 5 mPa·s to 20 mPa·s at 25° C., and a surface tension of the ink is 35 mN / m or less.

Owner:RICOH KK

Antireflective film, polarizing plate, image display device and coating composition for forming low refractive index layer

InactiveUS20100246014A1Inhibition of attachmentEasy to wipeSynthetic resin layered productsCoatingsTotal solid contentInorganic particle

An antireflective film includes: a transparent substrate film; and at least one low refractive index layer, the low refractive index layer is formed with a composition containing: a fluorine-containing antifouling agent having a weight average molecular weight of less than 10,000 and a structure represented by the following formula (F); a polyfunctional monomer having a polymerizable unsaturated group; and (C) an inorganic particle, and a content of the fluorine-containing antifouling agent is 1% by weight or more and less than 25% by weight based on a total solid content of the coating composition:(Rf)-[(W)-(RA)n]m Formula (F)wherein, Rf represents a (per)fluoroalkyl group or a (per)fluoropolyether group, W represents a connecting group, RA represents a functional group having a polymerizable unsaturated group, n represents an integer of from 1 to 3, and m represents an integer of from 1 to 3.

Owner:FUJIFILM CORP

Elastomeric rubber and rubber products without the use of vulcanizing accelerators and sulfur

A composition for producing an elastomeric thin film comprising a carboxylated acrylonitrile polybutadiene latex which is vulcanized without the use of conventional sulphur and accelerators thereby reducing the possibility of contacting immediate Type I hypersensitivity and delay Type IV hypersensitivity caused by the presence of natural rubber latex proteins and accelerators respectively. The dipping process for making gloves by using a latex composition provided by: premixing carboxylated acrylonitrile polybutadiene latex with methacrylic acid, or alternatively using a self-crosslinked latex, adding zinc oxide, adjusted to 9 to 10 of the pH level, and diluted with water to obtain 18% to 30% by weight of total solid content; dipping the glove former into the composition to form a layer of thin film of the latex composition on the former; drying the thin latex film on the former and crosslinking the latex film on the former.

Owner:KOSSAN +1

Coating composition and articles made therefrom

The instant invention provides an aqueous dispersion, a coating composition, coating layers and coated article made therefrom. The coating composition according to the present invention comprises: (1) the inventive aqueous dispersion comprising the melt blending product of: (a) from 50 to 99 percent by weight of one or more polyethylene terephthalate resins, based on the total solid content of the dispersion; (b) from 1 to 50 percent by weight of one or more stabilizing agents comprising at least one second polyester, based on the total solid content of the dispersion, wherein said second polyester (i) has a carboxylic acid group and an acid number equal to or greater than 15, based on the solid content of the second polyester; or (ii) is a self-dispersing sulfopolyester; (c) one or more neutralizing agents; and (d) from 15 to 90 percent by weight of water, based on the total weight of the dispersion; wherein said dispersion has a solid content of 10 to 85 percent, based on the total weight of the dispersion; and (2) optionally one or more cross-linking agents.

Owner:THE DOW CHEM CO +1

Method for preparing acrylonitrile-butadiene-styrene latex having high total solid content

The present invention relates to a method of acrylonitrile-butadiene-styrene (ABS) rubber latex, and the acrylonitrile-butadiene-styrene (ABS) rubber latex is prepared by graft-polymerizing butadiene rubber with the monomers of acrlylonitrile and styrene through emulsion-polymerization, so that the ABS rubber latex of the present invention has high solid content. The method of ABS rubber latex of the present invention comprises the step of emulsion-polymerizing i) polybutadiene rubber latex; ii) aromatic vinyl compound; and iii) vinyl cyanide with the addition of a reactive emulsifier. According to the method of the present invention, the ABS rubber latex has high solid content due to a decrease in the amount of coagulated materials and film which is formed on the rubber latex during polymerization, and an increase in the production volume.

Owner:LG CHEM LTD

Coating composition, optical film, polarizing plate, and image display apparatus

InactiveUS20110244218A1High hardnessExcellent optical propertiesImpression capsDiffusing elementsInorganic particleOrganic solvent

A coating composition is provided and includes: (a) inorganic particles having an average particle size of 1 to 100 nm; (b) an ionizing radiation-curing material for forming a binder; (c) a photopolymerization initiator; and (d) an organic solvent. The coating composition preferably includes a monomer having at least two hydroxyl groups per molecule in a mass fraction of 0.1 to 3.0 mass % relative to the total solid content of the composition.

Owner:FUJIFILM CORP

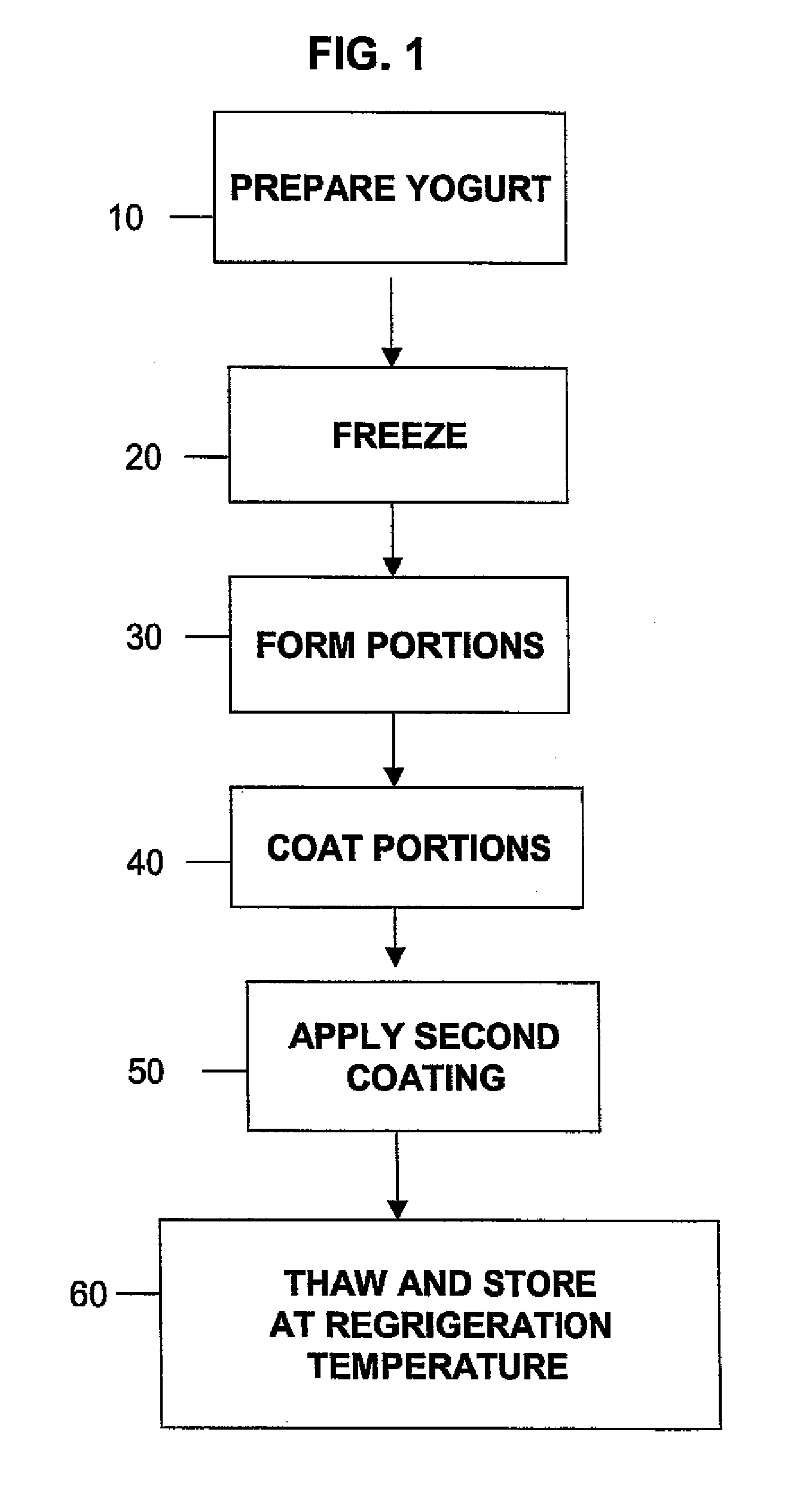

Bite sized refrigerated yogurt products

ActiveUS20110287147A1Convenient and portable wayMilk preparationFrozen sweetsTotal solid contentPortion size

Refrigerated yogurt products of small size suitable for eating with the fingers are prepared by providing a frozen yogurt composition in individual serving portions and coating the frozen yogurt portions with a fat based coating that is a solid at 45° F., thereby completely enveloping the frozen yogurt portions. The coated frozen yogurt portion is allowed to thaw to form a refrigerated yogurt product and is stored at a temperature of from about 32° F. to about 45° F. The yogurt composition has a final viscosity of from about 35,000 to about 150,000 cP at 4° C., and has a total solids content of at least about 22% and / or exhibits a viscosity reduction at 45° F. of less than 10% after two freeze / thaw cycles. Methods and products are described.

Owner:GENERAL MILLS INC

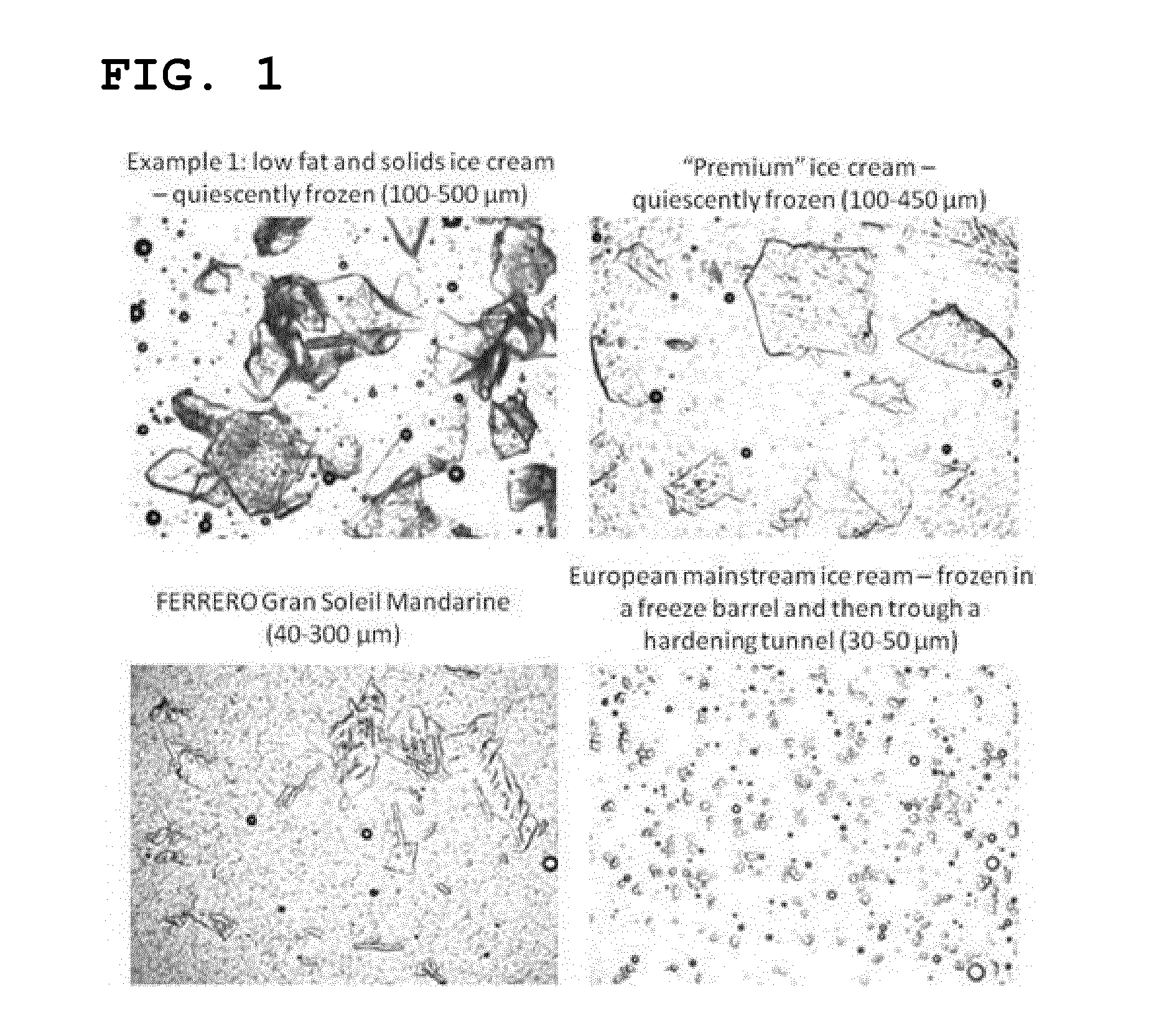

Stable mix of ingredients for a frozen dessert

The invention relates to a shelf-or chilled-stable mix of food ingredients for the preparation of a frozen dessert, wherein i) the ingredients mix is in a non-frozen state and contained in an aseptic, closed, preferably sealed, packaging, and wherein ii) the ingredient mix comprises propylene glycol monoester of fatty acid, preferably propylene glycol monostearate (PGMS) as sole emulsifier or in combination with at least one further emulsifier for frozen desserts; iii) the salt content of the non-frozen mix is at least 70 mg / 100 g product, and iiii) the non-frozen mix having a total solids content of less than 30%, preferably from 20 to 28%, and wherein optionally the ingredient mix may be aerated. The invention also relates to a method of making such a product.

Owner:NESTEC SA

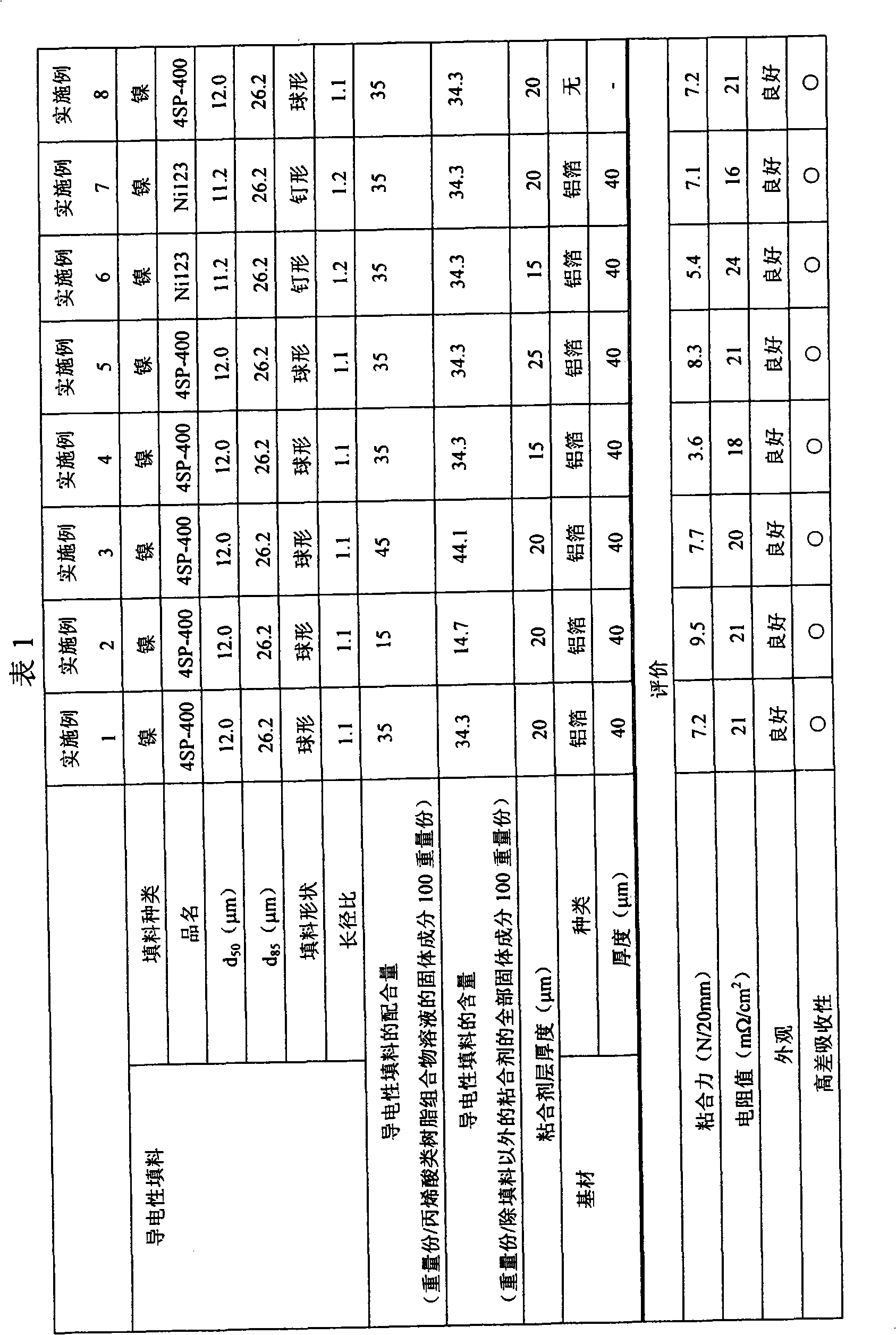

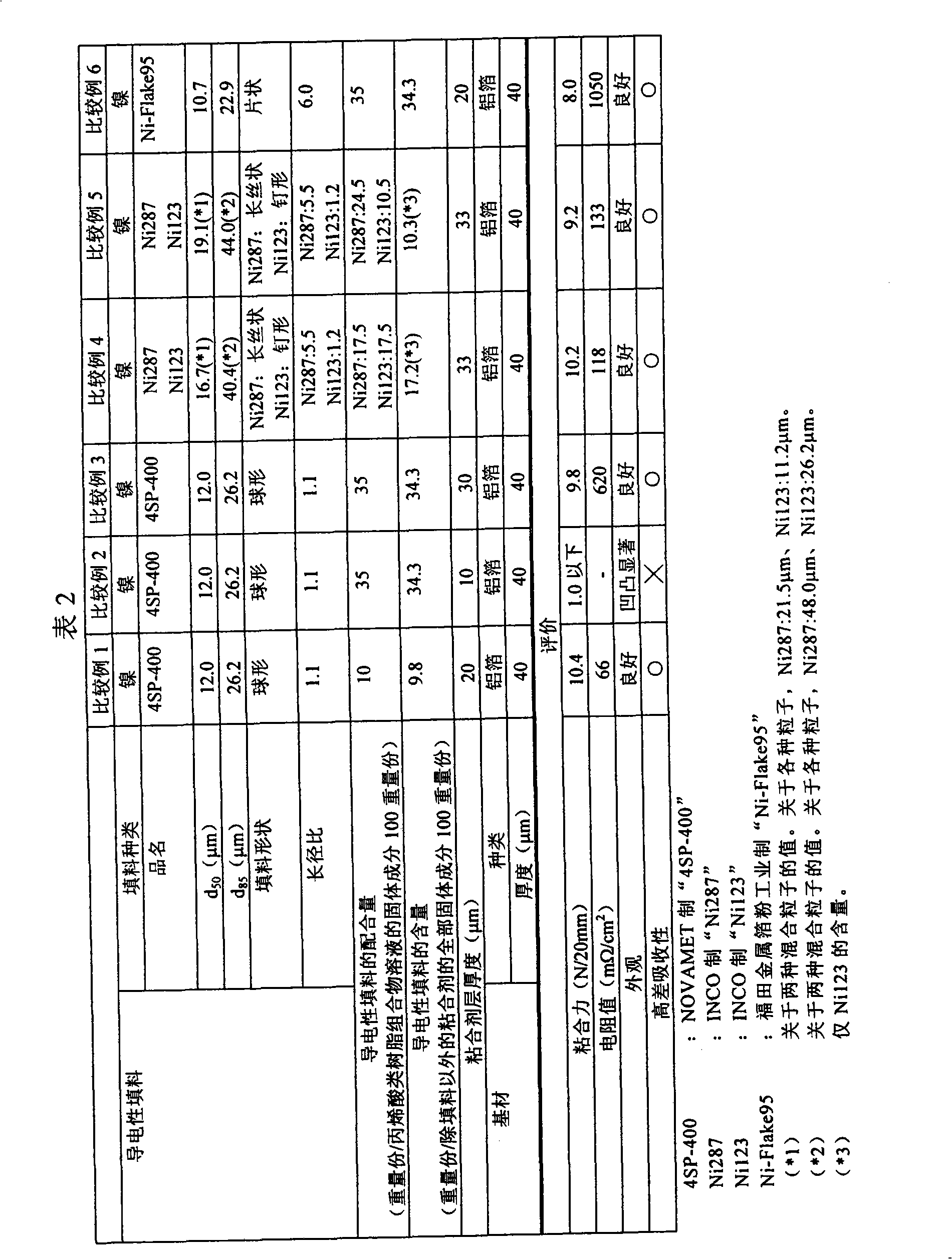

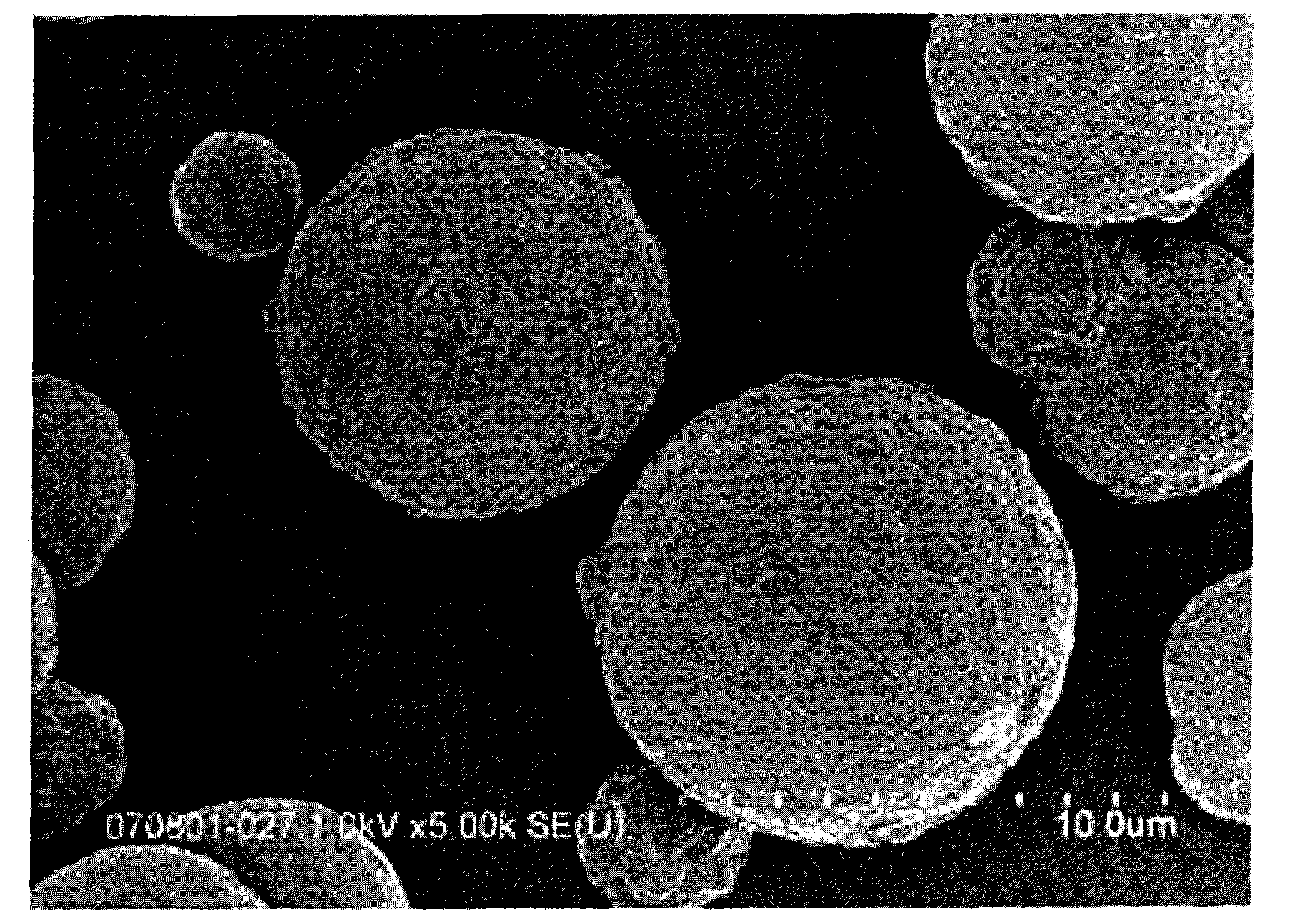

Electroconductive pressure-sensitive adhesive tape

ActiveCN101809105AImprove productivityImprove qualityNon-macromolecular adhesive additivesMagnetic/electric field screeningTotal solid contentPressure sensitive

This invention provides an electroconductive pressure-sensitive adhesive tape comprising a pressure-sensitive adhesive layer having a thickness of 10 to 30 [mu]m. The pressure-sensitive adhesive layer is formed of a pressure-sensitive adhesive containing spherical and / or spike-like electroconductive fillers having an aspect ratio of 1.0 to 1.5. The amount of the electroconductive fillers is 14 to45 parts by weight based on 100 parts by weight of the total solid content of the pressure-sensitive adhesive excluding the filler. Not less than 90% by weight of all the fillers in the pressure-sensitive adhesive is accounted for by the electroconductive filler. The pressure-sensitive adhesive tape is characterized in that the particle diameter of the electoconductive filler (d50, d85) and the thickness of the pressure-sensitive adhesive layer satisfy a relationship of d85 > thickness of pressure-sensitive adhesive layer > d50. The electroconductive pressure-sensitive adhesive tape, even when the thickness of the pressure-sensitive adhesive layer is reduced, possesses excellent pressure-sensitive adhesive properties and electroconductive properties. Further, the electroconductive pressure-sensitive adhesive tape, even when applied to a step difference part, has a step difference absorbing property high enough to avoid 'lifting' from an adherend. Accordingly, the electroconductive pressure-sensitive adhesive tape is useful, for example, for the production of electric and electronic apparatuses and the like.

Owner:NITTO DENKO CORP

Method for preparing granular animal feed additive and granular animal feed additive prepared by the method

ActiveUS20050220933A1Efficient preparationMaintenance contentAnimal feeding stuffAccessory food factorsIon contentTotal solid content

Provided are a method for preparing a granular animal feed additive and the granular animal feed additive prepared by the method. The method includes: filtering, with a membrane filter, a fermentation broth obtained from a lysine producing microorganism cultured in a lysine producing condition to obtain a lysine-containing filtrate and a microorganism-containing sludge; drying the filtrate to obtain a concentrate with a total solid content of 48 to 52 wt %; granule-drying the concentrate at a temperature of 50° C. to 60° C. to obtain granules; and coating the granules with a coating agent containing one or more selected from the group consisting of the sludge, a diluent or a free lysine as a lysine content adjustor, and a moisture prevention agent, to obtain lysine granules having the following properties: Lysine content (lysine sulfate)65% or moreGrain size 300-1,200 μm, 90% or moreApparent density 620-720 kg / m3Protein content 10-15%Total sugar content >0-1%Inorganic material content >0-3%Water content >0-3%Carboxylic acid content >0-8%SO4− ion content 20-25%

Owner:CJ CHEILJEDANG CORP

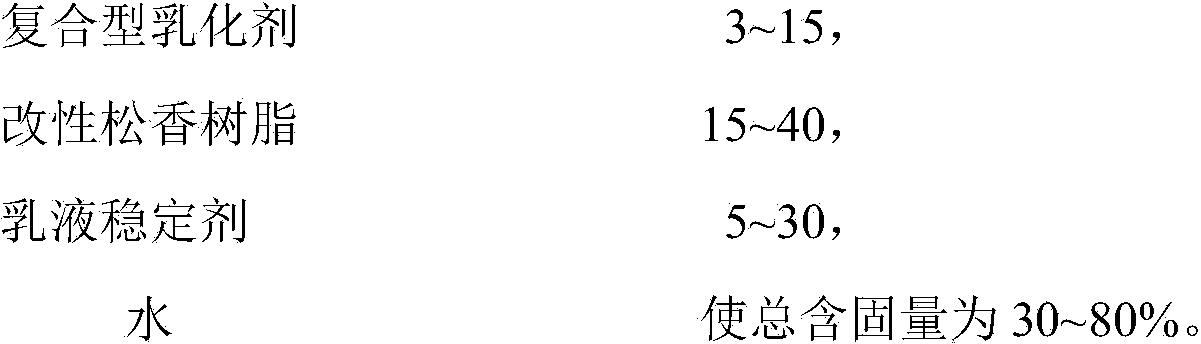

Novel cationic rosin sizing agent and application thereof

ActiveCN103628356AImprove mechanical stabilityGood chemical stabilityWater-repelling agents additionTotal solid contentEmulsion

The invention relates to the field of papermaking, aims at solving the problems that in the preparation process of the existing cation dispersing rosin latex, a solvent does not have a complete environment-friendly effect and is troublesome in recovery; after the solvent is removed, instability is possibly brought to an emulsifying agent and dispersed rosin, so that a rosin sizing agent is poor in mechanical stability, and the rosin sizing efficiency is not ell improved. The invention provides a novel cationic rosin sizing agent and application of the novel cationic rosin sizing agent in papermaking additive. The novel cationic rosin sizing agent comprises the following components by weight percent: 3-15% of a composite type emulsifying agent, 15-40% of modified rosin resin and 5-30% of an emulsion stabilizer; water is added into the components, so that the total solid content is 30-80%. When the sizing agent is used, emulsion particles are stable in performance, the sizing effect is remarkable, and the environment-friendly production is achieved.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

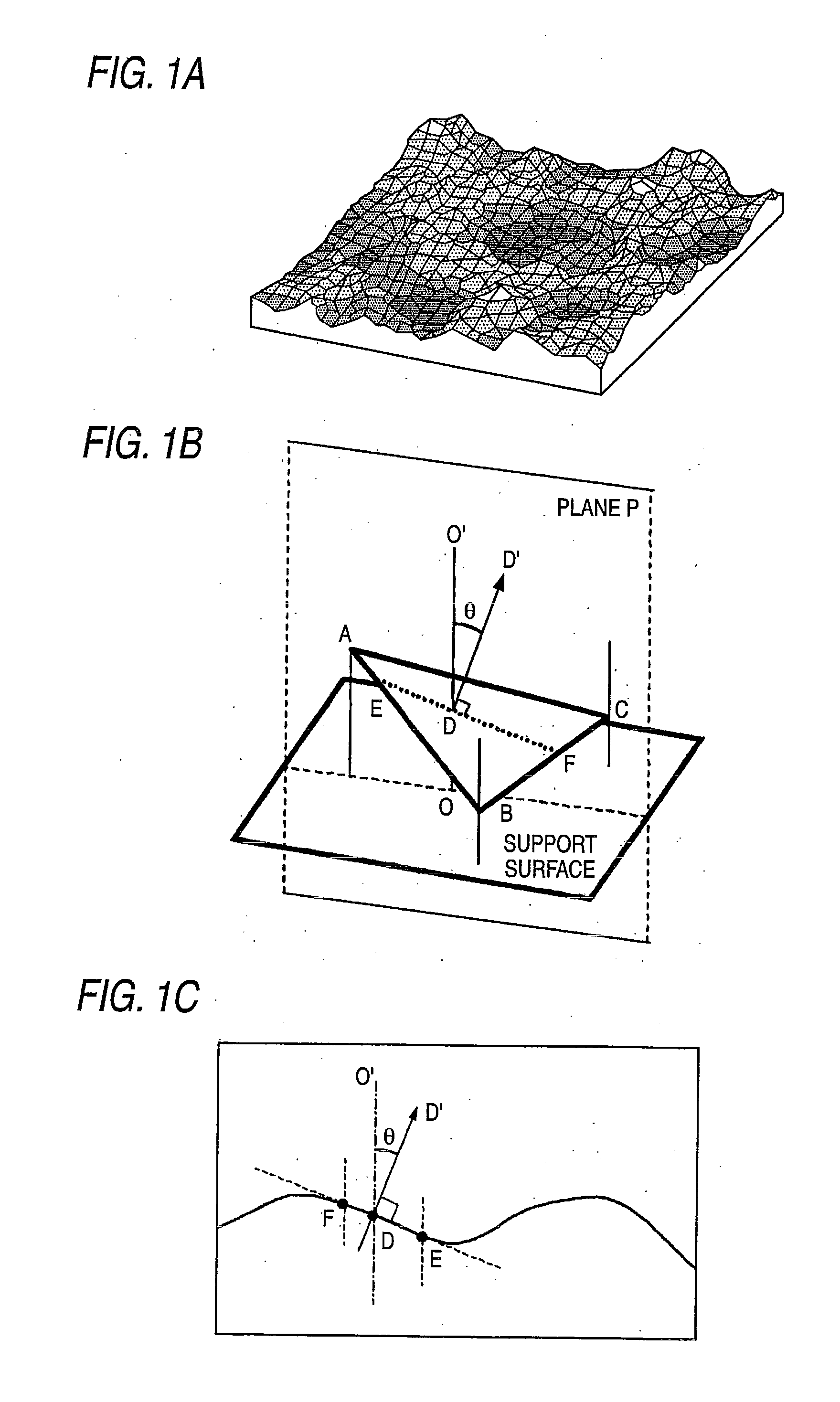

Antiglare film, antireflective film, polarizing plate and image display device

ActiveUS20100079869A1Excellent anti-glareHigh densityDiffusing elementsCoatingsTotal solid contentOragene

An antiglare film is provided, the antiglare film including: a support; and an antiglare layer including a surface that has asperities, wherein the antiglare layer contains at least first light-transmitting particles and second light-transmitting particles, the first light-transmitting particles have an average particle size that is 0.01 to 2.5 μm greater than an average thickness of the antiglare layer, the second light-transmitting particles have an average particle size that is at least 0.1 μm smaller than the average thickness of the antiglare layer, the first light-transmitting particles are contained in an amount of 0.1 to 2 mass % based on a total solid content in the antiglare layer, the second light-transmitting particles are contained in an amount of 2 to 30 mass % based on the total solid content in the antiglare layer, and the second light-transmitting particles include organic polymer-containing particles each of which has a core particle / shell layer structure.

Owner:FUJIFILM CORP

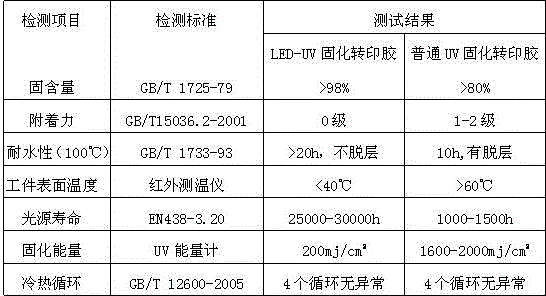

LED-UV-cured transfer printing adhesive and preparation method thereof

ActiveCN105733389AFast curingGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsTotal solid contentUltraviolet lights

The invention discloses an LED-ultraviolet light (LED-UV)-cured transfer printing adhesive and a preparation method thereof.The transfer printing adhesive is prepared from, by mass, 10%-15% of modified epoxy acrylate, 20%-35% of aliphatic urethane acrylate, 30%-40% of specially functional acrylic ester, 10%-20% of active diluent, 4%-6% of photoinitiator and 2%-5% of an adhesion promoter.A using method of the prepared transfer printing adhesive comprises the steps that firstly, the transfer printing adhesive is applied to a workpiece; secondly, a transfer printing adhesive coating is covered with a transfer printing ink film, and then the pattern transfer printing effect is achieved through LED ultraviolet light curing.The prepared transfer printing adhesive is a total-solid-content UV adhesive, effectively utilizes an LED-UV low-energy curing light source, is quick in deep curing and low in energy consumption, has the excellent adhesion and the good water resistance and can be widely applied to various workpieces needing pattern transfer printing.

Owner:HUNAN JINHAI SCI & TECH

Stable reactive thermosetting formulations of reducing sugars and amines

ActiveUS20120135152A1Sufficiently shelf-stableEconomical long distance supplyPretreated surfacesCoatingsGlass fiberTotal solid content

The present invention provides stable aqueous thermosetting binder compositions having a total solids content of 15 wt. % or higher, preferably, 20 wt. % or higher, and having extended shelf life comprising one or more reducing sugar, one or more primary amine compound, and one or more stabilizer acid or salt having a pKa of 8.5 or less. The total amount of stabilizer used may range from 5 to 200 mole %, based on the total moles of primary amine present in the binder. The stabilizer may be an organic stabilizer chosen from a monocarboxylic acid, a dicarboxylic acid, a fatty acid, an acid functional fatty acid ester, an acid functional fatty acid ether, or an inorganic stabilizer chosen from a mineral acid, a mineral acid amine or ammonia salt, and a Lewis acid, and mixtures thereof. The compositions can be used to provide binders for substrate materials including, for example, glass fiber.

Owner:ROHM & HAAS CO

Nano-graphene loaded wax liquor, and preparation method and use thereof

ActiveCN103468004AGood electrical and thermal conductivityGood self-lubricating performanceFibre treatmentInksTotal solid contentCvd graphene

The invention belongs to the technical field of fine chemical engineering polymer materials, and specifically relates to nano-graphene loaded wax liquor, and a preparation method and a use thereof. The wax liquor is a wax dispersion which is formed by loading ultrafine nano-graphene particles having the particle size in the range from 20 to 40 nm on wax particles having the particle size in the range from 200 to 800 nm; and the total solid content of the wax liquor is 15-25%. The preparation method provided by the invention is used for successfully solving the dispersion and aggregation problems of graphene while being used for a paint or an ink body; and the nano-graphene loaded wax liquor prepared by the preparation method is used for paint, ink or leather finishing, and has the effects of rub resistance, static resistance and electromagnetic wave blocking.

Owner:NANJING TIANSHI NEW MATERIAL TECH

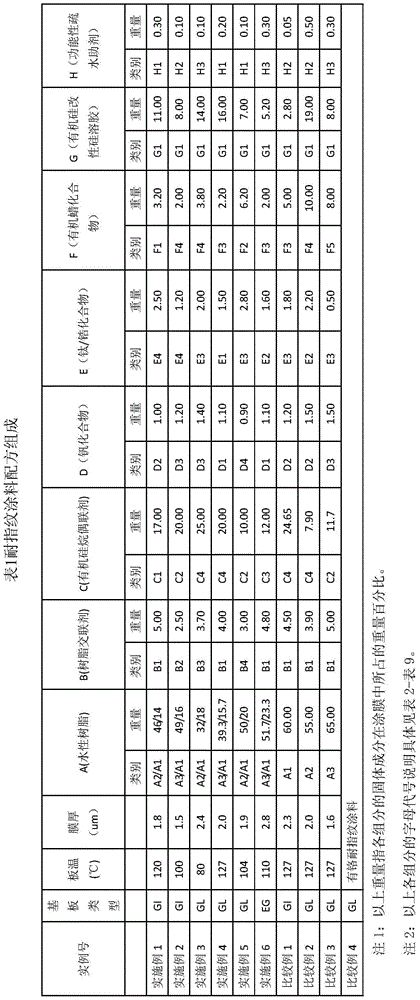

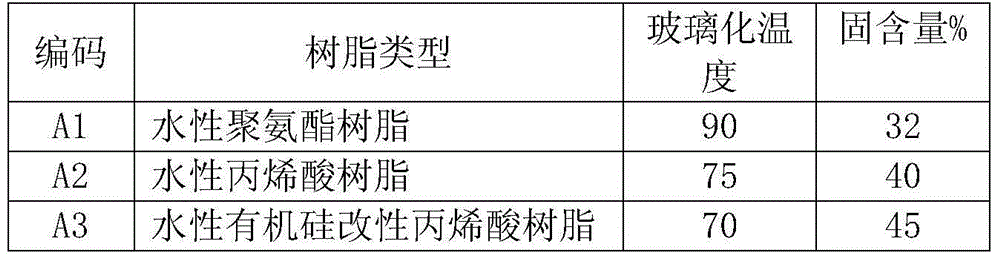

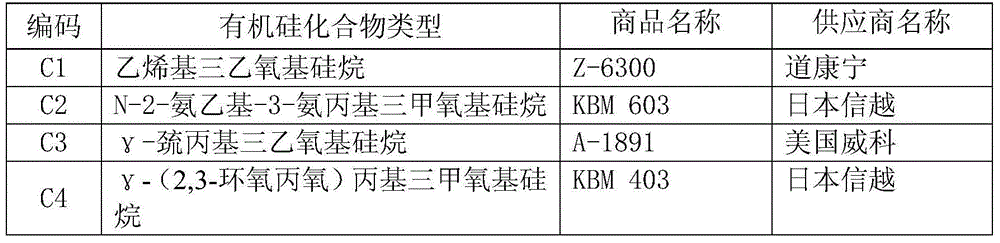

High-corrosion-resistance, high-weather-resistance and excellent-hydrophobicity chromium-free fingerprint-resistant coating used for galvanized steel sheet

InactiveCN104403538AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsChromium freeWater based

The invention relates to a high-corrosion-resistance, high-weather-resistance and excellent-hydrophobicity chromium-free fingerprint resistant coating used for a galvanized steel sheet. The water solution of the chromium-free fingerprint resistant coating consists of the following components: (A) at least two or more than two water-based resins accounting for 30-80wt% of the total solid content; (B) at least one water-based cross-linking agent accounting for 1-10wt% of the total solid content; (C) at least one organic silane coupling agent accounting for 5-40wt% of the total solid content; (D) at least one vanadium-containing compound accounting for 0.1-2wt% of the total solid content; (E) a compound of at least one element in titanium and zirconium accounting for 0.1-5wt% of the total solid content; (F) at least one organic wax compound accounting for 0.5-10wt% of the total solid content; (G) at least one organic silicon modified collosol accounting for 1-30wt% of the total solid content; (H) at least one functional hydrophobic agent accounting for 0.05-0.5wt% of the total solid content. The galvanized steel sheet on which the chromium-free fingerprint resistant coating is coated can completely meet the requirement of outdoor use.

Owner:上海华谊精细化工有限公司技术中心

ICP-MS measuring method of trace metal impurities in high purity lead

InactiveCN101551357AEasy to operateAvoid pollutionMaterial analysis by electric/magnetic meansTotal solid contentMinor metals

The invention relates to an ICP-MS measuring method of trace metal impurities in high purity lead, which adopts a high-purity nitric acid dissolving sample and uses the electrolytic method to remove lead in the high purity nitric acid dissolving sample, and utilizes inductive coupled plasma mass spectrometer and adopts peak jumping mode to scan and test blank, work-curve standard solution and sample elements to be detected so as to obtain the content of the elements to be detected. The ICP-MS measuring method of trace metal impurities in high purity lead is convenient in operation and can effectively eliminate matrix effect caused by excessively high total solid content and avoid pollution during the preparation process of samples, thus greatly reducing memory effect and obviously increasing measuring accuracy. The ICP-MS measuring method of trace metal impurities in high-purity lead is applicable to the analysis and testing of the content of a plurality of trace metal impurities.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

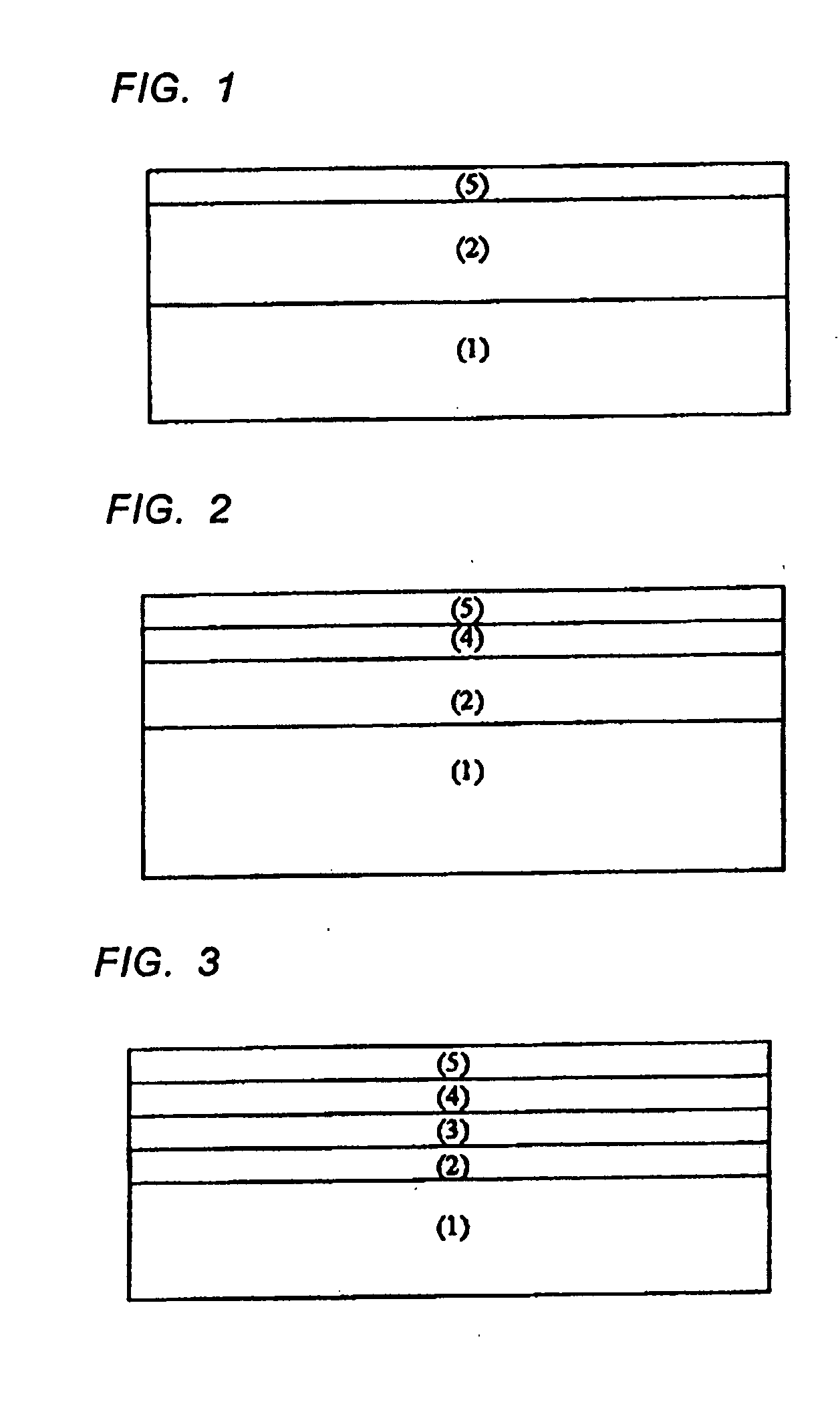

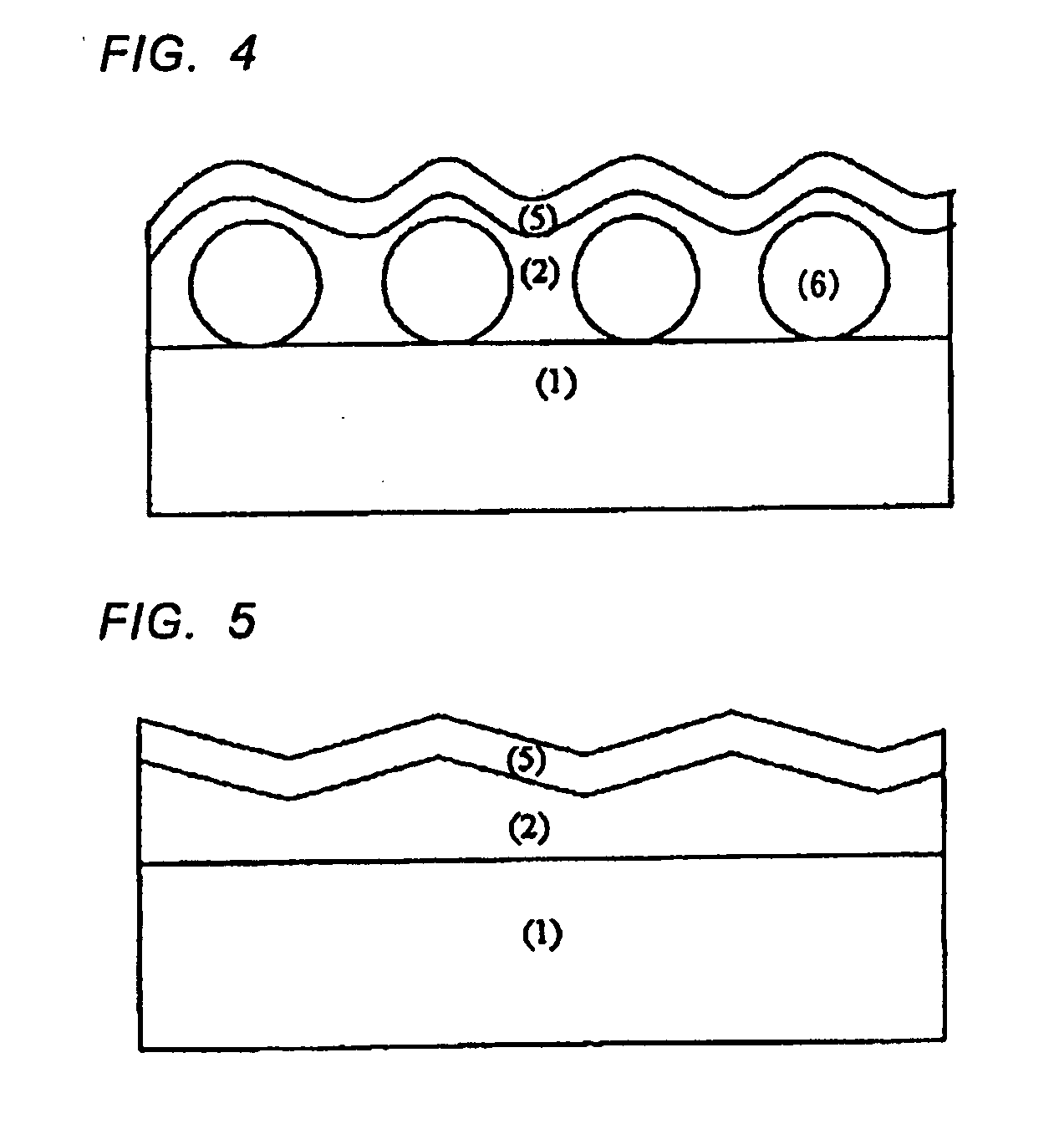

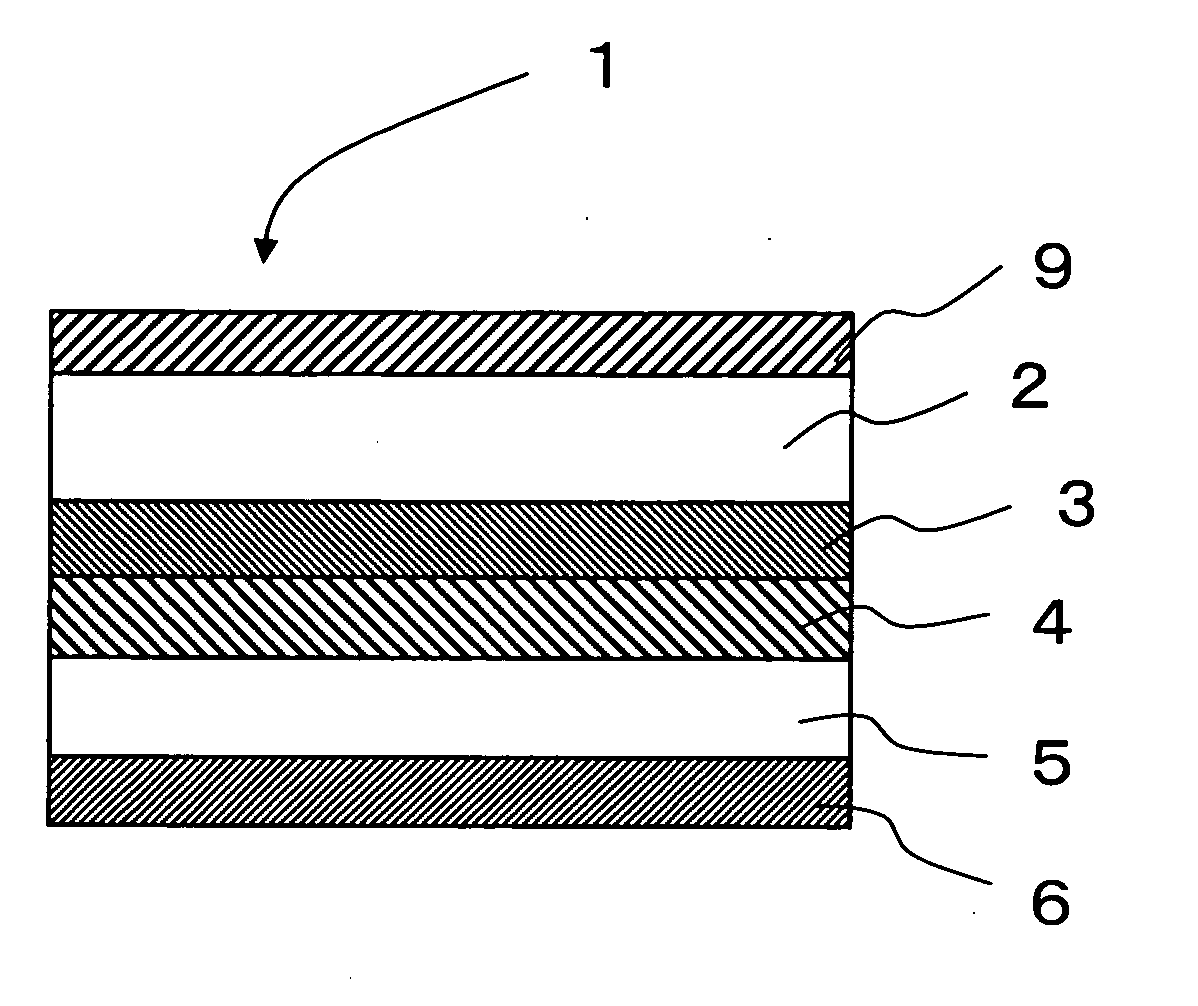

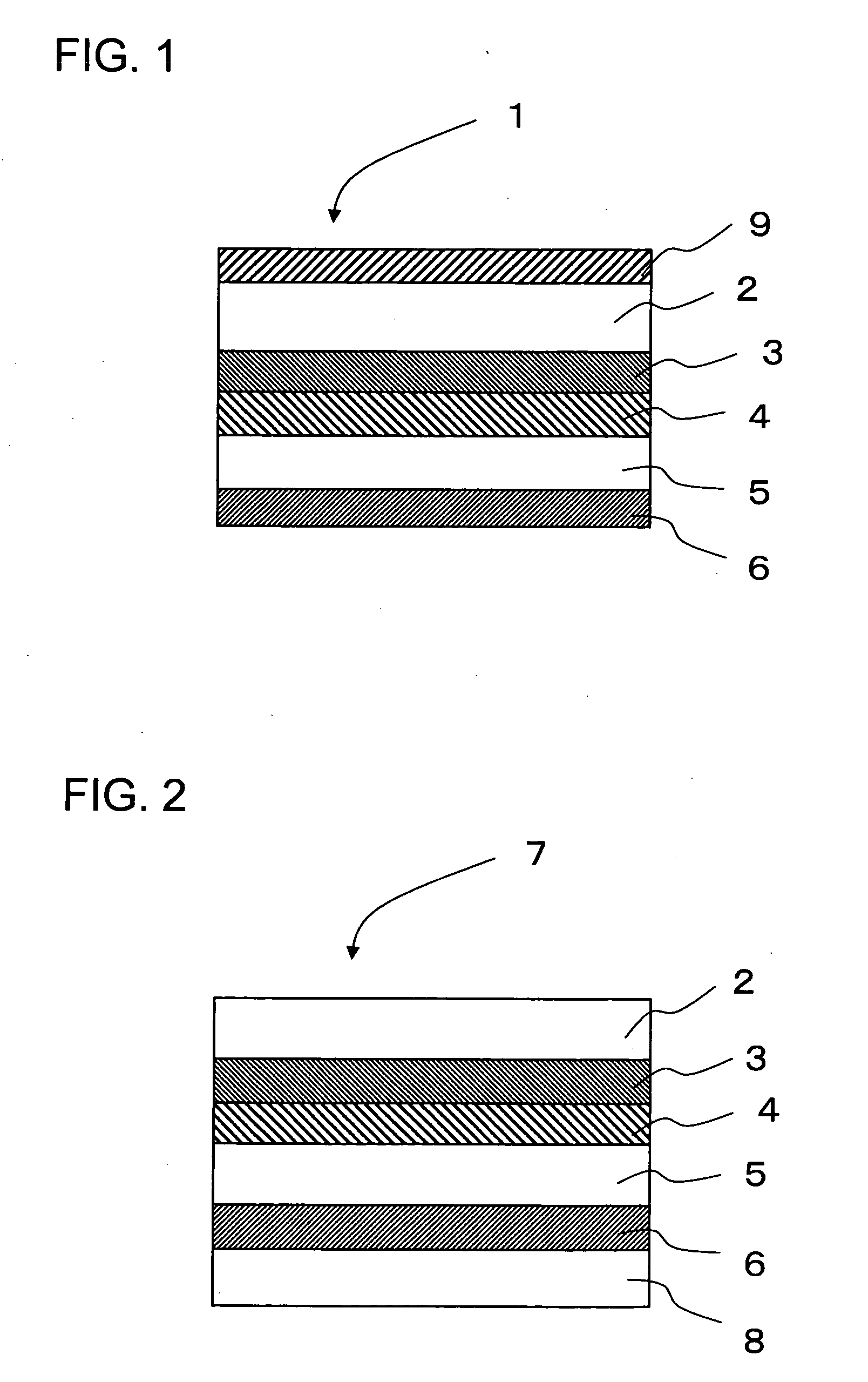

Hologram transfer sheet and intermediate transfer recording medium

ActiveUS20060127623A1Avoid crackingAvoid layeringLayered productsDecorative surface effectsChemical structureTotal solid content

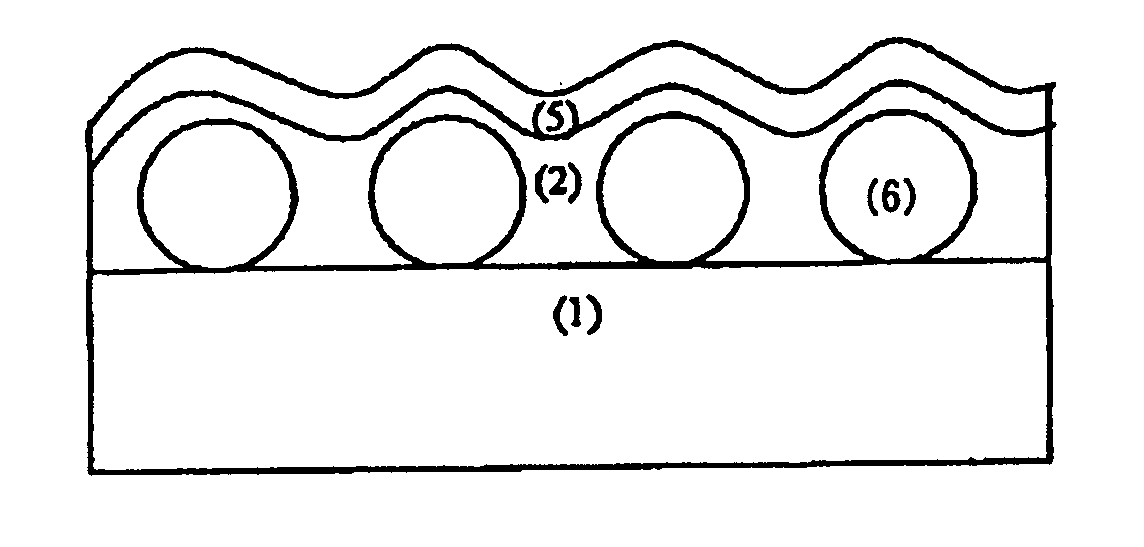

It is an object of the invention is to provide a hologram transfer sheet comprising: at least, a peelable layer; a relief formation layer having a relief; and a metal thin layer, which are sequentially formed on a substrate, capable of preventing a crack or discoloration of the metal thin layer which may be caused by heat or stress when a transfer layer is aligned with and transferred onto a transfer receiving body or preventing a disfigurement of the external appearance which may be caused by a crack mark of the metal thin layer following the thermal deformation of the substrate when performing an entire surface transfer by means of a heat roller. Such a hologram transfer sheet (1) comprising: at least, a peelable layer (3); a relief formation layer (4) having a relief; and a metal thin layer (5), which are sequentially formed on a substrate (2), is characterized in that the peelable layer (3) is made of a norbornene-based resin having a chemical structure containing a norbornene structure at least. The peelable layer preferably contains a resin incompatible with such a norbornene-based resin at a ratio from 5 to 30% by weight relative to a total solid content.

Owner:DAI NIPPON PRINTING CO LTD

Negative photosensitive resin composition

ActiveUS20050191580A1Reduce adhesionReduce concentrationRadiation applicationsOriginals for photomechanical treatmentPolymer scienceTotal solid content

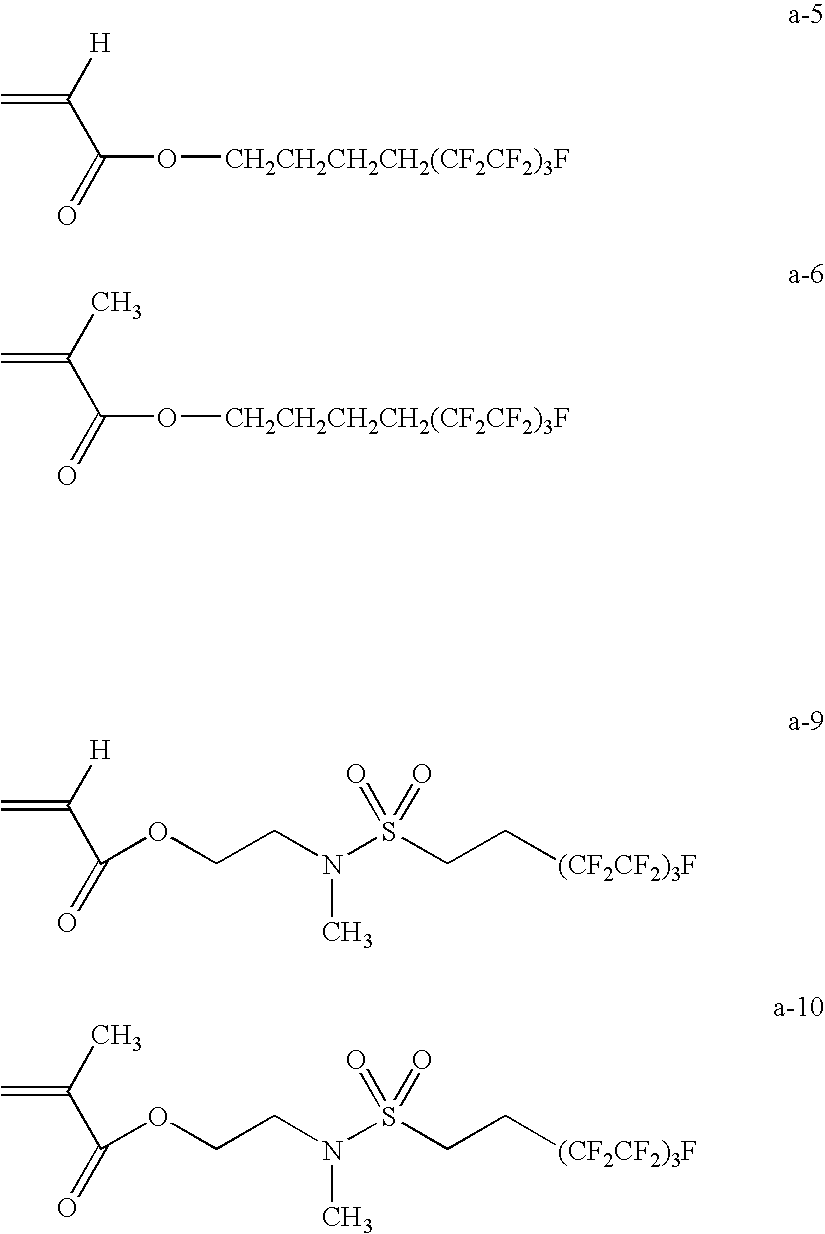

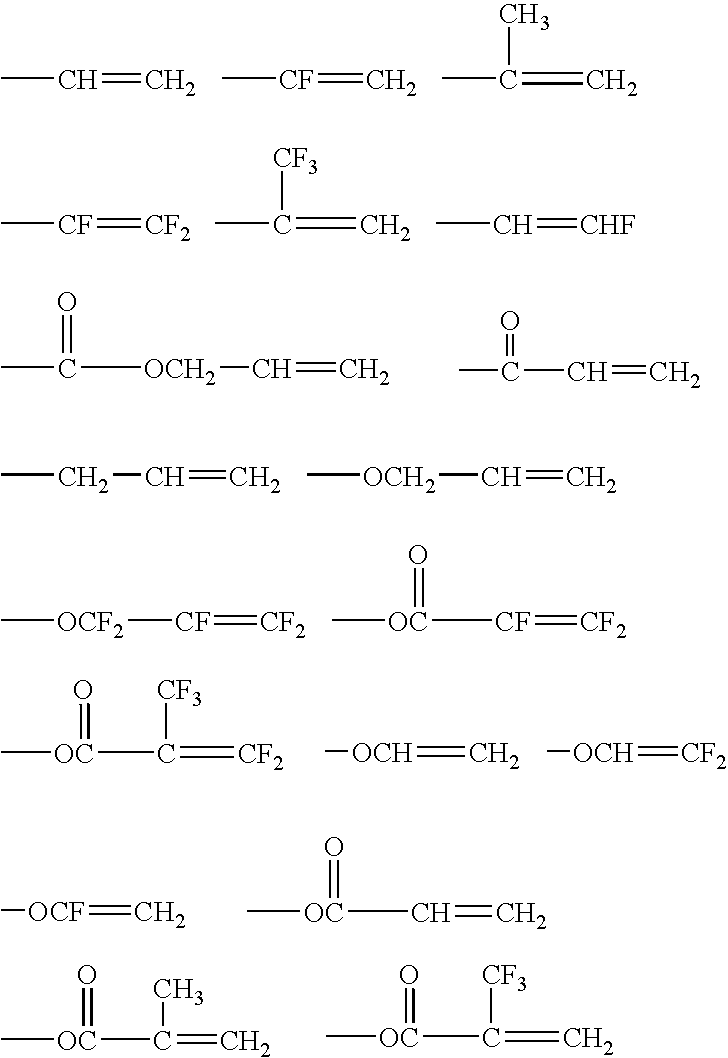

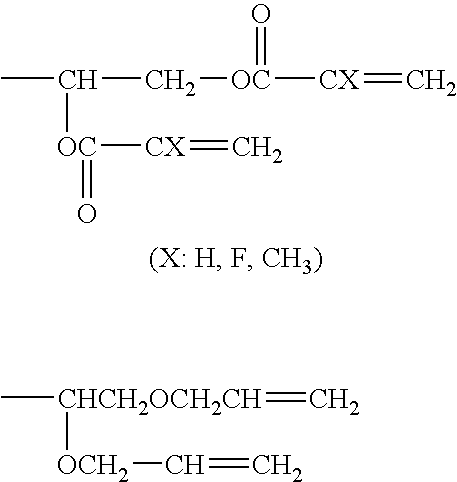

A negative photosensitive resin composition comprising an alkali-soluble photosensitive resin (A) having acidic groups and having at least three ethylenic double bonds per molecule, an ink repellent (B) made of a polymer having polymerized units (b1) having a C20 or lower alkyl group in which at least one of its hydrogen atoms is substituted by a fluorine atom (provided that the alkyl group may contain etheric oxygen), and polymerized units (b2) having an ethylenic double bond, and a photopolymerization initiator (C), wherein the fluorine content in the ink repellent (B) is from 5 to 25 mass %, and the proportion of the ink repellent (B) is from 0.01 to 20 mass %, based on the total solid content of the negative photosensitive resin composition. The negative photosensitive resin composition of the present invention is excellent in adhesion to a substrate, ink repellency and durability thereof and further excellent in alkali solubility and developability.

Owner:ASAHI GLASS CO LTD

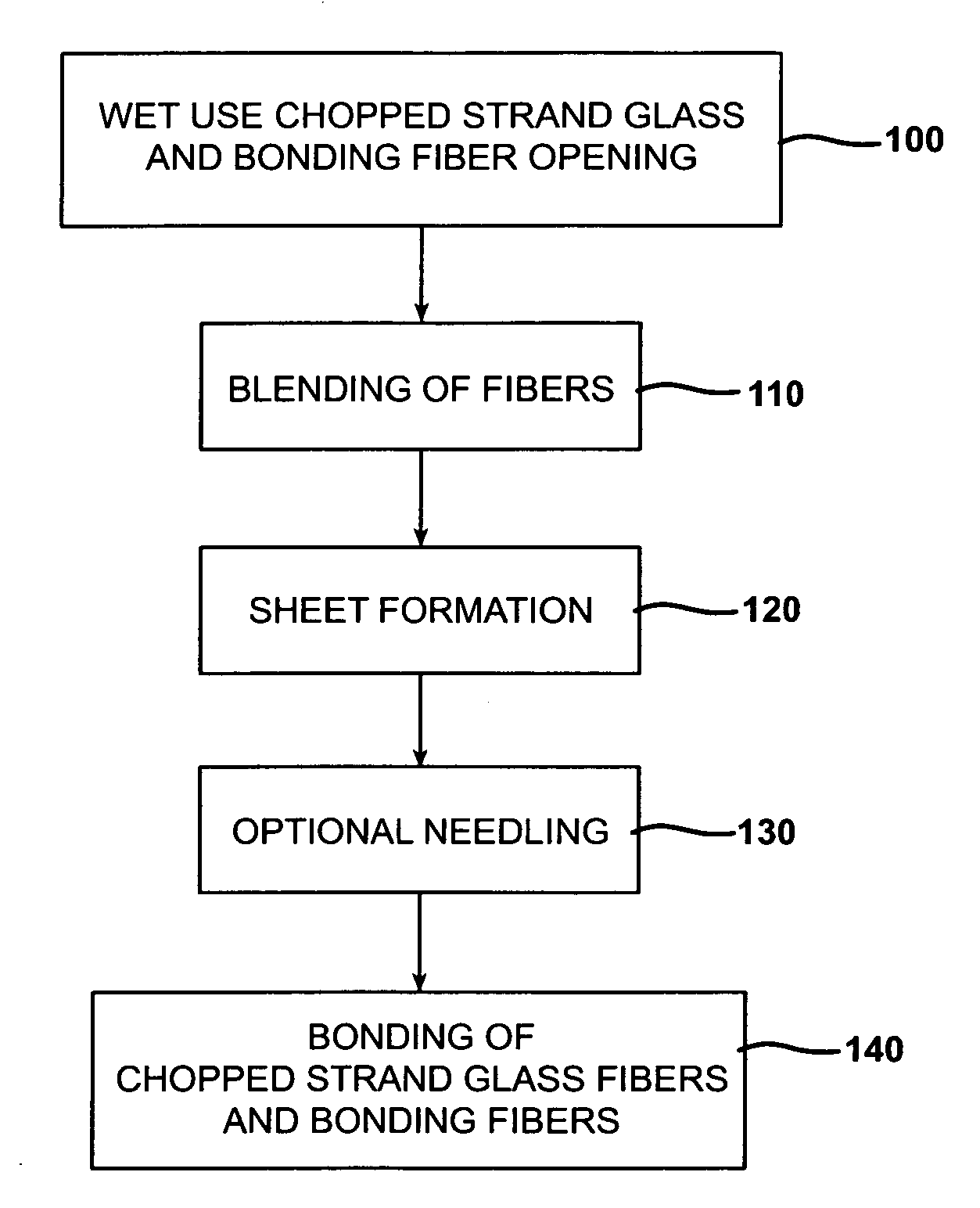

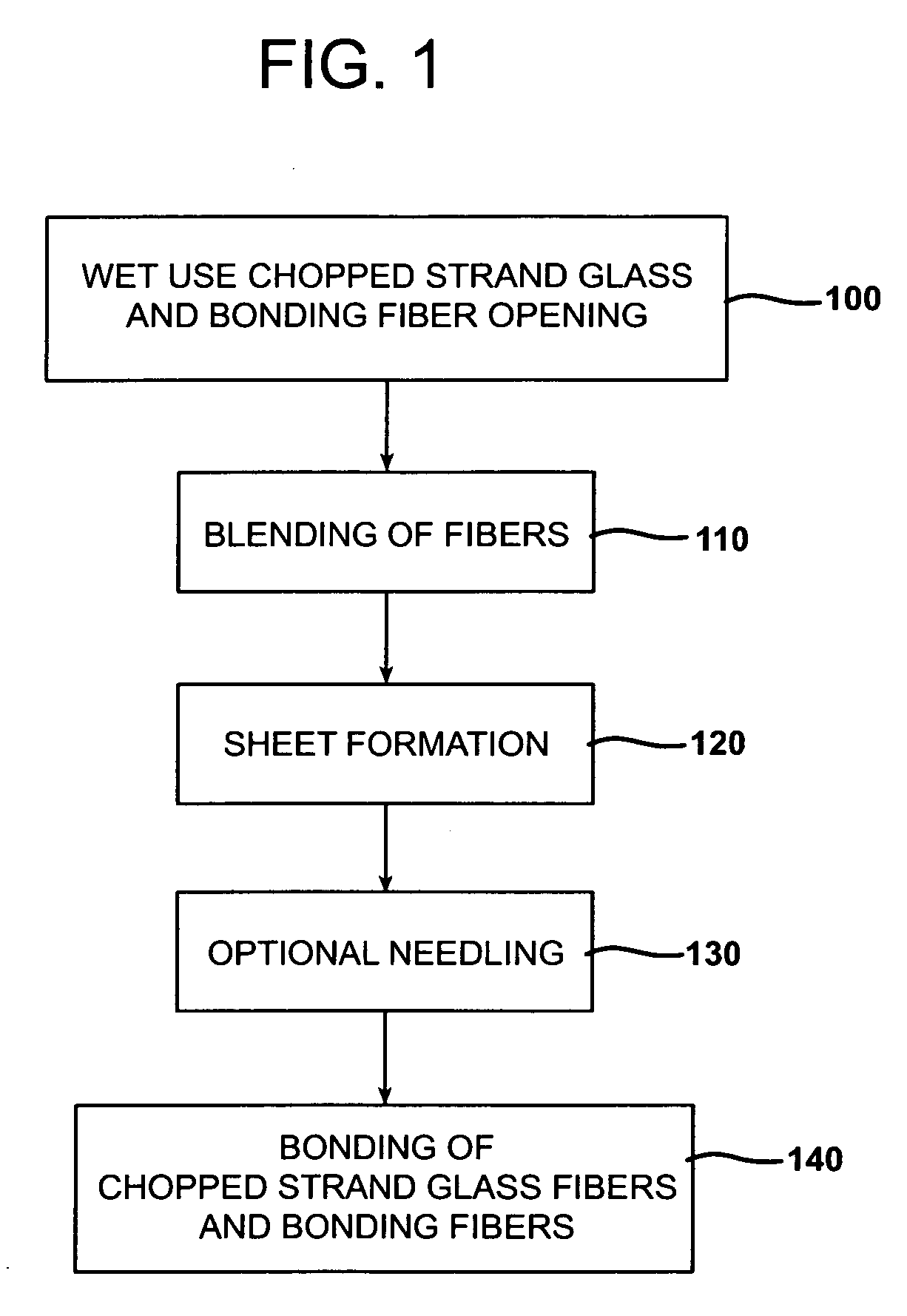

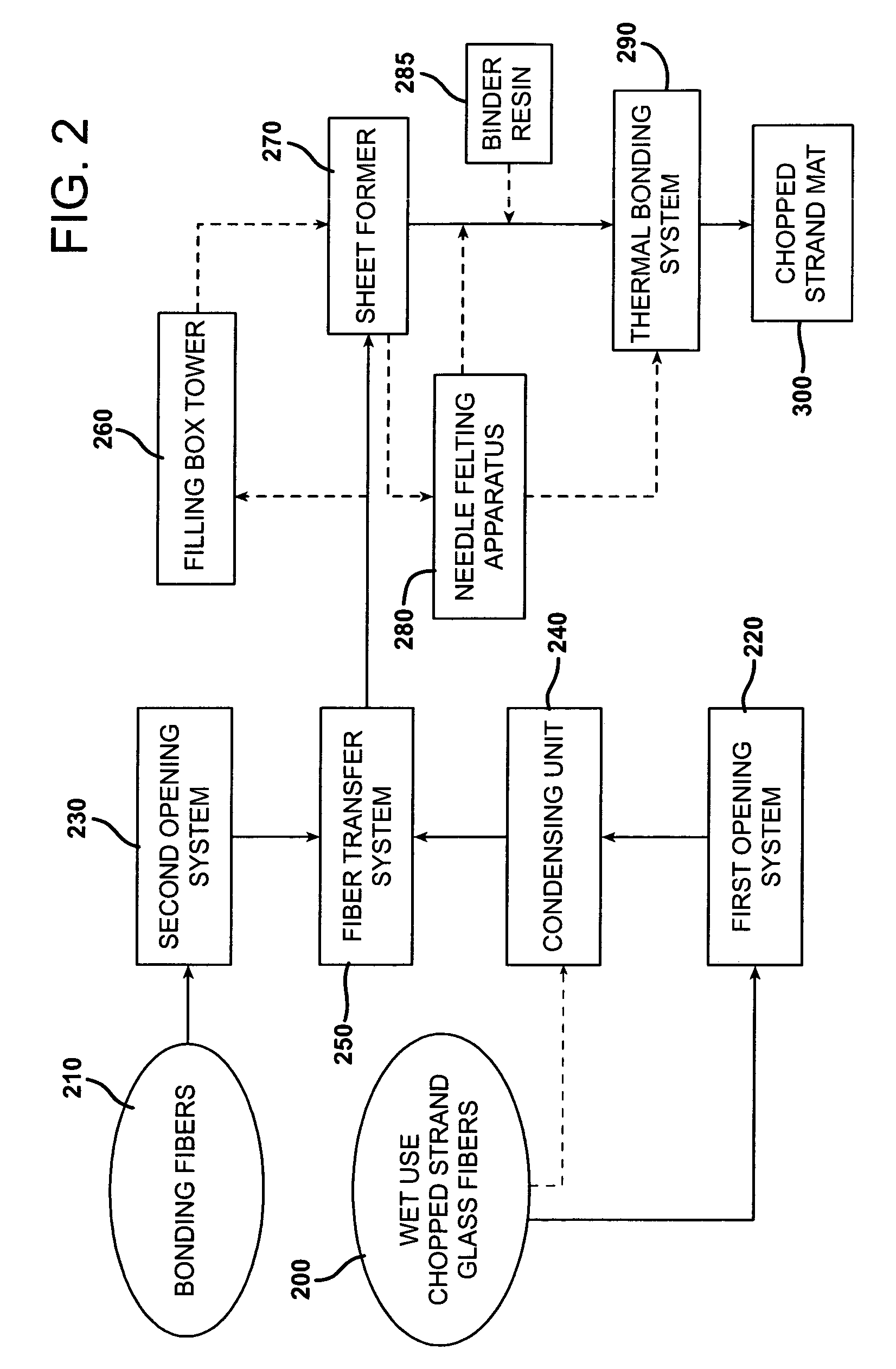

Static free wet use chopped strands (WUCS) for use in a dry laid process

InactiveUS20050266757A1Improve controlReduce staticInorganic fibres/flakesSynthetic resin layered productsGlass fiberAntistatic agent

A method of forming a chopped strand mat formed of bonding materials and wet use chopped strand glass fibers (WUCS) which demonstrate a reduced occurrence of static electricity is provided. In one exemplary embodiment, the occurrence of static electricity on the glass fibers is reduced or eliminated by increasing the total solids content on the glass fibers, such as by applying an increased or excess amount of size composition to the glass fibers. Alternatively, an anti-static agent may be added directly to the sizing composition and applied to the glass filaments by any suitable application device. The antistatic agent may be applied to the wet chopped strand glass prior to chopping the strands or as the wet chopped strands are packaged. The static free wet use chopped strand glass fibers may be used in dry-laid processes to form chopped strand mats having a reduced tendency to accumulate static electricity.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Barrier coating mixtures containing non-elastomeric acrylic polymer with silicate filler and coated articles

Barrier coating mixtures contain in a carrier liquid, (a) a non-elastomeric substantially polymerized acrylic polymer; (b) an exfoliated layered platelet-like silicate filler which has been acid treated and having an aspect ratio greater than 25; and (c) at least one additive, wherein the total solids content is less than 30% and the amount of filler is between 5% to about 60% of the total solids content. Coated articles and containers, freestanding films and packaging films are produced using the barrier coating mixtures. Methods of manufacturing such coated products and coating mixtures are also encompassed.

Owner:IPL

Ink for recording, and ink cartridge, ink recorded matter, inkjet recording apparatus and inkjet recording method using the same

InactiveUS8044114B2Good colorQuality improvementMeasurement apparatus componentsGroup 5/15 element organic compoundsTotal solid contentWater dispersible

There is provided an ink for recording, which contains: a coloring agent; a water-dispersible resin; a wetting agent; a surfactant; and water, wherein a total solid content of the coloring agent and the water-dispersible resin is 10% by mass to 30% with respect to a total mass of the ink, a ratio B / C is 0.1 to 1.6 where B is a solid content of the coloring agent in the ink, and C is a solid content of the water-dispersible resin in the ink, a viscosity of the ink is 5 mPa·s to 20 mPa·s at 25° C., and a surface tension of the ink is 35 mN / m or less.

Owner:RICOH KK

Method for manufacturing cellulose fibroin composite fiber by using solvent method

InactiveCN101220523AReduce production processLower energy costsWet spinning methodsSpinning solutions preparationCelluloseTotal solid content

The invention relates to a method for adopting a solvent method to prepare celluloses silk protein composite fibers and the method comprises: (1) the crushing celluloses and the silk protein are uniformly mixed with ionic liquids and the mixture is dissolved for 1 to 120 hours under the temperature of 25 to 160 DEG C, and the spinning solution is formed the total solid content of which is 3 to 40 percent, wherein, the mixture ratio of the celluloses and the silk protein is 99:1 to 1:99; (2) after filtering and deaeration, spinning and coagulating bath solidifying are carried out; (3) the composite fibers are formed after a plurality of steps such as tension, water-washing, bleaching, oiling and drying. By adopting the ionic liquids to prepare fibers, the long and complex production processes of the viscose method are avoided, the production process is significantly shortened, the energy consumption of technique and the operation cost are low, the cellulose composite fibers have good mechanical strength and the mechanical property is significantly higher than the corresponding conventional viscose fibers produced by the viscose method. The method can be used for manufacturing underclothes and handkerchief, and also various clothing materials can be made after blended spinning or pure spinning.

Owner:DONGHUA UNIV

Polymer latex suitable for the preparation of dip-molded articles

InactiveUS20060052513A1Easy to prepareImprove versatilityWoven fabricsEmulsion paintsTotal solid contentPolymer science

The present invention relates to a polymer latex made by free-radical emulsion polymerization comprising polymer particles containing structural units derived from at least one conjugated diene component, whereby said polymer particles comprise at least one hard phase segment having a glass transition temperature (Tg) of at least 50° C. and at least one soft phase segment having a glass transition temperature (Tg) of 10° C. at most, the total amount of hard phase segments being 2 to 40 wt-% and the total amount of the soft phase segments being 60 to 98 wt-% based on the total weight of the polymer particles, whereby the Tg is measured by DSC according to ASTM D3418-03 and said polymer latex having an electrolyte stability determined as critical coagulation concentration of less than 30 mmol / l CaCl2 (determined for a total solids content of the latex of 0.1% at pH 10) that is particularly suitable for the production of dip-molded articles. Furthermore, the present invention relates to a process for making such a polymer latex, to the use of said polymer latex for the production of dip-molded articles, to a compounded polymer latex composition that is suitable for the production of dip-molded articles, to a method for making dip-molded latex articles, as well as to the latex articles obtained thereby.

Owner:POLYMERLATEX GMBH & CO KG

Dasheen clear juice beverage and preparation method thereof

ActiveCN103704841AReduce contentRich in nutrientsFood ingredient as clouding agentFood homogenisationBiotechnologyEnzymatic hydrolysis

The invention relates to a preparation method of a dasheen clear juice beverage. The total solid content of the dasheen clear juice beverage is over 5 percent, the total fat content is less than 2 percent, and the sodium content is less than 0.1g / 100mL. The preparation method comprises the specific steps of (1) pretreating dasheens, water, composite enzymes, condiments, a stabilizing agent and a preservative, which serve as raw materials, to obtain clean dasheens; (2) performing grinding and gelatinization to obtain mashed dasheen; (3) preparing dasheen normal juice by an enzyme method to obtain the dasheen normal juice; (4) clarifying the rough dasheen normal juice to obtain clarified dasheen normal juice; (5) performing mixing, homogenizing and sterilizing to obtain the dasheen clear juice beverage. According to the preparation method disclosed by the invention, the dasheen clear juice beverage is prepared by a two-enzyme method, so that the enzymatic hydrolysis of the dasheens is increased; silicone soil is adopted for fine filtering, so that the problem that a dasheen clear juice beverage is turbid after a certain period of time is solved. The dasheen clear juice beverage prepared by the preparation method disclosed by the invention smells harmoniously good, tastes smooth, is uniform and stable and has a long storage period.

Owner:HEFEI UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com