Patents

Literature

6409results about How to "Reduce production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

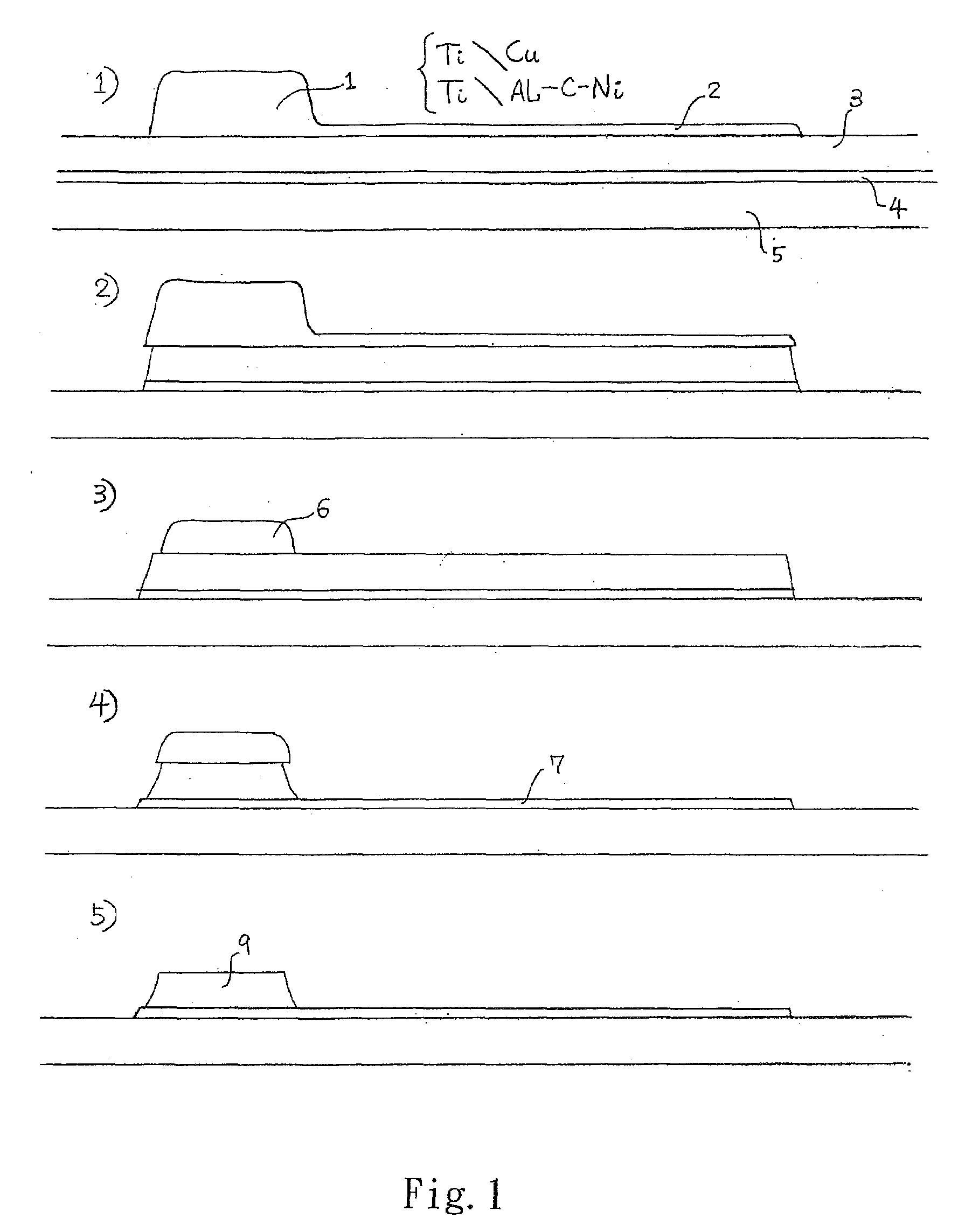

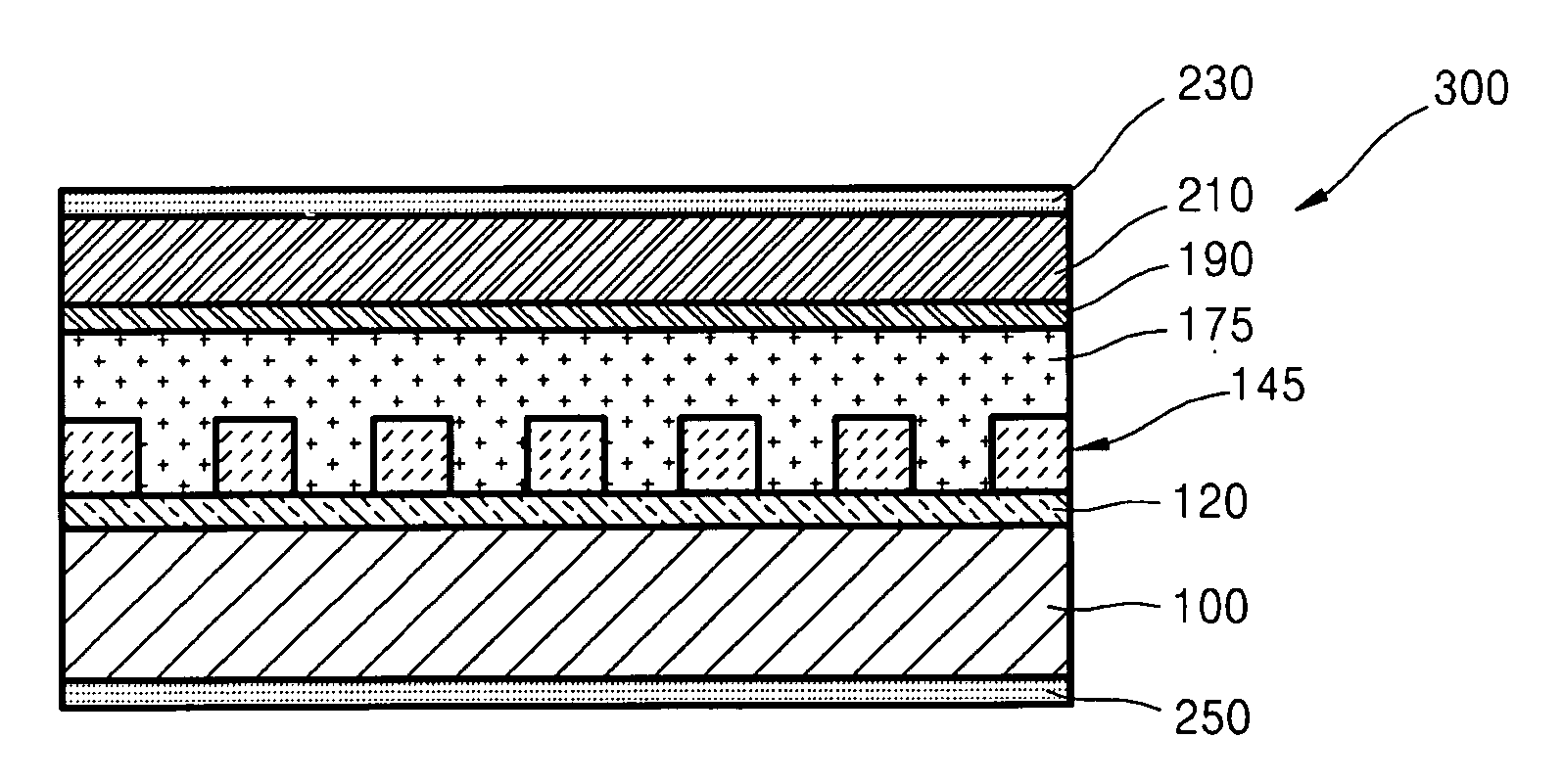

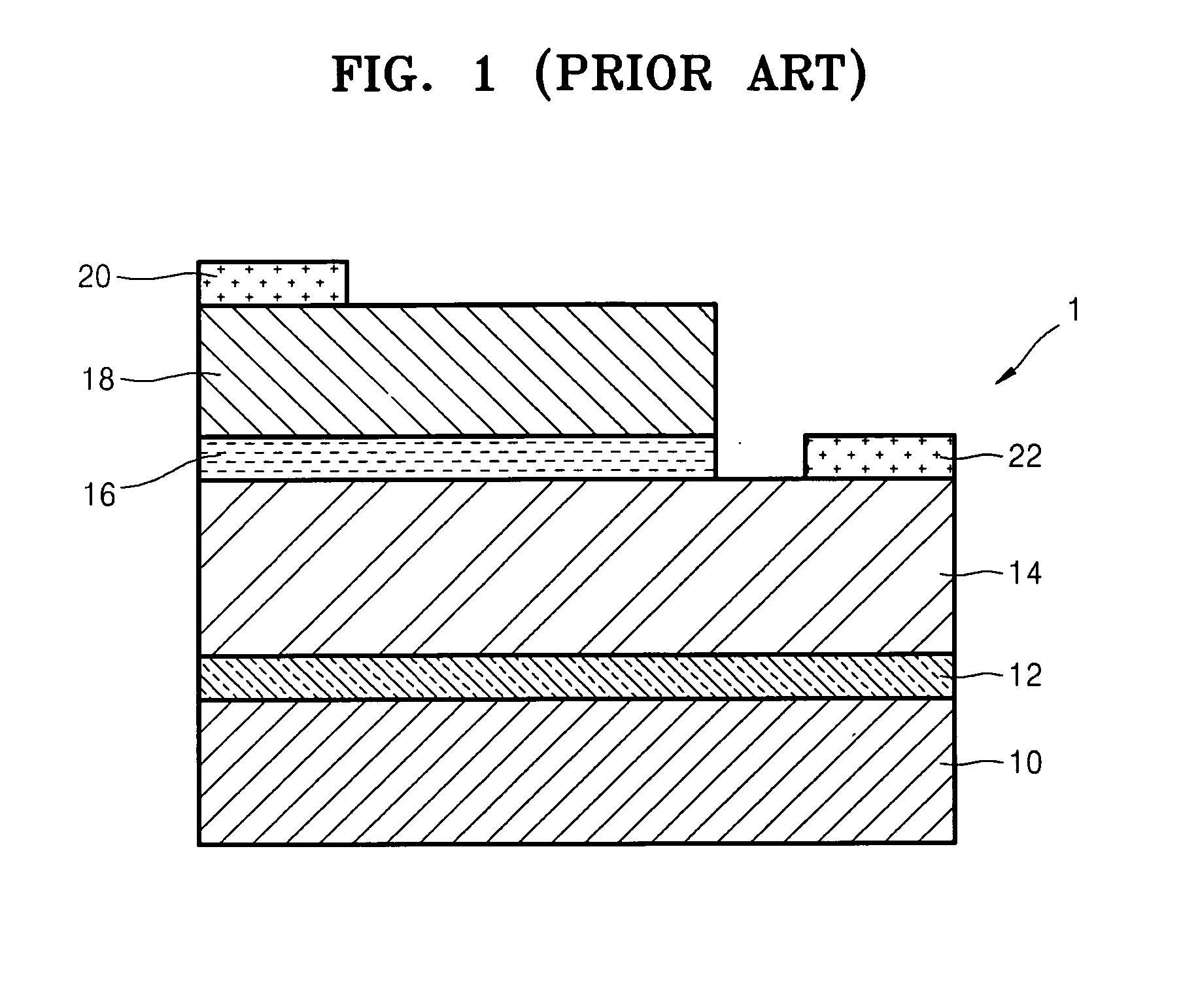

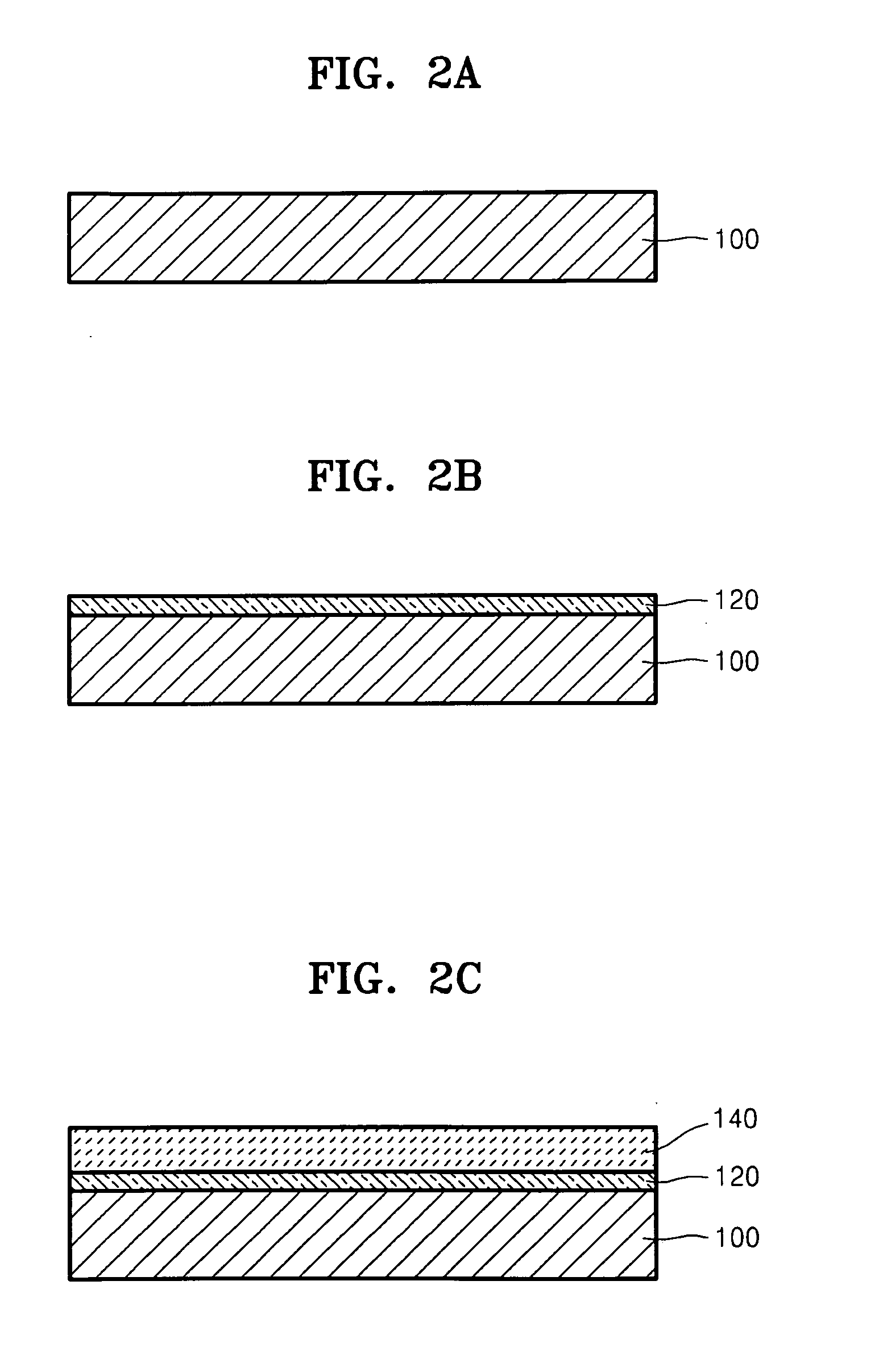

Method for manufacturing semiconductor device, and semiconductor device

InactiveUS20120241919A1High precision transmissionSmall misalignmentSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceSingle crystal

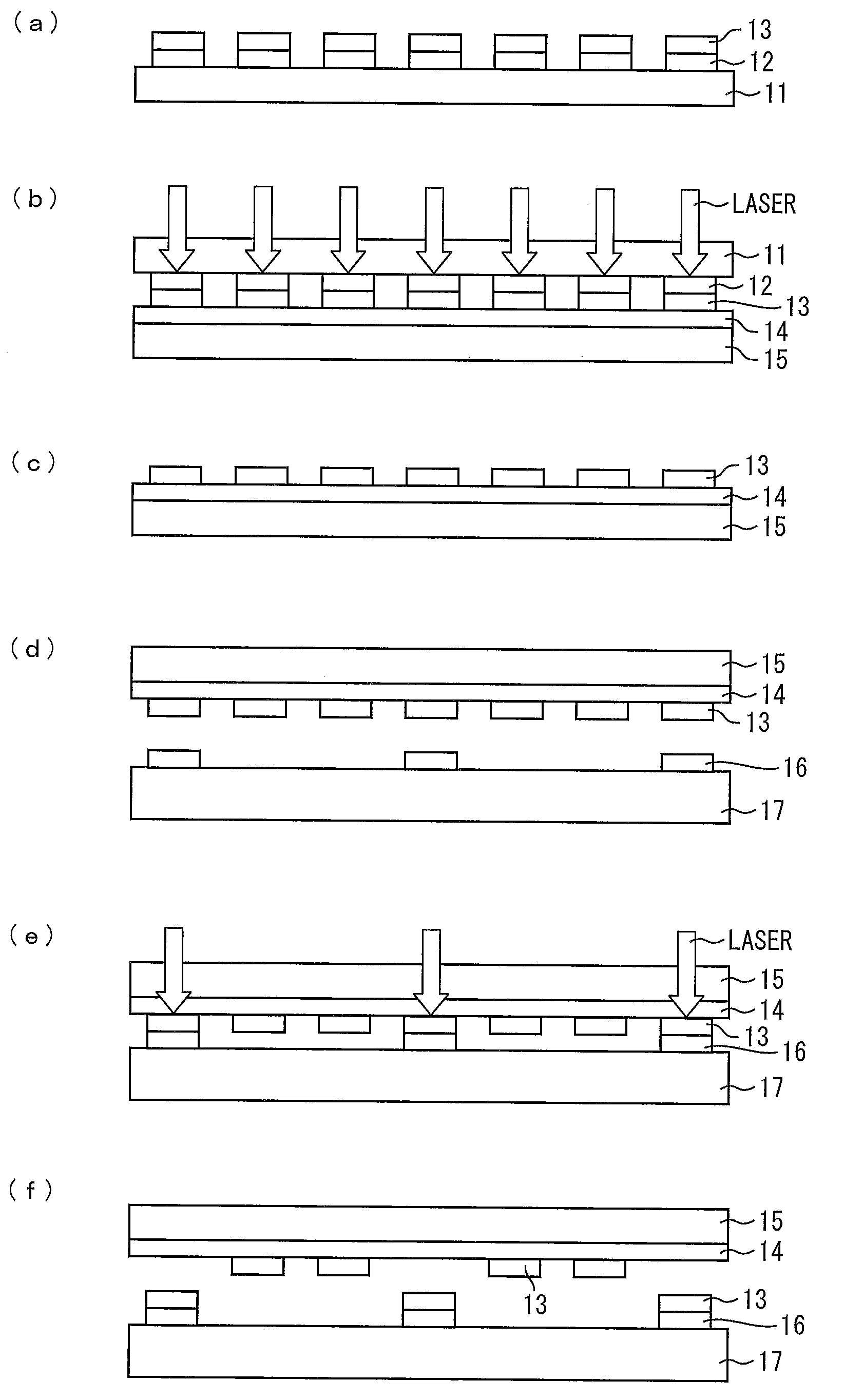

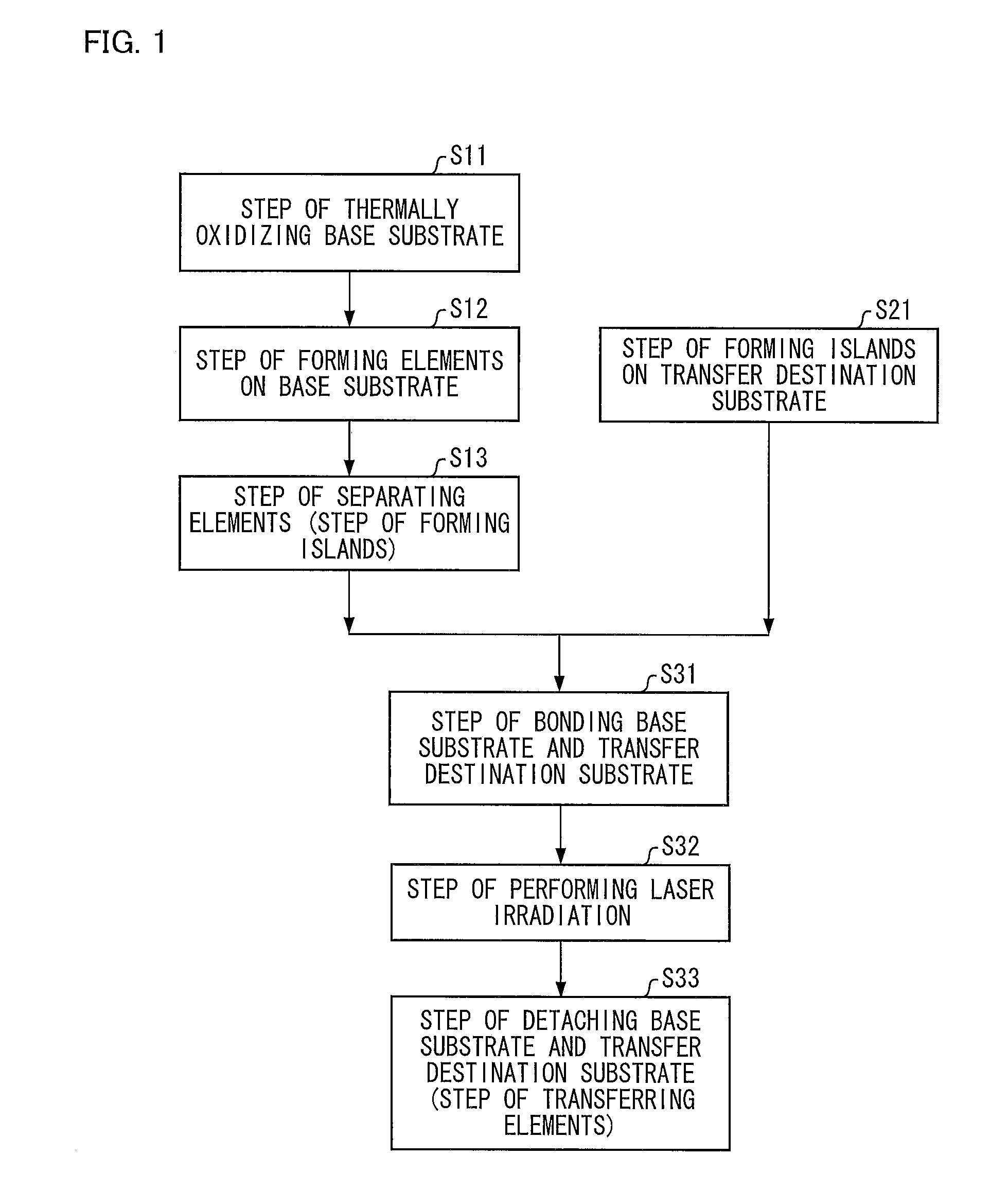

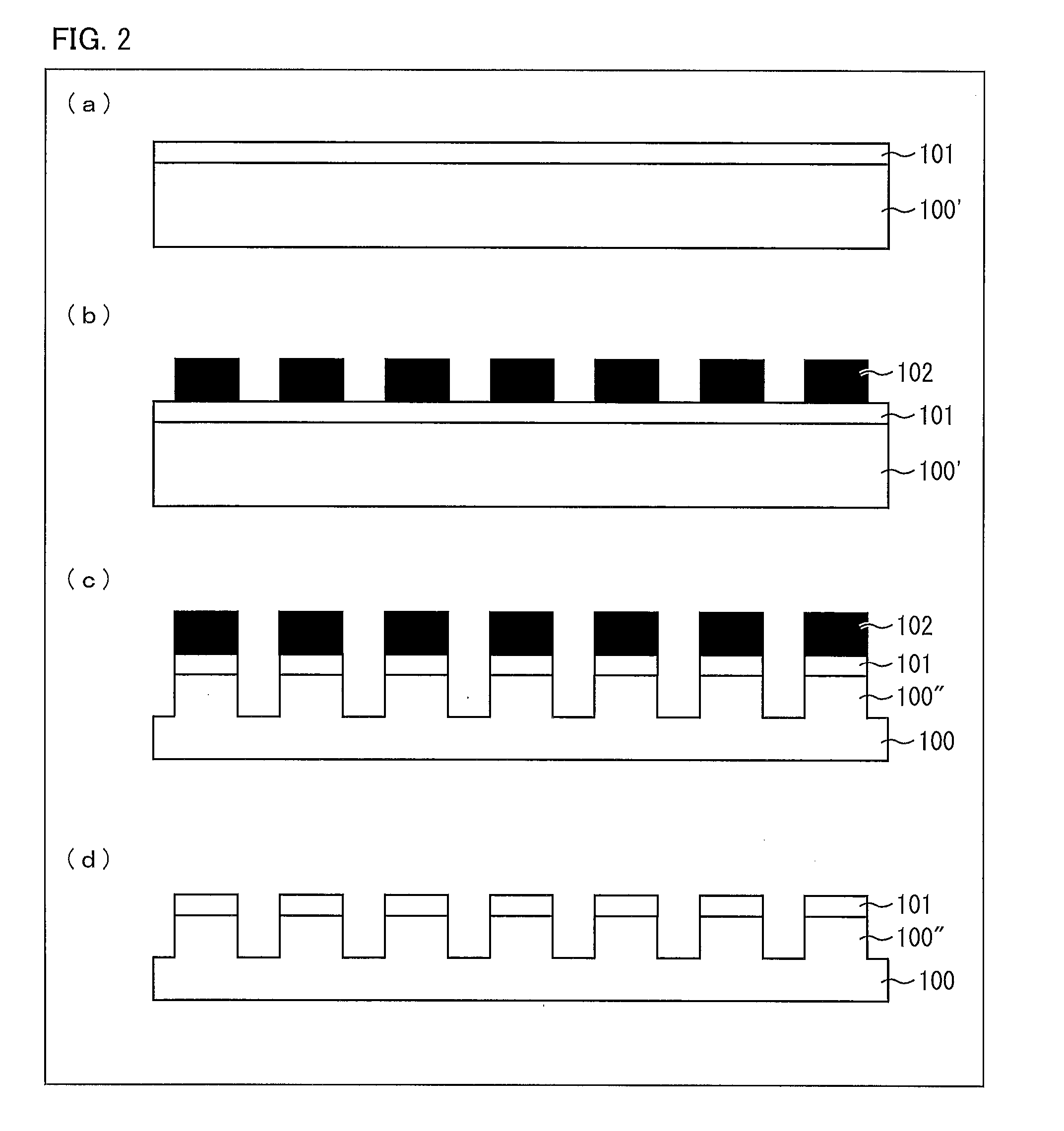

The present invention provides a method for selectively transferring elements such as monocrystalline Si thin films or elements made of monocrystalline Si from a base substrate (100) onto an insulating substrate without the use of an intermediate substrate. The base substrate (first substrate) (100) in which the elements are formed is selectively irradiated with a laser having a multiphoton absorption wavelength. Thus, elements to be transferred out of the elements and corresponding thin films on the base substrate (100) are transferred onto a transfer destination substrate (second substrate) (200).

Owner:SHARP KK

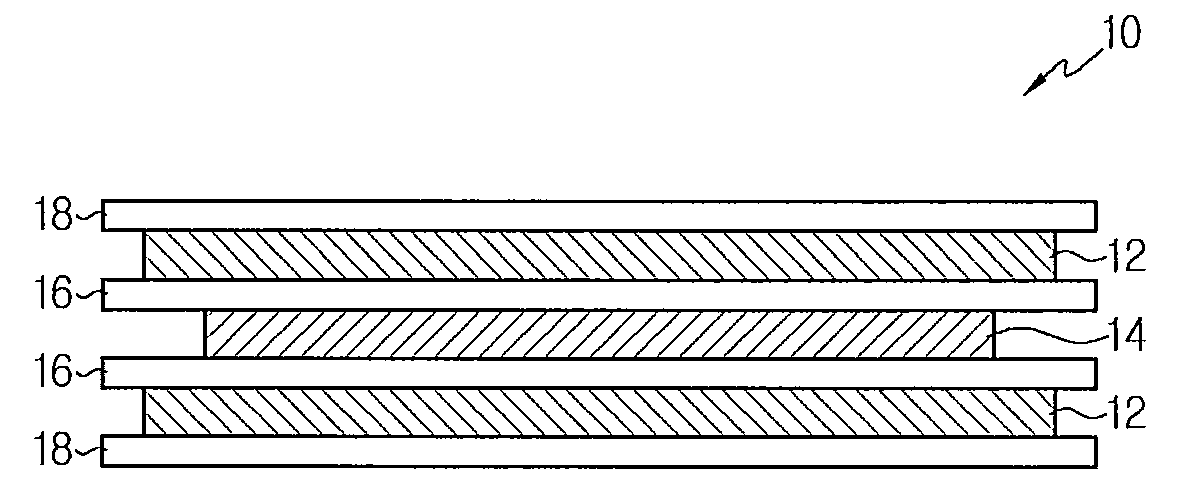

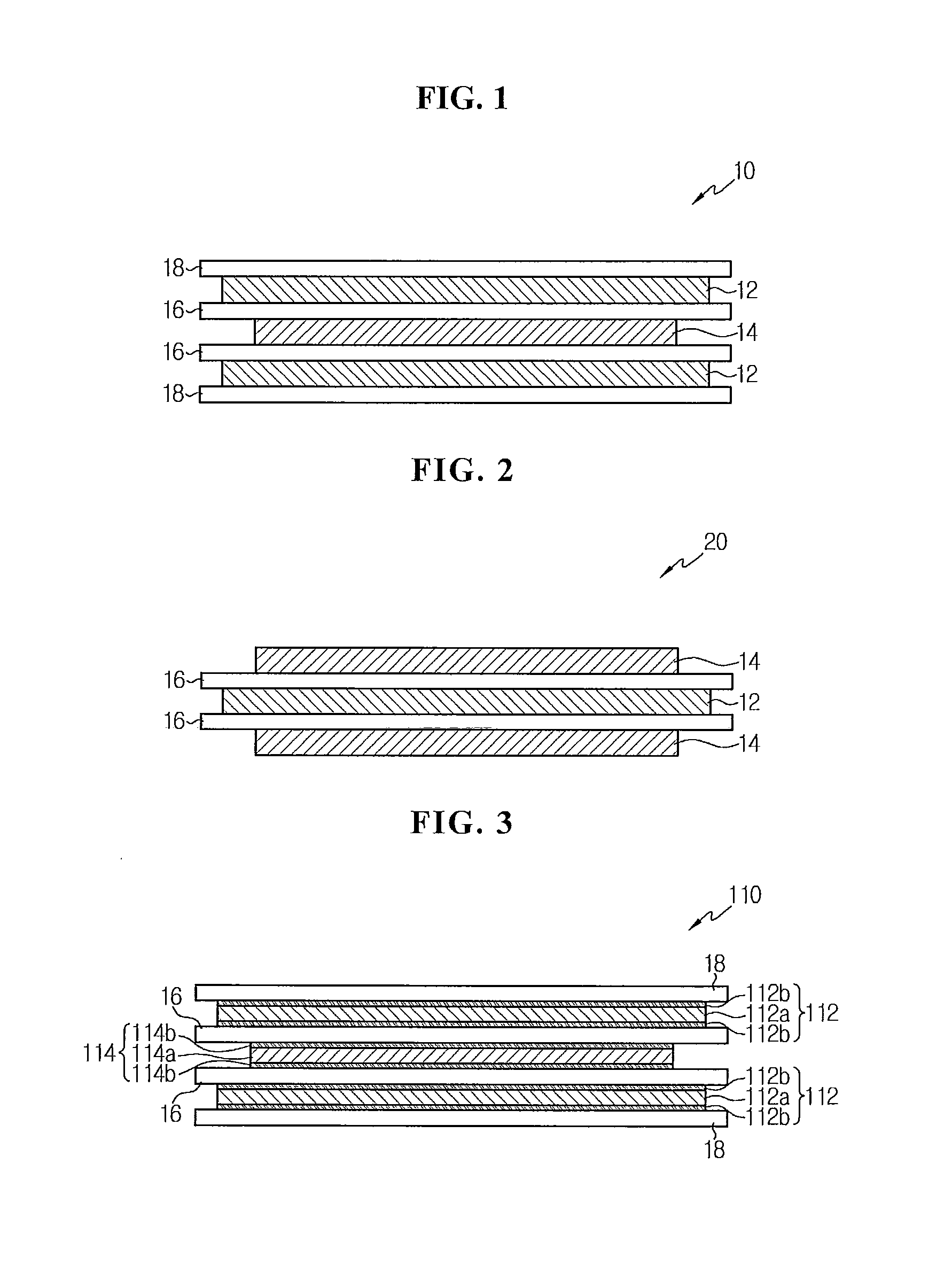

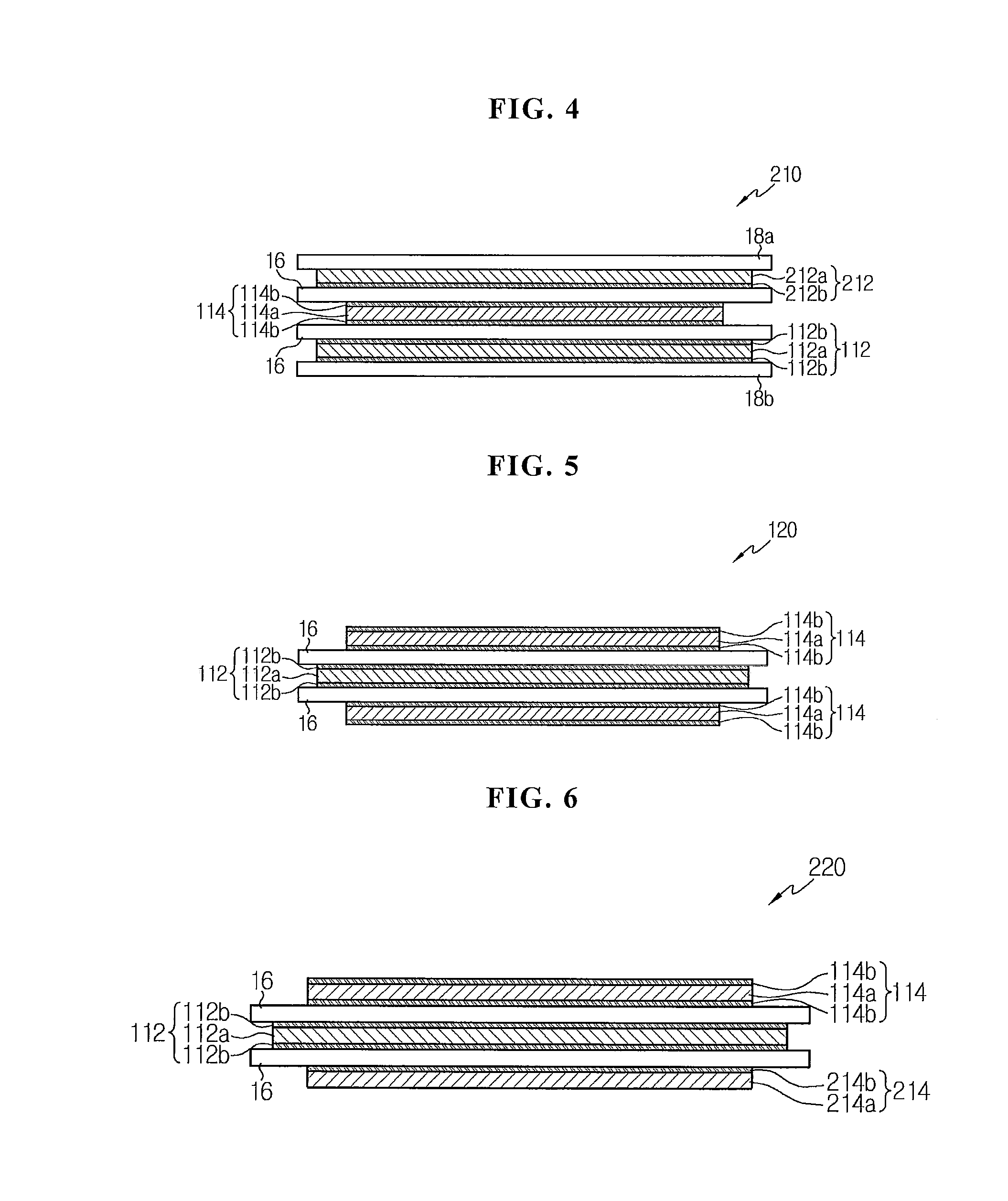

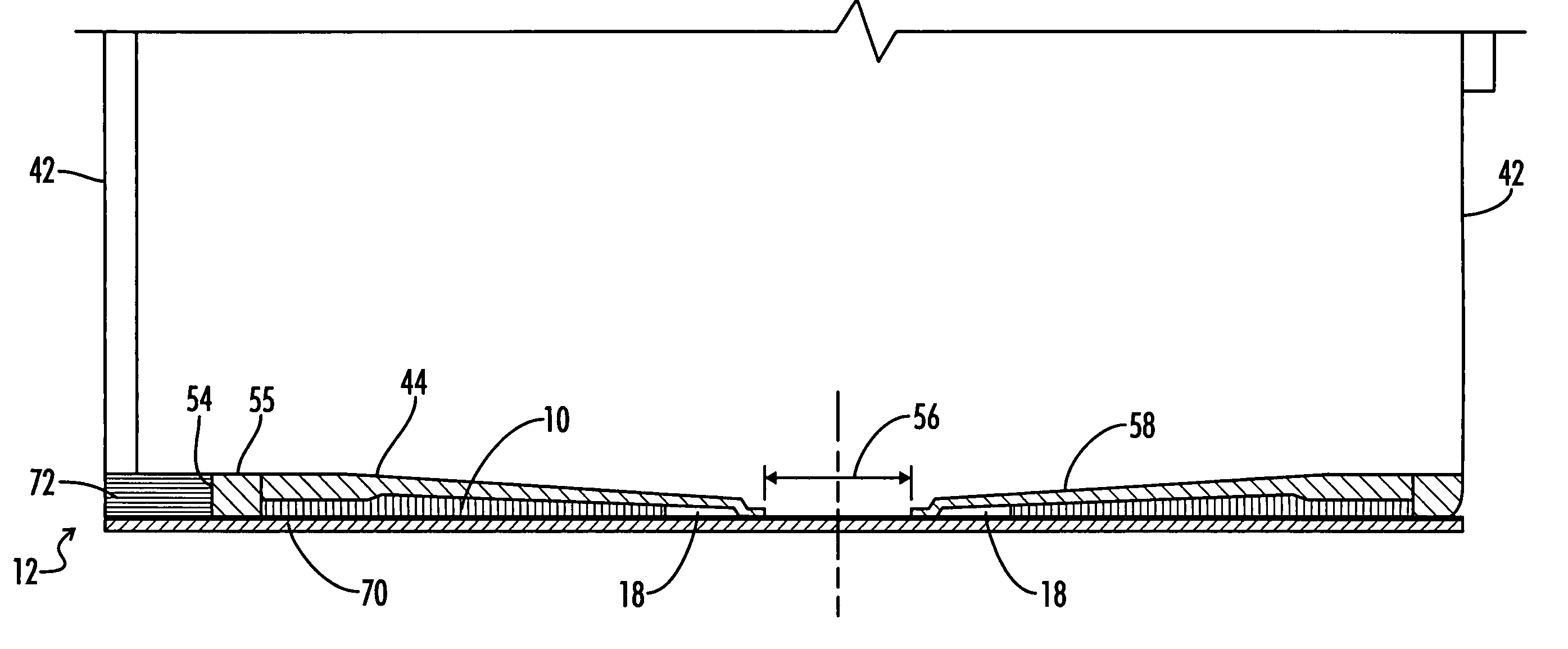

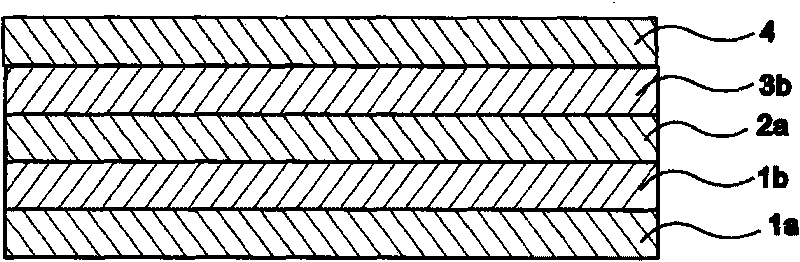

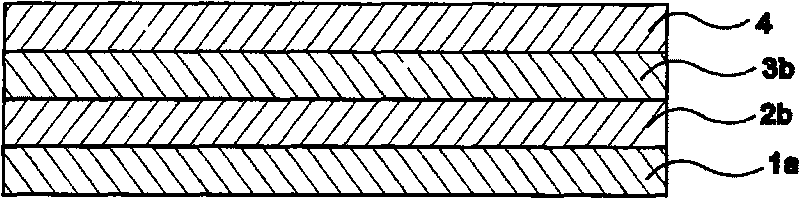

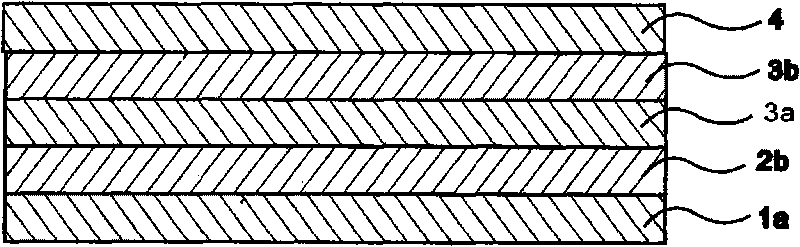

Stack-type cell or bi-cell, electrode assembly for secondary battery using the same, and manufacturing method thereof

InactiveUS20120225345A1Reduce production processImprove performanceLarge-sized flat cells/batteriesFinal product manufactureBattery cellBiomedical engineering

Provided is a stack-type cell for a secondary battery including a stack of first electrode / separator / second electrode / separator / first electrode arranged in order, and an outer separator stacked on each of the first electrodes. Also, the present invention provides an electrode assembly for a secondary battery using the stack-type cell and a manufacturing method thereof.

Owner:LG CHEM LTD

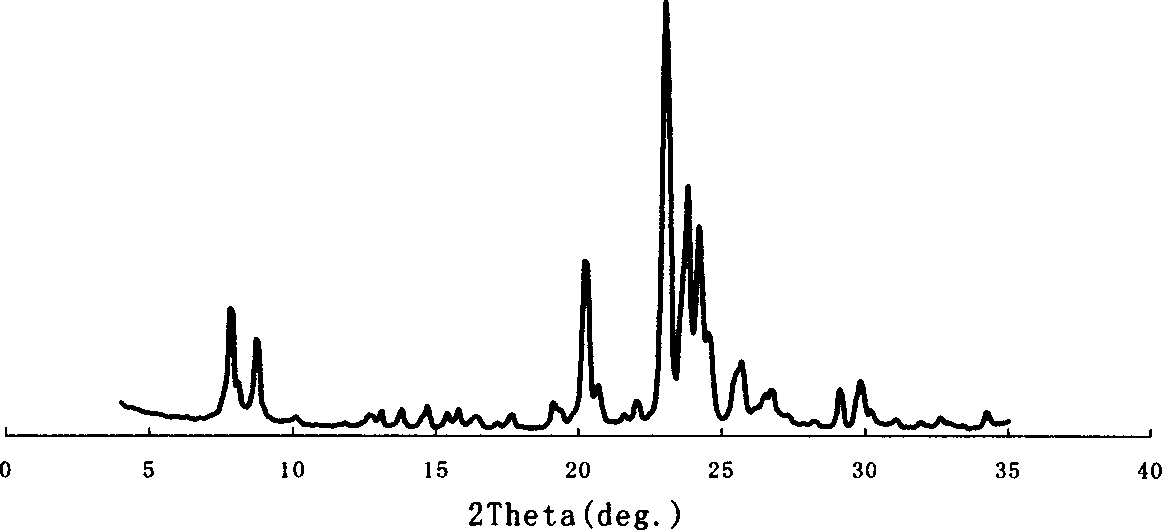

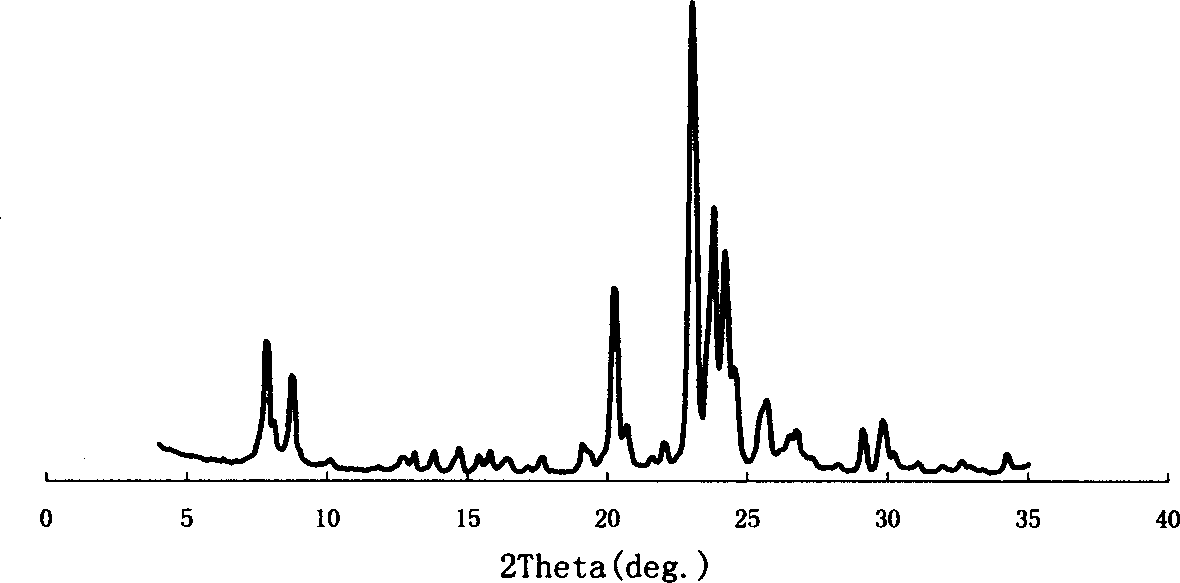

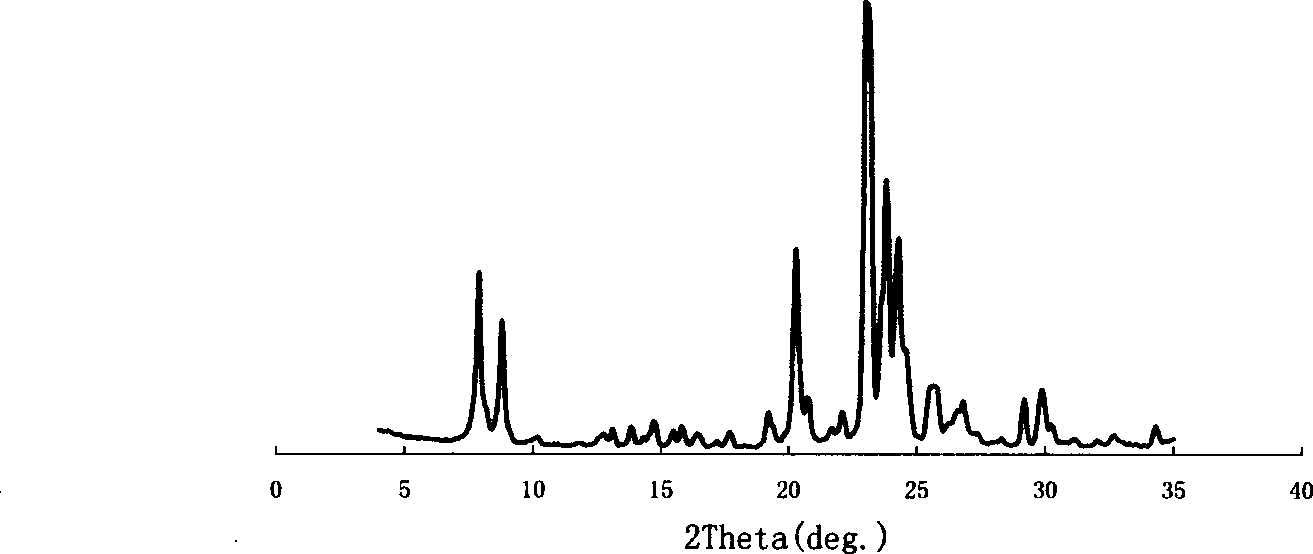

Mole cular sieve with composite structure and preparing method thereof

InactiveCN1552625AHigh activityHigh selectivityCrystalline aluminosilicate zeolitesMolecular sieveCrystallization

A composite molecular sieve with TON and MFI structures is prepared in static crystallizing condition. In the procedure of preparing gel, less crystal seeds and salt are added. The Si / Al ratio on its crystal lattice is greater than 50.

Owner:CHINA PETROLEUM & CHEM CORP +1

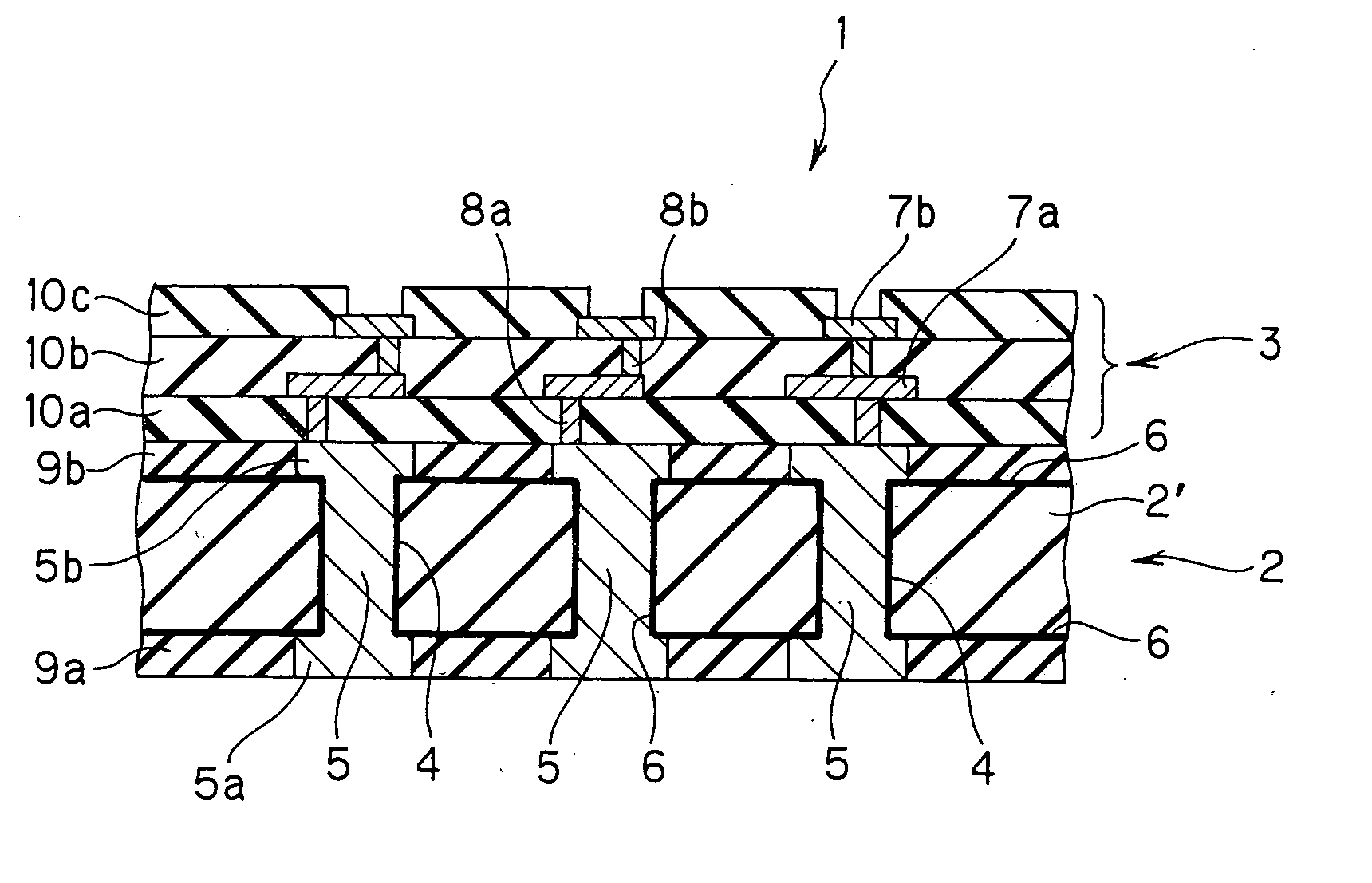

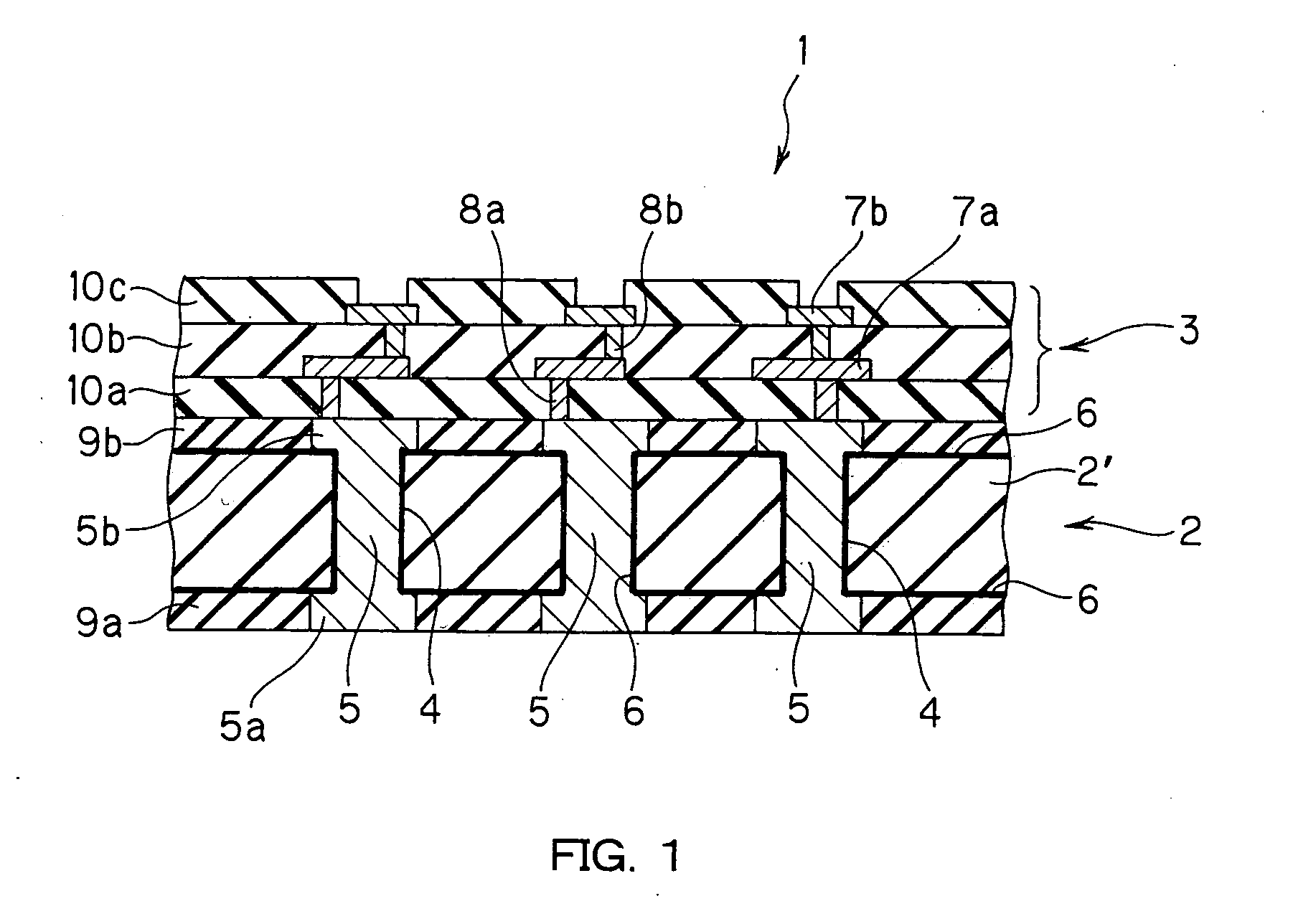

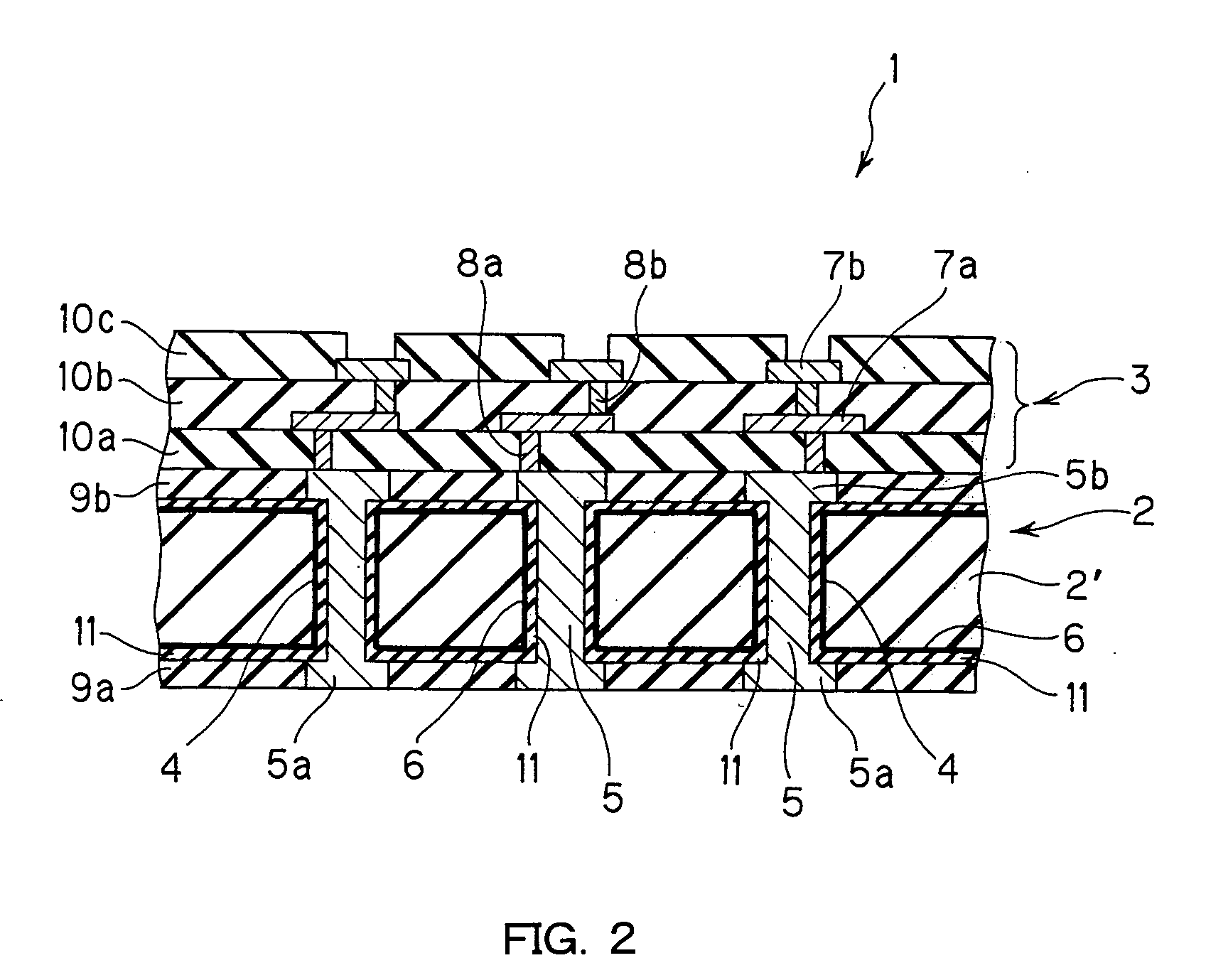

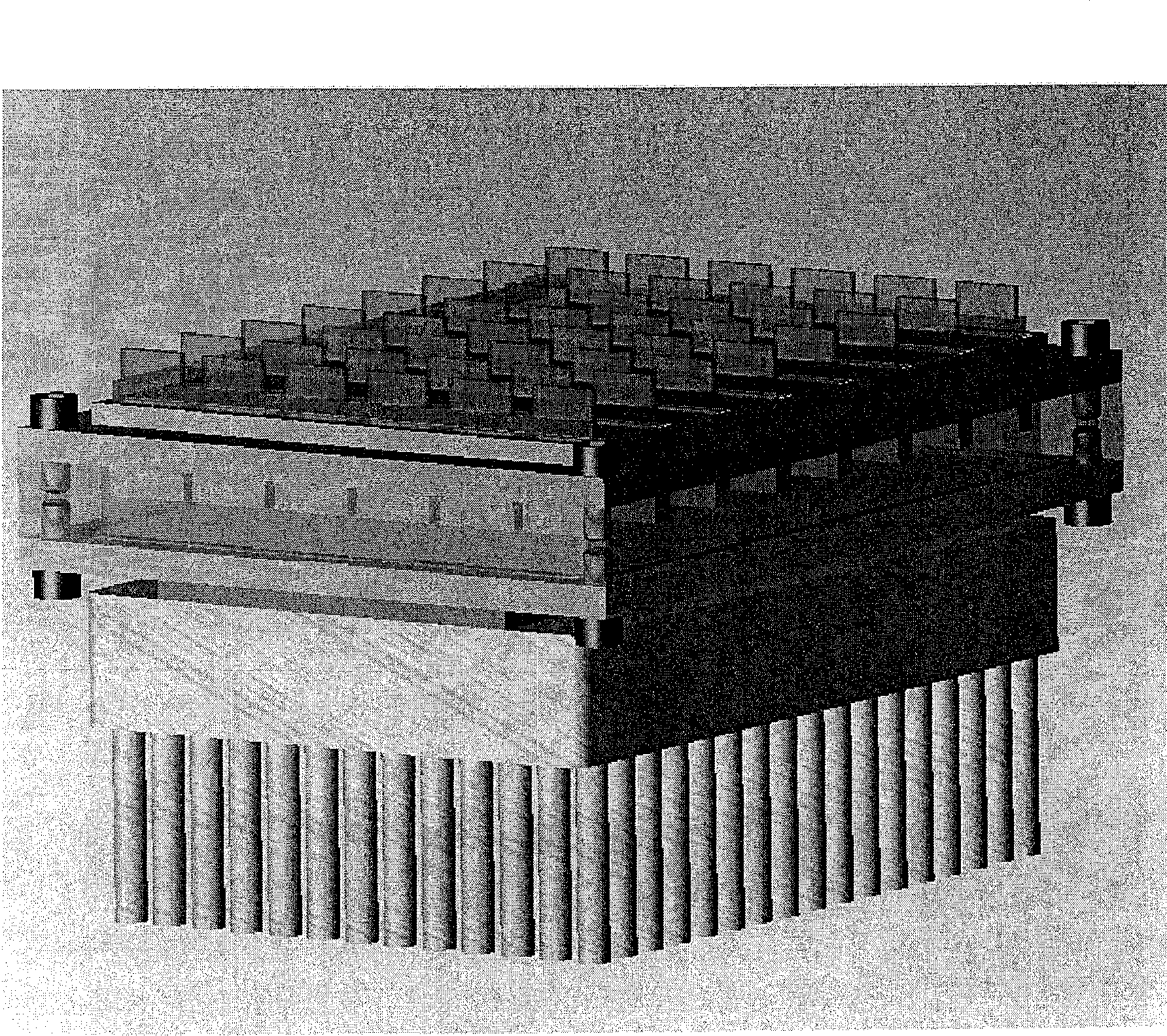

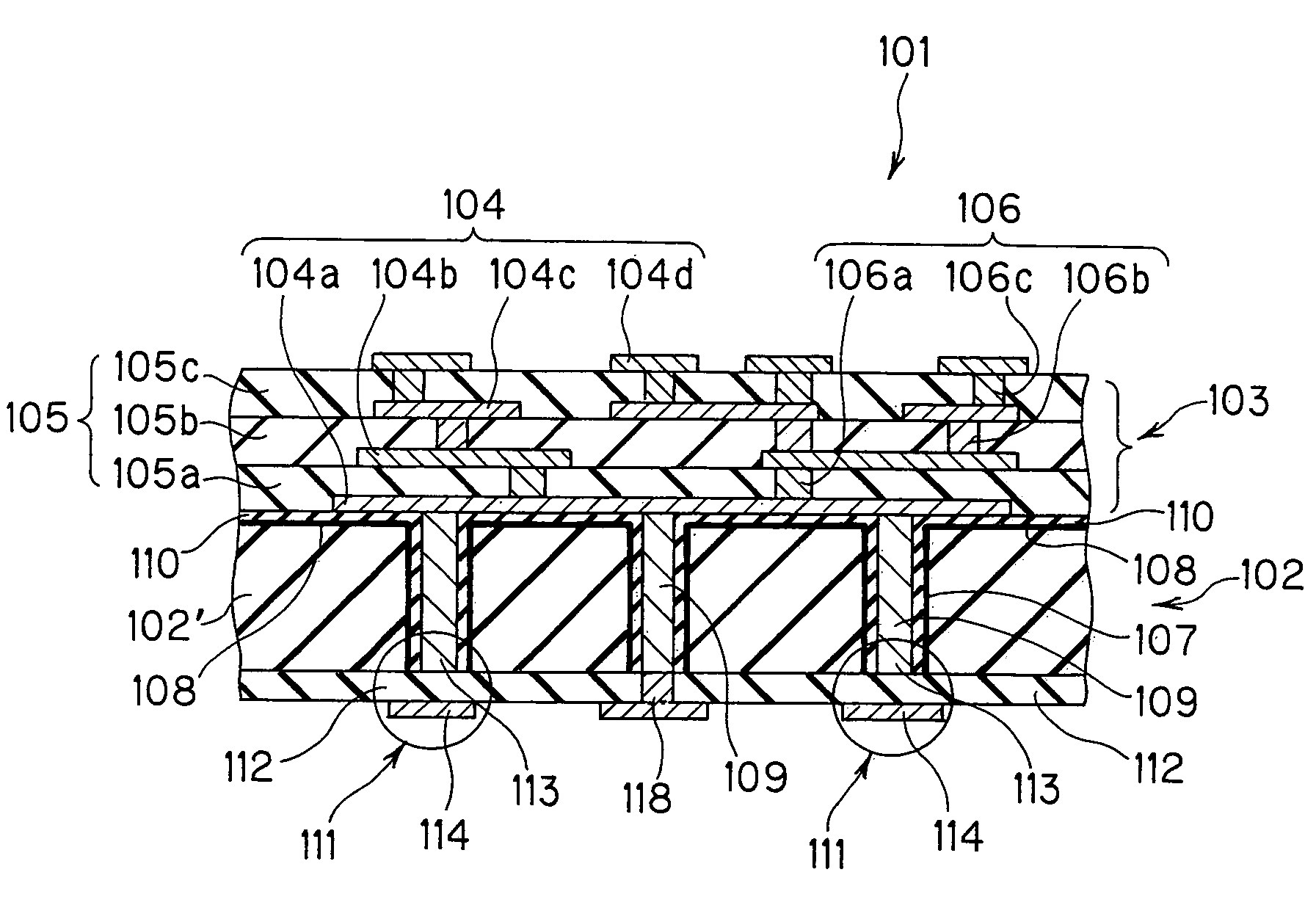

Multilayer wiring board and manufacture method thereof

ActiveUS20050012217A1Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringThermal expansion

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

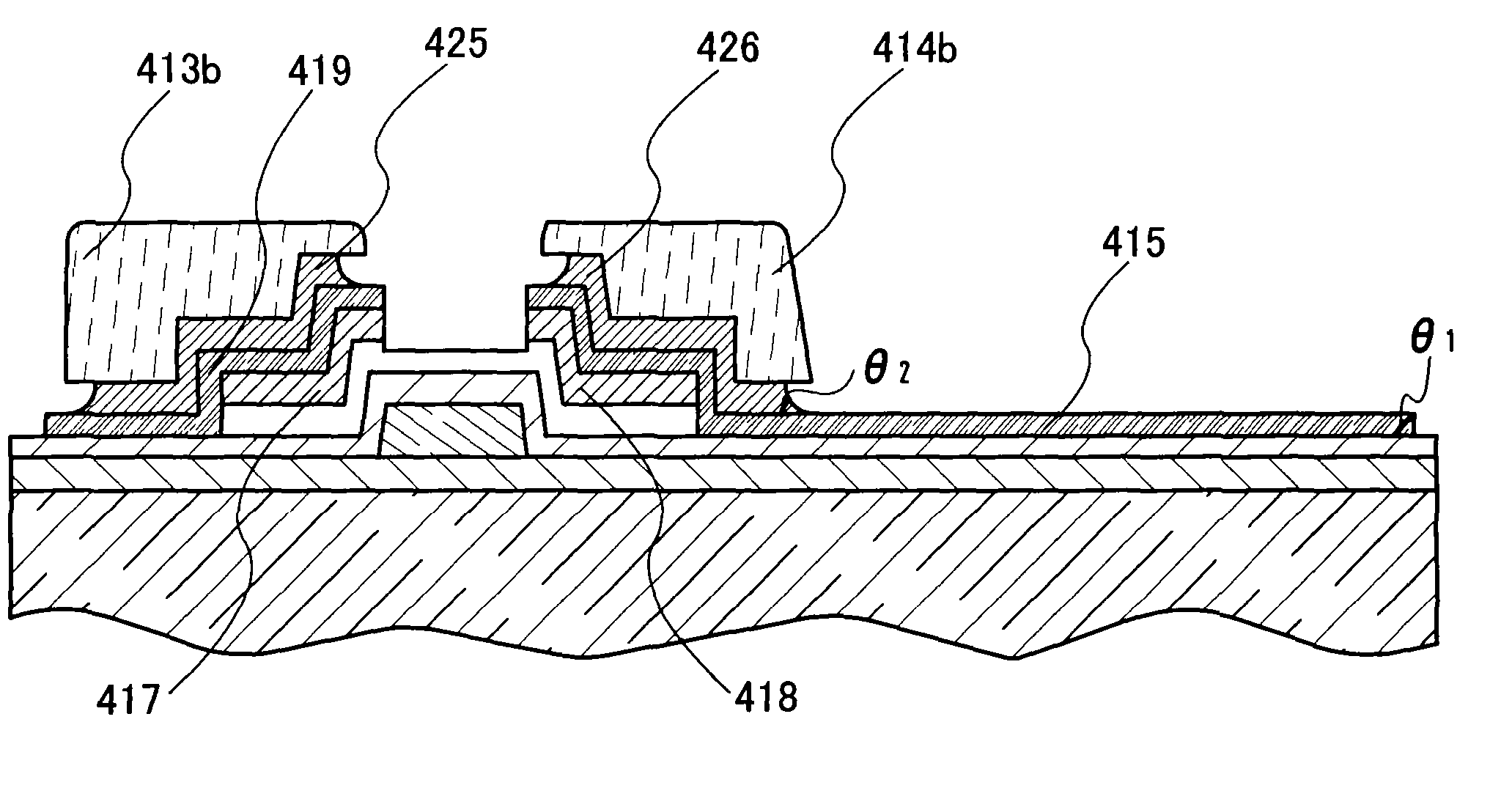

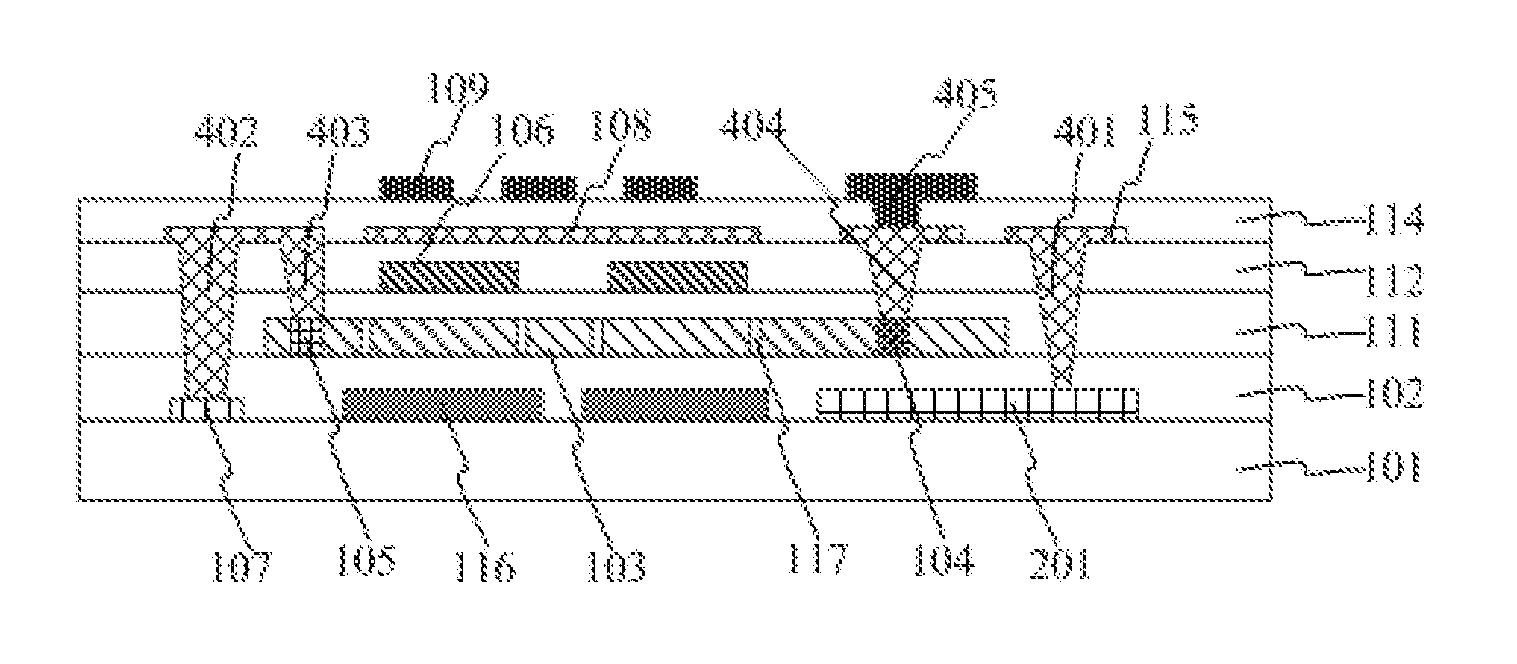

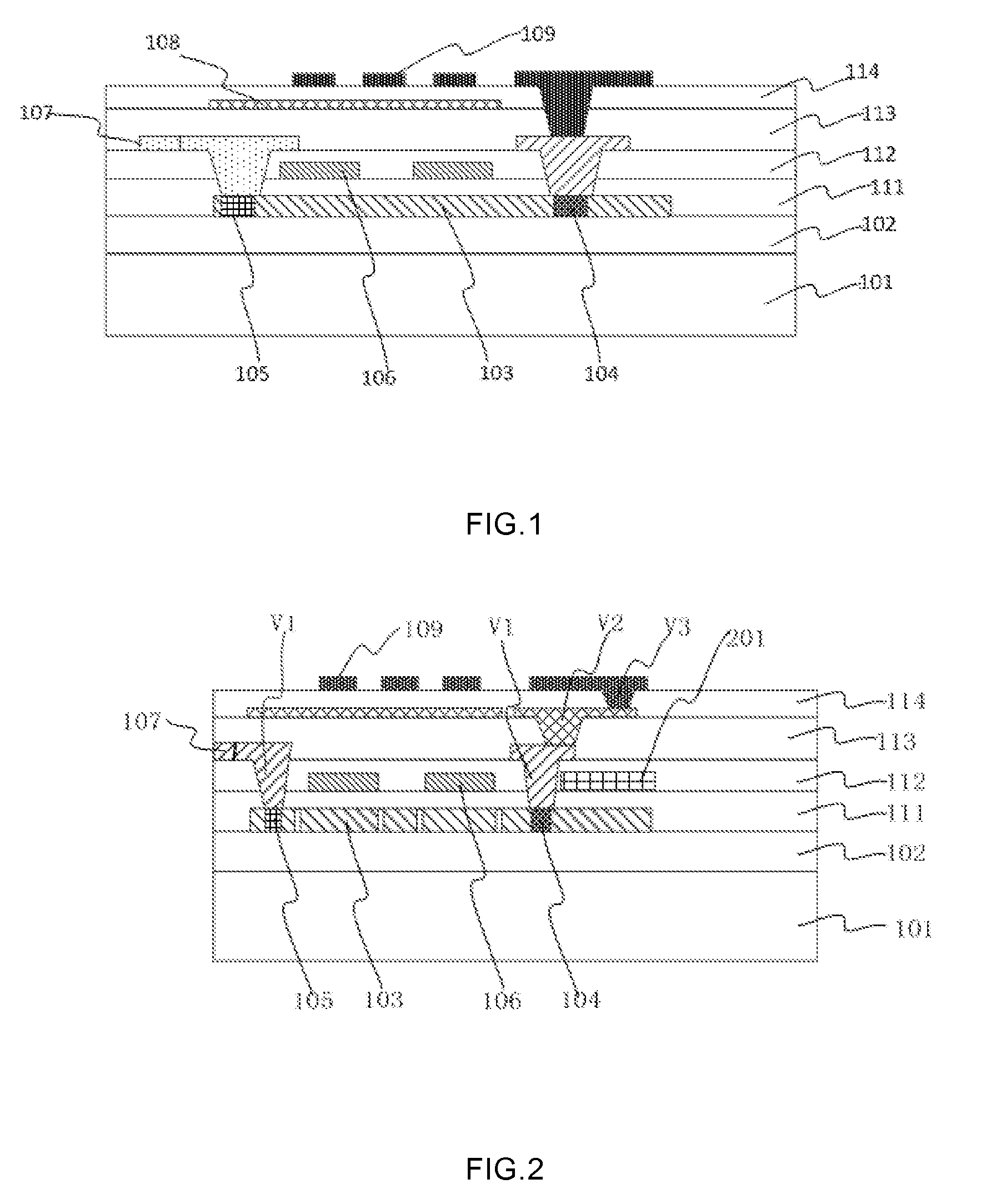

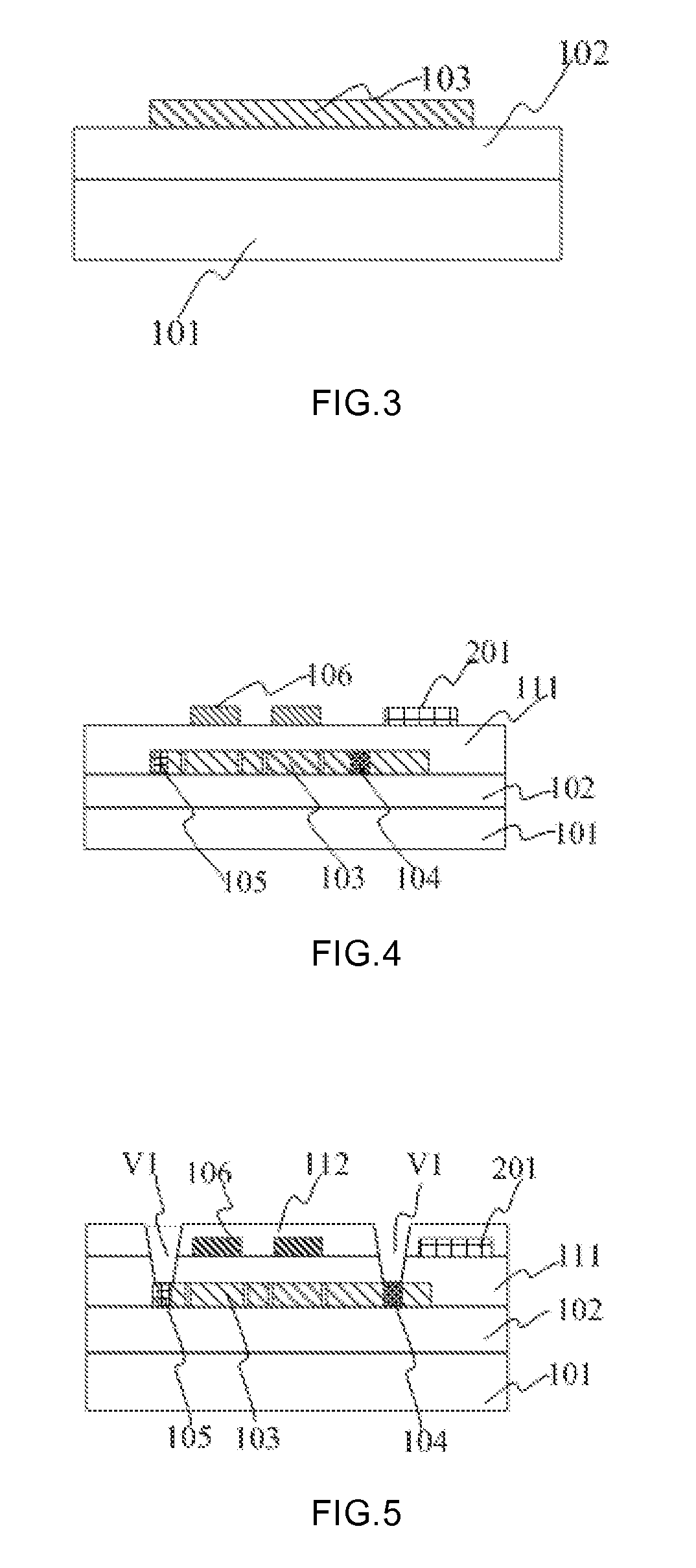

Display device and manufacturing method thereof

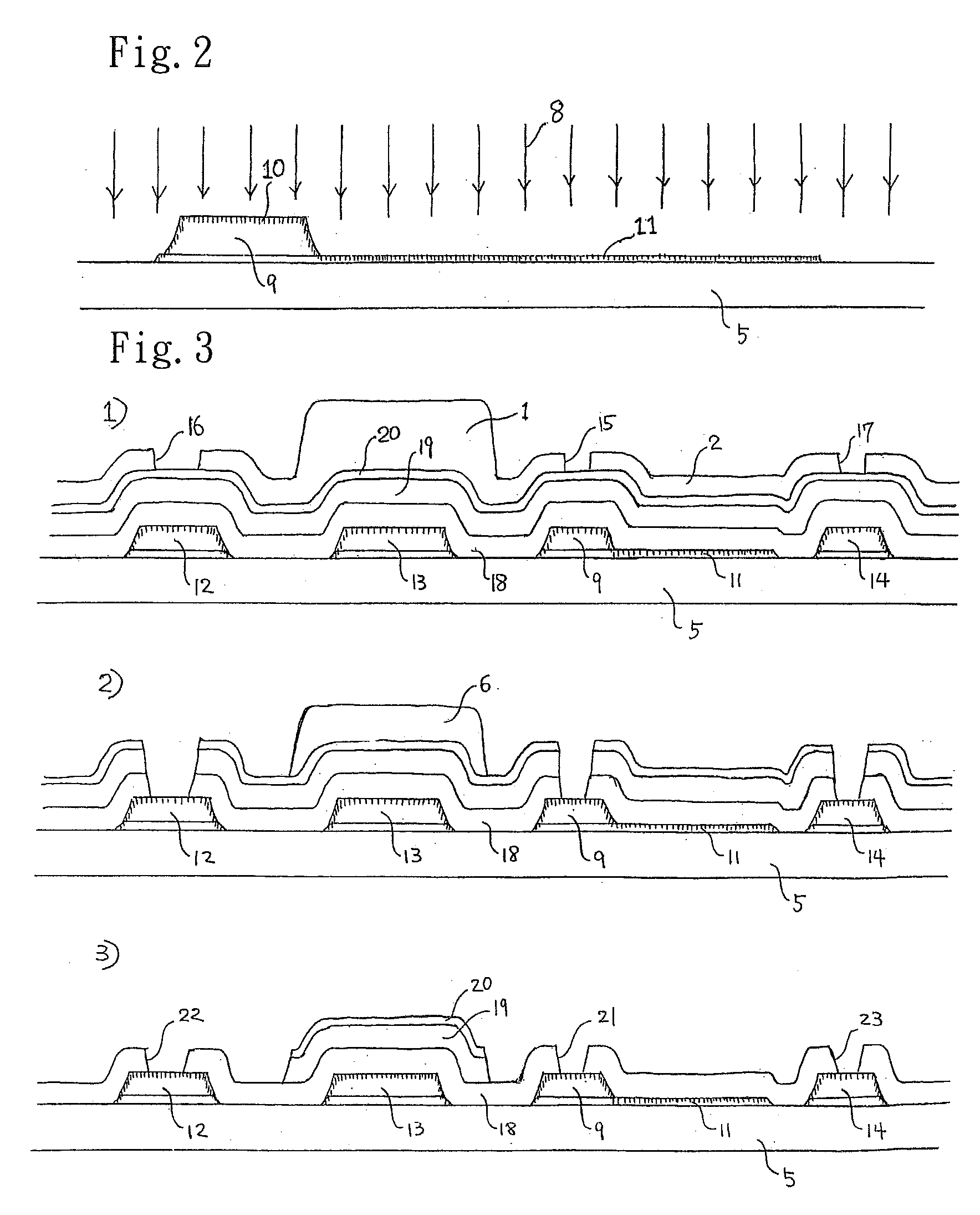

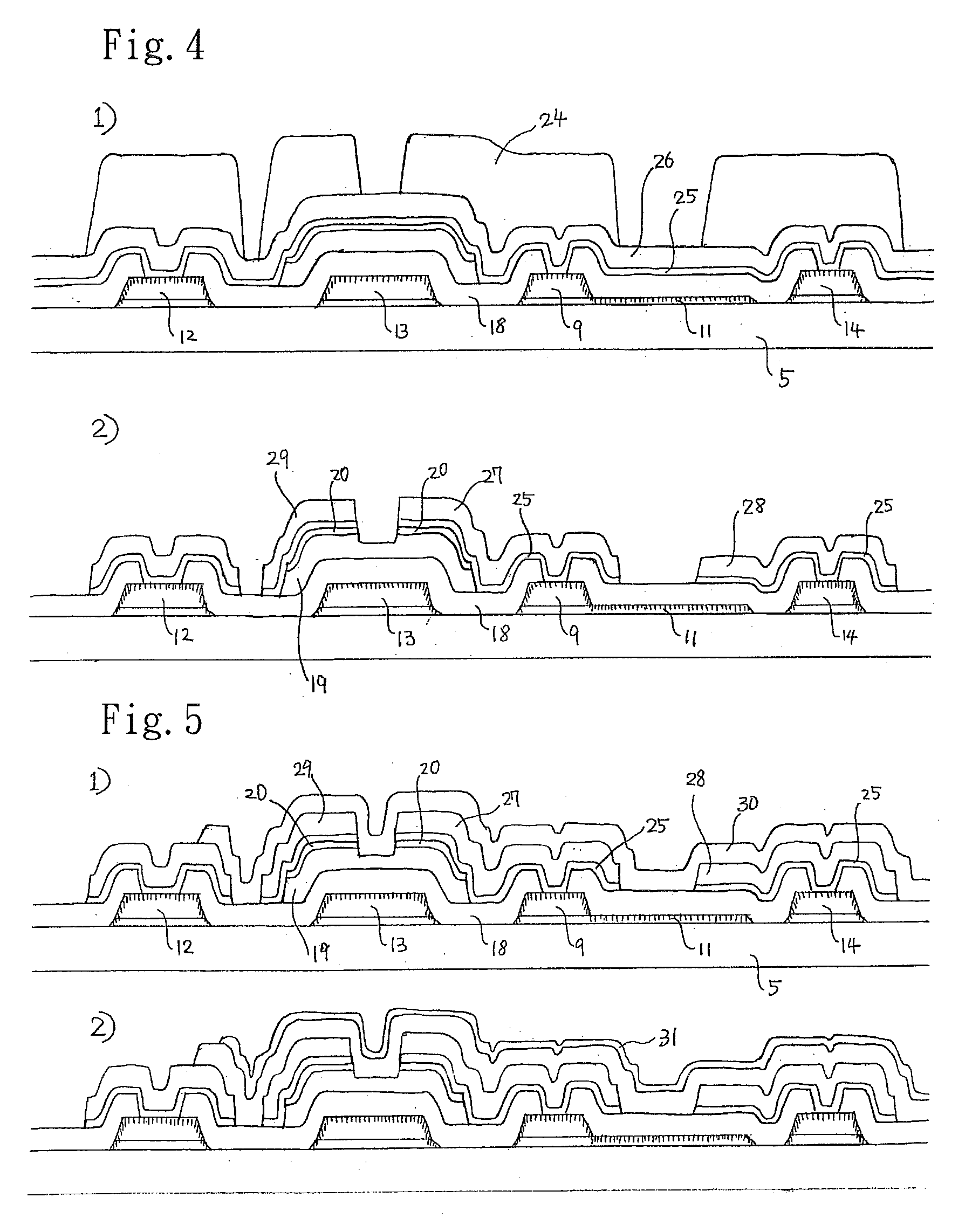

ActiveUS20070139571A1Reduce production processAvoid disconnectionElectroluminescent light sourcesSolid-state devicesDisplay deviceMetal membrane

It is an object of the present invention to form a pixel electrode and a metal film using one resist mask in manufacturing a stacked structure by forming the metal film over the pixel electrode. A conductive film to be a pixel electrode and a metal film are stacked. A resist pattern having a thick region and a region thinner than the thick region is formed over the metal film using an exposure mask having a semi light-transmitting portion. The pixel electrode, and the metal film formed over part of the pixel electrode to be in contact therewith are formed using the resist pattern. Accordingly, a pixel electrode and a metal film can be formed using one resist mask.

Owner:SEMICON ENERGY LAB CO LTD

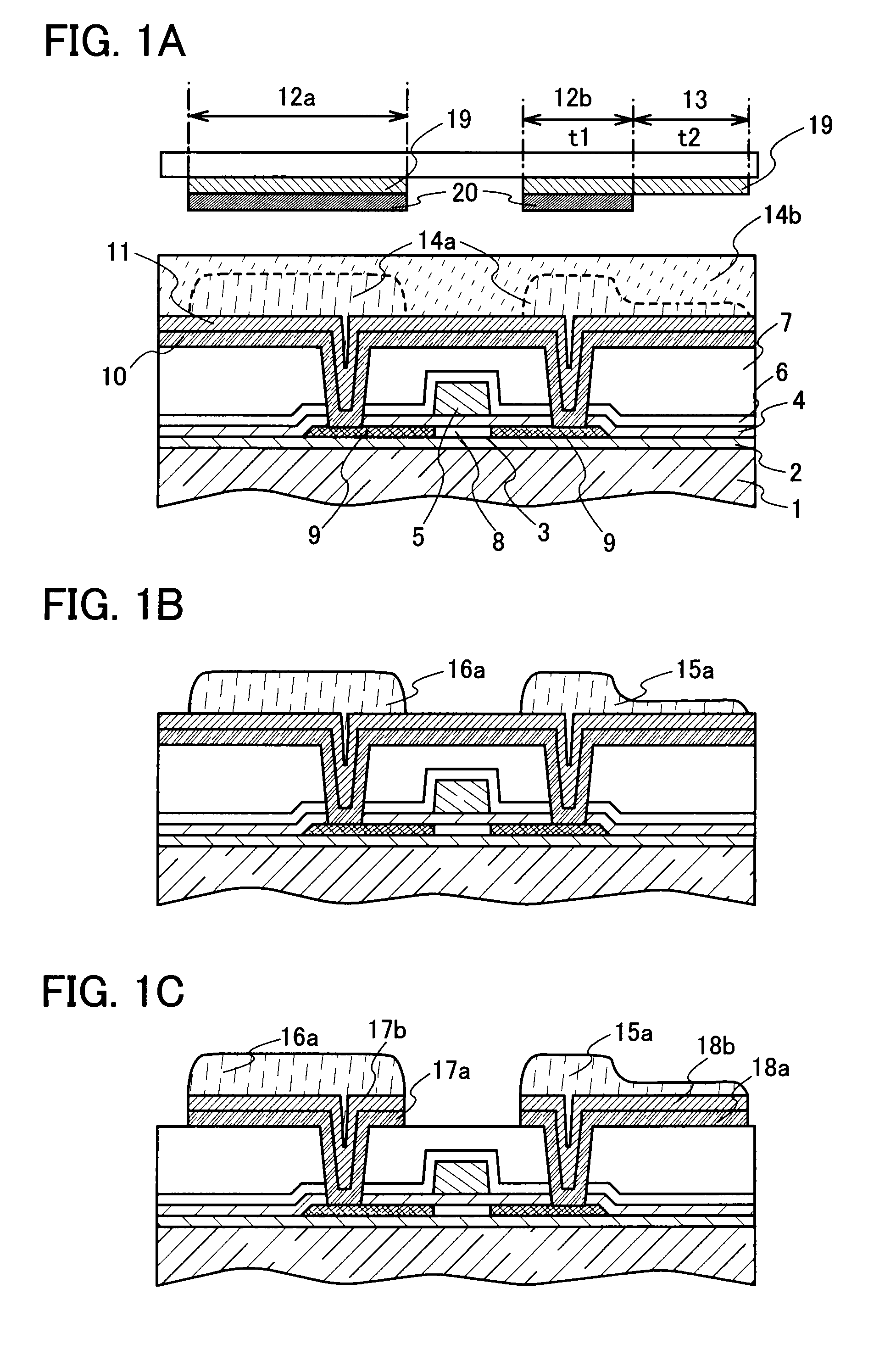

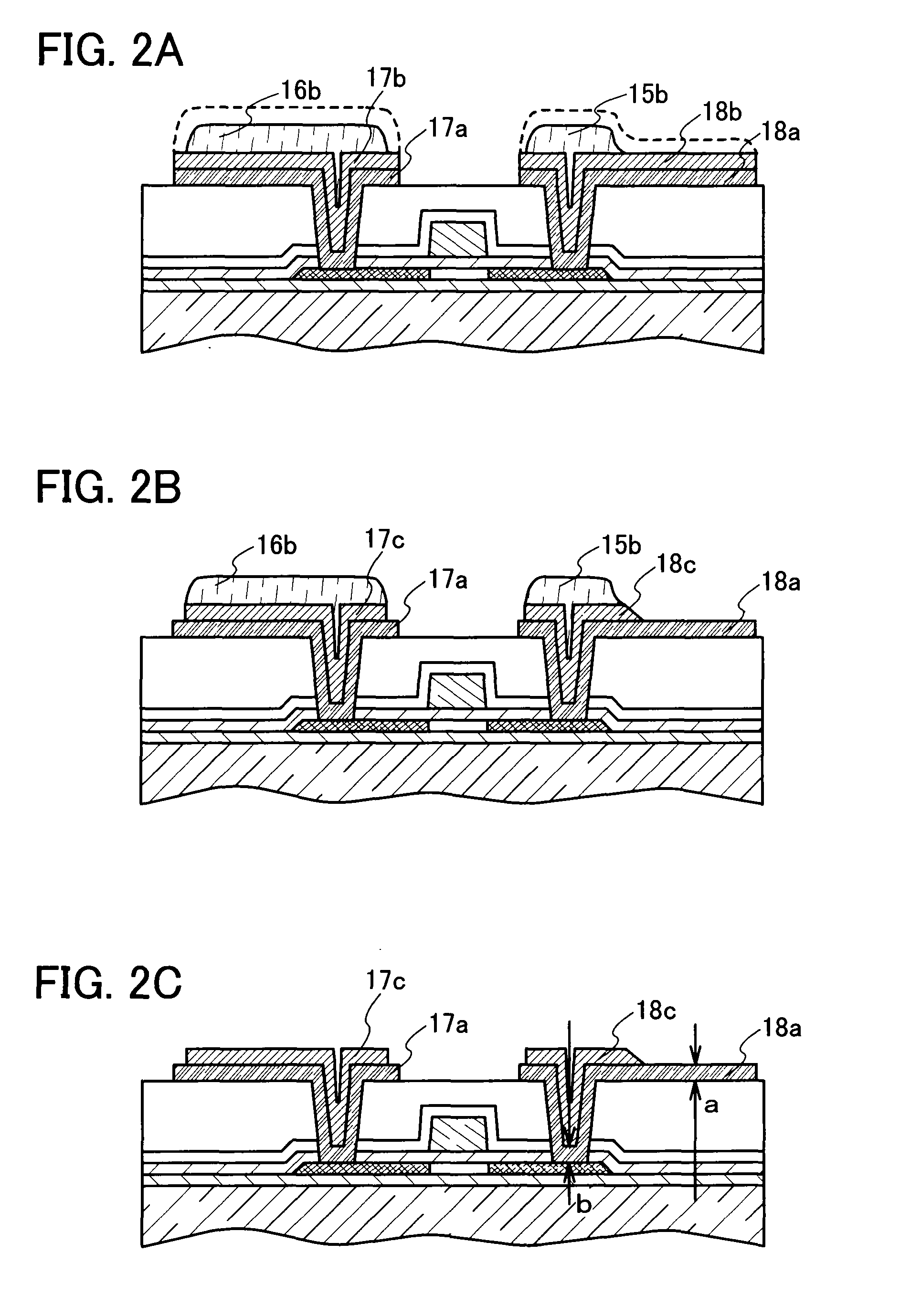

Method of manufacturing LCD apparatus by using halftone exposure method

InactiveUS20070269936A1Reduce production processIncrease contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingContact padNitrogen

The present invention discloses a method of manufacturing a super large wide-angle super high-speed response LCD apparatus by using a photolithographic process for three times. The invention adopts a halftone exposure technology and a nitrogen ion doped technology to form a gate electrode, a common electrode, a pixel electrode and a contact pad, and then uses the halftone exposure technology to form a silicon (Si) island and a contact hole, and a general exposure technology to form a source electrode, a drain electrode and an alignment control electrode. A P-CVD apparatus is provided for forming a passivation layer into a film by using a masking deposition method, or an ink-jet coating method is used to coat a protective layer at a partial area, and a photolithographic process is performed for three times to manufacture a TFT matrix substrate of the super large wide-angle super high-speed response LCD.

Owner:MIKUNI ELECTORON

Thermal cycling system

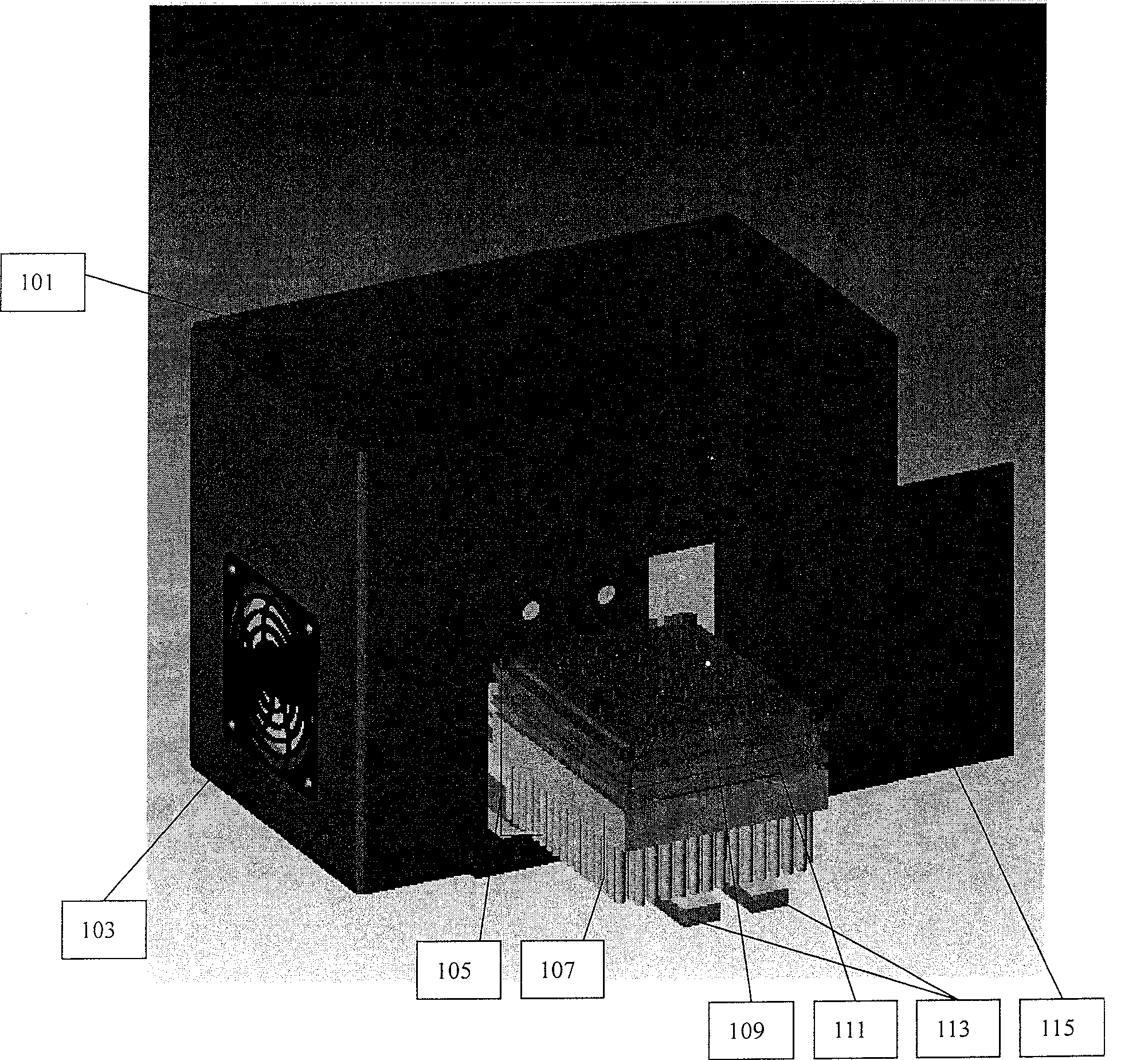

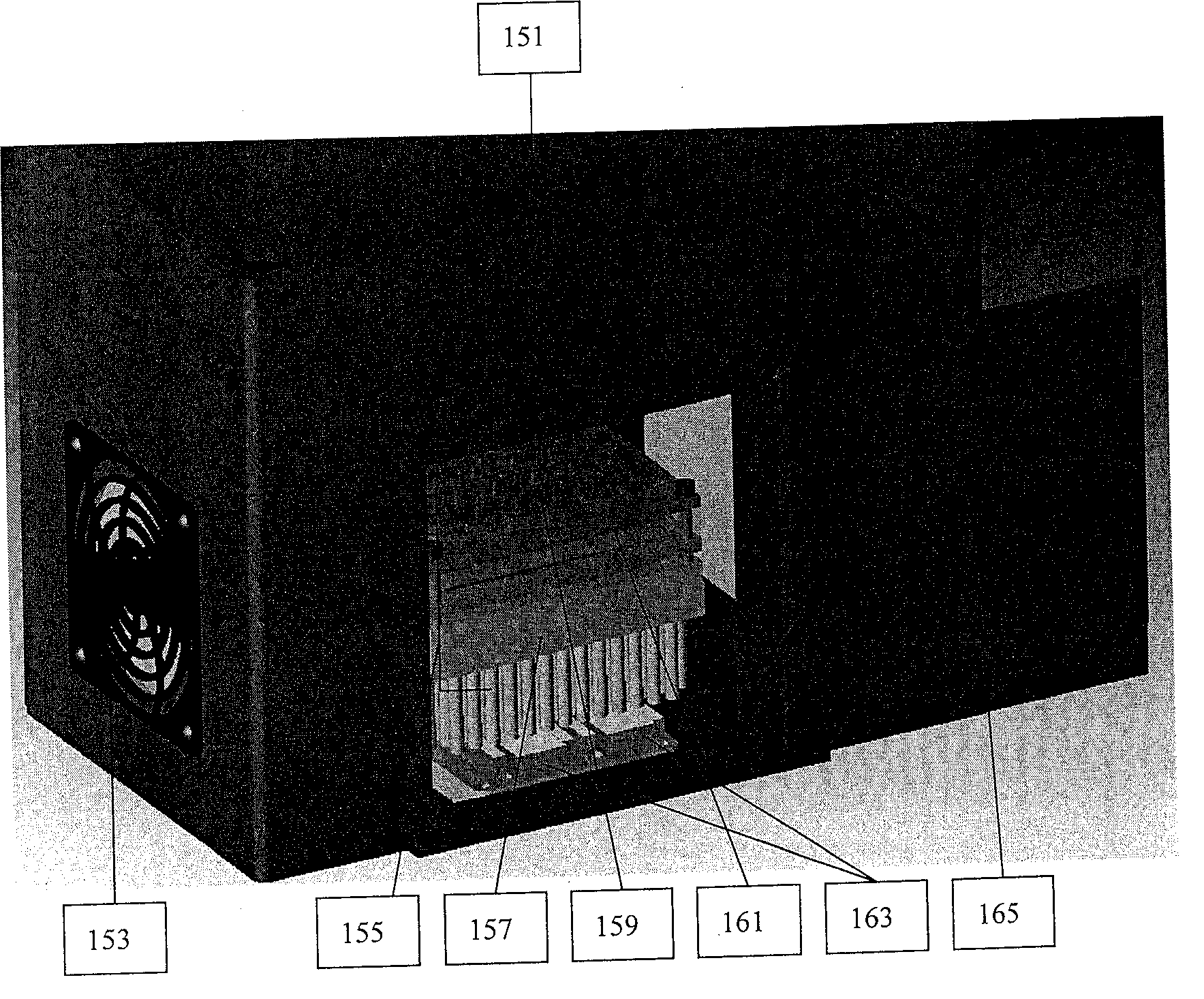

InactiveCN101522909ARapid productionReduce production processMicrobiological testing/measurementEngineeringLiquid metal

This invention provides a system for performing PCR, and real time PCR in particular, with great speed and specificity. The system employs a heat block containing a liquid composition to rapidly transfer heat to and from reaction vessels. The system makes use of the reflective properties of the liquid metal to reflect signal from the PCR into the vessel and out the top. In this way, the signal can be measured by an optical assembly in real time without removing the vessels from the heat block.

Owner:CALIFORNIA INST OF TECH

Multilayer wiring board and manufacture method thereof

InactiveUS7091589B2Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringConductive materials

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

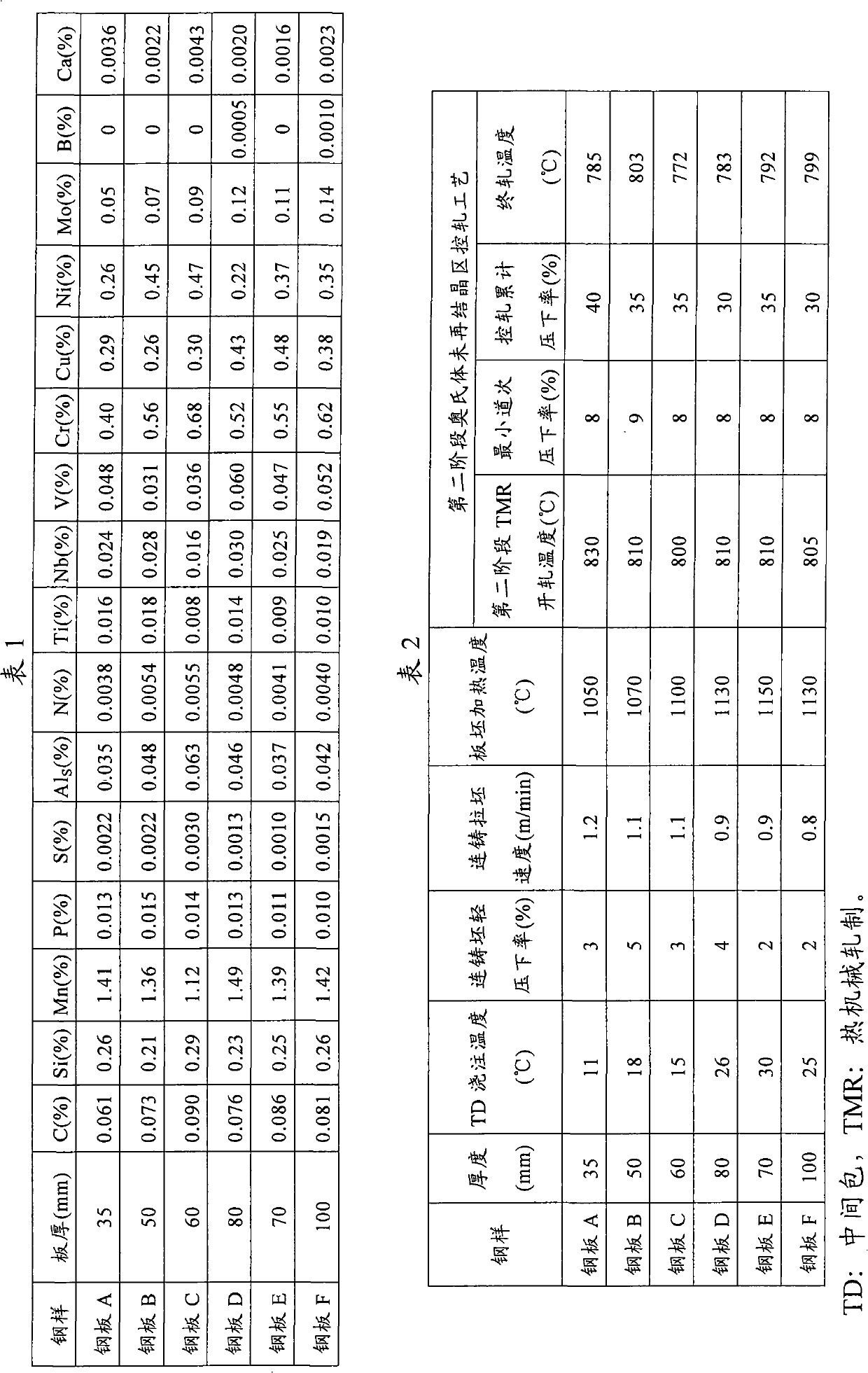

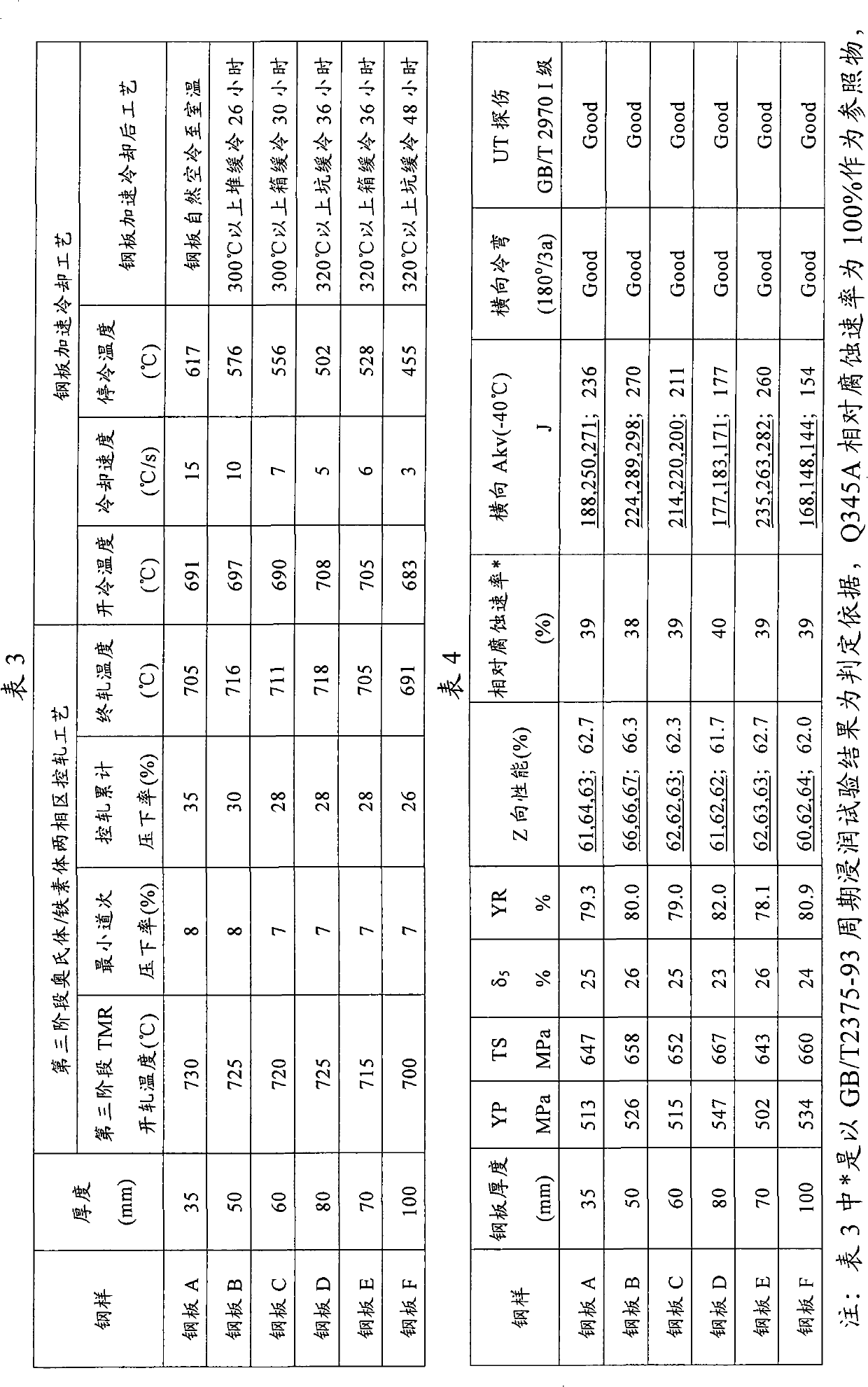

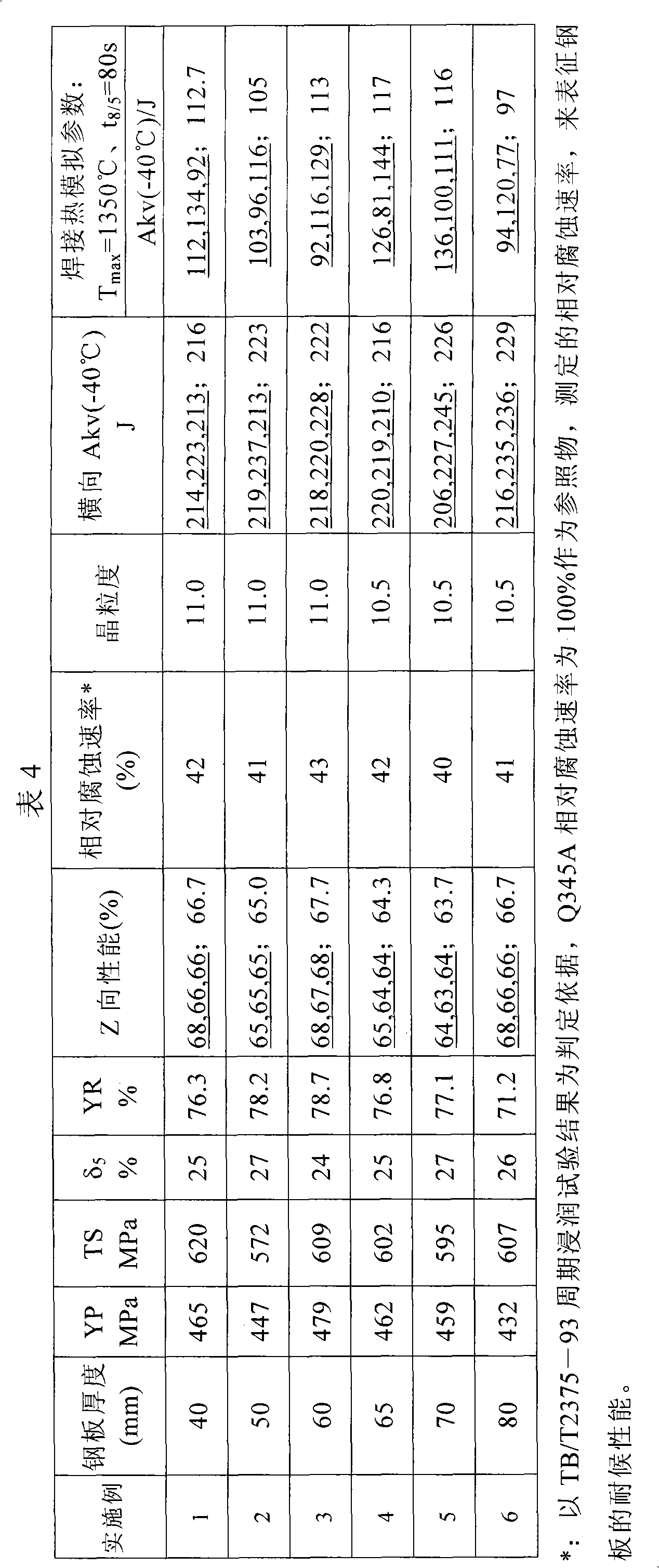

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

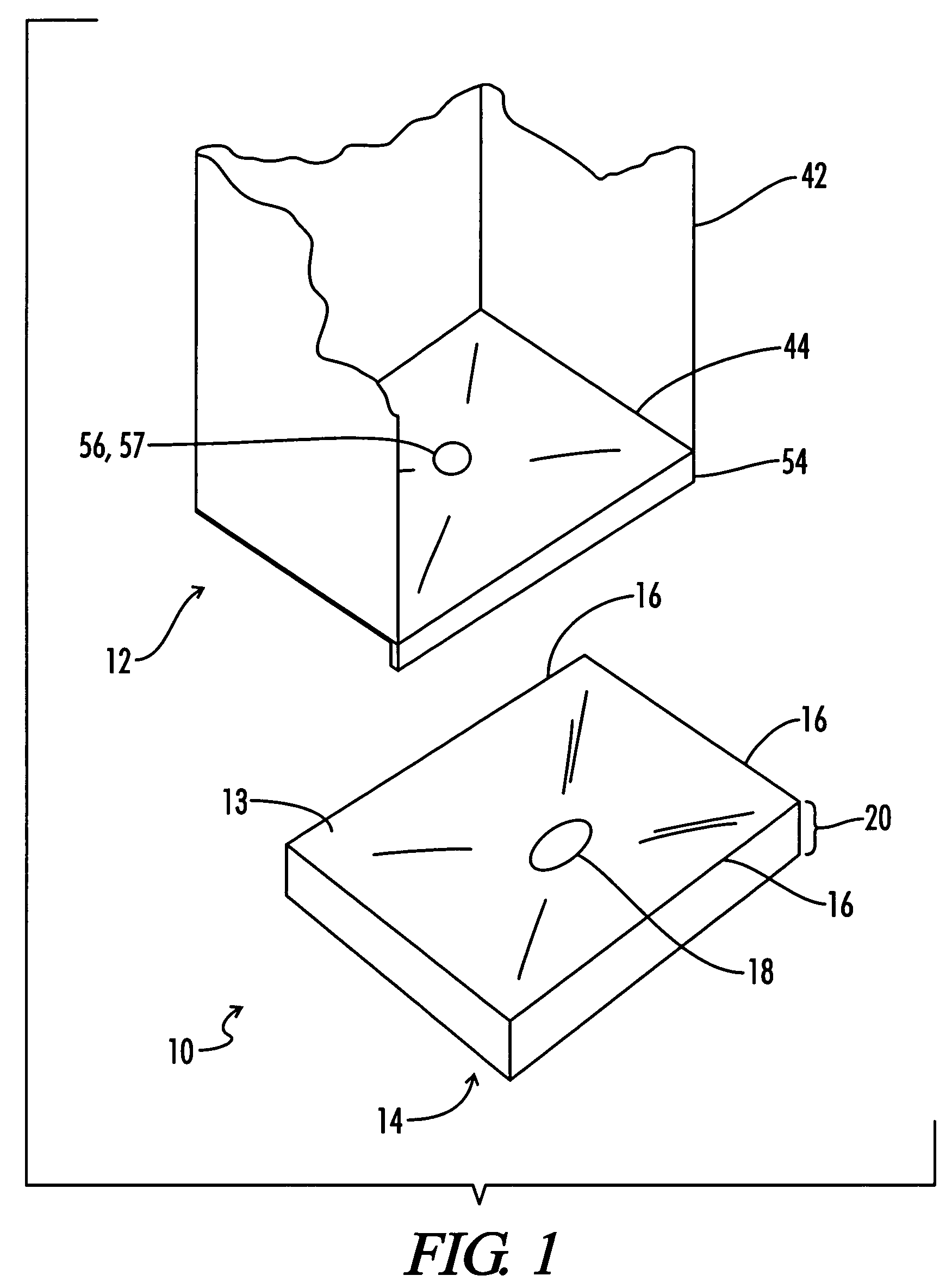

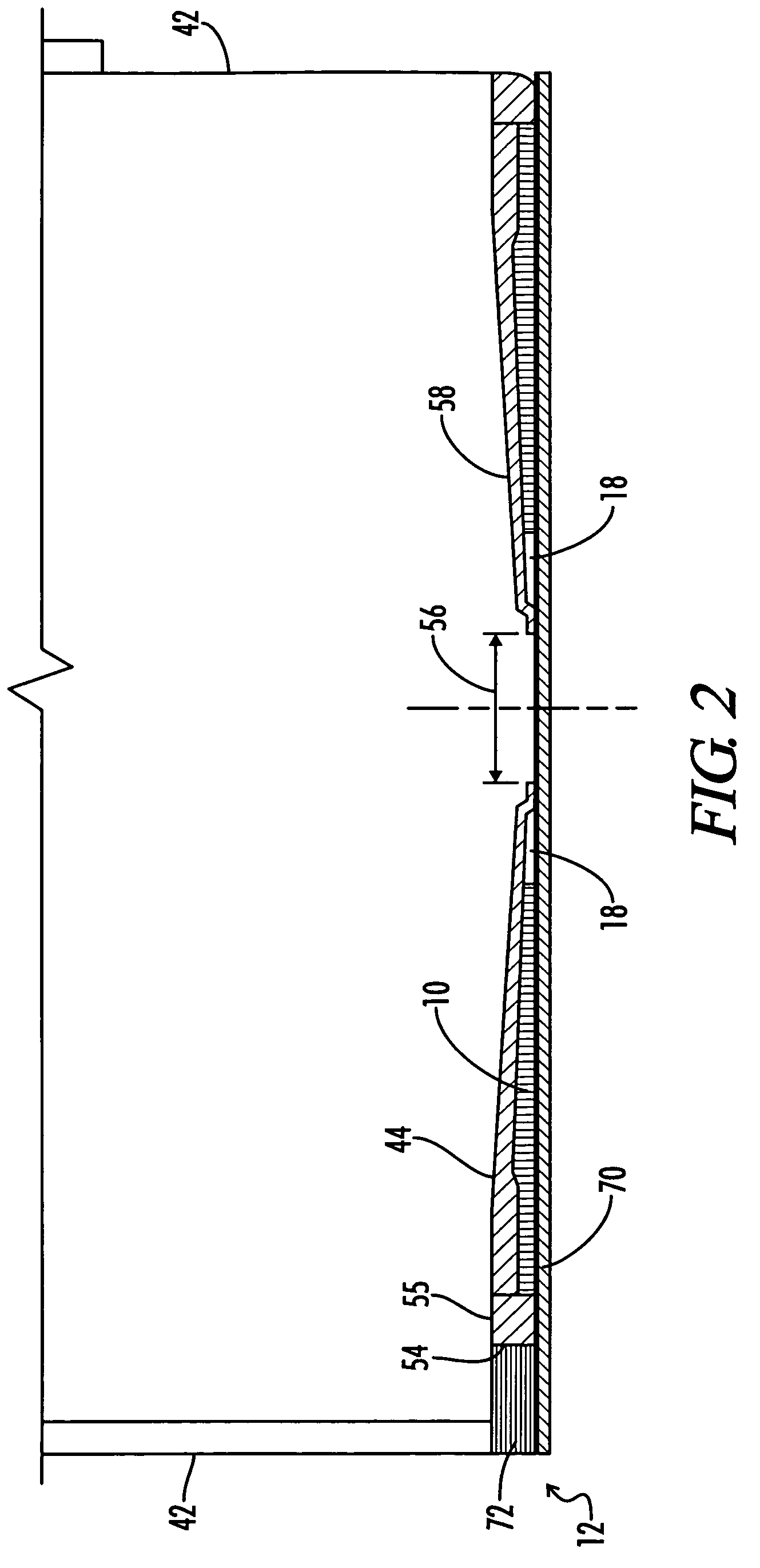

Self-sustaining base

A base for a shower stall comprising a first layer of fiber glass and resin, and layer of filament material, and a second layer of fiberglass and resin. The base also includes at least one external edge, an external opening, and a thickness that increases from the at least one external edge to the internal opening. Included is a shower stall comprising a plurality of shower walls, a sloped floor attached to the shower walls, and a base attached to the slope floor. Also included is a method of attaching a base to a shower stall. The method comprises creating the base by applying fiberglass, resin, and filament material to a mold, engaging the base to the shower stall by removably attached the mold to the shower stall, curing the base, and removing the mold from the shower.

Owner:PRAXIS IND

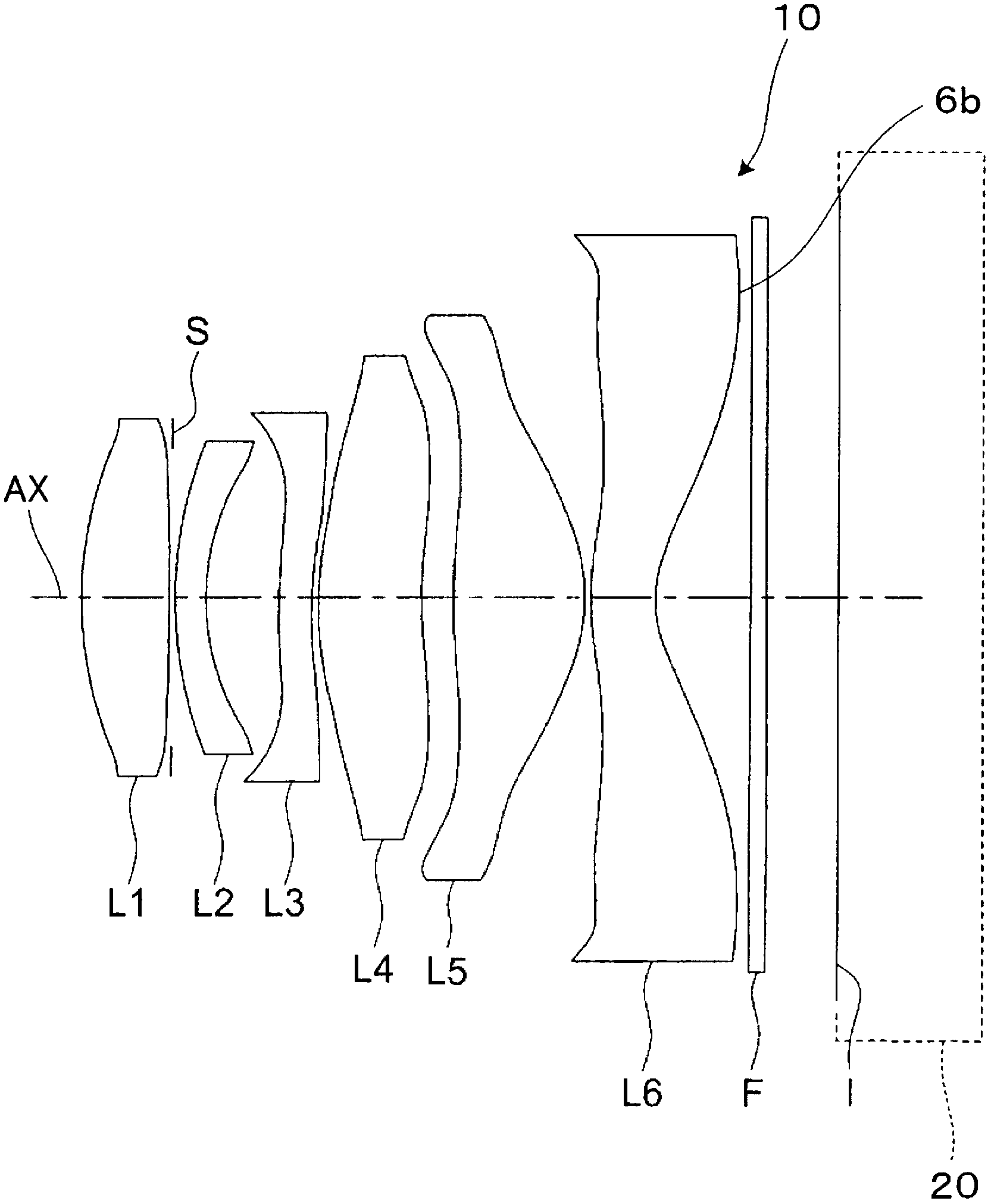

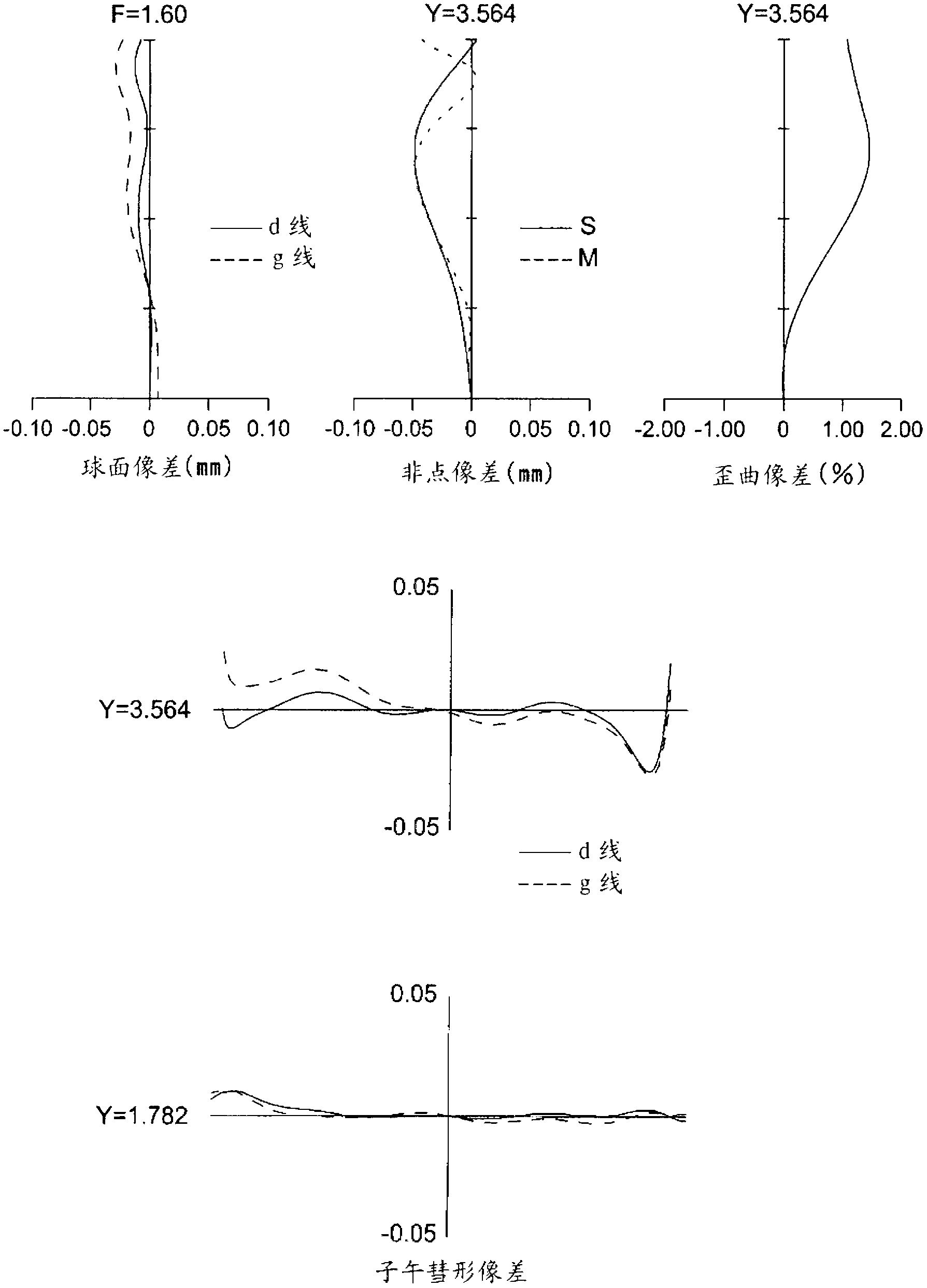

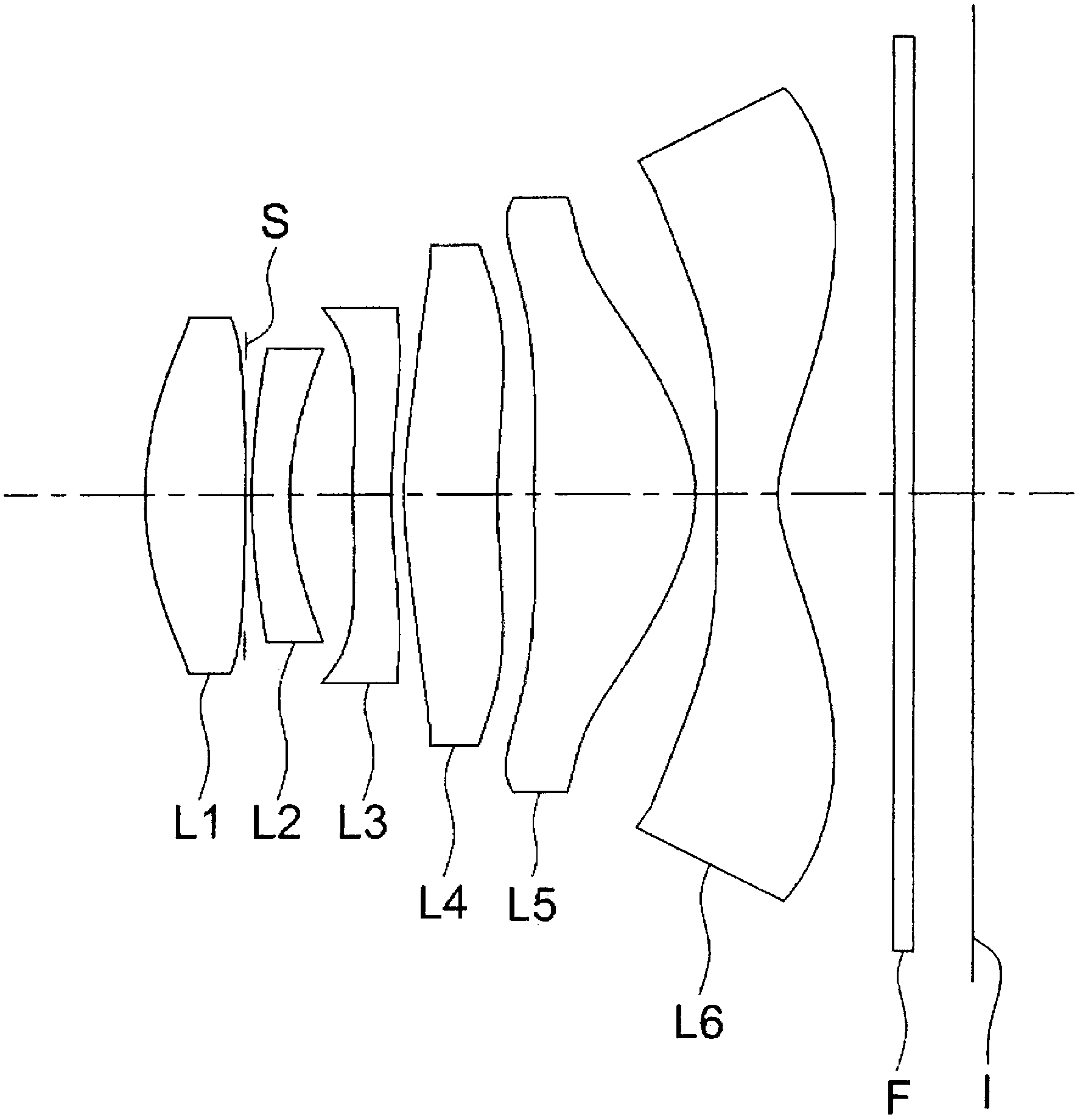

Image capture lens

ActiveCN102985865ASmall outer diameterInhibition lossTelevision system detailsLensNegative refractionCamera lens

Provided is a six-layer configuration image capture lens that is compact and has adequate light at F2 or less, and wherein all aberrations are effectually corrected. In order from the object side, the image capture lens is configured of a first lens having a positive refraction and with a convex face oriented toward the object side; a second lens having a negative refraction and with a concave face oriented toward the imaging side; a third lens having either a positive or a negative refraction; a fourth lens having a positive refraction; a fifth lens having a positive refraction and with a convex face oriented toward the imaging side; and a sixth lens having a negative refraction and with a concave face oriented toward the imaging side. The imaging side face of the sixth lens further comprises an aspherical face shape, has an inflection point in a location other than a point of intersection with the optical axis, and satisfies the following formulae: ? d1 > 50, and ? d2 = 30, wherein ? d1 is the Abbe's number of the first lens, and ? d2 is the Abbe's number of the second lens.

Owner:KONICA MINOLTA INC

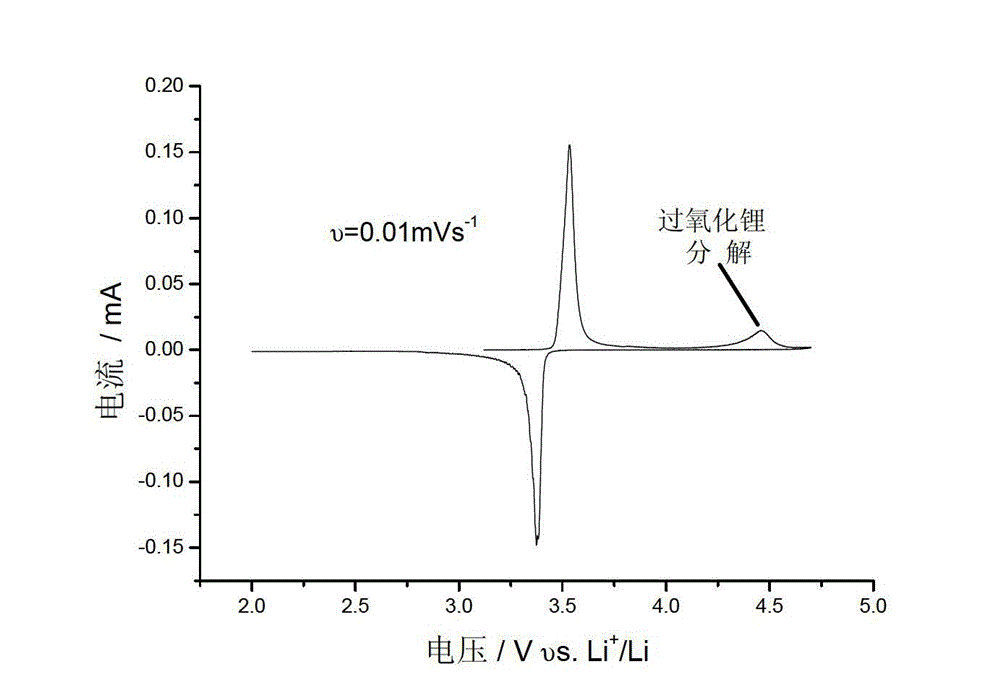

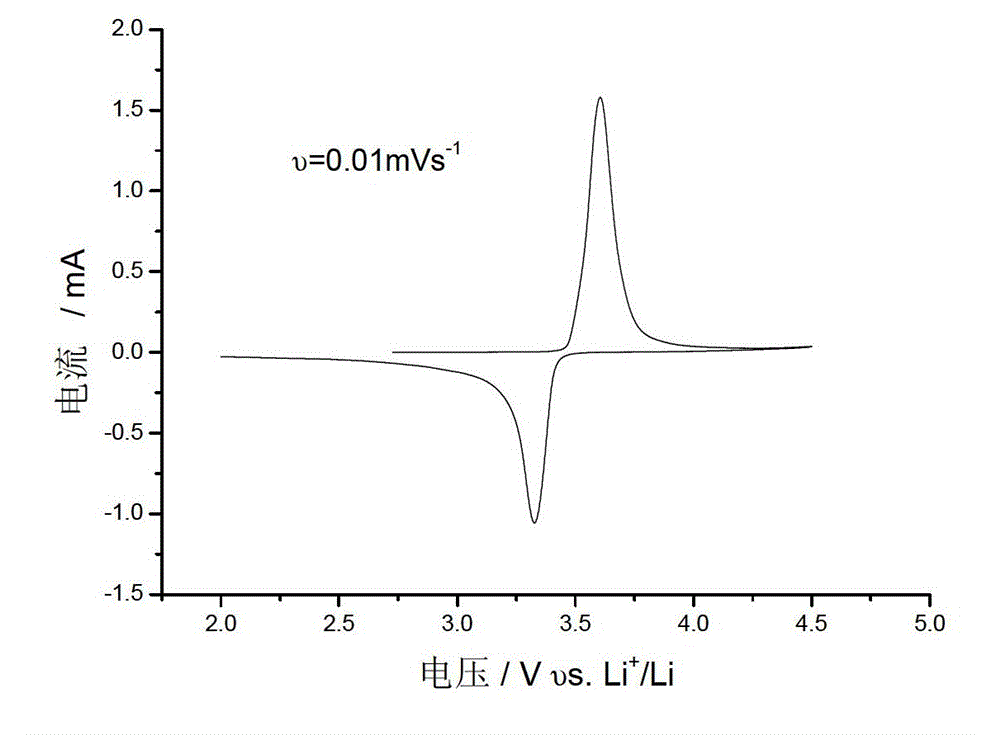

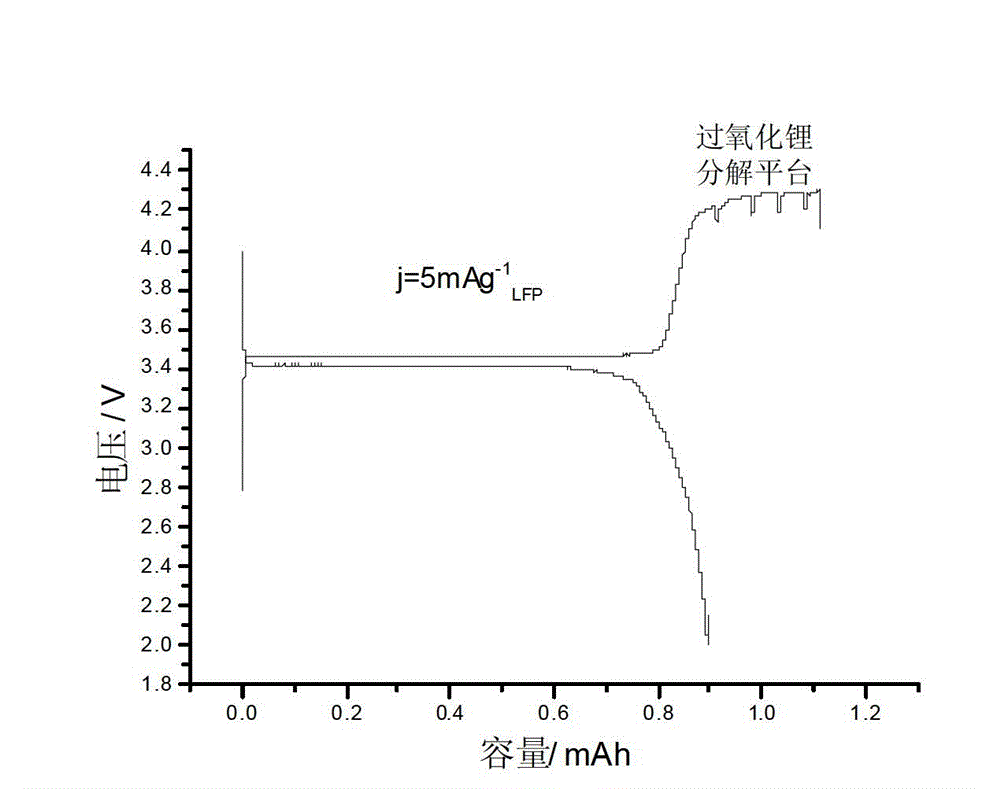

Lithium ion battery anode film, preparation and application thereof

InactiveCN104037418AImprove reversible charge and discharge capacityPerformance is not affectedLi-accumulatorsNon-aqueous electrolyte accumulator electrodesAdhesiveLithium electrode

Provided is a positive electrode film of a lithium battery, comprising: (i) a positive electrode material of a lithium intercalated transition metallic oxide; (ii) a lithium ion replenisher; and (iii) a conductive agent and an adhesive. The lithium ion replenisher in the positive electrode film decomposes during initial charging and then releases lithium ions, so as to make up for a loss of lithium ions forming an SEI film on a negative electrode surface, thereby improving the reversible charging and discharging capacity of the lithium ion battery. In the prepared positive electrode film, the lithium ion replenisher can be mixed in the positive electrode material or the conductive agent in advance, and can be coated on the surface of the positive electrode of the lithium ion battery as well.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

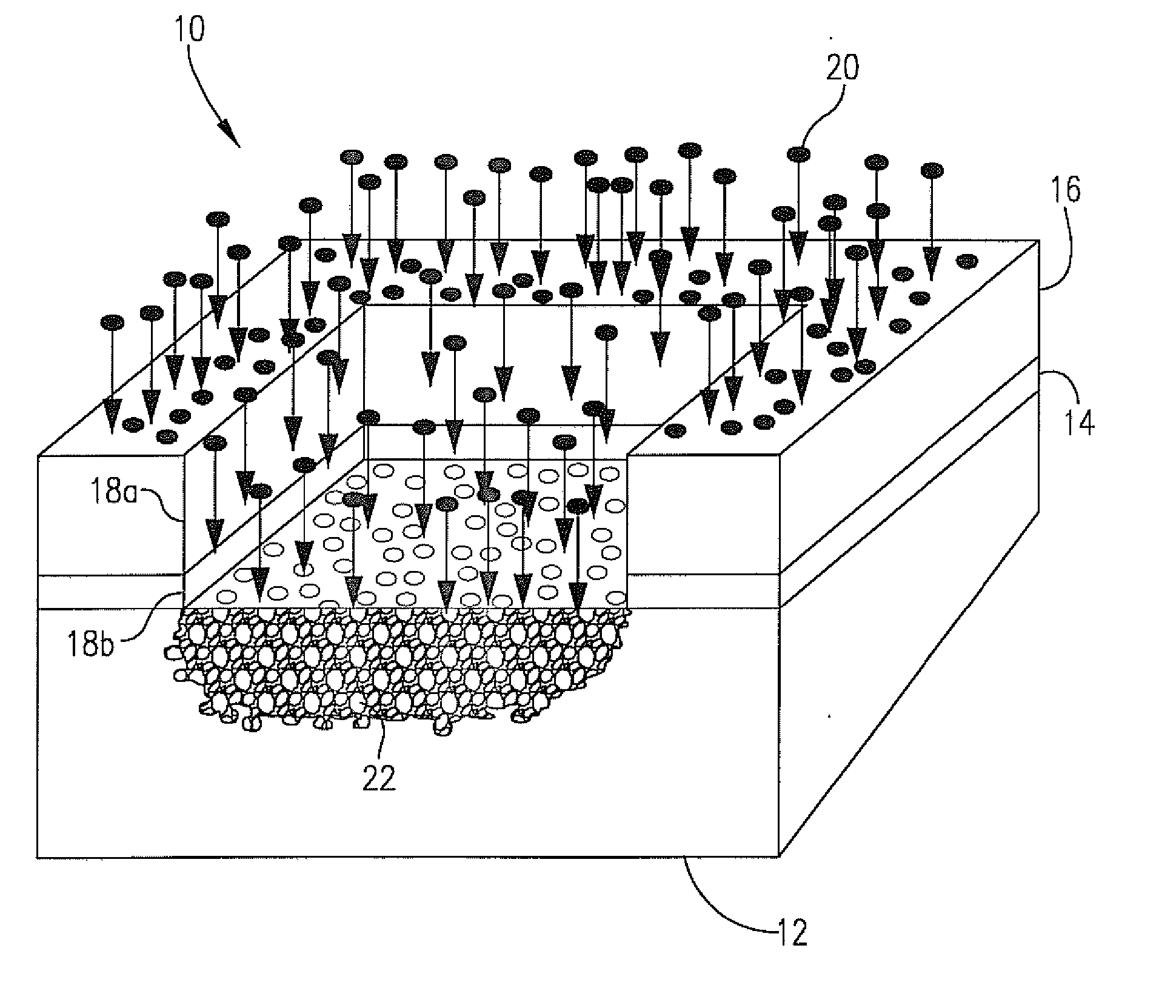

Method of growing gan crystal on silicon substrate, and light emitting device and method of manufacturing thereof

ActiveUS20080283821A1Improve conductivityReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalSilicon oxide

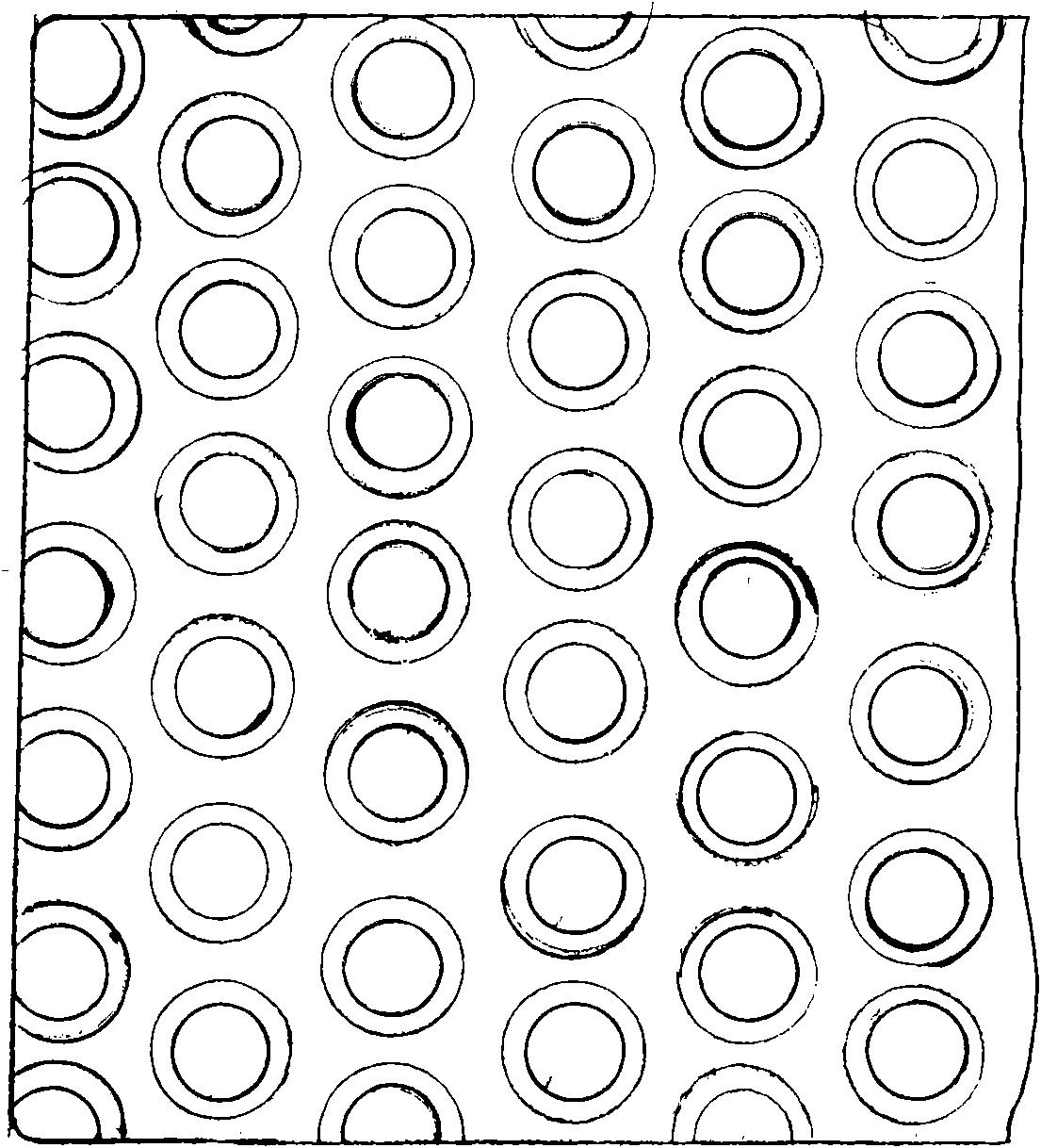

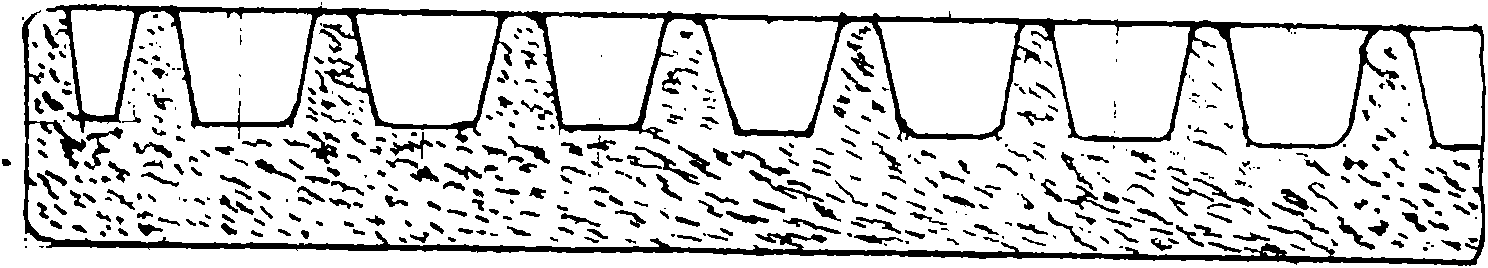

Example embodiments are directed to a method of growing GaN single crystals on a silicon substrate, a method of manufacturing a GaN-based light emitting device using the silicon substrate, and a GaN-based light emitting device. The method of growing the GaN single crystals may include forming a buffer layer including a TiN group material or other like material on a silicon substrate, forming a nano-pattern including silicon oxide on the buffer layer, and growing GaN single crystals on the buffer layer and the nano-pattern.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

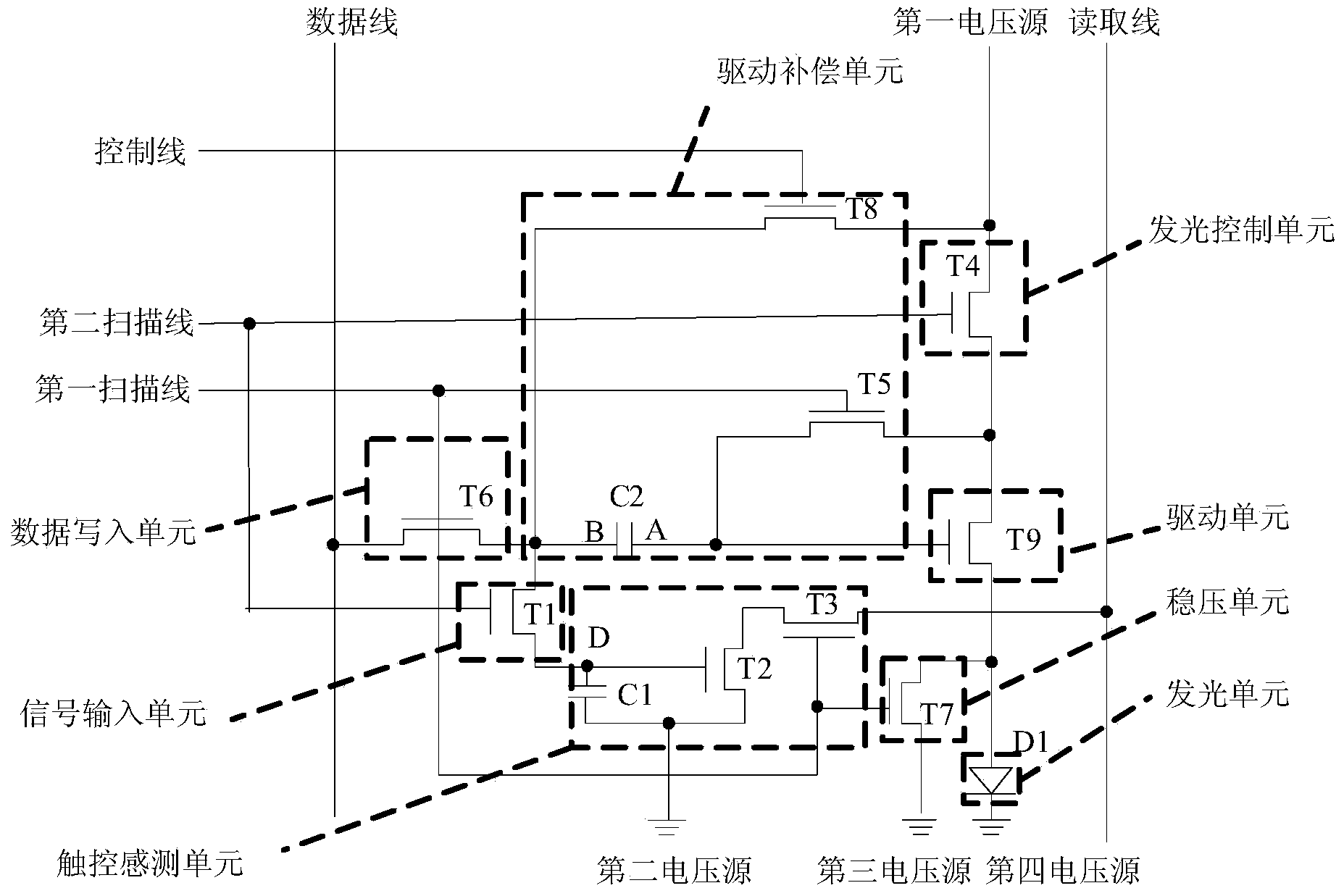

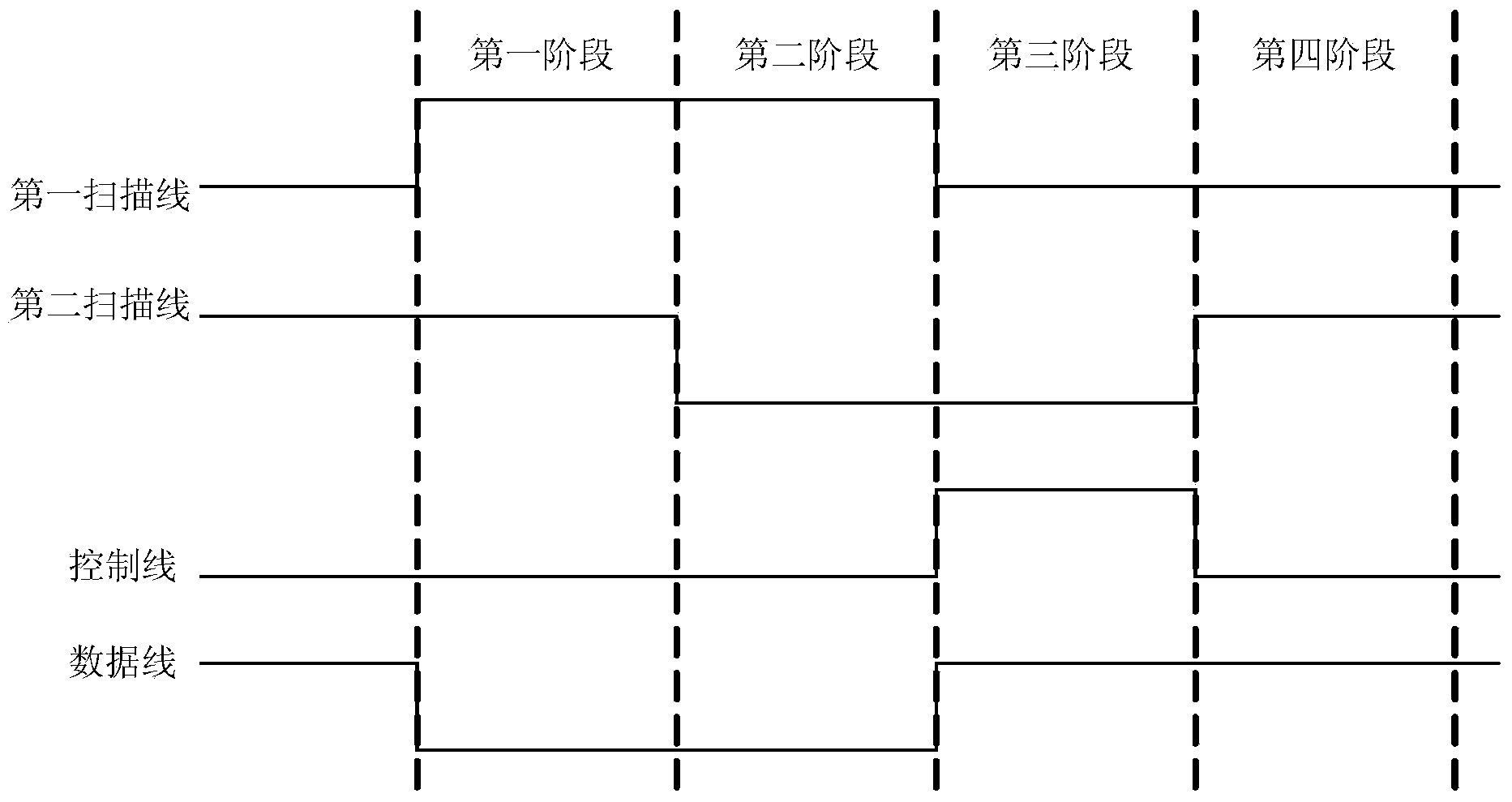

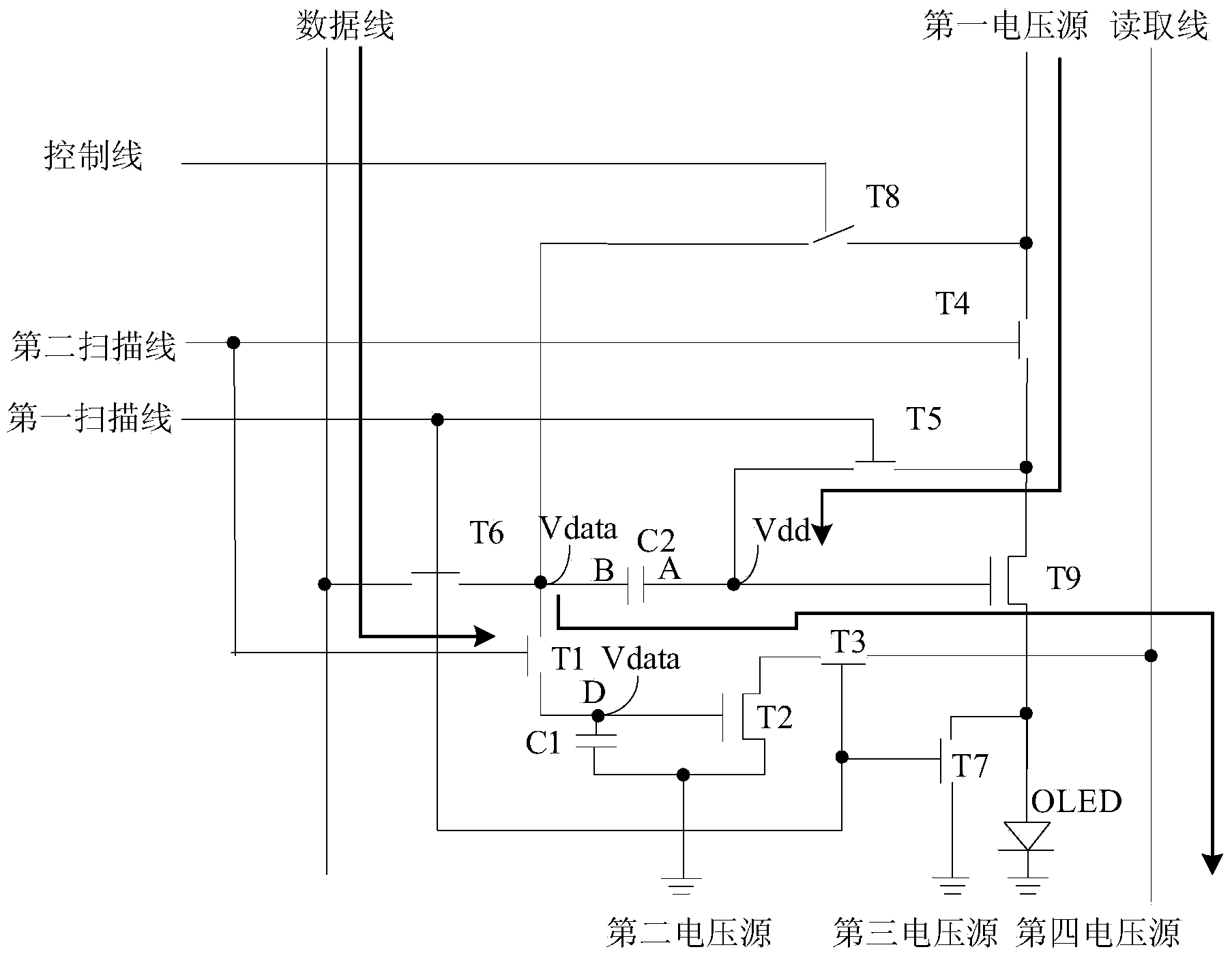

Touch display drive circuit and drive method and display device thereof

ActiveCN103456267AReduce production processLow costStatic indicating devicesInput/output processes for data processingControl lineComputer module

The invention provides a touch display drive circuit and a drive method and a display device thereof. The circuit comprises a touch module and a display drive module. The display drive module is connected with a data line, a fist scanning lie, a second scanning line, a control line, a first voltage source, a third voltage source and a fourth voltage source, and the display drive module is used for carrying out compensation on a drive unit, writing in data signals input by the data line, outputting the data signals to the touch module and driving a luminescent unit to give out light under the control of signals input by the data line, the first scanning line and the second scanning line. The touch module is connected with the first scanning line, the second scanning line, a reading line and a second voltage source, and the touch module is used for receiving the data signals input by the display drive module under the effect of the signals input by the first scanning line and the second scanning line to carry out reconfiguration on the touch module. When touches occur, the touch module provides touch signals, and the reading line confirms the positions where the touches occur according to collected touch signals.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

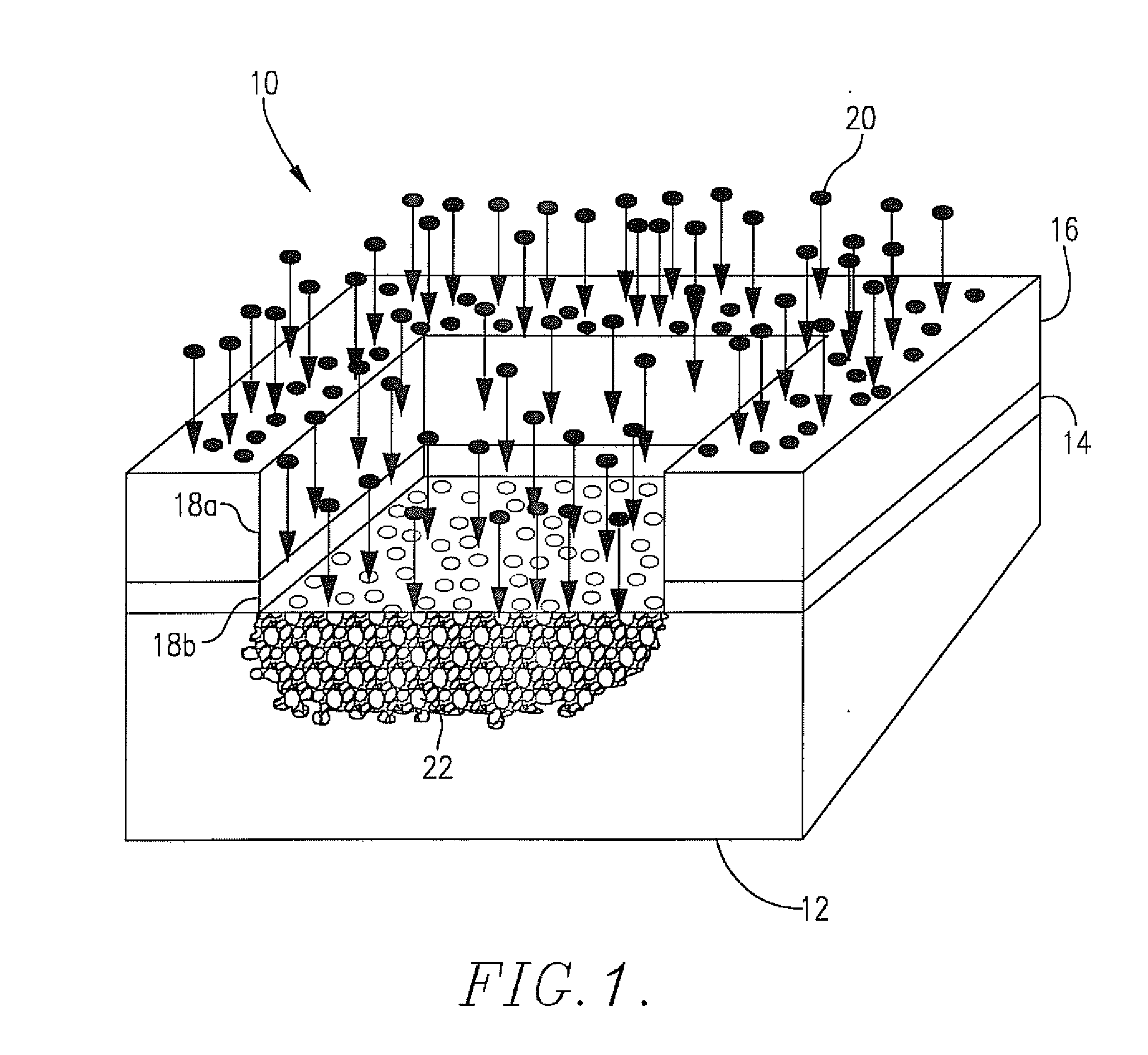

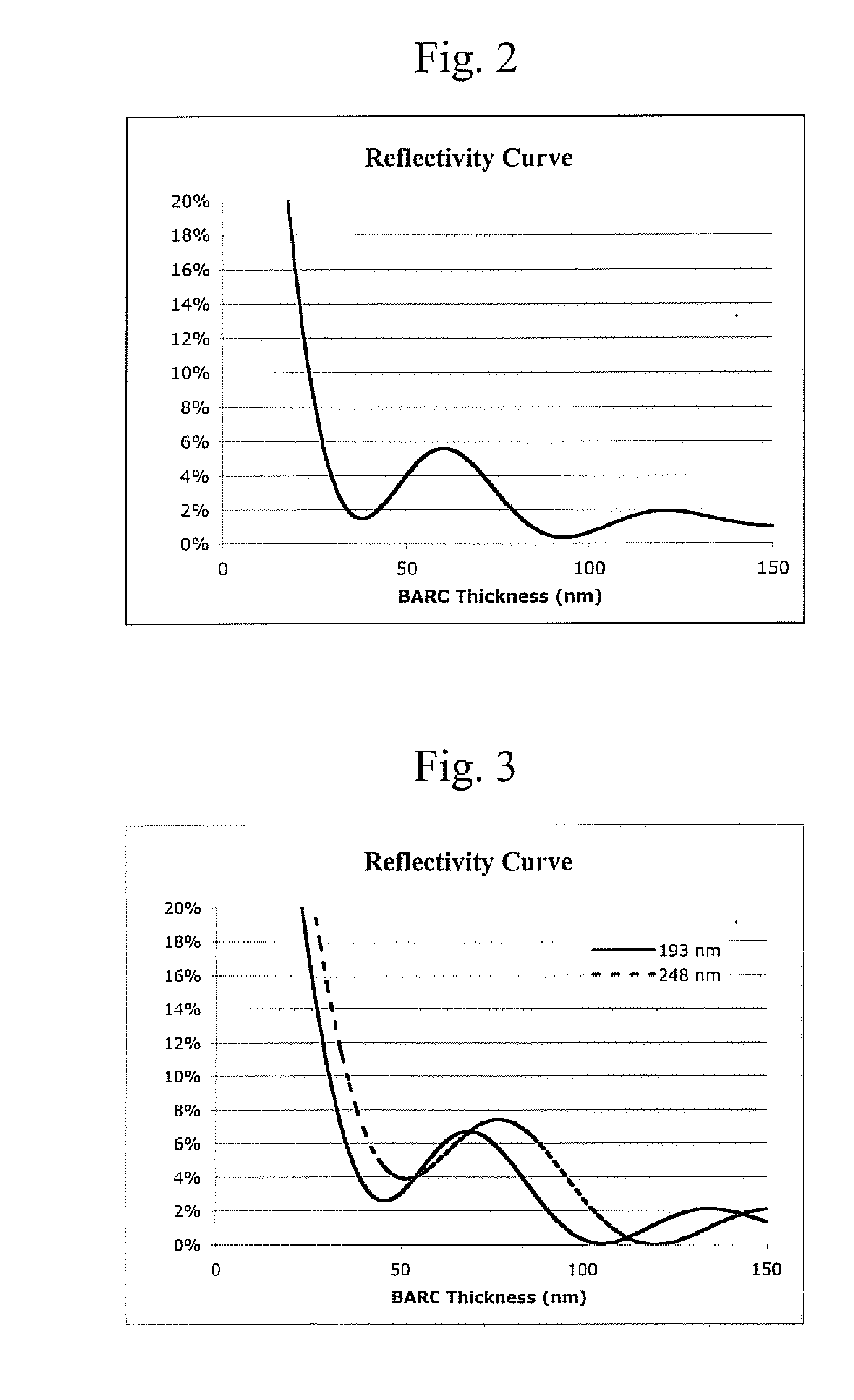

Anti-reflective coatings using vinyl ether crosslinkers

InactiveUS20070207406A1High percent solubilityReduce production processOrganic chemistrySilver halide emulsionsVinyl etherAnti-reflective coating

Novel, developer soluble anti-reflective coating compositions and methods of using those compositions are provided. The compositions comprise a polymer and / or oligomer having acid functional groups and dissolved in a solvent system along with a cross linker, a photoacid generator, and optionally a chromophore. The preferred acid functional group is a carboxylic acid, while the preferred crosslinker is a vinyl ether crosslinker. In use, the compositions are applied to a substrate and thermally crosslinked. Upon exposure to light (and optionally a post exposure bake), the cured compositions will decrosslink, rendering them soluble in typical photoresist developing solutions (e.g., alkaline developers). In one embodiment, the compositions can be used to form ion implant areas in microelectronic substrates.

Owner:BREWER SCI

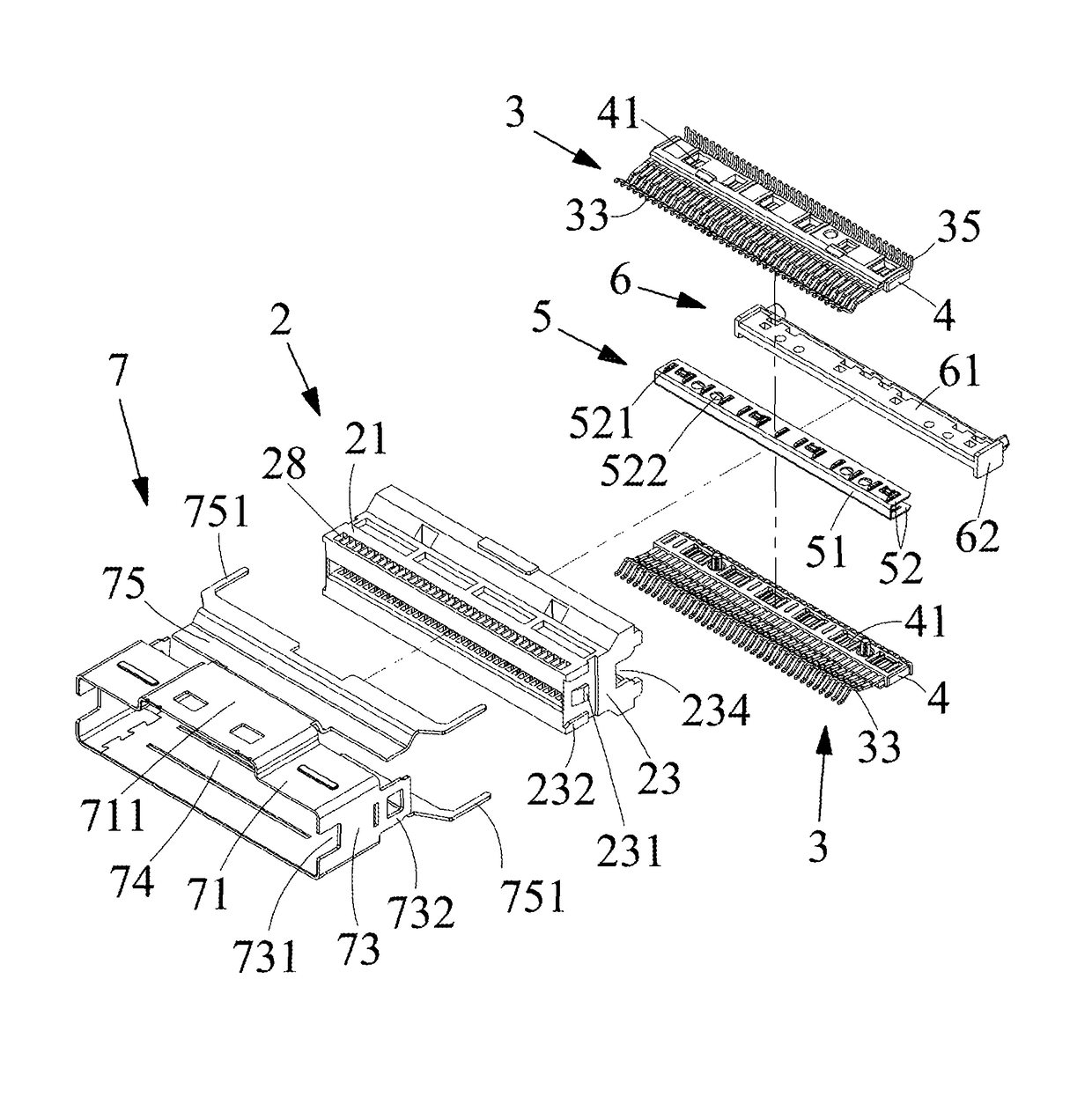

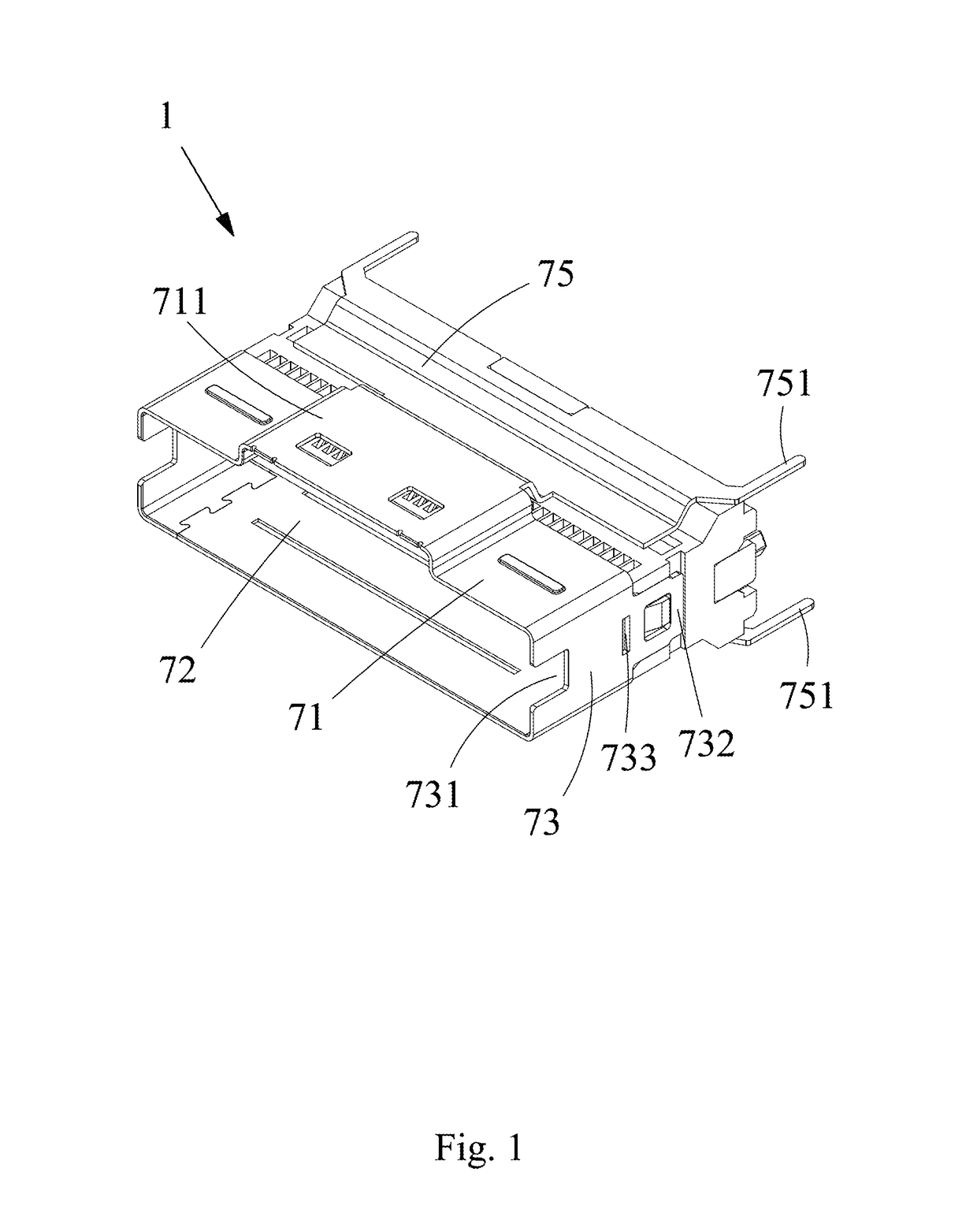

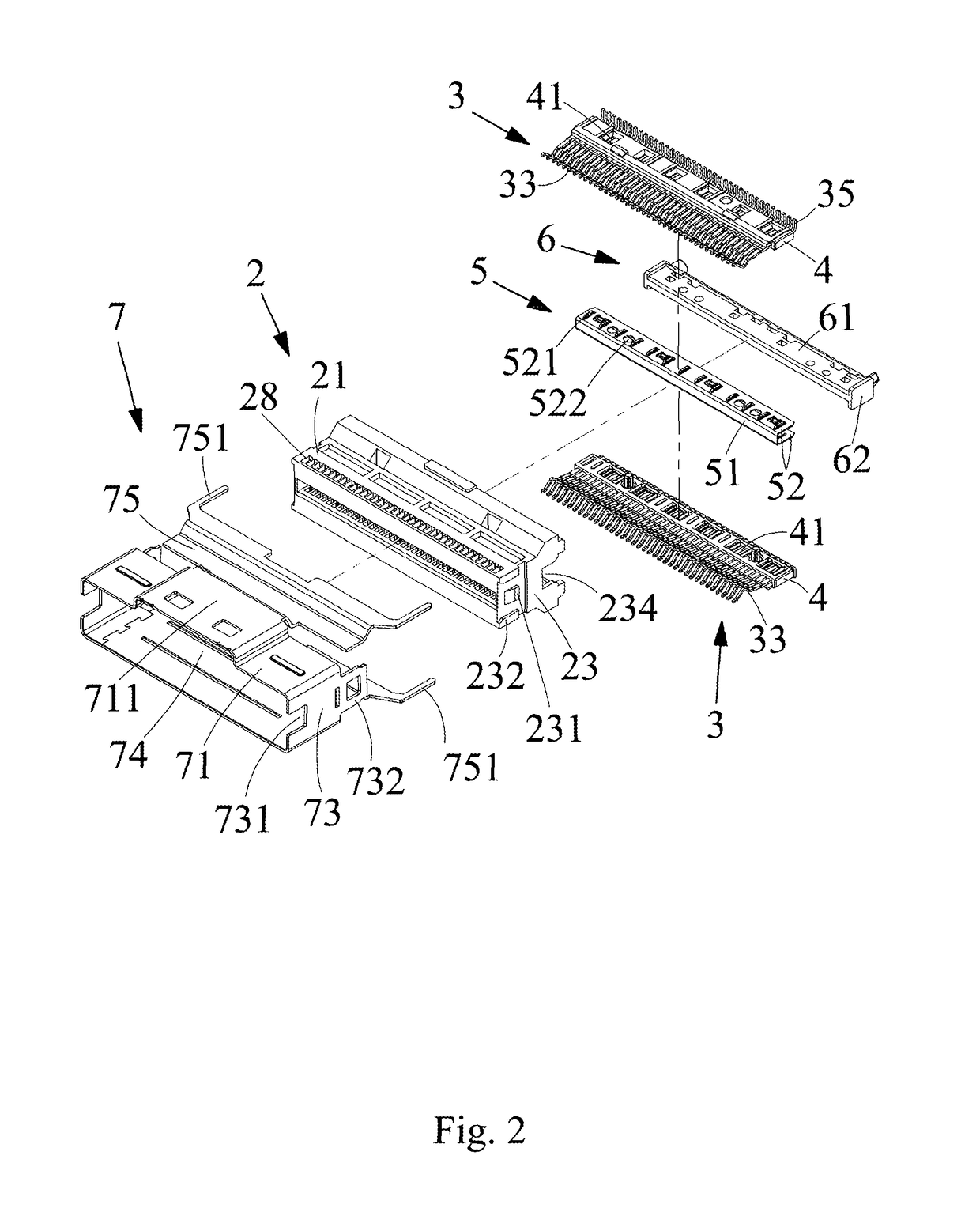

Electrical connector structure with improved ground member

ActiveUS9972945B1Suppress high frequency noiseImprove interferenceTwo-part coupling devicesCoupling protective earth/shielding arrangementsSolderingElectrical connector

A electrical connector structure includes ground terminals formed in two rows, which are fixed into two bases respectively, in which each of the ground terminals includes a contact portion, a soldering portion and a main body is connected to the contact portion and the soldering portion, and each main body is fixed into the bases, and each soldering portion extends out of the bases; and a ground member including two ground plates, in which the ground plates covering surfaces of the bases, respectively, and a surface of each ground plate has a plurality of contact arms protruding, the contact arms are electrically contacted to the ground terminals, respectively, in which two ends of each contact arm contact the ground plates, respectively.

Owner:SPEED TECH

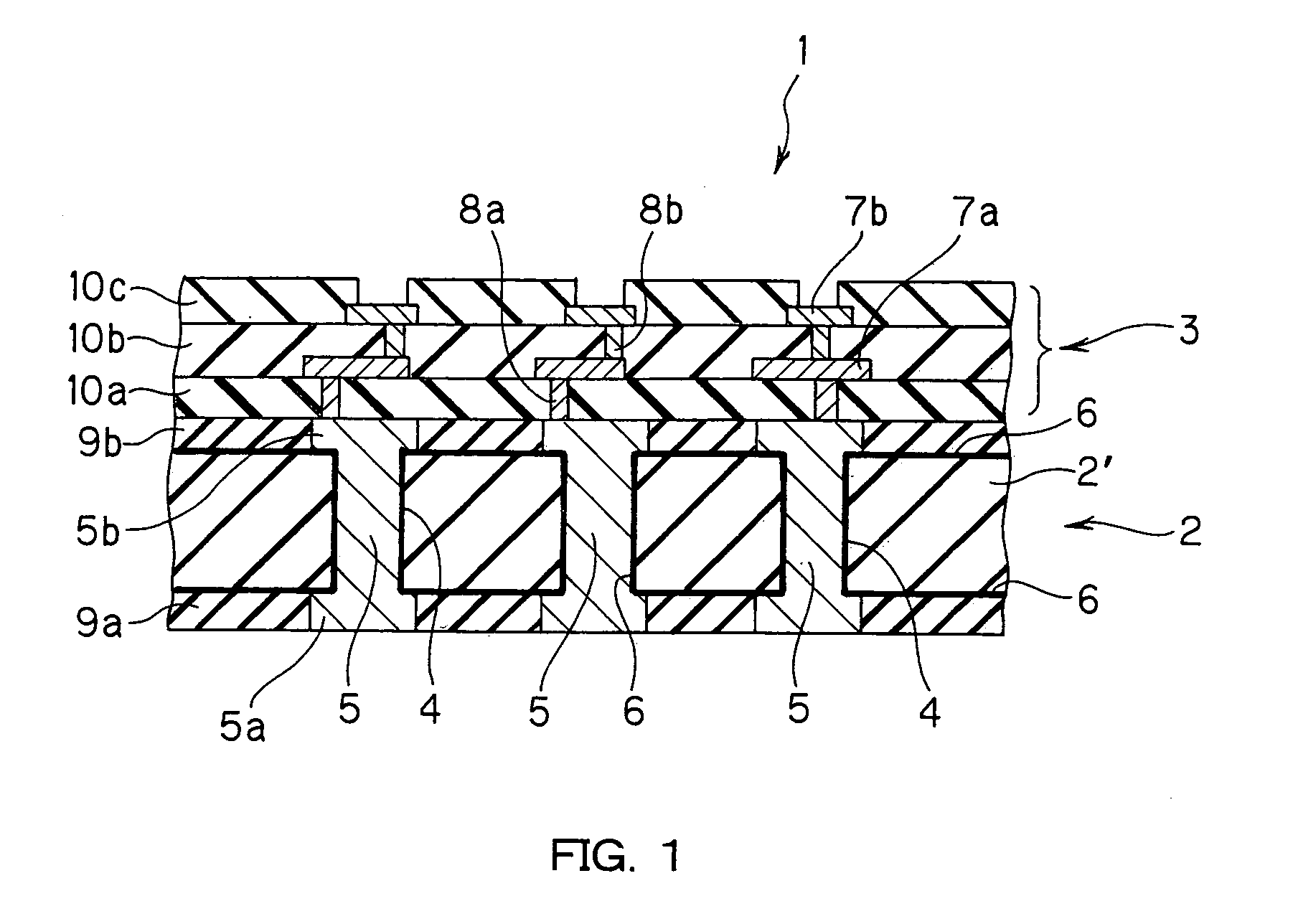

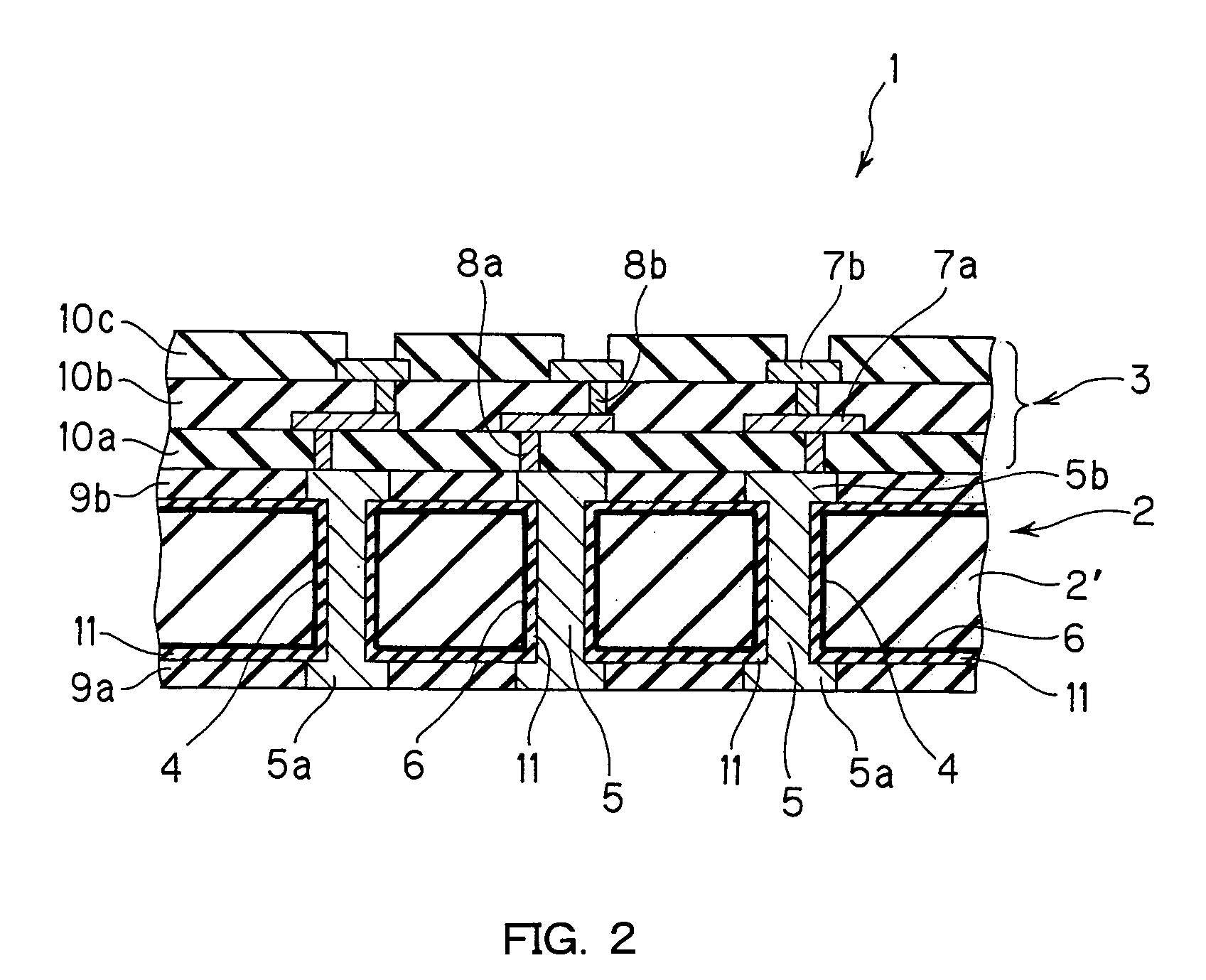

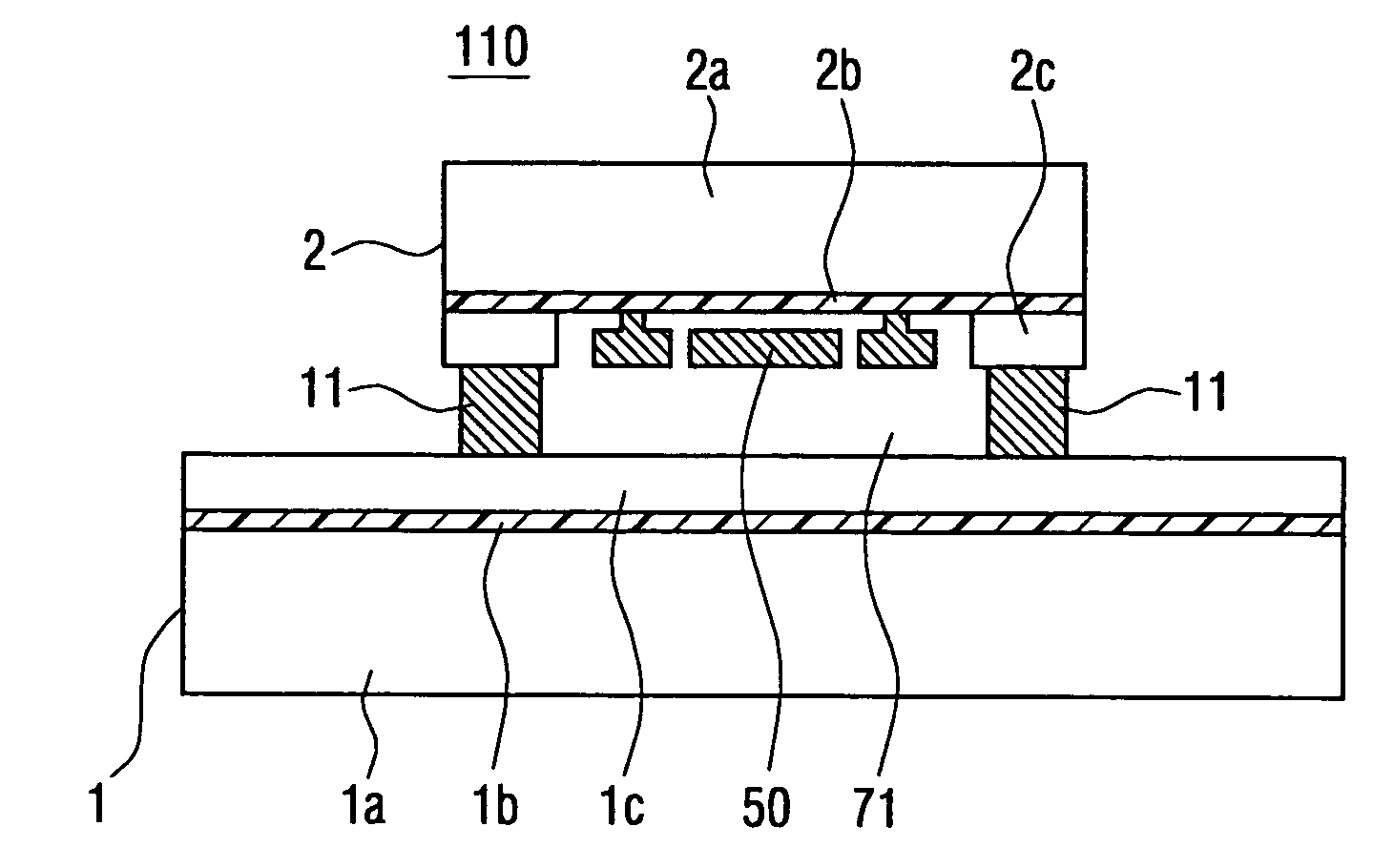

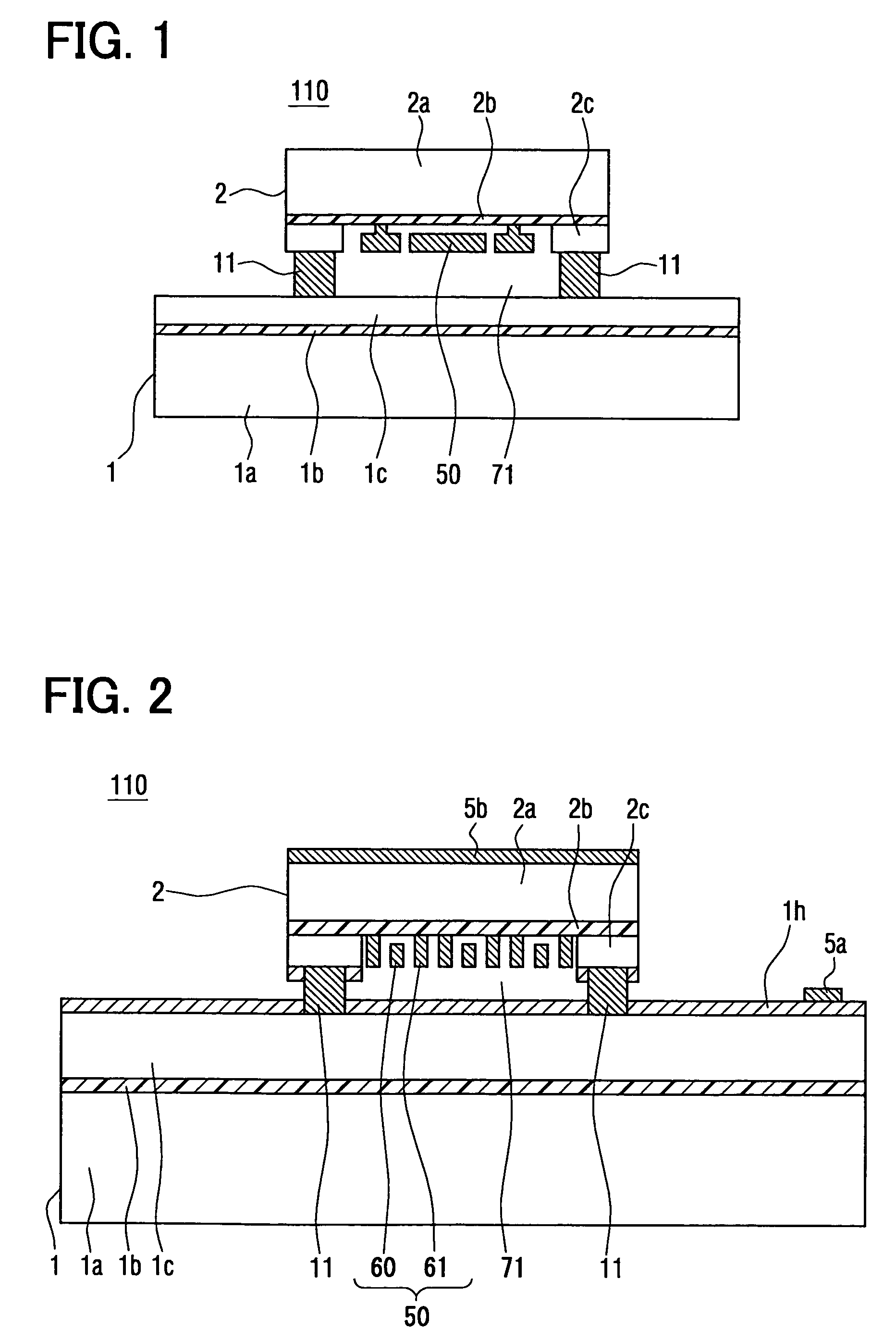

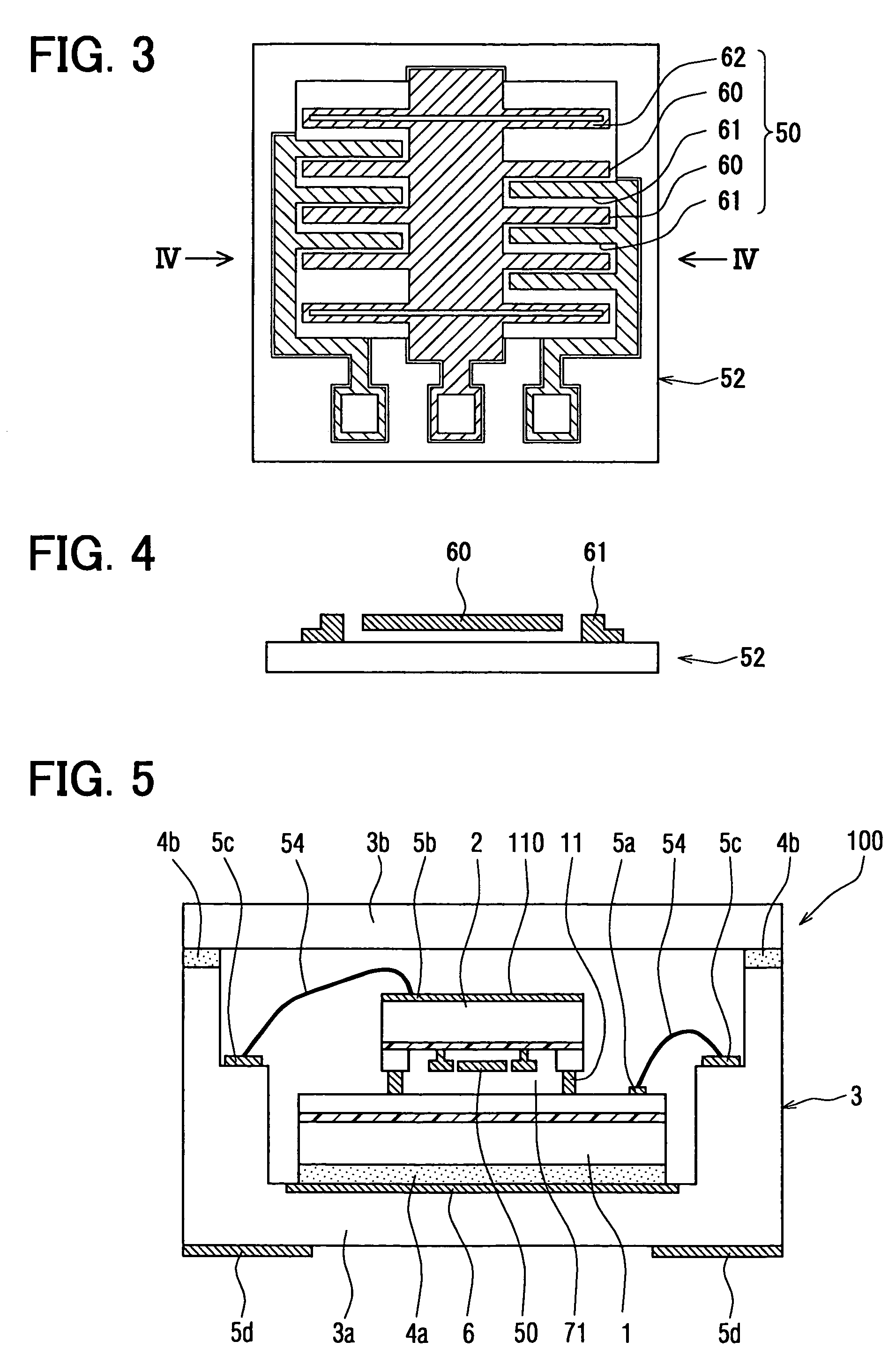

Semiconductor device having multiple substrates

ActiveUS6979873B2Protected from outside disturbanceReduce the number of partsAcceleration measurement using interia forcesSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device includes a first substrate including first, second and third layers; and a second substrate including fourth, fifth and sixth layers. The first substrate provides an electric device. The second substrate provides a physical quantity sensor. The first layer of the first substrate and the fourth layer of the second substrate are shields for protecting the electric device and the physical quantity sensor. The device is protected from outside disturbance without adding an additional shield.

Owner:DENSO CORP

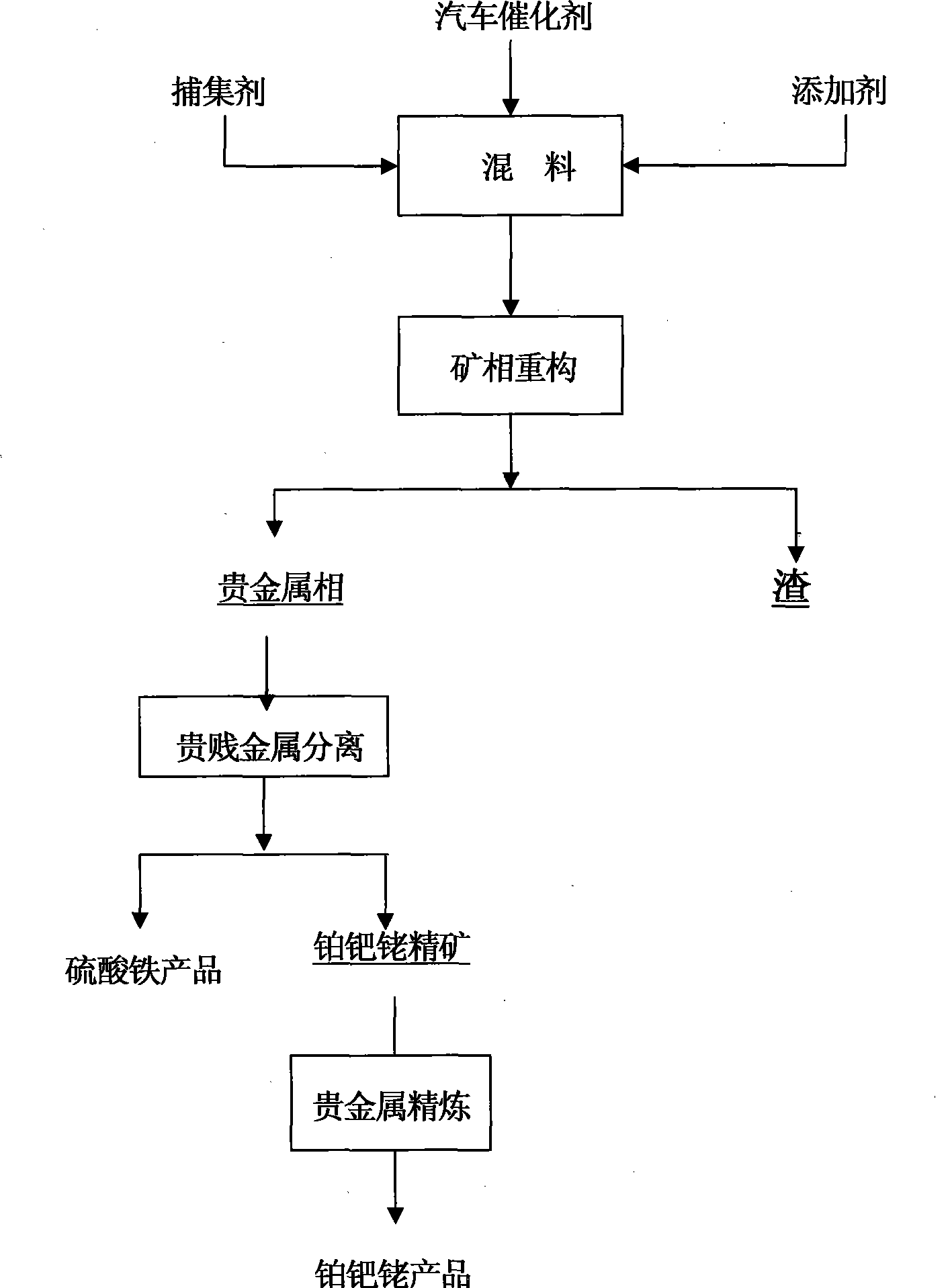

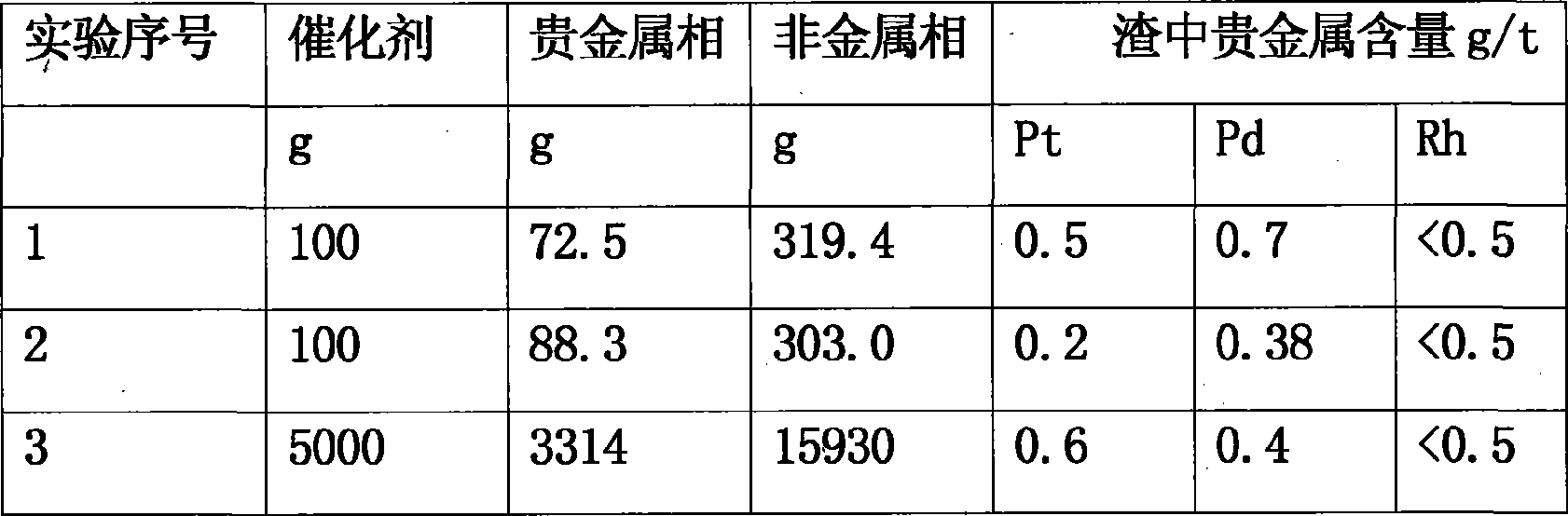

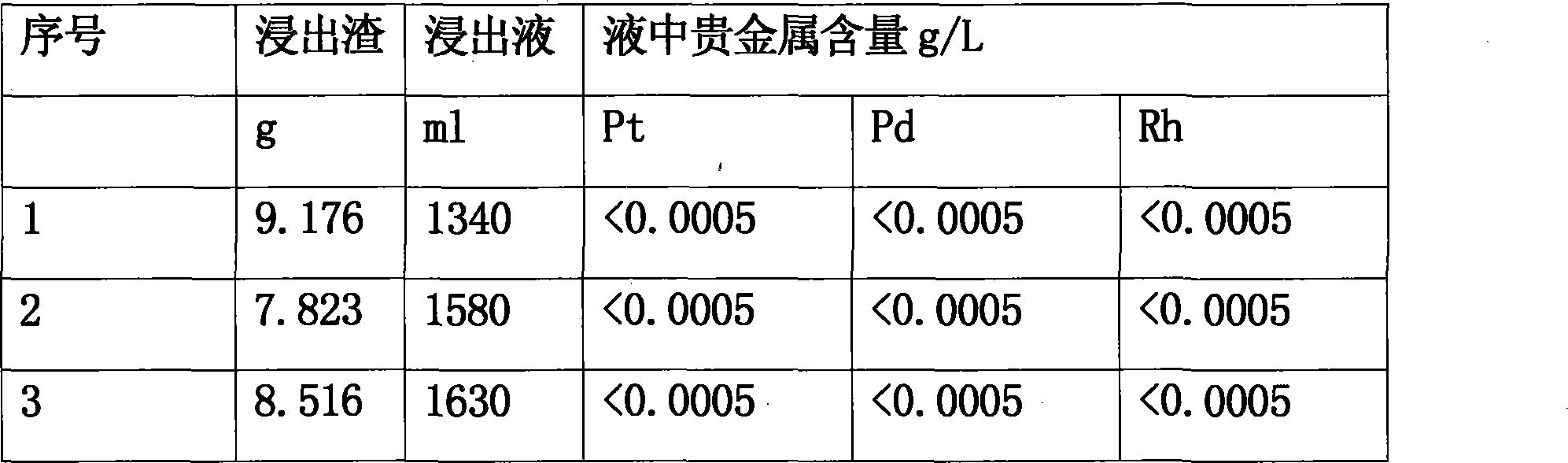

Method for extracting platinum, palladium, rhodium from automotive catalyst of ore phase reconstruction

InactiveCN101509077AEfficient captureReduce corrosionProcess efficiency improvementElectric arc furnaceSlag

The invention relates to a method for recovering noble metals from spent automotive exhaust catalysts, comprising the following processes: 1. mixing the spent automotive exhaust catalyst with a reducing agent, an additive and a trapping agent; 2. putting the mixed materials into a clay graphite crucible, and putting the clay graphite crucible into an electric furnace or an electric arc furnace for smelting, thus obtaining a noble metal phase; 3. selectively leaching base metals from the noble metal phase, thus obtaining the enrichment of the noble metal, refining the enrichment of the noble metal to produce platinum, palladium and rhodium products. The method is characterized by simple process flow and high recovery rates of noble metals. The platinum, palladium and rhodium in the waste slag are less than 1g / t and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

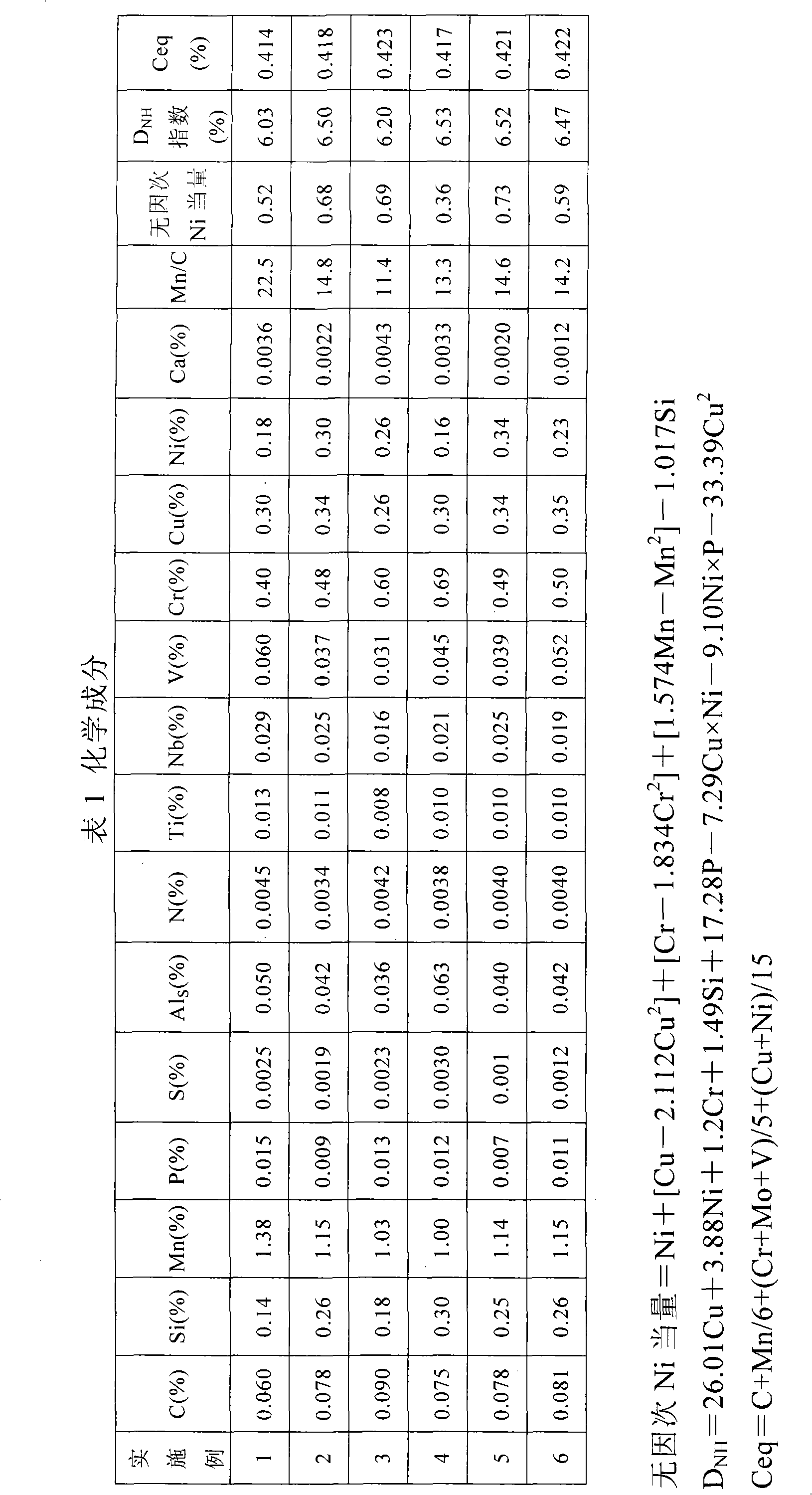

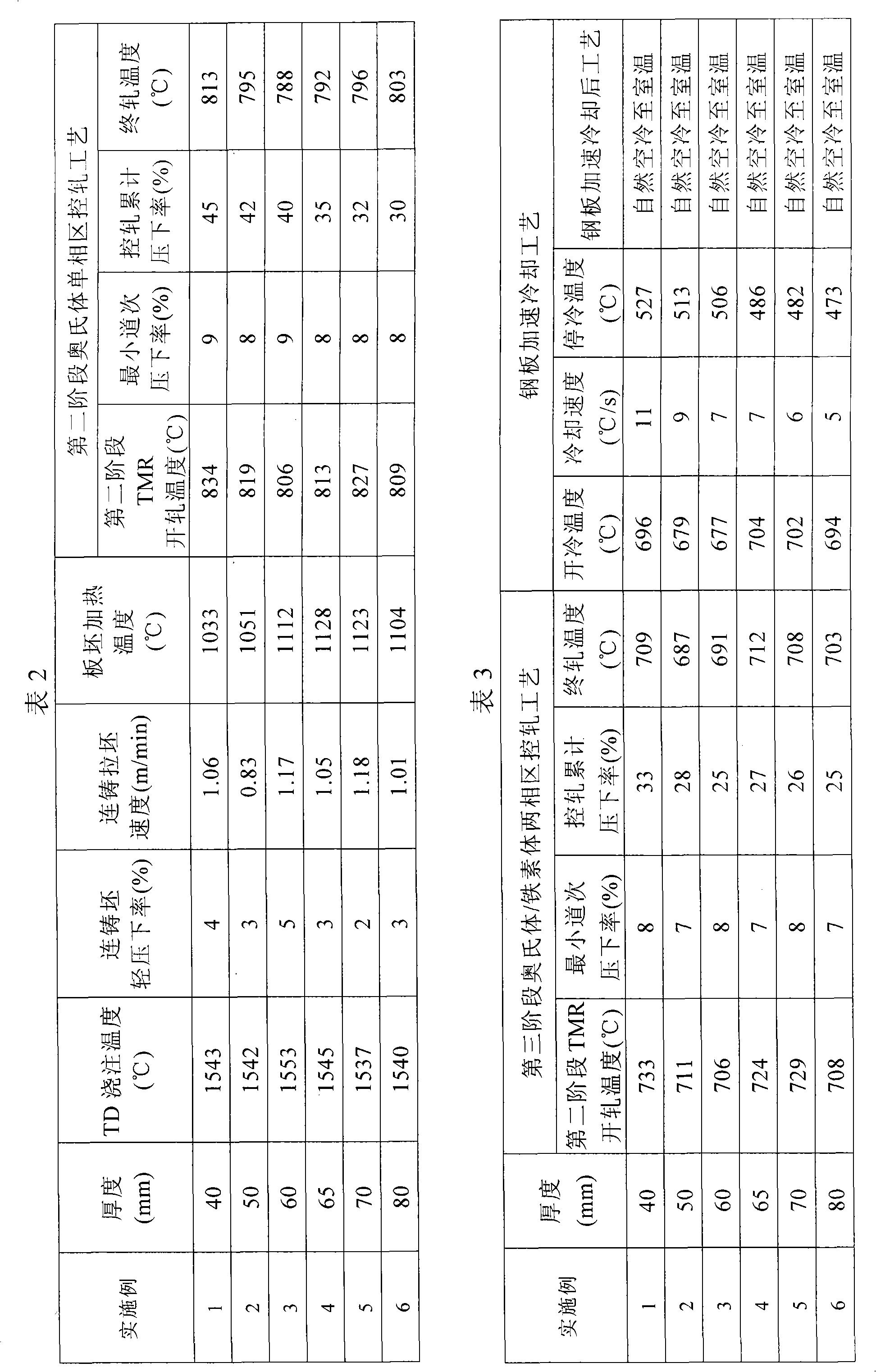

High-performance weather-proof building structural steel and manufacturing method thereof

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

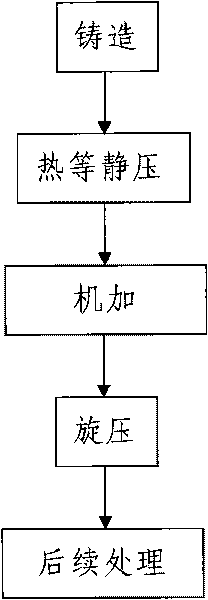

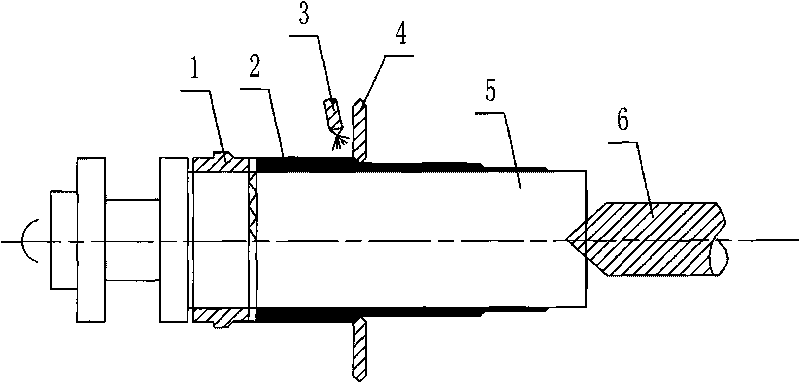

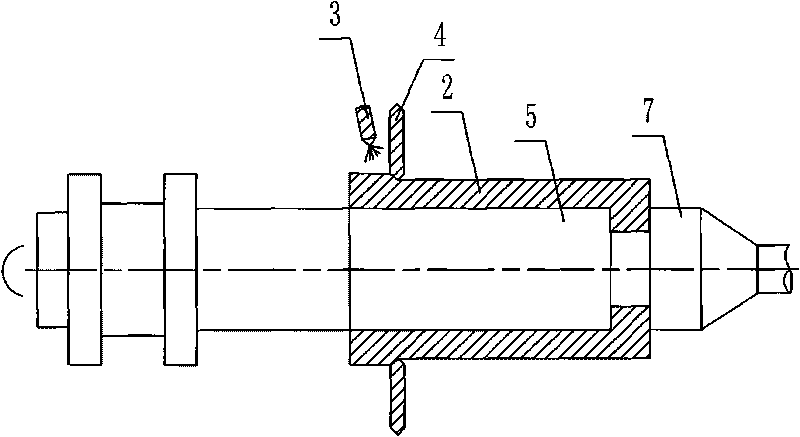

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

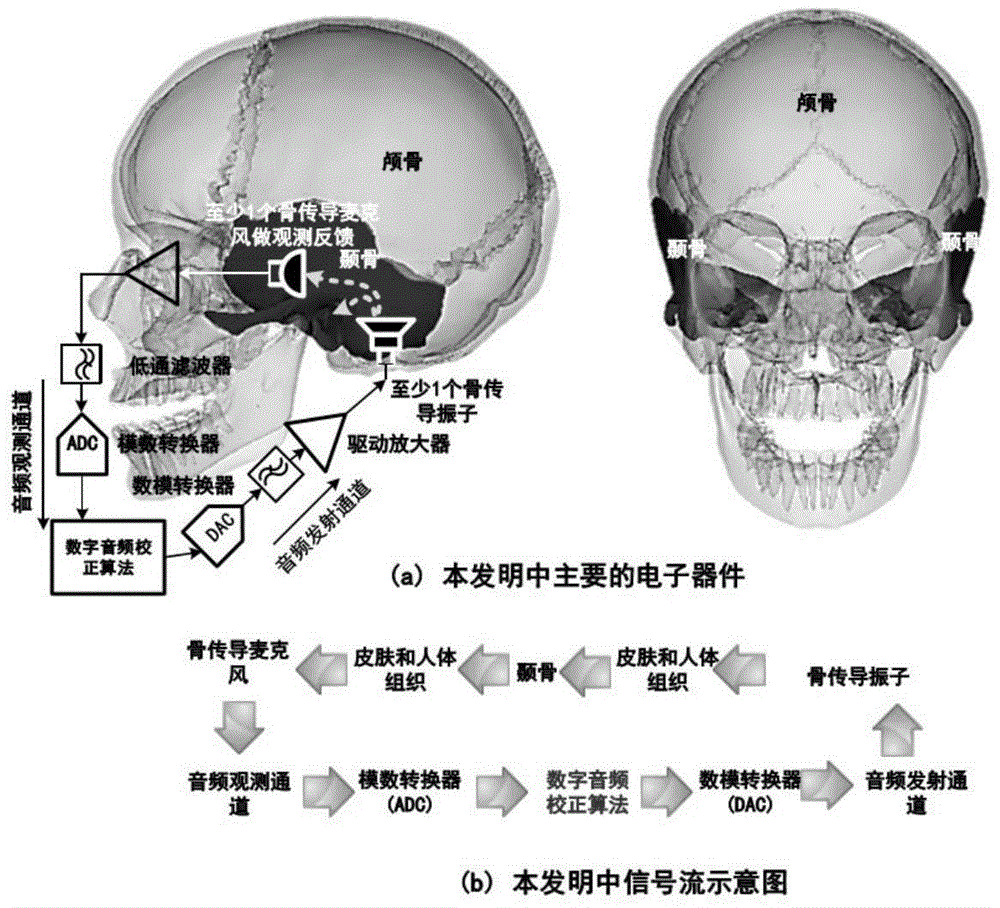

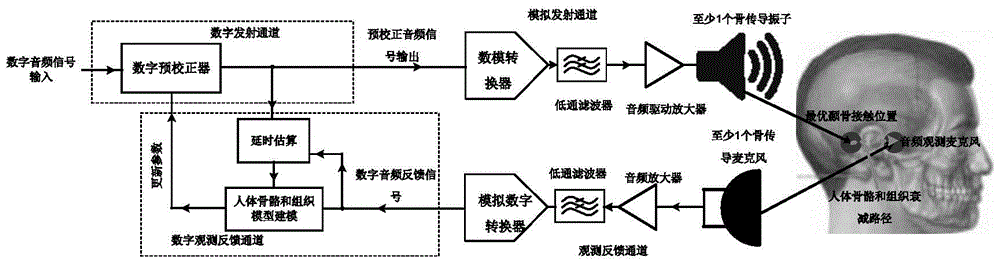

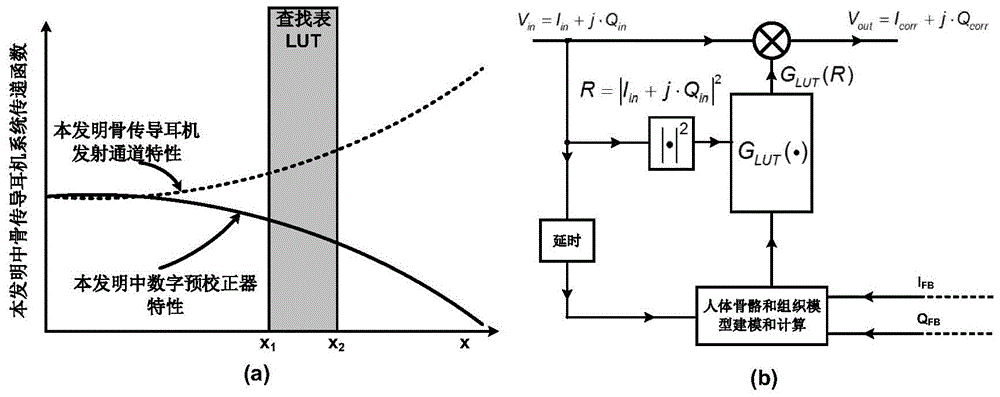

Bone conduction headset and audio processing method thereof

InactiveCN105721973ASimplify complexityReduce production processBone conduction transducer hearing devicesEarpiece/earphone attachmentsLow-pass filterBone conduction hearing

The invention discloses an audio processing method for a bone conduction headset, the bone conduction headset and an audio playback device based on the bone conduction headset. The bone conduction headset comprises a human bone and tissue model modeling module, a digital pre-corrector, a delay estimation unit, a digital-to-analog converter, an analog-digital converter, a first low-pass filter, a second low-pass filter, an audio amplifier, an audio driving amplifier, at least one bone conduction microphone, and at least one bone conduction vibrator. In the method, human bone and tissue attenuation effect information of different users is detected in real time; a compensating transfer function is generated based on the attenuation effect information; and an input audio signal is subjected to digital pre-correction via the compensating transfer function, and then the processed input audio signal is transmitted in human bones and tissues. Through adoption of the method, a problem that experience of the bone conduction headset is different caused by different tissue thickness of the different users is solved.

Owner:王泽玲

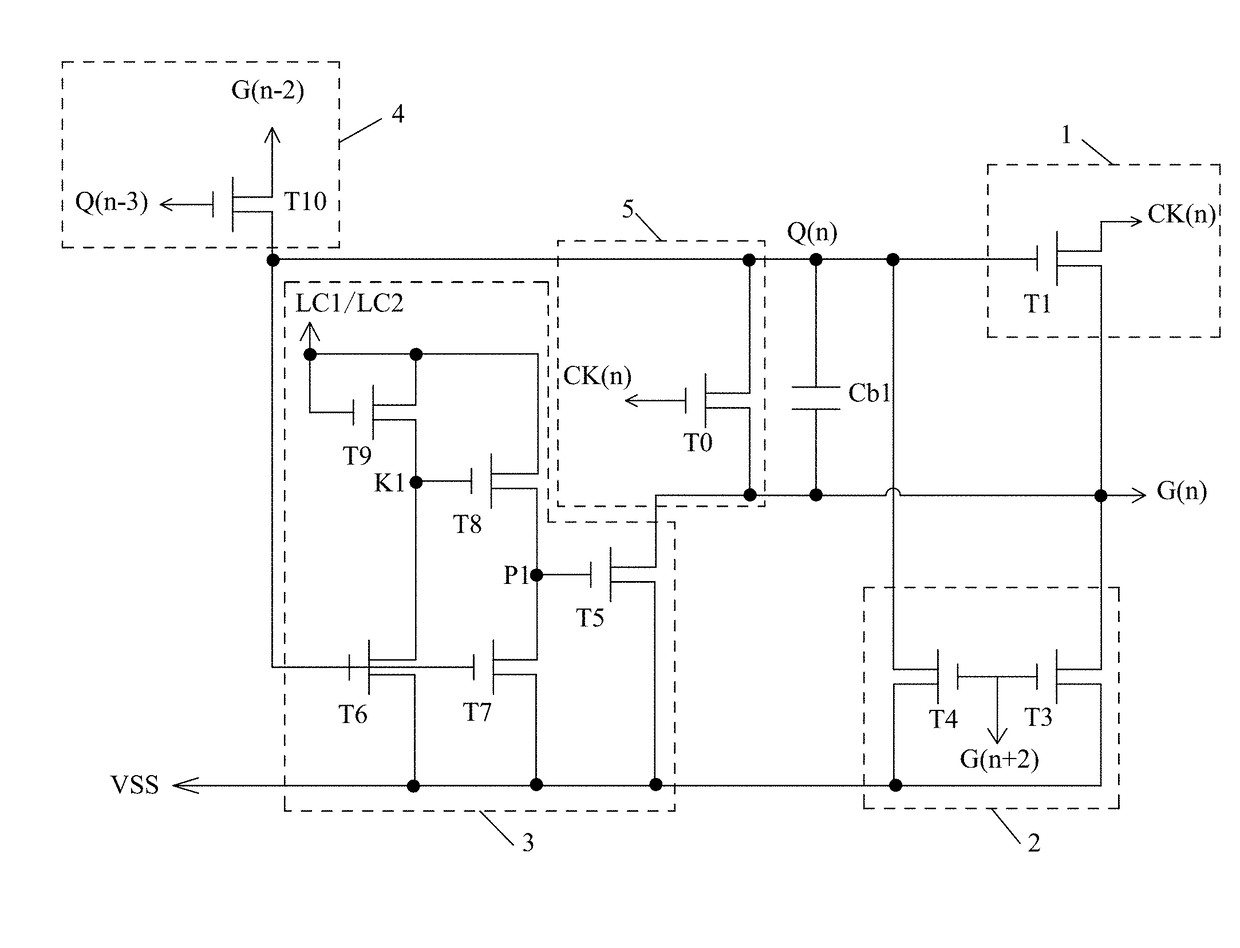

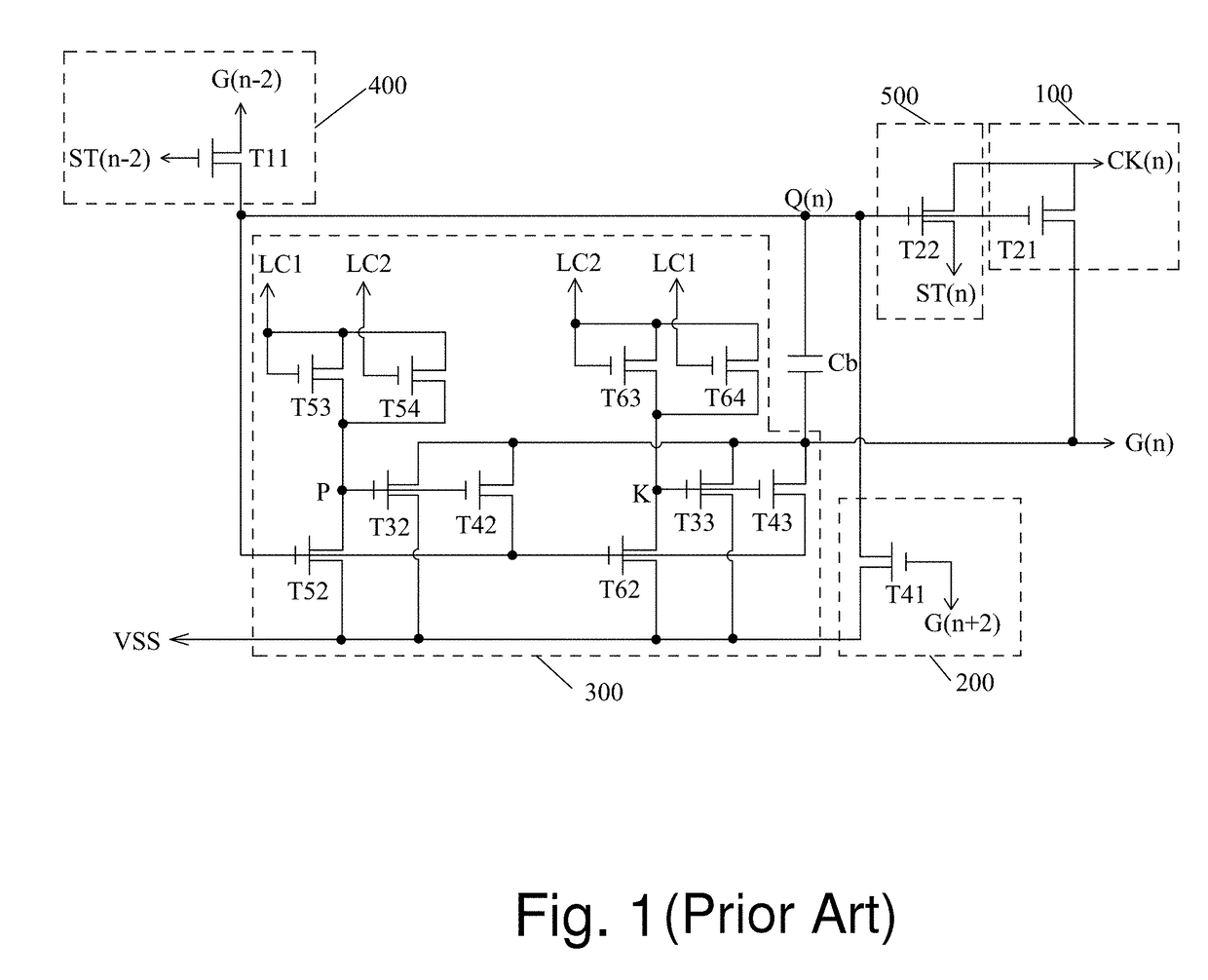

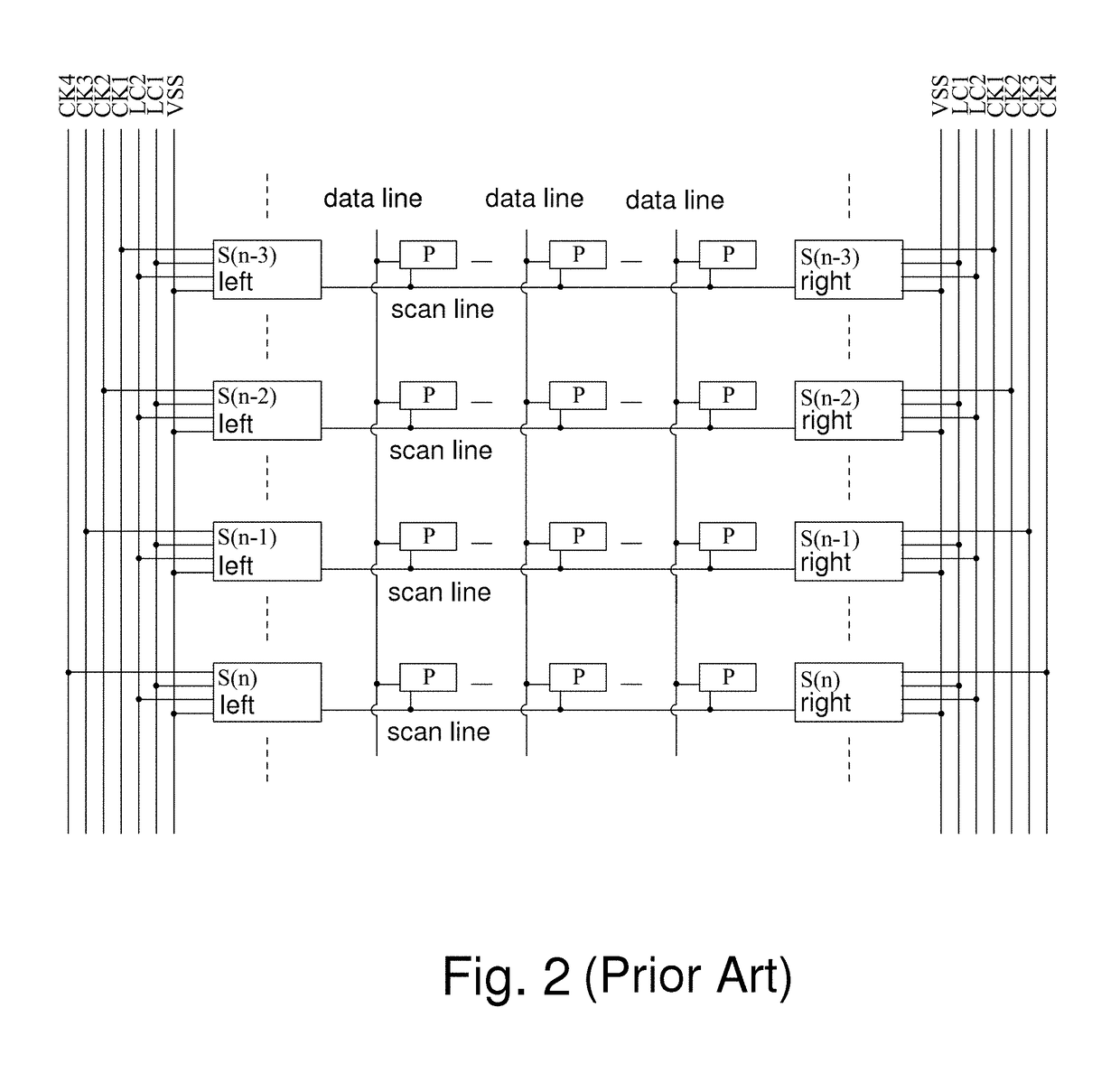

Complementary gate driver on array circuit employed for panel display

A complementary gate driver on array circuit employed for panel display includes a plurality of GOA units that are cascade connected, in which an nth GOA unit controls charge to an nth horizontal scanning line G(n) in a display area and includes a pull-up circuit module, a pull-down circuit module, a pull-down holding circuit module, a pull-up controlling circuit module, a pull-down circuit module of an nth gate signal point Q(n), and a bootstrap capacitor. The pull-up circuit module, the pull-down circuit module, the pull-down holding circuit module, the pull-down circuit module of the nth gate signal point Q(n), and the bootstrap capacitor are respectively coupled to the nth gate signal point Q(n) and the nth horizontal scanning line G(n), and the pull-up controlling circuit module is coupled to the nth horizontal scanning line G(n).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Organic light emitting device and manufacturing method thereof

ActiveCN106328816ASimple structureReduce production processLithium organic compoundsSolid-state devicesElectron holeOrganic light emitting device

The invention relates to an organic light emitting device, which comprises a substrate, and a light emitting device formed on the substrate, wherein the light emitting device is composed of a first electrode layer, a light emitting layer and a second electrode layer; the light emitting layer comprises a main body material and a dye; the main body material is formed by materials with a hole transport ability; the triplet energy level T1 of at least one material in the main body material is higher than a triplet energy level S1, and T1-S1 < / =0.3eV; or, the triplet energy level T1 of at least one material in the main body material is higher than the triplet energy level S1, and T1-S1 > / =1eV, and the difference between the doublet and triplet energy level and the singlet energy level is -0.1 to 0.1 eV. The device structure can make full use the triplet energy in the main body material and the dye, and while the light emitting efficiency is improved, the service life of the device is enhanced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD +1

Environmentally-friendly plate for raising rice seedlings and rice seedling production method

InactiveCN101828490AReduce enclosed herbicide useReduce the use effectCultivating equipmentsSlagFermentation

The invention relates to an environmentally-friendly plate for raising rice seedlings and a rice seedling production method, which belong to a rice seedling raising medium and a production method. The plate contains the following raw materials in percentage by weight: 40 to 60 mesh crushed coin straw 60-80, industrial paper pulp processing waste slag liquid 15-25, and 40 to 60 mesh industrial fluidized bed furnace ground slag 5-15. The method comprises: material preparation, raw material crushing, fermentation, mixing, material drying, stirring, pulping, mold loading, compression molding, demoulding and drying. The plate and the production method have the advantages of reducing damages to vegetation, namely plough layer surface soil, solving the problem of difficult soil digging, developing and utilizing straw resources, realizing energy conservation and emission reduction, integrating the medium and the plate, replacing a seedling raising plate and being suitable for the standardization of mechanical sowing, mechanical planting and seedling raising.

Owner:李旭东 +2

Array substrate and manufacturing method thereof and display device

InactiveUS20150311232A1Reduce leakage currentLow costTransistorSolid-state devicesCapacitanceElectricity

The invention discloses an array substrate and a manufacturing method thereof and a display device, which can solve the problems such as complicated, high cost, time-consuming process in the prior art, and increase the storage capacitance. In the array substrate, data lines and a common electrode line are provided in the same layer on the base substrate and below an active layer, the data lines and the common electrode line are provided separately, the common electrode is provided with a connection part which partly overlaps with the common electrode line in an orthographic projection direction, and the common electrode is electrically connected to the common electrode line through a first via between the connection part and the common electrode line.

Owner:ORDOS YUANSHENG OPTOELECTRONICS +1

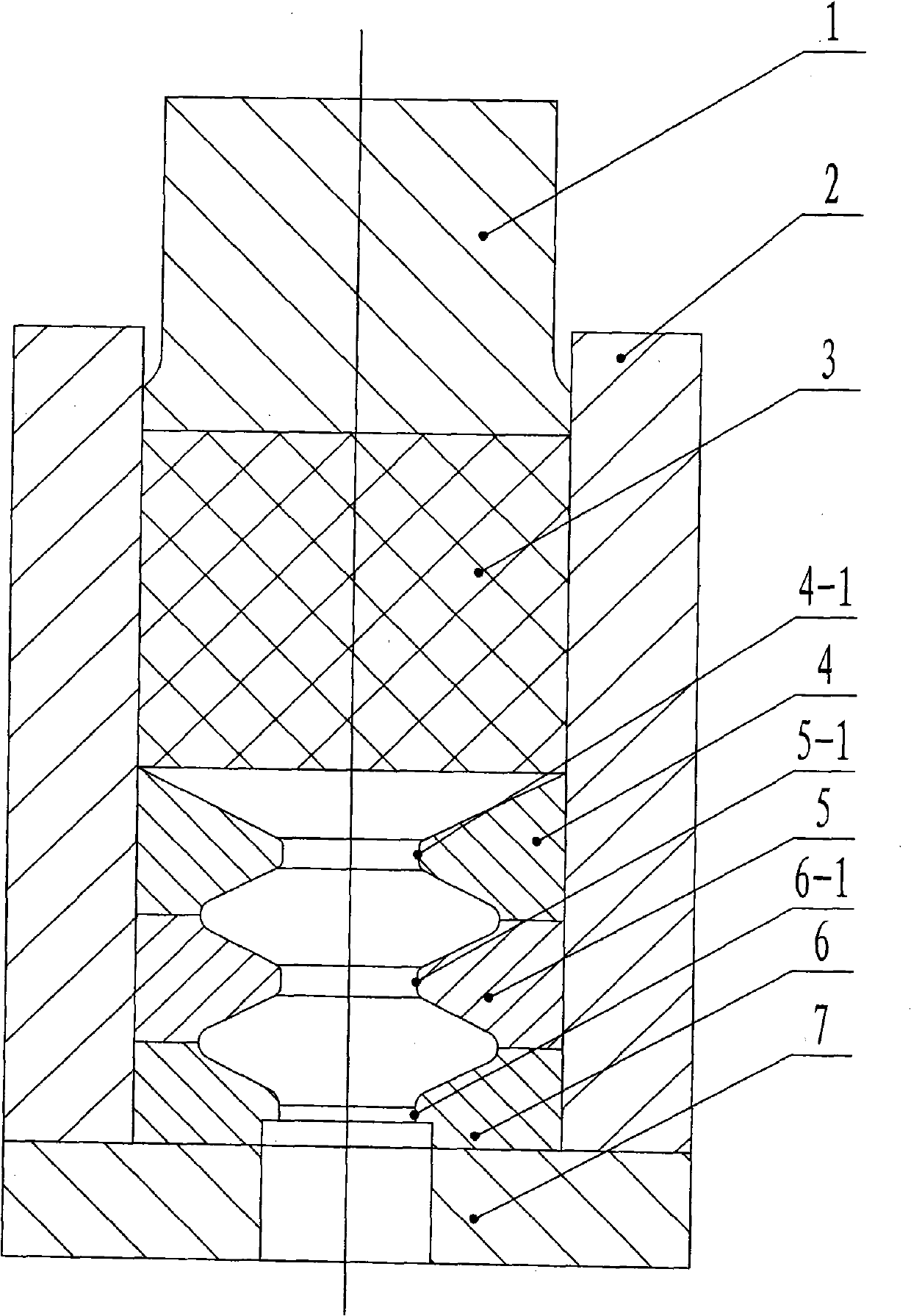

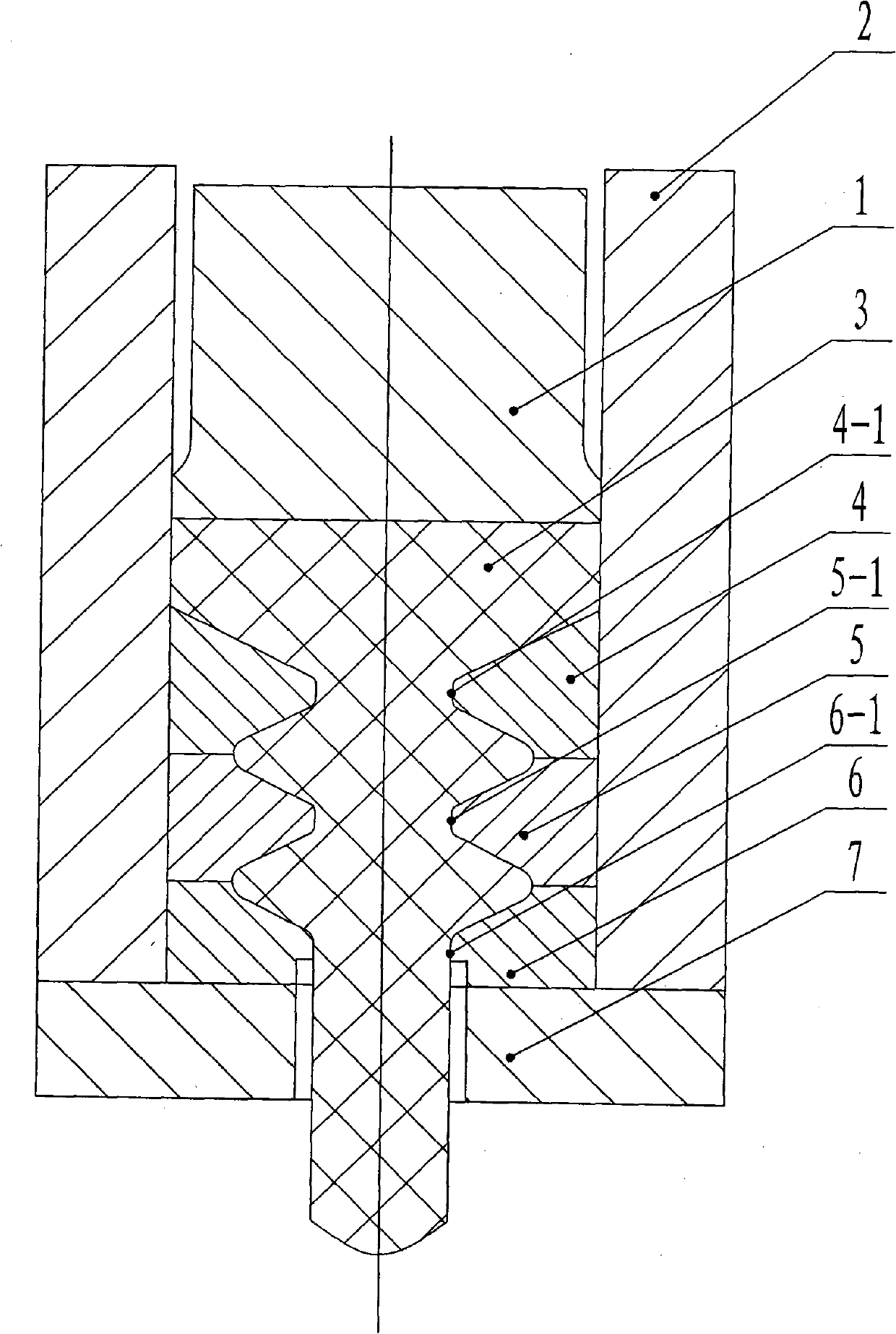

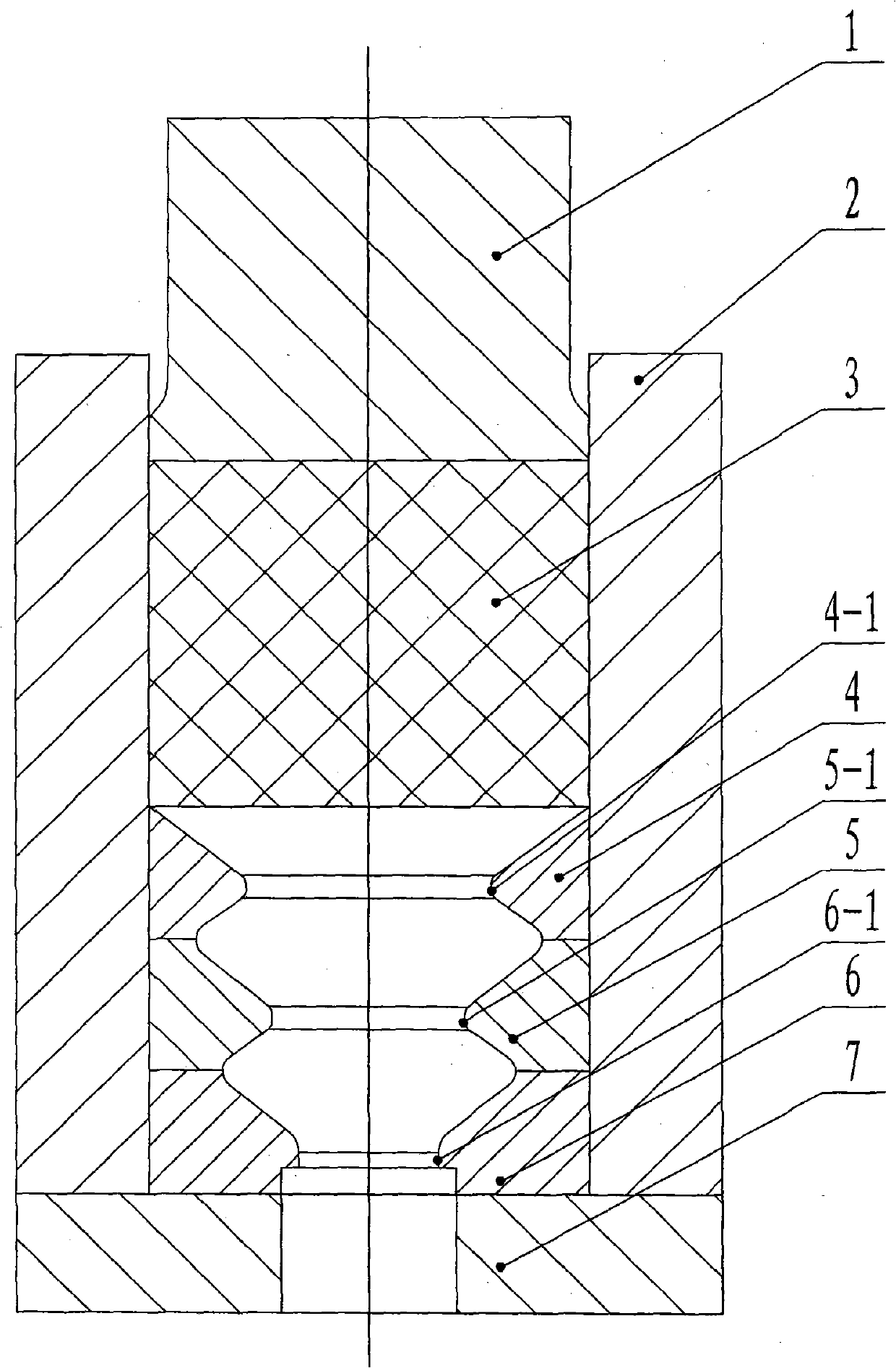

Device and method for preparing fine-grained material by directly extruding continuous variable cross section

InactiveCN101767120AUniform refinementImprove mechanical propertiesExtrusion diesExtrusion mandrelsMaterials preparationIngot

The invention relates to a device and a method for preparing fine-grained material by directly extruding a continuous variable cross section, which relate to a device and a method for preparing fine-grained material. The invention solves the problems of the traditional fine-grained material preparation methods that the procedures are complicated, the process requirements are high, the texture orientation is significant, the defects of folds and material interface superposition are easy to occur in processing and preparation and the preparation methods are difficult to be implemented in production. A primary transition die cavity, a secondary transition die cavity and a core die cavity of the preparation device of the invention are combined to form an axial corrugated extrusion cavity of the continuous variable cross section; the preparation method of the invention comprises the following steps: the preparation device is assembled; an ingot is arranged in a female die, a punch head is put it, a punch head is put in, the die orifice on a core die extrusion end is closed, the punch head descends, the ingot is extruded form a primary transition die orifice and a secondary transition die orifice, the punch head continues to descend, and the ingot is upset and deforms; and the closure is removed, the punch head continues to descend, and the ingot is extruded and formed. The invention requires simple equipment and few production procedures, and is easy to be implemented and popularized in production.

Owner:HARBIN UNIV OF SCI & TECH

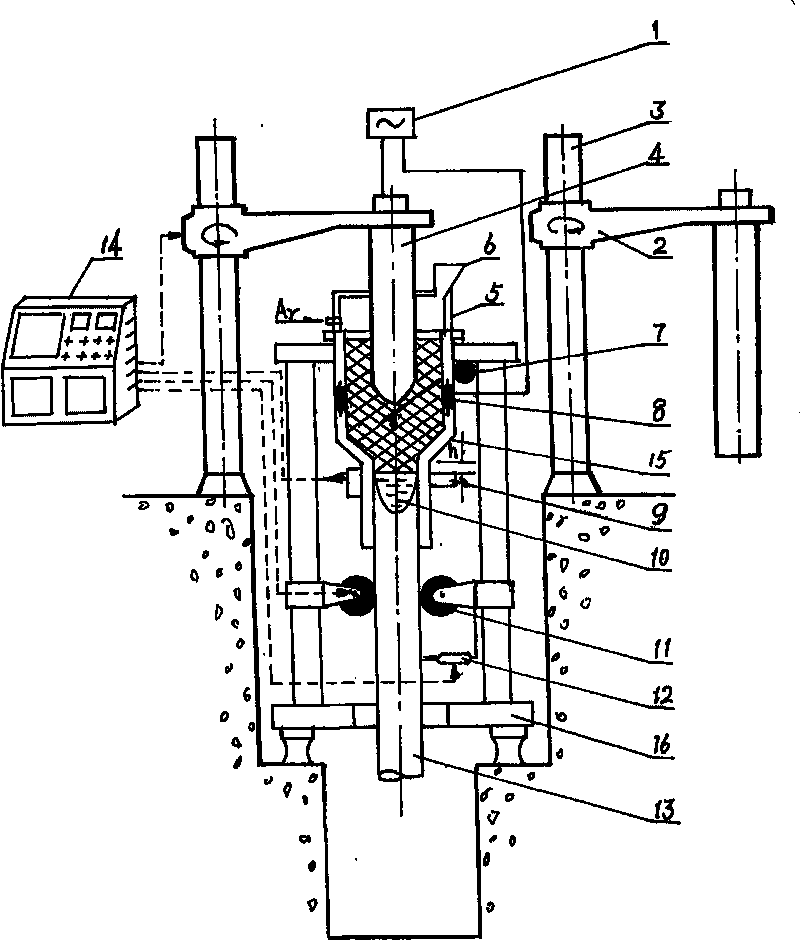

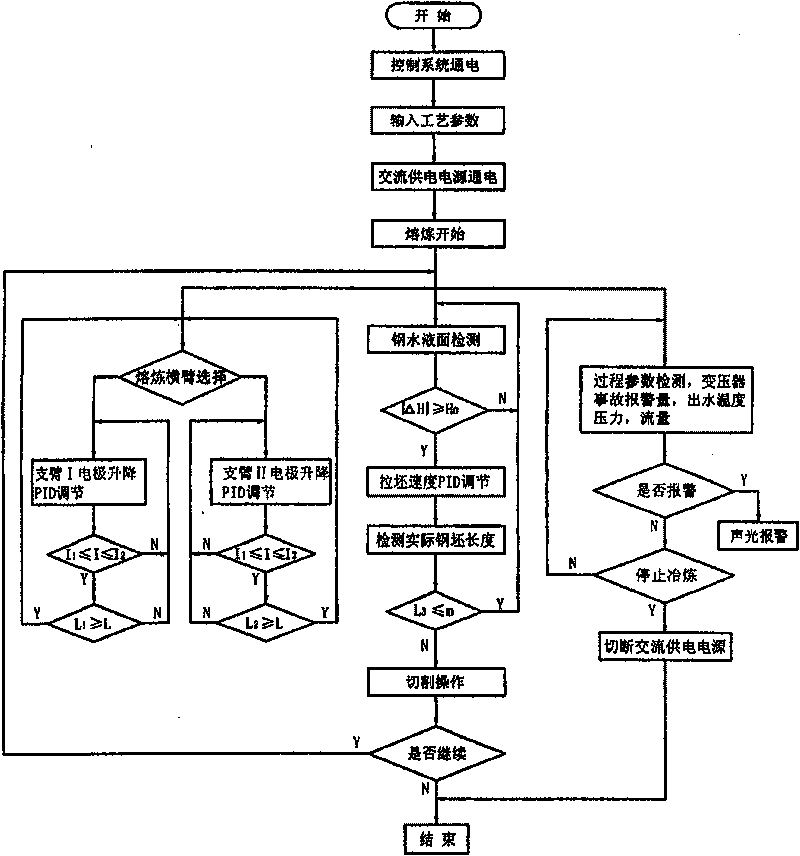

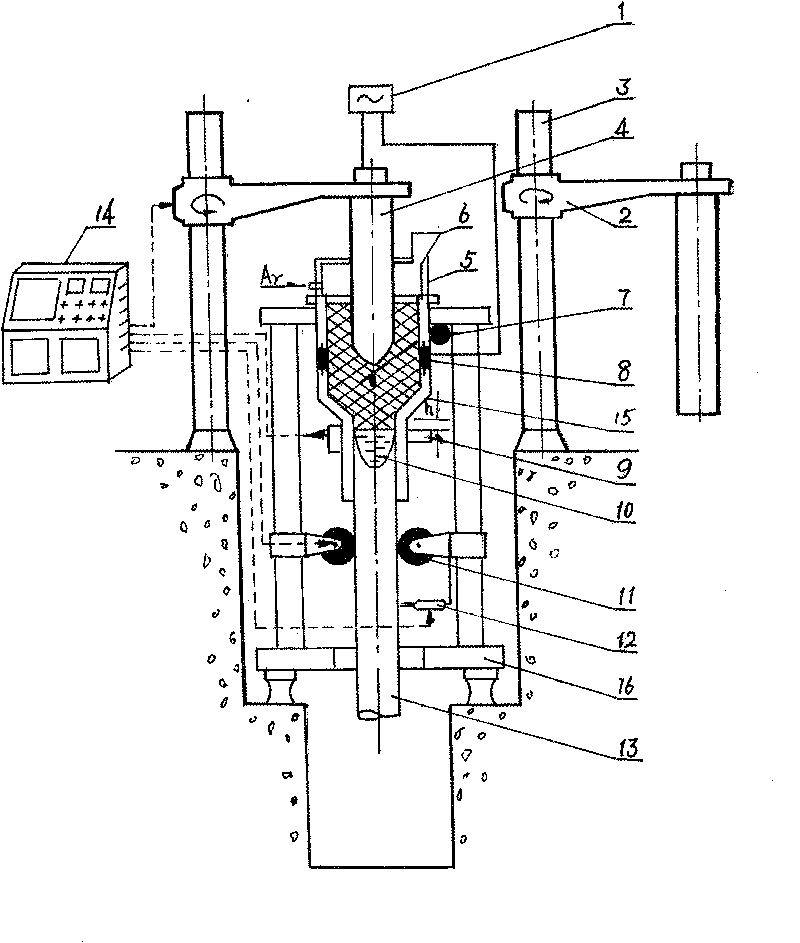

Protective atmosphere electro-slag continuous casting furnace

The invention discloses a protective atmosphere electro-slag continuous casting furnace, which belongs to metal electro-slag re-melting equipment. The furnace comprises an alternating current power supply, electrode lifting mechanisms, a consumable electrode, a conductive crystallizer, a supporting mechanism, a molten steel liquid level detection device, an argon protective cover, a vibration mechanism, a throwing mechanism, a cutting device and a control system. The electrode lifting mechanisms are fixed on two sides of the conductive crystallizer; one end of the consumable electrode is fixed on a cross arm of the electrode lifting mechanism and is connected with the alternating current power supply, while the other end passes through the argon protective cover and is placed inside the conductive crystallizer; the conductive crystallizer is a jacket type water-cooled crystallizer with combined upper and lower parts, a conductive ring is embedded at the upper wall, and the conductive ring is connected with the alternating current power supply through a cable so that a loop is formed from the alternating current power supply, the consumable electrode, furnace slag, the conductive ring to the alternating current power supply; the vibration mechanism is fixed on the supporting mechanism, and a cam of the vibration mechanism is tightly contacted with a shell of the conductive crystallizer; the joint of upper and lower cavities of the conductive crystallizer is provided with the molten steel liquid level detection device; the throwing mechanism and the cutting device are fixed under an ejection port of the conductive crystallizer in turn; and the control system is electrically connected with the cross arm of the electrode lifting mechanism, the molten steel liquid level detection device, the drawing mechanism and the cutting device respectively. The protective atmosphere electro-slag continuous casting furnace can realize electro-slag continuous casting.

Owner:SHENYANG HUASHENG METALLURGICAL TECH & INSTALLATION

Novel process for preparing xylitol

ActiveCN101823939AIncrease contentImprove qualityIon-exchange process apparatusOrganic compound preparationChromatographic separationDistillation

The invention relates to a novel process for preparing xylitol, which belongs to the technical field of functional sugar alcohol production. Pre-treatment, hydrolysis, neutralization, decoloring, ion exchange, evaporation and concentration and chromatography are carried out to corncob or bagasse and other agricultural waste which contains hemicellulose, high-content xylose solution is collected and distillated, and then continuously hydrogenated, so that the xylose solution is converted into xylitol solution, and finally a xylitol crystal is obtained through refining, concentration, crystallization, centrifugation and drying; the process comprises: corncob-> pre-treatment->hydrolysis->neutralization and decoloring->ion exchange->evaporation and concentration->chromatography->high-content xylose solution collection and distillation-> hydrogenatio->refining->concentration->crystallization->centrifugation->drying->finished crystal xylitol product obtaining. The novel process for preparing xylitol saves a xylose crystallization procedure and a conversion process xylose crystal into sugar, shortens a production procedure, adopts a chromatography technology to improve the content of thexylose solution, facilitates the obtaining of high-content xylitol solution after hydrogenation can prepare the high-grade xylitol product, adopts a continuous hydrogenation process, improves the hydrogenation efficiency, reduces the labor intensity of a worker, and saves the production cost.

Owner:FUTASTE PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com