Patents

Literature

1097 results about "Fiber glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

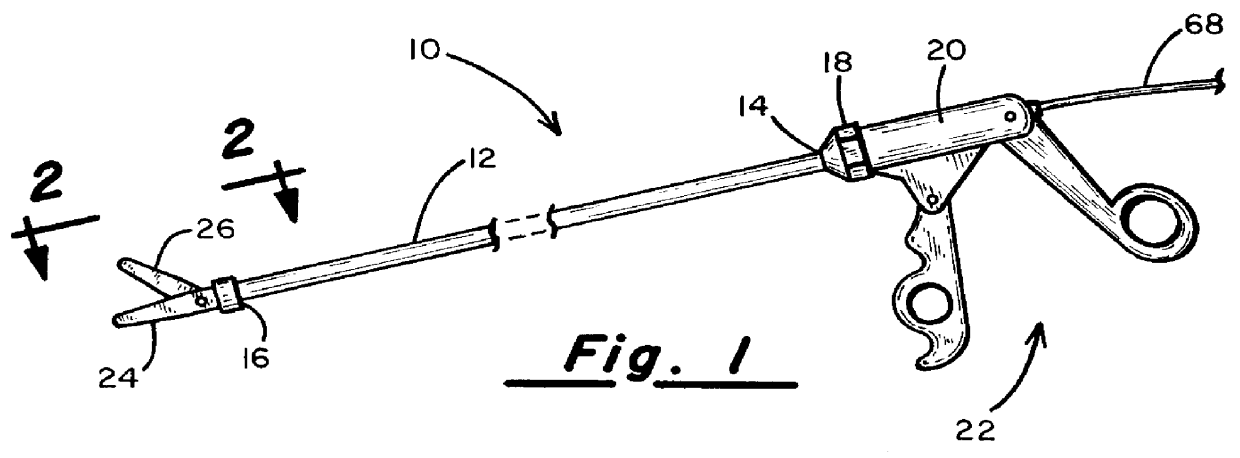

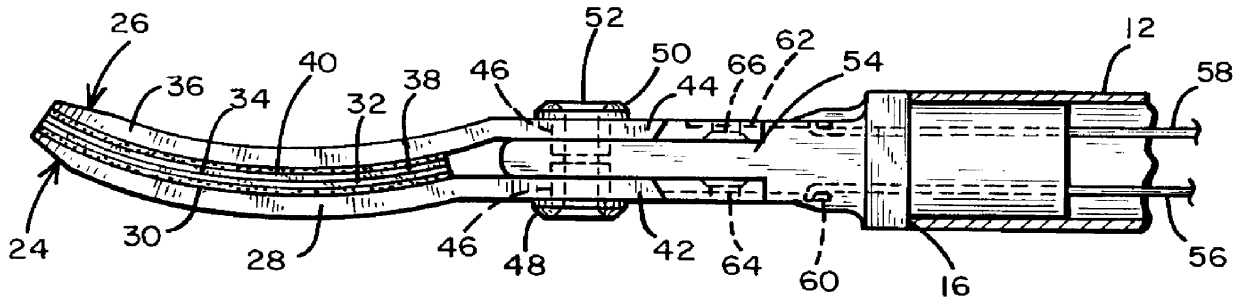

Surgical scissors with bipolar coagulation feature

A bipolar electrosurgical scissors for use in open or endoscopic surgery has a pair of opposed blade members pivotally joined to one another and to the distal end of the scissors itself by a rivet which extends through a insulated bushing member. Each of the blade members comprises a blade support and a blade itself, each fabricated from metal, such as stainless steel. The blades are affixed to their associated supports by means of a suitable adhesive or adhesive composite material such as a fiberglass reinforced epoxy exhibiting dielectric properties. Cutting is performed, steel-on-steel, without causing a short circuit between the two blade supports which themselves function as the bipolar electrodes.

Owner:THE GOVERNOR & COMPANY OF THE BANK OF SCOTLAND

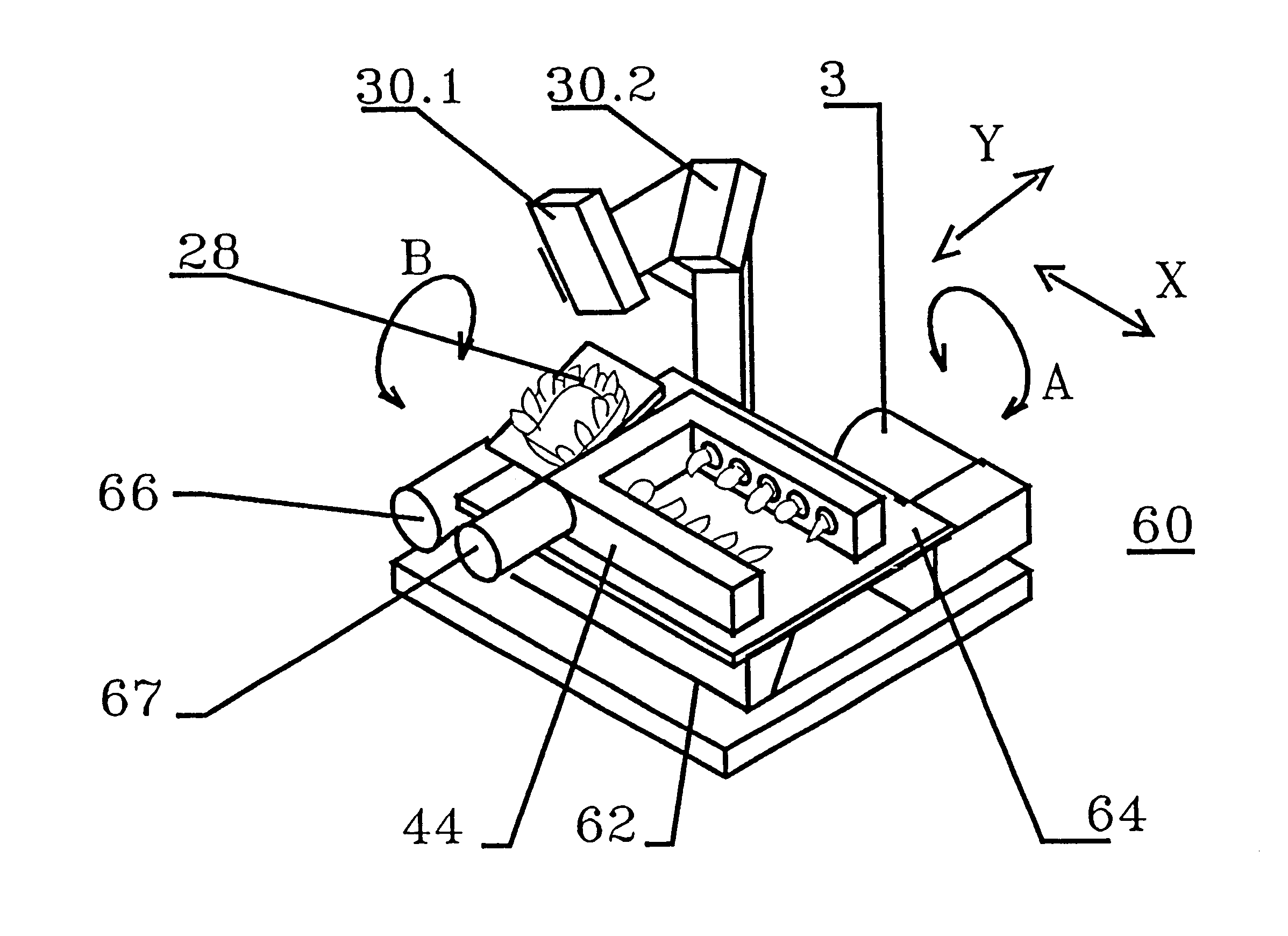

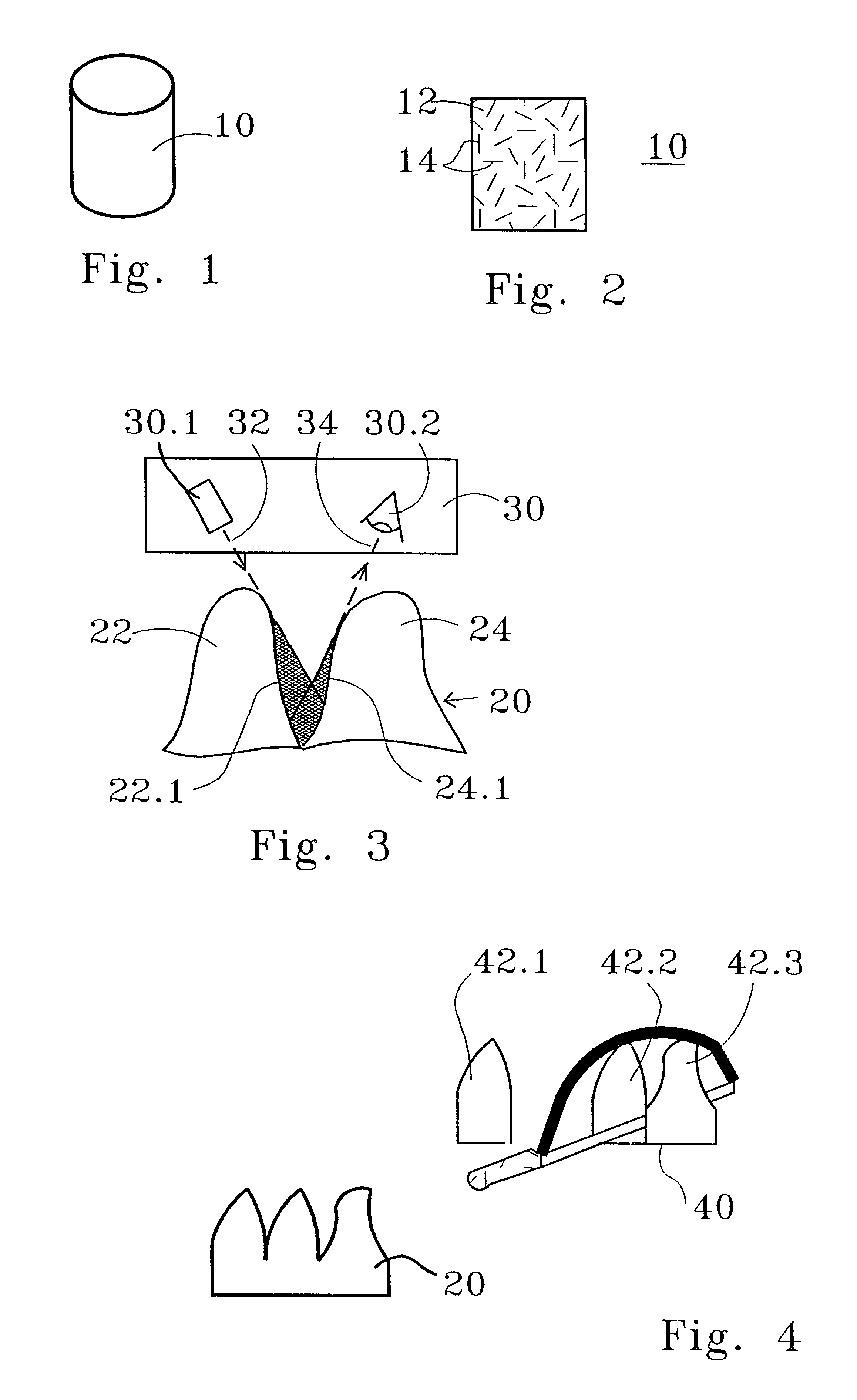

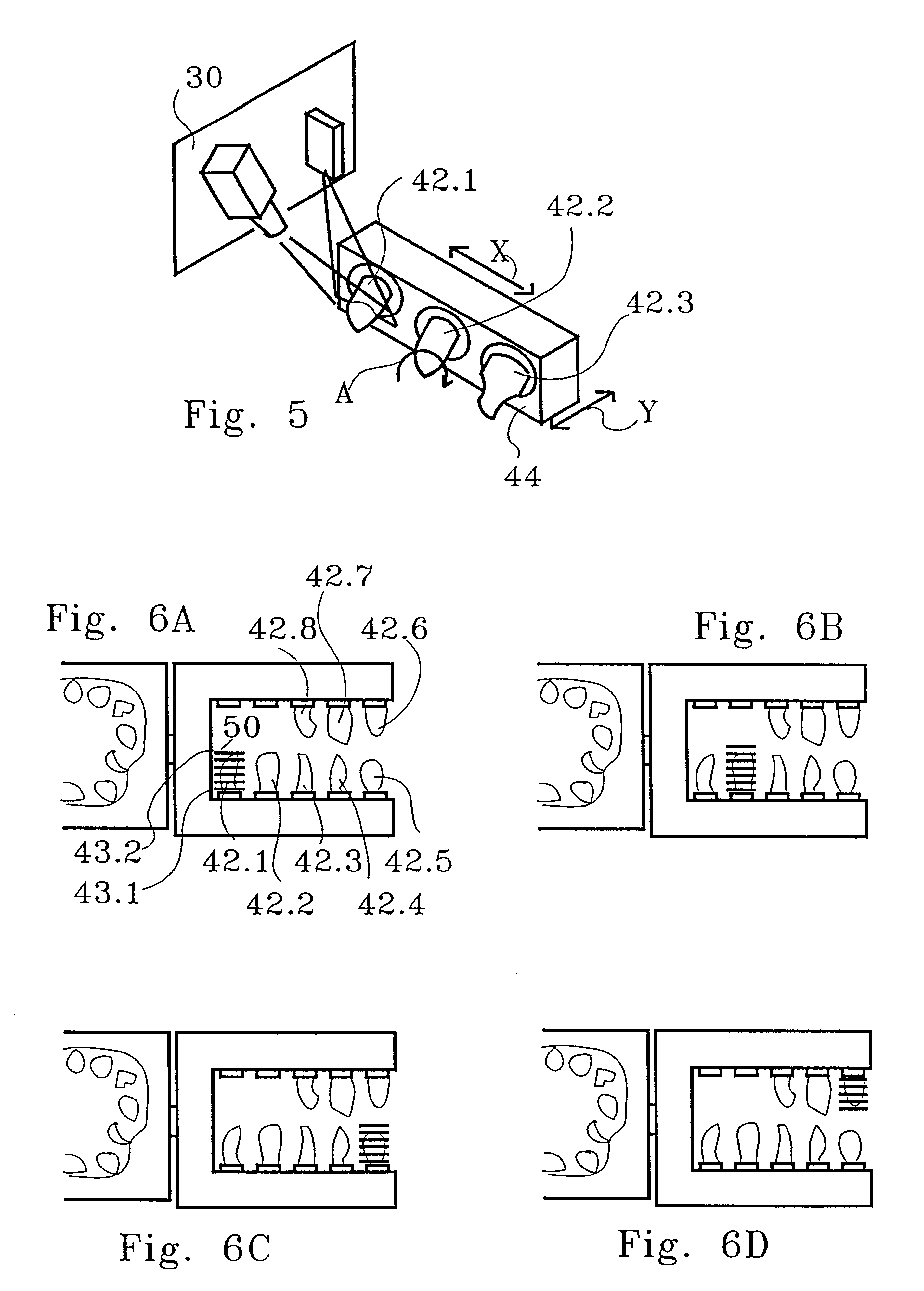

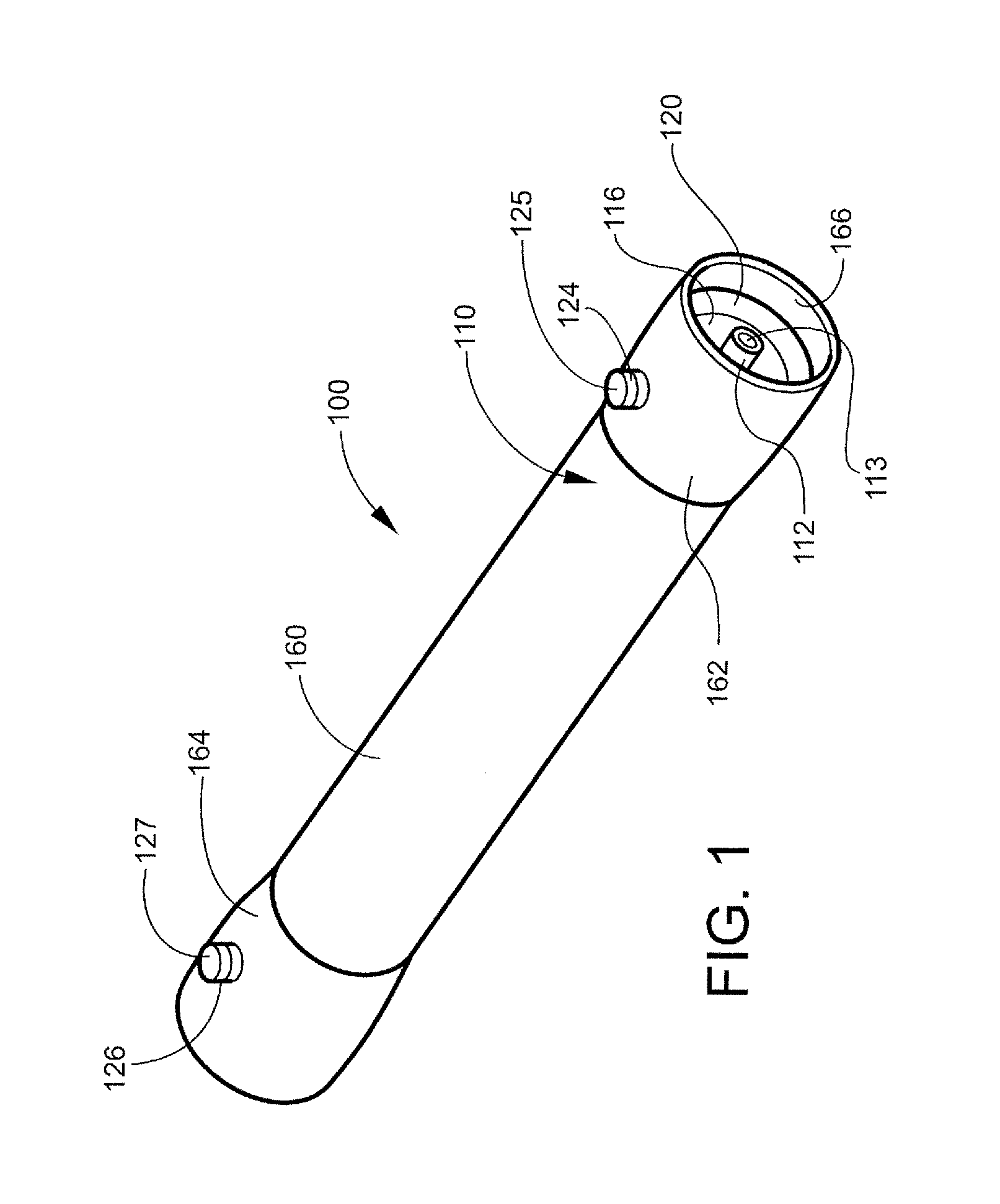

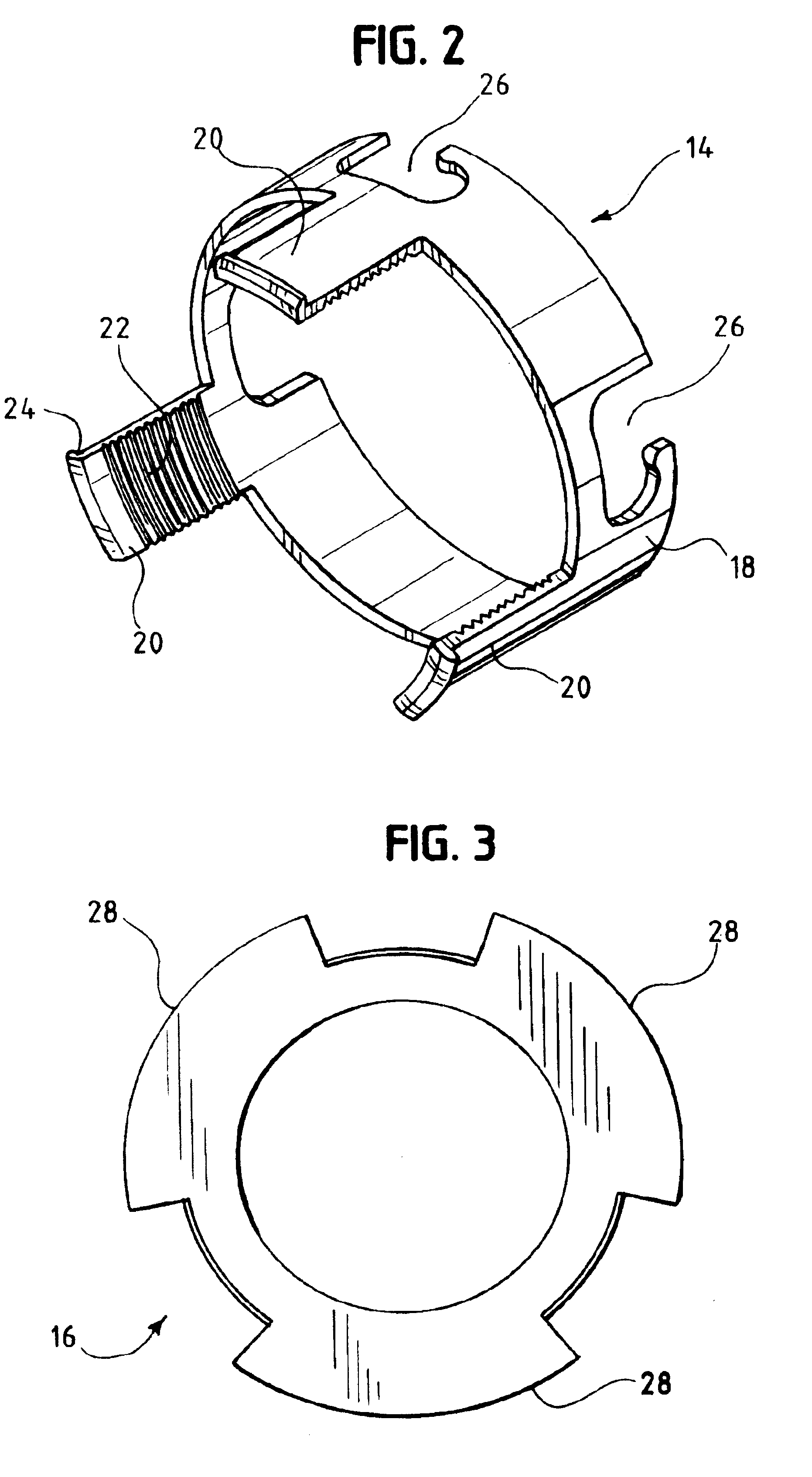

Material for a dental prosthesis, method and device for determining the shape of a remaining tooth area to be provided with a dental prosthesis, method and arrangement for producing a dental prosthesis and use of the arrangement

InactiveUS6287121B1Improve accuracySuitable for processingImpression capsTooth crownsDigital dataGlass fiber

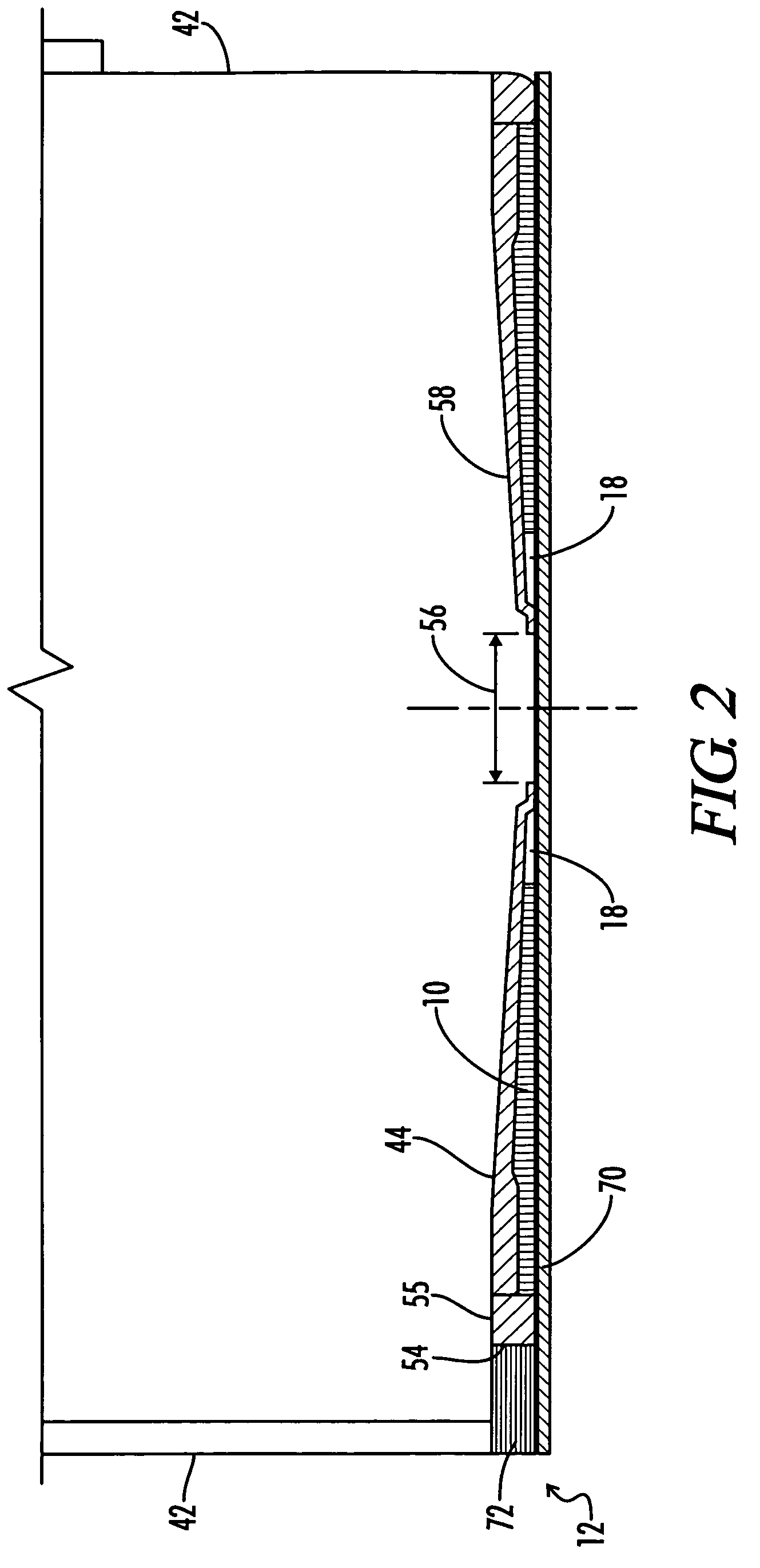

Material for a dental prosthesis consisting of fiber glass reinforced plastic. The material is used to produce a blank by means of a special injection-molding process, which can be worked by means of a machining process. A method and a device for determining the shape of a duplicate of a remaining tooth area to be provided with a dental prosthesis. The shape of the duplicate is determined, as is the shape of duplicate sections into which the duplicate has been divided, the determined data are stored and combined. A method and arrangement for producing a dental prosthesis. The shape of a duplicate (42) of a remaining tooth area to be provided with the dental prosthesis is determined by means of a shape determination device (110), the determined data are stored in the form of digital data (DD), and the dental prosthesis (143) is produced in a production machine (114), which is controlled by means of production data (FD). The shape determination device (110) and the production machine (114) are coupled by means of an EDP installation (118), which contains a memory unit for storing the digital data (DD) and performs the calculation of the production data (FD).

Owner:STRAUMANN HLDG AG +2

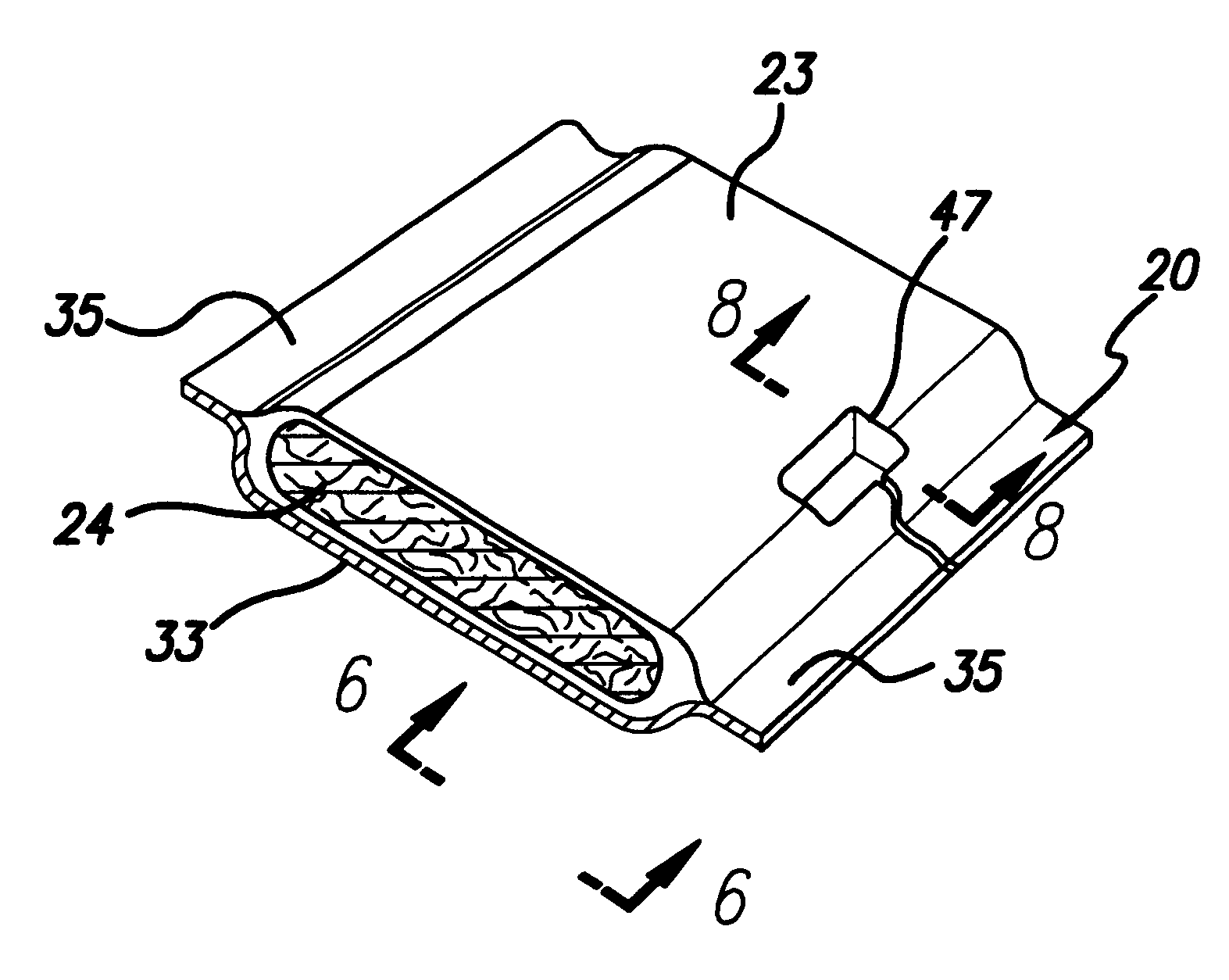

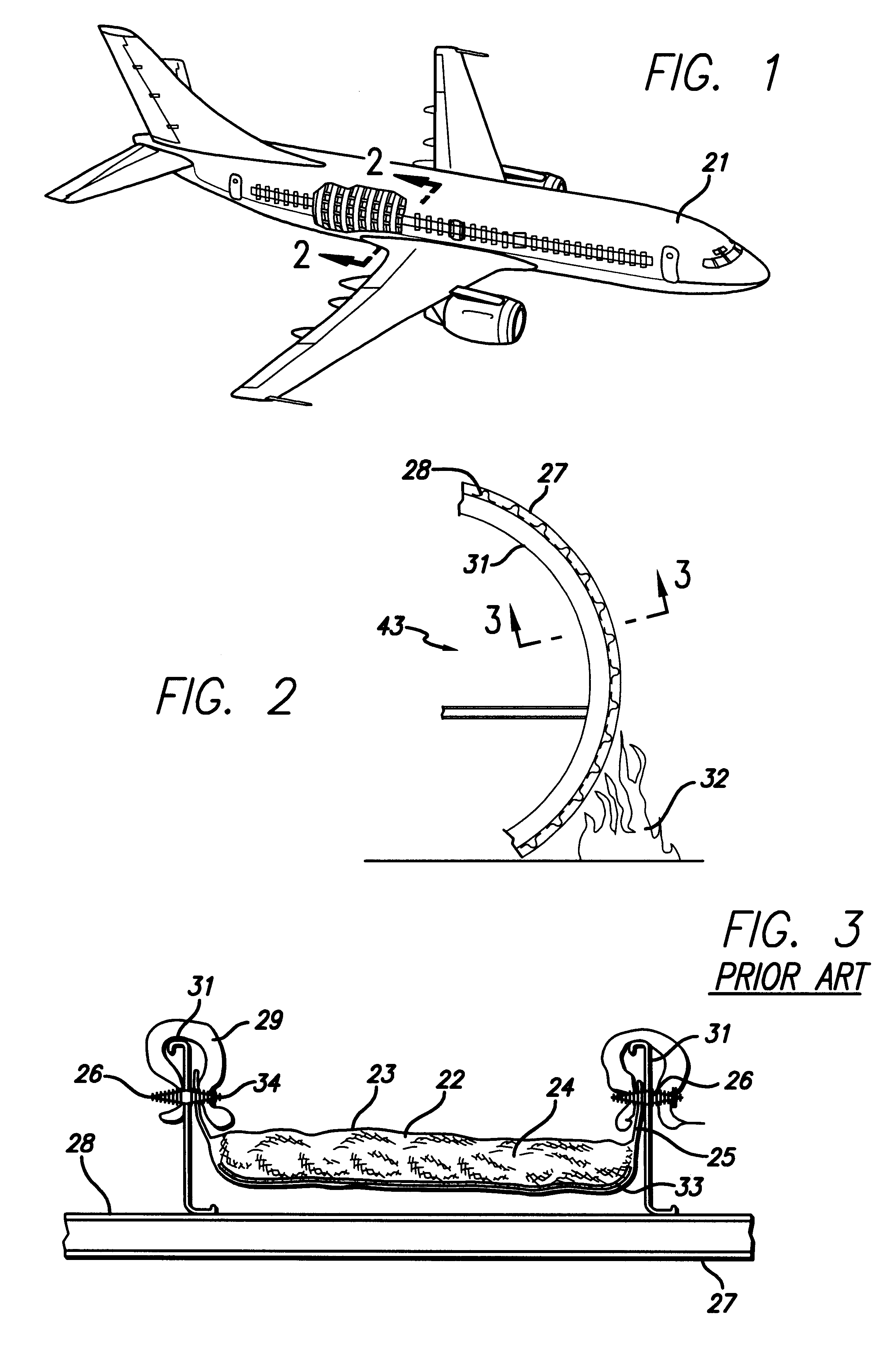

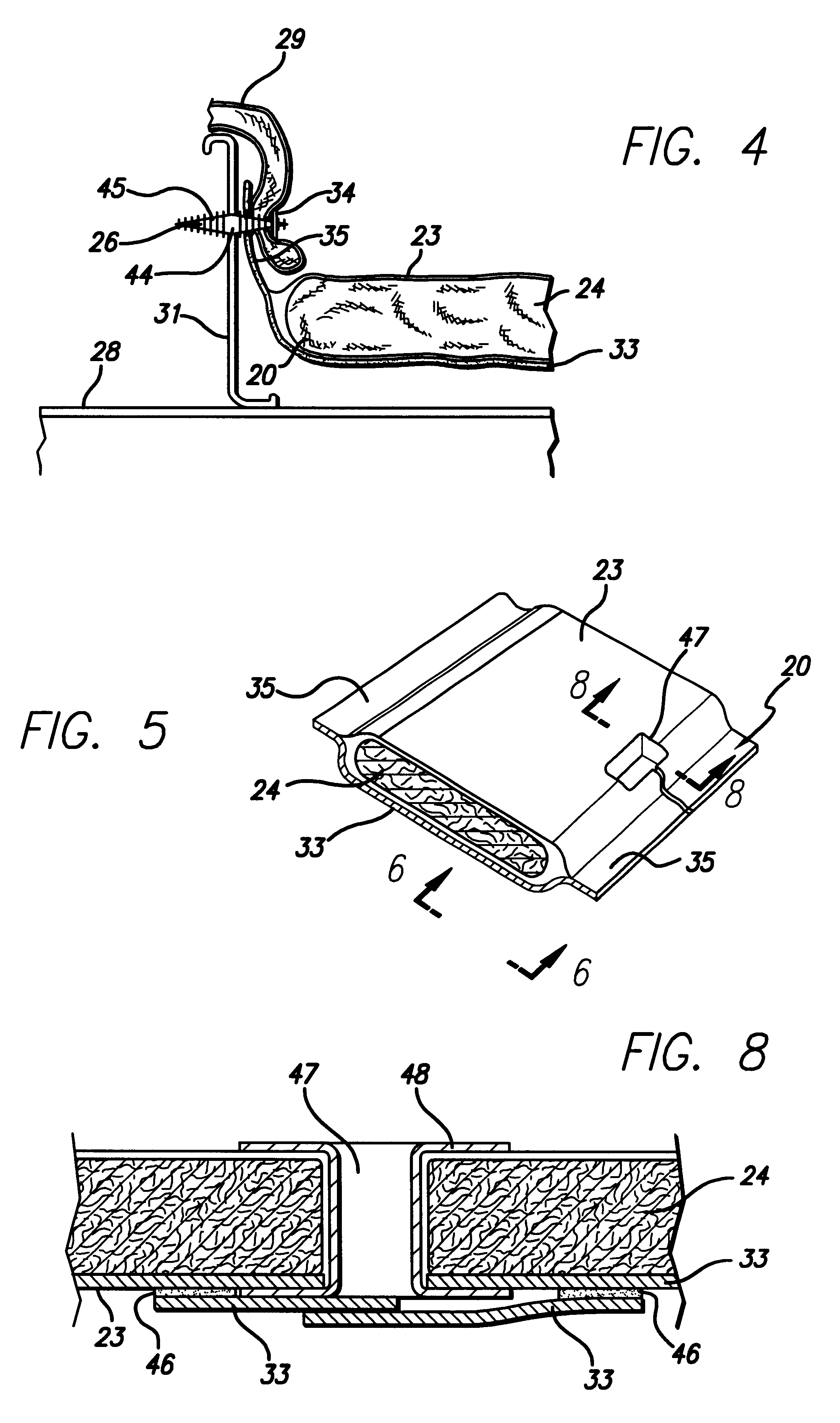

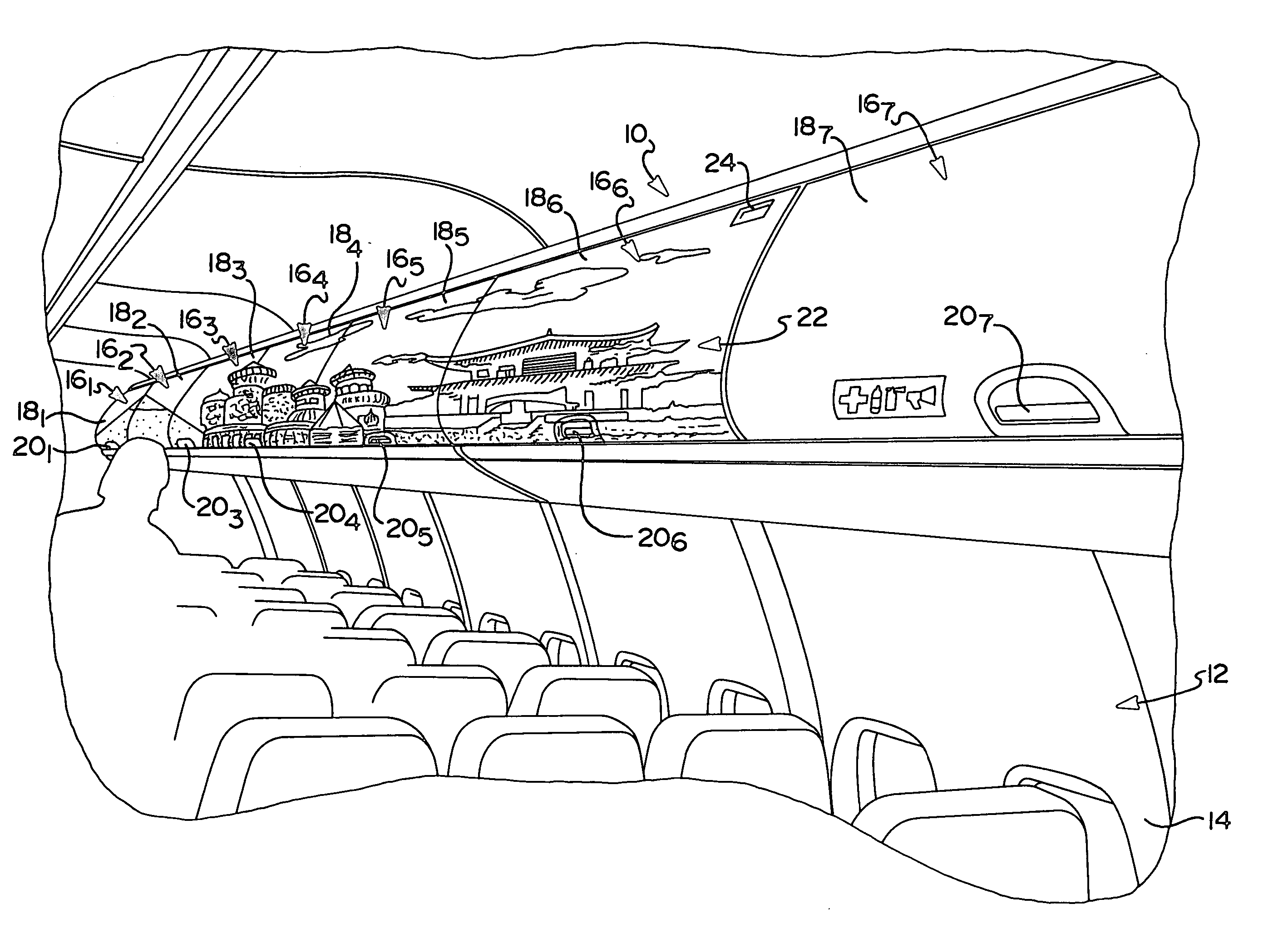

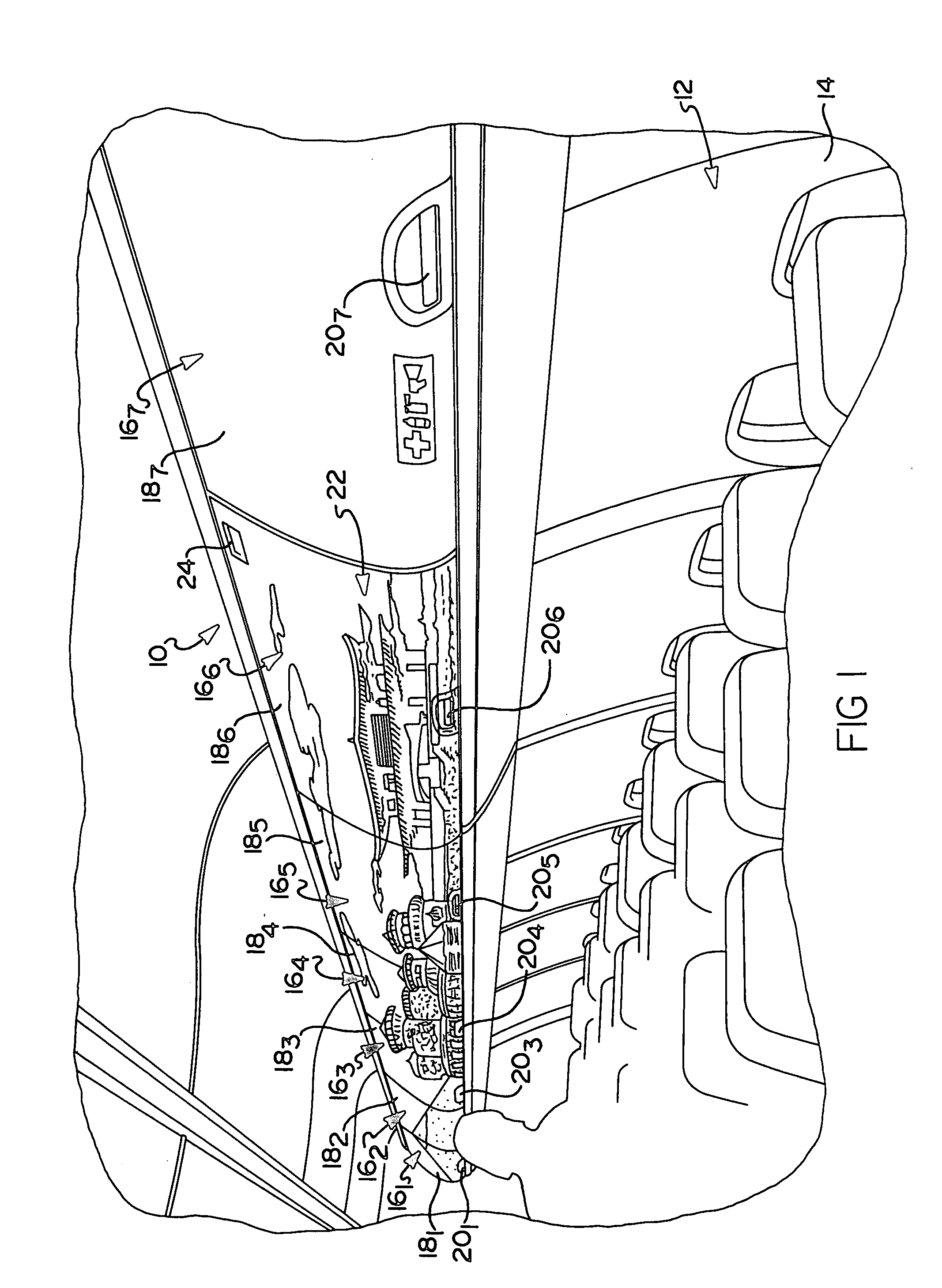

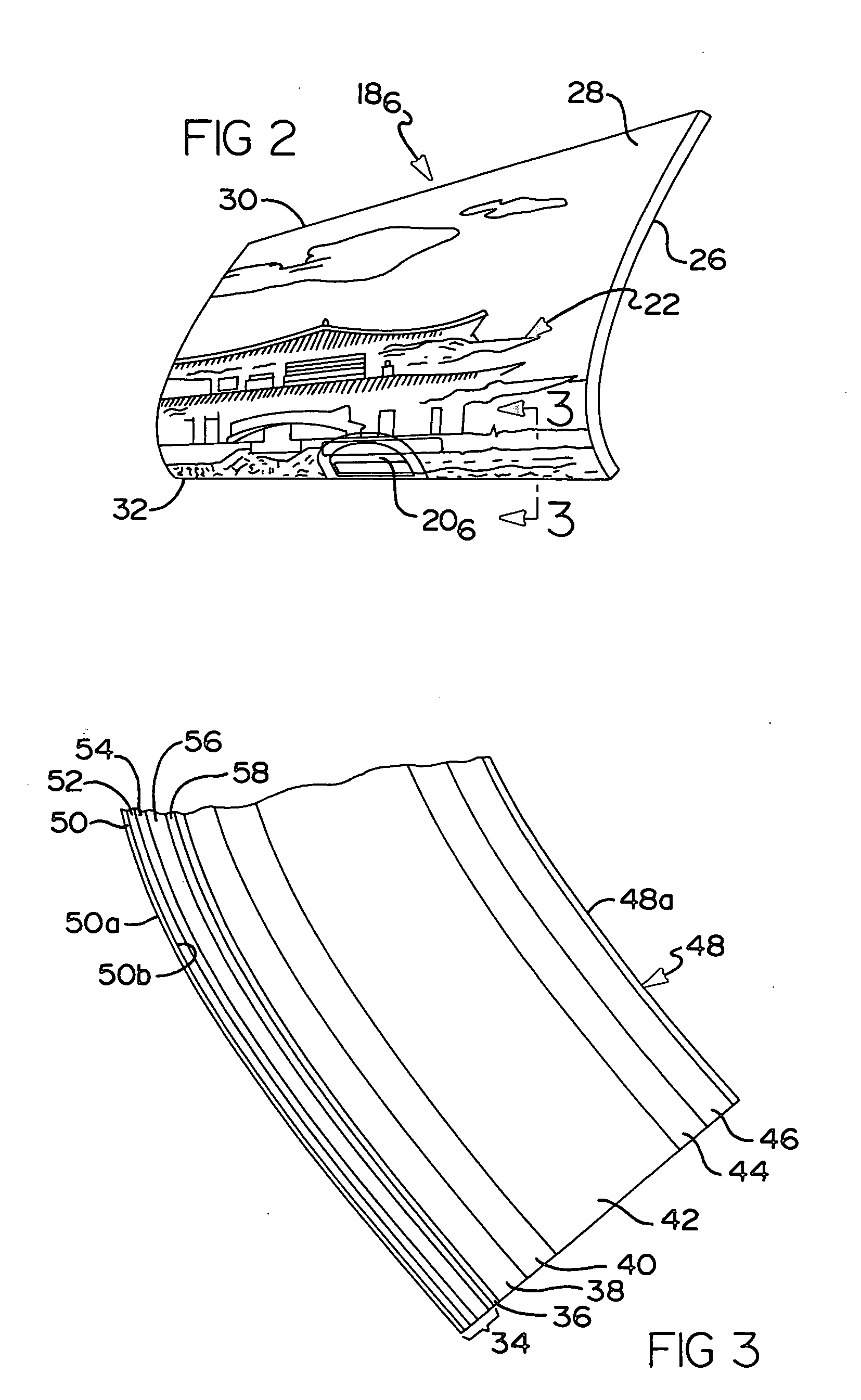

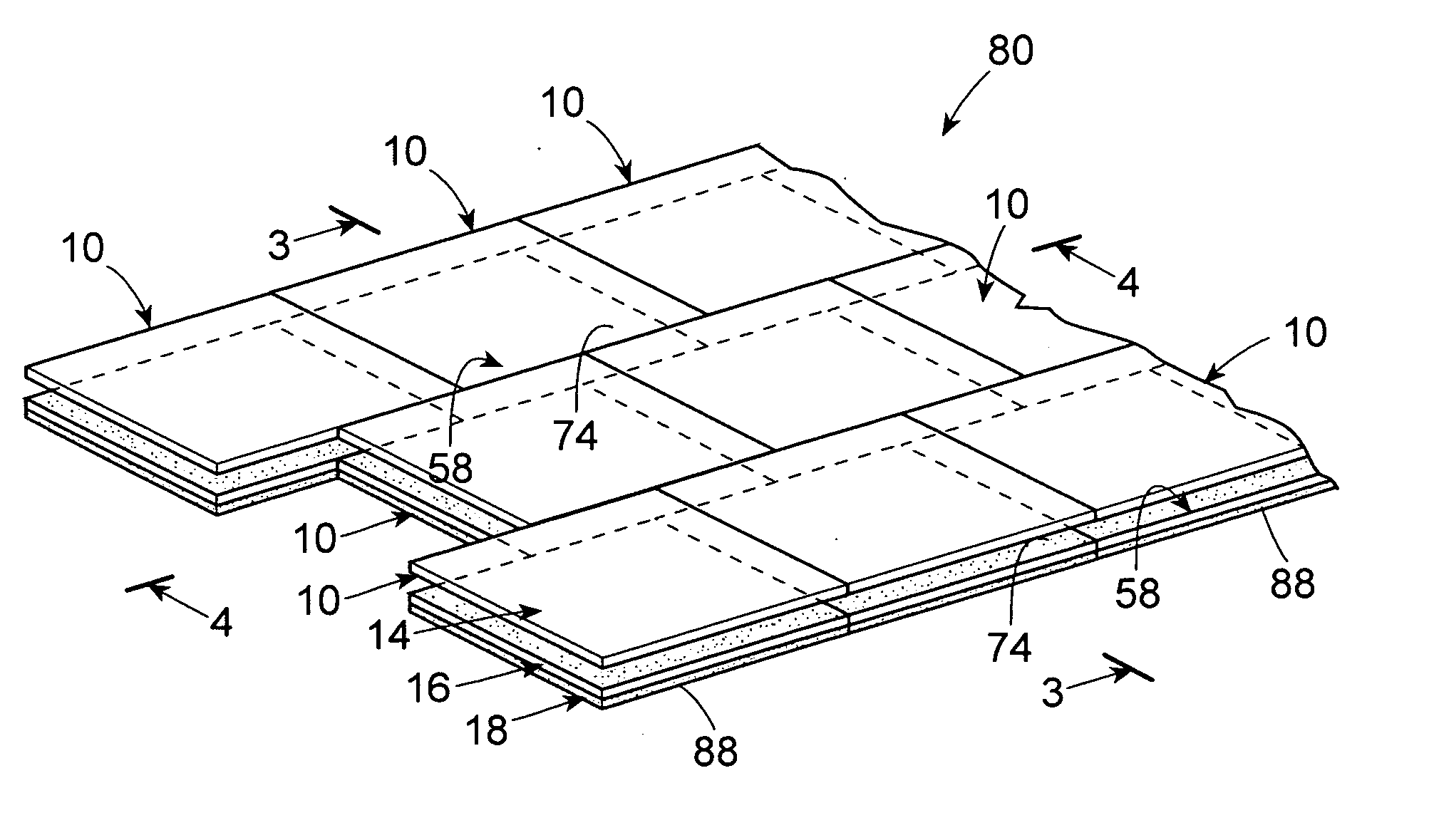

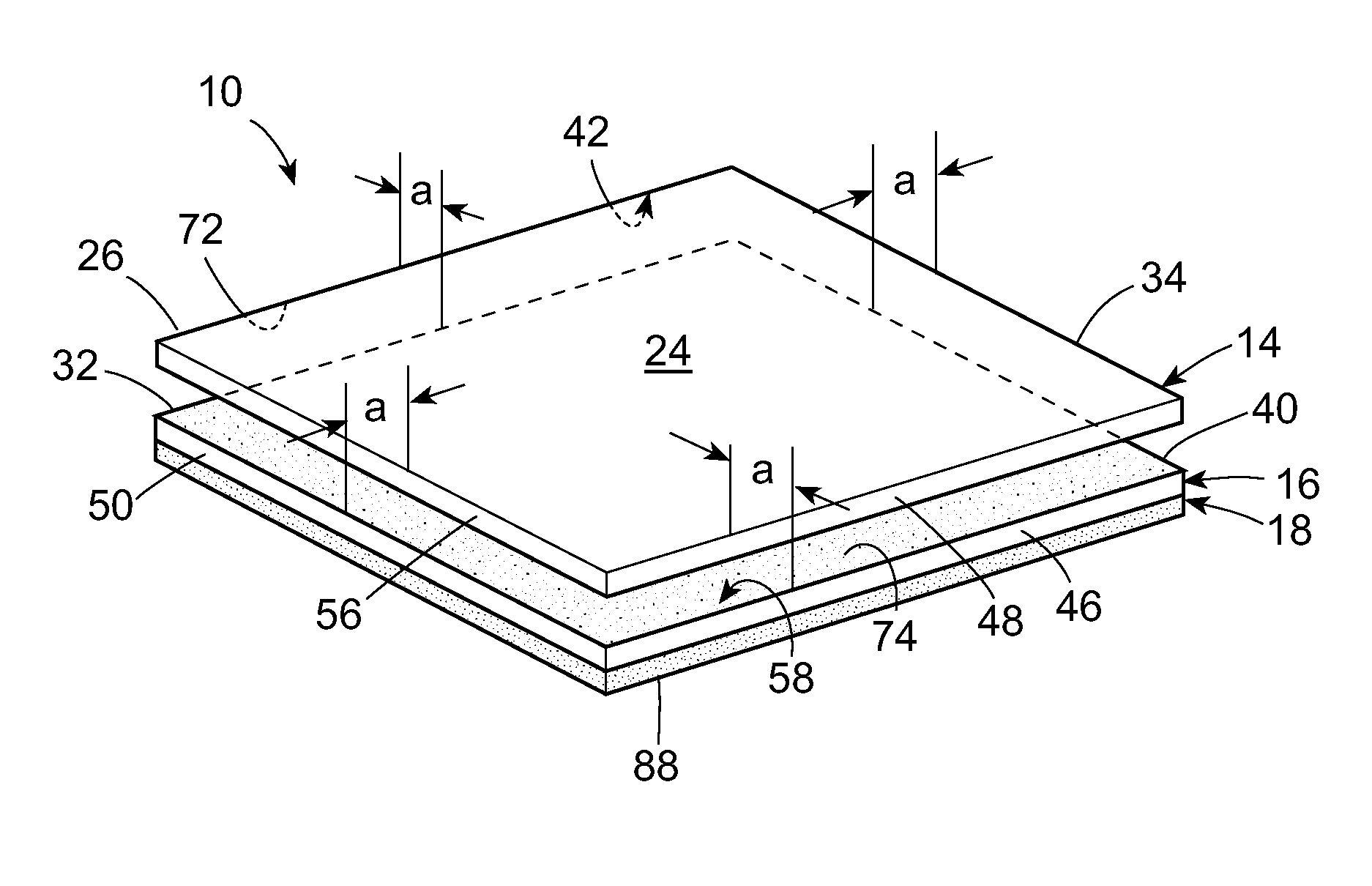

Fire-blocking insulation blanket

InactiveUS6358591B1Improve protectionLow costSynthetic resin layered productsCellulosic plastic layered productsGlass fiberFuselage

An insulation blanket is disclosed that contains fire-blocking materials for preventing rapid penetration of fire into an aircraft fuselage in case of a fire outside the aircraft. The insulation blanket contains at least one layer of fiberglass or other thermal-acoustic insulation material without fire-blocking properties, and one or more layers of fire-blocking material. The fire blocking material is wider than the thermal-acoustic insulation so that it may be folded against and attached to adjacent structural frame members of the fuselage. In the alternative, a thermal-acoustic insulation material is used that has fire-blocking properties instead of the separate layers of fire-blocking and thermal-acoustic insulation materials. A method for installing insulation blankets according to the present invention is disclosed, whereby a fire-blocking insulation portion of the blanket is folded against and attached to frame members of the aircraft using attachment posts or spring clips.

Owner:ORCON CORP

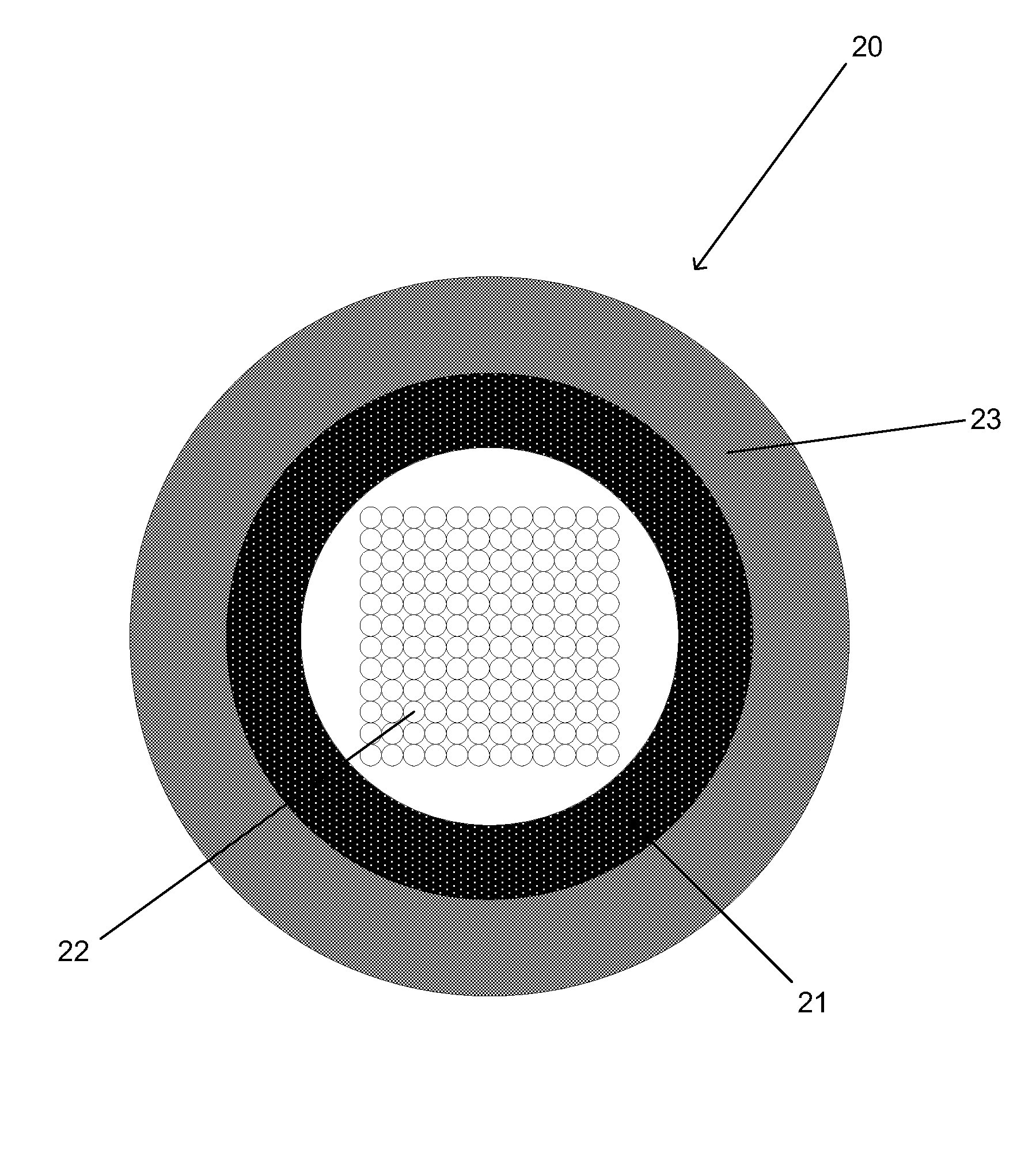

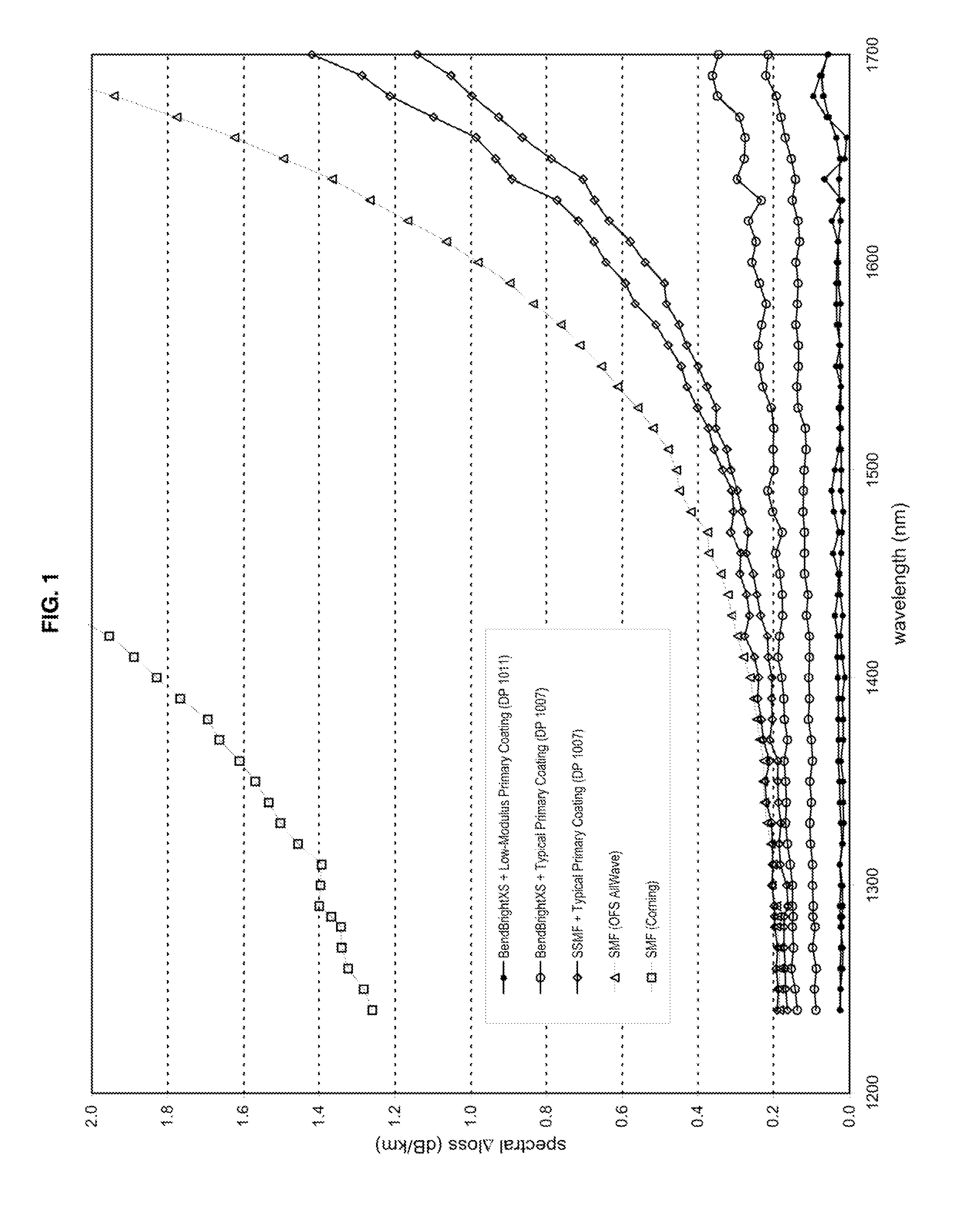

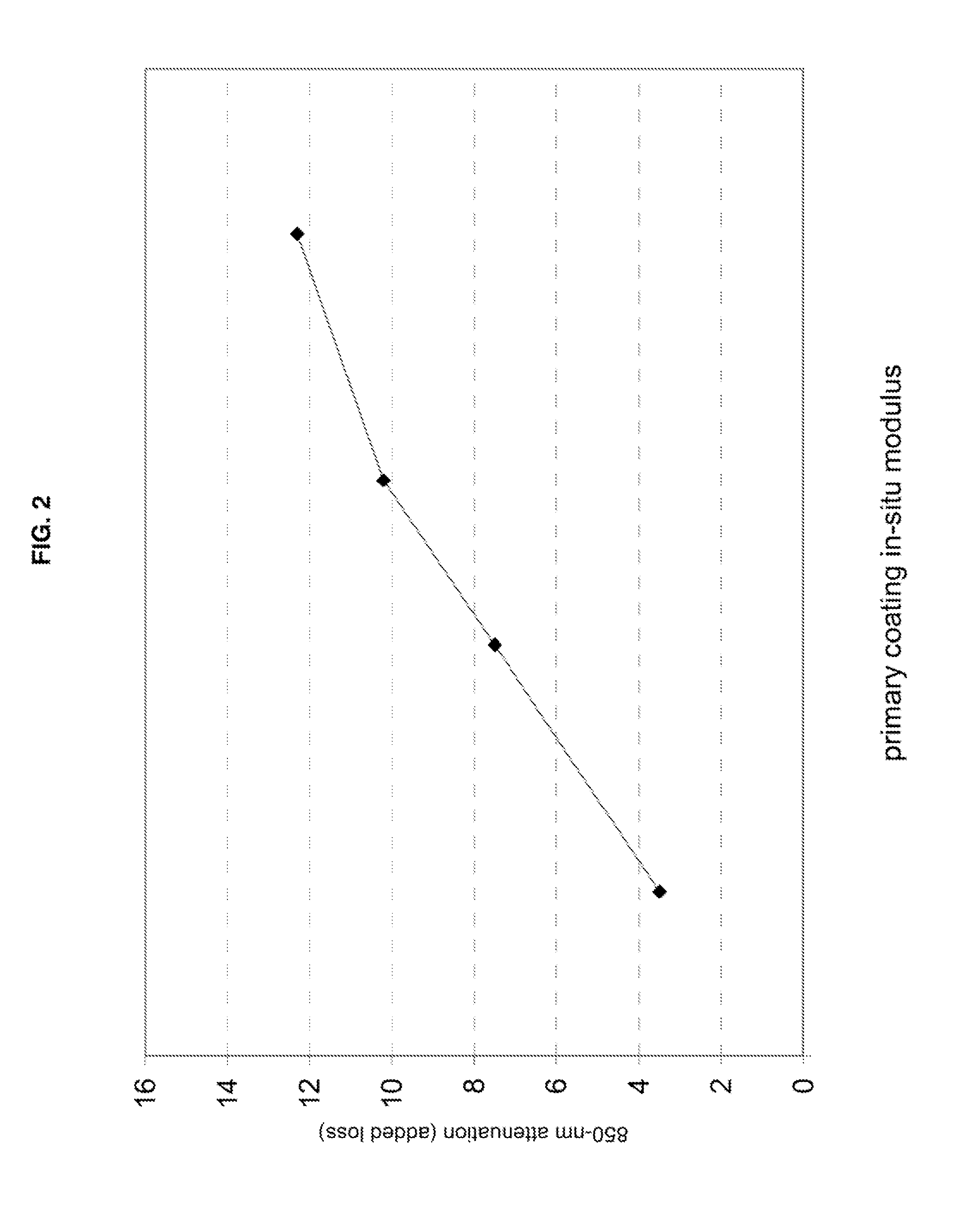

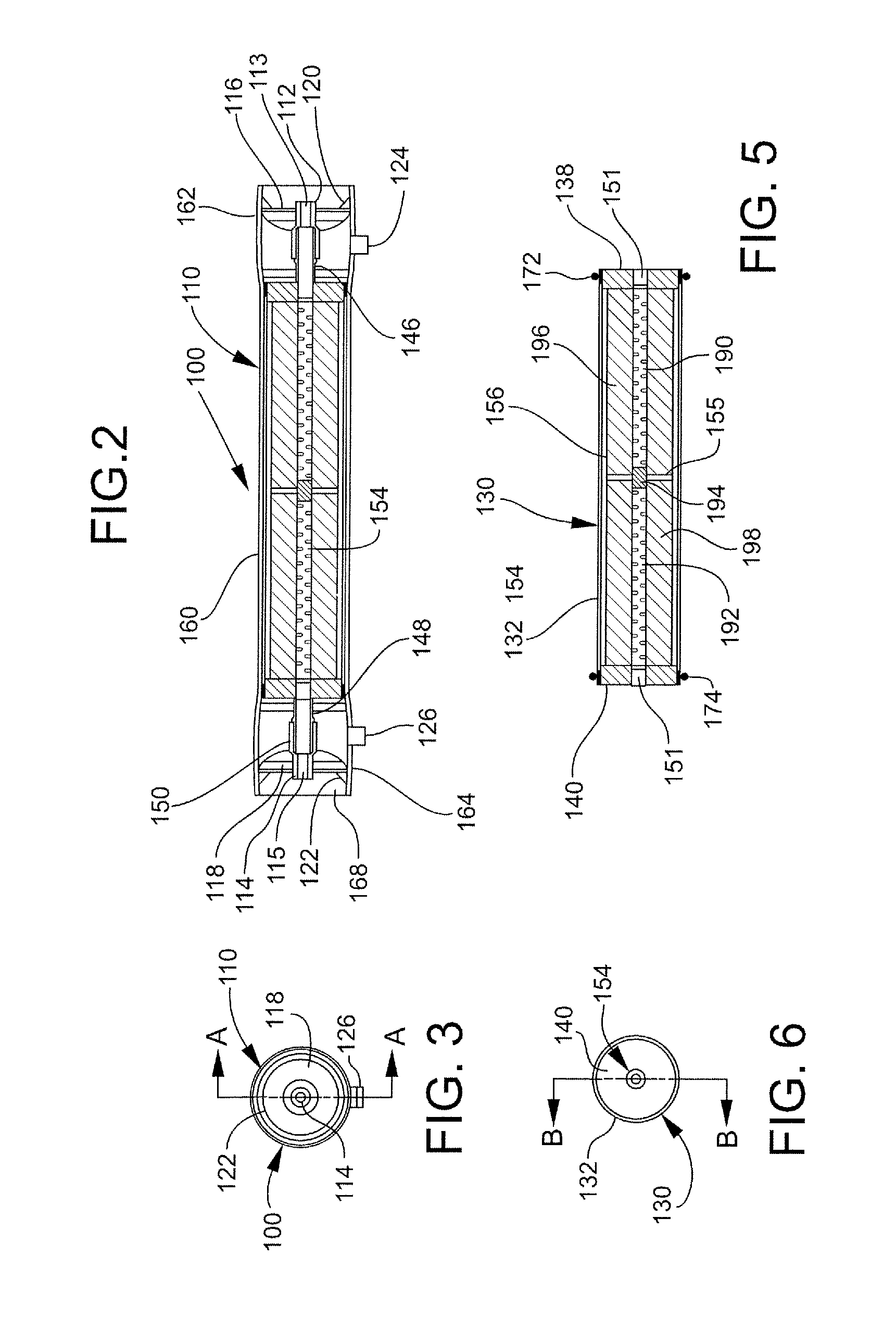

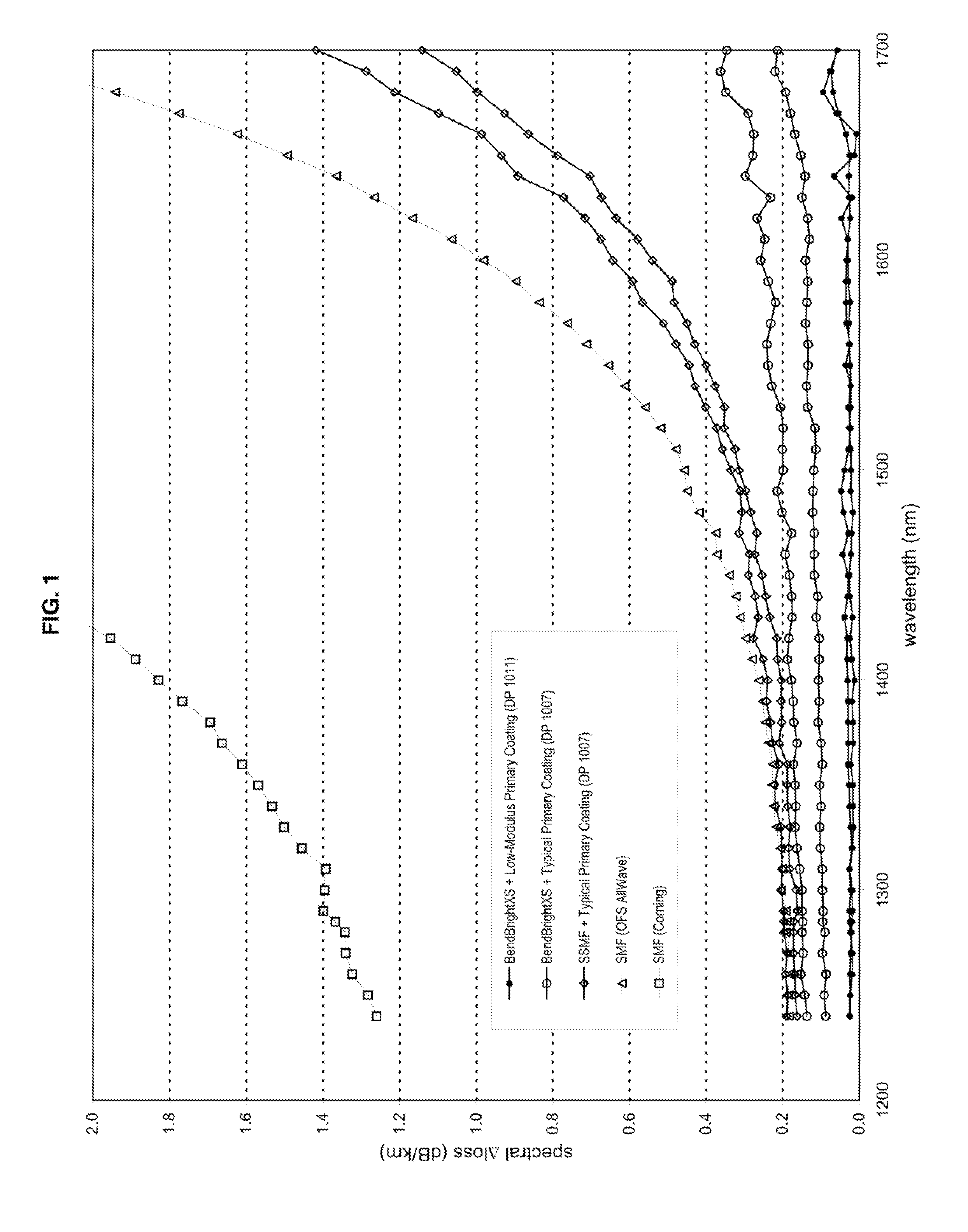

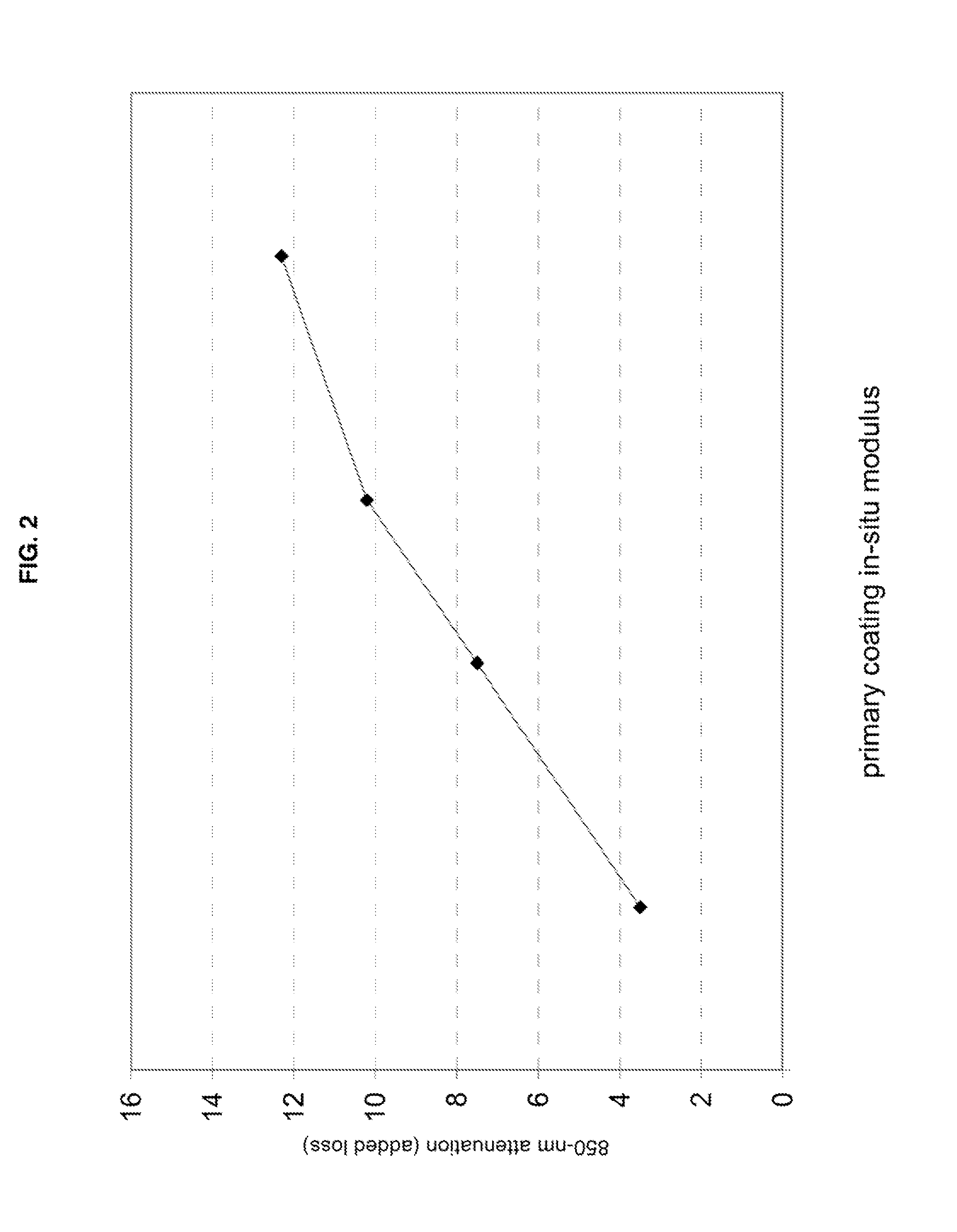

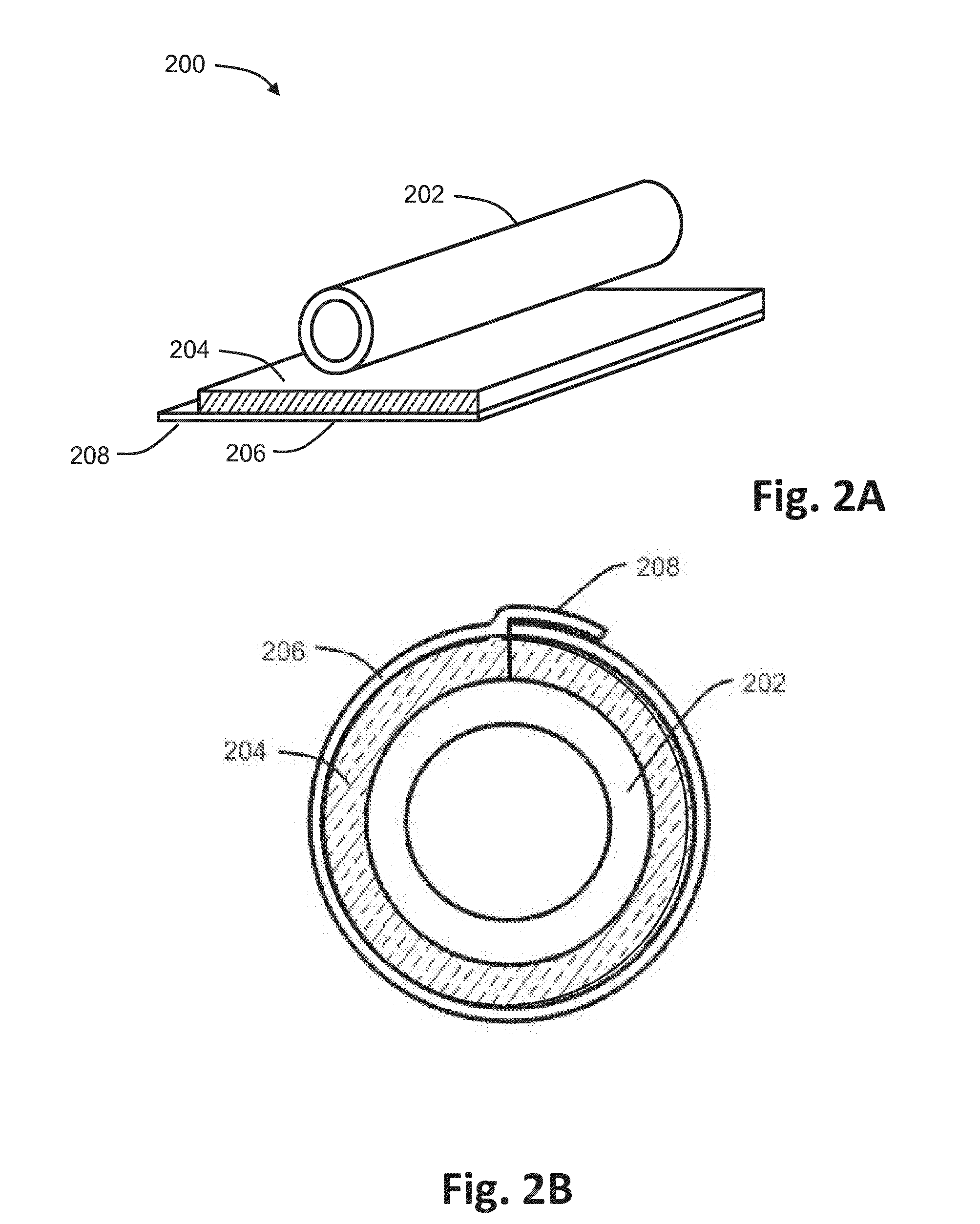

Reduced-Diameter Ribbon Cables with High-Performance Optical Fiber

ActiveUS20100135625A1Improve protectionEasily matedGlass optical fibreFibre mechanical structuresGlass fiberFiber

Disclosed is an improved optical fiber that employs a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses.The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped).The optional dual coating is specifically balanced for superior heat stripping in fiber ribbons, with virtually no residue left behind on the glass. This facilitates fast splicing and terminations. The improved coating system provides optical fibers that offer significant advantages for deployment in most, if not all, fiber-to-the-premises (FTTx) systems.

Owner:DRAKA COMTEQ BV

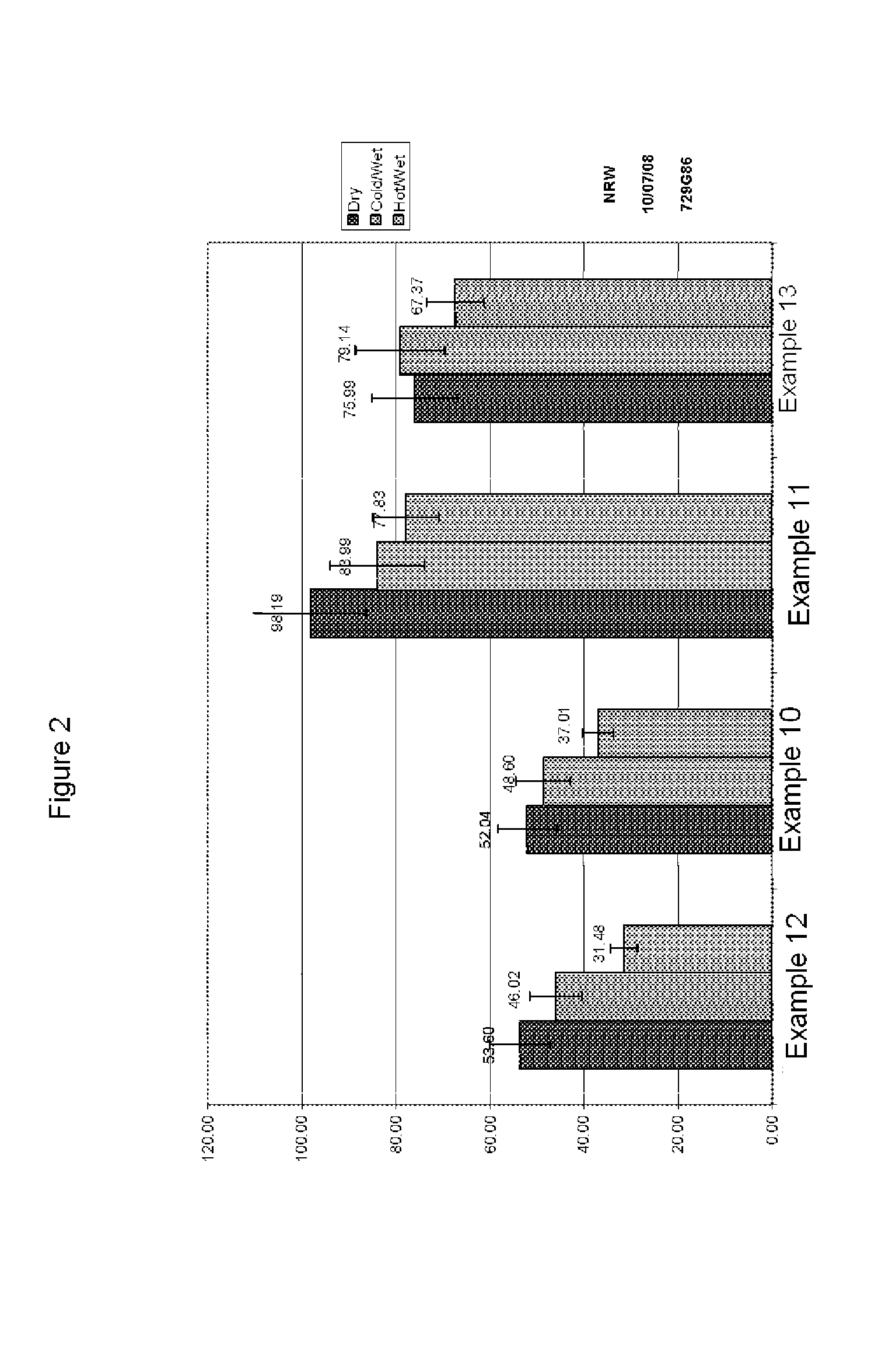

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

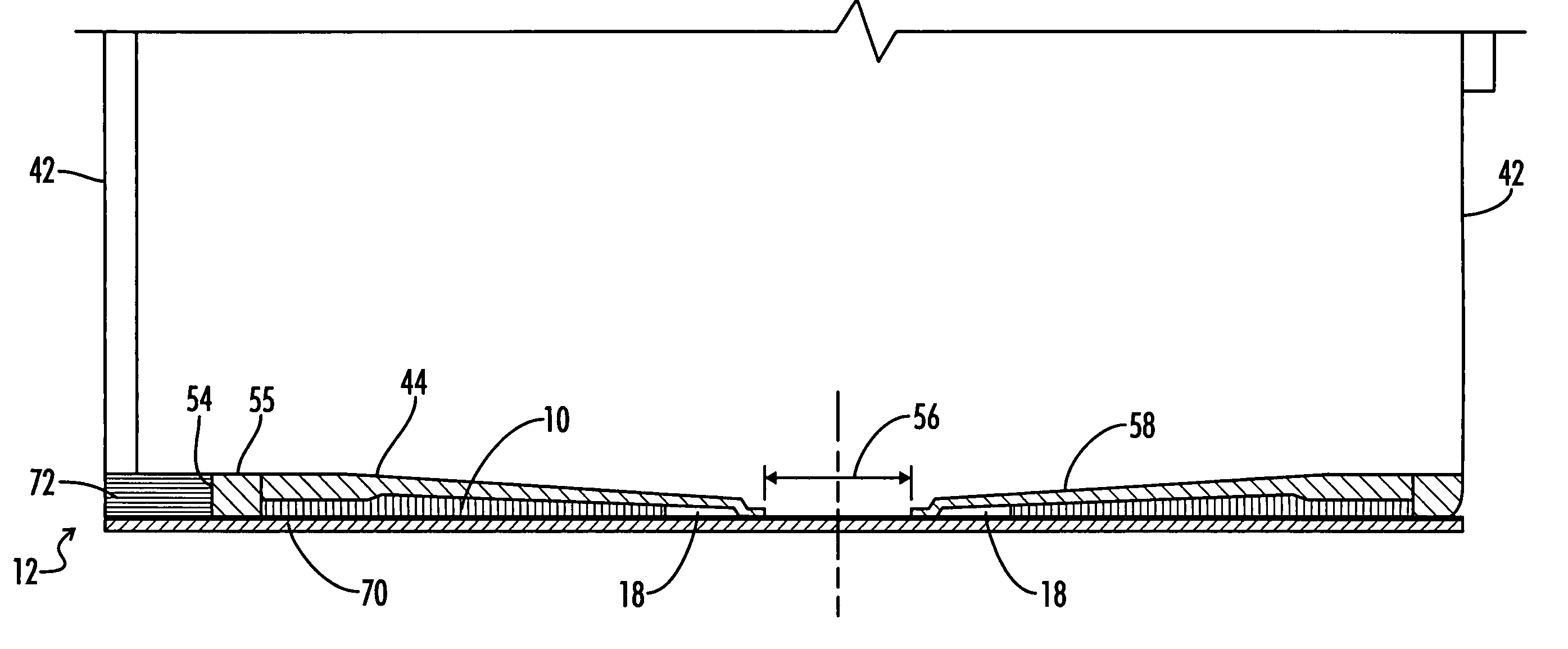

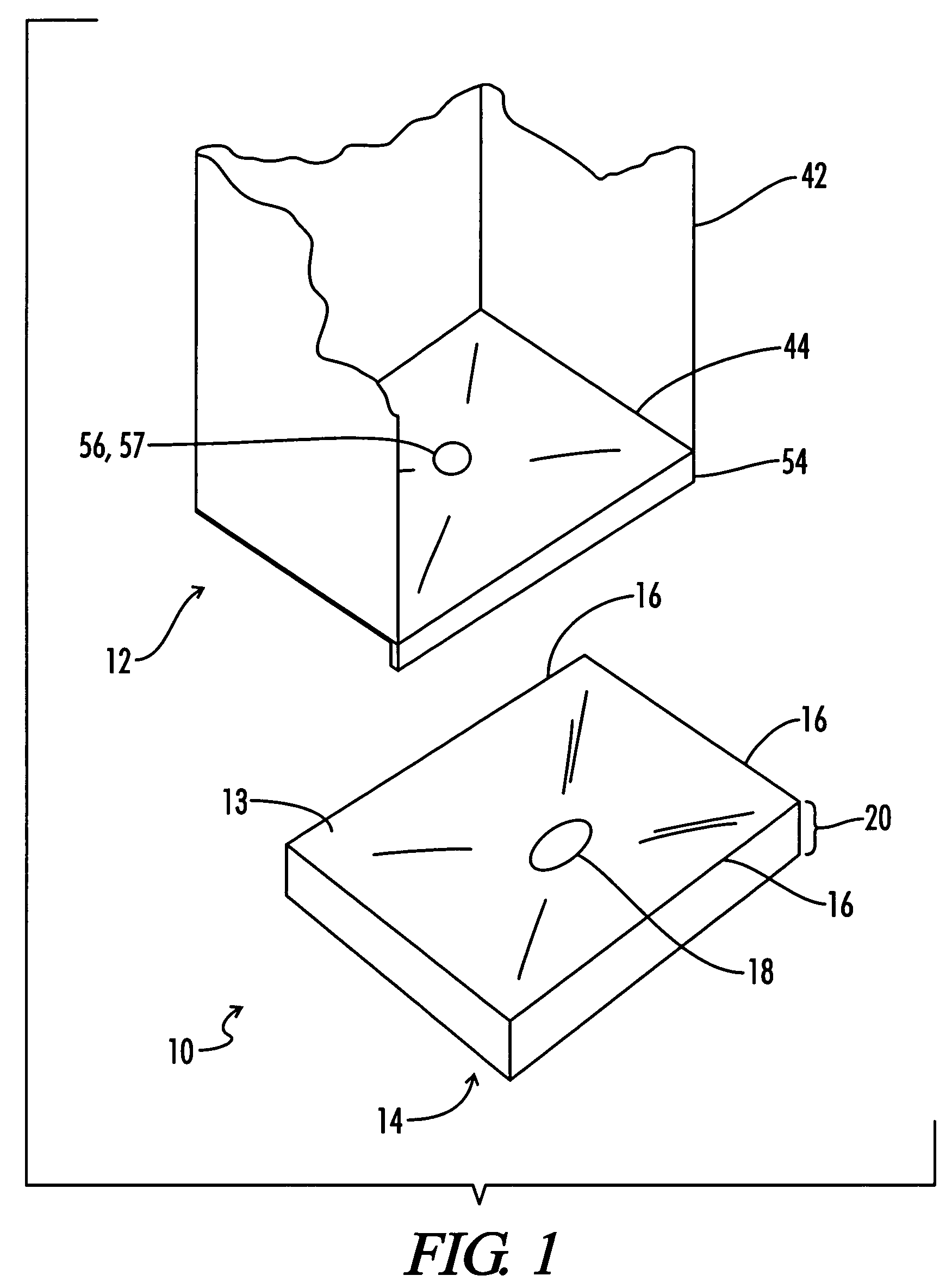

Self-sustaining base

A base for a shower stall comprising a first layer of fiber glass and resin, and layer of filament material, and a second layer of fiberglass and resin. The base also includes at least one external edge, an external opening, and a thickness that increases from the at least one external edge to the internal opening. Included is a shower stall comprising a plurality of shower walls, a sloped floor attached to the shower walls, and a base attached to the slope floor. Also included is a method of attaching a base to a shower stall. The method comprises creating the base by applying fiberglass, resin, and filament material to a mold, engaging the base to the shower stall by removably attached the mold to the shower stall, curing the base, and removing the mold from the shower.

Owner:PRAXIS IND

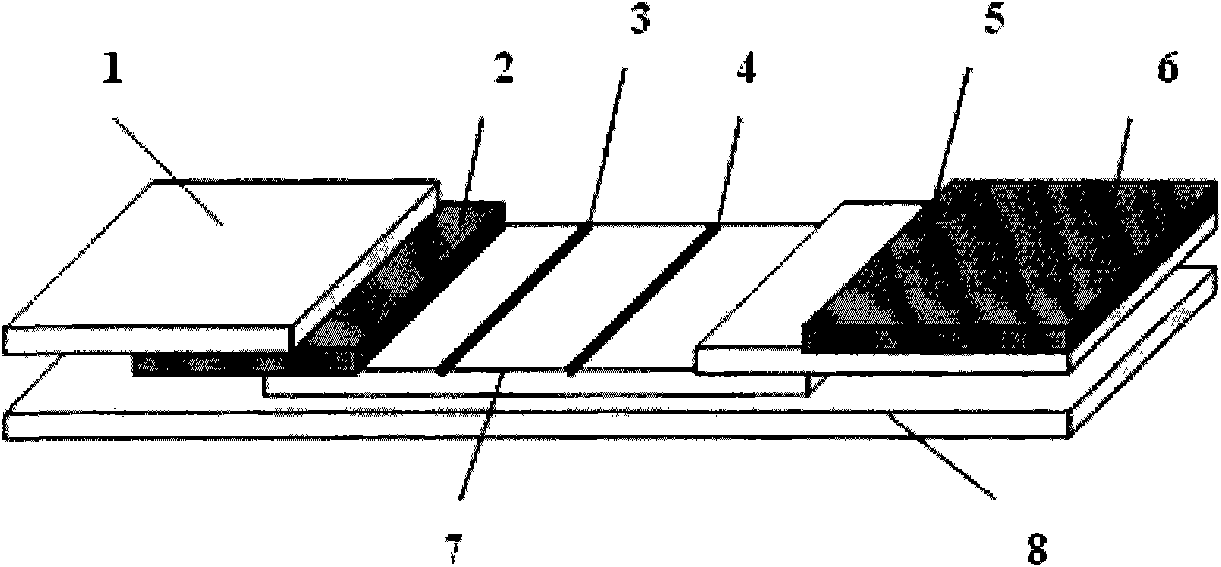

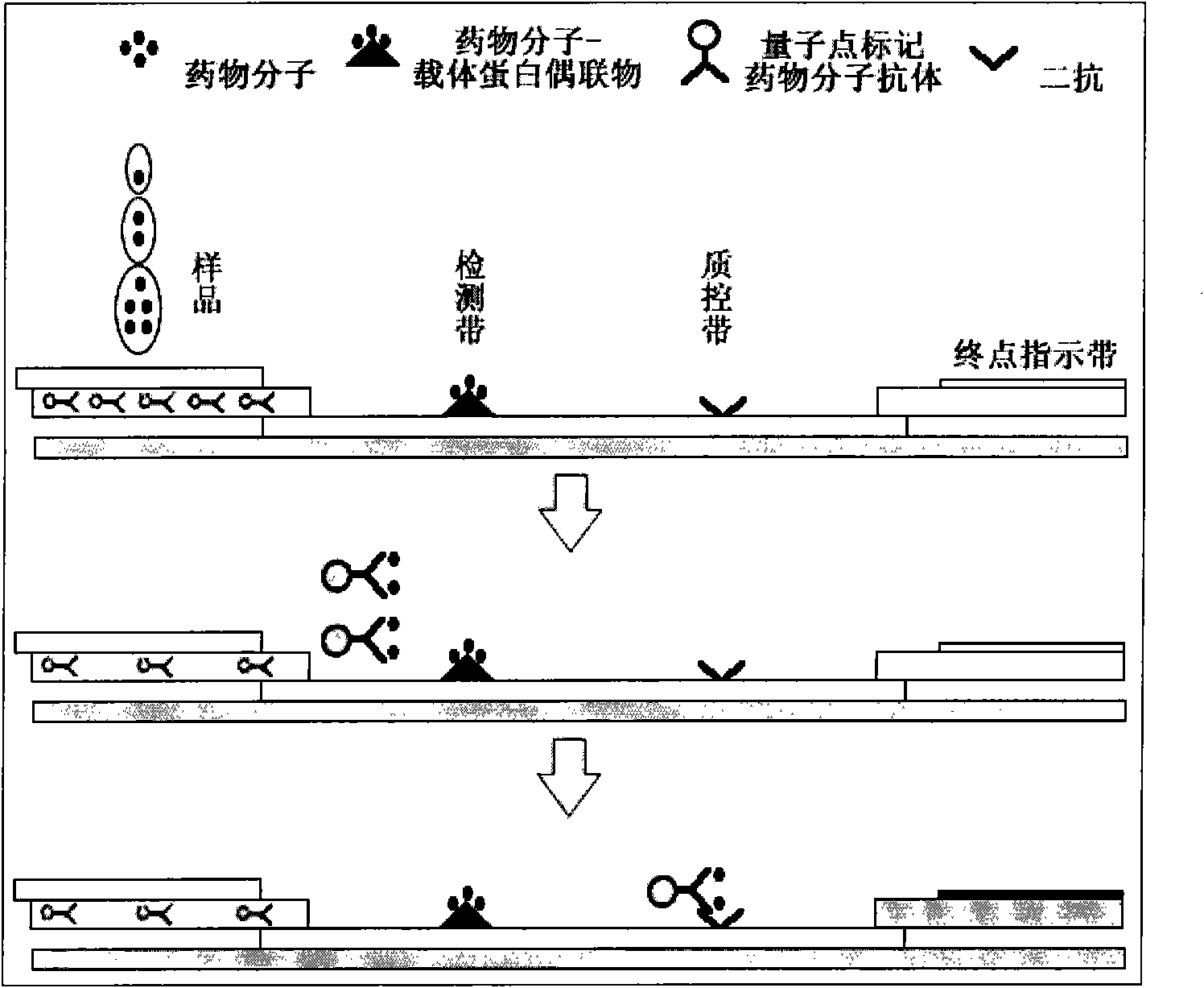

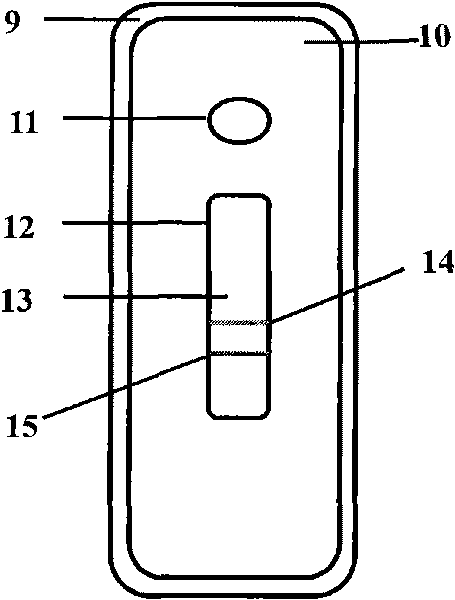

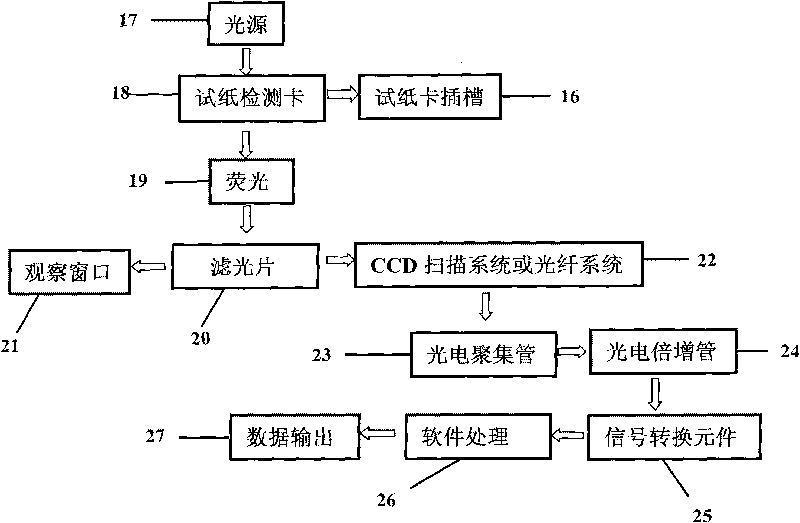

Fluorescent micro-ball immune chromatography test paper strip for detecting residual animal medicine and preparing method thereof

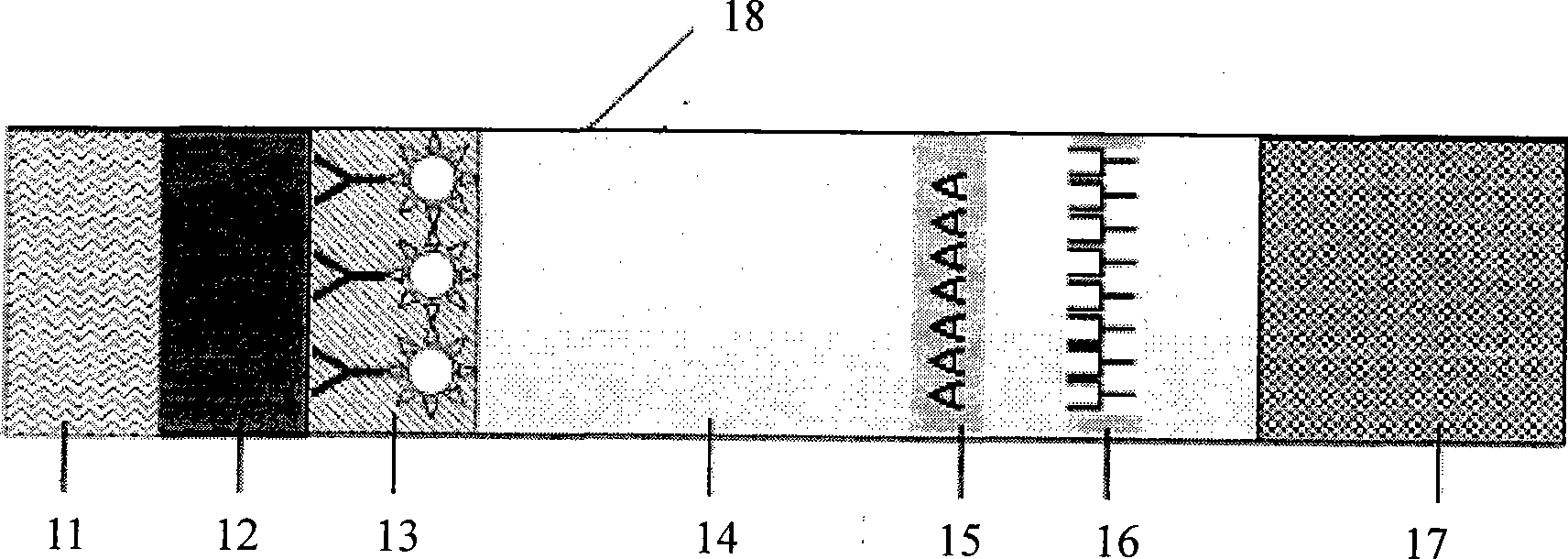

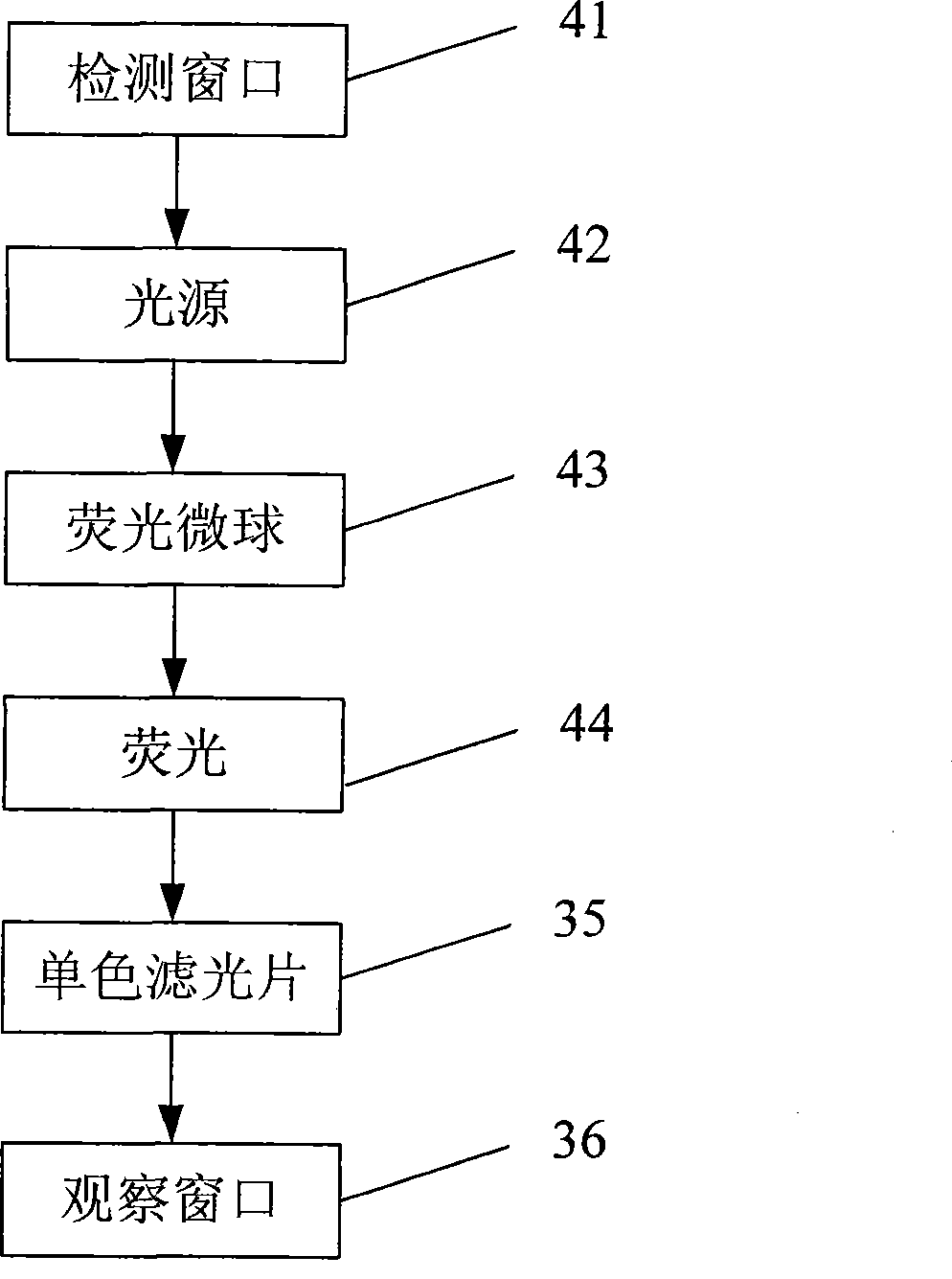

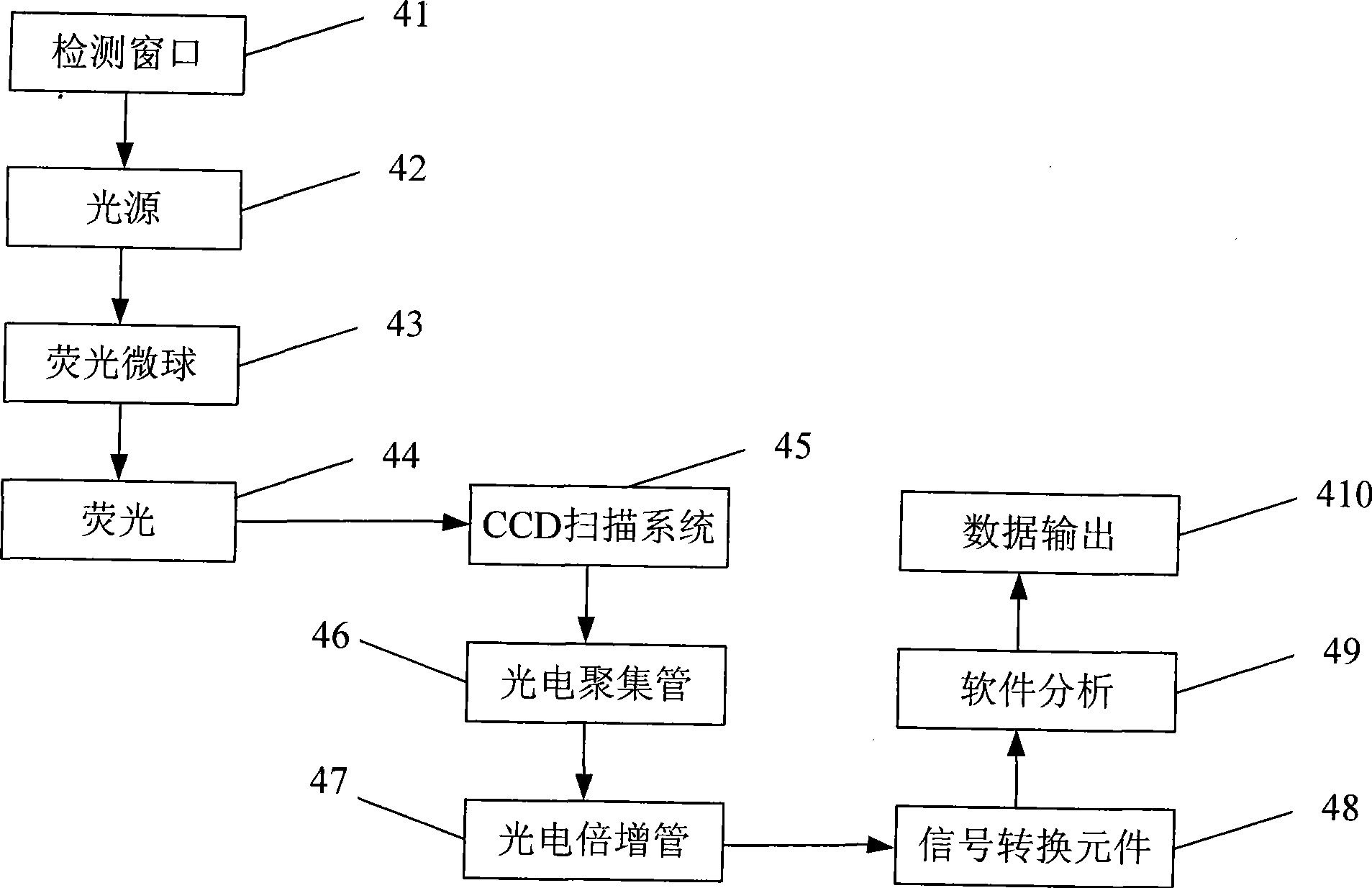

The invention discloses a test paper strip for the fluorescent bead immunochromatography of veterinary medicine remained in a detected sample and a preparation method thereof. A filter paper, a sample pad, a fiberglass membrane, a pyroxylin membrane and water sucking paper are sequentially stuck on a base plate in related joint; fluorescent beads are sprayed on the pyroxylin membrane for marking a veterinary medicine resistant molecule monoantibody; the pyroxylin membrane coated with a veterinary medicine molecule holoantigen is used as a detection region; the pyroxylin membrane coated with an anti-mouse antibody is used as a quality control region; and the test paper strip is prepared through the following steps: (1) the preparation of the pyroxylin membrane; (2) the preparation of a fluorescent bead pad; and (3) the assembling of the test paper strip. In the detecting process, emitted spectrums pass through a proper optical filter device; and all the emitted spectrums are collected through CCD scanning technology, are congregated, are multiplied and are analyzed through a fluorescence analyzer and relevant software to obtain a quantized fluorescence signal, thereby realizing quantitative detection. The test paper strip is mainly used for the qualitative detection and the quantitative detection of all the veterinary medicine classes in food safety detection.

Owner:WUXI ZODOLABS BIOTECH

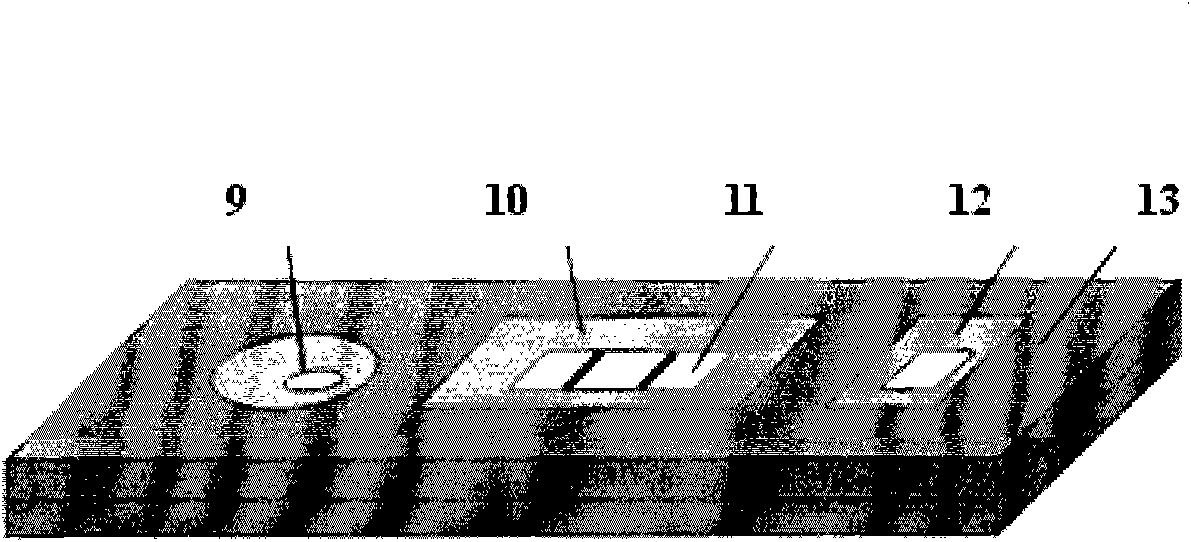

Drug residue competition-type quantum dot-labeled immunochromatography assay test-strip and observation device thereof

The invention provides a drug residue competition-type quantum dot-labeled immunochromatography assay test-strip / detection card and an observation device thereof, comprising the following preparation steps of coating the antibody of quantum dot-labeled drug molecule on a fiberglass film, coating the drug-molecular-carrier protein coupler and second antibody on a pyroxylin film or a cellulose acetate film respectively to form a detection belt and a quality control belt; preparing the immunochromatography assay test-strip from the fiberglass film and the pyroxylin film or the cellulose acetate film on a polyester or plastic plate, and assembling a shell. The quantum dots of the detection belt and the quality control belt on the test-strip is triggered by the ultraviolet LED source of the observation device, and the change of the fluorescent intensity of the observation belt and the quality control belt is observed, thus being capable of quantitatively analyzing the content of the drug molecule in the sample. The invention has simple operation, high sensitiveness and quick quantification, is suitable for detecting the drug residue in the food and can be widely applied to the customhouse, airport, health supervising department, household and the like.

Owner:CHINA JILIANG UNIV

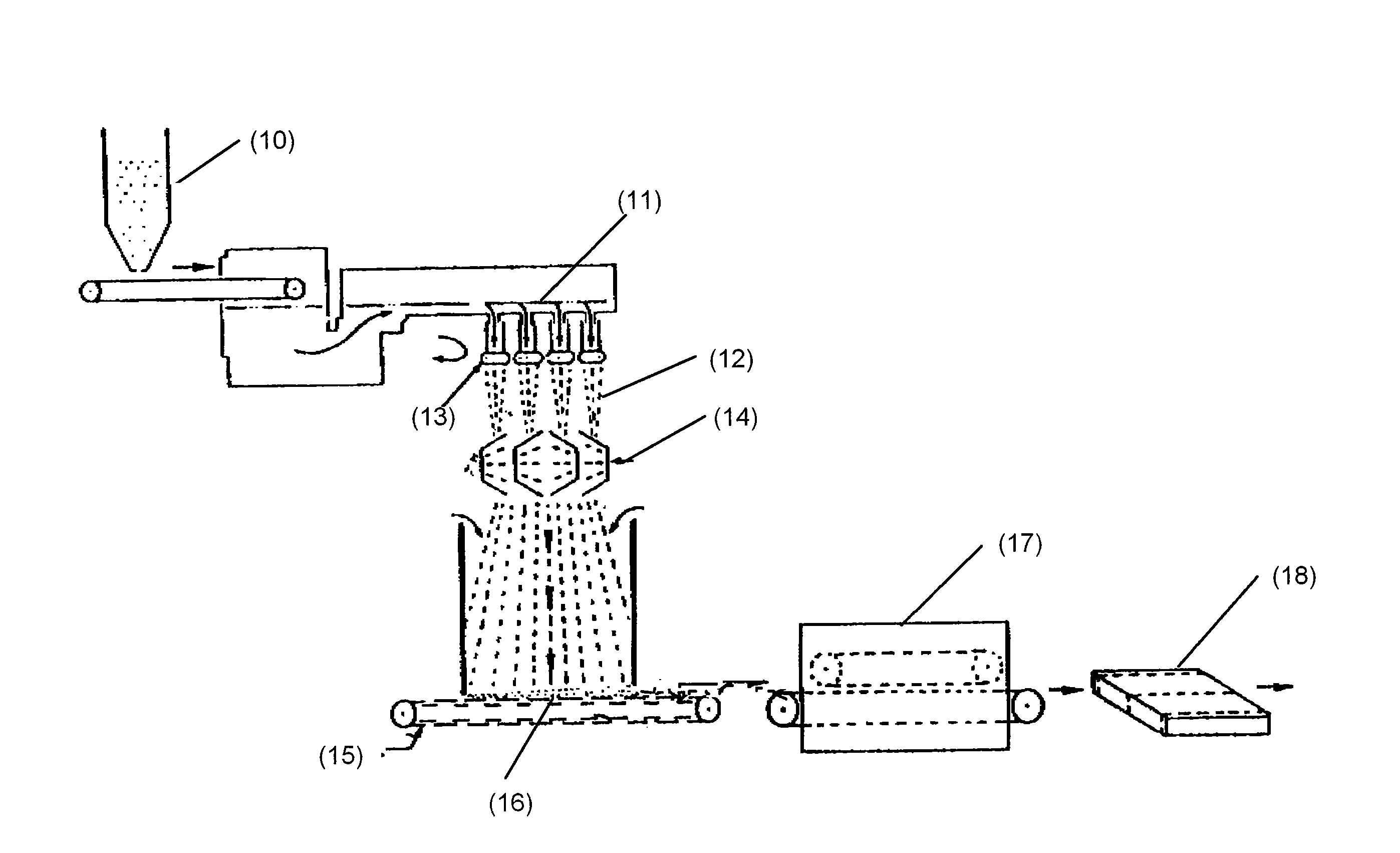

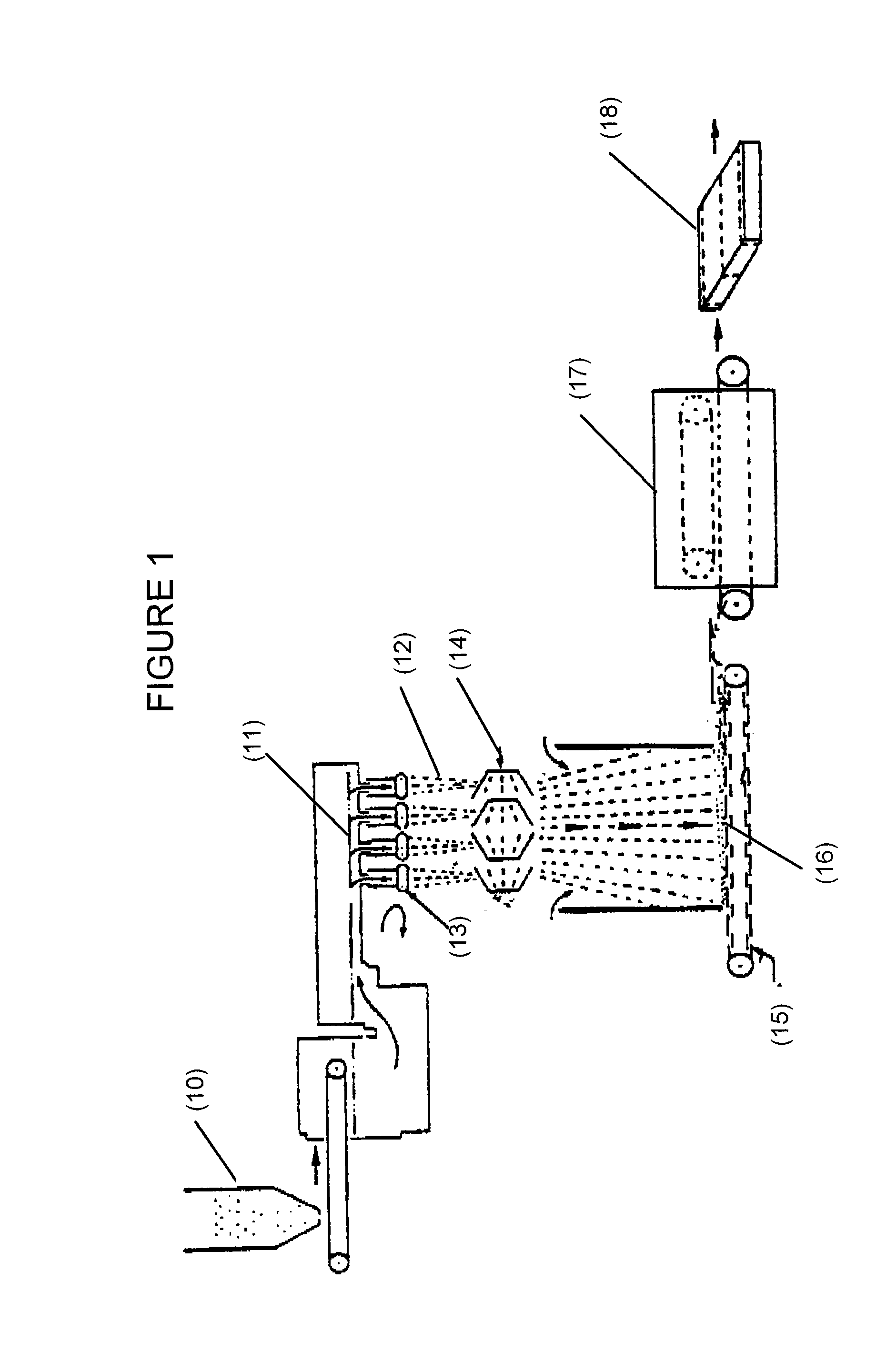

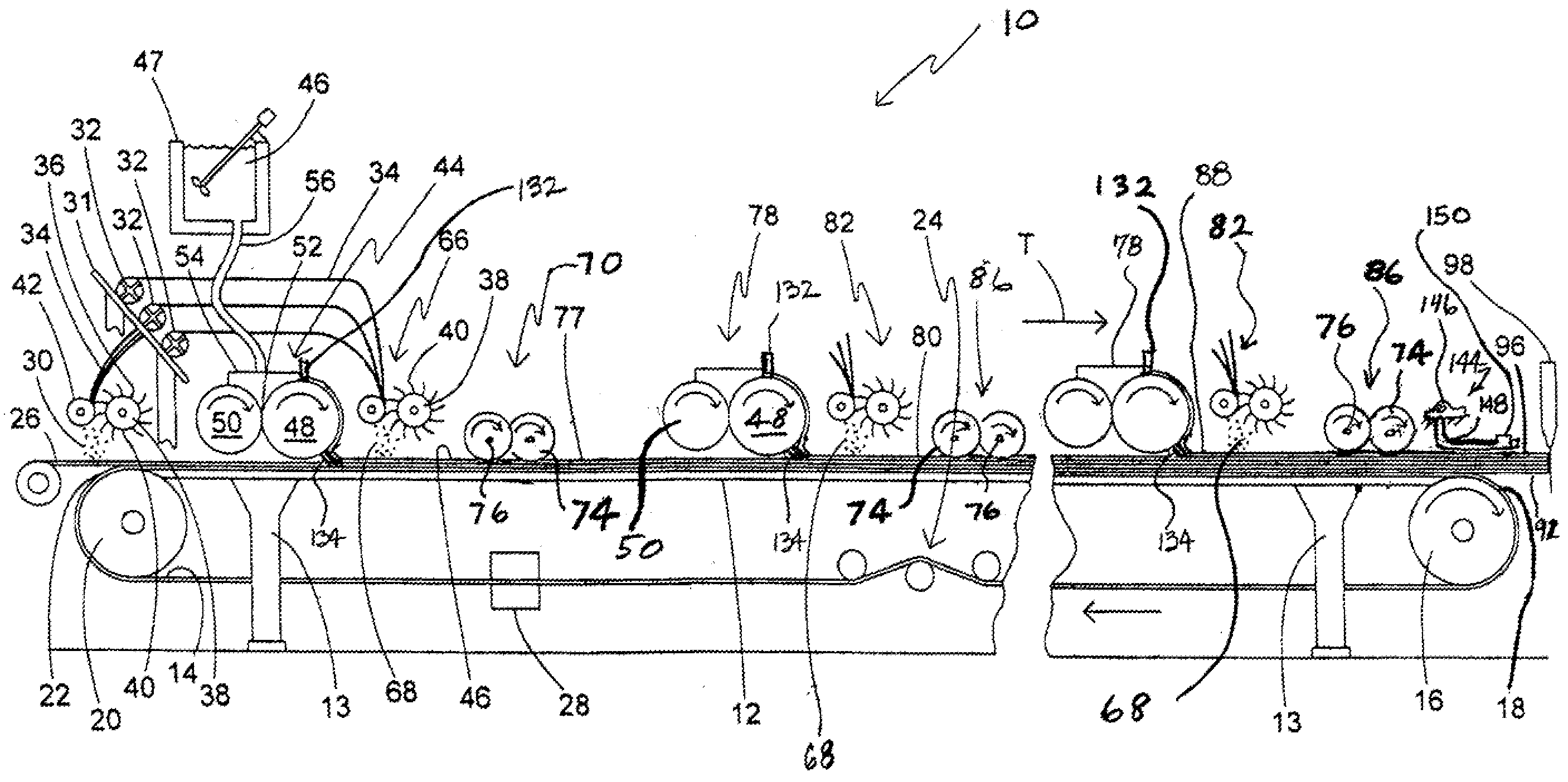

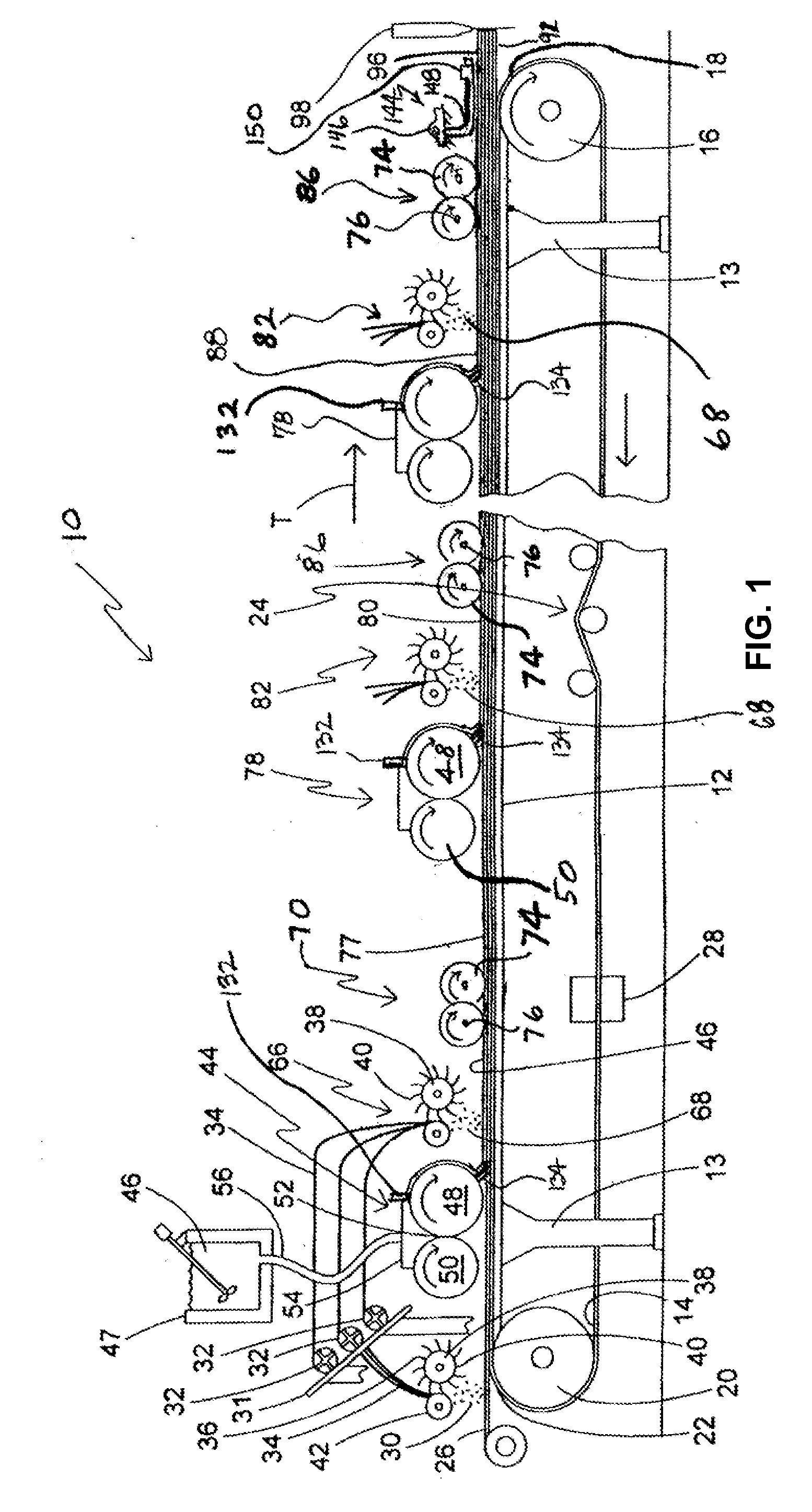

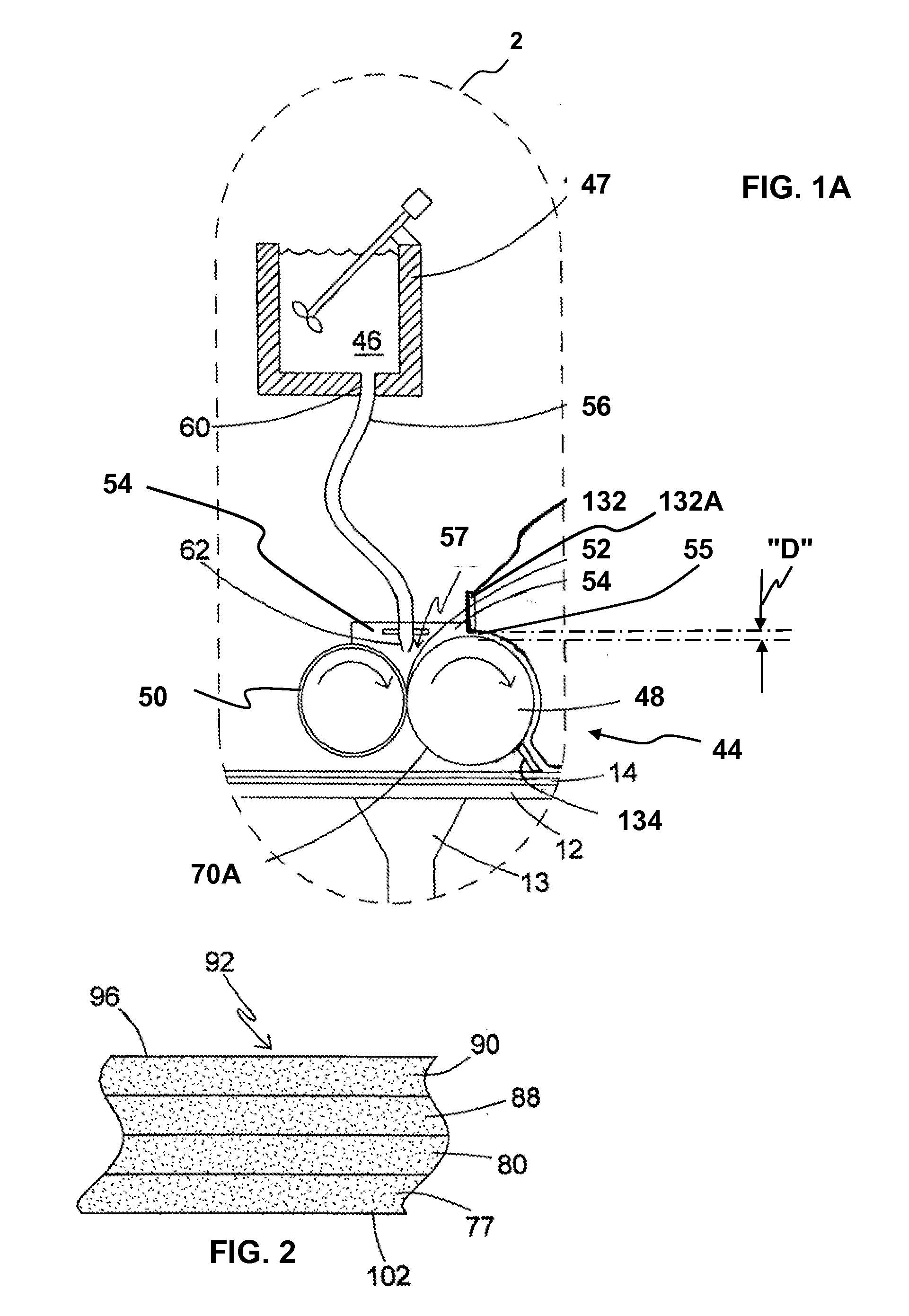

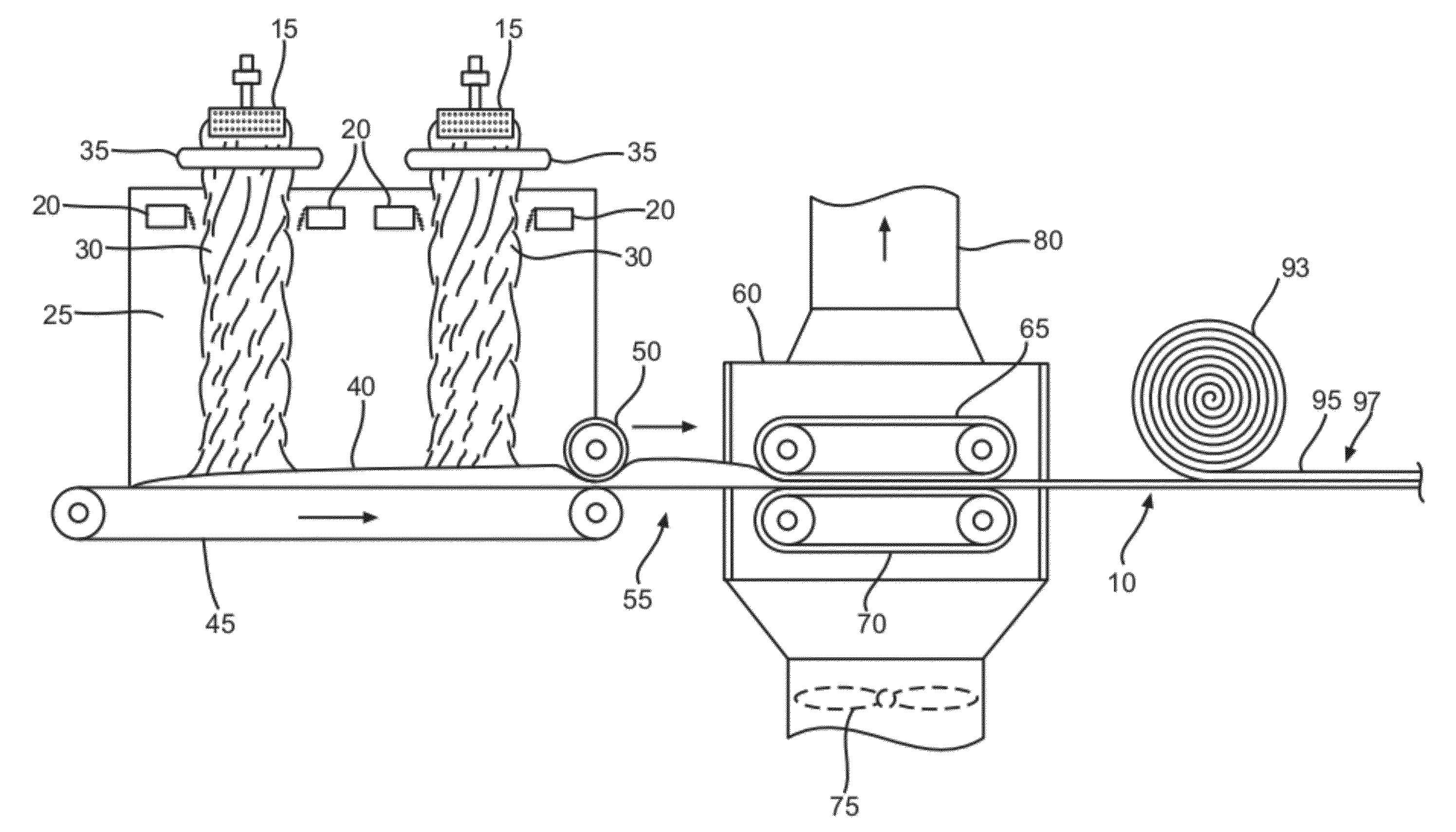

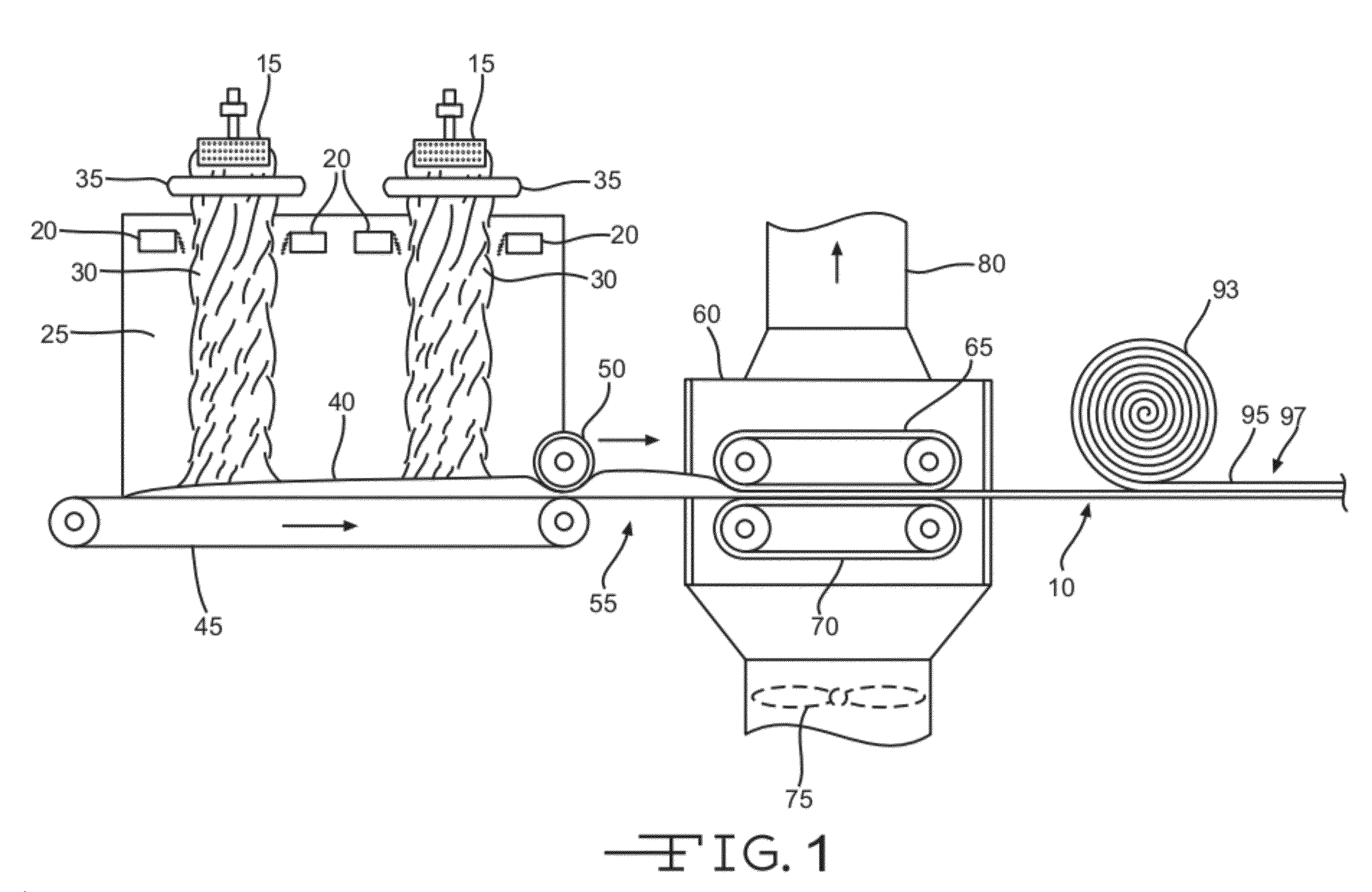

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080099171A1Good strength propertiesA large amountNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFibre reinforcement

A head-box for depositing slurry upon a moving web including a main metering roll, a companion roll disposed in closely spaced relation to the metering roll and a vibrating gate which forms a nip between the metering roller and the gate. The nip is arranged to retain a supply of the slurry, and the rolls are driven so slurry retained in the nip progresses over an upper outer peripheral surface of the metering roll to be deposited upon the web. Also, preferably included is a doctor blade disposed in operational relationship to the metering roll for directing the slurry downwardly from the outer metering roll surface to a point above the surface of a carrier for a fiberglass layer upon which the slurry layer is deposited. The vibrating gate and doctor blade may be pivotally mounted to either side of the surfaces of the head-box.

Owner:UNITED STATES GYPSUM CO

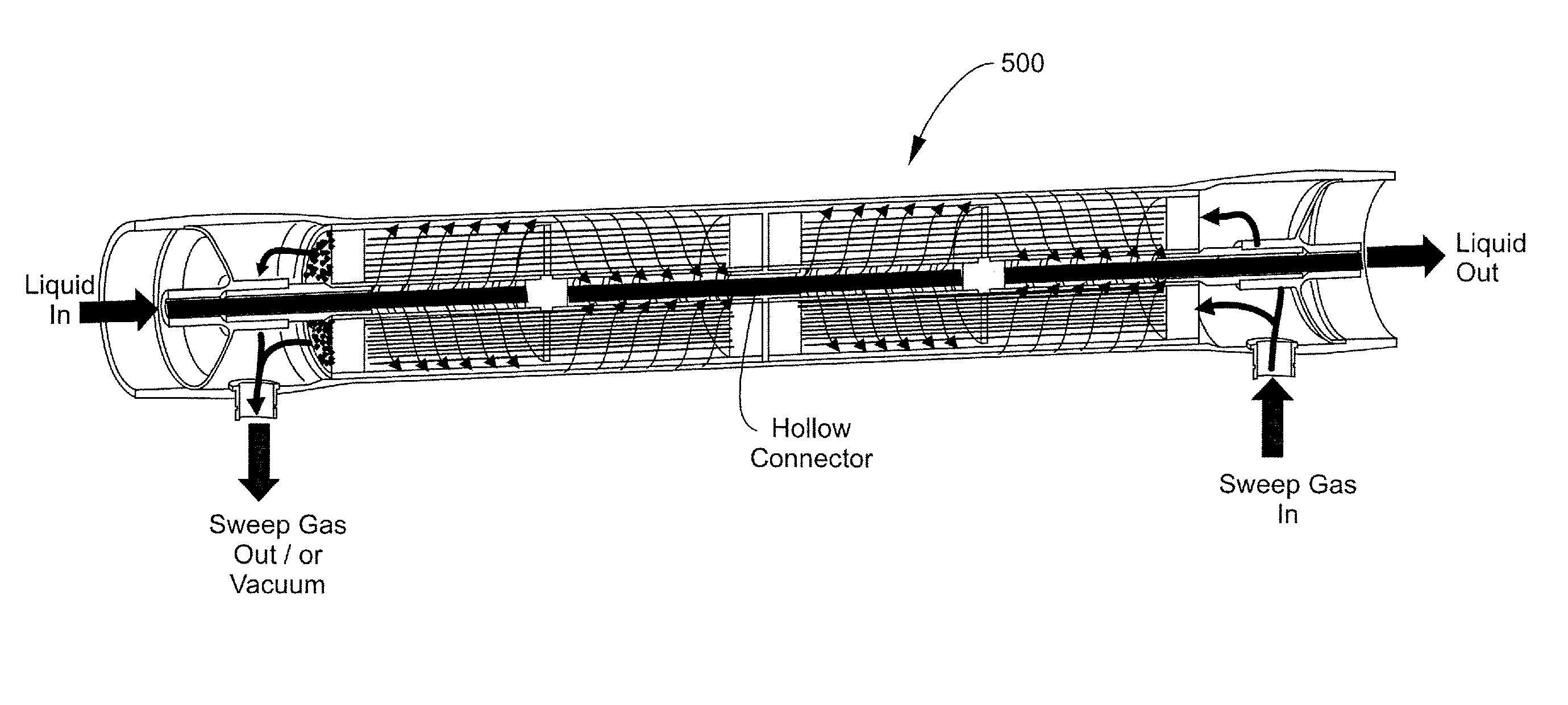

High pressure liquid degassing membrane contactors and methods of manufacturing and use

ActiveUS20110036240A1Cost-effectiveImprove water qualityMembranesIsotope separationPolypropyleneCorrosion resistant

In accordance with at least selected embodiments of the present invention, an improved liquid degassing membrane contactor or module includes a high pressure housing and at least one degassing cartridge therein. It may be preferred that the high pressure housing is a standard, ASME certified, reverse osmosis (RO) or water purification pressure housing or vessel (made of, for example, polypropylene, polycarbonate, stainless steel, corrosion resistant filament wound fiberglass reinforced epoxy tubing, with pressure ratings of, for example, 150, 250, 300, 400, or 600 psi, and with, for example 4 or 6 ports, and an end cap at each end) and that the degassing cartridge is a self-contained, hollow-fiber membrane cartridge adapted to fit in the RO high pressure housing.

Owner:3M INNOVATIVE PROPERTIES CO

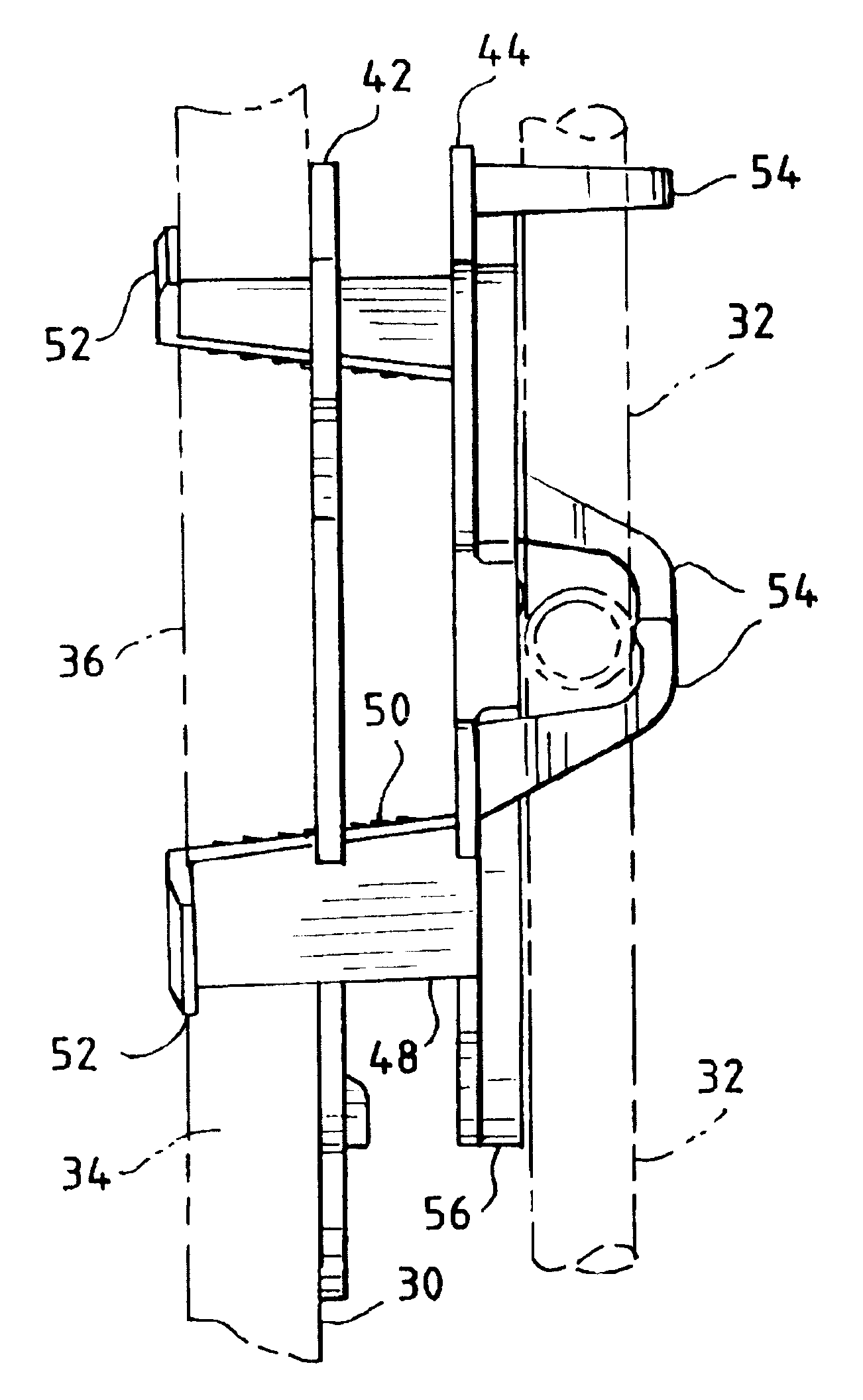

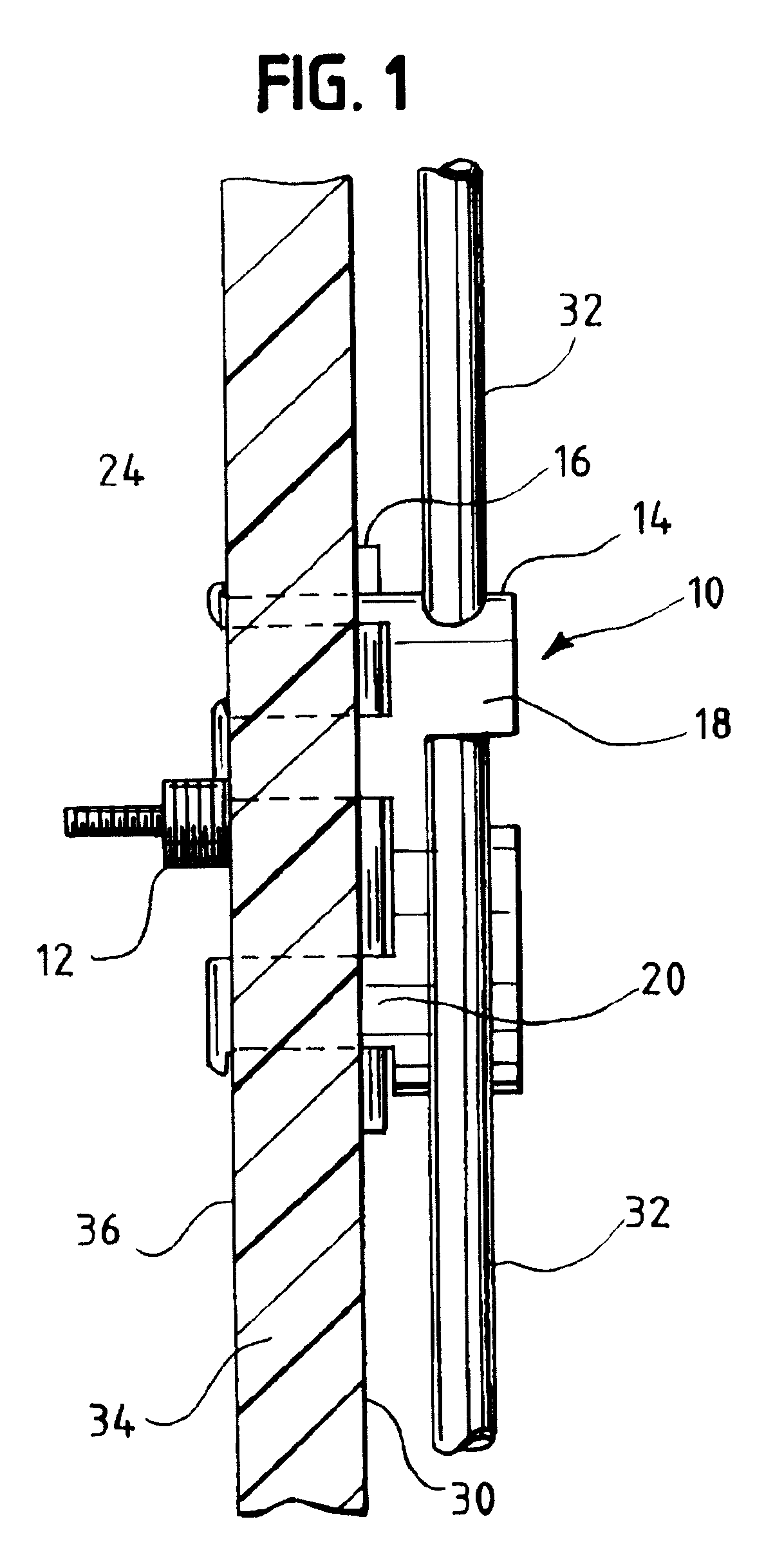

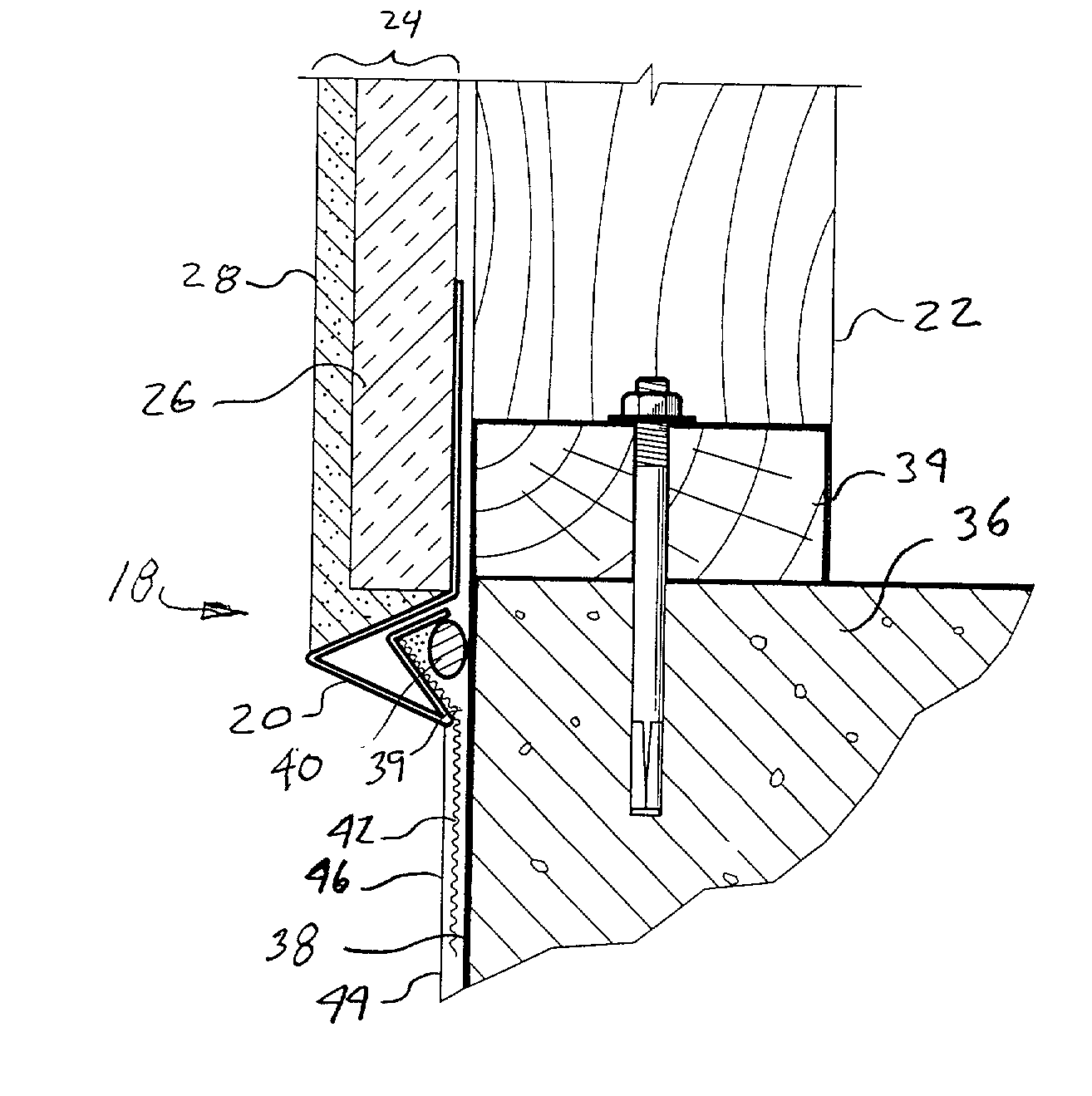

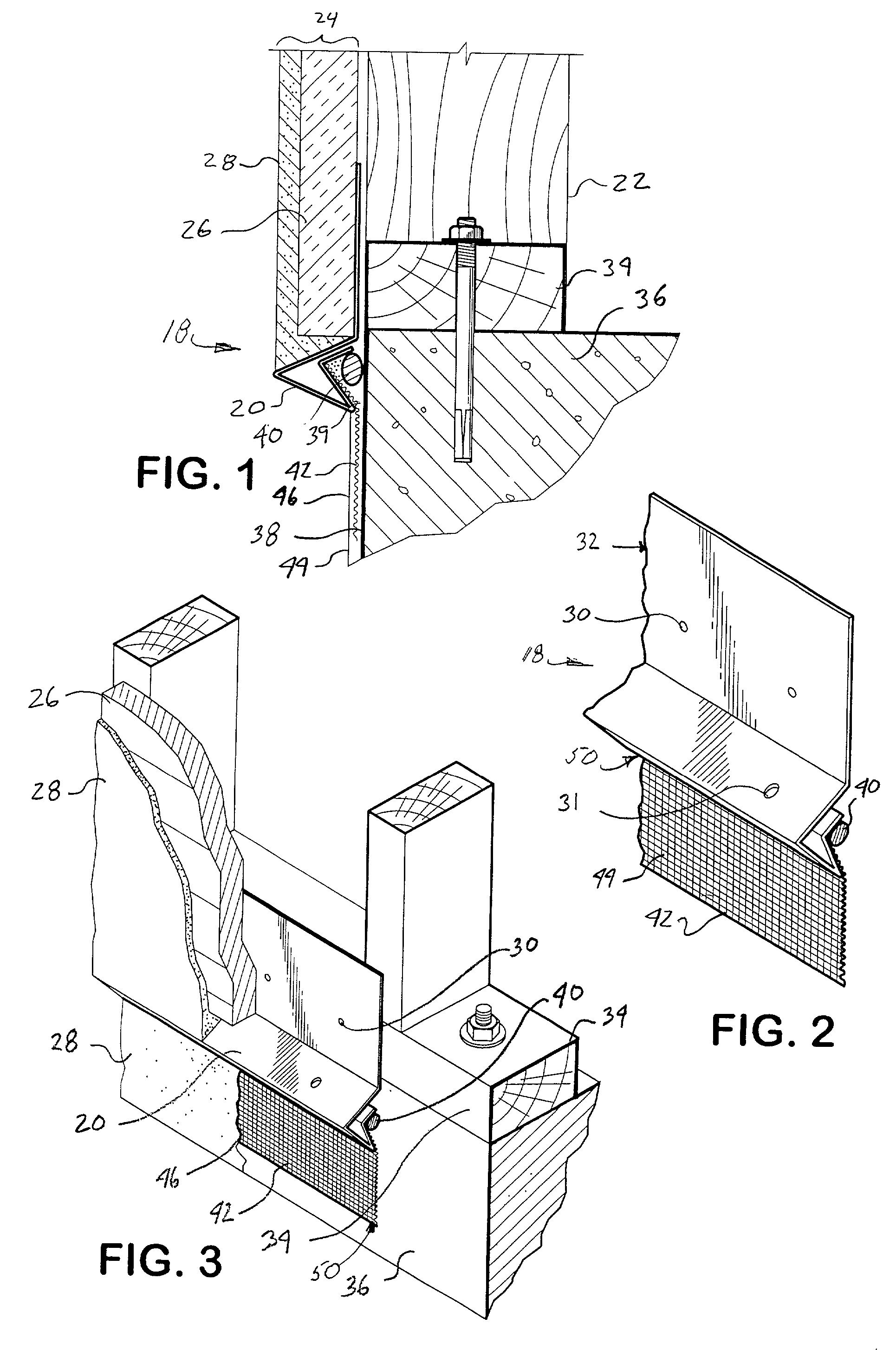

Mixing valve mounting assembly

An assembly for mounting a tub / shower mixing valve onto a fiberglass shower stall wall. The assembly comprises a valve mounting sleeve and a locking plate that helps secure the mounting sleeve to the shower stall wall. Alternatively, the mounting sleeve may be secured to the shower stall wall by bolts threadably connected to the mounting sleeve.

Owner:BRUNO JAMES

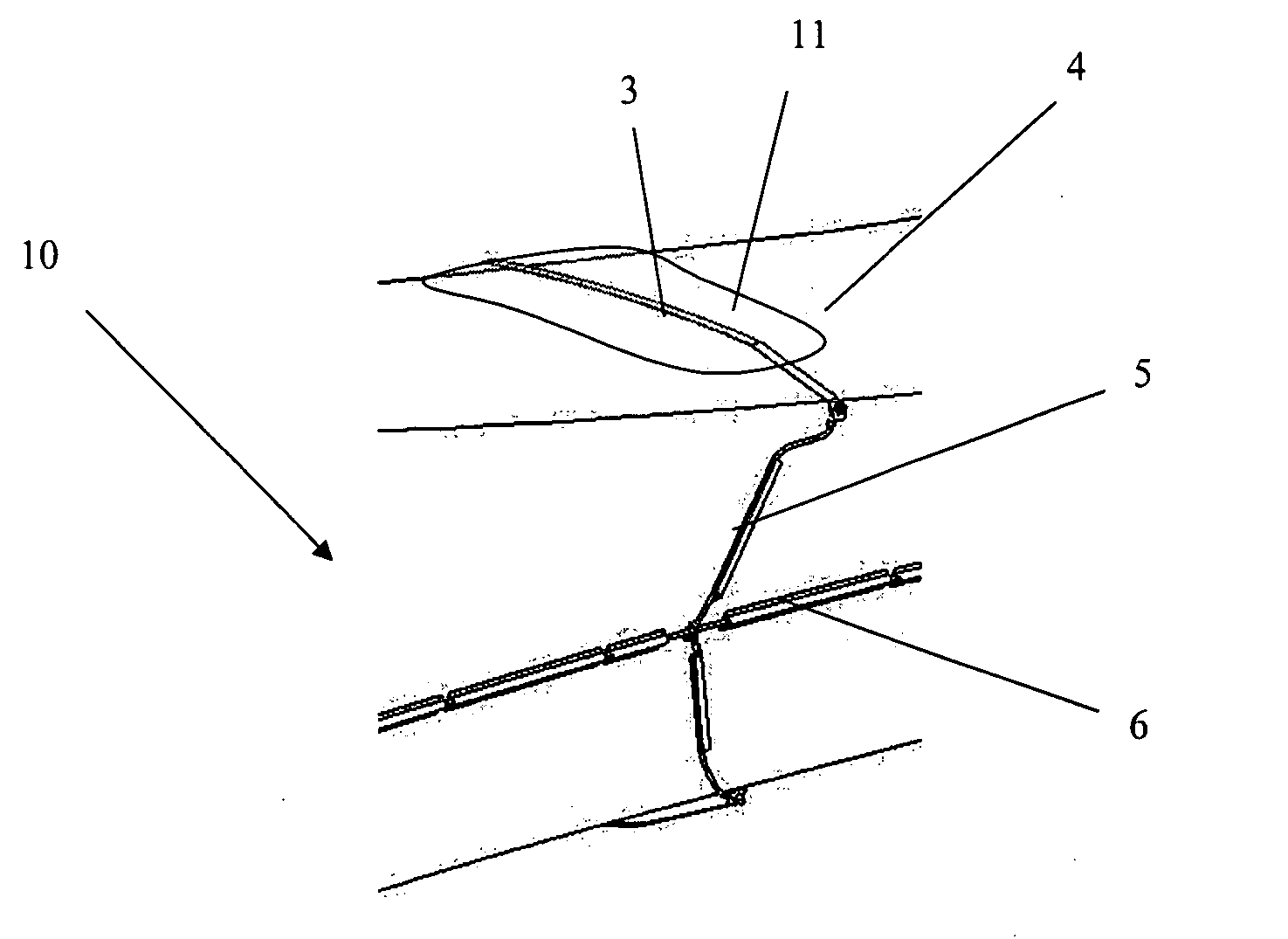

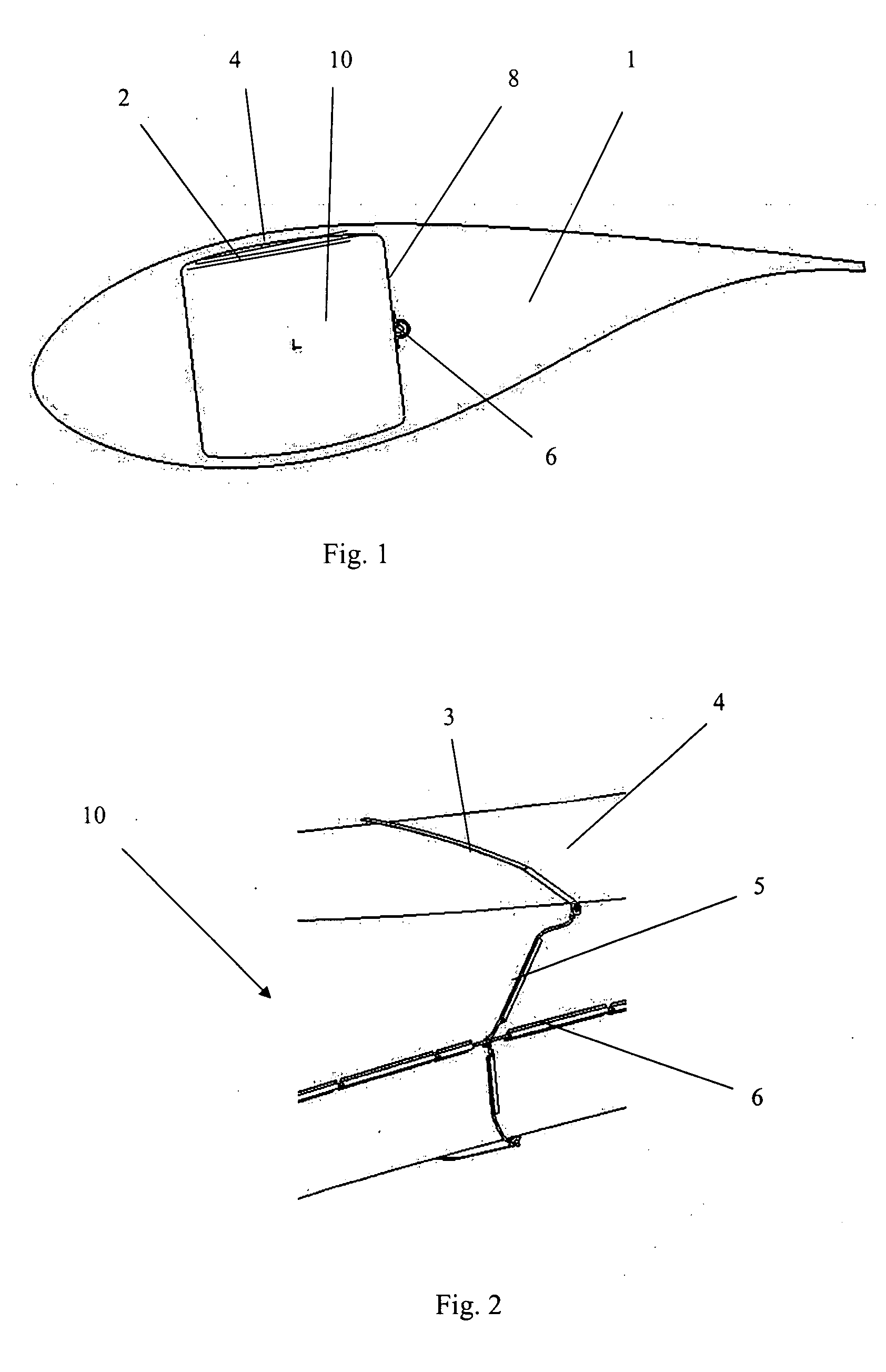

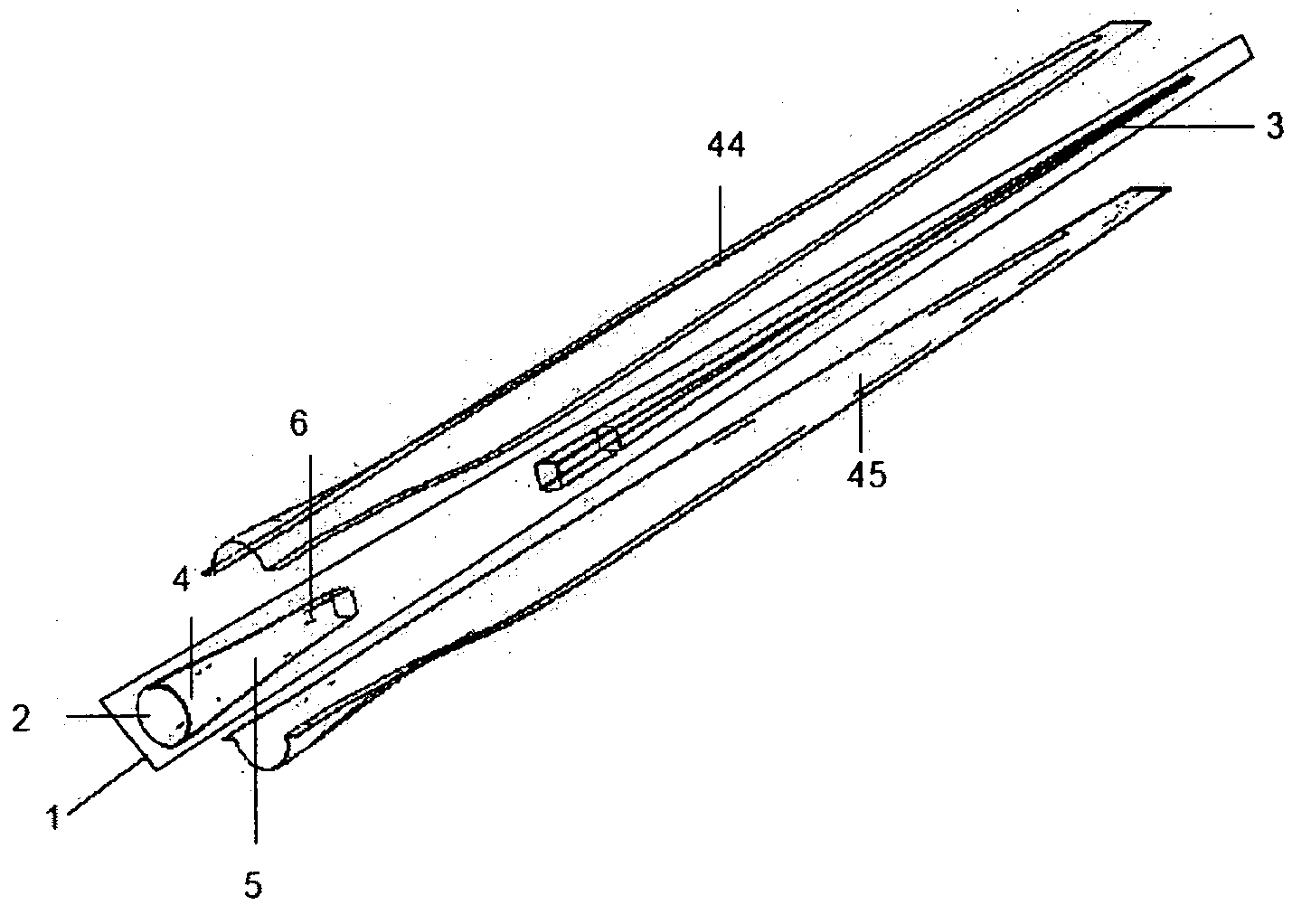

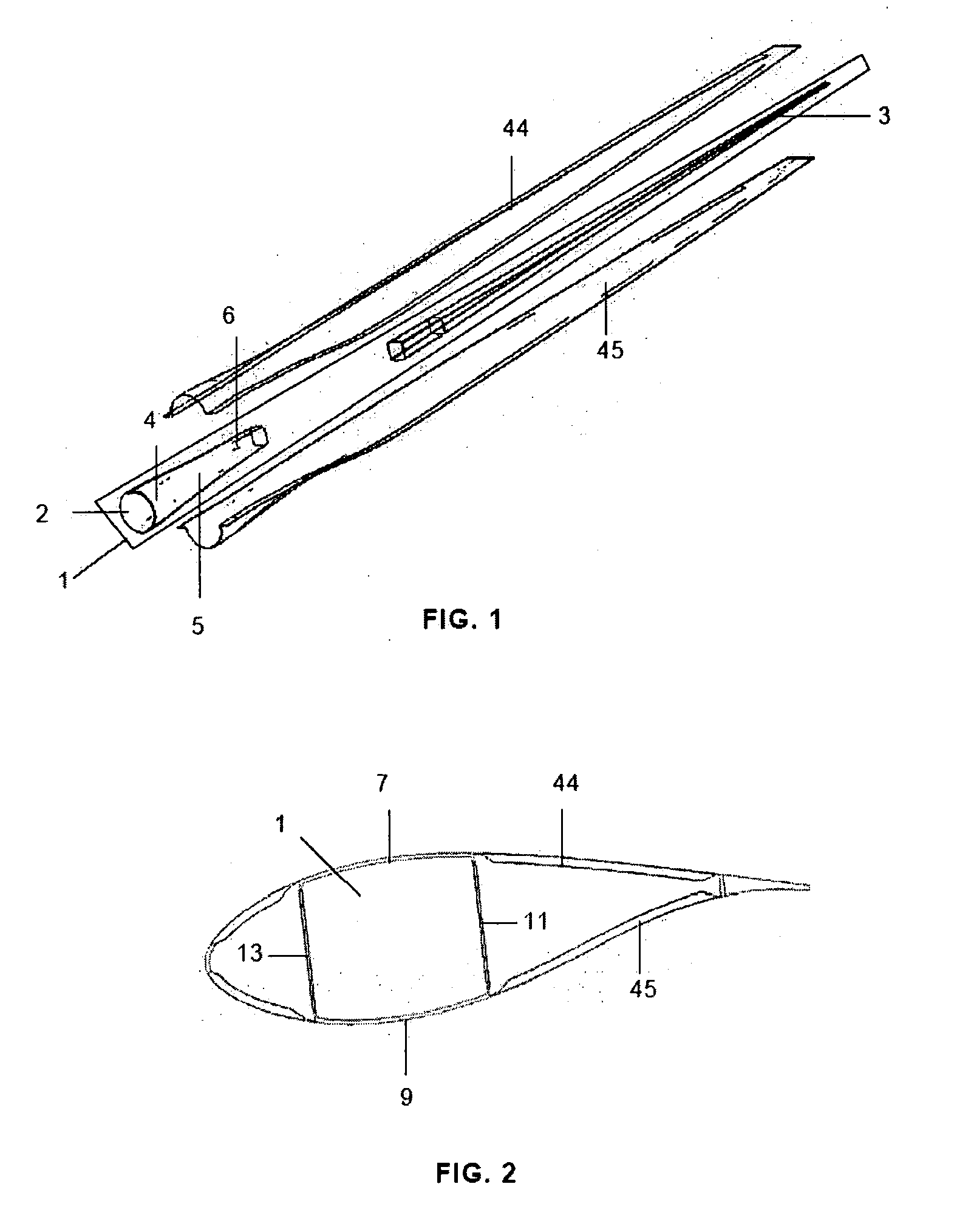

Devices, systems and methods for modular payload integration for unmanned aerial vehicles

InactiveUS8256715B2Improve flight performanceWeight is similarAdditive manufacturing apparatusAircraft stabilisationGlass fiberModularity

Devices, systems and methods are disclosed which relate to providing wing designs with payload integration capabilities on existing modularly assembled unmanned aerial vehicles (UAVs). Exemplary embodiments of the present invention present a novel technique of adding payloads to existing UAVs while improving flight performance over existing techniques by maintaining a similar overall weight with improved aerodynamic properties. The technique includes using a reinforced foam core center wing with a fiberglass epoxy skin. A lightweight payload canopy cover integrates onto the center wing as an agnostic enclosure for payloads. The payload canopy cover may contain venting holes for the cooling of electronic payloads. The systems may also include common devices such as antennas, GPS, and batteries for use with a wide range of payloads.

Owner:MAV6 LLC

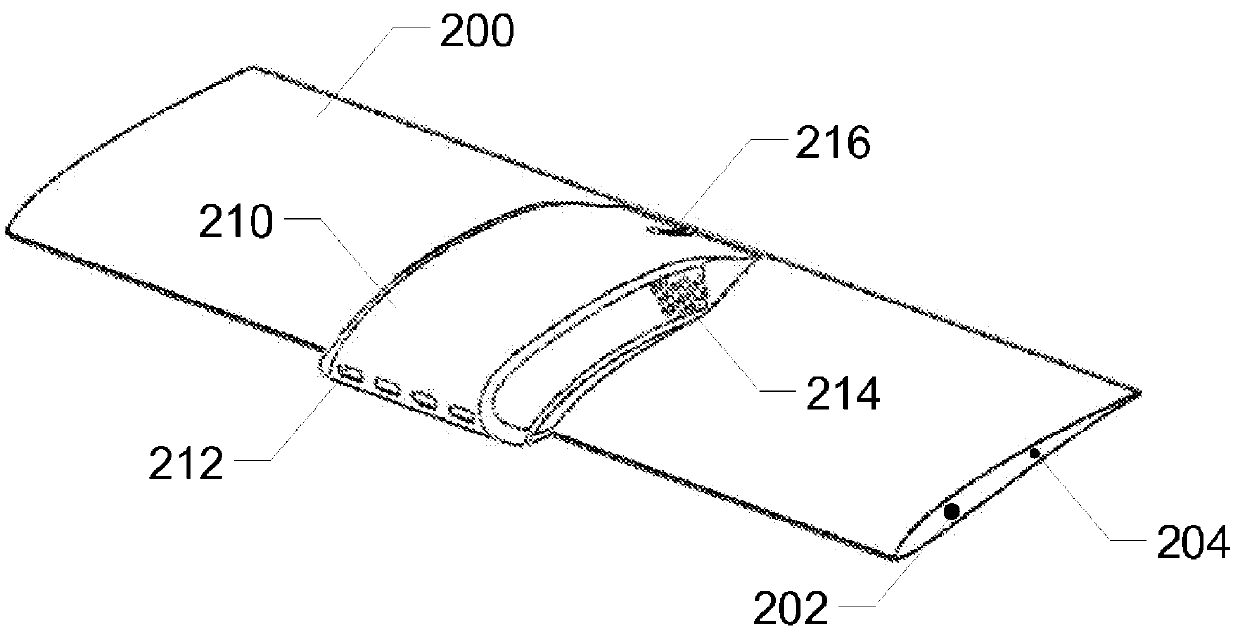

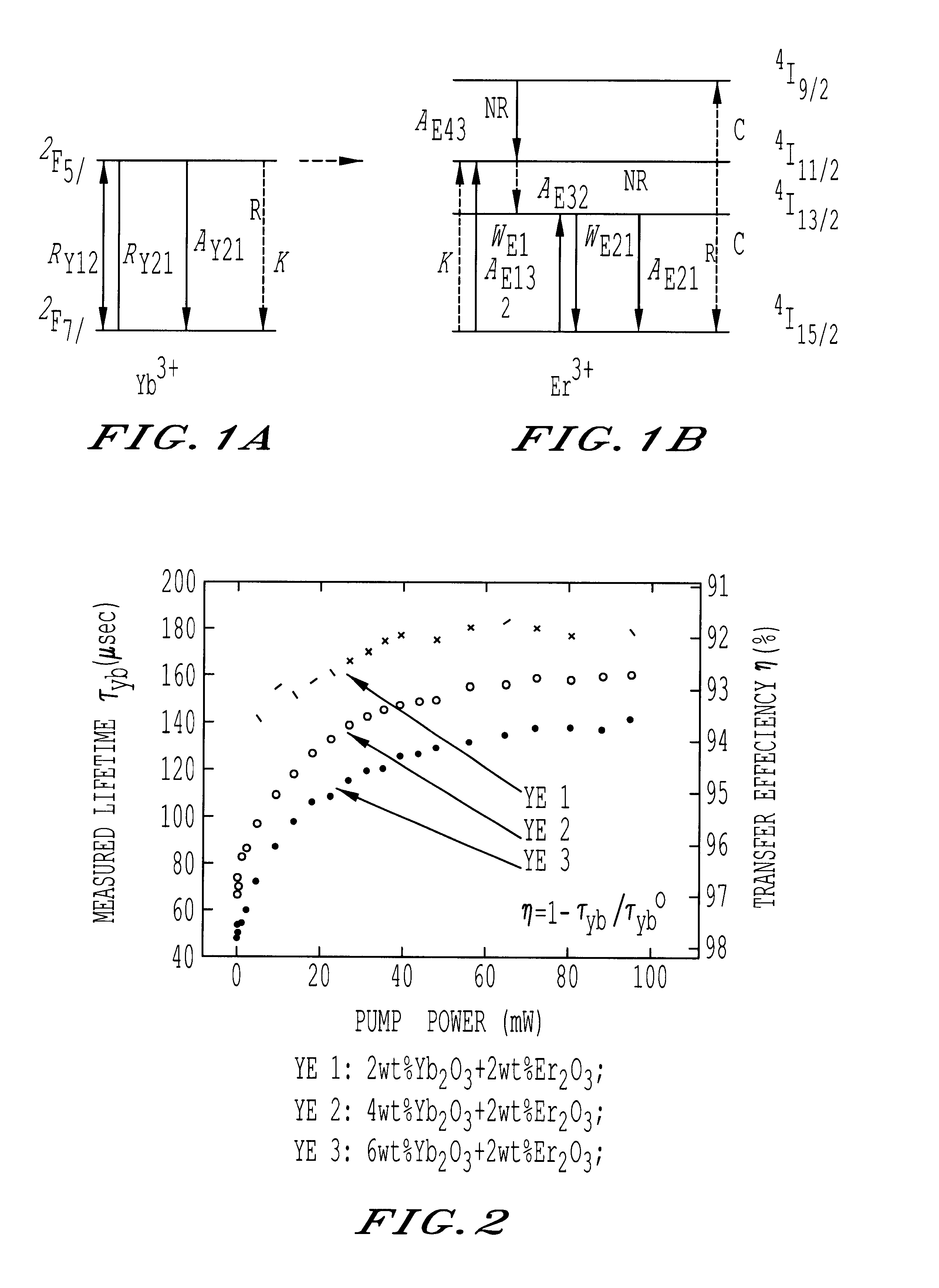

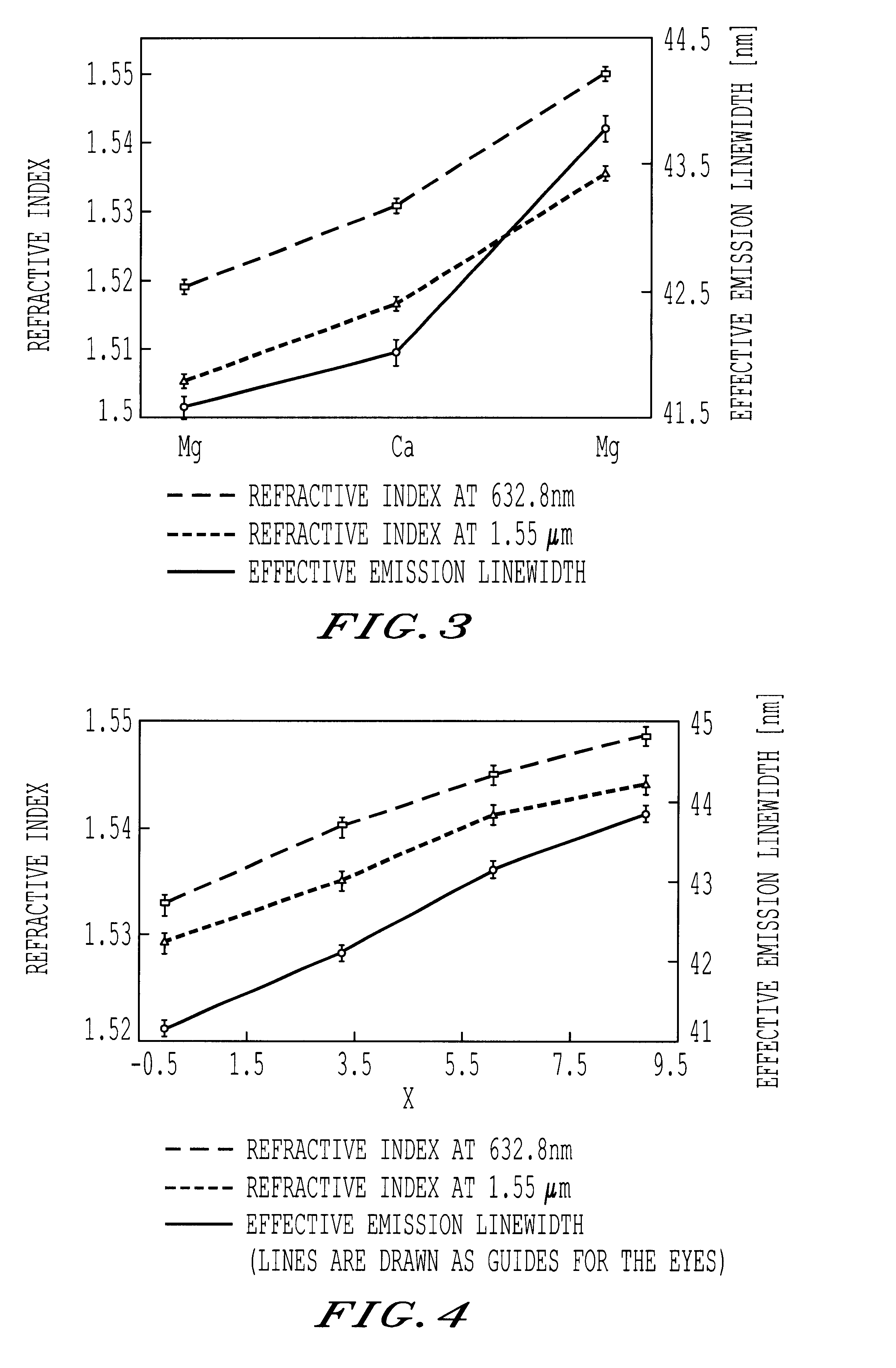

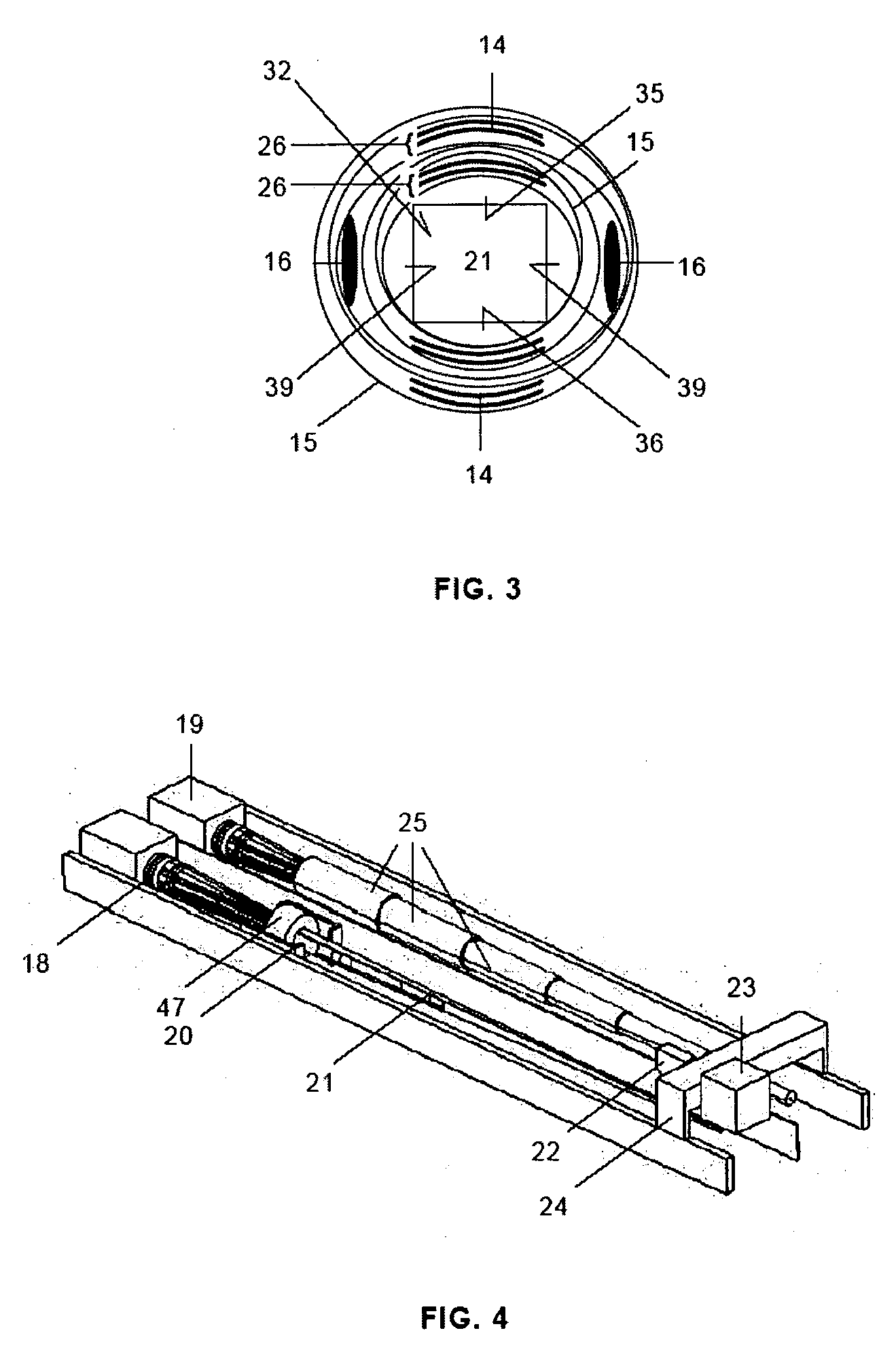

Erbium and ytterbium co-doped phosphate glass optical fiber amplifiers using short active fiber length

InactiveUS6611372B1High gain per unit lengthHigh gain amplificationLaser arrangementsActive medium materialErbium dopingPhosphate glass

An optical fiber amplifier utilizing a phosphate glass optical fiber highly doped with rare-earth ions such as erbium to exhibit high gain per unit length, enabling the use of short fiber strands to achieve the needed gain in practical fiber optical communication networks. The high-gain phosphate optical glass fiber amplifiers are integrated onto substrates to form an integrated optics amplifier module. An optical pump such as a semiconductor laser of suitable wavelength is used to promote gain inversion of erbium ions and ultimately provide power amplification of a given input signal. Gain inversion is enhanced in the erbium doped phosphate glass fiber by co-doping with ytterbium. A phosphate fiber amplifier or an integrated optics amplifier module utilizing this power amplification can be combined with other components such as splitters, combiners, modulators, or arrayed waveguide gratings to form lossless or amplified components that do not suffer from insertion loss when added to an optical network. The fiber amplifier can be a single fiber or an array of fibers. Further, the phosphate glass fibers can be designed with a temperature coefficient of refractive index close to zero enabling proper mode performance as ambient temperatures or induced heating changes the temperature of the phosphate glass fiber. Large core 50-100 .mu.m fibers can be used for fiber amplifiers. The phosphate glass composition includes erbium concentrations of at least 1.5 weight percentage, preferably further including ytterbium at 1.5 weight percentage, or greater.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

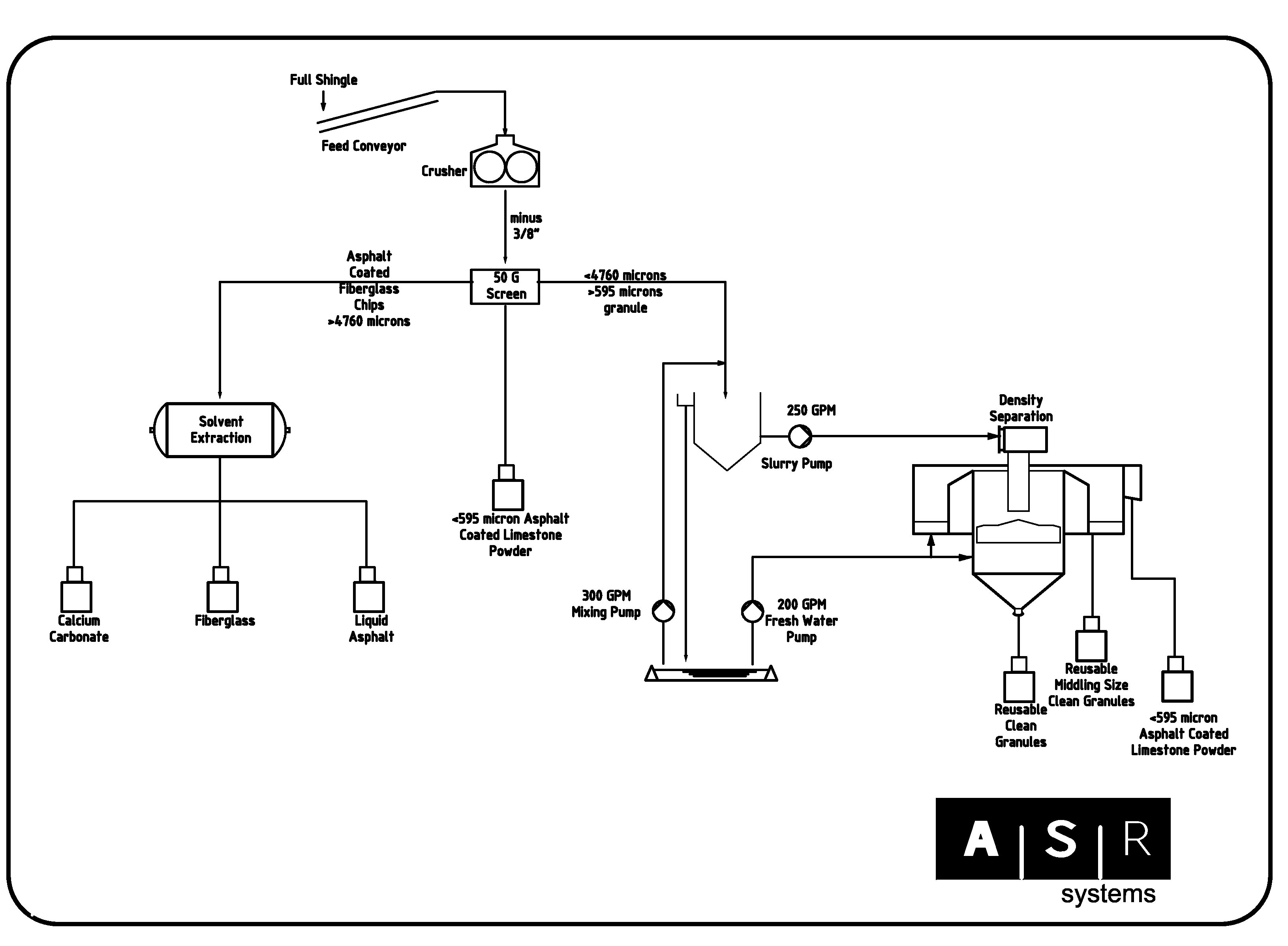

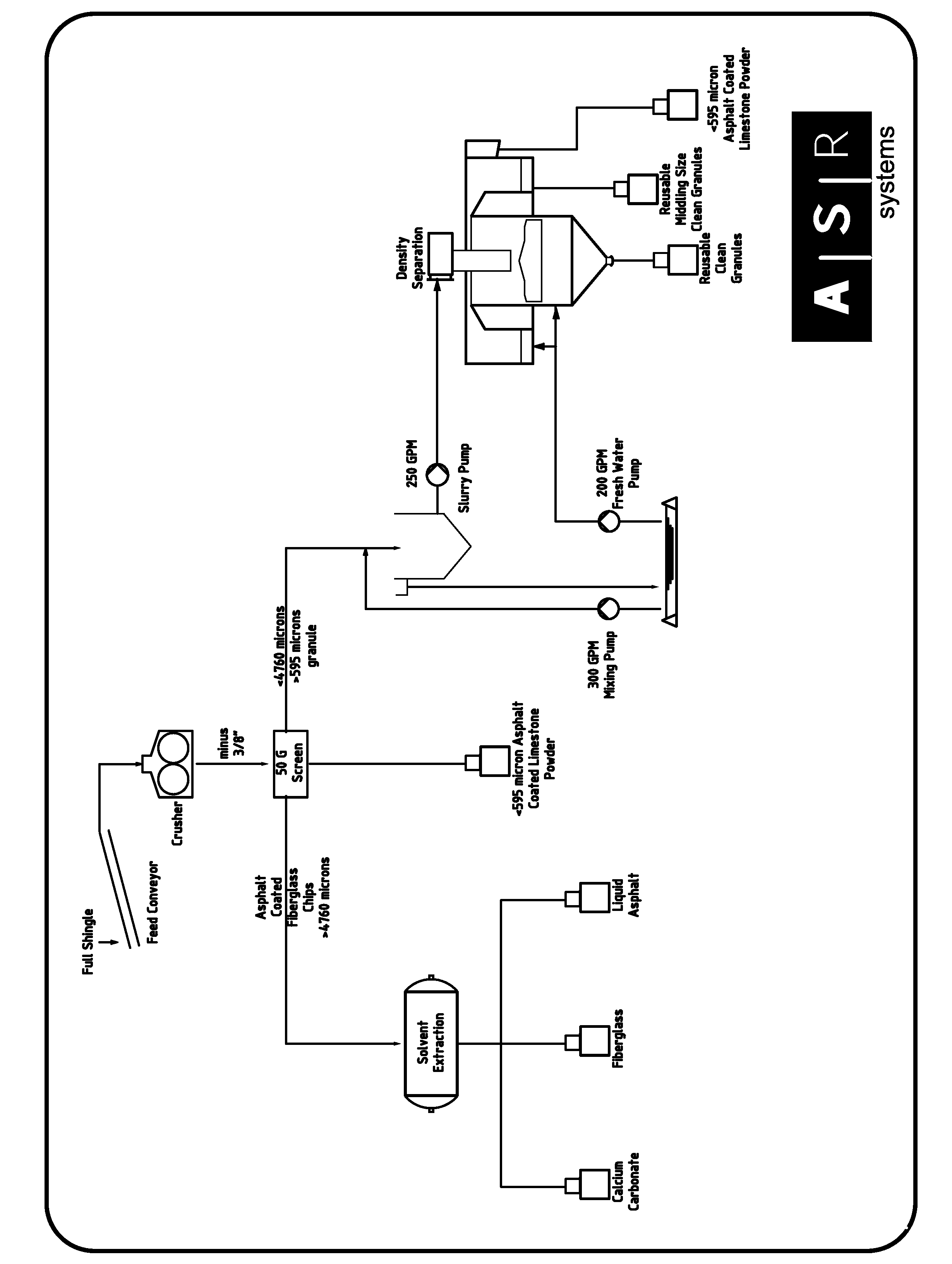

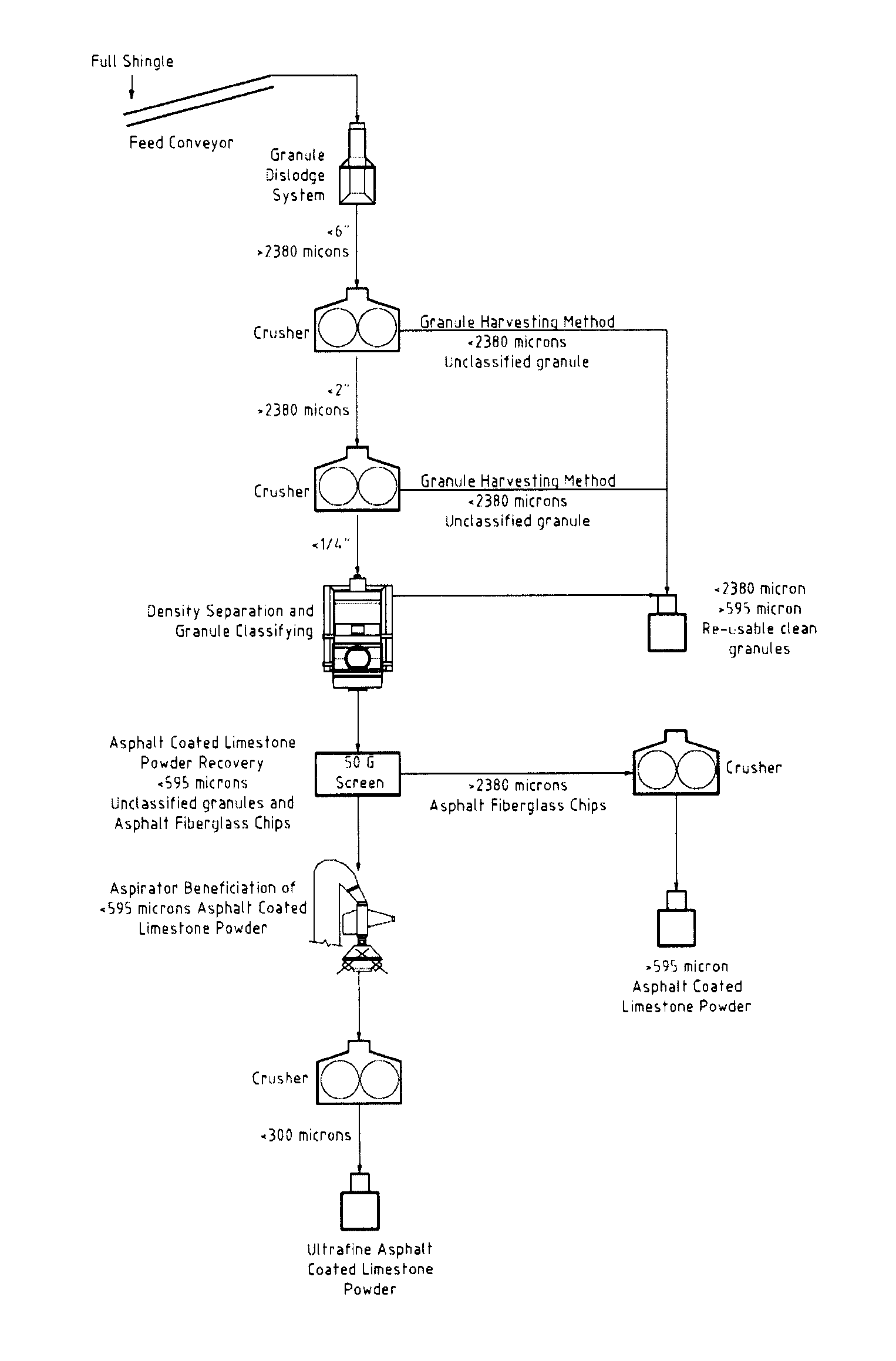

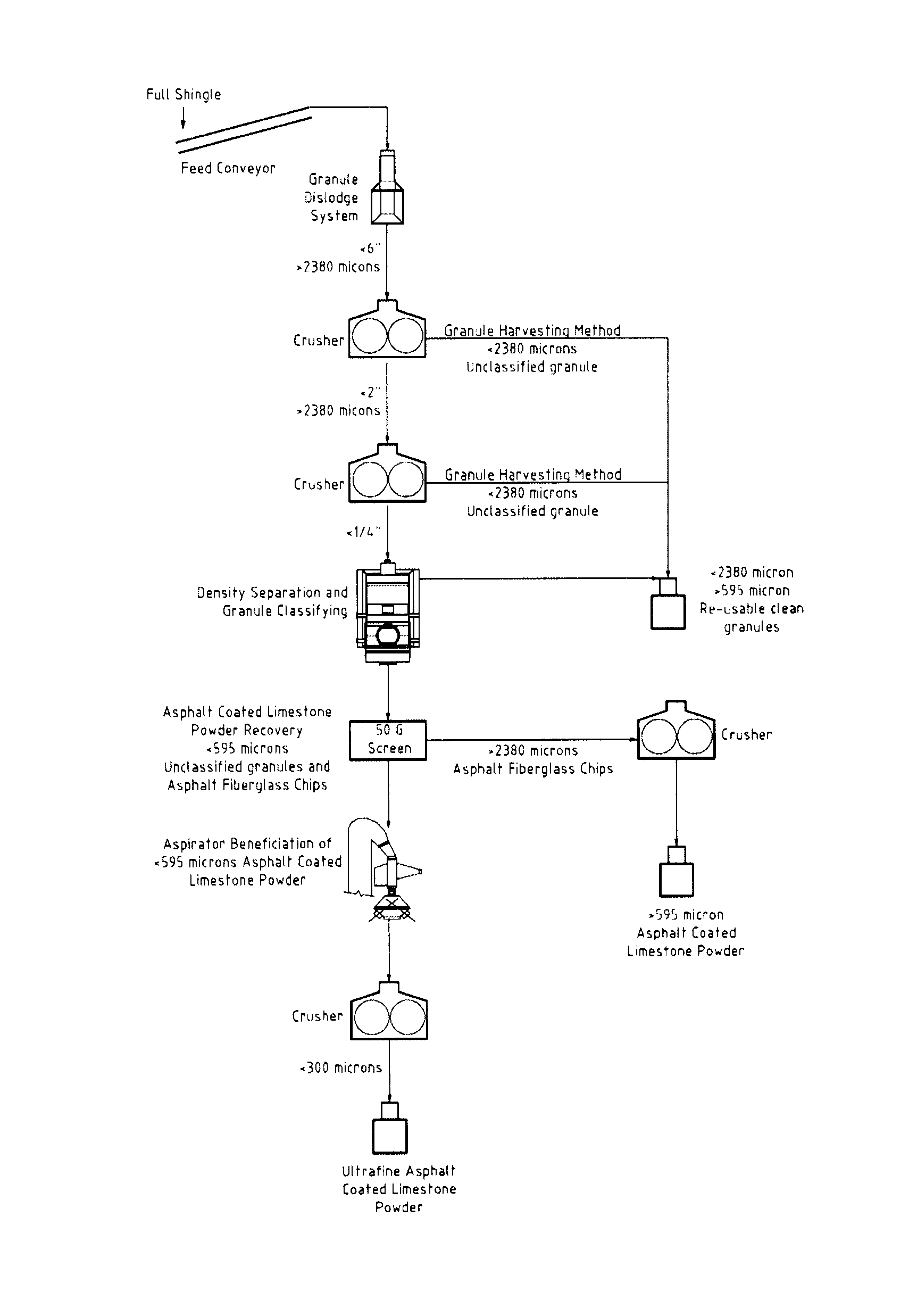

Method for progressive separation and extraction of raw materials from residential roofing products

This invention relates to a progressive method of separating and extracting raw materials from residential roofing products for re-use as ingredients for asphalt and fiberglass related products, including roofing materials. The method includes reduction, separation and then extraction of raw materials. The resulting products are alternative roofing granules, asphalt coated limestone, limestone, recycled asphalt and recycled fiberglass strand powders.

Owner:ASR HLDG

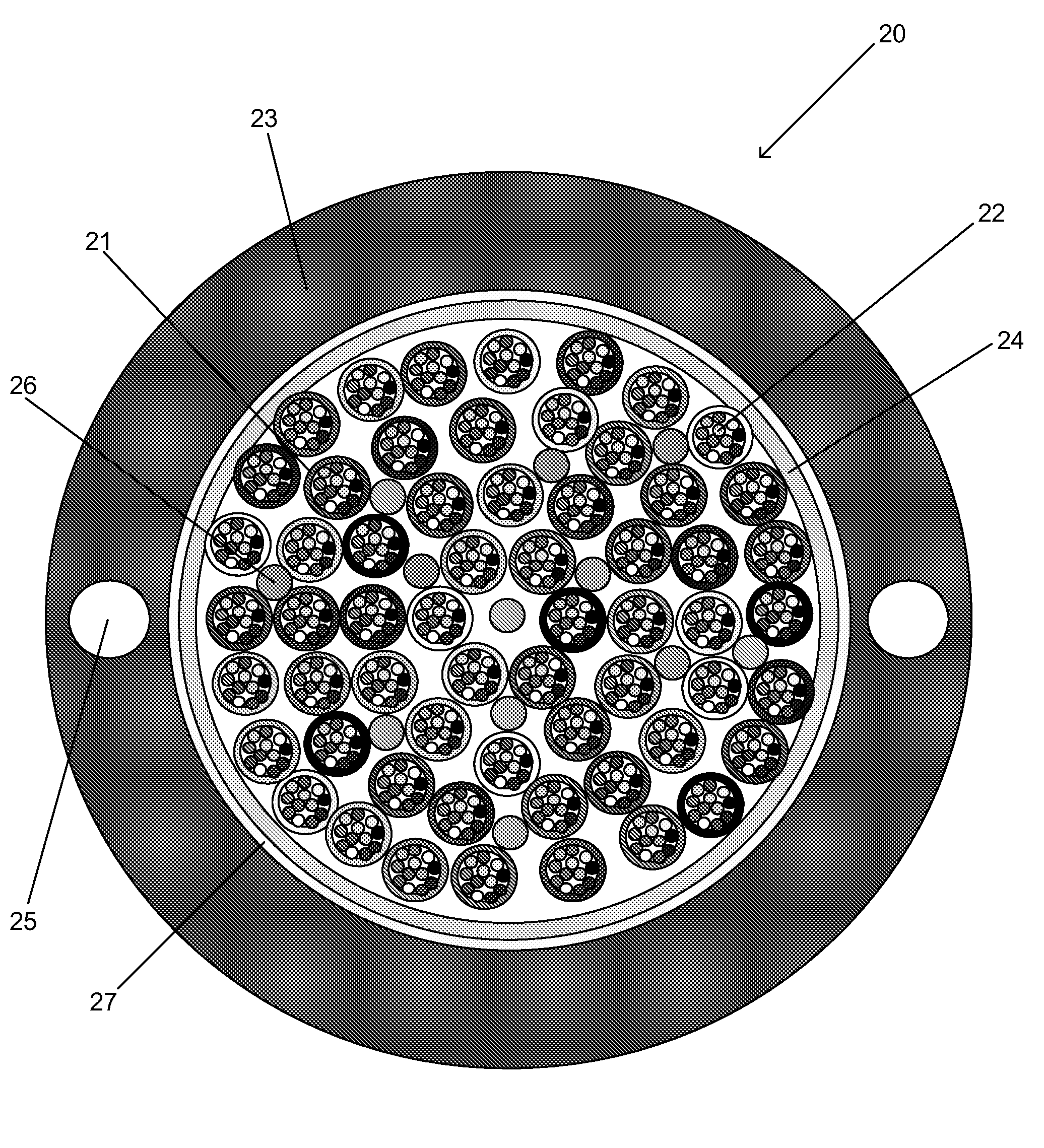

High-fiber-density optical-fiber cable

ActiveUS8467650B2Improve protectionGlass optical fibreOptical fibre with multilayer core/claddingCoating systemEngineering

Disclosed is an improved optical fiber possessing a novel coating system. When combined with a bend-insensitive glass fiber, the novel coating system according to the present invention yields an optical fiber having exceptionally low losses. The coating system features (i) a softer primary coating with excellent low-temperature characteristics to protect against microbending in any environment and in the toughest physical situations and, optionally, (ii) a colored secondary coating possessing enhanced color strength and vividness. The secondary coating provides improved ribbon characteristics for structures that are robust, yet easily entered (i.e., separated and stripped). The optical fibers in accordance in the present invention may be incorporated into a reduced-diameter optical-fiber cable that possesses a high fiber count and a high cable fiber density. The high-fiber-density optical-fiber cable, which is suitable for deployments in ducts, is capable of achieving outstanding attenuation performance when subjected to temperature variations of between about −40° C. and 70° C.

Owner:DRAKA COMTEQ BV

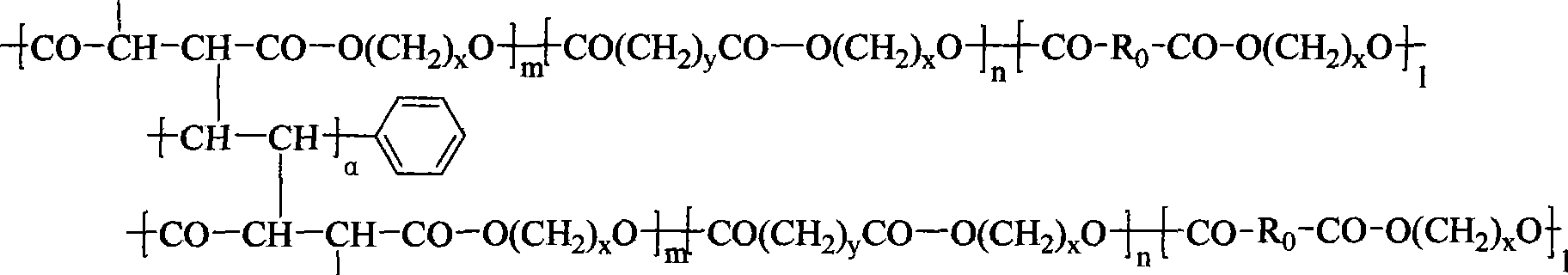

Laminate panel for use in structrual components

InactiveUS20050052516A1Quick and easy changeHigh ink loadingSynthetic resin layered productsGlass/slag layered productsGlass fiberAdhesive

A laminate panel especially well suited to help form an overhead stowage bin door on an aircraft, wherein the door includes a portion of a high contrast color advertising mural or message integrally formed therewith. The door includes a honeycomb support layer on which at least one fiberglass pre-preg layer is formed. A polyvinyl fluoride (PVF) film is used as a substrate for the color mural or message. A ultraviolet (UV) curable ink is deposited directly on the PVF film via an ink jet printing process that produces a high color density, high color contrast image. The PVF film in one form is a Tedlar® PVF film. The ink is cured virtually immediately after it is deposited on the PVF film. An additional layer of PVF film is then secured to a side of the printed-on PVF film opposite to that on which the ink is deposited via a layer of embossing resin to form the laminate panel. The laminate panel is then secured via a suitable adhesive to the fiberglass pre-preg and honeycomb support layer in a subsequent manufacturing step. The stowage bin door and process of making same enable a portion of a high color density, high contrast image, advertising mural or message to be integrally formed with the door.

Owner:THE BOEING CO

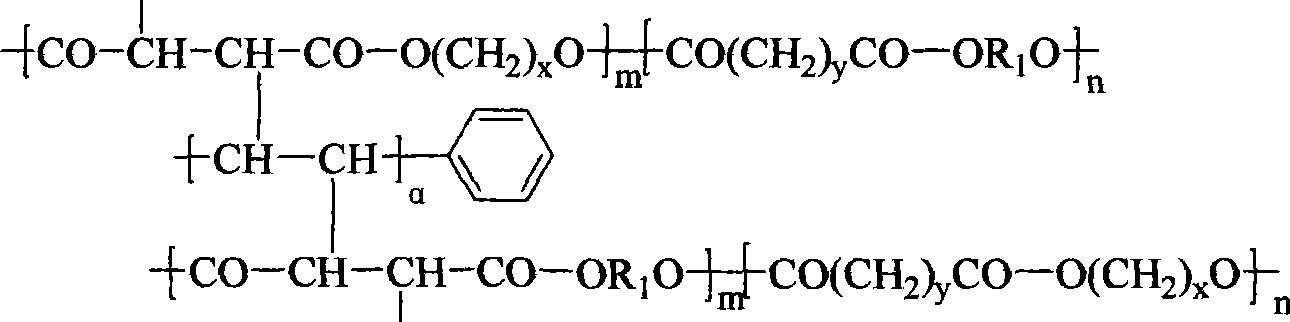

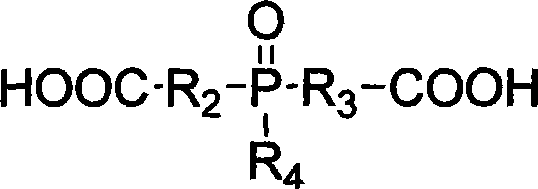

Reaction-type transparent halogen-free flameproof unsaturated polyester and preparation method thereof

The invention discloses a method for preparing a reaction type transparent halogen-free flame retardation unsaturated polyester. A program temperature control melting polycondensation reaction method is adopted; C2-6 dihydric alcohol, C3-8 saturated binary acid or anhydride, C4 unsaturated binary acid or anhydride, and a difunctional reactivity phosphatic flame retardant are used to synthesize an unsaturated polyester oligomer; styrene is taken as a crosslinking agent to prepare the unsaturated polyester which can be solidified at room temperature with transparent appearance, moderate viscosity and lower cost. After solidification, no added dissociated flame retardant component is contained in the cross linked network of the unsaturated polyester. The mechanical property, the flame retardation property and the electricity property of the product can be stable in a long period, the oxygen index of the product can be increased from 19 to 29 percent, and the product can pass the vertical firing UL94-V0 level. The reaction type transparent halogen-free flame retardation unsaturated polyester can be applied to the field of electronic and electric appliance insulating materials with higher performance requirements, construction flame retardation coating, ship-building material, flame retardation fiber glass reinforced plastics, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Flame-retardant antistatic reinforced nylon 6 composition and preparation

InactiveCN101469129AHigh strengthImprove flame retardant performanceOther chemical processesTO-18Glass fiber

The invention relates to a flame retardant antistatic reinforced nylon 6 composition and a method for preparing the same. 45 to 60 weight percent of nylon 6 slice, 10 to 40 percent of fiberglass, 15 to 18 percent of flame retardant, 2 to 4 percent of flame retardant boosting agent, 2 to 5 percent of anlistatig, 0.1 to 0.5 percent of antioxidant and 0.1 to 1 percent of lubricant by weight percentage are put in a high mixing machine, are mixed for 2 to 5 minutes and are discharged; the mixed raw materials and fiberglass are put to a screw extruder and is subjected to extrusion and pelletization; the rotational speed of the screw extruder is between 180 and 600 revolutions / minute; and the temperature is between 160 and 250 DEG C. Compared with the prior art, the flame retardant antistatic reinforced nylon 6 composition has the characteristics of high strength, excellent flame retardance, lasting antistatic property, easy processing and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Method of bonding a window to a substrate using a silane functional adhesive composition

The invention is an adhesive composition comprisinga) i) a trialkoxysilane functional polyether or polyurethane wherein the polyether or polyurethane has a weight average molecular weight of 6000 or greater and a dialkyltin carboxylate or dialkyltin alcoholate; orii) a dialkoxysilane functional polyether or polyurethane and a dialkyltin alcoholate; andb) a primary or secondary amino straight chain alkyl trialkoxysilane;wherein the dialkyltin carboxylate or dialkyltin alcoholate is present in an effective amount to facilitate bonding of the adhesive to a substrate of from about 0.1 to about 1.0 percent by weight based on the weight of the adhesive and the primary or secondary amino straight chained alkyl trialkoxysilane is present in an amount which is effective to facilitate bonding of the adhesive to a substrate wherein the amount is from about 0.5 to about 1.2 percent by weight. In another embodiment, the invention is a method of bonding a window in a vehicle. The process comprises applying to a window or a window frame of a structure an adhesive according to the invention; contacting the window with the window frame of a substrate wherein the adhesive is located between the window and the substrate; and allowing the adhesive to cure. This process is especially useful when the substrate is unprimed metal, plastic, fiberglass or a composite, optionally coated with a coating. In another embodiment it is useful when the window is unprimed.

Owner:ESSEX SPECIALITY PROD INC

Use of silicones to improve fiberglass insulation products

InactiveUS20120168054A1Improve water resistanceImprove stain resistanceStarch adhesivesPretreated surfacesFiberGlass fiber

Dispersions of reactive polysiloxanes are applied to fibrous products, such as construction panels to provide improved properties, like better resistance to staining and discoloration and better adhesion of facer layers The reactive polysiloxane may be applied directly to the fibrous product or mixed into binder compositions prior to application; and may be applied substantially uniformly or non-uniformly. The construction panels may form wall and / or ceiling panels. The reactive polysiloxane may include polysiloxanes functionalized with any of hydrogen, amino, hydroxyl or carboxyl reactive functionalities.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

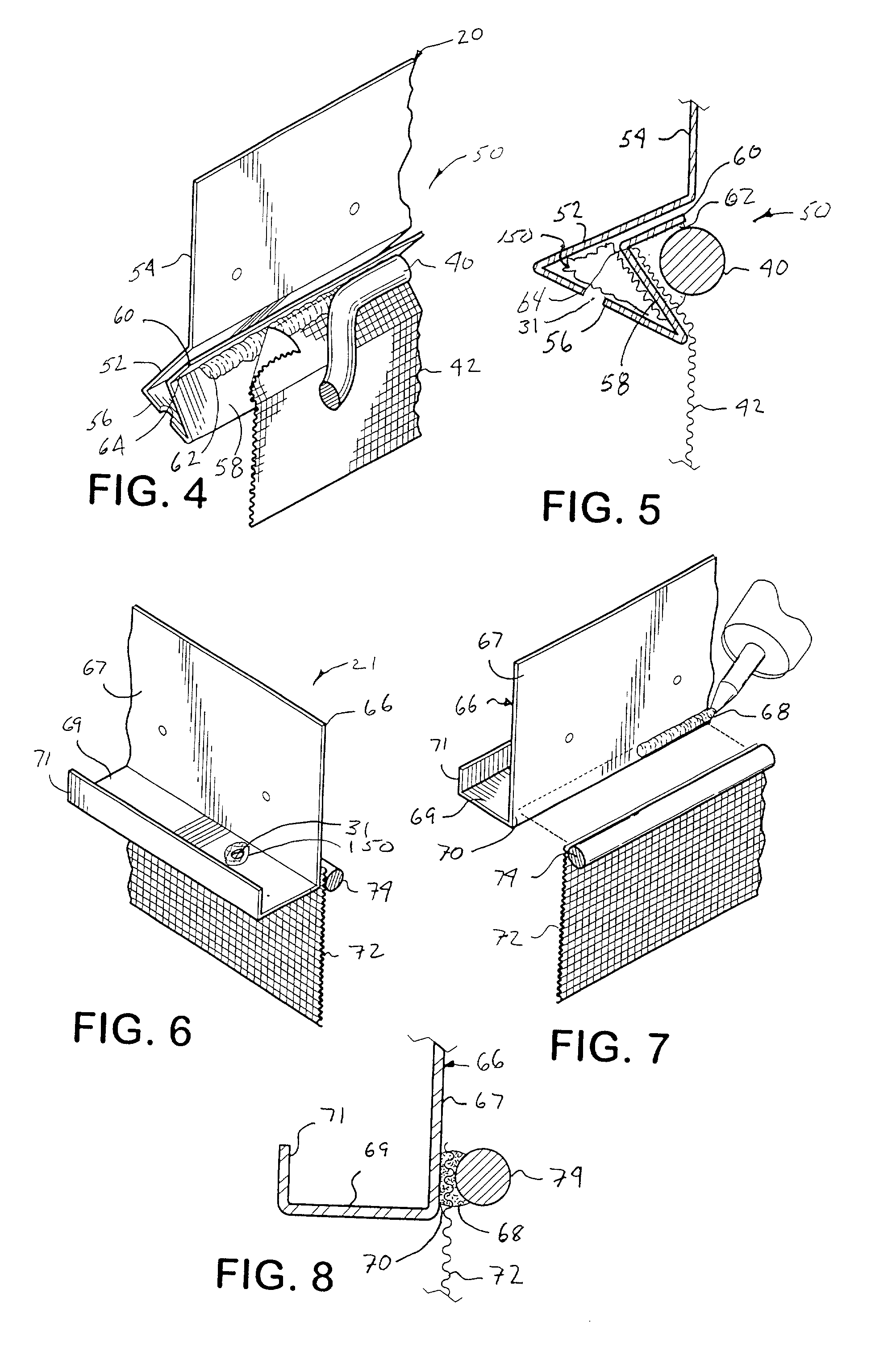

Exterior wall sealing system

A system for sealing the gaps that occur along the perimeter of a building envelope, particularly along with installation of an exterior finish system channel, or screed, as occurs in the installation and application of stucco. It is common to have gaps occur between the channel, base plate, and foundation of the building envelope. The system utilizes a foam sealing element in combination with the channel, caulking, a fiberglass netting that is installed along the bottom of the channel and the face of the foundation, and, an adhesive sealant that seals and adheres the fiberglass netting to the foundation. The system includes several embodiments for use in either new construction or as an aftermarket product.

Owner:CONTRERAS VICTOR +1

Fluorescent microsphere immunochromatographic testing card for testing five indexes of hepatitis b and method for preparing same

InactiveCN101726596ASimple and fast operationHigh sensitivityBiological testingLuminescent compositionsCelluloseHepatitis B virus

The invention discloses a fluorescent microsphere immunochromatographic testing card for testing five indexes of hepatitis b and a method for preparing the same. The testing card comprises a hepatitis b surface antigen test paper strip, a hepatitis b e surface antigen test paper strip, a hepatitis b surface antibody test paper strip, a hepatitis b e surface antibody test paper strip, and a hepatitis b core antibody test paper strip. Each test paper strip is formed by overlapping and bonding filter paper, a sample pad, a glass fiber film spray-coated with fluorescent microspheres, a cellulose nitrate film and water absorption paper on a bottom plate by glue in sequence, wherein the cellulose nitrate film is coated with antigens serving as a testing area and anti-rabbit antibodies serving as a quality control area; and during a test, after emitted fluorescent light passes a filter, the emitted spectrum is collected, accumulated and multiplied by the CCD scanning technology and then converted into a numerical signal, the numerical signal is multiplied by a correction factor, and the strength of the corrected fluorescent light is substituted in a standard curve of a fluorescence analyzer, so that the concentrations of the five indexes of hepatitis b of the sample can be automatically worked out. The test of hepatitis b viruses by the testing card has the characteristics of specificity, sensitivity, simpleness and accuracy.

Owner:WUXI ZODOLABS BIOTECH

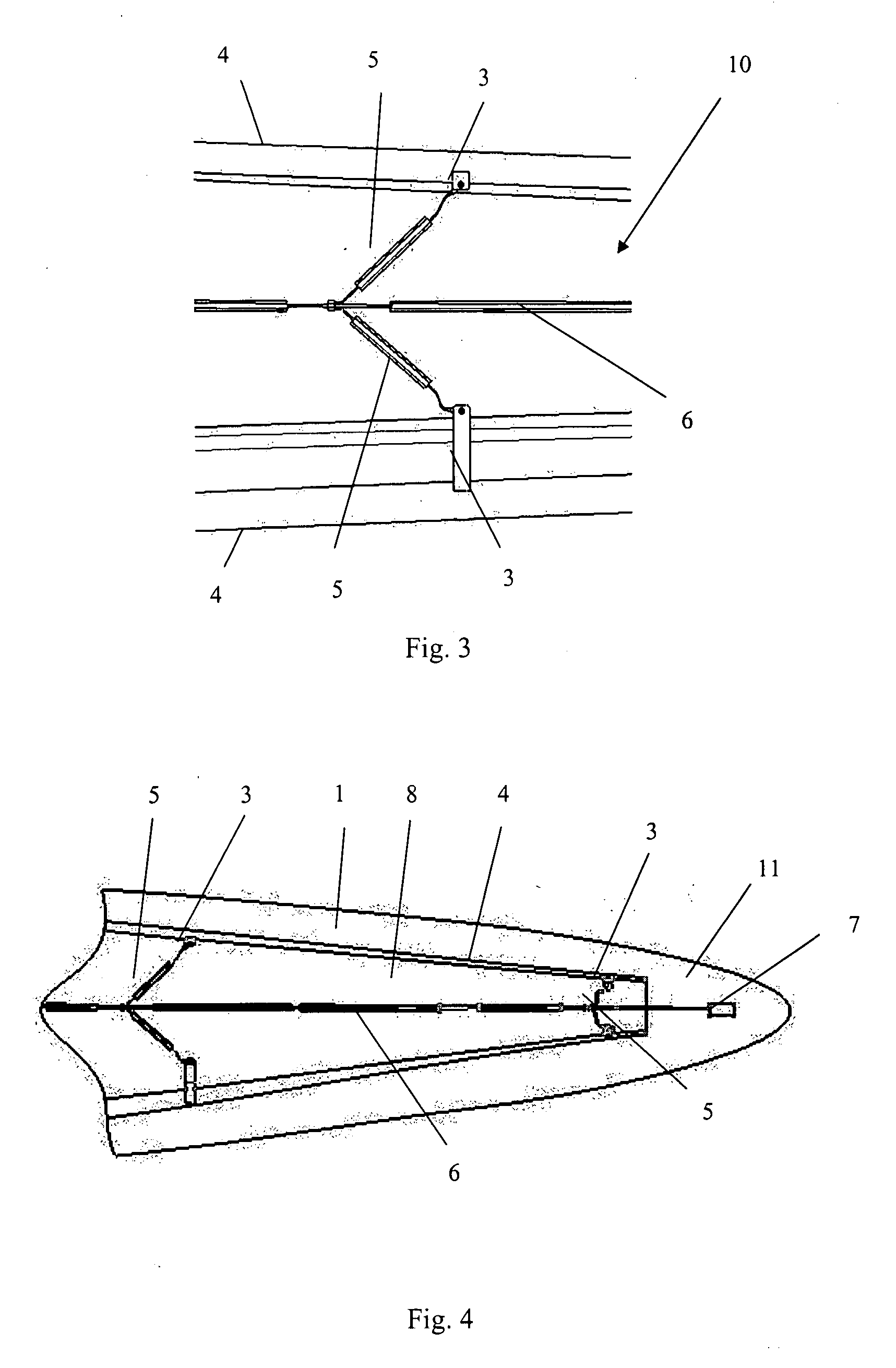

Lightning Conductor System for Wind Generator Blades Comprising Carbon Fibre Laminates

InactiveUS20080073098A1Improve electrical performanceMaterial nanotechnologyDischarge by conduction/dissipationLightning protection systemTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY INNOVATION & TECHOLOGY SL

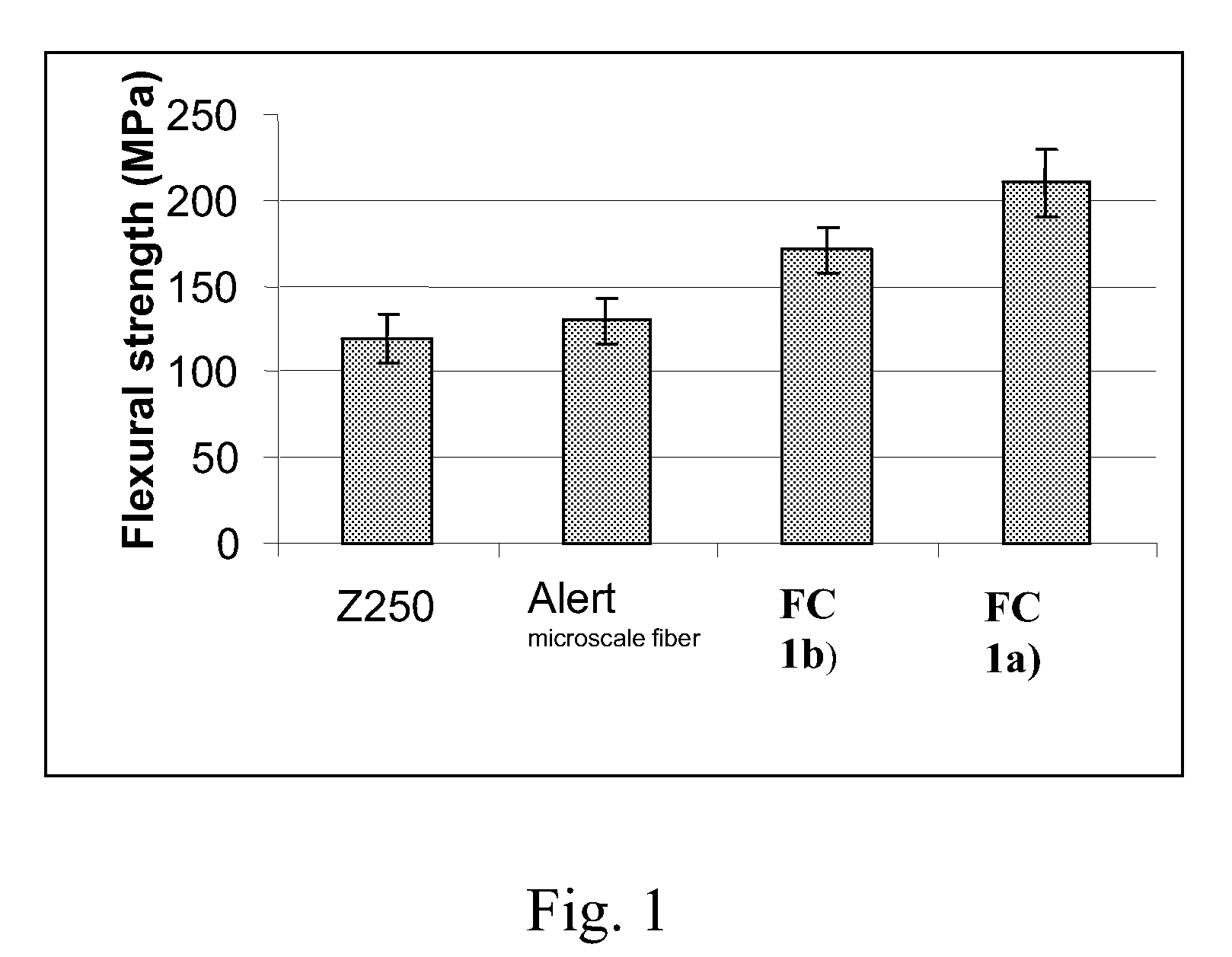

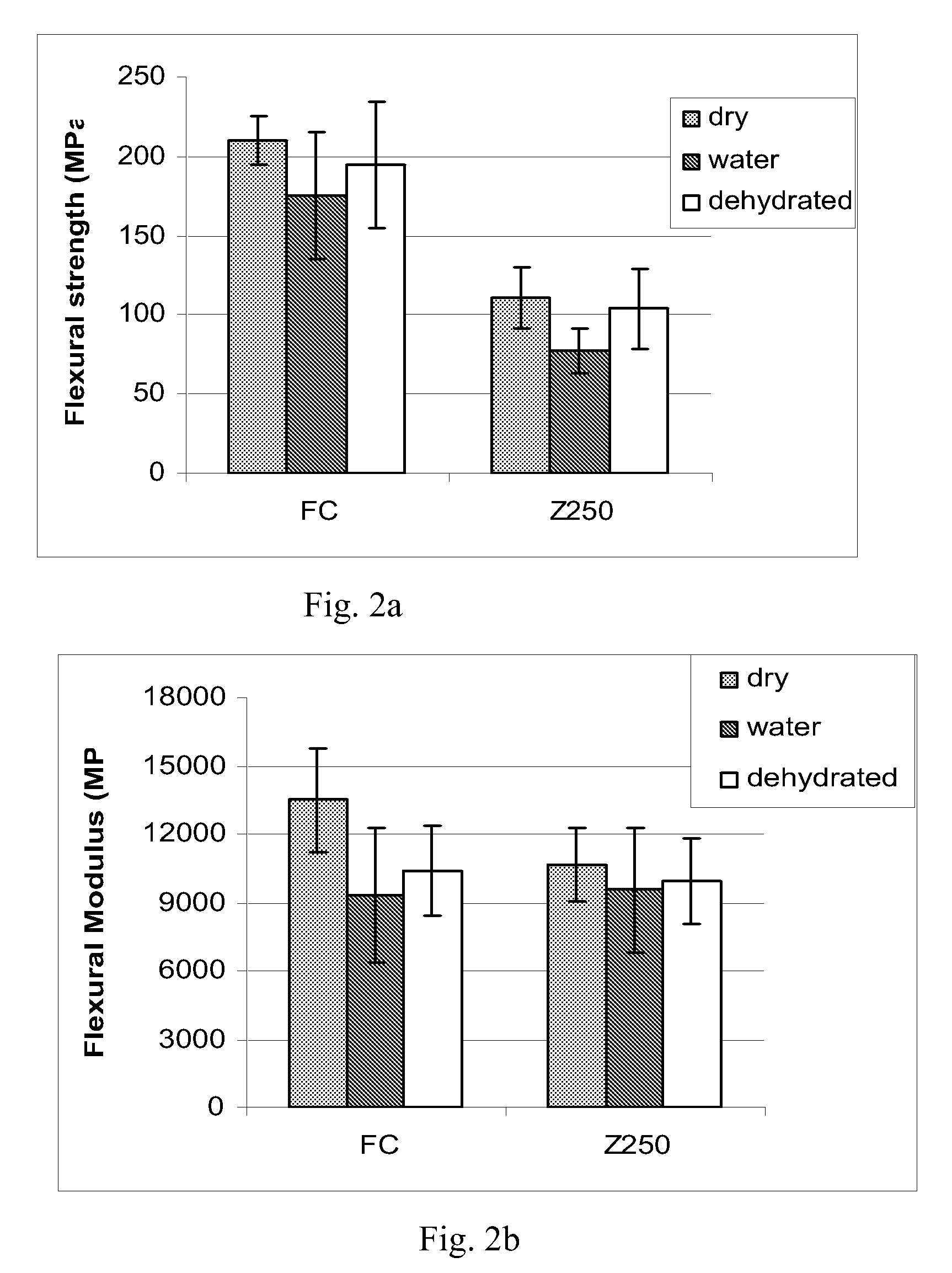

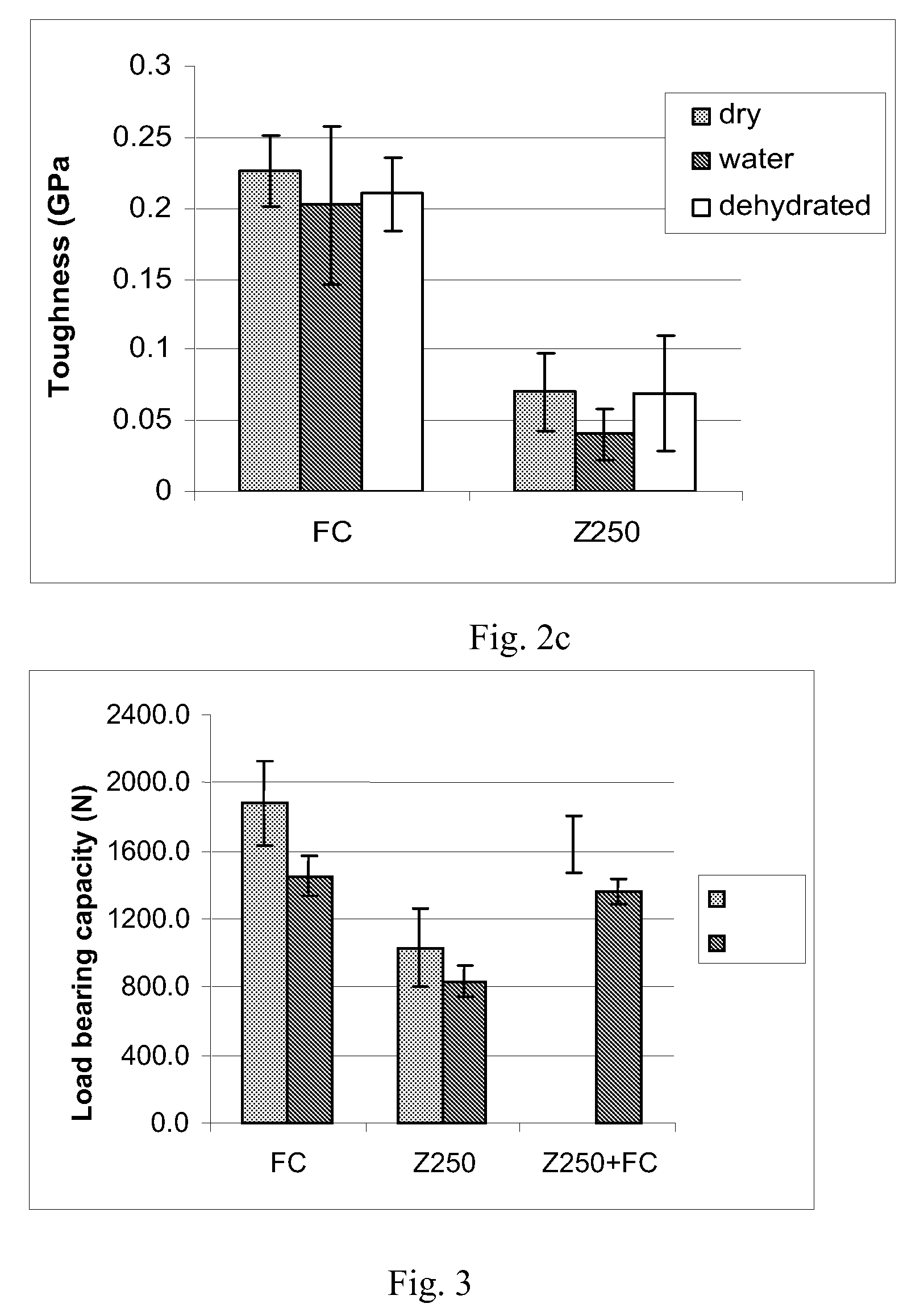

Fiber-reinforced composites and method for the manufacture thereof

The present invention relates to fiber-reinforced composites, particularly application-oriented composites useful in dental and medical applications / appliances, such as fiber reinforced dental composites, and to a method for the manufacture thereof. Particularly the invention concerns random glass fiber-reinforced restorative composite resins with semi-interpenetrating polymer network matrix and their use in dental applications like cavity fillings, core composites, provisional and semi-permanent crown and bridge composite, cements and adhesives.

Owner:STICK TECH OY

Stuctural Beam for a Wind Generator Blade Production Method Thereof

Structural beam of a wind turbine blade comprising a body-root and a body-trunk in the form of a box with a section decreasing towards the blade tip, comprising various piles each formed by various layers of carbon fibre impregnated with a synthetic resin, located on the upper and lower areas, intercalated between various layers of fibre glass impregnated with synthetic resin arranged along its perimeter, including between two piles, at least one layer of reinforcing material on each of the side areas enveloped by an adhesive resin film.The invention also comprises a procedure for the manufacture of the structural beam which, amongst other stages, includes the application of the layers mentioned onto a mould and the beam curing process.

Owner:GAMESA INNOVATION & TECH SA

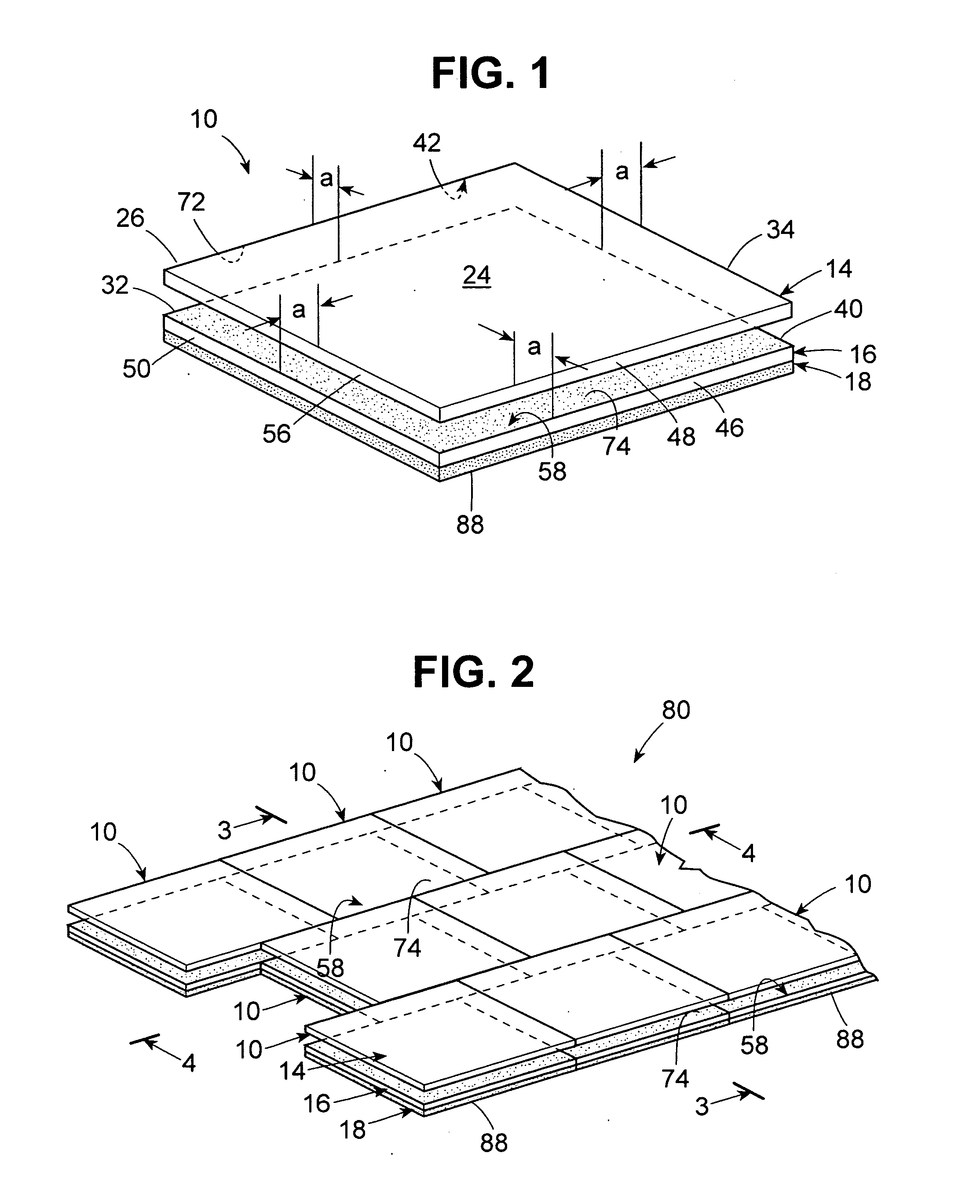

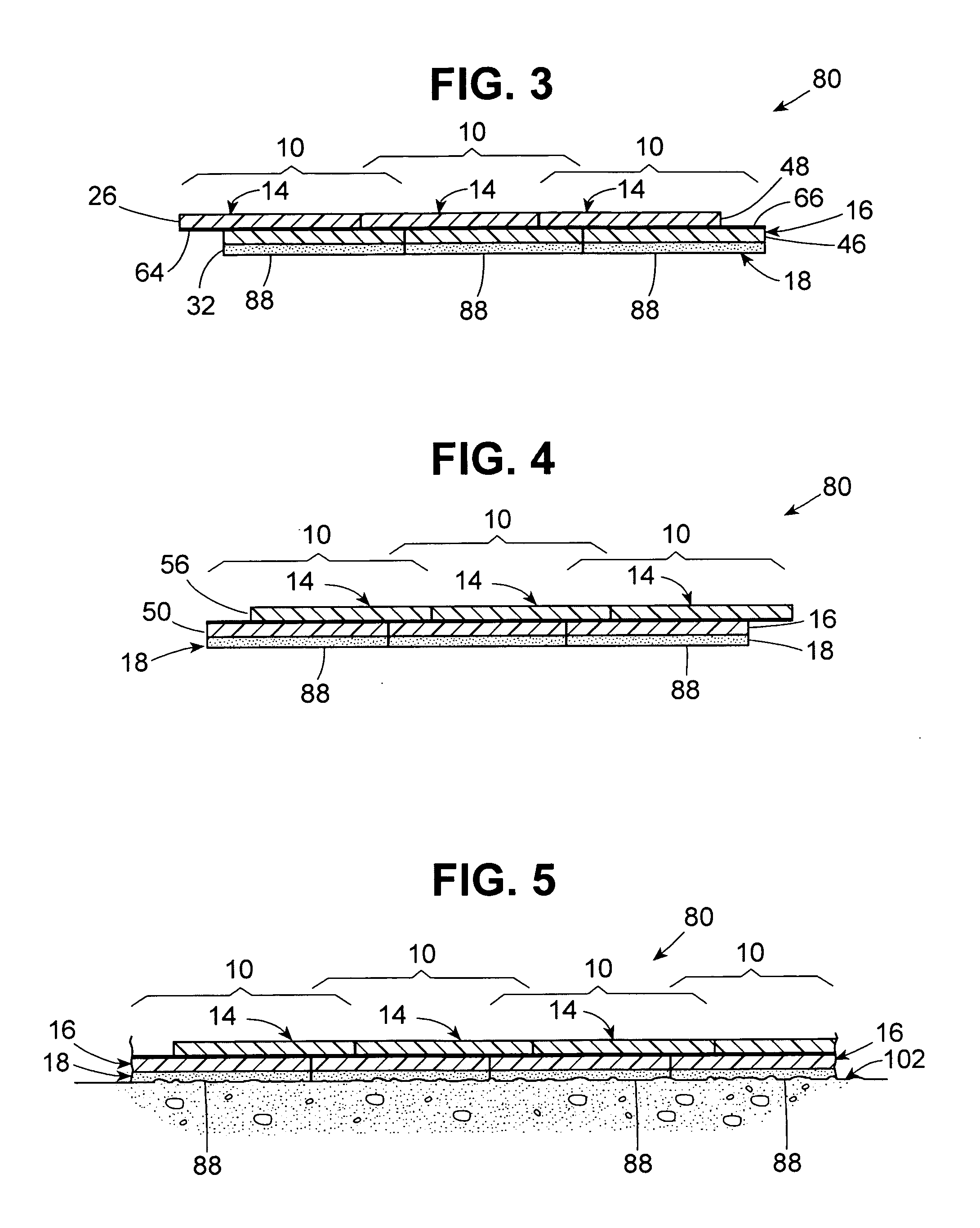

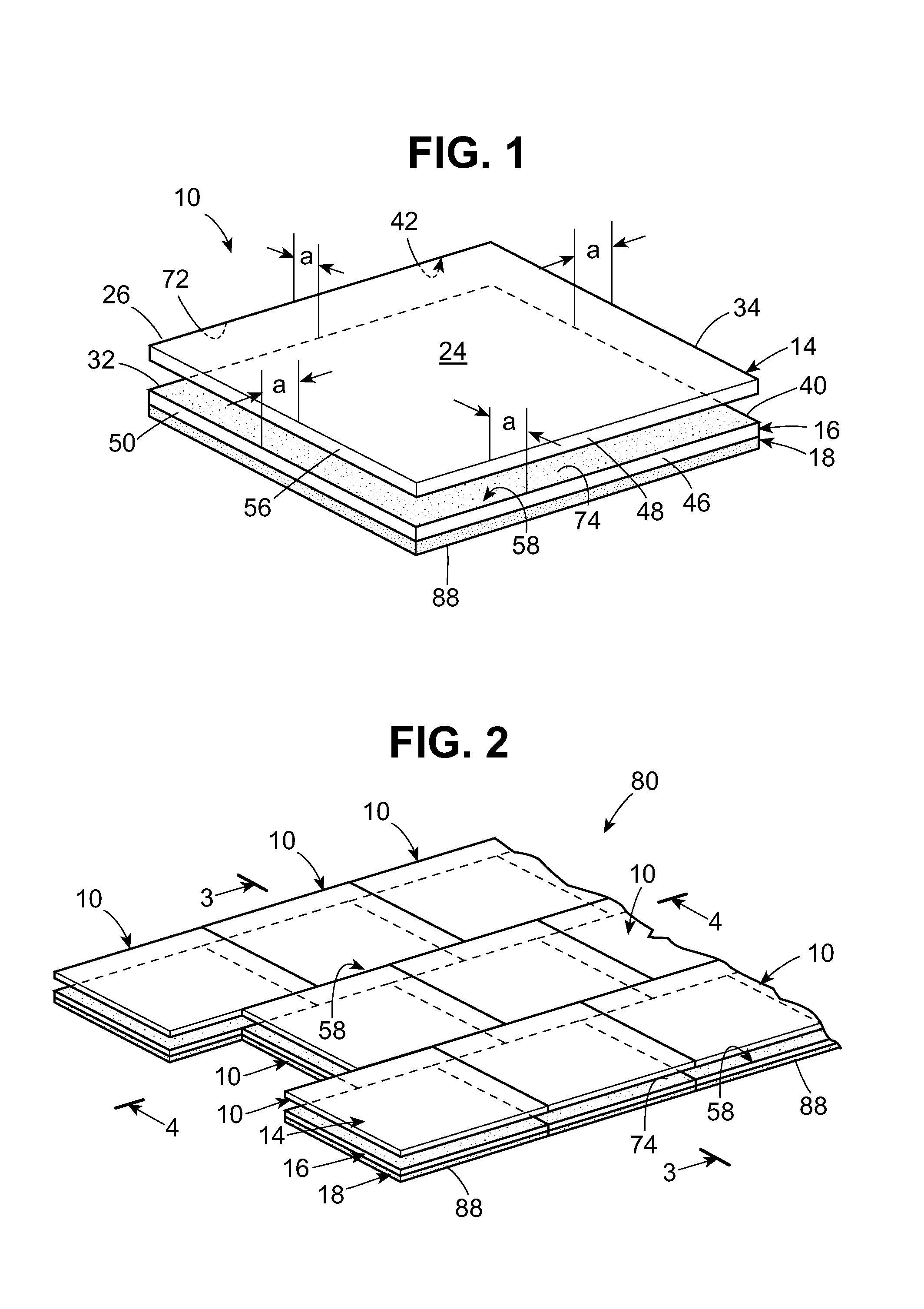

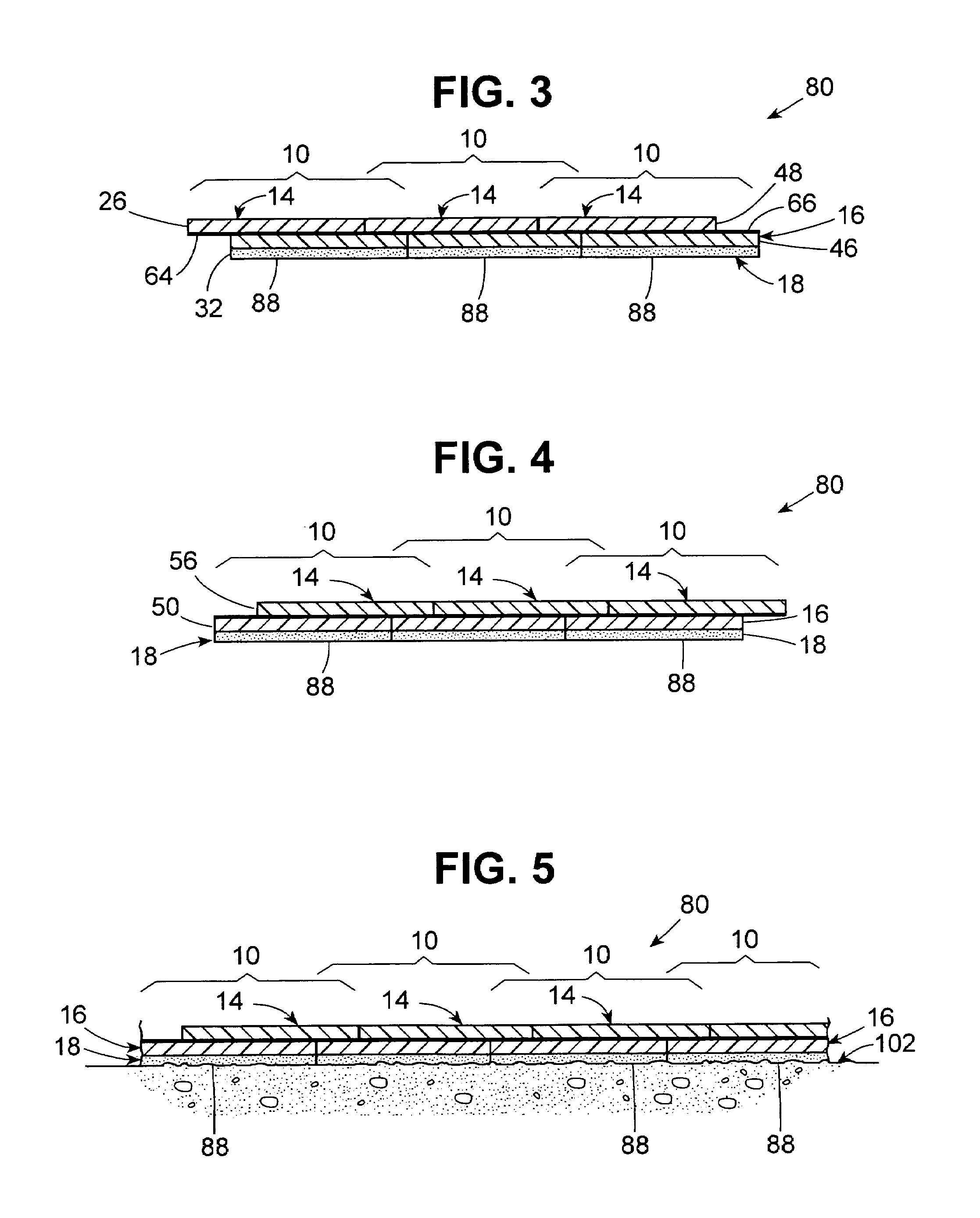

Floor tile

The floor tile is a laminate of two layers of flexible plastic sheet material laminated together in offset relationship to define an offset marginal portion for each of the layers. Each of the offset marginal portions have oppositely facing adhesive coated surfaces. A foam layer and / or a fiberglass sheet can also be included in the laminate structure of the floor tile. The floor tile can conform to surface contours of a floor base. The bottom layer of the floor tile, whether it is plastic sheet or foam, is conformable to surface irregularities of the floor base. A one piece releasable packaging device covers the oppositely facing adhesive coated surfaces of the offset marginal portions.

Owner:ZHANGJIAGANG ELEGANT HOME-TECH CO LTD

Method for progressive separation and extraction of raw materials from residential roofing products

ActiveUS9440239B1Small sizeHigh asphalt contentConstruction waste recoveryPlastic recyclingGlass fiberAdditive ingredient

This invention relates to a progressive method of separating and extracting raw materials from residential roofing products for re-use as ingredients for asphalt and fiberglass related products, including roofing materials. The method includes reduction, separation, beneficiation and extraction of raw materials. The resulting products are alternative roofing granules, asphalt coated limestone, limestone, recycled asphalt and recycled fiberglass strand powders.

Owner:ASR HLDG

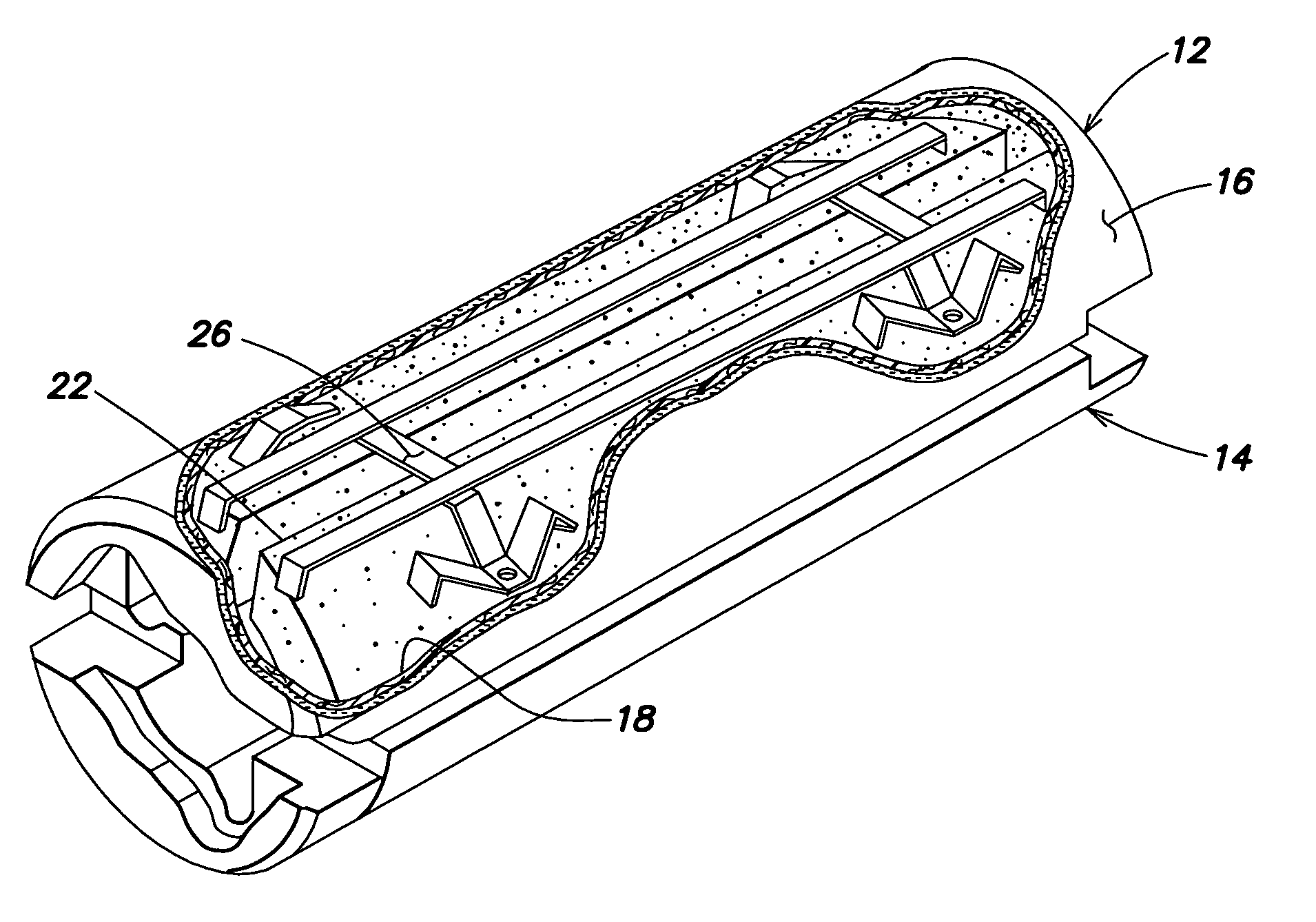

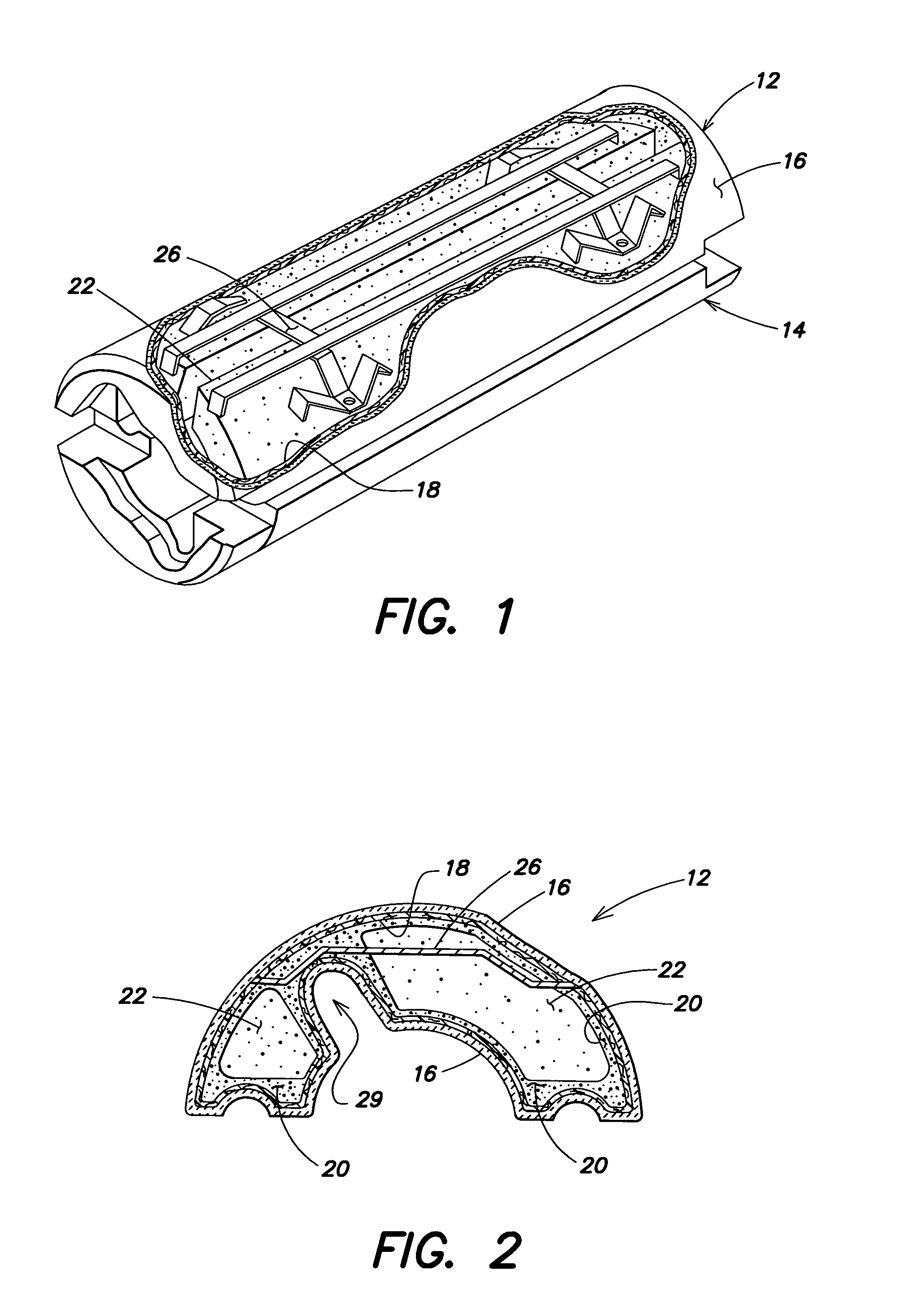

Rugged foam buoyancy modules and method of manufacture

InactiveUS7121767B1Increased durabilityImprove reinforcementDrilling rodsWaterborne vesselsFiberGlass fiber

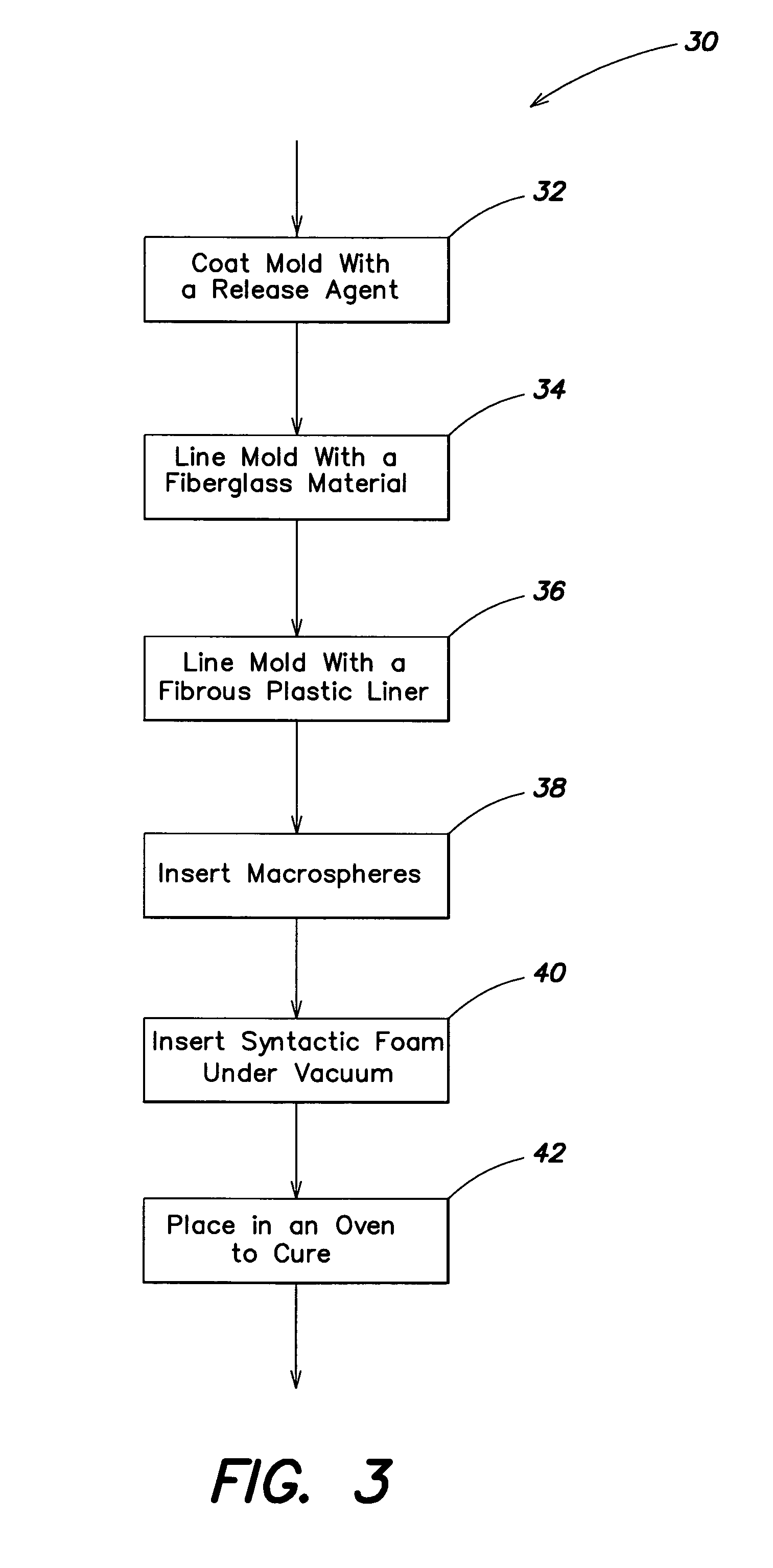

A buoyancy module comprises a multi-layer outer protective shell that has an exterior surface and an interior surface. A first layer of foam buoyancy material is located adjacent to the interior surface. A second layer of foam buoyancy material that includes macrospheres and syntactic foam is surrounded by the first layer of foam buoyancy material. The multi-layer outer protective shell can include a layer of fiberglass backed by a fibrous plastic liner. In this embodiment, the layer of fiberglass provides the exterior surface of the multi-layer outer protective shell, while the fibrous plastic liner provides the interior surface of the protective shell. The second layer of foam buoyancy material can be a precast material. The precast material can include for example macrospheres and syntactic foam. The first layer of foam buoyancy material is preferably a stronger layer than the second layer of foam buoyancy material. Advantageously, the buoyancy module has a plurality of different layers, wherein the components of greatest strength and density are located on the outside. The multi-component system improves ruggedness of the buoyancy material, and provides increased reinforcement at locations subject to increased bending strengths, and provides a buoyancy module of longer life. In addition the buoyancy module may also include steel support members where bolting loads and other forces are brought to bear when parts are attached.

Owner:CUMING CORP

Floor tile

The floor tile is a laminate of two layers of flexible plastic sheet material laminated together in offset relationship to define an offset marginal portion for each of the layers. Each of the offset marginal portions have oppositely facing adhesive coated surfaces. A foam layer and / or a fiberglass sheet can also be included in the laminate structure of the floor tile. The floor tile can conform to surface contours of a floor base. The bottom layer of the floor tile, whether it is plastic sheet or foam, is conformable to surface irregularities of the floor base. A one piece releasable packaging device covers the oppositely facing adhesive coated surfaces of the offset marginal portions.

Owner:ZHANGJIAGANG ELEGANT HOME-TECH CO LTD

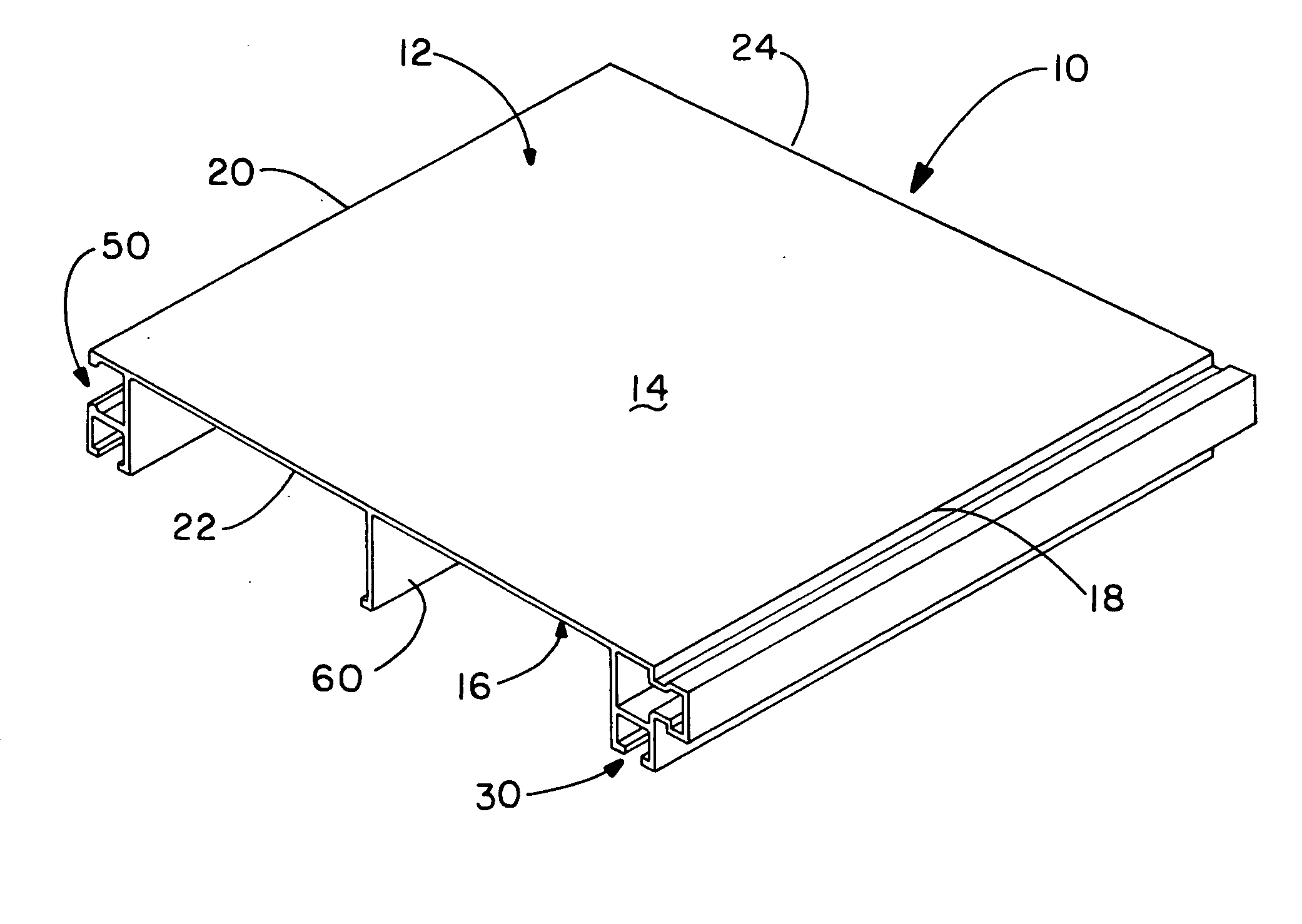

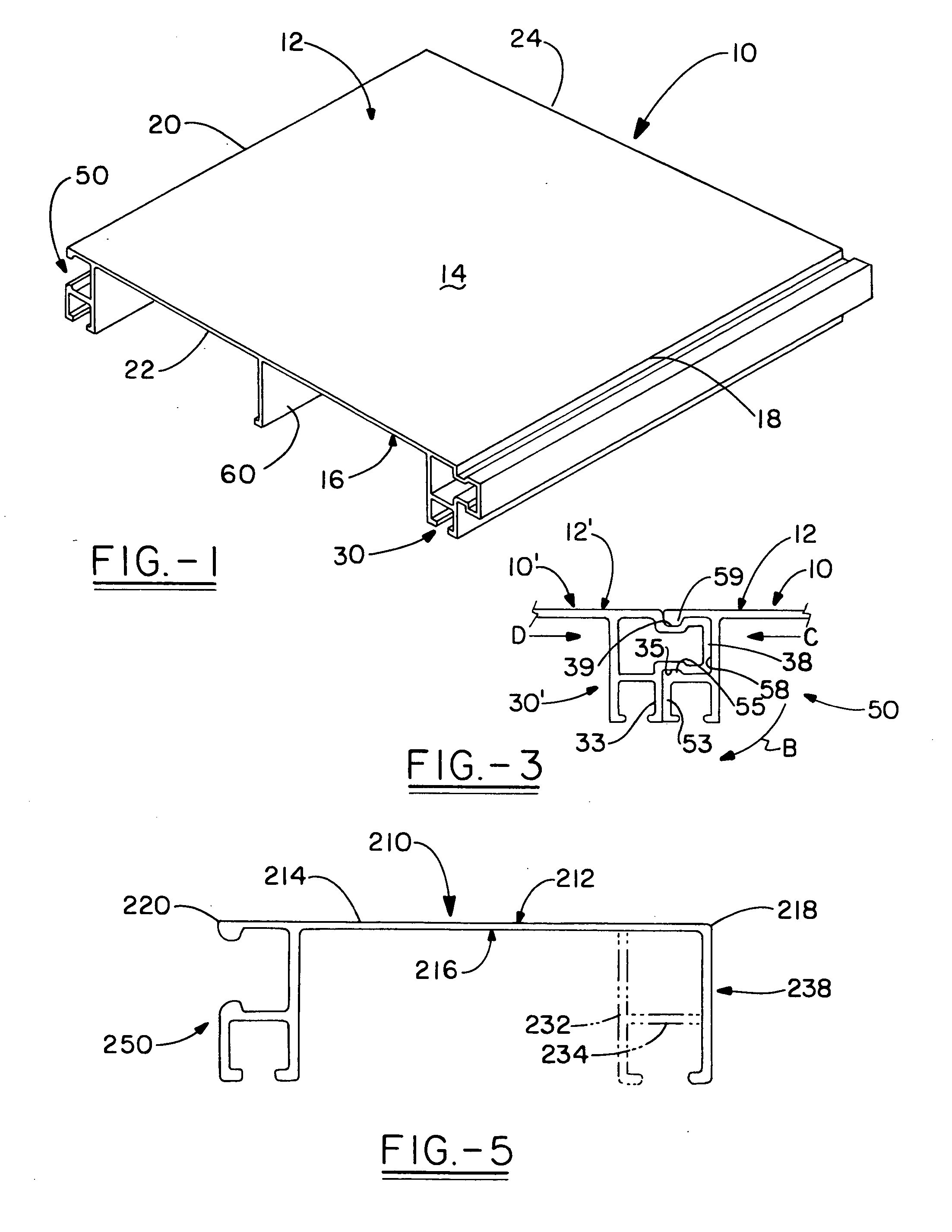

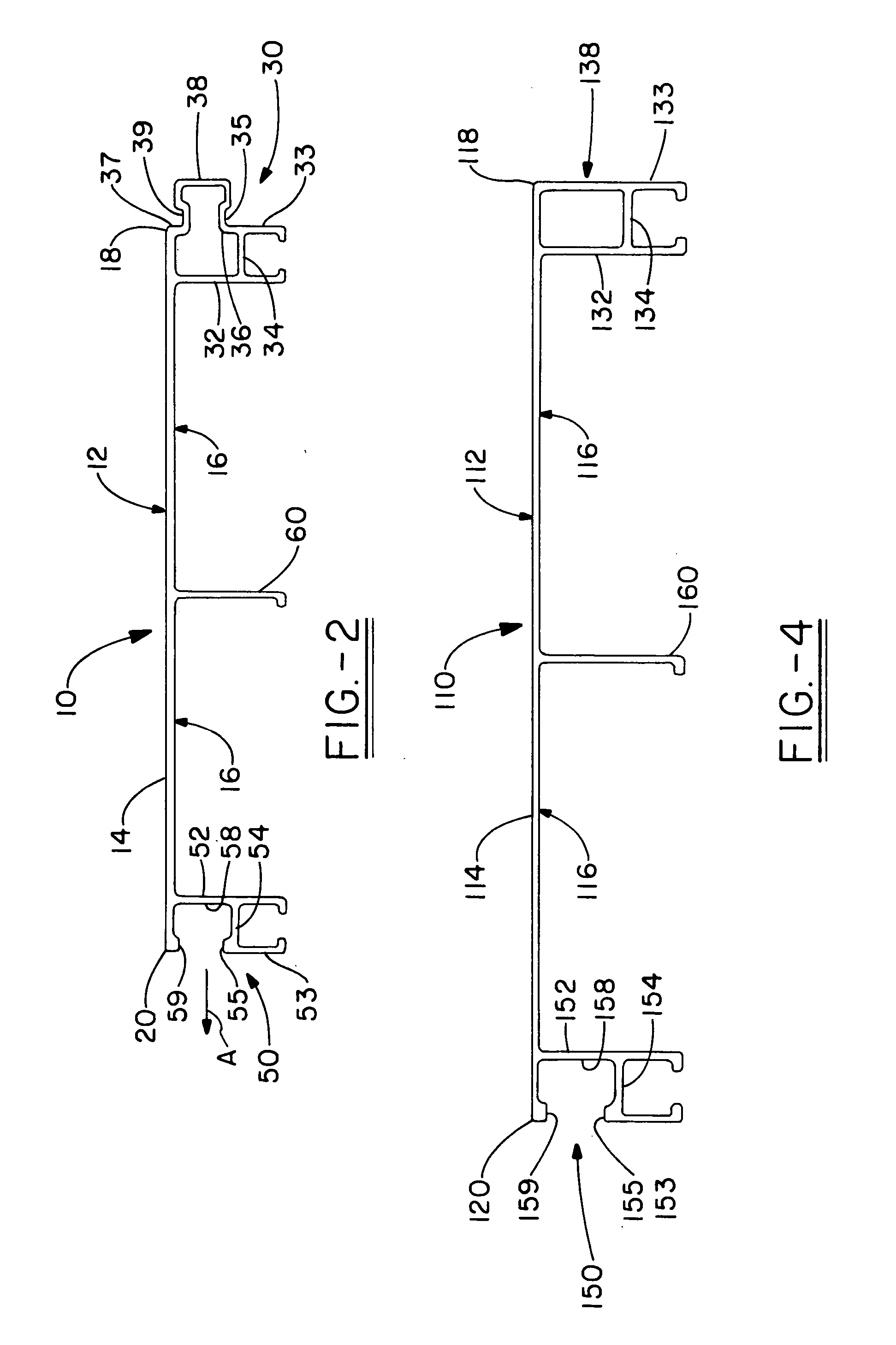

Modular system for forming a sign blank

A modular system for forming a sign blank includes a plurality of midpanels preferably formed from resin reinforced with fiberglass. Each of the plurality of midpanels includes a face portion having a sign side and a back side and a key end opposite a channel end. A male key extends beyond the key end at the back side, and a female channel is located at the back side of the face portion, at the channel end such that two of the plurality of midpanels may be joined by interlocking the male key of one such midpanel with the female channel of another such midpanel.

Owner:CARSONITE INT A DIV OF AMETEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com