Patents

Literature

376 results about "Phosphate glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate glass is a class of optical glasses composed of metaphosphates of various metals. Instead of SiO₂ in silicate glasses, the glass forming substrate is P₂O₅.

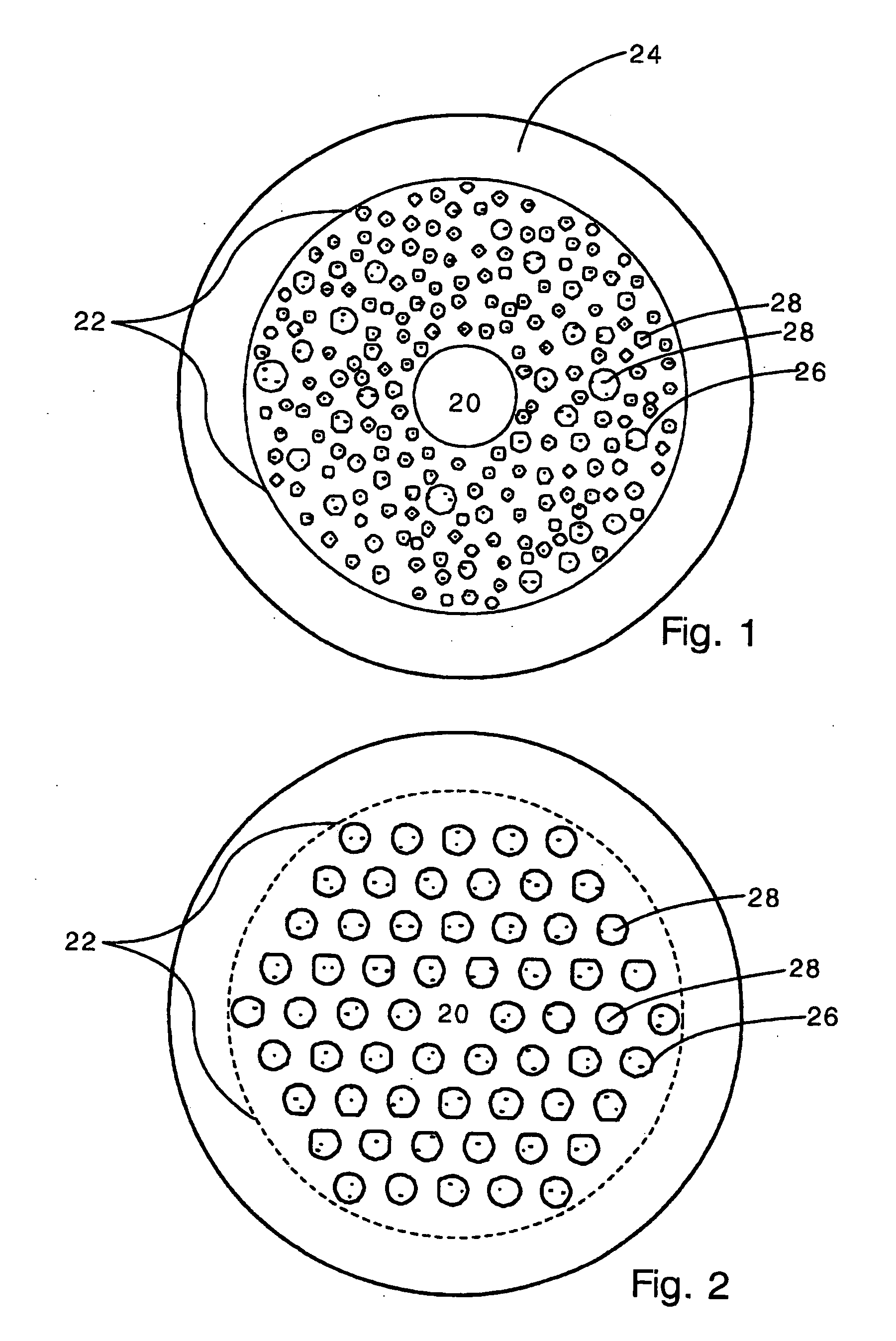

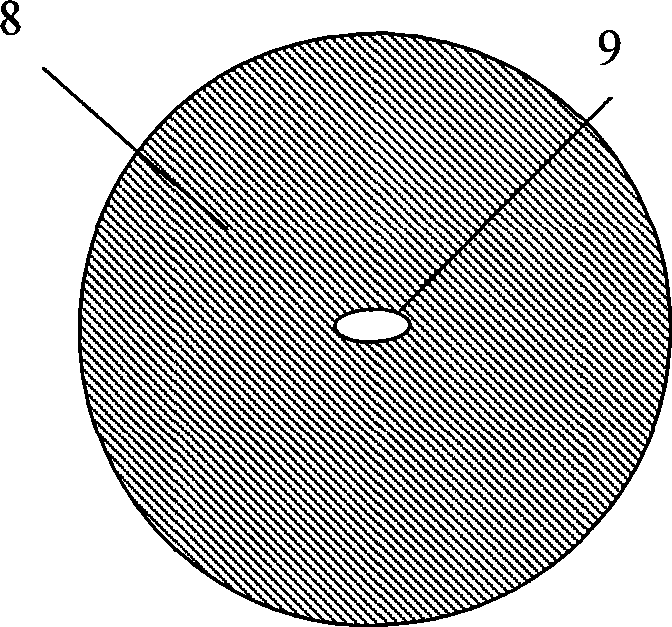

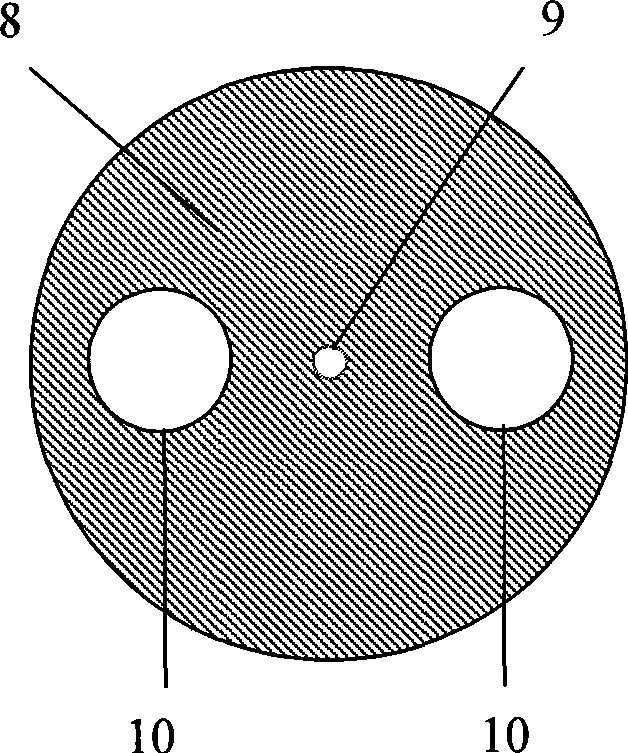

Optical fiber with quantum dots

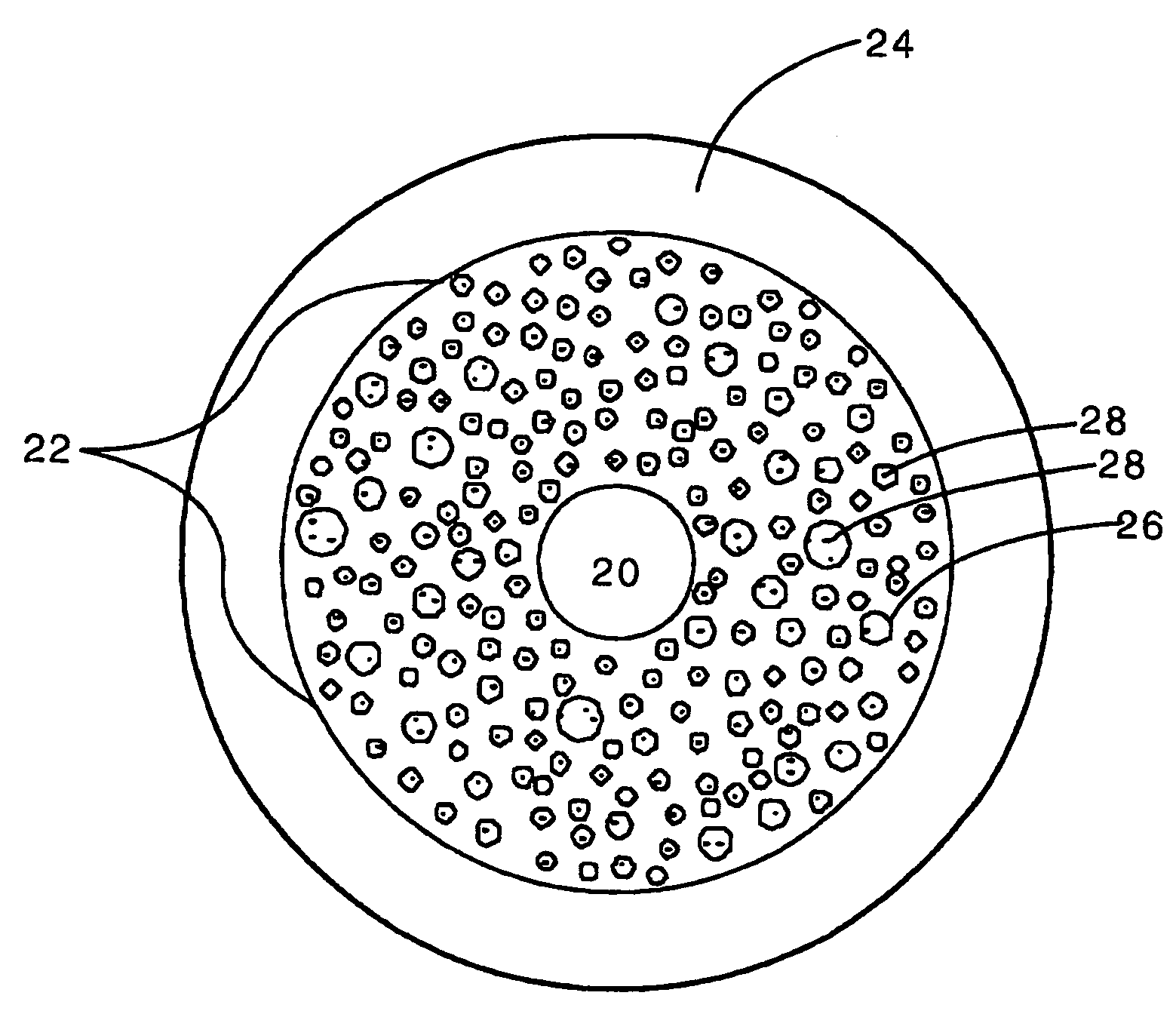

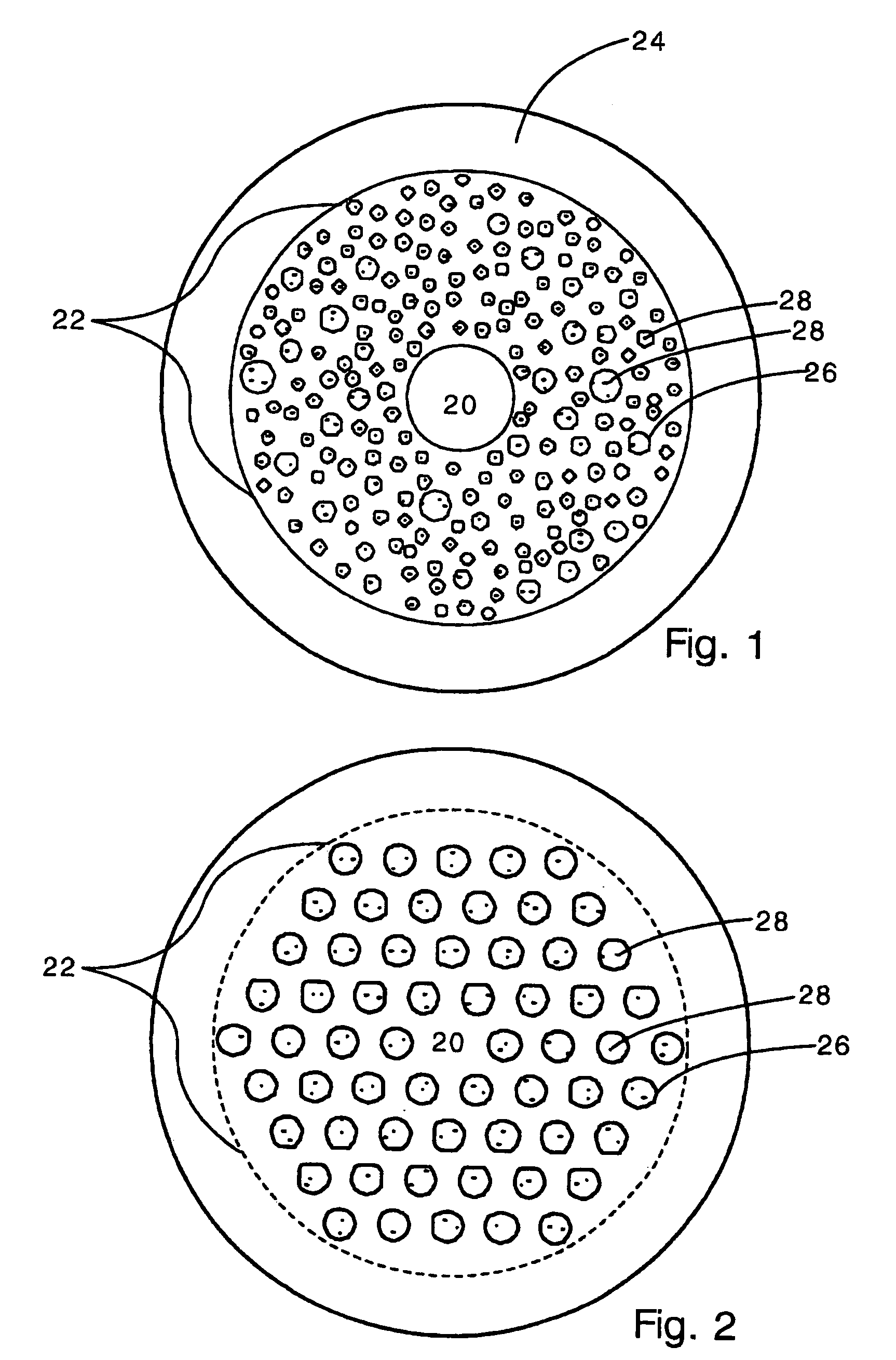

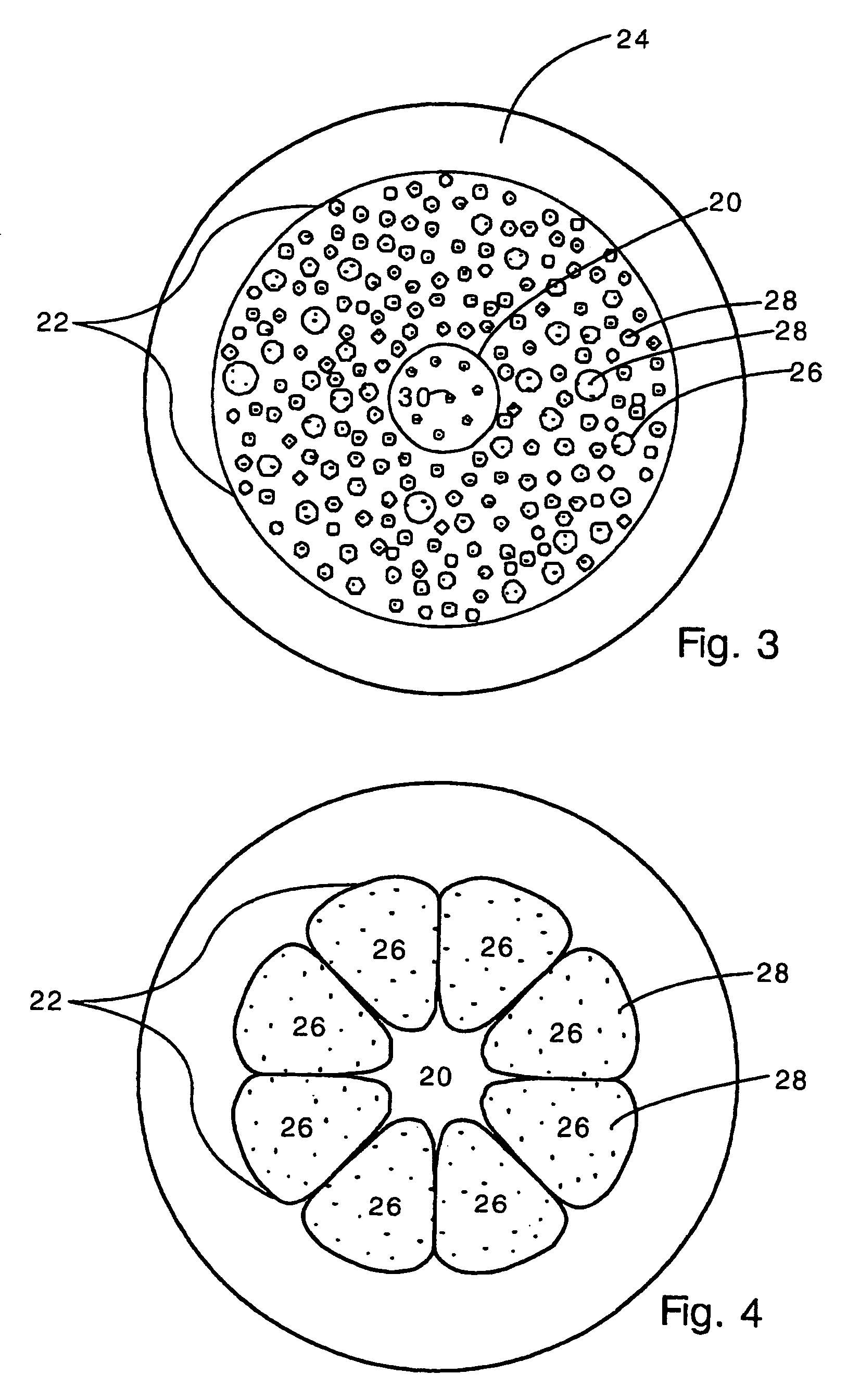

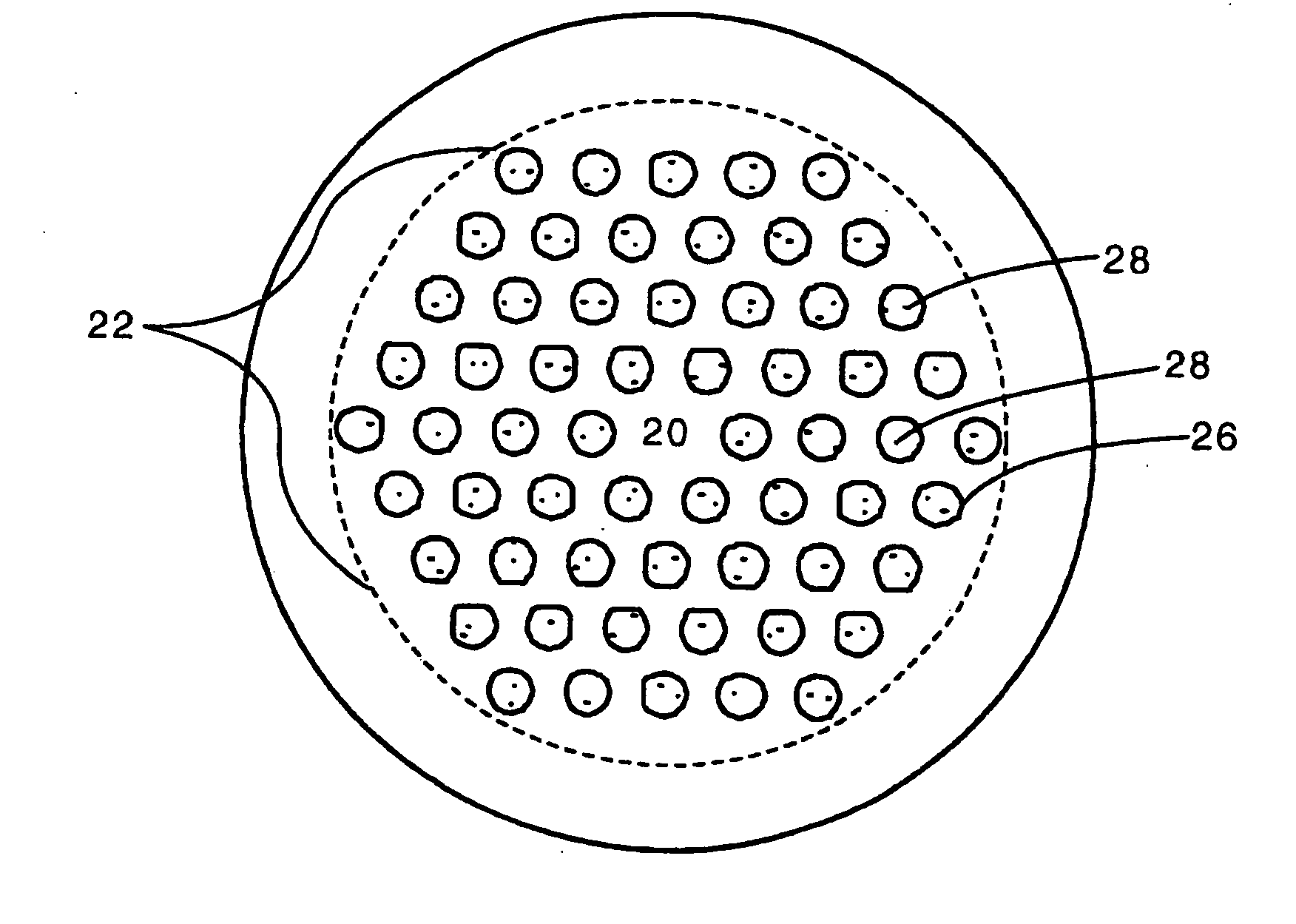

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

Optical fiber with quantum dots

Holey optical fibers (e.g. photonic fibers, random-hole fibers) are fabricated with quantum dots disposed in the holes. The quantum dots can provide light amplification and sensing functions, for example. When used for sensing, the dots will experience altered optical properties (e.g. altered fluorescence or absorption wavelength) in response to certain chemicals, biological elements, radiation, high energy particles, electrical or magnetic fields, or thermal / mechanical deformations. Since the dots are disposed in the holes, the dots interact with the evanescent field of core-confined light. Quantum dots can be damaged by high heat, and so typically cannot be embedded within conventional silica optical fibers. In the present invention, dots can be carried into the holes by a solvent at room temperature. The present invention also includes solid glass fibers made of low melting point materials (e.g. phosphate glass, lead oxide glass) with embedded quantum dots.

Owner:LAMBDA LABORATORY INSTRUMENTS +1

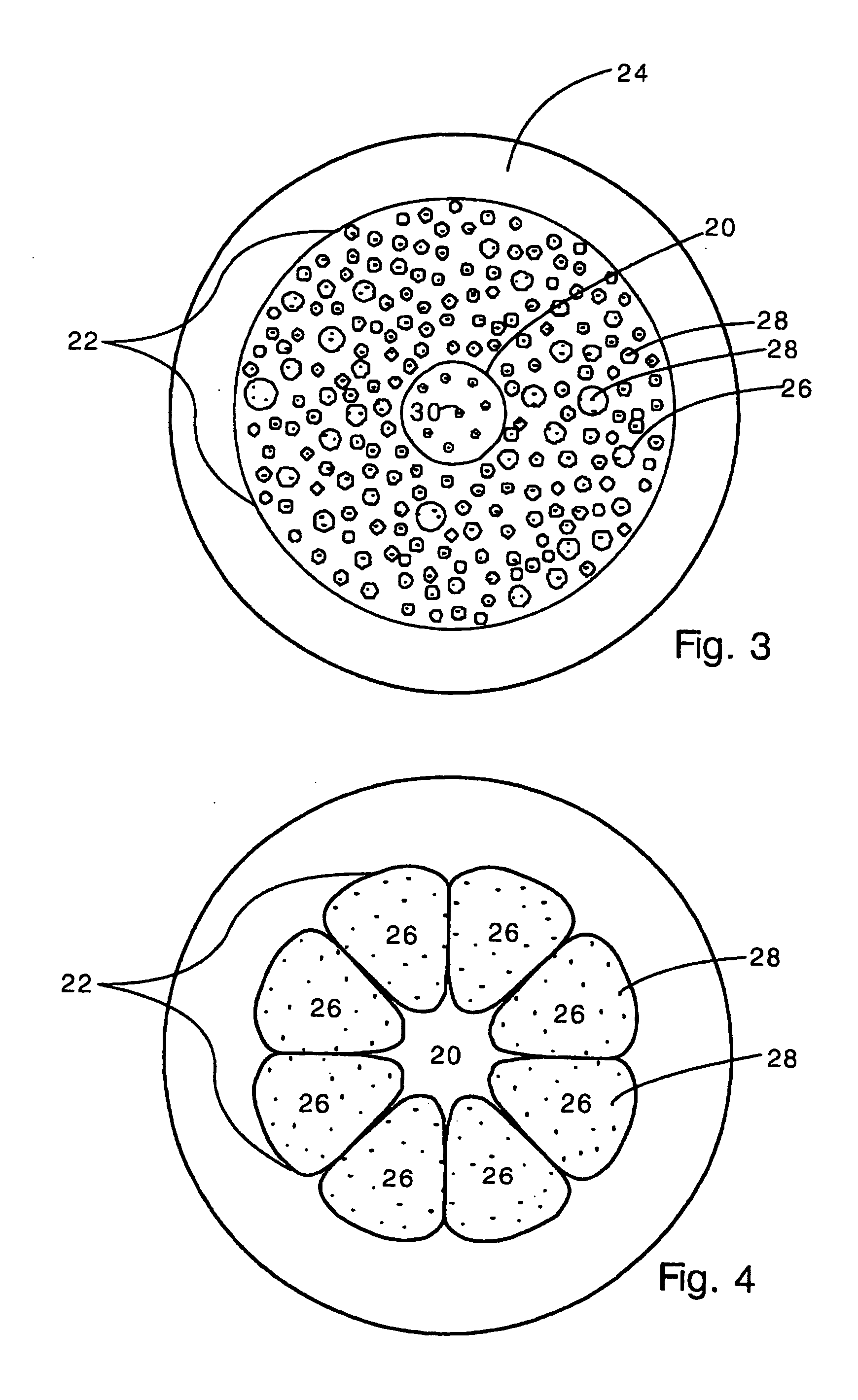

Solid-state luminescent filament lamps

InactiveUS20090212698A1Improve wavelength conversion efficiencyEliminate thermal quenching lossDischarge tube luminescnet screensPoint-like light sourcePhotonicsPhosphate glass

Traditional incandescent and halogen lamps produce a high CRI warm white light with indirect emission patterns at the cost of poor energy efficiency. This new advancement in solid-state lighting enables the production of a new solid-state filament wherein the tungsten filament is replaced with an array of high efficiency LED emitters which combine through an equiangular spiral, or t-spline / TNURCC lightpipe network to produce a single homogeneous blue light source which then pumps a luminescent filament comprised of a phosphor loaded silicone, phosphor loaded polymer, a lanthanide doped fluoro-phosphate glass, glass ceramic tape, quantum dot filled composite, or super-continuum spectrum producing photonic crystalline structure.

Owner:ILLUMINATION MACHINES

Lead-free phosphate glasses

Disclosed are zinc niobium phosphate glasses consisting essentially, expressed in terms of mole percent on the oxide basis of, 40-65% P2O5, 25-37% ZnO, 0.1-15% Nb2O5, 0-6% Al2O3, 0-5% Bi2O3, 0-3% Na2O and 0-5% B2O3, said glass exhibiting glass transition temperature below 450° C., a dilatometer softening point below 500° C., coefficient of expansion in the range of 80-120×10−7° C.−1, good chemical durability and blue color. The glass of the present invention is useful for sealing optical fiber to ferrule by local heating.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

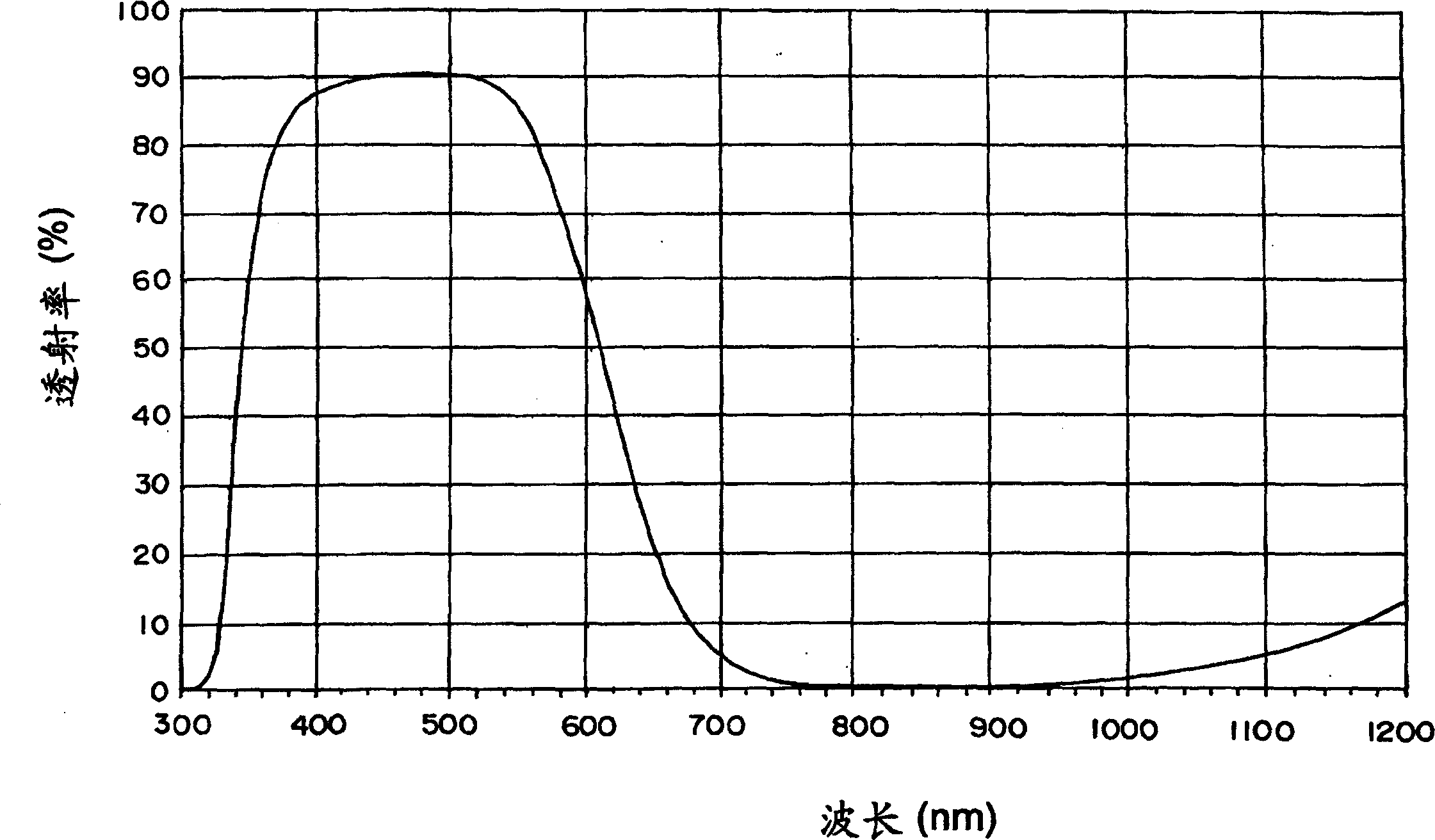

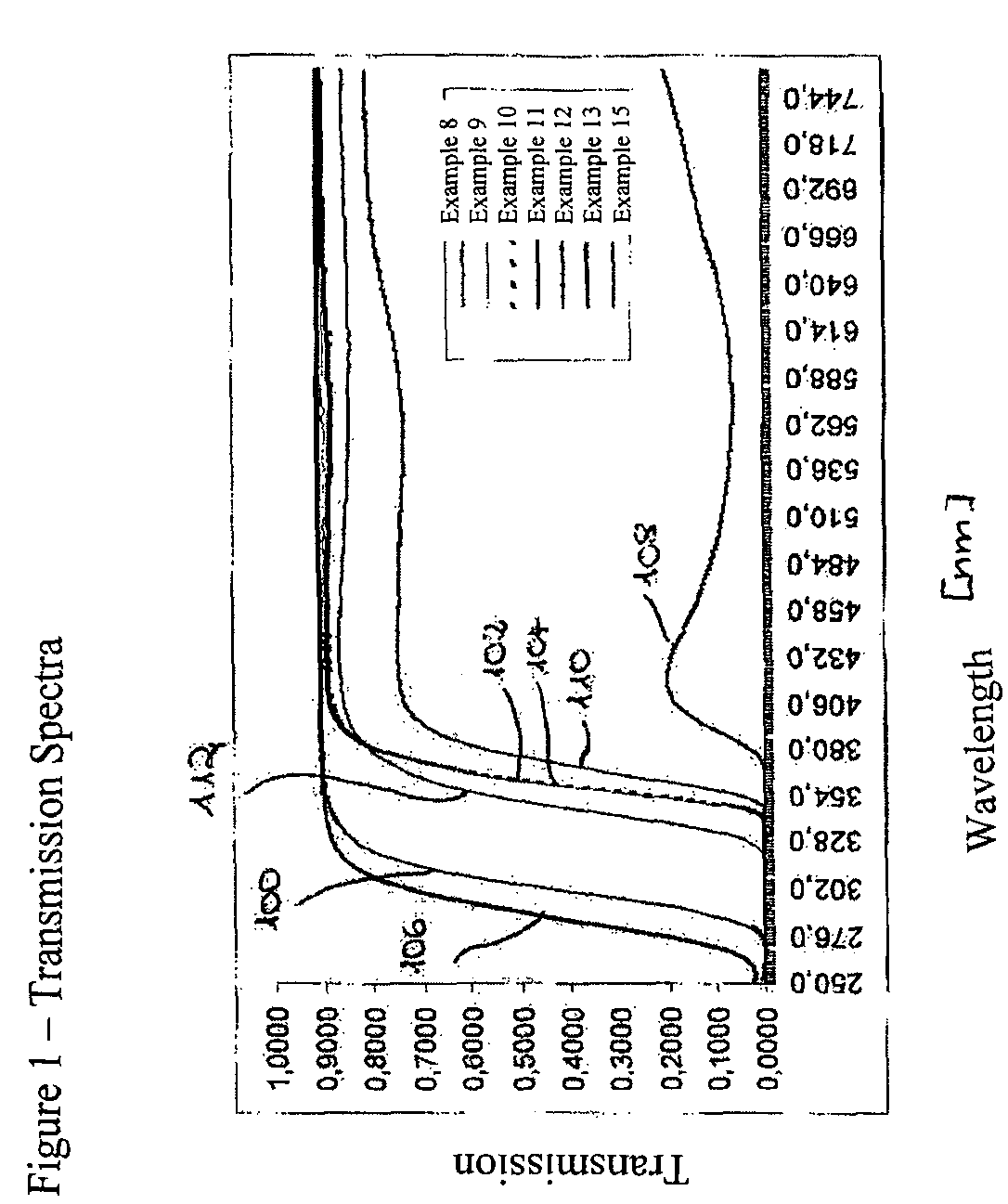

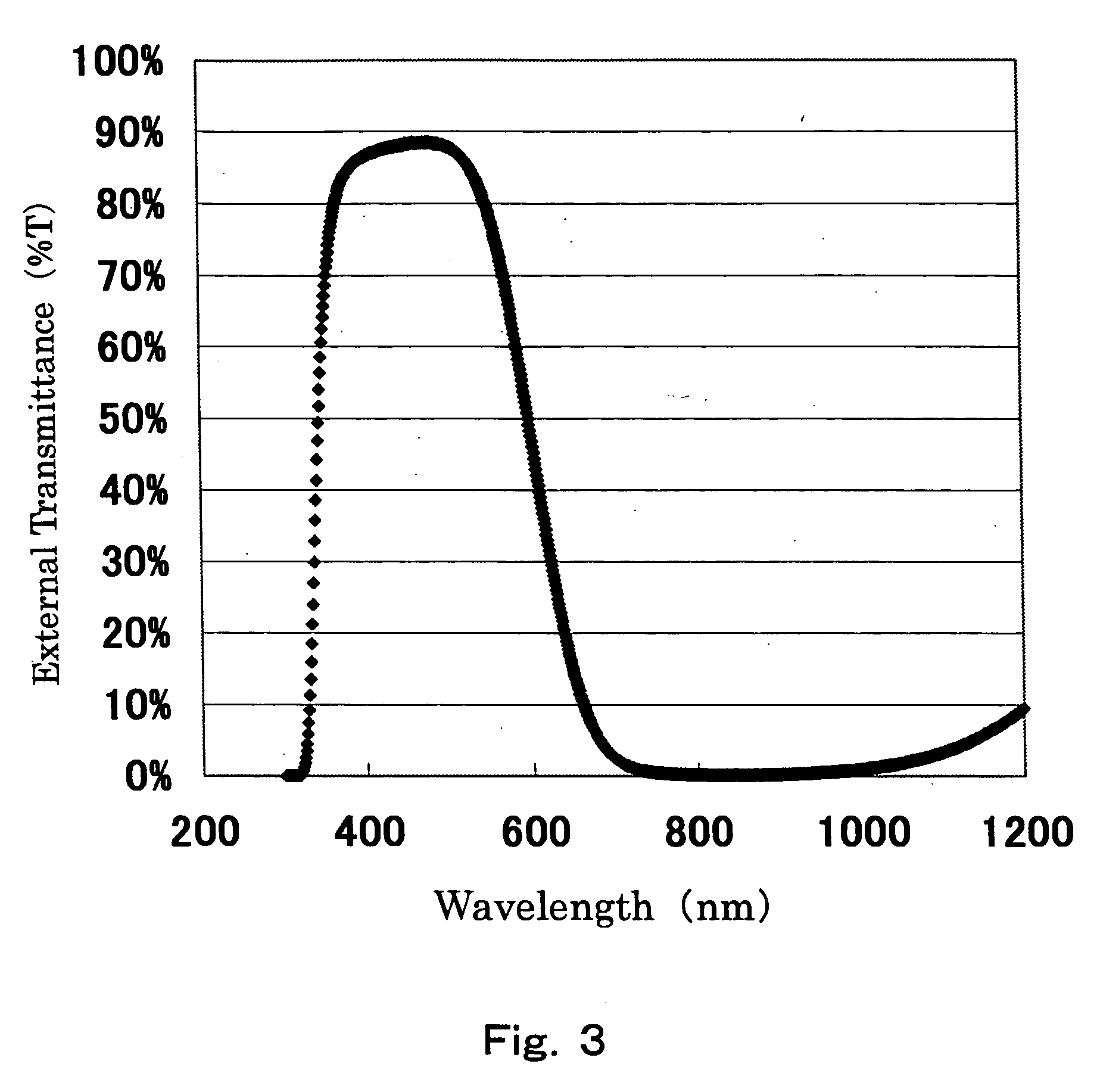

Nearinfrared-ray absorbing galss, element, light filter and their production method and copper-contained glass

InactiveCN1508087AGood color sensitivity correction characteristicsIncreasing the thicknessOptical filtersSpectral transmittanceThinning

Provided are near-infrared light-absorbing glass in which good color compensating characteristics are maintained even without containing harmful arsenic, permitting the thinning of the glass, and having good weatherability and forming properties; a near-infrared light-absorbing element comprised of such glass; a near-infrared light-absorbing filter employing such glass. Also provided, at low cost, are near-infrared light-absorbing glass permitting good color compensating, a near-infrared light-absorbing element comprised of such glass, and a near-infrared light-absorbing filter comprising such elements. The glass comprises cationic components with a certain composition as well as F<-> and O<2-> as anionic components. Alternatively, the glass is near-infrared light-absorbing glass, wherein the glass exhibits properties, based on a thickness of 0.5 mm, in the spectral transmittance of wavelengths of 400 to 700 nm, that wavelength, at which a 50 percent transmittance is exhibited, is less than 630 nm, transmittance at a wavelength longer than said wavelength is less than 50 percent, transmittance at a wavelength shorter than said wavelength is higher than 50 percent and the viscosity at a liquid phase temperature is 0.5 Pa.s or more. The near-infrared light-absorbing element is comprised of such glass. The near-infrared light-absorbing filter comprises a glass plate comprised of such glass. Alternatively, the glass is comprised of fluorophosphate glass or phosphate glass, and comprises 0.1 weight percent or more of copper based on CuO, 0.005 to 0.5 weight percent of iron based on Fe2O3, 0.01 to 1 weight percent of antimony based on Sb2O3, and no arsenic.

Owner:HOYA CORP

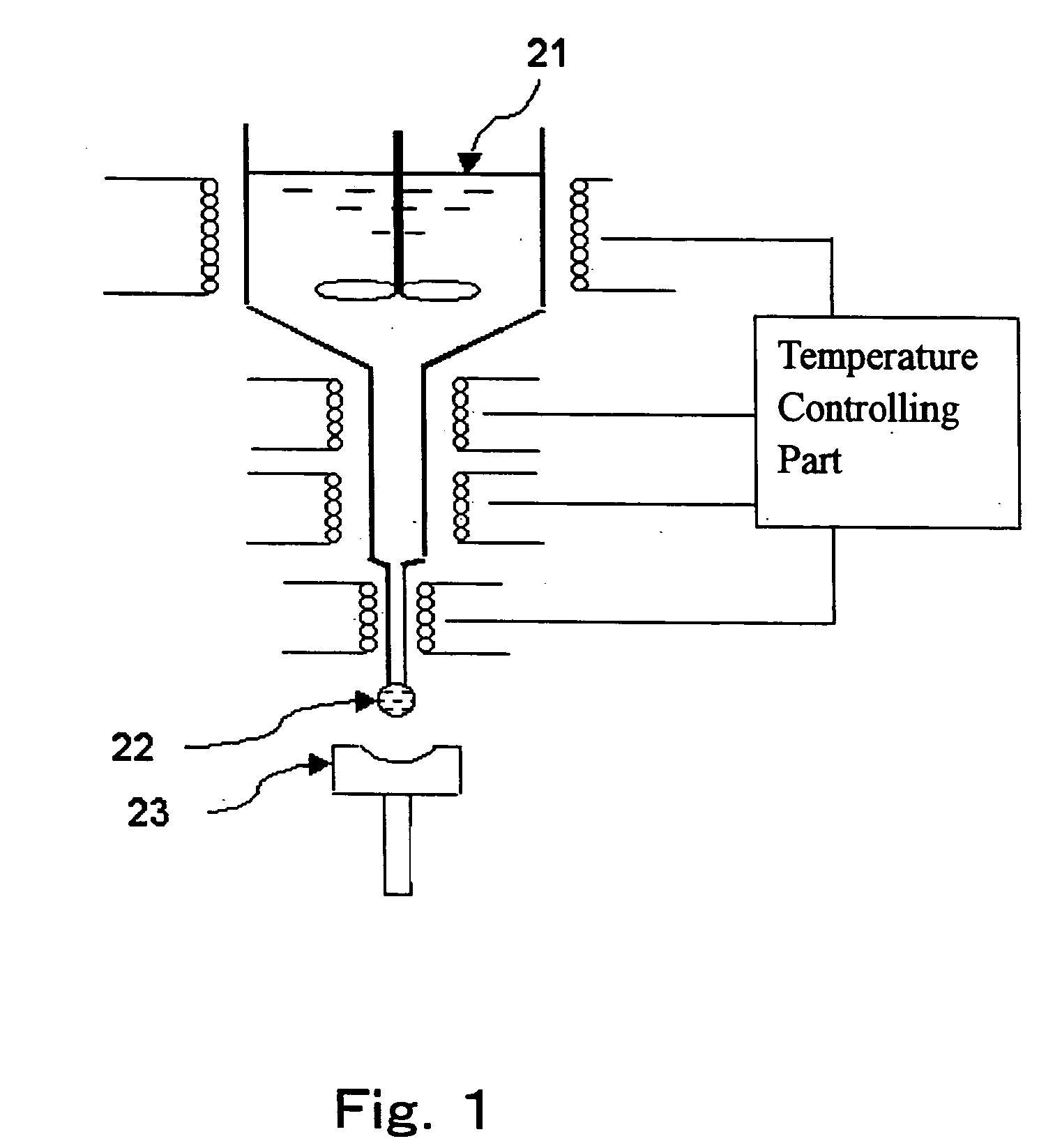

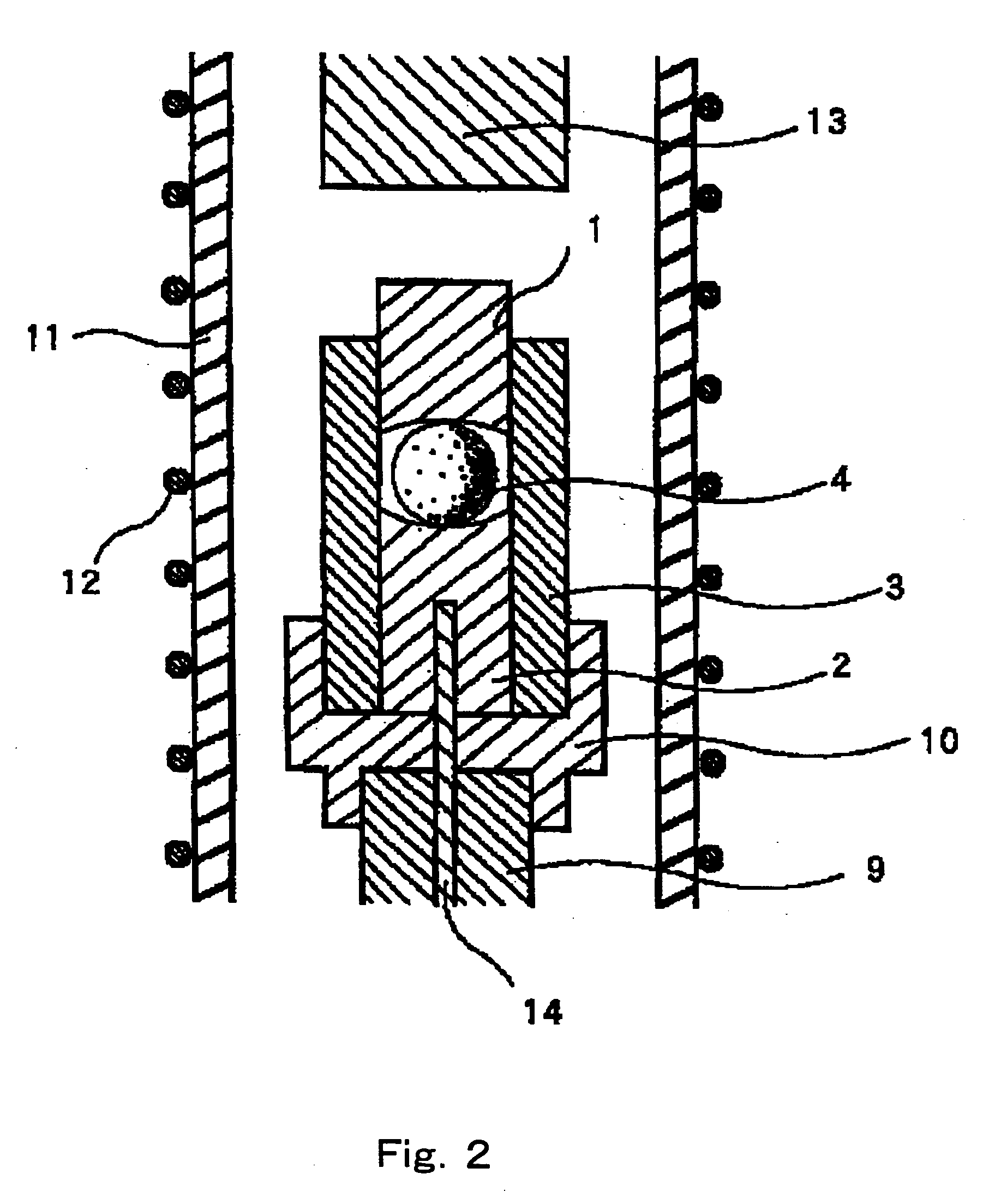

Glass scaffolds with controlled resorption rates and methods for making same

InactiveUS7005135B2Promote bone growthEconomical and simple methodPot furnacesGlass furnace apparatusFiberDissolution

The present invention relates to resorbable glass scaffolds for use in biological applications and methods for making same. Specifically, these scaffolds are composed of phosphate glass fibers, where the rate of dissolution into biological fluids is controlled by the length of time the glass is held above its melt temperature prior to spinning the fiber.

Owner:ADVANCED TECH & REGENERATIVE MEDICINE

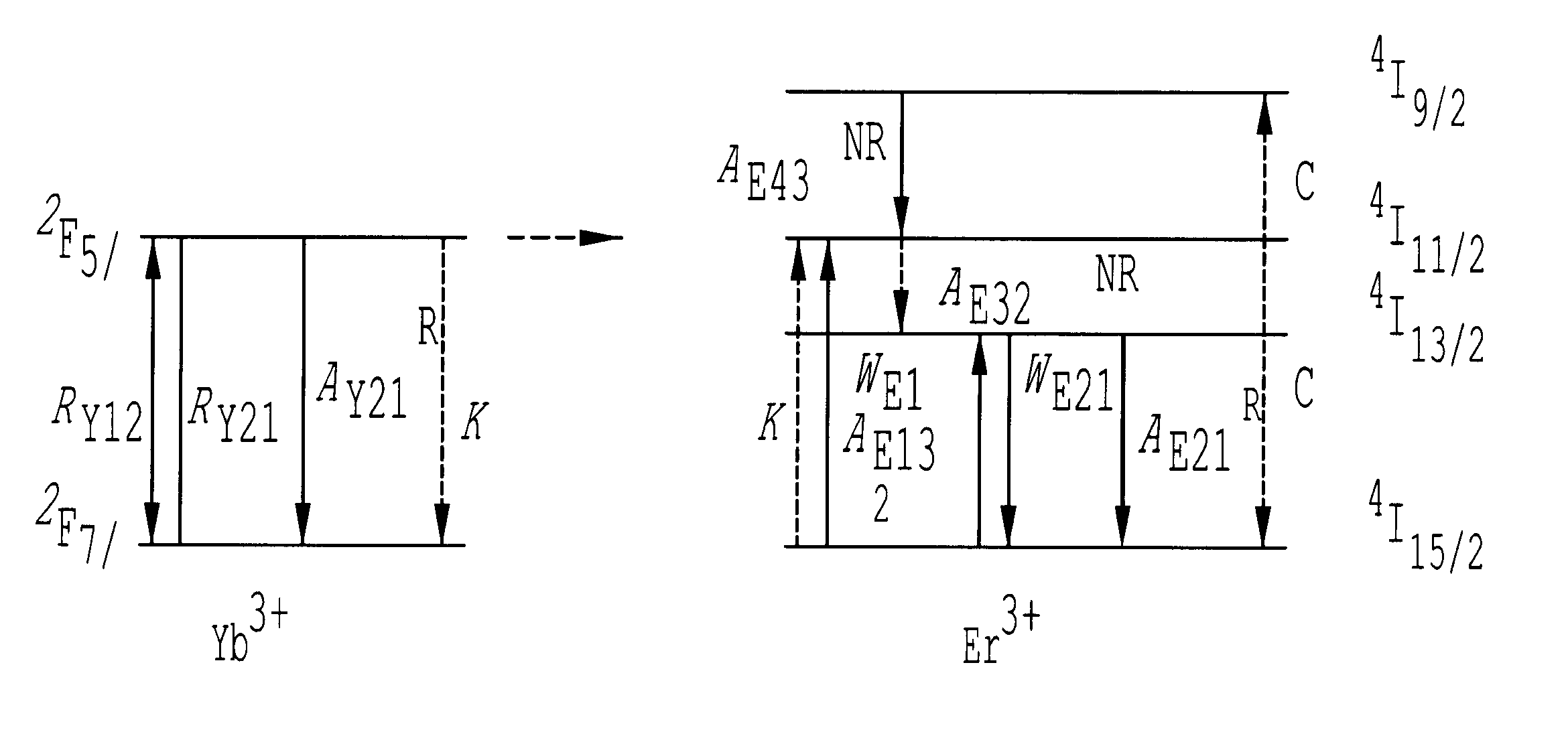

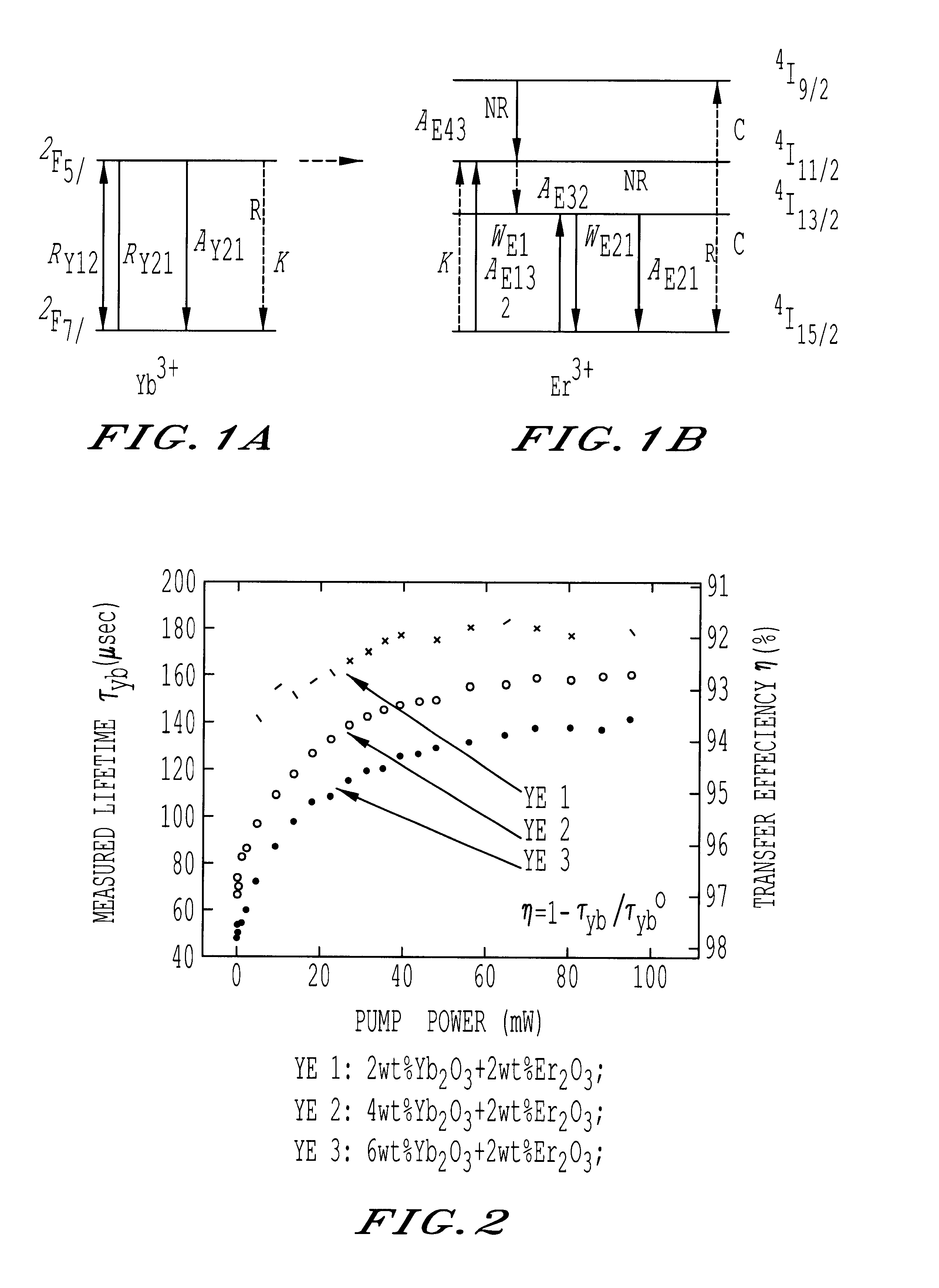

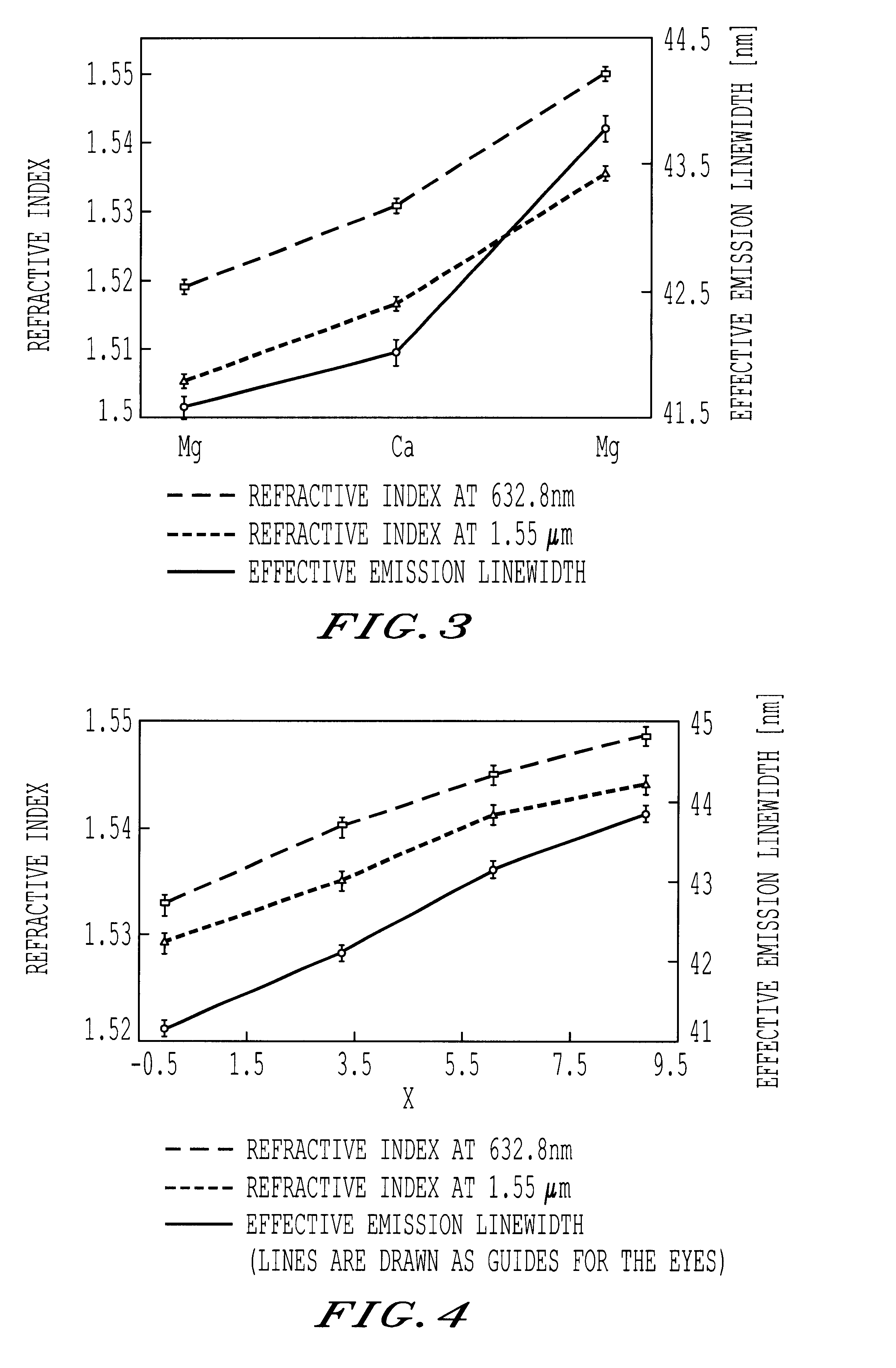

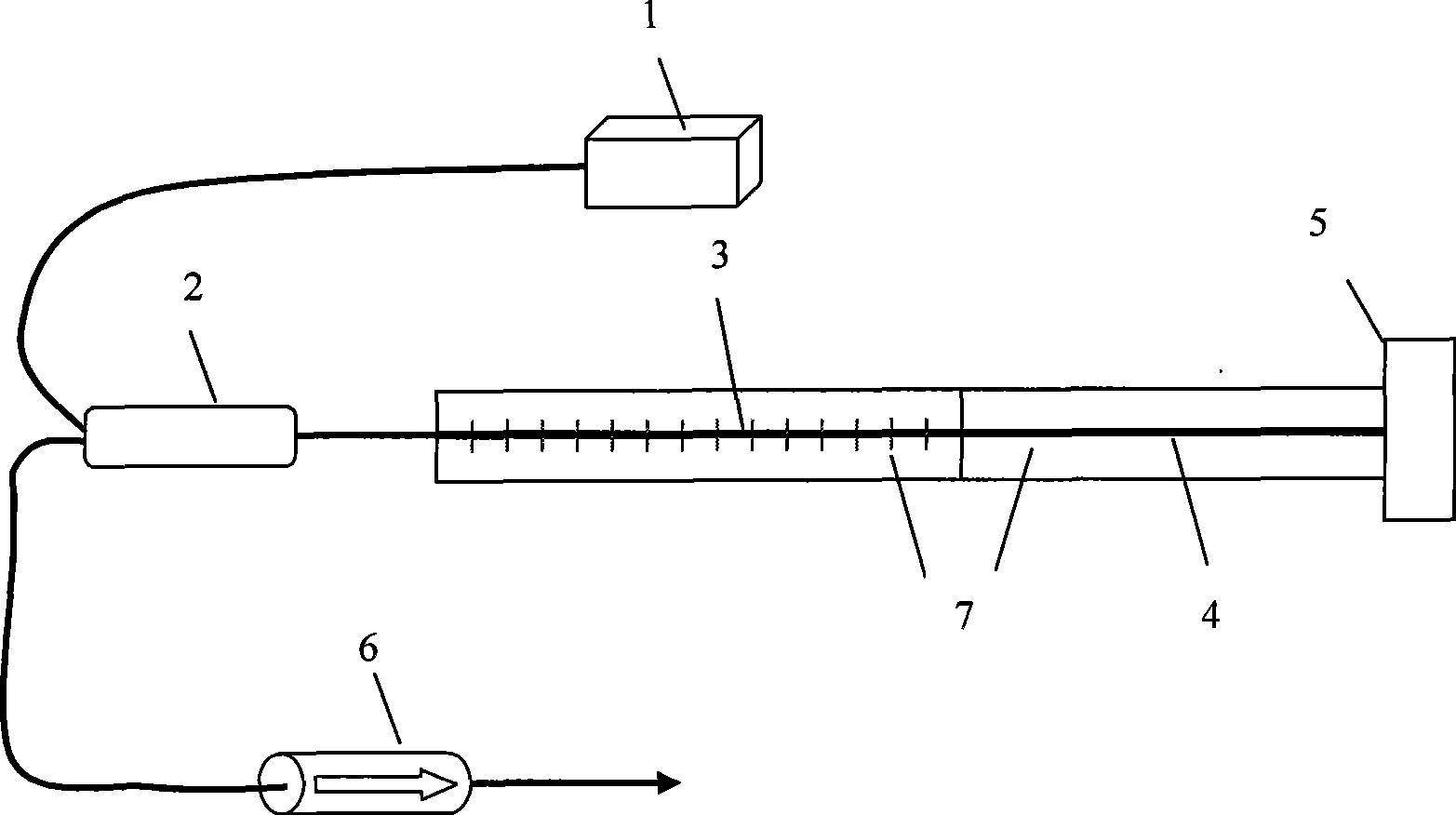

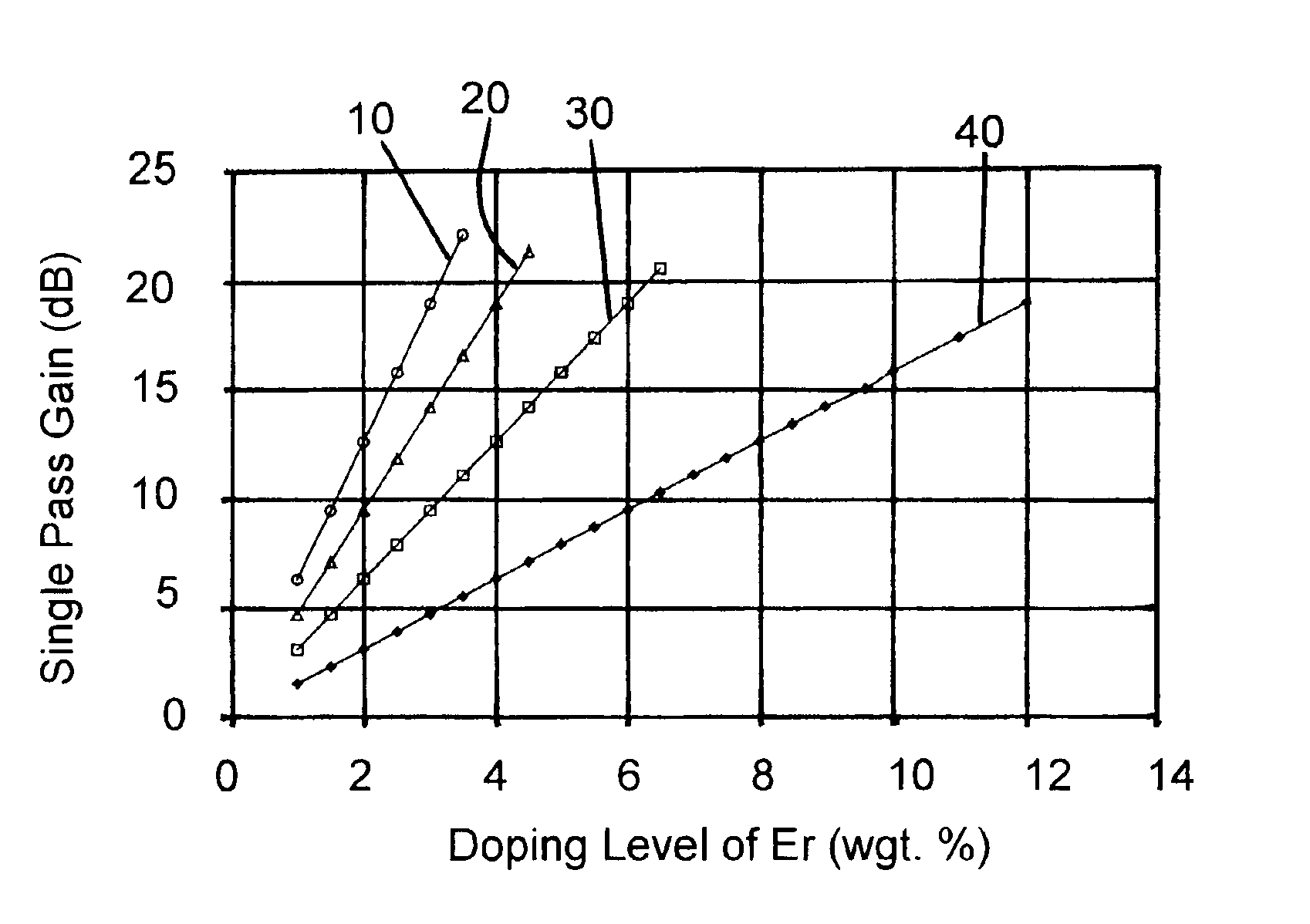

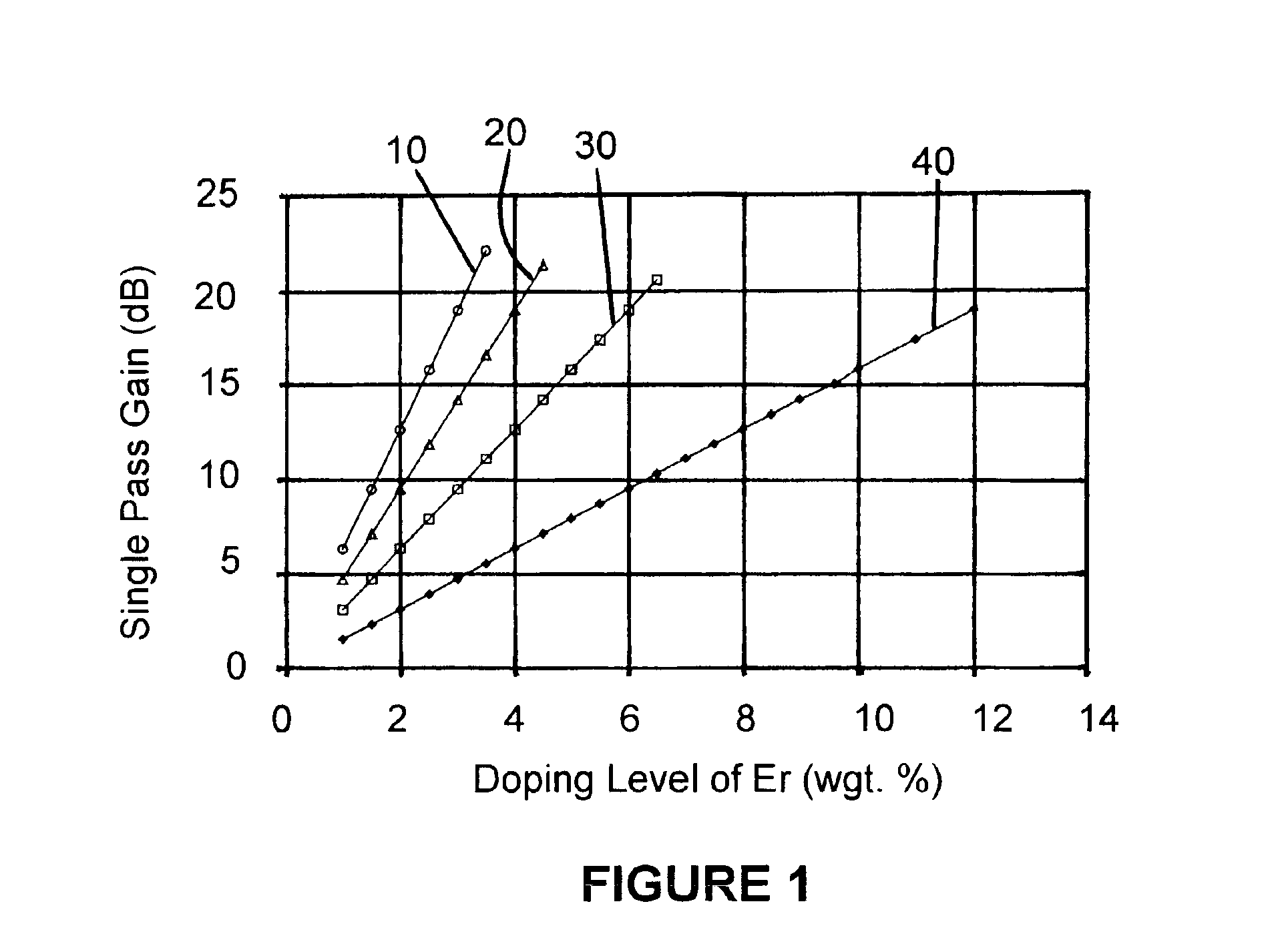

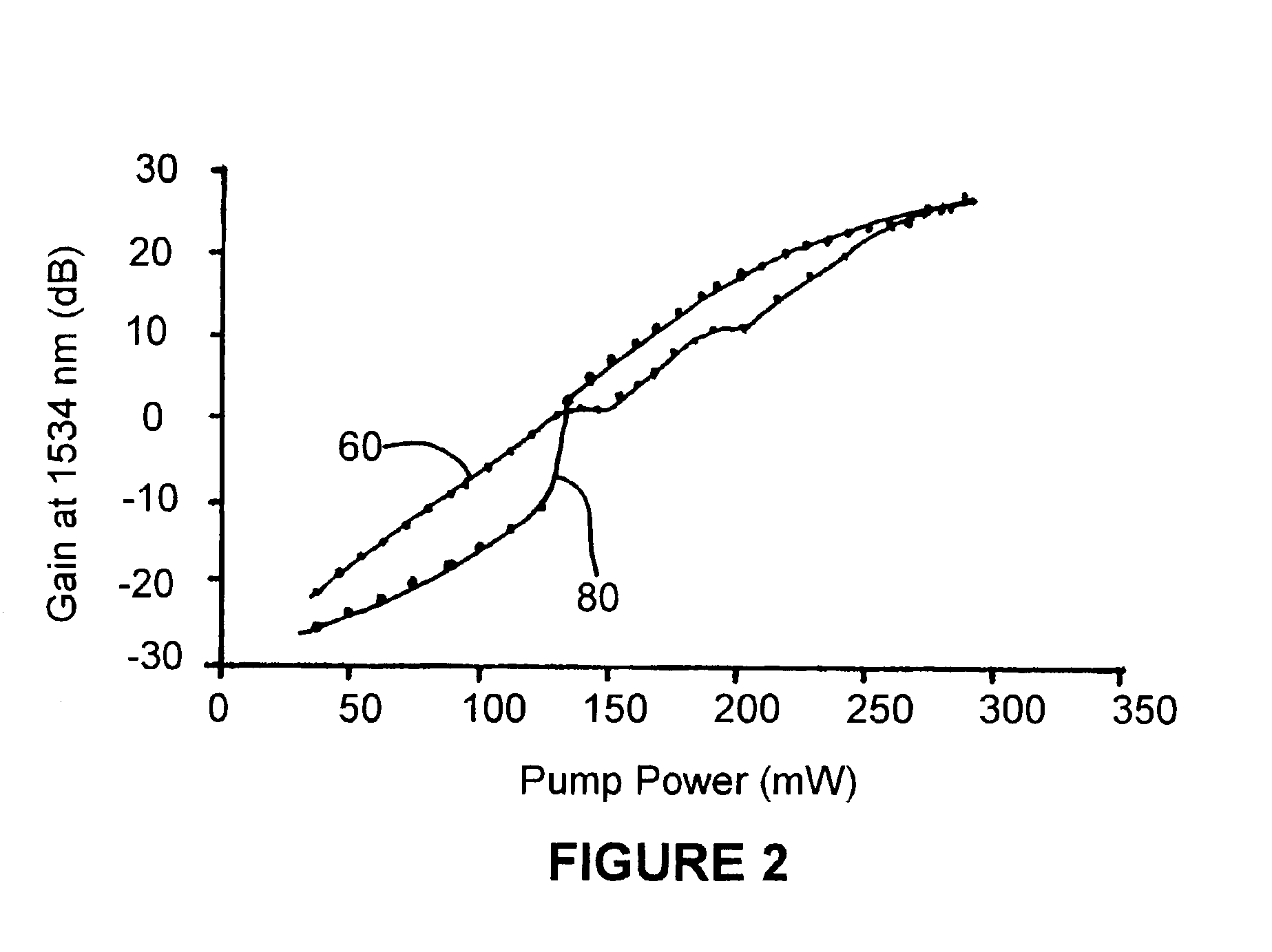

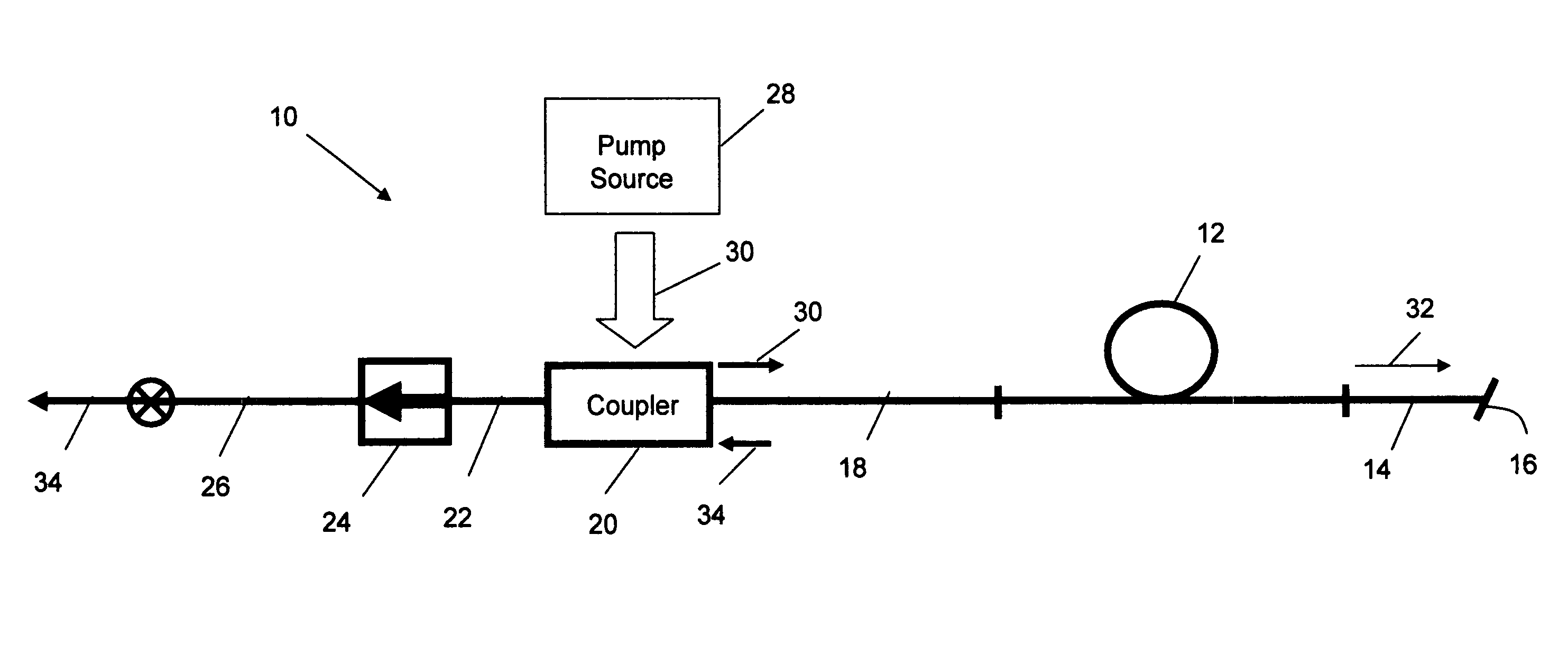

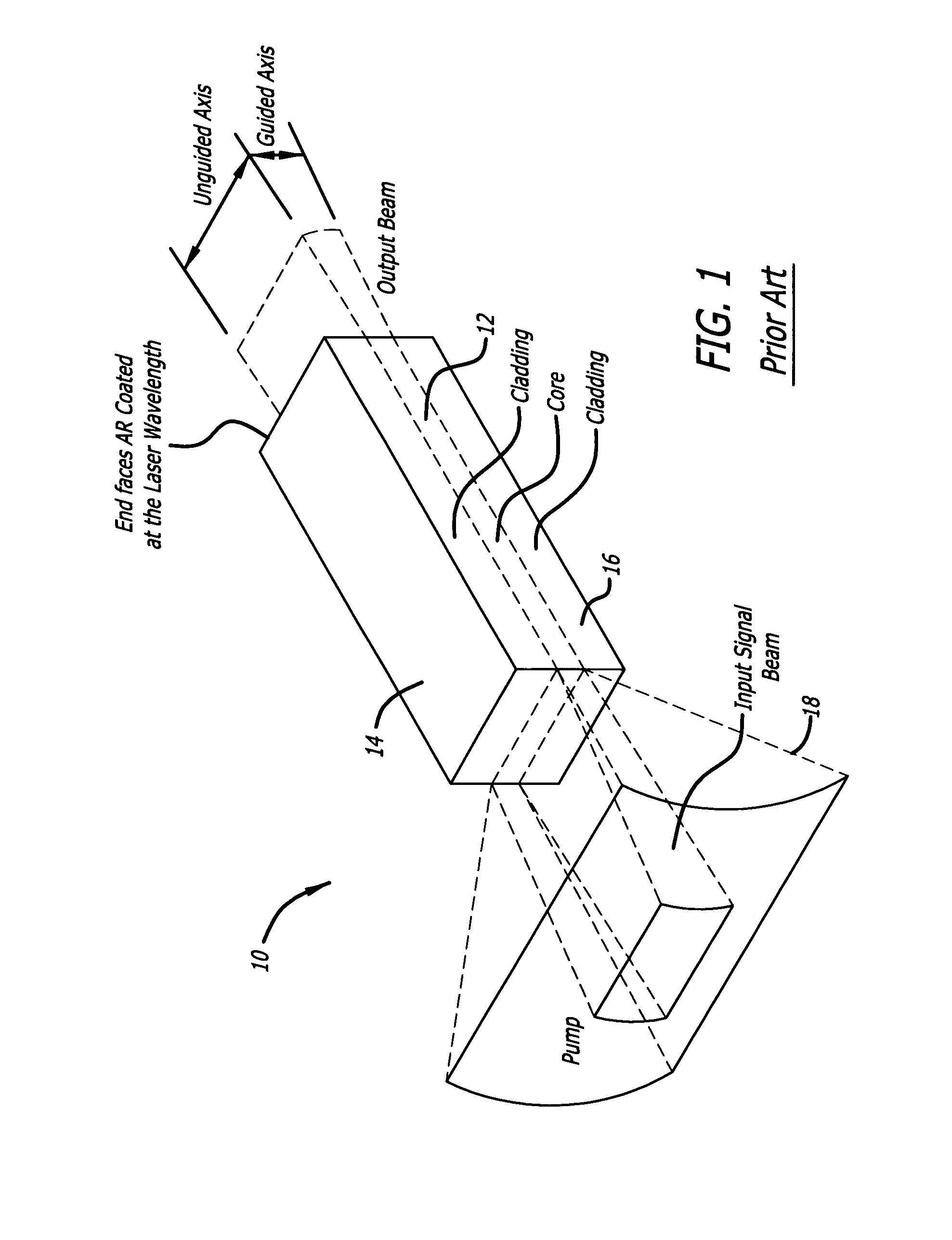

Erbium and ytterbium co-doped phosphate glass optical fiber amplifiers using short active fiber length

InactiveUS6611372B1High gain per unit lengthHigh gain amplificationLaser arrangementsActive medium materialErbium dopingPhosphate glass

An optical fiber amplifier utilizing a phosphate glass optical fiber highly doped with rare-earth ions such as erbium to exhibit high gain per unit length, enabling the use of short fiber strands to achieve the needed gain in practical fiber optical communication networks. The high-gain phosphate optical glass fiber amplifiers are integrated onto substrates to form an integrated optics amplifier module. An optical pump such as a semiconductor laser of suitable wavelength is used to promote gain inversion of erbium ions and ultimately provide power amplification of a given input signal. Gain inversion is enhanced in the erbium doped phosphate glass fiber by co-doping with ytterbium. A phosphate fiber amplifier or an integrated optics amplifier module utilizing this power amplification can be combined with other components such as splitters, combiners, modulators, or arrayed waveguide gratings to form lossless or amplified components that do not suffer from insertion loss when added to an optical network. The fiber amplifier can be a single fiber or an array of fibers. Further, the phosphate glass fibers can be designed with a temperature coefficient of refractive index close to zero enabling proper mode performance as ambient temperatures or induced heating changes the temperature of the phosphate glass fiber. Large core 50-100 .mu.m fibers can be used for fiber amplifiers. The phosphate glass composition includes erbium concentrations of at least 1.5 weight percentage, preferably further including ytterbium at 1.5 weight percentage, or greater.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Antimicrobial phosphate glass with adapted refractive index

ActiveUS7704903B2Good chemical resistanceImprove responseBiocideCosmetic preparationsRefractive indexPhosphate glass

The invention provides an antimicrobial phosphate glass composition including, in weight percent based on oxide: greater than 45 to 90 of P2O5, 0 to 60 of B2O3, 0 to 40 of SiO2, 0 to 20 weight percent of Al2O3, 0 to 30 of SO3, 0 to 0.1 of Li2O, 0 to 0.1 of Na2O, 0 to 0.1 of K2O, 0 to 40 of CaO, 0 to 40 of MgO, 0 to 15 of SrO, 0 to 40 of BaO, 0 to 40 of ZnO, 0 to 5 of Ag2O, 0 to 15 of CuO, 0 to 10 of Cr2O3, 0 to 10 of I—, 0 to 10 of TeO2, 0 to 10 of GeO2, 0 to 10 of TiO2, 0 to 10 of ZrO2, 0 to 10 of La2O3, 0 to 5 of Nb2O3, 0 to 5 of CeO2, 0 to 5 of Fe2O3, 0 to 5 of WO3, 0 to 5 of Bi2O3, and 0 to 5 of MoO3.

Owner:SCHOTT AG

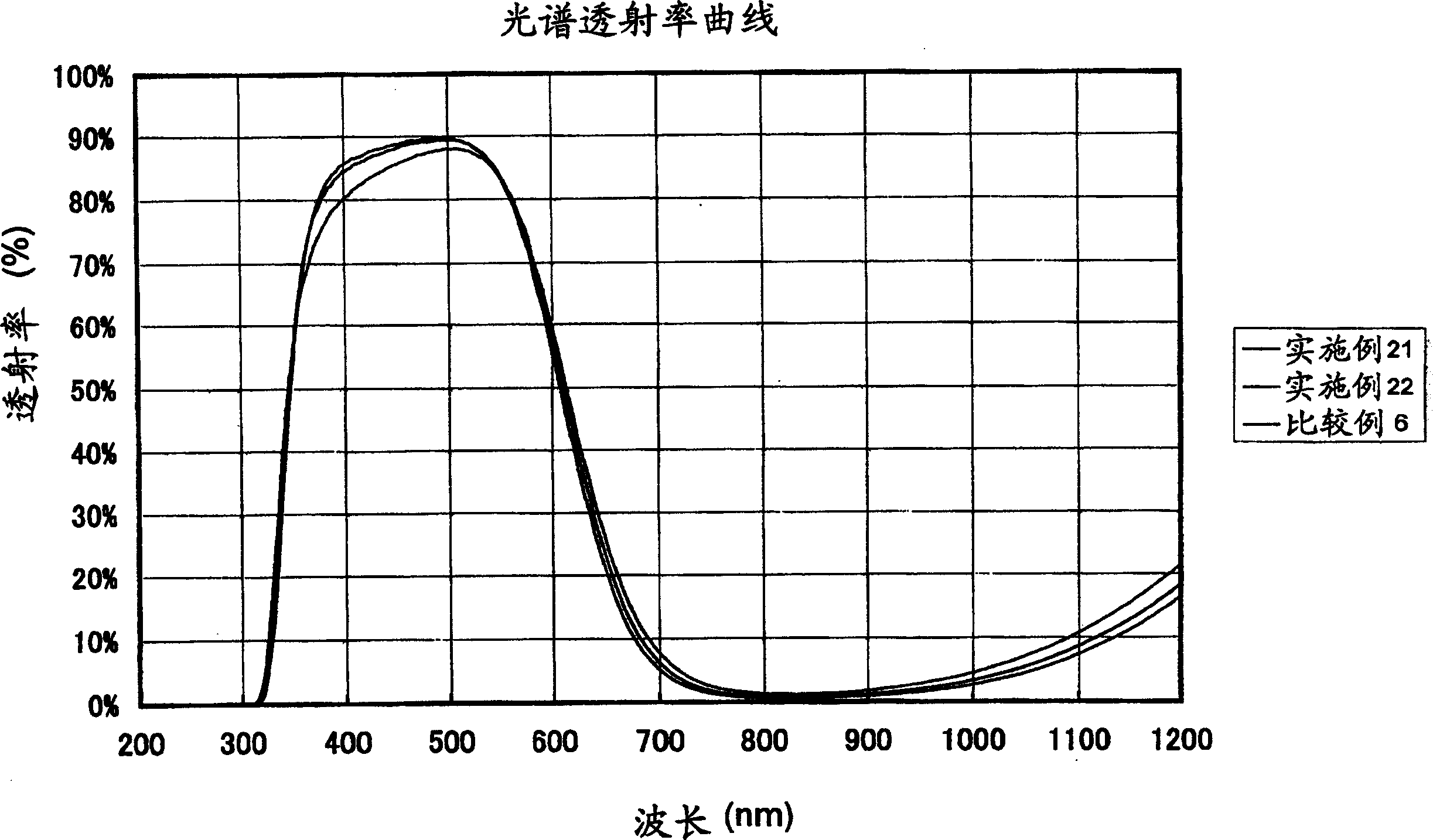

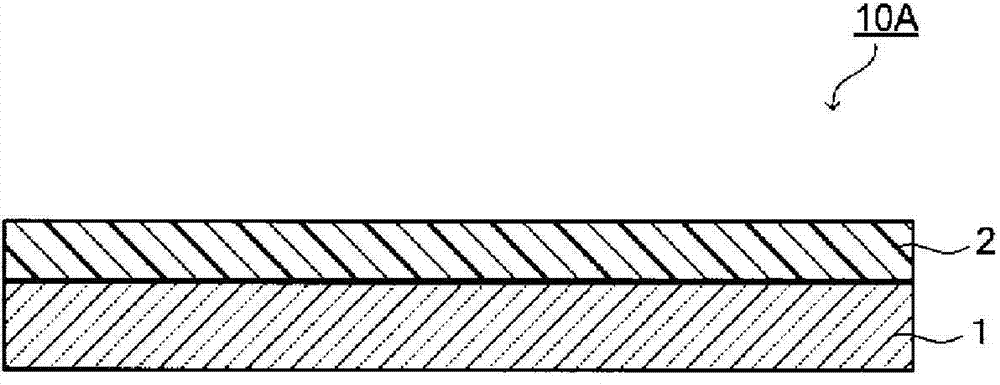

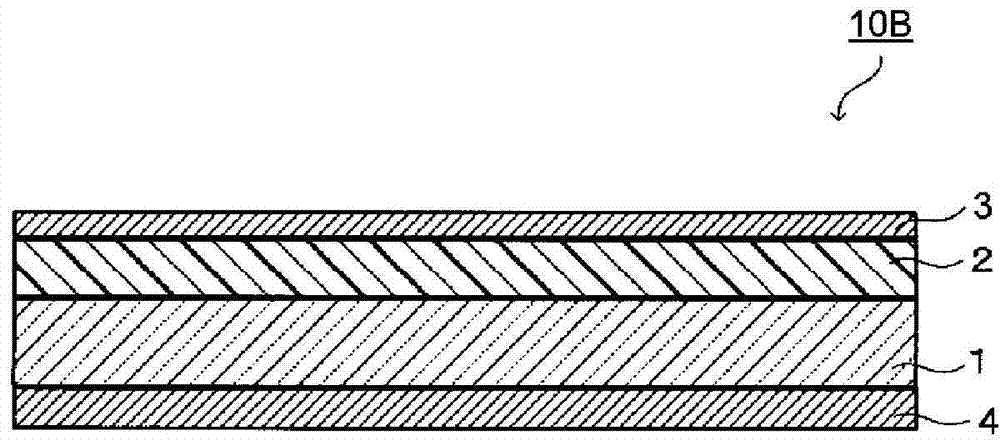

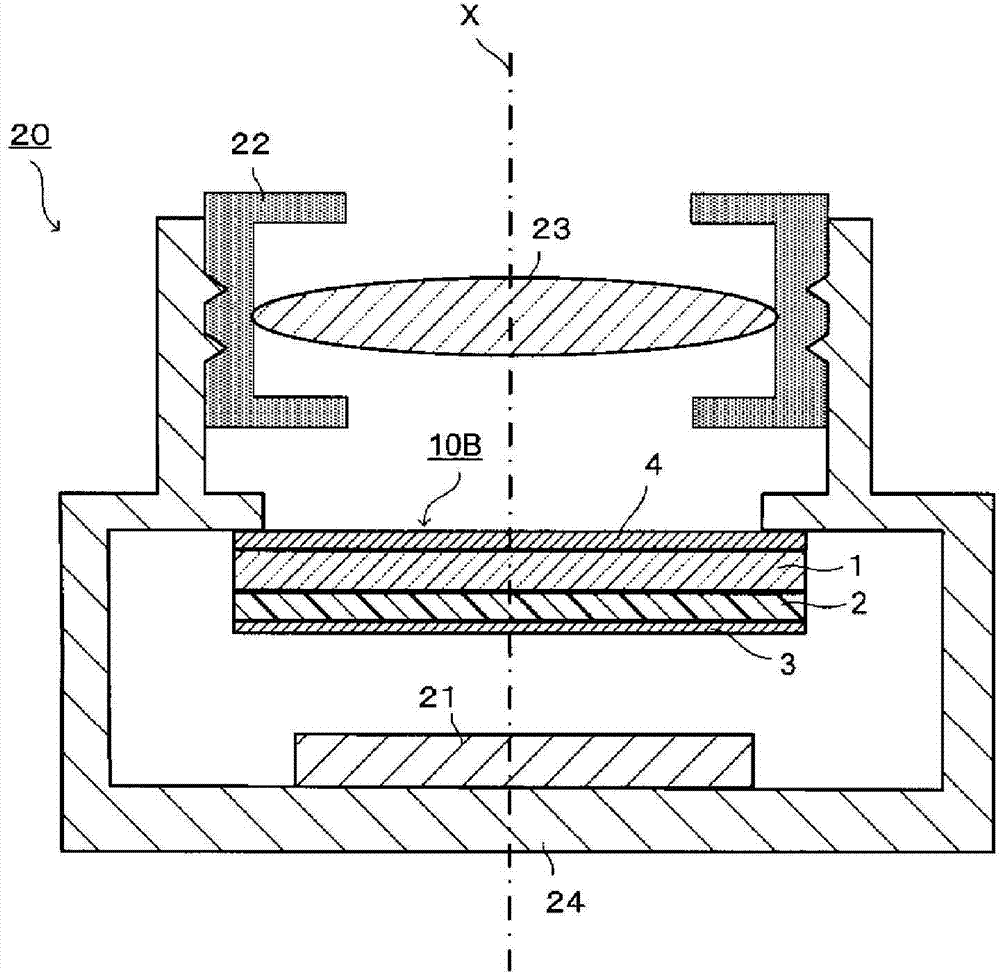

Near-infrared cut filter and solid-state imaging device

ActiveCN104755969AExcellent near-infrared shielding functionHigh sensitivityTelevision system detailsCoatingsInfraredTransmittance

There are provided a near-infrared cut filter that effectively uses near-infrared absorbing glass and a near-infrared absorbing dye and is excellent in a near-infrared shielding property, and a high-sensitivity solid-state imaging device including the same. A near-infrared cut filter includes: a near-infrared absorbing glass substrate made of CuO-containing fluorophosphate glass or CuO-containing phosphate glass; and a near-infrared absorbing layer containing a near-infrared absorbing dye (A) and a transparent resin (B), on at least one principal surface of the near-infrared absorbing glass substrate, wherein an average value of a transmittance in a 400 nm to 550 nm wavelength range is 80% or more, and an average value of a transmittance in a 650 nm to 720 nm wavelength range is 15% or less.

Owner:ASAHI GLASS CO LTD

Precision press-molding preform, process for the production thereof, optical element and process for the production of the optical element

InactiveUS20050054511A1Stable productionImage degradationGlass pressing apparatusLensAlkali metal oxidePhosphate glass

A precision press-molding preform for producing an optical element for use in an imaging device using a CCD type or MOS type solid image-sensing device, which is formed of a glass composition containing, by mol %, 25 to 45% of P205, 0.5 to 10% of CuO, 0 to 10% of B203, 0 to 10% of Al203, 2 to 30% of Li2O, 0 to 25% of Na2O, 0 to 15% of K2O, the total content of Li2O, Na2O and K2O being 3 to 40%, 3 to 45% of BaO, 0 to 30% of ZnO, 0 to 20% of MgO, 0 to 20% of CaO, 0 to 20% of SrO, 0 to 10% of Bi2O3, 0 to 5% of La2O3, 0 to 5% of Gd2O3 and 0 to 5% of Y2O3, the total content of these components being at least 98%, and a precision press-molding preform, which is formed of a phosphate glass containing CuO, an alkali metal oxide, BaO and ZnO and having a BaO content / ZnO content molar ratio (BaO / ZnO) of greater than 1.

Owner:HOYA CORP

Glass scaffolds with controlled resorption rates and methods for making same

The present invention relates to resorbable glass scaffolds for use in biological applications and methods for making same. Specifically, these scaffolds are composed of phosphate glass fibers, where the rate of dissolution into biological fluids is controlled by the length of time the glass is held above its melt temperature prior to spinning the fiber.

Owner:ADVANCED TECH & REGENERATIVE MEDICINE

Lead-free phosphate glasses

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Single longitudinal-mode optical fiber laser with low noise, narrow linewidth and high power

ActiveCN101447637AOptimizing Doping ConcentrationReduce noiseActive medium shape and constructionLow noiseHigh concentration

The invention discloses a single longitudinal-mode optical fiber laser with low noise, narrow linewidth and high power. Polarization maintaining optical fiber is rare-earth-doped phosphate single-mode glass optical fiber, the component of a fiber core is phosphate glass which consists of 70P2O5-8Al2O3-15BaO-4La2O3-3Nd2O3, the fiber core of the polarization maintaining optical fiber is doped with high-concentration luminous ions, the luminous ions are one or combination of more than one of lanthanide ions and transition metal ions, the doping density of the luminous ions is greater than 1*10<19>ions / cm<3> and the luminous ions are evenly doped in the fiber core. A polarization maintaining fiber Bragg grating with the narrow linewidth and a dichroscope form a front cavity mirror and a rear cavity mirror of the optical fiber laser, a centimeter-sized erbium-ytterbium co-doped phosphate glass polarization maintaining optical fiber is taken as a laser working substance, and polarization maintaining output laser generated by a single-mode semiconductor laser is taken as a pumping source, thus achieving the single longitudinal-mode laser output by designing and manufacturing the reflection spectrum width of the polarization maintaining fiber Bragg grating and controlling the cavity length of the whole laser cavity.

Owner:SOUTH CHINA UNIV OF TECH

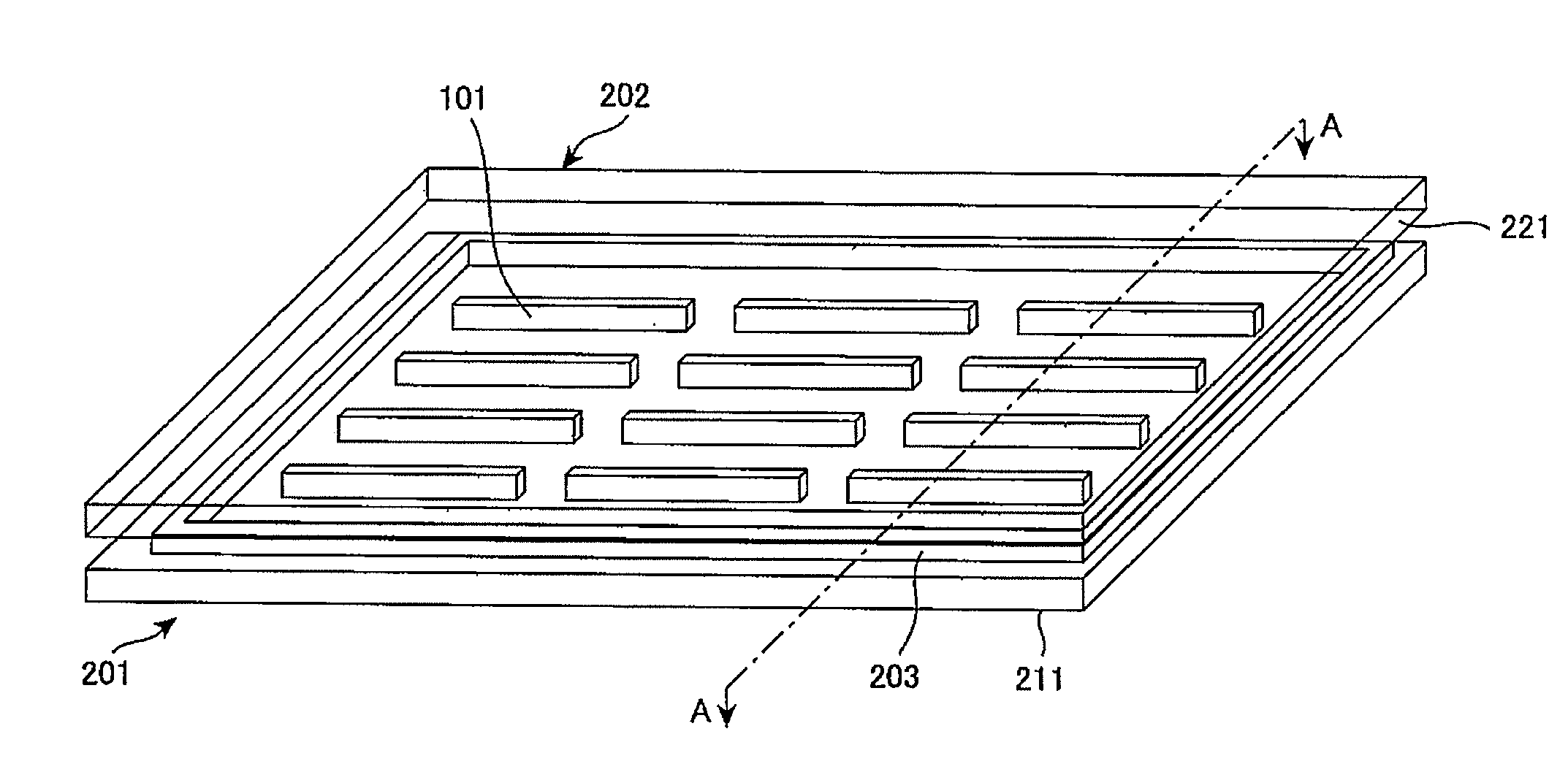

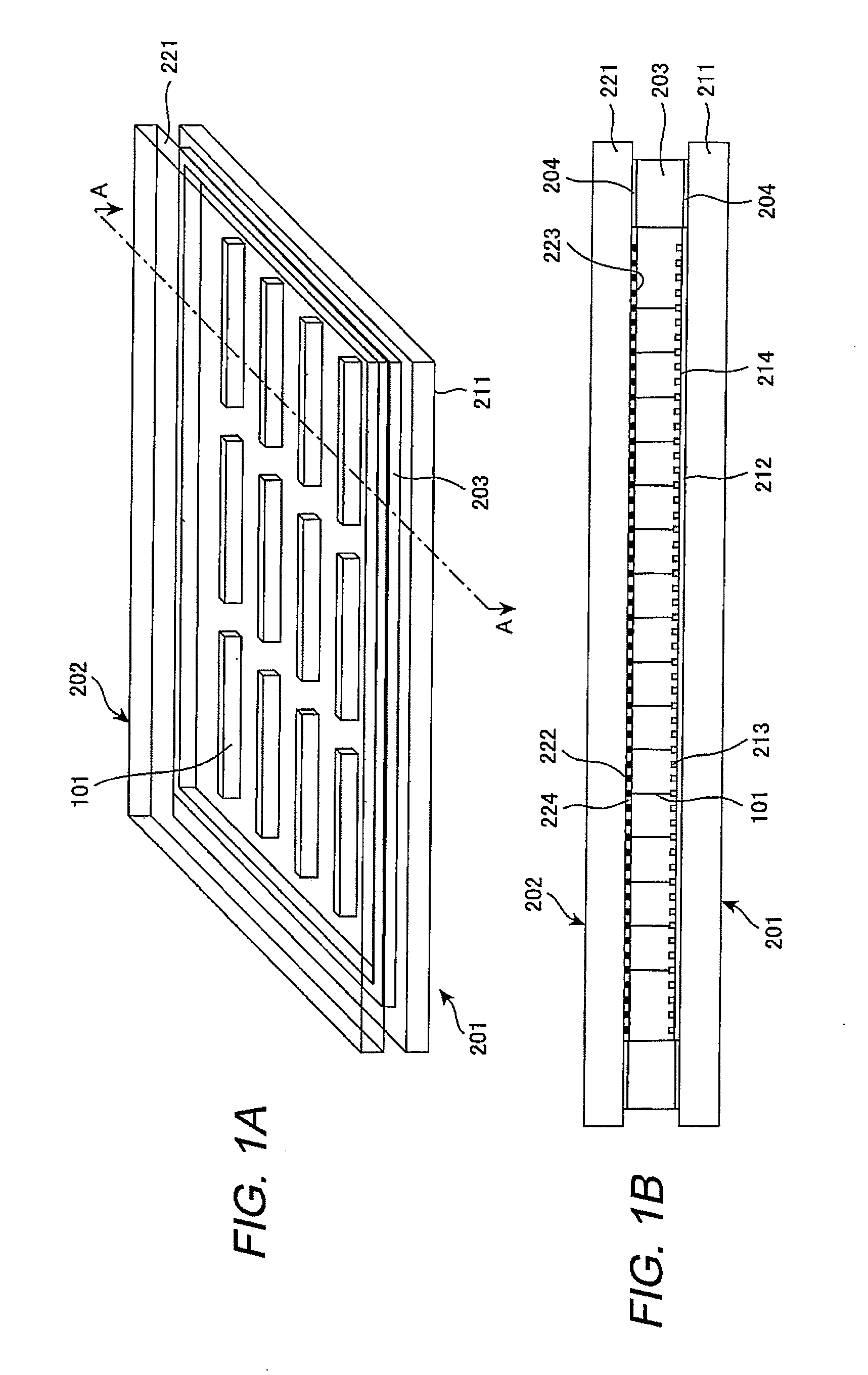

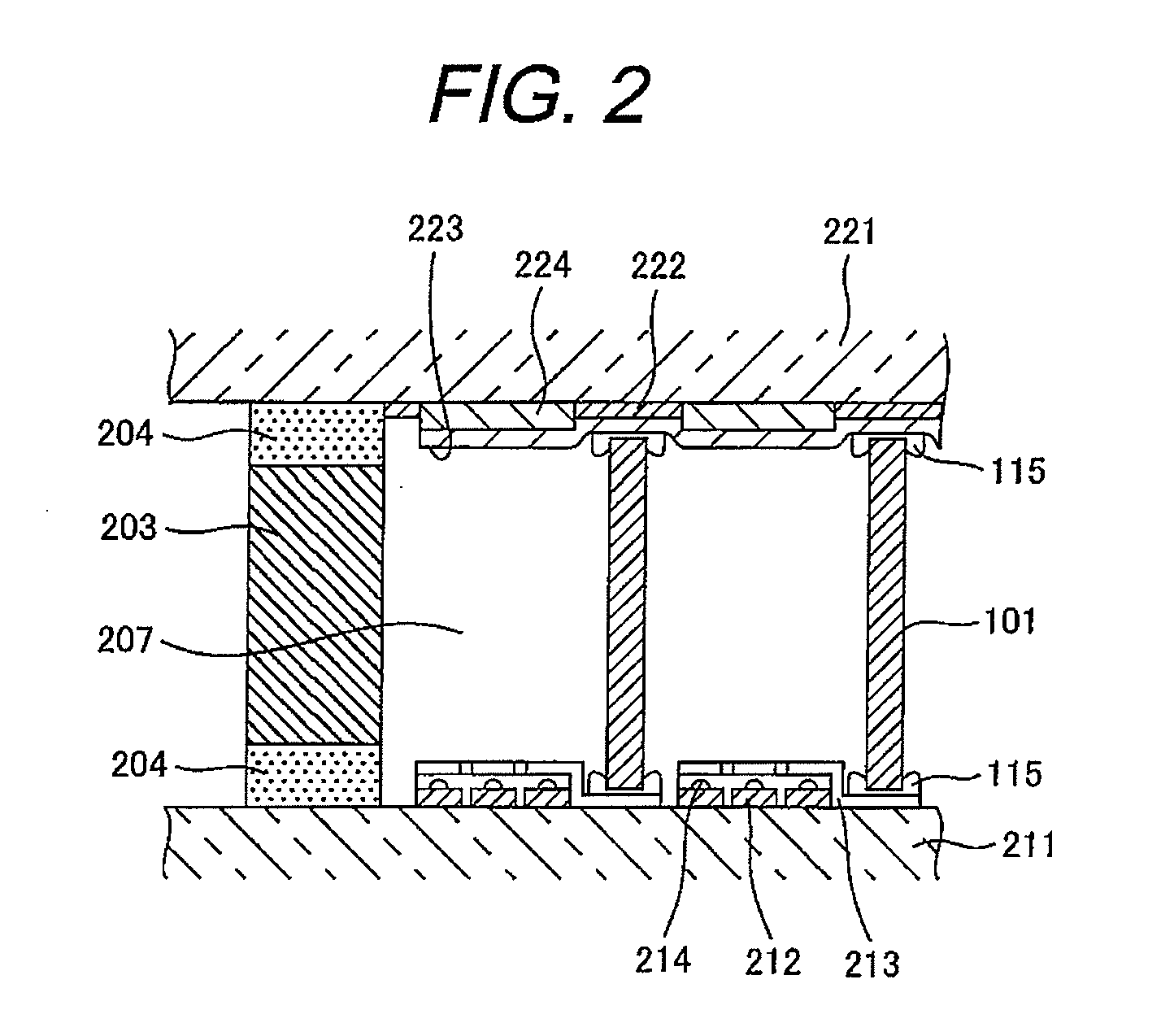

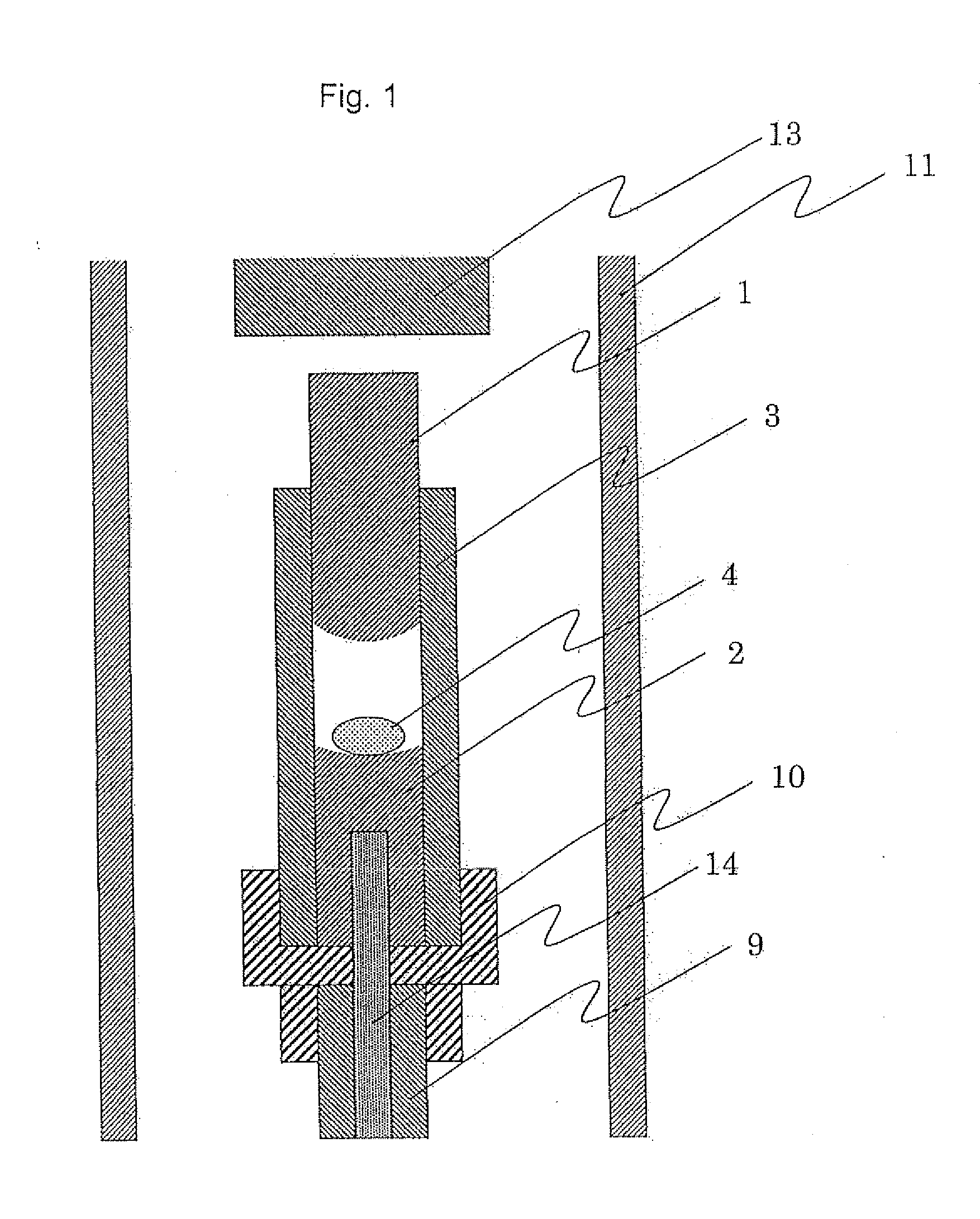

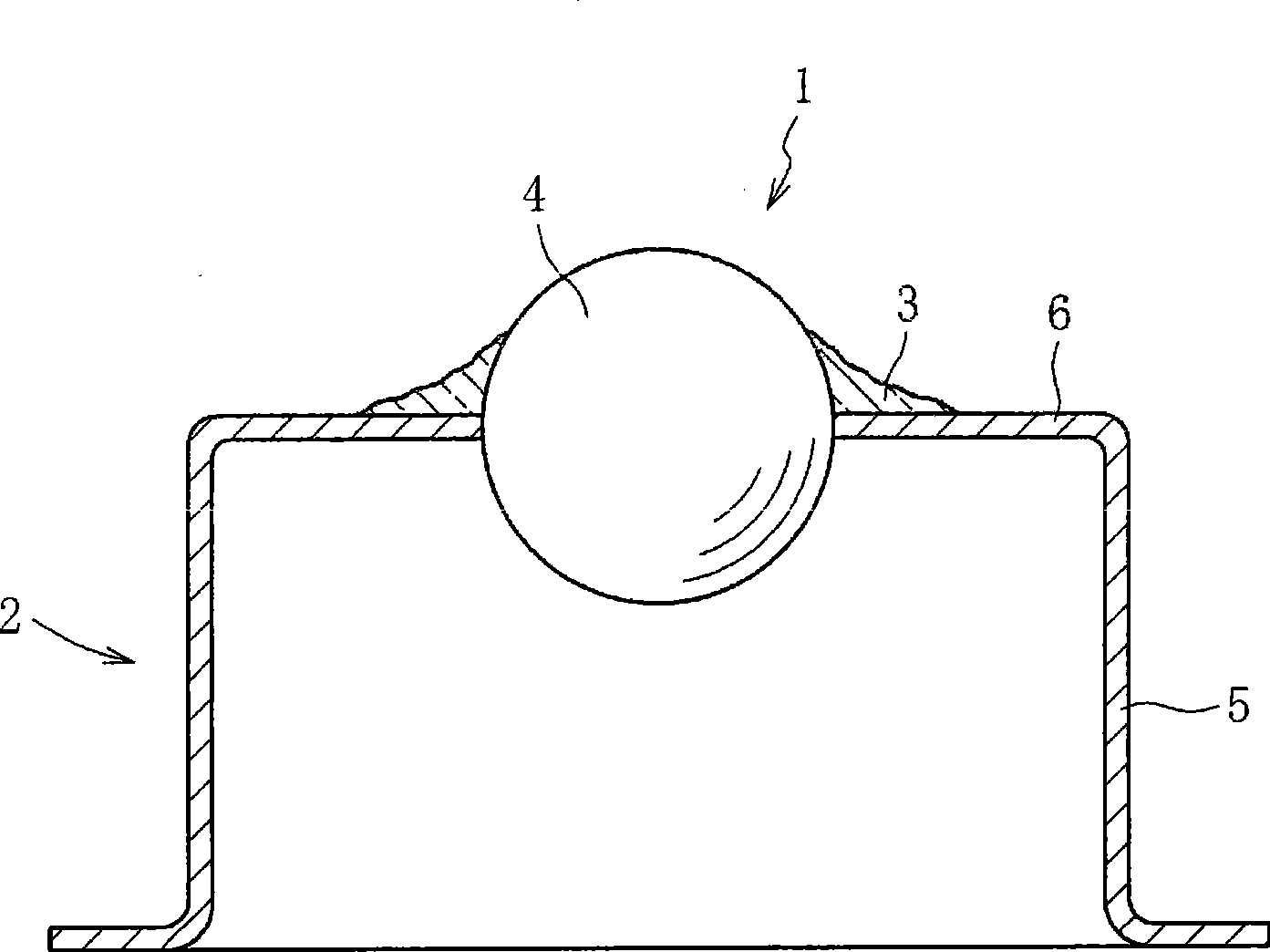

Display Apparatus

ActiveUS20070286973A1High bonding strengthAvoid environmental pollutionLiquid crystal compositionsStatic indicating devicesPhosphate glassVanadate

A sealing glass of a low melting point glass composition which is a phosphate glass that contains transition metal wherein the glass contains 15 to 35% of BaO and Sb2O3 (in total) and the ratio by weight of BaO to Sb2O3 or Sb2O3 to BaO is 0.3 or less. Particularly the transition metal is vanadium and the glass contains V2O5 of 45 to 60 wt % as vanadium oxide and P2O5 of 15 to 30 wt % as phosphorus oxide. The bonding material is a mixture of a filler and a vanadate-phosphate glass that contains V2O5 as the main ingredient and the glass contains V2O5 of 45 to 60%, P2O5 of 20 to 30%, BaO of 5 to 15%, TeO2 of 0 to 10%, Sb2O3 of 5 to 10%, and WO3 of 0 to 5%. The particle size of the filler is in the range of 1 to 150 μm and the ratio of filler is 80% by volume or less of the adhesive glass.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

Phosphate glass for use in the manufacture of ultra-short length lasers and amplifiers

ActiveUS6911160B2Improve thermal shock resistanceExcellent chemical durabilityGlass making apparatusActive medium materialSolubilityAudio power amplifier

A high-gain phosphate glass composition, which can be used to produce ultra-short gain length lasers and optical amplifiers is described wherein the composition of the glass in addition to exhibiting high gain for lasers and amplifiers, also exhibits high thermal shock resistance, high cross section, insignificant concentration quenching, and high solubility for rare earth ions and other properties which enable the material to be fabricated into a new class of ultra-short length micro-laser, fiber laser and amplifier configurations and designs.

Owner:L3HARRIS KIGRE INC

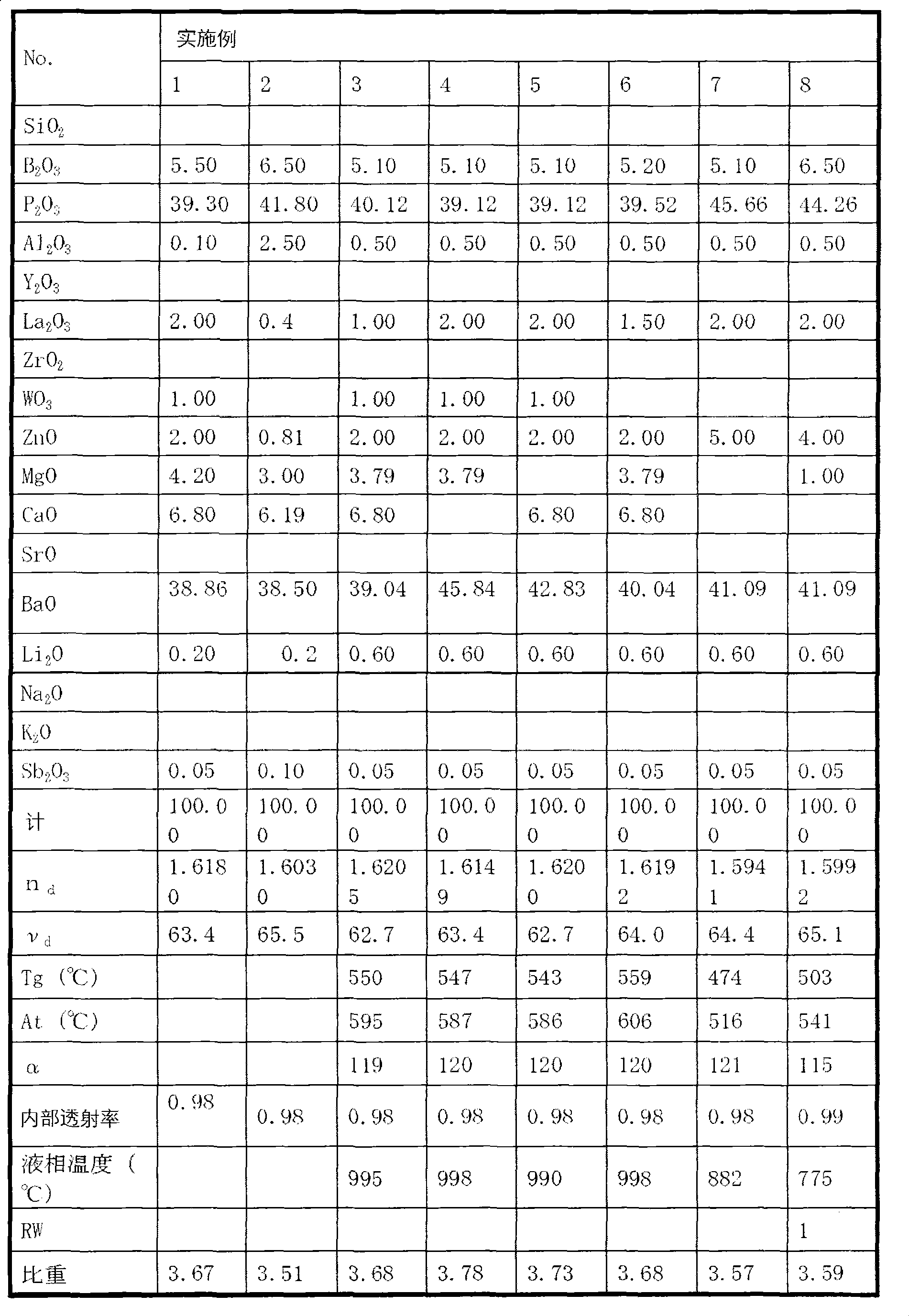

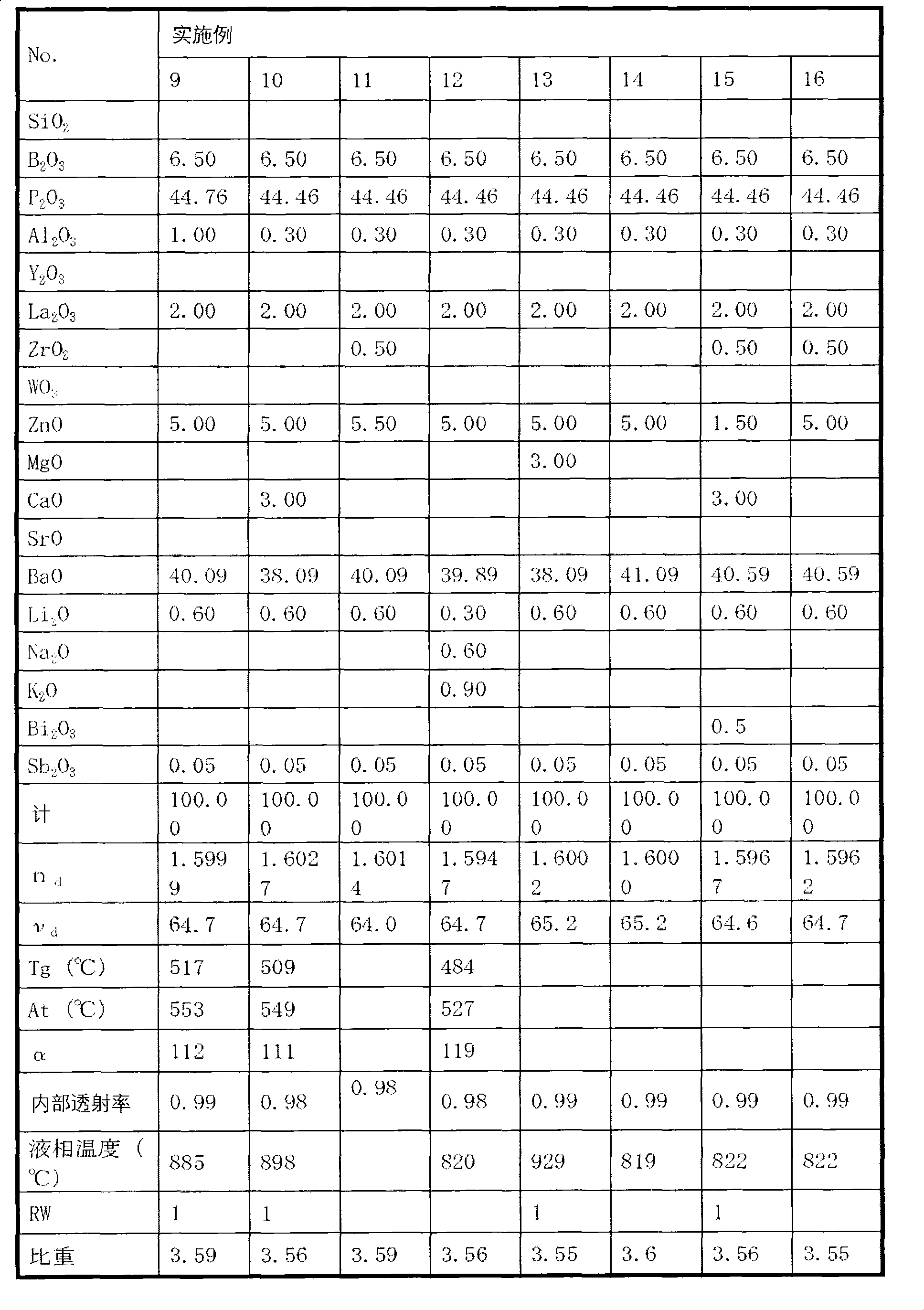

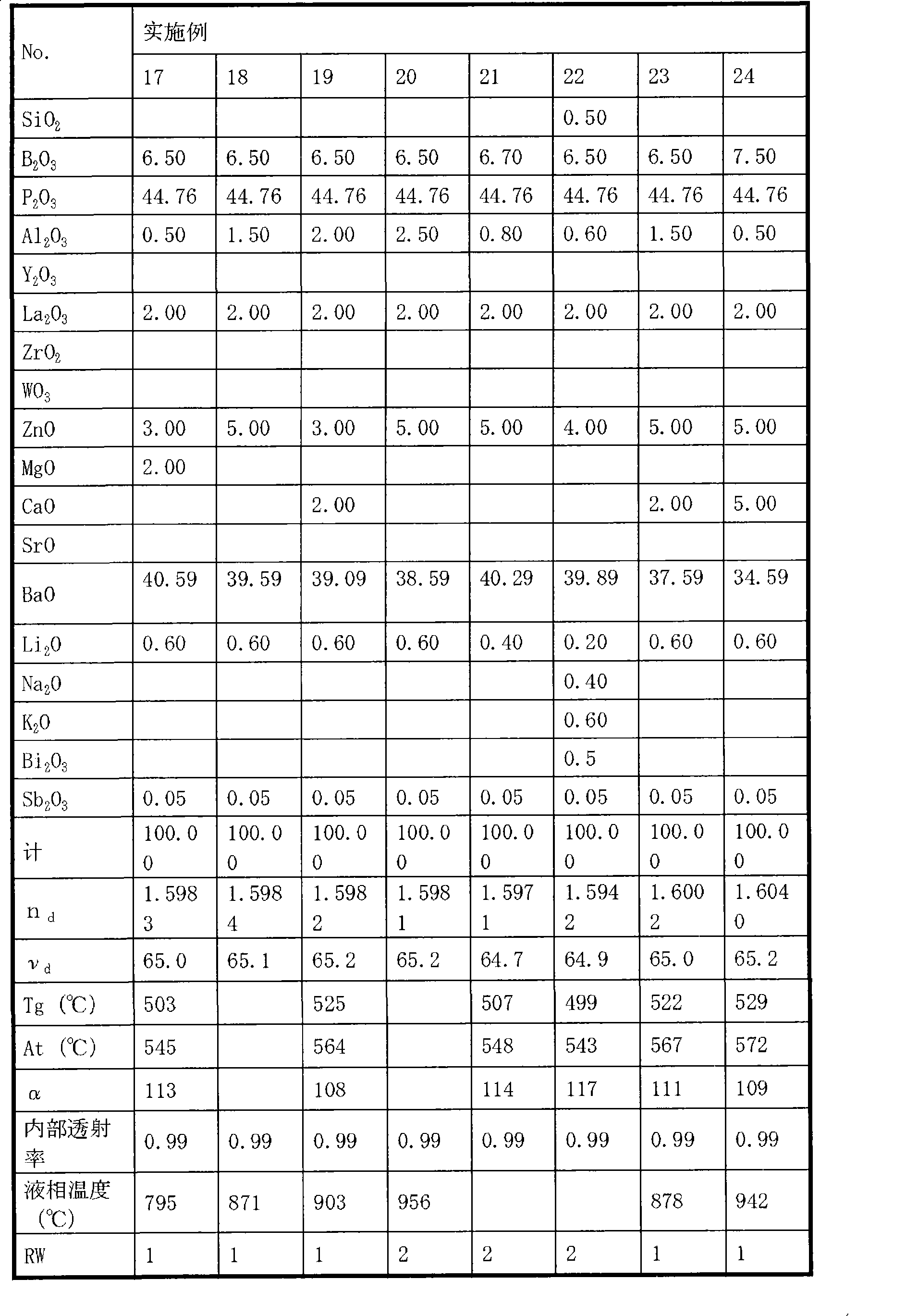

Opticla glass

The invention provides a phosphate glass, which is suitable for manufacturing a non-spherical die mold, a glass pre-forming blank, and the like due to low dispersivity, low glass transition temperature (Tg) and low average coefficient of linear expansion (alpha). An optical glass is characterized in that the optical glass contains P2O5, B2O3, BaO, Al2O3 and La2O3 as necessary components, on the basis of weight percent of an oxide, the total content of Al2O3 and La2O3 is 1 to 10 percent, the value of the Al2O3 content / the La2O3 content ranges from 0.05 to 8.0, and the water resisting property RW of the glass measured by a measuring method (powder method) for chemical durability of the optical glass by JOGIS06<-1999> is level 1 to 3.

Owner:OHARA

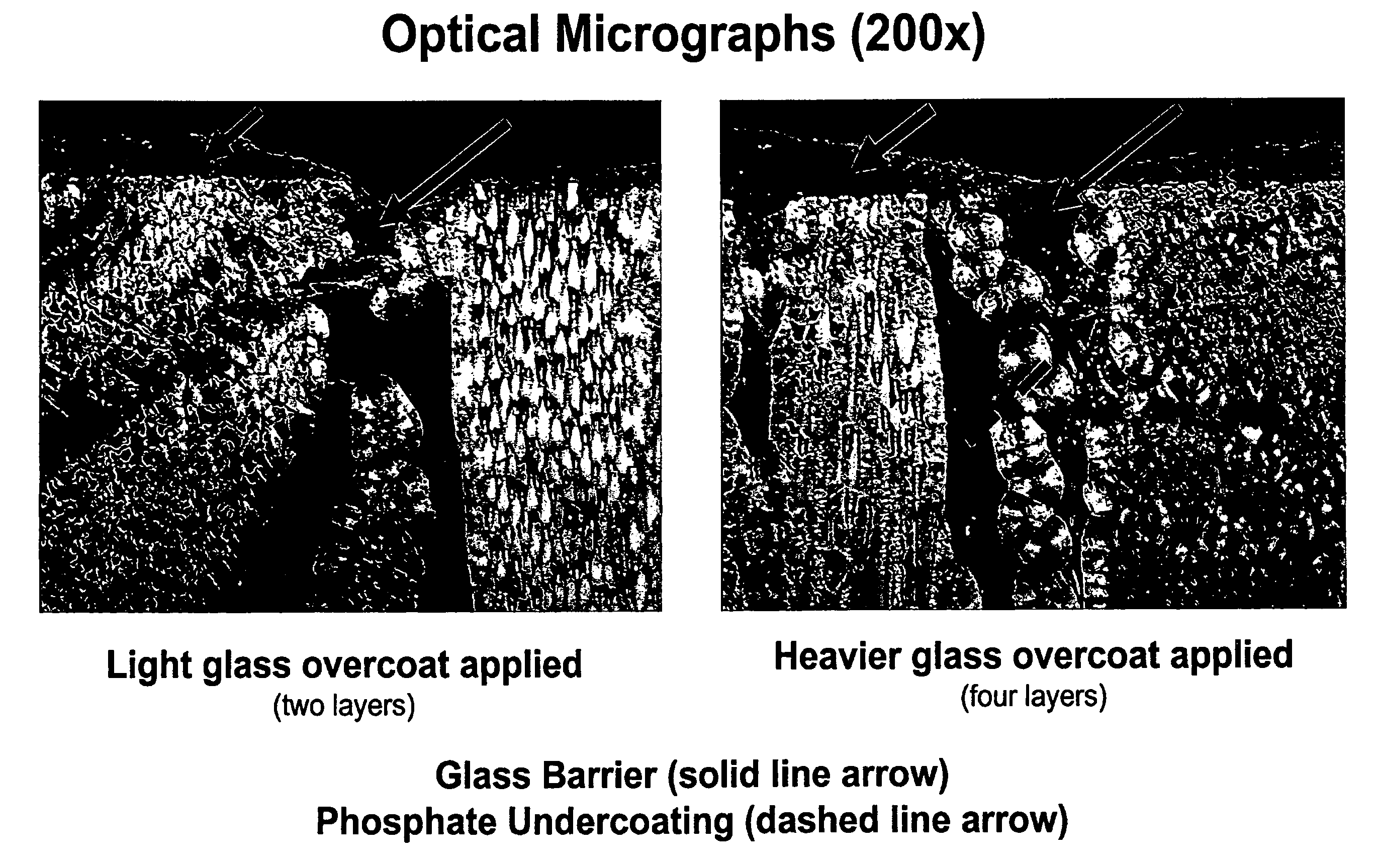

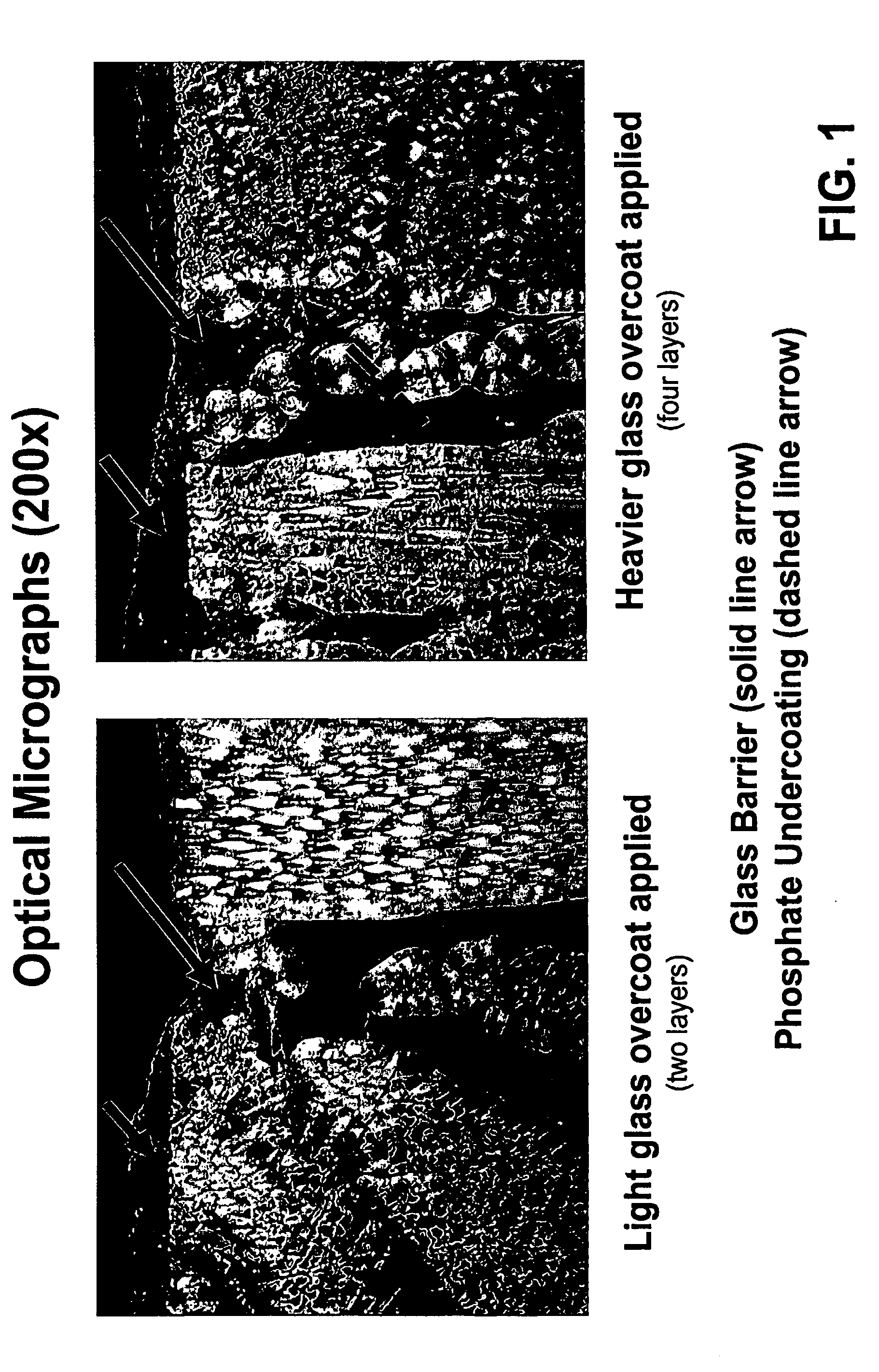

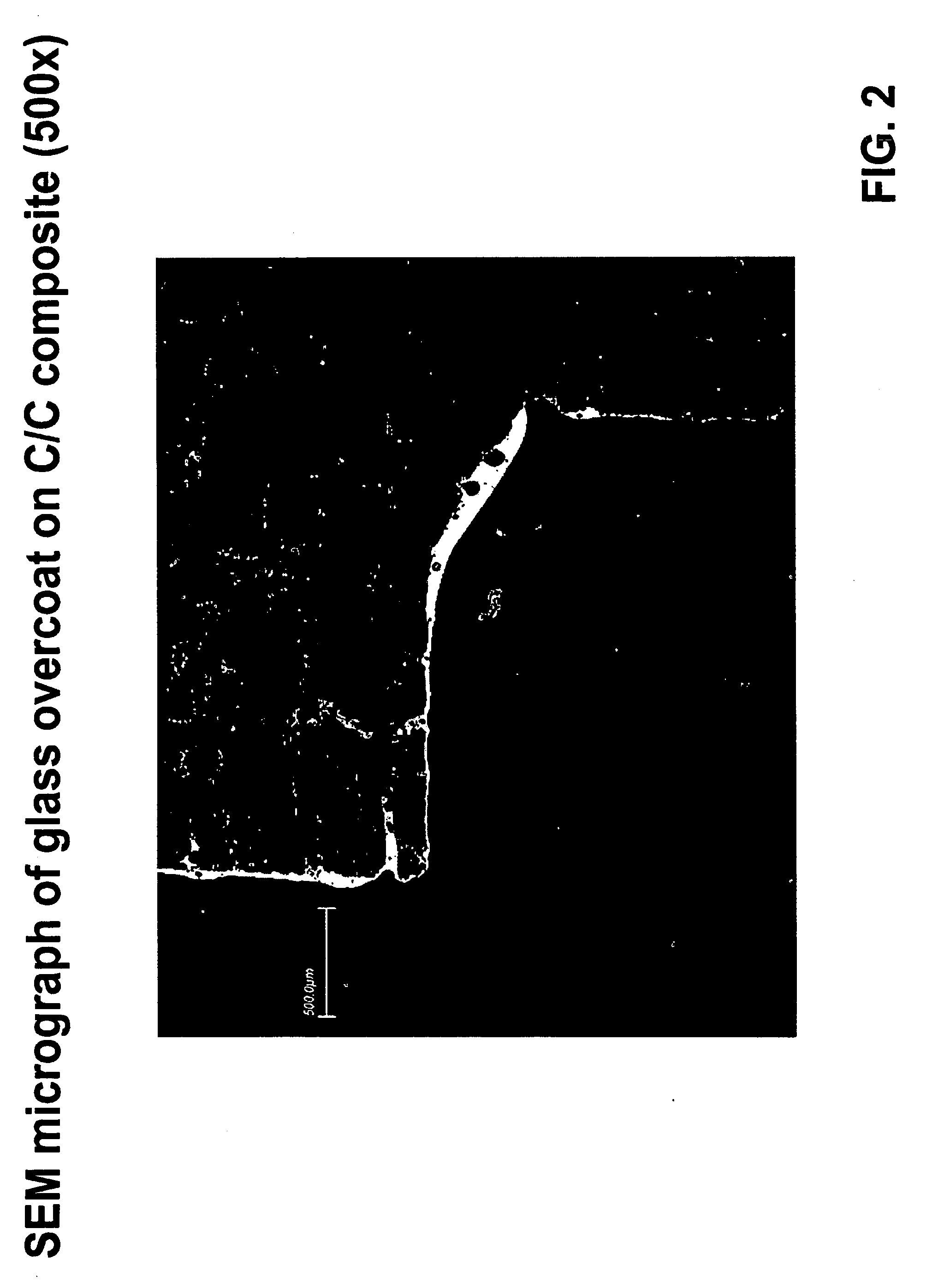

Oxidation inhibition of carbon-carbon composites

The disclosed invention relates to a method and a composition for treating a porous carbon-carbon composite with an oxidation inhibiting composition. The oxidation inhibiting composition comprises at least one phosphate glass. In one embodiment, the method optionally further comprises pretreating the composite with a pretreating composition prior to application of the oxidation inhibiting composition. Carbon-carbon composites treated by the foregoing method are disclosed.

Owner:THE BF GOODRICH CO

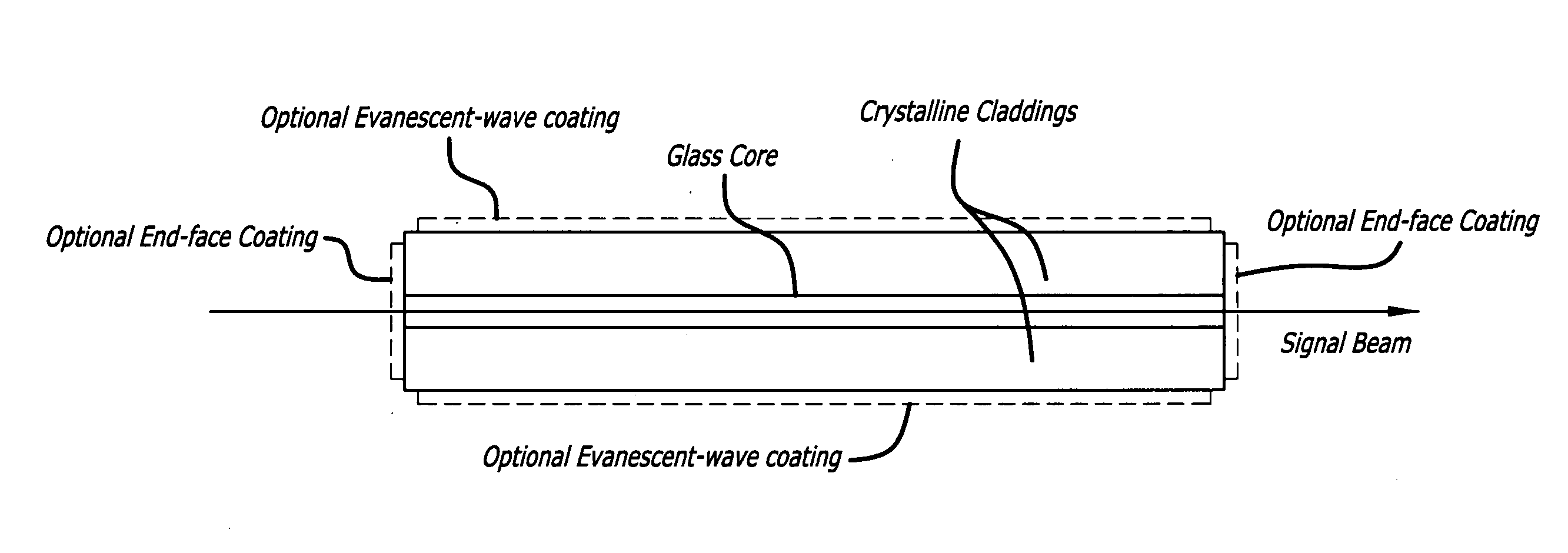

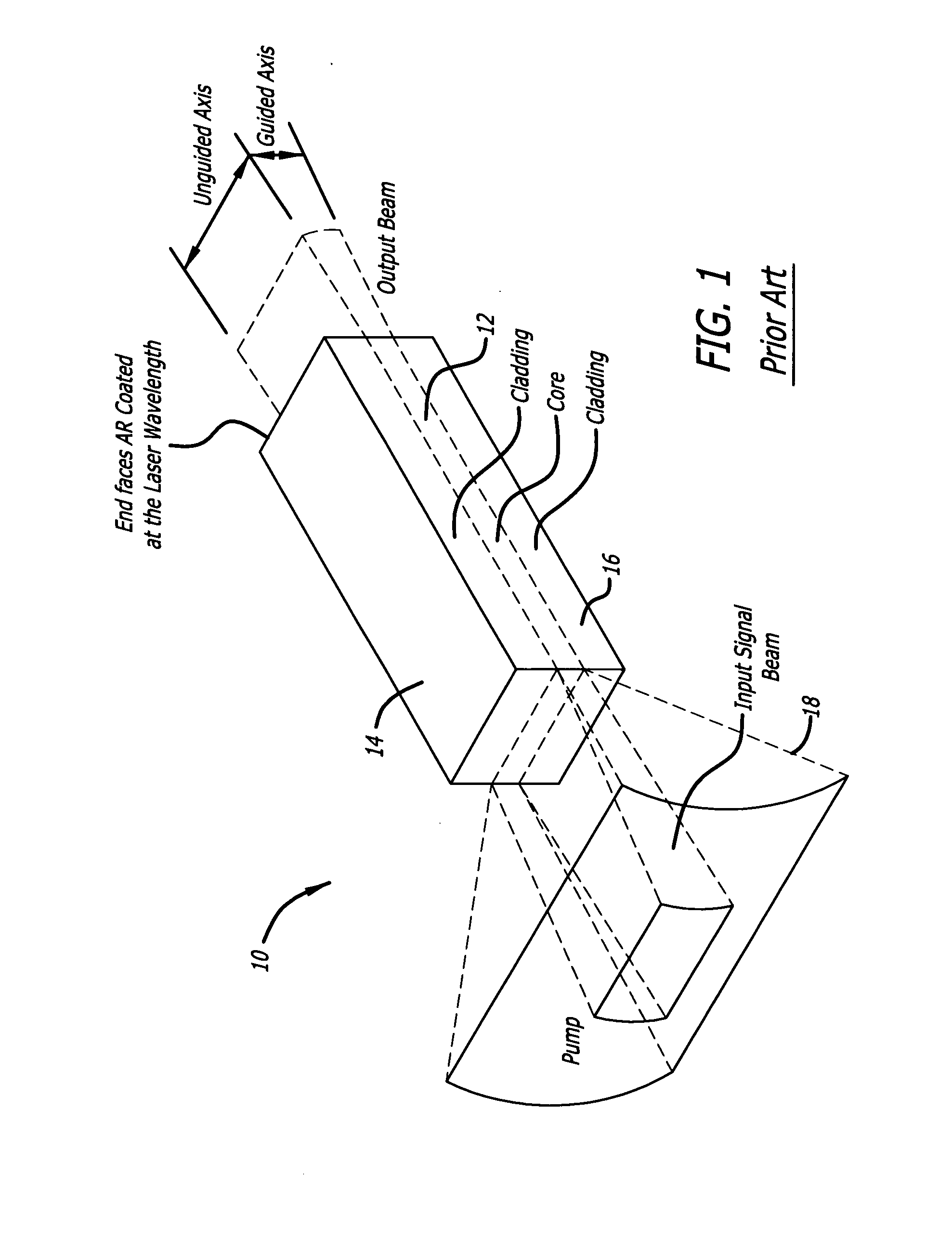

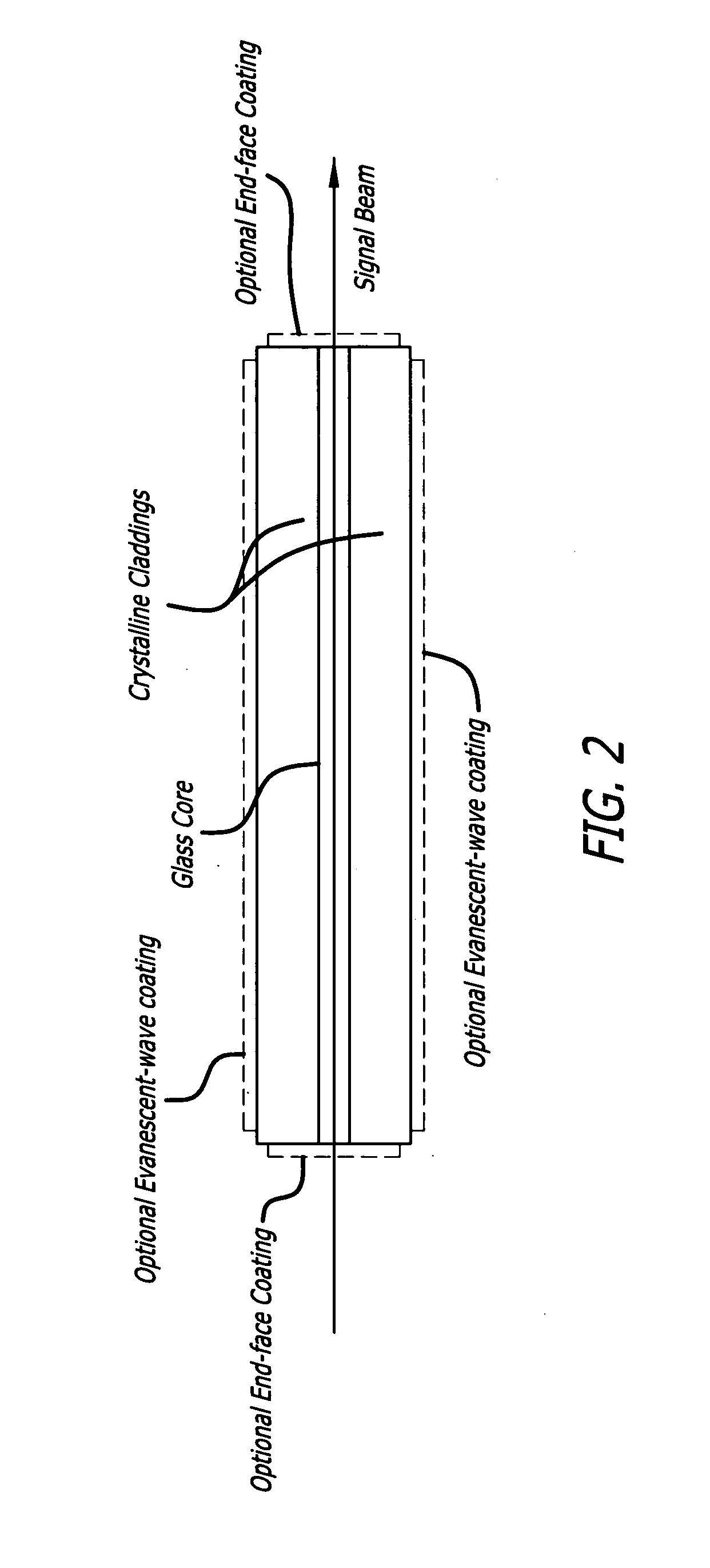

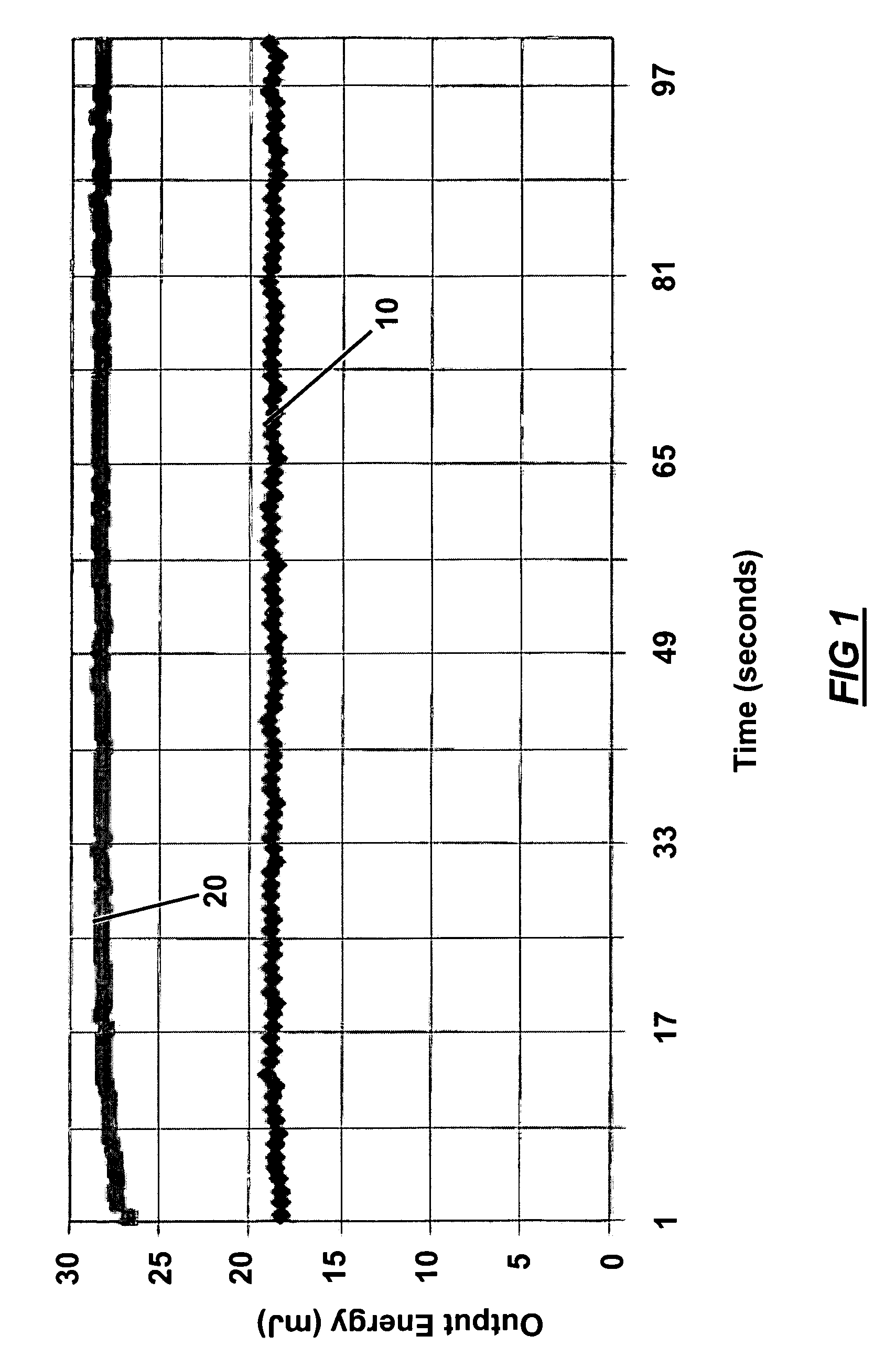

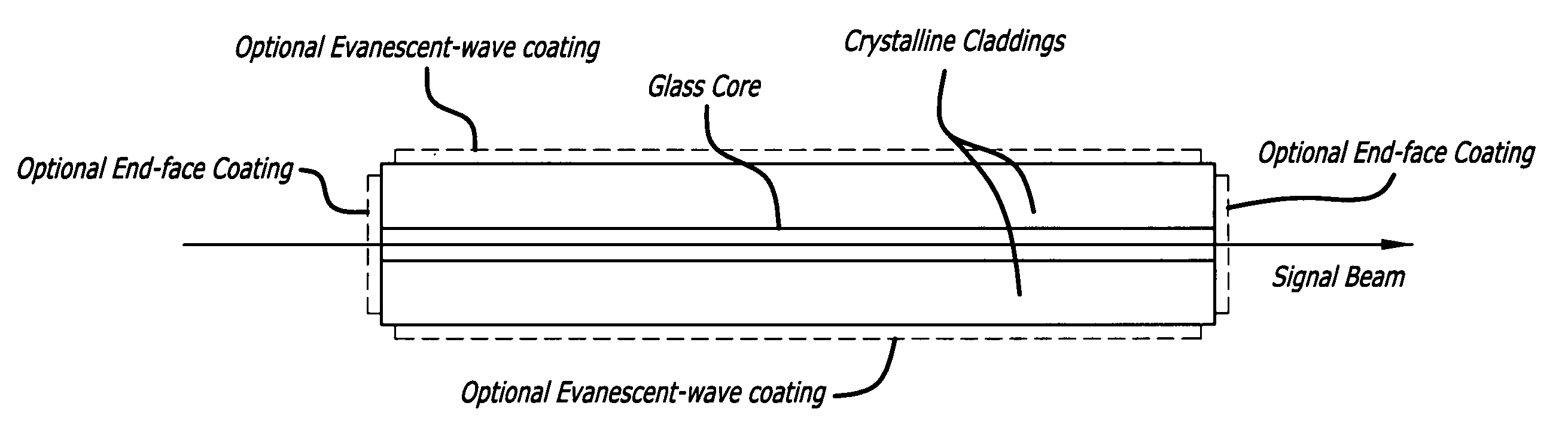

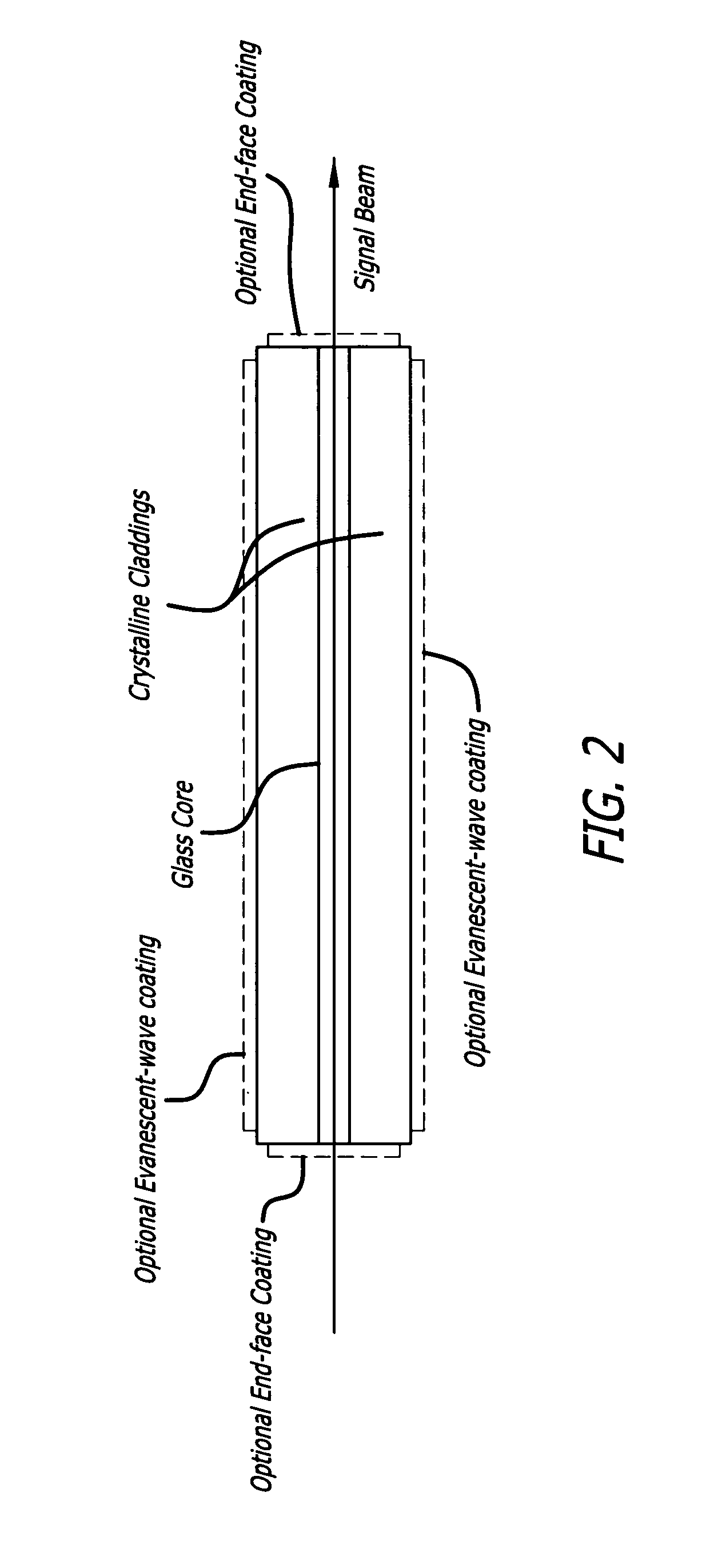

Glass core planar waveguide laser amplifier

ActiveUS20110200292A1High transparencyLow refractive indexLaminationLamination apparatusRefractive indexThermal expansion

A planar waveguide with a glass core and a crystalline cladding. In a specific embodiment, the core is doped preferably with Neodymium, Ytterbium, or Erbium. In the best mode, the core is athermal glass with a refractive index uniformity 10−6 or better and the crystalline cladding has a refractive index lower than that of the core by 10−4 to 10−3 with a refractive index uniformity of 10−4. The cladding has high transparency at pump and lasing wavelengths. The coefficient of thermal expansion of the cladding is close to that of the core. In illustrative embodiments, the cladding is Sapphire and the core is aluminate glass. In an alternative embodiment, the cladding is crystal quartz and the core—is phosphate glass. By utilizing different materials for the core and cladding, the properties of each are optimized. Use of glass for the core allows much more flexibility in tailoring the properties of the core and the PWG geometry readily accommodates the low thermal conductivity of a glass core because the overall thermal performance is dominated by the higher thermal conductivity of the crystalline cladding.

Owner:RAYTHEON CO

Ytterbium-phosphate glass

Owner:L3HARRIS KIGRE INC

Ceramized polyolefin material and preparation method thereof

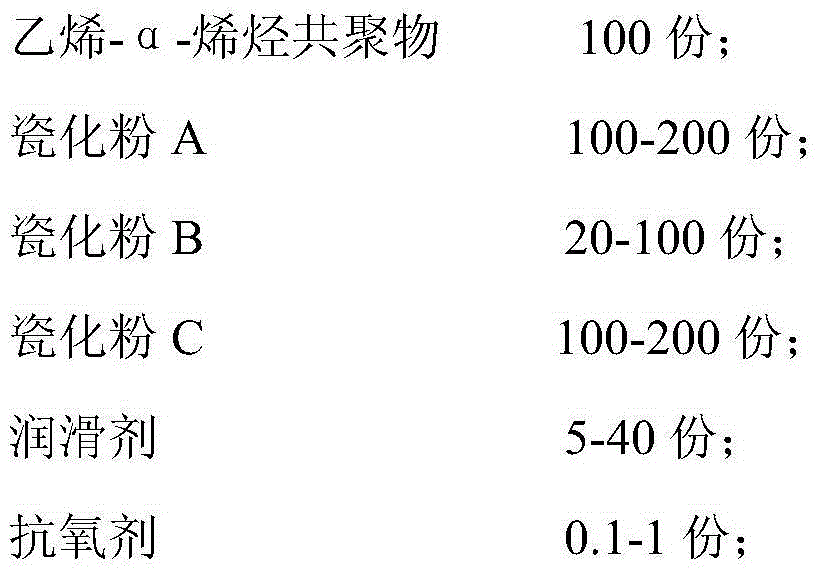

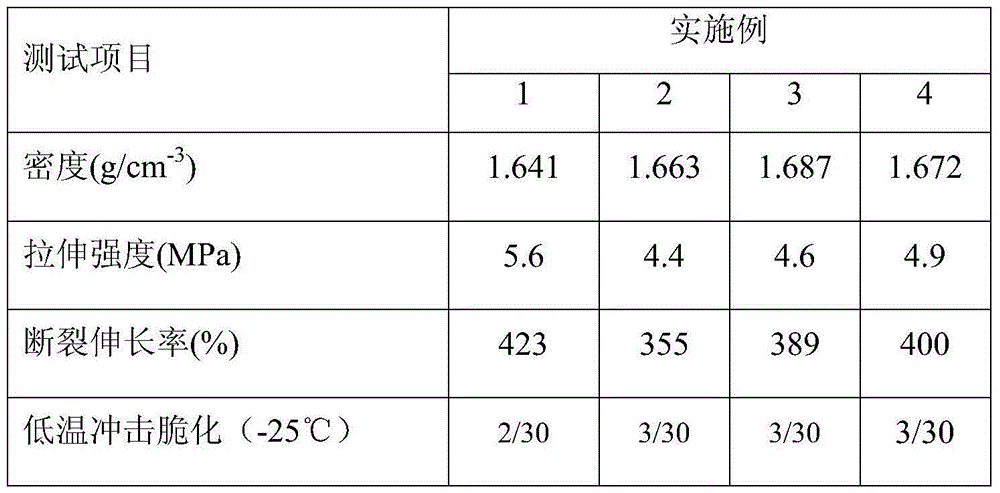

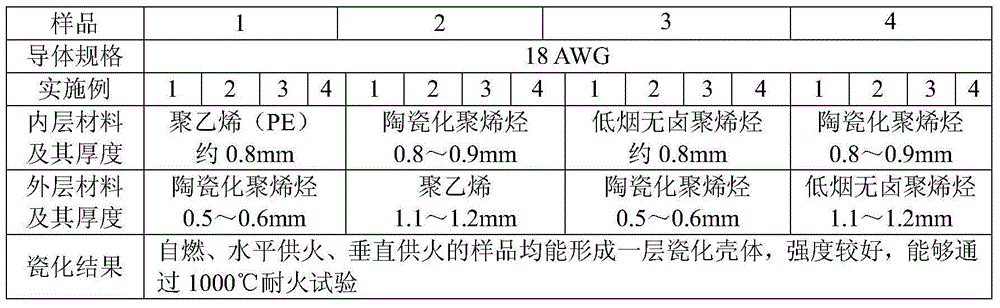

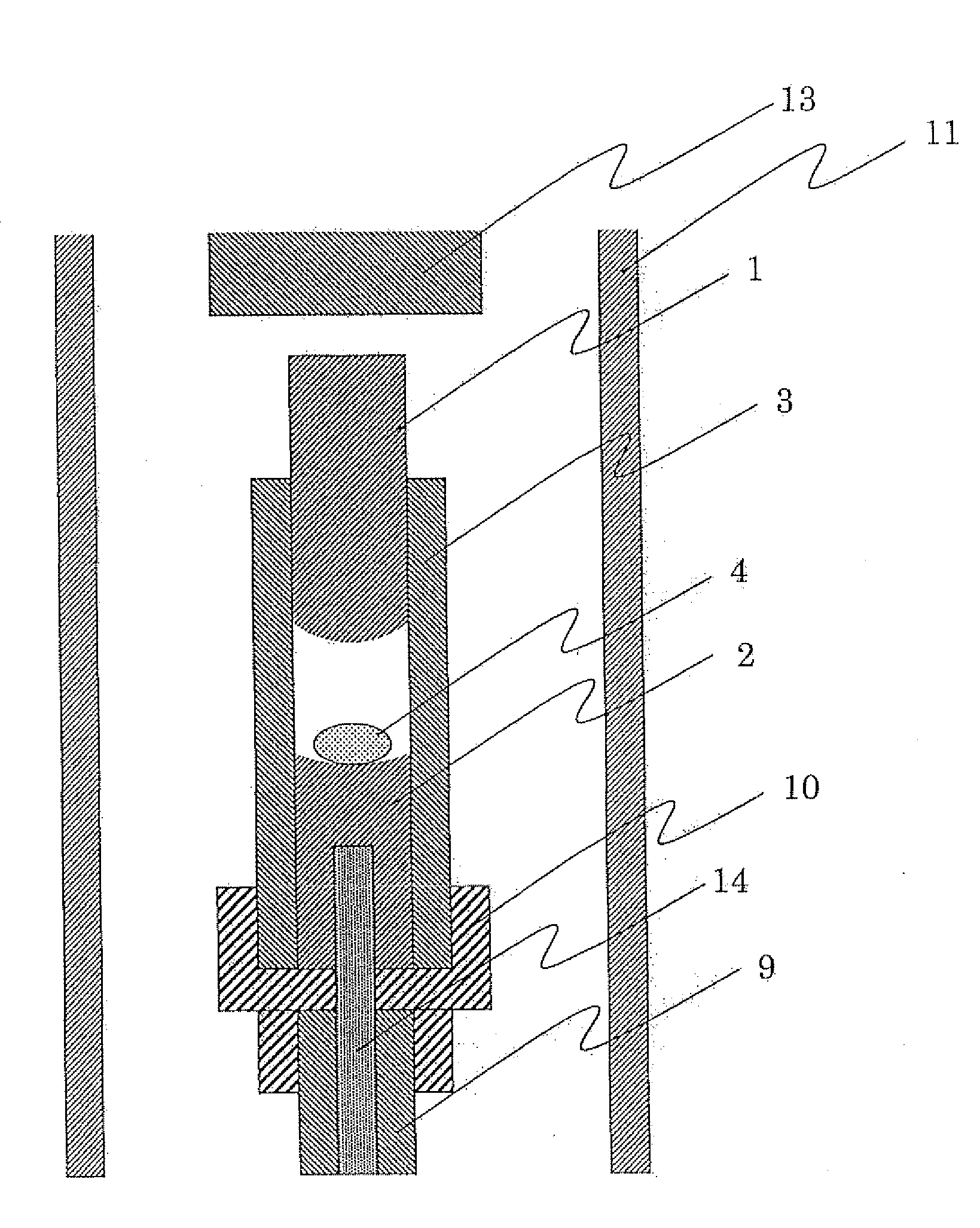

InactiveCN104558805AGood extrusion processing performanceGood porcelain performancePolyolefinAntioxidant

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 100-200 parts of ceramized powder A, 20-100 parts of ceramized powder B, 100-200 parts of ceramized powder C, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; the ceramized powder C is granular powder with excellent high-temperature insulativity; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Phosphate glass, fluorophosphate glass, preform for precision press-molding, optical element and process for the production of thereof

ActiveUS20090325774A1Quality improvementAvoid impuritiesGlass drawing apparatusGlass forming apparatusHalogenBromine

A fluorophosphate glass having a fluorine content of 25% or more by anionic %, which is produced from a glass raw material containing 0.1 to 0.5%, by anionic %, of a halide containing a halogen element selected from chlorine, bromine or iodine, and a phosphate glass having a fluorine content of less than 25% by anionic %, which is produced from a glass raw material containing 0.1 to 5% by anionic %, of a halide containing a halogen element selected from chlorine, bromine or iodine.

Owner:HOYA CORP

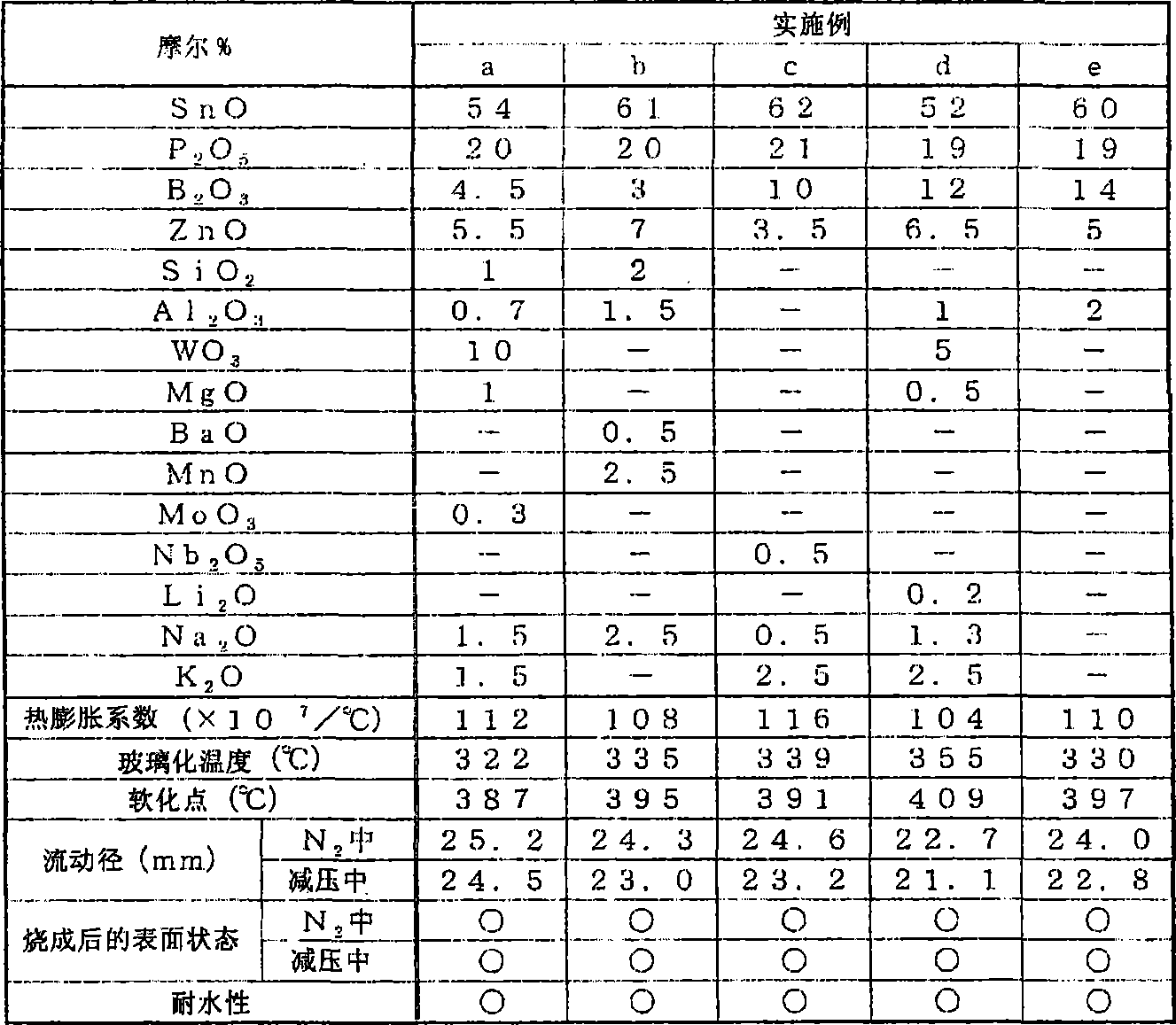

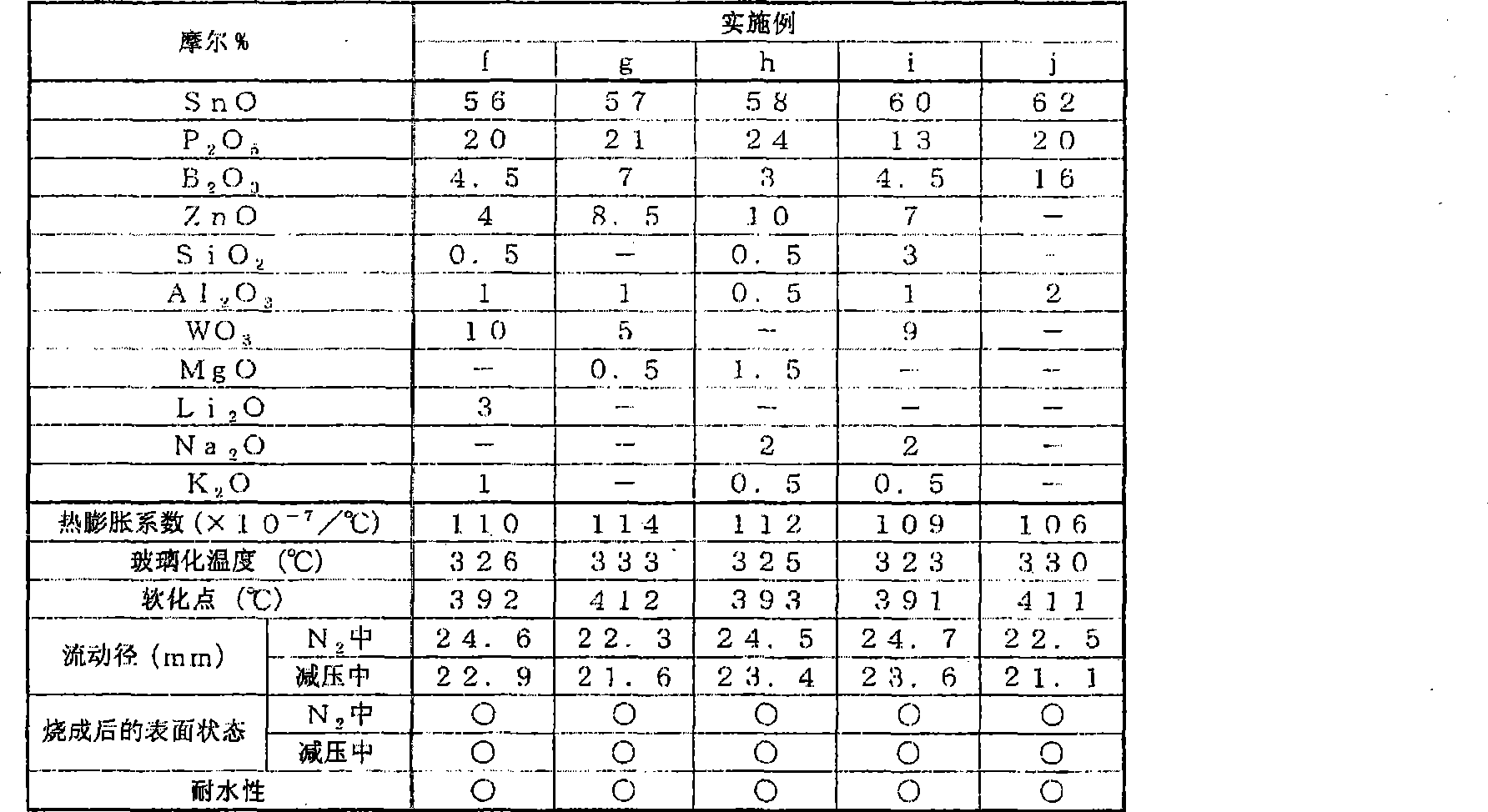

Glass composition for sealing and sealed material

InactiveCN101484396AProne to devitrificationImprove sealingGas-filled discharge tubesElectric discharge lampsPhosphoric acidPhosphate glass

To obtain a glass composition for sealing that not only improves the water resistance of tin phosphate glass but also attains appropriate sealing in low-oxygen atmosphere, especially vacuum atmosphere, and that further allows sealing at low temperature such as 490 DEG C or below, excelling in thermal stability, and obtain a relevant sealed material. There is provided a glass composition for sealing characterized by having a glass composition containing, by molar percentage in terms of oxide, 30 to 80% SnO, 10 to 25% (not including 25%) P2O5, 0 to 20% B2O3, 0 to 20% ZnO, 0 to 10% SiO2, 0 to 10% Al2O3, 0 to 20% WO3 and 0 to 20% R2O (R represents at least one of Li, Na, K and Cs) and characterized by being employed in sealing in low-oxygen atmosphere, especially vacuum atmosphere.

Owner:NIPPON ELECTRIC GLASS CO LTD

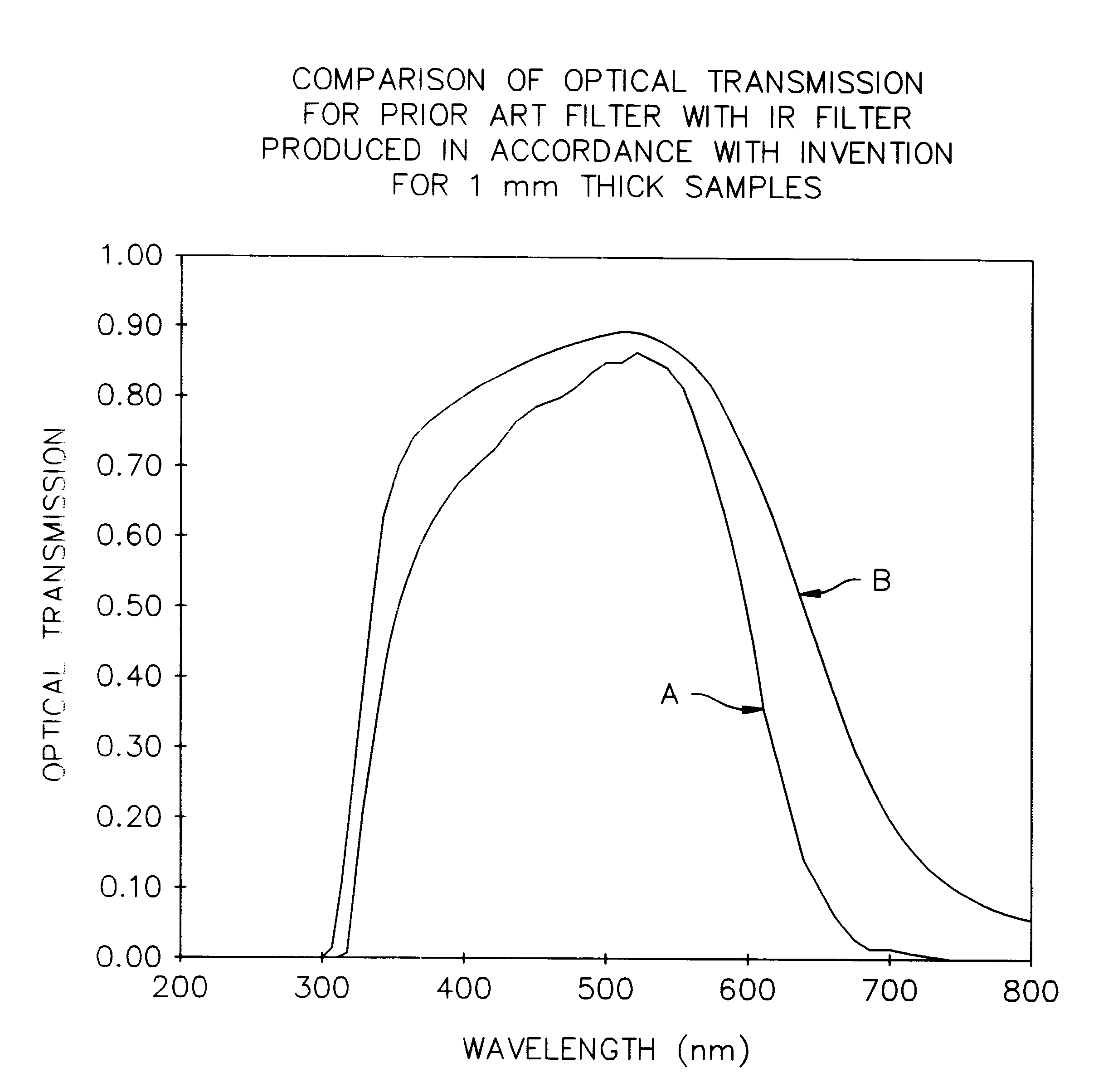

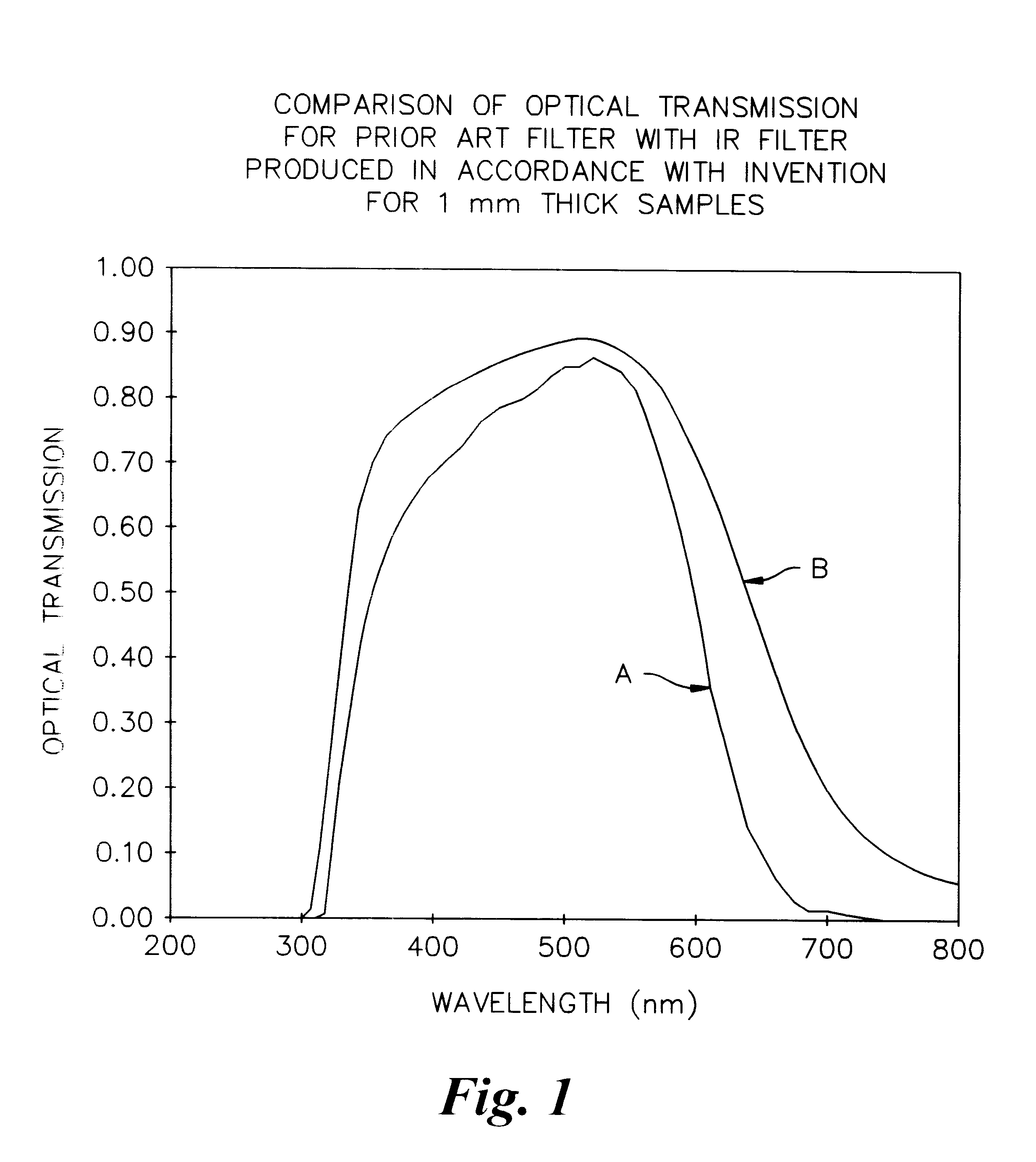

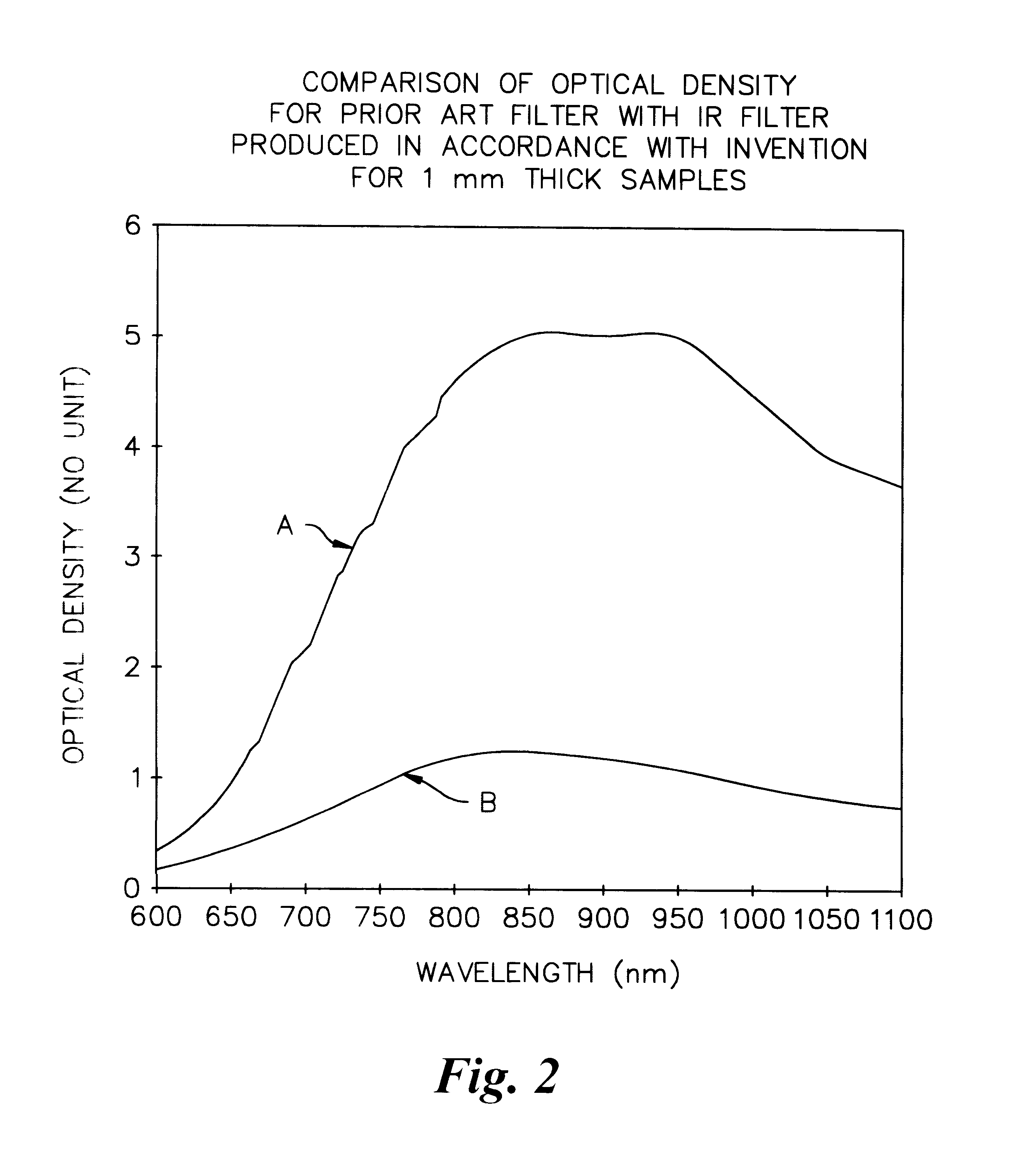

Infra red filter

InactiveUS6252702B1Improve air safetyReduce transmissionSensing by electromagnetic radiationOptical elementsNight visionCopper

A phosphate glass doped with copper in an amount of less than 2% by weight is formed to produce a lens for use on external aircraft lights. The glass attenuates infra red radiation to a degree where it does not pose a danger of temporarily blinding a pilot wearing night vision goggles yet remains visible. The glass has little appreciable effect on light transmission in the visible spectrum. Conveniently, the glass can be formed by slumping at a softening temperature against a mold to produce intricate lens shapes. In addition, the glass is able to withstand conventional toughening processes.

Owner:THALES OPTRONICS TAUNTON +2

Bismuth containing fluorophosphate glass and method for making thereof

ActiveUS20070010390A1Increased durabilityImprove efficiencyPot furnacesCharging furnaceRare-earth elementRefractive index

New and improved compositions of doped and co-doped bismuth fluorophosphate glasses for lasers is disclosed that have a high refractive index (nD) of approximately 1.6 and higher, high transmission in the near infrared part of the spectrum, and a wide glass forming domain. The disclosed glass systems Al(PO3)3-Ba(PO3)2-Bi(PO3)3-BaF2+RFx+dopands use dopants from the group of oxides and or fluorides of rare earth elements Nd, Er, Yb, Tm, Tb, Ho, Sm, Eu and Pr as well as MnO and mixtures thereof over 100 percent (wt %) of the glass-base composition. These glasses have high chemical durability, radiation resistance, efficiency of laser use in the infrared and blue spectrum, and improved duration of luminescence.

Owner:AFO RES INC

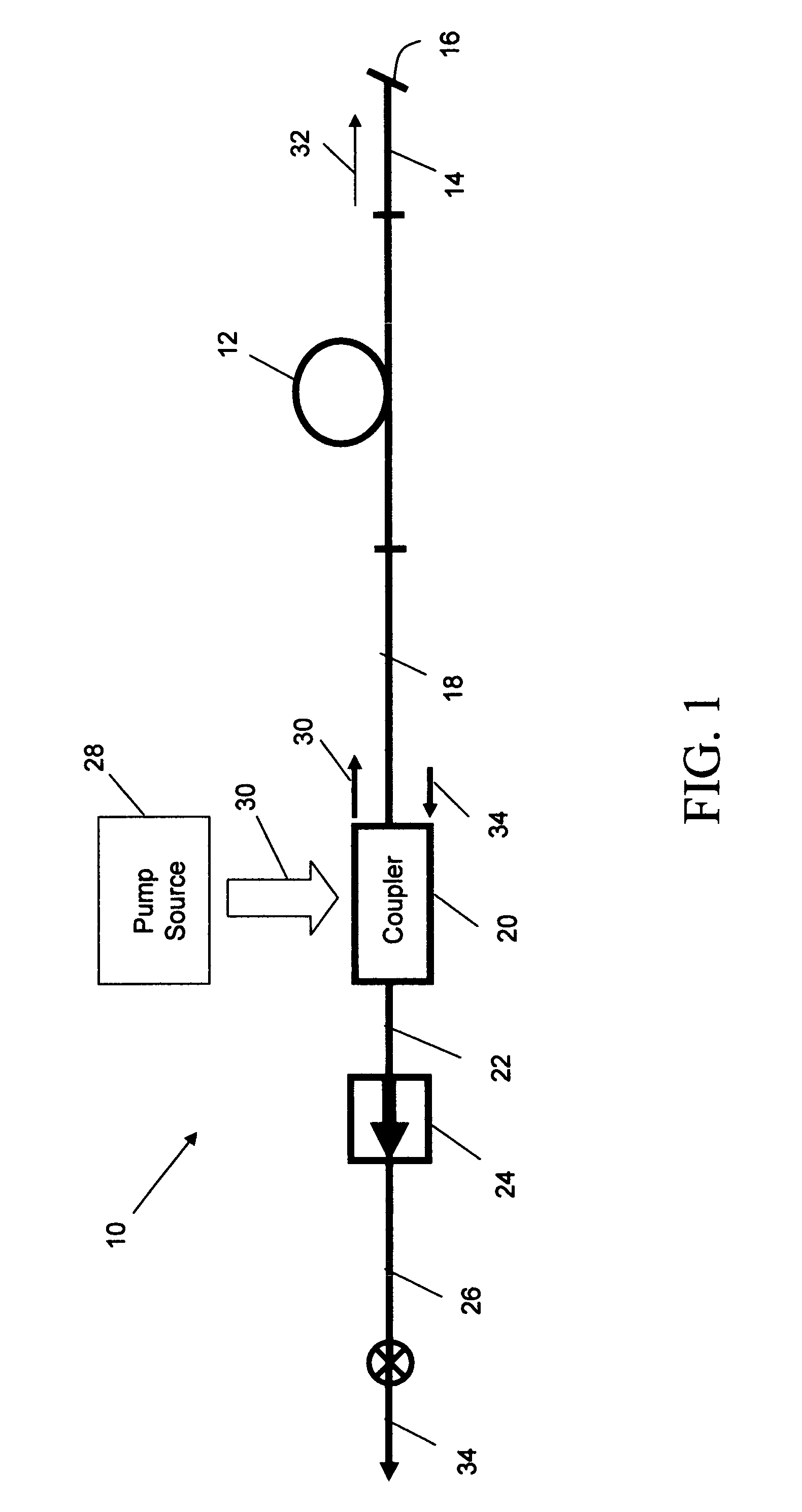

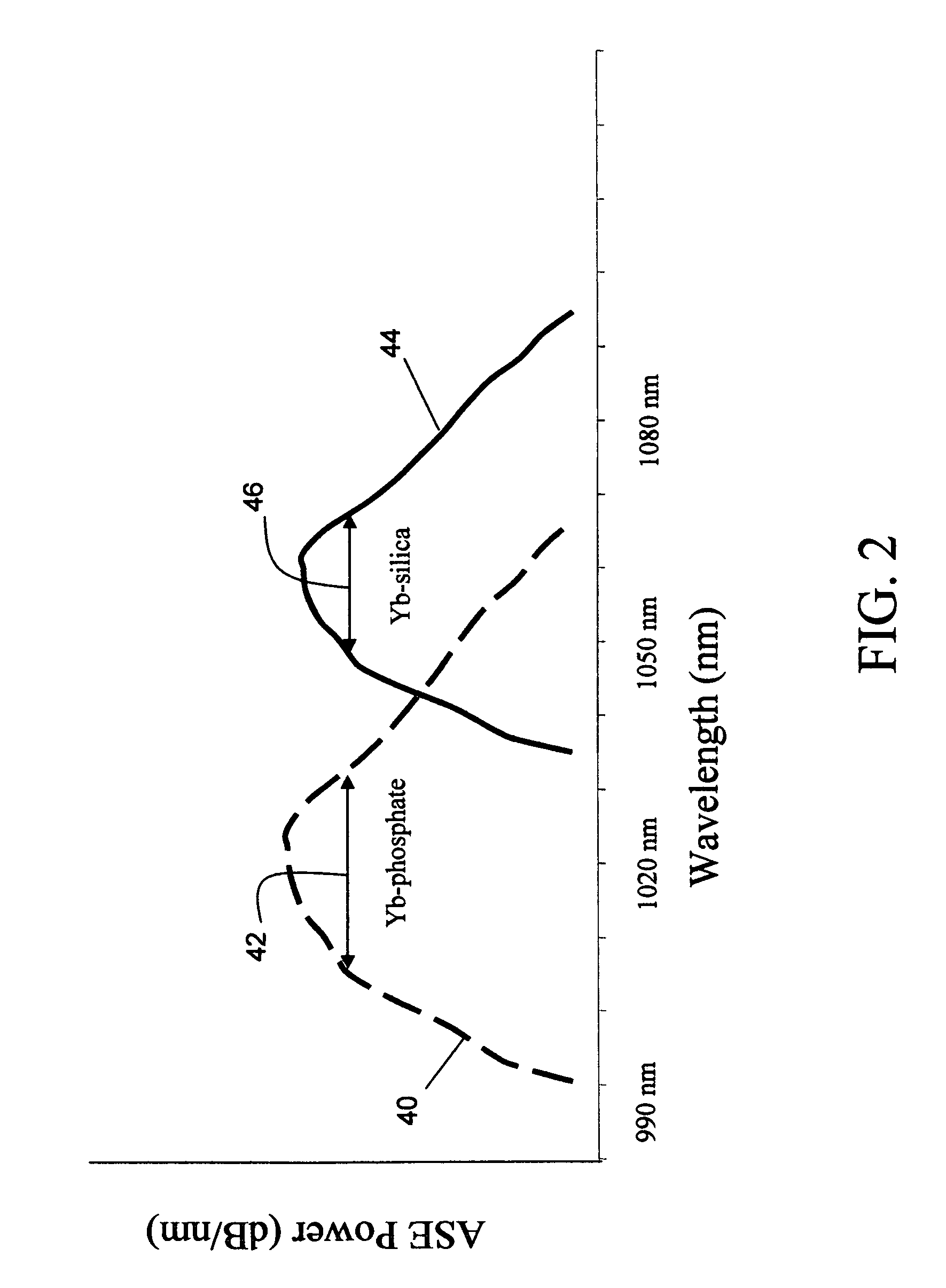

1-mum phosphate-glass fiber amplified spontaneous emission (ASE) source

ActiveUS7423803B1High levelImprove stabilityLaser using scattering effectsFibre transmissionHigh concentrationPhosphate glass

A phosphate glass 1-μm fiber ASE source provides high power and broadband emission that covers wavelengths on the short side of Yb-doped silica. A single-mode fiber formed from phosphate glass is doped with highly elevated concentrations of Yb dopants 0.5-30 wt. % and typically 2-10 wt. %, far higher than either silica or germano-silicate. The high concentration of Yb dopant absorbs the pump in a short length, typically 10-150 cm instead of tens of meters, to provide high saturated output power and a shifted emission spectrum. The excess power allows the fiber ASE source to be configured to provide the output powers, emission bandwidth and stability desired by many applications. Furthermore, the ASE can be configured to emit a nearly Gaussian spectral profile without sacrificing power or bandwidth. The backward emission spectrum of Yb-doped phosphate glass is centered near 1020 nm instead of 1060, which allows the ASE source to cover wavelength on the short side of Yb-doped silica, which may be important in certain applications such as ophthalmic OCT where water absorption has a transparency window.

Owner:NP PHOTONICS A CORP OF DELAWARE

Glass core planar waveguide laser amplifier

ActiveUS8977097B2Active medium materialActive medium shape and constructionRefractive indexThermal expansion

Owner:RAYTHEON CO

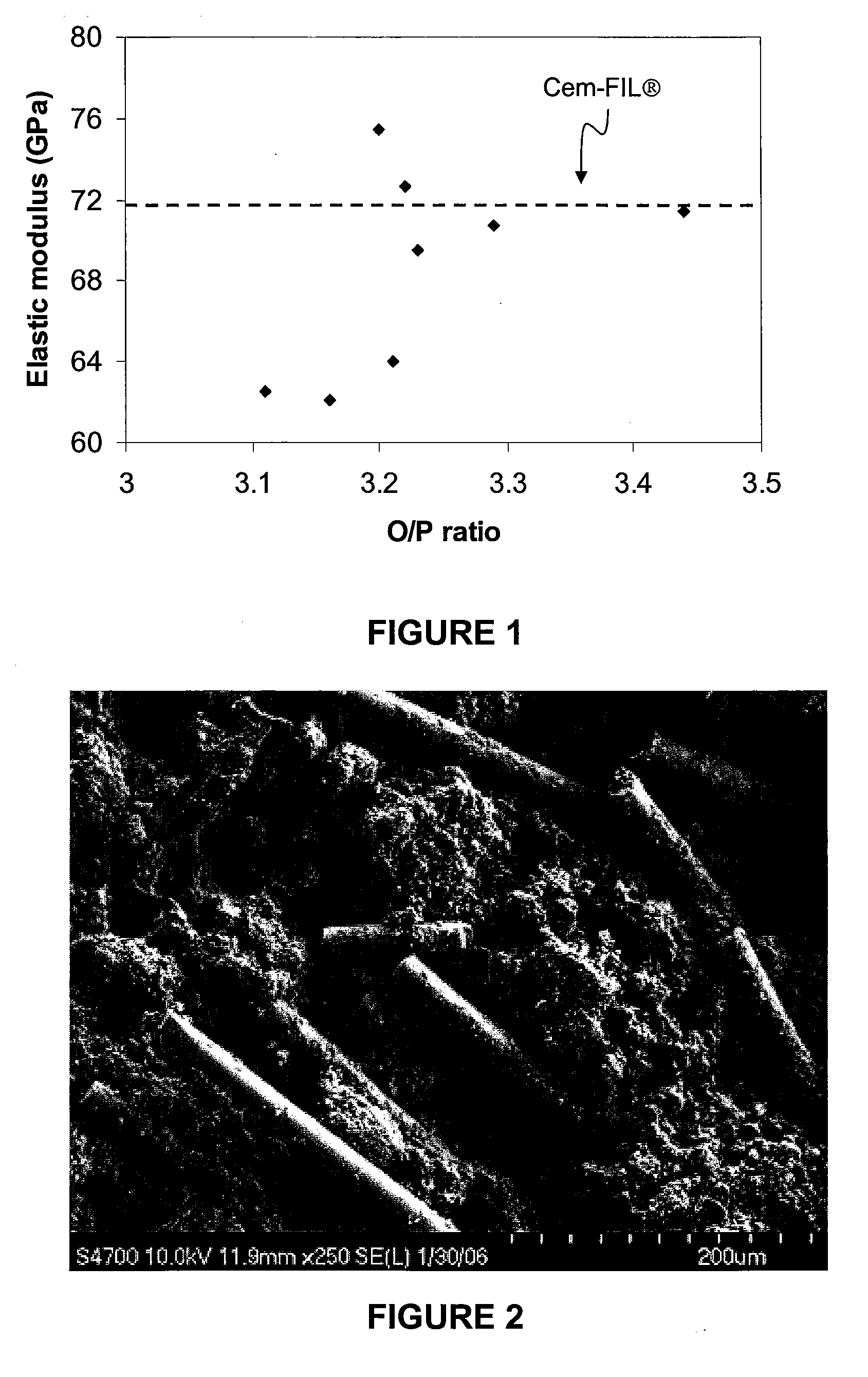

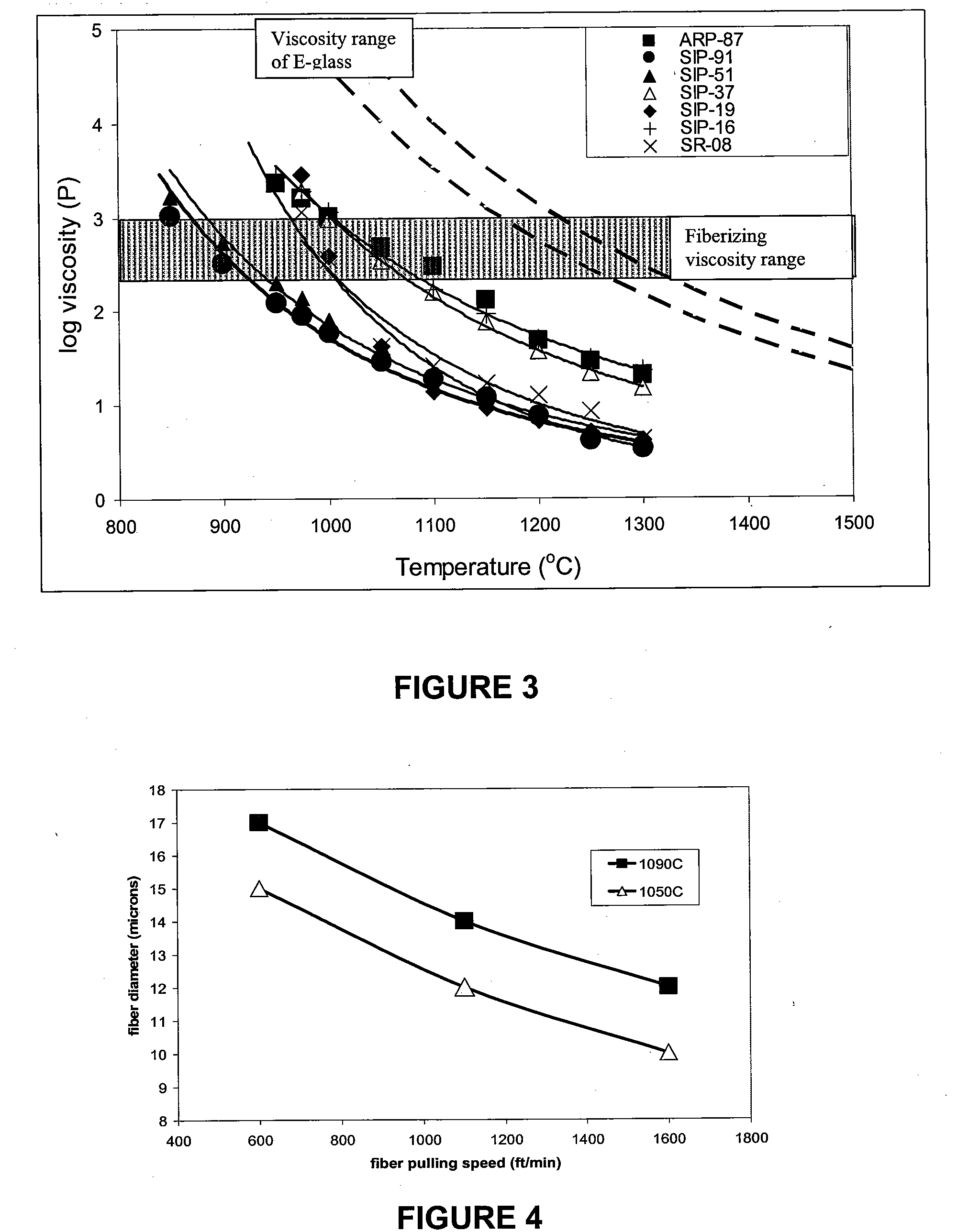

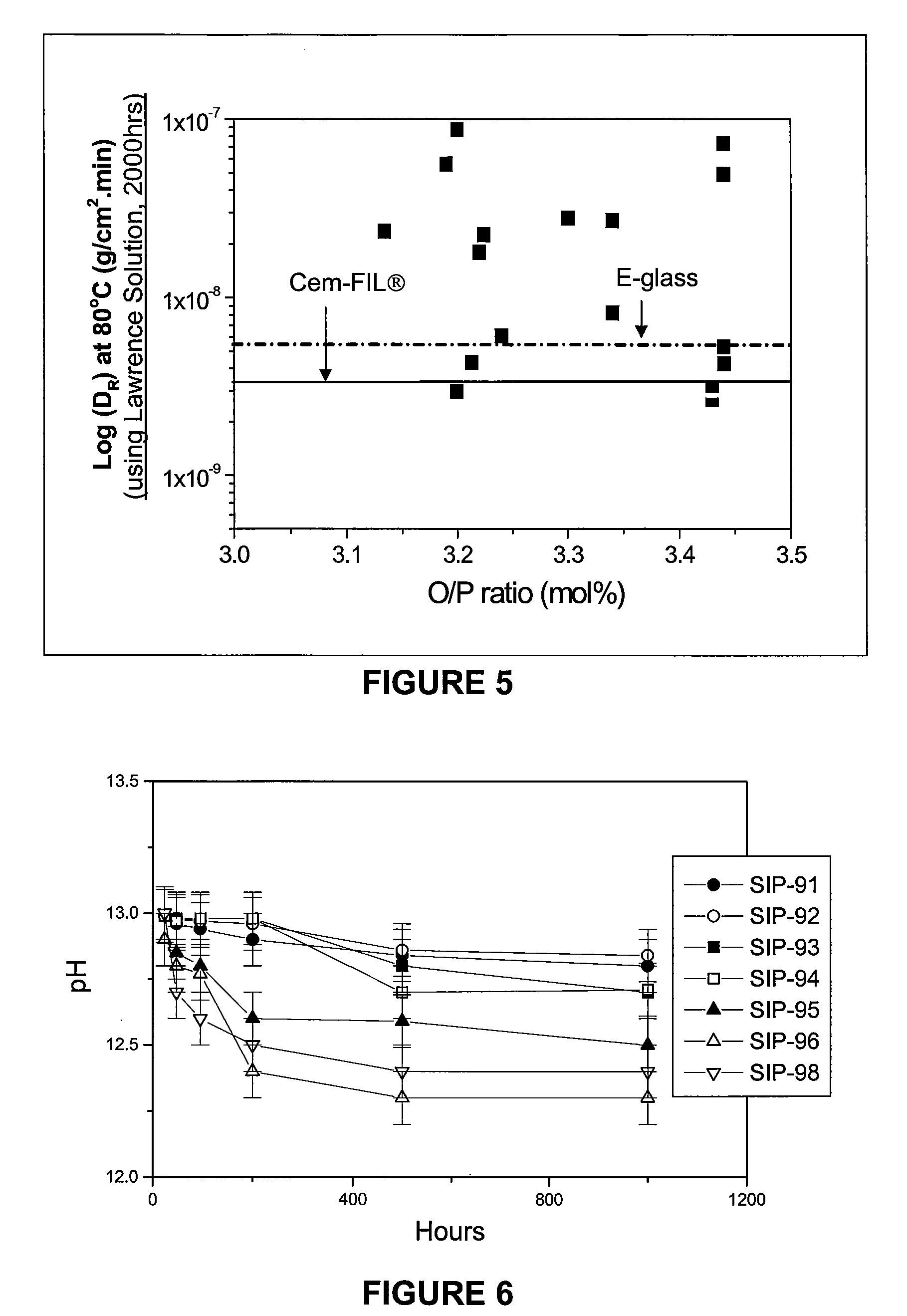

Alkaline resistant phosphate glasses and method of preparation and use thereof

A substantially alkaline resistant calcium-iron-phosphate (CFP) glass and methods of making and using thereof. In one application, the CFP glass is drawn into a fiber and dispersed in cement to produce glass fiber reinforced concrete (GFRC) articles having the high compressive strength of concrete with the high impact, flexural and tensile strength associated with glass fibers.

Owner:MO SCI +1

Ceramized polyolefin material and preparation method thereof

InactiveCN104558804AHigh strengthReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinAntioxidant

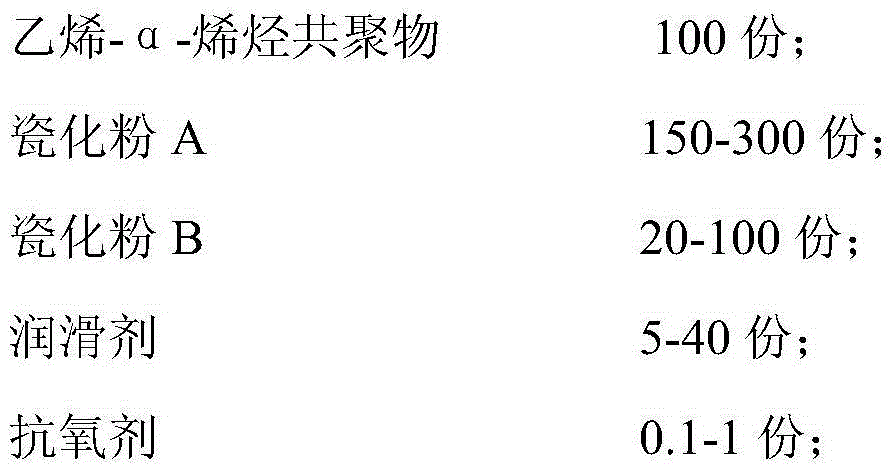

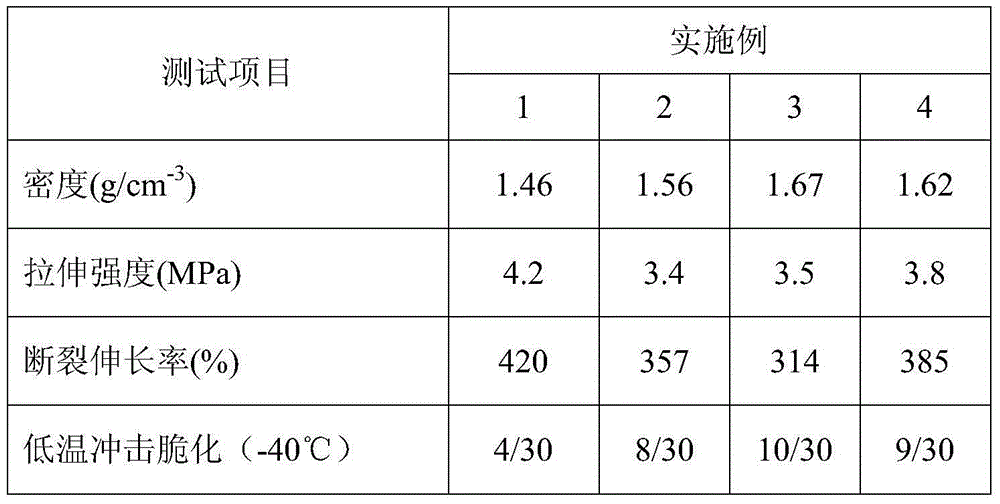

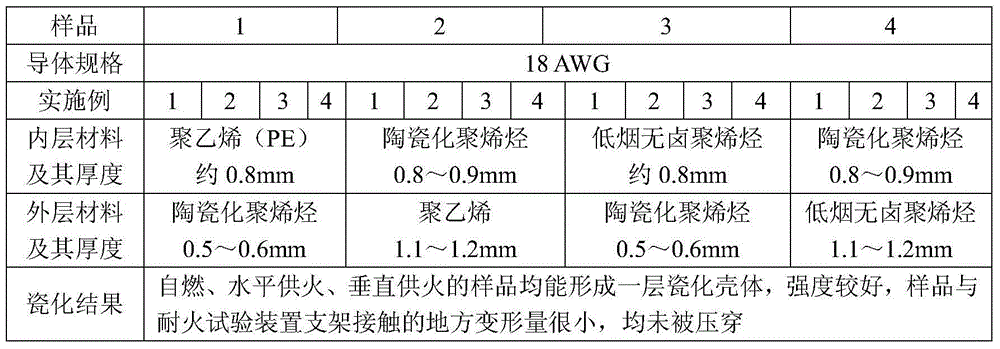

The invention discloses a ceramized polyolefin material and a preparation method thereof, belonging to the field of electric wire and cable materials. The ceramized polyolefin material comprises the following raw material components: 100 parts of an ethylene-alpha-olefin copolymer, 150-300 parts of ceramized powder A, 20-100 parts of ceramized powder B, 5-40 parts of a lubricating agent and 0.1-1 part of an antioxidant, wherein the ethylene-alpha-olefin copolymer is one or more selected from an ethylene and alpha-propylene copolymer, an ethylene and alpha-butylene copolymer, an ethylene and alpha-hexylene copolymer and an ethylene and alpha-octene copolymer; the ceramized powder A is one or a combination of more than one selected from layered inorganic powder, fibrous inorganic powder and needle-like inorganic powder; the ceramized powder B is at least one selected from borax, ammonium borate, a zinc borate and boron frit, phosphate glass powder with a low melting point, borate glass powder with a low melting point and silicate glass powder with a low melting point; and the antioxidant is at least one selected from 1010, 1076, 168, 626, 300 and DSTDP. The ceramized polyolefin material is reasonable in raw material and proportion, capable of ensuring normal operation of a route, good in flexibility, simple in process and low in cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

A preparation method of flame-retardant anti-melt drop polyester composite fiber

ActiveCN102277653AImprove flame retardant performanceExcellent resistance to drippingFilament/thread formingConjugated synthetic polymer artificial filamentsHeat stabilityPhosphate glass

The invention relates to a preparation method of inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention comprises the following steps of: (1) mixing aromatic dicarboxylic acid, dihydric alcohol and phosphorus-containing fire retardant and adding catalyst and heat stability; reacting to obtain an inflame-retardant copolyester; (2) pre-mixing SNF2, SnO, NH4H2PO4 or P2O5 for 30-60 min and melting at a temperature in a range of 400-500 DEG C for 60-90 min; cooling and carrying out a heat treatment at a temperature in a range of 70-100 DEG C for 90-120 minto obtain phosphate glass; and (3) blending the inflame-retardant copolyester with the phosphate glass and melting and spinning to obtain the inflame-retardant anti-dripping polyester composite fibers. The method provided by the invention has the advantages of simple process and easiness of being implemented; the prepared copolyester and fibers thereof have good inflame-retardant and anti-dripping performances; the limit oxygen index of the textiles is 29.8-33.2% and no melted drops are formed when the product is combusted so that the method provided by the invention has a good application prospect.

Owner:DONGHUA UNIV

Anti-infection biological ceramic artificial bone and application thereof

ActiveCN107185033AHigh strengthModulated release rateTissue regenerationProsthesisRelease timePhosphate glass

The invention provides an anti-infection biological ceramic artificial bone and application thereof. The artificial bone is prepared by the following method that biological ceramics, bioglass sintering auxiliary agents and bonding agents are mixed; the obtained mixture is formed to obtain a composite blank body; the bioglass sintering auxiliary agents are selected from silicate glass and / or phosphate glass; antibacterial ions and bone vascularization promotion ions are mixed in the bioglass sintering auxiliary agents; the antibacterial ions are selected from one or several kinds of materials from silver, gallium, copper and zinc; the bone vascularization promotion ions are selected from one or several kinds of materials from magnesium, strontium, iron, boron, cobalt and lithium; the total amount of substances of oxides of the antibacterial ions and oxides of the bone vascularization promotion ions accounts for 0.1 to 60 percent of the amount of substance of the bioglass sintering auxiliary agents; the mol ratio of the antibacterial ions to the bone vascularization promotion ions is (0.05 to 20):1; the composite blank body is sintered to obtain the biological ceramic artificial bone. The anti-infection biological ceramic artificial bone has the advantages of high intensity and low cell toxicity; the antibacterial ion release speed is controllable; the release time is long.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com