Nearinfrared-ray absorbing galss, element, light filter and their production method and copper-contained glass

A technology of near-infrared light and absorbing components, applied in the direction of optical filters, optical components, instruments, etc., can solve the problems of not being able to correct the color sensitivity well, difficult to correct the color sensitivity, and unable to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0222] The glass raw material Al(PO 3 ) 3 , AlF 3 , Li 2 CO 3 , NaF, MgF 2 , CaF 2 , SrF 2 、BaF 2 , ZnF 2 , Sb 2 o 3 , CuO, etc. were weighed and mixed to obtain the glass composition shown in Table 1 and Table 2. Put it into a platinum crucible, cover it and melt it at 790°C-850°C, stir and defoam, and after homogenization, flow Into the preheated metal mold, forming into the desired shape. The obtained glass molded body was moved into an annealing furnace heated to near the glass transition point, and gradually cooled to room temperature. Samples were cut out from the obtained glass, and various characteristics were measured as described below.

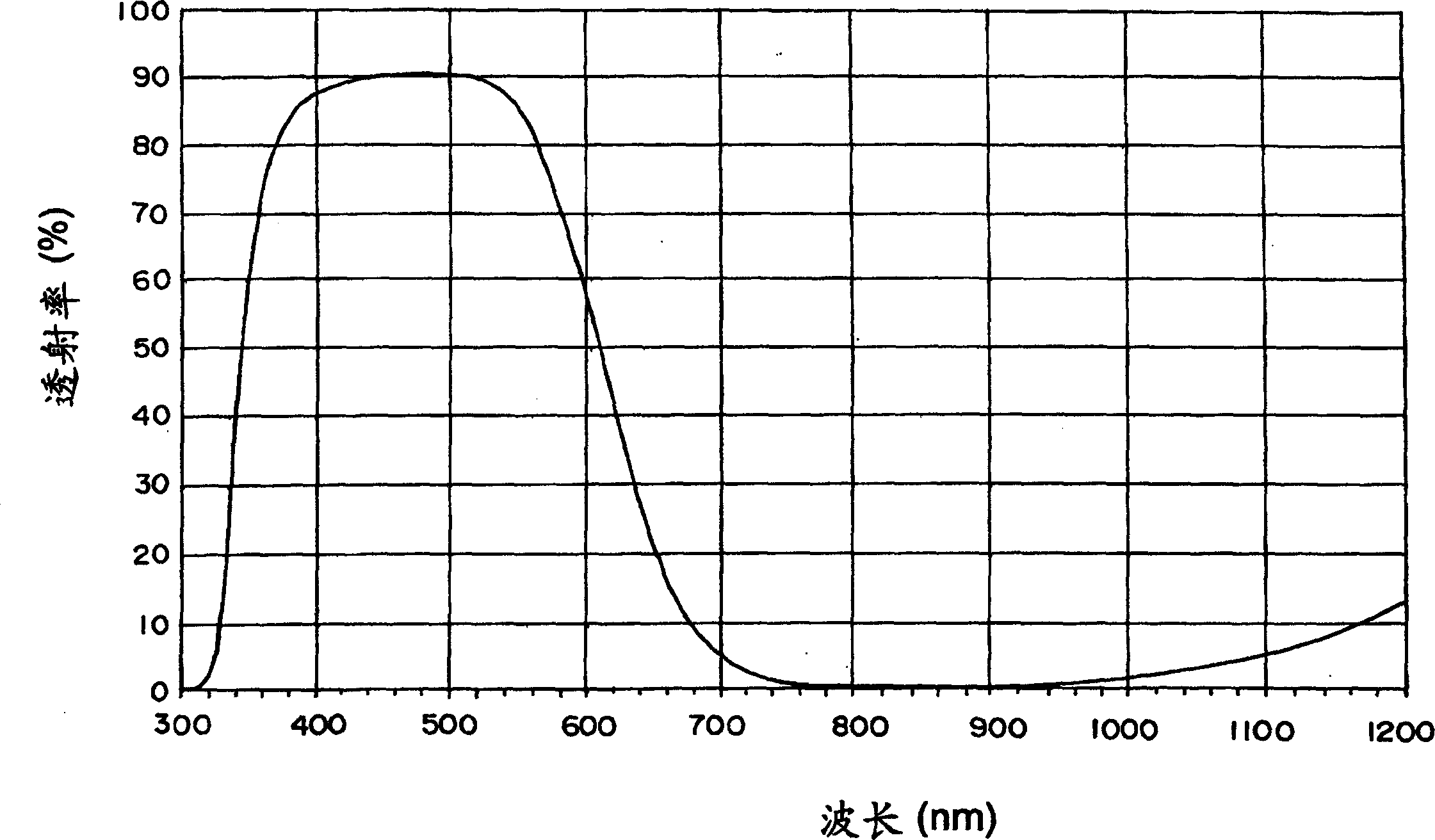

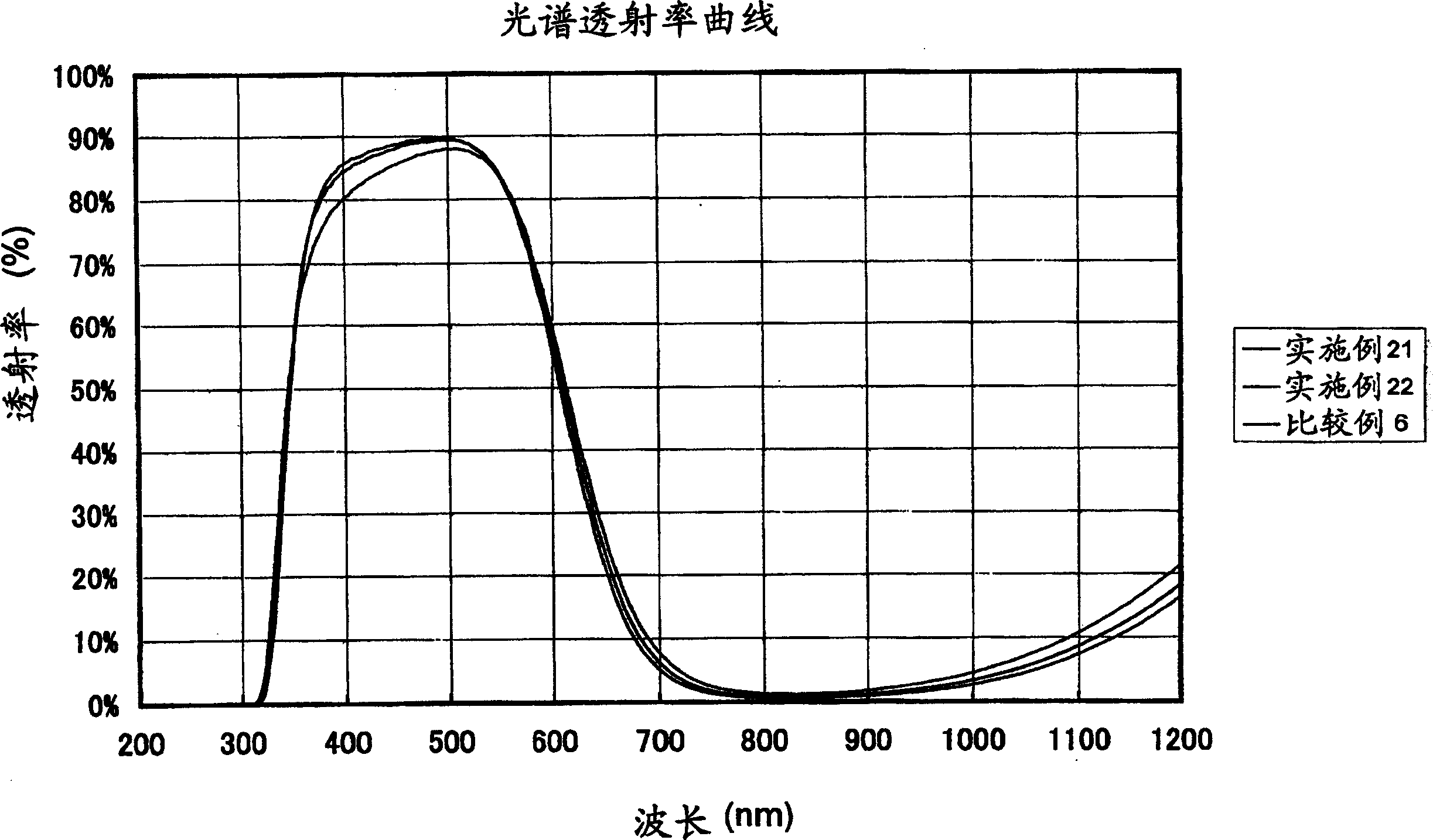

[0223] The spectral transmittance of glass is the transmittance at a wavelength of 200-1200 nm of glass with a thickness of 0.5 mm measured using a spectrophotometer. From the transmittance obtained in this way, the transmittance at each wavelength was calculated in terms of the thickness at which the transmittance is 5...

Embodiment 13

[0238] In the same manner as in Example 1-12, glass was melted, clarified, homogenized, and injected into a mold to form a glass plate made of glass having the same composition as in Example 1-12. After slicing such a glass plate, optical polishing is performed on both sides to obtain a thin plate of desired thickness. This thin plate is cut and processed to obtain a near-infrared light absorbing member having a size required for the above-mentioned thickness. The thickness of the element is a wall thickness with a transmittance of 50% at a wavelength of 615±10nm, and its size is 10mm×10mm˜30mm×30mm. Next, a sheet glass composed of crystal processed into a plate shape and two sheets of optical glass (BK-7) was prepared, and both surfaces of each were optically polished. Then, the optically polished surface is attached to each sheet so that the near-infrared light absorbing element, crystal, and two sheets of BK-7 thin plate glass are laminated on the outermost surface in this...

Embodiment 14

[0240] In the same manner as in Examples 1-12, the glass was melted, clarified, and homogenized to form a molten glass, which flowed down from a platinum nozzle. Then, an appropriate amount of molten glass is put into the mold to form a spherical glass preform. The molded preform is cooled to room temperature first, then reheated and softened in a non-oxidizing atmosphere such as nitrogen or a mixture of nitrogen and hydrogen, and then pressed with a pressing mold. The molding surfaces of the press molding dies are precision-processed in advance into a shape inverting the shape of the target optical element, and these molding surfaces are precisely replicated on the glass in the above-mentioned pressing process. After slowly cooling in the press-molding mold to a temperature at which the glass does not deform, the press-molded optical element is taken out of the molding mold and annealed. In this way, optical elements such as aspherical lenses and diffraction gratings can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com