Patents

Literature

190 results about "Powder method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• POWDER METHOD (noun) The noun POWDER METHOD has 1 sense: 1. a process for identifying minerals or crystals; a small rod is coated with a powdered form of the substance and subjected to suitably modified X-rays; the pattern of diffracted rings is used for identification. Familiarity information: POWDER METHOD used as a noun is very rare.

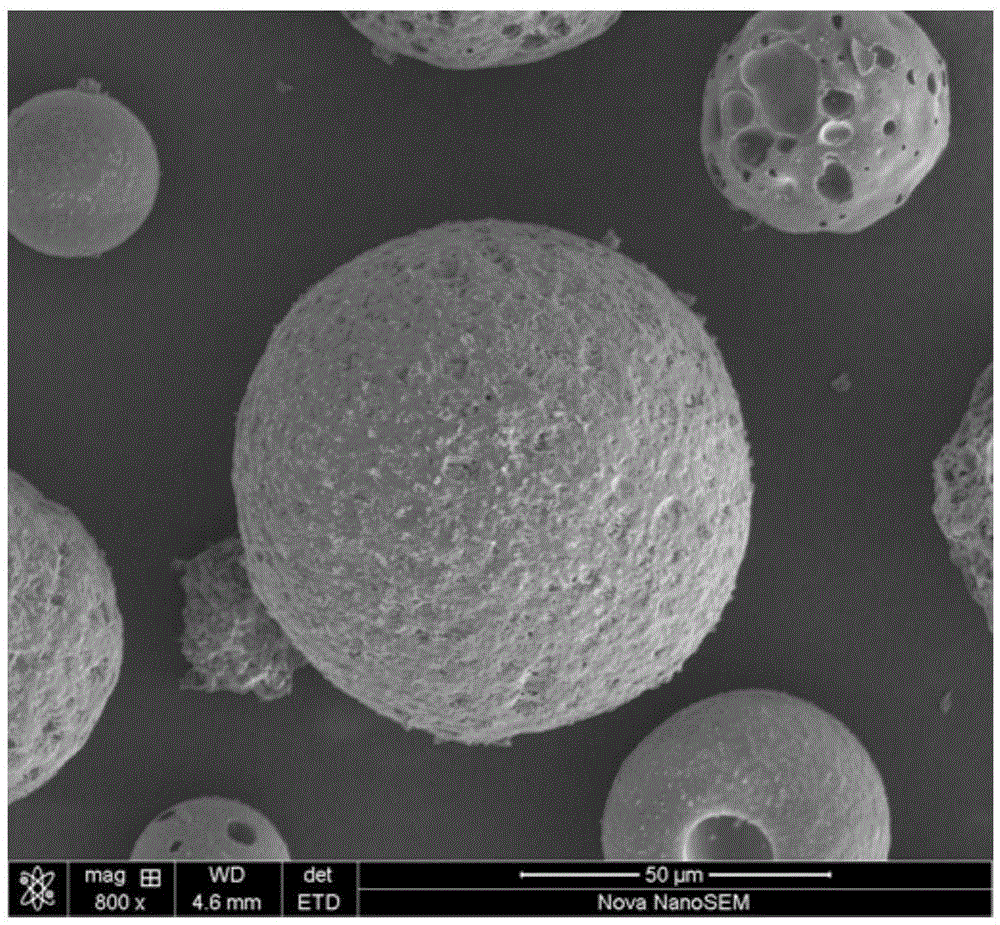

Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

ActiveCN102583973AHigh strengthHigh compressive strengthGlass shaping apparatusMicron scalePolymer science

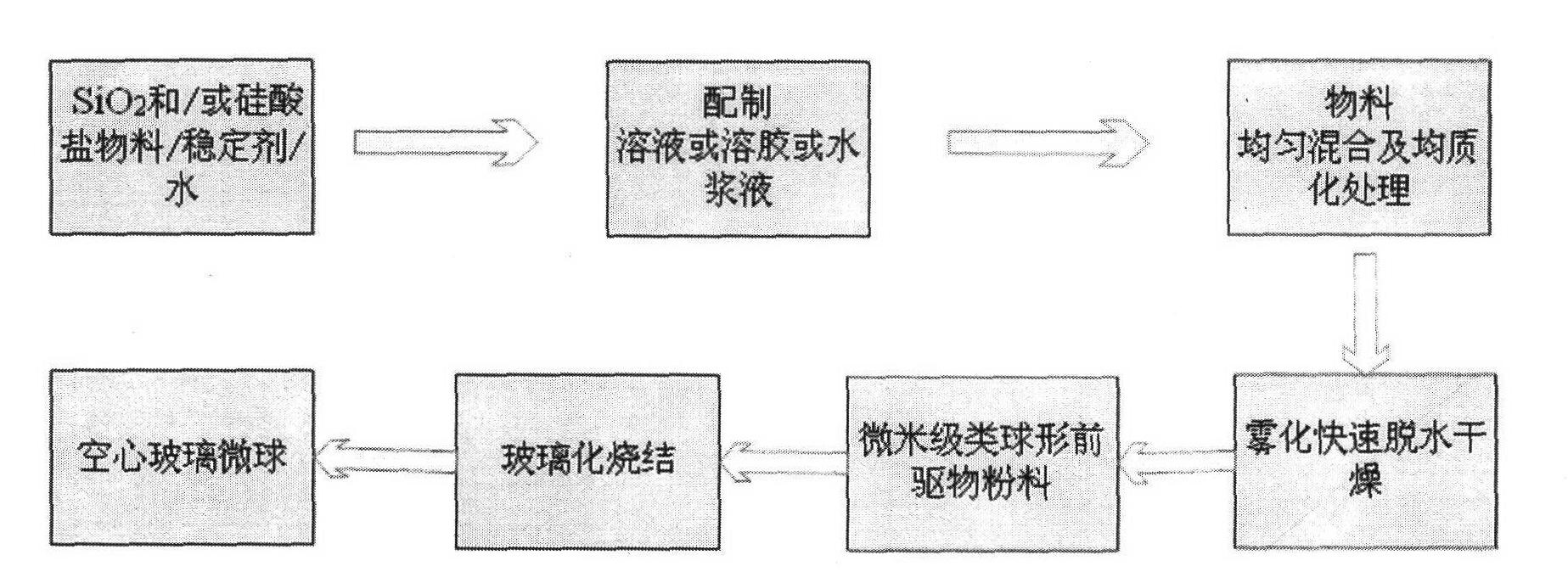

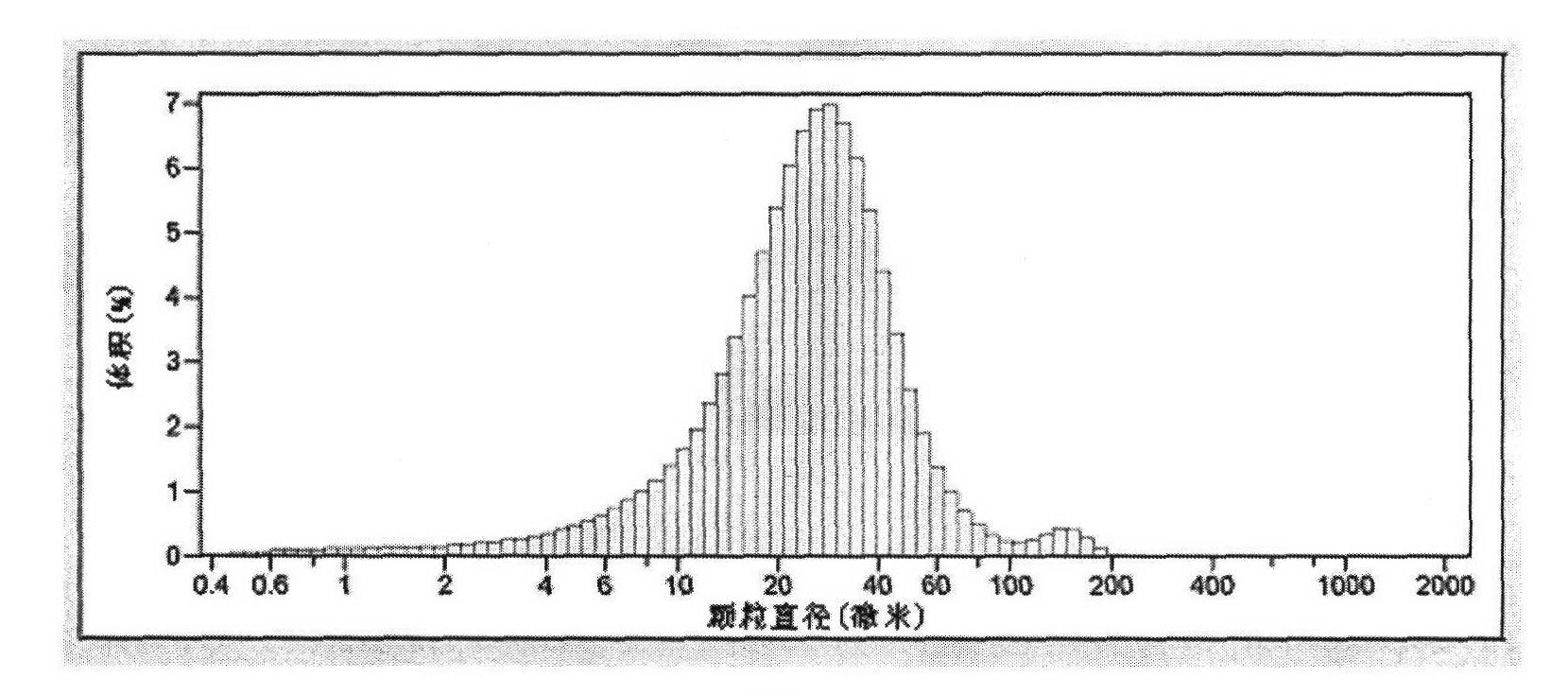

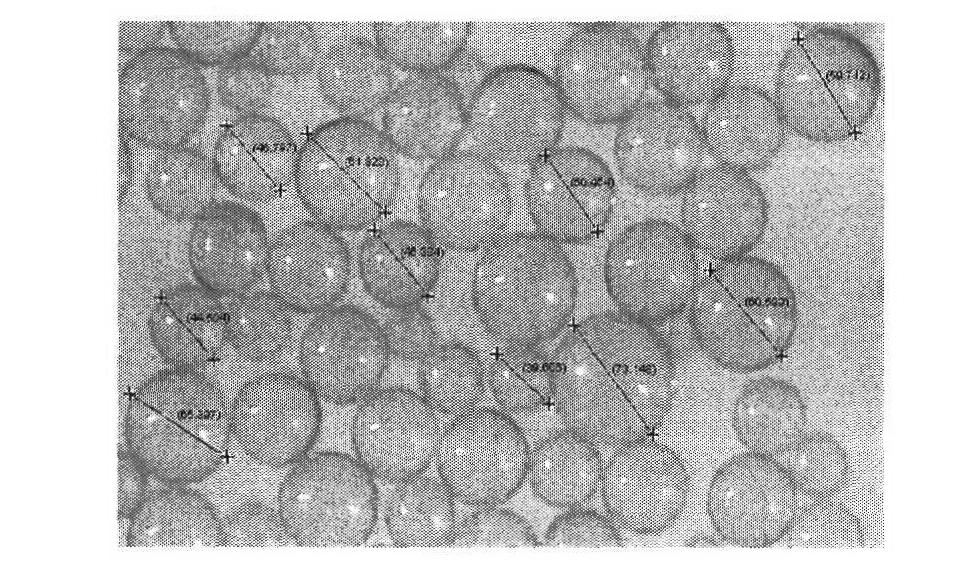

The invention belongs to the technical field of a soft chemical method. According to the invention, the method is used for overcoming the defects that the traditional solid-phase glass powder method for preparing a hollow glass micro-balloon is high in energy consumption, long in technical process and difficult in controlling grain size distribution and the hollow glass micro-balloon prepared according to a liquid-phase atomizing method is high in alkalinity, easy to absorb water, high in strength and easy to break, and the like. A liquid material system is compounded through a chemical reaction; after the system is homogenized, the system is quickly atomized, dewatered and dried, thereby obtaining approximate spherical precursor powder with required grain size and corresponding distribution; and the powder is treated under high temperature at 600-1100 DEG C, thereby obtaining a micron-scale hollow glass micro-balloon with the volume floating rate being above 90%, the SiO2 content (weight) being 55-88%, the true density being 0.1-0.7g / cm<3> and the compression strength being 1-50MPa. The method is low in energy consumption, free from fusion and sintering, and high in yield. The prepared hollow glass micro-balloon is high in compression strength, light in weight, low-alkali, waterproof, excellent in fluidity and dispersibility, and suitable for various high-performance light compound materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

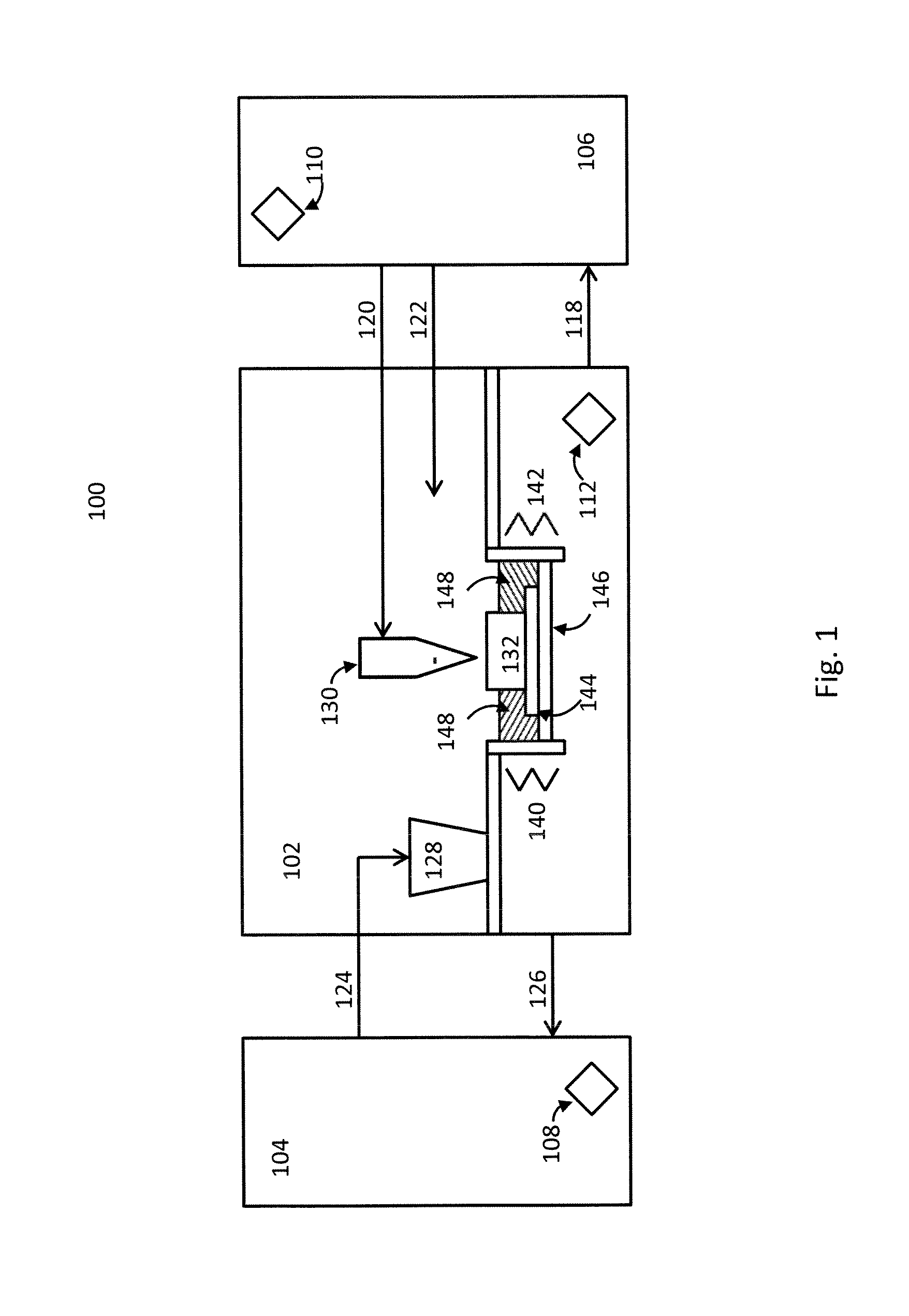

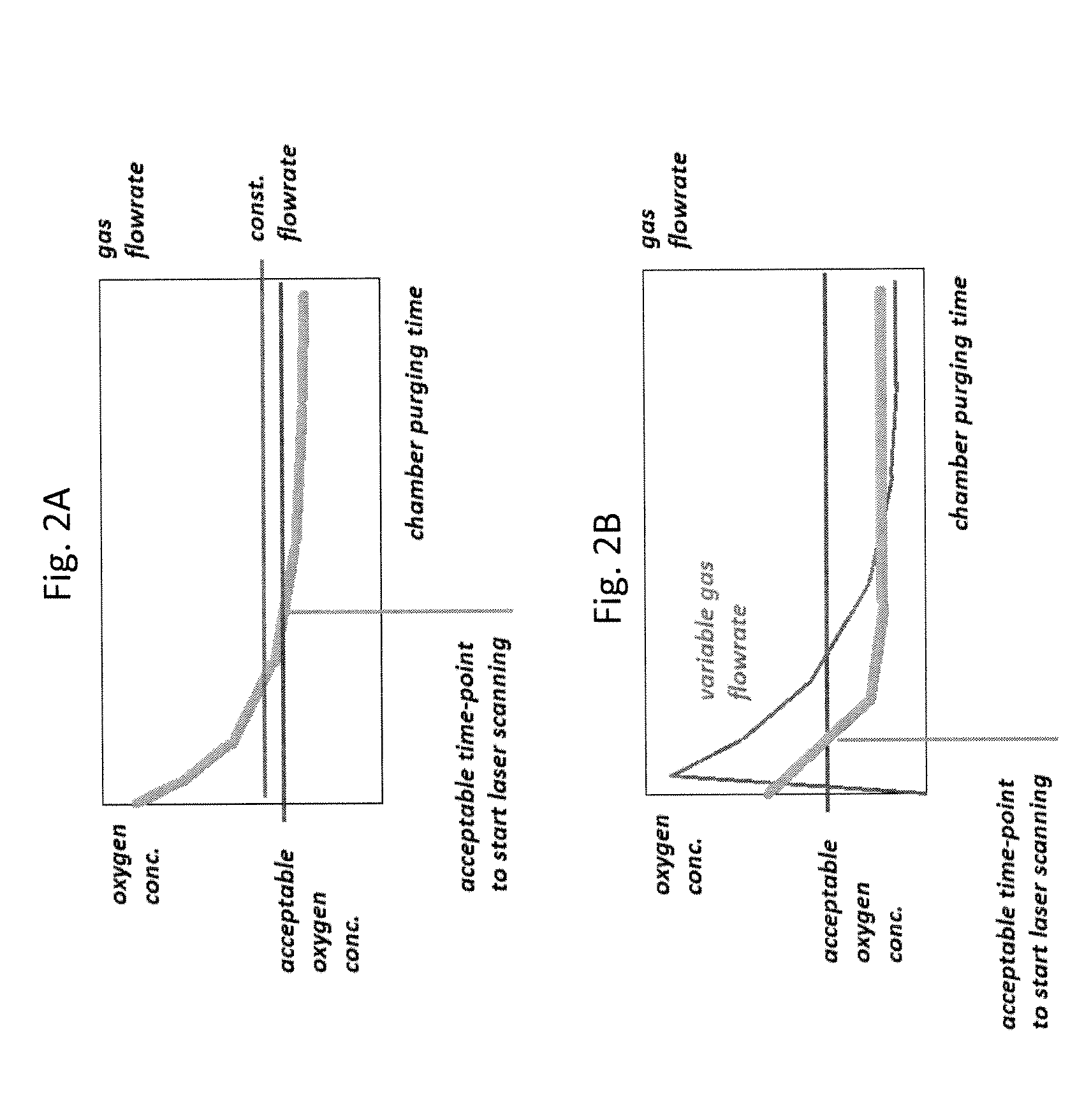

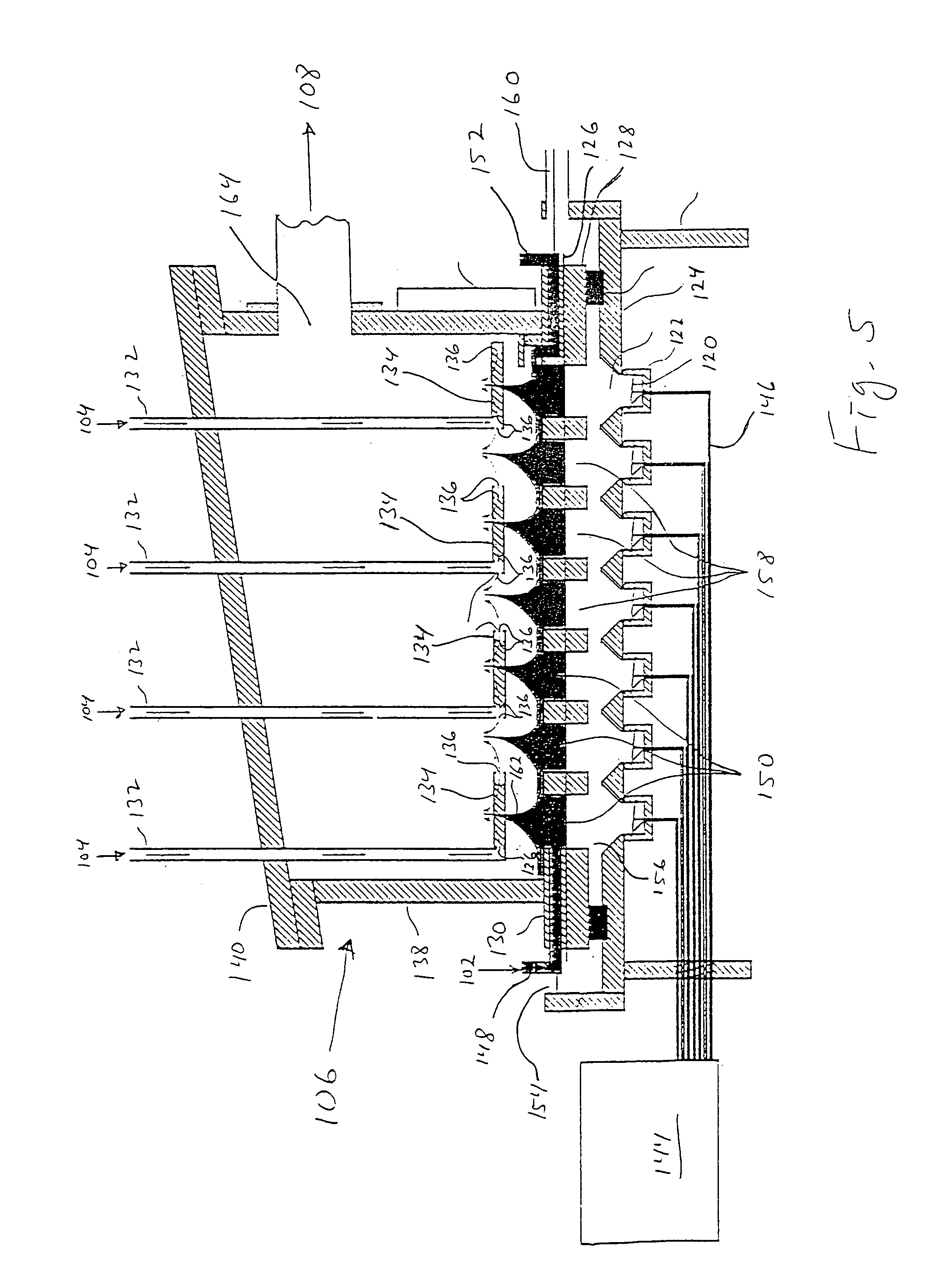

Gas Atmosphere Control In Laser Printing Using Metallic Powders

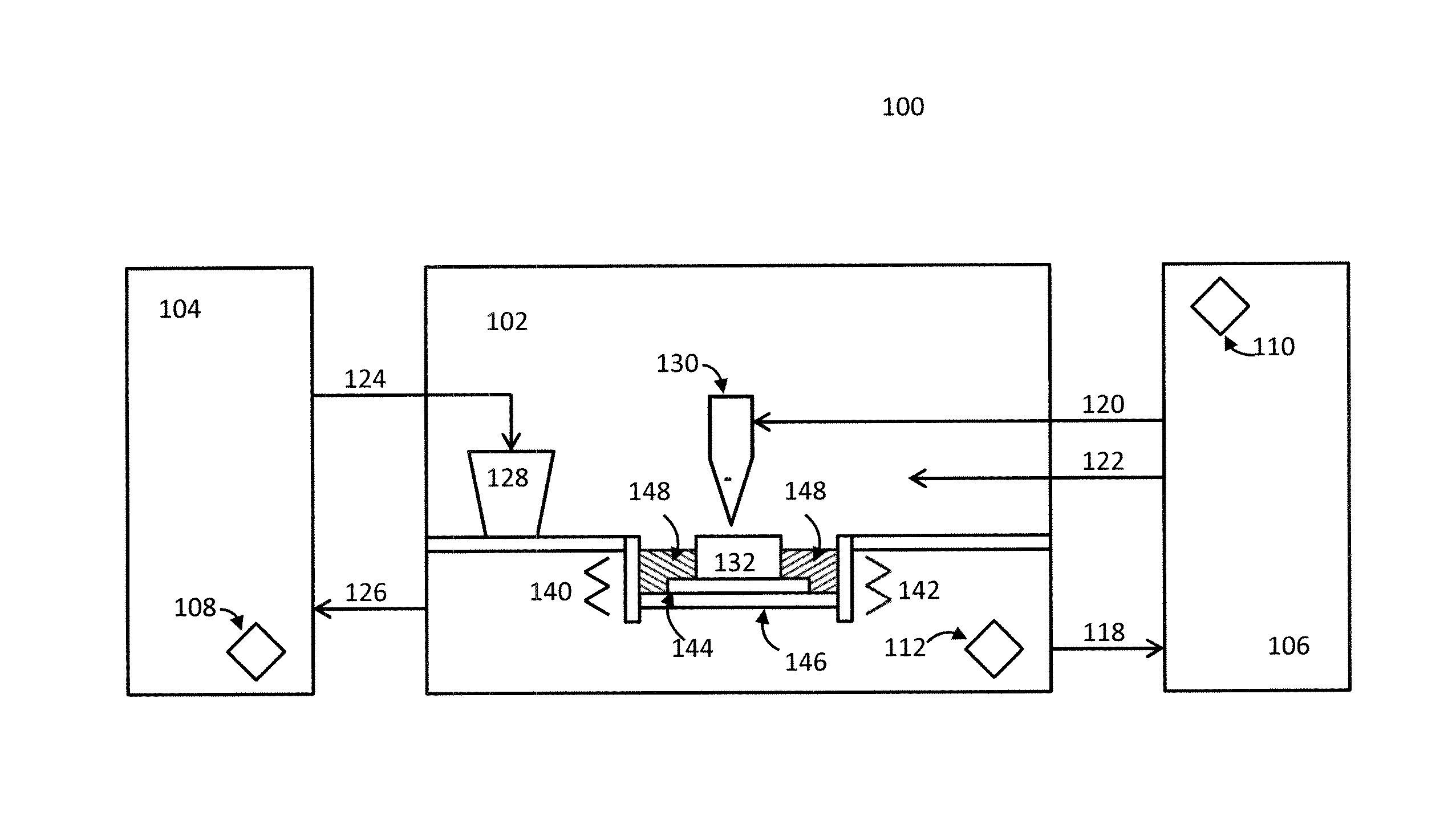

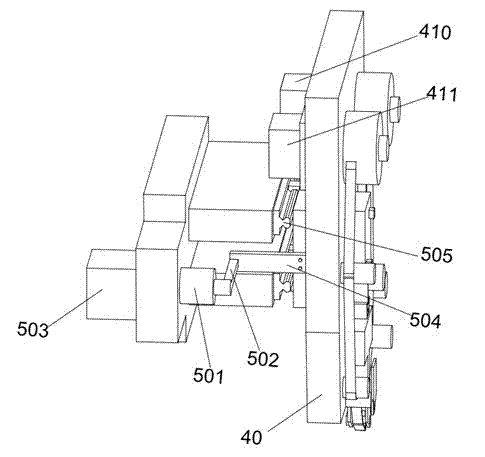

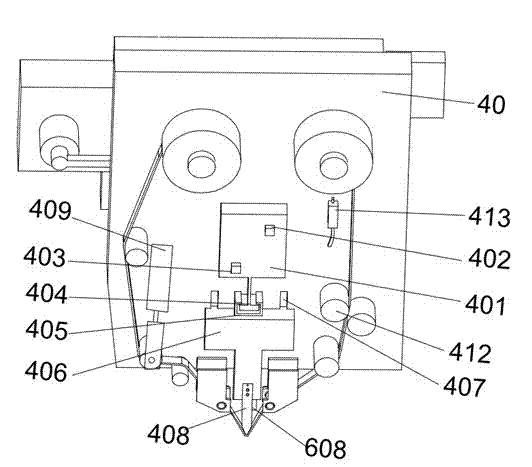

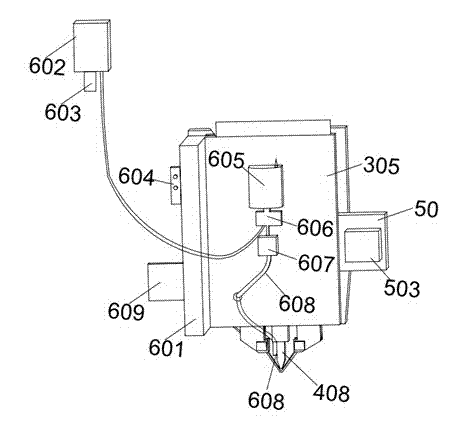

Methods and systems for controlling gas atmospheres in three-dimensional laser printing and weld overlay consolidation operations using metallic powders are provided. In one or more embodiments, such systems and methods comprise a printing chamber or laser weld overlay system, a gas supply system, a feed powder system, and one or more sensors employed to control the printing or welding operation. The methods and systems of the invention employ one or more inert gases having a purity greater than or equal to 99.995%

Owner:AIR PROD & CHEM INC

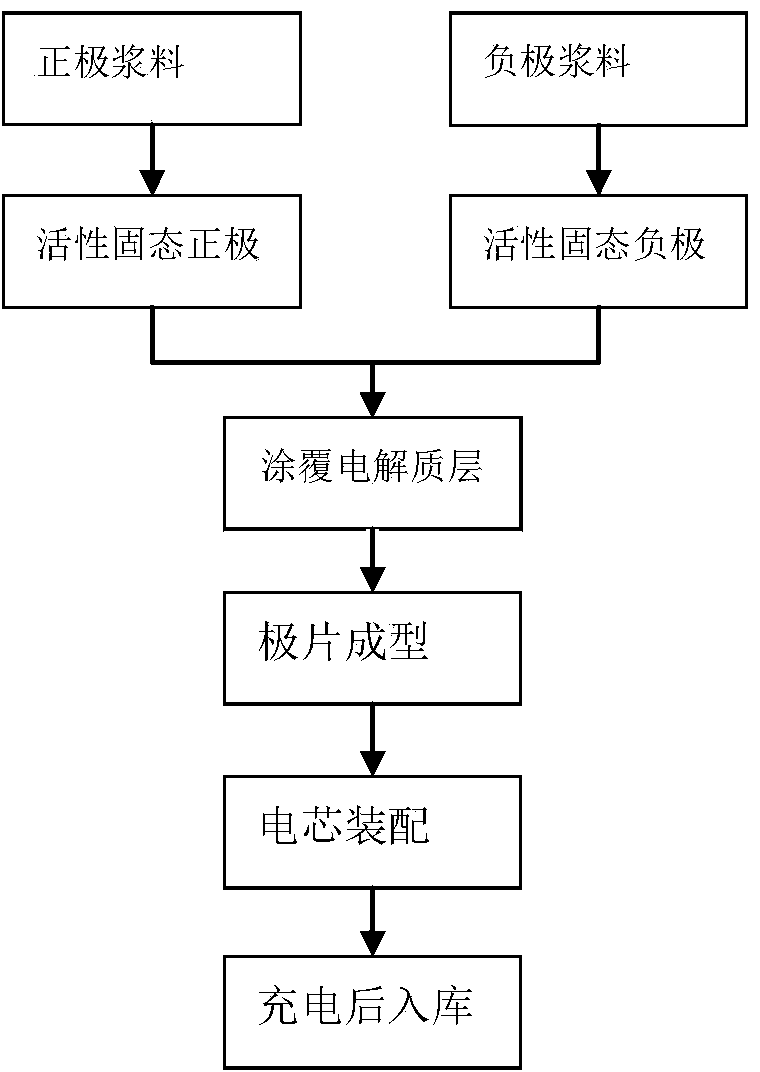

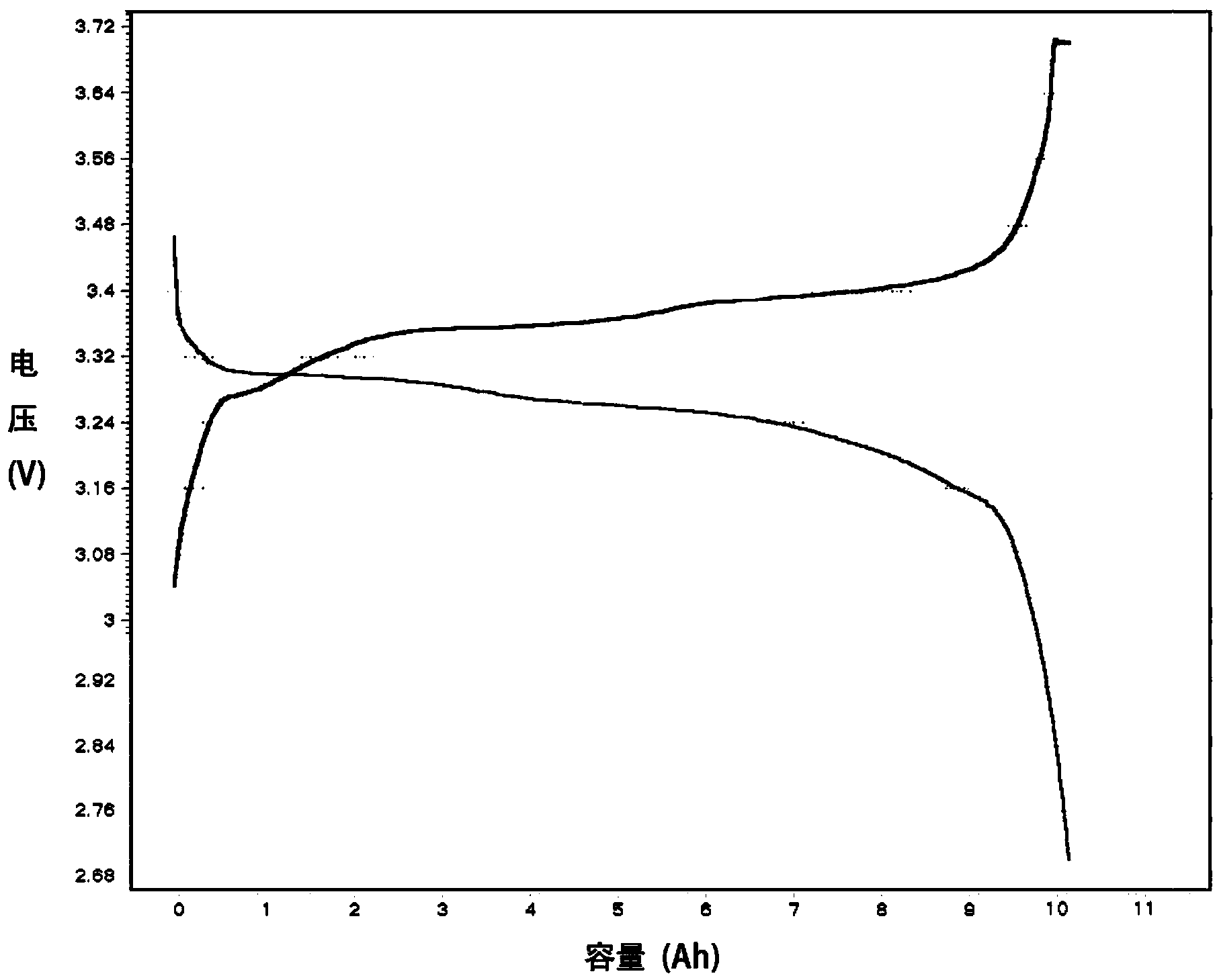

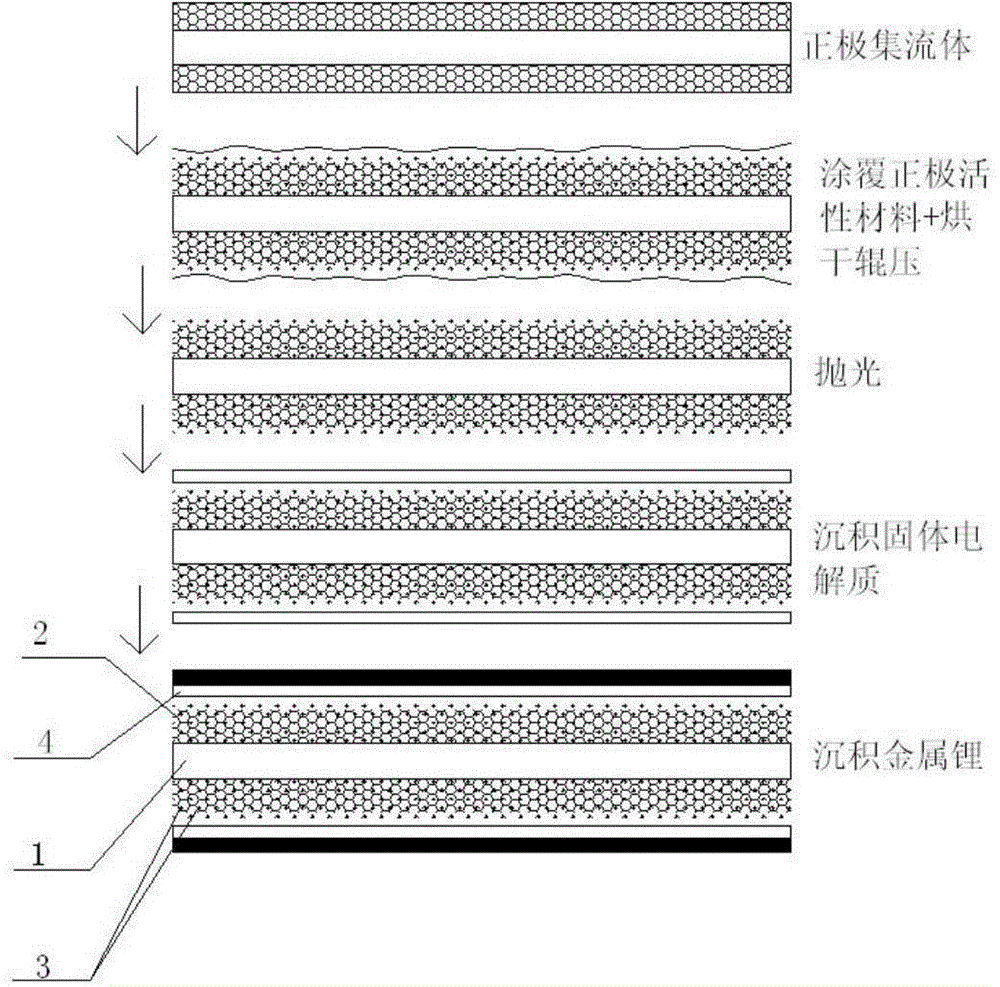

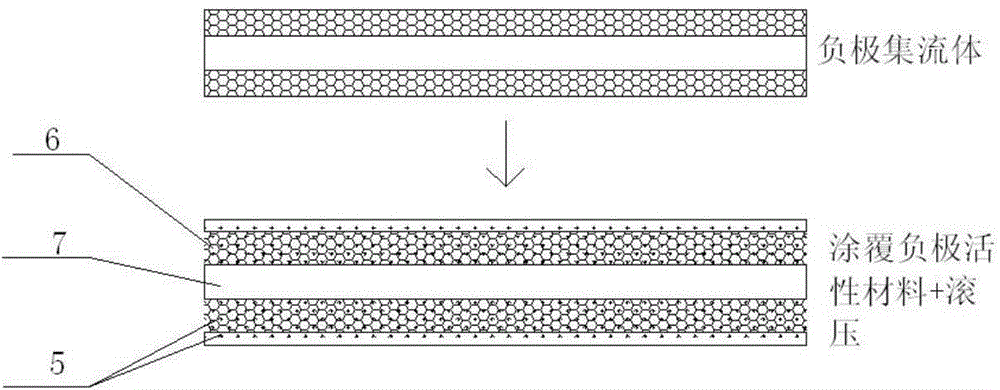

Solid-state lithium ion electrode, solid-state lithium ion battery and preparation method of solid-state lithium ion electrode

InactiveCN103474620ASuitable for continuitySuitable for productivityFinal product manufactureNon-aqueous electrolyte accumulator electrodesSolid state electrolytePowder method

The invention provides a solid-state lithium ion electrode, a solid-state lithium ion battery and a preparation method of the solid-state lithium ion electrode. The solid-state lithium ion battery electrode is composed of a metal current collector, and an active material, a conductive agent, solid electrolyte and a binder, which are attached on the current collector. During the electrode manufacture, the slurry containing the active material and the like is coated on the current collector, the method is suitable for continuous and batch production compared with a deposition method and a compression powder method.

Owner:向勇

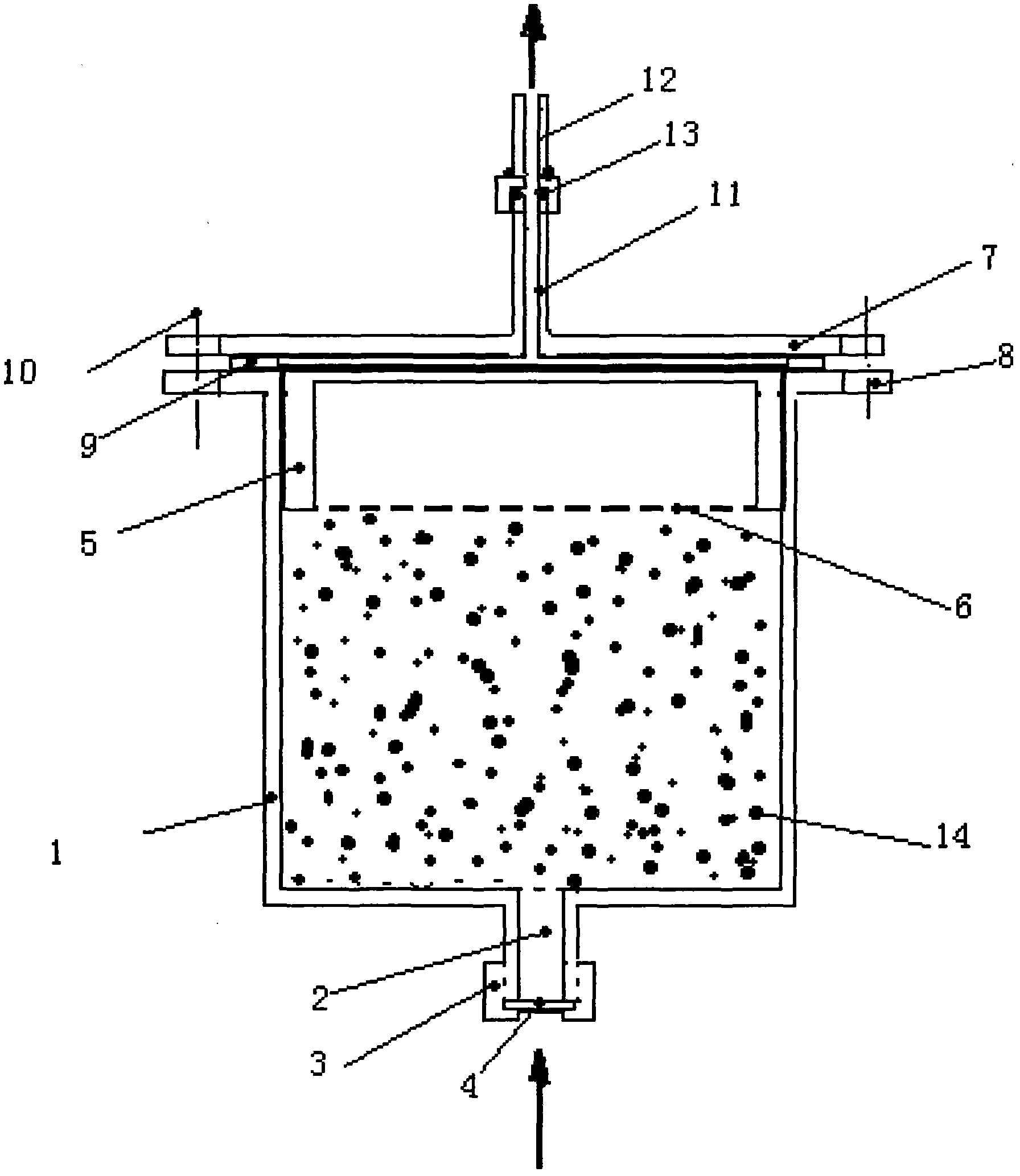

Technical method for electrorefining diamond

InactiveCN101049929AEliminate pollutionOperational securityPhotography auxillary processesUltra-high pressure processesElectricityElectrolysis

This invention relates to a method for purifying diamond by electrolysis. The method comprises: immersing diamond synthesized by powder method into the electrolyte in an electrolytic tank as the anode, electrolyzing, precipitating metals in the synthetic diamond onto the cathode plate under current action, and removing graphite by washing with water to obtain high-purity diamond. The method utilizes electricity power as a substitute for H2SO4 and HNO3 thus can effectively eliminate environmental pollution during the purification process, and the operation is safe and reliable. Metals in the synthetic diamond can be recovered, and the recovery rate is 80-90%.

Owner:ZHONGNAN DIAMOND CO LTD

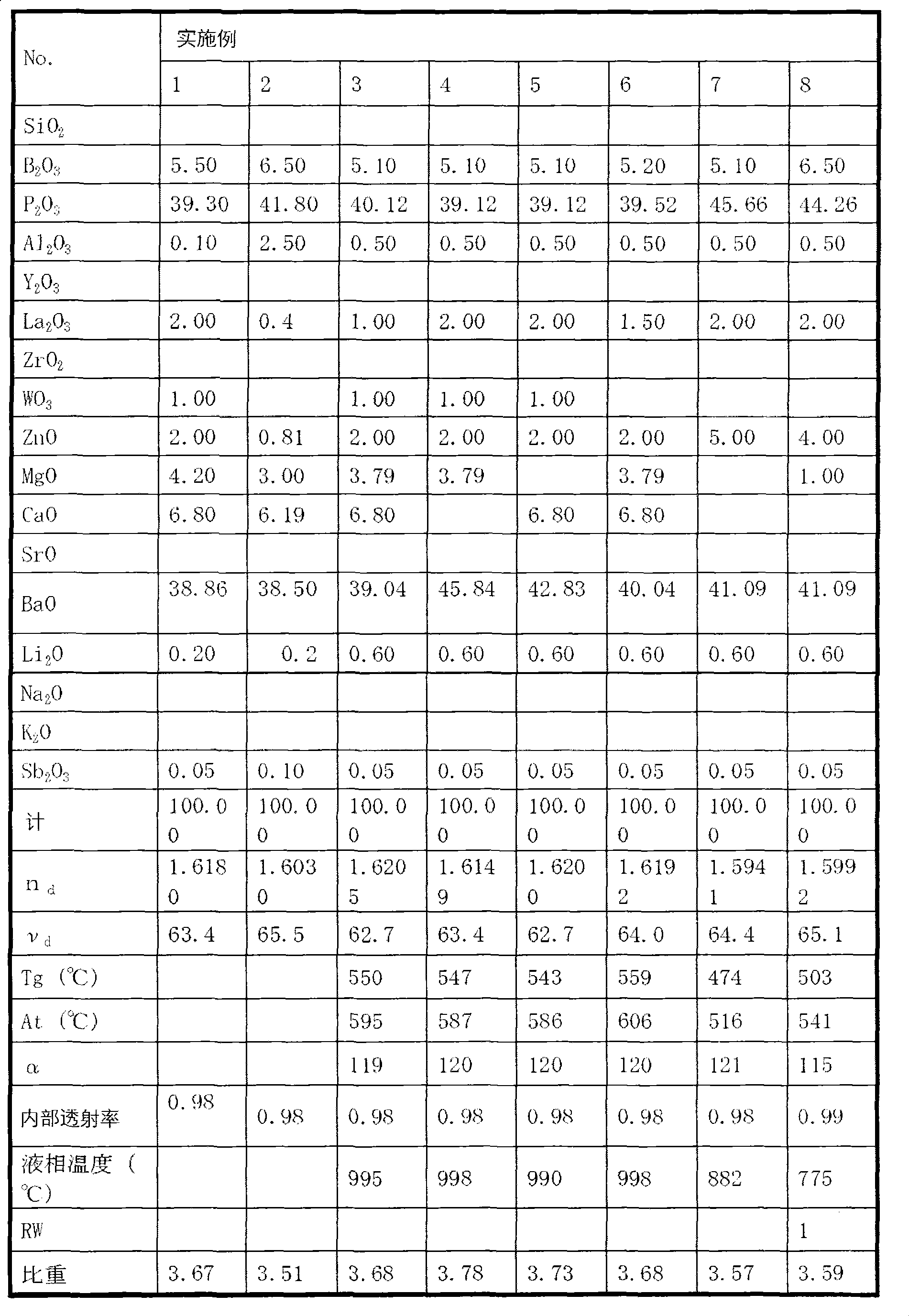

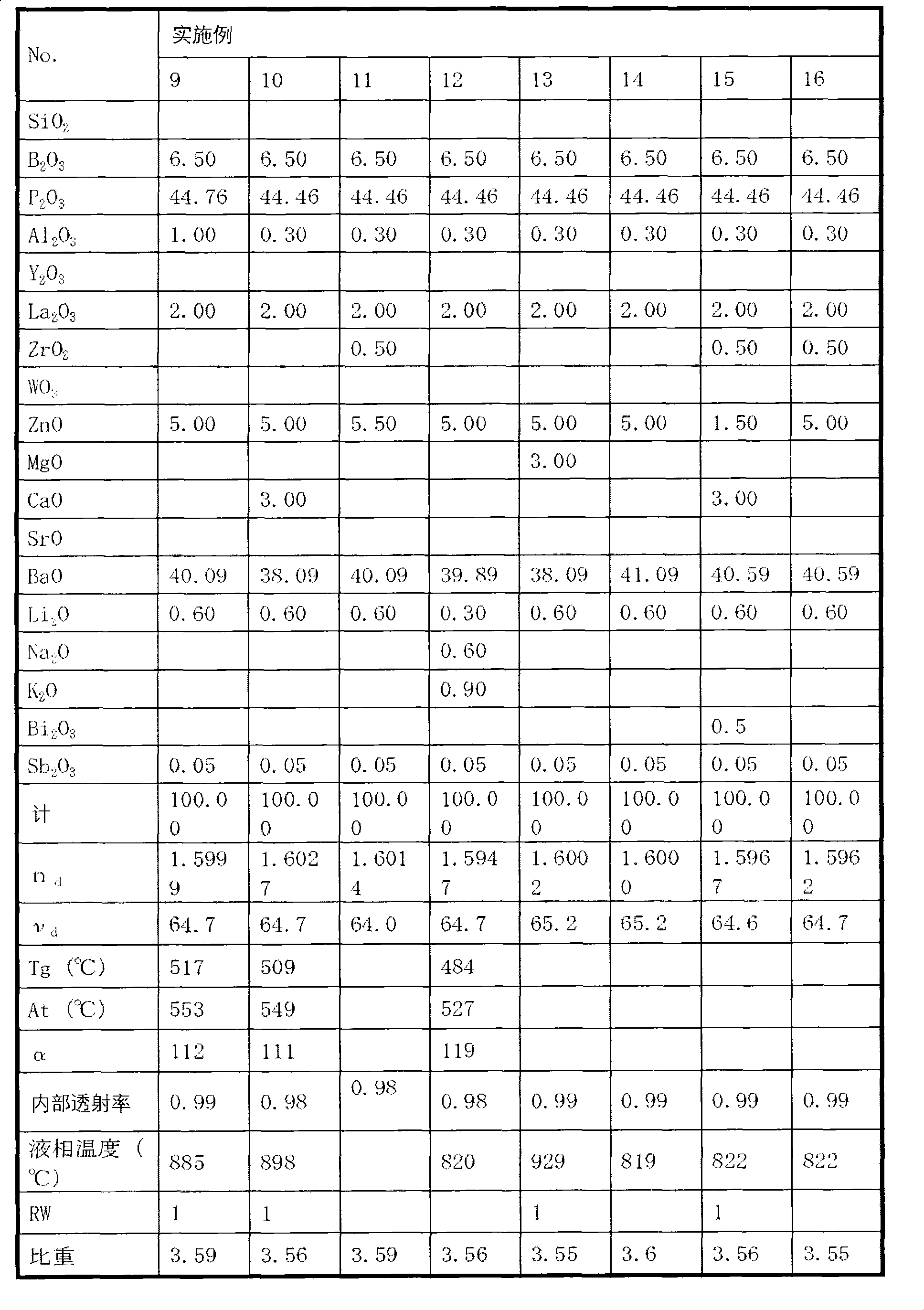

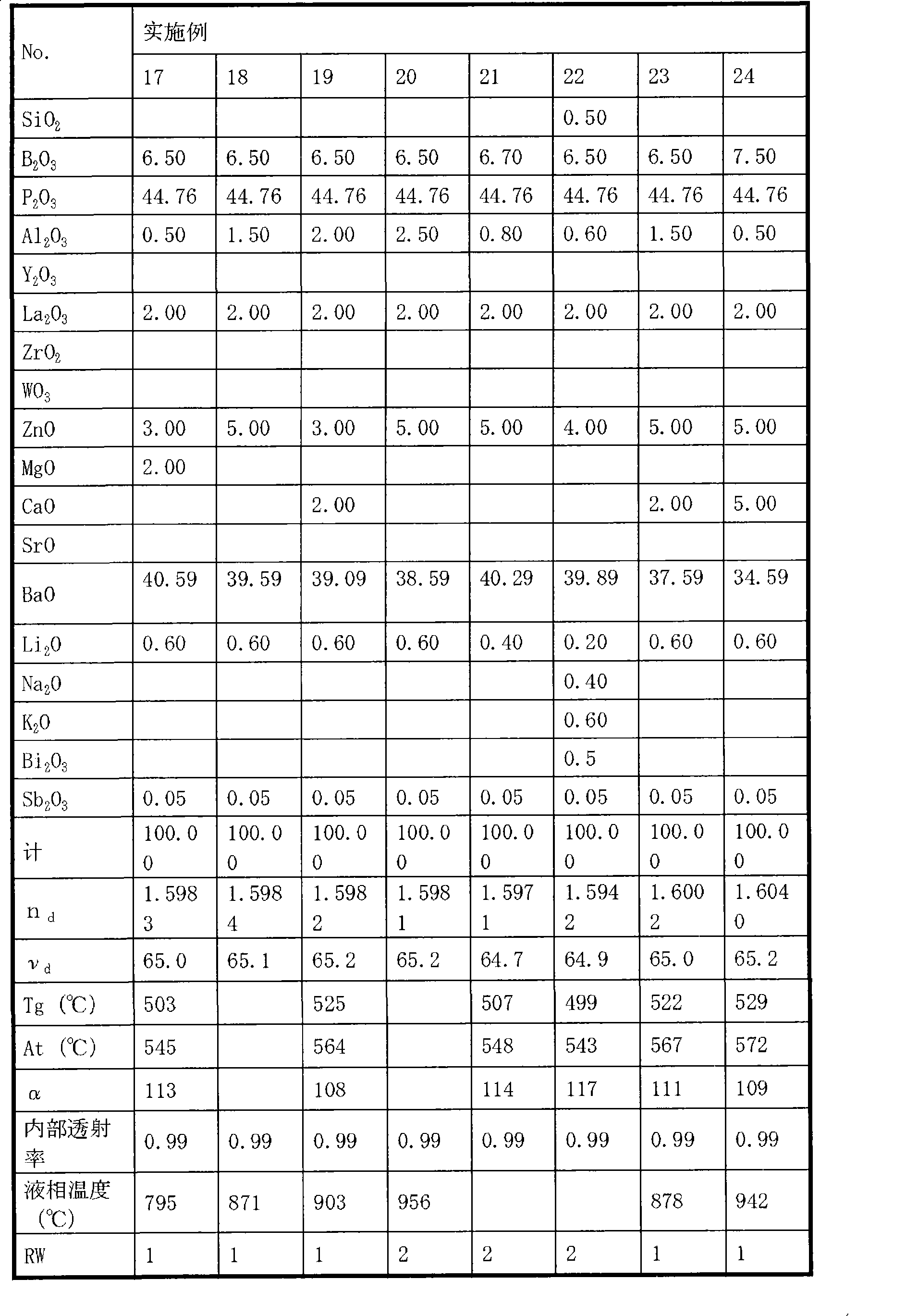

Opticla glass

The invention provides a phosphate glass, which is suitable for manufacturing a non-spherical die mold, a glass pre-forming blank, and the like due to low dispersivity, low glass transition temperature (Tg) and low average coefficient of linear expansion (alpha). An optical glass is characterized in that the optical glass contains P2O5, B2O3, BaO, Al2O3 and La2O3 as necessary components, on the basis of weight percent of an oxide, the total content of Al2O3 and La2O3 is 1 to 10 percent, the value of the Al2O3 content / the La2O3 content ranges from 0.05 to 8.0, and the water resisting property RW of the glass measured by a measuring method (powder method) for chemical durability of the optical glass by JOGIS06<-1999> is level 1 to 3.

Owner:OHARA

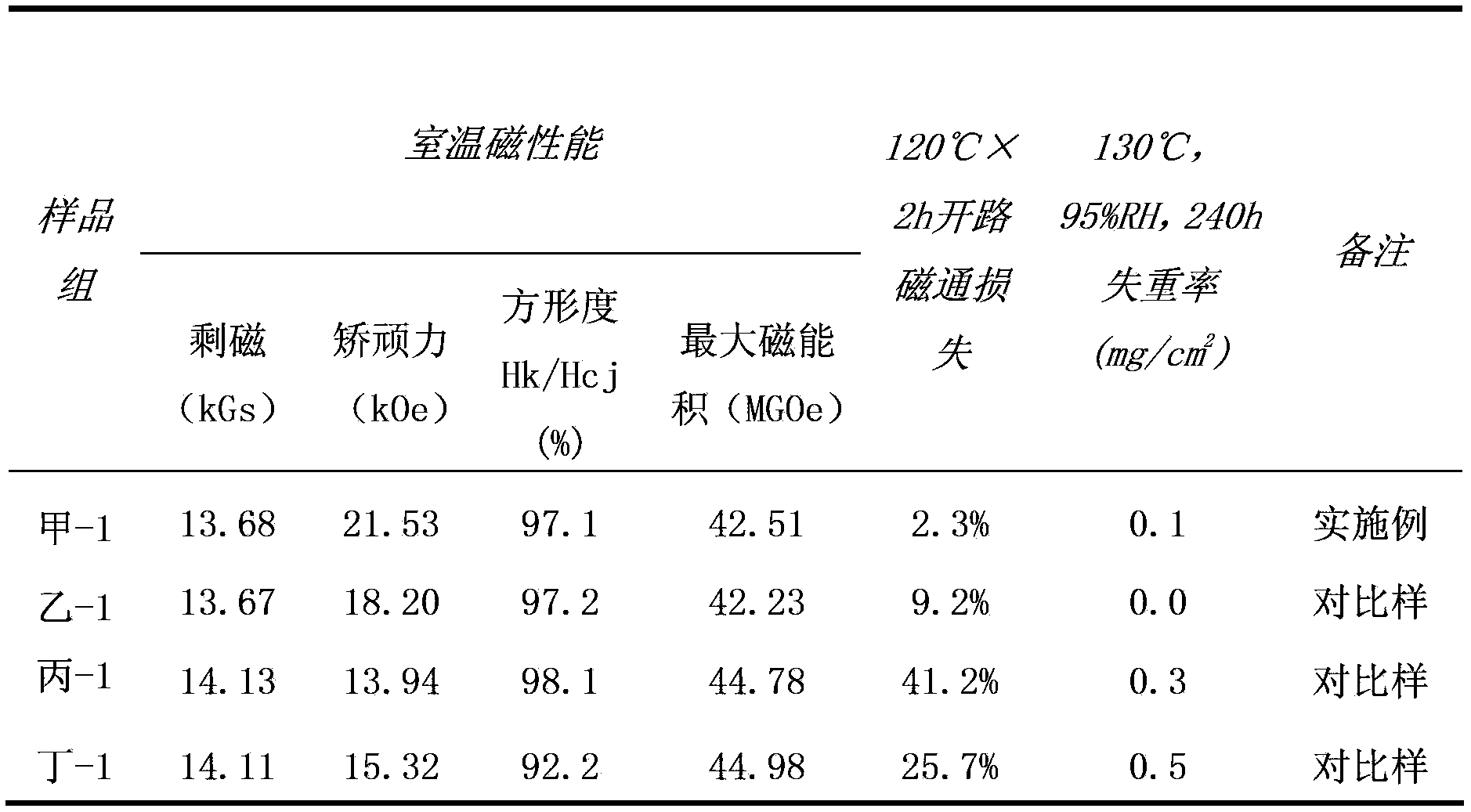

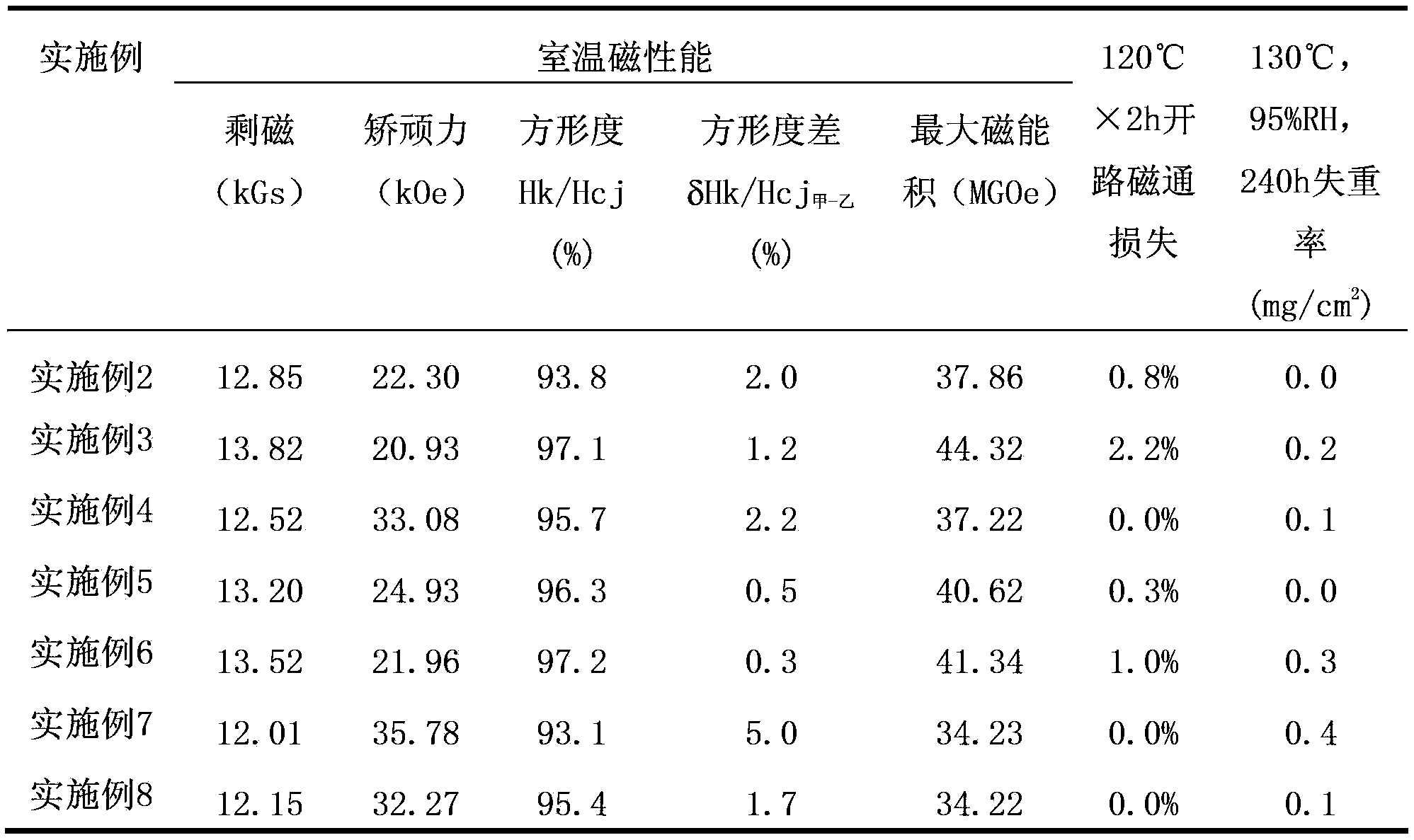

Rare-earth permanent magnet and preparation method thereof

ActiveCN104051101ALower activation energyEasy to spreadPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementPowder method

The invention discloses a rare-earth permanent magnet. The rare-earth permanent magnet mainly comprises the following components in percentage by atom: 12.1-16.2 percent of R, 0-3.4 percent of M1, 0-7.2 percent of M2, 5.1-7.4 percent of B and the balance of T, wherein the R is at least one of rear-earth elements including Y and Sc, and at least contains Nd; the M1 is at least one of Nb, Ti, Zr, V, Cr, Mo and Mn; the M2 is at least one of Al, Cu, Zn, Ga, In, Ge and Sn; the T is Fe or Fe and Co. A preparation method of the rare-earth permanent magnet comprises the processes of preparation of a magnet blank, coating, thermal treatment, and ageing, wherein the magnet blank is prepared by using a double-alloy method or a composite powder method. According to the magnet prepared by using the method, the coercive force, the temperature resistance and the corrosion resistance of a larger-size magnet can be improved, and the residual magnetism and the squareness of the magnet are not reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

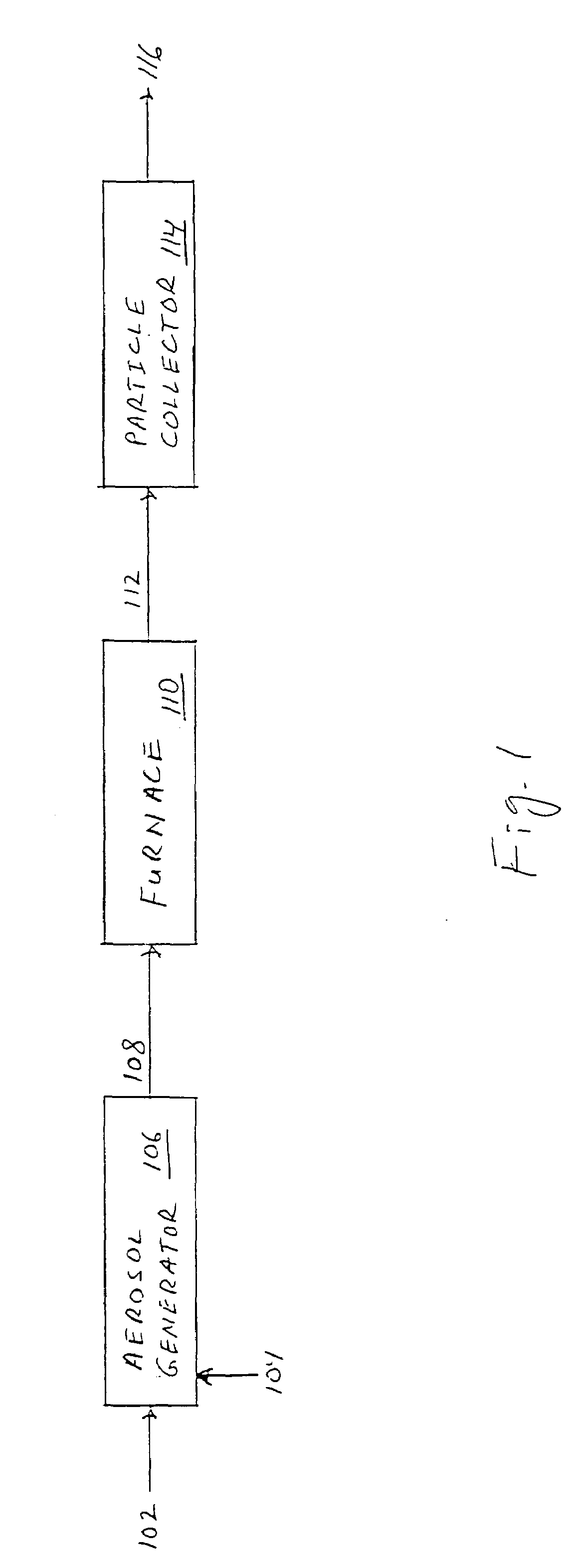

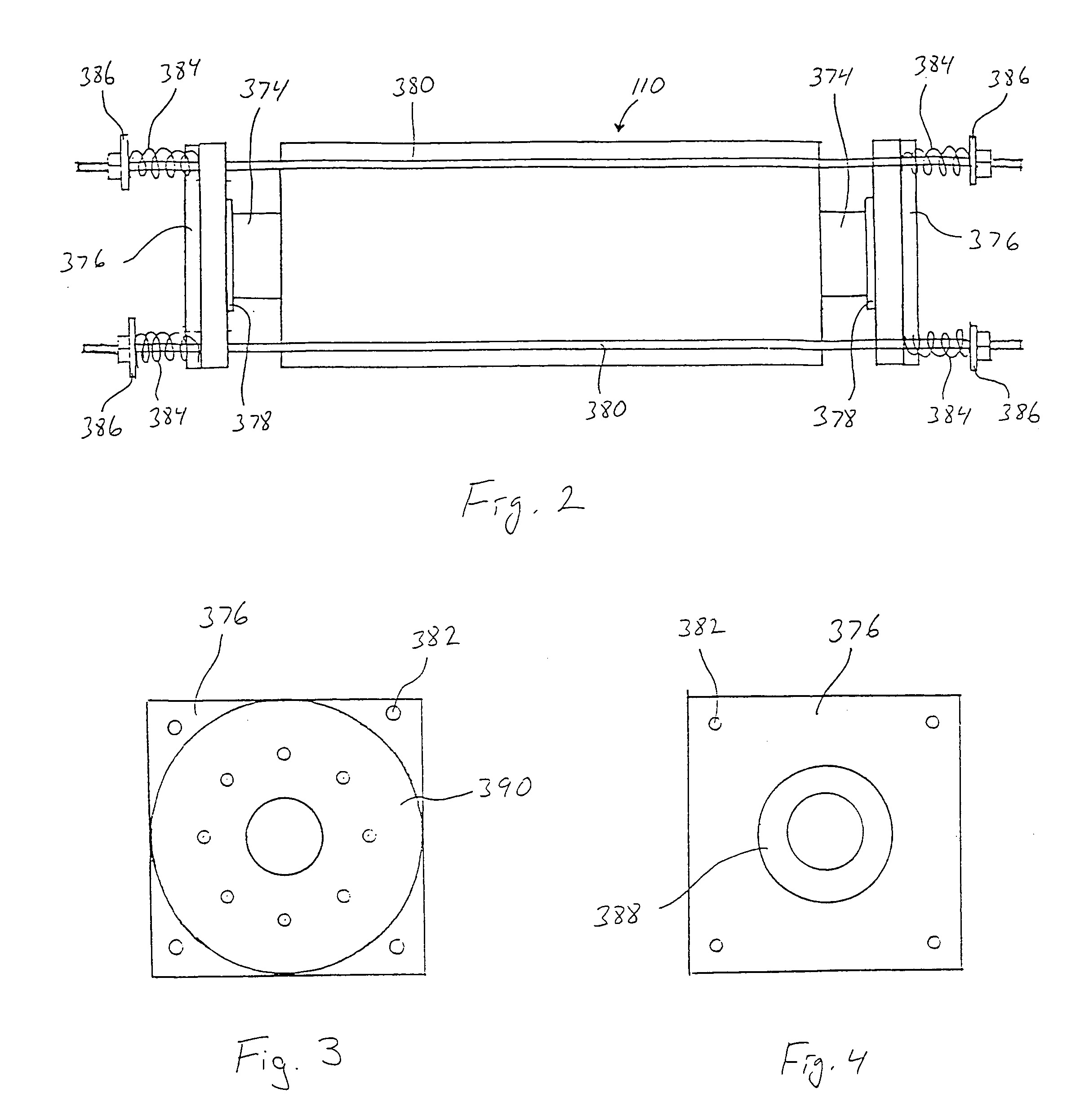

Copper powders methods for producing powders and devices fabricated from same

InactiveUS7316725B2High crystallinityHigh rateMaterial nanotechnologyMaterial granulation and coatingPowder methodSpherical morphology

Copper metal powders, methods for producing copper metal powders and products incorporating the powders. The copper metal powders have a small particle size, narrow size distribution and a spherical morphology. The method includes forming the metal particles in a continuous manner.

Owner:CABOT CORP

Method for producing high-efficiency washing soap powder by using sewer oil or swill oil

InactiveCN1603396ASolve processingSolve the use problemDetergent powders/flakes/sheetsSoap detergent compositionsOil and greasePowder method

The invention discloses a kind of use ditch oil or slops incompatible highly effective washes clothes with the soap powder method, including the ditch oil or slops the incompatible pretreatment, the ditch oil or slops the incompatible acidification, the ditch oil or slops the incompatible saponification, the saponified fluid synergize, bestows on the shape, makes grain, is dry and so on the step. The invention method, both reduced the ditch oil either slops incompatibly and has stopped up the derelict land ditch oil to the environment pollution from the source or slops incompatible two edible, has guaranteed people's health, moreover also provides the sufficient raw material supply for the fat chemistry, simultaneously this method also has the soap powder decontamination strength which the production cost low, makes to be strong, not injurying also the non- pollution characteristic, has the better application promotion value.

Owner:盛金英

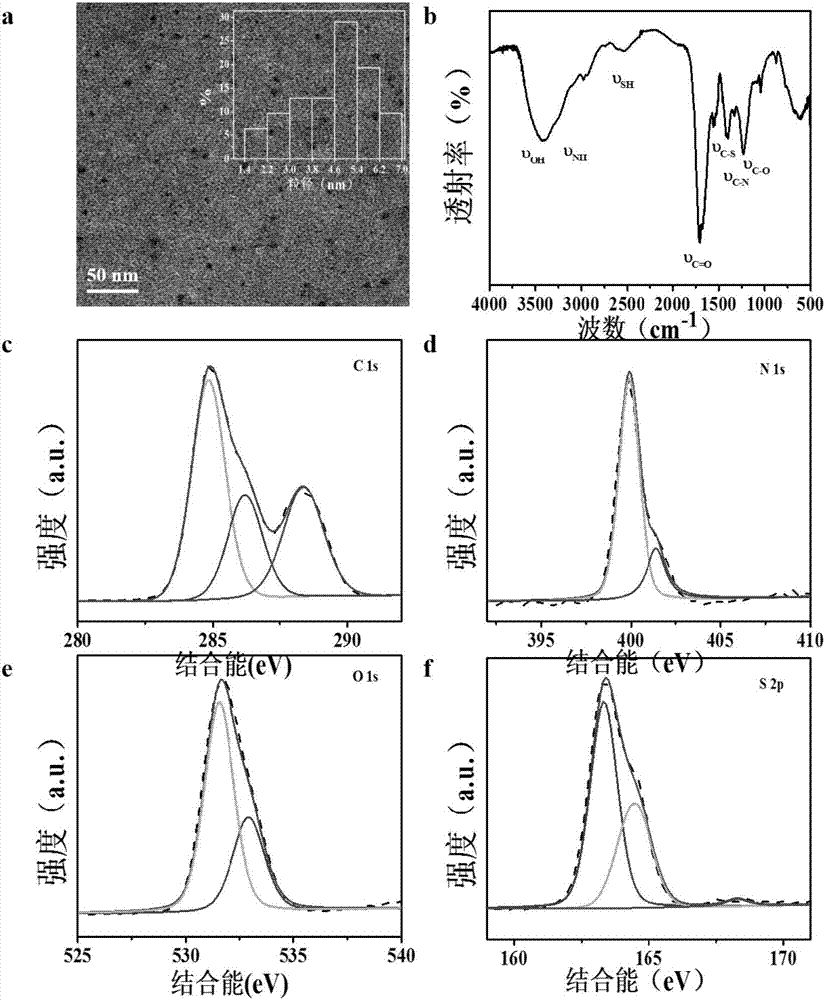

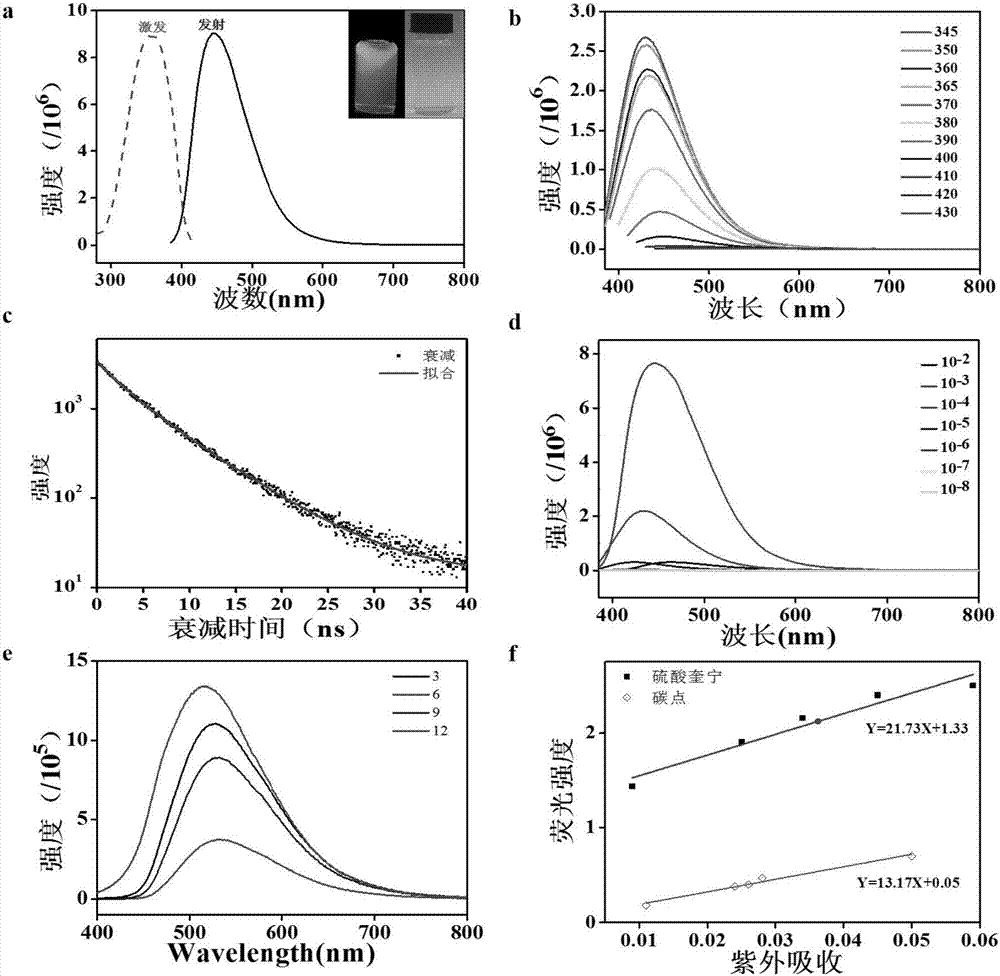

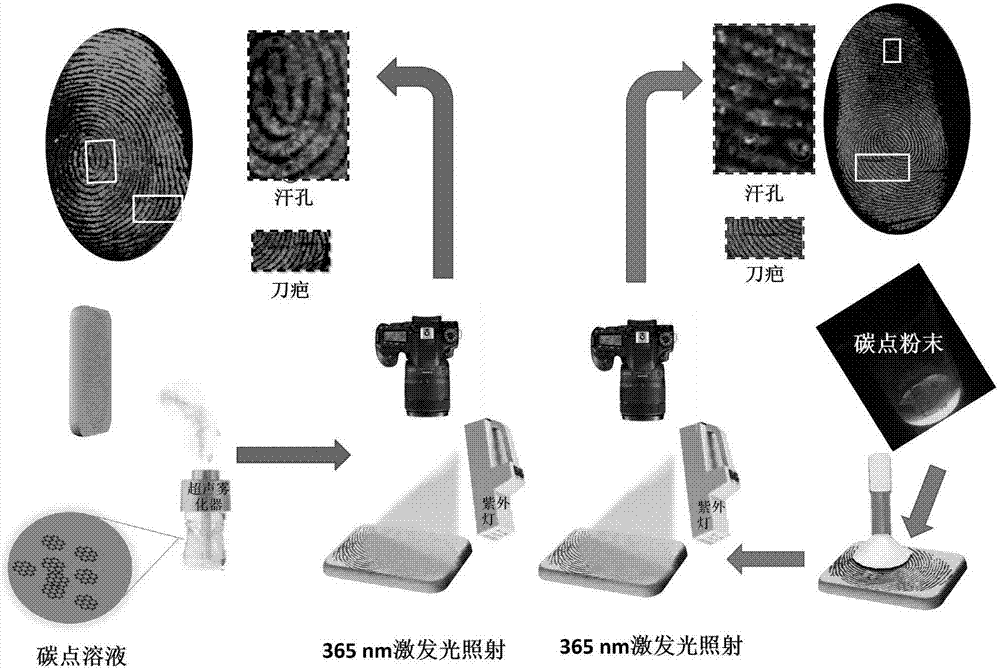

Preparation of solid fluorescent carbon dots and application thereof in aspect of latent fingerprint detection

ActiveCN106929014ARaw materials are safe and easy to obtainSimple manufacturing methodDiagnostic recording/measuringSensorsMicrowave methodLatent fingerprint

The invention discloses preparation of solid fluorescent carbon dots and application thereof in an aspect of latent fingerprint detection, belongs to the technical fields of material synthesis and fingerprint detection. The solid fluorescent carbon dots are synthesized by adopting glutathione as a nitrogen / sulfur source and adopting citric acid as a carbon source by virtue of a microwave method. Raw materials are safe and easy to obtain, a preparation method is simple and rapid, and particles are safe and nontoxic. The surfaces of the solid fluorescent carbon dots (SFCDs) provided by the invention contain an amino, a sulfydryl and a carboxyl functional group, a particle size is 2 to 7 nm, and the solid fluorescence property is excellent. The SFCDs are used as a fingerprint developing agent and can develop the aged fingerprint, and the developing time can reach 30 days in an experimental range; and the solid fluorescent carbon dots can be applied to a liquid spray method and powder method, the two methods are complementary to each other, and the universality of the developing agent is improved.

Owner:JIANGNAN UNIV

Glass

Glass has optical constants of a refractive index (nd) of 1.79 or over and an Abbe number (νd) of 27 or over and a specific gravity (D) of 3.20 or over and is free from devitrification in the interior of the glass in a reheat test. The glass has chemical durability according to the Powder Method (acid-proof property RA according to the Powder Method) which is Class 1.

Owner:OHARA

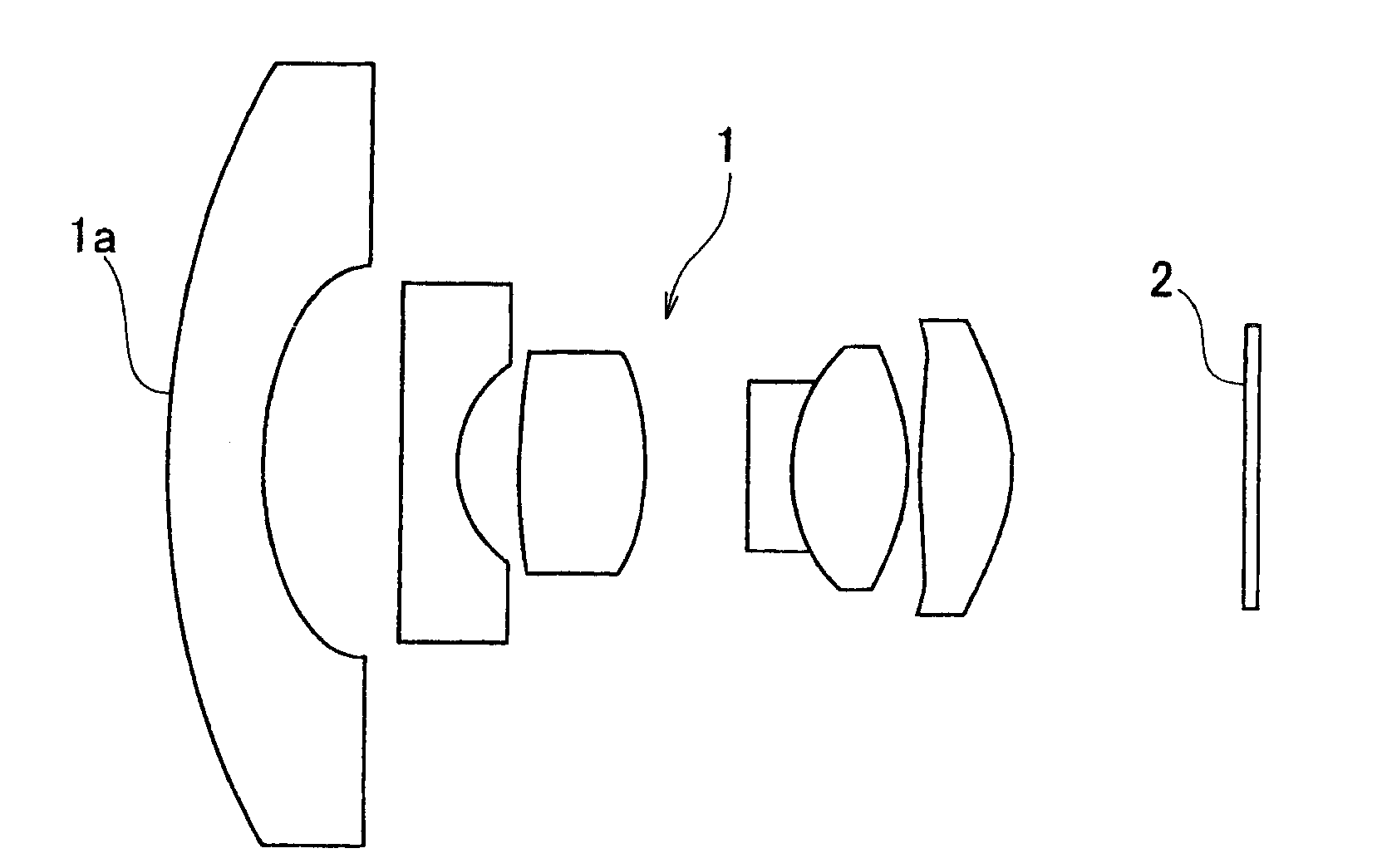

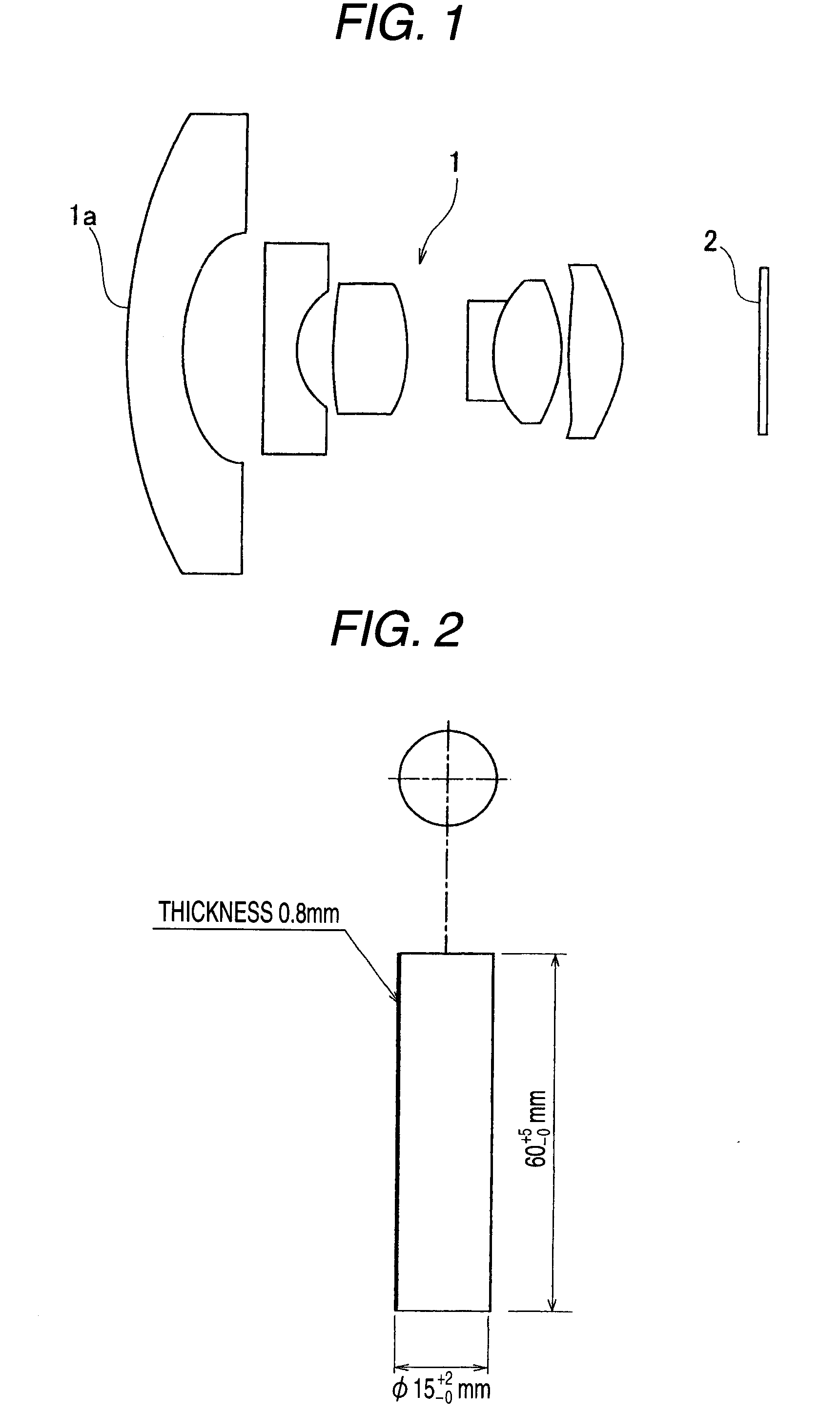

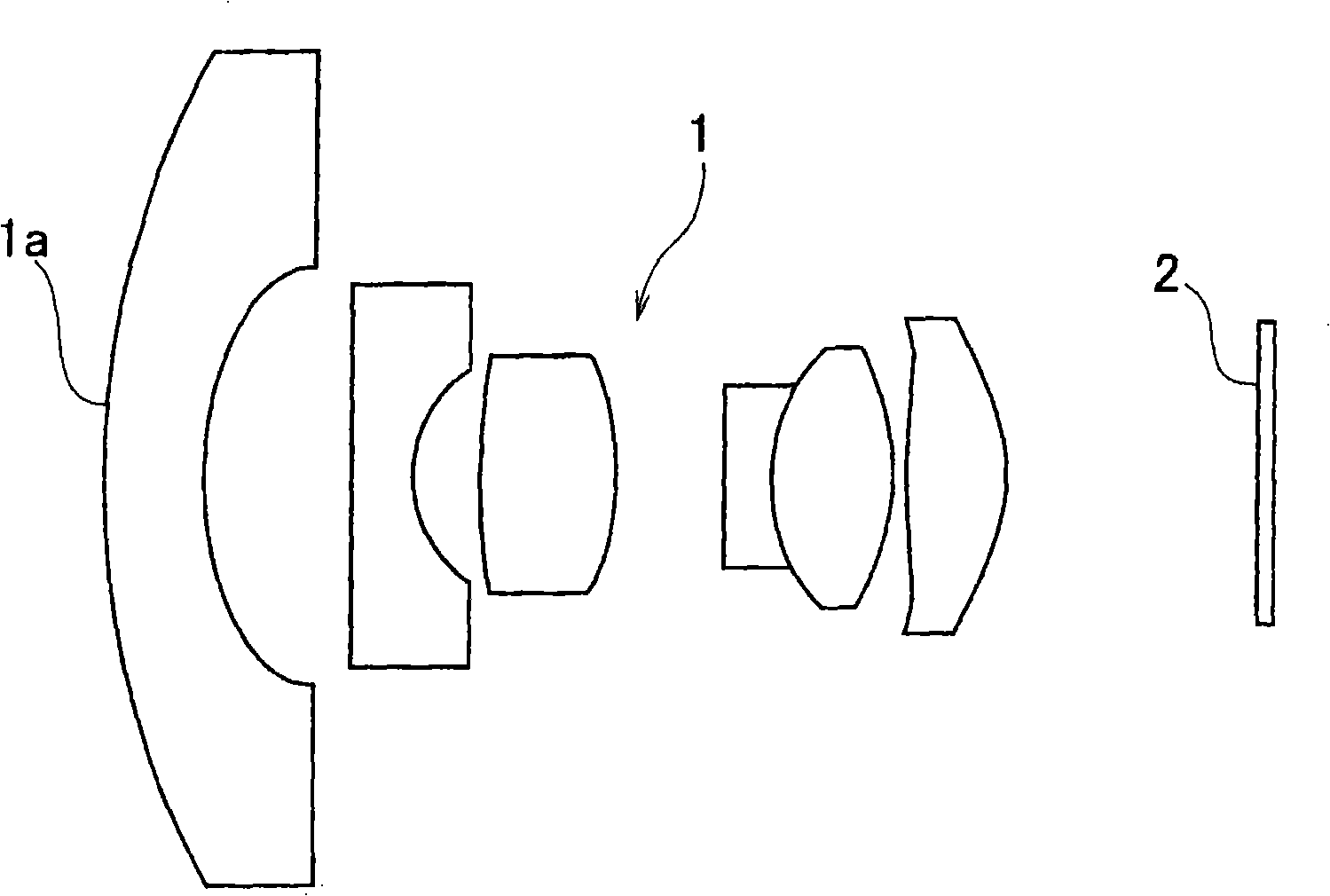

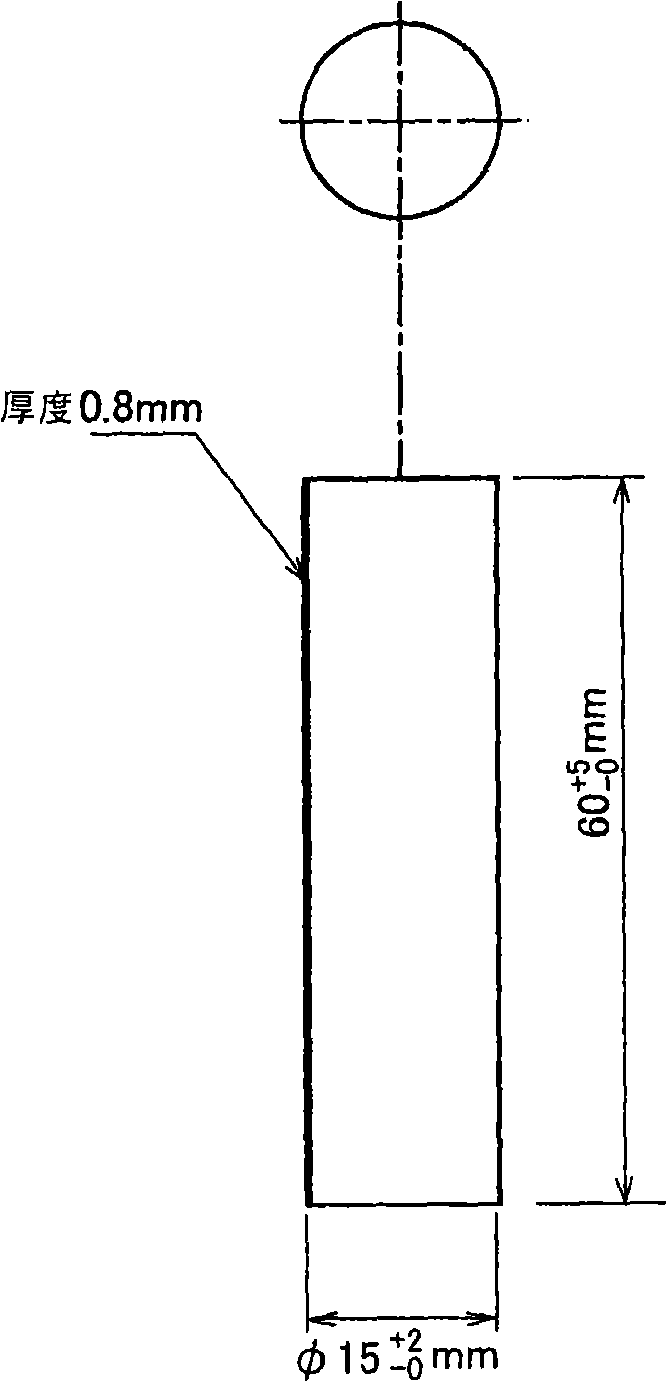

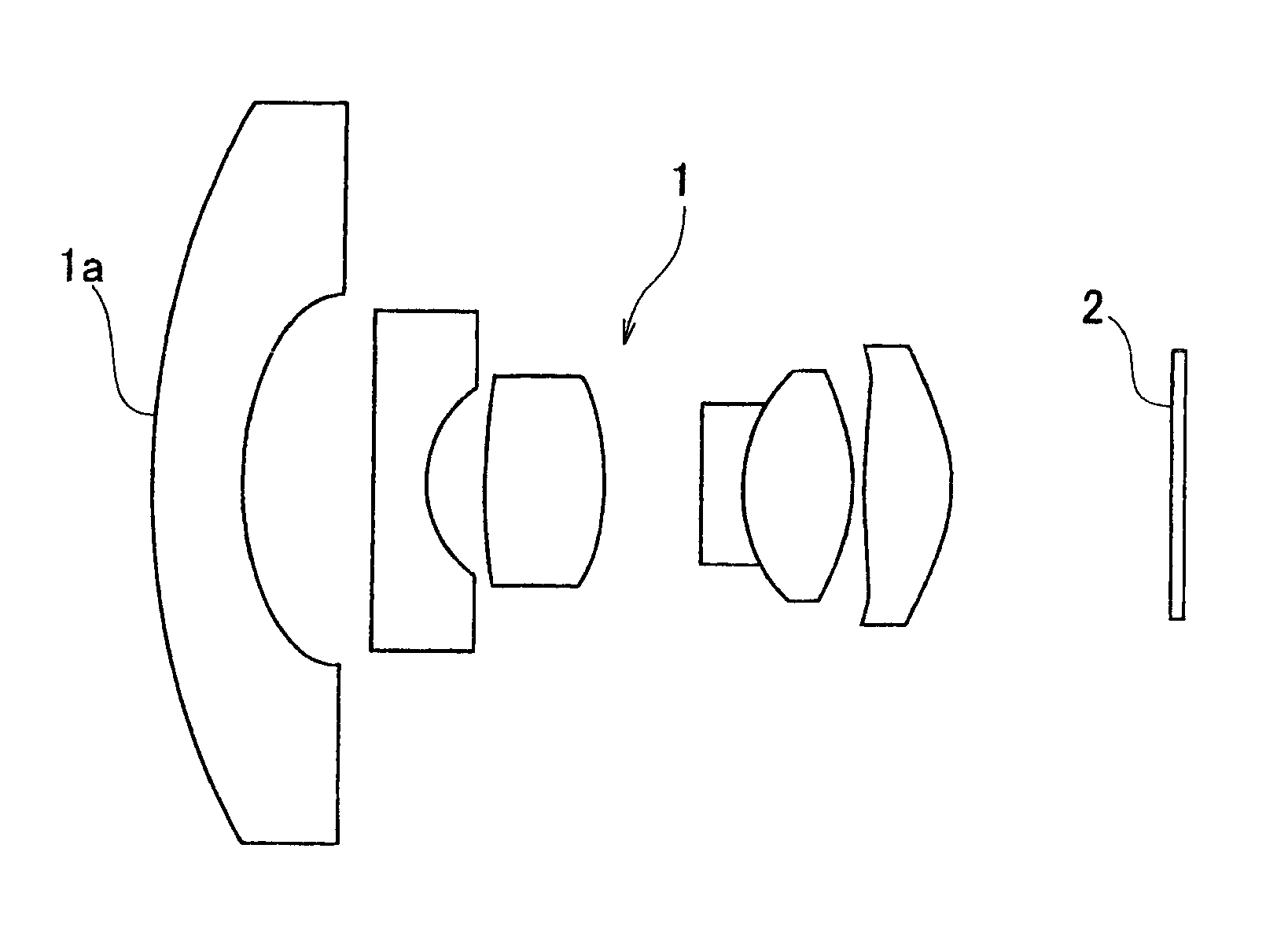

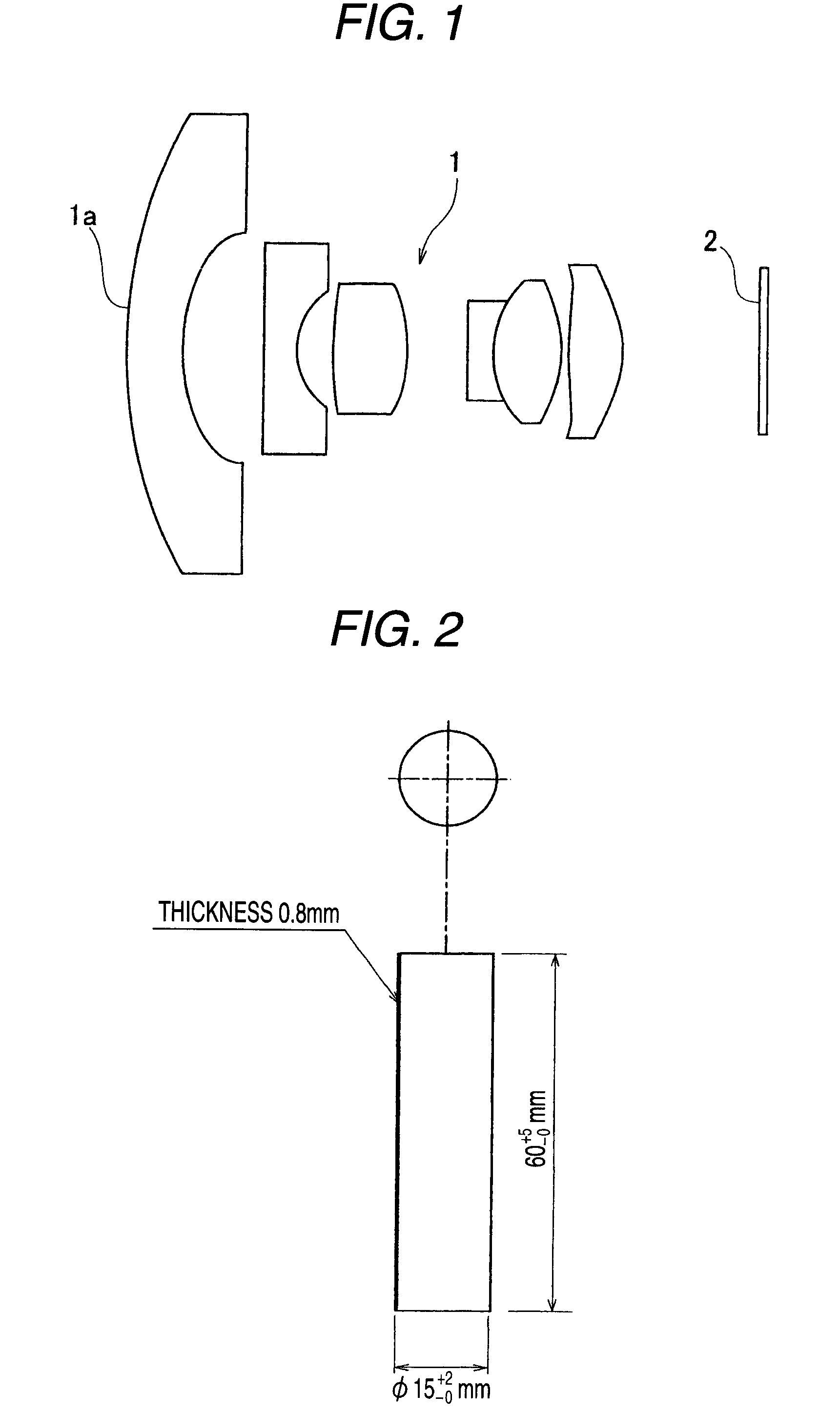

On-vehicle camera lens glass material and on-vehicle camera lens

ActiveUS20080231972A1Improve the immunityLess deteriorationOptical viewingLensCamera lensPowder method

An on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is 1st Class, a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 6th Class or higher, a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less, and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 100×10−7° C.−1 or less.

Owner:HOYA CORP

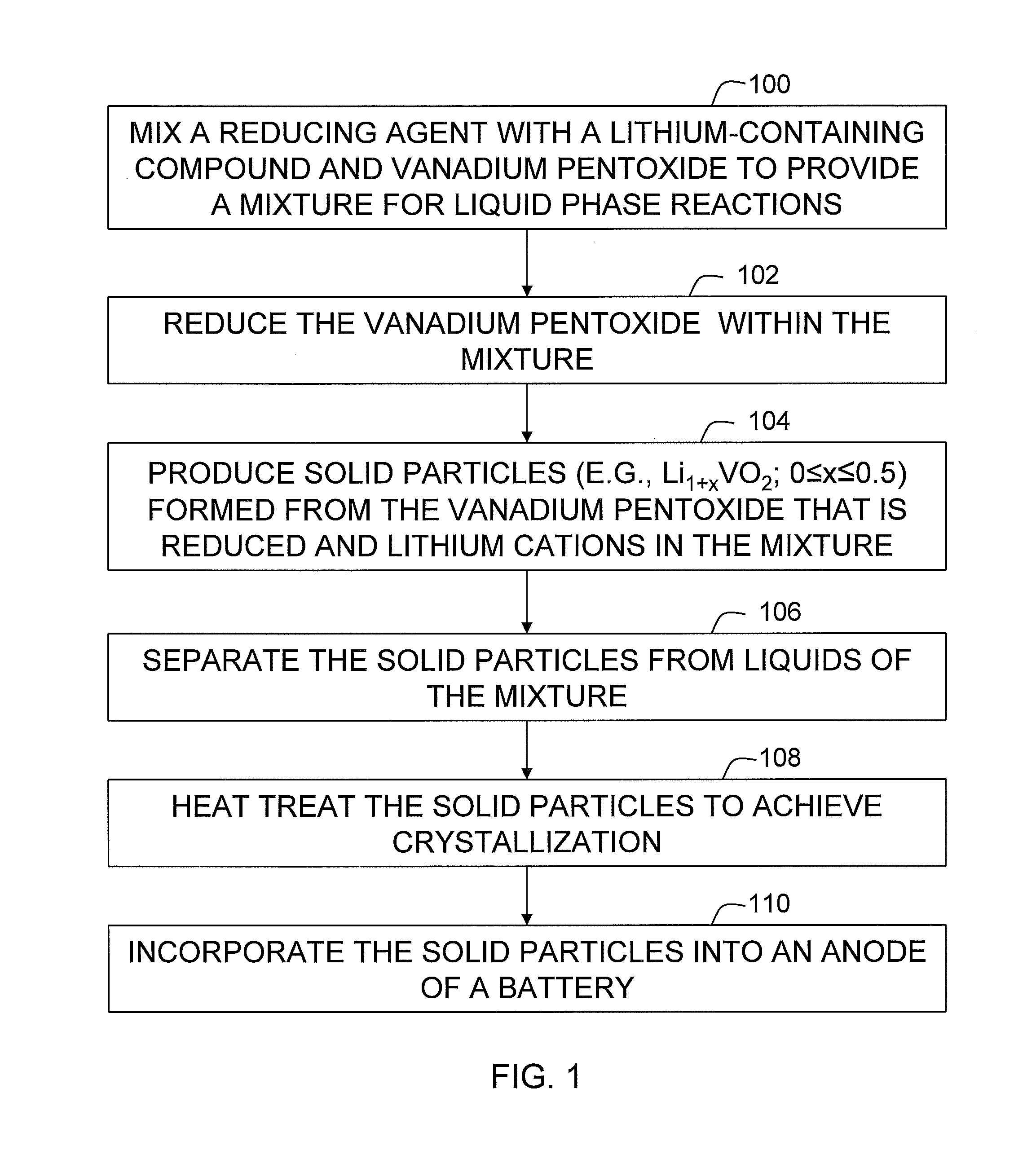

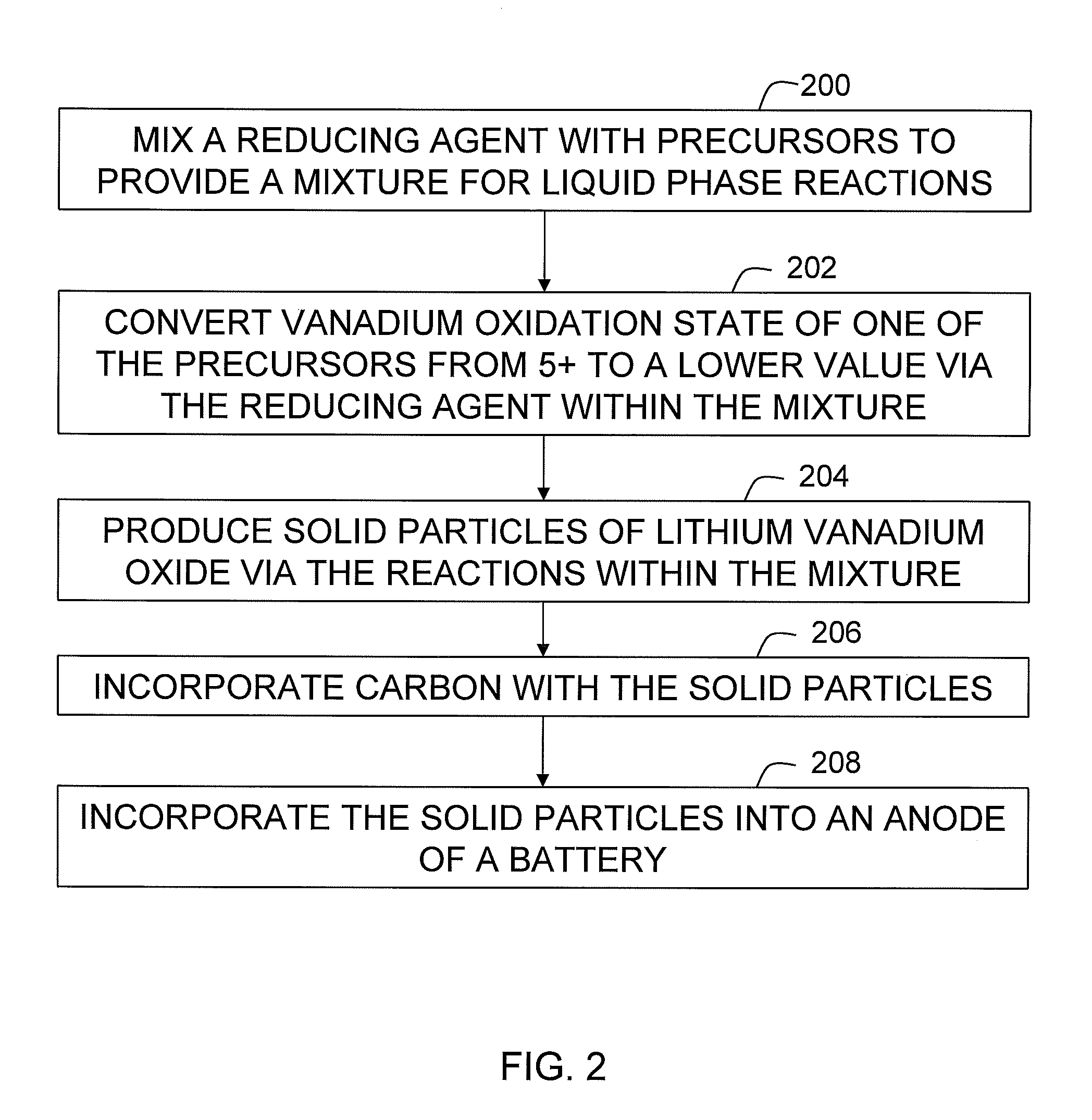

Methods of making lithium vanadium oxide powders and uses of the powders

Methods relate to making lithium vanadium oxide powders. Applications for the lithium vanadium oxide powders include use as a negative electrode or anode material for lithium ion batteries. Liquid phase reactions and reduction in vanadium oxidation state of precursor material facilitate in the making of the lithium vanadium oxide powders. Particles forming the lithium vanadium oxide powders may further contain carbon to provide electrical conductivity.

Owner:PYROTECK INC

On-vehicle camera lens glass material and on-vehicle camera lens

InactiveCN101271165AExcellent chemical durabilityImprove resistance to damageOptical viewingOptical elementsCamera lensRefractive index

This invention provides an on-vehicle camera lens glass material with excellent resistance to acid rain or medicine and full hardness, which comprises high reflection ratio through reducing the characteristic deterioration caused by ultraviolet ray, and is suitable for composing optical components such as on-vehicle camera lens on the on-vehicle camera which can be exposed under cruel environment, additionally, this invention provides an on-vehicle camera lens made of this on-vehicle camera lens glass material. The on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is the first class; a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is sixth class or higher; a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less; and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is less than 100*10(-7) DEG C (-1).

Owner:HOYA CORP

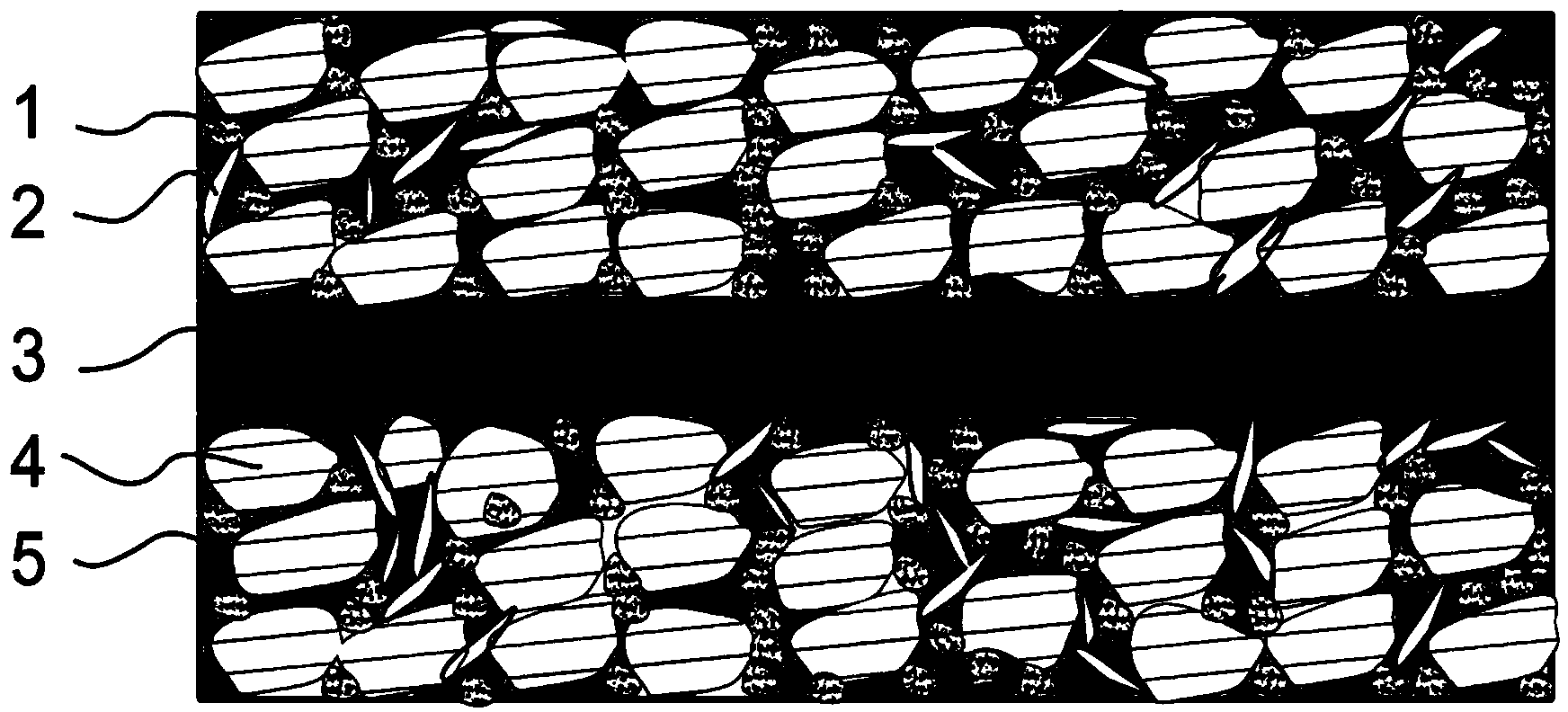

All-solid-state lithium ion battery and fabrication method thereof

ActiveCN106159314AEasy to assembleReduce manufacturing costFinal product manufactureElectrode collector coatingAll solid statePowder method

The invention relates to a lithium ion battery and a fabrication method thereof, in particular to an all-solid-state lithium ion battery and a fabrication method thereof. The all-solid-state lithium ion battery comprises a positive current collector, a positive active material layer, a negative current collector, a negative active material layer and a solid electrolyte, wherein the positive active material layer is fabricated on the positive current collector by a powder method, and the negative active material layer is fabricated on the negative current collector by a thin film method. By the fabrication method, the all-solid-state lithium ion battery which has excellent integral performance, is low in production cost and is suitable for large-scale industrial production can be obtained.

Owner:MICROVAST POWER SYST CO LTD

Eliminating scaling powder device and method used for hard disk drive printed circuit board (PCB) processing

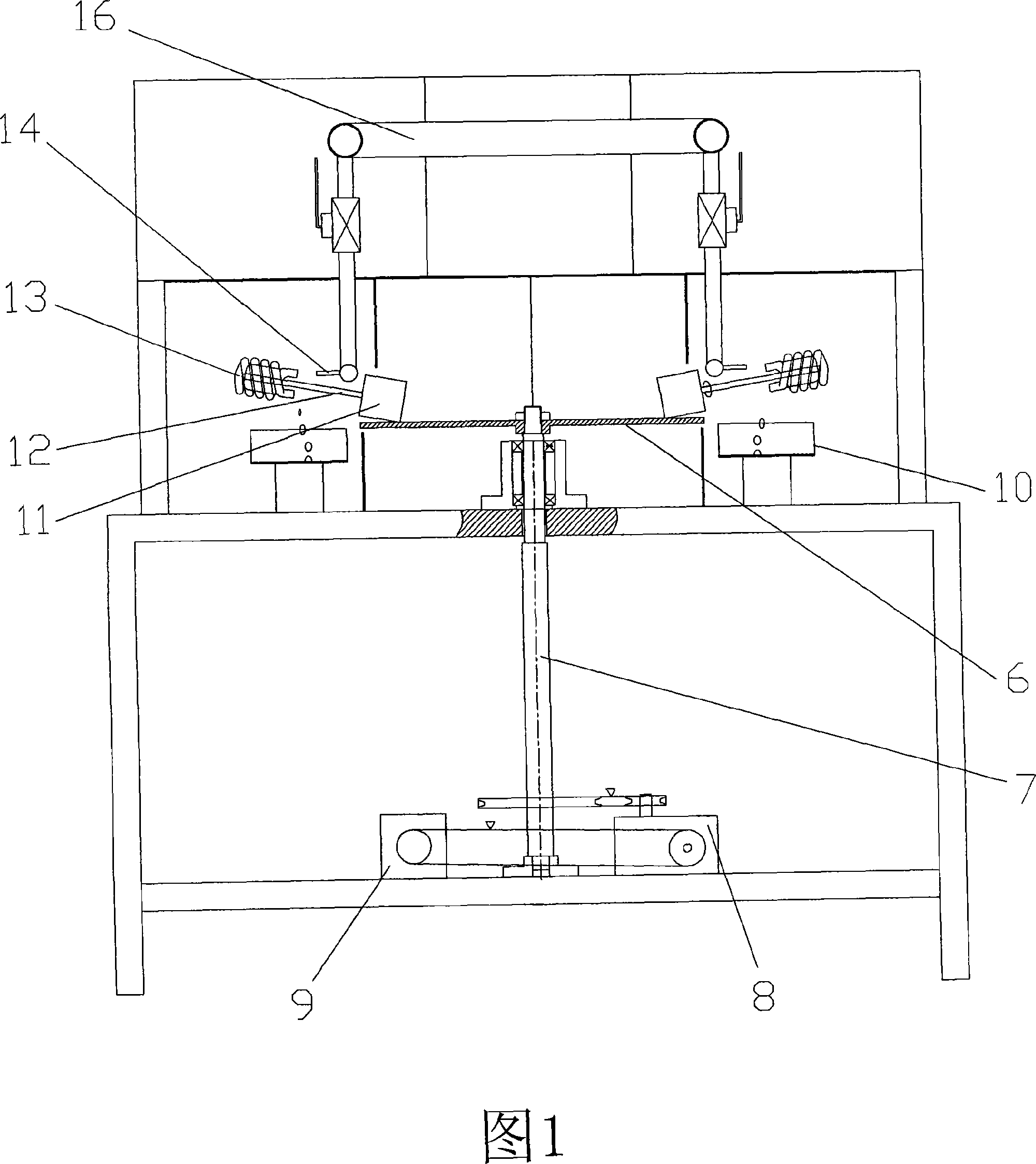

InactiveCN103096632AWill not cause repeated pollutionAchieving spot cleaningConductive pattern polishing/cleaningAutomatic controlEngineering

The invention discloses an eliminating scaling powder device used for hard disk drive printed circuit board (PCB) processing. A wiping step motor of a connecting rod motion system drives a wiping head of a wiping execution system to reach the wiping position of the PCB. A control system controls a wiping head control cylinder of the wiping execution system to be pressed downward and a cloth supporting cylinder to ascend. The control system controls the wiping step motor to rotate after receiving a triggered signal of a lower limiting magnetic rod of the wiping head cylinder, and therefore the wiping head is driven to wipe at the wiping position. In the process of wiping, the control system controls power-on interval of a high-frequency electromagnetic valve of a solvent adding control system, and therefore the wiper is provided with the solvent of optimizing quantity. The invention further provides an eliminating scaling powder method used for the hard disk drive PCB processing. The device and the method can conduct partial washing to the PCB, avoid the problem of repeating pollution, automatically achieves locating products, clamping the products, shifting the wiping head according to a set wiping position coordinate and switching rough wiping cloth and fine wiping cloth, and realizes automatic control of product cleaning.

Owner:精成科技电子(东莞)有限公司

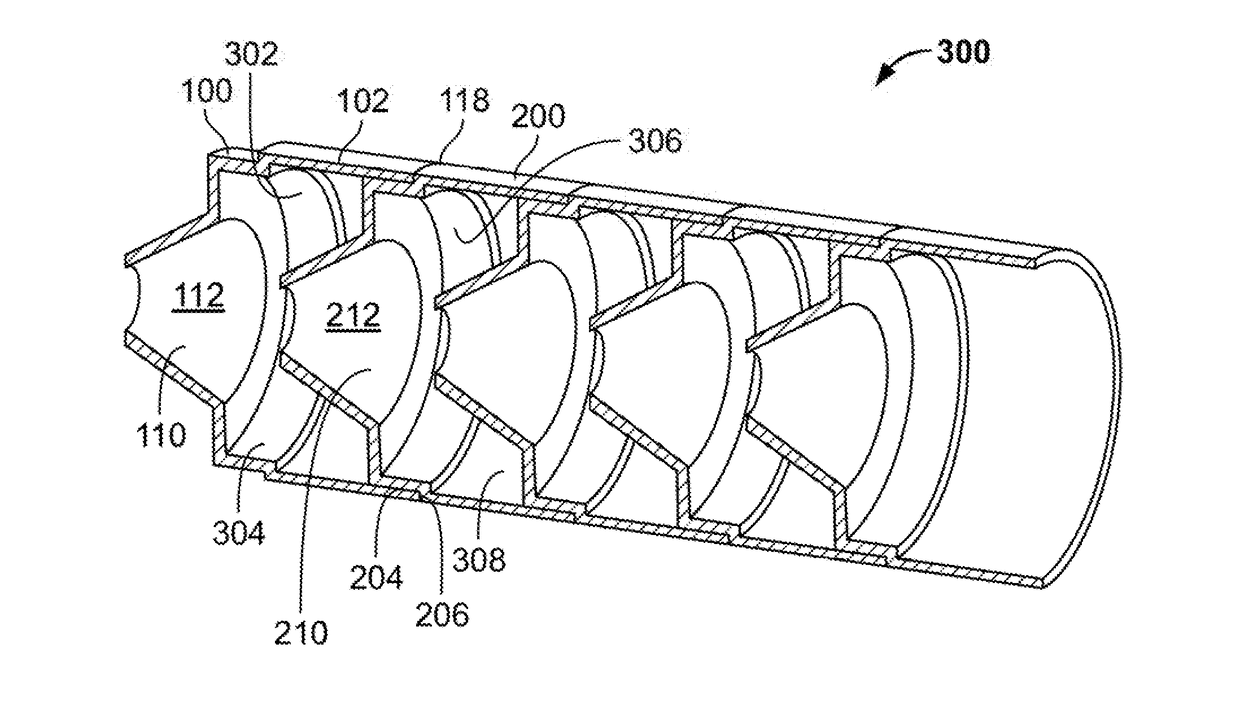

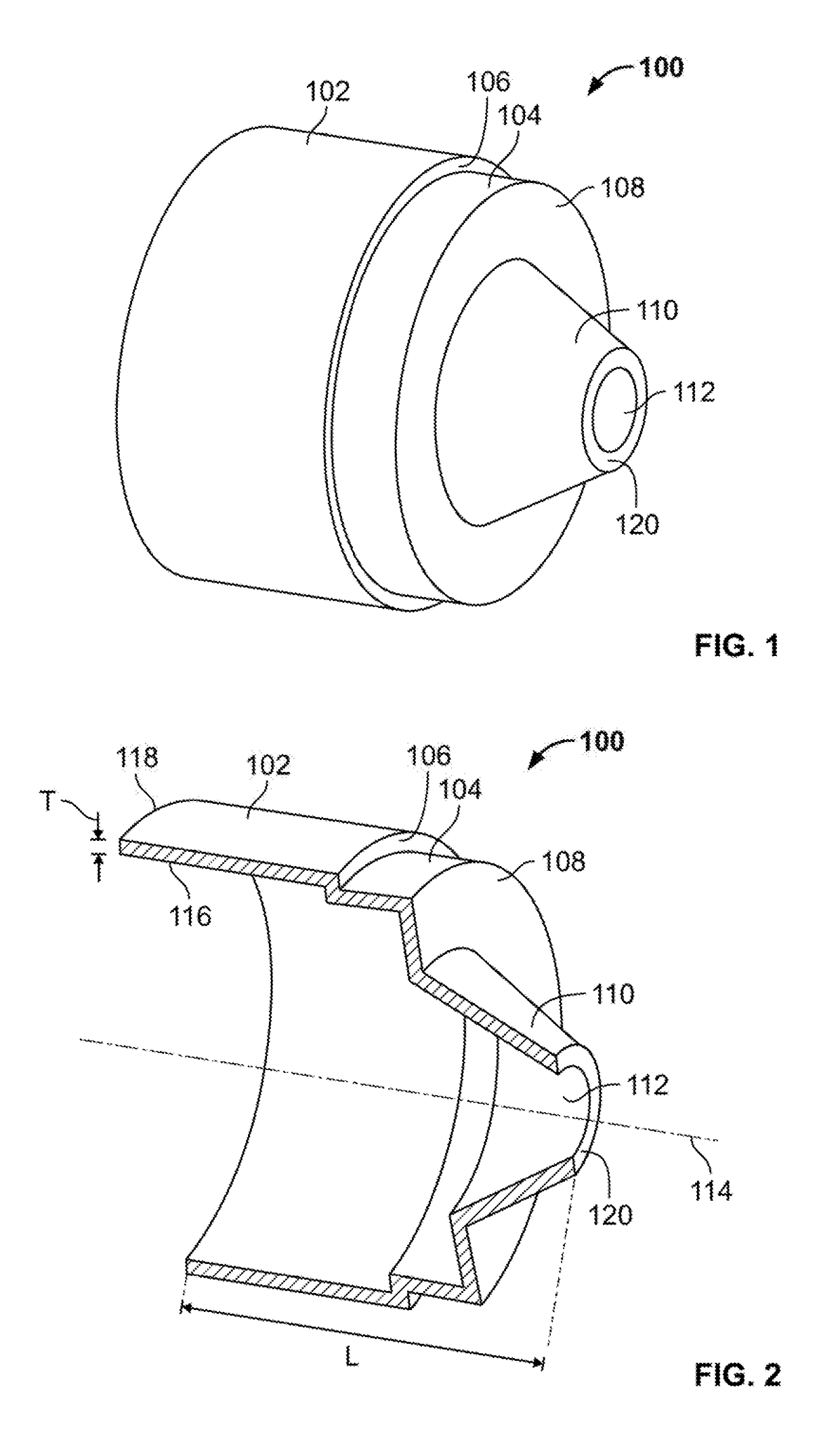

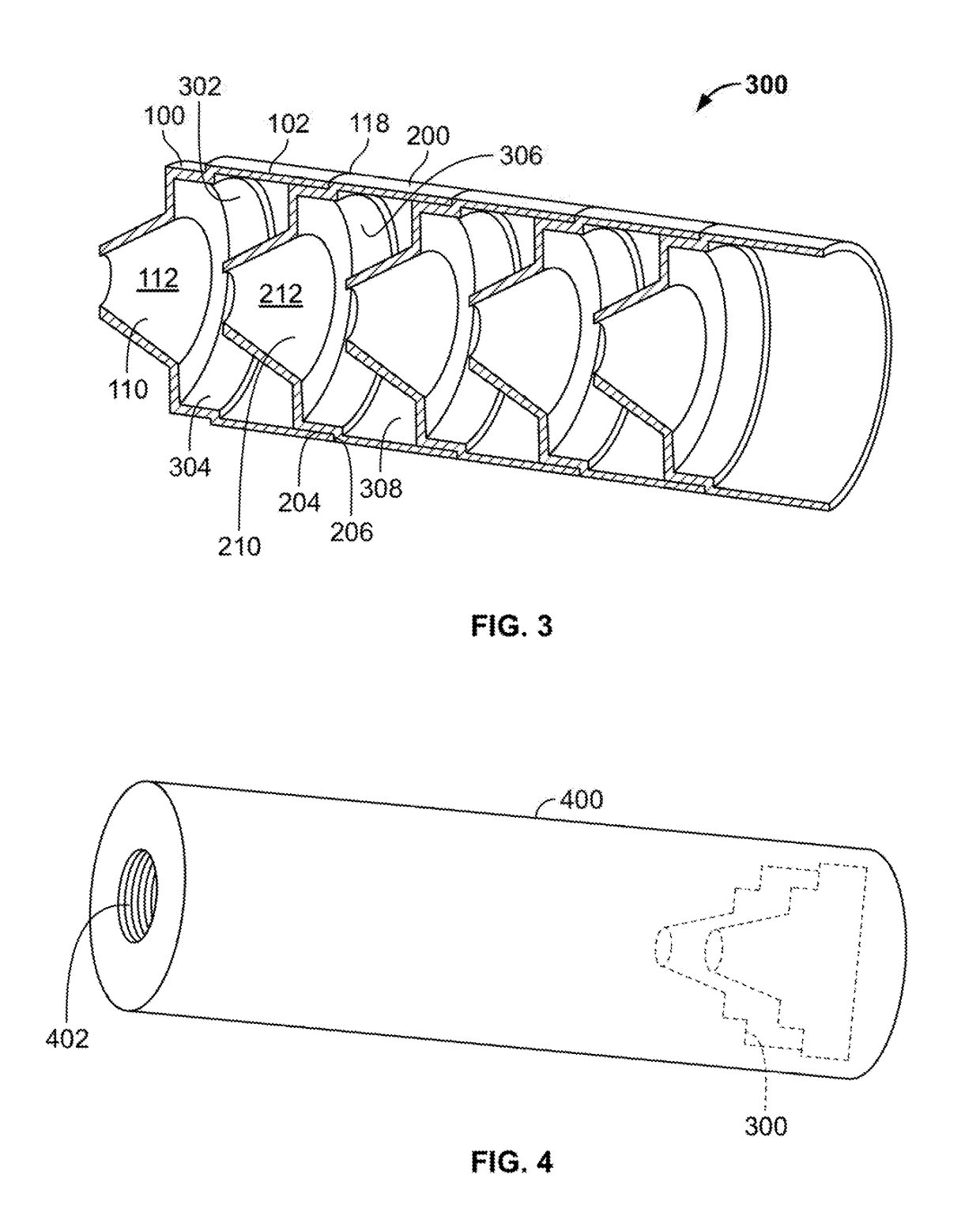

Baffles, suppressors, and powder forming methods

A method of forming a firearm suppressor baffle including preparing a titanium alloy powder system, forming of the powder system into a green shape, optionally green machining the green shape, sintering the green shape to create a firearm suppressor baffle formed from sintered material, where the firearm suppressor baffle has an elevated oxygen content of between 0.2 and 0.5 weight percent. The resultant sintered material may have a creep value of less than 1.5% at 50 hours at 450 C. Also, a method of forming a firearm suppressor baffle including preparing a titanium aluminide powder system, forming the titanium aluminide powder system into a green shape through one of compaction and powder metal injection molding, and sintering the green shape to create the firearm suppressor baffle. The titanium aluminide powder method may also include deoxygenating the firearm suppressor baffle. Also disclosed are baffles and suppressors formed using these methods.

Owner:PRAXIS POWDER TECH

Al-Cu-Mg-Ag powdered metallurgical heat-resisting aluminum alloy and preparation method thereof

The invention discloses an Al-Cu-Mg-Ag powdered metallurgical heat-resisting aluminum alloy and a preparation method thereof. The alloy comprises the components in percentage by weight: 4 to10 percent of Cu, 0.8 to 2.0 percent of Mg, 0.4 to 2.0 percent of Ag, 0 to 1.0 percent of Mn, 0 to 1.0 percent of Zr, 0 to 1.0 percent of Ti and the balance of Al. By adopting an element powder method, and ball milling, blank pressing, vacuum hot pressed sintering, and solid solution and aging methods, the powdered metallurgical heat-resisting aluminum alloy with fine grains is obtained; and the performance of the alloy is obviously better than that of the conventional cast Al-Cu-Mg-Ag heat-resisting aluminum alloy, and requirement of middle and high temperature structural materials on the heat-resisting aluminum alloy can be met; and industrial application can be realized, and application of the aluminum alloy in the field of the middle and high temperature structural materials is expanded.

Owner:CENT SOUTH UNIV

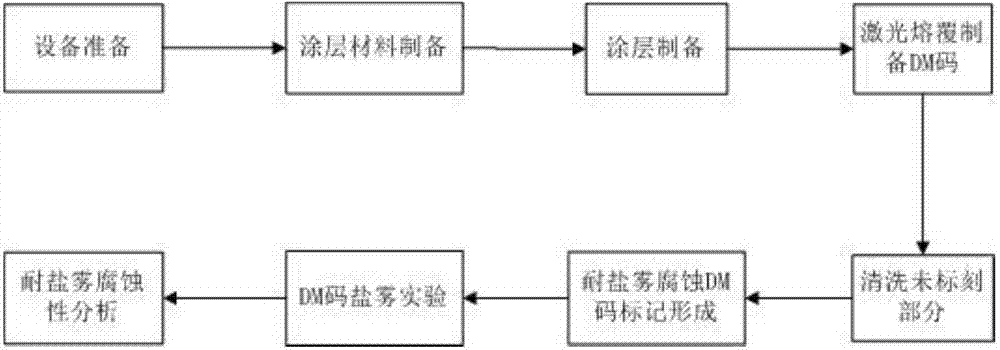

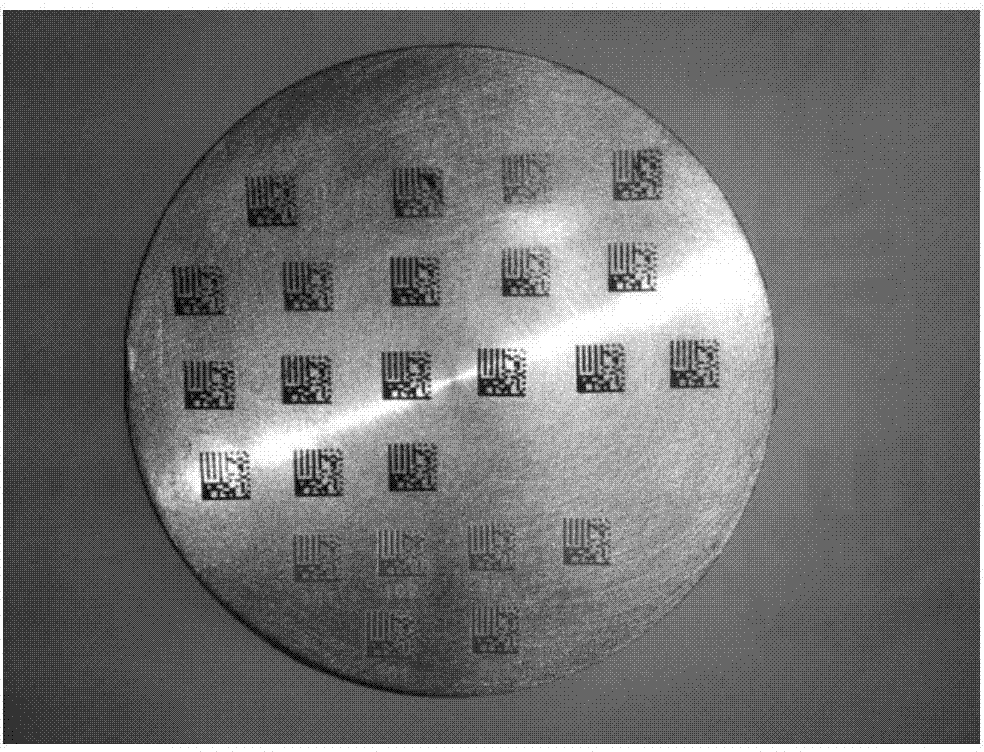

Aluminum alloy corrosion resistance two-dimensional code marking method based on laser cladding

ActiveCN104846368AImproved salt spray corrosion resistanceImprove salt spray corrosion resistanceMetallic material coating processesLacquerAlloy substrate

The invention provides an aluminum alloy corrosion resistance two-dimensional code marking method based on laser cladding. According to the method, a preset powder method is adopted for uniformly coating a layer of coating material on an aluminum alloy substrate; the coating material is formed by mixing nickel-based alloy powder, graphite powder, absolute ethyl alcohol and lacquer varnish; DM (digital matrix) codes are marked on the surface of the coating layer through laser so that the coating layer and a thin layer of the surface of the substrate are simultaneously melted, and a surface coating which has ultra-low dilution degree and forms metallurgical bonding with the substrate is formed after fast solidification; then, an ultrasonic cleaner is used for cleaning away unmarked parts, so that a DM code mark realizing salt spray corrosion resistance is formed. The salt spray corrosion resistance performance of the generated DM code mark is greatly improved, and in addition, the influence on part substrates outside the DM code mark region is smaller. Compared with other methods for improving the corrosion resistance of the DM code, the aluminum alloy corrosion resistance two-dimensional code marking method has the advantage that the efficiency is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production method for particle reinforced aluminum matrix composite ingots

The invention relates to a production method for particle reinforced aluminum matrix composite ingots. The method comprises the steps of naturally stacking small spherical porous bodies in a casting die inner cavity, adopting a vacuum-pressure infiltration molten metal method to produce ingot blank, enabling the composite ingot blank to be subjected to thermal plasticity such as extrusion, rolling or forging, and obtaining particle reinforced metal matrix composite products. Not only is the production method simple in production process and low in production cost, but also the products have higher performance than products produced through a powder method.

Owner:山西银光华盛镁业股份有限公司

On-vehicle camera lens glass material and on-vehicle camera lens

An on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is 1st Class, a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 6th Class or higher, a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less, and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 100×10−7° C.−1 or less.

Owner:HOYA CORP

Method for producing superphosphate and compound fertilizer thereof by means of concentrated acid slag powder method

InactiveCN103086338AReduce corrosionReduce or eliminate the introductionSuperphosphatesPhosphorus compoundsPowder methodSlag

The invention discloses a method for producing superphosphate and a compound fertilizer of the superphosphate by means of concentrated acid powder slag method, and belongs to the field of agricultural fertilizer. The superphosphates compound fertilizer is directly prepared by subjecting the mixing process of concentrated sulfuric acid and phosphorite to mechanical stirring and grinding force and organically combining the preparation and neutralization pretreatment of the superphosphate and the preparation of the compound fertilizer, complex process flow is prevented, production efficiency is improved, and production cost is reduced.

Owner:ZHENGZHOU UNIV

Powder method for preparing continaous SIC fiber reinforced Ti alloy base composite material

The present invention relates to composite material preparing technology, and is especially preparation process of continuous SiC fiber reinforced Ti alloy-based composite material. The prefabricated band prepared through mixing polyestyrene as adhesive, xylene as solvent and Ti alloy powder, and the fiber cloth made through continuously twisting SiC fiber are deaired, heated and hot pressed to obtain composite material plate. The present invention provides the practical technological path for preparing SiC fiber reinforced Ti alloy-based composite material in low cost, and the composite material may prepared with cheap alloy powder and polystyrene as adhesive in simple apparatus. The preparation process has no pollution, and is simple, practical and wide in application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

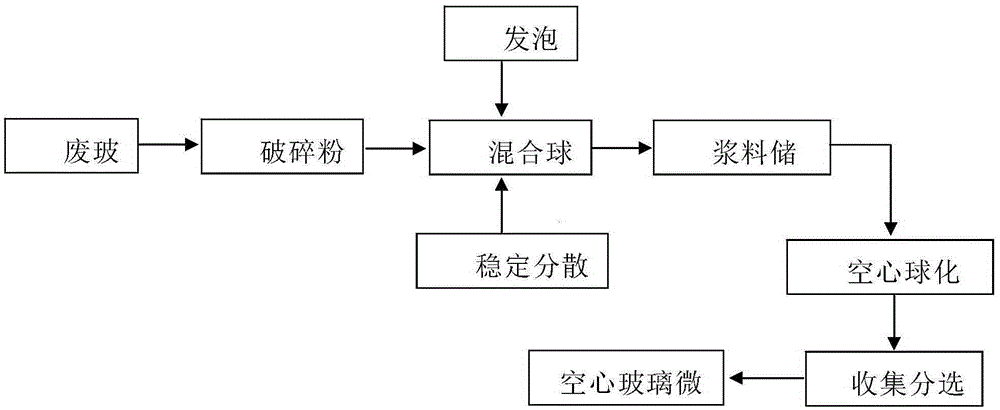

Method for preparing hollow glass beads through waste glass

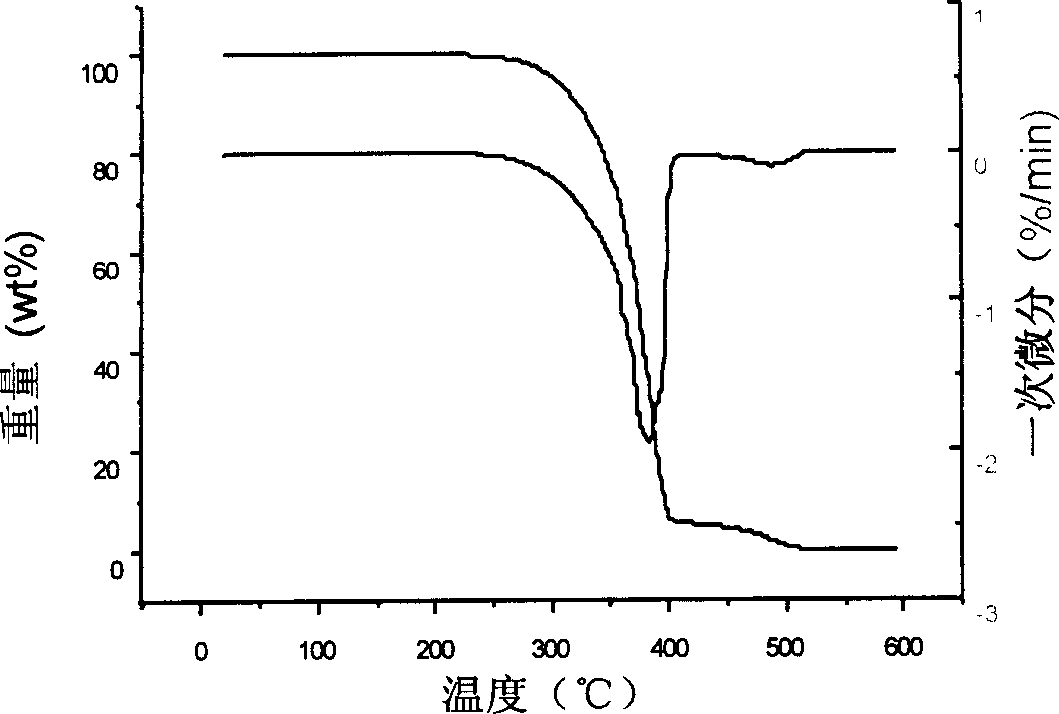

InactiveCN105271647AEliminate the step of granulation into precursorReduce manufacturing costGlass shaping apparatusFoaming agentPowder method

The invention discloses a method for preparing hollow glass beads through waste glass. The method includes the following steps that a, the waste glass, water, stabilizing agents and foaming agents are mixed and subjected to ball milling, and waste glass powder slurry with the high solid phase content is prepared; b, the waste glass powder slurry is directly conveyed to a bead forming furnace by a conveying pump to be dried and hollowly balled; c, the products obtained through heating of the bead forming furnace are collected, and then the hollow glass beads are separated with a float method. According to the preparing method, the waste glass serves as main raw materials, the slurry is directly and hollowly balled, the glass high-temperature melting process in a glass powder method is avoided in the technology, and meanwhile the step that the slurry is prilled into precursors with a spray prilling method is omitted. The method is short in technological process and low in energy consumption, the prepared cost of the hollow glass beads is greatly reduced, and the situation that due to high cost, the application of the hollow glass beads is limited can be easily broken through.

Owner:CHINA TRIUMPH INT ENG

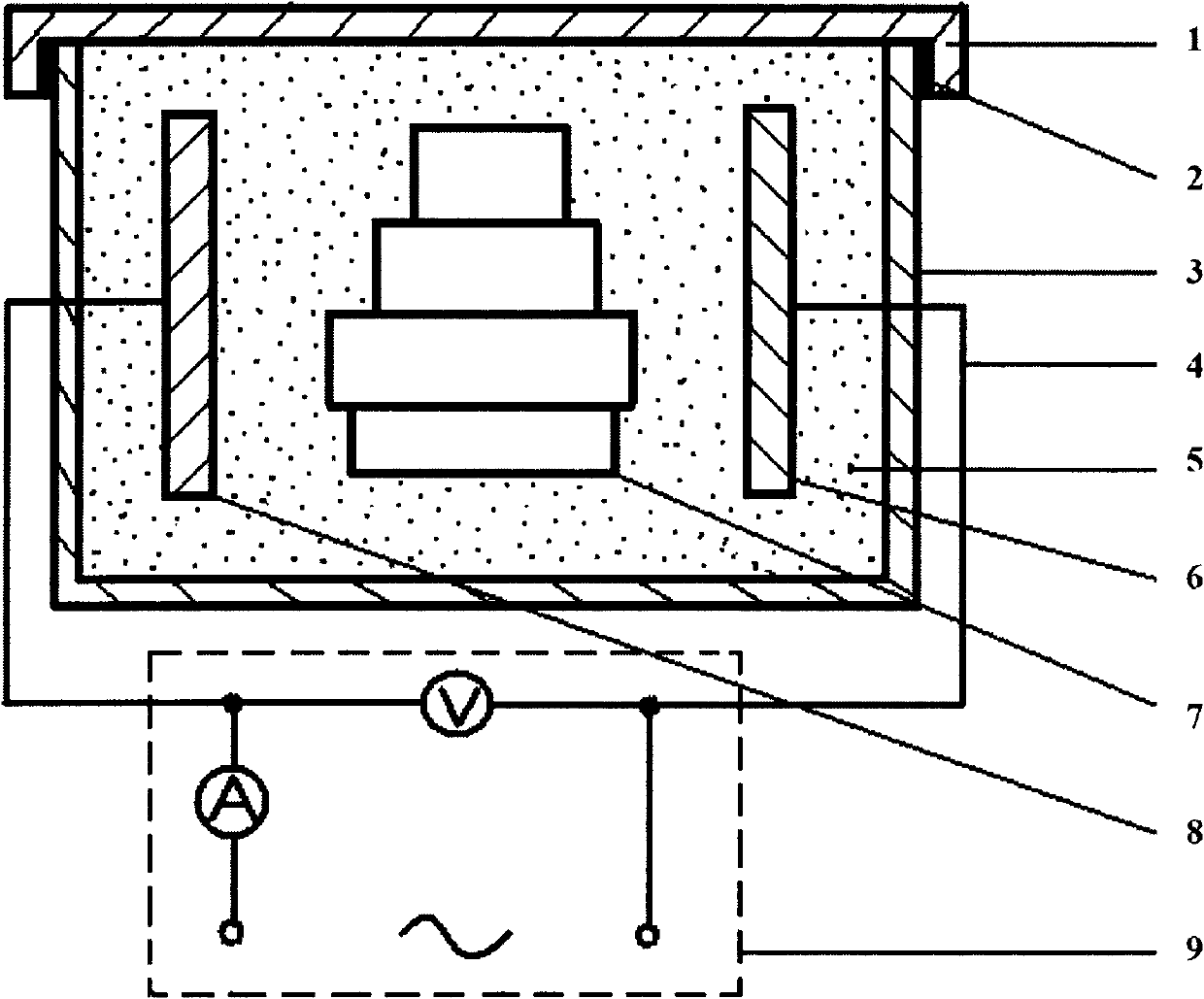

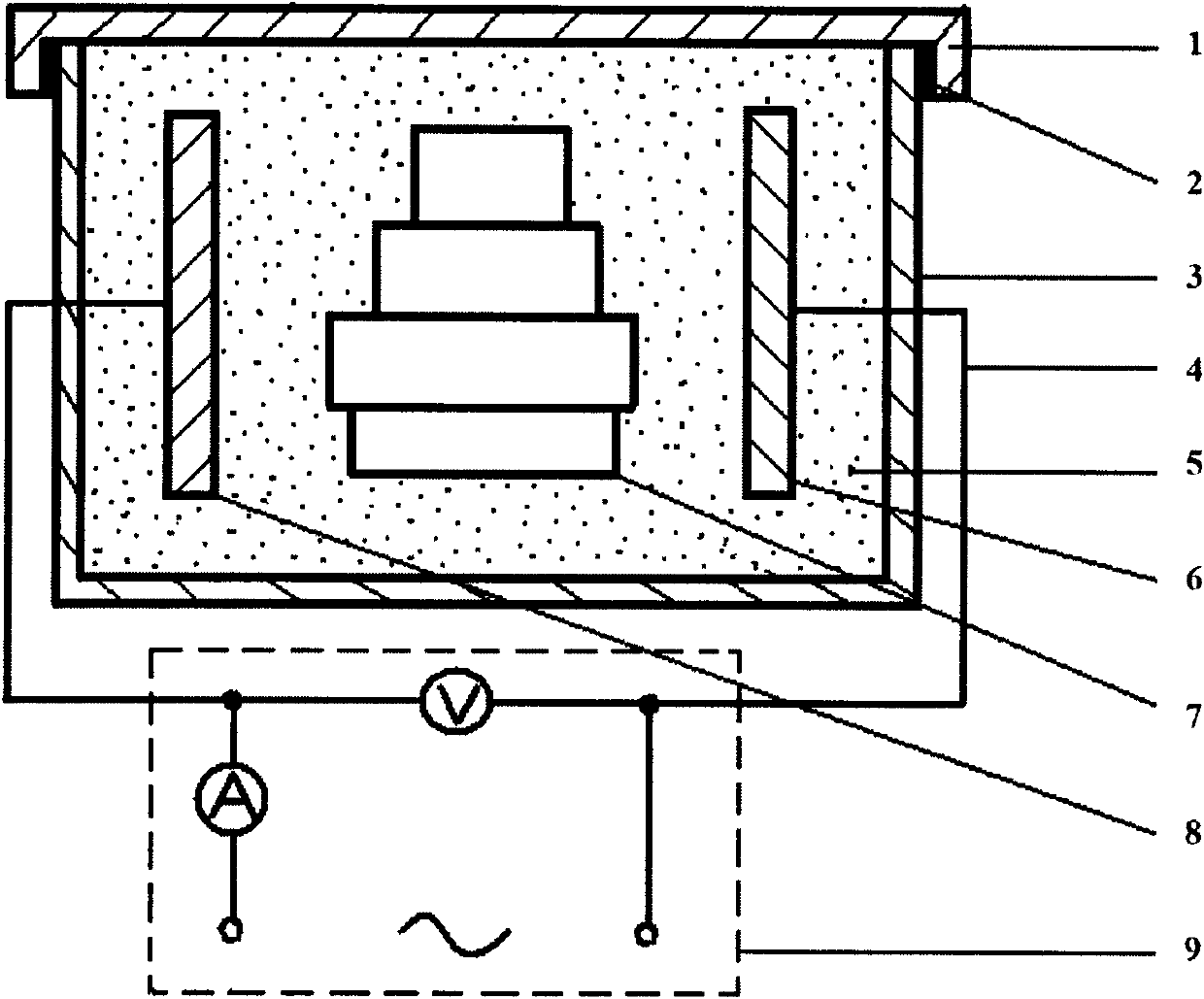

Method and device for accelerating powder method boronisation by alternating-current filed

InactiveCN102168243AIncrease concentrationHigh activitySolid state diffusion coatingPowder methodParallel plate

The invention discloses a method and a device for accelerating powder method boronisation by an alternating-current filed and used for strengthening the surface of a metal part. Two parallel plate-shaped electrodes are placed in powdered boronizing agent and by leads, the two electrodes are respectively connected on a 50Hz alternating current power supply of which the voltage is continuously adjustable within the range of 0-250V; a treated part is positioned between the two electrodes; the electrodes and the part are sealed together with the boronizing agent in a boronisation box and placed in a heat treatment furnace to heat; after the temperature of the furnace achieves a set value, appropriate alternating voltage is applied between the two electrodes; and then the rapid boronisation of the part can be realized. Compared with the existing method, the method of the invention has the advantages that the boronisation can be accelerated by at least 0.3-3 times and the usage amount of the boronizing agent is reduced by above 70%. Therefore, the method and the device can accelerate the powder method boronisation of the metal part, improve the utilization rate of the boronizing agent, lower the temperature of boronisation and reduce deformation of the part.

Owner:CHANGZHOU UNIV

Catalyst for producing ethyl orthosilicate by silicon powder method and preparation method thereof

InactiveCN102489299AHigh activitySolve easy lossSilicon organic compoundsCatalyst activation/preparationAlcoholActive component

The invention relates to a catalyst for producing ethyl orthosilicate by a silicon powder method and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 20%-50% of cuprous oxide, 10%-40% of copper oxide, 10%-40% of copper powder and 10%-30% of catalyst carrier. The preparation method comprises the following steps of: uniformly mixing the active components such as cuprous oxide, copper oxide and copper powder according to the composition of the catalyst; preparing a 30-40% alcohol or aqueous solution of the catalyst carrier; and adding the mixed active components in the alcohol solution of the catalyst carrier, stirring for 1-2 hours, then dripping a small amount of distilled water, continuously stirring for 1-24 hours, and then filtering,thus obtaining filter residue; and drying the filter residue at the temperature of 70-120 DEG C, and roasting for 8-24 hours with air isolation at the temperature of 400-700 DEG C, thus obtaining thecatalyst. The catalyst has the characteristics of high activity and stability, long service life and capability of being utilized repeatedly for multiple times.

Owner:KUNMING METALLURGY INST

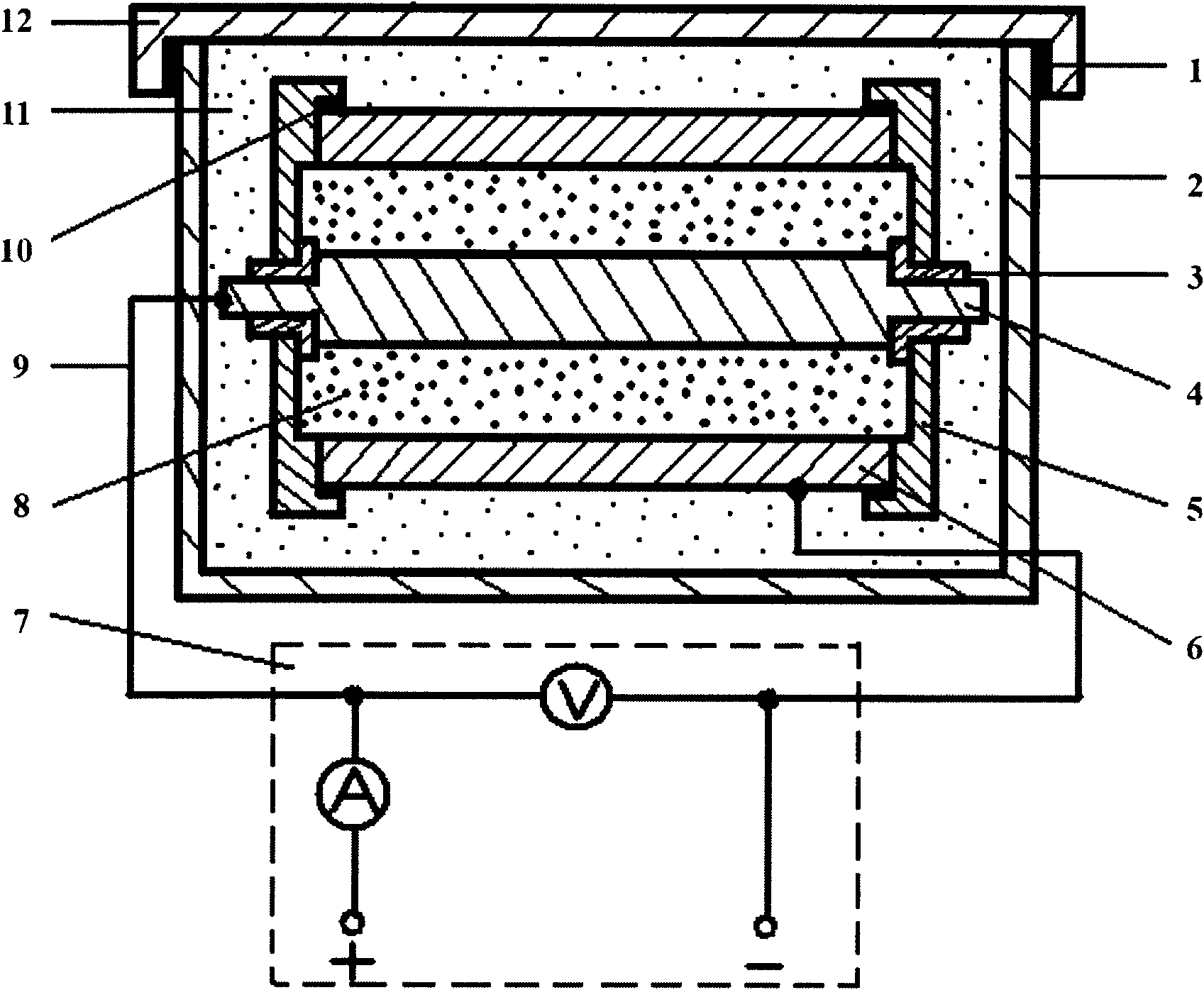

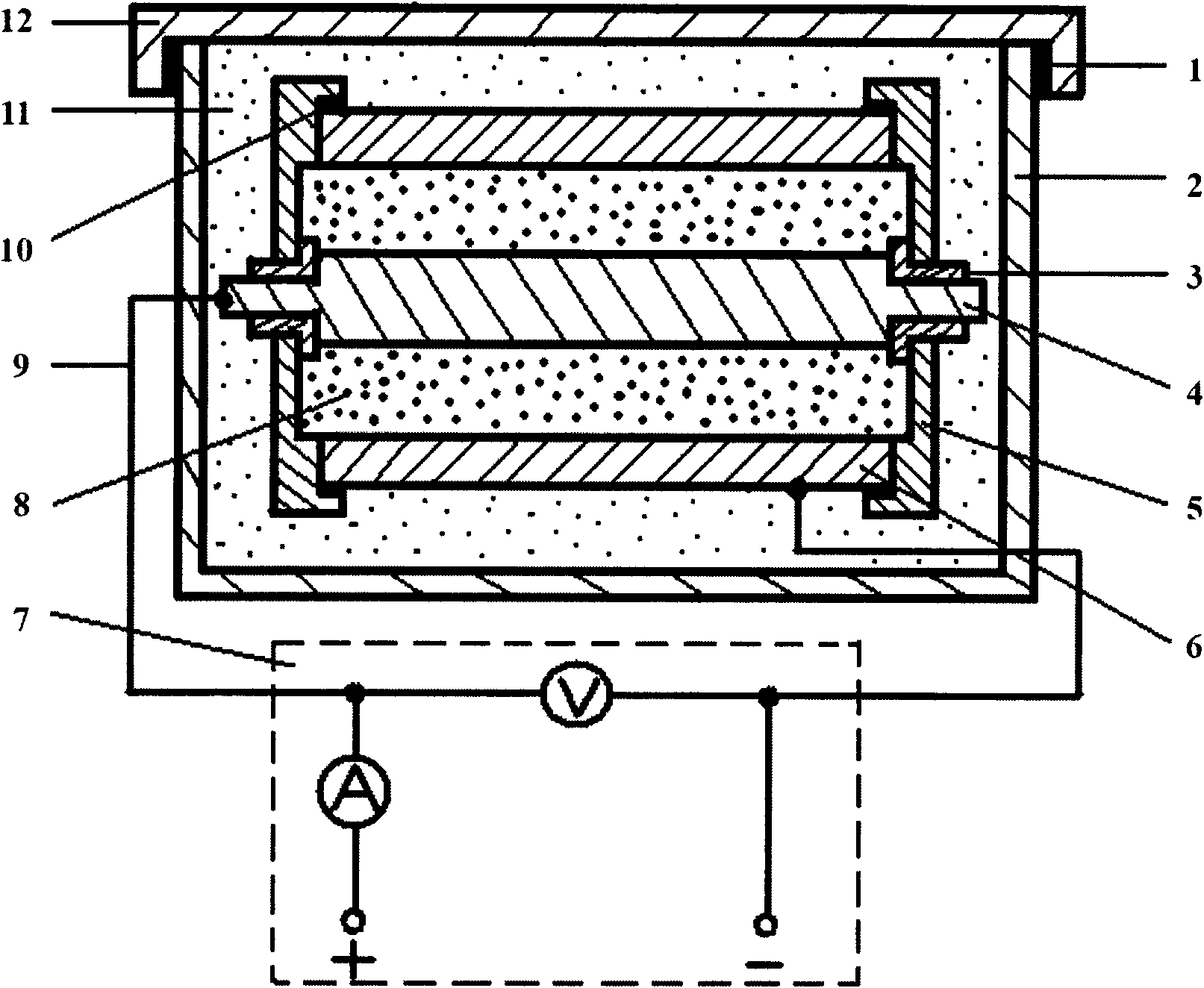

Boronizing method and device for inner surface of tubular component by using direct-current electric field enhanced powder method

InactiveCN102154616AIncrease profitReduce contentSolid state diffusion coatingPowder methodEngineering

The invention discloses a boronizing method and device for the inner surface of a tubular component by using a direct-current electric field enhanced powder method. In the method, a powdery boronizing agent is filled in the tubular component to be treated; a columnar electrode is arranged in the center of the boronizing agent; two ends of the tubular component are sealed and insulated; the columnar electrode is used as a positive electrode, the tubular component is used as a negative electrode, and the two electrodes are parallel to each other; the tubular component (comprising the columnar electrode) and an anti-oxidizing filler are sealed in a boronizing box together; the boronizing box is arranged in a box type furnace for heating; meanwhile, a direct-current electric field is applied between the tubular component and the positive electrode, so that rapid boronizing on the inner surface of the tubular component can be realized. Compared with the conventional method, the method has the advantage that: the boronizing speed can be at least increased by 0.5 to 2 times at different temperatures within a range of between 550 and 950 DEG C. Therefore, the boronizing speed of the powder method on the inner surface of the metal tubular component can be increased, the boronizing temperature can be reduced, and the utilization rate of the boronizing agent can be increased by adopting the method and the device.

Owner:CHANGZHOU UNIV

Rolling type powder-coating method for spiral fluorescent lamp tube and spiral lamp tube roller coating equipment

InactiveCN101071706ASolve the shadow phenomenonHigh light efficiencyLuminescent coatings applicationCircular discFluorescence

This invention involves a screw fluorescent lamp tube to roll the type to spread the powder method and the equipment. The goalies provides spreads the powder method and the equipment ought to beagle effectively to eliminate the spiral lamp tube endophragm the luminous powder shadow, has the lamp tube light effect high, spreads the powder to be even, the economical material characteristic. The technical plan is: The spiral fluorescent lamp tube rolls the type to spread the powder method, according to following step succession: 1.The luminous powder wheat-flour paste pours into the lamp tube; 2.Pours the excessive luminous powder wheat-flour paste; 3. Carries onto the spiral lamp tube rolls spreads; Inclines the certain angle the spiral lamp tube, and causes it to be at the rotational state; Fourth, the wheat-flour paste stereotypic is dry. The spiral lamp tube rolls spreads the equipment, including a disc as well as in the disc border certain rotations organization, each rotation organization stretches out hold-down bars, in order to spiral lamp tube spatial wrap and localization; The hold-down bars spool thread and the horizontal plane angle for 0-30degree, each rotation organization under meets the powder trough. Each rotation organization above also is equipped with as soon as blows the gusty area, carries on dryly catches a chill.

Owner:HANGZHOU YUZHONG GAOHONG LIGHTING ELECTRICAL

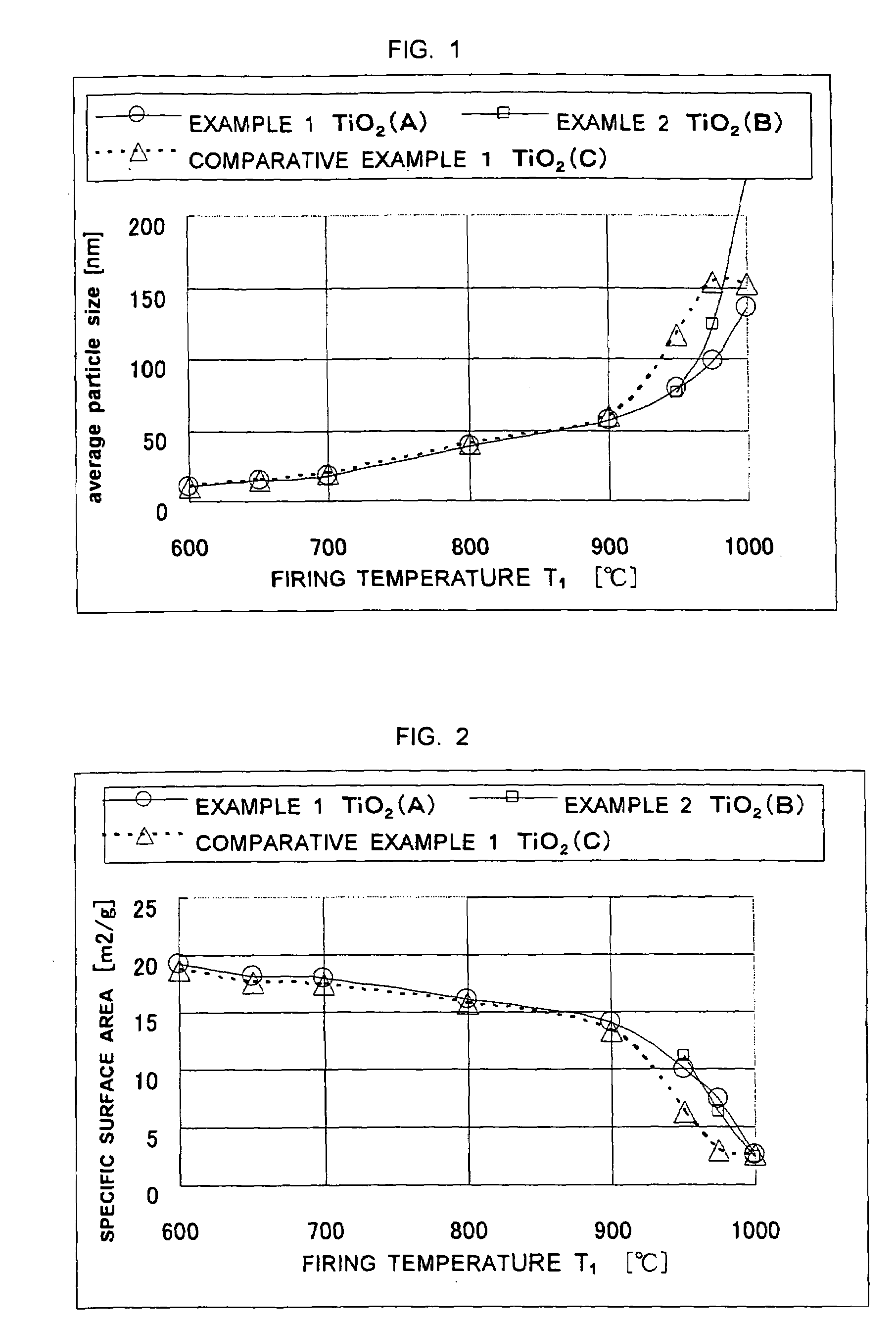

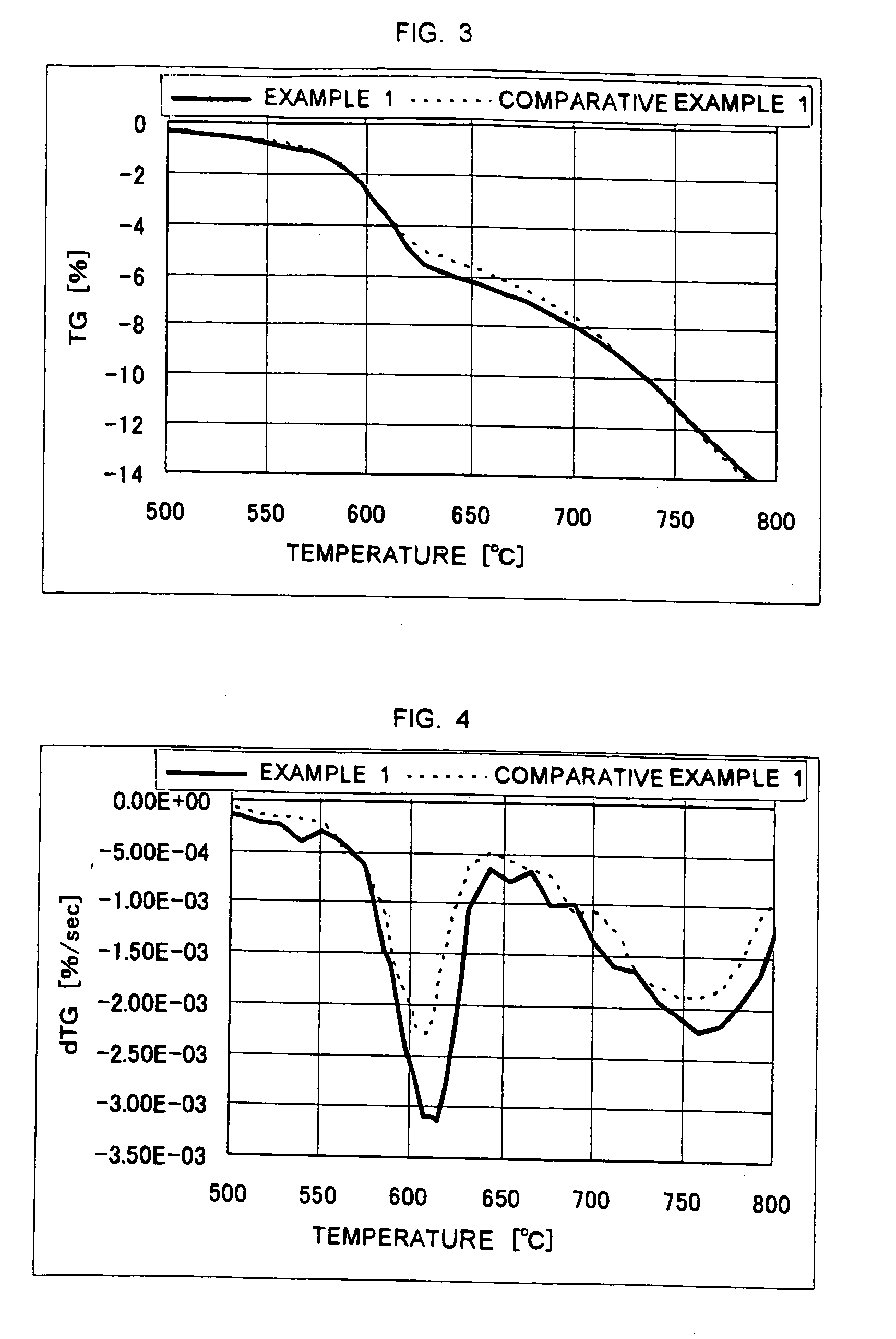

Method for producing dielectric powder

InactiveUS20090202426A1Uniform grain propertyHigh tetragonalityAlkaline earth titanatesMaterial nanotechnologyPowder mixturePowder method

Method for producing dielectric powder comprising steps of;preparing titanium dioxide powder having sum of surface chlorine amount and internal chlorine amount of 2000 ppm or less, surface chlorinity of 120 ppm or less, rutilated ratio of 30% or less, BET specific surface area of 30 m2 / g or more;preparing barium compound powder to produce barium oxide by thermolysis;preparing powder mixture of titanium dioxide powder and barium compound powder; andheat treating the powder mixture.

Owner:TDK CORPARATION

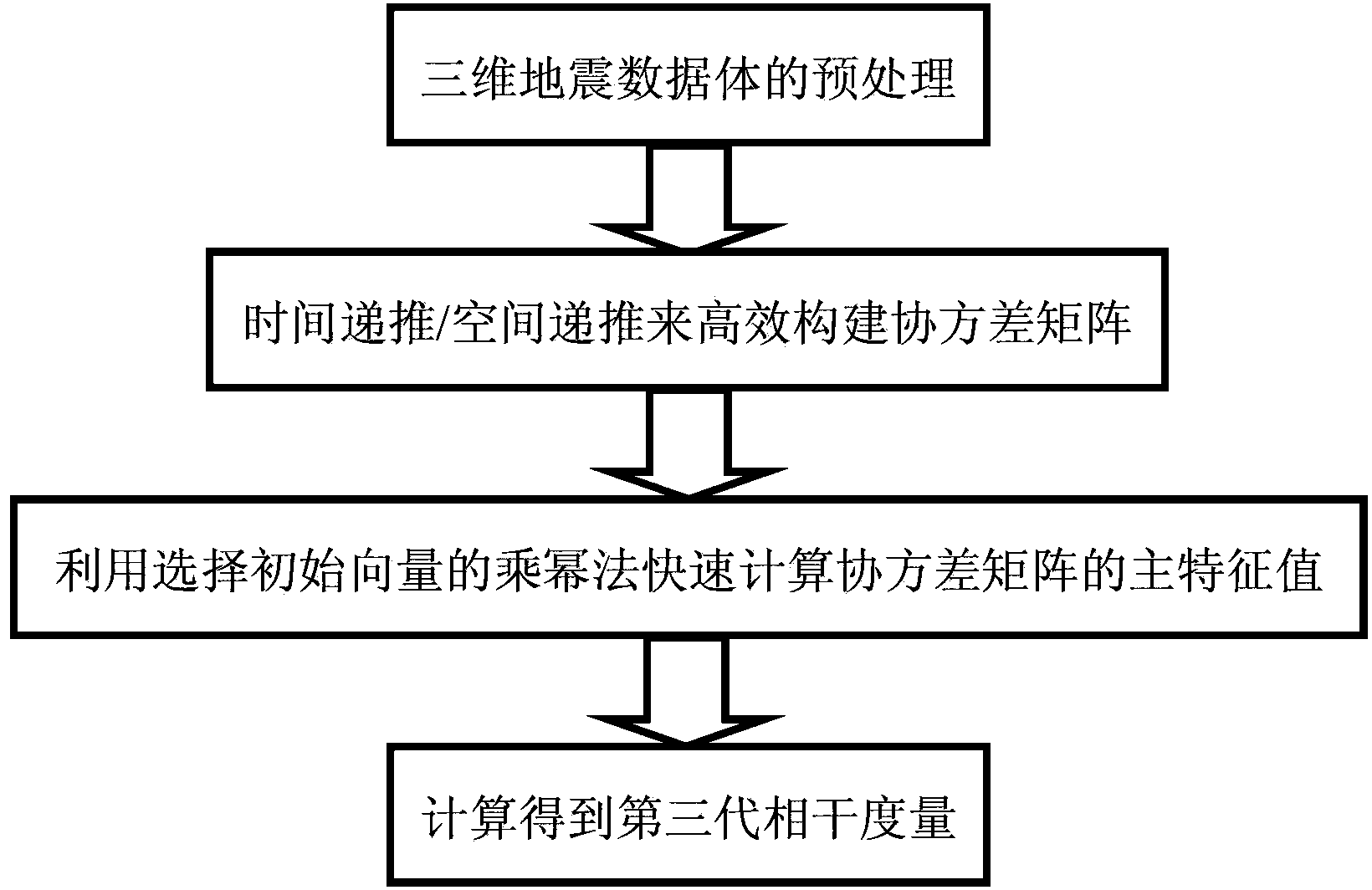

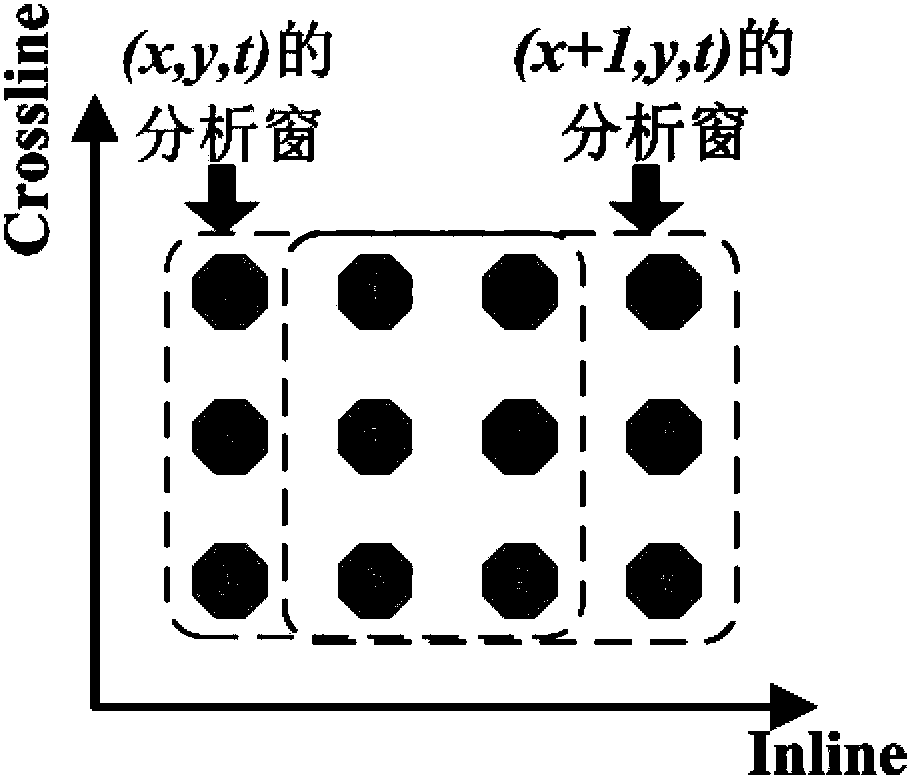

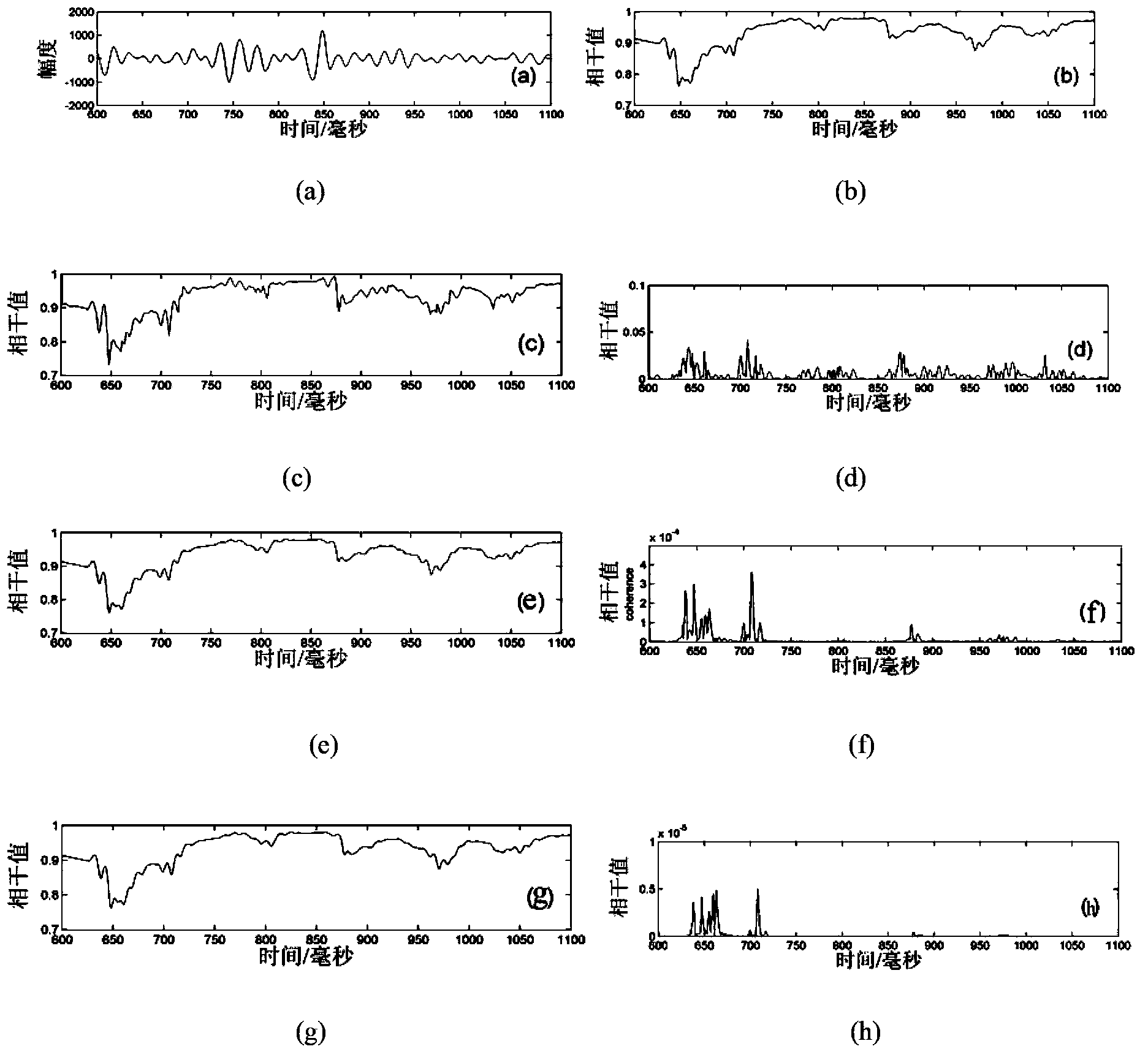

Third-generation coherence cube algorithm fast realization method based on recursion and power method

InactiveCN103364828AReduce computationReduce computing timeSeismic signal processingPowder methodCovariance matrix

The invention discloses a third-generation coherence cube algorithm fast realization method based on recursion and a power method. The recursion and the powder method for selecting an initial vector are used for quickly realizing a third-generation coherence cube algorithm. By utilizing the time / space recursion, the computation for establishing a covariance matrix can be greatly reduced; and when the covariance matrix is characteristically decomposed to get a main characteristic value, the initial vector of the power method is reasonably selected, so that the iteration times for calculating the main characteristic value of the covariance matrix by utilizing the power method can be reduced; and therefore, the computation of the third-generation coherence cube algorithm is greatly reduced, the computation time is reduced, and the error is small.

Owner:XI AN JIAOTONG UNIV

Method for preparing natural plant deodorant

The invention discloses a method for preparing a natural plant deodorant. The method comprises the following steps: irradiating picked plant leaves by using microwaves with power of between 20 and 60 W / g and drying the irradiated leaves in the shade, wherein the laying thickness of the leaves is between 5 and 30 millimeters; microwave frequency is 2,450 MHz; and irradiation time is between 1 and 3 minutes; smashing the dried leaves, extracting the smashed leaves by using 20 to 80 mass percent aqueous solution of ethanol and combining filtrate extracted every time to obtain extracting solution, wherein the mass ratio of the leaves to the aqueous solution of ethanol is 1:6-10; the extraction temperature is between 50 and 80 DEG C; extraction time is about 10 to 60 minutes; and the raw materials are extracted for 2 to 3 times; performing concentration on the extracting solution under reduced pressure until ethanol cannot be detected, filtering the extracting solution and removing impurities in the filtrate by macroporous adsorption resin column chromatography, wherein the macroporous adsorption resin column chromatography process of the filtrate comprises the following steps: elutingthe filtrate with water until effluent liquid becomes pale yellow, eluting the filtrate with 40 to 80 mass percent ethanol, detecting eluent by a hydrochloric acid-magnesium powder method, and collecting the eluent when flavone is detected until no flavone is detected; and performing concentration on the collected eluent under reduced pressure to recycle the ethanol and preparing into dry power to obtain dry powder of the natural plant deodorant. The method has the advantages of low production cost, simple process, no pollution, good effect and convenient and flexible use.

Owner:侯先槐 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com