Solid-state lithium ion electrode, solid-state lithium ion battery and preparation method of solid-state lithium ion electrode

A technology of lithium-ion batteries and solid-state electrolytes, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc. The effect of eliminating the injection process, simplifying the manufacturing process, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

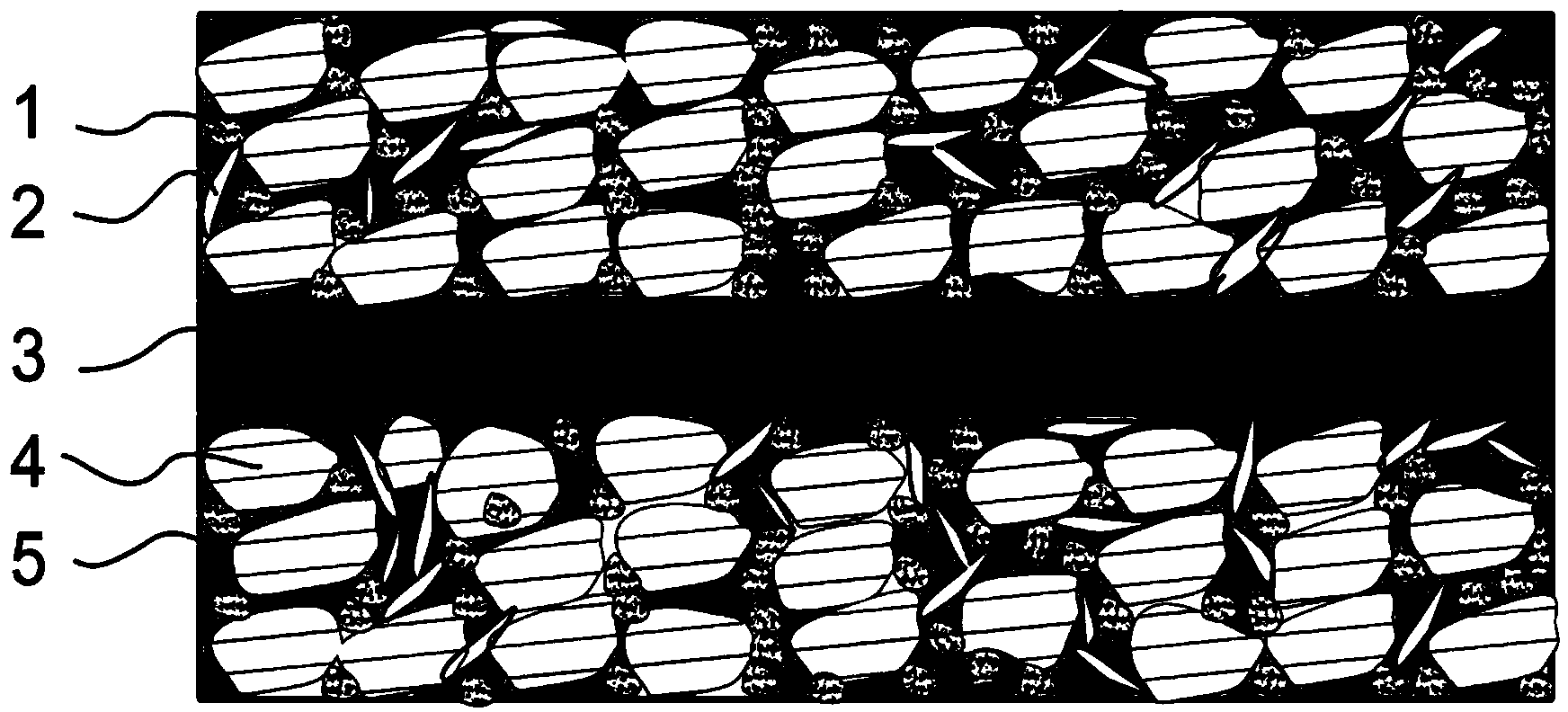

[0024] Slowly add 5kg of active material lithium iron phosphate, 165g of solid electrolyte LiPON, 110g of conductive carbon black, and 220g of binder PVDF into the double planetary mixer with a spoon, stir slowly at 10rpm for 30min, and divide 4100g of solvent NMP into four times Add to the mixed material, stir under vacuum state for 1-2 hours after each addition, and turn on the circulating water to cool the stirring tank, and the stirring speed is 15rpm, 20rpm, 30rpm, 40rpm in turn.

[0025] After the stirring, the obtained slurry was taken out, coated on both sides of the aluminum foil with a transfer coater and dried in an oven. The thickness of the aluminum foil used is 20um, the baking temperature of the oven is 80-120°C, and the coating surface density of the active material layer is 30±0.6mg / cm 2 .

[0026] After the coating is completed, use a roller press to roll the pole piece with a pressure of 170-260T. The above manufacturing processes are all carried out in an...

Embodiment 2

[0028] 4152.5g active material LiMnPO 4 , 550g solid electrolyte LLT, 247.5g carbon fiber, 550g binder polytetrafluoroethylene were slowly added to the double planetary mixer with a spoon, and after stirring slowly at 10rpm for 30min, 2357g solvent NMP was added to the mixture in four times, After each addition, stir under vacuum for 1-2 hours, and turn on the circulating water to cool the stirring tank, and the stirring speed is 15rpm, 20rpm, 30rpm, 40rpm in turn.

[0029] After the stirring, the obtained slurry was taken out, coated on both sides of the aluminum foil with an extrusion coater and dried in an oven. The thickness of the aluminum foil used is 20um, the baking temperature of the oven is 80-120°C, and the coating surface density of the active material layer is 30±0.6mg / cm 2 .

[0030] After the coating is completed, use a roller press to roll the pole piece with a pressure of 170-260T. The above manufacturing processes are all carried out in an environment with...

Embodiment 3

[0032] 5170g active material LiNi x co y mn z o 2 (x: 1 / 3, y: 1 / 3, z: 1 / 3), 110g solid electrolyte lithium vanadium silicon oxide compound, 110g acetylene black, 110g binder polyvinyl chloride are slowly added to the double planetary mixer with a spoon After stirring slowly at 10rpm for 30min, add 2357g solvent NMP into the mixture in four times, stir for 1-2 hours under vacuum after each addition, and turn on the circulating water to cool the stirring tank. The stirring rate is 15rpm, 20rpm, 30rpm, 40rpm.

[0033] After the stirring is finished, the obtained slurry is taken out, coated on both sides of the carbon-coated aluminum foil with a sprayer and dried in an oven. The thickness of the aluminum foil used is 20um, the baking temperature of the oven is 80-120°C, and the coating surface density of the active material layer is 30±0.6mg / cm 2 .

[0034] After the coating is completed, use a roller press to roll the pole piece with a pressure of 170-260T. The above manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com