Fluid mixer

A fluid mixing and main body technology, applied in the direction of mixers, shaking/oscillating/vibrating mixers, chemical instruments and methods, etc., can solve the problem of limited fluid pumping energy, inability to accurately control pumping volume, piezoelectric fluid mixer mixing The effect and mixing ratio accuracy need to be further improved to achieve the effect of strong fluid delivery capacity, good mixing effect and high ratio accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

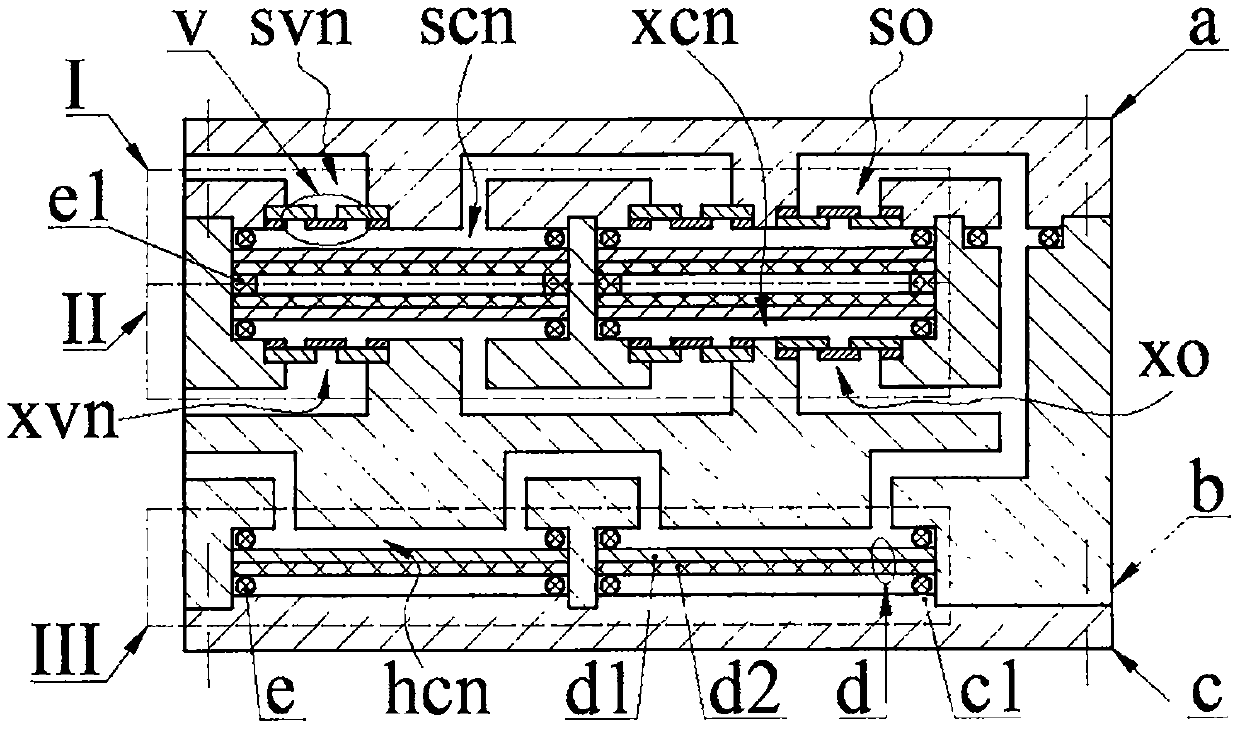

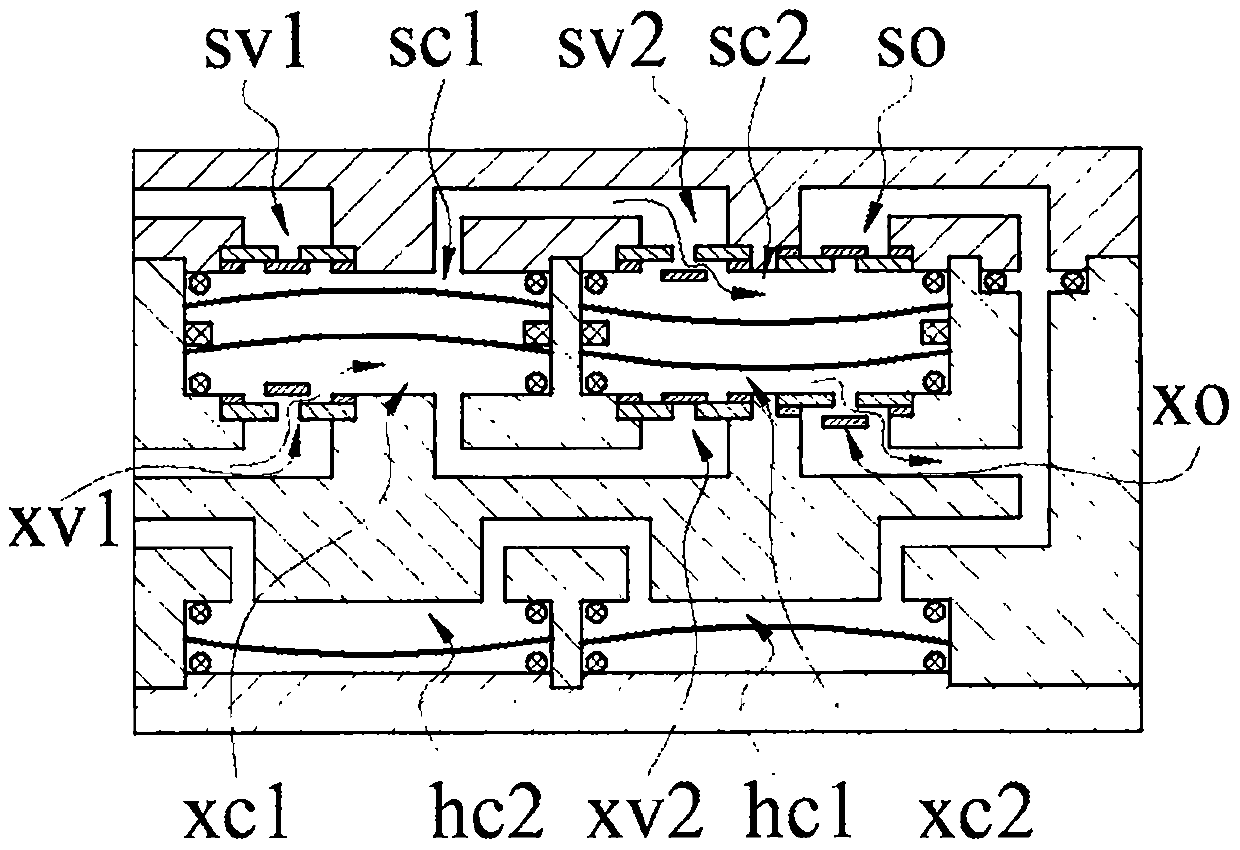

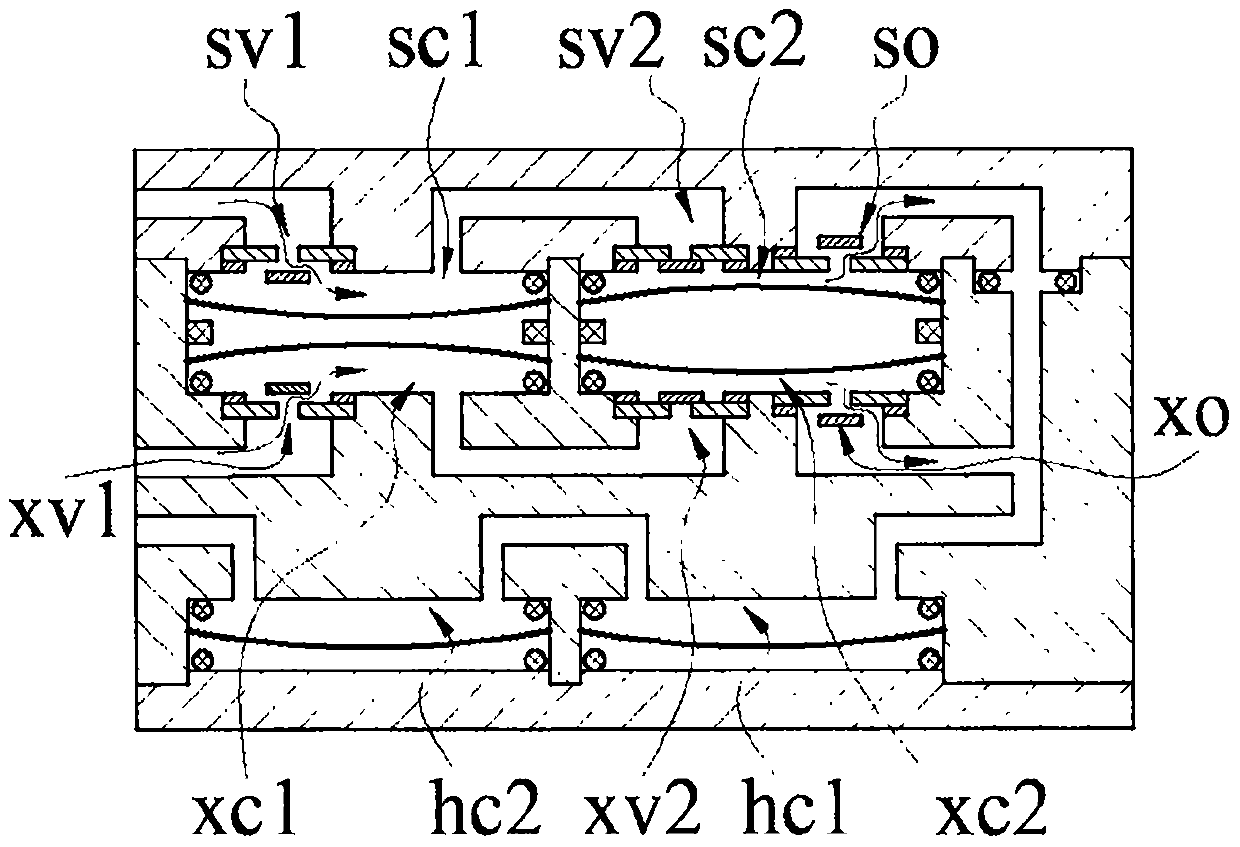

[0019]A fluid mixer of the present invention is composed of an upper cover a, a main body b, a lower cover c, a one-way valve v, a driver d, a sealing ring e and a gasket e1. The upper cover a is provided with an upper inlet hole a1, an upper cover circular platform a7 with an upper outlet hole a2, and at least two upper cover bosses a3, and the uppermost upper cover boss a3 is provided with an upper inlet cavity a4 and an upper outlet cavity a5, the other upper cover boss a3 is provided with an upper inlet a4 and an upper outlet a6; the leftmost upper inlet a4 communicates with the upper inlet a1, the upper outlet a5 communicates with the upper outlet a2, and the remaining upper inlets a4 It communicates with the upper outlet a6 on the adjacent upper cover boss a3; the main body b is provided with a lower inlet hole b1, a lower outlet hole b2, an outlet hole b12, and a drive chamber b3 equal in number to the upper cover boss a3, The main round chamber b7 and at least two mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com