Movable sludge material conveying box

A technology of mobile conveying and sludge, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of strong water-holding adhesion of sludge, reduced conveying efficiency, inability to unload by itself, etc., to achieve a convenient high-altitude state The effect of automatic unloading, automatic and smooth opening and closing, reliable and safe loading and unloading of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

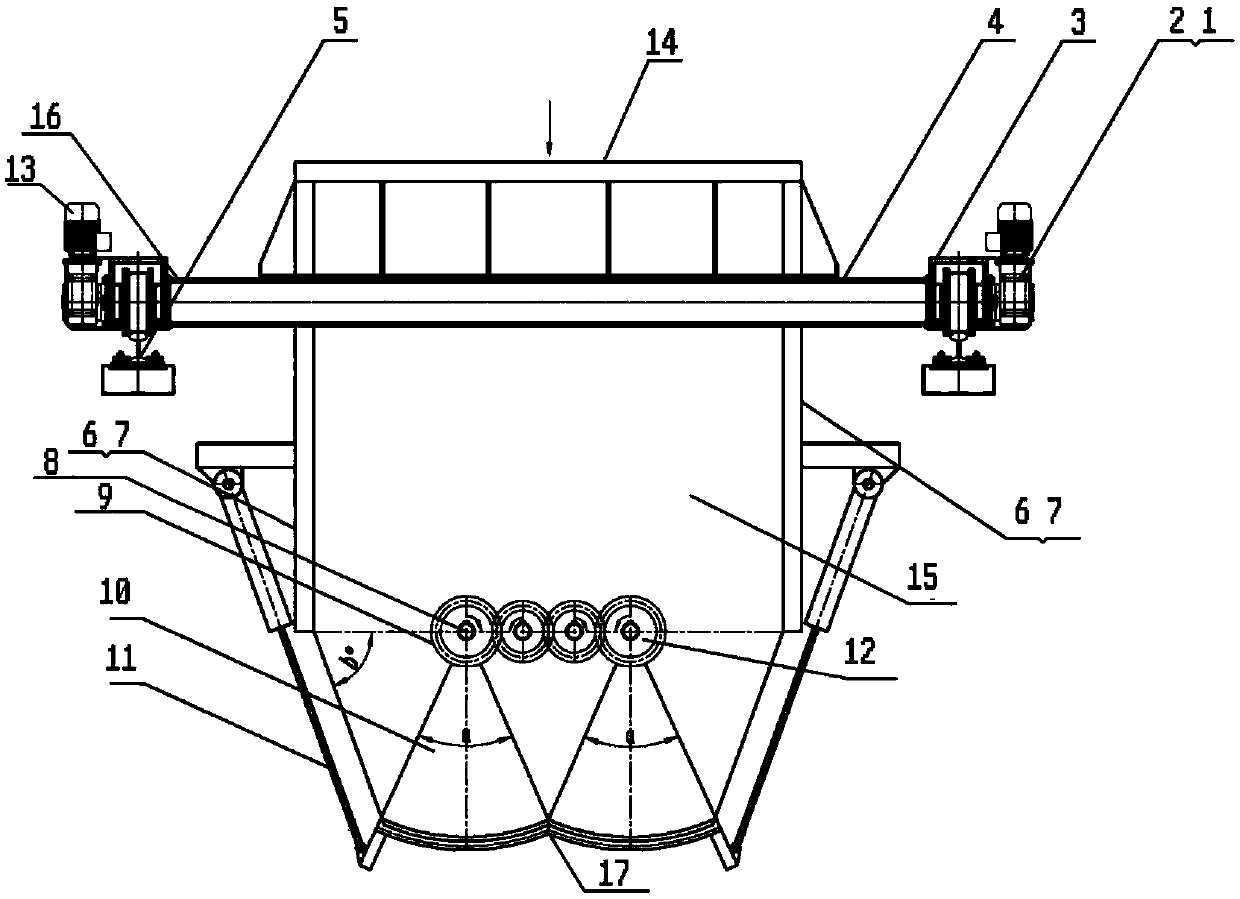

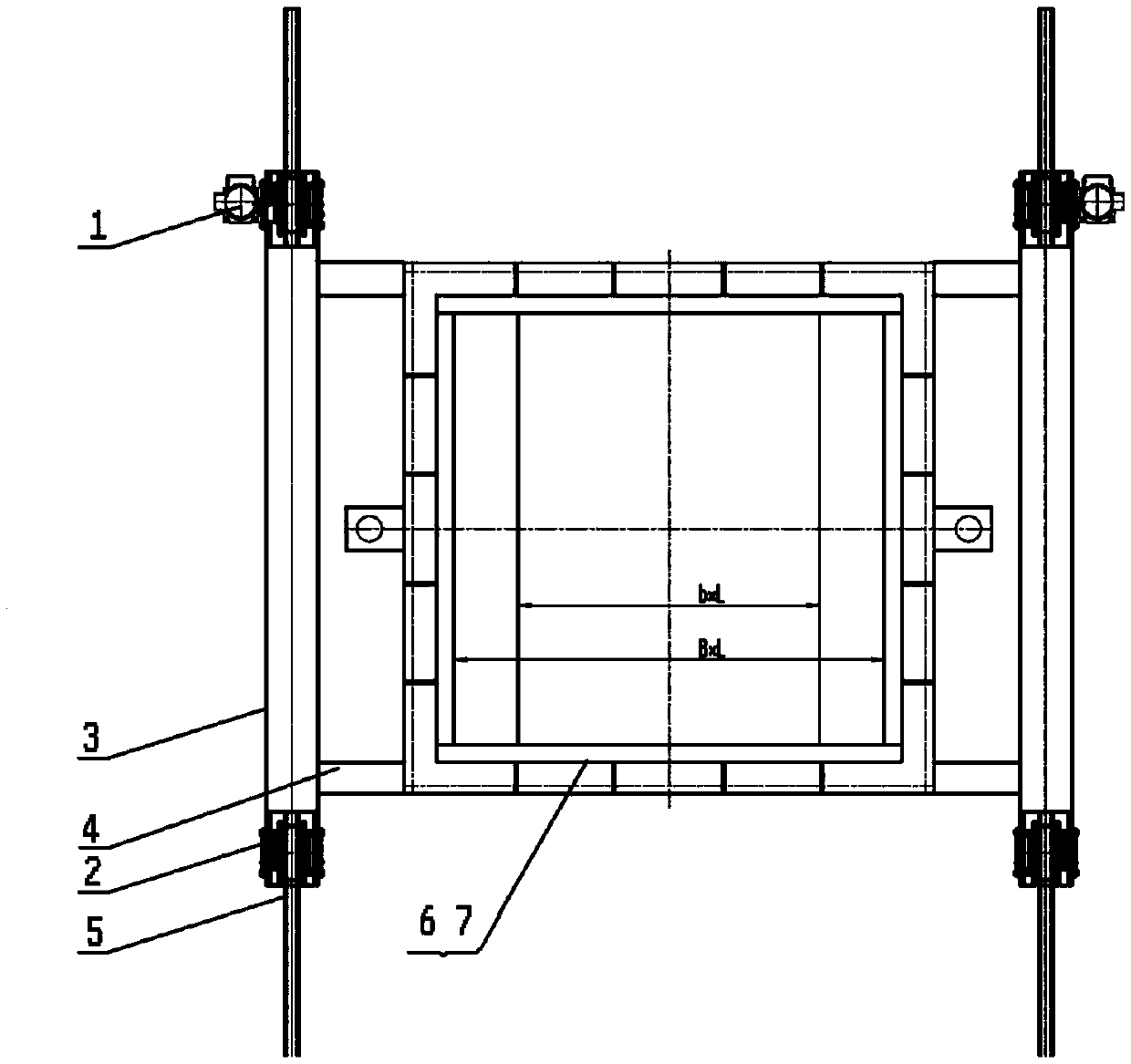

[0055] Such as Figure 1-2 As shown, a kind of mobile conveying sludge hopper in this implementation includes steel rail 5, steel beam mobile trolley 16, sludge self-discharging hopper 15 and electric control (not shown). There are two steel rails 5, which are parallel and suspended between the starting point and the end point of the material. The steel girder mobile trolley 16 includes a pair of driving wheel sets 1, a pair of driven wheel sets 2, two end beams 3, and a shaped steel frame beam platform 4. A pair of driving wheel sets 1 are driven by a motor and a reducer as a driving power source 13. The driving wheel set 1 and the driven wheel set 2 are assembled and connected through the end beam 3, and the driven wheel set 2 is preferentially arranged in front of the material transportation direction. The end beams 3 and the rails 5 are located on both sides correspondingly. The shaped steel frame beam platform 4 is a rectangular frame structure platform composed of two h...

Embodiment 2

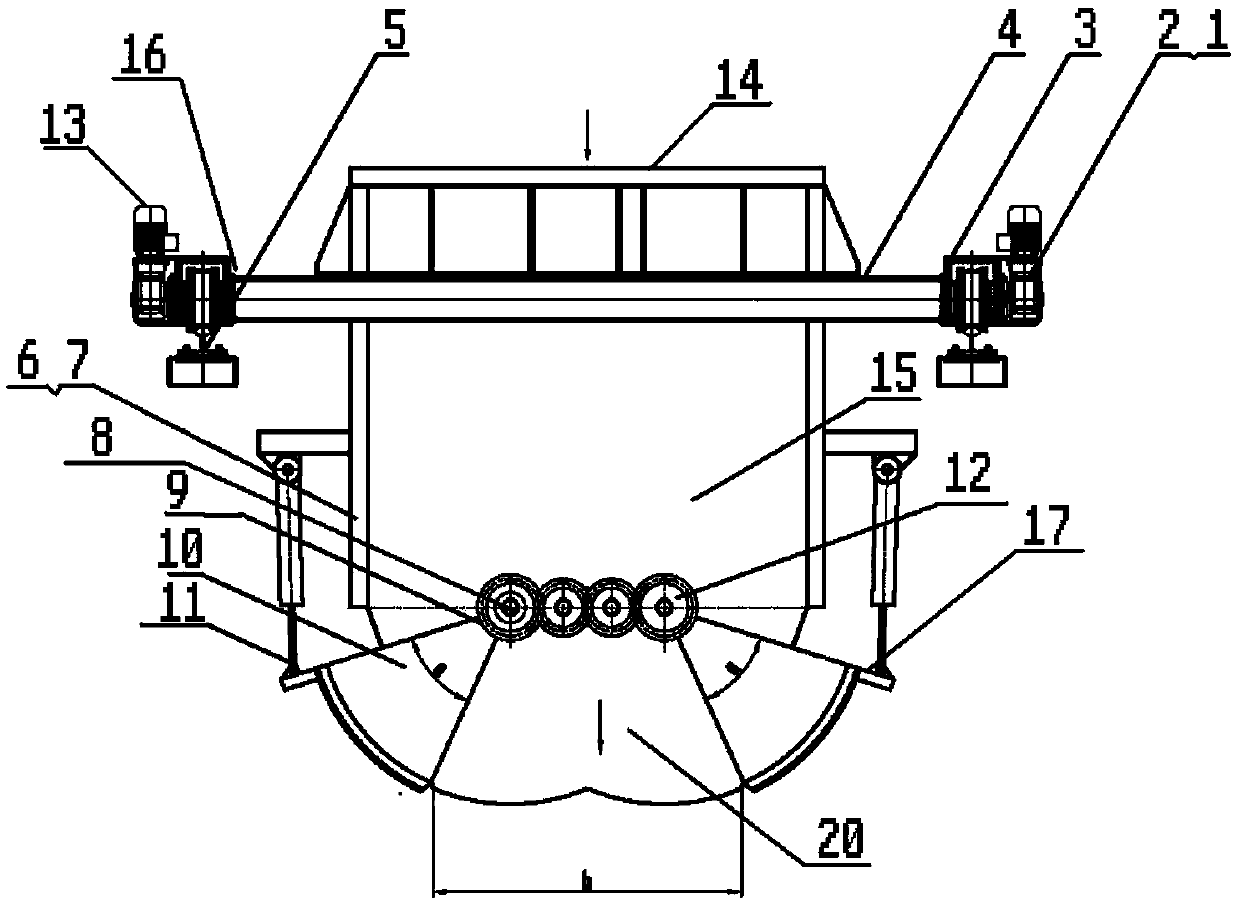

[0064] Such as Figure 5-6 As shown, a mobile conveying sludge hopper in this embodiment includes a steel rail 5, a steel beam mobile trolley 16, a sludge self-discharging hopper 15 and an electric control (not shown). There are two steel rails 5, which are parallel and suspended between the starting point and the end point of the material. The steel beam mobile trolley 16 includes a pair of driving wheel sets 1, a pair of driven wheel sets 2, two end beams 3, and a shaped steel frame beam platform 4. The shaped steel frame beam platform 4 is composed of two horizontal beams and two vertical beams. A rectangular frame structure platform is formed, the upper surface is a flange surface structure, and a pair of driving wheel sets 1 are driven by a motor and a reducer as a driving power source 13. The driving wheel set 1 and the driven wheel set 2 are located on the end beam 3, through The end beams 3 are assembled and connected, and the driven wheel set 2 is preferentially arra...

Embodiment 3

[0072] Such as Figure 10 As shown, a mobile sludge transporting bin in this embodiment has a larger volume transporting function. According to the conveying height, distance, space and process requirements, it can be carried out in the form of two bin trolleys with bin A+ bin B sharing the same track. Material transport, simultaneous or staged discharge.

[0073] It is also possible to adopt multiple groups of material boxes in the same steel beam mobile trolley 15 to arrange transportation and unload in stages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com